Features

2

■ I

C interface, slave address: 1001111

■ 7-bit adjustable sink current output

■ 2.25 V to 3.6 V logic supply voltage V

■

AVDD operating voltages

– 4.5 V to 20 V for V

– 4.5 V to 13 V for V

■ EEPROM for storing the optimum V

■ Guaranteed monotonic output over operating

from 2.6 V to 3.6 V

DD

from 2.25 V to 3.6 V

DD

DD

COM

setting

range

■ 400 kHz maximum interface bus speed

■ Operating temperature: –40 °C to 85 °C

■ Available in an 8-pin 3 mm x 3 mm TDFN8 or

3 mm x 3 mm TSSOP8 package

Applications

■ TFT-LCD panels

■ e-paper and e-book displays

Description

The STVM100 is a programmable VCOM

adjustment solution for thin-film transistor (TFT)

liquid-crystal displays (LCDs) to remove “flickers”.

It is also used in e-paper and e-book applications

to avoid the "ghosting" effect (residual pixels after

display refresh). It can replace a mechanical

potentiometer, so that the factory operator can

physically view the front screen when performing

the VCOM adjustment. This significantly reduces

labor costs, increases reliability, and enables

automation.

Table 1. Device summary

STVM100

I2C LCD/e-paper VCOM calibrator

TDFN8 (3 mm x 3 mm) (DC)

TSSOP8 (3 mm x 3 mm) (DS)

The STVM100 provides a digital I

control the sink current output (I

drives an external resistive voltage divider, which

can then be applied to an external V

Three external resistors R

1

mine the highest and lowest value of the V

An increase in the output sink current will lower

the voltage on the external divider so that the

V

can be adjusted by 128 steps within this

COM

range. Once the desired V

COM

achieved, it can be stored in the internal

EEPROM that will be automatically recalled during each power-up.

The STVM100 is available in an 8-pin,

3 mm x 3 mm TDFN8 or 3 mm x 3 mm TSSOP8

package.

2

C interface to

). This output

OUT

COM

, R2, and R

setting is

buffer.

SET

deter-

COM

.

Order code Optimum temperature range Package Packing

STVM100DC6E –40 °C to 85 °C TDFN8 ECOPACK

STVM100DS6F –40 °C to 85 °C TSSOP8 ECOPACK

December 2009 Doc ID 13236 Rev 8 1/27

®

package, tubes

®

package, tape and reel

www.st.com

1

Contents STVM100

Contents

1 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Device operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 2-wire bus characteristics and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Bus not busy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Start data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.3 Stop data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.4 Data valid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.5 Acknowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Read mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Write mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 V

power supply ramp-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DD

3 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Typical operating characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 Part numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/27 Doc ID 13236 Rev 8

STVM100 List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pin names and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 3. Bit P read and write mode values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 4. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 5. Operating and AC measurement conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 6. Capacitances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 7. DC and AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 8. AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 9. TDFN8 3 x 3 x 0.75 mm, pitch 0.65, package mechanical data . . . . . . . . . . . . . . . . . . . . . 23

Table 10. TSSOP8 – 8-lead, thin shrink small outline, 3 mm x 3 mm, mech. data . . . . . . . . . . . . . . . 24

Table 11. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 12. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Doc ID 13236 Rev 8 3/27

