STV7622

DB1

DB2

DB3

DB4

DB5

DB6

BS1 BS2 DIR CLK1 CLK2 VDD

/STB1

/BLK

POC

OUT1 OUT2 OUT3 ….. …. OUT192

VSSSUB

VCC

Shift register direction

Data decoding

VSSLOG

TEST1

TEST2

VREF

10nF

RS1

RS2

FS1

FS2

Output control / EMI control

VPP

VSSP

Output buffer stage

/STB2

Latch

Q1 Q2 Q3 Q4 Q192

32-bit Shift register

32-bit Shift register

32-bit Shift register

32-bit Shift register

32-bit Shift register

32-bit Shift register

3/6/2x3-bit & RSDS

selection

192 output plasma display panel data driver

Preliminary Data

Features

■

192 high-voltage outputs

■

Output pad placements: I-shape

■

90V absolute maximum supply

■

EMI control features:

– SmartSlope

– ConstantSlope

– Spread Spectrum Jitter (SSJ)

■

Configurable data bus:

– 3, 6 or 2 × 3 bits

– TTL and LVCMOS compatible

– RSDS mode

– Single- or dual-edge clocking mode

– 60MHz clock frequency

■

3.3/5V CMOS logic compatible

■

- 60/+24mA source/sink output current

capability

■

BCD Process

■

Packaging according to customer request:

wafer, die, bumped die/wafer, TCP or COF

The input data bus is configured by dedicated

input pins:

●

BS1 and BS2: bus width select (3, 6,

2 × 3 bits or RSDS mode)

●

DIR input: shift register loading direction

The STV7622 output stage integrates several ST

patented functions aimed at reducing EMI without

compromising addressing speed or performance

of the PDP modules.

These functions mainly consist of:

●

SmartSlope: controls the output falling edge

speed /shape

●

ConstantSlope: controls the output rising

edge speed

●

Spread Spectrum Jitter (SSJ): controls the

spread of the output rising edge

The STV7622 is powered by a separate 70V

supply for the high-voltage outputs and a 5V

supply for the logic. All command input levels are

5V CMOS as well as 3.3V compatible.

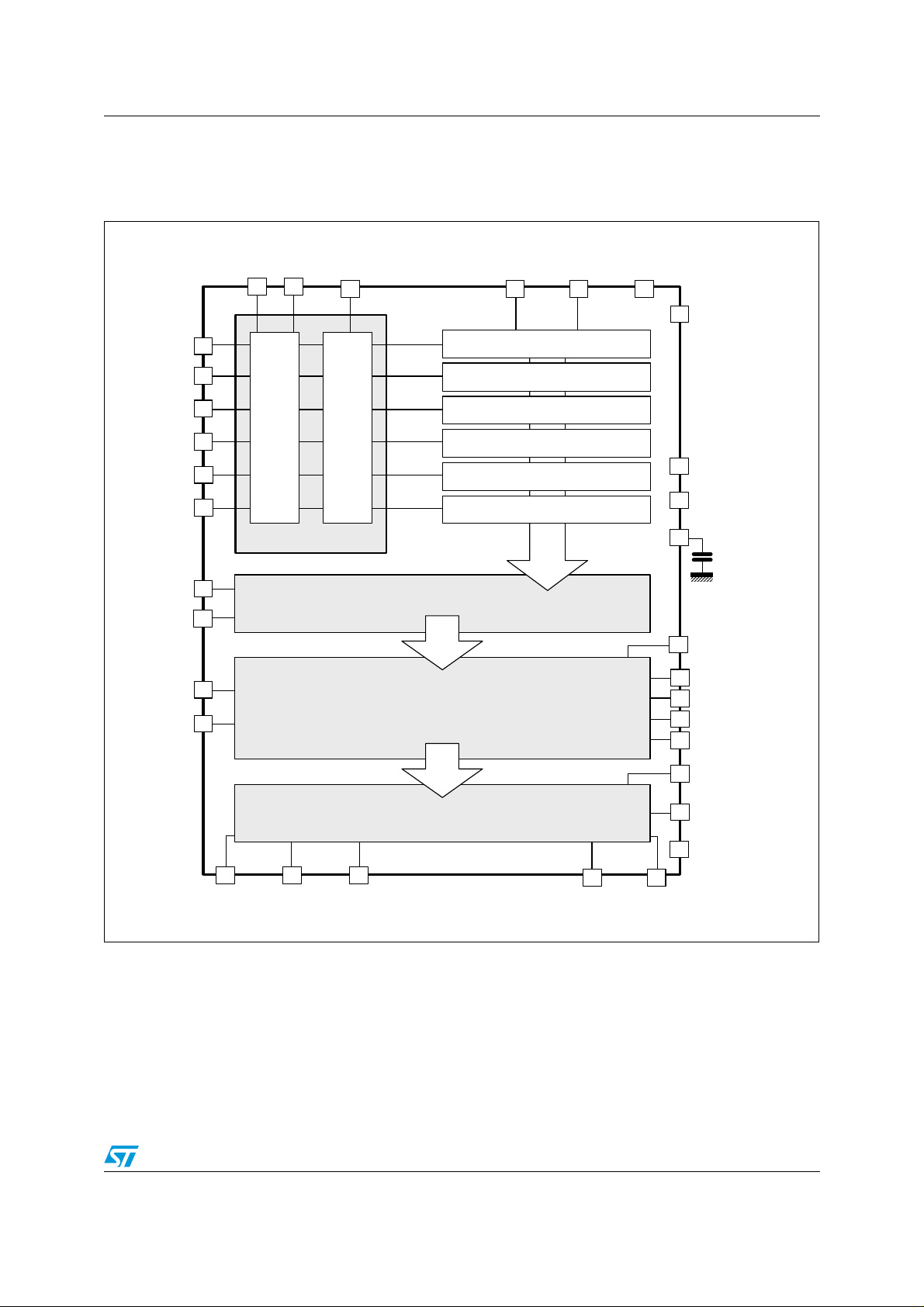

Figure 1. Block diagram

Description

The STV7622 is a data driver for Plasma Display

Panels (PDP) designed in the ST’s proprietary

BCD high-voltage technology.

It controls up to 192 outputs via an input data bus

(3, 6 or 2 × 3-bits wide) operating at up to 60MHz.

This large number of outputs reduces the number

of connections between the controller board and

the data driver ICs.

The STV7622 contains a new logic input stage

that minimizes EMI resulting from the

transmission of high speed TTL or LVCMOS data

and clock signals. This new input stage is RSDS

compliant. It enables increasing the operating

frequency without compromising noise immunity.

May 2007 Rev 1 1/32

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

www.st.com

32

Contents STV7622

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Output stage description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Pinout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.1 Data input block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2 3 x 64-bit data bus, standard transmission (BS1 = H, BS2 = L) . . . . . . . . . 8

5.3 6 x 32-bit data bus, standard transmission (BS1 = L, BS2 = L) . . . . . . . . . 8

5.4 2 x 3 x 32-bit data bus, standard transmission (BS1 = H, BS2 = H) . . . . . 9

5.5 Differential transmission mode: RSDS (BS1 = L, BS2 = H) . . . . . . . . . . . 10

5.6 Power output block and EMI control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Truth tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9 AC timing requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10 AC timing characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Pad dimensions and positions (in µm) . . . . . . . . . . . . . . . . . . . . . . . . . 22

