Sony HCD-N455KW Service Manual

Q

Q

3

7

6

3

1

5

1

5

0

HCD-N455KW

SERVICE MANUAL

TEL 13942296513 QQ 376315150 892498299

HCD-N455KW is the tuner, deck, CD

and amplifier section in LBT-N455KW.

Model Name Using Similar Mechanism HCD-D570/N355/N355K

TEL

13942296513

CD

SECTION

TAPE

DECK

Q

SECTION

CD Mechanism Type CDM37-5BD19

Base Unit Type BU-5BD19

Optical Pick-up Type KSS-213BA/S-N

Model Name Using Similar Mechanism HCD-V4500

7

3

Q

Tape Transport Mechanism Type TCM-220WR2E

8

6

3

9

1

5

2

1

5

4

0

2

9

8

9

2

9

8

9

Thailand Model

4

2

9

8

9

TEL 13942296513 QQ 376315150 892498299

9

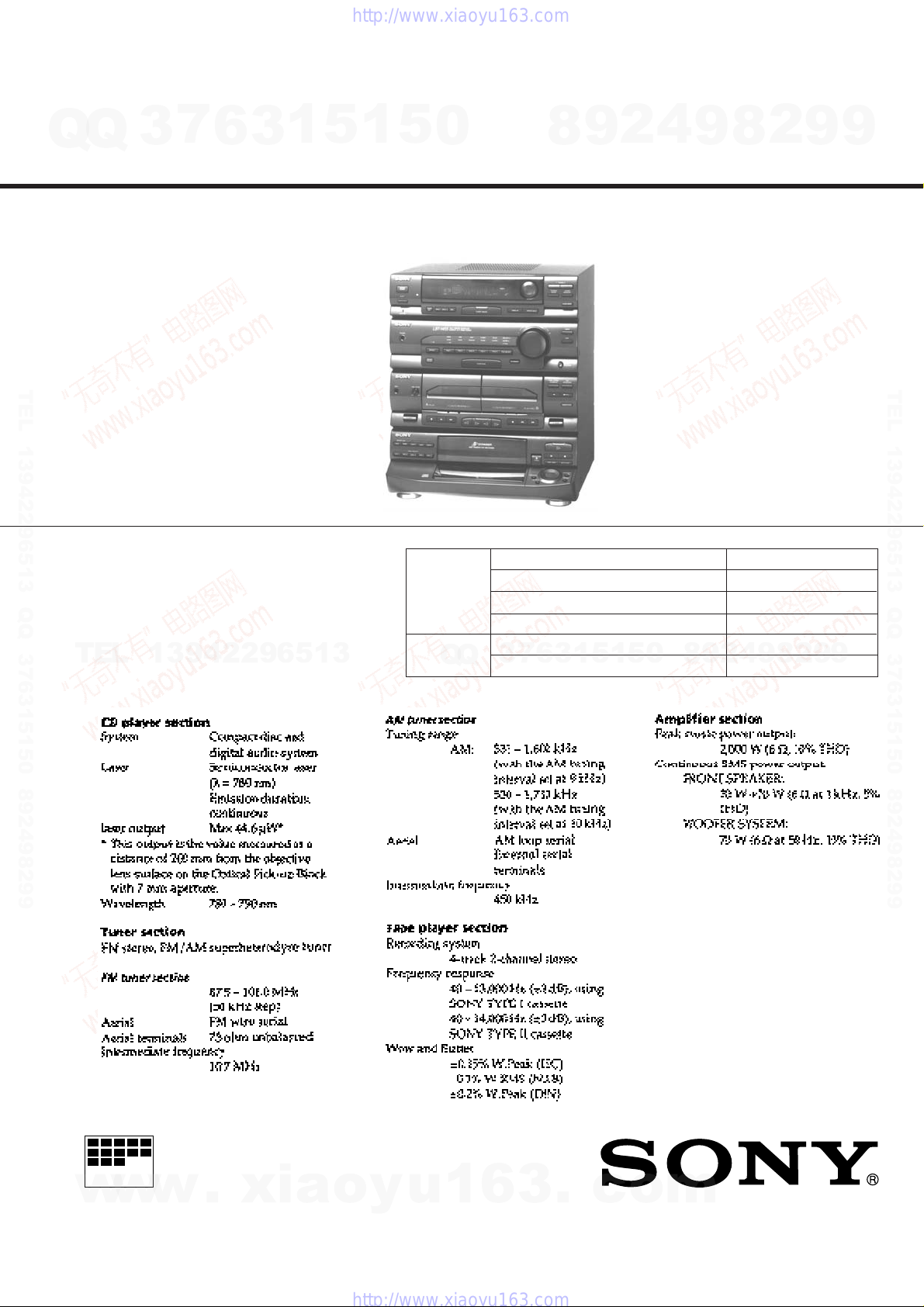

SPECIFICATIONS

— Continue on next page —

COMPACT Hi-Fi

STEREO SYSTEM

MICROFILM

w

w

w

.

xia

o

y

u

1

6

3

— 1 —

.

c

o

m

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

8

9

4

2

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

w

w

13942296513

w

.

xia

o

y

0

5

1

5

1

3

6

7

3

Q

Q

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

u

1

6

3

.

c

o

m

8

9

8

9

4

2

This caution

label is located

inside the unit.

2

9

9

— 2 —

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

3

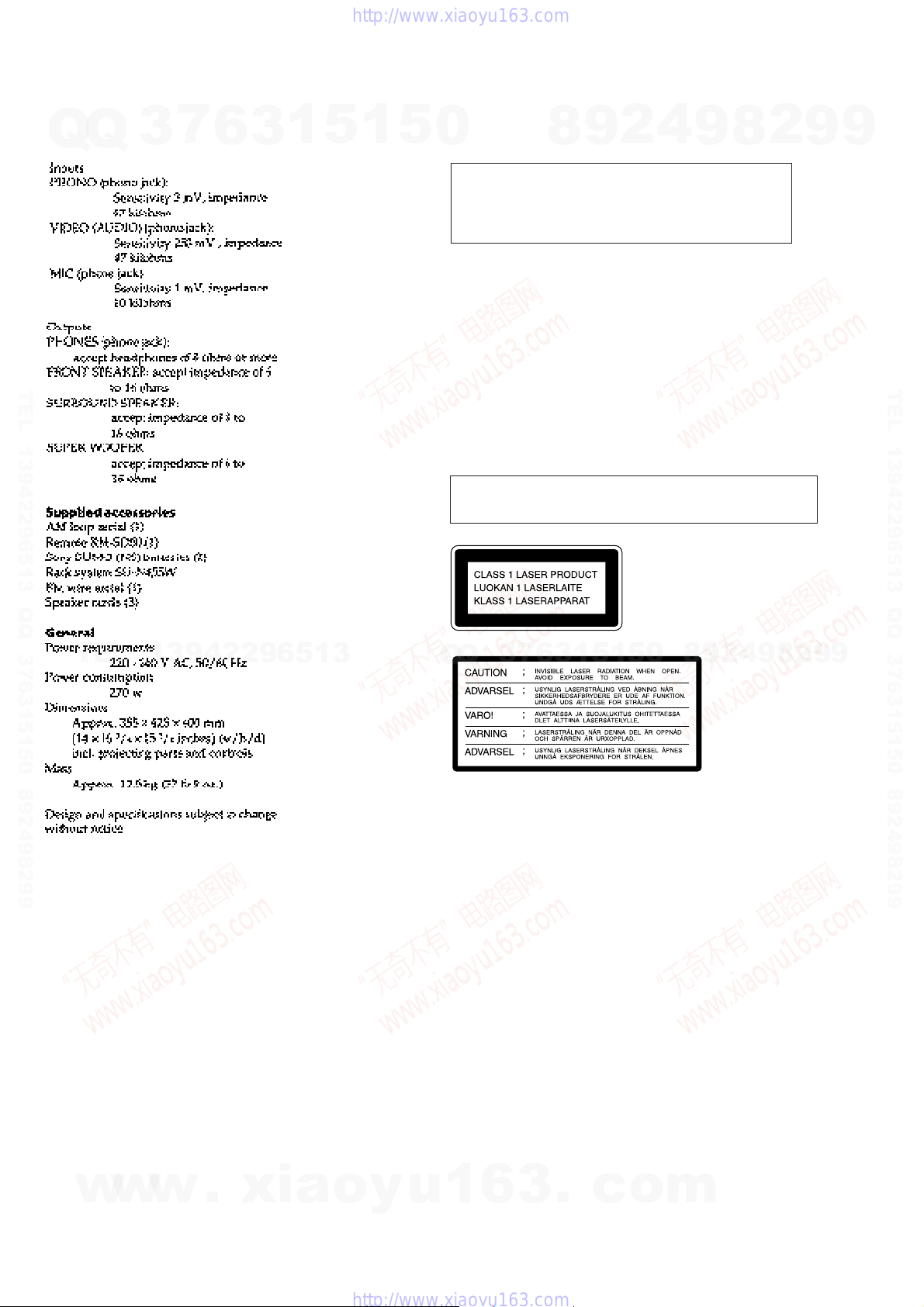

1. SERVICING NOTE

2. GENERAL ........................................................................... 4

3. DISASSEMBLY

3-1. Front Panel Assembly and Main Board ................................. 6

3-2. TC Mechanism Deck ............................................................. 6

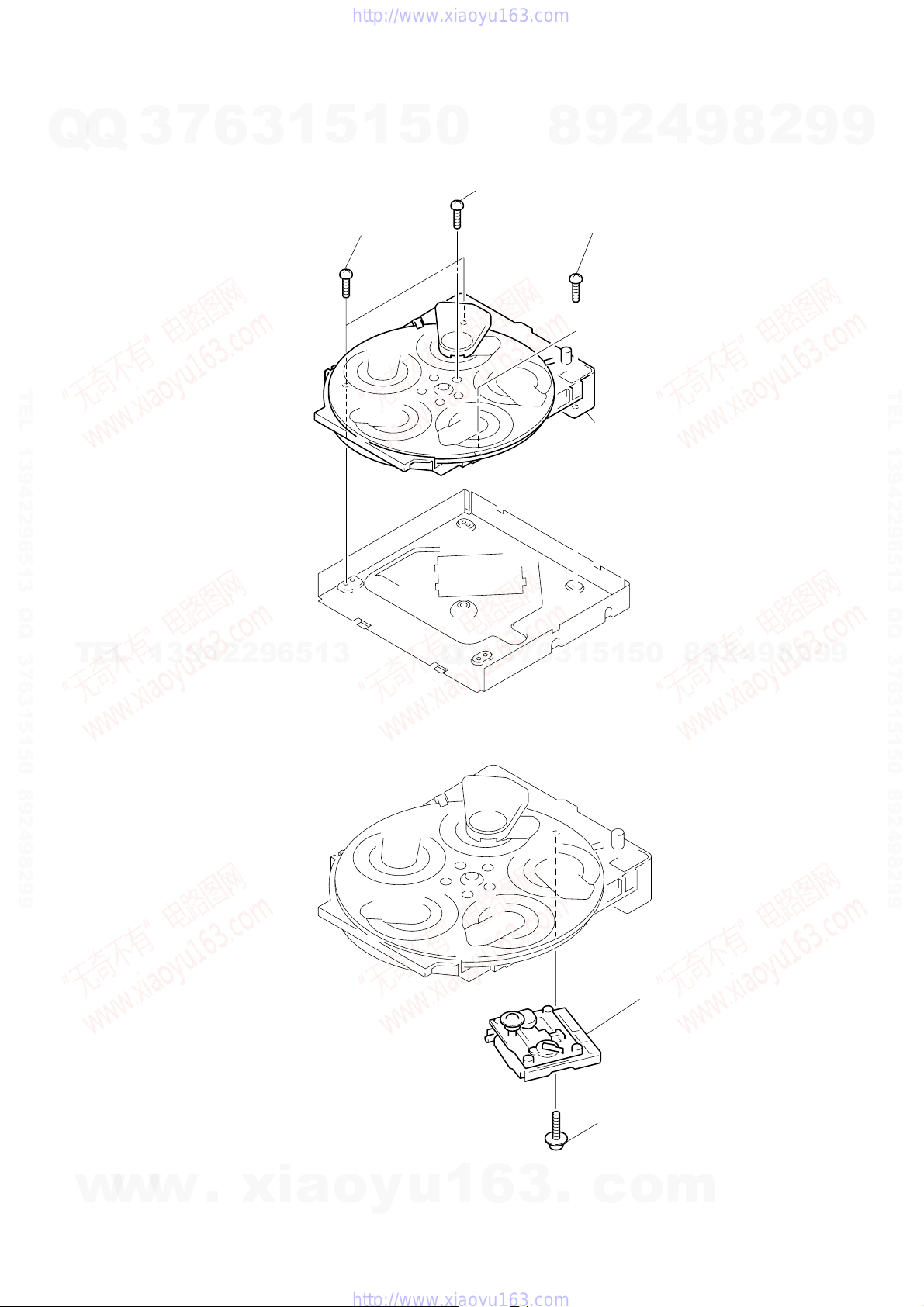

3-3. CD Mechanism Deck ............................................................. 7

3-4. BU Bracket Assembly............................................................ 7

