Page 1

○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Operating Manual

Model 34700-2K/17700-2K

Recovery/Recycling/Recharging Unit

Page 2

Model 17700-2K (for R-12 refrigerant)

Model 34700-2K (for R-134a refrigerant)

Recover, Recycle, and Recharge Unit

SAFETY DEFINITIONS: Follow all WARNING, CAUTION, IMPORTANT, and NOTE messages in this manual. These messages

are defined as follows: WARNING means you may risk serious personal injury or death; CAUTION means you may risk personal

injury, property damage, or unit damage; IMPORTANT means you may risk unit damage; and NOTEs provide clarity and helpful tips.

These safety messages cover situations ROBINAIR is aware of. ROBINAIR cannot know, evaluate, and advise you as to all possible

hazards. You must verify that conditions and procedures do not jeopardize your personal safety.

DISCLAIMER: Information, illustrations, and specifications contained in this manual are based on the latest information available at

the time of publication. The right is reserved to make changes at any time without obligation to notify any person or organization of

such revisions or changes. Further, ROBINAIR shall not be liable for errors contained herein or for incidental or consequential damages

(including lost profits) in connection with the furnishing, performance, or use of this material. If necessary, obtain additional health

and safety information from the appropriate government agencies and the vehicle, refrigerant, and lubricant manufacturers.

WARNINGS

ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE THE UNIT. Before operating the unit, read and follow

the instructions and warnings in this manual. The operator must be familiar with air conditioning and refrigeration

systems, refrigerants, and the dangers of pressurized components. If the operator cannot read English, operating

instructions and safety precautions must be read and discussed in the operator’s native language.

Si el operador no puede leer el inglés, las instrucciones de operación y las precauciones de seguridad deberán

leerse y comentarse en el idioma nativo del operador.

Si l’utilisateur ne peut lire l’anglais, les instructions et les consignes de sécurité doivent lui être expliquées

dans sa langue maternelle.

PRESSURIZED TANK CONTAINS LIQUID REFRIGERANT. Do not overfill the internal storage vessel because

overfilling may cause explosion and personal injury or death. Do not recover refrigerants into non-refillable

containers; use only federally authorized refillable containers (DOT spec. 4BW or 4BA).

ALL HOSES MAY CONTAIN LIQUID REFRIGERANT UNDER PRESSURE. Contact with refrigerant may

cause personal injury. Wear protective equipment, including safety goggles. Disconnect hoses using extreme

caution.

DO NOT BREATHE REFRIGERANT AND LUBRICANT VAPOR OR MIST. Exposure may cause personal

injury, especially to the eyes, nose, throat, and lungs. Use the unit in locations with mechanical ventilation that

provides at least four air changes per hour. If accidental system discharge occurs, ventilate the work area before

resuming service.

DO NOT USE AN EXTENSION CORD. An extension cord may overheat and cause fire. If you must use an

extension cord, use the shortest possible cord with a minimum size of 14 AWG.

TO REDUCE THE RISK OF FIRE, do not use the unit in the vicinity of spilled or open containers of gasoline or

other flammable substances.

DO NOT USE COMPRESSED AIR TO PRESSURE TEST OR LEAK TEST THE UNIT OR VEHICLE AIR

CONDITIONING SYSTEM. Some mixtures of air and R-134a refrigerant are combustible at elevated pressures.

These mixtures are potentially dangerous and may result in fire or explosion causing personal injury or property

damage.

USE THE 17700-2K UNIT WITH R-12 REFRIGERANT ONLY. The unit is for recovering, recycling, and

recharging only R-12 refrigerant! Do not attempt to adapt the unit for another refrigerant. Do not mix refrigerant

types through a system or in the same container; mixing of refrigerants will cause severe damage to the unit

and the vehicle air conditioning system.

USE THE 34700-2K UNIT WITH R-134a REFRIGERANT ONLY. The unit is for recovering, recycling, and

recharging only R-134a refrigerant! Do not attempt to adapt the unit for another refrigerant. Do not mix refrigerant

types through a system or in the same container; mixing of refrigerants will cause severe damage to the unit

and the vehicle air conditioning system.

HIGH VOLTAGE ELECTRICITY INSIDE THE UNIT HAS A RISK OF ELECTRICAL SHOCK. Exposure may

cause personal injury. Disconnect the power before servicing the unit.

OPERATING NOTE: At temperatures exceeding 120°F / 49°C, wait 10 minutes between recovery jobs.

Page 3

Table of Contents

Introduction .............................................................................................. 2

Glossary of Terms ................................................................................. 2

Setup Instructions.................................................................................... 2

Initial Setup ............................................................................................. 4

Vacuum Pump Initial Fill ......................................................................... 5

Installation Routine ................................................................................. 5

Operating Guidelines ............................................................................... 6

Using the Selection Menu....................................................................... 6

Change Filter .......................................................................................... 6

Recycle ................................................................................................... 7

Tank Refill............................................................................................... 7

Vacuum Oil Time .................................................................................... 7

Filter Capacity......................................................................................... 7

Basic/Advanced Prompts ....................................................................... 8

Selecting a Unit (Metric/English) ............................................................ 8

Language Select..................................................................................... 8

Change Defaults ..................................................................................... 9

Using the Control Panel.......................................................................... 9

Keypad Functions ................................................................................. 10

Operating Instructions........................................................................... 11

Operating Tips ...................................................................................... 11

Recovering Refrigerant......................................................................... 12

Evacuating the A/C System .................................................................. 14

Replenishing A/C System Oil ............................................................... 16

Recharging the A/C System ................................................................. 17

Maintenance Instructions ...................................................................... 19

Replacing the Filter-Drier...................................................................... 19

Changing the Vacuum Pump Oil .......................................................... 20

Checking for Leaks ............................................................................... 21

Electrical Protection .............................................................................. 22

General Maintenance ........................................................................... 22

Replacement Parts List ......................................................................... 22

Flow Diagram.......................................................................................... 24

Wiring Diagram....................................................................................... 25

Limited Warranty .................................................................................... 26

U.S. Patents: 4,523,897; 4,688,388 Re 33,212; 4,768,347; 4,805,416; 4,809,520; 4,878,356; 4,938,031;

5,005,369; 5,005,375; 5,038,578; 5,042,271; 5,209,653; 5,248,125; Australian Patent: 613,058; Canadian

Patents: 1,311,621; 1,311,622; 2,012,620; 2,026,348; European Patent: 0 315 296 Bl; German Patent: 031296

Mexican Patent: 16208 OTHER U.S. AND FOREIGN PATENTS PENDING.

Mfd. by Robinair, SPX Corporation, Montpelier, OH 43543

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

1

Page 4

CLOSED

RECOVER

VACUUM

RECOVER

VACUUM

CLOSED

1

0

0

0

3

5

0

0

0

3

4

0

0

5

1

0

0

1

0

0

5

5

1

0

0

1

0

5

1

5

0

0

2

0

5

2

1

0

0

0

3

2

0

0

0

2

5

0

2

0

5

1

0

2

0

3

0

3

2

0

0

0

3

0

D

R

A

E

T

R

4

0

0

0

2

1

1

0

0

0

2

2

0

0

4

3

7

8

8

7

0

0

8

0

5

6

0

0

6

0

0

0

1

0

1

1

9

0

0

0

6

0

0

5

0

0

4

4

0

0

0

7

0

5

8

0

HIGH

I

0

3

bar

psi

kPa

R-134A

0

5

4

0

0

3

0

0

0

4

0

0

2

5

0

5

0

0

bar

kPa

in Hg

VAC

psi

R-134A

OIL INJECT

CHARGE

2

0

5

8

MENU

CLEAR

7

1

4

START

RECOVER

VACUUM

F1

ENTER

9

3

6

STOP

CHARGE

VAC-CHARGE

CHARGE

0

4

MENU

7

CLEAR

1

START

5

6

9

ENTER

8

F1

STOP

2

RECOVER

VACUUM

VAC-CHARGE

Introduction

This manual contains important safety procedures concerning the

operation, use, and maintenance of this product. Failure to follow the

instructions contained in this manual may result in serious injury. If you

are unable to understand any of the contents of this manual, please bring

it to the attention of your supervisor. Do not operate this equipment

unless you have read and understood the contents of this manual.

The 34700-2K models are used for R-134a vehicles, whereas the 17700-2K models

are used for R-12 vehicles. Both models are designed to be compatible with

existing service equipment and standard service procedures.

The 34700-2K and the 17700-2K models are UL-listed, single-pass systems that

meet the SAE specifications for recycled refrigerant.

To validate your warranty, complete the warranty card attached to your unit, and

return it within ten days from date of purchase.

Glossary of Terms

A/C System The air conditioning system being serviced.

Unit The refrigerant recovery/recycling/recharging unit.

Internal Storage Vessel The refillable refrigerant storage vessel designed

specifically for this unit.

Source Tank A disposable tank of new refrigerant used to refill

the internal storage vessel.

