Page 1

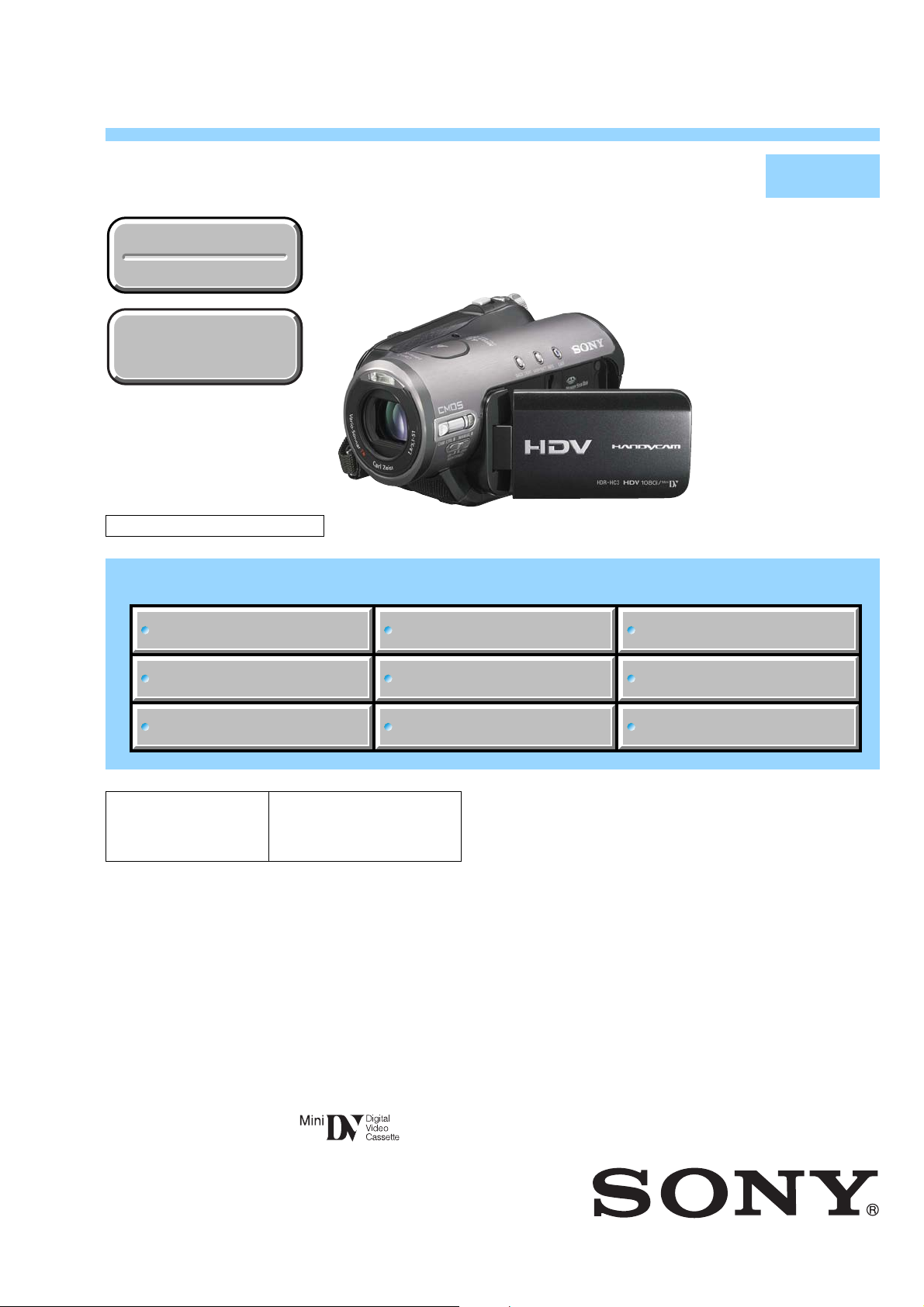

HDR-HC3/HC3E/HC3K/HC3EK

RMT-831

SERVICE MANUAL

Ver 1.2 2006.08

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

N MECHANISM (MDX-N110)

Link

Link

SPECIFICATIONS

Photo: HDR-HC3/Black

DISASSEMBLY

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

North European Model

E Model

Australian Model

Chinese Model

Hong Kong Model

Korea Model

Tourist Model

Japanese Model

SCHEMATIC DIAGRAMS

MODEL INFORMATION TABLE

SERVICE NOTE

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

PRINTED WIRING BOARDS

REPAIR PARTS LIST

HDR-HC3/HC3E/HC3K/HC3EK_L2

DIGITAL HD VIDEO CAMERA RECORDER

2006H0500-1

Sony EMCS Co.

Published by Kohda TEC9-876-939-31

© 2006.8

Page 2

These specifications are extracted

from instruction manual of HDR-HC3.

SPECIFICATIONS

ENGLISH JAPANESE

ENGLISH JAPANESE

System

Video recording system (HDV)

2 rotary heads, Helical scanning system

Video recording system (DV)

2 rotary heads, Helical scanning system

Still image recording system

Exif Ver. 2.2*

Audio recording system (HDV)

Rotary heads, MPEG-1 Audio Layer -2,

Quantization: 16 bits (Fs 48 kHz,

stereo)

transfer rate: 384 kbps

Audio recording system (DV)

Rotary heads, PCM system

Quantization: 12 bits (Fs 32 kHz, stereo

1, stereo 2), 16 bits (Fs 48 kHz, stereo)

Video signal

NTSC color, EIA standards

1080/60i specification

Usable cassette

Mini DV cassette with the mark

printed

Tape speed (HDV)

Approx. 18.81 mm/s

Tape speed (DV)

SP: Approx. 18.81 mm/s

LP: Approx. 12.56 mm/s

Recording/playback time (HDV)

60 min (using a DVM60 cassette)

Recording/playback time (DV)

SP: 60 min (using a DVM60 cassette)

LP: 90 min (using a DVM60 cassette)

Fast forward/rewind time

Approx. 2 min 40 s (using a DVM60

cassette and rechargeable battery pack)

Approx. 1 min 45 s (using a DVM60

cassette and AC Adaptor)

Viewfinder

Electric viewfinder (color)

Image device

5.9 mm (1/3 type) CMOS sensor

Gross: Approx. 2 103 000 pixels

Effective (movie, 4:3):

1 076 000 pixels

Effective (movie, 16:9):

1 434 000 pixels

Effective (still, 4:3):

1 991 000 pixels

Effective (still, 16:9):

1 493 000 pixels

Lens

Carl Zeiss Vario-Sonnar T

10 × (Optical), 20 ×, 80 × (Digital)

Focal length

f=5.1 ~ 51 mm (7/32 ~ 2 1/8 in.)

When converted to a 35 mm still

camera

In CAMERA-TAPE *

(1 11/16 ~ 19 1/8 in.) (16:9), 50.5 ~ 594

mm (2 ~ 23 1/2 in.) (4:3)

In CAMERA-MEMORY: 37 ~ 370 mm

(1 1/2 ~ 14 5/8 in.) (4:3), 40.4 ~ 404

mm (1 5/8 ~ 16 in.) (16:9)

F1.8 ~ 2.9

Filter diameter: 30 mm (1 3/16 in.)

1

2

: 41.3 ~ 485 mm

Color temperature

[AUTO], [ONE PUSH], [INDOOR]

(3 200 K),

[OUTDOOR] (5 800 K)

Minimum illumination

5 1x (lux) (F 1.8)

0 lx (lux) (during NightShot function)

*1“Exif” is a file format for still images,

established by the JEITA (Japan

Electronics and Information Technology

Industries Association). Files in this

format can have additional information

such as your camcorder’s setting

information at the time of recording.

2

The focal length figures are actual

*

figures resulting from wide angle pixel

read-out.

Output connectors

Audio/Video output

10-pin connector

Video signal: 1 Vp-p, 75Ω (ohms),

unbalanced

Luminance signal: 1 Vp-p, 75Ω

(ohms), unbalanced

Chrominance signal: 0.286 Vp-p, 75Ω

(ohms), unbalanced

Audio signal: 327 mV (at load

impedance 47 kΩ (kilohms)), Output

impedance with less than 2.2 kΩ

(kilohms)

COMPONENT OUT jack

Y: 1 Vp-p, 75Ω (ohms), unbalanced P

R

, CB/CR: +/- 350 mVp-p

P

HDMI OUT jack

TypeA (19-pin)

Input/Output connectors

LANC jack

Stereo mini-minijack (Ø 2.5 mm)

USB jack

mini-B

HDV/DV jack

i.LINK Interface (IEEE 1394, 4-pin

connector S100)

LCD screen

Picture

6.9 cm (2.7 type, aspect ratio 16:9)

Total dot number

211 200 (960 × 220)

General

Power requirements

DC 7.2 V (battery pack)

DC 8.4 V (AC Adaptor)

Average power consumption

During camera recording using the

viewfinder with normal brightness:

HDV recording 4.1 W

DV recording 3.9 W

During camera recording using the

LCD with normal brightness:

HDV recording 4.4 W

DV recording 4.2 W

Operating temperature

0 °C to + 40 °C (32 °F to 104 °F)

Storage temperature

-20 °C to + 60 °C (-4 °F to + 140 °F)

Dimensions (approx.)

82 × 78 × 139 mm

(3 1/4 × 31/8 × 51/2 in.) (w/h/d)

excluding the projecting parts

Mass (approx.)

500 g (1 lb 1 oz) main unit only

600 g (1 lb 5 oz) including the NP-FP60

rechargeable battery pack and DVM60

cassette.

Supplied accessories

AC Adaptor (1)

Power cord (1)

Wireless Remote Commander

A/V connecting cable (1)

Component video cable (1)

USB cable (1)

Rechargeable battery pack NP-FP60 (1)

Battery terminal cover (1)

Operating Guide (1)

See page 5-36.

(1)

AC Adaptor AC-L200

Power requirements

AC 100 - 240 V, 50/60 Hz

Current consumption

0.35 - 0.18 A

Power consumption

18 W

B

/

Output voltage

DC 8.4 V*

Operating temperature

0 °C to + 40 °C (32 °F to 104 °F)

Storage temperature

-20 °C to + 60 °C (-4 °F to + 140 °F)

Dimensions (approx.)

48 × 29 × 81 mm (1 15/16 × 13/16 ×

31/4 in.) (w/h/d) excluding the

projecting parts

Mass (approx.)

170 g (6.0 oz) excluding the power cord

* See the label on the AC Adaptor for other

specifications.

Rechargeable battery pack (NP-FP60)

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Capacity

7.2 Wh (1 000 mAh)

Dimensions (approx.)

31.8 × 33.3 × 45.0 mm

(1 5/16 × 15/16 × 1 13/16 in.) (w/h/d)

Mass (approx.)

80 g (2.9 oz)

Operating temperature

0 °C to + 40 °C (32 °F to 104 °F)

Type

Lithium ion

Design and specifications are subject to change

without notice.

HDR-HC3/HC3E/HC3K/HC3EK_L2

— 2 —

Page 3

概略仕様

ENGLISH JAPANESE

ENGLISH JAPANESE

システム

録画方式

(

HDV

録画方式

)

(

DV

静止画記録方

式

録音方式

(

HDV

録音方式

(

)

DV

映像信号

使用可能カ

セット

テープ速度

(

HDV

テープ速度

)

(

DV

録画

/

間(

HDV

録画

/

間(

DV

早送り、

巻き戻し時間

ファインダー 電子ファインダー:カラー

撮像素子

ズームレンズ カールツァイス バリオゾナー

色温度切り換え[オート]、[ワンプッシュ]、

最低被写体照

度

1

*

(社)電子情報技術産業協会(

された、撮影情報などの付帯情報を追加する

ことができる静止画用のファイルフォーマッ

ト。

2

*

広角画素読み出しによる実動作値

回転

回転

2

2

)

Exif Ver.2.2*

回転ヘッド

MPEG-1 Audio Layer2

)

ビット

16

転送レート

回転ヘッド

ビット

12

(ステレオ1、ステレオ2)

ビット

16

NTSC

1080/60i

セット

約

)

再生時

再生時

)

18.81mm/

:約

SP

:約

LP

分(

60

)

SP:60

LP:90

バッテリー使用時:

約

2分40

アダプター使用時:

AC

約

1分45

5.9mm(1/3

総画素数:約

動画時有効画素数(

約

108

動画時有効画素数(

ド):約

静止画時有効画素数(

ド):約

静止画時有効画素数(

ド):約

T

倍(光学)、20倍、80倍(デジタ

10

ル)

f=5.1〜51mm

35mm

「撮る−テープ」時

41.3〜485mm(16:9

モードでは

(

4:3

「撮る−メモリー」時:

37〜370mm(4:3

(

16:9

mm)

404

F1.8〜2.9

フィルター径

[屋内](

[屋外](

(ルクス)(

11 lx

(ルクス)(

0 lx

ヘッドヘリカルスキャン

ヘッドヘリカルスキャン

1

(ステレオ)

48kHz

384kbps

32kHz

(ステレオ)

48kHz

カラー、

マークのついたミニ

18.81mm/

12.56mm/

DVM60

分(

分(

万画素

143

199

149

カメラ換算では

方式

DVM60

DVM60

秒(

DVM60

秒(

DVM60

型)

210

万画素

万画素

万画素

標準方式

EIA

秒

秒

秒

使用時)

使用時)

使用時

CMOS

万画素

4:3

16:9

2

:

*

DV

)

使用時)

使用時)

センサー

モード):

モー

モー

4:3

モー

16:9

モード)

50.5〜594mm

モードでは

モード)

〜

40.4

30mm

)、

3 200K

)

5 800K

)

F1.8

JEITA

時)

)にて制定

NightShot

カ

)

出力端子

A/V OUT

端子

コンポーネン

トビデオ端子

HDMI OUT

端子

入

出力端子

/

端子 ステレオミニミニジャック

LANC

端子

USB

HDV/DV

子

ピン特殊コネクター

10

映像:

1 Vp-p、75

出力

Y

1Vp-p、75

出力

C

0.286Vp-p、75

衡

音声:

327mV(47 k

力インピーダンス

映像:コンポーネントビデ

D1/D3

オ端子

Y:1Vp-p、75

PB/PR. CB/C

タイプ

A(19

(

)

ø 2.5

mini-B

端

i.LINK(IEEE1394 4

クター

S100

Ω不平衡

2.2 k

Ω不平衡

:±

R

350mVp-p

ピン)

)

Ω不平衡

Ω不平

Ω負荷時)、出

Ω以下

ピンコネ

液晶画面

画面サイズ

総ドット数

6.9cm(2.7

16:9

211 200

横

960

)

×縦

型、アスペクト比

ドット

220

電源部、その他

電源電圧 バッテリー端子入力

消費電力 ファインダー使用時、明るさ標

動作温度

保存温度 −

外形寸法

本体質量 約

撮影時総質量 約

付属品

端子入力

DC

準:

記録時

HDV

記録時

DV

液晶画面使用時、明るさ標準:

記録時

HDV

記録時

DV

℃〜

0

+40

℃〜

20

+60

82×78×139mm

(最大突起部を除く)(幅×高さ×

奥行き)

(本体のみ)

500g

(バッテリー

600g

テープ(

DVM60

AC

アダプター(1)

電源コード(1)

ワイヤレスリモコン(1)

AV

接続ケーブル(1)

D

端子コンポーネントビデオケーブル(1)

USB

ケーブル(1)

リチャージャブルバッテリーパック

NP-FP60

(1)

バッテリー端子カバー(1)

取扱説明書(1)

保証書(1)

8.4V

4.1W

3.9W

4.4W

4.2W

℃

℃

7.2V

NP-FP60

)含む。)

、

アダプター

AC

電源

消費電力

定格出力

動作温度

保存温度 −

外形寸法 約

質量 約

その他の仕様についてはACアダプターのラ

*

ベルをご覧ください。

AC-L200

AC100〜240V、50/60Hz

18W

DC8.4V *

℃〜

0

をのぞく)(幅×高さ×奥行き)

℃

+40

℃〜

+60

℃

20

48×29×81mm

(本体のみ)

170g

(最大突起部

リチャージャブルバッテリーパック

NP-FP60

最大電圧

公称電圧

容量

最大外形寸法 約

質量 約

使用温度

使用電池

本機の仕様および外観は、改良のため予告なく変

更することがありますが、ご了承ください。

DC8.4V

DC7.2V

7.2Wh(1 000mAh

31.8×33.3×45.0mm

(幅×高さ×奥行き)

80g

℃〜

℃

0

+40

Li-ion

)

HDR-HC3/HC3E/HC3K/HC3EK_L2

— 3 —

Page 4

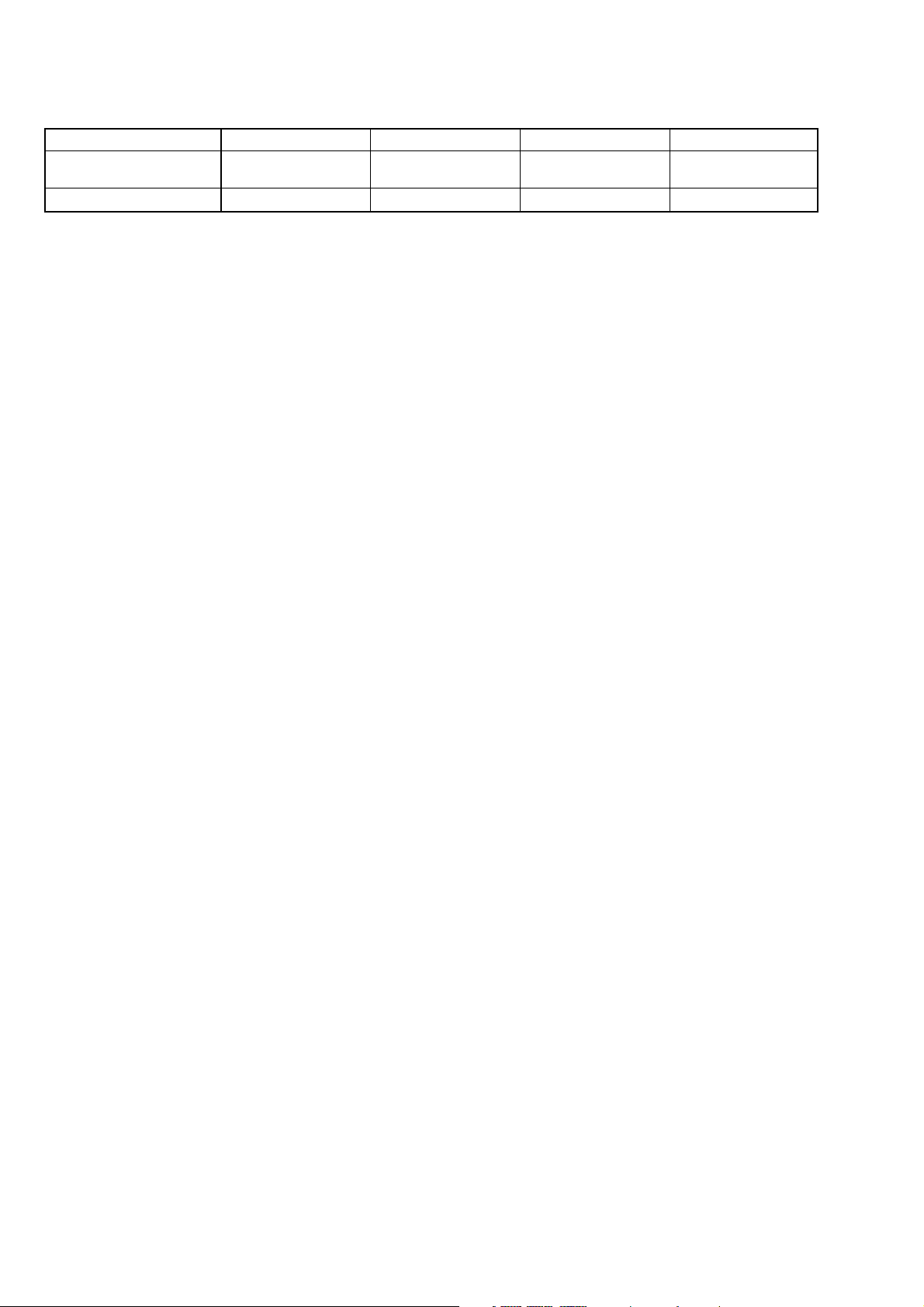

Model information table

Model HDR-HC3 HDR-HC3E HDR-HC3K HDR-HC3EK

Destination US, CND, E, KR, J

Color system NTSC PAL NTSC PAL

•Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

CH : Chinese model

CND : Canadian model

EE : East European model

HK : Hong Kong model

J: Japanese model

JE : Tourist model

KR : Korea model

NE : North European model

AEP, UK, NE, E, AUS,

CH, HK

JE JE

HDR-HC3/HC3E/HC3K/HC3EK_L2

— 4 —

Page 5

ENGLISH JAPANESE

ENGLISH JAPANESE

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

•Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

HDR-HC3/HC3E/HC3K/HC3EK_L2

— 5 —

Page 6

ENGLISH JAPANESE

ENGLISH JAPANESE

電池の交換は,正しく行わないと破裂する恐れがあり

注意

ます。電池を交換する場合には必ず同じ型名の電池

又は同等品と交換してください。

サービス,点検時には次のことにご注意下さい。

1. 注意事項をお守りください。

サービスのとき特に注意を要する個所については,

キャビネット,シャーシ,部品などにラベルや捺印で

注意事項を表示しています。これらの注意書き及び取

扱説明書等の注意事項を必ずお守り下さい。

2. 指定部品のご使用を

セットの部品は難燃性や耐電圧など安全上の特性を

持ったものとなっています。従って交換部品は,使用

されていたものと同じ特性の部品を使用して下さい。

特に回路図,部品表に0印で指定されている安全上重要

な部品は必ず指定のものをご使用下さい。

3. 部品の取付けや配線の引きまわしはもとどおりに

安全上,チューブやテープなどの絶縁材料を使用した

り,プリント基板から浮かして取付けた部品がありま

す。また内部配線は引きまわしやクランパによって発

熱部品や高圧部品に接近しないよう配慮されています

ので,これらは必ずもとどおりにして下さい。

4. サービス後は安全点検を

サービスのために取外したネジ,部品,配線がもとど

おりになっているか,またサービスした個所の周辺を

劣化させてしまったところがないかなどを点検し,安

全性が確保されていることを確認して下さい。

5. チップ部品交換時の注意

• 取外した部品は再使用しないで下さい。

• タンタルコンデンサのマイナス側は熱に弱いため交

換時は注意して下さい。

6. フレキシブルプリント基板の取扱いについて

• コテ先温度を270℃前後にして行なって下さい。

• 同一パターンに何度もコテ先を当てないで下さい。

(3回以内)