List of figures STVM100

List of figures

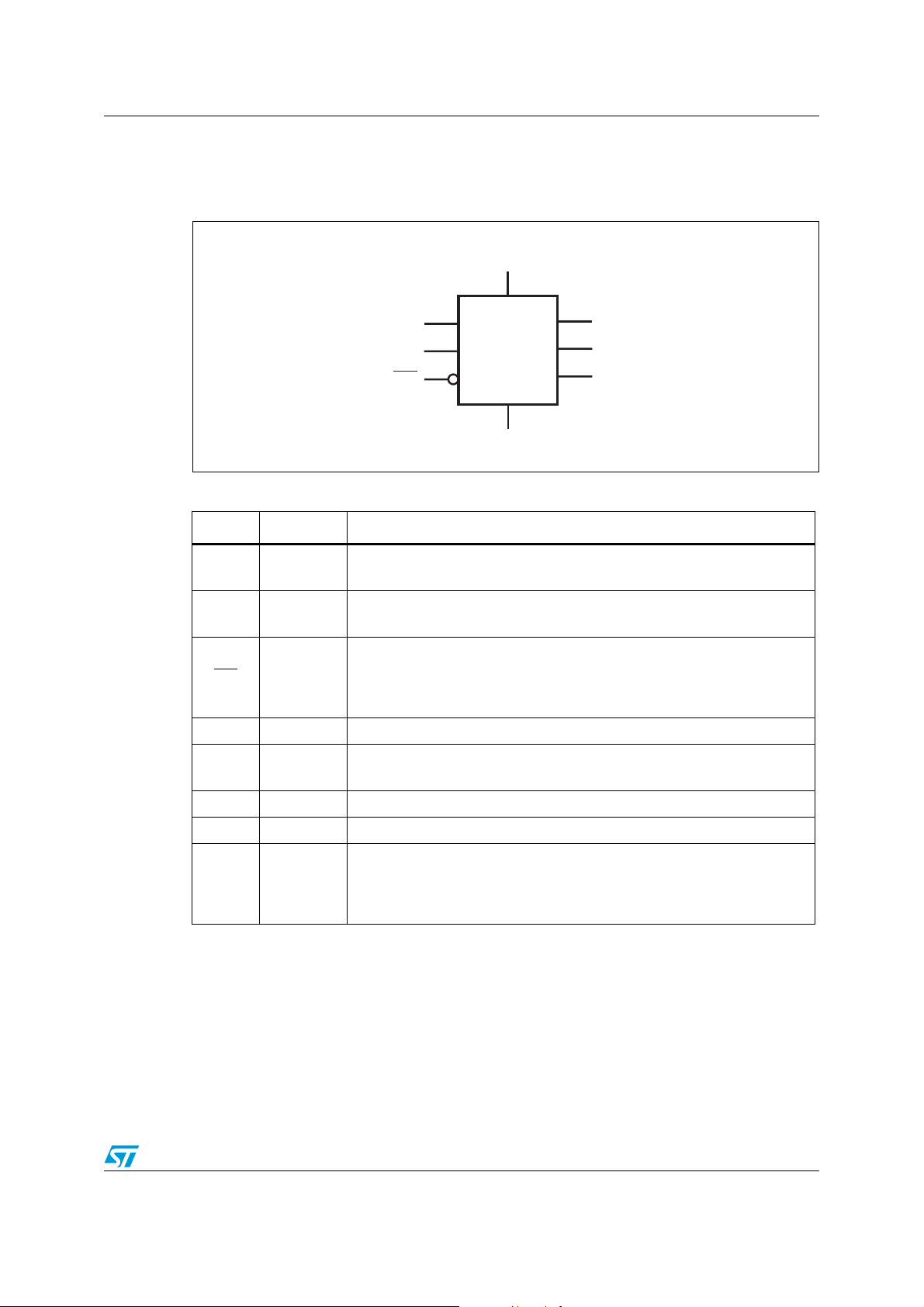

Figure 1. Logic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

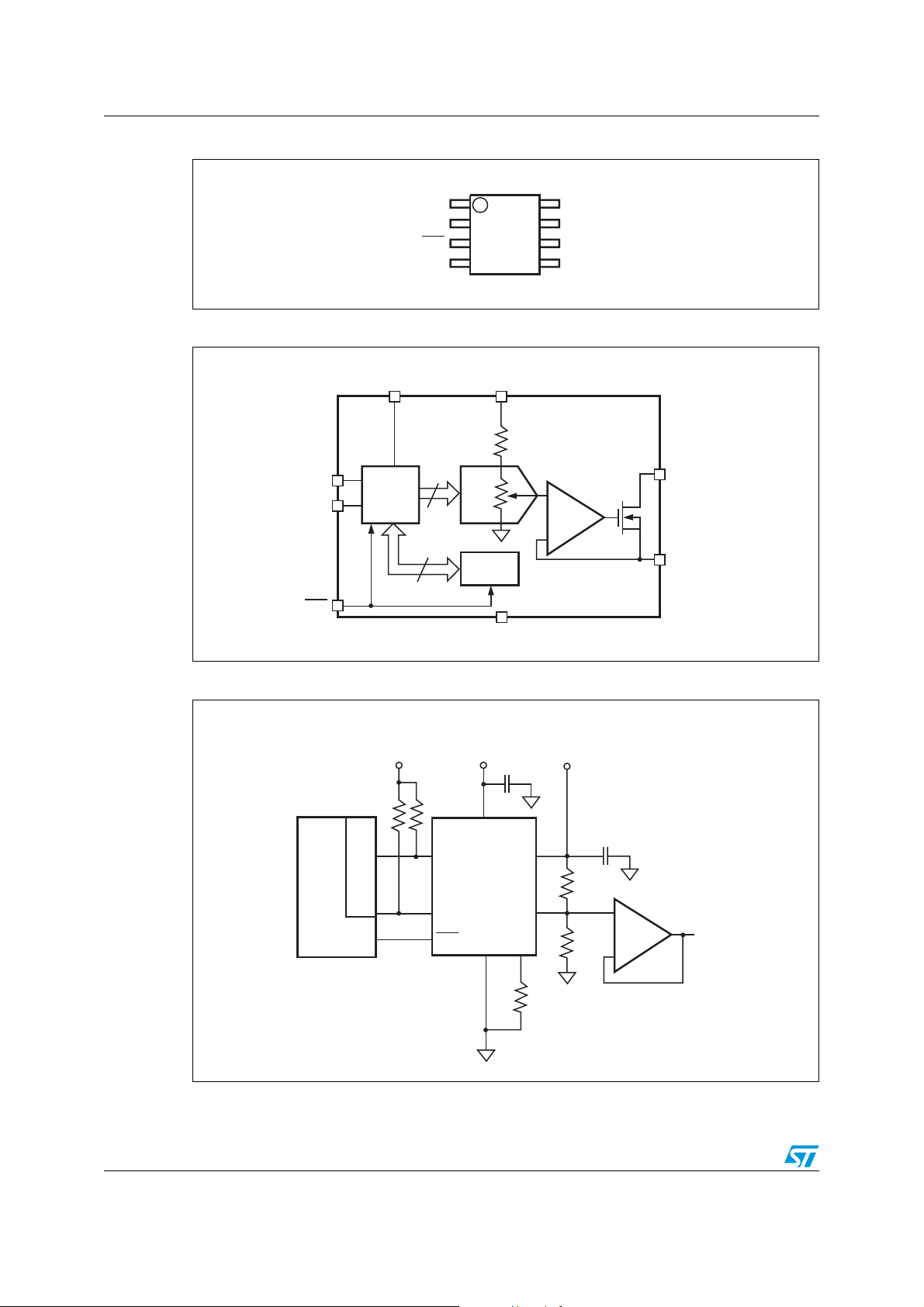

Figure 2. Connections diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. Hardware hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5. Serial bus data transfer sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. Acknowledgement sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7. Read/write mode sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8. R

