Sony XM-475-GSX Service manual

XM-475GSX

SERVICE MANUAL

Ver 1.2 2002. 07

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS (US MODEL)

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

75 watts per channel minimum continuous average power into

4 ohms, both channels driven from 20 Hz to 20 kHz with no more

than 0.04% total harmonic distortion per Car Audio Ad Hoc

Committee standards.

US Model

Canadian Model

Other Specifications

Circuit system OTL (output transformerless) circuit

Inputs RCA pin jacks

Outputs Speaker terminals

Speaker impedance 2 – 8 Ω (stereo)

Maximum outputs Four speakers: 170 W × 4 (at 4 Ω)

Rated outputs (supply voltage at 14.4 V)

Frequency response 5 Hz – 50 kHz ( dB)

Harmonic distortion 0.005% or less (at 1 kHz)

Pulse power supply

High level input connector

4 – 8 Ω (when used as a bridging amplifier)

Three speakers: 170 W × 2 + 400 W × 1 (at 4 Ω)

Two speakers: 400 W × 2 (at 4 Ω)

Four speakers:

75 W × 4 (20 Hz – 20 kHz, 0.04% THD, at 4 Ω)

100 W × 4 (20 Hz – 20 kHz, 0.1% THD, at 2 Ω)

Two speakers:

200 W × 2 (20 Hz – 20 kHz, 0.1% THD, at 4 Ω)

+0.5

–3

Input level adjustment range

High-pass filter 50 – 300 Hz, –12 dB/oct

Low-pass filter 50 – 300 Hz, –12 dB/oct

Low boost 0 – 10 dB (40 Hz)

Power requirements 12 V DC car battery

Power supply voltage 10.5 – 16 V

Current drain at rated output : 40 A (4 Ω)

Dimensions Approx. 358 × 50 × 264 mm

Mass Approx. 3.5 kg (7 lb. 11 oz.) not incl. accessories

Supplied accessories Mounting screws (4)

Design and specifications are subject to change without

notice.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

0.2 – 6.0 V (RCA pin jacks)

0.4 – 12 V (High level input)

(negative ground)

Remote input : 1.5 mA

(w/h/d) (14

projecting parts and controls

1/8 × 2 × 10 1/2 in.) not incl.

9-873-435-03

2002G0400-1

© 2002. 07

STEREO POWER AMPLIFIER

Sony Corporation

e Vehicle Company

Published by Sony Engineering Corporation

1

XM-475GSX

TABLE OF CONTENTS

1. GENERAL

Location and Function of Controls .......................................... 3

Connections ............................................................................. 4

