Page 1

RM-AV2000T

MICROFILM

SERVICE MANUAL

SPECIFICATIONS

AEP Model

UK Model

E Model

Operating distance Approx. 10 meters (32.8 ft.) (varies

Power requirements Remote control : Four R6 (size AA)

batteries

Battery life Apporox. 6 months (varies depending on

Dimensions Approx. 120 × 175 × 45 mm

(43/4 × 7 × 113/16 in.) (w × h × d)

Mass 290g (10.22 oz.) (not including batteries)

Design and specifications are subject to change without notice.

depending on components of different

manufacturers)

Backlight : Two R6 (size AA) batteries

frequency of use)

INTEGRATED REMOTE COMMANDER

Page 2

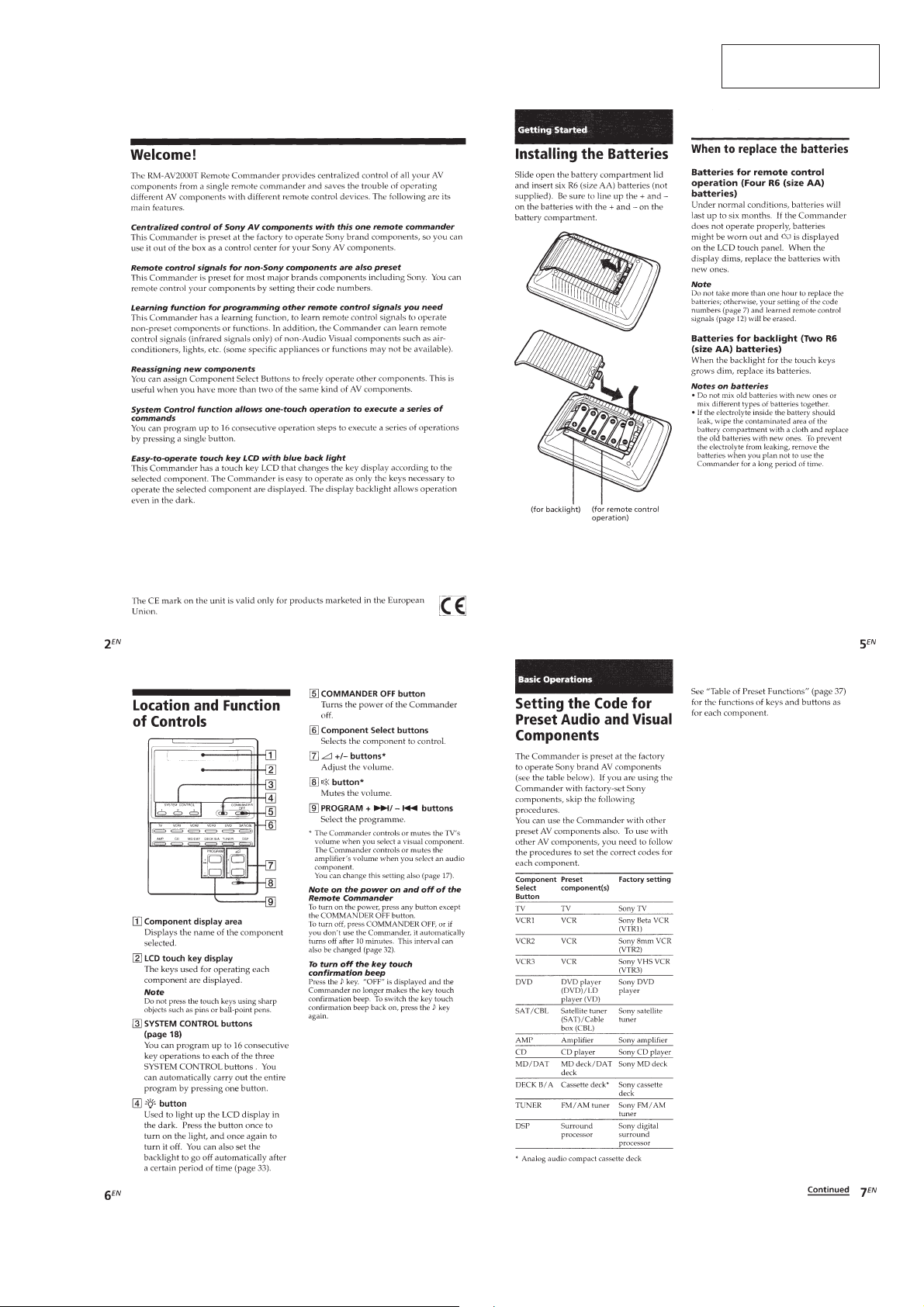

TABLE OF CONTENTS

1. GENERAL ······································································3

2. DISASSEMBLY

2-1. Removal of case (lower)··················································· 15

2-2. Removal of T.T.P, LCD, rubber switch, main bard ·········· 15

3. TEST MODE ································································ 16

4. DIAGRAMS

4-1. Printed Wiring Board –Main Section– ····························· 19

4-2. Schematic Diagram –Main Section – ······························· 21

4-3. IC Pin Functions ······························································· 23

5. EXPLODED VIEWS ··················································26

6. ELECTRICAL PARTS LIST ··································· 27

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

— 2 —

Page 3

SECTION 1

GENERAL

This section is extracted

from instruction manual.