Figure 9. Bus timing requirements sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10. V

Figure 11. AV

Figure 12. VDD supply current vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 13. AV

Figure 14. I

Figure 15. Total unadjusted error vs. DAC setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 16. Differential non-linearity vs. DAC setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 17. Integral non-linearity vs. DAC setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 18. AV

Figure 19. Full scale-up response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 20. Full scale-down response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 21. TDFN8 3 x 3 x 0.75 mm, pitch 0.65, package mechanical data . . . . . . . . . . . . . . . . . . . . . 23

Figure 22. TSSOP8 – 8-lead, thin shrink small outline, 3 mm x 3 mm, mech. data. . . . . . . . . . . . . . . 24

, R2, and R

1

supply current vs. V

DD

supply current vs. AV

DD

supply current vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

DD

error vs. temperature (STVM100 at middle scale) . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

OUT

power-up response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DD

connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SET

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DD

DD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4/27 Doc ID 13236 Rev 8

STVM100 Device overview

1 Device overview

Figure 1. Logic diagram

V

DD

SDA

SCL

STVM100

WP

GND

Table 2. Pin names and functions

Name Type Function

(1)

OUT Analog

AV

DD

Supply

Adjustable sink current output pin.

See Section 3: Application information on page 11.

High-voltage analog supply.

Bypass to GND with a 0.1 µF capacitor.

WRITE protectection.

WP Input

Active-low. To enable write operations to the DAC or to the EEPROM

writing, connect to 0.7 VDD or greater. Internally pulled down by a 130 kΩ

resistor.

GND Supply ground.

V

DD

Supply

SDA Input/Output I

SCL Input I

System power supply input.

Bypass to GND with a 0.1 µF capacitor.

2

C serial data input/output.

2

C serial clock input.

AV

OUT

SET

DD

AI12272

Maximum sink current adjustment point.

SET Analog

1. See SET pin function in this table for the maximum adjustable sink current setting.

Connect a resistor from SET to GND to set the maximum adjustable sink

current of the OUT pin. The maximum adjustable sink current is equal to

AVDD /20 divided by R

(see Figure 4 on page 6).

SET

Doc ID 13236 Rev 8 5/27

Device overview STVM100

Figure 2. Connections diagram

Figure 3. Block diagram

SDA

SCL

WP

Interface

V

I2C

DD

OUT

AV

GND

DD

WP

7

7

1

2

3

4

AV

DD

DAC

EEPROM

Block

GND

19R

R

SET

8

SCL

7

SDA

6

V

5

DD

AI12273

OUT

+

–

SET

AI12274

Figure 4. Hardware hookup

3.3V

MCU

2

C Interface

I

SDA

STVM100

SCL

WP

V

DD

V

DD

GND

0.1µF

AV

OUT

SET

DD

R

AV

SET

DD

0.1µF

R

1

+

R

2

–

VCOM

AI12275

6/27 Doc ID 13236 Rev 8

STVM100 Device operation

2 Device operation

The STVM100 operates as a slave device on the serial bus. Access is obtained by

implementing a start condition, followed by the 7-bit slave address (1001111), and the

eighth bit for READ/WRITE identification. The volatile DAC register and non-volatile

EEPROM values can be read out or written in.

2.1 2-wire bus characteristics and conditions

This bus is intended for communication between different ICs. It consists of two lines:

● a bi-directional data signal (SDA).

● a clock signal (SCL).

The SDA and SCL lines must be connected to a positive supply voltage via a pull-up

resistor. The following protocols have been defined:

● Data transfer may be initiated only when the bus is not busy.

● During data transfer, the data line must remain stable whenever the clock line is high.

● Changes in the data line while the clock line is high will be interpreted as control

signals.

2.1.1 Bus not busy

Both data and clock lines remain high.

2.1.2 Start data transfer

A change in the data line state from high-to-low while the clock is high indicate the start

condition.

2.1.3 Stop data transfer

A change in the data line state from low-to-high while the clock is high indicates the stop

condition.

