XR-C750

SERVICE MANUAL

SPECIFICA TIONS

AUDIO POWER SPECIFICA TIONS (US model)

POWER OUTPUT AND TOTAL HARMONIC DISTOR TION

17 watts per channel minimum continuous average power into

4 ohms, 4 channels driven from 20 Hz to 20 kHz with no more than

1 % total harmonic distortion.

US Model

E Model

Model Name Using Similar Mechanism XR-C500

T ape Transport Mechanism Type MG-52B-135

Cassette player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.08% (WRMS)

Frequency response 30 - 20,000 Hz

Signal-to-noise ratio

Cassette type Dolby B NR Dolby C NR Dolby NR off

TYPE II, III, IV 67 dB 73 dB 61 dB

TYPE I 64 dB 70 dB 58 dB

Tuner section

FM

Tuning range US model :

87.5 - 107.9 MHz

E model :

FM tuning interval :

50 kHz/200 kHz

switchable

87.5 - 108.0 MHz

(at 50 kHz step)

87.5 - 107.9 MHz

(at 200 kHz step)

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz

Usable sensitivity 9 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 65 dB (stereo),

68 dB (mono)

Harmonic distortion at 1 kHz

0.5% (stereo),

0.3% (mono)

Separation 35 dB at 1 kHz

Frequency response 30 - 15,000 Hz

Capture ratio 2 dB

AM (US model)

Tuning range 530 - 1,710 kHz

Antenna terminal External antenna connector

Intermediate frequency 10.71 MHz/450 kHz

Sensitivity 30 µV

MW (E model)

Tuning range MW tuning interval :

9 kHz/10 kHz switchable

531 - 1,602 kHz

(at 9 kHz step)

530 - 1,710 kHz

(at 10 kHz step)

Antenna terminal External antenna connector

Intermediate frequency 10.71 MHz/450 kHz

Sensitivity 30 µV

– Continued on next page –

FM/AM CASSETTE CAR STEREO

US Model

FM/MW/SW CASSETTE CAR STEREO

E Model

MICROFILM

– 1 –

SW1, 2 (E model)

Tuning range SW1 : 2,940 - 7,735 kHz

SW2 : 9,500 - 18,135 kHz

(except for 10,140 - 11,575

kHz)

Antenna terminal External antenna connector

Intermediate frequency 10.71 MHz/450 kHz

Sensitivity 50 µV

Power amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance 4 - 8 ohms

Maximum power output 40 W × 4 (at 4 ohms)

US model :

35 W × 4 (at AM band, 4

ohms)

E model :

35 W × 4 (at MW and SW

band, 4 ohms)

General

Outputs Line outputs (3)

Power antenna relay

control lead

Power amplifier control

lead

Tone controls Bass ± 8 dB at 100 Hz

Treble ± 8 dB at 10 kHz

Power requirements 12 V DC car battery

(negative earth)

Dimensions Approx. 184 × 50 × 176 mm

(7 1/4 × 2 × 6 7/8 in.)

(w/h/d)

Mounting dimensions Approx. 182 × 53 × 163 mm

(7 1/4 × 2 1/8 × 6 1/2 in.)

(w/h/d)

Mass Approx. 1.3 kg (2 lb. 14 oz.)

Supplied accessories Parts for installation and

connections (1 set)

Front panel case (1)

Rotary remote RM-X2S (1)

Wireless remote

RM-X45 (1) (E model)

Design and specifications are subject to change without

notice.

T ABLE OF CONTENTS

1. GENERAL

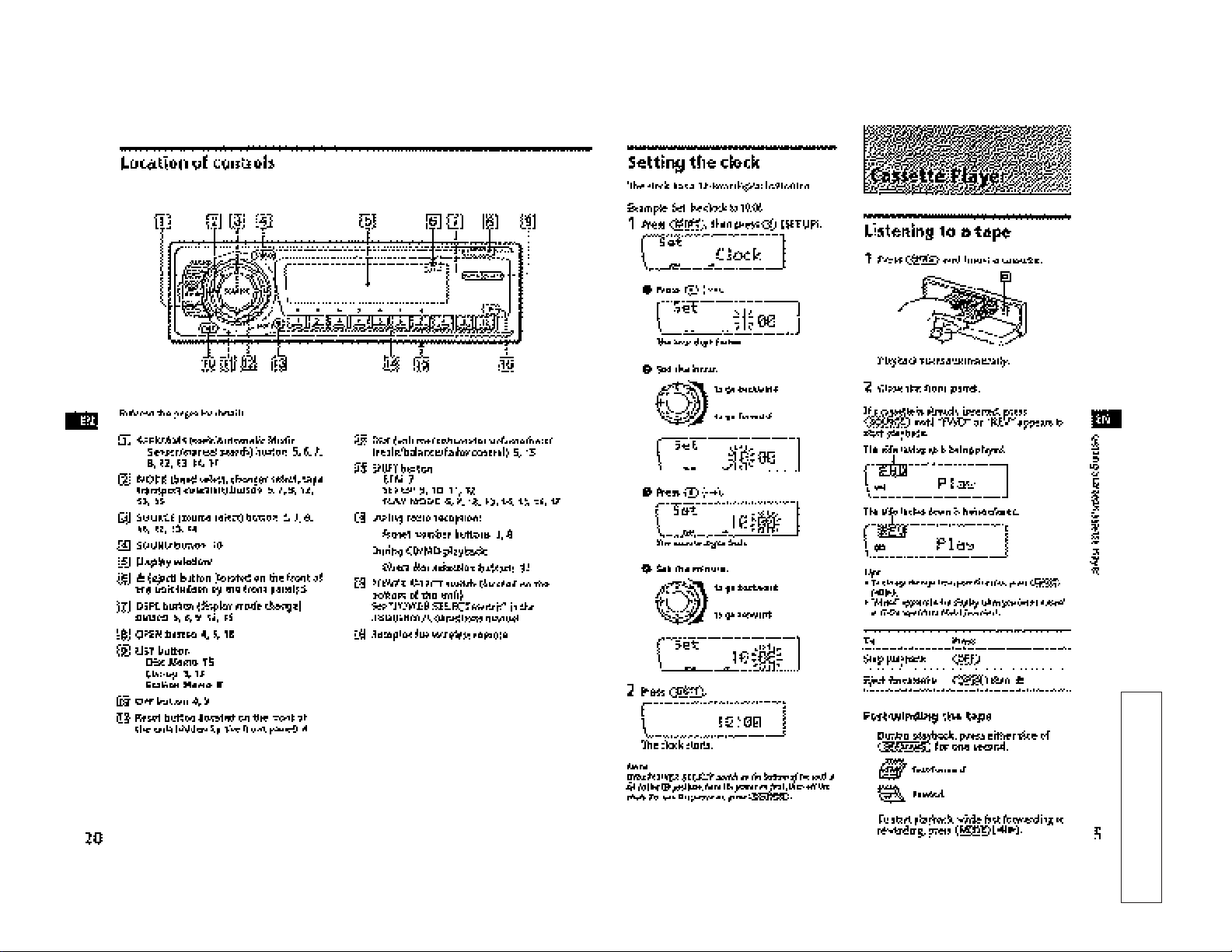

Location of Controls.................................................................. 3

