Sony HCD-MG510AV Service manual

)

HCD-MG510AV

SERVICE MANUAL

Ver 1.0 2001.04

HCD-MG510AV are the Amplifier, CD player, Tape

Deck and Tuner section in MHC-MG510AV.

This stereo system is equipped with the Dolby* Pro Logic

Surround decoder.

* Manufactured under license from Dolby Laboratories.

Dolby, Pro Logic, and the double-D symbol ; are

trademarks of Dolby Laboratories. Confidential

unpublished works. '1992-1997 Dolby Laboratories.

All rights reserved.

CD

Section

TAPE

Section

US Model

Model Name Using Similar Mechanism HCD-MG310AV

CD Mechanism Type CDM64-K1BD44A

Base Unit Name BU-K1BD44A

Optical Pick-up Name KSM-213BFN

Model Name Using Similar Mechanism HCD-MG310AV

T ape Transport Mechanism Type CM8L6Z511A

Amplifier section Inputs

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

with 8 ohm loads both channels driven, from

120 – 10,000 Hz; rated 75 watts per channel

minimum RMS power, with no more than 10%

total harmonic distortion from 250 milliwatts to

rated output.

Front speaker:

Continuous RMS power output

Total harmonic distortion less than 0.09%

Center speaker:

Continuous RMS power output

Rear speaker:

Continuous RMS power output

Sub woofer:

Continuous RMS power output

75 + 75 watts

(8 ohms at 1 kHz,

10% THD)

(8 ohms at 1 kHz,

40 watts)

45 watts

(8 ohms at 1 kHz,

10% THD)

45 + 45 watts

(8 ohms at 1 kHz,

10% THD)

45 watts

(8 ohms at 100 Hz,

10% THD

VIDEO/MD IN (phono jacks):

5.1CH:

FRONT (phono jacks): voltage 450 mV,

REAR (phono jacks): voltage 450 mV,

CENTER (phono jack): voltage 450 mV,

SUB WOOFER (phono jack):

Outputs

PHONES (stereo phone jack):

FRONT SPEAKER: accepts impedance of 8 to

SURROUND SPEAKER REAR:

SURROUND SPEAKER CENTER:

SURROUND SPEAKER SUB WOOFER:

SPECIFICATIONS

voltage 250 mV/450 mV,

impedance 47 kilohms

impedance 47 kilohms

impedance 47 kilohms

impedance 47 kilohms

voltage 450 mV,

impedance 47 kilohms

accepts headphones of

8 ohms or more

16 ohms

accepts impedance of 8 to

16 ohms

accepts impedance of

8 ohms

accepts impedance of

8 ohms

COMPACT DISC DECK RECEIVER

CD player section

System Compact disc and digital

Laser Semiconductor laser

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Wavelength 780 – 790 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

OPTICAL OUT (CD)

(Square optical connector jack, rear panel)

Wavelength 660 nm

Output Level –18 dBm

Tape player section

Recording system 4-track 2-channel stereo

Frequency response 40 – 13,000 Hz (±3 dB),

Wow and flutter ±0.15% W.Peak (IEC)

audio system

(λ = 780 nm)

Emission duration:

continuous

using Sony TYPE I

cassette

0.1% W.RMS (NAB)

±0.2% W.Peak (DIN)

– Continued on next page –

9-873-812-11 Sony Corporation

2001D0500-1 Home Audio Company

C 2001.4 Shinagawa Tec Service Manual Production Group

HCD-MG510AV

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 530 – 1,710 kHz

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 4

2. GENERAL ................................................................... 5

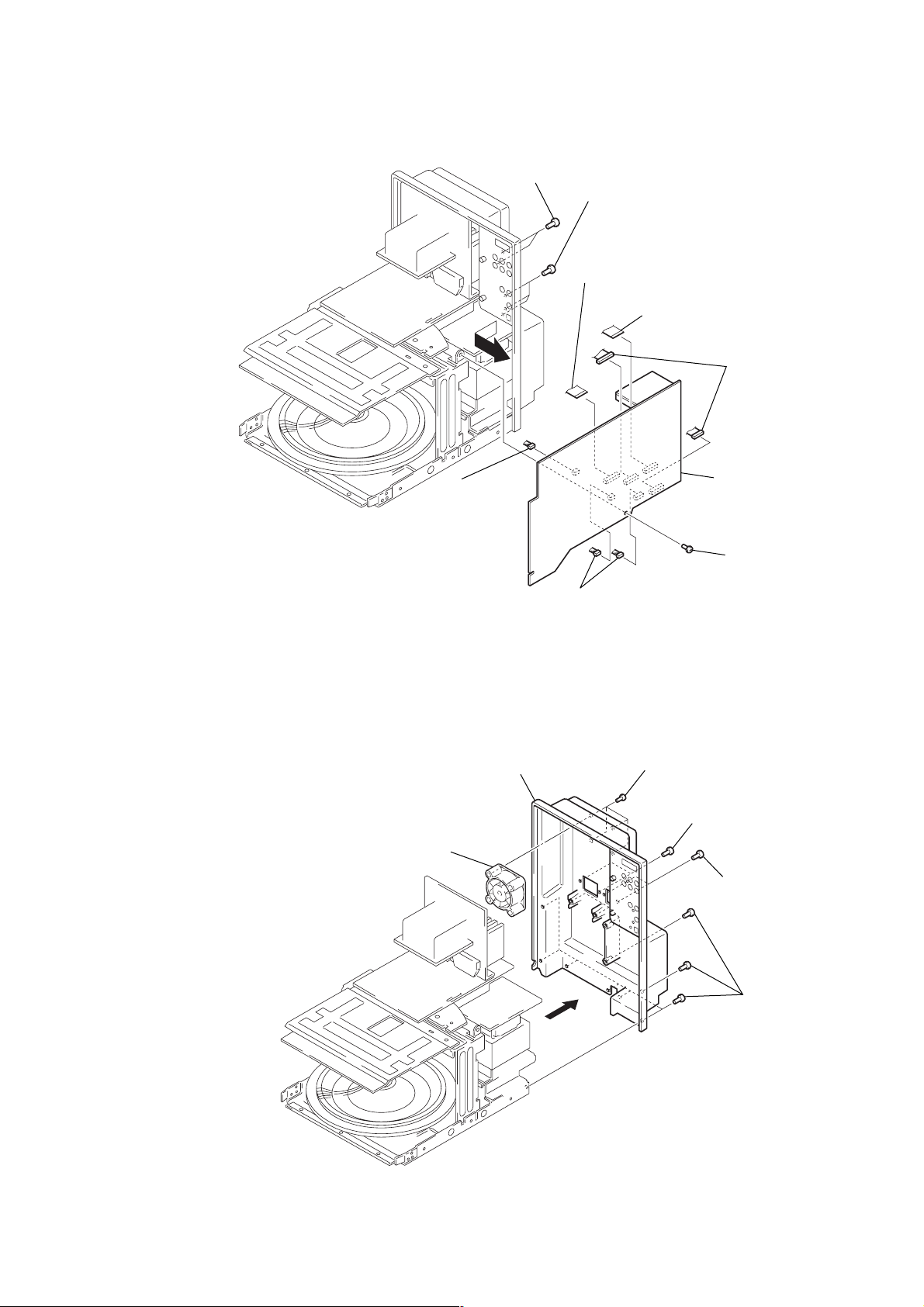

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Upper Cover .................................................................... 8

3-3. Front Block Assy............................................................. 8

3-4. MAIN Board ................................................................... 9

3-5. Back Panel, DC FAN (M391)......................................... 9

3-6. MAIN AMP Board, POWER Board............................... 10

3-7. Middle (F) Assy, Bracket (Middle-R),

Power Bracket ................................................................. 10

