Serial real-time clock (RTC) with audio

Features

Combination real-time clock with audio

■ Serial real-time clock (RTC) based on M41T00

■ Audio section provides:

– 300 mW differential audio amplifier

– 256 and 512 Hz tone generation

– –33 to +12 dB gain, 3 dB steps (16 steps

plus MUTE)

■ 0 °C to 70 °C operation

■ Small DFN16 package (5 mm x 4 mm)

Real-time clock details

■ Superset of M41T00

■ 3.0 to 3.6 V operation

– Timekeeping down to 1.7 V

■ Automatic backup switchover circuit

– Ultra-low 400 nA backup current at 3.0 V

(typ)

– Suitable for battery or capacitor backup

– On-chip trickle charge circuit for backup

capacitor

■ 400 kHz I

■ M41T00 compatible register set with counters

for seconds, minutes, hours, day, date, month,

years, and century

– Automatic leap year compensation

– HT bit set when clock goes into backup

■ RTC operates using 32,768 Hz quartz crystal

– Calibration register provides for

– Oscillator supports crystals with up to 40

■ Oscillator fail detect circuit OF bit indicates

when oscillator has stopped for four or more

cycles

2

C bus

mode

adjustments of –63 to +126 ppm

kΩ series resistance, 12.5 pF load

capacitance

M41T00AUD

DFN16 (5 mm x 4 mm)

Audio section

■ Power amplifier

– Differential output amplifier

– Provides 300 mW into 8 Ω

(THD+N = 2% (max), f

■ Summing node at audio input

– Inverting configuration with summing

resistors into the minus (-) terminal

– 0 dB gain with 10 kΩ feedback resistor and

20 kΩ input summing resistors

– Signal input centered at V

– 1.6 V

■ 256 or 512 Hz signal multiplexing with analog

analog input range (max)

P-P

input to provide audio with beep tones

■ Volume control, 4-bit register

– Allows gain adjustment from –33 dB to

+12 dB

– 3 dB steps

–MUTE bit

■ Audio automatically shuts off in backup mode

= 1 kHz)

in

DD

/2

February 2012 Doc ID 13480 Rev 5 1/42

www.st.com

1

Contents M41T00AUD

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 2-wire bus characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 READ mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 WRITE mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5 Data retention mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 M41T00AUD clock operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Clock registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.1 Halt bit operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.2 Oscillator fail detect operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.3 Trickle charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Reading and writing the clock registers . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Priority for IRQ

5.4 Switchover thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5 Trickle charge circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

/FT/OUT pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Clock calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 Digital calibration (periodic counter correction) . . . . . . . . . . . . . . . . . . . . 24

7 Audio section operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1 Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1.1 Gain tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.2 Wake-up time: T

2/42 Doc ID 13480 Rev 5

WU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

M41T00AUD Contents

8 Initial conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

12 Part numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

13 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Doc ID 13480 Rev 5 3/42

List of tables M41T00AUD

List of tables

Table 1. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. List of registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3. AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 4. M41T00AUD register map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 5. Priority for IRQ

Table 6. Digital calibration values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 7. MUTE and GAIN values (V

Table 8. Initial values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 9. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 10. Operating and AC measurement conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 11. Input/output characteristics (25 °C, f = 1 MHz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 12. DC characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 13. Crystal electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 14. RTC power down/up AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 15. RTC power down/up trip points DC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 16. Audio section electrical characteristics, valid for V

T

= 25 °C (except where otherwise noted) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 17. DFN16 (5 mm x 4 mm) package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 18. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 19. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

AMB

/FT/OUT pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

= 3.3 V and ambient temperature = 25 °C). . . . . . . . . . . . . 29

CC

= 3.3 V and

CC

4/42 Doc ID 13480 Rev 5

M41T00AUD List of figures

List of figures

Figure 1. Logic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Application diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Typical hookup example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. Serial bus data transfer sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6. Acknowledgement sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Bus timing requirements sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Slave address location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9. READ mode sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 10. Alternate READ mode sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 11. WRITE mode sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 12. Counter update diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 13. Switchover thresholds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 14. Trickle charge circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 15. Crystal accuracy across temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 16. Audio section diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 17. AC testing input/output waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 18. Power down/up mode AC waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 19. DFN16 (5 mm x 4 mm) package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 20. DFN16 (5 mm x 4 mm) footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Doc ID 13480 Rev 5 5/42

Description M41T00AUD

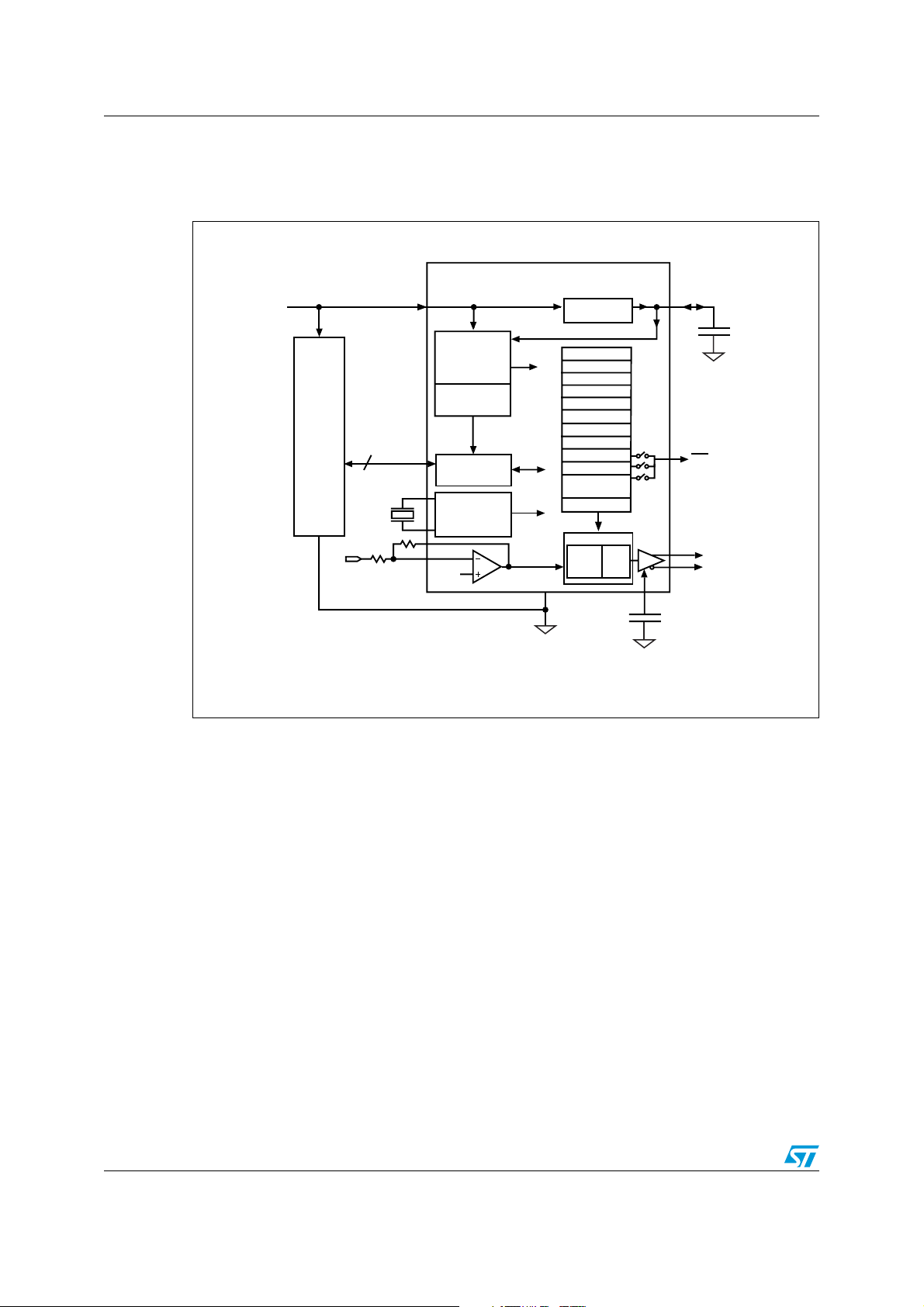

1 Description

The M41T00AUD is a low-power serial real-time clock (RTC) with an integral audio section

with tone generator and 300 mW output amplifier. The RTC is a superset of the M41T00

with enhancements such as a precision reference for switchover, an oscillator fail detect

circuit, and storing of the time at power-down. The audio section includes a summing

amplifier (inverting) at the input. An 8 kHz low-pass filter follows that with a 16-step

programmable gain stage next. A 256 or 512 Hz audio tone can be switched into the filter in

place of the input signal. From the gain stage, the 300 mW amplifier drives the output pins.

The M41T00AUD has a built-in power sense circuit which detects power failures and

automatically switches to the backup input when V

supplied by a capacitor or by a battery such as a lithium coin cell. The device includes a

trickle charge circuit for charging the capacitor.

The RTC includes a built-in 32.768 kHz oscillator controlled by an external crystal. Eight

register bytes are used for the clock/calendar functions and are superset compatible with the

M41T00. Two additional registers control the audio section and the trickle charger. The 10

registers (see Ta bl e 2 ) are accessed over a 400 kHz I

increments automatically after each byte READ or WRITE operation thus streamlining

transfers by eliminating the need to send a new address for each byte to be transferred.

is removed. Backup power can be

CC

2

C bus. The address register

Typical data retention times will be in excess of 5 years with a 50 mAh 3 V lithium cell (see

RTC DC characteristics, Ta bl e 1 2 for more information).

