Page 1

AR6400/AR6400L User Guide

Bedienungsanleitung AR6400/AR6400L

Guide de l’utilisateur AR6400/AR6400L

AR6400/AR6400L Guida per l’utente

Page 2

EN

The AR6400/AR6400L 6-channel Ultra-Micro receiver with integrated servos, speed control and

™

technology is designed for Ultra-Micro aircraft. Featuring DSM2™ technology the AR6400/

X-Port

AR6400L is compatible with all Spektrum

transmitters including: Spektrum DX7, DX6i, DX5e, Spektrum Module Systems, JR12X, JRX9303,

E-flite LP5DSM, E-flite HP6DSM, E-flite MLP4DSM and ParkZone’s 2.4GHz DSM2 Transmitter.

Note: The AR6400/AR6400L receiver is not compatible with the DX6 park flyer radio system.

Features

• 6-channel Ultra-Micro receiver

• Two integrated linear servos (elevator and rudder)

• Integrated brushed speed control

• Compatible with external brushless speed controls (optional)

• Weighs just 3.9 grams

• Compatible with optional Spektrum Ultra-Micro linear servos; 1.5-gram

(SPMAS2000) 1.7-gram (SPMAS2000L)

• Smart Bind™ technology

• X-Port allows for future expansion

Applications

The AR6400/AR6400L is designed for Ultra-Micro aircraft and is ideal for scratch-built

ultra-micro projects. The AR6400/AR6400L is designed to utilize a single cell LiPo

battery. Two sizes are available, 3.7V 110mAh (EFLB1101S/PKZ1034) and 3.7V 70mAh

(PKZ3001). An integrated brushed speed controller can be used to power a brushed

motor up to 2 amps of continuous current or an optional brushless controller can be

used. An integrated X-Port feature allows for future expansion.

Note: When X-Port is active, CH5 and CH6 are not available; however, reversed aileron

(CH2) is still available.

AR6400 Specications:

Type: DSM2 Ultra-Micro receiver with integrated brushed speed controller and two linear

servos

Channels: 6 channels or 4 channels plus X-Port

Modulation: DSM2

Dimension (WxLxH): 27.75 x 27.15 x 8.10mm

Weight: 3.9 g

Input Voltage Range: 1-cell LiPo 3.2 to 4.2V

Antenna Length: 31mm

Resolution: 1024

Compatibility: All DSM2 aircraft transmitters

Servos:

Force: 2.8 oz (79 g)

Stroke: 7.4mm

Speed: 0.14 sec

Speed Controller:

Type: Integrated brushed

Max continuous current: 2.0 amps

™

, JR®, E-flite® and ParkZone® 2.4GHz DSM2 technology

Page 3

AR6400L Specications:

Type: DSM2 Ultra-Micro receiver with integrated brushed speed controller and two linear

servos

Channels: 6 channels or 4 channels plus X-Port

Modulation: DSM2

Dimension (WxLxH): 27.75 x 27.15 x 8.10mm

Weight: 3.9 g

Input Voltage Range: 1-cell LiPo 3.2 to 4.2V

Antenna Length: 31mm

Resolution: 1024

Compatibility: All DSM2 aircraft transmitters

Servos:

Force: 2.8 oz (79 g)

Stroke: 9.1mm

Speed: 0.14 sec

Speed Controller:

Type: Integrated brushed

Max continuous current: 2.0 amps

US Patent D578,146. PRC patent ZL 200720069025.2. Other Patents Pending.

AR6400/AR6400L Features and Ports

EN

Antenna

Rudder (CH4)

servo

+ –

ESC Brushless

(signal + – )

– + open

Battery input

Brushed Motor output

(– + open)

Aileron (CH2)

Reversed Aileron (CH2)

or

Aux1 (CH6)

Elevator (CH3)

servo

X-Port (all 4 pins)

OR

Gear (CH5) (lower 3 pins)

Receiver Installation

It is recommended to use double-sided foam tape strips and/or minimal hot glue in the corners to

install your receiver in the fuselage. Note that the servos need to be in the appropriate position to

attach to and drive the elevator and rudder pushrods. Note: Installation will vary depending upon

application.

Page 4

EN

Servos

The AR6400/AR6400L incorporates integrated servos; optional servos are also available through

Spektrum (SPMAS2000/SPMAS2000L). Note that using any other servo may cause damage to the

receiver and/or the servo and may void the warranty.

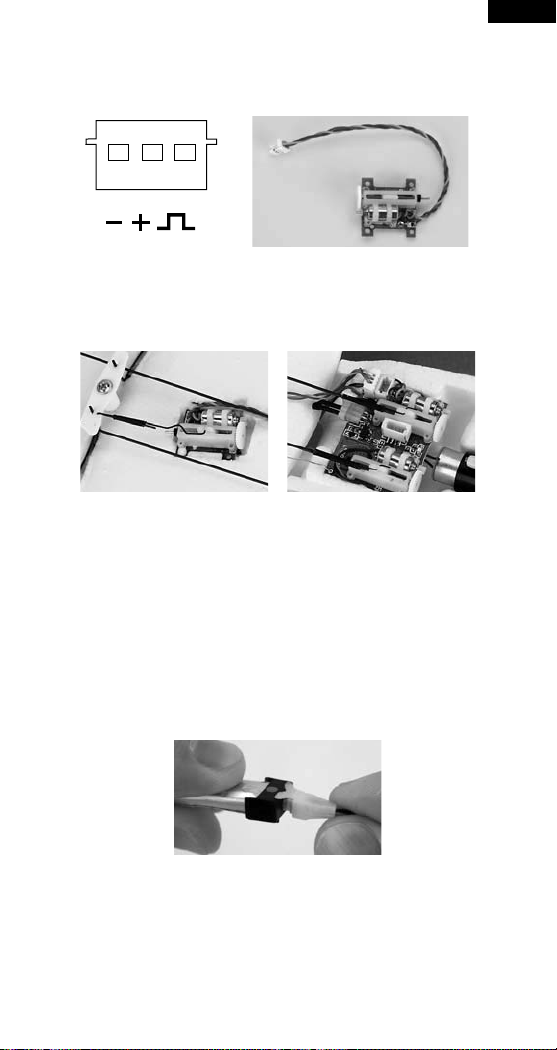

Optional Servo (SPMAS2000/SPMAS2000L)

Installing and Plugging in the Optional Servos

Use double-sided foam tape strips and/or minimal hot glue to mount the servos in place. Note that

the servos need to be in the appropriate position to attach to the corresponding pushrods. Plug the

servo leads into the appropriate servo ports in the receiver noting the polarity of the servo connector.

Note: Installation will vary depending upon application.

™

Smart Bind

The AR6400/AR6400L receiver must be bound to the transmitter before it will operate. Binding is

the process of teaching the receiver the specific code of the transmitter so it will only connect to that

specific transmitter. The AR6400/AR6400L features Smart Bind. When the receiver is first powered,

the receiver will look for the signal of its previously bound transmitter for 5 seconds. If no signal is

found the receiver will automatically go into bind mode indicated by the flashing LED.

Binding

1. Make sure the flight battery is fully charged.

2. Confirm the flight battery is disconnected from the receiver/ESC unit and the transmitter is turned

off.

3. Plug the flight battery into the receiver’s battery connector. After 5 seconds the LED on the receiver

unit will begin flashing indicating it is in bind mode.

4. After verifying the LED is flashing on the receiver, follow the steps necessary that allow your

transmitter to enter bind mode. (See your transmitter’s manual or the supplement on the following

pages.)

Page 5

LED

5. If you entered bind mode correctly, you will see a solid LED within about 10 seconds. You should

now be bound to the transmitter and have full control and function.

IMPORTANT: After Binding

Once the system is bound, the transmitter should always be turned on first and then the receiver to

prevent the receiver from re-entering bind mode. If your receiver inadvertently enters bind mode,

simply unplug the battery from the receiver and reinstall with the transmitter remaining on.

Advanced Programming Features

The following programming features are only recommended for advanced radio users. To safely accomplish

advanced programming feature changes, please enlist the use of a helper. One to hold the aircraft to prevent

unintended flyaways, and one to make the changes on the transmitter. The photos in this section show the

E-flite MLP4DSM transmitter, however, the procedures apply to all compatible transmitters.

Prior to making any advanced programming feature changes it is necessary to:

Computer Radios like the DX6i, DX7

1. Choose an empty model location

2. Select model type ACRO

3. Perform a model reset

4. Set all channels to normal reversing

5. Ensure a successful bind has been established

Note: Please secure the aircraft safely to a work bench or enlist the use of a helper while accessing the

advanced programming features. Mistakes in programming could cause the motor to run unexpectedly.

LP5DSM, HP6DSM

If you decide to use an E-flite LP5DSM or HP6DSM transmitter, please position your channel reversal dip

switches as follows:

EN

LP5DSM Transmitter HP6DSM Transmitter

Note: Keep a record of the existing settings in case you want to go back and fly your other aircraft.

Reversing Servos

Servo reversing may be achieved using the servo reversing function of your transmitter, or as

certain advanced applications require it, you may reverse the actual servos by following the

instructions and diagrams below.

Reversing The Servos on the Receiver Board

This feature reverses the servos at the board level, making it useful for implementing features such as

elevons while using transmitters with limited programming options.

Note: All changes made in advanced programming must start with the receiver powered down to

prevent the motor from running unexpectedly.

Page 6

EN

To safely accomplish advanced programming feature changes, please enlist the use of a helper. One to

hold the aircraft to prevent unintended flyaways, and one to make the changes on the transmitter.

Sticks must be held in this position while the transmitter is on and the receiver is off.

