Page 1

© 2009 Horizon Hobby, Inc.

4105 Fieldstone Road

Champaign, Illinois 61822 USA

(877) 504-0233

horizonhobby.com

3-Channel, 4-Model Memory

DSM® Racing System

Horizon Hobby UK

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

Horizon Hobby Deutschland GmbH

Hamburger Strasse 10

25335 Elmshorn

Germany

DSM and DSM2 are trademarks or registered trademarks of Horizon Hobby, Inc. The Spektrum trademark is used with permission of

Bachmann Industries, Inc. Spektrum radios and accessories are exclusively available from Horizon Hobby, Inc.

US patent number 7,391,320. Other patents pending.

Revised 08/09

.

9291.2

Page 2

2

3

Table of

Contents

Introduction............................................................................................................................. 3

DX3.0 Quick Start Setup.......................................................................................................... 3

DX3.0 Quick Start Setup (continued)....................................................................................... 4

DX3.0 Quick Start Setup (continued)....................................................................................... 5

Direct Trim Access .................................................................................................................. 5

DX3.0 with Digital Spectrum Modulation ................................................................................ 6

Binding ...................................................................................................................................6

Binding (continued) ................................................................................................................7

Antenna ...................................................................................................................................7

Receiver Power System Requirements ....................................................................................8

Power System Test Guidelines ................................................................................................ 8

Typical Range .......................................................................................................................... 8

System Features ...................................................................................................................... 9

Tips on Using Spektrum 2.4GHz ............................................................................................. 9

RC Safety Precautions ........................................................................................................... 10

Steering Tension Adjustment ................................................................................................. 10

Control Identification and Location .......................................................................................11

Receiver Compatibility ..........................................................................................................12

Receiver Connections and Installation................................................................................... 12

Charging Jack ....................................................................................................................... 13

Key Input and Display ...........................................................................................................13

Display Screens ....................................................................................................................14

Accessing the System Mode .................................................................................................15

Model Select ......................................................................................................................... 16

Model Name Entry ................................................................................................................ 16

Frame Rate ............................................................................................................................ 17

Auxiliary Channel 3 Function Select ..................................................................................... 17

Auxiliary Channel 3 Function Select (continued) .................................................................. 18

Grip Button C Function Select ............................................................................................... 18

Grip Button C Function Select (continued) ............................................................................ 19

Data Reset ............................................................................................................................. 20

Copy Model Data ..................................................................................................................20

RF Mode ...............................................................................................................................21

Accessing the Function Mode ............................................................................................... 22

Mode Key .............................................................................................................................. 22

Throttle Deadband ................................................................................................................. 23

Exponential ..........................................................................................................................24

Endpoint Adjustment ............................................................................................................. 25

Programmable Mixing........................................................................................................... 26

Lap Timer .............................................................................................................................. 27

Sub-Trim ............................................................................................................................... 28

Servo Reversing .................................................................................................................... 28

Accessing the Direct Trim Mode ............................................................................................ 29

Steering Trim (STC) .............................................................................................................. 30

Throttle Trim (THC) ...............................................................................................................31

Grip Lever B: Steering Dual Rate Trim Adjustment STG ......................................................... 32

Grip Lever A: Brake Endpoint Adjustment BRK/Auxiliary Channel 3 Access .......................... 33

Auxiliary Channel 3 Access (Fuel Mixture) ...........................................................................34

Auxiliary Channel 3 (Transmission Shift Selector) ................................................................ 34

Warranty and Service Information .........................................................................................35

FCC Information.................................................................................................................... 38

CE Compliance Information for the European Union ........................................................ 39

Introduction

DX3.0 Quick

Start Setup

Thank you for purchasing Spektrum’s DX3.0 radio system. The DX3.0 is designed to provide

RC racers with a bulletproof 2.4GHz spread spectrum radio link. With the DX3.0 DSM system

you’ll no longer have to wait for a frequency clip, worry about radio interference from noisy

motors or ESCs or be concerned that someone may turn on a radio on your channel causing

interference. In addition, the DX3.0’s programming is user-friendly and offers the most

important features and functions that racers demand. It’s important that you carefully read

this manual before attempting to operate your DX3.0 system.

For those who would like to get out to the track quickly with just the basic radio setup, please

refer to the Quick Start section that follows.

Included in this manual are in-depth instructions detailing all the steps and procedures

needed to program each of the DX3.0’s functions. For those racers who want to get to the

track fast, we have provided the Quick Start section below. Quick Start covers the basic

programming information necessary to get you racing right away.

Later, when you want to learn more about the specific functions of the DX3.0, refer to the

appropriate page(s) in this manual for more detailed programming information.

Note: If braking adjustment via Grip Lever A is required, refer to the third channel system

setup mode (page 32) for instructions.

Binding

It’s necessary to program the receiver to a specific transmitter so that the receiver will only

recognize that transmitter, ignoring signals from any other sources. If the receiver is not

bound to a transmitter, the system will not operate. Also, during the binding process, the

servo failsafe positions are set.

1. Make sure the transmitter and receiver are turned off.

2. With the receiver off, insert the bind plug into the BIND port on the receiver.

3. Power the receiver through any port. The green LED will flash continuously, indicating

the receiver is in bind mode.

4. Hold down on the SCROLL and CHANNEL buttons while turning on the transmitter.

To enter System Mode, press the SCROLL button until “BND” appears on the screen.

5. With the steering wheel and the throttle trigger in their desired failsafe positions, press

the INCREASE and DECREASE buttons at the same time to enter bind mode. “BND” will

flash when in bind mode.

6. After several seconds the LED on the receiver will quit flashing and remain solid,

indicating that the binding process was successful. Once binding is complete, the

system will automatically connect.

7. Once the bind process is complete and before power is cycled on the receiver, remove

the bind plug from the receiver and store it in a convenient place. Failure to remove the

bind plug will result in the receiver going back into bind mode.

Note: See page 6–7 for a detailed description of the binding process.

Page 3

4

5

DX3.0 Quick

Start Setup

(continued)

Servo Reversing

–

st

REV • NORM

–

1. With the transmitter power switch on, press the

SCROLL key to enter the Function mode.

2. Press the SCROLL key until REV.NORM appears on the screen.

The “ST” indicates the steering servo reversing screen.

3. Press the INCREASE or DECREASE key to move the cursor

to the desired servo direction (REV.NORM).

4. Press the CHANNEL key once to access the throttle servo reversing screen.

5. To select the direction of the throttle servo, repeat Step 3 above.

6. Repeat Steps 2 and 3 to adjust Auxiliary Channel 3 if needed.

Indicates Current Channel

ST = Steering

TH = Throttle

AUX = Auxiliary Channel 3 (optional)

Indicates Current Servo Direction

SCROLL

ENtER

ChaNNEL

INCREaSE

Endpoint (Travel) Adjustment

Indicates Current Adjustment Position

ST = Steering

TH = Throttle

AUX = Auxiliary Channel 3 (optional)

Indicates Current Value

R/B

–

E P A

st

I00

CLEaR

DECREaSE

DX3.0 Quick

Start Setup

(continued)

Direct Trim

Access

Servo Trim Adjustment

TRIM

TRIM

–

STC

0

THC

Indicates Steering

Trim Function

Indicates Current Value

Indicates Throttle

Trim Function

Indicates Current Value

0

Steering

1. With the transmitter power switch on, move the digital steering trim lever in the desired

position to be adjusted. The steering trim value screen will appear automatically.

Throttle

2. With the transmitter power switch on, move the digital throttle trim lever in the desired

position to be adjusted. The throttle trim value screen will appear automatically.

L/F = Left/Forward

R/B = Right/Brake

1. From the Servo Reverse function, press the SCROLL key once to access

the Endpoint (Travel) Adjustment function (the EPA screen with “ST” will appear).

