Page 1

STR-DE1015G

SERVICE MANUAL

US Model

Canadian Model

SPECIFICATIONS

— Continued on next page —

MICROFILM

FM STEREO FM-AM RECEIVER

— 1 —

Page 2

— 2 —

Page 3

TABLE OF CONTENTS

SAFETY CHECK-OUT

1. SERVICING NOTE

.......................................................... 4

2. GENERAL .......................................................................... 5

3. DISASSEMBLY

3-1. Front Panel .......................................................................... 26

3-2. Balance Board, Display Board and Volume Board............. 26

4. TEST MODE ..................................................................... 27

5. ELECTRICAL ADJUSTMENTS ............................... 28

6. DIAGRAMS

6-1. IC Pin Functions................................................................. 30

6-2. Circuit Boards Location ...................................................... 47

6-3. Block Diagrams

• Input/Output Section........................................................ 49

• Power Amp Section ......................................................... 51

• DA Section....................................................................... 53

• DSP Section ..................................................................... 55

• AC-3 (RF) Section........................................................... 57

• OSD Section .................................................................... 59

• OSD Control Section ....................................................... 61

• Panel Section ................................................................... 63

• Power Section .................................................................. 65

6-4. Printed Wiring Board — Input/Output Section — ............. 68

6-5. Schematic Diagram — Input/Output Section — ................ 71

6-6. Schematic Diagram — Power Amp Section —.................. 75

6-7. Printed Wiring Board — Power Amp Section — ............... 79

6-8. Printed Wiring Board — Digital Section — ....................... 83

6-9. Schematic Diagram — Digital (D/A) Section — ............... 87

6-10. Schematic Diagram — Digital (Control) Section — ....... 91

6-11. Schematic Diagram

— Digital (Dolby AC-3) Section —................................. 95

6-12. Printed Wiring Board — Panel Section —....................... 98

6-13. Schematic Diagram — Panel Section — ....................... 101

6-14. Schematic Diagram — OSD Section — ........................ 105

6-15. Printed Wiring Board — OSD Section —...................... 109

6-16. IC Block Diagrams......................................................... 112

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

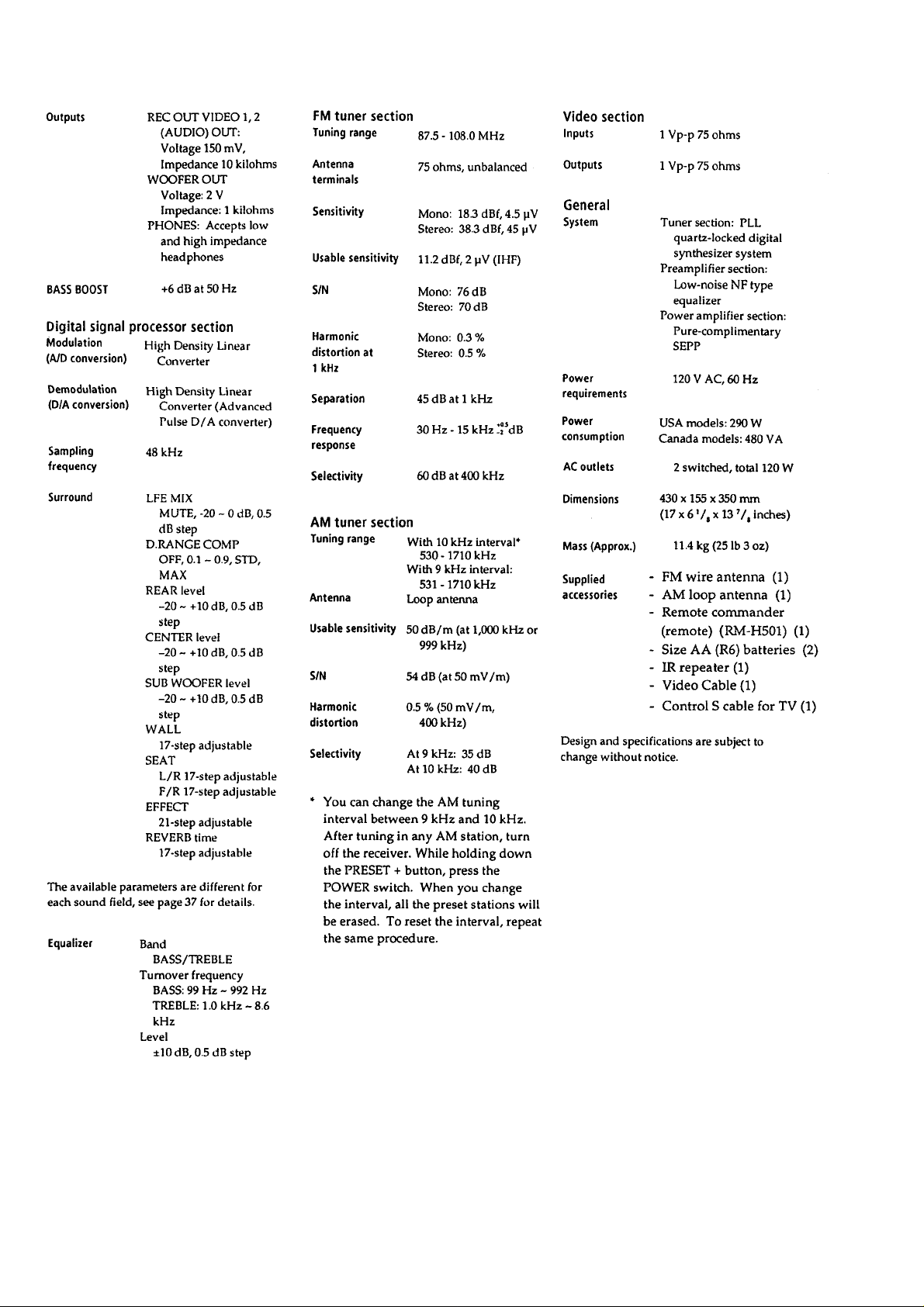

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated A C v oltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15µF

1.5k

Ω

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

7. EXPLODED VIEWS

7-1. Case Section...................................................................... 117

7-2. Front panel Section ........................................................... 118

7-3. OSD Board Section........................................................... 119

7-4. Chassis Section ................................................................. 120

8. ELECTRICAL PARTS LIST ...................................... 121

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

4-989-885-4

4-989-885-5

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLA CER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

US model

Canadian model

À LA SÉCURITÉ!!

Model

— 3 —

Parts No.

Page 4

SECTION 1

SERVICING NOTE

ALL CLEAR

Mode which erases all the user memories registered in this unit and

sets to setting at shipment.

Procedure:

1. With the power turned OFF, press the POWER button while

pressing the MODE button, AUDIO FUNCTION > and

VIDEO FUNCTION > button simultaneously to turn ON the

power.

2. ALL CLEAR 3/5 will be displayed on the fluorescent indicator

tube, and ALL CLEAR will be executed.

FACTORY SET

Mode which sets the memory of the unit to the setting of adjustment and check at factory. (Not used for servicing.)

Procedure:

1. With the power turned OFF, press the POWER button while

pressing the MODE button and AUDIO FUNCTION > button

simultaneously to turn ON the power.

2. FACTORY SET will be displayed on the fluorescent indicator

tube, and FACTORY SET will be executed.

Note: In case you return the unit to the customer, do not perform

FACTRY SET. If you do it, perform ALL CLEAR.

Fluorescent indicator tube, LED all lit mode

Adjustment of OSD Screen Position

The position of the screen can be adjusted freely to correct the deviation of the OSD screen caused by the monitor type that users are

using.

1. Move the cursor of the remote commander supplied as an accessory, and display the OSD screen.

2. Click the SET UP of the OSD screen.

3. Next click TV SET.

4. Next click GRAPHIC POSITION SET.

5. The screen for adjusting the OSD screen position will be displayed. Adjust the position with the remote commander supplied

as an accessory.

6. Click EXIT to end.

AM Tuning Step 9 kHz/10 kHz Selection

Method:

1. Turn ON the power, set the AUDIO FUNCTION to AM, and

turn OFF the power.

2. While pressing the TUNING + button or PRESET TUNING +

button, press the POWER button.

3. “AM 9K STEP” or “AM 10k STEP” will be displayed on the FL

display tube.

Procedure:

1. With the power turned OFF, press the POWER button while

pressing the MODE button and VIDEO FUNCTION > b utton

simultaneously to turn ON the power.

2. The fluorescent display tubes and LEDs will all light up. Release the buttons in the order of VIDEO FUNCTION > , and

MODE .

3. The Fluorescent indicator tube display changes as follows by

pressing the DPC MODE .

(Pressing the other buttons will exit this mode.)

9

Fluorescent indicator tubes, LEDs are all lit

DIGITAL

12345

AC-3 RF

SOUND FIELD

DISCRETE PRO LOGIC MONO STEREO

• Press DPC MODE button.

9

Partial lighting of fluorescent indicator tube 1, LEDs are OFF *1

• Press DPC MODE button.

9

Partial lighting of fluorescent indicator tube 2, LEDs are OFF *1

MEMORY

• Press DPC MODE button.

9

Fluorescent indicator tube and all LEDs are OFF

• Press DPC MODE button.

9

*1 Those other than the POWER LED go OFF.

4. To exit the mode, press the POWER button to turn OFF the

power.

