Page 1

CS4000 Mini Controller

with Ethernet

Technical Reference Manual

Page 2

24-Hour

Technical Support

Toll Free:

1-877-224-7377

SPX GSE tech-motive tool manufactures products under the GSE and tech-motive tool® brand names.

Page 3

Please Note:

has a new name. We are now

This change of name is not yet reflected in the documentation for this product where you will still find the old

logo and company name. The new address is:

SPX GSE tech-motive tool

42860 Nine Mile Road,

Novi MI 48375-4122

The toll free service number remains the same: 1-877-224-7377.

Page 4

LIMITED WARRANTY

Except for perishable items, such as the fuses and batteries, SPX GSE tech-motive tool warrants its

GSE tech-motive tool brand fastening products, GSE brand sensors and instruments, and fastening systems to be

free from defects in materials and workmanship for one year from the date of shipment from the manufacturing

facility.

The obligation of SPX GSE tech-motive tool is limited to repairing, or at their option, replacing the products and

components which, upon verification at the manufacturing facility in Novi, Michigan USA, prove to be defective. SPX

GSE tech-motive tool shall not be liable for installation charges, for expenses of the Buyer for repairs or

replacement, for damages from delay or loss of use, or other indirect or consequential damages of any kind. SPX

GSE tech-motive tool extends this warranty only upon proper use of the product in the application for which it is

intended. The warranty does not cover products that have been modified without the approval of

SPX GSE tech-motive tool or which have been subjected to unusual physical or electrical stress, or from or upon

which the original identification marks have been removed or altered.

Whenever the design of the system in which it is to be incorporated originates with the Buyer, the warranty is limited

specifically to furnishing the controllers and nutrunners free of defects in materials and workmanship and assumes

no responsibility for implied warranties of fitness for purpose or use.

In the event that a product is repaired or replaced under the terms of the warranty, the warranty period of the

repaired or replacement product shall be limited by the agreed upon level of warranty purchased by the customer.

Industrial installations are warranted by SPX GSE tech-motive tool for repairs at the installation site only if the

customer contracts with SPX GSE tech-motive tool to perform checkout and final adjustment at the installation site

and for the training of customer personnel in the operation and maintenance under the system. Under such

conditions, SPX GSE tech-motive tool agrees to perform field service for 90 days from date of checkout without

charge for labor or materials. The customer shall pay for travel expenses of SPX GSE tech-motive tool personnel.

Warranty of peripheral equipment, such as printers, recorders, plotters, etc., included with a GSE tech-motive tool

or GSE torque product or SPX GSE tech-motive tool fastening system, shall be extended to the Buyer on the

original manufacturer’s terms.

Transportation charges for materials shipped to the manufacturing facility for warranty repair are to be paid by the

shipper. SPX GSE tech-motive tool will return items repaired or replaced under warranty prepaid.

Information and technical diagrams in this document are subject to change without notice. Products and services

referred to in this book may be either trademarks and/or registered trademarks of their respective owners.

SPX GSE tech-motive tool manufactures products under the GSE and tech-motive tool® brand names in Novi, MI.

© 2002 SPX CORPORATION. ALL RIGHTS RESERVED.

Page 5

Acknowledgments

Special thanks are extended to the following SPX GSE tech-motive tool management, software and

hardware engineers who provided value information in the development and review of this manual.

Jim Grenier

Tom Jozwiak

Ken Lehoczky

Larry Piggins

Rick Szwast

Steve Urbanski

Bill Welch

Karen R. Francis, technical writer

Linda J. Ashley, editor

Page 6

Preface

The GSE tech-motive tool CS4000 Mini Controller with Ethernet typically is used with tech-motive

tool Intelligent nutrunners in a multi-spindle fastening system that communicates with other operations

in an assembly process over an Ethernet network. When used in this context, the controller contains an

Ethernet interface card and the RJ-45 connector that is used to link it to a host computer (that contains

an Ethernet network card). The Ethernet interface card in each device enables communication via the

network hub.

The CS4000 Mini Controller with Ethernet can optionally communicate over a 485 network. For this

application, it has an RS-485 connector and is linked to a host computer that contains a Synchronous

Data Link Control (SDLC) card.

In either scenario, the host computer is loaded with the tech-motive tool Visual Supervisor (VS) setup,

graphing and diagnostics program. Version 3.20 is used to program the parameters of each

tech-motive spindle (controller and nut runner) in the network, r emains on the host computer, and is

thus said to operate in permanent mode.

When operating a nutrunner off-network (in a single spindle, stand-alone system), the controller is

programmed using VS from a laptop PC, which is linked via cable to the RS-232 serial port on the

controller. Because the laptop can be disconnected from one CS4000 Mini Controller and reconnected

to another, VS is said to operate in portable mode.

An optional Interbus-S module can be added to the CS4000 Mini Controller with Ethernet, typically to

connect the controller to a Programmable Logic Controller (PLC). The module adds eight softprogrammable digital inputs and eight soft-programmable digital outputs to the system.

Who Should Use This Manual

This manual is written for the engineers, technicians and users who will set-up and/or operate the

CS4000 Mini Controller with Ethernet with any of the Intelligent (46, 66 or 116) nutrunners.

How to Use This Manual

This manual provides installation, maintenance and technical information about the CS4000 Mini

Controllers with Ethernet.

This Preface provides conventions and abbreviations used throughout this manual.

If you have never used a CS4000 Mini Controller with Ethernet, read this manual entirely. The first

three chapters will help you become familiar with safety requirements, the location of components,

software and features.

If you are already familiar with the CS4000 Mini Controller, look over Chapter 4. Installing the

CS4000 Mini Controller with Ethernet, which describes the power requirements and details the I/O

wiring and connectors.

May 2002 T-38324-A Page iii

Page 7

CS4000 Mini Controller with Ethernet

If you want to use the CS4000 Mini Controller with Ethernet with a network or laptop computer, refer

to Chapter 5. Setting Up the Ethernet, Chapter 6. Setting Up the 485 Network and Chapter 7. Setting

Up the RS-232 Link that describe the methods by which you can connect the CS4000 Mini Controller

to a network or laptop computer.

You will find Chapter 8. Maintenance/Troubleshooting and Chapter 9. Technical Information provide

you with technical details for maintaining and troubleshooting the controller.

Conventions

The following conventions are used throughout this manual for the safety of personnel, equipment,

software, and data. The conventions include warnings, cautions and notes, as follows:

WARNING! Information inside the WARNING! box concerns the

protection of either personnel (or an action that could result

in a systems failure). The information is indented and in

italicized boldface type.

CAUTION! Information next to CAUTION! concerns the protection of

equipment, software, and data. The information is indented

and in italicized boldface type.

NOTE: Information next to the NOTE caption is designed to bring your

attention to a certain characteristic of software or hardware

operation. The information is indented and italicized.

Page

iv

T-38324-A 39-30-38324

Page 8

Abbreviations

Some of the most common abbreviations used throughout this manual include the following:

API Application Program Interface

GFCI Ground Fault Circuit Interrupter

I/O Input/Output

IEEE Institute of Electrical and Electronic Engineers

IP Internet Protocol

kbps kilo-bits per second

kVA kilovolt-ampere

LAN Local Area Network

LED Light Emitting Diode

mbps million bits per second

PCI Peripheral Component Interconnect

TCM Tool Control Module

Preface

TCP/IP Transmission Control Protocol/Internet Protocol

RAM Random Access Memory

SDLC Synchronous Data Link Control

TINI TINI I

V Volts

nternet Interface

May 2002 T-38324-A Page v

Page 9

CS4000 Mini Controller with Ethernet

(This page is left blank intentionally.)

Page

vi

T-38324-A 39-30-38324

Page 10

Contents

Preface ................................................................................................................................... iii

Who Should Use This Manual....................................................................................... iii

How to Use This Manual................................................................................................ iii

Conventions.................................................................................................................... iv

Abbreviations...................................................................................................................v

1. Overview........................................................................................................................ 1-1

Receiving, Sending and Storing Data......................................................................... 1-1

Using Ethernet .............................................................................................................. 1-2

Example of a “Permanent” (Embedded) Ethernet Network ..................................... 1-3

Using a 485 Network using SDLC............................................................................... 1-4

Example of a “Permanent” (Embedded) 485 Network............................................. 1-5

(Using CS4000 KDM and Mini Controllers with SDLC)............................................ 1-5

Using the RS-232 Serial Port ....................................................................................... 1-6

Using an Interbus-S Digital I/O Module...................................................................... 1-6

Using the Siemens 3964R Barcode Protocol............................................................. 1-7

Deciding How to Set Up the Controller ...................................................................... 1-7

2. Think Safety First! ........................................................................................................ 2-1

General Machine Safety........................................................................................... 2-2

Electrical Safety........................................................................................................ 2-3

3. Identifying the Components........................................................................................ 3-1

