Sony HCD-RG55 Schematic

HCD-RG55/RG55S

SERVICE MANUAL

Ver 1.0 2002. 05

• HCD-RG55/RG55S is the tuner,

deck, CD and amplifier section in

MHC-RG55/RG55S.

CD

section CDM58FS-K6A

Tape deck

Section Tape Transport Mechanism Type

AEP Model

UK Model

HCD-RG55S

E Model

Australian Model

HCD-RG55

Model Name Using Similar Mechanism NEW

CD Mechanism Type

Optical Pick-up Name KSM-213DCP

Model Name Using Similar Machanism NEW

CDM58F-K6A

RG55: CWL43RR51

RG55S: CWL43FR50

Amplifier section

European model:

HCD-RG55S

Front speaker

DIN power output (rated)

50+50 watts (6 ohms at

1 kHz, DIN)

Continuous RMS power output (reference)

60+60 watts (6 ohms at

1 kHz, 10% THD)

Music power output (reference)

120+120 watts (6 ohms

at 1 kHz, 10% THD)

Sub woofer

DIN power output (rated)

100 watts (12 ohms at

40 Hz, DIN)

Continuous RMS power output (reference)

120 watts (12 ohms at

40 Hz, 10% THD)

Music power output (reference)

120 watts (12 ohms at

40 Hz, 10% THD)

Other models:

HCD-RG55

The following measured at AC 120, 220, 230 –

240 V, 50/60 Hz

DIN power output (rated)

100+100 watts (6 ohms

at 1 kHz, DIN)

SPECIFICATIONS

Continuous RMS power output (reference)

120+120 watts (6 ohms

at 1 kHz, 10% THD)

Inputs

MD/VIDEO (AUDIO) IN (phono jacks):

voltage 450/250 mV,

impedance 47 kilohms

GAME (AUDIO) IN (phono jack):

voltage 450 mV,

impedance 47 kilohms

MIC (phone jack) (except for European models):

sensitivity 1 mV,

impedance 10 kilohms

Outputs

PHONES (stereo mini jack):

accepts headphones of

8 ohms or more

Front speaker: accepts impedance of 6 to

16 ohms

Sub woofer speaker (MHC-RG55S only):

accepts impedance of 12

to 16 ohms

– Continued on next page –

COMPACT DISC DECK RECEIVER

9-874-003-01

2002E0400-1

© 2002. 05

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

1

HCD-RG55/RG55S

CD player section

System Compact disc and digital

audio system

Laser Semiconductor laser

(λ=780 nm)

Emission duration:

continuous

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Wavelength 780 – 790 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

CD OPTICAL DIGITAL OUT

(Square optical connector jack, rear panel)

Wavelength 660 nm

Output Level –18 dBm

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 50 – 13,000 Hz (±3 dB),

using Sony TYPE I

cassette

Wow and flutter ±0.15% W.Peak (IEC)

0.1% W.RMS (NAB)

±0.2% W.Peak (DIN)

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

European and Middle Eastern models:

531 – 1,602 kHz (with the

interval set at 9 kHz)

Other models: 531 – 1,602 kHz (with the

interval set at 9 kHz)

530 – 1,710 kHz (with the

interval set at 10 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

European model: 230 V AC, 50/60 Hz

Australian models: 230 – 240 V AC, 50/60 Hz

Mexican model: 120 V AC, 50/60 Hz

Argentine models: 220 V AC, 50/60 Hz

Korean model: 220 V AC, 60 Hz

Other models: 120 V, 220 V or 230 –

240 V AC, 50/60 Hz

Adjustable with voltage

selector

Power consumption

European models:

HCD-RG55S: 150 watts

0.5 watts (at the Power

Saving Mode)

Other models:

HCD-RG55: 200 watts

Dimensions (w/h/d) Approx. 280 × 325 × 421 mm

Mass

HCD-RG55S: Approx. 9.0 kg

HCD-RG55: Approx. 10.0 kg

Supplied accessories: AM loop antenna (1)

Remote Commander (1)

Batteries (2)

FM lead antenna (1)

Front speaker pads (8)

Design and specifications are subject to change without

notice.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

HCD-RG55/RG55S

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

SETTING AND RELEASING THE CD DISC TRAY LOCK

FUNCTION

This set has a disc tray lock function to prevent discs for

demonstration at shops from theft. While this lock function is set,

the tray will not be delivered out even when the OPEN/CLOSE

button is pressed.

MODEL IDENTIFICATION

– BACK PANEL –

PARTS No.

MODEL PARTS No.

AR, E2, E51, SP models 4-238-649-01

AUS, KR, MX models 4-238-649-21

AEP, UK models 4-238-649-31

• Abbreviation

AUS : Australian model AR : Argentina model

SP : Singapore model E2 : Central and South America model

KR : Korea model E51 : Chilean and Peruvian model

MX : Mexican model

Setting method:

Press the OPEN/CLOSE button while pressing the STOP button.

After a few seconds, the message “LOCKED” will appear on the

fluorescent indicator tube with the tray locked.

Releasing method:

Just as the lock is set, press the OPEN/CLOSE button while

pressing the STOP button.

After a few seconds, the message “UNLOCKED” will appear with

the lock released.

3

HCD-RG55/RG55S

TABLE OF CONTENTS

1. SERVICE NOTE ................................................................ 5

2. GENERAL

Main Unit ................................................................................ 6

Remote Control ....................................................................... 7

3. DISASSEMBLY

3-1. Case (Top) ........................................................................... 9

3-2. CD (Door) ........................................................................... 9

3-3. Front Panel Section (AEP, UK Model) ............................. 10

3-4. Front Panel Section (Except AEP, UK Model) ................. 11

3-5. Tape Mechanism Deck ...................................................... 12

3-6. Panel Board (AEP, UK Model) ......................................... 12

3-7. Panel Board (Except AEP, UK Model) ............................. 13

3-8. Key Board ......................................................................... 13

3-9. Sensor Board, DC Fan (FAN961) ..................................... 14

3-10. Main Board, Sub Woofer Board, P ower Board ................. 15

3-11. CD Board .......................................................................... 15

3-12. Base Unit ...........................................................................16

3-13. Driver Board, Motor Board, Sensor (CD) Board ..............16

4. TEST MODE ..................................................................... 17

5. ELECTRICAL ADJUSTMENTS................................. 21

6. DIAGRAMS

6-1. Circuit Boards Location .................................................... 23

6-2. Printed Wiring Boards –CD Section (1/2)– ...................... 25

6-3. Printed Wiring Boards –CD Section (2/2)– ...................... 26

6-4. Schematic Diagram –CD Section–.................................... 27

6-5. Printed Wiring Board –Main Section– .............................. 28

6-6. Schematic Diagram –Main Section (1/4)– ........................30

6-7. Schematic Diagram –Main Section (2/4)– ........................31

6-8. Schematic Diagram –Main Section (3/4)– ........................32

6-9. Schematic Diagram –Main Section (4/4)– ........................33

6-10. Printed Wiring Boards –Panel Section– ............................ 34

6-11. Schematic Diagram –Panel Section– ................................ 35

6-12. Printed Wiring Board –Key Section– ................................36

6-13. Schematic Diagram –Key Section–................................... 37

6-14. Printed Wiring Board –Sub Woofer Section– ................... 38

6-15. Schematic Diagram –Sub Woofer Section– ...................... 39

6-16. Printed Wiring Boards –Power Section (1/3)– ..................40

6-17. Printed Wiring Board –Power Section (2/3)– ................... 41

6-18. Printed Wiring Board –Power Section (3/3)– ................... 42

6-19. Schematic Diagram –Power Section– ...............................43

7. EXPLODED VIEWS

7-1. Main Section ..................................................................... 46

7-2. Front panel Section ........................................................... 47

7-3. Main Board Section .......................................................... 48

7-4. CD Mechanism Deck Section ........................................... 49

7-5. Optical Pick-up Section..................................................... 50

