Sony XR-C7350X Service manual

XR-C7350X

SERVICE MANUAL

SPECIFICATIONS

US Model

Model Name Using Similar Mechanism XR-C5100

T ape Transport Mechanism T ype MG-25F-136

FM/AM CASSETTE CAR STEREO

TABLE OF CONTENTS

1. SERVICE NOTE ............................................................. 2

2. GENERAL ........................................................................ 3

3. DISASSEMBLY .............................................................. 8

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

4. ASSEMBLY OF MECHANISM DECK................ 9

5. MECHANICAL ADJUSTMENTS ............................ 12

6. ELECTRICAL ADJUSTMENTS

6-1. Test Mode........................................................................ 12

• Tape Deck Section ........................................................ 12

• Tuner Section ................................................................ 12

7. DIAGRAMS

7-1. Block Diagrams

• TUNER/TAPE/MAIN Section..................................... 13

• DISPLAY/KEY CONTROL/BUS CONTROL/

POWER SUPPLY Section ........................................... 14

7-2. Schematic Diagram – PRE OUT Board – ...................... 15

7-3. Printed Wiring Board – PRE OUT Board – .................. 15

7-4. Printed Wiring Board – MAIN Board – ......................... 16

7-5. Schematic Diagram – MAIN Board (1/2) – ................... 17

7-6. Schematic Diagram – MAIN Board (2/2) – ................... 18

7-7. Printed Wiring Boards – KEY/SUB Boards – .............. 19

7-8. Schematic Diagrams – KEY/SUB Boards – .................. 20

7-9. IC Block Diagrams ......................................................... 21

7-10. IC Pin Function ............................................................... 22