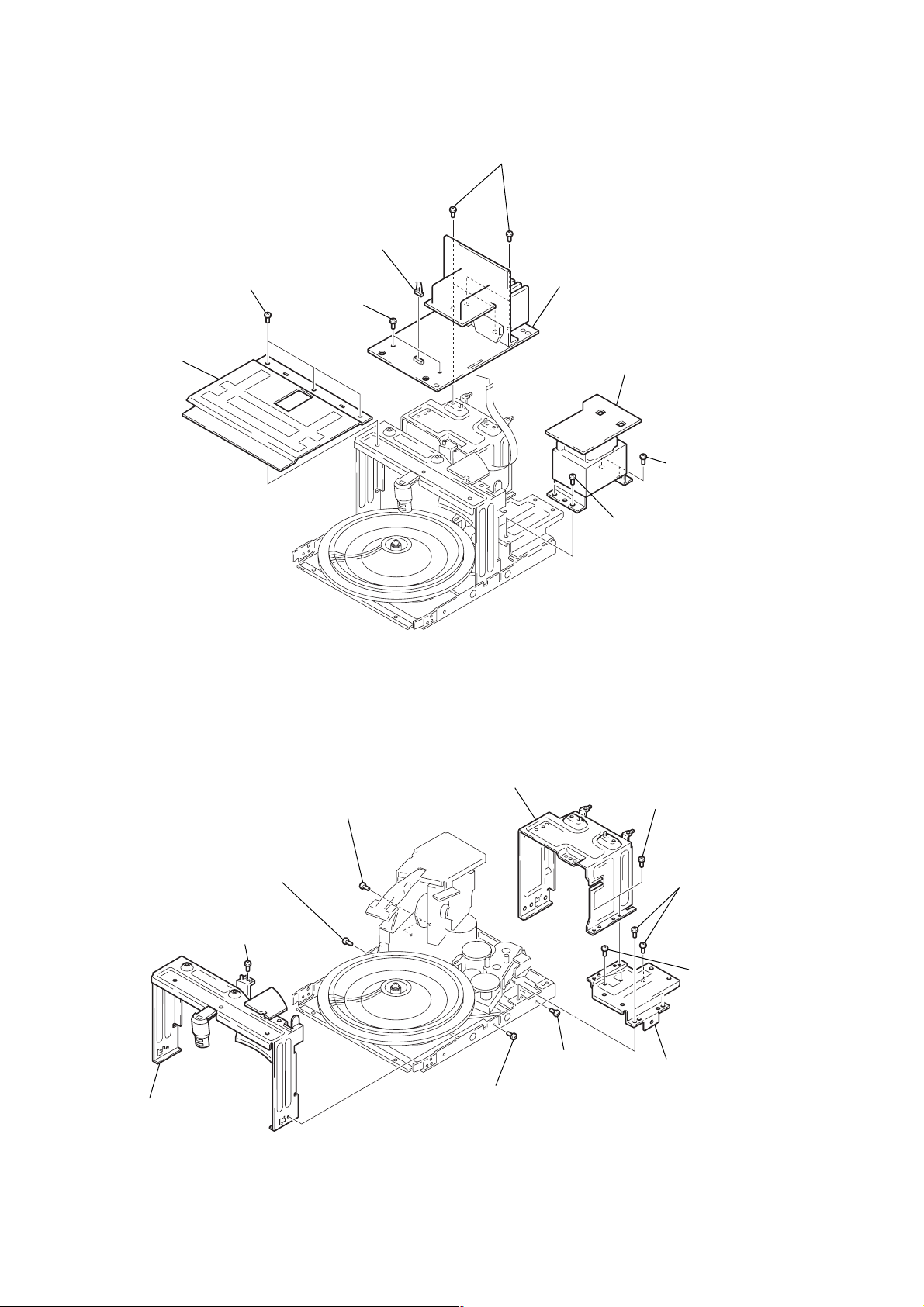

3-8. CD Mechanism Deck (CDM64-K1BD44A) .................. 11

3-9. Base Unit (BU-K1BD44A)............................................. 11

3-10. BU Holder Assy .............................................................. 12

3-11. Motor Gear Assy (Sled) (M102), CD Board.................. 12

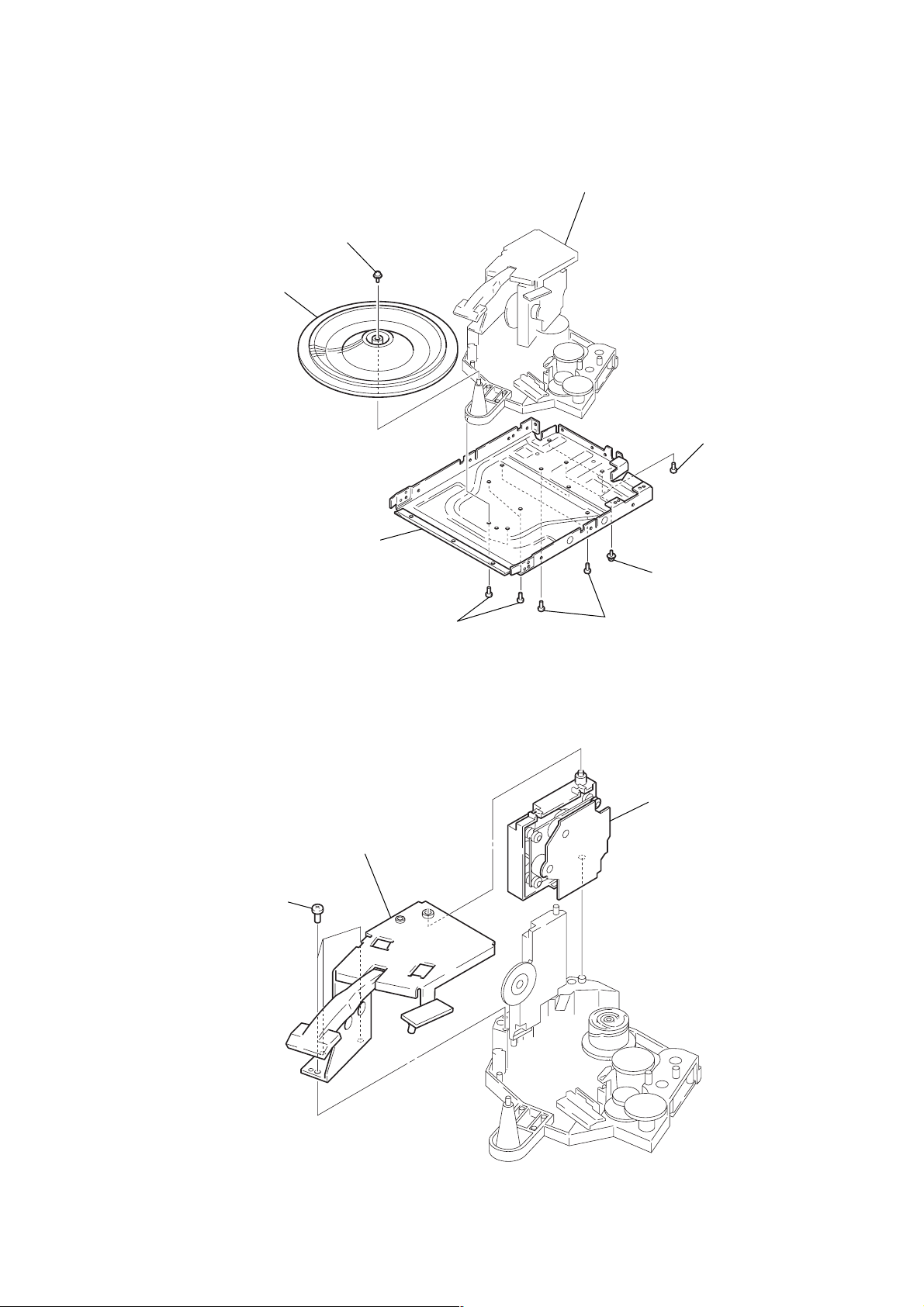

3-12. Op Base Assy (KSM-213BFN) ...................................... 13

3-13. Cassette Lid Assy (A)/(B)............................................... 13

