TEA3718

Stepper motor driver

Features

■ Half-step and full-step mode

■ Bipolar drive of stepper motor for maximum

motor performance

■ Built-in protection diodes

■ Wide range of current control 5 to 1500 mA

■ Wide voltage range 10 to 50 V

■ Designed for unstabilized motor supply voltage

■ Current levels can be selected insteps or

varied continuously

■ Thermal overload protection

■ Alarm output or pre-alarm output

Applications

The TEA3718 is a bipolar monolithic integrated

circuit intended to control and drive the current in

one winding of a bipolar stepper motor.

Description

The circuits consist of an LS-TTL compatible logic

input, a current sensor, a monostable and an

output stage with built-in protection diodes. Two

TEA3718 ICs and a few external components

form a complete control and drive unit for LS-TTL

or microprocessor-controlled stepper motor

systems.

Table 1. Device summary

Power DIP 12+2+2

Multiwatt™ 15

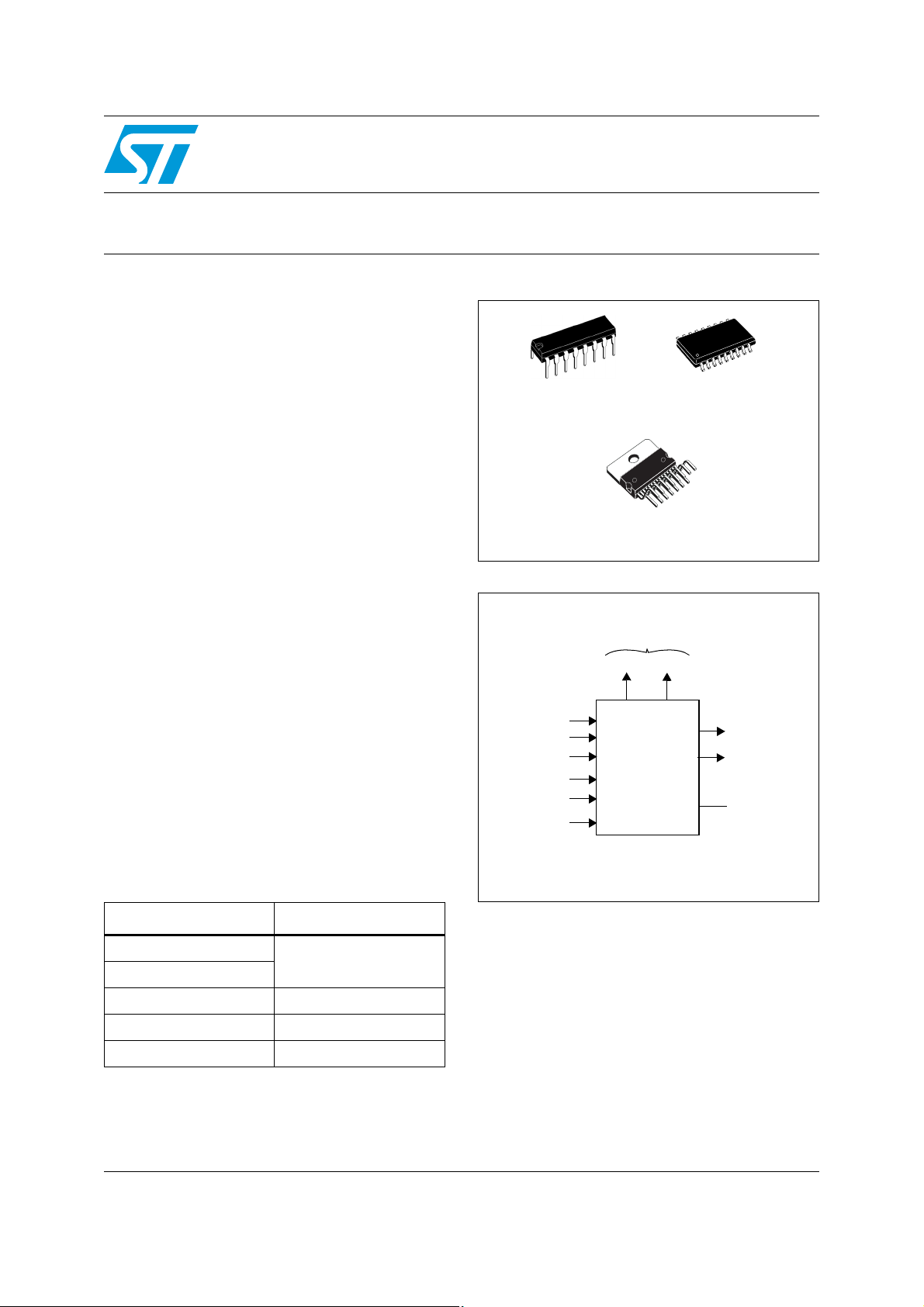

Figure 1. Block diagram

Motor winding

OUT A

OUT B

COMPARATOR

INPUT

PHASE

PULSE TIME

IN0

IN1

REFERENCE

TEA3718

SO20

ALARM

(TEA3718SP)