Steering Adjustment

2. Rotate the steering wheel in the desired direction (left or right) to be adjusted.

3. Press the INCREASE or DECREASE key to select the desired travel value.

Throttle Adjustment

4. Press the CHANNEL key once. TH will appear on the screen.

5. Pull the trigger for forward or push the trigger for brake adjustment.

6. Press the INCREASE or DECREASE key to select the desired travel value.

Auxiliary Channel 3 Adjustment

Note: AUX will need to be programmed for either Grip Lever A or Grip Button C.

See page 17.

If a third channel is not required, proceed to Step 10.

7. Press the CHANNEL key once. AUX will appear on the screen.

8. Toggle the appropriate lever/button to select the desired endpoint.

9. Press the INCREASE or DECREASE key to select the desired travel value.

10. Press the SCROLL and CHANNEL keys at the same time to exit the function mode.

Steering Trim

Throttle Trim

Page 4

6

7

DX3.0 with

Digital

Spectrum

Modulation

Binding

The DSM® system operates in the 2.4GHz band (that’s 2400MHz). This high frequency offers

a significant advantage, as it’s well out of the range of model-generated radio interference

(like motor and ESC noise). All the complex issues that now exist using 27 and 75MHz

radios with model-generated interfering noise are eliminated with this system. The DSM

system uses Direct Sequencing Spread Spectrum modulation to generate a wide signal on a

single frequency. The FCC requires that these systems be “smart”– incorporating collision

avoidance such that when a system is turned on, it scans the 2.4GHz band and selects a

channel that is not being used, then begins transmitting on that unused channel. Seventynine channels are available and the odds of one DSS spread spectrum system interfering

with another are astronomically remote.

During the first installation, the receiver(s) must be bound to the transmitter. Binding is

necessary to program the receiver(s) to distinguish its corresponding transmitter from

others. Also failsafe positions are transferred from the transmitter to the receiver during

binding.

It is necessary to bind the receiver to the transmitter during the first installation, and is

recommended when the receiver is moved from one vehicle to another. Receivers can be

re-bound to the same transmitter or to other transmitters an infinite number of times. Also

multiple receivers can be bound to a single transmitter, which is common when using one

transmitter to operate several models.

Only bound receivers and transmitters can connect. During power-up, the transmitter

scans for a free channel while the receiver scans for its bound transmitter. When control is

achieved, the LED on the receiver remains on continuously.

Binding

(continued)

Antenna

4. Hold down on the SCROLL and CHANNEL buttons while turning on the transmitter.

To enter System Mode, press the SCROLL button until “BND” appears on the screen.

-

-

b D

M

5. With the steering wheel and the throttle trigger in their desired failsafe positions, press

the INCREASE and DECREASE buttons at the same time to enter bind mode. “BND”

will flash when in bind mode.

6. After several seconds the LED on the receiver will quit flashing and remain solid,

indicating that the binding process was successful. Once binding is complete, the

system will automatically connect.

7. Once the bind process is complete and before power is cycled on the receiver, remove

the bind plug from the receiver and store it in a convenient place. Failure to remove the

bind plug will result in the receiver going back into bind mode.

At 3.6 inches in length, the receiver antenna is significantly shorter than conventional

antennas. Like all antennas, it’s important to mount the antenna vertically. In most cases the

antenna can be mounted inside the body with no loss of range. Mount the receiver antenna

as recommended by the manufacturer of the vehicle, however, it may be necessary to trim the

plastic antenna tube (included with your vehicle).

In the unlikely event that the link is lost during use, the receiver will drive the servos to

their failsafe positions that were preset during the binding process. If the receiver is turned

on prior to turning on the transmitter, the receiver will enter the failsafe mode, driving the

servos to their preset failsafe position. When the transmitter is turned on, normal control is

resumed.

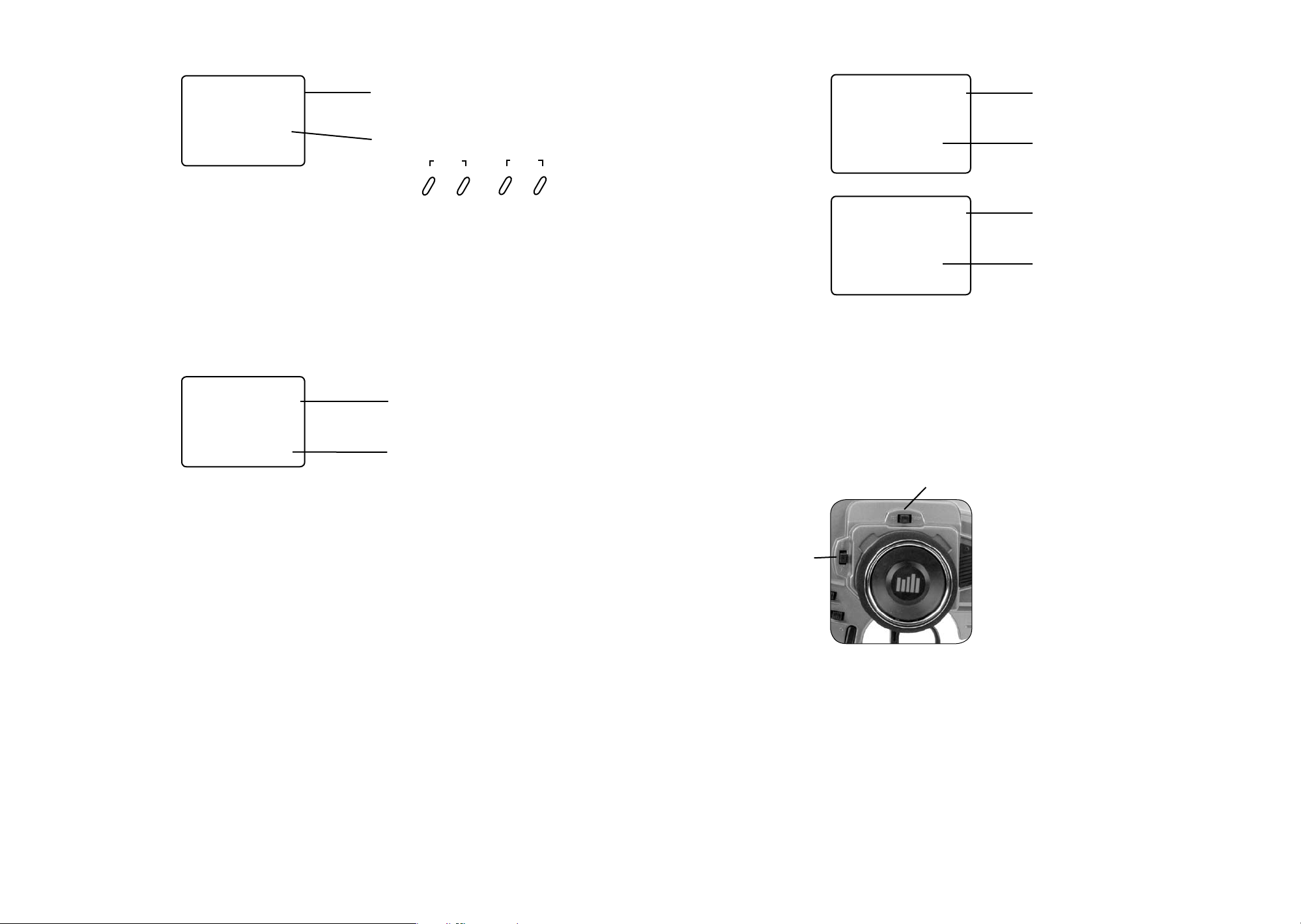

To bind the receiver to the transmitter

1. Make sure the transmitter and receiver are turned off.

LED

2. With the receiver off, insert the bind plug into the BIND port on the receiver.

3. Power the receiver through any port. The green LED will flash continuously, indicating

the receiver is in bind mode.

