Sony MHC-GTR66H, MHC-GTR88 Schematic

MHC-GTR66H/GTR88

RM-AMU053

MANUAL DE SERVIÇO

Brazilian Model

Ver. 1.2 05.2011

MHC-GTR66H MHC-GTR88

NOME DO MODELO DO COMPONENTE

MHC-GTR66H MHC-GTR88

COMPACT DISC RECEIVER HCD-GTR66 HCD-GTR88

CAIXA ACÚSTICA FRONTAL SS-GTR66 SS-GTR88

CAIXA ACÚSTICA SATÉLITE

SUBWOOFER SS-WGR88

• HCR-GTR88 é composto de HCD-GTR88 e SS-GTR88.

• SS-WGR88P é composto de SS-RSR88 e SS-WGR88.

ESPECIFICAÇÕES

Geral

Requisitos de alimentação

127 V ou 220 V CA, 60 Hz, ajustável com o seletor de tensão

Consumo de energia: MHC-GTR88: 460 W, MHC-GTR66H: 300 W

Dimensões (LxAxP) (excluindo caixas acústicas) (Aprox.)

HCD-GTR88/HCD-GTR66: 231 mm x 361 mm x 518 mm

Peso (excluindo caixas acústicas) (Aprox.) HCD-GTR88: 15,7 kg

HCD-GTR66: 13,0 kg

Acessórios fornecidos:

Controle Remoto (1), Pilhas (tipo AA) (2)

Antena loop de AM (1), Antena monofilar de FM (1)

Pés de proteção para as caixas acú

(Somente MHC-GTR88) (12)

(Somente MHC-GTR66H) (8)

Cabos de caixas acústicas (Somente MHC-GTR66H) (2)

Espacador A (somente MHC-GTR88) (2)

Espacador B (somente MHC-GTR88) (2)

sticas

SS-RSR88

ACESSÓRIOS

Ref. No. Part No. Description Remark

Y-8286-834-B CONTROLE REMOTO (RM-AMU053)

1-501-374-12 ANTENA, LOOP (AM )

1-793-184-51 CONECTOR (TIP F) (FM)

4-165-222-01 ESPAÇADOR A

4-165-315-01 ESPAÇADOR B

4-165-684-61 MANUAL DE INSTRUÇÕES

1-528-681-13 PILHA PEQUENA

2-655-032-01 PÉ DE APOIO (8) (GTR66)

4-170-443-01 PÉ (8)

4-191-705-01 PÉ (4)

HCR-GTR88

SS-WGR88P

Projeto e especificações técnicas sujeitos a

alteração sem prévio aviso.

Sony Corporation

Sony Brasil Ltda.

2010.04

©

Publicado por Product & Quality Div.

SISTEMA COMPACTO DE SOM

HCD-GTR66/GTR88

MANUAL DE SERVIÇO

Ver. 1.2 05.2011

- HCD-GTR88 é a seção de Amplificador, USB,

CD player e Sintonizador do MHC-GTR66H

- HCD-GTR88 é a seção de Amplificador, USB,

CD player e Sintonizador do MHC-GTR88

Seção de CD

Foto: HCD-GTR88

Modelo que utiliza mecanismo similar HCD-GTR33

Tipo do mecanismo de CD CDM88BL-DVBU101

Nome da Unidade Ótica KHM-313CAB/C2NP

Brazilian Model

2010.04

©

COMPACT DISC RECEIVER

Sony Corporation

Sony Brasil Ltda.

Publicado por Product & Quality Div.

Especificações

técnicas

Seção do amplificador

MHC-GTR88

Os valores a seguir foram mensurados a

127 V ou 220 V CA, 60 Hz

Potência total RMS: 1100 W

Caixa Acústica Frontal

Potência de saída RMS:

550 W (275 W por canal x2, a 8 Ω,

1kHz, 10% THD*)

Caixa Acústica Satélite

Potência de saída RMS:

220 W (110 W por canal x2, a 24 Ω,

1kHz, 10% THD*)

Subwoofer

Potência de saída RMS:

330 W (165 W por canal x2, a 6 Ω,

100 Hz, 10% THD*)

MHC-GTR66H

Os valores a seguir foram mensurados a

127 V ou 220 V CA, 60 Hz

Potência total RMS: 700 W

Potência de saída RMS:

700 W (350 W por canal x2, a 4 Ω,

1kHz, 10% THD*)

* Distorção Harmônica Total

3

Entradas

PC (AUDIO IN) R/L

Tensão de 700 mV, impedância de

47 kΩ

MIC

Sensibilidade de 1 mV, impedância de

10 kΩ

Porta (USB): Tipo A

Saídas

PHONES

Aceita fones de ouvido de 8 Ω ou mais

Seção USB

Taxa de bits suportada

MP3 (MPEG 1 Audio Layer-3):

32 kbps – 320 kbps, VBR

WMA: 48 kbps – 192 kbps

AAC: 48 kbps – 320 kbps

Frequências de amostragem

MP3 (MPEG 1 Audio Layer-3):

32 kHz/44,1 kHz/48 kHz

WMA: 44,1 kHz

AAC: 44,1 kHz

Velocidade de transferência

Velocidade total

Dispositivo USB compatível

Classe de Armazenamento em Massa

Corrente máxima

500 mA

Seção do reprodutor de discos

Sistema

Sistema de áudio digital e disco

compacto

Propriedades dos diodos laser

Duração da emissão: Contínua

Saída do laser*: Menor que 44,6 μW

* Valor de saída medido a uma

distância de 200 mm, a partir da

superfície da lente da unidade óptica

com 7 mm de abertura.

Resposta de frequência

20 Hz – 20 kHz

Relação sinal/ruído

Mais de 90 dB

Faixa dinâmica

Mais de 88 dB

Seção do sintonizador (rádio)

FM estéreo, sintonizador super-heteródino

de FM/AM

Seção do sintonizador de FM

Faixa de sintonização

87,5 MHz – 108,0 MHz (intervalo de

100 kHz)

Antena

Antena monofilar de FM

Terminais de antena

75 Ω, não balanceados

Frequência intermediária

10,7 MHz

Seção do sintonizador de AM

Faixa de sintonização

530 kHz – 1.710 kHz (com intervalo de

frequência de 10 kHz)

531 kHz – 1.710 kHz (com intervalo de

frequência de 9 kHz)

Antena

Antena loop de AM, terminal de antena

externa

Frequência intermediária

450 kHz

Geral

Requisitos de alimentação

127 V ou 220 V CA, 60 Hz, ajustá

com o seletor de tensão

Consumo de energia

MHC-GTR88: 460 W

MHC-GTR66H: 300 W

Dimensões (LxAxP) (excluindo caixas

acústicas) (Aprox.)

HCD-GTR88/HCD-GTR66:

231 mm x 361 mm x 518 mm

Peso (excluindo caixas acústicas) (Aprox.)

HCD-GTR88: 15,7 kg

HCD-GTR66: 13,0 kg

Acessórios fornecidos:

Controle Remoto (1)

Pilhas (tipo AA) (2)

Antena loop de AM (1)

Antena monofilar de FM (1)

Pes de proteção para as caixas acústicas

(Somente MHC-GTR88) (12)

(Somente MHC-GTR66H) (8)

Cabos de caixas acústicas

(Somente MHC-GTR66H) (2)

Espaçador A (somente MHC-GTR88) (2)

vel

Projeto e especificações técnicas sujeitos a

alteração sem prévio aviso.

4

HCD-GTR66/GTR88

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of soldering iron around 270 °C during repairing.

• Do not touch the soldering iron on the same conductor of the circuit

board (within 3 times).

• Be careful not to apply force on the conductor when soldering or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws, and

all other exposed metal parts for AC leakage.

Check leakage as described below.

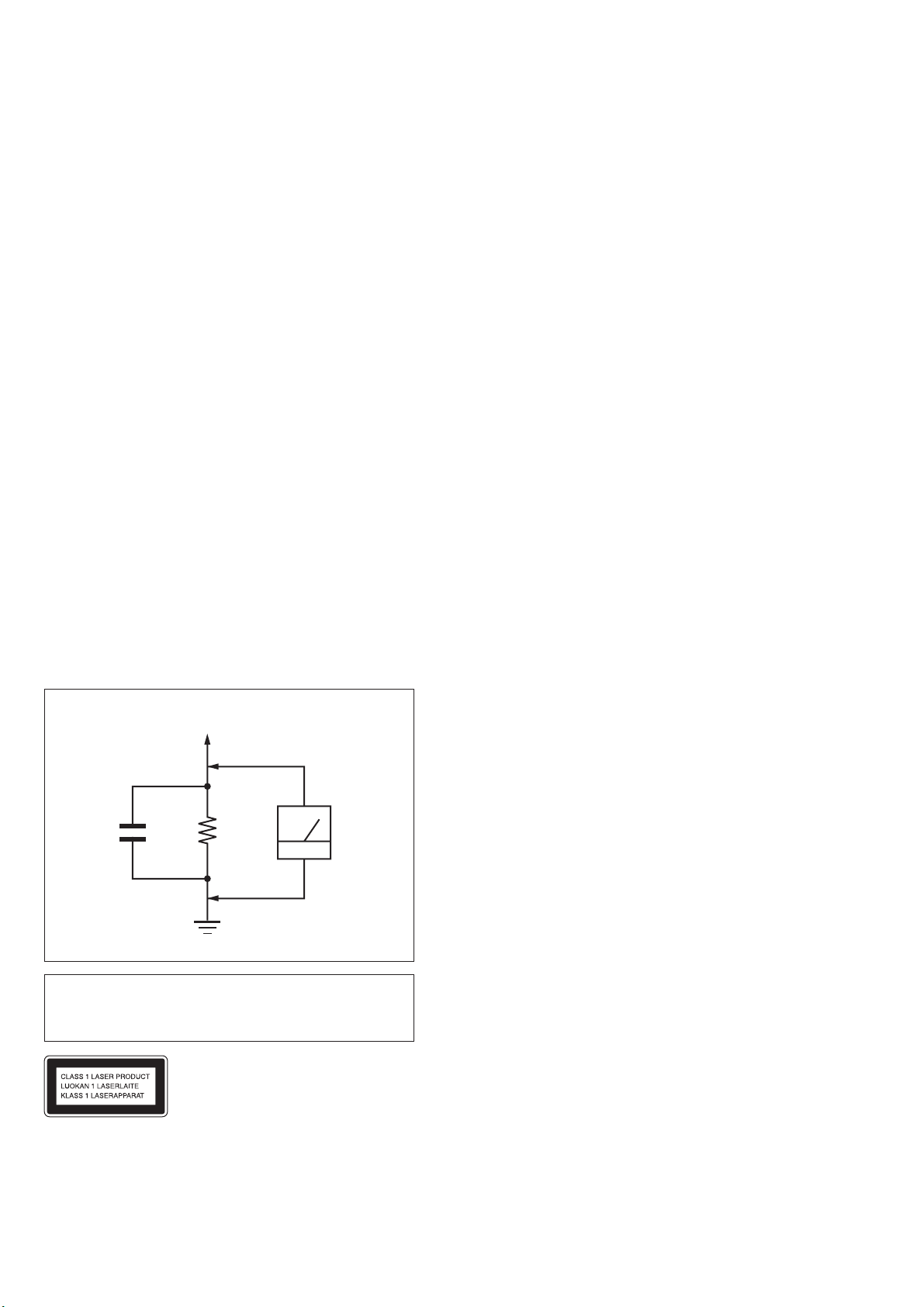

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and from all

exposed metal parts to any exposed metal part having a return to chassis,

must not exceed 0.5 mA (500 microamperes.). Leakage current can be

measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA WT-

540A. Follow the manufacturers’ instructions to use these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM or

battery-operated AC voltmeter. The “limit” indication is 0.75 V, so

analog meters must have an accurate low-voltage scale. The Simpson

250 and Sanwa SH-63Trd are examples of a passive VOM that is

suitable. Nearly all battery operated digital multimeters that have a 2

V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

AC

1.5 k0.15 F

voltmeter

(0.75 V)

ÍNDICE

1. NOTAS DE SERVIÇO

............................................ 6

2. DESMONTAGEM

2-1. Fluxo de Desmontagem ........

2-2. Tampa (Lateral-L/R) ........

2-3. Tampa Superior............................................................... 9

2-4. Painel Frontal, Placa HUBd, Placa DMB19 ...

2-5. Ventilador DC (M101) .............

2-6. Painel Traseiro, Placa SUBTRANS .....

2-7. Placa MAIN .................................................................. 12

2-8. Seção Ventilador DC (M101), Placa PT SHIELD,

Placa POWER AMP .................................................... 12

2-9. Placa POWER AMP, Placa SUBWOOFER .................. 13

2-10. Seção Chassis ....

......................................

2-11. Bloco de Mecanismo do CD

2-12. Bloco de Unidade Ótica (KHM-313CAB) ..................... 14

2-13. Correia (DLM3A) .........

.................

....

.............................

....................

.................

....................... 13

(CDM88BL-DVBU101

...........................

..................... 8

................. 9

...........

... 10

................. 11

........ 11

) ....... 14

...................... 15

3. MODO DE TESTE ................................................... 16

4. AJUSTES ELÉTRICOS ..

...................................

.... 18

5. DIAGRAMAS

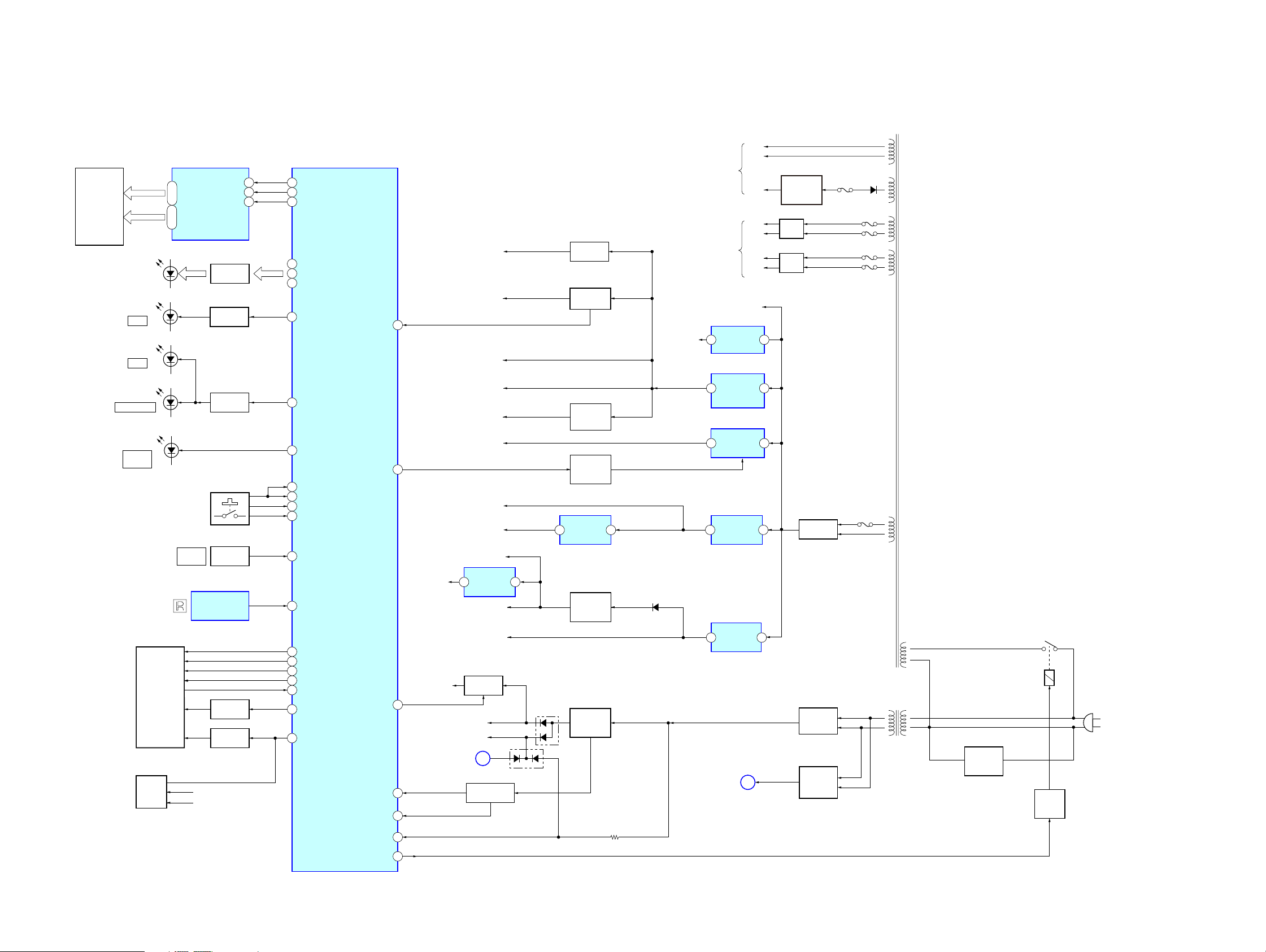

5-1. Diagrama em Bloco - Seção RF SERVO, USBn - ..

