Sony XM-5150-GSX Service manual

XM-5150GSX

SERVICE MANUAL

Ver 1.0 2001. 12

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

40 watts/150 watts per channel minimum continuous average power into

4 ohms, 5channels driven from 50 Hz to 20 kHz/20 Hz to 300 Hz

(subwoofer) with no more than 0.04% total harmonic distortion per Car

Audio Ad Hoc Committee Standards.

US Model

Canadian Model

Other Specifications

Circuit system OTL (output transformerless) circuit

Inputs RCA pin jacks

Outputs Speaker terminals

Speaker impedance 2 – 8 Ω (stereo)

Maximum outputs 80 watts × 4 + 300 watts × 1 (at 4 Ω)

Rated outputs (supply voltage at 14.4 V)

5 Speakers: 40 watts × 4 (50 Hz – 20 kHz, 0.04%

3 Speakers: 120 watts × 2 (50 Hz – 20 kHz, 0.1%

Frequency response 5 Hz – 50 kHz ( dB)

Harmonic distortion 0.005% or less (at 1 kHz, 4 Ω)

Pulse power supply

4 – 8 Ω (when used as a bridging amplifier)

THD, at 4 Ω) + 150 watts × 1 (20 –

300 Hz, 0.04% THD, at 4 Ω)

60 watts × 4 (50 Hz – 20 kHz, 0.1%

THD, at 2 Ω) + 180 watts × 1 (20 –

300 Hz, 0.1% THD, at 2 Ω)

THD, at 4 Ω) + 150 watts × 1 (20 –

300 Hz, 0.04% THD, at 4 Ω)

+0

–3

Input level adjustment range

High-pass filter 50 – 300 Hz, –12 dB/oct

Low-pass filter 50 – 300 Hz, –12 dB/oct

Power requirements 12 V DC car battery

Power supply voltage 10.5 – 16 V

Current drain at rated output : 42 A

Dimensions Approx. 358 × 50 × 264 mm

Mass Approx. 3.5 kg (7 lb. 11 oz.) not incl. accessories

Supplied accessories Mounting screws (4)

Design and specifications are subject to change without

notice.

0.2 – 6.0 V (RCA pin jacks)

(negative ground)

Remote input : 1.0 mA

(w/h/d) (14

projecting parts and controls

1/8 × 2 × 10 1/2 in.) not incl.

