Page 1

Products and Services

/

/

Page 2

Page 3

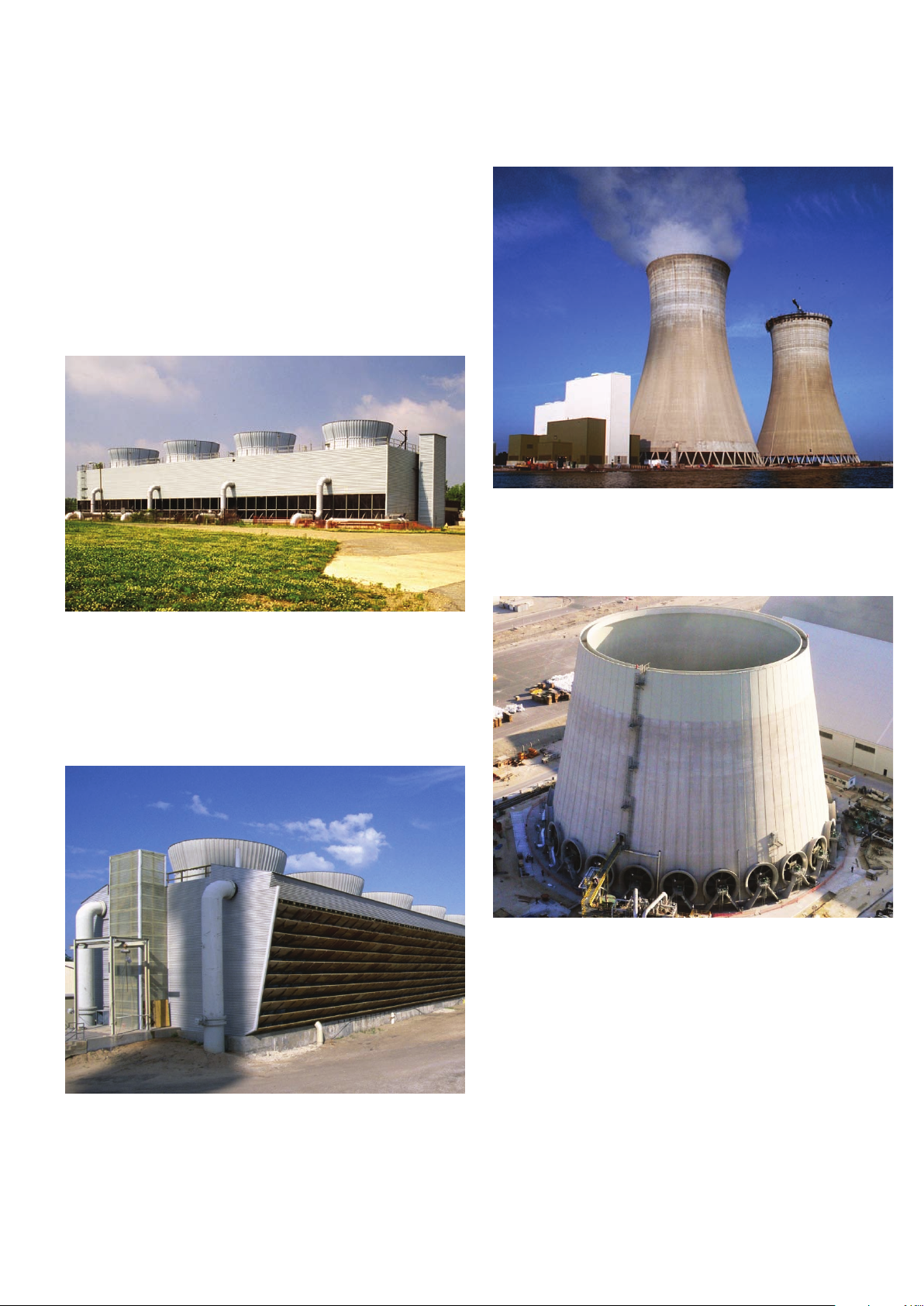

Cooling Towers

■ Heavy industrial

■ Chemical processing, refining

■ Power generation

Natural Draft Cooling Tower—Concrete natural draft counterflow

tower of varying sizes and configurations. Exceptionally efficient and

reliable, most commonly used in power generation. Each tower is

custom designed for flow rates up to 113,500 m3/hr or more.

