Sony PCM-D1 Service Manual

微电子时空 基准带 好音乐的休闲时光

fzmcu.taobao.com

SERVICE MANUAL

Ver. 1.0 2005.12

Recording media

PCM-D1

US Model

SPECIFICATIONS

Built-in flash memory 4 GB, “Memory Stick PRO (High Speed)”

(not supplied), Stereo recording

Maximum recordable time (Approximate)

The total maximum recordable time (approximate) of all the folders is as follows.

Built-in flash memory (4 GB)

Sampling frequency/ Maximum

quantifying bit number recordable time *

22.05 kHz 16 bit 13 hrs 10 min.

44.10 kHz 16 bit 6 hrs 35 min.

44.10 kHz 24 bit 4 hrs 20 min.

48.00 kHz 16 bit 6 hrs

48.00 kHz 24 bit 4 hrs

96.00 kHz 16 bit 3 hrs

96.00 kHz 24 bit 2 hrs

“Memory Stick PRO (High Speed)”

Sampling frequency/

quantifying bit number

22.05 kHz 16 bit 45 min. 1 hr 30 min. 3 hrs 5 min. 6 hrs 25 min. 12 hrs 45 min.

44.10 kHz 16 bit 20 min. 45 min. 1 hr 30 min. 3 hrs 10 min. 6 hrs 20 min.

44.10 kHz 24 bit 15 min. 30 min. 1 hr 2 hrs 5 min. 4 hrs 15 min.

48.00 kHz 16 bit 20 min. 40 min. 1 hr 25 min. 2 hrs 55 min. 5 hrs 50 min.

48.00 kHz 24 bit 10 min. 25 min. 55 min. 1 hr 55 min. 3 hrs 50 min.

96.00 kHz 16 bit 10 min. 20 min. 40 min. 1 hr 25 min. 2 hrs 55 min.

96.00 kHz 24 bit 5 min. 10 min. 25 min. 55 min. 1 hr 55 min.

* The maximum recordable time is varied depending on recording condition.

256 MB 512 MB 1 GB 2 GB 4 GB

Maximum recordable time *

– Continued on next page –

9-879-961-01

2005L04-1

© 2005.12

LINEAR PCM RECORDER

Sony Corporation

Connect Company

Published by Sony Engineering Corporation

PCM-D1

Quantization

16-bit linear, 24-bit linear

Frequency range (Input from the LINE IN jack

when recording/playing back) (0 to –2 dB)

Fs 22.05 kHz: 20 to 10,000 Hz

Fs 44.10 kHz: 20 to 20,000 Hz

Fs 48.00 kHz: 20 to 22,000 Hz

Fs 96.00 kHz: 20 to 44,000 Hz

Signal-to-noise ratio (S/N)

96 dB or above (1 kHz IHF-A)

(for 24 bit)

Total harmonic distortion (Input from the

LINE IN jack)

22.05 kHz 16 bit, 44.10 kHz 16/24 bit:

0.008% or below (1 kHz, 22 kHz LPF)

48.00 kHz 16/24 bit, 96.00 kHz

16/24 bit: 0.008% or below (1 kHz,

22 kHz LPF)

Wow and flutter

Below measurable limit (less than

± 0.001% W.PEAK)

Input/output

MIC jack (stereo mini jack)

Input impedance: 22kΩ

Rated input level: 2.5mV

Minimum input level: 0.7mV

i (headphone) jack (stereo mini jack)

Rated output level: 400mV

Maximum output level: 30mW +

30mW or more

Load impedance: 16Ω

LINE IN jack

Input impedance: 47kΩ

Rated input level: 2.0V

Minimum input level: 570mV

LINE OUT/optical DIGITAL OUT jack

Output impedance: 220Ω

Rated output level: 1.8V

Load impedance: 22kΩ

Output level: –21 to –15dBm

(for optical digital output)

Emission wavelength: 630 to 690 nm

(for optical digital output)

DC IN 6V jack

USB connector (Hi-speed USB, Mass

Storage Class)

Memory Stick slot

General

Power requirements

DC IN 6V (AC 120V, 60 Hz)

Four size AA (LR06) nickel metal

hydride rechargeable batteries NH-AA

(supplied)

Four size AA (LR06) alkaline batteries

(not supplied)

Power consumption

2.1W

Dimensions

Approx. 72.0 × 193.0 × 32.7 mm

(2

7/8 × 63/4 × 15/16) (w/h/d) (not

including projecting parts and

controls)

Mass 525 g (18.52 oz) (including batteries)

Supplied accessories

•Windscreen

•AC power adaptor (6V)

• USB cable

• Carrying case

For carrying the recorder and the tripod

(not supplied).

• Wrist strap

• Charging set

(Battery charger BCG-34HRE, four size AA

(LR06) nickel metal hydride rechargeable

batteries NH-AA)

• Size AA (LR06) battery case

•CD-ROM

(“DigiOnSound5”*, “DigiOnAudio2

(trial version)”*, “Driver for Windows

2000”)

* For instructions, refer to the help function

of each application.

• Operating Instructions (this book)

Optional accessories

“Memory Stick PRO (High Speed)”

MSX-1GN (1 GB), MSX-2GN (2 GB),

MSX-4GN (4 GB)

“Memory Stick PRO Duo (High Speed)”

MSX-M1GN (1 GB),

MSX-M2GN (2 GB)

Stereo headphones

MDR-V900, MDR-V700DJ

Audio connecting cable

RK-G129

Optical digital cable

POC-N120B (optical mini plug y

optical mini plug)

POC-N120AB (optical mini plug y

rectangular-shaped optical plug)

External microphone

ECM-MS957

Design and specifications are subject to change

without notice.

2

PCM-D1

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged

by heat.

UNLEADED SOLDER

•

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

3

PCM-D1

TABLE OF CONTENTS

1. GENERAL ................................................................... 5

2. DISASSEMBLY

2-1. Panel (Front) Block Assy ................................................ 10

2-2. Power Board .................................................................... 10

2-3. Meter (VU) ...................................................................... 11

2-4. VOL Block Assy.............................................................. 11

2-5. Audio (D/A) Board .......................................................... 12

2-6. Audio (A/D) Board .......................................................... 12

2-7. LCD Block Assy .............................................................. 13

2-8. Main Board ...................................................................... 13

2-9. Case (MIC-F) .................................................................. 14

2-10. MIC Block Assy .............................................................. 14

2-11. Microphone Unit (R) ....................................................... 15

2-12. Microphone Unit (L) ....................................................... 15

3. TEST MODE ............................................................... 16

4. ELECTRICAL ADJUSTMENTS .......................... 18

5. DIAGRAMS

5-1. Block Diagram – Audio A/D Section – ........................... 21

5-2. Block Diagram – Audio D/A Section – ........................... 22

5-3. Block Diagram – Power Section – .................................. 23

5-4. Printed Wiring Board – Audio A/D Section – ................. 24

5-5. Schematic Diagram – Audio A/D Section (1/2) – ........... 26

5-6. Schematic Diagram – Audio A/D Section (2/2) – ........... 27

5-7. Printed Wiring Board – Audio D/A Section – ................. 28

5-8. Printed Wiring Boards

– REC/HP VOL Flexible Section (VOL Block Assy) – .. 30

5-9. Schematic Diagram – Audio D/A Section –.................... 31

5-10. Printed Wiring Board – Main Section – .......................... 32

5-11. Schematic Diagram – Main Section (1/6) – .................... 34

5-12. Schematic Diagram – Main Section (2/6) – .................... 35

5-13. Schematic Diagram – Main Section (3/6) – .................... 36

5-14. Schematic Diagram – Main Section (4/6) – .................... 37

5-15. Schematic Diagram – Main Section (5/6) – .................... 38

5-16. Schematic Diagram – Main Section (6/6) – .................... 39

5-17. Printed Wiring Board – Power Section – ........................ 40

5-18. Schematic Diagram – Power Section – ........................... 42

6. EXPLODED VIEWS

6-1. Front Panel Section ......................................................... 47

6-2. LCD Section .................................................................... 48

6-3. VOL Section .................................................................... 49

6-4. Audio (A/D) Board, Audio (D/A) Board Section............ 50

6-5. Main Board Section ......................................................... 51

6-6. MIC Section .................................................................... 52

6-7. Rear Panel Section ........................................................... 53

7. ELECTRICAL PARTS LIST .................................. 54

4

Overview (continued)

