Page 1

UHF SYNTHESIZED TRANSMITTER

UTX-P03

UHF WIRELESS MICROPHONE PACKAGE

UWP-D16

SERVICE MANUAL

1st Edition

Page 2

!警告

このマニュアルは,サービス専用です。

お客様が,このマニュアルに記載された設置や保守,点検,修理などを行うと感電や火災,

人身事故につながることがあります。

危険をさけるため,サービストレーニングを受けた技術者のみご使用ください。

! WARNING

This manual is intended for qualifi ed service personnel only.

To reduce the risk of electric shock, fi re or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualifi ed to do so. Refer all servicing to

qualifi ed service personnel.

! WARNUNG

Die Anleitung ist nur für qualifi ziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifi ziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afi n

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifi é pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

UTX-P03

Page 3

注意

注意

FÖRSIKTIGHET!

指定以外の電池に交換すると,破裂する危険があります。

必ず指定の電池に交換してください。

使用済みの電池は,国または地域の法令に従って

処理してください。

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

When you dispose of the battery, you must obey the

law in the relative area or country.

ATTENTION

Il y a danger d’explosion s’il y a remplacement incor-

rect de la batterie. Remplacer uniquement avec

une batterie du même type ou d’un type équivalent

recommandé par le constructeur.

Lorsque vous mettez la batterie au rebut, vous devez

respecter la législation en vigueur dans le pays ou la

région où vous vous trouvez.

Fara för explosion vid felaktigt placerat batteri.

Byt endast mot samma eller likvärdig typ av batteri,

enligt tillverkarens rekommendationer.

När du kasserar batteriet ska du följa rådande lagar

för regionen eller landet.

PAS PÅ

Fare for eksplosion, hvis batteriet ikke udskiftes

korrekt.

Udskift kun med et batteri af samme eller tilsvarende

type, som er anbefalet af fabrikanten.

Når du bortskaffer batteriet, skal du følge

lovgivningen i det pågældende område eller land.

HUOMIO

Räjähdysvaara, jos akku vaihdetaan virheellisesti.

Vaihda vain samanlaiseen tai vastaavantyyppiseen,

valmistajan suosittelemaan akkuun.

Noudata akun hävittämisessä oman maasi tai

alueesi lakeja.

VORSICHT

Explosionsgefahr bei Verwendung falscher Batterien.

Batterien nur durch den vom Hersteller empfohlenen

oder einen gleichwertigen Typ ersetzen.

Wenn Sie die Batterie entsorgen, müssen Sie die

Gesetze der jeweiligen Region und des jeweiligen

Landes befolgen.

FORSIKTIG

Eksplosjonsfare hvis feil type batteri settes i.

Bytt ut kun med samme type eller tilsvarende

anbefalt av produsenten.

Kasser batteriet i henhold til gjeldende avfallsregler.

注意

如果更换的电池不正确,就会有爆炸的危险。

只更换同一类型或制造商推荐的电池型号。

处理电池时,必须遵守相关地区或国家的法律。

UTX-P03

1 (P)

Page 4

Page 5

Table of Contents

Manual Structure

Purpose of this manual ............................................................ 2 (E)

Related manuals ...................................................................... 2 (E)

1. Service Overview

1-1. About Destination Determination .............................1-1 (E)

1-2. Board Location ..........................................................1-1 (E)

1-3. Removal Procedure ...................................................1-2 (E)

1-3-1. Lower Case (P03)/Upper Case (P03)/

Case (P03) ........................................................ 1-2 (E)

1-3-2. CPU-458 Board ...............................................1-3 (E)

1-3-3. LCD Module .................................................... 1-3 (E)

1-3-4. RF-164 Board ..................................................1-4 (E)

1-3-5. XLA Connector Assembly ...............................1-5 (E)

1-4. Diagnosis of Failure ..................................................1-6 (E)

1-4-1. No Sound is Output/Service Area is Narrow/

There is a Noise ...............................................1-6 (E)

1-4-2. Sound is distorted ............................................1-6 (E)

1-5. Lead-free Solder ........................................................1-7 (E)

3. Spare Parts

3-1. Notes on Repair Parts ...................................................... 3-1

3-2. Exploded Views ............................................................... 3-2

3-3. Electrical Parts List .........................................................3-4

3-4. Packing Materials & Supplied Accessories ..................... 3-4

4. Block Diagrams

4-1. Circuit Description .................................................... 4-1 (E)

4-1-1. RF-164 Board ..................................................4-1 (E)

4-1-2. CPU-458 Board ...............................................4-1 (E)

4-2. Overall Block Diagrams .................................................. 4-3

Overall ............................................................................. 4-3

4-3. Frame Wiring...................................................................4-4

Frame Wiring...................................................................4-4

2. Operation Check

2-1. Preparation ................................................................2-1 (E)

2-1-1. Required Equipment ........................................2-1 (E)

2-1-2. Tool List ........................................................... 2-1 (E)

2-2. Check of Transmission Output ................................. 2-2 (E)

2-2-1. Required Equipment/Tool ................................2-2 (E)

2-2-2. Setting ..............................................................2-2 (E)

2-2-3. Procedure ......................................................... 2-3 (E)

2-3. Check of Sound Output ............................................. 2-4 (E)

2-3-1. Required Equipment/Tool ................................2-4 (E)

2-3-2. Setting ..............................................................2-4 (E)

2-3-3. Procedure ......................................................... 2-4 (E)

2-4. Check of Sound Level ............................................... 2-5 (E)

2-4-1. Required Equipment/Tool ................................2-5 (E)

2-4-2. Setting ..............................................................2-5 (E)

2-4-3. Procedure ......................................................... 2-5 (E)

2-5. Check of +48V .......................................................... 2-6 (E)

2-5-1. Required Equipment/Tool ................................2-6 (E)

2-5-2. Procedure ......................................................... 2-6 (E)

UTX-P03

1 (E)

Page 6

Purpose of this manual

Related manuals

Manual Structure

This manual is the Service Manual of the UHF Synthesized Transmitter UTX-P03.

