Page 1

SERVICE MANUAL

*Table of contents is on the last page. Please also utilize "Bookmarks“ function / "Find" function on Acrobat PDF data.

XE85 Series

ORIGINAL MANUAL ISSUE DATE: 3/2017

SI2C013500 - 1/5/2022 12:13 PM

Version Date Subject

1.0 3/2017 Original manual issue.

GN3TR CHASSIS

KH Segment

LCD TV

9-888-821-01

Page 2

MODEL LIST

MODEL COLOR COMMANDER DEST.

KD-55XE8505 Black RMF-TX300E CEI/UKA

KD-55XE8577 Silver RMF-TX300E UKA/RU3

RMF-TX301E CEI

KD-55XE8588 Black RMF-TX201ES CEI

KD-55XE8596 Black RMF-TX300E CEI/UKA/RU3

KD-55XE8599 Black RMF-TX201ES CEI

KD-65XE8505 Black RMF-TX300E CEI/UKA

KD-65XE8577 Silver RMF-TX300E UKA/RU3

RMF-TX301E CEI

KD-65XE8588 Black RMF-TX201ES CEI

KD-65XE8596 Black RMF-TX300E CEI/UKA/RU3

KD-65XE8599 Black RMF-TX201ES CEI

FW-65XE8501 Black RMF-TX300E CEI/UKA

RMT-TX210E

MODEL COLOR COMMANDER DEST.

KD-75XE8596 Black RMF-TX300E CEI/UKA/RU3

FW-75XE8501 Black RMF-TX300E CEI/UKA

RMT-TX210E

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

2

Page 3

WARNINGS AND CAUTIONS - ENGLISH

CAUTION

These servicing instructions are for use by qualified service personnel only.

To reduce the risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis.

The chassis of this receiver is directly connected to the ac power line.

CARRYING THE TV

Be sure to follow these guidelines to protect your property and avoid causing serious injury.

SI2C013500 - 1/5/2022 12:13 PM

• Carry the TV with an adequate number of people; larger size TVs require two or more people.

• Correct hand placement while carrying the TV is very important for safety and to avoid damages.

SAFETY-RELATED COMPONENT WARNING!!

Components identified by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace these components with Sony

parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that are critical for safe operation are identified in this manual.

Follow these procedures whenever critical components are replaced or improper operation is suspected.

CAUTION ABOUT THE LITHIUM BATTERY

• Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type.

• Outer case broken battery should not contact to water.

IMPORTANT REMINDER FOR TV MAINBOARD REPLACEMENT

It is mandatory for service centers to confirm the TV's system information after each repair carried out with Mainboard replacement.

Whenever a TV Mainboard is replaced, the correct TV Model and Serial number must be reinserted into memory.

This is a MANDATORY procedure that each service center must apply.

Please refer to the chapter of ADJUSTMENT in this service manual to find out how to set the model number and serial number in service mode.

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

3

Page 4

WARNINGS AND CAUTIONS - FRENCH

ATTENTION!!

Ces instructions de service sont à l’usage du personnel de service qualifi é seulement.

Pour prévenir le risque de choc électrique, ne pas faire l’entretien autre que celui contenu dans le Mode d’emploi à moins que vous soyez qualifi é faire ainsi.

WARNING!!

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout dépannage. Le chássis de ce récepteur est

directement raccordé à l’alimentation du secteur.

POUR TRANSPORTER LE TÉLÉVISEUR

Tenez compte de ce qui suit pendant l’installation du téléviseur :

• Débranchez tous les câbles avant de transporter le téléviseur.

• Transportez le téléviseur avec le nombre de personnes approprié ; un téléviseur de grande taille doit être transporté par au moins deux personnes.

• Lors du transport du téléviseur, l’emplacement des mains est très important pour votre sécurité, ainsi que pour éviter de causer des dommages.

ALERTE!!

Afi n d’eviter tout risque d’electrocution provenant d’un chassis sous tension, un transformateur d’isolement doit etre utilise lors de tout depannage. Le chassis de ce recepteur est

directement raccorde a l’alimentation du secteur.

ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque sur les schemas de principe, les vues explosees et les listes de pieces sont d’une importance critique pour la securite

du fonctionnement. Ne les remplacer que par des composants Sony dont le numero de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les

reglages de circuit dont l’importance est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de chaque remplacement de

composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

4

Page 5

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

When repairing the LCD panel on the wall, the LCD panel must be secured using the 4 mounting holes on the rear cover.

1) Do not press on the panel or frame edge to avoid the risk of electric shock.

2) Do not scratch or press on the panel with any sharp objects.

3) Do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause a short circuit within the module.

6) Disconnect the AC power when replacing the backlight (CCFL) or inverter circuit. (High voltage occurs at the inverter circuit at 650Vrms.)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

9) Protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

10) It is recommended not to exceed 1 hour of Power-On nor Burn-in period with LCD panel face down condition, in repair activity.

WARNINGS AND CAUTIONS

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

5

Page 6

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered connections. Check the entire board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and mounting hardware have been replaced. Be absolutely certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of deterioration. Point them out to the customer and recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend the replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs, screws, and all other exposed metal parts for AC leakage. Check leakage as described below.

8. For safety reasons, repairing the Power board and/or Inverter board is prohibited.

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

6

Page 7

SI2C013500 - 1/5/2022 12:13 PM

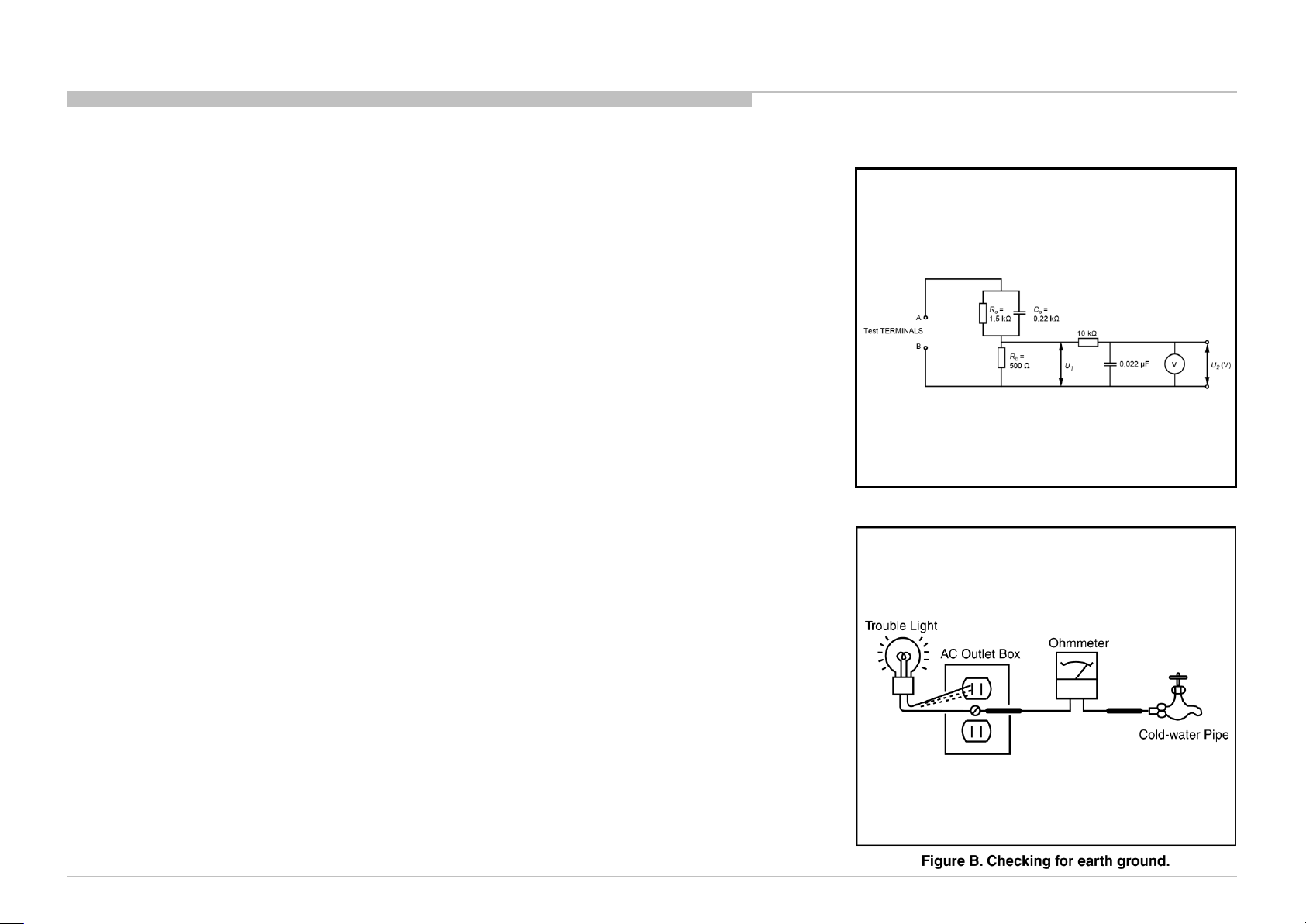

Leakage Test

(To protect electric shock when customer touch the terminal.)

Leakage current can be measured by V: Voltmeter or oscilloscope (r.m.s. or peak reading)

Stabilized power supply instrument and isolated voltage transformer:

Use too much current capacity and isolated voltage transformer does not need to use stabilized power supply

equipment

Specification of RMS volt meter: Input resistance > 1 Mohm, Input capacitance < 200 pF,

Frequency range: 15 Hz – 1MHz (Refer Figure A). Isolated type volt -meter (FLUKE 8921A etc *1)

*1 Not use FLUKE 8920A that connected to protective earth by diode

# Leakage current of measurement instrument is less than 10μArms when under test equipment AC plug is

opened

# Set up the following condition and turn on the set.

Applied voltage: Nominal input voltage (Description on Nameplate)

# Measure the leakage current between one phase conductor and neutral for terminal A and terminal B.

Read rms value, and then calculate to peak value PEAK VALUE =√2 RMS VALUE

Comply with the following requirement

Class II equipment (2-pin plug):

for each terminal, the worst value of measurement must not exceed AC 350uA peak).

Note: including AC adaptor, AC adaptor/DC operated unit combination

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining screw on most AC outlet boxes is also

at earth ground.

If the retaining screw is to be used as your earth ground, verify that it is at ground by measuring the resistance

between it and a cold-water pipe with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt trouble- light (not a neon lamp) between the hot

side of the receptacle and the retaining screw. Try both slots, if necessary, to locate the hot side on the line; the

lamp should light at normal brilliance if the screw is at ground potential (see Figure B).

SAFETY CHECK-OUT

Figure A. Measuring network for Leakage Current

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

7

Page 8

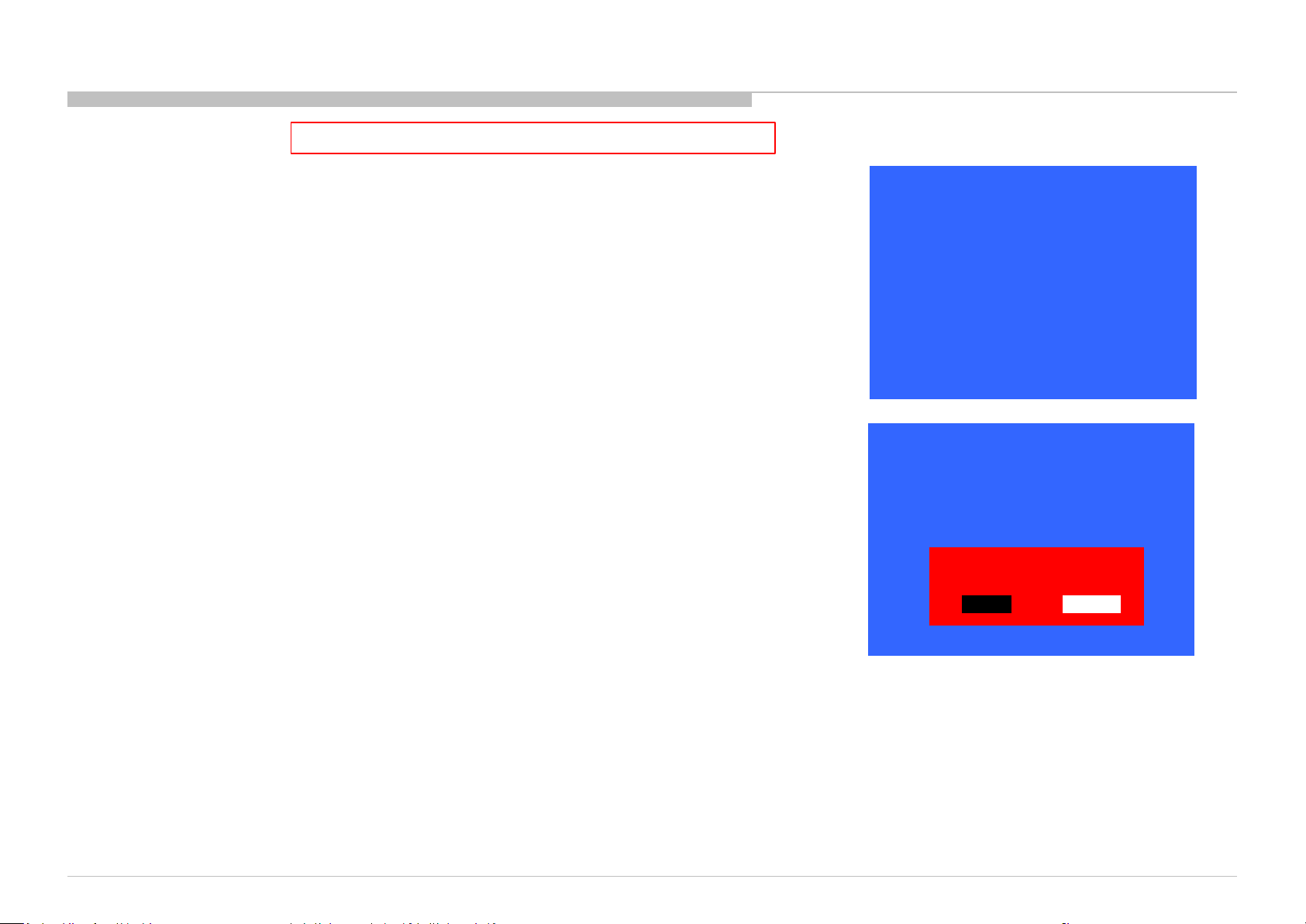

SELF DIAGNOSIS FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the Smart Core Red LED will automatically begin to flash.

The number of times the LED flashes translates to a probable source of the problem.

A definition of the Smart Core Red LED flash indicators is listed in the instruction manual for the user’s knowledge and reference.

If an error symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

DIAGNOSTIC TEST INDICATORS

When an error occurs, the Smart Core Red LED will flash a set number of times to indicate the possible cause of the problem.

If there is more than one error, the LED will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen.

If the screen displays a “0”, no error has occurred .

RED LED blinking count Detection Items

2x

3x

4x

5x

6x

7x

8x

<B/G> Main 12V over voltage [MAIN_POWER]

<B/G> Main 5.0V failure [DC_ALERT]

<B/S/G> Audio amp. protection [AUD_ERR]

None

<P/T/G/B> Panel ID EEPROM I2C No ACK (Also panel power failure is a suspect) [P_ID_ERR]

<G/P/B/LD> Backlight failure [BACKLIGHT]

Over temperature protection [TEMP_ERR]

<B/P> Temp. sensor I2C No ACK [TEMP_ERR]

<B> 4KPQ Error (4KPQ WDT)

<G>: Power supply board, <B>: Main board, <T>: T-con board, <LD> LD board,

<P>: Panel module, <S>: Speaker, <Tu>: Tuner board

The following items will be recorded and displayed on screen although they do not carry out the RED LED blinking count.

Record Only Item Detection Items

TU_DEMOD

TCON_ERR <T> T-CON device I2C communication failure

FRCTC_I2C

AUD_ERR_I2C <B> Audio amp I2C communication failure

4KPQ_ERR_I2C

Blue italic: detect at startup sequence only.