— 3 —

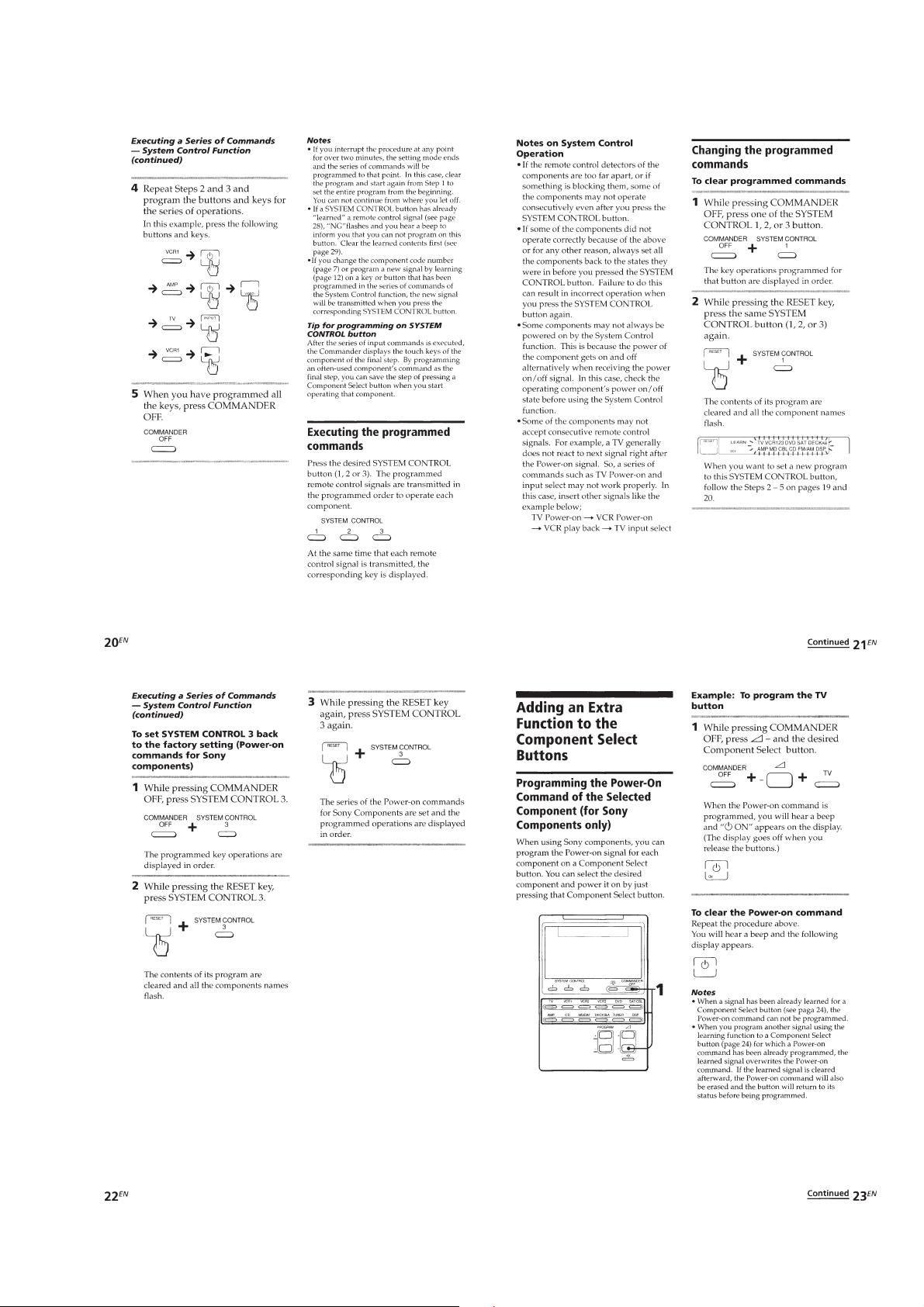

Page 4

— 4 —

Page 5

— 5 —

Page 6

— 6 —

Page 7

— 7 —

Page 8

— 8 —

Page 9

— 9 —

Page 10

— 10 —

Page 11

— 11 —

Page 12

— 12 —

Page 13

— 13 —

Page 14

— 14 —

Page 15

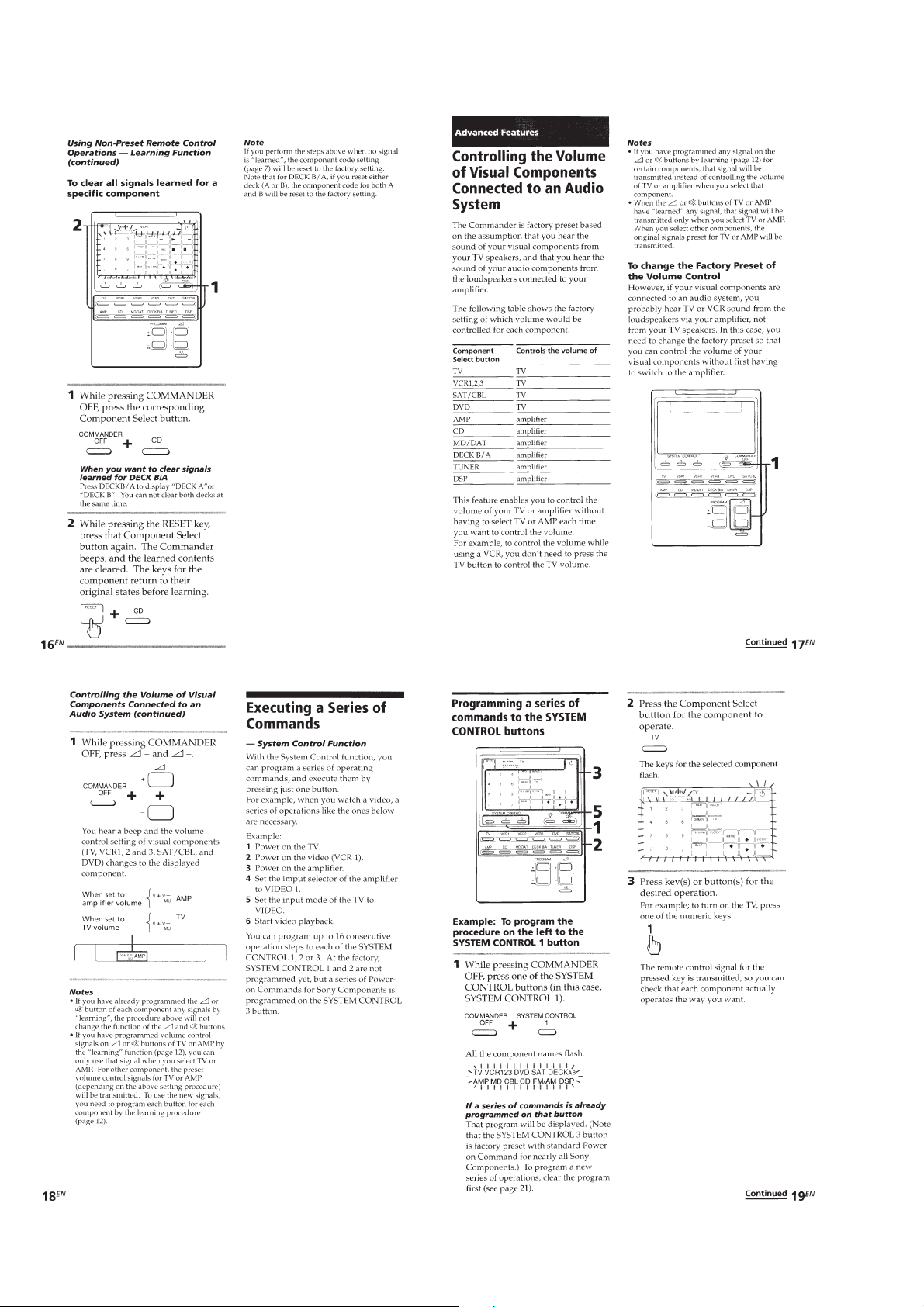

SECTION 2

)

e

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

2-1. REMOVAL OF CASE (LOWER)

4

1

Battery lid

Case (upper)

Precision screwdriver

2

+K2 ×8

Case (lower)

Case (upper)

×

6

Claw

3

Insert a precision screwdriver tip in between the Case (upper

and the Case (lower). When the Cases are opened a little,

2

+K2 ×8

insert nail of your thumb into the clearance. Open the Covers

while sliding the Covers upwards.

