Sony MEX-1-HD Service manual

MEX-1HD

SERVICE MANUAL

Ver 1.3 2004.02

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

(US model only)

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

23 watts per channel minimum continuous average power into 4 ohms,

4 channels driven from 20 Hz to 20 kHz with no more than 5% total

harmonic distortion.

CD Player section

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

“MG Memory Stick” section

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

Recording time (when using the supplied 64MB

“MagicGate Memory Stick”)

Recording format Adaptive Transform

HDD section

Capacity 10 GB

Recording format Adaptive Transform

Frequency response 20 to 20,000 Hz

Tuner section

FM

Tuning range 87.5 – 107.9 MHz

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

Approx. 60 min. (132kbps)

Approx. 80 min. (105kbps)

Acoustic Coding 3

(ATRAC3)

Acoustic Coding 3

(ATRAC3)

(single signal measurement)

72 dB (mono)

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

AM

Tuning range 530 – 1,710 kHz

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

Power amplifier secti on

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power output 52 W × 4 (at 4 ohms)

General

Outputs Audio outputs (front/rear)

Inputs Telephone ATT control

US Model

Canadian Model

Australian Model

Model Name Using Similar Mechanism NEW

CD Drive Mechanism Type MG-550D-156

Optical Block Name CDM-3021EBG

Optical Pick-up Name DAX-21EG

0.6 % (stereo),

0.3 % (mono)

(sure seal connectors)

Subwoofer output (mono)

Power antenna relay control

terminal

Power amplifier control

terminal

terminal

Illumination control

terminal

AUX IN terminal

Antenna input terminal

Tone c ontrols Bass ±8 dB at 100 Hz

Loudness +8 dB at 100 Hz

Power requirements 12 V DC car battery

Dimensions

Mounting dimensions

Mass Approx. 2.0 kg

Supplied accessories Parts for installation and

Note

This unit cannot be connected to a digital preamplifier

or an equalizer.

Design and specifications are subject to change

without notice.

Treble ±8 dB at 10 kHz

+2 dB at 10 kHz

(negative ground)

Approx. 178 × 50 × 182 mm

(7 1/8 × 2 × 7 1/4 in.)

(w/h/d)

Approx. 182 × 53 × 161 mm

1

(7

/4 × 2 1/8 × 6 3/8 in.)

(w/h/d)

(4 lb. 7 oz.)

connections (1 set)

Front panel case (1)

Cleaning cloth (1)

Digital I/O cable (1)

E Model

9-873-923-04 Sony Corporation

2004B05-1 e Vehicle Company

© 2004.02 Published by Sony Engineering Corporation

AUDIO LIBRARY SYSTEM

MEX-1HD

Ver 1.1

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 5

2. GENERAL

Location of Controls ....................................................... 7

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 10

3-2. Cover ............................................................................... 11

3-3. Base Panel Assy .............................................................. 11

3-4. Sub Panel (CD) Assy ...................................................... 12

3-5. Mechanism Deck (MG-550D-156) ................................ 12

3-6. Motor Block Assy, Cam Block Assy .............................. 13

3-7. Motor Assy (Front Panel Open/Close) (M601),

SWITCH Board............................................................... 13

3-8. MAIN Board, POWER Board ........................................ 14

3-9. Hard Disk Drive (2.5 inch) Unit..................................... 15

3-10. SUB Board ...................................................................... 15

3-11. Heat Sink, DC Fan (M501) ............................................. 16

3-12. Belt (L), LE Motor Assy (Tray Open/Close) (M103).... 16

3-13. Tray (UD) Assy ............................................................... 17

3-14. OP Assy (CDM-3021EBG) ............................................ 17

3-15. SERVO Board ................................................................. 18

4. ASSEMBLY

4-1. Assembly Flow ................................................................ 19

4-2. Motor Block Assy ........................................................... 19

4-3. Cam Block Assy .............................................................. 20

4-4. Phase Alignment of Motor Block Assy and

Cam Block Assy.............................................................. 20

6-28. Printed Wiring Board

– SUB Board (Conductor Side) – ................................... 55

6-29. Printed Wiring Board – POWER Board –..................... 56

6-30. Schematic Diagram – POWER Board – ........................ 57

6-31. Printed Wiring Board – DISPLAY Board – .................. 58

6-32. Schematic Diagram – DISPLAY Board – ..................... 59

6-33. IC Pin Function Description ........................................... 69

7. EXPLODED VIEWS

7-1. Cover Section................................................................. 97

7-2. Front Panel Section ........................................................ 98

7-3. ARM Section.................................................................. 99

7-4. Hard Disk, POWER Board Section...............................100

7-5. MAIN Board Section ..................................................... 101

7-6. Chassis Section ..............................................................102

7-7. SUB Board Section ........................................................103

7-8. Mechanism Deck Section (MG-550D-156) .................. 104

8. ELECTRICAL PARTS LIST ..............................106

5. TEST MODE.............................................................. 21

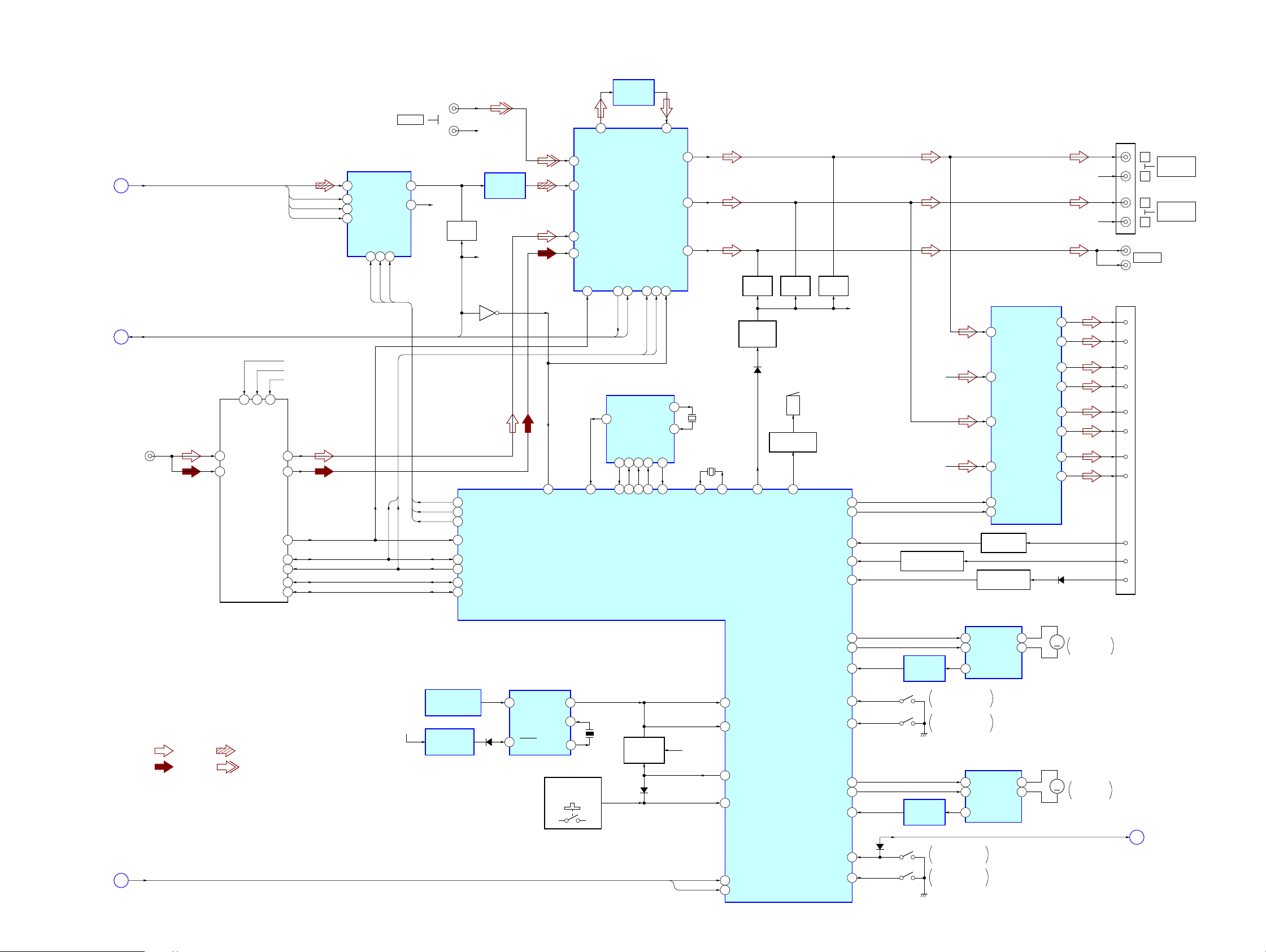

6. DIAGRAMS

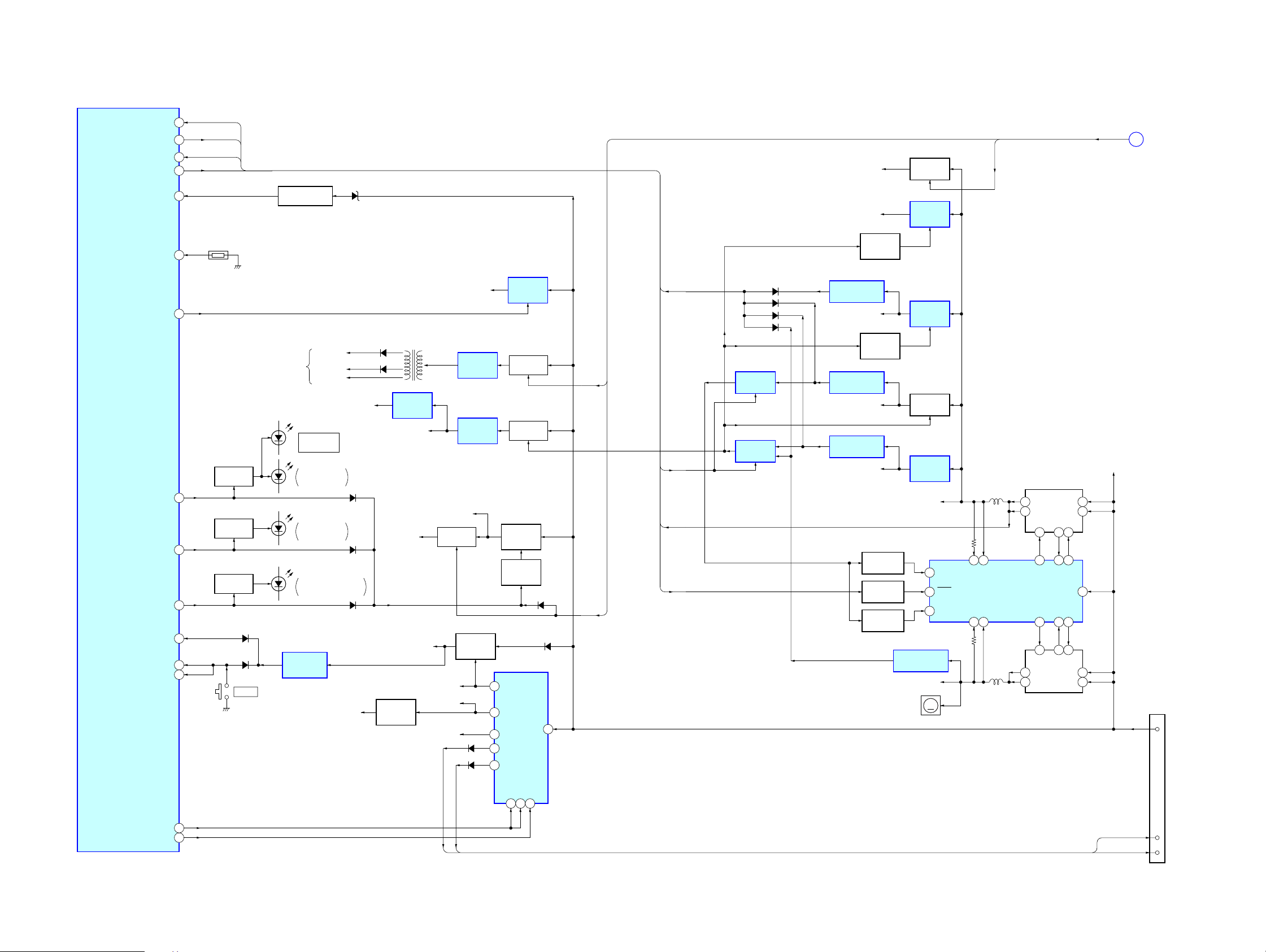

6-1. Block Diagram

– SERVO, HD/MS/USB INTERFACE Section – .......... 27

6-2. Block Diagram – CPU, DISPLAY Section – ................ 28

6-3. Block Diagram – AUDIO, SYSTEM Section – ............ 29

6-4. Block Diagram – POWER SUPPLY Section –............. 30

6-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 31

6-6. Printed Wiring Board – SERVO Board (Side A) – ....... 32

6-7. Printed Wiring Board – SERVO Board (Side B) – ....... 33

6-8. Schematic Diagram – SERVO Board (1/3) –................ 34

6-9. Schematic Diagram – SERVO Board (2/3) –................ 35

6-10. Schematic Diagram – SERVO Board (3/3) – ................ 36

6-11. Printed Wiring Board – MAIN Board (Side A) – ......... 38

6-12. Printed Wiring Board – MAIN Board (Side B) – ......... 39

6-13. Schematic Diagram – MAIN Board (1/9) – ................... 40

6-14. Schematic Diagram – MAIN Board (2/9) – ................... 41

6-15. Schematic Diagram – MAIN Board (3/9) – ................... 42

6-16. Schematic Diagram – MAIN Board (4/9) – ................... 43

6-17. Schematic Diagram – MAIN Board (5/9) – ................... 44

6-18. Schematic Diagram – MAIN Board (6/9) – ................... 45

6-19. Schematic Diagram – MAIN Board (7/9) – ................... 46

6-20. Schematic Diagram – MAIN Board (8/9) – ................... 47

6-21. Schematic Diagram – MAIN Board (9/9) – ................... 48

6-22. Schematic Diagram – SUB Board (1/5) – ...................... 49

6-23. Schematic Diagram – SUB (2/5)/SWITCH Boards – .... 50

6-24. Schematic Diagram – SUB Board (3/5) – ...................... 51

6-25. Schematic Diagram – SUB Board (4/5) – ...................... 52

6-26. Schematic Diagram – SUB Board (5/5) – ...................... 53

6-27. Printed Wiring Boards

– SUB (Component Side)/Switch Boards – ................... 54

2

MEX-1HD

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes

•The recorded music is limited to private use only.

Use of the music beyond this limit requires

permission of the copyright holders.

•Sony is not responsible for music files that are not

saved on this unit due to unsuccessful recording

from CD or music downloading.

•Sony is not responsible for any files that are

damaged or erased from the hard disc.

Notes on CD-Rs (recordable CDs)/CDRWs (rewritable CDs)

This unit can play the following discs:

Type of discs Label on the disc

Audio CD

MP3 files

•Some CD-Rs/CD- RWs (depending on the

equipment used for its recording or the

condition of the disc) may not play on this u nit.

•You cannot play a CD-R/CD-RW that is not

finalized*.

•You can play MP3 files recorded on CDROMs, CD-Rs, and CD-RWs.

•A CD-R/CD-RW to which a session can be

added can be played.

* A process necessary for a recorded CD-R/CD-RW

disc to be played on the audio CD player.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

3

MEX-1HD

Notes on MP3 files

MP3 (MPEG 1 Audio Layer-3) is a standard

technology and format for compressing a sound

sequence. The file is compressed to about 1/10 of

its original size. Sounds outside the range of

human hearing are compressed while the sounds

we can hear are not compressed.

Notes on discs

Yo u can play MP3 files recorded on CD-ROMs,

CD-Rs, and CD-RWs.

The disc must be in the ISO 9660*

level 2 format, or Joliet or Romeo in the

expansion format.

Yo u can use a disc recorded in Multi Session*

1

ISO 9660 Format

*

The most common international standard for

the logical format of files and folders on a

CD-ROM.

There are several specification levels. In

Level 1, file names must be in the 8.3 format

(no more than 8 characters in the name, no

more than 3 characters in the extension

“.MP3”) and in capital letters. Folder names

can be no longer than 8 characters. There can

be no more than 8 nested folder levels. Level

2 specifications allow file names up to 31

characters long.

Each folder can have up to 8 trees.

For Joliet or Romeo in the expansion format,

make sure of the contents of the writing

software, etc.