Counterflow Field-Erected Cooling Tower—The ultimate in versatility,

efficiency, and quality for large scale HVAC, power and industrial

facilities. Each tower is customized to meet your exact specifications

for performance, structure, drift, and sound. Available in pultruded

structural fiberglass, wood (Douglas fir or redwood), or concrete for

unsurpassed quality and reliability. Tower cells available from 295 to

6,815 m3/hr.

Round Forced-Draft Counterflow Cooling Tower—Reduced power

consumption, favorable space requirements, minimized recirculation

effects, optimum operational behavior for salt water application and

the aesthetic look are only some advantages of round concrete cooling

towers with forced draft fans.

Crossflow Field-Erected Cooling Tower—Large splash-fill towers

proven in hundreds of installations over the last fifty years. Available

in pultruded structural fiberglass or wood (Douglas fir or redwood) for

unsurpassed quality and reliability A variety of fill options makes this

the most versatile tower for heavy industrial use. Tower cells available

from 210 to 7,950 m3/hr.

3

Page 4

4

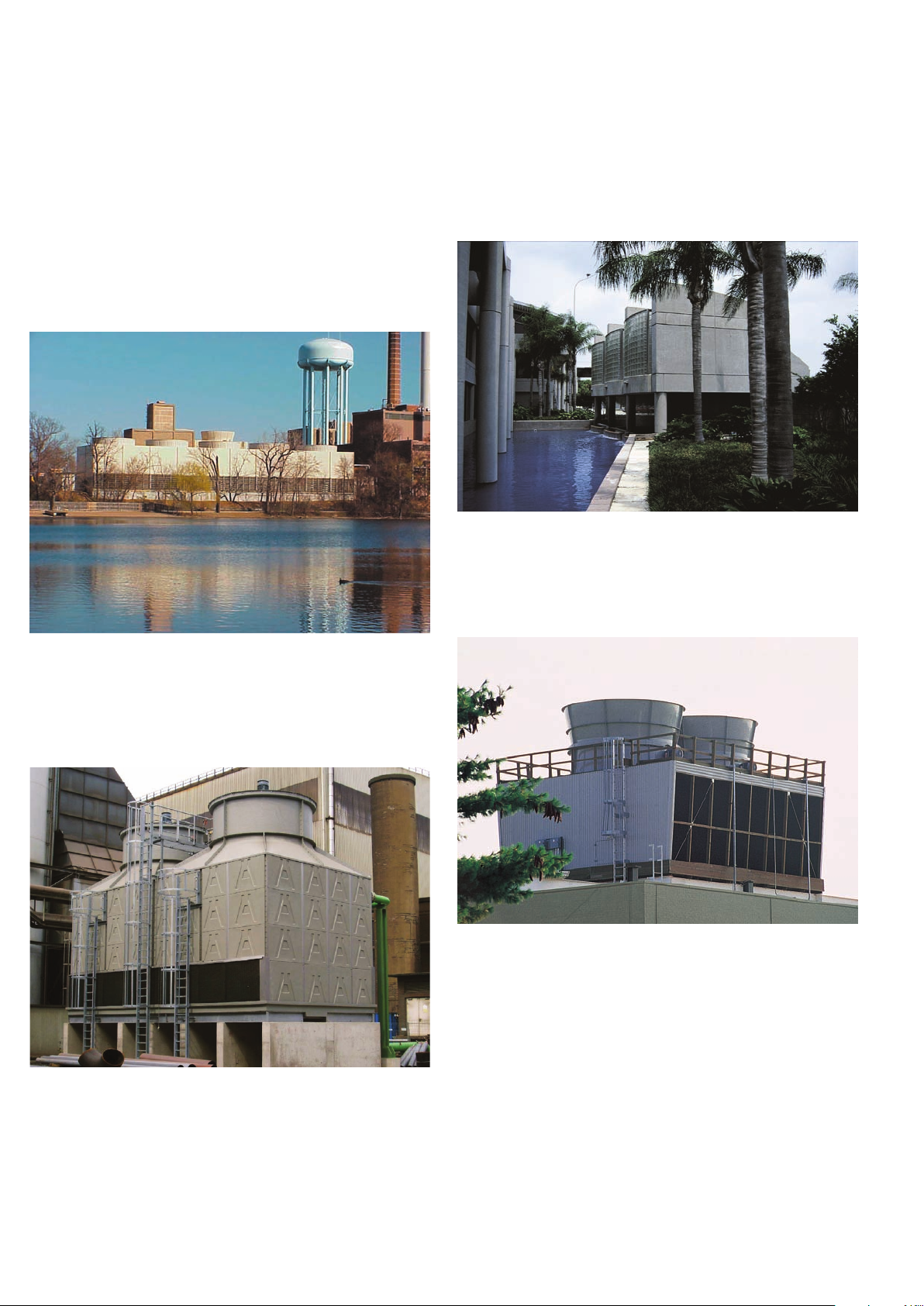

Cooling Towers

■ HVAC

■ Refrigeration

■ Light to medium industrial

Marley MS Cooling Tower—For those installations where aesthetics

preclude the use of a conventional cooling tower. Each tower is custom

designed to meet the needs of the individual installation. Available in a

wide range of flow rates.

Ceramic Unilite® Cooling Tower—Combined with superior composite

fiberglass materials and advanced heat transfer technology, the result

is a high-quality, cost-effective cooling tower that excels across a broad

range of HVAC and industrial applications. Tower cells available from

160 to 1,165 m3/hr. FM approval available.