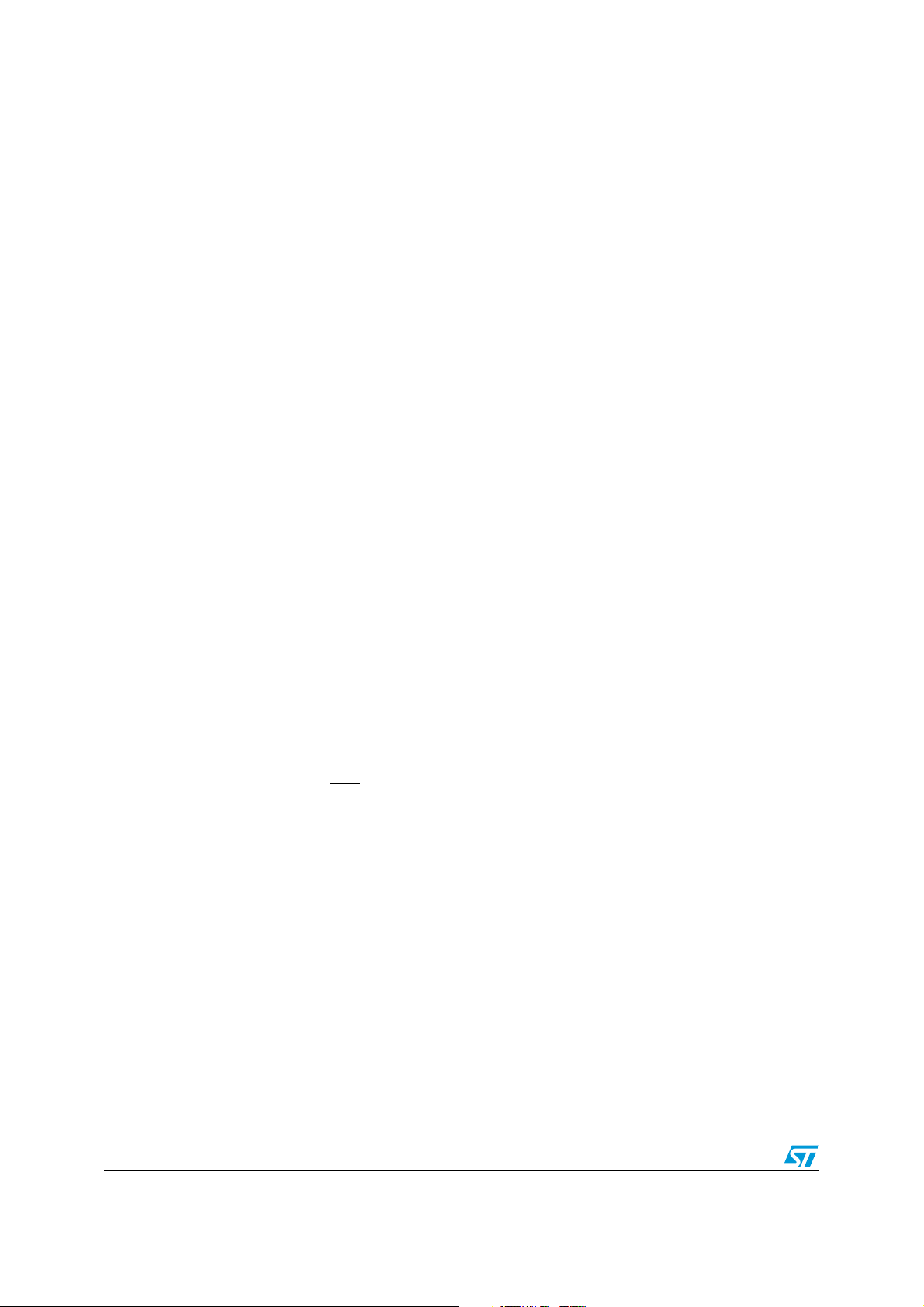

Figure 1. Logic diagram

V

CC

OSCI

V

BIAS

OSCO

IRQ/FT/OUT

SDA

V

BACK

SCL

AIN

M41T00AUD

V

SS

FBK

AOUT+

AOUT –

NC

ai13322

6/42 Doc ID 13480 Rev 5

M41T00AUD Pin settings

2 Pin settings

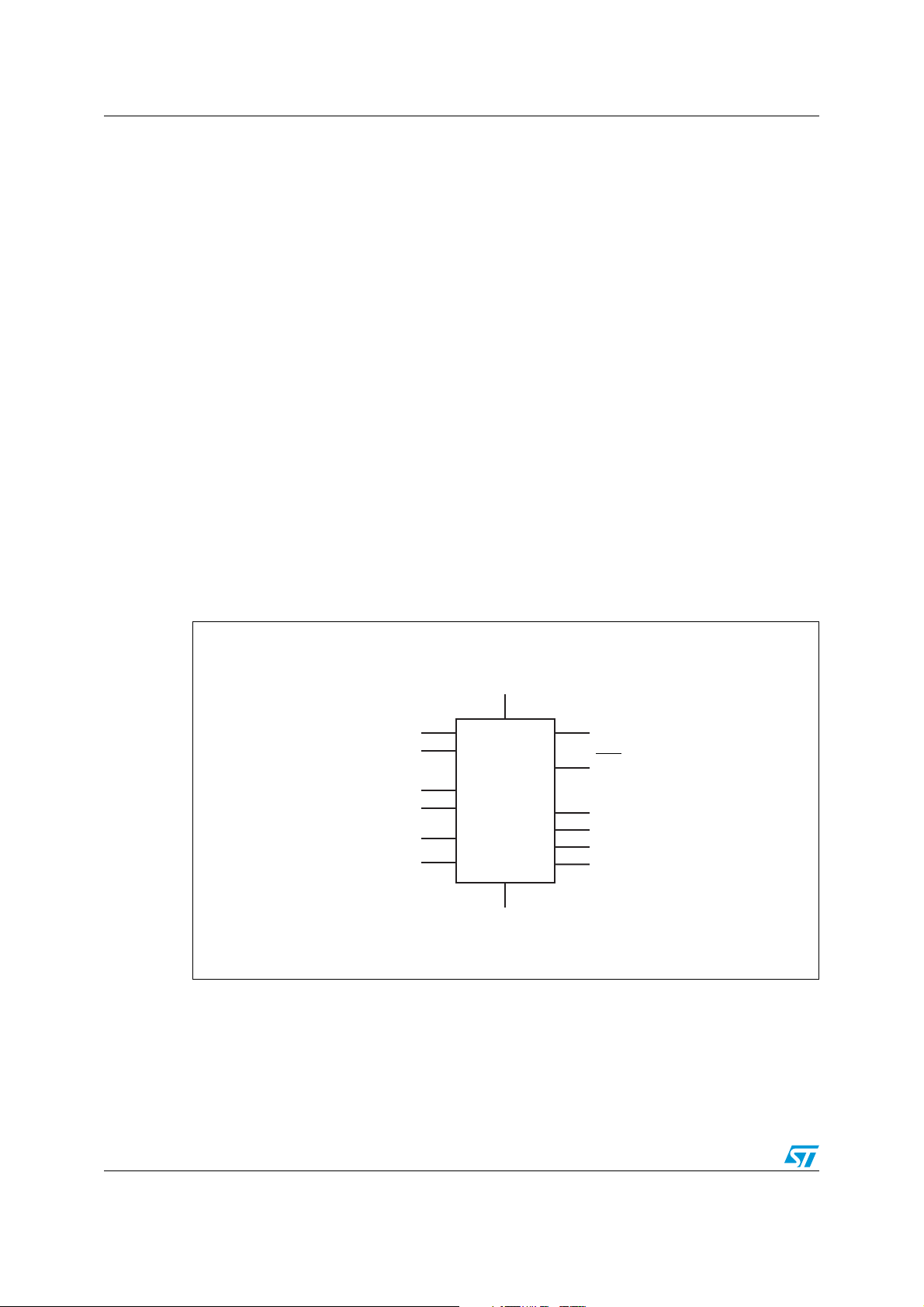

2.1 Pin connection

Figure 2. Pin connection

2.2 Pin description

Table 1. Pin description

Symbol Name and function

V

CC

OSCI Oscillator input

OSCO Oscillator output

SCL I

SDA I

AIN Audio input

OSCI

OSCO

V

SS

V

CC

IRQ/FT/OUT

V

BACK

SCL

SDA

1

2

3

4

5

6

7

8

Supply voltage

2

C serial clock

2

C serial data

16

15

14

13

12

11

10

9

AOUT–

V

CC

V

SS

AOUT+

FBK

V

BIAS

AIN

NC

ai13323

V

BIAS

V

SS

AOUT– Analog out, 180 phase

AOUT+ Analog out, 0 phase

IRQ/FT/OUT

V

BACK

FBK

NC No connection

No name; exposed pad on back of IC

package

Doc ID 13480 Rev 5 7/42

Input for decoupling capacitor

Ground

Interrupt output for oscillator fail detect, frequency

test output for calibration, or discrete logic output

Backup supply voltage

Feedback; connect feedback resistor between this

pin and AIN

Must be connected to ground

Application M41T00AUD

3 Application

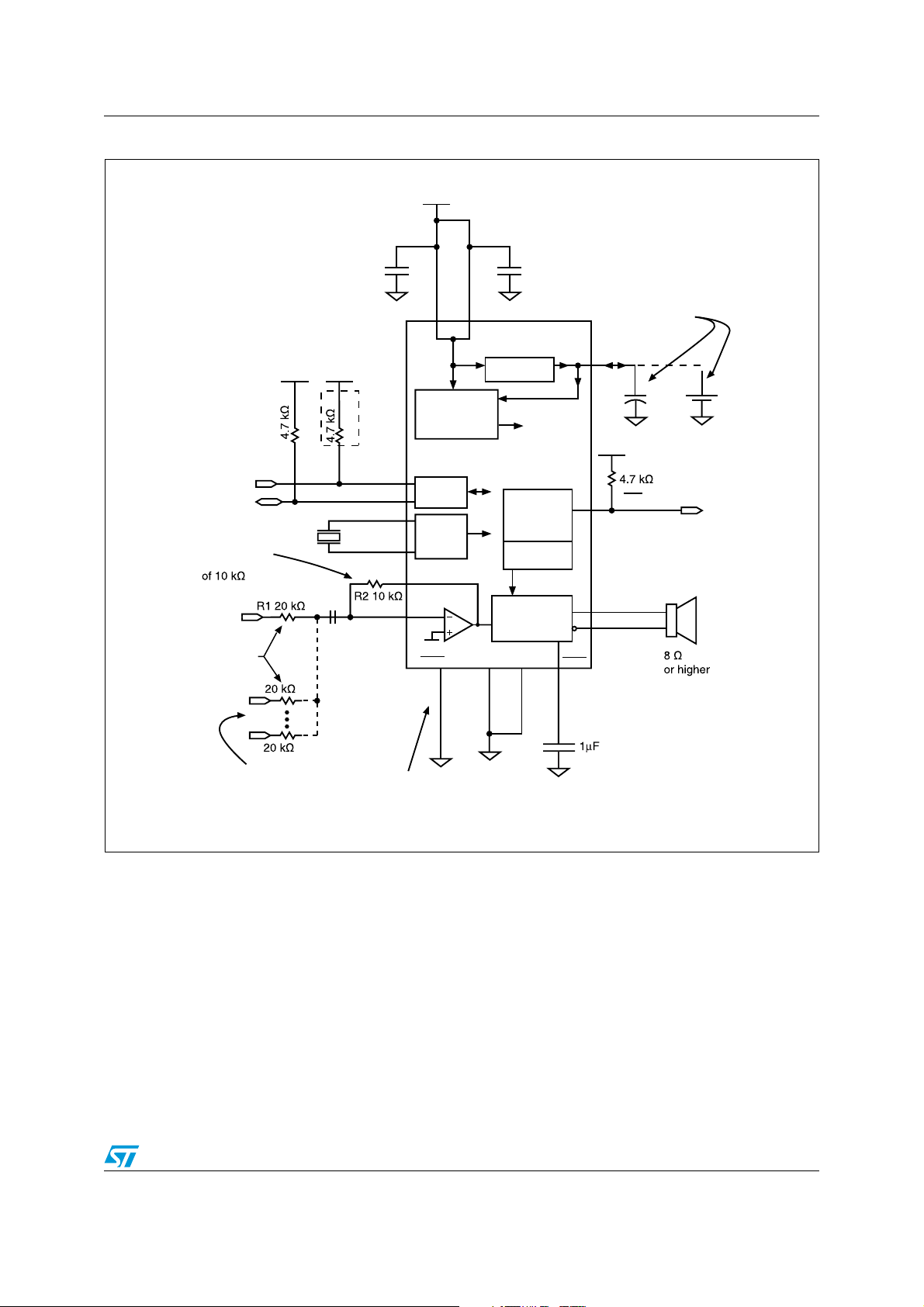

Figure 3. Application diagram

M41T00AUD

V

2

OSCI

OSCO

CC

I2C

(SDA,

SCL)

FBK

AIN

AUTOM ATIC

BATTERY

SWITCHOVER

& DESELEC T

REFERENCE

V

=2.80V

PFD

WRITE

PROTECT

400kHz I2C

INTER FACE

32KHz

OSCILL ATOR

TRICKLE

CHARGE

V

INT

SECS

MINS

HOURS

DATE

DAY

MONTH

YEAR

CENTURY BIT

CALIBRATION

OUT

OSCILLATOR

FAIL DETECT

256/512Hz

AUDIO

ADJ

BPF

GAIN

V

CC

V

CC

uC

I2C

Audio-in

V

BACK

IRQ/FT/OUT

AOUT+

AOUT–

V

SS

V

BIAS

ai13324

8/42 Doc ID 13480 Rev 5

M41T00AUD Application

Figure 4. Typical hookup example

3.3 V

SCL

SDA

R2 should

be a minimum

Audio

In

Set R1’s to 2x

R2 for unity gain

R1

3.3V

32.768 kHz

x

Place near

pin 4

0.1 µF

3.3V

*optional

SCL 7

SDA 8

OSCI

OSCO

FBK

0.1 µF

AIN

SWITCHOVER

1

2

12

10

V

CC

V

4

BATTERY

I2C

32 KHz

OSC

DD

2

PMH

CC

V

15

M41T00AUD

TRICKLE

CHARGE

V

3

SS

V

Place near

pin 15

1.0 µF

INT

RT C

256/512 Hz

ONE GEN

AUDIO

SECTION

11

14

SS

V

BIAS

V

Either/or, but

not both

V

6

BACK

+

0.22 µF

(typical)

3.3 V

IRQ/FT/OUT

5

Optional connection

to micro

13

AOUT+

AOUT–

16

V

DD

2

Lithium

Cell

Battery

(alternative)

R1

x

Optional: can

sum additional

audio inputs

Package Metal Heatsink:

exposed pad on back of

IC package

ai13325

Doc ID 13480 Rev 5 9/42

Operation M41T00AUD

4 Operation

The M41T00AUD clock operates as a slave device on the serial bus. Access is obtained by

implementing a start condition followed by the correct slave address (D0h). The 10 bytes

contained in the device can then be accessed sequentially in the following order:

Table 2. List of registers

Byte address Contents

00h Seconds register

01h Minutes register

02h Century/hours register

03h Day register

04h Date register

05h Month register

06h Years register

07h Calibration/control register

08h Audio register

09h Control2 register

The M41T00AUD continually monitors VCC for an out of tolerance condition. Should VCC fall

below V

, the device terminates an access in progress and resets the device address

PFD