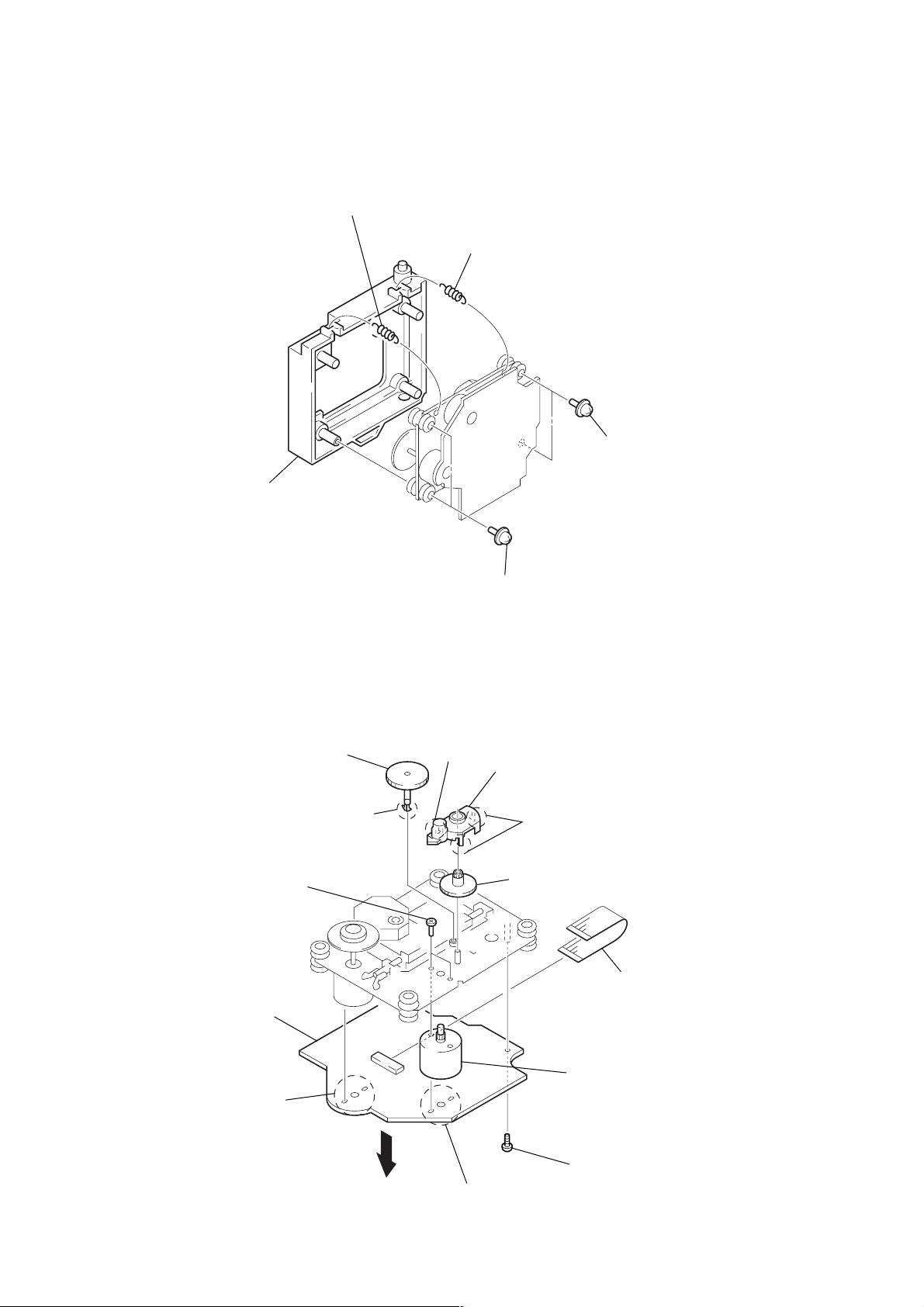

3-14. Mech Deck (Tape)........................................................... 14

4. MECHANICAL ADJUSTMENTS....................... 15

General

(with the interval set at

10 kHz)

531 – 1,710 kHz

(with the interval set at

9 kHz)

Power requirements 120 V AC, 60 Hz

Power consumption 220 watts

Dimensions (w/h/d) incl. projecting parts and controls

Mass Approx. 11.5 kg

Design and specifications are subject to change

without notice.

Approx. 280 × 383 × 480

mm

5-8. Printed Wiring Board – CD Section – ............................ 25

5-9. Printed Wiring Boards

– CD MOTOR/SENSOR Section – ................................ 26

5-10. Schematic Diagram

– CD MOTOR/SENSOR Section – ................................ 27

5-11. Printed Wiring Board – TC Section –............................. 28

5-12. Schematic Diagram – TC Section – ............................... 29

5-13. Schematic Diagram – MAIN Section (1/4) –................. 30

5-14. Schematic Diagram – MAIN Section (2/4) –................. 31

5-15. Schematic Diagram – MAIN Section (3/4) –................. 32

5-16. Schematic Diagram – MAIN Section (4/4) –................. 33

5-17. Printed Wiring Board – MAIN Section –....................... 34

5-18. Printed Wiring Boards – MAIN AMP Section – ............ 36

5-19. Schematic Diagram – MAIN AMP Section – ................ 37

5-20. Printed Wiring Board – SUB AMP Section – ................ 38

5-21. Schematic Diagram – SUB AMP Section – ................... 38

5-22. Printed Wiring Boards – DISPLAY Section – ............... 40

5-23. Schematic Diagram – DISPLAY Section – .................... 41

5-24. Printed Wiring Board – CONTROL Section – ............... 42

5-25. Schematic Diagram – CONTROL Section –.................. 43

5-26. Printed Wiring Boards – POWER Section – .................. 44

5-27. Schematic Diagram – POWER Section – ...................... 45

5-28. IC Pin Function Description ........................................... 46

5. DIAGRAMS

5-1. Block Diagram – CD SERVO Section – ........................ 17

5-2. Block Diagram – TUNER/TAPE DECK Section – ...... 18

5-3. Block Diagram – SURROUND Section –...................... 19

5-4. Block Diagram – AMP Section – ................................... 20

5-5. Block Diagram

– DISPLAY/POWER SUPPLY Section – ...................... 21

5-6. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 22

5-7. Schematic Diagram – CD Section – ............................... 24

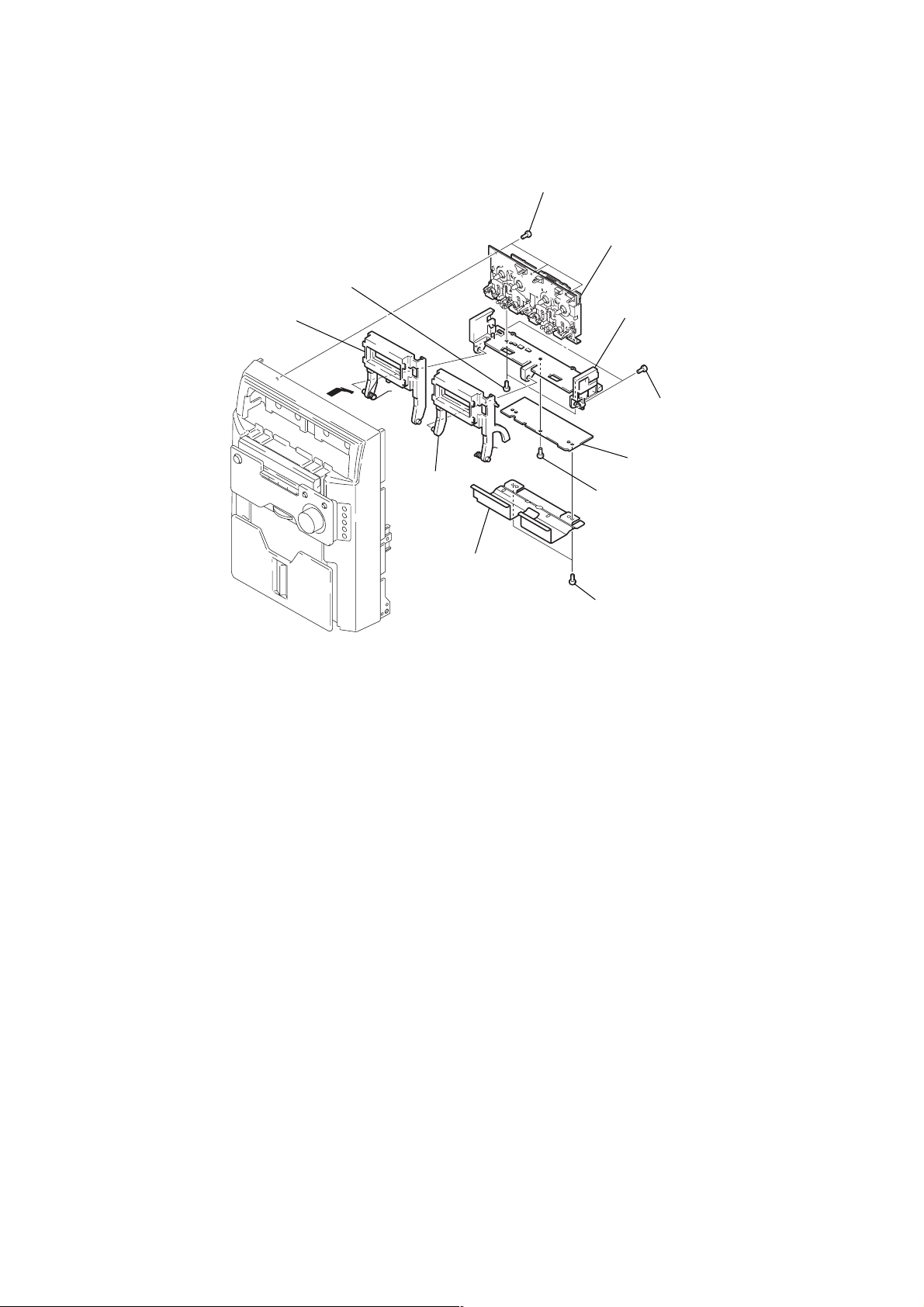

6. EXPLODED VIEWS

6-1. General Section ............................................................... 52

6-2. Front Panel Section ......................................................... 53

6-3. Chassis Section ............................................................... 54

6-4. CD Mechanism Deck Section (CDM64-K1BD44A)..... 55

6-5. Base Unit Section (BU-K1BD44A) ............................... 56

7. ELECTRICAL PARTS LIST ............................... 57

2

HCD-MG510AV

r

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V AC range are

suitable. (See Fig. A)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

To Exposed Metal

Parts on Set

AC

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Ω

Earth Ground

voltmete

(0.75 V)

3

HCD-MG510AV

SECTION 1

SERVICING NOTES

CD-TEXT TEST DISC

This unit is able to display the test data (character information)

written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:4-989-366-01) is used

for checking the display.

To check, perform the following procedure.

Checking Method:

1. Press the I/1 button to turn the power on, set the disc to the

disc table with the “test disc” label facing up, and chuck the

disc.

2. Press the [CD] button to set CD function, and press the n N button

to playback the disc.