12 Tested wafer disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

13 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

14 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2/32

STV7622 Block diagram

DB1

DB2

DB3

DB4

DB5

DB6

BS1 BS2 DIR CLK1 CLK2 VDD

/STB1

/BLK

POC

OUT1 OUT2 OUT3 ….. …. OUT192

VSSSUB

VCC

Shift register direction

Data decoding

VSSLOG

TEST1

TEST2

VREF

10nF

RS1

RS2

FS1

FS2

Output control / EMI control

VPP

VSSP

Output buffer stage

/STB2

Latch

Q1 Q2 Q3 Q4 Q192

32-bit Shift register

32-bit Shift register

32-bit Shift register

32-bit Shift register

32-bit Shift register

32-bit Shift register

3/6/2x3-bit & RSDS

selection

1 Block diagram

Figure 2. STV7622 block diagram

3/32

Pin description STV7622

2 Pin description

Table 1. Pin description

VPP Supply DC high-voltage supply of power outputs

VCC Supply Analog 5V supply

VDD Supply Digital 5V supply

VSSP Ground Ground for power outputs

VSSSUB Ground Substrate ground

VSSLOG Ground Ground for 5V logic

OUT1 to OUT192 Outputs Power outputs

DB1to DB6 Inputs Shift register inputs

/BLK Input Blanking input

POC Input Power output control input

DIR Input Selection of shift register direction

BS1 and BS2 Inputs Shift register configuration pins (3/6/2 × 3-bits and RSDS selection)

CLK1 and CLK2 Inputs Clock for data shift register

/STB1 and /STB2 Inputs Latch of data to power outputs

RS1 and RS2 Inputs Output rise time selection pins

Pin name Function Description

FS1 and FS2 Inputs Output “slow-slope” fall time selection pins

TEST1 Test pin Must be grounded

TEST2 Test pin Must be grounded

VREF Input

Filter for internal reference - must be connected to ground via a 10nF

capacitor

Note: Inputs /BLK, /STB1 and /STB2 are active Low.

4/32

STV7622 Output stage description

VCC VPP

Output control

Totem

pole

Output 1

to 192

VSSP

OUTn

Output stage

T1

T3

Rising edge

control

Falling edge

control

T4

T2

Delay

Rise time

RS1/RS2

Fall time

FS1/FS2

VCC

3 Output stage description

Figure 3. Output stage description

5/32

Pinout description STV7622

DB6

DB5

DB4

DB3

DB2

DB1

/STB2

/STB1

CLK2

CLK1

VDD3

/BLK

VSSLOG3

POC

VDD4

DUMMY

DUMMY

VREF

DUMMY

VSSLOG4

RS1

VDD5

RS2

VSSLOG5

FS2

VDD6

FS1

VSSLOG6

DIR

VDD7

BS1

VSSLOG7

BS2

VDD8

TEST1

TEST2

DUMMY

DUMMY

DUMMY

DUMMY

DUMMY

DUMMY

DUMMY

DUMMY

VSSP1

VSSP2

VSSP3

VPP1

VPP2

VPP3

DUMMY

VSSLOG1

VSSSUB1

VDD1

VCC1

VSSP4

VSSP5

VSSP6

VPP4

VPP5

VPP6

DUMMY

VSSLOG2

VSSSUB2

VDD2

VCC2

DUMMY

OUT192

OUT191

OUT190

OUT189

OUT188

OUT187

OUT186

OUT185

OUT184

OUT183

OUT182

OUT181

OUT180

OUT12

OUT11

OUT10

OUT9

OUT8

OUT7

OUT6

OUT5

OUT4

OUT3

OUT2

OUT1

Y

X

0/0

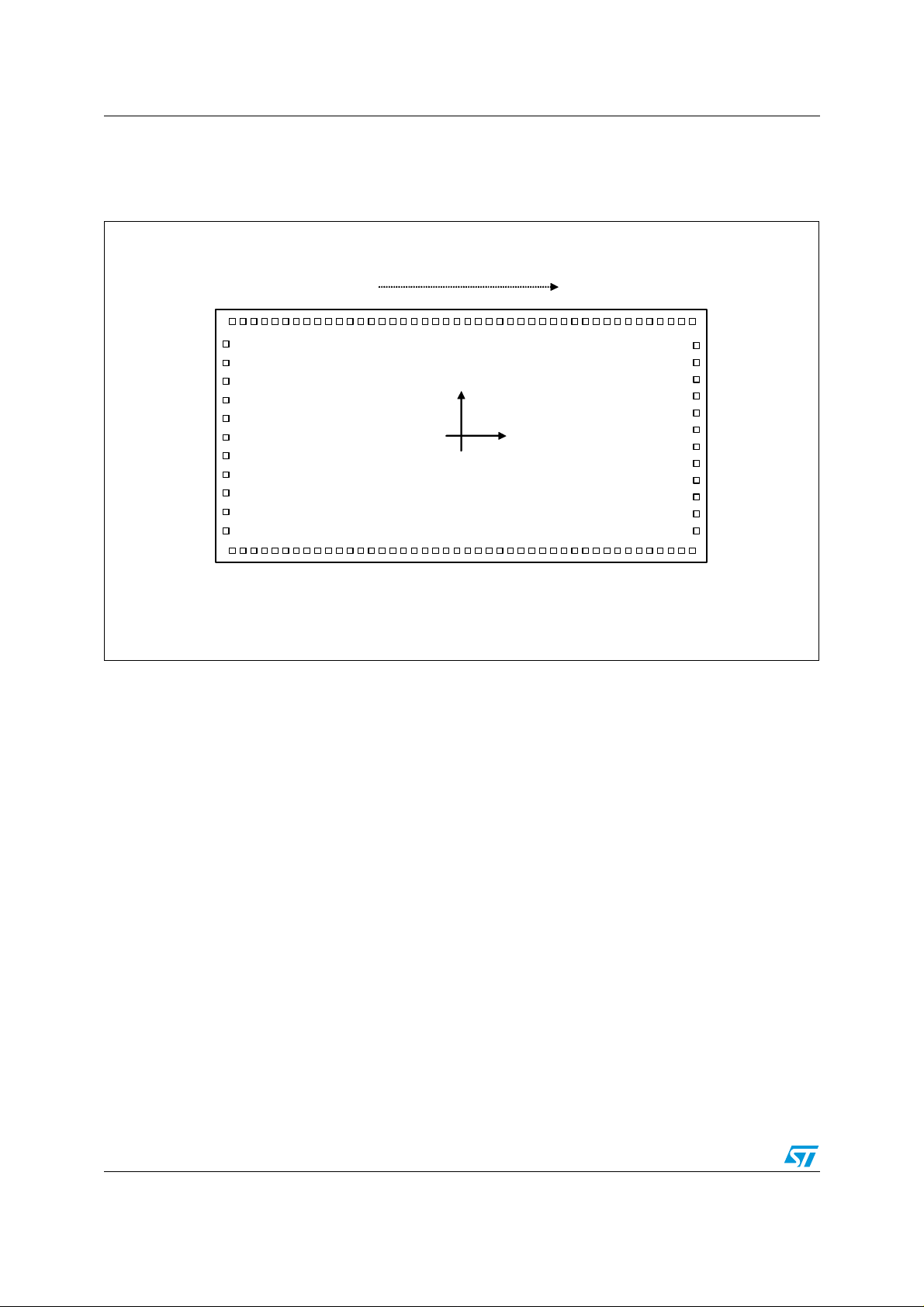

4 Pinout description

Figure 4. Pinout diagram

In the pinout diagram of Figure 4 above:

●

VDD1 to VDD8 are internally connected. It is not necessary to connect them together

on the tape carrier package (TCP) - the same applies to VCC1 and VCC2.

●

VSSLOG1 to VSSLOG2 are internally connected. It is not necessary to connect them

together on the TCP - the same for VSSSUB1 and VSSSUB2.

●

VSSLOG1 to VSSLOG7 are not internally connected to VSSSUB1 and VSSSUB2. We

recommend shorting them together very close to the die, either on the TCP or at the

TCP connector.

●

VDD1 to VDD8 are not internally connected to VCC1 and VCC2. For good test

coverage, they must not be shorted together on the TCP. In the application, VDD1 to

VDD8, VCC1 and VCC2 must be connected together at the TCP connector level.