9-873-437-01

2001L0400-1

© 2001. 12

STEREO POWER AMPLIFIER

Sony Corporation

e Vehicle Company

Published by Sony Engineering Corporation

1

XM-5150GSX

TABLE OF CONTENTS

1. GENERAL

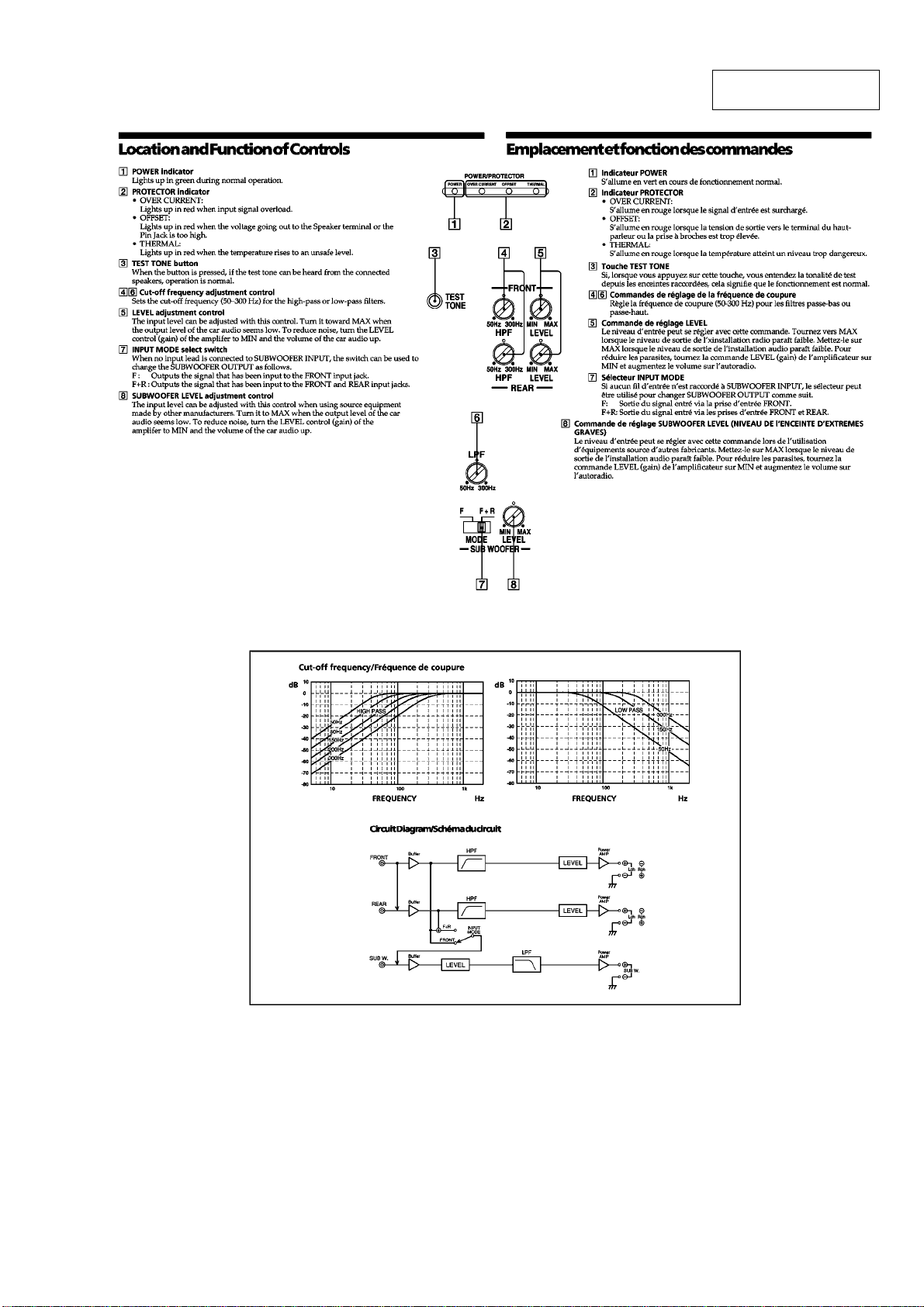

Location and Function of Controls.......................................... 3