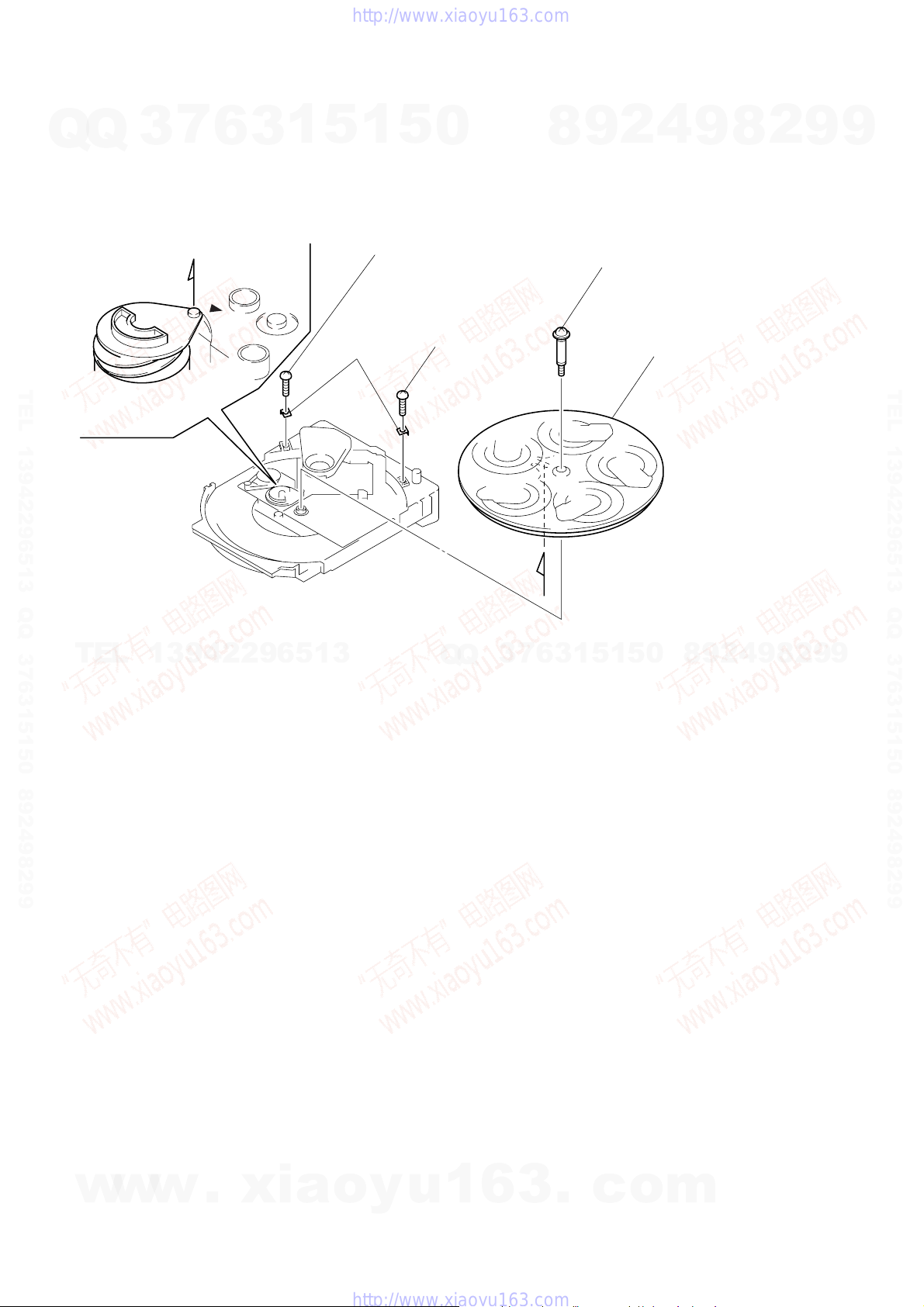

3-5. Disc Table .............................................................................. 8

4. MECHANICAL ADJUSTMENTS ................................. 9

5. ELECTRICAL ADJUSTMENTS

DECK Section ............................................................................... 9

TUNER Section........................................................................... 12

CD Section................................................................................... 13

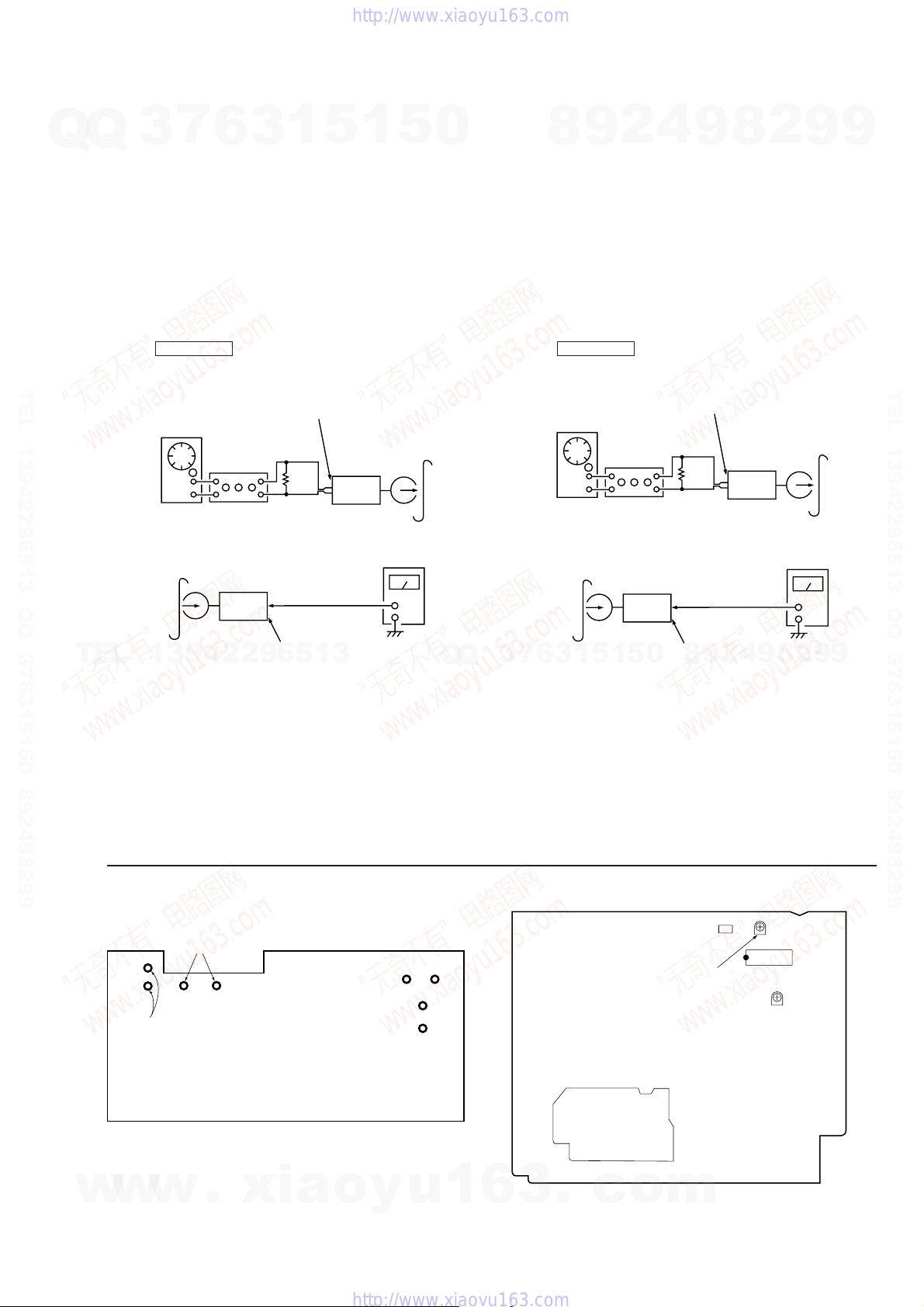

6. DIAGRAMS

6-1. Block Diagrams

• Tuner Section..................................................................... 15

• CD Section......................................................................... 17

• Deck Section...................................................................... 19

• Main Section...................................................................... 21

6-2. Circuit Boards Location ....................................................... 23

