Sony RMAX-1400 Service manual

RM-AX1400

SERVICE MANUAL

Ver. 1.2 2007.08

SPECIFICATIONS

Operating distance

Approx. 32.8 ft. (10 meters) (varies depending

on components of different manufacturers)

Power requirements

Remote control and button illumination:

Two size AA (R6) batteries

Battery life

Approx. 5 months (a Sony TV turned on/off

up to approx. 300 times per day)

Dimensions

Approx. 2 1/2 × 9 × 1 3/16 in. (w × h × d)

(60.4 × 227.5 × 29.4 mm)

Mass

6 oz. (170 g) (not including batteries)

Learnable signals*

Capacity per signal: up to 300 bit

Signal frequency range: 455 kHz and up to

300 kHz

Signal interval: up to 1 second

* Some signals cannot be learned by the

Remote Commander, even though the signals

comply with these specifications.

Supplied accessories

•Dedicated USB cable (1)

• CD-ROM* (1)

–AX1400 Remote Editor software

–Operating Instructions (PDF file)

*Do not attempt to play this CD-ROM in an

audio CD player.

•Operating Instructions (1)

•Warranty Card (1)

Design and specifications are subject to change

without notice.

US Model

Canadian Model

9-887-164-03

2007H16-1

© 2007.08

INTEGRATED REMOTE COMMANDER

Sony Corporation

Personal Audio Division

Published by Sony Techno Create Corporation

RM-AX1400

TABLE OF CONTENTS

1. GENERAL ................................................................... 3

2. DISASSEMBLY

2-1. Upper Case Assembly ..................................................... 4

2-2. Panel Light Guide Sub Assembly,

Switch Flexible Unit........................................................ 5

2-3. MAIN Board.................................................................... 6

3. TEST MODE ............................................................... 7

4. DIAGRAMS

4-1. Block Diagram – MAIN Section –.................................. 9

4-2. Printed Wiring Board – MAIN Board – .......................... 10

4-3. Schematic Diagram – MAIN Board (1/2) –.................... 11

4-4. Schematic Diagram – MAIN Board (2/2) – ................... 12

5. EXPLODED VIEWS ................................................. 16

6. ELECTRICAL PARTS LIST .................................. 17

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

2

SECTION 1

GENERAL

RM-AX1400

This section is extracted

from instruction manual.

