Spicer S110, S130 User Manual

Spicer® Single Drive Axles

Service Manual

AXSM0055

April 2011

S110 Series

S130 Series

General Information

General Information

The description and specifications contained in this service |

Any reference to brand name in this publication is made sim- |

publication are current at the time of printing. |

ply as an example of the types of tools and materials recom- |

|

mended for use and should not be considered an |

Dana reserves the right to discontinue or to modify its |

endorsement. Equivalents, if available, may be used. |

models and/or procedures and to change specifications |

|

at any time without notice. |

|

Important Notice

This symbol is used throughout this manual to call attention to procedures where carelessness or failure to follow specific instructions may result in personal injury and/or component damage.

Departure from the instructions, choice of tools, materials and recommended parts mentioned in this publication may jeopardize the personal safety

of the service technician or vehicle operator.

WARNING: Failure to follow indicated procedures creates a high risk of personal injury to the servicing technician.

CAUTION: Failure to follow indicated procedures may cause component damage or malfunction.

IMPORTANT: Highly recommended procedures for proper service of this unit.

NOTE: Additional service information not covered in the service procedures.

TIP: Helpful removal and installation procedures to aid in the service of this unit.

OEM |

Refer to the OEM vehicle specifications |

Always use genuine Spicer replacement parts.

Information General

i

Table of Contents

General Information ............................................. |

i |

Important Notice .......................................................... |

i |

Introduction ........................................................ |

1 |

Model Listing .............................................................. |

1 |

Model Information ...................................................... |

1 |

Model Identification .................................................... |

2 |

Part Identification........................................................ |

2 |

Ring Gear and Pinion .......................................... |

3 |

Inspection ........................................................... |

4 |

Failure Analysis ........................................................... |

4 |

How to Diagnose a Failure........................................... |

4 |

.........................Prepare the Parts for Inspection 5 |

|

Find the Cause of the Failure ....................................... |

5 |

Correct the Cause of the Problem ............................... |

5 |

Inspection ................................................................... |

6 |

Inspect Axle Housing .................................................. |

6 |

Inspect Components ................................................... |

7 |

Inspect Primary Gearing ............................................. |

7 |

Differential Carrier Assembly .............................. |

8 |

S110 Carrier Assembly ....................................... |

9 |

S130 Carrier Assembly ..................................... |

11 |

Remove Differential Carrier ............................... |

12 |

Standard Differentials................................................ |

12 |

Install Differential Carrier .................................. |

13 |

Remove Wheel Differential ................................ |

14 |

Pinion - Parts Exploded View ............................ |

15 |

Pinion Removal ................................................. |

16 |

Drive Pinion ...................................................... |

17 |

Rear Axle Pinion Assembly - Parts Exploded View.... |

17 |

Pinion Installation ............................................. |

18 |

Final Buildup ............................................................. |

18 |

Wheel Differential Assembly - Parts Exploded ..20

Disassemble, Overhaul, and Assemble Wheel |

|

Differential - S110 ............................................. |

21 |

Disassemble Wheel Differential ................................. |

21 |

Disassemble, Overhaul, and Assemble Wheel Differ- |

|

ential - S130 ..................................................... |

26 |

Disassemble Wheel Differential ................................. |

26 |

Measure and Adjust Carrier Assembly .............. |

32 |

Adjust Backlash and Preload ..................................... |

32 |

Change Backlash Setting ........................................... |

33 |

Measure Ring Gear Runout ....................................... |

33 |

Adjust Ring and Pinion Tooth Contact Pattern .. |

34 |

Install Axle Housing Breather ............................ |

36 |

Wheel End Seal - Parts Exploded View ............. |

37 |

Remove and Overhaul Wheel End Seal ............. |

38 |

Adjust Wheel Bearing ........................................ |

39 |

Wheel End ......................................................... |

41 |

Verify Wheel End-play Procedure .............................. |

41 |

Adjust End-play with Tire and Wheel Assembly ......... |

41 |

Adjust End-play with Wheel Hub................................ |

41 |

Readjust Wheel End-play Procedure.......................... |

41 |

Lubricate Wheel End ......................................... |

42 |

Lubrication ........................................................ |

44 |

Approved Lubricants ................................................. |

44 |

Recommendations for Viscosity/Ambient Temp ........ |

44 |

Lube Change Intervals ............................................... |

45 |

Change Lube ..................................................... |

46 |

Drain.......................................................................... |