●

TEST1 and TEST2 are used to test the device. For good test coverage, they must not

be shorted together on the TCP. In the application, TEST1 and TEST2 must be

6/32

grounded at the TCP connector level.

●

VREF must be connected to ground via a 10nF filter capacitor.

STV7622 Circuit description

5 Circuit description

The STV7622 includes all the logic and power circuits necessary to drive the column

electrodes of a Plasma Display Panel (PDP). A low-voltage logic block manages data

information, and a high-voltage block converts the low-voltage information stored in the logic

block into high-voltage signals applied to the display electrodes.

5.1 Data input block

The Data Bus is TTL- and LVCMOS-compatible and can also operate in an RSDS (Reduced

Swing Differential Signaling) mode. The maximum clock frequency is 60MHz.

The data input block consists of several shift registers operating in parallel to load the binary

values of the digital video. The number of cells in each shift register is defined by the BS pin

as described below in Table 2.

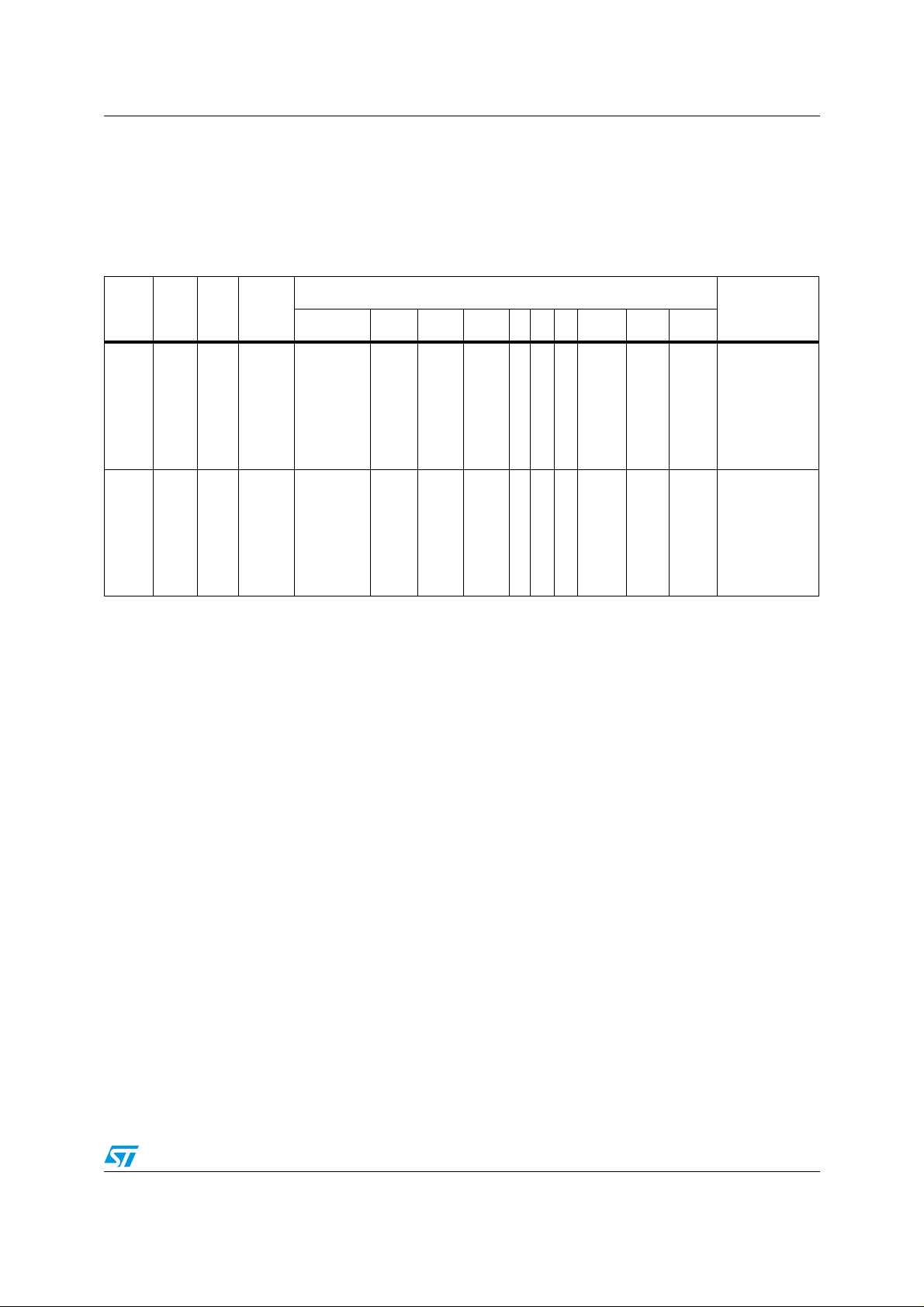

Table 2. BS1/BS2 truth table

BS1 BS2 Shift register configuration

L L 6 × 32 bits

H L 3 × 64 bits

L H RSDS mode

H H 2 × 3 × 32 bits (96 + 96)

For the 3 × 64 bit configuration, only pins DB1, DB2 and DB3 of the input data bus are used,

while for the 6 × 32 and 2 × 3 × 32 bit configurations all 6 bits of the input data bus input,

pins DB1 to DB6, are used.

The DIR input pin is used to select the shift register loading direction.

Data is shifted for each low-to-high transition of the clock signal (CLK1). The maximum

frequency of the clock is 60MHz, which is equivalent to a 360MHz serial shift register for a

6 × 32-bit arrangement.

When the /STB signal goes from high-to-low, data is transferred from the shift register to the

latch and to the power output stages. All output data is stored and held in the latch stage

when the latch input is pulled back High.

The core of the STV7622 is powered by 5V. All logic inputs can be driven either by 5V or

3.3V CMOS logic.

The tables in the following sections describe the position of the first data sampled by the first

rising edge of the CLK1 clock.

7/32

Circuit description STV7622

5.2 3 x 64-bit data bus, standard transmission (BS1 = H, BS2 = L)

The data bus is in 3-bit mode (DB1 to DB3 active) for BS1 = H and BS2 = L.

Data on DB1 is sampled by the first clock pulse and shifted from position 1 to position 190

after 64 clock pulses. The data is then applied to output 190, on the high-to-low transition of

/STB.

Table 3. 3 x 64-bit data bus transmission

BS1 BS2 DIR Input

Clock pulse number

Comment

Position 01 02 03 … 62 63 64

H L L

H L H

DB1

DB2

DB3

DB1

DB2

DB3

OUT

OUT

OUT

OUT

OUT

OUT

01

02

03

190

191

192

04

05

06

187

188

189

07

08

09

184

185

186

184

185

186

07

08

09

187

188

189

04

05

06

190

191

192

01

02

03

Left/Right

shift

Right/Left

shift

5.3 6 x 32-bit data bus, standard transmission (BS1 = L, BS2 = L)

The data bus is in 6-bit mode (DB1 to DB6 active) for BS1 = L and BS2 = L.

Table 4 below describes how data is shifted in the register.

