SPX Cooling Technologies Marley Aquatower User Manual

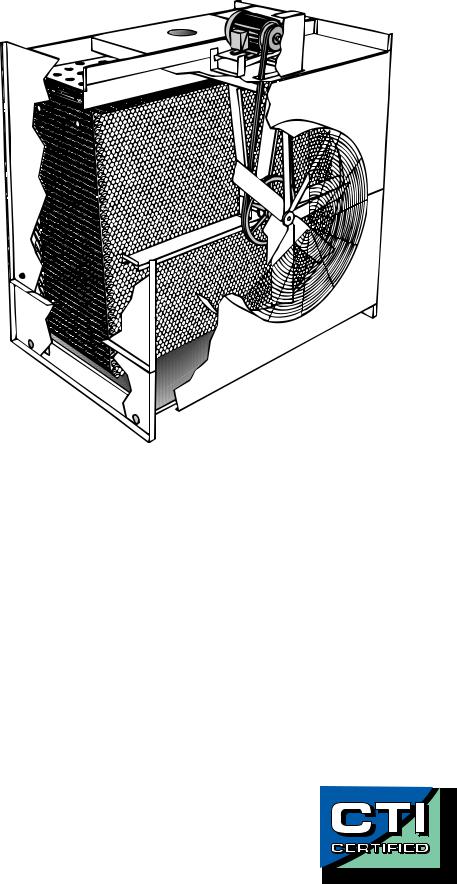

/ Marley Aquatower ® CoolingTower /

/ The Aquatower Advantage /

■Proven Performance. CTI Certified. Plus SPX stands by its responsibility for reliable thermal performance. We designed it. We rate it. We guarantee it!

■Induced-Draft Design. Save on fan power. The fan will operate in a warm atmosphere even in winter, so you’ll never have to work on frozen mechanical equipment.

■Crossflow Design. Save on pump power because you only pay to move the water to the top of the tower. Gravity does the rest. The mechanical equipment and water distribution system are out where you can easily maintain them.

■All-Season Reliability. Aquatowers perform as specified in the heat of summer. They respond well to energy management techniques in the spring and fall and

with appropriate fan controls, they can operate virtually ice-free in the dead of winter. Plus they offer simple maintenance all year long.

■Proven Corrosion Protection. Thousands of users over more than 40 years confirm the value of heavy galvanizing. And Marley’s Z-600 is the most effective galvanizing used in the industry.

■PVC Film Fill with Integral Drift Eliminators and

Louvers. If you’ve ever had to replace deteriorated eliminators or louvers, you’ll appreciate this advantage. Now those components are molded right in the PVC fill sheets. Integral honeycomb louvers keep the circulating water inside your tower—and off your roof!

■Select Your Aquatower on Our Website. The Marley

UPDATE web-based selection software—available at www.spxcooling.com—provides Aquatower model recommendations based on your specific design requirements

■Simple, Flexible Installation. Just mount the motor, belts and belt guard, install the outlet connection that suits your needs—both side suction and bottom outlet are provided, complete with screens—and adjust the float valve. Attach air-inlet screens on models 494A and larger and your Aquatower is ready for operation.

2

/ The Marley Difference /

Today’s Aquatower may be the most space/energyefficient cooling tower available. Your needs have dictated constant technological improvement. Thousands of Aquatower users enjoy the benefits of eight major redesigns and dozens of minor improvements in the past 40 years. For example, PVC film-fill enables the Aquatower to reject more heat per unit size. We also put the air inlet louvers and drift eliminators right on the fill sheets. This new arrangement saves you fanpower by improving airflow through the tower.

The Aquatower is a maintenance delight! You’ll appreciate the way the Aquatower simplifies maintenance. No hidden spray systems, tiny nozzles, or enclosed basins here! You can easily replace and align V-belts from outside the tower. You won’t have the chore and expense that goes with high-power, blower fan towers.

All primary components of the Aquatower are open to view. You can easily remove any debris from the upper basin or nozzles while the tower is in operation.

Heavy mill galvanizing on all steel components prevents base metal corrosion. You won’t have to worry about paint chips clogging your strainers and nozzles, because there is no paint to flake off. Heavy galvanizing also protects much better than paint.

Above all, the Aquatower is readily available. You won’t have to wait around—or accept second best—when you need a cooling tower. We maintain an impressive stock of completed towers at our own plants. A growing number of local distributors can draw from that stock.

Contact your local distributor or Marley representative. They’ll be glad to help you choose the proper model for your needs. They can also help you with your layout and piping.

You’ll enjoy single source responsibility and reliability because we design and manufacture virtually all major cooling tower components.

All Marley components are designed and selected to be a part of an integrated system. For example, the spray pattern from nozzles and the pressure drop through drift eliminators both affect a fill’s heat transfer capacity. So, we include that impact in our thermal analysis.

Drift eliminators must be effective at the air velocities where fill is most efficient. So, we’ve carefully designed both components to work together efficiently.

How many other cooling tower companies can offer you this assurance? They may use Brand “A” nozzles with Brand “B” fill and Brand “C” drift eliminators. When they all come together, the whole may be less than the sum of the parts.

Our total system approach assures that all the parts work together to provide you the greatest total performance.

And because we design specifically for cooling towers, all our components will provide many years of service with minimal maintenance.

Every Aquatower cooling tower carries a full one-year warranty. The Aquatower you buy from us will work on your job or we’ll make it right. Your warranty includes thermal performance and every component of the tower. The SPX Cooling Technologies warranty is your assurance of performance—for a full year.

The Aquatower has inspired many imitators. Only SPX Cooling Technologies can offer you the original.