2

*

Multi Session

This is a recording method that enables

adding of data using the Track-At-Once

method. Conventional CDs begin at a CD

control area called the Lead-in and end at an

area called Lead-out. A Multi Session CD is a

CD having multiple sessions, with each

segment from Lead-in to Lead-out regarded

as a single session.

CD-Extra: The format which records audio

(audio CD data) as tracks on session 1, and

records data as tracks on session 2.

Mixed CD: In this format, data is recorded as

track, and audio (audio CD data) is recorded

as track 2.

1

level 1 or

Notes

• With formats other than ISO 9660 level 1 and level 2,

fold er names or file names may not be displayed

correctly.

• When naming, be sure to add the file extension

“.MP3” to the file name.

• If you put the extension “.MP3” to a file other than

MP3, the unit cannot recognize the file properly and

will generate random noise that could damage your

speakers.

• The following discs take a longer time to start

playback.

–a disc recorded with a complicated tree structure.

–a disc recorded in Multi Session.

–a disc to which data can be added.

Cautions when playing a disc that is recorded in

Multi Session

• When the first track of the first session is audio CD

2

.

data:

Only audio CD data is played back.

• When the first track of the first session is not audio

CD data:

– If an MP3 file is in the disc, only MP3 file(s) play

back and other data is skipped. (Audio CD data is

not recognized.)

– If no MP3 file is in the disc, “NO Music” is

displayed and nothing is played back. (Audio CD

data is not recognized.)

4

SECTION 1

SERVICING NOTES

MEX-1HD

Ver 1.1

NOTES ON HANDLING THE OPTICAL PICKUP BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

Laser Diode Properties

• Material: GaAlAs

•Wavelength: 780 nm

• Emission Duration: continuous

• Laser Output Power: less than 44.6 µW*

*This output is the value measured at a distance of 200 mm

from the objective lens surface on the Optical Pick-up Block.

CHECKING THE VERSION BEFORE REPLACEMENT OF

FLASH MEMORY (IC1030 ON MAIN BOARD)

This set is available with two types, Initial Lot type and User Upgrade type, depending on the software version used in the microcomputer.

If the Flash Memory (IC1030 on MAIN board) or mounted MAIN

board was replaced, the work (*1) required after parts replacement is different according to the type. Therefore, before parts

replacement, check the type of set, and then perform the work

(*1) necessary for that type. However, if the version check is impossible because of a trouble in the set, handle it as a User Upgrade type.

*1: For the work required after parts replacement, refer to “Setup

After Parts Replacement” and “Ver sion Up After Microcomputer Software Related Parts Replacement” (page 22) in the

following section.

Procedure for check the version:

1. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

2. Rotate the right jog dial (PUSH LIST) to select the “Version”,

and press the right jog button (PUSH LIST) to enter the Version mode.

3. With the “Version” mode activated, press the right jog button

(PUSH LIST), and the versions of Main, Sub, CD Servo will

be displayed respectively. Check the version of “Main”.

Version by type:

Initial Lot type : 1.00.05

User Upgrade type : 2.03.02

SETUP AFTER PARTS REPLACEMENT

This set requires the work such as microcomputer software version up, system ID setting and HDD formatting, if either of flash

memory, microcomputer (or mounted MAIN, SUB, or SERVO

board) and hard disk drive (HDD) was replaced.

Perform the work required by referring to the “Test mode”, if either of the following parts was replaced.

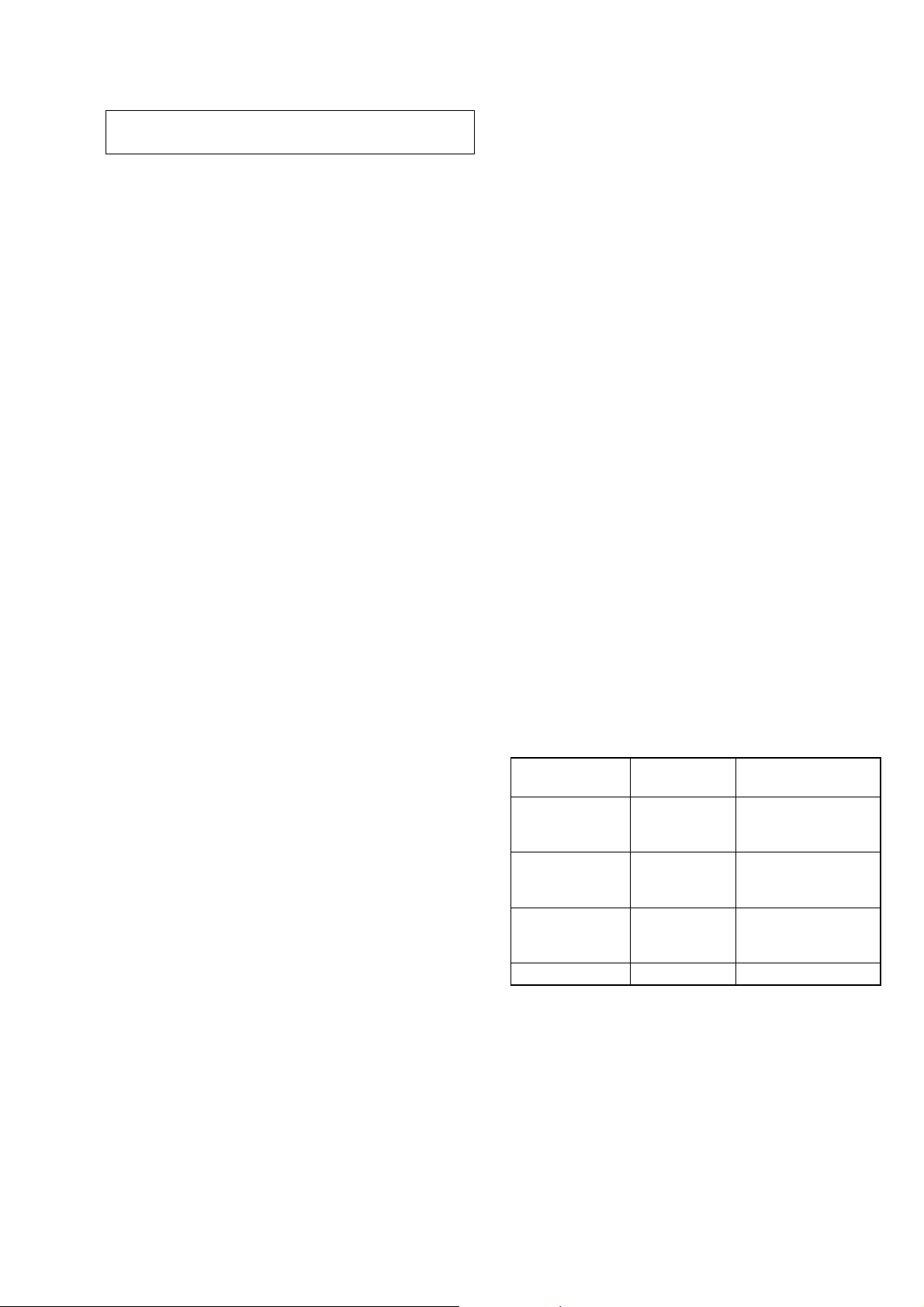

Replacement Version up System ID setting

parts and HDD processing

Flash memory

(IC1030 on MAIN

board) *1

Microcomputer

(IC501 on SUB

board) *1

Flash memory

(IC9 on SERVO

board) *1

HDD

*1: Including the case where the mounted board as a whole is re-

placed.

*2: Executing the HDD formatting causes the user’s recorded data

to be all erased, and therefore be careful not to execute this

operation by mistake if the HDD was not replaced.

aa

a –

a –

– a *2

Version up:

Refer to “Version Up After Microcomputer Software Related

Parts Replacement”.

System ID setting and HDD processing:

Refer to “Relating with ID”.

5

MEX-1HD

Ver 1.1

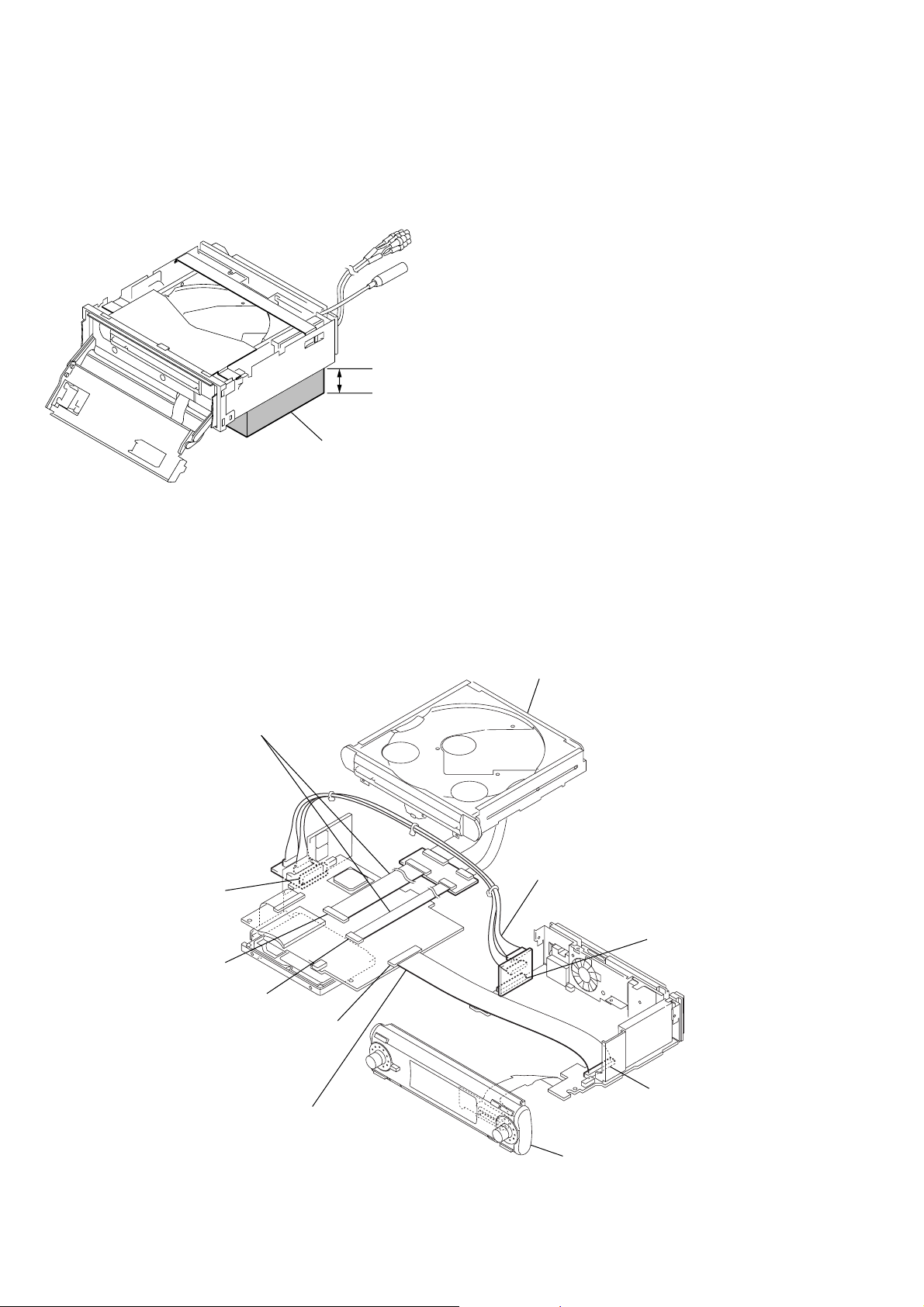

NOTE FOR THE OPENING OF THE FRONT PANEL

In this set, the front panel is lowered to below the bottom face

when it is opened.

When servicing the set, place it on a stand having a height of about

2 cm.

2 cm

stand

JIG ON REPAIRING

When repairing this set, connect the extension cables as the figure

shown below.

Connect jig (extension cables J-2502-069-3 :

0.5mm Pitch, 20/40 cores, Length 250mm)

to the mechanism deck and the main board

(CN2002, CN2003).

power board (CN702)

main board (CN2002)

main board (CN2003)

mechanism deck

Connect jig (extension cable J-2502-069-1 :

24 cores) to the power board (CN702) and

the sub board (CN525).

sub board (CN525)

main board (CN3002)

sub board (CN526)

Connect jig (extension cable J-2502-069-2 :

0.5mm Pitch, 50 cores, Length 300mm)

to the main board (CN3002) and

the sub board (CN526).

front panel section

6

SECTION 2

W

GENERAL

MEX-1HD

This section is extracted from

instruction manual.

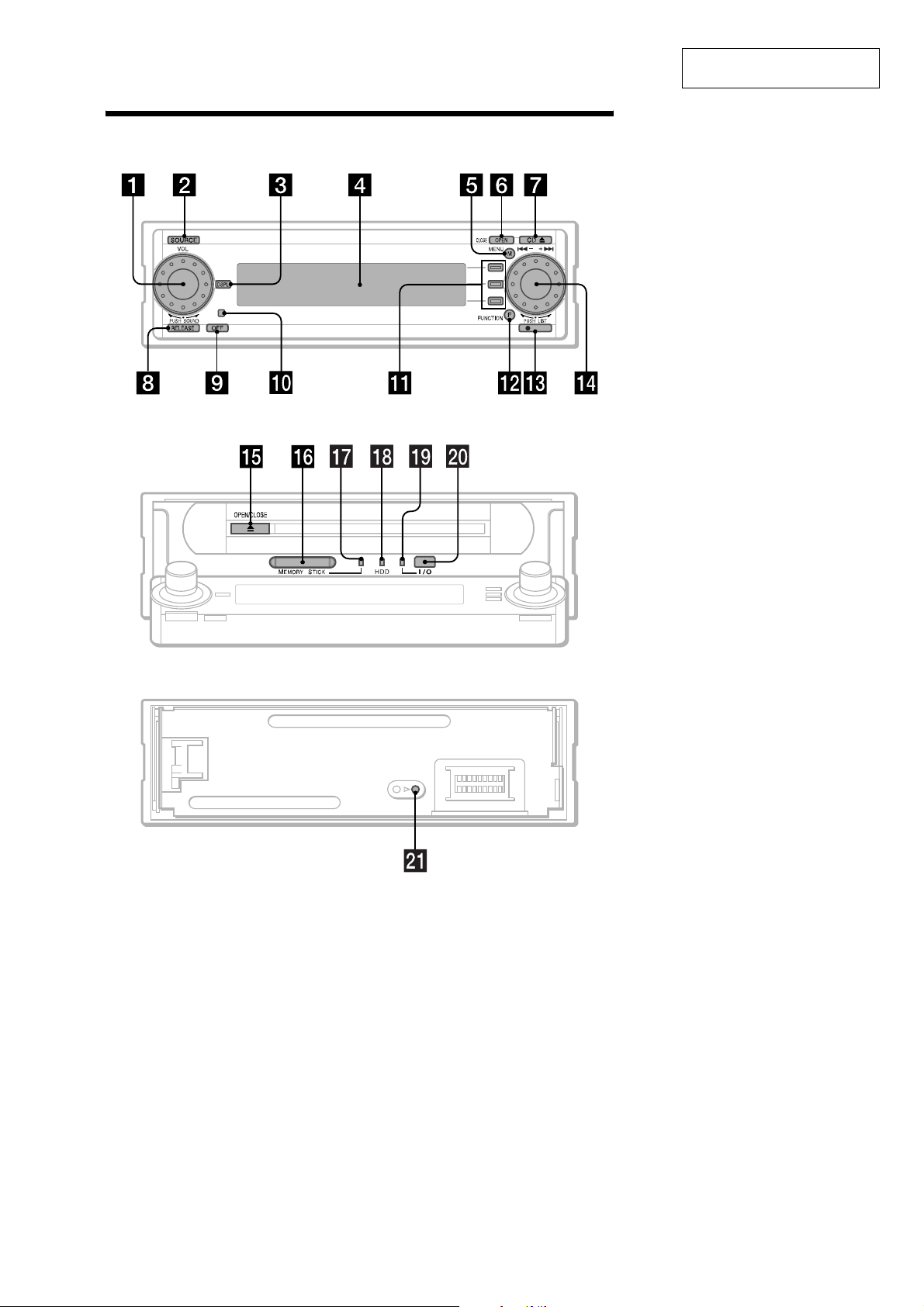

Location of controls

hen the front panel is opened

When the front panel is remove

a L (left) dial

Rotate to:

– Adjust the volume

– Select a sound item

Press to:

– Display the sound menu

– Enter a setting

b SOURCE button

To sel ect the source.

c DSPL button

d Display window

e MENU button

To display the menu s.

f OPEN (CLOSE) button

REC

d

g CD Z (eject) button

h RELEASE button

i OFF (Stop/Power of f) button*

j Receptor for remote commander

k F1/F2/F3 buttons

These buttons have different functions

depending on the si tu at i on.

l FUNCTION button

To change the function menu.

m z REC button

For record settings/to start recording.

n R (right) dial

Rotate to:

– Receive preset stations

– Skip tracks

– Select a menu item

Press to:

– Display the list

– Enter a setting

o Z (OPEN/CLOSE)

p “MG Memory Stick” Slot

q LED (“MG Memory Stick”)

Lights up while the unit is accessing the

“MG Memory Stick”.

r LED (HDD)

Lights up while the unit is accessing the

HDD.

s LED (I/O)

Lights up while the unit is accessing the

Digital I/O.

t Digital I/O terminal (4 pins)

To connect to the Network Walkman, etc.

u RESET button

* War ning when in s t a lling in a car without

an ACC (accessory) position on the

ignition switch

After turning off the ignition, be sure to press

on the unit for 2 seconds to turn off the

(OFF)

clock display.

