Page 1

DATA PROJECTOR

VPLEX100

9

VPL-ES5

VPL-EX5

VPL-EX50

VPL-EX5U

VPL-EW5

REMOTE COMMANDER

RM-PJ4

SERVICE MANUAL

1st Edition (Revised 1)

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE RULE IN REGION.

VPL-ES5/EX5/EX50/EX5U/EW5

Page 3

Table of Contents

1. Service Overview

1-1. Appearance Figure ..........................................................1-1

1-2. Board Locations ..............................................................1-1

1-3. Disassembly ....................................................................1-2

1-3-1. Upper Case Assembly ........................................... 1-2

1-3-2. Sub Rear Case Assembly ......................................1-3

1-3-3. Main Board ............................................................ 1-3

1-3-4. Power Board and Thermal Sensor Board ..............1-4

1-3-5. Front Case Assembly and IR Sensor Board ..........1-5

1-3-6. Fan (Exhaust) -1 ....................................................1-5

1-3-7. Fan (Exhaust) -2 ....................................................1-6

1-3-8. Optical Unit Assembly ..........................................1-7

1-3-9. Lamp Power Supply ..............................................1-8

1-3-10. Fan .........................................................................1-9

1-3-11. 3D GAMMA Service tool Application

Software .............................................................. 1-10

2. Electrical Adjustments

2-1. Initial Values of Adjustment Items .................................2-1

2-2. Memory Structure ...........................................................2-7

3. Troubleshooting

4. Spare Parts

4-1. Notes on Repair Parts ..................................................... 4-1

4-2. Exploded Views .............................................................. 4-2

4-3. Electrical Parts List ......................................................... 4-4

4-4. Packing Materials & Supplied Accessories ....................4-4

4-5. Optional Fixtures ............................................................ 4-4

5. Block Diagrams

Overall (VPL-ES5) ......................................................... 5-1

Overall (VPL-EX50) ...................................................... 5-2

Overall (VPL-EX5) ........................................................ 5-3

Overall (VPL-EX5U) ...................................................... 5-4

Overall (VPL-EW5) ........................................................ 5-5

6. Diagrams

6-1. Frame Schematic Diagrams ............................................6-1

Frame (VPL-ES5) ...........................................................6-1

Frame (VPL-EX50) ........................................................ 6-2

Frame (VPL-EX5/EX5U) ...............................................6-3

Frame (VPL-EW5) ......................................................... 6-4

3-1. Electric Troubleshooting ................................................ 3-1

3-2. Power Board Troubleshooting ........................................3-3

3-2-1. No Power ...............................................................3-3

3-2-2. Failure of Turn on Lamp ....................................... 3-4

3-3. Optical Troubleshooting ................................................. 3-6

VPL-ES5/EX5/EX50/EX5U/EW5

1

Page 4

Page 5

1-1. Appearance Figure

Section 1

Service Overview

1-2. Board Locations

Door detection switch

Lamp power supply

Main

Power

Thermal sensor

Door detection switch

IR sensor

VPL-ES5/EX5/EX50/EX5U/EW5

1-1

Page 6

1-3. Disassembly

1-3-1. Upper Case Assembly

Focus adjust gear knob

8

Press here strongly.

9

Remove the Upper case assembly

in the direction of the arrow.

0

Disengage the claws at

the 17 locations respectively.

Upper case assembly

Caution :

Remove the upper case assembly from this corner.

When attaching the upper case assembly, attach it while

aligning with the lower case assembly starting from this corner.

Lower case assembly

Upon completion of the upper

case assembly attachment,

check to see that the spacing

in the top is equal to the

Caution :

If the spacings in the top and bottom are not equal, go to

method of optical unit assembly and Focus/Zoom

(Refer to section 1-3-8. Steps 9 to 14.)

spacing in the bottom.

adjust assembly”.

!- Upper case assembly

These portions are fragile.

Be very careful not to

damage them.

6

Remove the filter

door in the direction

of the arrow

“Assembling

C

.

2 Loosen screw.

4

Screw

(+P M3 x 6)

B

Front Side

of Unit

1-2

3

Lamp door assembly

B

Lower case assembly

B

Front Side

of Unit

A

Screw

A

B

1

Five screws

(+P M3 x 6)

B

7

(+P M3 x 6)

AA

C

5

Two claws

A

VPL-ES5/EX5/EX50/EX5U/EW5

A

Page 7

1-3-2. Sub Rear Case Assembly

4

Sub rear case assembly, etc.

3

Two screws

(+K 3 x 12)

VPL-EX5

VPL-EX5U

2

Six hexagon

screws

Rear Side

of Unit

6

Speaker

Rear Side

of Unit

Route the speaker harness

under the MB bracket.

7

Sub rear case assembly

5

Two screws

(+PWH 3 x 6)

Main board

J11

1

Speaker harness

Sub rear case assembly

4

VPL-ES5

3

VPL-EX50

3

VPL-EW5

3

Two screws (+K 3 x 12)

Sub rear case assembly

2

Two screws (+K 3 x 12)

4

Sub rear case assembly

2

Two screws (+K 3 x 12)

4

Sub rear case assembly

2

Six hexagon screws

Four hexagon screws

Eight hexagon screws

8

One screw (+F 3 x 8)

1-3-3. Main Board

1 Sub rear case assembly,

etc.

(Refer to section 1-3-2, steps 1 to 4.)

J11

J17

2

Remove the

twelve connectors.

J16

J26

J21

J20

J14

J19

J18

Main board

J24 J22

J23

J6

Shield

4

Two screws

(+PWH 3 x 6)

5

Shield

3

Three screws

(+PWH 3 x 6)

6

Main board

VPL-ES5/EX5/EX50/EX5U/EW5

1-3

Page 8

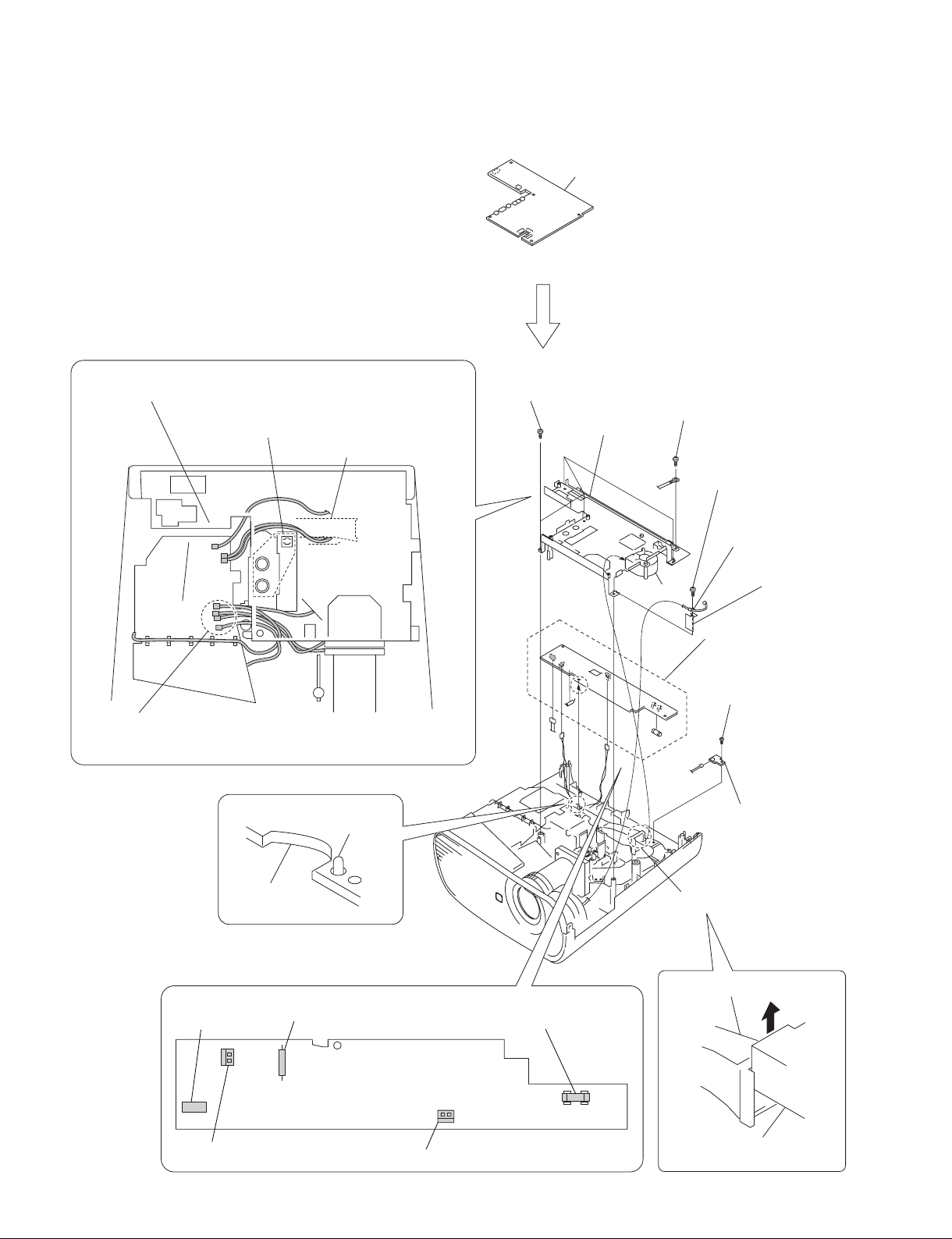

1-3-4. Power Board and Thermal Sensor Board

(Refer to section 1-3-3, steps 2 to 6.)

Check to see that the seven connectors are

protruding from the MB bracket.

Be careful that the harnesses must not override on

top of this port or must not be pinched by this portion.