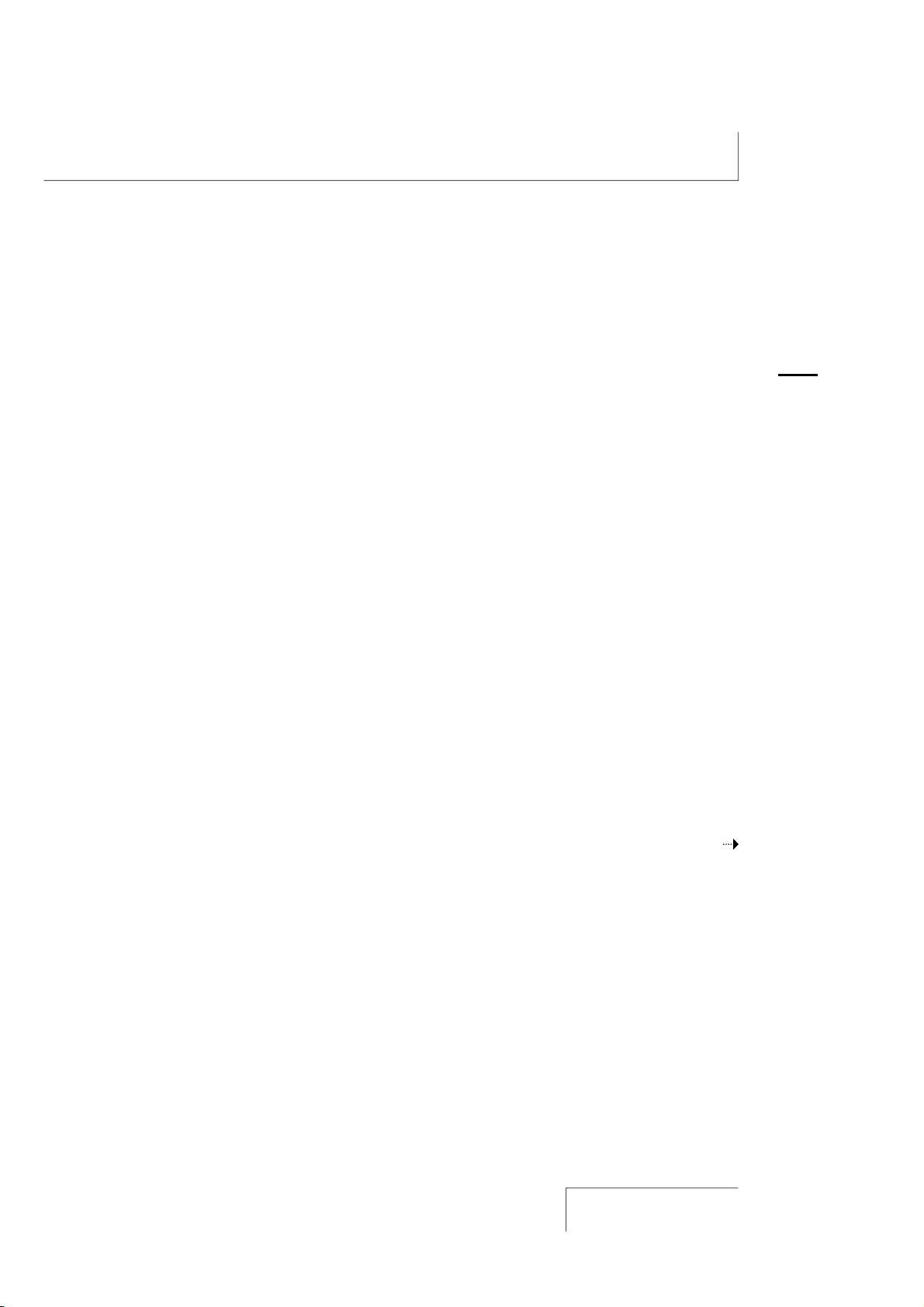

Identifying parts and controls

SECTION 1

GENERAL

PCM-D1

This section is extracted

from instruction manual.

Front

1

2

3

4

5

6

7

8

9

0

qa

qs

qd

qf

qg

qh

Right side

qj

qk

ql

w;

wa

ws

14

wd

5

PCM-D1

1

Built-in microphones (page 22)

2

Analog level meters (page 25)

Displays left and right volume levels of an

audio signal input from microphones in

analog values.

3

Display (page 16)

4

VOLUME dial

Adjusts the playback volume when turned in

+/– directions.

5

> FF (fast-forward) /UP button

(pages 21, 29)

6

MENU button (page 34)

7

LIGHT button

Turns on or off the backlight of the display

and the analog level meters.

8

. FR (fast-rewind) /DOWN button

(pages 21, 29)

9

REC LEVEL L/R (recording level left/right)

dials (page 24)

0

DISPLAY button (page 17)

Switches time information in the display.

qa

X PAUSE button/indicator (pages 25, 29)

qs

ACCESS indicator (pages 20, 38)

Flashes when accessing memory (except

during recording).

qd

z REC (recording) button/indicator

(page 24)

qf

DIVIDE button (page 30)

qg

N PLAY/ENTER button/indicator

(pages 21, 28)

qh

x STOP button (pages 25, 29)

qj

MIC (microphone) jack (page 27)

qk

i (headphone) jack (pages 26, 28)

ql

MIC (microphone) /LINE IN switch

(page 24)

When set to “MIC,” records an audio signal

input from the built-in microphones or an

external microphone that is connected to the

MIC jack. When set to “LINE IN,” records an

audio signal output from external equipment

that is connected to the LINE IN jack.

w;

Memory Stick slot (page 38)

wa

POWER switch

Turns on or off the power.

ws

Battery compartment lid (page 19)

wd

Slit for a wrist strap (page 18)

Continued on the next page

Overview

15

6

Overview (continued)

PCM-D1

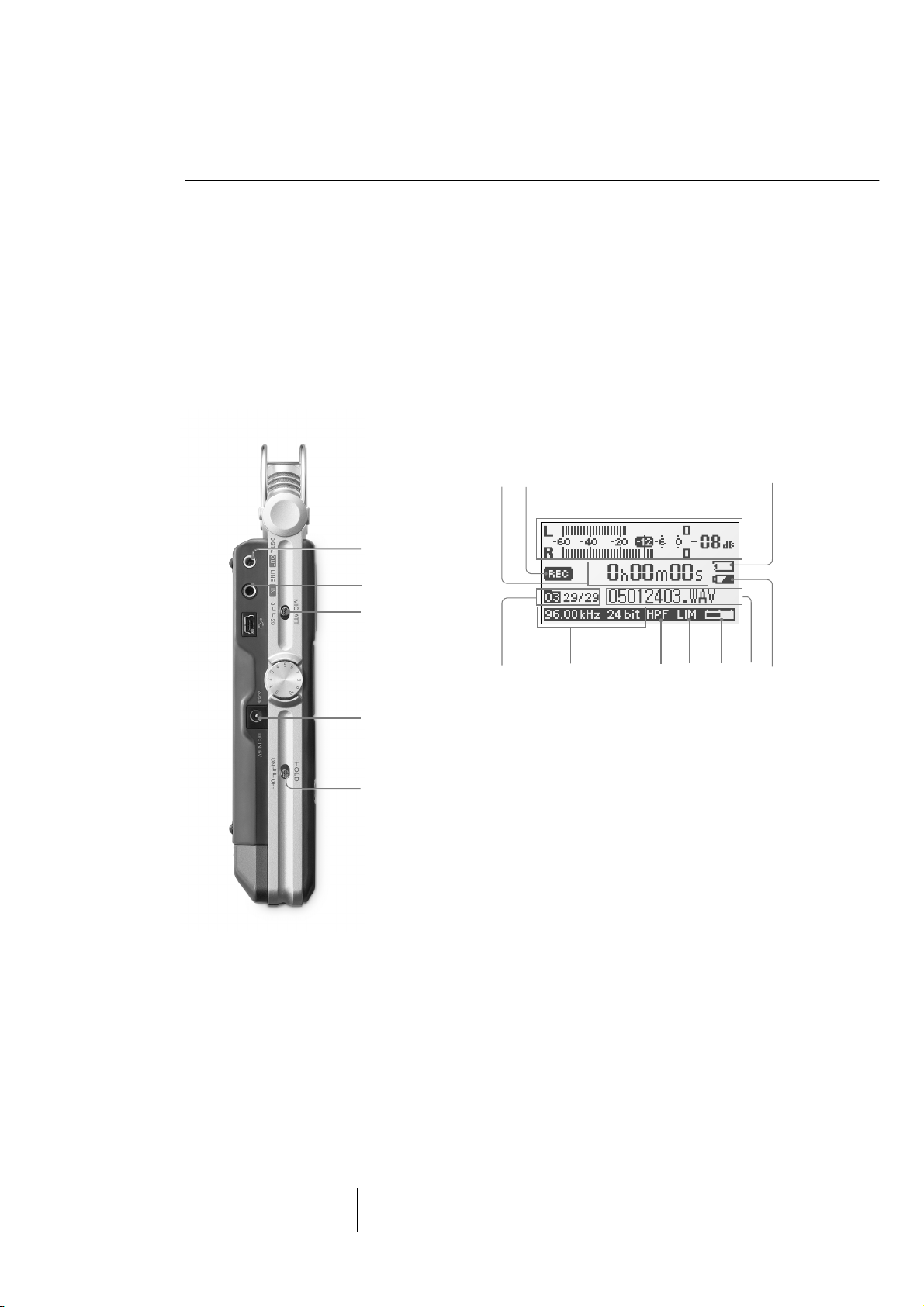

Left side

1

2

3

4

5

6

Display

7

8

qa

qs

9

qd

qf

qg

0

qjqh

16

7

PCM-D1

1

LINE OUT/optical DIGITAL OUT jack

(page 29)

2

LINE IN jack (page 27)

3

MIC ATT (microphone attenuator) switch

(page 23)

4

USB connector (page 30)

5

DC IN 6V jack (page 20)

6

HOLD switch

When set to “ON,” the buttons on the

recorder are locked to prevent accidental

operation. It is recommended to set to “ON”

during recording and playback. To unlock

the controls, set to “OFF.”

7

Time information

Each time the DISPLAY button is pressed,

the time information changes as follows

(Flashes when the recorder is paused):

Elapsed recording/playback time

Remaining recordable time of the current

memory (During playback: Remaining

time of the current track)

9

Peak meter (page 25)

0

Memory Stick indicator

Displayed when the current memory is a

“Memory Stick PRO (High Speed).”

qa

Folder number, track numbers

Track numbers are displayed as “current

track number/total numbers of tracks.”

qs

Sampling frequency and quantifying bit

number of currently recording/playing

track (page 35)

qd

HPF (High Pass Filter) setting

Displayed when “200Hz HPF” is set to “ON”

(page 36).

qf

Limiter setting

Displayed when “LIMITER” is set to “ON”

(page 35).

qg

Remaining memory volume

Displayed the remainig volume of current

memory (page 26).

qh

File name of currently recording/playing

track

qj

Remaining battery power (page 20)

Overview

Recorded date

(During recording: Recording start date)