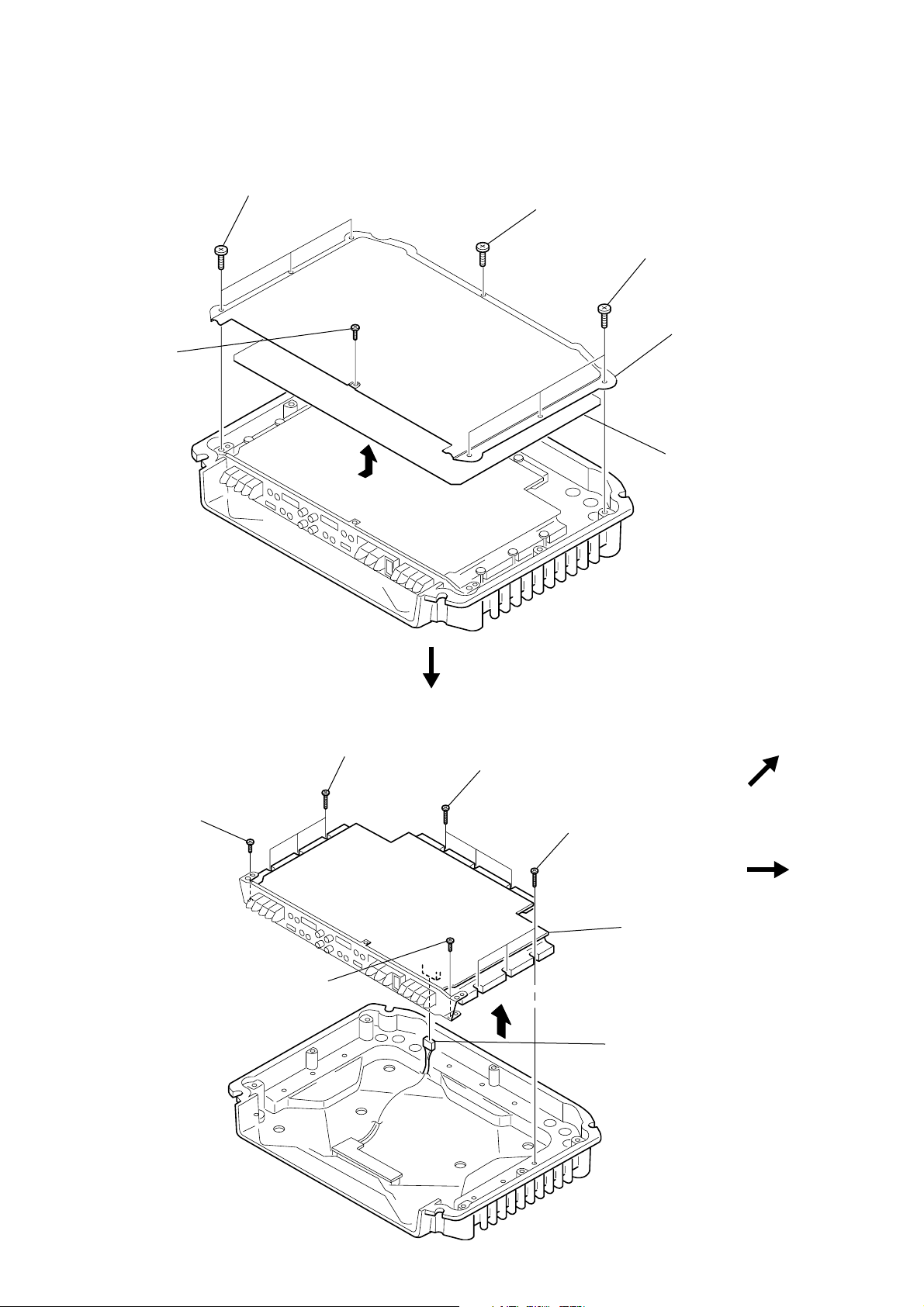

2. DISASSEMBLY

2-1. Bottom Plate ........................................................................ 6

2-2. Main Board Section ............................................................. 6

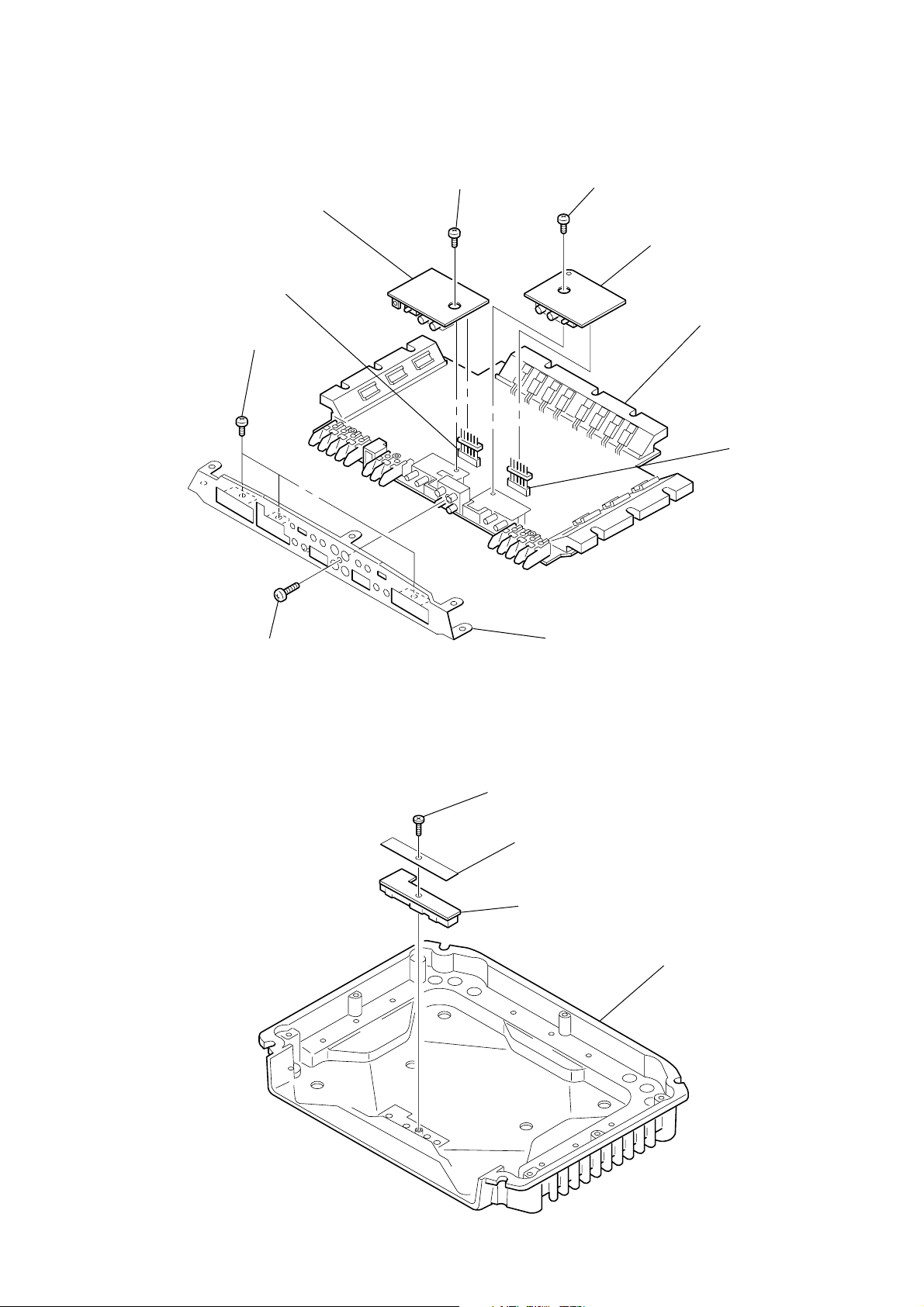

2-3. Main Board, Filter (F) Board, Filter (R) Board ................... 7

2-4. LED Board ........................................................................... 7