Otherwise, the clock display does not turn off

and causes battery drain.

7

MEX-1HD

3

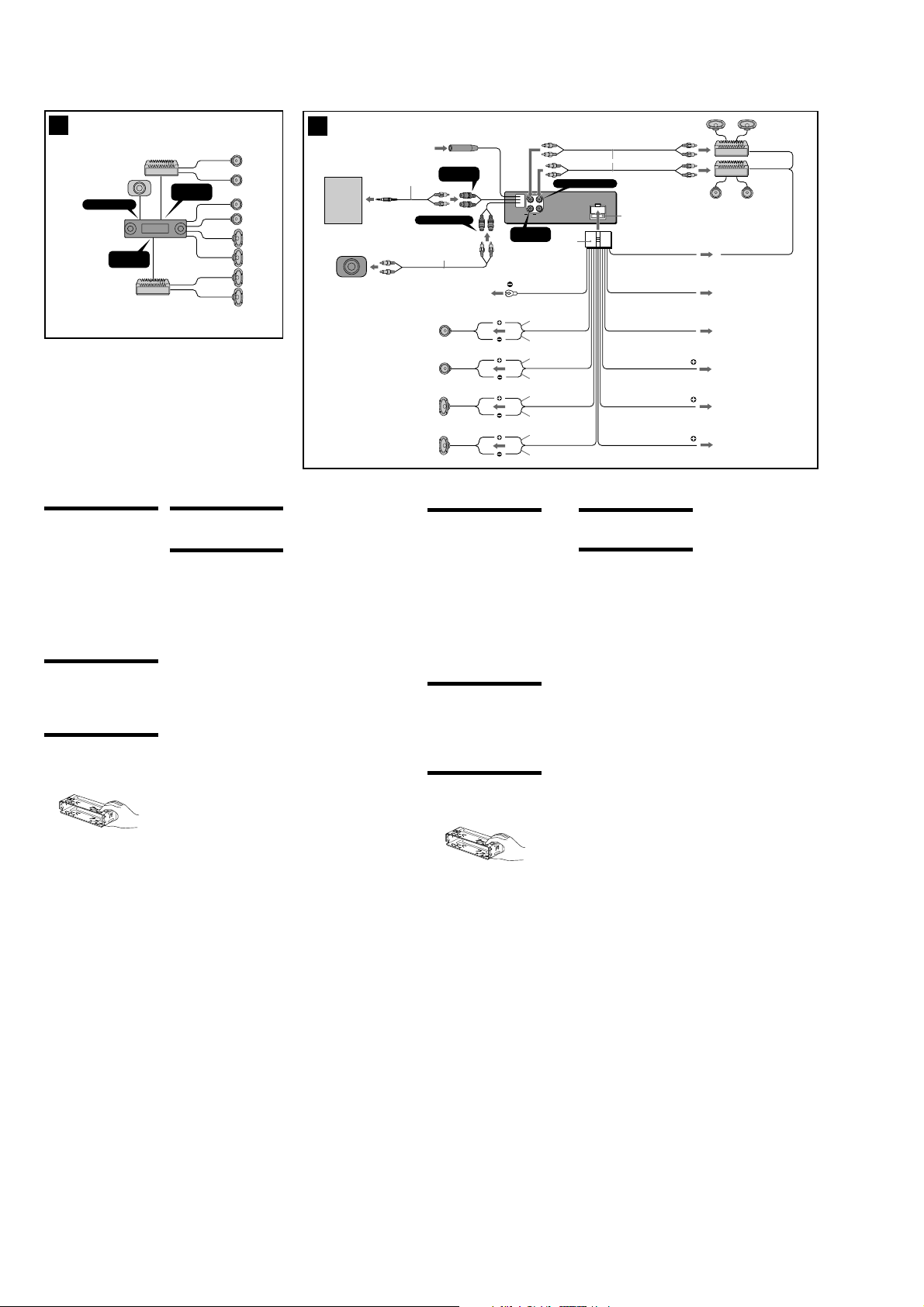

BUS AUDIO IN

SUB OUT (MONO)

AUDIO OUT

REAR

Cautions

•This unit is designed for negative ground 12 V

DC operation only.

•Do not get the wires under a screw, or caught

in moving parts (e.g. seat railing).

•Before making connections, turn the car

ignition off to avoid short circuits.

•Connect the yellow and red power input leads

only after all other leads have been connected.

•Run all ground wires to a common ground

point.

•Be sure to insulate any loose unconnected

wires with electrical tape for safety.

•The use of optical instruments with this

product will increase eye hazard.

Notes on the power supply cord (yellow)

•When connecting this unit in combination with

other stereo components, the connected car

circuit’s rating must be higher than the sum of

each component’s fuse.

•When no car circuits are rated high enough,

connect the unit directly to the battery.

Before installation ( 1)

Do not install the unit where its operation

interferes with driving.

Example:

—Opening and closing of the front panel or

disc tray interfere with operation of the gear

shift.

—With the front panel open, operation of

hazard lamps, switches etc., is impaired.

Parts Iist (2)

The numbers in the list are keyed to those in the

instructions.

Caution

Handle the bracket 1 carefully to avoid injuring

your fingers.

T

O

P

AUDIO OUT

FRONT

Connection example (3)

Note

Be sure to connect the ground cord before

connecting the amplifier.

Connection diagram (4)

1 To a metal surface of the car

• First connect the black ground lead, then

connect the yellow and red power input leads.

• Be sure to ground to the chassis of the car

securely.

2 To the power antenna control lead or power

supply lead of antenna booster amplifier

Notes

• It is not necessary to connect this lead if there

is no power antenna or antenna booster, or

with a manually-operated telescopic antenna.

•When your car has a built-in FM/AM antenna in

the rear/side glass, see “Notes on the control

and power supply leads.”

3 To AMP REMOTE IN of an optional power

amplifier

This connection is only for amplifiers. Connecting

any other system may damage the unit.

4 To the interface cable of a car telephone

5 To a car’s illumination signal

Be sure to connect the black ground lead to it

first.

6 To the +12 V power terminal which is energized

in the accessory position of the ignition key

switch

Notes

• If there is no accessory position, connect to the

+12 V power (battery) terminal which is

energised at all times.

Be sure to connect the black ground lead to it

first.

•When your car has a built-in FM/AM antenna in

the rear/side glass, see “Notes on the control

and power supply leads.”

7 To the +12 V power terminal which is energised

at all times

Be sure to connect the black ground lead to it

first.

4

Notes on the control and power supply leads

• The power antenna control lead (blue) supplies

+12 V DC when you turn on the tuner.

•When your car has built-in FM/AM antenna in the

rear/side glass, connect the power antenna control

lead (blue) or the accessory power input lead (red)

to the power terminal of the existing antenna

booster. For details, consult your dealer.

•A power antenna without relay box cannot be

used with this unit.

Memory hold connection

When the yellow power input lead is connected,

power will always be supplied to the memory circuit

even when the ignition key is turned off.

Notes on speaker connection

• Before connecting the speakers, turn the unit off.

•Use speakers with an impedance of 4 to 8 ohms,

and with adequate power handling capacities to

avoid its damage.

• Do not connect the speaker terminals to the car

chassis, or connect the terminals of the right

speakers with those of the left speaker.

• Do not connect the ground lead of this unit to the

negative (–) terminal of the speaker.

• Do not attempt to connect the speakers in parallel.

• Connect only passive speakers. Connecting active

speakers (with built-in amplifiers) to the speaker

terminals may damage the unit.

• To avoid a malfunction, do not use the built-in

speaker wires installed in your car if the unit shares

a common negative (–) lead for the right and left

speakers.

• Do not connect the unit’s speaker cords to each

other.

XM tuner

Récepter XM

DNR-XM01C

from car antenna

à partir de l’antenne de la

voiture

AUX IN

3

*

(AUDIO)

2

*

SUB OUT (MONO)

1

*

1

Left

Gauche

Right

Droit

Left

Gauche

Right

Droit

Prcautions

•Cet appareil est exclusivement conçu pour

fonctionner sur une tension de 12 V CC avec

masse négative.

•Evitez de fixer des vis sur les câbles ou de

coincer ceux-ci dans des pièces mobiles (par

exemple, armature de siège).

•Avant d’effectuer des raccordements, éteignez

le moteur pour éviter les courts-circuits.

•Raccordez les fils d’entrée d’alimentation

jaune et rouge seulement après avoir terminé

tous les autres raccordements.

•Rassemblez tous les fils de terre en un point

de masse commun.

•Veillez à isoler avec du chatterton tout fil lâche

non raccordé.

Remarques sur le cordon d’alimentation

(jaune)

•Lorsque cet appareil est raccordé à d’autres

appareils stéréo, la valeur nominale des

circuits de la voiture raccordée doit être

supérieure à la somme des fusibles de chaque

appareil.

•Si aucun circuit de la voiture n’est assez

puissant, raccordez directement l’appareil à la

batterie.

Avant linstallation ( 1)

N’installez pas l’appareil dans un endroit où il

pourrait gêner le conducteur dans ses

mouvements.

Exemple :

— dans un endroit où l’ouverture et la

fermeture de la façade ou du plateau de

disque pourraient nuire aux changements de

vitesse ;

— dans un endroit où l’ouverture de la façade

pourrait bloquer l’accès à l’interrupteur de

feux de détresse et aux autres commandes.

Liste des composants (2)

Les numéros de la liste correspondent à ceux des

instructions.

Attention

Manipulez avec précautions le support 1 pour

éviter de vous blesser aux doigts.

T

O

P

AUDIO OUT

REAR

Black

Noir

White

Blanc

White/black striped

Rayé blanc/noir

Gray

Gris

Gray/black striped

Rayé gris/noir

Green

Vert

Green/black striped

Rayé vert/noir

Purple

Mauve

Purple/black striped

Rayé mauve/noir

AUDIO OUT FRONT

L

R

FRONTAUDIO OUT REAR

5

Exemple de raccordement (3)

Remarque

Raccordez d’abord le fil de masse avant de raccorder

l’amplificateur.

Schma de raccordement (4)

1

À un point métallique de la voiture

•Branchez d‘abord le fil de masse noir et,

ensuite, les fils d‘entrée d‘alimentation jaune

et rouge.

•Assurez-vous de relier solidement le châssis du

véhicule à la masse.

2

Vers le fil de commande de l‘antenne électrique

ou le fil d‘alimentation de l‘amplificateur

d‘antenne

Remarques

• Il n'est pas nécessaire de raccorder ce fil s'il n'y

a pas d'antenne électrique ni d'amplificateur

d'antenne, ou avec une antenne télescopique

manuelle.

• Si votre voiture est équipée d'une antenne FM/

AM intégrée dans la vitre arrière/latérale, voir

“Remarques sur les fils de commande et

d'alimentation”.

3

Vers AMP REMOTE IN de l’amplificateur de

puissance en option

Ce raccordement s’applique uniquement aux

amplificateurs. Le branchement de tout autre

système risque d’endommager l’appareil.

4

Vers le câble d’interface d’un téléphone de

voiture

5

Au signal d’éclairage de la voiture

Raccordez d‘abord le fil de masse noir.

6

À la borne +12 V qui est alimentée quand la clé

de contact est sur la position accessoires

Remarques

• S'il n'y a pas de position accessoires, raccordez

la borne d'alimentation (batterie) +12 V qui

est alimentée en permanence.

Raccordez d‘abord le fil de masse noir.

• Si votre voiture est équipée d'une antenne FM/

AM intégrée dans la vitre arrière/latérale, voir

“Remarques sur les fils de commande et

d'alimentation”.

7

À la borne +12 V qui est alimentée en permanence

Raccordez d‘abord le fil de masse noir.

1

*

Fuse (10 A)

Fusible (10 A)

Blue/white striped

Rayé bleu/blanc

Blue

Max. supply current 0.1 A

Courant max. fourni 0,1 A

Bleu

Light blue

Bleu ciel

Orange/white striped

Rayé orange/blanc

Red

Rouge

Yellow

Jaune

ANT REM

ILLUMINATION

AMP REM

3

Max. supply current 0.3 A

Courant max. fourni 0,3 A

2

4

ATT

*1RCA pin cord (not supplied)

Cordon à broche RCA (non fourni)

5

2

*

RK-G129 (Stereo mini plug to Phono

plug) (not supplied)

RK-G129 (mini-prise stéréo allant à

la prise Phono) (non fournie)

3

*

Be sure to match the color-coded

code for audio to the appropriate

6

jacks from the unit.

Veillez à faire correspondre le code

couleur audio aux fiches de

l’appareil.

7

Remarques sur les fils de commande et

d'alimentation

• Le fil de commande de l’antenne électrique (bleu)

fournit une alimentation de + 12 V CC lorsque vous

mettez la radio sous tension.

• Lorsque votre voiture est équipée d’une antenne

FM/AM intégrée dans la vitre arrière/latérale,

raccordez le fil de commande de l’antenne (bleu)

ou le fil d’entrée d’alimentation des accessoires

(rouge) à la borne de l’amplificateur d’antenne

existant. Pour plus de détails, consultez votre

détaillant.

• Une antenne électrique sans boîtier de relais ne

peut pas être utilisée avec cet appareil.

Raccordement pour la conservation de la mémoire

Lorsque le fil d’entrée d’alimentation jaune est

raccordé, le circuit de la mémoire est alimenté en

permanence même si la clé de contact est sur la

position d’arrêt.

Remarques sur le raccordement des haut-parleurs

• Avant de raccorder les haut-parleurs, mettez

l’appareil hors tension.

•Utilisez des haut-parleurs ayant une impédance de

4 à 8 ohms avec une capacité de manipulation

adéquate pour éviter de les endommager.

• Ne raccordez pas les bornes du système de hautparleur au châssis de la voiture et ne raccordez pas

les bornes du haut-parleur droit à celles du hautparleur gauche.

• Ne raccordez pas le câble de masse de cet appareil

à la borne négative (–) du haut-parleur.

•N’essayez pas de raccorder les haut-parleurs en

parallèle.

• Raccordez uniquement des haut-parleurs passifs.

Le raccordement de haut-parleurs actifs (avec

amplificateurs intégrés) aux bornes des hautparleurs peut endommager l’appareil.

• Pour éviter tout dysfonctionnement, n’utilisez pas

les fils des haut-parleurs intégrés installés dans

votre voiture si l’appareil partage un fil négatif

commun (–) pour les haut-parleurs droit et gauche.

• Ne raccordez pas entre eux les cordons des hautparleurs de l’appareil.

