Page 1

CPD-220AS

SERVICE MANUAL

SPECIFICATIONS

Picture tube

CPD-220AS: 0.25 mm aperture grille

pitch, 17 inches measured diagonally

(16.0” viewable), 90-degree

deflection, AR coating

Viewable image size

CPD-220AS: Approx. 327 × 241 mm

(w/h) (12 7/8 × 9 1/2 inches) 16.0”

viewing image

Max resolution Horizontal: Max. 1280 dots

Vertical: Max. 1024 lines

VESA standards 640 × 480 at 85 Hz

800 × 600 at 85 Hz

1024 × 768 at 85 Hz

1280 × 1024 at 60 Hz

Deflection frequency

Horizontal: 30 to 70 kHz

Vertical: 50 to 120 Hz

Speaker Left, right: 3.5 W × 2, Sub-woofer:

10 W 50 to 20 kHz

Microphones Uni-direction, electret condenser

microphone

Microphones output

Miniplug

Audio input Stereo miniplug, input impedance

47 kΩ, input level 0.7 Vrms typical

AEP Model

Chassis No. SCC-L02C-A

V-2

Headphones output

Stereo minijack, 4 mW + 4 mW at

16 Ω

Microphones input

Minijack, plug-in-power

USB pass-through

Upsteam × 1, downstream × 1

Controls Contrast/Audio level/Picture

enhancement/Brightness/Bass

Boost/(Audio level)/H.Size/V.Size/

Pincusion/Color tempeature/Audio

muting

AC input voltage/current

100 to 240 V, 50 – 60 Hz, 1.5 – 0.5 A

Dimensions

CPD-220AS: Approx. 481.5 × 483 ×

427.5 mm (w/h/d) (19 × 19 1/8 ×

16 7/8 inches)

Mass CPD-220AS: Approx. 22 kg

(48 lb 1 oz)

Design and specifications are subject to change without notice.

CHASSIS

MICROFILM

TRINITRON® MULTIMEDIA COMPUTER DISPLAY

Page 2

CPD-220AS

DIAGNOSIS

Scan/S cap Failure Blink Amber

ABL Failure Blink Amber

Audio Failure Blink Amber Blink Amber

Aging Mode : Raster aging During Power Save, press "POWER switch" button for longer than 4 seconds.

Self Test : OSD color-bar indication During Power Save, press "POWER switch" button for longer than 8 seconds.

Power Saving Function

This display meets the power saving guidelines set by the International

ENERGY STAR Program. It is capable of reduced power consumption when

used with a computer equipped with Display Power Management Signaling

(DPMS). By sensing the absence of the sync signal coming from the computer,

it will reduce the power consumption as follows:

Failure Power LED Mute LED

(On 1.5 sec, Off 0.5 sec)

(On 0.5 sec, Off 1.5 sec)

(1 sec/cycle) (1 sec/cycle)

✔ CAUTION

The Power Saving function will automatically put the display into Active-off state if the

power switch is turned on without any video signal input. Once the horizontal and

vertical syncs are sensed, the display will automatically return to its Normal operation

state.

State

Normal

1

operation

Suspend (1st step

2

of power saving)

Active-off (2nd

3

step of power

saving)

Power-off

4

Power

consumption

CPD-120AS

130 W (max)

CPD-220AS

150 W (max)

15 W (max)

10 W (max)

Approx. 10 W

Required

resumption time

—

—

Approx. 3 sec.

Approx. 10 sec.

1)

—

u Power

indicator

Green

Green

Green ˜

Orange

Orange

Off

✔ Note

1) T o lower the power consumption to 0 W, disconnect the power cord.

Speaker

On

On

Off

Off

Off

– 2 –

Page 3

CPD-220AS

TIMING SPECIFICATION

PRIMARY MODE PRIMARY

MODE AT PRODUCTION

RESOLUTION 640 X 480 800 X 600 800 X 600 1024 X 768 1024 X 768 1280 X 1024 640 X 400 640 X 480 1152 X 864 1152 X 432

CLOCK 36.000 MHz 40.000 MHz 49.500 MHz 78.750 MHz 94.500 MHz 108.500 MHz 25.175 MHz 25.175 MHz 80.000 MHz 65.000 MHz

— HORIZONTAL —

H-FREQ 43.269 kHz 37.879 kHz 46.875 kHz 60.023 kHz 68.677 kHz 63.974 kHz 31.469 kHz 31.469 kHz 54.945 kHz 44.890 kHz

H. TOTAL 23.111 26.400 21.333 16.660 14.561 15.631 31.778 31.778 18.200 22.277

H. BLK 5.333 6.400 5.172 3.657 3.725 3.834 6.356 6.356 3.800 4.554

H. FP 1.556 1.000 0.323 0.203 0.508 0.590 0.636 0.636 0.800 1.354

H. SYNC 1.556 3.200 1.616 1.219 1.016 1.180 3.813 3.813 1.400 1.969

H. BP 2.222 2.200 3.232 2.235 2.201 2.065 1.907 1.907 1.600 1.231

H. ACTIV 17.778 20.000 16.162 13.003 10.836 11.797 25.422 25.422 14.400 17.723

— VERTICAL —

V. FREQ(Hz) 85.008 Hz 60.317 Hz 75.000 Hz 75.029 Hz 84.997 Hz 60.013 Hz 70.086 Hz 59.940 Hz 59.984 Hz 94.804 Hz

V. TOTAL 509 628 625 800 808 1066 449 525 916 473.5

V. BLK 29 28 25 32 40 42 49 45 52 41.5

V. FP 1111111210615

V. SYNC 3433332254.5

V. BP 25 23 21 28 36 38 35 33 41 22

V. ACTIV 480 600 600 768 768 1024 400 480 864 432

— SYNC —

INT(G) NO NO NO NO NO NO NO NO NO NO

EXT(H/V)/POLARITY YES -/- YES +/+ YES +/+ NO +/+ YES +/+ YES +/+ YES -/+ YES -/- YES +/+ YES +/+

EXT(CS)/POLARITY NO NO NO NO NO NO NO NO NO NO

INT/NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT INT

MODE 1 MODE 2 MODE 3 MODE 4 MODE 5 MODE 6 MODE 7 MODE 8 MODE 9 MODE 10

usec usec usec usec usec usec usec usec usec usec

lines lines lines lines lines lines lines lines lines lines

97.2.18 VER.

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN

WHICH THE DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

ON THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS

AND IN THE PARTS LIST ARE CRITICAL FOR SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL FOR SAFE OPERATION ARE IDENTIFIED

IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED

OR IMPROPER OPERATION IS SUSPECTED.

¡

– 3 –

Page 4

CPD-220AS

TABLE OF CONTENTS

Section Title Page

1. GENERAL................................................................... 5

2. DISASSEMBLY

2-1. Cabinet Removal ................................................. 11

2-2. U Board Removal ................................................ 11

2-3. J Board Removal .................................................. 11

2-4. EMI Shield Removal ............................................ 11

2-5. D Board Removal ................................................. 12

2-6. Stand Block Removal .......................................... 13

2-7. Picture Tube Removal .......................................... 13

3. SAFETY RELATED ADJUSTMENT ............. 14

4. ADJUSTMENTS ...................................................... 15

5. DIAGRAMS

5-1. Block Diagram

(with Frame Schematic Diagram) ................... 17

5-2. Circuit Boards Location ...................................... 20

5-3. Schematic Diagrams and Printed Wiring Boards ... 20

(1) Schematic Diagram of D Board .......................... 21

(2) Schematic Diagrams of A and AE2 Boards ....... 29

(3) Schematic Diagrams of DA, J and U Boards ...... 33

5-4. Semiconductors ................................................... 37

6. EXPLODED VIEWS

6-1. Chassis (1) ........................................................... 39

6-2. Chassis (2) ............................................................ 40

6-3. Stand Block .......................................................... 41

6-4. Packing Materials ................................................ 42

7. ELECTRICAL PARTS LIST ............................ 43

– 4 –

Page 5

SECTION 1

1

2

3

4

5

6

7

8

9

2

!º

!¡

!™

!£

!¢

!∞

!§

@¡

@™

!¶

@£

!•

@º

!ª

@¢

GENERAL

The operating instructions mentioned here are partial abstracts

from the Operating Instruction Manual. The page numbers of

the Operating Instruction Manual remein as in the manual.

Warning on Power Connection

• Use the supplied power cord.

For the customers in UK.

If you use the display in UK, please use the supplied UK cable with UK plug.

for 100 to 120 V AC for 220 to 240 V AC for 240 V AC only

• Before disconnecting the power cord, wait at least 30 seconds after turning

off the power switch to discharge static electricity from the CRT display

surface.

• After the power has been turned on, the CRT is demagnetized for

approximately 5 seconds. This generates a strong magnetic field around the

bezel which may affect the data stored on magnetic tape or disks near the

bezel. Place such magnetic recording equipment and tapes/disks at a distance

from this unit.

The socket-outlet shall be installed near the equipment and shall be easily

accessible.

GB

Precautions

6

Functions of Controls

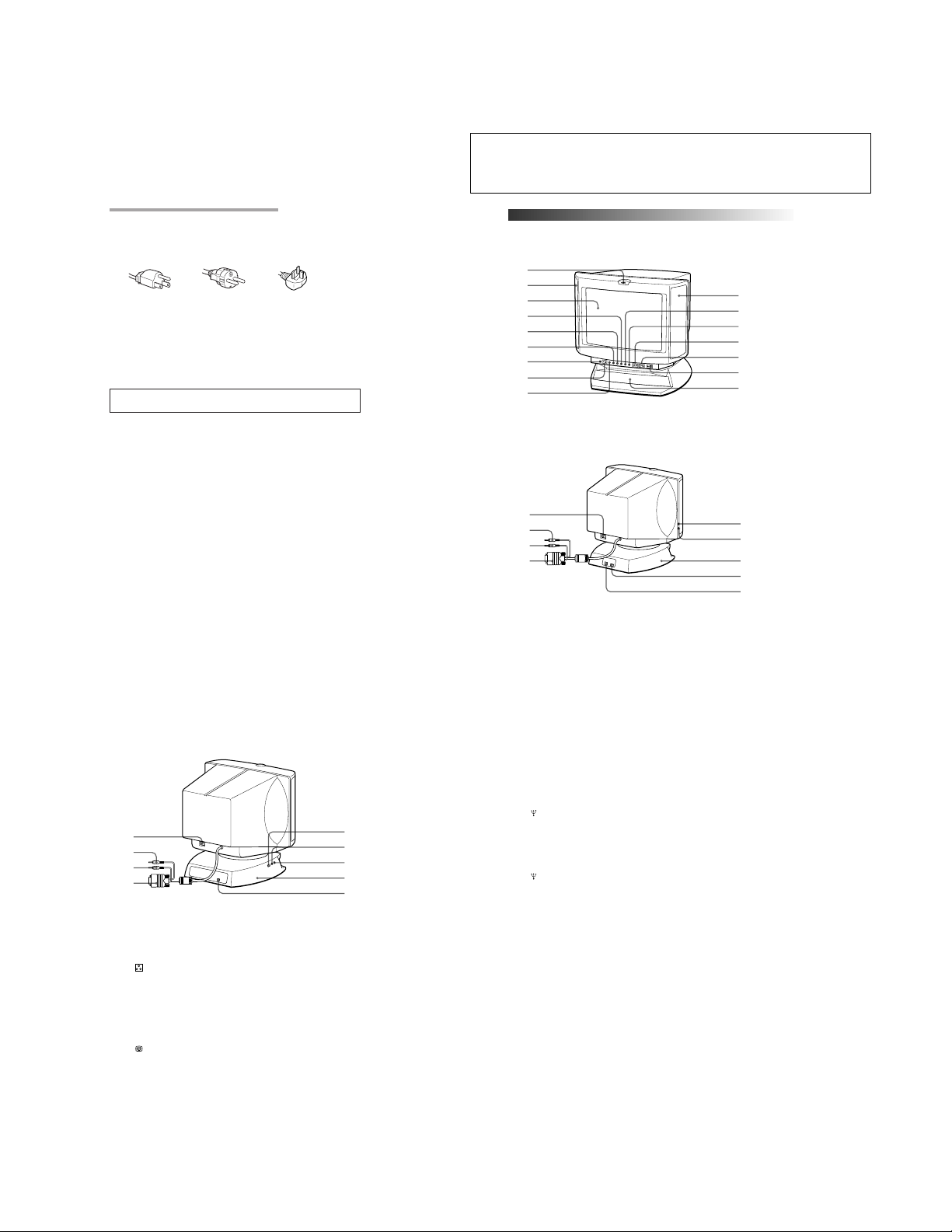

Front

Rear

p CPD-120AS

Continued to the next page ➔

Functions of Controls

7

GB

p CPD-220AS

!§

!¶

!•

!ª

Microphone

1

2

Main speaker

Display

3

Å Size button

4

5

d Geometry button

Color

6

temperature button

? Reset switch

7

¤ Mute button and

8

indicator

≥ Volume/Bass

9

boost button

S Centering

!º

button

Brightness/GPE

!¡

button

. Volume –/+

!™

buttons

> –/+ Contrast

!£

button

u Power switch

!¢

!∞

GB

8

and indicator

Sub woofer

Functions of Controls

The internal microphone is turned off when an

external microphone is connected.

