Sony PCMR-300 Service manual

PCM-R300

SERVICE MANUAL

Ver 1.1 2001. 06

SPECIFICATIONS

Canadian Model

Model Name Using Similar Mechanism

T ape T r ansport Mechanism T ype

US Model

AEP Model

UK Model

DTC-A6

DATM-110A

9-922-708-12

2001F0200-1

© 2001.6

– Continued on next page –

DIGITAL AUDIO RECORDER

Sony Corporation

Home Audio Company

Shinagawa Tec Service Manual Production Group

– 1 –

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

MODEL IDENTIFICATION

— Back Panel —

Parts No.

3-018-941-0π : US, Canadian model

3-018-941-1π : AEP, UK model

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT . NE REMPLA CER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

SAFETY CHECK-OUT

TABLE OF CONTENTS

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated A C milliammeter . The Data Precision 245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V , so analog meters must ha ve an accurate lo w-voltage scale. The

Simpson 250 and Sanwa SH-63Trd are examples of a passive V OM

that is suitable. Nearly all battery operated digital multimeters

that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15µF

1.5k

Ω

AC

voltmeter

(0.75V)

1. SERVICING NOTE ........................................................... 4

2. GENERAL .......................................................................... 5

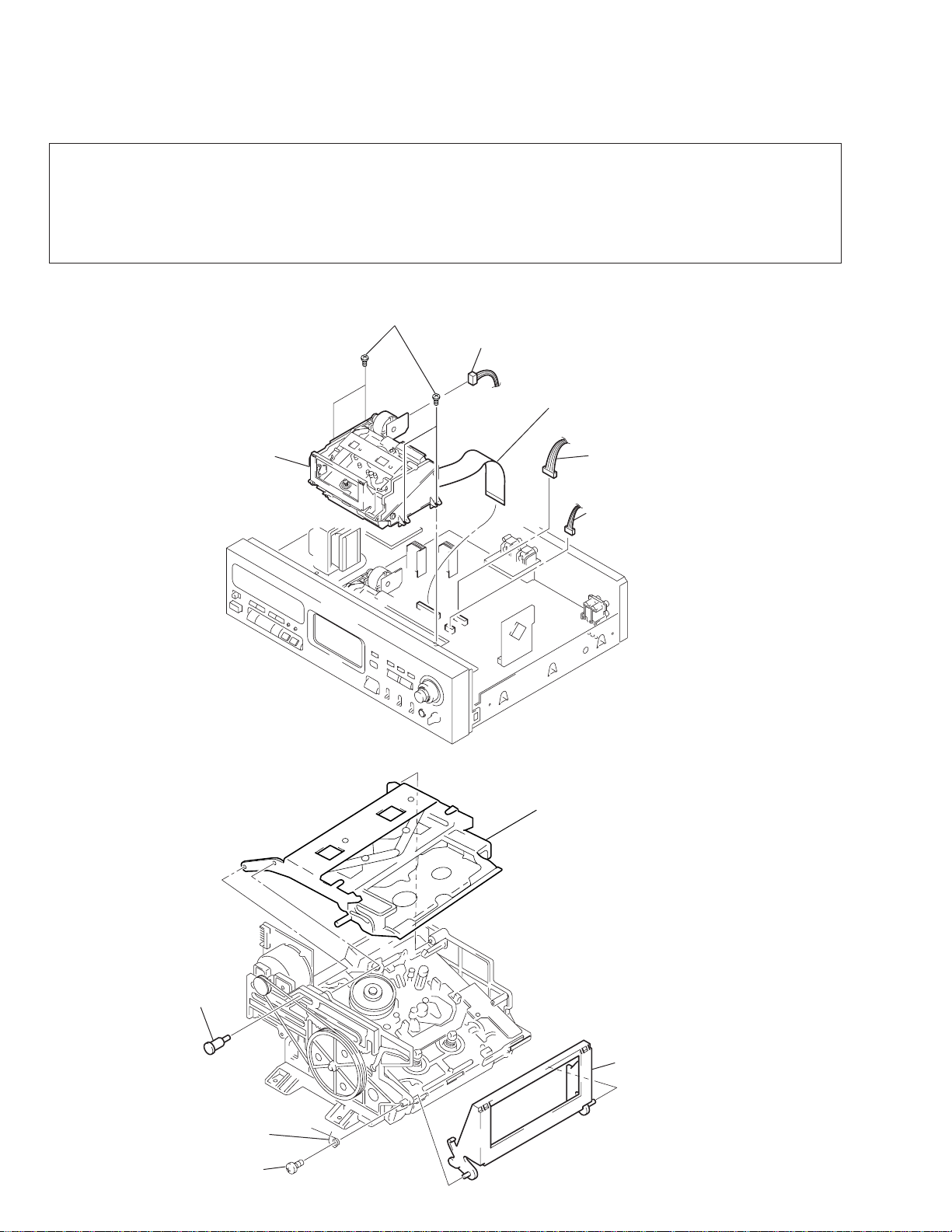

3. DISASSEMBLY

3-1. Case..................................................................................... 14