8

MEX-1HD

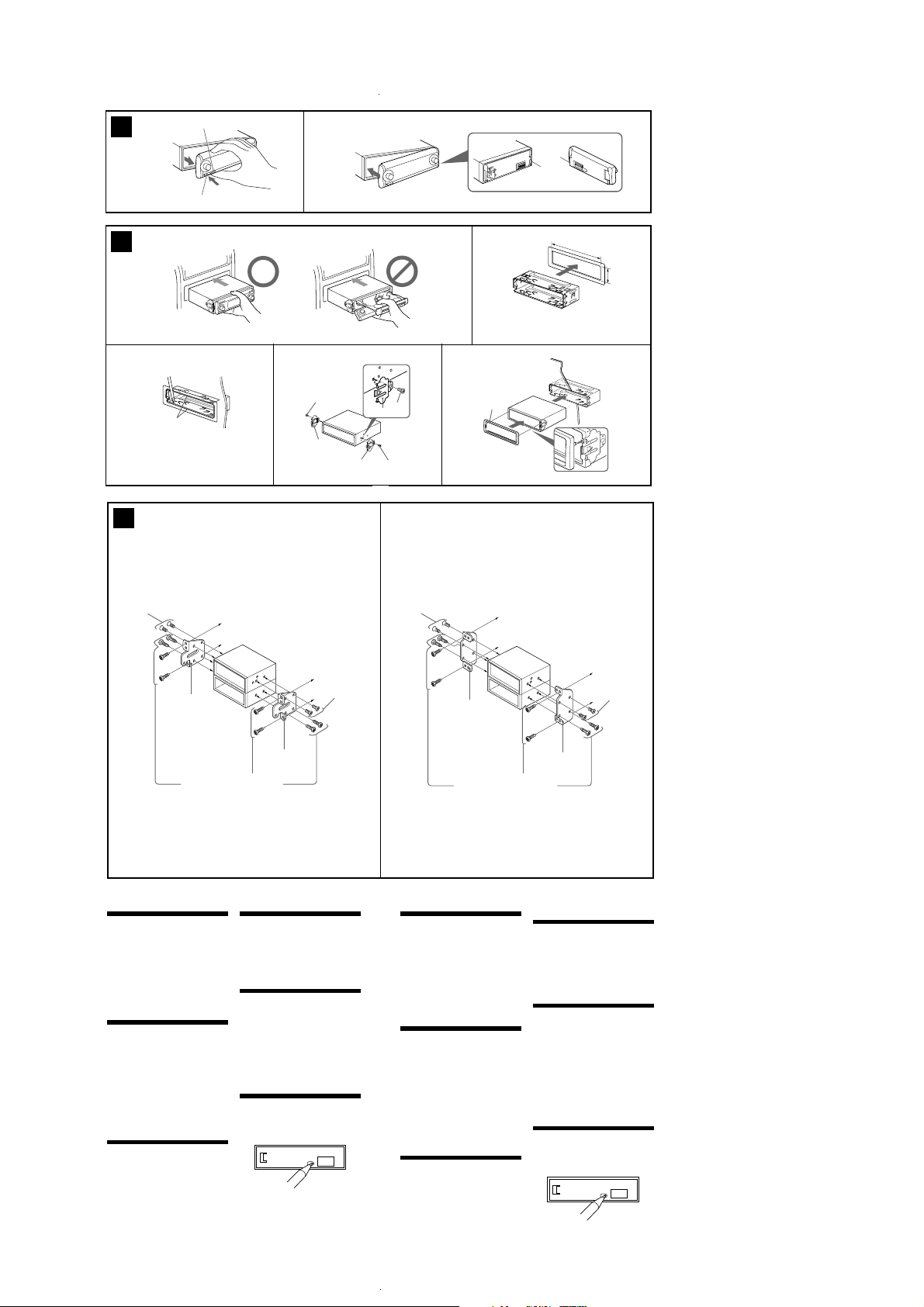

5 AB

(OFF)

A

B

(RELEASE)

6

*

234

Bend these claws outward

for a tight fit, if necessary.

Pliez ces griffes vers l’extérieur pour

assurer une prise correcte si nécessaire.

2

3

2

3

3

2

1

1

1

8

2

m

m

T

O

P

with the TOP marking up

avec l’inscription TOP vers le haut

Dashboard

Tableau de bord

TOP

1

4

7

A

TOYOTA

B

NISSAN

5

3

m

m

6

max. size

5 × 6 mm

7

(

/32 × 1/4 in.)

Dimension

max. 5 × 6 mm

7

/32 × 1/4 po.)

(

Bracket

Support

Existing parts supplied with your car

Pièces existantes fournies avec la voiture

Precautions

•Choose the installation location carefully so

that the unit will not interfere with normal

driving operations.

•Avoid installing the unit in areas subject to

dust, dirt, excessive vibration, or high

temperatures, such as in direct sunlight or near

heater ducts.

•Use only the supplied mounting hardware for

a safe and secure installation.

Mounting angle adjustment

Adjust the mounting angle to less than 30°.

How to detach and attach the

front panel ( 5)

Before installing the unit, detach the front

panel.

5-A To detach

Before detaching the front panel, be sure to

press (OFF). Press (RELEASE) to open up the

front panel and pull it off towards you.

5-B To attach

Attach part A of the front panel to part B of the

unit as illustrated and push the left side into

position until it clicks.

Mounting example ( 6)

Installation in the dashboard

When installing this unit, be sure to close the

front panel of the unit. (6-*)

Do not hold the unit by its front panel or disc

tray when installing as this can damage the unit,

or cause malfunction.

to dashboard/center console

au tableau de bord/console centrale

6

max. size

5 × 6 mm

7

(

/32 × 1/4 in.)

Dimension

max. 5 × 6 mm

7

/32 × 1/4 po.)

(

Bracket

Support

Mounting the unit in a Japanese

car (7)

You may not be able to install this unit in some

makes of Japanese cars. In such a case, consult

your Sony dealer.

Note

To prevent malfunction, install only with the

supplied screws 6.

Warning when installing in a car

without ACC (accessory)

position on the ignition key

switch

Be sure to press (OFF) on the unit for two

seconds to turn off the clock display after

turning off the engine.

When you press (OFF) only momentarily, the

clock display does not turn off and this causes

battery wear.

RESET button

When the installation and connections are

completed, be sure to press the RESET button

with a ball-point pen, etc., after removing the

front panel.

6

max. size

5 × 6 mm

7

(

/32 × 1/4 in.)

Dimension

max. 5 × 6 mm

7

/32 × 1/4 po.)

(

Bracket

Support

Existing parts supplied with your car

Pièces existantes fournies avec la voiture

Prcautions

•Choisissez soigneusement l’emplacement

d’installation pour que l’appareil ne gêne pas

le chauffeur pendant la conduite.

•Evitez d’installer l’appareil dans un endroit

exposé à la poussière, à la saleté, à des

vibrations excessives ou à des températures

élevées comme en plein soleil ou à proximité

de conduits de chauffage.

•Pour garantir un montage sûr, n’utilisez que le

matériel fourni.

Rglage de langle de montage

Ajustez l’inclinaison à un angle inférieur à 30°.

Retrait et pose de la fa ade (5)

Avant d’installer l’appareil, retirez la façade.

5-A Pour retirer

Avant de déposer la façade, n’oubliez pas

d’appuyer sur (OFF). Appuyez sur (RELEASE)

pour ouvrir la façade, puis retirez-la en tirant

vers vous.

5-B Pour poser

Fixez la partie A de la façade sur la partie B de

l’appareil, comme indiqué sur l’illustration, puis

poussez le côté gauche pour le mettre en place

jusqu’au déclic.

Exemple de montage (6)

Installation dans le tableau de bord

Pendant l’installation de l’appareil, vérifiez

que le panneau avant de cet appareil est

)

fermé. (6-

*

Ne tenez pas l’appareil par la façade ou le

plateau de disque lors de l’installation, car cela

risque d’endommager l’appareil ou d’entraîner

un problème de fonctionnement.

to dashboard/center console

au tableau de bord/console centrale

6

max. size

5 × 6 mm

7

/32 × 1/4 in.)

(

Dimension

max. 5 × 6 mm

7

/32 × 1/4 po.)

(

Bracket

Support

Installation de l appareil dans

une voiture japonaise ( 7)

Cet appareil ne peut pas être installé dans

certaines voitures japonaises. Consultez, dans ce

cas, votre revendeur Sony.

Remarque

Pour éviter tout dysfonctionnement, utilisez

uniquement les vis 6 pour le montage.

Avertissement en cas

dinstallation dans une voiture

dont le contact ne comporte

pas de position ACC

(accessoires)

Noubliez pas dappuyer sur le bouton

(OFF) de lappareil pendant deux

secondes aprs avoir coup le moteur de

faon dsactiver laffichage de l horloge.

Si vous appuyez brièvement sur (OFF),

l’affichage de l’horloge n’est pas désactivé, ce

qui provoque une usure de la batterie.

Touche RESET

Après avoir retiré la façade, une fois que

l’installation et les raccordements sont terminés,

appuyez sur la touche RESET avec un stylo à

bille, etc.

9

MEX-1HD

Ver 1.1

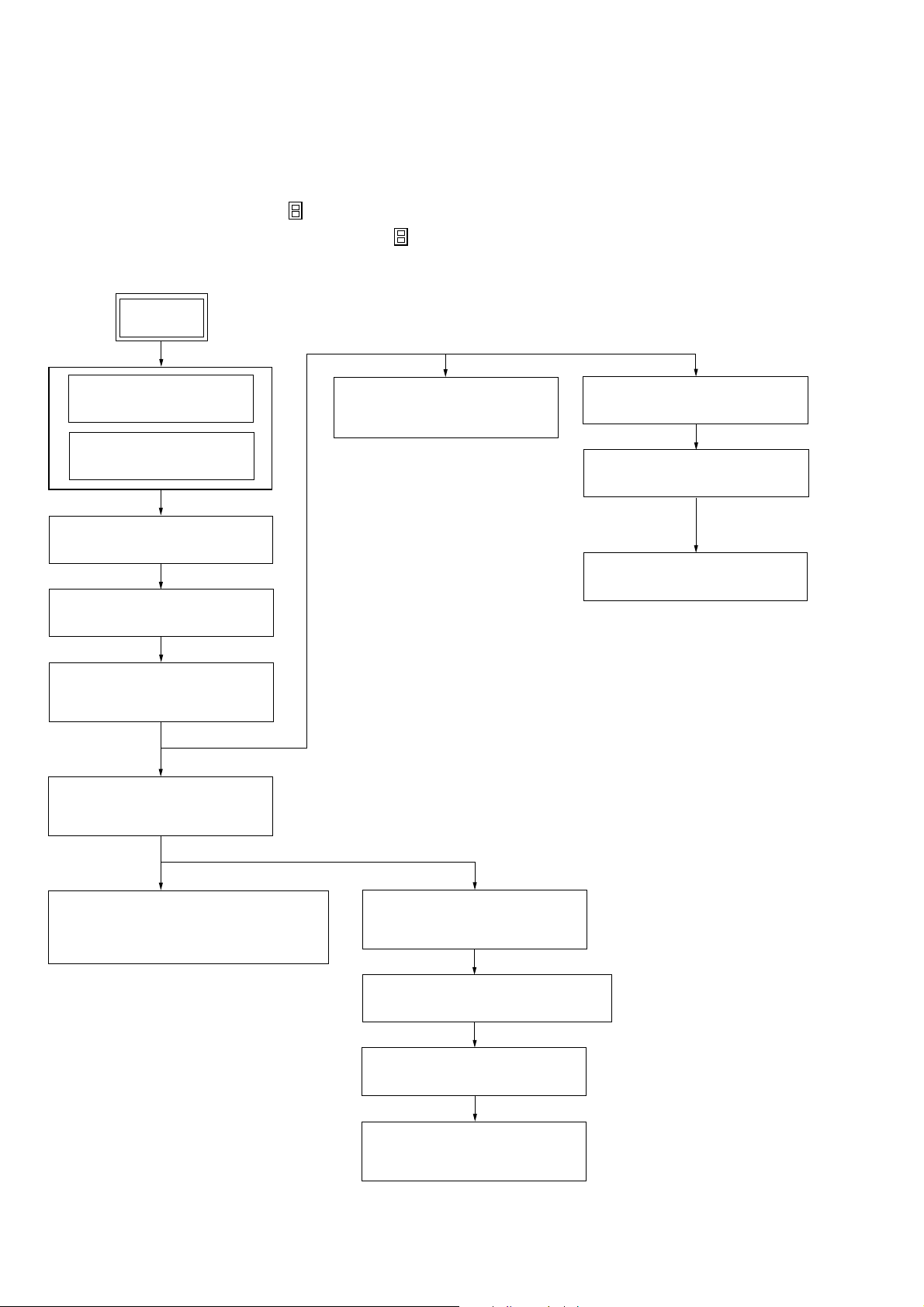

SECTION 3

DISASSEMBLY

3-1. DISASSEMBLY FLOW

• This set can be disassembled in the order shown below.

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

Note 3: Illustration of disassembly is omitted.

SET

FRONT PANEL ASSY

(Note 3)

3-2. COVER

(Page 11)

3-3. BASE PANEL ASSY

(Page 11)

3-4. SUB PANEL (CD) ASSY

(Page 12)

3-5. MECHANISM DECK

(MG-550D-156)

(Page 12)

3-6. MOTOR BLOCK ASSY,

CAM BLOCK ASSY

(Page 13)

3-12. BELT (L), LE MOTOR ASSY

(TRAY OPEN/CLOSE) (M103)

(Page 16)

3-13. TRAY (UD) ASSY

(Page 17)

3-14. OP ASSY (CDM-3021EBG)

(Page 17)

3-15. SERVO BOARD

(Page 18)

3-7. MOTOR ASSY

(FRONT PANEL OPEN/CLOSE) (M601),

SWITCH BOARD

(Page 13)

10

3-8. MAIN BOARD,

POWER BOARD

(Page 14)

3-9. HARD DISK DRIVE (2.5 inch) UNIT

(Page 15)

3-10. SUB BOARD

(Page 15)

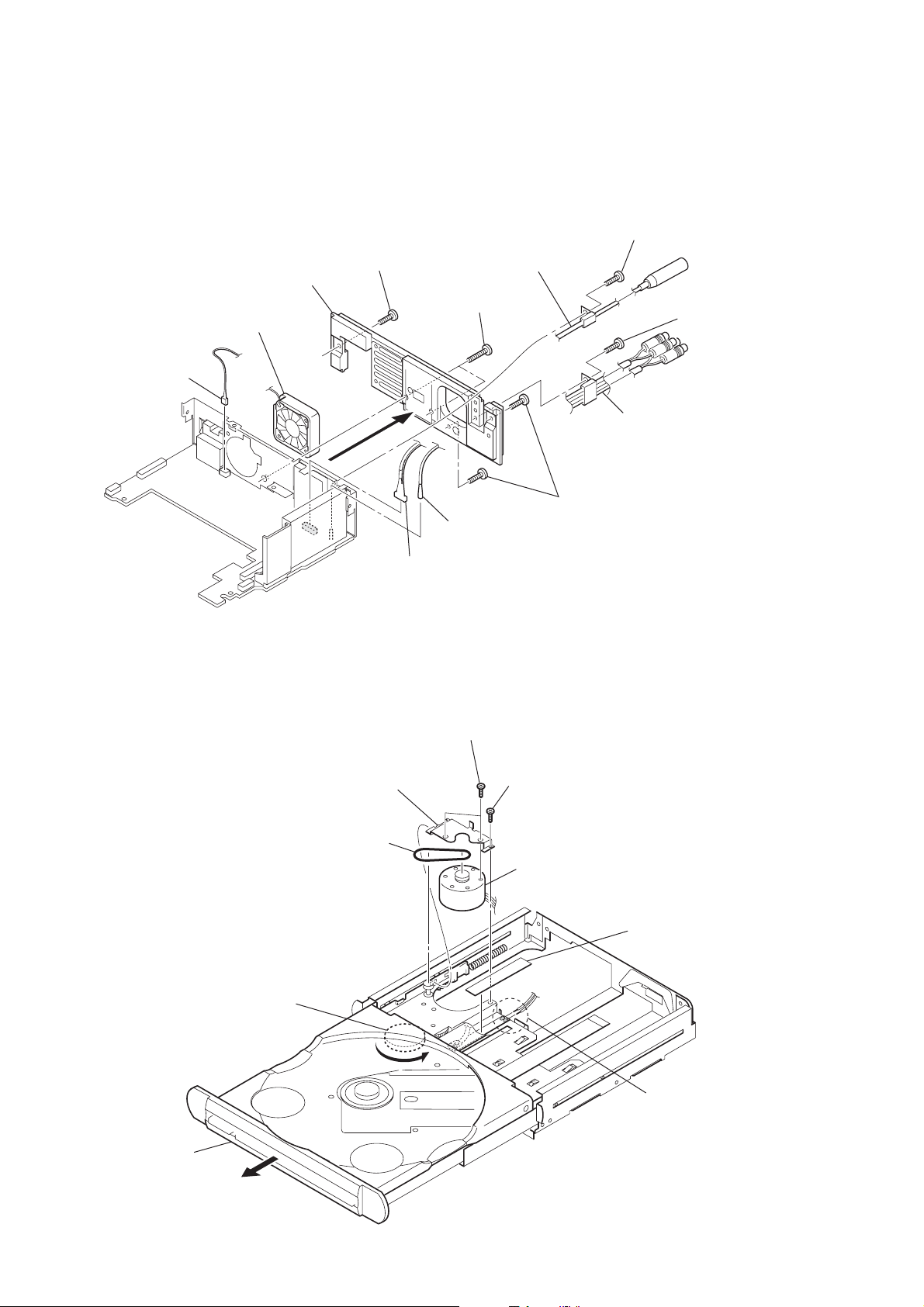

3-11. HEAT SINK,

DC FAN (M501)

(Page 16)

Note: Follow the disassembly procedure in the numerical order given.