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

<B/Tu> Tuner & Demodulator I2C communication failure

Tuner board set detect signal monitoring

<B> FRC device is not finished Initial sequence

FRC device I2C communication failure

<B> 4KPQ device I2C communication failure

8

Page 9

SI2C013500 - 1/5/2022 12:13 PM

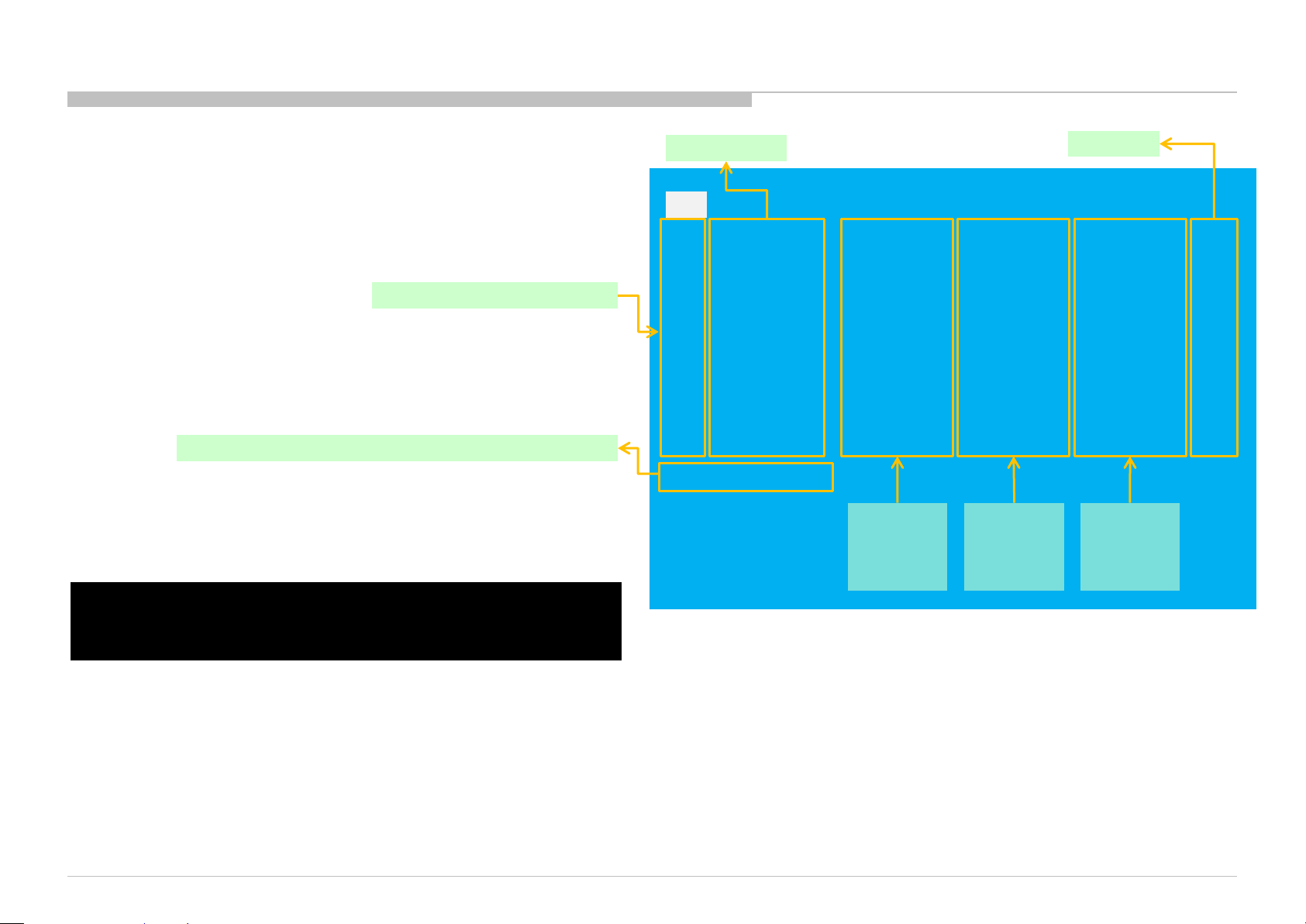

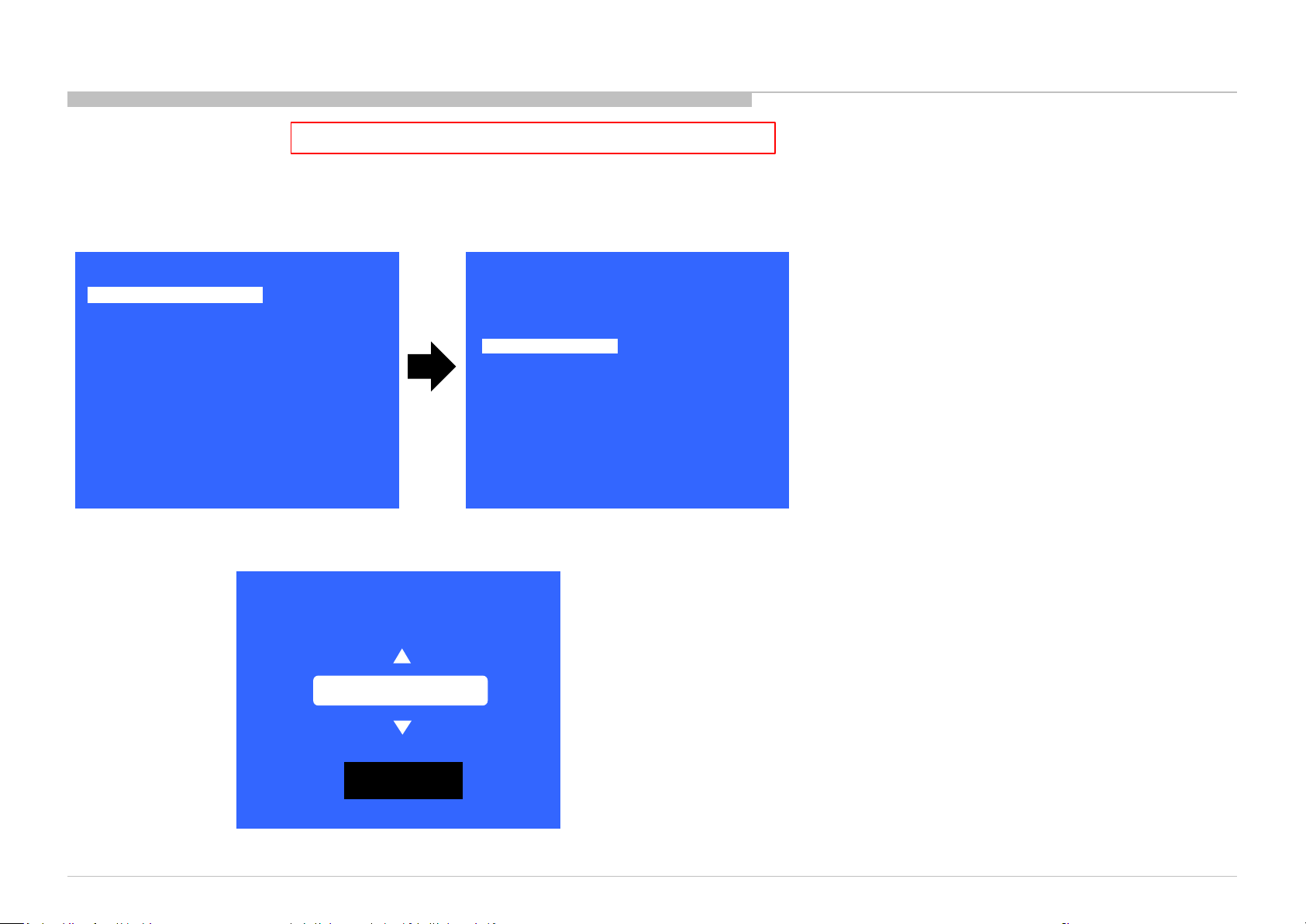

SELF DIAGNOSIS FUNCTION

[SELF DIAGNOSTIC SCREEN DISPLAY]

Format of error timestamps

YYMMDDhh mmss (in UTC)

Example :

120823132523 -> Aug 23 2012 13:25:23 UTC

* On ly whe n time is set, an err or times tam p is s ave d.

Smart Core Red LED blinking count

• Panel Ope rat ion Ti me is recorded ever y 30 min,

but Total Operation Ti me is recorded eve ry 1 h r .

Ther efo re, the panel op. time might bec ome l arg er t han th e total op. tim e.

Total Operation Time [hr] – Boot Count – Panel Operation Time [hr]

For errors with symptoms such as “power sometimes shuts off” or

“screen sometimes goes out” that cannot be confirmed,

it is possible to bring up past occurrences of failure for confirmation on the screen:

In standby mode, press buttons on the remote commander sequentially in rapid

succession as shown below:

Error Item

SELF CHECK

Back

<<

002 MAIN POWER 000000000000 000000000000 000000000000 000

003 DC ALERT 000000000000 000000000000 000000000000 000

003 AUD ERR 150101000018 150101000018 150101000018 003

003 AUD ERR I2C 000000000000 000000000000 000000000000 000

003 TU DEMOD 150101000218 150101000223 150101000105 003

004 LD ERR 000000000000 000000000000 000000000000 000

004 BCM ERR 000000000000 000000000000 000000000000 000

005 TCON ERR 150101000504 000000000000 000000000000 001

005 P ID ERR 000000000000 000000000000 000000000000 000

005 FRCTC I2C 000000000000 000000000000 000000000000 000

006 BACKLIGHT ERR 000000000000 000000000000 000000000000 000

007 TEMP ERR 150101000200 150101000002 000000000000 002

008 4KPQ ERR 000000000000 000000000000 000000000000 000

008 4KPQ ERR I2C 000000000000 000000000000 000000000000 000

00005 00414 00002

[Home]Exit

Error

timestamp

for last

recorded

error

Error

timestamp

for 2nd last

recorded

error

Error count

Error

timestamp

for 3rd last

recorded

error

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen.

After you have completed the repairs, clear the result display to “0”.

Panel Operation Time clear : Press the Channel 7 => Channel 0 .

Timestamps and Error Count clear : Press the Channel 8 => Channel 0 .

Total Operation Time and Boot Count clear: Press the Channel 9 => Channel 0 .

To exit the Self Diagnostic screen...

*If you want to finish service mode app, do AC OFF/ON → Service mode app is disabled perfectly

*if you want to move home menu, push <HOME>button → Service mode app do background(not disable perfectly)