Duct lamp assembly

1 Mai

6

Four tapping screws

(PAN 3 x 7)

8

n board

MB bracket

5

Screw

(+PSW M4 x 6)

2

Tapping screw

(PAN 3 x 7)

3

Clamp

Caution :

When attaching the MB bracket, bind the five harnesses into the shape

“U”

and attaching them to the MB bracket.

of

0

Dowel

Power board

CN701

Miniature fuse-links (F602)

Fuse (H.B.C.)

(F601)

Fan

!- Power board

Tapping screw

!=

(PAN 3 x 7)

J1

Thermal sensor board

1-3-5. Front Case Assembly and IR Sensor Board

5

Tapping screw

(M3 x 7)

J7

4

Front case assembly

3

Logo

1

Lens cap

2

Four claws

1-3-6. Fan (Exhaust) -1

1

Lamp door assembly

6

IR sensor board

2

MB bracket

4 Front

case assembly

(Refer to section 1-3-1, steps 2 to 4.)

Caution :

Because the harness has the shape of flat

cross-section, do not insert the harness into the

harness clamp section with excessive force.

Find out the direction in which the harness can

be inserted easily, and then insert the harness.

Harness

Harness clamp section

3

Power board

(Refer to section 1-3-4, steps 2 to 11.)

9

Lamp power supply

connector

0

Door detection switch

harness

(Refer to section 1-3-5, steps 1 to 3.)

8

Screw

(+PWH M3 x 6)

Lamp box assembly

VPL-ES5/EX5/EX50/EX5U/EW5

7

Lamp assembly

6 Loosen screw.

5

Screw (+P M3 x 6)

1-5

Page 10

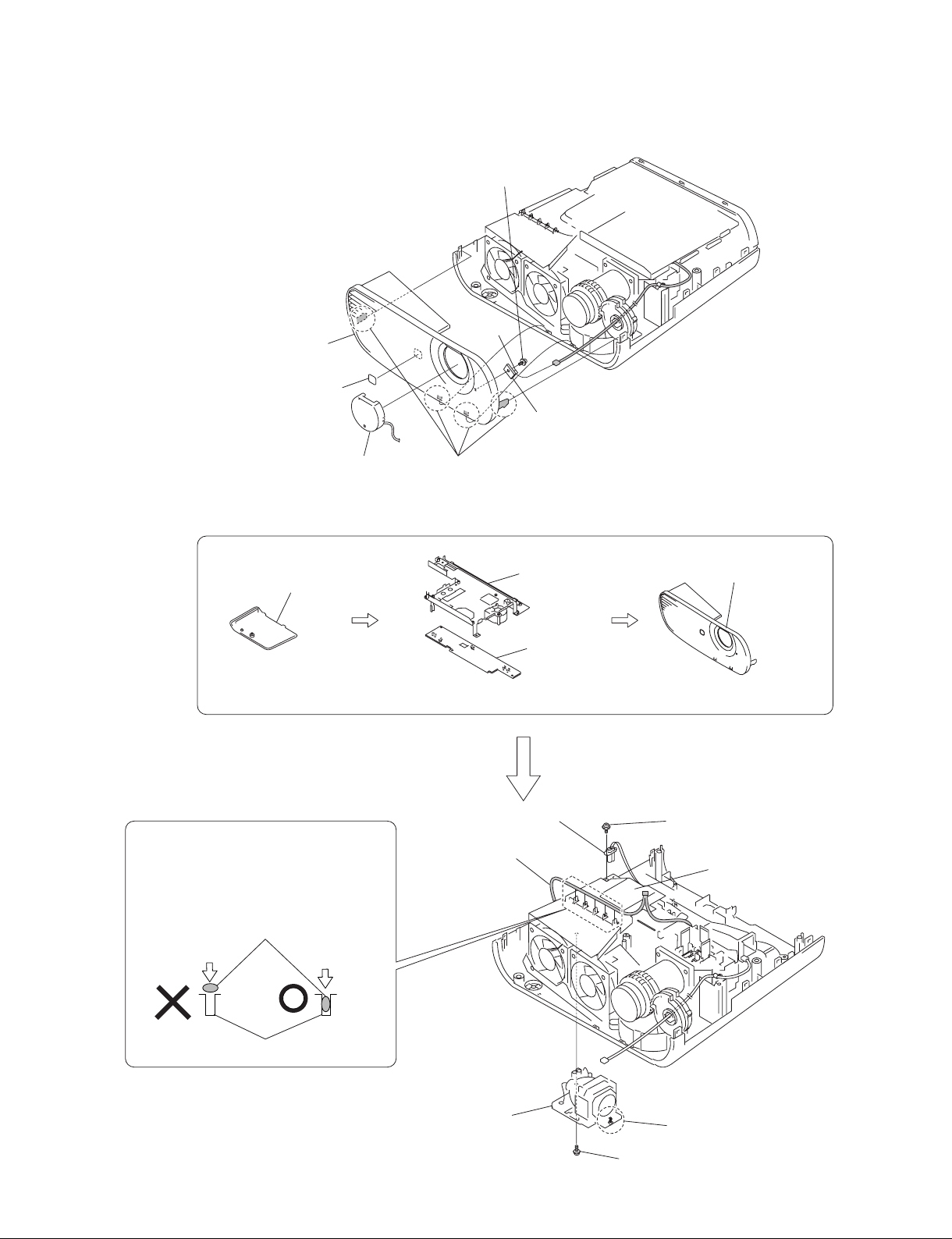

1-3-7. Fan (Exhaust) -2

Caution :

When attaching the lamp box assembly, insert the door detection

switch harness into the groove of the lower case assembly.

3

Fan (Exhaust)

*2 80*25 170MM AD0812UB/HB

4

Remove the door detection switch

harness in the direction of the arrow

5

Remove the protrusion in the

direction of the arrow

C

.

A

.

C

UB mark is

indicated.

HB mark is

indicated.

Lower case assembly

Door detection

switch board

Caution :

Two exhaust fans are the two different fans having the difference

characteristics. Be careful not to make mistake in choosing the

desired fan by confirming the indication on the fans.

1

Two tapping screws

(PAN 3 x 7)

B

A

protrusion

Lamp box assembly

2

Remove the fan harness in the direction of the arrow B.

1-6

7

Tapping screw

(PAN 3 x 7)

8

Door detection switch board

CN1

6

Lamp box assembly

VPL-ES5/EX5/EX50/EX5U/EW5

Page 11

1-3-8. Optical Unit Assembly

1

Lamp box assembly

(Refer to section 1-3-6, steps 5 to 10) and

(refer to section 1-3-7, steps 1,2, 4 to 6.)

Duct lamp assembly

Lamp power supply

CON thermal

145MM wire

connector

4

Duct lamp assembly

3

Tapping screw

(PAN 3 x 10)

7

Three tapping screws

(PAN 3 x 7)

8

Optical unit

assembly

Caution :

When attaching the dust lamp assembly, route that harnesses

in between the duct lamp assembly and optical unit assembly.

2

Two tapping screws

(PAN 3 x 7)

Thermal sensor harness,

Fan harness

5

Two tapping screws

(PAN 3 x 7)

6

Focus/Zoom adjust

assembly

Assembling method of optical unit assembly and

Focus/Zoom adjust gears assembly

0

Attach the Focus/Zoom Adjust assembly into the two

dowels of the lower case assembly after rotating the

Focus/Zoom Adjust assembly as far as it can be rotated

in the direction of clockwise direction.

9

Lens: Rotate the Focus/Zoom gears in

the counter-clockwise direction as far

as it can be rotated.

Lower case assembly

!- Fix the Focus/Zoom Adjust assembly

tentatively with the screw.

Two dowels

Lens: Focus/Zoom gears

Focus adjust gear

Zoom adjust gear

!= Rotate the focus adjust gear in the

counter-clockwise direction by one

tooth. Then, engage these gears

with the corresponding lens gears.

![ Attach the other screw while fixing

the gear position.

VPL-ES5/EX5/EX50/EX5U/EW5

!] Tighten the screw finally that has

been tightened tentatively.

1-7

Page 12

1-3-9. Lamp Power Supply

2

Fan (Exhaust)

*2 80*25 170MM AD0812UB/HB

1

Lamp box assembly

3

Duct lamp assembly

5

Optical unit assembly

4

Focus/Zoom adjust

assembly

(Refer to section 1-3-6, steps 5 to 10) and

(refer to section 1-3-7, steps 1 to 6.)

7

Two

harnesses

Lamp power supply

Door detection

!-

switch board

Caution :

When re-assembling the machine,

route the respective harnesses and

wires at the specified locations as shown.

D

Route the harness D

between them.

6

Two tapping screws

(PAN 3 x 7)

A

C

A

P1

(Refer to section 1-3-8, steps 2 to 8.)

B

D

9

Lamp power supply

CN1

E

0

Claw

Door detection

switch board

Lamp power supply

1-8

B

C

Route the harness

underneath this sheet.

Door detection switch board

A

8

Remove the lamp power supply

in the direction of the arrow

VPL-ES5/EX5/EX50/EX5U/EW5

E

.

Page 13

1-3-10. Fan

1

Lamp box assembly

2

Duct lamp assembly

4

Optical unit assembly

3

Focus/Zoom adjust

assembly

(Refer to section 1-3-6, steps 5 to 10) and

(refer to section 1-3-7, steps 1,2, 4 to 6.)

8

Dowel

Prism duct

!] Two tapping screws

(PAN 3 x 10)

!\

Fan

70*70*25 240MM AB07012UB

!= Tapping screw

(PH W/FL M3 x 35NI)

6

Two tapping screws

(PAN 3 x 7)

(Refer to section 1-3-8, steps 2 to 8.)