• パターンに力が加わらないよう注意して下さい。

7. 無鉛半田について

無鉛半田を使用している基板には,無鉛(LeadFree)を

意味するレッドフリーマークがプリントされています。

(注意:基板サイズによっては,無鉛半田を使用して

いてもレッドフリーマークがプリントされて

いないものがあります)

:レッドフリーマーク

無鉛半田には,以下の特性があります。

• 融点が従来の半田よりも約40℃高い。

従来の半田こてをそのまま使用することは可能です

が,少し長めにこてを当てる必要があります。

温度調節機能のついた半田こてを使用する場合,約

350℃に設定して下さい。

注意: 半田こてを長く当てすぎると,基板のパター

ン(銅箔)がはがれてしまうことがあります

ので,注意して下さい。

• 粘性が強い

従来の半田よりも粘性が強いため,IC端子などが半田

ブリッジしないように注意して下さい。

• 従来の半田と混ぜて使用可能

無鉛半田には無鉛半田を追加するのが最適ですが,

従来の半田を追加しても構いません。

HDR-HC3/HC3E/HC3K/HC3EK_L2

— 6 —

Page 7

TABLE OF CONTENTS

Section Title Page

1. SERVICE NOTE

1-1. Power Supply During Repairs ········································· 1-1

1-2. To Take Out a Cassette when not Eject (Force Eject) ·····1-1

1-3. Setting the “Forced Power On” Mode ·····························1-1

1-4. Using Service Jig ····························································· 1-2

1-5. Self-diagnosis Function ··················································· 1-2

1-6. Process After Fixing Flash Error ····································· 1-4

2. DISASSEMBLY

2-1. Disassembly····································································· 2-2

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/7)··········································· 3-1

3-2. Overall Block Diagram (2/7)··········································· 3-2

3-3. Overall Block Diagram (3/7)··········································· 3-3

3-4. Overall Block Diagram (4/7)··········································· 3-4

3-5. Overall Block Diagram (5/7)··········································· 3-5

3-6. Overall Block Diagram (6/7)··········································· 3-6

3-7. Overall Block Diagram (7/7)··········································· 3-7

3-8. Power Block Diagram (1/3)············································· 3-8

3-9. Power Block Diagram (2/3)············································· 3-9

3-10. Power Block Diagram (3/3) ···········································3-10

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagrams············································· 4-1

4-2. Schematic Diagrams ························································ 4-3

4-3. Printed Wiring Boards ···················································4-37

4-4. Mounted Parts Location ················································ 4-56

5. REPAIR PARTS LIST

5-1. Exploded Views ······························································· 5-2

5-2. Electrical Parts List ······················································· 5-16

HDR-HC3/HC3E/HC3K/HC3EK_L2

— 7 —

Page 8

ENGLISH JAPANESE

y

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V), the power is shut off so

that the unit cannot operate.

These following method is available to prevent this.

Method:

Use the AC power adaptor (AC-L200).

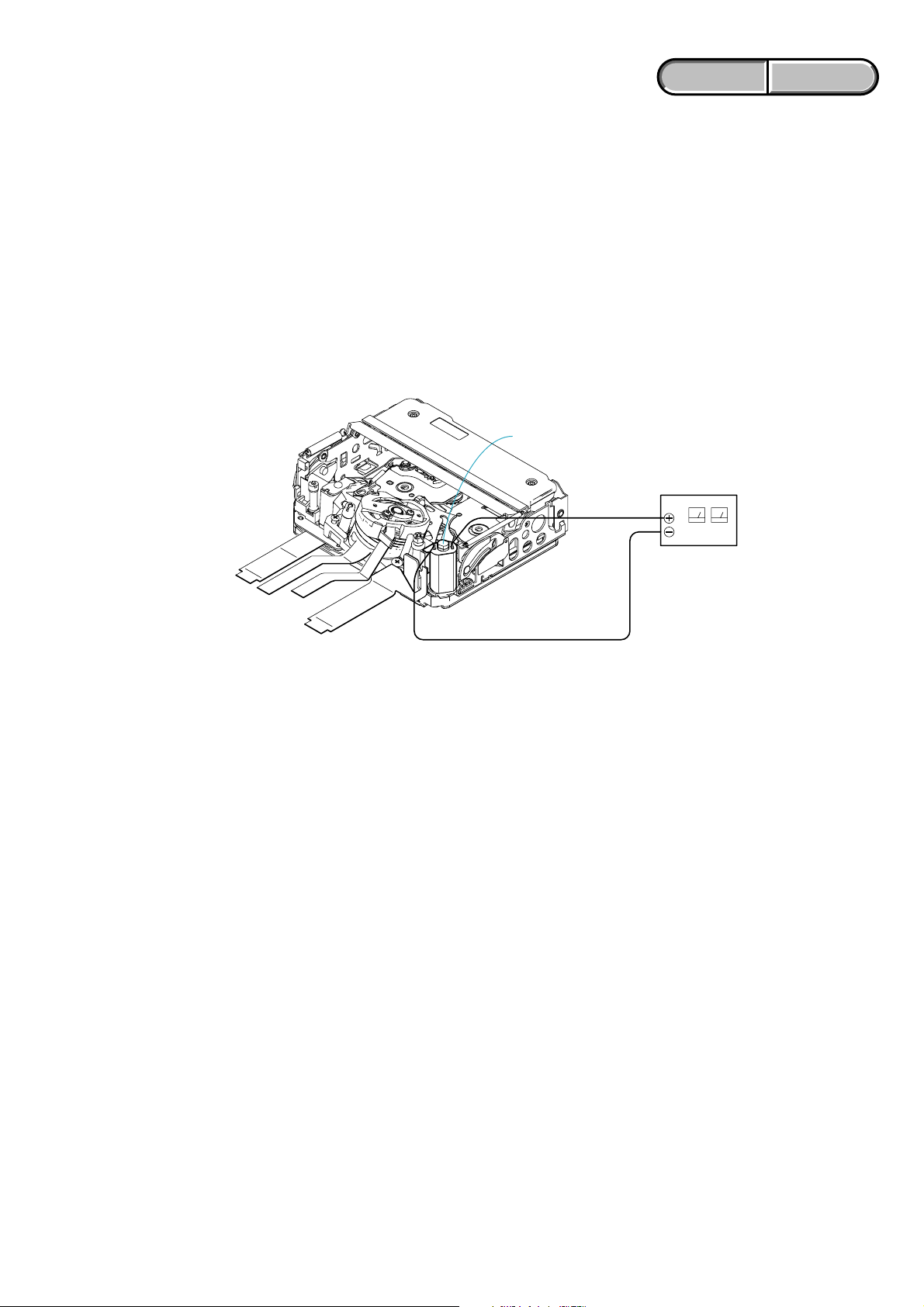

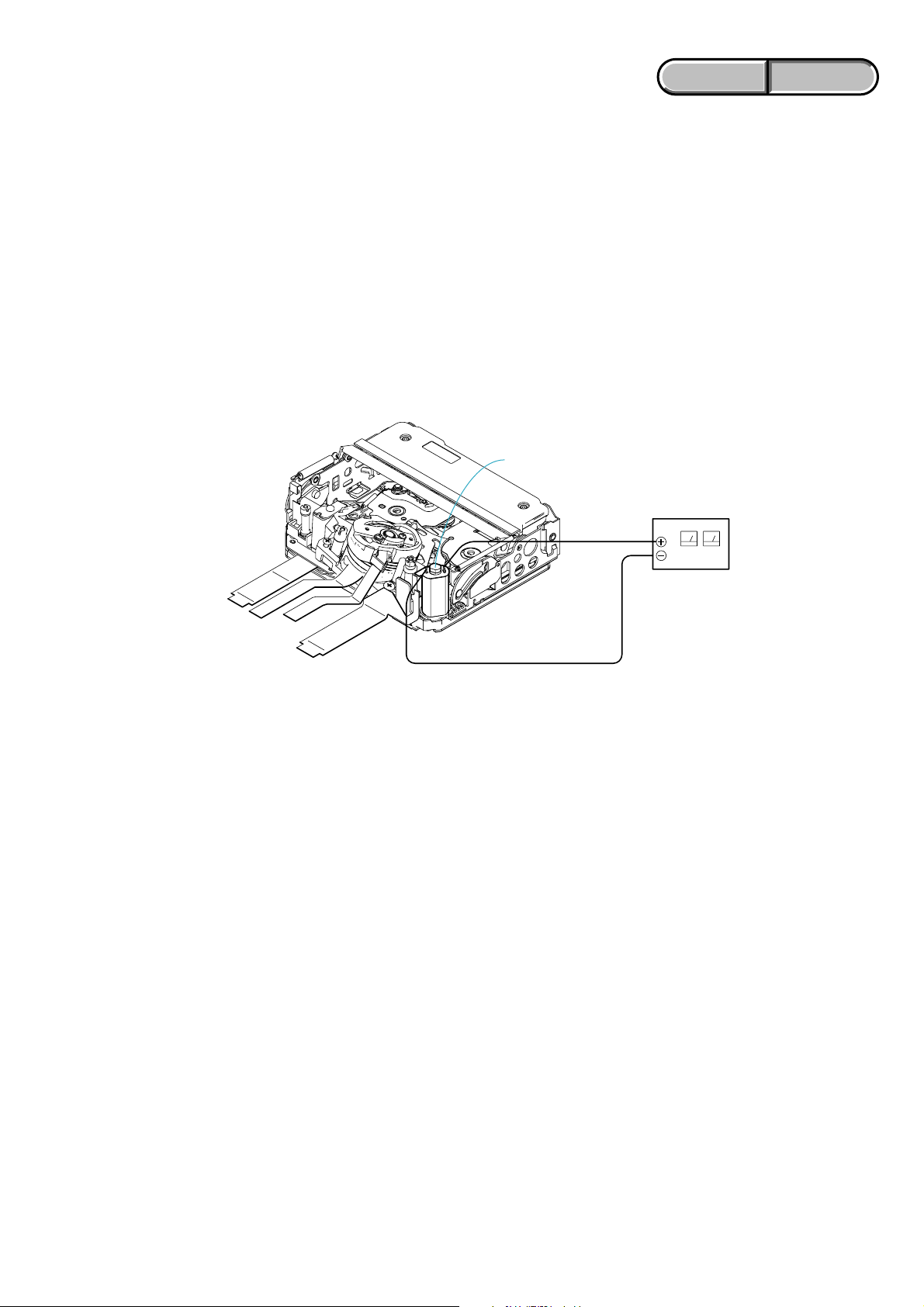

1-2. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to “2. DISASSEMBLY” to remove the mechanism deck block.

2 Supply +4.5V from the DC power supply to the loading motor and unload with a pressing the cassette compartment.

Loading motor

DC power suppl

(+ 4.5Vdc)

1-3. SETTING THE “FORCED POWER ON” MODE

It is possible to turn on power by adjustment remote commander (RM-95 or NEW LANC JIG).

Operate the VTR function using the adjustment remote commander.

1-3-1. Setting the “Forced Camera Power ON” Mode

1) Select page: 0, address: 01, and set data:01.

2) Select page: A, address: 10, set data:01 and press the “PAUSE (Write) ” button of the adjustment remote commander.

1-3-2. Setting the “Forced VTR Power ON” Mode

1) Select page: 0, address: 01, and set data:01.

2) Select page: A, address: 10, set data:02 and press the “PAUSE (Write) ” button of the adjustment remote commander.

1-3-3. Exiting the “Forced Power ON” Mode

1) Select page: 0, address: 01, and set data:01.

2) Select page: A, address: 10, set data:00 and press the “PAUSE (Write) ” button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

HDR-HC3/HC3E//HC3K/HC3EK_L2

1-1

Page 9

ENGLISH JAPANESE

ENGLISH JAPANESE

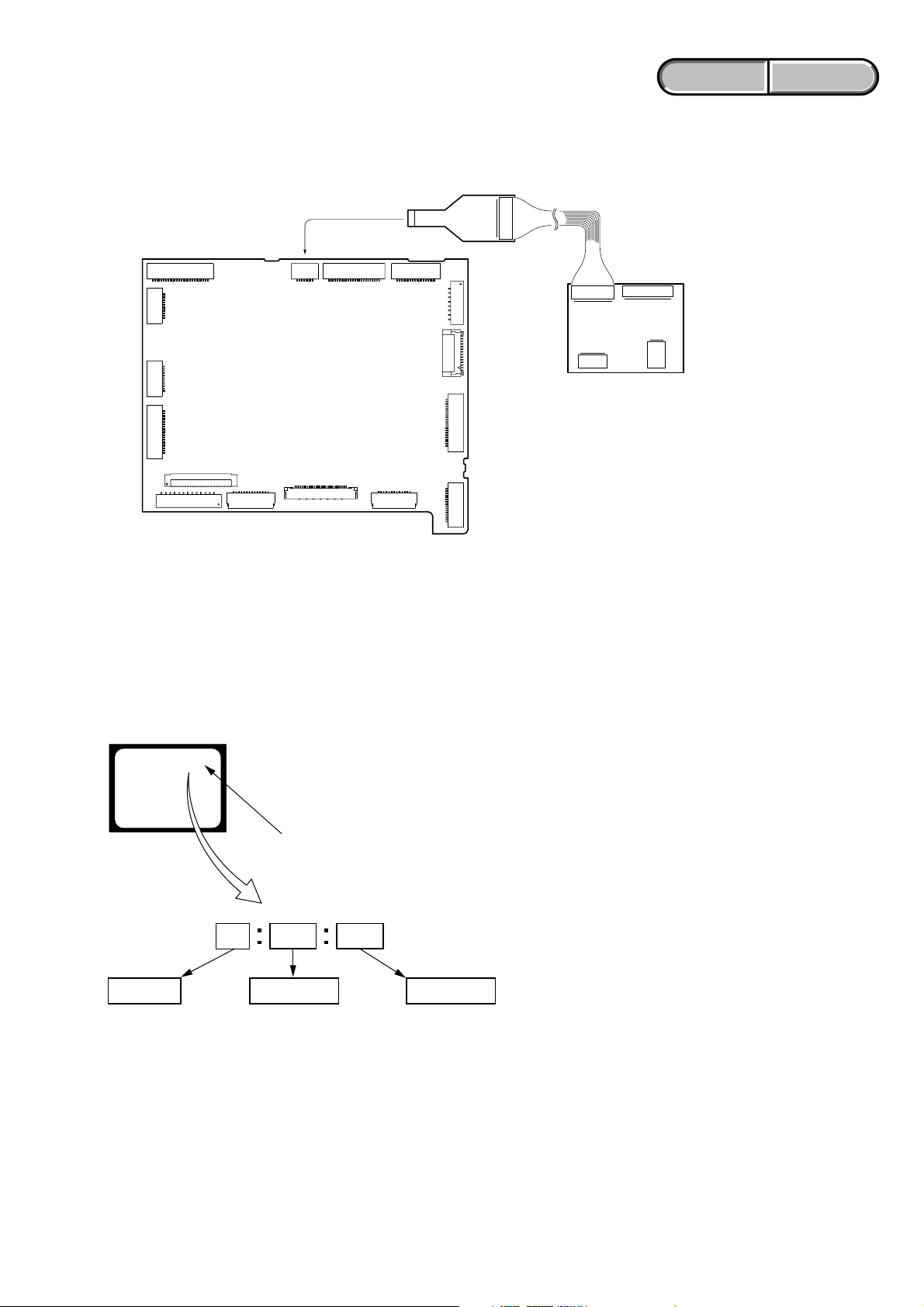

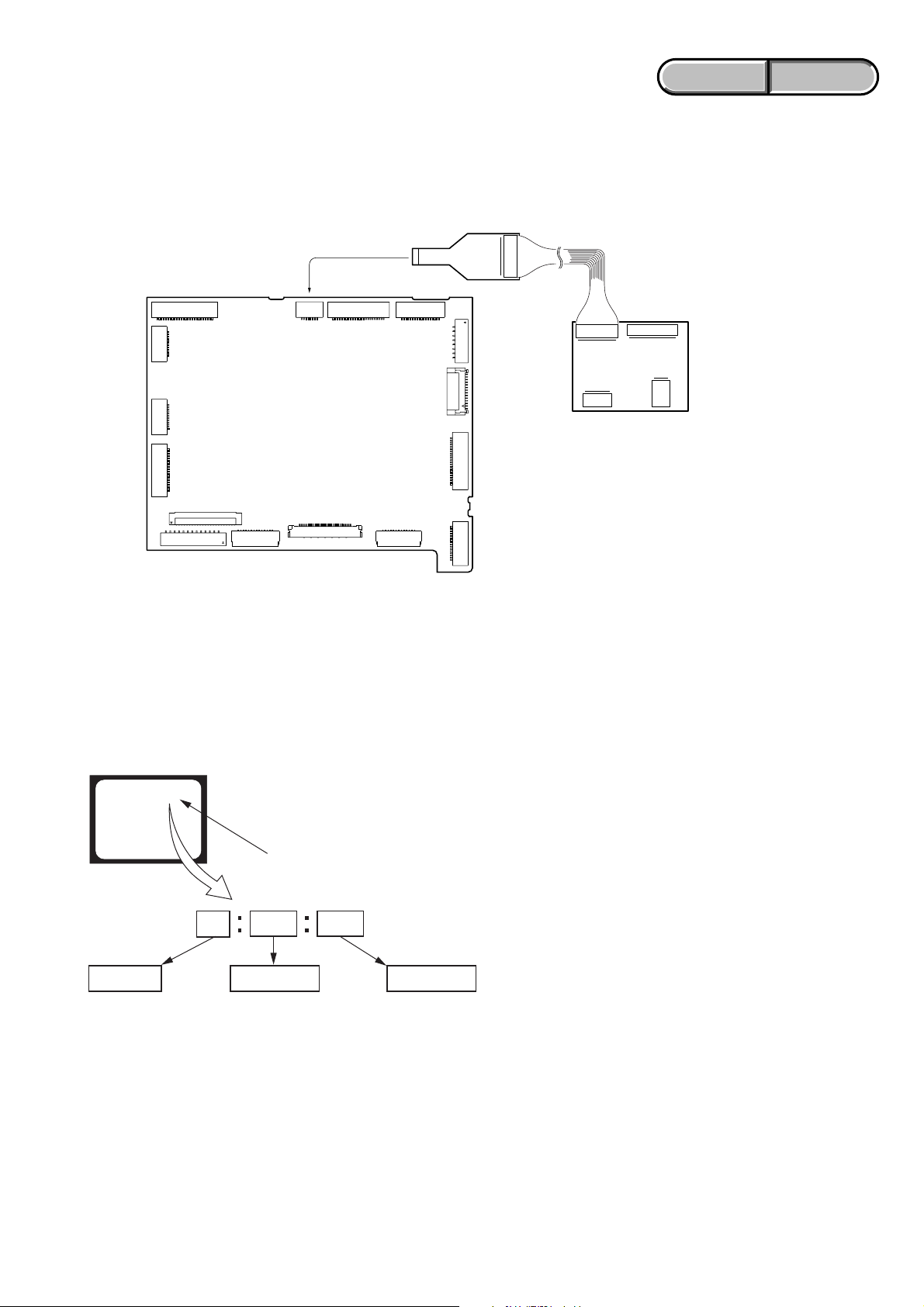

1-4. USING SERVICE JIG

Connect the CPC-15 jig connector (J-6082-564-A) and I/F unit for LANC control (J-6082-521 A) to the CN1009 on the VC-441 board.