3-2. Cassette W indow ................................................................. 14

3-3. Mechanism Deck ................................................................ 14

3-4. Cassette Holder Assembly ..................................................14

3-5. Cassette Compartment Motor (M901), Pulley,

Driving Gear and Slider ...................................................... 15

3-6. Drum Drive Board and Driving Chassis ............................. 15

3-7. Drum ................................................................................... 16

3-8. Capstan Motor (M902) .......................................................16

4. ADJUSTMENTS ............................................................ 17

5. DIAGRAMS

5-1. Circuit Boards Location ..................................................... 21

5-2. Block Diagrams

• MD Section ...................................................................... 22

• Main Section .................................................................... 23

• Display/Power Section..................................................... 25

5-3. Schematic Diagram — MD Section —.............................. 26

5-4. Printed Wiring Board — MD Section —........................... 29

5-5. Printed Wiring Board — Main Section —......................... 32

5-6. Schematic Diagram — Main Section (1/3) —................... 35

5-7. Schematic Diagram — Main Section (2/3) —................... 38

5-8. Schematic Diagram — Main Section (3/3) —................... 41

5-9. Printed Wiring Board — Dispaly Section —..................... 44

5-10. Schematic Diagram — Display Section — ...................... 47

5-11. IC Block Diagrams ...........................................................49

5-12. IC Pin Functions............................................................... 53

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

6. EXPLODED VIEWS

6-1. Case and Back Panel Section.............................................. 59

6-2. Front panel Section ............................................................. 60

6-3. Chassis Section ................................................................... 61

6-4. Cassette Compartment Section ........................................... 62

6-5. Chassis L/R Section............................................................ 63

6-6. Mechanism Section-1 (DATM-110A) ................................ 64

6-7. Mechanism Section-2 (DATM-110A) ................................ 65

6-8. Mechanism Section-3 (DATM-110A) ................................ 66

7. ELECTRICAL PARTS LIST ........................................ 67

– 3 –

SECTION 1

SERVICING NOTE

Fluorescent indicator tube lit, key check mode

The Fluorescent indicator tubes and keys can be checked in this test

mode.

Settings: INPUT switch : Center click

ID MODE switch : Center click

REC MODE switch : Center click

NOTE:The method differs for when the remote commander provided

is used or not.

Method:

1. Disconnect the AC plug from the outlet, and short-circuit the TP

(TEST) of the display board and ground.

2. Connect the AC plug to the outlet, and turn on the power to start

the check.

Flow:

The left and right segments of the Fluorescent indicator tubes and

level meters light up, and the grids light up in order from the right

side.

The level meters go off one by one.

Operate the remote commander for DAT in this state.

• Part Location

[DISPLAY BOARD] (Conductor side)

TP (TEST)

IC801

Test mode

(If the remote commander

is used)

Pressing the 6button will

display “NEXT KEY” and

set the key check mode.

Pressing a button on the panel or switching a switch will light up the

level meters one by one.

When all buttons and switches ha ve been operated, all the level meters

will be lit and “KEY OK” will be displayed instantaneously.

“TEST END” is displayed and the test mode is ended.

• To reset the test mode, turn the power off and disconnect the wire

shorting TP (TEST) and ground.

(If the remote commander

is not used)

Press the pSTOP button.

“NEXT RMC” will be displayed.

Press the ”PLA Y b utton for more than

1 second, and then press the PPAUSE

button.

“NEXT KEY” will be displayed and the

key check mode will be set.

(If the remote commander

is used)

Pressing the 4 button

will turn off the segments

on the left and right sides.

Pressing the 7button will

display “TEST END” and

end the test mode.

(If the remote commander

is not used)

To end the test mode,

disconnect the A C plug

from the outlet.