8. EXPLODED VIEWS................................................ 25

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

9. ELECTRICAL PARTS LIST ............................... 28

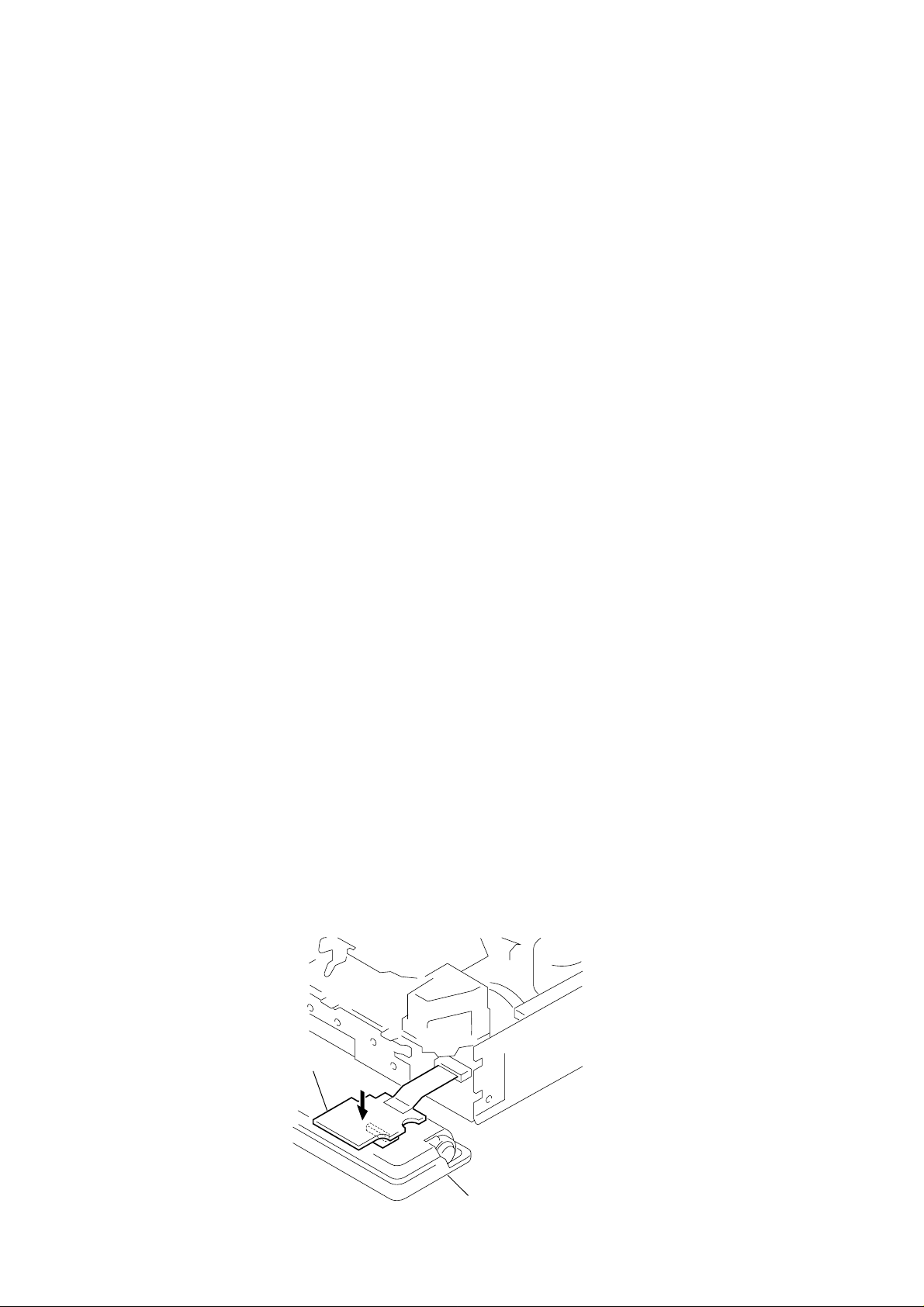

SECTION 1

SERVICE NOTE

Please press on the sub board from above when checking it.

This assures that the connector does not lose contact.