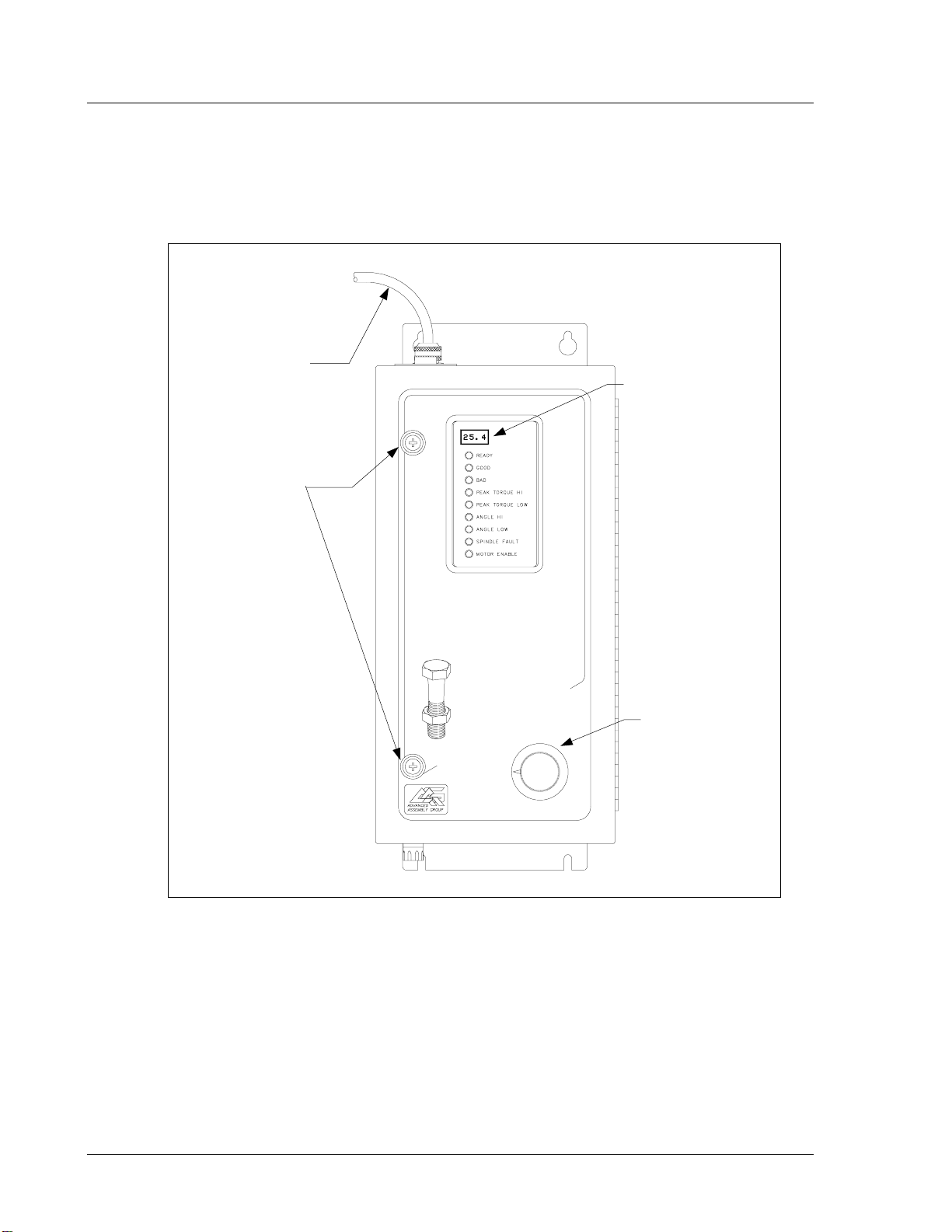

Front Panel.................................................................................................................... 3-2

LED Display....................................................................................................... 3-2

Parameter Set Switch........................................................................................ 3-3

Access Screws .................................................................................................. 3-3

Top and Bottom Panel ................................................................................................. 3-3

AC Power Cord.................................................................................................. 3-3

Interbus-S I/O Connector................................................................................... 3-3

I/O Connector .................................................................................................... 3-4

Tool Connector.................................................................................................. 3-4

RS-422 Connector............................................................................................. 3-5

Ethernet Connector............................................................................................ 3-5

Printer/Barcode Connector................................................................................ 3-5

SDLC I/O Network Connector ........................................................................... 3-5

RS-232 Connector............................................................................................. 3-5

Ground Fault Circuit Interrupter......................................................................... 3-5

Fuses................................................................................................................. 3-6

May 2002 T-38324-A Page vii

Page 11

CS4000 Mini Controller with Ethernet

Enclosure Interior......................................................................................................... 3-6

Tool Control Module................................................................................................. 3-8

Servo Amplifier................................................................................................ 3-10

Device Control Module .................................................................................... 3-10

Backplane .............................................................................................................. 3-11

Backplane Fuses............................................................................................. 3-12

Address Switches............................................................................................ 3-12

I/O Board................................................................................................................ 3-13

Power Supply......................................................................................................... 3-13

Ethernet Interface Card.......................................................................................... 3-14

Interbus-S Module.................................................................................................. 3-16

Ground Fault Circuit Interrupter ............................................................................. 3-18

Fuses ..................................................................................................................... 3-18

4. Installing the CS4000 Mini Controller with Ethernet................................................. 4-1

Mounting the CS4000 Mini Controller with Ethernet ................................................ 4-1

Power and Connection-Requirements....................................................................... 4-3

Meeting the AC Input Power Requirements .............................................................. 4-4

Grounding..................................................................................................................... 4-4

I/O Wiring ...................................................................................................................... 4-5

Connector Pinout Definitions.................................................................................... 4-11

Tool Connector ...................................................................................................... 4-11

I/O Connector......................................................................................................... 4-11

RS-422 Connector ................................................................................................. 4-12

Tool Control Module (TCM) Network Connector ................................................... 4-12

RS-232 Connector ................................................................................................. 4-12

Printer/Barcode Connector .................................................................................... 4-12

Interbus-S “IN” Connector...................................................................................... 4-12

Interbus-S “OUT” Connector.................................................................................. 4-13

Page

5. Setting Up the Ethernet ............................................................................................... 5-1

Programming the Ethernet Interface Card................................................................. 5-1

Working with the IP Address, Subnet Mask and Default Gateways ........................ 5-1

Updating Application Settings................................................................................ 5-10

Setting Up Visual Supervisor for an Ethernet Network.......................................... 5-13

Editing VSMain.ini for an Ethernet Network........................................................... 5-14

Using Ethernet Network Cables................................................................................ 5-16

Testing the Ethernet Network....................................................................................... 5-17

Testing Ethernet Network Cables.......................................................................... 5-24

6. Setting Up the 485 Network......................................................................................... 6-1

Installing the SDLC Card ............................................................................................. 6-1

Setting Up Visual Supervisor for a 485 Network....................................................... 6-1

Editing VSMain.ini for a 485 Network ...................................................................... 6-2

Assigning A Network Address.................................................................................. 6-4

Using 485 Network Cables ...................................................................................... 6-7

viii

T-38324-A 39-30-38324

Page 12

Contents

7. Setting Up the RS-232 Link.......................................................................................... 7-1

Setting Up Visual Supervisor ...................................................................................... 7-1

Using RS-232 Cables.................................................................................................... 7-1

8. Maintenance/Troubleshooting .................................................................................... 8-1

Replacement Parts ....................................................................................................... 8-1

Replacing Main Power Fuses...................................................................................... 8-2

Replacing Backplane Fuses........................................................................................ 8-2

Cleaning the Enclosure Window................................................................................. 8-2

Troubleshooting ........................................................................................................... 8-3

Ethernet Network ..................................................................................................... 8-3

RS-422 (Siemen’s 3964R) Interface........................................................................ 8-4

Application Program Interface (API)......................................................................... 8-4

9. Technical Information .................................................................................................. 9-1

Assembly Drawing........................................................................................................ 9-1

Index..............................................................................................................................Index-1

