Sony PCM-D50 Service Manual

PCM-D50

SERVICE MANUAL

Ver. 1.0 2007.10

SPECIFICATIONS

Recording media

Built-in flash memory 4 GB, “Memory Stick” (not supplied), Linear PCM

Stereo recordin g

Capacity

Part of the memory capacity is allocated to data management.

Actual usable capacity: Approx. 3.83 GB (4,116,611,072 bytes)

Maximum recordable time (Approximate)

The total maximum recordable time (approximate) of all the folders is as follows.

Built-in flash memory (4 GB)

Sampling frequency/

quantifying bit number

22.05 kHz 16 bit 12 hrs 55 min.

44.10 kHz 16 bit 6 hrs 25 min.

44.10 kHz 24 bit 4 hrs 15 min.

48.00 kHz 16 bit 5 hrs 55 min.

48.00 kHz 24 bit 3 hrs 55 min.

96.00 kHz 16 bit 2 hrs 55 min.

96.00 kHz 24 bit 1 hr 55 min.

“Memory Stick PRO-HG Duo”

Sampling frequency/

quantifying bit number

22.05 kHz 16 bit 3 hrs 5 min. 6 hrs 25 min. 12 hrs 50 min.

44.10 kHz 16 bit 1 hr 30 min. 3 hrs 10 min. 6 hrs 25 min.

44.10 kHz 24 bit 1 hr 0 min. 2 hrs 5 min. 4 hrs 15 min.

48.00 kHz 16 bit 1 hr 25 min. 2 hrs 55 min. 5 hrs 55 min.

48.00 kHz 24 bit 55 min. 1 hr 55 min. 3 hrs 55 min.

96.00 kHz 16 bit 40 min. 1 hr 25 min. 2 hrs 55 min.

96.00 kHz 24 bit 25 min. 55 min. 1 hr 55 min.

* The maximum recordable time varies depending on recording conditions.

Maximum

recordable time *

Maximum recordable time *

1 GB 2 GB 4 GB

US Model

Canadian Model

- Continued on next page -

9-887-869-01

2007J04-1

2007.10

©

LINEAR PCM RECORDER

Sony Corporation

Personal Audio Division

Published by Sony Techno Create Corporation

PCM-D50

Linear PCM

Quantization: 16-bit linear, 24-bit

linear

Frequency range (Input from the LINE

IN (OPT) jack when recording/

playing back) (0 to –2 dB):

Fs 22.05 kHz: 20 to 10,000 Hz

Fs 44.10 kHz: 20 to 20,000 Hz

Fs 48.00 kHz: 20 to 22,000 Hz

Fs 96.00 kHz: 20 to 40,000 Hz

MP3 compatible bit rates, sampling

frequencies

MPEG Ver. 1 Layer 3:

32, 44.1, 48 kHz

32 to 320 kbps, VBR

MPEG Ver. 2 Layer 3:

16, 22.05, 24 kHz

32 to 160 kbps, VBR

Signal-to-noise ratio (S/N) (Input from the

LINE IN (OPT) jack when recording/playing

back)

93 dB or above (1 kHz IHF-A)

(for 24 bit)

Total harmonic distortion (Input from the

LINE IN (OPT) jack)

22.05 kHz 16 bit, 44.10 kHz 16/24 bit:

0.01% or below (1 kHz, 22 kHz LPF)

48.00 kHz 16/24 bit, 96.00 kHz

16/24 bit: 0.01% or below

(1 kHz, 22 kHz LPF)

Wow and flutter

Below measurable limit (less than

±0.001% W.PEAK)

General

Power requirements

DC IN 6V

Four LR6 (size AA) alkaline batteries

(supplied)

Four nickel metal hydride

rechargeable batteries NH-AA (not

supplied)

Power consumption

0.75 W

Dimensions

Approx. 72.0 × 154.5 × 32.7 mm

7

(2

/8×61/8×15/16 inches) (w/h/d)

(not including projecting parts and

controls)

Mass 365 g (12.88 oz) (including batteries)

Supplied accessories

• USB cable

• AC power adapter (6V)

• Four LR6 (size AA) alkaline batteries

• CD-ROM (“Sound Forge Audio Studio LE”)

• Operating Instructions

Design and specifications are subject to change

without notice.

Input/output

N

(microphone) jack (stereo mini jack)

Input impedance: 22kΩ

Rated input level: 2.5mV

Minimum input level: 0.7mV

(headphone) jack (stereo mini jack)

J

Rated output level: 400mV

Maximum output level:

25mW + 25mW or more

Load impedance: 16Ω

LINE IN (OPT) jack

Input impedance: 40kΩ

Rated input level: 2.0V

Minimum input level: 450mV

Input level: –24.5 to –14.5 dBm

(for optical digital input)

Absorption wavelength:

630 to 690 nm

(for optical digital input)

LINE OUT (OPT) jack

Output impedance:

1 kΩ for European model/

220Ω for other models

Rated output level: 1.7V

Load impedance: 22kΩ

Output level: –21 to –15 dBm

(for optical digital output)

Emission wavelength: 630 to 690 nm

(for optical digital output)

DC IN 6V jack

USB connector (Hi-speed USB, Mass

Storage Class)

Memory Stick slot

2

PCM-D50

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

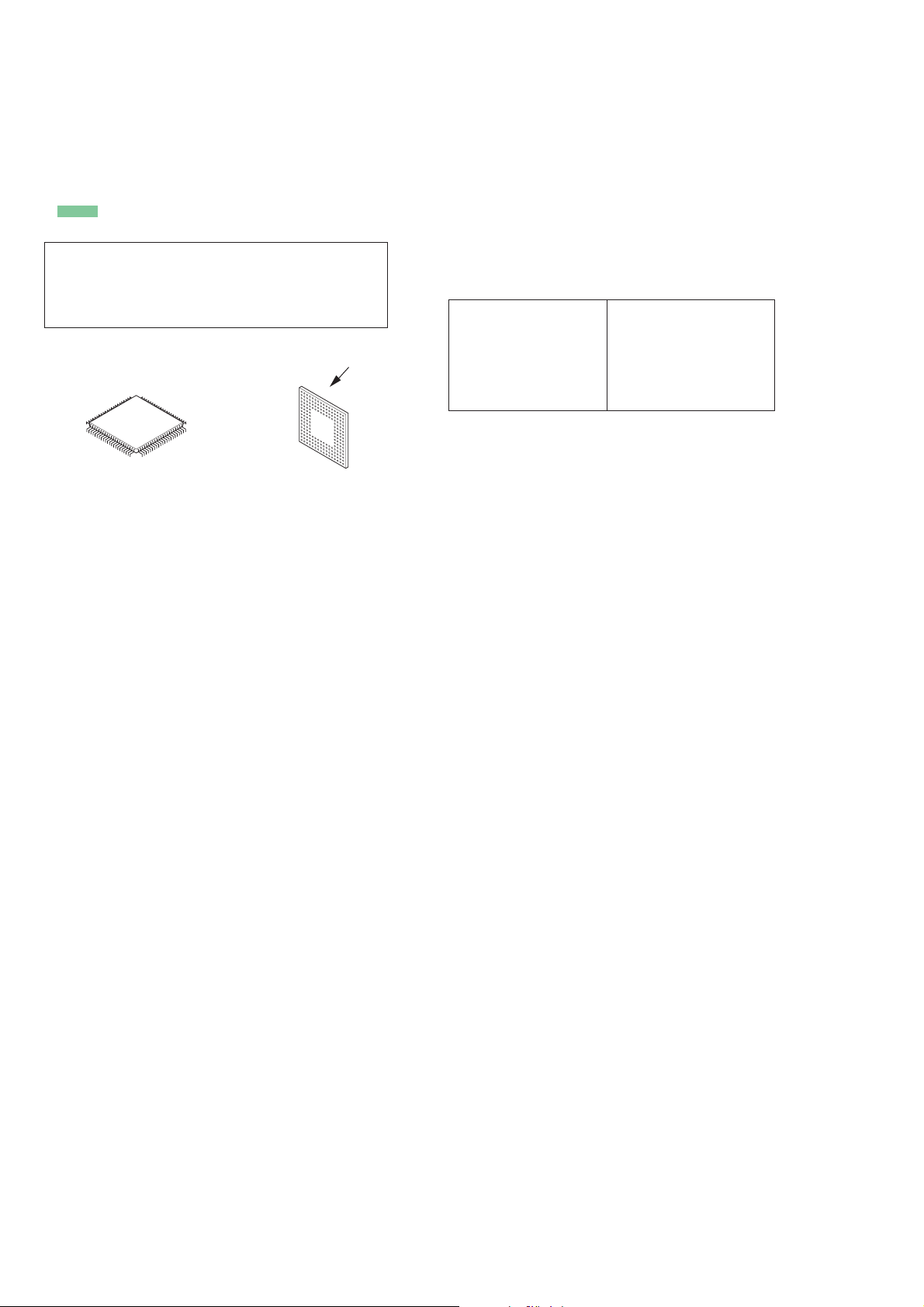

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONET WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS QUE

PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

3

PCM-D50

TABLE OF CONTENTS

1. GENERAL .................................................................. 5

2. DISASSEMBLY

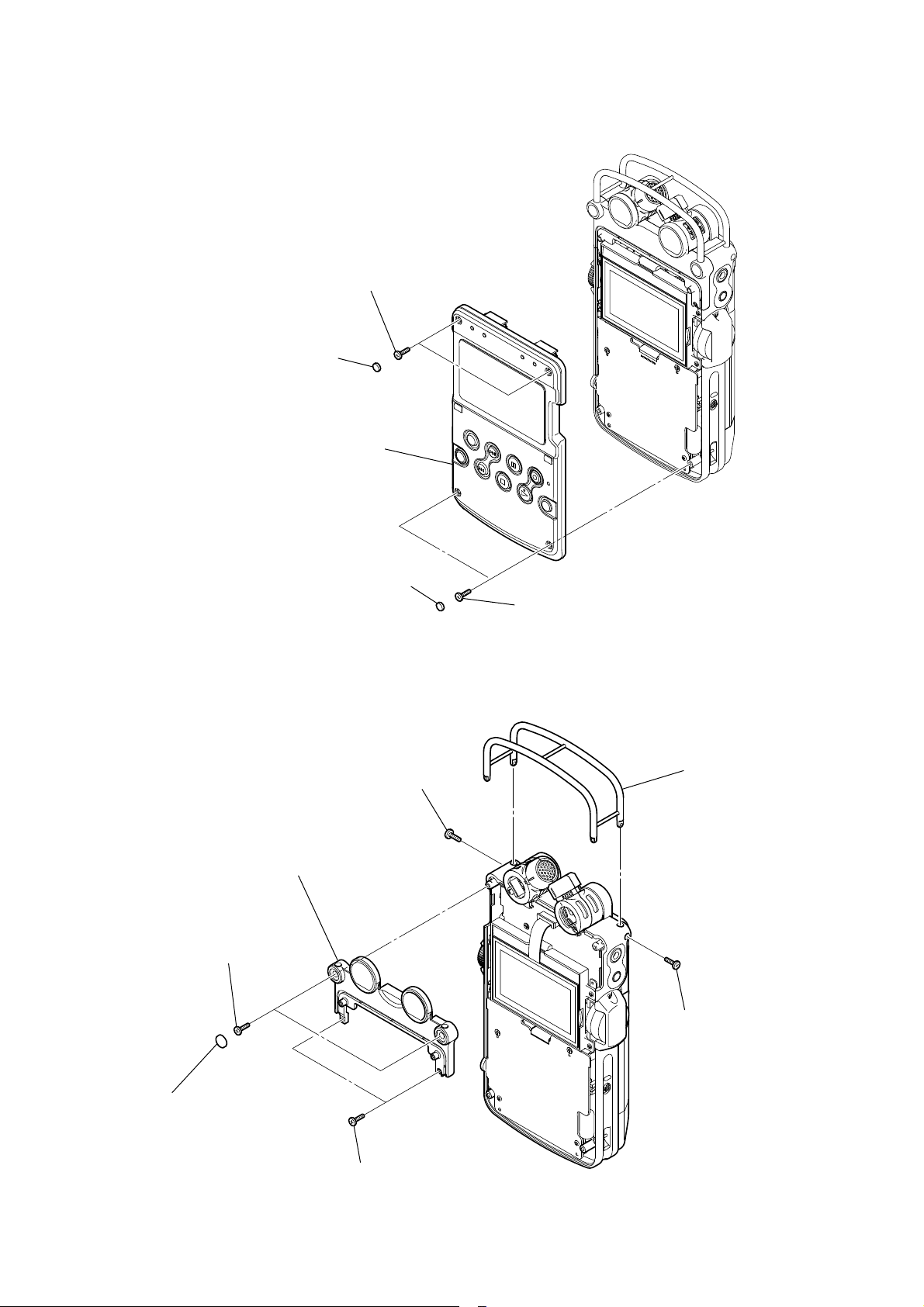

2-1. Panel (Front) Assy .......................................................... 11

2-2. Ornamental Belt (Upper) Assy ....................................... 11

2-3. Backlight Board .............................................................. 12

2-4. Power Board ................................................................... 12

2-5. REC VOL Assy, HP VOL Assy ...................................... 13

2-6. DA Board ........................................................................ 13

2-7. AD Board, MIC001, MIC002 ......................................... 14

2-8. System Board .................................................................. 14

3. TEST MODE ............................................................ 15

4. DIAGRAMS

4-1. Block Diagram - AD Section - ....................................... 20

4-2. Block Diagram - DA Section - ....................................... 21

4-3. Block Diagram - Power Section - .................................. 22

4-4. Printed Wiring Board - AD Section (1/2) - .................... 23

4-5. Printed Wiring Board - AD Section (2/2) - .................... 24

4-6. Schematic Diagram - AD Section (1/3) - ....................... 25

4-7. Schematic Diagram - AD Section (2/3) - ....................... 26

4-8. Schematic Diagram - AD Section (3/3) - ....................... 27

4-9. Printed Wiring Board - DA Section (1/2) - .................... 28

4-10. Printed Wiring Board - DA Section (2/2) - .................... 29

4-11. Printed Wiring Boards

- Backlight/HP Volume/REC VOL Flexible Section - .... 30

4-12. Schematic Diagram - DA Section - ................................ 31

4-13. Printed Wiring Board - System Section (1/2) - .............. 32

4-14. Printed Wiring Board - System Section (2/2) - .............. 33

4-15. Schematic Diagram - System Section (1/5) - ................. 34

4-16. Schematic Diagram - System Section (2/5) - ................. 35

4-17. Schematic Diagram - System Section (3/5) - ................. 36

4-18. Schematic Diagram - System Section (4/5) - ................. 37

4-19. Schematic Diagram - System Section (5/5) - ................. 38

4-20. Printed Wiring Board - Power Section (1/2) - ............... 39

4-21. Printed Wiring Board - Power Section (2/2) - ............... 40

4-22. Schematic Diagram - Power Section (1/4) - .................. 41

4-23. Schematic Diagram - Power Section (2/4) - .................. 42

4-24. Schematic Diagram - Power Section (3/4) - .................. 43

4-25. Schematic Diagram - Power Section (4/4) - .................. 44

5. EXPLODED VIEWS

5-1. Front Panel Section ......................................................... 64