—

Displays OSD when adjusting.

Adjusts picture size (page 20).

Adjusts pincushion and rotation (pages 21, 22).

Adjusts color temperature (page 23).

Resets adjustments to factory setting (page 24).

Mutes sound (page 17).

Adjusts speaker volume or selects bass boost mode

(page 26).

Adjusts picture centering (page 19).

Adjusts picture brightness or selects GPE mode (page

25).

Adjusts speaker volume (page 16).

The default setting of the volume level is 30 %.

Adjusts picture contrast (page 17).

Turns on and off the display.

—

@º

@¡

@™

@£

@¢

– 5 –

!§

AC IN connector

!¶

2 Audio plug (green)

h MIC plug (red)

!•

; Video signal cable

!ª

(blue)

USB downstream

@º

connector

h Microphone jack

@¡

2 Headphones jack

@™

Tilt-Swivel

@£

USB upstream

@¢

connector

Connect the supplied power cord (page 12).

Connect to the computer’s speaker output

(page 11).

Connect to the computer’s microphone input (page

11).

Connect to the computer’s video output

(page 11).

Connect to a USB device (page 11).

Connect a microphone (not supplied).

Connect headphones (not supplied). The speakers are

turned off when headphones are connected.

Adjusts the angle of the display (page 14).

Connect to the computer’s USB ports when using a

USB (universal serial bus) device connected to the

display (page 11).

Functions of Controls

GB

9

Page 6

Getting Started

Before using this display, please make sure that the following items are included

in your package:

• Multimedia computer display (1)

• Warranty card (1)

• Operating instruction manual (1)

• Windows 95 Monitor Information Disk and its instruction manual (1)

✎

Tip

This display will sync with any IBM or compatible system equipped with VGA

capability. Although this display will sync to other platforms running at horizontal frequencies

between 30 and 70 kHz, including Macintosh

required. Please consult Sony Technical Support for advice on which adapter is suitable for your

needs.

1) VGA is a trademark of IBM Corporation.

2) Macintosh is a trademark of Apple Computer Inc.

2)

and Power Macintosh systems, a cable adapter is

1)

or greater graphics

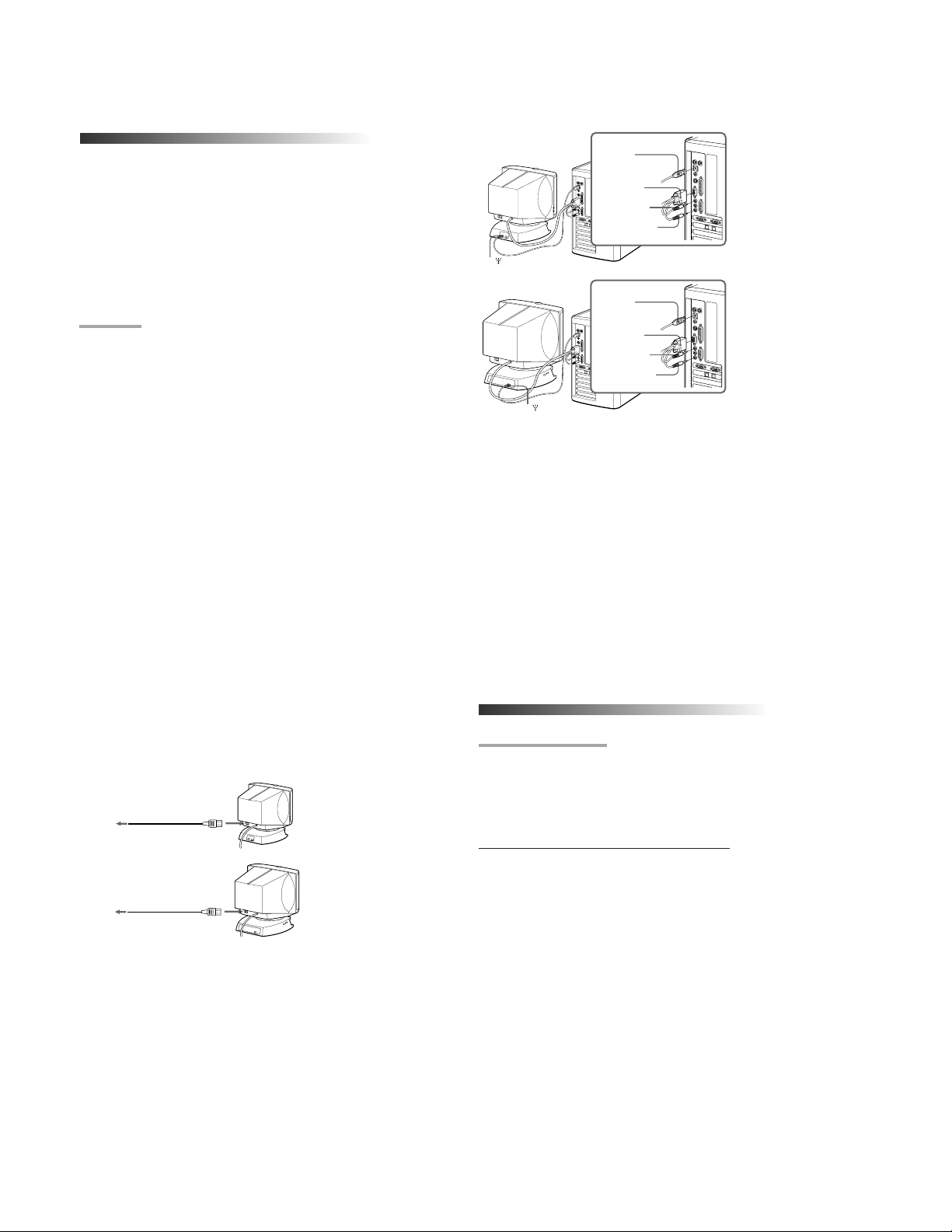

p CPD-120AS

to

p CPD-220AS

to USB port

Blue (to display

connector)

Green (to speaker

connector)

Red (to microphone

connector)

to USB port

Computer

Computer

Installation

p Step 1: Connect the computer

With the computer switched off, connect the video signal cable to the display

(VGA) connector on your computer. If your computer supports the DDC plugand-play standard, this connection will enable the DDC communication between

the display and the computer.

Also the video signal cable is combined with audio and microphone cables. If

your computer is equipped with sound capability, connect the audio and

microphone plugs to appropriate jacks located on your computer.

If you use a USB (universal serial bus) device, connect the USB device to the

USB downstream jack and the PC to the USB upstream jack.

GB

Getting Started

10

p Step 2: Connect the power cord

With the display switched off, connect the power cord to the display and the

other end to a power outlet.

p CPD-120AS

to a power outlet

Power cord (supplied)

p CPD-220AS

to a power outlet

Power cord (supplied)

p Step 3: Turn on the display and computer.

p Step 4: If necessary...

Adjust the user controls according to your personal preference.

The installation of your display is complete. Enjoy your display.

Blue (to display

connector)

Green (to speaker

connector)

Red (to microphone

connector)

to

✔

Note on handling the video signal cable

Do not touch the pins of the video signal cable.

✔

Note on USB ports

USB ports are included to provide state-of-the-art technology. Until USB support is

available at the operating system level, you must supply drivers to use USB devices.

You can upgrade your operating system to a version that supports USB at the

operating system level once a version becomes available.

See the manual that came with your USB device for more information on setting it up

and using it.

Continued to the next page ➔

Getting Started

11

Using Y our Display

Preset and user modes

The Multiscan CPD-120AS/220AS display has factory preset modes for the 10

most popular industry standards for true “plug and play” capability.

For less common modes, its Digital Multiscan Technology will perform all of

the complex adjustments necessary to ensure a high quality picture for any

timing between 30 and 70 kHz.

NO.

Resolution

(dots × lines)

640 × 400

1

640 × 480

2

640 × 480

3

800 × 600

4

800 × 600

5

1024 × 768

6

1024 × 768

7

1152 × 864

8

1152 × 864

9

1280 × 1024

10

✔

Note for Windows® 95 users

Install the new model information of the Sony computer display from “Windows 95 Monitor

Information disk” into your PC. (To install the file, refer to the attached “About the Windows 95

Monitor Infomration Disk”.)

This display complies with “VESA DDC,” the standards of Plug & Play. If your PC/graphic board

complies with DDC, select “Plug & Play Display (VESA DDC)” or this display’s model name (CPD120AS/220AS) as “Display type” from “Control Panel” on Windows 95. Some PC/graphic boards

do not comply with DDC. Even if they comply with DDC, that may have some problems on

connecting this display. In this case, select this display’s model name (CPD-120AS/220AS) as

“Display type” on Windows 95.

®

is a registered trademark of Microsoft Corporation in the United States and other

Windows

countries.

✔

Note on recommended horizontal timing conditions

Horizontal sync width should be more than 1.0 µsec.

Horizontal blanking width should be more than 3.6 µsec.

Horizontal

Frequency

31.5 kHz

31.5 kHz

43.3 kHz

37.9 kHz

46.9 kHz

60.0 kHz

68.7 kHz

44.8 kHz

54.8 kHz

64.0 kHz

Vertical

Frequency

70 Hz

60 Hz

85 Hz

60 Hz

75 Hz

75 Hz

85 Hz

47 Hz (95 Hz interlace)

60 Hz

60 Hz

Continued to the next page ➔

GB

12

GB

Getting Started

– 6 –

Using Your Display

GB

13

Page 7

p To enter new timings

When using a video mode that is not one of the 10 factory preset modes, some

fine tuning may be required to optimize the display to your preferences. Simply

adjust the display according to the adjustment instructions. The adjustments will

be stored automatically and recalled whenever that mode is used.

A total of 10 user-defined modes can be stored in memory. If an 11th mode is

entered, it will replace the first.

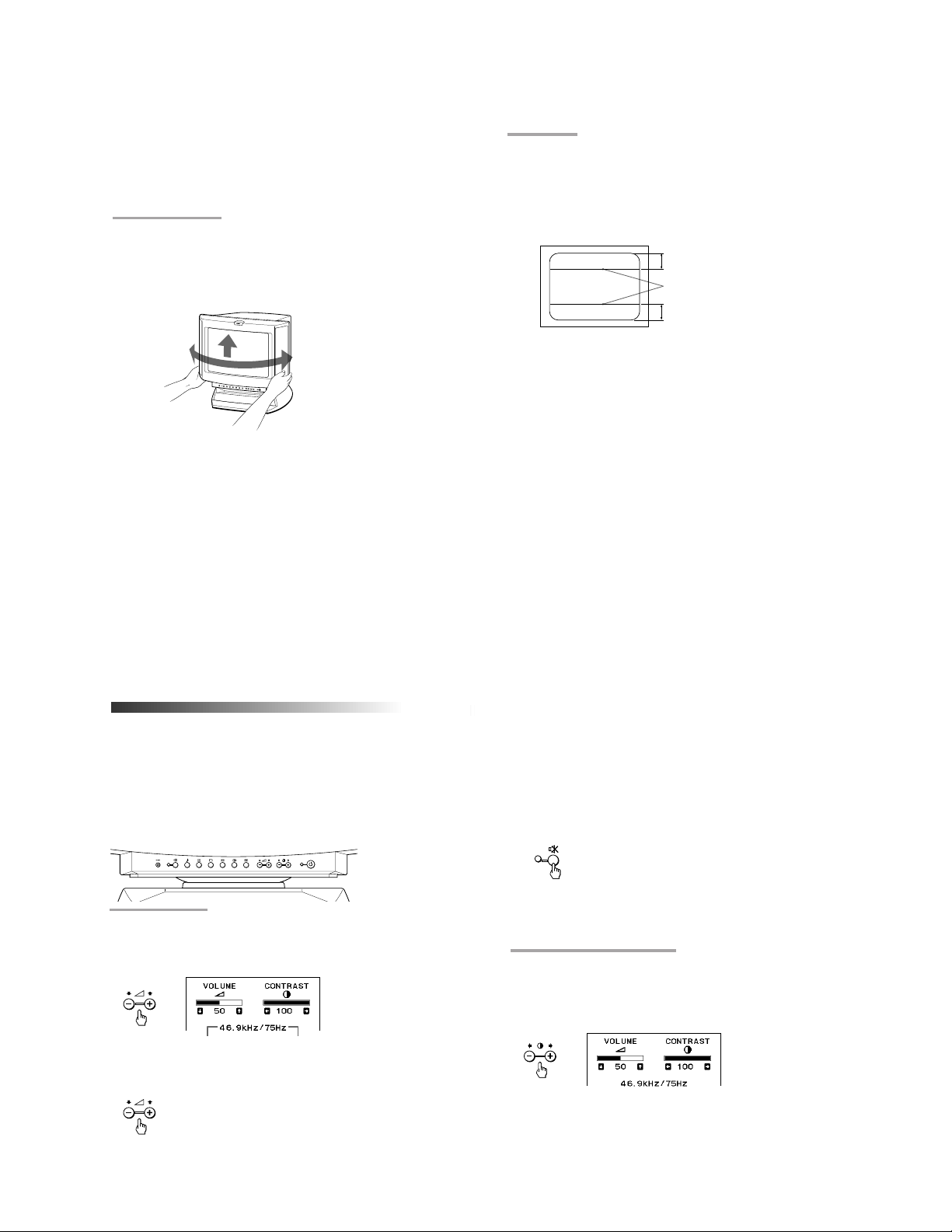

Using the tilt-swivel

With the tilt-swivel, this unit can be adjusted to be viewed at your desired angle

within 90° horizontally and 7° vertically.