— 4 —

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

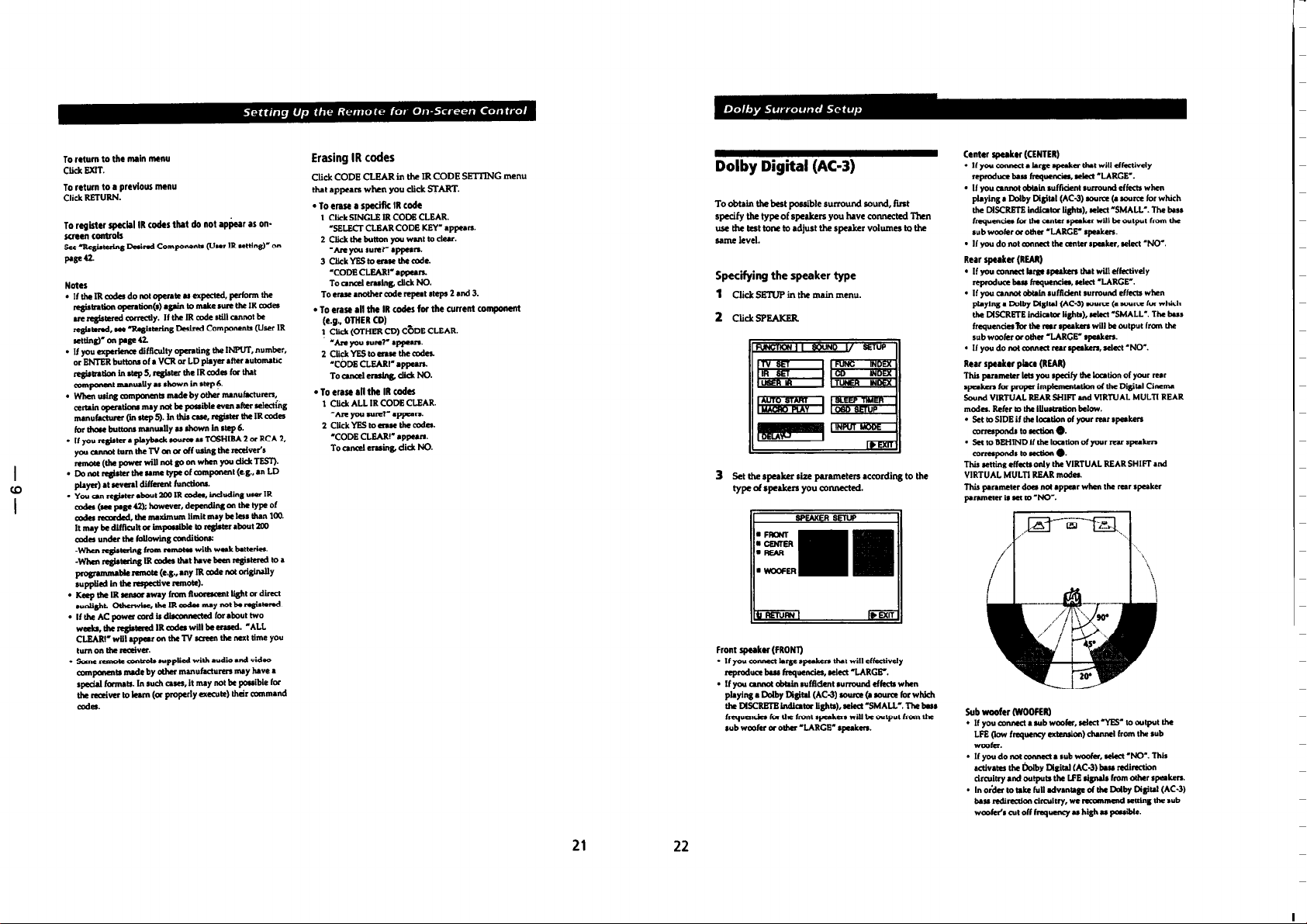

Page 21

Page 22

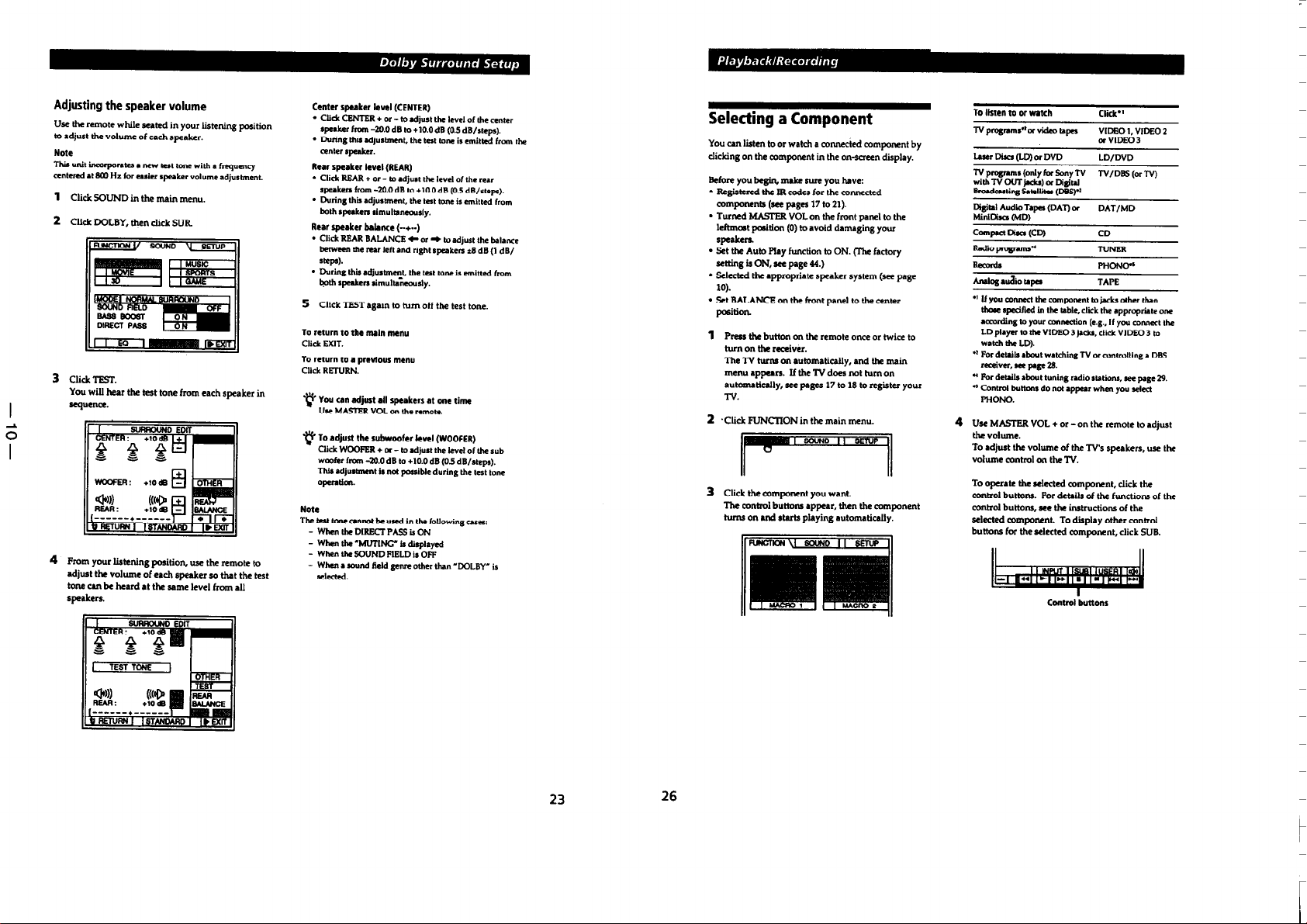

Page 23

Page 24

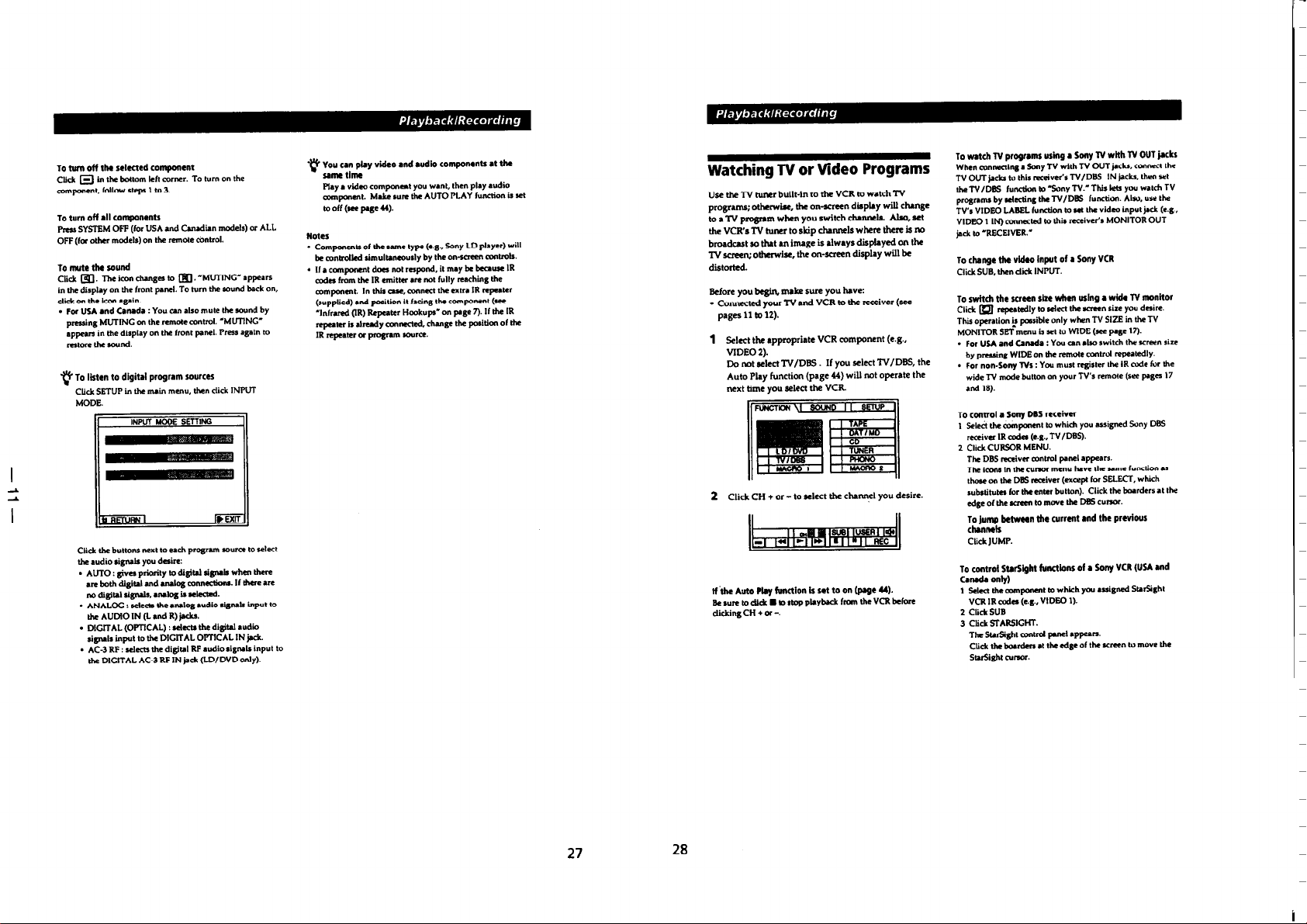

Page 25

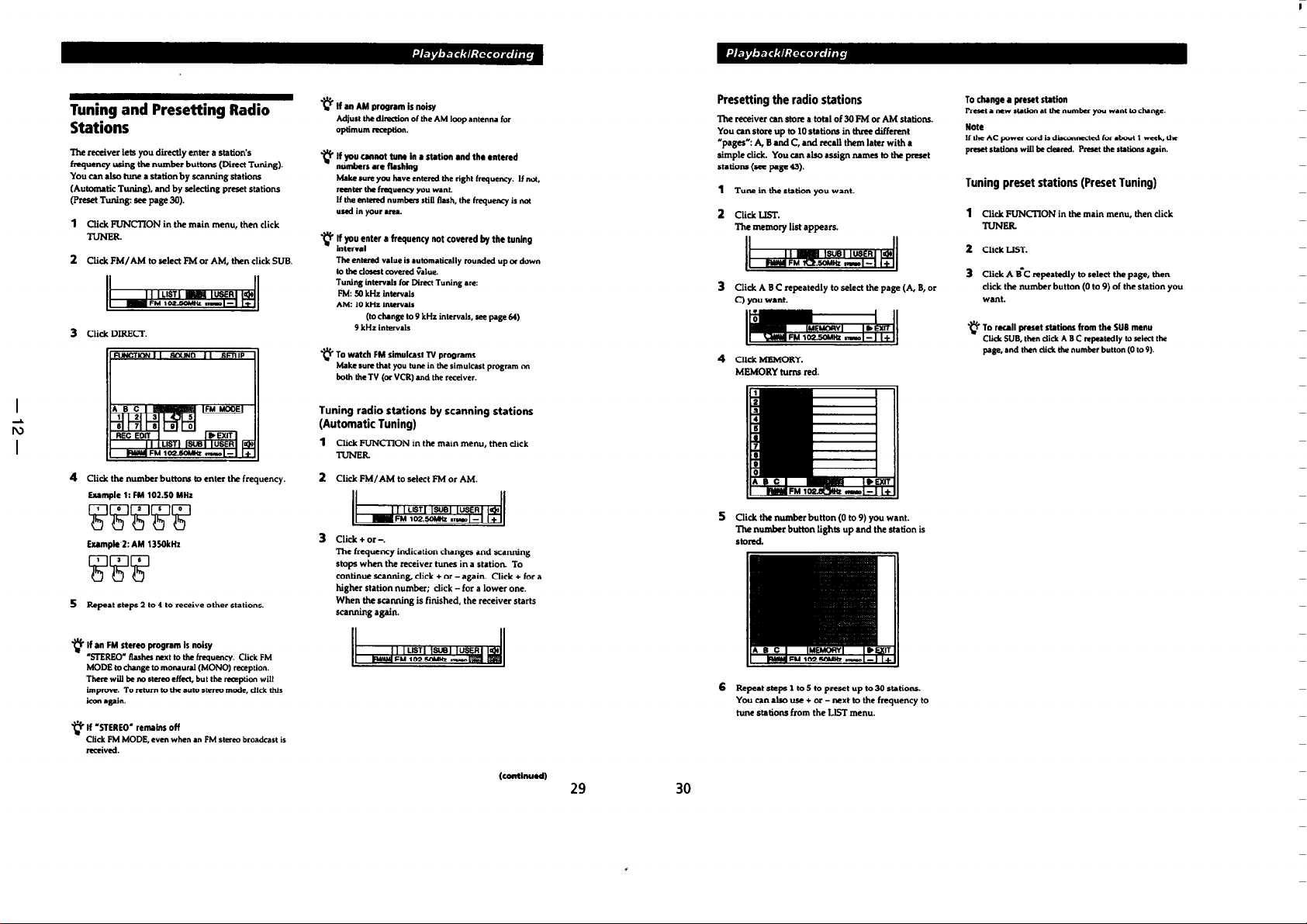

Page 26

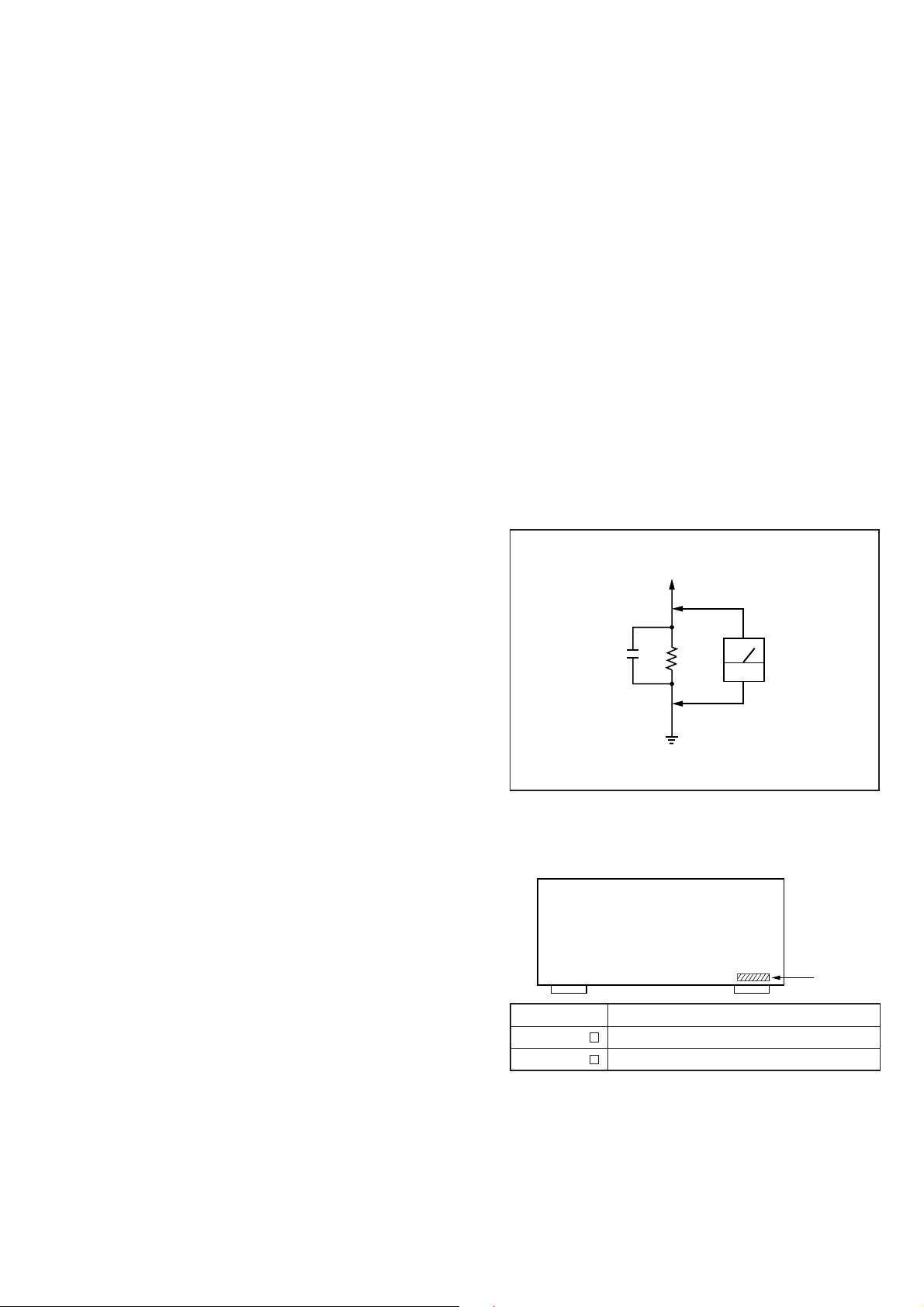

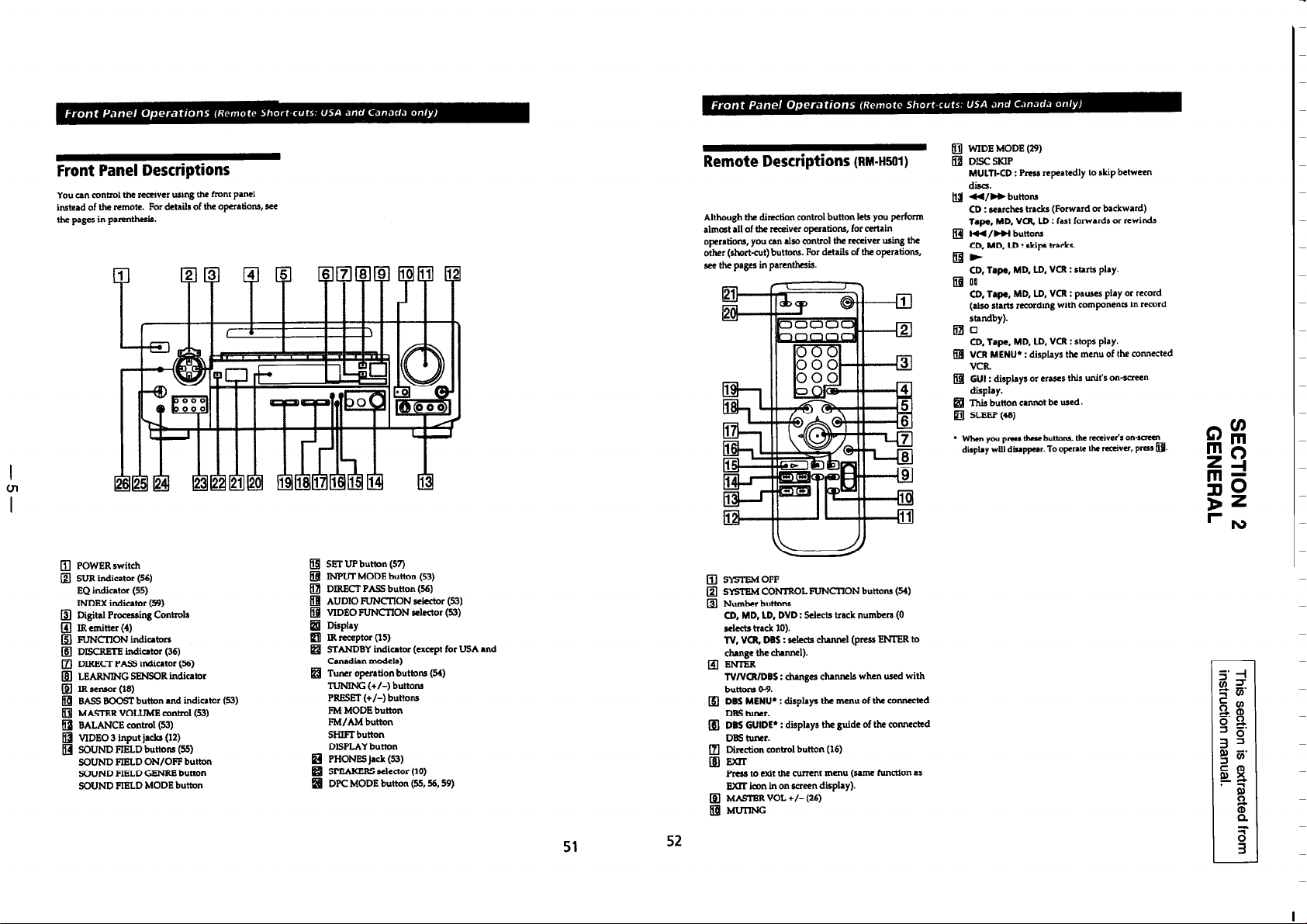

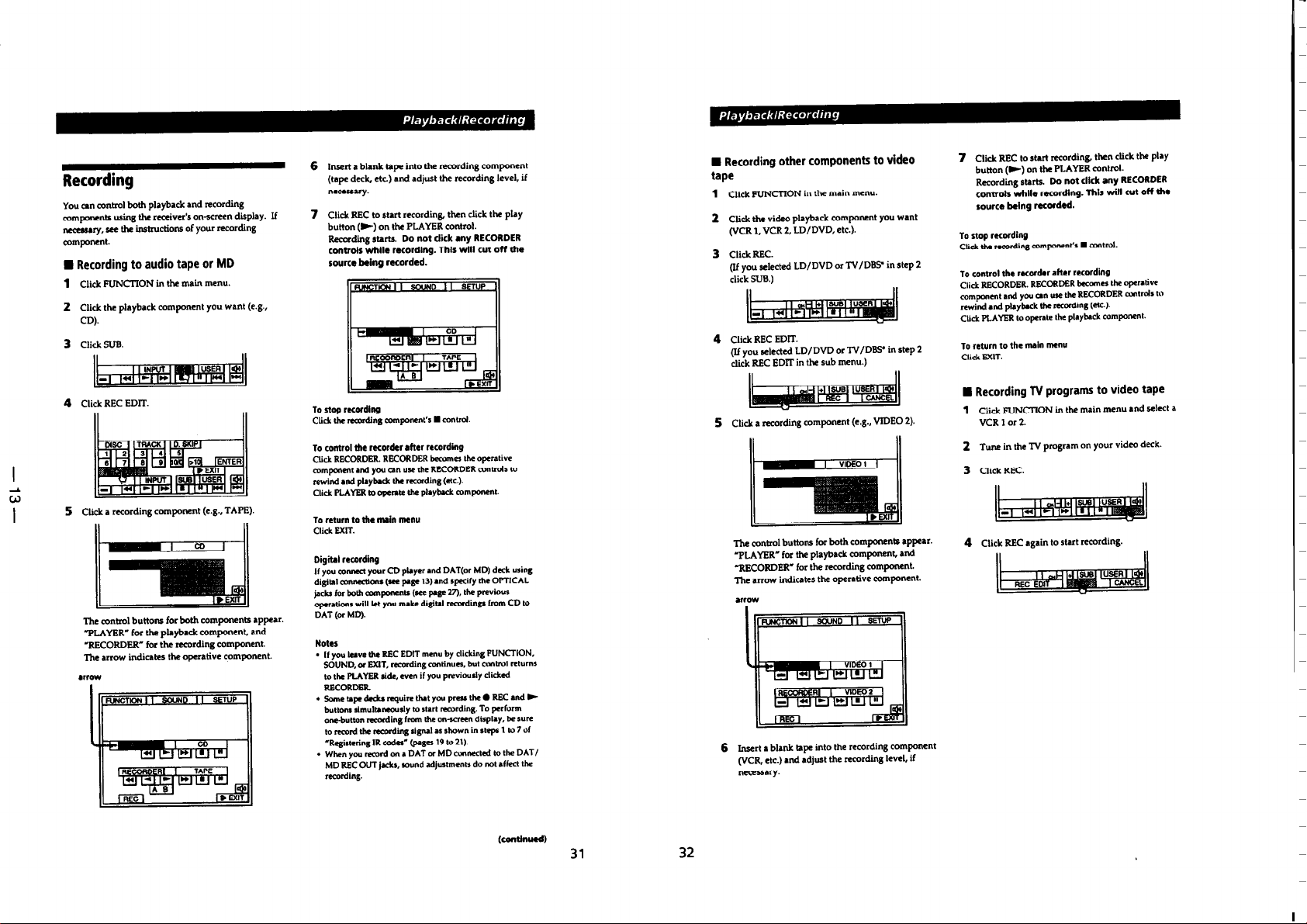

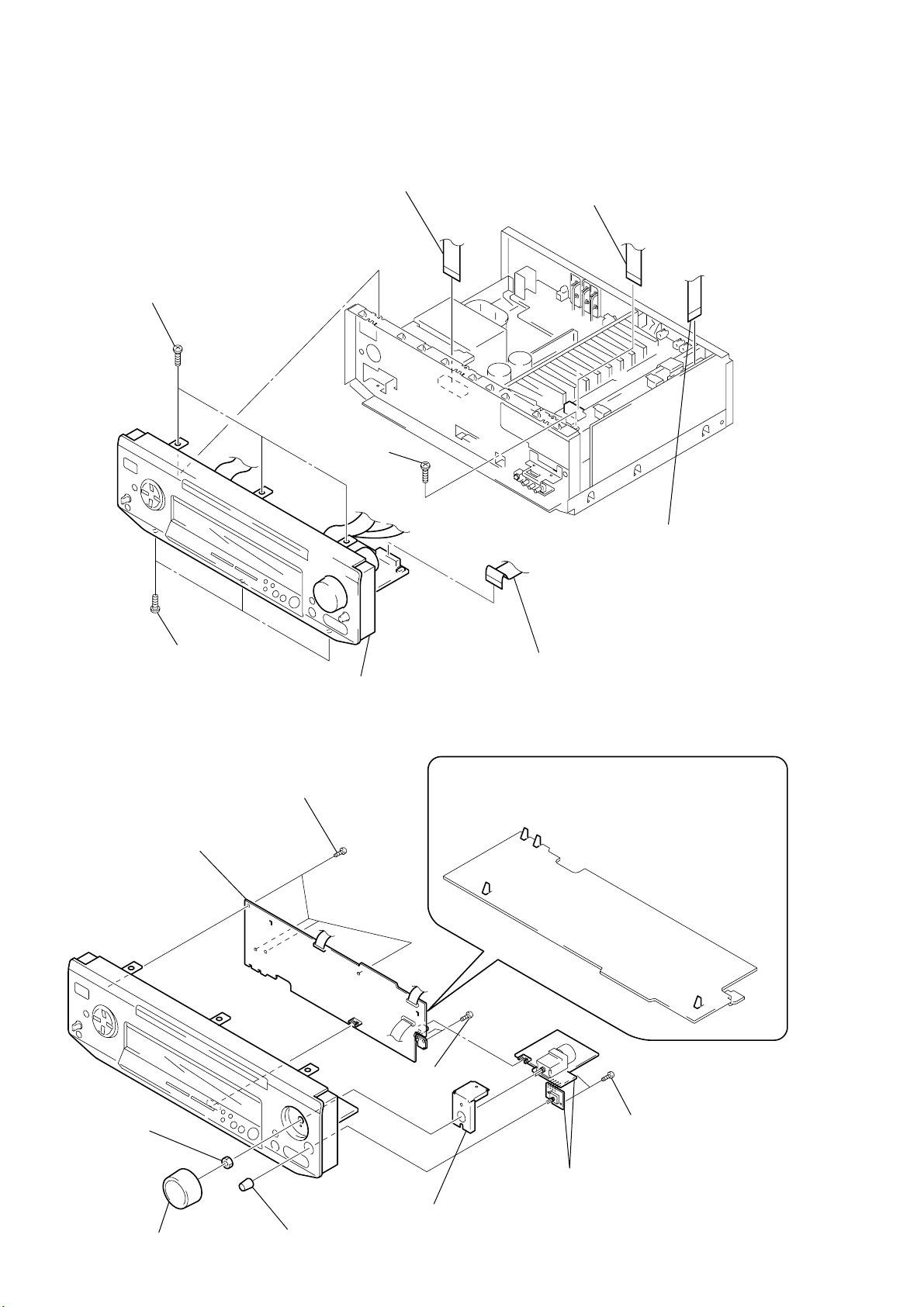

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

3-1. FRONT PANEL

3

Flat type wire (19 core)

(CNS701)

1

Three screws

(BVTP3x8)

2

Screw

(BVTP3x8)

4

Flat type wire (CNJ203)

6

Three screws

(BVTP3x8)

7

Front panel

3-2. BALANCE BOARD, DISPLAY BOARD AND VOLUME BOARD

8

0

DISPLAY board

Four screws

(BVTP2.6x8)

9

Remove the four claws.

5

Flat type wire (21 core)

(CN3301)

8

Flat type wire (19 core)

(CNS402)

2

Nut

1

Knob

(Volume)

3

Knob

(Balance)

7

Two screws

(BVTP2.6x8)

6

— 26 —

Bracket

5

BALANCE board and

VOLUME board

4

Two screws

(BVTP2.6x8)

Page 27

SECTION 4

TEST MODE

Self-Diagnosis and Test Mode

This unit is provided with a “self-diagnosis and self-recovery function” which detects DSP errors and automatically recovers the unit,

and a test mode for performing operation checks during repairs.

1. MAIN FUNCTIONS

• DSP self-diagnosis program for servicing and operation check

mode.

2. ENTERING THE TEST MODE

While pressing the MODE button and AUDIO FUNCTION <

button simultaneously in the power OFF state, press the POWER

button.

3. Self-diagnosis Mode for Servicing/Display of DSP

Errors

3-1. Self-diagnosis Mode for Servicing

Before entering the test mode, DSP self-diagnosis program for servicing will be run.

• When an error is detected:

The error message is displayed on the fluorescent display tube.

When several errors occur at the same time, only the last error

detected will be displayed.

4. OPERATION CHECK MODE

Outputs the Lch LD/DVD OPTICAL signal to the FRONT Lch,

REAR Lch, CENTER, and the Rch to the FRONT Rch, REAR Rch,

and CENTER.

5. NOTE AFTER USING THE TEST MODE

Be sure to unplug the AC plug after the test mode is performed.

• When no error is detected:

First, “DSP ERROR” will be displayed, then “DSP NO ERROR”