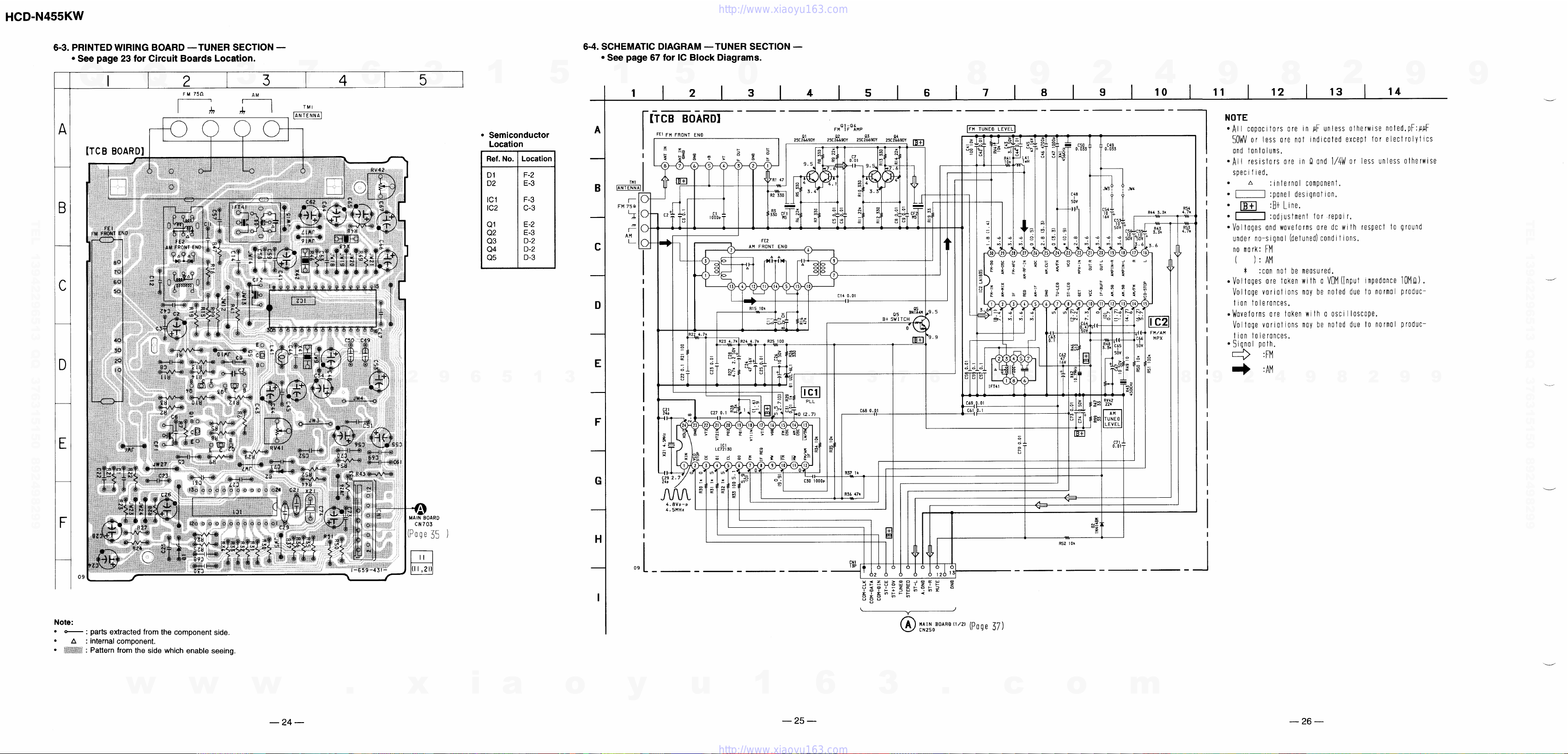

6-3. Printed Wiring Board — Tuner Section — .......................... 24

6-4. Schematic Diagram — Tuner Section —............................. 25

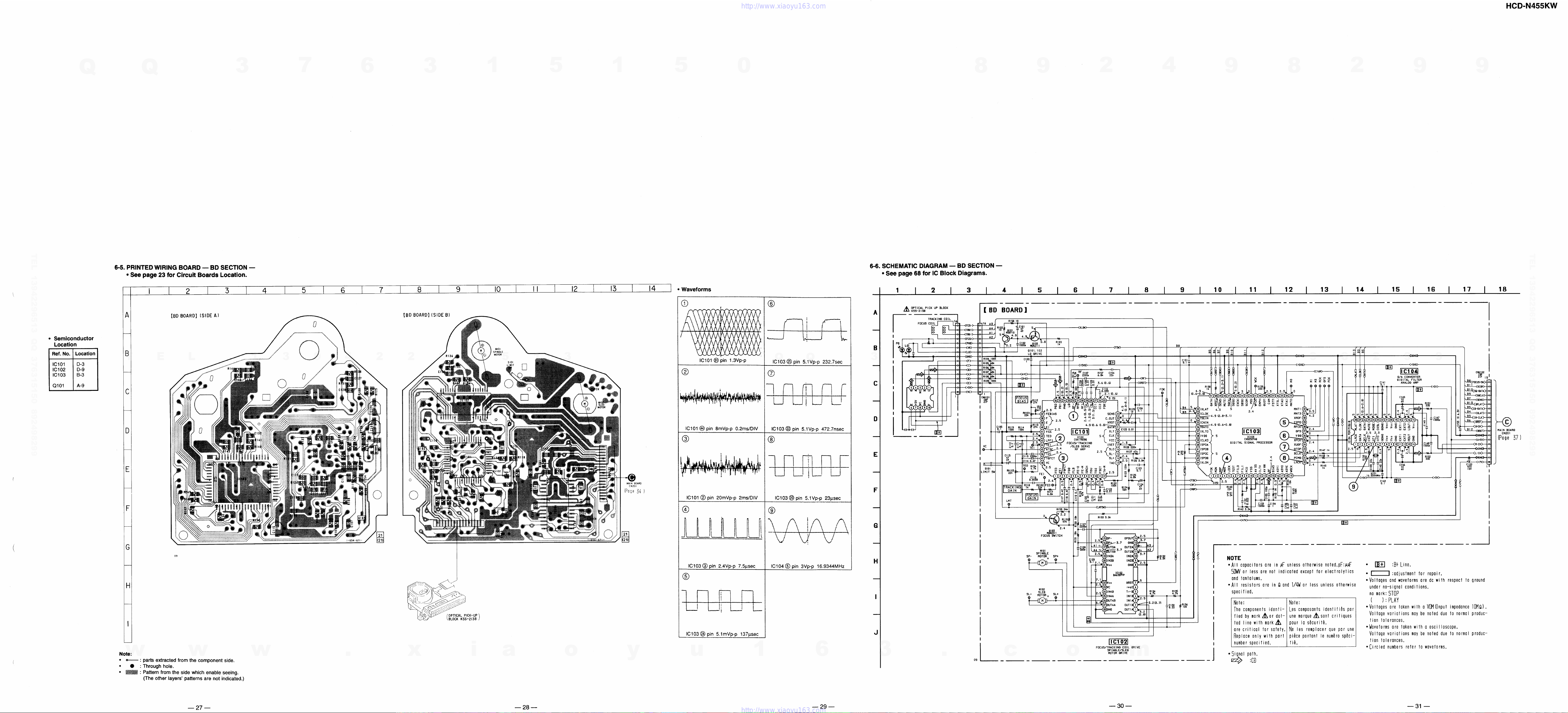

6-5. Printed Wiring Board — BD Section —.............................. 27

13942296513

6-6. Schematic Diagram — BD Section — ................................ 29

6-7. Printed Wiring Board — Main Section —.......................... 33

6-8. Schematic Diagram — Main Section — ............................. 37

6-9. Schematic Diagram — Deck Section — ............................. 41

6-10. Printed Wiring Board — Deck Section —......................... 45

6-11. Printed Wiring Board — Key Con Section — ................... 47

6-12. Schematic Diagram — Key Control Section — ................ 47

6-13. Printed Wiring Board — CD Motor Section —................. 49

6-14. Schematic Diagram — CD Motor Section —.................... 50

6-15. Printed Wiring Boar d — CD Panel Section — .................. 52

6-16. Schematic Diagram — CD Panel Section —..................... 53

6-17. Schematic Diagram — ST SW Section — ........................ 55

6-18. Printed Wiring Board — ST SW Panel Section —............ 57

6-19. Schematic Diagram — Panel Section — ........................... 59

6-20. Printed Wiring Boar d — Panel Section — ........................ 63

6-21. IC Block Diagrams............................................................. 67

6-22. IC Pin Functions

• IC501 Display Control (ASD0204GF-012-3BA)/

Panel board...................................................................... 72

• IC701 Master Control (TMP87CS64YF-6521)............... 73

6

1

5

1

3

............................................................ 4

5

0

TABLE OF CONTENTS

Q

Q

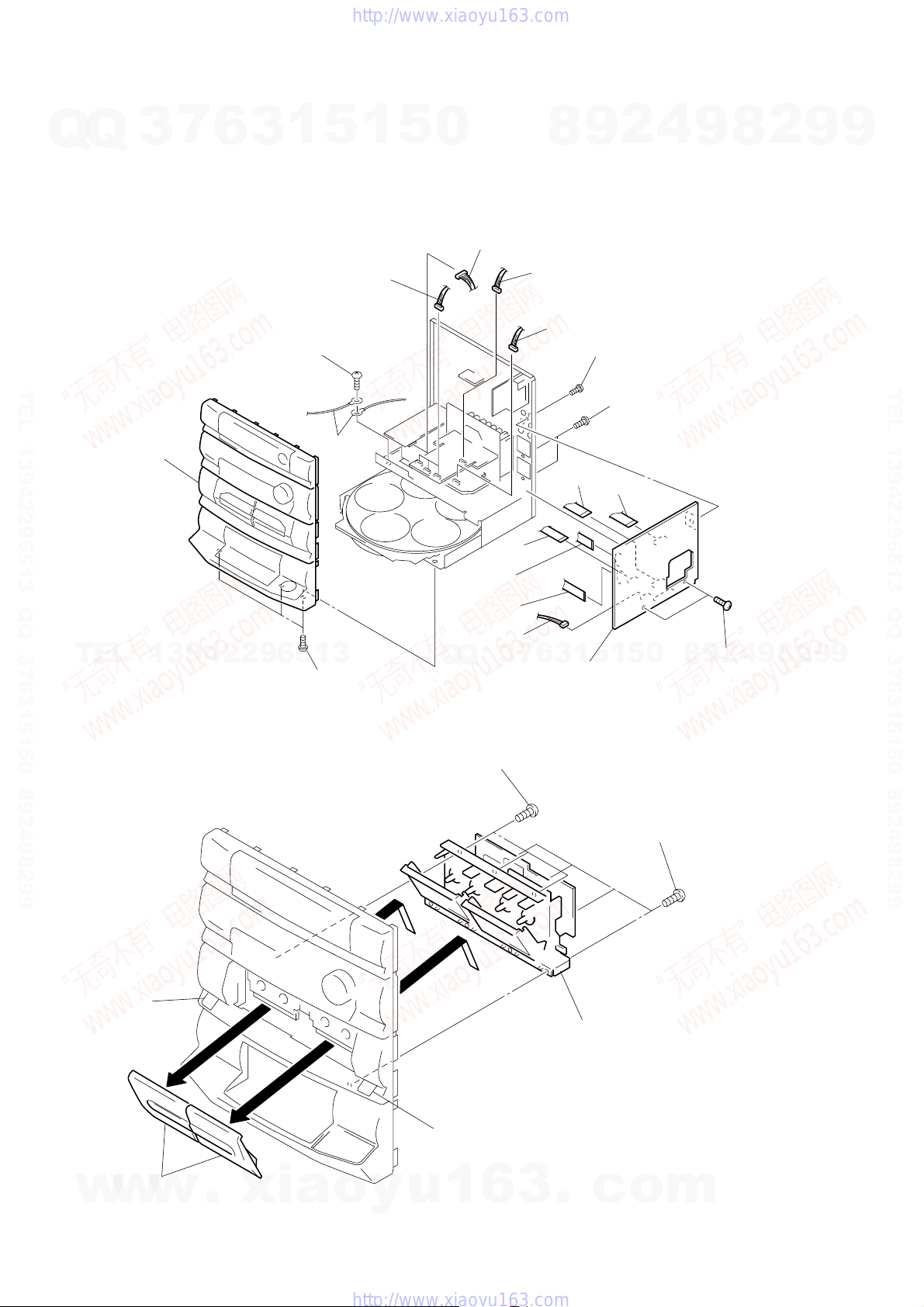

7. EXPLODED VIEWS

7-1. Cabinet and Back Panel Section .......................................... 76

7-2. Panel Board Section ............................................................. 77

7-3. Front Panel Section .............................................................. 78

7-4. Chassis Section .................................................................... 79

7-5. TC Mechanism Section 1 (TCM-220WR2E) ...................... 80

7-6. TC Mechanism Section 2 (TCM-220WR2E) ...................... 81

7-7. TC Mechanism Section 3 (TCM-220WR2E) ...................... 82

7-8. CD Mechanism Section (CDM37-5BD19).......................... 83

7-9. Base Unit Section (BU-5BD19)........................................... 84

8. ELECTRICAL PARTS LIST ......................................... 85

7

3

8

6

3

9

1

5

2

1

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

— 3 —

.

c

o

m

SECTION 1

7

Q

Q

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-do wn and also use

the procedure in the printed matter which is included in the repain

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

TEL 13942296513 QQ 376315150 892498299

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pick-up

block. Therefore, when checking the laser diode emission, observe

from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERA TION CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

3

6

3

1

SERVICING NOTE

5

1

5

0

FL Display Tube, LED All Lit and Key Check mode

When the TUNER/BAND , DISPLA Y/DEMO , and FILE 2 b uttons are pressed simultaneously, the FL display tube and LEDs will

all light up. Press any button to enter the key check mode.

When the key check mode is entered, the FL display tube displays

“K 1 J0 V0”. Each time a button is pressed, the counter increases in

the following order, K 2 n K 3 n K 4.

If buttons already pressed once are pressed again, the counter will

not increase. When the VOLUME knob is rotated in the + direction,

the count increases in the following order.

V1 n V2 n V3.

When rotated in the – direction, it decreases in the following order.

V0 n V9 n V8.

When the AMS dial is rotated in the clockwise direction, the count

increases in the following order.

J1 n J2 n J3.

When rotated in the counterclockwise direction, it decreases in the

following order.

J0 n J9 n J8.

T o exit form the test mode, press the TUNER/BAND , DISPLAY/

DEMO , FILE 2 buttons simultaneously again.

Switching the channel step 9 kHz/10 kHz

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Press ENTER/NEXT button and SYSTEM POWER button simultaneously to switch the AM channel step 9 kHz and 10 kHz. Be sure

not to change with carelessness.

All Reset

When TUNER/BAND , DISPLAY/DEMO , and FILE3 buttons

Q

Q

are pressed simultaneously, the contents of a preset are r estored to

those at shipping.

SECTION 2

GENERAL

3

7

6

3

1

9

8

0

5

1

5

This section is extracted from

instruction manual.

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

— 4 —

.

c

o

m

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

— 5 —

.

c

o

m

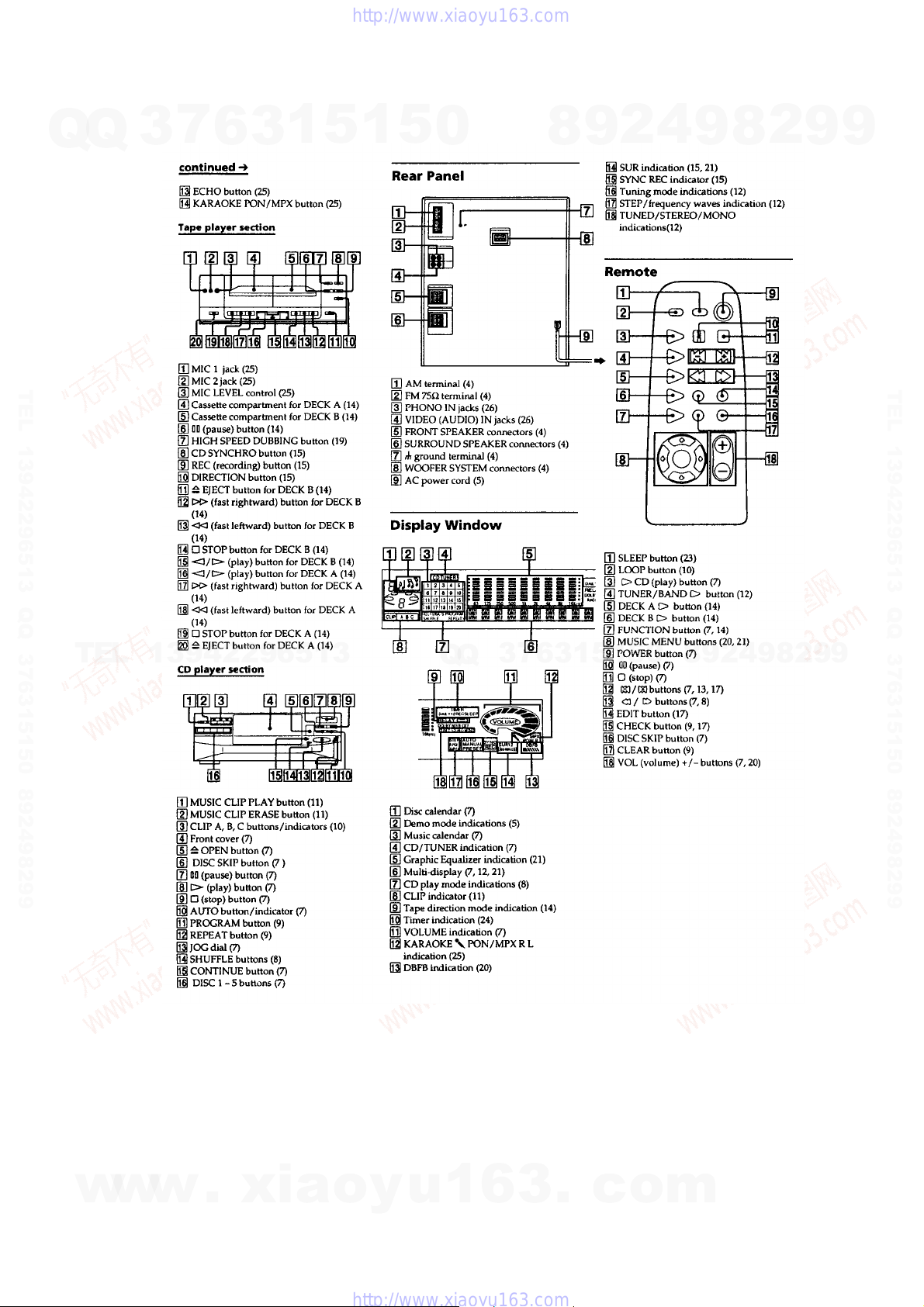

SECTION 3

7

Q

Q

Note : Follow the disassembly procedure in the numerical order given.

3-1. FRONT PANEL ASSEMBLY AND MAIN BOARD

1

Remove the connectors.