Setup Instructions

Low Side

Gauge

0

6

7

0

0

5

8

0

0

0

4

0

5

0

4

0

0

0

3

6

9

4

5

0

0

0

0

3

3

0

6

0

1

2

2

2

0

0

0

0

1

1

7

0

0

7

0

R-134A

0

8

1

0

0

1

0

0

1

0

8

bar

2

8

D

kPa

R

A

T

E

0

0

R

0

2

1

in Hg

0

0

4

VAC

psi

3

0

CLOSED

RECOVER

RECOVER

VACUUM

VACUUM

2

Low Side

Valve

High Side

Valve

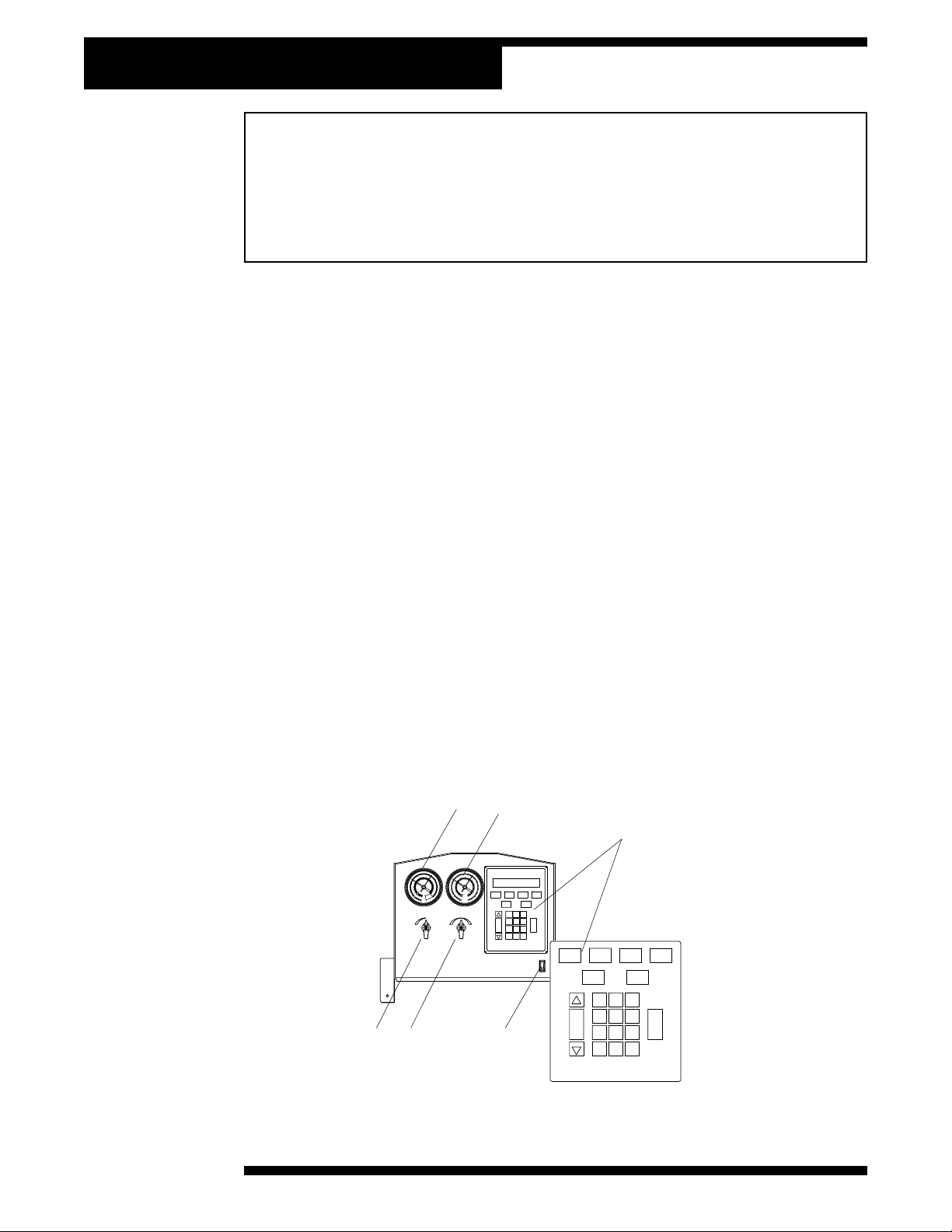

Diagram of the Control Panel

High Side

Gauge

0

5

2

3

0

0

0

0

2

2

0

0

0

0

5

0

1

3

5

0

2

0

5

0

5

2

1

0

1

5

0

0

2

0

0

0

5

1

1

1

0

0

5

0

0

5

0

R-134A

4

0

3

0

0

0

0

3

RECOVER

VACUUM

bar

5

kPa

0

0

0

0

5

0

4

4

3

0

psi

0

0

5

START

HIGH

CLOSED

1

4

MENU

OIL INJECT

7

CHARGE

CLEAR

Main Power

Switch

Keypad

VAC-CHARGE

CHARGE

STOP

332

5

6

F1

9

8

ENTER

0

VAC-CHARGE

RECOVER

0

I

VACUUM

START

1

4

MENU

7

CLEAR

CHARGE

STOP

2

3

5

6

F1

8

9

ENTER

0

INST0925

© 2001 Robinair, SPX Corporation

Page 5

240

220

200

180

80

120

100

140

60

20

40

160

3

4

2

1

8

7

6

5

340

320

MLS

280

300

260

12

11

10

9

OUNCES

CLOSED

RECOVER

RECOVER

CLOSED

CLOSE

VACUUM

VACUUM

CHARGE

OIL INJECT

2

0

5

8

MENU

CLEAR

7

1

4

START

RECOVER

VACUUM

F1

ENTER

9

3

6

STOP

CHARGE

VAC-CHARGE

FLOW

LOW

HIGH

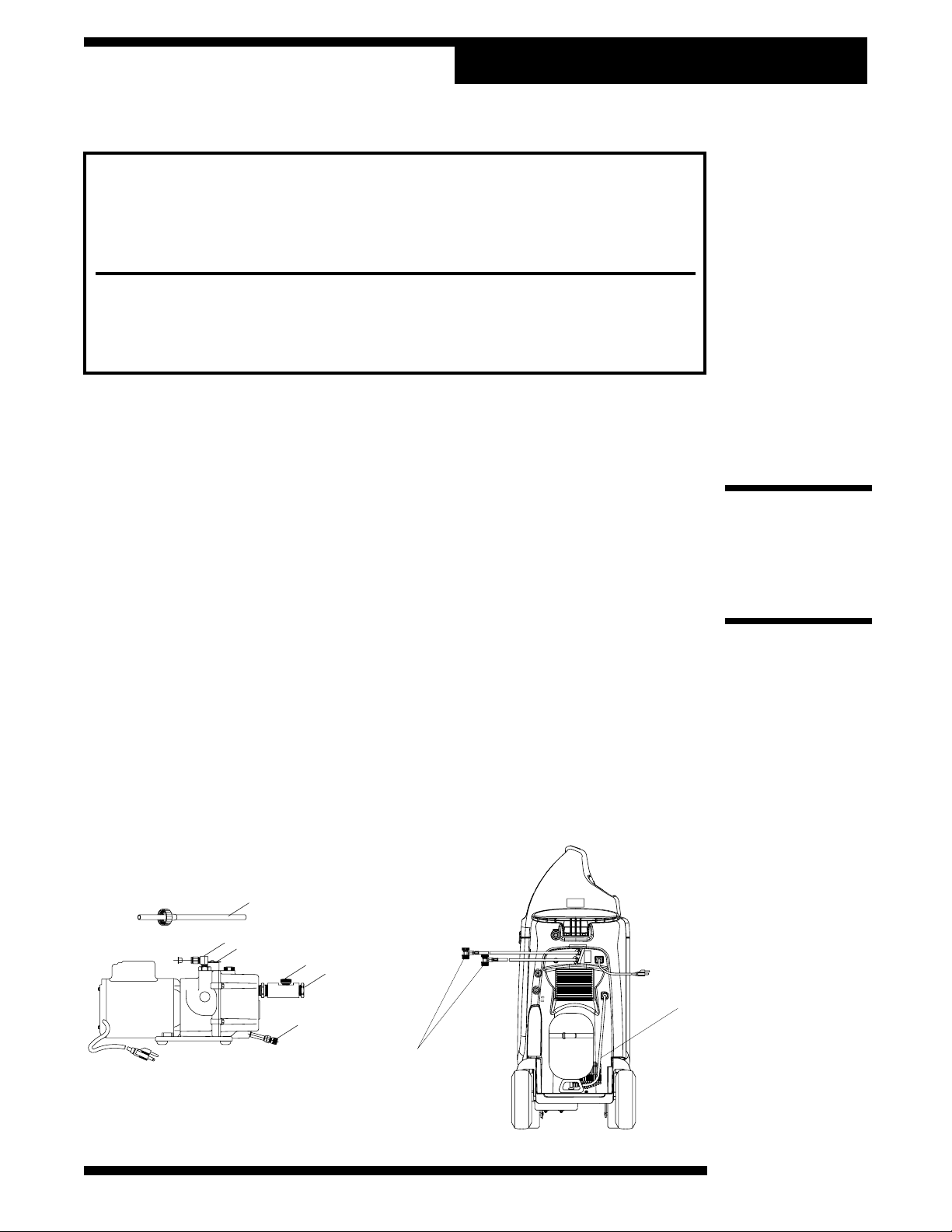

