SONY MECANICA C ADJUSTMENT MANUAL

DV MECHANICAL ADJUSTMENT MANUAL

Ver 1.1 1999.10

with SUPPLEMENT-1 (9-974-050-82)

C MECHANISM

File with the SERVICE MANUAL.

For details on schematic diagram, printed circuit boards diagram, and

electric parts list regarding this mechanism deck, refer to the service

manual for the unit mounting the C mechanism.

IV

MECHANISM

TABLE OF CONTENTS

1. EXPLODED VIEWS

1-1. Cassette Compartment, Drum and Reel Table Assembly ...3

1-2. Tape Guide, Pinch Slider Assembly and Brake Slider

Assembly ............................................................................ 4

1-3. Each Gears and Loading / Capstan Motor Assembly ......... 5

2. PARTS REPLACEMENT AND PREPARATION

FOR ADJUSTMENT

• About Mode Selector II

2-1. Outline ................................................................................ 6

2-2. Mechanism Condition (Position) Shifting Order List ........ 6

2-3. Mode Selector II (J-6082-282-A) Connection.................... 6

2-4. Service Jigs List .................................................................. 7

3. PARTS REPLACEMENT

3-1. Tape Fall Stopper, HC Roller and HC Arm ........................ 8

3-2. Drum Assembly and Drum Base Block Assembly............. 8

3-3. Damper Assembly, Cassette Compartment Assembly

and Extension Spring.......................................................... 9

3-4. Reel Table (S) / (T) Assembly .......................................... 10

3-5. Cassette Base Block Assembly,

Gooseneck Gear Assembly and Relay Gear ..................... 10

3-6. TG1 Adjustment Plate Assembly, Tension Coil Spring

(TG1), TG1 Arm Assembly, TG7 Retainer Spring

and TG7 Arm Block Assembly......................................... 11

3-7. Brake Slider Assembly, Pinch Slider Assembly

and Cam Gear ................................................................... 11

3-8. Pinch Arm Assembly, Torsion Spring (TG7LD),

Pinch Press Arm and Eject Arm ....................................... 12

3-9. GL Block Assembly, GL Driving Gear and

HC Driving Arm ............................................................... 12

3-10.Capstan Motor, Conversion Pulley,

Timing Belt and Holder .................................................... 13

3-11.L Motor Block Assembly and

FP-594 Flexible Board...................................................... 14

3-12.Reset Arm (S), Brake (S), Brake Rack (S), Brake (T),

Brake Gear (T), Brake Spring (T) and

Extension Spring............................................................... 15

3-13.Coaster (S) / (T) Assembly, GL Arm (S) / (T) Assembly,

Guide Rail, GL Gear (S) / (T) and

Torsion Spring (GLS) / (GLT) .......................................... 16

3-14.L Motor Assembly, Motor Shield,

FP-248 Flexible Board, TG1 Spring Hook, Spring Hook

Fulcrum Base, Spring Hook Driving Arm, Worm Shaft,

Deceleration Gear and Motor Holder ............................... 17

4. CHECK AND ADJUSTMENT

• Adjustment Position ......................................................... 18

• Adjustment Order (Flowchart) ......................................... 18

4-1. FWD Position Checking and Adjustment......................... 19

4-2. FWD Back Tension Checking and Adjustment ................ 19

4-3. Reel Table (S) / (T) Torque Check.................................... 20

4-4. Preparation for Tape Path Checking and Adjustment....... 20

4-5. Track Checking and Adjustment ...................................... 21

4-6. TG7 Slack Checking and Adjustment .............................. 21

4-7. Curl Checking and Adjustment......................................... 22

4-8. CUE and REV Check ....................................................... 22

4-9. Rising Check..................................................................... 22

5. PERIODIC CHECK

5-1. Cleaning of Rotary Drum Assembly ................................ 23

5-2. Cleaning of Tape Path System.......................................... 23

5-3. Periodic Checks ................................................................ 23

– 2 –

1. EXPLODED VIEWS

NOTE:

• Items marked “*” are not stocked since they are seldom required for routine

service. Some delay should be anticipated when ordering these items.

• The mechanical parts with no reference number in the exploded views are

not supplied.