5-2. LCD Section ................................................................... 65

5-3. VOL Section ................................................................... 66

5-4. MIC Section .................................................................... 67

5-5. Rear Panel Section .......................................................... 68

6. ELECTRICAL PARTS LIST .............................. 69

4

SECTION 1

GENERAL

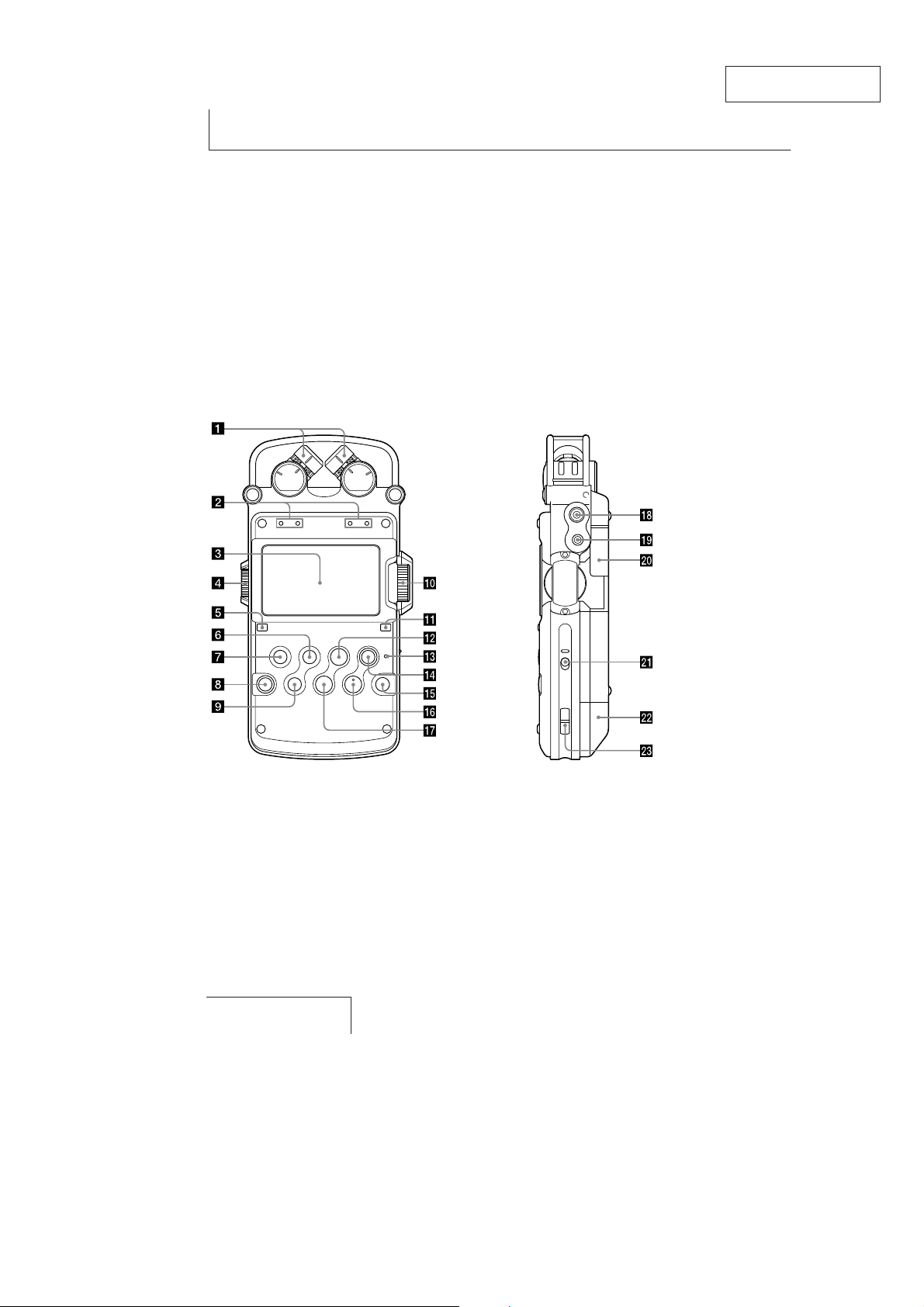

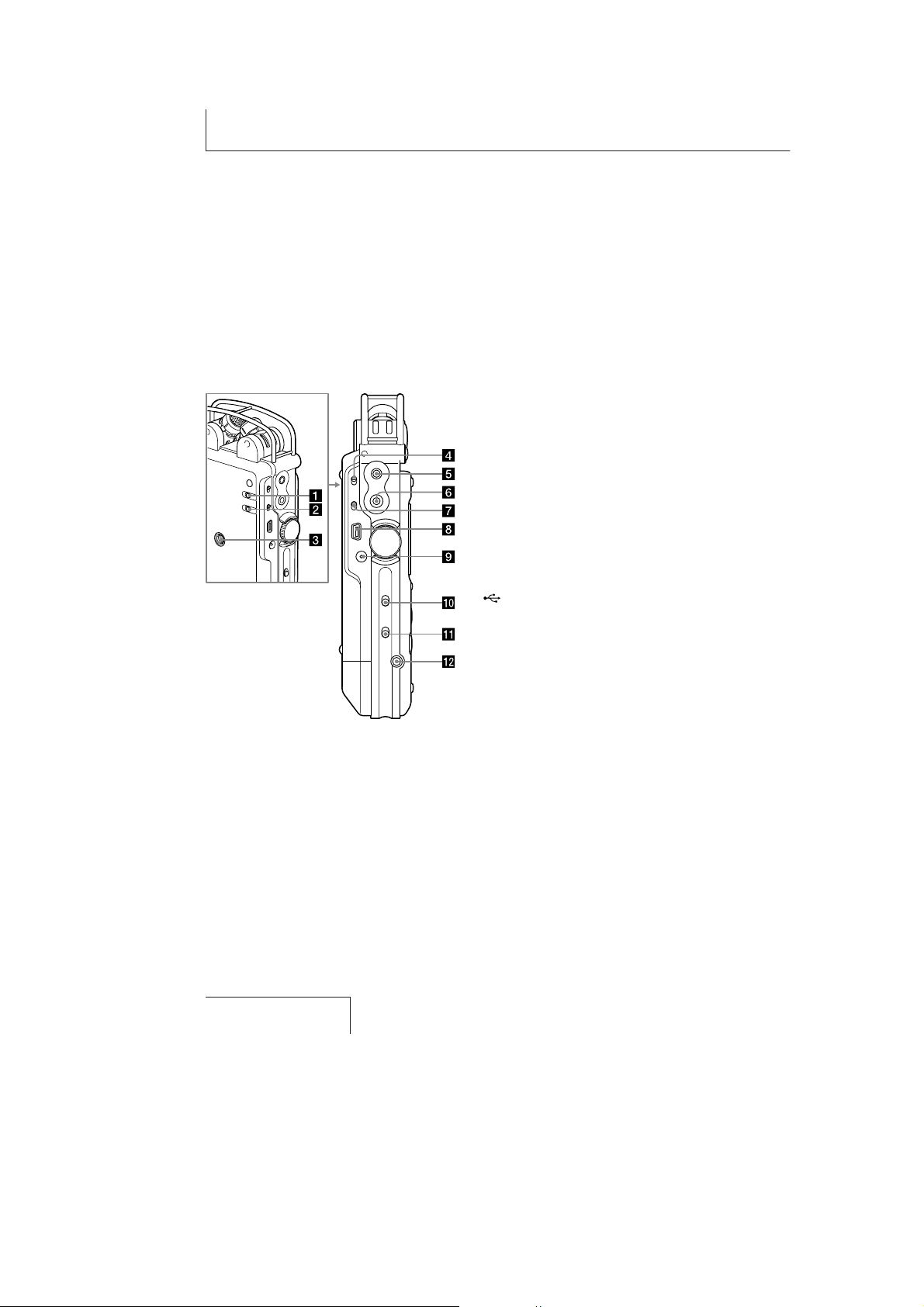

Identifying parts and controls

Front Right side

PCM-D50

This section is extracted

from instruction manual.

12

5

PCM-D50

Built-in microphones (page 21)

Peak level lamps (L/R) (page 24)

Displays left and right peak levels of an

audio signal input with -12dB (green) and

OVER (red) lamps.

Display (page 15)

Volume dial (page 26)

Adjusts the playback volume by turning the

dial to set the desired level (0 to 10) to the

“•” position.

A-B (repeat A-B) button (page 34)

FF (fast-forward) /W (up) button

(pages 19, 32)

(folder)/MENU button (pages 20, 23,

31, 40)

When pressed briefly, switches folders.

When pressed and held, displays the menu.

LIGHT button

Turns the backlight of the display on or off.

FR (fast-rewind) / 7 (down) button

(pages 19, 32)

REC LEVEL (recording level) dial (page 24)

Adjusts the recording volume by turning the

dial to set the desired level (0 to 10) to the

“•” position.

RB

DISPLAY button (page 15)

Switches time information on the display.

RT

PAUSE button/indicator (pages 24, 25,

9

32)

RE

ACCESS indicator (pages 18, 45)

Flashes when the recorder is accessing

memory (except during recording).

RG

REC (recording) button/indicator

[

(page 24)

RH

DIVIDE button (page 35)

RI

PLAY/ENTER button/indicator

/

(pages 31)

RK

STOP button (pages 25, 32)

Y

N

RL

(microphone) jack (page 27)

RM

LINE IN (OPT) (line input (optical)) jack

(pages 28 - 30)

X

Memory Stick slot (page 45)

XB

POWER switch (page 18)

Turns the power “ON” or “OFF.”

XT

Battery compartment lid (page 17)

XE

Slot for a wrist strap

(A strap is not supplied.)

Overview

Continued on the next page

13

6

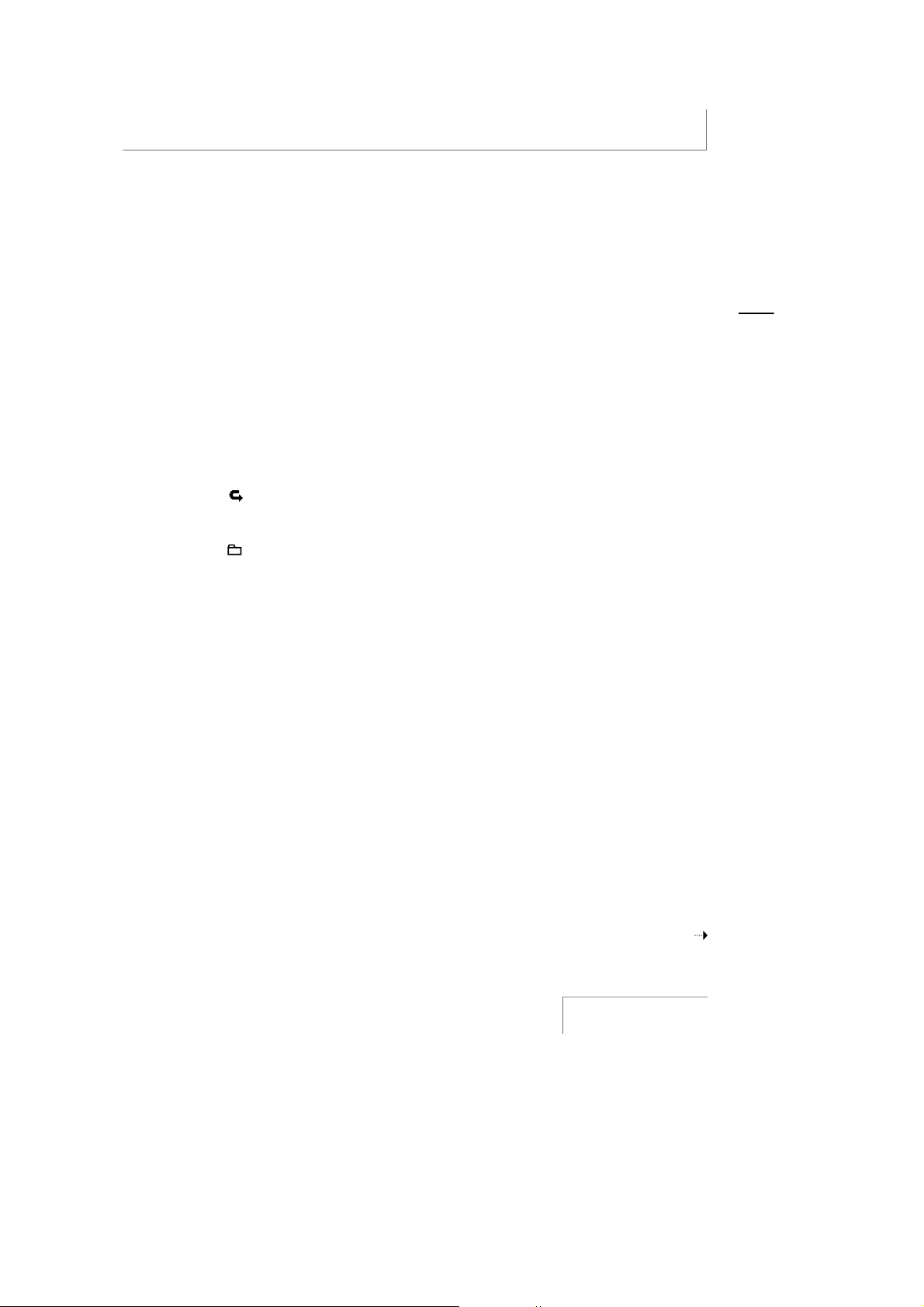

Identifying parts and controls (continued)

PCM-D50

Left side

LIMITER switch (pages 22, 43)

LOW CUT FILTER switch (pages 22, 43)

Hole for attaching the tripod (not supplied)

INPUT switch (pages 23, 28, 29, 30)

When set to “ N” (microphone), records an

audio signal input from the built-in

microphones or an external microphone that

is connected to the

When set to “LINE,” records an audio signal

output from external equipment that is

connected to the LINE IN (OPT) jack.

LINE OUT (OPT) (line output (optical)) jack

(page 34)

(headphone) jack (pages 26, 31)

J

MIC ATT (microphone attenuator) switch

(page 22)

USB connector (page 36)

DC IN 6V jack (page 19)

HOLD switch

When set to “ON,” the buttons on the

recorder are locked to prevent accidental

operation. It is recommended that you set

this switch to “ON” during recording and

playback. To unlock the controls, set it to

“OFF.”

RB

DPC (Digital Pitch Control) switch (pages

33, 42)

RT

REMOTE jack (page 30)

N

jack.