8

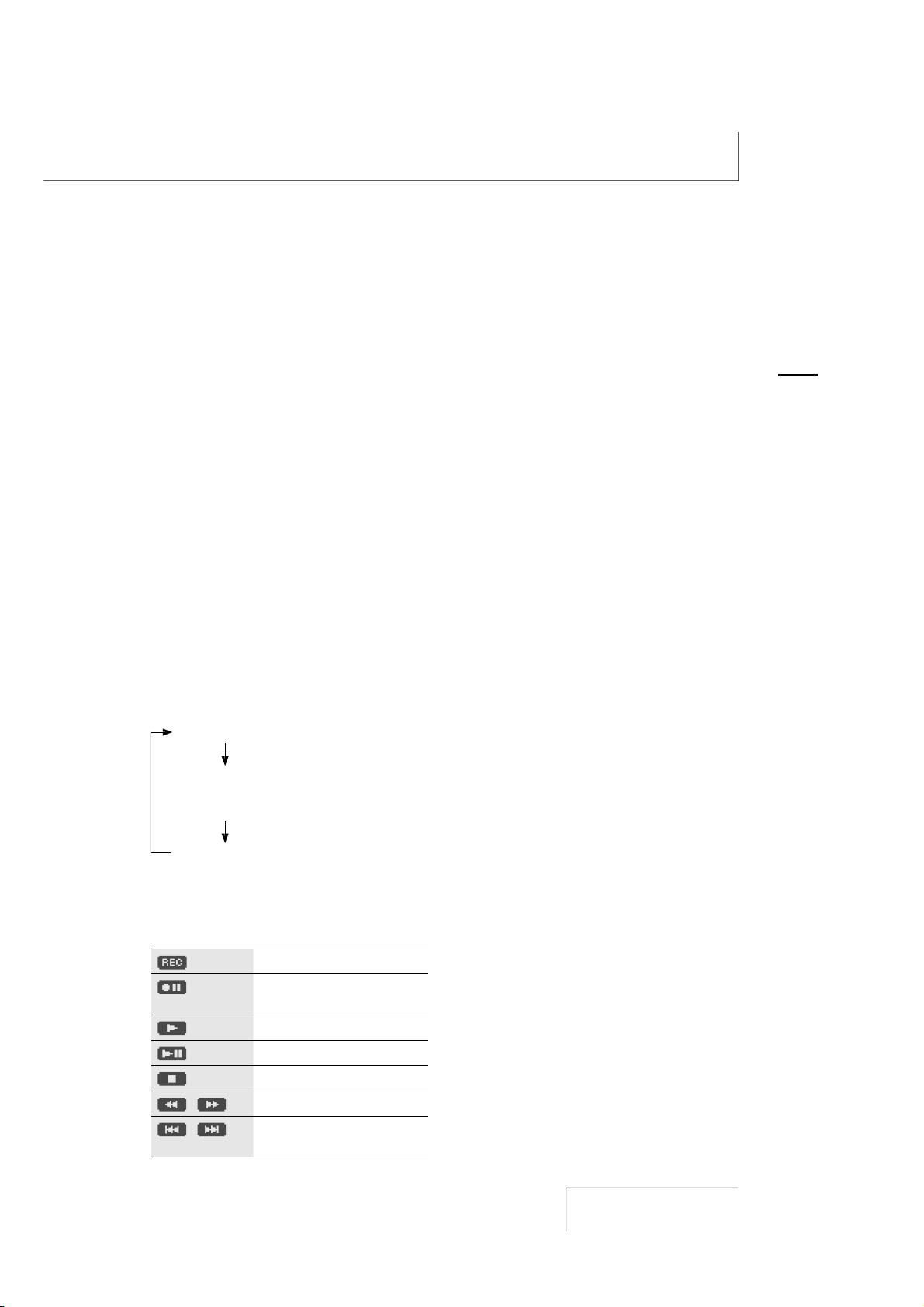

Recording/playing status

Displays as follows according to the current

operation:

Recording

(Flashing)

(Flashing)

/

/

Recording pause,

standby for recording

Playback

Playback pause

Stop

Fast reverse/forward

Go to previous/succeeding

tracks

17

8

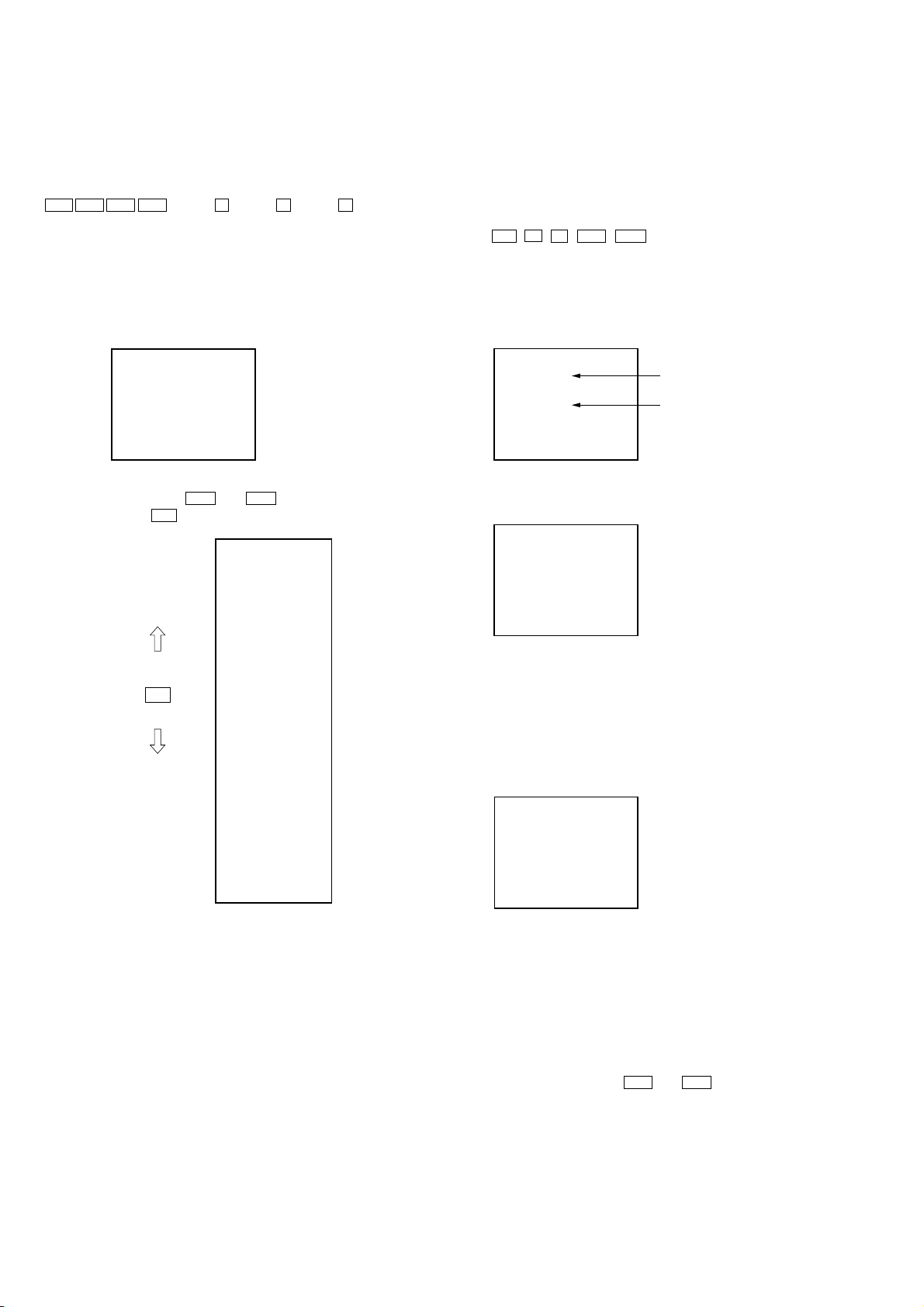

SECTION 2

DISASSEMBLY

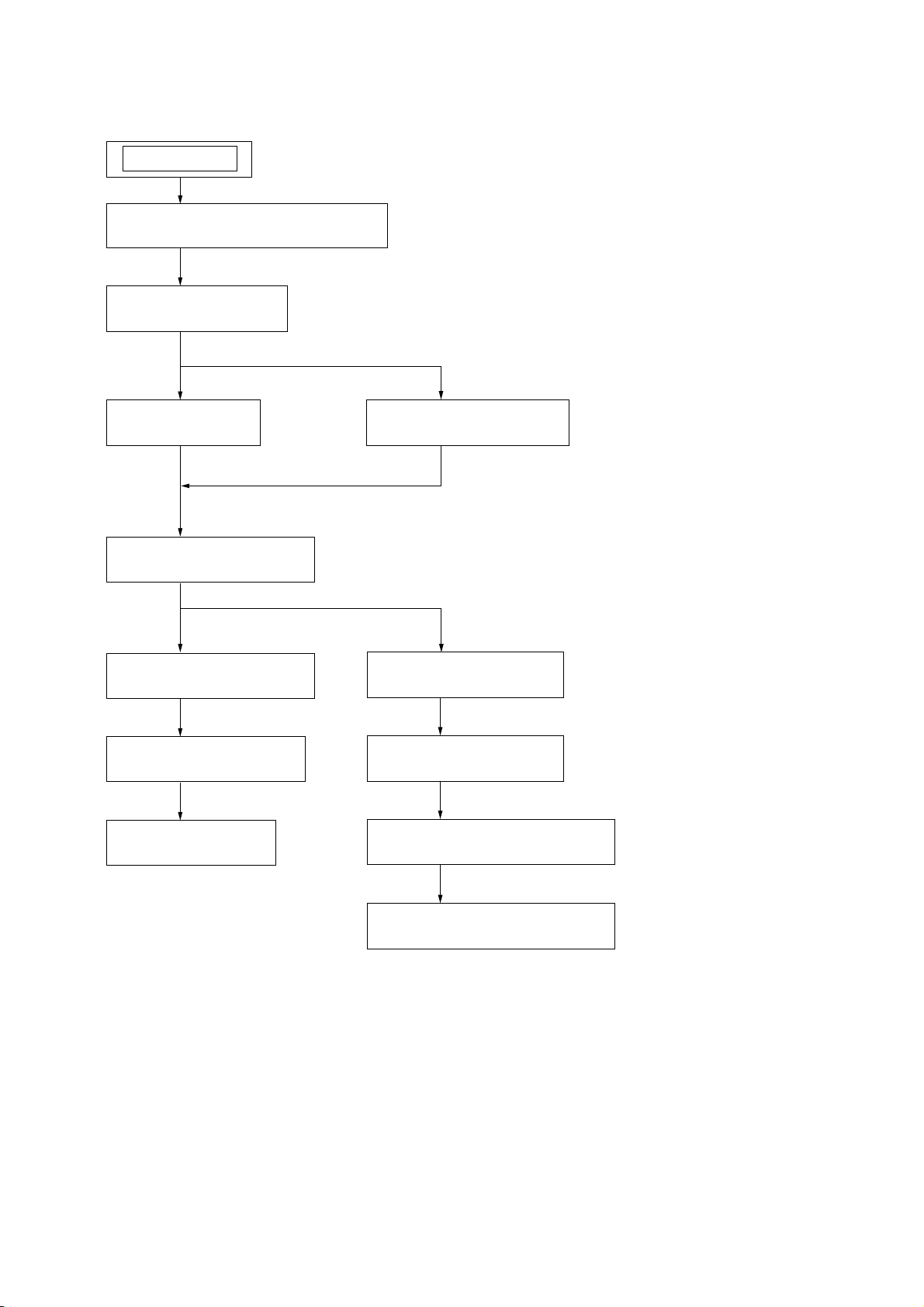

Note: This set can be disassemble according to the following sequence.