Table 4. 6 x 32-bit data bus transmission

BS1 BS2 DIR Input

L L L

DB1

DB2

DB3

DB4

DB5

DB6

Position 01 02 03

Clock pulse number

OUT

OUT

OUT

OUT

OUT

OUT

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

…

30 31 32

175

181

187

176

182

188

177

183

189

178

184

190

179

185

191

180

186

192

Comment

Left/Right

shift

DB1

DB2

L L H

8/32

DB3

DB4

DB5

DB6

OUT

OUT

OUT

OUT

OUT

OUT

187

188

189

190

191

192

181

182

183

184

185

186

175

176

177

178

179

180

13

14

15

16

17

18

07

08

09

10

11

12

01

02

03

04

05

06

Right/Left

shift

STV7622 Circuit description

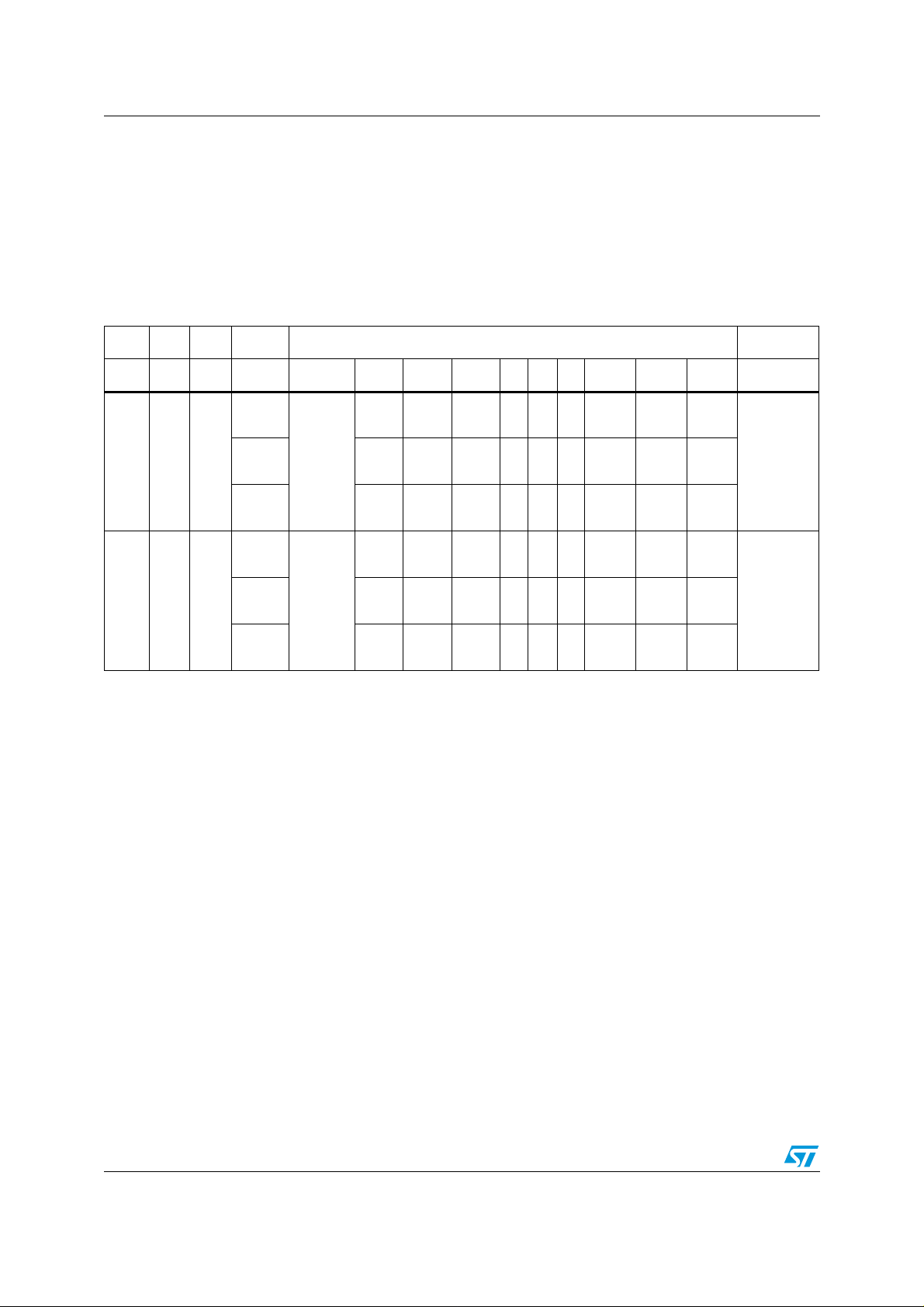

5.4 2 x 3 x 32-bit data bus, standard transmission (BS1 = H, BS2 = H)

The data bus is in 2 × 3-bit mode (DB1 to DB6 active) for BS1 = H and BS2 = H. Table 5

below describes how data is shifted in the register.

Table 5. 2 x 3 x 32-bit data bus transmission

BS1 BS2 DIR Input

Clock pulse number

Comment

Position 01 02 03

…

30 31 32

H H L

H H H

DB1

DB2

DB3

DB4

DB5

DB6

DB1

DB2

DB3

DB4

DB5

DB6

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

01

02

03

97

98

99

94

95

96

190

191

192

04

05

06

100

101

102

91

92

93

187

188

189

07

08

09

103

104

105

88

89

90

184

185

186

88

89

90

184

185

186

07

08

09

103

104

105

91

92

93

187

188

189

04

05

06

100

101

102

94

95

96

190

191

192

01

02

03

97

98

99

Left/Right shift

Right/Left shift

9/32

Circuit description STV7622

5.5 Differential transmission mode: RSDS (BS1 = L, BS2 = H)

In differential transmission mode, data is transmitted on two wires, one line transmits the

data value, the other the inverted data. The logic level of the data is determined by the

difference between data and inverted data. Two DB inputs are needed for the transmission

of 1 data value. The sampling clocks, CLK1 and CLK2, as well as strobes STB1/ and STB2

are also transmitted differentially. Data is sampled on the rising and falling edges of the

clock.

Table 6. 2 x 3 x 32-bit data bus transmission - differential mode

BS2 B12 DIR Input CLK1 clock pulse number Comment

H L L

H L H

In differential transmission operating mode, the biasing of the data input bus must be

carefully arranged to reduce static power consumption. In stand-by and non-active modes,

DB1, DB3, DB5, CLK1 and /STB1 should be set High to reduce bias current in the

differential input buffers.

For a High level, all differential pairs should be configured with DB1, DB3, DB5, CLK1 and

/STB1 High and with DB2, DB4, DB6, CLK2 and /STB2 Low.

When operating in differential transmission mode, a 100 ohm (1%) resistor termination must

be connected between:

●

●

●

●

●

Position 01↑ 01↓ 02↑

DB1

DB2

DB3

DB4

DB5

DB6

DB1

DB2

DB3

DB4

DB5

DB6

OUT

OUT

DB1 and DB2

DB3 and DB4

DB5 and DB6

CLK1 and CLK2

STB1 and STB2

…

01 04 07 184 187 190

02 05 08 185 188 191

03 06 09 186 189 192

190 187 184 07 04 01

191 188 185 08 05 02

192 189 186 09 06 03

31↓ 32↑ 32↓

Left/Right

shift

Right/Left

shift

with each resistor placed as close as possible to the STV7622 itself.

10/32

STV7622 Circuit description

t

PLHD

90%

10%

50%

OUTn

0 0

1.4V

1.0V

V

IA

V

IB

V

ID

10%

90%

50%

0.4V

-0.4V

t

PHLD

t

FD

t

RD

Video board

Data driver

board

DB1-DB2

DB3-DB4

DB5-DB6

CLK1-CLK2

STB1-STB2

STLVD31

STV7622

TCP

DB1-DB2

DB3-DB4

DB5-DB6

CLK1-CLK2

DB1-DB2

STLVD31

STV7622

TCP

DB1-DB2

DB3-DB4

DB5-DB6

CLK1-CLK2

DB1-DB2

STLVD31

STV7622

TCP

Display controller

100Ω

DB1-3-5

Differential

input buffer

V

0

V

IB

V

ID

DB2-4-6

(=DB1-3-5)

V

IA

Figure 5. Differential input buffer - waveform timing

11/32

Circuit description STV7622

90%

10%

t

F-SLOW

t

F-OUT

100ns01

200ns11

50ns10

10ns00

t

F-SLOW

FS1FS2

90%

10%

t

R-OUT

R

S

1

=

1

R

S

2

=

1

R

S

1

=

0

R

S

2

=

0

400ns01

560ns11

230ns10

120ns00

t

R-OUT

RS1RS2

5.6 Power output block and EMI control

The high-voltage output stage has a totem pole structure (see Figure 3). The capacitive load

is charged to Vpp by the high-side N-channel transistor, T1, and discharged to ground by

the low-side N-channel transistor, T2. The status of the power outputs can also be controlled

by the configuration pins, POC and /BLK, which can set the power outputs either all High or

all Low.