Setup Instructions

HIGH

LOW

1

2

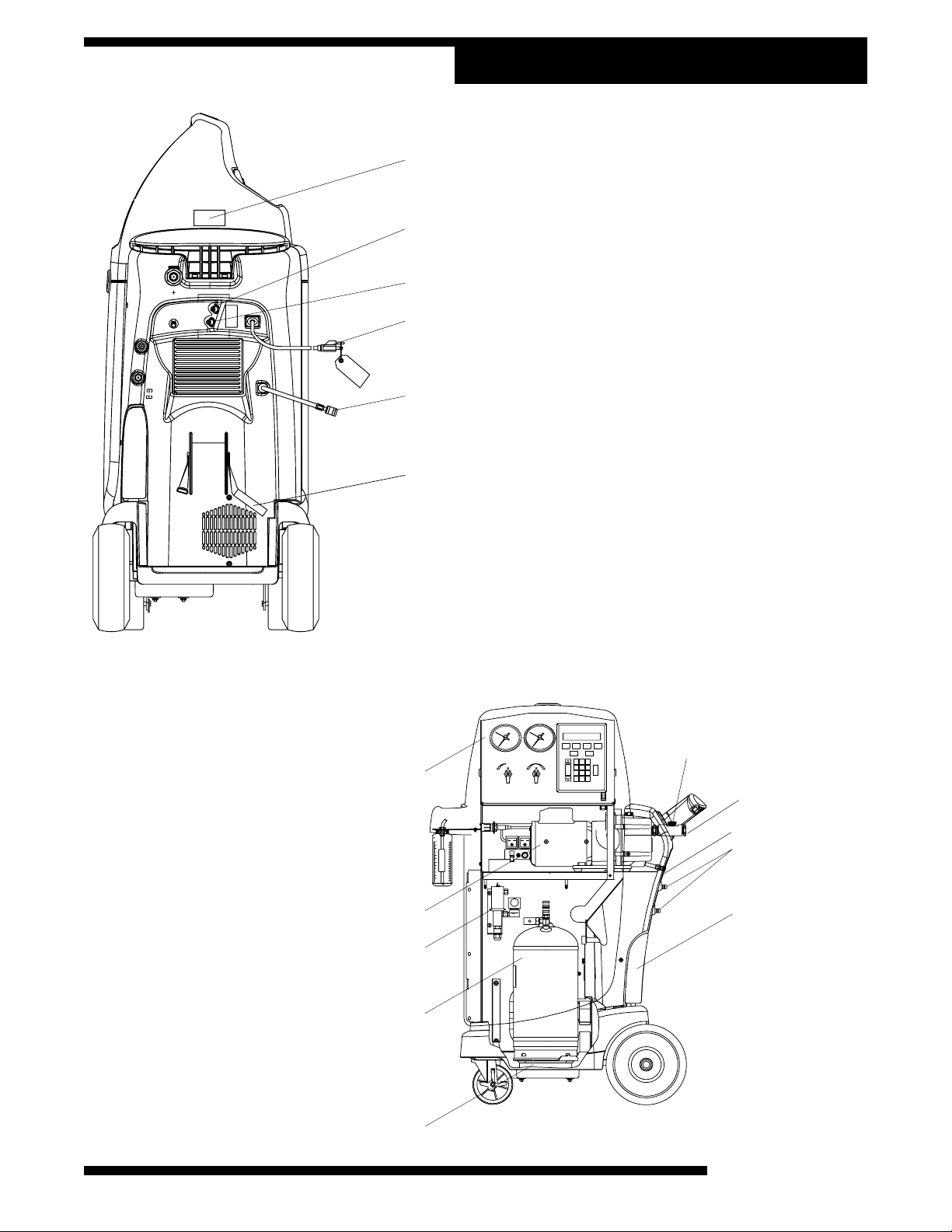

Diagram of Unit’s Components—

3

Side View

HIGH

LOW

4

1. 1-800 Phone Number Decal

2. High Side Inlet

3. Low Side Inlet

4. Power Cord with Tag

5

5. Fill Hose

6. Tank Strap

6

INST0691

VAC-CHARGE

CHARGE

RECOVER

VACUUM

STOP

LOW

CLOSED

RECOVER

RECOVER

VACUUM

1

VACUUM

Diagram of Unit’s Components—

MLS

OUNCES

12

340

11

320

Internal View

1. Control Panel Assembly

2. Vacuum Pump

3. Internal Storage Vessel

4. Scale Assembly

5. Oil Drain Bottle

6. Hose Holder

7. Air Purge Control

8. Vacuum Pump Oil Fill

300

10

280

9

260

240

8

220

7

200

180

6

160

5

140

120

4

100

3

80

60

2

40

1

20

2

FLOW

7

3

START

HIGH

CLOSED

1

2

3

5

4

6

F1

MENU

OIL INJECT

CHARGE

8

7

9

CLEAR

ENTER

0

CLOSE

8

9

10

6

5

9. Sight Glass

10. Oil Drain

4

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

INST0946

3

Page 6

Setup Instructions

MENU

CLEAR

START

RECOVER

VACUUM

F1

ENTER

STOP

CHARGE

VAC-CHARGE

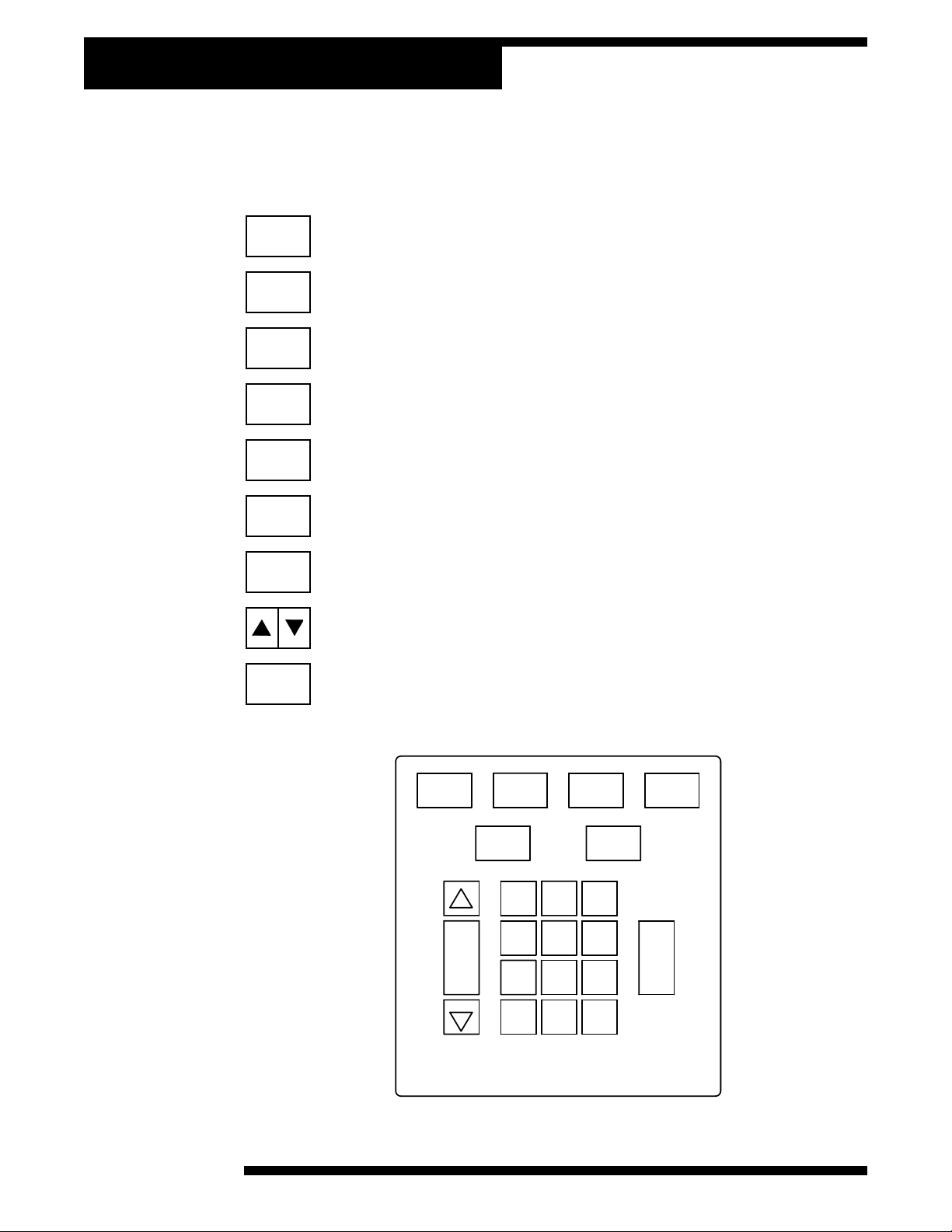

KEYPAD FUNCTIONS

In addition to the number keys, the keypad contains special keys that accomplish

specific operating functions.

START

STOP

RECOVER

VACUUM

VAC-CHARGE

CHARGE

MENU

F1

START— Begins, or resumes, a function.

STOP— Terminates, or pauses, a function.

RECOVER— Activates the recovery sequence.