Setting the Clock ....................................................................... 3

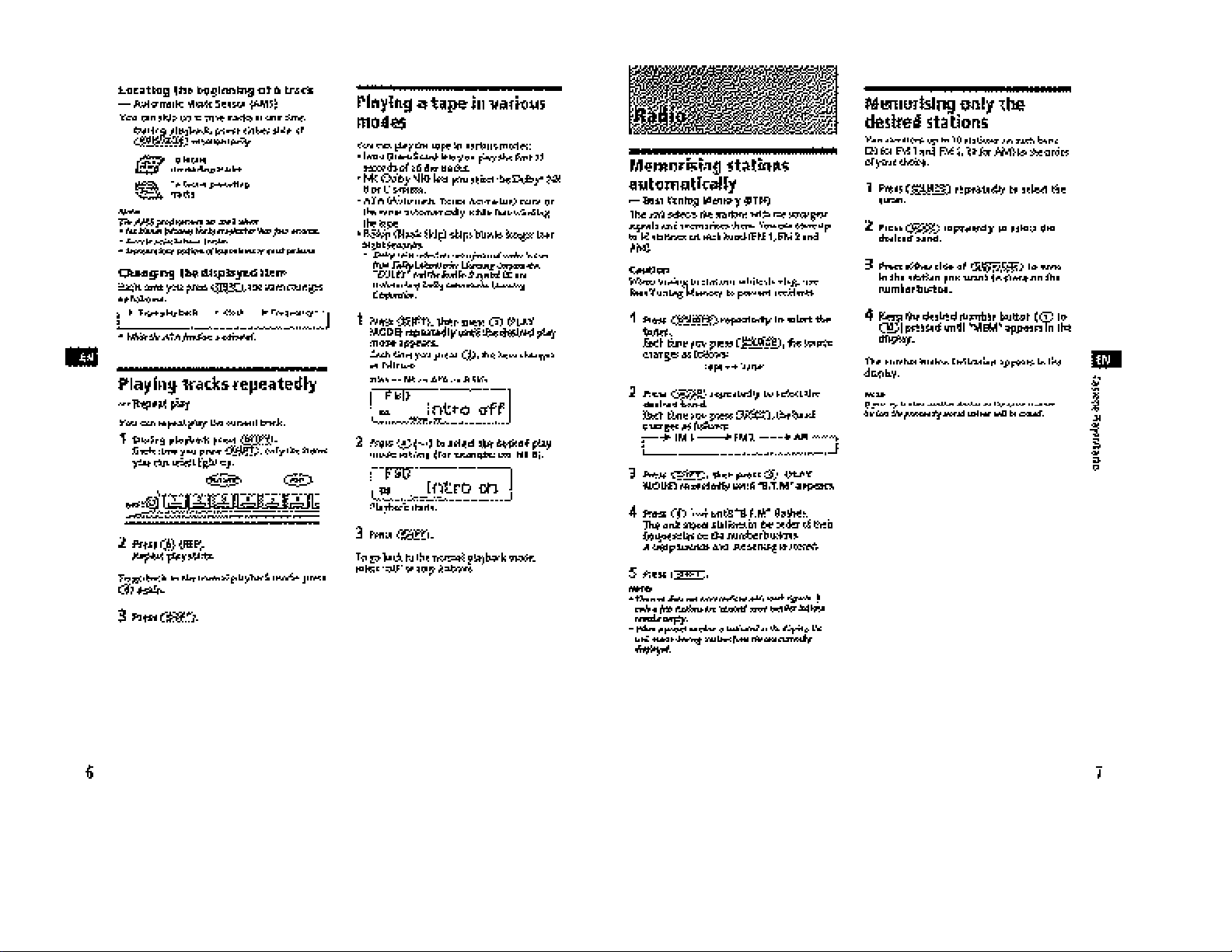

Cassette Player .......................................................................... 3

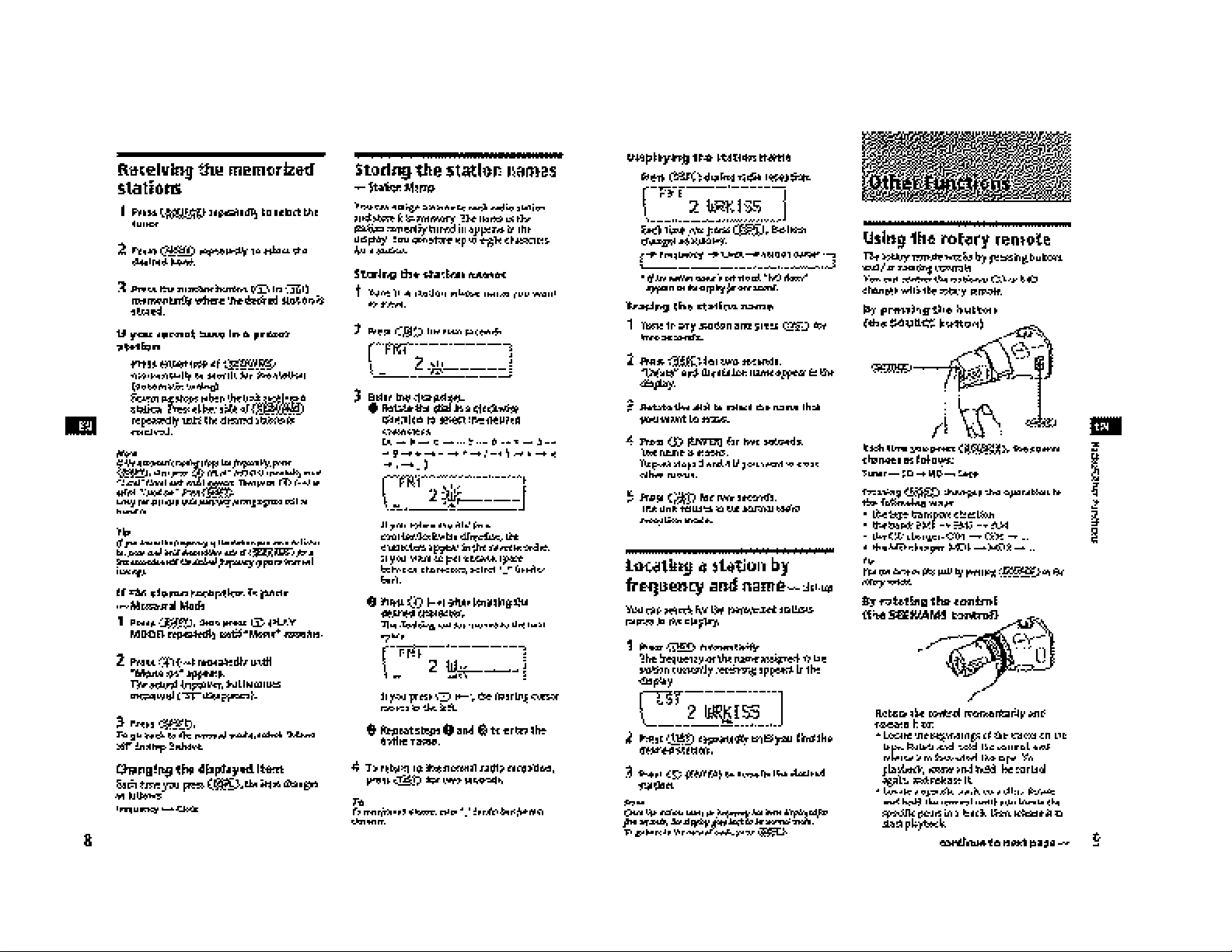

Radio ......................................................................................... 4