14

7

PCM-D50

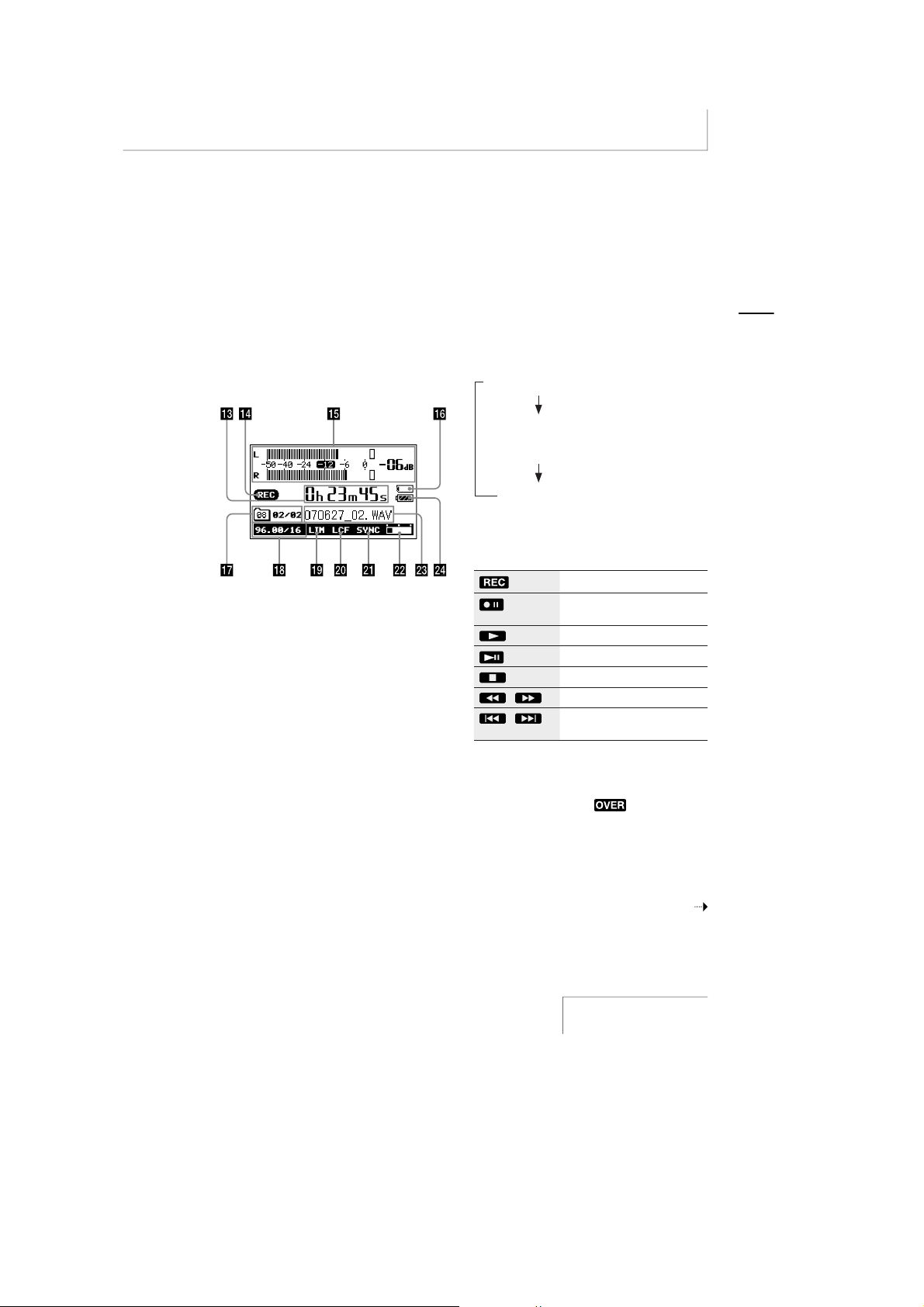

Display

RE

Time information

Each time theDISPLAY button is pressed,

the time information changes as follows

(Flashes when the recorder is paused):

/

Elapsed recording/playback time

Remaining recordable time of the

current memory (During playback:

Remaining time of the current track)

Recorded date

(During recording: Recording start date)

RG

Recording/playing status

Displays as follows according to the current

operation:

Recording

(Flashing)

(Flashing)

/

/

RH

Level meter/peak values (page 24)

Displays the level meter and the maximum

value of the peak level. When the level

exceeds the set value,

While an MP3 file is being played, displays

the artist name and title information.

Recording pause, standby for

recording

Playback

Playback pause

Stop

Fast reverse/forward

Go to previous/succeeding

tracks

appears.

Overview

Continued on the next page

15

8

Identifying parts and controls (continued)

RI

Memory Stick indicator

Displayed when the current memory is a

“Memory Stick.”

RK

Folder number, track numbers

Folders are classified into

recording and playback) and

playback only) (page 38). Track numbers are

displayed as “current track number/total

number of tracks.”

RL

Recording mode

Displays the recording mode currently

specified in the menu in the stop mode.

During playback or recording, displays the

recordin g mode of the c ur ren t t ra ck .

RM

Limiter setting

Displayed when the LIMITER switch is set to

“ON.”

X

LCF setting

Displayed when the LOW CUT FILTER switch

is set to “ON.”

XB

SYNC REC setting

Displayed when the “SYNC REC” is set to

“ON.”

XT

Remaining memory amount

Displays the remaining amount of current

memory (page 25).

XE

File information

Displays the file name of the track.

XG

Remaining battery power (page 18)

(a folder for

(a folder for

PCM-D50

16

9

PCM-D50

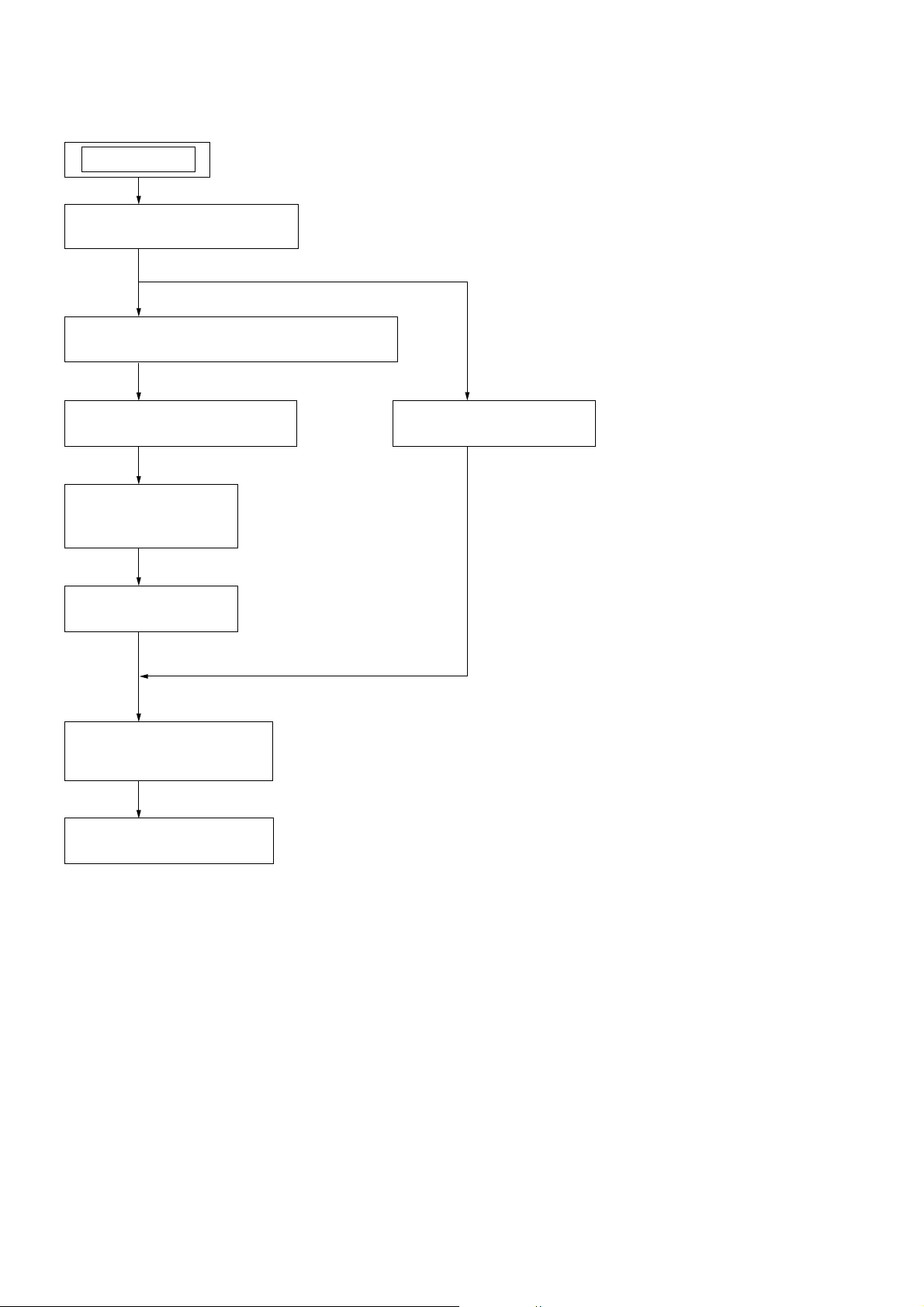

DISASSEMBLY

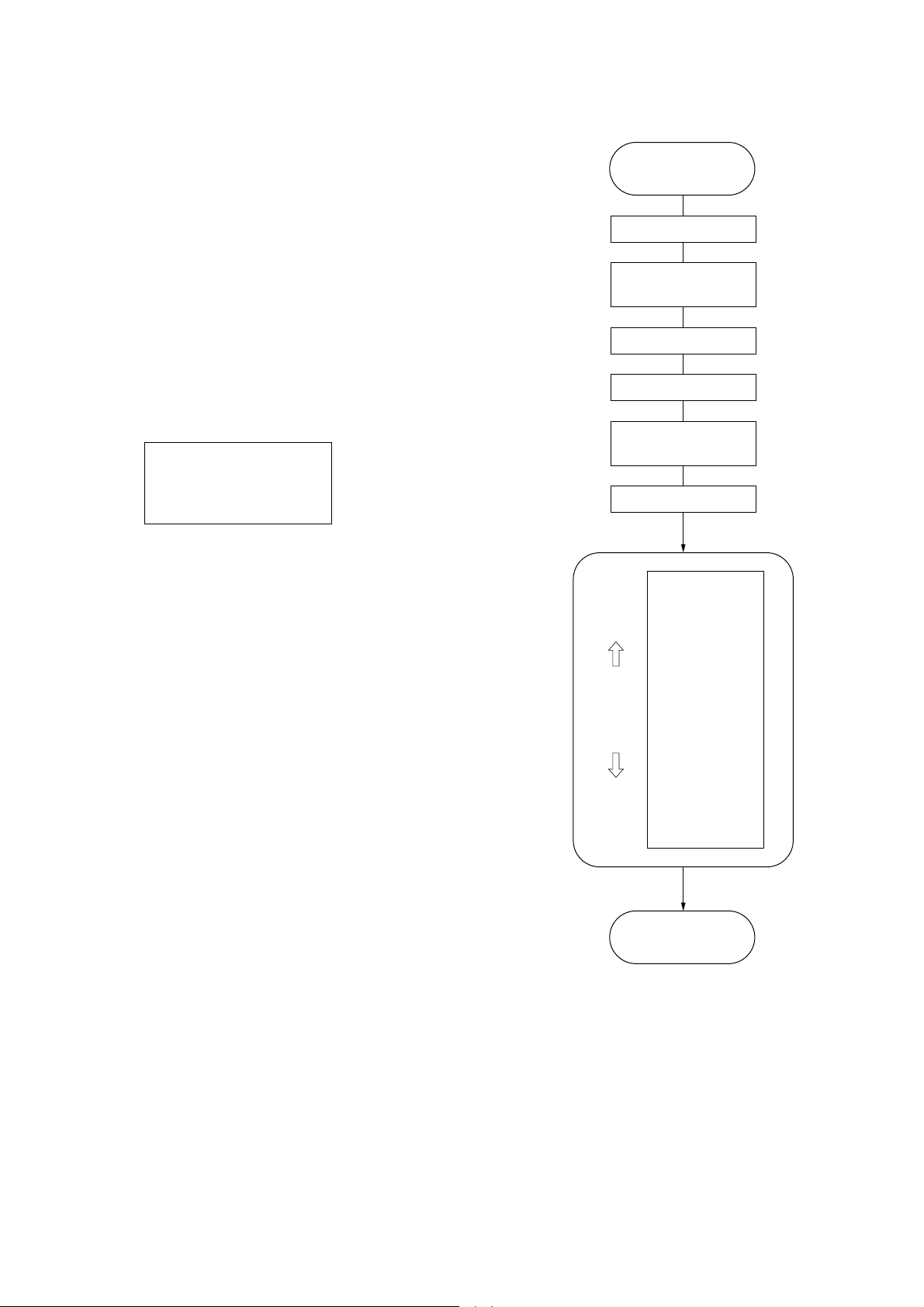

• This set can be disassembled in the order shown below.

SET

2-1. PANEL (FRONT) ASSY

(Page 11)

2-2. ORNAMENTAL BELT (UPPER) ASSY

(Page 11)

SECTION 2

2-3. BACKLIGHT BOARD

(Page 12)

2-5. REC VOL ASSY,

HP VOL ASSY

(Page 13)

2-6. DA BOARD

(Page 13)

2-7. AD BOARD,

MIC001, MIC002

(Page 14)

2-8. SYSTEM BOARD

(Page 14)

2-4. POWER BOARD

(Page 12)

10

Note: Follow the disassembly procedure in the numerical order shown below.