8. ELECTRICAL PARTS LIST ........................................ 51

4

SECTION 1

d

SERVICE NOTE

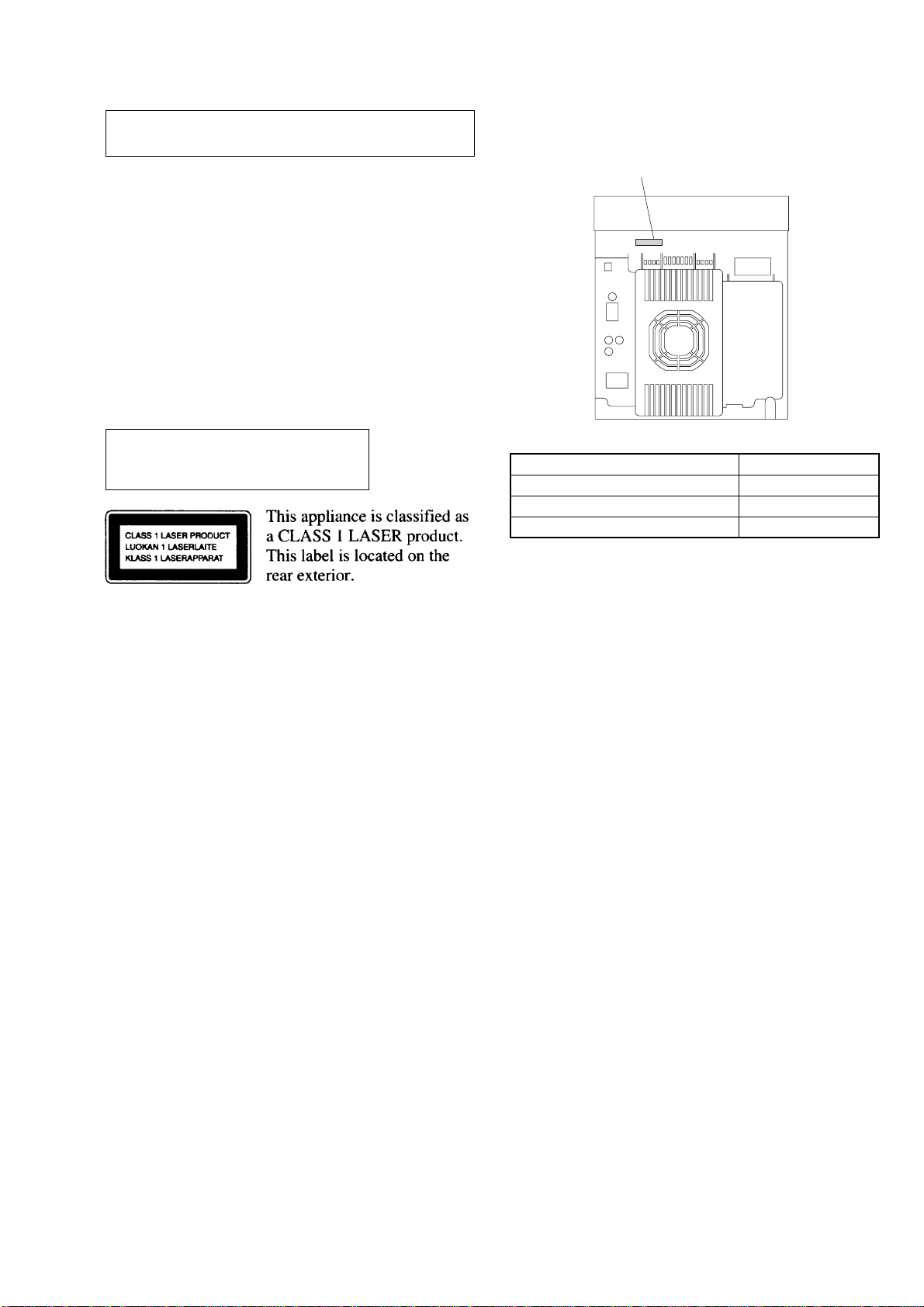

REMOVING THE PANEL BOARD AND THE KEY BOARD

* The panel board and the key board only are connected to the front panel

by means of hot-melting the plastics.

2

PANEL board

HCD-RG55/RG55S

4

KEY boar

1

Cut the fifteen melted-connection points

with a cutting plier.

Note for installing the panel board and the key board

PANEL board

(eleven screw holes)

3

Cut the seven melted-connection points

with a cutting plier.

KEY board

(six screw holes)

Screw hole

In order to re-install the panel board and the key board,

fix them by using the screws (+BVTP 2.6

Screw in to the respective screw holes.

Do not tighten the screws excessively.

×

8 ) respectively.

Hot melt

5

HCD-RG55/RG55S

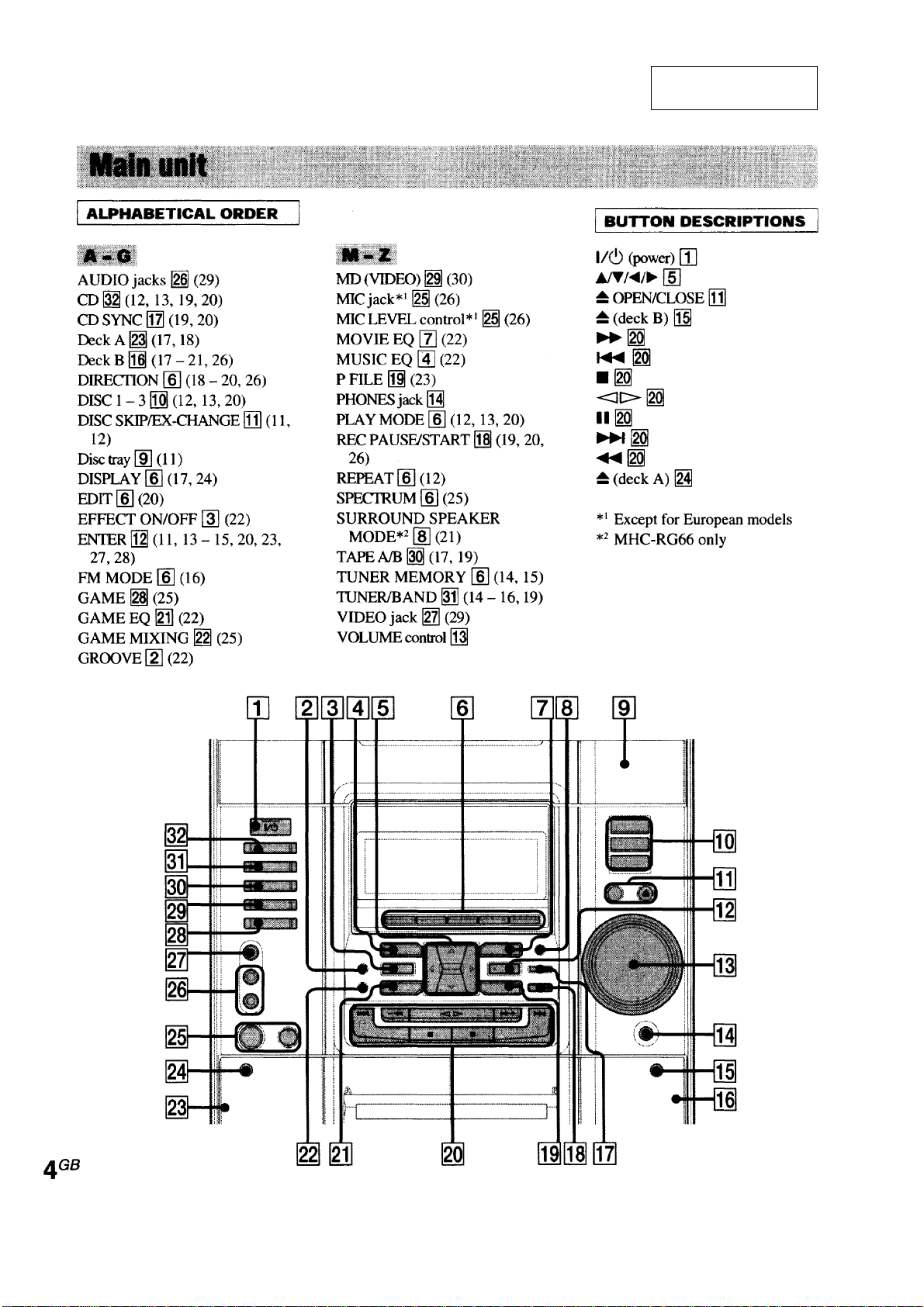

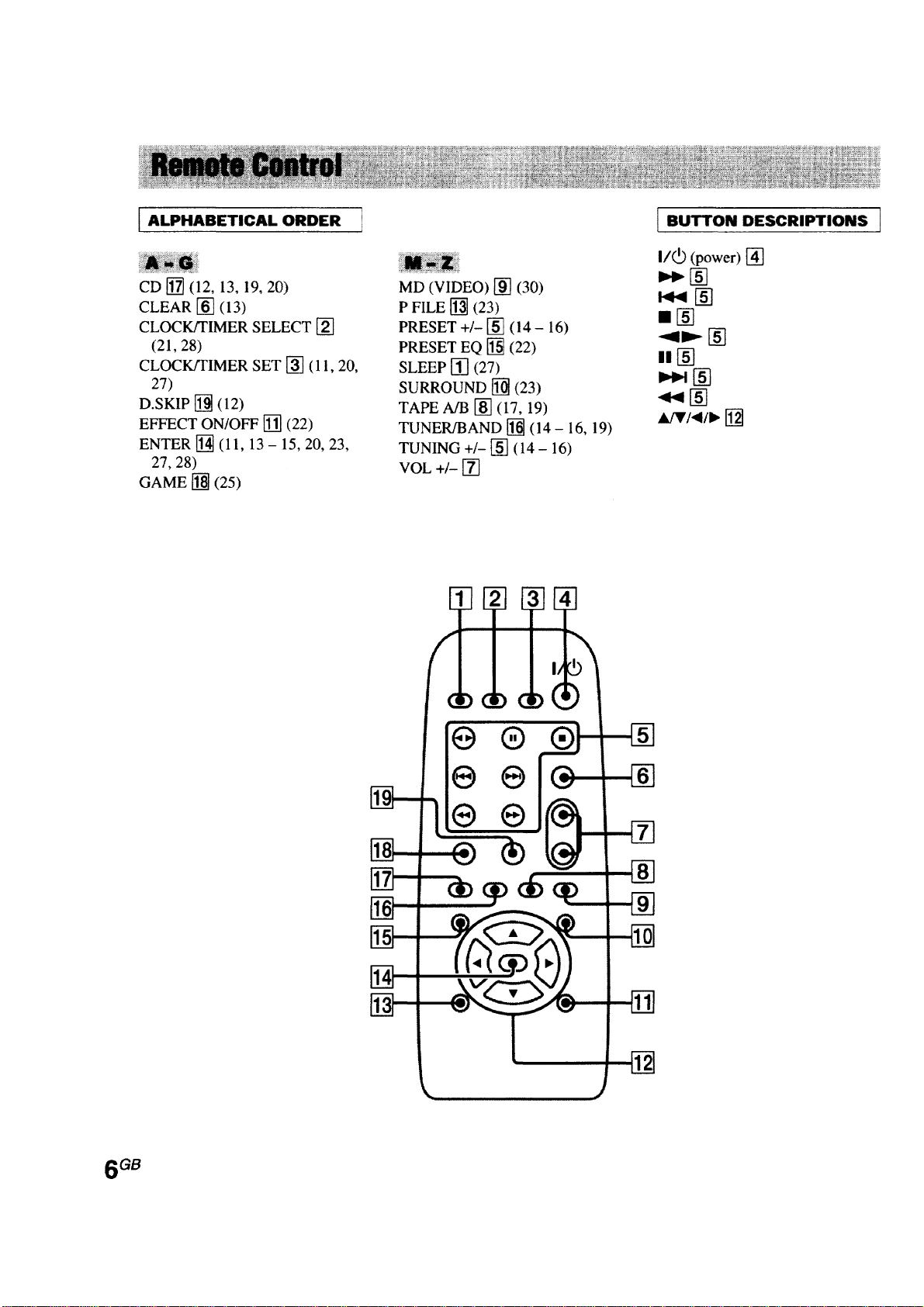

SECTION 2

GENERAL

This section is extracted

from instruction manual.