– 4 –

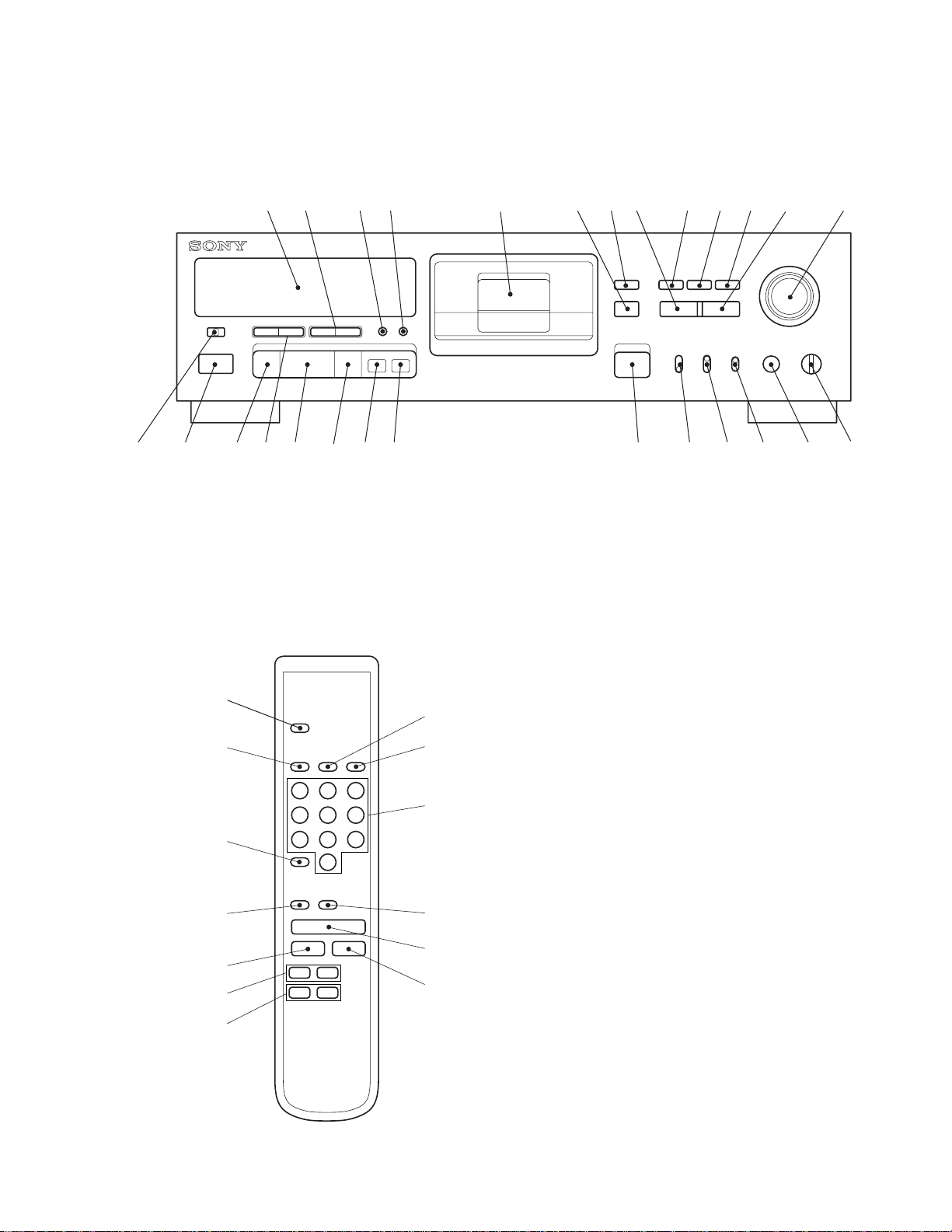

Location of Parts and Controls

27 26 25 24 23 22 21 20 19 18 17 16 15 14

13121110987654321

19

32

31

21

25

24

2

22

23

20

30

29

28

Front panel

SECTION 2

GENERAL

Remote commander (RM-D757)