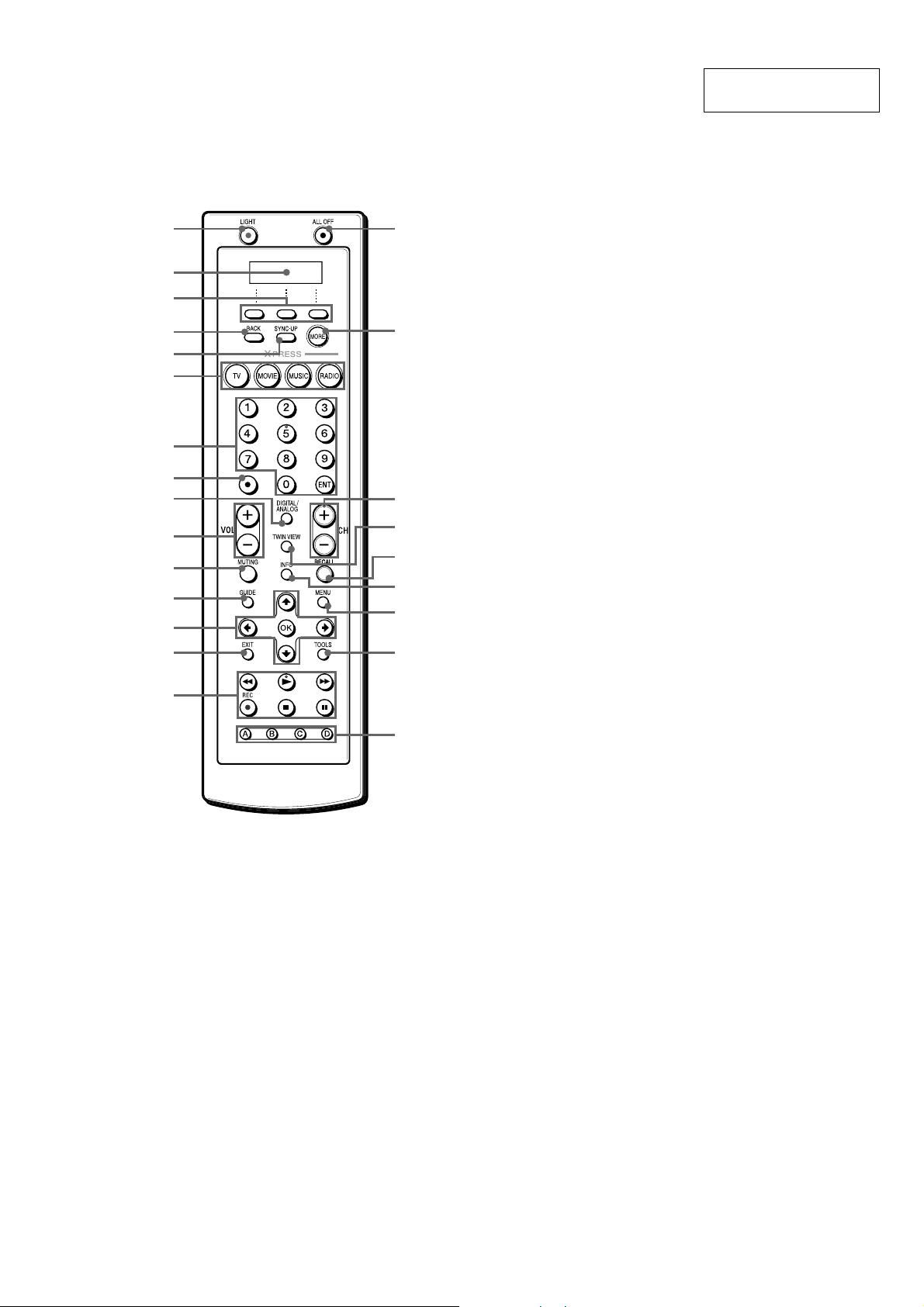

Location and function

of controls

1

2

3

4

5

6

7

8

9

q;

qa

qs

qd

qf

qg

The CHANNEL +, number 5 and N buttons

have a tactile dot.

1 LIGHT button (pages 18)

Used to brighten the button

illumination in the dark. Press the

button once to turn on/off the button

illumination.

2 Organic EL display

Displays the functions, setting menu

and transmission/battery marks.

3 MULTI-FUNCTION buttons (pages 15)

Used to select the desired function on

the screen.

4 BACK button

Used to return to the previous

component or XPRESS function.

qh

qj

qk

ql

w;

wa

ws

wd

wf

5 SYNC-UP button (pages 18)

Used to synchronize the Remote

Commander with the status of a

component.

6 XPRESS buttons (pages 15)

Used to perform the function.

7 Number/ENT buttons

Used to change the channel. For

example, to change to channel 5, press

0 and 5 (or press 5 and ENT).

8 Dot button

9 DIGITAL/ANALOG button

q; VOL +/– buttons* (pages 17)

Adjusts the volume.

qa MUTING button* (pages 17)

Silences the sound. Press the button to

silence, and again to return to the

previous volume level.

qs GUIDE button

qd OK and cursor buttons

qf EXIT button

qg Player control buttons

Used to fast-rewind/play/fastforward/record/stop/pause a

component.

qh ALL OFF button (pages 19)

qj MORE button (pages 15)

Used to display the functions on the

screen by pressing repeatedly.

qk CH +/– buttons

Selects the channel.

ql TWIN VIEW button

w; RECALL button

wa INFO button

ws MENU button

wd TOOLS button

wf ABCD buttons

Available for programming desired

settings.

Used to program various functions by

using “AX1400 Remote Editor.”

* Note on the VOL +/– and MUTING

buttons

When you select a visual component, the

TV’s volume will be controlled; when you

select an audio component, the amplifier’s

volume will be controlled.