5

Harness

0

Tapping screw

(PAN 3 x 7)

Washer

!-

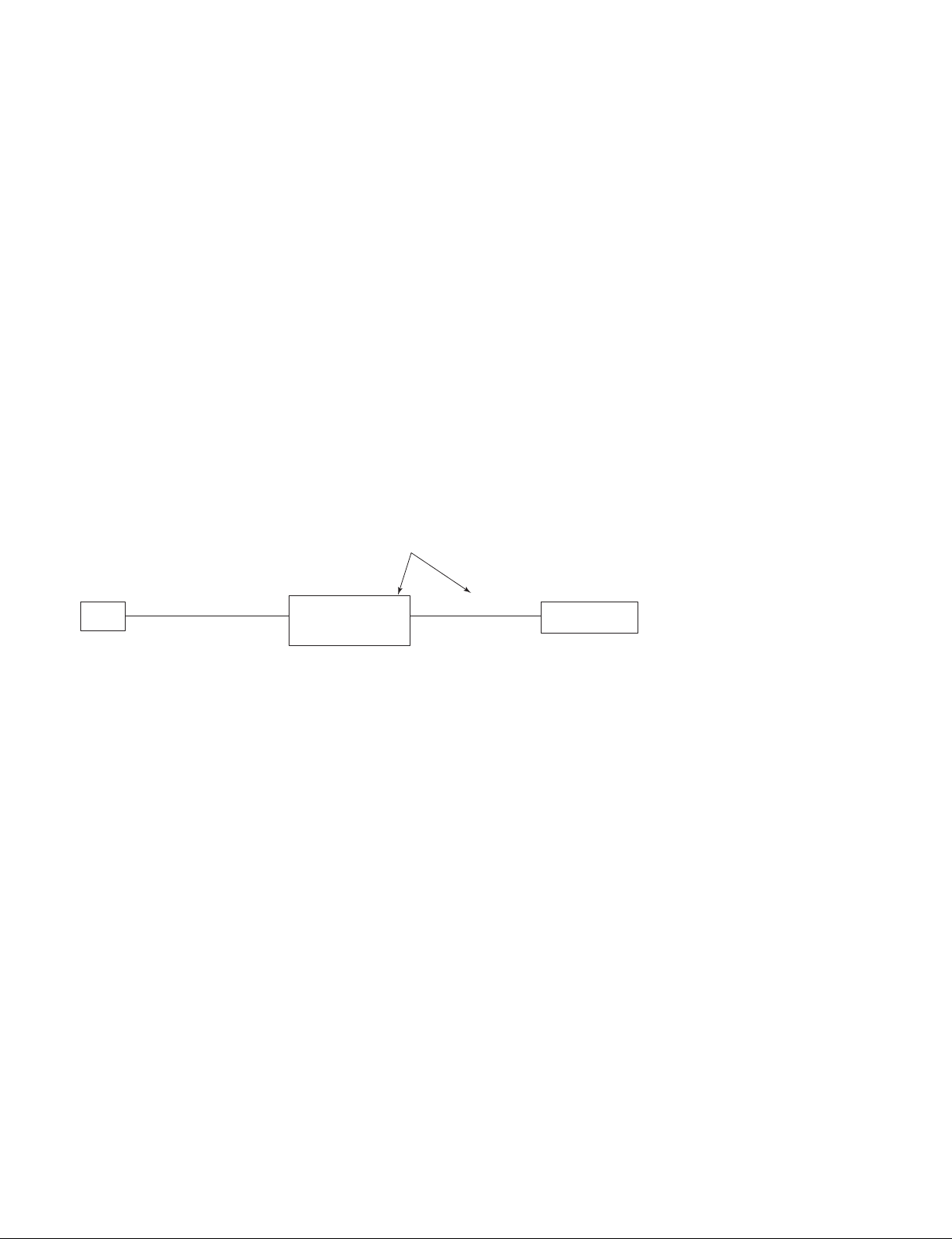

1-3-11. 3D GAMMA Service tool Application Software

Feature of 3D Gamma Quick Access :

. It can read 3D gamma data from a set and save it in a file.

. It can write 3D gamma data in a PC into a set.

When the optical unit is replaced, load 3D gamma data recorded on the micro floppy disk, which is

supplied together with the optical unit, into a set using the application software.

File configuration :

Executable : Ernie Service tool.exe

Readme File : readme_j.txt (Japanese)

readme_e.txt (English)

Software Acquisition :

Download the application software from the GSP website.

. VPL-ES5 set has not RS-232C terminal, use the PCBA MOTOR TEST BD E08S MI.

. Remove the rubber cap on the upper left of the rear side of the unit.

PCBA MOTOR TEST BD E08S MI

PC

RS-232C

Straight

cable

Dsub

9pin

PCBA MOTOR

TEST BD E08S MI

(Parts No. 9-885-122-51)

CN J8

5pin

CN 5P

J12

Set

Main board CN

1-10

VPL-ES5/EX5/EX50/EX5U/EW5

Page 15

Set

Dynamic Standard Game Living Cinema Dynamic Standard Game Living Cinema Dynamic Standard Game Living Cinema

Present-

ation

Present-

ation

Present-

ation

Present-

ation

Dynamic Standard Game Living Cinema

Picture Mode

Adjust Picture

Contrast

90 80 90 90 75 85 90 80 90 90 75 75 90 80 90 90 75 85 90 80 90 90 60 85

Bright

60 50 60 50 50 55 60 50 60 50 50 55 60 50 60 50 50 55 60 50 60 50 50 55

Color

50 50 68 60 58 50 50 50 68 60 58 50 50 50 68 60 58 50

Hue

50 50 50 50 50 50 50 50 50 50 50 50

Sharpness

60 30 50 50 30 50 60 30 40 40 30 40 60 30 40 40 30 40

DDE

Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film

Gamma Mode

Graphics Graphics Graphics Graphics Graphics Graphics

Color Temp

High Low High Low Low High High Low High Low Low High High Low High Low Low High High Low High Low Low

Volume

30

Adjust Signal

Dot Phase 31

H Size

Shift

Aspect refer to Aspect Default

Smart APA On

Auto Input Search Off

Input-A Signal Sel. Auto

Color System Auto

Power Saving Mode Off

IR Receiver Front & Rear

Panel Key Lock Off

Lamp Timer Reset

Status On

Language English

Menu Position Center

Start Up Image On

Auto Keystone *1

V Keystone *2

Auto

Keystone *10

0

Image Flip Off

Background Blue

Lamp Mode *1 Standard

High Altitude Mode

*1

Off

Security Lock Off

Key Enter x 4

Direct Power On Off

VIDEO

INPUT A (Component/VideoGBR) INPUT A (Computer), INPUT B (Computer)

PICTURE

SETTING

S VIDEO

INPUT

SETTING

SET

SETTING

MENU

SETTING

INSTALL

SETTING

*3

*3

*3

*3

INFORMATION

All information is

display only

Section 2

Electrical Adjustments

MORY No.).

2-1. Initial Values of Adjustment Items

VPL-ES5/EX5/EX50/EX5U/EW5

*1: VPL-EX5/EX50/EX5U/EW5 only

*2: VPL-ES5 only

*3: The “Picture Mode” items in the “PICTURE SETTING” menu have their respective initial values for each input signal (PRESET ME

n

There are some adjustment items that cannot be adjusted, depending on the input signal.

2-1

Page 16

SVGA(ES5) / XGA(EX5/EX50/EX5U) / WXGA(EW5)

No. Preset Signal

1 VIDEO/60 60Hz

2 VIDEO/50 50Hz

3 480/60i 480/60i

4 575/50i 575/50i

480/60p (progressive

5 480/60p

component)

575/50p (progressive

6 575/50p

component)

7 1080/60i 1035/60i, 1080/60i

8 1080/50i 1080/50i

10 720/60p 720/60p

11 720/50p 720/50p

21 *

640x350

VGA mode1

22 * VGA VESA 85Hz

23 *

640x400

NEC PC98

24 * VGA mode 2

PC Component Video GBR

*1

-

-

-

-

-

-

-

-

Full1

-

4:3 / Normal

4:3 / Normal

4:3 / Normal

4:3 / Normal

4:3 / Normal *14:3 / Normal

4:3 / Normal *14:3 / Normal

16:9 / Full

16:9 / Full

16:9 / Full

16:9 / Full

4:3 / Normal

*1

4:3 / Normal

*1

4:3 / Normal

*1

4:3 / Normal

*2

16:9 / Full

*2

16:9 / Full

*2

16:9 / Full

*2

16:9 / Full

Full1 - -

Full1 - 25 * VGA VESA 85Hz

26 *

640x480

VGA mode 3

27 * Macintosh 13"

28 * VGA VESA 72Hz

Full1

4:3 / Normal *14:3 / Normal

29 * VGA VESA 75Hz (IBM M3)

30 * VGA VESA 85Hz

31 *

800x600

SVGA VESA 56Hz

32 * SVGA VESA 60Hz

33 * SVGA VESA 72Hz

Full1 - 34 * SVGA VESA 75Hz

35 * SVGA VESA 85Hz

36 * 832x624 Macintosh 16"

37 *

1024x768

XGA VESA 60Hz

38 * XGA VESA 70Hz

39 * XGA VESA 75Hz

Full1

Full1 - -

--

40 * XGA VESA 85Hz

41 *

1152x864

42 SXGA VESA 75Hz

SXGA VESA 70Hz

Full1 - 43 SXGA VESA 85Hz

44 *

45 *

1152x900

1280x960

46 SXGA VESA 75Hz

47 *

1280x1024

48 SXGA VESA 75Hz

*

49 SXGA VESA 85Hz

50

1400x1050

55 1280x768 WXGA 60Hz

56 1280x720p WXGA 60Hz Full1

SUN LO

SXGA VESA 60Hz

SXGA VESA 60Hz

SXGA+ 60Hz

Full1

--

Full1 - -

Full1 - -

Full1

Full1

--

--

16:9 / Full

*2

16:9 / Full

60 1360x768 1360x768/60 Full1 - 61 1440x900 1440x900/60 Full1 - 63 1280x800 1280x800/60 Full1 - -