Page 5

8

9

Receiver

Power System

Requirements

Power

System Test

Guidelines

Inadequate or intermittent power to the receiver that is unable to provide the necessary

minimum voltage during operation is the number one cause of control failures with Spektrum

systems. Some of the power system components that affect the ability to properly deliver

adequate power include:

•Receiverbatterypack(numberofcells,batteryconstructionquality,connectorandstate

of charge)

•TheESC’scapabilitytodelivercurrenttothereceiverandservosinelectricvehicles

•Theswitchharness,batteryleads,servoleads,regulatorsetc.

All Spektrum receivers have a minimum operational voltage of 3.5 volts. If the voltage drops

below 3.5 volts, the system will cease control until power is regained.

If a questionable power system is being used (e.g. small or old battery, ESC that may

not have a BEC that will support the servo’s current draw, etc.), it is recommended that a

voltmeter be used to perform the following test.

Plug the voltmeter into an open channel port in the receiver and with the system on, load

the servos (apply pressure with your hand) while monitoring the voltage at the receiver. The

voltage should remain above 4.8 volts even when all servos are loaded. For gas vehicles,

tap and twist the receiver battery pack while watching the voltmeter. Some battery packs

have poorly welded tabs that give only intermittent power. Such a defect will show up during

shock and vibration, so this test will verify that the battery construction is good.

System

Features

Tips on Using

Spektrum

2.4GHz

•DSM2.4GHzSpreadSpectrumModulation

•NowcompatiblewithDSM2andMarinesurfacereceivers,inadditionto

DSM surface receivers

•Threechannels

•Easy-to-readLCDgraphicsdisplay

•Four-modelmemory

•Three-charactermodelnameentry

•Electronicdigitaltrimleversforthrottleandsteering

•Twoassignableelectronicgripswitches(LeverAandButtonC)

•ThirdchannelaccessiblethroughGripLeverAorGripButtonC

•Directdisplaytrimfunction

•Sub-trim

•Steeringrateadjustment

•Independentsteeringendpointadjustments

•Brake/throttleendpointadjustment

• Low battery alarm

• Charge jack receptacle (rechargeable batteries not included; order JRPB958)

While your DSM equipped 2.4GHz system is intuitive to operate, functioning nearly

identically to 27 and 75MHz systems, following are a few common questions from

customers.

1. Q: Which do I turn on first, the transmitter or the receiver?

Typical Range

Your system’s range can vary greatly due to your installation and the environment. In most

cases you should be able to have full control of your vehicle to the limits of sight (about 300

ft with a 1/10-scale car). If range issues exist your installation can be optimized by extending

the receiver’s antenna as vertically as possible locating it as high in the vehicle as practical

and also by routing the antenna away from any onboard electronics.

A: If the receiver is turned on first—all servos will be driven to their preset failsafe

positions set during binding. When the transmitter is then turned on the transmitter scans the

2.4GHz band and acquires an open channel. Then the receiver that was previously bound to

the transmitter scans the band and finds the GUID (Globally Unique Identifier code) stored

during binding. The system then connects and operates normally.

If the transmitter is turned on first—the transmitter scans the 2.4GHz band and acquires an

open channel. When the receiver is then turned on all servos are driven to their preset failsafe

positions for a short period of time (the time it takes to connect). The receiver scans the

2.4GHz band looking for the previously stored GUID and when it locates the specific GUID

code and confirms uncorrupted repeatable packet information, the system connects and

normal operation takes place. Typically this takes 2 to 6 seconds.

2. Q: Sometimes the system takes longer to connect and sometimes it doesn’t connect at all.

A: In order for the system to connect (after the receiver is bound) the receiver must

receive a large number of consecutive uninterrupted perfect packets from the transmitter.

This process is purposely critical of the environment ensuring that it’s safe to operate when

the system does connect. If the transmitter is too close to the receiver (less than 4 ft.) or if

the transmitter is located near metal objects (metal TX case, the bed of a truck, the top of a

metal work bench, etc.) connection will take longer and in some cases connection will not

occur as the system is receiving reflected 2.4GHz energy from itself and is interpreting this

as unfriendly noise. Moving the system away from metal objects or moving the transmitter

away from the receiver and powering the system again will cause a connection to occur. This

only happens during the initial connection. Once connected the system is locked in and

should a loss of signal occur (failsafe) the system connects immediately (4ms) when signal

is regained.

Page 6

10

11

3. Q: I’ve heard that the DSM system is less tolerant of low voltage. Is that correct?

Control

RC Safety

Precautions

Steering

Tension

Adjustment

A: All DSM receivers have an operational voltage range of 3.5 to 9.6 volts. With most

systems this is not a problem as in fact most servos cease to operate at around 3.8 volts.

When using multiple high-current draw servos with a single or inadequate battery/power

source, heavy momentary loads can cause the voltage to dip below this 3.5-volt threshold

thus causing the entire system (servos and receiver) to brown out.

4. Q: Sometimes my receiver loses its bind and won’t connect requiring rebinding. What

happens if the bind is lost during use?

A: The receiver will never lose its bind unless it’s instructed to. It’s important to understand

that during the binding process the receiver not only learns the GUID (code) of the

transmitter but the transmitter learns and stores the type of receiver that it’s bound to. If the

transmitter is placed into bind mode, the transmitter looks for the binding protocol signal

from a receiver. If no signal is present, the transmitter no longer has the correct information

to connect to a specific receiver and in essence the transmitter has been “unbound” from the

receiver.

For safe and reliable performance of your RC model, please carefully read and follow these

guidelines.

1. Radio control models are not toys. They are capable of inflicting serious injury to

people and property. Use caution at all times when operating your model.

2. You are responsible for the safe operation of your RC model. You must properly install,

test and operate your model with a clear sense of that responsibility. Do not take risks

that might endanger yourself or others.

3. Running an RC car in the streets is very dangerous to both drivers and models. Avoid

running your model in areas occupied by full-size automobiles. To locate areas where

you can safely operate your model, you should contact your local hobby shop for RC

tracks or clubs in your area.

4. When running an RC boat, keep it away from any swimmers, full-size boats, or wildlife.

Also, watch carefully for fishing lines that can get tangled in the propeller.

5. If at any time while operating your RC model you observe abnormal model functioning,

end your operation immediately. Do not operate your model again until you are certain

the problem has been corrected.

CAUTION: Control of your model is impossible without sufficient voltage for the

transmitter and receiver. A weak transmitter battery will decrease your range of

operation and a weak receiver battery will slow servo movement and decrease

your range of operation. Check your receiver pack voltage often to avoid losing

control of your model.

Steering tension is adjustable via the recessed screw located beneath the steering wheel

(see page 11 for exact location). Turning the screw clockwise increases the steering tension.

Identification

and Location

Digital Voltage Reading

Channel Button

Enter Function

Mode Button

Increase Button

Clear Function

Decrease Button

Electronic Digital

Throttle Trim Lever

Electronic Digital

Grip Lever A

(Access to Third Channel)

Electronic Digital

Grip Lever B

Charge Jack

* To remove the Battery Cover, press down on the ridges and push the cover in the direction

of the arrow. Remove the battery cover and install 8 AA batteries in the direction as molded

into the battery holder. If the transmitter voltage fails to register, check for correct battery

installation and review voltage again.

Multidata LCD Display

Three Character

Name Input

Antenna

Throttle Trigger

Grip Button C

Electronic Digital

Steering Trim Lever

Power Switch

Steering Wheel

Adjustable

Steering

Tension

Battery cover *

(8 AA Batteries Required)

Page 7

12

13

n

7.2V Battery

To Motor

Electronic

Speed Controller

Receiver

Servo

Receiver

Compatibility

The DX3.0 features DSM technology and is compatible with Spektrum DSM and DSM2

surface receivers and the marine receiver.

COMPATIBLE SPEKTRUM RECEIVERS

The DX3.0 is compatible with the following receivers.

Note: The DX3.0 operates in 11ms frame rate when in fast mode and 16.5ms frame

rate when in normal mode. See page 17 for more information about frame rates.