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

9

Page 10

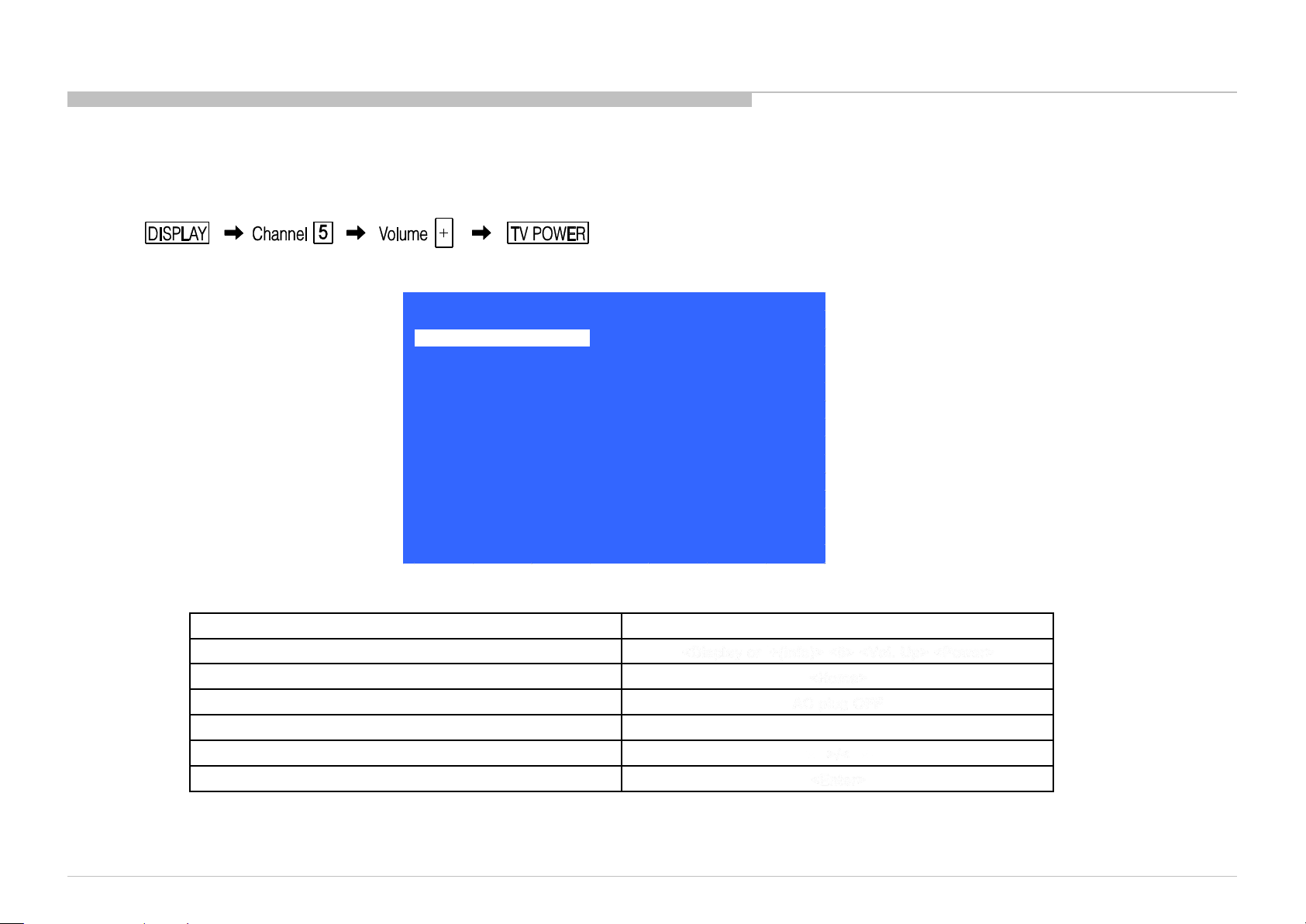

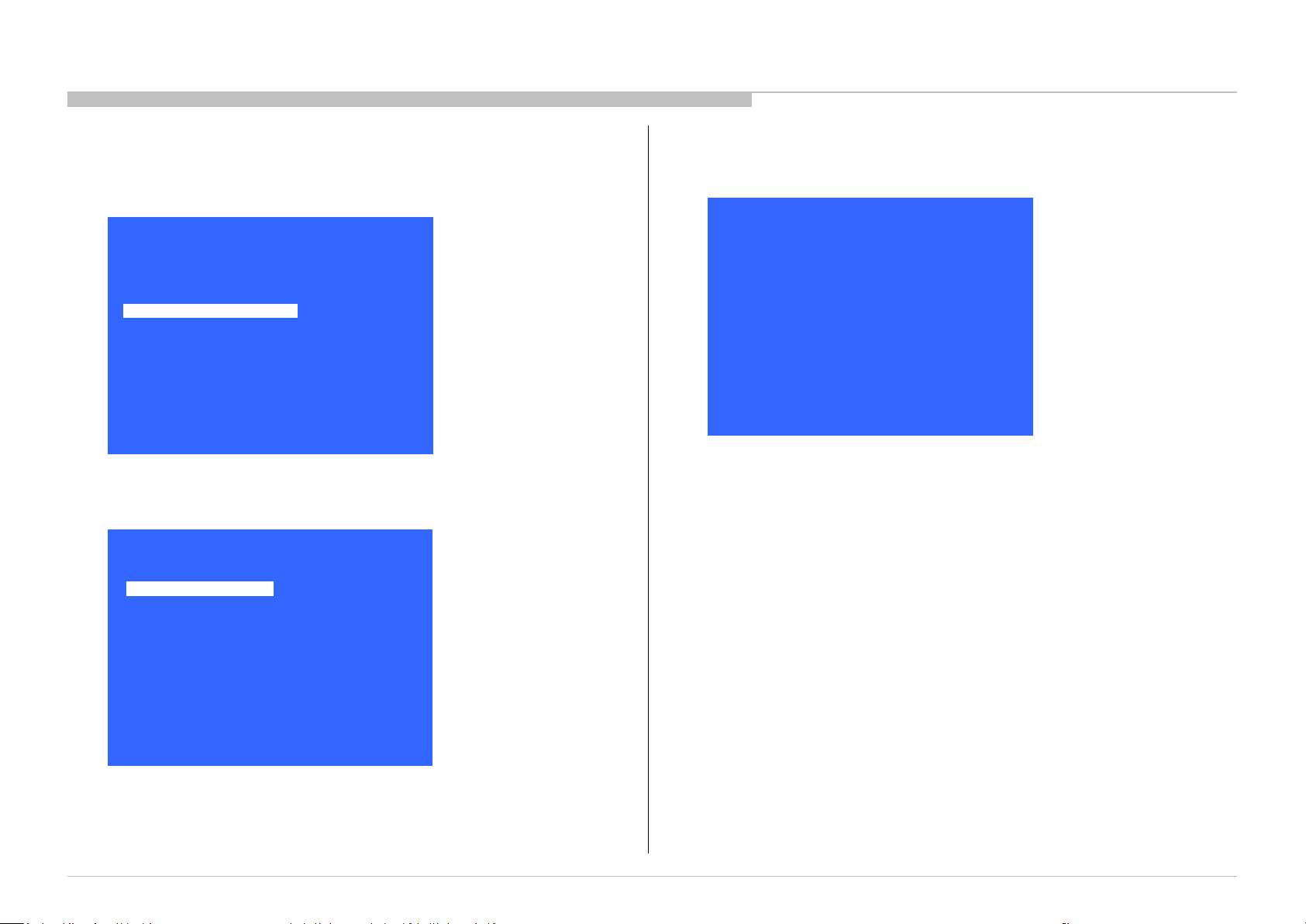

ADJUSTMENT

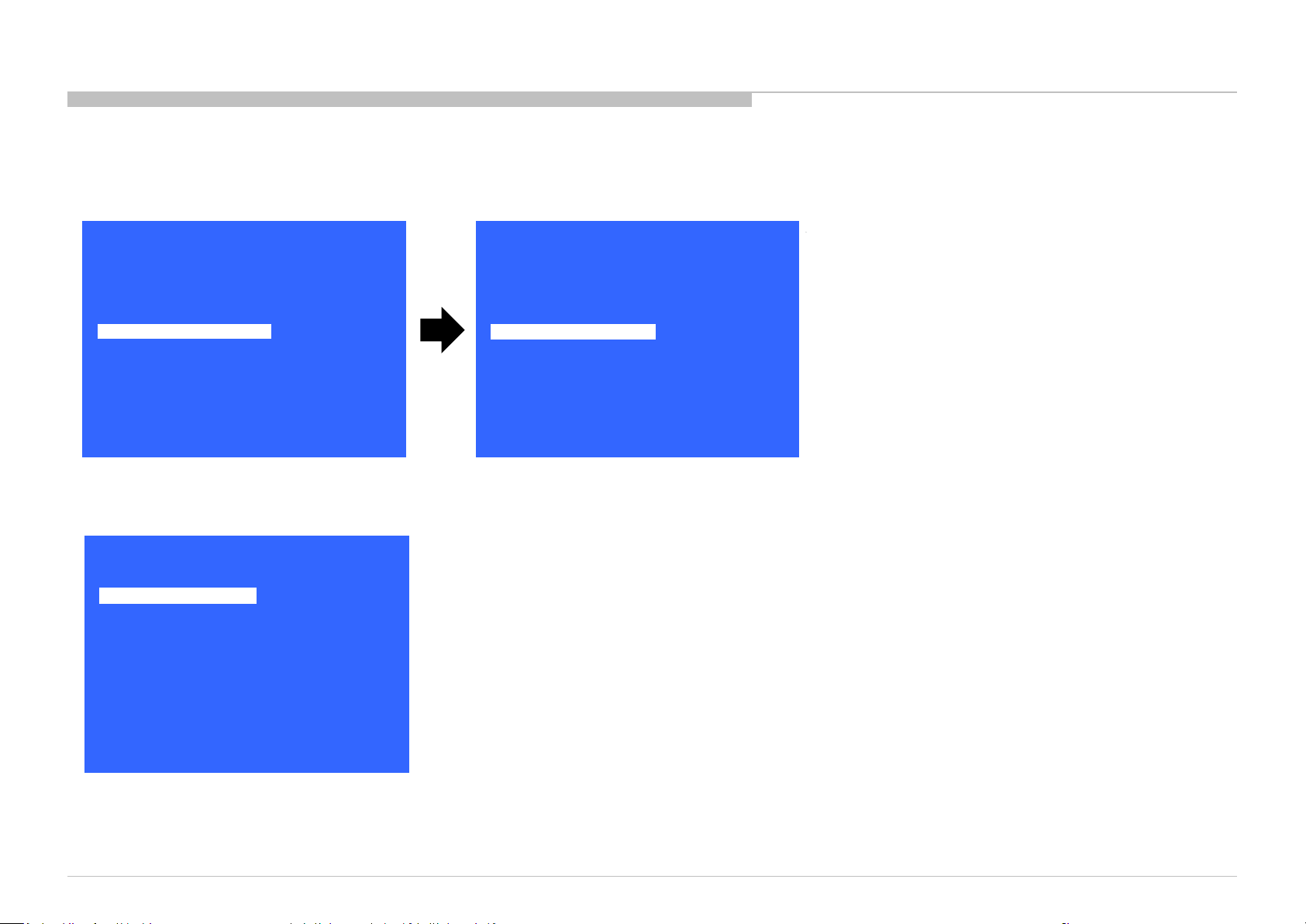

HOW TO ENTERING SERVICE MODE

1) Turn on the main power switch to place the set in standby condition.

2) Press the buttons on the remote commander as follows, and entering service mode.

3) Service mode display.

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

>>

>>

>>

>>

>>

>>

>>

>> SDB Service Menu

4) How to use the remote commander.

Function The flow of control

Service mode on <Display or i+ (in fo)> <5> <Vol. Up> <Power>

Close S ervice men u <Home>

Service mode off AC plu g OFF

Item up / down <↑>/ <↓ >

Item select left/right

Execute <Enter>

*When finished the operation of service mode, please AC Plug OFF/ON the TV set.

If you don’t do AC plug OFF/ON, remain the Service Mode App and User can see the Service Mode after RC ON.

(Refer the previous page.)

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

[Home]Exit

<←>/<→>

10

Page 11

SOFTWARE VERSION

1) In Service Mode, select “Model Information”, press “Enter” or “→” button to enter Status Information.

ADJUSTMENT

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

Service Mode

>>

>>

>>

SI2C013500 - 1/5/2022 12:13 PM

>>

>>

>>

>>

>> SDB Service Menu

[</>] Set [Home]Exit

2) Press “Enter” or “BACK” button to return to Service Mode.

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

>>

>>

>>

>>

>>

>>

>>

>> SDB Service Menu

Model

Status Information

Model Information

Model Number Setting

SERIAL NUMBER EDIT

>>

>>

>>

[</>] Set [Home]Exit

Main Micro

SW Version:

NVM Version:

Boot Version:

PQ Version:

AQ Version:

<ex>

exFRC:

CameraVID:

CameraPIC:

CameraFW:

<4k BE>

MLFW:

MAFW:

ADSP:

NDAT:

PDAT:

BDAT:

BCM:

FDAT:

UDAT:

BDIX:

PKG1.1.0.03.26.1.00.0

0043 CEI

V1.00000000

02000001

AQ2.5030

00.00.00.00

0

0

0

SF0.114

SF2.550

SF0.201

SD2.550

SP2.550

SD2.550

SF------SD0.001

SD0.000

SD2.550

[</>] Set [Home]Exit

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

11

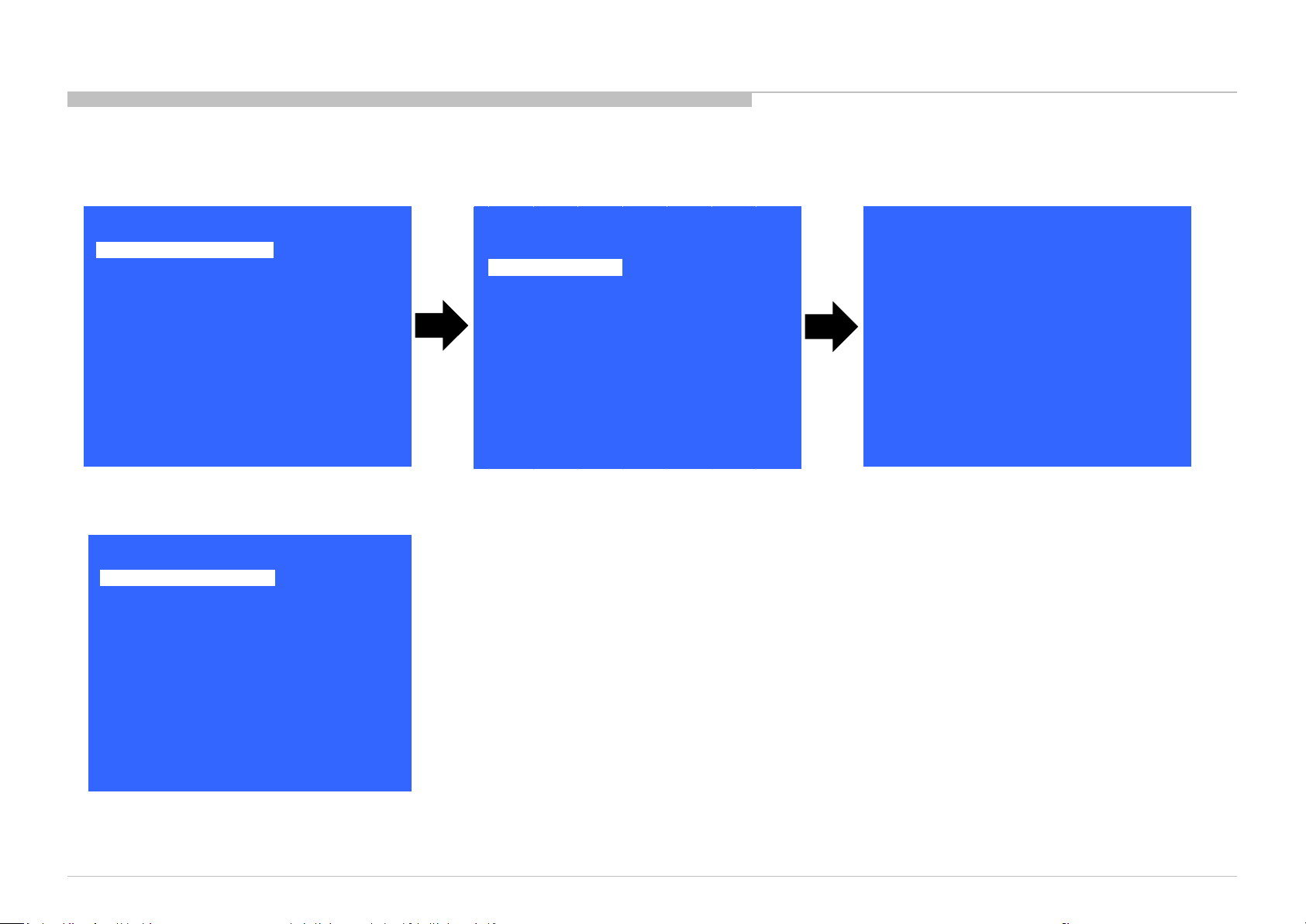

Page 12

ADJUSTMENT

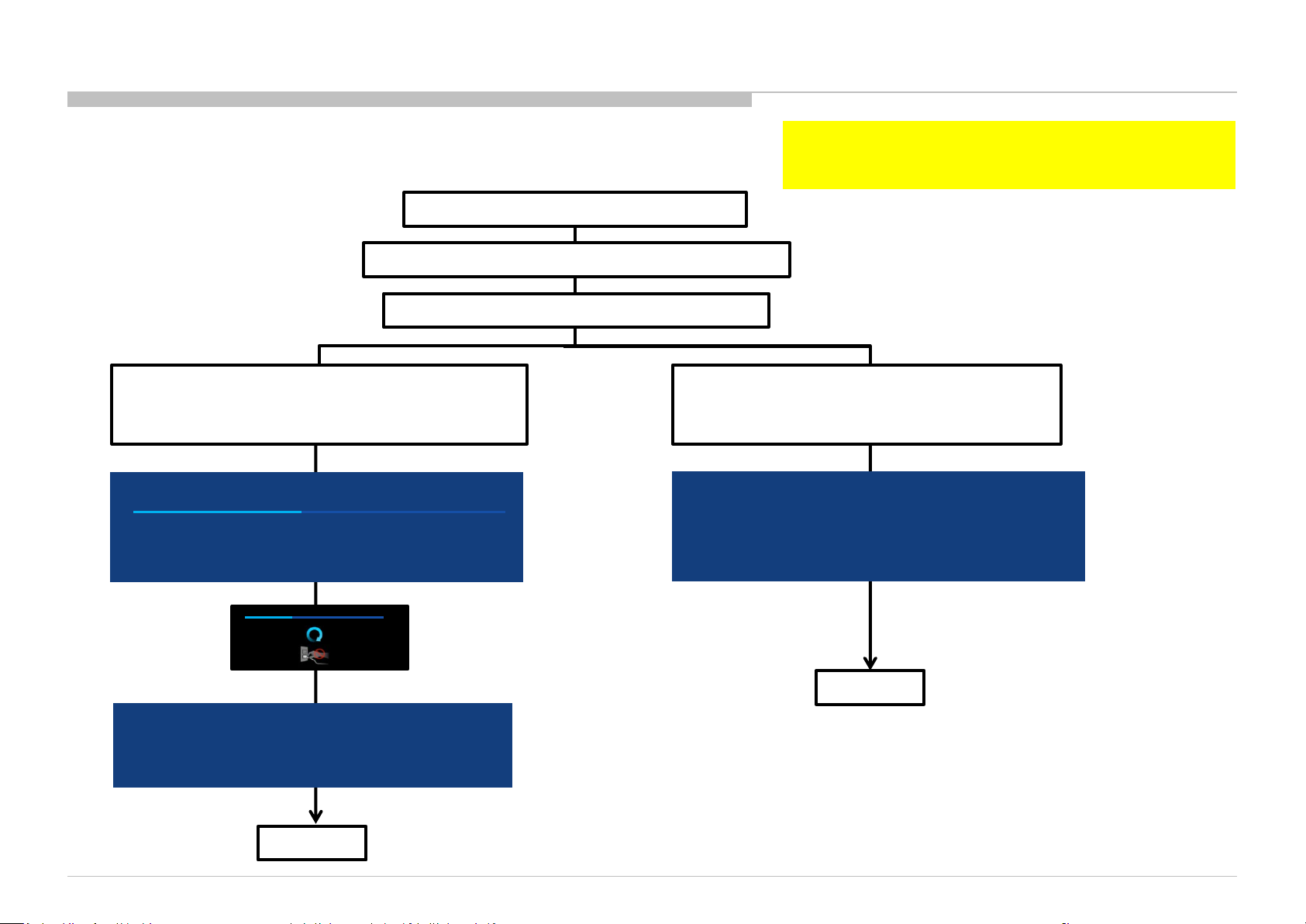

SERIAL NUMBER EDIT (1)

This step is MANDATORY after Main board replacement.

1) In “Service Mode”, select “Model Information” by pressing “↑” or “↓” button then pressing “Enter” or

“→” button to enter inside.

2) Select “Serial Number Edit” by pressing “↑” or “↓” button then pressing “→” button.

3) Press “↑” or “↓” button to input numbers.

4) After user input data, press <Enter> .

• Pop-up dialog appear to confirm input data correct

• Serial Number can be set ONLY ONCE

5) Press “→” or “←” button to select YES or NO.

Select YES if input data is correct.

Select NO if input data is incorrect.

Press <Enter> to save answer.

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

Status Information

Model Information

Model Number Setting

Serial Number Edit

Service Mode

>>

>>

>>

>>

>>

>>

>>

>> SDB Service Menu

[</>] Set [Home]Exit

Model

>>

>>

>>

_ _ _ _ _ _ _

[</>] Set [Home]Exit

* The font color of YES/NO is change to black when it is selected.

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

Model

Status Information

Model Information

Model Number Setting

Serial Number Edit 9 9 9 9 9 9 9

>>

>>

>>

Input Data correct?

Yes

No

[</>] Set [Home]Exit

12

Page 13

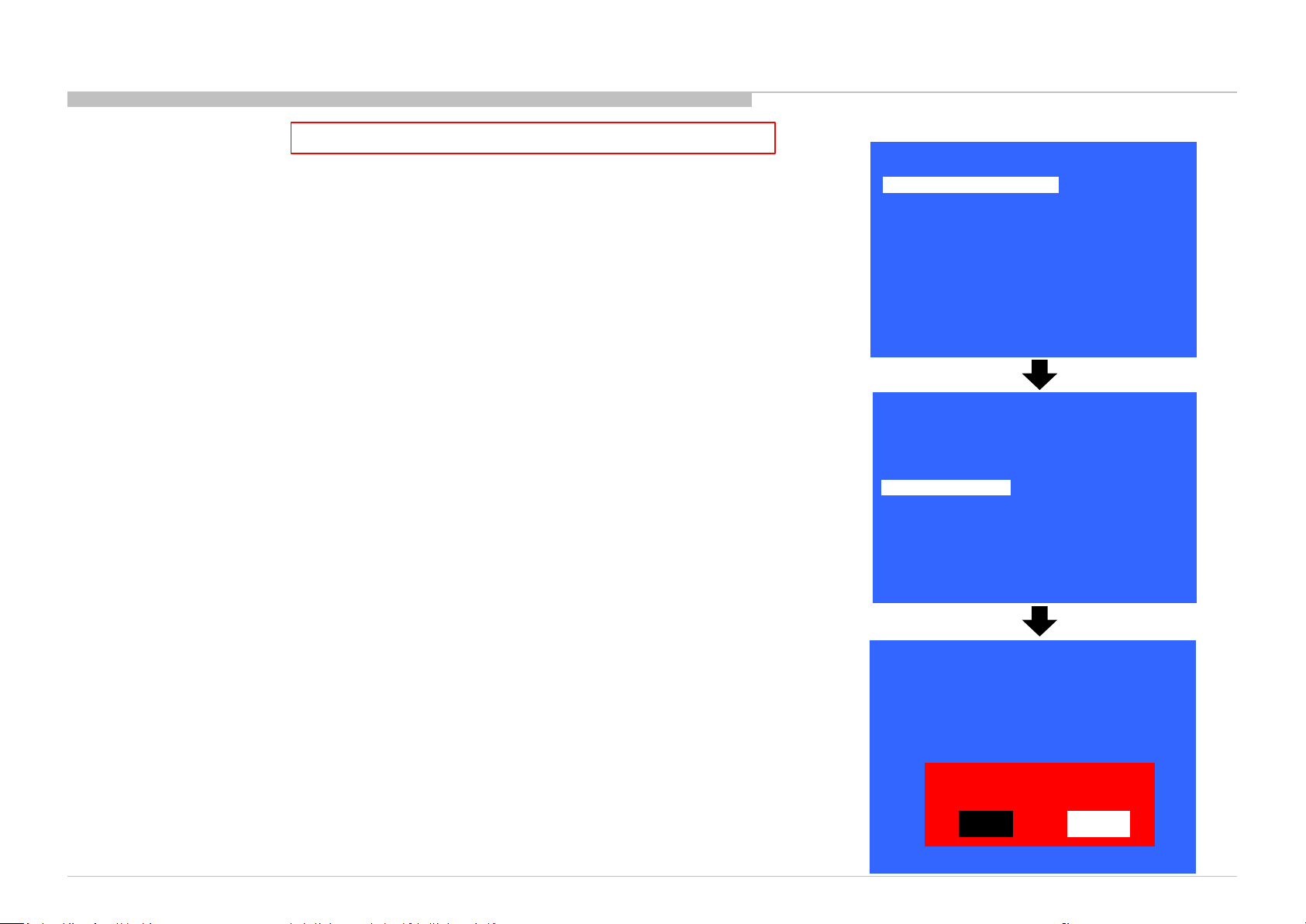

ADJUSTMENT

SERIAL NUMBER EDIT (2)

This step is MANDATORY after Main board replacement.

If YES is selected, the input data is saved into EEPROM.

SERIAL NUMBER EDIT is grayed out and the serial number that has been input is displayed.