*1

*1

*1

*1

*1

*1

*2

*2

*2

*2

*1

*2

*1: VPL-EW5 : Normal

*2: VPL-EW5 : Full

2-2

VPL-ES5/EX5/EX50/EX5U/EW5

Page 17

Set

ES5

Page Item Name R G B

EX5/EX50/EX5U

EW5

Color

P1-1

CXD9809

(ES5)

CXD3540

(EX5/EX50/

EX5U/EW5)

page1

P1-2

CXD9809

(ES5)

CXD3540

(EX5/EX50/

EX5U/EW5)

page2

TGHST Phase Hi

TGHST Phase Lo

SHSH1

TGHST Position

DEHPF On

DEHPF AAC

DEHPF TAP

DEUSC On

3D GammaSubCont

3D GammaSubBrt

DELUT SW

DEUF SW

Full Black/White SW

PC Hi Gain-R

PC Hi Gain-G

PC Hi Gain-B

PC Hi Bias-R

PC Hi Bias-G

PC Hi Bias-B

PC Lo Gain-R

PC Lo Gain-G

PC Lo Gain-B

PC Lo Bias-R

PC Lo Bias-G

PC Lo Bias-B

0

109

38

12

ON

ON

3

OFF

0

150

OFF

128

128

128

128

70

100

ON

ON

512

512

512

0

0

0

512

280

400

0

0

0

P1-3

CXD9809

(ES5)

CXD3540

(EX5/EX50/

EX5U/EW5)

page3

VPL-ES5/EX5/EX50/EX5U/EW5

Video Hi Gain-R

Video Hi Gain-G

Video Hi Gain-B

PC Mid Bias-R

Video Hi Bias-G

Video Hi Bias-B

Video Lo Gain-R

Video Lo Gain-G

Video Lo Gain-B

Video Lo Bias-R

Video Lo Bias-G

Video Lo Bias-B

128

80

120

128

70

100

512

320

480

0

0

0

512

280

400

0

0

0

2-3

Page 18

Page Item Name

PC Mid Gain-R

PC Mid Gain-G

P1-4

CXD980

(ES5)

PC Mid Gain-B

PC Mid Bias-R

PC Mid Bias-G

PC Mid Bias-B

CXD3540

(EX5/EX50/

EX5U/EW5)

page4

Video Mid Gain-R

Video Mid Gain-G

Video Mid Gain-B

Video Mid Bias-R

Video Mid Bias-G

Video Mid Bias-B

ES5

128

90

115

128

75

105

Set

EX5/EX50/EX5U

512

360

460

0

0

0

512

300

420

0

0

0

EW5

Color

RGB

P2

Fan Control

P3-1

CXA7006

(ES5)

CXA7009

(EX5/EX50/

EX5U/EW5)

page1

Temperature 1

Temperature 2

Display

only

Display only

Temperature 3 N/A

FanSpeed 1

FanSpeed 2

FanSpeed 3

FanSpeed 4

Display only

Display only

Display only

Display only

ManualFanSpeed OFF

Burn-In Cycle 0

Burn-In Cycle On min.

Burn-In Cycle Off min.

210

30

Burn-In Hour 50

Burn-In active OFF

Gain-R

Gain-G

Gain-B

SigCen-R

SigCen-G

SigCen-B

SidA-R

SidA-G

SidA-B

SidB-R

SidB-G

SidB-B

154

154

154

161

161

161

22

22

22

85

85

85

194

194

194

47

47

47

156

156

156

N/A

211

211

211

48

48

48

18

18

18

152

152

152

2-4

VPL-ES5/EX5/EX50/EX5U/EW5

Page 19

Page Item Name

Bias-R Normal

Bias-G Normal

P3-2

CXA7006

(ES5)

CXA7009

(EX5/EX50/

EX5U/EW5)

page2

Bias-B Normal

Bias-R Flip

Bias-G Flip

Bias-B Flip

Vcom-R Normal

Vcom-G Normal

Vcom-B Normal

Vcom-R Flip

Vcom-G Flip

Vcom-B Flip

RGB Calibrate

YUV Calibrate

RGB Offset 164 222 164

RGB Gain 93 105 93

YUV Offset 164 222 164

P4

ADC Calibration

YUV Gain 93 105 93

R Offset 164

G Offset 222

B Offset 164

R Gain 93

G Gain 105

B Gain 93

ES5

112

112

112

112

112

112

88

88

88

88

88

88

Set

EX5/EX50/EX5U

0

0

0

0

0

0

83

83

83

83

83

83

EW5

99

100

99

99

100

99

R

Color

GB

Power Savin

g Time 10

System Protect ON

Data Reset

Hard Reset *

ROM Version

P5

Lamp Timer

Operation Timer

Prev. Lamp Timer

SOG Threshold 9

P6

All value is display only

Error Count

* : Hard reset deletes the adjusted data and restores the default data.

VPL-ES5/EX5/EX50/EX5U/EW5

Not use

Display only

Display only

Display only

Display only

2-5

Page 20

Page Item Name

average time

Current Y Axis

Current Tout counts

Save T1 data

P7

T1:

Axis1:

Keystone

Adjustment

Save T2 data

T2:

Axis2:

set manual 'b' left key x

a

b

Calculate sensitivity

sensitivity

current g

ES5

Set

EX5/EX50/EX5U

Display

only

Display

only

Display

only

1

1

1

1

1000

1

1

1

Display

only

EW5

2-6

VPL-ES5/EX5/EX50/EX5U/EW5

Page 21

2-2. Memory Structure

Set memory Set memory Set memory

status

memory

Picture

memory

W/B

memory

Aspct memory

Common

Memory

No.01 No.01 Status memory

No.02 No.02

No.03 No.03

No.04 No.04

No.05 No.05

--- --No.50 No.50

No.55 No.55

No.56 No.56

No.60 No.60

No.61 No.61

No.63 No.63

Video

S-Video

Input-A

Input-B

Component

HDMI (video type) *1

HDMI (DVI type) *1

Computer

Other than

Computer

Video, S-Video

Input-A

Input-B

Smart APA

(Computer only)

Volume Volume

Auto Input Search Auto Input Search

Input-A Signal Sel. Input-A Signal Sel.

Color System

(Video/S-Video Only)

Power Saving Power Saving

IR Receiver IR Receiver

Panel Key Lock Panel Key Lock

Status Status

Language Language

Menu Position Menu Position

Start Up Image Start Up Image

Auto Keystone *2 Auto Keystone *2

Keystone Keystone

Image Flip Image Flip

Background Background

Lamp Mode Lamp Mode

High Altitude High Altitude

Security Lock Security Lock

Direct Power On Direct Power On

FLASH ROM EEP ROM

Dynamic Dynamic

Standard Standard

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic Dynamic

Standard Standard

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic Dynamic

Standard Standard

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic Dynamic

Standard Standard

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic Dynamic

Standard Standard

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic

Standard

Game

Living

Cinema

Presentation

Dynamic

Standard

Game

Living

Cinema

Presentation

High High

Mid Mid

Low Low

High High

Mid Mid

Low Low

Video/Svideo

status

memory

memory

W/B memory

No.1 No.1 Aspect memory

No.2 No.2

No.03 No.03

No.04 No.04

No.05 No.05

--- --No.50 No.50

No.55 No.55

No.56 No.56

No.60 No.60

No.61 No.61

No.63 No.63

No.21 No.21

No.22 No.22

No.23 No.23

--- --No.50 No.50

No.55 No.55

No.56 No.56

No.60 No.60

No.61 No.61

No.63 No.63

Aspct memory

Common

Memory

picture

Input-A/Input-B

/Component

Video

S-Video

Input-A

Input-B

Component

HDMI (video type) *1

HDMI (DVI type) *1

Computer

Other than

Computer

Video, S-Video

Input-A

Input-B

Smart APA

(Computer only)

Color System

(Video/S-Video Only)

Dynamic

Standard

Game

Living

Cinema

Presentation

Dynamic

Standard

Game

Living

Cinema

Presentation

Picture memory

*1 : VPL-EW5 only

W/B memory

Common Memory

*2 : VPL-EX5/EX50/EX5U/EW5 only

CPU RAM

VPL-ES5/EX5/EX50/EX5U/EW5

2-7

Page 22

Memory structure of this model consists of the followings.

1 Set memory

2 Status memory

3 Picture memory

4 Chroma memory

5 W/B memory

6 Channel memory

* The gamma memory is realized by giving offset to the Contrast and Brightness output values to the

devices in the gamma mode function.

Flow of data is described briefly. When the power plug is connected to the wall outlet for the first time

(Standby state), all data that are stored in the internal ROM are written in the NVM (non-volatile memory). When the POWER is turned ON, all the status memory data and other memory data that are required

for the present picture are selected from each memory block and expanded in the internal RAM.

When any adjustment is performed at this moment, the adjustment data (user mode items) are written in

the NVM (Service/Special Service) automatically triggered by the memory operation.

The adjustment items (W/B, Device Adjust) that can be adjusted in the Service Mode or in the Special

Service Mode, are memorized in the NVM at the time when the user performs adjustment and performs

the memory operation. Note that the factory adjustment data will be lost at this moment.

2-8

VPL-ES5/EX5/EX50/EX5U/EW5

Page 23

3-1. Electric Troubleshooting

Connect the Power

Section 3

Troubleshooting

System Standby?

Ye s

Power projector

Lamp ON ?

Ye s

System shut-down

And cooling

No

No Picture ?

No

No

No

Ye s

Ye s

1. Check the LED Message and find error.

2. Check lamp door, dust door.

3. Check the power board out voltage 5V.

4. Change main board.

1. check the Ballast power and control

signal wire.