counter. Inputs to the device will not be recognized at this time to prevent erroneous data

from being written to the device from an out of tolerance system. When V

falls below VSO,

CC

the device automatically switches over to the backup battery or capacitor and powers down

into an ultra low current mode of operation to conserve battery life. Upon power-up, the

device switches from battery to V

at VSO and recognizes inputs.

CC

10/42 Doc ID 13480 Rev 5

M41T00AUD Operation

4.1 2-wire bus characteristics

This bus is intended for communication between different ICs. It consists of two lines: one

bi-directional for data signals (SDA) and one for clock signals (SCL). Both the SDA and the

SCL lines must be connected to a positive supply voltage via a pull-up resistor.

The following protocol has been defined:

● Data transfer may be initiated only when the bus is not busy.

● During data transfer, the data line must remain stable whenever the clock line is high.

Changes in the data line while the clock line is high will be interpreted as control

signals.

Accordingly, the following bus conditions have been defined:

● Bus not busy. Both data and clock lines remain high.

● Start data transfer. A change in the state of the data line, from high to low, while the

clock is high, defines the START condition.

● Stop data transfer. A change in the state of the data line, from low to high, while the

clock is high, defines the STOP condition.

● Data valid. The state of the data line represents valid data when after a start condition,

the data line is stable for the duration of the high period of the clock signal. The data on

the line may be changed during the low period of the clock signal. There is one clock

pulse per bit of data.

Each data transfer is initiated with a start condition and terminated with a stop condition.

The number of data bytes transferred between the start and stop conditions is not limited.

The information is transmitted byte-wide and each receiver acknowledges with a ninth bit.

By definition, a device that gives out a message is called "transmitter", the receiving device

that gets the message is called "receiver". The device that controls the message is called

"master". The devices that are controlled by the master are called "slaves".

● Acknowledge. Each byte of eight bits is followed by one acknowledge bit. This

acknowledge bit is a low level put on the bus by the receiver, whereas the master

generates an extra acknowledge related clock pulse.

A slave receiver which is addressed is obliged to generate an acknowledge after the

reception of each byte. Also, a master receiver must generate an acknowledge after the

reception of each byte that has been clocked out of the slave transmitter.

The device that acknowledges has to pull down the SDA line during the acknowledge clock

pulse in such a way that the SDA line is a stable Low during the high period of the

acknowledge related clock pulse. Of course, setup and hold times must be taken into

account. A master receiver must signal an end-of-data to the slave transmitter by not

generating an acknowledge on the last byte that has been clocked out of the slave. In this

case, the transmitter must leave the data line high to enable the master to generate the

STOP condition.

