Page 1

DATA PROJECTOR

VPL-ES7

VPL-EX7

VPL-EX7IN

VPL-EX70

REMOTE COMMANDER

RM-PJ6

SERVICE MANUAL

1st Edition (Revised 2)

Page 2

!警告

このマニュアルは,サービス専用です。

お客様が,このマニュアルに記載された設置や保守,点検,修理などを行うと感電や火災,

人身事故につながることがあります。

危険をさけるため,サービストレーニングを受けた技術者のみご使用ください。

! WARNING

This manual is intended for qualifi ed service personnel only.

To reduce the risk of electric shock, fi re or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualifi ed to do so. Refer all servicing to

qualifi ed service personnel.

! WARNUNG

Die Anleitung ist nur für qualifi ziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifi ziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afi n

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifi é pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

警告

万一,異常が起きた際に,お客様が電源を切ることが

できるように,設置の際には,機器近くの固定配線内

に専用遮断装置を設けるか,機器使用中に,容易に抜

き差しできるコンセントに電源プラグを接続してくだ

さい。

WARNING

When installing the unit, incorporate a readily accessible

disconnect device in the fi xed wiring, or connect the

power cord to a socket-outlet which must be provided

near the unit and easily accessible, so that the user can

turn off the power in case a fault should occur.

WARNUNG

Beim Einbau des Geräts ist daher im Festkabel ein

leicht zugänglicher Unterbrecher einzufügen, oder

das Netzkabel muß mit einer in der Nähe des Geräts

befi ndlichen, leicht zugänglichen Wandsteckdose

verbunden werden, damit sich bei einer

Funktionsstörung die Stromversorgung zum Gerät

jederzeit unterbrechen läßt.

For kundene i Norge

Dette utstyret kan kobles til et IT-strømfordelingssystem.

VPL-ES7

Page 3

注意

FÖRSIKTIGHET!

指定以外の電池に交換すると,破裂する危険があります。

必ず指定の電池に交換してください。

使用済みの電池は,国または地域の法令に従って

処理してください。

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

When you dispose of the battery, you must obey the

law in the relative area or country.

ATTENTION

Il y a danger d’explosion s’il y a remplacement incor-

rect de la batterie. Remplacer uniquement avec

une batterie du même type ou d’un type équivalent

recommandé par le constructeur.

Lorsque vous mettez la batterie au rebut, vous devez

respecter la législation en vigueur dans le pays ou la

région où vous vous trouvez.

Fara för explosion vid felaktigt placerat batteri.

Byt endast mot samma eller likvärdig typ av batteri,

enligt tillverkarens rekommendationer.

När du kasserar batteriet ska du följa rådande lagar

för regionen eller landet.

PAS PÅ

Fare for eksplosion, hvis batteriet ikke udskiftes

korrekt.

Udskift kun med et batteri af samme eller tilsvarende

type, som er anbefalet af fabrikanten.

Når du bortskaffer batteriet, skal du følge

lovgivningen i det pågældende område eller land.

HUOMIO

Räjähdysvaara, jos akku vaihdetaan virheellisesti.

Vaihda vain samanlaiseen tai vastaavantyyppiseen,

valmistajan suosittelemaan akkuun.

Noudata akun hävittämisessä oman maasi tai

alueesi lakeja.

VORSICHT

Explosionsgefahr bei Verwendung falscher Batterien.

Batterien nur durch den vom Hersteller empfohlenen

oder einen gleichwertigen Typ ersetzen.

Wenn Sie die Batterie entsorgen, müssen Sie die

Gesetze der jeweiligen Region und des jeweiligen

Landes befolgen.

FORSIKTIG

Eksplosjonsfare hvis feil type batteri settes i.

Bytt ut kun med samme type eller tilsvarende

anbefalt av produsenten.

Kasser batteriet i henhold til gjeldende avfallsregler.

VPL-ES7

1 (P)

Page 4

Page 5

Table of Contents

1. Service Overview

1-1. Appearance Figure ..........................................................1-1

1-2. Board Location ................................................................ 1-1

1-3. Disassembly ....................................................................1-2

1-3-1. Upper Case Assembly ............................................ 1-2

1-3-2. Rear Case Pack Assembly......................................1-3

1-3-3. Main Board ............................................................ 1-3

1-3-4. Power Board and Thermal Sensor Board ..............1-4

1-3-5. Front Case Assembly and IR Sensor Board ........... 1-5

1-3-6. Fan (Exhaust)-1...................................................... 1-5

1-3-7. Fan (Exhaust)-2...................................................... 1-6

1-3-8. Optional Unit Assembly ........................................ 1-7

1-3-9. Lamp Power Supply...............................................1-8

1-3-10. Fan ......................................................................... 1-9

1-4. 3D GAMMA Service Tool Application Software ......... 1-10

1-5. Indicator ........................................................................1-10

1-6. Circuit Description ........................................................ 1-11

1-7. Replacing Fuse .............................................................. 1-13

1-8. Connecting/Disconnecting the Flexible Card Wire ....... 1-14

1-9. Lead-free Solder ............................................................ 1-14

2-7. Others .............................................................................. 2-9

2-7-1. Note When Replacing the Main Board ..................2-9

2-7-2. Status Information................................................2-10

2-7-3. ADC Calibration Value ........................................2-10

2-8. Memory Structure ......................................................... 2-11

2-9. Initial Values of Adjustment Items ................................ 2-13

3. Troubleshooting

4. Spare Parts

4-1. Notes on Repair Parts ......................................................4-1

4-2. Exploded Views ............................................................... 4-2

4-3. Electrical Parts List .........................................................4-4

4-4. Packing Materials & Supplied Accessories .................... 4-4

5. Block Diagrams

2. Electrical Adjustments

2-1. Preparation ......................................................................2-1

2-1-1. Required Equipment .............................................. 2-1

2-1-2. How to Enter the Service Mode ............................. 2-1

2-2. Adjustment of Main Board When it is Replaced ...........2-1

2-2-1. Save the Optical Data and Replacement ................2-1

2-3. EEPROM Replacement ...................................................2-2

2-4. ADC Calibration ............................................................2-2

2-4-1. RGB Alignment Procedure .................................... 2-2

2-4-2. YUV Alignment Procedure ................................... 2-3

2-5. V COM Adjustment ........................................................ 2-4

2-6. White Balance Adjustment .............................................. 2-6

2-6-1. HIGH Mode of PC ................................................2-6

2-6-2. MIDDLE Mode of PC ..........................................2-6

2-6-3. LOW Mode of PC ................................................. 2-7

2-6-4. HIGH Mode of VIDEO ......................................... 2-7

2-6-5. MIDDLE Mode of VIDEO .................................... 2-8

2-6-6. LOW Mode of VIDEO .......................................... 2-8

Overall (VPL-ES7) .......................................................... 5-1

Overall (VPL-EX70) ....................................................... 5-2

Overall (VPL-EX7) ......................................................... 5-3

Overall (VPL-EX7IN) ..................................................... 5-4

6. Schematic Diagrams

Frame Wiring (VPL-ES7) ............................................... 6-1

Frame Wiring (VPL-EX70) .............................................6-2

Frame Wiring (VPL-EX7) ...............................................6-3

Frame Wiring (VPL-EX7IN) .......................................... 6-4

VPL-ES7

1

Page 6

Page 7

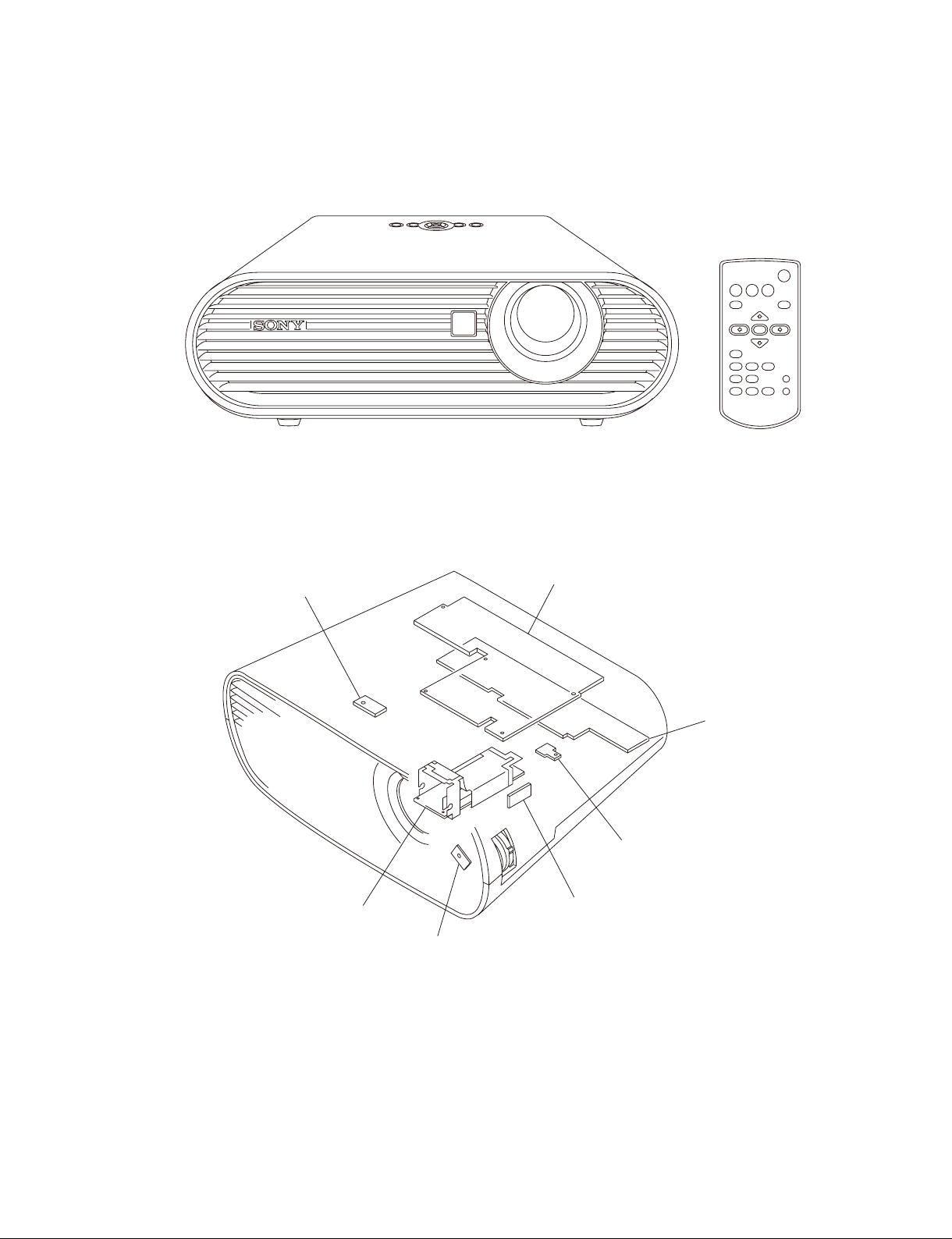

1-1. Appearance Figure

Section 1

Service Overview

1-2. Board Location

Door detection switch

Lamp power supply

Main

Power

Thermal sensor

Door detection switch

IR sensor

VPL-ES7

1-1

Page 8

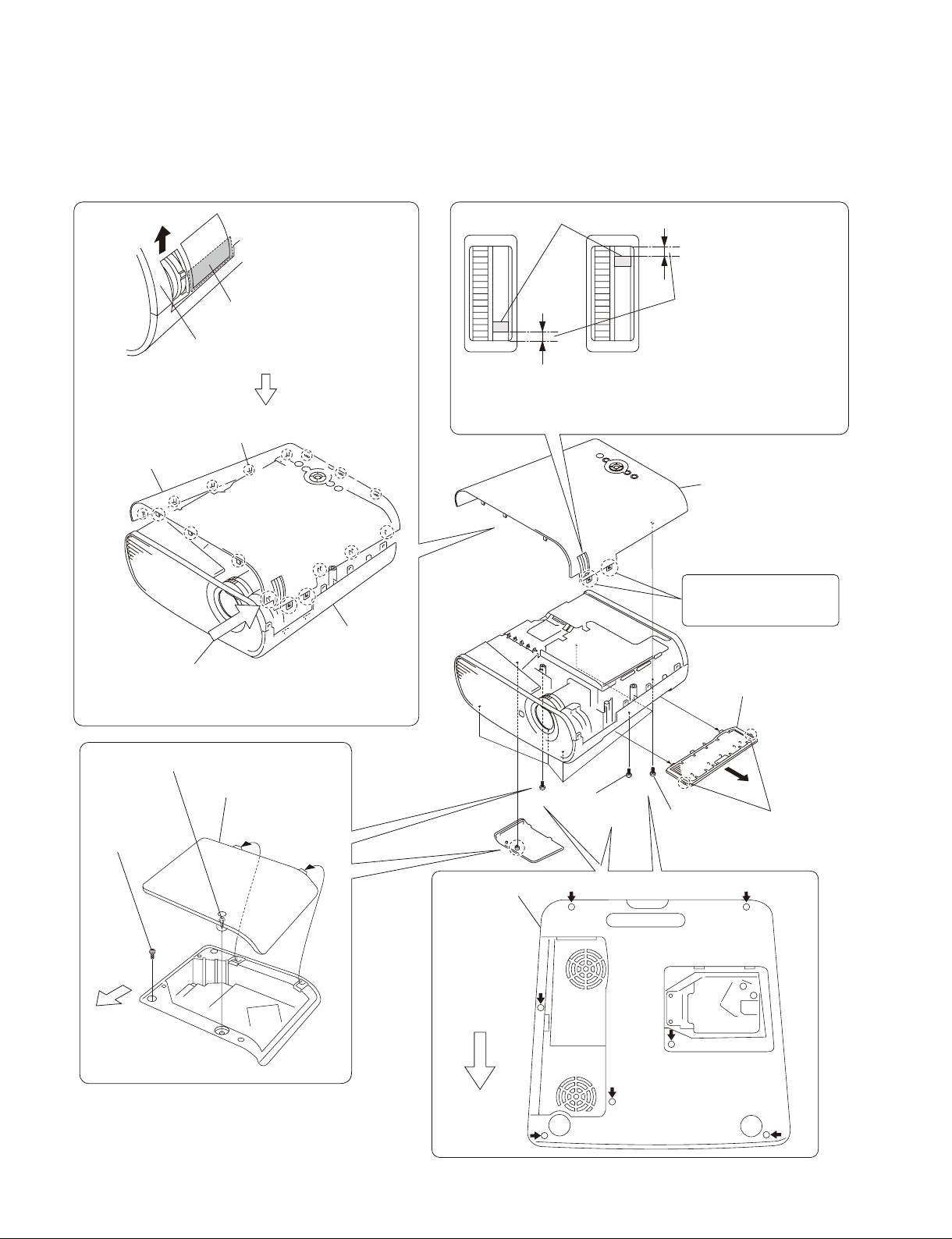

1-3. Disassembly

1-3-1. Upper Case Assembly

Zoom adjust gear knob

Press here strongly.