Several functions, patented by STMicroelectronics, are implemented in the STV7622 to

reduce EMI:

SmartSlope: The falling edge of the output pulse consist of 2 slopes (Figure 6 below): a

smooth slope followed by a steeper one (typically 4 times faster) The duration of the first

slope is set by two logic inputs, FS1 and FS2, according to the table in Figure 6.

Figure 6. Output falling edge

ConstantSlope: The duration of the output rising edge (Figure 7) is kept constant

independent of the value of the capacitive load connected to the output. This solution

minimizes the peak current in the power outputs as well as any oscillation phenomenon in

the power supplies. In addition, it reduces high-frequency components of the EMI spectrum

by suppressing very rapid rising edge transitions on the power outputs. The total duration of

the rising edge (t

) is set by another pair of logic inputs, RS1 and RS2, according to the

R-OUT

table in Figure 7 below.

Figure 7. Output rising edge

12/32

STV7622 Circuit description

OUT-1

OUT-x

t

SSJ-MIN

t

SSJ-MAX

OUT-1

OUT-x

Case #1: Dark picture Case #2: White picture

Spread Spectrum: To avoid having too large of a current in the driver during the rising edge

of the power outputs, all outputs are not triggered at the same time.

Instead, the STV7622 inserts a small delay between the rising edge of two consecutive

outputs. This delay depends on picture or image content (see Figure 8). For a dark picture,

we have t

SSJ-MIN

picture, we have t

= 1 to 2ns (typ.) between output 1 and any output X, while for a white

SSJ-MAX

= 100ns (typ.).

The SSJ function spreads the discharge current in the scan lines and, therefore, reduces

EMI by “spreading” the energy spectrum.

Figure 8. Spread spectrum filter

13/32

Truth tables STV7622

6 Truth tables

Table 7. Shift register truth table

Input pins Shift register function

BS2 BS1 DIR CLK1 CLK2

(1)

L L L N.C.

L L L H or L N.C. Steady

L L H N.C.

L L H H or L N.C. Steady

L H L N.C.

L H L H or L N.C. Steady

L H H N.C.

L H H H or L N.C. Steady

H L L

Q output

Left/Right shift

DB1,2,…6 input pins, 6 × 32-bit mode

Right/Left shift

DB1,2,…6 input pins, 6 × 32-bit mode

Left/Right shift

DB1,2,3 input pins, 3 × 64-bit mode

Right/Left shift

DB1,2,3 input pins, 3 × 64-bit mode

Left/Right shift

DB1,2,…6 input pins, RSDS mode

H L L H or L L or H Steady

H L H

H L H H or L L or H Steady

H H L N.C.

H H L H or L N.C. Steady

H H H N.C.

H H H H or L N.C. Steady

1. CLK2 is not used in LVCMOS operating mode and can be left “open” or “floating”.

Right/Left shift

DB1,2,…6 input pins, RSDS mode

Left/Right shift, DB1,2,… 6 input pins,

2 × 3 × 32-bit mode

Left/Right shift, DB1,2,…6 input pins,

2 × 3 × 32-bit mode

14/32

STV7622 Truth tables

Table 8. Truth table for power outputs

(1)

Q

n

/STB1 /STB2

(2)

BS1 BS2 /BLK POC

Driver

output

Note Comments

X X X X X L X all L Output at Low level

X X X X X H L all H Output at High level

X H X L L H H Q

X H L L H H H Q

X H X H L H H Q

X H X H H H H Q

L L X L L H H L

H L X L L H H H

L L H L H H H L

H L H L H H H H

L L X H L H H L

H L X H L H H H

L L X H H H H L

H L X H H H H H

n

n

n

n

(3)

Data latched

(4)

Data latched

(5)

Data latched (RSDS)

(6)

Data latched

(3)

Data copied

(3)

Data copied

(4)

Data copied (RSDS)

(4)

Data copied (RSDS)

(5)

Data copied

(5)

Data copied

(6)

Data copied

(6)

Data copied

1. Qn is the state of the shift register output (Figure 2). “X” means either High or Low (H or L).

2. /STB2 is not used in LVCMOS operating mode and can be left “open” or “floating”.

3. Q

4. RSDS mode: Q

5. Q

6. Q

n + 1

n + 1

n + 1

= DB1, Q

= DB1, Q

= DB1, Q

n + 2

n + 1

n + 2

n + 2

= DB2, Q

= DB1, Q

= DB2, Q

= DB2, Q

= DB3, Q

n + 3

= DB2, Q

n + 1

= DB3; n = {0, 3, 6, 9, … 186, 189}.

n + 3

= DB3, Q

n + 3

n + 4

n + 2

n + 97

= DB4, Q

= DB3, Q

= DB4, Q

n + 2

n + 5

n + 98

= DB5, Q

= DB4, Q

= DB5, Q

= DB6; n = {0, 6, 12, 18, … 186}.

n + 6

= DB5, Q

n + 3

n + 99

n + 3

= DB6; n = {0, 3, 6, 9, … 186, 189}.

= DB6; n = {0, 6, 12, 18, … 186}.

15/32

Absolute maximum ratings STV7622

7 Absolute maximum ratings

Table 9. Absolute maximum ratings

Symbol Parameter Value Units

Vdd Digital supply range -0.3, +7 V

Vcc Analog supply range -0.3, +7 V

Vpp Driver supply range -0.3, +90 V

Vin Logic input voltage range -0.3, Vcc+0.3 V

Ipout Driver output current x

Idout Diode output current

Vout Output power voltage range -0.3, +90 V

ESD susceptibility, Human Body Model (100pF

V

ESD

discharged through 1.5Kohms), on all except the VCC

(4)

pins

Tjmax Maximum junction temperature 100 °C

(1), (2), (3)

(1), (2), (3)

- 70/+35 mA

-200/+300 mA

2 KV

Tstg Storage temperature range -50, +150 °C

1. Measurements done on one single output, x. The other outputs are either not used or are connected to output x. Assumes

junction temperature remains less than Tjmax during measurement.

2. All transient current measurements are made under conditions close to those encountered in a typical application (that is,

with duration of any output current spike always less than 300 ns).

3. These parameters are measured during STMicroelectronics’ internal qualification which includes temperature

characterization on standard as well as corner batches of the process. These parameters are not tested in production.

4. VCC pins withstand 1.3 KV.

16/32

STV7622 Electrical characteristics

8 Electrical characteristics

VCC = VDD = 5V, VPP = 70V, VSSP = VSSLOG = VSSSUB = 0V, T

f

= 50MHz, unless otherwise specified.