3. The following will be displayed on the liquid crystal display.

Display : 1KHZ/0DB/L R

4. Pressing the [-- ] or [ +] button, select the track. The text

data of each track will be displayed.

For details of the displayed contents for each track, refer to “Table

1: CD-TEXT TEST DISC TEXT Data Contents”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly. These will be displayed as a space or a character resembling

it.

Table 1: CD-TEXT TEST DISC TEXT Data Contents

TRACK

No.

1 1kHz/0dB/L&R

2 20Hz/0dB/L&R

3 40Hz/0dB/L&R

4 100Hz/0dB/L&R

5 200Hz/0dB/L&R

6 500Hz/0dB/L&R

7 1kHz/0dB/L&R

8 5kHz/0dB/L&R

9 7kHz/0dB/L&R

10 10kHz/0dB/L&R

11 16kHz/0dB/L&R

12 18kHz/0dB/L&R

13 20kHz/0dB/L&R

14 1kHz/0dB/L&R

15 1kHz/–1dB/L&R

16 1kHz/–3dB/L&R

17 1kHz/–6dB/L&R

18 1kHz/–10dB/L&R

19 1kHz/–20dB/L&R

20 1kHz/–60dB/L&R

.>

(TRACKS No. 1 to 20:Normal Characters)

Displayed Contents

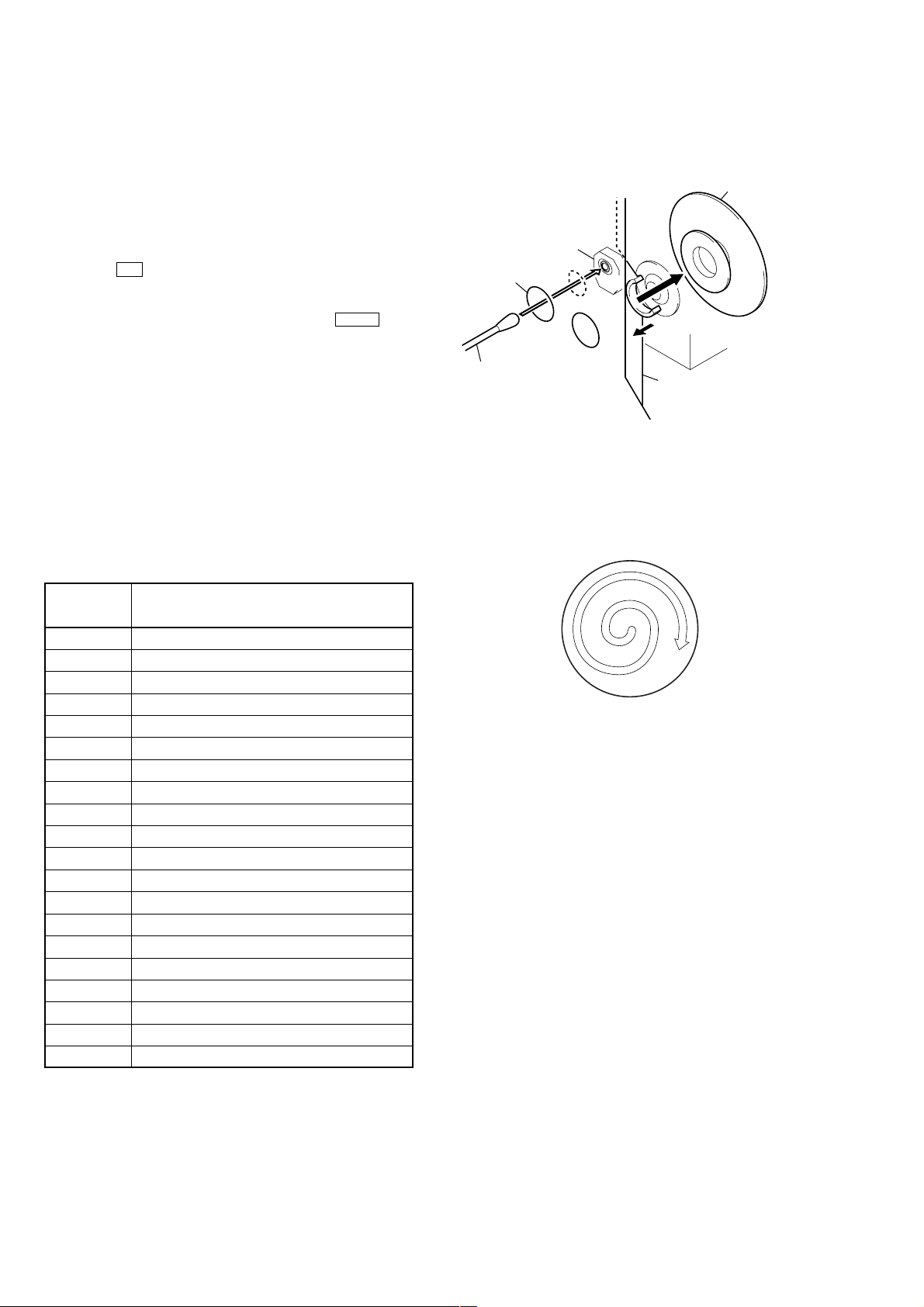

CLEANING OBJECTIVE LENS OF OPTICAL PICK-UP

• In cleaning the objective lens of optical pick-up, be sure the

following below.

2

Remove the

magnet assy.

optical pick-up

bracket (top 60) hole

A

3

Put a cotton bud into

the hole on the bracket

(top 60) and clean the

OP lens.

Note 1. In cleaning the lens, do not apply an excessive force.

As the optical pick-up is vulnerable, application of excessive

force could damage the lens holder.

Note 2. In cleaning, do not use a cleaner other than exclusive cleaning

liquid (KK-91 or isopropyl alcohol).

Note 3. Wipe the objective lens spirall y from center toward outside. (See

Figure A)

1

Open the torsion holder

(magnet) in direction of

arrow

A

.

(Figure A)

Note: Track No. 21 to 99 are not displayed.

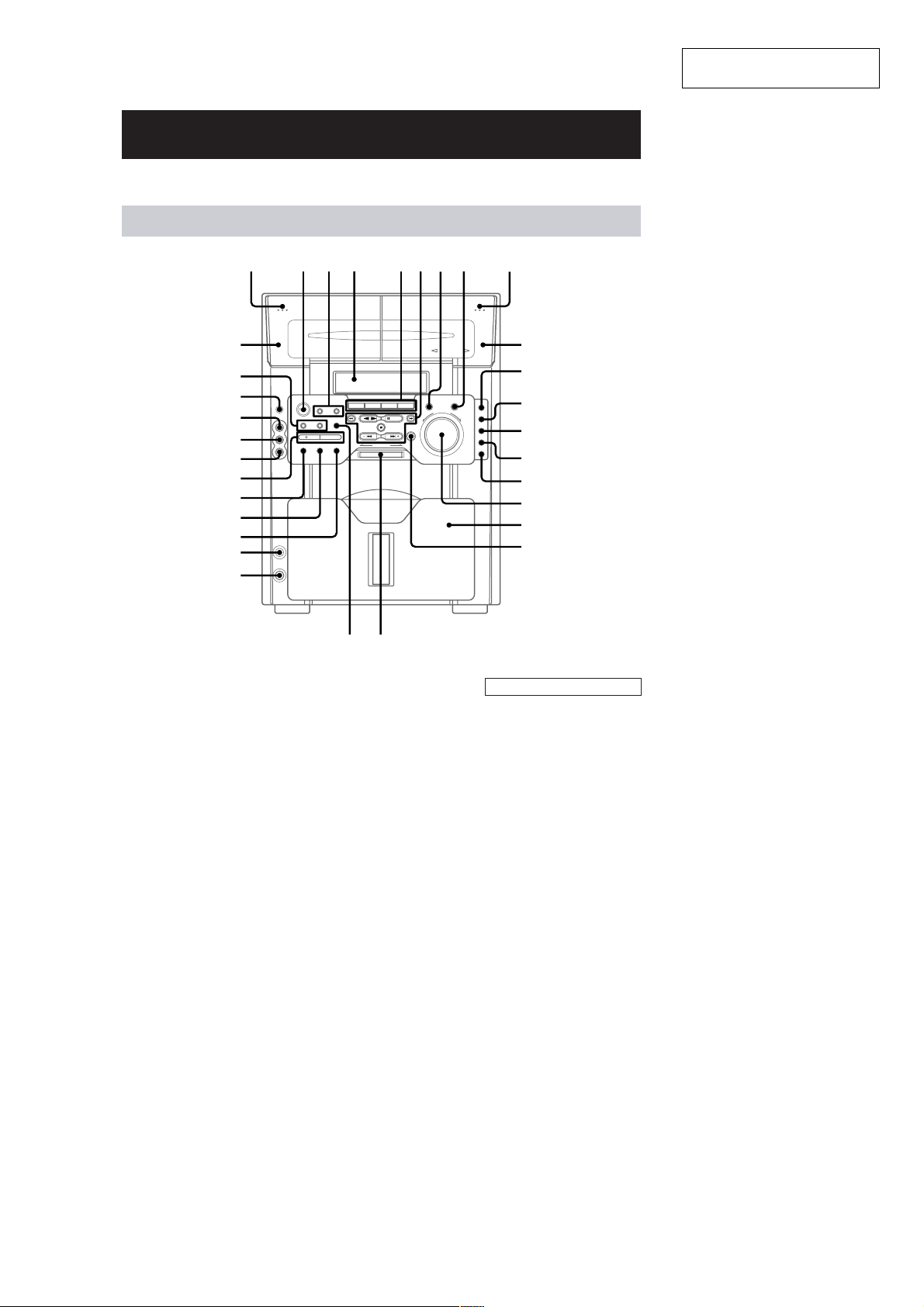

4

Parts Identification

The items are arranged in alphabetical order.