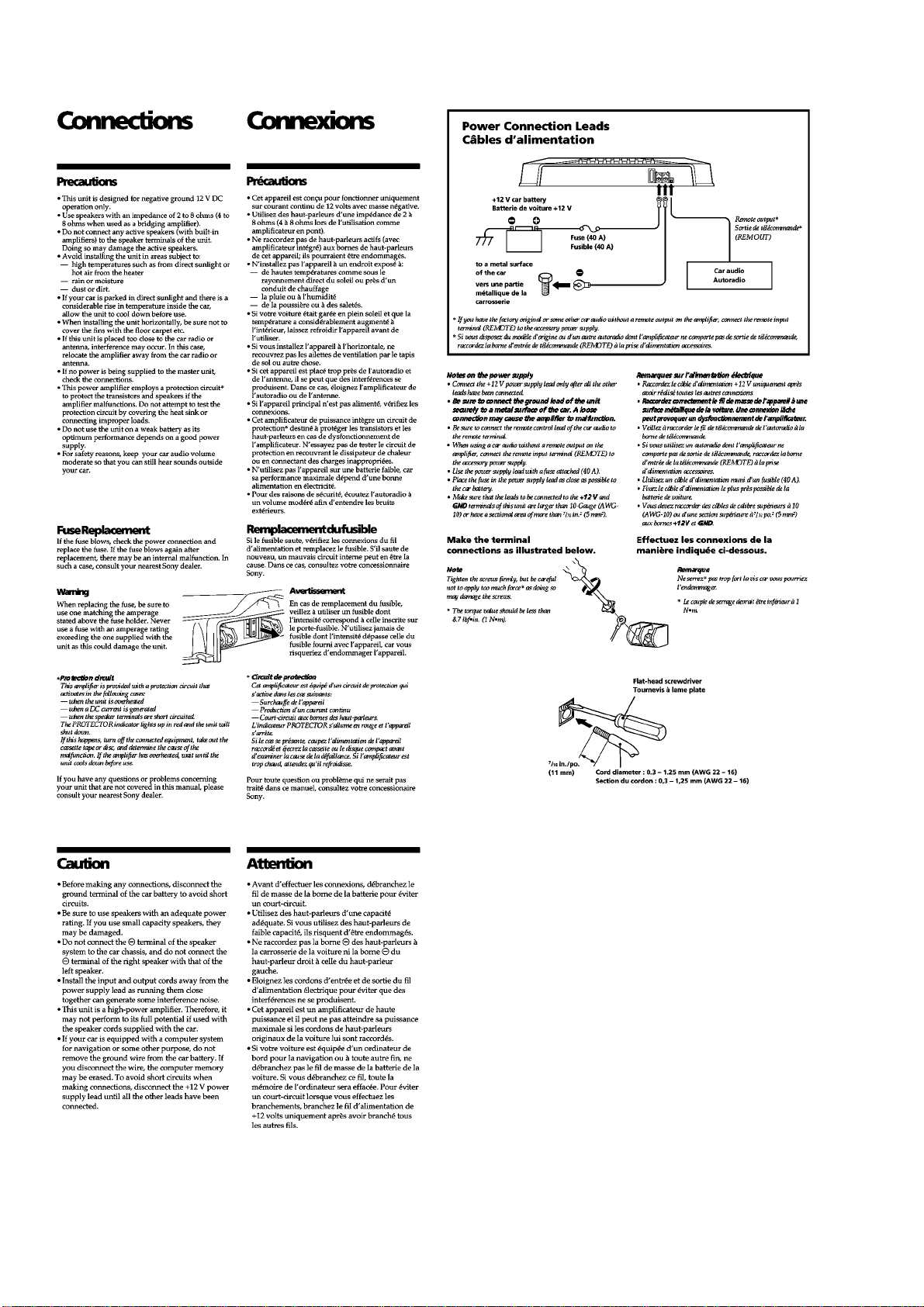

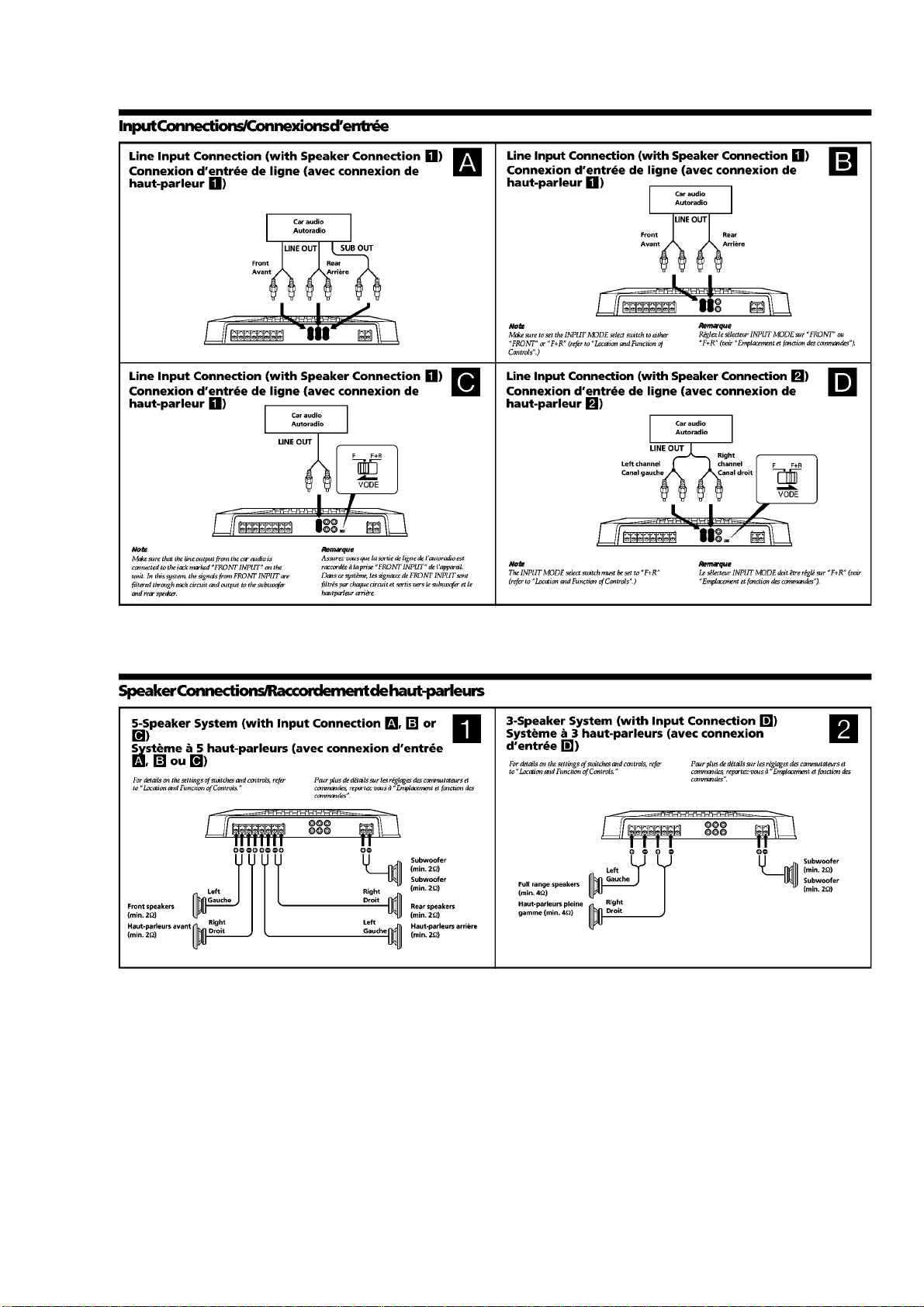

Connections ............................................................................. 4