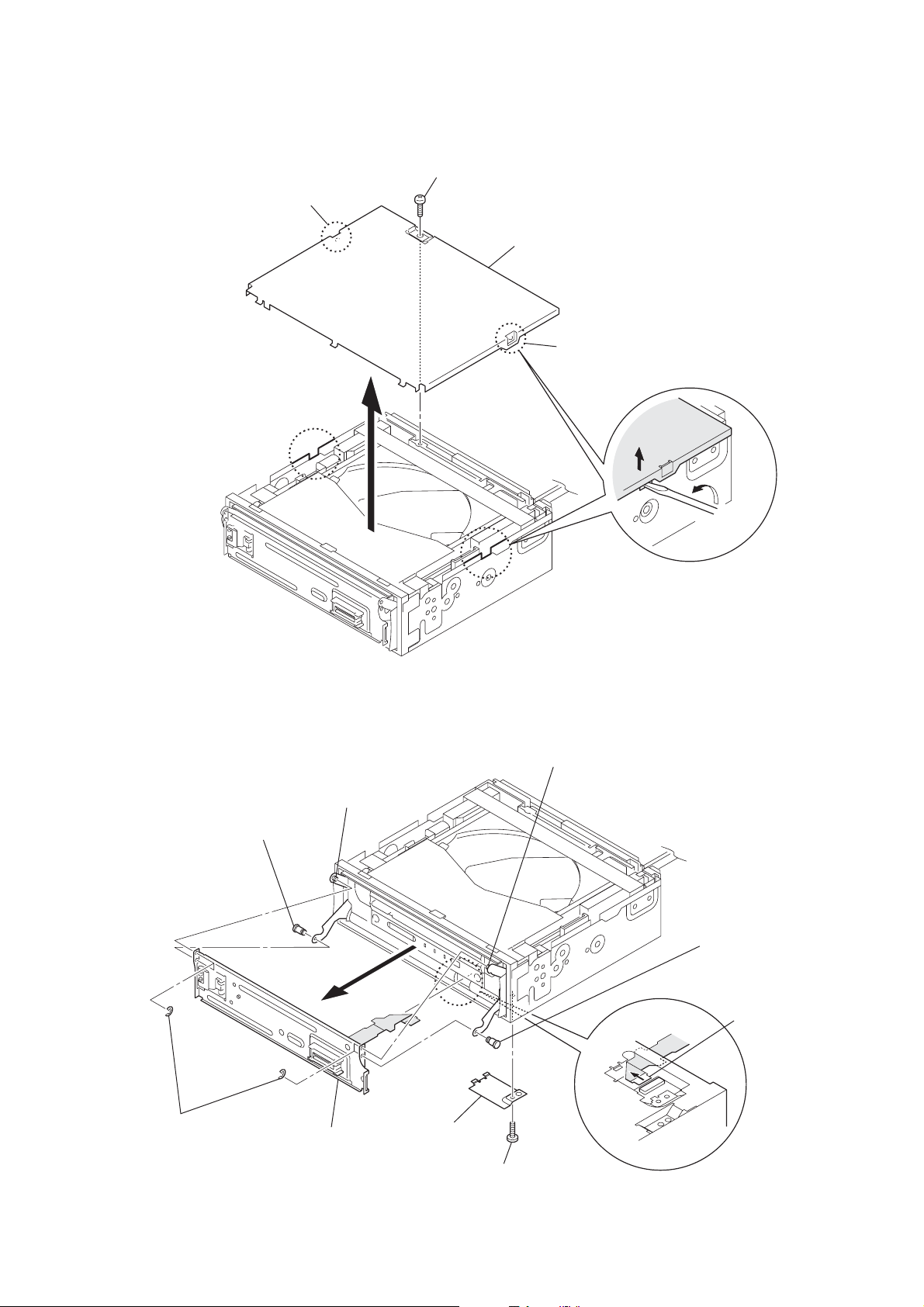

3-2. COVER

1

2

boss

screw

(PTT2.6 × 4)

3

cover

2

MEX-1HD

boss

3-3. BASE PANEL ASSY

5

shaft (base panel, D)

4

four E rings

(panel)

7

base panel assy

6

boss

2

cover

(chassis)

6

boss

5

shaft (base panel, D)

3

mounted flexible PWB

(FP) (CN524)

1

screw

(PTT2.6

×

4)

11

MEX-1HD

)

)

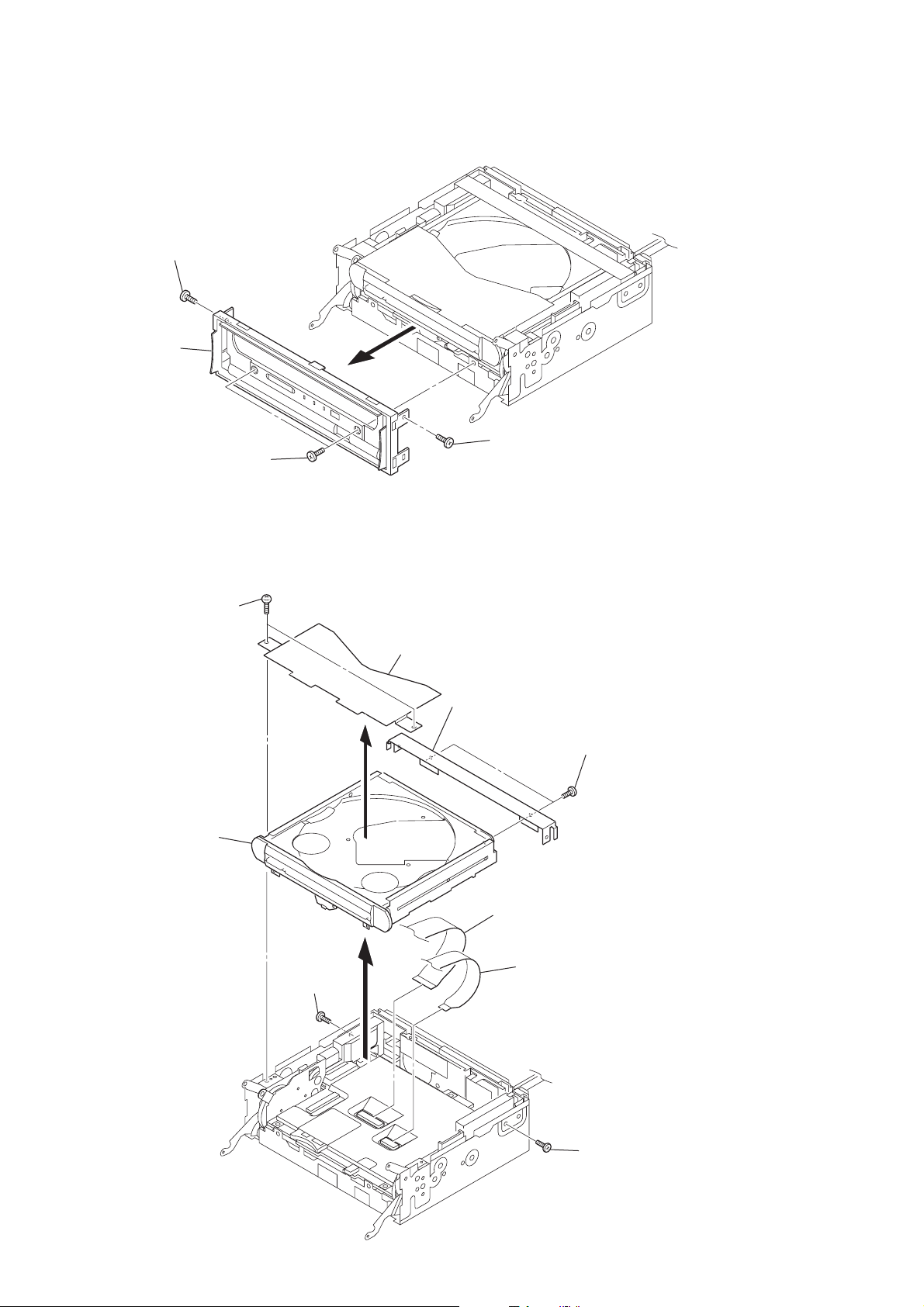

3-4. SUB PANEL (CD) ASSY

1

screw

(PTT2.6 × 6)

2

sub panel (CD) assy

1

two screws

(PTT2.6 × 6)

1

screw

(PTT2.6 × 6)

3-5. MECHANISM DECK (MG-550D-156)

1

two screws

(PTT2.6 × 6)

9

mechanism deck (MG-550D-156)

3

screw

(PTT2.6 × 4)

4

2

bracket (cover)

8

bracket (tray)

6

D40P flexible board

(CN2002)

5

7

two screws

(PTT2.6 × 4

D20P flexible board

(CN2003)

12

3

screw

(PTT2.6 × 4

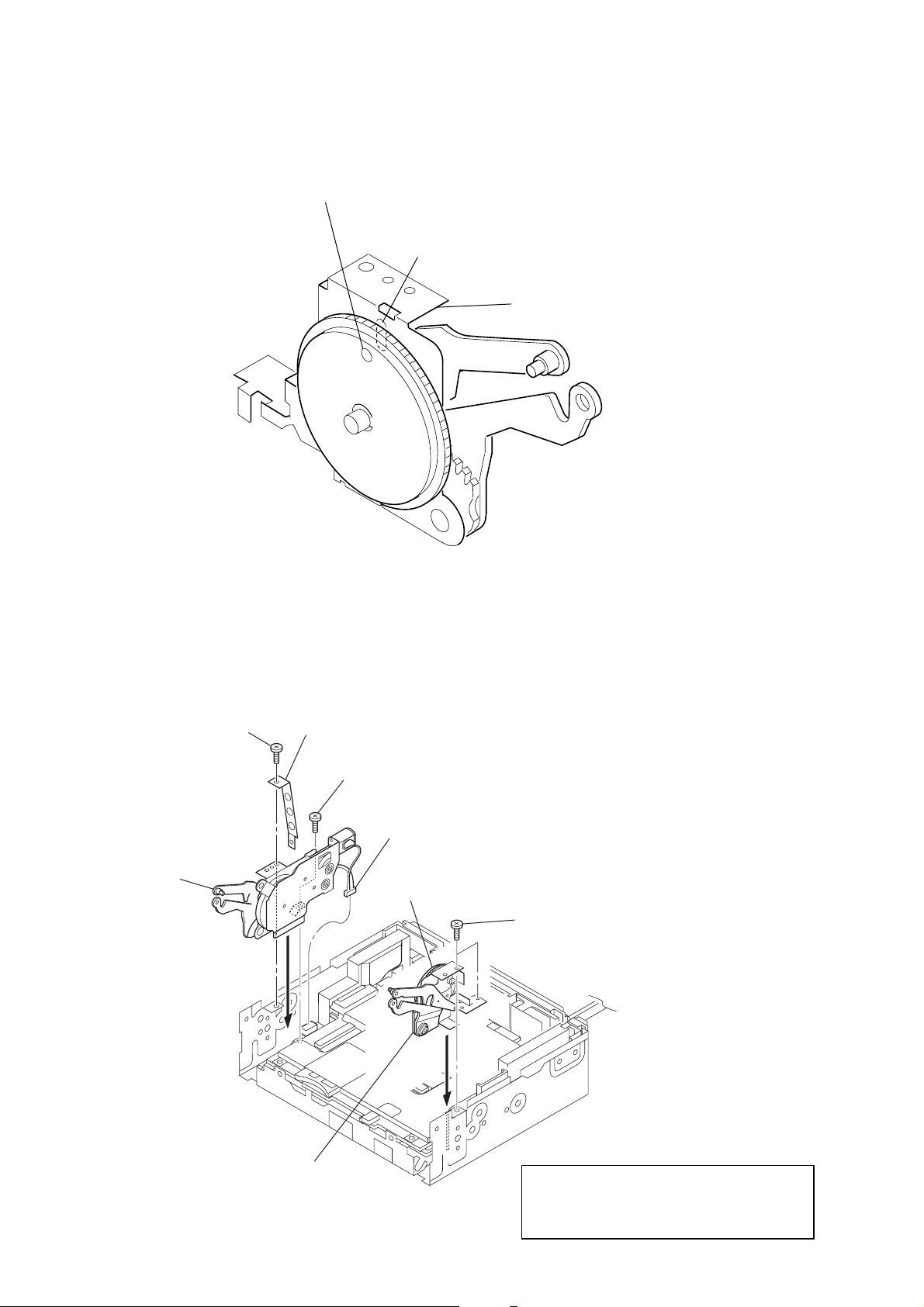

3-6. MOTOR BLOCK ASSY, CAM BLOCK ASSY

r

2

6

motor block assy

screw

(PTT2.6

×

6)

3

4

cover (protection)

1

screw

(PTT2.6 × 6)

5

connector

(CN411)

8

7

two screws

(PTT2.6

MEX-1HD

×

6)

9

cam block assy

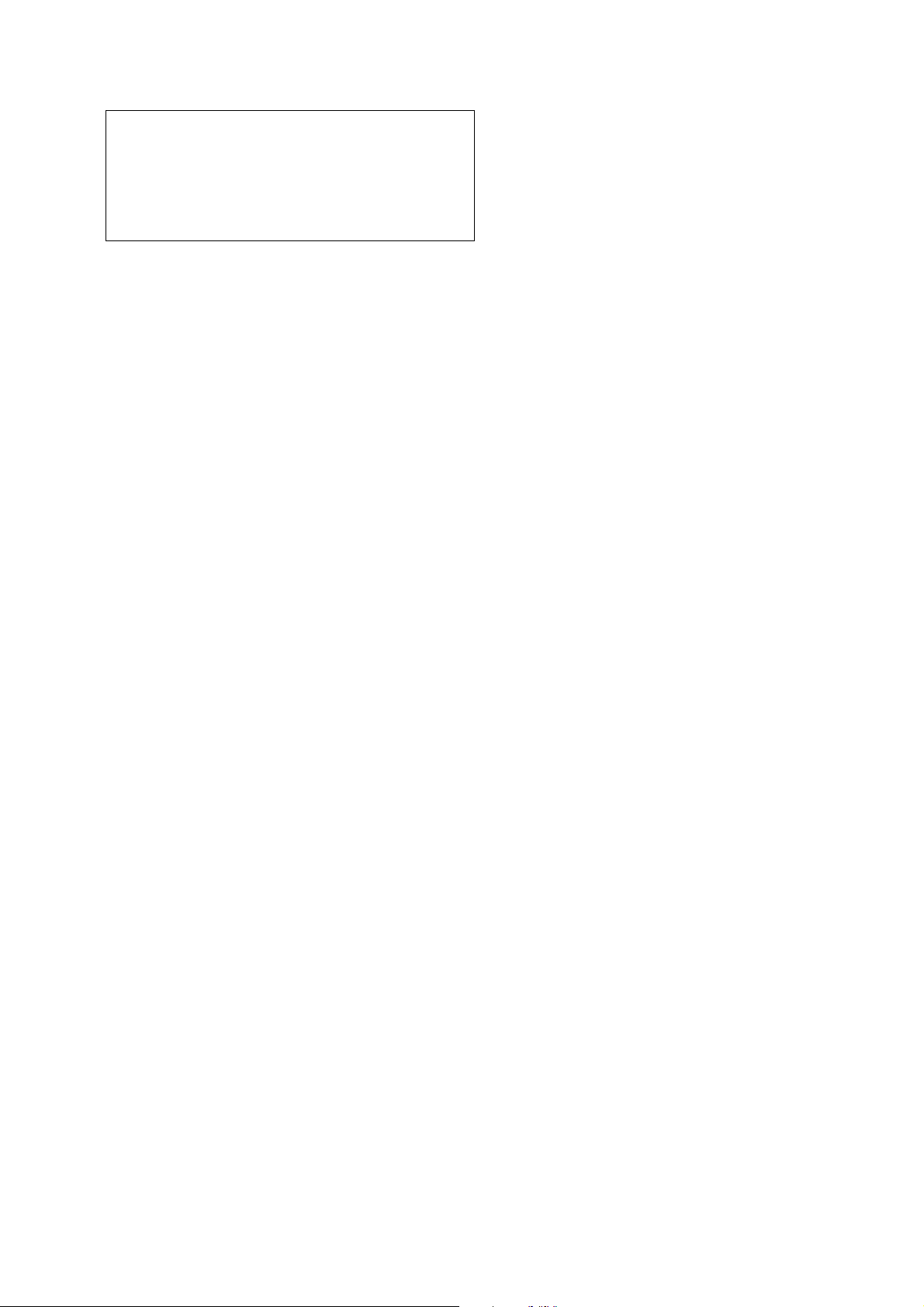

3-7. MOTOR ASSY (FRONT PANEL OPEN/CLOSE) (M601), SWITCH BOARD

1

Remove two solders of

the front panel open/close moto

lead wires.