CPC-15

(J-6082-564-A)

8

1

18

CN1009

VC-441 BOARD

(SIDE A)

1-5. SELF-DIAGNOSIS FUNCTION

1-5-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or LCD

screen what to do. This function consists of two display; selfdiagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen

C : 3 1 : 1 1

I/F unit for LANC control

(J-6082-521-A)

1-5-2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or LCD screen shows a 4-digit display consisting of an

alphabet and numbers, which blinks at 3.2 Hz. This 5-character

display indicates the “repaired by:”, “block” in which the problem

occurred, and “detailed code” of the problem.

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

HDR-HC3/HC3E/HC3K/HC3EK_L2

Blinks at 3.2Hz

3 1C

Block

1 1

Detailed Code

Refer to “1-5-3. Self-diagnosis Code Table”.

1-2

Page 10

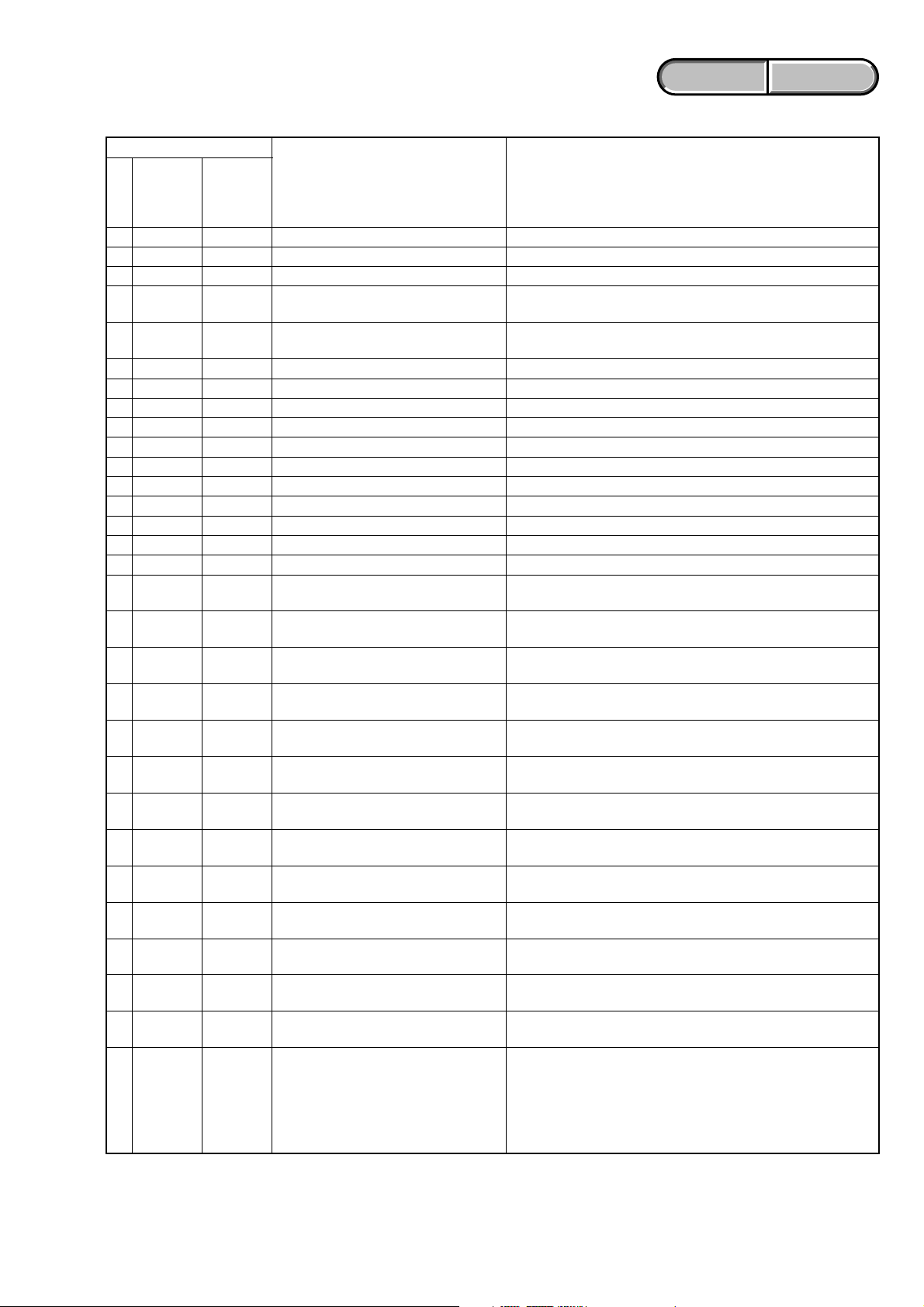

1-5-3. Self-diagnosis Code Table

Self-diagnosis Code

ENGLISH JAPANESE

ENGLISH JAPANESE

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Block

Function

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

32

32

32

32

Detailed

Code

00

00

00

10

11

20

21

22

23

30

31

40

41

42

43

44

10

11

20

21

22

23

30

31

40

41

42

43

44

60

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

S reel

side tape slacking when unloading

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum operations.

PG fault during normal drum operations.

Phase fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

S reel side tape slacking when

unloading.

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan

operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum

operations.

PG fault during normal drum

operations.

Phase fault during normal drum

operations.

Difficult to adjust focus

(Cannot initialize focus.)

Correction

Use the InfoLITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

If it does not recover, inspect the focus MR sensor of lens block

(Pin ql, wa of CN7103 on the LD-202 board).

If not faulty, inspect the focus motor drive circuit

(IC7204 on the LD-202 board).

HDR-HC3/HC3E//HC3K/HC3EK_L2

1-3

Page 11

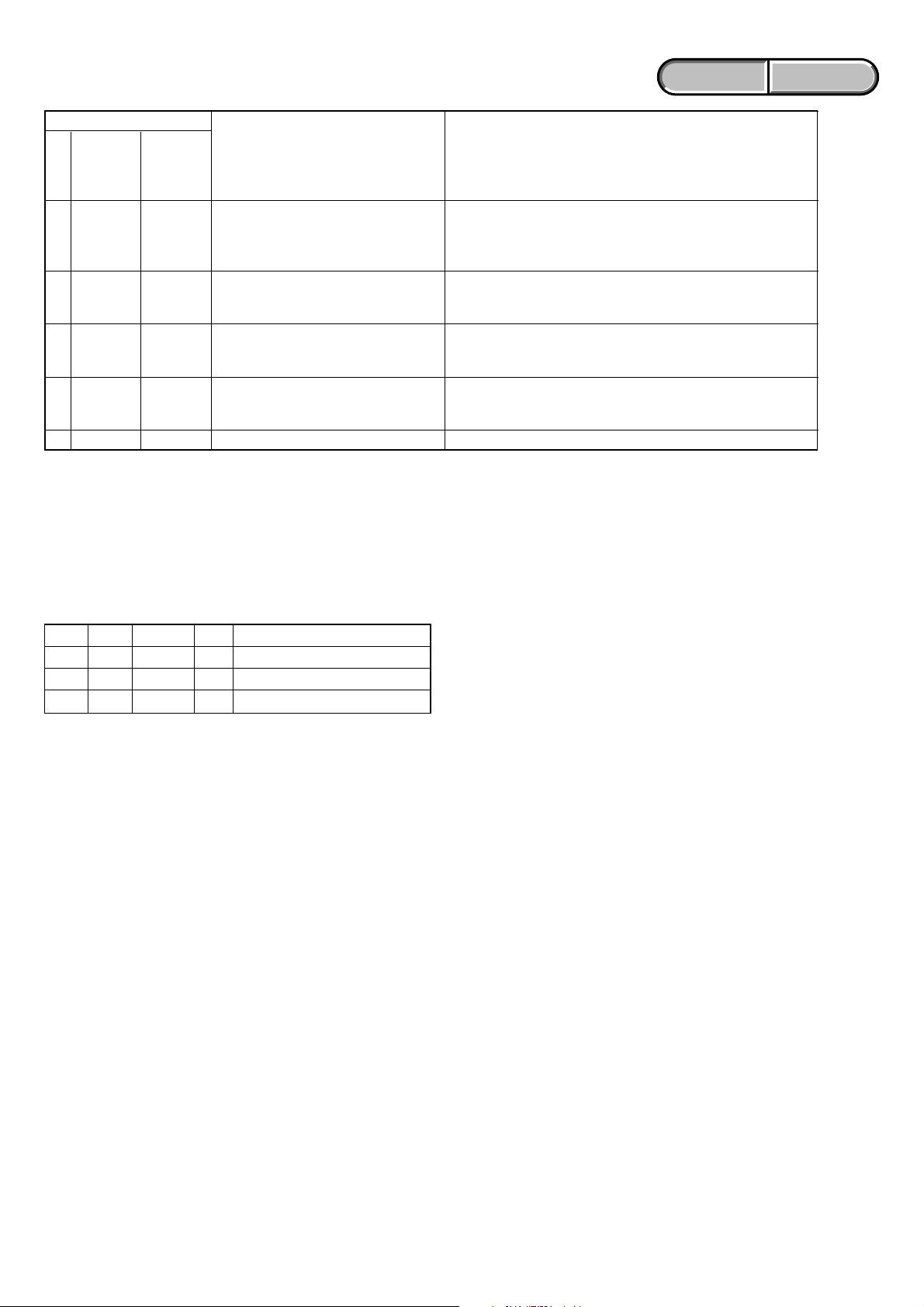

Self-diagnosis Code

ENGLISH JAPANESE

ENGLISH JAPANESE

Block

Function

Repaired by:

E

61

E

61

E

62

E

62

E

91

Note: After repair, be sure to perform “1-6. PROCESS AFTER FIXING FLASH ERROR”.

Detailed

Code

10

11

00

01

01

Symptom/State

Zoom operations fault

(Cannot initialize zoom lens.)

Focus lens initializing failure and zoom

lens initializing failure occur simultaneously.

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular velocity sensor output

stopped.)

Abnormality when flash is being charged.

Correction

Inspect the zoom MR sensor of lens block (Pin qh, qk of CN7103

on the LD-202 board) when zooming is performed when the zoom

switch is operated and the zoom motor drive circuit (IC7204 on

the LD-202 board) when zooming is not performed.

Check both C: 32: 60 and E: 61: 10 of the self-diagnosis code.

Inspect pitch angular velocity sensor (SE7702 on the CM-071

board) peripheral circuits.

Inspect yaw angular velocity sensor (SE7701 on the CM-071

board) peripheral circuits.

Checking of flash unit or replacement of flash unit. (Note)

1-6. PROCESS AFTER FIXING FLASH ERROR

When “FLASH error” (Self-diagnosis Code E:91:**) occurs, to prevent any abnormal situation caused by high voltage, setting of the flash is

changed automatically to disabling charge and flash setting.

After fixing, this setting needs to be deactivated. Connect the adjustment remote commander (RM-95 or NEW LANC JIG) and perform the

following process.

Order Page Address Data Procedure

17 0175

27 00 01 Press PAUSE (Write) button.

37 02 Check the data changes to “01”.

HDR-HC3/HC3E/HC3K/HC3EK_L2

1-4

Page 12

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. 修理時の電源供給について

本機では,安定化電源(8.4Vdc)からバッテリ端子に電源を供給した場合,約10秒後にシャットオフし,動作しなくなります。

これを避けるため,下記の方法を用いてください。

方法:

DC入力端子を使用する。(ACアダプタ(AC-L200)を使用する。)

1-2. イジェクトしない時のカセット取出し方法(強制イジェクト)

1 2.DISASSEMBLYを参照し,メカデッキを外す。

2 カセコン組立を押さえながら,安定化電源より+4.5Vをローディングモータに加え,アンローディングさせる。

ローディングモータ

安定化電源(+4.5Vdc)

1-3. 強制電源ONモードの設定

調整リモコン(RM-95またはNEWLANCJIG)を使用して,電源を入れることが出来ます。

VTR操作は調整リモコンで行えます。

1-3-1. 強制カメラ電源ONモードの設定

1) ページ:0,アドレス:01にデータ:01をセット。

2) ページ:A,アドレス:10にデータ:01をセットしPAUSE(Write)ボタンを押す。

1-3-2. 強制VTR電源ONモードの設定

1) ページ:0,アドレス:01にデータ:01をセット。

2) ページ:A,アドレス:10にデータ:02をセットしPAUSE(Write)ボタンを押す。

1-3-3. 強制電源ONモードの解除

1) ページ:0,アドレス:01にデータ:01をセット。

2) ページ:A,アドレス:10にデータ:00をセットしPAUSE(Write)ボタンを押す。

3) ページ:0,アドレス:01にデータ:00をセット。

HDR-HC3/HC3E/HC3K/HC3EK_L2

1-5

Page 13

ENGLISH JAPANESE

ENGLISH JAPANESE

1-4. 使用サービス治具

CPC-15治具コネクタ(J-6082-564-A),LANC変換用I/F(J-6082-521-A)をVC-441基板CN1009に接続します。

CPC-15

(J-6082-564-A)

8

1

18

CN1009

VC-441 BOARD

(SIDE A)

1-5. 自己診断機能

1-5-1.自己診断機能について

本機の動作に不具合が生じたとき,自己診断機能が働き,

ビューファインダまたはLCD 画面に,どう処置したらよい

か判断できる表示を行います。「自己診断表示」と「サービス

モード表示」の2つの表示があります。自己診断機能につい

ては取扱説明書にも掲載されています。

ビューファインダまたはLCD画面

C : 3 1 : 1 1

3.2Hz点滅

I/F unit for LANC control

(J-6082-521-A)

1-5-2.自己診断表示

本機の動作に不具合が生じたとき,ビューファインダまたは

LCD画面のカウンタ表示部分がアルファベットと数字の4桁

表示になり,3.2Hzで点滅します。この5文字の表示によっ

て対応者分類および不具合の生じたブロックの分類,不具合

の詳細コードを示します。

3 1C

対応者分類

C :お客さま自身で対応

H:販売店で対応

E :サービスエンジニア

で対応

HDR-HC3/HC3E/HC3K/HC3EK_L2

ブロック分類

対応方法の違いにより分類

例 31・・・テープを入れ直す

32・・・電源を入れ直す

1 1

詳細コード

「1-5-3.自己診断コード表」

を参照

1-6

Page 14

1-5-3.自己診断コード表

自己診断コード

対

応

者

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

ブロック

機能

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

32

32

32

32

詳細

コード

00

00

00

10

11

20

21

22

23

30

31

40

41

42

43

44

10

11

20

21

22

23

30

31

40

41

42

43

44

60

症状/状態

標準でないバッテリを使用している

結露している

ビデオヘッドが汚れている

LOAD方向,ローディング所定時間

内終了せず

UNLOAD方向,ローディング所定

時間内終了せず

UNLOAD時,Tリール側テープ弛み

UNLOAD時,Sリール側テープ弛み

Tリール異常

Sリール異常

キャプスタン起動時FG異常

キャプスタン定常時FG異常

ドラム起動時FG異常

ドラム起動時PG異常

ドラム定常時FG異常

ドラム定常時PG異常

ドラム定常時位相異常

LOAD方向,ローディング所定時間

内終了せず

UNLOAD方向,ローディング所定

時間内終了せず

UNLOAD時,Tリール側テープ弛み

UNLOAD時,Sリール側テープ弛み

Tリール異常

Sリール異常

キャプスタン起動時FG異常

キャプスタン定常時FG異常

ドラム起動時FG異常

ドラム起動時PG異常

ドラム定常時FG異常

ドラム定常時PG異常

ドラム定常時位相異常

フォーカスが合いにくい

(フォーカスの初期化ができない)

ENGLISH JAPANESE

ENGLISH JAPANESE

対応/方法

インフォリチウムバッテリを使用する

カセットを取り出して,約1時間してからもう一度入れ直す

別売のクリーニングカセットできれいにする

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

復帰しない場合,レンズブロックのフォーカスMRセンサ(LD-202

基板CN7103ql,waピン)を点検。問題がなければフォーカスモー

タドライブ回路(LD-202 基板 IC7204)を点検。

HDR-HC3/HC3E/HC3K/HC3EK_L2

1-7

Page 15

自己診断コード

対

ブロック

応

機能

者

E

61

詳細

コード

10

症状/状態

ズーム動作の異常(ズームレンズの

初期化ができない)

ENGLISH JAPANESE

ENGLISH JAPANESE

対応/方法

ズームレバーを操作した時,ズーム動作をすればレンズブ

ロックのズームMRセンサ(LD-202基板CN7103qh,qkピ

ン)を点検。ズーム動作をしなければズームモータドライブ

回路(LD-202基板IC7204)を点検。

E

61

E

62

E

62

E

91

注意:修理後は,必ず「1-6.フラッシュ異常修理後の処置」を行ってください。

11

00

01

01

フォーカスレンズ初期化異常,ズー

ムレンズ初期化異常の同時発生

手振れ補正が効きにくい

(PITCH角速度センサ出力張り付き)

手振れ補正が効きにくい

(YAW角速度センサ出力張り付き)

フラッシュの充電異常

自己診断コードC:32:60とE:61:10の両方を点検

PITCH角速度センサ(CM-071基板SE7702)周辺回路点検

YAW角速度センサ(CM-071基板SE7701)周辺回路点検

フラッシュユニットの点検または交換(注)