5-2. Diagrama em Bloco - Seção MAIN - ...

5-3. Diagrama em Bloco - Seção AMP - ....

....................

....................

5-4. Diagrama em Bloco - Seção DISPLAY,

POWER SUPPLY - .....

.....................................

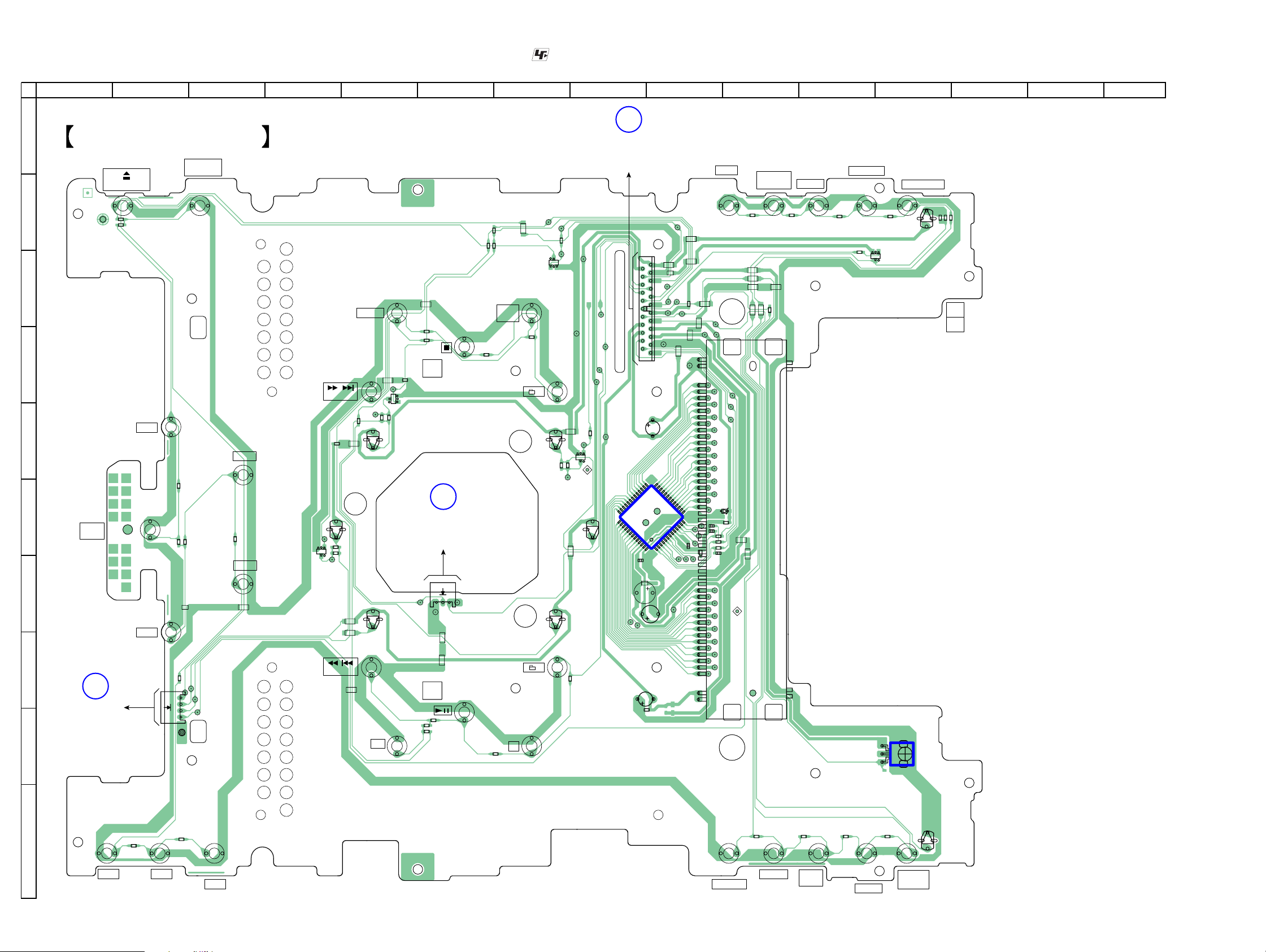

5-5. Placa de Circuito Impresso - Placa DISPLAY - ............. 24

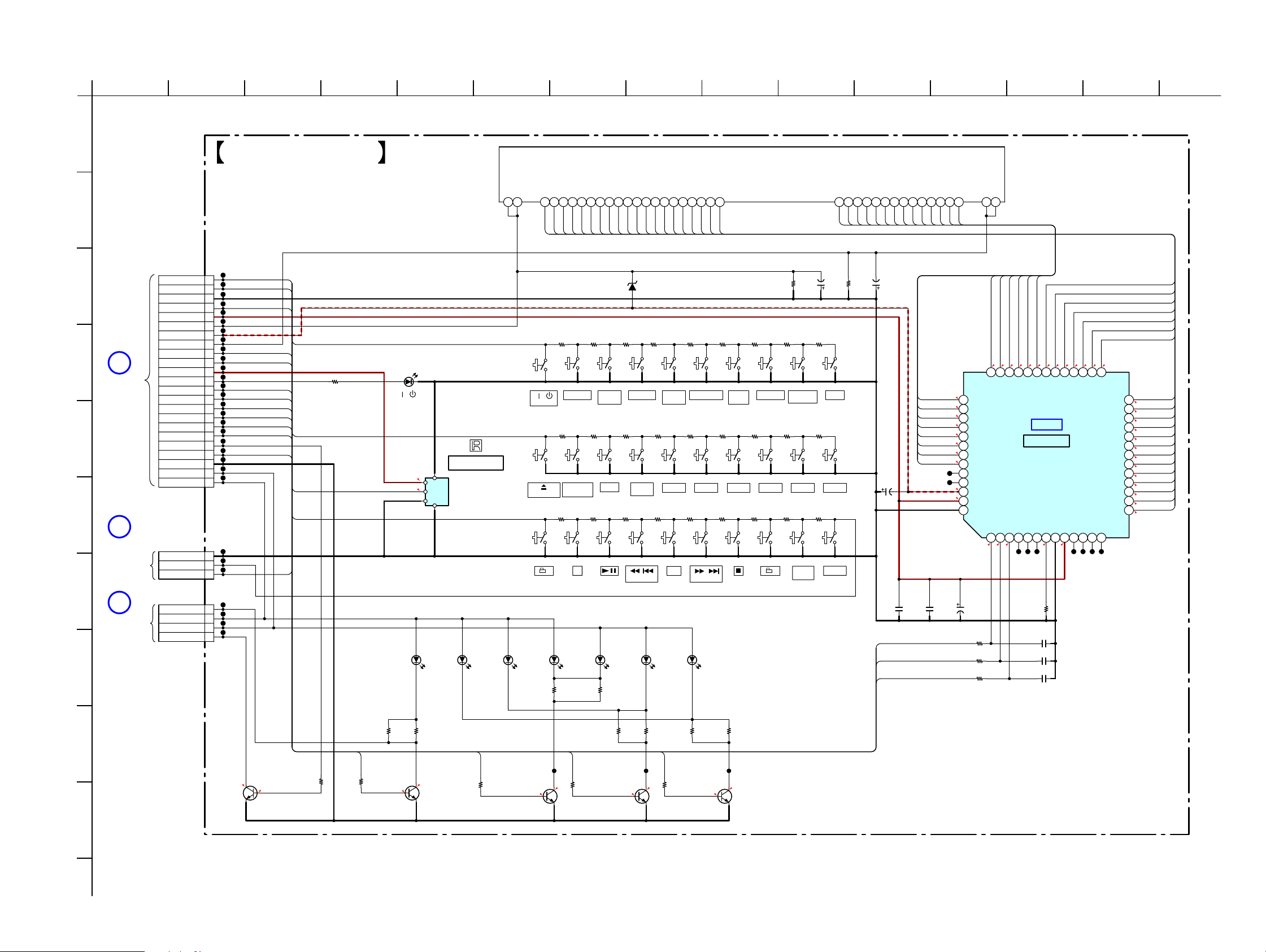

5-6. Diagrama Esquematico - Placa DISPLAY - ................... 25

5-7. Placa de Circuito Impresso - Placa DMB19 - ................ 26

5-8. Diagrama Esquematico - Placa DMB19 (1/3) - ............. 27

5-9. Diagrama Esquematico - Placa DMB19 (2/3) - ............. 28

5-10. Diagrama Esquematico - Placa DMB19 (3/3) - ............. 29

5-11. Placa de Circuito Impresso - Placa POWER AMP - ...... 30

5-12. Diagrama Esquematico - Placa POWER AMP - ............ 31

5-13. Placa de Circuito Impresso - Placa MAIN - ................... 32

5-14. Diagrama Esquematico - Placa MAIN (1/3) - ................ 33

5-15. Diagrama Esquematico - Placa MAIN (2/3) - ................ 34

5-16. Diagrama Esquematico - Placa MAIN (3/3) - ................ 35

5-17. Placa de Circuito Impresso -

Placas MIC, VOL e USB 5-18. Diagrama Esquematico - Placas MIC, VOL e USB 5-19. Placa de Circuito Impresso

- Placas TRANS e SUBTRANS - ....

.......................

5-20. Diagrama Esquematico

- Placas TRANS e SUBTRANS - ................................... 39

5-21. Placa de Circuito Impresso - Placa SUBWOOFER -

5-22. Diagrama Esquematico - Placa SUBWOOFER - ........... 41

5-23. Placa de Circuito Impresso - Placa HUB - ....

5-24. Diagrama Esquematico - Placa HUB - ........................... 43

.......

. 19

...... 20

........ 21

............... 22

.... 36

......

....... 38

.....

.............

.... 42

37

40

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

CAUTION

Use of controls or adjustments or performance of procedures

other than those speci¿ ed herein may result in hazardous radia-

tion exposure.

This appliance is classified as a CLASS 1

LASER product. This marking is located on

the rear exterior.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

5

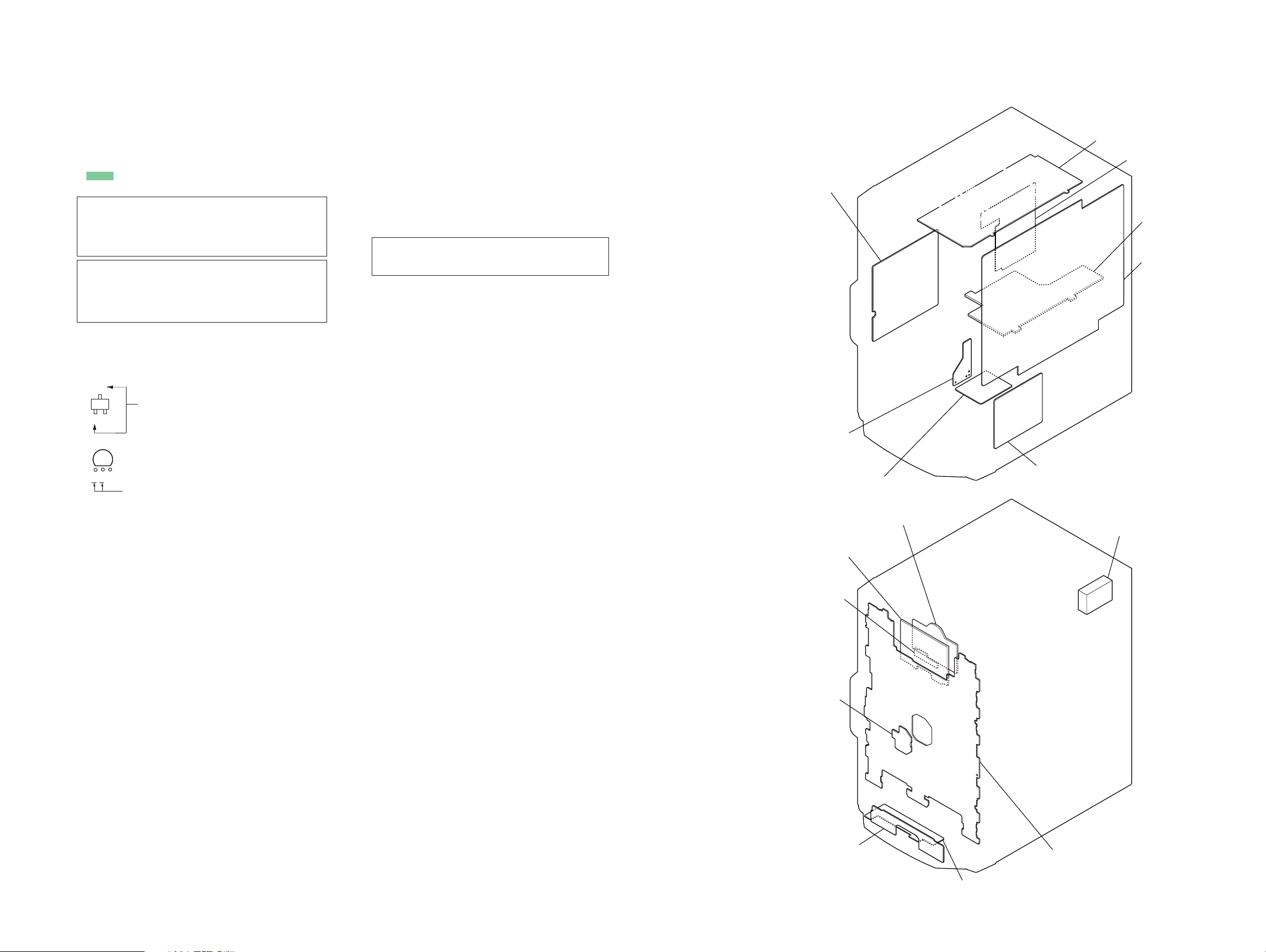

6. VISTA EXPLODIDAS

6-1. Seção Tampa ................................................................... 54

6-2. Seção Painel de Carregamento, Seção Placa HUB,

Seção Placa DMB19 ............

................................

........... 55

6-3. Seção Placa DISPLAY ................................................... 56

6-4. Seção Painel Frontal ....................................................... 57

6-5. Seçào Painel Traseiro ..................................................... 58

6-6. Seção Placa MAIN .....................