May 2002 T-38324-A Page ix

Page 13

CS4000 Mini Controller with Ethernet

Figures

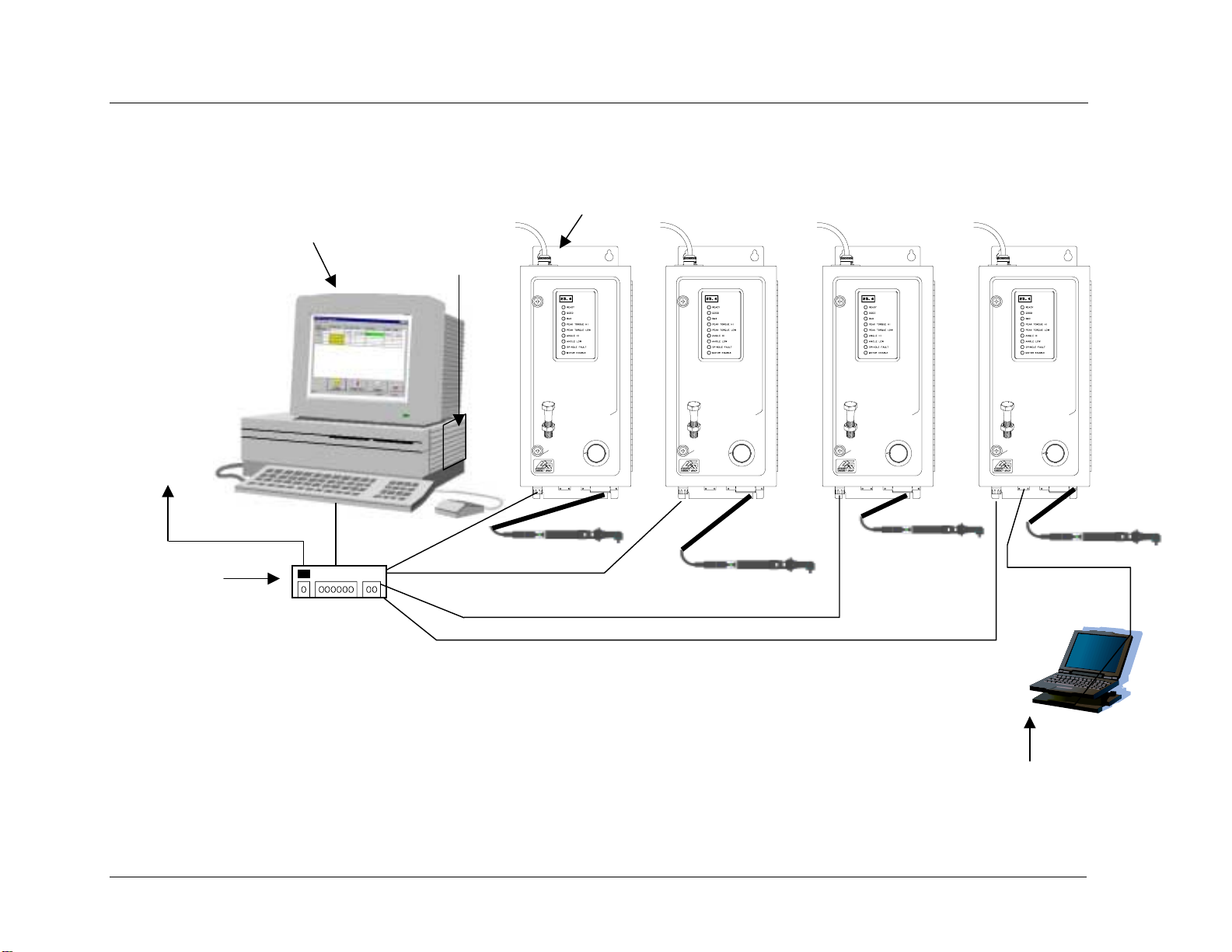

Figure 1-1. Example of an Ethernet Network with a Connected Portable Laptop............. 1-3

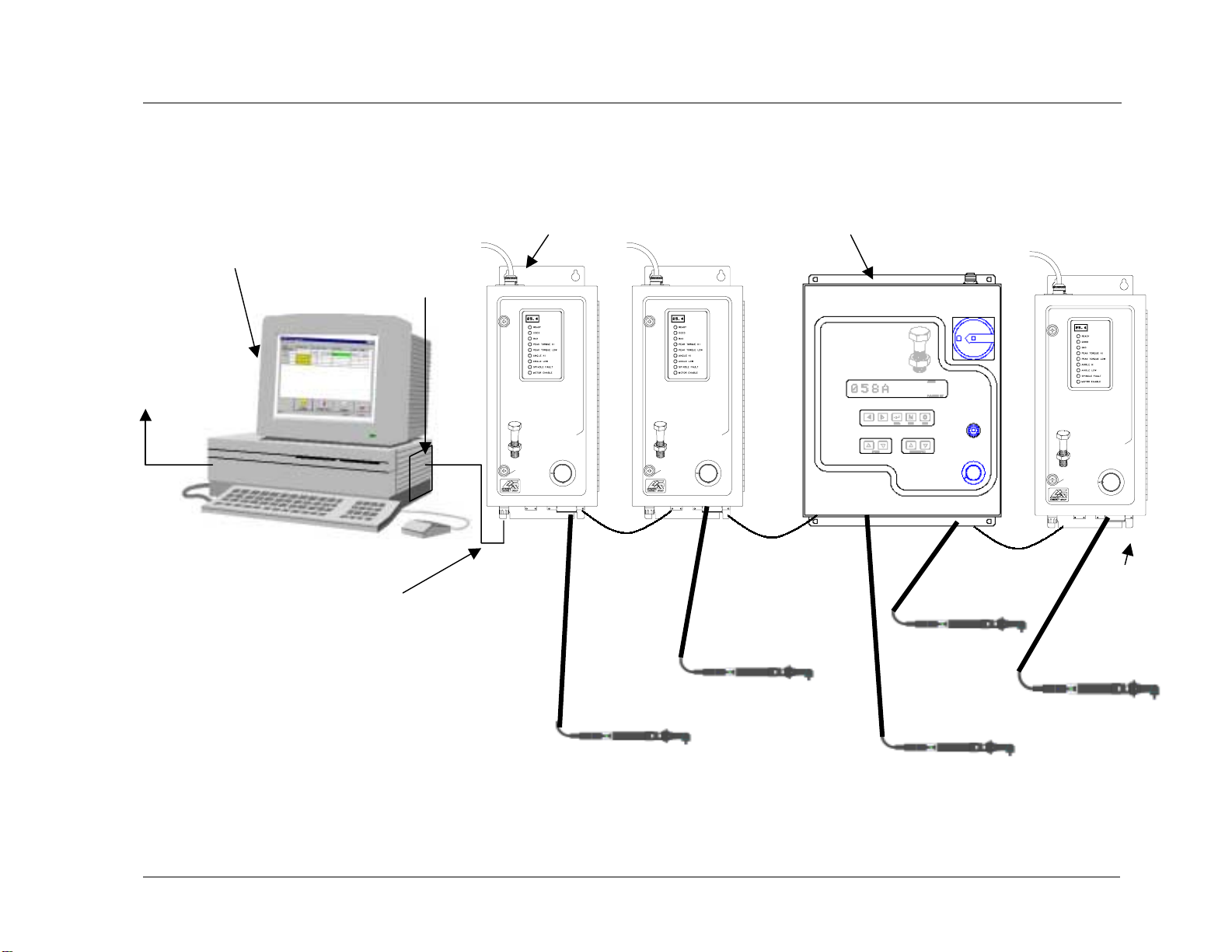

Figure 1-2. Example of a 485 Network.............................................................................. 1-5

Figure 3-1. Front Panel View............................................................................................. 3-2

Figure 3-2. Top Panel View............................................................................................... 3-3

Figure 3-3. Bottom Panel View.......................................................................................... 3-4

Figure 3-4. Components Inside the Enclosure of the CS4000 Mini Controller

with Ethernet................................................................................................... 3-7

Figure 3-5. Front View of the TCM.................................................................................... 3-8

Figure 3-6. Rear View of the TCM and Location of the Servo Amplifier Fuse .................. 3-9

Figure 3-7. DCM Board and DCM Battery Location........................................................ 3-10

Figure 3-8. CS4000 Mini Controller with Ethernet Backplane......................................... 3-11

Figure 3-9. I/O Board ...................................................................................................... 3-13

Figure 3-10. Ethernet Interface Card ................................................................................ 3-14

Figure 3-11. Interbus-S Module Side View........................................................................ 3-16

Figure 3-12. Interbus-S Module Top View ........................................................................ 3-17

Figure 3-13. Ground Fault Circuit Interrupter.................................................................... 3-18

Figure 4-1. CS4000 Mini Controller with Ethernet Dimensions......................................... 4-2

Figure 4-2. Power/Connection Requirements................................................................... 4-3

Figure 4-3. Remote Input Circuit Schematics ................................................................... 4-8

Figure 4-4. Example of CS4000 Controller Remote I/O Wiring − Sourcing Outputs ........ 4-9

Figure 4-5. Example of CS4000 Controller Remote I/O Wiring − Sinking Outputs......... 4-10

Figure 5-1. Message Upon Starting the TINI Ethernet Interface Flash Utility................... 5-3

Figure 5-2. Selecting the COM Port Menu........................................................................ 5-4

Figure 5-3. Selecting ‘COM1’ RS-232 Port ....................................................................... 5-4

Figure 5-4. Establishing A Successful Connection via COM1 ......................................... 5-5

Figure 5-5. Error Message Displayed when COM1 is Already In Use .............................. 5-5

Figure 5-6. Selecting the “Flash TINI…” Option................................................................ 5-6

Figure 5-7. Selecting the Application File.......................................................................... 5-6

Figure 5-8. Error Message Displayed when the Attempted Connection Fails................... 5-7

Figure 5-9. Error Message Following An Unsuccessful Flash Attempt............................. 5-7

Figure 5-10. Second Error Message Following An Unsuccessful Flash Attempt................ 5-7

Figure 5-11. Confirming the IP Address, Subnet Mask and Default Gateway.................... 5-8

Figure 5-12. Selecting the “Set TINI Application Info…” Menu Option.............................. 5-10

Figure 5-13. Viewing the Application Settings Window - General Info tab....................... 5-11

Figure 5-14. Selecting the Application Settings Window - Ip Address tab ....................... 5-11

Figure 5-15. Selecting the Application Settings Window - Comm Options tab ................ 5-12

Figure 5-16. VSMain.ini configured for an Ethernet Network............................................ 5-14

Figure 5-17. Select the Icon and Enter A Name for the Hyperterminal Connection.......... 5-18

Figure 5-18. Select Communications Port ........................................................................ 5-19

Figure 5-19. Setting the Communications Port Settings ................................................... 5-20

Figure 5-20. Hyperterminal Window Showing Ethernet Interface Card (TINI)

Login Prompt ................................................................................................ 5-21

Figure 5-21. Opening the Command Prompt Window...................................................... 5-23

Page

x

T-38324-A 39-30-38324

Page 14

Figure 6-1. VSMain.ini configured for a 485 Network........................................................ 6-2

Figure 6-2. Network Address DIP Switch Set for Address ‘5’............................................ 6-5

Figure 9-1. CS4000 Mini Controller with Ethernet Wiring of Standard Ethernet and

Figure 9-2. CS4000 Mini Controller with Ethernet Wiring of Standard Ethernet ............... 9-5

Tables

Table 3-1. Description of Ethernet Interface Card LEDs................................................ 3-15

Table 3-2. Description of LEDs on the Side of the Interbus-S Module........................... 3-17

Table 3-3. Description of LEDs on the Top of the Interbus-S Module............................ 3-17

Table 4-1. 19-Position Remote I/O Connector Pinout Signal Names and Descriptions .. 4-5

Table 4-2. Guidelines for Proper Operation of the Controller I/O Signals........................ 4-8

Table 5-1. Ethernet RJ-45 Modular Jack Pinout ............................................................ 5-16

Table 6-1. Switch Positions Representing Binary Numbers............................................. 6-4

Table 6-2. Setting Address Switches ............................................................................... 6-4

Contents

Interbus-S Module........................................................................................... 9-3

Table 8-1. Replacement Parts ......................................................................................... 8-1

Table 8-2. Ethernet Common Problems and Solutions.................................................... 8-3

Procedures

Procedure 5-1. Programming the Ethernet Interface Card...................................................... 5-2

Procedure 5-2. Editing Application Information...................................................................... 5-10

Procedure 5-3. Editing VSMain.ini for an Ethernet Network.................................................. 5-15

Procedure 5-4. Testing the Network From A Laptop Computer ............................................ 5-17

Procedure 5-5. Testing the Network From A Host Computer................................................ 5-23

Procedure 6-1. Editing VSMain.ini for a 485 Network.............................................................. 6-3

Procedure 6-2. Setting the Address for the Controller............................................................. 6-6

May 2002 T-38324-A Page xi

Page 15

CS4000 Mini Controller with Ethernet

(This page is left blank intentionally.)