3

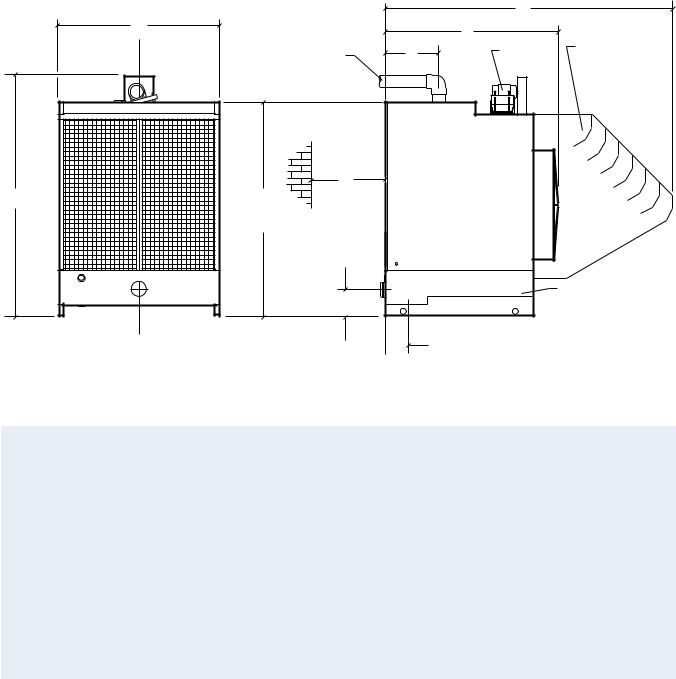

/ Schematic /

L

TOWER CL INLET

H

TOWER C OUTLET

L

INLET PIPING

(BY OTHERS)

|

D |

|

W |

A |

MOTOR |

C

S

USE FOR

STATIC LIFT

OUTLETSIDE

CL

B

CL BOTTOM OUTLET

E

E

VERTICAL DISCHARGE

(OPTION-NOTE 3)

TOWER COLLECTION BASIN

|

AIR INLET ELEVATION |

|

|

|

|

|

SIDE ELEVATION |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions |

|

|

|

|

|

|

Piping |

||

Tower |

Nominal Tons |

|

|

|

|

|

|

|

|

Motor |

Connection |

||||

|

|

|

|

|

|

|

|

|

|

||||||

Model |

note1 |

L |

W |

H |

A |

B |

|

C note 2 |

D |

E |

S |

kW |

Inlet |

|

Outlet |

|

|

|

|

|

note 6 |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

490A |

8 |

902 |

1292 |

1610 |

402 |

175 |

|

610 |

note 3 |

note 6 |

1318 |

.25 |

2" |

|

2" F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

490B |

10 |

902 |

1292 |

1610 |

402 |

175 |

|

610 |

1318 |

.75 |

2" |

|

2" F |

||

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

492A |

22 |

1206 |

1543 |

2248 |

432 |

241 |

|

1219 |

note 3 |

203 |

1956 |

.75 |

4" |

|

4" M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

492B |

28 |

1206 |

1543 |

2248 |

432 |

241 |

|

1219 |

203 |

1956 |

1.5 |

4" |

|

4" M |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

493A |

36 |

1816 |

1549 |

2248 |

432 |

241 |

|

1524 |

note 3 |

203 |

1956 |

1.5 |

4" |

|

4" M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

493B |

42 |

1816 |

1549 |

2248 |

432 |

241 |

|

1524 |

203 |

1956 |

2.2 |

4" |

|

4" M |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

494A |

51 |

1816 |

1972 |

2743 |

608 |

292 |

|

1829 |

3251 |

235 |

2403 |

1.5 |

6" |

|

6" MC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

494B |

57 |

1816 |

1972 |

2743 |

608 |

292 |

|

1829 |

3251 |

235 |

2403 |

2.2 |

6" |

|

6" MC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

494C |

68 |

1816 |

1972 |

2743 |

608 |

292 |

|

1929 |

3251 |

235 |

2403 |

3.7 |

6" |

|

6" MC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

495A |

80 |

2426 |

1975 |

2743 |

608 |

292 |

|

2134 |

3251 |

235 |

2403 |

3.7 |

6" |

|

6" MC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

495B |

91 |

2426 |

1975 |

2743 |

608 |

292 |

|

2134 |

3251 |

235 |

2403 |

5.5 |

6" |

|

6" MC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

496A |

111 |

3035 |

1984 |

2953 |

589 |

292 |

|

2743 |

3345 |

235 |

2610 |

3.7 |

6" |

|

6" MC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

496B |

126 |

3035 |

1984 |

2953 |

589 |

292 |

|

2743 |

3345 |

235 |

2610 |

5.5 |

6" |

|

6" MC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.Nominal tons are based upon 35°C HW, 29.5°C CW, 25.5°C WB and .68 m3/hr per ton.The Marley UPDATE web-based selection software provides Aquatower model recommendations based on specific design requirements.

2.Minimum clearance for adequate air supply. Consult your Marley sales representative or your local distributor if this clearance is impractical for your job.

3.Vertical discharge hood is for applications in restrictive enclosures or other locations where horizontal discharge is not desirable. CTI Certification does not apply when this option is selected. Available only on models 494A and larger.

4.Motors are 400 volt, 3-phase TEFC.

5.Motor, belt and belt guard ship uninstalled. Installation by others.

6.Outlet sizes shown are side outlets. All models except 490A and 490B have connections for both side and bottom outlet. Install the desired connection and seal the unused opening with the coverplate provided. Pump suction should use side outlet. See page 9 for size and flow capacities of bottom outlets.

7.Overflow is a 2" F connecton located in side of collection basin.

8.Drain is a 2" F connection located in collection basin floor.

9.Makeup valve connection is 3/4" M located in tower side.

4

Loading...

Loading...