1. Ensure a successful bind was completed

2. Turn transmitter on

3. Move THRO stick to full throttle position

4. Move control sticks to the corresponding position for the servo to be reversed (see illustration)

5. While holding this position, plug the battery into the receiver; power receiver

6. The LED on the receiver will go solid and within 5 seconds the LED will flash 3 times quickly,

indicating servo is now reversed

7. Disconnect battery from receiver

8. Turn transmitter off

Mode 2

CH2

1. Full THRO

2. Down ELEV

3. Left AILE

THRO/RUDD ELEV/AILE

CH3

1. Full THRO

2. Down ELEV

3. Right AILE

THRO/RUDD ELEV/AILE

CH4

1. Full THRO

THRO/RUDD ELEV/AILE ELEV/RUDD THRO/AILE

Reversing Optional 1.5-Gram/1.7-Gram Servo

Reversing the servo is useful when implementing certain installations, such as dual ailerons, flaps,

etc. Spektrum offers a servo reversing lead that can be plugged between the receiver and the optional

servo.

Note: All changes made in advanced programming must start with the receiver powered down to

prevent the motor from running unexpectedly.

To safely accomplish advanced programming feature changes, please enlist the use of a helper. One to

hold the aircraft to prevent unintended flyaways, and one to make the changes on the transmitter.

To reverse servo using the reversing lead:

1. Plug the reversing lead into the servo

2. Plug servo into CH2 or Reversed CH2/CH6 ports

3. Power receiver using a charged battery

4. Once receiver connects, the servo is now reversed

5. Disconnect battery from receiver

6. Remove servo reversing lead (be sure to store your reversing lead in a safe place for future use)

7. Reinstall servo lead into servo port

2. Up ELEV

3. Right AILE

Mode 1

ELEV/RUDD THRO/AILE

ELEV/RUDD THRO/AILE

Page 7

To Change Channel 6 to a Reversed Channel 2 for Dual Ailerons

or Reversed Channel 2 to Channel 6

Note: All changes made in advanced programming must start with the receiver powered down to

prevent the motor from running unexpectedly.

To safely accomplish advanced programming feature changes, please enlist the use of a helper. One to

hold the aircraft to prevent unintended flyaways, and one to make the changes on the transmitter.

Sticks must be held in this position while the transmitter is on and the receiver is off.

1. Ensure a successful bind was completed

2. Turn transmitter on

3. Move THRO stick to full throttle position

4. Move Control sticks to the corresponding position to change between the available options (see

illustration)

5. While holding this position, plug the battery into the receiver; power receiver

6. The LED on the receiver will go solid and within 5 seconds the LED will flash 3 times quickly,

indicating the option is now changed

7. Disconnect flight pack from receiver

8. Turn transmitter off

EN

Mode 2

Rev. CH2/CH6

1. Full THRO

2. Up ELEV

3. Left AILE

THRO/RUDD ELEV/AILE ELEV/RUDD THRO/AILE

To Change the Brushed Motor to Operate an Optional Brushless Motor ESC or

Brushless to Brushed Motor Control

The AR6400/AR6400L is capable of operating brushless motors with the use of an optional brushless

ESC, please see the illustration below for instructions.

Sticks must be held in this position while the transmitter is on and the receiver is off.

1. Ensure a successful bind was completed

2. Turn transmitter on

Move THRO stick to full throttle position (see illustration)

3.

4. Move Control sticks to the corresponding position to change between the available options (see

illustration)

5. While holding this position, plug the battery into the receiver; power receiver

6. The LED on the receiver will go solid and within 5 seconds the LED will flash 3 times quickly,

indicating the option is now changed

7. Disconnect battery from receiver

8. Turn transmitter off

Mode 2

Brushed/

Brushless

1. Full THRO

2. Left RUDD

THRO/RUDD ELEV/AILE ELEV/RUDD THRO/AILE

To Change Channel 5 to X-port or X-port to Channel 5

Note: When X-Port is active, CH5 and CH6 are not available; however, reversed aileron (CH2) is still

available.

Note: All changes made in advanced programming must start with the receiver powered down to

prevent the motor from running unexpectedly.

Mode 1

Mode 1

Page 8

EN

To safely accomplish advanced programming feature changes, please enlist the use of a helper. One to

hold the aircraft to prevent unintended flyaways, and one to make the changes on the transmitter.

Sticks must be held in this position while the transmitter is on and the receiver is off.

1. Ensure a successful bind was completed

2. Plug the X-Port accessory or the optional servo into the X-Port/CH5

3. Turn the transmitter on

THRO

4. Move the

5. Move Control sticks to the corresponding position to change between the available options. (see

illustration)

6. While holding this position, plug the battery into the receiver; power receiver

7. The LED on the receiver will go solid and within 5 seconds the LED will flash 3 times quickly,

indicating the option is now changed

8. Disconnect battery from receiver

9. Turn transmitter off

stick to the full throttle position

Mode 2

Mode 1

CH5/X-port

1. Full THRO

2. Right RUDD

THRO/RUDD ELEV/AILE ELEV/RUDD THRO/AILE

Optional Support Items

PKZ3502 Propeller with Spinner: Sukhoi (160mm x 70mm)

PKZ3516 Motor: Sukhoi (8.5mm diameter, 20mm length)

PKZ3527 Gearbox without Motor: Sukhoi (Gear ratio 4:1)

PKZ3528 Propeller Shaft: Sukhoi

PKZ3302 Propeller with Spinner: Vapor (140mm x 45mm)

PKZ3316 Main Motor: Vapor (6.0mm diameter, 15mm length)

PKZ3327 Gearbox without Motor: Vapor (Gear ratio 6:1)

PKZ3328 Propeller Shaft with Gear (2): Vapor

PKZ1034 110mAh 1S 3.7V LiPo: Sukhoi

PKZ3001 3.7V 70mAh LiPo Battery: Cessna 210, Citabria, Ember/2, Vapor

EFLB1101S 110mAh 1S 3.7V LiPo: Blade mCX

EFLC1003 1S 3.7V LiPo Charger, 0.3A: Blade mCX

EFLC1004 E-flite Celectra 4-Port Charger for 1C 3.7V LiPo Battery Packs

PKZ3240 DC 3.7V LiPo Charger

EFL9051 Prop with Spinner (2): Ultra-Micro 4-Site

EFL9052 Main Motor: Ultra-Micro 4-Site

EFL9053 Gearbox with Motor Shaft: Ultra-Micro 4-Site

EFL9054 Prop Shaft with Gear (2): Ultra-Micro 4-Site

EFLB1501S 1S 3.7V 150mAh LiPo Battery

EFLB1201S 1S 3.7V 120mAh LiPo Battery

Page 9

Transmitter Specic Binding Instructions

DX5e:

1. To bind your AR6400/AR6400L to the DX5e, plug the battery into the receiver. The LED

on the receiver will begin flashing.

2. Move the sticks and switches on the transmitter to the desired failsafe positions (low

throttle and neutral control positions).

3. Pull and hold the Trainer Switch on the transmitter while turning the transmitter on.

Release the trainer switch once the LEDs on the front of the transmitter flash.

4. The LED on the receiver will go solid and the system will connect after several

seconds.

DX6i:

1. To bind your AR6400/AR6400L to the DX6i, plug the battery into the receiver. The LED

on the receiver will begin flashing.

2. Move the sticks and switches on the transmitter to the desired failsafe positions (low

throttle and neutral control positions).

3. Pull and hold the Trainer Switch on the transmitter while turning the transmitter on.

Release the trainer switch once the word BIND flashes on the LCD screen on the front

of the transmitter.

4. The LED on the receiver will go solid and the system will connect after several

seconds.

DX7 (includes DX7se):

1. To bind your AR6400/AR6400L to the DX7, plug the battery into the receiver. The LED

on the receiver will begin flashing.

2. Move the sticks and switches on the transmitter to the desired failsafe positions (low

throttle and neutral control positions).

3. Press the bind button on the back of the transmitter while turning the transmitter on.

The bind button on the back of the transmitter will flash.

Release the button after 2-3 seconds.

4. The LED on the receiver will go solid and the system will connect after several

seconds.

EN

Page 10

EN

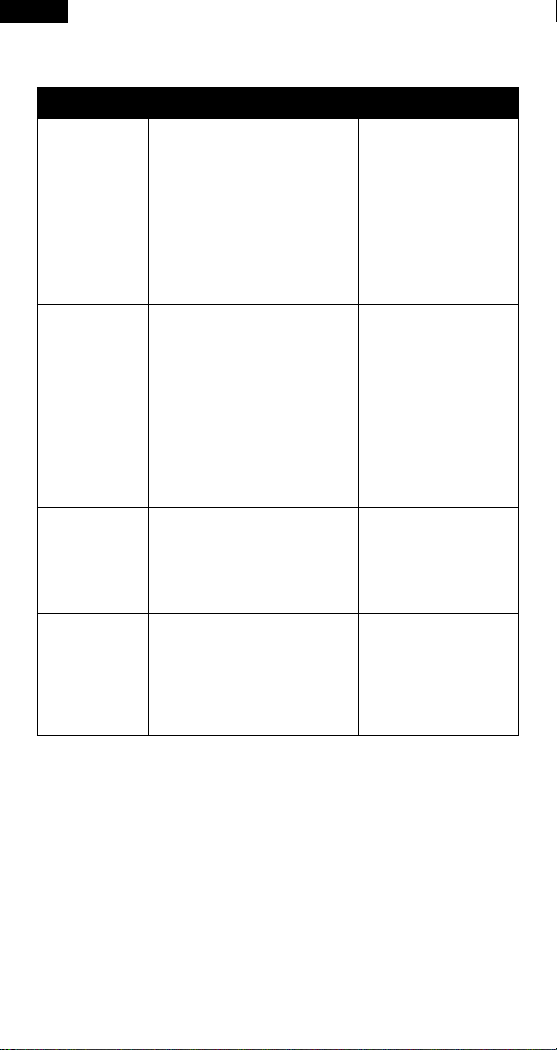

Troubleshooting Guide

Problem Possible Cause Solution

Aircraft will not

“throttle up”

but all other

controls seem

to function.

LED on aircraft

remains flashing

and cannot be

controlled by

transmitter.

Controls appear

to be

reversed after

binding to

a different

transmitter.

Aircraft does not

function after

connecting flight

battery and aircraft

smells burnt.

• User did not lower throttle trim and

throttle stick prior to initializing the

aircraft.

• Throttle channel is reversed.

Note: Futaba transmitters

(equipped with Spektrum modules)

may require you to reverse the

throttle channel.