Doc ID 13480 Rev 5 11/42

Operation M41T00AUD

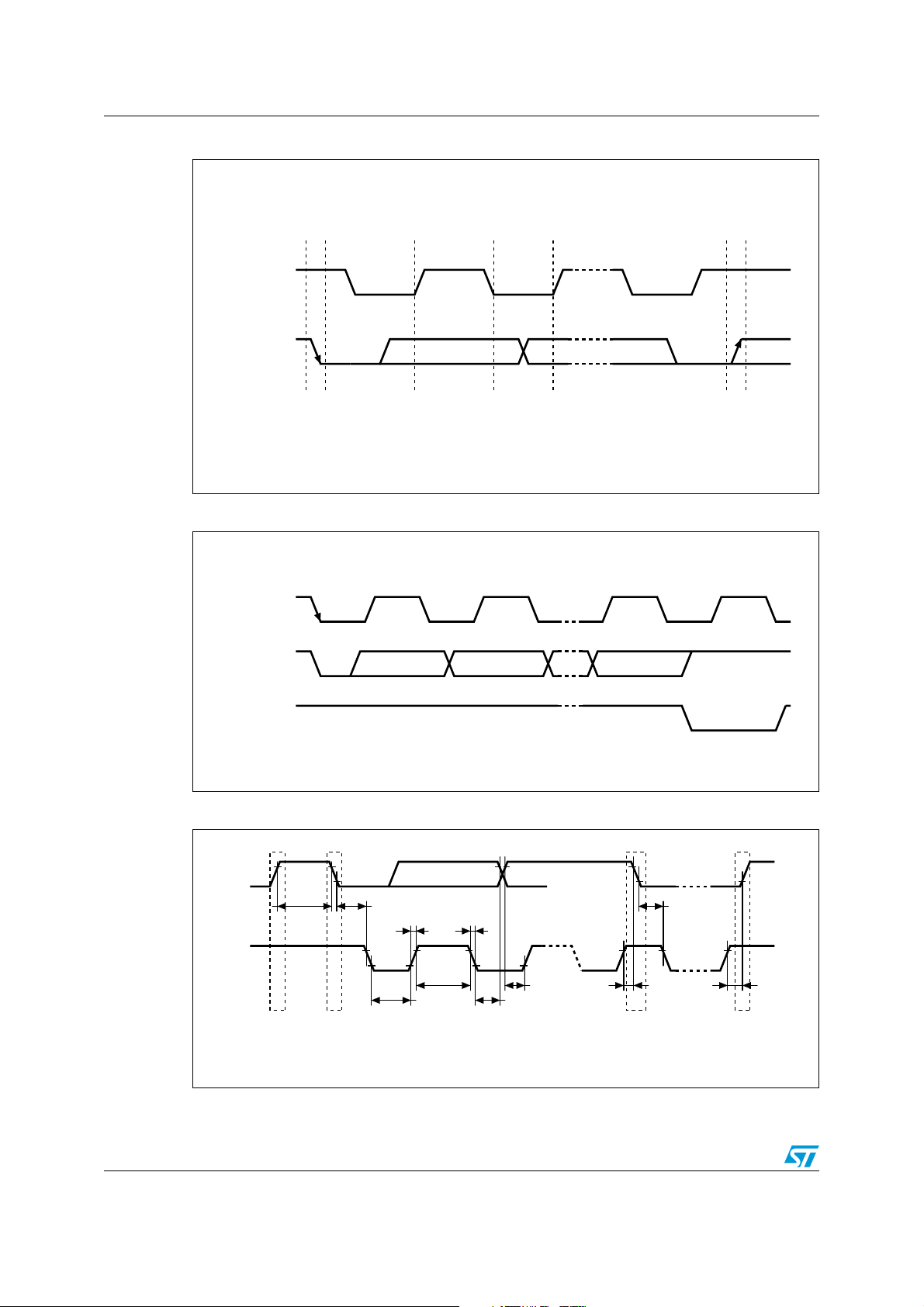

Figure 5. Serial bus data transfer sequence

DATA LINE

STABLE

DATA VALID

CLOCK

DATA

START

CONDITION

CHANGE OF

DATA ALLOWED

Figure 6. Acknowledgement sequence

START

SCLK FROM

MASTER

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

12 89

MSB LSB

Figure 7. Bus timing requirements sequence

STOP

CONDITION

AI00587

CLOCK PULSE FOR

ACKNOWLEDGEMENT

AI00601

SDA

t

HD:STA

t

R

SP

t

t

LOW

t

F

HIGH

t

HD:DAT

SCL

t

BUF

Note: P = STOP and S = START

12/42 Doc ID 13480 Rev 5

t

SU:DAT

SR

t

SU:STA

t

HD:STA

P

AI00589

t

SU:STO

M41T00AUD Operation

4.2 Characteristics

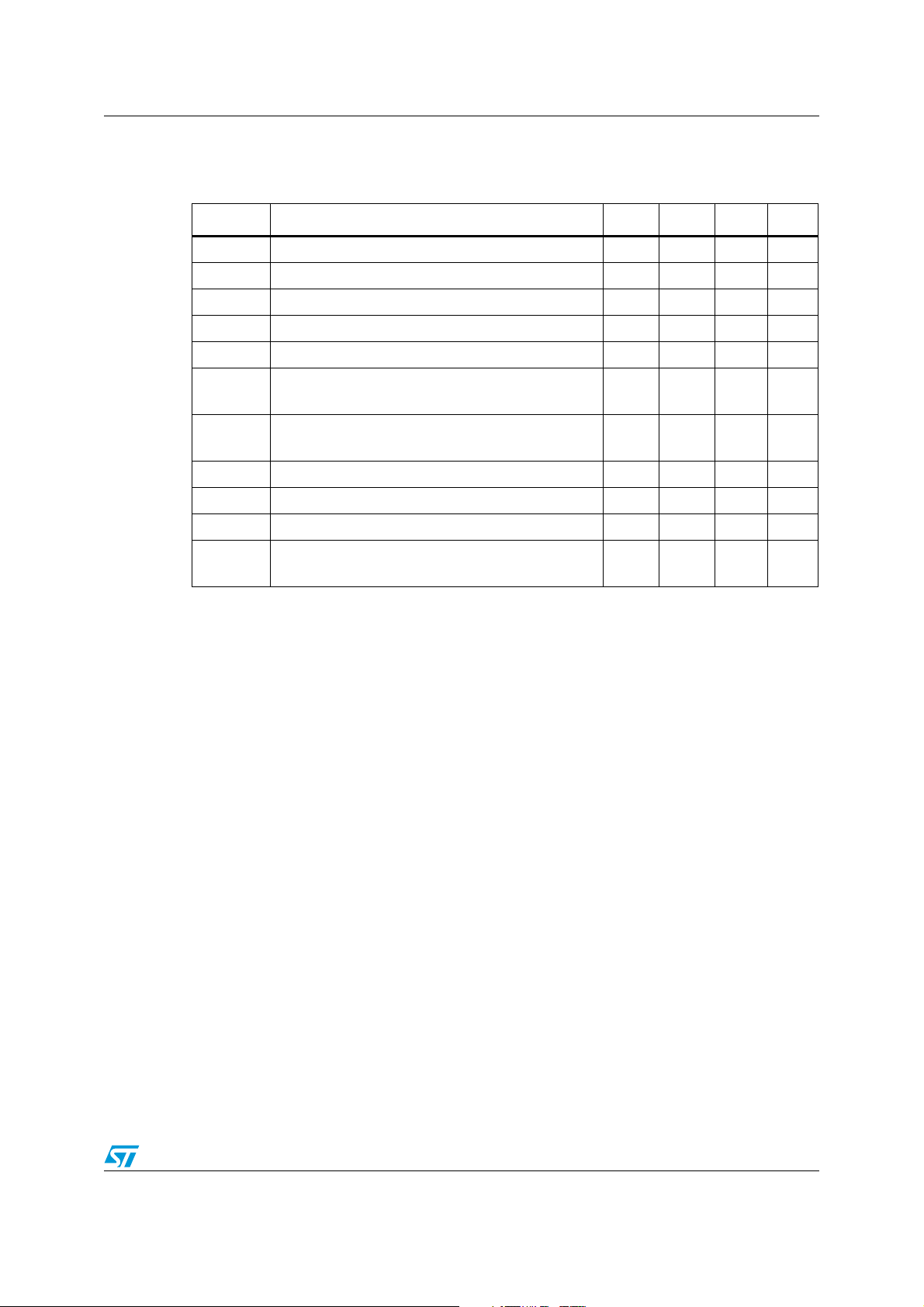

Table 3. AC characteristics

Symbol Parameter

(1)

Min Typ Max Units

f

SCL

t

LOW

t

HIGH

t

R

t

t

HD:STA

t

SU:STA

t

SU:DAT

t

HD:DAT

t

SU:STO

t

BUF

1. Valid for ambient operating temperature: TA = 0 to 70 °C; VCC = 3.0 to 3.6 V (except where noted).

2. Transmitter must internally provide a hold time to bridge the undefined region (300 ns max) of the falling

edge of SCL.

SCL clock frequency 0 400 kHz

Clock low period 1.3 µs

Clock high period 600 ns

SDA and SCL rise time 300 ns

SDA and SCL fall time 300 ns

F

START condition hold time

(after this period the first clock pulse is generated)

START condition setup time

(only relevant for a repeated start condition)

(2)

Data setup time 100 ns

Data hold time 0 µs

STOP condition setup time 600 ns

Time the bus must be free before a new

transmission can start

4.3 READ mode

600 ns

600 ns

1.3 µs

In this mode, the master reads the M41T00AUD slave after setting the slave address (see

Figure 8). Following the WRITE mode control bit (R/W = 0) and the acknowledge bit, the

word (register) address An is written to the on-chip address pointer. Next the START

condition and slave address are repeated, followed by the READ mode control bit (R/W = 1).

At this point, the master transmitter becomes the master receiver. The data byte which was

addressed will be transmitted and the master receiver will send an acknowledge bit to the

slave transmitter. The address pointer is only incremented on reception of an acknowledge

bit. The device slave transmitter will now place the data byte at address An+1 on the bus.

The master receiver reads and acknowledges the new byte and the address pointer is

incremented to An+2.

This cycle of reading consecutive addresses will continue until the master receiver sends a

STOP condition to the slave transmitter.

An alternate READ mode may also be implemented, whereby the master reads the

M41T00AUD slave without first writing to the (volatile) address pointer. The first address

that is read is the last one stored in the pointer (see Figure 10).

Doc ID 13480 Rev 5 13/42

Operation M41T00AUD

Figure 8. Slave address location

R/W

START A

Figure 9. READ mode sequence

BUS ACTIVITY:

MASTER

SDA LINE

BUS ACTIVITY:

START

S

SLAVE

ADDRESS

R/W

ADDRESS (An)

ACK

WORD

SLAVE ADDRESS

MSB

0100 011

START

S

ACK

ADDRESS

STOP

SLAVE

LSB

AI00602

R/W

DATA n DATA n+1

ACK

ACK

ACK

DATA n+X

P

NO ACK

Figure 10. Alternate READ mode sequence

BUS ACTIVITY:

MASTER

BUS ACTIVITY:

14/42 Doc ID 13480 Rev 5

START

S

SLAVE

ADDRESS

R/W

DATA n DATA n+1 DATA n+X

ACK

ACK

AI00899

STOP

PSDA LINE

ACK

ACK

NO ACK

AI00895

M41T00AUD Operation

4.4 WRITE mode

In this mode the master transmitter transmits to the M41T00AUD slave receiver. Bus

protocol is shown in Figure 11. Following the START condition and slave address, a logic '0'

(R/W = 0) is placed on the bus and indicates to the addressed device that word address An

will follow and is to be written to the on-chip address pointer. The data word to be written to

the device is strobed in next and the internal address pointer is incremented to the next

location within the device on the reception of an acknowledge clock. The M41T00AUD slave

receiver will send an acknowledge clock to the master transmitter after it has received the

slave address and again after it has received the word address and each data byte (see

Figure 8).