• Main board (Six connectors)

• ST SW board (Four connectors)

• AMPLIFIER board (One connector)

• TRANS board (One connector)

3

6

1

3

CN3103, CN3107,

CN3108

2

Screw (BVTT 3x6)

DISASSEMBLY

5

1

5

0

CN1604

8

CN3101

CN1204

2

9

6

Screw (BVTP 3x8)

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

3

5

Front panel

assembly

TEL

3-2. TC MECHANISM DECK

1

Push the eject button. (two positions)

13942296513

Wire

4

Three screws

(BVTP 3x8)

Q

Q

3

Three screws

(BVTP 2.6x8)

CN402

CN401

CN702

CN203

3

7

6

CN201

1

3

7

Two screws (BVTP 3x8)

CN703

0

5

1

5

9

Main board

4

Four screws

(BVTP 2.6x8)

8

9

8

Two screws

4

2

(BVTP 3x8)

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

Eject button

2

Two cassette lids

w

w

w

.

xia

Eject button

o

y

u

1

6

3

— 6 —

5

Mechanism deck

.

c

o

m

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

3-3. CD MECHANISM DECK

6

3

1

5

2

Two screws

(BVTP 3x8)

1

5

0

1

Screw (BVTP 3x8)

8

2

9

3

Two screws

(BVTP 3x8)

4

CD Mechanism

deck

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

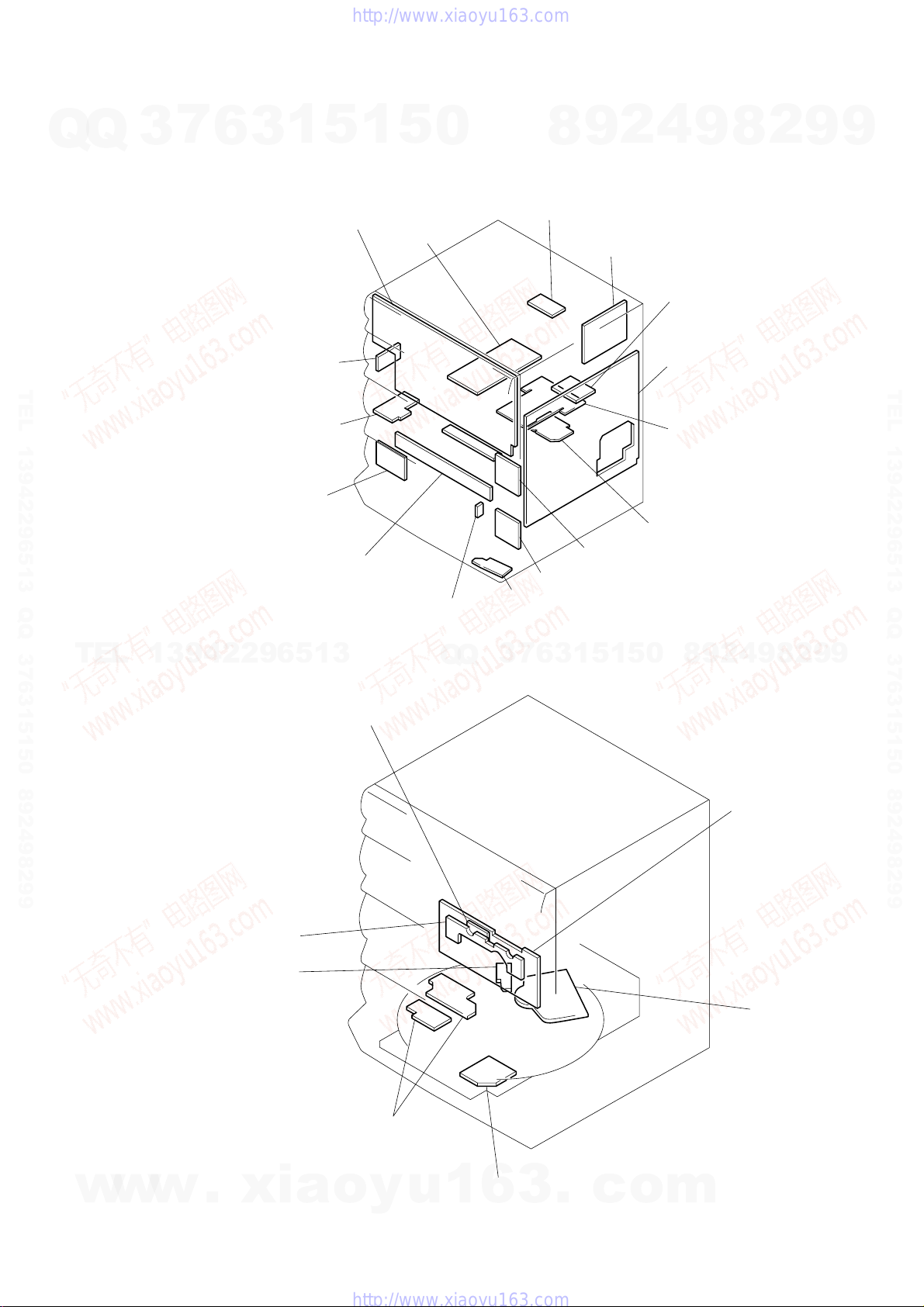

3-4. BU BRACKET ASSEMBLY

Q

Q

3

7

5

1

3

6

2

BU bracket assembly

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

— 7 —

.

1

Yoke bracket

c

o

m

7

Q

Q

3-5. DISC TABLE

Note :

When the Disc table is installed, adjust the positions

of Roller cam and mark ” as shown in the figure, then

set to the groove of disc table.

TEL 13942296513 QQ 376315150 892498299

3

6

A

3

1

5

3

Bracket (BU)

1

5

1

Screw (BVTP 3x8)

0

2

Screw (BVTP 3x8)

A

8

9

4

4

2

Step screw

5

9

Disc table

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

— 8 —

.

c

o

m

SECTION 4

MECHANICAL ADJUSTMENTS

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

3

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head dema gnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

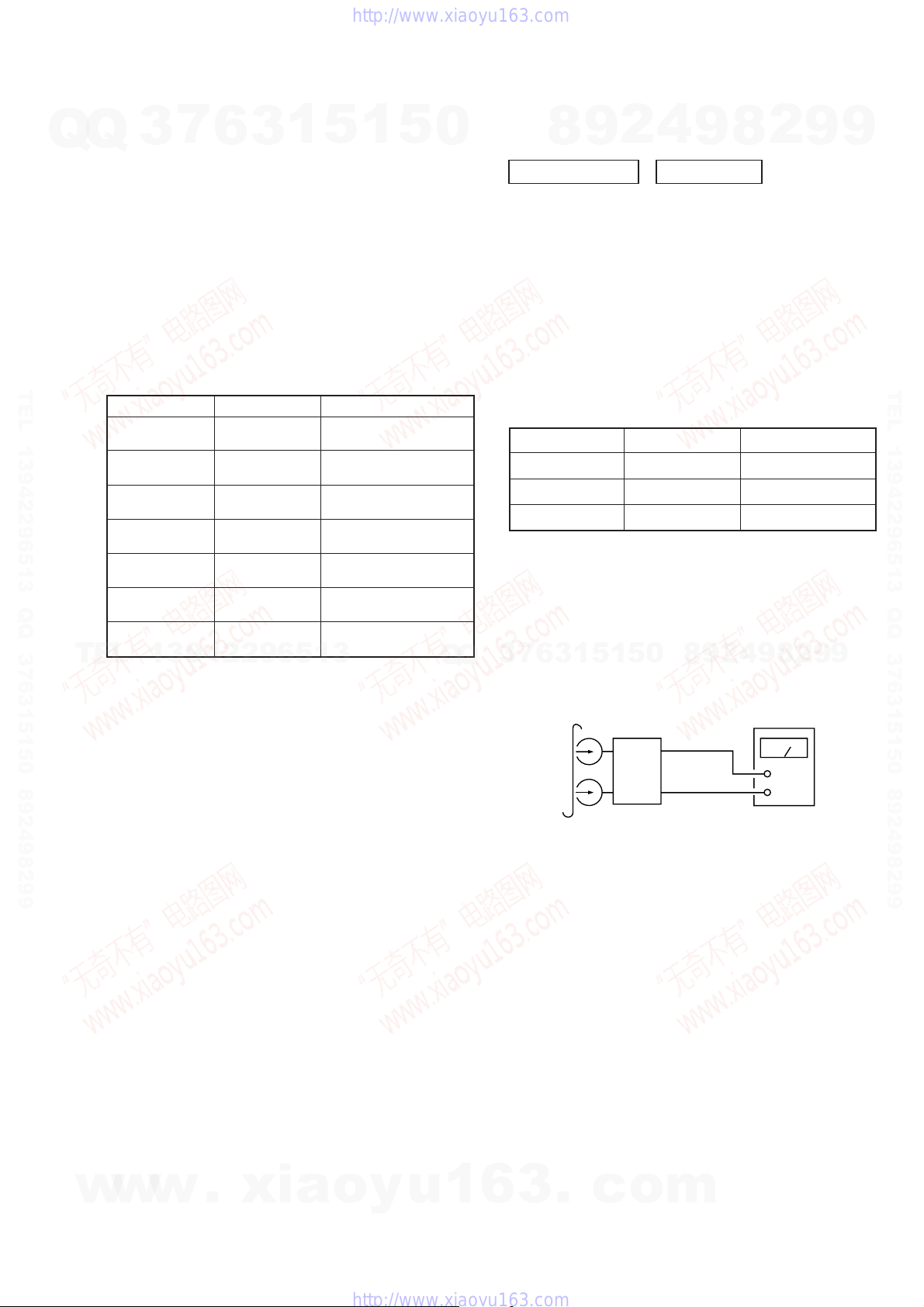

Torque Measurement

Torque

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

13942296513

6

Torque meter

3

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

1

5

1

Meter reading

36 to 61 g • cm

(0.5 - 0.84 oz • inch)

2 to 6 g • cm

(0.02 - 0.08 oz • inch)

36 to 61 g • cm

(0.5 - 0.84 oz • inch)

2 to 6 g • cm

(0.02 - 0.08 oz • inch)

61 to 143 g • cm

(0.85 - 1.99 oz • inch)

100 g or more

(3.53 oz or more)

100 g or more

(3.53 oz or more)

5

0

Q

Q

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head damagnetizer .

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit adjustment.)

6. The adjustments should be performed for both L-CH and R-CH.

7. Switches and controls should be set as follows unless otherwise

specified.

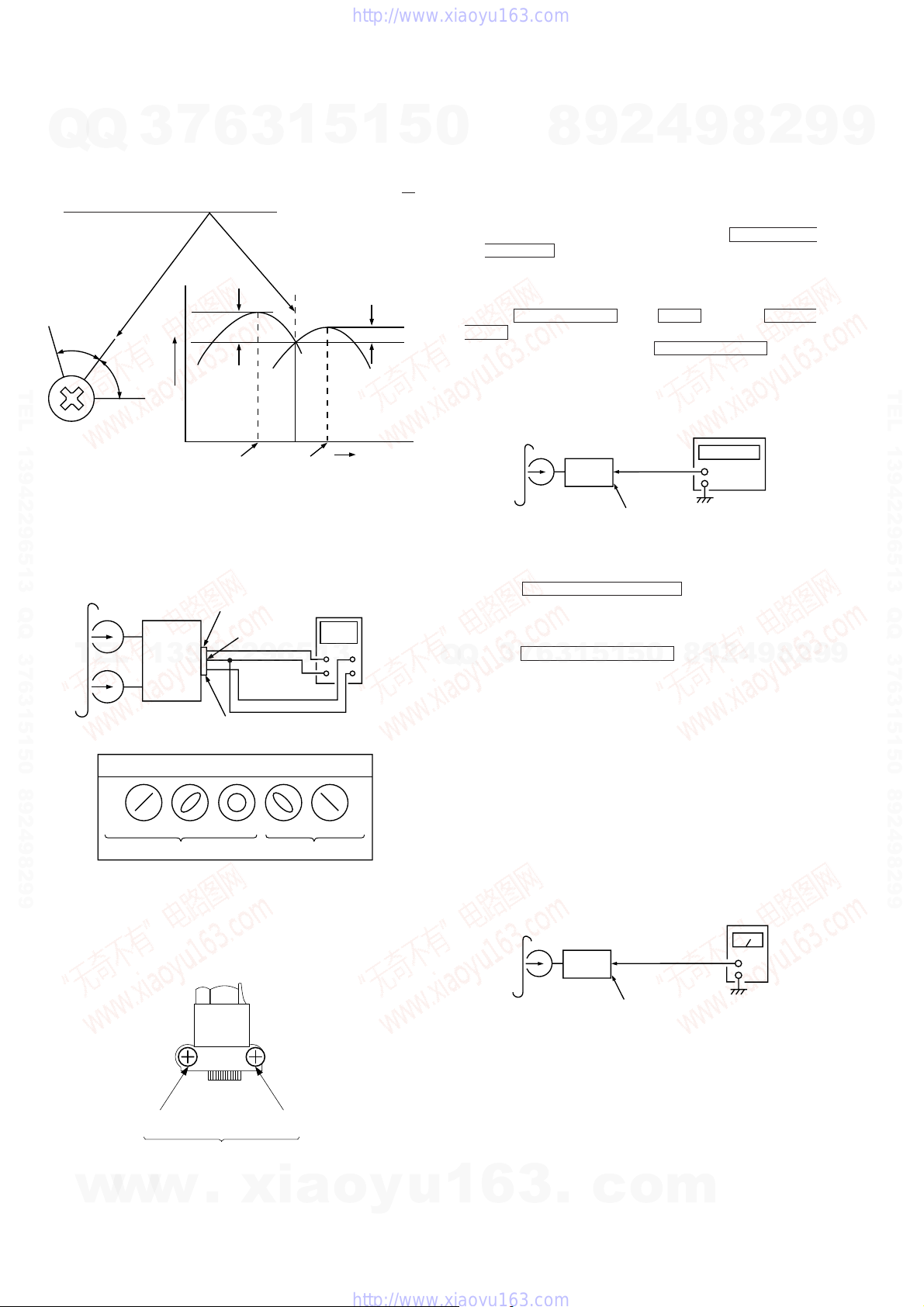

Record/Playback Head Azimuth Adjustment

(Deck A, Deck B)

Note: Perform this adjustments for both decks.