DSM: SR300 - 3-channel Sport - SPMSR300

SR3000 - 3-channel Standard - SPM1200

SR3001 - 3-channel Pro - SPM1205

SR3300T - 3-channel with built-in telemetry - SPMSR3300T

SR3500 - 3-channel Micro Race - SPM1210

Note: The SR3000HRS (SPM1202) receiver is designed to be used with

Spektrum’s Futaba HRS compatible module system only and is not compatible

with the DX3.0.

DSM2: SR3100 - 3-channel Pro - SPMSR3100

SR3520 - 3-channel Micro Pro - SPMSR3520

Charging Jack

Located on the left-hand side of the transmitter is the charging jack, which accepts only

JR® or Spektrum™ style wall chargers. Please do not attempt to use any other brand of wall

charger as it may be the reverse polarity and can cause damage to your system. Only use the

JR or Spektrum type wall charger when the DX3.0 is equipped with NiMH batteries.

Warning: Charge only rechargeable batteries. Non-rechargeable batteries may burst

causing injury to persons and/or damage to property.

Charger Pigtail For Transmitter

Black To Positive

Black With White Stripe To Negative

Spektrum Transmitter Charge Jack Polarity

Receiver

Connections

and

Installation

Marine: MR3000 - 3-channel Marine - SPMMR3000

Please note that DSM2 and marine compatible transmitters can be identified by the following

logo located on the back of the transmitter:

Note: When using a separate NiMH receiver as a power source, the operating voltage

range is 4.8–6.0V (4–5 cells) under load.

Attention: Make sure the male and female connectors have the correct polarity (+/–)

before connecting. Be sure to orient the servo plug correctly for proper insertion.

Most electronic speed controllers are set up for BEC (Battery Elimination Circuitry) operation

and plug directly into your receiver. See Figure A for a typical setup and check your speed

controller’s manual for correct installation.

Key Input and

Display

Key Use

SCROLL Used to move up through the available functions

CHANNEL Used to select the desired channel

INCREASE Used to increase the value of the selected function

DECREASE Used to decrease the value of the selected function

To enter the System Mode press the SCROLL andCHANNEL keys

simultaneously and hold while turning on the transmitter.

ENtER

SCROLL

ChaNNEL

To enter the Function Mode, press the

SCROLL key while the transmitter is on.

Press the INCREASE and DECREASE

keys simultaneously to clear the screen or

return to factory preset settings.

INCREaSE

CLEaR

DECREaSE

Figure A – Connections to BEC and receiver with electronic speed controller. NiMH battery

speed controller and servos are not included in the radio set.

Page 8

14

15

Display

Screens

Normal Display Screen

When the power switch is turned on, the LCD screen will read as shown below. This screen

is referred to as the Normal Display.

Note: If any of the electronic trim buttons are moved while in this screen, the screen

will automatically change to display the trim in use. This is called the Direct Trim

Mode. For more information on the feature, please see page 5 of this manual.

-

-

MD1

10.2

Low Battery Screen/Lithium Battery Backup

v

Accessing the

System Mode

To enter the System Mode, press both the SCROLL and CHANNEL keys at the same time

while turning on the transmitter power switch. By pressing the SCROLL key, you can now

choose Model Select, Model Name Input, Auxiliary Channel 3, Grip Button C function, Data

Reset or the Model Copy function as shown here on the System Mode flow chart. Information

for each function is located on the page number listed next to the function name on the flow

chart.

To exit the System Mode, press the SCROLL and CHANNEL keys at the same time, or

simply turn off the transmitter.

Note: If you turn the transmitter off and immediately enter System mode again, you

will be returned to the last System mode function used instead of the Model Select

function. While in System mode, there is no RF output generated by the transmitter.

Adjustments can be performed with reduced battery power consumption. If you exit

System mode by pressing the SCROLL and CHANNEL keys at the same time, RF

output will not be enabled until you first turn off the transmitter.

When the voltage of the eight AA batteries drops below 9.0 volts, the DX3.0’s display

screen will alternate between the Normal (see above) and Low Battery screen (BAT).

A beeping will occur, indicating that the batteries need to be replaced or recharged before

further use.

bat

8.9

Lithium Battery

Your DX3.0 radio system is equipped with a five-year lithium battery backup system.

This system is designed to protect and retain all radio programming in the event that

the transmitter batteries drop below the required 9.0 volts, or the transmitter battery case

is removed during battery changes. If after five years it becomes necessary to replace the

lithium battery, return your system to the Horizon Service Center for repair

(see address, page 34–36).

Memory Backup Screen

If the Memory Backup screen appears, this indicates the possibility of a memory issue or

the lithium battery is dead. If you switch the power off and on again, and the transmitter is in

default mode with all data lost, it is suggested that the DX3.0 transmitter be returned to the

Horizon Service Center for servicing (see Warranty Information, page 34–36).

bak

v

–

-

-

MDL

I

-

-

MDI

I

-

FRM

Model Select

(Page 16)

Model Name

Entry

(Page 16)

-

Frame Rate

(Page 17)

GBC

0

clr

I

CPY

–

Grip Button C

Function

(Page 19)

Data Reset

(Page 20)

Copy Model

Data

(Page 20)

2

-

-

b D

AUX

Auxiliary

Channel 3

Function

(Page 17)

M

Bind (Page 6)

0

RF Mode

RF

(Page 21)

–

ER

Page 9

16

17

Model Select

System Mode

The DX3.0 has memory for four models. This feature allows for four different models to

be operated with the same transmitter (additional receivers and servos must be purchased

separately) or one model with four different race setups.

-

-

MDL

Model Select Function

Frame Rate

System Mode

Two frame rates are available: F and N.

F = Fast (11ms)

N = Normal (16.5ms)

While most servos are compatible with the fast frame rate, some older analog servos require

the use of the slower normal frame rate.

Model Name

Entry

System Mode

I

Model Number

Accessing the Model Select Function

1. Press the SCROLL and CHANNEL keys at the same time and hold.

2. Turn the transmitter power switch on to enter System Mode.

3. If “MDL” does not appear on the screen, press the SCROLL key until MDL appears.

4. Press the INCREASE or DECREASE key to select the desired model number

(1, 2, 3, or 4).

5. Press the SCROLL key to access the Model Name Entry function.

6. To exit System Mode, either turn the transmitter power switch off or press the SCROLL

and CHANNEL keys at the same time.

The DX3.0 allows a three-character name to be input for each of the four models available.

The current model, with name, will then be displayed in the Normal display screen. This

feature is useful to help identify different models, setups, etc. For information on selecting

models 1, 2, 3 or 4, please refer to the Model Select function above.

-

-

MDI

I

Flashing character indicates

the character to be adjusted

Current Model Number

Auxiliary

Channel 3

Function

Select

System Mode

Accessing the Frame Rate Function

1. Press the SCROLL and CHANNEL keys at the same time and hold.

2. Turn on the transmitter power switch to enter the System Mode.

3. Press the SCROLL key until FRM appears on the screen.

4. Press the INCREASE or DECREASE key to select the desired frame rate (N or F).

5. Press the SCROLL key to access the Auxiliary Channel 3 function.

6. To exit the System Mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

The Auxiliary Channel 3 function of the DX3.0 allows you to select from two different types

of Channel 3 servo travel movements, or to inhibit the Auxiliary Channel 3 function. Use the

information below to select the correct Auxiliary Channel 3 function type for your particular

installation. It is suggested the O function (factory preset) be selected for most applications.

LN = The LN, or linear, servo travel function is designed to be used when an engine fuel

mixture servo is required. This function is most commonly used with gas-powered RC racing

boats and is accessible through the Grip Lever A. In this function, the maximum travel of the

servo is determined by the Endpoint Adjust function, page 24. The servo neutral position can

be altered proportionately via the Grip Lever A for fuel mixture adjustment. When activated,

fuel mixture trim values are visible for the Direct Trim function, page 28.