9

motor assy

(front panel open/close)

(M601)

6

ring E-2 retaining

7

gear (worm wheel)

3

8

two screws

(P2

×

2.5)

4

ground point screw

(PTT2.6

×

6)

5

switch board

2

two screws

(PTT2.6

×

6)

13

MEX-1HD

e

Ver 1.1

3-8. MAIN BOARD, POWER BOARD

3

three ground point screws

(PTT2.6

2

mounted PWB

(HDD connector)

(CN2001)

×

6)

4

connector (CN525)

1

flexible flat 50P cabl

(CN526, CN3002)

9

Bend two claws.

6

two bosses

qa

power board

5

connector

(CN3001)

0

sheild (DC2)

7

sheild (DC1)

qs

two claws

6

two bosses

8

Remove two solders.

qg

Bend six claws.

qh

shield (top)

qs

two claws

qj

main board

qf

Remove five solders.

14

qd

shield (bottom)

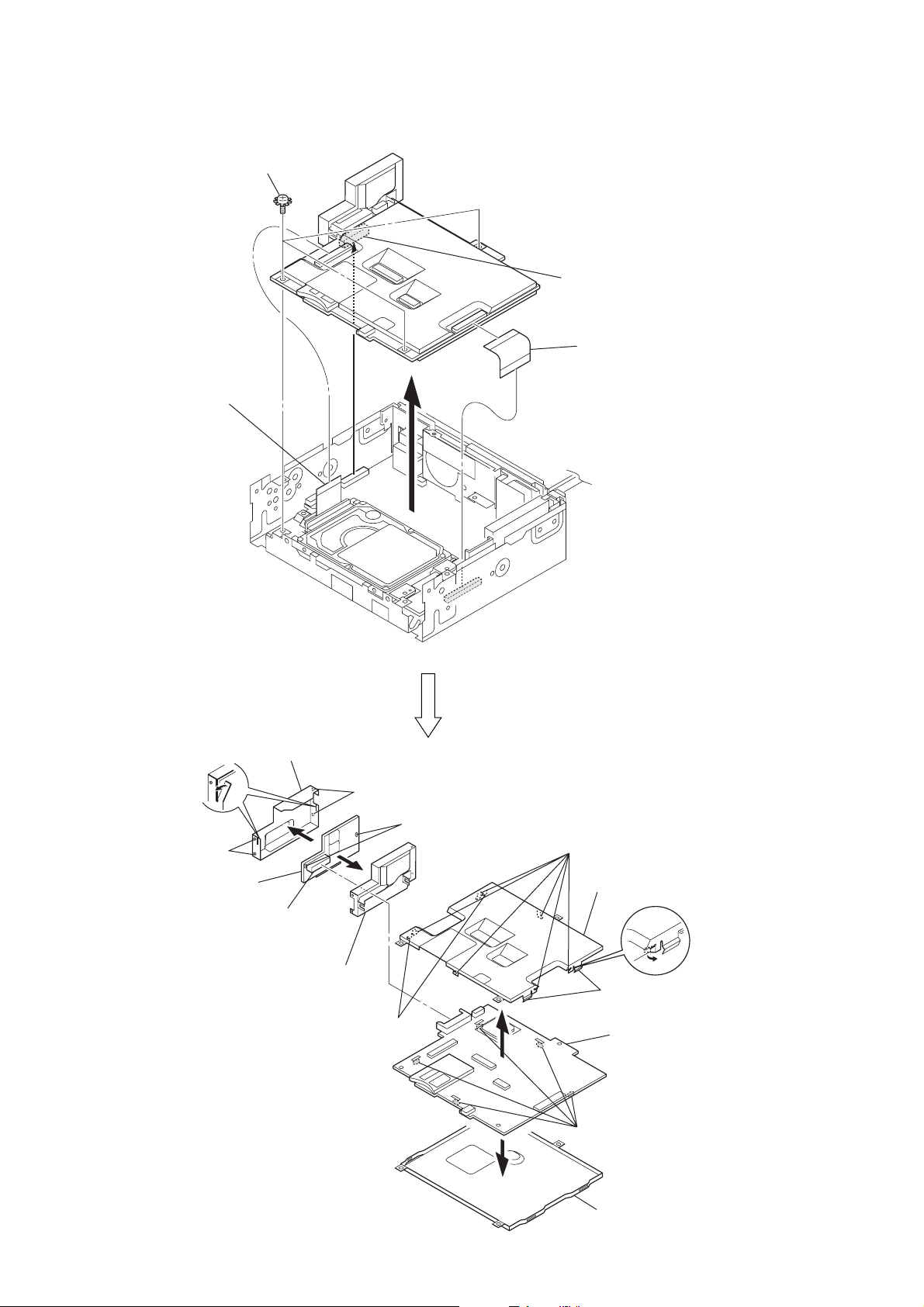

3-9. HARD DISK DRIVE (2.5 inch) UNIT

t

6

mounted PWB

(HDD connector)

1

screw

(B2.6

×

4)

5

bracket (H)

3

four screws

(M3

×

4)

4

7

hard disk drive (2.5 inch) uni

1

two screws

(B2.6 × 4)

MEX-1HD

3-10. SUB BOARD

2

three ground point screws

(PTT2.6

×

6)

2

1

screw

(PTT2.6 × 4)

3

4

sub board

1

screw (PTT2.6 × 4)

15

MEX-1HD

Ver 1.1

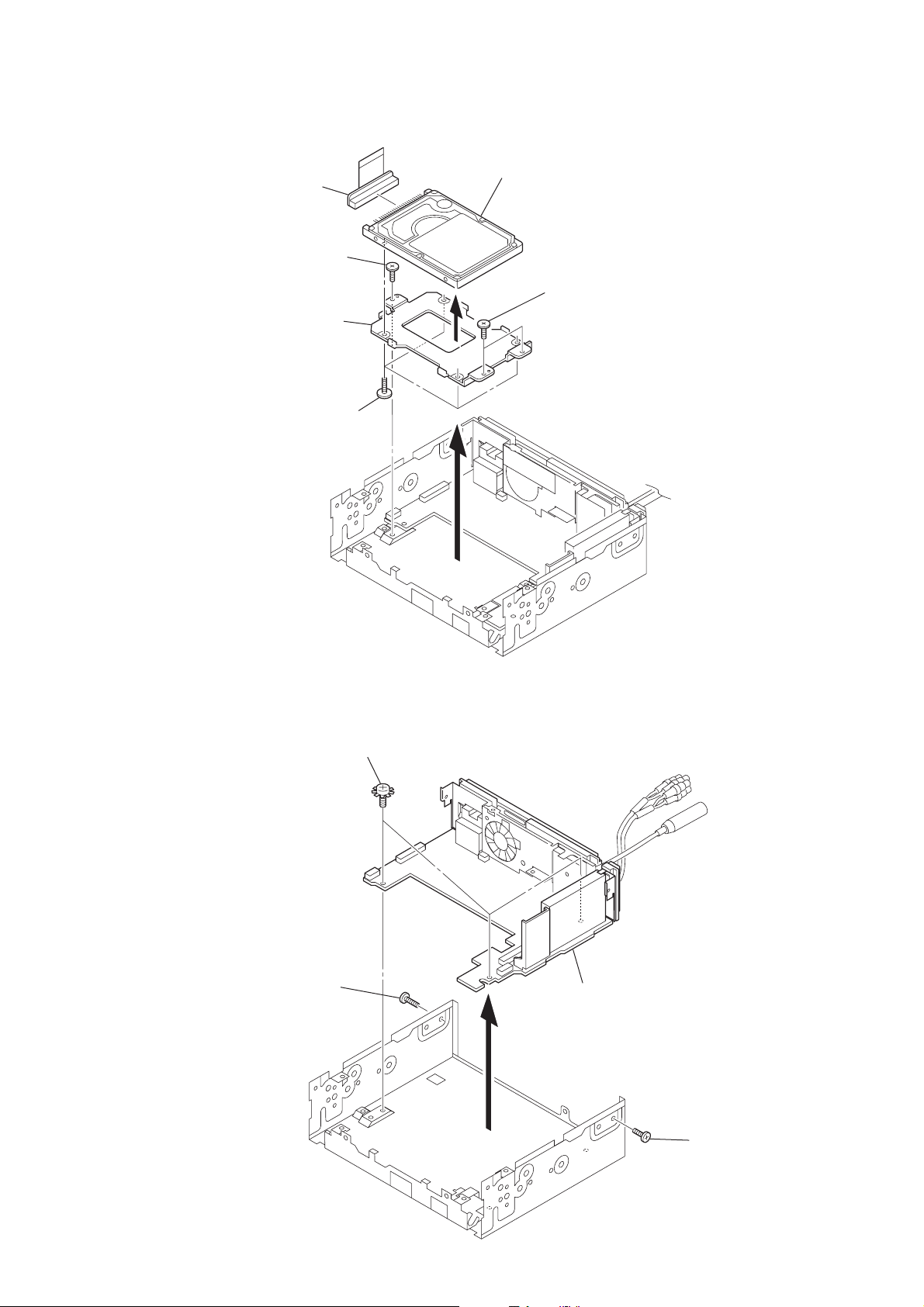

3-11. HEAT SINK, DC FAN (M501)

4

heat sink

qa

DC fan (M501)

0

connector

(CN528)

2

screw

(PTT2.6

×

8)

3

two screws

(PTT2.6

7

connection cord

(ANT)

×

16)

5

screw

(PTT2.6

9

×

connection cord (AUX)

(AUX IN/SUB OUT)

6)

1

screw

(PTT2.6

×

6)

6

terminal

(J101)

8

connector

(CN301)

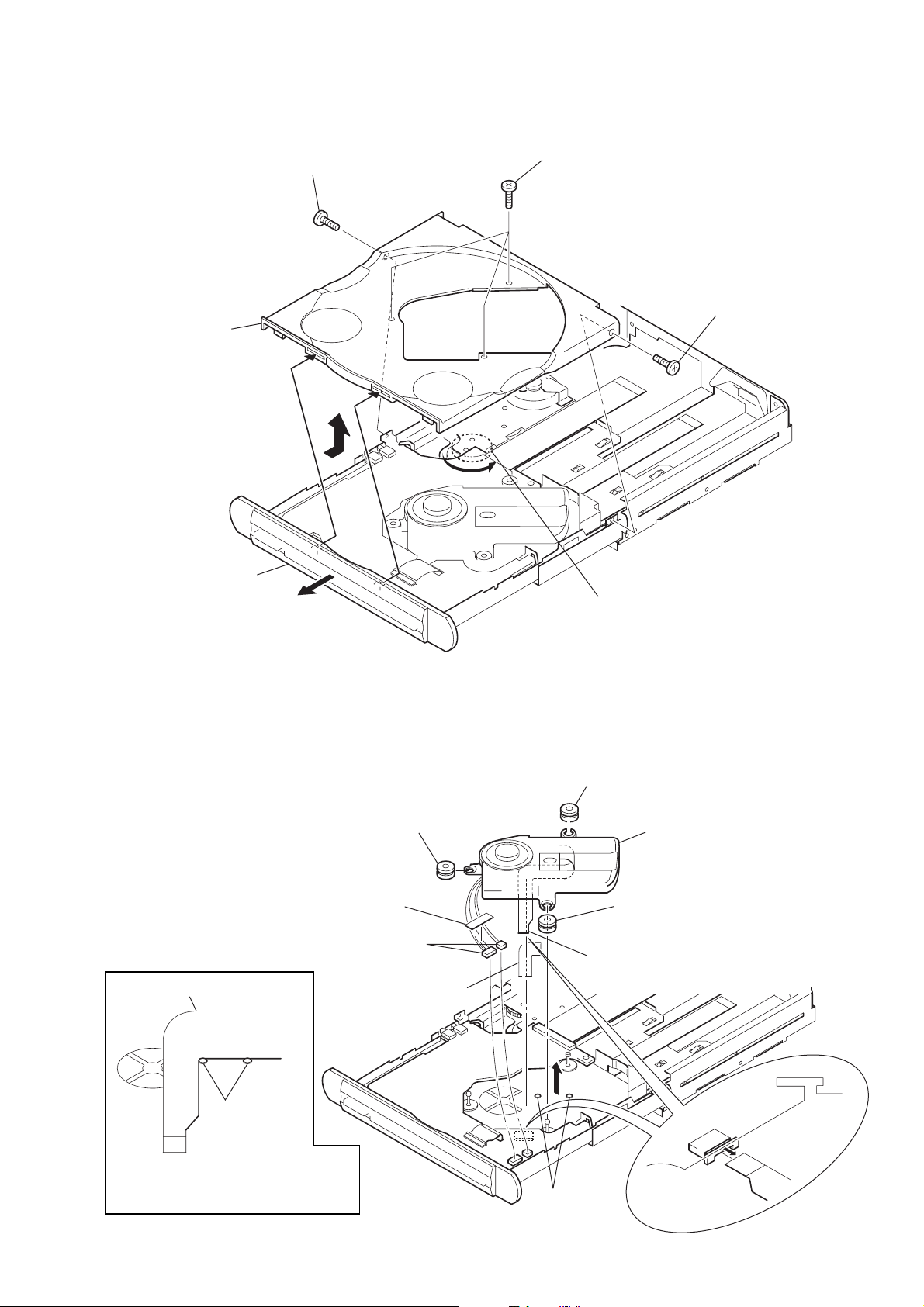

3-12. BELT (L), LE MOTOR ASSY (TRY OPEN/CLOSE) (M103)

7

two screws (P1.7 × 2)

8

bracket (motor)

3

belt (L)

2

two screws

(PTT2.6

6

screw (M1.7)

LE motor assy (tray open/close) (M103)

9

×

8)

4

saranet cushion (FPC)

1

2

Draw out the tray block

(D) assy fully in the

direction of arrow B.

16

Rotate the gear (5) in the

direction of arrow A

to release the mecha-lock.

B

A

5

Remove two solders of

the LE motor assy

(tray open/close) (M103)

lead wires.

3-13. TRAY (UD) ASSY

)

3

screw (M1.7 × 2.5)

5

tray (UD) assy

4

A

3

three screws (M1.7 × 2.5)

3

screw (M1.7 × 2.5

MEX-1HD

Ver 1.1

2

Draw out the tray block

(D) assy fully in the

direction of arrow

B

.