1-6. フラッシュ異常修理後の処置

フラッシュエラー(自己診断コードE:91:**)発生時は、高電圧による異常を防止するために自動的にフラッシュ充電・

発光禁止の設定になります。修理後は、この設定を解除する必要があります。調整用リモコン(RM-95またはNEWLANC

JIG)を接続し、下記の処置を行ってください。

順序 ページ アドレスデータ 作業内容

17 0175

27 00 01 PAUSE(Write)ボタンを押す

37 02 データが“01”になることを確認

HDR-HC3/HC3E/HC3K/HC3EK_L2

1-8E

Page 16

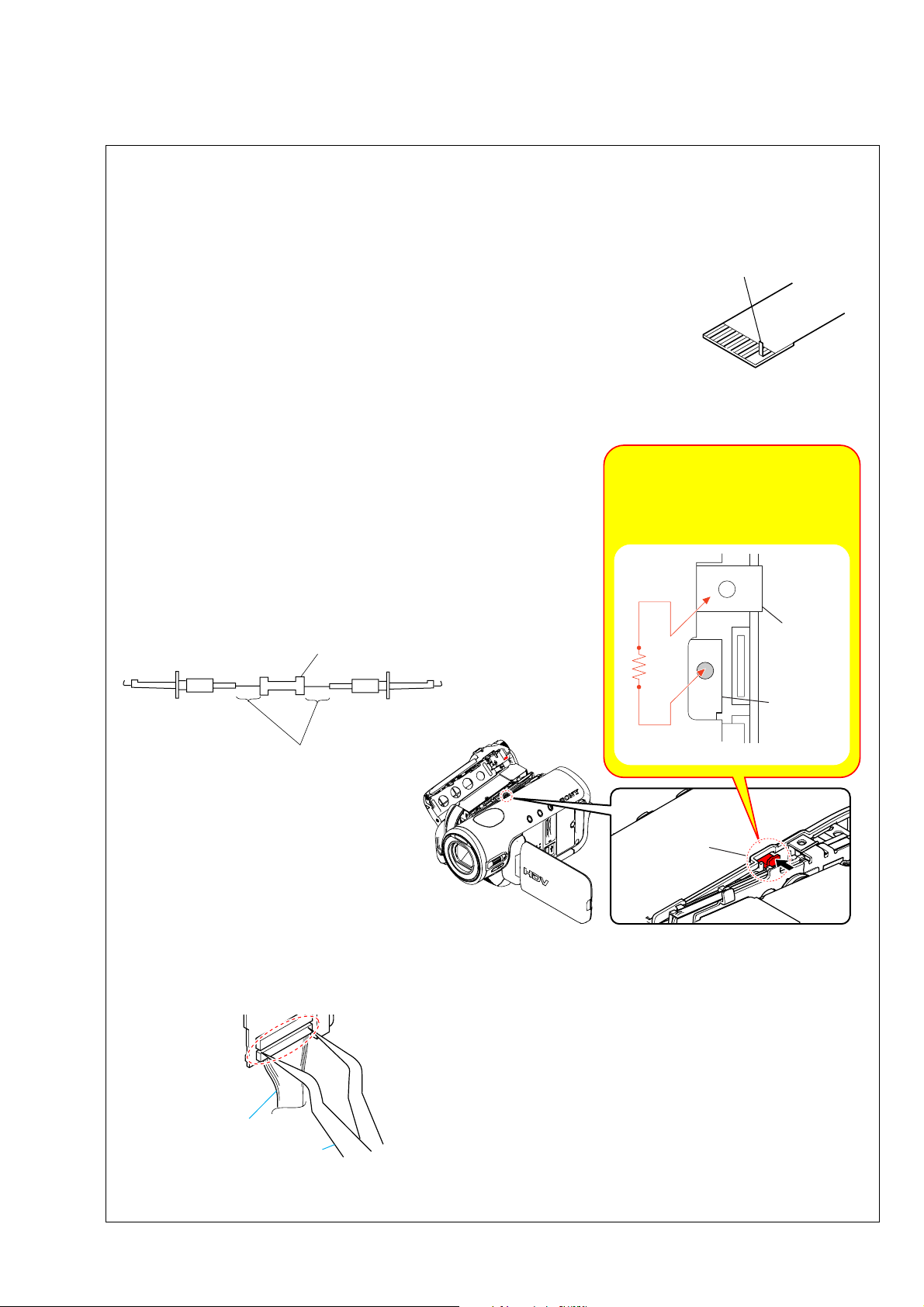

NOTE FOR REPAIR

2. DISASSEMBLY

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, dont’ pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, dont’ press down at wire of connector.

It is possible that a wire is snapped.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

DISCHARGING OF THE ST-139 BOARD’S CHARGING CAPACITOR (C901)

The charging capacitor (C901) of the ST-139 board is charged

up to the maximum 330 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by

the charged voltage which is kept without discharging when the

main power of the unit is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig, a small clip is attached to each end of

a resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to

prevent electrical shock.

1 kΩ/1 W

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points

with the short jig about 10 seconds.

Top cabinet

Wrap insulating tape.

R:1 kΩ/1 W

(Part code: 1-215-869-11)

Slide the cover.

NOTE FOR DISCONNECTING THE HARNESS (COAXIAL CABLE)

When disconnecting the harness (coaxial cable), do not pull the

harness part but pull off the connector body with tweezers etc.

Harness (coaxial cable)

Tw eezers etc.

ST-139 board

HDR-HC3/HC3E/HC3K/HC3EK_L2

2-1

Page 17

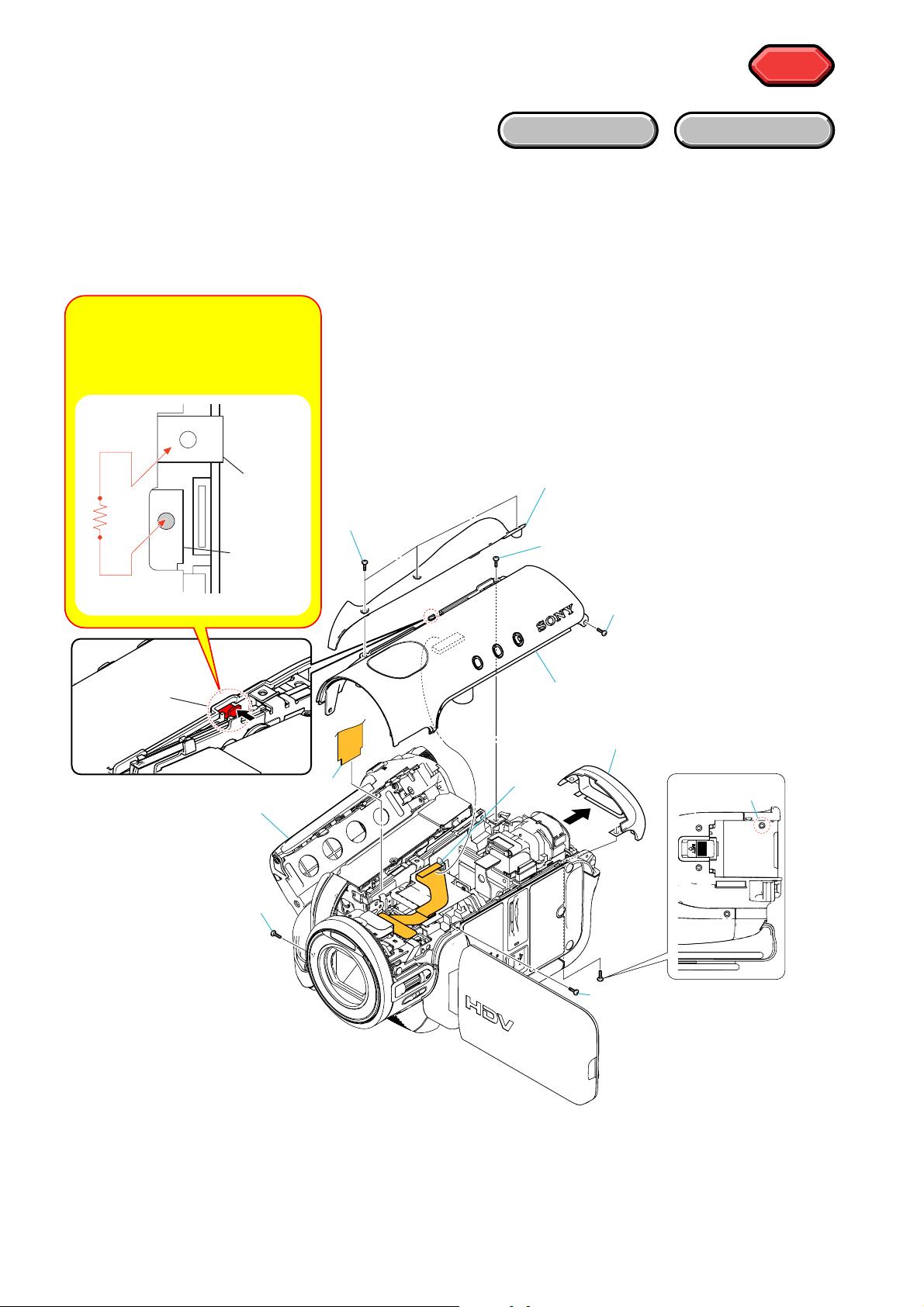

HELP

EXPLODED VIEW

HELP

2-1. DISASSEMBLY

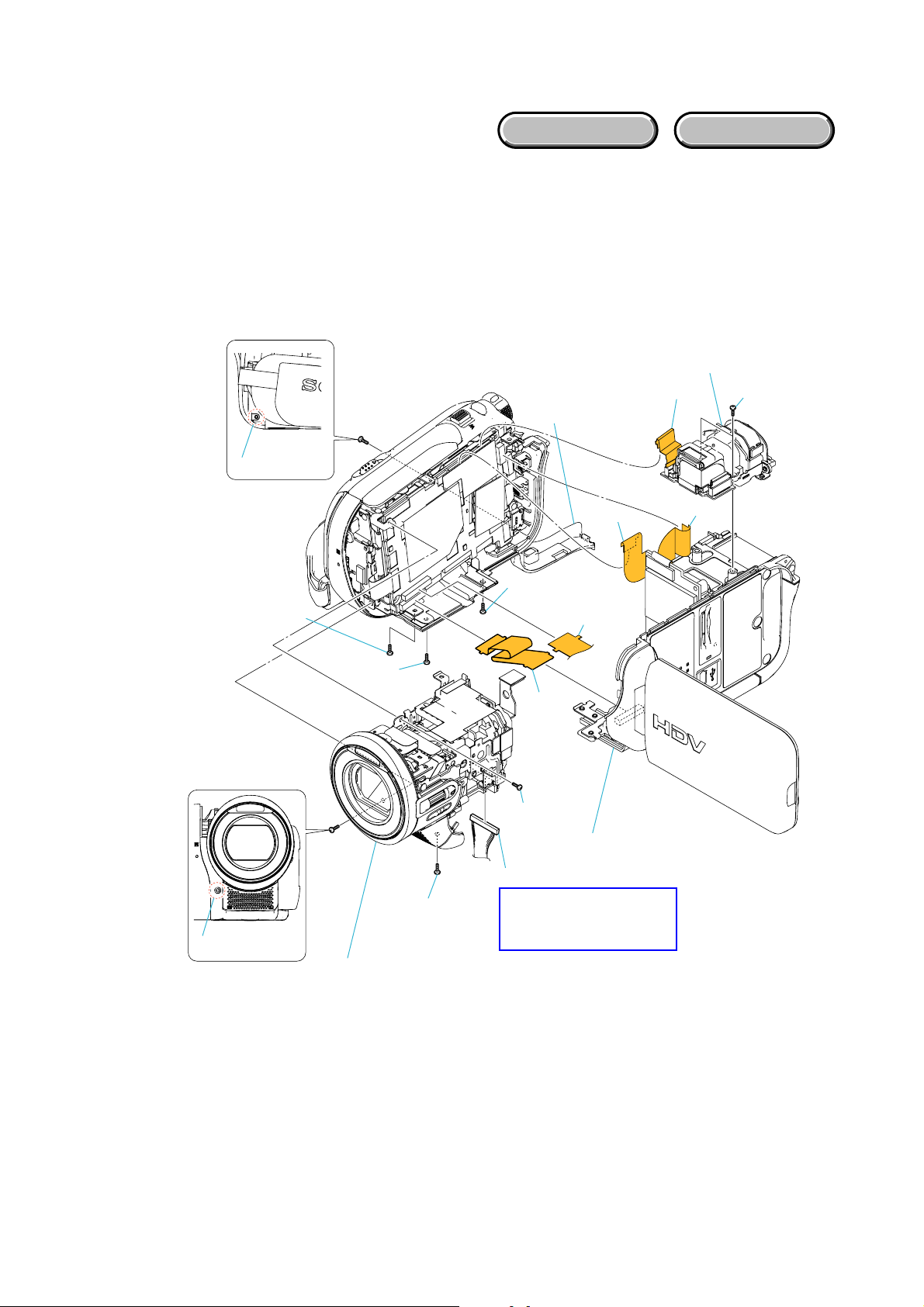

2-1-1. OVERALL ASSEMBLY-1

Follow the disassembly in the numerical order given.

1 Grip cover assy (1-1 to 1-2)

2 Top cabinet block (2-1 to 2-8)

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points

with the short jig about 10 seconds.

Top cabinet

ST-139 board

HARDWARE LIST

1 Grip Cover Assy

1-1 (#2/#10)

2-3 (#10)

R:1 kΩ/1 W

(Part code: 1-215-869-11)

Slide the cover.

1-2 (Open the cassette lid)

2-6 (#2/#10)

2-8

2-4 (#3)

2 Top Cabinet Block

2-2

2-7

2-5 (#1/#14)

2-1 (#2/#10)

HDR-HC3/HC3E/HC3K/HC3EK_L2

2-2

Page 18

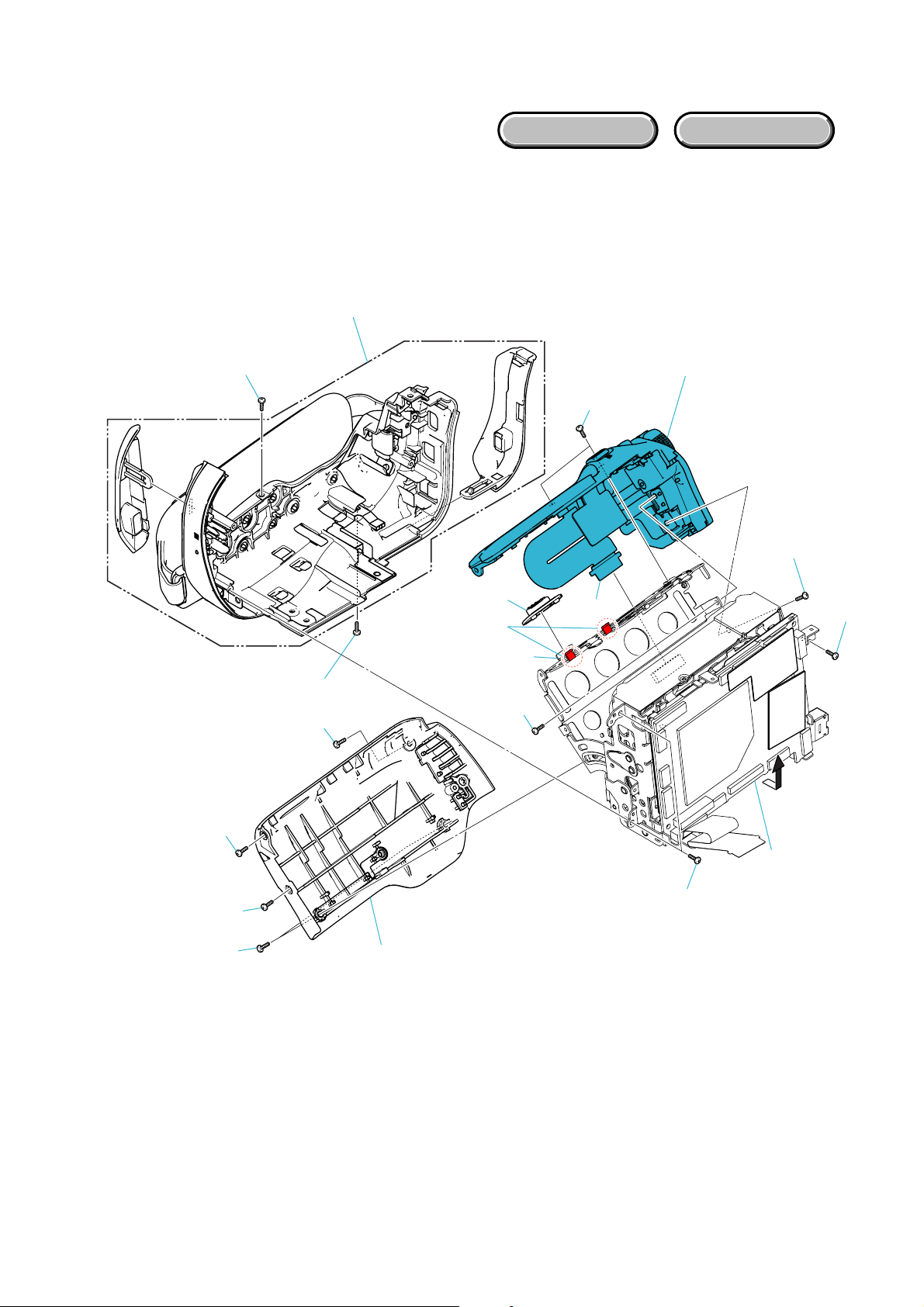

2-1-2. OVERALL ASSEMBLY-2

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 EVF block (1-1 to 1-2)

2 Cabinet (R) block (2-1 to 2-9)

3 Front panel Block (3-1 to 3-3)

HARDWARE LIST

1 EVF Block

2-4 (#9/#12)

2-7

(#1/#14)

2-6

(#2/#10)

2-3

(Open the jack cover)

2-2

2-5

(#2/#10)

3-4

2-9

3-3 (#3)

1-1

1-2 (#9)

2-1

3-2 (#2/#10)

HDR-HC3/HC3E/HC3K/HC3EK_L2

3-1

2-8

(#2/#10)

Refer to page 2-1 Note

for disconnecting the

harness (coaxial cable) .