Balcke CP Cooling Tower—Induced draft, counterflow cooling tower

design. The ideal solution for larger space-sensitive applications.

Its corrosion resistant fiberglass construction makes it an excellent

alternative to stainless steel products. Available in Europe, the Middle

East and Africa.

Marley Class 160 Cooling Tower—Similar in design to the Sigma,

these highly-efficient, low-maintenance towers offer a wide choice

of solutions for heavy industrial plants and large HVAC applications.

Available in wood (Douglas fir or redwood). Tower cells range from

340 to 2,650 m3/hr capacities.

Page 5

5

Cooling Towers

■ HVAC

■ Refrigeration

■ Light to medium industrial

Marley Series 10/Series 15 Cooling Tower—Splash-fill design for use

at high temperature or where poor water quality prevents the use of

film fill. Wood structure available in treated Douglas Fir or redwood.

Tower cells available from 50 to 1,090 m

3

/hr.

Marley Sigma Cooling Tower—These highly-efficient, low-

maintenance towers offer a wide choice of solutions for medium to

heavy industrial plants and large HVAC applications. Available in wood

(Douglas fir or redwood), steel (stainless or galvanized), or pultruded

structural fiberglass for unsurpassed quality and reliability. Tower cells

range from 90 to 2,295 m3/hr capacities.

Marley QuadraFlow® Cooling Tower—The first in the industry

protected by a five-year total product warranty covering virtually every

part of the tower. These fiberglass and stainless steel towers are field

assembled to facilitate siting, and are available from 570 to 4,605 kW

per cell. CTI Certified.

Marley SRC Cooling Tower—Induced draft, counterflow design.

Fiberglass field-erected structure. Stainless steel sub-structure option.

Not available in the US, Canada or Europe.