6

HCD-RG55/RG55S

7

HCD-RG55/RG55S

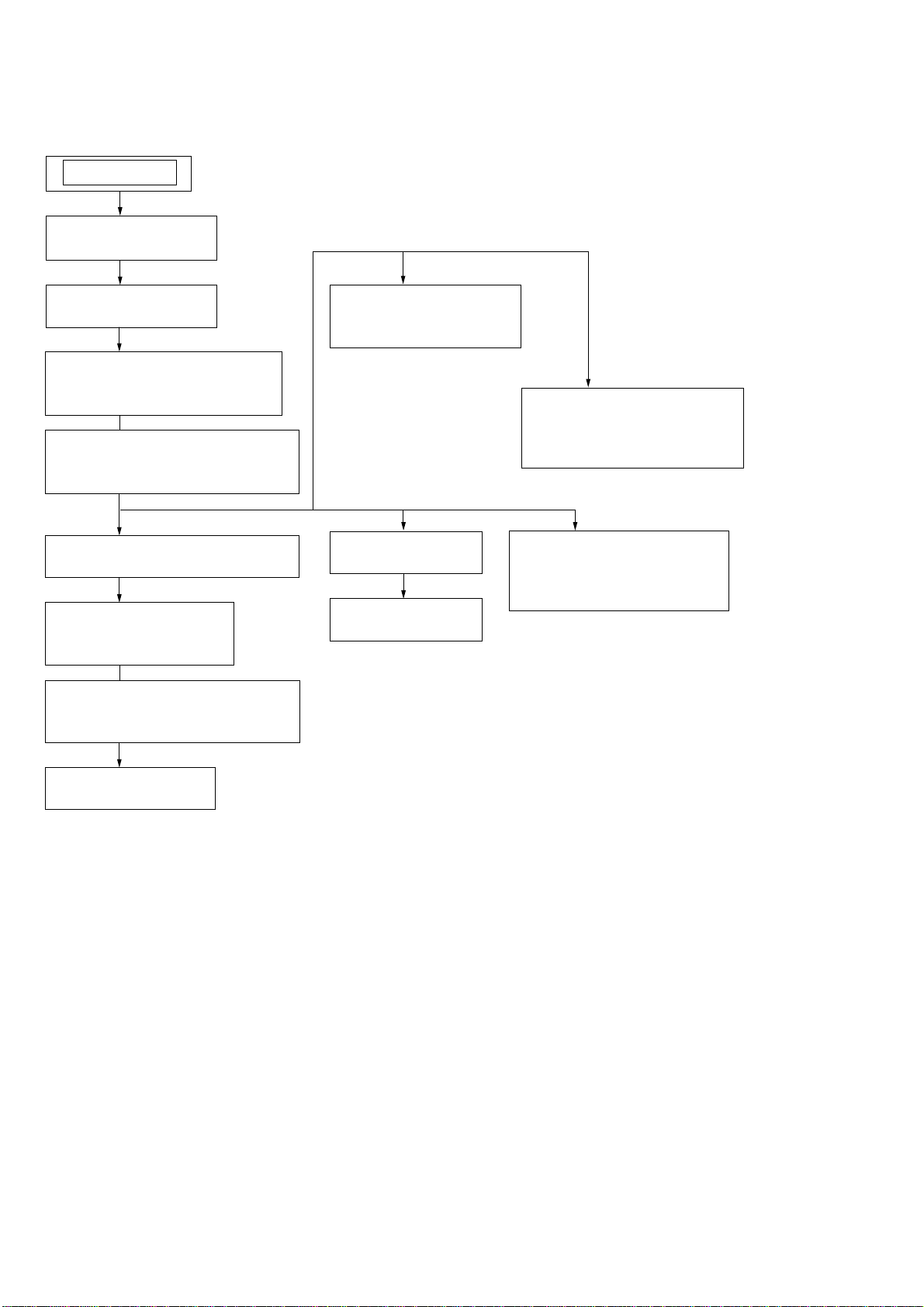

Note : Disassemble the unit in the order as shown below.

SET

3-1. CASE (TOP)

(Page 9)

SECTION 3

DISASSEMBLY

3-2. CD (DOOR)

(Page 9)

3-3. FRONT PANEL SECTION

(AEP, UK MODEL)

(Page 10)

3-4. FRONT PANEL SECTION

(EXCEPT AEP, UK MODEL)

(Page 11)

3-5. TAPE MECHANISM DECK

(Page 12)

3-6. PANEL BOARD

(AEP, UK MODEL)

(Page 12)

3-7. PANEL BOARD

(EXCEPT AEP, UK MODEL)

(Page 13)

3-9. SENSOR BOARD

DC FAN (FAN961)

(Page 14)

3-11. CD BOARD

(Page 15)

3-12 BASE UNIT

(Page 16)

3-10. MAIN BOARD,

SUB WOOFER BOARD ,

POWER BOARD

(Page 15)

3-13. DRIVE BOARD,

MOTOR (TC) BOARD,

SENSOR (TC) BOARD

(Page 16)

3-8. KEY BOARD

(Page 13)

8

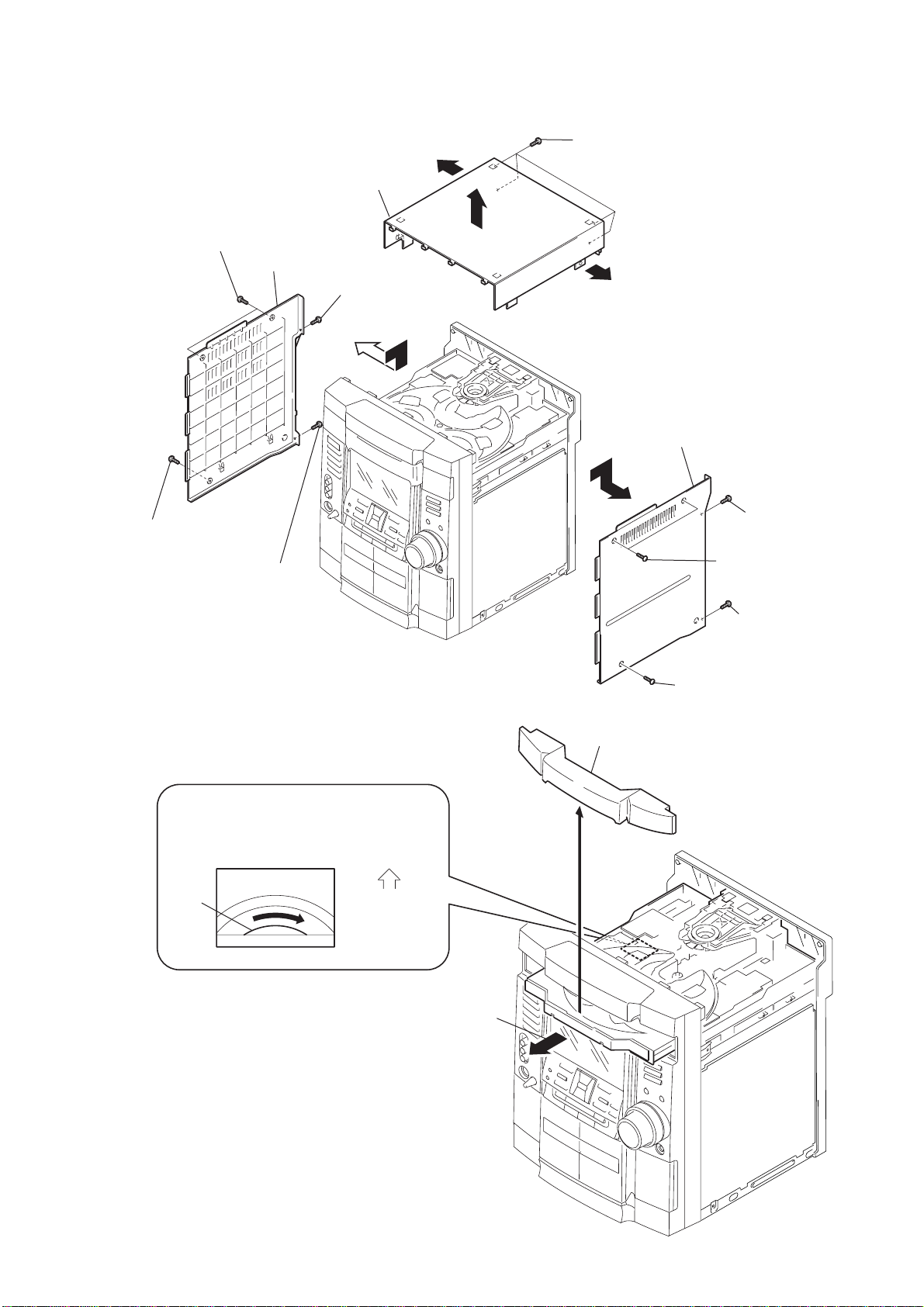

3-1. CASE (TOP)

6

two screws (case 3 TP2)

case (side-L)

case (top)

8

screw

(+BVTP 3

×

q;

qs

10)

qd

qa

four screws (+BVTP 3

qs

5

HCD-RG55/RG55S

×

10)

case (side-R)

7

screw (case 3 TP2)

3-2. CD (DOOR)

CD mechanism deck (CDM58F)

1

Turn the pulley to the direction of arrow.

pulley

9

screw

(+BVTT 3

×

8)

Front panel side

CD door

3

3

(+BVTP 3

1

two screws

(case 3 TP2)

4

(+BVTT 3

2

screw (case 3 TP2)

screw

screw

×

×

10)

8)

2

Pull-out the disc tray.