Doc ID 13236 Rev 8 7/27

Device operation STVM100

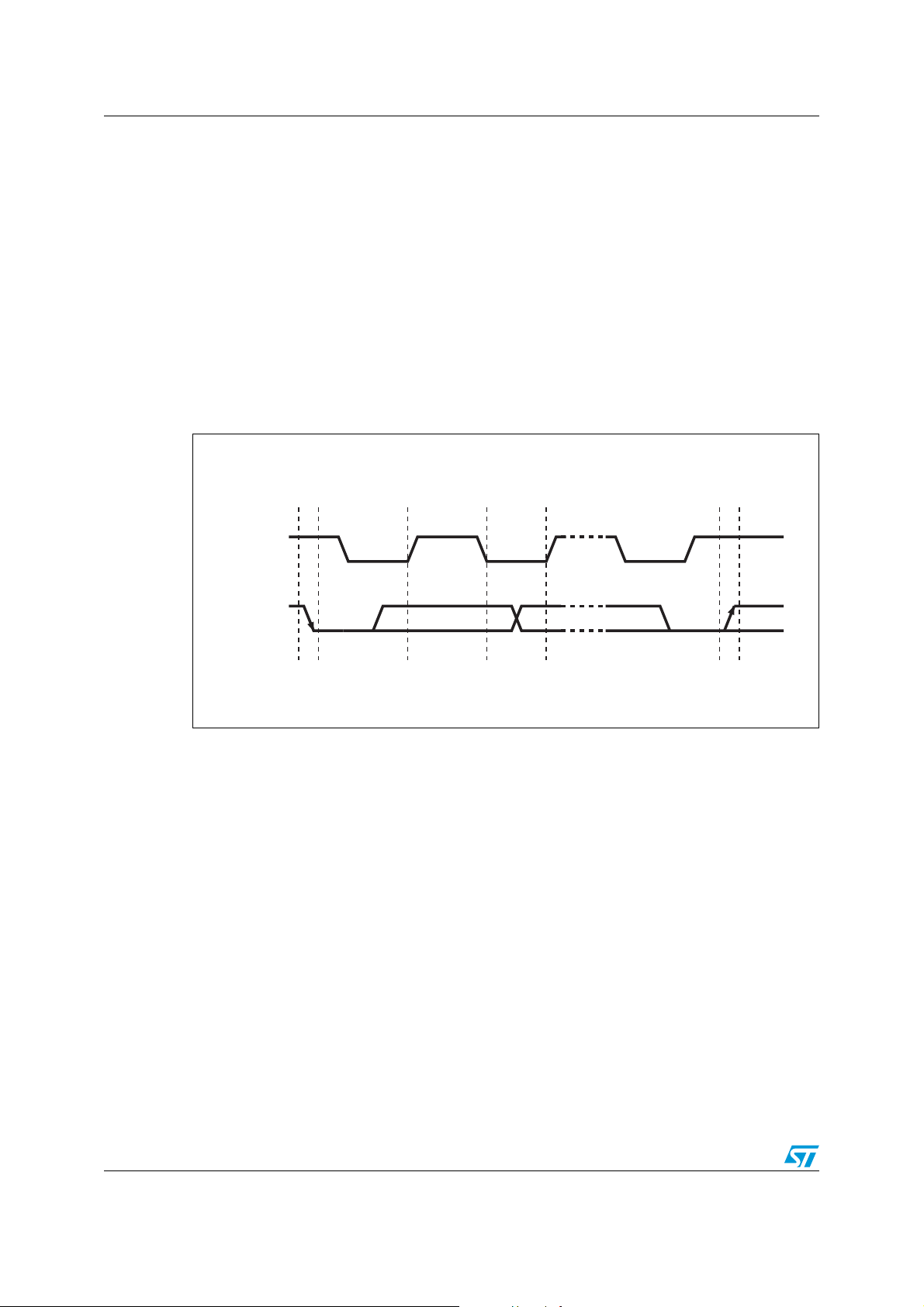

2.1.4 Data valid

The data on the SDA line must be stable during the high period of the clock. The high or low

state of the data line can only change when the clock signal on the SCL line is low (see

Figure 5). The data on the line may be changed during the clock signal low period. There is

one clock pulse per bit of data.

Each data transfer is initiated with a start condition and terminated with a stop condition.

The number of data bytes transferred between the start and stop conditions is not limited.

The information is transmitted byte-wide and each receiver acknowledges transmission with

a ninth bit.

By definition, the device that gives out a message is called “transmitter”, the device that gets

the message is called “receiver”. The device that controls the message is called the

“master”. The devices controlled by the master are called “slave” devices.

Figure 5. Serial bus data transfer sequence

DATA LINE

STABLE

DATA VALID

CLOCK

DATA

START

CONDITION

CHANGE OF

DATA ALLOWED

STOP

CONDITION

AI00587

8/27 Doc ID 13236 Rev 8

STVM100 Device operation

2.1.5 Acknowledge

Each byte of eight bits is followed by one acknowledge bit. This acknowledge bit is a low

level signal put on the bus by the receiver, whereas the master generates an extra

acknowledge-related clock pulse (see Figure 6). A slave receiver which is addressed is

obliged to generate an acknowledge signal after the reception of each byte that has been

clocked out of the slave transmitter.

The device that acknowledges transmissions has to pull down the SDA line during the

acknowledge clock pulse in such a way, that the SDA line is a stable low during the high

period of the acknowledge-related clock pulse. The setup and hold times must be taken into

account. A master receiver must signal an end of transmitted data to the slave transmitter

by not generating an acknowledge on the last byte that has been clocked out of the slave. In

this case, the transmitter must leave the data line high to enable the master to generate the

stop condition.

Figure 6. Acknowledgement sequence

CLOCK PULSE FOR

ACKNOWLEDGEMENT

SCL FROM

MASTER

START

12 89

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

MSB LSB

AI00601

Doc ID 13236 Rev 8 9/27

Device operation STVM100

2.2 Read mode

In READ mode, after the start condition, the master sets the slave address (see Figure 7).

Followed by the READ/WRITE mode control bit (R/W

=1) and the acknowledge bit, the value

in DAC register will be transmitted and the master receiver will send an acknowledge bit to

the slave transmitter. Finally the stop condition will terminate the READ operation. In READ

mode, the valid data is the first 7 bits and the P bit (the eight bit) is don’t care.