Refer to the pages indicated in parentheses ( ) for details.

Main unit

SECTION 2

GENERAL

HCD-MG510AV

This section is extracted from

instruction manual.

1

es

ea

e;

wl

wk

wj

wh

wg

wf

wd

ws

wa

5.1CH/VIDEO (MD) 5 (28 )

AUDIO IN L jack wk (29)

AUDIO IN R jack wj (29)

CD 5 (14, 21)

CD SYNCHRO wh (21, 22)

CLEAR w; (15, 19, 34)

Deck A es (20)

Deck B 0 (20)

DIRECTION ea (20)

DIS C ACCESS ql ( 12, 21)

Display window 4

DISPLAY wd (12, 17, 19, 34)

ENTER qk (11, 15, 18, 22, 26, 28)

FRONT qd (25)

GAME e; (26, 29)

KEYBOARD INPUT jack ws

(27)

LINK qg (25)

MENU ea (16, 18)

234

5

67 8 9

w; ql

PHONES jack wa

PLAY MODE wf (14, 22)

PRESET EQ 7 (24)

PRO LOGIC qs (11, 25)

PUSH OPEN (Front cover) qj

(12)

REAR qf (25)

REC PAUSE/START wh (21,22)

REPEAT wg (14)

STEREO/MONO wg (19)

SURROUND qa (25)

SURROUND MODE 8 (25)

TAPE A/B 5 (20)

TIMER SELECT 3 ( 23, 27)

TIMER SET 3 (11, 23, 26)

TUNER/BAND 5 (18)

VIDEO IN jack wl (29)

VOLUME control qh

0

qa

qs

qd

qf

qg

qh

qj

qk

BUTTON DESCRIPTIONS

Z (deck A) 1

=/1 (power) 2

m (rewind) 6

n N (play) 6

X PAUSE 6

M (fast forward) 6

x (stop) 6

– . (go back) 6

> + (go forward) 6

Z (deck B) 9

4

5

HCD-MG510AV

p

Remote Control

1234

wf

wd

ws

wa

w;

ql

qk

qj

qh

qg

5

6

7

8

9

0

qa

qs

qd

qf

5.1CH wa (30)

CD ql (14, 21)

CENTER +/– 5 (11)

DBFB qd (24)

DISPLAY 9 (12, 17, 19)

GAME 8 (26, 29)

GROOVE qf (24)

PLAY MODE 2 (14, 22)

PRESET EQ qk (24)

PRO LOGIC wf (11, 25)

REAR +/– 6 (11)

REPEAT 3 (14)

SCROLL qa (17)

SLEEP 1 (26)

SURROUND qh (25)

TAPE A/B w; (20)

TEST TONE ws (11)

TUNER/BAND 7 (18)

VIDEO (MD) wd (28)

VOL +/– qg

BUTTON DESCRIPTIONS

@/1 (power) 4

N (play) 0

X (pause) 0

x (stop) 0

. (go back) 0

m (rewind) 0

M (fast forward) 0

> (go forward) 0

TDISC/DISCt qs qj

Setting the time

1

Turn on the system.

2

Press TIMER SET.

When you set the clock for the first time, go

to step 5.

3

Press – . or > + repeatedly to

select “CLOCK SET”.

4

Press ENTER.

5

Press – . or > + repeatedly to set

the hour.

6

Press ENTER.

7

Press – . or > + repeatedly to set

the minute.

8

Press ENTER.

Tip

If you made a mistake or want to change the time,

start over from step 1.

Note

The clock settings are canceled when you disconnect

the

ower cord or if a power failure occurs.