Procedure:

1. Mode : Playback

7

3

SECTION 5

ELECTRICAL ADJUSTMENTS

9

8

P-4-A100

WS-48B

P-4-L300

5

1

3

6

2

1

5

4

9

Signal

10 kHz, –10 dB

3 kHz, 0 dB

315 Hz, 0 dB

9

8

0

2

2

8

Azimuth Adjustment

Ta pe Speed Adjustment

Level Adjustment

8

9

4

Used forTape

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

test tape

P-4-A100

(10kHz, –10dB)

set

main board

CN403

Pin

3

(L-CH)

1

(R-CH)

Pin

main board

CN403

Pin

2

(GND)

level meter

+

–

w

w

w

.

xia

o

y

u

1

6

3

— 9 —

.

c

o

m

7

Q

Q

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw so

that outputs match within 1 dB of peak.

L-CH

peak

TEL 13942296513 QQ 376315150 892498299

screw

position

3. Mode: Playback

test tape

P-4-A100

(10kHz, –10dB)

TEL

3

output

level

R-CH

peak

set

13942296513

6

within

1dB

L-CH

peak

main board

CN403

Pin

3

(L-CH)

L

R

Pin

1

(R-CH)

Wavefor m of oscilloscope

3

Pin

2

1

R-CH

peak

(GND)

5

within 1dB

oscilloscope

1

screw

position

5

0

Tape Speed Adjustment (Deck A)

Note: Start the T a pe Speed adjustment as belo w after setting the test

mode.

The tape speed can be changed with the HIGH SPEED

DUBBING button during the test mode.

Method :

1. Turn the power switch on.

2. Press the DISPLAY/DEMO button, FILE 1 button and TUNER/

BAND button simultaneously.

To exit from the test mode, Press the SYSTEM POWER button.

Procedure :

Mode: Playback

test tape WS-48B

(3kHz, 0dB)

1. Insert the WS-48B into the deck A to playback.

2. Press the HIGH SPEED DUBBING button. Then at HIGH

SPEED mode.

3. Adjust the RV652 on the AUDIO board so that the frequency

counter reading becomes 6,000 ± 30 Hz.

4. Press the HIGH SPEED DUBBING button again to be set the

Q

Q

NORMAL SPEED mode.

5. Set to the playback mode.

6. Adjust the RV651 on the AUDIO board so that the frequency

counter reading becomes 3,000 ± 15 Hz.

Frequency difference between deck A and deck B the beginning

of the tape should be within ± 1.5%.

3

7

8

6

3

9

set

main board

CN403 Pin

5

1

2

1

Pin

5

4

3

1

0

(L-CH)

(R-CH)

8

9

frequency counter

+

–

4

2

9

8

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

in phase

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Adjustment Location: Playback Head (Deck A)

FWD side

w

w

45˚

90˚

Record/Playback/Erase Head (Deck B)

Adjustment screw

w

.

135˚ 180˚

wronggood

REV side

xia

o

y

— 10 —

Adjustment Location: AUDIO board

Playback Level Adjustment (Deck A, Deck B)

Procedure:

Mode: Playback

test tape P-4-L300

(315Hz, 0dB)

set

main board

CN403 Pin

Deck A is RV311 (L-CH) and RV411 (R-CH), deck B is RV301

(L-CH) and RV401 (R-CH)

so that adjustment within the following adjustment level.

Adjustment level:

CN403 playback level: 301.5 to 338.3 mV (–8.2 to –7.2 dB)

level difference between the channels: within ± 0.5 dB

Adjustment Location: AUDIO board

u

1

6

3

.

c

Pin

o

3

(L-CH)

1

(R-CH)

m

level meter

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

Record Bias Adjustment (Deck B)

Procedure:

Reference)

When set to the test mode performed in T ape Speed Adjustment,

when the tape is rewound after recording, the “REC memory mode”

which rewinds only the recorded portion and stops is set.

This “REC memory mode” is convenient for performing this adjustment.

1. Press FUNCTION button to select VIDEO.

2. Mode: record

AF OSC

3. Mode: Playback

recorded

position

6

attenuator

1

3

VIDEO (AUDIO) IN

1) 315Hz

2) 10kHz

600

5

} 50 mV (–23.8 dB)

Ω

1

set

5

blank tape

CS-123

level meter

0

Record Level Adjustment (Deck B)

Procedure:

Reference)

When set to the test mode performed in T ape Speed Adjustment,

when the tape is rewound after recording, the “REC memory mode”

which rewinds only the recorded portion and stops is set.

This “REC memory mode” is convenient for performing this

adjustment.

1. Press FUNCTION button to select VIDEO.

2. Mode: record

3. Mode: Playback

8

AF OSC

recorded

position

9

2

attenuator

4

VIDEO (AUDIO) IN

315 Hz 50 mV (–23.8 dB)

9

Ω

8

set

2

level meter

9

blank tape

CS-123600

9

TEL 13942296513 QQ 376315150 892498299

set

TEL

13942296513

4. Confirm playback the signal recorded in step 2 become adjustment level as follows.

If these levels do not adjustment level, adjust the RV341 (L-CH)

and RV441 (R-CH) on the AUDIO board to repeat steps 2 and 3.

Adjustment level: The playback output of 10 kHz level difference

Adjustment Location: AUDIO board

Adjustment Location

[AUDIO BOARD] (Conductor Side)

RV341(Lch),RV441(Rch)

Record Bias

RV301

RV401

RV441 RV341

RV301(Lch),RV401(Rch)

Playback Level (Deck B)

main board

CN403 Pin

against 315 Hz reference should be ± 0.5 dB.

3

(L-CH)

Pin

1

(R-CH)

RV651 (Normal Speed)

RV652 (High Speed)

Tape Speed

RV311(Lch),RV411(Rch)

Playback Level (Deck A)

RV311

RV411

set

Q

4. Confirm playback the signal recorded in step 2 become adjustment level as follows.

If these levels do not adjustment level, adjust the RV301 (L-CH)

and RV351 (R-CH) on the main board to repeat steps 2 and 3.

Adjustment level:

CN403 PB level: 47.2 to 53.0 mV (–24.3 to –23.3 dB)

Adjustment Location: MAIN board

[MAIN BOARD] (Component Side)

RV652RV651

CN403 Pin

RV351

Record Level Adjustment

(R CH)

main board

0

5

1

5

1

3

6

7

3

Q

2

9

8

3

Pin

1

1 3

CN403

RV301

Record Level Adjustment

(L CH)

9

4

(L-CH)

(R-CH)

IC401

8

RV351

RV301

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

— 11 —

.

c

o

m

7

Q

Q

TUNER SECTION 0dB=1µV

Note: 1. As a front-end (FE1) is difficult to repair if faulty, replace

AM Tuned Level Adjustment

Note: FM Tuned Level adjustment should be performed after this

AM Tuned Level Adjustment.

Setting:

Band: MW

TEL 13942296513 QQ 376315150 892498299

3

it with new one.

AM RF SSG

30% amplitude

modulation by

400Hz signal

Modulation: 999 kHz (at 9 kHz step)

1,050 kHz (at 10 kHz step)

6

1

3

loop antenna

5

1

5

0

loop antenna

(Supplied accessories)

60cm

Field strength dB (µV/m) = SSG output level dB (µV/m) –26dB.

AM antenna

terminal (TM1)

8

set

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

Procedure:

TEL

1. Set the output of SSG so that the input level of the set becomes 55

dB.

2. Tune the set to 999 kHz or 1,050 kHz.

3. Adjust RV42 to the point (moment) when the TUNED indicator

will change from going off to going on.

Adjustment Location: TCB board

FM Tuned Level Adjustment

Note: This adjustment should be performed after the AM Tuned

Level Adjustment.

Setting:

Band: FM

FM RF SSG

Carrier frequency: 98MHz

Modulation: AUDIO 1kHz, 75kHz

Output level: 25dB (at 75

Procedure:

1. Supply a 25 dB 98 MHz signal from the ANTENNA terminal.

2. Tune the set to 98 MHz.

3. Adjust RV41 to the point (moment) when the TUNED indicator

will change from going off to going on.

13942296513

75 Ω coaxial

deviation (100%)

Ω

open)

FM ANTENNA terminal

(TM1)

set

Adjustment Location

Q

[TCB BOARD] (Component Side)

Q

3

3

6

7

RV41

FM Tuned Level

1

5

1

5

IC2

FE1

0

9

8

RV42

AM T uned

Level

2

4

TM1

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

— 12 —

.

c

o

m

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

3

CD SECTION

Note:

1. CD Block is basically constructed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10M impedance.

4. Clean the object lens by an applica tor with neutral detergent when

the signal level is low than specified value with the following

checks.

5. Adjust the focus bias adjustment when optical block is replaced.

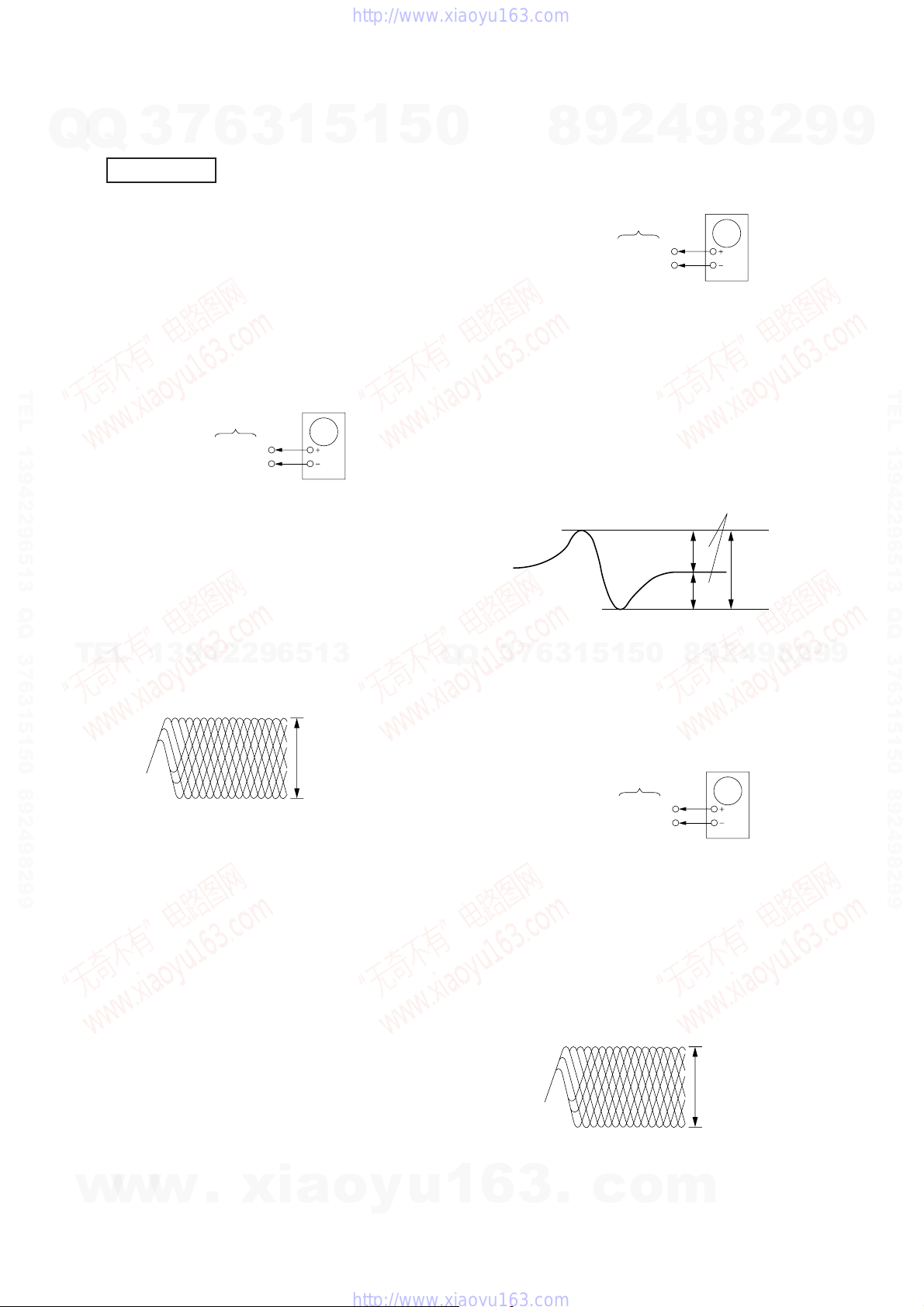

Focus Bias Adjustment

Procedure:

1. Connect oscilloscope to test point TP (RF).

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Adjust RV101 so that the waveform is clear.

(Clear RF signal waveform means that the shape “◊” can be clearly

distinguished at the center of the waveform.)

5. After adjustment, check the RF signal level.

• RF signal

13942296513

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

6

BD board

TP (RF)

TP (VC)

3

1

oscilloscope

5

1

5

0

Q

Q

S Curve Check

Procedure :

1. Connect oscilloscope to test point TP (FEO).

2. Connect between test point TP (FOK) and Ground by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc table

is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within 2.4 ± 0.7

Vp-p.

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure than the ratio of

7

3

4

2

9

8

BD board

TP (FEO)

TP (VC)

S-curve wavef orm

0

5

1

5

1

3

6

A : B or B : A is more than 10 : 7.