SET

2-1. PANEL (FRONT) BLOCK ASSY

(Page 10)

2-2. POWER BOARD

(Page 10)

PCM-D1

2-3. METER (VU)

(Page 11)

2-5. AUDIO (D/A) BOARD

(Page 12)

2-6. AUDIO (A/D) BOARD

(Page 12)

2-7. LCD BLOCK ASSY

(Page 13)

2-8. MAIN BOARD

(Page 13)

2-4. VOL BLOCK ASSY

(Page 11)

2-9. CASE (MIC-F)

(Page 14)

2-10. MIC BLOCK ASSY

(Page 14)

2-11. MICROPHONE UNIT (R)

(Page 15)

2-12. MICROPHONE UNIT (L)

(Page 15)

9

PCM-D1

Note: Follow the disassembly procedure in the numerical order given.

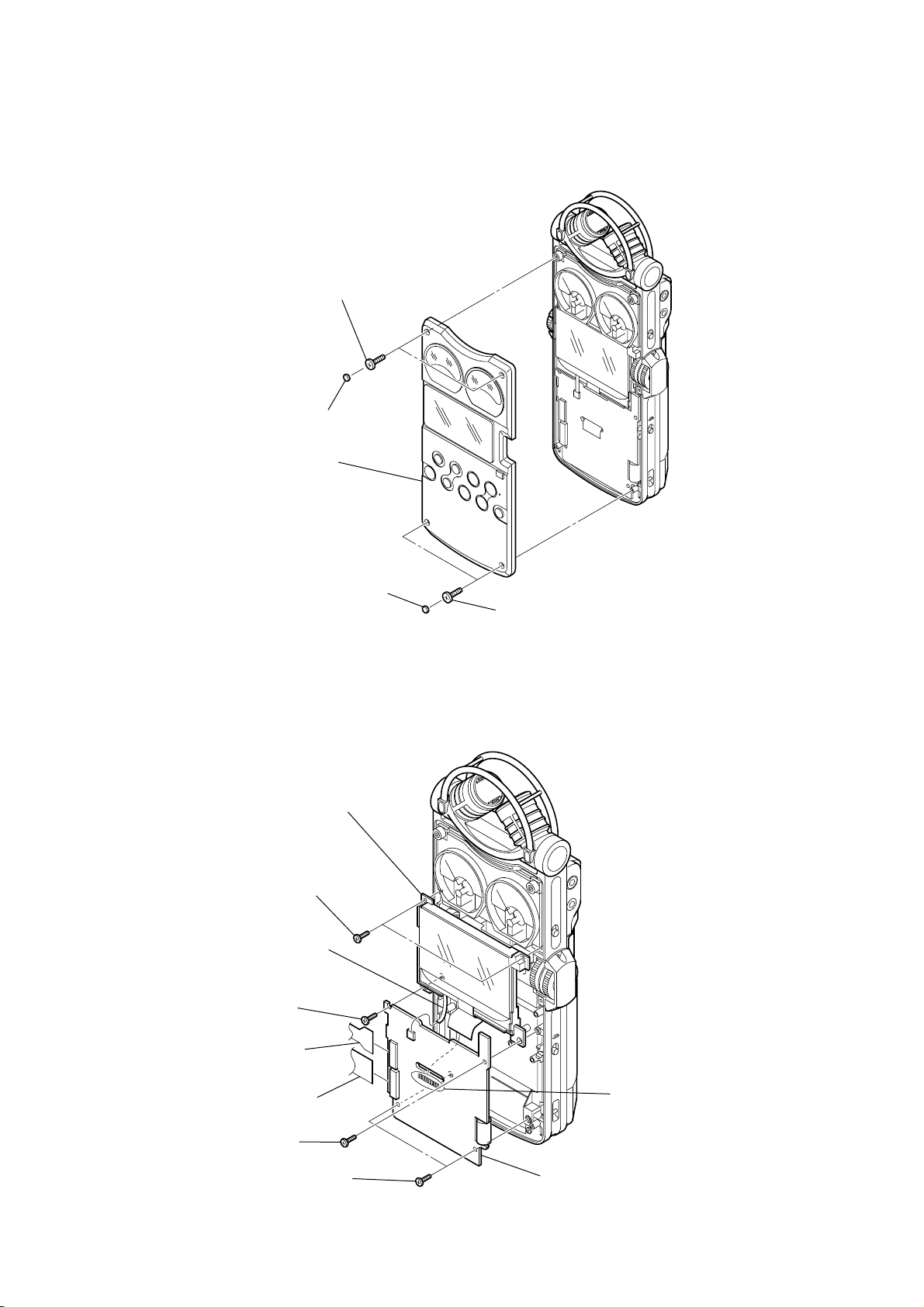

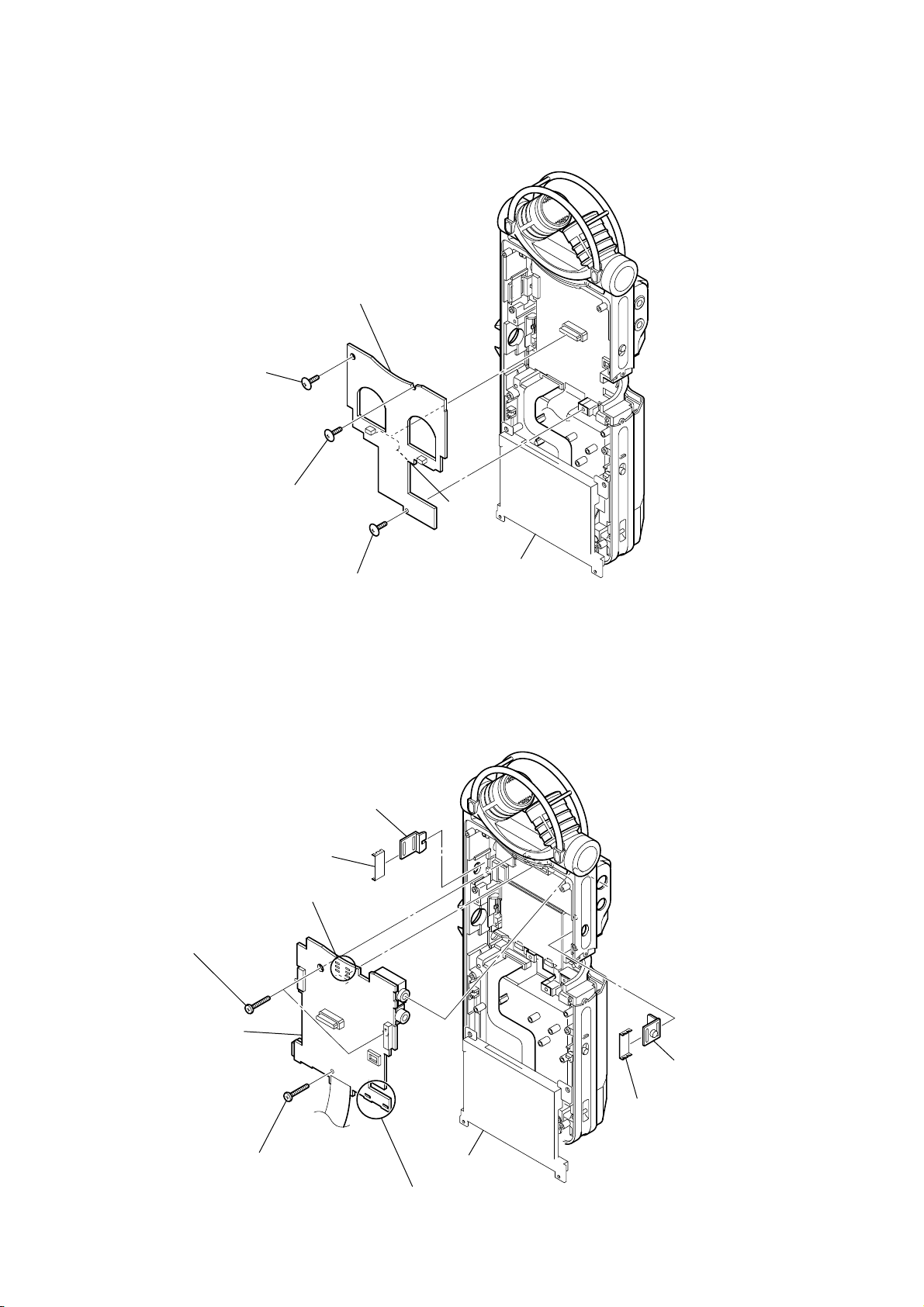

2-1. PANEL (FRONT) BLOCK ASSY

3

two

screws

(M1.7)

1

two cushions (panel)

5

panel (front) block assy

2-2. POWER BOARD

1

LCD back light unit (5 core)

(CN1503)

2

two cushions (panel)

0

9

two

screws

(P2 (M1.7))

7

screw

(P2 (M1.7))

LCD block assy

4

two

screws

(M1.7)

10

3

SIG FLEXIBLE board (24 core)

(CN1502)

2

POWER FLEXIBLE board (20 core)

(CN1501)

6

screw

(P2 (M1.7))

5

(P2 (M1.7))

two

screws

8

POWER board

4

Remove the ten solders.