To turn the unit vertically and horizontally, hold it at its bottom with both hands.

Pay attention not to get your hands caught between the display and the tiltswivel.

45˚

7˚

45˚

Damper wire

Using a white background, very thin horizontal lines on the screen are visible as

shown below. These lines are the damper wires.

The Trinitron tube has a vertically striped Aperture Grille inside. The Aperture

Grille allows more light to pass through to the screen giving the Trinitron CRT

more color and brightness.

The damper wires are attached to the Aperture Grille to prevent vibration of the

Aperture Grille wire so that the screen image is constantly stable.

Approx. 6 cm (2

(CPD-220AS only)

Damper wires

Approx. 6 cm (2

3

/8 inches)

3

/8 inches)

GB

Using Your Display

14

Adjustments

When one of the preset-type signals is input, no picture adjustment is necessary.

You can, however, adjust the picture to your preference by following the

procedure described below.

To adjust the display, turn on the display and computer.

Select the adjustment item. You can adjust all items via the OSD (On Screen

Display).

Adjustments are automatically stored in the display’s memory.

Control Panel

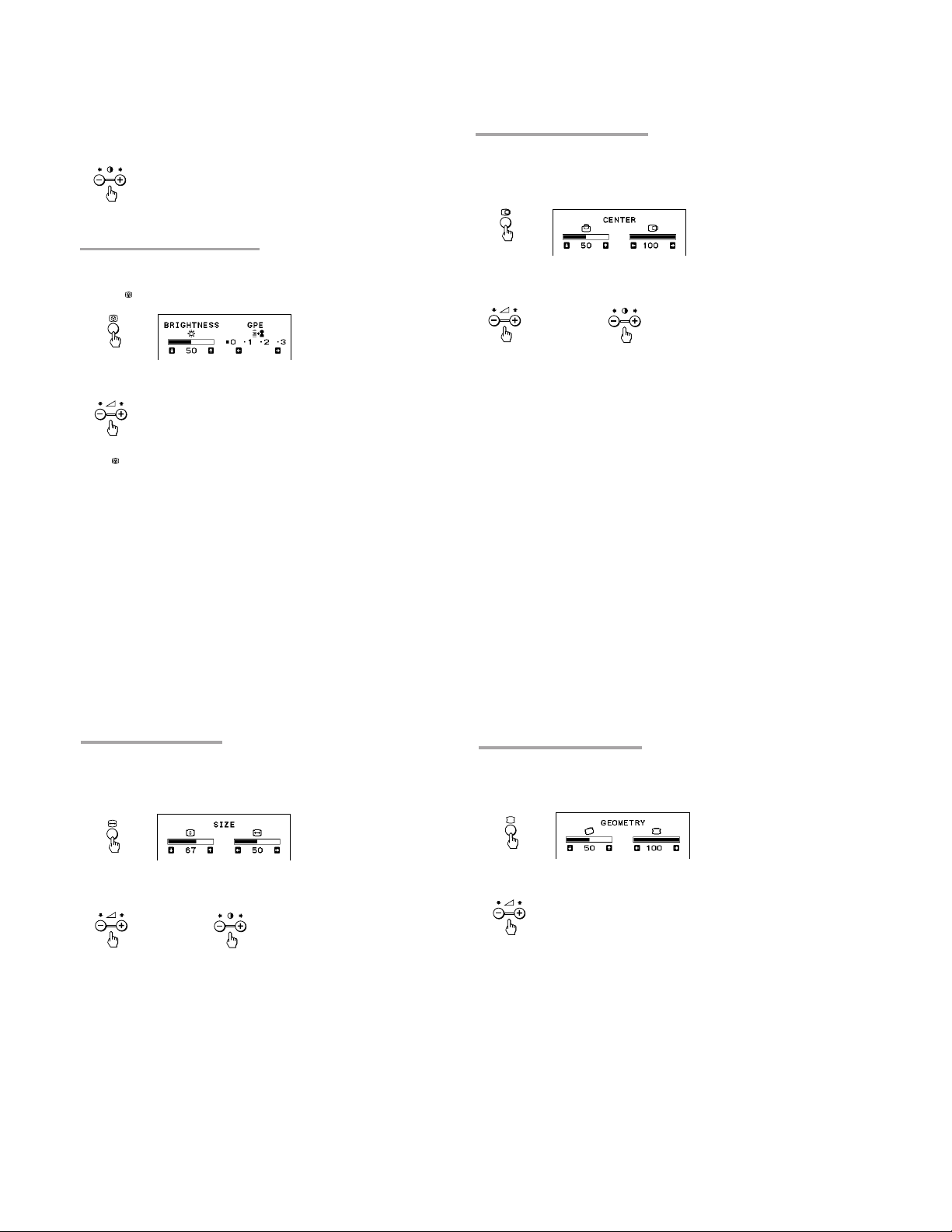

Adjusting volume

1.

Press the . + or – button.

The VOLUME/CONTRAST OSD appears.

The horizontal and vertical frequencies for each input signal received

appear.

Horizontal

2.

Press the . +/– buttons to adjust volume.

+ to increase volume

– to decrease volume

frequency

Vertical

frequency

Using Your Display

The VOLUME/CONTRAST OSD disappears 3 seconds after you release the

buttons.

✎

Tips

• The default setting of the volume level is 30 %.

• Adjust the volume while listening to the sound.

• Excessively high volume may cause howling.

p To mute the sound

Press the ¤ button. The ¤ indicator lights. The light indicates mute function is

in active mode.

Press again to cancel muting.

You can cancel muting also by pressing the . + button.

✎

Tip

¤ appears instead of . on the VOLUME/CONTRAST OSD while the sound is muted.

15

Adjusting the picture contrast

The adjustment data becomes the common setting for all input signals.

1.

Press the > + or – button.

The VOLUME/CONTRAST OSD appears.

The horizontal and vertical frequencies for each input signal received

appear.

GB

Continued to the next page ➔

GB

Adjustments

16

Adjustments

GB

17

– 7 –

Page 8

2.

Press the > +/– buttons to adjust the picture contrast.

+ for more contrast

– for less contrast

The VOLUME/CONTRAST OSD disappears 3 seconds after you release the

buttons.

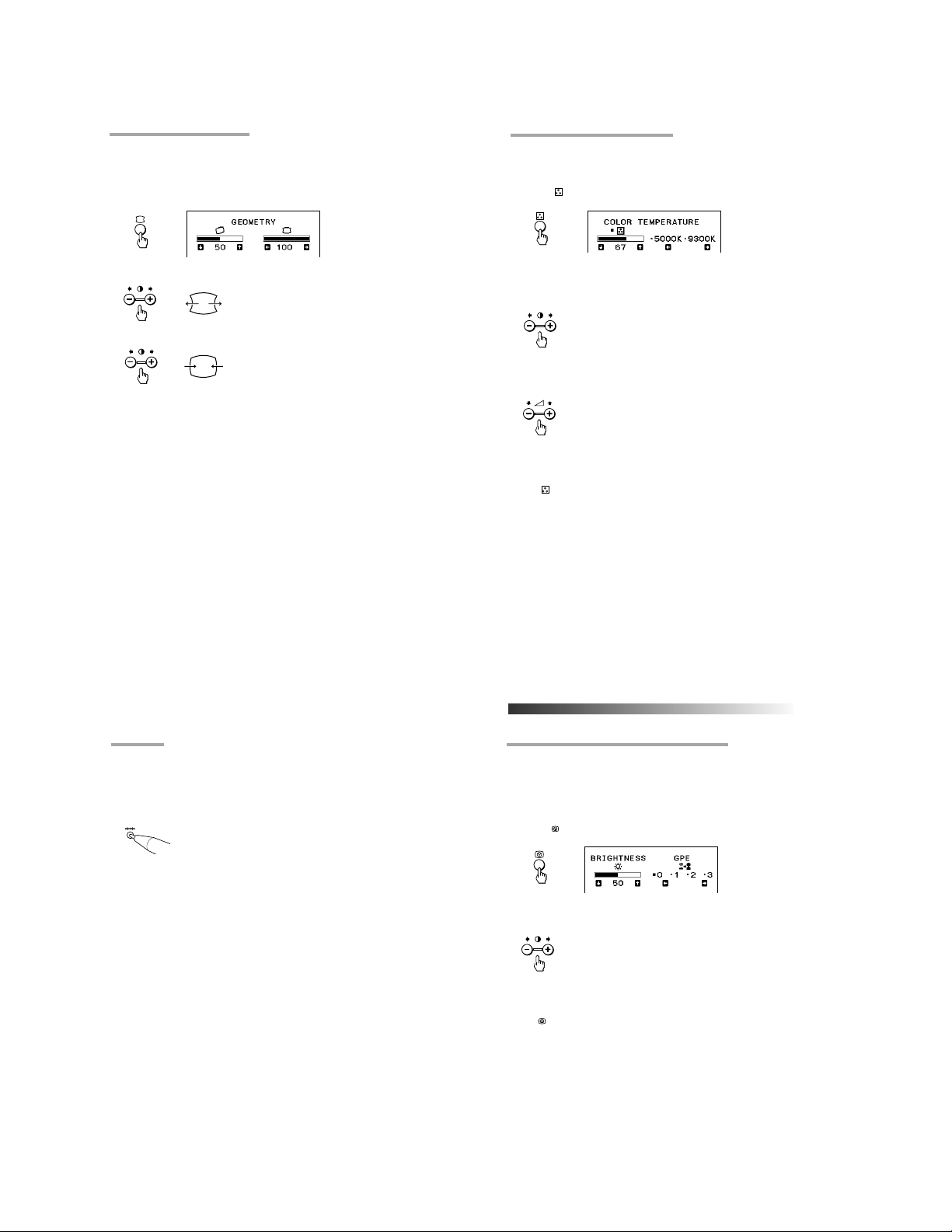

Adjusting the picture centering

The adjustment data becomes the individual setting for each input signal

received.

1.

Press the S button.

The CENTER OSD appears.

Adjusting the picture brightness

The adjustment data becomes the common setting for all input signals.

1.

Press the button.

The BRIGHTNESS/GPE OSD appears.

2.

Press the . +/– buttons to adjust the picture brightness.

+ for more brightness

– for less brightness

To exit the OSD

Press the button again.

✎

Tip

If you don’t touch any buttons the OSD automatically disappears after 10 seconds.

When you want to adjust another item, press the button of the item. The OSD of the selected item

appears.

GB

Adjustments

18

2.

For vertical adjustment For horizontal adjustment

Press the . +/– buttons. Press the > +/– buttons.

+ to move up + to move right

– to move down – to move left

To exit the OSD

Press the S button again.

✎

Tip

If you don’t touch any buttons, the OSD automatically disappears after 10 seconds.

When you want to adjust another item, press the button of the item. The OSD of the selected item

appears.