3 Front Panel Block

2-3

2 Cabinet (R) Block

Page 19

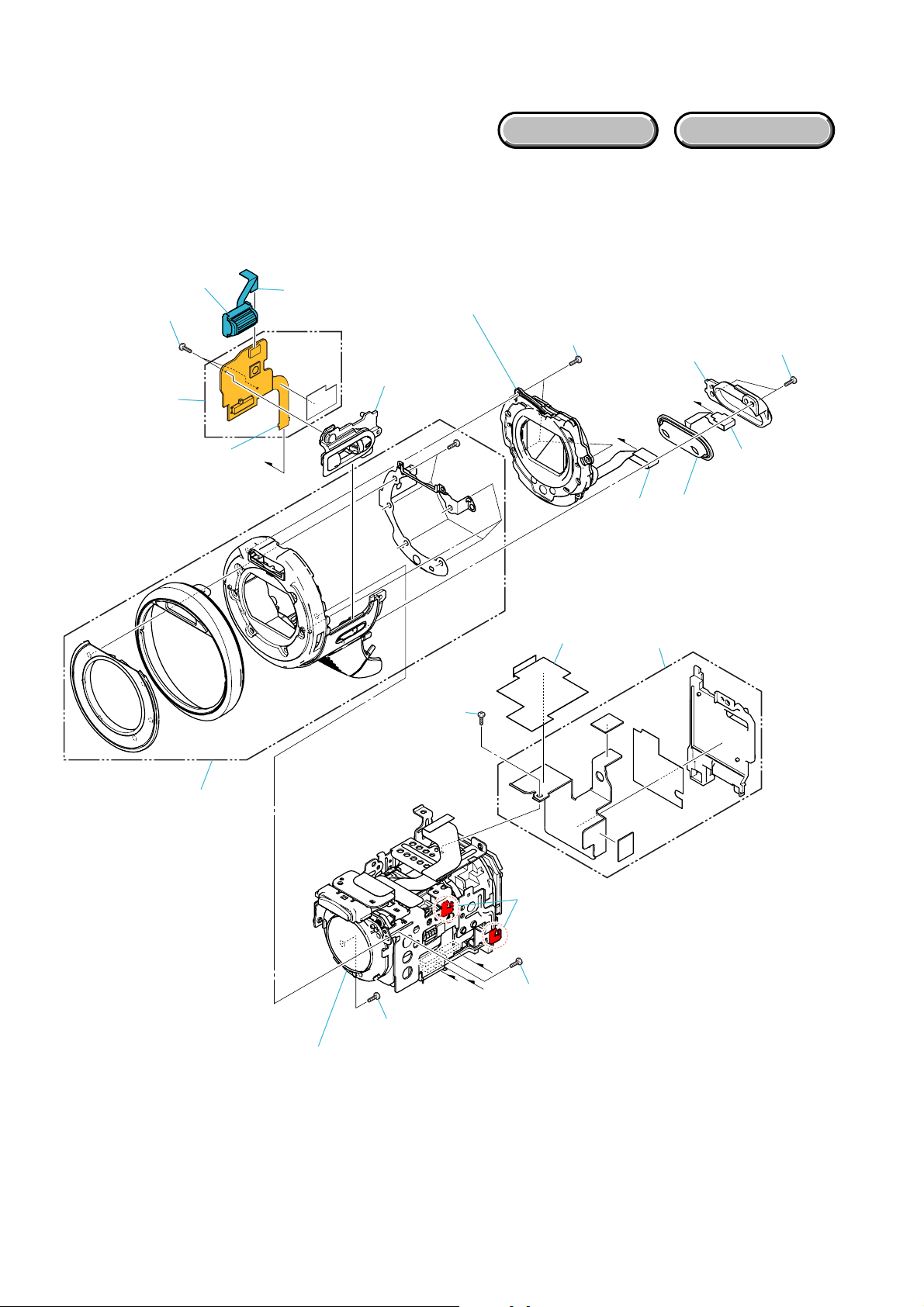

2-1-3. FRONT PANEL BLOCK

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Lens block (1-1 to 1-10)

2 Mic unit (2-1 to 2-2)

3 Motor Unit (3-1 to 3-6)

HARDWARE LIST

3-2 (#5)

3-3

3-4

1-7

C

3-1

3-5

1-2 (#3)

3 Motor Unit (Lens Barrier)

3-6 (#5)

B

1-1

2-2

A

1-6

2 Mic Unit

1-4

2-1 (#5)

1-5

1-10

1-9 (#5)

1 Lens Block

C

B

1-3 (Claw)

A

1-8 (#5)

HDR-HC3/HC3E/HC3K/HC3EK_L2

2-4

Page 20

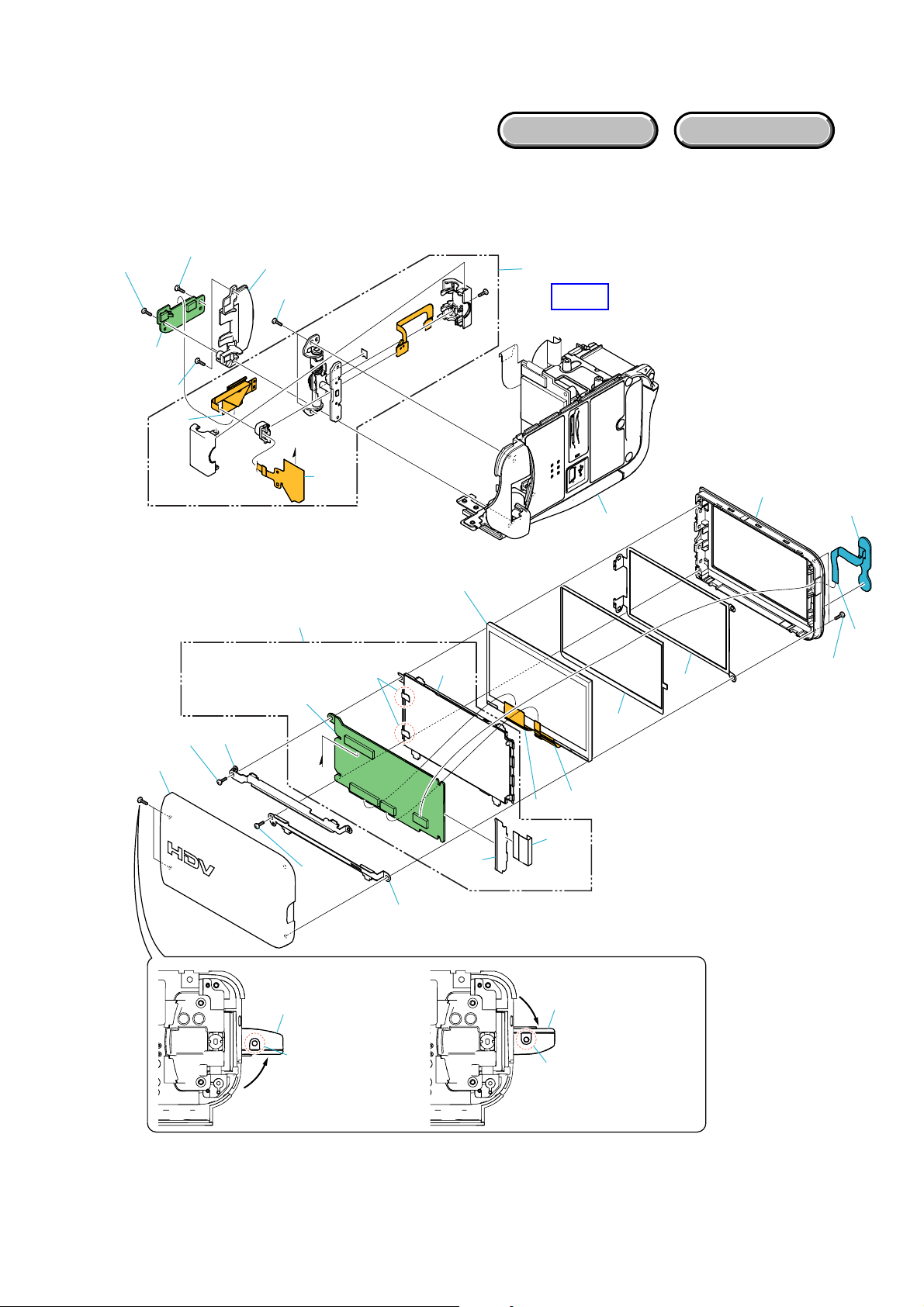

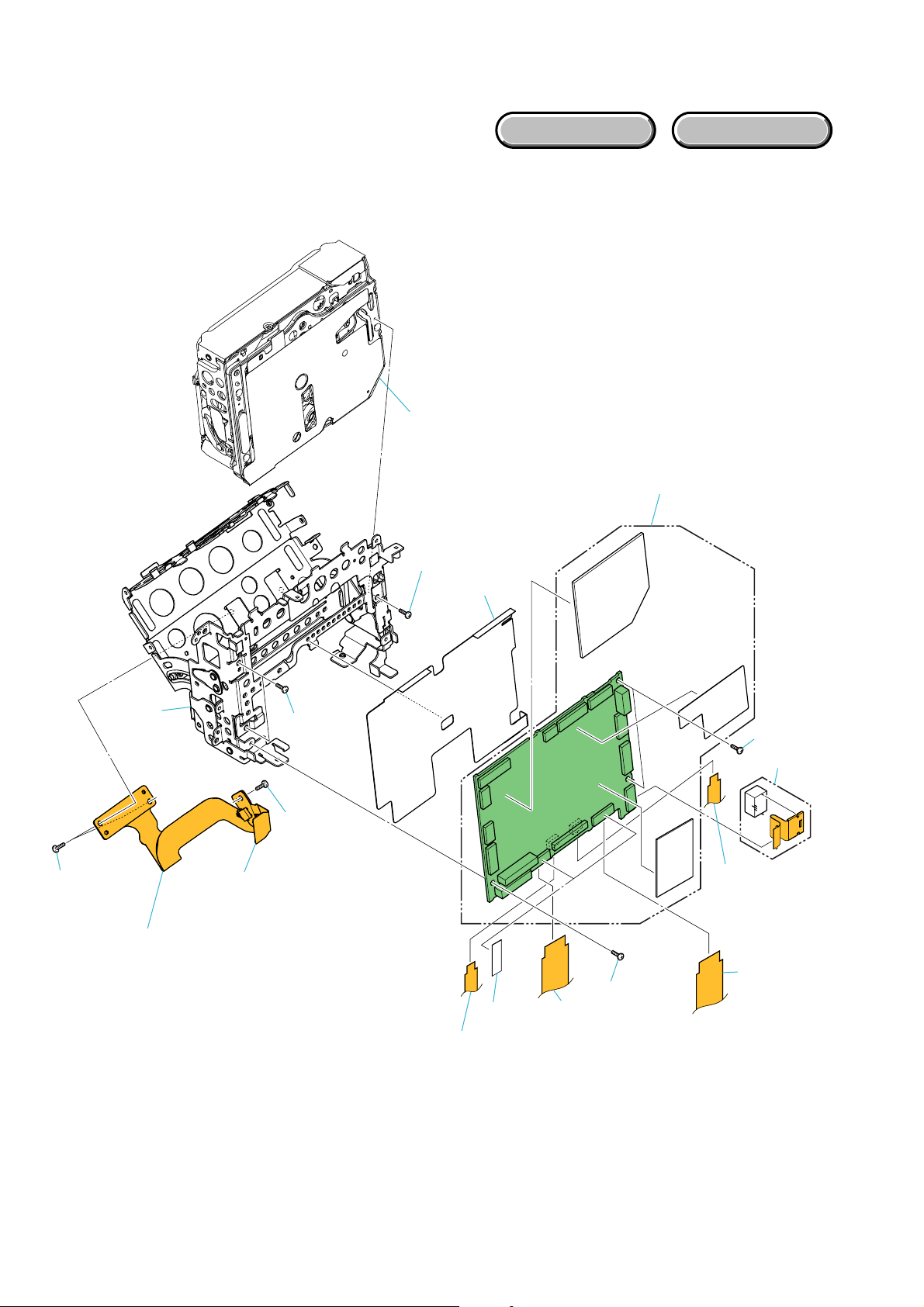

EXPLODED VIEW

PD-276

2 TP Block Assy

1 PD-276 Board

3-1

3-4

3-6

2-1

3 Hinge Block

3-3 (#5)

3-2 (#3)

3-7 (#2)

3-5 (#3)

1-1

(Turn the LCD panel)

1-2 (#2)

2-4

2-2

2-3

1-4 (#2)

1-11 (#5)

1-13

(#5)

1-5 (#12)

1-7

1-6

1-12

1-14

1-15

1-19

1-16

1-17

1-18(Claw)

1-8

1-9

1-3

(Turn the LCD panel)

1-10

3-8

HELP

Ver 1.1 2006.07

2-1-4. LCD PANEL BLOCK

Follow the disassembly in the numerical order given.

1 PD-276 board (1-1 to 1-19)

2 TP block assy (2-1 to 2-4)

3 Hinge block (3-1 to 3-8)

HARDWARE LIST

HDR-HC3/HC3E/HC3K/HC3EK_L2

2-5

Page 21

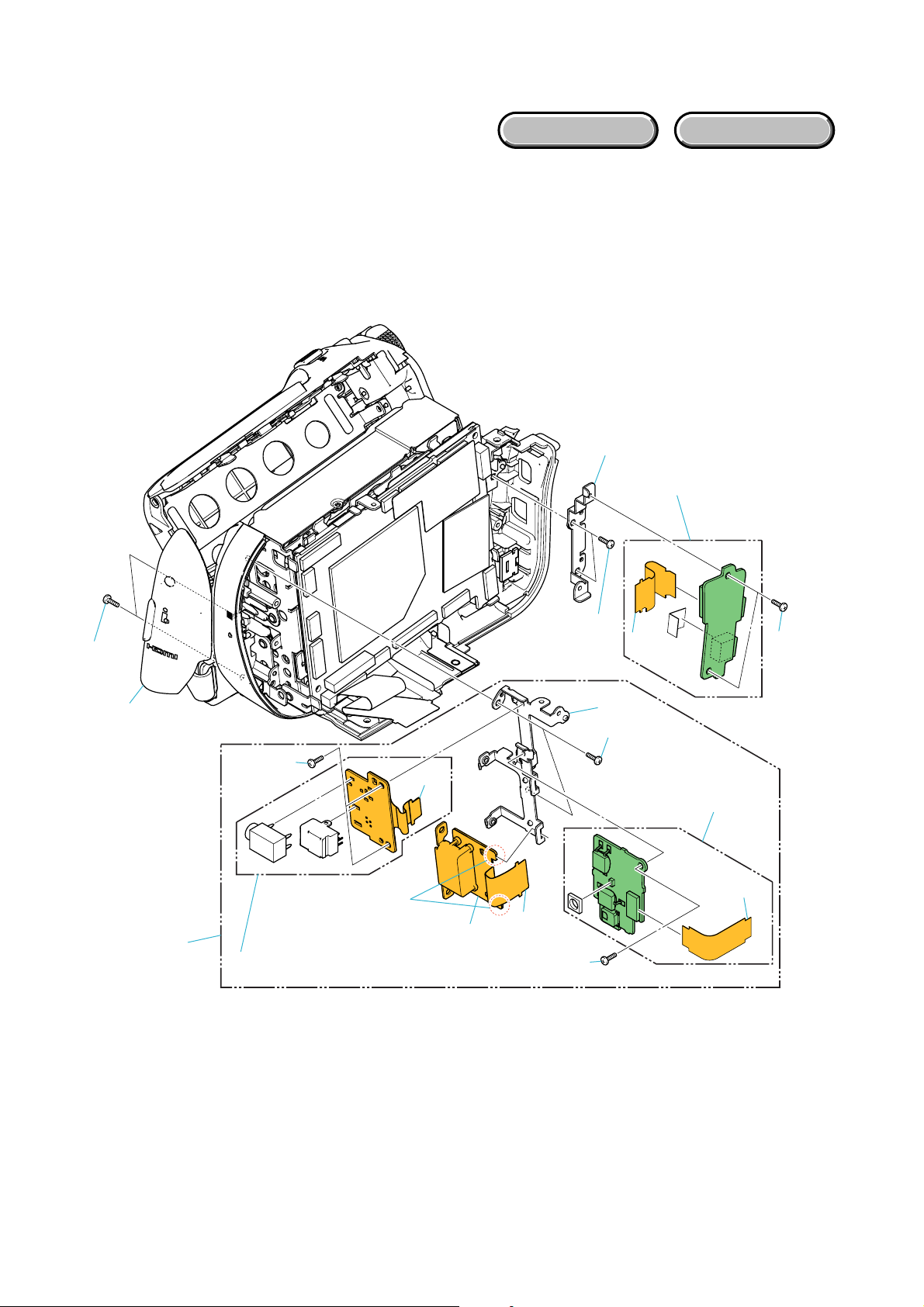

2-1-5. CABINET (L) BLOCK-1

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 FP-405 flexible board (1-1 to 1-10)

2 FP-417 flexible board (2-1 to 2-2)

3 DM-111 board (3-1 to 3-4)

HARDWARE LIST

3-4

3 DM-111 Board

1-5 (#1/#14)

1-4

(Open the jack cover.)

1-7

1-10 (#3)

1-1

2-1 (Claw)

2 FP-417 Flexible Board

1 FP-405 Flexible Board

1-3

1-8 (#3)

3-3 (#5)

2-2

1-6 (#3)

3-2

SI-046

DM-111

3-1 (#3)

1-9

1-2

HDR-HC3/HC3E/HC3K/HC3EK_L2

2-6

Page 22

2-1-6. CABINET (L) BLOCK-2

EXPLODED VIEW

2 Control Switch Block

1 Cabinet (G) Assy

2-1

2-2 (#3)

3 Cabinet (L) Assy

1-5 (#1/#14)

1-4 (#2/#10)

1-1 (#1/#14)

1-6 (#9)

2-3 (#9)

2-4 (Claw)

3-1 (#1/#14)

3-2 (#1/#14)

3-3 (#5)

3-5

(Remove in the

direction of the

arrow.)

3-4 (#5)

1-2 (#2/#10)

1-3

(Open the cassette lid.)

1-7

Follow the disassembly in the numerical order given.

1 Cabinet (G) assy (1-1 to 1-7)

2 Control switch block (2-1 to 2-4)

3 Cabinet (L) assy (3-1 to 3-5)

HARDWARE LIST

HDR-HC3/HC3E/HC3K/HC3EK_L2

2-7

Page 23

EXPLODED VIEW

2-1-7. MD FRAME BLOCK

Follow the disassembly in the numerical order given.

1 FP-418 flexible board (1-1 to 1-3)

2 VC-441 board (2-1 to 2-8)

3 Mechanism deck (3-1 to 3-4)

HARDWARE LIST

3 Mechanism Deck

2 VC-441 Board

3-2 (#15)

1-3 (#3)

3-4

1-1

3-3 (#15)

1-2 (#3)

1 FP-418 Flexible Board

3-1

2-2

2-6 (#3)

2-1

VC-441

2-7

2-4

2-5 (#3)

2-3

HDR-HC3/HC3E/HC3K/HC3EK_L2

2-8

2-8E

Page 24

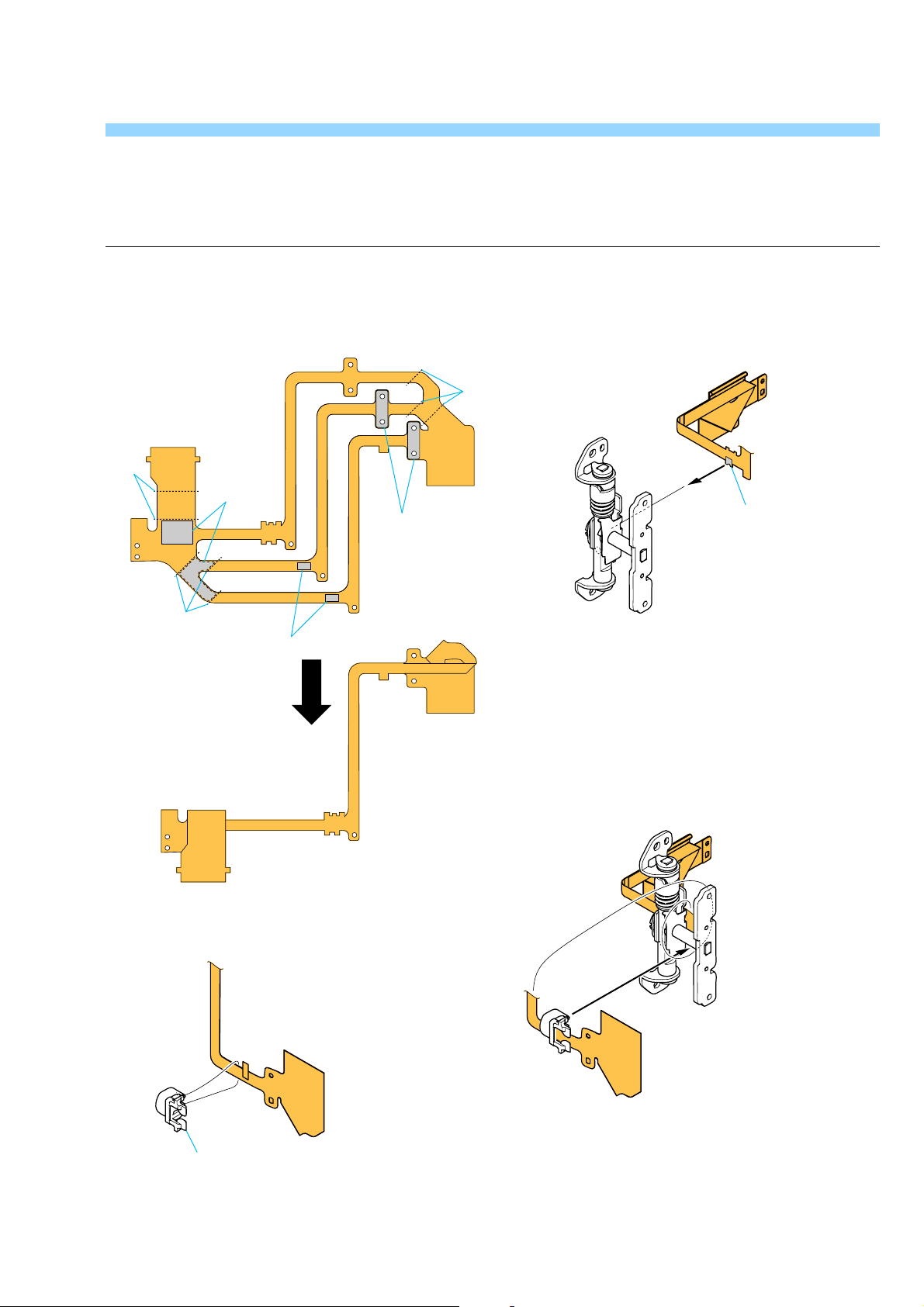

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

THE METHOD OF ATTACHMENT OF FP-412 FLEXIBLE BOARD

1 Fold dotted line parts of the FP-412 flexible board

as shown in figure.