2-1. PANEL (FRONT) ASSY

two screws

(M 1.7)

two cushions (panel)

panel (front) assy

PCM-D50

two cushions (panel)

2-2. ORNAMENTAL BELT (UPPER) ASSY

screw

(M 1.4)

ornamental belt (upper) assy

two screws

(M 1.4)

two screws

(M 1.7)

guard (MC)

screw

(M 1.4)

two cover (guard microphone)

two screws

P2 lock ace (M 1.7)

11

PCM-D50

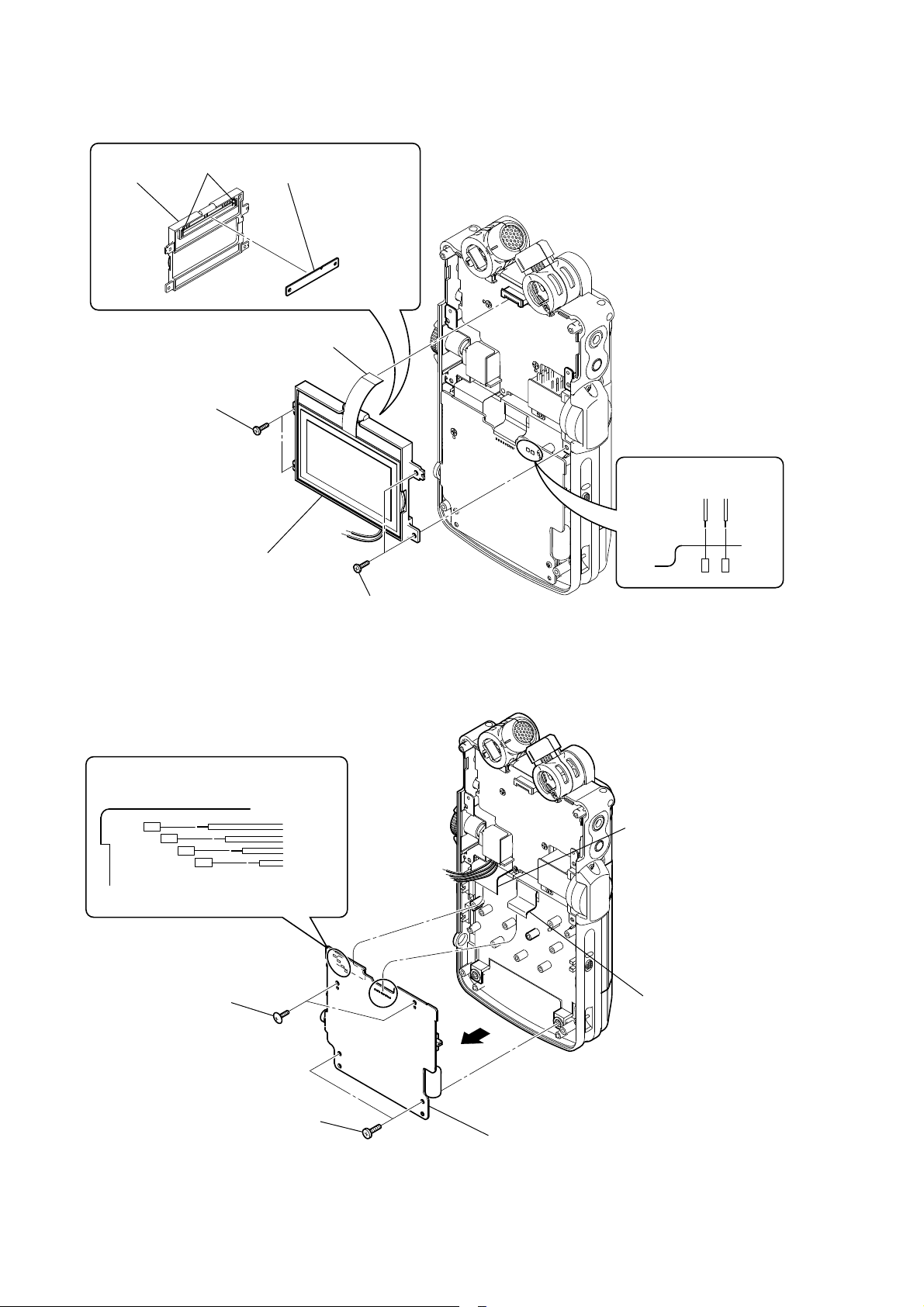

2-3. BACKLIGHT BOARD

LCD assy

two screws

P2 lock ace (M 1.7)

two claws

BACKLIGHT board

LCD unit (13 core)

(CN4201)

Remove the two solders.

redwhite

LCD assy

two screws

P2 lock ace (M 1.7)

2-4. POWER BOARD

Remove the four solders.

two screws

two screws

P2 lock ace (M 1.7)

black

red

gray

white

POWER board

flexible flat cable (30core)

(CN2002)

Remove the

flexible flat cable.

12

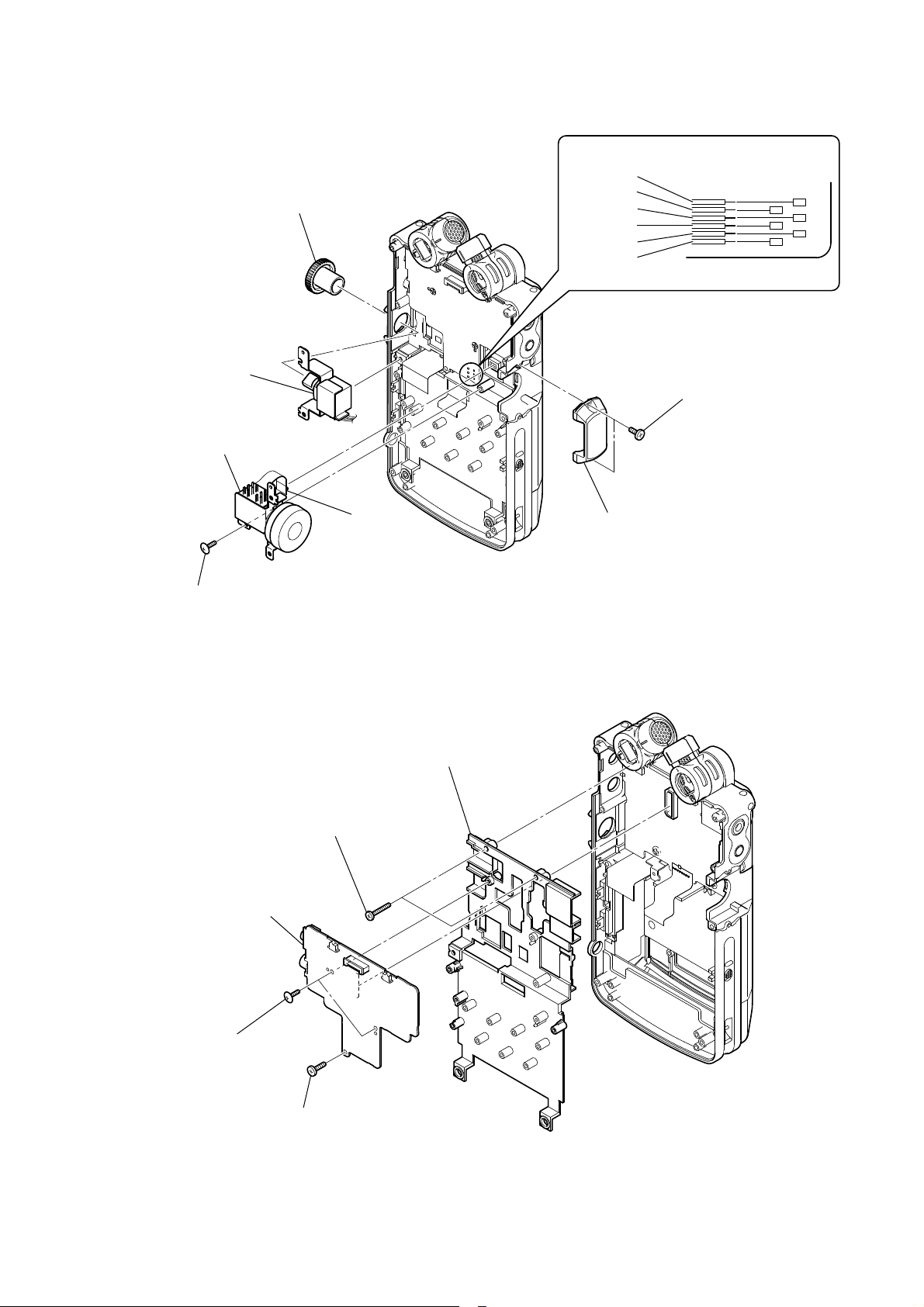

2-5. REC VOL ASSY, HP VOL ASSY

knob (VOL)

HP VOL assy

REC VOL assy

PCM-D50

Remove the six solders.

white

red

orange

yellow

gray

black

two screws

precision pan (M 1.4) (EG)

screw

2-6. DA BOARD

DA board

CN3001

two screws

(special head (M 2))

guard (VOL)

chassis (PWB)

two screws

screw

P2 lock ace (M 1.7)

13

PCM-D50

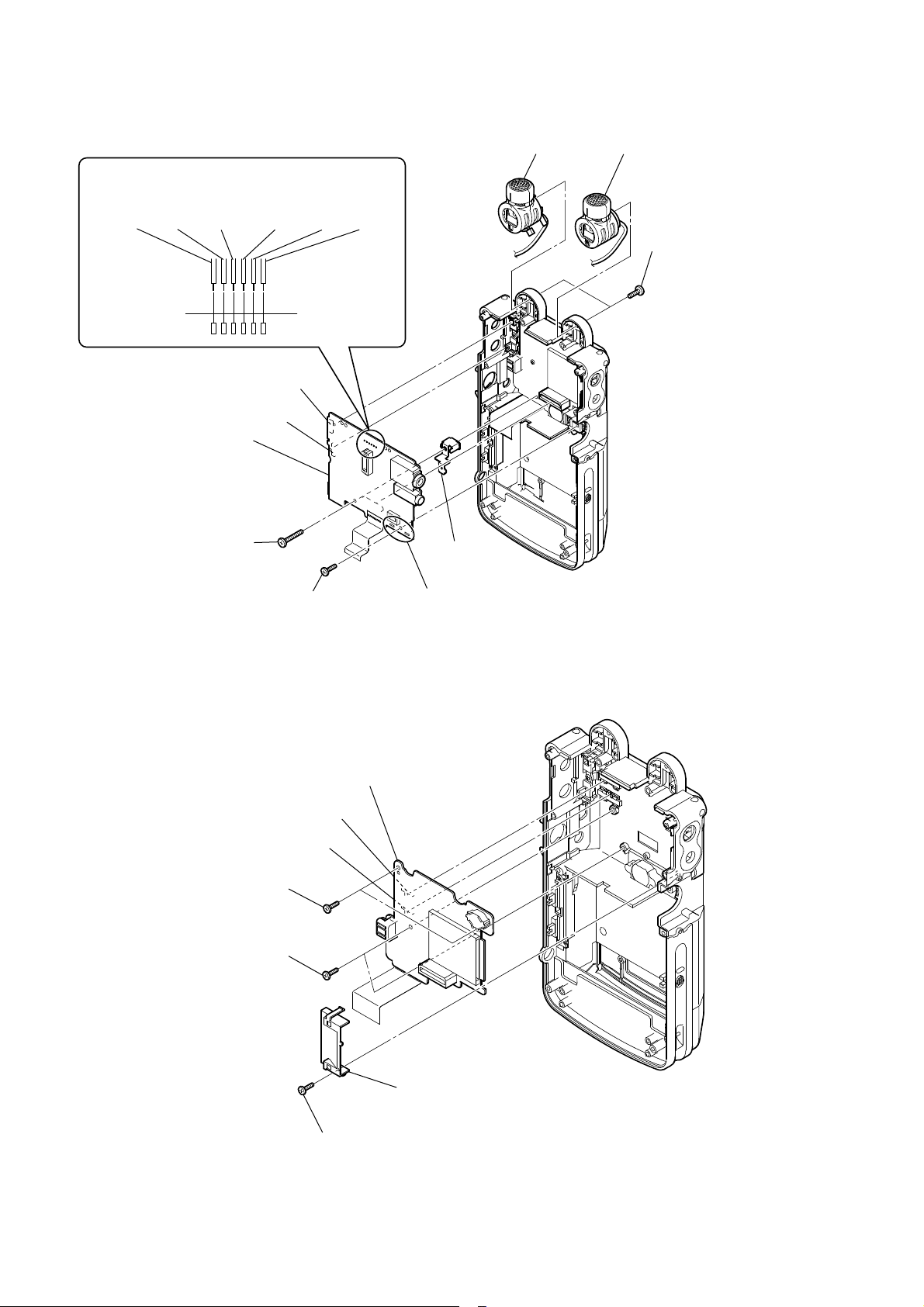

2-7. AD BOARD, MIC001, MIC002

Remove the six solders.

MIC001 MIC002

red redyellow yellowblack

S3002

S3003

AD board

MIC002 MIC001

black

two screws

P2 lock ace (M 1.7)

screw

(M2 grip)

2-8. SYSTEM BOARD

two screws

P2 lock ace (M 1.7)

two screws

P2 lock ace (M 1.7)

screw

(M 1.7)

S1601

S1602

ground plate

Remove the two solders.

SYSTEM board

14

guide (connector)

screw

P2 lock ace (M 1.7)

SECTION 3

TEST MODE

PCM-D50

This set provides the Test Mode that can be used for the following

check modes.

1. Setting and Exiting the TEST MODE

• Types of TEST MODE and setting the TEST MODE

1 Setting the SERVICE MODE:

(1) Turn on power to the set. Turn the LIMITER switch

on while pressing [A-B] button and [DIVIDE] button

at the same time.

• Exiting the SERVICE/TEST MODE

The TEST MODE is cancelled by turning off power (remov-

ing the battery).

(See Section 5. Flow Chart of the TEST MODE.)

2. Initial State of the TEST MODE and Exiting Method

• Initial state upon entry into the TEST MODE: “OK” is sent

to the PC through RS-232C.

Example of LCD display

Version

KeyChk+Fmt

DSP Loop

Lcd Contrast

Cluster Num

3. OK or NG Judgment

OK or NG judgment in each mode is returned by a LCD dis-

play and a status via UART.

4. How the Power of Each Section is Handled in the

TEST MODE

When TEST or SERVICE MODE is entered, the system will

keep the power state in a state equivalent to the Idle state. This

is for system to check the power device of each section for its

operation. However during execution of the Sleep command,

the system will take control based on the Sleep state since the

standby current need be measured.

5. Flow Chart of the TEST MODE

START

After power-on,

idle or sleep state

LIMITER SW OFF

Press [A-B]+[DIVIDE]

at the same time

LIMITER SW ON

Release [A-B]+[DIVIDE]

SERVICE MODE

established Menu Display

Release [A-B]+[DIVIDE]

:

Version

KeyChk+Fmt

DSP Loop

Lcd Contrast

Cluster Num

RTC Int

Battery

DCIN

VBUS

Sleep

App LogOut

Log Output

Log Clear

Menu Init

Key Check

Version

:

END

Exit from TEST MODE

6. Transitions in Each Mode

Power OFF

(Remove the battery)

15

PCM-D50

SERVICE MODE

The SERVICE MODE is entered and the details of the Service

Menu are as follows:

1 Version

Function: To check the version of the relevant module.

PCM-D50 : JP Boot : 11

ARM 1. 0. 00

DSP 1. 0. 00

Sep 18 2007 08 : 41 : 38

PCM-D50: Destination (JP, US, CN, CE)

Boot: Boot loader F/W version

ARM: F/W version for CPU (ARM section)

DSP: F/W version for CPU (DSP section)

Date: Date and time of build

2 Key Check

Function: To allow you to check inputs by pressing the cor-

responding keys.

Input checks as well as INT check. (KEY confi rmation checks

and KEY_WAKE interrupt check)

Target keys to be inputted:

STOP, PAUSE, FR, MENU/FOLDER, A-B,

LIGHT, DISPLAY, FF, DIVIDE,

PLAY, REC,

MIC/LINEIN, LIMITER, LCF, DPC, HOLD,

POWERSW, and MICLR

<KEY CHECK>

KEY : - REMAIN : 18

Display the key confirmed.

Count down the number of

the remaining keys.

When an input has been determined, the backlight is illuminated for 0.5s.

When all the inputs have been confi rmed at least once, OK is

displayed on the LCD and the LED (GREEN) is lit.