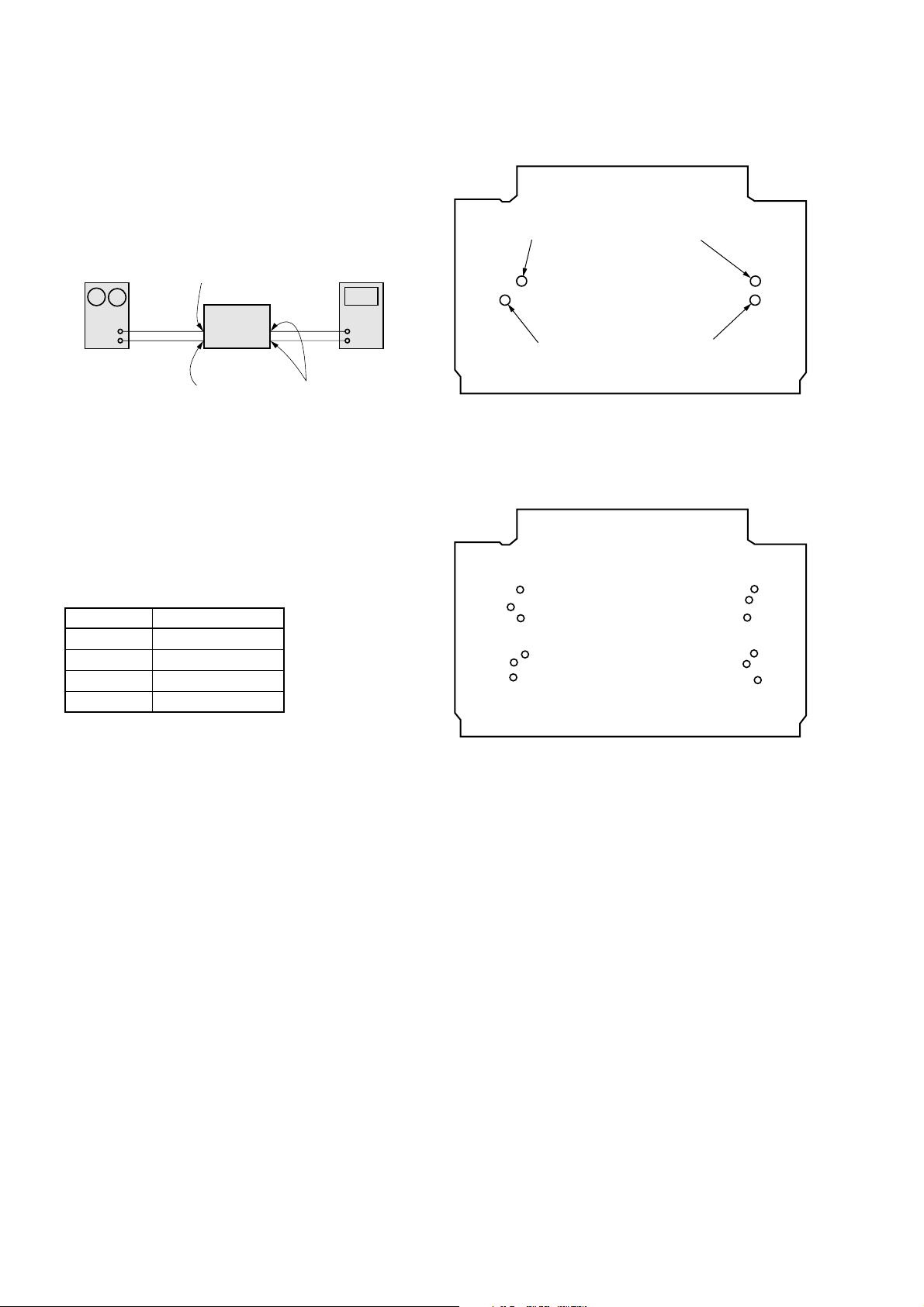

3. ELECTRICAL ADJUSTMENT...................................... 8

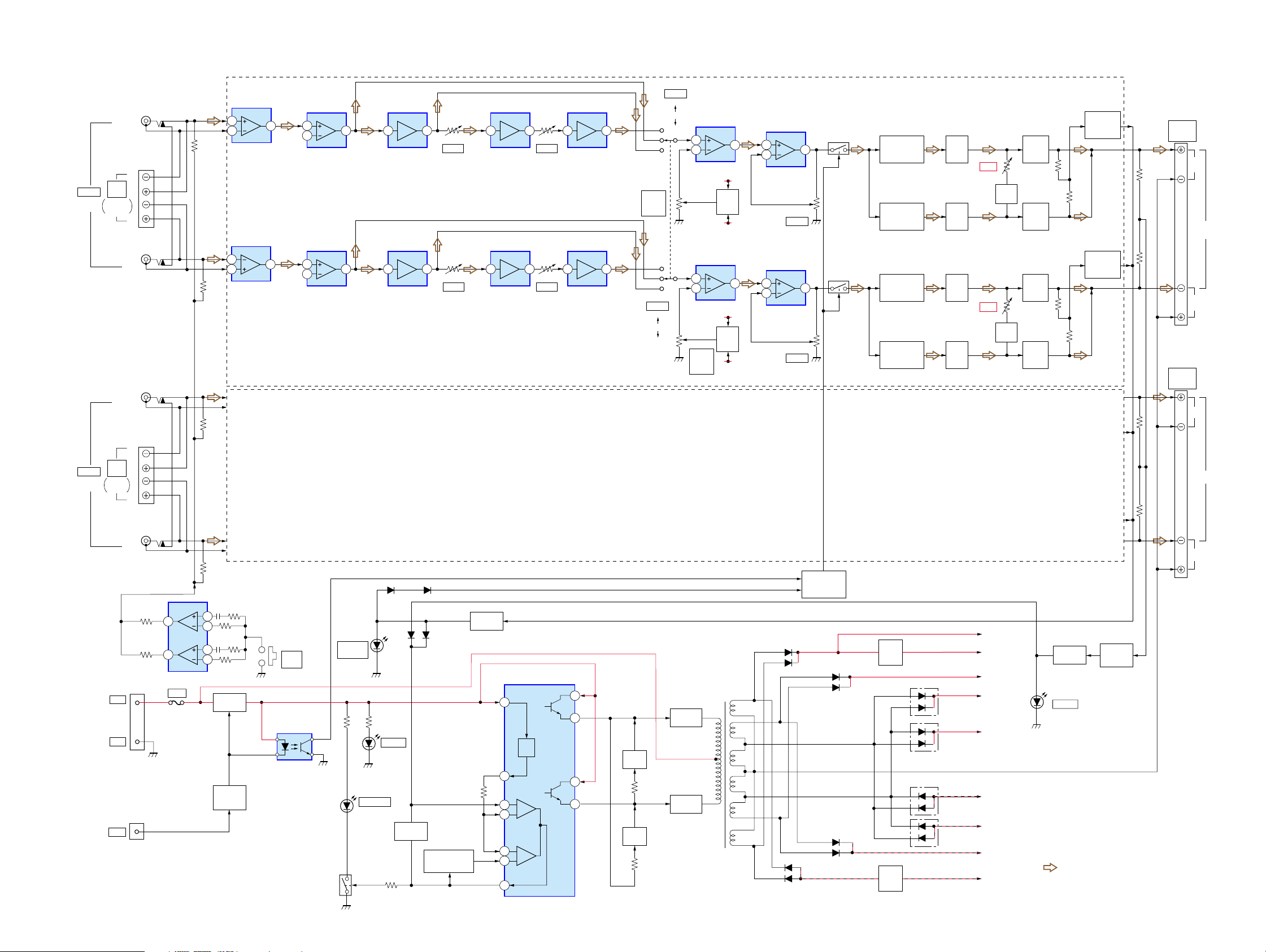

4. DIAGRAMS

4-1. Block Diagram ..................................................................... 9

4-2. Printed Wiring Boards –Filter (F), Filter (R),

LED Section– .................................................................... 10

4-3. Schematic Diagram –Filter (F), Filter (R),

LED Section– .................................................................... 11

4-4. Schematic Diagram –Main Section (1/2)– ........................ 12

4-5. Schematic Diagram –Main Section (2/2)– ........................ 13

4-6. Printed Wiring Board –Main Section– .............................. 14

5. EXPLODED VIEWS

5-1. Heat Sink (Main) Section .................................................. 16

5-2. Main Board Section ........................................................... 17

6. ELECTRICAL PARTS LIST......................................... 18

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES

SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT.

NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES

SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL

OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!!

2

SECTION 1

GENERAL

XM-475GSX

This section is extracted

from instruction manual.

3

XM-475GSX

4

XM-475GSX

5

XM-475GSX

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. BOTTOM PLATE

4 P 2.6x2.8

3 BTP 3x6

6

2 BTP 3x6

1 BTP 3x6

5 bottom plate

7 insulating sheet

2-2. MAIN BOARD SECTION

2 BTP 3x6

3 B.TT. 3x14

4 B.TT. 3x14

5 B.TT. 3x14

7 MAIN board

1 BTP 3x6

6

8 CN802

6