..............................

...... 59

6-7. Seção Chassis ................................................................. 60

6-8. Seção Mecanismo do CD (CDM88BL-DVBU101) ....... 61

7. LISTA DE PEÇAS ELÉTRICAS ......................... 62

SEÇÃO 1

NOTAS DE SERVIÇOS

NOTAS SOBRE O MANUSEIO DA BLOCO DE

UNIDADE Ó

O diodo laser da unidade optica e sensÍvel a descargas eletroestáticas

podendo vir a ser danificado por descargas causadas por roupas

ou mesmo pelo corpo humano. Durante o reparo tenha cuidado para não causar danos a unidade, devido a cargas eletroestáticas e siga

corretamente os procedimentos descritos nesse manual para a execução de reparos e troca de componentes.

As placas de circuito impresso podem ser facilmente danificadas.

Tenha cuidado ao manusea-las.

NOTAS SOBRE A EMISSÃO DO DIODO LASER

O feixe laser nesse modelo é concentrado e deve ser focado na superficie reflexiva do disco, pela lente objetiva da unidade optica. Quando

estiver observando a emissão do diodo laser, tome o cuidado de estar

no minimo a 30 cm da lente objetiva.

SOLDA SEM CHUMBO

Placas que exigem o uso de solda sem chumbo sã

a marca LF (lead free) indicando que a solda não contem chumbo.

(Atenção

TICA OU BASE DA UNIDADE

o impressas com

: Algumas placas de circuito impresso podem não ter essa

marca devido ao seu tamanho reduzido.)

HCD-GTR66/GTR88

: IDENTIFICAÇÃO DA SOLDA SEM CHUMBO

A solda livre de chumbo tem as seguintes caracteristicas:

• Derrete a uma temperatura 40 °C maior que a solda comum.

Ferros de solda comuns podem ser usados mas a ponta tem que

ser aplicada sobre a solda por um tempo maior.

Ferros de solda com ajuste de temperatura devem ser ajustados

no valor de 350 °C.

Atenção: A impressao da placa (trilhas de cobre) pode se soltar

se a ponta permanecer por muito tempo. Tenha cuidado!

mais viscosa

• É

A solda livre de chumbo é

lidade) que a solda comum, portanto tenha cuidado com as pontes de solda, especialmente entre os pinos de IC's.

• Pode ser utilizada com solda comum

E melhor usar apenas solda sem chumbo, mas este tipo també

pode ser adicionado a solda comum.

NATA SOBRE REPARO DO IC102 DA PLACA DMB19

IC102 da placa DMB19 não pode ser substituído individualmente.

Quando esta peça é com defeito, substitua a placa montada.

DESTRAVANDO A BANDEJA DO DISCO

Esta função serve para evitar o furto de discos de aparelhos em

demosntração em lojas.

mais viscosa (flui com menor faci-

m

Procedimento para Destravar:

1. Pressione a tecla [I/

2. Pressione a tecla [CD] para selecionar função CD.

3. Enquanto pressiona tecla [

(por mais de 5 segundos).

4. A menssagem “UNLOCKED” aparecera e a bandeja estará

liberada

Nota: Quando “LOCKED” é exibido, a bandeja não será liberada ao

desligar o aparelho através do botão [I/

1 STANDBY] para ligar o aparelho.

] , pressione [Z OPEN/CLOSE]

x

STANDBY].

1

6

HCD-GTR66/GTR88

a

COMO ABRIR A BANDEJA QUANDO APARELHO NÃO LIGA

Passo: 1) Execute após retirar as tampas laterais (lado-R e lado-L) consulte item “2.2. TAMPA (LATERAIS-L/R)” da desmontagem

2) Execute após retirar tampa superior consultando “2-3. TAMPA SUPERIOR” da desmontagem.

condição de abertura da bandeja do CD

Gire a engrenagem com

d

a chave de fenda fina até

que a alavanca sobe para

posiçào da figura.

Tente empurrar a engre-

(

alavanca

nagem ao mesmo tempo

puxe Painel frontal)

engrenagem

e

b

c

c

7

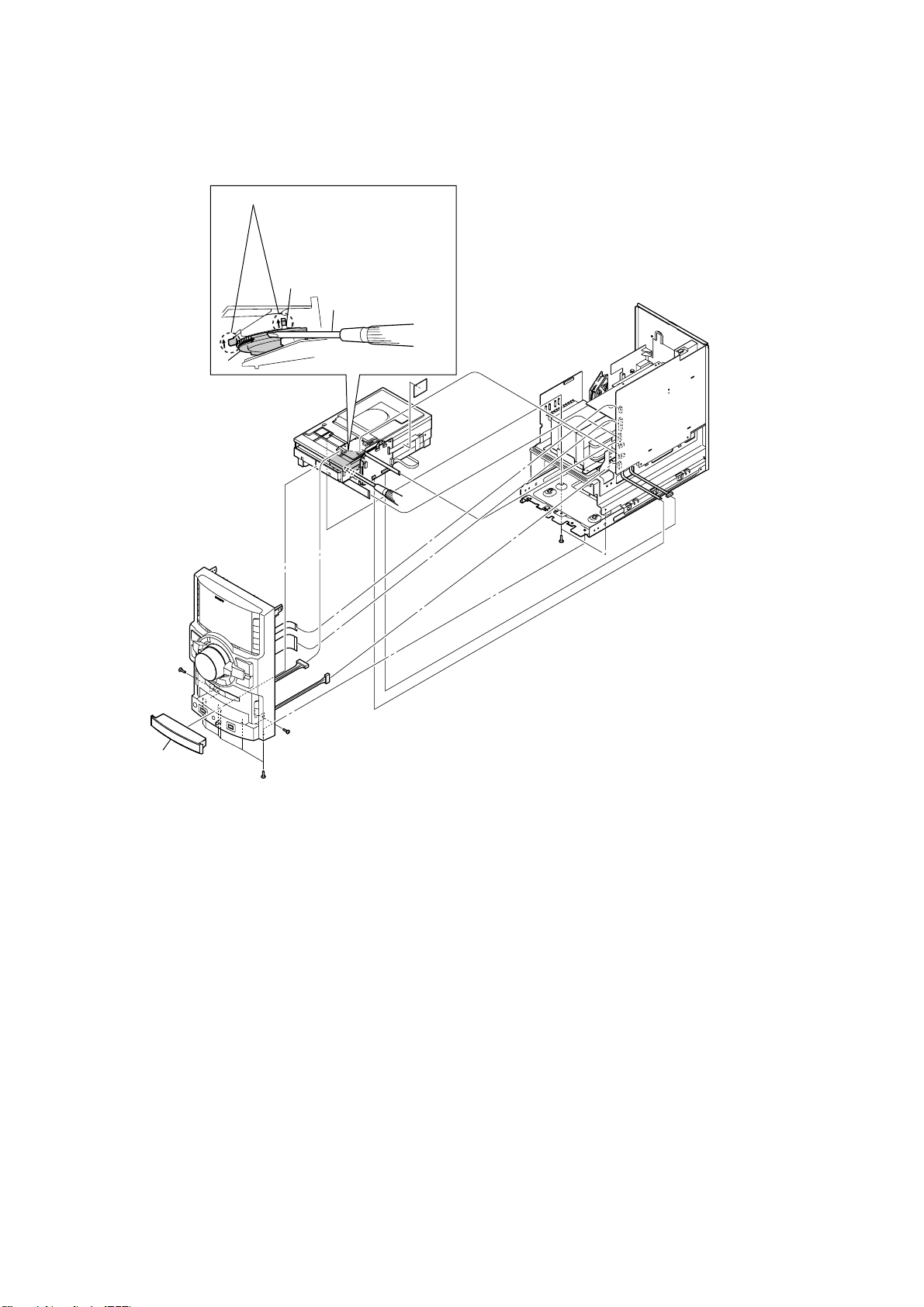

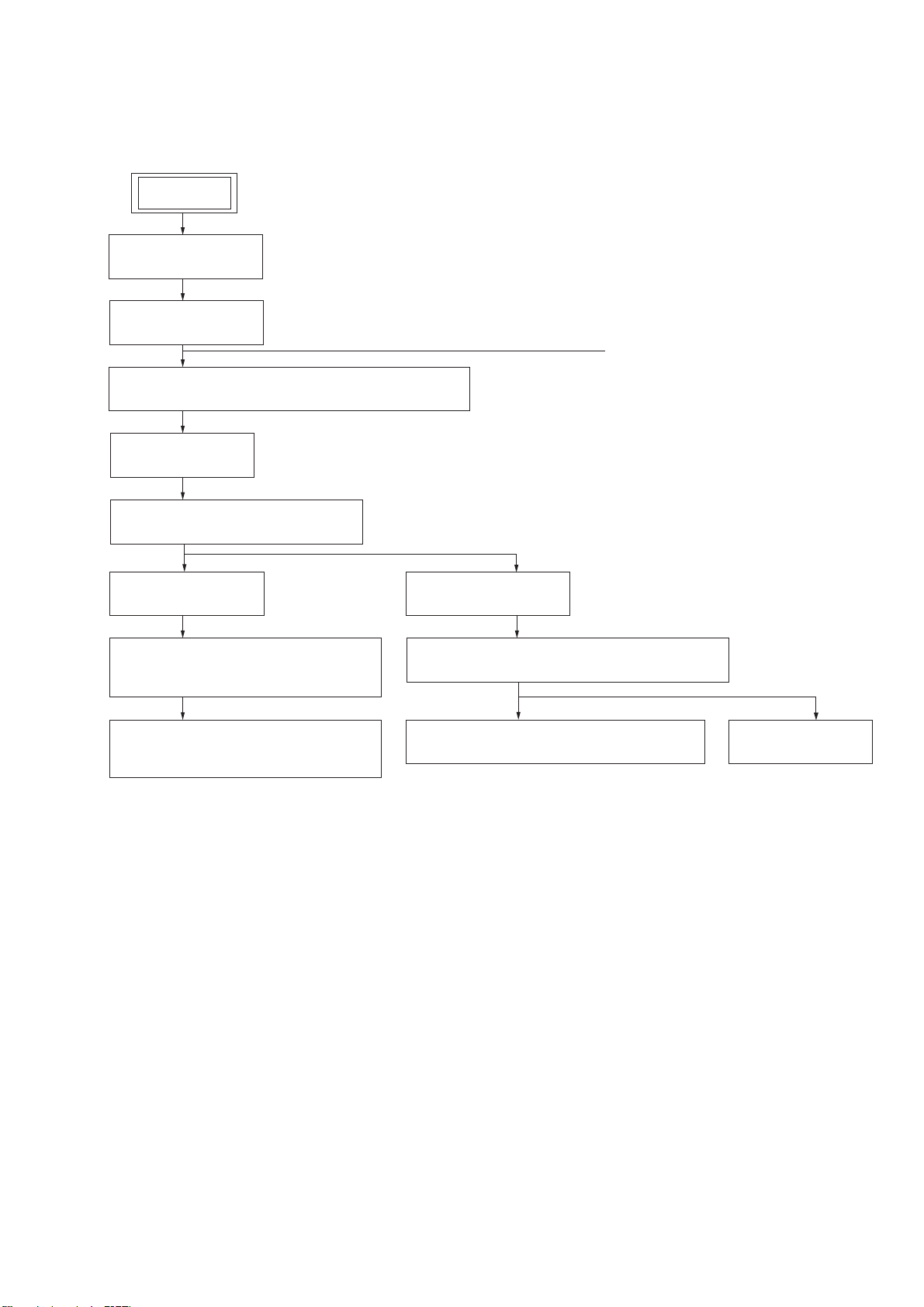

SEÇÃO 2

DESMONTAGEM

• Este aparelho pode ser desmontado conforme a ordem a seguir.

2-1. FLUXO DE DESMONTAGEM

APARELHO

2-2.

TAMPA LATERAL (R)/(L)

(Pag. 9)

2-3. TAMPA SUPERIOR

(Pag. 9)

2-5. BLOCO DE PAINEL FRONTAL, PLACAS HUB , DMB19

(Pag. 10)

2-6.

VENTILADOR (M101)

(Pag. 11)

HCD-GTR66/GTR88

2-7.

PAINEL TRASEIRO, PLACA SUBTRANS

(Pag. 11)

2-8. PLACA MAIN

(Pag. 12)

2-9. SEÇÃO VENTILADOR (M101),

PLACAS PT SHIELD,POWER AMP

(Pag. 12)

2-10. PLACA POWER AMP,

PLACA SUBWOOFER

(Pag. 13)

2-11. SEÇÃO CHASSIS

(Pag. 13)

BLOCO DE MECANISMO DO CD (CDM88BL-DVBU101)

2-12.

(Pag. 14)

2-13. BLOCO DE UNIDADE ÓTICA (KHM-313CAB)

(Pag. 14)

2-14. CORREIA (DLM3A)

(Pag. 15)

8

HCD-GTR66/GTR88

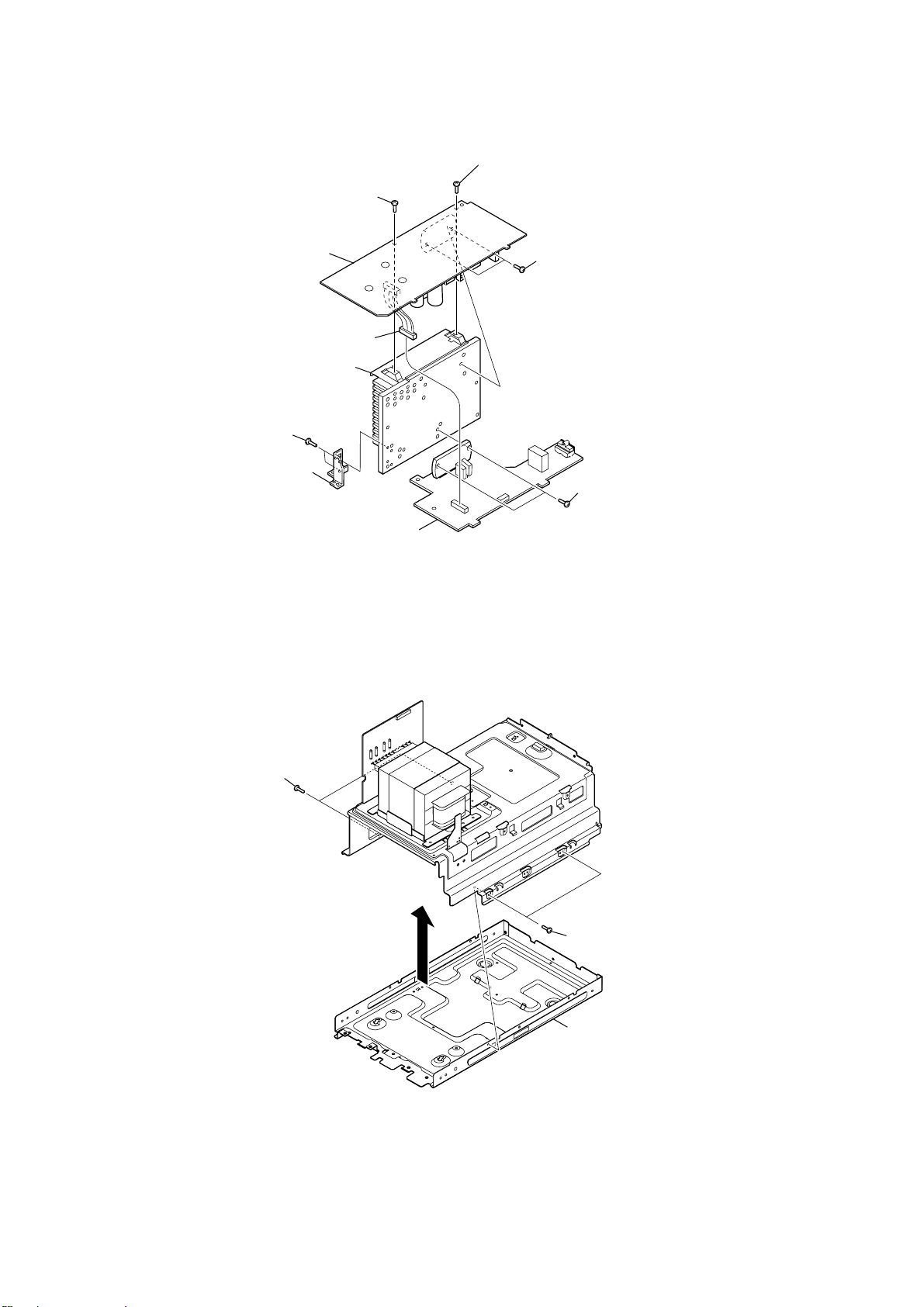

- Este aparelho pode ser desmontado seguindo a ordem numérica dada a seguir.