2. Check lamp door status.

3. Check lamp status.

1. Check the LED message and find error.

2. Check the Fan status or Thermal sensor

status.

3. Check the lamp door or dust door.

1. The picture is full-white pattern; please

check the LCD panel connector. (only ES5)

2. The picture is full-black pattern; please check

the LCD panel connector. (only EX5/EX50/

EX5U/EW5) please check the LCD driver on

the main board.

3. Check the system status: Is system in

burn-in mode?

Picture quality

No good ?

VPL-ES5/EX5/EX50/EX5U/EW5

No

Ye s

1. The picture a little green, blue, red,

please check the LCD panel connector.

2. The picture has dust, please check the

lens.

3. The picture flicker, please alignment

again.

1

3-1

Page 24

1

OSD flicker ?

No

Color temp wrong ?

No

Picture has

Vertical bar ?

No

IR remote control

No good ?

Yes

Yes

Yes

Yes

Please alignment V-com again.

Please alignment color temperature again.

Check the vertical bar color and find the

LCD panel connector. Then check the pin

of connector.

1. Please check the OSD setting

2. Check the front IR board.

No

Audio function is

No good ?

Yes

1. Check the OSD setting.

2. Check the speak wire.

3-2

VPL-ES5/EX5/EX50/EX5U/EW5

Page 25

3-2. Power Board Troubleshooting

3-2-1. No Power

No Power

Replace Q601 and F601

with new ones, and then

put power board into set.

If Q601 damages again,

check if other parts are

shorted.

Check if 15.25V or 12V

exist. If any voltage is

wrong, replace IC701 or

T602 with new ones.

Yes

Yes

F601

Open?

Yes

Q601 (D-S)

Short ?

No

Output

5V DC

exists ?

No

Voltage

outputs shut

down and built

repeatly ?

No

Yes

Check if CN701 inserted

properly.

Check if miss to solder

any SMD type of

components.

Check if D602 or IC602 is

broken.

if yes,replace it with now

one.

VPL-ES5/EX5/EX50/EX5U/EW5

No

Check LED circuit of

main board.

Check CN701 and find

out if some points are

shorted to gound.

3-3

Page 26

3-2-2. Failure of Turn on Lamp

Failure of turn on ballast.

Check main board.

A

Check if the input

voltage of ballast is

380V DC

No

Lamp

Broken ?

No

No

Control

Pin (SCI) is

normal ?

Yes

Replace ballast with new

one.

Yes

Yes

B

Replace lamp with new

one.

3-4

VPL-ES5/EX5/EX50/EX5U/EW5

Page 27

B

Check mian board.

A

No

exists at c-terminal

Yes

Check if there

is PFC_On/Off

signal.

Yes

Check if 18V

of Q603.

Yes

F602 Open ?

No

Q602 works

normally ?

No

Yes

Check Q701, IC604,

IC605, Q604, Q603,

Q653 or ZD603.

And then replace broken

parts.

Replace F602 with new

one.

VPL-ES5/EX5/EX50/EX5U/EW5

No

Check ZD602, R655 and

R656.

3-5

Page 28

3-3. Optical Troubleshooting

Connect the Power

Brightness

No good ?

No

Flicker ?

No

Color

No good ?

No

No Color Uniformity ?

No

No Focus ?

Yes

Yes

Yes

Yes

Yes

1. Check the EE setting (ADC calibration) /

Follow up EE alignment procedure.

2. Check the Lamp assembly.

1. Check the R,G,B VCOM.

1. Check the R,G,B Gain.

2. Check the Panel cable connector.

1. Check uniformity R,G,B value.

1. Check the Projection lens at datum surface.

3-6

No

Dust ?

No

Black level

No good ?

Yes

Yes

1. Cleaning the Lens array (front of lamp).

2. Cleaning the R,G,B Panel.

1. Check the FPC cable connecting.

VPL-ES5/EX5/EX50/EX5U/EW5

Page 29

4-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

[WARNHINWEIS][WARNHINWEIS]

[WARNHINWEIS]

[WARNHINWEIS][WARNHINWEIS]

Les composants identifiés par la marque ! sont

critiques pour la sécurité.

Ne les remplacer que par une pièce portant le numéro

spécifié.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts List has the present standardized repair parts.

Section 4

Spare Parts

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the Spare Parts list may not be stocked. Therefore, the

delivery date will be delayed.

Items with no part number and no description are not

stocked because they are seldom required for routine

service.

4. Units for Capacitors, Inductors and Resistors

The following units are assumed in Schematic Diagrams, Electrical Parts List and Exploded Views

unless otherwise specified.

Capacitors : μF

Inductors : μH

Resistors : Ω

5. Note for Electrical key

The components identified by mark contain confidential information.

Strictly follow the instructions whenever the components are repaired and/or replaced.

VPL-ES5/EX5/EX50/EX5U/EW5

4-1

Page 30

Overall

4-2. Exploded Views

22

46

11

3

36

12

33

46

16

51

B

37

A

3

31

3

A

3

3

B

44

46

15

3

3

28

14

3

20

3

39

40

13

3

19

47

21

35

52

42

42

VPL-EX5

VPL-EX5U

43

VPL-ES5

43

4-2

41

29

17

26

27

32

45

25

45

34

24

23

38

18

1

2

3

3

35

VPL-EX50

42

35

42

35

VPL-ES5/EX5/EX50/EX5U/EW5

43

VPL-EW5

53

43

Page 31

No. Part No. SP Description

1 ! 1-576-233-51 s FUSE (H.B.C.) (F601)

2 ! 1-576-973-11 s MINIATURE FUSE-LINKS (F602)

3 2-681-550-01 s SCREW, TAP PAN M3*7L

11 9-885-118-05 s WIRE 2P_CON+THERMAL 145MM E08X

12 ! 9-885-118-06 s FAN*2 80*25 170MM AD0812UB/HB

13 ! 9-885-118-07 s FAN 75*75*30 145MM AB7512UB

14 ! 9-885-118-08 s FAN 70*70*25 240MM AB7012UB

15 ! 9-885-118-09 s FAN 60*60*25 183MM AB0612MB

16 9-885-118-10 s PCBA MAIN BD 6L E08X MI (VPL-EX50)

16 9-885-118-11 s PCBA MAIN BD 6L E08XJR MI (VPL-EX5)

16 9-885-118-12 s PCBA MAIN BD 6L E08S MI (VPL-ES5)

16 9-885-118-13 s PCBA MAIN BD 6L E08W MI (VPL-EW5)

16 9-885-122-39 s PCBA MAIN BD 6L E08XU MI (VPL-EX5U)

17 9-885-118-14 s PCBA IR BD E08X MI

18 1-789-544-11 s PCBA THERMAL SENSOR BD MI

19 9-885-118-16 s PCBA POWER BD 2L E08W MI

20 9-885-118-17 s PCBA SWITCH BD E08X MI

21 9-885-118-18 s SPK 2W8OHM 130MM W4028CP-130

22 3-094-309-01 s MYLAR BRIGHTERA E08 (EXCEPT VPL-ES5)

23 9-885-118-22 s DOOR FILTER PC E08X

24 9-885-118-23 s MESH FILTER E08X

25 9-885-118-24 s ASSY ADJ FOOT E08X

26 9-885-118-26 s RUBBER FRONT FOOT E08X

27 9-885-118-27 s NUT HEX+WASHER M3*2.3H NI

28 ! 9-885-118-28 s MYLAR BALLAST PC E08X

Overall

29 9-885-118-29 s CAP LENS PC E08X

31 9-885-118-31 s ASSY, UPPER CASE E08X (EXCEPT VPL-EX5U)

31 9-885-121-00 s ASSY UPPER CASE E08XU (VPL-EX5U)

32 9-885-118-32 s ASSY, LAMP DOOR E08X

33 9-885-118-33 s ASSY LAMP BOX E08X

34 9-885-118-34 s ASSY LOWER CASE E08X

35 9-885-118-35 s ASSY REAR CASE E08X (VPL-EX50)

35 9-885-118-36 s ASSY REAR CASE E08XJR (VPL-EX5, VPL-EX5U)

35 9-885-118-37 s ASSY REAR CASE E08S (VPL-ES5)

35 9-885-118-38 s ASSY REAR CASE E08W (VPL-EW5)

36 9-885-118-39 s ASSY FRONT CASE E08X

37 9-885-118-40 s ASSY LAMP NOZZLE E08X

38 9-885-118-41 s ASSY ADJUST GEAR E08 E08X

39 9-885-118-42 s SCREW TAP W/FLA M3x10L PT ZN

40 9-885-118-43 s SCREW TAP W/FLA M3x35 NI D-PT

41 9-885-118-44 s LOGO XGA PC E08X SONY (VPL-EX50)

41 9-885-118-45 s LOGO JR PC E08XJR SONY (VPL-EX5)

41 9-885-118-46 s LOGO SVGA PC E08S SONY (VPL-ES5)

41 9-885-118-47 s LOGO WXGA PC E08W SONY (VPL-EW5)

41 9-885-120-99 s LOGO PC E08XU SONY (VPL-EX5U)

42 2-681-552-02 s SCRW MACH HEX #4-40*4

43 7-682-250-09 s SCRW +K 3X12

44 2-580-599-01 s SCRW +PSW M4X6

45 3-918-696-11 s SCRW (M3X6 LOCK ACE)

46 7-682-903-11 s SCRW +PWH 3X6

47 7-682-954-01 s SCRW +PSW M3X25

51 This part is not supplied as the repair part.

If this part is broken or lost, the part reference No. 39 can be used.

52 This part is not supplied as the repair part.

If this part is broken or lost, the part reference No. 46 can be used.