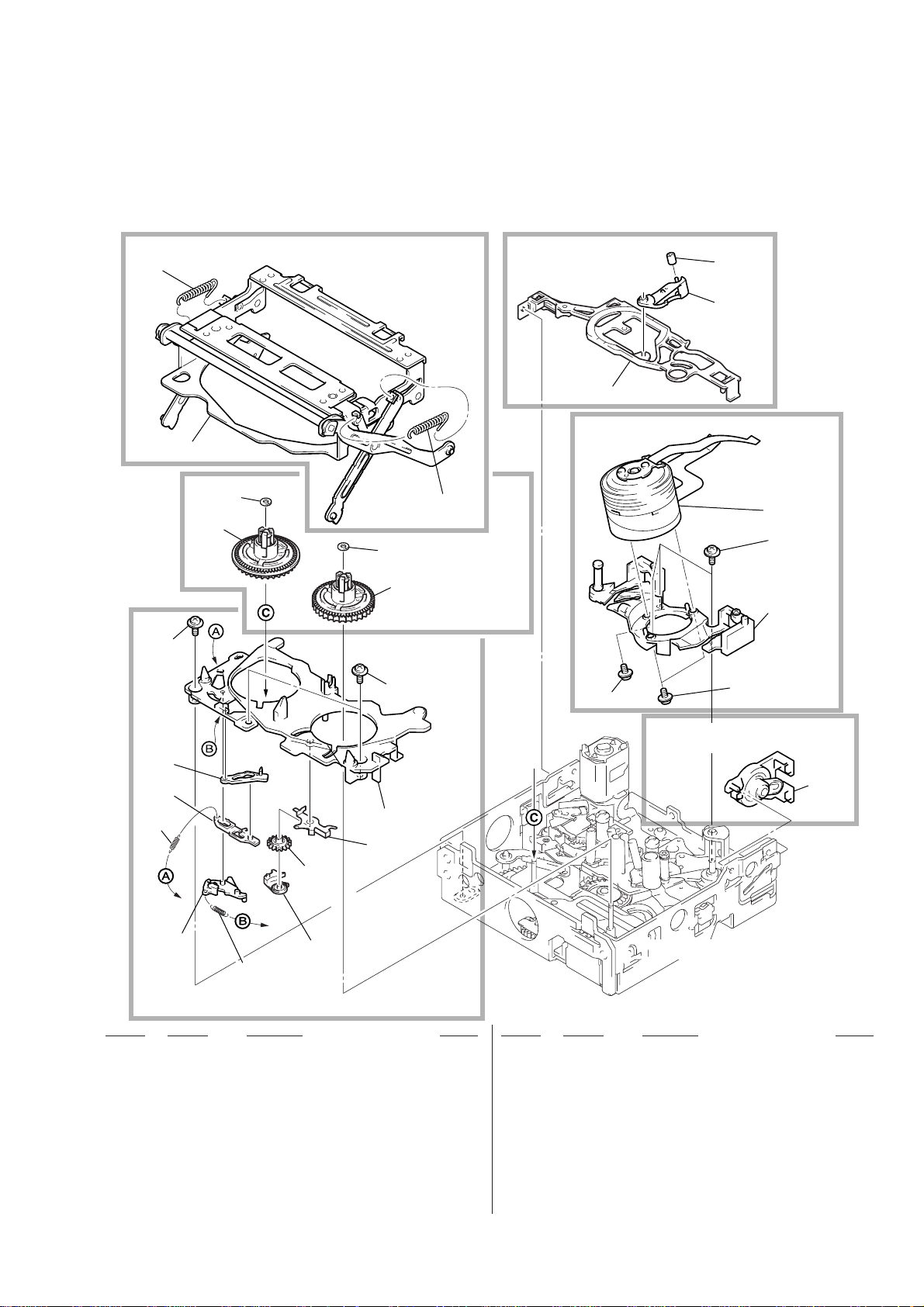

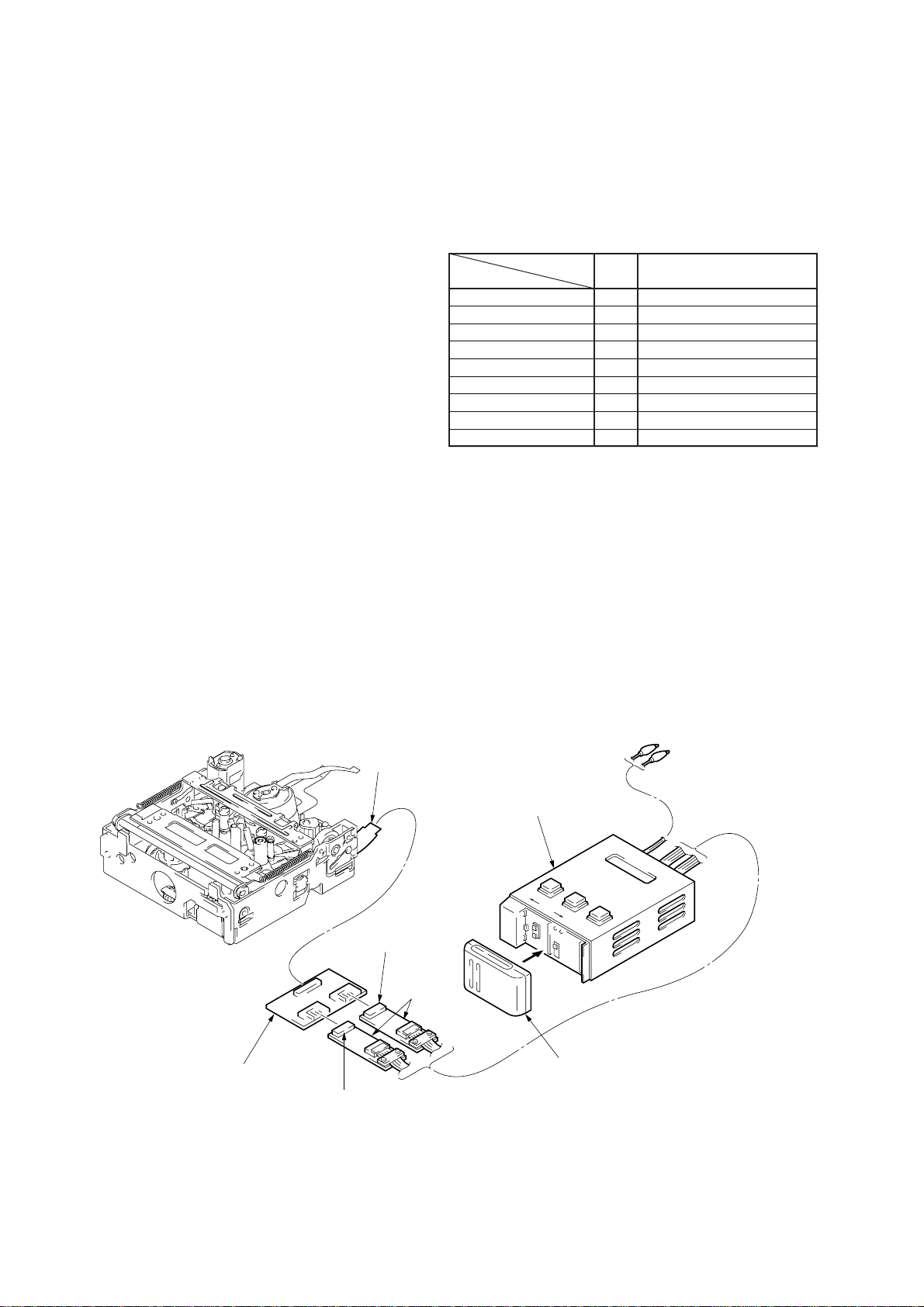

1-1. CASSETTE COMPARTMENT, DRUM AND REEL TABLE ASSEMBLY

714

Refer to page 9 for details of

replacement of parts.

715

Refer to page 8 for details of

replacement of parts.

719

Refer to page 8 for details of replacement of parts.

718

707

713

714

M901(Note)

712

713

710

711

Refer to page 10 for details

of replacement of parts.

717

710

710

710

Refer to page 9 for details of

replacement of parts.

710

709

708

701

705

716

704

703

706

702

701

Refer to pages 10 and 15 for details of replacement of parts.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

701 3-988-312-01 SPRING, EXTENSION

702 3-988-220-01 BRAKE (T)

703 3-988-221-01 GEAR (T), BRAKE

704 3-988-222-01 SPRING (T), BRAKE

705 3-988-215-02 BASE, CASSETTE

711 X-3948-445-1 TABLE (T) ASSY, REEL

712 X-3948-444-1 TABLE (S) ASSY, REEL

713 3-989-465-01 WASHER, STOPPER

714 3-988-298-01 SPRING EXTENSION

715 X-3948-441-2 CASSETTE COMPARTMENT ASSY

Note

:Refer to the proper service manual

since the model name of drum assembly and the Parts No. are different according to sets.

706 3-988-217-01 ARM (S), RESET

707 3-988-281-02 ARM, HC

708 3-988-219-01 RACK (S), BRAKE

709 3-988-218-01 BRAKE (S)

710 3-947-503-01 SCREW (M1.4X2.5)