• Tak e sweep time as long as possible and light up the brightness to obtain best waveform.

9

oscilloscope

symmetry

A

B

9

8

2

2

9

8

9

2

8

within 2.4 ± 0.7 Vp-p

4

9

9

9

TEL 13942296513 QQ 376315150 892498299

level: 1.3 ± 0.3 Vp-p

RF Level Check

oscilloscope

BD board

TP (RF)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal

level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

level: 1.3 ± 0.3 Vp-p

w

w

w

.

xia

o

y

u

1

6

3

— 13 —

.

c

o

m

7

Q

Q

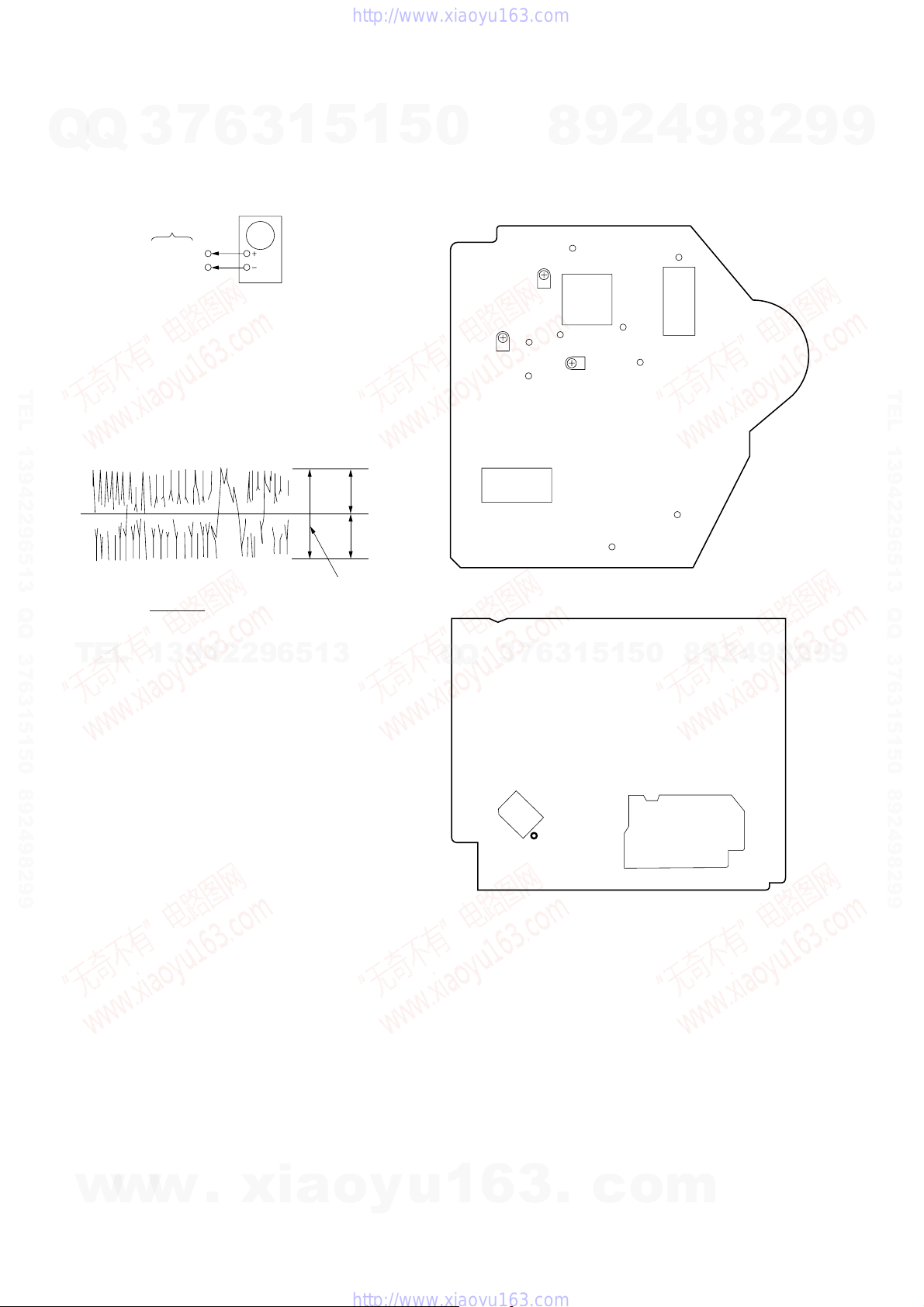

E-F Balance Check

Procedure:

1. Connect test point TP703 (ADJ2) on Main board to Ground with

a lead wire.

2. Connect oscilloscpe to test point TP (TEO).

3. Turned Power switch on.

TEL 13942296513 QQ 376315150 892498299

4. Put disc (YEDS-18) in and playback.

5. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0Vdc, and check this level.

Traverse waveform

0V

Specified level: • x 100 = less than ± 7 (%)

TEL

6. Remove the lead wire connected in step 1.

3

BD board

TP (TEO)

TP (VC)

A – B

2 (A + B)

• A + B = 300 ± 100 mVp-p

13942296513

6

oscilloscope

1

3

level: 300 ± 100 mVp-p

5

1

A

B

5

0

Adjustment Location:

[BD BOARD] — Component Side —

RV101

RV103

TEO

VC

IC104

[MAIN BOARD] — Conductor Side —

7

3

Q

Q

8

FEO

6

RF

RV102

3

9

IC101

1

5

GND

1

2

TEI

FEI

5

4

0

FOK

PCK

9

IC102

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Focus/Tracking Gain Adjustment (RV102, RV103)

This gain has a margin, so even if it is slightly off.

There is no problem.

Therfore, do not perform this adjustment.

Please note that it should be fixed to mechanical center position when

you moved and do not know original position.

IC701

TP703

(ADJ2)

w

w

w

.

xia

o

y

u

1

6

3

— 14 —

.

c

o

m

HCD-N455KW

SECTION 6

DIAGRAMS

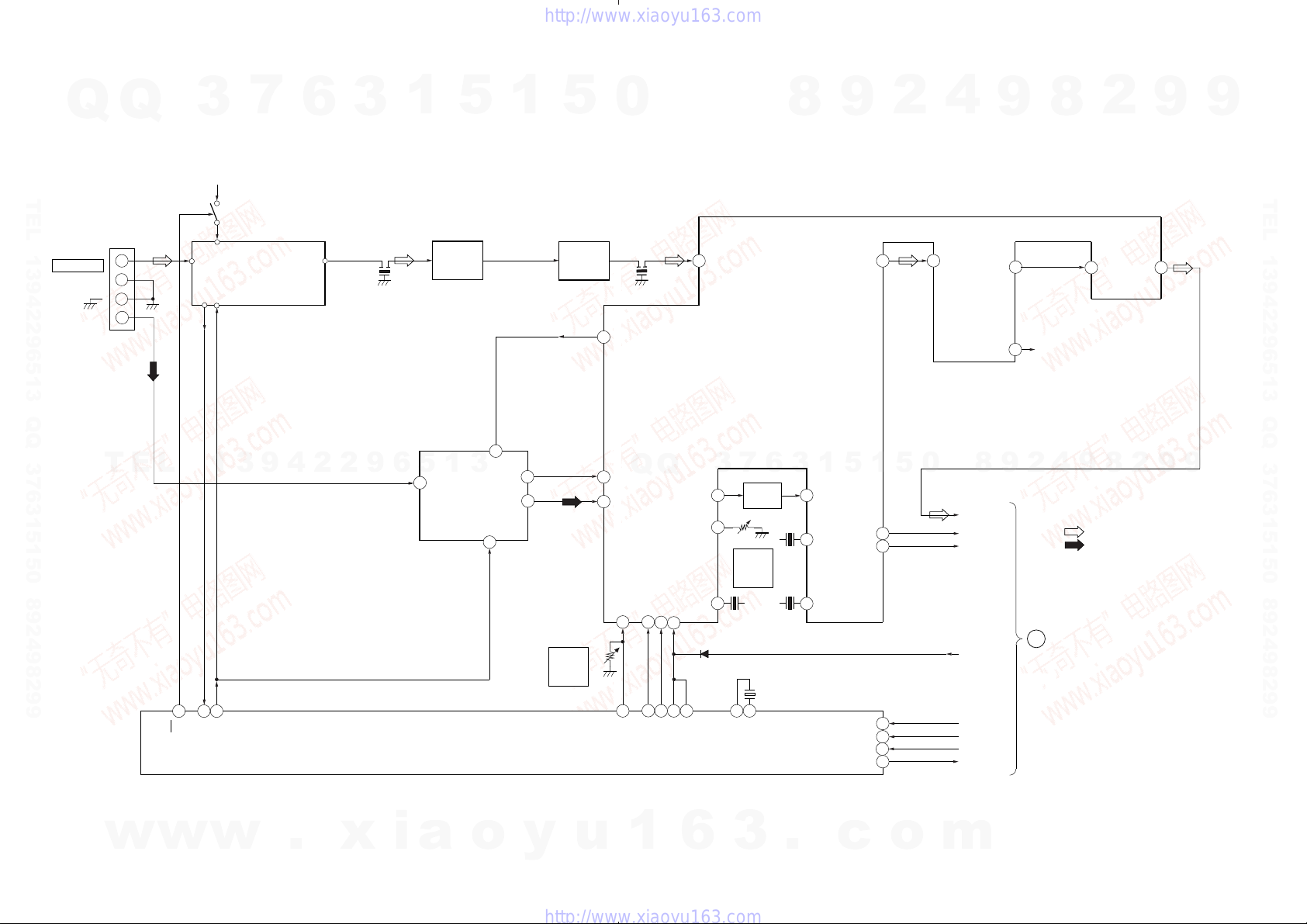

6-1. BLOCK DIAGRAMS

—TUNER SECTION—

Q

Q

3

ST +10V

7

6

3

1

5

1

TEL 13942296513 QQ 376315150 892498299

TM1

ANTENNA

FM 75Ω

Q5

ANT IN

F OUT

VT

AM

T

E

L

09

1

3

191510

FM

PD1

FM OSC

FE1

FM FRONT END

IF OUT

9

4

2

2

CF1

10.7MHz

9

6

IF AMP

Q1, 2

FE2

AM FRONT END

5

1

ANT IN

3

PLL

IC1

3

7

B+

F OUT

RF OUT

VT

14

5

9

13

RV41

FM

TUNED

LEVEL

IF AMP

Q3, 4

0

10.7MHz

4

REG

Q

29

AM OSC

27 AM RF IN

FM SD

30 14

AM OSC

CF2

AM/FM

7

FM

Q

VCO STOP

15

11

2

1214

VCO STOP

AM MIX

IF BUFF

8

IF

IF REQ

1 FM IN

FM/AM MPX

AM

SD

AM

SD

IC2

3

2

12

13

RV42

X43

450kHz

1 24

7

AM

TUNED

LEVEL

X IN

AM IF

IFT41

X21

4.5MHz

X OUT

6

10.7MHz

8

3

X42

X41

456kHz

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

5

0

MPX IN

OUT L

8

ST L

STEREO

TUNED

MUTE

ST CE

COM DIN

COM CLK

COM DATA

20

21OUT R R-CH

9

SECTION

(Page 21)