3 Key Chk+Format

Function: T

o allow you to check key inputs by pressing the cor-

responding keys.

Input checks as well as INT check. (KEY confi rmation checks

and KEY_WAKE interrupt check)

Target keys to be inputted:

STOP, PAUSE, FR, MENU/FOLDER, A-B,

LIGHT, DISPLAY, FF, DIVIDE,

PLAY, REC,

MIC/LINEIN, LIMITER, LCF, DPC, HOLD

POWERSW, and MICLR

<KEY CHECK>

KEY : - REMAIN : 18

Display the key confirmed.

Count down the number of

the remaining keys.

When an input has been determined, the backlight is illuminated for 0.5s.

When all the inputs have been confi rmed at least once, NAND

is formatted (all the issues are deleted) and the MENU settings

are defaulted. (However, LCD Contrast is held.)

When the formatting has been normally completed, the system

is restarted (rebooted).

Loop

4 DSP

Function: To perform a DSP LOOP BACK.

<DSP Loop>PLAY

Input->Output

HPMUTE : OFF LINEMUTE : OFF

LIMITER : OFF

LCF : OFF

[PLAY]: Starts Loop Back

[STOP]: Stops Loop Back

[MIC/LINEIN]: As per the set control.

[LIMITER]: As per the set control.

[LCF]: As per the set control.

[DPC]: Switches HP Mute

(OFF: Mute OFF; ON: Mute ON)

[HOLD]: Switches LINE Mute

(OFF: Mute OFF; ON: Mute ON)

Input: INTMIC, EXTMIC, LINEIN

Output: HPOUT, LINEO,

5 Lcd Contrast

Function: To adjust the contrast of the LCD.

<Lcd Contrast>

Value : 07

[FF] + [FR] -

Display the current UI value.

The default (initial value) is taken as Value=XX (XXh).

This represents 2-byte transmit data after 81h (V5 Output Voltage Set) of serial communication data to the LCD module. (UI

value: This is a value displayed in the TEST MODE.)

Initial value

UI value 00 01 02 ... 10 ... 19 20

LCD[h] 20 21 22 ... 27 ... 24 35

(Each value is provisional.)

6 Cluster Num

Function: For design. Read the cluster number from memory.

7 RTC Interrupt

Function: To perform a RTC self test.

<RTC Int>

01s

RTC Int OK

The count is displayed at every second.

8 Battery

Function: To display the current value of Battery A/D and

whether it can be detected by the 5T735 detection

register.

<Battery>

A/D : 68h

DETECT : OK

[STOP/MENU] : RET

16

PCM-D50

2

R

9 DCIN

Function: To display the current value of DCIN A/D and

whether it can be detected by the 5T735 detection

register.

<DCIN>

A/D : 84h

DETECT : OK

[STOP/MENU] : RET

0 VBUS

Function: VBUS detection check.

VBUS is checked by both the 5T735 register and the M66592

register and OK is displayed when it could be detected.

<VBUS>

DETECT (5T735) : OK

DETECT (M66592) : OK

[STOP/MENU] : RET

qa Sleep

Function: Sleep test

It is tested that the Sleep Mode can be entered.

qs App LogOut

Function: For design. Output of the application’s operation

log

qd Log Output

Function: For design. Log output.

qf Log Clear

Function: For design. Log clear.

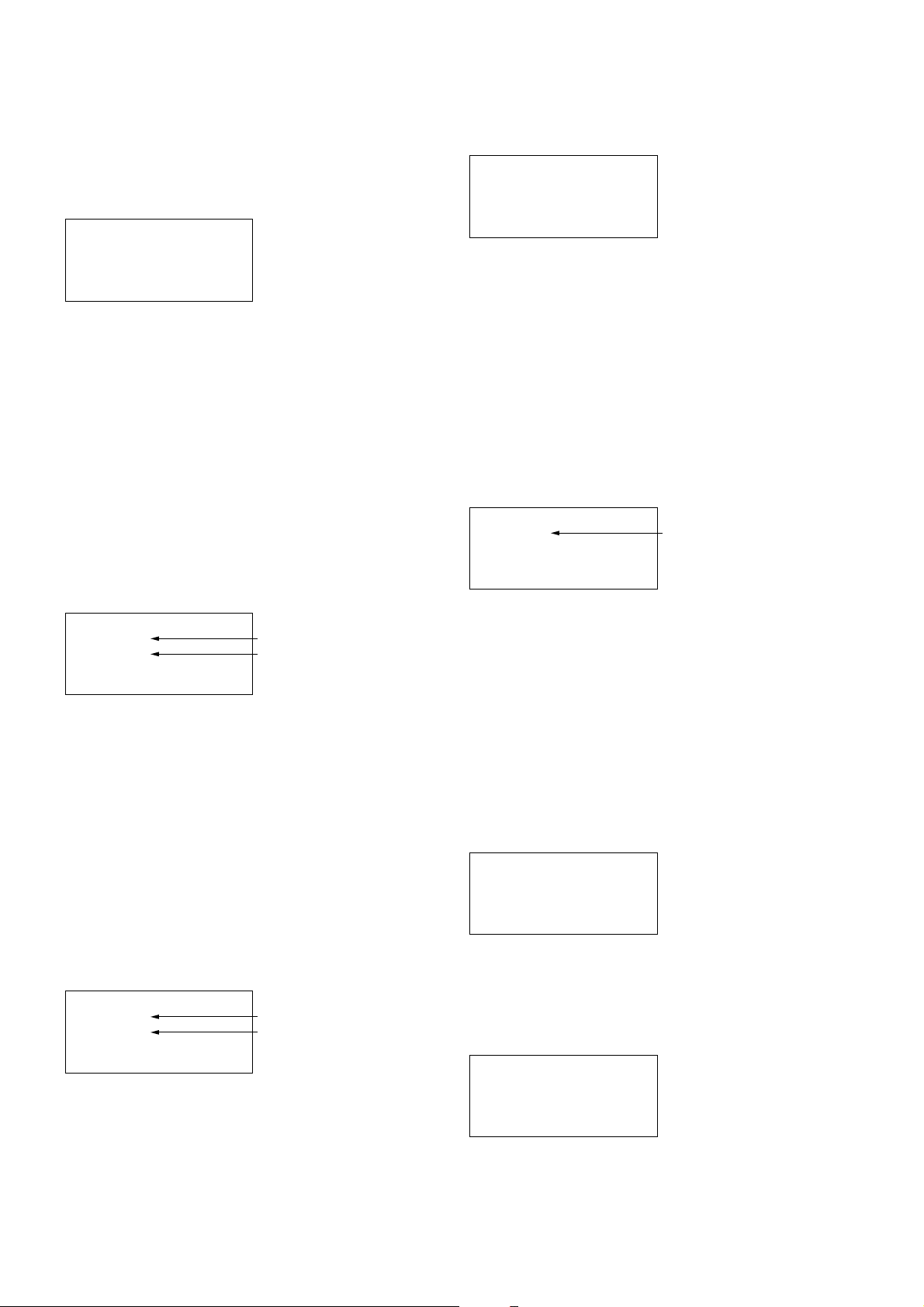

LCD Contrast Adjustment

When the system board or LCD1 has been replaced, the LCD contrast should be adjusted.

1. Enter the TEST MODE and select Lcd Contrast.

2. Connect a digital voltmeter between the test points VLCD and

DGND of the DA board.

3. Use [FF] key and [FR] key to adjust the contrast until the reading on the voltmeter is 14.45±0.05V.

4. When the voltage falls within the specifi ed range, press

[PLAY] key and make sure that the display is returned to the

Menu List.

5. Exit the TEST MODE.

– DA BOARD (Side A) –

VLCD DGND

24

64

1

JL4252

402

Q4221

S4202

MIC (L-CH)

DIRECTION

3

L

R4222

R4223

R4008

JL4005

OVER

D4253

R4207

VLCD

3

Q4222

R4226

3

4

DGND

1

64

3

R4225

45

IC4007

PH4001

R4037

34

1

2

1

1

Q4032

C4065

R4024

1

6

R4092

JL4001

JL4206

R4031

R4089

R4036

C4202

CN4201

R4048

C4203

R4052

13

122

JL4201

C4250

JL4202

C4251

qg Menu Init

Function: To return the Menu settings to the factory settings.

17

PCM-D50

SECTION 4

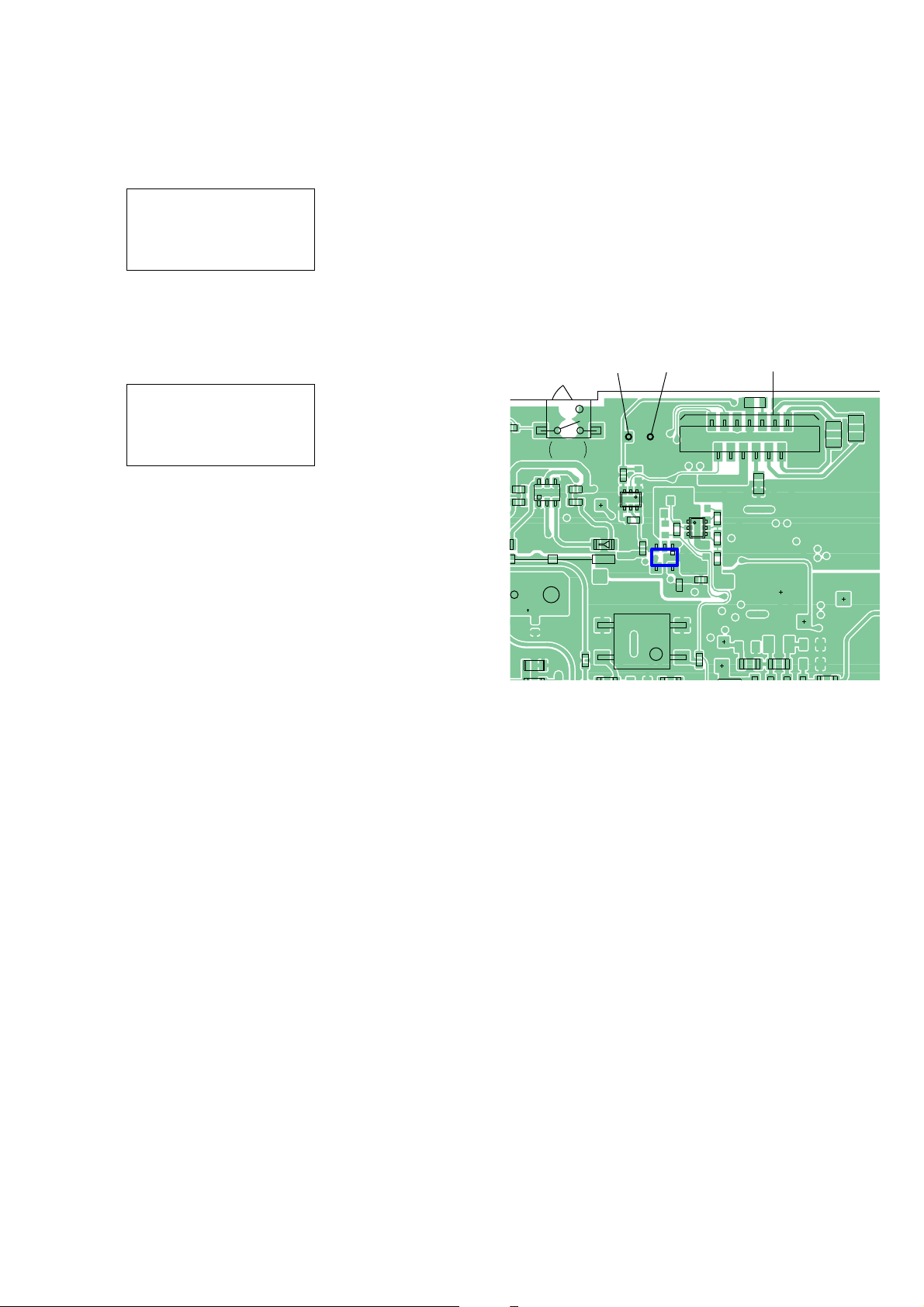

DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

• Lead layouts

Parts on the pattern face side seen from

the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

CSP (Chip Size Package) Lead layout of conventional IC

surface

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specifi ed.

• f : internal component.

• C : panel designation.

Note:

The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specifi ed.

• A : B+ Line.

• B : B– Line.

• Power voltage is dc 6.0V and fed with regulated dc power

supply from battery terminal.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark

[ ] : REC

• V oltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

• Circled numbers refer to waveforms.

• Signal path.

c : REC (DIGITAL)

L : REC (ANALOG)

J : PB (DIGITAL)

F : PB (ANALOG)

• The voltage and waveform of CSP (chip size package)

: PB

: Impossible to measure

*

tolerances.

tolerances.

cannot be measured, because its lead layout is different

from that of conventional IC.

1

/4 W or less unless otherwise

Note:

Les composants identifi és

par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par

une piéce portant le numéro spécifi é.