• Is the Brushed/Brushless option

correctly selected for the power

system?

• User did not wait at least 5 seconds

after powering the transmitter prior

to connecting the flight battery to

the aircraft.

• User bound the aircraft to a different

transmitter.

• Transmitter was too close to

aircraft during the initialization

process.

• User did not initially set up

transmitter prior to binding to the

aircraft.

• User may have accidentally plugged

the flight battery in the wrong

polarity.

• Lower throttle stick and

throttle trim to their lowest

settings.

• Reverse throttle channel

on specific transmitter if

applicable.

• Change to the correct

power system (brushed or

brushless).

• Unplug, then reconnect

flight battery.

• Rebind aircraft to your

desired compatible

transmitter.

• Move transmitter

(powered on) a few feet

from the aircraft prior to

reconnecting the flight

battery.

• See the “Advanced

Programming” section of

this manual.

• Replace AR6400/AR6400L

board

polarity marks are facing

the same direction when

connecting the flight

battery to the AR6400L

board.

and ensure

the RED

Page 11

Tips on Using Spektrum 2.4GHz

ModelMatch™

Some Spektrum and JR transmitters offer a patent pending feature called ModelMatch.

ModelMatch prevents the possibility of operating a model using the wrong model memory,

potentially preventing a crash. With ModelMatch each model memory has its own unique code

(GUID) and during the binding process the code is programmed into the receiver. Later, when the

system is turned on, the receiver will only connect to the transmitter if the corresponding model

memory is programmed on screen.

Note: If at any time you turn on the system and it fails to connect, check to be sure the correct

model memory is selected in the transmitter. Please note that the DX5e and Aircraft Modules do

not have ModelMatch.

Failsafe

Your AR6400/AR6400L features failsafe programming. Failsafe prevents accidental motor

operation before the system connects and, in the unlikely event of signal loss, Failsafe drives the

throttle to a preset (off) position and all other servos to their neutral positions.

While your DSM equipped 2.4GHz system is intuitive to operate, functioning nearly identically to

72MHz systems, following are a few common questions from customers.

1. Q: Sometimes the system takes longer to connect and sometimes it doesn’t connect

at all?

A: In order for the system to connect (after the receiver is bound) the receiver must receive a large

number of consecutive uninterrupted perfect packets from the transmitter. This process is

purposely critical of the environment ensuring that it’s safe to fly when the system does connect.

If the transmitter is too close to the receiver (less than 4 ft) or if the transmitter is located near

metal objects (metal TX case, the bed of a truck, the top of a metal work bench, etc.) connection

will take longer and in some cases connection will not occur as the system is receiving reflected

2.4GHz energy from itself and is interpreting this as unfriendly noise. Moving the system away

from metal objects or moving the transmitter away from the receiver and powering the system

again will cause a connection to occur. This only happens during the initial connection. Once

connected the system is locked-in and should a loss of signal occur (failsafe) the system

connects immediately (4ms) when signal is regained.

2. Q: Sometimes my receiver loses its bind and won’t connect requiring rebinding.

What happens if the bind is lost in ight?

A: The receiver will never lose its bind unless it’s instructed to. It’s important to understand that

during the binding process the receiver not only learns the GUID (code) of the transmitter but

the transmitter learns and stores the type of receiver that it’s bound to. If the transmitter is placed

into bind mode, the transmitter looks for the binding protocol signal from a receiver. If no signal

is present, the transmitter no longer has the correct information to connect to a specific receiver

and in essence the transmitter has been “unbound” from the receiver. We’ve had several DX7

customers that use transmitter stands or trays that unknowingly depress the bind button and the

system is then turned on losing the necessary information to allow the connection to take place.

We’ve also had DX7 customers that didn’t fully understand the range test process and pushed

the bind button before turning on the transmitter also causing the system to “lose its bind.”

EN

Page 12

EN

Warranty Period

Exclusive Warranty- Horizon Hobby, Inc., (Horizon) warranties that the Products purchased (the “Product”)

will be free from defects in materials and workmanship for a period of 1 year from the date of purchase by

the Purchaser.

Limited Warranty

(a) This warranty is limited to the original Purchaser (“Purchaser”) and is not transferable. REPAIR

OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE

PURCHASER. This warranty covers only those Products purchased from an authorized Horizon dealer.

Third party transactions are not covered by this warranty. Proof of purchase is required for warranty claims.

Further, Horizon reserves the right to change or modify this warranty without notice and disclaims all other

warranties, express or implied.

(b) Limitations- HORIZON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE

PRODUCT. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE

PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder shall be that Horizon will, at its option, (i)

repair or (ii) replace, any Product determined by Horizon to be defective. In the event of a defect, these are

the Purchaser’s exclusive remedies. Horizon reserves the right to inspect any and all equipment involved

in a warranty claim. Repair or replacement decisions are at the sole discretion of Horizon. This warranty

does not cover cosmetic damage or damage due to acts of God, accident, misuse, abuse, negligence,

commercial use, or modification of or to any part of the Product. This warranty does not cover damage due

to improper installation, operation, maintenance, or attempted repair by anyone other than Horizon. Return

of any goods by Purchaser must be approved in writing by Horizon before shipment.

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS OF

PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCT,

WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

Further, in no event shall the liability of Horizon exceed the individual price of the Product on which

liability is asserted. As Horizon has no control over use, setup, final assembly, modification or misuse,

no liability shall be assumed nor accepted for any resulting damage or injury. By the act of use, setup or

assembly, the user accepts all resulting liability.

If you as the Purchaser or user are not prepared to accept the liability associated with the use of this

Product, you are advised to return this Product immediately in new and unused condition to the place of

purchase.

Law: These Terms are governed by Illinois law (without regard to conflict of law principals).

Safety Precautions

This is a sophisticated hobby Product and not a toy. It must be operated with caution and common sense

and requires some basic mechanical ability. Failure to operate this Product in a safe and responsible

manner could result in injury or damage to the Product or other property. This Product is not intended

for use by children without direct adult supervision. The Product manual contains instructions for safety,

operation and maintenance. It is essential to read and follow all the instructions and warnings in the

manual, prior to assembly, setup or use, in order to operate correctly and avoid damage or injury.

Questions, Assistance, and Repairs

Your local hobby store and/or place of purchase cannot provide warranty support or repair. Once assembly,

setup or use of the Product has been started, you must contact Horizon directly. This will enable Horizon to

better answer your questions and service you in the event that you may need any assistance. For questions

or assistance, please direct your email to productsupport@horizonhobby.com, or call 877.504.0233 toll

free to speak to the Product Support department.

Inspection or Repairs

If this Product needs to be inspected or repaired, please call for a Return Merchandise Authorization

(RMA). Pack the Product securely using a shipping carton. Please note that original boxes may be

included, but are not designed to withstand the rigors of shipping without additional protection. Ship via a

carrier that provides tracking and insurance for lost or damaged parcels, as Horizon is not responsible for

merchandise until it arrives and is accepted at our facility. A Service Repair Request is available at www.

horizonhobby.com on the “Support” tab. If you do not have internet access, please include a letter with

Page 13

your complete name, street address, email address and phone number where you can be reached during

business days, your RMA number, a list of the included items, method of payment for any non-warranty

expenses and a brief summary of the problem. Your original sales receipt must also be included for

warranty consideration. Be sure your name, address, and RMA number are clearly written on the outside

of the shipping carton.

Warranty Inspection and Repairs

To receive warranty service, you must include your original sales receipt verifying the proof-of-purchase

date. Provided warranty conditions have been met, your Product will be repaired or replaced free of charge.

Repair or replacement decisions are at the sole discretion of Horizon Hobby.

Non-Warranty Repairs

Should your repair not be covered by warranty the repair will be completed and payment will be required

without notification or estimate of the expense unless the expense exceeds 50% of the retail purchase cost.

By submitting the item for repair you are agreeing to payment of the repair without notification. Repair

estimates are available upon request. You must include this request with your repair. Non-warranty repair

estimates will be billed a minimum of ½ hour of labor. In addition you will be billed for return freight.

Please advise us of your preferred method of payment. Horizon accepts money orders and cashiers

checks, as well as Visa, MasterCard, American Express, and Discover cards. If you choose to pay by credit

card, please include your credit card number and expiration date. Any repair left unpaid or unclaimed after

90 days will be considered abandoned and will be disposed of accordingly. Please note: non-warranty

repair is only available on electronics and model engines.

Electronics and engines requiring inspection or repair should be shipped to the following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822 USA

All other Products requiring warranty inspection or repair should be shipped to the following address:

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822 USA

Please call 877-504-0233 or e-mail us at productsupport@horizonhobby.com with any questions or

concerns regarding this product or warranty.

European Union:

Electronics and engines requiring inspection or repair should be shipped to one of the following

addresses:

Please call +44 (0) 1279 641 097 or email sales@horizonhobby.co.uk

with any questions or concerns regarding this product or warranty.

Please call +49 4121 46199 66 or email service@horizonhobby.de

with any questions or concerns regarding this product or warranty.

Please call +33 (0)1 60 47 44 70 or e-mail us at service@horizonhobby.

de with any questions or concerns regarding this product or warranty.

Horizon Hobby UK

Units 1-4 Ployters Rd

Staple Tye, Harlow

Essex CM18 7NS

United Kingdom

Horizon Technischer Service

Hamburger Str. 10

25335 Elmshorn

Germany

Horizon Hobby SAS

14 Rue Gustave Eiffel

Zone d’Activité du Réveil Matin

91230 Montgeron

France

EN

Page 14

EN

FCC Information

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Caution: Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This product contains a radio transmitter with wireless technology which has been tested and found

to be compliant with the applicable regulations governing a radio transmitter in the 2.400GHz to

2.4835GHz frequency range.

Compliance Information for the European Union

Declaration of Conformity

(in accordance with ISO/IEC 17050-1)

No. HH200900821

Product(s): AR6400/AR6400L Receiver

Item Number(s): SPMAR6400/SPMAR6400L

The object of declaration described above is in conformity with the requirements of the specifications listed below, following the provisions of the European R&TTE directive 1999/5/EC:

EN 301 489-1, 301 489-17 General EMC requirements for Radio equipment

Signed for and on behalf of:

Horizon Hobby, Inc.