This manual describes the information on the premise of providing the block level

service (such as service overview, diagnosis of failure, spare parts, circuit description, block diagrams, and frame wiring).

The UHF wireless microphone packages consists of the following.

. UWP-D16: UTX-B03, UTX-P03, URX-P03

The following manuals are provided for this unit in addition to this “Service Manual”.

. “Instruction Manual” CD-ROM (supplied with this unit)

This manual is necessary for installation of this unit.

. UTX-B03 Service Manual (available on request)

This manual describes the required information of service of UTX-B03.

. URX-P03 Service Manual (available on request)

This manual describes the required information of service of URX-P03.

2 (E)

UTX-P03

Page 7

Section 1

Service Overview

1-1. About Destination Determination

There are nine destinations in this unit.

Determine the destination by referring to the model number label and the following table.

Destinationon model

Indication of channel

number label

Model number label

Model name Destination Destination on model Indication of Part number on model

number label channel number label

UTX-P03 UC14 14 14-25 4-527-512-0X

UC30 30 30-36, 38-41 4-527-512-1X

UC42 42 42-51 4-527-512-2X

CE21 21 21-29 4-527-513-0X

CE33 33 33-40 4-527-513-1X

CE42 42 42-50 4-527-513-2X

CE51 51 51-59 4-527-513-3X

KR _ _ 4-527-514-0X

E _ _ 4-527-515-0X

Part number on model number label

(Example) Destination: UC

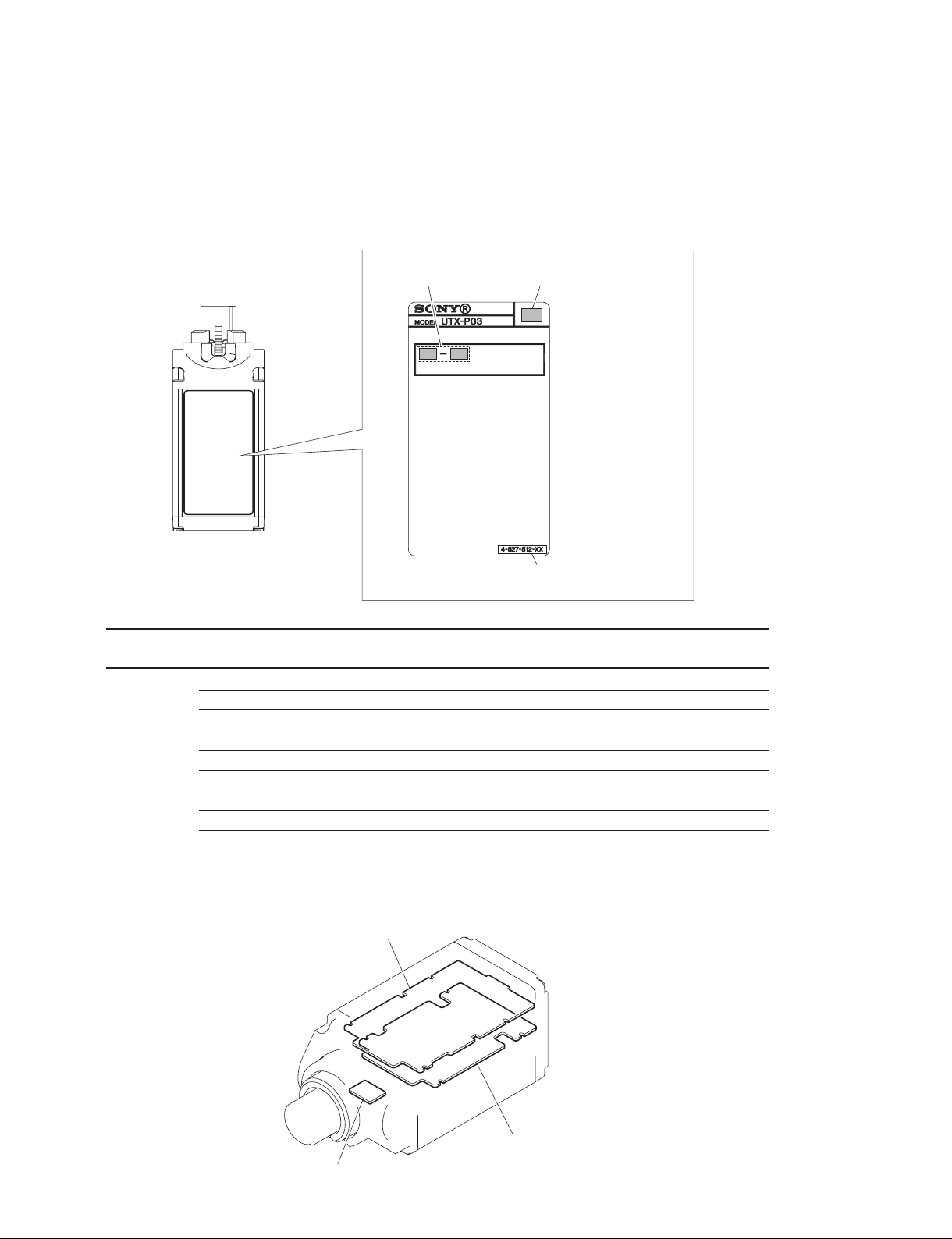

1-2. Board Location

CPU-458 board

UTX-P03

RF-164 board

CN-3708 board

1-1 (E)

Page 8

1-3. Removal Procedure

Tighten the following screws to the tightening torques as described below.

Tightening torque:

. M1.7 (+) screw: 0.15 ?0.01 N.m

. M2 (+) screw: 0.19 ?0.02 N.m

. B1.7 x 6 (+) tapping screw: 0.20 ?0.02 N.m

. P2 x 8 (+) tapping screw: 0.20 ?0.02 N.m

When using the torque driver with the unit representation of cN.m, calculate the value as follows.

Example: 0.8 N.m = 80 cN.m

n

In this section, remove the parts in numerical order shown in the illustration.

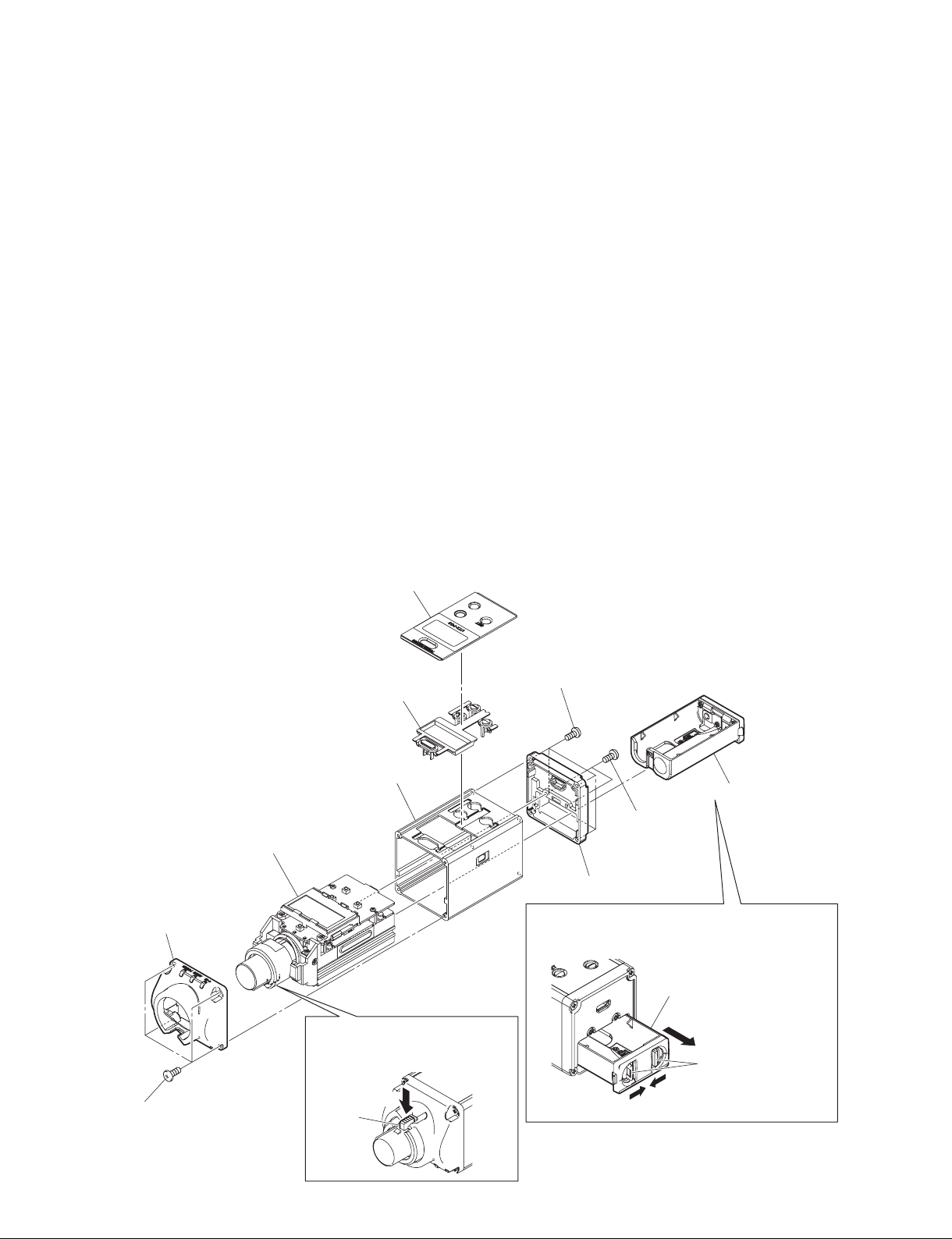

1-3-1. Lower Case (P03)/Upper Case (P03)/Case (P03)

n

When removing the window (P03), slowly take it off. Removing by force can cause damage.