2-2. REMOVAL OF T.T.P, LCD, RUBBER SWITCH, MAIN BOARD

2

Case (upper)

3

Remove soldering of th

T.T.P. and remove it.

4

LCD

5

Rubber switch

6

MAIN board

— 15 —

1

+P2 ×5

Case (lower)

Page 16

TEST Mode (Operation Check)

SECTION 3

TEST MODE

Preform the following operation checks using the TEST Mode before

starting the repair works.

1. All Keys Operation Check

Connection Method :

Regulated power supply

(+6V constant voltage output)

set

+6V pin

(See Fig. 3-1.)

1) While pressing the PROGRAM + key and the Á + key,

ture ON the main power of the regulated power supply (DC

+6V). (Refer to Fig. 1-1.)

2) Remove all hands from pressing the all keys described in abov e

step 1). The all indications of the LCD must be turned OFF.

(Refer to Fig. 1-2.)

3) When any key of the Operation panel-key block (except

the COMMANDER OFF key), or any key of the LCD touchkey block is pressed, the signal (carrier 40kHz) as shown in

Fig. 1-3 must be transmitted in accordance the pressed key , when

operation of the machine is normal.

4) Press all keys of the Operation panel-key block (except the

COMMANDER OFF key, and of the LCD touch-key block

sequentially. When all keys are pressed, confirm that the long

buzzar sound and all LCD displays are turned off.

NOTE : Be careful that all data in S-RAM is cleared

when the above TEST mode is performed.

+

–

LCD touch-key block

Operation

panel-key block

PROGRAM

+ +

While pressing both keys

at the same time;

COMMANDER OFF

Á

Fig. 1-1

PROGRAM +

Á

+

Turn ON the

main power (DC 6V)

• This TEST Mode can be terminated in its middle before testing

all keys by pressing the COMMANDER OFF key . However

the conduction check of the remairing keys cannot be checked.

(S-RAM is not cleared.)

• P-ROM (IC8) is diagnosed to be free from defects when the

steps from 1) to 4) are performed correctly.

Fig. 1-2

2.4mscc 2.4mscc 2.4mscc

600 µ sec 600 µ sec

— 16 —

Fig. 1-3

Page 17

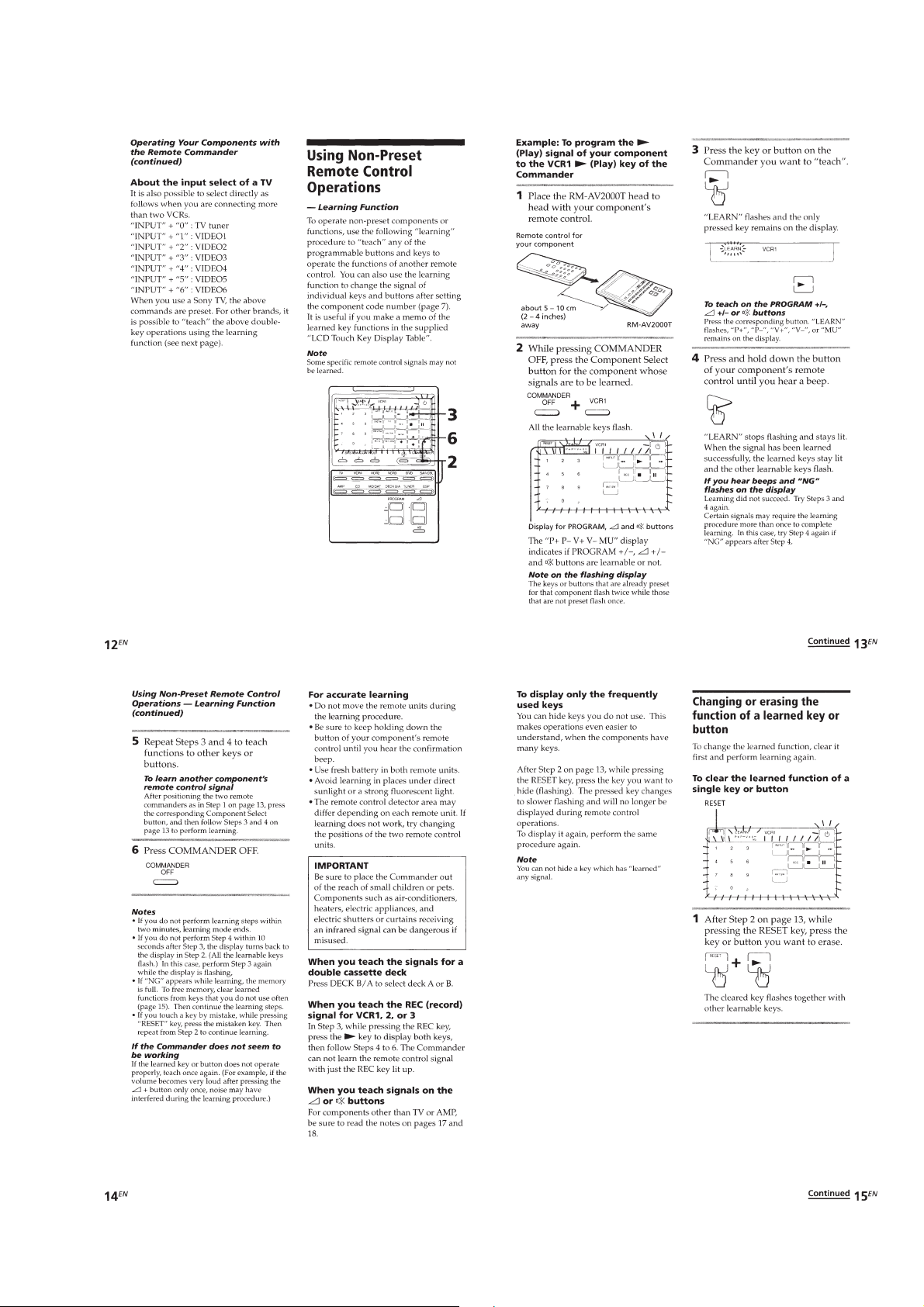

2. S-RAM (Learning Function) Operation Check

y

Connection Method :

3. Oscillation frequency Check

Connection Method :

MAIN board

Regulated power supply

(+6V constant voltage output)

set

+6V pin

+

–

1) While pressing the Á – key and the PROGRAM – key,

ture ON the main power of the regulated power supply (DC

+6V). (Refer to Fig. 2-1.)