will be displayed, and the operation check mode will be set.

Table-1:

Error Message/Fluorescent Display Tube

DSP ERROR

When a DSP error is detected, after this display, the contents of “3-2. Display of DSP Operations” will be displayed.

Possible Reasons

3-2. Display of DSP Operations

Display of error Possible cause

1

1 DSP BOOT

2

ERROR

1

2 DSP HREQ

2

ERROR

1

3 DSP VRFY

2

ERROR

4 DSP 1 RPLY

Mostly due to faulty connection (soldering) between

DSP and microprocessor

Faulty DSP clock (X3501 and onwards), faulty DSP

part, etc.

Overrunning of DSP due to heat, microprocessor

bugging, or IC3409 (DIGIT AL board PLL) is faulty

Faulty DSP part, or faulty microprocessor part, etc.

— 27 —

Page 28

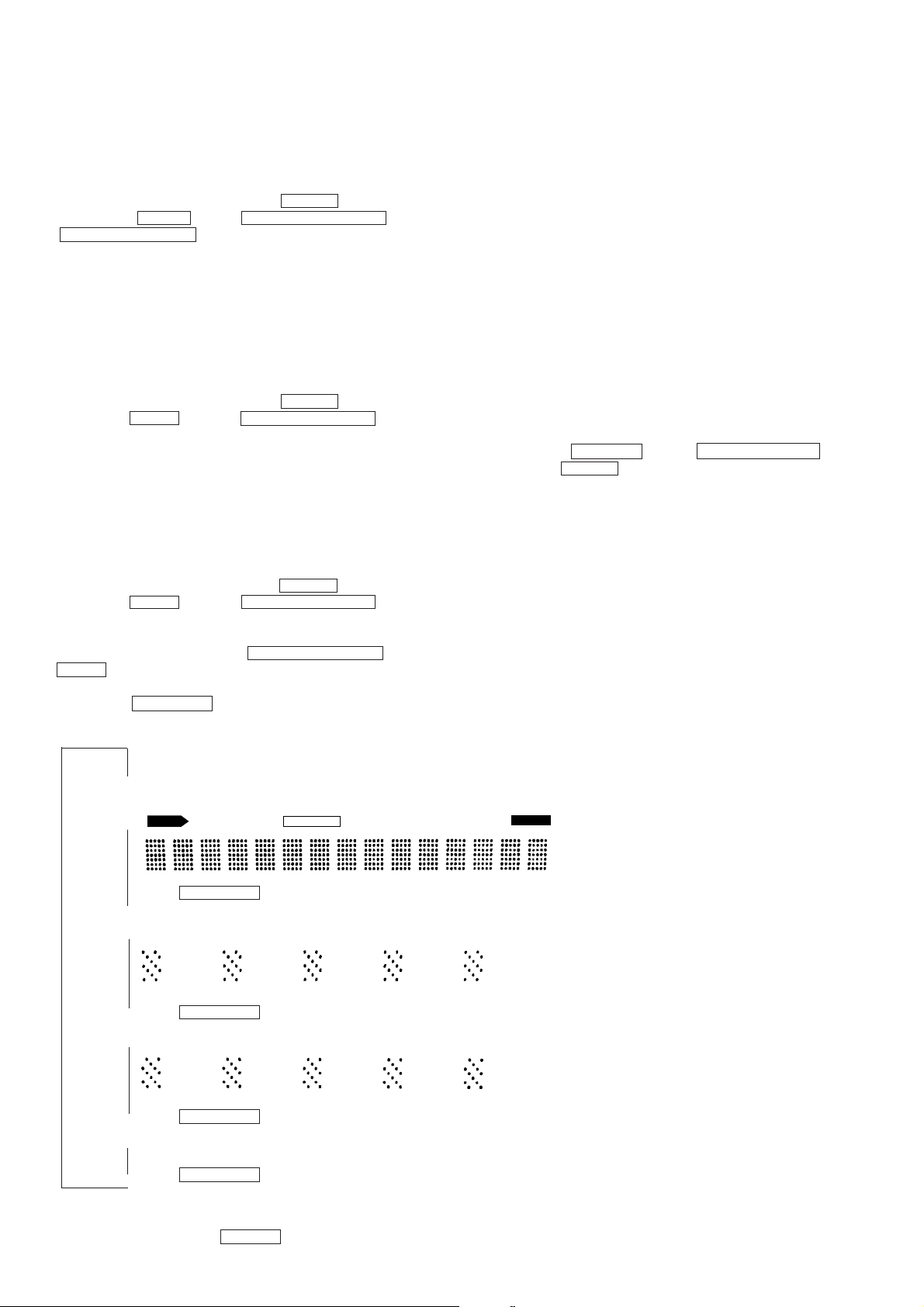

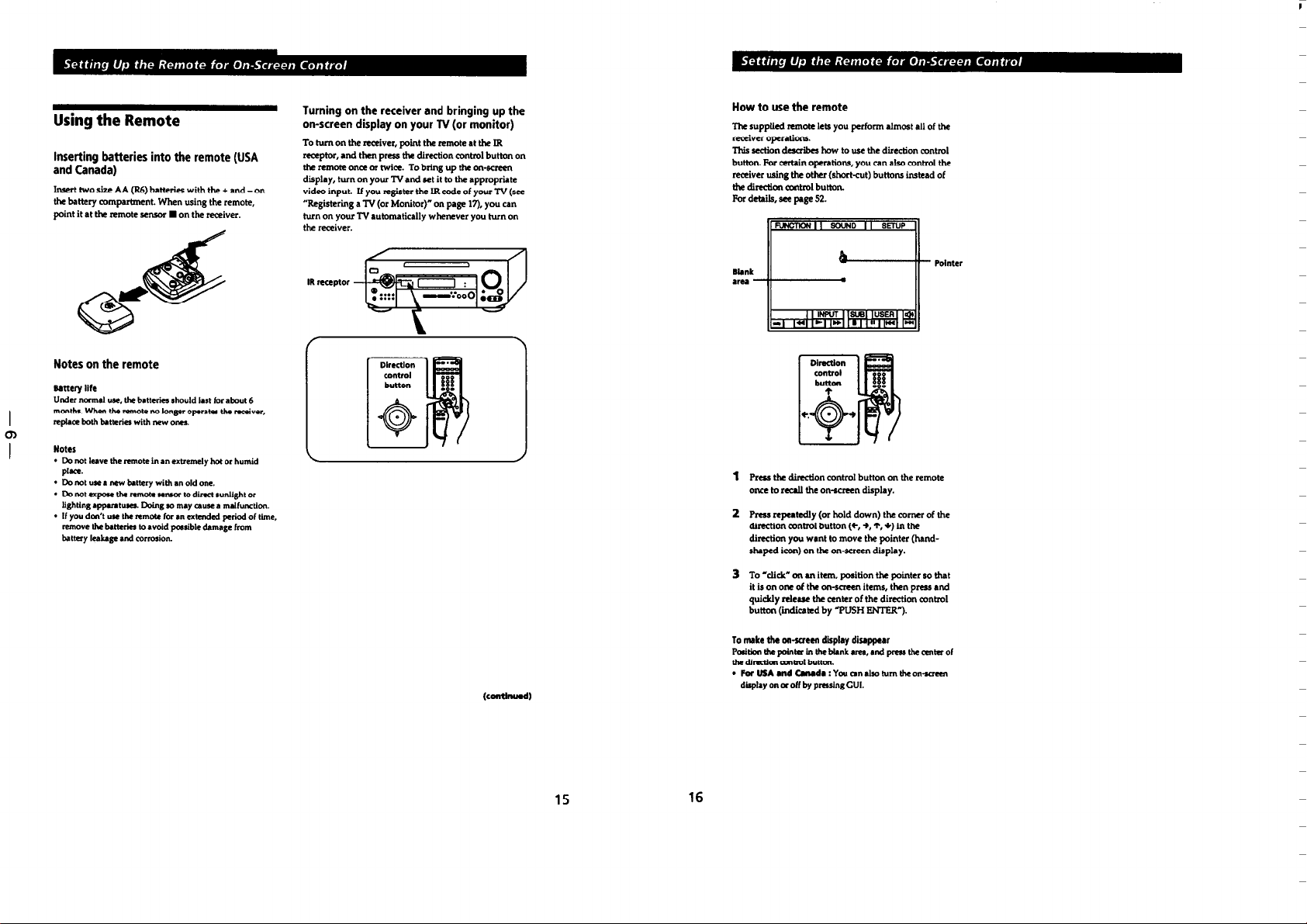

SECTION 5

r

ELECTRICAL ADJUSTMENT

TUNER SECTION

No adjustment is needed due to a tuner unit (TU401).

OSD SECTION

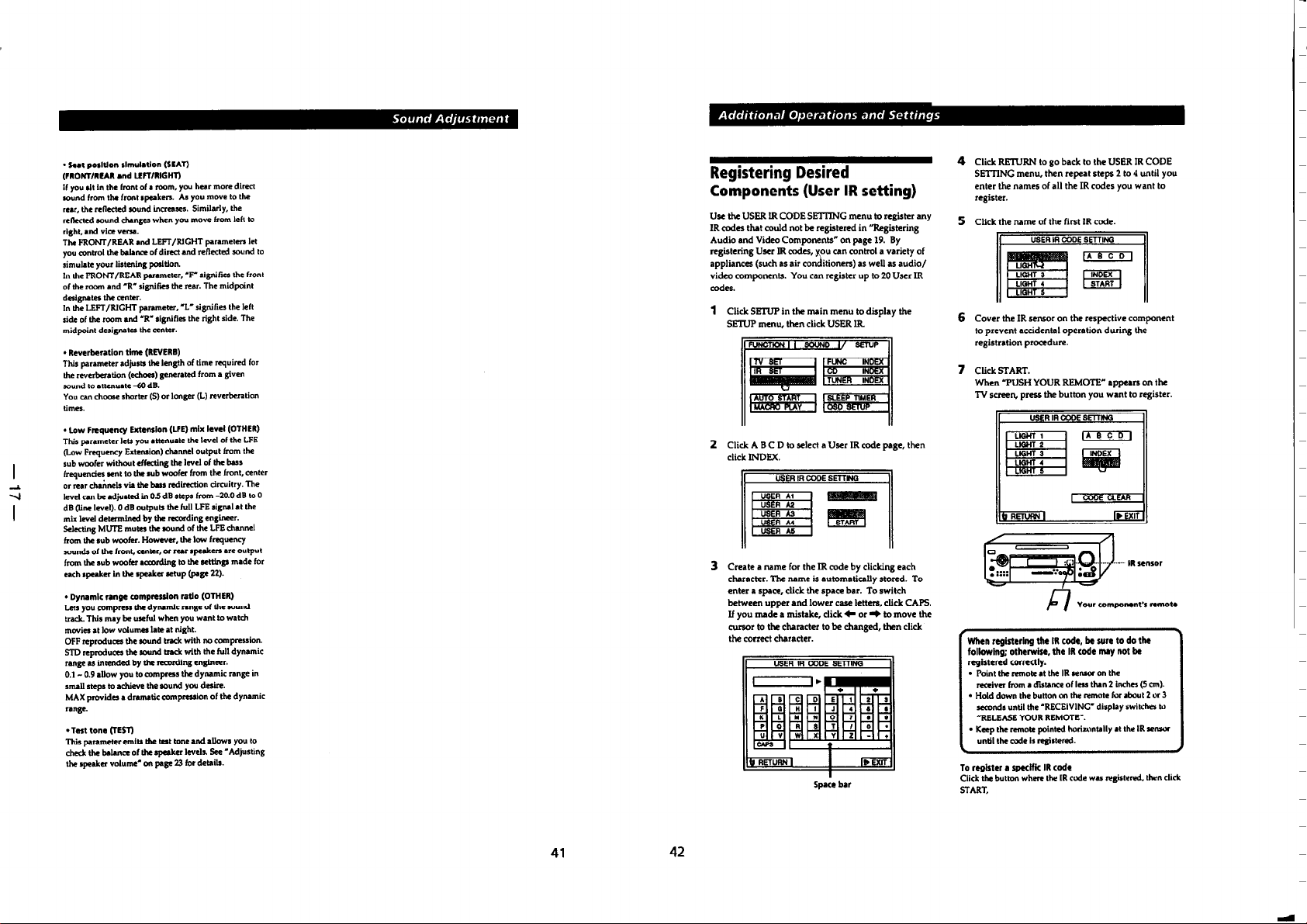

OSD WIDTH Adjustment

Note: Perform “ALL CLEAR” before this adjustment.

(Refer to Servicing note on page 4)

Connection:

MONITOR OUT

SET

Procedure:

1. Press the POWER button and turn ON the power.

2. The OSD function frame will be displayed on the monitor. This

screen will disappear in a few seconds automatically when the

input of codes using the remote commander stops.

If it disappears during adjustments, move the cursor of the remote commander supplied as an accessory. The screen will appear again.

3. While watching the monitor screen, adjust CT201 of the OSD

(V) board so that the following adjustment standard is satisfied.

monitor screen

Monitor

OSD COLOR BURST Adjustment

Connection:

frequency counte

OSD (V) board

JW232

+

–

Procedure:

1. Without anything connected to the external input terminal, press

the POWER button and turn ON the power.

2. Adjust CT202 of the OSD (V) board so that the reading on the

frequency counter becomes 3.579545 MHz ± 10 MHz.

OSD PICTURE Adjustment

Connection:

Connection 1:

Vectorscope

set

MONITOR OUT

Connection 2:

Monitor

FUNCTION SOUND SETUP

F1

A

OSD function frame

INPUT SUB USER

FPFpF)F(F0

F=

F™

F+

B

Adjustment standard:

Adjust so that the width B becomes one and a half times of width A.