Page

xii

T-38324-A 39-30-38324

Page 16

1. Overview

The GSE tech-motive tool CS4000 Mini Controller with Ethernet is the control component of one of

the most powerful DC elec t ric nutrunner fastening control systems available. The system uses 100%

digital technology to ensure accurate and reliable fastening, and torque angle data acquisition.

Microprocessors in both the tool (nutrunner) and the controller enable the system to pe rform to levels

of accuracy while providing easy setup and operation.

The system uses the industry’s first truly “Intelligent Tools.” With this technology you no longer need

to key tool identification, calibration, angle counts, speed and other information into the controller.

You simply plug in the tool, power up the system, program the desired tightening parameters and

begin production.

A complete fastening system is made up of the CS4000 Mini Controller (with or without) Ethernet, a

tech-motive tool nutrunner (46 , 66 or 116 Series) and a standard tech-motive tool cable. The CS4000

Mini Controller with Ethernet houses o ne Tool Contr ol Module (TCM), with fuses and ground fault

circuit interrupt (GFCI) protection. The powerful tech-motive tool Visual Supervisor software

program is used fo r system setup, graphing and d iagnostics.

Visual Supervisor runs on a computer attached to the controller, using:

• An Ethernet link, using an Ethernet interface card and an Ethernet RJ-45 port.

•

A 485 network link, using a Synchronous Data Link Control (SDLC) card and RS-485 port.

• An RS-232 compatible serial port.

NOTE: To find out more about using the Visual Supervisor software,

refer to the Visual Supervisor User’s Guide (part number

39-30-34823).

Receiving, Sending and Storing Data

You can use the following methods to link one or more controllers to the Visual Supervisor program

and/or I/O communications devices:

• An Ethernet link to a local area network (LAN). Here the controller has the standard Transmission

Control Protocol/Internet Protocol (TCP/IP), an Ethernet interface card, and an Ethernet RJ-45

port.

•

A 485 network link to a LAN. Here the computer uses an SDLC card inserted into a free

Peripheral Component Interconnect (PCI) slot, and an RS-485 port on the controller.

CAUTION! The 485 network and Ethernet link perform the same

function. If you set up the controller to use the 485 network,

you will not need the Ethernet link, nor vice versa.

•

An RS-232 serial link to a laptop computer using the RS-232 serial port.

May 2002 T-38324-A Page 1-1

Page 17

CS4000 Mini Controller with Ethernet

• A digital I/O communications link, using the optional Interbus-S digital I/O module in the

controller. The Interbus-S module does not connect the controller to a network, but does allow

I/O communications between the controller and a Programmable Logic Controller (PLC), or other

similar device.

To help you decide which method you require, read the rest of this chapter.

If you choose the Ethernet or 485 network method, the Visual Supervisor software installed on the

computer attached to the network allows you to make changes to controllers across the network and

monitor them. Thi s supervisory compute r is commonly referred to throughout this manua l as the host.

It is also possible to connect a laptop, via a cable and the RS-232 compatible serial port, to any

controller on the network and make individual changes to that controller. Refer to Using the RS-232

Serial Port later in this chapter for details.

NOTE: To program controllers across the network, and successfully use

an attached laptop to view, edit or collect data from a controller

on the network, you must have Visual Supervisor version 3.20 or

higher installed on the host and laptop computers, and DCM

4.06 or higher installed on the controllers.

The CS4000 Mini Controller with Ethernet also has an optional Application Program Interface (API)

which you can have built into each controller. This allows you to collect rundown data and send it to a

software application across the Ethernet network, other than Visual Supervisor.

NOTE: The API can be run concurrently with Visual Supervisor allowing

Using Ethernet

The Ethernet is a Local Area Network (LAN) technology developed by Xerox and then further

developed by Xerox, Digital Equipment Corporation (DEC), and Intel. The CS4000 Mini Controller

with Ethernet uses the most commonly installed type of Ethernet cable, 10Base-T. This type of cable

can provide transmission speeds of up to 10 million bits per second (mbps) and uses the standard

Transmission Control Protocol/Internet Protocol (TCP/IP) communications protocol.

This is a permanent mode of operation in which the computer and controllers are connected via the

same network hub. See Figure 1-1.

This type of network requires:

• Pentium Class computer (500 MHz or above).

•

Microsoft Windows 95, 98, 2000, or Windows NT, version 4.0 or above with TCP/IP

communications protocol installed.

•

At least 64 MB RAM for Windows 95, 98 or 2000, or 128 MB RAM for Windows NT.

•

Installed Ethernet Interface Card in the controller and the computer.

•

Visual Supervisor installed in permanent mode.

you to collect rundown data in Visual Supervisor and also send it

to another application, via the API.

Page

• Shielded 10Base-T cable and Ethernet connector.

In this configurat i on, the host computer running Visual Supervis or provides data collection,

diagnostics and configuration functions for all the controllers, but the hub is the connection point for

the LAN. See Figure 1-1 for details. To set up an Ethernet network, refer to Chapter 5. Setting Up the

Ethernet.

1-2

T-38324-A 39-30-38324

Page 18

Example of a “Permanent” (Embedded) Ethernet Network

(Using Mini Controllers with Ethernet)

Chapter 1. Overview

Pentium Class Computer running Windows 95, 98, 2000

or Windows NT, version 4.0 or above. It also has an

installed Ethernet interface card. Each controller has an

Ethernet connector.

Visual Supervisor is

Ethernet Card

running on the

computer, plus an

optional Application

Program Interface

(API) for data

collection.

LAN

Network

Hub

CS4000 Mini Controllers with Ethernet

CS4000 mini

SYSTEM

CONTROLLER

456

3

tech-motive tool

2

1

7

8

*

CS4000 mini

SYSTEM

CONTROLLER

456

3

tech-motive tool

2

1

CS4000 mini

SYSTEM

CONTROLLER

456

3

7

8

*

tech-motive tool

7

2

8

1

*

CS4000 mini

SYSTEM

CONTROLLER

456

3

tech-motive tool

2

1

7

8

*

NOTE: Each controller is attached to the hub, which is in turn attached to the host computer. Visual Supervisor

provides data collection, diagnostics and configuration functions, but the individual controllers may also

have changes made to them. These changes are then communicated back to the computer, via the

Ethernet, and the change recorded in Visual Supervisor.

A laptop running Visual Supervisor is

attached, via an RS-232 compatible

Figure 1-1. Example of an Ethernet Network with a Connected Portable Laptop

port, and used to make setup

changes for an individual controller

on or off the network.

May 2002 T-38324-A PRELIMINARY DRAFT Page 1-3

Page 19

CS4000 Mini Controller with Ethernet

Using a 485 Netw ork using SDLC

In a 485 network, the controller is linked to a LAN, via cable between the first controller’s RS-485

connector and the port for the Synchronous Data Link Control (SDLC) card installed on the host

computer. Each controller in the 485 network is connected to the next in a daisy chain fashion. The

computer is connected to the first controller, the first controller is connected to the second controller,

and so on until the network terminates with the last controller. See Figure 1-2. In this mode of

operation, you can have as many as 32 TCMs attached and running from a single sup ervising

computer.

This type of network requires:

•

Pentium class computer (500 MHz or above).

• Microsoft Windows NT, version 4.0 or above.

• At least 128 MB RAM.

•

Installed SDLC card.

• Visual Supervisor installed on the computer in permanent mode.

• RS-485 cable and connector.

In this configuration, the computer permanently connected to the network runs Visual Supervisor

which now takes on the role of supervising all of the controllers on the LAN for both data and

parameter set information, as well as being the connection point for the LAN. To set up a 485

network, refer to Chapter 6. Setting Up the 485 Network.

Page

1-4

T-38324-A 39-30-38324

Page 20

Example of a “Permanent” (Embedded) 485 Network

(Using CS4000 KDM and Mini Controllers with SDLC)

Pentium Class Computer running

Windows NT, version 4.0 or above, with an

SDLC card and RS-485 port on each

controller.

SDLC Card

CS4000 Mini Controller each contains

one Tool Control Module (TCM)

Chapter 1. Overview

KDM based CS4000 Compact Controller

(in read-only mode) contains one or two

TCMs

LAN

RS-485 Network

(A maximum of 32 TCMs can be

daisy chained or wired together)

NOTE: The computer is attached to the first controller, the first

controller is attached to the second controller, and so on

until the termination point of the network. The Visual

Supervisor software provides data collection, diagnostics

and configuration functions, as well as the connection

point for the LAN.