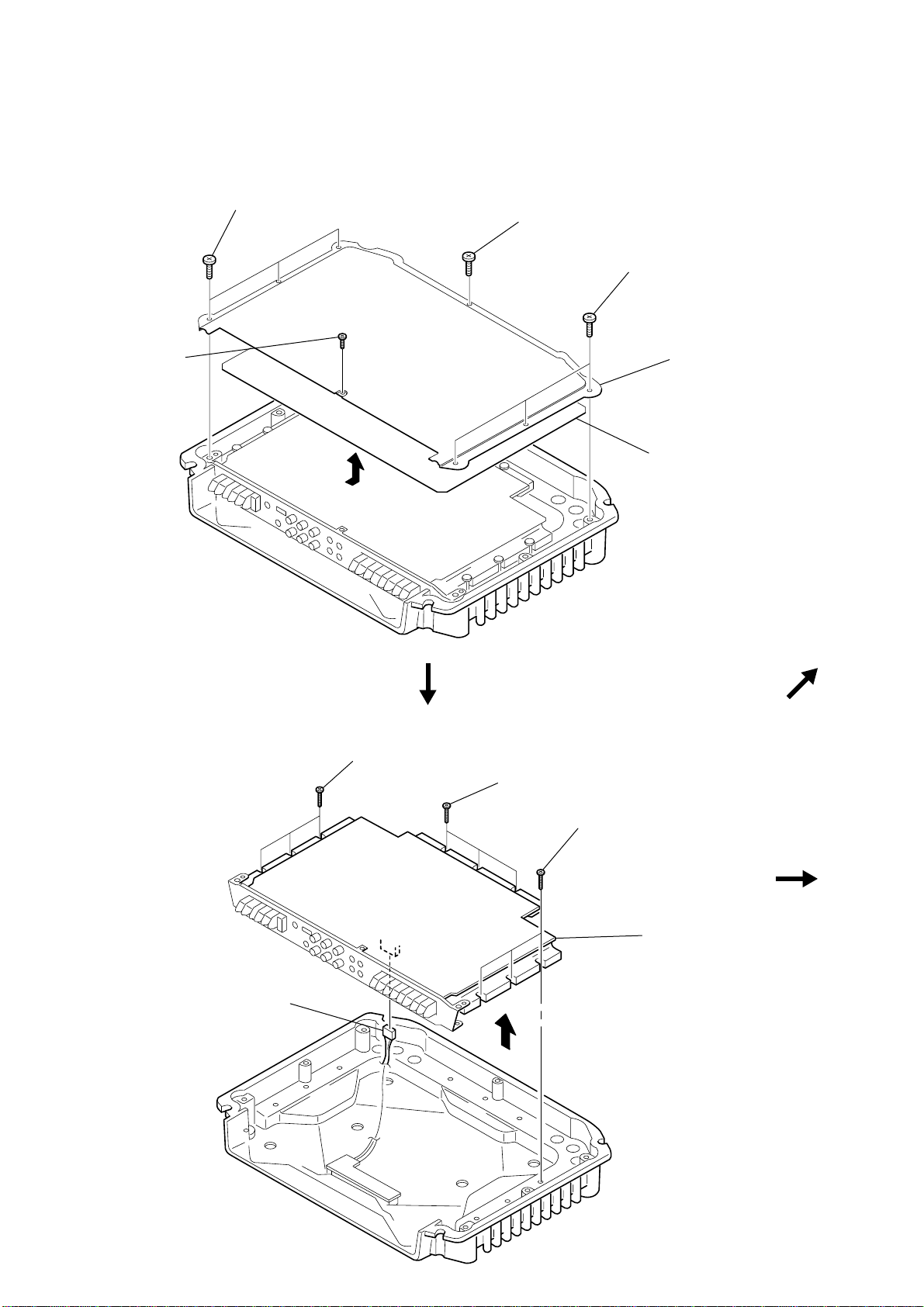

2. DISASSEMBLY

2-1. Plate, Bottom....................................................................... 6

2-2. Amp Board Section ............................................................. 6