1.5A = B

NOTE:

Extra margin is provided in this adjustment in consideration of the

deviation of the screen according to the type of monitor used.

Consequently, the user is able to adjust the position of the screen

freely. (For details, refer to “Adjustment of OSD Screen Position”

in 1. Servicing note. Refer to page 4.)

Monitor

VTR etc.

VIDEO 1 IN

Vectorscope

set

MONITOR OUT

Procedure 1:

1. Without anything connected to the external input terminal (connection 1), press the POWER button and turn ON the power.

2. Check that the OSD function frame screen is displayed on the

monitor. If no OSD function frame screen is displayed, move

the cursor button of the remote commander supplied as an accessory provided to display the screen.

3. Observe the vectorscope, and adjust RV201 of the OSD (V) board

so that the light dots converge in the BLUE area.

4. Connect a dynamic picture video device to the external input

terminal (VIDEO 1 IN jack) of this unit (Connection 2).

5. Press the VIDEO FUNCTION button and set the input source

to VIDEO 1.

6. Move the cursor of the remote commander supplied as an accessory provided, and display the OSD function frame.

7. Observe the vectorscope. Check that the light dots in the BLUE

range and the light dots adjusted at 3 are coinciding.

8. If they do not coincide, disconnect the external video device,

and adjust RV201 of the OSD (V) board again.

9. If the light dots when an external video device is connected and

not connected coincide, it indicates the end of the adjustment.

— 28 —

Page 29

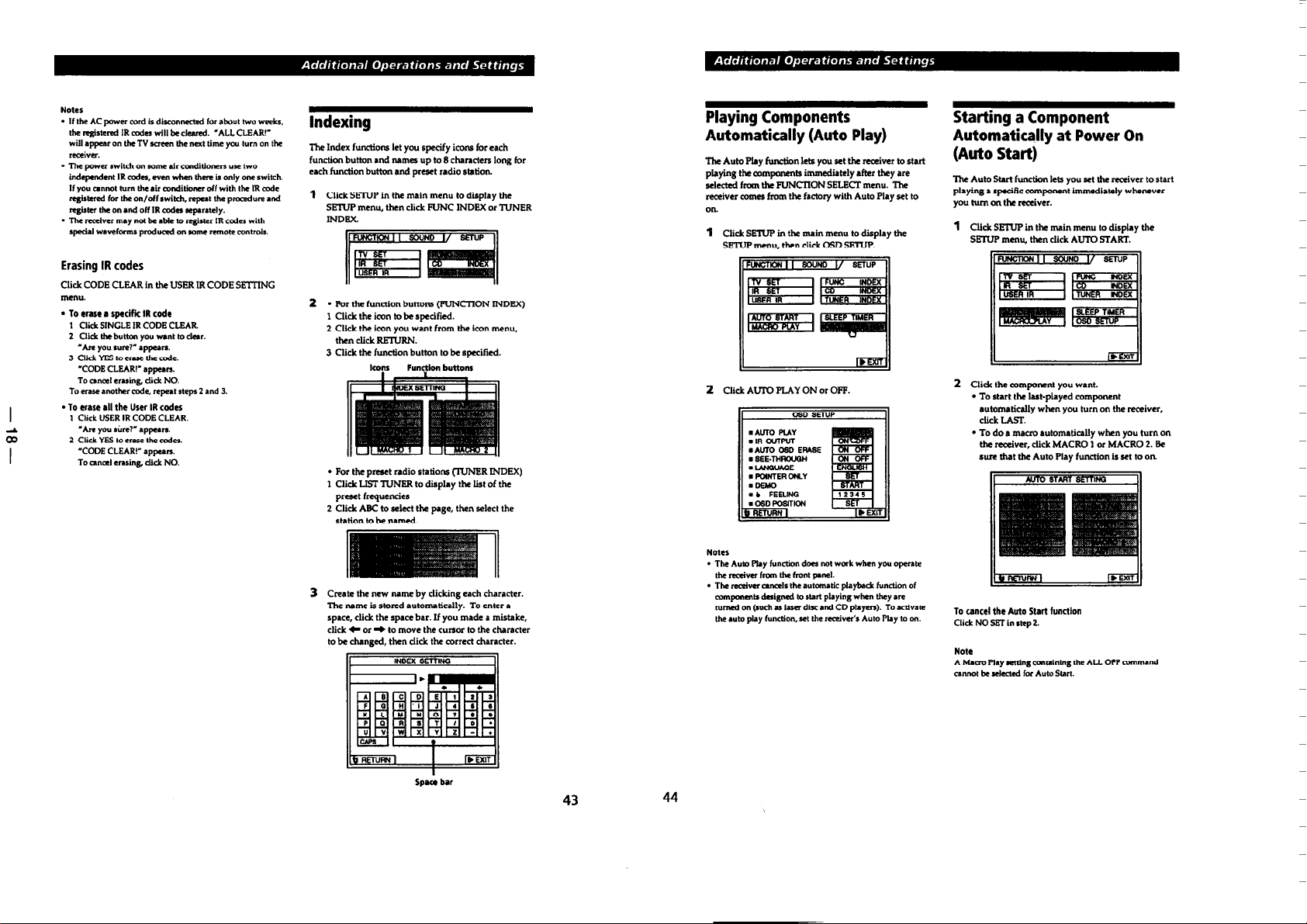

Procedure 2: (When no vectorscope is used)

monitor screen

FUNCTION SOUND SETUP

INPUT SUB USER

F™

F+

F=

FPFpF)F(F0

F1

OSD function frame

Blue area

Green area

Connection:

VTR etc. Monitor

VIDEO 1 IN

set

MONITOR OUT

Monitor

1. Connect a dynamic picture video device to the VIDEO 1 IN

jack of the unit.

2. Press the VIDEO FUNCTION button, and set the input source

to VIDEO 1.

3. Move the cursor of the remote commander supplied as an accessory provided, and display the OSD function frame.

4. Take note of the blue and green screens at the bottom left of the

OSD function frame.

5. Disconnect the video device connected at 1.

6. Adjust RV201 of the OSD (V) board so that the blue and green

parts at the bottom left of the OSD function frame to the same

color as the images checked at 4.

Note) Perform this adjustment when disconnecting the external video de-

vice. If the external video device is connected, there is no meaning

in performing this adjustment due to the use of the color burst of the

external device instead of the internal sync signal.

Adjustment Location

[OSD (V) BOARD] (Component side)

OSD COLOR BURST

JW232

OSD WIDTH

OSD PICTURE

IC215

CT201

CNP202

CT202

IC205

RV201

— 29 —

Page 30

6-1. IC PIN FUNCTIONS

• IC103 Mode controller (MB90673PF)

Pin No. Pin Name

MBUS-V2

1

MBUS-MON

2

MBUS-STATUS-OUT

3

—

4

—

5

—

6

LED STANDBY

7

LED SURR

8

LED TONE

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

LED INDEX

VSS

LED CD

LED DAT/MD

LED TAPE

LED TV

LED LD

LED V3

LED V2

LED V1

RX (SIN)

TX (SOUT)

BUSY

FL CLEAR

FL DATA

FL CLK

FL LAT

SIRCS

VCC (A)

+AVR

–AVR

GND (D)

AD KEY IN 1

AD KEY IN 2

VSS (D)

AD KEY IN 3

AD KEY IN 4

AD KEY IN 5

AD VERSION

VOL +

VOL –

SECTION 6

DIAGRAMS

I/O

–

Not used

–

Not used

–

Not used

–

Not used

–

Not used

–

Not used

O

STANDBY indicator drive signal output

O

SURROUND indicator drive signal output

O

TONE indicator drive signal output

O

INDEX indicator drive signal output

–

Ground

O

CD indicator drive signal output

O

DAT/MD indicator drive signal output

O

TAPE indicator drive signal output

O

TV indicator drive signal output

O

LD indicator drive signal output

O

VIDEO3 indicator drive signal output

O

VIDEO2 indicator drive signal output

O

VIDEO1 indicator drive signal output

O

Serial data output to OSD controller

I

Serial data input from OSD controller

I/O

Serial clock input/output with OSD controller

O

FL clear signal output to FL driver “H” : active

O

FL data output to FL diver

O

FL clock output to FL diver

O

FL latch output to FL driver “H” : active

I

Remote control signal input

–

+5V power supply (Back-up)

I

Reference voltage input (+) (+5V)

I

Reference voltage input (–) (Ground)

–

Ground

I

Key input 1

I

Key input 2

–

Ground

I

Key input 3

I

Key input 4

I

Key input 5

I

AD version setting input

O

Volume motor control signal output

O

Volume motor control signal output

Function

Function

• Abbreviation

OSD : On Screen Display

FL : Fluorescent indicator tube

— 30 —

Page 31

Pin No. Pin Name

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

MODE0

MODE1

MODE2

STANBY

STOP

U-RESET

U-SREQ

U-MREQ

U-DATA

U-CLOCK

(GND)

AUBUS IN

AUBUS OUT

(GND)

FUNCTION-B

FUNCTION-A

UP/DOWN-B

UP/DOWN-A

LEFT/RIGHT-B

LEFT/RIGHT-A

—

RESET

VSS (D)

XO

XI

VCC (D)

LED TUNER

LED PHONO

LED MUTE

LED LEARNING

LED D. PASS

LED INPUT

LED VOL

LED BASS B

SP-A

SP-B

PW-SW

—

—

MBUS-V1

I/O

I

Mode setting pin (Fixed at “H”)

I

Mode setting pin (Fixed at “H”)

I

Mode setting pin (Fixed at “L”)

I

Stanby signal input (Fixed at “H”)

I

STOP signal input “L” : active

O

Reset output to system controller “L” : reset

I

Slave data request signal input from system controller

O

Master request signal output to system controller

O

Master data output to system controller

O

Master clock output to system controller

–

Ground

–

Not used

–

Not used

–

Ground

–

Not used

–

Not used

–

Not used

–

Not used

–

Not used

–

Not used

–

Not used (Ground)

I

Reset signal input “L” : reset

–

Ground

O

Clock output (4MHz)

I

Clock input (4MHz)

–

+5V power supply (Back-up)

O

TUNER indicator drive signal output

O

PHONO indicator drive signal output

O

MUTE indicator drive signal output

O

LEARNING indicator drive signal output

O

DIRECT PASS indicator drive signal output

O

INPUT indicator drive signal output

O

Volume indicator drive signal output “H” : active

O

Bass boost indicator drive signal output “H” : active

O

Speaker select control signal output

O

Speaker select control signal output

I

Power on detect signal input

–

Not used

–

Not used

–

Not used

Function

Function

— 31 —

Page 32

• IC205 OSD (MB90095PF-G-186-BND)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Pin Name

YIN

CIN

VIN

AVCC

FSCO

VBLK

VCC

EXS

XS

HSYNC

VSYNC

EXHSYN

EXVSYN

GND

EXD

XD

VOB

VOC 2

VOC 1

VOC 0

TEST

S. CLK

S. DATA

CS

VOUT

COUT

YOUT

AGND

I/O

I

Luminous signal input for superimpose displays

I

Chroma signal input for superimpose displays

I

Composite signal input for superimpose displays

–

Power supply (+5V) (Analog)

O

Color burst phase signal output

O

Vertical blanking period output (Not used)

–

Power supply (+5V)

I

External circuit of the clock generator for color burst signals (14.3MHz)

O

External circuit of the clock generator for color burst signals (Not used)

O

H. SYNC/COMPOSIT SYNC singal output

O

V. SYNC signal output (Not used)

I

External H. SYNC signal input

I

External V. SYNC signal input

–

Ground

I

External circuit of the display dot clock generator

O

External circuit of the display dot clock generator

O

Character and background period signal output (Not used)

O

Chroma signal output (Not used)

O

Chroma signal output (Not used)

O

Chroma signal output (Not used)

I

Test pin (Fixed at “H”)

I

Shift clock input for serial transmission

I

Serial data input

I

Chip select input

O

Composite video signal output

O

Chroma signal output

O

Luminous signal output

–

Ground (Analog)

Function

• Abbreviation

OSD : On Screen Display

— 32 —

Page 33

• IC209 OSD Controller (MB90672PF-G-125-BND)

Pin No.

1, 2

3 to 6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Pin Name

AD14, AD15

A16 to A19

PCE

PCLK

PDATA OUT

PDATA IN

GND

ALE

RDX

WRLX

WRHX

MONITOR

VIDEO 2

STATUS-OUT

VIDEO 1

RX (SIN)

TX (SOT)

P PRES

TEST 1

DATA (OSD)

CLK (OSD)

LAT (OSD)

—

AVCC

AVR +

AVR –

AVSS

VOLA/D

PREADY

GND

PSTATUS

OK

MEMORY FULL

BACK UP NG

NG

P-IR

I/O

Address bus and data bus input/output

I/O

Address bus output

O

Chip Enable output to RC controller (For communication using personal computers)

O

Clock output to RC controller (For communication using personal computers)

O

Data output to RC controller (For communication using personal computers)

O

Data input from RC controller (For communication using personal computers)

I

Ground

–

Address latch enable output

O

Read strobe output to data bus

O

O

Write strobe output to data bus

O

Control-S input (Monitor) (Fixed at “L”)

I

Control-S input (VIDEO 2)

I

Control-S status output

O

Control-S input (VIDEO 1)

I

Serial data input from mode control (U-ART0 reception)

I

Serial data output to mode control (U-ART0 transmission)

O

Reset output (For communication using personal computers)

O

Test port (Not used)

O

Serial data output to OSD

O

Serial clock output to OSD

O

Latch output to OSD

O

Not used

–

Power supply (+5.6V)

–

Power supply (+5V)

–

–

Ground

–

Volume control signal input (Not used)

I

Learning code reception ready signal input “L” : nothing

I

Ground

–

Infrared rays transmission data status signal input from to RC controller

I

Learning OK signal input from RC controller

I

Memory full signal input from RC controller

I

Back up NG signal input from RC controller

I

Learning NG signal input from RC controller

I

Input to the integral calculus circuit of the remote control reception signal

I

Function

• Abbreviation

RC: Remote Commander

OSD: On Screen Display

— 33 —

Page 34

Pin No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67 to 100

Pin Name

MODE 0

MODE 1

MODE 2

HSTX

STOP

IR-IN (A6)

—

—

AUBUS IN

V. SIGNAL

SIRCS-IN

VD

AUBUS OUT

F. SW

VIDEO-MUT

—

—

—

—

IR ON/OFF

BUSY

RESET

GND

XO

XI

VCC

AD00 to AD13

I/O

Mode setting (Fixed at “H”)

I

Mode setting (Fixed at “L”)

I

Mode setting (Fixed at “L”)

I

Hardware standby (Fixed at “H”)

I

Request input of reset interrupt

I

IR sensor remote control input (Not used)

I

Not used

–

Not used

–

S-LINK control A1 signal input

I

H-sync switching signal input

I

SIRCS signal input

I

PAL: 60 [flame/s]/ NTSC: 50 [flame/s] signal detect VD input

I

S-LINK control A1 signal output

O

To control output into monitor (Not used)

O

Image mute output (Not used)

O

Not used

–

Not used

–

Not used

–

Not used

–

IR remote control ON/OFF output “H” off

O

Input/output to communicate with the mode control

I/O

Reset signal input

I

Ground

–

Clock (4 MHz)

O

Clock (4 MHz)

I

Power supply (+5.6V)

–

Address bus and data bus input/output

I/O

Function

— 34 —

Page 35

• IC215 RC Controller (LC86F5864A-5F53)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Pin Name

P70/INT0

P71/INT1

P72/INT 2/TOIN

P73/INT 3/TOIN

P30

P31

P32

P33

P34

P35

P36

P37

P40

P41

P42

P43

P44

P45

P46

P47

P50/SDA

P51/SCL

VSS2

VDD2

P20/SDA

P21/SCL

P22/TXD

P23/PXD

P24/UCLK

P25

P26

P27

P00

P01

P02

P03

P04

P05

P06

P07

I/O

I

Chip enable input from OSD controller

I

Chip enable input (For on-board) (Not used)

I

Not used (Fixed at “L”)

I

SIRCS signal input

I

Power supply normality signal input

O

Infrared rays transmission data status signal output to OSD controller “L” nothing

O

Learning NG signal output to OSD controller

O

Back-up NG signal output to OSD controller

O

Memory-full signal output to OSD controller

O

Learning OK signal output to OSD controller

O

Data reception ready signal output to OSD controller

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

–

Ground

–

+5V power supply

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

O

Not used (Fixed at “L”)

Function

• Abbreviation

RC: Remote Commander

OSD: On Screen Display

— 35 —

Page 36

Pin No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Pin Name

P10/SOO

P11/SI0/SB0

P12/SCKO

P13/SO1

P14/SI1

P15/SCK1

P16/BUZ

P17/PWM

TEST1

RES

XT1/P74

XT2

VSS1

CF1

CF2

VDD1

P80/AN0

P81/AN1

P82/AN2

P83/AN3

P84/AN4

P85/AN5

P86/AN6

P87/AN7

I/O

O

Serial data output to OSD controller

I

Serial data input to OSD controller

I

Serial clock input from OSD controller

–

Serial data output (For on-board) (Not used)

I

Serial data input (For on-board) (Not used)

I

Serial clock input (For on-board) (Not used)

O

Not used (Fixed at “L”)

O

SIRCS signal output (Carrier = PWM output)

O

Not used

I

Reset input “L” reset

–

Not used (Fixed at “H”)

–

Not used

–

Ground

I

Clock input (6MHz)

O

Clock output (6MHz)

–

+5V power supply

I

Not used (Fixed at “L”)

I

Not used (Fixed at “L”)

I

Not used (Fixed at “L”)

I

Not used (Fixed at “L”)

I

Not used (Fixed at “L”)

I

Not used (Fixed at “L”)

I

Not used (Fixed at “L”)

I

Not used (Fixed at “L”)

Function

• Abbreviation

OSD: On Screen Display

— 36 —

Page 37

• IC3104 A/D Converter (CXD8681M-TP)

Pin No. Pin Name

VRL+

1

VRL–

2

VCML

3

AINL+

4

AINL–

5

ZCAL

6

VD

7

DGND

8

CAL

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

RST

SMODE2

SMODE1

LRCK

SCLK

SDATA

FSYNC

MCLK

CMODE

SEL24/20

TEST

BGND

AGND

VA

AINR–

AINR+

VCMR

VRR–

VRR+

I/O

O

O

O

I

I

I

–

–

O

I

I

I

I/O

I/O

O

I/O

I

I

I

I

–

–

–

I

I

O

O

O

Function

Function

L-ch reference voltage (+) output (+3.75V)