CS4000 mini

SYSTEM

CONTROLLER

456

3

tech-motive tool

2

1

7

8

*

CS4000 mini

SYSTEM

CONTROLLER

456

3

tech-motive tool

2

1

7

8

*

Figure 1-2. Example of a 485 Network

CS4000 mini

SYSTEM

CONTROLLER

456

3

tech-motive tool

2

1

TCM

termination

point

7

8

*

May 2002 T-38324-A PRELIMINARY DRAFT Page 1-5

Page 21

CS4000 Mini Controller with Ethernet

Using the RS-232 Serial Port

In this configuration, a laptop PC loaded with the Visual Supervisor software is linked to the

controller’s RS-232 serial port. See Figure 1-1 on page 1-3. Because the laptop can be disconnected

from one Mini Controller and reconnected to another, VS is said to be operating in portable mode.

The controller in this scenar io may not be part of a network typically so that it, the cable and nut runner

comprise a stand-alone fastening system.

This type of operation requires:

• Pentium class laptop computer.

• Microsoft Windows 95, 98, 2000, or Windows NT version 3.0 or above.

•

At least 64 MB RAM for Windows 95, 98 or 2000, or 128 MB RAM for Windows NT.

• Visual Supervisor installed on the laptop in portable mode.

• RS-232 cable and connector.

If the laptop PC is connected to a controller that is also connected to a network, the host computer

adopts any changes made by the laptop PC to the controller. While the laptop computer is making

changes, the host cannot make setup changes to the same controller. The Visual Supervisor program

being run by the host computer grays out every field for that particular controller. When the laptop PC

is no longer connected to the controller, the host computer can once again make changes.

NOTE: To attach and use a laptop to view, edit or collect data from a

controller on a network, you must have Visual Supervisor

version 3.20 or higher installed on the host and laptop

computers, and DCM 4.06 or higher installed on the controllers.

Using an Interbus-S Digital I/O Module

The optional Interbus-S module can be added to the controller, to provide eight soft-programmable

digital inputs and eight soft-programmable digital outputs. You can assign the function of these inputs

and outputs using the Visual Supervisor program. Refer to the Visual Supervisor User’s Guide (part

number 39-40-34823) for details.

You can use the Interbus-S module to connect the controller to a Programmable Logic Controller

(PLC). When the PLC reads a barcode successfully, for example, it sends a signal as an Interbus-S

module input into the controller that tells the controller to allow the operator to perform a rundown.

The controller then sends a signal to the PLC as an Interbus-S module output that indicates when a

good rundown or a bad rundown has been performed.

Page

1-6

T-38324-A 39-30-38324

Page 22

Using the Siemens 3964R Barcode Protocol

The RS-422 port on the controller supports the Siemens 3964R barcode protocol. This protocol

provides an error checked point-to-point method of sending barcode data to the controller. If the

controller receives a corrupt or incomplete barcode, the scanner sends the barcode information again.

For example, you might choose to attach a barcode scanner and controllers to the same RS-422

network. A barcode is read by the scanner, which then sends the barcode to every controller attached

to the network. This means you do not have to scan the barcode at each individual controller.

NOTE: If, for any reason, the scanner does not send a barcode using

the RS-422 port, then the Printer/Barcode port on each

controller provides you with a backup. You can always scan the

barcode at an individual controller using a scanner attached to

the Printer/Barcode serial port until the scanner attached to the

RS-422 port starts sending barcode data again.

For further details about the Siemens 3964R Barcode Protocol, refer to the Protocol Definition of the

3964/3964R Procedures available from Siemens (Siemens Part Number C79000-B8576-C191-01).

Deciding How to Set Up the Controller

Chapter 1. Overview

It is more than likely that you will not need to use all methods of connecting the controller to a

network and/or external devices. If you decide to use the 485 network link then you will not need the

Ethernet link, nor vice versa, as they perform the same function. You may or may not want the

controller to communicate with a PLC and/or an external barcode scanner, in which case, you do not

need an Interbus-S I/O module or a link via the RS-422 port.

The following chapter describes the basic components of the controller so you can familiarize yourself

with them before you install it. Chapter 4. Installing the CS4000 Mini Controller with Ethernet

describes how to mount the controller and how to make sure you fulfill its power requirements.

Chapter 5. Setting Up the Ethernet, Chapter 6. Setting Up the 485 Network and Chapter 7. Setting Up

the RS-232 Link describe how to install the various components that have been discussed in this

chapter.

May 2002 T-38324-A Page 1-7

Page 23

CS4000 Mini Controller with Ethernet

(This page is left blank intentionally.)

Page

1-8

T-38324-A 39-30-38324

Page 24

2. Think Safety First!

Working with fastening tools can be dangerous if safe and proper procedures are not followed. As

with all machinery, certain hazards can be involved with the operation of the product. Using these

tools with respect and caution will considerably lessen the possibility of personal injury, however, if

normal safety precautions are overlooked or ignored personal injury to the operator may result.

Always use common sense and exercise caution when using these tools. They can produce high torque

that, unless properly compensated for, could cause personal injury. Remember, your personal safety is

your responsibility.

Only GSE tech-motive tool-qualified service technicians should perform the procedures covered in this

manual. If you are an operator or service technician, you should become familiar with the contents of

this manual before operating, servicing, or maintaining any part of the CS4000 Mini Controller with

Ethernet, including the 66 Series fastening tools. Familiarization with all components of the system

can minimize the possibility that an accident or injury might occur.

GSE tech-motive tool assumes no responsibility for personal injury or damage to equipment resulting

from misuse of these tools. After reviewing this manual you should also review all safety procedures

provided by your company and the equipment installer.

WARNING! Failure to follow these steps may result in serious personal

injury.

May 2002 T-38324-A Page 2-1

Page 25

CS4000 Mini Controller with Ethernet

General Machine Safety

• FOR YOUR OWN SAFETY READ THE INSTRUCTION MANUAL THOROUGHLY

PRIOR TO OPERATING THE TOOL.

• DO NOT WORK IN A DANGEROUS ENVIRONMENT. Do not use power tools in a

damp or wet location or expose them to rain, oils, or corrosive fluids.

• KNOW THE LOCATION OF POWER DISCONNECTS AND EMERGENCY STOP

BUTTONS PRIOR TO OPERATING THIS EQUIPMENT.

• KEEP ALL ELECTRICAL PANELS CLOSED DURING OPERATION. High voltage

present inside enclosure panels can result in personal injury. Do NOT bypass or defeat

electrical safety devices. Turn the power actuator to the OFF position prior to any

servicing or maintenance of the controller.

• OBSERVE ALL GOVERNMENT AND/OR COMPANY POWER LOCKOUT

STANDARDS.

• NEVER OPERATE SOLENOID VALVES, LIMIT SWITCHES OR RELAYS

MANUALLY as this practice can create dangerous, unexpected machine movements.

• SECURE THE TOOL. Tools that develop torque can produce hazardous torque

reactions. Always be sure that the tool is properly fixtured to absorb reaction as a

fastener is tightened. Never operate a tool capable of high torque without proper

fixturing.

• SECURE WORK. Avoid situations where the part being fastened breaks loose and can

cause damage.

• NEVER TOUCH OR ATTEMPT TO STOP MOVING MACHINERY OR PARTS

WITH YOUR HANDS, OTHER PARTS OF YOUR BODY, OR MAKESHIFT

DEVICES.

• DO NOT OPERATE THE TOOL WHILE UNDER THE INFLUENCE OF ALCOHOL,

DRUGS OR MEDICATION THAT CAN IMPAIR YOUR JUDGMENT.

• REPORT ALL UNSAFE WORKING CONDITIONS OR PRACTICES TO YOUR

SUPERVISOR AND / OR SAFETY DEPARTMENT FOR CORRECTION.

• WEAR APPROVED SAFETY GLASSES AT ALL TIMES.

• DO NOT WEAR JEWELRY, especially bracelets and rings, while operating the

fastening tools. Keep hands and fingers away from all rotating parts and avoid situations

where clothing can become tangled in the tool. Secure loose fitting clothing, neckties,

and long hair. Wear medical alert identification cautiously.

• DO NOT OVERREACH. Keep proper footing and balance at all times.

• KEEP YOUR WORK AREA CLEAN. Do not work on or near slippery floors or

surfaces. Avoid situations where the tool reacts against unexpected obstacles. Do not

operate electrical equipment while standing on a wet floor.

Page

2-2

T-38324-A 39-30-38324

Page 26

Chapter 2. Think Safety First!

• MAINTAIN TOOLS IN TOP CONDITION. Keep tools properly lubricated and clean.

If any wires become frayed or exposed, replace them immediately. Prevent dirt, grease

or contaminants from getting into the tool.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Be careful how the tool is

left unattended. Avoid resting it on its throttle lever to prevent false starts.

• CONTROL THE DIRECTION OF ROTATION. The reaction torque changes direction

when going from forward to reverse. Always be aware in which direction the tool will

rotate prior to using it. If the tool is not fixtured this will allow you to brace for the

proper direction of torque reaction.

• CHECK DAMAGED PARTS. Before further use of a tool, any part of the tool that is

damaged should be carefully checked to ensure that it will operate properly and perform

its intended function. Check for alignment of moving parts, breakage of parts, mounting,

and any other conditions that may affect its operation. Never operate a tool that has

damaged or exposed wires. Never operate a tool that has any part of the powertrain,

other than the output spindle, exposed.