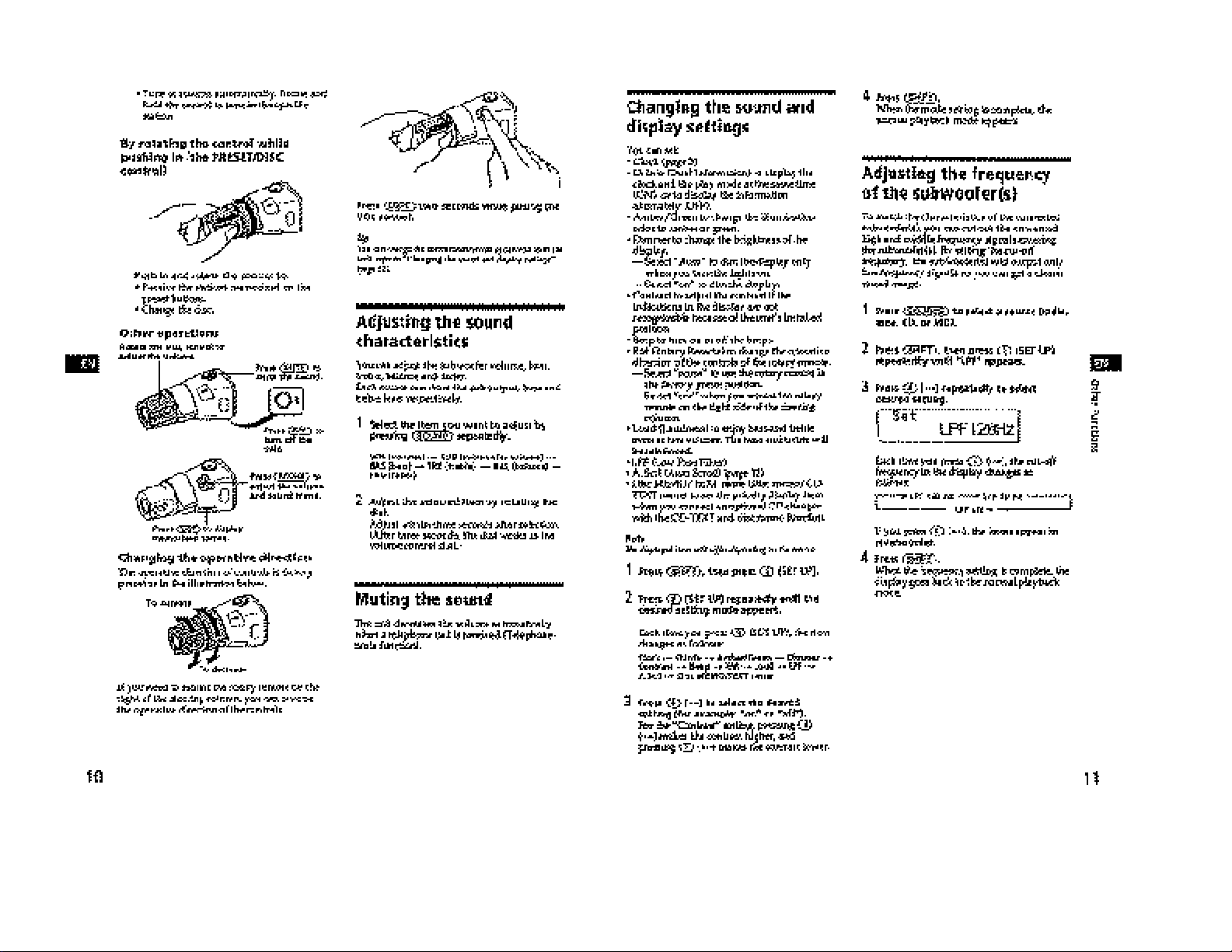

Other Functions ......................................................................... 5

CD/MD Changer ....................................................................... 7

Additional Information .............................................................. 9

Connections ............................................................................. 11

2. DISASSEMBL Y

2-1. Cover Assy .......................................................................... 13

2-2. Front Panel Assy ................................................................. 13

2-3. Sub Panel Assy.................................................................... 14

2-4. Mechanism Deck Block ...................................................... 14

2-5. Heat Sink ............................................................................. 15

2-6. Main Board ......................................................................... 15

3. ASSEMBL Y OF MECHANISM DECK

Alignment of Rotary Switch.................................................... 16

Gear (LDG-E).......................................................................... 16

Chassis (S) Assy ...................................................................... 17

Lever (Mode) ........................................................................... 17

Lever (Pinch Selection) ........................................................... 18

Head Plate Assy....................................................................... 18

Lever (Pinch) Assy .................................................................. 19

Housing ................................................................................... 19

Arm (Suction).......................................................................... 20

Lever (LDG-A)/(LDG-B)........................................................ 20

Gear (LDG-FT) ....................................................................... 21

Guide (C) ................................................................................. 21

4. MECHANICAL ADJUSTMENTS................................. 22

5. ELECTRICAL ADJUSTMENTS

Deck Section............................................................................ 22

Tuner Section........................................................................... 23

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

6. DIAGRAMS

6-1. IC Pin Descriptions ............................................................. 26

6-2. Block Diagram –TC Section– ............................................. 29

6-3. Block Diagram –Main Section–.......................................... 31

6-4. Printed Wiring Boards –Main Section– .............................. 33

6-5. Schematic Diagram –Main Section–................................... 37

6-6. Printed Wiring Boards –Panel Section–.............................. 42

6-7. Schematic Diagram –Panel Section– .................................. 44

7. EXPLODED VIEWS

7-1. Chassis Section ................................................................... 51

7-2. Front Panel Section ............................................................. 52

7-3. Mechanism Deck Section-1 ................................................ 53

7-4. Mechanism Deck Section-2 ................................................ 54

8. ELECTRICAL P ARTS LIST ...................................... 55

Dolby noise reduction manufactured under license from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

– 2 –

– 3 –

SECTION 1

GENERAL

This section extracted from

US model’s instruction manual.