Operator will not able to edit anymore.

SI2C013500 - 1/5/2022 12:13 PM

If NO is selected, the input data is not saved into EEPROM.

The serial number that has been input is displayed.

Operator can still edit the Serial Number.

Model

Status Information

Model Information

Model Number Setting

Serial Number Edit 9999999

Model

Status Information

Model Information

Model Number Setting

Serial Number Edit 9 9 9 9 9 9 9

>>

>>

>>

[</>] Set [Home]Exit

>>

>>

>>

Input Data correct?

Yes

No

>>

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

[</>] Set [Home]Exit

*The font color of YES/NO is change to black when it is selected.

>>

13

Page 14

ADJUSTMENT

MODEL NUMBER SETTING

This step is MANDATORY after Main board replacement.

1) In “Service Mode”, select “Model Information” by pressing “↑” or “↓” button then pressing “Enter” or “→” button to enter inside.

2) Select “Model Number Setting” by pressing “↑” or “↓” button then pressing “Enter” or “→” button.

3) Press “↑” or “↓” button to scroll Product Name Candidate.

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

>>

>>

>>

>>

>>

>>

>>

>> SDB Service Menu

Status Information

Model Information

Model Number Setting

SERIAL NUMBER EDIT

Model

>>

>>

>>

[</>] Set [Home]Exit

[</>] Set [Home]Exit

4) Select one Product Name from the list. After that select “[OK]” and press “Enter” button.

[MODEL_NUMBER_SETTING]

_ _ _ _ _ _ _ _ _ _ _ _

OK

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

14

Page 15

SI2C013500 - 1/5/2022 12:13 PM

ADJUSTMENT

WB ADJUSTMENT (If necessary)

In “Panel/PQ” service mode.

a. Go to “WB Adjustment” category by “↑” or “↓”.

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

Tuner

Wi-Fi / BT

SDB Service Menu

Service Mode

>>

>>

>>

>>

>> General Setting

>>

>>

>>

[</>] Set [Home]Exit

b. To select “WB Adjustment”, press “→” button.

Panel / PQ

Back

WB Adjustment

WB/Mura/CUC data transfer

<<

>>

>>

c. To change data, press “←” or “→” button on remote commander.

Back

R WB Gain

<<

<[ 0 ]>

<[ 0 ]> G WB Gain

<[ 0 ]> B WB Gain

<[ 0 ]> R WB Offset

<[ 0 ]> G WB Offset

<[ 0 ]> B WB Offset

[</>] Set [Home]Exit

[</>] Set [Home]Exit

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

15

Page 16

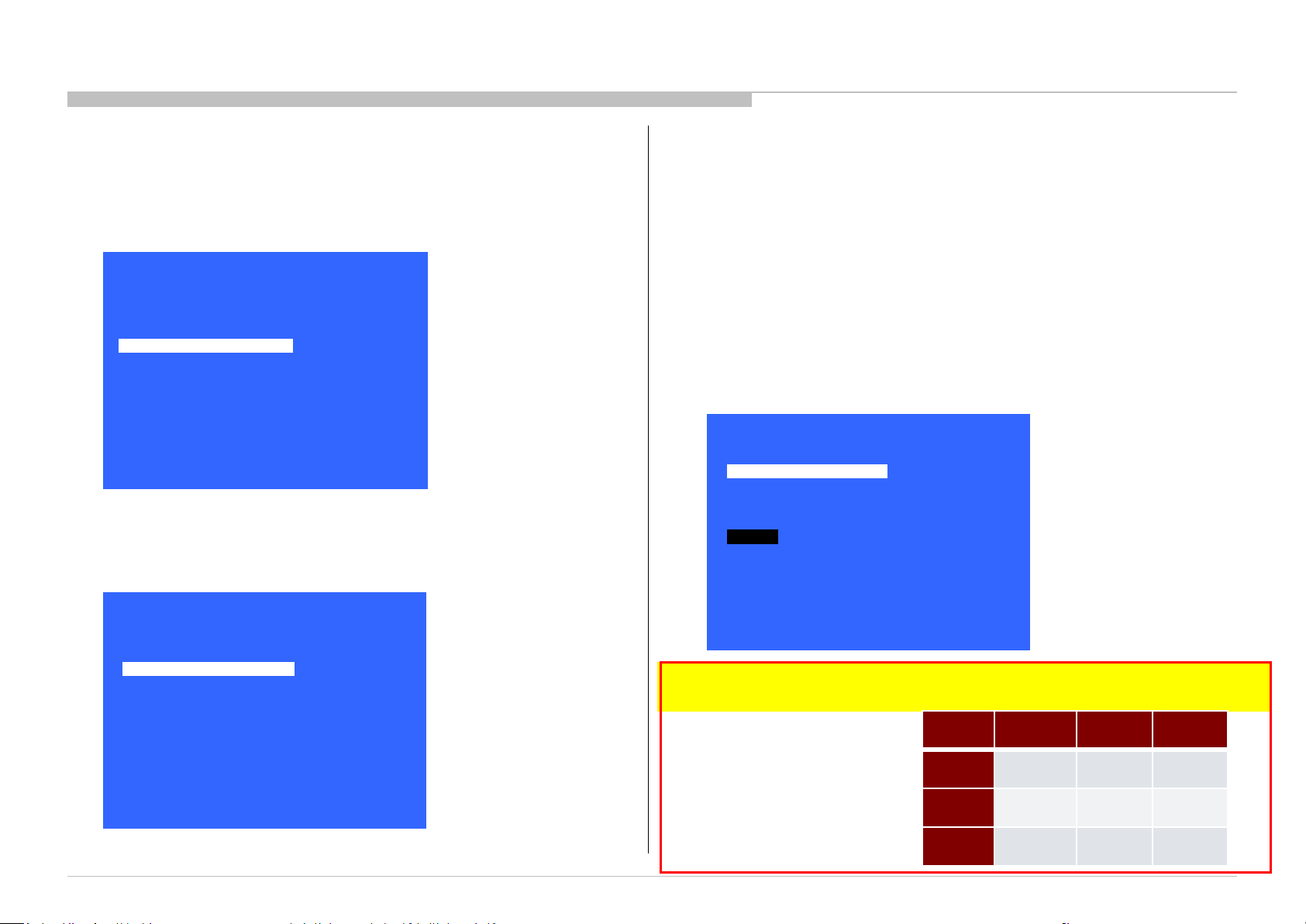

ADJUSTMENT

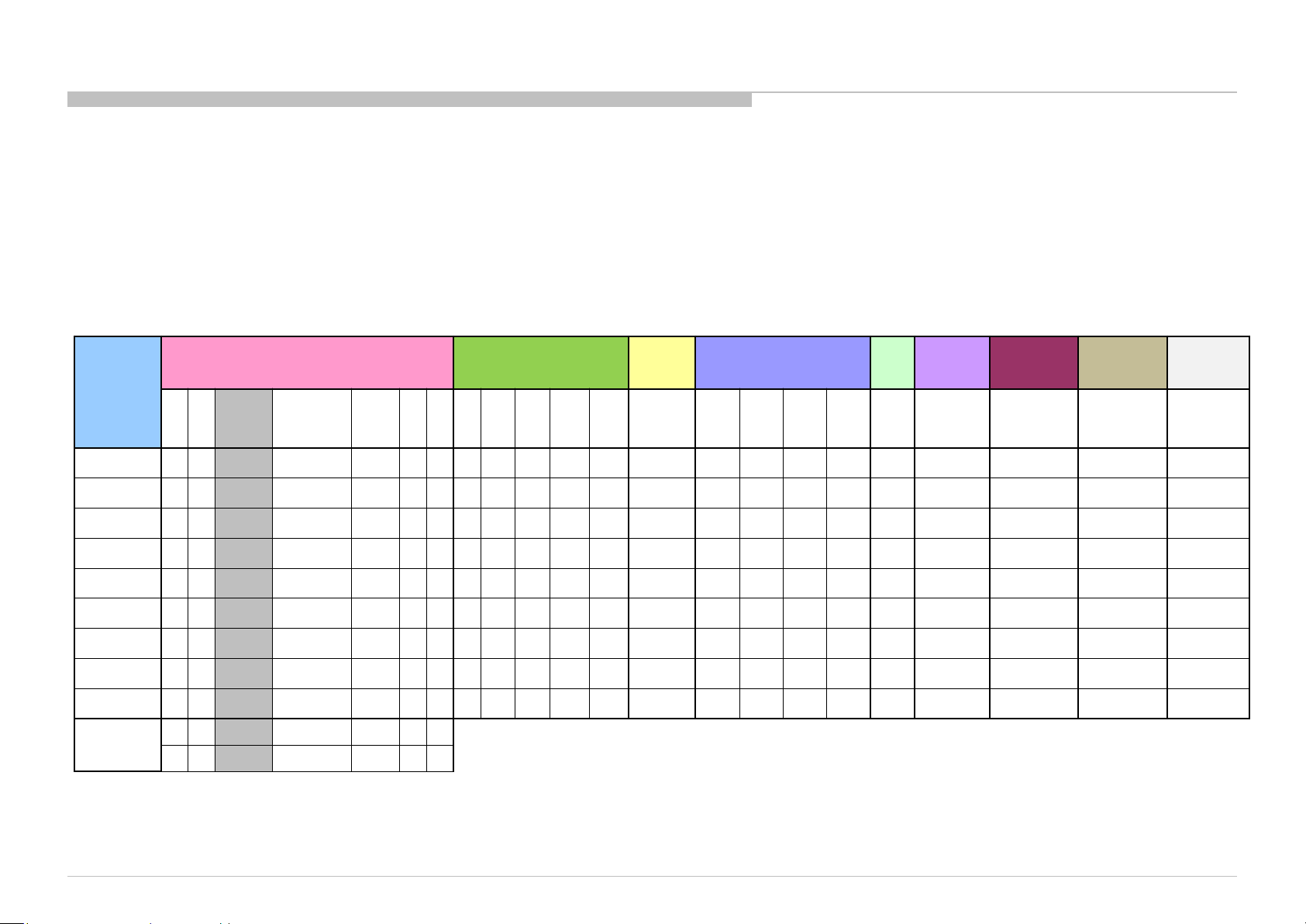

WB/MURA/CUC DATA TRANSFER

(Please apply Main board or panel is replaced.)

1. In “Panel/PQ” service mode.

a. Go to “WB/Mura/CUC data transfer” category by “↑” or “↓”.

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

Tuner

Wi-Fi / BT

SDB Service Menu

Service Mode

>>

>>

>>

>>

>> General Setting

>>

>>

>>

[</>] Set [Home]Exit

b. To select “WB/Mura/CUC data transfer”, press “→” button.

c. To change data, press “←” or “→” button on remote commander.

2. In “WB/Mura/CUC data transfer”.

a. Select “WB/Gamma data transfer” by pressing “↑” or “↓” button on remote commander.

b. To change the items, press “←” or “→” button on remote commander and press “Enter”

button.

Selectable items are:

0. SoC to T-con

1. T-con to SoC

2. No action

c. Similarly, to select the items in Mura and CUC data.

d. Select “[start]” and press “Enter” button to start transfer.

Back

WB / Gamma data transfer

Mura data transfer

Start

<<

<[ 0.Soc to T-con ]>

<[ 0.Soc to T-con ]>

<[ 0.Soc to T-con ]> CUC data transfer

Panel / PQ

Back

WB Adjustment

WB/Mura/CUC data transfer

<<

>>

>>

[</>] Set [Home]Exit

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

[</>] Set [Home]Exit

*Please refer to another manual “Service Procedure for Panel, Board and Software Change /

Upgrade(P/N:98881800x)” for details. GN3TR chassis is the same as GN1T chassis basically.

WB/

Gamma

Mura

CUC

B-board

replace

1.T-con to

SoC

1.T-con to

SoC

1.T-con to

SoC

T-con

replace

0.SoC to

T-con

0.SoC to

T-con

0.SoC to

T-con

Panel

replace

0.SoC to

T-con

1.T-con

to SoC

1.T-con

to SoC

16

Page 17

HDD PERFORMANCE CHECK

ADJUSTMENT

1. In “Service Mode”, select “General Setting” by pressing “↑” or “↓” button then

pressing “Enter” or “→” button to enter inside.

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

Tuner

Wi-Fi / BT

SDB Service Menu

Service Mode

>>

>>

>>

>>

>> General Setting

>>

>>

>>

[</>] Set [Home]Exit

SI2C013500 - 1/5/2022 12:13 PM

2. Select “HDD Performance check ” by pressing “↑” or “↓” button then pressing

“Enter” or “→” button to enter inside.

General Setting

Back

Aging mode

Ship Confirm

HDD Performance Ch

Update CI+ Credent

ECS_Enable

SCART RGB VREF

<<

<[ Off ]>

>>

>>

>> AAA

>>

<[ Off ]>

<[ Auto ]>

3. A message "Please wait" is displayed during performance check processing.

HDD Performance Check

Please wait…

[</>] Set [Home]Exit

4. Result OK or NG will be displayed after performance of HDD is checked.

HDD Performance Check

<[ ]>

Result

Back

<[ NG ]>

<<

[</>] Set [Home]Exit

[</>] Set [Home]Exit

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

17

Page 18

HDD RE-REGISTRATION

1. In “Service Mode”, select “General Setting” by pressing “↑” or “↓” button then pressing “Enter” or “→” button to enter inside.

2. Select “AAA” by pressing “↑” or “↓” button then pressing “Enter” or “→” button to enter inside.

ADJUSTMENT

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

Tuner

Wi-Fi / BT

SDB Service Menu

Service Mode

>>

>>

>>

>>

>> General Setting

>>

>>

>>

General Setting

Back

Aging mode

Ship Confirm

HDD Performance Ch

Update CI+ Credent

ECS_Enable

SCART RGB VREF

[</>] Set [Home]Exit

3. Result OK or NG will be displayed after HDD re-registration is succeed/failed.

HDD Re-Register

Result

Back

<[ NG ]>

<<

<<

<[ Off ]>

>>

>>

>> AAA

>>

<[ Off ]>

<[ Auto ]>

[</>] Set [Home]Exit

[</>] Set [Home]Exit

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

18

Page 19

USB UPDATE

*Please refer to another manual “Service Procedure for Panel, Board

and Software Change / Upgrade(P/N:98881800x)” for details.

GN3TR chassis is the same as GN1T chassis basically.

1:Download USB image and unzip file.

2: copy unzipped file to USB memory root folder.

3: Insert USB memory into USB port on TV.

4-a:USB image is newer soft version.

Automatically show message and start update.

Please follow directions.

System software update

SI2C013500 - 1/5/2022 12:13 PM

Copying USB update file. Please wait…

Preparing for system software update. During the system software update, the TV will

automatically restart. Please do not remove the USB device until an update complete

message is displayed . The update may take up to 15 minutes to complete.

System software update

The system software update is complete .

Some user settings may have changed during the update.

Please remove the USB device and select ”OK” to exit

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

5: finished

OK

46%

4-b:USB image is not newer soft version.

Automatically show message.

Please follow directions.

System software update

Your software is up to date

Please remove the USB device and select [OK] to exit

OK

5: finished

Caution:

Do not power off while the update is in progress.