Remove the Upper case assembly

in the direction of the arrow.

Disengage the claws at

the 17 locations respectively.

Upper case assembly

Lower case pack

Caution :

Remove the upper case assembly from this corner.

When attaching the upper case assembly, attach it while

aligning with the lower case

starting from this corner.

pack

assembly

assembly

Upon completion of the upper

case assembly attachment,

check to see that the spacing

in the top is equal to the

Caution :

If the spacings in the top and bottom are not equal, go to

method of optical unit assembly and Focus/Zoom

(Refer to section 1-3-8. Steps 9 to 14.)

spacing in the bottom.

adjust assembly”.

Upper case assembly

These portions are fragile.

Be very careful not to

damage them.

Remove the filter

door in the direction

of the arrow .

“Assembling

Loosen screw.

Screw

(+P M3 x 6)

Front Side

of Unit

1-2

Lamp door

Lower case pack

assembly

Front Side

of Unit

Screw

Five screws

(+P M3 x 6)

(+P M3 x 6)

Two claws

VPL-ES7

Page 9

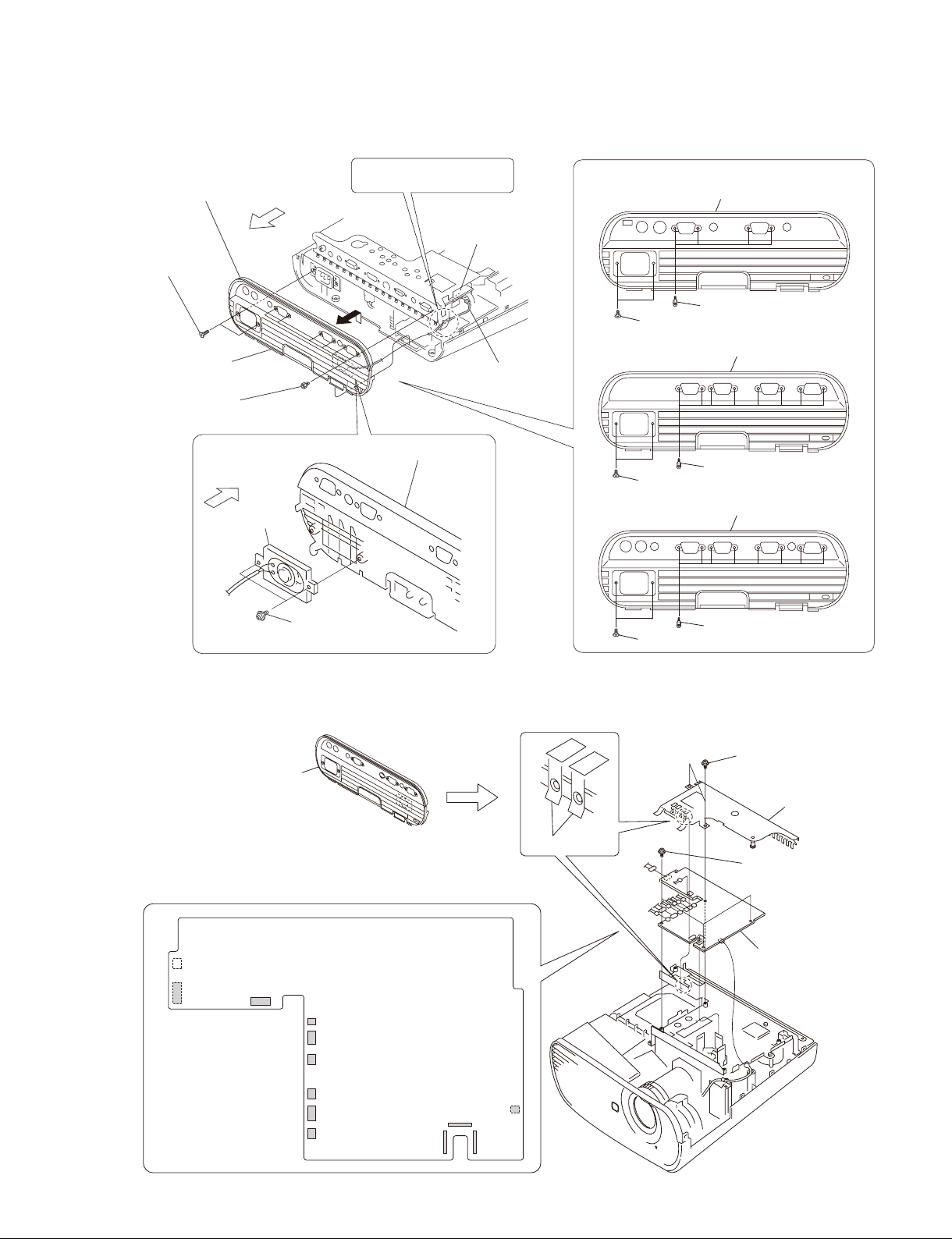

1-3-2. Rear Case Pack Assembly

Rear case pack assembly, etc.

Rear Side

Two screws

(+K 3 x 12)

VPL-EX7

Six hexagon

screws

of Unit

Rear Side

of Unit

Speaker

Route the speaker harness

under the MB bracket.

Rear case pack assembly

Main board

J11

Speaker harness

Rear case pack assembly

VPL-ES7

VPL-EX7IN

VPL-EX70

Rear case pack assembly

Four hexagon screws

Two screws (+K 3 x 12)

Rear case pack assembly

Eight hexagon screws

Two screws (+K 3 x 12)

Rear case pack assembly

1-3-3. Main Board

Rear case pack assembly,

etc.

(Refer to section 1-3-2, steps 1 to 4.)

J11

J17

J16

Two screws

(+PWH 3 x 6)

J26

J21

J20

Main board

Shield

Eight hexagon screws

Two screws (+K 3 x 12)

(+PWH 3 x 6)

Two screws

Shield

Three screws

(+PWH 3 x 6)

Main board

VPL-ES7

Remove the

twelve connectors.

J14

J19

J18

J23

J24 J22

J6

1-3

Page 10

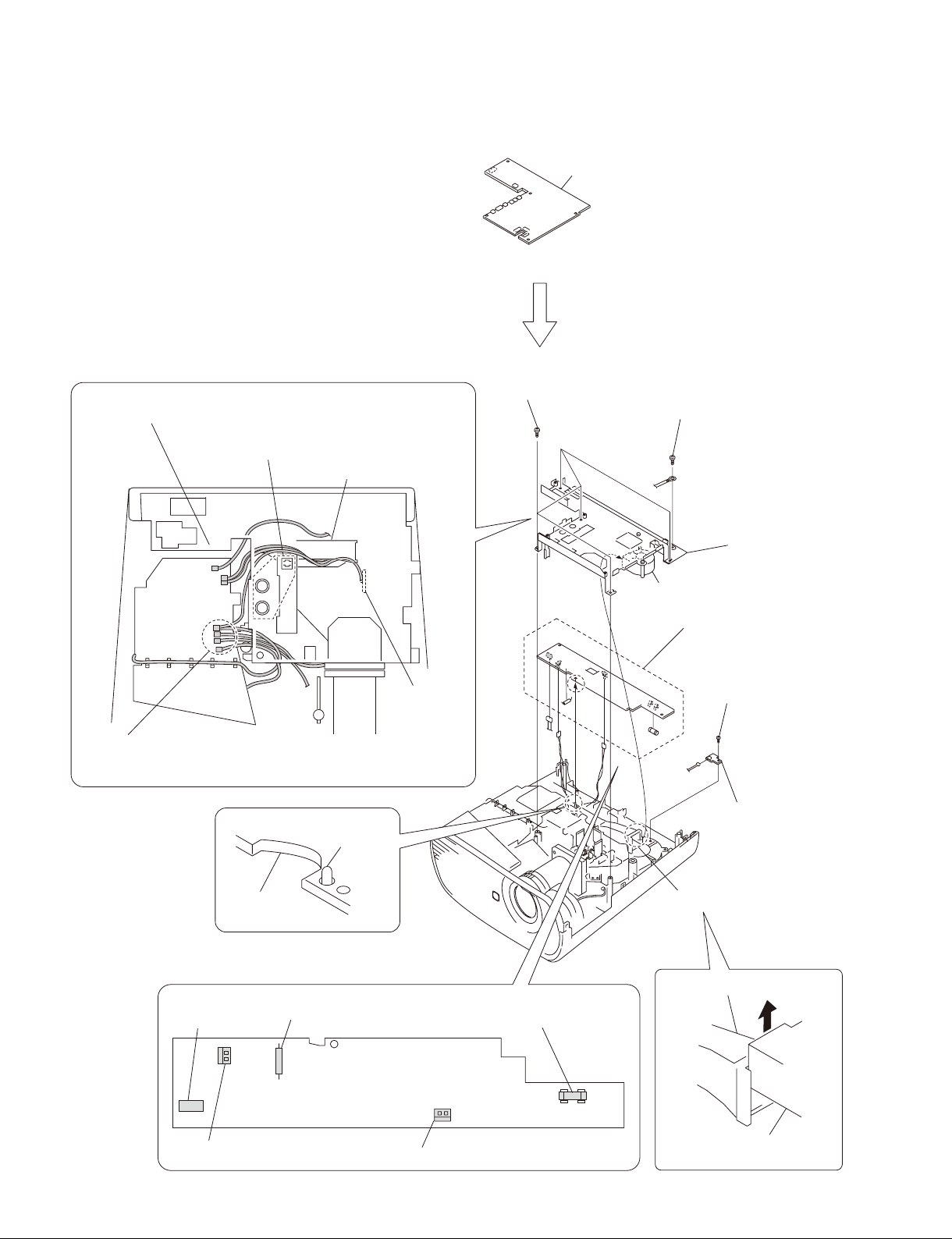

1-3-4. Power Board and Thermal Sensor Board

Check to see that the seven connectors are

protruding from the MB bracket.

Be careful that the harnesses must not override on

top of this port or must not be pinched by this portion.

Lamp nozzle assembly

Mai

n board

(Refer to section 1-3-3, steps 2 to 6.)

Five tapping screws

(PAN M3 x 7)

Screw

(+PSW M4 x 6)

MB bracket

Door detection

switch board

Caution :

When attaching the MB bracket, bind the four harnesses into the shape

of “U” and attaching them to the MB bracket.

Dowel

Power board

CN701

Miniature fuse-links (F602)

Fuse (H.B.C.)

(F601)

Fan

Power board

Tapping screw

(PAN M3 x 7)

J1

Thermal sensor board

Lamp nozzle assembly

Lamp nozzle assembly

1-4

CN605

Power board

CN603

Remove the three connectors.

Remove the fan in the

direction of the arrow.