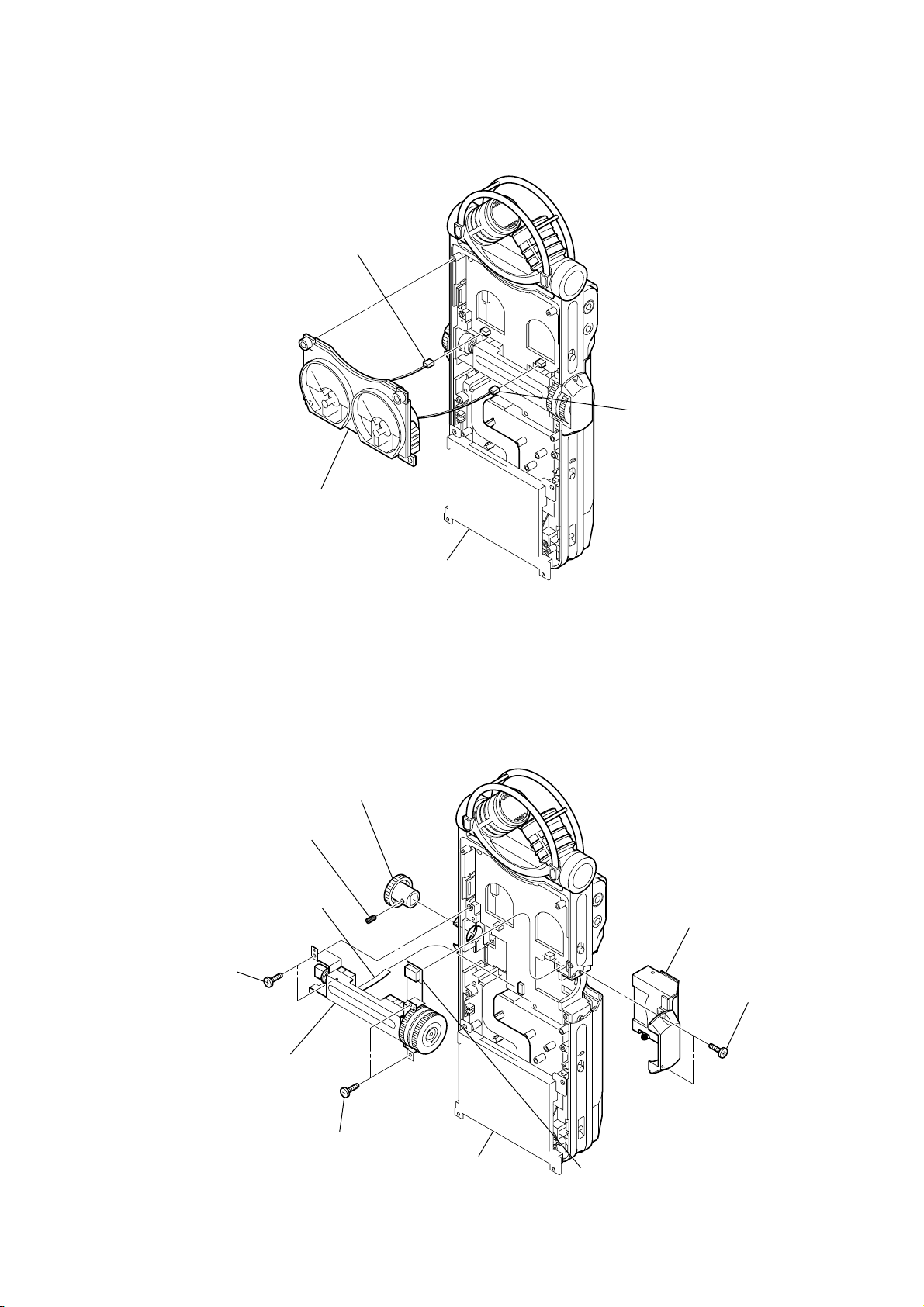

2-3. METER (VU)

y

1

CN2511

2

CN2521

PCM-D1

2-4. VOL BLOCK ASSY

3

set-SCT

(flat point HEX. 2.6

5

HP VOL FLEXIBLE board (8 core)

(CN2307)

3

meter (VU)

×

3)

4

knob (VOL)

LCD block assy

2

ornament (MS) block ass

8

two

screws

(P2 (M1.7))

9

VOL block assy

7

two

screws

(P2 (M1.7))

LCD block assy

1

two

(M1.4)

6

REC VOL FLEXIBLE board (16 core)

(CN2301)

screws

11

PCM-D1

2-5. AUDIO (D/A) BOARD

2

screw

4

AUDIO (D/A) board

2-6. AUDIO (A/D) BOARD

5

Remove the six solderings.

7

two screws

(M2 grip)

1

special head screw

(M1.7)

2

1

guide (knob)

3

screw

knob (MIC ATT)

CN2201

LCD block assy

12

9

AUDIO (A/D) board

8

screw

(M2 grip)

LCD block assy

6

Remove the two solders.

4

3

guide (knob)

knob (line)

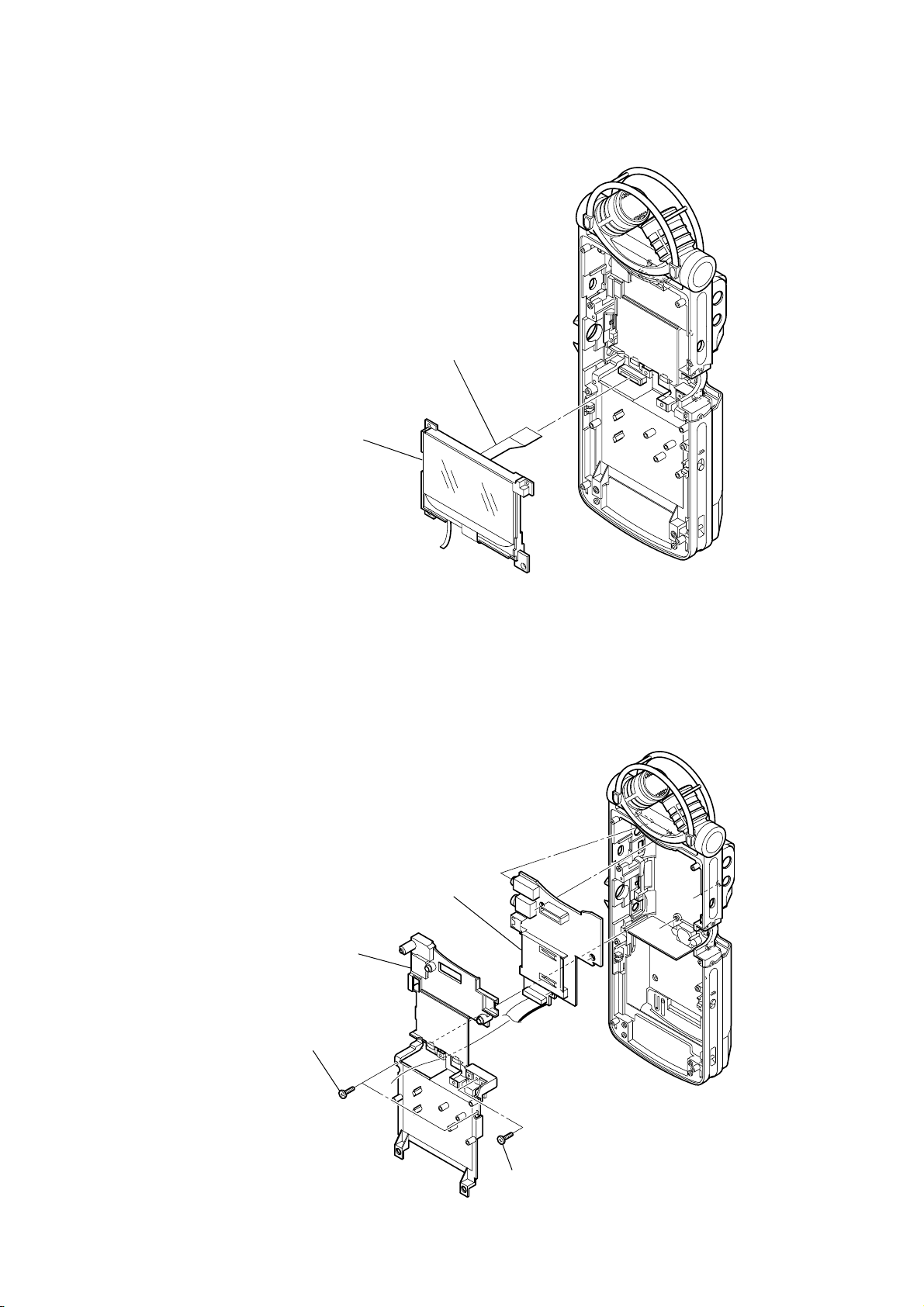

2-7. LCD BLOCK ASSY

2

LCD block assy

1

LCD unit (20 core)

(CN4151)

PCM-D1

2-8. MAIN BOARD

3

chassis

1

two

screws

(P2 (M1.7))

4

MAIN board

2

screw

(P2 (M1.7))