CLK

Table 10. Electrical characteristics

AMB

= 25°C,

Symbol Parameter Min. Typ. Max. Units

Supply

Vdd Digital supply voltage 4.50 5 5.5 V

Idd Digital supply current

Iddl Digital Dynamic Supply Current (CLK1 freq = 20MHz)

(1)

(2)

- 10 µA

- 15 20 mA

Idd Digital Supply Current @ VIH = 2.0V 250 500 900 µA

Vcc Analog supply voltage 4.50 5 5.5 V

Icc_1 Analog supply current in standard transmission mode - 1.1 2 mA

Analog supply current in RSDS mode (that is, with

Icc_2

BS1 = BS2 = L) and with DB1, DB3, DB5, CLK1 and

/STB1 less than DB2, DB4, DB6, CLK2 and /STB2,

- 5 10 mA

respectively

Vpp DC power output supply voltage 15 80 V

Ipph-1

Ipph-2

Power output supply current (steady outputs)

@ VCC = 0V

Power output supply current (steady outputs)

@ VCC = 5V and RS1 = RS2 = L

- - 20 µA

300 450 600 µA

OUT1 to OUT192

Vpouth

Vpoutl

Vdouth

Vdoutl

Power output high level (voltage drop versus Vpp)

@ Ipouth = -20mA and Vpp = 70V

Power output low level

@ Ipoutl = +20mA

Output upper diode voltage drop

@ Idouth = +30mA (see Figure 9)

Output lower diode voltage drop

@ Idoutl = -30mA (see Figure 9)

2 3.5 5 V

3 6 10 V

- 1 2 V

-2 -1 - V

Standard Mode, TTL/LVCMOS inputs: CLK1, DIR, /STB1, POC, /BLK, BS1, BS2 and DB1 to DB6

V

IH

V

IL

I

IH

I

IL

High level input voltage 2.0 - - V

Low level input voltage - - 0.8 V

High level input current (VIH ≥ 2.0V) - - 5 µA

Low level input current (VIL = 0V) - - 5 µA

17/32

Electrical characteristics STV7622

VPP

VSSP/VSSSUB

OUTn

Idouth (*)

+

ON

OFF

Vdouth

VPP

VSSP/VSSSUB

OUTn

Idoutl (**)

-

OFF

ON

Vdoutl

(*) Output sinking current is

considered as positive.

(**) Output sourcing current is

considered as negative.

Table 10. Electrical characteristics (continued)

Symbol Parameter Min. Typ. Max. Units

RSDS Mode, inputs: CLK1, CLK2, /STB1, /STB2 and DB1 to DB6

Vid

V

ic

Cin Input capacitance

1. For 5V CMOS input logic levels (0 or 5V)

2. All input data is switched at 10MHz rate.

3. Same for TTL and RSDS modes. This parameter is measured during qualification by ST Microelectronics which includes

temperature characterization on standard as well as corner batches of the process. This parameter is not tested in

production.

Magnitude of differential input voltage 100 400 600 mV

Common mode input range 0.5Vid

(3)

- - 15 pF

1.2

2.4 −

0.5Vid

V

Figure 9. Output test configuration

18/32

STV7622 AC timing requirements

9 AC timing requirements

VCC = VDD = 4.5V to 5.5V, Tamb = -20°C to +85°C,

input signal edge maximum rise and fall times (tr, tf) = 3ns.

Table 11. AC timing requirements

Symbol Parameter Min. Typ. Max. Units

t

CLK

t

WHCLK

t

WLCLK

t

SDAT

t

HDAT

t

HSTB

t

STB

t

SSTB

Data clock period 16.7 - - ns

Duration of clock pulse at high level 8.8 - - ns

Duration of clock pulse at low level 8.8 - - ns

Input data set-up time before low-to-high clock transition 5 - - ns

Input data hold-time after low-to-high clock transition 5 - - ns

Strobe hold-time after low-to-high clock transition 5 - - ns

Duration of strobe Low level 10 - - ns

Strobe set-up time before low-to-high clock transition 5 ns

19/32

AC timing characteristics STV7622

10 AC timing characteristics

VCC = VDD = 5V, VPP = 70V, VSSP = VSSLOG = VSSSUB = 0V, Tamb = 25°C,

Fclk= 60MHz, V

Table 12. AC timing characteristics

Symbol Parameter Min Typ Max Units

t

PHL1

t

PLH1

t

PHL2

t

PLH2

t

PHL3

t

PLH3

t

R-OUT

t

R-OUT

t

R-OUT

t

R-OUT

t

F-OUT

t

F-SLOW

t

F-SLOW

t

F-SLOW

t

F-SLOW

1. t

R-OUT

2. Measurement made on one of the 192 power outputs with FS1 = “H” and FS2 = “L”. Load capacitor CL = 50pF, all other

power outputs Low.

3. t

F-SLOW

Delay of power output change after CLK1/CLK2 transition

- high to low

- low to high

Delay of power output change after /STB1/STB2

transition

- high to low

- low to high

Delay of power output change after /BLK transition

- high to low

- low to high

Power output rise time

Power output rise time

Power output rise time

Power output rise time

Power output fall time

Soft slope duration

Soft slope duration

Soft slope duration

Soft slope duration

is set externally by inputs RS1 and RS2.

is set externally by inputs FS1 and FS2.

= 0.2 × VCC, V

ILmax

(1)

(RS = “L” and RS2 = “L”)

(1)

(RS = “H” and RS2 = “L”)

(1)

(RS= “L” and RS2 = “H”)

(1)

(RS = “H” and RS2 = “H”)

(2)

(3)

(FS1 = “L” and FS2 = “L”)

(3)

(FS1 = “H” and FS2 = “L”)

(3)

(FS1 = “L” and FS2 = “H”)

(3)

(FS1 = “H” and FS2 = “H”)

= 0.8 × VCC.

IHmin

-

-

-

-

-

35

30

25

20

100

100

-

-

95

95

90

90

ns

ns

ns

ns

ns

ns

90 120 150 ns

180 230 280 ns

320 400 480 ns

470 560 670 ns

50 - 200 ns

8 10 12 ns

40 50 60 ns

80 100 120 ns

160 200 240 ns

20/32

STV7622 AC timing characteristics

t

WHCLK

50%

CLK

DB (input)

/STB

OUT(n

)

/

BLK

OUTn

50%

50%

t

WLCLK

t

CLK

50% 50%

t

SDAT

t

HDAT

50% 50%

t

STB

50%

t

HSTB

t

SSTB

90%

10%

t

PLH2

90%

10%

t

PLH1

t

PHL2

t

PHL1

50% 50%

t

PHL3

90%

10%

10%

90%

t

PLH3

t

F-OUT

t

R-OUT

(See sections on output falling/rising edge)

t

WHCLK

50%

CLK1

DB1-3-5 (input)

50%

50%

t

WLCLK

t

CLK

50% 50%

t

SDAT

t

HDAT

CLK2

DB2-4-6 (input)

Standard mode

Differential mode

50% 50%

t

STB

50%

t

HSTB

t

SSTB

/STB1

/STB2

Figure 10. AC characteristic waveforms

21/32

Pad dimensions and positions (in µm) STV7622

11 Pad dimensions and positions (in µm)

The reference (x=0, y=0) is the centre of the die. Output pad pitch is 76.5µm.

Pad placement coordinate values correspond to the center of each bump pad center. Pad

size is specified for bumping.

Table 13. Pad placement and bump pad dimensions (in microns)

Lead pad name Pad placements Bump dimensions

X Y X Y

TOP SIDE from left to right

OUT192 -7303.1 624.2 43.5 65.6

OUT191 -7226.6 624.2 43.5 65.6

OUT190 -7150.1 624.2 43.5 65.6

OUT189 -7073.6 624.2 43.5 65.6

OUT188 -6997.1 624.2 43.5 65.6

OUT187 -6920.6 624.2 43.5 65.6

OUT186 -6844.1 624.2 43.5 65.6

OUT185 -6767.6 624.2 43.5 65.6

OUT184 -6691.1 624.2 43.5 65.6

OUT183 -6614.6 624.2 43.5 65.6

OUT182 -6538.1 624.2 43.5 65.6

OUT181 -6461.6 624.2 43.5 65.6

OUT180 -6385.1 624.2 43.5 65.6

OUT179 -6308.6 624.2 43.5 65.6

OUT178 -6232.1 624.2 43.5 65.6

OUT177 -6155.6 624.2 43.5 65.6

OUT176 -6079.1 624.2 43.5 65.6

OUT175 -6002.6 624.2 43.5 65.6

OUT174 -5926.1 624.2 43.5 65.6

OUT173 -5849.6 624.2 43.5 65.6

OUT172 -5773.1 624.2 43.5 65.6

OUT171 -5696.6 624.2 43.5 65.6

OUT170 -5620.1 624.2 43.5 65.6

OUT169 -5543.6 624.2 43.5 65.6

OUT168 -5467.1 624.2 43.5 65.6

OUT167 -5390.6 624.2 43.5 65.6

OUT166 -5314.1 624.2 43.5 65.6

22/32

STV7622 Pad dimensions and positions (in µm)