VPL-ES7

Page 11

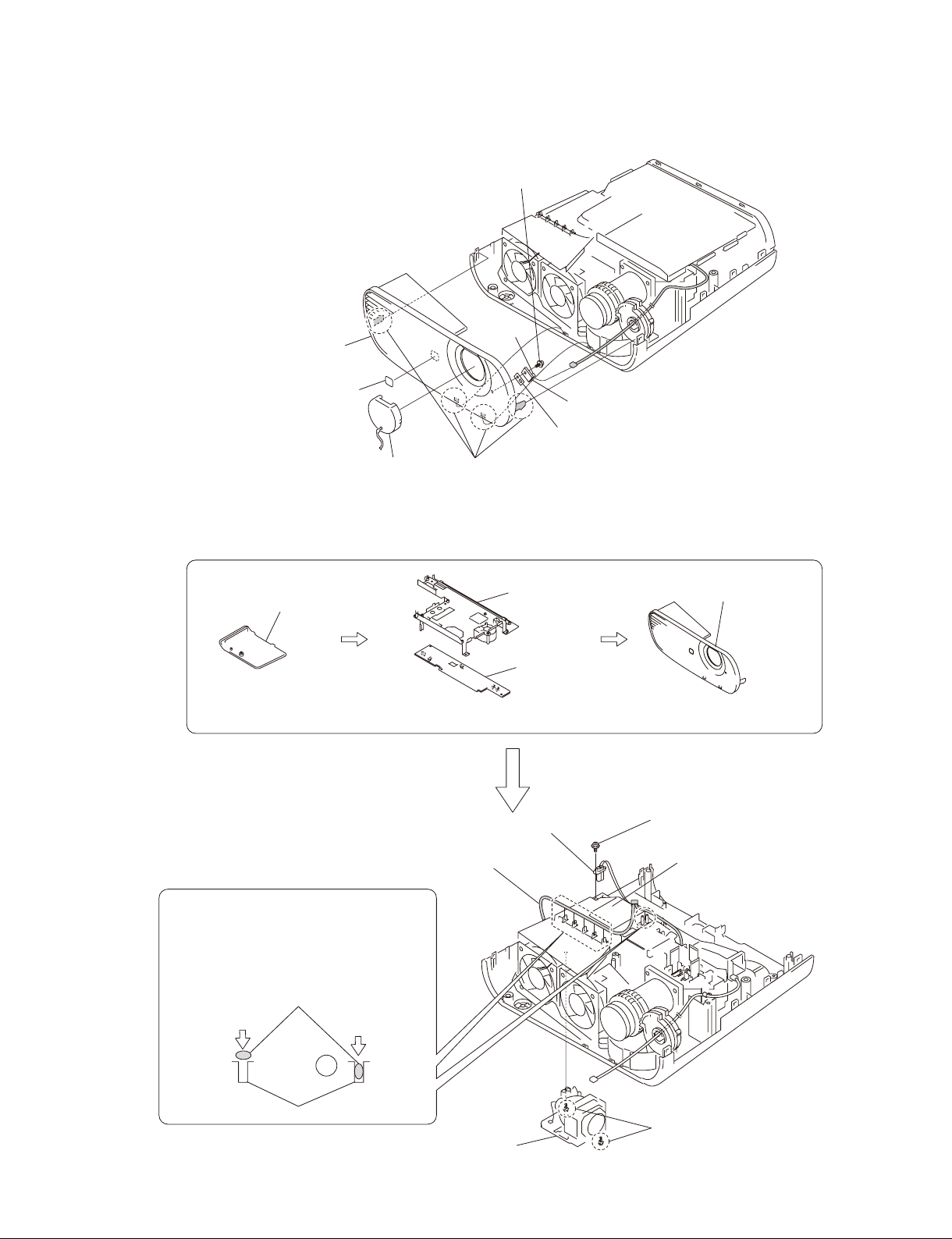

1-3-5. Front Case Assembly and IR Sensor Board

Tapping screw

(PAN M3 x 7)

Front case assembly

Logo

Lens cap

Four claws

1-3-6. Fan (Exhaust)-1

J7

IR sensor board

Sheet

Lamp door

(Refer to section 1-3-1, steps 2 to 4.)

(Refer to section 1-3-4, steps 2 to 8.)

Door detection switch

harness

Caution :

Because the harness has the shape of flat

cross-section, do not insert the harness into the

harness clamp section with excessive force.

Find out the direction in which the harness can

be inserted easily, and then insert the harness.

Harness

No good

Good

Lamp connector

assembly

MB bracket

Power board

Front

(Refer to section 1-3-5.)

case assembly

Screw

(+PWH 3 x 6)

Lamp box assembly

VPL-ES7

Harness clamp section

Lamp assembly

Loosen two screws.

1-5

Page 12

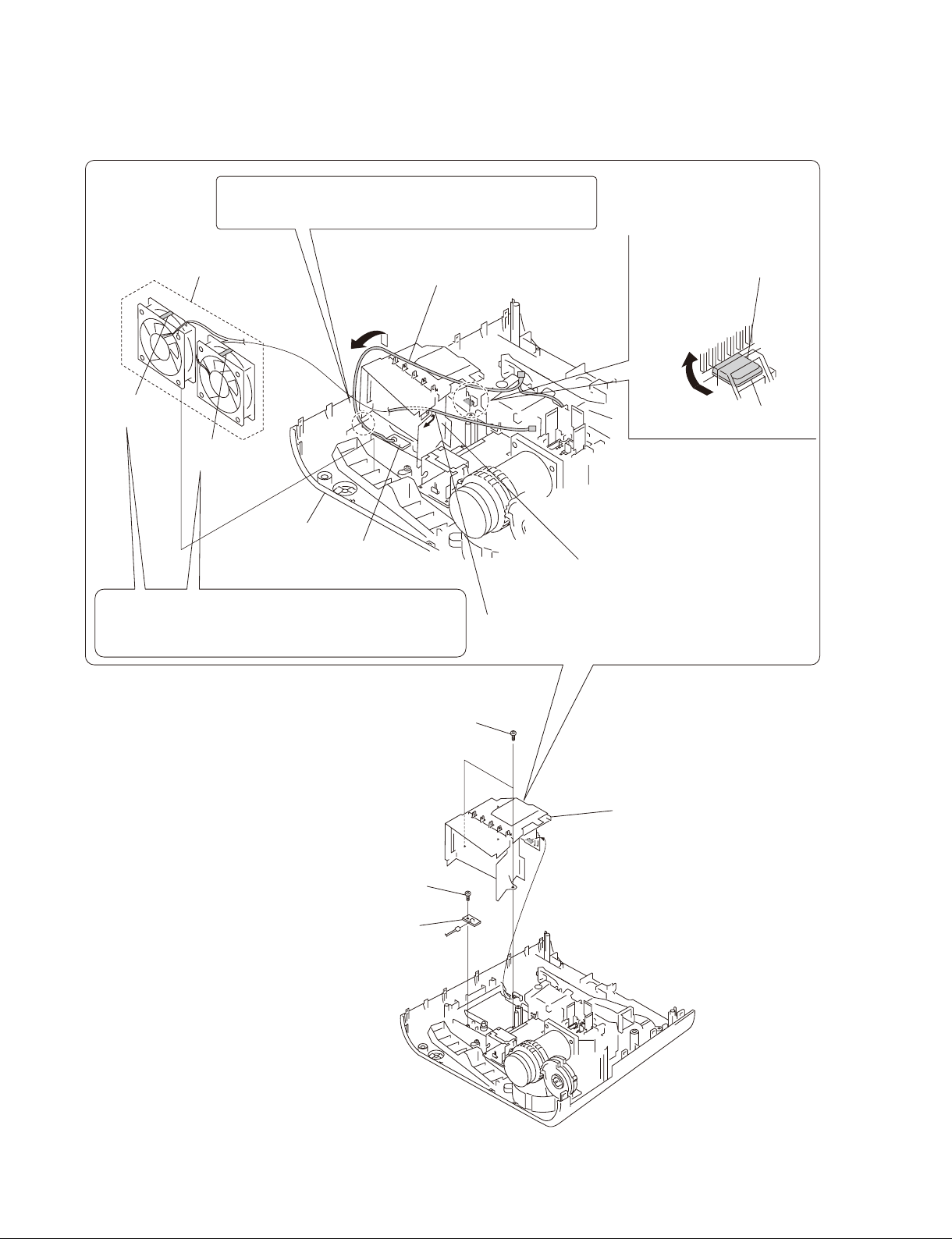

1-3-7. Fan (Exhaust)-2

Caution :

When attaching the lamp box assembly, insert the door detection

switch harness into the groove of the lower case pack assembly.

Fan (Exhaust)

80*25 AD0812HB/HB

Remove the door detection switch

harness in the direction of the arrow .

Remove the protrusion in the

direction of the arrow .

UB mark is

indicated.

HB mark is

indicated.

Lower case pack

assembly

Caution :

Two exhaust fans are the two different fans having the difference

characteristics. Be careful not to make mistake in choosing the

desired fan by confirming the indication on the fans.

Door detection

switch board

Two tapping screws

(PAN M3 x 7)

protrusion

Lamp box assembly

Remove the fan harness in the direction of the arrow .

1-6

Tapping screw

(PAN M3 x 7)

Door detection switch board

CN1

Lamp box assembly

VPL-ES7

Page 13

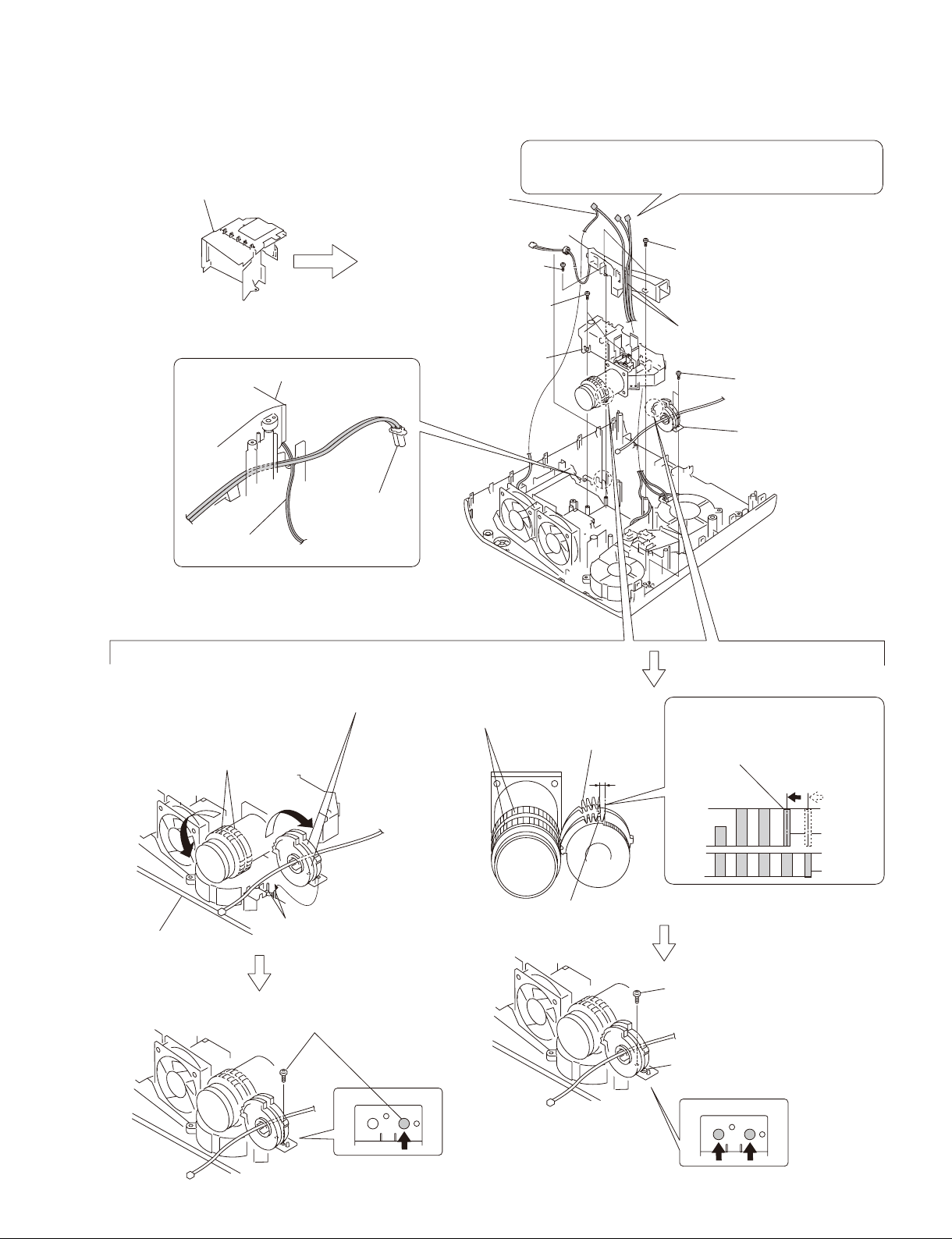

1-3-8. Optional Unit Assembly

Lamp box assembly

(Refer to section 1-3-6, steps 5 to 9) and

(refer to section 1-3-7, steps 1,2, 4 to 6.)

L

amp nozzle assembly

Lamp connector

assembly

CON thermal

145MM wire

Door detection

switch harness

Lamp nozzle assembly

Tapping screw

(PH W/FLA M3 x 10L PT ZN)

Three tapping screws

(PAN M3 x 7)

Optical unit

assembly

Caution :

When attaching the lamp nozzle assembly, route that harnesses

in between the lamp nozzle assembly and optical unit assembly.

Two tapping screws

(PAN M3 x 7)

Thermal sensor harness,

Fan harness

Two tapping screws

(PAN M3 x 7)

Focus/Zoom adjust

assembly

Assembling method of optical unit assembly and

Focus/Zoom adjust gears assembly

Attach the Focus/Zoom Adjust assembly into the two

dowels of the lower case pack assembly after rotating the

Focus/Zoom Adjust assembly as far as it can be rotated

in the direction of clockwise direction.

Lens: Rotate the Focus/Zoom gears in

the counter-clockwise direction as far

as it can be rotated.

Lower case pack assembly

Fix the Focus/Zoom Adjust assembly

tentatively with the screw.

Two dowels

Lens: Focus/Zoom gears

Zoom adjust gear

Focus adjust gear

Rotate the zoom adjust gear in the

counter-clockwise direction by one

tooth. Then, engage these gears

with the corresponding lens gears.

Attach the other screw while fixing

the gear position.

VPL-ES7

Tighten the screw finally that has

been tightened tentatively.