46 |

Fill.............................................................................. |

46 |

Proper Vehicle Towing ...................................... |

47 |

With Truetrac Limited Slip Differential ....................... |

47 |

Torque Flow ...................................................... |

48 |

Torque Chart ..................................................... |

49 |

Introduction

Introduction

Dana Commercial Vehicle Division, presents this publication to aid in maintenance and overhaul of Spicer single drive axles. Instructions contained cover the models listed. Their design is common, with differences in load capacity. Capacity variations are achieved by combining basic differential carrier assemblies with different axle housings, axle shafts and wheel equipment.

Model Listing

Rear Axle |

Load Capacity |

|

|

|

|

|

|

|

|

|

|

S10-110 |

10,000 |

Introduction |

|

|

|

||

S12-110 |

12,000 |

||

|

|||

|

|

|

|

S14-110 |

14,000 |

|

|

|

|

|

|

S16-130 |

16,000 |

|

|

|

|

|

Model Information

S 14 - 1 1 0 L

S - S i n g l e R e a r A x l e

G A W R a t i n g x 1 0 0 0 l b s .

G e a r T y p e

1- S t a n d a r d S i n g l e R e d u c t i o n

2- D u a l R a n g e

3- P l a n e t a r y D o u b l e R e d u c t i o n

4- C o n t r o l l e d T r a c t i o n D i f f e r e n t i a l

5- H e l i c a l R e d u c t i o n

O p t i o n s

B - B u s S p e c i f i c

D - D i f f e r e n t i a l L o c k

H- H e a v y W a l l

I- I n t e g r a l B r a k e

L- L i m i t e d - S l i p

R- R e t a r d e r / P a r k i n g B r a k e R e a d y

W- W i d e - t r a c k

F- R o l l O v e r

D e s i g n L e v e l

H e a d A s s e m b l y S e r i e s

1

Introduction

Model Identification

Drive Axle

Data plate is located on |

|

|

|

|

the axle centerline |

|

|

4 |

5 |

|

|

|

3 |

|

|

|

|

|

|

|

|

|

CUST. PART NO. |

Spicer® |

|

|

|

SPEC. |

SERIAL NO. |

|

|

|

MODEL PART NO. |

RATIO |

|

|

2 |

MADE IN: |

6 |

|

|

|

||

|

|

|

1 |

7 |

Rear Axle (Front View) |

|

|

|

|

1 - Country of origin |

4 |

- OEM part number assigned to the axle build |

||

2 - Axle model identification |

5 |

- Carrier assembly serial number assigned by the |

||

3 - Specification number assigned to the axle built by Spicer. |

|

|

manufacturing plant |

|

Identifies all component parts of the axle including special |

6 |

- Axle gear ratio |

|

|

special OEM requirements such as yokes or flanges. |

7 |

- Carrier assembly production or service part number |

||

Part Identification

Axle Housing |

Axle Shaft |

2

|

|

|

® |

|

|

|

LBS. |

|

. |

Spicer |

|

. NO . |

|

|

|

PT |

. CAP . |

|

|

HSG. I.D. NO |

|

IN |

|

HSG |

MADE |

|

|

HOUSING |

|

|

|

1

1

1 - ID Tag |

2 - Axle shaft part number |

2

Introduction

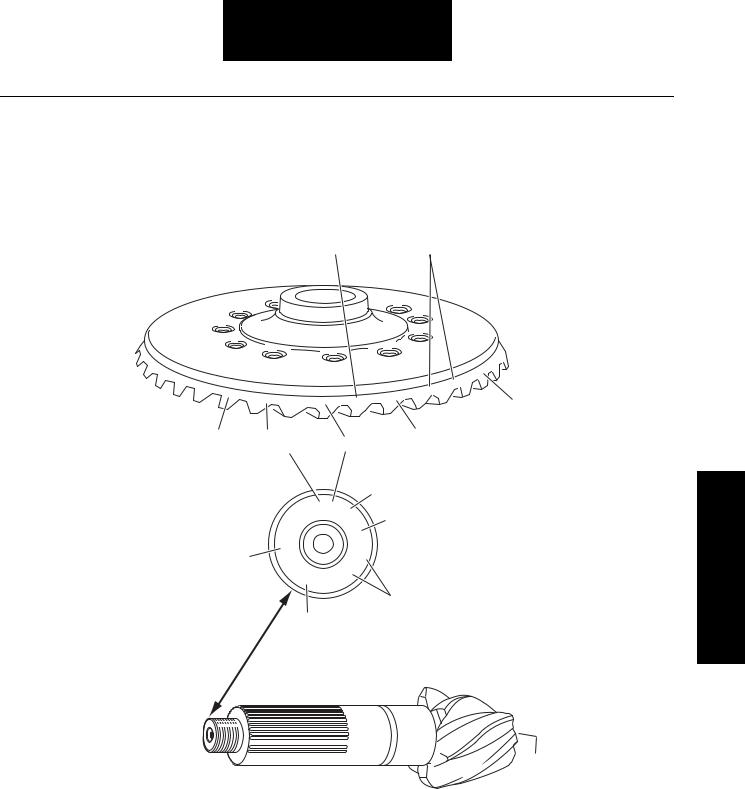

Ring Gear and Pinion

Note: Ring gear and drive pinion are matched parts and must be replaced in sets.

8 |

3 |

|

|

|

|

|

|

|

|

|

L7038 |

|

127381 |

|

|

|

|

|

|

17 |

G |

|

|

SPICER |

|

|

|

OF |

|

||

|

|

|

41-8 |

NL2 |

|

4 |

|||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|||

1 |

|

|

7 |

5 |

|

2 |

|

6 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

127 |

8-41 |

127 |