6

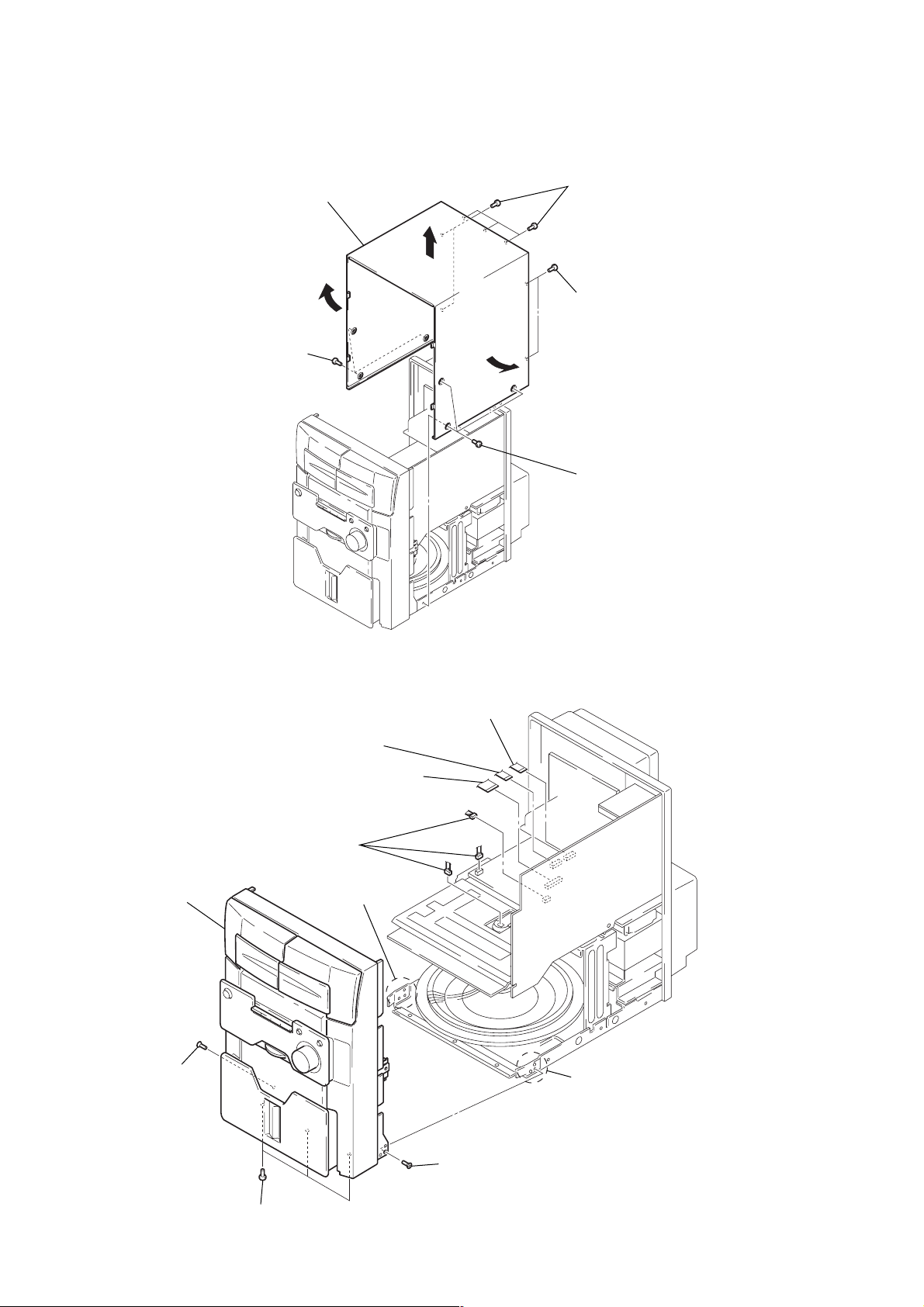

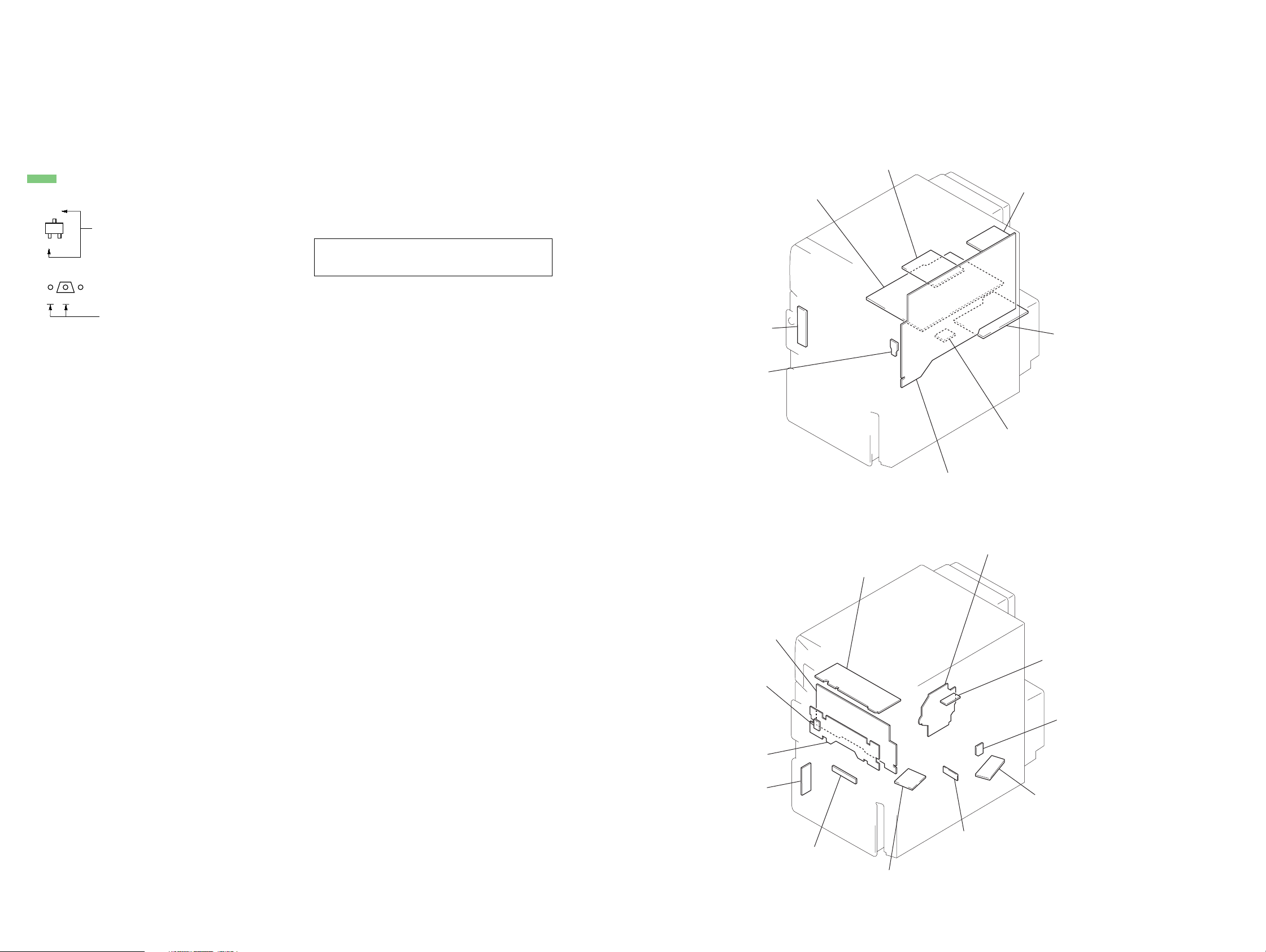

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. UPPER COVER

(Page 8)

HCD-MG510AV

SECTION 3

DISASSEMBLY

3-3. FRONT BLOCK ASSY

(Page 8)

3-4. MAIN BOARD

(Page 9)

3-5. BACK PANEL,

DC FAN (M391)

(Page 9)

3-6. MAIN AMP BOARD,

POWER BOARD

(Page 10)

3-7. MIDDLE (F) ASSY,

BRACKET (MIDDLE-R),

POWER BRACKET

(Page 10)

3-8. CD MECHANISM DECK

(CDM64-K1BD44A)

(Page 11)

3-13. CASSETTE LID ASSY (A)/(B)

(Page 13)

3-14. MECH DECK (TAPE)

(Page 14)

3-9. BASE UNIT

(BU-K1BD44A)

(Page 11)

3-10. BU HOLDER ASSY

(Page 12)

3-11. MOTOR GEAR ASSY

(SLED) (M102),

CD BOARD

(Page 12)

3-12. OP BASE ASSY

(KSM-213BFN)

(Page 13)

7

HCD-MG510AV

Note: Follow the disassembly procedure in the numerical order given.

3-2. UPPER COVER

3

upper cover

1

three screws

(BVTP3

×

8)

2

five screws

(BVTP3

2

two screws

(BVTP3

1

three screws

(BVTP3

×

8)

×

8)

×

8)

3-3. FRONT BLOCK ASSY

2

6

front block assy

4

screw (KTP3 × 8)

1

wire (flat type) (11 core)

(CN312)

1

wire (flat type) (17 core)

(CN301)

three connectors

(CN310, 503, 803)

5

two bosses

1

wire (flat type) (10 core)

(CN311)

5

two bosses

4

screw (KTP3 × 8)

3

three screws

(BVTP3 × 8)

8

3-4. MAIN BOARD

s

s

2

connector

(CN313)

3

two screws

(BVTP3 × 8)

3

three screws

(BVTP3 × 8)

1

wire (flat type) (18 core)

(CN309)

1

wire (flat type) (21 core)

(CN303)

HCD-MG510AV

2

two connector

(CN304, 903)

5

MAIN board

3-5. BACK PANEL, DC FAN (M391)

4

DC fan (M391)

5

back panel

2

two connectors

(CN305, 317)

2

3

four screws

(BVTP3 × 10)

4

1

two screws

(BVTP3 × 10)

1

screw

(BVTP3 × 8)

two screws

(BVTP3

×

eleven screw

1

(BVTP3 × 10)

10)

9

HCD-MG510AV

)

3-6. MAIN AMP BOARD, POWER BOARD

1

connector

(CN502)

4

three screws

5

center bracket

(BVTP3

×

8)

2

two screws

(BVTP3

×

8)

2

four screws

(BVTP3

×

8)

3

MAIN AMP board

7

POWER board

6

two screws

(BVTP4

×

8

3-7. MIDDLE (F) ASSY, BRACKET (MIDDLE-R), POWER BRACKET

6

bracket (middle-R)

4

two screws

2

screw (BVTP3 × 8)

1

screw (BVTP3 × 8)

(BVTP3

×

8)

6

two screws

(BVTP4

5

two screws

(BVTP3

×

8)

×

8)

8

three screws

(BVTP3

9

two screws

(BVTP3

×

8)

×

8)

10

3

middle (F) assy

2

screw

(BVTP3

×

7

8)

screw

(BVTP3

0

×

8)

power bracket

3-8. CD MECHANISM DECK

)

(CDM64-K1BD44A)

1

screw (2.6 × 8)

2

table (60)

5

CD mechanism deck

(CDM64-K1BD44A)

HCD-MG510AV

4

two screws

(BVTP3

×

8

3-9. BASE UNIT

(BU-K1BD44A)

1

three screws

(BVTP3

×

8)

lower chassis

2

bracket (top 60)

4

four screws

(BVTP3

3

screw

(PSW3

×

6)

4

×

8)

four screws

(BVTP3

×

3

base unit

(BU-K1BD44A)

8)

11

HCD-MG510AV

)

3-10. BU HOLDER ASSY

1

tension spring (F1)

2

tension spring (F-2)

3

two screws

(PTP2.6

×

8

4

BU holder assy

3-11. MOTOR GEAR ASSY (SLED) (M102), CD BOARD

7

2

two screws

(P2

gear

6

claw

×

3)

8

3

two screws

(PTP2.6

claw

9

gear cover

0

×

8)

8

gear

two claws

12

qd

1

Remove two

solders.

CD board

4

qa

Remove two solders.

5

parallel (FFC) (16 core) wire

(CN102)

qs

motor gear assy (SLED)

(M102)

3

screw (P2 × 5)

3-12. OP BASE ASSY

n

d

(KSM-213BFN)

3

Remove the optical pick-up

(KSM-213BFN) in the directio

of arrow B.

B

HCD-MG510AV

2

sled shaft

3-13. CASSETTE LID ASSY (A) / (B)

1

Open the cassette lid

assy (A)/(B).

A

1

Slide the lever

in the direction of arrow

A

.