1-7

Page 14

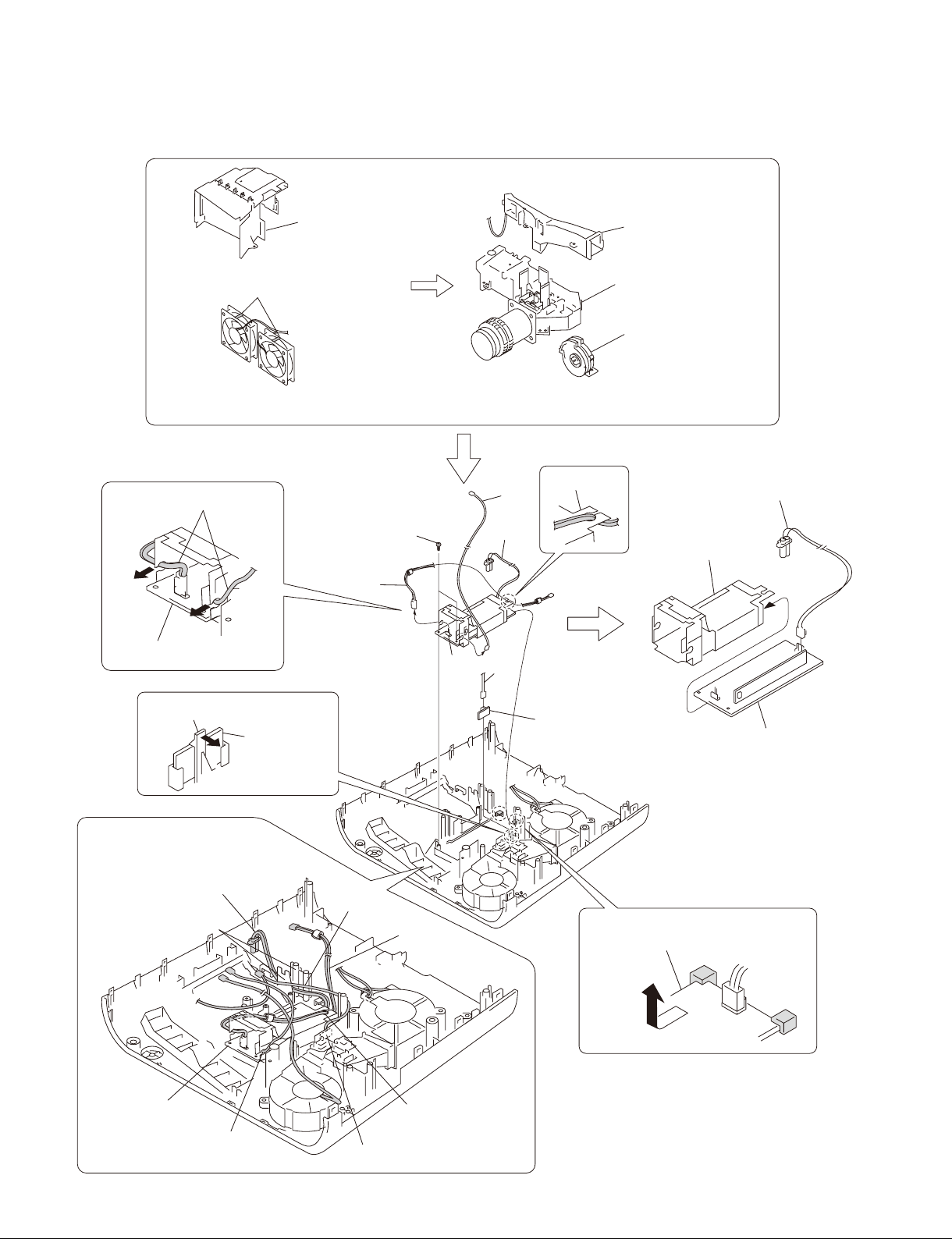

1-3-9. Lamp Power Supply

Fan (Exhaust)

80*25 AD0812HB/HB

Lamp box assembly

Lamp nozzle assembly

Optical unit assembly

Focus/Zoom adjust

assembly

(Refer to section 1-3-6, steps 5 to 9) and

(refer to section 1-3-7, steps 1 to 6.)

Two

harnesses

Lamp power supply

Claw

Door detection

switch board

Caution :

When re-assembling the machine,

route the respective harnesses and

wires at the specified locations as shown.

Route the Lamp connector

assembly

between them.

Two tapping screws

(PAN M3 x 7)

(Refer to section 1-3-8, steps 2 to 8.)

Mylar ballast

Door detection

switch board

Remove the lamp power supply

in the direction of the arrow .

X1

CN1

Mylar ballast

Lamp connector

assembly

Lamp power supply

Lamp power supply

1-8

Route the harness

through the hole of

this sheet.

Door detection switch board

VPL-ES7

Page 15

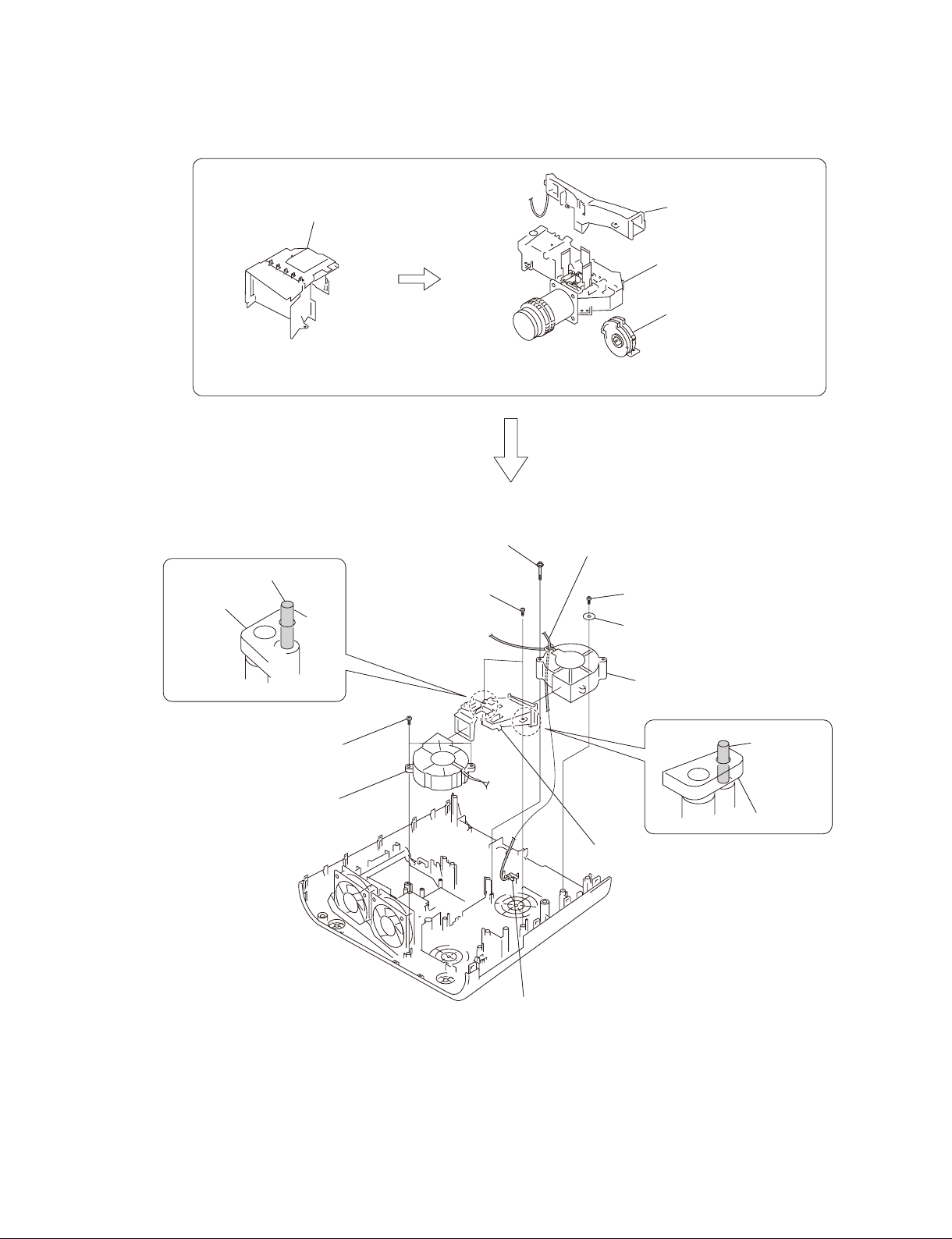

1-3-10. Fan

Lamp box assembly

Lamp nozzle assembly

Optical unit assembly

Focus/Zoom adjust

assembly

(Refer to section 1-3-6, steps 5 to 9) and

(refer to section 1-3-7, steps 1,2, 4 to 6.)

Dowel

Prism duct

Two tapping screws

(PH W/FLA M3 x 10L PT ZN)

Fan

70*70*25 240MM AB07012UB

Tapping screw

(PH W/FL M3 x 35 NI D-PT)

Two tapping screws

(PAN M3 x 7)

(Refer to section 1-3-8, steps 2 to 8.)

Harness

Tapping screw

(PAN M3 x 7)

Washer

Fan

75*75*30 145MM AB7512UB

Prism duct

Dowel

VPL-ES7

Prism duct

Thermal sensor board

1-9

Page 16

1-4. 3D GAMMA Service Tool Application Software

Feature:

The Ernie Service Tool is the application software for performing the tasks such as reading out and writing of the 3D GAMMA data on the projector that is connected to a PC via a communication function.

The Ernie Service Tool has the following features.

. It can read 3D GAMMA data from a set and save it in a fi le.

. It can write 3D GAMMA data in a PC into a set.

When the optical unit is replaced, write 3D GAMMA data recorded on the CD-ROM, which is supplied

together with the optical unit, into a set using the application software.

. VPL-ES7 set has not RS-232C terminal, use the QUICK ACCESS Assy.

. Remove the rubber cap on the upper left of the rear side of the unit.

QUICK ACCESS Assy

J12

Set

Main board CN

PC

RS-232C

Straight

cable

QUICK ACCESS

Dsub

Assy

9pin

(Parts No. A-1568-125-A)

CN 5P

CN J8

5pin

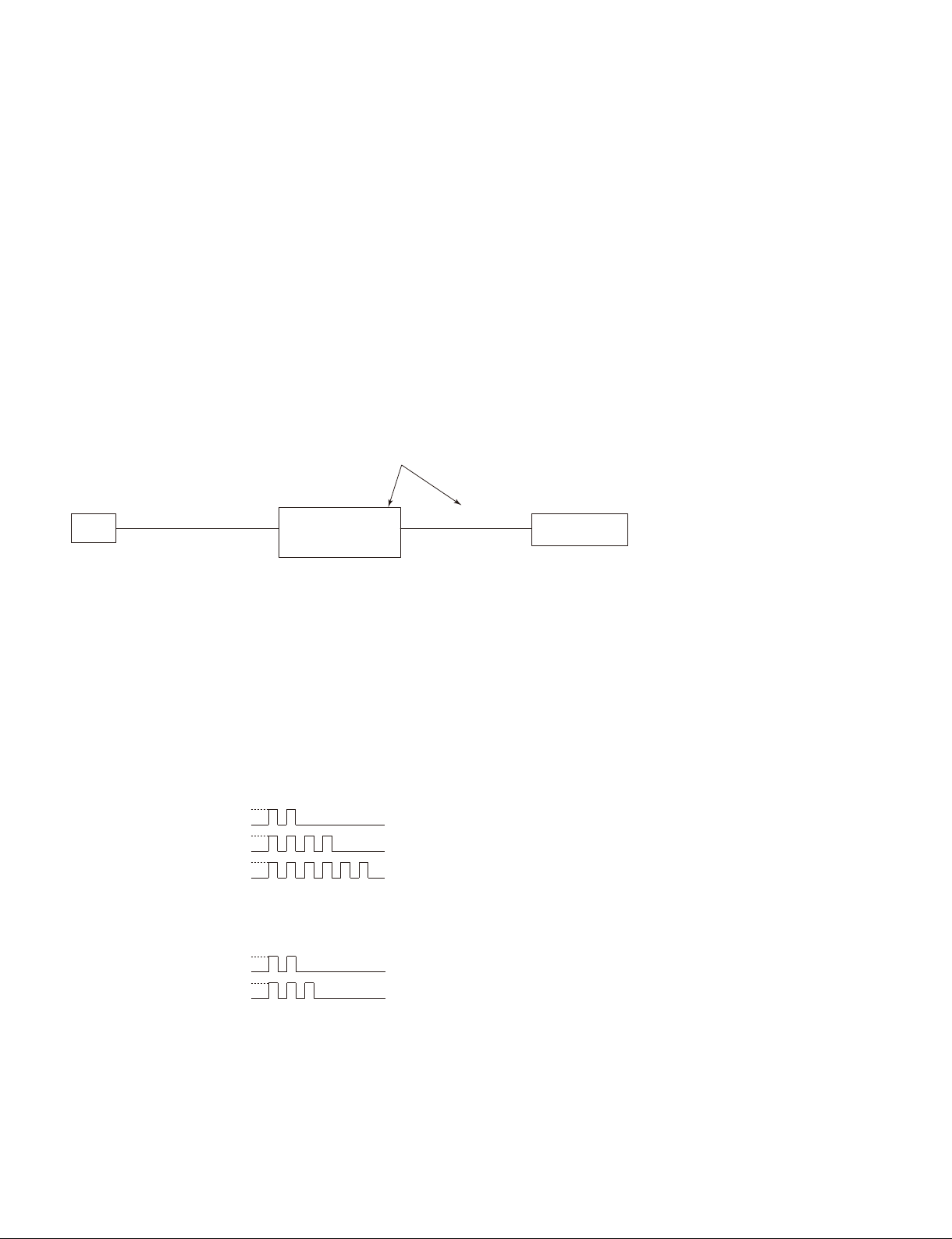

1-5. Indicator

The error status of the this units are indicated by the type of fl ashing of indicator. The top cover has the

ON/STANDBY indicator and the LAMP/COVER indicator. Various error contents are indicated by the

type of fl ashing of indicator. For details of the types of indicator fl ashing and the error statuses, refer to

the list shown below.

ON/STANDBY Indicator (Red fl ashing)

Error Name

Temperature Error

Fan Error

Power Error

LAMP/COVER Indicator (Orange fl ashing)

Cover Error

Lamp Error

Flash Frequency

ON

OFF

ON

OFF

ON

OFF

Flash FrequencyError Name Status

ON

OFF

ON

OFF

2 Times

4 Times

6 Times

2 Times

3 Times

Status

The temperature of the equipment is high.

Each fan dose not work normally.

The power is not turned on correctly.

The lamp or filter cover is opened.

The UHP lamp is not lighting.