PRE-ALARM

(TEA3718SFP)

SENSE

RESISTOR

Order code Package

TM: Multiwatt is a trademark of STMicroelectronics

E-TEA3718SDP

Power DIP

E-TEA3718DP

E-TEA3718SFP SO20

E-TEA3718SFPTR SO20 (tape and reel)

E-TEA3718SP Multiwatt™ 15

January 2009 Rev 2 1/26

www.st.com

26

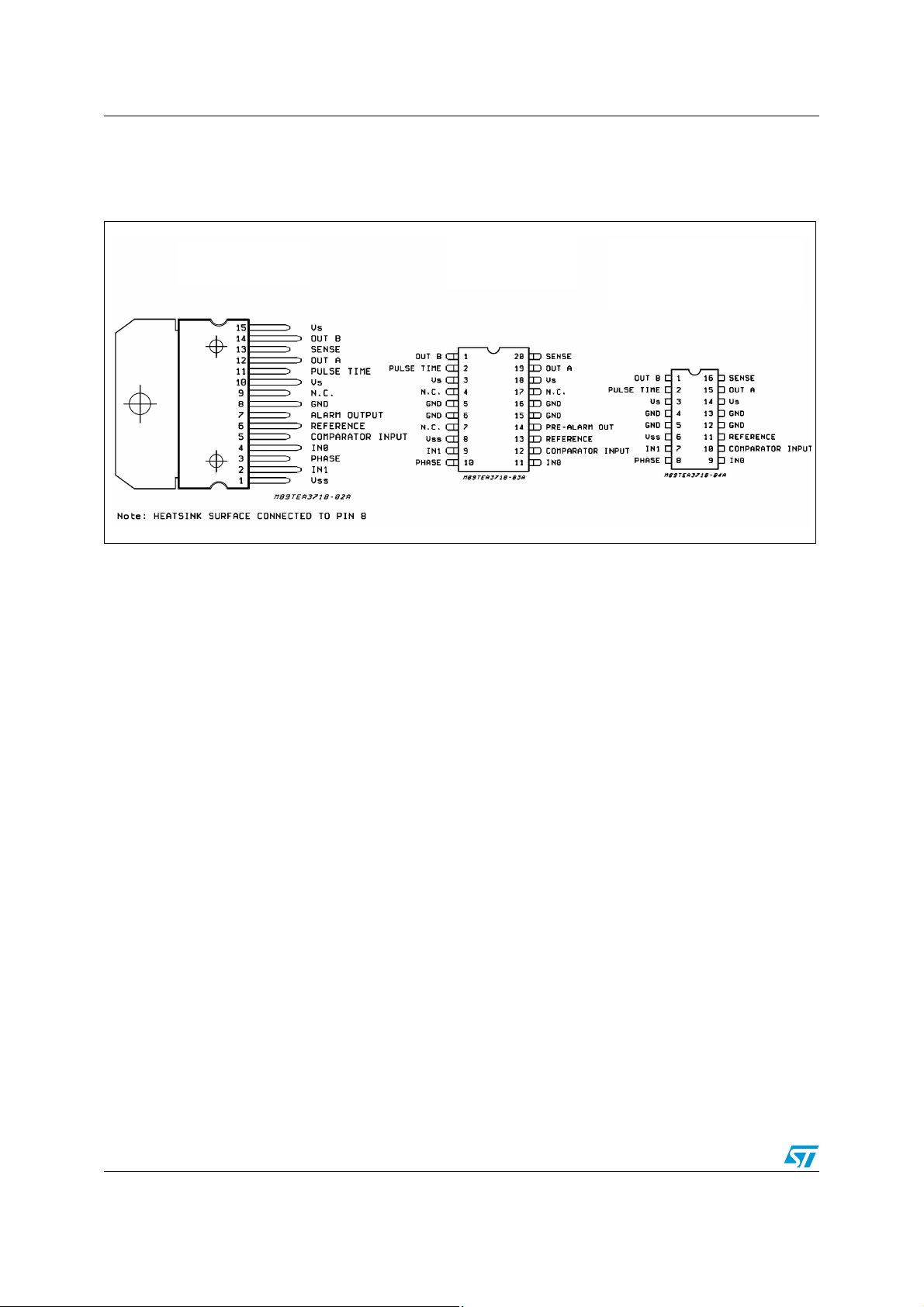

Pin connections

1 Pin connections

Figure 2. Package pin locations (top views)

E-TEA3718SP

(Multiwatt 15)

E-TEA3718SFP

(SO20)

E-TEA3718DP

E-TEA3718SDP

(Power DIP 12+2+2)

2/26

Contents

Contents

1 Pin connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Device diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Functional blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Alarm output (TEA3718SP, TEA3718DP and TEA3718SDP) . . . . . . . . . 14