VACUUM— Activates vacuum and automatic recycling sequence.

VAC-CHARGE— Activates vacuum and automatic recycling sequence,

followed by a charge.

CHARGE— Charges A/C system with a programmed amount of

refrigerant.

MENU— Enters the selection menu.

UP/DOWN ARROWS— Scroll through menu items.

F1 (Inject Oil)— Injects oil into A/C system (active at end of vacuum).

4

Diagram of Keypad

RECOVER

MENU

VACUUM

START

CLEAR

1

4

7

VAC-CHARGE

2

5

8

0

CHARGE

STOP

3

6

F1

9

ENTER

© 2001 Robinair, SPX Corporation

Page 7

Setup Instructions

HIGH

LOW

OPEN

CLOSE

INITIAL SETUP

CAUTION! R-134a systems have special fittings (per SAE

specifications) to avoid cross-contamination with R-12 systems. Do not

attempt to adapt your unit for another refrigerant — system failure will

result! Read and follow all warnings at the beginning of this manual

before operating the unit.

CAUTION! Avoid the use of an extension cord, because the

extension cord may overheat. However, if you must use an extension

cord, use a No. 14 AWG minimum, and keep the cord as short as

possible.

1. The first time the unit is powered up, it will start in the initial setup mode.

If the initial setup must be performed again, it may be selected using the

menu function.

2. The first step is to select a language. Use the UP and DOWN arrow keys to

select the desired language. Press START to save the currently displayed

language.

3. Next select the operating units. Toggle between UNITS ENGLISH and

UNITS METRIC using the arrow keys. Press START to save the currently

displayed choice.

IMPORTANT!

You must press

the MENU key

to access all the

functions.

4. Toggle between BASIC/ADVANCED using the ARROW keys. Use the

BASIC PROMPT option to receive step-by-step, on-screen prompting

through any procedure. Use ADVANCED PROMPT once you know the

procedure and no longer need the step-by-step routine. Press START to

save the currently displayed choice.

NOTE: This manual is written using the BASIC prompt option

Diagram of Hose Connections

Vacuum Pump Components

1. Oil Filler Tube

2. Pump Exhaust

3. Oil Fill Port

4. Sight Glass

5. Oil Drain Fitting

6. Inlet

OPEN

CLOSE

6

1

2

3

4

5

INST0692

1. Fill Hose

2. Quick-Couplers (34700 Only)

2

HIGH

LOW

1

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

INST0701

5

Page 8

240

220

200

180

80

120

100

140

60

20

40

160

3

4

2

1

8

7

6

5

340

320

MLS

280

300

260

12

11

10

9

OUNCES

CLOSED

RECOVER

RECOVER

CLOSED

CLOSE

VACUUM

VACUUM

CHARGE

OIL INJECT

2

0

5

8

MENU

CLEAR

7

1

4

START

RECOVER

VACUUM

F1

ENTER

9

3

6

STOP

CHARGE

VAC-CHARGE

FLOW

LOW

HIGH

Setup Instructions

NOTE: The vacuum pump is shipped without oil in the reservoir. Before starting

the pump, oil must be added to the pump, or damage to the pump may occur.

5. Press the START key to begin the oil fill process.

6. Attach the flexible tube and cap to the oil bottle, and pour eight ounces of

vacuum pump oil into the fill port.

7. Press the START key. While the vacuum pump is running, slowly add oil

until the level rises to the center of the reservoir's sight glass.

8. Press the STOP key, and replace the black plastic plug on the fill port.

9. Connect the service hoses, open both panel valves, and press START.

10. Connect the fill hose to a full source tank.

11. Open the tank valve. Invert the tank and install it on the back of the unit,

making sure to secure the tank strap.

NOTE: If using a refillable tank, install the tank upside down, and connect the fill

hose to the vapor valve.

12. Press START, and the unit will automatically run a

five-minute vacuum to clear all internal air.

LOW

13. After the vacuum is complete, press START to begin

filling the internal storage vessel.

HIGH

CLOSED

CLOSED

RECOVER

RECOVER

OIL INJECT

VACUUM

VACUUM

CHARGE

IMPORTANT!

For maximum

performance,

change the

vacuum pump

oil frequently.

IMPORTANT!

The pump must

be running

when adding

oil.

1

VAC-CHARGE

CHARGE

RECOVER

VACUUM

STOP

START

1

2

3

5

4

6

F1

MENU

8

7

9

CLEAR

ENTER

0

14. The unit stops when a sufficient amount of refrigerant

has been transferred to the internal tank, or when the

source tank is empty. Press the STOP key to pause the

MLS

OUNCES

12

340

11

320

300

10

280

9

260

240

8

220

7

200

180

6

160

5

140

120

4

100

3

80

60

2

40

1

20

FLOW

CLOSE

2

3

process. Press STOP again to exit, or START to

resume. This process takes 15-20 minutes.

1. Oil Fill

2. Sight Glass

3. Oil Drain

NOTE: Add at least 8 lb. (3.6 kg) of refrigerant before

stopping the process to ensure enough refrigerant is available

for charging.

INST0947

15. When the fill process is complete, you may press STOP

to exit.

16. The unit is now ready to operate.

NOTE: There is no need to calibrate the scale, because it is

calibrated at the factory.

6

© 2001 Robinair, SPX Corporation

Page 9

Operating Guidelines

USING THE SELECTION MENU

1. Press the MENU button. The top line of the display reads SETUP MENU.

2. Use the UP and DOWN arrow keys to scroll through the menu choices

displayed on the second line. The menu choices are:

1. SELECT LANGUAGE 7. VACUUM OIL TIME

2. SELECT UNITS (ENGLISH/METRIC) 8. CHANGE VACUUM PUMP OIL

3. TANK REFILL 9. SELECT PROMPTS

4. RECYCLE ONLY 10. CHANGE DEFAULTS

5. FILTER CAPACITY 11. VERSION X.XX

6. CHANGE FILTER

3. Press START to make a choice from the menu. Press STOP to pause any

process, and STOP a second time to exit any process.

(password protected)

CHANGE FILTER

The filter-drier removes acid, particulates, and water from the refrigerant. Change

the filter-drier after 150 pounds (68 kg) of refrigerant has been filtered. See the

REPLACING THE FILTER DRIER section on the following page, as well as the

Maintenance Section, for instructions.

RECYCLE

Manual recycling may be necessary if excessive air and/or moisture is recovered

from the A/C system.

1. Press the MENU key. Use the arrow keys to select RECYCLE ONLY, and

press START to begin.

2. Press the START button to start recycling. To pause recycling, press the

STOP key. To terminate recycling, press the STOP key again, or press

START to resume.

TANK REFILL

1. Press the MENU key. Use the arrow keys to select TANK REFILL, and press

START to begin.

2. Connect the fill hose to the source tank.

3. Open the tank valve. Invert the tank, install it on the back of the unit, and

secure the tank strap.

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

7

Page 10

Operating Guidelines

NOTE: If using a refillable tank, install the tank upside down, and connect the fill

hose to the vapor valve.

4. Press the START key, and the tank automatically refills. The unit stops when

a sufficient amount of refrigerant has been transferred to the internal tank, or

if the source tank is empty. Press the STOP key to pause the process. Press

STOP again to exit, or START to resume.

5. When the fill process is complete, press STOP to exit.

VACUUM OIL TIME

This function displays how long the vacuum pump has run since the last oil

change.

1. Press the MENU key. Use the arrow keys to select VACUUM OIL TIME, and

press START to begin.

2. The display reads: OIL TIME = XX:XX This shows how long the pump has

run since the last oil change. The time resets to zero after a VACUUM PUMP

OIL CHANGE. See page 20 of this manual for details.

3. Press STOP to exit.

FILTER CAPACITY

This function is used to show the operator how many pounds or kilograms of

refrigerant have been recovered since the last filter change.

1. Press the MENU key. Use the arrow keys to select FILTER CAPACITY, and

press START to begin.

2. The display reads: FILTERED= XXXlbs(kg). This shows how much

refrigerant has passed through the filter. The amount filtered resets to zero

after a FILTER CHANGE. See page 19 of this manual for details.

3. Press STOP to exit.

SELECT PROMPT (BASIC/ADVANCED)

Use the BASIC PROMPT option to receive step-by-step, on-screen prompting

through any procedure. Use ADVANCED PROMPT once you know the procedure

and no longer need the step-by-step routine.

1. Press the MENU key. Use the arrow keys to choose SELECT PROMPT, and

press START to begin.

2. Toggle between BASIC/ADVANCED using the ARROW keys.

3. Press START to save the current choice and exit.

NOTE: This manual is written for the BASIC PROMPT option.

8

© 2001 Robinair, SPX Corporation

Page 11

Operating Guidelines

SELECTING A UNIT (METRIC/ENGLISH)

1. Press the MENU key. Use the arrow keys to choose SELECT UNITS, and

press START to begin.

2. Toggle between UNITS ENGLISH and UNITS METRIC using the arrow

key.

3. Press START to save the current choice and exit.

LANGUAGE SELECT

The operator can choose between English, Spanish, French, Italian, or German.

1. Press the MENU key. Use the arrow keys to choose SELECT LANGUAGE,

and press START to begin.