2) When LEARN only of the LCD display appears, remove

hands from pressing the above mentioned keys. (Refer to Fig.

2-2.)

3) The display appears when the S-RAM is not defective. (The

diaplay NG appears when the S-RAM is defective.) (Refer to

Fig. 2-2.)

4) The display status as described in step 3) continues until any

key is pressed.

• S-RAM (IC3) is diagnosed to be free from defects when the

above steps from 1) to 4) are performed correctly.

PROGRAM –

PROGRAM

– –

While pressing both keys at the same time;

Á

Turn ON the

regulated power suppl

Á

MAIN BOARD (CONDUCTOR SIDE)

–

TP GND

TP VDD

2140

41

20

Regulated

power supply

(DV +6V constant

voltage)

+

−

IC1

60

61

TP3

24

25

1

80

1

80

IC1 ^¡ pin

IC1 ^º pin

SW1

SW2

TP3

+

−

frequency cunter

IC2

40

41

65

64

(NG) (OK)

Fig. 2-1

Fig. 3-1

LEARN

1) After turning the switches SW1 and SW2 both ON, turn on the

main power of a frequency counter and that of the regulated

power supply (DC +6V constant voltage).

2) Take r eading of frequenc y counter indication value. This v alue

is named fA.

3) Turn off the regulated power supply, then turn OFF the switch

SW1. After that, turn back ON the regulated power supply.

4) Take reading of frequency counter value in the same way as

step 2). This value is named fB.

5) Using the frequency values that are measured in steps 2) and

After a while

4), calculate the crystal oscillator frequency f1 and the crystal

oscillator frequency f2 using the following equations. Confirm

that the respective specification values are satisfied.

LEARNLEARN NG

U

Specification values:

f1 (4 Mz) = fB x 8

f2 (32.768 kHz) = fA x 4

Fig. 2-2

— 17 — — 18 —

Page 18

RM-AV2000T

SECTION 4

DIAGRAMS

4-1. PRINTED WIRING BOARD – MAIN SECTION –

12

345678910111213

A

B

C

D

E

F

G

• Semiconductor

Location

• Semiconductor Location

Ref. No. Location

D1 B-10

D2 B-9

D3 B-8

D4 B-7

D5 E-10

D6 A-9

D10 E-10

D11 E-10

IC1 B-9

IC2 D-8

IC3 E-9

IC4 B-10

IC5 E-10

Ref. No. Location

Ref. No. Location

IC6 B-8

IC7 C-9

IC8 E-8

Q1 B-9

Q2 B-7

Q4 E-10

Q9 D-9

Q10 D-10

Q11 E-10

Q12 D-9

Q13 D-9

Q14 F-9

Q15 F-9

— 19 — — 20 —

Note:

• X : parts extracted from the component side.

®

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• b : Switch pattern

: Through hole.

Page 19

4-2. SCHEMATIC DIAGRAM – MAIN SECTION – • See Page 23, 25 IC Pin Function.

RM-AV2000T

A

B

C

D

E

12

MAIN BOARD

D.SKIP

12 3

45 6

78 9

-/--

0

1-

CLEAR

ENTER

LCD1

u

CD

PGM

CONTINUE

REPEAT

SHUFFLE

2.4

2.5

2.5

8078797677747572737071

S8

S9

S11

2.5

2.4

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.4

2.5

2.4

2.5

2.4

2.4

2.4

2.5

2.4

2.5

S10

S12

1

S13

2

S14

3

S15

4

S16

5

S17

6

S18

7

S19

8

S20

9

S21

10

S22

11

S23

12

S24

13

S25

14

S26

15

S27

16

S28

17

S29

18

S30

19

S31

20

COM1

COM0

COM2

2123222524272629283130

2.5

2.5

C15

0.01

C16

0.01

C17

0.01

R41

100K

2.5

COM3

2.5

34567891011121314

2.5

S7

BIAS

5.0

R39

100k

R40

100k

S6

VLC0

5.0

2.402.402.5

S2

S3

S4

S5

IC1

SYSTEM CONTROL

IC1

uPD753017AGCE11

VLC2

VLC1

P41

P40

3.3

1.6

JP3

5.0

5.002.402.4

696768656663646162

S0

S1

P42

P71

P72

P73

RESET

P43

P50

VSS

P52

P51

323433363538374039

00000

TTP52

TTP51

TTP50

TTP43

5.0

P70

1

P53

0

P63

P00/INT4

TTP53

P62

P01

B+

5.0

TPBZ

3.0

RES

IP46

4.9

TPEL0

4.905.0

CLR

ICLK

OP67

uPD65012GF251

IP47

KINT

5.0

4.9

R50

4.7K

5.0

5.0

5.0

OP65

OP66

IC2

GATE ALLEY

IC2

IP50

IP52

IP51

5.0

5.0

R51

10k

VDD

GND

5.0

R57

BZ1

Q9

MSD601

BUZZER DRIVE

5.0

5.000

X1

P61

P60

X2

X1

VPP

XT2

XT1

VDD

P33

P32

P31

P30

P23

P22

P21

P20

P13

P12

P11

P10

P03

P02

4.9

5.0

TPOSC1

5.0

3.0

2.4

5.0

2.6

1.7

5.0

4.9

4.9

4.9

4.9

0

5.0

5.0

0

5.0

4.9

5.0

0

4.9

TPLCD

R21 330k

TPBATT

TPRES

R20

100K

C10

0.047

4.0MHz

C13 33p

IRDN

IWIN

IENN

4.9

R84

0

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

0

41

32.768kHz

C14 33p

ADB

R22 27

ADA

AD9

AD8

TP3

IC6

IC6

RN5VL45CTR

5.0

1 2

3

IC7

RN5VL40ATR

1 2

3

R19

100K

C12

0.01

X2

BATT

DOWN

5.0

C11

470

10V

IC7

5.0

RESET

5.0

P73

1

5.0

P72

2

5.0

P71

3

5.0

P70

4

5.0

P63

5

5.0

P62

6

5.0

P61

7

5.0

P60

8

0

P20

9

5.0

P21

10

5.0

P22

11

0

12

4.9

13

4.9

14

4.9

15

4.9

16

4.9

17

4.9

B+

18

4.9

19

4.9

20

4.9

21

4.9

22

4.9

23

4.9

1k

5.0

0

R56

4.7K

0

5.0

8078797677747572737071

INT

IALK

ID7

ID6

ID5

ID4

ID3

ID2

ID1

ID0

IENN

IWIN

IRDN

GND

IP30

IP31

IP32

IP33

IP34

IP35

IP36

IP37

IP40

IP41

IP42

IP43

IP45

IP44

2524272629283130323433363538374039

4.9

4.9

MSB709

TPEL1

5.0

GND

VDD

5.0

Q10

0

R52

470

Q10,11

EL SWITCH

(BRIGHT)