SUB board

Front panel assembly

2

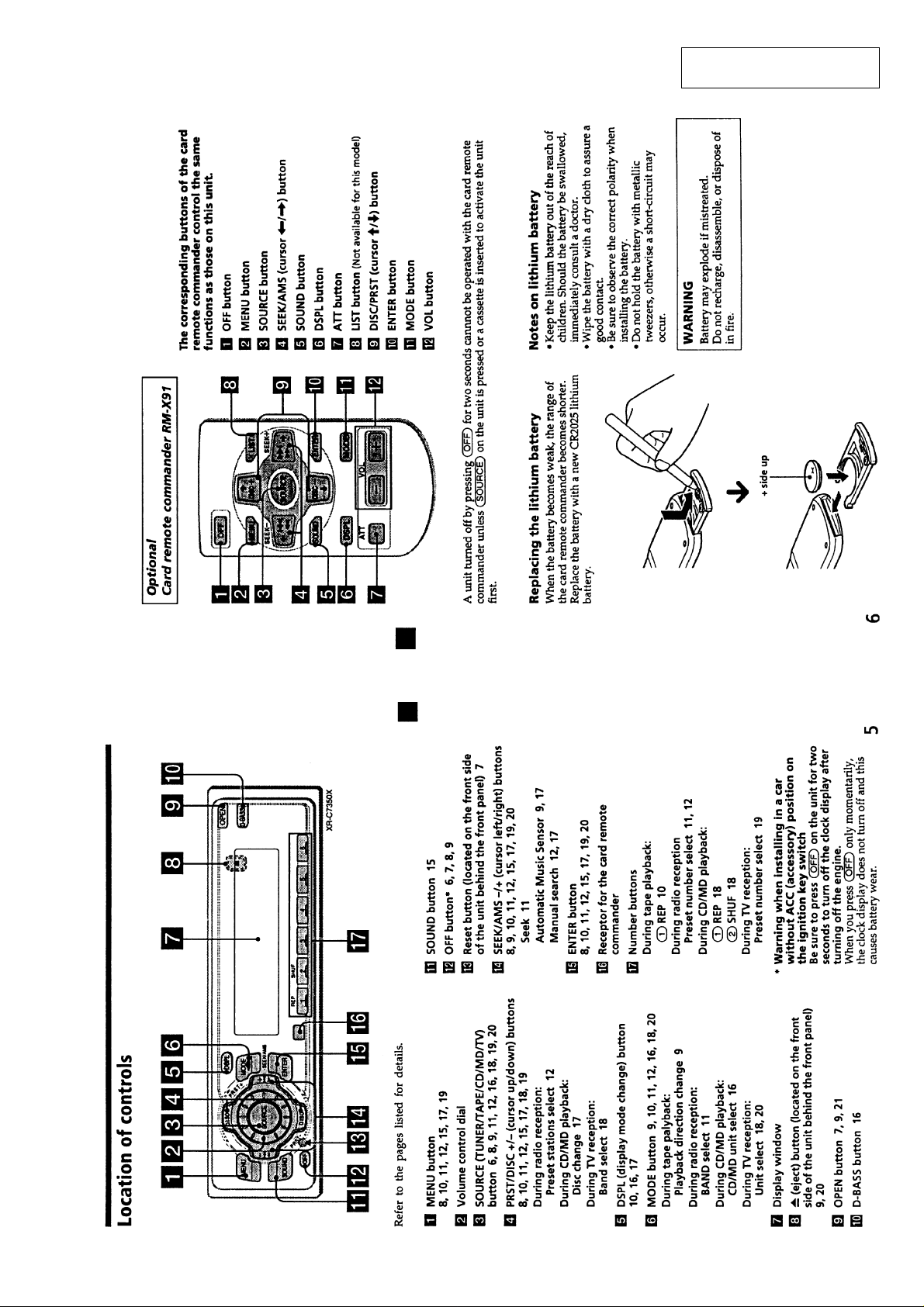

SECTION 2

GENERAL

This section is extracted from

instruction manual.