L-ch reference voltage (–) output (+1.25V)

L-ch common voltage (+) output (+2.5V)

L-ch analog voltage (+) input

L-ch analog voltage (–) input

Zero calibraton input (Fixed at “H”)

+5.5V power supply (Digital)

Ground (Digital)

Calibration status signal output

Reset input “L” : reset

Serial interface mode selection input (Fixed at “L”)

Serial interface mode selection input (Fixed at “L”)

L/R channel selection clock input/output

Serial data clock input/output

Serial data output

Frame sync clock input/output (Fixed at “H”)

Master clock input (12.288MHz)

Master clock selection input “L” : MCLK : 256Fs, “H” : MCLK : 384Fs (Fixed at “L”)

Output data range selection input “L” : 20 bit, “H” ; 24 bit (Fixed at “H”)

Test pin (Fixed at “L”)

Ground

Ground (Analog)

+5V power supply (Analog)

R-ch analog (–) input

R-ch analog (+) input

R-ch common voltage output (+2.5V)

R-ch reference voltage (–) output (+1.25V)

R-ch reference voltage (+) output (+3.75V)

— 37 —

Page 38

• IC3308 DOLBY AC-3 demodulator (SN-PM4007A)

Pin No. Pin Name

GND

1

VDD

2

RESET

3

OSCON

4

DATA

5

MCK

6

MLTB

7

IDST

8

IDCK

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

IDO

TM0

ECCK

DEN

DRY

MSYC

TM1

A0

A1

A2

A3

A4

A5

TM2

TM3

XOUT

XIN

NEXT

GND

VDD

A6

A7

GND

VDD

A12

A14

WE

A13

A8

A9

GND

A11

OE

A10

D7

D6

D5

D4

D3

D2

D1

I/O

–

Ground

–

+5V power supply

I

System reset input “L” : reset

I

Oscillation control signal input “H” : ON (Fixed at “H”)

I

Test pin (Fixed at “L”)

I

Test pin (Fixed at “L”)

I

Test pin (Fixed at “L”)

O

Test pin (Not used)

O

Test pin (Not used)

O

Test pin (Not used)

I

Test pin (Fixed at “L”)

O

Test pin (Not used)

O

Test pin (Not used)

O

Test pin (Not used)

O

Test pin (Not used)

I

Test pin (Fixed at “L”)

O

Address data output to SRAM

O

Address data output to SRAM

O

Address data output to SRAM

O

Address data output to SRAM

O

Address data output to SRAM

O

Address data output to SRAM

I

Test pin (Fixed at “L”)

I

Test pin (Fixed at “L”)

O

Test pin (Not used)

I

Test pin (Fixed at “L”)

I

Test pin (Fixed at “L”)

–

Ground

–

+5V power supply

O

Address data output to SRAM

O

Address data output to SRAM

–

Ground

–

+5V power supply

O

Address data output to SRAM

O

Address data output to SRAM

O

Write enable signal output to SRAM “L” : active

O

Address data output to SRAM

O

Address data output to SRAM

O

Address data output to SRAM

–

Ground

O

Address data output to SRAM

O

Output enable output to SRAM

O

Address data output to SRAM

I/O

Data bus input/output with SRAM

I/O

Data bus input/output with SRAM

I/O

Data bus input/output with SRAM

I/O

Data bus input/output with SRAM

I/O

Data bus input/output with SRAM

I/O

Data bus input/output with SRAM

I/O

Data bus input/output with SRAM

Function

Function

— 38 —

Page 39

Pin No. Pin Name

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

D0

VDD

GND

TI1

VIN

VOUT

TI2

TI3

TLD8

TCK

TRP

TD0

PD0

TI4

PDDI5

MUTO

TI5

VLDY

DASYO

DAOUT

DAIN

DAIN

TI8

C2F1

C2F0

C1F1

C1F0

MUTI

VDD

GND

AVDD

CPIN

CMIN

AGND

TM4

VDD

DIN

DOUT

DOUTB

C9M

GND

WINGT

SYST0

SYST1

ADST0

ADST1

TM5

BUNRI

AGND

AVDD

Function

I/O

I/O

Data bus input/output with SRAM

–

+5V power supply

–

Ground

I

Test pin (Fixed at “H”)

I

VCXO input (18.432MHz)

O

VCXO output (18.432MHz)

I

Test pin (Fixed at “L”)

I

Test pin (Fixed at “L”)

I

Test pin (Fixed at “L”)

I

Test pin (Fixed at “L”)

O

Test pin (Not used)

O

Test pin (Not used)

O

Output of internal phase comparator (3 state)

I

Test pin (Fixed at “L”)

I

PDO output control input “L” : output ON

O

Mute signal output “H” : mute

I

Test pin (Fixed at “L”)

O

Test pin (Not used)

O

Test pin (Not used)

O

Digital-out signal output (Serial data stream output)

I

Dgital external input Through out to DAOUT when DASEL is “H” (Not used)

I

Digital-out selection input (Fixed at “L”)

I

Test pin (Fixed at “L”)

O

C2 error correction state display Outputs if corrected properly (Not used)

O

C2 error correction state display Outputs number of errors at C2 (Not used)

O

C2 error correction state display Outputs whether error is present at C1 (Not used)

O

C2 error correction state display Outputs number of errors at C1 (Not used)

I

Muting input “H” mute

–

+5V power supply

–

Ground

–

+5V power supply (Analog)

I

Comparator input (+) (QPSK input)

I

Comparator input (–)

–

Ground (Analog)

I

Test pin (Fixed at “L”)

–

+5V power supply

I

Test pin (Fixed at “L”)

O

Comparate output

O

Comparate inverted output

O

9.216MHz output (Not used)

–

Ground

O

Test pin (Not used)

O

Test pin (Not used)

O

Test pin (Not used)

O

Test pin (Not used)

O

Test pin (Not used)

I

Test pin (Fixed at “L”)

I

Test pin (Fixed at “L”)

–

Ground (Analog)

–

+5V power supply (Analog)

Function

— 39 —

Page 40

• IC3311 Digital Audio Interface Receiver (CXD8521M)

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

I/O

DIN1

1

DIN2

2

E/DOUT

3

VDD

4

R

5

VIN

6

VCO

7

GND

8

CKSEL

9

XMODE

AVOCK

TST1

TST2

SCLK

XLAT

SWDT

SRDT

DQSY

CKOUT

FS128

BCK

LRCK

DA TAO

EROR

I

Data input with built-in amplifier (Responding to the coaxial optical module)

I

Data input (Responding to the optical module)

O

Emphasis, input bi-phase, validity flag output

–

Power supply (+5V)

I

VCO gain control input (Fixed at “H”)

I

VCO freerunning frequency setting input

O

LPF setting of PLL (Fixed at “L”)

–

Ground

I

System clock select input (384fs, 512fs) (Connected to the power supply.)

I

Reset input

I

Clock input for preventing PLL lock failure

I

Test input (Normally “L”)

I

I

Microcomputer IF clock input

I

Microcomputer IF latch/chip enable input

I

Microcomputer IF write data input

O

Microcomputer IF read data output

O

Microcomputer IF Sub-Q sync and ID sync output (Not used)

O

VCO clock output (Freerunning, 384fs, 512fs) (Not used)

O

128fs clock output (Not used)

O

Bit clock output

O

L/R clock output

O

Audio data output

O

PLL lock error mute output

Function

FunctionPin No. Pin Name

• Abbreviation

VCO: Voltage Controlled Oscillator

PLL: Phase Locked Loop

— 40 —

Page 41

• IC3410 DOLBY AC-3 decoder (DSP56009FJ88)

Pin No. Pin Name

AGND

1

MCS0

2

MA15

3

MA14

4

MA13

5

AVCC

6

MA12

7

AGND

8

QVCC

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

QGND

MA11

MA10

MA9

MA8

AGND

MA7

AVCC

MA6

MA5

MA4

AGND

MA3

MA2

MA1

MA0

SCK/SCL

EXTAL

QVCC

QGND

PINIT

PGND

PCAP

PVCC

SGND

MISO/SDA

RESET

MODA/IRQA

MODB/IRQB

MODC/NMI

SVCC

I/O

–

Address buffer ground

O

Chip select 0 output to S-RAM (Not used)

O

O

Address data output to S-RAM (Not used)

O

–

Address bus buffer power supply (+5V)

O

Address data output to S-RAM(Not used)

–

Ground for address bus buffer

–

Power supply for internal logic (+5V)

–

Ground for internal logic

O

O

Address data output to S-RAM (Not used)

O

O

Ground for address bus buffer

–

Address data output to S-RAM (Not used)

O

Power supply for address bus buffer (+5V)

–

O

Address data output to S-RAM (Not used)

O

O

Ground for address bus buffer

–

O

O

Address data output to S-RAM (Not used)

O

O

SPI serial clock signal input from system controller

I

External frequency input (3 MHz)

I

Power supply for internal logic (+5V)

–

Ground for internal logic

–

PLL initialize input (Fixed at “L”)

I

Ground for PLL

–

PLL filter input (Connected to 0.01 µF capacitor)

I

Power supply for PLL (+5V)

–

Ground for serial port

–

Master data signal input from system controller

I

Reset signal input from system controller

I

Mode select A (Fixed at “H”)

I

Mode select B (Fixed at “L”)

I

Mode select C (Fixed at “H”)

I

Power supply for serial port (+5V)

–

Function

Function

• Abbreviation

PLL: Phase Locked Loop

— 41 —

Page 42

Pin No. Pin Name

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

MOSI/HA0

SS/HA2

HREQ

SGND

SDO2

SDO1

SDO0

SVCC

SCKT

WST

SCKR

QGND

QVCC

SGND

WSR

SDI1

SDI0

DSO

DSI/OS0

DSCK/OS1

DR

MD7

MD6

MD5

MD4

DGND

MD3

MD2

MD1

DVCC

MD0

DGND

GPIO3

GPIO2

GPIO1

GPIO0

MRD

MWR

MA15/MCS1

MA16/MCS2/MCAS

Function

I/O

O

Master data signal output to system controller

I

SPI slave select signal input from system controller

I

Host request signal input from system controller

–

Ground for serial port

O

Audio serial data 2 signal output (Not used)

O

Audio serial data 1 signal output

O

Audio serial data 0 signal output

–

Power supply for serial port (+5V)

O

Serial clock transmission

O

Word select transmission

I

Serial clock reception

–

Ground for internal logic

–

Power supply for internal logic (+5V)

–

Ground for serial port

I

Word select reception

I

Audio serial data 1 signal input

I

Audio serial data 0 signal input

O

Debug serial signal output (Not used)

I

Debug serial signal input (Not used)

I

Debug serial clock signal input (Not used)

I

Debug request input (Fixed at “H”)

I/O

I/O

Data input/output with S-RAM (Not used)

I/O

I/O

Ground for data bus buffer

–

I/O

Data input/output with S-RAM (Not used)

I/O

I/O

Power supply for data bus buffer (+5V)

–

Data input/output with S-RAM (Not used)

I/O

Ground for data bus buffer

–

I/O

I/O

General DSP input/output (Not used)

I/O

I/O

Write strobe signal output to S-RAM (Not used)

O

Read strobe signal output to S-RAM (Not used)

O

Low address strobe signal output to S-RAM (Not used)

O

Column address strobe signal output to S-RAM (Not used)

O

Function

— 42 —

Page 43

• IC3412 DOLBY Surround Digital Signal Processor (SSP424023FJ88)

Pin No. Pin Name

AGND

1

MCS0

2

MA15

3

MA14

4

MA13

5

AVCC

6

MA12

7

AGND

8

QVCC

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

QGND

MA11

MA10

MA9

MA8

AGND

MA7

AVCC

MA6

MA5

MA4

AGND

MA3

MA2

MA1

MA0

SCK/SCL

EXTAL

QVCC

QGND

PINIT

PGND

PCAP

PVCC

SGND

MISO/SDA

RESET

MODA/IRQA

MODB/IRQB

MODC/NMI

SVCC

I/O

–

Address buffer ground

O

Chip select 0 output to S-RAM (Not used)

O

O

Address data output to S-RAM

O

–

Address bus buffer power supply (+5V)

O

Address data output to S-RAM

–

Ground for address bus buffer

–

Power supply for internal logic (+5V)

–

Ground for internal logic

O

O

Address data output to S-RAM

O

O

Ground for address bus buffer

–

Address data output to S-RAM

O

Power supply for address bus buffer (+5V)

–

O

Address data output to S-RAM

O

O

Ground for address bus buffer

–

O

O

Address data output to S-RAM

O

O

SPI serial clock signal input from system controller

I

External frequency input (3 MHz)

I

Power supply for internal logic (+5V)

–

Ground for internal logic

–

PLL initialize input (Fixed at “L”)

I

Ground for PLL

–

PLL filter input (Connected to 0.01 µF capacitor)

I

Power supply for PLL (+5V)

–

Ground for serial port

–

Master data signal input from system controller

I

Reset signal input from system controller

I

Mode select A (Fixed at “H”)

I

Mode select B (Fixed at “L”)

I

Mode select C (Fixed at “H”)

I

Power supply for serial port (+5V)

–

Function

Function

• Abbreviation

PLL: Phase Locked Loop

— 43 —

Page 44

Pin No. Pin Name

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

MOSI/HA0

SS/HA2

HREQ

SGND

SDO2

SDO1

SDO0

SVCC

SCKT

WST

SCKR

QGND

QVCC

SGND

WSR

SDI1

SDI0

DSO

DSI/OS0

DSCK/OS1

DR

MD7

MD6

MD5

MD4

DGND

MD3

MD2

MD1

DVCC

MD0

DGND

GPIO3

GPIO2

GPIO1

GPIO0

MRD

MWR

MA15/MCS1

MA16/MCS2/MCAS

I/O

O

Master data signal output to system controller

I

SPI slave select signal input from system controller

I

Host request signal input from system controller

–

Ground for serial port

O

Audio serial data 2 signal output

O

Audio serial data 1 signal output

O

Audio serial data 0 signal output

–

Power supply for serial port (+5V)

O

Serial clock transmission

O

Word select transmission

I

Serial clock reception

–

Ground for internal logic

–

Power supply for internal logic (+5V)

–

Ground for serial port

I

Word select reception

I

Audio serial data 1 signal input

I

Audio serial data 0 signal input

O

Debug serial signal output (Not used)

I

Debug serial signal input (Not used)

I

Debug serial clock signal input (Not used)

I

Debug request input (Fixed at “H”)

I/O

I/O

Data input/output with S-RAM

I/O

I/O

Ground for data bus buffer

–

I/O

Data input/output with S-RAM

I/O

I/O

Power supply for data bus buffer (+5V)

–

Data input/output with S-RAM

I/O

Ground for data bus buffer

–

I/O

General DSP input/output (Not used)

I/O

I/O

General DSP output to system controller

O

Write strobe signal output to S-RAM

O

Read strobe signal output to S-RAM

O

Low address strobe signal output to S-RAM (Not used)

O

Column address strobe signal output to S-RAM

O

Function

Function

— 44 —

Page 45

• IC3413 System Controller (MB90641APF-G-101-BND)

Pin No. Pin Name

RF ERR

1

RF RESET

2

STOP

3

RDATA

4

WDATA

5

DIRLAT

6

DIRCLK

7

DIRERR

8

ANG/DIG

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

A/DINT

VSS

HREQ

SS

MOSI

RESET

MISO

CLOCK

HREQ

SS

MOSI

RESET

MISO

VCC

CLOCK

D/AINT

D/ALAT

C

D/ACLK

D/ADATA

—

—

—

—

VCC

VCC

VSS

VSS

LOW FRQ LED

GAIN FRONT 8DB

GAIN FRONT 4DB

GAIN FRONT 2DB

VSS

—

—

—

—

—

STOP

MD0

MD1

I/O

I

Error input from DOLBY AC-3 demodulator “H” : error

O

Reset output to DOLBY AC-3 demodulator “L” : reset

I

Power supply failure detection input

I

Data read signal input from CXD8521M

O

Data write signal output to CXD8521M

O

Latch output to CXD8521M

O

Clock output to CXD8521M

I

Error signal input from CXD8521M “H” : error

O

Analog/Digital switching, Digital at “H”

O

Initialize output to A/D converter

–

Ground

O

Host request signal output to DSP56009FJ88

O

SPI slave select signal output to DSP56009FJ88

O

Master data signal output to DSP56009FJ88

O

Reset signal output to DSP56009FJ88 “L” : reset

I

Master data signal input from DSP56009FJ88

O

SPI serial clock output to DSP56009FJ88

O

Host request signal output to SSP424023FJ88

O

SPI slave select signal output to SSP424023FJ88

O

Master data signal output to SSP424023FJ88

O

Reset signal output to SSP424023FJ88 “L” : reset

I

Master data signal input from SSP424023FJ88

–

+5V power supply

O

SPI serial clock output to SSP424023FJ88

O

Initialize output to CXD8505BQ “L” : initialize

O

Latch output to CXD8505BQ

–

Connect to Capacitor

O

Clock output to CXD8505BQ

O

Data output to CXD8505BQ

O

Initialize output “L” : initialize (Not used)

–

Not used

–

Not used

–

Not used

–

+5V power supply

–

+5V power supply

–

Ground

–

Ground

I

Low frequency LED signal input from SSP424023FJ88

O

Front speaker 8dB gain signal output

O

Front speaker 4dB gain signal output

O

Front speaker 2dB gain signal output

–

Ground

–

Not used

–

Not used

–

Not used

–

Not used

–

Not used

I

Power supply failure detection input

I

Mode select input (Fixed at “H”)

I

Mode select input (Fixed at “H”)

Function

Function

— 45 —

Page 46

Pin No. Pin Name

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

MD2

STANDBY

—

DISPMR

DISPDATA

SLVDATA/REQ

DISPCLK

LAT

DAT A

CLK

DATAIN

AUTSTOP

STEREO

—

—

HIFI/ES

PROTEC

VIDEO-A

VIDEO-B

VIDEO-E

VIDEO-INH

FUNMUTE

TUNERMUTE

SURR-MUTE

AC-MUTE

RM-MUTE

RESET

RY-FRONT/A

RY-FRONT/B

RY FRONT

VSS

XIN

XOUT

VCC

RY-PREAMP

RY-CENTER

RY-REAR

RY-HP

RY-4/8

RY-POWER

—

—

—

RY-DIRECT-PASS

—

—

—

DIG-IN2

DIG-IN1

DIG-IN0

I/O

I

Mode select input (Fixed at “L”)