716 X-3948-443-2 DAMPER ASSY

717 A-7093-612-A DRUM BASE BLOCK ASSY

718 3-988-282-01 ROLLER, HC

719 3-988-283-01 STOPPER, TAPE FALL

M901

Note

DRUM ASSY

– 3 –

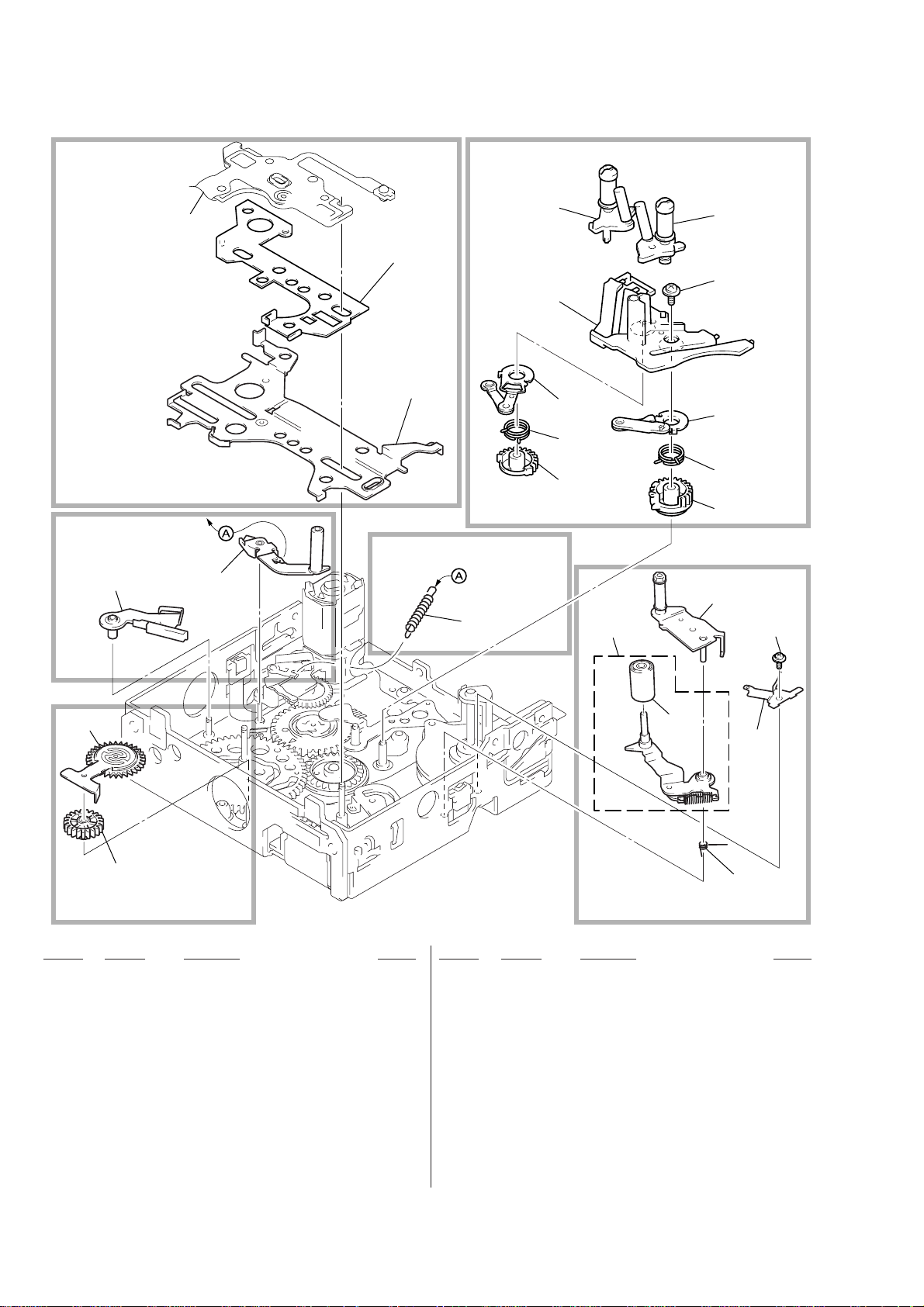

1-2. TAPE GUIDE, PINCH SLIDER ASSEMBLY AND BRAKE SLIDER ASSEMBLY

Refer to pages 12 and 16 for details of replacement of parts.

Including Ref No.

on page 5.

Refer to page 11 for details of replacement

of parts.

Refer to page 11 for details

of replacement of parts.

753

813

754

756

755

Refer to page 11 for details of

replacement of parts.

757

770

768

766

764

762

759

769

767

765

763

761

760

773

752

772

771

751

Refer to page 10 for details of

replacement of parts.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

751 3-988-263-01 GEAR, RELAY

752 X-3948-442-2 GEAR ASSY, GOOSENECK

753 X-3948-435-2 PLATE ASSY, TG1 ADJUSTMENT

754 X-3948-434-1 ARM ASSY, TG1

755 X-3948-428-4 SLIDER ASSY, PINCH

756 X-3948-766-1 SLIDER ASSY, BRAKE

757 3-988-270-01 SPRING (TG1), TENSION COIL

758 3-988-233-01 SPRING (TG7LD), TORSION

759 X-3948-433-2 ARM ASSY, PINCH

760 A-7093-501-A ARM BLOCK ASSY, TG7

761 3-988-257-02 GEAR (T), GL

762 3-988-252-03 GEAR (S), GL

763 3-988-258-01 SPRING (GLT), TORSION

764 3-988-253-01 SPRING (GLS), TORSION

765 X-3948-440-1 ARM (T) ASSY, GL

766 X-3948-439-3 ARM (S) ASSY, GL

767 3-947-503-01 SCREW (M1.4X2.5)

768 3-988-242-01 RAIL, GUIDE

769 X-3948-438-3 COASTER (T) ASSY

770 X-3948-437-1 COASTER (S) ASSY

771 3-988-690-02 SPRING, TG7 RETAINER

772 X-3748-630-2 ROLLER ASSY (DIA. 5.6), PINCH

773 3-050-334-01 SCREW (M1.4X5)

Refer to pages 11 and 12 for details of

replacement of parts.

