Page 1

S-Touch® advanced resistive touchscreen controller

Features

■ 8 GPIOs

■ 1.8 - 3.3 V operating voltage

■ Integrated 4-wire touchscreen controller

■ Interrupt output pin

■ Wakeup feature on each I/O

■ SPI and I

■ Up to 2 devices sharing the same bus in

2

I

C mode (1 address line)

■ 8-input 12-bit ADC

■ 128-depth buffer touchscreen controller

■ Touchscreen movement detection algorithm

■ 25 kV air-gap ESD protection (system level)

■ 4 kV HBM ESD protection (device level)

2

C interface

STMPE811

with 8-bit GPIO expander

QFN16

(3x3)

Description

The STMPE811 is a GPIO (general purpose

input/output) port expander able to interface a

main digital ASIC via the two-line bidirectional bus

2

(I

C). A separate GPIO expander is often used in

mobile multimedia platforms to solve the

problems of the limited amount of GPIOs typically

available on the digital engine.

Applications

■ Portable media players

■ Game consoles

■ Mobile and smartphones

■ GPS

Table 1. Device summary

Order code Package Packaging

STMPE811QTR QFN16 Tape and reel

The STMPE811 offers great flexibility, as each I/O

can be configured as input, output or specific

functions. The device has been designed with

very low quiescent current and includes a wakeup

feature for each I/O, to optimize the power

consumption of the device.

A 4-wire touchscreen controller is built into the

STMPE811. The touchscreen controller is

enhanced with a movement tracking algorithm (to

avoid excessive data), a 128 x 32 bit buffer and

programmable active window feature.

September 2011 Doc ID 14489 Rev 6 1/65

www.st.com

65

Page 2

Contents STMPE811

Contents

1 STMPE811 functional overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Pin configuration and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Pin functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 I2C and SPI interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Interface selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 I2C interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 I2C features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Data input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Read operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 Write operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 SPI interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 SPI protocol definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Register reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.2 Register write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.3 Termination of data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 SPI timing modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.1 SPI timing definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 STMPE811 registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 System and identification registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 Interrupt system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Analog-to-digital converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10 Touchscreen controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 Driver and switch control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.2 Touch detect delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2/65 Doc ID 14489 Rev 6

Page 3

STMPE811 Contents

11 Touchscreen controller programming sequence . . . . . . . . . . . . . . . . . 46

12 Temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13 GPIO controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

13.0.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

13.0.2 Power-up reset (POR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

14 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

14.1 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

15 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

16 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

17 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Doc ID 14489 Rev 6 3/65

Page 4

List of tables STMPE811

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pin assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3. Pin configuration for IN2, IN3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Pin configuration for X+, Y+, X-, Y-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5. Interface selection pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 6. I2C address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 7. I2C timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 8. Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 9. SPI timing modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 10. SPI timing specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 11. Register summary map table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 12. System and identification registers map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 13. ADC controller register summary table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 14. ADC conversion time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 15. Touchscreen controller register summary table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 16. Touchscreen controller DATA register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 17. Touchscreen parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 18. GPIO control registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 19. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 20. Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 21. DC electrical characteristics (-40 °C to 85 °C) all GPIOs comply to JEDEC standard JESD-

8-7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 22. AC electrical characteristics (-40 °C to 85 °C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 23. ADC specification (-40 °C to 85 °C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 24. Switch drivers specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 25. Package mechanical data for QFN16 (3 x 3 x 1 mm) - 0.50 pitch . . . . . . . . . . . . . . . . . . . 60

Table 26. Exposed pad variation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 27. Footprint dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 28. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4/65 Doc ID 14489 Rev 6

Page 5

STMPE811 List of figures

List of figures

Figure 1. STMPE811 functional block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. STMPE811 pin configuration (top through view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. STMPE811 interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. STMPE811 I2C interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. I

Figure 6. Read and write modes (random and sequential) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 7. SPI timing specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 8. Interrupt system diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 9. Touchscreen controller block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 10. Window tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 11. Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 12. Sampling time calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 13. Package outline for QFN16 (3 x 3 x 1 mm) - 0.50 pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 14. Recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 15. Carrier tape for QFN16 (3 x 3 x 1 mm) - 0.50 pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 16. Reel information for QFN16 (3 x 3 x 1 mm) - 0.50 pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2

C timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Doc ID 14489 Rev 6 5/65

Page 6

STMPE811 functional overview STMPE811

1 STMPE811 functional overview

The STMP811 consists of the following blocks:

2

● I

C and SPI interface

● Analog-to-digital converver (ADC)

● Touchscreen controller (TSC)

● Driver and switch control unit

● Temperature sensor

● GPIO controller

Figure 1. STMPE811 functional block diagram

INT

Data in

A0/Data out

SCLK/CLK

SDAT/

CS

GPIO

controller

Switches

and drivers

RC oscillator

2

I C / SPI

GND

interface

VCC

Thermal

sense

ADC , TSC

VREF

TSC: Touchscreen controller

GPIO 0-7

/ADC IN 0-7

/MODE

/REF-, REF+

6/65 Doc ID 14489 Rev 6

Page 7

STMPE811 Pin configuration and functions

2 Pin configuration and functions

Figure 2. STMPE811 pin configuration (top through view)

12 11 10 9

13

14

15

STMPE811

16

1 2 3 4

Table 2. Pin assignments

Pin Name Function

1 Y- Y-/GPIO-7

2 INT Interrupt output (VCC domain), open drain

2

3 A0/Data Out I

4SCLKI

5SDATI

6V

CC

7 Data in SPI Data In (V

C address in Reset, Data out in SPI mode (VCC domain)

2

C/SPI clock (VCC domain)

2

C data/SPI CS (VCC domain)

1.8 −3.3 V supply voltage

domain)

CC

8 IN0 IN0/GPIO-0

8

7

6

5

IN1/GPIO-1/MODE

9IN1

In RESET state, MODE selects the type of serial interface

2

C

"0" - I

"1" - SPI

10 GND Ground

11 IN2 IN2/GPIO-2

12 IN3 IN3/GPIO-3

13 X+ X+/GPIO-4

14 Vio Supply for touchscreen driver and GPIO

15 Y+ Y+/GPIO-5

16 X- X-/GPIO-6

Doc ID 14489 Rev 6 7/65

Page 8

Pin configuration and functions STMPE811

2.1 Pin functions

The STMPE811 is designed to provide maximum features and flexibility in a very small pin-

count package. Most of the pins are multi-functional. Ta bl e 3 and Ta bl e 4 show how to select

the pin’s function.

Table 3. Pin configuration for IN2, IN3

GPIO_AF = 1 GPIO_AF = 0

Pin / control

register

IN0 GPIO-0 ADC

IN1 GPIO-1 ADC

IN2 GPIO-2 ADC External reference +

IN3 GPIO-3 ADC External reference -

Table 4. Pin configuration for X+, Y+, X-, Y-

Pin / control

register

ADC control 1 bit 1 =

don’t care

GPIO_AF = 1 GPIO_AF = 0

TSC control 1 bit 0 =

don’t care

ADC control 1 bit 1 = 0 ADC control 1 bit 1 = 1

TSC control 1 bit 0 = 0 TSC control 1 bit 0 = 1

X+ GPIO-4 ADC TSC X+

Y+ GPIO-5 ADC TSC Y+

X- GPIO-6 ADC TSC X-

Y- GPIO-7 ADC TSC Y-

8/65 Doc ID 14489 Rev 6

Page 9

STMPE811 I2C and SPI interface

3 I2C and SPI interface

3.1 Interface selection

The STMPE811 interfaces with the host CPU via a I2C or SPI interface. The pin IN_1 allows

the selection of interface protocol at reset state.

Figure 3. STMPE811 interface

DIN

SPI I/F

module

DOUT

CLK

CS

SDAT

2

I C I/F

module

Table 5. Interface selection pins

Pin I2C function SPI function Reset state

3 Address 0 Data out CPHA for SPI

4CLOCKCLOCK

5 SDATA CS CPOL_N for SPI

7

9MODEI

SCLK

A0

−

MUX

unit

−

Data in

2

C set to ‘0’ Set to ‘1’ for SPI

−

Doc ID 14489 Rev 6 9/65

Page 10

I2C interface STMPE811

SC

SC

4 I2C interface

The addressing scheme of STMPE811 is designed to allow up to 2 devices to be connected

to the same I

Figure 4. STMPE811 I

LK

2

C bus.

2

C interface

LK

STMPE811

Table 6. I

2

C address

ADDR0 Address

00x82

10x88

For the bus master to communicate to the slave device, the bus master must initiate a Start

condition and be followed by the slave device address. Accompanying the slave device

address, is a read/write bit (R/W). The bit is set to 1 for read and 0 for write operation. If a

match occurs on the slave device address, the corresponding device gives an acknowledge

on the SDA during the 9

th

bit time. If there is no match, it deselects itself from the bus by not

responding to the transaction.