1-10

VPL-ES7

Page 17

1-6. Circuit Description

Main Board:

Video input block

*1

The video input has two channels: Composite video and S-Video. The 2-channel inputs are sent directly to

the video processor, and converted to the digital data by the built-in AD converter of the video processor.

PC input block

There are two channels: Input A and Input B, one of which is selected with the toggle switch. The selected

output is input to the video processor and the video buffer. At the video processor, the signal is converted

to the digital data by the built-in AD converter. The signal input to the video buffer is output as a monitor

out.

To Input A, PC signals, component signals, and video GBR signals can be input. To Input B, only PC

signals can be input. (VPL-EX7IN can input only PC signals.)

Audio input block

*1

Stereo mini jack input. The L/R input is synthesized internally into a monaural signal. The signal is synthesized by a resistance, so the output level varies between the case where only one channel is input and

the case where both channels are input. The standard is prescribed under the condition where only one

channel is input.

Monitor output block (PC)

The signals input to Input A and Input B are output. The signal of the channel that is selected with the

input toggle switch is output. No output is made if Video or S-Video is selected.

Monitor output block (Audio)

*1

The signal input to the audio input is output. This output is variable with the volume control. If a cable is

connected to this connector, the output from the built-in speaker stops.

Video processor & System control block

PW-190 made by Pixelworks Inc. is used. This IC performs pixel number conversion, aspect conversion,

and OSD addition to the input signals. This IC also controls brightness, sharpness, chroma, and hue.

In addition, the built-in CPU controls the system.

Control target: Control panel, OSD display, lamp cover switch, fi lter door switch, LED control, serial

control

LCD timing generator (DSD) block

The IC for LCD panel made by Sony is used. This IC generates the timing for driving the LCD panel.

This uses the method that inverts the driving direction for each frame. In addition to timing generation,

this IC performs white balance adjustment, gamma adjustment, and color shading adjustment.

LCD driver block

The drive IC for LCD panel made by Sony is used. This drives the LCD panel in a 12-phase drive method

at the timing generated by the timing generator IC. The GBR and the circuit for three channels are

equipped.

*1: Not valid for VPL-EX7IN.

VPL-ES7

1-11

Page 18

FAN control, Thermal sensor block

The IC with the built-in FAN control and thermal sensor function is used.

. FAN control

This detects the FG of the FAN, and controls the number of rotations. The number of rotations is set in

accordance with the internal temperature.

. Thermal sensor

The thermal sensor is placed at the lower part of the power board, and the internal temperature is mea-

sured.

Ballast drive block

This drives the ballast in synchronization with the input signal. The synchronous circuit is formed by the

microprocessor.

When the lamp mode is standard, ballast is driven in synchronization with the frequency 1.5 times higher

than that of the input signal. When the lamp mode is high, the ballast is driven in synchronization with the

input signal.

RS232C block

This is used to connect the PW-190 via the RS232C driver/receiver IC. Because the number of serial ports

is limited on the PW-190, the RS232C and network cannot be used at the same time. The RS232C block

is equipped with the circuit that switches them.

Sensor Board:

The sensor boards include the thermal sensor board, lamp cover switch board, fi lter door switch board,

and IR sensor board.

Power Board:

This supplies the lamp power and the system power. For the system power, +15.25 V, +12 V, and +5 V

are output, and the circuit power is generated on the main board.

1-12

VPL-ES7

Page 19

1-7. Replacing Fuse

w

The fuse is essential parts for safe operation.

Replace the components with Sony parts whose part numbers appear in the manual published by Sony. If

the components are replaced with any parts other than the specifi ed ones, this may cause a fi re or electric

shock.

c

If the fuse is replaced while the main power is kept on, this may cause electric shock.

Before replacing the fuse, not only turn off the POWER switch but also disconnect the AC power cord

that is connected to the AC IN connector.

This unit is equipped with fuses.

The fuses blow if an excessive current fl ows due to abnormality inside the equipment. If fuses blow, turn

off the main power of the equipment once, and inspect inside of the equipment and remove the cause of

excessive current. After that, replace the fuses. (Refer to Section 1-3-4.)

Board Ref. No. (Address) Part No./Name

POWER F601 ! 1-576-233-51 Fuse 6.3 A, 250 V

F602 ! 1-576-973-11 Fuse 2 A, 600 V

Miniature fuse-links (F602)

Power board

Fuse (H.B.C.)

(F601)

VPL-ES7

1-13

Page 20

1-8. Connecting/Disconnecting the Flexible Card Wire

m

. Be very careful not to fold the fl exible card wire. Life of fl exible card wire will be signifi cantly short-

ened if it is folded.

. The fl exible card wire has the conduction side and the insulation side. If the conduction side and the

insulation side are connected in the wrong direction, the circuit will not function.

. Insert the fl exible card wire straight.

. Ensure that the conduction surface of the fl exible card wire is not contaminated.

Disconnecting

Life portions A of the connector to unlock, and disconnect the fl exible card wire.

Connecting

1. Insert the fl exible card wire fi rmly as far as it will go, with the conduction side up.

2. Push portions A of the connector to lock.

Disconnecting Connecting

Connector

Portion A

Portion A

Flexible card wire

Connector

Conduction

side

Flexible card wire

1-9. Lead-free Solder

Boards requiring use of lead-free solder are printed with a lead free mark (LF) indicating the solder

contains no lead.

(Caution: Some printed circuit boards may not come printed with the lead free mark due to their particular

size.)

: LEAD FREE MARK

m

. Be sure to use the lead-free solder for the printed circuit board printed with the lead free mark.

. The lead-free solder melts at a temperature about 40 dC higher than the ordinary solder, therefore, it is

recommended to use the soldering iron having a temperature regulator.

. The ordinary soldering iron can be used but the iron tip has to be applied to the solder joint for a slightly

longer time. The printed pattern (copper foil) may peel away if the heated tip is applied for too long, so

be careful.

1-14

VPL-ES7

Page 21

Section 2

Electrical Adjustments

2-1. Preparation

2-1-1. Required Equipment

. NTSC, PAL, SECAM component signal generator Tektronix TG2000 + AVG1 (option module) +

AWVG1 (option module) or equivalent

. VG (programmable video signal generator) VG828 or equivalent

. Chroma meter KONICA MINOLTA CL-200

2-1-2. How to Enter the Service Mode

1. Power on the projector.

2. Push the switches on the remote controller or controller panel as below.

[Enter] → [Enter] → [&] → [Enter] key

3. Service mode menu will appear on the screen.

2-2. Adjustment of Main Board When it is Replaced

2-2-1. Save the Optical Data and Replacement

1. Try to read the optical data from the faulty unit using the Emie Service tool. If succeeded in reading,

replacement of the EEPROM is not necessary but the V COM Adjustment should be performed.

(Refer to “2-5 V COM Adjustment”.)

2. If the optical data could not be read from the faulty unit in step 1, remove the IC (EEPROM) from the

faulty board and replace the IC (EEPROM) of the new board with the removed one.

Reference number: U33, U48 (ES7), U20 (EX7/EX7IN/EX70)

3. Run the RGB and YUV calibration.

VPL-ES7

2-1

Page 22

2-3. EEPROM Replacement

EEPROM of the main board contains the following alignment data

System EEPROM (32 kbits) (U33)

. V com setting

. Color temperature

. RGB gain and offset for PC

. YUV gain and offset for YPbPr

. OSD setting

Gamma EEPROM (256 kbits)

(U48: ES7, U20: EX7/EX7IN/EX70)

. 3D gamma

. Panel gamma

Gamma EEPROM

(U20)

System EEPROM(U33)

EX7/EX7IN/EX70 Main Board

Gamma EEPROM

(U48) (Side B)

System EEPROM(U33)

ES7 Main Board

2-4. ADC Calibration

2-4-1. RGB Alignment Procedure

1. Power on the projector.

2. Input the following signal from the signal generator to the INPUT A connector.

Timing: VPL-EX7/EX7IN/EX70: 1024 x 768 : 60 Hz

VPL-ES7: 800 x 600 : 60 Hz

Pattern: 16 gray pattern

If the pattern shown in Fig. 1 is not available, the pattern shown in Fig. 3 can be used for the adjust-

ment. Use the signal shown in Fig. 2 to run APA. Then, input the signal shown in Fig. 3.

Fig.1 Fig.2 Fig.3

2-2

VPL-ES7

Page 23

3. Enter the service mode and change to page “ADC Calibration”.

4. Press [*] key to run calibration.

5. When calibration is executed, the screen brightness changes for approx. 5 seconds. After that, the

screen brightness, the RGB Offset data and the RGB Gain data become stabilized.

P4 ADC calibration

RGB Calibrate

YUV Calibrate

RGB Offset

RGB Gain

YUV Offset

YUV Gain

R Offset

G Offset

B Offset

R Gain

G Gain

B Gain

< or >

< or >

119 128 102

67 65 57

129 109 108

81 71 63

129

109

108

81

71

63

ES7

<< >>ADC calibration

RGB Calibrate

YUV Calibrate

RGB Offset

RGB Gain

YUV Offset

YUV Gain

R Offset

G Offset

B Offset

R Gain

G Gain

B Gain

138 88 122

62 55 60

147 68 144

71 27 69

EX7/EX7IN/EX70

< or >

< or >

138

88

122

52

55

60

2-4-2. YUV Alignment Procedure

1. Power on the projector.

2. Input the following signal from the signal generator to the INPUT A connector.

Timing: 480P

Pattern: SMPTE color bar

3. Enter the service mode and change to page “ADC Calibration”.

4. Press [*] key to run calibration.

5. When calibration is executed, the screen brightness changes for approx. 5 seconds. After that, the

screen brightness, the YUV Offset data and the YUV Gain data become stabilized.

P4 ADC calibration

RGB Calibrate

YUV Calibrate

RGB Offset

RGB Gain

YUV Offset

YUV Gain

R Offset

G Offset

B Offset

R Gain

G Gain

B Gain

VPL-ES7

< or >

< or >

119 128 102

67 65 57

129 109 108

81 71 63

129

109

108

81

71

63

ES7

<< >>ADC calibration

RGB Calibrate

YUV Calibrate

RGB Offset

RGB Gain

YUV Offset

YUV Gain

R Offset

G Offset

B Offset

R Gain

G Gain

B Gain

138 88 122

62 55 60

147 68 144

71 27 69

EX7/EX70

< or >

< or >

138

88

122

52

55

60

2-3

Page 24

2-5. V COM Adjustment

. By the Ernie Service tool, the V COM data is not replaced. Therefore, perform the V COM Adjustment

when optical data is replaced by the Ernie Service tool.

. When the EEPROM is replaced, the V COM data is inherited so that the V COM adjustment is not

necessary.

If fl icker is signifi cant on the screen, perform the V COM adjustment.

Procedure: VPL-ES7

1. Input the 100 % fl at-fi eld signal to the INPUT A connector and allow the warm-up of 10 minutes

aging at a minimum.

2. Enter the service mode and change to page 4 “Vcom & Misc” page.

3. Input the XGA, R-single color, 30 %, single-line ON/OFF signal.

4. Move the cursor key until it is positioned at Vcom-R Normal.

5. Adjust the V com-R Normal value until fl icker is reduced to minimal by [*], [&] key.

6. Change the input signal to the XGA, G-single color, 30 %, single-line ON/OFF signal.

7. Move the cursor key until it is positioned at Vcom-G Normal.

8. Adjust the V com-G Normal value until fl icker is reduced to minimal by [*], [&] key.

9. Change the input signal to the XGA, B-single color, 30 %, single-line ON/OFF signal.

10. Move the cursor key until it is positioned at Vcom-B Normal.

11. Adjust the V com-B Normal value until fl icker is reduced to minimal by [*], [&] key.

12. Reverse the “Image Flip” upside-down and right-to-left, and repeat the above adjustment procedure

from step 2 to step 11.

Vcom & Misc.

<< >>

Vcom-R Normal

Vcom-G Normal

Vcom-B Normal

Vcom-R Flip

Vcom-G Flip

Vcom-B Flip

EDID Write Protect

ROM Version:

82

89

83

88

88

88

ON

0.06

2-4

VPL-ES7

Page 25

Procedure: VPL-EX7/EX7IN/EX70

1. Input the 100 % fl at fi eld signal to the INPUT A connector and allow the warm-up of 10 minutes

aging at a minimum.

2. Enter the service mode and change to page 4 to select “Vcom & Misc”.

3. Input the XGA, G-single color, 80 %, fl at-fi eld signal.

4. Move the cursor key until it is positioned at Vcom-G Normal.

5. Adjust the V com-G Normal value until fl icker is reduced to minimal by [*], [&] key.

6. Change the input signal to the XGA, R-single color, 80 %, fl at-fi eld signal.

7. Move the cursor key until it is positioned at Vcom-R Normal.

8. Adjust the V com-R Normal value until fl icker is reduced to minimal by [*], [&] key.

9. Change the input signal to the XGA, B-single color, 80 %, fl at-fi eld signal.

10. Move the cursor key until it is positioned at Vcom-B Normal.

11. Adjust the V com-B Normal value until fl icker is reduced to minimal by [*], [&] key.

12. Reverse the “Image Flip” upside-down and right-to-left, and repeat the above adjustment procedure

from step 2 to step 11.

Vcom & Misc.

<< >>

Vcom-R Normal

Vcom-G Normal

Vcom-B Normal

Vcom-R Flip

Vcom-G Flip

Vcom-B Flip

94

90

92

83

83

83

EDID Write Protect

ROM Version:

ON

1.00

VPL-ES7

2-5

Page 26

2-6. White Balance Adjustment

Preparation before adjustment

Input the 100 % fl at fi eld signal to the INPUT A connector and allow the warm-up of 10 minutes aging at a mini-

mum.