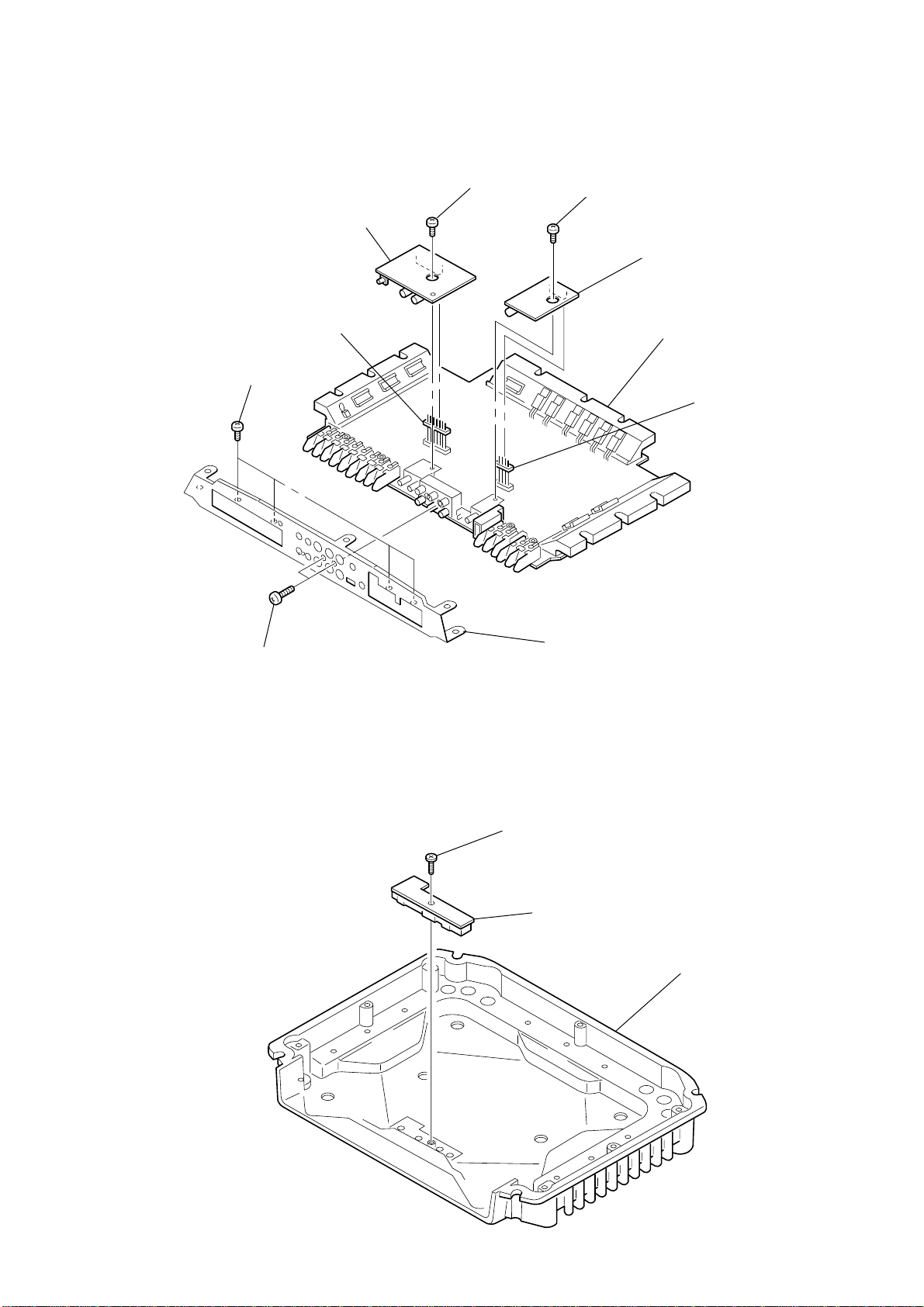

2-3. Amp Board, HPF Board, LPF Board .................................. 7

2-4. LED Board .......................................................................... 7

3. ELECTRICAL ADJUSTMENT...................................... 8

4. DIAGRAMS

4-1. Block Diagram .................................................................... 9

4-2. Printed Wiring Boards –HPF, LPF, LED Section– ........... 10

4-3. Schematic Diagram –HPF, LPF, LED Section–................ 11

4-4. Schematic Diagram –Amp Section (1/2)– ........................ 12

4-5. Schematic Diagram –Amp Section (2/2)– ........................ 13

4-6. Printed Wiring Board –Amp Section– ..............................14

5. EXPLODED VIEWS

5-1. Heat Sink (Main) Section.................................................. 16

5-2. Amp Board Section ........................................................... 17

6. ELECTRICAL PARTS LIST ........................................ 18

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES

SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT.

NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES

SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL

OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

SECTION 1

GENERAL

XM-5150GSX

This section is extracted

from instruction manual.

3

XM-5150GSX

4

XM-5150GSX

5

XM-5150GSX

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. PLATE, BOTTOM

4 P 2.6x2.8

3 BTP 3x6

6

2 BTP 3x6

1 BTP 3x6

5 plate, bottom

7 sheet, insulating

2-2. AMP BOARD SECTION

6 CNP808

1 B.TT. 3x14

2 B.TT. 3x14

3 B.TT. 3x14

5 AMP board section

4

6

2-3. AMP BOARD, HPF BOARD, LPF BOARD

XM-5150GSX

2 P 3x8

6 HPF board

5 CNP806

4 BVTT 3x5

7 BVTT 3x5

9 LPF board

0 AMP board

8 CNP807

2-4. LED BOARD

1 P 3x8

3 panel (5ch), front

1 BTP 3x6

2 LED board

heat sink (main)