2-3. MAIN BOARD, FILTER (F) BOARD, FILTER (R) BOARD

XM-475GSX

5 CNP101

2 P 3x8

6 FILTER (F) board

4 BVTT 3x5

7 BVTT 3x5

9 FILTER (R) board

0 MAIN board

8 CNP201

2-4. LED BOARD

1 P 3x8

3 front panel (4ch)

1 BTP 3x6

2 insulating sheet (LED)

3 LED board

heat sink (main)

7

XM-475GSX

SECTION 3

ELECTRICAL ADJUSTMENT

Bias Adjustment

Note : The Bias adjustment should be performed only if any of

Q109, Q110, Q209, Q210, Q309, Q310, Q409 and Q410

are replaced.

Setting :

Stabilized

Power supply

B+,REM terminals

set

GND terminal test points

Procedure:

1. Rotate the variable resistors RV104, RV204, RV304 and RV404

fully in the clockwise direction to minimize the idling current

of the stabilized power supply.

2. The input signal is to be no signal.

3. Set the power voltage to +14.4 V, and turn the remote mode ON

(Connect between the REM terminal and B+ terminal).

4. Connect on digital voltmeter between each test points.

5. Adjust RV104, RV204, RV304 and RV404 so that the digital

voltmeter reading is 2.5 ± 0.5 mV.

RV Ref. No. Test points

RV104 TP11 and TP12

RV204 TP21 and TP22

RV304 TP31 and TP32

RV404 TP41 and TP42

Digital

Voltmeter

+

_

Adjustment Location :

– MAIN BOARD (CONDUCTOR SIDE) –

RV304

BIAS ADJUSTMENT

(REAR L-CH)

RV404

BIAS ADJUSTMENT

(REAR R-CH)

Test Point Location :

– MAIN BOARD (CONDUCTOR SIDE) –

TP31

TP32

TP42

TP33

TP41

TP43

RV204

BIAS ADJUSTMENT

(FRONT R-CH)

RV104

BIAS ADJUSTMENT

(FRONT L-CH)

TP22

TP12

TP21

TP23

TP11

TP13

6. Check the power supply current is at 1.2 to 1.6 A.

8

4-1. BLOCK DIAGRAM

CNJ100-1

L

(BTL)

CN101

L

HIGH

INPUT

LEVEL

INPUT

(FRONT)

(

)

FRONT

R

CNJ100-2

R

CNJ100-3

L

(BTL)