2. Use the UP and DOWN arrows to scroll through the languages.

3. Press START to save the current choice. Press STOP to exit without saving.

CHANGE DEFAULTS

For service use only.

VERSION

Displays the current software revision.

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

9

Page 12

VACUUM

RECOVER

CLOSED

CLOSED

VACUUM

RECOVER

STOP

R-134A

in Hg

VAC

psi

kPa

bar

OIL INJECT

CHARGE

psi

kPa

bar

R-134A

START

MENU

CLEAR

ENTER

RECOVER

VACUUM

VAC-CHARGE

F1

CHARGE

HIGH

Operating Guidelines

USING THE CONTROL PANEL

The control panel has various components that control specific operating functions.

MAIN POWER SWITCH—Supplies electrical power to the control panel.

DIGITAL DISPLAY—Used on the visual interface between the operator and

the machine.

LOW SIDE MANIFOLD GAUGE—Connects to an A/C system and shows the

system’s low side pressure.

HIGH SIDE MANIFOLD GAUGE—Connects to an A/C system and shows the

system’s high side pressure.

LOW SIDE VALVE—Controls the low side flow from the A/C system through

the unit.

HIGH SIDE VALVE—Controls the high side flow from the A/C system through

the unit. It has three positions: 1) Recover/Vacuum, 2) Closed, 3) Oil Inject/Charge.

1

2

3

0

6

7

0

0

5

8

0

0

0

4

0

5

0

4

0

0

0

3

6

9

4

5

0

0

3

2

0

1

0

RECOVER

VACUUM

0

0

2

1

0

0

0

0

0

0

3

6

1

2

0

0

0

1

7

0

7

R-134A

0

8

0

1

0

0

1

8

bar

2

8

D

kPa

R

A

T

E

0

R

0

2

1

in Hg

0

0

4

VAC

psi

3

0

CLOSED

RECOVER

VACUUM

6

7

0

5

2

3

0

0

0

0

2

2

0

0

0

0

5

0

1

3

0

1

5

CLOSED

5

2

0

5

0

2

1

5

0

2

0

5

0

0

0

R-134A

4

3

0

0

0

3

RECOVER

bar

kPa

0

0

0

5

0

4

4

3

0

psi

0

0

5

HIGH

VACUUM

START

1

4

OIL INJECT

CHARGE

MENU

7

CLEAR

2

5

8

0

VAC-CHARGE

STOP

3

6

9

ENTER

CHARGE

F1

0

I

0

5

0

1

0

0

1

1

0

0

5

0

0

5

0

4

5

INST0926

Diagram of Control Panel

1. Low Side Gauge

2. High Side Gauge

3. Display

4. Bezel & Keypad Assembly

5. Main Power Switch

6. Low Side Valve

7. High Side Valve

10

© 2001 Robinair, SPX Corporation

Page 13

Operating Instructions

OPERATING TIPS

Follow the SAE-J1991 recommended service procedure for the containment of

R-12, and the SAE-J2210 recommended service procedure for the containment of

R-134a.

The recovery compressor is not a vacuum pump. The compressor pulls the A/C

system to a partial vacuum only. You must use the unit’s vacuum cycle to remove

moisture from the A/C system. We recommend a minimum 15-minute vacuum, or

follow the system manufacturer's recommendations.

This unit is designed to be used with the manifold gauge set built into the

control panel.

The unit includes a 6 cfm (142 l/m) Robinair high vacuum pump for fast, thorough

evacuation. Change the vacuum pump oil after every 10 hours of use.

R-134a systems require special oils. Refer to the A/C system manufacturer’s

service manuals for oil specifications.

Pressing the START and STOP keys together for several seconds will exit any

mode and reset the control.

NOTE: The following operating instructions are written to be used with the

BASIC PROMPTS mode of operation. It is recommended that the BASIC

PROMPTS mode is used until the operator becomes very familiar with the

operation of the unit. See the OPERATING GUIDELINES section of this manual

for instructions on how to select between BASIC PROMPTS and ADVANCED

PROMPTS.

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

11

Page 14

RECOVER

VACUUM

CLOSED

RECOVER

VACUUM

CLOSED

VAC-CHARGE

ENTER

R-134A

R-134A

in Hg

VAC

psi

bar

kPa

psi

bar

kPa

RECOVER

CHARGE

OIL INJECT

0

0

3

0

0

5

4

0

0

2

0

0

0

5

0

0

4

3

5

4

7

CLEAR

MENU

8

0

1

5

2

VACUUM

START

F1

9

6

3

CHARGE

STOP

0

0

2

0

0

0

1

0

3

0

2

1

0

0

4

7

5

0

2

3

0

R

5

3

0

0

4

0

0

2

8

3

2

1

0

3

0

4

0

4

0

8

2

1

0

D

R

A

T

E

0

8

0

1

1

0

0

0

0

8

7

6

0

0

0

5

6

0

7

0

0

1

0

0

9

0

1

0

5

5

1

0

0

1

5

0

0

0

0

0

0

5

0

0

1

0

5

0

2

1

0

5

0

0

1

3

0

0

5

0

4

0

0

2

0

5

0

2

0

3

0

6

0

2

5

0

HIGH

Operating Instructions

RECOVERING REFRIGERANT

Wear safety goggles when working with refrigerant. Read and follow

all warnings at the beginning of this manual before operating the unit.

1. Connect the power cord to the back of the unit, and plug it into the correct

voltage outlet.

2. Turn on the MAIN POWER and, if necessary, empty the oil drain bottle

located on the right hand side of the unit.

3. Press the RECOVER button.

4. If 150 pounds (68 kg) or more of refrigerant has been recovered since the last

filter-drier change, the display reads FILTER WEIGHT XXX lb (XX kg).

Press START.

NOTE: Refer to the filter change procedure on page 19 of this manual for details

about replacing the filter.

WARNING

5. Connect the high and low side hoses to the A/C system, and open the coupler

valves.

6. Put the Low Side Valve in the Recover/Vacuum position. Put the High Side

Valve in the Recover/Vacuum position. Press START to continue.

7. If the system pressure is below 25 psi, the display reads: LOW SYSTEM

PRESSURE until the pressure increases or the START button is pressed. You

may press STOP to exit at this point.

8. If the unit has refrigerant in the low-side plumbing, it begins the clearing

process and displays CLEARING IN PROGRESS. If you wish to skip the

clearing operation or stop the clearing prematurely, press the START key.

Manifold Gauges

0

6

0

5

0

0

4

0

4

0

0

3

4

0

3

3

0

0

2

2

2

0

1

1

0

0

R-134A

0

1

0

0

bar

kPa

0

0

in Hg

VAC

3

0

CLOSED

RECOVER

VACUUM

0

5

2

7

0

3

0

0

0

0

8

2

0

2

0

5

0

0

0

0

5

0

0

1

3

6

5

0

0

6

7

7

8

0

0

8

2

8

D

R

A

T

E

0

R

2

1

0

0

4

psi

5

9

0

2

0

0

5

0

5

2

1

0

1

5

0

0

2

0

0

0

5

1

1

1

0

0

0

1

0

0

0

5

0

0

5

0

R-134A

4

0

3

0

0

0

0

1

0

1

3

bar

kPa

5

0

0

0

0

5

0

4

4

3

0

psi

0

0

5

HIGH

CLOSED

RECOVER

OIL INJECT

CHARGE

VACUUM

RECOVER

MENU

VAC-CHARGE

VACUUM

START

1

2

5

4

7

8

CLEAR

0

Recover

CHARGE

STOP

3

6

F1

9

ENTER

INST0928

0

I

Diagram of Control Panel

During Recovery

Valves Open

12

© 2001 Robinair, SPX Corporation

Page 15

Operating Instructions

60

80

20

40

12

220

200

180

160

120

140

100

11

10

320

340

280

300

260

240

OUNCES

360

9. When the system has recovered to a vacuum level of approximately 13 in. Hg.,

the compressor automatically shuts off.

10. The unit then goes into automatic oil drain, and the display reads: OIL

DRAINING. Oil draining can require up to 90 seconds to complete.

11. After the oil drain is complete, the display alternates between:

RECOVERY COMPLETE CHECK OIL BOTTLE

RECOVERED XX.XX lbs. (X.XX kg) RECOVERED XX.XX lbs. (X.XX kg)

NOTE: The displayed recovered weight can vary depending on ambient conditions,

and should not be used as an indicator of scale accuracy.

12. Check the oil drain bottle, and note the amount of oil that was removed from

the A/C system. This is the amount of oil that must be charged into the A/C

system after evacuation is complete.

13. To ensure complete recovery of refrigerant, wait 5 minutes, and watch the

manifold gauges for a rise in pressure above 0 in. Hg. A pressure rise may

occur if there was freezing in the A/C system during recovery. If a rise occurs,

press the START button to resume the recovery process. Repeat as needed

until the system pressure holds for two minutes, then press STOP to exit.

Recovery is now complete. You are now ready to make any repairs to the A/C

system, if necessary, or advance to the Evacuation Process.