2

two claws

3

cassette lid

assy (A)

4

two claws

5

cassette li

assy (B)

13

HCD-MG510AV

)

3-14. MECH DECK (TAPE)

4

cassette holder assy (A)

0

two screws

(BVTP2.6)

1

three screws

(BVTP3

×

10)

qs

mech deck (tape)

qa

MD bracket

3

5

cassette

holder

assy (B)

7

shield plate (MD)

2

9

TC board

8

screw (BVTP2.6)

6

two screws

(BVTP2.6)

two screws

(BVTP3 × 10

14

SECTION 4

MECHANICAL ADJUSTMENTS

HCD-MG510AV

• TAPE MECHANISM DECK SECTION

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

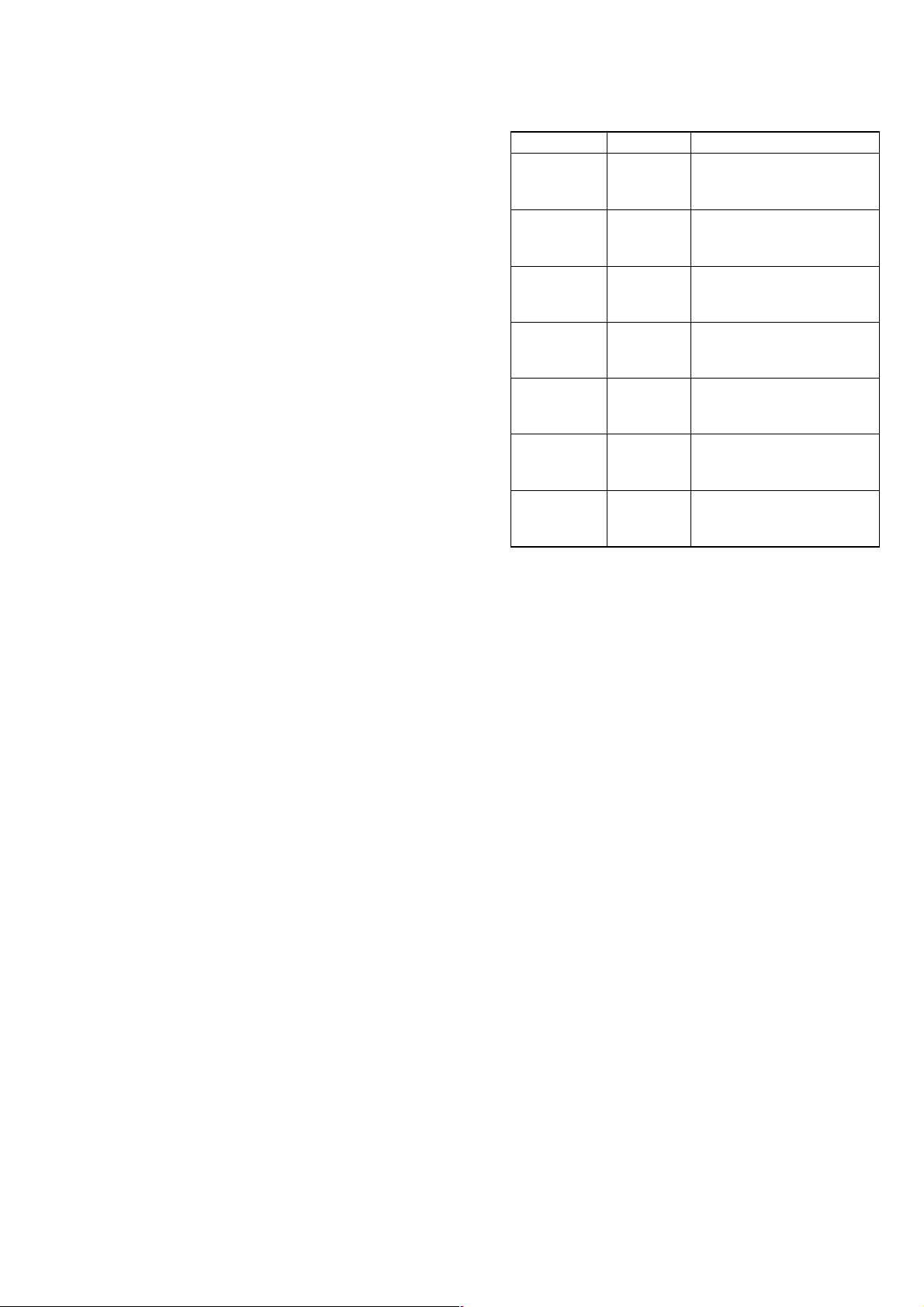

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

2.94 mN • m to 7.84 mN • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.14 mN • m to 0.59 mN • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

2.94 mN • m to 7.84 mN • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.14 mN • m to 0.59 mN • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

6.86 mN • m to 17.64 mN • m

71 to 143 g • cm

(0.98 – 1.99 oz • inch)

more than 0.98 N • m

100 g or more

(3.53 oz or more)

more than 0.98 N • m

100 g or more

(3.53 oz or more)

15

HCD-MG510AV

MEMO

16

SECTION 5

DIAGRAMS

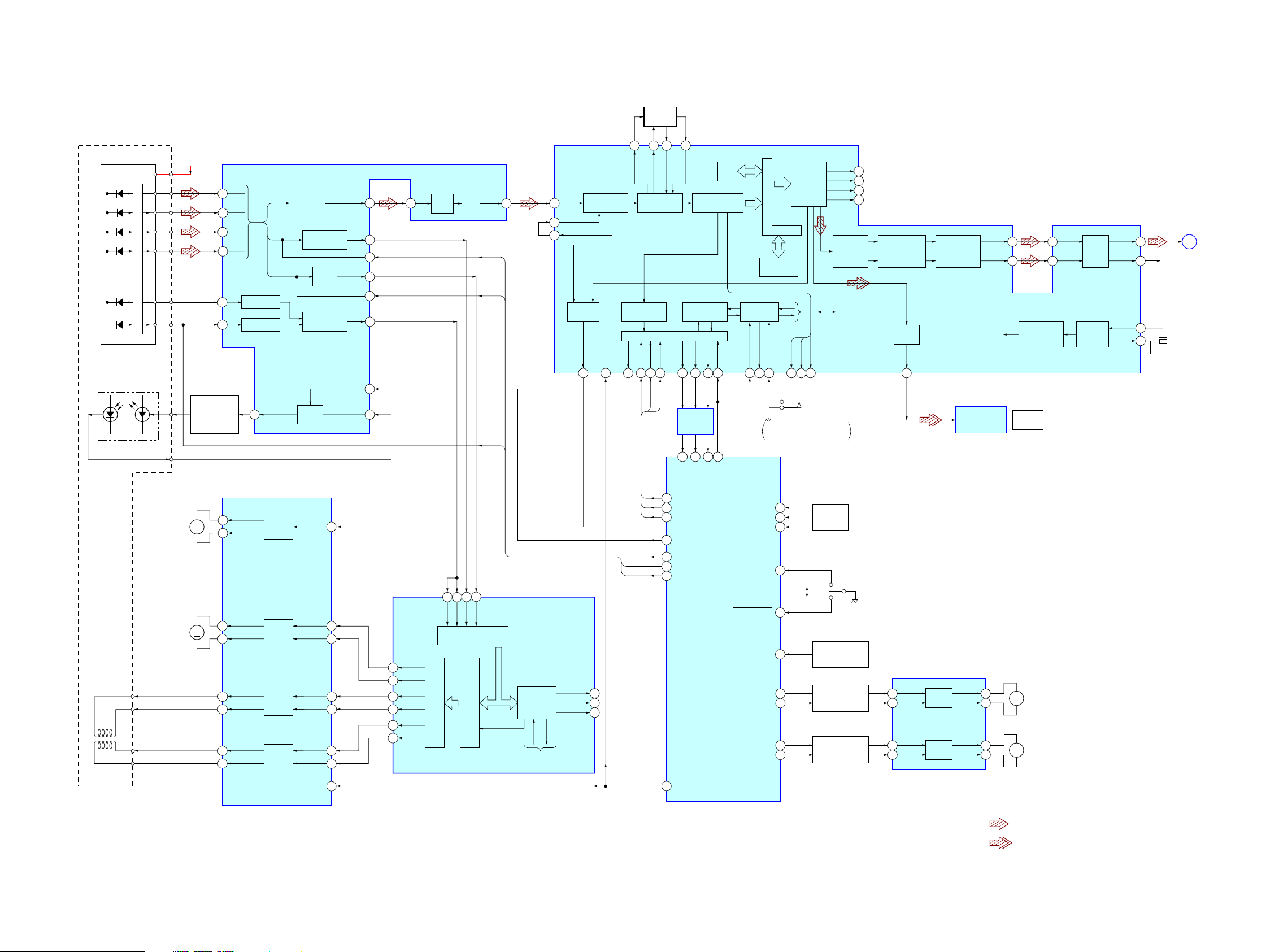

5-1. BLOCK DIAGRAM – CD SERVO Section –

HCD-MG510AV

DETECTOR

A

B

C

D

F

E

OPTICAL PICK-UP

BLOCK

(KSM-213BFN)

LASER DIODE

PD

I-V AMP

LD

CD +5V

6

7

8

9

11

10

AUTOMATIC

POWER

CONTROL

Q101

A

B

C

D

F

E

F I-V AMP

E I-V AMP

LD

1

FOCUS/TRACKING ERROR AMP

RF

SUMMING

AMP

FOCUS

ERROR AMP

RF DC

AMP

TRACKING

ERROR AMP

APC LD

AMP

AC

SUM

RFDCO

RFDCI

SW

RF AMP,

IC103

FE

FEI

TE

PD

FILTER

53

54 56

FILO

EQ

IN

4

16

17

28

29

18

12

2

RFAC

3

VCA

RFAC

EQ

15

PWM1

PWM3

PWM2

RFAC

51

49

48

ASYMMETRY

CORRECTION

ASYI

ASYO

DIGITAL

CLV

MDP

XRST

26 7 8

3

SUBCODE

PROCESSOR

XLON

DATA

CLOK

14 5

PCO

CLTV

DIGITAL

PLL

CPU INTERFACE

XLAT

SENS

6

84 19

55

DIGITAL SIGNAL PROCESSOR,

DIGITAL FILTER, D/A CONVERTER

FILI

LEVEL

SHIFT

IC803

EFM

DEMODULATOR

SERVO AUTO

SEQUENCER

SQSO

SCOR

20

1 2

32 33

16K

RAM

SQCK

IC101 (1/2)