5 Window (P03)

0 Chassis assembly

8 Upper case assembly (P03)

7 Four screws

M2 Flat EG grip

(Tightening torque: 0.40 ?0.03 N.m)

6 SET button (P03)

9 Case (P03)

Push the latch portion in the direction

of the arrow A to remove the upper

case assembly (P03).

A

Latch

2 Four screws

M2 Flat EG grip

(Tightening torque: 0.40 ?0.03 N.m)

1 Battery case (B) assembly

3 Two screws

(PTP2 x 8)

4 Lower case (P03)

Pinch the battery slides in the directions of the

arrows A to remove the battery case (B) assembly

in the direction of the arrow B.

1 Battery case (B) assembly

B

Battery slides

A

A

1-2 (E)

UTX-P03

Page 9

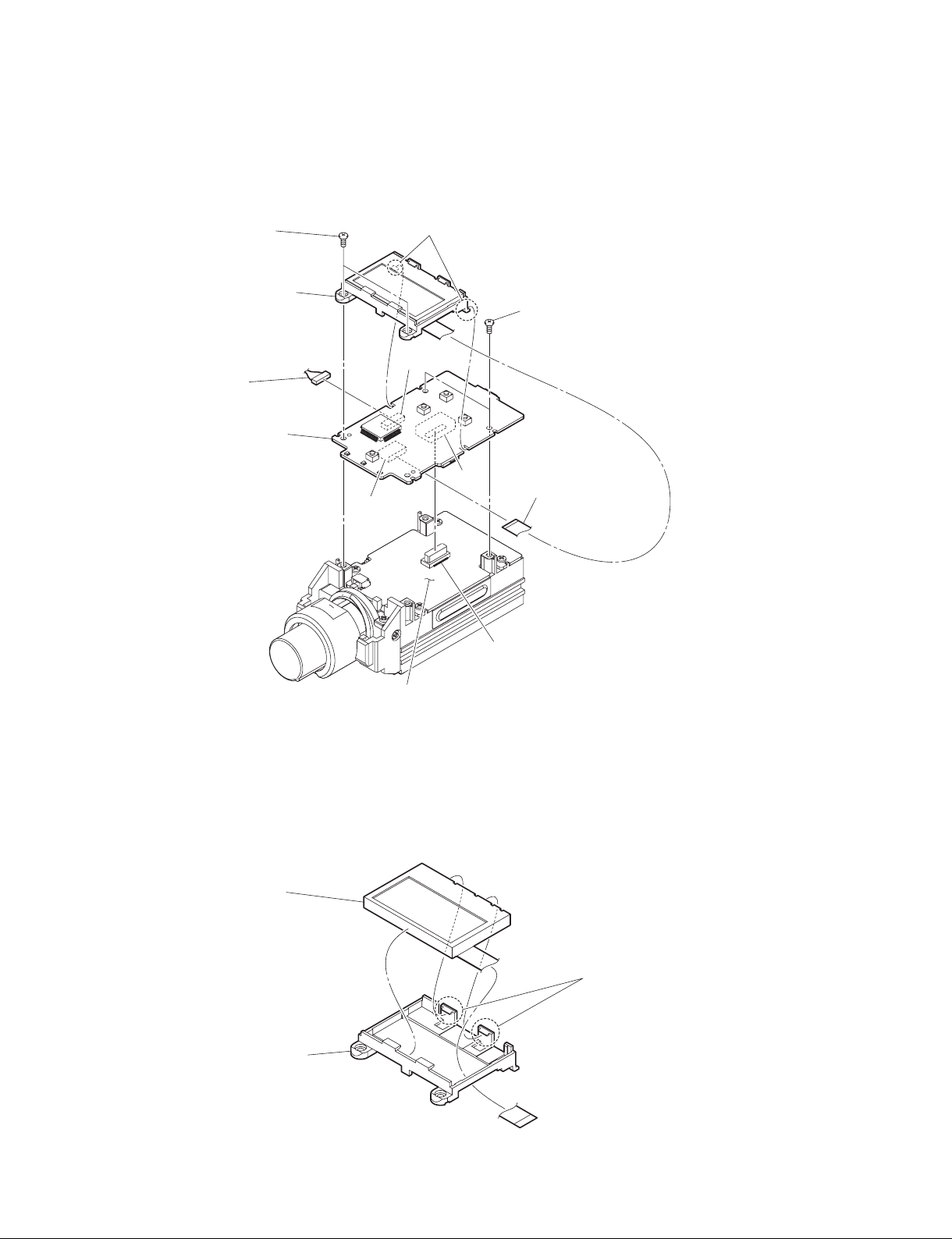

1-3-2. CPU-458 Board

Workflow: Lower case (P03)/upper case assembly (P03)/case (P03) (Section 1-3-1) → CPU-458 board

2 Two screws

(BTP1.7 x 6)

7 LCD frame (P03)

4 Harness

3 CPU-458 board

6 Two hooks

1 Two screws

(BTP1.7 x 6)

CN102

CN403

5 Flexible wiring board

CN401

CN502

RF-164 board

1-3-3. LCD Module

Workflow: Lower case (P03)/upper case assembly (P03)/case (P03) (Section 1-3-1) → CPU-458 board

(Section 1-3-2) → LCD module

3 LCD module

1 Two hooks

2 LCD frame (P03)

UTX-P03

1-3 (E)

Page 10

1-3-4. RF-164 Board

Workflow: Lower case (P03)/upper case assembly (P03)/case (P03) (Section 1-3-1) → CPU-458 board

(Section 1-3-2) → RF-164 Board

n

When attaching the screw, make sure that it is not loose.