4.2 Pre-alarm output (TEA3718SFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Current reduction in alarm condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Typical application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Input logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Phase input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 Current sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Single-pulse generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 Output stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.6 V

5.7 Analog control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

, VS and V

SS

R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3/26

Contents

6 Application notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Motor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Unused inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.4 Operating sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4/26

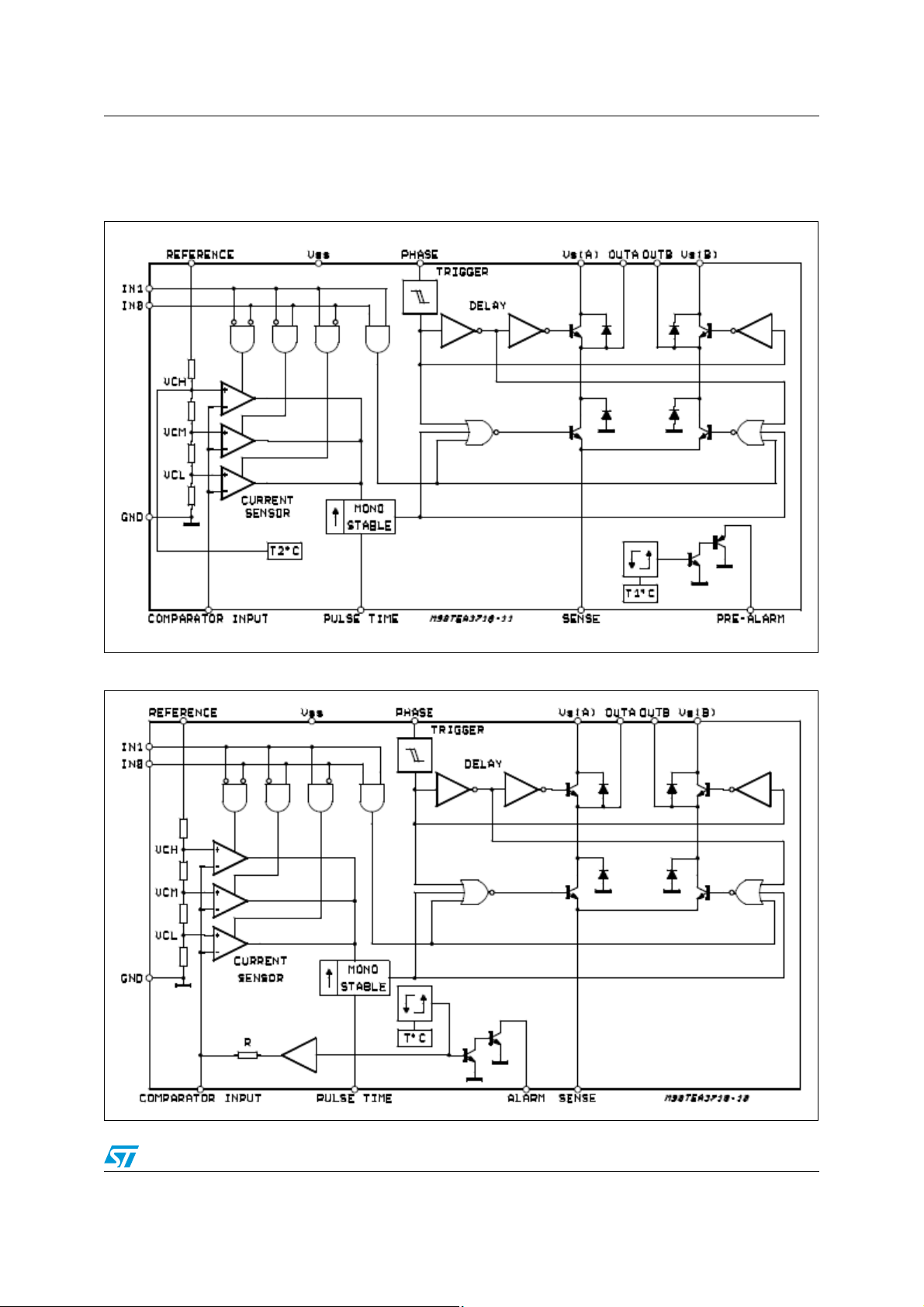

Device diagrams

2 Device diagrams

Figure 3. Detailed block diagram (TEA3718SFP)

Figure 4. Detailed block diagram (TEA3718SP)