2.3 Write mode

In WRITE mode the master transmits to the STVM100 slave receiver. The bus protocol is

shown in Figure 7. Following the start condition and slave address, a logic '0' (R/W

placed on the bus to identify a WRITE operation. After the acknowledgement by the slave,

the data will be transmitted to the slave with the 7-bit which indicates the data is valid as well

as the eighth bit “P” for the register’s identification. When P = 1, the DAC register is written

to, and when P = 0, the EEPROM is written to (Programming). After receiving the data, the

slave will generate an acknowledge signal, then a stop condition will terminate the WRITE

operation. STVM100 is pre-programmed with 80H in the EEPROM after manufacturing.

= 0) is

A period of t

(see Table 8) is needed for EEPROM programming. During this period, the

W

slave will not acknowledge any WRITE operation.

The bit P values in both READ and WRITE modes are shown in Table 3.

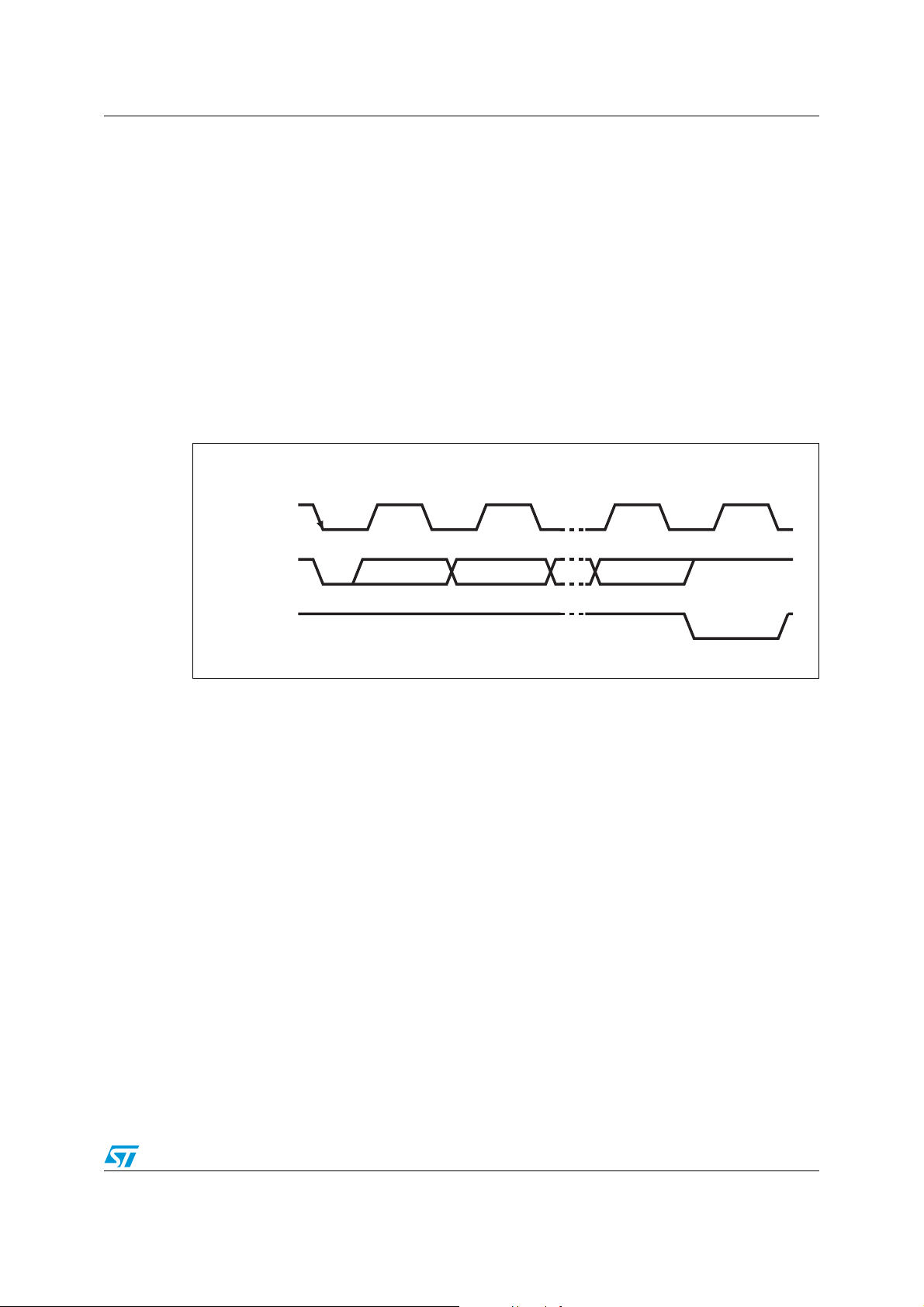

Figure 7. Read/write mode sequence

STA RT SLAVE ADDRESS

1001111

SCL

SDA

Table 3. Bit P read and write mode values

1

001111

STA RT STOP

Operation P-bit value Description

READ X Don’t care

WRITE

R/W

6543 210P

R/W AA6543 210P

A STOP

A

1 DAC register WRITE

0

EEPROM WRITE

(programming)

AI12276_b

2.4 VDD power supply ramp-up

The ramp-up from 10% VDD to 90% VDD level should be achieved in less than or equal to

10ms to ensure that the EEPROM and power-on reset circuits are synchronized, and the

correct value is read from the EEPROM.