1 Display window

2 0/) (REW/FF), DATA buttons

3 MODE, MENU button

4 RESET, ENTER button

5 Cassette holder

6 Remote sensor

7 MARGIN RESET button

8 WRITE button

9 START ID AUTO button

10 START ID RENUMBER button

11 START ID REHEARSAL button

12 ERASE button

13 REC LEVEL control

14 PHONE LEVEL control

15 PHONES jack

16 SBM switch

17 REC MODE switch

18 ID MODE switch

19 6 OPEN / CLOSE button

20 r REC button

21 R REC MUTE button

22 P PAUSE button

23 ( PLAY button

24 =/+ AMS, SELECT buttons

25 p STOP button

26 POWER button

27 INPUT switch

28 COUNTER MODE button

29 COUNTER RESET button

30 Numeric buttons

31 CLEAR button

32 REPEAT button

– 5 –

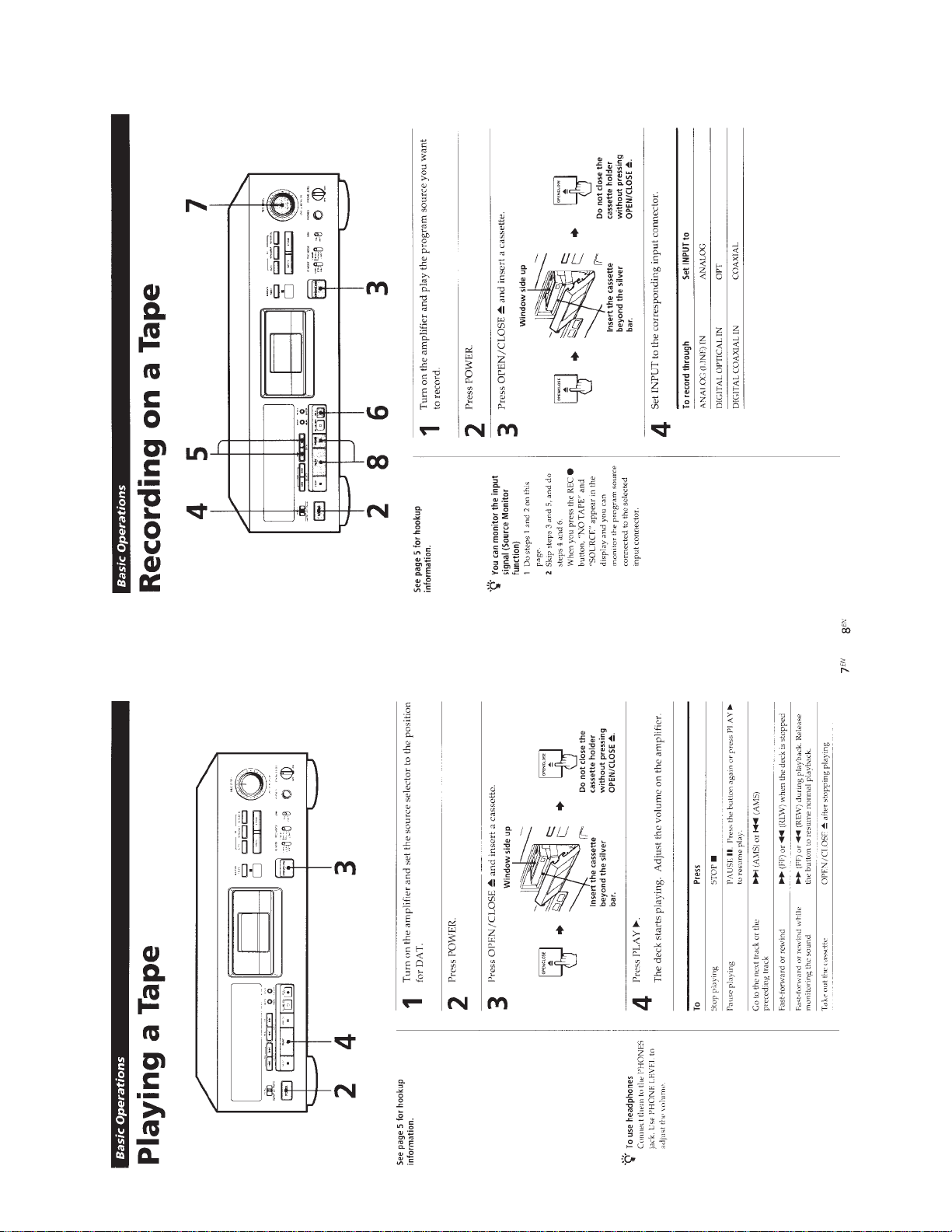

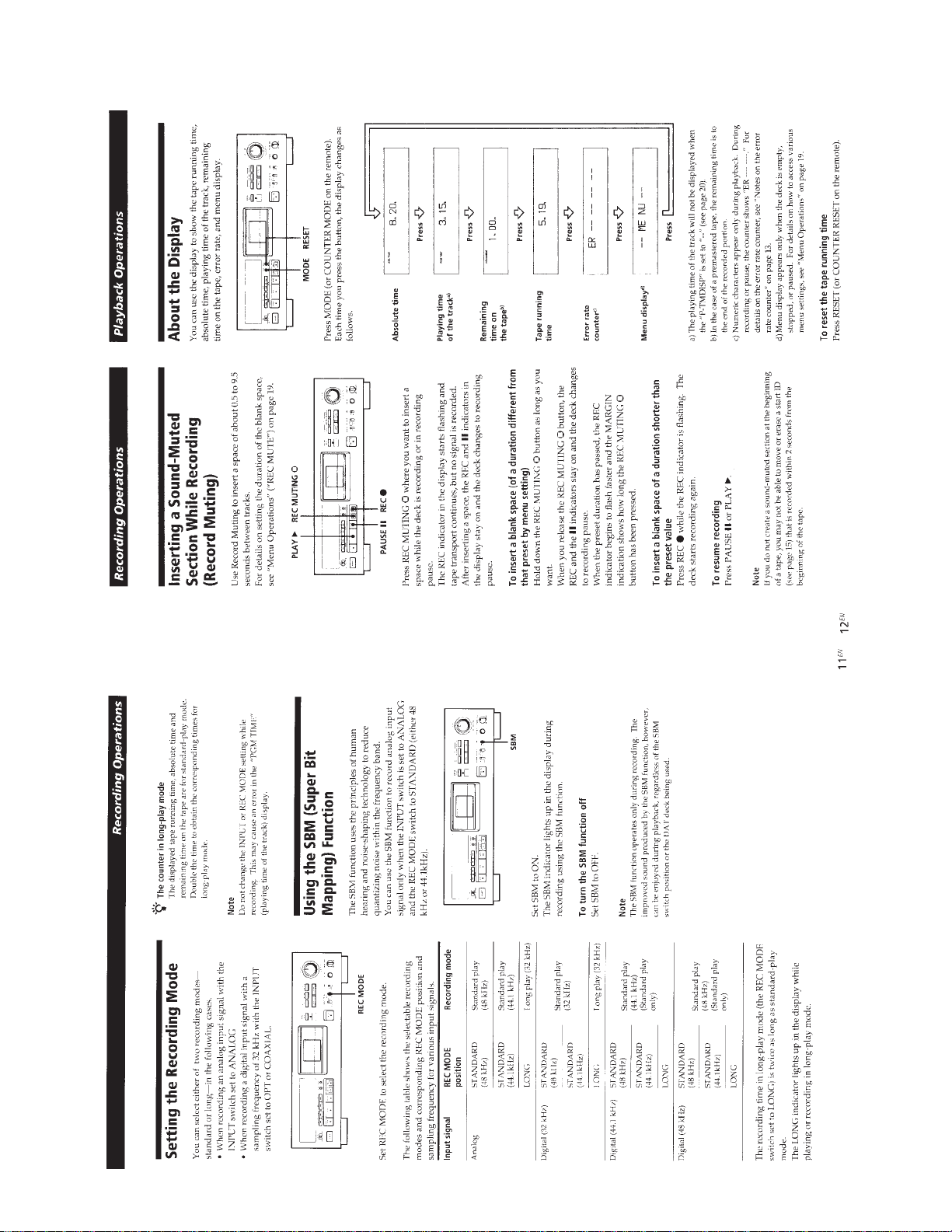

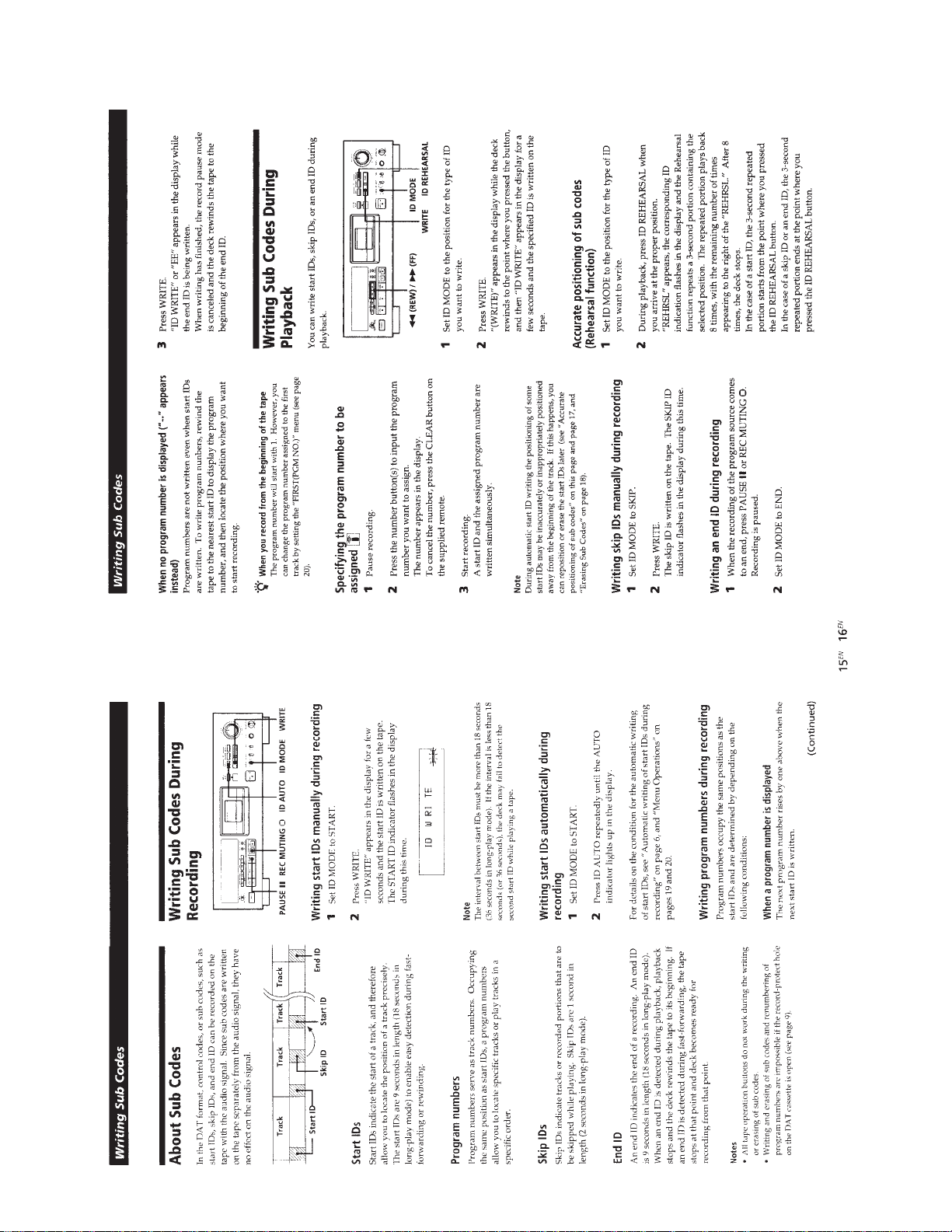

This section is extracted from

instruction manual.