18

PCM-D50

PCM-D50

1919

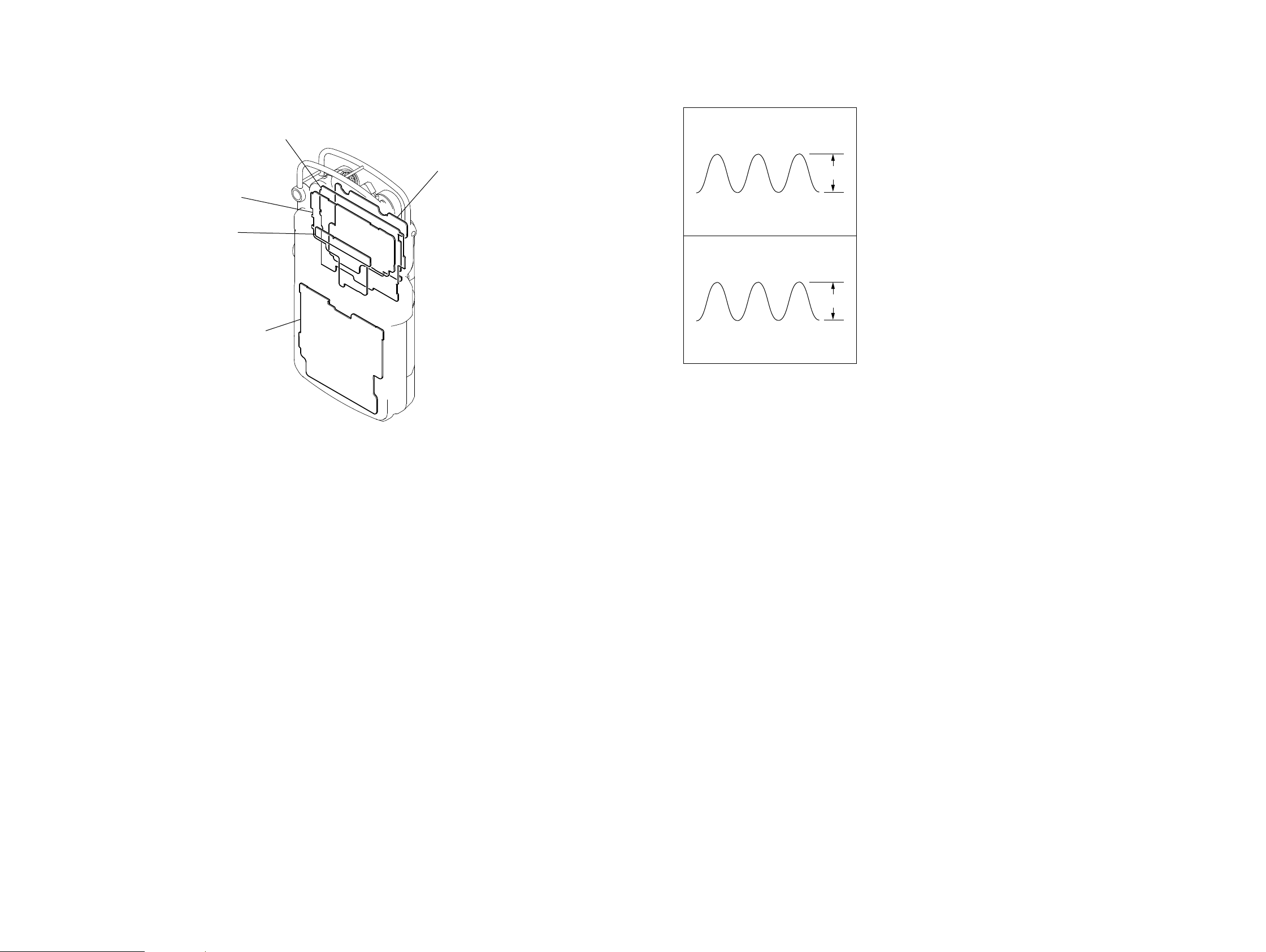

• CIRCUITS BOARDS LOCATION

BACKLIGHT board

DA board

AD board

SYSTEM board

POWER board

• Waveforms

– SYSTEM Board –

IC1001 "$ (OSCOUT)

(X1401)

32.768 kHz

0.5 V/DIV, 20 μsec/DIV

IC1001 7 (CKI)

(X1101)

12 MHz

0.5 V/DIV, 50 nsec/DIV

1.3 Vp-p

2 Vp-p

PCM-D50

PCM-D50

2020

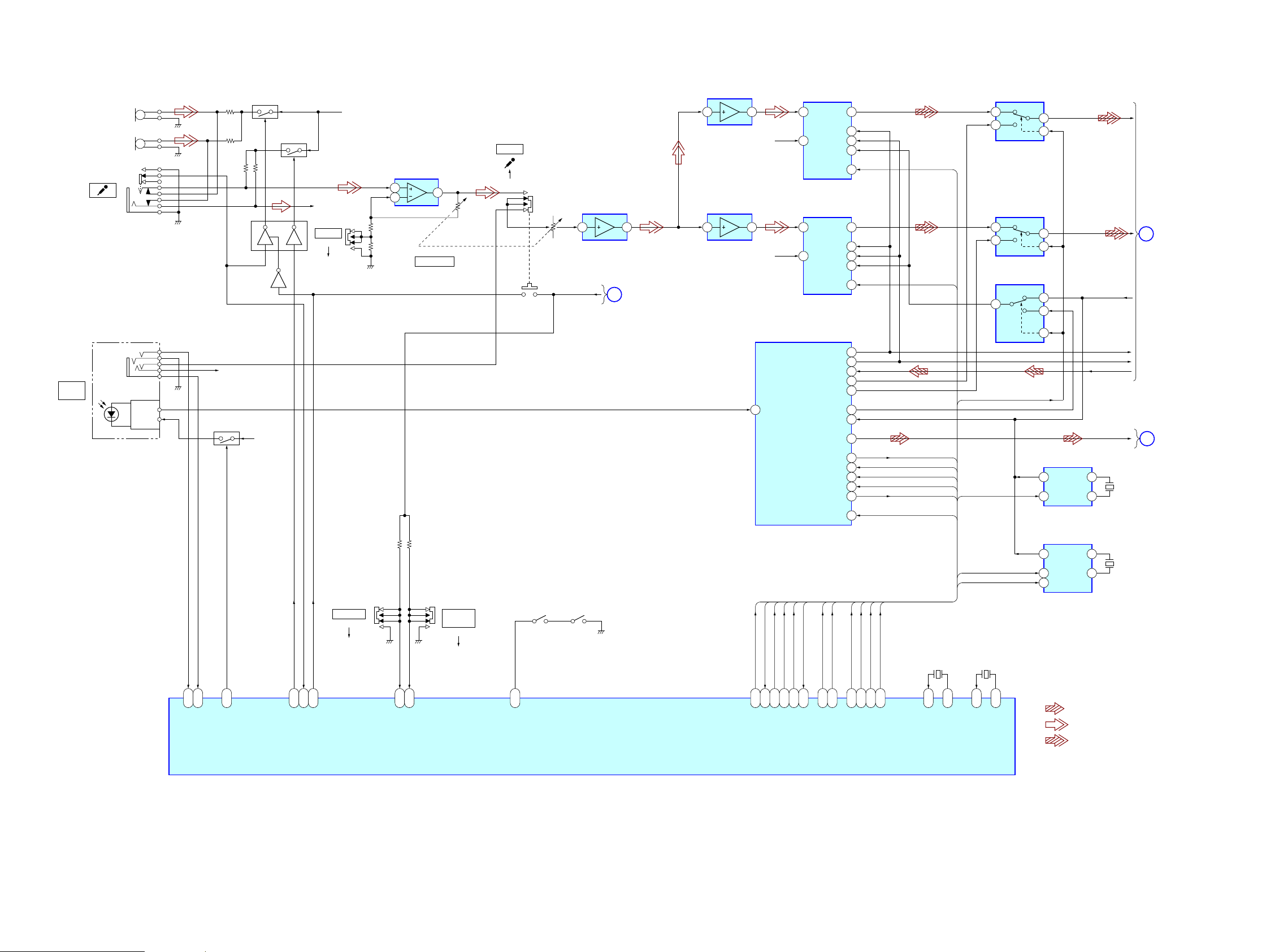

4-1. BLOCK DIAGRAM – AD Section –

3

2

1

5 7 5 7 2 6

5 7

R-CH

+D2.85VCC

DVCC_CONT

S3002 (2/2)

S3002 (1/2)

AINL

LINE AMP

IC3004

LINE AMP

IC3003

A/D CONVERTER

IC3006

DIGITAL AUDIO

I/F TRANSCEIVER

IC3404

LINE AMP

IC3002

MIC AMP

IC3001

Q3001

MIC001

(L-CH)

MIC002

(R-CH)

Q3002

Q3009

Q3008

Q3005

MIC BIAS

1

AINR

AD2_XRST

AD1_XRST

PCM0_ADDT

PCM0_BCK

PCM_MCLK

PCM0_LRCK

OPT_OUT

RX0

SDTO

12

BCK

10

LRCK

11

MCLK

R-CH

13

PDN

26

BICK

24

LRCK

28

DAUX

25

SDTO

19

UOUT

23

MCLK01

30

42

FOUT

1

CONT

4

XT1

16

TX1

36

INT0

35

OCKS0/CSN/CAD0

34

OCKS1/CCLK/SCL

33

CM1/CDTI/SDA

32

CM0/CDTO/CAD1

31

PDN

VOUT

VCC

GPI06

LINEIN_DET

OPTIN_DET

OPTIN_CONT

EXTMICBIAS_CONT

KEY_MICXLINE

EXTMIC_XDET

AB4

GPI05

AC4

CAM_CLK

AB12

CAM_YUV4

AE10

GPIO14

W2

CAM_YUV7

AB10

NAND_DA14

H12

SPI1_SI

AB8

SPI1_SO

W8

SPI1_SK

V10

SPI1_CSZ0

W10

D_TRSTZ

V19

NAND_DA12

J10

NAND_DA11

H10

NAND_DA10

H9

CAM_SCLK

AB14

CAM_STR

AB13

CAM_HS

AD12

OSCIN

AB26

OSCOUT

AC26

GPIO9

AA3

GPIO10

AA2

D_TMS

V17

S1601

LIMITER

ON

OFF

S1602

S4202

MIC (L-CH)

DIRECTION

S4201

MIC (R-CH)

DIRECTION

KEY_XLRMIC

SYSTEM CONTROL/DSP

IC1001 (1/3)

LOW CUT

FILTER

OFF

ON

S3003

MIC ATT

J3002

LINE IN

(OPT)

RV003

REC LEVEL

20

0

S3002

LINE

INPUT

2 6 3

4

6

1

AINL

A/D CONVERTER

IC3005

DATA SELECT

IC3406

DATA SELECT

IC3407

CLOCK SELECT

IC3405

CLOCK GENERATOR

IC3401

1

AINR

SDTO

12

BCK

10

LRCK

11

MCLK

R-CH

R-CH

13

PDN

3

4

6

1

3

4

6

1

DIF_INT

DIF_XCS

SPT1_CLK

SPT1_MOSI

DIF_XRST

SPT1_MISO

X11M_CONT

PCM1_ADDT

A

DA

SECTION

B

DA

SECTION

X3401

11.2896MHz

53XT

XXT

FOUT

6

CONT

1

IN1

7

CLOCK GENERATOR

IC3403

X3402

24.576MHz

32XT–

XT

X24M_CONT

DIV24M_CONT

DIF_XRST

SPT1_MISO

SPT1_MOSI

SPT1_CLK

DIF_XCS

DIF_INT

AD2_XRST

AD1_XRST

SDTO1_XAD1

DIV24M_CONT

X24M_CONT

X11M_CONT

X1401

32.768KHz

CKI

U26

CKO

T26

X1101

12MHz

E

POWER

SECTION

J3001

• R-ch is omitted due to same as L-ch.

PCM0_DADT

SDTO1_XAD1

• SIGNAL PATH

: REC (ANALOG)

: PB (DIGITAL)

: REC (DIGITAL)

(Page 22)

(Page 21)

(Page 21)

PCM-D50

PCM-D50

2121

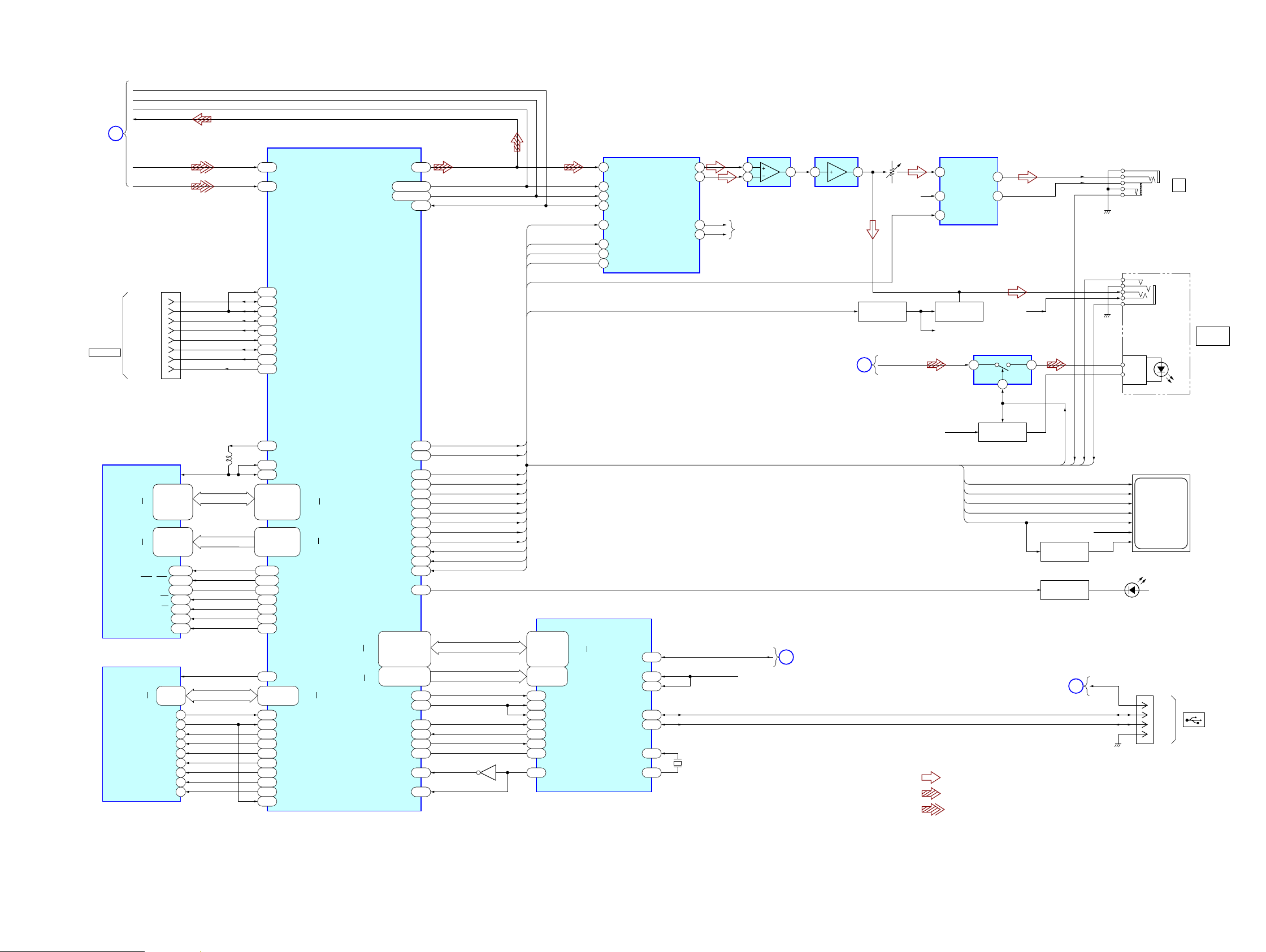

4-2. BLOCK DIAGRAM – DA Section –

H13

AB18

19

XWP

NAND_XWP

NAND_XWR

NAND_ALE

NAND_CLE

NAND_XCS1

NAND_XCS0

USB_XINT

USB_INT

USB_XRST

AB0_XDACK

AB0_XDEQ

AB0_XWR

AB0_XRD

USB_XCS

NAND_XRD

NAND_RXB0

NAND_RXB1

VDD_GP3

NAND ROM

IC1301

MS_INSZ

J5

SDR_DATA30

AB3

GPIO7

E2

XOUT

E1

XIN

B1

DM

C1

DP

G1

VIF

D7

VIF

C2

VBUS

H16

AB0_WRZ

AC23

PWM0

AD2

GPIO3

AC5

GPIO4

Y2

GPIO13

AC12

CAM_VS

U19

D_TCK

AC6

SPI0_CSZ0

W22

D_TDI

AD7

SPI0_CSZ2

AC7

SPI0_SK

AC8

SPI0_SO

H11

NAND_DA13

J9

NAND_DA9

E7

NAND_DA8

W19

EXTPCMCLK

AB22,AB20

PM0_SEN, PM1_SEN

AC21,AB21

PM0_CLK, PM1_CLK

AC22

PM0_SO

J19

AB0_RDZ

H5

SDR_DATA31

F23

AB0_A24/DAK

E24

AB0_A25/DRQ

H17

AB0_CSZ0

NAND_DA15

A4

NAND_WEZ

D3

NAND_ALE

C6

INT_N

A2

RST_N

D4

DACK0_N

DREQ0_N

A5

CS_N

B5

WR1_N

C5

WR0_N

A6

RD_N

A1–5,A6/ALE

USB I/F

IC1503

D/A CONVERTER

IC4005

SYSTEM CONTROL/DSP

IC1001 (2/3)