Figure 5. I

SDA

SCL

2

C timing diagram

tHD:STAtBUF

SP

tHD:STA

tHIGH

tLOW

tF

tSU:DAT

tHD:DAT

SR

tSU:STOtSU:STA

P

AI00589

tR

10/65 Doc ID 14489 Rev 6

Page 11

STMPE811 I2C interface

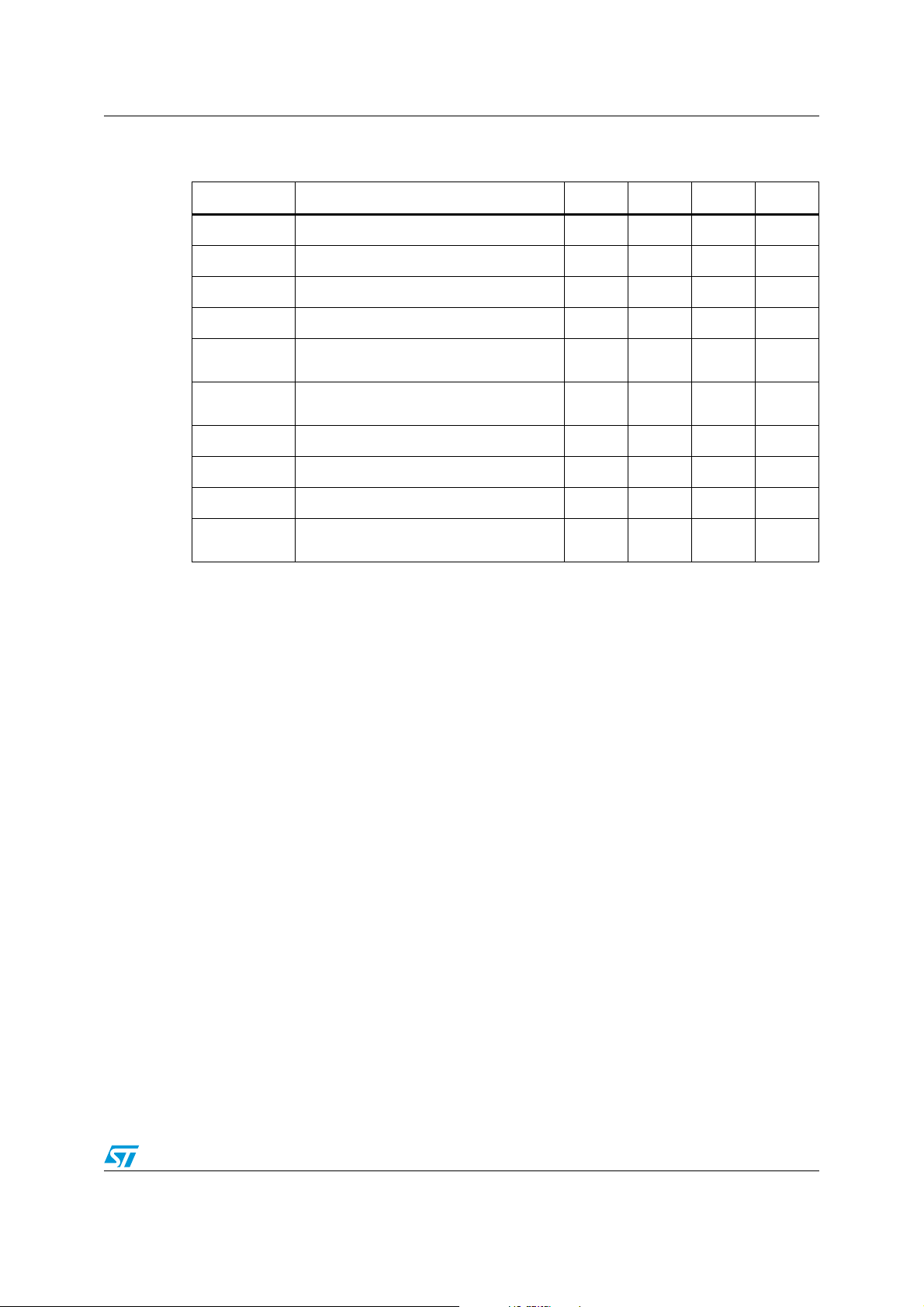

Table 7. I2C timing

Symbol Parameter Min Typ Max Uni

f

SCL

t

LOW

t

HIGH

t

F

t

HD:STA

t

SU:STA

t

SU:DAT

t

HD:DAT

t

SU:STO

t

BUF

SCL clock frequency 0

Clock low period 1.3

Clock high period 600

SDA and SCL fall time

START condition hold time (after this

period the first clock is generated)

START condition setup time (only relevant

for a repeated start period)

600

600

Data setup time 100

Data hold time 0

STOP condition setup time 600

Time the bus must be free before a new

transmission can start

1.3

−

400 kHz

−−

−−

−

300 ns

−−

−−

−−

−−

−−

−−

µs

ns

ns

ns

ns

µs

ns

µs

Doc ID 14489 Rev 6 11/65

Page 12

I2C interface STMPE811

4.1 I2C features

The features that are supported by the I2C interface are listed below:

2

● I

C slave device

● Operates at 1.8 V

● Compliant to Philips I

● Supports standard (up to 100 Kbps) and fast (up to 400 Kbps) modes

Start condition

A Start condition is identified by a falling edge of SDATA while SCLK is stable at high state.

A Start condition must precede any data/command transfer. The device continuously

monitors for a Start condition and does not respond to any transaction unless one is

encountered.

Stop condition

A Stop condition is identified by a rising edge of SDATA while SCLK is stable at high state. A

Stop condition terminates communication between the slave device and the bus master. A

read command that is followed by NoAck can be followed by a Stop condition to force the

slave device into idle mode. When the slave device is in idle mode, it is ready to receive the

2

next I

C transaction. A Stop condition at the end of a write command stops the write

operation to registers.

2

C specification version 2.1

Acknowledge bit

The acknowledge bit is used to indicate a successful byte transfer. The bus transmitter

releases the SDATA after sending eight bits of data. During the ninth bit, the receiver pulls

the SDATA low to acknowledge the receipt of the eight bits of data. The receiver may leave

the SDATA in high state if it does not acknowledge the receipt of the data.

12/65 Doc ID 14489 Rev 6

Page 13

STMPE811 I2C interface

4.2 Data input

The device samples the data input on SDATA on the rising edge of the SCLK. The SDATA

signal must be stable during the rising edge of SCLK and the SDATA signal must change

only when SCLK is driven low.

Table 8. Operating modes

Mode Byte Programming sequence

Read ≥1

Start, Device address, R/W

Restart, Device address, R/W

If no Stop is issued, the Data Read can be continuously performed. If

= 0, Register address to be read

= 1, Data Read, Stop

the register address falls within the range that allows an address autoincrement, then the register address auto-increments internally after

every byte of data being read.

Start, Device address, R/W

= 0, Register address to be written, Data

Write, Stop

If no Stop is issued, the Data Write can be continuously performed. If

Write ≥1

the register address falls within the range that allows address autoincrement, then the register address auto-increments internally after

every byte of data being written in. For those register addresses that

fall within a non-incremental address range, the address is kept static

throughout the entire write operation. Refer to the memory map table

for the address ranges that are auto and non-increment.

Figure 6. Read and write modes (random and sequential)

R/W=0

R/W=0

Ack

Ack

Reg

Address

Reg

Address

Ack

Ack

Device

Address

Device

Address

Restart

R/W=1

R/W=1

Data

Ack

Read

Data

Ack

Read

One byte

Read

More than one byte

Read

Start

Start

Device

Address

Device

Address

Stop

No Ack

Ack

Data

Read + 1

Ack

Data

Read + 2

Stop

No Ack

One byte

Write

More than one byte

Read

Start

Start

Device

Address

Device

Address

Master

Slave

R/W=0

R/W=0

Ack

Ack

Reg

Address

Reg

Address

Ack

Ack

Data

to be

written

Data to

Write

Ack

Ack

Write + 1

Stop

Data to

Ack

Write + 2

Data to

Ack

Stop

AM00775V1

Doc ID 14489 Rev 6 13/65

Page 14

I2C interface STMPE811

4.3 Read operation

A write is first performed to load the register address into the Address Counter but without

sending a Stop condition. Then, the bus master sends a reStart condition and repeats the

Device Address with the R/W bit set to 1. The slave device acknowledges and outputs the

content of the addressed byte. If no additional data is to be read, the bus master must not

acknowledge the byte and terminates the transfer with a Stop condition.

If the bus master acknowledges the data byte, then it can continue to perform the data

reading. To terminate the stream of data bytes, the bus master must not acknowledge the

last output byte, and be followed by a Stop condition. If the address of the register written

into the Address Counter falls within the range of addresses that has the auto-increment

function, the data being read are coming from consecutive addresses, which the internal

Address Counter automatically increments after each byte output. After the last memory

address, the Address Counter 'rolls-over' and the device continues to output data from the

memory address of 0x00. Similarly, for the register address that falls within a non-increment

range of addresses, the output data byte comes from the same address (which is the

address referred by the Address Counter).