Figure 11. WRITE mode sequence

BUS ACTIVITY:

MASTER

BUS ACTIVITY:

START

S

ADDRESS

R/W

WORD

ADDRESS (An)

ACK

SLAVE

4.5 Data retention mode

With valid VCC applied, the M41T00AUD can be accessed as described above with READ

or WRITE cycles. Should the supply voltage decay, the M41T00AUD will automatically

deselect, write protecting itself when V

DATA n DATA n+1 DATA n+X

ACK

falls (see Figure 13).

CC

ACK

ACK

STOP

PSDA LINE

ACK

AI00591

Doc ID 13480 Rev 5 15/42

M41T00AUD clock operation M41T00AUD

5 M41T00AUD clock operation

5.1 Clock registers

The 10-byte register map (see Ta bl e 2 ) is used to both set the clock and to read the date

and time from the clock, in a binary coded decimal format.

Seconds, minutes, and hours are contained within the first three registers. Bits D6 to D0 or

register 00h (seconds register) contain the seconds count in BCD format with values in the

range 0 to 59. Bit D7 is the ST or stop bit, described below, and is not affected by the

timekeeping operation, but users must avoid inadvertently altering it when writing the

seconds register.

Setting the ST bit to a 1 will cause the oscillator to stop. If the device is expected to spend a

significant amount of time on the shelf, the oscillator may be stopped to reduce current drain

on the backup battery. When reset to a 0 the oscillator restarts within one second.

In order to ensure oscillator start-up after the initial power-up, set the ST bit to a 1 then write

it to 0. This sequence enables the "kick start" circuit which aids the oscillator start-up by

temporarily increasing the oscillator current. This will guarantee oscillator start-up under

worst case conditions of voltage and temperature. This feature can be employed anytime

the oscillator is being started but should not occur on subsequent power-ups when the

oscillator is already running.

Bits D6 to D0 of register 01h (minutes register) contain the minutes count in BCD format

with values in the range 0 to 59. Bit D7 always reads 0. Writing it has no effect.

Bits D5 to D0 of register 02h (century/ hours register) contain the hours in BCD format with

values in the range 0 to 23. Bits D7 and D6 contain the century enable bit (CEB) and the

century bit (CB). CB provides a one-bit indicator for the century. The user can apply his

preferred convention for defining the meaning of this bit. For example, 0 can mean the

current century, and 1 the next, or the opposite meanings may be used.

When enabled, CB will toggle every 100 years. Setting CEB to a 1 enables CB to toggle at

the turn of the century, either from 0 to 1 or from 1 to 0, depending on its initial state, as

programmed by the user. When CEB is a 0, CB will not toggle.

Bits D2 through D0 of register 03h (day register) contain the day of the week in BCD format

with values in the range 0 to 7. Bits D3 and D7 will always read 0. Writes to them have no

effect. Bits D6, D5 and D4 will power up in an indeterminate state.

Register 04h contains the date (day of month) in BCD format with values in the range 01 to

31. Bits D7 and D6 always read 0. Writes to them have no effect.

Register 05 h is the Month in BCD format with values in the range 1 to 12. Bits D7, D6 and

D5 always read 0. Writes to them have no effect.

Register 06h is the years in BCD format with values in the range 0 to 99. Writing to any of

the registers 00h to 06h, including the control bits therein, will result in updates to the

counters and resetting of the internal clock divider chain including the 256/512 Hz tone

generator. The updates do not occur immediately after the write(s), but occur upon

completion of the current write access. This is described in greater detail in the next section.

Registers 07h and 09h also contain clock control and status information. These registers

can be written at any time without affecting the timekeeping function.

16/42 Doc ID 13480 Rev 5

M41T00AUD M41T00AUD clock operation

Register 08 is the calibration register. Calibration is described in detail in the clock

calibration section. Bit D7 is the OUT bit and controls the discrete output pin IRQ

described in Ta b le 5 .

/FT/OUT as

5.1.1 Halt bit operation

Bit D7 of register 09 h is the HT or halt bit. Whenever the device switches to backup power,

it sets the HT bit to 1 and stores the time of power-down in the transfer buffer registers. This

is known as power-down time stamp. During normal timekeeping, once per second, the

transfer buffer registers are updated with the current time. When HT is 1, that updating is

halted. The clock continues to keep time but the periodic updates do not occur.

Upon power-up, reads of the clock registers will return the time of power-down (assuming

adequate backup power was maintained while V

by writing it to 0, subsequent reads of the clock registers will return the current time.

At power-up, the user can read the time of power-down, and then clear the HT bit to allow

updates. The next read will return the current time. Knowing both the power-up time and the

power-down time allows the user to calculate the duration of power-off.

In addition to the HT bit getting set to 1 automatically at power-down, the user can also write

it to 1 to halt updating of the registers.

was off). After the user clears the HT bit

CC

5.1.2 Oscillator fail detect operation

Bits D5 and D4 of register 09 h contain the oscillator fail flag (OF) and the oscillator fail

interrupt enable bit (OFIE). If the 32 KHz oscillator drops four or more pulses in a row, as

might occur during an extended outage while backed up on a capacitor, the OF bit will be set

to 1. This provides an indication to the user of the integrity of the timekeeping operation.

Whenever the OF bit is a 1, the system should consider the time to be possibly corrupted

due to operating at too low a voltage. The OF bit will always be 1 at the initial power-up of

the device. The OF bit is cleared by writing it to 0. At the initial power-up, users should wait

three seconds for the oscillator to stabilize before clearing the OF bit.

OFIE can be used to enable the device to assert its interrupt output whenever an oscillator

failure is detected. The oscillator fail interrupt will drive the IRQ

Table 5. The interrupt is cleared by writing the OF bit to 0. Setting OFIE enables the

oscillator fail interrupt. Clearing it to 0 disables it, but the OF will continue to function

regardless of OFIE.

5.1.3 Trickle charger

Bits D6 and D3 to D0, of register 09h, control the trickle charge function. It is described in

detail in the trickle charge circuit section.

/FT/OUT pin as described in

Doc ID 13480 Rev 5 17/42

M41T00AUD clock operation M41T00AUD

5.2 Reading and writing the clock registers

The counters used to implement the timing chain in the real-time clock are not directly

accessed by the serial interface. Instead, as depicted in Figure 12, reads and writes are

buffered through a set of transfer registers. This ensures coherency of the timekeeping

function.

During writes of the timekeeping registers (00h to 06h), the write data is stored in the buffer

transfer registers until all the data is written, then the register contents are simultaneously

transferred to the counters thus updating them. The update is triggered either by a STOP

condition or by a write to one of the non RTC registers, 07h to 09h. If any of the buffer

transfer registers are not written, then the corresponding counters are not updated. Instead,

those counters will retain their previous contents when the update occurs.

Similar to the writes, reads access the buffer transfer registers. The device periodically

updates the registers with the counter contents. But during reads, the updates are

suspended. Timekeeping continues, but the registers are frozen until after a STOP

condition or a non RTC register (07h to 09h) is read. Suspending the updates ensures that

a clock roll-over does not occur during a user read cycle.

The seven clock registers may be read one byte at a time, or in a sequential block. The

calibration, audio and Control2 registers, location 07 h to 09 h, may be accessed

independently.

Provision has been made to ensure that a clock update does not occur while any of the

seven clock addresses are being read. During a clock register read (addresses 00h to 06h),

updates of the clock transfer buffer registers are halted. The clock counters continue to keep

time, but the contents of the transfer buffer registers is frozen at the time that the read

access began.

This prevents a transition of data during the READ. For example, without the halt function, if

the time incremented past midnight in the middle of an access sequence, the user might

begin reading at 11:59:59pm and finish at 12:00:00am. The data read might appear as

12:59:59 because the seconds and minutes were read before midnight while the hours were

read after. The device prevents this by halting the updates of the registers until after the read

access has occurred.

18/42 Doc ID 13480 Rev 5

M41T00AUD M41T00AUD clock operation

Table 4. M41T00AUD register map

(1)

Bit

Addr

Register name Range

D7 D6 D5 D4 D3 D2 D1 D0

00h ST 10 seconds Seconds Seconds 00-59

01h

0

10 minutes Minutes Minutes 00-59

(2)

02h CEB CB 10 hours Hours (24 hour format) Century/hours 0-1/00-23

03h 0 Y

(3)

YY 0 Day of week Day 1-7

04h 0 0 10 date Date: day of month Date 01-31

05h 0 0 0 10M Month Month 01-12

06h 10 years Year Year 00-99

07h OUT FT S <------------- Calibration ------------> Cal/control

08h 256/512 TONE TCH2 MUTE <--------------GAIN ------------> Audio

09h HT TCFE OF OFIE TCHE3 TCHE2 TCHE1 TCHE0 Control2

1. Key:

S = SIGN bit

FT = Frequency test bit

ST = STOP bit

OF = Oscillator fail detect flag

OFIE = Oscillator fail interrupt enable

OUT = Logic output

TCHE3:TCHEO = Trickle charge enable bits

TCFE = Trickle charge FET bypass enable

HT = Halt bit

TCH2 = Trickle charge enable #2

TONE = Tone on/off select

CB = Century bit

CEB = Century enable bit

256/512 = Tone frequency select bit

2. 0 bits always read as 0. Writing them has no effect.

3. Y bits are indeterminate at power-up. These are the factory test mode bits, and must be written to 0.

Doc ID 13480 Rev 5 19/42

M41T00AUD clock operation M41T00AUD

Figure 12. Counter update diagram

32KHz

OSC

READ/WRITE

BUFFER

TRANSFER

REGISTERS

REGISTER

SECONDS

DIVIDE BY

32768

1 Hz

COUNTER

12C SERIAL BUS

SERIAL

TRANSFER

REGISTER

REGISTER

REGISTER

REGISTER

REGISTER

REGISTER

REGISTER

MINUTES

HOURS

DAY

DATE

MONTHS

YEARS

CENTURIES

COUNTER

COUNTER

COUNTER

COUNTER

COUNTER

COUNTER

ai13329

20/42 Doc ID 13480 Rev 5

M41T00AUD M41T00AUD clock operation

5.3 Priority for IRQ/FT/OUT pin

Three functions share pin 5 of the M41T00AUD. The oscillator fail interrupt (IRQ), the

calibration frequency test output (FT) and the discrete logic output (OUT) all use this pin.