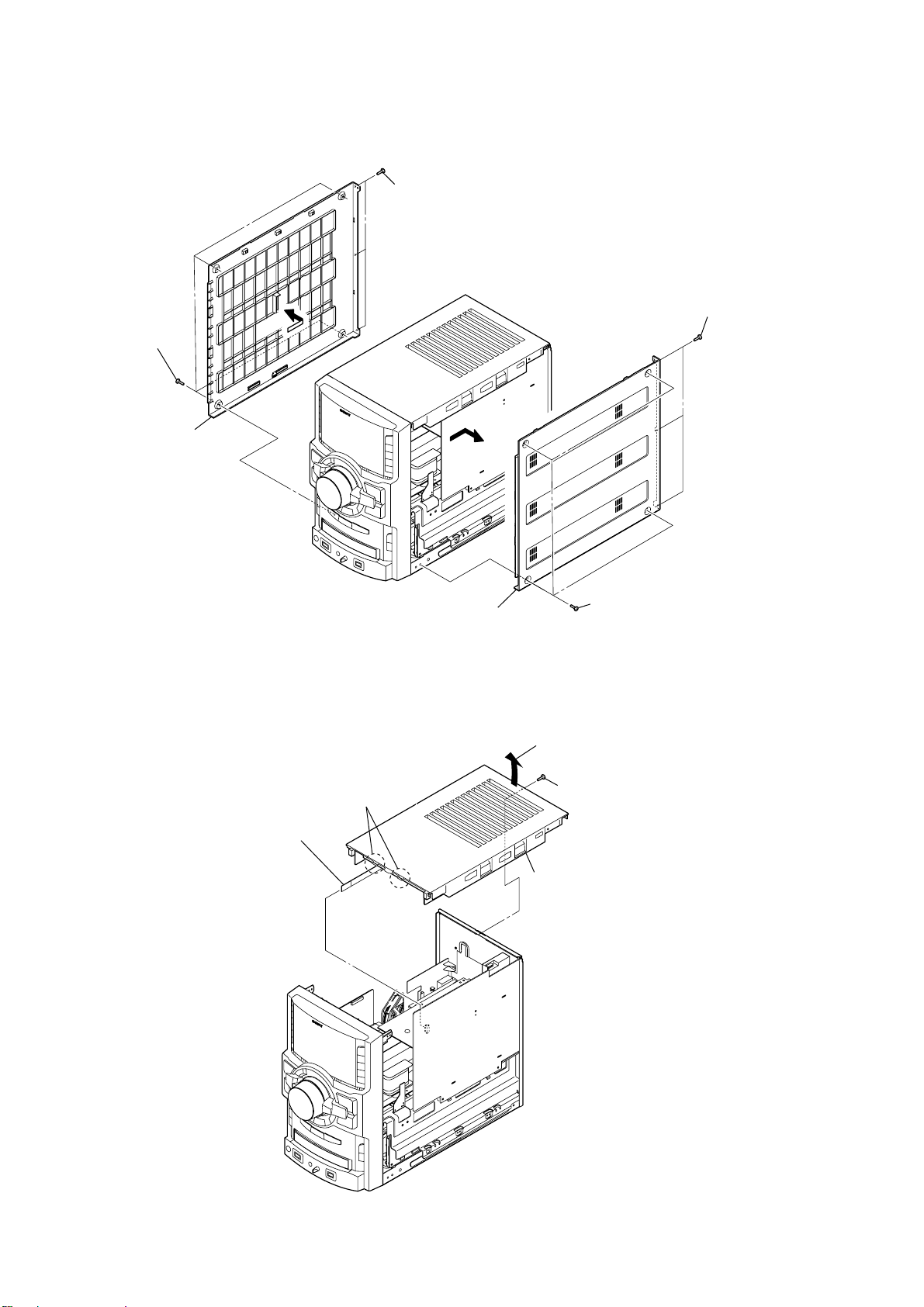

2-2. TAMPA (LATERAL-L/R)

2 três parafusos

(BVTP3 u 10)

1 quatro parafusos

(case 3 TP2)

4 tampa (lado-L)

3

3

2 três parafusos

(BVTP3 u 10)

2-3. TAMPA SUPERIOR

2 cabo tipo flat (9 vias)

(CN450)

3 duas travas

4 tampa (lado-R)

4 Levante parte traseira

da tampa superior

5 tampa superior

1 quatro parafusos

(case 3 TP2)

1 um parafuso

(BVTP3 u 10)

9

HCD-GTR66/GTR88

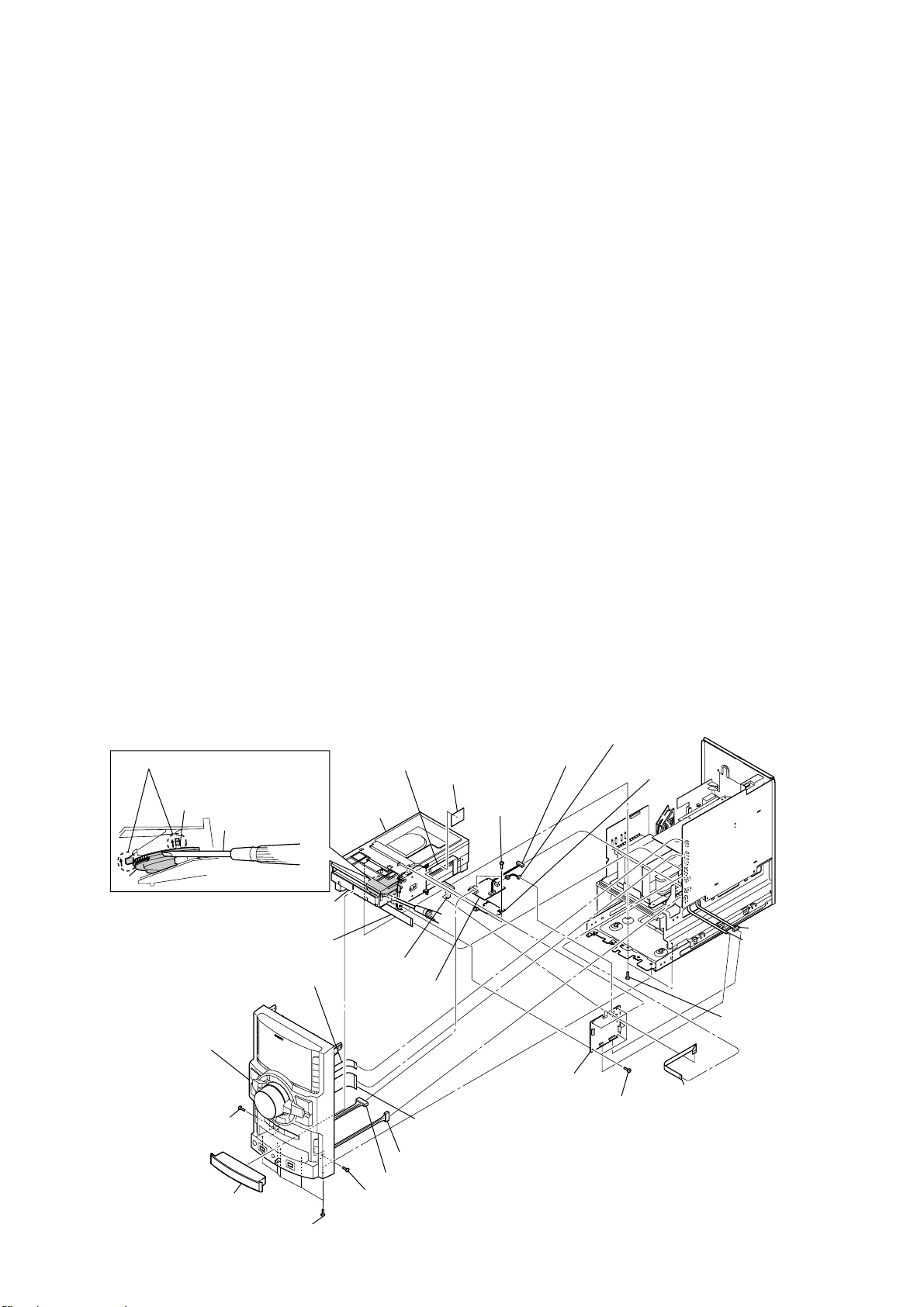

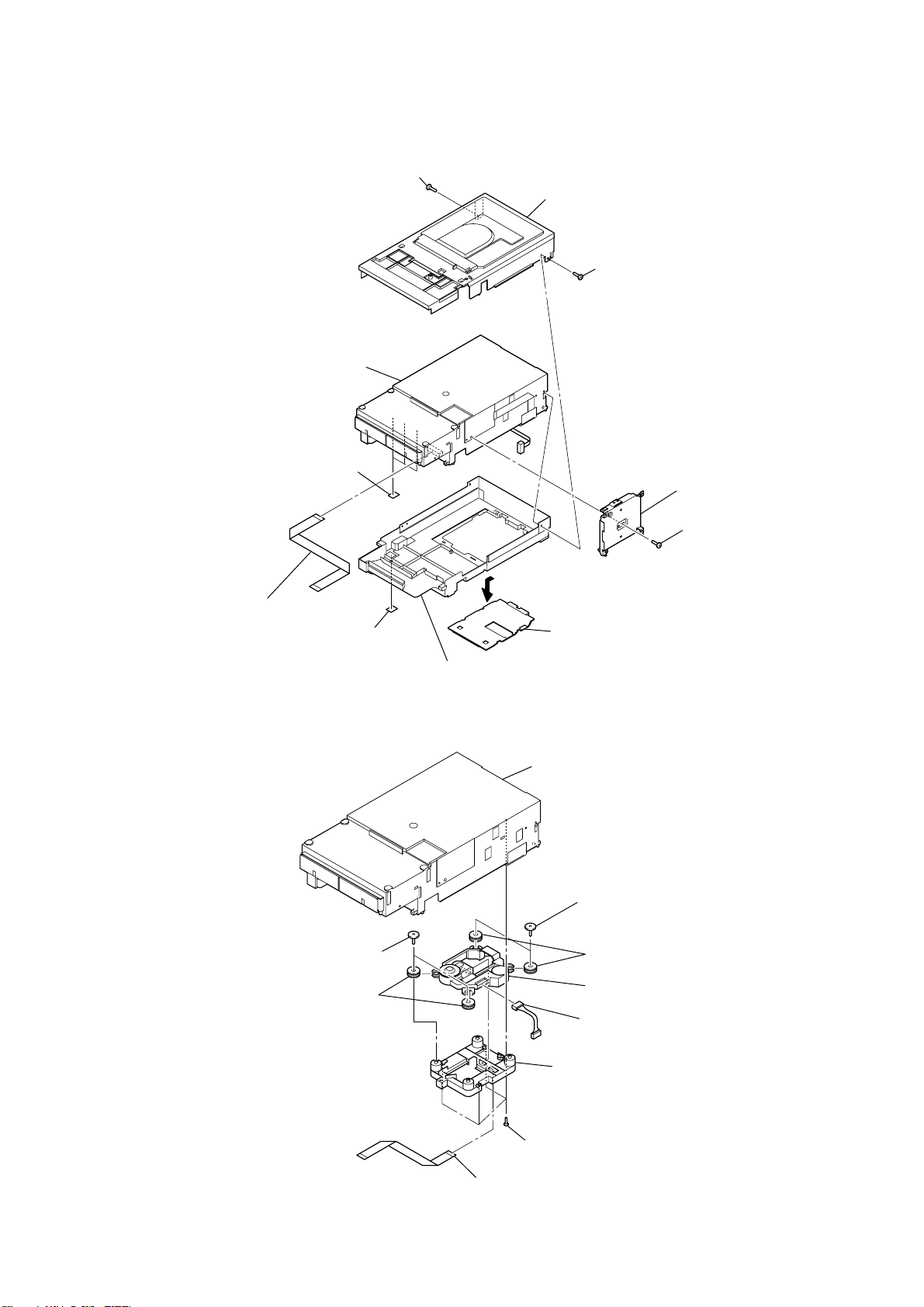

2-4. BLOCO DE PAINEL FRONTAL, PLACAS HUB E DMB19

qk placa DMB19: CN1105 (4P)/

placa HUB : CN1500 (4P)

condição de abertura da bandeja do CD

1 Gire a engrenagem com

a chave de fenda fina até

lever

que a alavanca sobe para

posição da figura.

gear

2 Puxe bandeja com a mão

qd cabo tipo flat (13 vias)

(CN410)

5 cabo tipo flat (11 vias)

(CN403)

q; bloco de painel frontal

8 um parafuso

(BVTP3 u 10)

3 painel de carregamento

9 cinco parafusos

(BVTP3 × 8)

qs cabo tipo flat (24 vias)

(CN101)

qa bloco CD

qh CN201 (6P)

8 um parafuso

(BVTP3 × 10)

qf calço saranet

qj placa

HUB

4 cabo tipo flat (23 vias)

(CN405)

6 CN470 (7P)

7 CN1501 (10P)

qg dois parafusos

(BVTP3 u8)

w; CN650 (8P)

wh placa DMB19

ql suporte

(ground hub)

wg quatro parafusos

(BVTP3 u8)

wa CN601 (9P)

ws cabo tipo flat (7 vias)

(CN4602)

wd dois parafusos

(BVTP3 u10)

wf cabo tipo flat (9 vias)

(CN1106)