Diagram of the Oil

Injection System

1. Oil Injector Bottle

2. Oil Drain Bottle

OUNCES

360

1

12

340

11

320

300

10

280

9

260

240

8

220

7

200

180

6

160

5

140

120

4

100

3

80

60

2

40

1

20

2

INST0699

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

13

Page 16

RECOVER

VACUUM

CLOSED

RECOVER

VACUUM

CLOSED

VAC-CHARGE

ENTER

R-134A

R-134A

in Hg

VAC

psi

bar

kPa

psi

bar

kPa

RECOVER

CHARGE

OIL INJECT

CLEAR

MENU

VACUUM

START

F1

CHARGE

STOP

HIGH

Operating Instructions

EVACUATING THE A/C SYSTEM

Wear safety goggles when working with refrigerant. Use only

authorized refillable refrigerant tanks. Read and follow all warnings

at the beginning of this manual before operating the unit. In addition

IMPORTANT!

Evacuate the

system for at

least 15

minutes to

ensure

adequate

moisture and

contaminant

removal.

to the number keys, the keypad contains special keys that

accomplish specific operating functions.

NOTE:

• If any oil was drained from the system during recovery, DO NOT use the VAC-

CHARGE feature. The oil must be replenished into the A/C system, which is not

possible when the VAC-CHARGE function is used.

• If the vacuum pump has been run more than 10 hours since the last oil change,

the display reads: VACUUM OIL TIME XX:XX. Press the STOP key to change

the vacuum pump oil, or press the START key to continue. Instructions for

changing the vacuum pump oil are located in the maintenance section of this

manual. NOTE: Vacuum pump oil should be changed after every 10 hours of

use to maintain maximum performance and endurance levels.

WARNING

IMPORTANT!

If the vacuum

pump has run

for 10 or more

hours without

an oil change,

the message

VACUUM OIL

TIME XX:XX

appears on the

display.

Change the

pump oil

following the

procedures in

the

MAINTENANCE

INSTRUCTIONS.

• If the system being evacuated contains a pressure over 25 psi at any point during

the evacuation, the display reads PRESSURE EXISTS. This message indicates

that the A/C system contains refrigerant; press any key to continue. Press the

RECOVERY key to recover any refrigerant in the system (See RECOVERING

REFRIGERANT, page 12). After recovery is complete, return to evacuating the

A/C system.

VAC-CHARGE

1. Press the VAC-CHARGE key to select the VAC-CHARGE feature.

2. Ensure the service hoses are connected and both panel valves are in the

VACUUM/ RECOVER position. Press START.

Vacuum

0

2

0

RECOVER

6

7

0

0

5

0

0

4

0

5

0

4

0

0

0

3

4

5

0

3

3

0

6

0

2

2

1

1

0

0

R-134A

0

8

1

0

0

8

bar

2

D

kPa

R

A

T

E

0

R

0

in Hg

0

0

4

VAC

psi

3

0

CLOSED

VACUUM

The Control Panel

During Evacuation

0

5

2

3

0

0

0

0

8

2

0

2

0

0

0

0

5

0

1

3

RECOVER

VACUUM

5

0

2

0

5

0

5

2

1

0

1

5

0

0

2

0

0

0

5

1

1

1

0

0

5

0

0

5

0

R-134A

4

0

3

0

0

0

0

3

RECOVER

bar

kPa

5

0

0

0

0

5

0

4

4

3

0

psi

0

0

5

HIGH

CLOSED

OIL INJECT

CHARGE

6

9

0

0

0

1

0

0

0

7

0

7

0

1

0

0

1

8

0

2

1

VACUUM

START

1

4

MENU

7

CLEAR

Vac-Charge

VAC-CHARGE

CHARGE

STOP

2

3

5

6

F1

8

9

ENTER

0

0

I

INST0929

14

© 2001 Robinair, SPX Corporation

Page 17

Operating Instructions

NOTE: It is not necessary to change the High side panel valve from vacuum to

charge when performing the VAC-CHARGE function.

3. Press the START key to charge the default amount of refrigerant, or use the

number keys to enter the desired charge weight. Then press the START key.

4. If the weight entered leaves less than 3 lbs (1.36 kg) of refrigerant in the

internal storage vessel, the VAC-CHARGE process does not begin, and the

display reads INSUFFICIENT REFRIG. At this point, refrigerant must be

added to the internal storage vessel. See page 6 of this manual for internal

storage vessel refill instructions, and then return to Step 1 of EVACUATING

the A/C system.

5. If the internal storage vessel contains a sufficient amount of refrigerant, press

the START key to accept the default evacuation time of 15:00 minutes, or

enter the desired vacuum time by using the number keys. Then press the

START key.

6. The unit automatically charges the A/C system after the specified vacuum

time has elapsed.

IMPORTANT!

Evacuate the

A/C system for

at least 15

minutes to

ensure

adequate

moisture and

contaminant

removal.

7. Advance to Step 4 of RECHARGING the A/C SYSTEM in this manual to

complete the charging process.

VACUUM

1. Press the VACUUM key.

2. Ensure the service hoses are connected and panel valves are in the correct

position. Press START.

3. Press the START key to accept the default evacuation time of 15:00 minutes,

or enter the desired vacuum time by using the number keys, and press the

START key.

4. The unit evacuates the A/C system and stops when the specified time has

elapsed. Pressing the STOP key will pause the process. Press START to

resume, or STOP again to exit.

5. You are now ready to replenish the A/C system oil (if necessary), or to

recharge the system with refrigerant.

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

15

Page 18

RECOVER

VACUUM

CLOSED

RECOVER

VACUUM

CLOSED

VAC-CHARGE

ENTER

R-134A

R-134A

in Hg

VAC

psi

bar

kPa

psi

bar

kPa

RECOVER

CHARGE

OIL INJECT

CLEAR

MENU

VACUUM

START

F1

CHARGE

STOP

HIGH

3

2

1

60

80

20

40

12

220

7

5

4

6

200

180

160

120

140

100

11

9

8

10

320

340

280

300

260

240

OUNCES

360

Operating Instructions

REPLENISHING A/C SYSTEM OIL

CAUTION! To prevent air from entering the A/C system, never let the

oil level drop below the pickup tube while charging or replenishing.

Before charging the A/C system, you must replenish any oil removed from the A/C

system during the recovery process. Charge only the amount of oil that was

removed from the A/C system during recovery. Check the oil drain bottle to

determine the amount of oil that was removed during recovery. Empty the oil drain

bottle before recovering the next A/C system to prevent an inaccurate oil charge.

NOTE: If no oil was removed from the A/C system during recovery, DO NOT

charge any oil into the A/C system.

THE VACUUM CYCLE MUST RUN COMPLETELY OR THE OIL INJECT

WILL NOT OPERATE.

1. Select the correct oil for the A/C system being serviced. Refer to the vehicle

manufacturer's service manual.

2. Adjust the o-ring around the oil injector bottle to the required oil charge level.

For example, if the bottle's oil level is at 4 ounces, and you need 1/2 ounce of

oil to replenish the A/C system, place the o-ring at the 3 1/2 ounce level.

3. Reattach the oil injector bottle to the unit.

4. Close the Low Side manifold valve. Put the High Side valve in the Oil Inject/

Charge position.

5. Press the F1 (INJECT OIL) button once and release it when it “beeps.” Press

the F1 button again and hold it until the oil level reaches the o-ring.

6. Press the STOP button after the oil charge is complete to recharge the A/C

system with refrigerant. You must recharge the AC system with refrigerant at

this time to ensure all of the oil is delivered.

0

6

7

0

0

5

8

0

0

4

0

5

0

4

0

0

0

3

6

4

5

0

0

0

3

3

0

6

0

2

2

2

0

1

1

7

0

0

R-134A

0

8

1

0

0

0

8

bar

2

8

D

kPa

R

A

T

E

0

R

0

in Hg

0

0

4

VAC

psi

3

0

CLOSED

RECOVER

VACUUM

INST0930

Control Panel

0

5

2

3

0

0

0

0

2

0

0

1

2

0

0

0

0

5

0

1

3

9

0

1

0

0

0

0

7

0

1

1

0

2

RECOVER

VACUUM

5

0

2

0

5

0

5

2

1

0

1

5

0

0

2

0

0

0

5

1

1

1

0

0

5

0

0

5

0

R-134A

4

0

3

0

0

0

0

3

bar

kPa

5

0

0

0

0

5

0

4

4

3

0

psi

0

0

5

HIGH

CLOSED

OIL INJECT

CHARGE

VAC-CHARGE

RECOVER

VACUUM

STOP

START

1

2

3

5

4

6

MENU

7

8

9

CLEAR

ENTER

0

Inject

Oil

CHARGE

Button

F1

Oil

Inject

0

I

Bottle

OUNCES

360

12

340

11

320

300

10

280

9

260

240

8

220

7

200

180

6

160

5

140

120

4

100

3

80

60

2

40

1

20

Oil

Drain

Bottle

INST0699

Diagram of the Oil Injection System

16

© 2001 Robinair, SPX Corporation

Page 19

Operating Instructions

RECHARGING THE A/C SYSTEM

WARNING

Wear safety goggles when working with refrigerant. Use only

authorized refillable refrigerant tanks. Disconnect hoses with

extreme caution! All hoses may contain liquid refrigerant under

pressure. Read and follow all warnings at the beginning of this

manual before operating the unit.