– 6 –

– 7 –

– 8 –

– 9 –

– 10 –

– 11 –

– 12 –

– 13 –

DISASSEMBLY

)

Note: Follow the disassembly procedure in the numerical order given.

SECTION 3

3-1. CASE

Unscrew the four case attachment screws and remove the

case.

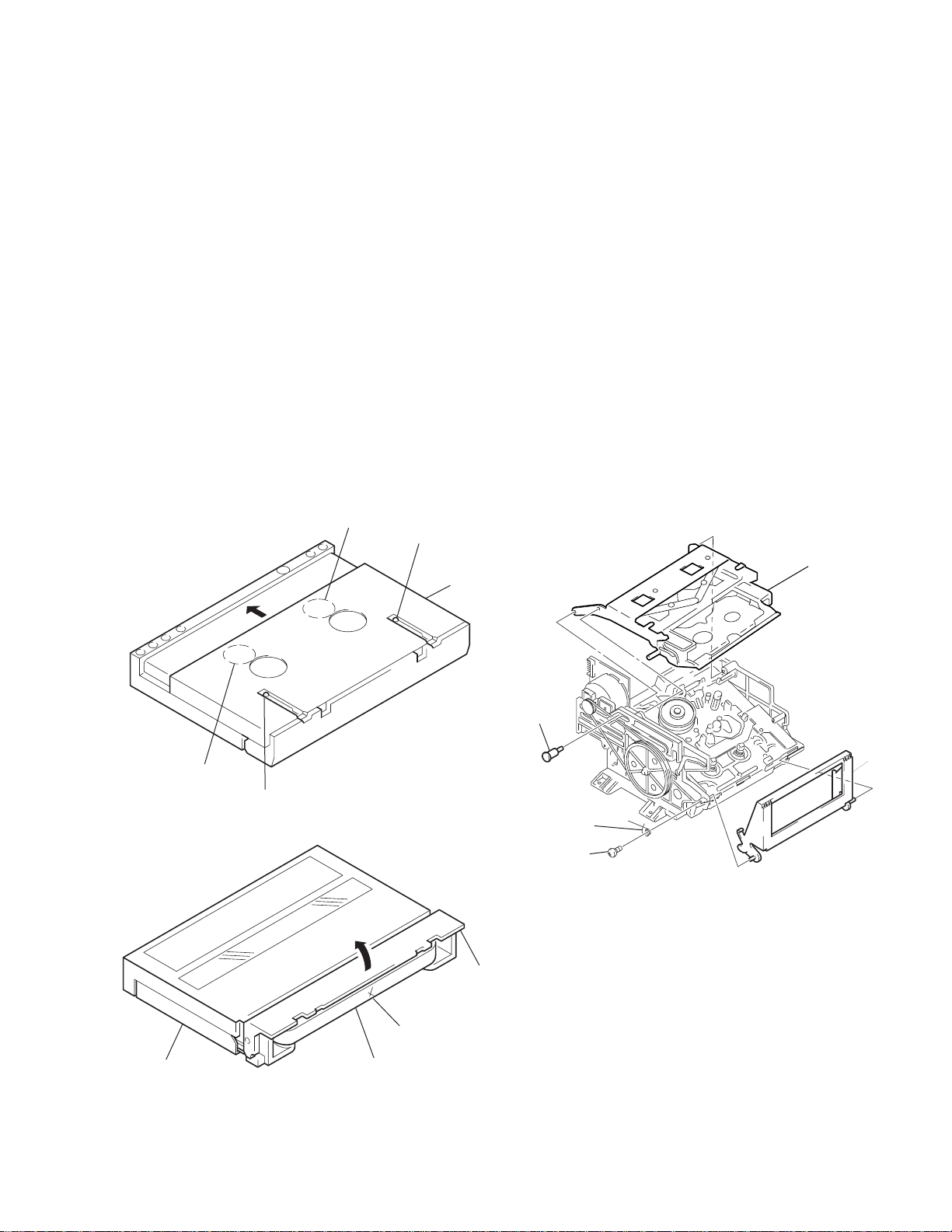

3-3. MECHANISM DECK

6

Mechanism deck

1

Four screws

(PTTWH3x6)

3-2. CASSETTE WINDOW

1 Press the OPEN/CLOSE switch to effect LOADING OUT

STATE (if power is not supplied) rotate the pulley in the

left side of the Mechanism Deck counterclockwise.)