B

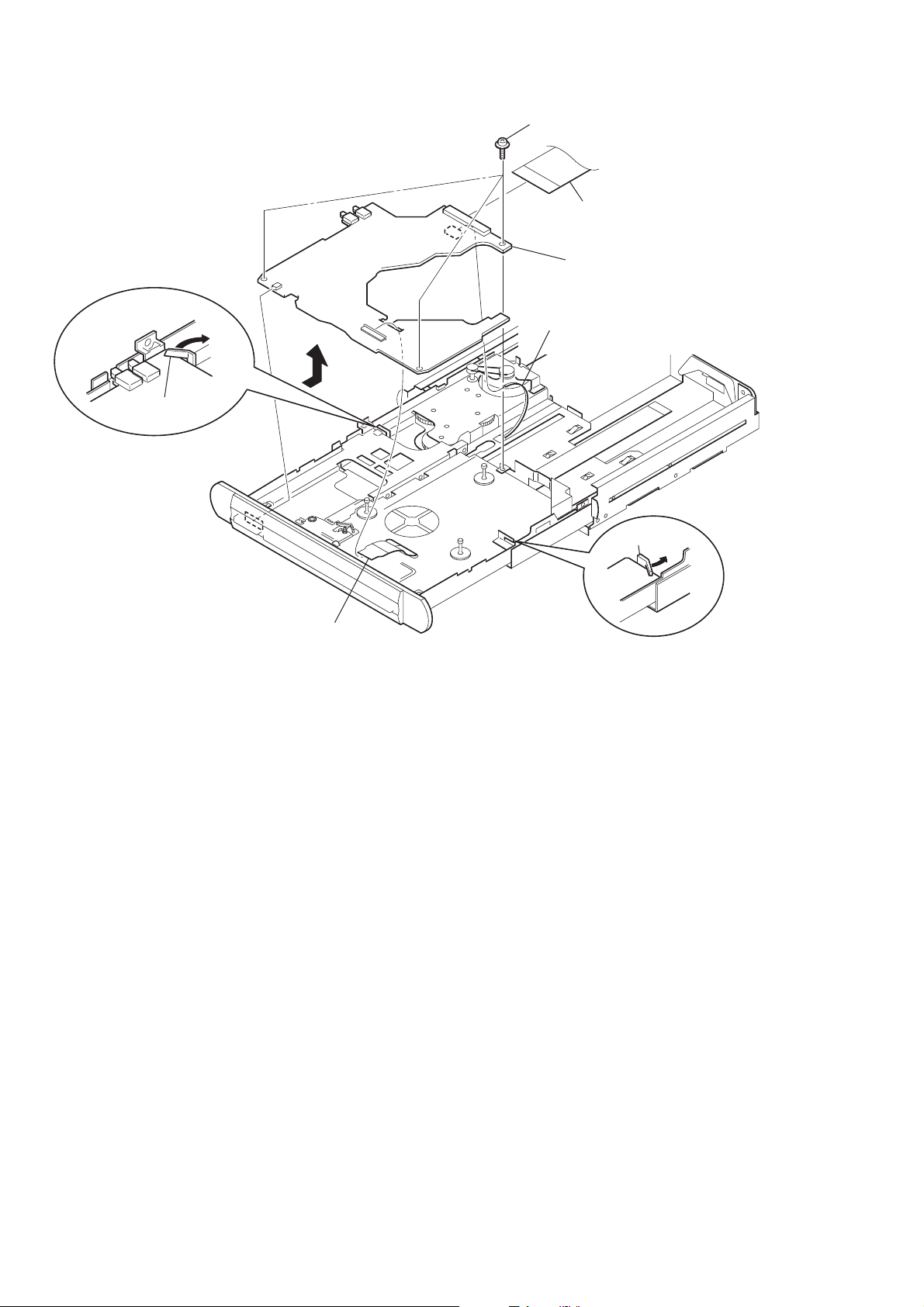

3-14. OP ASSY (CDM-3021EBG)

Note: Do not reuse the adhesive sheet (MD)

after removing the OP assy (CDM-3021EBG).

Be sure to replace a brand-new adhesive sheet (MD).

1

saranet cushion

2

two connectors (CN2, CN3)

base flexible board

4

adhesive sheet (MD)

6

insulator

1

Rotate the gear (5) in the direction

of arrow

6

insulator

6

5

base flexible board (CN1)

A

to release the mecha-lock.

7

OP assy (CDM-3021EBG)

insulator

positioning

dowels

Note: To install the base flexible board,

fix it along the dowels on the tray.

3

positioning

dowels

17

MEX-1HD

Ver 1.1

3-15. SERVO BOARD

1

Bend the claw.

5

4

three screws (M2 × 3.5)

3

D40P flexible board (CN7)

7

servo board

6

motor flexible board (CN5)

1

Bend the claw.

2

D20P flexible board (CN6)

18

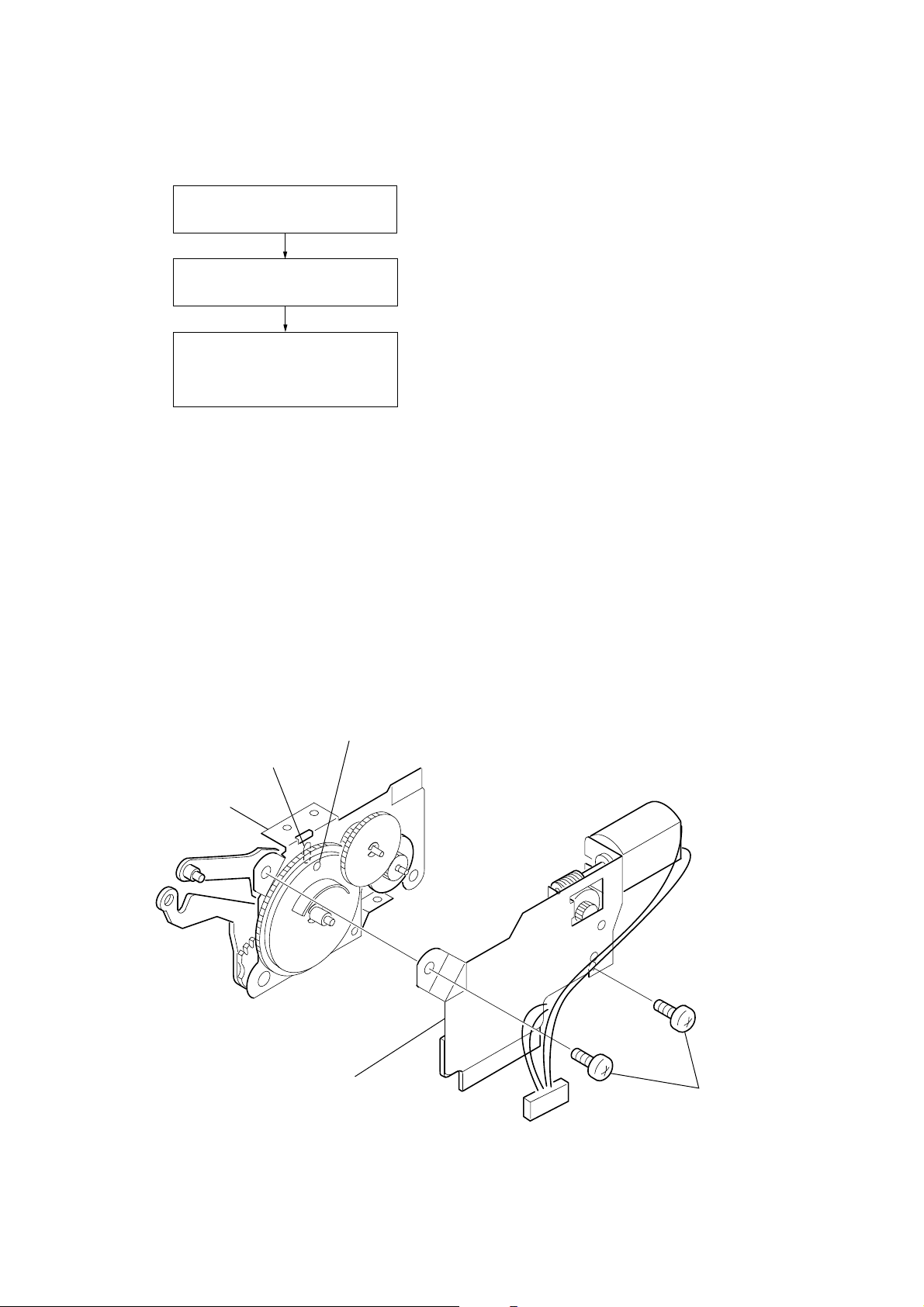

4-1. ASSEMBLY FLOW

)

• This set can be assembled in the order shown below.

4-2. MOTOR BLOCK ASSY

(Page 19)

4-3. CAM BLOCK ASSY

(Page 20)

4-4. PHASE ALIGNMENT OF

MOTOR BLOCK ASSY AND

CAM BLOCK ASSY

(Page 20)

SECTION 4

ASSEMBLY

MEX-1HD

Ver 1.1

Note: Follow the assembly procedure in the numerical order given.

4-2. MOTOR BLOCK ASSY

1

Align the gear (cam L) position setting hole with

the center mark on the bracket (main L) assy.

center mark

bracket (main L) assy

2

bracket (sub, L) assy

3

two screws (PTT2.6 × 6

19

MEX-1HD

y

Ver 1.1

4-3. CAM BLOCK ASSY

1

Align the gear (cam R) position setting hole with

the center mark on the bracket (main R) assy.

center marking

bracket (main R) ass

4-4. PHASE ALIGNMENT OF MOTOR BLOCK ASSY AND CAM BLOCK ASSY

5

2

motor block assy

screw (PTT2.6 × 6)

4

cover (protection)

3

screw (PTT2.6 × 6)

gear (cam R)

1

connector (CN411)

7

two screws (PTT2.6 × 6)

20

6

cam block assy

Note : Touch the gear (cam R) with fingers in the

direction of rotation and make sure that

there is no phase difference with the motor

block assy side position setting hole.

SECTION 5

TEST MODE

MEX-1HD

Ver 1.2

Note: The test mode of this set contains the items not used for the

service. If you activated another mode by mistake, press the function button 1 or the

Particularly, for the menu commands and Factory Setting saved

in the HDD menu, never execute them except when the hard

disk drive was replaced. Otherwise, the hard disk drive will not

operate or the data saved by the user in the hard disk will be

erased.

[M] (Menu) button to deactivate that mode.

[ENTERING THE TEST MODE]

1. In the standby state, perform the following operation.

(1) Rotate clockwise the right jog dial (PUSH LIST) 4 clicks.

(2) Press the left jog button (PUSH SOUND).

(3) Rotate counterclockwise the right jog dial (PUSH LIST) 5

clicks.

(4) Press the left jog button (PUSH SOUND).

(5) Rotate clockwise the right jog dial (PUSH LIST) 1 click.

(6) Press the left jog button (PUSH SOUND) for more than 2

seconds.

2. When the test mode is activated, a peep will be heard and the

“TEST MODE” will be displayed on the screen. (“TEST

MODE” disappears soon)

3. Press the [M] (Menu) button, and the test mode main menu

screen will be displayed.

[RELEASING THE TEST MODE]

To release the test mode, perform either of the following operations.

•Turn the main power off.

• Remove the front panel.

•Press the [OFF] button for more than 2 seconds.

Note: In exiting the test mode, the system is reset automatically and the

data are erased. Then, when the power is turned on again, the initial setting (AM 9K/10K step choice, date and time setting) screen

is displayed, but this setting is also erased in certain time after the

main power was turned off.

Accordingly, re-setting is not necessary but normal operation and

the test mode operation are disabled unless the initial setting has

completed. In such a case, therefore, press the right jog button

(PUSH LIST) repeatedly and enter tentative initial set values.

[BASIC OPERATION]

In the test mode, basically the following dial and buttons are used

for the operation.

• Right jog dial (PUSH LIST) : Selects an item.

• Right jog button (PUSH LIST) : Enters the selected item.

• Function button 1 : Returns to the one-level high-

er menu

[DIAGNOSTIC FUNCTION]

Procedure:

1. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

2. Rotate the right jog dial (PUSH LIST) to select the “DIAG”,

and press the right jog button (PUSH LIST) to enter the DIAG

mode.

3. With the “ALL -Auto-” selected, pressing the right jog button

(PUSH LIST) allows all of the following items to be checked

automatically.

• PEACOCK (MAIN board IC2003)

• HUMMING BIRD (MAIN board IC3003)

• ISP1161 (MAIN board IC4301)

• CXD1859 (MAIN board IC4001)

• E2PROM (MAIN board IC4002) *1

•ATA0 (HDD) (Hard disk drive) *2

• ATA1 (CDD) (CD servo block)

• WM (USB connection) *3

•RTC (SUB board IC502)

*1) A checking without inserting a memory stick causes an

error, and the “E2PROM NO MS” is displayed.

*2) If the ATA0 (HDD) check results in NG, try to repeat the

check several times.

If repetitional check results in NG, a communication error is doubtful, besides faulty hard disk drive.

*3) A checking without connecting the USB causes an error,

and the “NWWM NG!” is displayed.

4. After automatic check of all items completed, if all items are

OK, “OK ALL” will be displayed. In case of erroneous items,

NG indication is given to respective erroneous items.

5. To return to the DIAG menu, press the left jog button (PUSH

SOUND).

[VERSION DISPLAY]

Besides the version display for the users in normal mode, the version of each section of the system is displayed.

Procedure:

1. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

2. Rotate the right jog dial (PUSH LIST) to select the “Version”,

and press the right jog button (PUSH LIST) to enter the Version mode.

3. With the “Version” mode activated, pressing the right jog button (PUSH LIST) allows the following versions to be displayed:

• Main (version of main section)

• Sub (version of sub section)

• CD (version of CD servo section)

[Making CD-R For Service]

At the replacement of parts, this set may require jobs such as version updating of the main section and sub section and data installing to a HDD, and for these jobs, the CD-R for service is needed.

Make the CD-R for service by downloading the data from the “ftp”

server for service. The data to be downloaded are available with

two types, for initial lot type and for upgraded type, and further as

regards the upgraded type, the latest version at that time must be

confirmed, thus requiring extreme care. (See table “The version

of each section” on page 22)

Note on making CD-R: The file format should be ISSO9660.

Store all files in the ROOT directory.

21

MEX-1HD

Ver 1.2

[VERSION UP AFTER MICROCOMPUTER SOFTWARE RELATED PARTS REPLACEMENT]

If either of the following ICs was replaced with new one, the part

supplied for repair contains old version programs, and thus the

version of microcomputer software must be updated.

1) Main section (when IC1030 was replaced)*

1-1. MAIN board replacement

1-2. Flash memory (IC1030 on the MAIN board) replacement

2) Sub section (when IC501 was replaced)

2-1. SUB board replacement

2-2. Microcomputer (IC501 on the SUB board) replacement

3) CD servo section (when IC9 was replaced)

3-1. SERVO board replacement

3-2. Flash memory (IC9 on the SERVO board) replacement

*) If the flash memory (IC1030 on the MAIN board) or MAIN

board was replaced, the work including the system ID setting

is required, besides this work described here. For details, see

“Relating with ID” in the next paragraph, after the completion

of this work.

Procedure:

• Check the versions

1. After replacing the parts, turn the power on and enter the test

mode. (Refer to page 21 “Entering The Test Mode”)

2. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

3. Rotate the right jog dial (PUSH LIST) to select the “Version”,

and press the right jog button (PUSH LIST) to enter the Version mode.

4. Rotate the right jog dial (PUSH LIST) to select the “Version”,

and press the right jog button (PUSH LIST) to display the version of each section (main, sub, CD servo)

5. Update the version in each section by referring to the operation for version up, if each version is not as listed below.

The version of each section:

Section Initial Lot type User Upgrade type

Main 1.00.05 2.03.0D *

Sub 1.00.02 1.00.0D *

CD servo 0.03.60 0.03.60 *

*) There are several kinds of versions in the upgraded type (CDDB

compatible), and this table lists the latest version as of the end

of May in 2003.

The latest version may be updated after this Service Manual

was issued, and therefore make sure the latest version by referring to the Technical News issued at the version updating.

(1) Main Section

Note (for User Upgrade type only):

The version updating work must be performed without connecting

the HDD, if only the flash memory (IC1030 on MAIN board) or the

MAIN board is replaced without replacing the HDD at the same time.

In this case, perform the version updating work with the flat cable

between CN2001 on MAIN board and HDD disconnected, and after

the version updating completed, reconnect it.

1. Chech the version of CD-R for service and insert the disc to

the set.

2. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

3. Rotate the right jog dial (PUSH LIST) to select the “Version”,

and press the right jog button (PUSH LIST) to enter the Version mode.

4. Rotate the right jog dial (PUSH LIST) to select the “Version

Up”, and press the right jog button (PUSH LIST) to enter the

Version Up mode.

5. Rotate the right jog dial (PUSH LIST) to select the “Main”,

and press the right jog button (PUSH LIST) to display the

present version information of main section.

6. Press the function button 1 (“UPDATE”) to display confirmation screen of start the processing.

7. Rotate the right jog dial (PUSH LIST) to select the “OK”, and

press the right jog button (PUSH LIST) to start the processing.

(process time: about 14 minutes)

8. Upon completion of the processing, the “Update is Finished”

will be displayed.

9. The version displayed at this time is the one before version

up, and therefore turn off the main power to exit the T est mode

once, and then enter the T est mode again to check the ver sion.

10. Perform the work including the ID setting by referring to “Relating with ID” in the next paragraph.

(2) Sub Section

1. Chech the version of CD-R for service and insert the disc to

the set.

2. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

3. Rotate the right jog dial (PUSH LIST) to select the “Version”,

and press the right jog button (PUSH LIST) to enter the Version mode.

4. Rotate the right jog dial (PUSH LIST) to select the “Super

Version Up”, and press the right jog button (PUSH LIST) to

enter the Super Version Up mode.