Table 13. Pad placement and bump pad dimensions (in microns) (continued)

Lead pad name Pad placements Bump dimensions

X Y X Y

OUT165 -5237.6 624.2 43.5 65.6

OUT164 -5161.1 624.2 43.5 65.6

OUT163 -5084.6 624.21 43.5 65.6

OUT162 -5008.1 624.2 43.5 65.6

OUT161 -4931.6 624.2 43.5 65.6

OUT160 -4855.1 624.2 43.5 65.6

OUT159 -4778.6 624.2 43.5 65.6

OUT158 -4702.1 624.2 43.5 65.6

OUT157 -4625.6 624.2 43.5 65.6

OUT156 -4549.1 624.2 43.5 65.6

OUT155 -4472.6 624.2 43.5 65.6

OUT154 -4396.1 624.2 43.5 65.6

OUT153 -4319.6 624.2 43.5 65.6

OUT152 -4243.1 624.2 43.5 65.6

OUT151 -4166.6 624.2 43.5 65.6

OUT150 -4090.1 624.2 43.5 65.6

OUT149 -4013.6 624.2 43.5 65.6

OUT148 -3937.1 624.2 43.5 65.6

OUT147 -3860.6 624.2 43.5 65.6

OUT146 -3784.1 624.2 43.5 65.6

OUT145 -3707.6 624.2 43.5 65.6

OUT144 -3631.1 624.2 43.5 65.6

OUT143 -3554.6 624.2 43.5 65.6

OUT142 -3478.1 624.2 43.5 65.6

OUT141 -3401.6 624.2 43.5 65.6

OUT140 -3325.1 624.2 43.5 65.6

OUT139 -3248.6 624.2 43.5 65.6

OUT138 -3172.1 624.2 43.5 65.6

OUT137 -3095.6 624.2 43.5 65.6

OUT136 -3019.1 624.2 43.5 65.6

OUT135 -2942.6 624.2 43.5 65.6

OUT134 -2866.1 624.2 43.5 65.6

OUT133 -2789.6 624.2 43.5 65.6

23/32

Pad dimensions and positions (in µm) STV7622

Table 13. Pad placement and bump pad dimensions (in microns) (continued)

Lead pad name Pad placements Bump dimensions

X Y X Y

OUT132 -2713.1 624.2 43.5 65.6

OUT131 -2636.6 624.2 43.5 65.6

OUT130 -2560.1 624.2 43.5 65.6

OUT129 -2483.6 624.2 43.5 65.6

OUT128 -2407.1 624.2 43.5 65.6

OUT127 -2330.6 624.2 43.5 65.6

OUT126 -2254.1 624.215 43.5 65.6

OUT125 -2177.6 624.2 43.5 65.6

OUT124 -2101.1 624.2 43.5 65.6

OUT123 -2024.6 624.2 43.5 65.6

OUT122 -1948.1 624.2 43.5 65.6

OUT121 -1871.6 624.2 43.5 65.6

OUT120 -1795.1 624.2 43.5 65.6

OUT119 -1718.6 624.2 43.5 65.6

OUT118 -1642.1 624.2 43.5 65.6

OUT117 -1565.6 624.2 43.5 65.6

OUT116 -1489.1 624.2 43.5 65.6

OUT115 -1412.6 624.2 43.5 65.6

OUT114 -1336.1 624.2 43.5 65.6

OUT113 -1259.6 624.2 43.5 65.6

OUT112 -1183.1 624.2 43.5 65.6

OUT111 -1106.6 624.2 43.5 65.6

OUT110 -1030.1 624.2 43.5 65.6

OUT109 -953.6 624.2 43.5 65.6

OUT108 -877.1 624.2 43.5 65.6

OUT107 -800.6 624.2 43.5 65.6

OUT106 -724.1 624.2 43.5 65.6

OUT105 -647.6 624.2 43.5 65.6

OUT104 -571.1 624.2 43.5 65.6

OUT103 -494.6 624.2 43.5 65.6

OUT102 -418.1 624.2 43.5 65.6

OUT101 -341.6 624.2 43.5 65.6

OUT100 -265.1 624.2 43.5 65.6

24/32

STV7622 Pad dimensions and positions (in µm)

Table 13. Pad placement and bump pad dimensions (in microns) (continued)

Lead pad name Pad placements Bump dimensions

X Y X Y

OUT99 -188.6 624.2 43.5 65.6

OUT98 -112.1 624.2 43.5 65.6

OUT97 -35.6 624.2 43.5 65.6

OUT96 40.9 624.2 43.5 65.6

OUT95 117.4 624.2 43.5 65.6

OUT94 193.9 624.2 43.5 65.6

OUT93 270.4 624.2 43.5 65.6

OUT92 346.9 624.2 43.5 65.6

OUT91 423.4 624.2 43.5 65.6

OUT90 499.9 624.2 43.5 65.6

OUT89 576.4 624.2 43.5 65.6

OUT88 652.9 624.2 43.5 65.6

OUT87 729.4 624.2 43.5 65.6

OUT86 805.9 624.2 43.5 65.6

OUT85 882.4 624.2 43.5 65.6

OUT84 958.9 624.2 43.5 65.6

OUT83 1035.4 624.2 43.5 65.6

OUT82 1111.9 624.2 43.5 65.6

OUT81 1188.4 624.2 43.5 65.6

OUT80 1264.9 624.2 43.5 65.6

OUT79 1341.4 624.2 43.5 65.6

OUT78 1417.9 624.2 43.5 65.6

OUT77 1494.4 624.2 43.5 65.6

OUT76 1570.9 624.2 43.5 65.6

OUT75 1647.4 624.2 43.5 65.6

OUT74 1723.9 624.2 43.5 65.6

OUT73 1800.4 624.2 43.5 65.6

OUT72 1876.9 624.2 43.5 65.6

OUT71 1953.4 624.2 43.5 65.6

OUT70 2029.9 624.2 43.5 65.6

OUT69 2106.4 624.2 43.5 65.6

OUT68 2182.9 624.2 43.5 65.6

OUT67 2259.4 624.2 43.5 65.6

25/32

Pad dimensions and positions (in µm) STV7622

Table 13. Pad placement and bump pad dimensions (in microns) (continued)

Lead pad name Pad placements Bump dimensions

X Y X Y

OUT66 2335.8 624.2 43.5 65.6

OUT65 2412.3 624.2 43.5 65.6

OUT64 2488.9 624.2 43.5 65.6

OUT63 2565.4 624.2 43.5 65.6

OUT62 2641.9 624.2 43.5 65.6

OUT61 2718.4 624.2 43.5 65.6

OUT60 2794.9 624.2 43.5 65.6

OUT59 2871.4 624.2 43.5 65.6

OUT58 2947.9 624.2 43.5 65.6

OUT57 3024.4 624.2 43.5 65.6

OUT56 3100.9 624.2 43.5 65.6

OUT55 3177.4 624.2 43.5 65.6

OUT54 3253.9 624.2 43.5 65.6

OUT53 3330.4 624.2 43.5 65.6

OUT52 3406.9 624.2 43.5 65.6

OUT51 3483.4 624.2 43.5 65.6

OUT50 3559.9 624.2 43.5 65.6

OUT49 3636.4 624.2 43.5 65.6

OUT48 3712.9 624.2 43.5 65.6

OUT47 3789.4 624.2 43.5 65.6

OUT46 3865.9 624.2 43.5 65.6

OUT45 3942.4 624.2 43.5 65.6

OUT44 4018.9 624.2 43.5 65.6

OUT43 4095.4 624.2 43.5 65.6

OUT42 4171.9 624.2 43.5 65.6

OUT41 4248.4 624.2 43.5 65.6

OUT40 4324.9 624.2 43.5 65.6

OUT39 4401.4 624.2 43.5 65.6

OUT38 4477.9 624.2 43.5 65.6

OUT37 4554.4 624.2 43.5 65.6

OUT36 4630.9 624.2 43.5 65.6

OUT35 4707.4 624.2 43.5 65.6

OUT34 4783.9 624.2 43.5 65.6

26/32

STV7622 Pad dimensions and positions (in µm)