PRE AMP

IC801 (1/2)

3

2

PRE AMP

IC801 (2/2)

6

5

XM-475GSX

SECTION 4

DIAGRAMS

S801-1

RV802-1

LOW

BOOST

(40Hz)

S801-2

FILTER

LPF

OFF

HPF

FILTER

LPF

OFF

HPF

PRE AMP

IC802 (1/2)

1

7

3

2

PRE AMP

IC802 (2/2)

5

6

1 3 1 6 7 2 1

7 5 7 2 1 6 7

H.P.F

IC803 (1/2)

H.P.F

IC803 (2/2)

RV801-1

FILTER

RV801-2

FILTER

L.P.F

IC804 (2/2)

L.P.F

IC805 (1/2)

RV801-3

FILTER

RV801-4

FILTER

L.P.F

IC804 (1/2)

L.P.F

IC805 (2/2)

LOW BOOST

IC806 (2/2)

5

6

LOW BOOST

IC807 (2/2)

5

6

RV802-2

LOW

BOOST

(40Hz)

(FRONT)

7

B+

(+14.2V)

LEVEL

SHIFT

Q101

B–

(–14.2V)

7

B+

(+14.2V)

LEVEL

SHIFT

Q201

B–

(–14.2V)

(REAR)

GAIN AMP

IC806 (1/2)

3

2

GAIN AMP

IC807 (1/2)

3

2

RV803-1

LEVEL

RV803-2

LEVEL

LINE

SWITCH

Q102

1

LINE

SWITCH

Q202

1

DIFFERENTIAL

AMP

Q103

DIFFERENTIAL

AMP

Q104

DIFFERENTIAL

AMP

Q203

DIFFERENTIAL

AMP

Q204

DRIVE

AMP

Q107

DRIVE

AMP

Q108

DRIVE

AMP

Q207

DRIVE

AMP

Q208

RV104

BIAS

RV204

BIAS

BIAS

Q111

BIAS

Q211

POWER

AMP

Q109

POWER

AMP

Q110

POWER

AMP

Q209

POWER

AMP

Q210

OVERLOAD

DET

Q112

OVERLOAD

DET

Q212

CN810

FRONT

SPEAKER

OUT

CN811

REAR

SPEAKER

OUT

L

BTL

R

L

INPUT

(REAR)

CN201

HIGH

LEVEL

INPUT

(

REAR

CNJ100-4

+12V

GND

REM

L

)

R

R

TEST TONE

GENERATOR

IC815

CN800

2

1

CN803

1

7

F901

40A

3

2

5

6

REG

Q901,902

POWER

ON/OFF

Q903

SW805

TEST

TONE

DC DET

IC902

D809

OVER

CURRENT

(PROTECTOR)

THERMAL

(PROTECTOR)

SWITCH

Q808

D828 D829

D822

D808

POWER

D811

LED DRIVE

Q809

D823

TEMP.DET

THN801,804-807

LED DRIVE

Q812,813

DC-DC CONVERTER

12

REF.

REG

14

1

2

15

16

3

IC901

BTL

R

SWITCH

CONTROL

Q801,802

D903,904

RECT

D903

D905,906

D911,912

D917,918

RECT

D905

D906

RECT

RECT

D911

D912

DC-DC

CONVERTER

TRANSFORMER

11

10

DRIVER

Q908

8

9

DRIVER

Q909

INVERTER

Q904,905

INVERTER

Q906,907

T801

D904

D917

D918

B+

REG

Q910

B–

REG

Q911

D907

D909

D907-910

RECT

D908

D910

B+

(+23.5V)

B+

(+14.2V)

B+

(+42V)

B+

(+36V)

B+

(+36V)

B–

(–35V)

B–

(–35V)

B–

(–42V)

B–

(–14.2V)

LED DRIVE

Q810,811

D810

OFFSET

(PROTECTOR)

OFFSET

DET

Q803-805

• Signal path

: AUDIO

• Rear-ch is omitted due to same as Front-ch.