5/26

Device diagrams

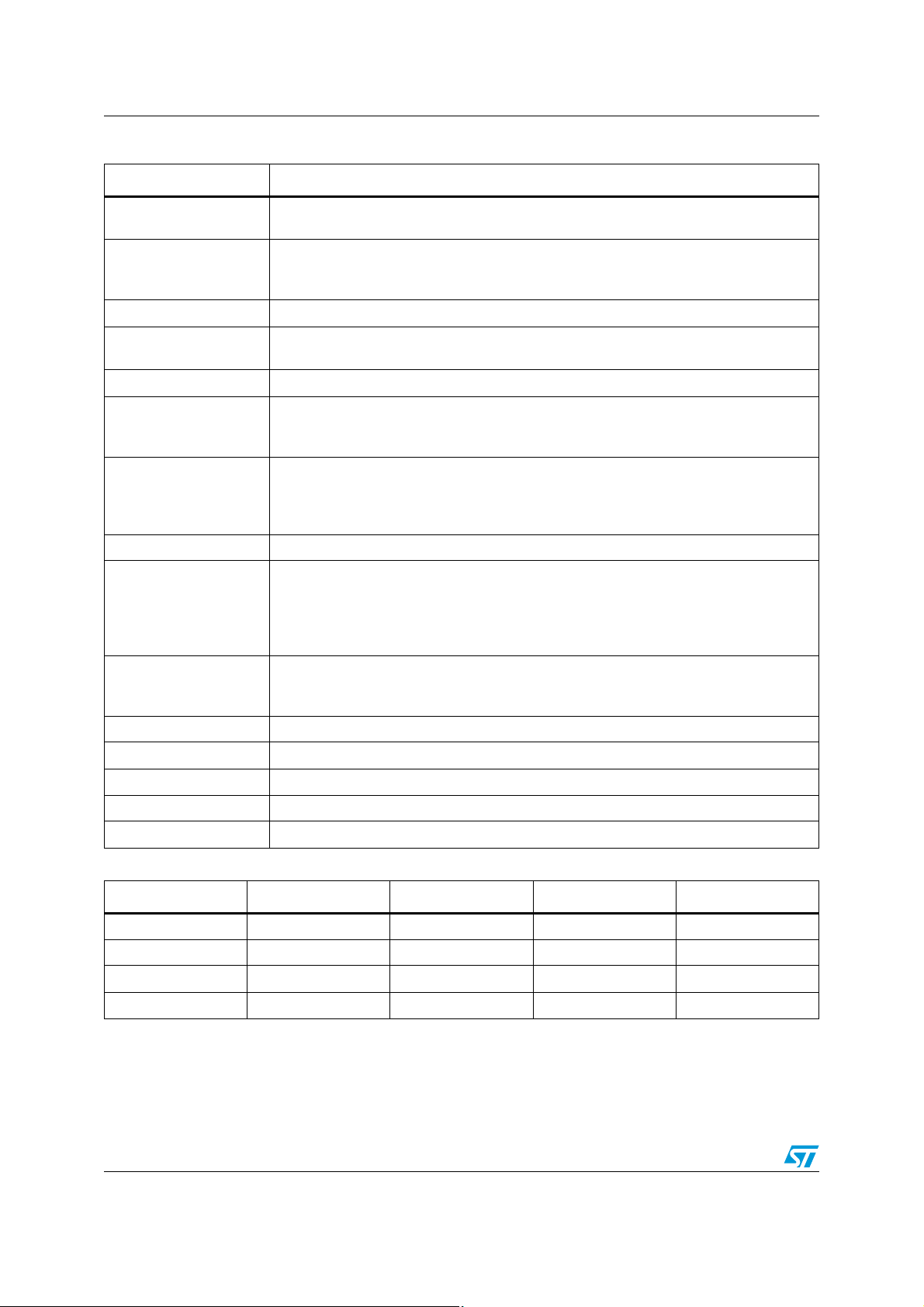

Table 2. Pin functions

Name Function

OUTB

Output connection (with pin OUT A). The output stage is a "H" bridge formed by four

transistors and four diodes suitable for switching applications.

A parallel RC network connected to this pin sets the OFF time of the lower power

PULSE TIME

V

(B) Supply voltage input for half output stage

S

GND

V

SS

transistors. The pulse generator is a monostable triggered by the rising edge of the

output of the comparators (t

= 0.69 RT CT).

off

Ground connection. In SO20 and power DIP these pins also conduct heat from die to

printed circuit copper.

Supply voltage input for logic circuitry

This pin and pin IN0 are logic inputs which select the outputs of three comparators to set

IN1

the current level. Current also depends on the sensing resistor and reference voltage.

Ta b l e 8 : Tr ut h ta bl e

See

.

This TTL-compatible logic input sets the direction of current flow through the load. A

PHASE

high level causes current to flow from OUT A (source) to OUT B (sink). A Schmidt trigger

on this input provides good noise immunity and a delay circuit prevents output stage

short circuits during switching.

IN0 See IN1

Input connected to the three comparators. The voltage across the sense resistor is

feedback to this input through the low pass filter RCCC. The lower power transistor are

COMPARATOR INPUT

disabled when the sense voltage exceeds the reference voltage of the selected

comparator. When this occurs the current decays for a time set by RT CT,

= 0.69 RT CT.

T

off

A voltage applied to this pin sets the reference voltage of the three comparators.

REFERENCE

Reference voltage with the value of R

output current.