19

Page 20

TROUBLE SHOOTING

Remote

Bluetooth (BT)

TU_

DEM

OD

TCON

_ERR

FRCTC

_I2C

AUD_

4KPQ_

No White Power

LED & does not

remote (Dead

Stationary

dots

No video

No video

all Inputs

No Remote

Smart Core no LED

Power

Power

(Backlight)

TEMP

4KPQ

Audio

TRIAGE

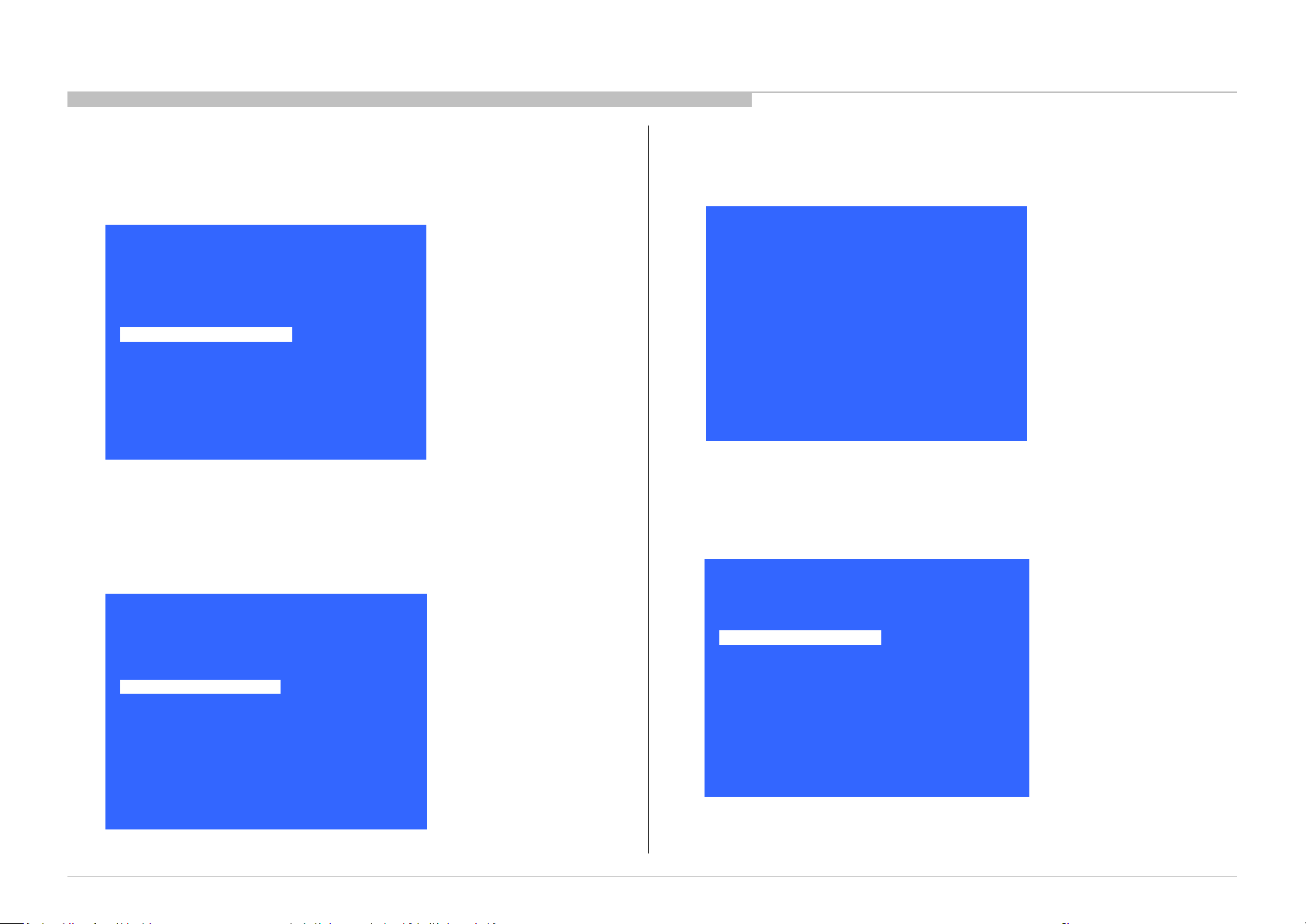

1. Confirm the symptom from the customer.

2. Select that symptom from the chart.

3. Bring all the boards and cables listed for that symptom.

4. Follow the troubleshooting charts in the technical guides to isolate the board.

5. Chart Color Code.

RED DOT: Most likely defective part

BLUE TRIANGLE: Secondary possible defective part

BLACK TEXT: Board that may correct the symptom

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

Reference

2 3 4 5 6 7 8

B* Board

G* Board

H* Board

Speaker

Tuner board

Wifi & BT

Module

V By One FFC

Tcon

LCD Panel

Problem

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

p l

l p

p p l l p p l l l p p l l l p p l p p

p l

p

p

l

p l p

LD

BCM

Panel

(Communication)

Panel

Symptoms - no shutdown

Error log record only

ERR_

l

p

l

I2C

ERR_

I2C

No

Power

respond to

Set)

l

p

Video

- missing or distorted

colored

One of

lines or

Inputs

p l

p

p

l

NO RF

input

Network Audio Smart Core

Wireless

can't connect

p

p

p

l

l

No Audio

p

l

(Set is still alive)

l

Bluetooth /

Voice Remote

can't connect

l

20

Page 21

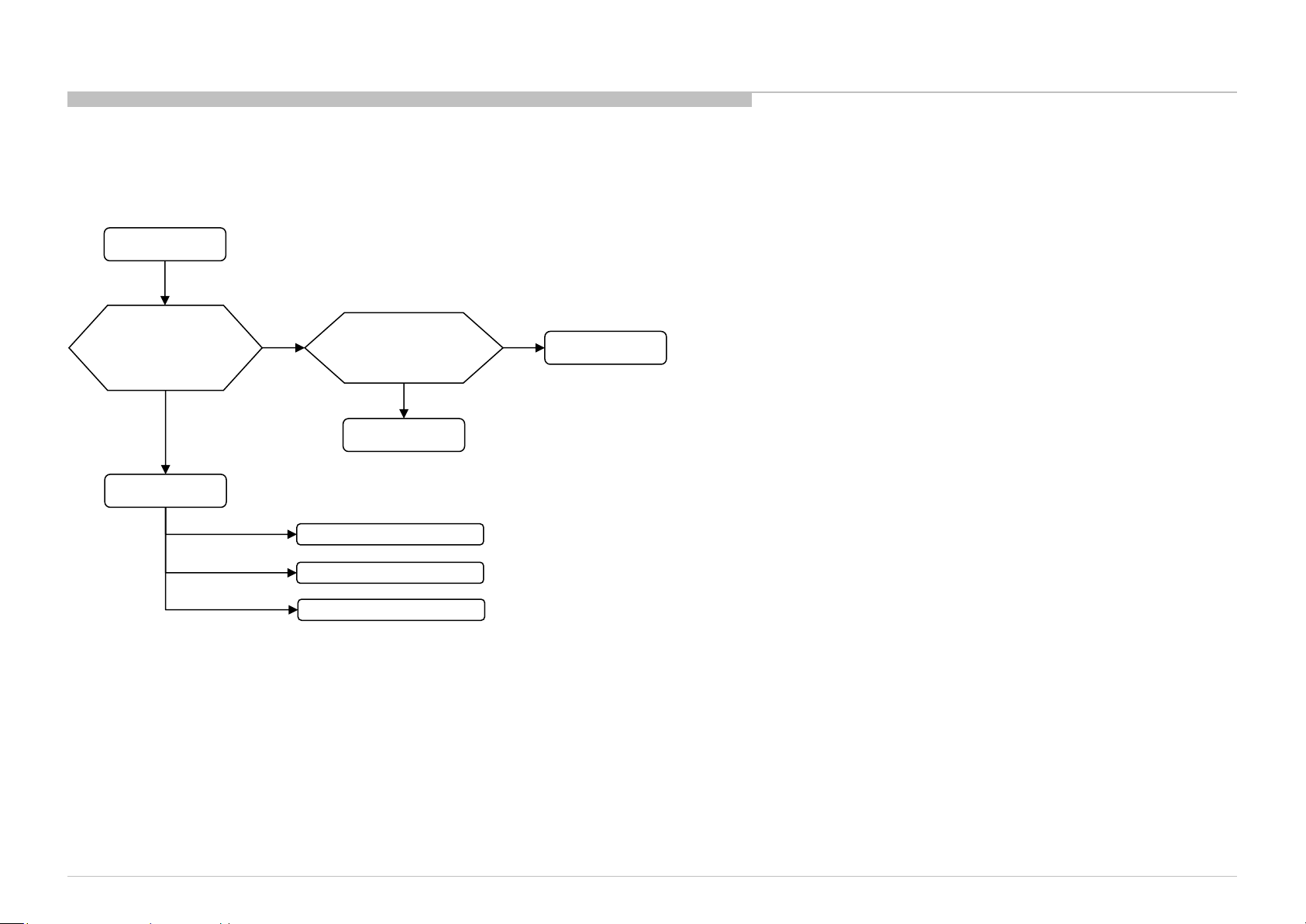

FLOW

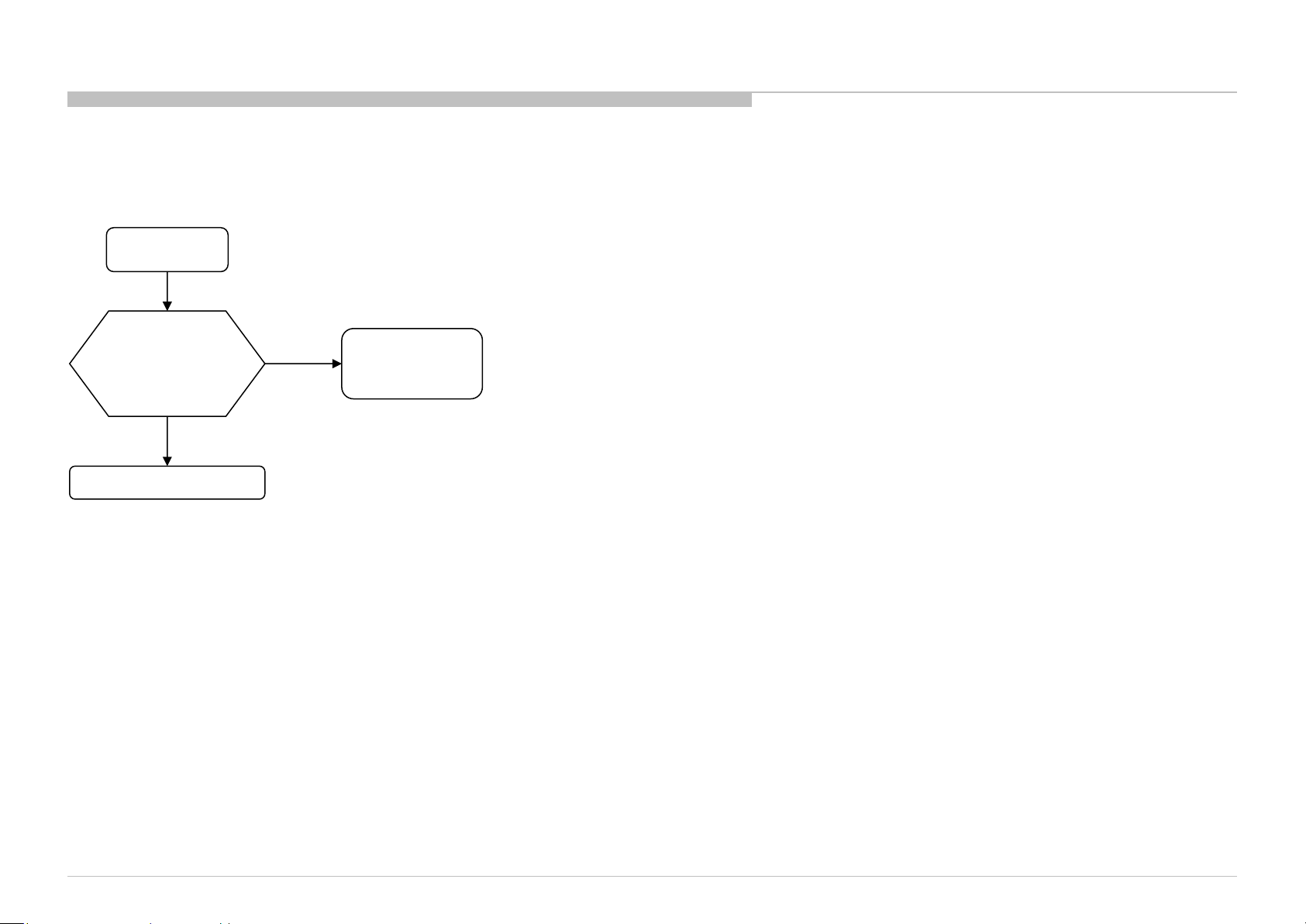

1-1. NO POWER

WITH G* BOARD

No Power

TROUBLE SHOOTING

SI2C013500 - 1/5/2022 12:13 PM

Check STBY 3.3V

C518

near CN400

on B* board

OK

B* board

NG

Replace

Between G* board to

B* board Harness

OK

Harness

u-Com Failure

DDCON/LDO

Main Device Failure

NG

G* board

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

21

Page 22

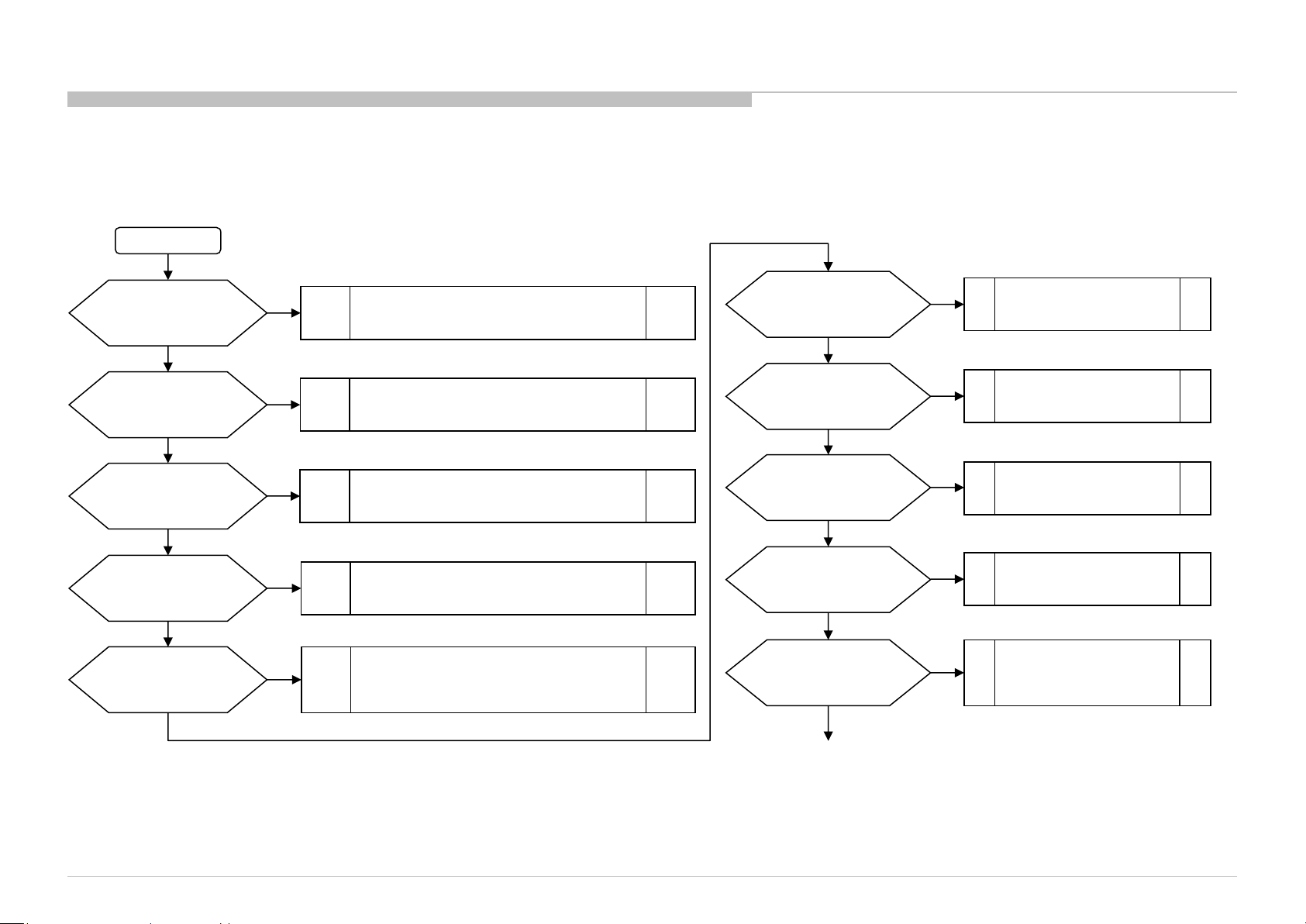

FLOW

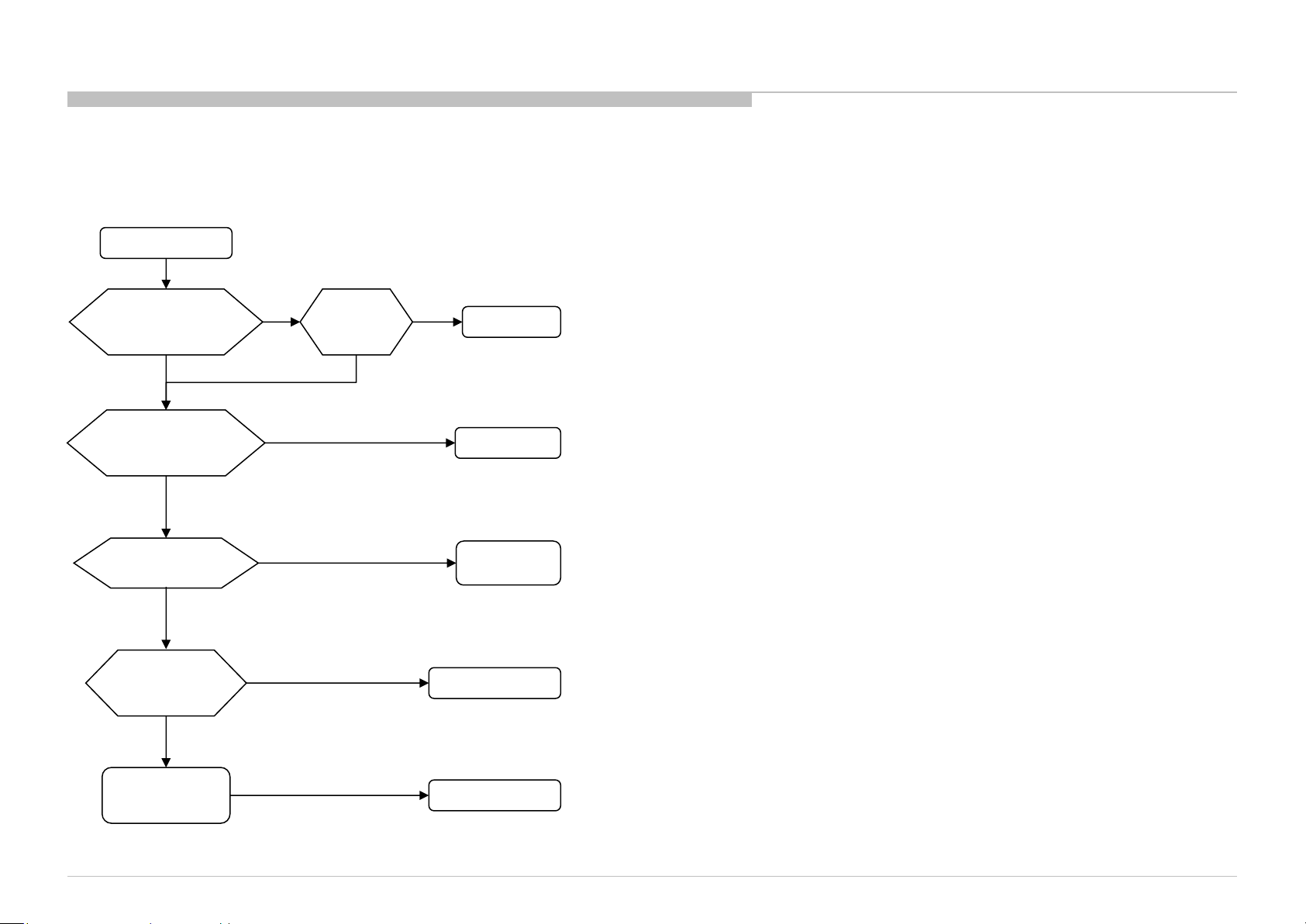

1-2. NO POWER U-COM FAILURE

START

TROUBLE SHOOTING

Check VDD

C506 Voltage.