53 4-654-811-21 s SCRW +F M3X8 EG (VPL-EW5)

VPL-ES5/EX5/EX50/EX5U/EW5

4-3

Page 32

4-3. Electrical Parts List

Ref. No.

or Q’ty Part No. SP Description

1pc ! 1-576-233-51 s FUSE (H.B.C) (F601)

1pc ! 1-576-973-11 s MINITURE FUSE-LINKS (F602)

4-4. Packing Materials & Supplied

-------------------SUPPLIED ACCESSORIES

------------------- Ref. No.

or Q’ty Part No. SP Description

1pc 1-479-775-12 s CARD COMMANDER

1pc 1-832-428-11 s CABLE SINGAL VGA

1pc 9-885-118-30 s BAG CARRY E08X SONY

1pc 3-293-835-03 s CD MANUAL WW E08 E08XJR

(EXCEPT CH/VPL-EX5U)

1pc 3-293-836-02 s MANUAL QUICK REF WW E08 E08XJR

(EXCEPT CH/VPL-EX5U)

(JAPANESE, ENGLISH, FRENCH,

SPANISH, GERMAN, ITALIAN,

SIMPLIFIED CHINESE)

1pc 3-293-838-71 s MANUAL INSTRUCTIONS (CH)

1pc 3-870-419-01 s MANUAL INSTRUCTIONS (E08XU)

(VPL-EX5U)

1pc 3-877-599-11 s MANUAL QUICK REF (E08XU) (VPL-EX5U)

1pc ! 1-783-795-64 s CORD SET, POWER (J)

1pc ! 1-833-570-11 s POWER-SUPPLY CORD (CH)

4-5. Optional Fixtures

Ref. No.

or Q’ty Part No. SP Description

Accessories

1pc 9-885-122-51 s PCBA MOTOR TEST BD E08S MI

4-4

VPL-ES5/EX5/EX50/EX5U/EW5

Page 33

GPSIG

HCKx_R

DCK1_B

DCK1x_R

DCK1_B

HCK_R

HCK

LCDPCG

LCDENB

VST

VD

DCK1x_G

HCKx_R

HST

HCKx

VCK

DCK2_G

HCKx

CLK_B

FRP

DCK1x_G

HST

PRG

DCK1_R

CLK_G

RPSIG

DCK2x_R

VD

DCK1_G

DCK1_R

RGT

HCKx

GSIG[6:1]

DWN

HCK_G

VCK

HCK_R

HCKx_G

HCK_B

DCK2x_B

LCDVCK

LCDRGTx

PCG

HCK_G

ENB

DCK2x_B

DCK2_G

DWN

HCK

ENB

FRP

PRG

DCK1x_R

PCG

LCDVST

RSIG[6:1]

VCK

HCKx_B

PCG

LCDRGT

HCK

BSIG[6:1]

VD

DCK2_B

PRG

DCK2x_G

VST

DCK2x_R

DCK2_R

LCDHST

BPSIG

RGTx

HST

LCDR[11:0]

DCK1_G

DCK2_R

DWN

RGT

VCK

PRG

DCK1x_B

GVCOM

CLK_R

HST

HCK_B

FRP

DWN

HCKx_G

HCKx_B

BVCOM

LCDG[11: 0]

RVCOM

ENB

RGT

DCK2_B

VD

FRP

RGTx

DCK[6:1]

LCDDWN

LCDB[11: 0]

ENB

PCG

DCK2x_G

DCK1x_B

VST

VST

SDA

SCL

WP

DR[9:0]

DG[9:0]

DB[9:0]

DCLK

DHS

DVS

SDATA

SEN

SDATA

SDATA

SCLK

SEN

SCLK

SEN

SCLK

SDATAi

SCLKi

SENi

PC-RIN2

PC-GIN2

PC-BIN2

HSYNC2

VSYNC2

R_OUT

G_OUT

B_OUT

HSYNCO

VSYNCO

LUMA

CHROMA

CVBS

PC-RIN

PC-GIN

PC-BIN

HSYNC

VSYNC

AUDIO_O_

AUDIO_O

AUDIO_MUT

AUDIO_VOL1

AUDIO_VOL2

TXD

RXD

AUDIO_M

AUDIO_O+

I2C_SW

FAN_SW

FG1

FG2

Fan3

FG3

Fan4

FG4

Fan5

FG5

Fan2

SDA

IRR5

IRF5

IRR

IRF

SCL

LED[4:1]

P15VP

P12V

P5V

PWR_fail

POWER_ON

LCD_SCL

LCD_SDA

Dust_SW

ROMOEn

ROMWEn

A[0:21]

D[0:15]

LampLIT

LampEN

Eco_mode

Door_SW

P15VP

P12V

P5V

P15VP

P5V

P15V

P5VC

P5V

P5VP1P8V

P2P5V

P3P3V

P33V

P5VCV33

P2P5V

P135V P15V

R

LCD

Generator

R

LCD

B

LCD

B

LCD

Driver

LCD

Timing

Generator

G

LCD

G

LCD

Driver

Video

Processor

&

Controller

Reset

IC

EEPROM

Speaker

Fan Control

EEPROM

IR Receiver

IR Receiver

S-Video

Video

INPUTA

Monitor

Output

Audio

Audio out

RS-232

Thermal

Sensor 1

Thermal

Sensor 2

Analog RGB

Input/Output

32.768 KHz

LED

Driver

Keypad

Input

27 MHz

Power

Fail DET

Dust SW

Door SW

Flash

memory

Reset

IC

Power

Control

Power

Switch

Ballast

Fan 1

Fan 2

Fan 3

Fan 4

Audio

Input/Output

&

volume

control

+2.5V

REG

+3.3V

REG

+3.3V

REG

+1.8V

REG

+3.3V

REG

+1.8V

REG

+3.3V

REG

U33

AT24C32CN

U48

AT24C256N

VPL-ES5

Overall (VPL-ES5)Overall (VPL-ES5)

Section 5

Block Diagrams

VPL-ES5/EX5/EX50/EX5U/EW5

5-1

5-1

Page 34

VPL-EX50

GPSIG

HCK2_R

B_DCK1

R_DCK2

B_DCK1

HCK1_R

HCK

LCDPCG

LCDENB

VST

VD

HCK2_R

HST

HCKx

VCK

HCKx

CLK_B

FRP

G_DCK2

HST

PRG

R_DCK1

CLK_G

RPSIG

R_DCK4

VD

G_DCK1

R_DCK1

SCAN

HCKx

GSIG[12:1]

DWN

HCK1_G

VCK

HCK1_R

HCK2_G

HCK1_B

B_DCK4

LCDVCK

LCDXSCAN

PCG

HCK1_G

ENB

B_DCK4

G_DCK3

DWN

HCK

ENB

FRP

PRG

R_DCK2

PCG

LCDVST

RSIG[12:1]

VCK

HCK2_B

PCG

LCDSCAN

HCK

BSIG[12:1]

VD

B_DCK3

PRG

G_DCK4

VST

R_DCK4

R_DCK3

LCDHST

BPSIG

XSCAN

HST

LCDR1[11:0]

G_DCK1

R_DCK3

DWN

SCAN

VCK

PRG

B_DCK2

GVCOM

CLK_R

HST

HCK1_B

FRP

DWN

HCK2_G

HCK2_B

BVCOM

LCDG1[11:0]

RVCOM

ENB

SCAN

B_DCK3

VD

FRP

XSCAN

DCK[4:1]_R(G,B)

LCDDWN

ENB

PCG

B_DCK2

VST

VST

DR[9:0]

DG[9:0]

DB[9:0]

DCLK

DHS

DVS

SCL_7009

SDA_7009

SDA_7009

SCL_7009

SDA_7009

SDA_7009i

SCL_7009i

PC-RIN1

PC-GIN1

PC-BIN1

HSYNC1

VSYNC1

PC-RIN2

PC-GIN2

PC-BIN2

HSYNC2

VSYNC2

R_OUT

G_OUT

B_OUT

HSYNCO

VSYNCO

LUMA

CHROMA

CVBS

PC-RIN

PC-GIN

PC-BIN

HSYNC

VSYNC

AUDIO_M

AUDIO_O-

AUDIO_O

AUDIO_MUT

AUDIO_VOL1

AUDIO_VOL2

TXD

RXD

AUDIO_S

TX.DL

RX.DL

AUDIO_O+

FAN_SW

Fan4

FG4

Fan5

FG5

AUDIO_SW

IRR5

IRF5

IRR

IRF

SCL

LED[4:1]

P15VP

P12V

P5V

PWR_fail

POWER_ON

Dust_SW

ROMOEn

ROMWEn

A[0:21]

D[0:15]

LampLIT

Eco_mode

Door_SW

FG2

Fan2

FG3

Fan1

FG1

AUDIO_PWR

PG_XCLR_OUT

PG_PLLSTB_OUT

SCL_7009

PVCC_POWER_ON

G_DCK2

G_DCK3

G_DCK4

LCDB1[11:0]

LCDB2[11:0]

LCDG2[11:0]

LCDR2[11:0]

LampEN

Lamp_SyncEN

SDA

SCL_DSD

SDA_DSD

P15VP

P12V

P5V

P5VP5VC

P5V

P5VP1P8V

P2P5V

P3P3V

P33V

P5VC3.3V

P15VPP15V

2.5V

1.8V

VST

R

LCD

Driver

B

LCD

LCD

Timing

Generator

G

LCD

G

LCD

Driver

Video

Processor

&

Controller

EEPROM

Speaker

RS232

Driver

Receiver

Fan Control

EEPROM

IR Receiver

IR Receiver

S-Video

Video

INPUT A

INPUT B

Monitor

Output

Audio

Audio A/B

Audio out

RS-232

Remote

Control

Thermal

Sensor 2

Analog RGB

Input/Output

LED

Driver

Keypad

Input

27 MHz

Power

Fail DET

Dust SW

Door SW

Flash

memory

Reset

IC

Power

Control

Power

Switch

Ballast

Fan 5

Fan 4

Audio

Input/Output

&

volume

control

+2.5V

REG

+3.3V

REG

+3.3V

REG

+1.8V

REG

+3.3V

REG

+1.8V

REG

Fan 3

Fan 1

Fan 2

+2.5V

REG

Lamp

Control

Keystone

Sensor

32.768 KHz

B

LCD

Driver

R

LCD

U33

AT24C32CN

AT24C256N

U20

Overall (VPL-EX50)Overall (VPL-EX50)