Page 6

6

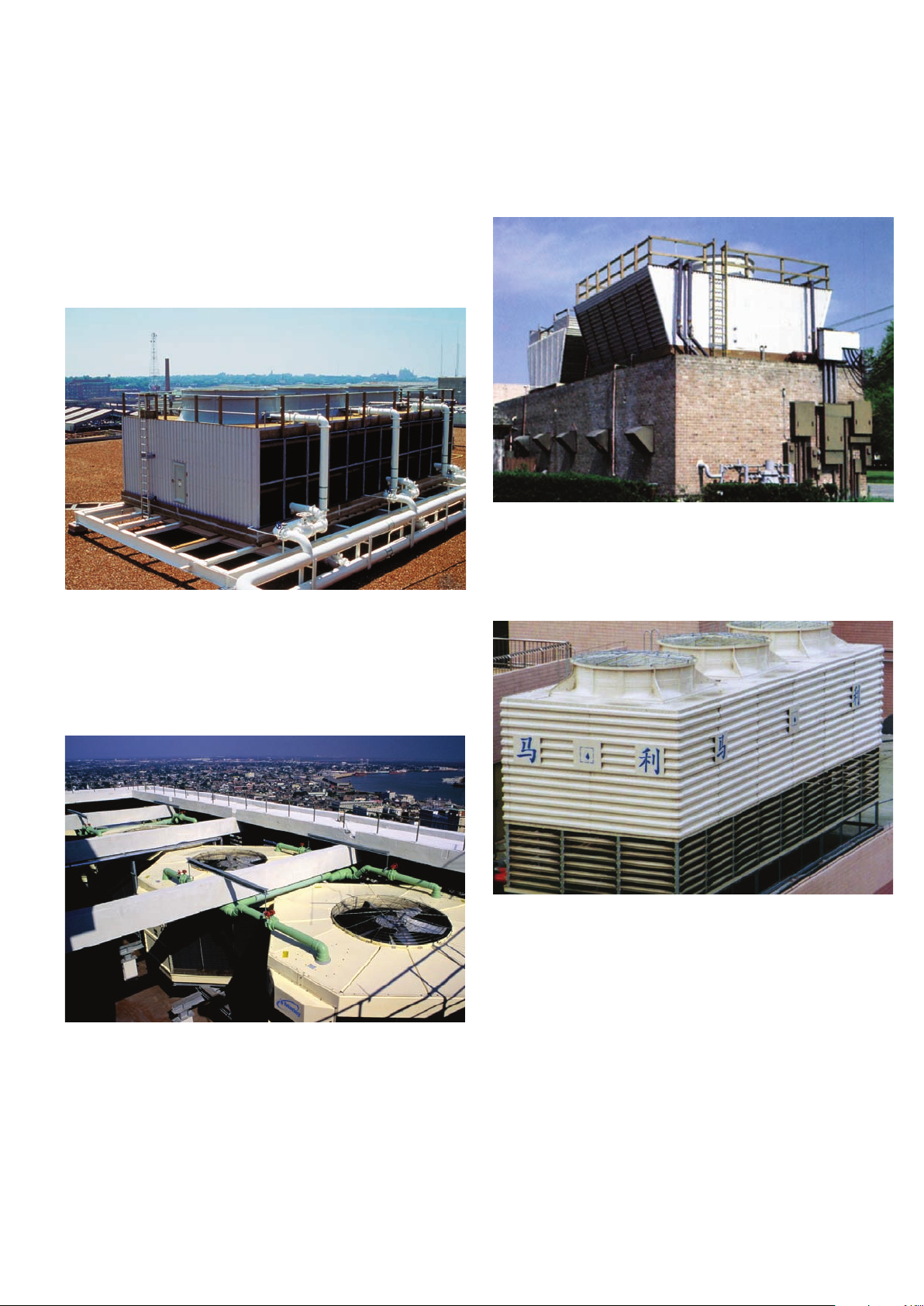

Cooling Towers

■ HVAC

■ Refrigeration

■ Light to medium industrial

®

Marley NC

warranty and guaranteed thermal performance. Factory assembly and

G-600 galvanized steel construction are standard. Cells available from

435 to 5,715 kW per cell. The all stainless steel option enhances the

versatility of the NC Class line. Factory Mutual Approval standard on

most models and available on all models. CTI Certified.

Class Cooling Tower—Five-year mechanical equipment

Marley MD Cooling Tower—Counterflow, induced-draft design

requires less plan area than crossflow towers. Factory assembly and

G-235 galvanized steel construction are standard. Tower available

from 725 to 2200 kW per cell. The all stainless steel option enhances

the versatility of the MD. Five-year mechanical equipment warranty.

CTI Certified.