(A) Supply voltage input for half output stage

V

S

OUTA See pin OUT B

and the two inputs IN0 and IN1 determines the

S

SENSE RESISTOR Connection to lower emitters of output stage for insertion of current sense resistor

ALARM When T

PRE-ALARM When T

reaches T1 oC the alarm output becomes low (TEA3718SP)

j

reaches T2 oC the pre-alarm output becomes low (T2<T1) (TEA3718SFP)

j

Table 3. Device comparison table

Device Current Package Alarm Pre-alarm

TEA3718SDP 1.5 A Power DIP 12+2+2 Not connected

TEA3718SFP 1.5 A SO20 Connected

TEA3718SP 1.5 A Multiwatt 15 Connected

TEA3718DP 1.5 A Power DIP 12+2+2 Not connected

6/26

Electrical specifications

3 Electrical specifications

3.1 Absolute maximum ratings

Table 4. Absolute maximum ratings

Symbol Parameters Value Unit

V

SS

V

S

Supply voltage

50

7

V

Input voltage:

V

I

– logic inputs

– analog inputs

– reference input

V

6

SS

15

V

Input current:

i

i

I

O

T

J

T

op

T

stg

– logic inputs

– analog inputs

-10

-10

mA

Output current ±1.5 A

Junction temperature +150

o

Operating ambient temperature range 0 to 70 oC

Storage temperature range -55 to +150 oC

C