Champaign, IL USA

Aug 21, 2009

Steven A. Hall

Vice President

International Operations and Risk Management

Horizon Hobby, Inc.

Instructions for Disposal of WEEE by Users in the

European Union

This product must not be disposed of with other waste. Instead, it is the user’s

responsibility to dispose of their waste equipment by handing it over to a

designated collection point for the recycling of waste electrical and electronic

equipment. The separate collection and recycling of your waste equipment at

the time of disposal will help to conserve natural resources and ensure that it is

recycled in a manner that protects human health and the environment. For more

information about where you can drop off your waste equipment for recycling,

please contact your local city office, your household waste disposal service or

where you purchased the product.

Page 15

DE

Bedienungsanleitung AR6400/AR6400L

Der AR6400/AR6400L-6-Kanal-Ultra-Micro-Empfänger mit integrierten Servo-, Motorregler- und

X-Port Techno- logie wurde speziell für Micro-Flugmodelle entwickelt. Durch die DSM2-Technologie

ist der AR6400/AR6400L kompatibel mit allen Spektrum-, E-flite-und ParkZone-Sendern. Das sind

die DSM2-Sender Spektrum DX7, DX6i, DX5e, alle Spektrum-Modul-Systeme, E-flite LP5DSM,

HP6DSM, MLP4DSM und alle ParkZone-Sender.

Achtung: Der AR6400/AR6400L ist nicht kompatibel mit dem DX6 Park-Flyer Sender-System.

Merkmale

• 6-Kanal Ultra-Micro-Empfänger

• Zwei integrierte linear-Servos (Höhen- und Seitenruder)

• Integrierter Motorregler

• Kompatibel mit externen Brushless-Reglern (optional)

• 3,9g Gewicht

• Kompatibel mit 1,5g Spektrum linear-Servos SPMAS2000

• SmartBind-Technologie

• X-Port für zukünftige Erweiterungen

Anwendungen

Der AR6400/AR6400L wurde speziell für Ultra-Micro Flugmodelle entwickelt und ist

ideal für alle Ultra-Micro-Projekte. Der AR6400L ist für den Betrieb mit einzelligen

LiPo-Akkus ausgelegt. Zwei Grössen können verwendet werden, EFLB1101S 3,7V

110mAh, PKZ3001 3,7V 70mAh, und PKZ1034 3,7V 110mAh. Der integrierte BürstenMotorregler kann für Motoren bis 2A verwendet werden, optional ist auch der Einsatz

eines externen Brushless- Reglers möglich. Der integrierte X-Port macht zukünftige

Erweiterungen möglich

Achtung: Wenn der X-Port aktiv ist, dann sind Kanal 5 und 6 nicht verfügbar, Kanal 2 ist

aber weiter aktiv.

AR6400 Technische Daten:

Typ: DSM2 Ultra-Micro-Empfänger mit integriertem Motorregler

(Bürstenmotoren) und zwei linear-Servos

Kanalzahl: 6 Kanäle

Modulation: DSM2

Größe (LxBxH): 27,7mm x 27,1mm x 8,1mm

Gewicht: 3,9g

Eingangsspannung: 1-zelliger LiPo 3,2 – 4,2V

Antennenlänge: 31mm

Auösung: 1024

Kompatibilität: mit allen DSM2 Flug-Sendern und Modulen

Servos:

Gewicht: 79g

Stellweg: 7,4mm

Stellgeschwindigkeit: 0,14 sec

Motorregler:

Typ: integriert für Bürstenmotoren

Belastung A Max.: 2 A

Page 16

DE

AR6400L Technische Daten:

Typ: DSM2 Ultra-Micro-Empfänger mit integriertem Motorregler

(Bürstenmotoren) und zwei linear-Servos

Kanalzahl: 6 Kanäle

Modulation: DSM2

Größe (LxBxH): 27,7mm x 27,1mm x 8,1mm

Gewicht: 3,9g

Eingangsspannung: 1-zelliger LiPo 3,2 – 4,2V

Antennenlänge: 31mm

Auösung: 1024

Kompatibilität: mit allen DSM2 Flug-Sendern und Modulen

Servos:

Gewicht: 79g

Stellweg: 9,1mm

Stellgeschwindigkeit: 0,14 sec

Motorregler:

Typ: integriert für Bürstenmotoren

Belastung A Max.: 2 A

US-Patentnummer D578,146. PRC patentnummer ZL 200720069025.2. Weitere Patente angemeldet.

AR6400/AR6400L Eigenschaften und Anschlüsse

Antenne

Rudder (CH4)

servo

+ –

Brushless-Regleranschluss

(Signal/+/–)

– + frei

Akkuanschluss

Motoranschluss

(–/+/ frei)

Querruder (CH2)

AUX1( 2. Querruder)

Höhenruderservo (CH3)

X-Port (alle 4 pins)

oder

Gear (CH5)

(die unteren 3 pins)

Empfängerinstallation

Benutzen Sie doppelseitiges Klebeband oder ein wenig Heißkleber um den Empfänger im Rumpf

zu fixieren. Achten Sie darauf das die Servos in Neutralstellung sind und die Anlenkungen sich frei

bewegen können.

Page 17

Servos

Der AR6400/AR6400L verfügt über integrierte Servos, Sie können aber noch bis zu 3 Servos

SPMAS200/SPMAS200L einsetzen. Bitte beachten Sie das der Einsatz anderer Servos zu Defekten

des Empfängers oder der Servos führen kann und dadurch die Garantie erlischt.

DE

Installation zusätzlicher Servos

Optional Servo (SPMAS2000/SPMAS2000L)

Benutzen Sie doppelseitiges Klebeband oder ein wenig Heißkleber um die Servos zu befestigen. Bitte

bringen Sie die Servos in die Neutralstellung bevor die Schubstangen ein gehangen werden. Dann

stecken Sie die Servostecker in die Steckplätze am Empfänger. Bitte auf die richtige Polarität achten.

Smart Bind

™

Der AR6400/AR6400L muss mit einem Sender gebunden werden bevor er funktioniert. Beim Binden

wird vom Sender ein spezifischer Code gesendet, der im Empfänger während des Bindeprozesses

gespeichert

wird. Der AR6400/AR6400L besitzt Smart Bind, das heißt das der Empfänger beim einschalten in

den ersten 5 Sekunden nach einem gebundenem Sender sucht. Findet er diesen nicht, geht der

Empfänger in den Bindemodus und zeigt dies durch eine schnell blinkende LED an.

Binden

1. Stellen Sie sicher das der Flugakku voll geladen ist

2. Setzen Sie den Akku ein

3. Verbinden Sie jetzt den Akku und den Empfänger. Nach 5 sec. Fängt die LED am AR6400/AR6400L

an

schnell zu blinken und geht in den Bind-Mode

4. Jetzt können Sie ihren Sender in den Binde-Modus versetzen. Lesen Sie dazu die Anleitung

Ihres Senders.

Page 18

DE

LED

5. Wenn Sie den Bindevorgang erfolgreich abgeschlossen haben, dann leuchtet die LED nach

10 sec. konstant. Jetzt ist der AR6400L gebunden.

Wichtig: nach dem Binden

Wenn das System gebunden ist, schalten Sie erst den Sender und danach den Empfänger ein. Wenn

erst der Empfänger eingeschaltet wird geht der AR6400/AR6400L in den Bindemodus und muss neu

gebunden werden.

Senderprogrammierung

Die Senderprogrammierung sollte von einem erfahrenen Piloten erfolgen. Wenn Sie nicht über

Programmierkenntnisse verfügen, holen Sie sich die Hilfe eines erfahrenen Modellbauers.

Computersender z.B. DX6i, DX7

1. Einen Modellspeicher auswählen

2. Model Typ ACRO einstellen

3. Modell binden

4. Servo-Laufrichtungen einstellen

Achtung: Stellen Sie sicher das das Modell fest auf der Werkbank oder am Boden steht um Verletzun-

gen durch einen anlaufenden Motor zu vermeiden.

LP5DSM, HP6DSM

Wenn Sie einen E-Flite LP5DSM oder HP6DSM verwenden, stellen Sie die Servoreversschalter wie auf

den Bildern unten ein.

LP5DSM Transmitter HP6DSM Transmitter

Achtung: Bitte machen Sie Notizen von den ursprünglichen Einstellungen.

Laufrichtungsumkehr der Servos

Oft ist es nötig die Laufrichtung der Servos umzukehren. Benutzen Sie dafür die Reverse

Funktion

Ihres Senders.

Servoreverse am Empfänger

Diese Option bietet die Möglichkeit die Servolaufrichtung zu ändern, wenn Sender mit begrenzten

Programmier-Optionen verwendet werden.

Achtung: Bitte nehmen Sie alle Einstellungen mit ausgeschaltetem Empfänger vor, um ein unkontrolliertes Anlaufen des Motors zu vermeiden.

Um Fehler bei der Programmierung zu vermeiden nehmen Sie bitte die Hilfe eines erfahrenem

Modellbauers in Anspruch.

Page 19

Die Knüppel müßen in die folgenden Positionen gebracht werden bei eingeschaltetem

Sender und abgeschaltetem Empfänger.

1. Stellen Sie sicher das der Bindevorgang abgeschlossen ist.

2. Schalten Sie den Sender ein

3. Bewegen Sie den Gas-Knüppel nach oben

4. Bringen Sie den Knüppel mit der umzukehrenden Funktion in die beschriebenen Positionen

5. Halten Sie diese Position und stecken den Akku an den Empfänger

6. Die Empfänger-LED leuchtet jetzt konstant für 5sec danach blinkt die LED 3 mal schnell und

zeigt damit an das die Funktion umgekehrt ist.

7. Entfernen Sie den Flugakku

8. Schalten Sie den Sender aus

Mode 2

CH2

1. Gas Voll

Höhe nach unten

2.

3.