– 4 –

– 5 –

– 6 –

– 7 –

– 8 –

– 9 –

– 10 –

– 11 –

– 12 –

SECTION 2

DISASSEMBL Y

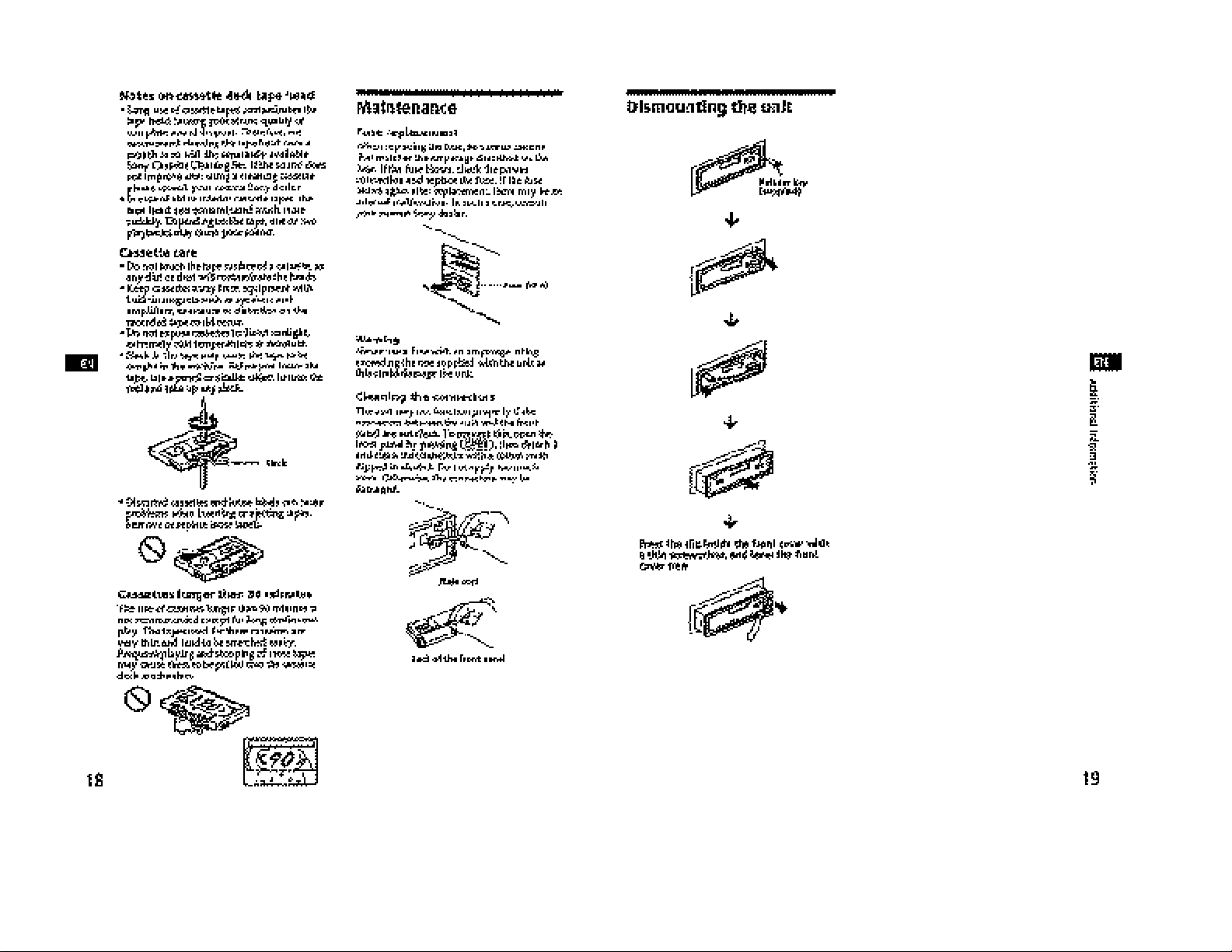

Note : Follow the disassembly procedure in the numerical order given.