7

XM-5150GSX

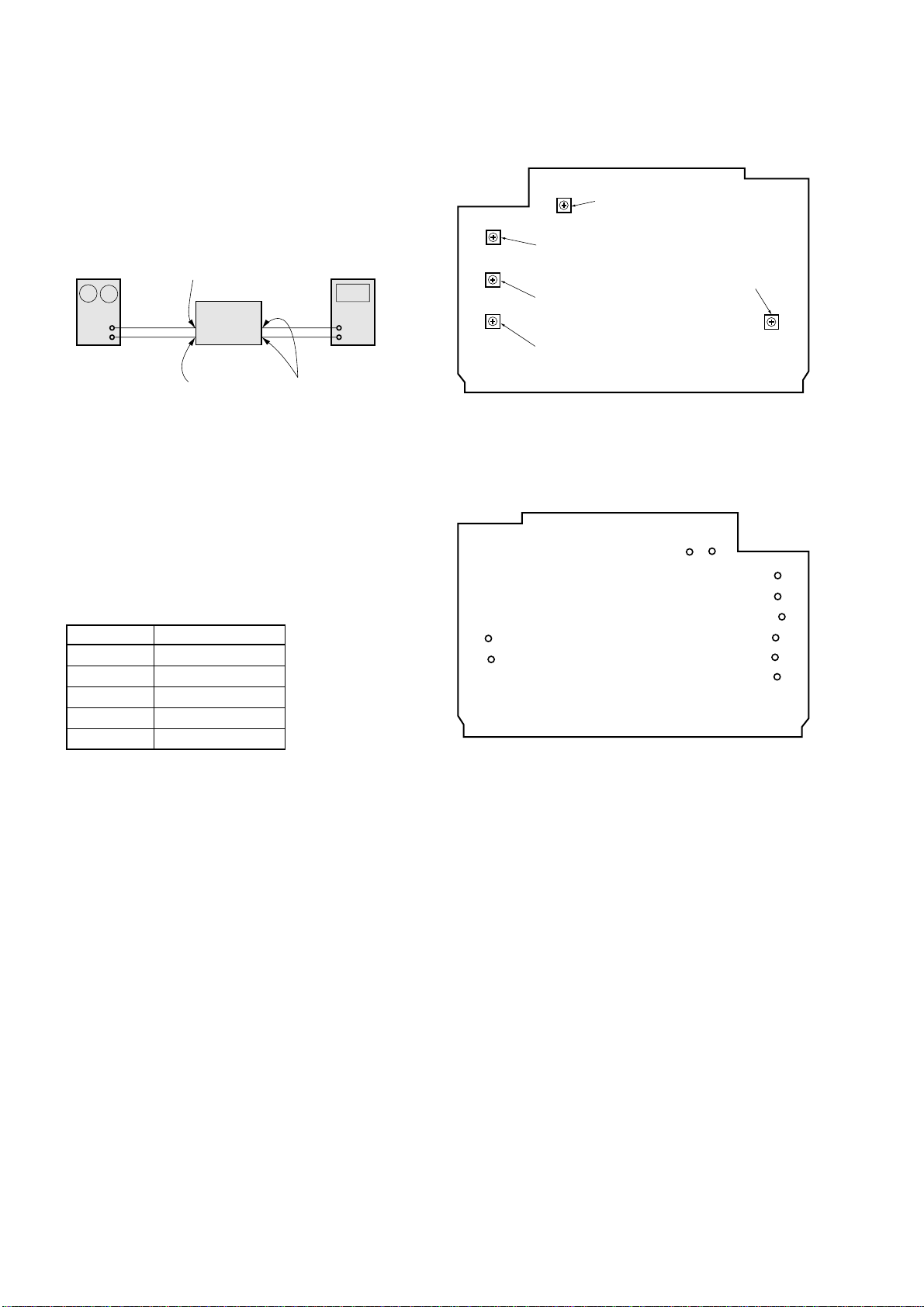

SECTION 3

ELECTRICAL ADJUSTMENT

Bias Adjustment

Note : The Bias adjustment should be performed only if any of

Q106, Q107, Q206, Q207, Q306, Q307, Q406, Q407, Q506,

Q507, Q509 and Q510 are replaced.

Setting :

Stabilized

Power supply

B+,REM terminals

set

GND terminal test points

Procedure :

1. Rotate the variable resistors VR101, VR201, VR301, VR401

and VR501 fully in the clockwise direction to minimize the

idling current of the stabilized power supply.

2. The input signal is to be no signal.

3. Set the power voltage to +14.4 V, and turn the remote mode ON

(Connect between the REM terminal and B+ terminal).

4. Connect on digital voltmeter between each test points.

5. Adjust VR101, VR201, VR301 and VR401 so that the digital

voltmeter reading is 5 ± 0.5 mV.

6. Adjust VR501 so that the digital voltmeter reading is

3.5 ± 0.5 mV.

VR Ref. No. Test points

VR101 TP101 and TP102

VR201 TP201 and TP202

VR301 TP301 and TP302

VR401 TP401 and TP402

VR501 TP501 and TP502

Digital

Voltmeter

+

_

Adjustment Location :

– AMP BOARD (COMPONENT SIDE) –

BIAS ADJUSTMENT

(REAR L-CH)

BIAS ADJUSTMENT

(FRONT R-CH)

BIAS ADJUSTMENT

(FRONT L-CH)

Test Point Location :

– AMP BOARD (CONDUCTOR SIDE) –

TP502

TP501

VR401

BIAS ADJUSTMENT

(REAR R-CH)

VR301

VR201

VR101

VR501

BIAS ADJUSTMENT

(SUB WOOFER)

TP401TP402

TP301

TP302

TP201

TP202

TP101

TP102

8

Loading...

Loading...