Acknowledgement in read operation

For the above read command, the slave device waits, after each byte read, for an

acknowledgement during the ninth bit time. If the bus master does not drive the SDA to a

low state, then the slave device terminates and switches back to its idle mode, waiting for

the next command.

4.4 Write operations

A write is first performed to load the register address into the Address Counter without

sending a Stop condition. After the bus master receives an acknowledgement from the slave

device, it may start to send a data byte to the register (referred by the Address Counter).

The slave device again acknowledges and the bus master terminates the transfer with a

Stop condition.

If the bus master needs to write more data, it can continue the write operation without

issuing the Stop condition. Whether the Address Counter autoincrements or not after each

data byte write depends on the address of the register written into the Address Counter.

After the bus master writes the last data byte and the slave device acknowledges the receipt

of the last data, the bus master may terminate the write operation by sending a Stop

condition. When the Address Counter reaches the last memory address, it 'rolls-over' to the

next data byte write.

14/65 Doc ID 14489 Rev 6

Page 15

STMPE811 SPI interface

5 SPI interface

The SPI (serial peripheral interface) in STMPE811 uses a 4-wire communication connection

(DATA IN, DATA OUT, CLK, CS). In the diagram, “Data in” is referred to as MOSI (master

out slave in) and “DATA out” is referred to as MISO (master in slave out).

5.1 SPI protocol definition

The SPI follows a byte-sized transfer protocol. All transfers begin with an assertion of CS_n

signal (falling edge). The protocol for reading and writing is different and the selection

between a read and a write cycle is dependent on the first captured bit on the slave device.

A '1' denotes a read operation and a '0' denotes a write operation. The SPI protocol defined

in this section is shown in Figure 3.

The following are the main features supported by this SPI implementation.

● Support of 1 MHz maximum clock frequency.

● Support for autoincrement of address for both read and write.

● Full duplex support for read operation.

● Daisy chain configuration support for write operation.

● Robust implementation that can filter glitches of up to 50 ns on the CS_n and SCL pins.

● Support for all 4 modes of SPI as defined by the CPHA, CPOL bits on SPICON.

5.1.1 Register reading

The following steps need to be followed for the register read through the SPI.

1. Assert CS_n by driving a '0' on this pin.

2. Drive a '1' on the first SCL launch clock on MOSI to select a read operation.

3. The next 7 bits on MOSI denote the 7-bit register address (MSB first).

4. The next address byte can now be transmitted on the MOSI. If the autoincrement bit is

set, the following address transmitted on the MOSI is ignored. Internally, the address is

incremented. If the autoincrement bit is not set, then the following byte denotes the

address of the register to be read next.

5. Read data is transmitted by the slave device on the MISO (MSB first), starting from the

launch clock following the last address bit on the MOSI.

6. Full duplex read operation is achieved by transmitting the next address on MOSI while

the data from the previous address is available on MISO.

7. To end the read operation, a dummy address of all 0's is sent on MOSI.

Doc ID 14489 Rev 6 15/65

Page 16

SPI interface STMPE811

5.1.2 Register write

The following steps need to be followed for register write through SPI.

1. Assert CS_n by driving a '0' on this pin.

2. Drive a '0' on the first SCL launch clock on MOSI to select a write operation.

3. The next 7 bits on MOSI denote the 7-bit register address (MSB first).

4. The next byte on the MOSI denotes data to be written.

5. The following transmissions on MOSI are considered byte-sized data. The register

address to which the following data is written depends on whether the autoincrement

bit in the SPICON register is set. If this bit has been set previously, the register address

is incremented for data writes.

5.1.3 Termination of data transfer

A transfer can be terminated before the last launch edge by deasserting the CS_n signal. If

the last launch clock is detected, it is assumed that the data transfer is successful.

16/65 Doc ID 14489 Rev 6

Page 17

STMPE811 SPI interface

5.2 SPI timing modes

The SPI timing modes are defined by CPHA and CPOL,CPHA and CPOL are read from the

"SDAT" and "A0" pins during power-up reset. The following four modes are defined

according to this setting.

Table 9. SPI timing modes

CPOL_N (SDAT pin) CPOL CPHA (ADDR pin) Mode

1000

1011

0102

0113

The clocking diagrams of these modes are shown in ON reset. The device always operates

in mode 0. Once the bits are set in the SPICON register, the mode change takes effect on

the next transaction defined by the CS_n pin being deasserted and asserted.

5.2.1 SPI timing definition

Table 10. SPI timing specification

Symbol Description

CS_n falling to

t

CSS

t

CL

t

CH

t

LDI

t

LDO

t

t

CCS

t

CSH

DI

first capture

clock

Clock low

period

Clock high

period

Launch clock

to MOSI data

valid

Launch clock

to MISO data

valid

Data on MOSI

valid

Last clock

edge to CS_n

high

CS_n high

period

Timing

Min Typ Max

1

500

500

−−

−−

1

1

2

−−

−−

−−

20 ns

330 µs

−−

−−

−−

Unit

µs

ns

ns

µs

µs

µs

Doc ID 14489 Rev 6 17/65

Page 18

SPI interface STMPE811

Table 10. SPI timing specification (continued)

Timing

Symbol Description

Min Typ Max

Unit

t

CSCL

t

CSZ

CS_n high to

first clock edge

CS_n high to

tri-state on

MISO

300

Figure 7. SPI timing specification

−−

1

−−

ns

µs

18/65 Doc ID 14489 Rev 6

Page 19

STMPE811 STMPE811 registers

6 STMPE811 registers

This section lists and describes the registers of the STMPE811 device, starting with a

register map and then provides detailed descriptions of register types.

Table 11. Register summary map table

Address Register name Bit Type Reset value Function

0x00 CHIP_ID 16 R 0x0811 Device identification

Revision number

0x02 ID_VER 8 R 0x03

0x03 SYS_CTRL1 8 R/W 0x00 Reset control

0x04 SYS_CTRL2 8 R/W 0x0F Clock control

0x08 SPI_CFG 8 R/W 0x01 SPI interface configuration

0x09 INT_CTRL 8 R/W 0x00 Interrupt control register

0x0A INT_EN 8 R/W 0x00 Interrupt enable register

0x0B INT_STA 8 R 0x10 interrupt status register

0x0C GPIO_EN 8 R/W 0x00

0x0D GPIO_INT_STA 8 R 0x00

0x01 for engineering sample

0x03 for final silicon

GPIO interrupt enable

register

GPIO interrupt status

register

0x0E ADC_INT_EN 8 R/W 0x00

0x0F ADC_INT_STA 8 R 0x00 ADC interrupt status register

0x10 GPIO_SET_PIN 8 R/W 0x00 GPIO set pin register

0x11 GPIO_CLR_PIN 8 R/W 0x00 GPIO clear pin register

0x12 GPIO_MP_STA 8 R/W 0x00

0x13 GPIO_DIR 8 R/W 0x00 GPIO direction register

0x14 GPIO_ED 8 R/W 0x00 GPIO edge detect register

0x15 GPIO_RE 8 R/W 0x00 GPIO rising edge register

0x16 GPIO_FE 8 R/W 0x00 GPIO falling edge register

0x17 GPIO_AF 8 R/W 0x00 Alternate function register

0x20 ADC_CTRL1 8 R/W 0x1C ADC control

0x21 ADC_CTRL2 8 R/W 0x01 ADC control

0x22 ADC_CAPT 8 R/W 0xFF

0x30 ADC_DATA_CH0 16 R 0x0000 ADC channel 0

0x32 ADC_DATA_CH1 16 R 0x0000 ADC channel 1

ADC interrupt enable

register

GPIO monitor pin state

register

To initiate ADC data

acquisition

Doc ID 14489 Rev 6 19/65

Page 20

STMPE811 registers STMPE811

Table 11. Register summary map table (continued)

