STA-RITE DMH-171, DH2H-112, DMH3-171, DHH3-169, DM2H3-110 Owner's Manual

...

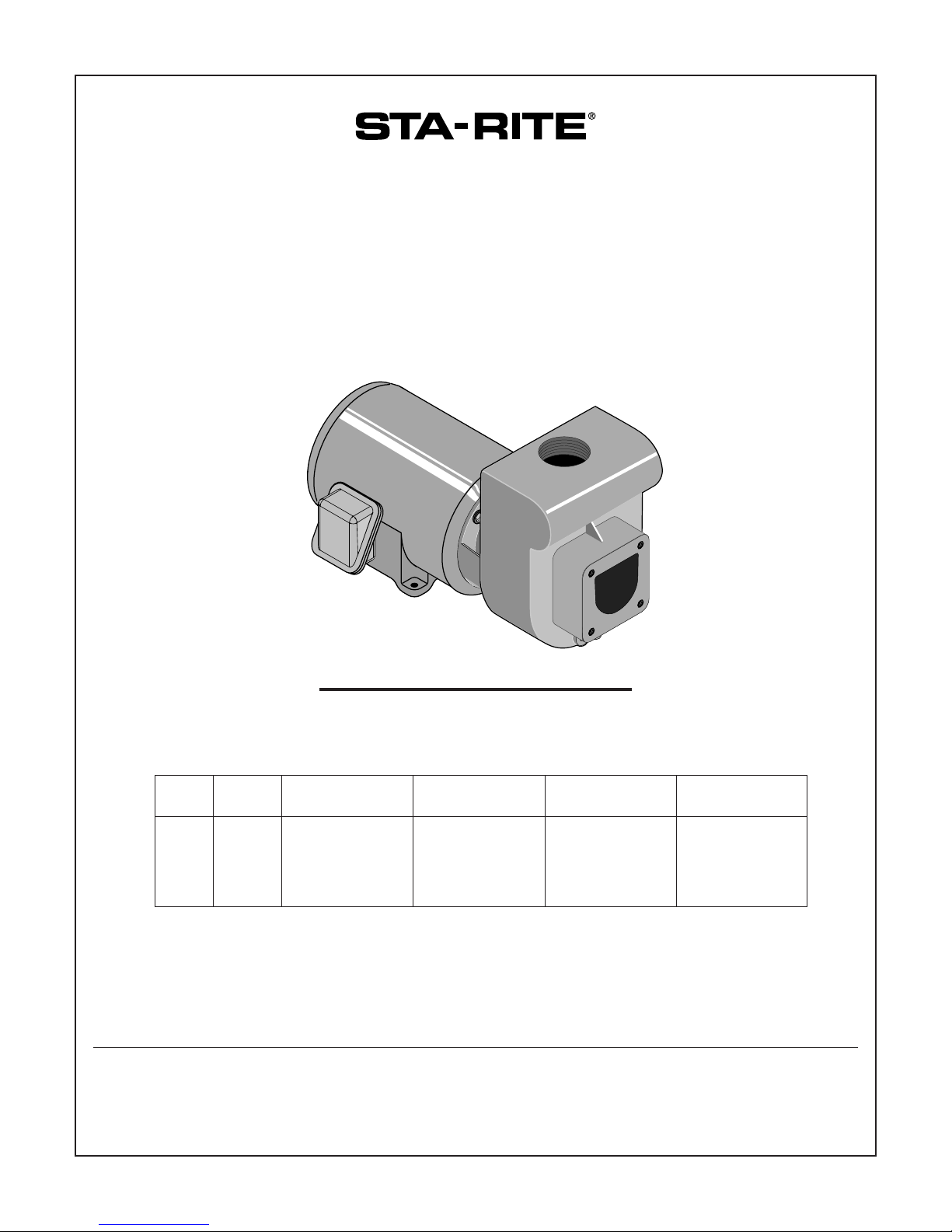

“D” SERIES

CENTRIFUGAL PUMPS WITH TRAP

FOR SWIMMING POOL USE

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

Sta-Rite Pool/Spa Group

293 Wright Street, Delavan, WI 53115

International: 262-728-5551, FAX: 262-728-7550

www.starite.com

Union City, TN • Delavan, WI • Mississauga, Ont. • Murrieta, CA

© 2005, Sta-Rite Industries S409 (Rev. 9/6/05)

This manual should be furnished to

the end user of this pump; its use will

reduce service calls and chance of

injury and will lengthen pump life.