3

RM-AX1400

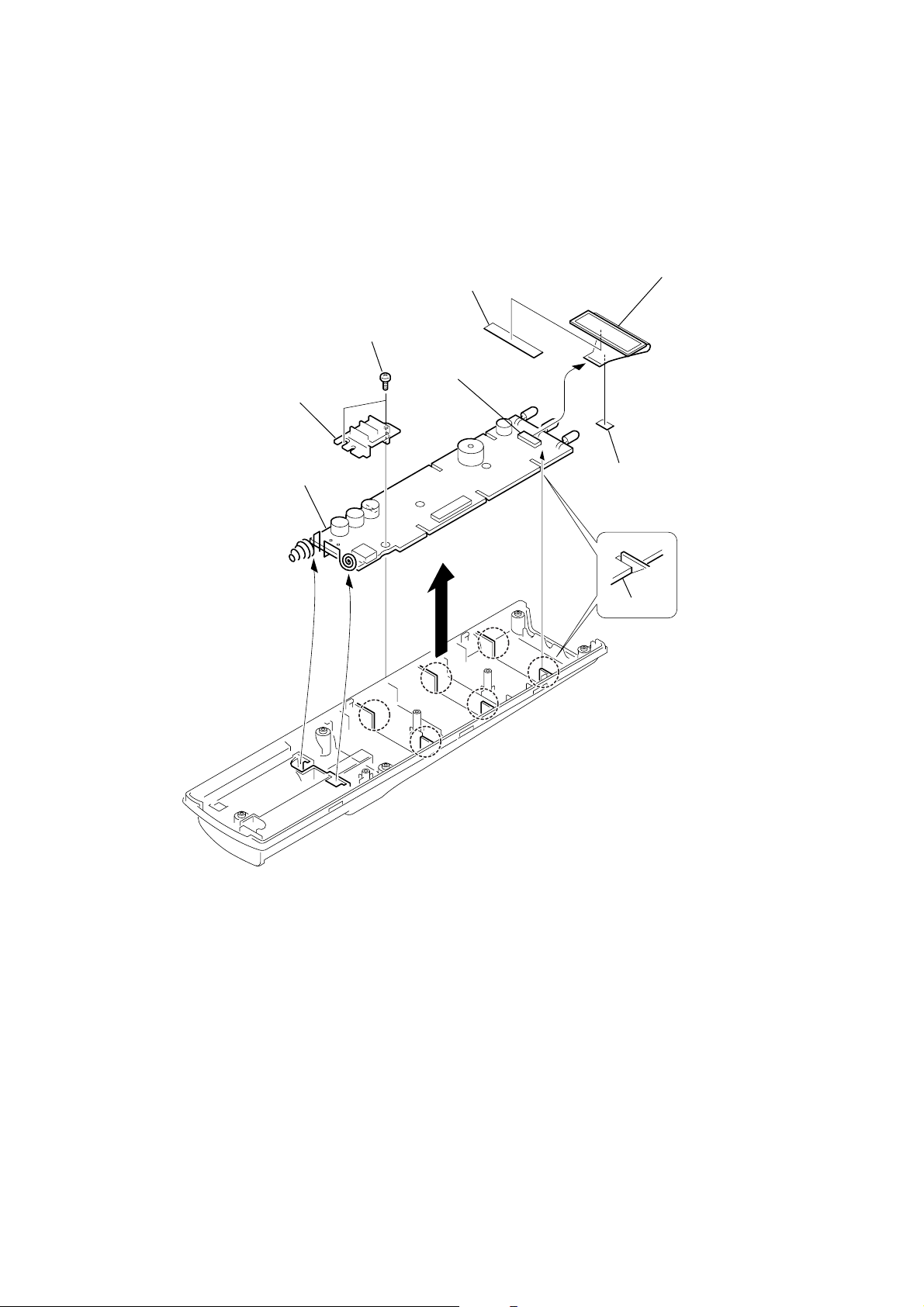

SECTION 2

DISASSEMBLY

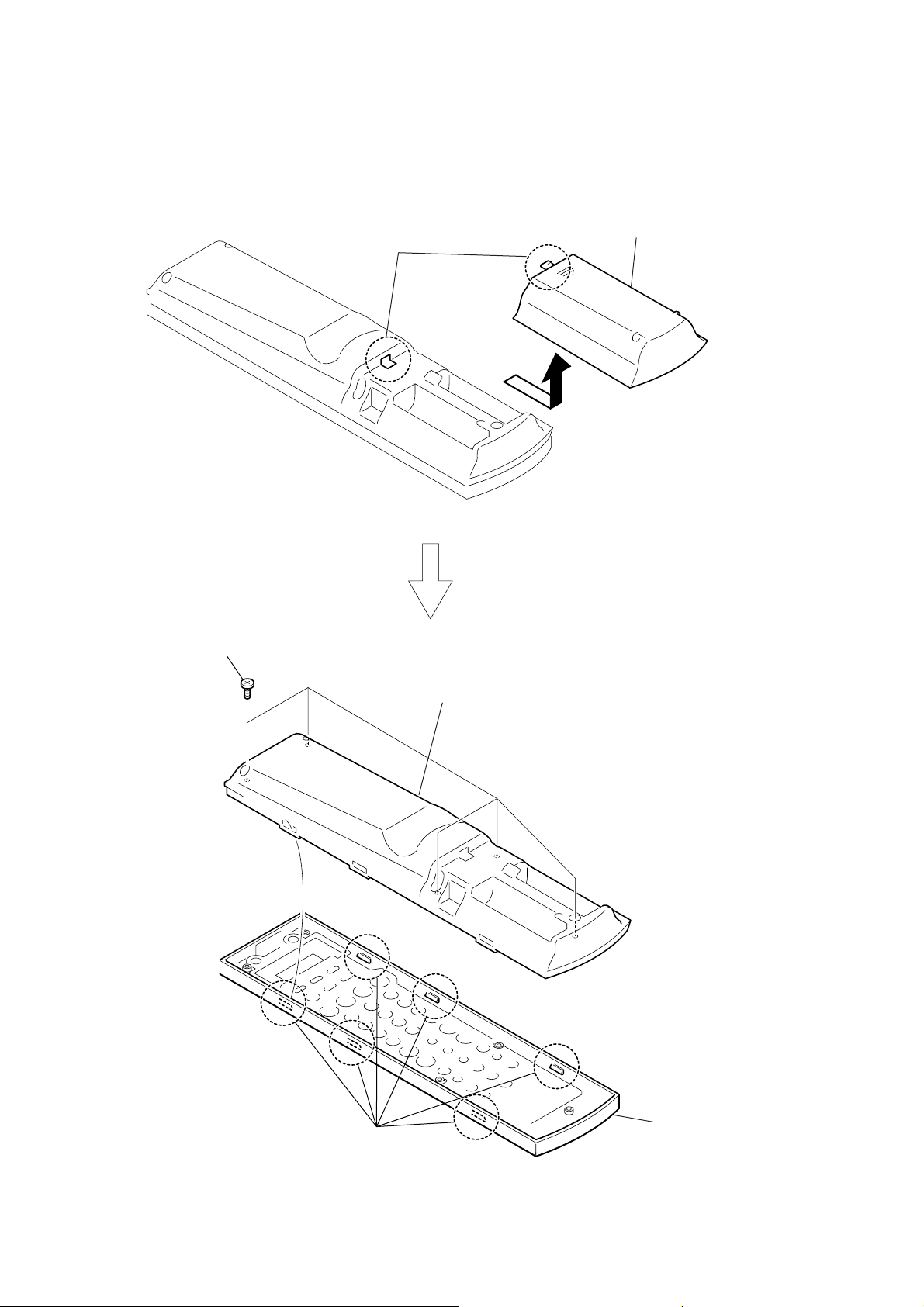

Note: Follow the disassembly procedure in the numerical order given.

2-1. UPPER CASE ASSEMBLY

1

claw

2

Remove the battery lid in the

direction of the arrow.

3

five tapping screws

(M2

×

6

)