Address Register name Bit Type Reset value Function

0x34 ADC_DATA_CH2 16 R 0x0000 ADC channel 2

0x36 ADC_DATA_CH3 16 R 0x0000 ADC channel 3

0x38 ADC_DATA_CH4 16 R 0x0000 ADC channel 4

0x3A ADC_DATA_CH5 16 R 0x0000 ADC channel 5

0x3C ADC_DATA_CH6 16 R 0x0000 ADC channel 6

0x3E ADC_DATA_CH7 16 R 0x0000 ADC channel 7

0x40 TSC_CTRL 8 R/W 0x90

0x41 TSC_CFG 8 R/W 0x00

0x42 WDW_TR_X 16 R/W 0x0FFF Window setup for top right X

0x44 WDW_TR_Y 16 R/W 0x0FFF Window setup for top right Y

4-wire touchscreen

controller setup

Touchscreen controller

configuration

0x46 WDW_BL_X 16 R/W 0x0000

0x48 WDW_BL_Y 16 R/W 0x0000

0x4A FIFO_TH 8 R/W 0x00

0x4B FIFO_STA 8 R/W 0x20 Current status of FIFO

0x4C FIFO_SIZE 8 R 0x00 Current filled level of FIFO

0x4D TSC_DATA_X 16 R 0x0000

0x4F TSC_DATA_Y 16 R 0x0000

0x51 TSC_DATA_Z 8 R 0x0000

0x52 TSC_DATA_XYZ 32 R 0x00000000

0x56

0x57 TSC_DATA 8 R 0x00

0x58 TSC_I_DRIVE 8 R/W 0x00

0x59 TSC_SHIELD 8 R/W 0x00

TSC_FRACTION

_Z

8 0x00

Window setup for bottom left

X

Window setup for bottom left

Y

FIFO level to generate

interrupt

Data port for touchscreen

controller data access

Data port for touchscreen

controller data access

Data port for touchscreen

controller data access

Data port for touchscreen

controller data access

Touchscreen controller

FRACTION_Z

Data port for touchscreen

controller data access

Touchscreen controller drive

I

Touchscreen controller

shield

0x60 TEMP_CTRL 8 R/W 0x00 Temperature sensor setup

20/65 Doc ID 14489 Rev 6

Page 21

STMPE811 STMPE811 registers

Table 11. Register summary map table (continued)

Address Register name Bit Type Reset value Function

0x61 TEMP_DATA 8 R 0x00

0x62 TEMP_TH 8 R/W 0x00

Temperature data access

port

Threshold for temperature

controlled interrupt

Doc ID 14489 Rev 6 21/65

Page 22

System and identification registers STMPE811

7 System and identification registers

Table 12. System and identification registers map

Address Register name Bit Type Reset Function

0x00 CHIP_ID 16 R 0x0811 Device identification

0x02 ID_VER 8 R 0x03

Revision number

(0x03 for engineering sample)

0x03 SYS_CTRL1 8 R/W 0x00 Reset control

0x04 SYS_CTRL2 8 R/W 0x0F Clock control

0x08 SPI_CFG 8 R/W 0x01 SPI interface configuration

22/65 Doc ID 14489 Rev 6

Page 23

STMPE811 System and identification registers

CHIP_ID Device identification

Address: 0x00

Type: R

Reset: 0x0811

Description: 16-bit device identification

ID_VER Revision number

Address: 0x02

Type: R

Reset: 0x03 (0x01 for engineering samples)

Description: 16-bit revision number

SYS_CTRL1 Reset control

76543 2 1 0

RESERVED SOFT_RESET HIBERNATE

Address: 0x03

Type: R/W

Reset: 0x00

Description: The reset control register enables to reset the device

[7:2] RESERVED

[1] SOFT_RESET: Reset the STMPE811 using the serial communication interface

[0] HIBERNATE: Force the device into hibernation mode.

Forcing the device into hibernation mode by writing ‘1’ to this bit would disable the hot-key

feature. If the hot-key feature is required, use the default auto-hibernation mode.

SYS_CTRL2 Clock control

76543 2 1 0

----TS_OFFGPIO_OFFTSC_OFFADC_OFF

Address: 0x04

Type: R/W

Reset: 0x0F

Description: This register enables to switch off the clock supply

[7:4] RESERVED

[3] TS_OFF: Switch off the clock supply to the temperature sensor

1: Switches off the clock supply to the temperature sensor

[2] GPIO_OFF: Switch off the clock supply to the GPIO

1: Switches off the clock supply to the GPIO

Doc ID 14489 Rev 6 23/65

Page 24

System and identification registers STMPE811

[1] TSC_OFF: Switch off the clock supplyto the touchscreen controller

1: Switches off the clock supply to the touchscreen controller

[0] ADC_OFF: Switch off the clock supply to the ADC

1: Switches off the clock supply to the ADC

SPI_CFG SPI interface configuration

76543 2 1 0

RESERVED AUTO_INCR SPI_CLK_MOD1 SPI_CLK_MOD0

Address: 0x08

Type: R/W

Reset: 0x01

Description: SPI interface configuration register

[7:3] RESERVED

[2] AUTO_INCR:

This bit defines whether the SPI transaction follows an addressing scheme that internally

autoincrements or not

[1] SPI_CLK_MOD1:

This bit reflects the value of the SCAD/A0 pin during power-up reset

[0] SPI_CLK_MOD0:

This bit reflects the value of the SCAD/A0 pin during power-up reset

24/65 Doc ID 14489 Rev 6

Page 25

STMPE811 Interrupt system

8 Interrupt system

The STMPE811 uses a 2-tier interrupt structure. The ADC interrupts and GPIO interrupts

are ganged as a single bit in the “interrupt status register”. The interrupts from the

touchscreen controller and temperature sensor can be seen directly in the interrupt status

register.

Figure 8. Interrupt system diagram

GPIO

interrupt

status

GPIO

interrupt

enable

ADC

interrupt

status

ADC

interrupt

enable

FIFO status,

TSC touch,

Temp sensor

AND

AND

Interrupt

status

Interrupt

enable

AND

Doc ID 14489 Rev 6 25/65

Page 26

Interrupt system STMPE811

INT_CTRL Interrupt control register

76543 2 1 0

RESERVED INT_POLARITY INT_TYPE GLOBAL_INT

Address: 0x09

Type: R/W

Reset: 0x00

Description: The interrupt control register is used to enable the interruption from a system-related

interrupt source to the host.

[7:3] RESERVED

[2] INT_POLARITY: This bit sets the INT pin polarity

1: Active high/rising edge

0: Active low/falling edge

[1] INT_TYPE: This bit sets the type of interrupt signal required by the host

1: Edge interrupt

0: Level interrupt

[0] GLOBAL_INT: This is master enable for the interrupt system

1: Global interrupt

0: Stops all interrupts

INT_EN Interrupt enable register

76543 2 1 0

GPIO ADC TEMP_SENS FIFO_EMPTY FIFO_FULL FIFO_0FLOW FIFO_TH TOUCH_DET

Address: 0x0A

Type: R/W

Reset: 0x00

Description: The interrupt enable register is used to enable the interruption from a system related

interrupt source to the host.

[7] GPIO: Any enabled GPIO interrupts

[6] ADC: Any enabled ADC interrupts

[5] TEMP_SENS: Temperature threshold triggering

[4] FIFO_EMPTY: FIFO is empty

[3] FIFO_FULL: FIFO is full

[2] FIFO_OFLOW: FIFO is overflowed

[1] FIFO_TH: FIFO is equal or above threshold value.

[0] TOUCH_DET: Touch is detected

INT_STA Interrupt status register

76543 2 1 0

GPIO ADC TEMP_SENS FIFO_EMPTY FIFO_FULL FIFO_OFLOW FIFO_TH TOUCH_DET

26/65 Doc ID 14489 Rev 6

Page 27

STMPE811 Interrupt system

Address: 0x0B

Type: R

Reset: 0x10

Description: The interrupt status register monitors the status of the interruption from a particular

interrupt source to the host. Regardless of whether the INT_EN bits are enabled, the

INT_STA bits are still updated. Writing '1' to this register clears the corresponding

bits. Writing '0' has no effect.

[7] GPIO: Any enabled GPIO interrupts

[6] ADC: Any enabled ADC interrupts

[5] TEMP_SENS: Temperature threshold triggering

[4] FIFO_EMPTY: FIFO is empty

[3] FIFO_FULL: FIFO is full

[2] FIFO_OFLOW: FIFO is overflowed

[1] FIFO_TH: FIFO is equal or above threshold value.

This bit is set when FIFO level equals to threshold value. It will only be asserted again if FIFO

level drops to < threshold value, and increased back to threshold value.

[0] TOUCH_DET: Touch is detected

GPIO_INT_EN GPIO interrupt enable register

76543 2 1 0

IEG[x]

Address: 0x0C

Type: R/W

Reset: 0x00

Description: The GPIO interrupt register enables the GPIO interruption of a particular GPIO

source to the host.

[7:0] IEG[x]: Interrupt enable GPIO mask (where x = 7 to 0)

1: Writing ‘1’ to the IE[x] bit enables the interruption to the host

GPIO_INT_STA GPIO interrupt status register

76543 2 1 0

ISG[x]

Address: 0x0D

Type: R

Reset: 0x00

Description: The GPIO interrupt status register monitors the status of the interruption from a

particular GPIO pin interrupt source to the host. Regardless of whether or not the

GPIO_INT_STA bits are enabled, the corresponding GPIO_STA bits are still updated.

Doc ID 14489 Rev 6 27/65

Page 28

Interrupt system STMPE811

The ISG[7:0] bits are the interrupt status bits corresponding to the GPIO[7:0] pins.

Writing '1' to this register clears the corresponding bits. Writing '0' has no effect.

[7:0] ISG[x]: GPIO interrupt status (where x = 7 to 0)

Read:

Interrupt status of the GPIO[x]. Reading the register clears any bits that have been set to '1'

Write:

Writing to this register has no effect

ADC_INT_EN ADC interrupt enable register

76543 2 1 0

IEAC[x]

Address: 0x0E

Type: R/W

Reset: 0x00

Description: The ADC enable register enables the interruption of a particular ADC source to the

host.