3 RF lug (P03)

2 Screw

(P1.7 x 1.8)

1 Solder

5 RF-164 board

n

When attaching the RF lug (P03), make sure that the solder

portion of the RF lug (P03) terminal portion is not raised and

that the land portion of the board is not removed.

6 Harness

When attaching, route the lead wires of the battery

plate (P03) assembly along the groove as shown

in the illustration, and retain them with the earth

plate (P03).

7 Earth plate (P03)

Lead wire (black)

CN501

2 Screw

(P1.7 x 1.8)

3 RF lug (P03)

4 Four screws

(BTP1.7 x 6)

5 RF-164 board

7 Earth plate (P03)

1-4 (E)

Lead wire (red) Lead wire (orange)

Boss

8 Battery plate (P03) assembly

UTX-P03

Page 11

1-3-5. XLA Connector Assembly

Workflow: Lower case (P03)/upper case assembly (P03)/case (P03) (Section 1-3-1) → CPU-458 board

(Section 1-3-2) → RF-164 Board (Section 1-3-4) → XLA connector assembly

Removal procedure

Remove the hook by rotating the connector assembly (P03)

in the direction of the arrow B, then remove it in the

direction of the arrow C.

B

Connector assembly (P03)

C

Hook

7 XLA connector assembly

Installation procedure

Compress the coil spring by pushing the ring (P03) in the

direction of the arrow D, then attach the connector

assembly (P03) in the direction of the arrow E.

n

Check that the hook is hooked on the chassis.

Coil spring

E

D

Connector assembly (P03)

Ring (P03)

Hook

Chassis

4 Connector holder

Hook

6 Remove the coil spring while

pushing the latch portion in the

direction of the arrow A.

5 Ring (P03)

Latch

3 Screw

(P2 x 7)

A

2 Screw

(P2 x 7)

1 Two screws

(P2 x 7)

UTX-P03

1-5 (E)

Page 12

1-4. Diagnosis of Failure

When replacing the parts or boards, perform the operation check of this unit. (Refer to Section 2.)

1-4-1. No Sound is Output/Service Area is Narrow/There is a Noise

Sound is output with

strong radio wave.

Check the receiver.

Symptom pointed out: . No sound is output.

Perform the check using the checking

receiver (URX-P03).

Sound is output with

weak radio wave.

. Service area is narrow.

. There is a noise.

No sound is output

(there is a noise) with

strong radio wave.

The “COMPANDER”

setting is not correct.

(Change the setting

according to the

receiver type to be

used.)

Check the connected

microphone unit.

No sound is output

(there is a noise) with

weak radio wave.

. Check the destination.

(Are the destinations

of receiver and

transmitter correct?)

. Check the transmission

channel. (Does it match

with the reception

channel?)

Change RF POWER

(transmission output

level) from “L” to “H”.

Check the connection

of FFC and harness,

and the connector.

t

FFC: Flexible flat cable

Check the disconnection

of RF lug (P03), and

replace it as required.

(Refer to Section 1-3-4.)

t

The possible causes of the RF lug (P03) disconnection are

as follows. (Refer to Section 1-3-4.)

. Screw is loose.

. Solder is raised.

. Land is

1-4-2. Sound is distorted

1-6 (E)

RF-164 board failure.

Replace the RF-164

board. (Refer to Section

1-3-4.)

Symptom pointed out: Sound is distorted.

The setting of ATT (attenuator) is not correct.

Change the setting of ATT so that the audio indicator blinks in green.

→

The setting of IN LEVEL (audio input level) is not correct.

Change it to the appropriate setting (MIC or LINE).

→

CPU-458 board failure.

Replace the CPU-458

board. (Refer to Section

1-3-2.)

UTX-P03

Page 13

1-5. Lead-free Solder

All boards mounted in this unit use lead-free solder. Be sure to use lead-free solder when repairing the

boards of this unit. A lead free mark (LF) indicating that the solder contains no lead is printed on each

board.

(Caution: Some printed circuit boards may not come printed with the lead free mark due to their particular

size.)

: LEAD FREE MARK

n

. The lead-free solder melts at a temperature about 40 dC higher than the ordinary solder, therefore, it is

recommended to use the soldering iron having a temperature regulator.

. The ordinary soldering iron can be used but the iron tip has to be applied to the solder joint for a slightly

longer time. The printed pattern (copper foil) may peel away if the heated tip is applied for too long, so

be careful.

UTX-P03

1-7 (E)

Page 14

Page 15

Section 2

Operation Check

When replacing the parts or boards, perform the operation check of this unit.