13

PCM-D1

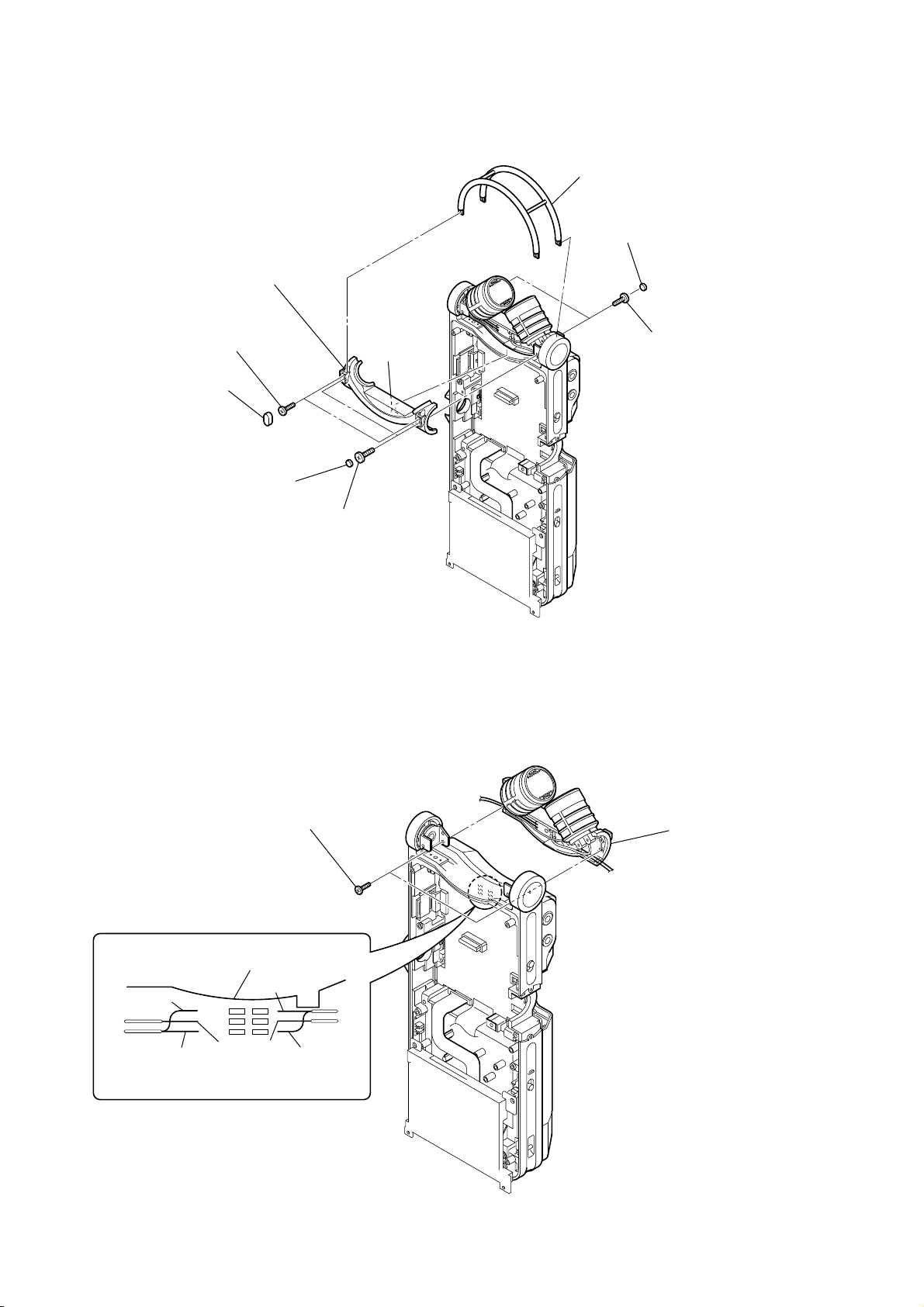

s

2-9. CASE (MIC-F)

1

two

(MIC-F)

8

2

two

(M1.4)

cushions

6

(MIC-F)

case (MIC-F)

screws

two

spacers

claw

7

two

screws

(M1.7)

5

guard (MIC)

3

(MIC-R)

two

cushions

4

(M1.4)

two

screw

2-10. MIC BLOCK ASSY

2

two

screws

(0 plate +P2 main EG grip M1.7)

1

Remove the six solders.

blue

orange

MAIN board

silver

blue

silver

orange

3

MIC block assy

14

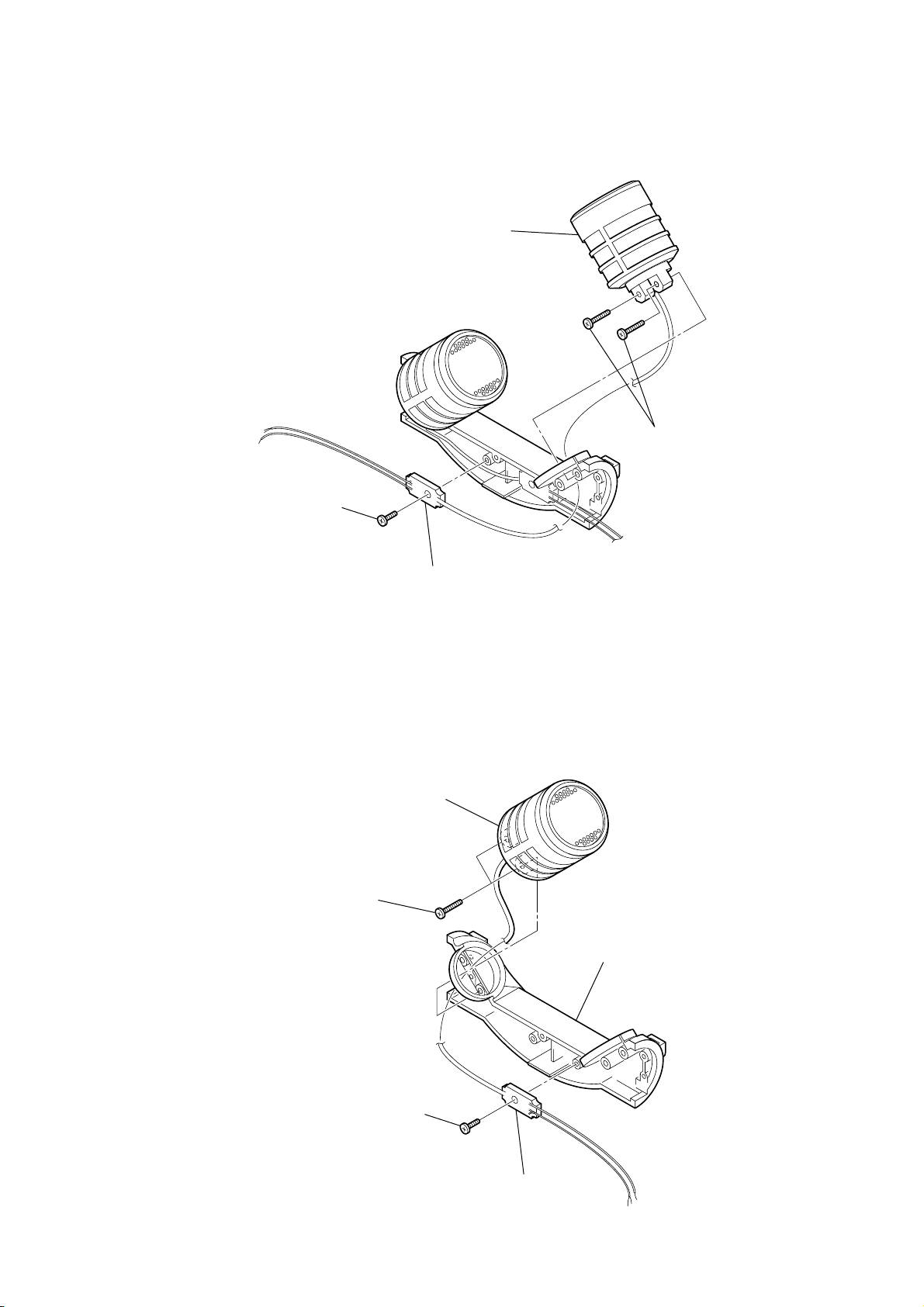

2-11. MICROPHONE UNIT (R)

1

screw

(M1.4)

2

AMP board

5

case (MIC-R)

3

two

screws

(M1.4)

4

microphone unit (R)

4

microphone unit (R)

3

two

screws

(M1.4)

PCM-D1

2-12. MICROPHONE UNIT (L)

1

screw

(M1.4)

2

AMP board

15

PCM-D1

SECTION 3

TEST MODE

This set provides the Test Mode that can be used for the following

check modes.

Setting the Test Mode

With the power on, press the following buttons:

> > . . [LIGHT] x [LIGHT] x [MENU] x

Canceling the Test Mode

Turn the [POWER] switch “OFF”, or remove the battery.

Test Mode Menu

When the Test Mode is entered, the following menu appears on the

LCD:

Version

F/W Update

Keychk+Fmat

Lcd Contrast

Lcd Check

Language

Loop Back

Select an item using the > and . keys, and determine its

selection using the u key.

:

Key Check

Version

F/W Update

.

Determine

using u key

>

KeyChk+Fmat

Lcd Contrast

Lcd Check

Language

Loop Back

RTC Int

System

Battery

DC-IN

VBUS

Sleep

Log Output

Log Clear

Initialize

Nand init

Nand Format

Dsp, Adjust

Reboot

:

:

1. Key Check

A specific key is inputted by pressing it for input check and INT

check.

(It is verified that input of a key is confirmed and that KEY_XWAKE

interrupt occurs)

Key to be inputted:

[REC]/ N / X / x / > / . /[MENU] / [LIGHT]/ [DIVIDE ] /

[DISPLAY]/ [HOLD] ON/OFF

Total of 11 locations

When a key is inputted and its input is confirmed, the backlight

turns on for 0.5 sec.

LCD display

<KEY CHECK>

KEY:- -

REMAIN:11

Once all key checks are completed,

OK appears on the LCD and

the LCD (ACCESS) is turned on.

<KEY CHECK>

KEY:- -

OK

Displays an input

confirmed key.

All eleven (11) keys

are counted.

2. Key Chk + Fmat Test

•When all inputs have been confirmed in Item 1, Key Check, the

system performs NAND formatting (deletion of all conditions)

and takes defaults for settings in the menu (language setting and

LCD contrast are held).

<KeyChk+Fmat>

Exec Comp

NAND formatting

(deletion of all conditions)

and default menu settings

are completed.