Table 13. Pad placement and bump pad dimensions (in microns) (continued)

Lead pad name Pad placements Bump dimensions

X Y X Y

OUT33 4860.4 624.2 43.5 65.6

OUT32 4936.9 624.2 43.5 65.6

OUT31 5013.4 624.2 43.5 65.6

OUT30 5089.9 624.2 43.5 65.6

OUT29 5166.4 624.2 43.5 65.6

OUT28 5242.9 624.2 43.5 65.6

OUT27 5319.4 624.2 43.5 65.6

OUT26 5395.9 624.2 43.5 65.6

OUT25 5472.4 624.2 43.5 65.6

OUT24 5548.9 624.2 43.5 65.6

OUT23 5625.4 624.2 43.5 65.6

OUT22 5701.9 624.2 43.5 65.6

OUT21 5778.4 624.2 43.5 65.6

OUT20 5854.9 624.2 43.5 65.6

OUT19 5931.4 624.2 43.5 65.6

OUT18 6007.9 624.2 43.5 65.6

OUT17 6084.4 624.2 43.5 65.6

OUT16 6160.9 624.2 43.5 65.6

OUT15 6237.4 624.2 43.5 65.6

OUT14 6313.9 624.2 43.5 65.6

OUT13 6390.4 624.2 43.5 65.6

OUT12 6466.9 624.2 43.5 65.6

OUT11 6543.4 624.2 43.5 65.6

OUT10 6619.9 624.2 43.5 65.6

OUT9 6696.4 624.2 43.5 65.6

OUT8 6772.9 624.2 43.5 65.6

OUT7 6849.4 624.2 43.5 65.6

OUT6 6925.9 624.2 43.5 65.6

OUT5 7002.4 624.2 43.5 65.6

OUT4 7078.9 624.2 43.5 65.6

OUT3 7155.4 624.2 43.5 65.6

OUT2 7231.9 624.2 43.5 65.6

OUT1 7308.4 624.2 43.5 65.6

27/32

Pad dimensions and positions (in µm) STV7622

Table 13. Pad placement and bump pad dimensions (in microns) (continued)

Lead pad name Pad placements Bump dimensions

X Y X Y

RIGHT SIDE from top to bottom

VSSP4 7461.3 635.2 65.6 43.5

VSSP5 7473.2 560.3 65.6 43.5

VSSP6 7473.2 485.4 65.6 43.5

VPP4 7473.2 260.1 65.6 43.5

VPP5 7473.2 185.2 65.6 43.5

VPP6 7473.2 110.3 65.6 43.5

DUMMY 7473.2 35.5 65.6 43.5

VSSLOG2 7473.2 -39.4 65.6 43.5

VSSSUB2 7473.2 -114.3 65.6 43.5

VDD2 7473.2 -189.2 65.6 43.5

VCC2 7473.2 -555.2 65.6 43.5

DUMMY 7461.3 -633.5 65.6 43.5

BOTTOM SIDE from right to left

DUMMY 6838.2 -622.5 43.5 65.6

DUMMY 6749.7 -622.5 43.5 65.6

DUMMY 6673.1 -622.5 43.5 65.6

DUMMY 6486.3 -622.5 43.5 65.6

DUMMY 6409.8 -622.5 43.5 65.6

DUMMY 6333.3 -622.5 43.5 65.6

DUMMY 6256.8 -622.5 43.5 65.6

DUMMY 6103.6 -622.5 43.5 65.6

TEST2 5928.9 -622.5 43.5 65.6

TEST1 5617.8 -622.5 43.5 65.6

VDD8 4783.9 -622.5 43.5 65.6

BS2 4634.4 -622.5 43.5 65.6

VSSLOG7 4466.3 -622.5 43.5 65.6

BS1 4325.9 -622.5 43.5 65.6

VDD7 4095.4 -622.5 43.5 65.6

DIR 3949.6 -622.5 43.5 65.6

VSSLOG6 3709.5 -622.5 43.5 65.6

FS1 3560.2 -622.5 43.5 65.6

VDD6 3327.0 -622.5 43.5 65.6

28/32

STV7622 Pad dimensions and positions (in µm)

Table 13. Pad placement and bump pad dimensions (in microns) (continued)

Lead pad name Pad placements Bump dimensions

X Y X Y

FS2 3178.1 -622.5 43.5 65.6

VSSLOG5 2944.5 -622.5 43.5 65.6

RS2 2798.8 -622.5 43.5 65.6

VDD5 2629.4 -622.5 43.5 65.6

RS1 2486.6 -622.5 43.5 65.6

VSSLOG4 2314.1 -622.5 43.5 65.6

DUMMY 648.6 -622.5 43.5 65.6

VREF 117.6 -622.5 43.5 65.6

DUMMY -271.1 -622.5 43.5 65.6

DUMMY -424.1 -622.5 43.5 65.6

VDD4 -572.067 -622.5 43.5 65.6

POC -870.5 -622.5 43.5 65.6

VSSLOG3 -1110.0 -622.5 43.5 65.6

BLK/ -1458.1 -622.5 43.5 65.6

VDD3 -1722.0 -622.5 43.5 65.6

CLK1 -1958.7 -622.5 43.5 65.6

CLK2 -2567.3 -622.5 43.5 65.6

STB1/ -3018.9 -622.5 43.5 65.6

STB2/ -3561.8 -622.5 43.5 65.6

DB1 -4021.4 -622.5 43.5 65.6

DB2 -4632.8 -622.5 43.5 65.6

DB3 -5015.9 -622.5 43.5 65.6

DB4 -5840.8 -622.5 43.5 65.6

DB5 -6114.5 -622.5 43.5 65.6

DB6 -7094.6 -622.5 43.5 65.6

29/32

Pad dimensions and positions (in µm) STV7622

Table 13. Pad placement and bump pad dimensions (in microns) (continued)

Lead pad name Pad placements Bump dimensions

X Y X Y

LEFT SIDE from bottom to top

VCC1 -7474.9 -555.2 65.6 43.5

VDD1 -7474.9 -189.2 65.6 43.5

VSSSUB1 -7474.9 -114.3 65.6 43.5

VSSLOG1 -7474.9 -39.4 65.6 43.5

DUMMY -7474.9 35.5 65.6 43.5

VPP3 -7474.9 110.3 65.6 43.5

VPP2 -7474.9 185.2 65.6 43.5

VPP1 -7474.9 260.1 65.6 43.5

VSSP3 -7474.9 485.5 65.6 43.5

VSSP2 -7474.9 560.3 65.6 43.5

VSSP1 -7462.9 635.2 65.6 43.5

30/32

STV7622 Tested wafer disclaimer

12 Tested wafer disclaimer

All wafers are tested and guaranteed to comply with this specification until the wafer sawing

stage, for a period of ninety (90) days from the delivery date.

Please remember that it is the customer’s responsibility to test and qualify their application

using the STMicroelectronics die. STMicroelectronics is ready to support customers when

qualifying the product.

13 Ordering information

Table 14. Order codes

Part number Description

STV7622/BMP Tested and usawn bump wafer (u = die)

14 Revision history

Table 15. Document revision history

Date Revision Changes

29-May-2007 1 Initial release

31/32

STV7622

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

32/32

Loading...

Loading...