6 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

SPICER |

|

|

|

|

|

|

|

|

|

|

0H |

|

|

|

|

|

|

7 |

|

|

|

17 |

|

|

|

|

|

|

|

|

G |

|

|

|

|

|

|

|

|

127428 |

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

1 |

|

|

|

|

|

6-39 JD77

68

4

4

1 |

- Part number |

4 |

- Matching gear set number |

7 |

- Indicates genuine Spicer parts |

2 |

- Number of ring gear teeth |

5 |

- Number of pinion teeth |

8 |

- Heat Code |

3 |

- Manufacturing numbers |

6 |

- Date code |

|

|

Introduction

3

General Information

Inspection

Failure Analysis

Failure analysis is the process of determining the original cause of a component failure in order to keep it from happening again. Too often, when a failed component is replaced without determining its cause, there will be a recurring failure. If a carrier housing is opened, revealing a ring gear with a broken tooth, it is not enough to settle on the broken tooth as the cause of the carrier failure. Other parts of the carrier must be examined. For a thorough understanding of the failure and possible insight into related problems, the technician needs to observe the overall condition of the vehicle.

No one benefits when a failed component goes on the junk pile with the cause unknown. Nothing is more disturbing to a customer than a repeat failure. Systematically analyzing a failure to prevent a repeat occurrence assures quality service by avoiding unnecessary downtime and further expense to the customer.

The true cause of a failure can be better determined by knowing what to look for, determining how a piece of the equipment was running and learning about previous problems. In the case of a rebuilt rear axle, mismatched gears may have been installed. The more successful shops prevent repeat equipment failures by developing good failure analysis practices. Knowing how to diagnose the cause of a premature failure is one of the prerequisites of a good heavy-equipment technician.

How to Diagnose a Failure

The following five steps are an effective approach to good failure diagnostics.

1.Document the problem.

2.Make a preliminary investigation.

3.Prepare the parts for inspection.

4.Find the cause of the failure.

5.Correct the cause of the problem.

Document the Problem

Here are some guidelines for starting to learn about a failure, including questions to ask:

1.Talk to the operator of the truck.

2.Look at the service records.

3.Find out when the truck was last serviced.

4.Ask: In what type of service is the truck being used?

5.Ask: Has this particular failure occurred before?

6.Ask: How was the truck working prior to the failure?

You need to be a good listener. Sometimes, insignificant or unrelated symptoms can point to the cause of the failure:

7.Ask: Was the vehicle operating at normal temperatures?

8.Ask: Were the gauges showing normal ranges of operation?

9.Ask: Was there any unusual noise or vibration?

After listening, review the previous repair and maintenance records. If there is more than one driver, talk to all of them and compare their observations for consistency with the service and maintenance records. Verify the chassis Vehicle Identification Number (VIN) number from the vehicle identification plate, as well as the mileage and hours on the vehicle.