Querruder

Gas/Seite Höhe/Querruder

Gas/Seite Höhe/Querruder

Gas/Seite Höhe/Querruder Höhe/Seite Gas/Querruder

Umkehr des optionalen 1,5g/1,7g-Servos,

Die Laufrichtung eines Servos umzustellen ist oft nötig, wenn der Einbau es nicht anders zulässt, z.B.

bei Verwendung von zwei Querruderservos. Spektrum bietet hierfür die Möglichkeit die Laufrichtung

des Servos umzukehren wenn es am Empfänger angeschlossen ist.

Achtung: Alle Einstellungen und Programmierungen müßen mit abgeschaltetem Empfänger

begonnen werden.

Um die Laufrichtung zu ändern benutzen Sie bitte das Reverse-Kabel:

1. Schliessen Sie das Reversekabel am Servo an

2. Schliessen Sie nun das Kabel an CH2, oder CH2/CH6 an

3. Schalten Sie den Empfänger ein, benutzen Sie einen vollen Akku

4. Wenn der Empfänger eingeschaltet ist, ist jetzt die Laufrichtung umgekehrt

5. Entfernen Sie den Flugakku

6. Entfernen Sie das Reverse-Kabel

7. Stecken Sie das Servokabel an den zugehörigen Steckplatz

links

CH3

1. Gas Voll

Höhe nach unten

2.

3.

Querruder

rechts

CH4

1. Gas Voll

Höhe nach oben

2.

3.

Querruder

rechts

Höhe/Seite Gas/Querruder

Höhe/Seite Gas/Querruder

Mode 1

DE

Page 20

DE

Wechsel von CH6 zu reversed CH2 für zwei Querruderservos

Achtung: Alle Änderungen in der Programmierung nur bei ausgeschaltetem Empfänger durchführen

Die Steuerknüppel müssen in folgenden Positionen gehalten werden wenn der Sender

angeschaltet ist und der Empfänger ausgeschaltet ist.

1. Stellen Sie sicher das der Bindevorgang komplett ist.

2. Schalten Sie den Sender ein

3. Stellen Sie den Gashebel auf Vollgas

4. Bewegen Sie nun die Steuerhebel in die abgebildeten Positionen

5. Halten Sie diese Positionen und schalten jetzt den Empfänger ein

6. Die LED am Empfänger lechtet für 5sec konstant und bestätigt die Eingabe mit 3 mal blinken

7. Ziehen Sie den Flugakku ab

8. Schalten Sie den Sender aus

Mode 2

Rev. CH2/CH6

1. Gas Voll

2. Höhe nach oben

3. Querruder links

Gas/Seite Höhe/Querruder Höhe/Seite Gas/Querruder

Wechsel von Bürsten-Motor-Mode in Brushless-Regler-Mode

Der AR6400/AR6400L ist für den Betrieb mit Brushless-Motoren und dazu gehörigen Reglern

ausgelegt.

Die Steuerknüppel müssen in folgenden Positionen gehalten werden wenn der Sender

angeschaltet ist und der Empfänger ausgeschaltet ist.

1. Stellen Sie sicher das der Bindevorgang vollständig ist

2. Schalten Sie den Sender ein

Bewegen Sie den Gashebel nach oben

3.

4. Bewegen Sie die Hebel in die abgebildeten Positionen

5. Halten Sie diese Positionen und schalten jetzt den Empfänger ein

6. Die LED am Empfänger leuchtet nun für 5sec, danach blinkt die LED 3 mal und zeigt an, das

der Mode geändert wurde

7. Schalten Sie den Empfänger ab

8. Schalten Sie den Sender ab

Mode 2

Brushed/

Brushless

1. Gas Voll

2. Seite links

Gas/Seite Höhe/Querruder Höhe/Seite Gas/Querruder

Mode 1

Mode 1

Wechsel von CH5 in X-Port oder X-Port in CH5

Achtung: Wenn der X-Port aktiv ist sind CH5 und CH6 nicht mehr verfügbar, Doppelquerruder sind

noch verfügbar.

Die Steuerknüppel müssen in folgenden Positionen gehalten werden wenn der Sender

angeschaltet ist und der Empfänger ausgeschaltet ist.

1. Stellen Sie sicher das der Bindevorgang vollständig ist

2. Stecken Sie das X-Port-Modul an den Steckplatz für X-Port/CH5

3. Schalten Sie den Sender ein

4. Bewegen Sie den Gashebel nach oben

5. Bewegen Sie die Hebel in die abgebildeten Positionen

6. Halten Sie diese Positionen und schalten jetzt den Empfänger ein

7. Die LED am Empfänger leuchtet nun für 5sec, danach blinkt die LED 3 mal und zeigt an, das der

Page 21

mode geändert wurde

8. Schalten Sie den Empfänger ab

9. Schalten Sie den Sender ab

DE

Mode 2

Mode 1

CH5/X-port

1. Gas Voll

2. Seite rechts

Gas/Seite Höhe/Querruder Höhe/Seite Gas/Querruder

Optionales Zubehör:

PKZ3502 Propeller mit Spinner: Sukhoi (160mm x 70mm)

PKZ3516 Motor: Sukhoi

PKZ3527 Getriebesatz ohne Motor: Sukhoi

PKZ3528 Propellerwelle: Sukhoi

PKZ3302 Propeller mit Spinner: Vapor (140mm x 45mm)

PKZ3316 Motor: Vapor

PKZ3327 Getriebesatz ohne Motor: Vapor

PKZ3328 Propellerwelle (2): Vapor

PKZ1034 110mAh 1S 3,7V LiPo: Sukhoi

PKZ3001 70mAh 1S 3,7V LiPo: Ember/2, Vapor

EFLB1101S 110mAh 1S 3,7V LiPo: Blade mCX

EFLC1003 1S 3,7V LiPo Charger, 0,3A: Blade mCX

EFLC1004 E-flite Celectra 4-Port Charger für 1C 3,7V LiPo Akku

PKZ3240 DC 3,7V LiPo Charger

EFL9051 Propeller mit Spinner (2): Ultra-Micro 4-Site

EFL9052 Motor: Ultra-Micro 4-Site

EFL9053 Getriebe: Ultra-Micro 4-Site

EFL9054 Propellerwelle (2): Ultra-Micro 4-Site

EFLB1501S 1S 3,7V 150mAh LiPo Akku

EFLB1201S 1S 3,7V 120mAh LiPo Akku

Page 22

DE

Anleitung zum Binden von Spektrum Sendern

DX5e:

1. Den Akku mit dem AR6400/AR6400L verbinden. Die LED am Empfänger beginnt schnell

zu blinken.

2. Bringen Sie alle Steuerknüppel in ihre Fail-Safe-Positionen (Gas unten, alles andere

auf mitte)

3. Den Trainerschalter ziehen und halten, dann den Sender einschalten. Dabei beginnt die

LED am Sender zu blinken.

4. Wenn die LED am Empfänger aufhört zu blinken, ist der Bindevorgang beendet und das

System ist betriebsbereit.

DX6i:

1. Den Akku mit dem AR6400/AR6400L verbinden. Die LED am Empfänger beginnt schnell

zu blinken.

2. Bringen Sie alle Steuerknüppel in ihre Fail-Safe-Positionen (Gas unten, alles andere

auf mitte)

3. Den Trainerschalter ziehen und halten, dann den Sender einschalten. Dabei beginnt im

Display das Wort „BIND“ zu blinken.

4. Wenn die LED am Empfänger aufhört zu blinken, ist der Bindevorgang beendet und das

System ist betriebsbereit.

DX7 (includes DX7se):

1. Den Akku mit dem AR6400/AR6400L verbinden. Die LED am Empfänger beginnt schnell

zu blinken.

2. Bringen Sie alle Steuerknüppel in ihre Fail-Safe-Positionen (Gas unten, alles andere

auf mitte)

3. Drücken Sie die Bind Taste an der Rückseite des Senders und halten Sie diese. Jetzt

schalten Sie den Sender ein und warten 2-3sec.

4. Wenn die LED am Empfänger aufhört zu blinken, ist der Bindevorgang beendet und das

System ist betriebsbereit.

Page 23

Problemlösungen

Problem Ursache Lösung

Die Drehzahl lässt

sich

nicht

herunterregeln.

Alle anderen

Funktionen

laufen normal

LED beginnt zu

blinken, Servos

sind nicht

Steuerbar

Die

Steuerfunktionen

laufen falsch herum

nach dem Binden

mit einem anderen

Sender

Der Empfänger hat

keine Funktion

und riecht

verbrannt

• Die Gas-Trimmung ist nicht in der

unteren Position

• Gas-Kanal läuft falsch herum

(Bei Futaba Sendern mit Spektrum-

Modul Muss der Gas-Kanal reversed

werden)

• Ist die Brushed/Brushless-Option

richtig Eingestellt?

• Sie haben direkt nach einschalten

des Senders den Empfänger

eingeschaltet (min 5sec warten)

• Sie haben den Empfänger mit einem

Anderen Sender gebunden

• Der Sender war beim Einschalten zu

dicht am Sender

• Die richtigen Sendereinstellungen

wurden beim Einschalten vergessen

einzustellen

• Das Anschlusskabel wurde falsch

herum am Akku angeschlossen.

• Bringen Sie den Gas

Knüppel und die

Gastrimmung in die

unteren Positionen

• Laufrichtung Gas Kanal

umkehren

• Die richtige Option

einstellen

• Abschalten und wieder

einschalten des Senders

• Erneut mit dem

verwendetem Sender

binden

• Halten Sie beim

einschalten einen Abstand

von 30cm ein

• Bitte sehen Sie dazu unter

dem Punkt „Senderprogrammierung“ nach

• Den AR6400/AR6400L

ausbauen und die roten

Markierungen kontrollieren

die am Stecker und am

Akku sind

DE

Page 24

DE

Tips zum Umgang mit Spektrum 2,4GHz

ModelMatch™

Einige unserer Spektrum-Sender besitzen ModelMatch. Dies verhindert, das man ein Modell mit

dem falschen Speicherplatz im Sender betreiben kann. Bei ModelMatch besitzt jedes Modell einen

individu- ellen Code (GUID), der beim Binden an den Empfänger übermittelt wird. Nach dem

Binden funktioniert der Empfänger nur mit diesem Modellspeicherplatz.