MODELS

Medium Head High Head Medium Head High Head

H.P. Phase Models Models Models Models

3 1 DMH-171 DHH-169 DM2H-110 DH2H-112

3 3 DMH3-171 DHH3-169 DM2H3-110 DH2H3-112

5 1 DMJ-111 DHJ-113 DM2J-111 DH2J-113

5 3 DMJ3-111 DHJ3-113 DM2J3-111 DH2J3-113

2

‘

D’ SERIES SELF-PRIMING

CENTRIFUGAL PUMP and

STRAINER

To avoid unneeded service calls, prevent possible injuries, and get the most

out of your pump, READ THIS MANUAL CAREFULLY!

The Sta-Rite ‘D’ Series Self-priming Centrifugal pump:

• Is designed for use with commercial swimming pools and spas.

• Is an excellent performer; durable, reliable.

Table of Contents

Safety Instructions ......................................................................................3

Uncrating and Inspection ............................................................................4

Installation...............................................................................................4-6

Electrical..................................................................................................7-8

Operation ...................................................................................................9

Service ...............................................................................................10-12

Troubleshooting Guide..............................................................................13

Repair Parts List ...................................................................................14-15

Warranty...................................................................................................16

3

READ AND FOLLOW SAFETY

INSTRUCTIONS!

This is the safety alert symbol. When you see this symbol on your system

or in this manual, look for one of the following signal words and be alert

to the potential for personal injury.

warns about hazards that will cause death, serious personal

injury, or major property damage if ignored.

warns about hazards that can cause death, serious personal

injury, or major property damage if ignored.

warns about hazards that will or can cause minor personal injury

or property damage if ignored.

NOTICE indicates special instructions not related to hazards.

Carefully read and follow all safety instructions in this manual and on equipment. Keep safety labels in good condition; replace if missing or damaged.

Incorrectly installed or tested equipment may fail, causing

severe injury or property damage.

Read and follow instructions in owner's manual when installing

and operating equipment. Have a trained pool professional

perform all pressure tests.

1. Do not connect system to a high pressure or city water system.

2. Use equipment only in a pool or spa installation.

3. Install pump with at least 2 hydraulically balanced main drains equipped

with correctly installed, screw-fastened, anti-entrapment certified covers.

See Page 4.

4. Trapped air in system can cause explosion. BE SURE all air is out of system

before operating or testing equipment.

Before pressure testing, make the following safety checks:

• Check all clamps, bolts, lids, and system accessories before testing.

• Release all air in system before testing.

• Tighten Sta-Rite trap lids to 25 ft. lbs. (3.5 kg-m) torque for testing.

• Water pressure for test must be less than 25 PSI (7.5 kg/cm

2

).

• Water Temperature for test must be less than 100oF. (38oC).

• Limit test to 24 hours. After test, visually check system to be sure it is ready

for operation. Remove trap lid and retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment only.

For non-Sta-Rite equipment, consult manufacturer.

IMPORTANT

SAFETY

INSTRUCTIONS

Always follow basic safety precautions with this equipment, including the following.

To reduce the risk of

injury, do not permit children to

use this product unless they are

closely supervised at all times.

This pump is for use

with permanently installed pools

and may also be used with hot

tubs and spas if so marked. Do

not use with storable pools. A

permanently installed pool is constructed in or on the ground or in

a building such that it cannot be

readily disassembled for storage.