VDD_IOA

PSW_VCC.BUS

SPI0_MOST

+D2.85VCC

OPT_OUT

INL+

R-CH

R-CH

OPTOUT_DET

OPTOUT_CONT

LINEOUT_XDET

HP_DET

SPI0_CLK

BLCD_A0

BLCD_CS

BLCD_XRST

VDD_GP2

VLCD

VDD

VBUS

VBUS

1

3

2

5

D+

D–

GND

E9

NAND_CLE

C2

NAND_CSZ1

M9

NAND_CSZ0

E3

NAND_REZ

D2

NAND_RBZ0

H8

NAND_RBZ1

AF23

VGP3

18

XWE

17

ALE

16

CLE

10

XCE2(NC)

9

XCE1

8

XRE

7

R/B1

VCC

6

R/B2(NC.GND)

29–32,

41–44

B4,C4,D4,E4,

L9,E6,K9,E8

I/O0

I/O7

NAND_DA0

NAND_DA7

H18,H19,D18,

E18,C20,D20

AB0_A1

AB0_A6

NAND_D00–07

AB0_A1–6

AB0_D00–15

OPTOUT_DET

LINEOUT_XDET

HP_DET

OPTOUT_CONT

BLCD_XRST

BLCD_CS

BLCD_A0

DA_XCS

SPI0_CLK

SPI0_MOST

DA_XRST

LINEOUT_MUTE

CPU_EXTPMCLK

PCM0_LRCK

PCM0_BCK

PCM0_DADT

HP_XMUTE

DA_XCS

HP_XMUTE

LINEOUT_MUTE

SPI0_CLK

SPI0_MOST

DA_XRST

BLCD_LIGHT

T1

CKE

SDR_CKE0

SDR_CLK

SDR_CS0

SDR_XWR

SDR_DQM0, DQM1

SDR_XRAS, XCAS

SDR_BA0, BA1

VDD_SDR

L1402

VDD_GP4

9

8

7

6

5

4

3

2

SDRAM

IC1201

CN1603

MEMORY

STICK

PRO DUO

SDR_TKE0

AA5

SDR_CLK

T3

SDR_CSZ0

R5

F3

F2

G9

F9

SDR_WEZ

P5,R4E8,F1

F8,F7

G7,G8

SDR_DQM0,DQM1

T5,U8

SDR_RASZ,CASZ

AB5,T4

SDR_BA0,BA1

AE3

DD2VFBK

AF4

DD2VFBK2

AE22

VGP4

AC18

MS_SCK0

AB15

MS_DATA3

W3

GPIO15

AB16

MS_DATA2

AB17

MS_DATA0

AC16

MS_DATA1

AC17

MS_BS

AD24

STM_DATA

SMUTE/CSN

ACKS/CCLK

DIF0/CDTI

R-CH

PDN

MCLK

LRCK

BICK

SDTI AOUTL+

PCM1_ADDT

AD20

PM1_SI

AD22

PM0_SI

AF7–9

DD2LX1–3

CLK

CS

WE

LDQM, DQM1

RAS, CAS

BA0, BA1

VCC

VCC

CLK

DATA3

INS

DATA2

DATA0

VCC/DATA1

BS

H7,H8,J8,J7,

J3,J2,H3,H2,

H1,G3,H9,G2

AA4,Y5,Y4,W5,

W4,V5,V4,V8,

U5,U4,U3,U2

A0

A11

SDR_A0

SDR_A11

SDR_A0–11

A8,B9,B8,C9,

C8,D9,D6,E9,

E1,D2,D1,C2,

C1,B2,B1,A2

R1,R8,P4,P3,

P2,P1,P8,N8,

N5,N4,N3,N2,

N1,M8,M5,M4

DQ0

DQ15

SDR_DATA0

SDR_DATA15

D24,C25,D25,F24,

E25,F25,H25,H24,

H22,H23,J22,J23,

J24,G25,G24,G23

H2,F4,G3,H3,

E4,G4

H4,F5,E5,H5,

G5,H6,G6,H7,

G7,H8,G8,F6,

F7,F8,E6,E7

AB0_D0

AB0_D15

D0,

D1/AD1

D6/AD6,

D7–15

SDR_D0–15

PCM0_ADDT

PCM0_DADT

PCM0_BCK

PCM0_LRCK

PCM_MCLK

X1501

24MHz

Q1501

D

POWER

SECTION

C

POWER

SECTION

B

AD

SECTION

CN1501

D2601–2603

(LCD BACKLIGHT)

LCD UNIT

OPT OUT SWITCH

IC4007

HEADPHONE AMP

IC4008

LINE AMP

IC4002

RV5501

(HP VOLUME)

LOW PASS FILTER

IC4004

(USB)

LED DRIVE

Q2201

+B SWITCH

Q4030

MUTE

PH4001

MUTE DRIVE

Q4032

DISCHARGE

Q4222

LCD1

LIQUID

CRYSTAL

DISPLAY

4

21

J4002

J4001

LINE OUT

(OPT)

VIN

VCC

3 12

AOUTL–

11

5

6

7 5

AOUTR+

10

AOUTR–

9

2

4

1

5

8

7

6

A

AD

SECTION

7 15

INR+

7

OUTR

R-CH

10

OUTL

12

SHDN

16

J

• R-ch is omitted due to same as L-ch.

C4

• SIGNAL PATH

: PB (DIGITAL)

: PB (ANALOG)

: REC (DIGITAL)

(Page 20)

(Page 20)

(Page 22)

(Page 22)

PCM-D50

PCM-D50

2222

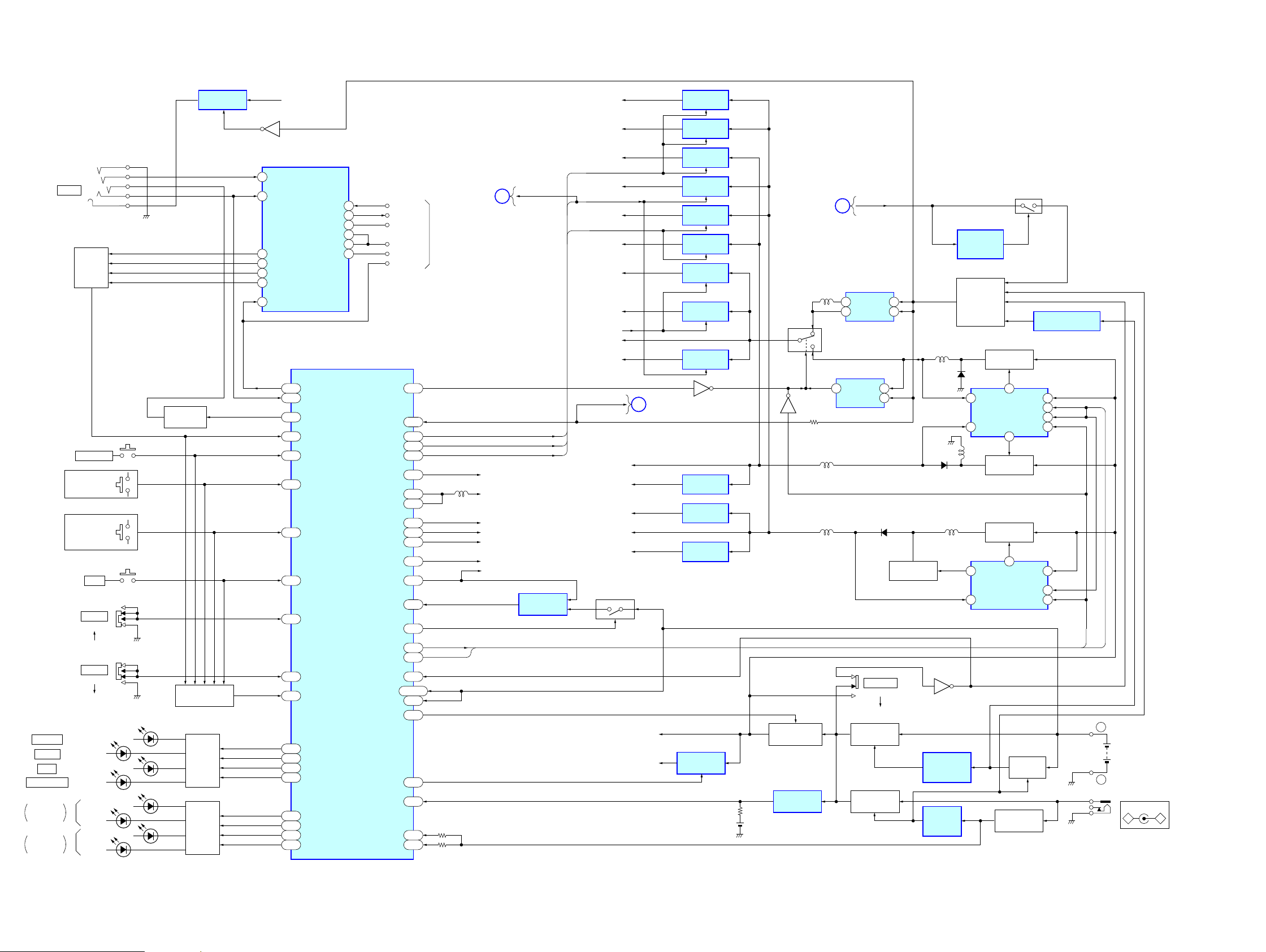

4-3. BLOCK DIAGRAM – POWER Section –

K5

B17

H4

K4

J4

LED

DRIVE

Q4220,

4221

D4250

D4251

D4252

D4253

PEAK LEVEL

(R-CH)

PEAK LEVEL

(L-CH)

PKLED_R_GRE

SDR_DATA26

SDR_DATA27

VCCADP

B6

ADIN4

AD17

BKBAT

AE11

CAM_YUV0

V18

D_TDO

AD19

IIC_SDA

AA26

VANA

C6

ADIN3

AF22

VGP2

AF20

VGP1

AC10

CAM_YUV6

Y3

GPIO12

E10

B17,D17

BATSEL

VCCVBAT1

SDR_DATA28

SDR_DATA29

SDR_DATA22

SDR_DATA24

SDR_DATA23

SDR_DATA25

GPIO0

GPIO8

GPIO1

GPIO2

PKLED_R_RED

PKLED_L_GRE

PKLED_L_RED

L2

L5

L1

H3

AD5

AB2

LED

DRIVE

Q2202,

2203

D2203

D2201

D2204

D2202

LED_GREEN

RTC_BKBAT

UNREG

POWER_ON

HP_CONT

DDC_PWM

VDD_ANA

BATT_AD

VDD_GP2

+5.3V UPDDC

-5.3V UPDDC

+5V

(IC4005)

Q1401,1402

+5V

VDD_GP1

ADA_PWM

POWERSW_OFF_DET

+3.5V

(IC4008)

LED_RED

LED_YELLOW

LED_ORANGE

KEY_XDPC

KEY_HOLD

KEY_REC

KEY_AD0

KEY_AD1

KEY_AD2

KEY_AD3

LED_ANSWER

ACCESS

PAUSE

REC

PLAY/ENTER

KEY WAKE DETECT

Q2206, 2207

AD4

AD3

ADIN5

C7

S2213

OFF

ON

DPC

S2211

OFF

ON

HOLD

S2201

REC

ADIN7

C8

SDR_DATA21

SIRCS_KEY_STOP

SIRCS_KEY_REC

SIRCS_KEY_PAUSE

SIRCS_KEY_DIVIDE

L3

ADIN8

B8

GPIO11

AA1

PWM1

nRESET

P00/TI000

P01/TI010/TO00

ANI0/P20

ANI1/P21

AD23

S2207

PLAY/ENTER

KEY NETWORK

S2202, 2206,

S2209, 2210,

S2212

NETWORK

SWITCH

Q2204,

Q2205

ADIN6

B7

KEY NETWORK

S2203–2205,

S2208

LED DRIVER

Q2301

4

3

2

1

P30/INTP2/OCD1A

RESET_OUT

FLMD0

CLK

DATA

(OCD)

RX

TX

P14/RXD6

18

22

P13/TXD6

23

P32/INTP3/OCD1B

16

P31/INTP2/OCD1A

17

P122/X2/EXCLK/OCD03

8

FLMD0

7

P120/INTP0/EXLVI

DDCOUT33

5

6

+2.9V REG.

IC2303

SIRCS CONTROL

IC2301

SYSTEM CONTROL/DSP

IC1001 (3/3)

DC-DC CONVERTER

IC2101

UNREG

ADA_PWM

ADA_PWM

DDC_PWM

DC-DC CONVERTER

IC2102

LEVEL DETECT

IC2105

+3.3V REG.

IC2103

DELAY SWITCH

Q2006

DELAY

Q2005, 2009

DC IN

DETECT

IC2003

BATTERY LEVEL

DETECT

IC2004

B+ SWITCH

Q2016, 2011

B+ SWITCH

Q2017, 2019

SWITCHING

Q2104

SWITCHING

Q2103

SWITCHING

Q2102

VBUS SWITCH

Q2008,

Q2001, 2023

SWITCHING

Q2105, 2106

B+ SWITCH

Q2030, 2020 (1/2)

+3.3V REG.

IC2001

+3.5V REG.

IC4204

+5V REG.

IC4203

+5V REG.

IC4202

-5V REG.

IC4201

+2.8V REG.

IC3209

VBUS LEVEL

DETECT

IC2002

BATT LEVEL DETECT

IC2005

LEVEL BUFFER

IC1401

DC IN 6V

J3301

DRY BATTERY

SIZE “A”

(IEC DESIGNATION LR6)

4PCS. 6V

BH1401

Li-ion

BATTERY

–

+

+

–

S2002

L2102L2104

L2105

VCC_VBUS

D2106

Q2020 (2/2)

VCC_ADP

Q2026

(2/2)

Q2026 (1/2)

Q2113,

Q2114

L2103

POWER

OFF

ON

AE4

DD2VFBSW

VDD_IOA

B9

ADVCC

VDD_ADC

U25

VPLL

AF15

DD1LX2

AF14

DD1LX1

VLO

W26

AC11

CAM_YUV2

AB11

CAM_YUV3

AD10

CAM_YUV5

A17

VCCVBUS

AC19

IIC_SCL

MIC BIAS

+MIC VCC

-MIC VCC

AD_VCC

AD+5VCC

AD-5VCC

VDD_IOP

DDCOUT33

+D2.85VCC

PSW_VCCBUS

+3.1V

(IC1503)

+1.5V

(IC1503)

MICVCC_CONT

AD5_CONT

DVCC_CONT

DVCC_CONT

VDD_PLL

VDD_L1

L1401

Q2302

VDD_L0

VBUS_SELF_PWR

PSW_VCCVBUS

MICVCC_CONT

AD5_CONT

DVCC_CONT

-5V

FB

6

CE

4

PWM

3

EXT2

8

VCC

EXT1

2

1

FB2

8

PWM2

7

EN2

6

PWM1

4

FB1

3

VOUT VIN

1 3

VSEN

4

LX VIN

5

VOUT

4

1

CE

3

VDD

EXT1

EXT2

D2102

VBUS

Q2028

L2101

L2103

D2105

2

1

10

+1.5V REG.