3.2 Recommended operating conditions

Table 5. Recommended operating conditions

Symbol Parameters SO20 Power DIP Multiwatt 15 Unit

V

SS

Vs Supply voltage 10 - 45 V

Supply voltage 4.75 5 5.25 V

I

T

t

t

m

amb

r

f

Output current 0.020 - 1.2 A

Ambient temperature 0 - 70

o

Rise time for logic inputs - - 2 µs

Fall time for logic inputs - - 2 µs

7/26

C

Electrical specifications

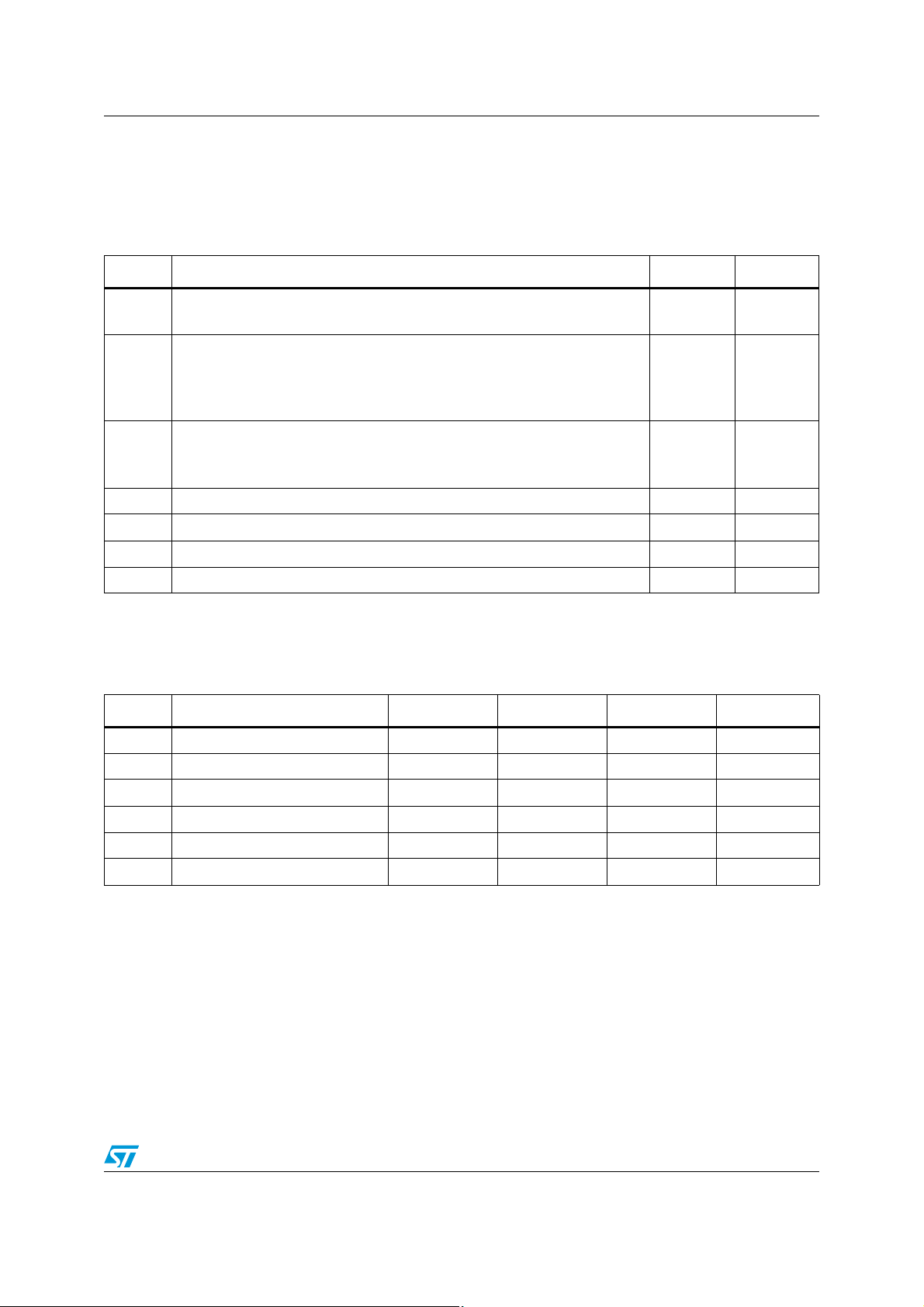

3.3 Thermal data

Table 6. Thermal data

Symbol Parameters SO20 Power DIP Multiwatt 15 Unit

(j-c) Maximum junction-case thermal resistance 16 11 3

R

th

R

(j-a) Maximum junction-ambient thermal resistance 60

th

1. Soldered on a 35 µm thick 4 cm2 PC board copper area

(1)

45

(1)

40

o

C/W

o

C/W

Figure 5. Maximum power dissipation

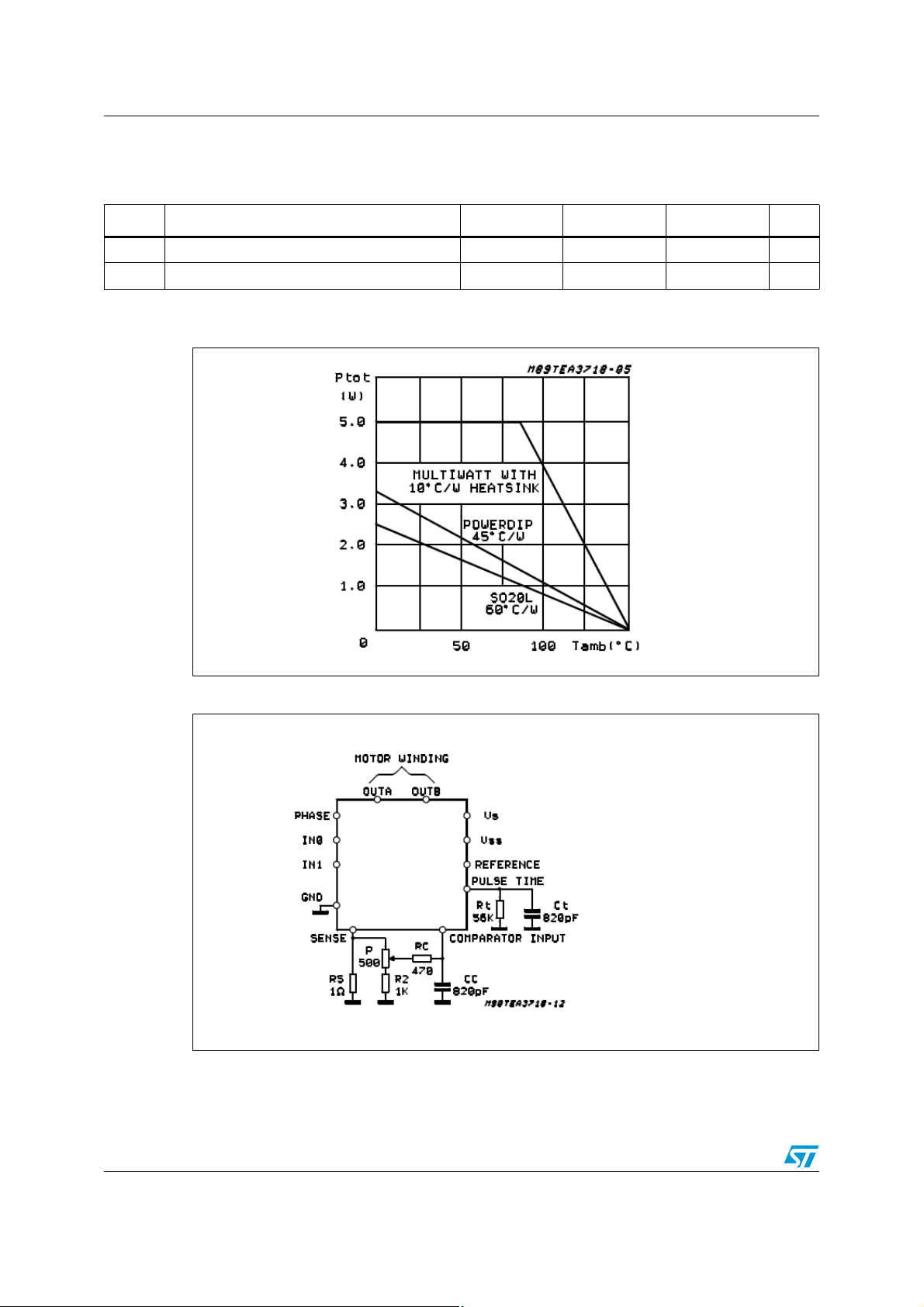

Figure 6. Typical external component configuration

RS = 1 ohm inductance free

= 470 ohms

R

C

CC = 820 pF ceramic

Rt = 56 kohms

Ct = 820 pF ceramic

P = 500 ohms

R2 = 1 kohm

8/26

Electrical specifications

Figure 7. Output waveforms

9/26

Electrical specifications

3.4 Electrical characteristics

Table 7. Electrical characteristics

Symbol Parameter Min.