69

OP63

OP64

IP54

IP53

5.0

MSD602

68

OP62

IP55

5.0

Q11

2.7

5.00000

67

OP61

IP56

5.0

5.0

66

OP60

REC

R53

4.7k

MSB709

65

RMO

RDO

5.0

5.0

Q12

OUTP

ADA

ADB

AD9

AD8

AD7

AD6

AD5

AD4

AD3

AD2

GND

AD1

AD0

OD7

OD6

OD5

OD4

OD3

OD2

OD1

OD0

OCE

WTO

0

5.0

D11

MA738

MA738

0

0

R55

470

R54

10k

MSD602

64

4.9

63

4.9

62

4.9

61

4.9

60

5.0

59

5.0

58

1.1

57

1.1

56

4.1

55

4.1

54

53

1.2

52

0

51

2.0

50

3.8

49

2.7

48

2.0

47

3.8

46

0.2

45

3.8

44

3.0

43

5.0

42

5.0

41

TPREC

Q12,13

EL SWITCH

(DARK)

D10

2.7

Q13

TPVDD3

DC1.5X2

10V

R61

R60

82

1.5k

3.1

TPELOSC

2.8

3.1

Q14

MSD1328

SWITCHING

C20

OSC

470

0

1

5.0

2

ADC

5.0

AD7

3

5.0

AD6

4

1.1

AD5

5

1.1

AD4

6

4.1

AD3

7

4.1

AD2

8

1.2

AD1

9

0

AD0

10

3.0

OP0

11

3.8

OP1

12

0.2

OP2

13

GND

14

C23

10

16V

C22

0.1

IC3

SRAM

IC3

W24257S

L1

1

2

3

4

5

6

12

11

8

7

TPEGND

VCC

WE

ADD

AD8

AD9

ADB

OE

ADA

CE1

OP7

OP6

OP5

OP4

OP3

TPELOUT

TPSEL

C3

TPGC

0.01

4.8

28

5.0

27

0

26

4.9

25

4.9

24

4.9

23

0

22

4.9

21

0

20

2.0

19

3.8

18

2.7

17

2.0

16

3.8

15

C4(GC)

0.047F

64K-256K

JP1 JP2

R10

10K

0

0

Q4

MSD601

INVERTER

D5

1SS294

0

R8

15K

R9

47K

EL

F

G

H

J

TPVDD

DC 1.5X4

TPGND

IC5

RH5RE50AA

2 3

1

5.06.0

TPVDD2

IC5

REGULATOR

0.01

C2

C6

3300p

C5

220p

PRE AMP

uPD4069UBG

4.5

1

4.5

2

4.5

3

4.5

4

4.5

5

4.5

6

5.0 4.9

7

C7 0.047

R12

10k

R13

10k

R14

2.2M

R11

6.8k

R15

39k

IC4

B+

5

MSD601

SELECT

SWITCH

Q15

CHIP

R70 10K

R72

47K

0

R71

15K

D6

TPS705

IC4

5.0

14

5.0

13

12

5.0

11

4.7

10

9

4.7

B+

R18

120k

B+

0.01

5.0

1

5.0

2

ADC

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

OP0

OP1

OP2

GND

IC8

ROM

IC8

LH5359PA

5.0

3

5.0

4

1.1

5

1.1

6

4.1

7

4.1

C9

8

1.2

9

0

10

3.0

11

3.8

12

0.2

13

14

VCC

ADE

ADD

AD8

AD9

ADB

ADA

CE1

OP7

OP6

OP5

OP4

OP3

5.0

28

0

27

0

26

4.9

25

4.9

24

4.9

23

0

22

OE

4.9

21

5.0

20

2.0

19

3.8

18

2.7

17

2.0

16

3.8

15

8

R16 560

R17 27k

C8

TPCONT

0.047

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

• Voltages and waveforms are dc with respect to ground in

playback mode.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to wave forms.

TTP

R3

470

00

Q1,2

LED DRIVE

R1

8.2

TPR1

D1

D2

Q1

MSD1328

C1

100

10V

R2

S2-10

u

R31

S2-2

B+

R32

R33

R34

R35

R36

R37

R38

100K*8

RESET

S2-1

S2-9

DISPLAY

S2-8

INPUT

S2-7

RED

S2-6

3

S2-5

2

S2-4

1

S2-3

S2-18

S2-17

ANGLE

S2-16

TV

S2-15

GREEN

S2-14

6

S2-13

5

S2-12

4

S2-11

EXECUTE

S2-26

PGM

S2-25

MENU

S2-24

TELE TEXT

S2-23

YELLOW

S2-22

9

S2-21

8

S2-20

7

S2-19

S2-34

CONTINUE

S2-33

S2-32

RETURN

S2-31

T.TONE

S2-30

ENTER

S2-29

0

S2-28

-/--

S2-27

IP40

IP41

IP42

IP43

IP44

IP45

IP46

IP47

COMMANDER OFF

R23

R24

R25

SYSTEM

CONTROL3

R26

S1-3

SYSTEM

CONTROL2

R27

S1-2

SYSTEM

CONTROL1

R28

R29

B+

R30

100K*8

S1-5

S1-4

SAT/CBL

S1-11

S1-10

S1-9

S1-8

S1-7

S1-6S1-1

DVD

VCR3

VCR2

VCR1

TV

DSP

S1-17

DECK B/A

S1-15

MD/DAT

S1-14

CD

S1-13

TUNER

S1-16

AMP

S1-12

S1-22

Á Á¤

PROGRAM PROGRAM

S1-18

S1-21S1-19

S1-20

IP30

TPP30

IP31

TPP31

IP32

TPP32

IP33

TPP33

IP34

TPP34

IP35

TPP35

IP36

TPP36

IP37

TPP37

B+

TPRMO

R4

470

Q2

MSD1328

8.2

TPR2

D3

D4

4.0 4.0

D1-D4

UR64LD1

I

16

• Waveform

1 IC1 %∞

32.768kHz

2.8Vp-p

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specified.

• C : panel designation.

• U : B+ Line.

• Power voltage is dc 6V and fed with regulated dc power

supply from battery terminal.

— 21 — — 22 —

Page 20

4-3. IC PIN FUNCTION

• IC1 (µPD753017)

µPD753017 is the 4-bit single-chip microprocessor for the LCD panel display with the built-in controller and driver.

Pin No.