[7:0] IEAC[x]: Interrupt enable ADC mask (where x = 7 to 0)

1: Writing ‘1’ to the IE[x] bit enables the interruption to the host

ADC_INT_STA ADC interrupt status register

76543 2 1 0

ISA[x]

Address: 0x0F

Type: R

Reset: 0x00

Description: The ADC interrupt status register monitors the status of the interruption from a

particular ADC source to the host. Regardless of whether or not the ADC_INT_EN

bits are enabled, the corresponding ADC_STA bits are still updated. The ISA[7:0] bits

are the interrupt status bits corresponding to the ADC[7:0] pins. Writing '1' to this

register clears the corresponding bits. Writing '0' has no effect.

[7:0] ISA[x]: ADC interrupt status (where x = 7 to 0)

Read:

Interrupt status of the ADC[x]. Reading the register clears any bits that have been set to '1'

Write:

Writing to this register has no effect.

Note: Refer to Ta bl e 1 3 for the associated ADC intput pins to each ADC channels.

28/65 Doc ID 14489 Rev 6

Page 29

STMPE811 Analog-to-digital converter

9 Analog-to-digital converter

An 8-input,12-bit analog-to-digital converter (ADC) is integrated in the STMPE811. The ADC

can be used as a generic analog-to-digital converter, or as a touchscreen controller capable

of controlling a 4-wire resistive touchscreen.

Table 13. ADC controller register summary table

Address Register name Size Description

0x20 ADC_CTRL1 8 ADC control

0x21 ADC_CTRL2 8 ADC control

0x22 ADC_CAPT 8 ADC channel data capture

0x30 ADC_DATA_CH0 8 ADC channel 0 (X+/GPIO-4)

0x32 ADC_DATA_CH1 8 ADC channel 1 (X-/GPIO-6)

0x34 ADC_DATA_CH2 8 ADC channel 2 (Y+/GPIO-5)

0x36 ADC_DATA_CH3 8 ADC channel 3 (Y-/GPIO-7)

0x38 ADC_DATA_CH4 8 ADC channel 4 (IN0/GPIO0)

0x3A ADC_DATA_CH5 8 ADC channel 5 (IN1/GPIO-1)

0x3C ADC_DATA_CH6 8 ADC channel 6 (IN2/GPIO-2)

0x3E ADC_DATA_CH7 8 ADC channel 7 (IN3/GPIO-3)

Doc ID 14489 Rev 6 29/65

Page 30

Analog-to-digital converter STMPE811

ADC_CTRL1 ADC control 1

76543210

RESERVED SAMPLE_TIME2 SAMPLE_TIME1 SAMPLE_TIME0 MOD_12B RESERVED REF_SEL RESERVED

Address: 0x20

Type: R/W

Reset: 0x1C

Description: ADC control register.

[7] RESERVED

[6:4] SAMPLE_TIMEn: ADC conversion time in number of clock

000: 36

001: 44

010: 56

011: 64

100: 80

101: 96

110: 124

111: Not valid

[3] MOD_12B: Selects 10 or 12-bit ADC operation

1: 12 bit ADC

0: 10 bit ADC

[2] RESERVED

[1] REF_SEL: Selects between internal or external reference for the ADC

1: External reference

0: Internal reference

[0] RESERVED

ADC_CTRL2 ADC control 2

76543 2 1 0

RESERVED ADC_FREQ_1 ADC_FREQ_0

Address: 0x21

Type: R/W

Reset: 0x01

Description: ADC control.

[7] RESERVED

[6] RESERVED

[5] RESERVED

[4] RESERVED

[3] RESERVED

[2] RESERVED

30/65 Doc ID 14489 Rev 6

Page 31

STMPE811 Analog-to-digital converter

[1:0] ADC_FREQ: Selects the clock speed of ADC

00: 1.625 MHz typ.

01: 3.25 MHz typ.

10: 6.5 MHz typ.

11: 6.5 MHz typ.

ADC_CAPT ADC channel data capture

76543 2 1 0

CH[7:0]

Address: 0x22

Type: R/W

Reset: 0xFF

Description:

To initiate ADC data acquisition.

[7:0] CH[7:0]: ADC channel data capture

Write '1' to initiate data acquisition for the corresponding channel. Writing '0' has no effect.

Reads '1' if conversion is completed. Reads '0' if conversion is in progress.

ADC_DATA_CHn ADC channel data registers

11109876543 2 1 0

DATA[11:0]

Address: Add address

Type: R/W

Reset: 0x0000

Description:

ADC data register 0-7 (DATA_CHn=0 -7)

[11:0] DATA[11:0]: ADC channel data

If TSC is enabled, CH3-0 is used for TSC and all readings to these channels give 0x0000

The ADC in STMPE811 operates on an internal RC clock with a typical frequency of

6.5 MHz. The total conversion time in ADC mode depends on the "SampleTime" setting,

and the clock division field 'Freq'.

The following table shows the conversion time based on 6.5 MHz, 3.25 MHz and 1.625 MHz

clock.

Table 14. ADC conversion time

Sample time

setting

000 36 5.5 µs (180 kHz) 11 µs (90 kHz) 22 µs (45 kHz)

001 44 6.8 µs (147 kHz) 13.6 µs (74 kHz) 27 µs (36 kHz)

010 56 8.6 µs (116 kHz) 17.2 µs (58 kHz) 34.4 µs (29 kHz)

011 64 9.9 µs (101 kHz) 19.8 µs (51 kHz) 39.6 µs (25 kHz)

Conversion time

in ADC clock

Doc ID 14489 Rev 6 31/65

6.5 MHz

(154 ns)

3.25 MHz

(308 ns)

1.625 MHz

(615 ns)

Page 32

Analog-to-digital converter STMPE811

Table 14. ADC conversion time

Sample time

setting

100 80 12.3 µs(81.5 kHz) 24.6 µs (41 kHz) 49.2 µs (20 kHz)

101 96 14.8 µs (67.6 kHz) 28.8 µs (33 kHz) 59.2 µs (17 kHz)

110 124 19.1 µs (52.3 kHz) 38.2 µs (26 kHz) 56.4 µs (13 kHz)

Conversion time

in ADC clock

6.5 MHz

(154 ns)

3.25 MHz

(308 ns)

1.625 MHz

(615 ns)

32/65 Doc ID 14489 Rev 6

Page 33

STMPE811 Touchscreen controller

10 Touchscreen controller

The STMPE811 is integrated with a hard-wired touchscreen controller for 4-wire resistive

type touchscreen. The touchscreen controller is able to operate completely autonomously,

and interrupt the connected CPU only when a pre-defined event occurs.

Figure 9. Touchscreen controller block diagram

Movement

&

window tracking

FIFO

FIFO

&

interrupt control

10.1 Driver and switch control unit

The driver and switch control unit allows coordination of the ADC and the MUX/switch. With

the coordination of this unit, a stream of data is produced at a selected frequency.

The touchscreen drivers can be configured with 2 current ratings: 20 mA or 50 mA. In the

case where multiple touch-down on the screen is causing a short, the current from the driver

is limited to these values. Tolerance of these current setting is +/- 25%.

Movement tracking

10/12 bit

ADC

Driver

&

switch control

Switch

&

drivers

s

The "Tracking Index" in the TSC_CTRL register specifies a value, which determines the

distance between the current touch position and the previous touch position. If the distance

is shorter than the tracking index, it is discarded.

The tracking is calculated by summation of the horizontal and vertical movement. Movement

is only reported if:

(Current X - Previously Reported X) + (Current Y - Previously Reported Y) > Tracking Index

If pressure reporting is enabled (X/Y/Z), an increase in pressure override the movement

tracking and report the new data set, even if X/Y is within the previous tracking index. This is

to ensure that a slow touch is not discarded.

If pressure data is not used, select X/Y mode in touchscreen data acquisition. (Opmode field

in TSCControl register).

Doc ID 14489 Rev 6 33/65

Page 34

Touchscreen controller STMPE811

Window tracking

The -WDW_X and WDW_Y registers allow to pre-set a sub-window in the touchscreen such

that any touch position that is outside the sub-window is discarded.

Figure 10. Window tracking

Top right coordinates

Active window

Bottom left coordinates

FIFO

FIFO has a depth of 128 sectors. This is enough for 128 sets of touch data at maximum

resolution (2 x 12 bits). FIFO can be programmed to generate an interrupt when it is filled to

a pre-determined level.

Sampling

The STMPE811 touchscreen controller has an internal 180 kHz, 12-bit ADC able to execute

autonomous driving/sampling. Each "sample" consists of 4 ADC readings that provide the X

and Y locations, as well as the touch pressure.

Figure 11. Sampling

Drive X

ADC

takes X reading

Settling

period

Drive Y

Settling

period

ADC

takes Y reading

34/65 Doc ID 14489 Rev 6

Page 35

STMPE811 Touchscreen controller

Sampling time calculation

The equation for a complete sampling cycle is described below.