Auxiliary Channel 3

AUX

Function

Linear Movement

(fuel mixture servo)

Accessing the Model Name Entry Function

1. Press the SCROLL and CHANNEL keys at the same time and hold.

2. Turn on the transmitter power switch to enter the System Mode.

3. Press the SCROLL key until MD1 appears on the screen.

4. Press the INCREASE or DECREASE key to select the correct letter/number for the first

character (flashing).

5. To change the remaining two characters, press the CHANNEL key until the desired

character to be changed is flashing.

6. Press the SCROLL key to access the Frame Rate function.

7. To exit the System Mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

2P = The 2P, or 2 position, Servo Travel function is designed to be used as a transmission

gear shift channel. This feature is designed for use only with vehicles such as the Traxxas

T-Maxx. This function is accessible through the Grip Button C or Grip Lever A if Grip Button

C is occupied by another function. The left and right travel values are determined by the

Endpoint Adjustment function, page 24.

Auxiliary Channel 3

AUX

2P

Function

Non-linear Two-Position Movement

(Traxxas shiftable transmission use)

Page 10

18

19

Auxiliary

Channel 3

Function

Select

System Mode

(continued)

0 = The 0 or Inhibit function allows the Brake Endpoint Adjustment function, page 32, to be

used. This function is designed to be used with most types of electric and gas-powered RC

cars. This feature is extremely popular, as it allows the amount of panic braking accessible

through the throttle trigger’s braking position to be adjusted during operation for maximum

effectiveness. When activated, the braking valves will be visible via the Direct Trim function,

page 28.

Auxiliary Channel 3

AUX

0

Function

Channel 3 is inhibited

(Grip Lever A braking function is now activated)

Accessing the Auxiliary Channel 3 Function

LN = Linear servo movement

2P = 2-position servo movement

0 = Inhibited (Grip Lever A Braking is now activated)

Grip Button C

Function

Select

System Mode

(continued)

2P = The 0 or off function is the default setting and does not assign a function to Grip Button

C. If the Auxiliary Channel 3 function is set to “2P” or 2-position, “2P” will appear in this

screen in place of “0” and Grip Button C will function as the gear select button.

Grip Button C

GBC

0

E6 = The Eb or Emergency Steering Button function is designed to momentarily override

the value of Grip Lever B and provide 100% steering rate. This feature is useful if you have

reduced the steering rate to make your vehicle easier to drive but need full steering in an

emergency situation such as a collision. The override occurs only while the Grip Button C is

depressed.

GBC

Function

Grip Button C is inhibited

Grip Button C

Function

Grip Button C

Function

Select

System Mode

1. Press the SCROLL and CHANNEL keys at the same time and hold.

2. Turn on the transmitter power switch to enter the System Mode.

3. Press the SCROLL key until AUX appears on the screen.

4. Press the INCREASE or DECREASE key to select the correct Auxiliary Channel 3

function type to be used.

5. Press the SCROLL key to access the Grip Button C Select function.

6. To exit the System mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

The Grip Button C function of the DX3.0 allows you to select from three different functions

available. Use the information below to select the correct Grip Button C assignment for your

particular installation.

Grip Button C

GBC

A

“0”: Off. (Default) If “AUX” is “2P”, then “2P” replaces “0” in this screen.

“Eb”: ESB (Emergency Steering Button). To cancel the “STG” regulation

for panic steering.

“LA”: Lap Timer.

Function

Lap Timer

Emergency Steering Button

E6

LA = The LA or Lap Timer function is designed to be used when you want to enable the

recording of individual lap time. The Lap Timer function is described on page 26.

GBC

LA

1. Press the SCROLL and CHANNEL keys at the same time and hold.

2. Turn on the transmitter power switch to enter System Mode.

3. Press the SCROLL key until GBC appears on the screen.

4. Press the INCREASE or DECREASE key to select the correct Grip Button C function

type to be used.

5. Press the SCROLL key to access the Data Reset function.

6. To exit System mode, either turn the transmitter power switch off or press the SCROLL

and CHANNEL keys at the same time.

is activated

Grip Button C

Function

Lap Timer Button

is activated

Note: If “LA” or “Eb” is selected and “2P” is assigned to the Auxiliary Channel 3 function,

the Auxiliary Channel 3 function is moved to Grip Lever A (factory preset).

Page 11

20

21

Data Reset

System Mode

The Data Reset function allows you to reset all the programming in the selected model

(1, 2, 3 or 4) to the factory default settings and to copy model data from one model memory

to another. Before using the Data Reset function, it’s important to enter the Model Select

function and check to make sure the current model number indicated (1, 2, 3 or 4) is the

model which you want to reset to the factory default settings. The Model Select function is

described on page 16.

CLR

Model to be Reset

I

RF Mode

The DX3.0 features a selectable RF mode. N is the standard RF mode. FR is the France RF

mode and should only be selected if the transmitter is used in France.

Accessing the RF Mode Function

To access the RF Mode function, follow the steps below:

1. Press the SCROLL and CHANNEL keys at the same time and hold.

2. Turn on the transmitter power switch to enter the System Mode.

3. Press the SCROLL key until RF appears on the screen.

4. Press the INCREASE and DECREASE keys to select the desired RF mode.

5. To exit the System Mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

Copy Model

Data

System Mode

Accessing the Data Reset Function

1. Press the SCROLL and CHANNEL keys at the same time and hold.

2. Turn on the transmitter power switch to enter the System Mode.

3. Press the SCROLL key until CLR appears on the screen.

4. Press the INCREASE or DECREASE key at the same time to reset the data. To confirm

that the selected model’s programming has been reset, a beep will sound and the model

number selected (1, 2, 3 or 4) will stop flashing.

5. Press the SCROLL key to access the Copy Model Data function.

6. To exit the System mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

CPY

Model being copied to

2

Accessing the Copy Model Data Function

1. Press the SCROLL and CHANNEL keys at the same time and hold.

2. Turn on the transmitter power switch to enter the System Mode.

3. Press the SCROLL key until CPY appears on the screen.

4. Press the INCREASE or DECREASE key to select the desired model number you want

the current model data copied to. The selected model number should be flashing.

5. Press the INCREASE and DECREASE keys at the same time to copy the current model

data into the selected model number. To confirm that the selected model has been copied

to, a beep will sound and the model number selected (1, 2, 3 or 4) will stop flashing.

6. To exit the System mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

RF

Page 12

22

23

Accessing

the Function

Mode

Mode Key

TDB

To enter the Function Mode, turn on the transmitter and then press the SCROLL key. The

display will change to show the first function listed on the Function Mode flow chart as

shown below. Press the SCROLL key to scroll down through the functions one by one, as

shown in the flow chart. Once the desired function has been reached, use the CHANNEL key

to select the appropriate channel (if applicable). To adjust the values of the function, simply

press the INCREASE (+) or DECREASE (-) keys until the desired value is displayed on the

screen. To exit function mode, press the SCROLL and CHANNEL keys at the same time.

The next time you enter Function mode, you will be returned to the last function accessed.

Channel Key

Throttle

Deadband

(page 22)

Throttle

Deadband

Function Mode

The throttle deadband feature is used to reduce/eliminate the dead throttle area that exists at

neutral to the starting point of throttle and from neutral to the starting point of braking. This

area is sometimes known as deadband. As more throttle trim (also known as static brake)

is applied, more of the dead trigger area right off neutral exists. To eliminate the throttle

deadband, adjust a forward value such that your vehicle’s wheels just start to turn when the

trigger is slightly squeezed. This provides the most accurate feel and eliminates the dead

area in the throttle. To eliminate the braking deadband, adjust the brake value such that

your vehicle starts to slow down when the trigger is slightly pushed. This provides the most

accurate brake feel and eliminates the dead area when braking.