Make a Preliminary Investigation

These steps consist of external inspections and observations that will be valuable when combined with the results of the parts examination.

1.Look for leaks, cracks or other damage that can point to the cause of the failure.

2.Make note of obvious leaks around plugs and seals. A missing fill or drain plug would be an obvious cause for concern.

3.Look for cracks in the carrier housing (harder to see, but sometimes visible).

4.Does the general mechanical condition of the vehicle indicate proper maintenance or are there signs of neglect?

5.Are the tires in good condition and do the sizes match?

6.If equipped with a torque-limiting device, is it working properly?

During the preliminary investigation, write down anything out of the ordinary for later reference. Items that appear insignificant now may take on more importance when the subassemblies are torn down.

4

Inspection

Prepare the Parts for Inspection

After the preliminary investigation, locate the failure and prepare the part for examination. In carrier failure analysis, it may be necessary to disassemble the unit.

1.When disassembling subassemblies and parts, do not clean the parts immediately since cleaning may destroy some of the evidence.

2.When tearing down the drive axle, do it in the recommended manner. Minimize any further damage to the unit.

3.Ask more questions when examining the interior of the carrier. Does the lubricant meet the manufacturer specifications regarding quality, quantity and viscosity? As soon as you have located the failed part, take time to analyze the data.

Find the Cause of the Failure

Here begins the real challenge to determine the exact cause of the failure. Keep in mind that there is no benefit to replacing a failed part without determining the cause of the failure. For example, after examining a failed part and finding that the failure is caused by a lack of lubrication, you must determine if there was an external leak. Obviously, if there is an external leak, just replacing the failed gear is not going to correct the situation.

Another important consideration is to determine the specific type of failure which can be a valuable indicator for the cause of failure. The following pages show different types of failures and possible causes. Use this as a guide in determining types of failures and in correcting problems.

Correct the Cause of the Problem

Once the cause of the problem has been determined, refer to the appropriate service manual to perform the repairs.

Inspection

5

Inspection

Inspection

Clean

1.Wash steel parts with ground or polished surfaces in solvent. There are many suitable commercial solvents available. Kerosene and diesel fuel are acceptable.

WARNING

WARNING

Gasoline is not an acceptable solvent because of its extreme combustibility. It is unsafe in the workshop environment.

2.Wash castings or other rough parts in solvent or clean in hot solution tanks using mild alkali solutions.

Note: If a hot solution tank is used, make sure parts are heated thoroughly before rinsing.

3.Rinse thoroughly to remove all traces of the cleaning solution.

4.Dry parts immediately with clean rags.

5.Oil parts.

•If parts are to be reused immediately: Lightly oil.

•If parts are to be stored: Coat with oil, wrap in corrosion resistant paper and store in a clean, dry place.

Inspect Axle Housing

Axle housing inspection and repairs are limited to the following checks or repairs.

•Visually inspect axle housing for cracks, nicks and burrs on machined surfaces.

•Check carrier bolt holes and studs for foreign material.

•Replace damaged fasteners. Look for loose bolts or cross-threaded holes

CAUTION

CAUTION

Any damage which affects the alignment or structural integrity of the housing requires housing replacement. Do not repair by bending or straightening. This process can affect the material’s properties and cause it to fail completely under load.

•Check all seals and gaskets.

Note: Replace conventional gaskets with silicone rubber gasket compound (included in many repair kits). The compound provides a more effective seal against lube seepage and is easier to remove from mating surfaces when replacing parts.

1

2

1 - Axle housing

2 - Machined surface

6

Inspection

Inspect Components

Inspect all steel parts for:

•Notches, visible steps or grooves created by wear.

•Pitting or cracking along gear contact lines.

•Scuffing, deformation or discolorations. These are signs of excessive heat in the axle and are usually related to low lubrication levels or improper lubrication practices.

In addition, inspect the following for damage:

•Differential gearing

•Bearings for loose fit on drive pinion, and differential bearings.

•All fasteners for rounded heads, bends, cracks or damaged threads.

•Inspect machined surfaces of cast or malleable parts. They must be free of nicks, burrs, cracks, scoring, and wear.

•Look for elongation of drilled holes, wear on surfaces machined for bearing fits and nicks or burrs in mating surfaces.

Inspect Primary Gearing

Before reusing a primary gear set, inspect teeth for signs of excessive wear. Check tooth contact pattern for evidence of incorrect adjustment.