10/27 Doc ID 13236 Rev 8

STVM100 Application information

3 Application information

The STVM100 is a programmable V

avoid the “ghosting effect” (residual pixels during refresh) in e-paper and e-books. It

provides a digital I

2

C interface to control the sink current output. This output drives an

external resistive voltage divider, which can then be applied to an external V

The highest and lowest V

value is determined by three resistors, R1, R2, and R

COM

calibrator to remove flickers in TFT-LCDs or to

COM

COM

buffer.

SET

. The

connection is shown in Figure 8.

The sink current from the STVM100 OUT pin is given in Equation 1. This current then flows

through R

Figure 8. R

. This current must be less than 120 µA (see I

SET

, R2, and R

1

connection

SET

AV

DD

AV

DD

STVM100

OUT

SET

R

SET

I

OUT

AV

DD

R1

R2

value in Table 7 on page 15).

SET

+

V

COM

–

AI12933

Note: In order to choose an appropriate device to buffer the output of STVM100, please see our

operational amplifier product portfolio available at:

http://www.st.com/stonline/products/families/amplifiers_comparators/amplifiers_comparators.htm

Equation 1

I

OUT

D1+

-------------128

AV

DD

--------------------------

⋅=

20 R

()

SET

Note: “D” is a user-selected value, an integer ranging from 0 to 127.

The V

value can be obtained in Equation 2.

COM

Equation 2

V

COM

R

2

-------------------R1R2+

⋅=

D1+

⎛⎞

--------------

AV

1

DD

⎝⎠

128

R

1

--------------------------

⋅–

20 R

()

SET

Doc ID 13236 Rev 8 11/27

Application information STVM100

If the user-selected value is 0 (zero scale), the minimum current is sunk. The maximum

V

value is obtained in Equation 3.

COM

Equation 3

V

COM max()

R

2

-------------------R1R2+

⋅=

1

⎛⎞

----------

AV

1

DD

⎝⎠

128

R

1

--------------------------

⋅–

20 R

()

SET

If the user-selected value is 127 (full scale), the maximum current is sunk and the minimum

V

value is obtained in Equation 4.

COM

Equation 4

R

During operation, the V

V

COM min()

COM(max)

-------------------R1R2+

and V

2

⋅=

COM(min)

⎛⎞

AV

1

DD

⎝⎠

range is set, based on different TFT-LCD

processes.The R1 value is given based on the acceptable power loss from the AV

rail. Using Equation 3 and Equation 4, the R

put into Equation 1 on page 11 and maximum I

and R

2

SET

≥ 120 µA, then R1 should be increased.

OUT

R

–

1

-------------------------20 R

()

SET

DD

values can be calculated. If R

supply

is

SET

12/27 Doc ID 13236 Rev 8

STVM100 Maximum ratings

4 Maximum ratings

Stressing the device above the ratings listed in the absolute maximum ratings table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the operating sections of

this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability. Refer also to the STMicroelectronics SURE

Program and other relevant quality documents.

Table 4. Absolute maximum ratings

Symbol Parameter Value Unit

T

STG

T

SLD

T

V

OUT

V

AV

V

SET

Storage temperature (VDD off, AVDD off) –55 to 150 °C

(1)

Lead solder temperature for 10 seconds 260 °C

Maximum junction temperature (plastic package) 150 °C

J

Output voltage (OUT pin to GND) –0.3 to 20 V

VDD to GND +5.5 V

DD

AVDD input voltage to GND –0.3 to 20 V

DD

Output voltage (SET pin to GND) –0.3 to 5.5 V

TDFN8 2.66 W

P

DIS

1. Reflow at peak temperature of 260 °C. The time above 255 °C must not exceed 30 seconds.

Power dissipation

TSSOP8 0.53 W

Doc ID 13236 Rev 8 13/27

DC and AC parameters STVM100

5 DC and AC parameters

This section summarizes the operating measurement conditions, and the dc and ac

characteristics of the device. The parameters in the DC and AC characteristics tables that

follow, are derived from tests performed under the measurement conditions summarized in

Table 5. Designers should check that the operating conditions in their circuit match the

operating conditions when relying on the quoted parameters.

Table 5. Operating and AC measurement conditions

Parameter Conditions Unit

V

supply voltage 2.25 to 3.6 V

DD

EEPROM programming supply voltage 2.25 to 3.6 V

V

DD

AV

reference voltage 4.5 to 20 V

DD

Ambient operating temperature (T

Table 6. Capacitances

Symbol Parameter

) –40 to 85 °C

A

(1)(2)

Min Max Unit

C

b

C

SDA

Bus capacitive load 400 pF

Capacitance on SDA 10 pF

WP = 0 10 pF

C

S

1. Effective capacitance measured with power supply at 3 V. Sampled only, not 100% tested.

2. At 25 °C, f = 1 MHz.

Capacitance on SCL

WP = 1 22 pF

14/27 Doc ID 13236 Rev 8

STVM100 DC and AC parameters

Table 7. DC and AC characteristics

Sym Description Test condition

Supply voltage 2.25 3.6 V

V

EEPROM

DD

programming supply

voltage

(2)

I

DD

AV

I

AVD D

SET

SET

SET

SET

I

SET

SET

AV

SET

OUT

V

SET

V

I

IL(WPN)

V

1. Valid for ambient operating temperature: TA = –40 to 85 °C; VDD = 3 V; AVDD = 10 V; typical TA = 25 °C;

OUT = 1/2AV

2. Simulated maximum current draw when Programming EEPROM is 23 mA; should be considered when

designing a power supply.