5

lower case assembly

6

4

six claws

upper case assembly

4

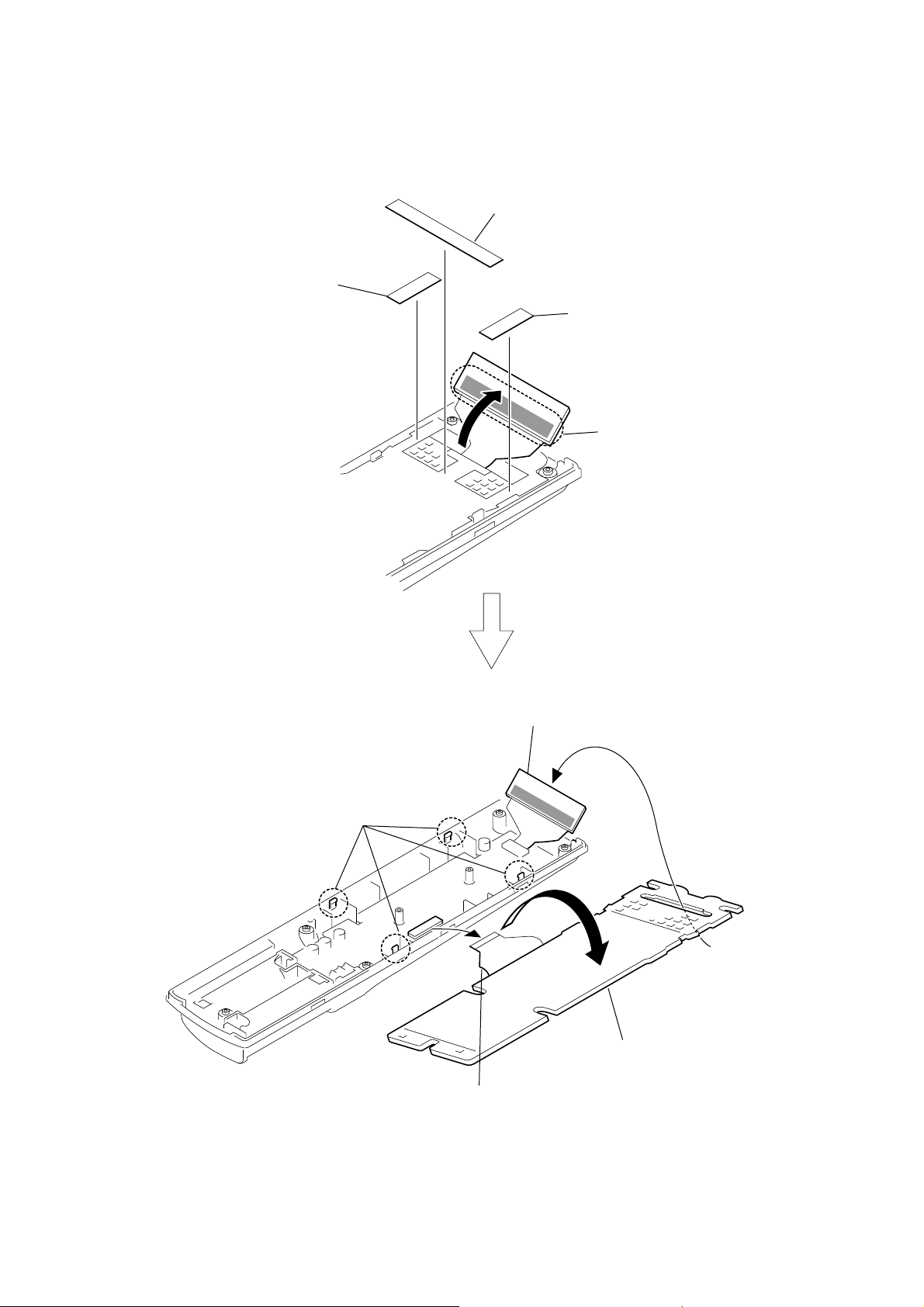

2-2. PANEL LIGHT GUIDE SUB ASSEMBLY, SWITCH FLEXIBLE UNIT

1

LCD sheet (A)

2

LCD sheet (B)

3

LCD sheet (B)

4

RM-AX1400

Remove the adhesive part.

5

four claws

8

connector

(CN1)

6

Through the organic EL

indicator module.

7

Return the panel light guide sub assembly,

and the switch flexible unit.

5

RM-AX1400

)

2-3. MAIN BOARD

2-3. MAIN BOARD

6

USB case

7

5

(M1.7

MAIN board

3

adhesive sheet LCD

two tapping screws

×

4

)

1

connector

(CN2)

4

organic EL

indicator module (LCD101

2

sheet

(PWD rib)