Forward Adjustment

TDB

(depends on trigger position)

R/B

E X P

E P A

L/F

M I X

L A P

0

–

ST

–

ST

I00

–

STL

0

40

Channel

Key

Channel

Key

Channel

Key

E X P

E P A

R/B

M I X

THF

TH

I00

THB

0

Lap Timer (If Grip Button C is activated for Lap Timer)

(page 26)

Exponential

(page 23)

Channel

Key

Mixing

(page 25)

E P A

L/F

AUX

I00

Endpoint

Adjustment

(page 24)

Current Value

L/F

R/B

0

TDB

0

Brake Adjustment

(depends on trigger position)

Current Value

Value: 0% to 100%

Clear = 0%

Accessing the Throttle Deadband Function

1. Turn the transmitter power switch on.

2. Press the SCROLL key to access Function mode.

3. Press the SCROLL key until TDB appears on the screen.

4. Move the trigger accordingly to adjust the forward or braking deadband.

5. Press the INCREASE or DECREASE key to select the desired value necessary to

eliminate dead area.

6. Press the SCROLL key to access Exponential mode.

7. To exit the Function mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

TRIM

20

–

STS

0

–

ST

REV • NORM

–

–

Channel

Key

Channel

Key

TRIM

SB • TRM

–

THS

0

TH

REV • NORM

–

Channel

Key

Channel

Key

TRIM

SB • TRM

–

AUS

0

AUX

REV • NORM

–

Sub-Trim

(page 27)

Servo

Reversing

(page 27)

Page 13

24

25

Exponential

Function Mode

The Exponential feature of the DX3.0 allows you to alter the response rate of the steering or

throttle control around neutral without affecting the maximum amount of steering or throttle

available. The adjustment range is from -100% to 0% (Linear) to +100%. Exponential is

factory-set to linear for both steering and throttle. Exponential is often used to settle down a

car that is twitchy around center without giving up maximum steering response. The DX3.0

provides both positive (increase sensitivity at neutral) and negative (decrease sensitivity at

neutral) exponential values.

Endpoint

Adjustment

Function Mode

The Endpoint Adjustment feature of the DX3.0 allows the maximum travel for the steering,

throttle and Auxiliary Channel 3 (optional) servos to be increased or decreased in each

direction to achieve the exact servo movement needed. The Endpoint Adjustment range is

from 0% to 125% and is factory-set to 100% for all three channels. The value displayed on

the screen depends on the current position of the steering wheel, trigger, or trim lever to be

adjusted. This feature is very useful either to maximize servo travel or to reduce servo overtravel to eliminate servo binding (servos move further than the control mechanism allows),

without the need for mechanical linkage adjustment.

Steering Exponential

Adjustment

Current Value

E X P

–

ST

Forward Throttle Exponential

E X P

THF

Adjustment

Current Value

Braking Exponential

E X P

THB

Adjustment

Current Value

Values: -100% to Linear (LN) to +100%

Accessing the Exponential Function

1. Turn the transmitter power switch on.

2. Press the SCROLL key to access Function mode.

3. Press the SCROLL key until EXP appears on the screen.

4. Press the INCREASE or DECREASE key to select the desired exponential value.

5. Press the SCROLL key to access the travel Endpoint Adjustment function.

6. To exit the Function mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

The screens below are accessed by turning the wheel to the desired direction to be adjusted

(left or right), by moving the trigger to the forward or backward (brake) position, or by

toggling the Grip Button C.

L/F

R/B

E P A

I00

E P A

I00

–

ST

ST

Steering Left

Endpoint Adjustment

Current Value

Values: 0 to 125

Clear = 100

Steering Right

Endpoint Adjustment

Current Value

Values: 0 to 125

Clear = 100

E P A

L/F

E P A

R/B

TH

I00

TH

I00

Forward Throttle

Endpoint Adjustment

Current Value

Values: 0 to 125

Clear = 100

Backward Throttle (Brake)

Endpoint Adjustment

Current Value

Values: 0 to 125

Clear = 100

Channel 3 Screens (optional)

Left/Right Travel

Adjustment (function LN)

AUX

E P A

L/F

I00

Functions & 2P Functions 2P only

or Forward Travel Adj.

(function 2P) accessible

through Grip Button C

Current Value

Values: 0 to 90

Clear = 100

E P A

R/B

I00

AUX

Rearward Travel

Adjustment

(function 2P)

accessible through

Grip Button C

Current Value

Values: 0 to 90

Clear = 100

Accessing the Endpoint Adjustment Function

1. Turn the transmitter power switch on.

2. Press the SCROLL key to access Function mode.

3. Press the SCROLL key until EPA appears on the left side of the screen.

4. Press the CHANNEL key to select the desired channel to be adjusted.

5. Move the steering wheel, trigger or Grip Button C in the desired direction for adjustment

(left/right, forward/reverse or brake). Press the INCREASE or DECREASE key to

achieve the desired amount of travel. Move the wheel, trigger or Grip Button C in the

opposite direction to adjust travel in the opposite direction.

Note: For Auxiliary Channel 3 function, if LN is selected, only L/F is adjustable. And if

Emergency Steering Button is Eb or LA, Auxiliary Channel 3 defaults to Grip Lever A.

6. Press the SCROLL key to access the Mixing Adjustment function.

7. To exit the Function mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

Note: When setting the Endpoint Adjustment values for the Steering function, it is

suggested that, if possible, the maximum travel values be set to an equal value in both

directions to maintain proper steering control.

Page 14

26

27

Programmable

Mixing

Function Mode

The DX3.0 offers two different mixing adjustments that allow for mixing one channel to another

channel. The mixes available are Steering-to-Auxiliary Channel Mixing and Throttle-to-Auxiliary

Channel Mixing. Each direction is independently adjustable. Popular use of this function

includes 4-wheel steering and independent front and rear wheel brakes.

For example, Throttle-to-Auxiliary channel mixing can be used for independent front and rear

wheel brakes. Each time the throttle/brakes are moved, the auxiliary channel will move in the

direction and to the value input being given by the throttle channel. Mixing is proportional, so

small inputs to the throttle will result in small output from the auxiliary

channel. The adjustment range is from -125% to 0% to 125%. If the rate is negative, the

channel is mixed in the opposite direction.

Both mixes share a single mixing “offset.” The purpose of the mixing offset is to redefine the

neutral position of the auxiliary channel, which can be set using Grip Lever A when

“LN” is selected in the Auxiliary Channel 3 function. If the “LN” selection is turned off in the

Auxiliary Channel 3 function with an offset value currently present, the value will

continue to act as a mixing offset until the value is either cleared or changed. If a mix is not

required, it is strongly suggested the mixing rate be set for 0%, which is the default.

Lap Timer

Function Mode

The Lap Timer function of the DX3.0 allows the recording of individual lap times based on a

999 second up-timer. Up to 50 laps and times from 3.0 to 99.9 seconds can be stored in

memory for review at a later time. The Lap Timer function will only be enabled and shown in

Function mode if Grip Button C (System Mode) is set to “LA.” With the Lap Timer enabled,

pressing the channel key will alternate between the Normal display screen and Up-Timer

display screen.

The Lap Timer is started by pressing Grip Button C. Once active, as shown by the blinking word

“LAP,” pressing Grip Button C again will begin recording the time of the next lap.

Note: A 3.0-second lap is the quickest lap allowed. This prevents accidental double pushing of

Grip Button C when recording lap times. If more than 50 laps are recorded, each new lap will

overwrite the oldest lap held in memory.

To stop the Lap Timer, press the Increase and Decrease keys at the same time. To restart the Lap

Timer, press Grip Button C. To reset the Up-Timer, press the Channel key to show the Up-Timer

display screen. With the Up-Timer stopped, press the Increase and Decrease keys at the same

time to reset.

–

M I X

STL

I0

M I X

–

THB

I0

Accessing the Mixing Adjustment Function

1. Turn the transmitter power switch on.

2. Press the SCROLL key to access Function mode.

3. Press the SCROLL key until MIX appears in the screen.

4. Press the CHANNEL key to select the desired mix to be used.

5. Move the steering wheel or trigger in the desired direction for adjustment (left/right,

forward/reverse or brake). Press the INCREASE or DECREASE key to achieve the

desired amount of mixing. Move the wheel or trigger in the opposite direction to adjust

the mixing in the opposite direction.