Adjustments

GB

19

Adjusting the picture size

The adjustment data becomes the individual setting for each input signal

received.

1.

Press the Å button.

The SIZE OSD appears.

2.

For vertical adjustment For horizontal adjustment

Press the . +/– buttons. Press the > +/– buttons.

+ to increase + to increase

– to decrease – to decrease

To exit the OSD

Press the Å button again.

✎

Tip

If you don’t touch any buttons, the OSD automatically disappears after 10 seconds.

When you want to adjust another item, press the button of the item. The OSD of the selected item

appears.

GB

Adjustments

20

Adjusting the picture rotation

The adjustment data becomes the common setting for all input signals.

1.

Press the d button.

The GEOMETRY OSD appears.

2.

Press the . +/– buttons.

+ to rotate clockwise

– to rotate counterclockwise

To exit the OSD

Press the d button again.

✎

Tip

If you don’t touch any buttons, the OSD automatically disappears after 10 seconds.

When you want to adjust another item, press the button of the item. The OSD of the selected item

appears.

– 8 –

Adjustments

GB

21

Page 9

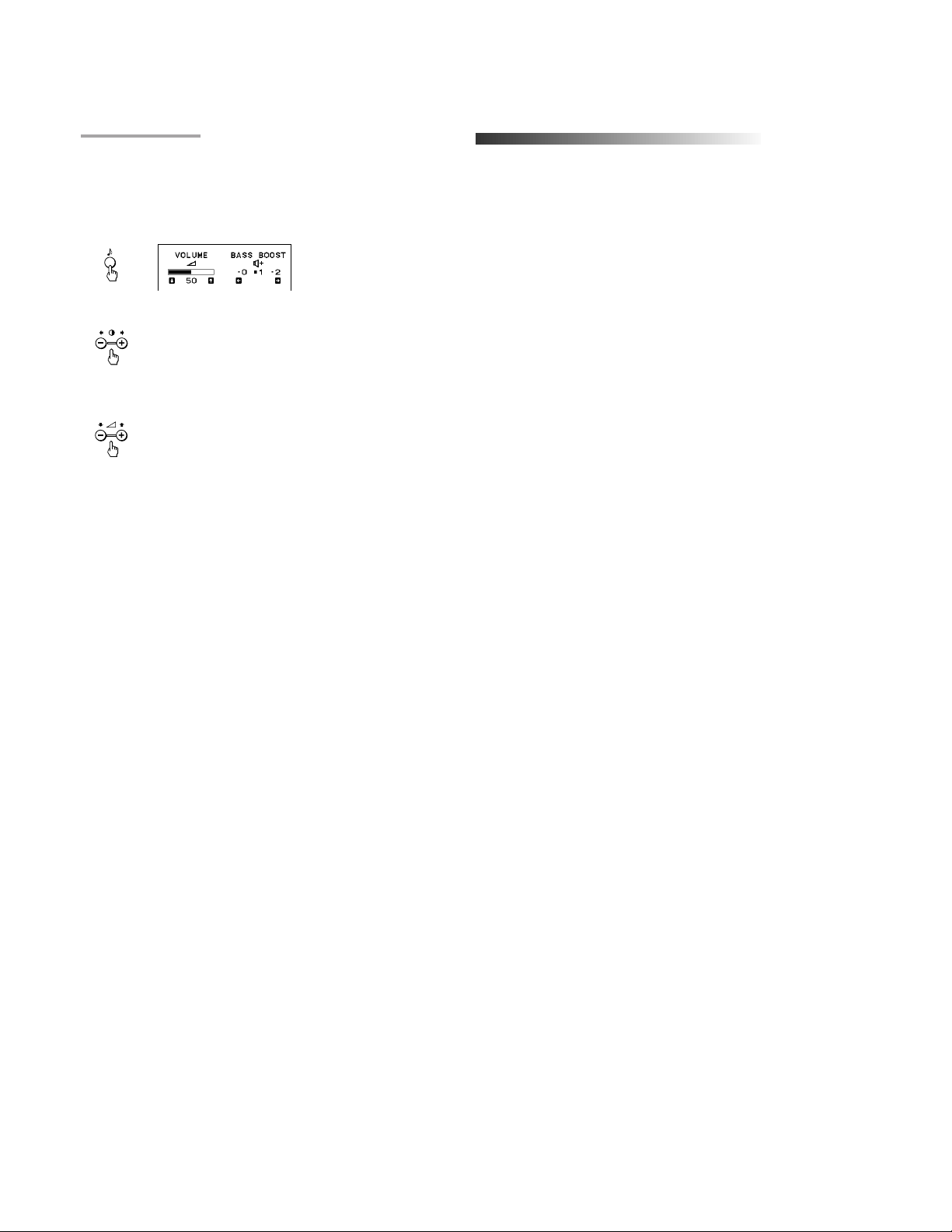

Adjusting the pincushion

The adjustment data becomes the individual setting for each input signal

received.

1.

Press the d button.

The GEOMETRY OSD appears.

2.

Press the > +/– buttons.

+ to expand the picture sides

– to diminish the picture sides

To exit the OSD

Press the d button again.

✎

Tip

If you don’t touch any buttons, the OSD automatically disappears after 10 seconds.

When you want to adjust another item, press the button of the item. The OSD of the selected item

appears.

GB

Adjustments

22

Setting the color temperature

The selected color temperature becomes the common setting for all input

signals.

1.

Press the button.

The COLOR TEMPERATURE OSD appears.

2.

Adjust with the . +/– and > +/– buttons.

To select 5000K or 9300K

Press > +/– buttons.

The selected color temperature is indicated.

+ to select 9300K

– to select 5000K

To obtain the desired color temperature between 5000K and

9300K

Press . +/– buttons.

+ for higher temperature

– for lower temperature

✎

Tip

The first press of . + or – button recalls the color temperature which was obtained at the last

adjustment.

To exit the OSD

Press the button again.

✎

Tip

If you don’t touch any buttons, the OSD automatically disappears after 10 seconds.

When you want to adjust another item, press the button of the item. The OSD of the selected item

appears.

Adjustments

GB

23

Resetting

p To recall the factory settings for individual adjustment

item

Press the button of the adjustment item you want to recall the factory settings,

and then press the ? button immediately before the OSD disappears.

p To recall the factory settings for the current mode

Press the ? button immediately when no OSD is shown.

p To recall the factory settings for all modes

Press and hold the ? button for 2 seconds.

All adjustments return to the factory settings.

GB

Adjustments

24

Available Features

Selecting Graphic Picture Enhancement

(GPE)

There are 4 GPE modes from “0” through “3,” and the picture is more vivid at a

higher number. You can enjoy movies and games with striking visuals by

enhancing the picture sharpness.

Default setting is “0.”

1.

Press the button.

The BRIGHTNESS/GPE OSD appears.

2.

Press the > +/– buttons to select the GPE mode.

+ for higher number

– for lower number

You can adjust the brightness on the same OSD by pressing the

. +/– buttons.

To exit the OSD

Press the button again.

✎

Tip

If you don’t touch any buttons, the OSD automatically disappears after 10 seconds.

When you want to adjust another item, press the button of the item. The OSD of the selected item

appears.

✔

Notes on GPE mode

For text oriented applications such as word processing and spreadsheets, set the GPE

mode to “0” (default setting).

GPE (Graphic Picture Enhancement) mode is reset to “0” when:

• you turn off the display

• the PC recovered from the power saving mode

• the resolution is changed

Available Features

25

GB

– 9 –

Page 10

Selecting Bass Boost

There are 3 Bass Boost modes from “0” through “2,” and bass is boosted more

at a higher number. The factory setting is “1” (normal mode).

You can enjoy games and music programs with lively sound by selecting “2.”

When you use the PC phone, select “0.” You will be able to hear the caller’s

voice more easily as the high-pitched tone is reduced.

1.

Press the ≥ button.

The VOLUME/BASS BOOST OSD appears.

2.

Press the > +/– buttons to select the BASS BOOST mode.

+ for higher number

– for lower number

After selecting the Bass Boost mode, you can adjust the volume on the same

OSD.

Press the . +/– buttons.

+ to increase volume

– to decrease volume

To exit the OSD

Press the ≥ button again.

✎

Tip

If you don’t touch any buttons, the OSD automatically disappears after 10 seconds.

When you want to adjust another item, press the button of the item. The OSD of the selected item

appears.

GB

Available Features

26

Troubleshooting

This section may help you isolate a problem and as a result, eliminate the need

to contact technical support, allowing continued productivity.

No picture

If the u indicator is not lit

m Check that the power cord is properly connected.

m Check that the u switch is in the “ON” position.

If the u indicator is lit in orange, or alternately in orange and green

m Check that your computer power switch is in the “ON” position.

m The display may recover when you press any key on the keyboard of the

computer.

m Check that the video cable is properly connected.

m Ensure that no pins are bent or pushed in the HD15 connector of the cable.

m Check that the video card in your computer is seated completely in a proper

bus slot.

m Check that the video sync signal is within that specified for the display.

m This display has a self-diagnostics function. To activate the function, turn off

the computer and the display. Press and hold the u switch of the display for

about 8 seconds. If the display is operating correctly, the screen will become

white first and then the color bars will appear.

If the u indicator is flashing in orange

m Check that the video sync signal is specified for the display.

m There is a potential display failure. Contact Sony Technical Support.

No sound from speaker

If the ¤ indicator is lit

m Press the ¤ button to cancel muting.

m Check that the audio plug is properly connected.

m Adjust the volume with . +/– buttons.

m Check that the headphones are not connected.

m Check that the sound board of the computer is properly connected.

m Check that the volume control, muting, sound selector, etc. of the sound

board. (See the computer’s manual.)

Microphone mixing is not possible

m Check that the MIC plug is properly connected.

m Check that the sound board of the computer is properly connected.

m Check that the microphone control, sound selector, etc. of the sound board.

(See the computer’s manual.)

GB

Troubleshooting

30

Howling (feed-back) is heard

m Decrease the volume with . +/– buttons, or turn down the microphone

input volume of the sound board.

Picture is scrambled

m Check your graphics board manual for the proper display setting on the

display.

m Check this manual and confirm that the graphic mode and the frequency at

which you are trying to operate is supported. Even within the proper range,

some video boards may have a sync pulse that is too narrow for the display to

sync correctly.

Color is not uniform

m Trip the u switch once to activate the Auto-degauss cycle*.

Picture is flickering

m If the refresh rate is not appropriate, the picture may flicker. Set the refresh

rate of the non-interlace mode as high as possible on the computer. For

details on how to set the refresh rate, consult the dealer of your computer or

video board.

Screen image is not centered or sized properly

m Adjust picture centering, size, or geometry (rotation/ pincushion) on the OSD

(pages 19–22).

m Some video modes do not fill the screen to the edge of the display. There is

no single answer to solve the problem. There is a tendency for this problem

to occur on higher refresh timings.

Picture is fuzzy

m Adjust the contrast and brightness on the OSD (pages 17, 18). Some brands

of SVGA boards have an excessive video output level which creates a fuzzy

picture at maximum contrast.

m The GPE setting may not be proper for the picture. Selecting a lower GPE

number may improve the picture (page 25).

m Trip the u switch once to activate the Auto-degauss cycle*.

Picture bounces or has wavy oscillations

m Isolate and eliminate any potential sources of electric or magnetic fields.

Common causes for this symptom are electric fans, fluorescent lighting, laser

printers, etc.

m If you have another display close to this display, increase the distance

between them to reduce interference.

m Try plugging the display into a different AC outlet, preferably on a different

circuit.

Picture appears to be ghosting

m Eliminate the use of video extension cables and/or video switch boxes if this

symptom occurs. Excessive cable length or weak connections can produce

this symptom.

Continued to the next page ➔

Troubleshooting

Fine horizontal lines (wires) are visible

m These wires stabilize the vertically striped Aperture Grille. The Aperture

Grille allows more light to pass through to the screen giving the Trinitron

CRT more color and brightness.

Wavy or elliptical (moire) pattern is visible

m Due to the relationship between resolution, display Aperture Grille pitch and

the pitch of some image patterns, certain screen backgrounds, especially gray,

sometimes show moire which looks like wavy lines. This can only be

eliminated by changing your desktop pattern.

Hum is heard right after the power is turned on

m When the power is turned on, the Auto-degauss cycle* is activated. While the

Auto-degauss cycle is activated, a hum may be heard for about 3 seconds.

This is not a malfunction.

* The Auto-degauss function demagnetizes the metal frame of the CRT to obtain a

neutral field for uniform color reproduction. If a second degauss cycle is needed, allow

a minimum interval of 20 minutes for the best result.