I

Supply current - - 25 mA

CC

V

IH

V

IL

I

IH

I

IL

V

CH

High level input voltage - logic inputs 2 2 - - V

Low level input voltage - logic inputs - - 0.8 V

High level input current - logic inputs - - 20 µA

Low level input current - logic inputs (VI = 0.4 V) -0.4 - - mA

Comparator threshold voltage (VR = 5V)

VCM

V

CL

I

I

CO

off

Comparator input current -20 - 20 µA

Output leakage current (IO = 0, I1 = 1 T

(1)

(2)

IO = 0, I1 = 0

IO = 0, I1 = 0

I

= 0, I1 = 0

O

= 25oC) - - 100 µA

amb

390

230

65

Typ.

420

250

80

(2)

Max.

440

27090mV

Total saturation voltage drop (Im = 1 A)

V

(total)

sat

P

tot

t

off

t

d

(alarm) Alarm output saturation voltage IO = 2 mA (Multiwatt) - 0.8 - V

V

sat

I

ref

V

(source)

sat

Total power dissipation - Im = 1 A, fs = 30 kHz - 3.1 3.6 W

Cut off time (see

V

> 5 µs

ton

Turn off delay (see

Figure 6

Figure 6

and

and

Figure 7

Figure 7

dVC/dt > 50 mV/µs)

Reference input current, VR = 5 V - 0.4 1 mA

Source diode transistor pair

saturation voltage

SO20/Power DIP

Multiwatt

, Vmm = 10 V

) T

= 25oC,

amb

Power DIP I

= 0.5 A

m

Power DIP Im = 1 A

Multiwatt I

= 0.5 A

m

Multiwatt Im = 1 A

-

-

-

-

2.8

3.2

25 30 35 ms

-1.6-µs

-

-

-

-

1.05

1.35

-

-

1.2 (1.3)

1.5 (1.7)

1.3

1.7

(2)

Unit

V

V

V

I

(source) = 0.5 A - 1.1 1.5 (1.6)

Vf(source diode) Source diode forward voltage

f

V

If(source) = 1 A - 1.25 1.7 (1.9)

I

sub

Vsat(sink)

V

(sink diode) Sink diode forward voltage

f

1. Vs = Vss = 5 V, ± 5%, Vmm = 10 V to 45V, Tamb = 0 to 70oC (Tamb = 25oC for TEA3718SFP) unless otherwise specified.

2. Values in parentheses apply only to E-TEA3718SFP and E-TEA3718SFPTR mounted in SO20 package.

Substrate leakage current If = 1A - - 5 mA

Sink diode transistor pair

saturation

Power DIP I

= 0.5 A

m

Power DIP Im = 1 A

Multiwatt I

= 0.5 A

m

Multiwatt Im = 1 A

If(sink) = 0.5 A

If(sink) = 1 A

-

-

-

-

-

-

1

1.2

1

1.1

1.2 (1.3)

1.3 (1.5)

-

-

1.4 (1.6)

1.5 (1.9)

1.3

1.5

V

V

V

10/26

Electrical specifications

Figure 8. Sink driver VCE sat against I

Figure 9. Lower diode Vf against I

OUT

and T

out

and T

j

j

Figure 10. Source driver VCE sat against I

11/26

OUT

and T

j

Electrical specifications

Figure 11. Upper diode Vf against I

Figure 12. I

against junction temperature

ref

OUT

and T

j

Figure 13. Comparator input current against T

12/26

and V

j

C

Functional blocks

4 Functional blocks

Figure 14. Alarm output (TEA3718SP)

Figure 15. Pre-alarm output (TEA3718SFP)

13/26

Functional blocks

4.1 Alarm output (TEA3718SP, TEA3718DP and TEA3718SDP)

The ALARM output pin becomes low when the junction temperature reaches T ° C. When an

alarm condition occurs, parts of the supply voltage (dividing bridge R - R

comparator input pin (

Figure 16

). Depending on the RC value the behavior of the circuit on

an alarm condition is as follows:

● RC > 80 ohms, the output stage is switched off

● RC > 60 ohms, the current in the motor windings is reduced according to the

approximate formula: (see also

Figure 18

V

Im

----------

TH

RS

and

V

CC

------------ ------

RRC+

Figure 19

R

C

------- -

•–=

RS

)

) is fed to the

C

with V

= threshold of the comparator (VCH, VCM, VCL) R = 700 ohms (typical).