9

4

2

• R-CH: Same as L-CH

• SIGNAL PATH

: FM

: AM

A

MAIN

18

AMP IN L

8

2

L16

9

9

24 22

AM/FM

1

5

1

5

AM IF

8

ST LED

9

DET

VCO

23

TU LED

7

3

CE

4

DI

5

CL

DO

6

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

— 16 —— 15 —

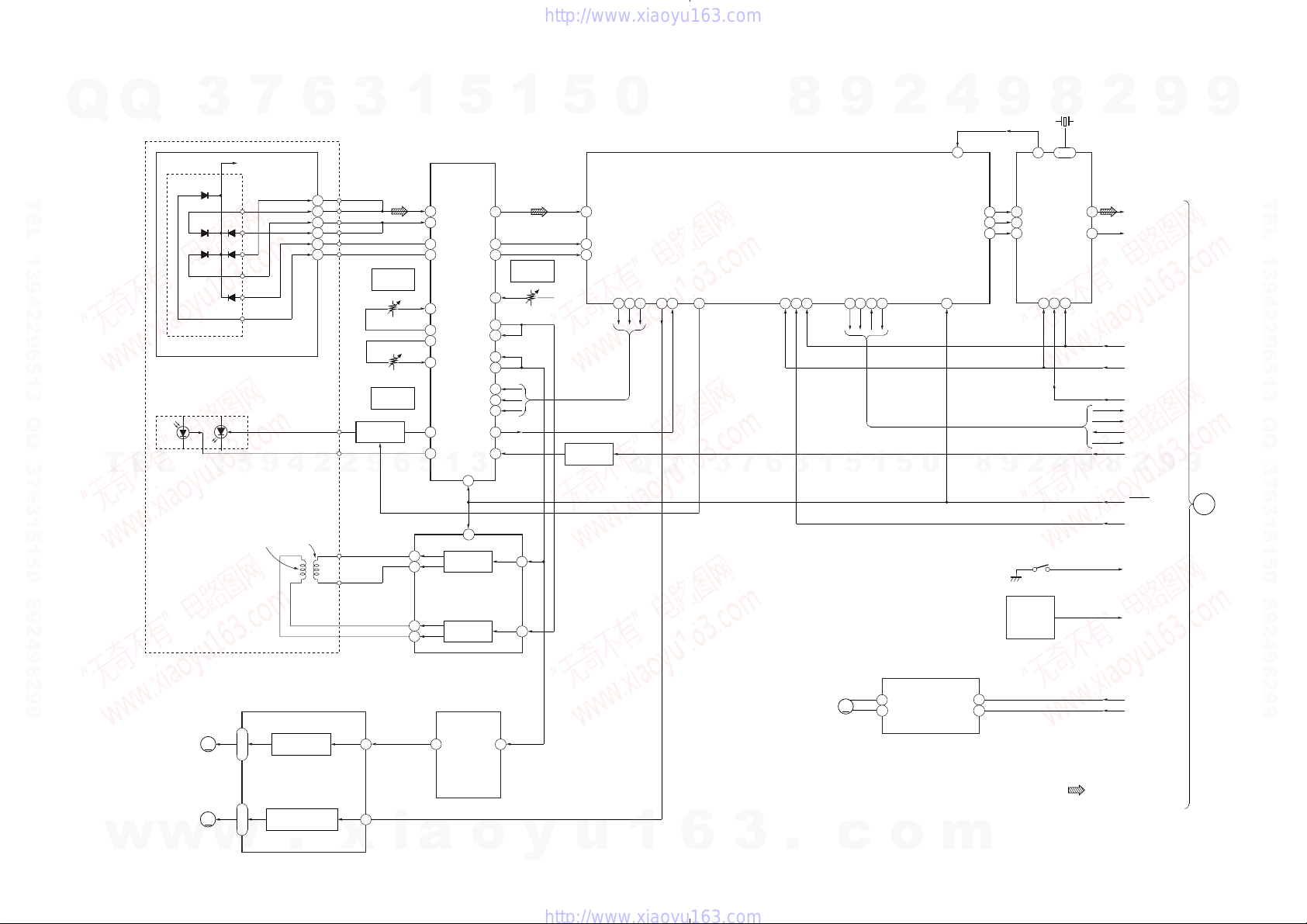

HCD-N455KW

—CD SECTION—

Q

Q

3

OPTICAL PICK-UP BLOCK

DETECTOR

TEL 13942296513 QQ 376315150 892498299

LASER

E

DIODE

L

T

E

A

B

1

7

B+

K

A

D

D

C

C

B

F

3

9

FOCUS

COIL

6

4

TRACKING

COIL

10

2

2-AXIS

DEVICE

3

1

4

2

5

6

2

RV102

FOCUS

RV103

TRACKING

LD DRIVE

Q101, 102

9

T+

–

T

–

F

F+

GAIN

GAIN

1

6

18

17

12

11

5

FOCUS/TRACKING SERVO.

EFM COMPARATOR

IC101 (1/2)

5

35

36

38

39

42

44

3334LD

RF1

PD2

F

E

FE BIAS

FEI

2

FEO

1

TEO

TEI

PHD

1

XRST

X RESET

TRACKING

COIL DRIVE

FOCUS/TRACKING

COIL DRIVE

IC102 (1/2)

FOCUS

COIL DRIVE

C.OUT

SENS

DATA

3

25

7

RFO

FE-O

FE-M

TA-M

TAO

XLT

CLK

FOK

FGD

31

23

24

37

6

7

12

13

21

20

19

25

4

1

FOCUS

BIAS

19

9

5

RV101

B+

14

55

54

FOCUS SW

Q103

RF

CNIN

SEIN

0

DATAO

CLKO

FOK

XLTO

Q

XLON

MDP

3 156 57 59 64 51 52 53 43 46 47 49 50

7

Q

3

8

DIGITAL SIGNAL PROCESSOR,

CLV SERVO

IC103

DATA

3

6

XLAT

CLOK

1

9

5

SCOR

SQSO

SQCK

1

2

SENS

5

0

4

34

XTAI

PCMD

LRCK

BCLK

XRST

8

9

21

20

22

9

2

1

3

DISC

TABLE

SENSOR

IC202

DATA

LRCK

BCLK

2

4

CKO

26 28 27

S201

UP SW

8

5 • 6

XTI

L OUT

R OUT

DATA

MLAT

4

16.9344MHz

•

XTO

CLOK

9

X101

16

13

2

DIGITAL FILTER

D/A CONVERTER

IC104

L-CH

R-CH

CD CLK

CD DATA

DF LAT

SCOR

SQ DATA

SQ CLK

SENS

FOCUS SW

2

8

XRST

XLAT

UP SW

T.SENS

9

9

9

C

MAIN

SECTION

(Page 21)

9

TEL 13942296513 QQ 376315150 892498299

w

M102

SLED MOTOR

M101

SPINDLE

MOTOR

w

09

M

M

w

26

•

27

1

•

2

SLED/SPINDLE

MOTOR DRIVE

IC102 (2/2)

SLED MOTOR

DRIVE

SPINDLE MOTOR

DRIVE

.

x

MOTOR DRIVER

IC201

SLED

SERVO

IC101 (2/2)

SLO

4

i

a

SL+

o

141625

y

u

1

6

3

.

M201

TABLE

MOTOR

M

c

OUT1

7

OUT2

3

o

9

IN1

1

IN2

m

— 18 —— 17 —

• R CH: Same as L ch

• SIGNAL PATH

: CD

TBL.L

TBL.R

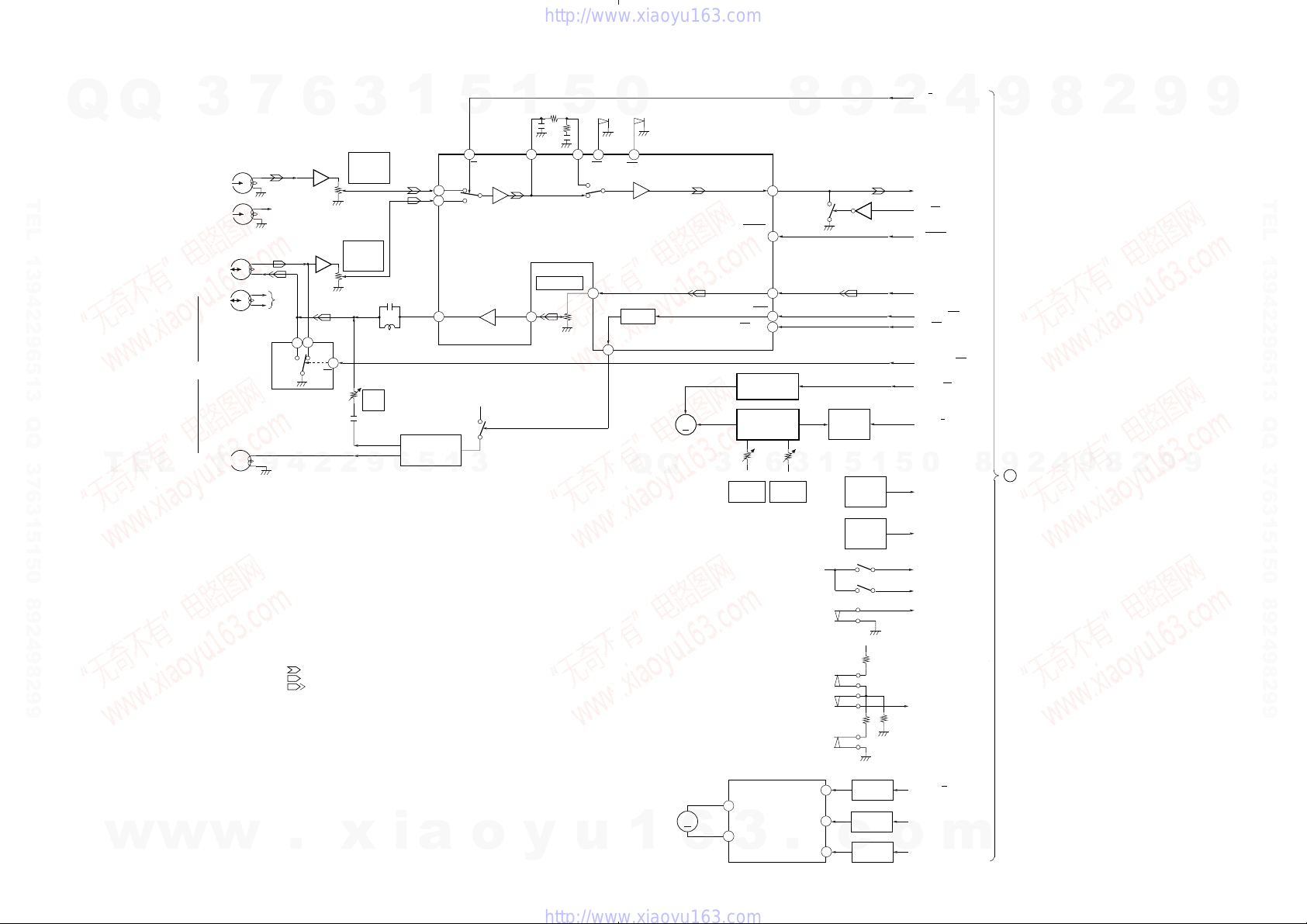

HCD-N455KW

—DECK SECTION—

L

3

HP101

PB HEAD

(DECK A)

REC/PB HEAD

(DECK B)

HRPE101

ERASE HEAD

Q

Q

TEL 13942296513 QQ 376315150 892498299

T

E

1

09

7

L

R

L

R

X

3

R CH

R CH

P

ERASE BIAS

9

4

• R-CH : Same as L-CH

• SIGNAL PATH

:PB (DECK A)

:REC (DECK B)

6

IC611

1

3

R

REC/PB

:PB (DECK B)

IC601

IC602

2

4

PLAYBACK

2

3

PLAYBACK

RV301

LEVEL

DECK B

RV311

LEVEL

DECK A

RV341

REC

BIAS

REC BIAS

9

1

T621, Q621, 622

6

BIAS OSC

5

5

A IN

2

BIN

3

EQ OUT

13

1

A/B

+7.5V

3

Q623, 901

1

EQ IN

414

ABO

11

5

RV301

REC LEVEL

A C O

15

r

IC401

0

2

REC OUT

B OUT

27

17

B 120/70

BIAS SW

Q

S1008

B C O

r

CAPSTAN

MOTOR

2

M1

Q

Q301

MUTE

1

+5V

S1003

(A HALF)

S1005

(REC A)

S1006

(B HALF)

9

Q402

SWITCH

Q406

5

REEL

DETECT

Q1001

REEL

DETECT

Q1002

S1001 (A PLAY)

S1002 (B PLAY)

+5V

1

8

PB OUT

8

NORM/

16

HIGH

REC IN

6

BIAS ON/OFF

18

19

RM ON/OFF

CAP M SWITCH

Q405, 407

SPEED

3

7

RV651

NORMAL

SPEED

CONTROL

Q651

6

RV652

HIGH

SPEED

3

M

S1004

5

C IN

A 120/70

70

120

HEAD AMP

10

2

5

B HALF

PB A/B

4

PB L

LM ON/OFF

NORM/HIGH

REC L

BIAS ON/OFF

RM ON/OFF

RELAY REC/PB

CAP M ON/OFF

CAP M H / L

0

A SHUT

B SHUT

A PLAY

B PLAY

A HALF

8

9

9

B

MAIN

SECTION

(Page 21)

2

8

4

9

2

8

2

9

9

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

S1009

(REC B)

4

6

5

Q408-410

c

SWITCH

SWITCH

Q412

SWITCH

Q411

VZ

2

OUT1

10

OUT2

3

TRIGGER

MOTOR

DRIVE

IC402

.

IN2

IN1

M2

TRIGGER

M

MOTOR

.

x

— 19 — — 20 —

i

a

o

y

u

1

6

o

TRIG H / L

B TRIG

A TRIG

m

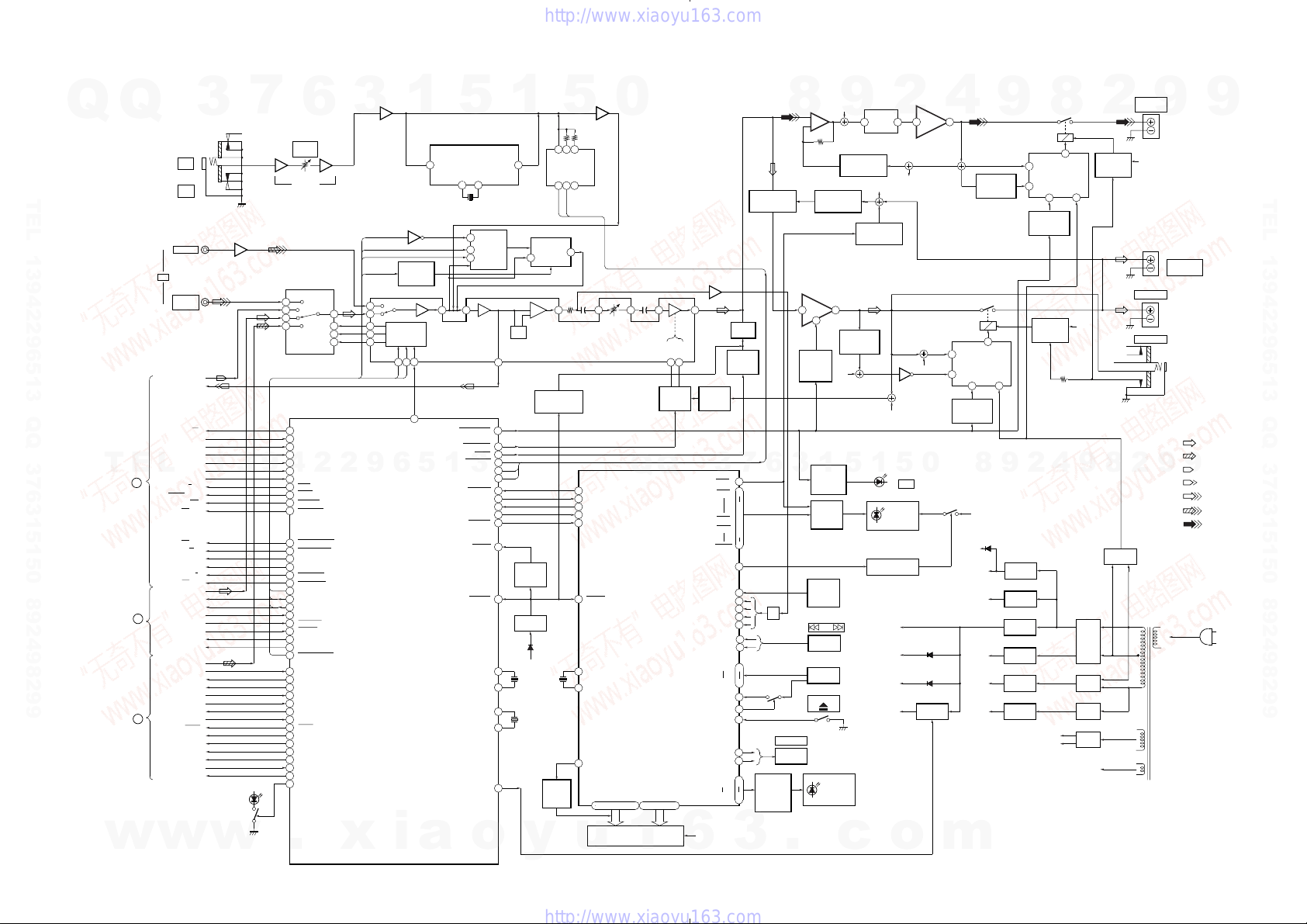

HCD-N455KW

3

10

6

2

x

IC808 (1/2)