I

Power on detect input (Fixed at “H”)

–

Not used

I

Master request signal input from mode controller

I

Master data input from mode controller

O

Slave data request signal output to mode controller

I

Master clock input from mode controller

O

Latch output to ATT (Rear, Center, woofer)

O

Signal data output to ATT (Rear, Center, woofer)

O

Signal clock output to ATT (Rear, Center, woofer)

O

Serial data output to tuner

O

Auto stop signal output to tuner

O

Stereo ID output to tuner

–

Not used

–

Not used

–

Not used (Fixed at “H”)

O

Protector signal output

O

Video-input switching signal output

O

Video-input switching signal output

O

Video control E signal output

O

Video-out inhibit signal output “L” : inhibit

O

Function muting signal output “H” : mute

O

Tuner muting signal output “H” : mute

O

Surround muting signal output “H” : mute

O

Mute signal output to Front/Rear power amp

O

–20dB muting signal output “H” : mute

I

Reset signal input “L” : reset

O

Not used

O

Not used

O

Front speaker relay switching output “H” : ON

–

Ground

I

System clock input (4MHz)

O

System clock output (4MHz)

–

+5V power supply

–

Not used

O

Center speaker/Super woofer relay switching output “H” : ON

O

Rear speaker relay switching output “H” : ON

O

Headphones relay switching output “H” : ON

O

Not used

O

Power relay switching output “H” : ON

–

Not used

–

Not used

–

Not used

–

Direct pass relay switching output “H” : ON

–

Not used

–

Not used

–

Not used

O

Digital-input selection signal output

O

Digital-input selection signal output

O

Digital-input selection signal output

Function

— 46 —

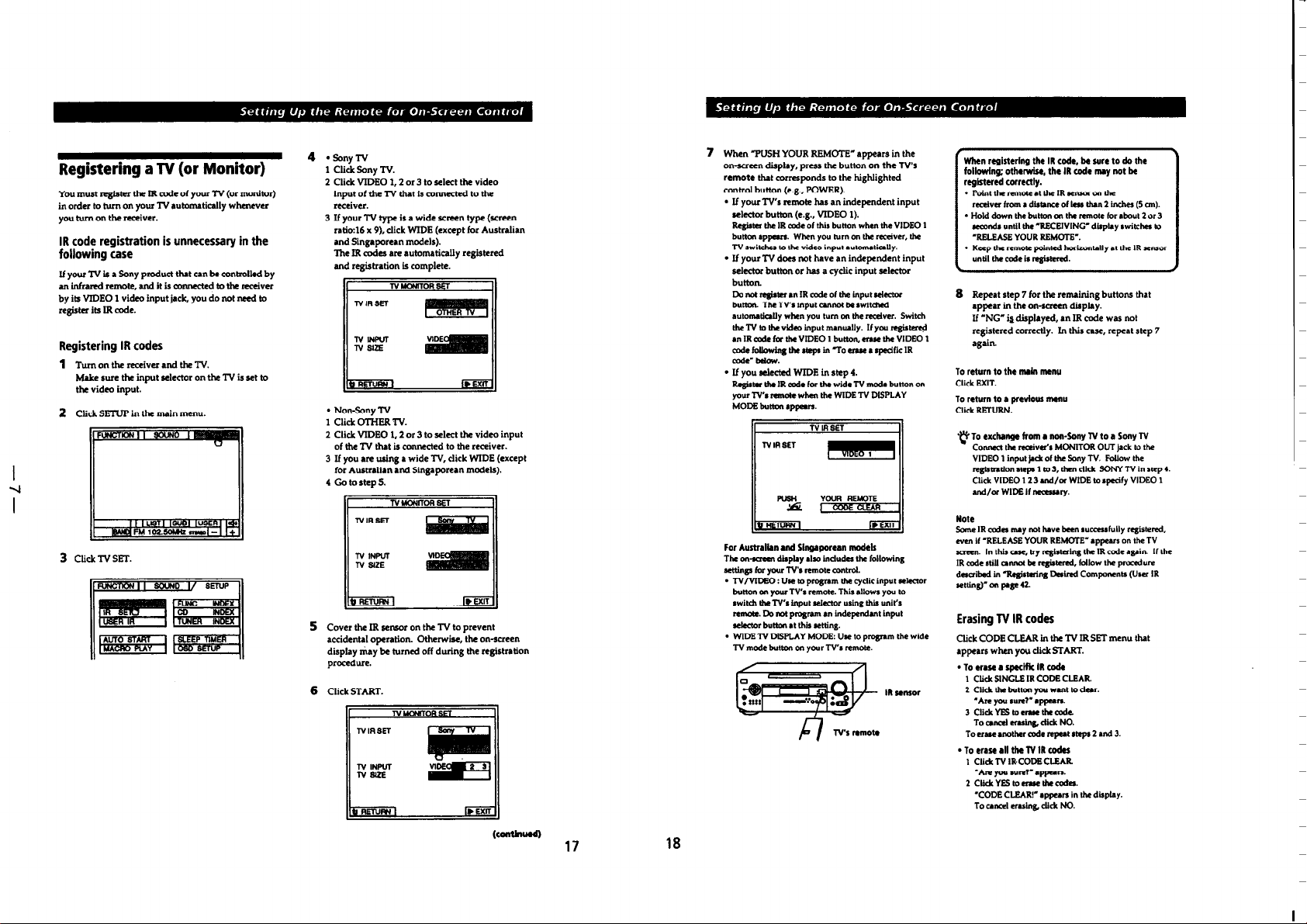

Page 47

d

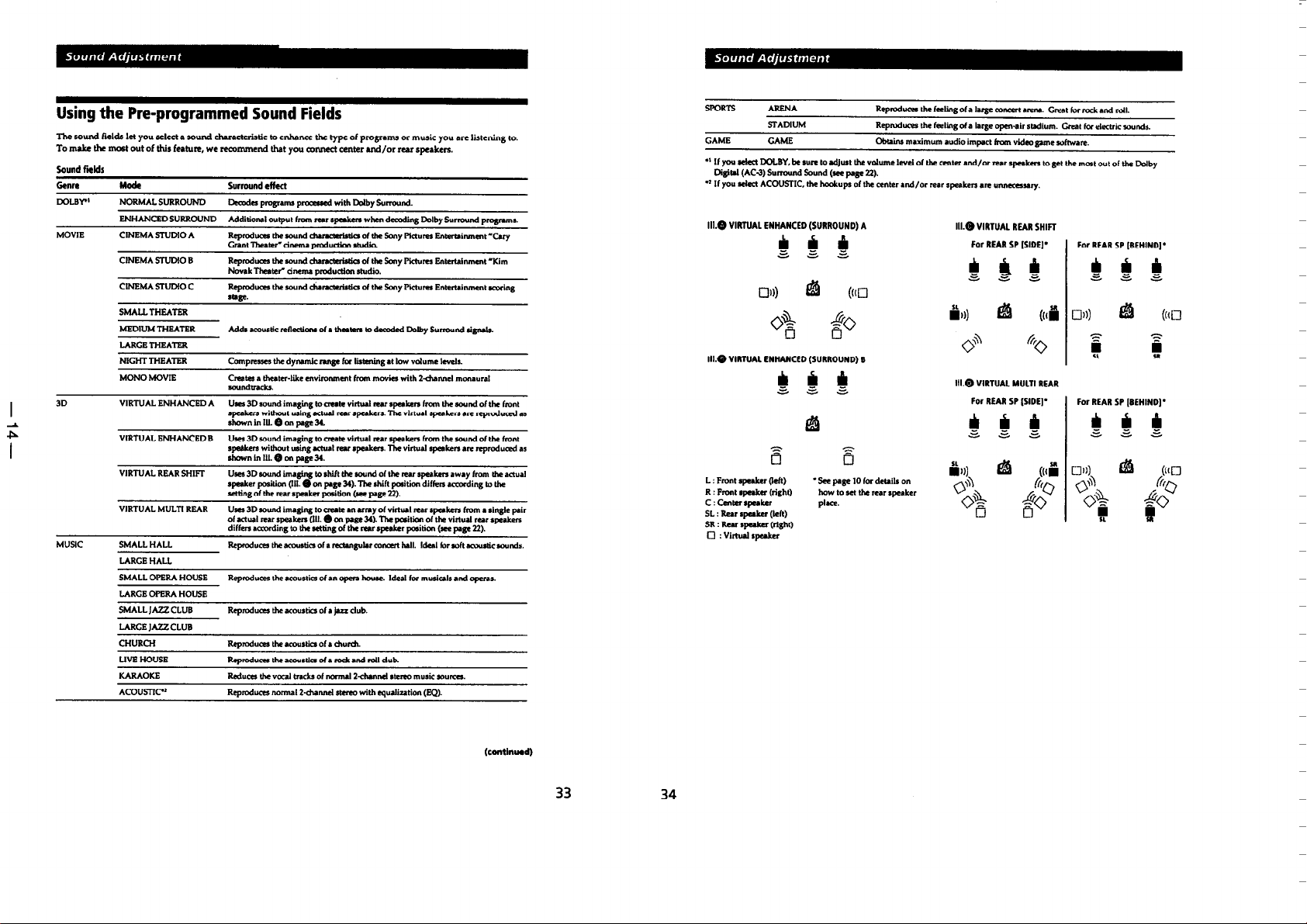

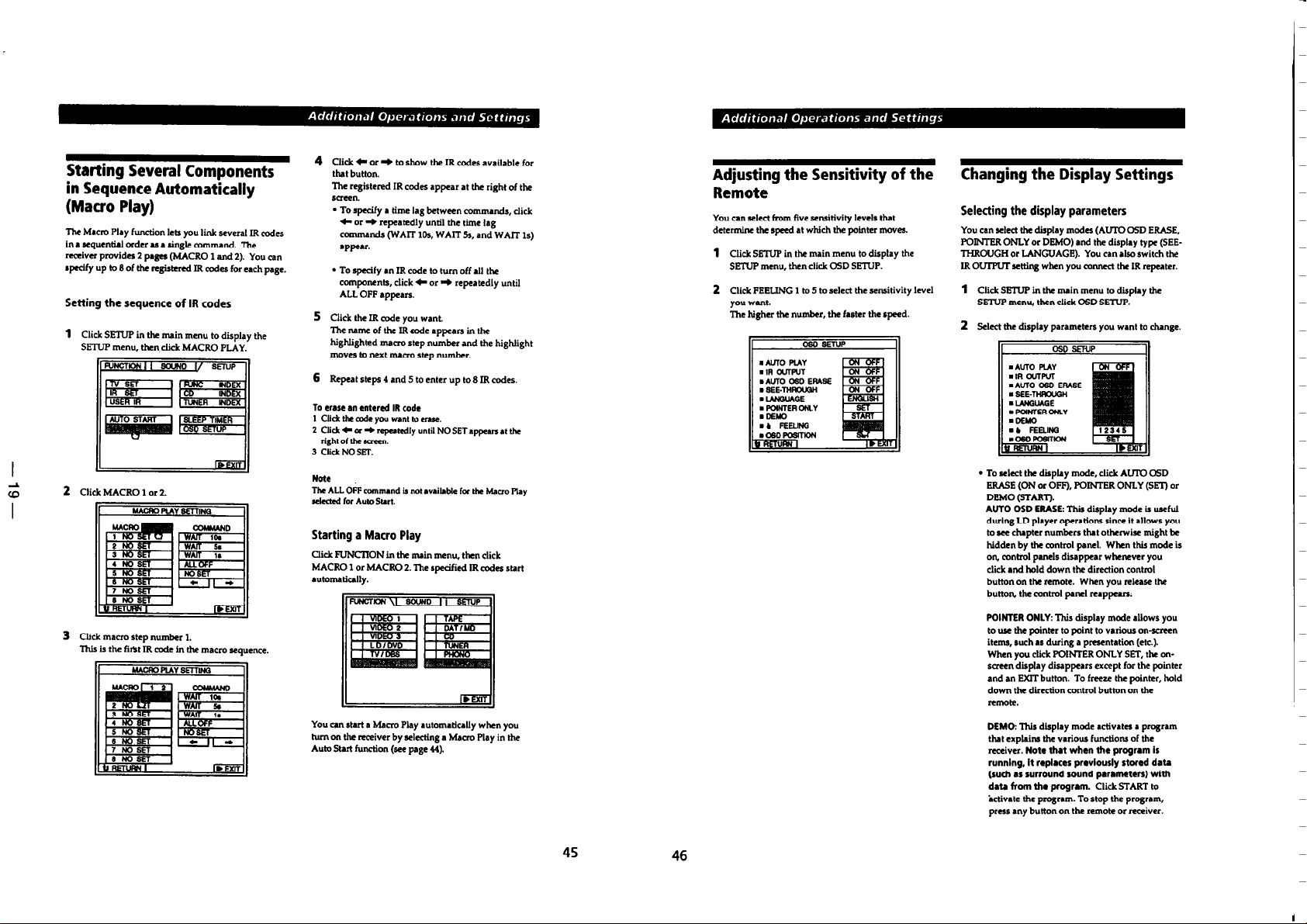

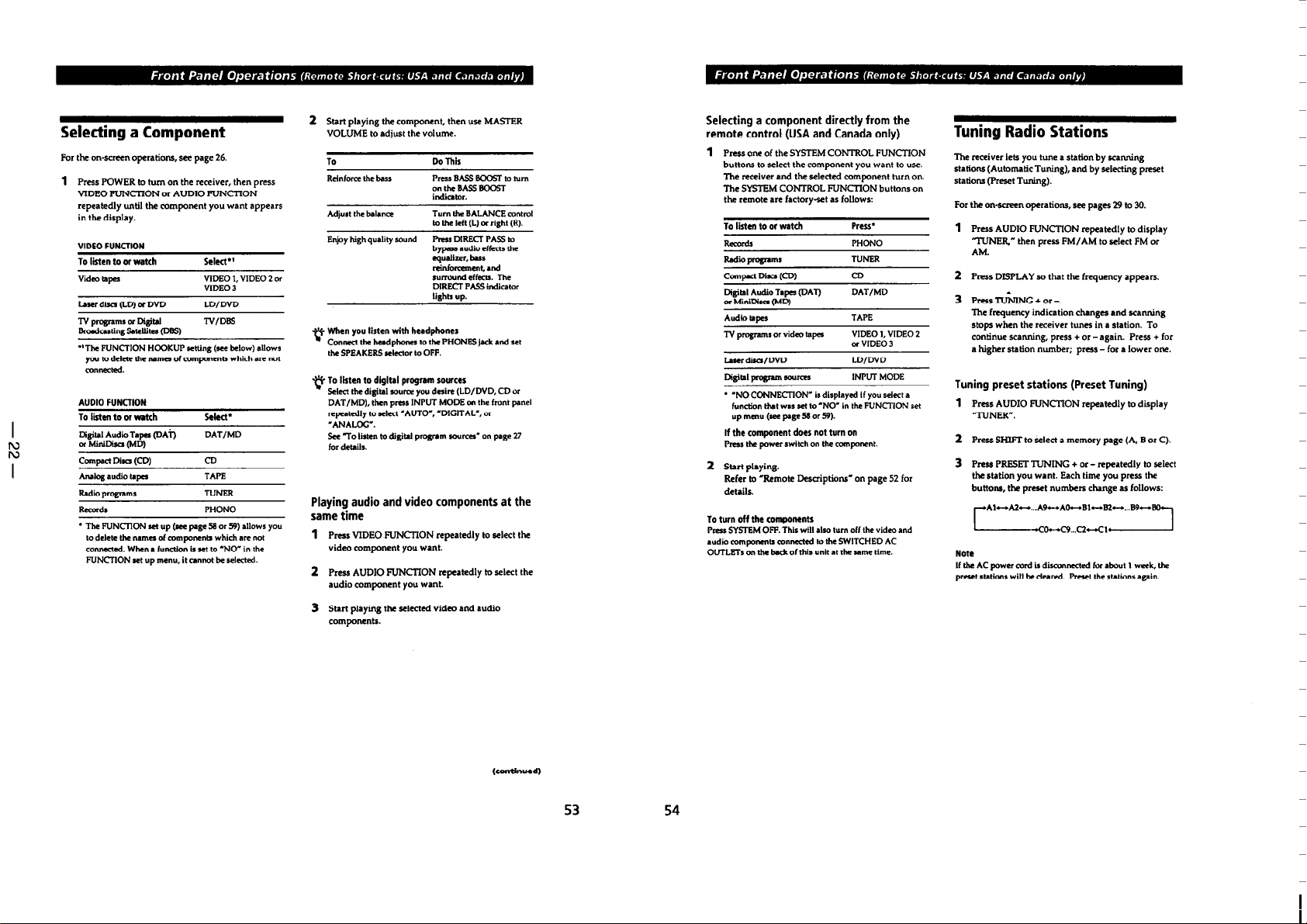

6-2. CIRCUIT BOARDS LOCATION

S-A-P board

REAR AMP board

SW board

PS board

SP (2F) board

AUDIO2F board

SURR-AUDIO2F boar

SECONDARY board

DISPLAY board

(including L.B SW board)