16

3. DSP Adjust

•This mode executes DSP LOOP BACK.

4. Lcd Contrast

• This mode adjusts the LCD contrast.

The initial value is 40.

• Adjust the contrast using the > and . keys.

PCM-D1

5. Lcd Check

•This mode verifies that all LCD indicators are on and off, and it

checks the PATTERN, vertical scroll and horizontal scroll displays.

[PLAY]: All On > : Vertical scroll

[REC]: All Off

[DIVIDE]: PATTERN

. : Horizontal scroll

x : Exit

6. Language

• Not used.

7. Loop Back

•This mode executes DSP LOOP BACK.

• MENU is turned on and off.

[PLAY]: Execute (only at a stop).

[DIVIDE]: MUTE ON/OFF.

[MENU]: Exit from Submenu.

(After an execution is stopped during execution.)

x : During execution: Termination of execution.

At a stop: Exit from submenu.

8. RTC Int

•This mode checks for RTC operation.

9. System

•This mode checks the NOR, NAND, UNIQUE and MS.

10. Battery

•This mode checks the current value of A/D.

11. DC-IN

•This mode checks the current value of DC-IN A/D.

• NG is displayed for non-connection.

12. Initialize

•This mode initializes the set values (to the values established at

the factory).

13. Nand init

• Band Block and NAND formatting of the NAND FLASH.

14. Nand Format

•NAND formatting.

15. F/W update

• Update of the F/W.

15-1. F/W UpGrade method

If the F/W need be updated for reasons such as modification of

bugs after mass production, the F/W should be updated as follows:

1. Copy the following files just under the drive of the memory stick

Duo.

(The files below will be distributed when bugs are modified.)

• ldrasm.mot (upgrade driver)

• CHIPEXEC.MOT (F/W for the set)

• update.pls (upgrade MS identification file)

2. Insert the MS described in step 1 into the set and turn on power.

(Use a new battery or the AC adapter.)

3. When the ACCESS screen remains as it is and the OPE-LED

(red) lights up, the update is completed.

Remove the battery and remove the MS Duo. The F/W update is

complete.

Enter the Test Mode and check the version.

4. Once the F/W is updated, the update.pls file is automatically

deleted.

If you are repeating to upgrade the F/W, the update.pls file should

be copied again.

Supplement:

If you are upgrading a large number of sets for mass production,

the testmode.ind file should be added which enables repeated

upgrade.

• ldrasm.mot (upgrade driver)

• CHIPEXEC.MOT (F/W for the set)

• update.pls (upgrade MS identification file)

• testmode.ind (special file for the factory)

Caution:

If the power is down during upgrade or the memory stick is removed,

this upgrade fails.

(This will cause malfunctions, failure of power-on, and errors during

operation.)

If these conditions are caused, the set must be disassembled and

upgraded. Contact the design department.

The following files can be created by creating an arbitrary text file

and changing its name.

• update.pls (upgrade MS identification file)

• testmode.ind (special file for the factory)

17

PCM-D1

SECTION 4

ELECTRICAL ADJUSTMENT

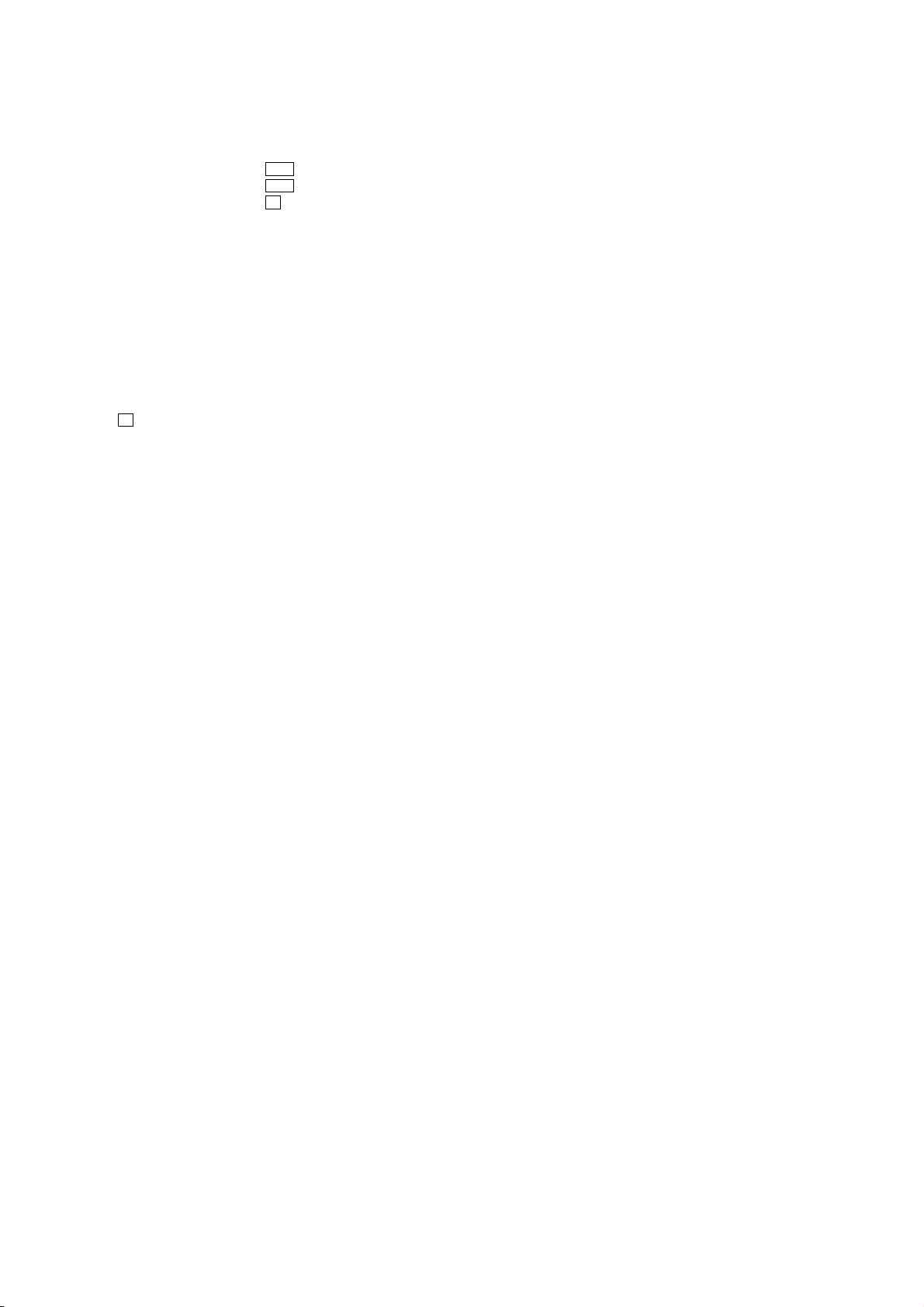

Level Meter Adjustment

1. Reproduce the WAVE file (DIGITAL DATA) (1kHz, –12dBs)

standard signal.

2. Adjust RV2102 so that the pointer of the L-CH level meter

indicates the center of “12”.

3. Adjust RV2202 so that the pointer of the R-CH level meter

indicates the center of “12”.

Adjusting Location:

– AUDIO D/A BOARD (Component Side) –

CN2511

RV2102

(L-CH)

CN2521

RV2202

(R-CH)

18

SECTION 5

DIAGRAMS

PCM-D1

Note on Schematic Diagrams:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal tolerance.

• C : panel designation.

• A : B+ Line.

•Power voltage is dc 6.0V and fed with regulated dc power

supply from battery terminal.

•Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : PB

[]: REC

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

c : REC (DIGITAL)

L : REC (ANALOG)

J : PB (DIGITAL)

F : PB (ANALOG)

*

• The voltage and waveform of CSP (chip size package)

cannot be measured, because its lead layout is different

from that of conventional IC.

: Impossible to measure

∗

Replacement of IC6001, 8101 and 8201 used in this

set requires a special tool.