Figure 12. Sampling time calculation

-

-

Settling Time

Sampling X

Settling Time

Sampling Y

Settling Time

To uch Detect Delay

A complete sampling cycle

Sampling Z

To uch Detect Delay

Time taken for sampling;

- Touch Detect Delay x 2 + Settling Time x 3 + (AVE_CTRL x ADC_SAMPLE_TIME) x 3 for X/Y/Z mode

- Touch Detect Delay x 2 + Settling Time x 2 + (AVE_CTRL x ADC_SAMPLE_TIME) x 2 for X/Y mode

AM08681V3

Oversampling and averaging function

The STMPE811 touchscreen controller can be configured to oversample by 2/4/8 times and

provide the averaged value as final output. This feature helps to reduce the effect of

surrounding noise.

Table 15. Touchscreen controller register summary table

Address Register name Bit Type Function

0x40 TSC_CTRL 8 R/W 4-wire touchscreen controller setup

0x41 TSC_CFG 8 R/W TSC configuration register

0x42 WDW_TR_X 16 R/W Window setup for top right X

0x44 WDW_TR_Y 16 R/W Window setup for top right Y

0x46 WDW_TR_X 16 R/W Window setup for bottom left X

0x48 WDW_TR_Y 16 R/W Window setup for bottom left Y

0x4A FIFO_TH 8 R/W FIFO level to generate interrupt

0x4B FIFO_STA 8 R/W Current status of FIFO

0x4C FIFO_SIZE 8 R Current filled level of FIFO

0x4D TSC_DATA_X 16 R Data port for TSC data access

0x4F TSC_DATA_Y 16 R Data port for TSC data access

Doc ID 14489 Rev 6 35/65

Page 36

Touchscreen controller STMPE811

Table 15. Touchscreen controller register summary table

Address Register name Bit Type Function

0x51 TSC_DATA_Z 8 R Data port for TSC data access

0x52 TSC_DATA_XYZ 32 R Data port for TSC data access

0x56 TSC_FRACT_Z 8 R/W Touchscreen controller FRACTION_Z

0x57 TSC_DATA 8 R Touchscreen controller data access port

0x58 TSC_I_DRIVE 8 R/W Touchscreen controller drive I

0x59 TSC_SHIELD 8 R/W Touchscreen controller shield

36/65 Doc ID 14489 Rev 6

Page 37

STMPE811 Touchscreen controller

TSC_CTRL touchscreen controller control register

76543 2 1 0

TSC_STA TRACK OP_MOD EN

Address: 0x40

Type: R/W

Reset: 0x90

Description: 4-wire touchscreen controller (TSC) setup.

[7] TSC_STA: TSC status

Reads '1' when touch is detected

Reads '0' when touch is not detected

Writing to this register has no effect

[6:4] TRACK: Tracking index

000: No window tracking

001: 4

010: 8

011: 16

100: 32

101: 64

110: 92

111: 127

[3:1] OP_MOD: TSC operating mode

000: X, Y, Z acquisition

001: X, Y only

010: X only

011: Y only

100: Z only

This field cannot be written on, when EN = 1

[0] EN: Enable TSC

TSC_CFG Touchscreen controller configuration register

76543 2 1 0

AVE_CTRL_1 AVE_CTRL_0

TOUCH_DET

_DELAY_2

Address: 0x41

Type: R/W

Description: Touchscreen controller configuration register.

[7:6] [AVE_CTRL_1/0: Average control

00=1 sample

01=2 samples

10=4 samples

11=8 samples

TOUCH_DET

_DELAY_1

TOUCH_DET

_DELAY_0

SETTLING_2 SETTLING_1 SETTLING_0

Doc ID 14489 Rev 6 37/65

Page 38

Touchscreen controller STMPE811

[5:3] TOUCH_DET_DELAY_2/1/0: Touch detect delay

000 - 10 μs

001 - 50 μs

010 = 100 μs

011 = 500 μs

100=1ms

101=5ms

110 = 10 ms

111 = 50 ms

[2:0] SETTLING: Panel driver settling time

000 = 10 μs

001 = 100 μs

010 = 500 μS

011=1ms

100=5ms

101 = 10 ms

110 = 50 ms

111=100ms

1. For large panels (> 6”), a capacitor of 10 nF is recommended at the touchscreen terminals for noise filtering.

In this case, settling time of 1 ms or more is recommended.

(1)

38/65 Doc ID 14489 Rev 6

Page 39

STMPE811 Touchscreen controller

10.2 Touch detect delay

Touch Detect Delay is an additional method used to compensate for the time it takes for the

panel voltage to be pulled high during a non-touch condition.

For example, the way it works to detect a touch:

X+ is pulled high and Y+ is driven low. After Touch Detect Delay is expired the level of X+ is

read. If no touch, X+ is high. If there is a touch, X+ is low.

If the initial voltage of X+ is low before being pulled high by the internal resistor, especially if

a filtering capacitor is connected, this time needs to be compensated. The Touch Delay

setting provides time for the voltage to be pulled high in a non-touch condition and avoids a

false report of a touch condition.

Normally the Touch Detect Delay needs to be long enough to allow the voltage to rise to V+

in a non-touch condition and this will depend on the presence of external filtering capacitors.

For more details on recommendation of Touch Detect delay register setting, refer to

STMPE811 Application Note (AN2825 ST document).

Doc ID 14489 Rev 6 39/65

Page 40

Touchscreen controller STMPE811

WDW_TR_X Window setup for top right X

7 6543 2 1 0

TR_X [11:0]

Address: 0x42

Type: R/W

Reset: 0x0FFF

Description:

Window setup for top right X coordinates.

[11:0] TR_X: Bit 11:0 of top right X coordinates

WDW_TR_Y Window setup for top right Y

7 6543 2 1 0

TR_Y [11:0]

Address: 0x44

Type: R/W

Reset: 0x0FFF

Description:

Window setup for top right Y coordinates.

[11:0] TR_X: Bit 11:0 of top right Y coordinates

WDW_BL_X Window setup for bottom left X

7 6543 2 1 0

BL_X [11:0]

Address: 0x46

Type: R/W

Reset: 0x0000

Description:

Window setup for bottom left X coordinates.

[11:0] BL_X: Bit 11:0 of bottom left X coordinates

WDW_BL_Y Window setup for bottom left Y

7 6543 2 1 0

BL_Y [11:0]

Address: 0x48

Type: R/W

Reset: 0x0000

Description:

40/65 Doc ID 14489 Rev 6

Window setup for bottom left Y coordinates.

[11:0] BL_X: Bit 11:0 of bottom left Y coordinates

Page 41

STMPE811 Touchscreen controller

FIFO_TH FIFO threshold

76543 2 1 0

FIFO_TH

Address: 0x4A

Type: R/W

Reset: 0x00

Description:

Triggers an interrupt upon reaching or exceeding the threshold value. This field must not be set

as zero.

[7:0] FIFO_TH: touchscreen controller FIFO threshold

FIFO_STA FIFO status

765432 1 0

FIFO_OFLOW FIFO_FULL FIFO_EMPTY FIFO_TH_TRIG RESERVED FIFO_RESET

Address: 0x4B

Type: R/W

Reset: 0x20

Description:

Current status of FIFO..

[7] FIFO_OFLOW:

Reads 1 if FIFO is overflow

[6] FIFO_FULL:

Reads 1 if FIFO is full

[5] FIFO_EMPTY:

Reads 1 if FIFO is empty

[4] FIFO_TH_TRIG:

0 = Current FIFO size is still below the threshold value

1 = Current FIFO size is at or beyond the threshold value

[3:1] RESERVED

[0] FIFO_RESET:

Write '0' : FIFO put out of reset mode

Write '1' : Resets FIFO. All data in FIFO are cleared.

When TSC is enabled, FIFO resets automatically.

Doc ID 14489 Rev 6 41/65

Page 42

Touchscreen controller STMPE811

FIFO_SIZE FIFO size

76543 2 1 0

RESERVED FIFO_SIZE

Address: 0x4C

Type: R

Reset: 0x00

Description: Current number of samples available.

[7:0] FIFO_SIZE: Number of samples available

TSC_DATA_X TSC_DATA_X

11109876543 2 1 0

DATAY[11:0]

Address: 0x4D

Type: R

Reset: 0x0000

Description: Bit 11:0 of X data.

[11:0] DATAY[11:0]: Bit 11:0 of X data

TSC_DATA_Y TSC_DATA_Y

11109876543 2 1 0

DATAY[11:0]

Address: 0x4F

Type: R

Reset: 0x0000

Description: Bit 11:0 of Y data.

[11:0] DATAY[11:0]: bit 11:0 of Y data

TSC_DATA_Z TSC_DATA_Z

76543 2 1 0

DATAZ[7:0]

Address: 0x51

Type: R

Reset: 0x0000

Description: Bit 7:0 of Z data.