Achtung: Wenn der Empfänger eingeschaltet wird und kein Verbindung vorhanden ist, prüfen

Sie bitte den Modellspeicherplatz im Sender. Bitte beachten Sie, das die DX5e und alle Module

nicht über ModelMatch verfügen.

Failsafe

Der AR6400/AR6400L besitzt eine FailSafe Programmierung. Dies verhindert ein Anlaufen des

Motors bevor eine Verbindung zum Sender hergestellt ist. Im Fall eines Signalverlustes wird der

Motor abgeschaltet und alle Servos in ihre neutral-Positionen gestellt.

Im folgenden die am meisten gestellten Fragen zum Thema 2,4GHz:

1. Warum braucht das System manchmal länger um die Verbindung herzustellen, und

warum kommt keine Verbindung zustande?

Beim Einschalten des Systems muss der Empfänger eine Reihe von unbeschädigten Da tenpaketen

empfangen um eine Verbindung herstellen zu können. Dieser Prozess ist sehr wichtig um eine

sichere Verbindung zu erhalten. Wenn der Sender zu nah am Empfänger ist, oder der Sender

sich in der Nähe von metallischen Objekten befindet kann der Aufbau der Verbindung länger

dauern. Auch kommt es vor das die 2,4Ghz-Energie durch sich selbst reflektiert wird und der

Verbindungsaufbau etwas länger dauert. Halten Sie daher den Sender und den Empfänger fern von

metallischen Objekten und halten Sie einen gewissen Abstand von Sender und Empfänger ein.

Wenn sich das System eingeloggt hat und das Signal trotzdem verloren geht, dann benötigt das

System ca. 4ms, um sich bei wiederfinden des Signals, wieder zu aktivieren.

2. Manchmal verliert mein Empfänger die Bindung und muss neu gebunden werden.

Was ist wenn die Verbindung im Flug verloren geht?

Der Empfänger kann die Bindung nicht verlieren. Während des Bind-Prozesses lernt nicht

der Emfänger den GUID (Code), sondern der Sender speichert denTyp des Empfängers beim

Binden. Wenn der Sender in den Bind-Mode versetzt wird, sucht er nach einem Signal von einem

Empfänger. Wenn der Sender kein Signal erkennt wird der Bind-Prozess abgebrochen und der

Sender bleibt ungebunden.

Wir haben DX7-Besitzer, die unwissentlich die Bind-Taste währen des Betriebs drücken und der

Sender im Betrieb in den Bind-Mode geht und alle Bind-Infos gelöscht werden. Wir haben ebenso

DX7-Kunden, die den Range-Test nicht richtig benutzen und beim Einschalten die Bind-Taste

drücken und dabei den Bind-Mode aktivieren. Dabei werden alle Bind-Infos auf dem Speicherplatz

gelöscht und die Bindung geht verloren.

Page 25

Garantiezeitraum

Exklusive Garantie – Horizon Hobby Inc (Horizon) garantiert, dass das gekaufte Produkt (Produkt) frei

von Material- und Montagefehlern ist. Der Garantiezeitraum entspricht den gesetzlichen Bestimmung des

Landes, in dem das Produkt erworben wurde. In Deutschland beträgt der Garantiezeitraum 6 Monate und

der Gewährleistungszeitraum 18 Monate nach dem Garantiezeitraum.

Garantieeinschränkungen

(a) Die Garantie wird nur dem Erstkäufer (Käufer) gewährt und kann nicht übertragen werden. Der

Anspruch des Käufers besteht in der Reparatur oder dem Tausch im Rahmen dieser Garantie. Die

Garantie erstreckt sich ausschließlich auf Produkte, die bei einem autorisierten Horizon Händler erworben

wurden. Verkäufe an dritte werden von dieser Garantie nicht gedeckt. Garantieansprüche werden nur

angenommen, wenn ein gültiger Kaufnachweis erbracht wird. Horizon behält sich das Recht vor, diese

Garantiebestimmungen ohne Ankündigung zu ändern oder modifizieren und widerruft dann bestehende

Garantiebestimmungen.

(b) Horizon übernimmt keine Garantie für die Verkaufbarkeit des Produktes, die Fähigkeiten und die

Fitness des Verbrauchers für einen bestimmten Einsatzzweck des Produktes. Der Käufer allein ist dafür

verantwortlich, zu prüfen, ob das Produkt seinen Fähigkeiten und dem vorgesehenen Einsatzzweck

entspricht.

(c) Ansprüche des Käufers – Es liegt ausschließlich im Ermessen von Horizon, ob das Produkt, bei dem

ein Garantiefall festgestellt wurde, repariert oder ausgetauscht wird. Dies sind die exklusiven Ansprüche

des Käufers, wenn ein Defekt festgestellt wird.

Horizon behält sich vor, alle eingesetzten Komponenten zu prüfen, die in den Garantiefall einbezogen

werden können. Die Entscheidung zur Reparatur oder zum Austausch liegt nur bei Horizon. Die Garantie

schließt kosmetische Defekte oder Defekte, hervorgerufen durch höhere Gewalt, falsche Behandlung des

Produktes, falscher Einsatz des Produktes, kommerziellen Einsatz oder Modifikationen irgendwelcher Art

aus. Die Garantie deckt Schäden, die durch falschen Einbau, falsche Handhabung, Unfälle, Betrieb, Service

oder Reparaturversuche, die nicht von Horizon ausgeführt wurden, aus. Rücksendungen durch den Käufer

direkt an Horizon oder eine seiner Landesvertretung bedürfen der schriftlichen Genehmigung von Horizon.

Schadensbeschränkung

HORIZON IST NICHT FÜR DIREKTE ODER INDIREKTE FOLGESCHÄDEN, EINKOMMENSAUSFÄLLE ODER

KOMMERZIELLE VERLUSTE, DIE IN IRGENDEINEM ZUSAMMENHANG MIT DEM PRODUKT STEHEN

NICHT VERANTWORTLICH, UNABHÄNGIG AB EIN ANSPRUCH IM ZUSAMMENHANG MIT EINEM

VERTRAG, DER GARANTIE ODER DER GEWÄHRLEISTUNG ERHOBEN WERDEN. Horizon wir darüber

hinaus keine Ansprüche aus einem Garantiefall akzeptieren, die über den individuellen Wert des Produktes

hinaus gehen. Horizon hat keine Einfluss auf den Einbau, die Verwendung oder die Wartung des Produktes

oder etwaiger Produktkombinationen, die vom Käufer gewählt werden. Horizon übernimmt keine Garantie

und akzeptiert keine Ansprüche für in der folge auftretende Verletzungen oder Beschädigungen. Mit der

Verwendung und dem Einbau des Produktes akzeptiert der Käufer alle aufgeführten Garantiebestimmungen

ohne Einschränkungen und Vorbehalte. Wenn Sie als Käufer nicht bereit sind, diese Bestimmungen im

Zusammenhang mit der Benutzung des Produktes zu akzeptieren, werden Sie gebeten, dass Produkt in

unbenutztem Zustand in der Originalverpackung vollständig bei dem Verkäufer zurückzugeben.

Sicherheitshinweise

Dieses ist ein hochwertiges Hobby Produkt und kein Spielzeug. Es muss mit Vorsicht und Umsicht

eingesetzt werden und erfordert einige mechanische wie auch mentale Fähigkeiten. Ein Versagen, das

Produkt sicher und umsichtig zu betreiben kann zu Verletzungen von Lebewesen und Sachbeschädigungen

erheblichen Ausmaßes führen. Dieses Produkt ist nicht für den Gebrauch durch Kinder ohne die Aufsicht

eines Erziehungsberechtigten vorgesehen. Die Anleitung enthält Sicherheitshinweise und –vorschriften

sowie Hinweise für die Wartung und den Betrieb des Produktes. Es ist unabdingbar, diese Hinweise vor der

ersten Inbetriebnahme zu lesen und zu verstehen. Nur so kann der falsche Umgang verhindert und Unfälle

mit Verletzungen und Beschädigungen vermieden werden.

Frage, Hilfe, Reparaturen

Ihr lokaler Fachhändler und die Verkaufstelle können eine Garantiebeurteilung ohne Rücksprache mit

Horizon nicht durchführen. Dies gilt auch für Garantiereparaturen. Deshalb kontaktieren Sie in einem

solchen Fall den Händler, der sich mit Horizon kurz schließen wird, um eine sachgerechte Entscheidung

zu fällen, die Ihnen schnellst möglich hilft. Sollten Sie Fragen haben oder weitergehende technische Hilfe

brauchen, können Sie sich von Deutschland und Österreich an Horizon unter service@horizonhobby.

de wenden oder das Servicetelefon +49 4121 4619966 anrufen. Wir werden alles tun, um Ihre Fragen

kompetent zu beantworten.

DE

Page 26

DE

Wartung & Reparatur

Muss Ihr Produkt gewartet oder repariert werden, wenden Sie sich entweder an Ihren Fachhändler

oder direkt an Horizon. Packen Sie das Produkt sorgfältig ein. Beachten Sie, dass der Originalkarton

in der Regel nicht ausreicht, um beim Versand nicht beschädigt zu werden. Verwenden Sie einen

Paketdienstleister mit einer Tracking Funktion und Versicherung, da Horizon bis zur Annahme keine

Verantwortung für den Versand des Produktes übernimmt. Bitte legen Sie dem Produkt einen Kaufbeleg

bei, sowie eine ausführliche Fehlerbeschreibung und eine Liste aller eingesendeten Einzelkomponenten.

Weiterhin benötigen wir die vollständige Adresse, eine Telefonnummer für Rückfragen, sowie eine Email

Adresse.

Garantie und Reparaturen

Garantieanfragen werden nur bearbeitet, wenn ein Originalkaufbeleg von einem autorisierten Fachhändler

beiliegt, aus dem der Käufer und das Kaufdatum hervorgeht. Sollte sich ein Garntiefall bestätigen wird das

Produkt repariert oder ersetzt. Diese Entscheidung obliegt einzig Horizon Hobby.