BALANCE board

VOLUME board

JOINT (OSD) board

OSD (V) board

JOINT (B) board

L.B SW board

VIDEO3 board

— 47 —

OSD (S) board

MEMORY board

Page 48

SP SW board

d

HEADPHONE board

AMP JOINT (F) board

AMP JOINT (B) board

SUR boar

AMP board

DIGITAL board

— 48 —

Page 49

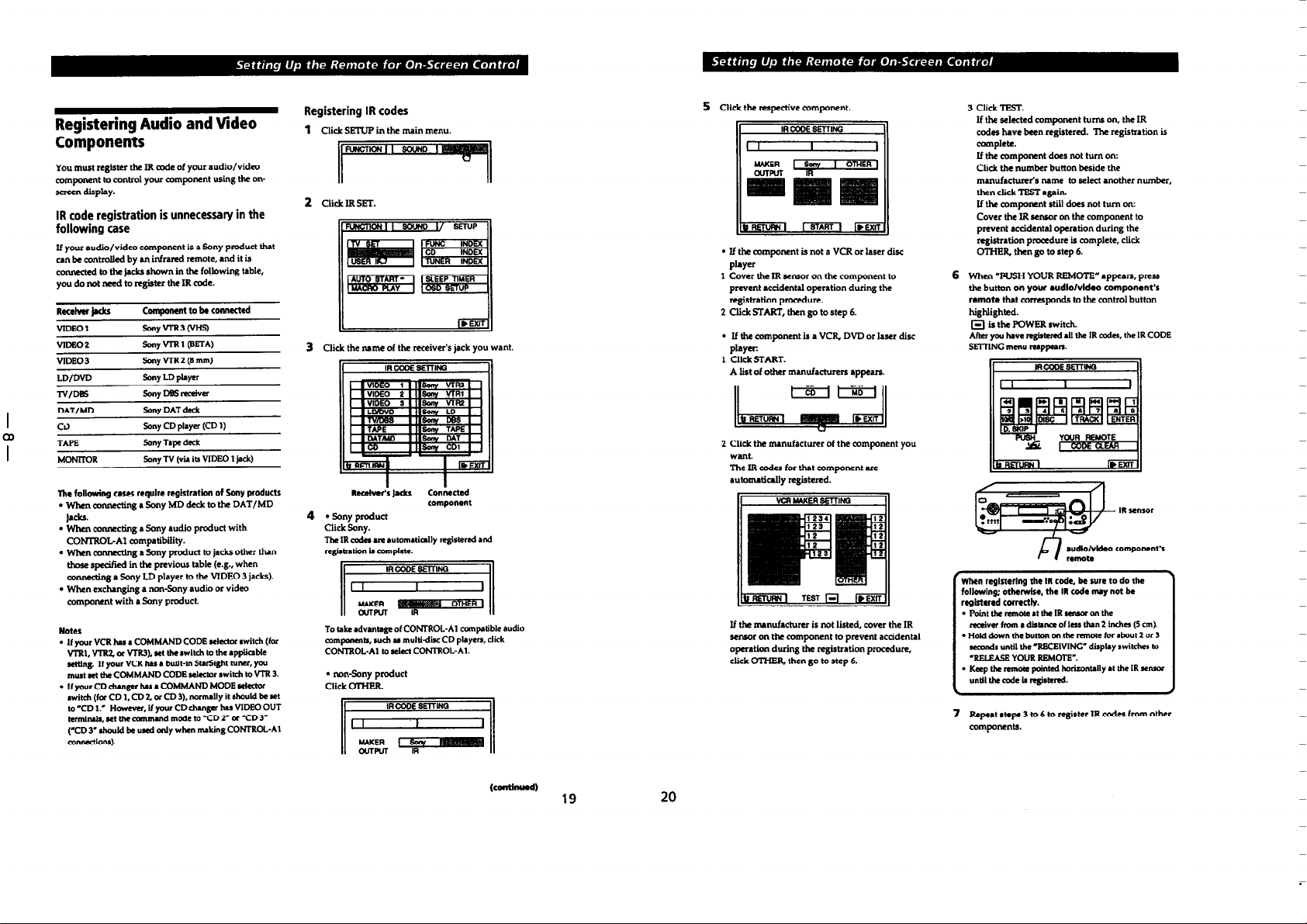

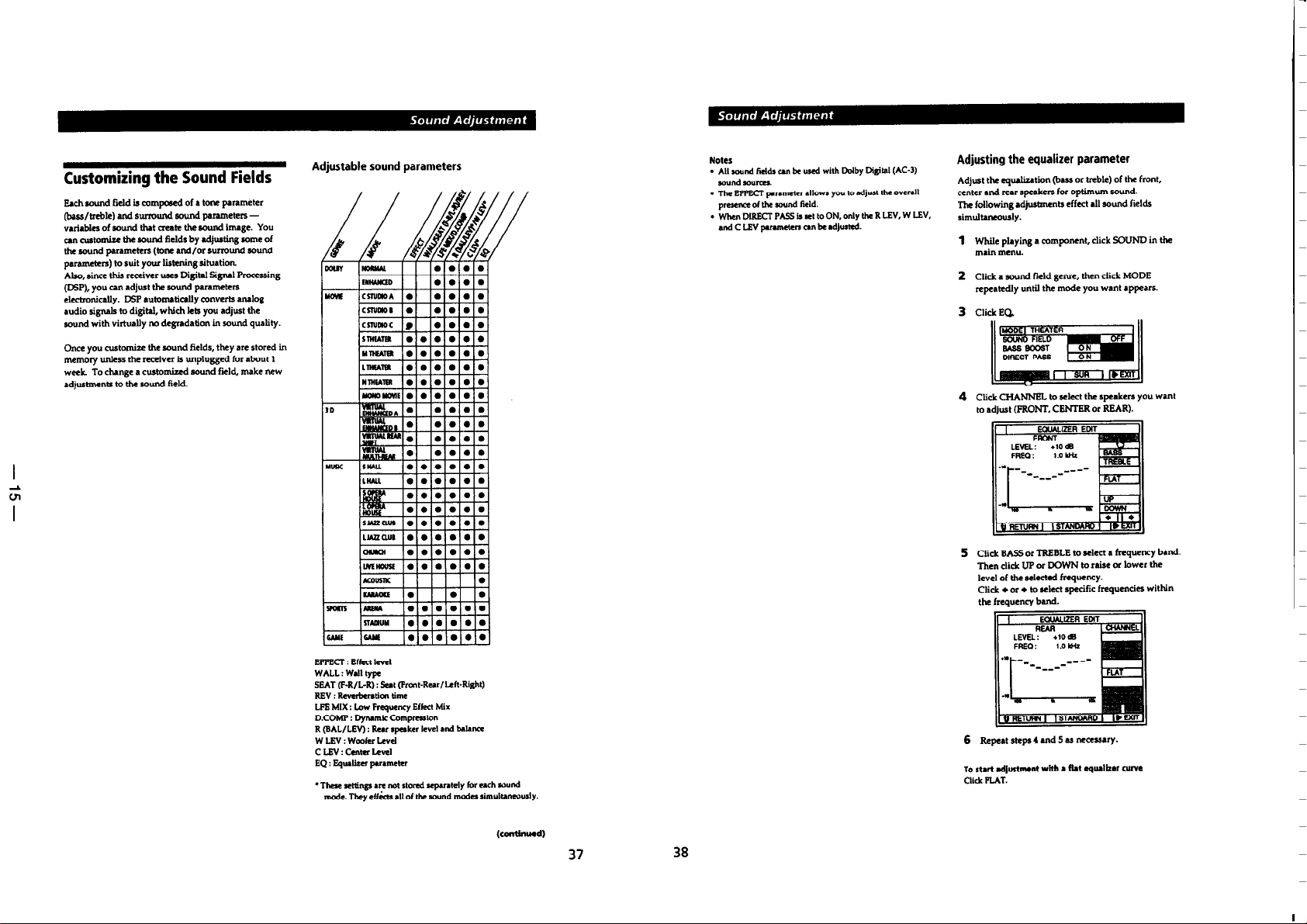

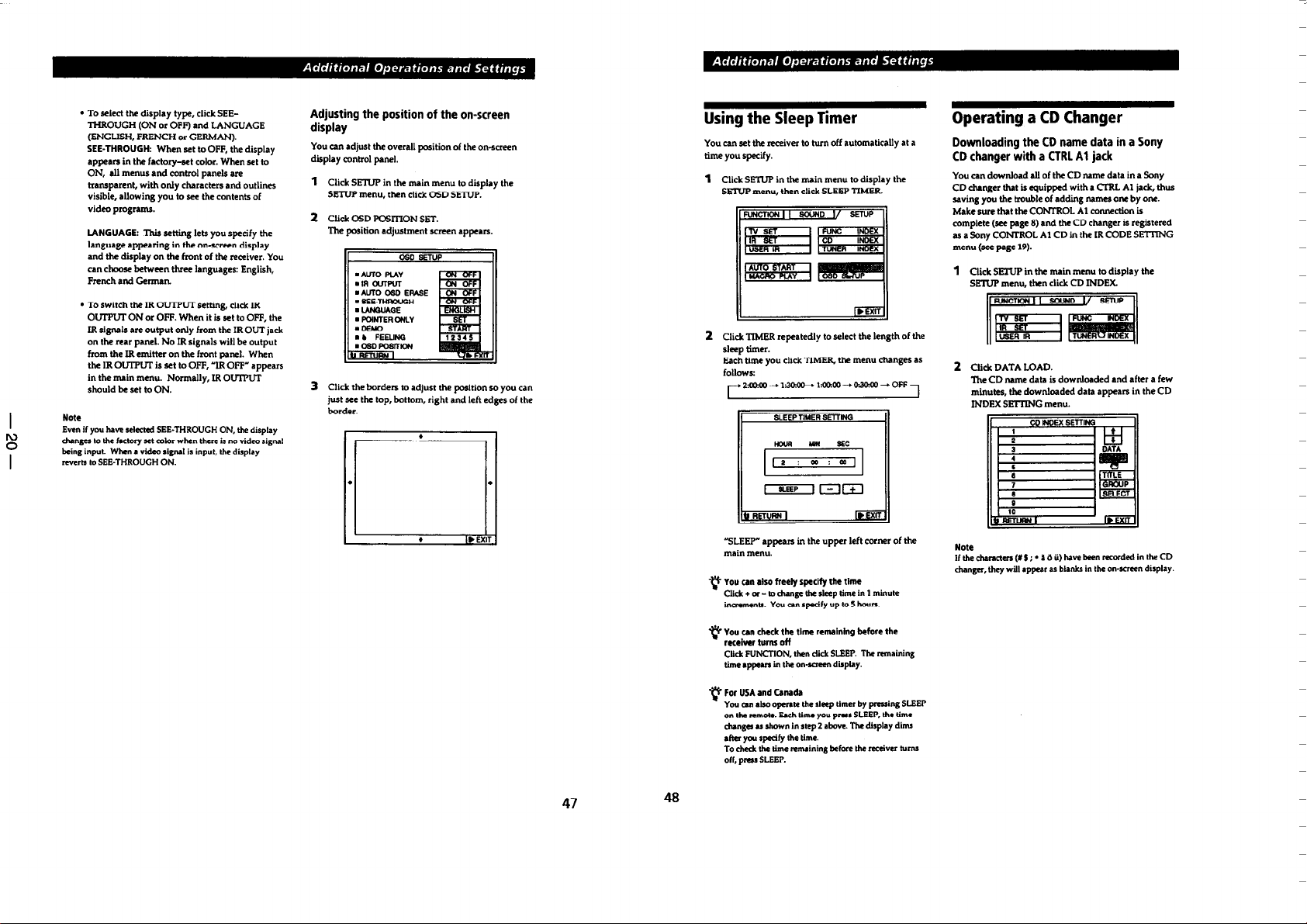

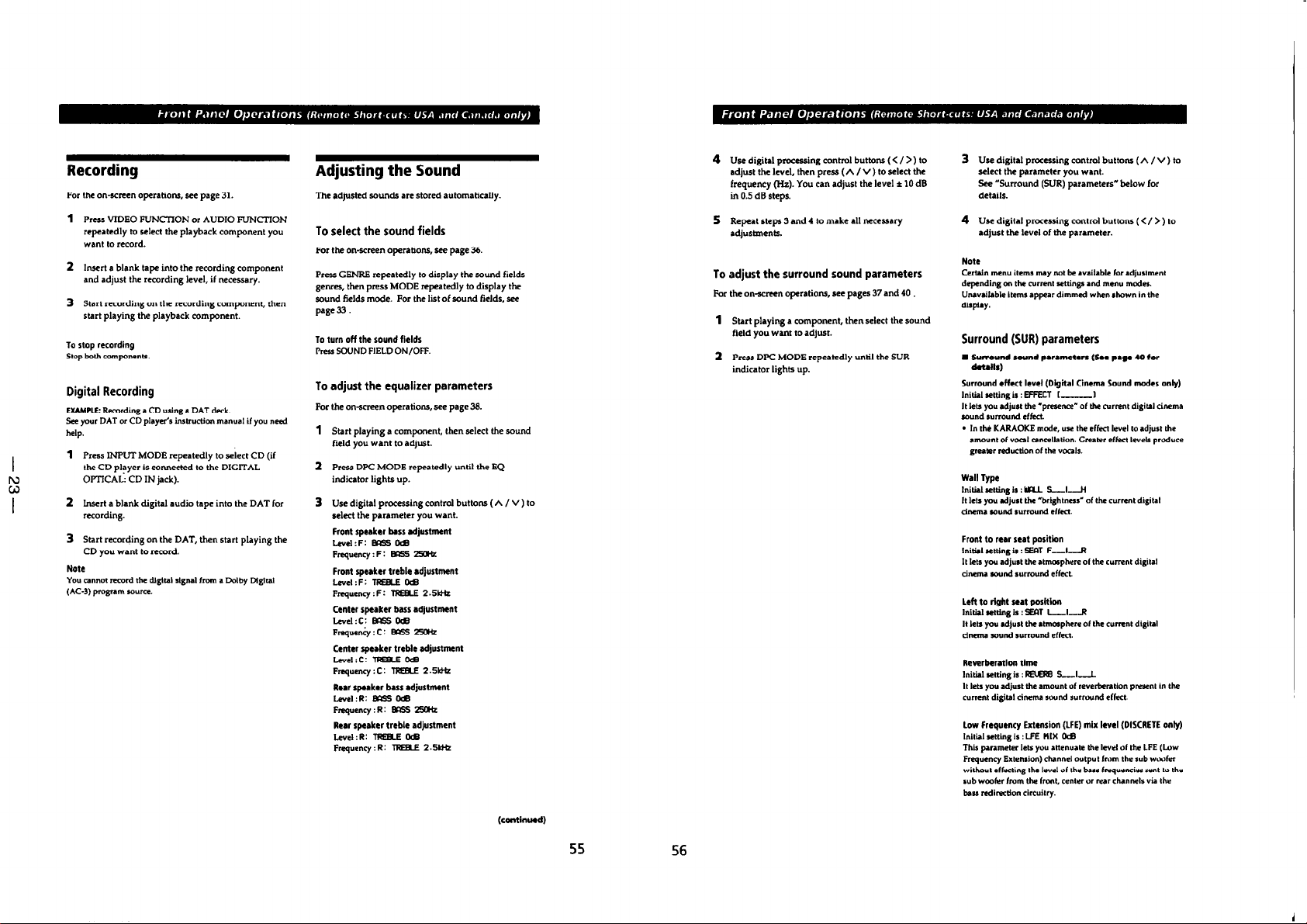

6-3. BLOCK DIAGRAMS

— INPUT/OUTPUT SECTION —

ANTENNA

FM 75Ω

COAXIAL

AM

CD IN

PHONO IN

DAT/MD

REC OUT

DAT/MD

IN

TAPE

REC OUT

TAPE

IN

VIDEO 3

INPUT AUDIO

TV/DBS

AUDIO IN

LD/DVD

AUDIO IN

VIDEO 2

AUDIO OUT

VIDEO 2

AUDIO IN

VIDEO 1

AUDIO OUT

VIDEO 1

AUDIO IN

09

TM401

J302 (1/2)

L

R

L

R

L

R

J302 (2/2)

J303

L

R

L

R

L

R

J299

L

R

J305

L

R

L

R

L

R

L

R

L

R

L

R

J304

FM/AM TUNER

TU401

STEREO STEREO

22

A STOP

IC302 (1/2)

2

3

IC302 (2/2)

2

5

3

6

T MUT

CLOCK

DATA

EQ AMP

EQ AMP

21

202

9

IFD

84

7

CE

6

17

L ch

19

R ch

1

7

(75)

AM ANT

AUTO STOP

T MUTE

IF DATA IN

3

2

1

AUDIO IN/OUT SELECTOR

3

1 4

21

28

30 27

29

5

6 8

7

26

25 23

24

9

10

21

22

AUDIO SELECTOR

1

2

30

29

6

7

24

25

9

10

21

22

IC303

A

DSP SECTION

(Page 55)

IC301

S LAT

S DATA

S CLK

STR-DE1015G

L

R

R-CH

CENTER

R-CH

S WOOFER

REAR L

REAR R

CENTER

S WOOFER

REAR L

REAR R

L

R

VOL UP

VOL DOWN

VOL LED

SORCE L

RY DPASS

FMUTE

3

SCLK

2

SDATA

1

SLAT

RV401

MASTER

VOLUME

RV402

BALANCE

RY401

MUTE

Q401

R-CH

MUTE

SWITCH

Q411

AMP

IC304

6

5

11

20

1

13

S LAT

2

14

S DATA

3

15

S CLK

4

27

8

23

11

20

1

13

2

14

3

15

RELAY

DRIVE

Q410

7

• R-CH is ommited.