5-2

5-2

VPL-ES5/EX5/EX50/EX5U/EW5

Page 35

VPL-EX5

GPSIG

HCK2_R

B_DCK1

R_DCK2

B_DCK1

HCK1_R

HCK

LCDPCG

LCDENB

VST

VD

HCK2_R

HST

HCKx

VCK

HCKx

CLK_B

FRP

G_DCK2

HST

PRG

R_DCK1

CLK_G

RPSIG

R_DCK4

VD

G_DCK1

R_DCK1

SCAN

HCKx

GSIG[12:1]

DWN

HCK1_G

VCK

HCK1_R

HCK2_G

HCK1_B

B_DCK4

LCDVCK

LCDXSCAN

PCG

HCK1_G

ENB

B_DCK4

G_DCK3

DWN

HCK

ENB

FRP

PRG

R_DCK2

PCG

LCDVST

RSIG[12:1]

VCK

HCK2_B

PCG

LCDSCAN

HCK

BSIG[12:1]

VD

B_DCK3

PRG

G_DCK4

VST

R_DCK4

R_DCK3

LCDHST

BPSIG

XSCAN

HST

LCDR1[11:0]

G_DCK1

R_DCK3

DWN

SCAN

VCK

PRG

B_DCK2

GVCOM

CLK_R

HST

HCK1_B

FRP

DWN

HCK2_G

HCK2_B

BVCOM

LCDG1[11:0]

RVCOM

ENB

SCAN

B_DCK3

VD

FRP

XSCAN

DCK[4:1]_R(G,B)

LCDDWN

ENB

PCG

B_DCK2

VST

VST

DR[9:0]

DG[9:0]

DB[9:0]

DCLK

DHS

DVS

SCL_7009

SDA_7009

SDA_7009

SCL_7009

SDA_7009

SDA_7009i

SCL_7009i

PC-RIN2

PC-GIN2

PC-BIN2

HSYNC2

VSYNC2

R_OUT

G_OUT

B_OUT

HSYNCO

VSYNCO

LUMA

CHROMA

CVBS

PC-RIN

PC-GIN

PC-BIN

HSYNC

VSYNC

AUDIO_M

AUDIO_O-

AUDIO_O

AUDIO_MUT

AUDIO_VOL1

AUDIO_VOL2

TXD

RXD

TX.DL

RX.DL

AUDIO_O+

FAN_SW

Fan4

FG4

Fan5

FG5

AUDIO_SW

IRR5

IRF5

IRR

IRF

SCL

LED[4:1]

P15VP

P12V

P5V

PWR_fail

POWER_ON

Dust_SW

ROMOEn

ROMWEn

A[0:21]

D[0:15]

LampLIT

Eco_mode

Door_SW

FG2

Fan2

FG3

Fan1

FG1

AUDIO_PWR

PG_XCLR_OUT

PG_PLLSTB_OUT

SCL_7009

PVCC_POWER_ON

G_DCK2

G_DCK3

G_DCK4

LCDB1[11:0]

LCDB2[11:0]

LCDG2[11:0]

LCDR2[11:0]

LampEN

Lamp_SyncEN

SDA

SCL_DSD

SDA_DSD

P15VP

P12V

P5V

P5VP5VC

P5V

P5VP1P8V

P2P5V

P3P3V

P33V

P5VC3.3V

P15VPP15V

2.5V

1.8V

VST

EEPROM

Speaker

EEPROM

S-Video

Video

INPUT A

Monitor

Output

Audio

Input

Audio out

27 MHz

32.768 KHz

R

LCD

Driver

B

LCD

LCD

Timing

Generator

G

LCD

G

LCD

Driver

Video

Processor

&

Controller

RS232

Driver

Receiver

Fan Control

Analog RGB

Input/Output

Audio

Input/Output

&

volume

control

B

LCD

Driver

R

LCD

LED

Driver

Keypad

Input

Power

Fail DET

Dust SW

Door SW

Flash

memory

Reset

IC

Power

Control

Power

Switch

Ballast

Lamp

Control

Keystone

Sensor

IR Receiver

IR Receiver

+2.5V

REG

+3.3V

REG

+3.3V

REG

+1.8V

REG

+3.3V

REG

+1.8V

REG

+2.5V

REG

RS-232

Remote

Control

Fan 5

Fan 4

Fan 3

Fan 1

Fan 2

Thermal

Sensor 2

U33

AT24C32CN

AT24C256N

U20

Overall (VPL-EX5)Overall (VPL-EX5)

VPL-ES5/EX5/EX50/EX5U/EW5

5-3

5-3

Page 36

VPL-EX5U

GPSIG

HCK2_R

B_DCK1

R_DCK2

B_DCK1

HCK1_R

HCK

LCDPCG

LCDENB

VST

VD

HCK2_R

HST

HCKx

VCK

HCKx

CLK_B

FRP

G_DCK2

HST

PRG

R_DCK1

CLK_G

RPSIG

R_DCK4

VD

G_DCK1

R_DCK1

SCAN

HCKx

GSIG[12: 1]

DWN

HCK1_G

VCK

HCK1_R

HCK2_G

HCK1_B

B_DCK4

LCDVCK

LCDXSCAN

PCG

HCK1_G

ENB

B_DCK4

G_DCK3

DWN

HCK

ENB

FRP

PRG

R_DCK2

PCG

LCDVST

RSIG[12: 1]

VCK

HCK2_B

PCG

LCDSCAN

HCK

BSIG[12: 1]

VD

B_DCK3

PRG

G_DCK4

VST

R_DCK4

R_DCK3

LCDHST

BPSIG

XSCAN

HST

LCDR1[11:0]

G_DCK1

R_DCK3

DWN

SCAN

VCK

PRG

B_DCK2

GVCOM

CLK_R

HST

HCK1_B

FRP

DWN

HCK2_G

HCK2_B

BVCOM

LCDG1[11: 0]

RVCOM

ENB

SCAN

B_DCK3

VD

FRP

XSCAN

DCK[4:1]_R(G,B)

LCDDWN

ENB

PCG

B_DCK2

VST

VST

DR[9:0]

DG[9:0]

DB[9:0]

DCLK

DHS

DVS

SCL_7009

SDA_7009

SDA_7009

SCL_7009

SDA_7009

SDA_7009i

SCL_7009i

PC-RIN2

PC-GIN2

PC-BIN2

HSYNC2

VSYNC2

R_OUT

G_OUT

B_OUT

HSYNCO

VSYNCO

LUMA

CHROMA

CVBS

PC-RIN

PC-GIN

PC-BIN

HSYNC

VSYNC

AUDIO_M

AUDIO_O-

AUDIO_O

AUDIO_MUT

AUDIO_VOL1

AUDIO_VOL2

TXD

RXD

TX.DL

RX.DL

AUDIO_O+

FAN_SW

Fan4

FG4

Fan5

FG5

AUDIO_SW

IRR5

IRF5

IRR

IRF

SCL

LED[4:1]

P15VP

P12V

P5V

PWR_f ail

POWER_ON

Dust_SW

ROMOEn

ROMWEn

A[0:21]

D[0:15]

LampLI T

Eco_mode

Door_SW

FG2

Fan2

FG3

Fan1

FG1

AUDIO_PWR

PG_XCLR_OUT

PG_PLLSTB_OUT

SCL_7009

PVCC_POWER_ ON

G_DCK2

G_DCK3

G_DCK4

LCDB1[11: 0]

LCDB2[11: 0]

LCDG2[11: 0]

LCDR2[11:0]

LampEN

Lamp_Sync EN

SDA

SCL_DSD

SDA_DSD

P15VP

P12V

P5V

P5VP5VC

P5V

P5VP1P8V

P2P5V

P3P3V

P33V

P5VC3.3V

P15VPP15V

2.5V

1.8V

VST

R

LCD

Driver

R

LCD

B

LCD

B

LCD

Driver

LCD

Timing

Generator

G

LCD

G

LCD

Driver

Video

Processor

&

Controller

EEPROM

Speaker

RS232

Driver

Receiver

Fan Control

EEPROM

IR Receiver

IR Receiver

S-Video

Video

INPUT A

Monitor

Output

Audio Input

Audio out

RS-232

Remote

Control

Thermal

Sensor 2

Analog RGB

Input/Output

LED

Driver

27 MHz

Power

Fail DET

Dust SW

Door SW

Flash

memory

Reset

IC

Power

Control

Power

Switch

Ballast

Fan 5

Fan 4

Audio

Input/Output

&

volume

control

+2.5V

REG

+3.3V

REG

+3.3V

REG

+1.8V

REG

+3.3V

REG

+1.8V

REG

Fan 3

Fan 1

Fan 2

+2.5V

REG

Lamp

Control

Keystone

Sensor

32.768 KHz

Overall (VPL-EX5U)Overall (VPL-EX5U)

5-4

5-4

VPL-ES5/EX5/EX50/EX5U/EW5

Page 37

VPL-EW5

GPSIG

HCK2_R

B_DCK1

R_DCK2

B_DCK1

HCK1_R

HCK

LCDPCG

LCDENB

VST

VD

HCK2_R

HST

HCKx

VCK

HCKx

CLK_B

FRP

G_DCK2

HST

PRG

R_DCK1

CLK_G

RPSIG

R_DCK4

VD

G_DCK1

R_DCK1

SCAN

HCKx

GSIG[12: 1]