MAIN board

6

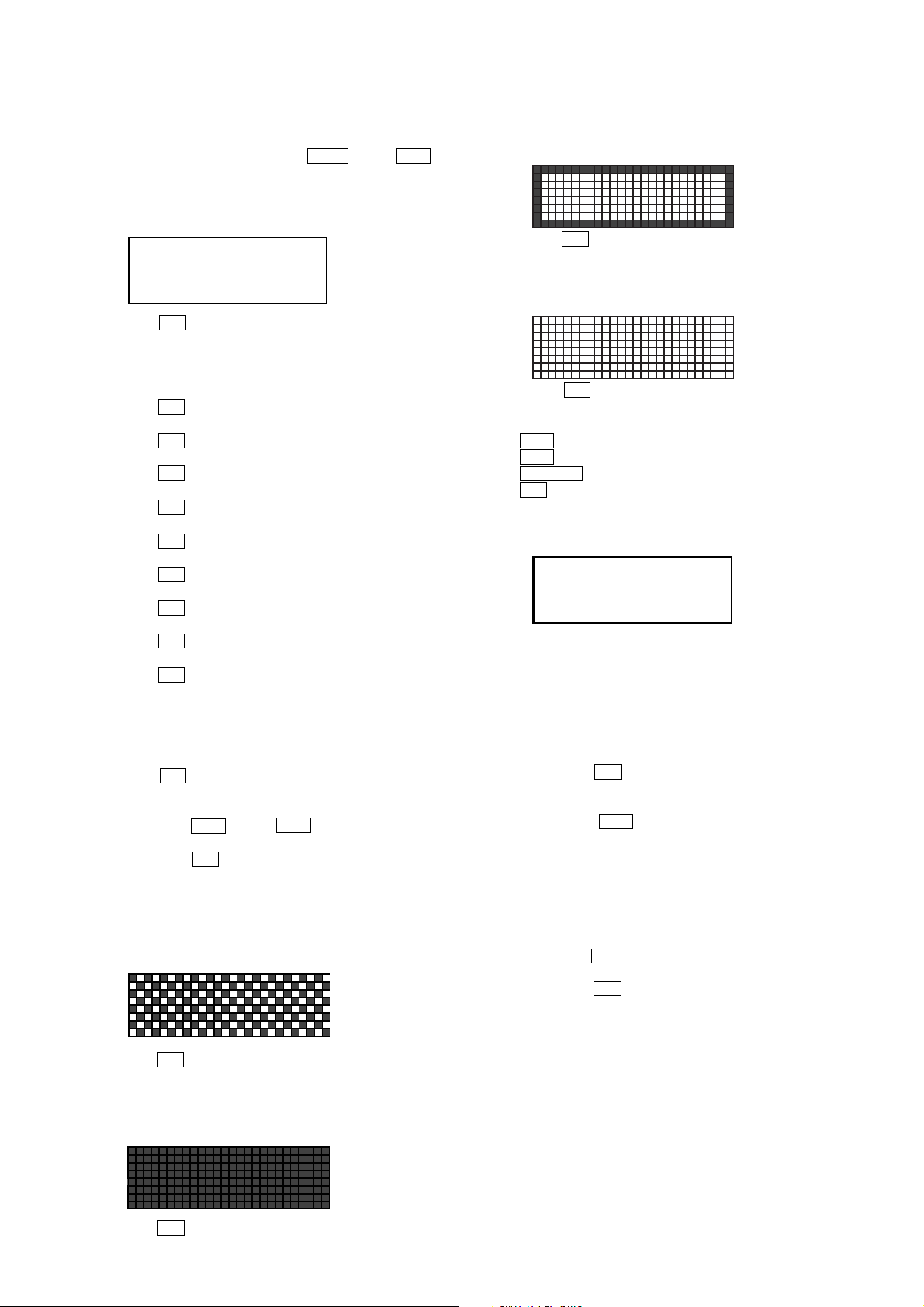

SECTION 3

TEST MODE

RM-AX1400

How to Enter the Test Mode

Install the battery while holding the VOL+ and the CH+ buttons

to enter the test mode.

When the unit enters the test mode, the following screen is displayed

showing the Boot block version No., the FRM block version No.,

country code and the Build date.

Test Mode

B-V:X X (US) F-V:X X

Build : Feb X X 2006

Press the OK button to proceed to the Flash Write Test.

Flow: The test mode is performed in the following order.

Flash Write Test

r OK button

OLED Contrast Test

r OK button

OLED Display Test (Pattern 1)

r OK button

OLED Display Test (Pattern 2)

r OK button

OLED Display Test (Pattern 3)

r OK button

OLED Display Test (Pattern 4)

r OK button

Key Light Test

r OK button

Key Press Test

r OK button

Learn T est

OK button after the test is complete.

1. Flash Write Test

Data is written in the BANK3 and is then erased.

When the test has ended with success, “OK” is display.

Press the OK button to proceed to the OLED Contrast Test.

Pattern 3

Frame of the OLED is displayed.

Press the OK button to proceed to the OLED Display T est (P attern

4).

Pattern 4

All segments of the OLED are turned off.

Press the OK button to proceed to the Key Light Test.

4. Key Light Test

CH+ button : Turns on the backlight at LEVEL 15.

CH– button : Turns on the backlight at LEVEL 1.

MUTING button: Turns off the backlight.

OK button : Proceed to the Key Press Test.

5. Key Press Test

52 characters are displayed.

************

********************

********************

52 characters

1. Pressing a hard key, the “*” character at the corresponding

position disappears.

Note: This operation is invalid when more than one button is pressed at

the same time.

2. After all the buttons are checked. “OK” appears on the third

line.

3. Press the OK button to proceed to the Learn Test.

2. OLED Contrast Test

1. Press the CH+ and the CH– buttons and confirm that the

contrast level changes.

2. Press the OK button to proceed to the OLED Display Test

(Pattern 1).

3. OLED Display Test (four patterns)

Pattern 1

The OLED is displayed in checkered pattern.

Press the OK button to proceed to the OLED Display T est (P attern

2).

Pattern 2

All segments of the OLED are displayed in the checkered pattern.

Press the OK button to proceed to the OLED Display T est (P attern

3).

6. Learn Test

1. Press the CH+ button to activate the learning circuit, and

learning starts.

When learning has ended with success, “OK” appears on the

third line.

When learning has ended with failure, “NG” appears on the

third line, and NG-BEEP (2) is activated.

(The data is stored in the RAM and is not written in a flash

memory.)

2. Press the CH+ button to send IR signal and confirm IR signal

is corrected.

3. Press the OK button to quit the test mode.

It can be confirmed that TV and TV remote commander are

used.