Inspection

7

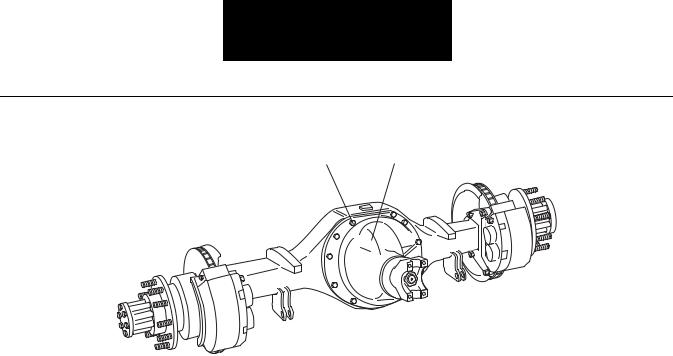

Differential Carrier Assembly

Differential Carrier Assembly

1 |

2 |

1 - Carrier fastener

2 - Carrier assembly

8

Carrier Assembly

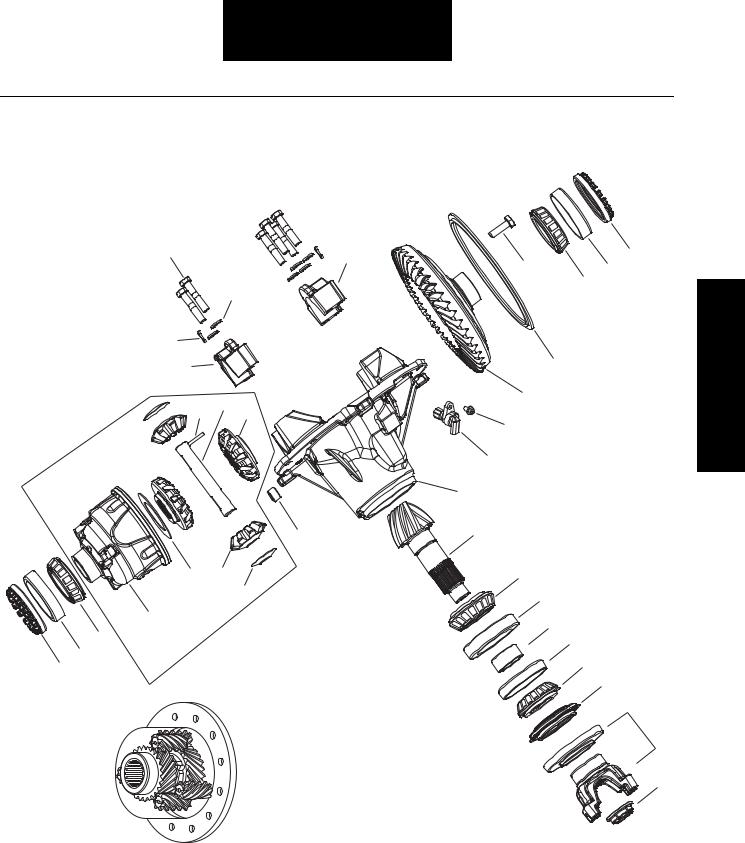

S110 Carrier Assembly

21 |

23 |

|

|

|

22 |

25

24

19

20 18

31

26 17

16

27

28

29

30

32

(Optional Truetrac)

(Optional Truetrac)

15

12 |

14 |

|

13 |

10D

11

10C

10B

10, 10A

(10A includes items 10B, 10C and 10D)