99

XM-475GSX

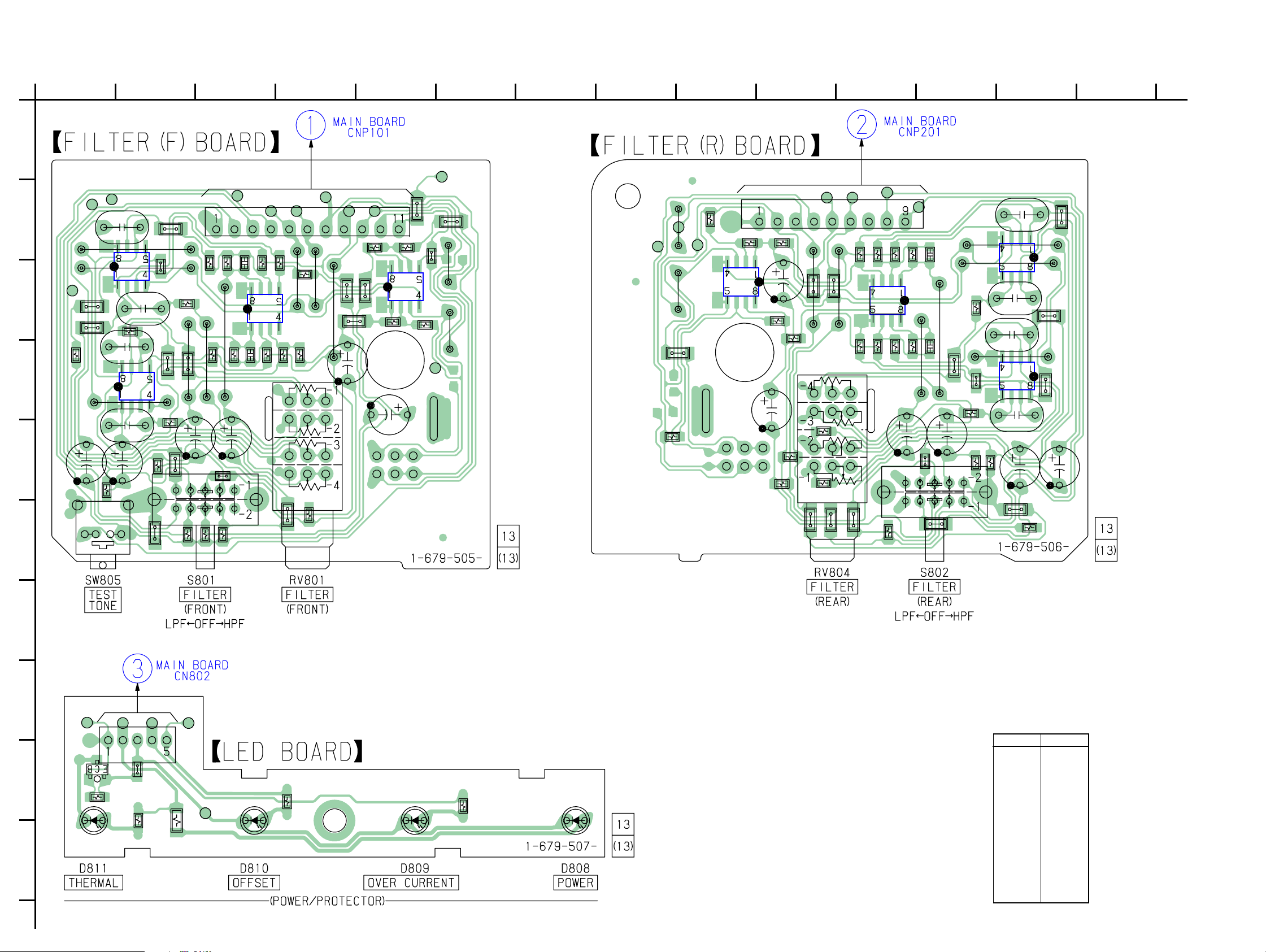

4-2. PRINTED WIRING BOARDS — FILTER (F), FILTER (R), LED SECTION — • Refer to page 15 for Common Note on Printed Wiring Boards.

A

B

C

D

E

F

1

J8

J9

R213

JW99

IC805

IC804

R116

SW805

C207

C210

C106

C107

2 3 4 5 6 7 8 9 10 11 12 13 14

(Page 14)(Page 14)

R315

C306

C407

R316

C307

C406

JW113

C410

J30

R416

J18

J19

J20

C310

C206

C110

R111

R115

J14

J6

JW97

JW98

J11

R113

J13

J7

R211

JW100

R216

J12

R212

JW101

R214

R209

R112

C109

J15

C205

JW102

R109

S801

R215

R208

C105

C209

R210

R110

R108

J16

JW103

IC803

RV801

CNJ101

R207

JW104

R107

R114

JW105

J209

J210

C108

R261

J211

R161

C208

R260

R160

J213

J212

IC802

J214

C229

C129

J25

R460

C429

C329

R360

IC809

R361

R307

R461

R314

R414

R407

C408

C308

J26

CNJ201

JW107

J24

R413

R313

RV804

J23

R310

JW108

R410

J27

R312

IC810

J28

R308

R408

R412

J31

J29

R415

R309

JW109

R409

C405

C309

C305

JW110

S802

JW111

IC811

JW112

R311

J22

IC812

J21

R411

C409

G

H

J

(Page 14)