7

RM-AX1400

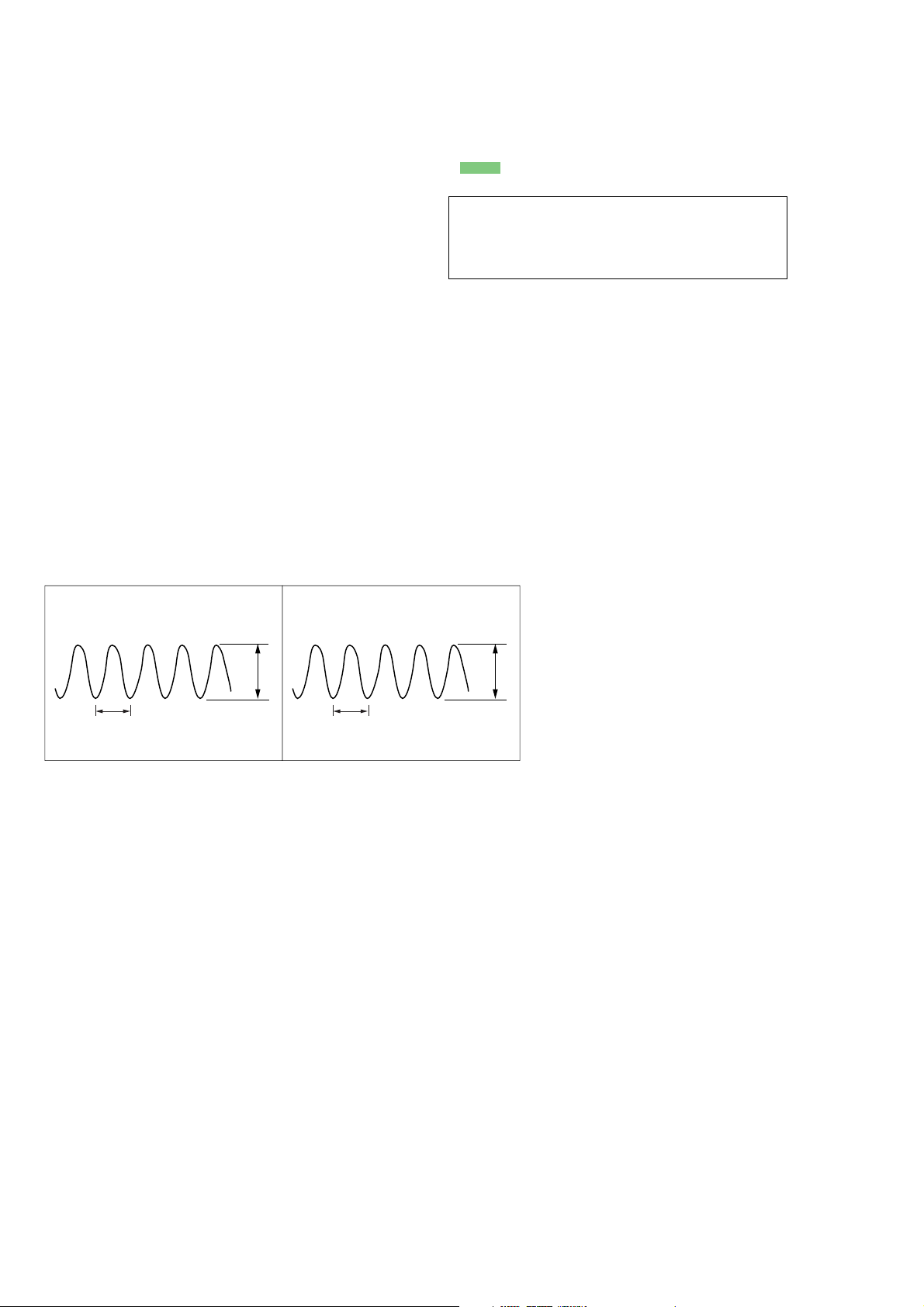

SECTION 4

DIAGRAMS

Note on Schematic Diagrams:

• All capacitors are in µF unless otherwise noted. (p: pF) 50 WV or

less are not indicated except for electrolytics and tantalums.

• All resistors are in Ω and 1/

• f : internal tolerance.

• C : panel designation.

• A : B+ Line.

•Voltages and wavefor ms are dc with respect to ground under nosignal (detuned) conditions.

no mark : Power on

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

4

W or less unless otherwise specified.

•Waveforms

– MAIN Board –

Note on Printed Wiring Boards:

• Y : parts extracted from the conductor side.

•

(The other layers' patterns are not indicated.)

: Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

1

IC1 qg (PI21/OSC-I)

200 ns

1 V/DIV, 100 ns/DIV

3.5 Vp-p

2

IC2A wh (XIN)