• If the problem persists, call your authorized Sony dealer from a location near

you, or call Sony Technical Support.

• Note the model name and the serial number of your display. Also note the

make and name of your computer and video board.

GB

GB

31

32

Troubleshooting

– 10 –

Page 11

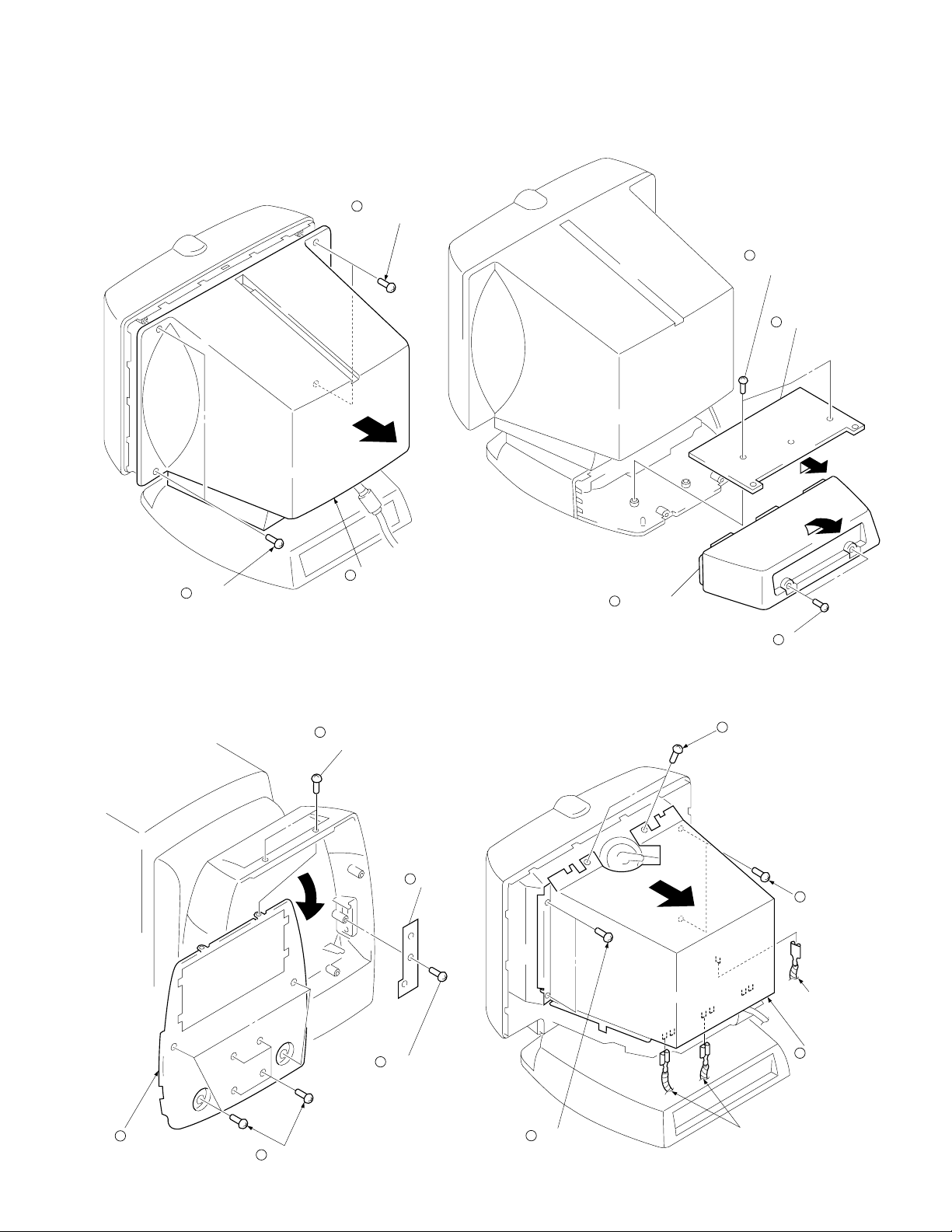

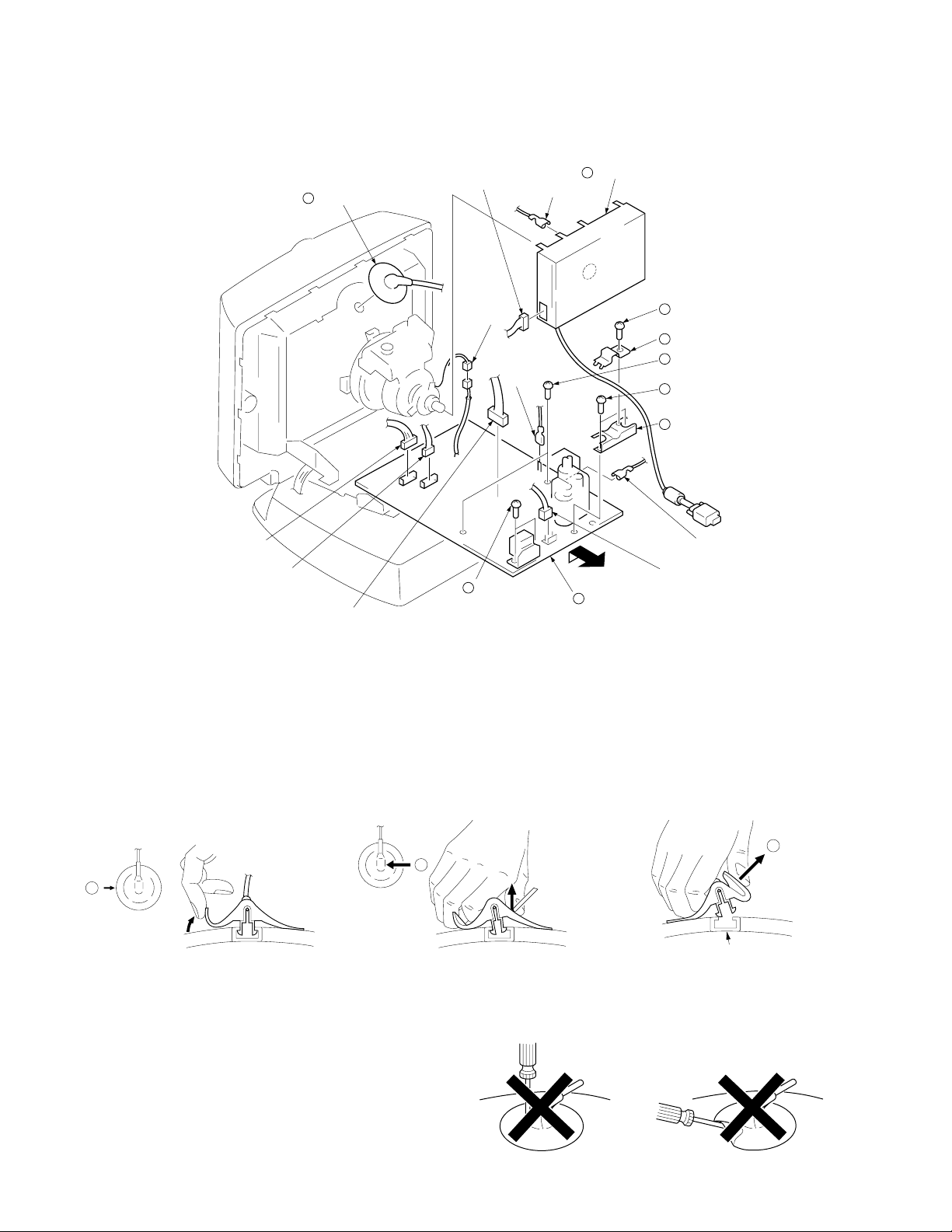

SECTION 2

DISASSEMBLY

2-1. CABINET REMOVAL 2-2. U BOARD REMOVAL

1

Two screws

(+BVTP 4 x 16)

3

Two screws

(+BVTP 3 x 12)

4

U board

CPD-220AS

3

Cabinet

2

Two screws

(+BVTP 4 x 16)

2

Stand base (Rear)

2-3. J BOARD REMOVAL 2-4. EMI SHIELD REMOVAL

1

2

Two screws

(+BVTP 4 x 16)

5

J board

Two screws

(+BVTT 3 x 8)

1

Two screws

(+BVTP 4 x 16)

2

Two screws

(+BVTT 3 x 8)

GND

3

Stand base

(Lower)

1

Eight screws

(+BVTP 4 x 16)

4

Screw

(+BVTP 3 x 12)

– 11 –

3

Two screws

(+BVTT 3 x 8)

GND

4

EMI shield

Page 12

CPD-220AS

2-5. D BOARD REMOVAL

1

Anode cap

CN311

CN503

GND

GND

2

A block

3

Screw

(+BVTT 4 x 8)

4

Cable stopper

7

Two screws

(+BVTP 3 x 12)

5

Two screws

(+BVTP 3 x 12)

6

Cable blacket

CN507

CN607

CN501

8

Two screws

(+BVTP 3 x 12)

9

D board

GND

CN601

• REMOVAL OF ANODE-CAP

NOTE: Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or carbon painted on the CRT, after

• REMOVING PROCEDURES

1

• HOW TO HANDLE AN ANODE-CAP

1

2 Don’t press the rubber hardly not to hurt inside of anode-caps!

3 Don’t turn the foot of rubber over hardly!

removing the anode.

b

a

Turn up one side of the rubber cap in

the direction indicated by the arrow a.

2 Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b.

Don’t hurt the surface of anode-caps with shartp shaped material!

A material fitting called as shatter-hook terminal is built in the

rubber.

The shatter-hook terminal will stick out or hurt the rubber.

c

Anode Button

3 When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in the

direction of the arrow c.

– 12 –

Page 13

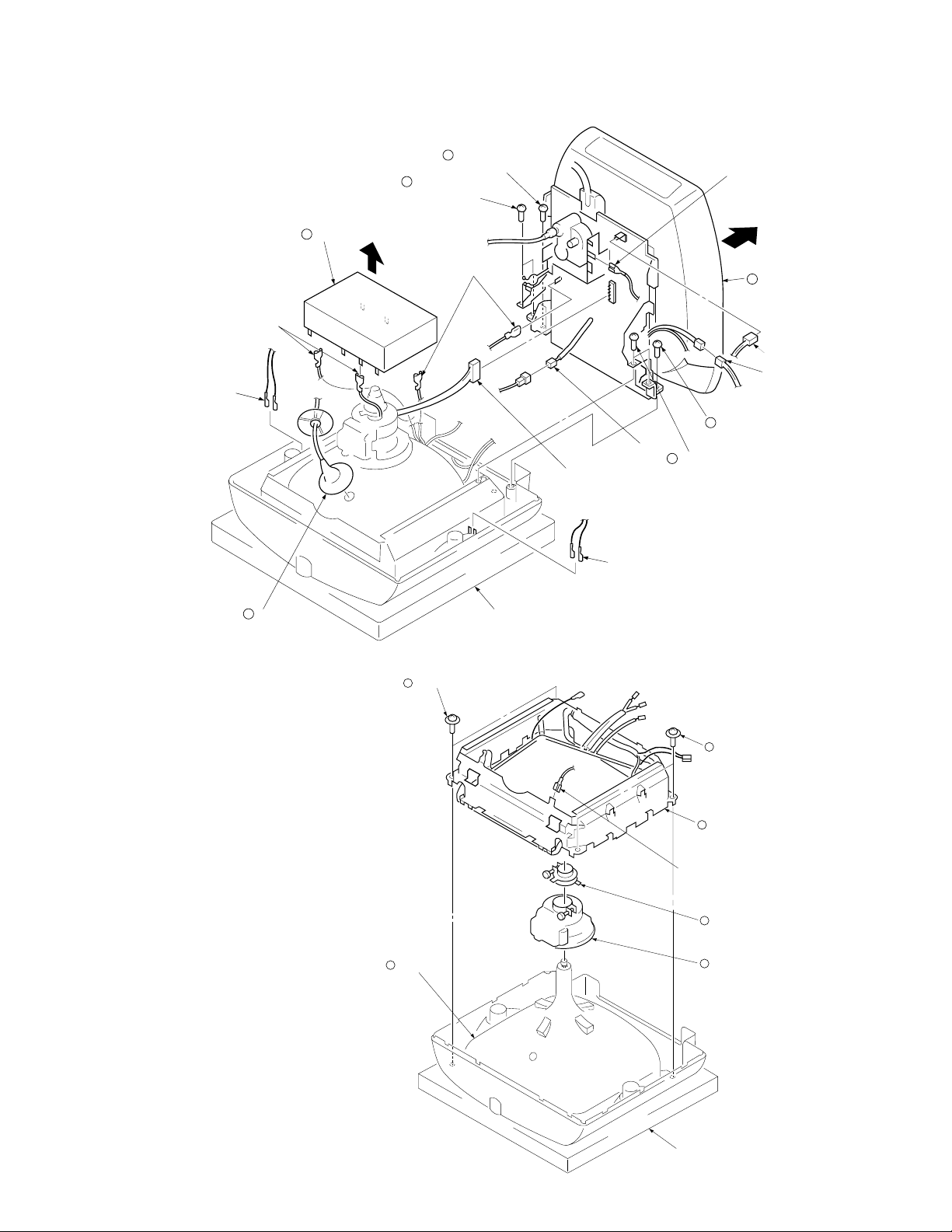

CPD-220AS

2-6. STAND BLOCK REMOVAL

2

A block

GND

Speaker

lead

4

Screw

(+BVTP 4 x 16)

3

Two screws

(+BVTT 4 x 10)

GND

CN501

CN503

Speaker lead

GND

6

Screw

(+BVTP 4 x 16)

5

Two screws

(+BVTT 4 x 10)

7

Stand block

CN601

Connector

1

Anode cap

2-7. PICTURE TUBE REMOVAL

1

Two tapping screws (5)

6

Picture tube

Cushion

2

Two tapping

screws (5)

3

Picture tube shied

GND

4

Neck assy

5

Deflection yoke

– 13 –

Cushion

Page 14

CPD-220AS

SECTION 3

SAFETY RELATED ADJUSTMENT

When replacing or repairing the shown below table, the

following operational checks must be performed as a

safety precaution against X-rays emissions from the unit.