10

HCD-GTR66/GTR88

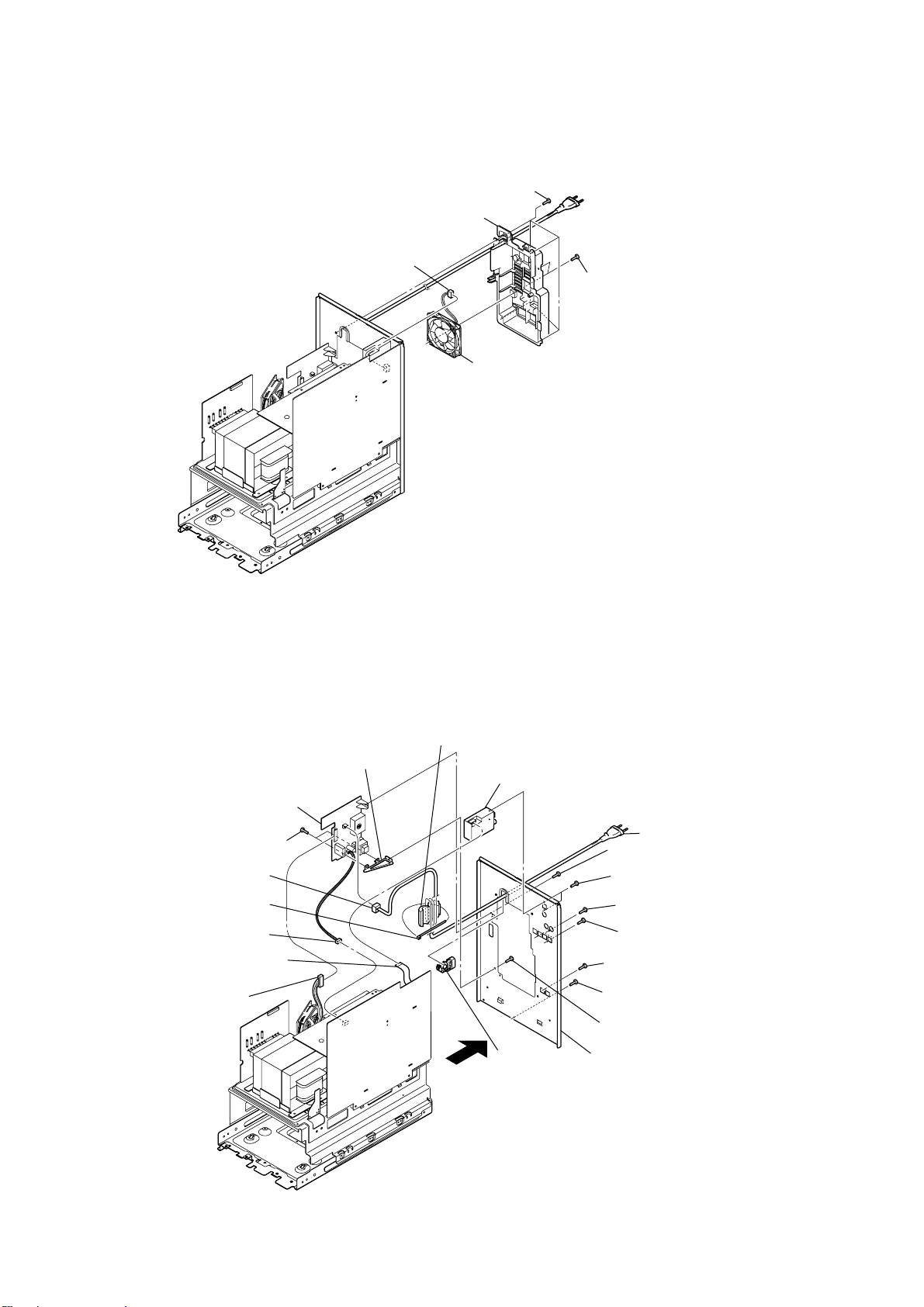

2-5. VENTILADOR DC (M101)

1 quatro parafusos

(BVTP3 u 8)

2 tampa do ventilador (GVX7S)

5 CN600 (3P)

2-6. PAINEL TRASEIRO, PLACA SUBTRANSFORMADOR

3 dois parafusos

(BVTP3 u 8)

4 ventilador DC (M101)

qd placa SUBTRANS

qs dois parafusos

(BVTP3 u 8)

2 CN1200 (3P)

qj presilha de fixação

4 CN691 (4P)

1 cabo tipo flat (9 vias)

(CN220)

3 CN1201 (4P)

qk filtro

(núcleo de ferrite)

qf suporte (Subtrans)

qa

qh sintonizador (FM/AM)

5 um parafuso

(BVTP3 u 8)

qg dois parafusos

(BVTT3 u 6)

6 um parafuso

(BVTP3 u 8)

7 dois parafusos

(BVTP3 u 8)

8 um parafuso

(BVTP3 u 8)

9 um parafuso

(BVTP3 u 8)

q; um parafuso

(BVTP3 u 8)

ql prensa cabo

wa painel traseiro

w; cabo de força

11

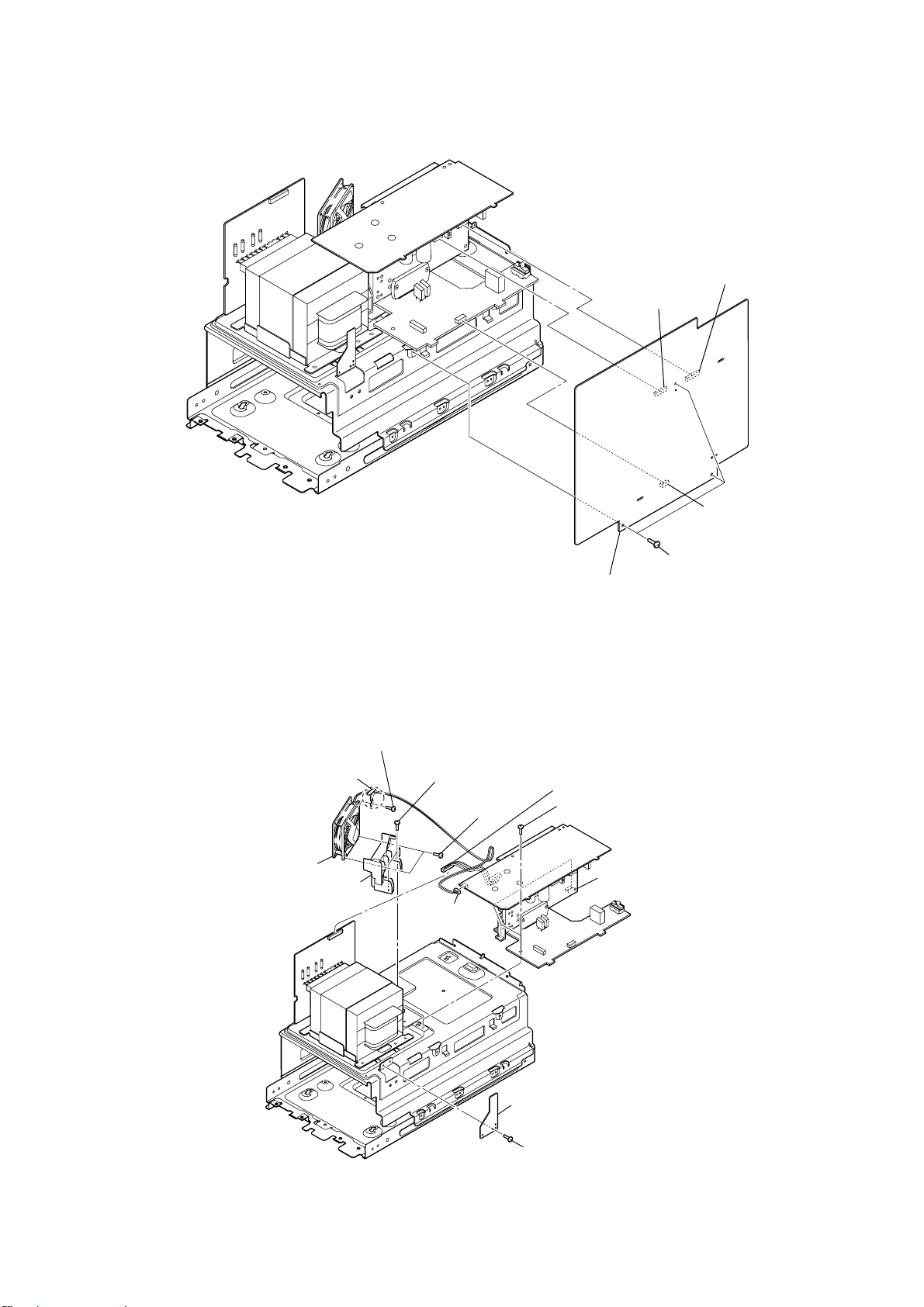

2-7. PLACA MAIN (PRINCIPAL)

HCD-GTR66/GTR88

3 CN200 (12P)

2 CN100 (10P)

5 placa MAIN

2-8. SEÇÃO VENTILADOR (M101), PLACAS PT SHIELD E POWER AMP

qa um parafuso

(BVTP3 u 8)

7 dois parafusos

qs presilha

q; ventilador DC (M101)

(GTR88)

8 suporte ventilador

(BVTP3 u 8)

9 dois parafusos

(BVTP3 u 8)

5 CN1302 (3P)

4 CN1250 (13P)

3 três parafusos

(BVTP3 u 8)

6 seção placa POWER AMP

4 CN550 (6P)

1 três parafusos

(BVTP3 u 8)

2 placa PT SHIELD

1 um parafuso

(BVTP3 u 8)

12

HCD-GTR66/GTR88

2-9. PLACA POWER AMP, PLACA SUBWOOFER (somente para GTR88)

2 um parafuso

1 um parafuso

(BVTP3 u 8)

(BVTP3 u 8)

5 placa POWER AMP

6 dois parafusos

(BVTP3 u 8)

2-10. SEÇÃO CHASSIS

3 dois parafusos

(transistor)

4 CN803 (7P)

8 heat sink

7 suporte (PWB)

9 dois parafusos

(transistor)

q; placa SUBWOOFER

(somente para GTR88)

1 dois parafusos

(BVTP3 u8)

2

1 dois parafusos

(BVTP3 u8)

3 chassis block

13

2-11. BLOCO DE MECANISMO DO CD (CDM88BL-DVBU101)

8 um parafuso

(BVTP3 u8)

q; bloco de mecanismo do CD

(CDM88BL-DVBU101)

7 três folhas (CDM)

HCD-GTR66/GTR88

9 tampa contra poeira (CDM88-A-superior)

8 um parafuso

(BVTP3 u 8)

3 suporte

(MTK)

2 um parafuso

(BVTP3 u8)

1 cabo tipo flat (13 core)

(placa MOTOR)

qa folha (CDM)

6 tampa contra poeira (CDM88-A-BTM)

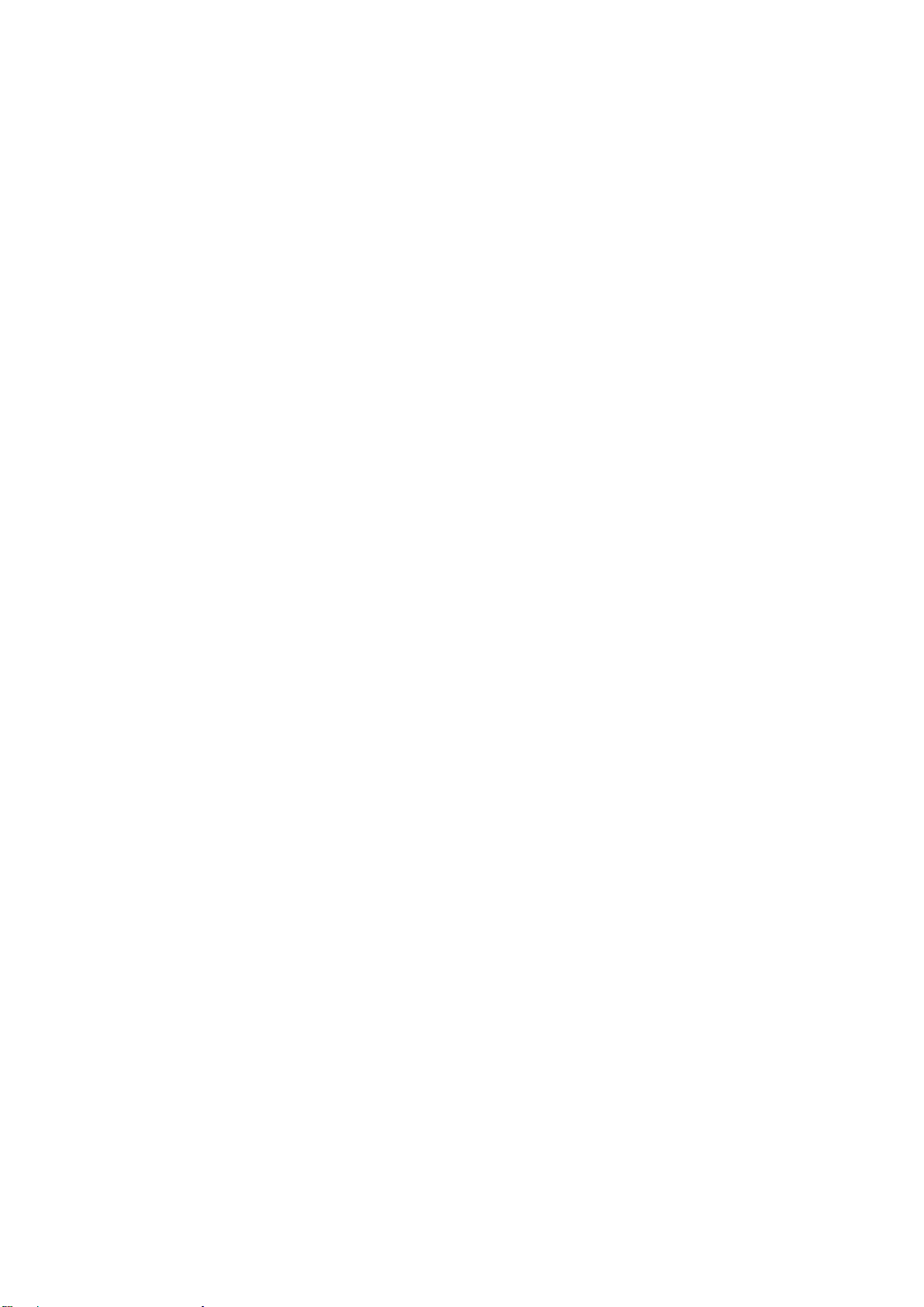

2-12. BLOCO DE UNIDADE ÓTICA (KHM-313CAB)

4 dois parafusos dos amortecedores

5 dois amortecedores

7 bloco de unidade ótica

4

5 tampa (shutter)

bloco de mecanismo do CD

(CDM88BL-DVBU101)

4 dois parafusos dos amortecedores

5 dois amortecedores

(KHM-313CAB)

3 conector

6 suporte BU

1 quatro parafusos

(BVTP2.6)

2 cabo tipo flat (24 vias)

14

HCD-GTR66/GTR88

2-13. CORREIA (DLM3A)

posição da correia

belt

correia

tampa

3

quatro parafusos

2

duas correias (DLM3A)

4

condição de abertura da bandeja do CD

1 Gire a engrenagem até

que sobe para posição

da figura

alavanca

engrenagem

15

SEÇÃO 3

MODO DE TESTE

HCD-GTR66/GTR88

MODO DE TESTE DO DIPLAY DE FLUORESCENTE

This mode is used to check the À uorescent indicator tube, LEDs,

keys, [MASTER VOLUME] jog, [OPERATION DIAL] jog, model, destination and software version.

Procedure:

1. Press [x], button, [METER MODE] button and [DISC SKIP/

EX-CHANGE] button simultaneously.

2. All LEDs and segments in À uorescent indicator tube are light-

ed up.

3. When you want to enter to the software version display mode,

press [DISC 1] button. The model information appears on the

À uorescent indicator tube.

• “GVX 7S” is shown for MHC-GTR88.

Press [DISC 1] button again to view the destination

information.

4. During the destination information display, press [DISC 1]

button. Each time [DISC 1] button is pressed, the À uorescent

indicator tube shows the version of each category software in

the following sequence: SC, MTK (DMB Board ¿ rmware ver-

sion), GC, SYS, CD, CDMA, CDMB, ST, TC TA, TM, MTR

(METER) and return back to model information display.

5. When [DISC 3] button is pressed while the version numbers

are being displayed except model and destination, the date

of the software creation appears. When [DISC 3] button is

pressed again, the display returns to the software version display. When [DISC 1] button is pressed while the date of the

software creation is being displayed, the date of the software

creation is displayed in the same order of software version display.