1. Press the CHARGE button. (If an oil inject has been performed, the

CHARGE key does not have to be pressed.)

2. Put the Low Side Valve in the Closed position. Put the High Side Valve in

the Oil Inject/Charge position. Press START to continue.

3. Accept either the default weight by pressing START, or type in a weight

with the number keys, and press START.

IMPORTANT!

Evacuate the

A/C system for

at least 15

minutes for

adequate

moisture and

contaminant

removal.

4. If the weight entered will leave less than 3 lbs (1.36 kg) of refrigerant in the

refrigerant tank, the charge function will not start, and the display reads:

INSUFFICIENT REFRIG.

PRESS ANY KEY TO EXIT

See the Operating Guidelines section of the manual for refill instructions.

5. Upon entering a valid charge weight, the display reads:

CHARGE IN PROGRESS

CHARGED= X.XX lbs. (X.XX kg)

6. If, during the charge cycle, the weight fails to charge 0.05 lbs (0.02 kg) in 30

seconds, the unit intermittently beeps while the display alternates between:

CHARGING HAS SLOWED CHARGE HAS SLOWED

PRESS START TO RETRY OR STOP TO EXIT

7. Pressing the START button when the charging is slowed causes the charge

to resume. If charging does not complete, see the SLOW CHARGE

PROCEDURE below.

8. When the charge is complete the display will show

CHARGE COMPLETE

X.XXlb (kg) CHARGED

9. For R-134a systems, close the high and low side coupler valves. Remove the

service hoses from the A/C system.

The A/C system is now ready for use.

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

17

Page 20

Operating Instructions

SLOW CHARGE PROCEDURE

Before starting the vehicle's engine, verify that it is in PARK or

NEUTRAL, with the emergency brake ON.

Never run a vehicle without adequate ventilation in the work area.

CAUTION! Close the high side manifold valve before starting the

vehicle A/C system.

1. Close the High Side Valve. Put the Low Side Valve in the Recover/Vacuum

position.

2. Start the vehicle, and set the AC system to its maximum setting.

3. Press START. The unit charges out of the low side inlet only, allowing the

vehicle's compressor to pull the refrigerant into the A/C system.

WARNING

4. When the unit is finished charging, the display reads:

CHARGE COMPLETE

X.XX lb (kg) CHARGED

5. Close the LOW SIDE manifold valve.

6. Turn off the vehicle's engine.

7. For R-134a systems, close the high and low side coupler valves. Remove the

service hoses from the A/C system.

The A/C system is now ready for use.

18

© 2001 Robinair, SPX Corporation

Page 21

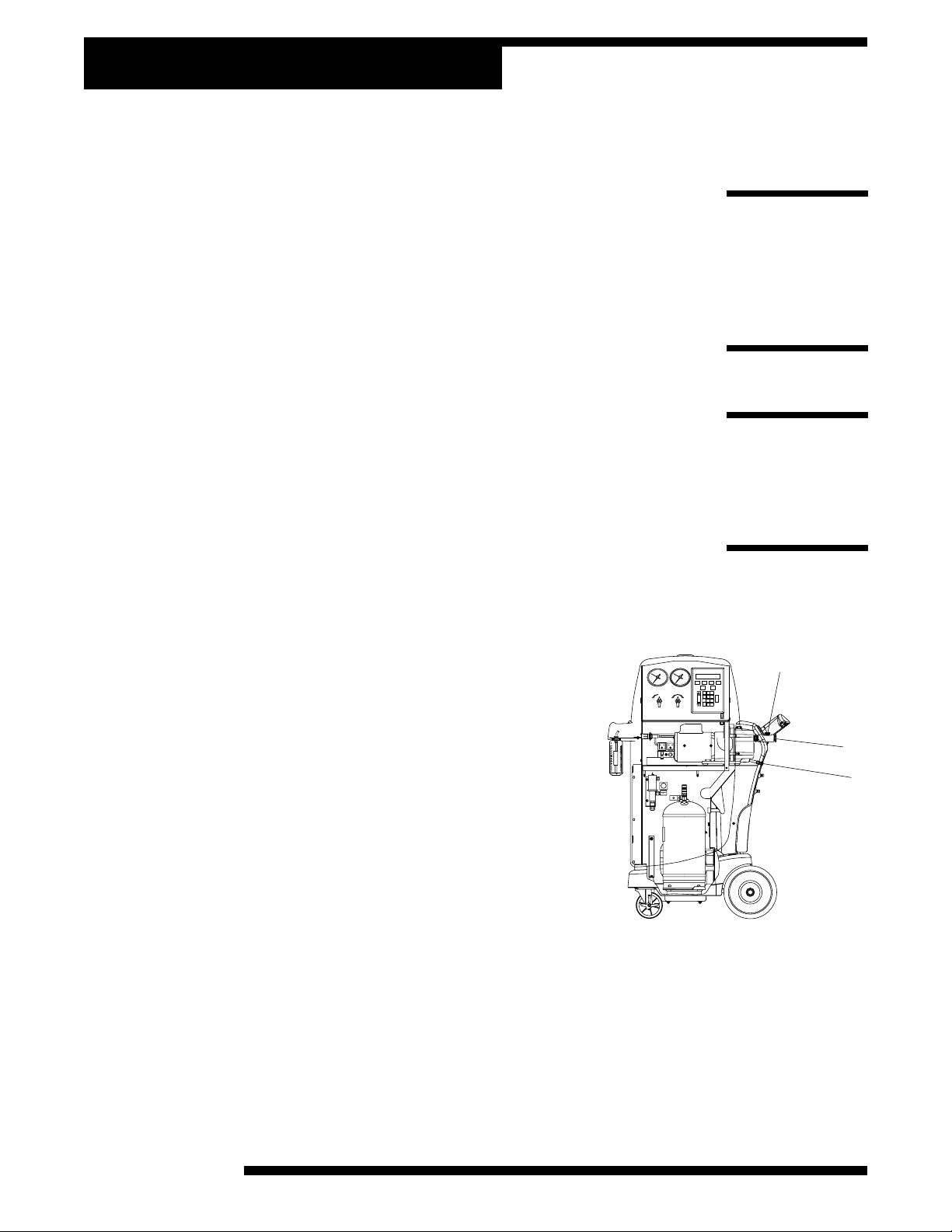

Maintenance Instructions

REPLACING THE FILTER-DRIER

Order part no. 34724 for a replacement filter-drier. The filterdrier on this unit is designed to trap acid and particulates, and

is formulated to remove water from the refrigerant. You must

change the filter-drier to ensure adequate moisture and

contaminant removal.

Typically, you can recycle up to 150 pounds (68 kilograms)

of refrigerant between filter changes.

CAUTION! For best results, use Robinair filter-

driers (part no. 34724). All performance tests and

claims are based on using this specially blended

filter-drier. Use of another may affect performance

results.

1. Press the MENU button.

2. Scroll through the menu to CHANGE FILTER and

press START.

3. Press START again, and the unit will begin clearing the

filter.

4. When clearing is complete, the display reads:

TURN UNIT OFF AND REPLACE FILTER

5. Turn off the main power, and unplug the machine.

6. Open the unit door, and replace the old filter with

the new filter.

7. Close the unit door, plug in the machine, and turn

on the Main Power.

The filter change is now complete.

MAIN POWER BREAKER

Filter-Drier

CONTROL BREAKER

INST0478

OUNCES MLS

12

340

11

320

300

10

280

9

260

240

8

220

7

200

180

6

160

5

140

120

4

100

3

80

60

2

40

1

20

Filter

Drier

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

INST0948

Location of the Filter-Drier

19

Page 22

Maintenance Instructions

240

220

200

180

80

120

100

140

60

20

40

160

3

4

2

1

8

7

6

5

340

320

MLS

280

300

260

12

11

10

9

OUNCES

CLOSED

RECOVER

RECOVER

CLOSED

CLOSE

VACUUM

VACUUM

CHARGE

OIL INJECT

2

0

5

8

MENU

CLEAR

7

1

4

START

RECOVER

VACUUM

F1

ENTER

9

3

6

STOP

CHARGE

VAC-CHARGE

FLOW

LOW

HIGH

CHANGING THE VACUUM PUMP OIL

For maximum vacuum pump performance, change the vacuum pump oil after

every 10 hours of operation.

1. Turn on the MAIN POWER switch.

IMPORTANT!

Review current

local, state, and

federal statutes,

cases, laws, and

regulations to

determine the

current status and

appropriate

disposal method

for pump oil. It is

the responsibility

of the user to

determine if a

material is a

hazardous waste

at the time of

disposal. Ensure

that you are in

compliance with

all applicable laws

and regulations.

2. Press the MENU button.

NOTE: Do not connect the service hoses to a vehicle.

3. Use the arrow keys to select CHANGE VACUUM PUMP OIL, and press

START.

4. Press START again to begin.

5. The vacuum pump will run for two minutes. Allow the vacuum pump to run

until it automatically stops.

6. Remove the black plastic plug on the oil fill port of the vacuum pump.

7. Remove the oil drain cap from the vacuum pump, and drain the oil into a

suitable container for correct disposal.

8. Replace the oil drain cap.

9. Attach the flexible tube and cap to the oil bottle, and pour eight ounces of

vacuum pump oil into the fill port.