Is the voltage >3.0V?

yes

(only for AC-ADP model)

Check TYPE_DET

C503 Voltage.

Is the voltage 0V?

yes

(only for G-board model)

Check TYPE_DET

C503 Voltage.

Is the voltage 2.6±0.2V?

yes

Check OPWRSB

R443 Voltage.

Is the voltage 0V?

yes

Check POWER_ON

R526 or P-on ucom #pin10

Is the voltage >3.0V?

yes

no

no

no

no

no

Check +3.3V_STBY LIne (C521, CN400 #14pin)

And (only for AC-ADP model)

3.3V_DDCON (IC403)

Type Detection Circuit problem.

Check TYPE_DET Line (R521, R522, R523).

Check Power supply harness (CN400 #9pin,10pin).

Type Detection Circuit problem.

Check TYPE_DET Line (R521, R522, R523).

Check Power supply harness (CN400 #9pin,10pin).

SOC

Muffin 2

problem

Try AC Off and On after few minutes.

If #pin19 keep Low, change IC401.

If #pin19 goes High few seconds and downs to Low,

Check +12V_MAIN Line (G board or JK board).

Check 12V_MON

R446 Voltage.

Is the voltage >2.6V?

yes

(only for AC-ADP model)

Check DC_MON

R439 Voltage.

Is the voltage >1.8V?

yes

Check DC_OFF_DET

R448 or P-on ucom #pin3

is >3.0V?

yes

Check P_ON_#1

CL418 or P-on ucom #pin12

is >3.0V?

yes

Check PGOOD_1

R440 Voltage.

Is the voltage >3.0V?

yes

no

no

no

no

no

Check +12V_MAIN Line

(G board or JK board).

Check POWER_MAIN Line

(JK board).

Change IC401

Change IC401

No POWER - DDCON/LDO

Check 1.0V DDCON (IC604)

And (only for AC-ADP model)

12V DDCON (IC9000 on JK).

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

Continue next page

22

Page 23

FLOW

1-2. NO POWER U-COM FAILURE

Previous page

SI2C013500 - 1/5/2022 12:13 PM

Check P_ON_#2

CL417 or P-on ucom #pin13

is >3.0V?

yes

no

Change IC401

TROUBLE SHOOTING

Check P_ON_HL

CL414 or P-on ucom #pin18

is >3.0V?

yes

Check ORESETB

CL416 or P-on ucom #pin14

Is the voltage >3.0V?

yes

Check X_SYSTEM_RST

CL412 or P-on ucom #pin20

Is the voltage >3.0V?

yes

If X_BL_MUTE (R441) is >3.0V

Check BL_ON

R527 or P-on ucom #pin7

Is the voltage >3.0V?

yes

no

Change IC401

no

Change IC401

no

Change IC401

no

Change IC401

END

Ucom IC401 is working OK

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

23

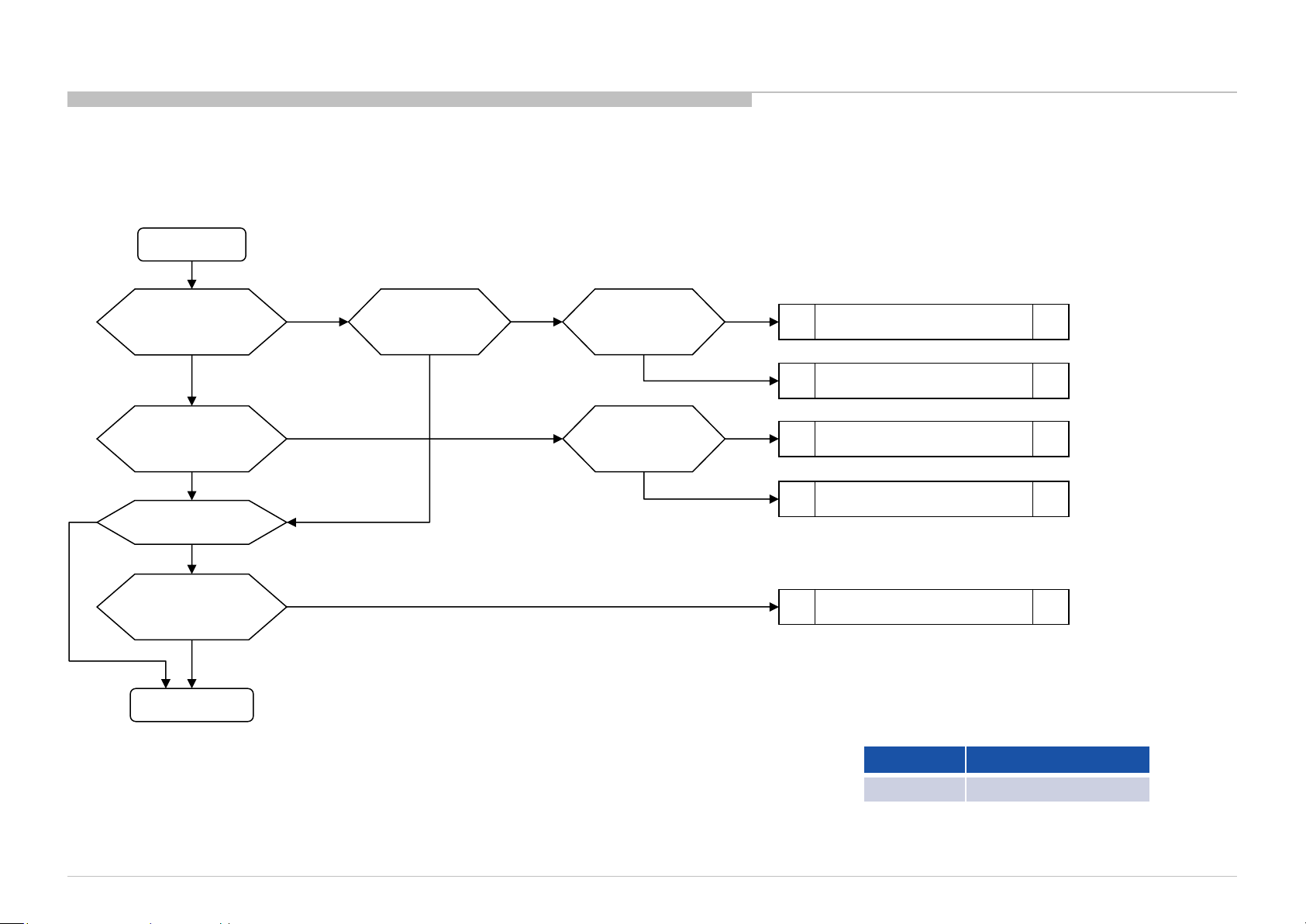

Page 24

FLOW

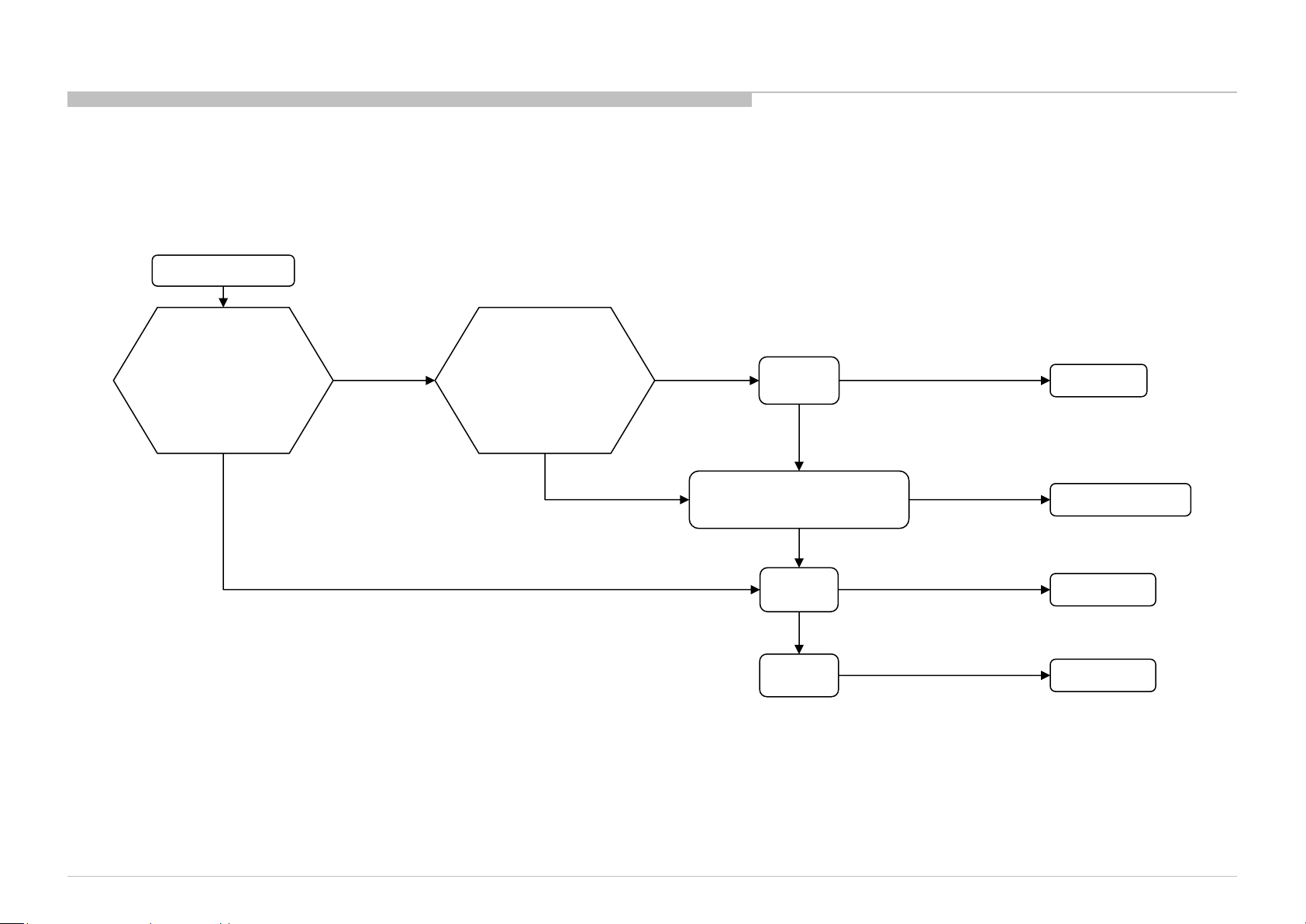

1-3. NO POWER DDCON/LDO

DDCON CHECK

START

TROUBLE SHOOTING

Check IC402 Vcc voltage

Is voltage >12V?

Check Vcc voltage

Is voltage >4V?

Is IC600 mounted?

no

Check Enable

IC600 #pin1

Is voltage >2.5V?

Change DDCON

C423

C602

IC601

yes

yes

yes

yes

no

no

no

Check Vcc voltage

C602

Is voltage >3V?

yes

no

Check

D600

Is diode alive?

yes

Check

D601

Is diode alive?

yes

no

Change D600

Check +3.3V_STBY.

G* board or IC403

no

Change D601

Check +5V_MAIN DDCON (IC402)

Change IC600

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

IC Ref Voltage supply

IC601 +1.5V_DDR

24

Page 25

FLOW

1-3. NO POWER DDCON/LDO

TROUBLE SHOOTING

DDCONs CHECK

START

Check fuse

F4xx or F6xx

Is fuse OK?

yes

Check Vcc voltage

C4xx or C6xx

Is voltage >12.0V?

yes

Check Enable pin

voltage

Is voltage >2.5V?

SI2C013500 - 1/5/2022 12:13 PM

yes

Change DDCON IC

no

no

no

Change Fuse

1) Check POWER_ON P-on ucom #pin10

(Refer to No Power U-Com Failure)

2) Check G* board

3) Check IC9000 on JK* (only AC-ADP Models)

No Power U-Com Failure

or

Enable source

LDOs CHECK

START

Check Vcc voltage

C6xx

Is voltage >3V?

yes

Check Enable pin

voltage

Is voltage >3V?

yes

Change LDO IC

no

no

Check +3.3V_DDC_OUT

DDCON (IC403)

or

+3.3V_STBY (G* board)

No Power U-Com Failure

or

Enable source

IC Ref Voltage supply

IC402 +5.0V_VBUS/+5V_MAIN

IC403

IC405 +1.8V_TU/+1.8V_BE

IC404 +1.0V_BE

IC409 +1.5V_FRC

IC410 +0.95V_FRC

IC604 +1.0V_M2

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

+3.3V_STBY (AC-ADP only)

/+3.3V_MAIN

IC Ref Voltage supply

IC602 +1.05V_M2_STBY

IC603 +1.05V_M2_A_1

IC605 +1.05V_M2_ST_ET

IC606 +1.05V_M2_A_2

IC607 VCC3IO_EMMC (1.8V)

25

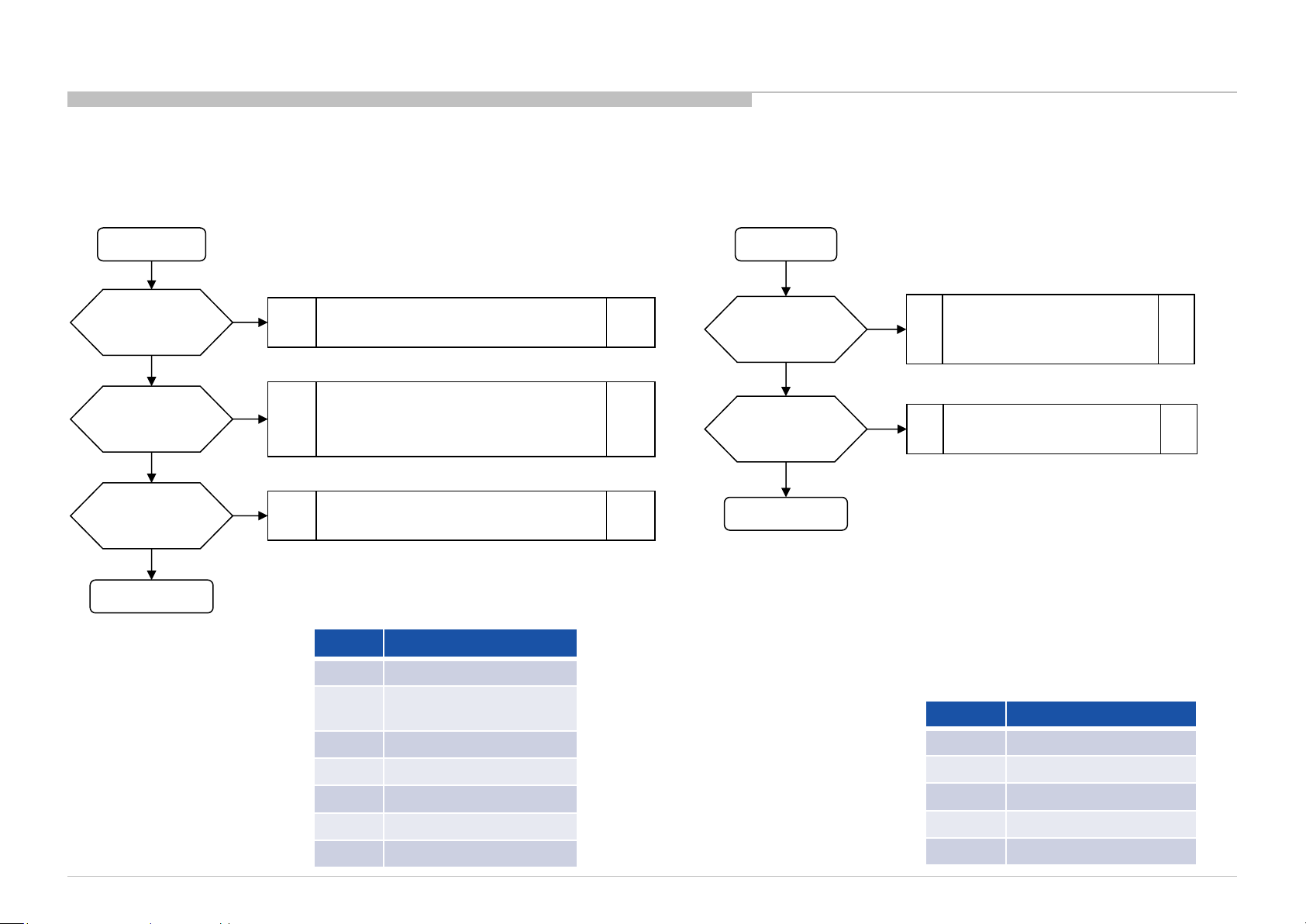

Page 26

FLOW

2-1. LED BLINKING 2X (MAIN POWER ERROR)

LED 2x blinking

TROUBLE SHOOTING

Check “+12V_MAIN”

at pin 11/13 of CN400

on B* board,

Voltage > 13.2V ?