Note: For Auxiliary Channel 3 function, if LN is selected, only L/F is adjustable.

6. Press the SCROLL key to access the Lap Timer (if enabled) or Sub-Trim function.

7. To exit the Function mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

To review or reset lap times you must be in the Lap Timer function mode screen. Upon entering

this function, the screen will always show the last lap time recorded. Use the

Increase or Decrease keys to view the desired lap(s).

Note: If a recorded lap time is greater than 99.9 seconds, “OVR” will be displayed.

To clear all lap times, press the Increase and Decrease keys at the same time.

Recorded Lap Time to 1/10th of a second

(e.g., 40.1 sec.)

Current Lap Number

–

L A P

4 0I

20

Accessing the Lap Timer Function

1. Turn the transmitter power switch on.

2. Press the SCROLL key to access Function mode.

3. Press the SCROLL key until LAP appears in the screen.

4. Press the INCREASE or DECREASE key to view the desired lap time(s).

5. To reset all lap times, press the INCREASE and DECREASE keys at the same time.

6. Press the SCROLL key to access the Sub-Trim function.

7. To exit the Function mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

Page 15

28

29

Sub-Trim

Function Mode

The Sub-Trim function of the DX3.0 is an electronic trimming feature that allows the neutral

position of the servo on either the steering, throttle or auxiliary channel (optional) to be moved,

while allowing the electronic trim lever for that channel to remain in the center position. This

feature is very useful as it allows the servo arm/wheel position to be moved to help with control

linkage installation, eliminating the need to make mechanical linkage adjustments.

Although the Sub-Trim function is a very useful feature, it is suggested that only small amounts

of Sub-Trim be used so that no unwanted, non-equal servo travel is created. It is suggested that

less than 30 points of Sub-Trim be used during adjustment. If more than 30 points of Sub-Trim

are required, it is suggested that a mechanical linkage adjustment be performed.

Accessing the

Direct Trim

Mode

The Direct Trim Mode function of the DX3.0 is accessible through the use of the electronic

throttle or steering trim levers, as well as the two electronic grip levers (A&B) located on

the upper portion of the grip handle. This function allows for quick trim adjustment of these

controls.

–

–

Steering Trim

TRIM

STS

(page 29)

0

Servo

Reversing

Function Mode

–

TRIM

–

STS

0

Values: R/B 125 0 R/F 125

Current Channel

STS = Steering

THS = Throttle

AUS = Auxiliary Channel 3

Current Value

Accessing the Sub-Trim Function

1. Turn the transmitter power switch on.

2. Press the SCROLL key to access Function mode.

3. Press the SCROLL key until TRIM appears in the screen.

4. Press the CHANNEL key to select the desired channel to be adjusted (Steering, Throttle

or Auxiliary Channel 3).

5. Press the INCREASE or DECREASE key until the proper servo position is achieved.

6. Press the SCROLL key to access the Servo Reversing function.

7. To exit the Function mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

The Servo Reversing feature of the DX3.0 is a very convenient feature when setting up a new

model. The purpose of the servo reversing function is to change the direction of the

servo rotation in relation to the wheel/trigger movement. The Servo Reversing function is

available for the steering, throttle and Auxiliary Channel 3.

–

ST

REV • NORM

–

Current Channel

STS = Steering

THS = Throttle

AUS = Auxiliary Channel 3

Current Servo Direction

Accessing the Servo Reversing Function

1. Turn the transmitter power switch on.

2. Press the SCROLL key to access Function mode.

3. Press the SCROLL keyuntilREV•NORMappearsinthescreen.

4. Press the CHANNEL key to select the desired channel to be changed (Steering, Throttle

or Auxiliary Channel 3).

5. Press the INCREASE or DECREASE key to move the cursor to the desired direction

of travel.

6. To exit the Function mode, either turn the transmitter power switch off or press the

SCROLL and CHANNEL keys at the same time.

Throttle Trim

TRIM

THC

(page 30)

0

RATE

–

STG

Steering Dual-Rate

(Grip Lever B)

(page 30)

70

To access the Direct Trim Mode function, turn the transmitter power switch on. Next, move

the desired trim lever to be adjusted. The appropriate screen for the selected trim lever will

be displayed. To adjust, simply move the trim lever in the desired direction until the correct

amount of trim is achieved. Once the desired trim is achieved, the screen will return to the

Normal display screen after approximately two seconds from the last trim input. If the

Increase or Decrease keys are pressed any time during the two seconds, the system will

return to the previous screen in use.

Only present when Auxiliary function “0” is selected

Brake Travel Adjustment

(Grip Lever A), (page 32)

Only visible when the Auxiliary Channel

3 function “0” has been selected. Refer to

Auxiliary Channel 3 function, page 17,

for clarification.

Auxiliary Channel 3 Trim Adjustment (LN

mode only). Refer to Auxiliary Channel 3

function, page 33, for clarification.

*

E P A

R/B

BRK

50

AUX

0

*

*Note: When Auxiliary Channel 3 function 2P is selected, the two screens above are not

present.

Page 16

30

31

Steering Trim

(STC)

The DX3.0 electronic Steering Trim lever, located just above the steering wheel, allows the

center position of the servo to be manipulated in either direction to achieve precise centering

of the steering assembly. Steering Travel Endpoint Adjustment values (page 24) remain

completely independent from the steering trim, unless the trim value exceeds the selected

endpoint values. (For example: If trim value is set at 30 and endpoint values at 15, steering

trim will override/alter the endpoint value.)

Throttle Trim

(THC)

The DX3.0’s electronic Throttle Trim lever, located to the left of the steering wheel, allows the

center position of the servo to be manipulated in either direction to achieve precise centering

of the throttle trigger neutral position. Throttle Endpoint adjustment values (page 24) remain

completely independent from the throttle trim, unless the trim value exceeds the selected

endpoint values. (For example: If the trim value is set at 40 and the endpoint values at 30,

Throttle Trim will override/alter the endpoint value.)

–

TRIM

stC

0

Values: L/F 30 0 R/B 30

Each click will provide 0.3° of trim to the center of the steering servo with a maximum of 12° allowed.

Note: Each click will not always result in a change of the value displayed.

To adjust the steering trim servo position, move the electronic Steering Trim lever either to

the left (+) or the right (-). As soon as the trim is moved, the STC Steering Trim screen will

appear and will continue to be displayed unless the trim lever is untouched for a period of

two seconds. To reset the trim value to 0, press the INCREASE and DECREASE keys at the

same time while the “STC” screen is displayed.

Steering Trim Screen

Indicates current value

Steering Trim

TRIM

Values: L/F 60 0 R/B 60

Each click will provide 0.3° of trim to the throttle servo with a maximum of 24° allowed.

Note: Each click will not always result in a change of the value displayed.

To adjust the Throttle Trim servo position, move the electronic steering trim lever either up

(+) or down (-). As soon as the trim is moved, the THC Throttle Trim screen will appear and

will continue to be displayed unless the trim lever is untouched for a period of two seconds.

To reset the trim value to zero, press the INCREASE and DECREASE keys at the same time

while the “THC” screen is displayed.

Throttle Trim

Increase

Decrease

THC

0

Current value

Steering Trim Location

Throttle Trim Location

Page 17

32

33

Grip Lever B:

Steering Dual

Rate Trim

Adjustment

STG

The Steering Dual Rate Trim Adjustment, located at Grip Lever B, allows the dual rate value

(maximum servo travel) to be increased or decreased within a range from 100% through

20% of the total endpoint value established in the steering EPA function. This function

is very useful in race conditions as it allows you to custom tailor the steering radius and

sensitivity for the current track conditions. Please note that since the Dual Rate value shown

in the “STG” screen is the percentage of the endpoint value established in the steering EPA

function, the value will not always increase or decrease each time the Grip Lever B is moved.