2 Remove the cassette by lifting the window up.

2

Connector (CN1)

3

Connector (CN302)

4

Connector (CN341

5

Connector (CN301)

3-4. CASSETTE HOLDER ASSSEMBLY

1

Screw (Step)

4

Spring (Cassette)

3

Screw

(BVTP3x6)

– 14 –

2

Cassette holder assembly

5

Holder (Window)

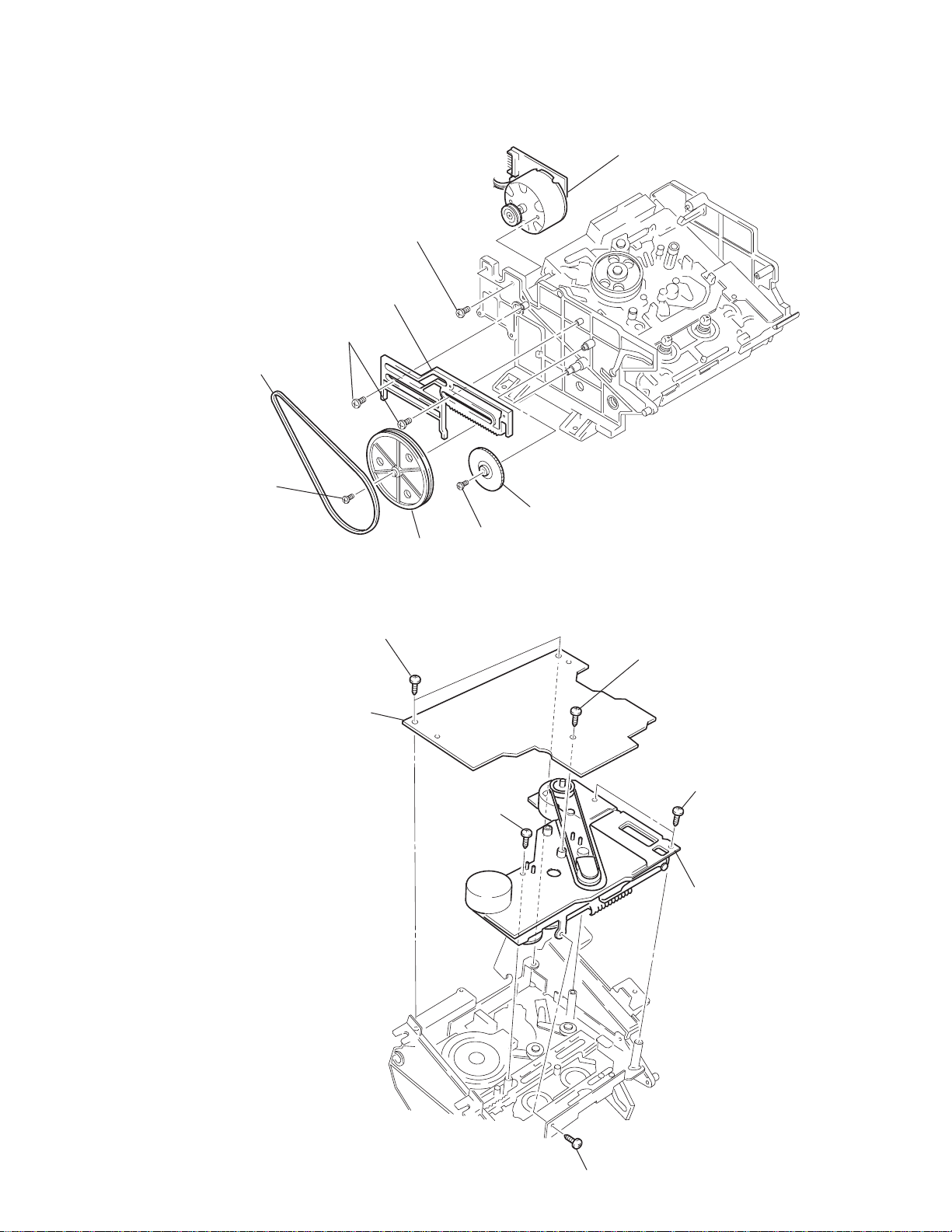

3-5. CASSETTE COMPARTMENT MOTOR (M901), PULLEY, DRIVING GEAR AND SLIDER

s

9

Cassette compartment motor

(M901)

8

Two screws

(P2.6x3)

7

Slider

6

Two screws

(BTP1.7x3)

1

Belt (Driving)

2

Screw

(BTP1.7x3)

5

Driving gear

4

3

Pulley

Screw

(BTP1.7x3)

3-6. DRUM DRIVE BOARD AND DRIVING CHASSIS

3

Remove the lead wires

from connectors on the

drum drive board.

4

Drum drive board

2

Two screw

(B2.6x4)

6

Screw

(BTP2.6x8)

1

Screw

(BTP2.6x6)

5

Two screw

(BTP2.6x8)

8

Driving chassi

– 15 –

7

Screw

(B2.6x4)

3-7. DRUM

y

4

Remove the drum lead

wires from connectors.

5

Drum

2

Four screws

(B2x4)

3

Shield case

1

Lever (Cleaner) assembl

3-8. CAPSTAN MOTOR (M902)

1

Three screws

(P1.7x4)

2

Capstan motor

(M902)

– 16 –

Hub hole

Hub hole

Slider lock

Slider

Slider lock

Lid

Slider

Cut here.

Tape

Step screw

Spring

(cassette)

Screw

(BVTP3x6)

Holder

Holder

(window)

SECTION 4

ADJUSTMENTS

4-1. Notes When Making Adjustments

1. Adjustments should be performed in the order listed.

2. Use the following test tapes:

TY-7111X (8-909-823-00)............................... Level

TY-7252 (8-909-822-00).................................. Tracking

TY-7551 (8-909-814-00).................................. Functions

TY-30B (8-892-358-00) ................................... Blank

Use the following torque meter:

TW-7131 (8-909-708-71) ................................ FWD

3. Switches and controls should be set as follows unless otherwise

specified.