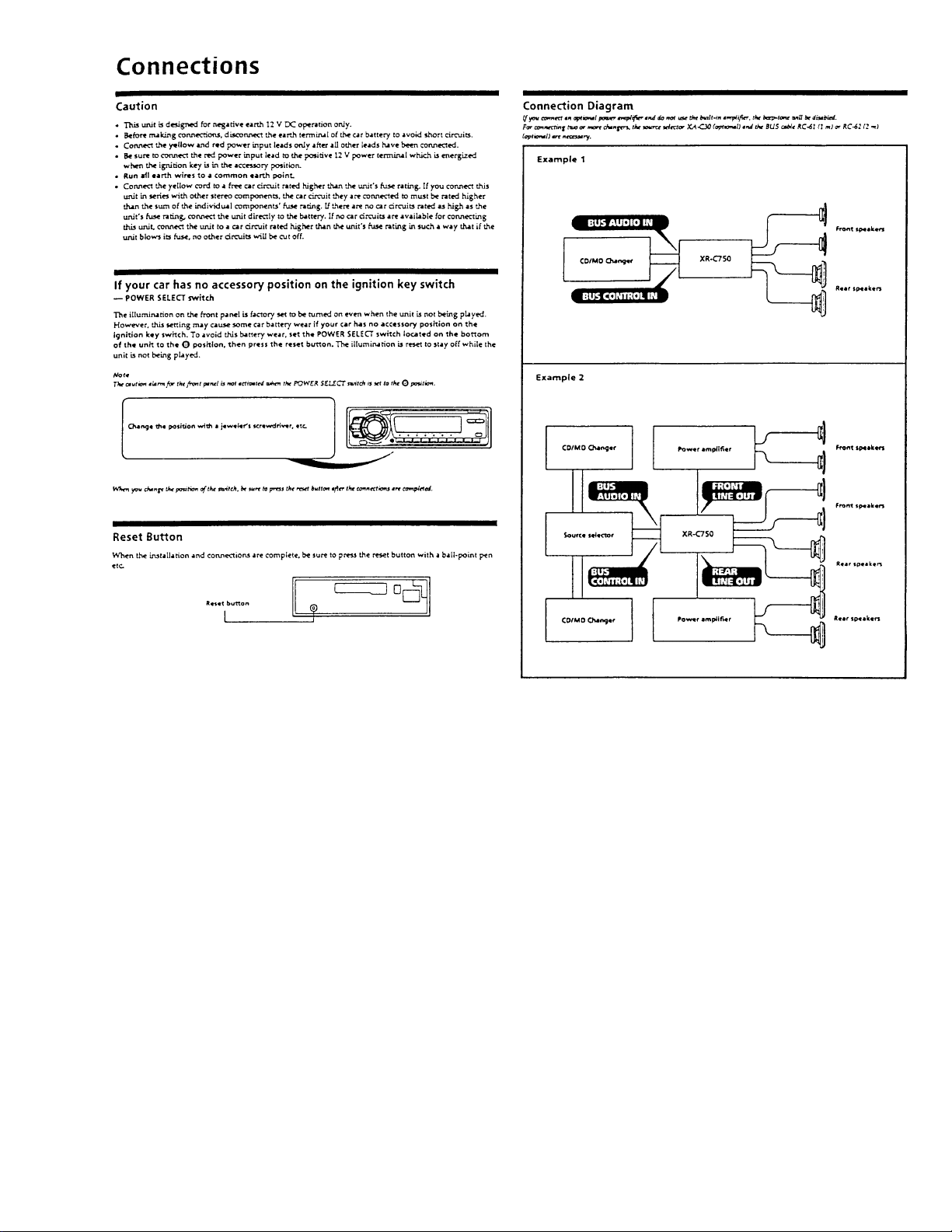

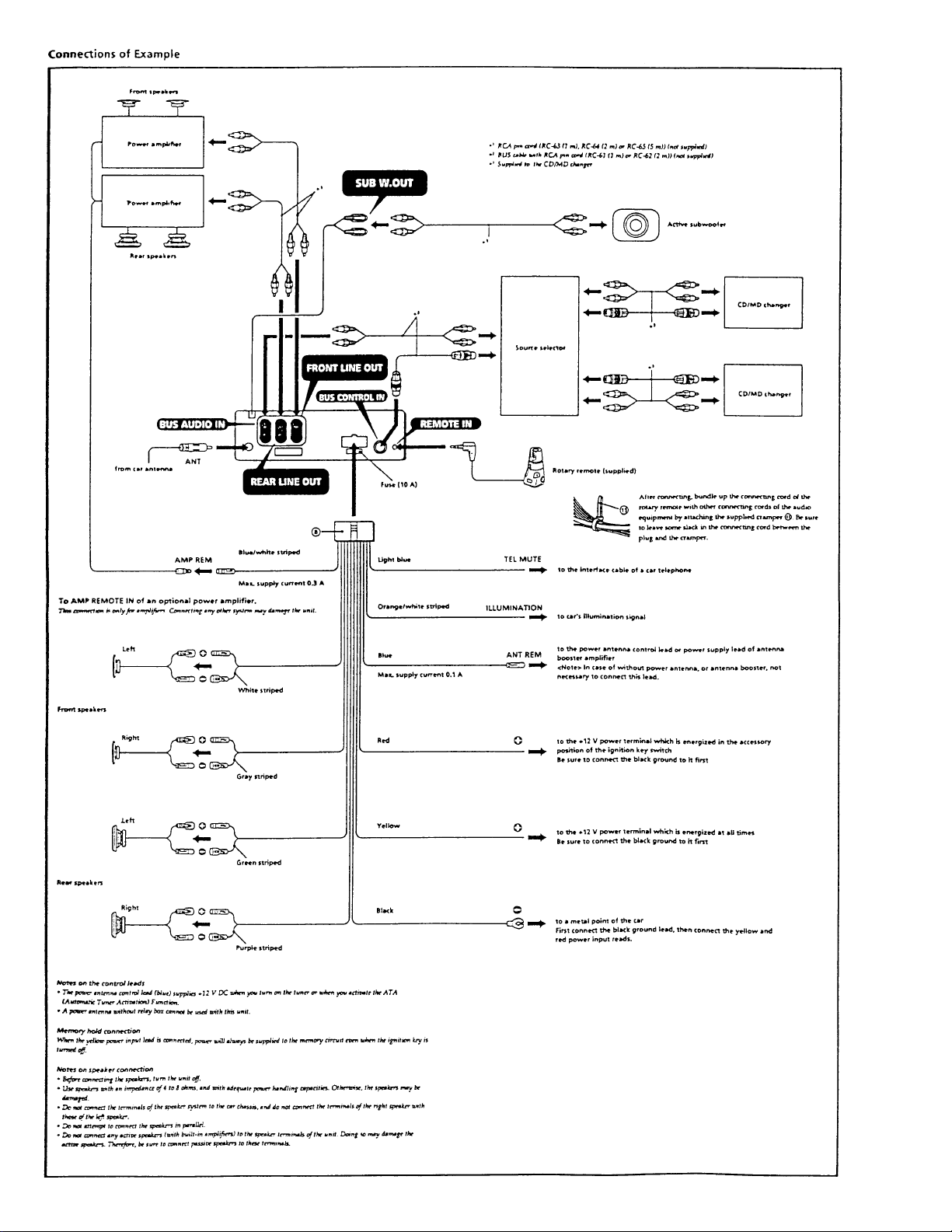

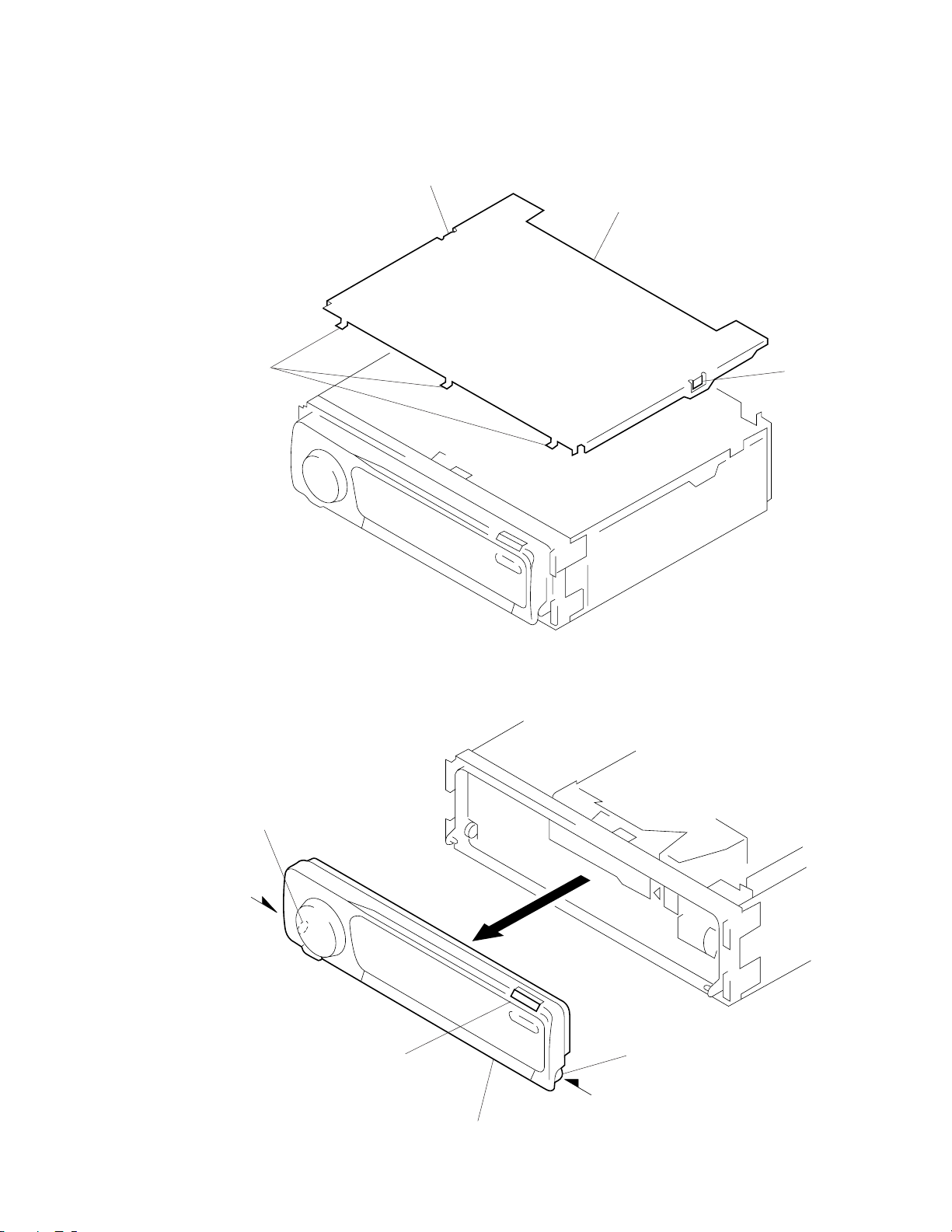

2-1. COVER ASSY

1 claw

4 cover assy

3 claws

2-2. FRONT P ANEL ASSY

2 claw

3 Push the bearing (L).

1 Push the button (OPEN).

2 Push the bearing (R).

4 front panel assy

– 13 –

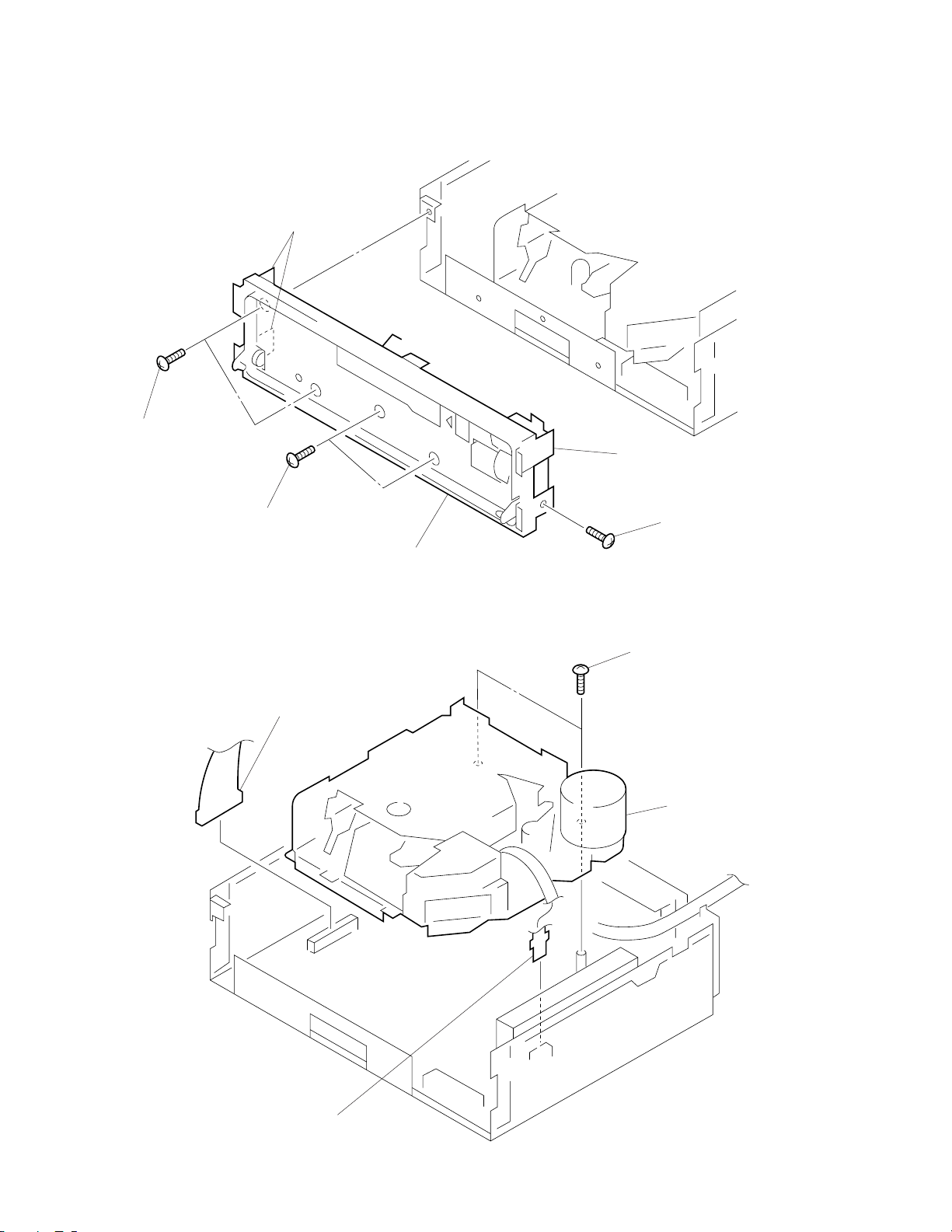

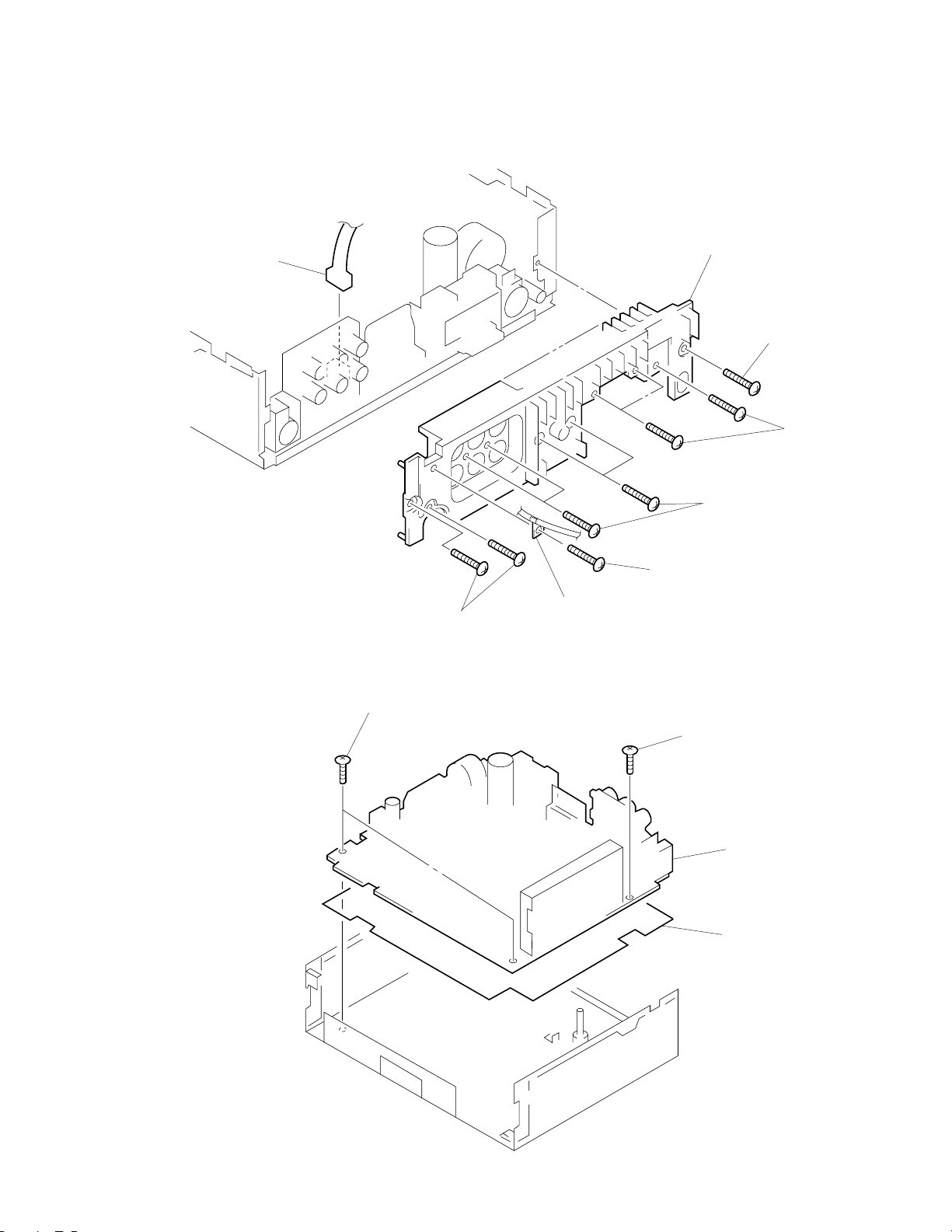

2-3. SUB P ANEL ASSY