• Semiconductor

Location

Ref. No. Location

CN801

I

Q808

R818

D811

J161

R817

R812

D810

R814

D809

D808

R813

D808 J-7

D809 J-5

D810 J-3

D811 J-1

IC802 C-5

IC803 C-3

IC804 D-2

IC805 C-2

IC809 C-9

IC810 C-11

IC811 B-13

IC812 D-13

Q808 I-1

10 10

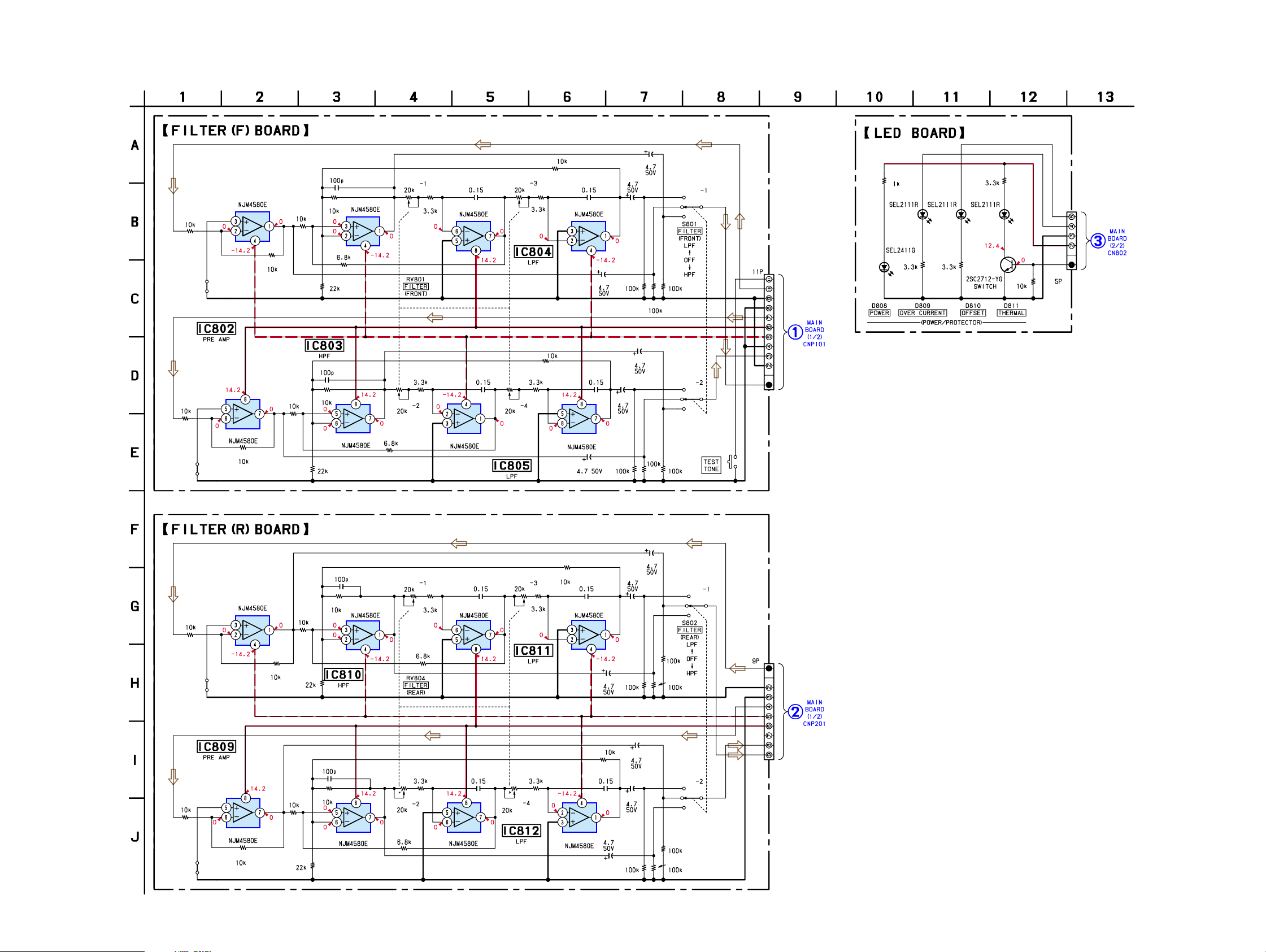

4-3. SCHEMATIC DIAGRAM — FILTER (F), FILTER (R), LED SECTION — • Refer to page 15 for Common Note on Schematic Diagrams.

XM-475GSX

R160

R260

C229

C129

IC802(1/2)

IC802(2/2)

R261

R161

R207

R107

C205

R209

R208

C105

R109

R108

IC803(1/2)

R110

IC803(2/2)

RV801

R211 C206

R210

R111

C106

IC804(2/2)

IC805(1/2)

RV801RV801

RV801

R113

R212

R213

R112

C107

IC804(1/2)

IC805(2/2)

C208

C108

C207

C210

R216

C110

C209

C109

R114

R214

R115R116

R215

S801

S801

SW805

CNJ101

(Page 12)

R812

D809 D810 D811

D808

R814R813

R817

Q808

R818

(Page 13)

CN801

R360

R460

C429

C329

IC809(1/2)

IC809(2/2)

R461

R361

R407

R408

R307

R308

C405

R409

C305

R309

IC810(2/2)

IC810(1/2)

RV804

RV804

R410

R310

R411

R311

IC811(2/2)

IC812(2/2)

C306

RV804

RV804

R313

R413C406

R312

IC811(1/2)

IC812(1/2)

C307

R412

C309

C407

C409

C308

C310

R314

R315R316

C408

C410

R414

R416 R415

S802

CNJ201

(Page 12)