In normal operation, when operating from V

frequency test function which in turn has priority over the discrete output function.

In the backup mode, when operating from V

and frequency test functions are disabled, and only the discrete output function can be

used.

When operating from V

09h), the pin is an interrupt output which will be asserted anytime the OF bit (D5 of register

09h) goes true. (See Section 5 for more details.)

During calibration, the pin can be used as a frequency test output. When FT is a 1 (and

OFIE a 0), the device will output a 512 Hz test signal on this pin. Users can measure this

with a frequency counter and use that result to determine the appropriate calibration register

value.

Otherwise, when OFIE is a 0 and FT is a 0, it becomes the discrete logic OUT pin and

reflects the value of the OUT bit (D7 of register 07h).

When operating from V

IRQ

/FT/OUT pin will reflect the contents of the out bit.

Note: The IRQ

Table 5. Priority for IRQ/FT/OUT pin

State

, the interrupt function has priority over the

CC

, the priorities are different. The interrupt

BACK

, if the oscillator fail interrupt enable bit is set (OFIE, D4 of register

CC

, the discrete output function can still be used. The

BACK

/FT/OUT pin is open drain and requires an external pull-up resistor.

Register bits

IRQ/FT/OUT pin

OFIE FT OUT

On V

On V

CC

BACK

1X X OF

0 1 X 512 Hertz

00 1 1

00 0 0

XX 1 1

XX 0 0

Doc ID 13480 Rev 5 21/42

M41T00AUD clock operation M41T00AUD

5.4 Switchover thresholds

While the M41T00AUD includes a precision reference for the backup switchover threshold, it

is not a fixed value, but depends on the backup voltage, V

switchover at the lesser of the reference voltage (V

This ensures that it stays on V

As shown in Figure 13, whenever V

drops below V

Conversely, when V

V

. Ta bl e 1 4 provides the values of these voltages.

BACK

PFD

.

BACK

Figure 13. Switchover thresholds

as long as possible before switching to the backup supply.

CC

BACK

is less than V

, approximately 2.8 V) and V

PFD

is greater than V

, switchover occurs when VCC drops below

PFD

. The device will always

BACK

BACK

, switchover occurs when VCC

PFD

.

VCC (= 3.3V)

V

(> V

BACK

Switchover voltage

VSO = V

S TATE

VCC (= 3.3V)

V

= 2.8V

PFD

Switchover voltage

VSO = V

PFD

PFD

BACK

)

(= 2.8V)

(< V

PFD

Condition 1: V

On V

CC

Condition 2: V

)

BACK

BACK

> 2.8V (V

< 2.8V (V

PFD

On V

PFD

)

BACK

)

On V

CC

S TATE

On V

CC

22/42 Doc ID 13480 Rev 5

On V

BACK

On V

CC

ai13326

M41T00AUD M41T00AUD clock operation

5.5 Trickle charge circuit

The M41T00AUD includes a trickle charge circuit to be used with a backup capacitor. It is

illustrated in Figure 14. V

supply input. (The input nature is not depicted in the figure.) The trickle charge output

function is a secondary capability, and reduces the need for external components.

To enable trickle charging, two switches must be closed. A diode is present to prevent

current from flowing backwards from V

path.

An additional switch allows the diode to be bypassed through a 20 k resistor. This should

charge the capacitor to a higher level thus extending backup life. This switch automatically

opens when the device switches to backup thus preventing capacitor discharge to V

Furthermore, at switchover to backup, the other switches open as well. The application

must close them after power-up to re-enable the trickle charge function.

The use of two switches in the chain is to protect against accidental, unwanted charging as

might be the case when using battery backup. Additionally, one of the two switches requires

four bits to be changed from the default value before it will close. This prevents single bit

errors from closing the switch. The four bits, TCHE3:TCHE0, reside in register 09h at bits

D3 to D0.

The control bit for the second switch, TCH2, resides in register 08h at bit D5. With this bit in

a separate register, two bytes must be written before charging will occur, again protecting

against inadvertent charging due to errors.

is a bi-directional pin. Its primary function is as the backup

BACK

to VCC. A current limiting resistor is also in the

BACK

CC

.

The control bit for the bypass switch, TCFE, resides in register 09h at bit D6.

To enable trickle charging, the user must set TCHE3:TCHE0 to 5h, and TCH2 to 1. To

bypass the diode, TCFE must be set to 1. All three fields must be enabled after each powerup.

Figure 14. Trickle charge circuit

TCFE

TCFE = 0

OPEN

V

CC

TCHE

TCHE/ = 5h

OPEN

TCHE = 5h

CLOSED

TCH2

TCH2 = 0

OPEN

TCH2 = 1

CLOSED

TCFE=1

CLOSED

V

BACK

ai13327

Doc ID 13480 Rev 5 23/42

Clock calibration M41T00AUD

6 Clock calibration

The M41T00AUD oscillator is designed for use with a 12.5 pF crystal load capacitance. With

a nominal ±20 ppm crystal, the M41T00AUD will be accurate to ±35 ppm. When the

calibration circuit is properly employed, accuracy improves to better than ±2 ppm at 25 °C.

The M41T00AUD design provides the following method for clock error correction.

6.1 Digital calibration (periodic counter correction)

This method employs the use of periodic counter correction by adjusting the number of

cycles of the internal 512 Hz signal counted in a second. By adding an extra cycle, for 513,

a long second is counted for slowing the clock. By reducing it to 511 cycles, a short second

is counted for speeding up the clock.

Not every second is affected. The calibration value (bits D4-D0 of register 07h) and its sign

bit (D5 of same register) control how often a short or long second is generated.

The basic nature of a 32 KHz crystal is to slow down at temperatures above and below

25 °C. Whether the temperature is above or below 25 °C, the device will tend to run slow.

Therefore, most corrections will need to speed the clock up. Hence, the M41T00AUD

calibration circuit uses a non-symmetric calibration scheme. Positive values, for speeding

the clock up, have more effect than negative values, for slowing it down. A positive value will

speed the clock up by approximately 4 ppm per step. A negative value will slow it by

approximately 2 ppm per step.

In the M41T00AUD's calibration circuit, positive correction is applied every 8

whereas negative correction is applied every 16

applied twice as often, it has twice the effect for a given calibration number, N. When the

calibration sign bit is positive, N seconds of every 8

of the 512 Hz clock. When the calibration sign bit is negative, N seconds of every 16

minute will be lengthened to 513 cycles of the 512 Hz clock.

th

minute. Because positive correction is

th

minute will be shortened to 511 cycles

th

minute

th

When N is positive, one minute will have N seconds which are 511 cycles and the remaining

seconds will be 512 cycles. The next seven minutes are nominal with all seconds 512

cycles each.

Example 1:

Sign is 1 and N is 2 (00010b)

The 8-minute interval will be:

2 * 511 + (60-2) * 512 + 7 * 60 * 512 = 245758 cycles long out of a possible

512 * 60 * 8 = 245760 cycles of the 512 Hz clock in an 8-minute span.

This gives a net correction of (245760-245758) / 245760 = -8.138 ppm

When N is negative, one minute will have N seconds which are 513 cycles and the

remaining seconds will be 512 cycles. The next 15 minutes are nominal with all seconds

512 cycles each.

24/42 Doc ID 13480 Rev 5

M41T00AUD Clock calibration

Example 2:

Sign is 0 and N is 3 (00010b). The 16-minute interval will be:

3 * 513 + (60-3) * 512 + 15 * 60 * 512 = 491523 cycles long out of a possible

512 * 60 * 16 = 491520 cycles of the 512 Hz clock in an 16-minute span.

This gives a net correction of (491520-491523) / 491520 = +6.104 ppm

Therefore, each calibration step has an effect on clock accuracy of either -4.068 or +2.034

ppm. Assuming that the oscillator is running at exactly 32,768 Hz, each of the 31 steps in

the calibration byte would represent subtracting 10.7 or adding 5.35 seconds per month,

which corresponds to a total range of –5.5 or +2.75 minutes per month.

Note: The modified pulses are not observable on the frequency test (FT) output, nor will the effect

of the calibration be measurable real-time, due to the periodic nature of the error

compensation.

Doc ID 13480 Rev 5 25/42

Clock calibration M41T00AUD

Table 6. Digital calibration values

Calibration value

DC4-DC0

Calibration result, in ppm, rounded to the nearest integer

Decimal Binary

Slowing

sign DCS = 0

Speeding

sign DCS = 1

0 00000 + 0 ppm – 0 ppm

1 00001 + 2 ppm – 4 ppm

2 00010 + 4 ppm – 8 ppm

3 00011 + 6 ppm – 12 ppm

4 00100 + 8 ppm – 16 ppm

5 00101 + 10 ppm – 20 ppm

6 00110 + 12 ppm – 24 ppm

7 00111 + 14 ppm – 28 ppm

8 01000 + 16 ppm – 33 ppm

9 01001 + 18 ppm – 37 ppm

10 01010 + 20 ppm – 41 ppm

11 01011 + 22 ppm – 45 ppm

12 01100 + 24 ppm – 49 ppm

13 01101 + 26 ppm – 53 ppm

14 01110 + 28 ppm – 57 ppm

15 01111 + 31 ppm – 61 ppm

16 10000 + 33 ppm – 65 ppm

17 10001 + 35 ppm – 69 ppm

18 10010 + 37 ppm – 73 ppm

19 10011 + 39 ppm – 77 ppm

20 10100 + 41 ppm – 81 ppm

21 10101 + 43 ppm – 85 ppm

22 10110 + 45 ppm – 90 ppm

23 10111 + 47 ppm – 94 ppm

24 11000 + 49 ppm – 98 ppm

25 11001 + 51 ppm – 102 ppm

26 11010 + 53 ppm – 106 ppm

27 11011 + 55 ppm – 110 ppm

28 11100 + 57 ppm – 114 ppm

29 11101 + 59 ppm – 118 ppm

30 11110 + 61 ppm – 122 ppm

31 11111 + 63 ppm – 126 ppm

N +N/491520 (per minute) –N/245760 (per minute)

26/42 Doc ID 13480 Rev 5

M41T00AUD Clock calibration

Figure 15. Crystal accuracy across temperature

Frequency (ppm)

20

0

–20

–40

–60

–80

–100

–120

–140

–160

DF

= K x (T –TO)

F

K = –0.036 ppm/˚C2 ± 0.006 ppm/˚C

TO = 25˚C ± 5˚C

0 10203040506070

Temperature °C

2

2

80–10–20–30–40

AI00999b

Doc ID 13480 Rev 5 27/42

Audio section operation M41T00AUD

7 Audio section operation

The audio section is comprised of five main parts. The input includes a summing amplifier.