3

456

7

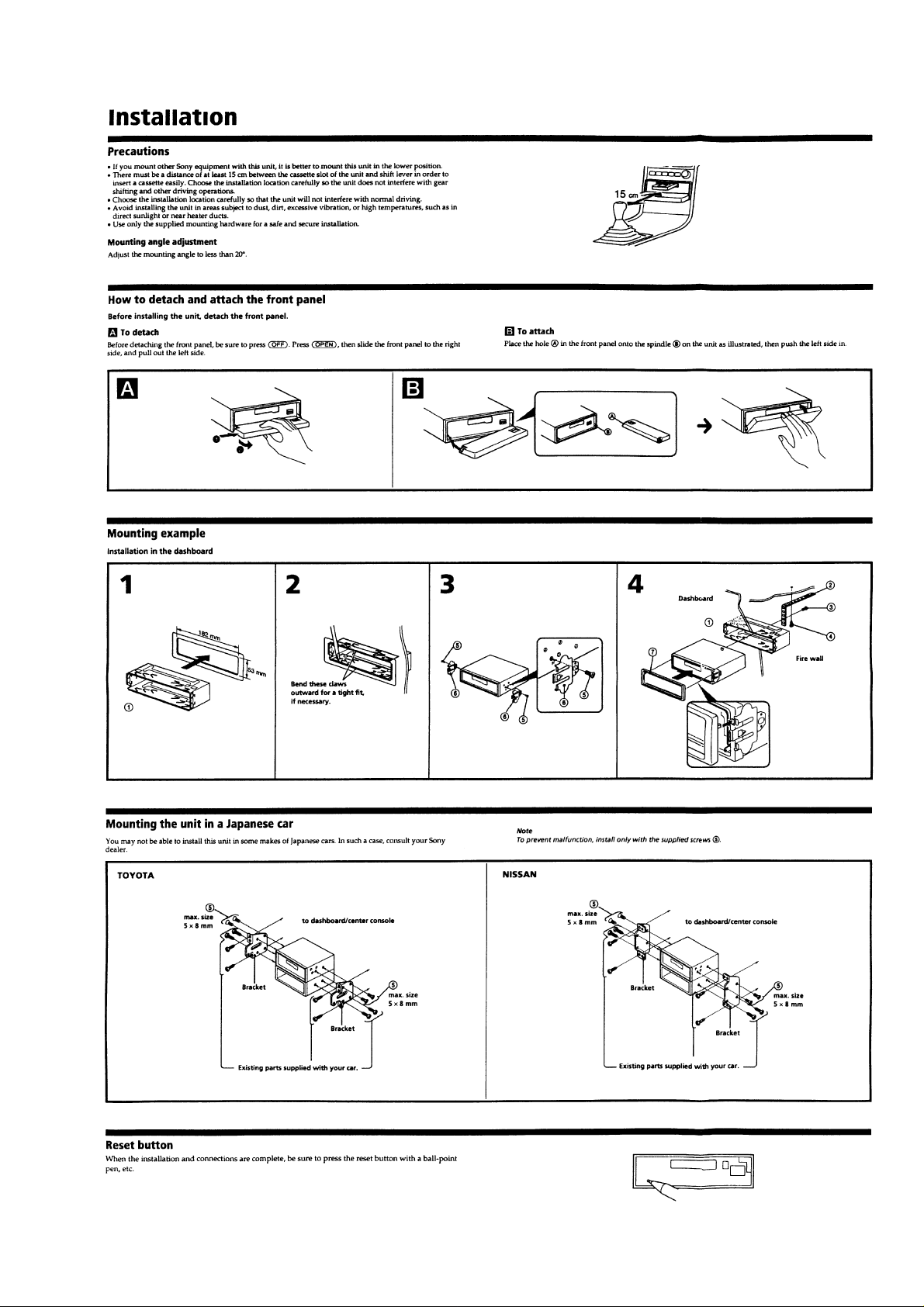

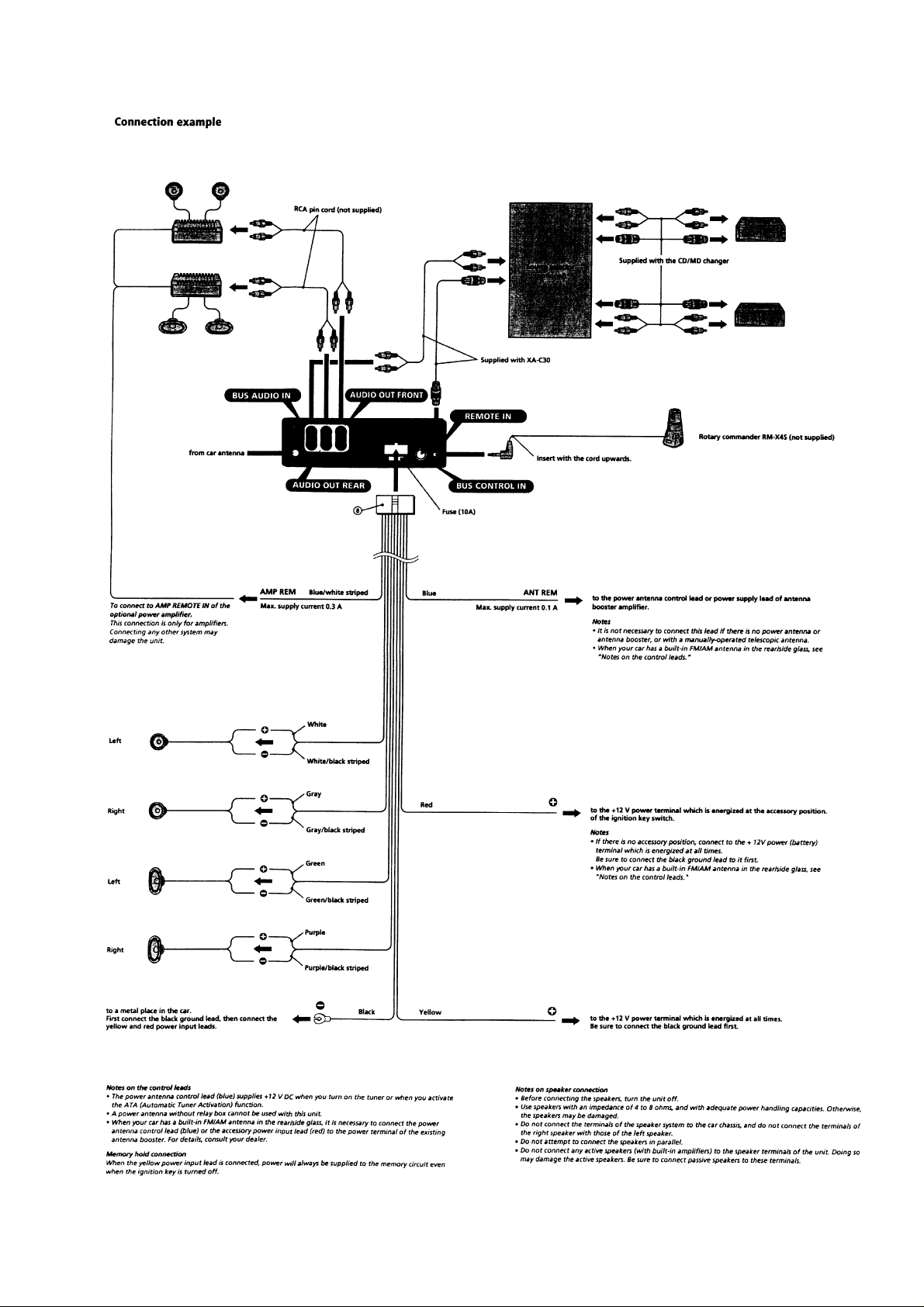

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

SUB PANEL, MECHANISM DECK (MG-25F-136)

0 Mechanism deck

(MG-25F-136)

8 Connector(CN351)

5 Sub panel ass'y

3 Screw

(PTT2.6 × 6)

9 Screw

(PTT2.6 × 6)

7 Flexible flat cable

(CNP301)

2 T wo screws

(PTT2.6 × 6)

MAIN BOARD, HEAT SINK

7 Two ground screws

8 Main board

Sub board

1 T wo screws

(PTT2.6 × 6)

5 Rubber cap(25)

6 Flat cable (WR801)

4 Screw (PTT2.6 × 6)

6 Ground screw

1 Eight screws

(PTT2.6 × 8)

2 T wo screws

(PTT2.6 × 12)

9 Insulated

plate

8

3 Heat sink

4 Ground plate(TU)

SECTION 4

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

HOUSING

5 Fit projection on C part.

2 Install the hanger onto

two claws of the housing.

4 Fit claw on B part.

7 Holder the hanger by bending the claw.

1 Install the catch to the hanger.

hanger

3 Put the housing

under A part.

ARM (SUCTION)

6 Fit projection on D part.

housing

C part

8 Hold the hanger by

bending the claw.

D part

A part

B part

projection

2 Move the arm (suction) in the arrow

direction and fit on projection.