No

BMKS / BMKP board

Yes

G board

JK board

AC Adaptor

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

26

Page 27

FLOW

2-2. LED BLINKING 3X (DC ALERT AND AUDIO ERROR)

TROUBLE SHOOTING

DC_ALERT

3-times blinking

(DC Alert)

Check “POWER_MAIN”

at pin 17/19 of CN400

on B* board,

Voltage = 18.0~20.0V or

22.5~24.5V ?

NG

G board

JK board

AC Adaptor

OK

Check “+5.0V_VBUS”

at C431 on B* board

4.959V<Voltage<5.285V?

NG

BMKS / BMKP board

OK

Other flows

AUDIO ERROR

3-times blinking

(Audio Error)

Go to No Sound (Power Off Check)

Go to No Sound (Power On Check)

Power Off Check

Power On Check

Replace

G board or JK board

or AC Adaptor

NG

Measure the Speaker

impedance by multi-meter

Less than 3Ω ?

No

OK

Yes

G or JK board

or AC Adaptor

Replace

Speaker

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

Speaker Harness

27

Page 28

FLOW

2-3. LED BLINKING 5X (PANEL ID READ ERROR)

5-times blinking

TROUBLE SHOOTING

Check

“+12.5V_TCON”

at C400 on BMKS

OK

Replace the Harness

Between G/JK board

and BMKS

NG

Replace

the V-By-One FFC

NG

Replace

BMKS board

NG

NG

Symptom improve

Symptom improve

Symptom improve

Replace

G/JK board

NG

OK

G/JK board

Harness

V-By-One FFC

is suspicious

BMKS board

Replace

Panel (T-con)

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

Symptom improve

G/LD Board: G board or LD board

Panel (T-Con)

28

Page 29

SI2C013500 - 1/5/2022 12:13 PM

FLOW

2-4. LED BLINKING 6X (BACKLIGHT ERROR)

6-times blinking

Check Voltage of

“BL_LD_ERR_DET”

at CL1038 on BMKS

Voltage ≥ 1.9 V

harness/connection

G/LD board to BMKS

Check

Harness /

Connection

broken

Replace

harness

No

improvement

Symptom

Improvement

TROUBLE SHOOTING

Harness

Voltage < 1.9 V

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

Harness /

Connection OK

LED driver or G board

Replace LD board or G board.

No

improvement

Replace

BMKS

No

Improvement

Replace

Panel

Symptom

Improvement

Symptom

Improvement

Symptom

Improvement

G/LD Board: G board or LD board

LD board/G board

BMKS Board

Panel

29

Page 30

FLOW

2-5. LED BLINKING 7X (TEMPERATURE ERROR)

TROUBLE SHOOTING

2-6. LED BLINKING 8X (4KPQ ERROR)

7-times blinking

Ambient conditions

(temperature , ventilation, etc.)

are OK?

Yes

Replace BMKS/BMKP

board, and Aging a few

hours

Symptom

improvement

BMKS/BMKP board

No

NG

Set to another

location, etc.

Panel

8-times blinking

Replace

BMKS board

Symptom

Improvement

BMKS board

No

improvement

Other flows

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

30

Page 31

FLOW

3-1. NO SOUND

No Sound

Without LED 3x

TROUBLE SHOOTING

AV receiver is connected

to HDMI in ?

No

[Speakers] setting is

[Audio System] ?

No

Headphone is connected to

HP/Audio Out terminal ?

SI2C013500 - 1/5/2022 12:13 PM

[Headphone Speaker Link]

setting is [On] ?

(POWER OFF CHECK)

No

[Sound]

No

Go to

NO SOUND

Yes

Yes

Yes

Yes

Select [External Inputs]

[BRAVIA Sync Settings]

[BRAVIA Sync Control] [off]

Change the setting to

[TV Speakers]

Disconnect the Headphone

Change [Sound]

[Headphone Speaker Link]

to [Off], OK ?

Yes

HP/Audio out terminal

or Headphone detect

GPIO may be broken

No

Replace B board

No sound only

Analog RF and Digital RF ?

No

No sound only HDMI ?

No

Replace B board

Yes

Yes

NO SOUND ( TUNER)

Go to

Go to

NO SOUND (HDMI)

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

31

Page 32

FLOW

Speaker Impedance

3-2. NO SOUND (POWER OFF CHECK)

Power Off Check

From LED BLINKING 3X

(AUDIO ERROR)

Power Off Check

From NO SOUND

TROUBLE SHOOTING

3-3. NO SOUND (POWER ON CHECK)

PVDD (POWER_AU) voltage is

Power On Check

From LED BLINKING 3X

(AUDIO ERROR)

240W AC Adaptor model : 24.0V

200W AC Adaptor model : 19.5V

Built-in power supply model : 12.5V

Measurement point is same as (1) PVDD-GND

short check.

PVDD-GND short ?

LDO out short ?

Fuse broken ?

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

(1) B board

No

(2) B board

No

(3) B board

No

Yes

Yes

Yes

Replace B board

KP woofer 4ohm less than 3.2ohm

KP front 6ohm less than 4.8ohm

KS/KH 8ohm less than 6.4ohm

Rated Impedance NG Value

Measure the Speaker

impedance by multi-meter.

NG value of

right table?

No

Confirm the speaker

harness

Cut or shorted

to the chassis ?

No

Return to

LED BLINKING 3X

(AUDIO ERROR)

or NO SOUND

Yes

Yes

Replace Speaker

Replace Speaker Harness

(4) PVDD check

PVDD is supplied to

B board for a moment

before LED 3x blinking ?

Replace Power-Supply *

Return to LED BLINKING 3X

(AUDIO ERROR)

*Power-Supply is

AC Adaptor model : JK board & AC Adaptor

built-in power supply model : G board

No

No

OK ?

No

Yes

Yes

Finish

32

Page 33

FLOW

3-4. NO SOUND (AUDIO HP/AUDIO OUT)

TROUBLE SHOOTING

3-5. NO SOUND ( TUNER)

No Sound Audio

HP/Audio out

[Sound]

[Headphone/Audio out]

is set to ?

[Audio Out (Fixed)]

[Audio Out (Variable)]

[Subwoofer]

SI2C013500 - 1/5/2022 12:13 PM

[Headphone]

Headphone Volume

is set to MIN?

No

Volume

is set to MIN?

Yes

Increase Headphone Volume

Replace B* board

Replace B* board

Yes

Increase Volume

No

Replace B* board

Set [Headphone/Audio Out]

to [Headphone] or [Audio Out]

No Sound with normal picture

Only RF tuner input?

YES

Check IC1000 (SoC)

NO

Please refer Audio

troubleshooting

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

33

Page 34

FLOW

3-6. NO SOUND (HDMI)

No Sound

TROUBLE SHOOTING

Check the picture

OK

Check the mode

of Source equipment

HDMI

Does this model have

Analog Audio In

(Stereo minijack)?

NO

Check Sound by other TV set

which is same model

NG

Is Distributor used ?

YES

Connect Source

equipment directly

NG

DVI

YES

NO

Refer to NO PICTURE (HDMI)

Does this model have

Analog Audio In

(Stereo minijack)?

No

“HDMI/DVI Audio Source”

setting is?

Auto or HDMI Audio

OK

Check Source equipment

by Reference TV set

(For example, RB2, RB1)

Check the settings of

Source equipment

YES

Analog Audio In

NG

OK

Connect Stereo minijack cable between Source and the TV,

And Change “HDMI/DVI Audio Source” to Auto or Analog Audio In.

Change the mode of Source equipment to HDMI

Change “HDMI/DVI Audio Source” to Auto or HDMI Audio In

Refer to No Sound

Change B board.

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

34

Page 35

FLOW

4-1. NO PICTURE

No Picture

TROUBLE SHOOTING

SI2C013500 - 1/5/2022 12:13 PM

BL_ON (L or H): IC401 #7pin (for 4K BMKS/BMKP board)

Got Any Normal

Display?

Yes

Check Other

Portion:

Tuner - No Picture

No

Ext. Video Input -

No Picture

HDMI - No Picture

Check Smart Core

Behavior

(5x Blinking)

Yes

5x Blinking

No

Check

BL_ON

on the B board

BL_ON:L

Backlight

BL_ON:H

Video Analog Signal Path

Video2/Component

(Back/Side)

the V by One FFC

VIDEO_DET

CR_DET

Replace

Harness

Symptom

improvement

V by One FFC

Harness

NG

Replace

The B board

Symptom

improvement

B board NG

SCART_FB/COMP_Y

CVBS2P

SCART_SB/COMP_Y

SCART_SG/COMP_PB

SCART_SR/COMP_PR

NG

LCD Panel

AT35:GPIO56

N35:SOY0

M35:CVBS2P

M38:Y0P

L38:PB0P

L37:PR0P

A16:SD_CLK

(T-CON)

M2

IC1000

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

Video1

(Side Mini Jack)

CVBS3P

VIDEO2_DET

L36:CVBS3P

G16:GPIO66

35

Page 36

FLOW

4-2. NO PICTURE (VIDEO 1/VIDEO 2/COMPONENT)

VIDEO 1

No Picture

Video 1

No Picture

TROUBLE SHOOTING

Check if input OSD

is GRAY OUT

OK if it is highlighted

Check wave between

C2628 and IC1000

OK

OK (Vpp: 1 V)

Muffin [IC1000]

Problem

NG

NG (Vpp: 0 V)

* Check J2601

Connection,

VIDEO_DET

At R2631

OK (Vpp: 3.3 V)

** Detailed check all

parts at VIDEO2_DET

signal Path [R2630]

OK (Vpp: 3.3V)

J2601

Connector

Problem

NG (Vpp: 0V)

NG (Vpp: 0V)

** Detailed check all parts

at CVBS3P signal path

[D2609/R2629/R2621/C2612

C2628/R2643/VD207]

OK

J2601

Connectivity

Problem

* OK Condition : No solder splash can be seen

NG Condition : Solder splash can be seen

NG

Parts Broken

** OK Condition : No part short-circuited

NG Condition : Part short-circuited

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

36

Page 37

FLOW

4-2. NO PICTURE (VIDEO 1/VIDEO 2/COMPONENT)

COMPONENT / VIDEO 2

No Picture

TROUBLE SHOOTING

Component

No Picture

SI2C013500 - 1/5/2022 12:13 PM

Check if input OSD

is GRAY OUT

OK if it is highlighted

OK

Check wave

Between

C2602/C2605/C2607

and IC1000

OK (Vpp: 1 V)

Muffin [IC1000]

Problem

NG

* Check J2600 Con

VIDEO_DET at R2626,

CR_DET at R2650

** Detailed check all

parts at VIDEO_DET

signal path [R2627]

signal path [R2637]

NG (Vpp: 0 V)

OK (Vpp: 3.3 V)

and CR_DET

OK (Vpp: 3.3 V)

J2600

Connector

Problem

NG (Vpp: 0 V)

NG (Vpp: 0 V)

R2639/R2604/VD2602/C2602]

PB0P : [VD2603/R2603/C2601/

PR0P : [VD2601/R2610/C2606/

J2600

Connectivity

Problem

** Detailed check all parts

at signal path of:

Y0P : [D2601/R2606/C2603/

R2638/R2607/C2605]

R2611/C2607]

OK

NG

Parts Broken

Video 2

No Picture

Check if input OSD

is GRAY OUT

OK if it is highlighted

OK

Check wave between

C2611 and IC1000

OK (Vpp: 1 V)

Muffin [IC1000]

Problem

NG

** Detailed check all

parts at VIDEO_DET

signal Path [R2627]

NG (Vpp: 0 V)

* Check J2600

Connection,

VIDEO_DET

At R2626

OK (Vpp: 3.3 V)

OK (Vpp: 3.3 V)

J2600

Connector

Problem

NG (Vpp: 0 V)

NG (Vpp: 0 V)

Connectivity

J2600

Problem

** Detailed check all parts

at CVBS2P signal path

[D2601/R2606/C2603/

R2640/R2619/

C2611/VD2602]

OK

NG

Parts Broken

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

* OK Condition : No solder splash can be seen

NG Condition : Solder splash can be seen

** OK Condition : No part short-circuited

NG Condition : Part short-circuited

37

Page 38

FLOW

4-3. NO PICTURE (TUNER)

RF input no picture / noisy picture

Check RF source cable

and antenna, OK?

OK

Check Tuner power line:

3.3V at JL2800 = 3.3V?

1.8V at JL2801 = 1.8V?

A_RESET value at JL2807 = 3.3V?

OK

All broadcasting channel

cannot be received?

NO

NG

YES

NG

Change RF cable and antenna

Please refer DDCON

troubleshooting

Check part mounting condition

for I2C SDA & SCL line. (Refer Note I2C)

And

Check Tuner module connection.(CN2800)

OK

Notes: I2C

I2C line for all tuners except Japan_SKP

- Parts for I2C SDA line: R2800, C2803.

- Parts for I2C SCL line : R2801, C2804.

I2C line for Japan_SKP

- Parts for I2C SDA line: R2804

- Parts for I2C SCL line : R2805

NG

Change NG parts

connected to I2C bus

TROUBLE SHOOTING

Digital

Analog

Refer Analog Tuning

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

Refer Digital Tuning 1

Terrestrial/Cable

For TW, NA-ATSC(MX/UC),

JP_SKP(Opticast) and LA-ISDB-T

Refer Digital Tuning 2

OK

For AEP_W, JP_SKP, PA_T2,

CH/HK, and LA-T2(COL)

Check Tuner power line

12V at JL2822 = 12V?

Satellite

NG

12V LNB Voltage Checking

38

Page 39

FLOW

4-4. NO PICTURE (TUNER)

FOR 12V LNB VOLTAGE CHECKING

+12V_LNB Voltage Checking

TROUBLE SHOOTING

Check fuse F2800

NG

Change the fuse

OK

Check LNB power line

+12V_MAIN at R495 = 12V?

NG

AC adaptor or G-board

G-board

SI2C013500 - 1/5/2022 12:13 PM

Check harness between

B-Board and G-board

OK

Please refer G-board

troubleshooting

OK

AC adaptor

NG

Check P_ON_HL signal line

at R451 (CL414) = 3.3V?

NG

Please refer DDCON

troubleshooting

Harness broken

OK

MOSFET Q408/Q409

broken

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

39

Page 40

FLOW

4-4. NO PICTURE (TUNER)

FOR ANALOG TUNING

Analog Tuning

For LA-ISDB(BR/AR), LA-T2(COL) and TW only

TROUBLE SHOOTING

For Other destination

Can it preset broadcast?

Check part mounting condition

for analog control line

“IFOUT_N, IFOUT_P, IFAGC”

Change NG parts

Confirm ANT or Cable connection

NG

NG

OK

OK

OK

NG

A

Tuner module connection (CN2800)

Notes:

- Parts for IFOUT_N line : FB2801, C2807, C2826

- Parts for IFOUT_P line : FB2802, C2808, C2825

- Parts for IFAGC line : R2838, C2827

: Insert correct signal in correct terminal. A

Check IC1000 (SoC)

Check IC1000 (SoC) &

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

40

Page 41

FLOW

4-4. NO PICTURE (TUNER)

FOR DIGITAL TUNING 2

TROUBLE SHOOTING

Digital Tuning 2

LA-T2(COL)

Confirm ANT or Cable connection Confirm ANT or Satellite connection

OK

Digital cable/ Terrestrial

Cable

Refer to Digital Tuning 1

SI2C013500 - 1/5/2022 12:13 PM

NG

A A A

Terrestrial

Sound is normal?

Display the service mode screen

Check part mounting condition for digital data line

“TU1_TS_DATA0, TU1_TS_CLK,

TU1_TS_VALID, TU1_TS_SYNC”

(Refer Notes)

Change NG parts

For PA_T2 and

CH/HK

OK

No sound

CASE B

TS_LOCK ?

UEC ?

CASE A

NG

For AEP-W

OK

Check IC1000 (SoC)

Change Tuner module

OK

Check IC1000 (SoC) &

Confirm an insertion state of the

connector

For JP_SKP

NG NG

All except SKP_Opticast

Confirm ANT or Satellite connection

OK

BS/CS or SKP_Opticast/

SKP_Premium or terrestrial

SKP_Opticast

Refer to Digital Tuning 1

Notes:

- Parts for TU1_TS_DATA0 line : R2847

- Parts for TU1_TS_CLK line : R2844

- Parts for TU1_TS_VALID line : R2845

- Parts for TU1_TS_SYNC line : R2846

- CASE A : TS _LOCK = LOCK and UEC constant

- CASE B : TS _LOCK = UNLOCK or UEC is increasing

A

: Insert correct signal in correct terminal.

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

41

Page 42

FLOW

4-5. NO PICTURE (HDMI)

HDMI1

No Picture

TROUBLE SHOOTING

Check other

HDMI input

All Inputs are NG

Check Picture by other TV set

which is same model

Target board & other TV set

both NG

Is Distributor used ?

NO

Check Source equipment

by Reference TV set

(For example, RB1)

Reference TV set

NG

Check the settings of

Source equipment

Other Input is OK

Other TV set

OK

YES

Reference TV Set

OK

Replace

IC1000

Connect Source

equipment directly

Change B* board.

And inform the designer of it

+5V line only NG

Spec:4.7~5.3V

Replace

R3646

Check the below point at

Connector side

- Check +5V line

- Check HPD line

- Check DDC lines

- Check TMDS lines

+5V line is OK

and HPD line is NG

Spec:2.4~5.3V

Replace

R3627,R3634,R3639,

R3643,Q3602

NG

Replace IC1000.