9

HCD-RG55/RG55S

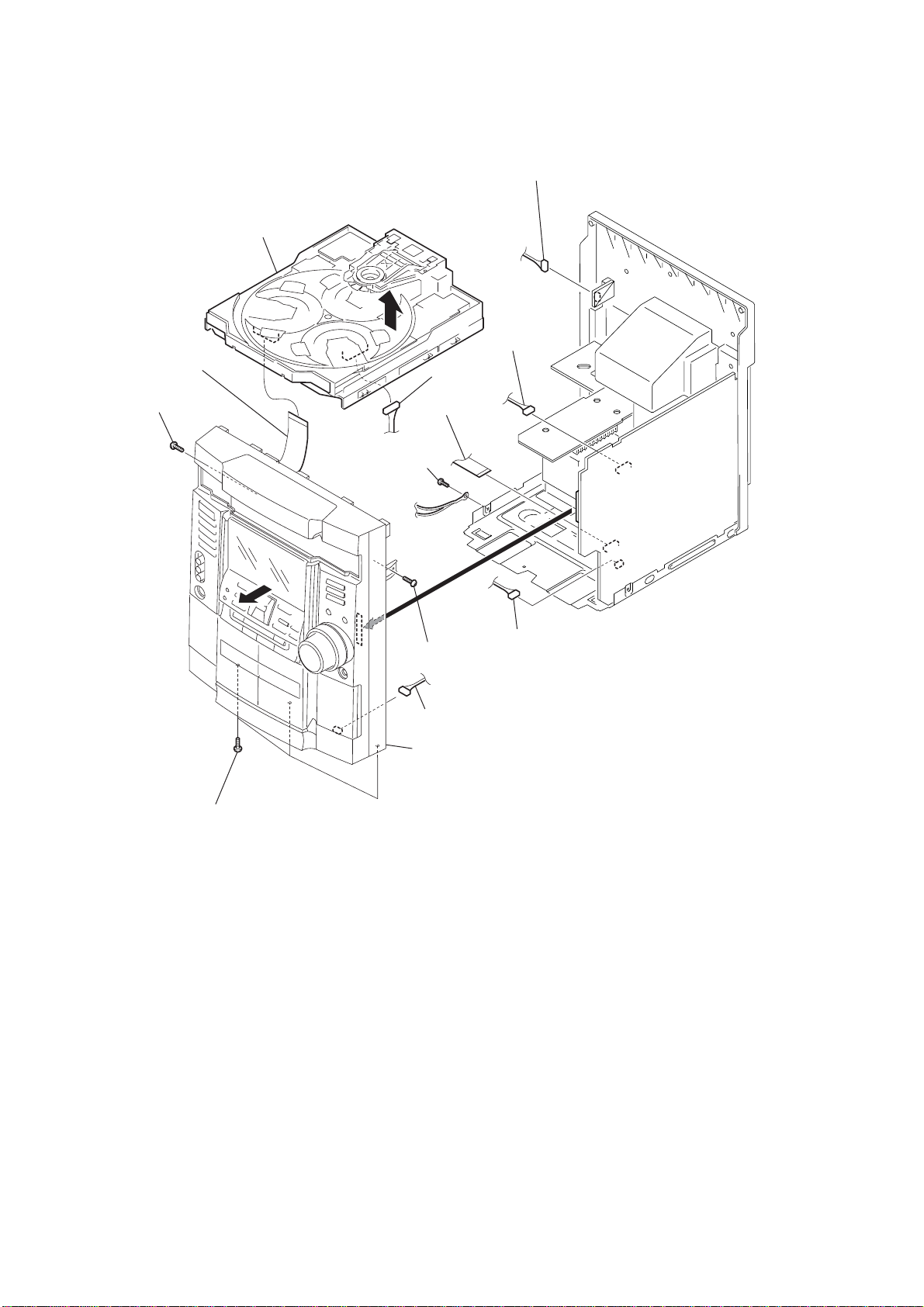

3-3. FRONT PANEL SECTION (AEP, UK MODEL)

CD mechanism deck (CDM58F)

qd

2

CN733 (flat type)

9

screw

(+BVTP 3

×

10)

7

screw

(+BVTP 3

1

CN605

4

CN305

qf

CN302

(flat type)

3

CN302

(flat type)

×

10)

qa

0

three screws (+BVTP 3

qs

× 6

front panel section

)

8

screw

(+BVTP 3

5

connector 6p

6

×

10)

connector 3p

10

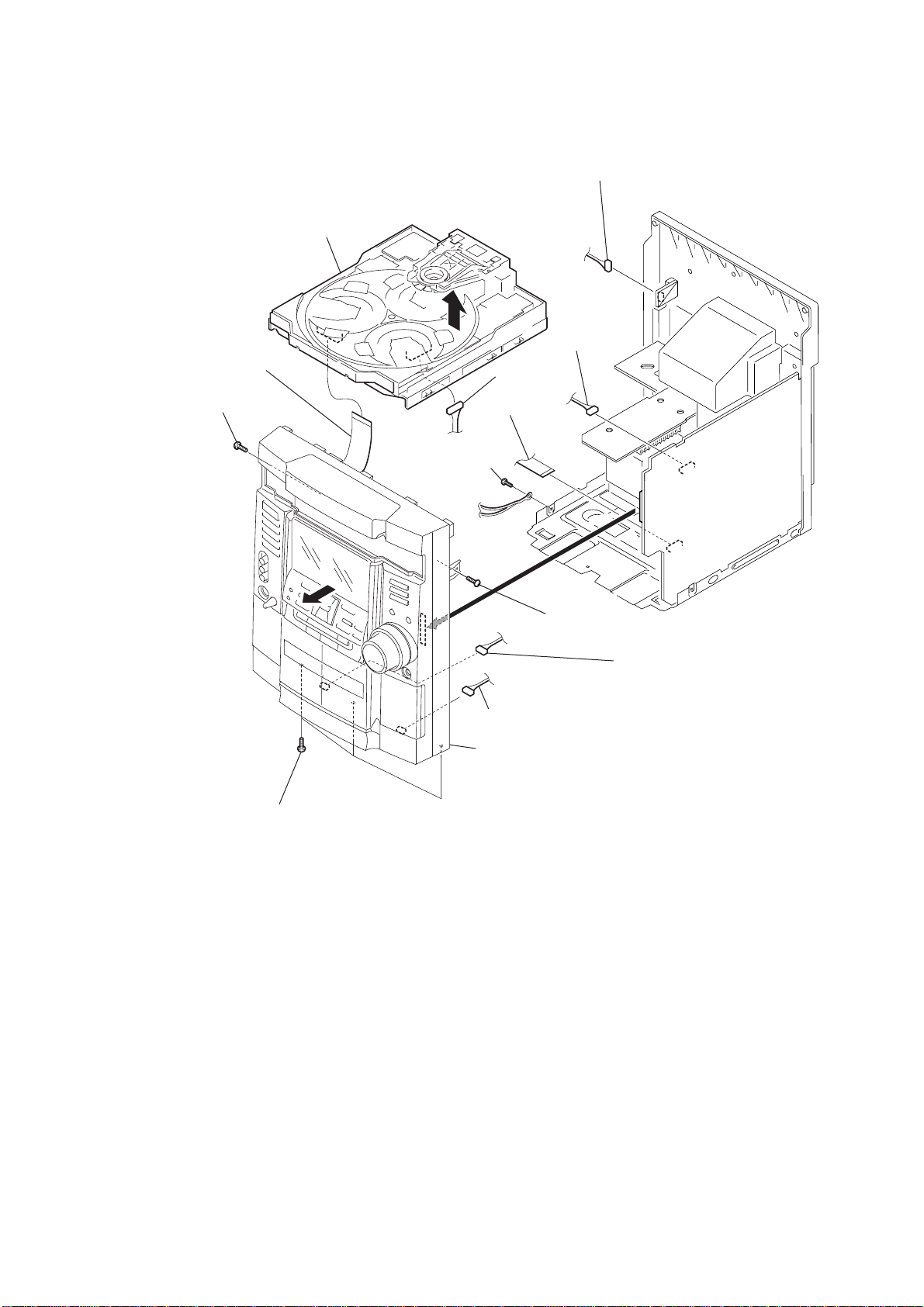

3-4. FRONT PANEL SECTION (EXCEPT AEP, UK MODEL)

CD mechanism deck (CDM58F)

qd

2

CN733 (flat type)

9

screw

(+BVTP 3

×

10)

7

screw

(+BVTP 3

qf

3

×

10)

CN302

(flat type)

CN302

(flat type)

4

1

CN605

CN305

HCD-RG55/RG55S

qa

0

three screws (+BVTP 3

qs

× 6

)

8

screw

(+BVTP 3

5

connector 6p

front panel section

×

10)

6

connector 3p

11

HCD-RG55/RG55S

)