[7:0] DATAZ[7:0]: bit 7:0 of Z data

42/65 Doc ID 14489 Rev 6

Page 43

STMPE811 Touchscreen controller

TSC_DATA_XYZ Touchscreen controller DATA

76543 2 1 0

DATA

Address: 0x57 (auto-increment), 0xD7 (non-auto-increment)

Type: R

Reset: 0x00

Description: Data port for TSC data access

[11:0] DATA: data bytes from TSC FIFO

The data format from the TSC_DATA register depends on the setting of "OpMode" field in

TSC_CTRL register. The samples acquired are accessed in "packed samples". The size of

each "packed sample" depends on which mode the touchscreen controller is operating in.

The TSC_DATA register can be accessed in 2 modes:

● Autoincrement

● Non autoincrement

To access the 128-sets buffer, the non autoincrement mode should be used.

Table 16. Touchscreen controller DATA register

TSC_CTRL in

operation

mode

000 4 [11:4] of X

001 3 [11:4] of X

010 2 [11:4] of X [3:0] of X

011 2 [11:4] of Y [3:0] of Y

100 1 [7:0] of Z -

Number of

bytes to read

from

TSC_DATA_XYZ

Byte0 Byte1 Byte2 Byte3

[3:0] of X

[11:8] of Y

[3:0] of X

[11:8] of Y

[7:0] of Y [7:0] of Z

[7:0] of Y

−

−−

−−

−−

Doc ID 14489 Rev 6 43/65

Page 44

Touchscreen controller STMPE811

TSC_FRACTION_Z Touchscreen controller FRACTION_Z

76543 2 1 0

RESERVED FRACTION_Z

Address: 0x56

Type: R

Reset: 0x00

Description: This register allows to select the range and accuracy of the pressure measurement

[7:3] RESERVED

[2:0] FRACTION_Z:

000: Fractional part is 0, whole part is 8

001: Fractional part is 1, whole part is 7

010: Fractional part is 2, whole part is 6

011: Fractional part is 3, whole part is 5

100: Fractional part is 4, whole part is 4

101: Fractional part is 5, whole part is 3

110: Fractional part is 6, whole part is 2

111: Fractional part is 7, whole part is 1

TSC_I_DRIVE Touchscreen controller drive I

76543 2 1 0

RESERVED DRIVE

Address: 0x58

Type: R/W

Reset: 0x00

Description: This register sets the current limit value of the touchscreen drivers

[7:1] RESERVED

[0] DRIVE: maximum current on the touchscreen controller (TSC) driving channel

0: 20 mA typical, 35 mA max

1: 50 mA typical, 80 mA max

TSC_SHIELD Touchscreen controller shield

76543 2 1 0

RESERVED X+ X- Y+ Y-

Address: 0x59

Type: R

Reset: 0x00

Description: Writing each bit would ground the corresponding touchscreen wire

[7:4] RESERVED

44/65 Doc ID 14489 Rev 6

Page 45

STMPE811 Touchscreen controller

[3:0] SHIELD[3:0]:

Write 1 to GND X+, X-, Y+, Y- lines

Doc ID 14489 Rev 6 45/65

Page 46

Touchscreen controller programming sequence STMPE811

11 Touchscreen controller programming sequence

The following are the steps to configure the touchscreen controller (TSC):

a) Disable the clock gating for the touchscreen controller and ADC in the SYS_CFG2

register.

b) Configure the touchscreen operating mode and the window tracking index.

c) A touch detection status may also be enabled through enabling the corresponding

interrupt flag. With this interrupt, the user is informed through an interrupt when

the touch is detected as well as lifted.

d) Configure the TSC_CFG register to specify the “panel voltage settling time”, touch

detection delays and the averaging method used.

e) A windowing feature may also be enabled through TSCWdwTRX, TSCWdwTRY,

TSCWdwBLX and TSCWdwBLY registers. By default, the windowing covers the

entire touch panel.

f) Configure the TSC_FIFO_TH register to specify the threshold value to cause an

interrupt. The corresponding interrupt bit in the interrupt module must also be

enabled. This interrupt bit should be masked off during data fetching from the

FIFO in order to prevent an unnecessary trigger of this interrupt. Upon completion

of the data fetching, this bit can be re-enabled

g) By default, the FIFO_RESET bit in the TSC_FIFO_CTRL_STA register holds the

FIFO in Reset mode. Upon enabling the touchscreen controller (through the EN

bit in TSC_CTRL), this FIFO reset is automatically deasserted. The FIFO status

may be observed from the TSC_FIFO_CTRL_STA register or alternatively through

the interrupt.

h) Once the data is filled beyond the FIFO threshold value, an interrupt is triggered

(assuming the corresponding interrupt is being enabled). The user is required to

continuously read out the data set until the current FIFO size is below the

threshold, then, the user may clear the interrupt flag. As long as the current FIFO

size exceeds the threshold value, an interrupt from the touchscreen controller is

sent to the interrupt module. Therefore, even if the interrupt flag is cleared, the

interrupt flag is automatically asserted, as long as the FIFO size exceeds the

threshold value.

i) The current FIFO size can be obtained from the TSC_FIFO_Sz register. This

information may assists the user in how many data sets are to be read out from

the FIFO, if the user intends to read all in one shot. The user may also read a data

set by a data set.

j) The TSC_DATA_X register holds the X-coordinates. This register can be used in

all touchscreen operating modes.

k) The TSC_DATA_Y register holds the Y-coordinates. TSC_DATA_Y register holds

the Y-coordinates.

l) The TSC_DATA_Z register holds the Z value. TSC_DATA_Z register holds the Z-

coordinates.

m) The TSCDATA_XYZ register holds the X, Y and Z values. These values are

packed into 4 bytes. This register can only be used when the touchscreen

operating mode is 000 and 001. This register is to facilitate less byte read.

n) For the TSC_FRACT_Z register, the user may configure it based on the

touchscreen panel resistance. This allows the user to specify the resolution of the

46/65 Doc ID 14489 Rev 6

Page 47

STMPE811 Touchscreen controller programming sequence

Z value. With the Z value obtained from the register, the user simply needs to

multiply the Z value with the touchscreen panel resistance to obtain the touch

resistance.

o) The TSC_DATA register allows facilitation of another reading format with minimum

2

I

C transaction overhead by using the non autoincrement mode (or equivalent

mode in SPI). The data format is the same as TSC_DATA_XYZ, with the

exception that all the data fetched are from the same address.

p) Enable the EN bit of the TSC_CTRL register to start the touch detection and data

acquisition.

q) During the auto-hibernate mode, a touch detection can cause a wake-up to the

device only when the TSC is enabled and the touch detect status interrupt mask is

enabled.

r) In order to prevent confusion, it is recommended that the user not mix the data

fetching format (TSC_DATA_X, TSC_DATA_Y, TSC_DATA_Z, TSC_DATA_XYZ

and TSC_DATA) between one reading and the next.

s) It is also recommended that the user should perform a FIFO reset and TSC

disabling when the ADC or TSC setting are reconfigured.

Doc ID 14489 Rev 6 47/65

Page 48

Temperature sensor STMPE811

12 Temperature sensor

The STMPE811 internal temperature sensor can be used as a reference for compensation

of the touchscreen parameters. Temperature measurement is optimised for temperature

from 0

Table 17. Touchscreen parameters

° C to 85 ° C.

Address Register name Bit Function

0x60 TEMP_CTRL 8 Temperature sensor setup

0x61 TEMP_DATA 16 Temperature data access port

0x63 TEMP_TH 16 Threshold for temperature controlled interrupt

48/65 Doc ID 14489 Rev 6

Page 49

STMPE811 Temperature sensor

TEMP_CTRL Temperature sensor setup

765 4 3 2 1 0

RESERVED THRES_RANGE THRES_EN ACQ_MOD ACQ ENABLE

Address: 0x60

Type: R/W

Reset: 0x00

Description:

Temperature sensor setup

[7:5] RESERVED

[4] THRES_RANGE:

'0' assert interrupt if temperature is >= threshold

'1' assert interrupt if otherwise

[3] THRES_EN: temperature threshold enable

[2] ACQ_MOD:

'0' to acquire temperature for once only

'1' to acquire temperature every 10mS

[1] ACQ

[0] ENABLE

TEMP_DATA Temperature data

11109876543 2 1 0

TEMPERATURE

Address: 0x61 is MSB, 0x62 is LSB

Type: R

Reset: 0x00

Description:

Temperature data access port

[11:0] TEMPERATURE: Temperature reading

Absolute temperature

* temperature [11:0] ) / 7.51 (12-bit ADC)

= ( V

IO

= ( V

* temperature [9:0] ) / 7.51 (10-bit ADC)

IO

Note that V

Variations in V

is used as a reference in temperature acquisition.

IO

directly affect the accuracy of temperature acquired.