6. Press [DISC 2] button, the key check mode is activated.

7. In the key check mode, the À uorescent indicator tube displays

“K0 V0”.

Each time a button is pressed, “K” value increases. However,

once a button has been pressed, it is no longer taken into account.

“V” value increases in the manner of 0, 1, 2, 3 ... if [MASTER

VOLUME] knob is turned clockwise, or it decreases in the

manner of 0, 9, 8, 7 ... if [MASTER VOLUME] knob is turned

counterclockwise.

8. When [DISC SKIP/EX-CHANGE] button is pressed after all

LEDs and segments in À uorescent indicator tube light up, al-

ternate segments in À uorescent indicator tube and LEDs would

light up. If you press [DISC SKIP/EX-CHANGE] button

again, another half of alternate segments in À uorescent indi-

cator tube and LEDs would light up. Pressing [DISC SKIP/

EX-CHANGE] button again would cause all segments in À uo-

rescent indicator tube and LEDs light up.

9. To release from this mode, press three buttons in the same

manner as step 1, or disconnect the power cord.

MODO DE TESTE DO AMPLIFICADOR

This mode is used to check operations of the Ampli¿ er section.

To enter Common Test Mode

Procedure:

1. Press [x], button, [METER MODE] button and [OPEN/

CLOSE] button simultaneously.

2. The CD ring indicators À ash on the À uorescent indicator tube.

The function is changed to AUDIO and the volume is changed

to VOLUME MIN.

Check of Ampli¿ er

Procedure:

1. Press [EQ BAND/SURROUND] button repeatedly until a

message “GEQ MAX” appears on the À uorescent indicator

tube. GEQ increases to its maximum.

2. Press [EQ BAND/SURROUND] button repeatedly until a

message “GEQ MIN” appears on the À uorescent indicator

tube. GEQ decreases to its minimum.

3. Press [EQ BAND/SURROUND] button repeatedly until a

message “GEQ FLAT” appears on the À uorescent indicator

tube. GEQ is set to À at.

4. When the [MASTER VOLUME] knob is turned clockwise

even slightly, the sound volume increases to its maximum and

a message “VOLUME MAX” appears on the À uorescent indi-

cator tube.

5. When the [MASTER VOLUME] knob is turned counterclockwise even slightly, the sound volume decreases to its minimum

and a message “VOLUME MIN” appears on the À uorescent

indicator tube.

To release from Common Test mode

1. To release from this mode, press [

2. The cold reset is enforced at the same time.

STANDBY] button.

?/1

COLD RESET

The cold reset clears all data including preset data stored in the

EEPROM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press [

2. Press [x] button, [ENTER] button, and [

ton simultaneously.

3. “COLD RESET” appears on the À uorescent indicator tube.

After that, the À uorescent indicator tube becomes blank for a

while, and the system is reset.

STANDBY] button to turn on the system.

?/1

?/1

STANDBY] but-

VACS ON/OFF

This mode is used to switch ON and OFF the VACS (Variable Attenuation Control System).

Procedure:

1. Press [

2. Press [x] button, [RETURN], and [DISPLAY] button simultaneously. The message “VACS OFF” or “VACS ON” appears

on the À uorescent indicator tube.

STANDBY] to turn on the system.

?/1

MUDANÇA DE INTERVALO DA FREQUÊNCIA AM

The step interval of AM channels can be toggled between 9 kHz

and 10 kHz.

Procedure:

1. Press [

2. Press [TUNER/BAND] button repeatedly to select the “AM”.

3. Press [

4. Press [ENTER] button and [

neously. The system turns on automatically. The message “AM

9K STEP” or “AM 10K STEP” appears on the À uorescent in-

dicator tube and thus the channel step is changed.

MODO DE TRANSPORTE CD (COM RESET DA MEMÓRIA

This mode moves the optical pick-up to the position durable to

vibration and clears all data including preset data stored in the EEPROM to initial conditions during the next AC-In. Use this mode

when returning the set to the customer after repair.

Procedure:

1. Press [

2. Select CD function.

3. Press [x] button, [OPEN/CLOSE] button and [

BY] button simultaneously. The system turns off automatically.

4. After the “STANDBY” blinking display ¿ nishes, a message

“MECHA LOCK” is displayed on the À uorescent indicator tube

and the CD ship mode is set.

STANDBY] button to turn on the system.

?/1

STANDBY] button to turn off the system.

?/1

STANDBY] button simulta-

?/1

STANDBY] button to turn on the system.

?/1

?/1

)

STAND-

16

HCD-GTR66/GTR88

MODO DE TRANSPORTE CD (SEM RESET DA MEMÓRIA)

This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press [

2. Select CD function.

3. Press [DISC SKIP/EX-CHANGE] button and [

BY] button simultaneously. The system turns off automatically.

4. After the “STANDBY” blinking display ¿ nishes, a message

“MECHA LOCK” is displayed on the À uorescent indicator

tube and the CD ship mode is set.

STANDBY] button to turn on the system.

?/1

?/1

STAND-

MODO DE TRAVAMENTO DA BANDEJA DO CD

This mode let you lock the disc tray. When this mode is activated, the disc tray will not open when [Z OPEN/CLOSE] button

or [DISC SKIP/EX-CHANGE] button is pressed. The message

“LOCKED” will be displayed on the À uorescent indicator tube.

This mode only applied when there is disc(s) on the tray.

Procedure:

1. Press [

2. Select CD function.

3. Press [x] button and [Z OPEN/CLOSE] button simultaneously and hold down until “LOCKED” or “UNLOCKED” displayed on the À uorescent indicator tube (around 5 seconds).

STANDBY] button to turn on the system.

?/1

CONFIGURAÇÃO DA FÁBRICA

This mode is use to load all the factory use preset frequencies

into FM 1-FM 20 and AM 1-AM 10. Originally, frequency of FM

1-FM 20 and AM 1-AM10 are set to the minimum frequency.

Procedure:

1. Press [

2. Press [EQ BAND/SURROUND], [x] button, and [DISC 1]

button simultaneously and the message “FACTORY” appears

on the À uorescent indicator tube. The function is changed to

TUNER automatically.

STANDBY] button to turn on the system.

?/1

VACS DISPLAY

This mode is used to check the VACS level.

Procedure:

1. Press [

2. Press [ERASE], [x] button and [ENTER] button simultaneously.

3. The À uorescent indicator tube displays “V0AP0”.

“V” represents Conventional VACS (Triggered by signal level)

“AP” represents AP VACS (Abuse Protection Variable Attenuation Control System)

• To release from VACS display mode

To release from this mode, do the step (2) again.

STANDBY] button to turn on the system.

?/1

METER SWITCH TOUCH COUNT DISPLAY

This mode is used to display the total count of meter pointer touch

initial switch and max switch.

Procedure:

1. Press [

2. Press [x] button, [ENTER] button and [DISPLAY] button simultaneously.

3. The À uorescent indicator tube displays “IxxxxxMyyyyy”.

“I” represents the Initial Switch touch.

“xxxxx” represents the total count of Initial Switch touch.

(Maximum Value of “xxxxx” = 65535)

“M” represents the Max Switch touch.

“yyyyy” represents the total count of Max Switch touch.

(Maximum Value of “yyyyy” = 65535)

• To release from Meter Switch Touch Count Display Mode.

To release from this mode, do the step (2) again.

The À uorescent indicator tube displays “MODE OUT”.

STANDBY] button to turn on the system.

?/1

MODO DE TESTE DO METER

This mode is used to check the meter device.

Procedure:

1. Press [

2. Press [x] button, [ENTER] button and [METER MODE] but-

ton simultaneously.

3. Meter Backlight LEDs, Meter Pointer LEDs, Power Illuminator LEDs and À uorescent indicator tube are lighted up.

4. When you want to perform count total step from Initial Switch

to Max Switch operation mode, press [M/>/TUNING +]

button. The meter pointer will move from Initial Switch to

Max Switch and ¿ nally move back to the middle position. The

total step count information appears on the À uorescent indica-

tor tube. “xxx STP yy” is shown.

“xxx” represents the total step.

(Value of “xxx” should between 430 steps to 470 steps)

“yy” represents the status of total step count.

(If total step between 430 steps to 470 steps, “yy” is OK, Else

“yy” is NG)

5. When you want to perform count total step from Max Switch

to Initial Switch operation mode, press [m/./TUNING –]

button. The meter pointer will move from Max Switch to Initial Switch and ¿ nally move back to the middle position. The

total step count information appears on the À uorescent indica-

tor tube. “xxx STP yy” is shown.

“xxx” represents the total step.

(Value of “xxx” should between 430 steps to 470 steps)

“yy” represents the status of total step count.

(If total step between 430 steps to 470 steps, “yy” is OK, else

“yy” is NG)

• To release from Meter Test Mode.

To release from this mode, do the step (2) again.

The À uorescent indicator tube displays “TST MODE OUT”.

STANDBY] button to turn on the system.

?/1

MODO DE AGING DO CDM

This mode is used to display the total count of all disc playing.

Procedure:

1. Press [

2. Select CD function and All DISC play mode.

3. Put discs on all trays and close the tray.

4. Press [GROOVE] button, [x] button and [RETURN] button

simultaneously.

5. The À uorescent indicator tube displays Aging Display “AG

xxxx/yyyy”.

“xxxx” represents the error counter

(Maximum Value of “xxxx” = 9999)

“yyyyy” represents the cycle counter

(Maximum Value of “yyyy” = 9999)

6. Press [m/./TUNING –] or [M/>/TUNING +] to

search for Aging History Error Display

The À uorescent indicator tube displays “Mx E1E2E3E4”.

x: error history number

E1: Loading sequence JCP high

E2: Loading sequence JCP low

E3: Loading operation JCP

E4: Cam position operation JCP

7. Press [RETURN] to Aging Display

• To release from CDM Aging Mode.

To release from this mode, press [

perform COLD RESET operation.

STANDBY] button to turn on the system.

?/1

STANDBY] button or

?/1

17

HCD-GTR66/GTR88

ADUSTES ELÉTRICOS

SEÇÃO TUNER

VERIFICAÇÃO DO NÍVEL DE SINTONIA FM

FM signal generator

SEÇÃO 4

SET

Procedure:

1. Turn the power on.

2. Input the following signal from signal generator to FM antenna

input directly.

* Carrier frequency : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Use 75 ohm coaxial cable to connect signal generator and the set.

You cannot use video cable for checking.

Use signal generator whose output impedance is 75 ohm.

3. Set to FM tuner function and tune A, B and C signals.

4. Con¿ rm “TUNED” is lit on the display for A, B and C signals.

When mark of “TUNED” means “The selected station signal is

received in good condition.”

OUT (75 Ω)

18

SEÇÀO 5

DIAGRAMAS

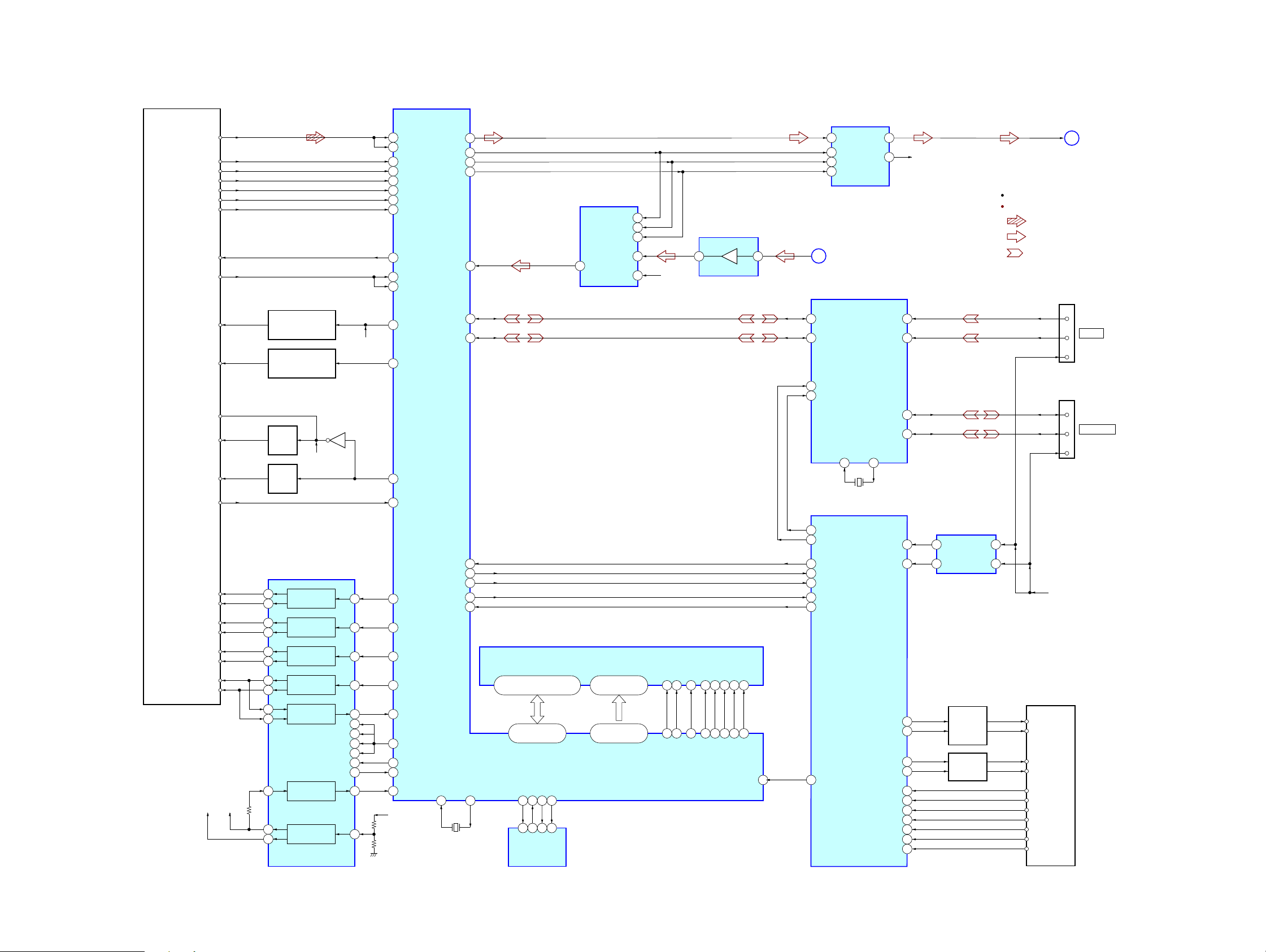

5-1. DIAGRAMA EM BLOCO - Seção RF SERVO, USB -

RF

VOA/A

VOB/B

VOC/C

VOD/D

PD

AUTOMATIC POWER

CONTROL

OPTICAL PICK-UP

BLOCK

(KHM-313CAB)

VR (780)

VR (650)

LIMIT SW

MSW

Q102-1

AUTOMATIC POWER

CONTROL

Q102-2

CD ON

SWITCH

Q101-1

REGO1

CD ON

SWITCH

Q101-2

REGO2

Q103

RF_IP

125

OPOUT126

RF_C

3

RF_B

2

RF_A

1

RF_D

4

RF_F6VOE/E+G

RF_E5VOF/F+H

V2O12VC

MDI115

MDI216

LDO117LD (780)

18LD (650)

LDO2

RF AMP, SERVO DSP,

AUDIO PROCESSOR

MSW

23

118

GPIO

IC101

GPIO

GPIO

GPIO

GPIO

GPIO19

USB_DP 27

USB_DM 28

HCD-GTR66/GTR88

D/A CONVERTER

IC4602

AOUT-L

SDATA

B

USBUP_DP

31

USBUP_DM

30

VBUS_DET27

26

RESET_N

1

SCLK

2

LRCK

3

ACLK

4

(Page 20

USB CONTROLLER

IC1501

XTAL1/

CLKIN

33

X1500

24MHz

120

115

119

114

A/D CONVERTER

IC4601

BCK

8

LRCK

7

SCKI

6

VINL

VINR

13

R-CH

14

DOUT

106

9

USB RECORD PREAMP

IC251

7 5

AOUT-R

)

XTAL2

32

8

R-CH

5

2USBDN1_DP

1USBDN1_DM

4USBDN2_DP

3USBDN2_DM

L-OUT

A

(Page 20

)

R-CH is omitted due to same as L-CH.