10. Press the START key. While the vacuum pump is

running, slowly add oil until the level rises to the center of

the reservoir's sight glass.

1

VAC-CHARGE

CHARGE

RECOVER

VACUUM

STOP

LOW

CLOSED

RECOVER

VACUUM

MLS

OUNCES

12

340

11

320

300

10

280

9

260

240

8

220

7

200

180

6

160

5

140

120

4

100

3

80

60

2

40

1

20

START

HIGH

CLOSED

1

2

3

5

4

6

F1

MENU

RECOVER

OIL INJECT

VACUUM

CHARGE

8

7

9

CLEAR

ENTER

0

CLOSE

FLOW

1. Oil Fill

2. Sight Glass

3. Oil Drain

INST0947

11. Press the STOP key and replace the black plastic plug on

the fill port.

12. The unit is now ready to operate.

2

3

20

© 2001 Robinair, SPX Corporation

Page 23

Maintenance Instructions

OPEN

CLOSE

1

6

2

OPEN

CLOSE

Diagram of Vacuum Pump

3

4

5

1. Oil Filler Tube

2. Pump Exhaust

3. Oil Fill Port

4. Sight Glass

5. Oil Drain Fitting

6. Inlet

CHECKING FOR LEAKS

Every three months, or as specified by local or state laws, you should check the

unit for leaks.

1. Turn off the MAIN POWER switch, and disconnect the power cord from the

outlet.

2. Open the rear door. Remove the top cover and front panel.

3. Use a leak detector to probe all connections for refrigerant leaks. Tighten

fittings if a leak is indicated.

4. Reassemble the body panels and close the rear door.

IMPORTANT!

Inspect the unit

periodically for

leaks. The

manufacturer

does not

reimburse for

lost refrigerant.

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

21

Page 24

Replacement Parts List

ELECTRICAL PROTECTION

The unit is equipped with two circuit breakers. If either circuit breaker trips, the

unit will not function correctly and may lose all power. Press the circuit breaker

button to reset. The circuit breakers are on the back of the unit.

GENERAL MAINTENANCE

1. On a regular basis, wipe off the unit with a clean cloth to remove grease, dust,

or other dirt.

2. Periodically check the internal components for leaks—over time, fittings can

loosen as the unit is moved. Open the unit door panel, and trace lines with a

leak detector. Also, check connections on the back of the unit. Tighten any

loose fittings or connections you may find.

REPLACEMENT PARTS LIST

The following is a list of replacement parts and accessories you may need to

service or maintain your unit.

We suggest you keep several filter-driers on hand so you will always be able to

change them and complete any recycling job that is in progress.

Premium High Vacuum Pump Oil is also available in handy quart containers, or in

convenient gallon containers:

Quart (shipped 12 quarts per case) No. 13203

Gallon (shipped 4 gallons per case) No. 13204

Because of ongoing product improvements,

we reserve the right to change design, specifications,

and materials without notice.

22

© 2001 Robinair, SPX Corporation

Page 25

Replacement Parts List

34700-2K 17700-2K

R-134a R-12

Replacement Replacement

Component Part Number Part Number

96" Red Hose 63096 68396A

96" Blue Hose 62096 68296A

Fan RA17416 RA17416

Filter-Drier 34724 34724

Compressor RA19458 RA19458

Vacuum Pump RA15425 RA15425

High Pressure Switch RA19427 RA19427

Main Power Switch RA40994 RA40994

Vacuum Switch RA18752 RA18752

Pump Protection Switch RA19429 RA19429

Automatic Expansion Valve RA19592 RA19592

Oil Catch Bottle RA17419 RA17419

Scale Assembly RA19603 RA19603

Control Module RA19768 RA19768

High Side Gauge RA19742 RA19742

Low Side Gauge RA19741 RA19741

Low Side Coupler 18190A 18190A

High Side Coupler 18191A 18191A

Automatic Air Purge RA19743 RA19744

Solenoid Rebuild Kit RA19258 RA19258

Castors RA19631 RA19631

ISV (Internal Storage Vessel) RA19612 RA19612

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

23

Page 26

Flow Diagram

INST0576

7. Expansion Valve

6. Vacuum Pump

5. Oil Injector Check Valve

4. High Side Coupler

3. Low Side Manifold Valve

2. High Side Manifold Gauge

1. Low Side Manifold Gauge

14

13

12

11

3

4

6

9

5

7

1

2

14. Filter-Drier

13. Accumulator

12. Return Oil Separator

11. Lower Block

10. Air Purge Control

9. Compressor

8

8. Upper Block

10

24

© 2001 Robinair, SPX Corporation

Page 27

Wiring Diagram

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

25

Page 28

Limited Warranty

This product is warranted to be free from defects in workmanship, materials, and

components for a period of one year from date of purchase. All parts and labor required to

repair defective products covered under the warranty will be at no charge. The following

restrictions apply:

1. The limited warranty applies to the original purchaser only.

2. The warranty applies to the product in normal usage situations only, as described in the

Operating Manual. The product must also be serviced and maintained as specified.

3. If the product fails, it will be repaired or replaced at the option of the manufacturer.

4. Transportation charges for warranty service will be reimbursed by the factory upon

verification of the warranty claim and submission of a freight bill for normal ground

service. Approval from the manufacturer must be obtained prior to shipping to an

authorized service center.

5. Warranty service claims are subject to authorized inspection for product defect(s).

Robinair Limited Warranty Statement

Rev. July 11, 2003

6. The manufacturer shall not be responsible for any additional costs associated with a

product failure including, but not limited to, loss of work time, loss of refrigerant,

cross-contamination of refrigerant, and unauthorized shipping and/or labor charges.

7. All warranty service claims must be made within the specified warranty period. Proofof-purchase date must be supplied to the manufacturer.

8. Use of recovery/recycling equipment with unauthorized refrigerants, sealants, or dyes

will void the warranty.

• Authorized refrigerants are listed on the equipment or are available through the

Technical Service Department.

• The manufacturer prohibits the use of the recovery/recycling equipment on air

conditioning (A/C) systems containing leak sealants, either of a seal-swelling or

aerobic nature.

• The manufacturer prohibits the use of dyes injected through the oil injection device

on the recovery/recycling equipment.

This Limited Warranty does NOT apply if:

• The product, or product part, is broken by accident.

• The product is misused, tampered with, or modified.

• The product is used for recovering or recycling any substance other than the specified

refrigerant type. This includes, but is not limited to, materials and chemicals used to seal

leaks in A/C systems.

26

• The product is equipped with an oil injection device that has been used to inject dye.

The manufacturer only endorses the use of separate dye injection devices, and does not

support the use of the oil injection feature for this purpose.

Note: Refillable refrigerant tanks are reusable.

© 2001 Robinair, SPX Corporation

Page 29

Notes

34700-2K/17700-2K Cool-Tech Recovery/Recycling/Recharging Unit

27

Page 30

Notes

28

© 2001 Robinair, SPX Corporation

Page 31

Page 32

CONVERSION

TABLE

Visit our web site at

OZ. LBS.

0.5 0.03

1.0 0.06

1.5 0.09

2.0 0.13

2.5 0.16

3.0 0.19

3.5 0.22

4.0 0.25

4.5 0.28

5.0 0.31

5.5 0.34

6.0 0.38

6.5 0.41

7.0 0.44

7.5 0.47

8.0 0.50

8.5 0.53

9.0 0.56

9.5 0.59

10.0 0.63

10.5 0.69

11.0 0.69

11.5 0.72

12.0 0.75

12.5 0.78

13.0 0.81

13.5 0.84

14.0 0.88

14.5 0.91

15.0 0.94

15.5 0.97

16.0 1 lb.

www.robinair.com

or

%

Call our Toll-Free

Technical Support Line at

800-822-5561

in the continental U.S. or Canada.

In all other locations, contact your local distributor. To help us serve

you better, please be prepared to provide the model number, serial

number, and date of purchase of your unit.

To validate your warranty, you must complete the warranty card

attached to your unit, and return it within ten days from date of

purchase.

NATIONWIDE NETWORK OF AUTHORIZED SERVICE CENTERS

If your unit needs repair or replacement parts, contact the service

center in your area. For help in locating a service center, call the

toll-free technical support line.

Due to ongoing product improvements,

we reserve the right to change design,

specifications, and materials without notice.

The 347002K/177002K is designed to meet all applicable agency certifications, including

Underwriter's Laboratories, Inc., SAE Standards, and CUL. Correct maintenance of this

equipment will provide accurate A/C service for many years.

Certain state and local jurisdictions dictate that using this equipment to sell refrigerant

by weight may not be permitted. We recommend charging for any A/C service by the

job performed.

This weight scale provides a means of metering the amount of refrigerant needed for

optimum A/C system performance as recommended by OEM manufacturers.

SPX Corporation

655 Eisenhower Drive

Owatonna, MN 55060-0995 USA

Tech Services:1-800-822-5561

Fax: 1-800-822-7805

Customer Service: 1-800-533-6127

Fax: 1-800-322-2890

Web site: www.robinair.com

124080 (Rev. C, 7-09-03) 347002K/177002K Cool-Tech © SPX Corporation

Loading...

Loading...