Electrical Safety

Only qualified and properly trained personnel should perform electrical/electronic

troubleshooting and repair. Consider the following electrical system safety guidelines:

• Before you troubleshoot or service a fastening system station, be sure you have an up-

to-date and appropriate set of electrical drawings for that station.

• Remove metal items, such as rings, metal necklaces, wristwatches and jewelry, as these

can create electrical hazards. Wear medical alert identification cautiously.

• Wear safety glasses, but avoid wearing those that have metal rims or metal side shields.

• It may be necessary to troubleshoot equipment while the power is ON. ONLY qualified,

trained personnel should do this. During these instances, open only the panels, doors, or

covers which need to be opened. Know the voltage present at all points before you begin

troubleshooting.

• Use properly insulated tools when working on electrical equipment to reduce the

possibility of shock. Make sure the insulation is adequate to safeguard against the high

voltages present.

• If you must work on the electrical system, be sure the main disconnect switch on the

power panel is in the OFF position and locked out with locks from each trade involved

in the repair.

• Do not attempt to modify or repair the machine without the approval of the proper

authorities.

• Use approved fuse pullers when changing fuses.

• Never use jumper wires or fuse substitutes to replace specified fuses.

May 2002 T-38324-A Page 2-3

Page 27

CS4000 Mini Controller with Ethernet

• Always use fuses of a capacity smaller than or equal to the safe capacity of the line or

the equipment it serves.

• Before you work on any circuit, check it with an appropriate testing device to be sure

voltage is not present.

• Install temporary wiring as safely as possible and replace it with permanent wiring as

soon as possible. Install grounding wherever it is needed in the final installation. If

modifications are made to the system wiring, drawings must be revised to illustrate this

change.

• Know how to deal with electrical fires properly. Keep carbon dioxide and powder

extinguishers handy.

Page

2-4

T-38324-A 39-30-38324

Page 28

3. Identifying the Components

The CS4000 Mini Controller with Ethernet houses all the standard functions of the standard CS4000

Mini Controller, but also has the ability to communicate across an Ethernet Local Area Network

(LAN) using the standard Ethernet protocol, Transmission Control Protocol/Internet Protocol

(TCP/IP).

This chapter is designed to familiarize you with the components of the CS4000 Mini Controller

with Ethernet. It has three sections to help you locate all the major components easily:

•

Front Panel

•

Top and Bottom Panel

•

Enclosure Interior

Each section includes figures that call out the components. Descriptions of the components follow the

figures.

May 2002 T-38324-A Page 3-1

Page 29

CS4000 Mini Controller with Ethernet

Front Panel

Figure 3-1 shows the front panel components of the CS4000 Mini Controller with Ethernet.

AC Power

Cord

Access Screws

LED

Display

NOTE: The AC power cord is described in the Top and Bottom Panel

LED Display

CS4000 mini

SYSTEM

CONTROLLER

tech-motive tool

Figure 3-1. Front Panel View

section later in this chapter.

Parameter

5

4

6

3

2

1

7

8

*

Select Switch

Page

The LED display shows you the torque, or torque and angle value for the most recent rundown. It also

scrolls messages for the operator. For example, if a barcode scan is required before the next rundown,

the operator sees a barcode prompt on the LED display.

3-2

T-38324-A 39-30-38324

Page 30

Parameter Set Switch

Turn the dial to select the parameter set you wish to use for the next rundown. Select parameter sets

using the parameter set switch or Visual Supervisor.

Access Screws

The access screws keep the front panel of the controller fastened. To un-fasten them you need a No.2

cross-tip (Phillips) head screwdriver.

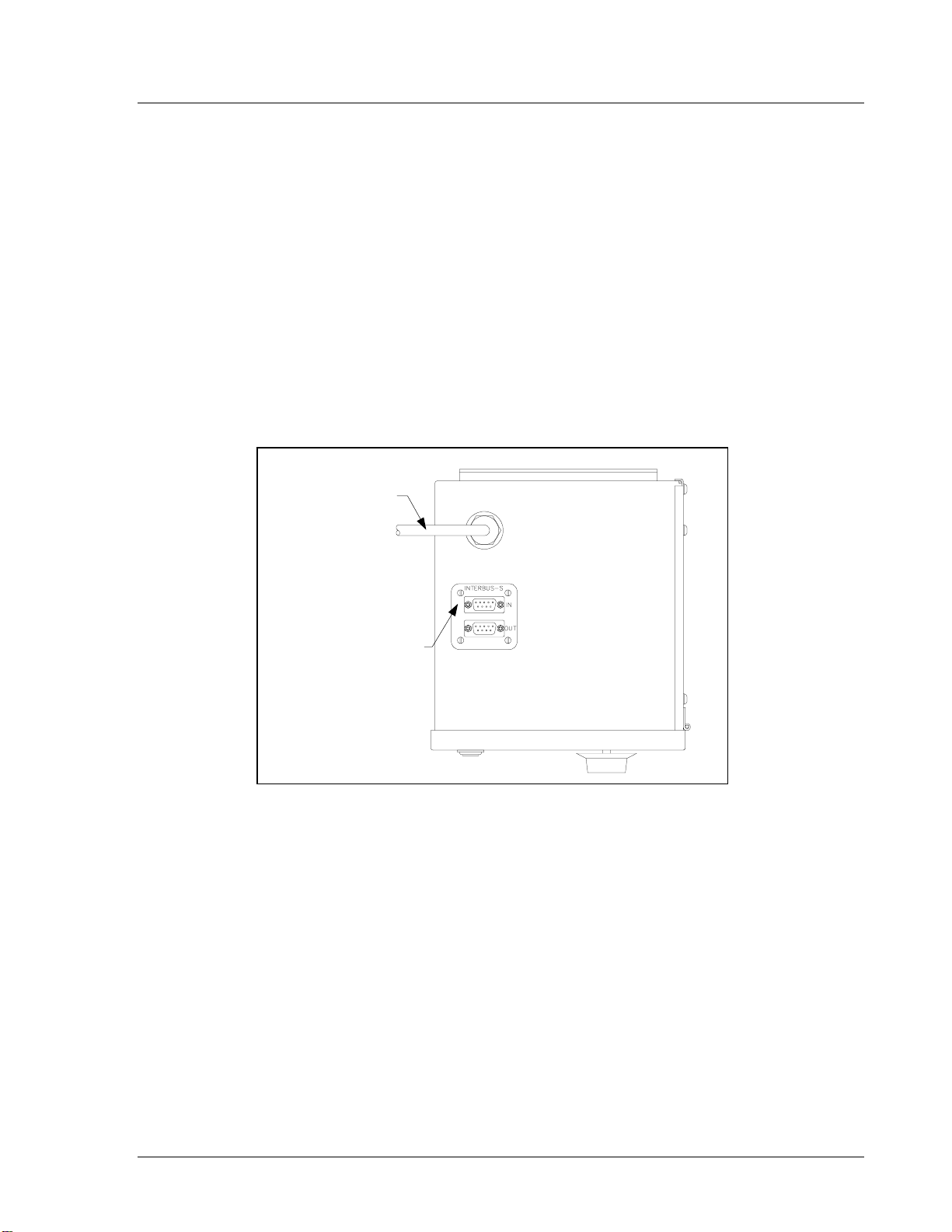

Top and Bottom Panel

Figure 3-2 shows the top panel components of the CS4000 Mini Controller with Ethernet.

AC Power Cord

Chapter 3. Identifying the Components

Interbus-S I/O Connect or

(Optional)

Figure 3-2. Top Panel View

AC Power Cord

A power cord connection is available on the top of CS4000 Mini Controller with Ethernet. The power

cords it accepts are the 6-ft American style 20A, 240V AC power cord (part number 299250-32835)

or the 2.5-m European style 10A, 240V power cord (part number 22-30-1021).

Interbus-S I/O Connector

A nine-position, serial Interbus-S connector may be mounted optionally on the top of the CS4000 Mini

Controller with Ethernet. This enables the controller to exchange up to eight digital inputs and outputs

with an external Programmable Logic Controller (PLC). If an Interbus-S module is not included in the

controller, the Interbus-S I/O connector is covered. To find out details about the Interbus-S module,

refer to the Interbus-S Module section later in this chapter.

May 2002 T-38324-A Page 3-3

Page 31

CS4000 Mini Controller with Ethernet

Figure 3-3 shows the bottom panel components of the CS4000 Mini Controller with Ethernet.

Descriptions are provided in clockwise order, starting with the I/O connector.

Fuses

I/O Connector

Tool Connector

RS-422 Connector

RJ-45 Ethernet Connector

Printer/Barcode Connector

Ground Fault Circuit

Interrupter (GFCI)

RS-232 Connector

FUSE 1

FUSE 2

I/O

TCM SDLC NETWORK

IN

A

RS232

ETHERNET

OUT

PRINTER/BARCODE

RS422

SDLC I/O Network Connector

Figure 3-3. Bottom Panel View

I/O Connector

The 19-position remote I/O connector provides the interface between external control/monitoring

devices and the internal control electronics. tech-motive tool accessories, such as socketrays, are

connected here.

Page

The mating connector for this port is a 14-shell, 19-pin, strain relief (SR) connector

(part number 23-10-5200). The mating connector enables connection of your own remote control

and/or monitoring devices, such as external annunciato r lamps or remote cycle -on contacts. Refer to

I/O Wiring in Chapter 4. Installing the CS4000 Mini Controller with Ethernet for pinout details.

Tool Connector

The 37-position connector is the interface between the 46, 66 and 116 Series nutrunner cable and

control electronics. Refer to Connector Pinout Definitions in Chapter 4. Installing the CS4000 Mini

Controller with Ethernet for pinout details.