SIGNAL PATH

: CD PLAY

: AUDIO

: USB

CN1001

3

D+

2

1

CN1000

3

2

1

PLAY A

REC/PLAY B

D–

VBUS

D+

D–

VBUS

FCS+

FCS– 37

TRK+ 35

TRK– 34

SL+ 29

SL– 30

SP+ 27

SP– 28

REGO2

REGO1

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

IC201

36

46

47

41

31

32

FOCUS

COIL DRIVE

TRACKING

COIL DRIVE

SLED

MOTOR DRIVE

SPINDLE

MOTOR DRIVE

BUFFER

BUFFER

REGULATOR

HUB_RST45

44

VBUS_DET

IFSDI 35

41

IFSOD

40

IFSCK

IFCS#

9

IFBSY

XTALI

27MHz

X101

88

87

SD-RAM

IC104

DG0, DQ1 – DQ15

2, 4, 5, 7, 8, 10, 11, 13, 42,

44, 45, 47, 48, 50, 51, 53

45 – 49, 51 – 53,

64 – 61, 56 – 59

RD0 – RD15

SF_CS#CS_

XTALO

10

SF_DO37SF_DI

38

2SI5

SO

SF_CKSCK

36

39

1

6

A0 – A11

23 – 26,

29 – 34, 22, 35

82, 83, 85, 86,

74 – 69, 81, 67

RA0 – RA11

20

21

38

15

39

18

17

16

78

80

66

55

65

77

76

75

BA0 BA0

BA1 BA1

RCLK CLK

DQM0 LDQM

DQM1 UDQM

RAS# RAS

CAS# CAS

PRST#

RWE# WE

43

1

4

10

13

45

7

6

19

PS

21

20

22

40

8

FOO25

TRO24

FMO21

DMO20

SPFG/OPINN128

GPIOMUTE123 116

MUTE4MUTE4 22

GPIOTSD-M 94

IOPMON/

127

OPINP

RF +3.3V

MTK-TXD

35

36

MTK-RXD

37

MTK-CLOCK

MTK-XIFCS

34

39

MTK-BUSY

MTK-RST38

SYSTEM

CONTROLLER

IC401 (1/4)

SW-CHUCK

SW-STOCK

M1+

M1- 25

M2+

M2- 26

SW1

SW3

SW2

SW-CLOSE 7

SW-OPEN 5

47MTK-OC1

1

VBUS OVER

CURRENT DETECT

50MTK-OC2

23

24

21

22

18

19

6

IC1500

7

MOTOR

DRIVE

Q640, 641,

Q643, 644

MOTOR

DRIVE

Q645 - 648

3

5

USB +5V

CD MECHANISM

DECK

M1+

M1-

M2+

M2-

SW1

SW3

SW2

SW7-CHACK

SW5-STOCK

SW6-CLOSE

SW8-OPEN

HCD-GTR66/GTR88

FLASH ROM

IC102

19

HCD-GTR66/GTR88

5-2. DIAGRAMA EM BLOCO - Seção MAIN -

J700

IC700 MIC AMP

HP DET

C

(Page 21)

MIC

PC IN

(Page 19)

PC_L

PC_R

R-CH

R-CH

46 MIC

4430PC-L

55 PC-R

CD-L

40

3 CD-R

INPUT SELECTOR,

ELECTRICAL VOLUME

IC400

RECAR

AGC OUTL

(SW OUTL)

AGC OUTR

(SW OUTR)

OUTR

SA2

9

BAND-PASS

FILTER

Q210

OUTL

BB2L

BB2R

BB1R

29 VOLINLTONEOUTL 26

37RECAL

R-CH

6

25

R-CH

20

D104

R-CH

BASS AGC

Q128

BASS AGC

Q178

28BB1L

27

19

18

17

REC-L

OUT

SW OUT

BASS AGC

B

(Page 19)

D

(Page 21)

E

(Page 21)

F

(Page 21)

1375

RV700

MIC LEVEL

J020

R-CH

A

L-OUT

FM 75:

COAXIAL

AM

ANTENNA

TUNER (FM/AM)

FM ANT

AM ANT

ST-L

ST-R

ST-DOUT

ST-DIN

ST-CLK

ST-CE

TUNED

R-CH

46 ST-DOUT

52 ST-DIN

51 ST-CLK

53 ST-CE

54 ST-TUNED

66

HP/MIC DET

R-CH

43 ST-L

56 ST-R

DATA22CLK

21

58

57

R2A15216FP-CLK

R2A15216FP-DATA

SYSTEM CONTROLLER

IC401 (2/4)

D201

70

VACS IN

D116

G

(Page 22)

69

R-CH is omitted due to same as L-CH.

SIGNAL PATH

: AUDIO

: TUNER (FM/AM)

POWER ILLUMINATOR

15X-IN

X402

8MHz

13X-OUT

10XC-IN

11XC-OUT

X401

32.768kHz

: MIC

HCD-GTR66/GTR88

20

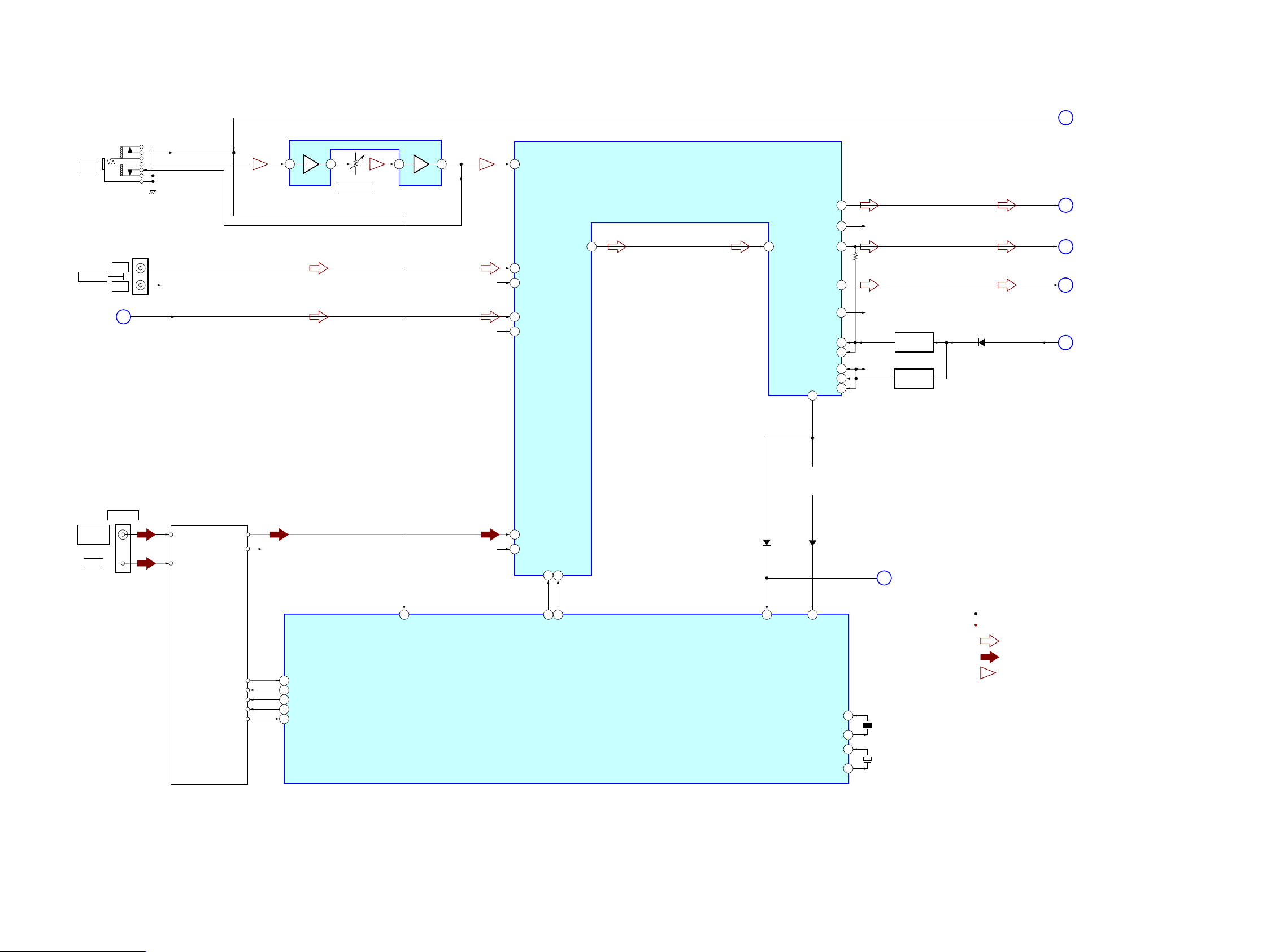

5-3. DIAGRAMA EM BLOCO - Seção AMP -

HP DET

(Page 20

(Page 20

(Page 20

C

)

BASS AGC

F

)

OUT

D

)

FR PREAMP

IC252

13

R-CH

MUTING

Q220

MUTING

Q270

18 11

14 8

POWER

AMP

IC1300

HCD-GTR66/GTR88

L

R

L

R

J702

PHONES

FRONT

SPEAKER

SATELLITE

SPEAKER

(Somente para GTR88)

R-CH

RY1300

TB1300

+

–

R-CH

M101

M

(DC FAN)

M101

M

OVER LOAD

16

DETECT

Q1300

OVER LOAD

DETECT

Q800

OVER LOAD

DETECT

Q1301

OVER LOAD

DETECT

Q850

D1036

DC

DETECT

Q1302, Q1303

THERMAL

DETECTOR

Q1305, Q1307

PROTECT

DETECT

Q1304, 1306

FAN MOTOR

DRIVE

Q602

FAN SW

Q600

(DC FAN)

RELAY

DRIVER

Q032

RELAY

DRIVER

Q033

R-CH

–

+

TB1301

+

–

–

+

(Page 20)

SW PREAMP

IC253

SW OUT

E

75

SW PREAMP

IC254

75

R-CH

SW PREAMP

IC255

MUTING

Q295

75

MUTING

CONTROL

Q290

63

LINE MUTE

MUTING

Q245

15

11

POWER

AMP

IC800

6

4

MUTE

Q1309, Q1308

60

STK MUTE

R-CH

SYSTEM CONTROLLER

IC401 (3/4)

TH1301

61

PROTECT

43

CONTROL

FAN HIGH SPEED

RY862

R-CH

TB801

+

–

+

L

R

SUBWOOFER

(Somente para GTR88)

–

RELAY

DRIVER

Q030

RELAY

DRIVE

Q031

48

59

R-CH is omitted due to same as L-CH.

SIGNAL PATH

FR SPK RELAY

SW SPK RELAY

H

: AUDIO

(Page 22)

HCD-GTR66/GTR88

21

HCD-GTR66/GTR88

5-4. DIAGRAMA EM BLOCO - Seção DISPLAY, POWER SUPPLY -

FLUORESCENT INDICATOR

FL1100

FLUORESCENT

INDICATOR

TUBE

D1105 – 1107, SEL A

D1108 – 1110, SEL B

(STREAM)

D1002, 1003

USB B

D1000

USB A

TUBE DRIVER

SG5/KS5 –

SG24/KS24

14 – 33

GR1 – GR14

34 – 47

IC1101

LED DRIVE

Q1118 – 1120

LED DRIVE

DIN

CLK

STB

Q1121

SYSTEM CONTROLLER

FL-DRIVER-DATA2 2

FL-DRIVER-CLK1 1

FL-DRIVER-CS3 100

88

LED-VOL1. 2

91

LED-VOL3. 4

90

LED-VOL5. 6

86 USB-LED CTRL

IC401 (4/4)

CDM-SD

PT1250

MAIN POWER

TRANSFORMER

VF

M+9V

UNREGULATE

+12V

REGULATOR

IC040

–VG

+VH

–VH

+VL

–VL

VF

F1255

F1250

F1251

F1252

F1253

D1250

I

–32V

REGULATOR

Q1250

RECT

D1300

RECT

D1301

FOR

FLUORESCENT

INDICATOR

TUBE

FAN

+12V

AMP

SECTION

B+

O

LED SEL A,

LED SEL B

CD MOTOR B+

27

LED+9V

B+ SWITCH

Q300 – 303

REGULATOR

Q655 – 658

D1104

SUBWOOFER

D1011

I/1

STANDBY

METER

DISPLAY

BLOCK

LED

S1100 – 1109,

S1110 – 1119,

S1124 – 1133,

S1302

S1301

MASTER

VOLUME

LED DRIVE

Q1122

ROTARY

ENCODER

REMOTE CONTROL

RECEIVER

IC1100

LED DRIVE

Q582

LED DRIVE

Q230

LED SEL A

LED SEL B

AD KEY0

94 SW/USB CTRL

95 STBY LED

74

POWER/DISPLAY-KEY

AD-KEY0

97

89

AD-KEY1

85

AD-KEY2

87 MASTER VOL

4 SIRCS

METER-IN179

80 METER-IN2

78 METER-IN3

77 METER-IN4

81 METER SW

METER PTR

82

LED

83 METER BL CTL

M+9V

+5V

D351

REGULATOR

Q360

POWER

CONTROL

Q090

+1.8V

REGULATOR

IC 111

+5V

REGULATOR

Q696

+4V

REGULATOR

Q352-354

81

D623, 624

(Page 21)

M +5V

USB +5V

49MTK OE

D+3.3V

+1.8V

DVDD +5V

RF+3.3V

JOG B+

3AD SUPPLY SW

(Page 20

12RESET

20AC CUT

REGULATOR

B+ SWITCH

Q400, 500

VCC +3.3V

EVER +3.3V

)

RESET SWITCH

3.3V

IC107

AVDD +5V

A+9V

G

Q350, 351

54

D571

+9V

2 1

REGULATOR

IC055

+5V

21

REGULATOR

IC065

+3.3V

IC075

+9V

IC200

H

12

1

AC DETECT

D1201, 1202

DETECTOR

REGULATOR

REGULATOR

2

RECT

D600

RECT

AC CUT

D1203

F1254

PT1200

SUB POWER

TRANSFORMER

RY1200

(AC IN)

VOLTAGE

SELECTOR

S1200

RELAY

DRIVE

Q1200

HCD-GTR66/GTR88

71OVERVOLTAGE

75STBY RELAY

22

HCD-GTR66/GTR88

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• Y : Parts extracted from the conductor side.

• f : Internal component.

• : Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated.)

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

• DMB19 board is multi-layer printed board.

However, the patterns of intermediate layers have not

been included in diagrams.

• Indication of transistor.

C

Q

B

E

CEB

These are omitted.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

These are omitted.

For Schematic Diagrams.

Note:

• All capacitors are in F unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in and 1/4 W or less unless otherwise

speci¿ ed.

• f : Internal component.

• 2 : NonÀ ammable resistor.

• 5 : Fusible resistor.

• C : Panel designation.