758

– 4 –

Ver 1.1 1999.10

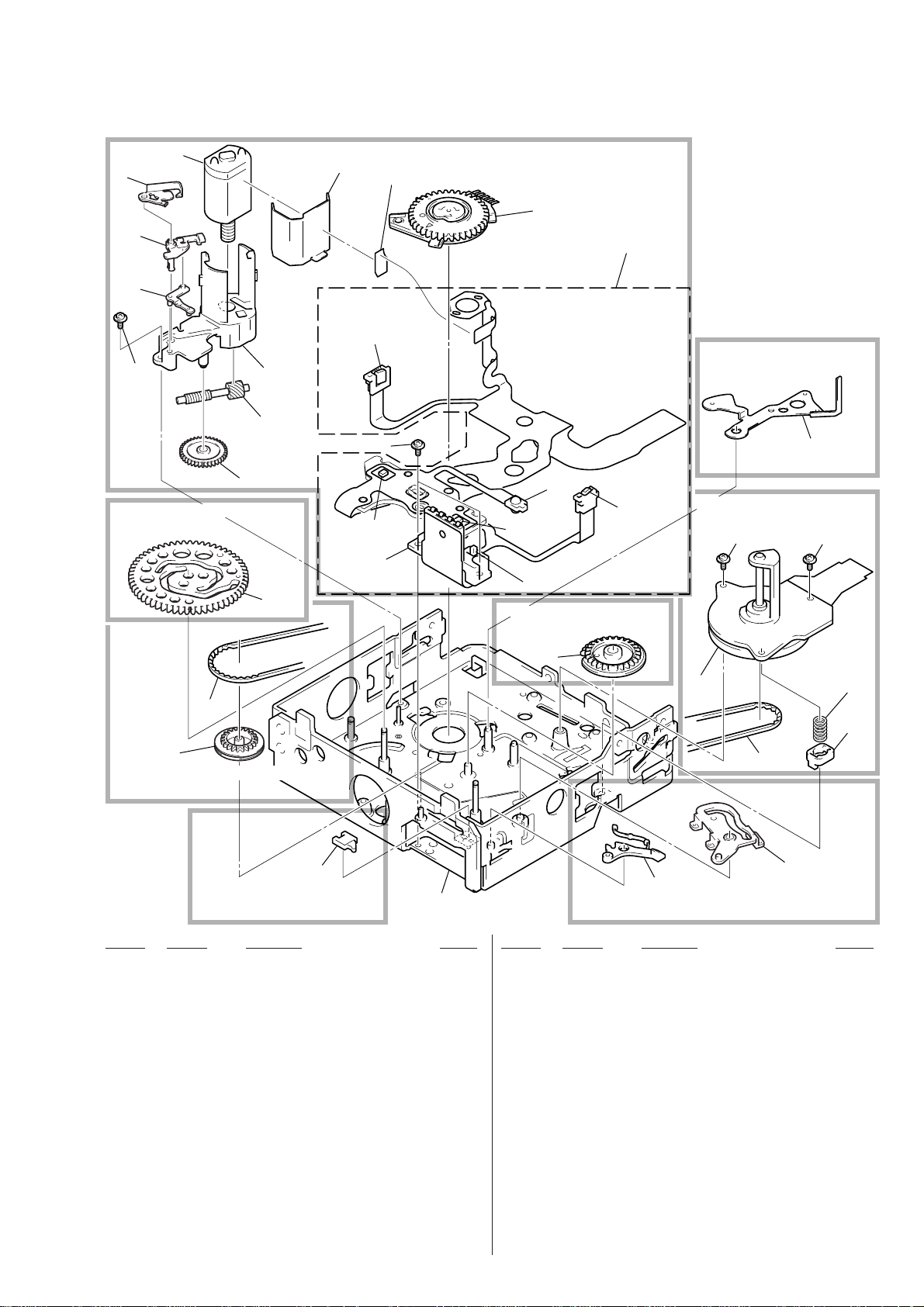

1-3. EACH GEARS AND LOADING / CAPSTAN MOTOR ASSEMBLY

M902

810

809

808

807

806

805

804

Refer to page 11 for details of

replacement of parts.

803

811

Q901

807

H901

CN901

812

Refer to pages 14 and 17 for details of

replacement of parts.

S903

813

D901

Q902

H902

S902

Refer to page 12 for details of

replacement of parts.

Refer to page 12 for details of

replacement of parts.

814

Refer to page 13 for details of

replacement of parts.

807

807

802

801

Refer to page 13 for details of

replacement of parts.

S901

Refer to page 14 for details of

replacement of parts.