Fold

Fold

Adhesive

tape

Adhesive tape

Adhesive tape

3 Put the FP-412 flexible board on the

hinge assy with adhesive tape.

Fold

Adhesive tape

4 Wrap the FP-412 flexible board around

the stick by 1.5 rotations, and install it

with the clamp.

2 Install the FP-412 flexible board in the

clamp, and put it with the adhesive tape.

Adhesive tape

HDR-HC3/HC3E/HC3K/HC3EK_L2

HELP

Page 25

Link

Link

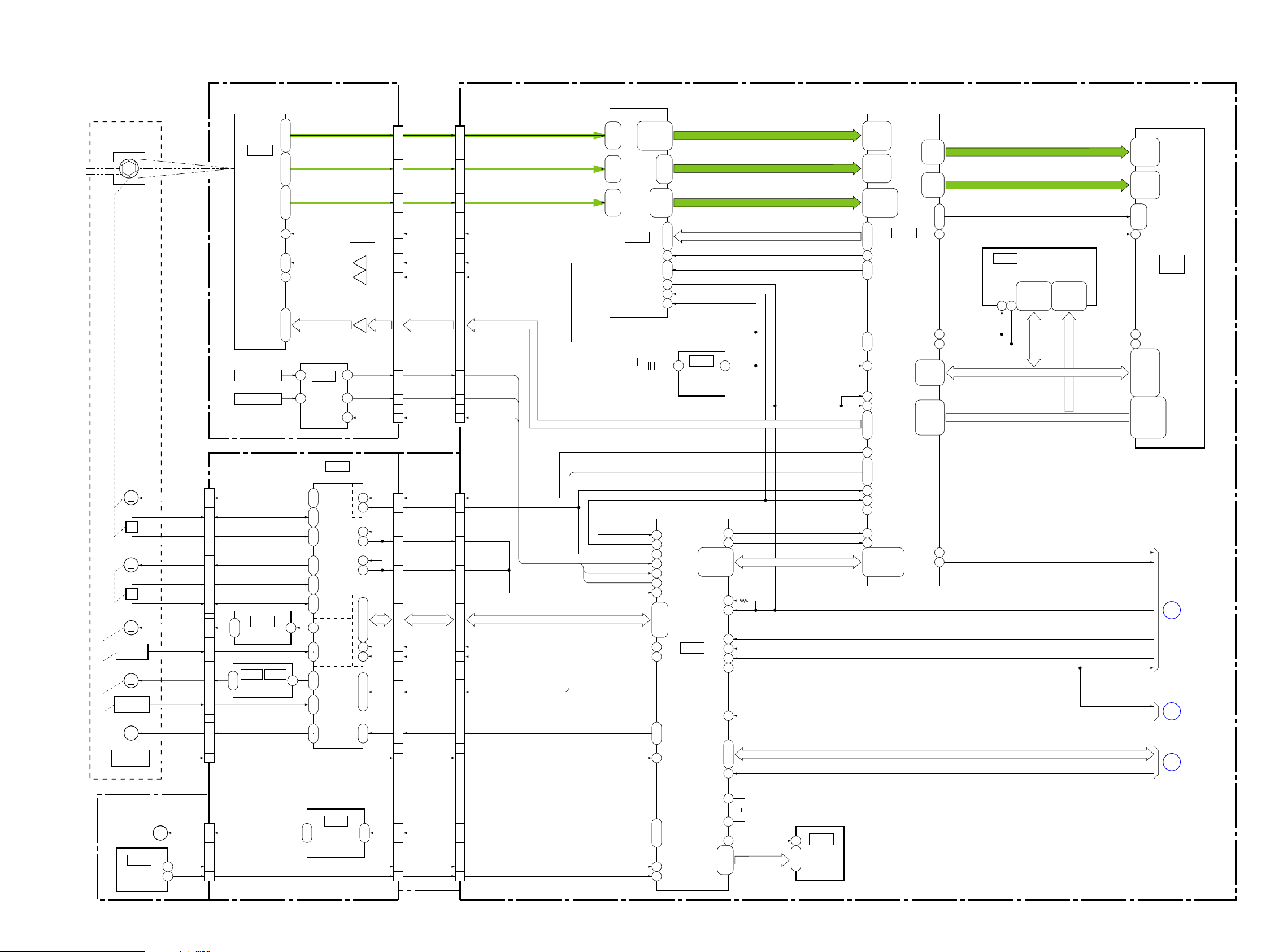

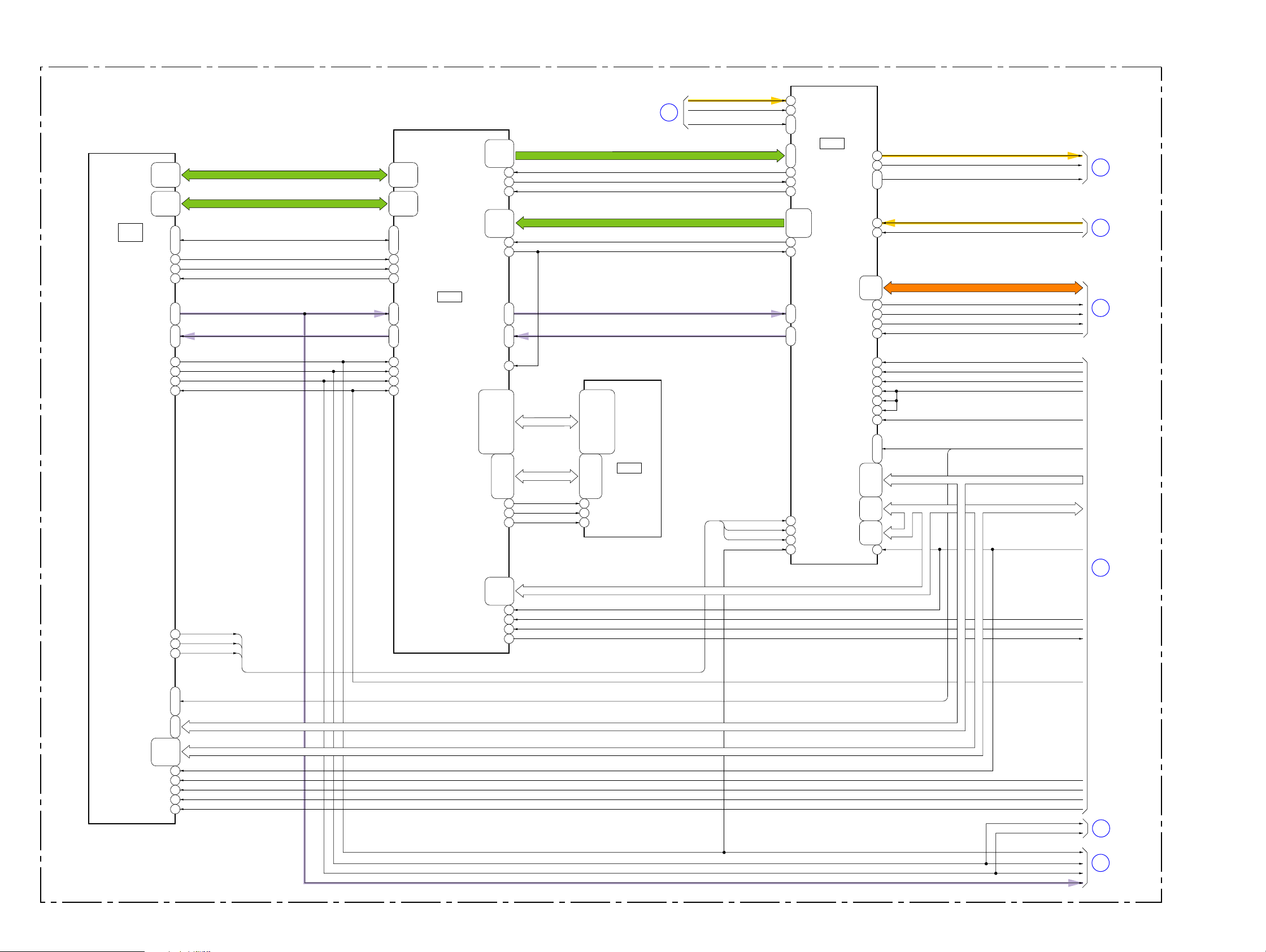

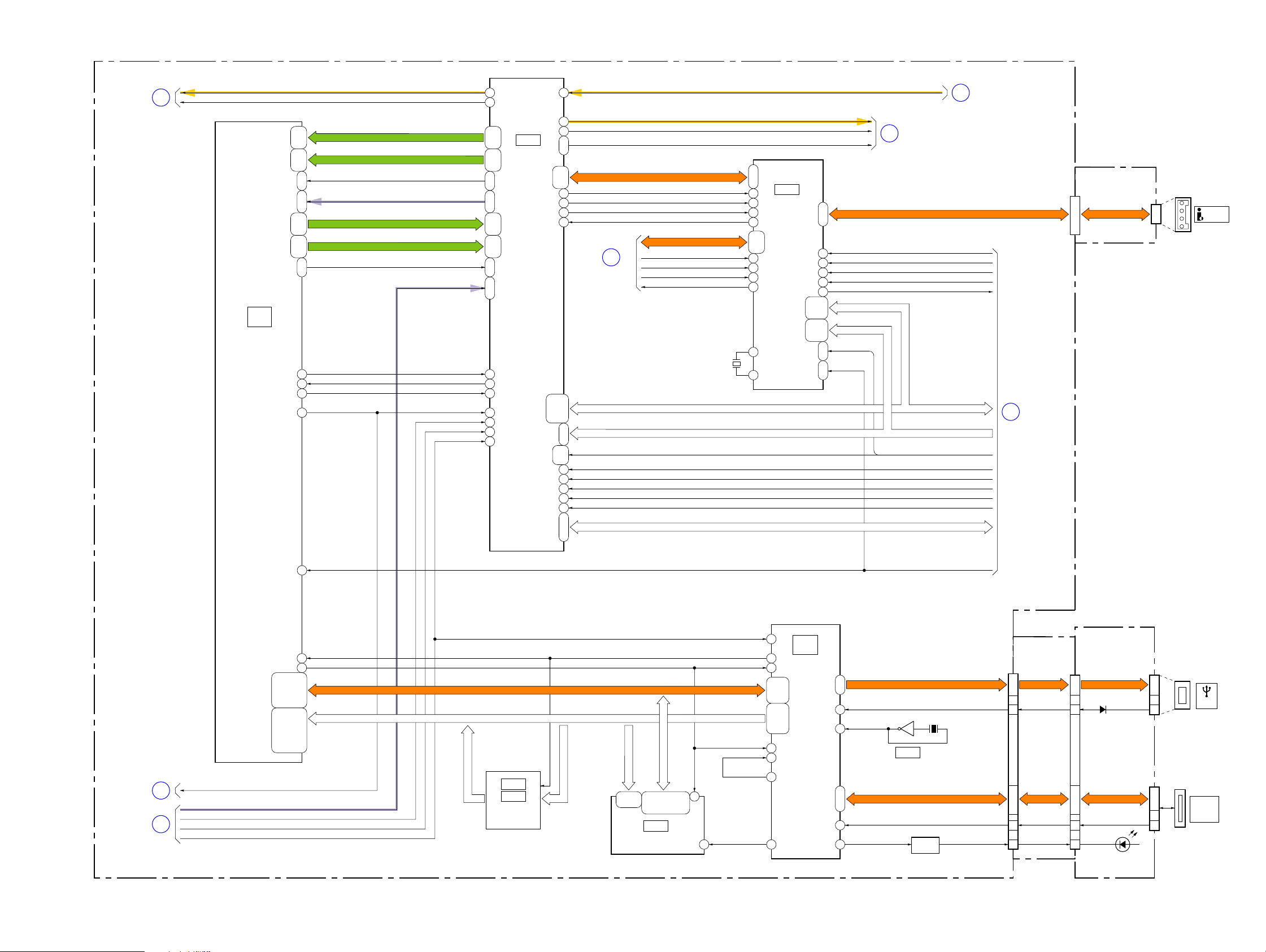

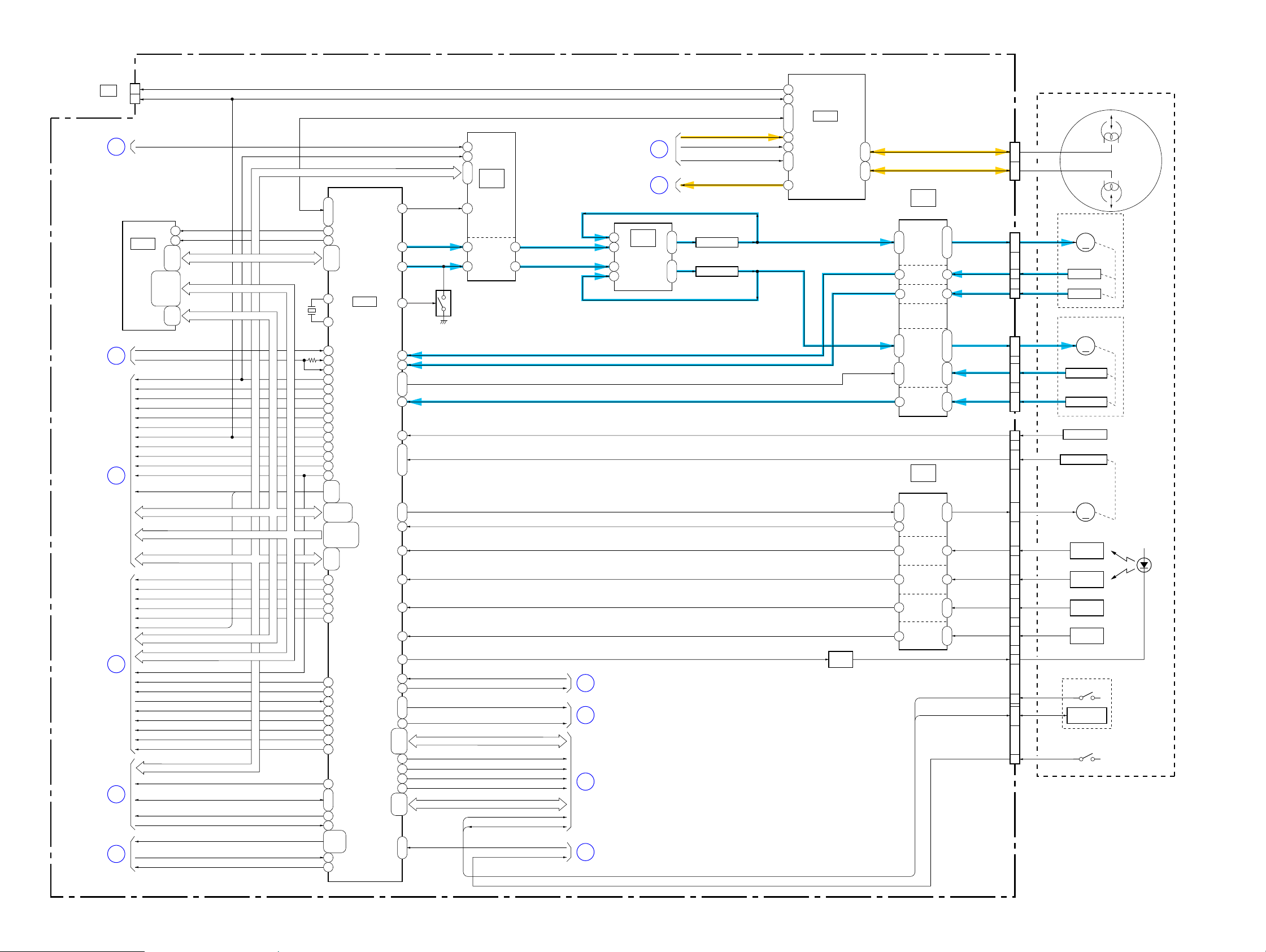

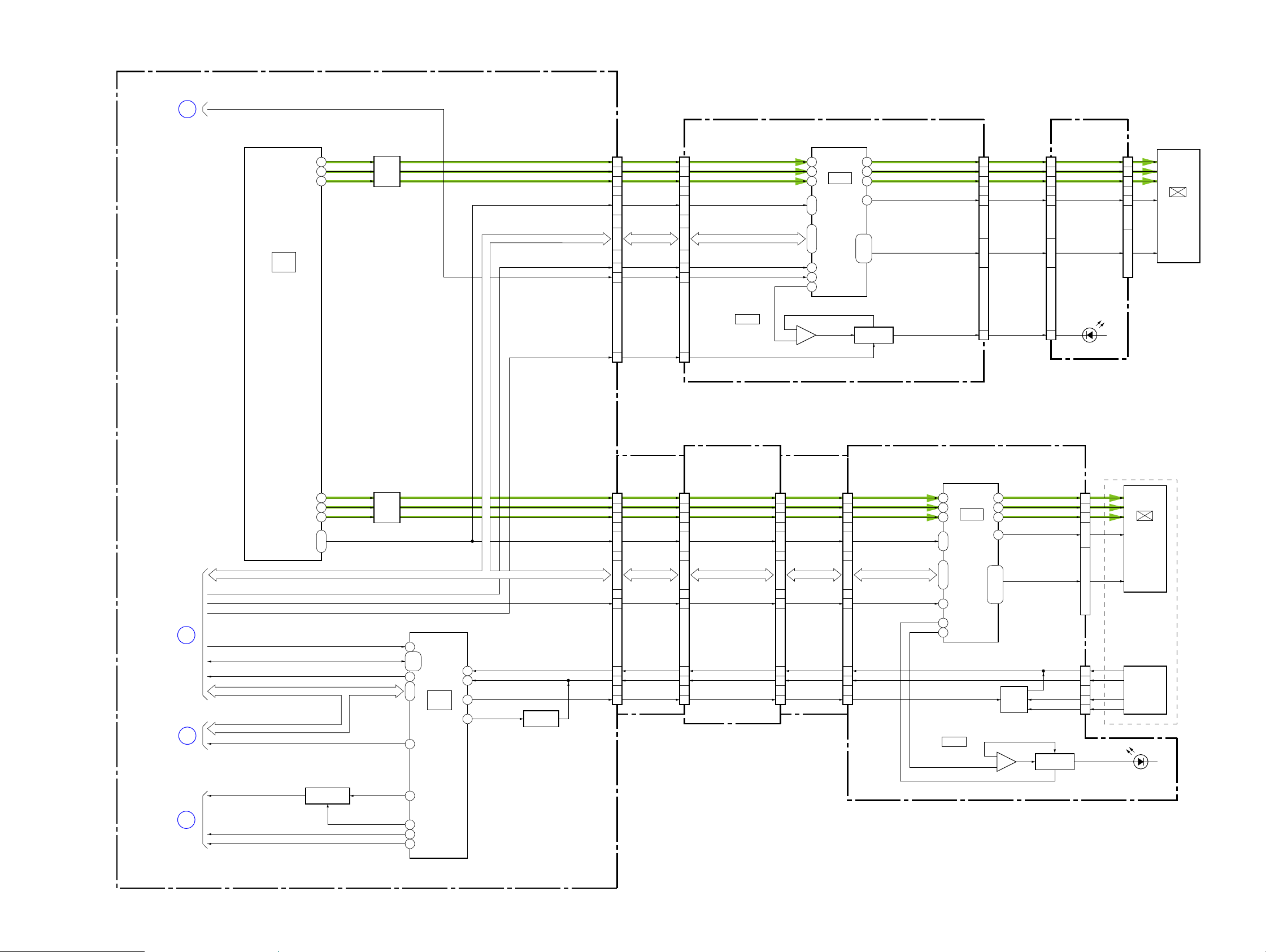

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/7)