3. Tested at AVDD = 20 V.

4. A typical Current of 20 µA is calculated using AVDD = 10 V and R

SET current should be 120 µA.

5. Simulated and determined via design and NOT directly tested.

VDD supply current 50 µA

= 2.6 V to 3.6 V 4.5 20 V

V

Analog supply voltage

DD

(3)

AVDD supply current 25 µA

SET voltage resolution 7 Bits

VR

SET differential

DN

nonlinearity

SET zero scale error ±2 LSB

ZSE

SET full scale error ±8 LSB

FSE

(4)

SET current Through R

SET external

ER

resistance

to

AVDD to SET voltage

DD

attenuation

OUT settling time 8 µs

ST

OUT voltage

OUT

SET voltage drift

VD

SDA, SCL, WP input

IH

logic high

SDA, SCL, WP input

V

IL

logic low

SDA, SCL

hysteresis

(5)

(5)

(5)

DD

V

= 2.25 V to 3.6 V 4.5 13 V

DD

Monotonic over

temperature

To GND, AV

To G ND, AV

T = 25 °C to 55 °C <10 mV

WPN input current 15 25 35 µA

SDA, SCL output logic

OL(s)

low

DD

; R

= 24.9 kΩ (except where noted).

SET

At 3 mA 0.4 V

(1)

Min Typ Max Unit

2.25 3.6 V

±1 LSB

SET

= 20 V 10 200 kΩ

DD

= 4.5 V 2.25 45 kΩ

DD

120 µA

20 V/V

V

+

SET

0.5V

0.7 V

DD

0.22 V

DD

= 24.9 kΩ. The maximum suggested

SET

13 V

0.3V

DD

V

V

V

Doc ID 13236 Rev 8 15/27

DC and AC parameters STVM100

Figure 9. Bus timing requirements sequence

SDA

tHD:STAtBUF

tR

SCL

SP

Table 8. AC characteristics

tF

tHIGH

tLOW

Sym Description Test Condition

f

t

LOW

t

HIGH

t

SU:DAT

t

HD:DAT

SCL clock frequency 0 400 kHz

SCL

Clock low period 1.3 µs

Clock high period 0.6 µs

Data setup time 100 ns

Data hold time 0 900 ns

t

SDA and SCL rise time

R

t

SDA and SCL fall time 300 ns

F

Dependent on load (see

Table 6 on page 14)

tSU:DAT

tHD:DAT

(1)

SR

Min T yp Max Unit

tHD:STA

20 +

0.1 C

b

Bus free time before

t

new transmission can

BUF

1.3 µs

start

t

DSP

t

SU:STA

t

HD:STA

t

SU:STO

1. Valid for ambient operating temperature: TA = –40 to 85 °C; VDD = 3.0 V to 3.6 V; AVDD = 10 V;

OUT = 1/2AVDD; R

I2C spike rejection filter

pulse width

Repeated start

condition setup time

Repeated start

condition hold time

Stop condition setup

time

t

WRITE cycle time 100 ms

W

= 24.9 kΩ (except where noted, see Figure 9).

SET

050ns

0.6 µs

0.6 µs

0.6 µs

tSU:STOtSU:STA

P

AI00589

300 ns

16/27 Doc ID 13236 Rev 8

STVM100 Typical operating characteristics

6 Typical operating characteristics

Typical operating characteristics for the STVM100 are TA = 25 °C, VDD = 3 V, AVDD = 10 V,

OUT = 1/2AV

, and R

DD

= 24.9 kΩ except where noted.

SET

Figure 10. V

Figure 11. AV

(µA)

AVDD

I

supply current vs. V

DD

27. 5

27

26.5

26

(µA)

DD

I

25.5

25

24.5

24

.2. 2 2.4 2.6 2.8 3.0 3.2 3.4 3.6

supply current vs. AV

DD

10

9

8

7

6

5

4

3

2

1

0

4.5 6 7.5 9 10.5 12 13.5 15 16.5 18 19.5

DD

V

DD

DD

(V)

AI13362

AVDD (V)

AI13363

Doc ID 13236 Rev 8 17/27

Typical operating characteristics STVM100

Figure 12. VDD supply current vs. temperature

35

30

(µA)

25

DD

I

20

15

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

Figure 13. AV

Temperature°C

supply current vs. temperature

DD

4.95

4.9

4.85

4.8

(µA)

4.75

4.7

AVDD

I

4.65

4.6

4.55

4.5

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

Temperature°C

AI13364

AI13365

18/27 Doc ID 13236 Rev 8

STVM100 Typical operating characteristics

Figure 14. I

error vs. temperature (STVM100 at middle scale)

OUT

0.06

0.05

0.04

0.03

error (LSB)

0.02

OUT

I

0.01

0

-40 -20 0 20 40 60 80

Temperature°C

Figure 15. Total unadjusted error vs. DAC setting

0.022474

AI13366

0.020395

0.018316

0.016237

0.014158

0.012079

Total unadjusted error (LSB)

0.01

1 173349 658197113

DAC setting (decimal)

AI13367

Doc ID 13236 Rev 8 19/27

Typical operating characteristics STVM100

Figure 16. Differential non-linearity vs. DAC setting

0.2

0.15

0.1

0.05

0

-0.05

-0.1

Differential non-linearity (LSB)