Ref. No. Part No. Description Remark

801 3-988-274-01 PULLEY, CONVERSION

802 3-988-276-02 BELT, TIMING

803 3-988-216-01 GEAR, CAM

804 3-988-211-01 GEAR, DECELERATION

805 3-988-210-01 SHAFT, WORM

806 3-988-207-01 HOLDER, MOTOR

807 3-947-503-01 SCREW (M1.4X2.5)

808 3-988-303-01 ARM, SPRING HOOK DRIVING

809 3-988-271-01 BASE, SPRING HOOK FULCRUM

810 3-988-302-01 HOOK, TG1 SPRING

818

815

M903

820

819

802

817

816

Ref. No. Part No. Description Remark

816 3-988-223-01 ARM, EJECT

817 3-988-224-01 ARM, PINCH PRESS

818 X-3948-431-4 CHASSIS ASSY

819 3-050-170-01 HOLDER

820 3-051-787-02 SPRING (CAP), COMPRESSION COIL

CN901 1-784-723-11 PIN, CONNECTOR 4P

D901 8-719-067-13 DIODE GL453K

H901 8-719-061-28 DIODE HW-105C-FT-V (S REEL SENSOR)

H902 8-719-061-28 DIODE HW-105C-FT-V (T REEL SENSOR)

M901 X-3948-346-1 MOTOR ASSY, L (LOADING)

Refer to page 12 for details of

replacement of parts.

811 3-988-208-01 SHIELD, MOTOR

812 1-657-785-11 FP-248 FLEXIBLE BOARD (DEW SENSOR)

813 A-7073-418-A FP-594 BOARD, COMPLETE

814 3-988-280-03 ARM, HC DRIVING

815 3-988-239-01 GEAR, GL DRIVING

M903 8-835-606-01 MOTOR, DC SCD15A/C-NP (CAPSTAN)

Q901 8-729-907-25 PHOTO TRANSISTOR PT4850F (TAPE END)

Q902 8-729-907-25 PHOTO TRANSISTOR PT4850F (TAPE TOP)

S901 1-771-039-51 SWITCH, PUSH (C IN SW)

S902 1-572-719-32 SWITCH, PUSH (1 KEY) (REC PROOF)

S903 1-771-325-11 ENCODER, ROTARY (SWITCH) (MODE)

– 5 –

2. PARTS REPLACEMENT AND PREPARATION FOR ADJUSTMENT

• About Mode Selector II

2-1. OUTLINE

This unit is a mechanism drive tool which supplements the

maintenance of each mechanism deck. Its functions are

described below.

1. Manual test

A mode which drives the motor only while the switch is ON.

It enables the operator to control the motor as desired.

2. Step test

A mode which drives the motor until the current condition

detected by the sensor changes to another condition. It enables

the movements made by the motor in each operation to be

controlled while being checked.

3. Auto test

A mode that checks if the mechanism operates normally

according to the condition shift table recorded in the unit for

each mechanism deck. All the conditions of the decks are checked

through a series of operations.

An error message is displayed if incorrect shifts and conditions

are detected and operations are stopped.

2-2. MECHANISM CONDITION (POSITION)

SHIFTING ORDER LIST

After selecting the mechanism deck, select one of the two test

modes other than the auto test, and press the RVS and FF button

to specify the mechanism state (position).

MD name

Code

ABCD

1110

1010

1011

1001

0111

0011

1101

1100

1

2

3

4

5

6

7

8

C mechanism

EJECT

ULE

SR

HL

LE

STOP

RP

REW

2-3. MODE SELECTOR II (A-6082-282-A) CONNECTION

C mechanism

Mode selector conversion

board (C)

Connector (Black) 6P

FP-594 flexible board

Connector (White) 6P

Relay boards

Mode serector

Battery of NP-55, 77, etc.

(Power supply)