And inform the designer of it

All lines

are NG

DDC lines

only NG

Replace

RB3603,R3664,R3665

NG

Replace

CN3603

TMDS lines

only NG

Replace

RB3619,RB3620,

RB3611,RB3612

NG

NG

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

42

Page 43

TROUBLE SHOOTING

FLOW

4-5. NO PICTURE (HDMI)

HDMI2

No Picture

Check other

HDMI input

Check Picture by other TV set

which is same model

Is Distributor used ?

Check Source equipment

by Reference TV set

(For example, RB1)

SI2C013500 - 1/5/2022 12:13 PM

All Inputs are

NG

Target board & other TV

set both NG

NO

Reference TV set

NG

Other Input is OK

Other TV set

OK

YES

Reference TV Set

OK

Replace

IC1000

Connect Source

equipment directly

Change B* board.

And inform the designer of it

+5V line only NG

Spec:4.7~5.3V

Replace

R3647

Check the below point at

Connector side

- Check +5V line

- Check HPD line

- Check DDC lines

- Check TMDS lines

+5V line is OK

and HPD line is NG

Spec:2.4~5.3V

Replace

R3619

NG

Replace IC1000.

And inform the designer of it

All lines

are NG

DDC lines

only NG

Replace

RB3604,R3658,R3659

NG

Replace

CN3600

TMDS lines

only NG

Replace

RB3613,RB3614,

RB3605,RB3606

NG

NG

Check the settings of

Source equipment

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

43

Page 44

FLOW

4-5. NO PICTURE (HDMI)

HDMI3

No Picture

TROUBLE SHOOTING

Check other

HDMI input

All Inputs

are NG

Check Picture by other TV set

which is same model

Target board & other TV

set both NG

Is Distributor used ?

NO

Check Source equipment

by Reference TV set

(For example, RB1)

Reference TV set

NG

Check the settings of

Source equipment

Other Input is OK

Other TV set

OK

YES

Reference TV Set

OK

Replace

IC1000

Connect Source

equipment directly

Change B* board.

And inform the designer of it

+5V line only NG

Spec:4.7~5.3V

Replace

R3644

Check the below point at

Connector side

- Check +5V line

- Check HPD line

- Check DDC lines

- Check TMDS lines

+5V line is OK

and HPD line is NG

Spec:2.4~5.3V

Replace

R3625,R3632,R3637,

R3641,Q3600

NG

Replace IC1000.

And inform the designer of it

All lines

are NG

DDC lines

only NG

Replace

RB3601,R3660,R3661

NG

Replace

CN3601

TMDS lines

only NG

Replace

RB3615,RB3616,

RB3607,RB3608

NG

NG

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

44

Page 45

FLOW

4-5. NO PICTURE (HDMI)

HDMI4

No Picture

TROUBLE SHOOTING

Check other

HDMI input

All Inputs

are NG

Check Picture by other TV set

which is same model

Target board & other TV

set both NG

Is Distributor used ?

NO

Check Source equipment

by Reference TV set

(For example, RB1)

Reference TV set

NG

Check the settings of

Source equipment

Other Input is OK

Other TV set

OK

YES

Reference TV Set

OK

Check the below point at

Connector side

- Check +5V line

- Check HPD line

- Check DDC lines

- Check TMDS lines

Replace

IC1000

SI2C013500 - 1/5/2022 12:13 PM

Connect Source

equipment directly

Change B* board.

And inform the designer of it

+5V line only NG

Spec:4.7~5.3V

Replace

R3645

R3626,R3633,R3638,

Replace IC1000.

And inform the designer of it

+5V line is OK

and HPD line is NG

Spec:2.4~5.3V

Replace

R3642,Q3601

NG

All lines are

NG

DDC lines

only NG

Replace

RB3602,R3662,R3663

NG

Replace

CN3602

TMDS lines

only NG

Replace

RB3617,RB3618,

RB3609,RB3610

NG

NG

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

45

Page 46

FLOW

5. KEY SWITCH BUTTONS ERROR

TROUBLE SHOOTING

Side key buttons error

Resistor value

[BMKS]

R1108 : 0 [ohm]

R1049 : 47k [ohm]

R1222 : 4.7k [ohm]

[BMKP]

R250 : 0 [ohm]

R232 : 47k [ohm]

R1222 : 4.7k [ohm]

Resistor value

[BMKS]

R1028 : 4.7k [ohm]

R1107 : 0 [ohm]

R1050 : 20k [ohm]

R1051: 22k [ohm]

[BMKP]

R1028 : 4.7k [ohm]

R249 : 0 [ohm]

R230 : 20k [ohm]

R231: 22k [ohm]

Check harness connection

between B*board and switch

Change harness between B*

Check resistor value on B*

Check resistor value on B*

module

NG

board to switch module

harness

NG

Change switch module Switch module issue

NG

board

OK

In case that power key error

board

In case that buttons error except power key

OK

OK

OK

OK

NG

NG

Harness connection issue

B* board to switch module harness

issue

Parts issue

Main device issue

Change B* board

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

46

Page 47

FLOW

6. IR REMOTE COMMANDER ERROR

TROUBLE SHOOTING

SI2C013500 - 1/5/2022 12:13 PM

Resistor value

[BMKS]

R1110 : 0 [ohm]

R1259 : 47k [ohm]

[BMKP]

R252 : 0 [ohm]

R1259 : 47k [ohm]

IR remote commander does not

respond

Center white LED blinks when

pushing buttons of remote

commander at close to IR

sensor.

NG

Check harness connection

between B*board and Smart

Core

NG

Change harness between B*

board to Smart Core harness

NG

Change Smart Core Smart Core issue

NG

Check resistor value on B*

board

OK

OK

OK

OK

OK

NG

Battery of remote commander

Harness connection

B* board to Smart Core harness

Change B* board

Main device issue

could be weak.

Change battery.

issue

issue

Parts issue

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

47

Page 48

FLOW

7. LIGHT SENSOR ERROR

Backlight level does not change

when ambient light changed

TROUBLE SHOOTING

Check UI setting and make

sure light sensor setting is

“ON”

Setting is “OFF”

Setting issue

Change setting to “ON”

Resistor value

[BMKS]

R1109 : 0 [ohm]

R1052 : 150k [ohm]

[BMKP]

R251 : 0 [ohm]

R233 : 150k [ohm]

Setting is “ON”

Check harness connection

between B*board and Smart

Core

NG

Check harness connection

between B*board and H-

board

NG

Change harness between B*

board to Smart Core harness

NG

Change Smart Core Smart Core issue

NG

Check resistor value on B*

board

OK

OK

OK

OK

OK

NG

Battery of remote commander

could be weak.

Change battery.

Harness connection

issue

B* board to Smart Core harness

issue

Parts issue

Change B* board

Main device issue

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

48

Page 49

FLOW

8. NETWORK MALFUNCTION

ETHERNET (WIRED)

[Network Set-up]

>[Wired Set-up]

on the TV

TROUBLE SHOOTING

Connection Results

Cable Connection

Check cable

Ethernet Cable

B Board

CHK1

Any scratches

along

TX+/-, RX+/-

lines?

Failed

NG

YES

OK

OK

NO

B* board

CHK2

Check Ethernet

Connector pins

Soldering

Check

OK

Auto

NG

Check

Local router

DHCP server

OK

Connection Results

Local Access

Failed

Wired Set-up

IP address setting

SI2C013500 - 1/5/2022 12:13 PM

Check IP address

Local router setting

OK

J3400

NG NG

Manual

&

CHK3

Pulse Transformer

soldering

T3400,T3401

Connection Results

Internet Access

CHK4

Check CMF

Soldering

L3400

Failed

Proxy setting

OK

OK

B* board

IC1000 problem.

Change B* board

Change B* board

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

Change

Ethernet Connector

Change Pulse Trans

Change CMF

49

Page 50

FLOW

9. NETWORK MALFUNCTION

INTERNAL WIRELESS NETWORK MALFUNCTION

Wireless Network

on the TV

TROUBLE SHOOTING

Error message or no scan result appear in

the network setting?

Yes

Hardware defect suspected

Check harness

connection is OK

between Wi-Fi and B*

OK

Check with another Wi-Fi module

OK

Wi-Fi module

NG

NG

No

Is the Wi-Fi radio

strength too weak

or even No signal?

Yes

Check with another Wi-Fi

module

OK

Connect properly

NG

Change harness

between B* board and Wi-Fi

OK

Main Harness

OK

NG

No

NG

B* board

Access Point

WiFi module

Loose harness

B* board

If Wi-Fi malfunction happens,

・Wi-Fi module

・Harness between WiFi and B*

・B* board

are suspected.

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

50

Page 51

FLOW

10. BLUETOOTH MALFUNCTION

TROUBLE SHOOTING

Voice Remote doesn’t work

Bluetooth Keyboard/Mouse doesn’t work

Home > Settings >

Bluetooth Settings

NG

else

Check harness

connection is OK

between BT and B*

OK

Change BT module

or

OK

Can read

Near discoverable

Bluetooth Device

NG

NG

Check BT antenna

Connection is OK

Connect properly

NG

Between B* board and BT

NG

Change harness

OK

NG

Connect properly

OK

NG

OK

Loose harness

Change B* board

Please refer

Voice Remote manual

or

Bluetooth Keyboard/Mouse operation manual

Loose BT antenna

connection

OK

BT module

KD-55/65/75XE8505,8577,8588,8596,8599,FW-65/75XE8501

OK

Main Harness

51

Page 52

PCB PARTS MAP

BMKS (A side view)

cam013

cam001

cam033

1

cam027

2

2

R4083

4

cam003

KA002

43

42

44 4

5 4

6

400

CN4

4

7 4

8

49

141

51

50

53

52 61

5

1

4

CN4401

5

95

1

60

1

CN4000

2313

03

R11

R1101

R1100

S1000

ON

30

CN400

2

F3200

C414

cam004

KJ001 KJ002

R4071

R4081

R4077

R4072

R4066

IC4002

CN4001

CN4003

1

5 6

cam026

IRM002

D4400

R4408

Q4400

R4414

D4401

R4416

Q4401

R4412

cam021

CL4417

R4439

CL4418

R4440

CL4419

CL4436

C4411

CL4420

R4441

CL4421

C4412

R4241

CL4422

R4442

CL4

C4413

423

CL4424

R4443

C4414

CL4425

R4239

CL4426

R4444

C4415

CL4427

R4445

CL4428

C4416

R4452

CL4429

R4446

CL4430

C4417

CL4431

CL4437

R4451

C4418

CL4432

RB4400

RB4402

RB4401

RB4403

R1079

R1080

R1081

R1082

TP209

R1083

84

R10

cam022

RB4404

RB4405

RB4406

RB4407

C4402

R4425

CL4402

R4426

CL4403

C4403

R4427

CL4404

CL4406

R4429

R4428

CL4405

CL1214

R4430

C4408

CL4407

R4405

R4431

C4404

C4405

CL4408

R4432

R4406

CL1213

RB4408

C4409

R4418

R4062

R4433

R4058

C4410

R4434

CL4434

CL4433

CL4412

CL4413

CL4414

CL4415

C4406

R4436

R4435

R4437

R4438

C4407

R4449

C40

R4057

C4420

C4419

C4085

R4447

C4071

C4068

C3816

C3812

C3806

C3804

R4424

C4069

C3818

C3802

C3800

C3810

C3814

CL4416

C3808

R3803

R3804

R4422

R4423

R4421

R4059

C4094

R4041

C4065

CL4045

R4036

R4052

RB4000

C4063

R546

CM406

cam44

C4088

C4084

C4080

C4070

66

C40

C4075

C4091

C4082

C4067

C4077

C4073

C4086

R4045

C4025

C4026

R4012

C4027

CL4053

C4059

C4061

C4064

R4013

C4028

R4014

CL4043

CL4042

C4029

R4015

R4037

R4043

R4042

R4016

C4030

R4022

R4018

C4031

R4029

C4019

C4032

C4033

R4098

C4034

R482

C450

R480

R483

02

C449

8 5

C451

R481

9

IC404

C453

41

C454

C452

F402

cam50

L403

cam002

cam100007

C400

29

C401

C405

R403

C402

R400

C407

R405

C403

R401

C408

R406

C404

R402

C411

R407

C406

R404

C412

R408

C409

C410

D402

C517

C516

TP204

C518

C515

R409

C417

R411

R522

C492

R410

C416

R412

R523

C415

56

14

1

R413

cam043

C433

cam45

C413

C3243

R3239

R3242

611

C3244

1732

C3252

C3254

C3274

C3249

L3203

C3275

L3201

C3276

C3265

cam012

cam32

1 4

cam005

5 6

cam901

cam006

CN4200

R4079

54815

R4065

R4064

13

R4082

14

14

R4086

R4063

R4090

CL4051

C4104

1

ET212

C4235

C4234

R4240

C4237

C4232

C4233

R4213

R4211

CL4210

CL4208

cam039

C4230

R4212

CL4209

CL4211

C4231

R4214

C4228

C4229

C4226

C4227

C4224

C4225

C4222

C4223

C4220

C4221

C4218

C4219

C4216

C4217

C3851

C3857

C3893

C3885

C3891

C3888

C3892

C3852

C3856

R4225

5

ET21

1

R4224

R4256

R4257

CM4201

CM4200

C4248

X4200

31

45

R4060

R4061

C471

2

C472

IC408

cam55

R423

CM404

R424

R429

CM405

R3801

92

C4089

C3819

C3817

C4087

C3815

C3813

C4081

C3809

C3811

C3807

C3805

C4078

C3801

C3803

C4076

C4074

RB4006

RB4007

C4072

C3833

C3828

C4060

C3823

RB4005

RB4004

C4058

CL4046

R4053

R4101

C4097

C3820

C3825

C3830

C3831

C3821

C3826

C4096

R4054

IC4001

X4000

R4056

C4095

R4055

C4098

C4099

2

C406

C3945

R4038

C3946

R4023

CL4039

R4030

R4024

cam52

CL4038

9

C410

C4108

C4020

C4046

C4043

C4042

C4047

C4052

C4053

C4039

C4021

C4022

C4044

C4049

C4045

C4048

C4051

C4054

C4055

C4050

R4034

R486

R4100

R538

R4099

C456

R485

R4094

R4091

R438

Q4005

C4107

D4003

R4093

Q4003

R4097

R4102

R4096

R4095

Q4004

R4092

C4105

C4106

Q4006

C623

C624

R621

C622

cam51

R625

22

18

R620

17

1

L601

R623

IC604

R622

12

6

11

7

R624

C614

R626

C621

C620

C625

C619

R627

C626

C618

R628

C627

R629

C616

R630

C628

C615

C629

C617

F600

C434

C435

F401

C446

C447

R473

R472

R470

R450

R471

Q406

C521

L400

R476

R475

C448

R521

Q407

R520

R519

CM403

CN1201

R479

R478

CL3218

CL3217

CL3219

CL3220

C3245

C3246

cam3

CM400

CL403

C3273

33

IC3202

C3250

C3251

C3253

R417

Q403

R418

Q402

C3248

cam048

Q401

C418

R414

R419

L3202

C3260

C3259

L3200

R1314

CL1216

C3258

C3257

C3263

C3266

R1303

R1302

C3264

17

18

CN3201

cam095

cam029

cam034

R4204

R4205

1

56

481

R4221

CN4201

14

IC4201

R421

9

C4249

13

D4200

R4218

cam203

CL4202

FB38

02

C4238

C4239

C4243

C4246

C4247

C4242

C3909

C3915

C3913

C3914

C4236

C4245

C4244

C4241

C4240

C3911

C3912

cam025

IC4600

R4206

CL4200

R4220

R4208

R4207

CL4201

C4202

C4203

C4207

R4223

R4229

R4226

R4230

C4200

C4201

C4204

C4205

C4250

R4222

R4228

R4227

R4231

CL4048

CL4049

C4103

CL4050

C4102

C3841

C3839

C3829

R3802

C3838

C3840

C3824

C3832

C4100

C3827

R4070

C3822

R4073

X4001

R4075

R4084

R4068

C4101

R4069

C3835

R4067

C3837

R4007

C4016

C3836

C4018

C3834

R4009

CL2005

R4044

C4017

R4008

R4010

CL4052

CL4009

C4037

R4033

R4028

C4035

R4032

C4038

R4027

R4025

C4036

C4024

R4026

R4021

C4023

R4031

CL4041

C4090

R4051

CL4040

C4093

R4050

R4046

1

ET217

C4083

CL4044

C4056

C4057

R4049

R4048

R4039

C4079

R4040

R4047

S4000

C632

ON

cam040

5

2

IC606

314

R633

R4089

R4085

R4087

R4088

R465

Q4000

D4000

R4002

R463

R464

R469

C439

R468

C440

R467

R466

cam041

C441

51

18

6

C443

IC403

15

9

C436

14 10

C442

C438

C437

C444

C445

L402

TP211

R3221

R3223

R4258

R3207

C1258

R4262

5 4

IC4601

1

3

C425

6

5 4

R3222

IC1207

1

3

Q4202

R4260

R4261

cam024

R1326

R1325

R1327

cam010

CL418

CL400

CL410

R425

CL401

R499

R447

C419

R525

R439

R524

C505

R437

R446

C504

R426

CL402

11

15

R434

R440

1016

C497

R427

R428

IC401

R445

C503

6520

R441

C498

1

R451

R527

C507

C506

C499

C500

C502

CL414

CL411

R443

R442

R430

R449

R448

CL406

R422

cam47

R431

C420

CL405

R432

1

CL42

CL412

CL404

4

1

IC400

3

2

D400

R1306

R1291

4

cam10000

CL1215

cam100003

R1313

1

1

3

3

4

4

6

6

IC1202

IC1203

R1295

R1294

C1237

R1292

R1293

D120

6

R1266