Part Replaced ([)

RV501HV ADJ

Part Replaced (])

HV Regulator

Circuit

HV Protector

Circuit

Beam Current

Protector Circuit

D board IC801, C509, C542,

C548, C802, C814,

C815, R538, R539,

R540, R541, R807,

R822, R823, R824,

RV501,T501 (FBT)

D board IC801, IC904, D511,

D515, C515, C516,

C517, C910, R532,

R533, R534, R535,

R996, T501 (FBT)

• Mounted D board

D board IC901, D596, C519,

C528, C549, C904,

R542, R543, R544,

R545, R939

• Mounted D board

• Beam Current Protector Check

Using an external DC Power Supply, applying voltage of

7.00 ± 0.05 V between !] pin of FBT (T501) and GND,

and confirm that the vlotage of both ends C519 is with in

the Voltage range shown below.

• Standard voltage : Less than 3.26 V DC

Check Condition

• Input voltage : 240.0 V AC

• Input signal : Cross hatch at 64.0 kHz

(VESA 1024 x 768)

• Beam control : CONT : 100 %, BRT : 40 %

• B+ Voltage Check

Standard voltage : 150.0 ± 2.0 V DC

Check Condition

• Input voltage : 240.0 ± 2.0 V AC

Note : Use NF power supply or make sure that

distortion factor is 3% or less.

• Input signal : Cross hatch at 64.0 kHz

• Beam control : CONT : 100 %, BRT : 40 %

Confirm one minute later turning on the power.

*

• HV Protector Circuit Check

Confirm that the HV protector circuit works and CRT

screen disappearing when apply the voltage as shown

below between Cathode of D511 on D board and GND

using an external DC Power Supply.

• Standard voltage : 35.00 V DC

Check Condition

• Input voltage : 240.0 ± 2.0 V AC

• Input signal : Cross hatch at 64.0 kHz

(VESA 1024 x 768)

• Beam control : CONT : 100 %, BRT : 40 %

+0.00

–0.10

– 14 –

Page 15

SECTION 4

ADJUSTMENTS

CPD-220AS

• Landing Rough Adjustment

1. Enter the full white signal. (or the full black dots signal)

2. Set the contrast to “CONT”=MAX.

3. Make the screen monogreen.

Note: Off the outputs from R ch and B ch of SG.

4. Reverse the DY, and adjust coarsely the purity magnet (2pole Mg) so that a green raster positions in the center of

screen.

The 2-pole Mg adjustment must be done on the DY side (do

not use 2-pole Mg on the neck assy side).

Note: Stack 2-pole Mg on neck assy side with their sides flushed.

Adjust color Knob

to non-color Knob.

5. Moving the DY forward, adjust so that an entire screen becomes monogreen.

6. Adjust the tilt of DY, and fix lightly with a clamp.

Note: “TILT” shall be set at 0.

• Landing Fine Adjustment

1. Put the set inside the Helmholtz coil.

2. Input the single green signal.

(Adjust to L/D control brightness)

[L/D control brightness]

Adjust L/D after aging for 2 hours with L/D control brightness

(1) L/D control brightness ......... 1/2 between cool L/D and

hot L/D (Reference : ∑Ik =

200 uA)

(2) Practical max brightness ...... 110 cd/m

[L/D control specification]

In Y axis : ± 7.5 um

At corners : ± 5.0 um

3. Demagnetize the CRT surface with the hand degausser , and

perform auto degaussing.

Note: Adjust in a non-magnetic field.

4. Attach the wobbling coil to the designated part of the CRT

neck.

5. Pull out the TLH correction piece up to the position where a

stopper is engaged.

6. Attach the sensor of the landing adjustment unit on the CRT

surface.

7. Adjust the DY position and purity, and the DY tilt.

For the purity adjustment, use 2-pole Mg on DY side.

8. Fasten DY with screw.

Note: Torque 22 ±2kg·cm (2.2 ± 0.2 Nm)

Perform auto degaussing.

2

∑Ik = 595 uA

Fixing DY with wedges.

a

c

b

9. Adjust vertical swing with vertical pins, and also adjust horizontal swing so that horizontal keystone and vertical tilt are

optimum, then fix with four wedges.

(When fixing DY with wedges, insert wedges completely so

that the DY does not shake.)

Note:

(1) Do not paste more than 2 magnets to one corner.

(2) Paste within 80 to 100 mm from the DY on the diagonal line

of the magnet.

<How to drive in wedges>

10. Check the landing of each corner, and if they do not satisfy

the specification, paste a Disk-Mg onto the funnel and adjust.

11. If using the magnet, be sure to demagnetize with the hand

degausser and check.

12. Remove the sensor and wobbling coil.

13. Check that the DY is not tilting, and fix the purity Mg with a

white pen.

“a” and “b” must be equal, and

“c” and “d” must be almost equal.

d

Apply a locking agent to the

upper wedges only.

In such a case, apply agent so that

it enters both sides of wedge and

also inside the DY.

– 15 –

Page 16

CPD-220AS

Connect the communication cable of the computer to the connector located on the D board on the monitor. Run the service software and

then follow the instruction.

1-690-391-21

1

A-1500-819-A

2

Interface Unit

IBM AT Computer

as a Jig

D-sub

(9 Pin [female])

*The parts above ( ) are necessary for DAS adjustment.

mini Din

(8Pin)

1

3

• Convergence Rough Adjustment

1. Enter the white crosshatch signal (white lines on black).

2. Adjust roughly the horizontal and vertical convergence at

four-pole magnet.

3. Adjust roughly HMC and VMC at six-pole magnet.

Standard: ± 0.1mm (In the center of screen)

2-pole Mg

4-pole Mg

Fig. 1

Purity Mg

6-pole Mg

YCH

TLV

YBH

Fig. 2

XCV

XBV

TLH

3-702-691-01

3

Connector Attachment

To BUS CONNECTOR

4 Pin

4 Pin 4 Pin

• Convergence Specification

B

A

MODE All mode

0.24 mm

A

0.32 mm

B

• White Balance Adjustment Specification

(1) 9300K

x = 0.283 ± 0.008

y = 0.298 ± 0.008

(2) 5000K

x = 0.345 ± 0.008

y = 0.358 ± 0.008

XBV XCV

B

R

YBH TLV

R B

<6 Pole Magnet>

Tab A

Tab B

H. TILT

R

B

R

B BR

• Vertical and Horizontal Position and Size

Specification

A

b

MODE All mode

R

B

R

B

YCH

BR

a 1.6 mm

b 1.6 mm

B

a

312 mm

A

234 mm

B

• Focus adjustment

Adjust the focus volume 1 and 2 for the optimum focus.

Standard: HMC, VMC ± 0.1 mm (In the center of screen)

FBT

Fig. 4Fig. 3

Focus volume 1 (V)

Focus volume 2 (H)

Fig. 5

– 16 –

Page 17

SECTION 5

(

)

DIAGRAMS

5-1. BLOCK DIAGRAMS (with FRAME SCHEMATIC DIAGRAM)

PPE LEVEL

PPE LEVEL

5

10

4

9

3

8

2

7

1

6

SIGNAL IN

HD15

PIG-TAIL

()

R

15

G

B

14

H.SYNC

V.SYNC

13

SDA

SCL

12

DDC

11

PPE LEVEL

A

SYNC ON G

B

C

CN701

GND

CLAMP

GND

+8V

GND

B IN

G IN

R IN

GND

NC

GND

B OUT

G OUT

R OUT

CN800

R IN

G IN

B IN

GND

-5V

GND

R OUT

G OUT

B OUT

GND

+8V

GND

CLAMP

GND

CN307

B GND

BLUE

G GND

GREEN

R GND

RED

GND

VD

HD

CN310

NC

DDC SCL

DDC SDA

GND

CN309

CBLK

GND

VS OUT

HS OUT

GND

BPCLP

CN306

VRTRC

HRTRC

GND

IIC CLK

IIC DATA

RESET

1

2

3

+8V

4

5

6

7

8

9

10

11

12

13

14

15

15

14

13

12

11

10

-5V

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

1

2

3

4

8

7

6

5

4

3

2

1

1

2

3

4

5

6

CN605

THP601

THP601A

CN600

AC IN

CN601

DGC2

NC

DGC1

CN607

AUDIO 16V

AUDIO 16V

AUDIO GND

AUDIO GND

AUDIO GND

RGB AMP

IC701

17

B OUT

19

G OUT

12

PPELVL

13

CLAMP

5

B IN

3

G IN

1

R IN

IC009

+12V

PS600

2

3

8V REG

SYNC ON GREEN

SEPARATOR

Q002,003,006

VCLK

SCL

SDA

DDC

IC006

INVERTER

IC008

10 13

41

1

2

1

2

3

1

2

3

4

5

(POWER DEFLECTION)

D

21

R OUT

RGB PRE-AMP

5

R IN

8

G IN

11

B IN

16

BLK

13

CLAMP/

9

INVERTER

1

1

LINE FILTER

4

LF601

D658

RECT

IC001

R OUT

G OUT

B OUT

GDRV

BDRV

CONT

IC007

VOS

BRT

ROI

GOI

BOI

23

20

18

27

26

4

25

13

1

2

3

15

12

RGB OUTPUT

IC002

9

VIN2

11

VIN1

8

VIN3

OSD

IC003

1

PWM0

2

PWM1

3

FBLK

11

PWM2

12

PWM3

19

R

20

G

21

B

4

VSYNC

5

HSYNC

15

SCL

16

SDA

17

RESET

RELAY DRIVE

Q670

D601

AC RECT

AE2

3

VOUT2

1

VOUT1

5

VOUT3

14

PWM5

23

PWM6

24

PWM7

13 3

PWM4

(VIDEO<GPE>)

789

VOC3

VOC2

VOC1

1

VI1

2

VI2

3

VI3

RGB CUT OFF CONTROL

CUT OFF/BRT

CONTROL

T601

BOOST

SWITCHING

Q602

IC004

IC005

VCC

6

2

1

SWITCHING

8

9

SPOT KILLER

Q001

MAIN

Q608

J001

7

KR

KG

KB

G2

H2

10

5

CN302

CN304

+12V

D014

(VIDEO)

A

T603

PRT T602

1

2

3

4

5

DRIVE

Q613 Q612

5

4

3

2

1

5

4

3

2

1

2

1

2

3

4

5

6

7

8

9

10

11

12

7

8

SOFT START

Q654

DRIVE

CN312

R IN

GND

L IN

GND

MIC OUT

CN311

MIC OUT

GND

L IN

GND

R IN

TO FBT FV1

TO FBT FV2

CRT

HV

(TO FBT)