2-1. Preparation

2-1-1. Required Equipment

Name Specification Device name

Spectrum analyzer Frequency: 10 kHz to 3 GHz Advantest R3371B or the equivalent

Audio analyzer . Analog input Audio Precision system2 or the equivalent

. Frequency range: 20 to 100 kHz

Tester

2-1-2. Tool List

Name Specification Device name/part number

Checking receiver _ URX-P03 (works properly)

Checking transmitter _ UTX-P03 (works properly)

(for comparison)

Measuring antenna _ 1-501-952-22

Measuring cable XLR (female) - XLR (male) Optional accessory

Measuring cable BMP-XLR (male) 1-792-249-23

Headphone Stereo mini-jack Optional accessory

Dynamic microphone _ F-780 or the equivalent

UTX-P03

2-1 (E)

Page 16

2-2. Check of Transmission Output

2-2-1. Required Equipment/Tool

. Spectrum analyzer

. Measuring antenna

2-2-2. Setting

Set the transmission frequency, transmission level and spectrum analyzer of this unit.

1. Transmission frequency

Destination Channel Frequency

U14 1601 482.125

U30 3201 578.125

U42 4401 650.125

CE21 2233 482.125

CE33 3433 578.125

CE42 4333 650.125

CE51 5233 722.125

KR 50 931.250

E 6901 800.125

2. Transmission level

Transmission level: H

3. Spectrum analyzer

. Center Frequency: Set according to “1. Transmission frequency”.

. Reference Level: 20 dBm

. Frequency Span: 200 kHz

. RBW: Auto

. VBW: Auto

. ATT: Auto

2-2 (E)

UTX-P03

Page 17

2-2-3. Procedure

1. Connect the measuring antenna to the RF input of the spectrum analyzer.

2. Connect the dynamic microphone to this unit.

Spectrum analyzer

Dynamic microphone

Antenna

3. Check the transmission output level by bringing the antenna portion of the transmitter into contact

with the measuring antenna.

t

Perform the measurement while holding the dynamic microphone.

Specification: 0 dBm or more

20 dBm

0 dBm or more

v:10 dB/div

H:20 kHz/div

UTX-P03

2-3 (E)

Page 18

2-3. Check of Sound Output

2-3-1. Required Equipment/Tool

. Audio analyzer

. Checking receiver

. Headphone

. Microphone for transmitter

2-3-2. Setting

1. Set this unit by referring to Section 2-2-2.

2-3-3. Procedure

1. Set the channels of this unit and the checking receiver so that they match each other.

2. Make a voice toward the microphone, and check the sound with the headphone output of the checking

receiver.

3. Tap this unit lightly, and check the following.

. Sound can be heard clearly.

. Noise is not mixed.

. Sound is not interrupted.

. Audio input level meter is displayed in accordance with the sound.

2-4 (E)

UTX-P03

Page 19

2-4. Check of Sound Level

2-4-1. Required Equipment/Tool

. Audio analyzer

. Checking receiver

. Measuring cable BMP-XLR (male/female)

. Measuring cable XLR (female) - XLR (male)

2-4-2. Setting

. Transmitter (UTX-P03)

Transmission channel (GP/CH): Refer to “1. Transmission frequency” in Section 2-2-2.

Transmission level (RF POWER): H

Sound attenuator level (ATT): 0

Sound input level (IN LEVEL): MIC

. Receiver

Sound output level (OUTPUT LEVEL): 0

. Audio analyzer

Output: Level (_60 dBV)

Frequency (1 kHz)

Input: Filter (A-weighted)

2-4-3. Procedure

1. Connect each device according to the following illustration.

Measuring cable

XLR (female) – XLR (female)

Audio analyzer

Transmitter Receiver

Measuring cable

BMP-XLR (male)

2. Check the sound output level of this unit with the audio analyzer.

Specification:

Sound output level from the receiver: _60 dBV ?3 dB

UTX-P03

2-5 (E)

Page 20

2-5. Check of +48V

2-5-1. Required Equipment/Tool

. Tester

2-5-2. Procedure

1. Set “IN LEVEL” to “MIC” with the operation menu of this unit.

2. Set “+48 V” to “ON” with the operation menu of the main unit.

3. Measure the voltage between No.1 (minus) and No.2 (plus) of the Audio Input connector.

Specification: 43 ?3 V

2

1

3

Audio Input connector

2-6 (E)

UTX-P03

Page 21

Section 3

Spare Parts

3-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may not be stocked. Therefore, the

delivery date will be delayed.

4. Harness

Harnesses with no part number are not registered as

spare parts.

3-1. 補修部品注意事項

1. 安全重要部品

! 警告

! 印のついた部品は安全性を維持するために重要

な部品です。したがって,交換する時は必ず指定

の部品を使ってください。

2. 部品の共通化

ソニーから供給する補修用部品は,セットに使われて

いるものと異なることがあります。

これは部品の共通化,改良等によるものです。

3. 部品の在庫

部品表の SP(Supplycode)欄に“o”で示される部品は

在庫していないことがあり,納期が長くなることがあ

ります。

4. ハーネス

部品番号の記載されていないハーネスは,サービス部

品として登録されていません。

UTX-P03

3-1

Page 22

Case

3-2. Exploded Views

6

5

4

8

P2 x 8

1

7

3

8

2

No. Part No. SP Description

1 A-1901-011-A s BATTERY CASE (B) ASSY

2 A-2015-557-A s PLATE (P03) ASSY, BATTERY

3 X-2589-603-1 s UPPER CASE ASSY (P03)

4 4-527-780-01 s CASE (P03)