3 PTT 2.6x8

4 claws

5 claw

2 PTT 2.6x8

2-4. MECHANISM DECK BLOCK

1 PTT 2.6x8

6 sub panel assy

1 screws

(2.6x6) (C TIGHT)

2 CN201

4 mechanism deck block

3 CN231

– 14 –

2-5. HEA T SINK

1 CN302

2-6. MAIN BOARD

8 heat sink

7 PTT 2.6x8

5 PTT 2.6x8

4 PTT 2.6x8

2 PTT 2.6x8

3 cord (with connector)

6 PTT 2.6x8

2 ground point screws

1 ground point screw

3 MAIN board

4 insulator

– 15 –

SECTION 3

ASSEMBL Y OF MECHANISM DECK

Note : Follow the assembly procedure in the numerical order given.

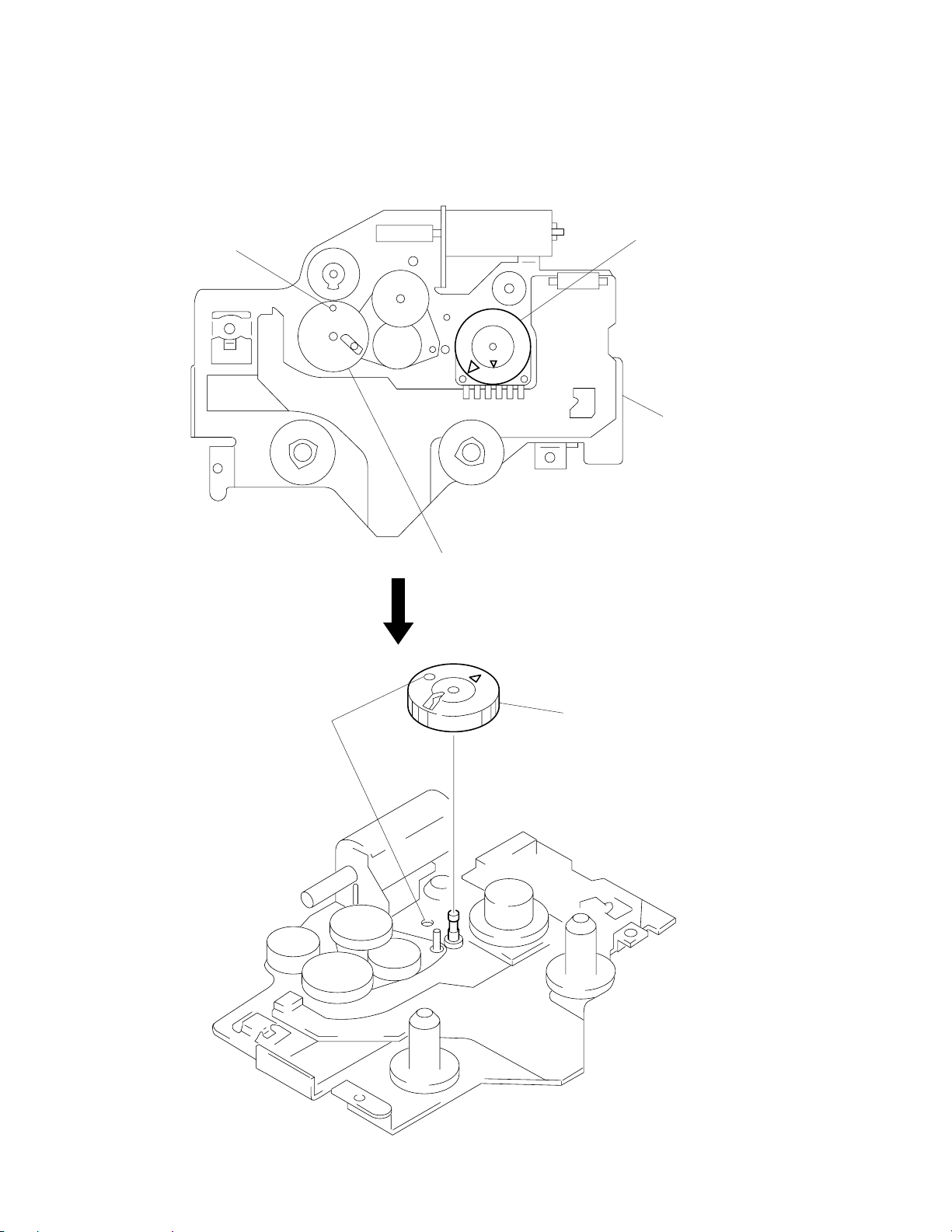

ALIGNMENT OF ROT ARY SWITCH

hole

1 Align ¢ mark on the rotary switch

the position shown in the figure.

chassis (S) assy

GEAR (LDG-E)

1 Align hole as shown in the figure.

2 Align hole in the gear (LDG-D) with

the position shown in the figure.