Marley NC® Fiberglass Cooling Tower—Fiberglass and galvanized

steel, field-erected, crossflow cooling tower designed to serve air

conditioning and refrigeration systems as well as light or medium

industrial process loads on clean water. Stainless steel structure option

available. Cells available from 460 to 4,172 kW per cell.

CTI Certified. Not available in the US, Canada or Europe.

Marley AV Cooling Tower—Singleflow, induced-draft crossflow design

offers pump and fan energy savings in a small footprint installation.

Factory assembly and G-600 galvanized steel construction are

standard. Tower cells available from 515 to 1,715 kW per cell. The all

stainless steel option enhances the versatility of the AV. CTI Certified.

Page 7

7

Cooling Towers

■ HVAC

■ Refrigeration

■ Light to medium industrial

Marley Aquatower® Cooling Tower—Reliable performance has made

this design the industry standard for more than 50 years.

G-600 galvanized steel factory assembled structure. Also available in

300 series stainless steel. Capacities from 35 to 555 kW per cell.

CTI Certified and FM Approved.

Recold JT Cooling Tower—Forced-draft, low profile design.

G-600 galvanized steel factory assembled structure. Also available in

300 series stainless steel. Capacities from 135 to 1815 kW per cell.

Marley MCW Cooling Tower—Maximizes forced-draft, counterflow

technology and high-performance. The ideal solution for urban and

industrial applications. Available in G-600 galvanized or 300 series

stainless steel construction. Capacities from 625 to 2,150 kW per cell.

CTI Certified.

Marley CTF Series Cooling Tower—Forced draft, counterflow design.

Fiberglass factory assembled modular structure. Film-fill or splash-fill

option. Available in Europe only.

Page 8

8

Fluid Coolers

■ HVAC

■ Refrigeration

■ Light to medium industrial

Marley MC Fluid Cooler—Forced draft, counterflow design.

G-600 galvanized steel factory assembled structure. Also available in

300 series stainless steel. The ideal solution for sound- and spacesensitive applications. CTI Certified.

Marley MH Fluid Cooler—The MH Fluid Cooler with CoolBoost

Technology is the most efficient system on the market. It incorporates

fill media and more circuits of coil to increase performance as much

as 10 percent over other systems and still maintain a space-saving

footprint. CTI Certified.

Recold JW Fluid Cooler—Forced-draft, low profile design. G-600

galvanized steel factory assembled structure. Also available in 300

series stainless steel. Proven copper coil technology.

Recold MW Fluid Cooler—Induced draft, counterflow design. G-600

galvanized steel factory assembled structure. Also available in 300

series stainless steel. Proven copper coil technology.

Page 9

9

Evaporative Condensers

■ HVAC

■ Refrigeration

Recold MC Evaporative Condenser—Induced draft, counterflow

design. G-600 galvanized steel factory assembled structure. Also

available in 300 series stainless steel. Proven copper coil technology.

Recold JC Evaporative Condenser—Forced-draft, low profile design.

G-600 galvanized steel factory assembled structure. Also available in

300 series stainless steel. Proven copper coil technology.

Page 10

10

Dry Cooling

■ Power generation

■ Steam condensing

Air Cooled Condenser—The modularized A-Frame design is used

on power plants of all sizes. The integral features are long-term

mechanical and thermal integrity, excellent corrosion and freeze

resistance, low fan power consumption, reliable operation and low

maintenance. Over 800 installations world-wide.

Hexacool® Air Cooled Condenser—Smaller power and industrial

applications. Standardized modular system that is low cost, easy to

erect and robust in performance.

Page 11

11

Special Applications

■ Heavy industrial

■ Chemical processing, refining

■ Power generation

Wet-Dry Hybrid Cooling—The wet-dry hybrid cooling tower offers

efficient cold water temperatures with reduced visible plume and

enhanced water conservation.

AirFin™ Air Cooled Heat Exchangers—Innovative technology for

petrochemical, process and power applications. AirFin heat exchangers

have been designed, manufactured and supplied worldwide for over

40 years.

Indirect Dry Cooling—An indirect dry natural draft condensing

system, in the example above, couples a dry cooling tower with a

steam surface condenser. Such a condensing system is particularly

suited for large power plants. The concept can also be applied with

mechanical draft dry towers over a wide range of plant sizes.