5 4-527-782-01 s BUTTON (P03), SET

6 4-527-783-01 s WINDOW (P03)

7 4-527-785-01 s CASE (P03), LOWER

8 4-645-214-72 s GRIP, M2

7-685-105-19 s SCREW +P 2X8 TYPE2 NON-SLIT

3-2

UTX-P03

Page 23

No. Part No. SP Description

101 A-2015-418-A s MOUNTED CIRCUIT BOARD, CPU-458

102 A-2015-423-A s MOUNTED CIRCUIT BOARD, RF-164 (UC14)

A-2015-424-A s MOUNTED CIRCUIT BOARD, RF-164 (UC30)

A-2015-425-A s MOUNTED CIRCUIT BOARD, RF-164 (UC42)

A-2015-426-A s MOUNTED CIRCUIT BOARD, RF-164 (CE21)

A-2015-427-A s MOUNTED CIRCUIT BOARD, RF-164 (CE33)

A-2015-428-A s MOUNTED CIRCUIT BOARD, RF-164 (CE42)

A-2015-429-A s MOUNTED CIRCUIT BOARD, RF-164 (CE51)

A-2015-632-A s MOUNTED CIRCUIT BOARD, RF-164 (E)

A-2042-774-A s MOUNTED CIRCUIT BOARD, RF-164 (KR)

103 A-2015-556-A s CONNECTOR ASSY (P03)

104 1-811-964-11 s LCD MODULE

105

105 3-318-203-11 s SCREW (B1.7X6), TAPPING

106 4-527-787-01 s LUG (P03), RF

7-627-553-88 s SCREW,PRECISION +P 2X7

7-627-852-37 s PRECISION SCREW +P1.7X1.8TYPE3

101

Chassis

104

105

103

P2 x 7

P1.7 x 1.8

105

106

102

UTX-P03

P2 x 7

P2 x 7

3-3

Page 24

3-3. Electrical Parts List

------------CPU-458 BOARD

------------ Ref. No.

or Q'ty Part No. SP Description

1pc A-2015-418-A s MOUNTED CIRCUIT BOARD, CPU-458

3-4. Packing Materials & Supplied

Accessories

---------------------------------------PACKING MATERIALS & SUPPLIED ACCESSORIES

--------------------------------------- Ref. No.

or Q'ty Part No. SP Description

1pc 2-693-884-11 s CASE, SOFT

1pc

!

4-530-734-01 s CD-ROM (INSTRUCTION MANUAL)

MANUAL (PDF), INSTRUCTION

-----------RF-164 BOARD

----------- Ref. No.

or Q'ty Part No. SP Description

1pc A-2015-423-A s MOUNTED CIRCUIT BOARD, RF-164 (UC14)

A-2015-424-A s MOUNTED CIRCUIT BOARD, RF-164 (UC30)

A-2015-425-A s MOUNTED CIRCUIT BOARD, RF-164 (UC42)

A-2015-426-A s MOUNTED CIRCUIT BOARD, RF-164 (CE21)

A-2015-427-A s MOUNTED CIRCUIT BOARD, RF-164 (CE33)

A-2015-428-A s MOUNTED CIRCUIT BOARD, RF-164 (CE42)

A-2015-429-A s MOUNTED CIRCUIT BOARD, RF-164 (CE51)

A-2015-632-A s MOUNTED CIRCUIT BOARD, RF-164 (E)

A-2042-774-A s MOUNTED CIRCUIT BOARD, RF-164 (KR)

QUICK START GUIDE(PDF)

FREQUENCY LIST (PDF)

(JAPANESE, ENGLISH, FRENCH,

GERMAN, ITALIAN, SPANISH, KOREAN,

TURKISH)

3-4

UTX-P03

Page 25

Section 4

Block Diagrams

4-1. Circuit Description

4-1-1. RF-164 Board

The RF-164 board consists of the following:

1. Audio circuit

2. Radio frequency circuit

1. Audio circuit

An audio signal is input from CN501. Power (48 VDC) for microphone phantom is supplied from

CN501. The phantom power is generated using a DC-DC converter (IC602) and ON/OFF-controlled

using CPU (IC404: CPU-458 board). The audio signal input from CN501 is selected as “LINE” or “MIC”

according to the input level using switches (PH501, PH502, and PH503). The audio signal selected on the

“LINE” side is attenuated by 24 dB using a resistance attenuator and input to a head amplifier (IC501).

The audio signal selected on the “MIC” side is input to a head amplifier (IC501).

The gain of the head amplifier is controlled by CPU (IC404: CPU-458 board). Gain setting can be selected in ten level using “AF ATT” in an operation menu (only during “MIC” selection). The audio signal

whose volume was controlled by gain setting is input to DSP (IC506). DSP processes a compander or

tone signal.

The compander or tone signal is selected using “COMPANDER” in an operation menu.

2. Radio frequency circuit

An oscillator circuit is based on a PLL frequency synthesizer system.

The audio signal that was processed using DSP is input through a low-pass filter (LPF) to VCO (VoltageControlled Oscillator) (VCO201) for modulation. The modulated audio signal is then processed as a radio

frequency (RF) signal.

The RF signal amplified using a radio frequency amplifier (consisting of Q204 and Q206) is adjusted in

an output level using IC205 and IC209 that are controlled by CPU, input to LPF and isolators (ISO201

and ISO202), and radiated from an antenna.