3

CLK

DATA

LATCH

K CON

69

71

29

28

30

9

MASTER CONTROL

1

3

INTERFACE

32 33

CK

6

IC701

i

1

KEY CON

SWITCH

Q1401

MICON

34

DA

LATCH

62

62427 LAT

5

IC806 ECHO AMP

23

LPF1 IN

2 3

Q1403

65 64 45 44 43 42 38

5

1

DELAY LEVEL A

DELAY LEVEL B

a

8

7

CONTROL

9

POWER ON

DBFB HIGH

MUTE

DELAY ON

3

GM REQ

MG CLK

GM DATA

MG DATA

MG RDY

RESET

AC CUT

XOUT

XOUT

CD POWER

o

LPF2 OUT

X801

320kHz

IC1401

KEY

XIN

XIN

REC 2A

62

67

77

70

97

98

99

34

35

36

37

32

4

8

2

3

5

6

68

1

13

5

EQ

RESET

SWITCH

Q701

RESET

IC702

D705

+5.6V

X701

10MHz

X702

32kHz

y

KEY CON

SWITCH

—MAIN SECTION—

Q

Q

TEL 13942296513 QQ 376315150 892498299

T

E

B

DECK

SECTION

(Page 20)

A

TUNER

SECTION

(Page 16)

C

CD

SECTION

(Page 18)

w

09

3

J901

MIC 1

J902

MIC 2

J801

PHONO

IN

J801

VIDEO

(AUDIO)

PB L

REC L

RELAY REC/PB

A SHUT

B SHUT

B HALF

A HALF

L

A PLAY

B PLAY

PB A / B

NORM/HIGH

BIAS ON/OFF

RM ON/OFF

LM ON/OFF

CAP M H/L

A TRG

B TRG

TRIG H/L

CAP M ON/OFF

ST L

COM DIN

COM CLK

COM DATA

STEREO

TUNED

ST CE

MUTE

L CH

UP. SW

TBL. L

TBL. R

SCOR

T. SENS

DF LAT

SENS

X RST

CD CLK

CD DATA

FOCUS SW

SQ CLK

SQ DATA

X LAT

w

7

PHONO EQ AMP

IC801

57

1

3

D+5V

D201

(DISC No.)

w

31

V

TC

ST

CD

9

Q201

6

RV901

MIC

LEVEL

57

MIC AMP

IC901

INPUT SELECT

IC802

1

2

4

5 9

INH

55

TC RELAY

56

A SHUT

57

B SHUT

58

B HALF

59

A HALF

4

2

60

220 A PLAY

61

220 B PLAY

80

TC A

81

NORM

82

BIAS OFF

83

REC MUTE

LINE MUTE ON

87

88

CAP M HIGH

89

A TRG

90

B TRG

91

TRG LOW

92

CAP M ON

63

K CON LAT

73

COM DATA

71

COM CLK

72

COM DIN

93

STEREO

TUNED

94

95

ST CE

10

ST MUTE ON

74

KEY CON ON

UP SW

15

23

TBL L

24

TBL R

SCOR

25

26

TBL SENS

29

DF LAT

30

SENS

31

XRST

38

CD CLK

40

CD DATA

43

FOCUS SW

44

SQ CLK

45

SQ DATA

46

X LAT

75

LIDDED LED

.

B

A

5

12 2 5

IC861

ECHO LEVEL

1011 9

DLY A

DLY ON

IC1403

EQUALIZER / VOLUME

POWER ON/OFF

MUTE SWITCH

Q823

X3001

4MHz

GRID

DRIVE

Q636

IC808(2/2)

7

5

0

DLY B

4

+ +

IC901

21

REQ GM

CLK MG

22

DATA GM

23

24

DATA MG

38

RDY MG

10

RESET

12

11X1X2

GR1

100

GR14 - 2

87 - 99

FLUORESCENT INDICATOR TUBE

u

Q

GRAPHIC CONTROL

SEG32 - 1

54 - 78 80 - 86

FL501

1

Q

IC501

40 41

DBFB

SWITCH

Q901

•

IC902(2/2)

BB22

BB12

S.TWITTER ON/LED8

LED SELECT

VF

6

3

FEED

BACK

Q902

3

SIRCS IN

SPEANA 1

SPEANA 2

SPEANA 3

SPEANA 4

KEY SEL

DOR SW

VOL A

VOL B

LEDS1

LEDS5

LED1

LED5

LED9

LED13

JOG A

JOG B

KEY 3

KEY 1

KEY 4

1

GAIN CONTROL

MUTE

Q954

MUTE

SWITCH

Q820

7

2

9

5

•

18

•

17

•

45

43

42

39

29

28

27

26

37

15

31

33

30

19

41

36

20

53

49

3

S.TWITTER

IC3101,3102

6

D/A

KEY SELECT

IC503

LED

CONTROL

IC504,Q601

Q603,605

Q626,635

8

3

S579

VOLUME

ROTARY

ENCODER

.

PRE AMP

IC3103

5

+

6

-

S.TWITTER

CONTROL SW

POWER AMP

IC1201

1 10

6

POWER

OFF

MUTE

Q1206

LED

1

SWITCH

IC504,

Q3151,3152

LED

SWITCH

Q621-625,

Q629-634

REMOTE

CONTROL

RECEIVER

IC502

S502

AMS

ROTARY

ENCODER

KEY

MATRIX

S591

OPEN

D601 - 604

D621, 622

D634, 635

R-CH

9

7

GAIN CONTROL

Q3101

OVER LOAD

Rch

5

c

5

S.WOOFER

Q3103

DET

Q1201

PRE AMP

IC3003

IN

R-CH

S.TWITTER

SWITCH

Q3105-3107

1

LED CONTROL

2

OUT

Rch

5

D3151-3154

D611-620,

D628-633,

D636-640

IC504

+5.6V

+5V

D +5V

D +5V

(CD)

o

POWER AMP

IC3001

4

1

1

13

R-CH

Rch

Q1204

0

5CD

Q611,612

D706

D1018

+5V REG

Q1001,1002

2

1

PROTECTOR

TC +5V

PROTECTOR

7

SWITCH

Q1205

+7.5V

CD +7V

–7.5V

ST +10V

DF DP

OVER LOAD

Q3001,3002

RY1201

IC1202

8

D+5V

D1016,1017

D1021,1022

9

DET

6

4

9

+7V REG

IC1003

+7V REG

IC1002

+5V REG

IC1001

–7V REG

IC1004

+10V REG

Q1003

–25V REG

Q1006

2

1

PROTECTOR

2

8

PROTECTOR

7

SWITCH

Q3109

RELAY

DRIVE

Q1207,1208

+B

–B

RY3001

IC3002

4

6

D1003 - 1006

4

+B

9

RECT

D1001,1002

RECT

D1013, 1014

RECT

D1250

RECT

VF

2

RELAY

DRIVE

Q3108

Rch

8

D1309,1310

RECT

J3101

WOOFER

SYSTEM

+B

TM1201

SPEAKER

J601

PHONES

2

T1601

POWER

TRANSFORMER

9

TM1202

SURROUND

SPEAKER

9

9

• Rch : Same as Lch

• Signal path

: FM

: CD

: PB

9

: REC

: VIDEO

: PHONO

: SUPER WOOFER

AC

IN

TEL 13942296513 QQ 376315150 892498299

m

— 21 —

— 22 —

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

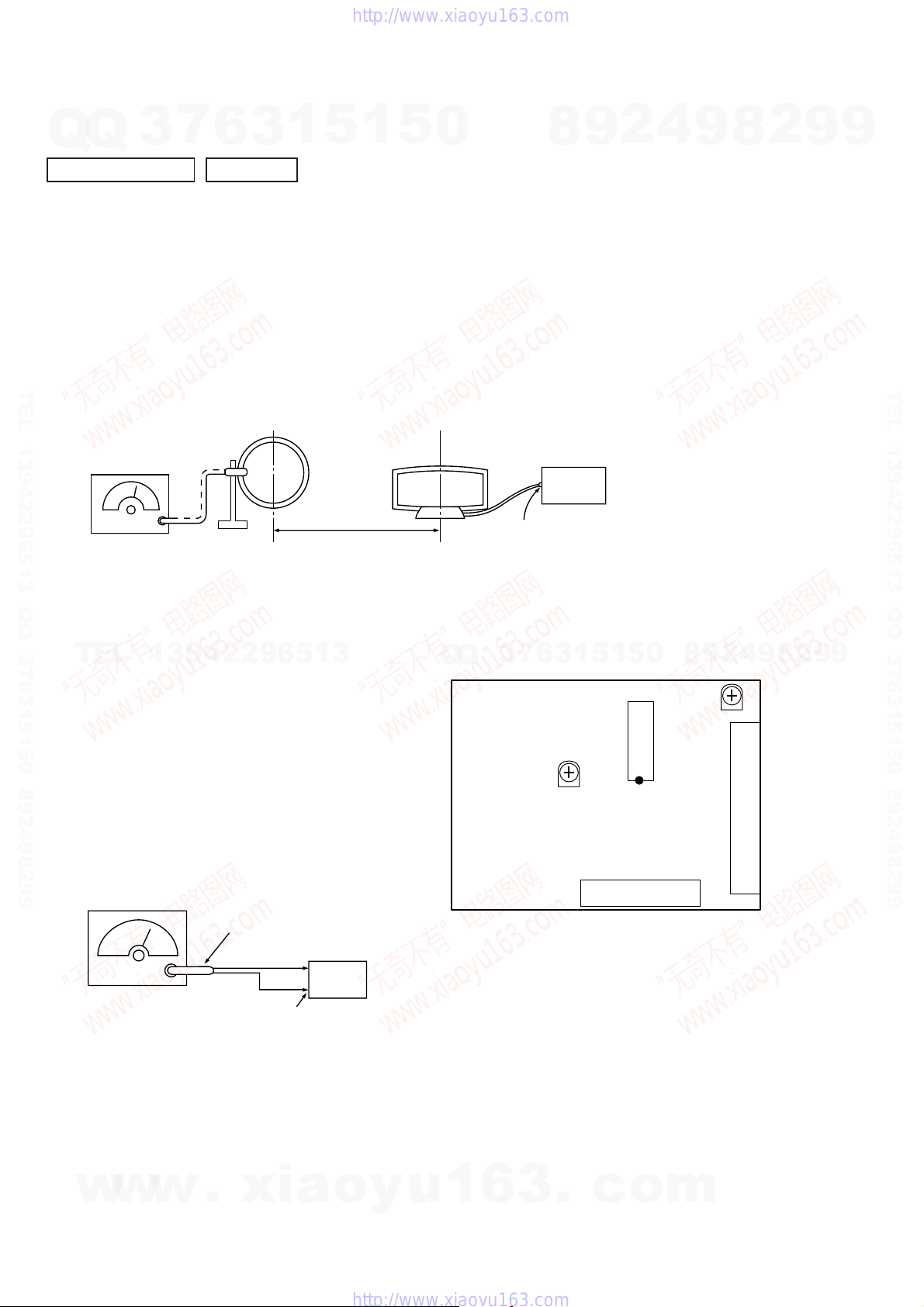

6-2. CIRCUIT BOARDS LOCATION

6

3

1

5

PANEL board

HP board

MIC board

CD-L board

TC CONTROL board

1

5

TRANS board

DOOR-SW board

0

SP TERMINAL board

CD-JOG board

9

8

TC SW board

CD-R board

4

2

TCB board

KEY CON board

MAIN board

ST SW board

POWER AMPLIFIER board

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Note: pA is including in AUDIO board.

LEAF SWITCH board

TABLE SENSOR board

p

A

MOTOR board

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

2

8

9

4

AUDIO board

(including

p

BD board

A)

9

9

w

w

w

.

xia

CD MOTOR board

o

y

u

1

— 23 —

LED board

6

3

.

c

o

m

Q

TEL 13942296513 QQ 376315150 892498299

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

T

E

L

1

3

9

4

2

2

9

6

5

1

3

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

T

E

L

1

3

9

4

2

2

9

6

5

1

3

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Loading...

Loading...