IC1502

-5V REG.

IC3205

+5V REG.

IC3206

+5V REG.

IC3207

-5V REG.

IC3201

+5V REG.

IC3202

+5V REG.

IC3203

+3.1V REG.

IC1501

D

DA

SECTION

E

AD

SECTION

C

DA

SECTION

J2301

SIRCS

(Page 20)

(Page 21)

(Page 21)

PCM-D50

PCM-D50

2323

1234567891011 121314

A

B

C

D

E

F

G

H

I

J

+

+

+

+

+

+

+

+

115

216

1

1

1

13

64

5

10

6

12

1324

25

36

37 48

3

5

4

1

1

4

8

5

3

64

13

64

MIC

(L-CH)

MIC001 MIC002

1

2

39

40

RED

RED

BLK

BLK

YEL

YEL

MIC

(R-CH)

AD BOARD (SIDE A)

–

+

DC IN 6V

J3301

J3002 (1/2)

LINE IN

(OPT)

11

(11)

1-875-142-

–

+

DRY BATTERY

SIZE "A"

(IEC DESIGNATION LR6)

4PCS, 6V

REC VOL

FLEXIBLE BOARD

E

POWER BOARD

C

DA BOARD

CN4202

B

IC3206

IC3404

IC3401

IC3403

IC3405

IC3406

R3418

R3419

R3225

R3422

R3423

R3424

R3231

R3425

R3232

R3428

R3436

R3437

R3438

R3439

R3440

R3441

R3446

R3448

LF001

JL3301

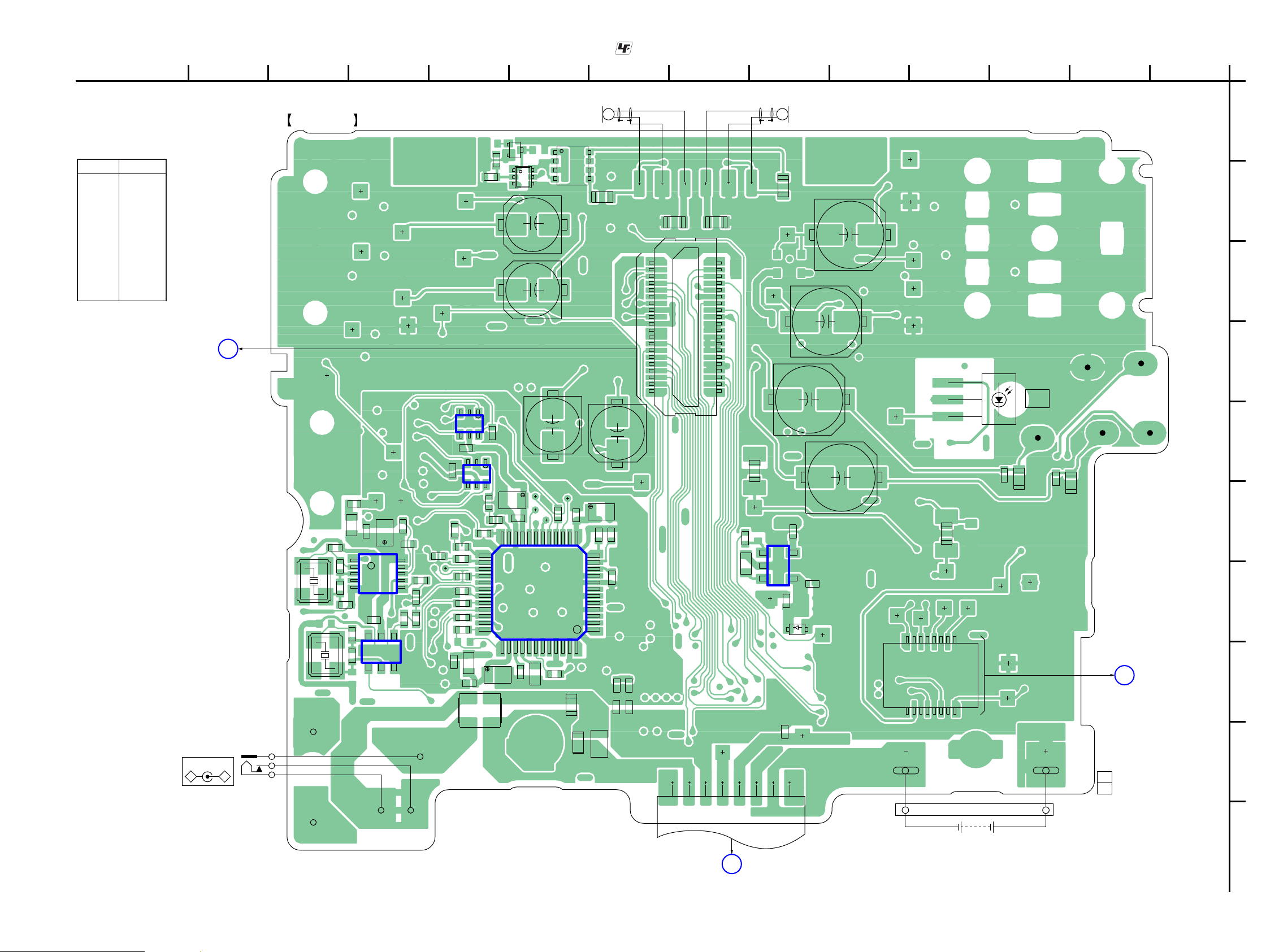

JL3302

CN3304

C3302

X3401

X3402

FB3402

R3303

R3320

R3321

L3401

L3402

R3136

R3139

R3140

R3145

R3147

R3152

R3153

JL3009

JL3201

JL3202

JL3203

JL3010

JL3011

JL3206

JL3012

JL3013

JL3208

JL3014

JL3019

JL3401

JL3402

JL3403

JL3210

JL3405

JL3212

JL3213

JL3407

JL3214

JL3020

JL3215

JL3216

JL3023

JL3217

JL3218

JL3024

JL3029

CN3001

JL3220

JL3030

JL3031

C3002

C3003

Q3001

C3007

Q3008

Q3009

C3202

C3401

C3405

C3406

C3407

C3408

C3217

C3028

C3410

R3001

C3029

C3411

C3412

C3413

C3414

C3416

C3417

C3030

C3418

R3009

C3031

C3419

VDR001

C3226

C3036

D3206

C3037

C3420

R3402

R3403

R3404

R3408

R3216

R341

1

R3412

R3220

R3414

R3415

C3056

C3057

R3417

JL3025

JL3026

JL3032

JL3003JL3006 JL3017 JL3001JL3008 JL3016

JL3005

JL3021

JL3004

JL3209

JL3022

R3426

R3442

R3444

R3450

R3451

JL331

1 JL3314 JL3316 JL3318

JL3310 JL3313 JL3315 JL3317

4-4. PRINTED WIRING BOARD – AD Section (1/2) –

Ref. No. Location

• Semiconductor

Location

D3206 G-6

IC3206 G-6

IC3401 H-11

IC3403 G-11

IC3404 G-9

IC3405 E-10

IC3406 E-10

Q3001 B-9

Q3008 A-9

Q3009 B-9

• : Uses unleaded solder.

• See page 19 for Circuit Boards Location.

(Page 29)

(Page 39)

(Page 30)

PCM-D50

PCM-D50

2424

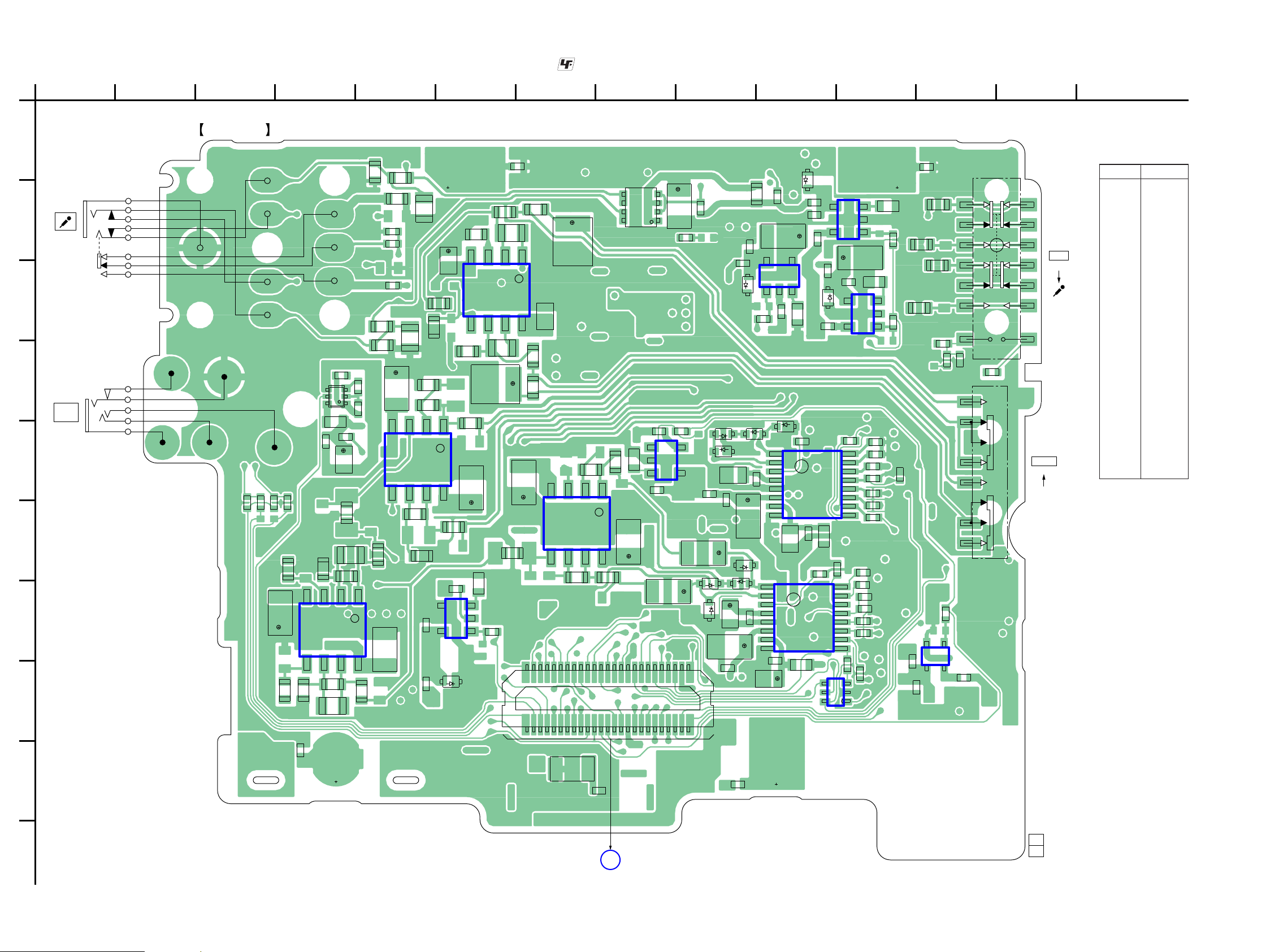

4-5. PRINTED WIRING BOARD – AD Section (2/2) –

• : Uses unleaded solder.

• See page 19 for Circuit Boards Location.

1

A

B

C

D

E

F

G

H

I

J

234567891011 121314

AD BOARD (SIDE B)

J3001

J3002 (2/2)

LINE IN

(OPT)

S3002

INPUT

LINE

S3003

MIC ATT

0

20

1

2

49

50

11

(11)

1-875-142-

1

1

1

1

1

8

16

9

1

14

85

1

3

6

4

8

16

9

3

5

4

3

54

4

8

5

4

85

1

1

3

5

4

1

3

6

4

4

85

14

85

IC3001

IC3002

IC3003

IC3005

IC3006

IC3205

IC3201

IC3202

IC3203

IC3004

IC3209

IC3407

IC3207

R3224

C3058

C3059

R3226

R3229

R3036

C3060

R3038

R3039

R3230

R3040

R3041

R3043

R3044

R3045

R3047

R3048

R3051

R3052

R3055

R3056

R3057

R3058

R3059

R3060

R3066

R3069

R3071

R3072

R3073

R3074

R3075

R3090

R3091

R3092

R3093

R3094

R3095

R3096

R3097

R3098

R3099

JL3320

JL3322

JL3323

JL3324

CN3301

R3100

R3101

R3102

R3103

R3104

R3105

R3107

R3109

R3304

R3305

R3308

R3309

L3001

L3002

L3003

R3132

R3133

R3135

R3141

R3143

R3144

R3146

R3149

R3150

C3001

C3005

Q3002

Q3005

C3009

C3201

C3204

C3010

C3205

C3011

C3206

C3012

C3013

C3014

C3019

C3211

C3212

C3020

C3021

C3216

C3022

C3023

C3024

C3219

C3025

C3026

C3027

D3005

D3006

R3002

R3003

D3007

D3008

D3009

R3005

R3006

R3007

R3008

D3201

C3225

C3032

D3202

C3227

D3203

C3033

D3010

C3034

R3201

C3035

C3229

D3205

D3011

R3202

D3012

R3203

R3204

R3010

C3038

C3039

R3206

R3012

R3207

R3013

R3014

C3230

R3209

R3015

C3232

C3233

R3210

C3044

C3045

C3046

C3047

R3214

R3215

R3022

R3217

R3023

R3024

R3025

C3050

R3029

C3051

C3052

C3053

C3054

R3221

C3055

R3223

R3064

R3108

C3213

R3211

R3037

R3042

R3004

SYSTEM BOARD

CN1602

A

Ref. No. Location

• Semiconductor

Location

D3005 E-9

D3006 D-10

D3007 F-9

D3008 G-9

D3009 E-9

D3010 E-9

D3011 G-9

D3012 F-9

D3201 C-9

D3202 C-10

D3203 A-10

D3205 H-6

IC3001 C-6

IC3002 G-4

IC3003 E-5

IC3004 F-7

IC3005 E-10

IC3006 G-10

IC3201 C-10

IC3202 C-11

IC3203 B-11

IC3205 G-6

IC3207 E-8

IC3209 G-12

IC3407 H-10

Q3002 B-8

Q3005 D-4

(Page 32)

Loading...

Loading...