Note: The components identi¿ ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number speci¿ ed.

• A : B+ Line.

• B : B– Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

- TC Board -

no mark : TAPE PLAY

( ) : TAPE REC

- Other Boards -

no mark : TUNER (FM/AM)

( ) : CD PLAY

<< >> : TAPE PLAY

[ ] : TAPE REC

< > : USB

{ } : PC

* : Impossible to measure

• Voltages are taken with VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

f : TUNER (FM/AM)

N : MIC

J : CD PLAY

c : DIGITAL

I : USB

• Localização das Placas de Circuito

POWER AMP board

SUBTRANS board

TRANS board

SUBWOOFER board

(GTR88)

MAIN board

PT SHIELD board

DMB19 board

HUB board

MOTOR DRIVE board

included in METER DISPLAY ASSY

TUNER (FM/AM)

LED (GVX) board

included in METER DISPLAY ASSY

SW (GVX) board

included in METER DISPLAY ASSY

HCD-GTR66/GTR88

23

VOL board

USB board

DISPLAY board

MIC board

HCD-GTR66/GTR88

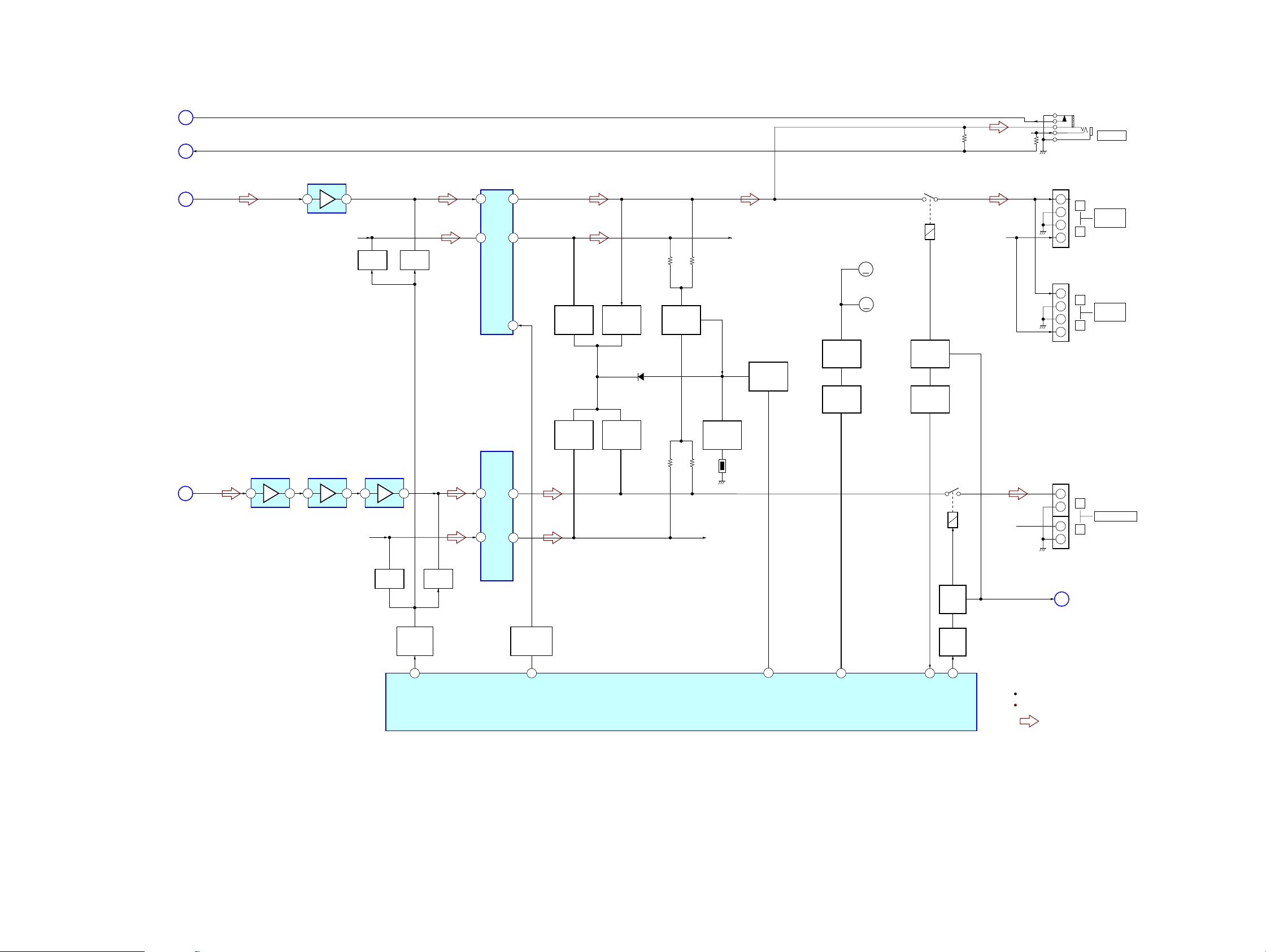

5-5. PLACA DE CIRCUITO IMPRESSO - Placa DISPLAY -

1 2 3 4 5 6 7 8 9 10 11 14 1512 13

A

B

DISPLAY BOARD

DISC SKIP/

EX-CHANGE

OPEN/CLOSE

R1113

R1114

S1132

S1133

C

D

E

USB B

F

REC TO

USB B

S1128

JR1035

ENTER

S1127

R1115

Q1120

TP0075

E

S1126

R1116

R1117

R1118

RETURN

S1125

G

JR1027

JR

USB A

JR

JR1003

S1124

H

R1119

1 4

TP0060

CN1102

TP0059

TP0058

TP0057

L

USB BOARD

NO1000

(Page 36)

I

TUNING +

JR

R1198

R1199

TP0076

JR1025

TUNING -

JR1015

JR1026

JR

JR

JR

TAPE/PC

JR

D1110

JR1032

JR

TP0074

JR1014

D1109

USB

JR1022

JR

S1115

R1195

S1113

JR1023

TP0077

E

R1196

D1105

JR

JR1028

S1119

R1105

R1108

JR

Q1119

K

VOL BOARD

NO1103

(Page 36)

1 3

TP0033

TP0032

R1102

R1103

R1104

S1114

JR

JR

TP0034

JR1034

JR1024

CN1103

• : Utilizada solda sem chumbo

N

MAIN BOARD

CN405

(Page 32)

2

22

C1150

JR

TP0062

R1160

1

23

27

52

TP0015

C1137

26

1

C1147

C1136

JR1006

JR

CN1105

TP0004

TP0071

C1155

TP0023

JR

TP0017

TP0012

JR1008

TP0014

JR

14

13

TP0068

JR1036

TP0007

TP0063

TP0016

Q1121

R1107

+

-

TP0022

R1207

TP0078

TP0027

E

JR1012

R1190

TP0073

TP0019

TP0024

TP0018

TP0020

TP0026

S1117

R1201

JR

E

R1189

JR

S1110

TP0009

TP0072

Q1118

IC1101

39

40

D1107

JR1011

JR1001

TP0061

R1100

S1118

D1108

D1106

S1111

JR

JR

JR1002

R1203

R1205

S1116

R1106

S1112

R1101

TUNER

BAND

JR1004

CD

JR

JR

JR

TP0011

JR1019

TP0079

C1156

TP0069

JR1007

JR1009

JR1033

JR

JR1020

TP0066

TP0065

TP0070

JR

JR

JR1018

TP0006

TP0081

TP0083

TP0085

TP0087

TP0089

TP0091

TP0093

TP0095

TP0097

TP0098

TP0064

R1215

TP0100

TP0102

TP0104

TP0106

TP0108

TP0110

TP0112

ERASE

TP0010

TP0080

TP0082

TP0084

TP0086

TP0088

TP0090

TP0092

TP0094

TP0096

C1152

C1153

R1211

R1210

R1209

C1151

TP0099

TP0101

TP0103

TP0105

TP0107

TP0109

TP0111

12 54535 503118

TP0008

D1102

R1158

S1104

TP0002

TP0001

TP0005

JR

R1170

JR1021

FL1100

JR1016

JR

JR

JR

JR

EQ BAND/

SURROUND

JR1013

JR1029

JR

JR

JR1031

JR1005

JR1017

PRESET EQ

GROOVE

S1105

R1169

JR

JR1030

R1161

S1106 S1107

R1168

R1171

E

R1167

Q1122

1-881-085-

SUBWOOFER

S1109

D1104

R1166

R1174

R1173

12

(12)

IC1100

VCC

O

J

DISC 3

HCD-GTR66/GTR88

S1131

R1120

DISC 2

S1130

R1121

DISC 1

S1129

24

REC TIMER

S1108

R1165

OPTIONS

S1103

R1164

METER

MODE

R1163

DISPLAY

R1162

S1101S1102

"/1

STANDBY

D1101

S1100

5-6. DIAGRAMA ESQUEMÁTICO - Placa DISPLAY -

1 2 3 4 5 6 7 8 9 10 11 14 1512 13

A

HCD-GTR66/GTR88

B

C

D

E

F

G

H

N

MAIN

BOARD

(1/3)

CN405

(Page 33)

K

VOL

BOARD

NO1103

(Page 37

L

USB

BOARD

NO1000

(Page 37

DISPLAY BOARD

FL1100

FLUORESCENT INDICATOR TUBE

156789101112131415161718313233343536373839404142434445464748495054 253

G1

G2

G3

G4

G5

G6

G7

G8

G9

G10

G11

G12

G13

S1S2S3S4S5S6S7S8S9

CN1105

23P

TP0015

TP0016

TP0007

TP0014

TP0008

TP0006

TP0005

TP0004

TP0009

TP0017

TP0023

TP0022

TP0001

TP0019

TP0020

TP0010

TP0018

TP0012

TP0002

TP0011

TP0024

TP0026

TP0027

TP0032

TP0033

TP0034

TP0057

TP0058

TP0059

TP0060

FL_DATA

FL_CLK

FL_CS

AD_KEY0

SIRCS

SW_LED

LED_VOL3.4

LED_VOL5.6

AD_KEY1

LED_VOL1.2

AD_KEY2

R1162

R1163

680

AD_KEY0

D1101

SLI-325URT31WR

R1161

1k

VOL

AD_KEY2

SIRCS

AD_KEY1

VOL

D1104

SLR-325MCT31

SUBWOOFER

/

STANDBY

IC1100

3.5

3.5

REMOTE CONTROL

1

VCC

2

OUT

3

GND

RECEIVER

IC1100

PNA4823M03S0

D1110 D1109 D1108 D1106 D1105

S1100 S1102 S1103S1101 S1109S1108 S1107 S1106 S1104S1105

/

STANDBY

R1113

OPEN/CLOSE

R1100

S1110 S1111 S1112 S1113 S1114 S1115 S1116 S1117 S1118 S1119

- +

1k

DISPLAY OPTIONS GROOVE

R1114

680

DISC SKIP/

EX-CHANGE

R1101

1k

680

D1105-1110

1L0351V22F0MIT01

STREAM

R1189

R1190

680

680

23

FL-DATA

22

FL-CLK

21

DGND

20

FL-CS

19

FL+3.3V

18

VF

17

-VG

16

VF

15

AD KEY0

14

SIRCS

EVER +3.3V

13

STBY LED

12

AD KEY1

AD KEY2

LED GND

DGND

LED SEL B

LED SEL A

LED2

LED3

LED1

SEL A

SEL B

11

10

9

8

7

6

VOL

5

4

3

2

1

CN1103

3P

1

2

3

VOL

CN1102

4P

1

2

3

4

SW/USB_LED

USB LED CTRL

DET SWITCH

)

SW/USB_LED

USB LED CTRL

)

S10

S12

S13

S14

S15

S16

S17

S18

S19

S11

D1102

MAZ8082GMLS0

R1165

R1164

1.5k

METER

MODE

R1115

1.5k

1k

REC TO

USB B

USB B

R1102

1.5k

TUNING -

D1107

1.5k

R1103

R1116

1.5k

R1166

REC

TIMER

1.5k

S1124S1128 S1127 S1125S1126 S1130S1132 S1131 S1129S1133

R1104

USB

S20

R1158

C1137

47k

50V

R1168

R1167

2.2k

3.3k

SUBWOOFER

R1117

2.2k

2.2k

TUNING +

PRESET

EQ

R1118

3.3k

ENTER RETURNUSB A DISC 3 DISC 2 DISC 1

R1105

3.3k

R1106

4.7k

R1119

4.7k

R1169

6.8k

EQ BAND/

SURROUND

R1120

6.8k

4.7k

R1107

6.8k

TUNER/

BAND

G14

C1136

R1160

2.2

47k

2.2

R1170

10k

R1121

10k

R1108

10k

TAPE/PCCD

ERASE

50V

-31.0

G7

G8

-31.0

-31.0

G9

-31.0

G10

G11

-31.0

-31.0

G12

-31.0

G13

-31.0

G14

C1156

TP0061

TP0062

-33.2

3.3

C1150

0.1

0.1

C1147

22

50V

FL_CLK

FL_DATA

FL_CS

G6

40

GR7

41

GR8

42

GR9

43

GR10

44

GR11

45

GR12

46

GR13

47

GR14

48

GR15

49

GR16

50

VEE

51

VDD

52 14

GND

12345678910111213

2.9 0.8 2.6 1.8 3.3

C1155

47

10V

R1209

100

R1210

100

R1211

100

G4

G5

-31.0

-31.0

GR5

GR6

CLK

DIN

G2

G3

G1

-31.0

-31.0

-31.0

-31.0

GR1

GR2

GR3

GR4

IC B/D

IC1101

FLUORESCENT INDICATOR

TUBE DRIVER

IC1101

PT6324-Q

STB

DOUTK1K2

TP0068

TP0069

TP0070

R1215

100k

C1151

100p

C1152

100p

C1153

100p

-24.4

SG23/KS23

SG24/KS24

OSC

GND

-26.5

SG22/KS22

VDD

-22.3

SG21/KS21

SG1/KS1

TP0063

-26.5

2930313233343536373839

SG20/KS20

SG2/KS2

TP0064

-30.8

28

SG19/KS19

SG3/KS3

TP0065

-24.4

-32.9

27

SG18/KS18

SG17/KS17

SG16/KS16

SG15/KS15

SG14/KS14

SG13/KS13

SG12/KS12

SG11/KS11

SG10/KS10

SG9/KS9

SG8/KS8

SG7/KS7

SG6/KS6

SG5/KS5

SG4/KS4

TP0066

26

25

24

23

22

21

20

19

18

17

16

15

S1

S2

S3

S4

S5

S6

S7

S8

-26.5

S9

-32.7

S10

-29.8

S11

-24.3

S12

-20.0

S13

-24.2

S14

-24.2

S15

-22.1

S16

-26.3

S17

-32.7

S18

-32.7

S19

-26.4

S20

-30.6

I

J

HCD-GTR66/GTR88

6.0

0.1

Q1121

2SC3052EF-T1-LEF

R1207

R11731kR1174

1k

SW_LED

10k

R1171

10k

Q1122

2SC3052EF-T1-LEF

LED DRIVELED DRIVE

0.1(0.5)

<<0.5>>

6.0(2.1)<<2.1>>

LED_VOL1.2

R1201

10k

Q1118

2SC3052EF-T1-LEF

7.4

0

LED_VOL3.4

R1203

10k

R1195

680

Q1119

2SC3052EF-T1-LEF

R1196

10k

Q1120

2SC3052EF-T1-LEF

LED DRIVELED DRIVELED DRIVE

R1199

TP0075TP0074TP0073

680

8.3

0

7.5

R1198

680

LED_VOL5.6

R1205

680

0

25

Loading...

Loading...