3-5. TAPE MECHANISM DECK

2

tape mechanism deck

1

six

screws

(+BVTP 2.6

×

8

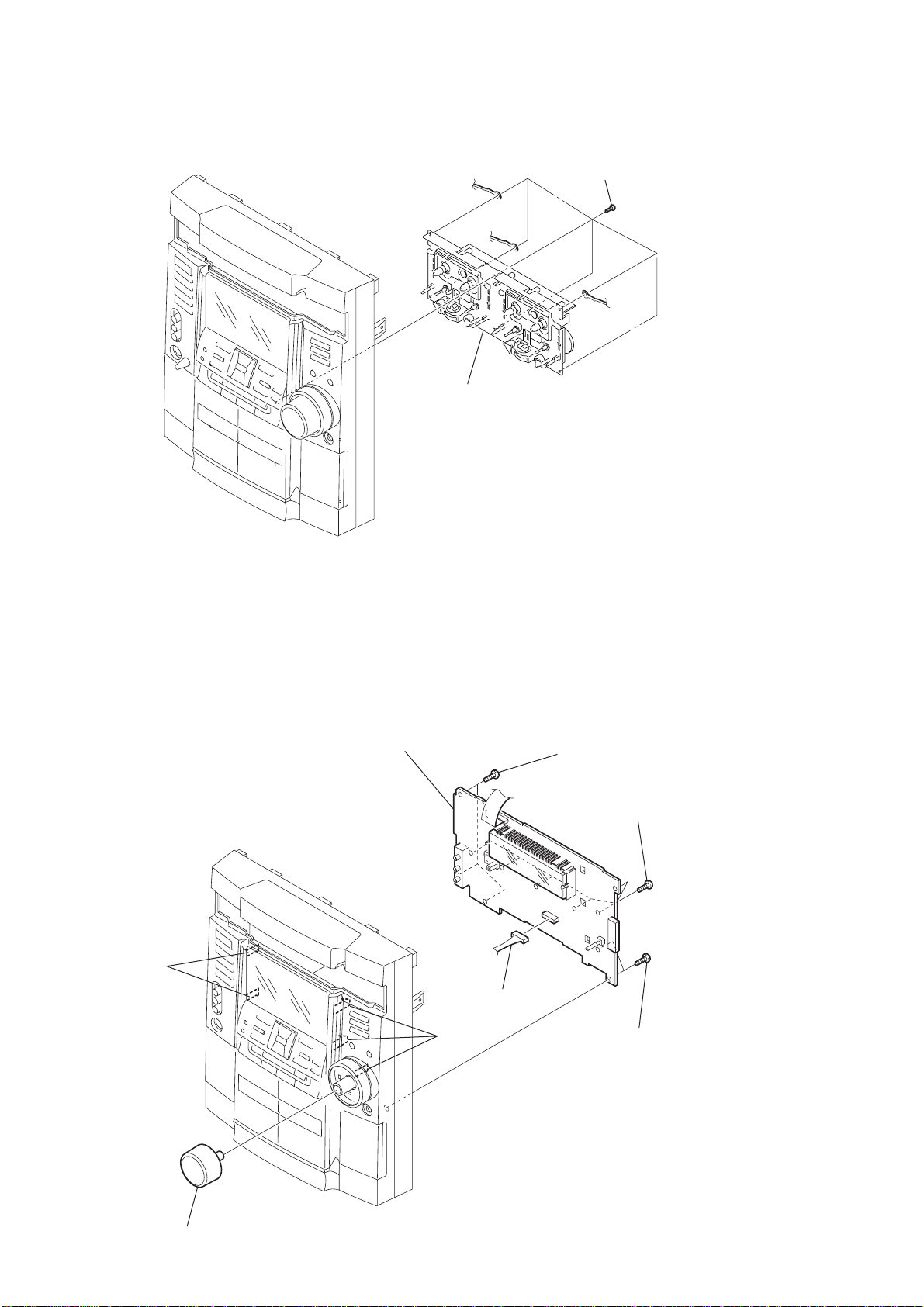

3-6. PANEL BOARD (AEP, UK MODEL)

claws

5

PANEL board

claws

6

CN661

2

three

(+BVTP 2.6

screws

×

8)

3

six

screws

(+BVTP 2.6

4

two

screws

(+BVTP 2.6

×

8)

×

8)

12

1

volume knob

3-7. PANEL BOARD (EXCEPT AEP, UK MODEL)

2

CN663

claws

6

PANEL board

7

CN661

3

three

(+BVTP 2.6

screws

HCD-RG55/RG55S

×

8)

4

six

screws

(+BVTP 2.6

×

8)

3-8. KEY BOARD

1

volume knob

claw

claws

3

two

screws

(+BVTP 2.6

2

two

(+BVTP 2.6

×

8)

screws

5

two

screws

(+BVTP 2.6

×

8)

×

8)

4

KEY board

1

two

screws

(+BVTP 2.6

×

8)

13

HCD-RG55/RG55S

)

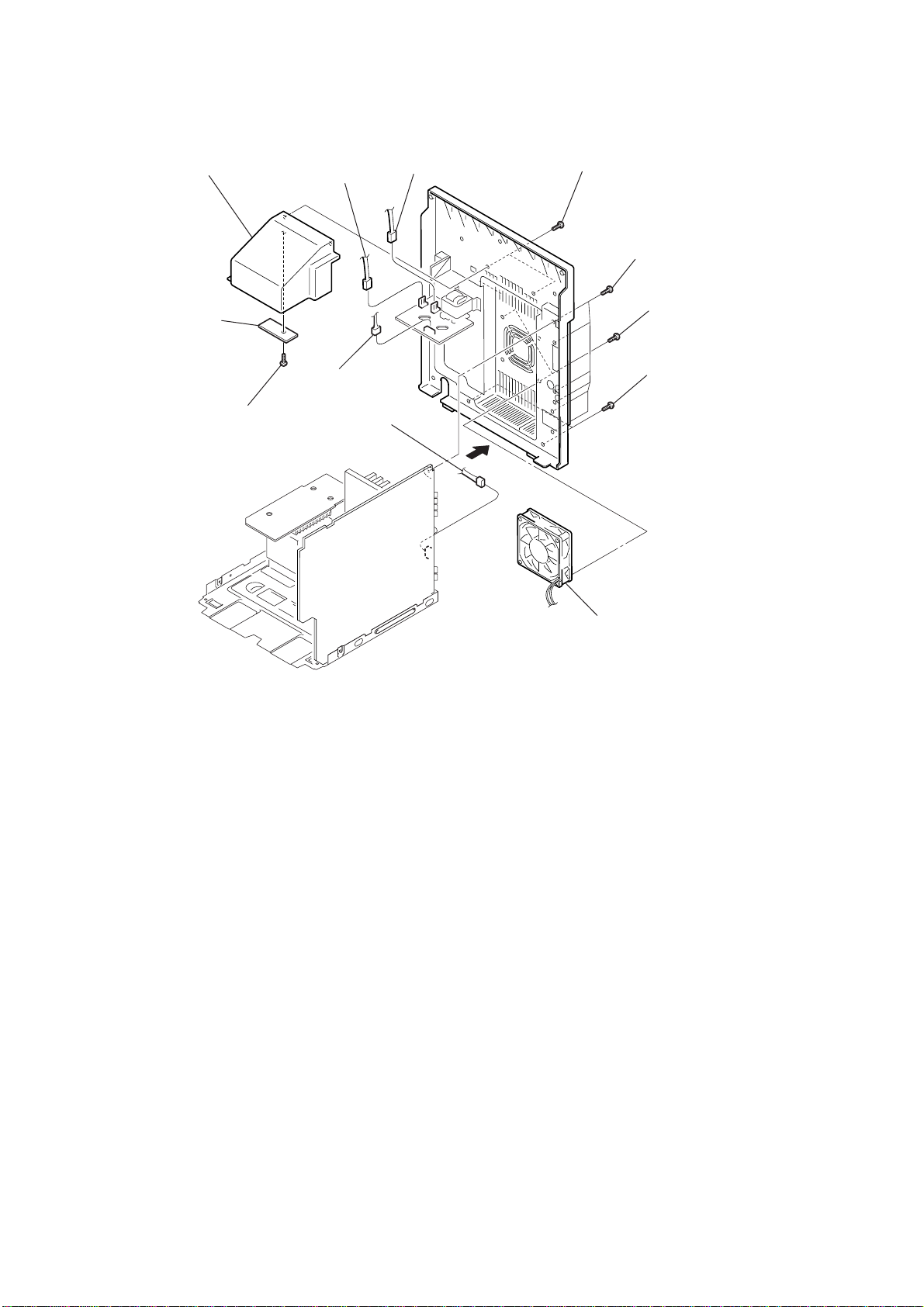

3-9. SENSOR BOARD, DC FAN (FAN961)

6

cover (duct)

8

SENSOR board

7

screw

(+BVTP 2.6

×

1

3

8)

CN901

CN903

4

2

CN2

CN304

qa

5

two screws

(+BVTP 3

9

(+BVTP 3

×

10)

six screws

qs

(+BVTP 3

0

(+BVTT 3

×

two screws

two screws

10)

×

×

16

6)

qd

DC fan (FAN961)