S802

11 11

XM-475GSX

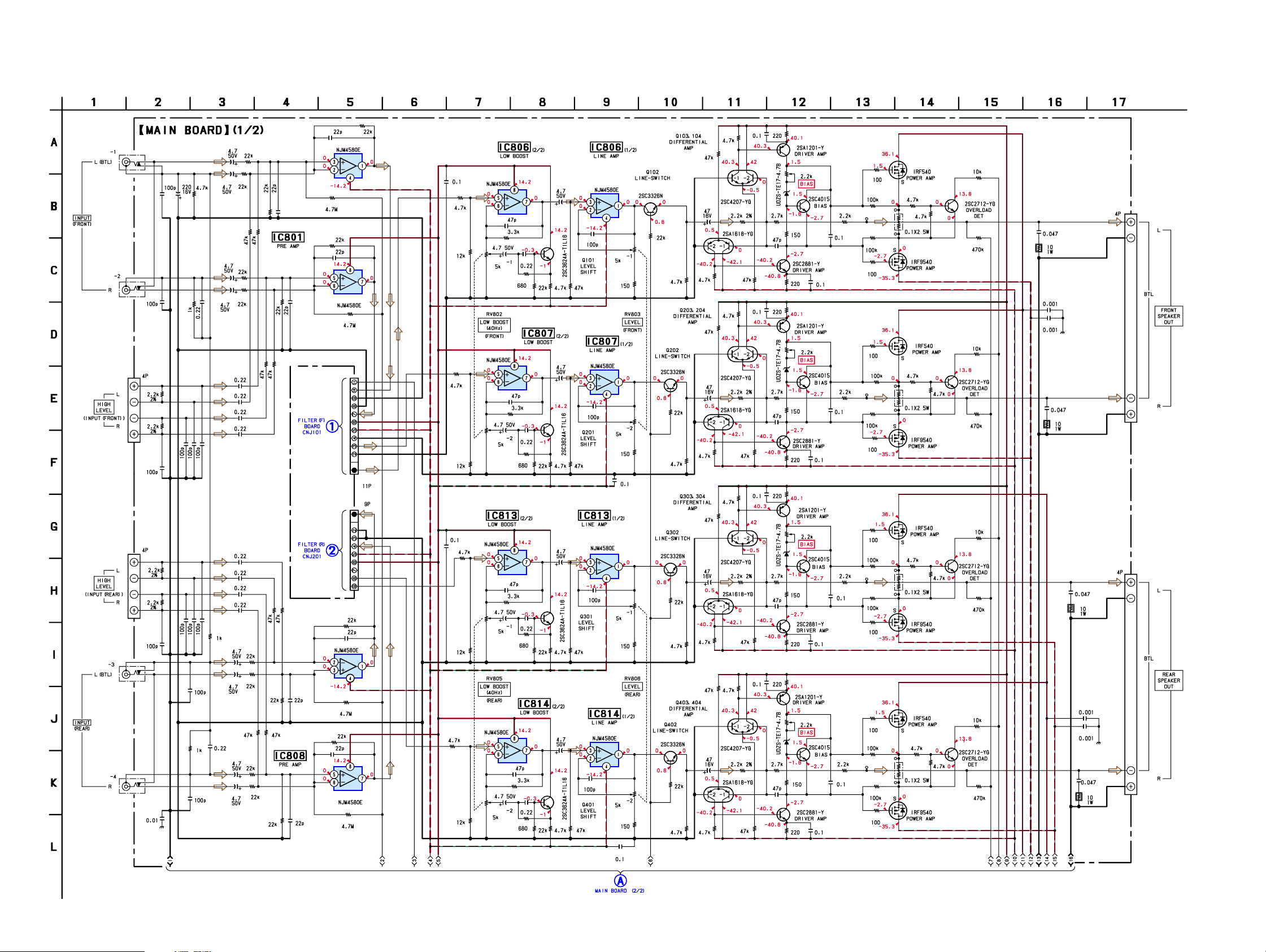

4-4. SCHEMATIC DIAGRAM — MAIN SECTION (1/2) — • Refer to page 15 for Common Note on Schematic Diagrams.

C104 R106

R153

R206

C204

R406

C404

IC801(1/2)

IC801(2/2)

R253

R306

C304

IC808(1/2)

R353

IC808(2/2)

R453

CNP101

CNP201

C901

R217

C907

R417

R117

R118

R218

R317

R318

R418

IC806(2/2)

C111

R119

C112

RV802

IC807(2/2)

C211

R219

C212

RV802

IC813(2/2)

C311

R319

C312

RV805

IC814(2/2)

C411

C412

RV805

R419

C113

R120

R121 R122 R123

C213

R220

R221 R222 R223

C313

R320

R321 R322 R323

C413

R420

R421 R422 R423

C114

C214

C314

C414

Q101

Q201

Q301

Q401

IC806(1/2)

C115

RV803

R124

IC807(1/2)

C215

RV803

R224

C902

IC813(1/2)

C315

RV806

R324

IC814(1/2)

C415

RV806

R424

CNJ100

CNJ100

CNJ100

CNJ100

CN101

CN201

C222

R125

R225

C217

R325

R425

C417

C819

C122

C121

C218

C418

R226

C118

C318

C322

R426

C422

R126

C221

C117

C317

R326

C421

C102

C201

C202

C101

C302

C301

C401

C402

R102

R201

R202

C119

C120

C219

C220

C319

C320

C419

C420

R101

R103

R302

R301

R404

R401

R104

R402

C103

R105

R205

R203

R204

R304

R303

R305 C303

R403

R405

C203

(Page 11)

(Page 11)

C403

Q102

R127

R128

Q202

R227

R228

Q302

R327

R328

Q402

R427

R428

R129

R131

Q103

C123

R139

Q104

R130

R231

C223

R230

R331

C323

R330 R332

R431 R429

C423

R430

R132

R229

Q203

R239

Q204

R232

R329

Q303

R339

Q304

Q403

R439

Q404

R432

C133

C233

C333

C433

R133

R140

C126

R233

R240

C226

R333

R340

C326

R433

R440

C426

R141

R241

R341

R441

R142

R134

R242

R234

R342

R334

R442

R434

Q107

RV104

Q108

Q207

RV204

Q208

RV304

Q308

Q407

RV404

Q408

Q111

Q307

C134

Q211

C234

Q311

C334

Q411

C434

R143

C127

R243

C227

R343

C327

R443

C427

R135

R137 R145

TP11

TP12

TP13

R138

R136

R235

R237

TP21

TP22

TP23

R238

R236

R335

R337

TP31

TP32

TP33

R338

R336

R435

R437

TP41

TP42

TP43

R438

R436

R245

R345

R445

R458

R144

R158

R258

R358

Q109

Q110

Q209

Q210

Q309

Q310

Q409

Q410

R244

R344

R444

R148

R150

R248

Q212

R250

R348

Q312

R350

R448

Q412

R450

Q112

CN810

C128

R151

C904

C903

C228

R251

CN811

C328

R351

C906

C905

C428

R451

C908

(Page 13)

12 12

Loading...

Loading...