3-4

T-38324-A 39-30-38324

Page 32

Chapter 3. Identifying the Components

Tool cables are available in lengths of:

• 3 ft / 0.91 m (part number 51-3066-0003)

• 6 ft / 1.83 m (part number 51-3066-0006)

•

10 ft / 3.05 m (part number 51-3066-0010)

• 15 ft / 4.57 m (part number 51-3066-0015)

• 30 ft / 9.14 m (part number 51-3066-0030)

•

50 ft / 15.24 m (part number 51-3066-0050)

• 70 ft / 21.34 m (part number 51-3066-0070)

RS-422 Connector

The 10-position male asynchronous RS-422 serial I/O connector enables the controller to receive a

barcode read by a scanner. The RS-422 communications currently supports the Siemens 3964R

barcode protocol.

Ethernet Connector

The RJ-45 Ethernet connector enables the controller to communicate and send data to and from a host

device on the same Local Area Network (LAN) using standard Ethernet protocols (Transmission

Control Protocol/Internet Protocol, TCP/IP). Refer to Chapter 4. Installing the CS4000 Mini

Controller with Ethernet for details.

Printer/Barcode Connector

The nine-position asynchronous RS-232-compatible serial output connector allows you to use a

printer. The printer can be used to generate hard copies of torque, or torque and angle readings, system

configuration information, or statistical data upon command from the controller. This port can also be

used to receive barcode information.

SDLC I/O Network Connector

The 10-position female RS-485 connector enables a permanent network connection to and from the

controller, other controllers in the network and a permanently connected computer.

RS-232 Connector

The nine-position asynchronous RS-232 compatible serial output connector allows you to use a laptop

computer. T he laptop comput er can be running the V isual Supervisor software program, the Ethernet

Interface Flash Utility, or other program that allows you to program (also referred to as ‘flash’) the

latest Device Control Module and Tool Control Module firmware into the controller.

Ground Fault Circuit Interrupter

The 250V Ground Fault Circuit Interrupter (GFCI) (part number 13-20-2000) is a safety device,

approved by Underwriters Laboratories, that is designed to protect you from potentially dangerous

electrical shock.

May 2002 T-38324-A Page 3-5

Page 33

CS4000 Mini Controller with Ethernet

Fuses

Fuse 1 and Fuse 2 are 15A, 250V, SLO-BLO fuses, Littelfuse 326015 or equivalent

(part number 13-10-1015).

Enclosure Interior

The enclosure interior for the CS4000 Mini Controller with Ethernet includes the following

components and sub-components:

•

Tool Control Module (TCM), that includes:

• Servo amplifier

• Servo amplifier fuse (inside TCM)

•

Device Contro l Module (DCM)

• DCM battery

• Backplane

• Address switch

•

TCM fuse

•

DCM fuse

•

TCM I/O power supply (24 VDC)

• Ethernet interface card

• Interbus-S digital I/O module (optional)

• Ground Fault Circuit Interrupter (GFCI)

• Fuses

See Figures Figure 3-4 and Figure 3-3.

Page

3-6

T-38324-A 39-30-38324

Page 34

AC Power Cord

Interbus-S Module

(Optional)

Ethernet Interface

Card

Chapter 3. Identifying the Components

Tool Control

Module

Exterior Wall

Power Supply

Backplane

Figure 3-4. Components Inside the Enclosure of the CS4000

Mini Controller with Ethernet

NOTE: The AC power cord is described in Top and Bottom Panel earlier

in this chapter.

May 2002 T-38324-A Page 3-7

Page 35

CS4000 Mini Controller with Ethernet

Tool Control Module

The Tool Control Module (TCM), shown in Figure 3-5, is a device that controls a single DC electric

tool. The TCM and its attached tool are referred to as a spindle. The TCM houses both the servo

amplifier and Device Control Module (DCM). For the location of the TCM inside the CS4000 Mini

Controller with Ethernet, see Figure 3-4 on page 3-7.

Thumbscrews

Side Panel

Front Panel

Figure 3-5. Front View of the TCM

Page

3-8

T-38324-A 39-30-38324

Page 36

Chapter 3. Identifying the Components

,

(

)

The TCM has a small four-digit display, a column of nine indicator LEDs, and two potentiometers.

The LEDs provide status and condition information about the connected nutrunner. The indicator

LEDs are labeled:

• READY • ANGLE HI

• GOOD • ANGLE LOW

• BAD • SPINDLE FAULT

• PEAK TORQUE HI • MOTOR ENABLE

• PEAK TORQUE LOW

The potentiometers are labeled:

• TACH GAIN • SPEED TRIM

When the TCM is removed from the controller, the two servo amplifier boards, servo amplifier fuse,

DCM board, and full backplane containing the address switch and TCM fuse can be seen.

Figure 3-6 is a rear view of the TCM. It allows you to see where the two servo amplifier boards, servo

amplifier fuse, and DCM are located. Descriptions of the TCM sub-components follow the figure.

Servo

Amplifier

Board

Servo Amplifier

Fuse 20A

250V

Servo

Amplifier

Board

Device

Control

Module

DCM

Figure 3-6. Rear View of the TCM and Location of the Servo Amplifier Fuse

May 2002 T-38324-A Page 3-9

Page 37

CS4000 Mini Controller with Ethernet

Servo Amplifier

The servo amplifier is a three-phase, brushless DC motor controller that provides electrical power to

the nutrunner motor. It receives control signals from the Device Control Module (DCM). Based on the

state of these inputs, the servo amplifier energizes the motor windings to rotate the motor.

The servo amplifier serves as a closed-loop speed controller. It modulates the motor winding currents

in order to maintain a constant motor speed despite changes in load. Additionally, the servo amplifier

can stop the motor quickly by way of dynamic braking. The servo amplifier boards are paired with the

DCM board and are housed inside the TCM.

A 20A, 250V servo amplifier fuse (part number 13-10-0700) is located on the first servo amplifier

board.

Device Control Module

The Device Control Module (DCM) is an electronic circuit board that contains powerful 80186EA

processor. It is paired with the servo amplifier inside the TCM. The DCM is the brain of the CS4000

Controller with Ethernet. It receives signals from the nutrunner control switches, the set point inp uts,

the nutrunner tor que sensor, and remote control inp ut s and generates the appropriate outputs to the

servo amplifier c ontrol inputs, the status output relays, a nd the nutrunner status LEDs. The DCM has

plug-in electrical connections. It is easy to remove and replace.

A 3V lithium battery is located on the DCM board. You must remove the DCM board from the TCM

in order to replace this battery. A generic 3V lithium battery (Duracell DL 2450, Sanyo

CR 2450, or similar) can be used.

3V Lithium Battery

+ side up

Page

3-10

Figure 3-7. DCM Board and DCM Battery Location

T-38324-A 39-30-38324

Page 38

Chapter 3. Identifying the Components

Backplane

The backplane (part number 420890-35327) is a printed circuit board into which many of the internal

component cables plug. It also contains address switch SW-1, and the DCM fuse, F4. See Figure 3-8.

Device Control Module

(DCM) Fuse, F4

Jumpers, JP1 to JP8

Jumper, JP9

+24VDC Fuse to Tool, F2

+24V Input, J8

Address Switch,

SW-1

+24VDC Input Fuse, F3

I/O Board, J2

Figure 3-8. CS4000 Mini Controller with Ethernet Backplane

May 2002 T-38324-A Page 3-11

Page 39

CS4000 Mini Controller with Ethernet

Backplane Fuses

Fuse F4 is Littelfuse 239001, 5x20 mm, 1A, SLO BLO (SB) 250V (part number 13-10-61001). Fuse

F4 protects the DCM board inside the TCM.

Fuses F2 and F3 are Littelfuse 255.500, subminiature 0.5A (part number 13-10-4050). Fuse F2

protects the 24VDC to the tool, and Fuse F3 protects the 24VDC used with the discrete I/O circuits.

Address Switches

Each TCM has a unique serial address. The first six DIP switches on the address switch, SW-1, allow

you to set up the communication address, 1 to 32, for the TCM.

Switch 7 assigns the baud rate at which the TCM sends data to an attached computer. When switch 7

is in the OFF position, a baud rate of 9600 kbps is used. When switch 7 is in the ON position, a baud

rate of 57600 kbps is used. Switch 8 is used to set up the TCM for the “PFCS” Mode used by the

DaimlerChrysler Plant Floor Communication System.

Page

3-12

T-38324-A 39-30-38324

Page 40

Chapter 3. Identifying the Components

I/O Board

The I/O board shown in Figure 3-9 is inserted into a connector, J2, on the backplane. It interfaces to

all of the connectors available on the bottom of the controller, see Figure 3-3 on page 3-4. On the top

side of the I/O board are some diagnostic connections (J19 and J20) for digital I/O.

Ground

Mounting Hole

Digital I/O Connector, J20 Digital I/O Connector,

J19

Ground

Mounting Hole

I/O Connector, J1

Figure 3-9. I/O Board

Power Supply

A 1.2A, 24V power supply provides power for the TCM I/O and Ethernet interface card.

May 2002 T-38324-A Page 3-13

Page 41

CS4000 Mini Controller with Ethernet

Ethernet Interface Card

The Ethernet interface card (part number 420959-38093) is a printed circuit board into which internal

component cables of the Ethernet ne twork are plugged. It requires a 1 A, 5V power supply that it draws

from the 24VDC power supply inside the controller and converts to the necessary voltage.