A storable pool is constructed so

that it may be readily disassembled for storage and reassembled

to its original integrity.

SAVE THESE

INSTRUCTIONS

4

UNCRATING AND INSPECTION

Handle with care.

Check items received against packing list to be sure that all equipment has

been received.

Inspect for shipping damage. If found, file claim with carrier immediately.

Cleanup

Clean up foundation and surrounding area. Remove all trash and other materials which will interfere with installation.

For easy assembly, make sure all threaded joints and mating surfaces are

clean. If necessary, clean with wire brush and solvent.

To reduce danger of explosion and fire, do not use gasoline as a

cleaning solvent.

Remove all foreign material (packing, etc.) from pump and strainer.

Fire and burn hazard. Modern motors run at high temperatures.

To reduce the risk of fire, do not allow leaves, debris, or foreign matter to collect around the pump motor. To avoid burns when handling the motor, let it

cool for 20 minutes before trying to work on it.

INSTALLATION

Only qualified, licensed personnel should install pump and wiring.

Pump is designed for use in fresh water only.

Foundation

Foundation must:

Be located away from corrosive or flammable liquids.

Have enough ventilation to maintain air temperature at less than the maxi-

mum ambient temperature rating (Max. Amb.) listed on the motor model

plate. If this pump is installed in an enclosure/pump house, the enclosure

must have adequate ventilation and air circulation to keep the temperature in

the enclosure at or below the motor’s rated ambient temperature whenever

the pump is running.

Be Solid - Level - Rigid - Vibration free.

Be provided with necessary hold-down bolts, washers, and shims.

Allow pump inlet to be as close to water level as possible.

Use short, direct suction pipe (to reduce friction losses).

Maximum suction lift is 10’ (3 m).

Allow for isolation valves in suction and discharge piping.

Have adequate floor drainage to prevent flooding.

Be protected from excess moisture.

Allow adequate access for servicing pump and piping.

POOL PUMP SUCTION

REQUIREMENTS

Pump suction is hazardous and can trap and drown or disembowel bathers. Do not use or allow anyone else to use a pool, spa, or hot tub

unless it has at least two suction outlets to each pump suction line (see

“Outlets Per Pump,” Page 5). Do not use or operate swimming pools, spas,

or hot tubs if a suction outlet cover is missing, broken, or loose. Follow the

guidelines below for a pump installation which minimizes risk to users of

pools, spas, and hot tubs.

5

Entrapment Protection

The pump suction system

must

provide protection against the hazard of

suction entrapment or hair entrapment/entanglement.

Suction Outlet Covers

All suction outlet covers must be maintained. They must be replaced if

cracked, broken, or missing.

See Page 5 for outlet cover certification requirements.

All suction outlets must have correctly installed, screw-fastened covers in

place.