IO

Doc ID 14489 Rev 6 49/65

Page 50

Temperature sensor STMPE811

TEMP_TH Temperature threshold

11109876543 2 1 0

TEMP_TH

Address: 0x63 is MSB, 0x64 is LSB

Type: R/W

Reset: 0x00

Description:

Threshold for temperature controlled interrupt

[11:0] TEMP_TH: temperature threshold

50/65 Doc ID 14489 Rev 6

Page 51

STMPE811 GPIO controller

13 GPIO controller

A total of 8 GPIOs are available in the STMPE811 port expander device. Most of the GPIOs

share physical pins with some alternate functions. The GPIO controller contains the

registers that allow the host system to configure each of the pins into either a GPIO, or one

of the alternate functions. Unused GPIOs should be configured as outputs to minimize

power consumption.

A group of registers are used to control the exact function of each of the 8 GPIOs. The

registers and their respective addresses are listed in the following table.

Table 18. GPIO control registers

Address Register name

0x10 GPIO_SET_PIN 8 Set pin register

0x11 GPIO_CLR_PIN 8 Clear pin state

0x12 GPIO_MP_STA 8 Monitor pin state

0x13 GPIO_DIR 8 Set pin direction

0x14 GPIO_ED 8 Edge detect status

0x15 GPIO_RE 8

0x16 GPIO_FE 8

0x17 GPIO_ALT_FUNCT 8 Alternate function register

Size

(bit)

Function

Rising edge detection

enable

Falling edge detection

enable

All GPIO registers are named as GPIO-x, where x represents the functional group.

76543 2 1 0

GPIO-7 GPIO-6 GPIO-5 GPIO-4 GPIO-3 GPIO-2 GPIO-1 GPIO-0

GPIO_SET_PIN GPIO set pin register

Address: 0x10

Type: R/W

Reset: 0x00

Description: GPIO set pin register.

Writing 1 to this bit causes the corresponding GPIO to go to 1 state.

Writing 0 has no effect.

Doc ID 14489 Rev 6 51/65

Page 52

GPIO controller STMPE811

GPIO_CLR_PIN Clear pin state register

Address: 0x11

Type: R/W

Reset: 0x00

Description: GPIO clear pin state register.

Writing ‘1’ to this bit causes the corresponding GPIO to go to 0 state.

Writing ‘0’ has no effect.

GPIO_MP_STA GPIO monitor pin state register

Address: 0x12

Type: R/W

Reset: 0x00

Description: GPIO monitor pin state.

Reading this bit yields the current state of the bit. Writing has no effect.

GPIO_DIR GPIO set pin direction

Address: 0x13

Type: R/W

Reset: 0x00

Description: GPIO set pin direction register.

Writing ‘0’ sets the corresponding GPIO to input state, and ‘1’ sets it to output state.

All bits are ‘0’ on reset.

GPIO_ED_STA GPIO edge detect status

Address: 0x14

Type: R/W

Reset: 0x00

Description: GPIO edge detect status register. An edge transition has been detected.

52/65 Doc ID 14489 Rev 6

Page 53

STMPE811 GPIO controller

GPIO_RE Rising edge register

Address: 0x15

Type: R/W

Reset: 0x00

Description: GPIO rising edge detection enable register.

Setting this bit to ‘1’ would enable the detection of the rising edge transition.

The detection would be reflected in the GPIO edge detect status register.

GPIO_FE Falling edge detection enable register

Address: 0x16

Type: R/W

Reset: 0x00

Description: Setting this bit to ‘1’ would enable the detection of the falling edge transition.

The detection would be reflected in the GPIO edge detect status register.

GPIO_ALT_FUNCT Alternate function register

Address: 0x17

Type: R/W

Reset: 0x0F

Description: Alternate function register. "‘0’ sets the corresponding pin to function as

touchscreen/ADC, and ‘1’ sets it into GPIO mode.

13.0.1 Power supply

The STMPE811 GPIO operates from a separate supply pin (VIO). This dedicated supply pin

provides a level-shifting feature to the STMPE811. The GPIO remains valid until V

IO

is

removed.

The host system may choose to turn off V

not allowed to turn off supply to V

, while keeping the Vcc supplied.

IO

The touchscreen is always powered by V

supply while keeping VIO supplied. However it is

cc

. For better resolution and noise immunity, VIO

IO

above 2.8 V is advised.

13.0.2 Power-up reset (POR)

The STMPE811 is equipped with an internal POR circuit that holds the device in reset state,

until the V

On power-up reset, all GPIOs are set as input.

supply input is valid. The internal POR is tied to the VIO supply pin.

IO

Doc ID 14489 Rev 6 53/65

Page 54

Maximum rating STMPE811

14 Maximum rating

Stressing the device above the ratings listed in the “Absolute maximum ratings” table may

cause permanent damage to the device. These are stress ratings only, and operation of the

device at these or any other conditions above those indicated in the operating sections of

this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect the device’s reliability.

Table 19. Absolute maximum ratings

Symbol Parameter Value Unit

V

V

Supply voltage 4.5 V

CC

GPIO supply voltage 4.5 V

IO

ESD ESD protection on each GPIO pin (air discharge) 4 kV

T Operating temperature -40 - 85 °C

T

Storage temperature -65 - 155 °C

STG

Thermal resistance junction-ambient 96 °C/W

T

J

54/65 Doc ID 14489 Rev 6

Page 55

STMPE811 Maximum rating

14.1 Recommended operating conditions

Table 20. Power consumption

Val ue

Symbol Parameter Test condition

Min Typ Max

Unit

Vcc I/O supply voltage

V

I

CC-active

I

IO-active

I

IO-active

I

CC-

hibernate

I

IO-hibernate

Core supply voltage 1.65

IO

Core supply current

I/O supply current

I/O supply current

Core supply current

I/O supply current

Vio >= Vcc

Touchscreen

controller at 100 Hz

sampling

=1.8− 3.3 V

V

CC

Touchscreen

controller at 100 Hz

sampling

=1.8V

V

IO

Touchscreen

controller at 100 Hz

sampling

=3.3V

V

IO

Hibernate state, no

I2C/SPI activity

=1.8V

V

CC

Hibernate state, no

I2C/SPI activity

VIO=1.8− 3.3 V

Hibernate state, no

I2C/SPI activity

VIO=3.3V

1.65

−

−

−

−

−

−

−

−

3.6 V

3.6 V

0.5 1.0 µA

0.8 1.2 mA

2.0 2.8 mA

0.5 1 µA

0.5 1 µA

1.0 3.0 µA

Doc ID 14489 Rev 6 55/65

Page 56

Electrical specifications STMPE811

15 Electrical specifications

Table 21. DC electrical characteristics (-40 ° C to 85 ° C) all GPIOs comply to JEDEC

standard JESD-8-7)

Val ue

Symbol Parameter Test condition

Min Typ Max

Unit

V

V

V

V

V

(I2C/SPI)

V

(I2C/SPI)

Input voltage low state VIO=1.8 − 3.3 V -0.3 V

IL

Input voltage high state VIO=1.8 − 3.3 V 0.80 V

IH

V

Output voltage low state

OL

Output voltage high

OH

state

OL

Output voltage low state

Output voltage high

OH

state

= 1.8 V,

IO

IOL= 4 mA

= 3.3 V,

V

IO

IOL= 8 mA

= 1.8 V,

V

CC

= 4 mA

I

OL

= 3.3 V,

V

CC

IOL= 8 mA

0.85 V

0.85 V

Table 22. AC electrical characteristics (-40 ° C to 85 ° C)

Symbol Parameter Test condition

CLKI2C

CLKSPI

I2C maximum SCLK VIO=1.8-3.3V 400

max

=1.8V 800

V

SPI maximum clock

max

IO

V

= 3.3 V 1000

IO

0.20 V

−

VIO+0.3V V

−

IO

-0.3 V

IO

-0.3 V

CC

0.15 V

−

−−

0.15 V

−

VCC+0.3V V

−

Val ue

Min Typ Max

−−

−−

−−

IO

IO

CC

V

V

V

V

Unit

kHz

kHz

kHz

56/65 Doc ID 14489 Rev 6

Page 57

STMPE811 Electrical specifications

Table 23. ADC specification (-40 ° C to 85 ° C)

Val ue

Parameter Test condition

Min Typ Max

Unit

Full-scale input span 0

Absolute input range

Input capacitance

Leakage current

Resolution

No missing codes 11

Integral linearity error

Offset error

Gain error

Noise Including internal V

Power supply rejection ratio

Throughput rate

ref

Table 24. Switch drivers specification

Parameter Test condition

−

−−

−

−

−

25

0.1

12

V

ref

VCC+0.2 V

−

−

−

−

−

−

−

−

−

−

Min Typ Max

±4

±5

±14 ±18 LSB

70

50

180

Val ue

−

−

−

−

−

V

pF

µA

Bits

Bits

Bits

LSB

µVrms

dB

ksps

Unit

ON resistance X+, Y+

ON resistance X-, Y-

Drive current Duration 100 ms

−

−

5.5

7.3

−−

−

−

50 mA

Ω

Ω

Doc ID 14489 Rev 6 57/65

Page 58

Package mechanical data STMPE811

16 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®