14

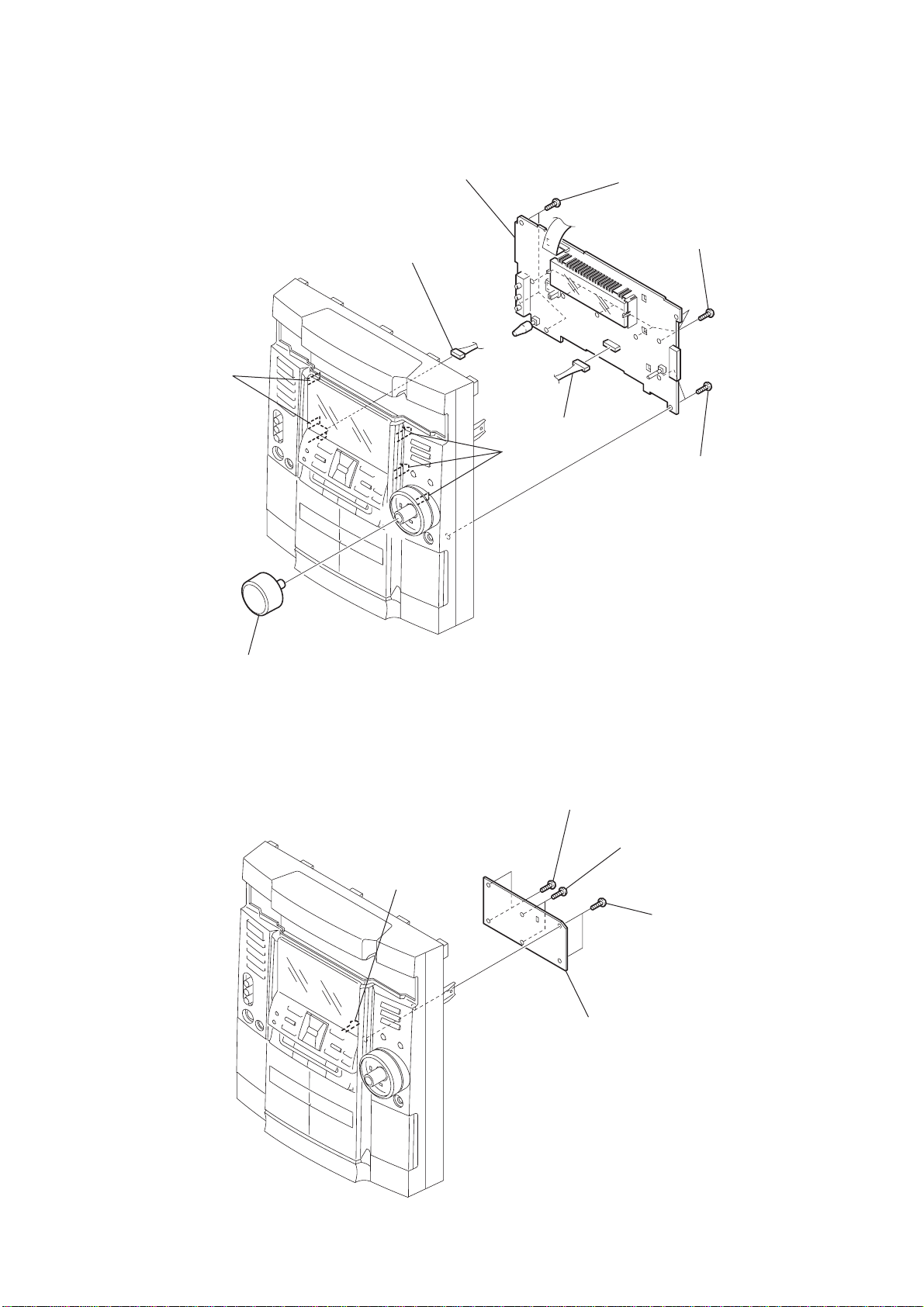

3-10. MAIN BOARD, SUB WOOFER BOARD, POWER BOARD

8

two

screws

(+BVTP 3

×

16)

1

qa

(+BVTP 3

qs

POWER board

three

screws

×

0

two

screws

(+BVTP 3

3

CN915

10)

×

2

16)

7

screw

(+BVTP 3

CN508

×

10)

CN509

6

(+BVTP 3

9

SUB WOOFER board

(AEP, UK model)

screw

×

10)

HCD-RG55/RG55S

MAIN board

5

MAIN board

3-11. CD BOARD

3

CN735

2

CN731

(flat type)

1

CN732

4

two

screws

(+BVTP 3

×

10)

5

CD board

4

four

screws

(+BVTP 2.6

×

8)

15

HCD-RG55/RG55S

)

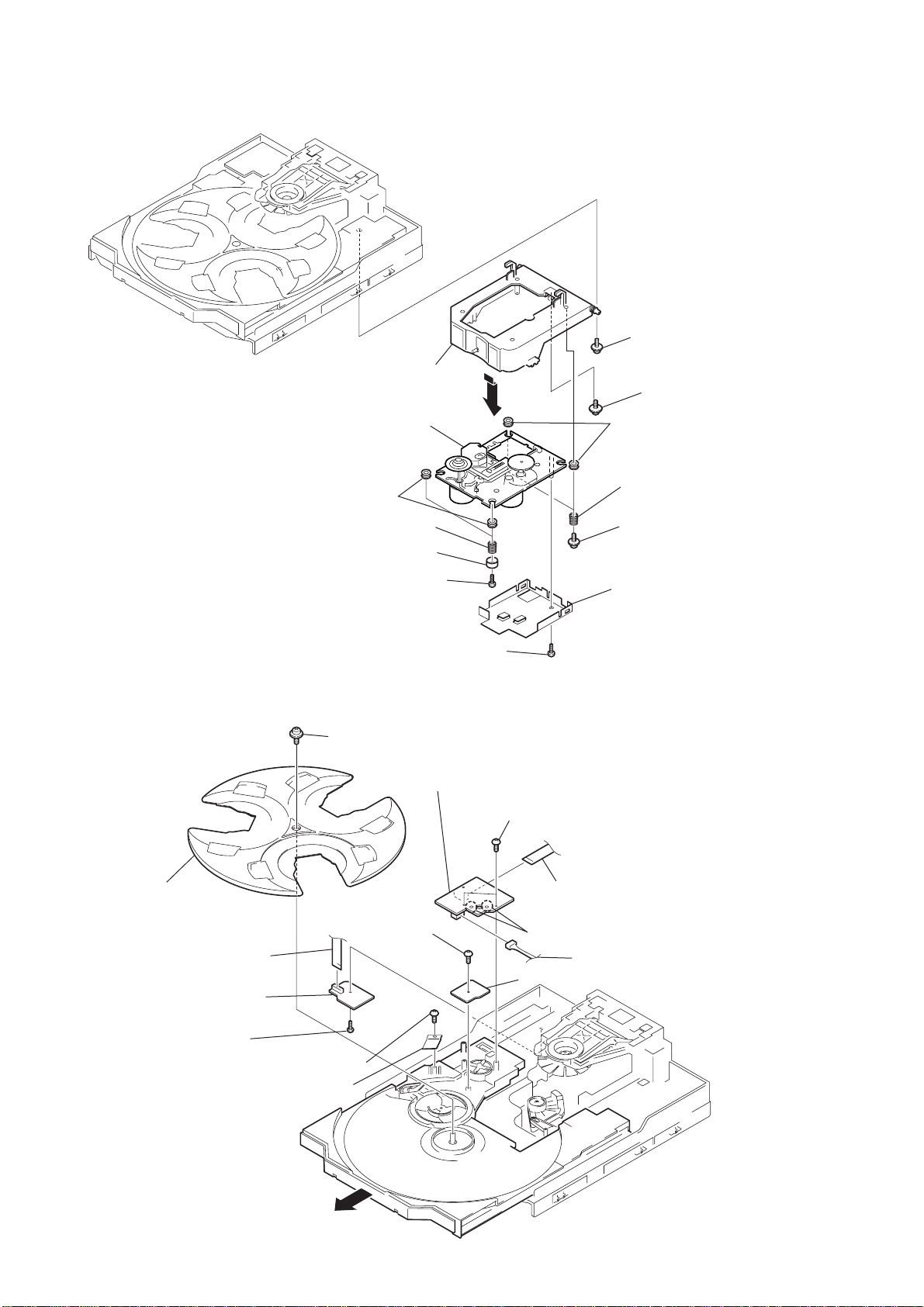

3-12. BASE UNIT

4

holder (BU) assy

qs

3

screw (+PTPWH M2.6)

5

screw (DIA. 12)

base unit

qa

two insulators

0

two

springs (insulator), coil

9

two stoppers (BU)

8

two screws (+BVTP 2.6

1

×

8)

screw (+BVTP 2.6

×

8)

3-13. DRIVER BOARD, MOTOR BOARD, SENSOR (CD) BOARD

qs

screw (+PTPWH 2.6

0

×

8)

MOTOR board

6

two screws (+BVTP 2.6

qs

two insulators

7

two

6

two

2

shild cover

×

springs (insulator), coil

screws (+PTPWH M2.6

8)

16

qd

tray

3

CN702 (flat type)

2

DRIVER board

1

screw

(+BVTP 2.6

×

8)

4

screw (+BVTP 2.6

qf

screw

(+BVTP 2.6

×

8)

5

plate

qa

Pull-out the disc tray.

×

8

CN721(flat type)

8)

7

Remove the two solderings of motor.

9

CN722

qg

SENSOR (CD) board

SECTION 4

TEST MODE

HCD-RG55/RG55S

[Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning the

set to the customer.

Procedure:

1. Press three buttons x , GROOVE , and ?/1 simultaneously.

2. The fluorescent indicator tube displays “COLD RESET” and

the set is reset.

[CD Ship Mode]

• This mode moves the pickup to the position durable to vibration.

Use this mode when returning the set to the customer after repair.

Procedure:

1. Press ?/1 button to turn the set ON until “STANDBY”

appears.

2. Press CD button and ?/1 button simultaneously.

3. When you releaset he buttons, a message “LOCK” is displayed

on the fluorescent indicator tube, and the CD ship mode is set.

[Hot Reset]

• This mode resets the set with the preset data kept stored in the

memory. The hot reset mode functions same as if the power cord

is plugged in and out.