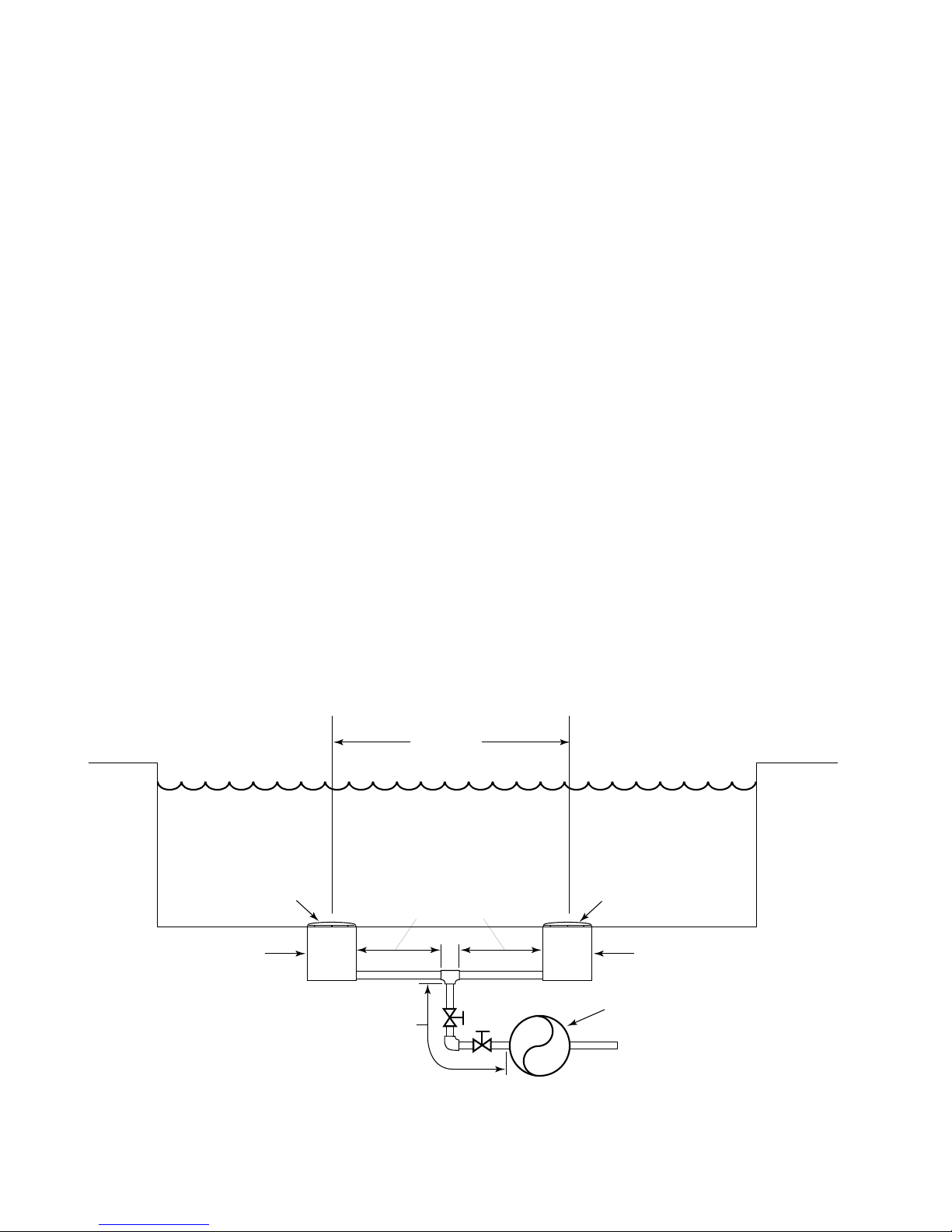

Outlets Per Pump

Provide at least two hydraulically balanced main drains, with covers (see

Page 4), for each swimming pool pump suction line. The centers of the main

drains (suction outlets) must be at least three feet apart.

The system must be built so that it cannot operate with the pump drawing

water from only

one

main drain (that is, there must be at least two main drains

connected to the pump whenever it is running). (See Figure 1). However, if

two main drains run into a single suction line, the single suction line may be

equipped with a valve which will shutoff

both

main drains from the pump

(see Figure 1).

More than one pump can be connected to a single suction line as long as the

requirements above are met.

Water Velocity

If 100% of the pump’s flow comes from the main drain system, the maximum

water velocity in the pump suction hydraulic system must be seven feet per

second or less even if one main drain (suction fitting) is completely blocked.

The flow through the remaining main drain(s) must comply with the latest

ASME/ANSI Specification for

Suction Fittings For Use in Swimming Pools,

Spas, Hot Tubs, and Whirlpool Bathtub Applications.

Figure 1 – Recommended pump suction layout.

Anti-entrapment

Cover, screw-fastened

to Main Drain Sump

Main Drain Main Drain

Valves OK between

pump and Tee

At Least

3 Feet

No valves between

Tee and Main Drains

Anti-entrapment

Cover, screw-fastened

to Main Drain Sump

Pump

2515 0497

Loading...

Loading...