Alligator Clip

II

– 6 –

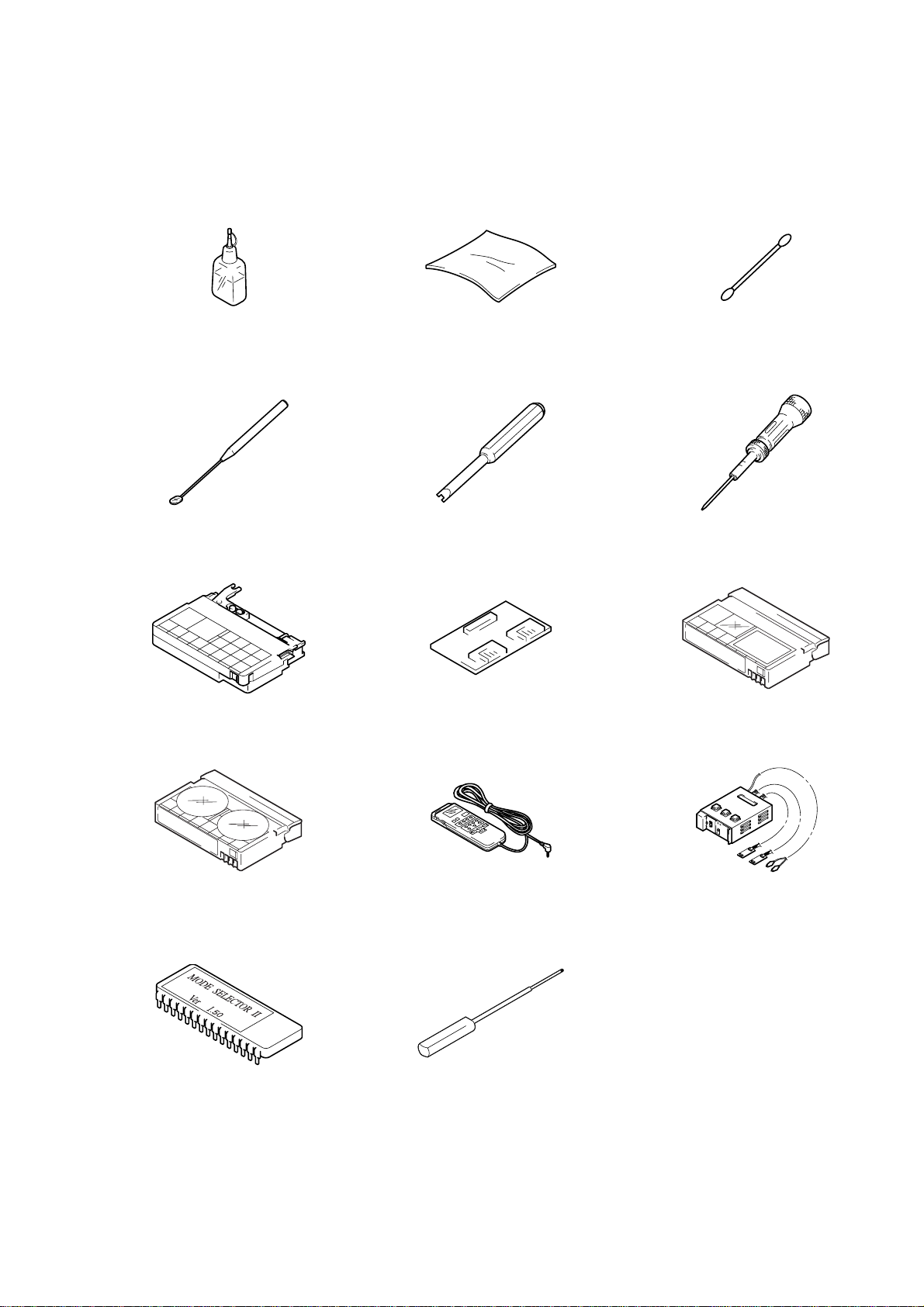

2-4. SERVICE JIGS LIST

J-1. Cleaning fluid

(Y-2031-001-0)

J-4. Mirror (Small oval type)

(J-6082-840-A)

J-7. TG1 adjustment jig

(FWD position adjustment)

(J-6082-420-A)

J-2. Wiping cloth

(7-741-900-53)

J-5. Screwdriver for tape path

(J-6082-026-A)

J-8. Mode selector conversion board (C)

(J-6082-417-A)

J-3. Super fine applicator

(Made by NIPPON APPLICAT OR(P752D))

J-6. Torque driver

(J-9049-330-A)

J-9. Tracking tape (XH2-1) (NTSC/PAL)

(8-967-997-01)

J-10. Mini DV torque cassette

(J-6082-360-A)

II

J-13. Mode selector

(Corresponds to C mechanism: Note 2)

(J-6082-314-D)

ROM

J-11. Adjusting remote commander

(RM-95 remodeled partly : Note 1)

(J-6082-053-B)

J-14. Bending stick

(J-6082-419-A)

Note 1 : If the micro processor IC in the adjusting remote com-

Note 2 :ROM for version upgrading to allow use of the mode se-

J-12. Mode selector

(J-6082-282-A)

II

mander is not the new micro processor (UPD7503G-C56-

12), the pages cannot be switched. In this case, replace

with the new micro processor (8-759-148-35).

lector II with the C mechanism.