Procedure:

1. Press three buttons x , GAME EQ , and DISPLAY

simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

[CD Service Mode]

• This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the pickup.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press three buttons x , GAME EQ , and OPEN/CLOSE

simultaneously.

4. The CD service mode is selected.

5. With the CD in stop status, press the > key to move the pickup

to outside track, or turn the shuttle knob counter-clockwise to

inside track.

6. To exit from this mode, perform as follows:

1) Move the pickup to the most inside track.

2) Cold reset.

Note: • Always move the pickup to most inside track when exiting

from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear

can be chipped.

[Change-over of AM Tuner Step between 9 kHz and 10

kHz]

• A step of AM channels can be changed over between 9 kHz and

10 kHz.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND

button to select the BAND “MW”.

3. Press ?/1 button to turn the set OFF.

4. Press ENTER and ?/1 buttons simultaneously, and the

display of fluorescent indicator tube changes to “ AM 9 k STEP”

or “ AM 10 k STEP”, and thus the channel step is changed over.

[GC Test Mode]

• This mode is used to check the software version, FL tube, LED,

keyboard, headphone and volume.

Procedure:

1. Press three buttons x , GAME EQ and DISC2

simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

3. When GAME EQ and DISC2 are pressed at the same time,

the key number check mode starts up. In this mode, the key

numbers of each key series are displayed.

4. In the key check mode, the fluorescent indicator tube displays

“KEY 000”. Each time a button is pressed.

5. When GAME EQ and DISC2 are pressed at the same time,

the key count check mode starts up. In this mode, the message

“KEY CNT @@” is displayed on the FL display tube. When

each button is pressed, the key row number is incremented f irst.

Then the key value is then incremented. However, one the

button is pressed, the key value cannot be counted.

6. When GAME EQ and DISC2 are pressed at the same time,

the headphones check mode starts up. In this mode, the

message “H_P ON” is displayed when the headphones are inserted. When the headphones are not inserted, the message “H_P

OFF” is displayed.

7. When GAME EQ and DISC2 are pressed at the same time,

the volume check mode starts up. In this mode, the message

“VOLUME STOP” is displayed on the FL display tube. When

the volume control knob is rotated in the positive (+) direction,

the message “VOLUME UP” is displayed. When the volume

control knob is rotated in the negative (–) direction, the

message “VOLUME DOWN” is displayed.

8. In order to quit the mode, either press GAME EQ and DISC2

at the same time or press the three buttons at the same time as in

step 1.

9. To exit from this mode, cold reset or disconnect the po wer cord.

17

HCD-RG55/RG55S

[MC Test Mode]

• This mode is used to check operations of the respective sections

of Amplifier, TUNER, CD and Tape.

Procedure:

1. Press the ?/1 button to turn on the set.

2. Press the three buttons of x , GAME EQ and DISC 3

simultaneously.

3. A message “TEST MODE” appears on the FL display tube.

•The messages VACS1 to VACS5 are displayed when the VACS

is changed in this mode.

•The number of repeats of TAPE and CD is set to the infinite

number as the default setting.

4. When MUSIC EQ button is pressed, GEQ increases to its

maximum and a message “GEQ MAX” appears.

5. When MUSIC EQ button is pressed, GEQ decreases to its

minimum and a message “GEQ MIN” appears.

6. When EFFECT ON/OFF button is pressed, GEQ is set to flat

and a message “GEQ FLAT” appears.

7. In the test mode, the default-preset channel is called even when

the TUNER is selected and an attempt is made to call the preset

channel that has beeen stored in memory, by operating the

Shuttle knob. (It means that the memory is cleared.)

8. When a tape is inserted in the Deck B and the T APE B function

is selected, and when the REC PAUSE/START buttton is

pressed twice, recording starts.

The VIDEO function is selected automatically as the input

source.

9. Select the desired loop by pressing the PLAY MODE button

in the TAPE B function. Insert a test tape AMS-110A or AMSRO to Deck A.

10. Press the SPECTRUM button to enter the AMS test mode.

11. After a tape is r ewound first, the FF AMS is checked, and the

mechanism is shut off after detecting the AMS signal twice.

12. Then the REW AMS is checked and the mechanism is shut off

after detecting the AMS signal twice.

13. When the check is complete, a message of either OK or NG

appears.

14. When the two buttons of SPECTR UM and DISC1 are pressed

at the same time in any function modes, either the “VACS ON”

display to enable the VACS function or the “VACS OFF”

display to disable the VACS function can be selected.

15. When you want to exit this mode, press the ?/1 button twice.

The cold reset is enforced at the same time.

[Microprocessor version display]

• If the following operation is performed during the POWER OFF

in the modes other than the POWER SAVE mode (i.e., while the

Demo display shows the watch time).

1. When three buttons of STOP , GAME EQ , MOVIE EQ are

pressed at the same time, the model name and destination are

displayed as “GYO AS1A3”.

2. When three buttons of STOP , GROOVE ar e pressed at the

same time, the MC and the GC microprocessor version

numbers are displayed as “V01.02:01.12.24”.

18

[Aging mode]

This mode can be used for operation check of CD section and tape deck section.

• If an error occurred:

The aging operation stops and display status.

• If no error occurs:

The aging operation continues repeatedly.

1. Operating method of Aging Mode

Turn on the main power and select “CD” of the function.

1) Set a disc in DISC1 tray. Select ALL DISC CONTINUE, and REPEAT OFF.

2) Load the tapes recording use into the decks A and B respectively.

3) Press three buttons x , GAME EQ , and

DISC SKIP EX-CHANGE simultaneously.

4) Aging operations of CD and tape are started at the same time.

5) To exit the aging mode, perform [Cold Reset].

2. Aging Mode in CD section

1) Display state

• No error occurs Display

*

*

*

AGING

*

HCD-RG55/RG55S

Note:

*

*

*

*

: Number of aging operations

Error display

E ** s ## $$ %%

123 45

1 ** The error No. 00 indicates the newest error. As the error No. increases, it means the older error.

When you want to retrieve the error history, press the PLAY MODE button in the case of mechanism error.

Or press the REPEAT button in the case of NO DISC error.

2 s M: Mechanism error D: No disc error

3 ## Don’t care 01: FOCUS ERROR

02: GFS ERROR

03: SETUP ERROR

4 $$ High order digits only 01: NO DISC judgment without chucking retry

D: Stopped during closing due to problems other than mechanism. 02: NO DISC judgment after chucking retry

E: Stopped during opening due to problems other than mechanism.

C: Stopped during chucking due to problems other than mechanism.

F: Stopped during EX-opening due to problems other than mechanism.

5 %% Emergency related errors (High order digits only) Status at the time of NO DISC judgment

1: Stopped during chuck-up (High order digits only)

2: Stopped during chuck-down 1: STOP

3: Time out by EX-OPEN 2: SETUP

5: Time out by EX-CLOSE 3: TOC READ

4: ACCESS

5: PLAY BACK

6: PAUSE

7: MANUAL SEARCH (PLAY)

8: MANUAL SEARCH (PAUSE)

• When the buttons x , ENTER and DISC 1 are pressed simultaneously, number of time of the mechanism error and the NO DISC error

can be checked.

Display: EMC**EDC** ** : Number of times of error (Maximum three times)

EMC : Mechanism error

EDC : No DISC error

•When aging operation is complete, be sure to perform the MC Cold Reset to reset the error history.

19

HCD-RG55/RG55S

2) Operation during aging mode

In the aging mode, the program is executed in the following

sequence.

(1) The disc tray opens and closes.

(2) The mechanism accesses DISC 2 and makes an attempt to read

TOC. Howev er, since there are no discs, a message “CD2 NO

DISC” appears.

(3) The mechanism accesses DISC 3 and a message “CD3 NO

DISC” appears.

(4) The disc tray turns to select a disc1.

(5) A disc is chucked.

(6) TOC of disc is read.

(7) The pickup accesses to the track 1, and playing 2 seconds.

(8) The pickup accesses to the last track, and playing 2 seconds.

(9) Every time when an aging operation of step 1 to step 8 is

*

*

*

complete, the display “ A GING ” value increases as

the number of aging operations is counted up.

(10) Returns to step 1.

3. Aging Mode in Tape Deck section

1) Display state

• No error occurs

Display action now

• Error occurred

Display action last time

*

NO. Display action Action contents Final timing

TAPE A AG-6 Rewind the TAPE A

1

TAPE B AG-1 Rewind the TAPE B

2TAPE A AG-2 FWD play the TAPE A 2 minutes playing

3TAPE A AG-3 EE the TAPE A

4TAPE A AG-4 REV play the TAPE A 2 minutes playing

5TAPE A AG-5 Rewind the TAPE A The top of tape

6TAPE B AG-2 FWD play the TAPE B 2 minutes playing

7TAPE B AG-3 EE the TAPE B

8TAPE B AG-4 REV paly the TAPE B 2 minutes playing

9TAPE B AG-5 Rewind the TAPE B The top of tape

2) Operation during aging mode

In the aging mode, the program is executed in the following

sequence.

(1) Rewind is executed up to the top of tape A and B.

(2) A tape on FWD side is played for 2 minutes.

(3) FF is executed up to either made for 20 second or the end of

tape.

(4) A tape is reversed, and the tape on REV side is played for 2

minutes.

The tape on the REV side is played in both A and B.

(5) Rewind is executed up to the top of tape.

(6) Returns to step 2, and repeat steps from 2 to 5.

The top of tape

20 second FF or

the end of tape

20 second FF or

the end of tape

[Function Change Mode]

* elect either VIDEO or MD of the external FUNCTION input.

Procedure:

1. Turn on the power.

2. Press the two buttons MD (VIDEO) and ?/1 at the same

time.

The main power is turned on and the other function of the

previous function is selected and displayed. “MD” or “VIDEO”.