2-6-1. HIGH Mode of PC

1. Input the 80 % fl at fi eld computer signal to the INPUT-A connector.

2. Set the picture quality mode to STANDARD, and set color temperature to HIGH.

3. The target chromaticity (x, y) is (0.282, 0.299).

4. Enter the service mode and change to CXD9809-Page 2 (ES7) or White Balance 1 page (EX7/EX7IN/EX70).

5. Adjust the PC Hi Gain-R and PC Hi Gain-B until the target chromaticity (x, y) as shown is obtained.

6. Repeat steps 2 to 5 until the chromaticity (x ?0.002, y ?0.002) with reference to the target chromaticity (x, y)

is obtained.

P1-2 CXD9809-page2

PC Hi Gain-R

PC Hi Gain-G

PC Hi Gain-B

PC Hi Bias-R

PC Hi Bias-G

PC Hi Bias-B

PC Lo Gain-R

PC Lo Gain-G

PC Lo Gain-B

PC Lo Bias-R

PC Lo Bias-G

PC Lo Bias-B

112

83

128

0

0

0

128

78

93

0

0

0

ES7

White Balance 1

<< >>

PC Hi Gain-R

PC Hi Gain-G

PC Hi Gain-B

PC Hi Bias-R

PC Hi Bias-G

PC Hi Bias-B

PC Lo Gain-R

PC Lo Gain-G

PC Lo Gain-B

PC Lo Bias-R

PC Lo Bias-G

PC Lo Bias-B

433

410

494

- 5

0

- 6

478

430

452

5

0

- 6

EX7/EX7IN/EX70

2-6-2. MIDDLE Mode of PC

1. Input the 80 % fl at fi eld computer signal to the INPUT-A connector.

2. Set the picture quality mode to STANDARD, and set color temperature to MIDDLE.

3. The target chromaticity (x, y) is (0.390, 0.321).

4. Enter the service mode and change to CXD9809-Page4 (ES7) or White Balance 3 page (EX7/EX7IN/EX70).

5. Adjust the PC Mid Gain-R and PC Mid Gain-B until the target chromaticity (x, y) is obtained.

6. Repeat steps 2 to 5 until the chromaticity (x ?0.002, y ?0.002) with reference to the target chromaticity (x, y)

is obtained.

P1-4 CXD9809-page4

PC Mid Gain-R

PC Mid Gain-G

PC Mid Gain-B

PC Mid Bias-R

PC Mid Bias-G

PC Mid Bias-B

Video Mid Gain-R

Video Mid Gain-G

Video Mid Gain-B

Video Mid Bias-R

Video Mid Bias-G

Video Mid Bias-B

2-6

125

100

126

127

100

122

0

0

0

0

0

0

ES7

White Balance 3

<< >>

PC Mid Gain-R

PC Mid Gain-G

PC Mid Gain-B

PC Mid Bias-R

PC Mid Bias-G

PC Mid Bias-B

Video Mid Gain-R

Video Mid Gain-G

Video Mid Gain-B

Video Mid Bias-R

Video Mid Bias-G

Video Mid Bias-B

451

445

486

0

0

0

466

445

508

35

0

44

EX7/EX7IN/EX70

VPL-ES7

Page 27

2-6-3. LOW Mode of PC

1. Input the 80 % fl at fi eld computer signal to the INPUT A connector.

2. Set the picture quality mode to STANDARD, and set color temperature to LOW.

3. The target chromaticity (x, y) is (0.312, 0.334).

4. Enter the service mode and change to CXD9809-Page 2 (ES7) or White Balance 1 page (EX7/EX7IN/EX70).

5. Adjust the PC Lo Gain-R and PC Lo Gain-B until the target chromaticity (x, y) is obtained.

6. Repeat steps 2 to 5 until the chromaticity (x ?0.002, y ?0.002) with reference to the target chromaticity (x, y)

is obtained.

P1-2 CXD9809-page2

PC Hi Gain-R

PC Hi Gain-G

PC Hi Gain-B

PC Hi Bias-R

PC Hi Bias-G

PC Hi Bias-B

PC Lo Gain-R

PC Lo Gain-G

PC Lo Gain-B

PC Lo Bias-R

PC Lo Bias-G

PC Lo Bias-B

112

83

128

0

0

0

128

78

93

0

0

0

ES7

White Balance 1

<< >>

PC Hi Gain-R

PC Hi Gain-G

PC Hi Gain-B

PC Hi Bias-R

PC Hi Bias-G

PC Hi Bias-B

PC Lo Gain-R

PC Lo Gain-G

PC Lo Gain-B

PC Lo Bias-R

PC Lo Bias-G

PC Lo Bias-B

433

410

494

- 5

0

- 6

478

430

452

5

0

- 6

EX7/EX7IN/EX70

2-6-4. HIGH Mode of VIDEO

1. Input the 80 % fl at fi eld 480/60i or 575/50i signal to the INPUT A connector.

2. Set the picture quality mode to STANDARD, and set color temperature to HIGH.

3. The target chromaticity (x, y) is (0.282, 0.299).

4. Enter the service mode and change to CXD9809-Page 3 (ES7) or White Balance 2 page (EX7/EX70).

5. Adjust the PC Hi Gain-R and PC Hi Gain-B until the target chromaticity (x, y) is obtained.

6. Repeat steps 2 to 5 until the chromaticity (x ?0.002, y ?0.002) with reference to the target chromaticity (x, y)

is obtained.

P1-3 CXD9809-page3

Video Hi Gain-R

Video Hi Gain-G

Video Hi Gain-B

Video Hi Bias-R

Video Hi Bias-G

Video Hi Bias-G

Video Lo Gain-R

Video Lo Gain-G

Video Lo Gain-B

Video Lo Bias-R

Video Lo Bias-G

Video Lo Bias-B

117

84

128

0

0

0

128

79

88

0

0

0

ES7

White Balance 2

<< >>

Video Hi Gain-R

Video Hi Gain-G

Video Hi Gain-B

Video Hi Bias-R

Video Hi Bias-G

Video Hi Bias-G

Video Lo Gain-R

Video Lo Gain-G

Video Lo Gain-B

Video Lo Bias-R

Video Lo Bias-G

Video Lo Bias-B

442

410

512

19

0

38

503

430

475

35

0

26

EX7/EX70

VPL-ES7

2-7

Page 28

2-6-5. MIDDLE Mode of VIDEO

1. Input the 80 % fl at fi eld 480/60i or 575/50i signal to the INPUT A connector.

2. Set the picture quality mode to STANDARD, and set color temperature to MIDDLE.

3. The target chromaticity (x, y) is (0.390, 0.321).

4. Enter the service mode and change to CXD9809-Page 4 (ES7) or White Balance 3 page (EX7/EX70).

5. Adjust the PC Mid Gain-R and PC Mid Gain-B until the target chromaticity (x, y) is obtained.

6. Repeat steps 2 to 5 until the chromaticity (x ?0.002, y ?0.002) with reference to the target chromaticity (x, y)

is obtained.

P1-4 CXD9809-page4

PC Mid Gain-R

PC Mid Gain-G

PC Mid Gain-B

PC Mid Bias-R

PC Mid Bias-G

PC Mid Bias-B

Video Mid Gain-R

Video Mid Gain-G

Video Mid Gain-B

Video Mid Bias-R

Video Mid Bias-G

Video Mid Bias-B

125

100

126

0

0

0

127

100

122

0

0

0

ES7

White Balance 3

<< >>

PC Mid Gain-R

PC Mid Gain-G

PC Mid Gain-B

PC Mid Bias-R

PC Mid Bias-G

PC Mid Bias-B

Video Mid Gain-R

Video Mid Gain-G

Video Mid Gain-B

Video Mid Bias-R

Video Mid Bias-G

Video Mid Bias-B

451

445

486

0

0

0

466

445

508

35

0

44

EX7/EX70

2-6-6. LOW Mode of VIDEO

1. Input the 80 % fl at fi eld 480/60i or 575/50i signal to the INPUT A connector.

2. Set the picture quality mode to STANDARD, and set color temperature to LOW.

3. The target chromaticity (x, y) is (0.312, 0.224).

4. Enter the service mode and change to CXD9809-Page 3 (ES7) or White Balance 2 page (EX7/EX70).

5. Adjust the PC Lo Gain-R and PC Lo Gain-B until the target chromaticity (x, y) is obtained.

6. Repeat steps 2 to 5 until the chromaticity (x ?0.002, y ?0.002) with reference to the target chromaticity (x, y)

is obtained.

P1-3 CXD9809-page3

Video Hi Gain-R

Video Hi Gain-G

Video Hi Gain-B

Video Hi Bias-R

Video Hi Bias-G

Video Hi Bias-G

Video Lo Gain-R

Video Lo Gain-G

Video Lo Gain-B

Video Lo Bias-R

Video Lo Bias-G

Video Lo Bias-B

2-8

117

128

128

84

79

88

0

0

0

0

0

0

ES7

White Balance 2

<< >>

Video Hi Gain-R

Video Hi Gain-G

Video Hi Gain-B

Video Hi Bias-R

Video Hi Bias-G

Video Hi Bias-G

Video Lo Gain-R

Video Lo Gain-G

Video Lo Gain-B

Video Lo Bias-R

Video Lo Bias-G

Video Lo Bias-B

442

410

512

19

0

38

503

430

475

35

0

26

EX7/EX70

VPL-ES7

Page 29

2-7. Others

2-7-1. Note When Replacing the Main Board

The new Main board of VPL-ES7 is shipped with the 3D Gamma set to OFF.

After replacing the Main board and upon completion of adjustment, set the 3D Gamma setting to ON.

For the VPL-EX7/EX7IN/EX70, the following work is not necessary since the projector is shipped from

the factory with the 3D Gamma set to ON.

1. Enter the Factory Mode and display page 1.

2. Move the cursor to DELUT SW.

3. Operate the [*] key and set the 3D Gamma setting to ON.

P1-1 CXD9809-page1

TGHST Phase Hi

TGHST Phase Lo

SHSH1

TGHST Position

DEHPF On

DEHPF AAC

DEHPF TAP

DEUSC On

3D GammaSubCont

3D GammaSubBrt

DELUT SW

DEUF SW

0

111

31

18

ON

ON

3

OFF

8

50

OFF

ON

How to Enter the Factory Mode

1. Power on the projector.

2. Push the switches on the remote controller or controller panel as below.

[Enter] → [Enter] → [&] → [PIC|MUTING] key

3. Factory mode menu will appear on the screen.

n

In the factory mode, do not enter any items except the specifi ed one because the data cannot be returned

back to the original value if it is changed once.

VPL-ES7

2-9

Page 30

2-7-2. Status Information

The error status count is displayed.

P6 Error Count

Lamp can’t be

Light on

Fan operation

Abnormal

Thermal Sensor

Abnormal

Temperature

Abnormal

Fan Controller

Abnormal

Door switch open

Power level

Abnormal

Power Off

Abnormal

Lamp error

Fan 1 error

Fan 2 error

Fan 3 error

Fan 4 error

Sensor 1 open error

Sensor 2 open error

Sensor 1 short error

Sensor 2 short error

Temperature 1 error

Temperature 2 error

Fan IC I2C error

LampCovOpen in normal

FilterCovOpen in normal

Power error in normal

3540 Init error

System Crash

Reset error count

2-7-3. ADC Calibration Value

. RGB Offset: Offset value of computer signal

. RGB Gain: Gain adjustment of computer signal

. YUV Offset: Offset value of video signal

. YUV Gain: Gain adjustment of video signal

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

< or >

ES7

<< >>Error Count

Lamp error

Fan 1 error

Fan 2 error

Fan 3 error

Fan 4 error

Sensor 1 open error

Sensor 2 open error

Sensor 1 short error

Sensor 2 short error

Temperature 1 error

Temperature 2 error

Fan IC I2C error

LampCovOpen in normal

FilterCovOpen in normal

Power error in normal

3540 Init error

System Crash

Reset error count

EX7/EX7IN/EX70

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

< or >

P4 ADC calibration

RGB Calibrate

YUV Calibrate

RGB Offset

RGB Gain

YUV Offset

YUV Gain

R Offset

G Offset

B Offset

R Gain

G Gain

B Gain

100 124 121

164 222 164

< or >

< or >

69 61 65

93 105 93

100

124

121

69

61

65

2-10

VPL-ES7

Page 31

2-8. Memory Structure

Set memory Set memory Set memory

1

2

Status

Memory

3

Picture

Memory

4

W/B

Memory

5

Aspct Memory

6

Common

Memory

7

VPL-ES7

No.01 No.01 Status memory

No.02 No.02

No.03 No.03

No.04 No.04

No.05 No.05

--- --No.50 No.50

No.55 No.55

No.56 No.56

No.60 No.60

No.61 No.61

No.63 No.63

Dynamic Dynamic

Standard Standard

Video

S-Video

Input-A

Input-B

Component

Computer

Other than

Computer

Video, S-Video

Input-A

Input-B

Smart APA

(Computer only)

Volume Volume

Auto Input Search Auto Input Search

Input-A Signal Sel. *2 Input-A Signal Sel. *2

Color System *2

(Video/S-Video Only)

Power Saving Power Saving

IR Receiver IR Receiver

Panel Key Lock Panel Key Lock

Status Status

Language Language

Menu Position Menu Position

Start Up Image Start Up Image

Auto Keystone *1 Auto Keystone *1

Keystone Keystone

Image Flip Image Flip

Background Background

Lamp Mode Lamp Mode

High Altitude High Altitude

Security Lock Security Lock

CC Display *2 CC Display *2

FLASH ROM EEP ROM

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic Dynamic

Standard Standard

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic Dynamic

Standard Standard

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic Dynamic

Standard Standard

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic Dynamic

Standard Standard

Game Game

Living Living

Cinema Cinema

Presentation Presentation

High High

Mid Mid

Low Low

High High

Mid Mid

Low Low

No.1 No.1 Aspect memory

No.2 No.2

No.03 No.03

No.04 No.04

No.05 No.05

--- --No.50 No.50

No.55 No.55

No.56 No.56

No.60 No.60

No.61 No.61

No.63 No.63

No.21 No.21

No.22 No.22

No.23 No.23

--- --No.50 No.50

No.55 No.55

No.56 No.56

No.60 No.60

No.61 No.61

No.63 No.63

Status

Memory

Picture

Memory

W/B

Memory

Aspct Memory

Common

Memory

Video/Svideo

Input-A/Input-B

/Component

Video

S-Video

Input-A

Input-B

Component

Computer

Other than

Computer

Video, S-Video

Input-A

Input-B

Smart APA

(Computer only)

Color System *2

(Video/S-Video Only)

Direct Power OnDirect Power On

*1 : VPL-EX70 only

*2 : Not valid for VPL-EX7IN.