1 Fit the arm (suction) on the shaft.

9

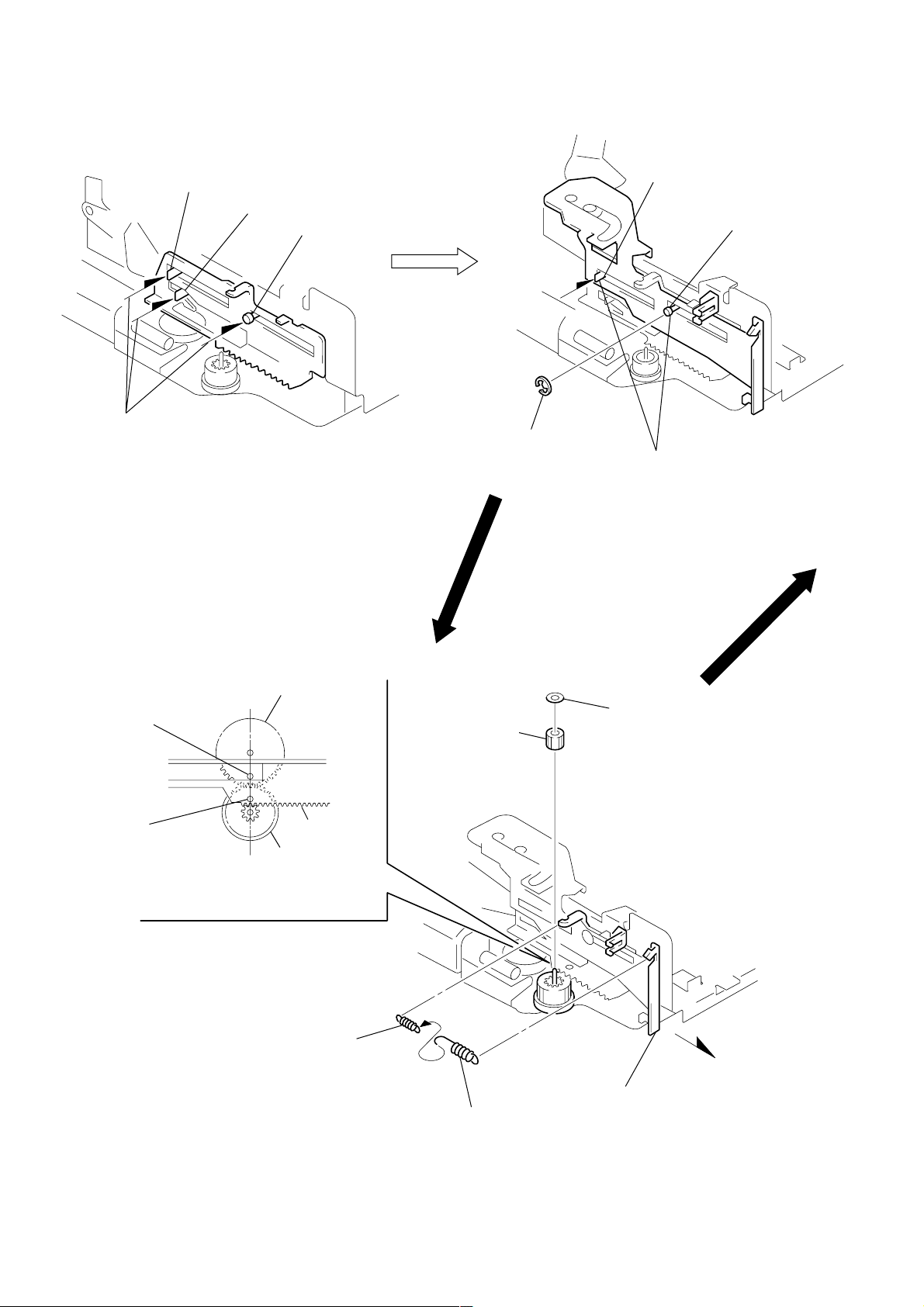

LEVER (LDG-A)/(LDG-B)

shaft A

shaft B

1 Fit the lever (LDG-A) on

shafts A – C and install it.

shaft C

shaft A

shaft B

3 type-E stop ring 2.0

2 Fit the lever (LDG-B) on

shafts A and B and

install it.

GEAR (LDG-FT)

hole

hole

gear (LDG-D)

lever (LDG-A)

gear (LDG-FB)

4 Align hole in the gear (LDG-D)

with hole the lever (LDG-A).

2 tension spring (LD-2)

5 gear (LDG-FT)

1

2 tension spring (LD-1)

6 polyethylene washer

3 Move the lever (LDG-B)

in the arrow direction.