5. Rotate the right jog dial (PUSH LIST) to select the “Sub”, and

press the right jog button (PUSH LIST) to display the present

version information of sub section.

6. Press the function button 1 (“UPDATE”) to display confirmation screen of start the processing.

7. Rotate the right jog dial (PUSH LIST) to select the “OK”, and

press the right jog button (PUSH LIST) to start the processing.

(process time: about 4 minutes)

8. Upon completion of the processing, the “Update is Finished”

will be displayed, and then will be release the test mode automatically.

9. Enter the test mode again, and check the version.

(3) CD Servo Section

Note: The version updating of the CD servo section is performed not

from the CD-R but from the Memory Stick. Download the

“CMX550D.MOT” from the “ftp” server for service and store

it in the ROOT directory of the Memory Stick for use.

1. Insert the memory stick for service to the set.

2. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

3. Rotate the right jog dial (PUSH LIST) to select the “Version”,

and press the right jog button (PUSH LIST) to enter the Version mode.

4. Rotate the right jog dial (PUSH LIST) to select the “Version

Up”, and press the right jog button (PUSH LIST) to enter the

Version Up mode.

5. Rotate the right jog dial (PUSH LIST) to select the “CD Drive”,

and press the right jog button (PUSH LIST) to display the

present version information of CD servo section.

22

MEX-1HD

Ver 1.2

6. Press the function button 1 (“UPDATE”) to display confirmation screen of start the processing.

7. Rotate the right jog dial (PUSH LIST) to select the “OK”, and

press the right jog button (PUSH LIST) to start the processing.

(process time: about 15 seconds)

8. Upon completion of the processing, the “Update is Finished”

will be displayed.

9. The version displayed at this time is the one before version

up, and therefore turn off the main power to exit the T est mode

once, and then enter the T est mode again to chec k the version.

[RELA TING WITH ID]

This set relates the main block (flash memory) and the HDD (hard

disk drive) with a unique ID to protect the copyright.

If the MAIN board or flash memory (IC1030 on MAIN board)

and HDD were replaced, the relationship between flash memory

and HDD is lost, thus causing the HDD to fail. Therefore, the ID

relational work is required.

Perform the work by proper methods, since the work required var ies as follows depending on the parts to be replaced.

1) When the MAIN board or flash memory (IC1030 on the

MAIN board) and HDD were replaced at the same time

2) When the only MAIN board or flash memory (IC1030

on the MAIN board) was replaced

3) When the only HDD was replaced

Note: The CD-R for service used when installing the data to the

hard disk must have same version as that of the set. Before

starting the work, be sure to check the version of the set and

the CD-R for service. (See “Making CD-R for service” on

page 21 and “Check the versions” on page 22)

1) When The MAIN Boar d or Flash Memory (IC1030

on The MAIN Board) and HDD Were Replaced at

The Same Time

Note: Executing this operation without replacing the hard disk drive

causes the user data to be erased. Accordingly, do not execute

this operation by mistake.

When the MAIN board or flash memory (IC1030 on the MAIN

board) and HDD were replaced at the same time, the processing

such as system ID setting and formatting are required. After the

MAIN board or flash memory (IC1030 on the MAIN board) and

HDD replacement, be sure to execute all of the following steps.

1. MAIN board or flash memory (IC1030 on the MAIN

board) and HDD replacement

r

2. Version up of flash memory

(Refer to page 22 “V ersion Up After Microcomputer Software Related Parts Replacement)

r

3. The date and time setting

r

4. HDD formatting

r

5. ID creating and copy to the HDD

r

6. Data installing to the HDD

r

7. Operation check

r

8. The Factory Setting

Procedure:

• The date and time setting

1. After replacing the parts and version up of flash memory , turn

the power on and press the [M] (MENU) button.

2. The menu screen is displayed when the date and time setting

screen is not displayed automatically, select the “Setup” and

press the right jog button (PUSH LIST) to enter the Setup mode.

3. Set the present year, month, day, hour, minute in this order

with the right jog dial and button (PUSH LIST), and finally

press the right jog button (PUSH LIST), and the date and time

display screen (standby screen) will appear, and thus the date

and time setting is over.

Right jog dial (PUSH LIST) : Change numeric value

Right jog button (PUSH LIST) : Enter the set numeric value,

and select next item or terminate the setting

Function button 1 : Return to previous item

• HDD formatting

1. Enter the test mode. (Refer to page 21 “Entering The Test

Mode”)

2. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

3. Rotate the right jog dial (PUSH LIST) to select the “HDD”,

and press the right jog button (PUSH LIST) to enter the HDD

mode.

4. Rotate the right jog dial (PUSH LIST) to select the “FORMAT”, and press the right jog button (PUSH LIST) to enter

the FORMAT mode.

5. With the Format mode activated, press the right jog button

(PUSH LIST), and the “HDD-FORMAT hddDbInit... ” will be

displayed and then the HDD formatting will start soon.

6. Upon successful completion of HDD formatting, “HDD-FORMAT OK” will be displayed. Then, press the right jog button

(PUSH LIST) to return to the FORMAT menu, and further

press the function button 1 to return to the HDD menu.

• ID creating and copy to the HDD

1. Select the “ID” from the HDD menu by rotating the right jog

dial (PUSH LIST), and press the right jog button (PUSH LIST)

to enter the ID mode.

2. Rotate the right jog dial (PUSH LIST) to select the “CREATE”, and press the right jog button (PUSH LIST) to enter the

ID CREATE mode.

3. Rotate the right jog dial (PUSH LIST) to select the “(OK)”,

and press the right jog button (PUSH LIST) to execute ID creating of the system ID.

4. Upon completion of ID creating, if the “ID-CREATE OK” or

“ID-CREATE NG” is displayed. (Even if “NG” is displayed,

there is no problem and proceed to the next step as it is)

5. Select the “COPY” from the ID menu by rotating the right jog

dial (PUSH LIST), and press the right jog button (PUSH LIST)

to enter the ID COPY mode.

6. Rotate the right jog dial (PUSH LIST) to select the “(OK)”,

and press the right jog button (PUSH LIST) to execute ID copy

to the HDD of the system ID.

7. Upon successful completion of ID copy , if the “ID-COPY OK”

is displayed, release the test mode. (Power off)

• Data installing to the HDD

1. When the power is turned on, the initial setting screen is displayed. Press the right jog button (PUSH LIST) button repeatedly until tentative setting completed.

Note: Exact date and time need not be set.

2. Chech the version of CD-R for service and insert the disc to

the set.

23

MEX-1HD

Ver 1.2

3. Again in the test mode, select the “Test Mode” from the test

mode main menu by rotating the right jog dial (PUSH LIST)

and press the right jog button (PUSH LIST) to enter the Test

Mode.

4. Rotate the right jog dial (PUSH LIST) to select the “INST ALL”, and press the right jog b utton (PUSH LIST) to enter

the INSTALL mode.

5. Rotate the right jog dial (PUSH LIST) to select the “ ALL(U)”,

and press the right jog button (PUSH LIST), and the “INSTALL-ALL(U) “ will be displayed and the installation will

start soon.

(process time: about 10 seconds (Initial Lot type), about 30

minutes (User Upgrade type))

6. Upon successful completion of installation, the “INSTALLALL(U) OK” will be displayed, and then remove the CD-R

for service and release the test mode. (Power off)

• Operation check

1. Turn the power on again, and the initial setting screen will be

displayed. Then, press the right jog button (PUSH LIST) button repeatedly until tentative setting completed.

Note: Exact date and time need not be set.

2. In the normal mode, insert a music CD and press the [SOURCE]

button to play.

3. Press the [ REC] button, rotate the right jog dial (PUSH

z

LIST) to select the third item (musical note mark), and press

the right jog button (PUSH LIST).

4. Press the function button 2 (ALL) to cancel the selection of all

tracks. (A check mark on the right side of track number will

disappear)

5. With the track number 1 selected, press the right jog button

(PUSH LIST). (A check mark will be displayed on the right

side of track number 1 only)

6. Press the [ REC] button to start the recording.

z

7. Upon completion of the recording, a peep will be heard and

z

the [ REC] button will change its color from red to blue.

8. Press the [SOURCE] button to start the play of HDD. Check

that the HDD is played back normally.

•Factory Setting

Note: The “Factory Setting” command deletes the data recorded on the

hard disk. Only if the hard disk drive was replaced, execute this

command to erase the data for operation check before returning the

set to the customer.

1. Remove the CD and press the [OFF] button to activate the

standby state, and then enter the test mode.

2. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST) and press the right jog

button (PUSH LIST) to enter the Test Mode.

3. Rotate the right jog dial (PUSH LIST) to select the “Factory

Setting”, and press the right jog button (PUSH LIST) to start

the processing.

4. Upon completion of all of the processing, “Factory SettingOK” will be displayed, and then the system will be reset and

will restart automatically.

2) When The Only MAIN Board or Flash Memory

(IC1030 on The MAIN Board) Was Replaced

When the MAIN board or flash memory (IC1030 on the MAIN

board) was replaced, the processing such as system ID setting is

required. After the MAIN board or flash memory (IC1030 on the

MAIN board) replacement, be sure to execute all of the following

steps.

1. MAIN board or flash memory (IC1030 on the MAIN

board) replacement

r

2. Version up of flash memory *

(Refer to page 22 “V ersion Up After Microcomputer Software Related Parts Replacement)

r

3. The date and time setting

r

4. ID creating and copy to the HDD

r

5. Operation check

* (for User Upgrade type only):

The version updating work must be performed without connecting

the HDD, if only the flash memory (IC1030 on MAIN board) or the

MAIN board is replaced without replacing the HDD at the same time.

In this case, perform the version updating work with the flat cable

between CN2001 on MAIN board and HDD disconnected, and after

the version updating completed, reconnect it.

Procedure:

• The date and time setting

1. After replacing the parts and version up of flash memory , turn

the power on and press the [M] (MENU) button.

2. The menu screen is displayed when the date and time setting

screen is not displayed automatically, select the “Setup” and

press the right jog button (PUSH LIST) to enter the Setup mode.

3. Set the year, month, day, hour, minute in this order with the

right jog dial and button (PUSH LIST), and finally press the

right jog button (PUSH LIST), and the date and time display

screen (standby screen) will appear, and thus the date and time

setting is over.

Right jog dial (PUSH LIST) : Change numeric value

Right jog button (PUSH LIST) : Enter the set numeric value,

and select next item or terminate the setting

Function button 1 : Return to previous item

• ID creating and copy to the HDD

1. Enter the test mode. (Refer to page 21 “Entering The Test

Mode”)

2. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

3. Rotate the right jog dial (PUSH LIST) to select the “HDD”,

and press the right jog button (PUSH LIST) to enter the HDD

mode.

4. Rotate the right jog dial (PUSH LIST) to select the “ID”, and

press the right jog button (PUSH LIST) to enter the ID mode.

5. Rotate the right jog dial (PUSH LIST) to select the “CREATE”, and press the right jog button (PUSH LIST) to enter the

ID CREATE mode.

6. Rotate the right jog dial (PUSH LIST) to select the “(OK)”,

and press the right jog button (PUSH LIST) to execute ID creating of the system ID.

7. Upon completion of ID creating, if the “ID-CREATE OK” or

“ID-CREATE NG” is displayed. (Even if “NG” is displayed,

there is no problem and proceed to the next step as it is)

8. Select the “COPY” from the ID menu by rotating the right jog

24

MEX-1HD

Ver 1.2

dial (PUSH LIST), and press the right jog button (PUSH LIST)

to enter the ID COPY mode.

9. Input the password for ID copy with the right jog dial and

button (PUSH LIST).

10. Rotate the right jog dial (PUSH LIST) to select the “(OK)”,

and press the right jog button (PUSH LIST) to execute ID copy

to the HDD of the system ID.

11. Upon successful completion of ID copy , if the “ID-COPY OK”

is displayed, release the test mode. (Power off)

• Data installing to the HDD (User Upgrade type only)

Note 1: This operation is required for the User Upgrade type only. For

Initial Lot type, skip this operation and go to the next step “Operation check”.

Note 2: Data installing may fail, if there is less available space in the

hard disk.

If data installing failed, make a checking through the following

procedure. Less space remains if “FULL CAPACITY” is displayed.

Checking procedure:

(1) In the standby state with normal mode, press the [M] (MENU)

button to display the menu screen.

(2) Rotate the right jog dial (PUSH LIST) to select the “Library”,

and press the right jog button (PUSH LIST) to enter the Library mode.

(3) Rotate the right jog dial (PUSH LIST) to select the “CDDB

Install”, and press the right jog button (PUSH LIST) and

display confirmation screen of start the processing.

(4) Rotate the right jog dial (PUSH LIST) to select the “OK”,

and press the right jog button (PUSH LIST). Less space remains if “FULL CAPACITY” is displayed.

6. With the track number 1 selected, press the right jog button

(PUSH LIST). (A check mark will be displayed on the right

side of track number 1 only)

7. Press the [ REC] button to start the recording.

z

8. Check that the progress bar is processing and remaining amount

of time for recording indicated next to the bar is decreasing.

9. Press the function 1 (s) button to quit recording.

1. When the power is turned on, the initial setting screen is displayed. Press the right jog button (PUSH LIST) button repeatedly until tentative setting completed.

Note: Exact date and time need not be set.

2. Chech the version of CD-R for service and insert the disc to

the set.

3. Again in the test mode, select the “Test Mode” from the test

mode main menu by rotating the right jog dial (PUSH LIST)

and press the right jog button (PUSH LIST) to enter the Test

Mode.

4. Rotate the right jog dial (PUSH LIST) to select the “INST ALL”, and press the right jog b utton (PUSH LIST) to enter

the INSTALL mode.

5. Rotate the right jog dial (PUSH LIST) to select the “ ALL(U)”,

and press the right jog button (PUSH LIST), and the “INSTALL-ALL(U) “ will be displayed and the installation will

start soon.

(process time: about 30 minutes)

6. Upon successful completion of installation, the “INSTALLALL(U) OK” will be displayed, and then remove the CD-R

for service and release the test mode. (Power off)

• Operation check

1. Turn the power on again, and the initial setting screen will be

displayed. Then, press the right jog button (PUSH LIST) button repeatedly until tentative setting completed.

Note: Exact date and time need not be set.

2. In the normal mode, press the [SOURCE] button to select the

HDD mode and play recorded contents. Check that the recorded

contents are played back normally.

3. Insert a music CD and press the [SOURCE] button to play.

4. Press the [ REC] button, rotate the right jog dial (PUSH

z

LIST) to select the third item (musical note mark), and press

the right jog button (PUSH LIST).

5. Press the function button 2 (ALL) to cancel the selection of all

tracks. (A check mark on the right side of track number will

disappear)

25

MEX-1HD

Ver 1.2

3) When The Only HDD Was Replaced

Note: Executing this operation without replacing the hard disk drive

causes the user data to be erased. Accordingly, do not execute

this operation by mistake.

When the hard disk drive (HDD) was replaced, the processing such

as formatting is required. After the HDD replacement, be sure to

execute all of the following steps.

1. HDD replacement

r

2. HDD formatting

r

3. ID copy to the HDD

r

4. Data installing to the HDD

r

5. Operation check

r

6. The Factory Setting

Procedure:

• HDD formatting

1. After replacing the HDD, turn the power on and enter the test

mode. (Refer to page 21 “Entering The Test Mode”)

2. Select the “Test Mode” from the test mode main menu by rotating the right jog dial (PUSH LIST), and press the right jog

button (PUSH LIST) to enter the Test Mode.

3. Rotate the right jog dial (PUSH LIST) to select the “HDD”,

and press the right jog button (PUSH LIST) to enter the HDD

mode.

4. Rotate the right jog dial (PUSH LIST) to select the “FORMAT”, and press the right jog button (PUSH LIST) to enter

the FORMAT mode.

5. With the Format mode activated, press the right jog button

(PUSH LIST), and the “HDD-FORMAT hddDbInit... ” will be

displayed and then the HDD formatting will start soon.

6. Upon successful completion of HDD formatting, “HDD-FORMAT OK” will be displayed. Then, press the right jog button

(PUSH LIST) to return to the FORMAT menu, and further

press the function button 1 to return to the HDD menu.

• ID copy to the HDD

1. Select the “ID” from the HDD menu by rotating the right jog

dial (PUSH LIST), and press the right jog button (PUSH LIST)

to enter the ID mode.

2. Rotate the right jog dial (PUSH LIST) to select the “COPY”,

and press the right jog button (PUSH LIST) to enter the ID

COPY mode.