1 to 12

13 to 20

21 to 24

25

26 to 28

29 to 32

33

34 to 37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

Pin Name

S12 to S23

BP0 to BP7/

S24 to S31

COM0 to COM3

BIAS

VLC0 to VLC2

P40 to P43

Vss

P50 to P53

P00/INT4

P01/SCK

P02/SO/SB0

P03/S1/SB1

P10/INT0

P11/INT1

P12/INT2

P13/TIO

P20/PTO0

P21/PTO1

P22/PCL

P23/BUZ

P30/LCD CL

P31/SYNC

P32

P33

I/O

O

Segment signal output terminals.

O

1-bit output port (BIT-PORT). Used also as the segment signal output terminal.

O

Common signal output terminal.

O

Output terminal for cutting off the externally connected dividing resistor.

–

Power supply terminal for LCD drive. Dividing resistor are built-in. (mask option)

N-ch open-drain 4-bit input/output port. (PORT 4).

I/O

Pull-up resistor can be built-in in units of bit. (mask option).

10V withstand voltage in the open-drain connection.

–

GND terminal.

N-ch open-drain 4-bit input/output port. (PORT 5).

I/O

Pull-up resistor can be built-in in units of bit. (mask option).

10V withstand voltage in the open-drain connection.

Edge detection vector interrupt input terminal.

I

(Both of the rise-up and fall-down edge detections are usable.)

I/O

Serial clock input/output terminal.

Serial data output terminal.

I/O

Serial bus input/output terminal.

Serial data input terminal.

I/O

Serial bus input/output terminal.

Equipped with noise-rejection function.

I

Clock-synchronous type.

I

Asynchronous

Edge detection teatble input terminal.

I

(Rise-up edge detection). Asynchronous.

External event pulse input

I

terminal to the timer/event counter.

I/O

Timer/event counter output terminal.

I/O

Timer/event counter output terminal.

I/O

Clock output terminal.

Fixed frequency output terminal.

I/O

(For buzzer or for trimming the system clock.

I/O

Clock output terminal for driving the external expansion driver.

I/O

Clock output terminal for synchronizing the external expansion driver.

I/O

I/O

Pin Function

Edge detection vector interrupt

input terminal.(Detection edge

selectable.)

4-bit input port (PORT 0).

The pull-up resistor built-in can be

specified in units of 3 bits by

software for PO1 to PO3.

4-bit input port (PORT 1).

The pull-up resistor built-in can

be specified in units of 4 bits by

software.

4-bit input port (PORT 2).

The pull-up resistor built-in can be

specified in units of 4 bits by

software.

Programmable 4-bit input/output

port. (PORT 3).

Input and output can be set in units

of bit.

The pull-up resistor built-in can be

specified in units of 4 bits by

software.

Pin No.

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69 to 80

Pin Name

VDD

XT1

XT2

VPP

X1

X2

P60/KR0

P61/KR1

P62/KR2

P63/KR3

P70/KR4

P71/KR5

P72/KR6

P73/KR7

RESET

S0 to S11

I/O

–

Positive power supply terminal.

Terminal to which sub-system clock oscillating crystal is connected.

I

When external clock is used, input the ext. clock to XT1 and leave XT2 open.

–

XT1 can be used as the 1-bit input (TEST) terminal.

–

Internally connected to VDD.

I

Terminal to which main system clock oscillating crystal/ceramic is connected.

–

When external clock is used, input the ext. clock to X1, and connect the inverted phase signal to XT2.

I/O

I/O

Parallel fall-down edge detection

I/O

testable input terminal.

I/O

I/O

I/O

Parallel fall-down edge detection

testable input terminal.

I/O

I/O

System reset input terminal.

I

Segment signal output terminals.

O

Pin Function

Programmable 4-bit input/output port. (PORT 8).

Input and output can be specified in units of bit.

The pull-up resistor built-in can be specified in units of

4 bits by software.

4-bit input/output port. (PORT 7).

The pull-up resistor built-in can be specified in units of

4 bits by software.

— 23 — — 24 —

Page 21

• IC2 (µPD65012)

Pin No.

1 to 8

9 to11

12

13 to 20

21 to 28

29

30 to 32

33

34

35 to 38

39

40 to 42

43 to 50

51 to 52

53

54 to 59

60 to 63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Pin Name

ID7 to ID0

IENN/IWIN

IRDN.

GND

IP30 to IP37

IP40 to IP47

KINT

IP50 to IP52

GND

VDD

KINT

IP53 to IP56

REC

RDO.WTO

OCE

OD0 to OD7

AD0 to AD1

GND

AD2 to AD7

AD8 to AD11

OUTP

RMO

OP60

OP61

OP62

OP63

OP64

GND

VDD

OP65

OP66

OP67

CLR

ICLK

RES

INT

IALE

I/O

I/O

Data transfer between µPD65012 and microprocessor.

I

Control input from microprocessor.

—

GND terminal.

I

Key scan input.

I

Key scan input.

I

Not used.

—

GND terminal.

—

Positive power supply terminal.

I

Not used.

I

Remote control signal received input.

O

External memory control output.

I/O

Data transfer between µPD65012 and external memory.

O

Terminals to which external memory is connected. Lower address (ADO to AD1)

—

GND terminal.

O

Terminals to which external memory is connected. Lower address (AD2 to AD7)

O

Terminals to which external memory is connected. Upper address (AD8 to AD11)

O

Not used.

O

Remote control signal output.

O

Remote control signal receiver block ON/OFF output.

O

SRAM IC3 (W24257S) ADD and IC8 (LH5359PA) ADD.

O

SRAM IC3 (W24257S) ADE and IC8 (LH5359PA) ADE.

O

Selector SRAM IC3 (W242575S) or ROM IC8 (LH5359PA)

O

EL control output. (Dark)

—

GND terminal.

—

Positive power supply terminal.

O

Terminals to which external memory is connected. Upper address. (AD12)

O

EL control output. (Bright).

O

Buzzer

I

GA reset input.

I

GA clock input.

I

Not used.

O

Microprocessor interrupt output.

I

Address latch enable input.