The Ethernet interface card lets you connect individual controllers to a host device forming a LAN,

using TCP/IP. The card comes with its own software and fits into the interior of the CS4000 Mini

Controller with Ethernet, forming a connection with the Ethernet connector on the bottom panel of the

controller. To attach to the Ethernet network, you need an Ethernet connector on the computer that

will be the host, and an Ethernet cable with RJ-45 modular jacks attached to both ends. One of these

RJ-45 modular jacks plugs into the Ethernet connector on the PC and the other plugs into the Ethernet

connector on the controller.

Figure 3-10 shows the Ethernet interface card and its sub-components.

COM1, J21

COM2, J22

9-position

serial port, J7

LED 1

LED 2 to LED 7

Page

3-14

Ethernet connector, J 12

Figure 3-10. Ethernet Interface Card

T-38324-A 39-30-38324

Page 42

Chapter 3. Identifying the Components

The nine-position RS-232 serial port, J7, is used for setup and diagnostics of the Ethernet interface

card. You can change the Ethernet application program or the TCP/IP information by using TINI

Ethernet Interface Flash Utility on a laptop connected to the Ethernet interface card, via J7. Refer to

Chapter 4. Installing the CS4000 Mini Controller with Ethernet for further details.

You can also o btain diagnostics information on the stat e of the Ethernet network through the Ethernet

interface card using Hyperterminal. Refer to Chapter 8. Maintenance/Troubleshooting for further

details.

Table 3-1 describes the LEDs on the Ethernet interface card. Each LED lights up steadily or flashes to

indicate the current state of I/O connections.

Table 3-1. Description of Ethernet Interface Card LEDs

LED Name Description

LED1 (5V)

LED2 (A)

LED3 (B)

LED4 (C)

LED5 (D)

LED6 (E)

LED7 (F)

Steady red light indicates the power supply is connected to the Ethernet interface

card.

Flashing red light indicates communication between the controller and the host

device of the Ethernet LAN using the Application Program Interface (API).

Flashing red light indicates Visual Supervisor communication between the

controller and the host device of the Ethernet LAN.

Flashing red light indicates local Visual Supervisor communication between the

controller and any PC that is attached to it, via an RS-232 connection.

Flashing red light indicates communication (Siemens 3964R) between the

controller and the scanner using the RS-422 communications port.

Flashing yellow light indicates communication between the Ethernet interface

card and the TCM.

Steady green light indicates successful power up initialization of the Ethernet

interface card software.

May 2002 T-38324-A Page 3-15

Page 43

CS4000 Mini Controller with Ethernet

Interbus-S Module

The Interbus-S digital I/O module (part number 41-30-0300) is optional and is supplied only when it is

specified at the time of order. When it is included in the controller enclosure, it provides another I/O

interface, usually to an external, remote PLC. The module is housed inside the CS4000 Mini

Controller with Ethernet enclosure. See Figure 3-4 on page 3-7.

Figure 3-11 shows the position of LEDs on the side of the Interbus-S module. Each LED lights up

steadily to indicate the current state of I/O connections.

24V Power

Supply LED

1

6

IN OUT

18

Remote Bus

Connected LED

Page

3-16

Figure 3-11. Interbus-S Module Side View

T-38324-A 39-30-38324

Page 44

Chapter 3. Identifying the Components

Table 3-2 describes the LEDs.

Table 3-2. Description of LEDs on the Side of the Interbus-S Module

LED Name Description

24V Power Supply

Steady yellow light indicates the +24V power supply is connected to

the Interbus-S module.

Remote Bus Connected

Steady green light indlicates the remote bus is connected.

Figure 3-2 shows the position of the six-pin input terminal, nine-pin output terminal and LEDs on the

top of the Interbus-S module. Each LED lights up steadily to indicate the current state of I/O

connections.

IN

Data Refresh

LED

Figure 3-12. Interbus-S Module Top View

Table 3-3 describes the LEDs.

Table 3-3. Description of LEDs on the Top of the Interbus-S Module

LED Name Description

Data Refresh (BA)

Remote Bus Disabled (RD)

BA RD

OUT

Steady green light indicates data is being refreshed.

Steady red light indicates the remote bus is disabled.

Remote Bus

Disabled LED

May 2002 T-38324-A Page 3-17

Page 45

CS4000 Mini Controller with Ethernet

Ground Fault Circuit Interr upter

The Ground Fault Circuit Interrupter (GFCI) is wired in series from the AC power input to the servo

amplifier. It monitors both AC power leads to the servo amplifier, ensuring that current flowing in one

lead is the same as the current flowing out the other lead. If, due to a ground fault, the GFCI detects a

net difference in the AC power exceeding 30 milliamps (30mA or .300 Amps), it shuts off the AC

power to the servo amplifier automatically.

Test Switch in

Figure 3-13. Ground Fault Circuit Interrupter

ON position

Fuses

The main power fuses use a 15A, 250V, SLO-BLO Littelfuse 326015 or equivalent

(part number 13-10-1015).

Page

3-18

T-38324-A 39-30-38324

Page 46

4. Installing the CS4000 Mini

Controller with Ethernet

This chapter shows you how to mount and wire the CS4000 Mini Controller with Ethernet.

Mounting the CS4000 Mini Controller with Ethernet

The CS4000 Mini Controller with Ethernet is installed vertically with the back flat against the

mounting surface. Allow sufficient space around the controller to attach the power cable, tool cable,

I/O cable and printer cable. Also be sure to allow space to remove the cover from the enclosure.

CAUTION! Mount the CS4000 Mini Controller with Ethernet away from

moving machinery and lift trucks on a structure that does

not vibrate. Do not mount the CS4000 Mini Controller with

Ethernet near large electrical systems, motors, welding

equipment, or in an area of temperature or moisture

extremes.

Figure 4-1 shows the dimensions and mounting holes on the CS4000 Mini Controller with Ethernet.

May 2002 T-38324-A Page 4-1

Page 47

CS4000 Mini Controller with Ethernet

NOTE: All dimensions are in inches with

millimeters in square brackets.

Figure 4-1. CS4000 Mini Controller with Ethernet Dimensions

To mount the controller you require four 1/4-20-in bolts or screws.

Page

4-2

T-38324-A 39-30-38324

Page 48

Chapter 4. Installing the CS4000 Mini Controller with Ethernet

Power and Connection-Requirements

WARNING! 230 VAC SINGLE PHASE INPUT ONLY. Internal capacitors

store a high voltage charge and discharge slowly after

external power is removed.

Figure 4-2 shows the power supply and connection requirements of the CS4000 Mini Controller with

Ethernet.

Figure 4-2. Power/Connection Requirements

May 2002 T-38324-A Page 4-3

Page 49

CS4000 Mini Controller with Ethernet

Meeting the AC Input Power Requirements

CAUTION! Failure to provide the proper power source can cause the

following problems in your CS4000 Mini Controller with

Ethernet:

!

The nutrunner might shut down before it reaches the

target torque during a rundown cycle.

!

The nutrunner might not turn when a cycle-on signal is

applied to the system.

! The maximum free speed of the nutrunner might be

lower than specified.

For proper operation, especially during peak power draw periods, be sure to connect the CS4000 Mini

Controller with Ethernet to a clean source of AC power that is capable of maintaining the specified

line voltage under the required load conditions. If the AC line is subject to frequent over-voltage and

under-voltage conditions, some type of power line conditioning will be required.

NOTE: The maximum no-load speed of all tech-motive tool nutrunners

is based on an AC input voltage of 230V; if the actual input

voltage is lower, the maximum no load speed of the nutrunner

will be lower than specified.

It is recommended that the input voltage be between 208 and 250 VAC (single phase). A power source

capable of delivering 1 to 1.5 kVA should be sufficient in most applications.

Grounding

It is extremely important that you connect the CS4000 Mini Controller with Ethernet enclosure

properly to an earth ground. The CS4000 Mini Controller with Ethernet has a ground prong on the

power cord, (if supplied) but the AC outlet that will be used must be grounded properly, as well.

Also make sure that all other machinery, such as conveyors, which will transport or hold parts that will

come in physical co ntact with the nutrunner, a re proper ly grounded.

WARNING! The Ground Fault Circuit Interrupter cannot protect you

against any potential difference that exists between the

nutrunner body and any other metal fixturing or machinery.

You must observe the grounding requirements below as a

safety protection.

Page

4-4

T-38324-A 39-30-38324

Page 50

Chapter 4. Installing the CS4000 Mini Controller with Ethernet

I/O Wiring

The CS4000 Mini Controller with Ethernet is equipped with a 19-pin I/O connector for field I/O. The

settings described in Table 4-1 are Visual Supervisor (VS) default settings.

NOTE: The 14-shell, 19-pin strain relief mating connector for the I/O

connector is part number 23-10-5200.

Table 4-1. 19-Position Remote I/O Connector Pinout Signal Names and Descriptions

Pin Signal Description

A Cycle On/Cycle On Enable

Clear Outputs

(Black wire - internal)

(Black wire - external)

B Forward/Reverse input

(White wire internal)

(White wire - external)

C Discrete Input #7

(Gray wire - internal)

(Red wire - external)

This is a dual-purpose input.

When Set Defaults is clicked, VS sets this input to Start, this input

functions as a cycle on input. This means a fastening cycle can be

started by either pressing the throttle/trigger switch on the nutrunner OR

by activating this input.

When remote mode for the spindle is set to enable, this input functions

as a cycle on enable input. This means a fastening cycle can be started

only by pressing both the throttle/trigger switch on the nutrunner and

activating this input.

In addition, it is also set to Clear Outputs.

This is a level-sensitive input. For the fastening cycle to proceed, this