20

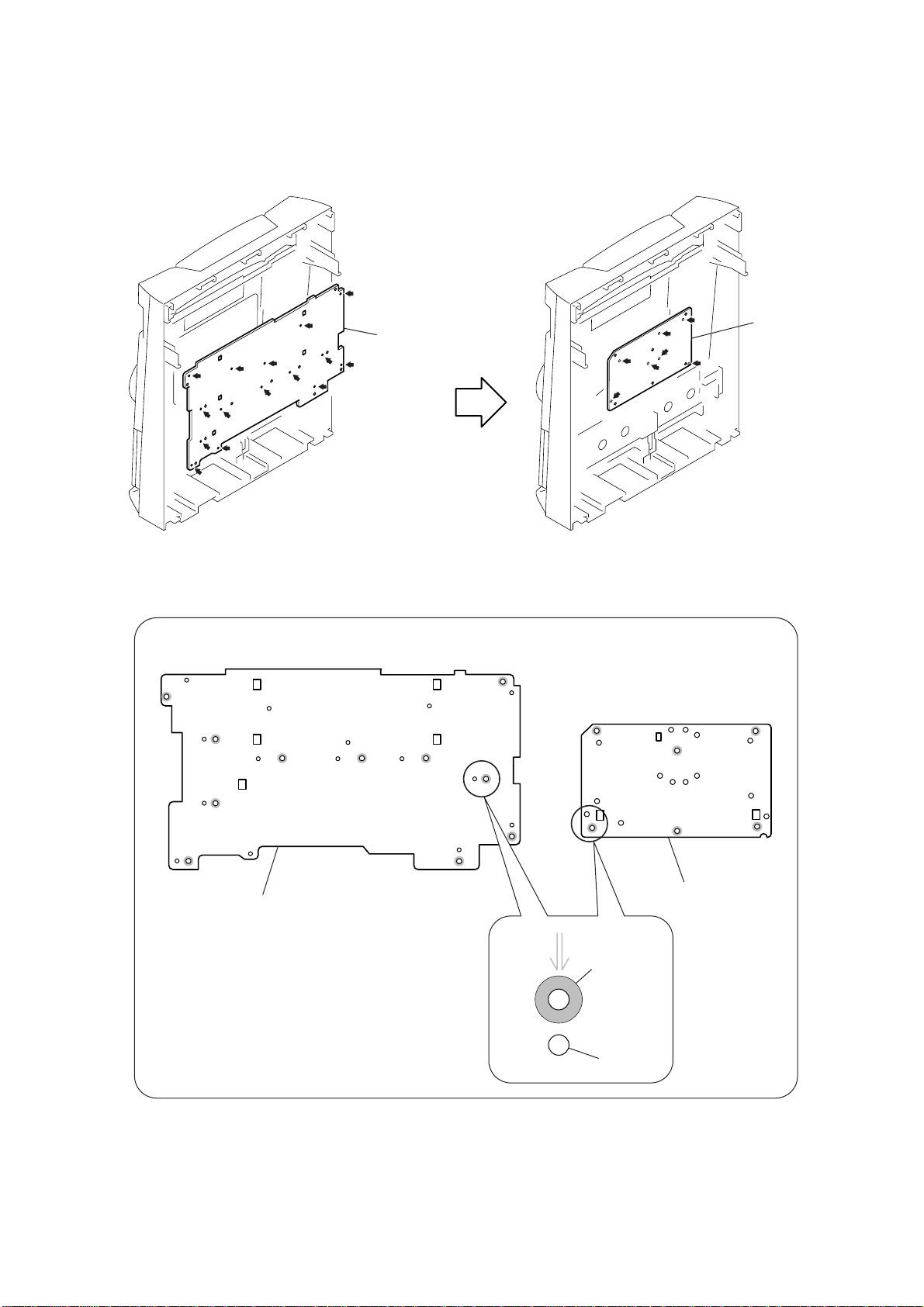

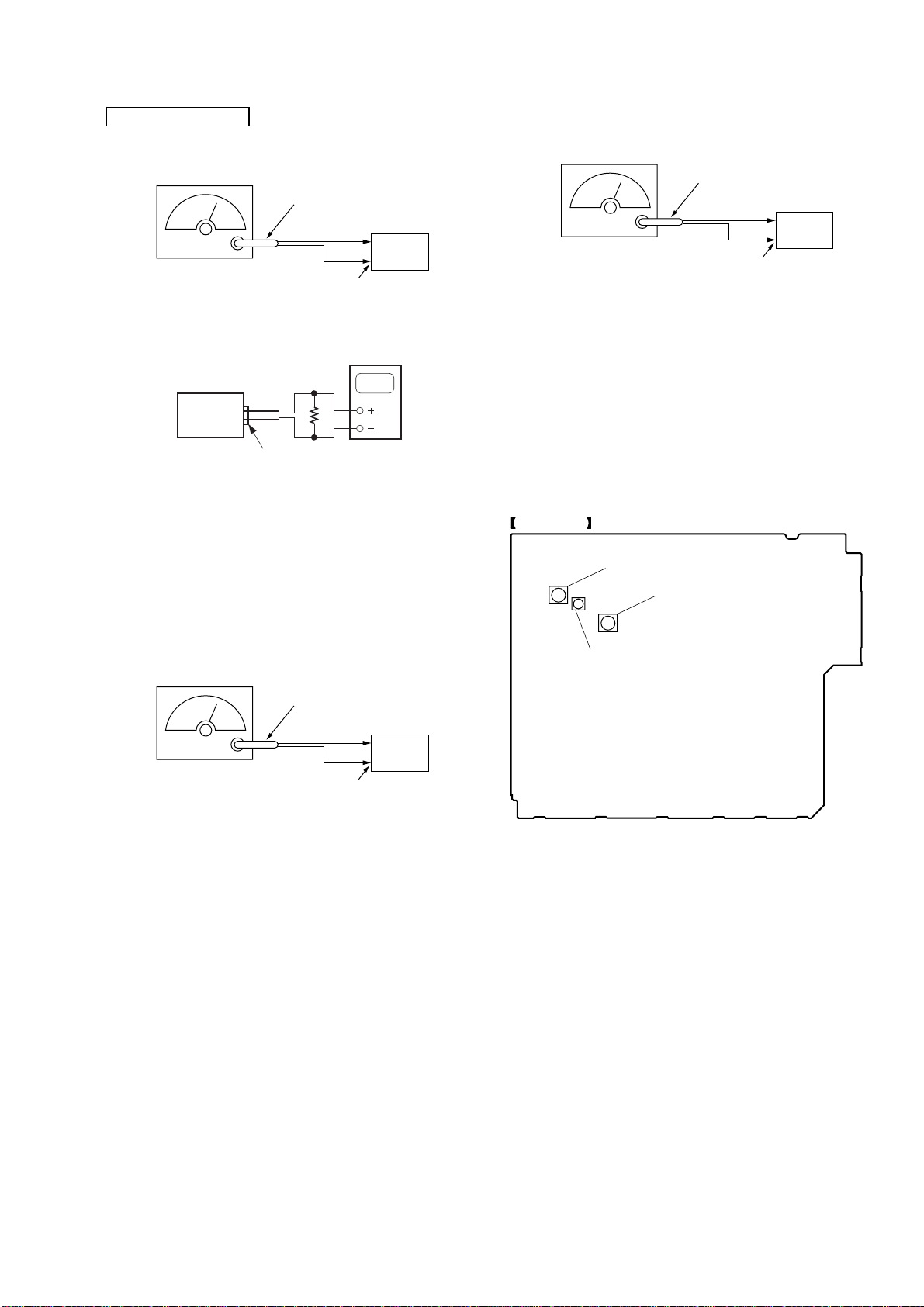

SECTION 5

l

l

MAIN BOARD Component side

RV101: FM TUNED LEVEL

T101:NULL

IFT101:AM IF

ELECTRICAL ADJUSTMENTS

HCD-RG55/RG55S

TUNER SECTION

AM IF Adjustment

AM RF Signalgenerator

75

Ω

coaxial

set

30% amplitude

Modulation by

400Hz signal

Output level : as low as possible

set

Procedure:

1. Set the frequency of the AM RF signal generator to 1000 kHz

(at 10 kHz step) or 999 kHz (at 9 kHz step).

2. Tune the set to AM 1000 kHz (at 10 kHz step) or 999 kHz (at 9

kHz step).

3. Adjust IFT101 so that the reading on level meter becomes in

maximum.

AM ANTENNA terminal

(JK101)

level meter

Ω

16

PHONES jack(JK801)

Null Adjustment

FM RF Signalgenerator

Ω

coaxial

75

set

Carrier frequency : 98MHz

Modulation : AUDIO 1kHz,75kHz

Output level : 60dB (at 75

deviation (100%)

Ω

open)

FM ANTENNA termina

(JK101)

Procedure:

1. Supply a 98 MHz signal at 60 dB from the ANTENNA

terminal.

2. Tune the set to 98 MHz.

3. Measure voltage between pin 21 and pin 23 of IC 101. Adjust

T101 ubtil the voltage becomes 0 V.

Adjustment Location: MAIN board

Adjustment Location:

FM Tuned Level Adjustment

FM RF Signalgenerator

Carrier frequency : 98MHz

Modulation : AUDIO 1kHz,75kHz

Output level : 28dB (at 75

Procedure:

1. Supply a 98 MHz signal at 28 dB from the ANTENNA

terminal.

2. Tune the set to 98 MHz.

3. Adjust RV101 to the point (moment) when the TUNED

indicator will change from going off to going on.

Adjustment Location: MAIN board

Ω

75

deviation (100%)

Ω

open)

coaxial

set

FM ANTENNA termina

(JK101)

21

Loading...

Loading...