9

8

7

6

5

4

3

2

1

Assembly Carrier

9

Carrier Assembly

1 |

- Pinion Nut |

15 |

- Ring Gear Bearing Adjuster |

2 |

- End Yoke |

16 |

- Side Pinion Thrust Washer |

3 |

- Slinger |

17 |

- Side Pinion |

4 |

- Outer Pinion Bearing Cone |

18 |

- Side Gear |

5 |

- Outer Pinion Bearing Cup |

19 |

- Differential Shaft |

6 |

- Pinion Spacer |

20 |

- Pin |

7 |

- Inner Pinion Bearing Cup |

21 |

- Capscrew |

8 |

- Inner Pinion Bearing Cone |

22 |

- Flat Washer |

9 |

- Drive Pinion |

23 |

- Flanged Half Cap |

10 |

- Carrier Housing |

24 |

- Plain Half Cap |

10A - Carrier Housing Assembly |

25 |

- Cotter Pin |

|

10B - Switch |

26 |

- Side Gear Thrust Washer |

|

10C - Capscrew |

27 |

- Differential Case |

|

10D - Backing Ring |

28 |

- Differential Case Bearing Cone |

|

11 |

- Ring Gear |

29 |

- Differential Bearing Cup |

12 |

- Ring Gear Bolt |

30 |

- Differential Case Bearing Adjuster |

13 |

- Ring Gear Bearing Cone |

31 |

- Pipe Plug |

14 |

- Ring Gear Bearing Cup |

32 |

- Optional Truetrac |

10

Carrier Assembly

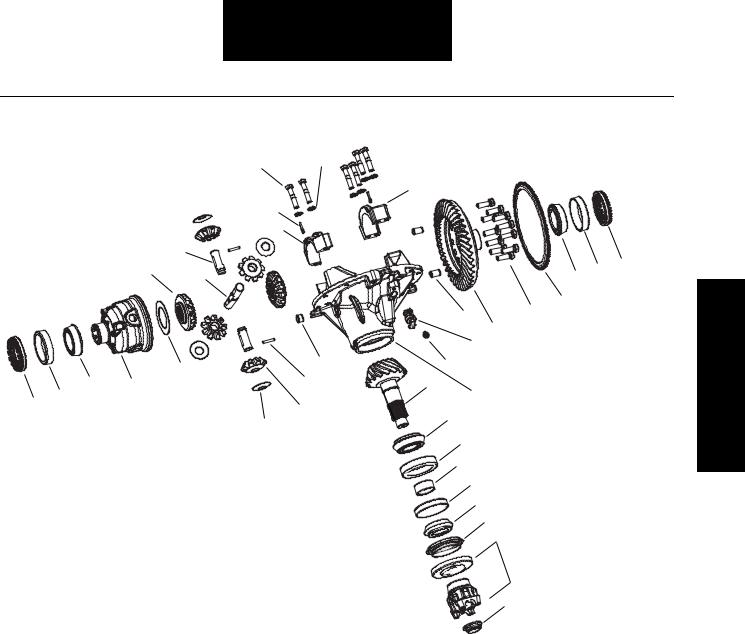

S130 Carrier Assembly

22 23

26

25

20B

19 20A

|

|

27 |

32 |

|

|

21 |

|

29 |

28 |

|

|

|

|

31 |

30 |

|

18 |

||

|

||

|

17 |

24

|

|

14 |

15 |

16 |

|

|

|

||

|

|

|

|

|

11 |

13 |

10D (Optional) |

||

|

|

|

||

12 |

|

|

|

|

|

|

|

|

|

|

10B (Optional) |

|

|

|

10C (Optional) |

|

|

|

|

9

10, 10A (Optional)

(10A includes items 10B, 10C and 10D)

8

7

6

5

4

3

2

1

1 |

- Pinion Nut |

16 |

- Fland Half Bearing Adjuster |

2 |

- End Yoke |

17 |

- Side Pinion Thrust Washer |

3 |

- Slinger |

18 |

- Side Pinion |

4 |

- Outer Pinion Bearing Cone |

19 |

- Side Gear |

5 |

- Outer Pinion Bearing Cup |

20A - Differential Shaft |

|

6 |

- Pinion Spacer |

20B - Differential Stub Shaft |

|

7 |

- Inner Pinion Bearing Cup |

21 |

- Pin |

8 |

- Inner Pinion Bearing Cone |

22 |

- Capscrew |

9 |

- Drive Pinion |

23 |

- Flat Washer |

10 |

- Carrier Housing |

24 |

- Flange Half Cap |

10A - Carrier Housing Assembly |

25 |

- Plain Half Cap |

|

10B - Switch |

26 |

- Cotter Pin |

|

10C - Capscrew |

27 |

- Side Gear Thrust Washer |

|

10D - Backing Ring |

28 |

- Plain Half Diff Case |

|

11 |

- Diff Case Dowels |

29 |

- Plain Half Bearing Cone |

12 |

- Ring Gear |

30 |

- Plain Half Bearing Cup |

13 |

- Ring Gear Bolt |

31 |

- Plain Half Bearing Adjuster |

14 |

- Flange Half Bearing Cone |

32 |

- Pipe Plug |

15 |

- Flange Half Bearing Cup |

33 |

- Optional Truetrac |

Assembly Carrier

11

Differential Carrier Assembly

Remove Differential Carrier

Standard Differentials

1.Block the vehicle.