10

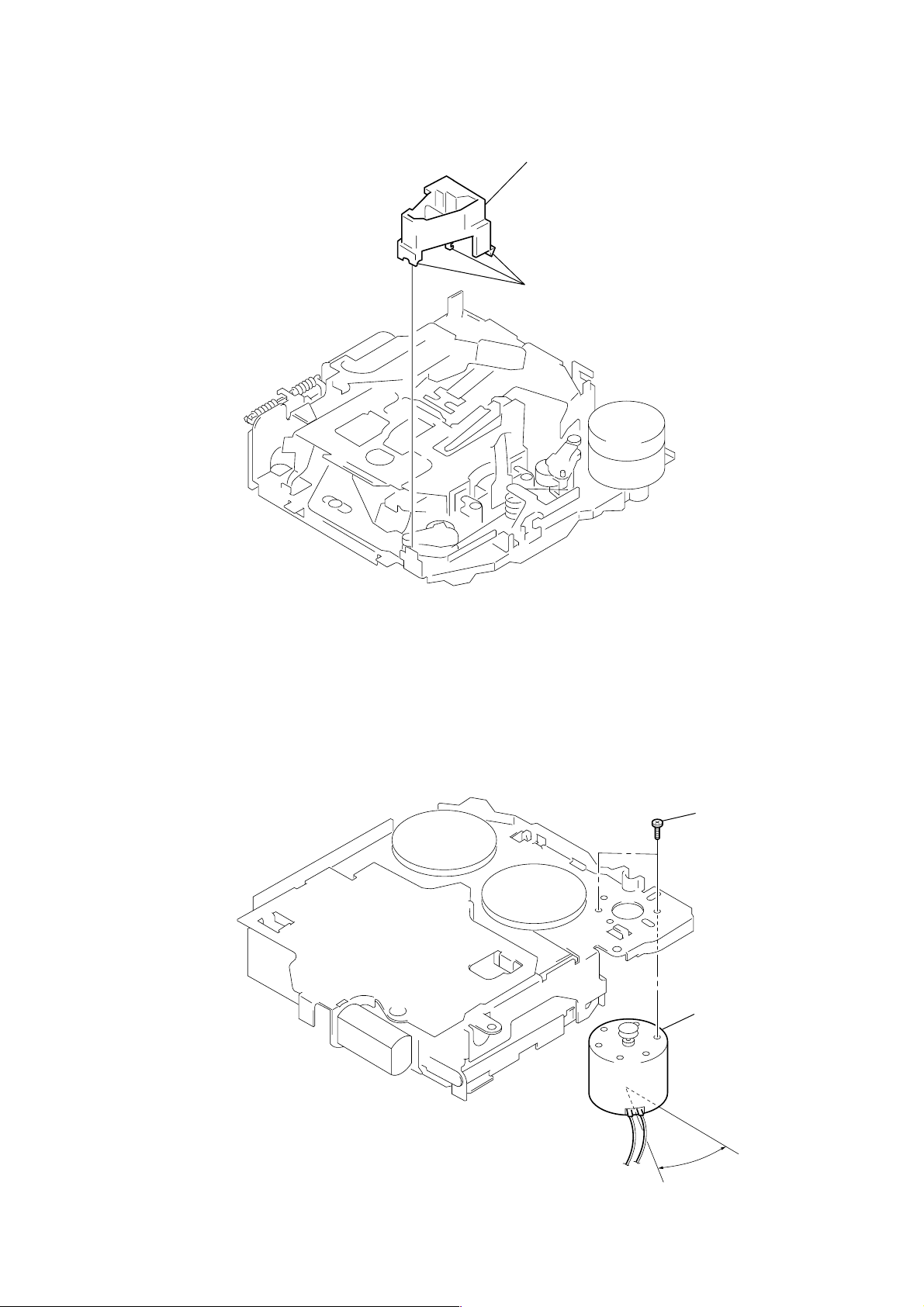

GUIDE (C)

2 guide (C)

1 three claws

MOUNTING POSITION OF CAPSTAN/REEL MOTOR (M901)

two precision screws

(P2

×

2)

capstan/reel motor

(M901)

30˚

11

Loading...

Loading...