DWN

HCK1_G

VCK

HCK1_R

HCK2_G

HCK1_B

B_DCK4

LCDVCK

LCDXSCAN

PCG

HCK1_G

ENB

B_DCK4

G_DCK3

DWN

HCK

ENB

FRP

PRG

R_DCK2

PCG

LCDVST

RSIG[12: 1]

VCK

HCK2_B

PCG

LCDSCAN

HCK

BSIG[12: 1]

VD

B_DCK3

PRG

G_DCK4

VST

R_DCK4

R_DCK3

LCDHST

BPSIG

XSCAN

HST

LCDR1[11:0]

G_DCK1

R_DCK3

DWN

SCAN

VCK

PRG

B_DCK2

GVCOM

CLK_R

HST

HCK1_B

FRP

DWN

HCK2_G

HCK2_B

BVCOM

LCDG1[11: 0]

RVCOM

ENB

SCAN

B_DCK3

VD

FRP

XSCAN

DCK[4:1]_R(G,B)

LCDDWN

ENB

PCG

B_DCK2

VST

VST

DR[9:0]

DG[9:0]

DB[9:0]

DCLK

DHS

DVS

SCL_7009

SDA_7009

SDA_7009

SCL_7009

SDA_7009

SDA_7009i

SCL_7009i

HDMI_CKN/P

HDMI_D0N/P

HDMI_D1N/P

HDMI_D3N/P

DSCL1/DSDA1

PC-RIN2

PC-GIN2

PC-BIN2

HSYNC2

VSYNC2

R_OUT

G_OUT

B_OUT

HSYNCO

VSYNCO

LUMA

CHROMA

CVBS

PC-RIN

PC-GIN

PC-BIN

HSYNC

VSYNC

AUDIO_M

AUDIO_O-

AUDIO_O

AUDIO_MUT

AUDIO_VOL1

AUDIO_VOL2

TXD

RXD

AUDIO_S

TX.DL

RX.DL

AUDIO_O+

FAN_SW

Fan4

FG4

Fan5

FG5

AUDIO_SW

IRR5

IRF5

IRR

IRF

SCL

LED[4:1]

P15VP

P12V

P5V

PWR_f ail

POWER_ON

Dust_SW

ROMOEn

ROMWEn

A[0:21]

D[0:15]

LampLI T

Eco_mode

Door_SW

FG2

Fan2

FG3

Fan1

FG1

AUDIO_PWR

PG_XCLR_OUT

PG_PLLSTB_OUT

SCL_7009

PVCC_POWER_ ON

G_DCK2

G_DCK3

G_DCK4

LCDB1[11: 0]

LCDB2[11: 0]

LCDG2[11: 0]

LCDR2[11:0]

LampEN

Lamp_Sync EN

SDA

SCL_DSD

SDA_DSD

HDMI_D2N/P

HDMI_R/Cr[9..2]

HDMI_B/Cb [9..2]

HDMI_G/Y[9..2]

HDMI_DE

HDMI_VS

HDMI_HS

HDMI_CLK

P15VP

P12V

P5V

P5VP5VC

P5V

P5VP1P8V

P2P5V

P3P3V

P33V

P5VC3.3V

P15VPP15V

2.5V

1.8V

VST

R

LCD

Driver

R

LCD

B

LCD

B

LCD

Driver

LCD

Timing

Generator

G

LCD

G

LCD

Driver

Video

Processor

&

Controller

EEPROM

Speaker

RS232

Driver

Receiver

Fan Control

EEPROM

IR Receiver

IR Receiver

S-Video

Video

INPUT A

INPUT B

Monitor

Output

Audio

Audio A/B

Audio out

RS-232

Remote

Control

Thermal

Sensor 2

Analog RGB

Input/Output

LED

Driver

Keypad

Input

27 MHz

Power

Fail DET

Dust SW

Door SW

Flash

memory

Reset

IC

Power

Control

Power

Switch

Ballast

Fan 5

Fan 4

Audio

Input/Output

&

volume

control

+2.5V

REG

+3.3V

REG

+3.3V

REG

+1.8V

REG

+3.3V

REG

+1.8V

REG

Fan 3

Fan 1

Fan 2

+2.5V

REG

Lamp

Control

Keystone

Sensor

32.768 KHz

HDMI receiver

Input/Output

Overall (VPL-EW5)Overall (VPL-EW5)

VPL-ES5/EX5/EX50/EX5U/EW5

5-5

5-5

Page 38

Page 39

Section 6

CN601

CN605

HALOGEN

LAMP

BALLAST UNIT

POWER BOARD

FAN2

FAN3

FAN1(FRONT BOTTOM)

FAN5

(REAR BOTTOM)

FAN4

(REAR TOP)

CN701J17

SPEAKER

J11

RS232C

CONNECTOR

J12

J22

J6

J1

J20

J19

J14

J21

J16

J23

J24

J25

J2

INPUT

INPUT A

J3

OUTPUT

MONITOR

J4

VIDEO

J5

S VIDEO

INPUT

INPUT

CN1

CN1

J18

J1

THERMAL

SENSOR

BOARD

DETECTION

SWITCH

BOARD

(LAMP DOOR)

DETECTION

SWITCH

BOARD

(DUST DOOR)

LCD R

IR

SENSOR

BOARD

MAIN

BOARD

LCD G

LCD B

INPUT

J9

AUDIO

OUTPUT

J10

AUDIO

Diagrams

Frame (VPL-ES5) Frame (VPL-ES5)

6-1. Frame Schematic Diagrams

VPL-ES5

1

2

3

4

5

VPL-ES5/EX5/EX50/EX5U/EW5

A BCDEFGH

6-1

6-1

Page 40

CN601

CN605

HALOGEN

LAMP

BALLAST UNIT

POWER BOARD

FAN2

FAN3

FAN1(FRONT BOTTOM)

FAN5

(REAR BOTTOM)

FAN4

(REAR TOP)

CN701J17

SPEAKER

J11

J18

J6

J1

J20

J21

J14

J19

J16

J22

J23

J24

J1

INPUT

INPUT B

J2

INPUT

INPUT A

J3

OUTPUT

MONITOR

J14

VIDEO

J5

S VIDEO

INPUT

INPUT

J7

RS-232C

REMOTE

CN1

CN1

J26

J1

THERMAL

SENSOR

BOARD

DETECTION

SWITCH

BOARD

(LAMP DOOR)

DETECTION

SWITCH

BOARD

(DUST DOOR)

LCD R

IR

SENSOR

BOARD

MAIN

BOARD

LCD G

LCD B

INPUT

J9

AUDIO A/B

INPUT

J8

AUDIO

OUTPUT

J10

AUDIO

Frame (VPL-EX50) Frame (VPL-EX50)

VPL-EX50

1

2

3

4

5

6-2

6-2

VPL-ES5/EX5/EX50/EX5U/EW5

ABCDEFGH

Page 41

CN601

CN605

HALOGEN

LAMP

BALLAST UNIT

POWER BOARD

FAN2

FAN3

FAN1(FRONT BOTTOM)

FAN5

(REAR BOTTOM)

FAN4

(REAR TOP)

CN701J17

SPEAKER

J11

J18

J6

J1

J20

J21

J14

J19

J16

J22

J23

J24

J2

INPUT

INPUT A

J3

OUTPUT

MONITOR

J14

VIDEO

J5

S VIDEO

INPUT

INPUT

J7

RS-232C

REMOTE

CN1

CN1

J26

J1

THERMAL

SENSOR

BOARD

DETECTION

SWITCH

BOARD

(LAMP DOOR)

DETECTION

SWITCH

BOARD

(DUST DOOR)

LCD R

IR

SENSOR

BOARD

MAIN

BOARD

LCD G

LCD B

INPUT

J9

AUDIO

OUTPUT

J10

AUDIO

VPL-EX5/EX5U

Frame (VPL-EX5/EX5U) Frame (VPL-EX5/EX5U)

1

2

3

4

5

VPL-ES5/EX5/EX50/EX5U/EW5

6-3

6-3

A BCDEFGH

Page 42

Frame (VPL-EW5) Frame (VPL-EW5)

CN601

CN605

HALOGEN

LAMP

BALLAST UNIT

POWER BOARD

FAN2

FAN3

FAN1(FRONT BOTTOM)

FAN5

(REAR BOTTOM)

FAN4

(REAR TOP)

CN701J17

SPEAKER

J11

J18

J6

J1

J20

J21

J14

J19

J16

J22

J23

J24

J1

HDMI

J2

INPUT

INPUT A

J3

OUTPUT

MONITOR

J14

VIDEO

J5

S VIDEO

INPUT

INPUT

J7

RS-232C

REMOTE

CN1

CN1

J26

J1

THERMAL

SENSOR

BOARD

DETECTION

SWITCH

BOARD

(LAMP DOOR)

DETECTION

SWITCH

BOARD

(DUST DOOR)

LCD R

IR

SENSOR

BOARD

MAIN

BOARD

LCD G

LCD B

INPUT

J9

AUDIO A

INPUT

J8

AUDIO

OUTPUT

J10

AUDIO

VPL-EW5

1

2

3

4

5

6-4

6-4

VPL-ES5/EX5/EX50/EX5U/EW5

ABCDEFGH

Page 43

Page 44

VPL-ES5 (SY)

VPL-ES5 (CH)

VPL-EX5 (SY)

VPL-EX5 (CH)

VPL-EX50 (SY)

VPL-EX50 (CH)

VPL-EX5U (SYY)

VPL-EW5 (SY)

VPL-EW5 (CH) E

9-883-651-02

English

Sony EMCS Corporation 2008DR16-1

Ichinomiya Tec ©2008

Loading...

Loading...