Kostenpichtige Reparaturen

Liegt eine kostenpflichtige Reparatur vor, erstellen wir einen Kostenvoranschlag, den wir Ihrem

Händler übermitteln. Die Reparatur wird erst vorgenommen, wenn wir die Freigabe des Händlers

erhalten. Der Preis für die Reparatur ist bei Ihrem Händler zu entrichten. Bei kostenpflichtigen

Reparaturen werden mindestens 30 Minuten Werkstattzeit und die Rückversandkosten in Rechnung

gestellt. Sollten wir nach 90 Tagen keine Einverständniserklärung zur Reparatur vorliegen

haben, behalten wir uns vor, das Produkt zu vernichten oder anderweitig zu verwerten. Achtung:

Kostenpflichtige Reparaturen nehmen wir nur für Elektronik und Motoren vor. Mechanische

Reparaturen, besonders bei Hubschraubern und RC-Cars sind extrem aufwendig und müssen

deshalb vom Käufer selbst vorgenommen werden.

Serviceadresse:

Europäische Union:

Elektronik und Motoren müssen regelmäßig geprüft und gewartet werden.

Für Servicezwecke sollten die Produkt an die folgende Adresse gesendet werden:

Horizon Technischer Service

Hamburger Str. 10

25335 Elmshorn

Germany

Bitte rufen Sie +49 4121 46199 66 an oder schreiben Sie uns ein Email

anservice@horizonhobby.de um jede mögliche Frage zum Produkt oder

derGarantieabwicklung zu stellen.

Page 27

Entsorgungsrichtlinien in der Europäischen Union

Konformitätserklärung

DE

Konformitätserklärung gemäß Gesetz über Funkanlagen und Telekomunikationseinrichtungen (FTEG) und der

Declaration of conformity in accordance with the Radio and Telecommunications Terminal Equipment Act (FETG) and directive 1999/5/EG

Horizon Hobby Deutschland GmbH

Hamburger Straße 10

D-25335 Elmshorn

erklärt das Produkt:

declares the product:

Geräteklasse:

equipment class

den grundlegenden Anforderungen des §3 und den übrigen einschlägigen Bestimmungen des FTEG (Artikel 3 der R&TTE) entspricht.

complies with the essential requirments of §3 and other relevant provisions of the FTEG (Article 3 of the R&TTE directive).

Angewendete harmonisierte Normen:

Harmonised standards applied:

EN 301 489-1 V1.6.1

EN 301 489-17 V1.2.1

CE

Elmshorn, 01.08.2009

________________________

Jörg Schamuhn

Geschäfstführer

Managing Director

Es gelten unsere allgemeinen Geschäftsbedingungen, die in unseren Geschäftsräumen eingesehen werden können. Ware bleibt bis zur vollständigen Bezahlung Eigentum der

Tel.: +49 4121 4619960 • Fax: +49 4121 4619970 eMail: info@horizonhobby. de; Internet: www.horizonhobby.de

Richtlinie 1999/5/EG (R&TTE)

(R&TTE)

AR6400, AR6400L

Spektrum

SPMAR6400, SPMAR6400L

1

Schutzanforderungen in Bezug auf elektromagnetische Verträglichkeit

§3 (1) 2, (Artikel 3 (1) b))

Protection requirement concerning electromagnetic compatibility

§3 (1) 2, (article 3 (1)b))

_______________________________

Birgit Schamuhn

Geschäftsführerin

Managing Director

Horizon Hobby Deutschland GmbH; Hamburger Str. 10; D-25337 Elmshorn

HR Pi: HRB 1909; UStIDNr.:DE812678792; Str.Nr.: 1829812324

Geschäftsführer Jörg & Birgit Schamuhn, Uffe Kloster

Horizon Hobby Deutschland GmbH

Richtlinie für die Entsorgung von Elektro- und

Elektronikalt- bzw. Schrottgeräten in der EU

Dieses Produkt muss getrennt entsorgt werden. Es ist bestehende Nutzerpflicht,

Elektro- und Elek- tronikalt-bzw. Schrottgeräte an den dafür vorgesehenen Sammelstellen abzugeben. Eine getrennte Entsorgung und evtl. Wiederaufbereitung

dieser Produkte trägt zum Umweltschutz und zum sparsamen Umgang mit natür-

lichen Ressourcen bei und kann zur Zukunft einer intakten Umwelt beitragen. Für

weitere Informationen zur Abgabe Ihres Altgerätes wenden Sie sich bitte an den

zuständigen Recyclinghof, die zuständige Gemeinde-/Stadtverwaltung oder an Ihren

Händler.

Page 28

FR

Guide de l’utilisateur - AR6400/AR6400L

Le récepteur 6 voies AR6400/AR6400L Ultra-Micro à servos intégrés, contrôleur de vitesse et à

technologie X-Port

l'AR6400/AR6400L est compatible avec tous les émetteurs Spektrum

™

a été conçu pour les aéronefs Ultra-Micro. Equipé de la technologie DSM2™,

™

, JR®, E-flite® et ParkZone® à

technologie 2,4GHz DSM2, y compris les émetteurs suivants : Spektrum DX7, DX6i, DX5e, systèmes

modulaires Spektrum, JR12X, JRX9303, E-flite LP5DSM, E-flite HP6DSM, E-flite MLP4DSM ainsi

que l'émetteur ParkZone 2,4GHz DSM2.

Nota : le récepteur AR6400/AR6400L n'est pas compatible avec le système de radio DX6 parkflyer.

Caractéristiques

• Récepteur Ultra Micro 6 voies

• Deux servos linéaires intégrés (gouverne de profondeur et gouvernail)

• Contrôleur de vitesse intégré pour moteurs à charbons (brushed)

• Compatible avec des contrôleurs de vitesse externes brushless (en option)

• Ne pèse que 3,9 grammes

• Compatible avec les servos linéaires optionnels Spektrum Ultra-Micro ;

1,5 grammes (SPMAS2000) 1,7 grammes (SPMAS2000L)

• Technologie Smart Bind™

• Le X-Port permet des extensions futures

Applications

L'AR6400/AR6400L a été conçu pour les aéronefs Ultra-Micro et est idéal pour les

projets ultra-micro construits en partant de rien. L'AR6400/AR6400L a été conçu

pour utiliser une batterie LiPo 1 élément. Deux tailles sont disponibles : 3,7 V 110

mAh (EFLB1101S/PKZ1034) et 3,7 V 70 mAh (PKZ3001). Il est possible d'utiliser un

contrôleur de vitesse intégré brushed pour alimenter un moteur à charbons (brushed)

jusqu'à 2 ampères de courant continu ou d'utiliser un contrôleur brushless optionnel.

L'équipement X-Port intégré permet des extensions futures.

Nota : Lorsque le X-Port est actif, les canaux CH5 et CH6 ne sont pas disponibles ;

l'aileron inversé (CH2) reste néanmoins disponible.

Spécications - AR6400 :

Type : récepteur DSM2 Ultra-Micro à contrôle de vitesse intégré pour moteurs à charbons

(brushed) et deux servos linéaires

Canaux : 6 voies ou 4 voies et un X-Port

Modulation : DSM2

Dimensions (l x L x h) : 27,75 x 27,15 x 8,10 mm

Poids : 3,9 g

Gamme de tension d’entrée : batterie 1 élément LiPo 3,2 à 4,2 V

Longueur de l’antenne : 31mm

Résolution : 1024

Compatibilité : tous les émetteurs pour aéronefs DSM2

Servos :

Force : 2,8 onces (79 g)

Course : 7,4 mm

Vitesse : 0,14 sec

Contrôleur de vitesse :

Type : intégré, brushed = moteurs à charbons

Courant continu maxi : 2,0 ampères

Page 29

Spécications - AR6400L :

Type : récepteur DSM2 Ultra-Micro à contrôle de vitesse intégré pour moteurs à charbons

(brushed) et deux servos linéaires

Canaux : 6 voies ou 4 voies et un X-Port

Modulation : DSM2

Dimensions (l x L x h) : 27,75 x 27,15 x 8,10 mm

Poids : 3,9 g

Gamme de tension d'entrée : batterie 1 élément LiPo 3,2 à 4,2 V

Longueur de l'antenne : 31mm

Résolution : 1024

Compatibilité : tous les émetteurs pour aéronefs DSM2

Servos :

Force : 2,8 onces (79 g)

Course : 9,1mm

Vitesse : 0,14 sec

Contrôleur de vitesse :

Type : intégré, brushed = moteurs à charbons

Courant continu maxi : 2,0 ampères

Brevet US D578,146. Brevet RPC ZL 200720069025.2. Autres brevets en instance.

Caractéristiques et ports - AR6400/AR6400L

Antenne

– + ouvert

Entrée de la batterie

Sortie du moteur à charbons

(brushed)(– + ouvert)

Aileron (CH2)

Aileron inversé (CH2)

ou

Aux1 (CH6)

FR

Servo du

gouvernail

(CH4)

+ –

Contrôleur électro-

nique de vitesse

brushless

(signal + – )

Servo de la gouverne

de profondeur (CH3)

X-Port (les 4 broches)

OU

Réducteur (CH5) (les 3

broches inférieures)

Installation du récepteur

Nous recommandons d'utiliser des rubans adhésifs double face en mousse et/ou de mettre un

minimum de colle chaude dans les coins afin d'installer votre récepteur dans le fuselage. Veuillez

noter que les servos doivent se trouver dans la position appropriée pour prendre et actionner les

tiges de commandes de la gouverne de profondeur et du gouvernail. Nota : l'installation variera en

fonction de l'application.

Page 30

FR

Servos

L'AR6400/AR6400L incorpore des servos intégrés ; des servos optionnels sont également disponibles auprès de Spektrum (SPMAS2000/SPMAS2000L). Veuillez noter que l'utilisation de tout

autre servo peut endommager le récepteur et/ou le servo et invalider la garantie.