– 7 –

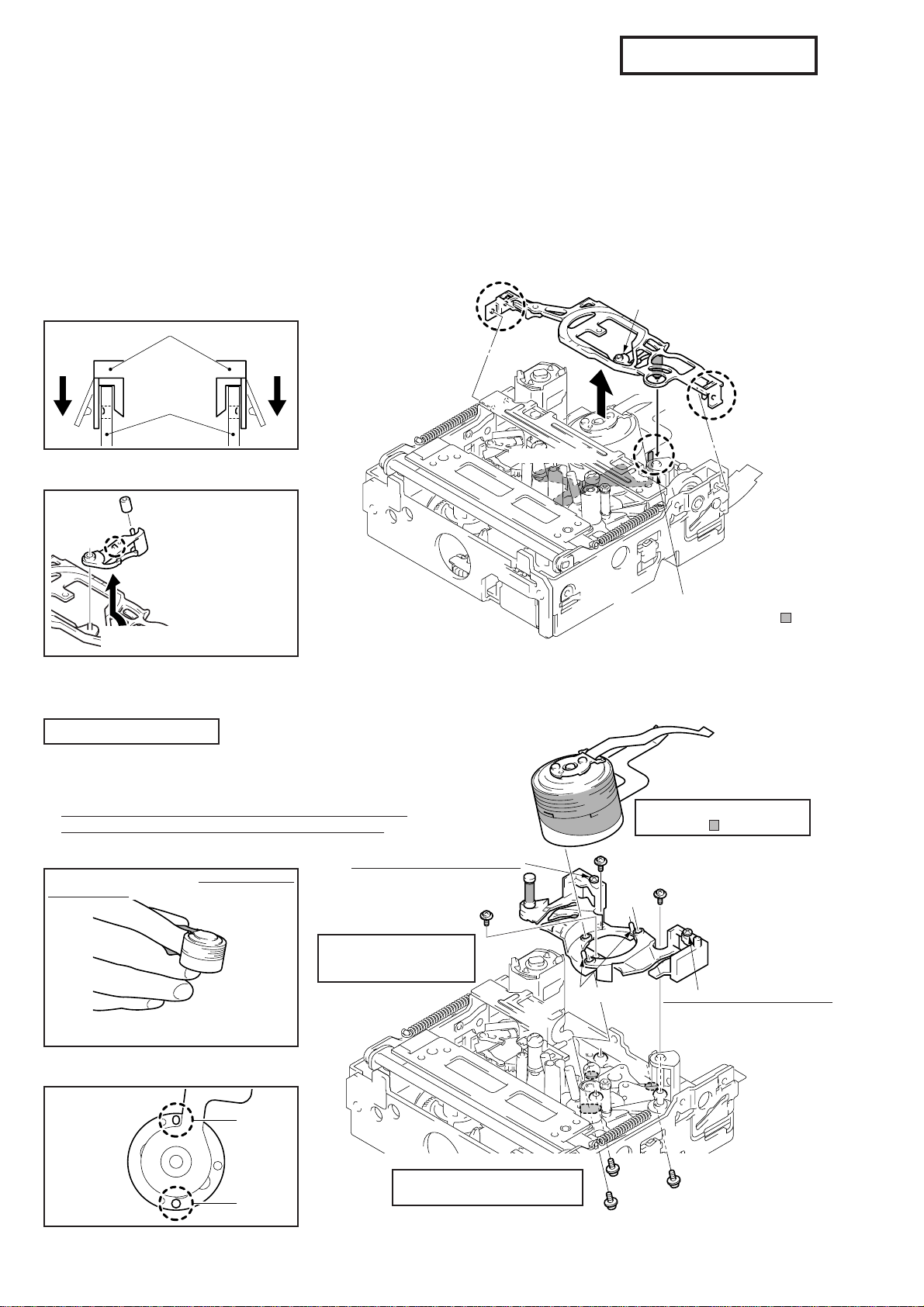

Screw tightening torque tolerance.

1

3

4

2

3

3

0.0098 N.m (0.1 kg.cm)

3. PARTS REPLACEMENT

• Precautions

For details on removing the cabinet and board, refer to "DISASSEMBL Y" in the respective service manuals. For details on the replacement

of mechanism parts (removal or attaching), refer to the respective flowcharts, and perform the procedure given.

3-1. TAPE FALL STOPPER, HC ROLLER AND HC ARM

Removing method :Spread out the left and right attaching parts

and remove them upwards.

Attaching method : Refer to the Details diagram.

Details diagram on attachment of Tape

Fall Stopper

The left and right attaching parts are fixed to

the chassis.

Chassis

Spread outwards.

Tape fall stopper

HC arm

Spread outwards.

Details diagram on removal and

attachment of HC Arm and HC Roller

HC roller

Claw

HC arm

Rotate slightly and

release the lock.

Tape fall stopper

Note:There should be no scratches

or dirt on the HC roller.

3-2. DRUM ASSEMBLY AND DRUM BASE BLOCK ASSEMBLY

Remove the

“3-1. Tape Fall Stopper”.

Removing method : Remove in the order of 1/2/3/4 .

Attaching method : Attach in the order of 4/3/2/1 .

(Note:Tighten the screws in the order of A, B, and C.)

After attaching all the parts, refer to the flowchart on page 18,

and perform the adjustments from Starting adjustments-2.

Holding the Drum Assembly

Insert your second finger between the two

flexible boards, and hold the top and bottom

boards.

Note:Do not touch the running face of the

Details diagram on attachment of Drum

drum assembly.

Blast screw (Do not rotate.)

Drum base block assembly

tightening torque

0.0686 N•m (0.7 kg•cm)

Assembly (Positioning pins)

Drum assembly

B

Screw

HC driving arm

Positioning pins

When attaching the tape fall stopper,

make sure that the HC arm (

outside the HC driving arm (capstan

motor side).

Do not touch the running face

A

Screw

of the tape (

C

Drum base block assembly

).

Screw

Blast screw (Do not rotate.)

) is

Pin at rear side

Pin at side of

reel table

Long hole

Hole

Drum assembly tightening torque

0.0588 N•m (0.6 kg•cm)

– 8 –

C

B

Screw

Screw

A

Screw

Loading...

Loading...