Page 12

12

Parts and Accessories

■ Quality engineered

■ Precision crafted

■ Availableforvirtuallyanytower

You can count on us for your cooling parts. We design, manufacture,

and stock all primary cooling components, including:

•Fans •Fill

•Gearboxes •Nozzles

•Driveshafts •Drifteliminators

•Beltdrivecomponents •Valves

•Fancylinders •Structuralcomponents

Weareuniquelyabletomeetalmostanyrepairorpartsneedonany

sizeortypeofcoolingtowerregardlessofitsageormanufacturer.

Note SPX purchases and stocks specially designed cooling tower

motors from a number of qualified suppliers.

Page 13

13

Reconstruction and Services

■ Repair and reconstruction

■ Inspections and condition reports

■ Performance testing

Letourreconstructionexpertsrebuildyourtowertoenhanceits

performance; whatever its manufacture; whether it’s large or small,

crossflow or counterflow.

Cooling Tower Reconstruction For many older towers, reconstruction

is a cost-effective alternative to replacement. Our reconstruction

experts work with our engineering staff to make old towers as good as

new—if not better!

Services

Concrete Tower Repair and Reconstruction Our skilled task

force of engineering, production and construction specialists stands

ready to upgrade, refurbish and repair your concrete cooling tower,

whether manufactured by Balcke, Marley or others. Tap into our

extensive concrete experience—going back over 70 years to the very

first concrete natural draft hyperbolic tower.

Inspections and Condition Reports Our reconstruction

specialists have been trained to analyze the condition of your cooling

equipment—and its capability to be successfully repaired, rebuilt, or

upgraded. Your SPX Cooling Technologies sales representative can

arrange an inspection of your cooling system.

Maintenance Let our cooling system experts help your maintenance

experts. We can contract with you to provide as much “hands-on”

maintenance assistance as you need.

Performance Testing You can’t know how much any reconstruction

effort has improved your tower unless you know how your tower is

performing now. Our staff of Testing and Ratings Engineers can help

you to gain that vital information.

Page 14

14

Temporary Cooling

■ Disaster response

■ Maintenance outages

■ Repair/replacement cooling

A sense of urgency that gives new meaning

to the word “fleet.”

In this business, every minute of cool water flow, and every minute

variation in water temperature counts, regardless of whether you

provide emergency backup or increase production capacity.

Because it all equates to profits.

Marley Temporary Cooling Solutions is geared entirely toward making

your performance our priority—including a fleet of ultra-efficient

induced-draft towers, and regional support teams who are on the

ground and ready to move.

Page 15

15

BiomediaSystems

■ Municipal wastewater

■ Industrial wastewater

■ Upgradeexistingrocktricklingfilters

The Marley Biomedia System—A set a products specially designed

to work together for waste water treatment applications. Make your

projects and expansions as simple as possible with MarDek, MarGrid,

MarPier, and MarPak.

MarDek™—A high-strength grating support system designed to

accommodate all loads associated with trickling filter operation.

With cross-bar construction, MarDek allows the grating panel to be

easily cut and modified to fit almost any tank configuration. MarDek

can be supported by MarPier, concrete piers, or concrete blocks.

MarPier™—A specialized support system for the Biomedia System

that can be configured to accommodate various media loads, support

heights, and floor slopes. MarPier provides a firm foundation for all

common filter configurations. MarPier installs quickly and is designed

specifically to be used in conjunction with MarDek to provide a strong,

versatile, and reliable support for years of trouble-free operation.

MarPak®—A modular PVC corrugated fill media specifically designed

for biological treatment applications as part of the Biomedia System.

Page 16

UNIT 505, BLOCK B

PHILEO DAMANSARA 2

NO. 15 JALAN 16/11

OFF JALAN DAMANSARA

46350 PETALING JAYA, MALAYSIA

60 3 7665 1018

spxcooling.asiapacinfo@spx.com

spxcooling.com

In the interest of technological progress,

all products are subject to design and/or

material change without notice.

©2008 SPX Cooling Technologies

sea_G-08A

Loading...

Loading...