41.7 ns

1 V/DIV, 20 ns/DIV

500 mVp-p

8

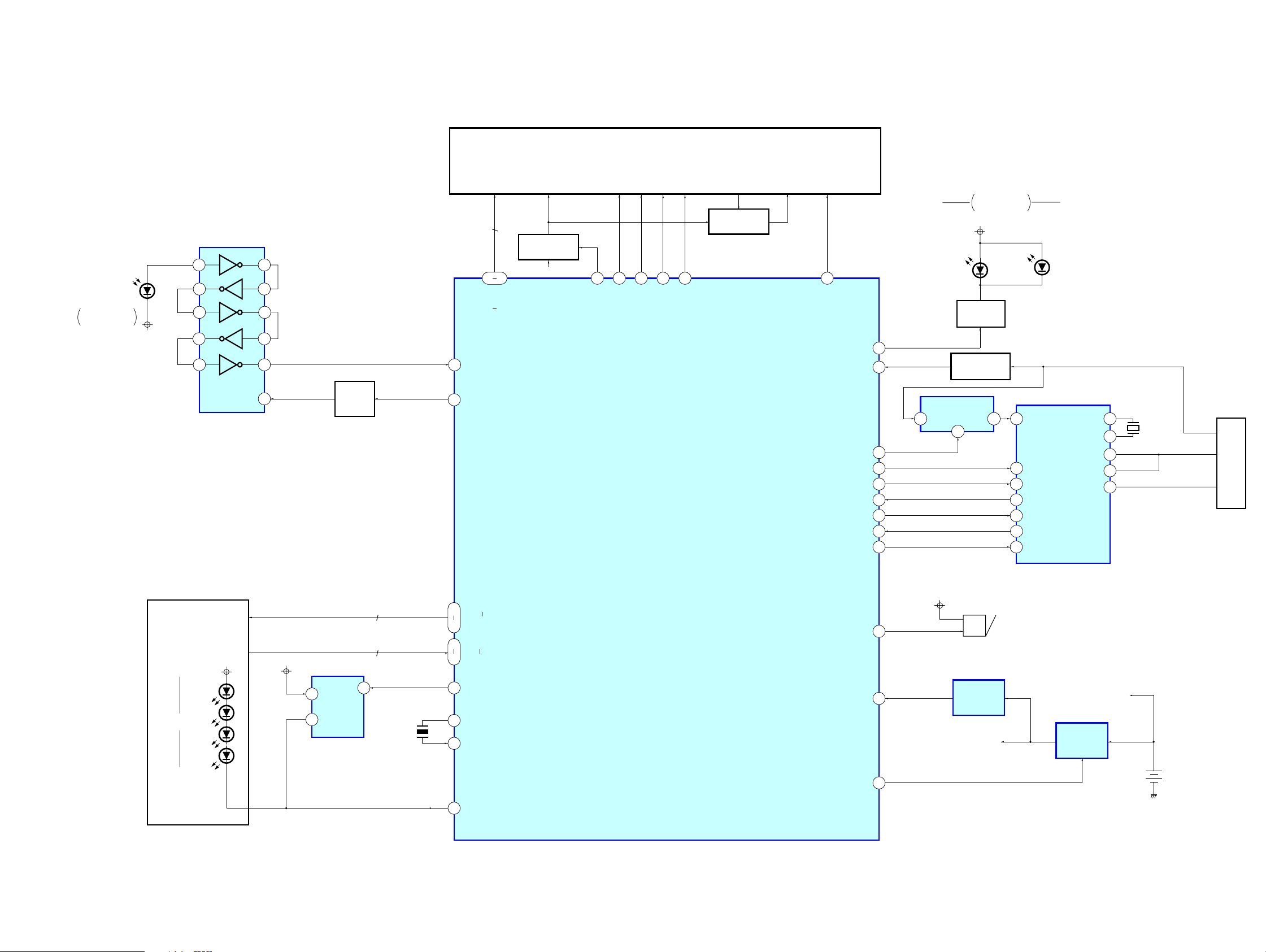

4-1. BLOCK DIAGRAM – MAIN SECTION –

RM-AX1400

LED3

RECEIVED

INFRARED RAYS

+3V

IC6

PRE AMP

1

4 3

5 6

10 11

9 8

VSS

(ORGANIC EL INDICATOR MODULE)

LCD101

SEND

INFRARED RAYS

Q801

8

Q802

OLED CONTROL

2

9

2

P47/LCD_D0

P40/LCD_D7

74

P00/LRN_I

Q15

7

LEARN

CONTROL

73

P01/LRN_O

+3V

70 78 77 76 72 79

P142/DC

P143/XLB

P04/OLED

P144/XRE

P02/XRST

IC1

SYSTEM CONTROLLER

SWITCH

P141/XCS5

P16/IR_O

P30/INT1/VBUS_I

P56/VBUS_O

P57/CS_O

P11/USBTX_O

P11/USBRX_I

P12/SI_O

P32/USB_SM_INT_I

P06/T1011/T001

48

46

USB CONTROL

15

57

58

54

53

52

40

38

+3V

LED1

Q14

LED DRIVER

Q6

VBUS CONTROL

IC3

3

LED2

IC2A

USB MODE CONTROLLER

22 VCC

1I_CS

3 I_WR/SK

8 O_DO/SO

7 I_AC/SLE/SI

4 I_INTR

16 RESET

27XOUT

26XIN

19D+

18V3.3

20D–

X702

24MHz

VBUS

D+

D–

CN3

(USB)

RM-AX1400

SWITCH FLEXIBLE

UNIT

(BACK LIGHT)

+3V

+3V

IC71

LED DRIVER

5

LX

2

FB

8

8

1

CE

X1

5 MHz

P27/KEYS_O

61

P20/KEYS_O

68

P77/KEYD_I

30

37

P70/KEYD_I

55

P54/BL_EN

P122/OSC_O

14

P121/OSC_I

15

47

P17/PWM_O

P15/BZ_O

RESET_I

P03/IC6_EN

49

10

71

+3V

BZ1

(BUZZER)

IC4

RESET

+3.3V

IC5

+3.3V REG

+3V

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION R6)

2PCS, 3.0V

99

Loading...

Loading...