4

W or less unless otherwise

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

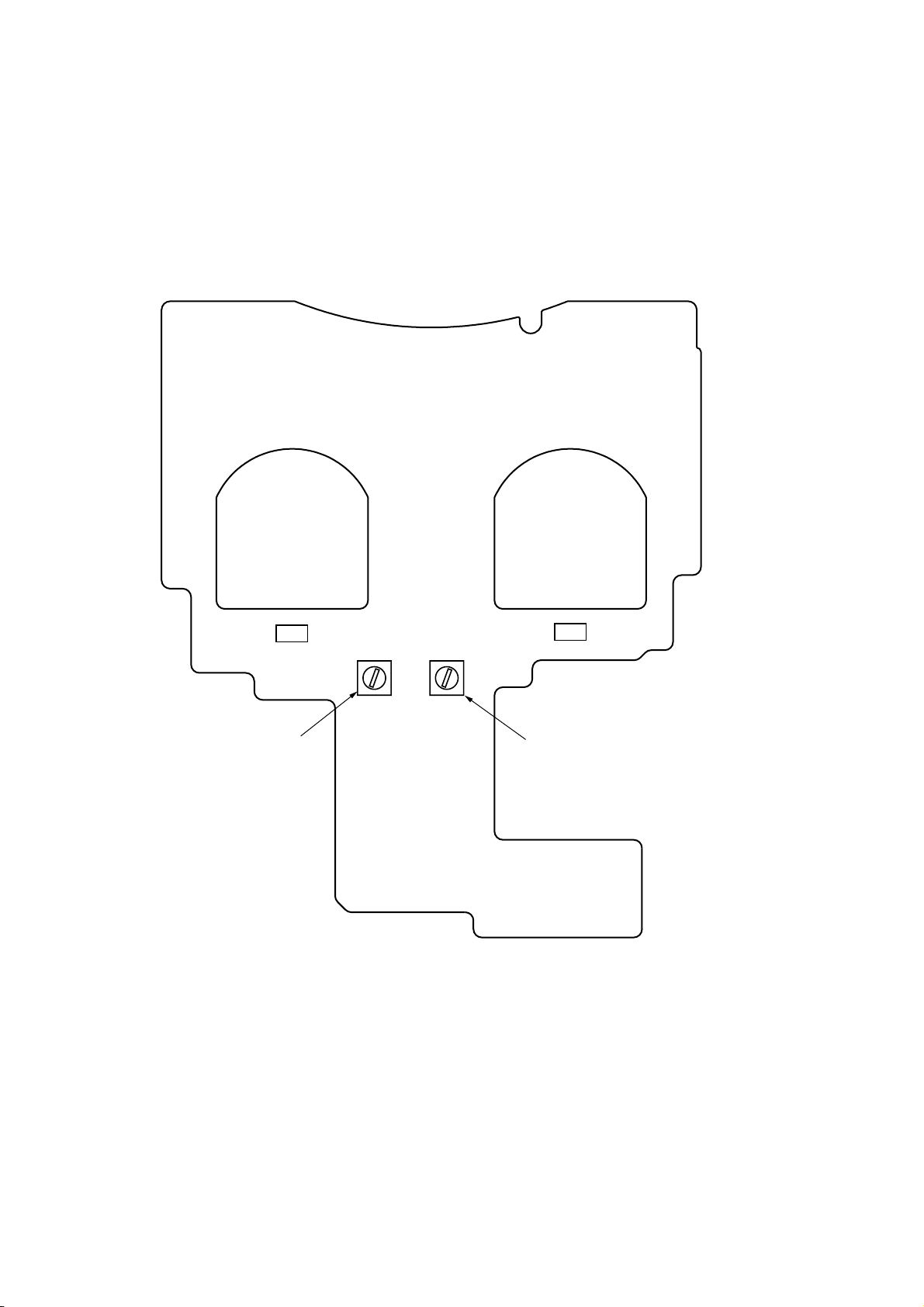

Replacement of IC6001, 8101 and 8201 used in this set

*

requires a special tool.

• Lead layouts

Lead layout of

conventional IC

CSP (chip size package)

surface

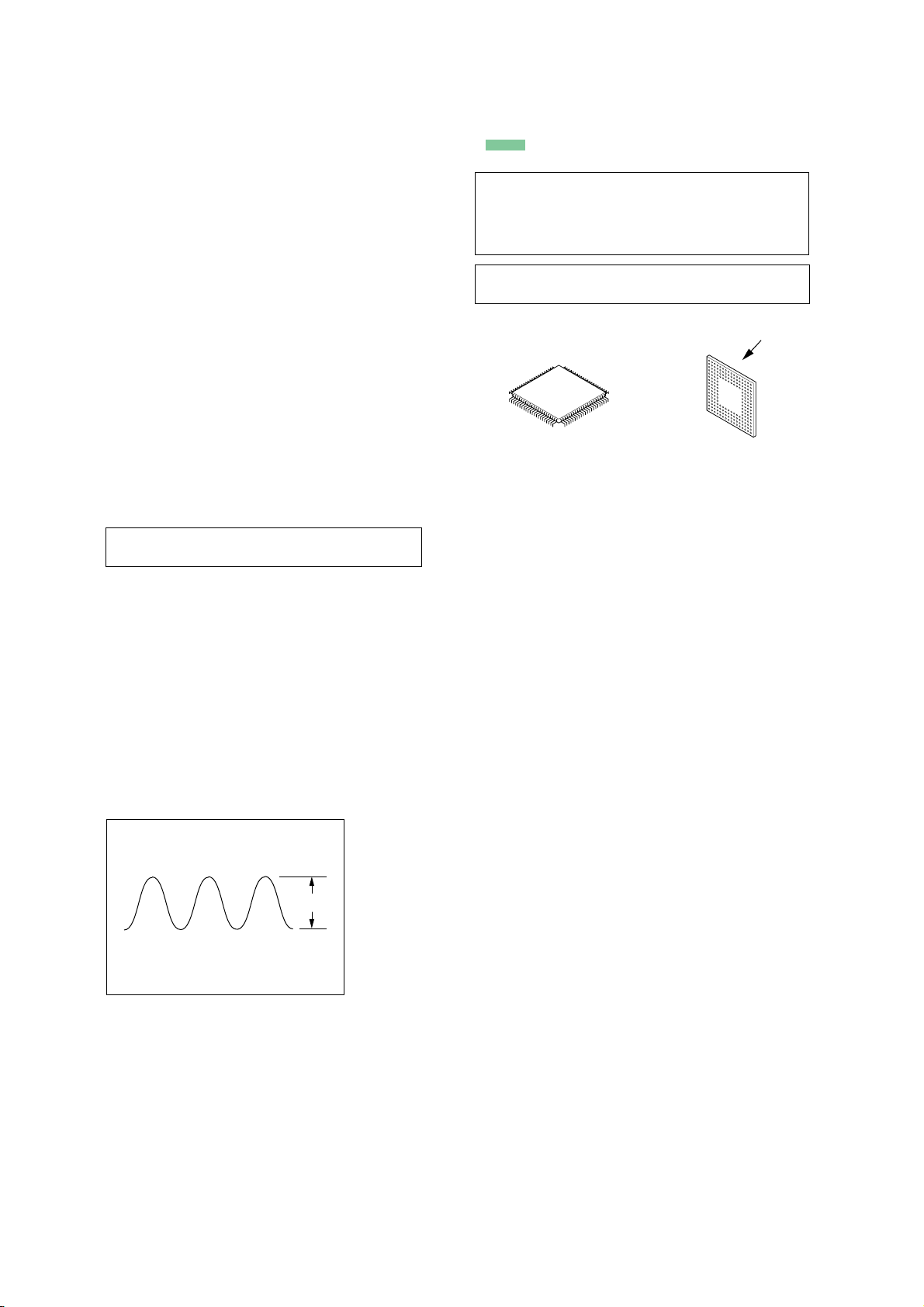

• Waveform

— MAIN Board —

IC7001 ws (X0)

1

11.095MHz

1V/DIV, 50nsec/DIV

3Vp-p

19

PCM-D1

d

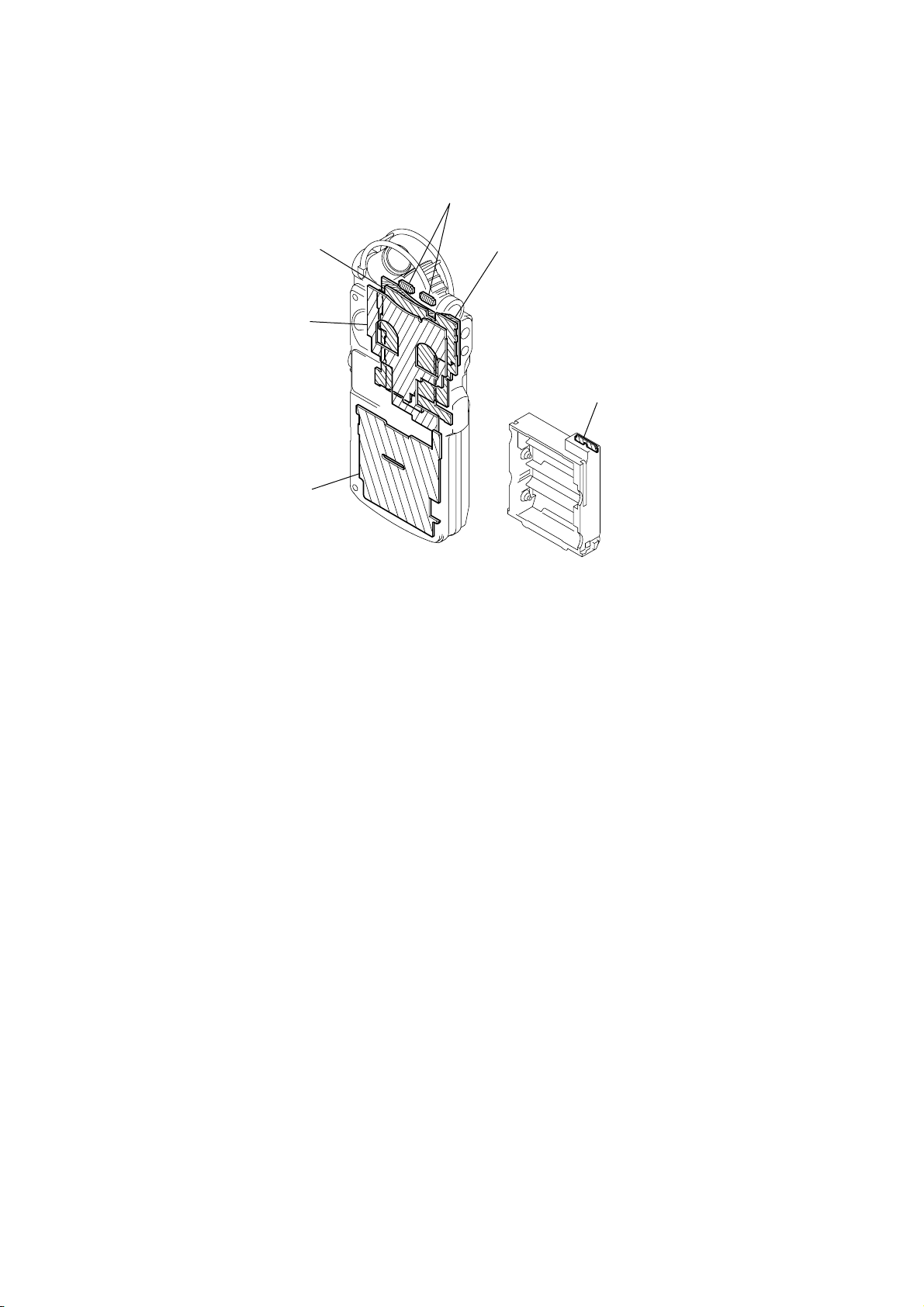

• CIRCUIT BOARDS LOCATION

AMP board

AUDIO A/D board

AUDIO D/A board

POWER board

MAIN board

BATTERY boar

20

Loading...

Loading...