Picture memory

W/B memory

Common Memory

CPU RAM

2-11

Page 32

Memory structure of this model consists of the followings.

1 Set memory

2 Status memory

3 Picture memory

4 W/B memory

5 Aspct memory

6 Common memory

7 FLASH ROM/EEPROM

*

* The gamma memory is realized by giving offset to the Contrast and Brightness output values to the

devices in the gamma mode function.

Flow of data is described briefl y. When the power plug is connected to the wall outlet for the fi rst time

(Standby state), all data that are stored in the internal ROM are written in the NVM (non-volatile memory). When the POWER is turned ON, all the status memory data and other memory data that are required

for the present picture are selected from each memory block and expanded in the internal RAM.

When any adjustment is performed at this moment, the adjustment data (user mode items) are written in

the NVM automatically triggered by the memory operation.

The adjustment items (W/B, V com) that can be adjusted in the Service Mode, are memorized in the NVM

at the time when the user performs adjustment and performs the memory operation. Note that the factory

adjustment data will be lost at this moment.

2-12

VPL-ES7

Page 33

2-9. Initial Values of Adjustment Items

PICTURE

SETTING

INPUT

SETTING

SET

SETTING

MENU

SETTING

Picture Mode

Adjust Picture

Contrast

Bright

Color

Hue

Sharpness

DDE

Gamma Mode

Color Temp

Volu me

Adjust Signal

Dot Phase 31

H Size

Shift

Aspect refer to Aspect Default

Smart APA On

Auto Input Search Off

Input-A Signal Sel. *4Auto

Color System *4Auto

Power Saving Mode Off

Panel Key Lock Off

CC Display *4

Lamp Timer Reset

Status On

Language English

Menu Position Center

Start Up Image On

Set

30

Off

VIDEO *4

Dynamic Standard Game Living Cinema Dynamic Standard Game Living Cinema

*3

90 80 90 90 75 85 90 80 90 90 75 75

60 50 60 50 50 55 60 50 60 50 50 55

50 50 68 60 58 50 50 50 68 60 58 50

50 50 50 50 50 50 50 50 50 50 50 50

60 30 50 50 30 50 60 30 40 40 30 40

Film Film Film Film Film Film Film Film Film Film Film Film

High Low High Low Low High High Low High Low Low High

Present-

ation

S VIDEO *4

*3

Present-

ation

INSTALL

SETTING

INFORMATION

Auto Keystone *1

Keystone *10

V Keystone *2

Image Flip Off

Background Blue

Lamp Mode Standard

High Altitude Mode Off

Security Lock Off

Key Enter x 4

Direct Power On Off

All information is

display only

Auto

0

*1: VPL-EX70 only.

*2: VPL-ES7/EX7 only.

*3: The “Picture Mode” items in the “PICTURE SETTING” menu have their respective initial values for each input signal

(PRESET MEMORY No.).

n

There are some adjustment items that cannot be adjusted, depending on the input signal.

*4: Not valid for VPL-EX7IN.

(Continue)

VPL-ES7

2-13

Page 34

PICTURE

SETTING

INPUT

SETTING

SET

SETTING

MENU

SETTING

Picture Mode

Adjust Picture

Contrast

Bright

Color

Sharpness

DDE

Gamma Mode

Color Temp

Volu me

Adjust Signal

Dot Phase

H Size

Shift

Aspect

Smart APA

Auto Input Search

Input-A Signal Sel.

Color System

Power Saving Mode

Panel Key Lock

CC Display

Lamp Timer Reset

Status

Language

Menu Position

Start Up Image

INPUT A (Component/VideoGBR) *4 INPUT A (Computer), INPUT B (Computer)

Dynamic Standard Game Living Cinema

*3

90 80 90 90 75 85 90 80 90 90 60 85

60 50 60 50 50 55 60 50 60 50 50 55

50 50 68 60 58 50

Hue

60 30 40 40 30 40

Film Film Film Film Film Film

High Low High Low Low High High Low High Low Low

Present-

Dynamic Standard Game Living Cinema

ation

Graphics Graphics Graphics Graphics Graphics Graphics

*3

Present-

ation

Auto Keystone *1

Keystone *1

V Keystone *2

INSTALL

SETTING

INFORMATION

Image Flip

Background

Lamp Mode

High Altitude Mode

Security Lock

Key

Direct Power On

All information is

display only

*1: VPL-EX70 only.

*2: VPL-ES7/EX7 only.

*3: The “Picture Mode” items in the “PICTURE SETTING” menu have their respective initial values for each input signal

(PRESET MEMORY No.).

n

There are some adjustment items that cannot be adjusted, depending on the input signal.

*4: Not valid for VPL-EX7IN.

2-14

VPL-ES7

Page 35

SVGA(ES7) / XGA(EX7/EX7IN/EX70)

No. Preset Signal

1 VIDEO/60 *1 60Hz

2 VIDEO/50 *1 50Hz

3 480/60i *1 480/60i

4 575/50i *1 575/50i

480/60p (progressive

5 480/60p *1

component)

575/50p (progressive

6 575/50p *1

component)

7 1080/60i *1 1035/60i, 1080/60i

8 1080/50i *1 1080/50i

10 720/60p *1 720/60p

11 720/50p *1 720/50p

21

640x350

VGA mode1

22 VGA VESA 85Hz

23

640x400

NEC PC98

24 VGA mode 2

PC Component Video GBR

-

-

-

-

-

-

-

-

Full1

-

4:3 / Normal

4:3 / Normal

4:3 / Normal

4:3 / Normal

4:3 / Normal 4:3 / Normal

4:3 / Normal 4:3 / Normal

16:9 / Full

16:9 / Full

16:9 / Full

16:9 / Full

4:3 / Normal

4:3 / Normal

4:3 / Normal

4:3 / Normal

16:9 / Full

16:9 / Full

16:9 / Full

16:9 / Full

Full1 - -

Full1 - 25 VGA VESA 85Hz

26

640x480

VGA mode 3

27 Macintosh 13"

28 VGA VESA 72Hz

Full1

4:3 / Normal 4:3 / Normal

29 VGA VESA 75Hz (IBM M3)

30 VGA VESA 85Hz

31

800x600

SVGA VESA 56Hz

32 SVGA VESA 60Hz

33 SVGA VESA 72Hz

Full1 - 34 SVGA VESA 75Hz

35 SVGA VESA 85Hz

36 832x624 Macintosh 16"

37

1024x768

XGA VESA 60Hz

38 XGA VESA 70Hz

39 XGA VESA 75Hz

Full1

Full1 - -

--

40 XGA VESA 85Hz

41

1152x864

42 SXGA VESA 75Hz

SXGA VESA 70Hz

Full1 - 43 SXGA VESA 85Hz

44

1152x900

45

1280x960

46 SXGA VESA 75Hz

47

1280x1024

48 SXGA VESA 75Hz

SUN LO

SXGA VESA 60Hz

SXGA VESA 60Hz

Full1

--

Full1 - -

Full1 - 49 SXGA VESA 85Hz

50

1400x1050

55 1280x768 WXGA 60Hz

56 1280x720p WXGA 60Hz Full1

SXGA+ 60Hz

Full1

Full1

--

--

16:9 / Full 16:9 / Full

60 1360x768 1360x768/60 Full1 - 61 1440x900 1440x900/60 Full1 - 63 1280x800 1280x800/60 Full1 - -

*1: Not valid for VPL-EX7IN.

VPL-ES7

2-15

Page 36

Set

Page Item Name R G B

PC Hi Gain-R

PC Hi Gain-G

White Balance1

CXD9809

(ES7)

CXD3548

(EX7/EX7IN/EX70)

page1

PC Hi Gain-B

PC Hi Bias-R

PC Hi Bias-G

PC Hi Bias-B

PC Lo Gain-R

PC Lo Gain-G

PC Lo Gain-B

PC Lo Bias-R

PC Lo Bias-G

PC Lo Bias-B

Video Hi Gain-R

Video Hi Gain-G

White Balance2

CXD9809

(ES7)

CXD3548

(EX7/EX7IN/EX70)

Video Hi Gain-B

PC Mid Bias-R

Video Hi Bias-G

Video Hi Bias-B

Video Lo Gain-R

Video Lo Gain-G

Video Lo Gain-B

page2

Video Lo Bias-R

Video Lo Bias-G

Video Lo Bias-B

PC Mid Gain-R

PC Mid Gain-G

White Balance3

CXD9809

(ES7)

CXD3548

(EX7/EX7IN/EX70)

page3

PC Mid Gain-B

PC Mid Bias-R

PC Mid Bias-G

PC Mid Bias-B

Video Mid Gain-R

Video Mid Gain-G

Video Mid Gain-B

Video Mid Bias-R

Video Mid Bias-G

Video Mid Bias-B

Vcom & Misc

CXA7006

(ES7)

CXA7009

(EX7/EX7IN/EX70)

page4

Vcom-R Normal

Vcom-G Normal

Vcom-B Normal

Vcom-R Flip

Vcom-G Flip

Vcom-B Flip

EDID Write Protect

ROM Version

ES7 EX7/EX7IN/EX70

128

128

128

512

512

512

0

0

0

128

70

100

512

280

400

0

0

0

128

80

120

512

320

480

0

0

0

128

70

100

512

280

400

0

0

0

128

90

115

512

360

460

0

0

0

128

75

105

512

300

420

0

0

0

88

88

88

88

88

88

83

83

83

83

83

83

ON

1.00

Color

RGB Calibrate

YUV Calibrate

RGB Offset 164 222 164

RGB Gain 93 105 93

YUV Offset 164 222 164

ADC Calibration

YUV Gain 93 105 93

R Offset 164

G Offset 222

B Offset 164

R Gain 93

G Gain 105

B Gain 93

Error Count

All value is display only

average time

Current Y Axis

Current Tout counts

Display only

Display only

Display only

Save T1 data

Keystone

Adjustment

(VPL-EX70 only)

T1:

Axis1:

Save T2 data

T2:

Axis2:

set manual 'b' left key x

a

b

1

1

1

1

1000

1

1

Calculate sensitivity

sensitivity

current g

1

Display only

2-16

VPL-ES7

Page 37

Section 3

Troubleshooting

Connect the power cord to the unit.

Change the

main board.

1

The ON/STANDBY

The ON/STANDBY

No

No

lamp illuminated ?

LED indicator

is flashing

in red ?

Yes

LED indicator

is flashing

in green ?

Yes

The projector

Yes

Any image

is projected ?

No No

No

CN701 on the

power board is connected

to J17 on the

main board?

Yes

Check the power board.

F601 on the

power board

blows out ?

No

The temperature fuse

works normally ?

Yes

Change the power board.

Yes

No

Connect the

harness securely.

Change F601.

Change the

temperature fuse.

Check the R/G/B

LCD connectors.

Color is normal ?

Yes

Run the ADC calibration.

VPL-ES7

No

Yes

Yes

Strange color

One of the 3 color is

Change the main board

or the optical unit.

or

missing ?

No

3

All white screen ?

(only ES7/EX7/EX7IN)

All black screen ?

(only EX70)

No

Change the main board.

Nothing is projected ?

Yes

Change the optical unit.

Yes

Check the R/G/B

LCD connectors.

3-1

Page 38

1

The LAMP/COVER

LED indicator

flash 2 times ?

No

The LAMP/COVER

LED indicator

flash 3 times ?

No

The ON/STANDBY

red LED indicator

flash 2 times ?

No

The ON/STANDBY

red LED indicator

flash 4 times ?

Yes

Yes

Yes

Yes

Check the lamp cover

and filter cover.

Change the lamp.

1. Check the fan rotation.

2. Clean the filter.

Check the fan rotation.

No

The ON/STANDBY

red LED indicator

flash 6 times ?

No

2

Yes

Change the power board.

The projector

illuminates ?

No

Change the main board.

3-2

VPL-ES7

Page 39

2

F602 on the

power board

blows out ?

No

The lamp ballast

is connected to

J16 on the main board

with the harness

normally ?

Yes

The harness

between the

lamp and ballast

is normal ?

Yes

The lamp is broken ?

Yes

No

No

Yes

Change F602.

Connect the harness securely.

Connect the harness securely.

Change the lamp.

VPL-ES7

No

Change the ballast ?

No

Change the main board.

Yes

Change the ballast.

3-3

Page 40

3

Adjust

the white balance.

Adjust

the RGB V-com.

Yes

Yes

Yes

Screen is dark ?

No

Strange color ?

No

Screen flickers ?

No

Vertical stripes

on the screen ?

Yes

Run the ADC calibration.

The screen brightness

is normal ?

No

Change the lamp.

Screen bright

is normal ?

No

Clean the lens and

the panel to remove dust.

Yes

Yes

End

End

No

The IR remote control

does not function ?

Yes

No problem. The set is normal.

Check another device and cable.

No

Check the IR sensor board

and harness.

3-4

VPL-ES7

Page 41

Section 4

Spare Parts

4-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specifi ed parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may not be stocked. Therefore, the

delivery date will be delayed.

4. Harness

Harnesses with no part number are not registered as

spare parts.