CN301

1.2KV

CN305

+150V

NC

+B SW

+80V

GND

H1

H2

+5V

GND

+12V

GND

-5V

D611D603

D608

4

3

REG

Q607

VCC SW

Q601

INT

MIC

D

B

E

A

REG

IC611

MAIN/STBY

SELECT

Q655-657

AUDIO IN/

MIC OUT

PIG-TAIL

WOOFER DC

PPE LEVEL

SYNC ON GRN

WOOFER DC

1

5

D605 D606

CN602

10

LATCH OUT

9

LATCH

8

0VP

7

AC SEN

6

V SEN

5

VCC

4

I SEN

3

DRV

2

P GND

1

S GND

CN5200

E

INT MIC

MIC OUT

E

L IN

E

R IN

CN5204

D GND

IIC DATA

IIC CLK

D GND

MUTE

MIC MUTE

A GND

POWER SW

FUNCTION

CN508

RESET

IIC DATA

IIC CLK

GND

HRTRC

VRTRC

CN511

CBLANK

GND

VSYNC

HSYNC

GND

BPCLAMP

CN509

TXD

RXD

+5V

D GND

CN507

HD

VD

D GND

IIC DATA

IIC CLK

D GND

MUTE

,IC MUTE

A GND

POWER SW

6

5

D609

4

2

1

D604

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

SW

6

5

4

3

2

1

8

7

6

5

4

3

2

1

4

3

2

1

11

10

9

8

7

6

5

4

3

2

1

RESET

IC903

+5V

PIT

7

8

9

10

11

12

13

14

CN1600

LATCH OUT

LATCH

AC SEN

V SEN

I SEN

P GND

S GND

D655

0VP

VCC

DRV

D656

D650

10

9

8

7

6

5

4

3

2

1

E-VOL/TONE CONTROL

BUFFER

BUFFER

D654

6

Q5201

Q5202

X900

8MHz

D652

D653D651

R IN

11

L IN

18,19

SW DATA

25

RESET

53

IIC DATA

54

IIC CLK

49

HRTRC

20

VFBACK

23

DA10

27

VSYNC

29

HSYNC

31

CSYNC1

30

HDRIVE

22

CLMPO

42

TX

13

RX

32

OSC OUT

33

OSC IN

36

MUTE

50

MIC MUTE

16

WOOFER DC

39

REMOTE ON/OFF

21

VSYNCI2

+B OCP SW

Q671-673

+80V

23

-12V REG

IC613

D657

1

CONTROLLER

2

IC1601

A

IC5200

1

L OUT

R OUT

MUTING LED

POWER LED

H DRV VCC

HTR STDBY

CPU

IC901

D671

17

16

18

BG

20

SCL

19

SDA

VDDA

PIN PAL

KEY BAL

PIN

KEY

V CENT

V SIZE

VLINBAL

VLIN

POWER

SAVE LED

VDRIVE

TEMP

S0-S2

H CENT

ABL

+B SW

ROTATION

+150V

+15V

-12V

8

5

CN5205(1/2)

EXT MIC

MIC GND

INT MIC

+9V

2

3

POWER

IC5204

MUTE

Q5001

+9V REG

13

+16V

1

5

6

7

8

9

10

11

12

41

37

38

26

35

14

44-46

47

15

43

34

40

LED DRIVE

Q905

LED DRIVE

Q904

3

5V/12V

2

1

HEATER

5

SWITCH

IC5601

V.BLANK

Q902

MUTE

POWER SAVE

POWER

SW

Q401

SW

Q400

REG

IC604

IC612

31

(AUDIO)

U

5

6

7

1

+9V

36

V.BLANK

22

SBLKOUT

17

HSYNC

26

VREF

42

PIN/BAL

41

KEY BAL IN

39

E/W AMP

38

KEYST

33

V.POS

31

V.AMP

29

VS.CENT

28

VS.AMP

+5V

14

PLL

34

V.SYNC

+12V+5V

7

6

2

3

Q1603

REG

IC1603

2

JUNGLE

IC904

D1604

MIC MUTE

Q5204

5

3

5

3

3

W L/HPF

POWER SW

Q5207

+16V

V.FOCUS

XRAY IN

E/W OUT

H.OUTCOL

V.OUT

V.DC OUT

V.DC IN

H FLY

MIC VCC

Q5203

HP AMP

IC5205

HPF

IC5202

IC5203

+B SW

Q5206

BUFFER

1

Q501

16

27

21

H DRIVE

Q504,505 Q502

1

30

7

32

35

5

H.DRV

Q528,529

H CENT

Q515 Q508,509

1

ROTATION

2

3

-12V

D1605

LATCH

Q1604-1606

+9V

7

1

7

1

7

D511

V OUT

IC401

+IN

-INFBOUT

DRIVE

IC400

+16V

POPING SOUND

PREVENTION

Q5205

HP MUTE

Q5218,5219

6

5

DF AMP

Q500

H DRIVE OUT

3

5

H CENT DRIVE

+15V

5

4

DA

Q5215,5216

7

Q5217,5220

D5206

T503

DFT

1

5

T504

HDT

4

1

D903

(POWER)

MUTE

MUTE

10

11

12

9

8

7

6

8

J5600

USB UP STREAM

5

L/R POWER

1

AMP

IC5201

1

WOOFER

5

POWER AMP

IC5207

PROTECT

IC5206

T505 HST

1

3

2

5

S-CAP CHANGE

Q512-514

+12V

THERMAL

PROTECTION

TH501

H OUT

Q507

CN5602

1

VCC

2

-DATA

3

+DATA

4

GND

5

CN5205(2/2)

4

HP.L

3

HP.GND

2

SP MUTE SW

Q5214

8

10

10

8

22 21 20

5

6

HP.R

1

SP.SW

CN5202

4

L-SP

3

E

2

R-SP

1

E

CN5201

1

WOOFER+

2

WOOFER-

CN5601

1

AUDIO 16V

2

AUDIO 16V

3

AUDIO GND

4

AUDIO GND

5

AUDIO GND

BUFFER

SAW TOOTH

SAW TOOTH

111 12 13

GEN

GEN

BUFFER

SPEAKER

(L)

SPEAKER

(R)

SPEAKER

WOOFER

C

PWM CONTROL

IC801

D513

D512

J6000

USB DOWN STREAM

1

2

3

4

SHIELD GNDSHIELD GND

CN6000

VCC

-DATA

+DATA

GND

1

2

3

4

5

J

(AUDIO)

CN6001

4

HP.L

3

HP.GND

2

HP.R

1

SP.SW

J6003

EXT

MIC

ERROR AMP

18

Q803

17

COMPARATOR

16

15

ERROR AMP

CN6002

1

2

3

+B PWM

Q801,802

HV REG DRIVE

Q804

J6002

HEADPHONE

EXT MIC

MIC GND

INT MIC

+12V +5V

A

CHOPPER

Q503

HV REG OUT

Q510

D507

+150V+80V

B-SS3433<AEP>-B/D

1

3

4

5

15

C511

T501

FBT

CN501

6

V DY+

5

V DY-

4

H DY-

3

H DY-

2

H DY+

1

H DY+

CN510

1

1.2KV

CN503

1

ROTAIION+

2

ROTATION-

CN505

1

+150V

2

NC

3

+B SW

4

+80V

5

GND

6

H1

7

H2

8

+5V

9

GND

10

+12V

11

GND

12

HV2

14

13

FV1

17

16

FV2

11

9

10

8

7

612

TO CRT

ANODE CAP

RV501

HV ADJ

TO A BOARD

J001

TO A BOARD

J001

D515

D

E

5-2. CIRCUIT BOARDS LOCATION

J (Stand block assy)

A

AE2

D

U

(Stand block assy)

DA

5-3. SCHEMATIC DIAGRAMS AND

PRINTED WIRING BOARDS

Note:

• All capacitors are in µF unless otherwise noted. (pF: µµF)

Capacitors without voltage indication are all 50 V.

• Indication of resistance, which does not have one for rating

electrical power, is as follows.

Pitch: 5 mm

Rating electrical power 1/4 W (CHIP : 1/10 W)

• All resistors are in ohms.

f : nonflammable resistor.

•

F : fusible resistor.

•

¢ : internal component.

•

• p : panel designation, and adjustment for repair.

• All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

e : earth-ground.

•

E : earth-chassis.

•

• The components identified by

have been carefully factory-selected for each set in order to

satisfy regulations regarding X-ray radiation.

Should replacement be required, replace only with the value

originally used.

• When replacing components identified by

necessary adjustments indicated. (See page 14)

• When replacing the part in below table, be sure to perform the

related adjustment.

Note: The components identified by shading and mark

¡ are critical for safety. Replace only with part

number specified.

[ in this basic schematic diagram

], make the

Part replaced ( [ )

HV ADJ

RV501

Part replaced ( ] )

HV Regulator

Circuit

D board IC801, C509, C542,

C548, C802, C814,

C815, R538, R539,

R540, R541, R807,

R822, R823, R824,

RV501,T501 (FBT)

HV Hold-Down

Circuit

D board IC801, IC904, D511,

D515, C515, C516,

C517, C910, R532,

R533, R534, R535,

R996, T501 (FBT)

• Mounted D board

Beam Current

Protector Circuit

D board IC901, D596, C519,

C528, C549, C904,

R542, R543, R544,

R545, R939

• Mounted D board

• All voltages are in V.

• Readings are taken with a 10 M digital multimeter.

• Readings are taken with a color-bar signal input.

• Voltage variations may be noted due to normal production

tolerances.

•

• Circled numbers are waveform references.

•

: Can not be measured.

*

s : B + bus.

• S : B – bus.

Terminal name of semiconductors in silk screen

printed circuit ( )

Device Printed symbol Terminal name

Transistor

1

Transistor

2

3

Diode

4

Diode

Diode

5

Diode

6

Diode

7

8

Diode

Diode

9

Diode

0

Diode

!¡

Transistor

!™

(FET)

Transistor

!£

(FET)

Transistor

!¢

(FET)

Transistor

!∞

Discrete semiconductot

–

Chip semiconductors that are not actually used are included.

*

Collector

Base

Collector

Base

Cathode

Cathode

Anode

Cathode

Anode

Common

Anode

Common

Anode Cathode

Common

Anode

Common

Anode Anode

Common

Cathode

Common

Cathode

Drain

Drain

Emitter

Emitter

Anode

(NC)

(NC)

Cathode

Anode

Cathode

Cathode

Source

Gate

Source

Gate

Source

Drain

Gate

Emitter

Collector

Base

Circuit

D

G

D

S

D

G

S

S

D

G

S

G

Ver.1.4

– 17 – – 18 –

– 19 –

– 20 –

Page 18

(1) Schematic Diagram of D Board

• D BOARD VOLTAGE LIST

Ref. Pin No. Voltage [V]

IC400 1 1.1

2 1.1

4 –0.2

IC401 1 1.1

3 –11.8

5 0.3

6 13.4

7 1.1

IC604 3 4.1

IC611 1 134.9

3 2.4

4 11.4

IC612 2 5.1

3 6.4

4 5.1

5 7.3

IC801 1 6.0

2 9.0

4 6.6

5 0.7

6 4.9

8 7.0

9 4.1

10 5.1

11 5.9

12 6.0

13 6.0

14 6.8

15 6.0

16 7.9

17 2.5

18 4.6

19 5.3

20 4.6

21 5.0

22 5.0

IC901 1 8.1

2 2.0

3 1.9

4 3.1

5 3.3

6 2.9

7 3.2

8 2.7

9 2.5

10 2.7

11 2.7

12 2.6

13 5.1

14 1.9

15 4.2

16 1.0

17 5.1

18 5.0

19 5.0

20 –0.4

21 0

22 5.1

23 0

24 3.4

25 5.1

26 0.1

27 4.4

29 4.5

30 0.7

31 0.7

32 1.9

33 2.4

34 2.6

35 1.4

36 0.1

37 5.1

38 0

39 4.1

40 5.1

41 3.9

42 5.1

43 0.7

44 5.1

45 5.1

46 5.1

47 1.3

49 1.0

50 0

51 0

52 0

53 4.7

54 4.6

IC903 2 5.1

IC904 1 5.5

2 5.1

3 3.4

4 2.0

5 0.3

60

7 8.0

8 1.6

9 6.4

10 4.0

11 2.8

12 2.8

13 8.0

14 0.1

15 4.2

16 5.7

17 0.6

21 4.8

22 4.6

24 0

25 5.1

26 8.1

27 3.5

28 3.7

29 3.8

30 3.5

31 4.0

32 3.5

33 4.1

34 0.1

35 3.5

36 0.1

Ref. Pin No. Voltage [V]