4-1-2. CPU-458 Board

The CPU-458 board consists of the following:

1. CPU

2. Power circuit

1. CPU

CPU (IC403) controls various functions of this unit.

. RF signal output level . LCD display . USB connection

. PLL . LED display . Current control

. DSP . Button operation . Charge control

. Audio signal level . Infrared operation . Remaining battery detection

. 48 VDC power control

The information below is recorded in EEPROM and controlled by CPU.

EEPROM1 (RF-164 board): . Electrical alignment information . Destination information

EEPROM2 (CPU-458 board): . Last memory . Software for main unit control

UTX-P03

4-1 (E)

Page 26

2. Power circuit

The power circuit of UTX-P03 has the four functions below.

(1) Driving by dry battery

(2) Driving by USB power

(3) Charging to nickel metal hydride by USB power

(4) Circuit power generation from various input power supplies

(1) Driving by dry battery

The power (3 VDC) input from a dry battery is supplied to DC-DC converters (IC107 and IC109) through

CN102.

(2) Driving by USB power

UTX-P03 can be operated by the power (+5 V) supplied from USB.

The power input from a USB terminal is generated as +3.65 V using a DC-DC converter (IC106) and

supplied from CN403 to an RF-163 board through a transistor switch (Q109). At that time, USB power is

selected when the voltage input from the USB terminal is detected by CPU (IC404). Power is switched to

the dry battery side when the power supply from the USB terminal is interrupted. (The USB power has

priority.)

(3) Charging to nickel metal hydride by USB power

The power (+5 V) input from a USB terminal is generated as +3.65 V using a DC-DC converter (IC106)

and input to a transistor switch (Q109). The voltage input from the USB terminal is detected using CPU

(IC404). It turns on a transistor switch (Q106) and supplies USB power to a charging control circuit

(IC108). In the charging control circuit (IC108), the internal resistance values of batteries are read from

the voltages of two batteries for charging control. The charging control circuit (IC108) controls Q111,

Q112, and Q113 to perform charging.

(4) Circuit power generation from various input power supplies

A circuit power of +3.3 V and +5.5 V is generated from various input power supplies.

Various power supplies selected using Q101, Q104, and Q109 generate +3.3 V in a DC-DC converter

(IC107) and generate +5.5 V in IC109. The circuit power is supplied from CN403 to an RF-164 board.

4-2 (E)

UTX-P03

Page 27

4-2. Overall Block Diagrams

OverallOverall

XLA 3P

CN-3708

RF-164

CN501

IC602

+5.5V

48V

DDC

+48V

48V_SHDN

48V_LOAD

to CPU

PH501

PH502

PH503

LINE

ATT

MIC

24 dB

IC602

+5V

REG

IC501

IC503

GAIN

CONTROL

+5.0V

HEAD

AMP

AF ATT

to CPU

IC506

X501

TCXO

26 MHz

DSP

DSP

to CPU

MOD

LPF

IC203

ACTIVE

LOOP FILTER

X201

TCXO

19.2 MHz

IC204

VCO201

IC201

+5.5V

+5 V

REG

+5.0V

VCO

Vt

LOOP

FILTER

PLL

Q202

+3.3V

Q204

IC209

DIGITAL

POTENTIOMETER

Q206

RF ADJ (2)

PLL

IC205

RF POWER ADJ

RF ADJ (1)

*1

ISO201: UC14. CE21

ISO202: UC30, UC42, CE33, CE42, CE51

*1

ISO201

ISO202

LPF

ISOLATOR

J201

RF TEST

POINT

DC 3 V

CHARGE

VOLTAGE

CHECK

MicroUSB

CPU-458

CN102

CN101

Q101, Q104

Q106

Q112

Q113

BATT

CHECK

to CPU

IC108

BATTERY

CHARGE

CONTROLER

Q111

CONSTUNT

CURRENT

FET

IC106

+3.65 V

DDC

IC101

USBUART

Q109

IC107

+3.3 V

DDC

IC109

+5.5 V

DDC

CPU

+3.3 V

Q114

+3.3 V

+5.5 V

AF ATT

from IC503

DSP

from IC506

POWER

CHARGE LED

BATT

CHECK

from CN102

USB POWER DETECT

USB FIRMWARE WRITING

CPU

CN502

CN403

IC404

48V_SHDN

48V_LOAD

from IC602

IC208

EEPROM1

EEPROM2

TACT SW

IR

RECEIVER

IC402

LED

CN401

LCD

Overall

UTX-P03

4-3

4-3

Page 28

4-3. Frame Wiring

CONNECTOR ASSEMBLY (P03)

XLA 3P

Frame WiringFrame Wiring

RF-164

CN-3708

DC 3 V

CN501

1HOT

COLD

2

GND

3

CPU-458

CN102

1 BATT_

NC

2

NC

3

BATT+/_

4

NC5

NC6

BATT+7

CN101

CN502

CN403

J201

CN401

RF TEST

POINT

LCD

MicroUSB

Frame Wiring

4-4

4-4

UTX-P03

Page 29

Page 30

UTX-P03 (CE)

UTX-P03 (E)

UTX-P03 (KR)

UTX-P03 (UC) J, E

9-878-548-01

Sony Corporation

Printed in Japan

2014. 1 08

©2014

Loading...

Loading...