(Same as L-CH)

• Signal path

: FM

: AM

: CD

: TAPE

: DAT/MD

: TAPE (REC)

: DAT/MD (REC)

: PHONO

: AUDIO

: SURROUND

M

B

DA SECTION

(Page 54)

C

POWER AMP SECTION

(Page 51)

D

PANEL SECTION

(Page 63)

E

DA SECTION

(Page 53)

F

DSP SECTION

(Page 56)

— 49 —

— 50 —

Page 50

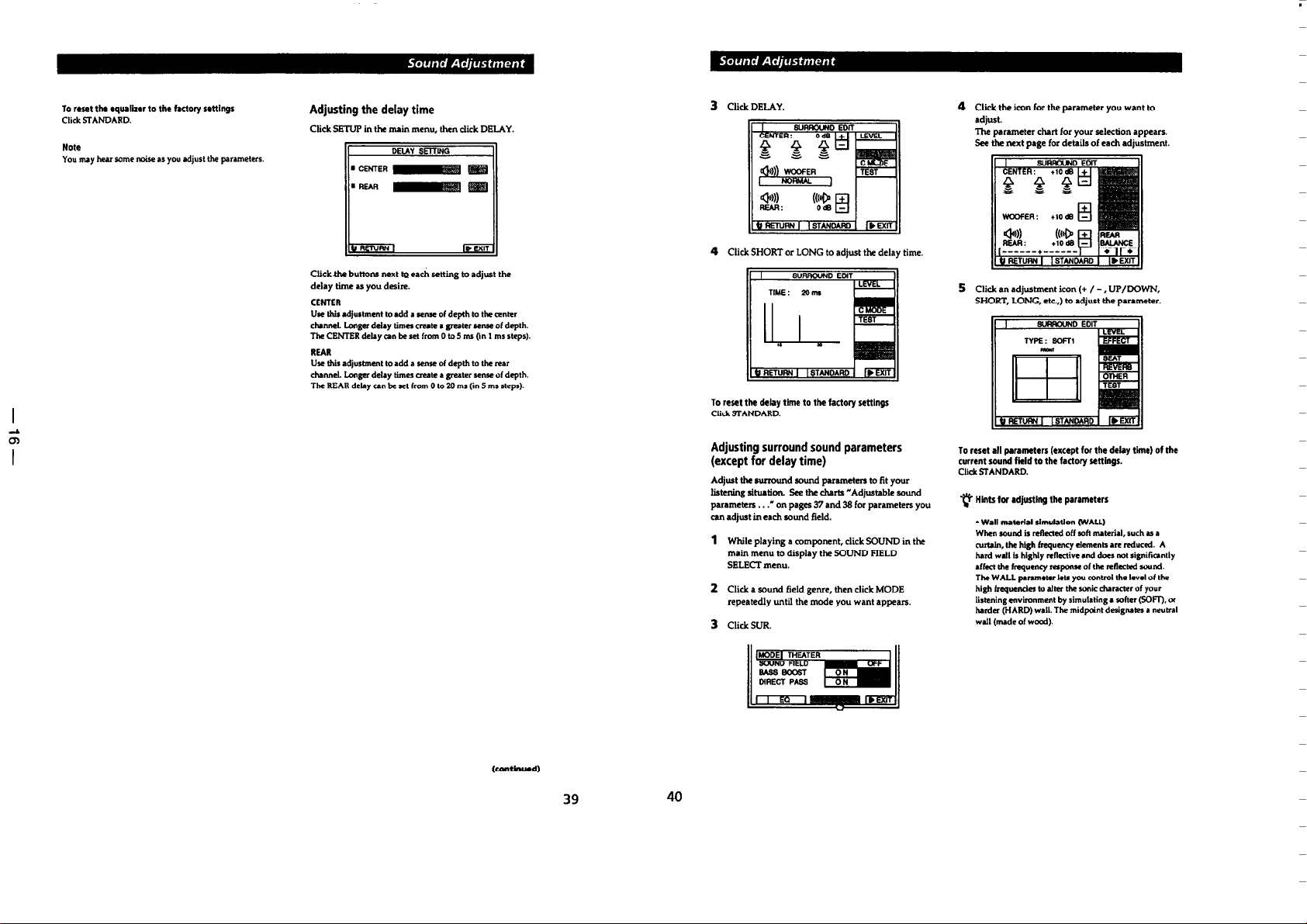

STR-DE1015G

— POWER AMP SECTION —

INPUT/OUTPUT

SECTION

(Page 50)

G

POWER SECTION

(Page 65)

09

CENTER RY

SURR RY

RY HP

PRT INPUT

AC MUTE

SP/A RY

SP/B RY

RY602

RY501

RY502

RY601

RY701

H

DSP SECTION

(Page 55)

I

PANEL SECTION

(Page 64)

REAR

REAR

RY503

SURR

CENTER

WOOFER

TM501

TM701

• Signal path

: FM

: SURROUND

L/R DRIVER

IC501

2

DRIVE

3

DRIVE

MUTE

BUFFER

IC601

BUFFER

–VE OUT

+VE OUT

4

5

9

10

11

12

CENTER

21

5

6

CENTER

MUTE

SWITCH

CENTER

6

PRE DRIVE

PRE DRIVE

8

1

L

R

Q503, 504

C

SL/SR DRIVER

IC701

2

DRIVE

3

4

REAR L

REAR R

S WOOFER

REAR

6

PRE DRIVE

REAR

MUTE

SWITCH

Q701, 703

WOOFER

LS

PRE DRIVE

8

DRIVE

1

MUTE

PRE AMP

IC602

3

2

REAR

5

REAR

9

10

11

12

1

POWER AMP

Q504–507

POWER AMP

Q554–557

POWER AMP

Q604–607

POWER AMP

Q704–707

POWER AMP

Q754–757

PROTECTOR

Q508

PROTECTOR

Q558

PROTECTOR

Q608

PROTECTOR

Q708

PROTECTOR

Q758

OVER LOAD SW

Q509–511

OVER LOAD SW

Q559–561

INVERTER

Q611

OVER LOAD SW

Q609, 610

OVER LOAD SW

Q709, 710

BUFFER

Q547–549

PRT INPUT

D507, 508

RY HP

SP/A RY

SP/B RY

CENTER RY

SURR RY

HEADPHONE

RELAY DRIVE

Q601

FRONT

A RELAY DRIVE

Q546

FRONT

B RELAY DRIVE

Q596

CENTER

RELAY DRIVE

Q645

SURR

RELAY DRIVE

Q745

WOOFER

RELAY DRIVE

Q544

J501

WOOFER

AUDIO OUT

J701

PHONES

L

A

R

L

B

R

CENTER

L

REAR

R

CNJ701

WIRELESS

REAR SPEAKER

FRONT SPEAKERS

SURROUND

SPEAKERS

— 51 —

— 52 —

Page 51

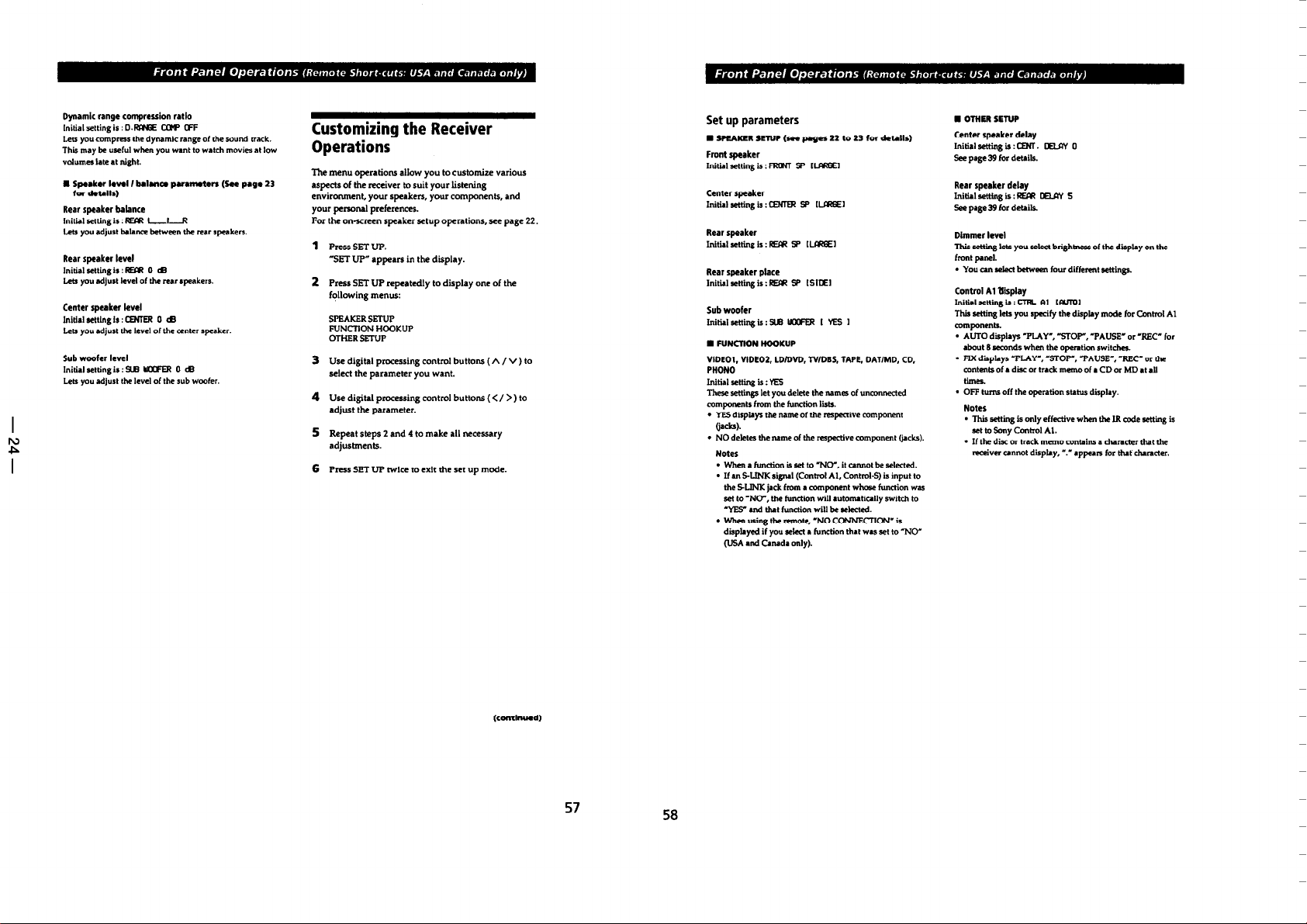

— DA SECTION —

STR-DE1015G

J

AC-3 (RF)

SECTION

(Page 58)

K

DSP

SECTION

(Page 56)

L

DSP

SECTION

(Page 55)

E

INPUT/OUTPUT

SECTION

(Page 50)

M

DSP SECTION

(Page 55)

09

DAO

DIG-IN0

DIG-IN1

DIG-IN2

DIRCLK

DIRLAT

DIWDAT

DIRDAT

DIRERR

DIRRST

ADINT

SORCE L

SELECTOR

DIGITAL

LD/DVD IN

OPTICAL

CD IN

OPTICAL

DAT/MD

OPTICAL

EXTAL

IN

3

OUT

INPUT

IC3301

DIGITAL

3

OUT

INPUT

IC3302

DIGITAL

3

OUT

INPUT

IC3303

PRE BUFFER

IC3101

6

• FRONT R-CH is ommited. (Same as FRONT L-CH).

• REAR L-CH, R-CH and SUPER WOOFER part were ommited.

(Same as CENTER)

• Signal path

: FM

: Digital in

: Digital out

: RF (AC-3)

: SURROUND

IC3313

3 5

D1 OUT

1

D3

15

D4

14

D5

4

D0

ABC

11 10 9

PRE BUFFER

IC3102

2

7

6

1

7

DIGITAL AUDIO

INTERFACE RECEIVER

IC3311

DATAO

DIN2

2

E/D

OUT

AVOCK

LRCK

BCK

SCLK

14

15

XLAT

SWDT

16

SRDT

17

EROR

24

XMODE

10

A/D CONVERTER

IC3104

AINL+

4 15

SDATA

AINL–

5 13

LRCK

SCLK

RST

10

MCLK

17

CLOCK COUNTER

IC3108

2QD

1CLK

1

1QB

BUFFER

IC3107

2

7

23

3

11

22

21

14

8

4

3

6

X3501

12.288MHz

SELECTOR

IC3414 (1/2)

10

B2A2Y2

11

1

VIN

DIGITAL

OUTPUT

IC3304

3

2

6

5

SELECTOR

IC3414 (2/2)

B0

A0

B1

A1

DSP SECTION

(Page 55)

9 DATA

BCKO

LRCKO

DAT/MD

OUT

OPTICAL

Y0

4

7

Y1

S

1

P

SOA

SOC

Q

DSP SECTION

(Page 56)

BUFFER

IC3417

LRCK

10

13

BCK

4

1

9 1

CLOCK COUNTER

IC3407

2QC 1CLK

PHASE

COMPARATOR

IC3409

R

8

7

S

8

6

PD OUT

DIGITAL FILTER, D/A CONVERTER (FRONT)

DATAI

40

DIGITAL

LRCKI

FILTER

39

BCKI

38

CLOCK

GENERATOR

XIN

DIGITAL FILTER, D/A CONVERTER

(CENTER, SUPER WOOFER)

DATAI

40

DIGITAL

LRCKI

FILTER

39

BCKI

38

128FSO

PLL

Q701–705

CLOCK

GENERATOR

L3401

47

3 13

IC3401

MODE

IC3402

MODE

D/A

CONVERTER

ATT

D/A

CONVERTER

ATT

BUFFER

IC3408

SHIFT

SHIFT

LATCH

LATCH

L1 (–)

L2 (+)

L1 (+)

L2 (–)

L1 (–)

L2 (+)

L1 (+)

L2 (–)

61

2

63

4

INIT

3736353410

61

2

63

4

XIN

10

INIT

37363534

8

10

IC3501

L. P. F.

IC3502

MIX

H. P. F.

AMP

AMP

IC3505

7

IC3506

L. P. F.

AMP

IC3514

7

5

6

R-CH

IC3507

ATT

IC3516

CENTER

H. P. F.

CENTER

5dB

2

IN1

SUPER

WOOFER

CENTER

1dB

8

OUT

SUPER WOOFER

18 1917

REAL L

REAL R

MIX

AMP

5dB

5

5

OUT1

1dB

7

IN1

WOOFER

REAR

REAR

CLK

DI

CE

ATT

SHIFT

LATCH

INIT

MUTE

GAIN

FRONT

L

R

CENTER

S WOOFER

REAL L

REAL R

CLK

DATA

LAT

DADAT

DACLK

DALAT

DAINT

ANADIG

N

DSP

SECTION

(Page 56)

B

INPUT/OUTPUT

SECTION

(Page 50)

O

DSP

SECTION

(Page 56)

— 53 —

— 54 —

Page 52

STR-DE1015G

— DSP SECTION —

P

DA

SECTION

(Page 53)

M

DA

SECTION

(Page 53)

L

DA

SECTION

(Page 53)

R

AC-3 (RF)

SECTION

(Page 58)

S

PANEL

SECTION

(Page 63)

A

INPUT/OUTPUT

SECTION

(Page 49)

H

POWER AMP

SECTION

(Page 52)

T

POWER

SECTION

(Page 65)

09

DATA

BCKO

LRCKO

EXTAL

DIRDAT

DIWDAT

DIRLAT

DIRCLK

DIRERR

DIRRST

ADINT

AC. RST

MUTO

MRST

STOP

U-MREQ

U-DATA

U-SREQ

U-CLOCK

IF DATA IN

AUTO STOP

T MUTE

STEREO

AC MUTE

RY HP

PRT INPUT

SURR RY

CENTER RY

RY POWER

IF

AUTOS

TMUTE

STEREO

RY HP

PROT

RY R

RY CNT

BCK

LRCK

RDATA

4

WDATA

5

6

DIRLAT

DIRCLK

7

DIRERR

8

A/D INT

10

RF RES

2

RF ERR

1

48

STOP

RESET

77

STOPIN

3

54

DISP MR

DISP DATA

55

SLV DATA/REQ

56

DISP CLK

57

57

•

56

SCKR

51

WSR

55

IC3425 (1/2)

SDI0

SDI1

DIGITAL SIGNAL PROCESSOR

IC3410

AUDIO

MEMORY

PLL

SCK/SCL

EXTAL

27

5

3

17 16 14 13 12 15

I/F

DIGITAL SIGNAL

PROCESSOR

HOST

I/F

MOSI/HAO

SS/HA2

MISO/SDA

413526

MISO

MOSI

CLOCK

DIGITAL SIGNAL PROCESSOR

IC3412

SDO0

SS/HA2

HREQ

SS

CONTROL

SDO2

SDO1

36

HREQ

SURR MUTE

RM MUTE

74 76

MUTE

D3407

RESET

RESET

GPIO0

7643

47

45

46

LDW FRQ IEQ

D3402

REAR

MEMORY

I/F

MRD

MWR

24 29 12

CE

MCAS

MD0 MD7

80 71 • 69–67 • 65-62 25–22 • 20–18 • 16 • 14–11 • 7 • 5–378773526

13–15 • 17–21 23 • 25–28 • 31 • 2

D0 D7

A16

R/W

S RAM

IC3411

SYSTEM CONTROL

IC3413

39 40

Q3307–3314

SWITCH

Q3406

MA0 MA15

A0 A15

GAIN FRONT 8dB

GAIN FRONT 4dB

GAIN FRONT 2dB

41

MUTE

8dB

ATT

4dB

GAIN SWITCH

Q3501–3503

2dB

V-E

VIDEO E

MUTE

Q3511,3512,

3515,3516

V-B

VIDEO B

V-A

68

VIDEO A

DIG-IN2

98 99 100

DIG-IN1

DIG-IN0

726970

FUNMUTE

SWITCH

D/AINT

D/ALAT

D/ACLK

D/ADATA

ANG/DIG

Q3315

LAT

58

DATA

59

CLK

60

25

26

28

29

9

• REAR is ommited.

• Signal path

: Digital in

47

SDO0

•

46

SDO1

SCKT

49

WST

50

HREQ

RESET

364342

SS

HREQ

RESET

DATA IN

61

AUT STOP

62

TUNER MUTE

73

STEREO

63

RY HP

88

PROTEC

67

RY REAR

87

RY CENTER

86

RY POWER

90

AC MUTE

75

IF

AUTOS

TMUTE

STEREO

RY HP

PROT

RY R

RY CNT

LRCK

BCK

57

•

56

51

55

49

50

IC3425 (2/2)

SDI0

SDI1

SCKR

WSR

SCKT

WST

MEMORY

RY FRONT

8280

X3401

4MHz

PLL

XIN

27

EXTAL

7

1

XOUT

83

AUDIO

I/F

DIGITAL SIGNAL

PROCESSOR

HOST

I/F

MOSI/HAO

SCK/SCL

MISO/SDA

42

41

24 22 20 19 18 21 38

MISO

MOSI

CLOCK

RY DIRECT

PASS

94

SOA

SOC

V-E

V-A

V-B

RY DPASS

FMUTE

SLAT

SDATA

SCLK

LAT

DATA

CLK

DAINT

DALAT

DACLK

DADAT

ANADIG

DIG-IN0

DIG-IN1

DIG-IN2

MUTE

GAIN FRONT

Q

DA

SECTION

(Page 53)

U

OSD

SECTION

(Page 59)

F

INPUT/OUTPUT

SECTION

(Page 50)

O

DA

SECTION

(Page 54)

K

DA SECTION

(Page 53)

N

DA SECTION

(Page 54)

: VIDEO

SWITCH

Q3407

D3409,3410

RY F

V

PANEL

SECTION

(Page 64)

— 55 —

— 56 —

Page 53

— AC-3 (RF) SECTION —

J3302

LD/DVD

IN

AC-3 RF

BUFFER

Q3301

BUFFER

Q33

6

IC3305 (1/2)

IC3305 (2/2)

L.P.F.

21

STR-DE1015G

DIGITAL SIGNAL PROCESSOR

(AC-3 RF DEMODULATOR)

ERROR

CORRECTOR

IC3308

DAI

CONTROL

DIVIDER

DIGITAL

OUT

DAOUT

70

DAO

J

DA

SECTION

(Page 53)

FILTER

BUFFER

7

Q3302

FL3301

1

6

4