Pin Function

— 25 —

Page 22

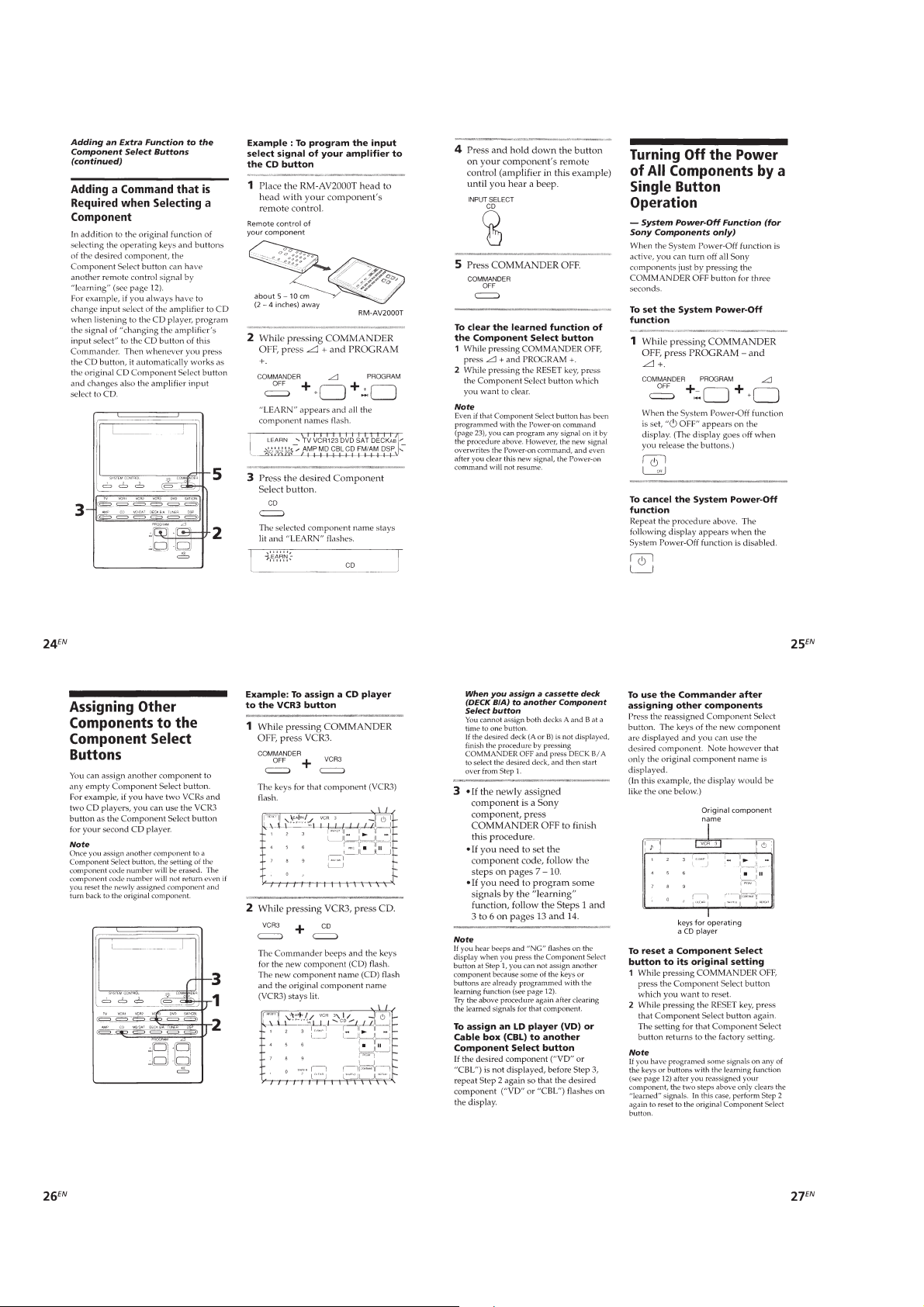

SECTION 5

EXPLODED VIEWS

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

2

• The mechanical parts with no reference number

in the exploded views are not supplied.

12

19

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

11

10

22

9

21

EL1

6

8

20

17

18

7

16

15

14

1

1

23

5

3

4

13

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 7-685-205-19 SCREW +KTP2 × 8 TYPE2 NON-SLIT

* 2 9-880-055-01 HOLDER

3 9-880-050-01 LID, BATTERY CASE

4 7-685-103-19 SCREW +P2 × 5 TYPE2 NON-SLIT

5 9-995-523-01 FOOT, RUBBER

13 9-995-521-01 COMMON TERMINAL

* 14 9-995-529-01 TERMINAL (+)

15 9-995-522-01 COMMON TERMINAL

* 16 9-995-530-01 TERMINAL (–)

* 17 9-995-528-01 TERMINAL (+)

6 9-880-048-01 RUBBER SWITCH

7 9-880-049-01 CASE (LOWER)

* 8 9-880-057-01 SPACER

* 9 9-995-525-01 LCD BRACKET

* 10 9-880-051-01 SEAL

11 9-995-518-01 SMOKE PLATE

12 9-880-458-01 CASE (UPPER)

* 18 9-995-531-01 TERMINAL (–)

* 19 9-880-053-01 ZEBRA CONNECTOR

* 20 9-880-235-01 MAIN BOARD, COMPLETE

21 9-880-459-01 LCD

22 9-880-056-01 TTP

23 9-880-460-01 LABEL, CE

EL1 9-880-153-01 ELECTRO LUMINESCENT

— 26 —

Page 23

SECTION 6

ELECTRICAL PARTS LIST

MAIN

NOTE:

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* 9-880-235-01 MAIN BOARD,COMPLETE

********************

< BUZZER >

BZ1 9-880-012-01 BUZZER

< CAPACITOR >

C1 1-104-658-91 ELECT 100uF 20% 10V

C2 1-104-329-11 CERAMIC CHIP 0.01uF 10% 50V

C3 1-104-329-11 CERAMIC CHIP 0.01uF 10% 50V

C4 9-880-016-01 GOLD CAP 0.047F

C5 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C6 1-163-015-91 CERAMIC CHIP 3300PF 10% 100V

C7 1-104-760-11 CERAMIC CHIP 0.047uF 10% 50V

C8 1-104-760-11 CERAMIC CHIP 0.047uF 10% 50V

C9 1-104-329-11 CERAMIC CHIP 0.01uF 10% 50V

C10 1-104-760-11 CERAMIC CHIP 0.047uF 10% 50V

C11 1-126-925-11 ELECT 470uF 20% 10V

C12 1-104-329-11 CERAMIC CHIP 0.01uF 10% 50V

C13 1-162-642-91 CERAMIC CHIP 33PF 5% 50V

C14 1-162-642-91 CERAMIC CHIP 33PF 5% 50V

C15 1-104-329-11 CERAMIC CHIP 0.01uF 10% 50V

C16 1-104-329-11 CERAMIC CHIP 0.01uF 10% 50V

C17 1-104-329-11 CERAMIC CHIP 0.01uF 10% 50V

C20 1-126-925-11 ELECT 470uF 20% 10V

C22 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C23 1-126-964-11 ELECT 10uF 20% 50V