-0.15

-0.2

1 17334965 8197113

DAC setting (decimal)

AI13368

Figure 17. Integral non-linearity vs. DAC setting

0.3

0.2

0.1

0

-0.1

-0.2

Integral non-linearity (LSB)

-0.3

1 173349658197113

DAC setting (decimal)

AI13369

20/27 Doc ID 13236 Rev 8

STVM100 Typical operating characteristics

Figure 18. AVDD power-up response

AV

: 5V/DIV, VDD: 5V/DIV, V

DD

Figure 19. Full scale-up response

5ms/DIV

OUT

: 1V/DIV, V

SET

: 1V/DIV

20µs/DIV

SCL: 5V/DIV, SDA: 5V/DIV, V

Doc ID 13236 Rev 8 21/27

: 1V/DIV, V

OUT

SET

: 1V/DIV

Typical operating characteristics STVM100

Figure 20. Full scale-down response

20µs/DIV

SCL: 5V/DIV, SDA: 5V/DIV, V

: 1V/DIV, V

OUT

SET

: 1V/DIV

22/27 Doc ID 13236 Rev 8

STVM100 Package mechanical data

7 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

Figure 21. TDFN8 3 x 3 x 0.75 mm, pitch 0.65, package mechanical data

Note: Drawing is not to scale.

Table 9. TDFN8 3 x 3 x 0.75 mm, pitch 0.65, package mechanical data

A

E2

E

A3 A1

D

D2

1

8

e

L

b

0.08

EZ_ME

mm inches

Sym

Typ Min Max Typ Min Max

A 0.75 0.70 0.80 0.0295 0.0276 0.0315

A1 0.02 0.00 0.05 0.0008 0.0000 0.0020

A3 0.20 0.0079

b 0.30 0.25 0.35 0.0118 0.0098 0.0138

D 3.00 0.1181

D2 2.38 2.23 2.48 0.0937 0.0878 0.0976

E 3.00 0.1181

E2 1.64 1.49 1.74 0.0646 0.0587 0.0685

e0.65– –0.0256– –

L 0.40 0.30 0.50 0.0157 0.0118 0.0197

Doc ID 13236 Rev 8 23/27

Package mechanical data STVM100

Figure 22. TSSOP8 – 8-lead, thin shrink small outline, 3 mm x 3 mm, mech. data

D

CP

Note: Drawing is not to scale.

Table 10. TSSOP8 – 8-lead, thin shrink small outline, 3 mm x 3 mm, mech. data

Sym

Typ Min Max Typ Min Max

A 1.100 0.0433

A1 0.050 0.150 0.0020 0.0059

A2 0.850 0.750 0.950 0.0335 0.0295 0.0374

b 0.250 0.400 0.0098 0.0157

c 0.130 0.230 0.0051 0.0091

8

1

5

EE1

4

A2A

A1

eb

L

L1

c

TSSOP8BM

mm inches

CP 0.100 0.0039

D 3.000 2.900 3.100 0.1181 0.1142 0.1220

e 0.650 – – 0.0256 – –

E 4.900 4.6500 5.150 0.1929 0.1831 0.2028

E1 3.000 2.900 3.100 0.1181 0.1142 0.1220

L 0.550 0.400 0.700 0.0217 0.0157 0.0276

L1 0.950 0.0374

α 0° 6° 0° 6°

N8 8

24/27 Doc ID 13236 Rev 8

STVM100 Part numbering

8 Part numbering

Table 11. Ordering information scheme

Example: STVM100 DC 6 F

Device type

STVM100, V

Package

DC = TDFN8

DS = TSSOP8

Temperature range

6 = –40 to 85°C

calibrator with 7-bit DAC and I2C interface

COM

Shipping method

E = ECOPACK

F = ECOPACK

®

package, tubes

®

package, tape & reel

For other options, or for more information on any aspect of this device, please contact the

ST sales office nearest you.

Doc ID 13236 Rev 8 25/27

Revision history STVM100

9 Revision history

Table 12. Document revision history

Date Revision Changes

09-May-2006 1 Initial release.

14-Jul-2006 2 Graphical and textual updates

Document status upgraded to Preliminary Data; changed the

wording of Input function to include ‘WRITE operations’ instead of

‘programming’ in Table 2: Pin names and functions; deleted some

bracketed text and modified the P bit function in Section 2.2: Read

08-Nov-2006 3

12-Feb-2007 4

20-Apr-2007 5 Value added in Section 2.3: Write mode.

24-Jul-2007 6 Document status upgraded to full datasheet.

mode; ensured that all of Equation 2 and Equation 3 were visible;

amalgamated 2 cells containing the same information (VDD) in

Table 7: DC and AC characteristics; deleted footnotes 2 and 3 of

Table 8: AC characteristics; updated package mechanical

information in Figure 21, Table 9, and Table 10.

Reformatted inside cover page according to new template; renamed

section 1 Device overview and section 2 Device operation; deleted

Signal names table; moved and renamed Table 2: Pin names and

functions, addedSection 6: Typical operating characteristics and

Figure 10 to Figure 20.

04-Nov-2009 7

09-Dec-2009 8

Added “Note” to Figure 8; updated footnote of Table 4; minor textual

changes.

Updated title of datasheet, Applications, Description, and Section 3:

Application information.

26/27 Doc ID 13236 Rev 8

STVM100

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR E QUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 13236 Rev 8 27/27

Loading...

Loading...