Servo optionnel (SPMAS2000/SPMAS2000L)

Installation et branchement des servos optionnels

Utilisez des rubans adhésifs double face en mousse et/ou mettez un minimum de colle chaude

pour monter les servos à demeure. Veuillez noter que les servos doivent se trouver dans la position

appropriée pour actionner les tiges de commandes correspondantes. Branchez les raccordements

des servos dans les prises de servo appropriés du récepteur en tenant compte de la polarité du

connecteur de servo. Nota : l'installation variera en fonction de l'application.

Système Smart Bind

™

Avant de pouvoir fonctionner, le récepteur AR6400/AR6400L doit être affecté à l'émetteur. L'affectation

est le processus qui apprend au récepteur le code spécifique de l'émetteur, de sorte qu'il se connecte

uniquement à cet émetteur. L'AR6400/AR6400L est équipé du système Smart Bind. Lorsque l'on

allume d'abord le récepteur, il recherche pendant 5 secondes le signal de l'émetteur auquel il a été

précédemment affecté. S'il ne trouve aucun signal, le récepteur passe automatiquement en mode

affectation (indiqué par le clignotement de la DEL).

Affectation

1. Assurez-vous que la batterie de propulsion est complètement chargée.

2. Confirmez que la batterie de propulsion est déconnectée du récepteur/de la commande électronique

de vitesse et que l'émetteur est éteint.

3. Branchez la batterie de vol sur le connecteur de batterie du récepteur. Au bout de 5 secondes, la DEL

du récepteur commence à clignoter, indiquant qu'il est en mode affectation.

4. Après avoir vérifié que la DEL du récepteur clignote, suivez les étapes requises permettant à votre

émetteur d'entrer en mode affectation. (Consultez à cet effet le manuel de votre émetteur ou le

supplément se trouvant dans les pages suivantes.)

Page 31

DEL

5. Si vous êtes entré correctement en mode affectation, vous verrez la DEL rester allumer en l'espace

de 10 secondes. Vous devriez à présent être relié à l'émetteur et disposer du contrôle ainsi que des

fonctions.

IMPORTANT : après l'affectation

Une fois que le système est affecté, il faut toujours allumer l'émetteur en premier, puis allumer le

récepteur, ceci afin d'éviter que le récepteur passe à nouveau en mode affectation. Si votre récepteur

entre en mode affectation par inadvertance, débranchez simplement la batterie du récepteur et

rebrancher, l'émetteur restant allumé.

Options de programmation avancées

Les options de programmation suivantes sont uniquement recommandées pour les utilisateurs avancés

de systèmes radio. Pour effectuer des modifications au niveau des options de programmation avancées, il

convient de s'assurer l'assistance d'un aide. Une personne tient l'aéronef pour éviter un envol intempestif,

une autre effectue les modifications au niveau de l'émetteur. Les images de cette section présentent

l'émetteur E-flite MLP4DSM. Néanmoins, ces procédures s'appliquent à tous les émetteurs compatibles.

Avant d'effectuer une quelconque modification au niveau des options de programmation avancées, il faut :!

Radios-ordinateurs telles la DX6i ou la DX7

1. Sélectionnez un emplacement de modèle vide

2. Sélectionnez le type de modèle ACRO

3. Effectuez une remise à zéro du modèle

4. Réglez toutes les voies sur la position NORMALE (inversion des servos)

5. Assurez-vous que l'affectation a été réussie

Note : veuillez sécuriser l'aéronef sur un établi ou vous assurer de l'assistance d'un aide lorsque vous

accédez aux options de programmation avancées. Des erreurs de programmation peuvent provoquer une

mise en route inattendue du moteur.

LP5DSM, HP6DSM

Si vous décidez d'utiliser un émetteur E-flite LP5DSM ou HP6DSM, positionnez vos interrupteurs

d'inversion de canal comme suit:

FR

Emetteur LP5DSM Emetteur HP6DSM

Note : conservez une trace écrite des réglages existants si vous voulez revenir en arrière et faire voler votre

autre aéronef.

Inversion des servos

L'inversion des servos peut s'effectuer en utilisant la fonction d'inversion de l'émetteur ou,

comme certaines applications avancées l'exigent, en inversant les servos en place en suivant

les instructions et diagrammes ci-dessous.

Inversion des servos sur le panneau du récepteur

Cette option inverse les servos au niveau du panneau de commande, ce qui la rend utile pour mettre

en oeuvre des options telles que les élevons lorsque vous utilisez des émetteurs ayant des options de

programmation limitées.

Nota : toutes les modifications de programmation avancée doivent commencer récepteur éteint pour

éviter une mise en route inattendue du moteur.

Pour effectuer des modifications au niveau des options de programmation avancées, il convient de

Page 32

FR

s'assurer l'assistance d'un aide. Une personne tient l'aéronef pour éviter un envol intempestif, une

autre effectue les modifications au niveau de l'émetteur.

Les manettes doivent être maintenues dans cette position, l'émetteur étant allumé et

le récepteur éteint.

1. Assurez-vous que l'affectation a réussi

2. Allumez l'émetteur

3. Déplacez la manette THRO vers la position plein gaz

4. Déplacez les manettes de commande vers la position correspondante pour que les servos soient

inversés (cf. illustration).

5. En maintenant cette position, raccordez la batterie au récepteur ; alimentez le récepteur

6. La DEL du récepteur reste allumée en permanence et clignotera rapidement 3 fois dans les

5 secondes, indiquant que le servo est maintenant inversé

7. Déconnectez la batterie du récepteur

8. Eteignez l'émetteur

Mode 2

CH2

1. THRO à fond

2. ELEV bas

3. AILE gauche

THRO/RUDD ELEV/AILE

CH3

1. THRO à fond

2. ELEV bas

3. AILE droite

THRO/RUDD ELEV/AILE

CH4

1. THRO à fond

2. ELEV haut

3. AILE droite

THRO/RUDD ELEV/AILE ELEV/RUDD THRO/AILE

Inversion du servo optionnel 1,5 grammes/1,7 grammes

Inverser le servo est utile lorsque l'on met en place certaines installations, telles les ailerons doubles,

les volets etc. Spektrum propose un câble d'inversion de servo qui peut se brancher entre le récepteur

et le servo optionnel.

Nota : toutes les modifications de programmation avancée doivent commencer récepteur éteint pour

éviter une mise en route inattendue du moteur.

Pour effectuer des modifications au niveau des options de programmation avancées, il convient de

s'assurer l'assistance d'un aide. Une personne tient l'aéronef pour éviter un envol intempestif, une

autre effectue les modifications au niveau de l'émetteur.

Pour inverser le servo à l'aide du raccordement d'inversion :

1. Branchez le raccordement d'inversion sur le servo

2. Branchez le servo sur le port CH2 ou sur les ports CH2/CH6 inversés

3. Alimentez le récepteur à l'aide d'une batterie chargée

4. Une fois que le récepteur se connecte, le servo est inversé

5. Déconnectez la batterie du récepteur

6. Retirez le câble d'inversion du servo (assurez-vous de ranger votre raccordement d'inversion dans

un endroit sûr en vue d'une utilisation future)

7. Remettez le raccordement de servo dans la prise du servo

Mode 1

ELEV/RUDD THRO/AILE

ELEV/RUDD THRO/AILE

Page 33

Pour permuter le canal 6 en un canal 2 inversé pour les ailerons avec 2 servos ou le

canal inversé 2 en canal 6

Nota : toutes les modifications de programmation avancée doivent commencer récepteur éteint pour

éviter une mise en route inattendue du moteur.

Pour effectuer des modifications au niveau des options de programmation avancées, il convient de

s'assurer l'assistance d'un aide. Une personne tient l'aéronef pour éviter un envol intempestif, une

autre effectue les modifications au niveau de l'émetteur.

Les manettes doivent être maintenues dans cette position, l'émetteur étant allumé et

le récepteur éteint.

1. Assurez-vous que l'affectation a réussi

2. Allumez l'émetteur

3. Déplacez la manette THRO vers la position plein gaz

4. Déplacez les manettes de commande vers la position correspondante pour permuter entre les

options disponibles (cf. illustration)

5. En maintenant cette position, raccordez la batterie au récepteur ; alimentez le récepteur

6. La DEL du récepteur reste allumée en permanence et clignotera rapidement 3 fois dans les

5 secondes, indiquant que l'option est maintenant changée

7. Déconnectez le pack de vol du récepteur

8. Eteignez l'émetteur

Mode 2

CH2/CH6 inv.

1. THRO à fond

2. ELEV haut

3. AILE gauche

THRO/RUDD ELEV/AILE ELEV/RUDD THRO/AILE

Pour enlever le moteur brushed pour faire fonctionner un contrôleur électronique de

vitesse brushless optionnel ou permuter la commande de moteur brushless en brushed

L'AR6400/AR6400L est capable de faire fonctionner des moteurs brushless à l'aide d'un contrôleur

électronique de vitesse brushless optionnel. Référez-vous aux illustrations ci-dessous pour les instructions.

Les manettes doivent être maintenues dans cette position, l'émetteur étant allumé et

le récepteur éteint.

1. Assurez-vous que l'affectation a réussi

2. Allumez l'émetteur

Déplacez la manette THRO vers la position plein gaz (cf. illustration)

3.

4. Déplacez les manettes de commande vers la position correspondante pour permuter entre les

options disponibles (cf. illustration)

5. En maintenant cette position, raccordez la batterie au récepteur ; alimentez le récepteur

6. La DEL du récepteur reste allumée en permanence et clignotera rapidement 3 fois dans les

5 secondes, indiquant que l'option est maintenant changée

7. Déconnectez la batterie du récepteur

8. Eteignez l'émetteur

Mode 2

Brushed/

Brushless

1. THRO à fond

2. RUDD gauche

THRO/RUDD ELEV/AILE ELEV/RUDD THRO/AILE

Mode 1

Mode 1

FR

Page 34

FR

Pour permuter le canal 5 vers le X-port et inversement

Note : Lorsque le X-Port est actif, les canaux CH5 et CH6 ne sont pas disponibles ; l'aileron inversé

(CH2) reste néanmoins disponible.