2 Install the gear (LDG-E).

– 16 –

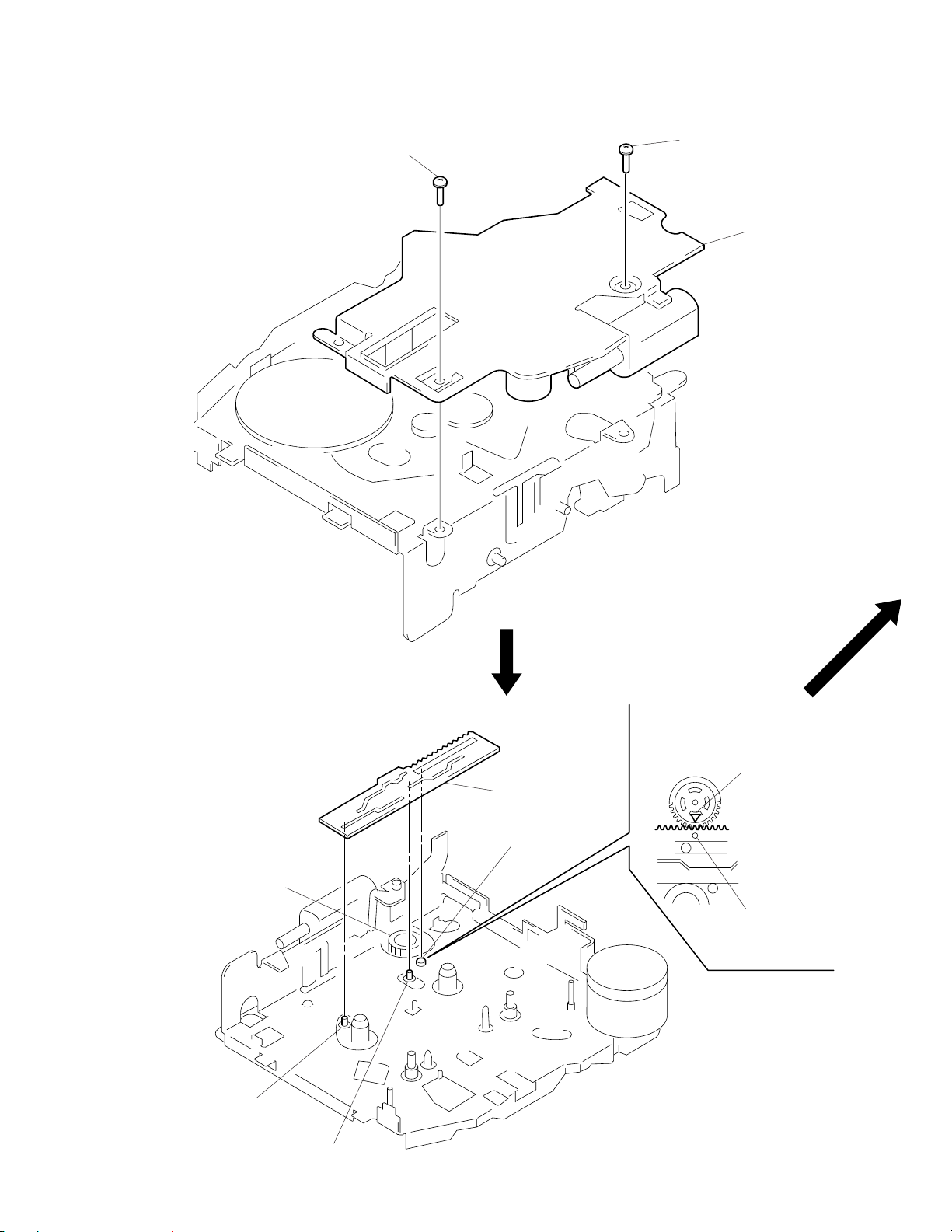

CHASSIS (S) ASSY

3 screw (PS 2x4)

2 screw (PS 2x4)

1 chassis (S) assy

LEVER (MODE)

1. Align ¢ mark on the rotary switch with

hole in the lever (mode).

2. Fit on positions A, B and C and install

the lever (mode).

rotary switch

A

¢ mark on rotary switch

lever (mode)

C

hole in lever (mode)

B

– 17 –

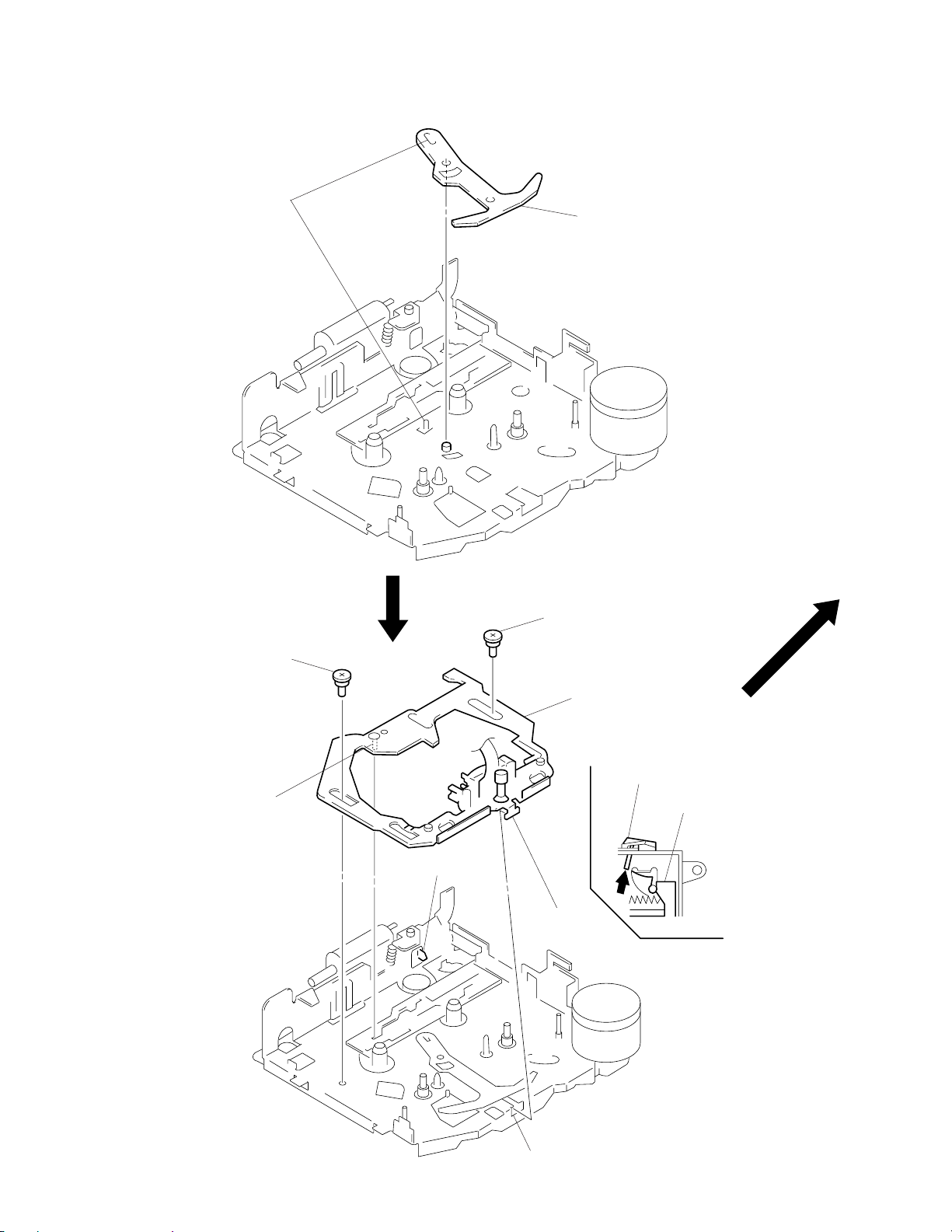

LEVER (PINCH SELECTION)

1 Align.

2 lever (pinch selection)

HEAD PLA TE ASSY

2 Fit shaft in groove.

6 step screw (HP)

5 step screw (HP)

head plate sub assy

3 Press the ATS lever .

4 Position the head plate sub

assy as shown in the figure.

ATS lever

1 Fit in groove.

– 18 –

groove

Loading...

Loading...