OVERALL BLOCK DIAGRAM (2/7)

OVERALL BLOCK DIAGRAM (3/7)

OVERALL BLOCK DIAGRAM (4/7)

OVERALL BLOCK DIAGRAM (5/7)

OVERALL BLOCK DIAGRAM (6/7)

OVERALL BLOCK DIAGRAM (7/7)

POWER BLOCK DIAGRAM (1/3)

POWER BLOCK DIAGRAM (2/3)

POWER BLOCK DIAGRAM (3/3)

HDR-HC3/HC3E/HC3K/HC3EK_L2

Page 26

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/7) ( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

LENS BLOCK

(SHUTTER)

ND FILTER

METER

FOCUS

MOTOR

ZOOM

MOTOR

LENS TEMP

IRIS

IRIS

METER

M

H

M

H

M

FOCUS MR

SENSOR

M

ZOOM MR

SENSOR

NF MOTOR

M

SENSOR

I_DRIVE±

I_BIAS±

I_HALL±

ND_DRIVE±

ND_BIAS±

ND_HALL±

FOCUS ±

F_MR_A,

F_MR_B

ZOOM_A,

ZOOM_B,

Z00M_XA,

ZOOM_XB

Z_MR_A,

Z_MR_B

NF_DRIVE±

TEMP_OUT

CM-071 BOARD

IC7502

IC7501

YAW_AD

16

PITCH_AD

20

VST_C_RESET

17

K12

L12

C9

A4

A10

D10

J12

H11

CN7501

1

1, 37, 5

62

20

6, 3, 12, 5, 7

23

24

22

CN7105

(1/3)

11

22

2 44

1

K11, J11, H12, J12

18

23

K9, L9, M9, J9

L8, M8

9

DRVOUT1_RB1, DCOUT1_RB1,

DRVOUT4_GG1, DCOUT4_GG1

(1/2)

(1/2)

7, 8, 42, 419, 10, 40, 39

DRVOUT2_RB2, DCOUT2_RB2,

DRVOUT5_GG2, DCOUT5_GG2

DRVOUT3_RB3, DCOUT3_RB3,

DRVOUT6_GG3, DCOUT6_GG3

11, 12, 38, 37

23

16, 17

27

19, 18, 15

2

2

10

CHCK CHCK

TGHD_BO,

TGVD_BO

XSYS_RST_BO XSYS_RST

AHS_SO_BO,

AHS_SCK_BO,

XCS_AHS_BO

IC7701

PITCH/YAW

SENSOR

6

AMP

IC7204

(1/2)

IRIS

DRIVE,

HALL

AMP

ND

FILTER

DRIVE,

A11, A9C10, B11E12, E10

HALL

AMP

F3

FOCUS

MOTOR

DRIVE

B1, C4

ZOOM

F1, K6L6, L7 H1, J1C6, A5C5, B6K2, L2

MOTOR

DRIVE

NF MOTOR

DRIVE

IC7601

2M CMOS

IMAGER

SE7701

YAW SENSOR

SE7702

PITCH SENSOR

LD-202 BOARD (1/3) FP-409

CN7103

7, 12, 43, 514, 811, 912, 10

IC7201

7, 1

NOISE FILTER

29, 2824 - 2730 - 33 21, 1918, 16

IC7202 IC7203

7, 1

NOISE FILTER

23

26, 27

30 - 28 6 - 310 - 714 - 11

FLEXIBLE

BOARD (1/3)

19 - 21, 18

6, 727, 26 3, 5, 4

VC-441 BOARD (1/7)

CN1004

DRVOUT1_RB1, DCOUT1_RB1,

DRVOUT4_GG1, DCOUT4_GG1

DRVOUT2_RB2, DCOUT2_RB2,

DRVOUT5_GG2, DCOUT5_GG2

DRVOUT3_RB3, DCOUT3_RB3,

DRVOUT6_GG3, DCOUT6_GG3

1

26, 27

20

30 - 28 6 - 310 - 714 - 11

YAW_AD

23

PITCH_AD

24

VST_C_RESET

22

CN1019

(1/3)

PNDCK

35

CAM_VD

24

I_HALL_AD

ND_HALL_AD

45

27 - 25, 28

XCS_IC_7204

28

XRST_IC_7204

23

EN1, DIRA1, DIRB1

43, 41, 42

NF_EN, NF_SW

40, 3919, 20

LENS_TEMP_AD

37

K10, K9

J10, J9,

F10, F9

E10, E9,

B10, B9

A10, A9,

IC1301

TGHD, TGVD

YAW_AD

CAM_SI, CAM_SO, CAM_SCK, XCS_IC_7204

CDS,

CONVERTER

(1/17)

A_2.8V

80.9191 MHz : NTSC

62.3700 MHz : PAL

AHS_SO, AHS_SCK, AHS_XCS0

TG_FLD

CAM_VD_HS

PITCH_AD

VST_C_RESET

A/D

X1401

K2 - K4

J2 - J4,

D13

D7

A7

P23

P22

T2

P20

C22

B14

R22

H3, H4

F3 - F5,

G3 - G5

B2 - H2

B1 - H1,

A5 - E5

A4 - E4,

A3 - D3,

F7, E6, E7

H5

G6, F6

D6

D7

K5

1 5

AB10, C22

AB11, Y11,

N22, N20AB18, AC18

XSYS_RST

CAM_VD_HS

CHCK

IC1402

CLOCK

GENERATOR

(2/17)

IC4801

CAMERA

CONTROL

(12/17)

AD0_0 - AD0_13

AD1_0 - AD1_13

AD2_0 - AD2_13

ADC_SO, ADC_SCK, ADC_XCS0

CLPOB

ADC_TGHD, ADC_TGVD

J1

K1

AA2, Y2,

P2, P1, N4,

N2, N1, M4

V4, V2, W1,

W4, W2, Y1,

F2

F4

ZOOM_SW_AD ZOOM_SW_AD

M22

SIRCS_SIG SIRCS_SIG

A10

NTSC/XPAL_DET NTSC/XPAL_DET

A17

SYS_V SYS_V

B8

XSLOWSHUT_NR

B13

HI_SI, HI_SO, XHI_SCK

Y7, AB7, AB6

XCS_CAMERA

AC6

AHS_TGHD, AHS_TGVD

CHCK

XSYS_RST

PNDCK

EN1, DIRA1, DIRB1

CAM_VD

CAM_VD_HS

TG_FLD

XCS_IC_1401_BUS

IC_1401_BUS_CLK

D24A00_CAM - D31A07_CAM,

DXXA08_CAM - DXXA13_CAM

AA13 - AA16,

AB12 - AB16,

AC14 - AC17,

AA17 - AA20,

AB17 - AB21,

AC18 - AC21,

U22, U23,

V21 - V23,

AA21 - AA23,

G23, J22, H21

K21

K23, M24J23, L22

U1

AB4

T4

H23, K22, J21G22, E23, F21

AC11

AC7

AA6

L21

AA3

AC5

AA7 - AA9,

AB8 - AB10,

AA11, AA12,

Y13

Y17

Y21 - Y23

W21 - W23,

IC1401

CAMERA

SIGNAL

PROCESSOR

(2/17)

Y10, Y12

AC13, Y8,

AC8, AC9,

E2, E1,

C3 - C1

D3 - D1,

H1,

F3 - F1

G4 - G1,

H4 - H2

A3

A10

C20, D17

C17, C18,

A16 - A21,

B17 - B22,

A11 - A15,

D12, D13, D15

B12, B13, B15,

C12, C13, C15,

F23

H22

HDI_Y0 - HDI_Y7

HDI_C0 - HDI_C7

HDI_HD, HDI_VD, HDI_OE

IC1601

128M SDRAM

(2/17)

A8, B9, B8, C9,

C8, D9, D8, E9,

E1, D2, D1, C2,

G9

F2

C1, B2, B1, A2

SD_CK

SD_XCS

SD_DQ0 - SD_DQ15

SD_A0 - AD_A11, SD_BA0, SD_BA1

VCK

H7, H8, J8, J7,

J3, J2, H3 - H1,

G3, H9, G2, G7,

G8

HI_SI, HI_SO, XHI_SCK

U1R1

AE23

V22

STROBE_ON

EXT_STROBE_ON

XSYS_RSTXSYS_RST

SYS_V

XSLOWSHUT_NR

XCS_CAMERA

Y19, AD22,

AE20, W19,

AA22, AD23

AC19, AE21,

Y17, AC17,

Y18, AD20,

AB18, AC18

AD19, W18,

AC22

AE22, AC20,

IC1801

(1/5)

BASE BAND

SIGNAL

PROCESSOR

(3/17)

R19, T22, T24, T25,

R22, R23, P24, N19

T20, V25, U25, U23,

T23, P19, R20, N24,

Y25, U20

Y24, W22, U19,

AC25, V19, V20,

W20, AB25, Y23,

AB23, AD24, AB24,

1

2

3

OVERALL (7/7)

(PAGE 3-7)

OVERALL (4/7)

(PAGE 3-4)

OVERALL (5/7)

(PAGE 3-5)

MOTOR UNIT

(LENS BARRIER)

M001

LENS COVER

MOTOR

LENS COVER

OPEN/CLOSE

05

IC001

SENSOR

MM

2

3

HDR-HC3/HC3E/HC3K/HC3EK_L2

CN7102

COVER_DRIVE+,

COVER_DRIVE- LENS_COVER_DIR_PWM, LENS_COVER_DRV_ON

1, 8

COVER_CLOSE

6

COVER_OPEN

5

IC7301

LENS COVER

MOTOR DRIVE

F3, F2

(1/2)

C6, B6

24

25

LENS_COVER_CLOSE

22

LENS_COVER_OPEN

21

D5

B5

3-1

C1

D1

XCS_EEP_C

F1

AB13,

EEP_SI_C,

AB14, AC14,

EEP_SO_C,

EEP_SCK_C

X4801

20MHz

IC4803

1

128k EEPROM

(12/17)

2, 5, 6

A : VIDEO SIGNAL

Page 27

3-2. OVERALL BLOCK DIAGRAM (2/7)

VC-441 BOARD (2/7)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

IC1801

(2/5)

BASE BAND

SIGNAL

PROCESSOR

(3/17)

B17, F17,

C18, F18,

A19, G17,

C21, C20,

B19, D19,

B20, D20,

B24

D23

B21

K1

P25

M25

Y16

F8

D9

G9

A20, C19

C22, G20

A22, D21, B22

ADATAIN0, ADATAIN1

L19, K24

AUIN21, AUIN22

P23, M24

CK27MFO1

IC_1801_PCRERR

IC_1801_SRCH

IC_1801_FLD27MF

IC_2202_YO0 - IC_2202_YO7

HDV REC/PB, HDV-i.LINK

IC_2202_CO0 - IC_2202_CO7

TRN_HD, TRN_VD, TRN_FLD

CKFSO

CK64FSO

MCLK

TRN_VF_SYNC

CKTRNO

CKTRNI

E24, E21,

D23, E23,

D18, C24,

B23, D17,

E14 - E16

E18

F24

A22

M23, M21N23, N211

A20

P21

M24

P24

C23, D21

D20, D24,

A21, B18

B21, B20,

IC2202

HDV-MPEG VIDEO

ENCODER/DECODER,

MPEG AUDIO

SIGNAL PROCESSOR

(4/17)

Y13, AC13,

AD15, AC16

AA14, AC14,

AA15, AC15,

AD12

AD16

AD17

AD19, AC20

AA19, AC19,

AD21, AA21,

AD20, AA18,

AA17

AD22

AA16, Y17AC17, AC18

AD18

BMDT16 - BMDT47

AD6, AC4, AD5, AC5, AD4,

F1, H2, E2, D2, F2, G2, D7,

A4, B5, A5, B7, B6, D8, A6,

AA5, AD3, AB2, Y8, W2, Y9,

U2, AA2, W1, V2, V1, G1, H1,

OMAD00 – OMAD12,

OMADB0, OMADB1

P2, P1, N1, L5, M4

T1, U1, T2, R4, R2,

R1, P5, N5, N2, M2,

OMCEX

J1

OMCLK

L1

OMCLKX

K1 G3

D24A00_SIM - D31A07_SIM

R23, R24

T20, T21,

T23, T24,

R20, R21,

ALE_SIM

N24

XCS_IC_2202

M20

XRST_IC_2202

D16

INT_IC_2202

P20

OVERALL (3/7)

(PAGE 3-3)

HDV REC, HDV-i.LINK

EBS[0] - EBS[7]

HDV PB, HDV-i.LINK

BS[0] - BS[7]

DJCLK

AUDAI, AUENI

AUDAO, AUENO

C3, B2, B3, A2

P3, R2, A8, B7, B8, C7, C8,

D7, D8, E7, E3, D2, D3, C2,

L7, L3, M2, M3, N2, N3, P2,

R8, P7, P8, N7, N8, M7, M8,

IC2501

256M SDRAM

(4/17)

K3, J1, J2, J3, H1,

J8, J9, K7, K9, K1,

J7, H2, H3, H8, H9

H7

G2

KCLK

ERDY

ERE

BSEN

4

CRECDT

CRECCK

CRECA1, CRECA2

IC_1801_PCRERR

IC_1801_SRCH

IC_1801_FLD27MF

CK27MFO1

DV REC

73

74

76, 77

297 - 304

296

316

321

11 13 14

27

10

276, 277279, 281

3

5

7

1

HDV STREAM

PROCESSOR,

MUX/DEMUX

22 23

17 18 21

IC2801

(5/17)

80

82

84, 85

71

72

193

197

-

187,

195,

189

185

200

201

199

203

225

240

40

230

348

232

FRRV, TRRT, DRP

235, 229, 228

DXXA00_SIM - DXXA10_SIM

205, 207

204,

248, 249, 251,

241, 243 - 246,

224

219,

214,

D24A00_SIM - D31A07_SIM

-

-

213,

222

217

256, 257,

259, 260,

263 - 266

203

HDV REC, DV REC

HDV PB

HDV-i.LINK

FRRV, TRRT, TRRV, DRP

DXXA00_SIM - DXXA10_SIM

D24A00_SIM - D31A07_SIM

RECDT

RECCK

RECA1, RECA2

VITDT

VITCK

PD10 - PD17

PCLK1

DIR1

XPEN1

XPACC1

XCS_IC_2801

SCWIN_IC_2801

XCS_IC_2801_2

XRST_IC_2801_0

XRST_IC_2801_1

ALE_SIM

XCS_IC_2202

XRST_IC_2202

INT_IC_2202

OVERALL (4/7)

5

OVERALL (3/7)

6

OVERALL (3/7)

7

OVERALL (4/7)

8

(PAGE 3-4)

(PAGE 3-3)

(PAGE 3-3)

(PAGE 3-4)

FRRV, TRRV, DRP

W17, W16, N20

DXXA08_SIM, DXXA09_SIM

W13, AD13

D24A00_SIM - D31A07_SIM

Y14, AD15,

W14, AB13,

AE13, AD14

AD16, AB14,

Y15

AC14

AE15

AB16

AC15

ALE_SIM

SD_OSD_VD

VREF

IC_1801_OEREF

XCS_IC_1801_SIM

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : VIDEO/AUDIO SIGNAL

A : VIDEO/AUDIO/SERVO SIGNAL

05

HDR-HC3/HC3E/HC3K/HC3EK_L2

3-2

MCLK

SD_OSD_VD

VREF

IC_1801_OEREF

XCS_IC_1801_SIM

CKFSO

CK64FSO

CK27MFO1

CKFSO

CK64FSO

ADATAIN0, ADATAIN1

9

10

OVERALL (6/7)

(PAGE 3-6)

OVERALL (3/7)

(PAGE 3-3)

Page 28

3-3. OVERALL BLOCK DIAGRAM (3/7)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-441 BOARD (3/7)

OVERALL (2/7)

(PAGE 3-2)

6

VITDT

VITCK

HDV PB

IC1801

(3/5)

BASE BAND

SIGNAL

PROCESSOR

(3/17)

L2, M7

L4, K7,

N2, M1

M2, M3,

K2, L3

M20, L20

P6, R2

P2, N1,

T2, R4

P1, P4,

N3, P3

R1

ADATAOUT0, ADATAOUT1

FLAT_SYNC_FYO0

VLAT_SYNC_FCI

VLAT_IN_FYO1

RYI0 - RYI3

DV PB

RCI0 - RCI3

HYI, HCI

RYO0 - RYO3

DV REC

RCO0 - RCO3

HYO, HCO

ADATAIN0, ADATAIN1

CK13MFO1

CK27MFO1

CK64FSO

CKFSO

86

30

13, 72,

123, 166,

12, 75

167, 126

119, 162,

70, 121,

164, 165

168, 127

18B9

76A9

77F9

143

15

21

78

14, 73

DV SIGNAL

PROCESSOR

124, 125

120, 163

71, 122

IC3001

(6/17)

RFIN

139

CRECDT

45

CRECCK

41

CRECA1, CRECA12

48, 47

DV-i.LINK

7

LBUS0 - LBUS3

TRCKO

DIR

XENA

XACC

PCLK1

DIR1

XPEN1

XPACC1

150, 187

149, 186,

104

51

106

151

OVERALL (2/7)

(PAGE 3-2)

D24A00_SIM - D31A07_SIM

190, 109

54, 107, 152,

189, 55, 153,

155, 192

FRRV, TRRT, TRRV, DRP

112, 59

58, 111,

ALE_SIM ALE_SIM

57

CS_IC_3001_BUS

188

XCS_IC_3001

158

XRST_IC_3001

62

SWP

60

HDV PB, DV PB

HDV-i.LINK

PD10 - PD17

24.576MHz

DV REC

X3401

104

109

94

93

87

91

76

75

149

150

95 - 98

81 - 85

77 - 79,

IC3401

HDV/DV

i.LINK

INTERFACE

(8/17)

CRECDT

CRECCK

CRECA1, CRECA2

139 - 136

5

50

43

88

106

73, 74

65 - 67

69 - 71,

58, 59,

61 - 64

51 - 56,

FRRV, TRRT

105,10814, 151

RFIN

OVERALL (2/7)

4

(PAGE 3-2)

HDV-i.LINK, DV-i.LINK

TPA+, TPA-, TPB+, TPB-

D24A00_SIM - D31A07_SIM

DXXA00_SIM - DXXA11_SIM

D24A00_SIM - D31A07_SIM

DXXA00_SIM - DXXA11_SIMDXXA08_SIM, DXXA09_SIM

FRRV, TRRT, TRRV, DRP

OVERALL (4/7)

12

IC_3401_PLL_ON

XCS_IC_3401

XIC_3401_INT

FR1

OFR2

CS_IC_3001_BUS

XCS_IC_3001

XRST_IC_3001

SWP

(PAGE 3-4)

13

CN1003

OVERALL (4/7)

(PAGE 3-4)

(1/2)

10, 11, 8, 7

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : VIDEO/AUDIO SIGNAL

A : VIDEO/AUDIO/SERVO SIGNAL

FP-405 FLEXIBLE

BOARD (1/2)

TPA, NTPA, TPB, NTPB

CN801

1 - 4

HDV/DV

05

OVERALL (4/7)

(PAGE 3-4)

OVERALL (2/7)

(PAGE 3-2)

11

10

CK13MFO1

ADATAIN0, ADATAIN1

CK27MFO1

CK64FSO

CKFSO

XRST_VTR

D17

AE3

DSCK_VM

AD10

AA2, Y3, Y1,

T7, U6, T4, T6

AB3, AC2, W4,

AD2, AE2, AC1,

AA4, AC3, AD3,

A1_VM - A12_VM, A13_VM_LO, A14_VM, A15_VM, A16_VM_LO, A17_VM - A19_VM

AC6, AC5, AD4

W8, AC6, Y7, AE4,

AE8, Y10, Y9, AD8,

AC8, AC7, AB8, W9,

AE6, AD7, AB6, AE5,

IC1802

A13_VM_LO, A16_VM_LO

IC1803

DATA SELECTOR

(3/17)