ID MODE switch : START

REC MODE switch : LONG

INPUT switch : OPT

SBM switch : OFF

REC LEVEL control : Min.

PHONE LEVEL control : Min.

4. Creating an end sensor cassette

(1)Press the tape slider lock and move the slider in the direction

indicated by the arrow.

5. Cleaning of the Revolving Drum

(1)Fold a cleaning piece (2-034-697-00) or a knit cloth into 4 or

more files, slightly impregnate it with a head cleaning fluid (9919-573-00), and softly touch the drum with it and manually

rotate the drum slowly counterclockwise by 2 to 3 turns for

cleaning.

(2)At that time, be careful not to move the cleaning piece vertically

to the head tip. Otherwise, the head tip may probably be

damaged.

6. Be careful not to move RV1 to RV2 on the RF AMP board in the

mechanism assemlby

7. To adjust the tape path and guides, remove the holder assembly as

shown in the diagram and use the DAT cassette holder jig (J-8000002-A). This will make it easier to perform the adjustments.

• First turning the pulley counterclockwise to put it in loading out

status will make removal and reattachment of the holder assembly

easier.

• T o perform adjustments, turn the pulley clockwise to put it in loading

in status, load the cassette tape and set the IN switch to the ON

position.

(2)Open the lid and cut the tape.

(3) Turn the hubs until the tape is completely inside the cassette

(both T and S sides).

The end sensor cassette for end sensor adjustments is now ready

for use.

8. Test mode

To set the test mode, short-circuit JW091 (X TEST) and ground

of the main board. (At this time, the dB display of the fluorescent

display level meter will blink.)

Perform the following adjustments in the test mode.

• FWD torque adjustment

• FWD back tension check

• Tape path fine adjustments

• DPG adjustment

• AGC voltage check

• End sensor check

• T o reset the test mode (main), disconnect the wire shorting JW091

(X TEST) and ground. After completion of adjusting, be sure to

reset the test mode (main).

– 17 –

9. Check the following items f or correct tape speed, after completion

of adjusting.

(1)Set the REC MODE switch to 48k and check for normal recording

and playback. (x1)

(2)Set the REC MODE switch to LONG and check for normal

recording and playback. (x0.5)

(3)With QUE (”+)) or REVIEW (”+0), check that qurr r, qurrr

sound is heard. (x3, x8)

(4)Check that correct time is displayed after FF ()) or REV (0).

(x16)

(5)Check that AMS (+, =) is normal.

4-2. ELECTRICAL ADJUSTMENTS

FWD T orque Adjustment

Procedure:

1. Set the test mode (main) and load the FWD torque meter TW7131 (8-909-708-71) .

2. Set the PLAY (() mode.“TORQUE” will be displayed on the

fluorescent indicator tube.

3. Adjust RV451 so that the minimum value of FWD take up torque

(take-up side rewinding torque) is between 9-10g • cm (0.13-0.14

oz • inch).

Also, make sure that the maximum reading does not exceed 15g •

cm (does not exceed 0.21 oz • inch).

4. Confirm that the value indicated by the torque meter is maintained

for one full cycle.

FWD Back Tension Check and Adjustment

Check procedure:

1. Put the set into the test mode (main • servo) and load the FWD

torque meter TW-7131 (8-909-708-71).

2. Put the set into the PLAY (() mode.

3. Turn the FWD back tension adjustment screw locked on the

mechanical deck side so that the minimum value of FWD back

tension torque (supply side) is between 4.5 to 7.5g • cm- (0.06-

0.1 oz • inch).

Also, make sure that the maximum reading does not exceed 8g •

cm (does not exceed 0.11 oz • inch).

After completion of adjusting, be sure to apply screw lock.

4. Confirm that value indicated by the torque meter is maintained

for one full cycle.

5. If the specified values are not satisfied, replace the lever (BT)

assembly (X-3363-024-1).

– 18 –

FWD back tension

adjustment screw

(+P2x2.5)

To tighten (clockwise) - back tension becomes larger.

to loosen (counterclockwise)-back tension becomes smaller.

Tape Path Fine Adjustment (x1.5 FWD Mode)

Perform the following adjustment when the drum has been replaced.

Procedure:

1. Connect an oscilloscope CH-1 to JW183 (PBRF) and CH-2 to

JW092 (SWP) on the main board.

2. Set the test mode (main) and load test tape TY-7252 (8-909-822-

00).

3. Press the AMS (+) key. “DPG” will be displayed on the

fluorescent indicator tube.

Each part of switches on Test Mode.

OFFSET

–0+

ANALOG

OPT COAXIAL

INPUT

REC MODE

STANDARD

48 kHz

44.1 kHz

LONG

OFF

AFT

ON

Loading...

Loading...