–

RATE

stG

Grip Lever A:

Brake Endpoint

Adjustment

BRK/Auxiliary

Channel 3

Access

The Brake Endpoint Adjustment, located at Grip Lever A, allows the maximum servo travel

on the braking side of the throttle trigger to be increased or decreased from 100% to 0%

(off). This function is very useful in race conditions as it allows the racer to custom tailor

the “panic” brake value to maximize the car’s braking power for the current track conditions.

Please note that since the brake endpoint value shown in the BRK screen is a percentage of

the total braking value established in the Endpoint Adjustment function (page 24), the value

will not always increase or decrease each time the Grip Lever A is moved.

Note: If Grip Lever A is assigned an Auxiliary Channel 3 function by selecting “LN” or “2P”

with Grip Button C in use, the Brake Endpoint Adjustment will not be available.

%

70

If the Emergency Steering button function (page 18) is active, pressing Grip Button C will

restore the steering dual rate to 100% until the button is released.

To adjust the Steering Dual Rate value, move the electronic Grip Lever B either left (-) or right

(+). As soon as the trim is moved, the STG Steering Dual Rate screen will appear and will

continue to be displayed unless the Grip Lever B is untouched for a period of two seconds.

To reset the trim value to the factory preset setting of 70%, press the INCREASE and

DECREASE keys at the same time while the “STG” screen is displayed.

Grip Lever B

Steering

Dual-Rate Trim

Current Value

(20% to 100%)

Decrease

Increase

To adjust the brake endpoint value, move the electronic Grip Lever A either left (–) or right (+).

As soon as the grip lever is moved, the BRK Endpoint Adjustment screen will appear and will

continue to be displayed unless the Grip Lever A is untouched for a period of two seconds.

E P A

R/B

BRK

50

Grip Lever A

Brake Trim

Current Value

(100 to 0%)

Decrease Increase

Move the Grip Lever A to the left or right to

decrease or increase values.

Page 18

34

35

Auxiliary

Channel 3

Access

(Fuel Mixture)

Auxiliary

Channel 3

(Transmission

Shift Selector)

When selected, Grip Lever A can be used to access the Auxiliary Channel 3 function of the

DX3.0 for use as a fuel mixture channel.

AUX

0

Current value

When the LN (linear) Auxiliary Channel 3 function is selected, Grip Lever A can be used to

change the neutral position of the servo to lean or richen the engine’s fuel mixture. Once the

desired fuel mixture has been achieved, the Grip Lever A value indicated on this screen can

be transferred manually to the Sub-Trim function (page 27) and the value of the AUX screen

can be returned to zero. Please refer to the diagram below for proper grip lever operation.

When the 2P Auxiliary Channel function is selected, the Grip Lever A can be used to move

the Auxiliary 3 Channel servo to one of two positions (left/right or forward/reverse) when LA

or Eb is selected for the Grip Button C function. Please refer to diagram A below for proper

shifting procedures.

Note: The Endpoint Adjustment function (page 24) is used to set the forward and reverse

gear servo travel positions.

(Transmission Use)

(Fuel Mixture Use)

Forward Gear Reverse Gear

Decrease

Grip Lever A

Brake Trim

Increase

Warranty

and Service

Information

Warranty Period

Exclusive Warranty- Horizon Hobby, Inc., (Horizon) warranties that the Products

purchased (the “Product”) will be free from defects in materials and workmanship

for a period of 1 year from the date of purchase by the Purchaser.

Limited Warranty

(a) This warranty is limited to the original Purchaser (“Purchaser”) and is

not transferable. REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS

WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER. This warranty

covers only those Products purchased from an authorized Horizon dealer. Third

party transactions are not covered by this warranty. Proof of purchase is required

for warranty claims. Further, Horizon reserves the right to change or modify this

warranty without notice and disclaims all other warranties, express or implied.

(b) Limitations- HORIZON MAKES NO WARRANTY OR REPRESENTATION,

EXPRESS OR IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCT. THE PURCHASER

ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT

WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S INTENDED

USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder shall be that Horizon

will, at its option, (i) repair or (ii) replace, any Product determined by Horizon

to be defective. In the event of a defect, these are the Purchaser’s exclusive

remedies. Horizon reserves the right to inspect any and all equipment involved

in a warranty claim. Repair or replacement decisions are at the sole discretion of

Horizon. This warranty does not cover cosmetic damage or damage due to acts of

God, accident, misuse, abuse, negligence, commercial use, or modification of or

to any part of the Product. This warranty does not cover damage due to improper

installation, operation, maintenance, or attempted repair by anyone other than

Horizon. Return of any goods by Purchaser must be approved in writing by

Horizon before shipment.

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN

ANY WAY CONNECTED WITH THE PRODUCT, WHETHER SUCH CLAIM IS BASED

IN CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY. Further, in

no event shall the liability of Horizon exceed the individual price of the Product

on which liability is asserted. As Horizon has no control over use, setup, final

assembly, modification or misuse, no liability shall be assumed nor accepted for

any resulting damage or injury. By the act of use, setup or assembly, the user

accepts all resulting liability.

If you as the Purchaser or user are not prepared to accept the liability associated

with the use of this Product, you are advised to return this Product immediately in

new and unused condition to the place of purchase.

Law: These Terms are governed by Illinois law (without regard to conflict of law

principals).

Safety Precautions:

This is a sophisticated hobby Product and not a toy. It must be operated with

caution and common sense and requires some basic mechanical ability. Failure

to operate this Product in a safe and responsible manner could result in injury

Page 19

36

37

or damage to the Product or other property. This Product is not intended for

use by children without direct adult supervision. The Product manual contains

instructions for safety, operation and maintenance. It is essential to read and

follow all the instructions and warnings in the manual, prior to assembly, setup or

use, in order to operate correctly and avoid damage or injury.

Questions, Assistance, and Repairs

Your local hobby store and/or place of purchase cannot provide warranty support

or repair. Once assembly, setup or use of the Product has been started, you must

contact Horizon directly. This will enable Horizon to better answer your questions

and service you in the event that you may need any assistance. For questions or

assistance, please direct your email to productsupport@horizonhobby.com, or

call 877.504.0233 toll free to speak to the product support department.

Inspection or Repairs

If this Product needs to be inspected or repaired, please call for a Return

Merchandise Authorization (RMA). Pack the Product securely using a shipping

carton. Please note that original boxes may be included, but are not designed

to withstand the rigors of shipping without additional protection. Ship via a

carrier that provides tracking and insurance for lost or damaged parcels, as

Horizon is not responsible for merchandise until it arrives and is accepted at our

facility. A Service Repair Request is available at www.horizonhobby.com on the

“Support” tab. If you do not have internet access, please include a letter with

your complete name, street address, email address and phone number where you

can be reached during business days, your RMA number, a list of the included

items, method of payment for any non-warranty expenses and a brief summary

of the problem. Your original sales receipt must also be included for warranty

consideration. Be sure your name, address, and RMA number are clearly written

on the outside of the shipping carton.

United States:

Electronics and engines requiring inspection or repair should be shipped to the

following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822 USA

All other Products requiring warranty inspection or repair should be shipped to

the following address:

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822 USA

Please call 877-504-0233 or e-mail us at productsupport@horizonhobby.com

with any questions or concerns regarding this product or warranty.

United Kingdom:

Electronics and engines requiring inspection or repair should be shipped to the

following address:

Horizon Hobby UK

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

Please call +44 (0) 1279 641 097 or e-mail us at sales@horizonhobby.co.uk with

any questions or concerns regarding this product or warranty.

Warranty Inspection and Repairs

To receive warranty service, you must include your original sales receipt verifying

the proof-of-purchase date. Provided warranty conditions have been met, your

Product will be repaired or replaced free of charge. Repair or replacement