VPL-ES7

4-1

Page 42

Overall

4-2. Exploded Views

36

12

33

46

31

3

3

11

51

46

16

3

3

3

44

46

52

47

21

15

VPL-EX7

42

43

35

VPL-ES7

42

43

4

3

28

3

56

14

20

3

3

39

40

3

19

13

4-2

41

55

29

17

26

27

32

45

25

54

45

34

23

24

38

18

1

2

3

3

35

VPL-EX7IN

42

43

35

VPL-EX70

42

43

35

VPL-ES7

Page 43

No. Part No. SP Description

1 ! 1-576-233-51 s FUSE (H.B.C.) (F601)

2 ! 1-576-973-11 s MINIATURE FUSE-LINKS (F602)

3 2-681-550-01 s SCREW TAP PAN M3*7L NI D-PT

4 4-140-315-01 s MYLAR BALLAST

11 9-885-118-05 s WIRE 2P_CON+THERMAL 145MM E08X

12

! 1-787-869-11 s FAN 80*25 AD0812HB/HB

13 ! 1-787-872-11 s FAN 75*75*30 145MM AB7512UB

14 ! 1-787-871-11 s FAN 70*70*25 240MM AB07012UB

15 ! 1-787-870-11 s FAN 60*60*25 183MM AB0612HB

16 1-857-422-11 s MOUNTED CIRCUIT BOARD, MAIN (VPL-EX70)

1-857-424-11 s MOUNTED CIRCUIT BOARD, MAIN (VPL-EX7)

1-857-423-11 s MOUNTED CIRCUIT BOARD, MAIN (VPL-ES7)

1-857-468-11 s MOUNTED CIRCUIT BOARD, MAIN (VPL-EX7IN)

17 9-885-118-14 s MOUNTED CIRCUIT BOARD, IR

18 1-789-544-11 s MOUNTED CIRCUIT BOARD, THERMAL

19 1-857-381-11 s MOUNTED CIRCUIT BOARD, POWER

20 9-885-118-17 s MOUNTED CIRCUIT BOARD, SWITCH

21 9-885-118-18 s SPK 2W8OHM 130MM W4028CP-130

23 9-885-118-22 s DOOR FILTER PC E08X

24 9-885-118-23 s MESH FILTER E08X

25 9-885-118-24 s ASSY ADJ FOOT E08X

26 9-885-118-26 s RUBBER FRONT FOOT E08X

27 9-885-118-27 s NUT HEX+WASHER M3*2.3H NI

28 ! 1-487-368-11 s BALLAST EUC200DW/C01

29 9-885-118-29 s CAP LENS PC E08X

31 4-140-316-01 s ASSY UPPER CASE

32 4-140-317-01 s LAMP DOOR

33 4-140-318-01 s ASSY LAMP BOX

Overall

34 4-140-319-01 s PACK ASSY LOWER CASE

35 4-140-320-01 s PACK ASSY REAR CASE (VPL-EX70)

4-140-321-01 s PACK ASSY REAR CASE (VPL-EX7)

4-141-652-01 s PACK ASSY REAR CASE (VPL-ES7)

4-150-976-01 s PACK ASSY REAR CASE (VPL-EX7IN)

36 4-140-323-01 s ASSY FRONT CASE

38 9-885-118-41 s ASSY ADJUST GEAR E08 E08X

39 9-885-118-42 s SCRW TAP PH W/FLA M3*10L PT ZN

40 9-885-118-43 s SCRW TAP PH W/FL M3*35 NI D-PT

41 4-140-324-01 s LOGO (VPL-EX70)

4-140-325-01 s LOGO (VPL-EX7)

4-140-326-01 s LOGO (VPL-ES7)

4-150-980-11 s LOGO (VPL-EX7IN)

42 2-681-552-02 s SCRW MACH HEX #4-40*4

43 7-682-250-09 s SCRW +K 3X12

44 2-580-599-01 s SCRW +PSW M4X6

45 3-918-696-11 s SCRW (M3X6 LOCK ACE)

46 7-682-903-11 s SCRW +PWH 3X6

47 7-682-954-01 s SCRW +PSW M3X25

51 This part is not supplied as the repair part.

If this part is broken or lost, the part reference No. 39 can be used.

52 This part is not supplied as the repair part.

If this part is broken or lost, the part reference No. 46 can be used.

54 9-885-118-25 s RUBBER PAD ADJ FOOT E08X

55 9-885-114-31 s LENS WIRE CAP SL700X

56 1-910-057-82 s LAMP CONNECTOR ASSY 4P

VPL-ES7

4-3

Page 44

4-3. Electrical Parts List

Ref. No.

or Q'ty Part No. SP Description

1pc ! 1-576-233-51 s FUSE (H.B.C) (F601)

1pc ! 1-576-973-11 s MINITURE FUSE-LINKS (F602)

4-4. Packing Materials & Supplied Accessories

-------------------SUPPLIED ACCESSORIES

------------------- Ref. No.

or Q'ty Part No. SP Description

1pc A-1568-125-A s QUICK ACCESS ASSY (VPL-ES7)

1pc

1pc 1-832-428-11 s CABLE, VGA

1pc 9-885-118-30 s BAG CARRY E08 SONY

1pc 4-135-544-01 s CD-ROM MANUAL (For SY)

1pc 4-135-539-01 s QUICK REFERENCE MANUAL (For SY)

(JAPANESE, ENGLISH, FRENCH,

SPANISH, GERMAN, ITALIAN,

SIMPLIFIED CHINESE)

1pc 4-135-541-81 s OPERATING INSTRUCTIONS (For CN)

(SIMPLIFIED CHINESE)

1pc 4-150-509-01 s MANUAL INSTRUCTION (For IN)(ENGLISH)

1pc 1-833-570-11 s POWER-SUPPLY CORD (For CN)

! 1-487-177-11 s REMOTE RM-PJ6

4-4

VPL-ES7

Page 45

Section 5

Block Diagrams

Overall (VPL-ES7)Overall (VPL-ES7)

VPL-ES7

IR Receiver

S-Video

Video

INPUTA

Monitor

Output

Audio

Audio out

RS-232

Fan 2

Fan 3

Fan 4

Fan 1

IRR5 IRR

LUMA

CHROMA

CVBS

PC-RIN2

PC-GIN2

PC-BIN2

HSYNC2

VSYNC2

R_OUT

G_OUT

B_OUT

HSYNCO

VSYNCO

AUDIO_M

AUDIO_O+

AUDIO_O

AUDIO_O_

Analog RGB

Input/Output

Input/Output

Speaker

TXD

RXD

FG1

Fan2

FG2

Fan3

FG3

Fan4

FG4

Fan5

FG5

Fan Control

Audio

&

volume

control

PC-RIN

PC-GIN

PC-BIN

HSYNC

VSYNC

AUDIO_MUT

AUDIO_VOL1

AUDIO_VOL2

I2C_SW

FAN_ SW

SDA

SCL

U33

EEPROM

AT24C32CN

32.768 KHz

Video

Processor

&

Controller

Reset

IC

U48

EEPROM

AT24C256N

DR[9:0]

DG[9:0]

DB[9:0]

DCLK

DHS

DVS

LCD_SCL

LCD_SDA

27 MHz

LED[4:1]

PWR_fail

POWER_ON

RXD

TXD

Lamp PWR

Lamp EN

WP

Dust_SW

Door_SW

SDA

SCL

LCD

Timing

Generator

LED

Driver

Keypad

Input

Power

Fail DET

Ballast

P15VP

P12V

P5V

PRG

FRP

VD

LCDRGT

LCDRGTx

LCDENB

LCDHST

LCDVST

LCDVCK

LCDPCG

LCDDWN

HCK

HCK

HCK

HCKx

HCKx

HCKx

DCK[6:1]

SENi

SCLKi

SDATAi

P15VP

P12V

P5V

Power

Switch

LCDR[11:0]

CLK_R

P15V

P5VC

RGT

RGTx

ENB

HST

VST

VCK

PCG

DWN

HCK_R

HCK_G

HCK_B

HCKx_R

HCKx_G

HCKx_B

LCDG[11: 0]

CLK_G

DCK1_R

DCK2_R

DCK1_G

DCK2_G

DCK1_B

DCK2_B

DCK1x_R

DCK2x_R

DCK1x_G

DCK2x_G

DCK1x_B

DCK2x_B

LCDB[11: 0]

CLK_B

Power

Control

Dust SW

Door SW

P5V

P15VP

P5V

R

PRG

FRP

VD

SEN

SCLK

SDATA

PRG

FRP

VD

SEN

SCLK

SDATA

PRG

FRP

VD

SEN

SCLK

SDATA

LCD

Generator

LCD

Driver

LCD

Driver

RSIG[6:1]

RVCOM

RPSIG

G

GSIG[6:1]

GVCOM

GPSIG

B

BSIG[6:1]

BVCOM

BPSIG

+3.3V

REG

P2P5V

P135V P15V

+1.8V

REG

+3.3V

REG

+1.8V

REG

P2P5V

+2.5V

REG

P5VCV33

P5VP1P8V

DCK1_R

DCK1x_R

DCK2_R

DCK2x_R

HCK_R

HCKx_R

RGT

HST

ENB

VCK

VST

DWN

PCG

DCK1_G

DCK1x_G

DCK2_G

DCK2x_G

HCK_G

HCKx_G

RGTx

HST

ENB

VCK

VST

DWN

PCG

DCK1_B

DCK1x_B

DCK2_B

DCK2x_B

HCK_B

HCKx_B

RGT

HST

ENB

VCK

VST

DWN

PCG

R

LCD

G

LCD

B

LCD

VPL-ES7

Thermal

Sensor 1

Thermal

Sensor 2

D[0:15]

A[0:21]

memory

Flash

ROMOEn

ROMWEn

Reset

IC

5-1

5-1

P3P3V

P33V

+3.3V

REG

+3.3V

REG

Overall (VPL-ES7)

Page 46

Overall (VPL-EX70)Overall (VPL-EX70)

VPL-EX70

IR Receiver

S-Video

Video

INPUT B

INPUT A

Monitor

Output

Audio

Audio out

RS-232

Remote

Control

Fan 1

Fan 2

Fan 3

Fan 4

Fan 5

IRR5 IRR

LUMA

CHROMA

CVBS

PC-RIN1

PC-GIN1

PC-BIN1

HSYNC1

VSYNC1

PC-RIN2

PC-GIN2

PC-BIN2

HSYNC2

VSYNC2

R_OUT

G_OUT

B_OUT

HSYNCO

VSYNCO

AUDIO

Analog RGB

Input/Output

Input/Output

volume

AUDIO_O+

AUDIO_O

AUDIO_O-

control

Speaker

TX.DL

RX.DL

Fan1

FG1

Fan2

FG2

FG3

Fan4

FG4

Fan5

FG5

RS232

Receiver

Fan Control

32.768 KHz

Audio

&

Driver

Thermal

Sensor 2

PC-RIN

PC-GIN

PC-BIN

HSYNC

VSYNC

AUDIO_PWR

AUDIO_SW

AUDIO_MUT

AUDIO_VOL1

AUDIO_VOL2

TXD

RXD

FAN_ SW

SCL

U33

EEPROM

AT24C32CN

Keystone

Sensor

SDA

A[0:21]

D[0:15]

Flash

memory

Video

Processor

&

Controller

ROMOEn

ROMWEn

Reset

IC

U20

EEPROM

AT24C256N

SCL_DSD

SDA_DSD

DR[9:0]

DG[9:0]

DB[9:0]

PG_XCLR_OUT

PG_PLLSTB_OUT

DCLK

DHS

DVS

27 MHz

LED[4:1]

PWR_fail

POWER_ON

PVCC_POWER_ON

Dust_SW

Door_SW

Lamp_PWR

TXD

RXD

DVS

Lamp_SyncEN

LCD

Timing

Generator

LED

Driver

Keypad

Input

Power

Fail DET

Ballast

Lamp_EN

Lamp

Control

SCL_7009i

SDA_7009i

P15VP

P12V

P5V

PRG

FRP

VD

LCDSCAN

LCDXSCAN

LCDENB

LCDHST

LCDVST

LCDVCK

LCDPCG

LCDDWN

HCK

HCK

HCK

HCKx

HCKx

HCKx

DCK[4:1]_R(G,B)

P15VP

P12V

P5V

Power

Switch

VST

LCDR1[11:0]

LCDR2[11:0]

CLK_R

SCAN

XSCAN

ENB

HST

VST

VCK

PCG

DWN

HCK1_R

HCK1_G

HCK1_B

HCK2_R

HCK2_G

HCK2_B

LCDG1[11:0]

LCDG2[11:0]

CLK_G

R_DCK1

R_DCK3

G_DCK1

G_DCK3

B_DCK1

B_DCK3

R_DCK2

R_DCK4

G_DCK2

G_DCK4

B_DCK2

B_DCK4

LCDB1[11:0]

LCDB2[11:0]

CLK_B

Power

Control

Dust SW

Door SW

P5V

R_DCK1

R_DCK2

R_DCK3

R_DCK4

HCK1_R

P5VC3.3V

P5VP1P8V

HCK2_R

SCAN

HST

ENB

VCK

VST

DWN

PCG

G_DCK1

G_DCK2

G_DCK3

G_DCK4

HCK1_G

HCK2_G

XSCAN

HST

ENB

VCK

VST

DWN

PCG

B_DCK1

B_DCK2

B_DCK3

B_DCK4

HCK1_B

HCK2_B

SCAN

HST

ENB

VCK

VST

DWN

PCG

R

LCD

G

LCD

B

LCD

RSIG[12:1]

PRG

FRP

VD

SCL_7009

SDA_7009

PRG

FRP

VD

SCL_7009

SDA_7009

PRG

FRP

VD

SCL_7009

SDA_7009

P15VPP15V

P5VP5VC

R