Q500 B 1.7

Q501 B 1.1

Q502 B –0.2

Q503 G 147.1

Q504 B 4.8

Q505 B 4.8

Q507 B –0.5

Q508 B 52.9

Q509 B 52.8

Q510 G 7.9

Q512 G 5.1

Q513 G 5.1

Q514 G 5.1

Q515 B 1.3

Q528 B 1.3

Q529 B 72.1

Q601 B 14.2

Q602 G 9.4

Q607 B 18.0

Q608 1(C1) 186.8

2(B1) –1.3

4(C2) 186.8

5(B2) 185.5

6(E2) 376.0

Q612 B 9.7

Q613 B 9.6

Q654 B 11.0

Q655 B 13.9

Q656 B 0

Q657 B 4.1

Q670 B 0

Q671 B 148.6

Q672 B 0

Q673 B 4.1

Q801 B 8.0

Q802 B 8.0

Q803 B 0.3

Q804 B 7.9

Q901 B *

Q902 B –0.4

Q904 B 0.1

Q905 B 5.1

37 2.9

38 3.7

39 4.1

40 4.1

41 3.9

42 4.2

C 71.5

E 1.2

E 1.7

C 70.4

D 48.9

E 4.9

E 5.0

C 49.0

C 38.3

E 51.7

C 57.1

E 51.7

D 8.3

D0

D0

D0

C 52.8

E 0.7

C 72.1

E 0.8

E 70.9

E 14.9

D 92.9

S 0.1

C 29.1

E 17.4

C 17.4

E 9.4

C0

E 9.5

E 11.4

C 2.5

E 13.9

C 13.9

C0

C 12.1

C0

E 149.1

C 4.1

C0

E 4.1

E 7.9

E 7.9

C 8.1

E 7.8

C *

E 0.1

C 5.0

C –0.6

DGC

D

POWER

DEFLECTION

()

5V

R1822R1801C1801

3.3k

3.3k

:RN

:RN

B

C1803

0.22

:MPS

R1810

470

:RN

R1811

330

:RN

R1812

390

:RN

R1813

560

:RN

R1814

680

:RN

R1815

820

:RN

R1816

1.2k

:RN

R1817

1.8k

:RN

R1818

2.7k

:RN

R1819

4.7k

:RN

R1820

100k

:RN

C621

330p

500V

:HR

D613

1SS119

D614 D612

1SS119 1SS119

R636

4.7

C628

0.33

:MPS

C630

C631

330p

500V

0.15

:HR

:MPS

4

5

D658

D4SBS4

RECT

C655

4700

25V

R667

10k

D607

1SS119

C670

2.2

50V

R669

4.7k

10

134

2

L601

68µH

1

C603C604

4700p

4700p

250V

250V

:E

:E

1

4

2 3

R601

1/2W

:RC

LNG

AC IN

R640

0.47 1/2W :RF

R633

100k

1W

:RS

1SS119

R638R639

2222

R637

4.7

C632

0.15

:MPS

2

3

6

7

D611

1SS119

T601

515UH

789

6

5

R612

100k

1/2W

R613

100k

1/2W

TH601

5.1

300V

R602

1

10W

C602VA602

1

250V

CN602

10P

R1823

470

:RN

R1824

100k

:RN

1

8

C607

400V

C608

470p

250V

Schematic diagram

(d) board

SOFT START

1

CN607

5P

RED

AUDIO 16V

AUDIO 16V

AUDIO GND

AUDIO GND

AUDIO GND

CN601

3P

DGC1

NC

DGC2

CN605

2P

:LAGE

THP601

THP601A

1

2

3

4

5

3

2

1

1

2

+16V

12V

TH602

300V

:POS

R670

4.7k

R671

4.7k

RY601

VA601

CONT+

CONT-

VOL+

VOL-

BRT/GPE

CENTER

SIZE

GEOM

COLOR

SOUND

MUTING

R631

100k

:RS

R632

100k

:RS

C627

330p

500V

PS600

5A

Q670

2SK940

C675

100

16V

D670

1SS119

1W

1W

D615

:HR

R659

R672

5MM

21

65

43

D4SB60L

AC RECT

LF601

:LFT

C601

0.47

250V

F601

4A

250V 560k

CN600

330p

S1801

S1802

S1803

S1804

S1805

S1806

S1807

S1808

S1809

S1810

S1811

L654

10µH

5MM

D601

R945

3.9k

C1802

330p

B

S1812

POWER

S1813

RESET

C923

0.01

:PT

R634

100k

1W

:RS

Q608

MX0541B

MAIN SWITCHING

C633

0.0082

1000V

VA603

TNR10V621

Q607

2SD2012 REG

C629

0.33

:MPS

RD18ESB2

T603

PRT

Q654

2SA1309A

Q655

DTA124ESA

MAIN/STBY

SELECT

Q656

DTC124ESA

MAIN/STBY

SELECT

S

R610

0.22

3W

:RS

10

0VP

LATCH

AC SEN

LATCH OUT

TO DA BOARD CN1600 TO A BOARD CN305

ll

l

ll

:PP

C620

R635

22

2.2 1/2W :RF

100V

D609

DINL20

R630

2.2k

D608

1SS119

R604 R606

10k 10

V SEN

R616

JW(5)

D606

DINL20

R614C625

0.47

22

:FPRD

50V

D605

D604

1SS119

R663

47

D660

1SS119

MAIN/STBY SELECT

FB602

0.45UH

Q602

2SK2194

BOOST SWITCHING

:FPRD

Q613

2SA1048

DRIVE

R618

4.7

:FPRD

123456789

VCC

DRV

I SEN

P GND

S GND

C943

0.022

:PT

T602

PIT

6

5

4

2

1

C658

0.01

:MPS

R673

10k

Q657

DTC124ESA

D603

D5L60

D602

1SS119

C615

47

25V

Q612

2SC2458

DRIVE

HSS82

R665

47k

:RN

D903

C925

220

16V

C900

1

:MPS

D1NL20

7

8

9

D654

DINL20

10

11

R615

0.47

:FPRD

12

13

14

IC611

DM-58

R662

470k

0.047

C924

0.1

:PT

D650

C651

33

100V

D657

D2S4M

REG

C659

1000p

200V

:PT

C614

0.01

630V

R605

47k

+15V

CN505

:S-MICRO

C944 C946

4700p

4700p

:PT

:PT 4.7k

D944

1SS119

C940

:PT

D1NL20

D1NL20D1NL20

C939

0.047

:PT

D652

D653D651

D655

D656

D2S4M

C653

2200 25V

C654

2200

10V

C926

0.001

:PT

C961

0.1

:PT

C650

33

200V

D2S4M

5

234

R957

6.8k

:RN

12V

L650

22µH

D662

R2KS

L651

100µH

R650

0.47 :FPRD

C652

2200 25V

1

SI-3050F

12345

R661

R660

1k

12k

:FPRD

R978

JW(5)

Q601

2SA1309A

VCC SW

R623

360k

:RN

C613

R619

330k

220

:RN

450V

R625

330k

:RN

C616

220

25V

12V

10

11

12

GND

-5V

12P

WHT

+12V

D906

1SS119

D905

1SS119

R958

1.8k

0.033

C934

2.2

50V

L900

100µH

C960

0.1

:PT

0.01

:PT

R652

0.47

1W

:RS

R653

1

D661

:FPRD

1SS119

12

2 3

1

R651

3

0.47

:FPRD

R656 C657

180

:RN4725V

IC612

R657

820

:RN

R975

JW(5)

R642

150

R643

4.7k

R624

270k

:RN

R627

330k

:RN

R628

330k

:RN

R629

47k

:RN

R626

22k

5V

H2

H1

GND

+5V

R960

C928

:PT

C947C949

0.1

:MPS

80V

GND

C948

0.1

:PT

+12V

C937

1000

150V

80V

C660

+80V

3.9k 2.2k

R905

4.7k

R909

47k

C910

47

25V

C945

0.015

:PT

R996

1k

C936

0.1

:PT

16V

IC613

R654

NJM7912FA

0.47

:FPRD

-12V REG

L652

22µH

R655

0.47

:FPRD

L653

47

22µH

25V

-12V

R644

22k

150V

1

123456789

NC

+B SW

+150V

R965

680

:RN

R831

220

:RN

15V

R674 C671

390

:RN2250V

R675

220k

:RN

2

12345

H DY+

H DY+

H DY-

H DY-

R986R944 R956

10k

:RN

TDA9105 JUNGLE

123456789101112131415161718192021

V.FOCUS

HLK/ULK

PLL2C

P/K BAL OUT

H.DUTY

H.FLY

H.GND

H.REF

FC2

FC1

CO

RO

PLL1F

H.LOCKCAP

PLL1INHIB

H.POS

XRAYIN

H.SYNC

VCC

GND

H.OUTEM

H.OUTCOL

R910

470k

R963

10k

Q671

2SA1091O

+B OCP

5

C909

22

50V

R913

1k

R547

100

4

3

6

CN501

6P

DY

V DY-

V DY+

C915

4.7

35V

:BP

IC904

PIN/BAL

KEY BAL IN

E/W AMP

KEYST

E/W OUT

V.BLANK

V.DCIN

V.SYNC

V.POS

V.DCOUT

V.AMP

V.OUT

VS.CENT

VS.AMP

V.CAP

V.REF

V.AGCAP

V.GND

MOIRE.IN

SBLKOUT

+5V

C930

R997

330p

:B

5V

IC604

TDA8138A

OUTPUT2

OUTPUT1

NC

GND

DISABLE

INPUT2

1 2 3 4 5 6 7

INPUT1

C662

25V

D671

1SS119

R679

10k

R678

470k

R681R677

C672

10k150k

47

25V

12V

C501

0.22

:MPS

12V

R512

100k

:RN 10k

C505

10

50V

R513 C506

10k

:RN

Q501

2SA1309A

BUFF

HDY

R979

27k

R980

150k

R989

10k

C935

0.22

:MPS

22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

1k

12V

5V

C634

C635

470

470

25V

16V

R666

10k

+15V

47

R680

10k

Q673

2SA1309A

+B OCP

R676

1k

Q672

2SC3311A

+B OCP

Q528

2SC3209LK

H.DRIVE

R555

0.47

:FPRD

Q504

2SC3311A

H.DRIVE

C502

0.01

:PT

Q505

2SA1309A

H.DRIVE

R514

Q500

0.01

:PT

R548

2.7k

:RN

-12V

+5V +5V

C951

R929

10

39k

R938C907

C906

22k4.7

50V

R972

10k

R961

82k

:RN

C902

0.001

:PT

R955

100

80V

R550

10k

C521

1

50V

R500

100

:FPRD

R501

22k

R516

270k

:RN

R515

220k

:RN

DF-AMP

2SC3941A-Q

C507

0.001

500V

:B

0.1

:PT

R942 R940

2.2

50V

C933

220

0.1

:PT

R923

1k

D595

1SS119

C523

0.022

100V

:PT

C518

3300p 500V

T503

:DFT

16V

R914

470k

C420

0.0047

:PT

15V

-12V

Q529

2SD1276B

H.DRIVE

R509

4.7

:FPRD

1

2

C599

10

100V

3

4

R504

220

2W

:RS

C527

S

100p

500V

12

12

11

11

10

10

R510

4.7

9

9

8

8

C550

0.36

250V

:PP

C931 C932

0.22

:MPS

Q902

5V

2SC3623TP

V.BLANK

R551

1.2k

:RN

Q502

IRFU214

H.DRIVE OUT

D502

MTZJ-T-77-18

R527

220 3W :RS

L513

:HLC

1

1

3

3

R556

1k

1/2W

:RC

4

4

5

5

C508

67

33p

6 7

2kV

:SL

XVDY

XVDY

27k 18k 27k 27k

27k27k

R964

R968

150k

150k

2.2

50V

R424

12k

:RN

R423

5.6k

:RN

D403

GP08D

C401

470

25V

:HT

C967

100p

B

T504

:HDT

8

7

6

T505

:B

:HST

1 5

4

2 3

C503 L501

2.2 160V 1.2mH

27 2W :RS

0.18

200V

:PP

R517

1k

:FPRD

C566

0.01

:PT

S2

IRLI530G

S-CAP CHANGE

27k

R948 R947

150k150k

2.2

2.2

50V

50V

+IN

FLYBACK

VDD

1 2 3 4 5 6 7

+15V

C403

0.1

:PT

-12V

R401

4.7k

R976

4.7k

D401

MTZJ-T-77-4.7B

D508

SB340L

R508

1.8

3W

:RS

R506

1.8

3W

:RS

R546

:FPRD

C565

0.22

:MPS

R528 C569

68