A minimum 10 kΩ feedback resistor is required. With that and 20 kΩ input resistors, the

input signals will be summed at unity gain.

An audio switch follows the amplifier. A tone, selectable between 256 and 512 Hz, can be

inserted into the audio stream in lieu of the input amplifier's output.

A low pass filter is next with a cut off of 8 kHz. To get a band pass with a 100 Hz low end,

the user should place an appropriate coupling capacitor at the input pin.

Figure 16. Audio section diagram

register bits

R2 should

be a minimum

S

IN

R1

x

Sum multiple audio

signals through external

resistors, but single input

Set R1’s to 2x R2 for unity gain

0.1 µF

From internal

RTC timing chain

FBK

AIN

V

V

DD

2

DD

256 Hz

512 Hz

256/512

SELECT

TONE

ON/OFF

Switch 256/512 signal

in place of audio signal

BPF

100 Hz - 8 kHz

Low end of band pass filter is actually

implemented by blocking capacitor at

input pin. Only the high end (low-pass

section) is implemented at this point in the

audio section.

GAIN, 3 dB steps,

–33 dB to +12 dB

(4-bit register)

V

BIAS

AOUT+

300 mW

V

DD

2

1 µF

AOUT–

28/42 Doc ID 13480 Rev 5

ai13328

M41T00AUD Audio section operation

Table 7. MUTE and GAIN

(1)

values (VCC = 3.3 V and ambient temperature = 25 °C)

MUTE GAIN Audio gain (dB) AV. scalar gain

Binary Hex Min Typ Max Typ

1 XXXX X Off Off

01111F +12 4

0 1110 E +7 +9 +11 2.8

01101D +6 2

01100C +3 1.4

01011B -1 0 +1 1

0 1010 A -3 0.708

010019 -6 0.5

0 1000 8 -9 0.355

0 0111 7 -12 0.251

0 0110 6 -15 0.178

0 0101 5 -20 -18 -16 0.126

0 0100 4 -23 -21 -19 0.089

0 0011 3 -24 0.063

0 0010 2 -27 0.045

0 0001 1 -30 0.032

0 0000 0 -33 0.022

1. Target specification. Further testing will determine final min/max limits for GAIN values of E, B, 5 and 4.

Doc ID 13480 Rev 5 29/42

Audio section operation M41T00AUD

7.1 Gain

The programmable gain stage follows the band pass filter. It provides between –33 and

+12 dB of gain, in 3 dB steps (+/-1 dB per step). The gain is selected by the GAIN bits, D3D0 of register 08h, as listed in Tab l e 4 . A MUTE bit, D4 of the same register, allows the

audio to be cut off altogether.

At the first power-up, GAIN will be initialized to its lowest value, 0, corresponding to a gain of

–33 dB. Furthermore, MUTE will be set thus cutting off all audio.

On subsequent power-ups, GAIN is unaffected, but the MUTE bit is always set to turn off the

audio at power-up.

The final section is the output driver. It has a differential output capable of driving 300mW

into an 8 Ω load.

The overall gain of the M41T00AUD is defined as the ratio of the AC output voltage, A

and the AC input voltage, S

, as shown in Figure 16. The 0.1 uF input coupling capacitor

IN

OUT

,

blocks any DC in the input signal.

Equation 1 Overall gain = A

A

is measured between the output pins AOUT+ and AOUT–.

OUT

A

= AOUT

OUT

/ S

OUT

+

- AOUT

IN

–

Each of the output levels is determined by the ratio of the feedback and input resistors along

with the GAIN value.

+

where A

AOUT

AOUT

is the scalar gain as shown in Ta b le 7 . Substituting these into Equation 1 above

V

= SIN x AV x R2/R1

–

= -S

x AV x R2/R1

IN

yields:

A

OUT

= SIN x A

x R2/R1 - (-S

V

x AV x R2/R1) = 2 SIN x AV x R2/R1

IN

With R1 = 2*R2, this reduces to A

= SIN x AV. Thus, when R1 = 2*R2, the gain levels in

OUT

Ta bl e 7 reflect overall gain of the circuit (at mid-band frequencies, about 1kHz with the

indicated 0.1 uF capacitor). For GAIN set to B (0 dB, A

equal to the input (

±1 dB).

7.1.1 Gain tolerance

Two tolerance parameters apply to the gain levels. As shown in Ta bl e 7 , upper and lower

limits are listed for four of the GAIN values (4, 5, Bh and Eh). For GAIN=Bh, the tolerance is

±1 dB. This means the end-to-end gain of the part, with R1 = 2*R2, will be 0±1 dB. For

GAIN = 4, 5 and Eh, the tolerance is ±2 dB. At each of these three settings, as shown in

table 7, the gain will be within 2 dB of the listed typical value. For GAIN =E, the end-to-end

gain will be between +7 and +11 dB (9±2 dB).

30/42 Doc ID 13480 Rev 5

= 1), the output voltage will be

V

M41T00AUD Audio section operation

The other parameter pertains to the gain step size, a relative measurement. It is shown in

Ta bl e 1 6 as 3±1 dB. For any gain setting in Ta bl e 7 , the next higher (or lower) setting is

guaranteed to be between 2 and 4 dB higher (or lower). For example, even though no upper

and lower limits are shown for GAIN = Ch, it is tested to be at 3±1 dB of the case when

GAIN=Bh, one step below. If GAIN=Bh tests to -0.5 dB, then GAIN=Ch is tested to have an

end-to-end gain of 2.5±1 dB. If GAIN=Bh tests to +0.5 dB, then GAIN=Ch is tested to be

3.5±1 dB.

This applies to all steps except the lowest one (from GAIN=0 to GAIN=1) which is not tested.

In summary, for GAIN=1 to GAIN=Fh, all steps are tested to have a 1dB step size tolerance

of the listed 3 dB step size. The unity gain setting, Bh, will have an end-to-end gain of

0±1dB while the three levels for GAIN=4, 5 and Eh are tested to be within ±2 dB of the

typical gain values listed in Ta bl e 7 .

7.2 Wake-up time: T

When the device powers on, the bypass capacitor C

C

is directly linked to the bias of the amplifier, the amplifier will not work properly until

BIAS

the capacitor is charged. The time to reach this voltage is called the wake-up time or T

and is specified in the electrical characteristics, Ta bl e 1 6 , for C

WU

will not be charged immediately. As

BIAS

= 1 µF.

BIAS

WU

Doc ID 13480 Rev 5 31/42

Initial conditions M41T00AUD

8 Initial conditions

The first time the M41T00AUD is powered up, some of its registers will automatically have

their bits set to pre-determined levels as depicted in the Ta bl e 5 . Typically, these values are

set to benign levels to ensure predictable operation of the device.

ST, the stop bit, is a 0 at first power-up thus enabling the oscillator to run without need of

user intervention. On subsequent power-ups, it is not altered by the device and remains at

the last value programmed by the user. All other bits listed as unchanged (UC) in the table

behave similarly during power cycles.

The HT or halt bit is always set to 1 thus halting updates of the transfer buffer registers. The

user must write it to 0 to allow updates to resume.

The discrete output function available on the IRQ

drain output, and thus a 1 represents a high impedance condition.

FT or frequency test is always disabled on power-ups. The OF or oscillator fail bit will

always be 1 on the first power-up since the oscillator is always off prior to the first application

of V

.

CC

The trickle charger is always turned completely off after any power-up. The bits affecting it

are set to levels which keep all the trickle charge switches open. Both TCH2 and TCFE are

0 which opens their corresponding switches. TCHE3:TCHE0 are set to Ah, which is the

exact opposite of the value (5) required to close the corresponding switch.

On first power-up, the tone selects bits, 256/512 and TONE, are set to select the 512 hertz

tone, but have the function disabled (see Section 7). On subsequent power-ups, the

256/512 select bit remains unchanged, but TONE is always cleared. Furthermore, the

MUTE bit is always set to MUTE on all power-ups, disabling all audio.

The four-bit audio gain value is always set to the lowest setting (0) on initial power-up, but

remains unaffected by subsequent power cycles.

The 5-bit calibration register and its associated sign bit are set to 0 on initial power-up thus

resulting in no correction applied to the timekeeping operation. On subsequent power-ups,

the contents are not altered.

Table 8. Initial values

Condition ST HT OUT FT OF OFIE

TCHE

3:0

/FT/OUT pin is set to 1. This is an open

TCH2 TCFE

256

TONE MUTE GAIN

512

Cali-

bration

Initial

power-up

Subsequent

power-up

(with

battery

backup)

1. State of other control bits undefined

2. UC = unchanged

32/42 Doc ID 13480 Rev 5

(1)

UC

0

1101

On

(2)

1 UC 0 UC UC

0

OffAhOff0Off0Off15120Off1MUTE0–33 dB

Ah

Off0Off0Off

UC

0

Off1MUTE

0

UC UC

M41T00AUD Maximum ratings

9 Maximum ratings

Stressing the device above the rating listed in the absolute maximum ratings table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the operating sections of

this specification is not implied.