2.Drain axle lubricant. Remove bottom two (2) capscrews.

3.Disconnect driveline.

4.Remove axle shafts. (If used, remove lock washers and taper dowels.)

WARNING

WARNING

Do not lie under carrier after fasteners are removed. Use transmission jack to support differential carrier assembly prior to loosening fasteners.

CAUTION

CAUTION

Do not strike the shaft head with a steel hammer. Do not use chisels or wedges to loosen shaft or dowels.

5.Remove carrier capscrews and washers.

6.Remove differential carrier assembly.

12

Differential Carrier Assembly

Install Differential Carrier

IMPORTANT

IMPORTANT

Before installing carrier assembly, inspect and thoroughly clean interior of axle housing using an appropriate solvent and clean rag.

1.Apply Spicer approved RTV compound on axle housing mating surface as shown in the illustration. Completely remove all old gasket material prior to applying new material. Compound will set in 20 minutes. Install carrier before compound sets or reapply.

1

1 - Apply RTV gasket in this pattern

TIP: To assist in installing complete differential carrier use two pieces of threaded rod (M14 X 2) threaded into carrier capscrew holes. Rod should be approximately 4" (102 mm) long. Use these to pilot the carrier into the housing.

2.Install carrier to housing, lock washers and capscrews. Torque to proper specification. Torque to 142–158 lbs. ft. (193–214 N•m).

3.Install axle shafts and axle stud nuts.

4.Add axle lubricant. Fill to bottom of filler hole in carrier.

5.Connect main driveline and lubricate joints.

Carrier Differential

yAssembl

13

Differential Carrier Assembly

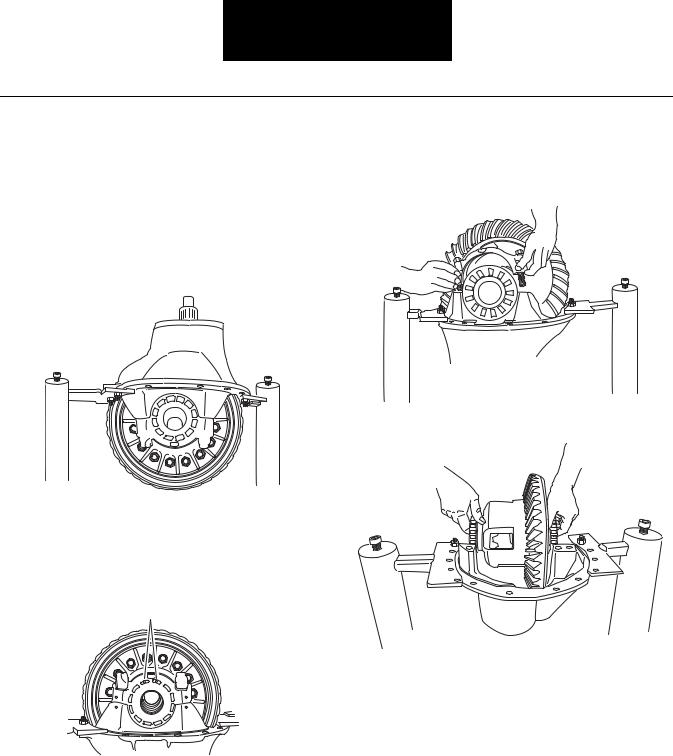

Remove Wheel Differential

Note: Omit this step if the gear set is to be replaced. If gear set is to be reused, check tooth contact pattern and ring gear backlash before disassembling differential carrier. When checking backlash, a yoke must be installed and torqued to get an accurate reading. Best results are obtained when established wear patterns are maintained in used gearing.

1.Mount differential carrier in repair stand.

Note: For easier disassembly, loosen but do not remove pinion (self-locking) nut.

2.Punch mark bearing caps. If reusing gear set, also punch mark bearing adjusters for reference during assembly.

1

3.Remove capscrews and bearing caps. Back off bearing adjusters and remove adjusters and bearing cups.

4.Lift ring gear and differential assembly out of carrier.

1 - Punch Marks

14

Loading...

Loading...