< CONNECTOR >

* CN1 9-880-019-01 CONNECTOR 14P

* CN2 9-880-018-01 CONNECTOR 4P

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they may

have some difference from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• CAPA CITORS:

uF: µF

IC6 9-880-042-01 IC RN5VL45CTR

IC7 9-880-041-01 IC RN5VL40ATR

IC8 9-880-456-01 IC LH5359PA

* L1 9-880-011-01 TRANSFORMER EL TRANSFORMER

Q1 9-880-040-01 TRANSISTOR MSD1328RT1

Q2 9-880-040-01 TRANSISTOR MSD1328RT1

Q4 8-729-010-25 TRANSISTOR MSD601-RT1

Q9 8-729-010-25 TRANSISTOR MSD601-RT1

Q10 8-729-010-05 TRANSISTOR MSB709-RT1

Q11 8-729-010-35 TRANSISTOR MSD602-RT1

Q12 8-729-010-05 TRANSISTOR MSB709-RT1

Q13 8-729-010-35 TRANSISTOR MSD602-RT1

Q14 9-880-040-01 TRANSISTOR MSD1328RT1

Q15 8-729-010-25 TRANSISTOR MSD601-RT1

R1 1-247-302-11 CARBON 8.2 5% 1/4W

R2 1-247-302-11 CARBON 8.2 5% 1/4W

R3 1-216-041-00 RES,CHIP 470 5% 1/10W

R4 1-216-041-00 RES,CHIP 470 5% 1/10W

R8 1-216-077-00 RES,CHIP 15K 5% 1/10W

R9 1-216-089-91 RES,CHIP 47K 5% 1/10W

R10 1-216-073-00 RES,CHIP 10K 5% 1/10W

R11 1-216-069-00 RES,CHIP 6.8K 5% 1/10W

R12 1-216-073-00 RES,CHIP 10K 5% 1/10W

R13 1-216-073-00 RES,CHIP 10K 5% 1/10W

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

< COIL >

< TRANSISTOR >

< RESISTOR >

< DIODE >

D1 9-880-014-01 DIODE UR64LD1

D2 9-880-014-01 DIODE UR64LD1

D3 9-880-014-01 DIODE UR64LD1

D4 9-880-014-01 DIODE UR64LD1

D5 8-719-938-72 DIODE SB01-05CP

D6 9-880-013-01 DIODE TPS705WMATU2

D10 8-719-421-51 DIODE MA738-TX

D11 8-719-421-51 DIODE MA738-TX

< IC >

IC1 9-880-457-01 IC uPD753017E11

IC2 9-995-541-01 IC uPD65012F251

IC3 9-880-455-01 IC W24257S70LL

IC4 8-759-009-10 IC MC14069UBF

IC5 8-759-512-51 IC RH5RE50AA

R14 1-216-129-00 RES,CHIP 2.2M 5% 1/10W

R15 1-216-087-91 METAL,CHIP 39K 0.5% 1/10W

R16 1-216-043-91 RES,CHIP 560 5% 1/10W

R17 1-216-083-00 RES,CHIP 27K 5% 1/10W

R18 1-216-099-00 RES,CHIP 120K 5% 1/10W

R19 1-216-097-91 RES,CHIP 100K 5% 1/10W

R20 1-216-097-91 RES,CHIP 100K 5% 1/10W

R21 1-216-109-00 RES,CHIP 330K 5% 1/10W

R22 1-216-011-00 RES,CHIP 27 5% 1/10W

R23 1-216-097-91 RES,CHIP 100K 5% 1/10W

R24 1-216-097-91 RES,CHIP 100K 5% 1/10W

R25 1-216-097-91 RES,CHIP 100K 5% 1/10W

R26 1-216-097-91 RES,CHIP 100K 5% 1/10W

R27 1-216-097-91 RES,CHIP 100K 5% 1/10W

R28 1-216-097-91 RES,CHIP 100K 5% 1/10W

— 27 —

Page 24

RM-AV2000T

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R29 1-216-097-91 RES,CHIP 100K 5% 1/10W

R30 1-216-097-91 RES,CHIP 100K 5% 1/10W

R31 1-216-097-91 RES,CHIP 100K 5% 1/10W

R32 1-216-097-91 RES,CHIP 100K 5% 1/10W

R33 1-216-097-91 RES,CHIP 100K 5% 1/10W

R34 1-216-097-91 RES,CHIP 100K 5% 1/10W

R35 1-216-097-91 RES,CHIP 100K 5% 1/10W

R36 1-216-097-91 RES,CHIP 100K 5% 1/10W

R37 1-216-097-91 RES,CHIP 100K 5% 1/10W

R38 1-216-097-91 RES,CHIP 100K 5% 1/10W

R39 1-216-097-91 RES,CHIP 100K 5% 1/10W

R40 1-216-097-91 RES,CHIP 100K 5% 1/10W

R41 1-216-097-91 RES,CHIP 100K 5% 1/10W

R50 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R51 1-216-073-00 RES,CHIP 10K 5% 1/10W

R52 1-216-041-00 RES,CHIP 470 5% 1/10W

R53 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R54 1-216-073-00 RES,CHIP 10K 5% 1/10W

R55 1-216-041-00 RES,CHIP 470 5% 1/10W

R56 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R57 1-216-049-91 RES,CHIP 1K 5% 1/10W

R60 1-216-053-00 RES,CHIP 1.5K 5% 1/10W

R61 1-216-022-91 RES,CHIP 82 5% 1/10W

R70 1-213-073-91 RES,CHIP 10K 5% 1/10W

R71 1-216-077-00 RES,CHIP 15K 5% 1/10W

6 9-880-048-01 RUBBER SWITCH

13 9-995-521-01 COMMON TERMINAL

* 14 9-995-529-01 TERMINAL (+)

15 9-995-522-01 COMMON TERMINAL

* 16 9-995-530-01 TERMINAL (–)

* 17 9-995-528-01 TERMINAL (+)

* 18 9-995-531-01 TERMINAL (–)

* 19 9-880-053-01 ZEBRA CONNECTOR

21 9-880-459-01 LCD

22 9-880-056-01 TTP

EL1 9-880-153-01 ELECTRO LUMINESCENT

************************************************************

3-862-795-11 INSTRUCTION (CORD LIST)

MISCELLANEOUS

**************

ACCESSORIES & PACKING MATERIALS

********************************

3-862-793-11 MANUAL,INSTRUCTION (English,Dutch)

3-862-793-21 MANUAL,INSTRUCTION (German,Spanish)

3-862-793-31 MANUAL,INSTRUCTION (French,Italian)

3-862-793-41 MANUAL,INSTRUCTION (Swedish,Finnish)

R72 1-216-089-91 RES,CHIP 47K 5% 1/10W

R84 1-216-295-91 CONDUCTOR,CHIP 0

< VIBRATOR >

X1 9-880-017-01 VIBRATOR,CERAMIC (4.00MHz)

X2 9-880-015-01 VIBRATOR,CRYSTAL (32.768kHz)

***********************************************************

9-923-336-11

Sony Corporation

Personal A&V Products Company

— 28 —

Printed in Japan © 1998.2

98B1666-1

Published by Quality Engineering Dept.

(Shibaura)

Loading...

Loading...