Exposure to absolute maximum rating conditions for extended periods may affect device

reliability. Refer also to the STMicroelectronics SURE Program and other relevant quality

documents

Table 9. Absolute maximum ratings

Symbol Parameter Value Unit

T

STG

T

R

THJA

V

CC

T

SLD

V

I

OA

I

OD

P

1. Reflow at peak temperature of 260 °C. The time above 255 °C must not exceed 30 seconds.

Storage temperature (VCC off, oscillator off) –55 to 150 °C

Maximum junction temperature 150 °C

J

Thermal resistance junction to ambient 200 °C/W

Supply voltage –0.3 to 4.5 V

(1)

Lead solder temperature for 10 seconds 260 °C

Input or output voltages –0.3 to Vcc + 0.3 V

IO

Audio output current 300 mA

Digital output current 20 mA

Power dissipation Internally limited

D

Caution: Negative undershoots below –0.3 V are not allowed on any pin while in the backup mode.

Doc ID 13480 Rev 5 33/42

DC and AC parameters M41T00AUD

10 DC and AC parameters

This section summarizes the operating and measurement conditions, as well as the DC and

AC characteristics of the device. The parameters in the following DC and AC characteristic

tables are derived from tests performed under the measurement conditions listed in the

relevant tables. Designers should check that the operating conditions in their projects match

the measurement conditions when using the quoted parameters.

Table 10. Operating and AC measurement conditions

Parameter M41T00AUD

Supply voltage (V

Ambient operating temperature (T

Digital load capacitance (C

Audio load resistance (R

) 3.0 to 3.6 V

CC

) 0 to 70 °C

A

) 100 pF

L

) ≥ 8 Ω

L

Digital input rise and fall times

(1)

≤

5 ns

Digital input pulse voltages 0.2VCC to 0.8V

Digital input and output timing reference voltages 0.3VCC to 0.7V

1. Output Hi-Z is defined as the point where data is no longer driven.

Figure 17. AC testing input/output waveform

0.8V

CC

0.2V

CC

Table 11. Input/output characteristics (25 °C, f = 1 MHz)

Symbol

C

C

OUTD

t

1. Effective capacitance measured with power supply at 3.3 V; sampled only, not 100% tested

2. Outputs deselected

Input capacitance, digital inputs 7 pF

IND

(2)

Output capacitance, digital outputs 10 pF

LP

I2C low-pass filter input time constant (SDA and SCL)

Parameter

(1)

0.7V

CC

0.3V

CC

AI02568

Min Max Unit

50 ns

CC

CC

34/42 Doc ID 13480 Rev 5

M41T00AUD DC and AC parameters

Table 12. DC characteristics

Symbol Parameter

I

LI

I

LO

I

CC1

I

CC2

V

IL

V

IH

V

OL

V

BACK

I

BACK

1. Valid for ambient operating temperature: TA = 0 to 70 °C; VCC = 3.0 to 3.6 V (except where otherwise noted).

2. For open drain pins IRQ

3. STMicroelectronics recommends the RAYOVAC BR1225 or BR1632 (or equivalent) when a battery is used.

Table 13. Crystal electrical characteristics

Symbol

f

O

R

C

1. Externally supplied if using the SO8 package. STMicroelectronics recommends the KDS DT-38: 1TA/1TC252E127, Tuning

Fork Type (thru-hole) or the DMX-26S: 1TJS125FH2A212, (SMD) quartz crystal for industrial temperature operations. KDS

can be contacted at http://www.kds.info/index_en.htm for further information on this crystal type.

2. Load capacitors are integrated within the M41T00AUD. Circuit board layout considerations for the 32.768 kHz crystal of

minimum trace lengths and isolation from RF generating signals should be taken into account.

Test condition

Input leakage current

Output leakage current

Active supply current

0V

0V

OUT and SDA pins

No audio (AIN = V

2

I

C bus active at 400 kHz

≤ V

IN

SCL pin

OUT

≤ V

No audio (AIN = V

2

I

Standby supply current

Input low voltage –0.3

C bus not active, SCL = 0 Hz

All inputs ≥ VCC – 0.2 V

or

≤ V

SS

(1)

≤ VCC,

≤ VCC,

BIAS

BIAS

+ 0.2 V

Input high voltage

= 3.0 mA

Output low voltage

Output low voltage (open

(2)

drain)

Pull-up supply voltage

(open drain)

(3)

RTC backup supply voltage 1.7

RTC backup supply current

/FT/OUT and SDA

Parameter

(1)(2)

I

OL

= 3.0 mA

I

OL

IRQ

/FT/OUT, SDA, SCL Vcc V

T

= 25 °C, VCC = 0 V

A

oscillator ON,

= 3 V

V

BACK

Resonant frequency 32.768 kHz

S

L

Series resistance 40 KΩ

Load capacitance 12.5 pF

Min Typ Max Unit

±1 µA

±1 µA

),

6.6 14.7 mA

),

6.4 14.3 mA

0.3V

CC

V

0.7V

CC

CC

+ 0.3

0.4 V

0.4 V

V

CC

0.6 1 µA

Min Typ Max Units

V

V

V

Doc ID 13480 Rev 5 35/42

DC and AC parameters M41T00AUD

Figure 18. Power down/up mode AC waveforms

V

CC

VSO

t

SDA

SCL

Table 14. RTC power down/up AC characteristics

Symbol

t

PD

t

rec

1. Valid for ambient operating temperature: TA = 0 to 70 °C; VCC = 3.0 to 3.6 V (except where otherwise

noted).

fall time should not exceed 5 mV/µs.

2. V

CC

Table 15. RTC power down/up trip points DC characteristics

Symbol

V

PFD

PD

DON'T CARE

Parameter

(1)(2)

Min Typ Max Unit

SCL and SDA at VIH before power-down 0 ns

SCL and SDA at VIH after power-up 10 µs

Parameter

(1)(2)

Min Typ Max Unit

Power-fail deselect 2.60 2.8 2.95 V

Hysteresis 10 mV

t

REC

AI00596

V

Backup switchover voltage

SO

(V

CC

< V

BACK

; VCC < V

PFD

2.0 < V

)

V

BACK

BACK

> V

< V

PFD

PFD

V

V

BACK

PFD

Hysteresis 10 mV

1. All voltages referenced to VSS.

2. Valid for ambient operating temperature: T

noted).

Table 16. Audio section electrical characteristics, valid for VCC = 3.3 V and

T

= 25 °C (except where otherwise noted)

AMB

= 0 to 70 °C; VCC = 3.0 to 3.6 V (except where otherwise

A

(1)

Symbol Parameter Condition Min Typ Max Unit

V

P

O-MAX

Output offset voltage

OO

Maximum output power

No input signal,

RL = 8 Ω

THD = 2% Max, f = 1 kHz,

RL = 8 Ω

10 100 mV

300 375 mW

RL = 8 Ω, Av = 2,

P

Power supply rejection

SRR

ratio

V

audio input grounded

RIPPLE

= 200 mV

PP

55 61 dB

f = 217 Hz

Gain step size GAIN steps 1-2 to E-F (1) 2 3 4 dB

TWU

1. The lowest step, from GAIN = 0 to GAIN = 1, is not tested.

Wake-up time after

power-up

C

BIAS

= 1 µF

150 ms

V

V

36/42 Doc ID 13480 Rev 5

M41T00AUD Package mechanical data

11 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

Doc ID 13480 Rev 5 37/42

Package mechanical data M41T00AUD

Figure 19. DFN16 (5 mm x 4 mm) package outline

D

INDEX AREA

E

TOP VIEW

Note: Drawing is not to scale.

Table 17. DFN16 (5 mm x 4 mm) package mechanical data

Sym

Min Typ Max Min Typ Max

A 0.80 0.90 1.00 0.032 0.035 0.039

A1 0.00 0.02 0.05 0.0000 0.0008 0.0020

b 0.20 0.25 0.30 0.008 0.010 0.012

A

INDEX AREA

PIN#1 ID

k

SIDE VIEW

e

D2

BOTTOM VIEW

SEATING

PLANE

A1

b

E2

L

mm inches

7964660_C

D 5.00 0.197

E 4.00 0.158

D2 4.20 4.35 4.45 0.165 0.171 0.175

E2 2.30 2.45 2.55 0.091 0.096 0.100

e 0.50 0.020

k 0.20 0.0078

L 0.30 0.40 0.50 0.012 0.016 0.020

38/42 Doc ID 13480 Rev 5

M41T00AUD Package mechanical data

Figure 20. DFN16 (5 mm x 4 mm) footprint

7964660_B

Doc ID 13480 Rev 5 39/42

Part numbering M41T00AUD

12 Part numbering

Table 18. Ordering information scheme

Example: M41T00AUD D 1 F

Device type

M41T00AUD

Package

D = Lead-free 5 mm x 4 mm DFN

Temperature range

1 = 0 °C to 70 °C

Shipping method

®

E = ECOPACK

lead-free ICs in tube

F = ECOPACK® lead-free ICs in tape & reel

40/42 Doc ID 13480 Rev 5

M41T00AUD Revision history

13 Revision history

Table 19. Document revision history

Date Revision Changes

01-May-2007 1 Initial release.

13-Dec-2007 2 Minor text changes; updated footnote 1 in Ta b le 1 3 .

01-Dec-2008 3 Minor reformatting; updated Figure 14.

06-Mar-2009 4 Updated text in Section 11: Package mechanical data; added

footprint Figure 20.

06-Feb-2012 5 Updated package (cover page, Figure 19 and Ta b le 1 7 ); updated

footnote of Table 9: Absolute maximum ratings.

Doc ID 13480 Rev 5 41/42

M41T00AUD

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

42/42 Doc ID 13480 Rev 5

Loading...

Loading...