VSP_SI, VSP_SO, XVSP_SCK

157, 114, 3

A13_VM, A14_VM

A13_VM, A16_VM

A1_VM - A11_VM,

20 - 26,

29 - 35

D0_VM - D15_VM

2, 4, 5, 7, 8, 10,

11, 13, 42, 44, 45,

47, 48, 50, 51, 53

IC4402

16M SDRAM

(11/17)

XCS_IC_1801_VMXCS_IC_1801_VM

D0_VM - D15_VMD0_VM - D15_VM

A1_VM - A19_VM

38

XCS_SDRAM_VM

19

CKFSO

DSCK_VM

DSCK_VM

XCS_FLASH

124

74

122

16 - 18,

21 - 24,

279 - 286,

289 - 292,

309

307

69

71

IC4001

(1/3)

DS CONTROL,

FLASH

(11/17)

27 - 35

1 - 4, 7 - 9

VSP_SI, VSP_SO, XVSP_SCK

185, 186

USB_DET

168

USB_CLK

177

81, 85, 78

80

MS_LED_ON XACCESS_LED

277

USB_D±

24

IC4004

OSC DRIVE

(11/17)

MS_DIO, MS_BS, MS_SCLK

XMS_INSERT

Q4011

LED

DRIVER

XRST_VTR

X4003

48MHz

CN1016

(1/3)

18, 17

16 9

10, 12, 4

8 17

23 2

FP-416

FLEXIBLE

BOARD (1/3)

MS-304 BOARD

(1/3)

CN8006

(1/3)

7, 8

D8001

DIO, BS, SCLK

15, 13, 21

D8003

(MS ACCESS)

CN8003

D±

VCC

CN8005

INS

1

6

3, 2

4, 2, 8

(USB)

MEMORY

STICK

DUO

HDR-HC3/HC3E/HC3K/HC3EK_L2

3-3

Page 29

3-4. OVERALL BLOCK DIAGRAM (4/7)

VC-441 BOARD (4/7)

CN1009

RF_MON

1

(FOR CHECK)

OVERALL (3/7)

(PAGE 3-3)

OVERALL (7/7)

(PAGE 3-7)

OVERALL (3/7)

(PAGE 3-3)

OVERALL (2/7)

(PAGE 3-2)

OVERALL (6/7)

(PAGE 3-6)

OVERALL (6/7)

(PAGE 3-6)

CPC

11

14

13

15

16

SWP

2

F1

B4

FLASH_A15 - FLASH_A20

B2, C3, D4

C6, D6, E6,

DXXA00_SIM - DXXA14_SIM

D5, B6, A6

A2, B5, A5, C5,

G6, E1, D1, C1,

A1, B1, D2, C2,

D24A00_SIM - D31A07_SIM

H2 - H5

E2 - E5,

NTSC/XPAL_DET

XSYS_RST

XRST_VTR

IC_3401_PLL_ON

XCS_IC_3401

XIC_3401_INT

FR1

OFR2

SWP

CS_IC_3001_BUS

XCS_IC_3001

XRST_IC_3001

ALE_SIM

FRRV, TRRT, TRRV, DRP

D24A00_SIM - D31A07_SIM

DXXA00_SIM - DXXA11_SIM

VSP_SI, VSP_SO, XVSP_SCK

XCS_IC_2801

SCWIN_IC_2801

XCS_IC_2801_2

XRST_IC_2801_0

XRST_IC_2801_1

FRRV, TRRT, TRRV, DRP

D24A00_SIM - D31A07_SIM

DXXA00_SIM - DXXA10_SIM

ALE_SIM

XCS_IC_2202

XRST_IC_2202

INT_IC_2202

MCLK

SD_OSD_VD

VREF

IC_1801_OEREF

XCS_IC_1801_SIM

VSP_SI, VSP_SO, XVSP_SCK

XCS_IC_5800

HDMI_SDA, HDMI_SCL

XRST_HDMI

INT_HDMI

XLINE_CNT1A, XLINE_CNT1B, XLINE_CNT2,

XLINE_CNT3A, XLINE_CNT3B

XD4CN

XPSV_D4

8

IC2601

16M FLASH

(13/17)

XRST_VTR

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

RF_MON

SWP

CONT1, SW_PS, ALL_PSCONT1, SW_PS, ALL_PS

HDV REC, DV REC

RECDT

RECCK

5

RECA1, RECA2

HDV PB, DV PB

RFIN

Q1107, Q1109

SWITCHING

C15, B15A13, A14

SWITCHING

Q1108, Q1110

XCS_FLASH

XRST_FLASH

X5201

20MHz

A18, B5, A5

H2

Y16

AB5, Y5, AB4,

AB3, AC3, AB2

D1

C1

B4

F2

F4

Y18

F23

J2

E20

D22

D9

B21

M1

B2

G2

K4

A16, A21

B18, D15,

Y1, V4,

W4, W2,

AA2, Y2,

T4, T2, U1,

U4, U2, V1,

R4, R2, P2,

AC7

AC8, AB8,

H4

D18

G1

D13

B13

J1

E22

A6

K1

B8

B7

Y8

G4

AB10

D10, B10

Y15

D5

N20

P20, F20,

P22, P23,

R22

N23

IC5203

MECHA

CONTROL

(13/17)

V2, W1

P1, N4, N2,

N1, M4, M2

CK13MFO1CK13MFO1

XRST_VTR

VSP_SO, XVSP_SCK

XCS_IC_5401

AB9

DRUM_PWM

Y14

CAP_PWM

AC15

XFFREW_UP

AC13

A9

B9

CAP_FWD, CAP_ON

D19, B20

D11

DEW_DET

V23

MODE_SW_A - MODE_SW_C

AB22

-

AB20

LOAD, UNLOAD

D16, A17

LM_LIM_DET LM_LIM_DET

L22

TAPE_END

AB11

TAPE_TOP

Y11

TREEL_FG

B11

SREEL_FG

A11

TAPE_LED_ON

B15

D14

V22

AB17, Y17

AC17

Y12

Y13, AC12,

D6

D8

K22

AC6

AB6

Y7, AB7,

Y22, Y23

35

34

IC5401

38, 36

(3/3)

(14/17)

SERIAL

37

INTERFACE

44

LPF

41

Q5401

VD_SI, VD_SO, XVD_SCK

HI_SI, HI_SO, XHI_SCK

CHIME_SDA, CHIME_SCK

HOTSHOE_ID1, HOTSHOE_ID2

DRUM_ERROR

45

CAP_ERROR

43

DRUM_FG

DRUM_PG

CAP_FG

SYS_V

XSLOWSHUT_NR

XPWAD, XPWDA

XCS_IC_3601

XCS_EVF

XCS_LCD

EVF_OUT_EN

XCS_IC_5203

REC_PROOF

XCC_DOWN

2

17

18

19

OVERALL (2/7)

(PAGE 3-2)

OVERALL (3/7)

(PAGE 3-3)

E15

C14

B12

PWM DRIVE

A11

OVERALL (1/7)

(PAGE 3-1)

OVERALL (6/7)

(PAGE 3-6)

OVERALL (5/7)

(PAGE 3-5)

OVERALL (7/7)

(PAGE 3-7)

IC1103

(1/2)

DRUM/

CAPSTAN

(16/17)

12

30

38

39, 37, 45

46

44

40, 42

35

IC3201

REC/PB AMP

(7/17)

DRUM_VS

10, 93, 4

DRUM_FG

DRUM_PG

CAP_VS

CAP_FWD, CAP_ON

CAP_FG

LOAD, UNLOAD

TAPE_END

TAPE_TOP

TREEL_FG

SREEL_FG

Q5403

LED

DRIVE

IC5401

(1/3)

(14/17)

DRUM

MOTOR

64, 67

DRIVE

FG AMP

53

PG AMP

50

CAPSTAN

75, 771, 80

MOTOR

DRIVE

FG AMP

4

MODE_SW_A - MODE_SW_C

IC5401

(2/3)

(14/17)

LOADING

MOTOR

32, 33

DRIVE

31

TAPE END

21 20

DETECT

TAPE TOP

19

DETECT

T REEL

29

FG AMP

S REEL

25

FG AMP

CHIME_SDA, CHIME_SCL

XODD, YODD

XEVEN, YEVEN

DRUM_U, V, W

63, 65, 6874, 76, 78

52

49

CAP U, V, W

10 - 157, 8

FG1, FG2

DEW_DET

69, 7226, 2722, 23

TAPE_END_C

TAPE_TOP_C

18

T_REEL ±

S_REEL ±

TAPE_LED_K

REC_PROOF

XCC_DOWN

FG

PG

UHE±,

VHE±,

WHE±

LM ±

CN3201

CN5402

CN5403

CN5401

N MECHA DECK

(MDX-N110)

VIDEO HEAD

6, 52, 3

M901

DRUM MOTOR

1 - 6

10

9

20 - 92 - 77 - 91 - 420, 1922, 2313, 14 27, 24

6

M

DRUM FG

DRUM PG

M903

CAPSTAN MOTOR

M

HU, HV, HW

CAPSTAN FG

DEW SENSOR

S902

MODE SWITCH

M902

LOADING MOTOR

M

Q901

28

16

25

11

18

TAPE END

SENSOR

Q902

TAPE TOP

SENSOR

H902

T REEL

SENSOR

H901

S REEL

SENSOR

MIC902

REC PROOF

4PIN

CONNECTOR

S903

CC DOWN

A : VIDEO/AUDIO/SERVO SIGNAL

A : SERVO SIGNAL

ODD

EVEN

TAPE LED

D901

05

HDR-HC3/HC3E/HC3K/HC3EK_L2

3-4

Page 30

3-5. OVERALL BLOCK DIAGRAM (5/7)

VC-441 BOARD (5/7)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

OVERALL (7/7)

(PAGE 3-7)

20

XSYS_RST

IC1801

(4/5)

BASE BAND

SIGNAL

PROCESSOR,

D/A CONVERTER

(3/17)

K22

F24

J20

Q2004 - Q2006

BUFFER

EVRE

EVGR

EVBL

CN1007

EVRE

EVGR

EVBL

VD_SI, VD_SO, XVD_SCK

XCS_EVF

XSYS_RST

9

7

5

10

16

17

14, 15

11 - 13

VF-175 BOARD LB-119 BOARD

CN8101

9

7

5

14, 15

11 - 13

10

16

17

EVRE

EVGR

EVBL

EP_XHD, EP_XVDEP_XHD, EP_XVD

VD_SI, VD_SO, XVD_SCK

XCS_EVF

XSYS_RST

IC8102

EVF BACKLIGHT

CONTROL

EVF_BL_ONEVF_BL_ON

EXTDA

CN8102

EVF_VR

EVF_VG

EVF_VB

EVF_COM

LED_K

15

16

14

18

3 - 13, 17

20

IC8101

20

21

22

26

EVF_HST, EVF_HCK2, EVF_HCK1,

EVF_RGT, EVF_DWN, EVF_REF,

EVF_STB, EVF_VST, EVF_VCK,

EVF_EN, EVF_PCG, EVF_PSIG

16, 30, 24

5 - 12, 14,

Q8102

BACKLIGHT

DRIVE

34

33

32

EVF DRIVE

42, 45, 44 48, 1

43

3

31

2

–

1

3

+

CN6501

6

5

7

3

18 - 8, 4

(EVF BACKLIGHT)

1

D6501

CN6502

18

19

17

21

5 - 8, 10 - 16, 20

LCD902

COLOR

EVF

UNIT

OVERALL (4/7)

(PAGE 3-4)

OVERALL (1/7)

(PAGE 3-1)

18

3

XCS_EVF

EVF_OUT_EN

REC_PROOF

CHIME_SDA, CHIME_SCK

XCS_IC_5203

HI_SI, HI_SO, XHI_SCK

HI_SI, HI_SO, XHI_SCK

XCS_CAMERA

BEEP

K25

J25

L22

B16, C17

Q4007, Q4009

MODULATOR

Q2001 - Q2003

BUFFER

EP_XHD, EP_XVD EP_XHD, EP_XVD

MELODY

PLRE

PLGR

PLBL

231

135, 136,

234

97 - 99

230

227

243, 244

IC4001

(2/3)

HI CONTROL

(11/17)

137

138

245

246

TP_SEL2

VD_SI, VD_SO, XVD_SCKVD_SI, VD_SO, XVD_SCK

Q4010

TP SELECT

SWITCH

CN1020

PLRE

PLGR

PLBL

XCS_LCDXCS_LCD

TP_X

TP_Y

TP_SEL1

(1/2)

FP-411

FLEXIBLE

BOARD (1/2)

23

25

24

20, 16

12, 11, 9

10

5

7

6

CK-159 BOARD (1/2) PD-276 BOARD (1/2)

FP-412

CN6701

(1/2)

4

2

3

17

22

20

21

PLRE

PLGR

PLBL

EP_XHD, EP_XVD

7, 11

VD_SI, VD_SO, XVD_SCK

15, 16, 18

XCS_LCD

TP_SEL1

TP_X

TP_Y

CN6703

(1/2)

FLEXIBLE

BOARD (1/2)

3

1

2

6, 10

14, 15, 17

16

21

19

20

CN6101

(1/2)

22

24

23

9

4

6

5

PLRE

PLGR

PLBL

EP_XHD, EP_XVD

19, 15

VD_SI, VD_SO, XVD_SCK

11, 10, 8

XCS_LCD

TP_X

TP_Y

TP_SEL1

PWM

EXTDA

LCD BACKLIGHT

34

33

32

LCD DRIVE

42, 45, 44 48, 1

43

31

18

IC6101

CONTROL

IC6102

20

21

22

26

RGT, PSIG, HCK1, HCK2,

REF, HST, PCG, XSTBY,

DWN, EN, VCK, VST

5 - 12,

14, 16, 28, 24

TOUCH

PANEL

I/F

Q6101, Q6102

2

–

1

3

+

CN6104

COM

CN6102

TP_TOP

TP_L

TP_R

TP_BOT

Q6104 - Q6107

BACKLIGHT

DRIVE

R

4

G

5

B

3

1, 23, 242, 6 - 8, 11 - 14, 19 - 22

5

2

1

4

LCD901

2.7 inch

WIDE

COLOR

LCD

UNIT

TOUCH

PANEL

D6105 - D6107

(LCD BACKLIGHT)

05

OVERALL (6/7)

(PAGE 3-6)

21

HDR-HC3/HC3E/HC3K/HC3EK_L2

ZOOM_MIC_CONT

SUB/INT_CTRL

MELODY_ENV

249

154

260

A : VIDEO SIGNAL

3-5

Page 31

3-6. OVERALL BLOCK DIAGRAM (6/7)

VC-441 BOARD (6/7)

HM_Y0 - HM_Y7

G1, J6

J1, K6,

H1, J7,

H4, H2,

HM_R0 - HM_R7

C1, E3

D3, F3,

E4, D2,

G6, C3,

HM_B0 - HM_B7

E2, F4

G4, F2,

H6, E1,

H7, G2,

HM_HD, HM_VD

C2, D5

IC_1801_ADAO2

N25

IC_1801_ADAO1

M19

CK_HM

J3

CK74MFO

J2

CK256FSO

C24

IC1801

(5/5)

BASE BAND

SIGNAL

PROCESSOR,

DOWN

CONVERTER

(3/17)

H23

G22

E25

Q2007 - Q2009

BUFFER

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

OVERALL (4/7)

(PAGE 3-4)

VSP_SI, VSP_SO, XVSP_SCK

XCS_IC_5800

15

HDMI_SDA, HDMI_SCL

XRST_HDMI

INT_HDMI

LINE_OUT_Y

LINE_OUT_C/PB

HM_Y0 - HM_Y7

HM_R0 - HM_R7

HM_B0 - HM_B7

HM_HD, HM_VD

IC_1801_ADAO2

IC_1801_ADAO1

VSP_SO, XVSP_SCK

23, 24

10

7

CK_HM

CK74MFO

CK256FSO

CK64FSO

CKFSO

88

3

90

B12 - B9,

D12, C12,

D1, C1,

B4 - B2,

A8 - A5

B8 - B5,

C7, C6

E9

PROCESSOOR

C11

E1

G1

D10

E10

E11

D3, D2, F2

C2

LNOY

LNOPB

LNOPR

S_Y_I/O

S_C_I/O

VIDEO_I/O

A10, A9

A4 - A2

IC5800

HDMI

SIGNAL

(9/17)

DE_HDMI, D0_HDMI - D23_HDMI

K2, K12

L1 - L11,

M3 - M11

J1, J12, K1,

HSYNC_HDMI, VSYNC_HDMI

J9, K10G9, G10

ADAO1_HDMI, ADAO2_HDMI

F12

H12

G11

F10

OVERALL (4/7)

(PAGE 3-4)

16

IDCK

256FS_HDMI

64FS_HDMI

HDMI_SDA, HDMI_SCL

XRST_HDMI

INT_HDMI

XLINE_CNT1A, XLINE_CNT1B,

XLINE_CNT2,

XLINE_CNT3A, XLINE_CNT3B

XD4CN

XPSV_D4

65 - 61, 58 - 49

80 - 75, 70 - 67,

IC6000

1, 2

HDMI

TRANSMITTER

10, 9

(9/17)

66

6

12

44, 43

42

17

2

4

6

44

18

IC2001

COMPONENT

OUT AMP,

D-TERMINAL

DRIVER

(3/17)

1, 48 - 45

TMDS DATA0± - TMDS DATA2±

30, 29, 33, 32, 36, 35

27, 2619, 20

18

35

33

31

43 - 41

40

TMDS CLOCK±

IC6001

(9/17)

2

4

1

Q6000

LEVEL

SHIFT

LINE_CNT1 - LINE_CNT3

D_3.3V

SDA, SCL

D3_LNO_Y

D3_LNO_PB

D3_LNO_PR

D3_CN

S_Y_I/O

S_C_I/O

VIDEO_I/O

CN6000

CN1011

FP-417 FLEXIBLE BOARD

TMDS DATA0± - TMDS DATA2±

12, 11, 15, 14, 18, 17

9, 8

2

5, 6

25

21

23

5 - 7

8

19

17

15

TMDS CLOCK±

HPD

SDA, SCL

FP-415 FLEXIBLE

BOARD

CN3511

DM-111 BOARD

CN8304

3

7

5

CTRL1 - CTRL3

23 - 21

20

9

11

VIDEO_I/O

13

7, 9, 4, 6, 1, 310, 1216, 15

19

S_Y_I/O

S_C_I/O

PB

PR

SW

CN8302

Y

CN8303

HDMI

OUT

1

3

5

COMPONENT

6 - 8

10

10

5

9

OUT

MIC901

MICROPHONE

UNIT

L

R

OVERALL (5/7)

(PAGE 3-5)

OVERALL (4/7)

(PAGE 3-4)

LD-202 BOARD (2/3)

CN7101

INT_MIC_L

3

INT_MIC_R

6

05

P22

M22

21

17

CN901

(1/2)

HOT SHOE

(1/2)

IC7101

MIC PRE AMP

2

–

3

+

5

+

6

–

OVERALL (2/7)

(PAGE 3-2)

BEEP

ZOOM_MIC_CONT

SUB/INT_CTRL

XPWAD, XPWDA

XCS_IC_3601

FP-410 FLEXIBLE

BOARD (1/2)

3

2

CN7105

(2/3)

1

7

9

AUIN11

KASYAON

MIC_FL

MIC_FR

LANC_SIG

FP-409

FLEXIBLE

BOARD

(2/3)

42

44

CKFSO

CK64FSO

17

16

2412

4

2

CN1006

(1/2)

CN1019

(2/3)

SHOE_MIC_FL

SHOE_MIC_FR

INT_MIC_PREOUT_L

INT_MIC_PREOUT_R

9

11

10

12

8