TH

For several Multiwatt packages a common detection can be obtained as in

Figure 16. Alarm detection for power DIP package

Figure 17

.

14/26

Functional blocks

Figure 17. Common detection for several Multiwatt packages

4.2 Pre-alarm output (TEA3718SFP)

When the junction temperature reaches T1° C (typically = 170 ° C) a pre-alarm signal is

generated on the PRE-ALARM output pin.

Soft thermal protection occurs when function temperature reaches T2 (T2 > T1).

4.3 Current reduction in alarm condition

Note: The resistance values given in this section are for the V

adjusted when using other comparator thresholds or V

Figure 18. Current reduction in the motor on alarm condition (typical curve)

threshold. They should be

CH

values.

ref

15/26

Functional blocks

Figure 19. Half-current on alarm condition circuit (Vref = 5V)

4.4 Typical application

Figure 20. Typical application circuit

16/26

Functional description

5 Functional description

The circuit is intended to drive a bipolar constant current through one motor winding. The

constant current is generated through switch mode regulation.

There is a choice of three different current levels with the two logic inputs lN0 and lN1. The

current can also be switched off completely.

5.1 Input logic

If any logic input is left open, the circuit treats it as a high-level input.

l

Table 8 . Truth t a b l e

IN0 IN1 Current level

H H No current

L H Low current

H L Medium current

L L Maximum current

5.2 Phase input

The PHASE input pin determines the direction of current flow in the winding, depending on

the motor connections. The signal is fed through a Schmidt trigger for noise immunity, and

through a time delay in order to guarantee that no short-circuit occurs in the output stage

during phase-shift. A high level on the PHASE input causes the motor current flow from

OUTA through the winding to OUTB.

The lH0 and lH1 input pins select the current level in the motor winding. The values of the

different current levels are determined by the reference voltage VR together with the value of

the sensing resistor R

5.3 Current sensor

This part contains a current sensing resistor (RS), a low pass filter (RC, CC) and three

comparators. Only one comparator is active at a time. It is activated by the input logic

according to the current level chosen with signals IN0 and IN1. The motor current flows

through the sensing resistor RS. When the current has increased so that the voltage across

RS becomes higher than the reference voltage on the other comparator input, the

comparator output goes high, which triggers the pulse generator and its output goes high

during a fixed pulse time (t

causing the motor current to decrease during t

.

S

), thus switching off the power feed to the motor winding, and

off

off

.

17/26

Functional description

5.4 Single-pulse generator

The pulse generator is a monostable triggered on the positive going edge of the comparator

output. The monostable output is high during the pulse time, t

timing components R

and CT. toff = 0.69 ⋅ RT C

T

T

, which is determined by the

off

The single pulse switches off the power feed to the motor winding, causing the winding

current to decrease during t

. If a new trigger signal should occur during t

off

, it is ignored.

off

5.5 Output stage

The output stage contains four Darlington transistors and four diodes, connected in an Hbridge. The two sinking transistors are used to switch the power supplied to the motor

winding, thus driving a constant current through the winding.

Note: It is not permitted to short circuit the outputs.

5.6 VSS, VS and V

R

The circuit stands any order of turn-on or turn-off the supply voltages VSS and VS. Normal

dV/dt values are then assumed.

Preferably, V

should track VSS during power on and power off if VS is established.

R

5.7 Analog control

The current levels can be varied continuously if VR is varied with a circuit varying the voltage

on the comparator terminal.

Figure 21. Power losses against

output current

18/26

Application notes

6 Application notes

6.1 Motor selection

Some stepper motors are not designed for continuous operation at maximum current. As the

circuit drives a constant current through the motor, its temperature might increase

excessively both at low and high speed operation.

Also, some stepper motors have such high core losses that they are not suited for switch

mode current regulation.

6.2 Unused inputs

Unused inputs should be connected to proper voltage levels in order to get the highest noise

immunity.

6.3 Interference

As the circuit operates with switch mode current regulation, interference generation

problems might arise in some applications. A good measure might then be to decouple the

circuit with a 15 nF ceramic capacitor, located near the package between power

line V

S and ground. The ground lead between R

short as possible. This applies also to the lead between the sensing resistor R

See

Section 4: Functional blocks

.

, CC and circuit GND should be kept as

S

and point S.

S

19/26

Application notes

6.4 Operating sequence

Figure 22. Principal operating sequence

20/26

Package mechanical data

7 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at:

ECOPACK® is an ST trademark.

www.st.com

.

21/26

Package mechanical data

22/26

Package mechanical data

23/26

Package mechanical data

24/26

Revision history

Revision history

Table 9. Document revision history

Date Revision Changes

24-Jan-2006 1 Initial release.

21-Jan-2009 2

Document reformatted.

Added

Figure 1

.

25/26

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

26/26

Loading...

Loading...