CORRECTOR

SERVO

INTERFACE

SCLK

COUT

9 21

D/A

INTERFACE

INTERNAL BUS

ERROR

SSTP

EMPH

WFCK

GFS

64 15

27

ON :

18

S101

(LIMIT)

When the optical pick-up

is inner position

PCMD

62

BCK

63

LRCK

61

C2PO

19

SERIAL

IN

INTERFACE

TO MIRR/DFCT/

FOK DETECTOR

DIGITAL

FILTER,

NOISE SHAPER

DIGITAL

OUT

DOUT

60

PWM

&

INTEGRATOR

TRANSCEIVER

OPTICAL

IC361

AOUT1

AOUT2

70

77

OPTICAL

OUT (CD)

71

76

CLOCK

GENERATOR

AIN1

AIN2

BUFFER

TIMING

LOGIC

LOUT1

LOUT2

XTAI

XTAO

CD

L-CH

72

75

R-CH

66

67

A

X101

16.9344MHz

(Page 19)

2-AXIS

DEVICE

(TRACKING)

(FOCUS)

M101

(SPINDLE)

M102

(SLED)

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

IC102

CH4OUTF

15

M

M

16

17

18

11

12

13

14

CH4OUTR

CH3OUTF

CH3OUTR

CH2OUTR

CH2OUTF

CH1OUTR

CH1OUTF

MOTOR

DRIVE

MOTOR

DRIVE

COIL

DRIVE

COIL

DRIVE

CH4SIN

CH3FIN

CH3RIN

CH2RIN

CH2FIN

CH1RIN

CH1FIN

MUTE

25

PWM1

PWM2

PWM3

43

39

40

41

FE

TE

SE

24

23

SFDR

28

SRDR

29

6

5

3

2

20

TFDR

30

TRDR

31

FFDR

32

FRDR

33

PWM GENERATOR

FOCUS/TRACKING/SLED

RFDC

A/D

CONVERTER

SERVO DSP

FOCUS/TRACKING/SLED

DIGITAL SERVO

PROCESSOR

IC101 (2/2)

MIRR/DFCT/

FOK

DETECTOR

TO SERVO INTERFACE

FOK

MIRR

DFCT

24

22

23

85

87

86

88

22

24

26

83

C-SENS

C-DATA

C-CLK

C-LATCH

LD ON

PWM1

PWM2

PWM3

C-XRST

C-SQCK

C-SCOR

C-SQSO

LOAD IN SW 6

LOAD OUT SW 7

SYSTEM CONTROLLER

IC801 (1/5)

LOAD NEG 3

LOAD POS

TABLE POS 5

TABLE NEG

T-SENS1

T-SENS2

T-SENS3

D-SENS 92

93

18

91

2

100

LOAD IN

LOAD OUT

TABLE

SENSOR

IC11 – 13

S842

(LOAD)

DISC IN

DETECT SENSOR

D841, Q841

LOADING

MOTOR CONTROL

Q881 – 884

TABLE

MOTOR CONTROL

Q885 – 888

2

3

17

16

LOADING/TABLE

MOTOR DRIVE

FN1

RN1

FIN2

RIN2

IC881

MOTOR

DRIVE

MOTOR

DRIVE

OUT1 +

OUT1 –

OUT2 +

OUT2 –

8

9

11

10

M

M

M51

(LOADING)

M52

(TABLE)

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: CD PLAY (ANALOG)

: CD PLAY (DIGITAL OUT)

1717

HCD-MG510AV

5-2. BLOCK DIAGRAM – TUNER/TAPE DECK Section –

FM 75Ω

HP101

(PLAY)

AM

L-CH

R-CH

L-CH

R-CH

R-CH

R-CH

FM ANT

ANT GND

AM ANT

ANT GND

TUNER PACK

R-CH R-CH

L-CH

R-CH

TU-CLK

TU-CE

TUNED

DI

DO

REC/PB SWITCHING

13

TUNER

L-CH

R-CH

DI

DO

CLK

CE

TUNED

5.1CH

INPUT SELECT

SWITCH

PB AMP

IC401 (1/2)

A IN-L

24

B IN-L

23

IC402

A/B SW

19

R-CH

PB

AMP

R-CH

PB-L

20

MIX

OUT

6

+

AMS DET

Q404, 405

MUTING

Q102

MUTING

Q101

R-CHR-CH

IC306

1 2

4 3

5 13

TAPE

L-CH

R-CHR-CH

B

C

D

(Page 19)

(Page 19)

(Page 19)

HRPE101

(REC/PLAY/ERASE)

R-CH

M1

(CAPSTAN)

BIAS OSC

T401

SENSOR B+

MM

T403

2

BIAS OSC

C429, R429

Q401

MOTOR DRIVE

BIAS

TRAP

REC BIAS

Q402, 403

CAPSTAN

Q381, 382

SWITCH

MOTOR

+12V

4

AU +9V

58 MO-ON

54

53

PB/REC

PB-A/B

(DECK A PLAY)

61

A-PLAY

16

67

AMS

B-PLAY

56

(DECK B PLAY)

REC

OUT-L

REC AMP

IC401 (2/2)

REC

AMP

(DECK A HALF)

TAPE MECHANISM

DECK BLOCK

(1/2)

REC

IN-L

66

14

R-CH

A-HALF

MUTING

Q112

50

REC-MUTE

(DECK B HALF)

(DECK B REC)

68

PB-MUTE

B-HALF

90

69

TAPE

(DECK A REC)

70

DVD

SYSTEM CONTROLLER

TAPE MECHANISM

DECK BLOCK

(2/2)

ROTATION

DETECT SENSOR

(DECK A)

97

A-SHUT

IC801 (2/5)

ROTATION

DETECT SENSOR

(DECK B)

89

B-SHUT

TRIGGER PLUNGER

(DECK A)

TRIGGER

PLUNGER DRIVE

(DECK A)

Q383, 384

59

A-TRIG

TRIGGER PLUNGER

(DECK B)

TRIGGER

PLUNGER DRIVE

(DECK B)

Q385, 386

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: TUNER

: TAPE PLAY (DECK A)

: TAPE PLAY (DECK B)

60

B-TRIG

DI

DO

CLK

78

80

79

TU-DI

TU-DO

TU-CLK

: REC

: 5.1CH INPUT

CE

77

TUNED

76

TU-CE

TU-TUNED

REC

L-CH

E

(Page 19)

1818

5-3. BLOCK DIAGRAM – SURROUND Section –

HCD-MG510AV

5.1CH

INPUT

VIDEO IN

AUDIO

FRONT

REAR

CENTER

SUPER

WOOFER

(Page 21)

(Page 18)

(Page 17)

(Page 18)

(Page 18)

L

R

L

R

VIDEO

(Page 18)

L

R

L

R

J302

J701

J301

F

E

A

B

D

C

SPE ANA

REC

L-CH

CD

L-CH

TUNER

L-CH

TAPE

L-CH

R-CH

R-CH

5.1CH

R-CH

R-CH

3

5

7

1

9

J304

VIDEO OUT

FRONT

REAR

CENTER

WOOFER

B1

C1

D1

A1

E1

INPUT SELECT

IC302 (1/2)

INPUT SELECT

LOGIC

DATA

DATA

+

R-CH

CLK

1514

CLK

DATA

CLK

LINE

OUT

LOW-PASS

FILTER

IC304 (1/2)

DOLBY PRO LOGIC

SURROUND PROCESSOR

IC301

AUTO-BALANCE

L–R

SW

OUT

INPUT

DS2L

OUT

WOOFER

FRONT

32

CENTER

REAR

79

80

72

74

76

77

SWIN

VRSWIN

LIN

LTIN

CIN

SLIN

L+R

R-CH

2

SWVOL

IN

SELECTOR

COMMAND

REQ

TRIMMER,

VOLUME

ADAPTIVE

MATRIX

S

DIN

R-CH

L

R

C

10KBIT S-RAM

LOGIC

CIRCUIT

PSEUDO

STEREO

PS

RIN

CENTER

MODE

CONTROL

PS

LIN

DELAY

VOLUME

1615

NOISE

SEQUENCER

26 27

CPU

INTERFACE

DATA

SCK

22 23 24 8 7 6

27 28 25

R-CH

DVOL

OUT

OUT

SL

OUT

SWVOL OUT

+

MODIFIED

BNR

BNR

IN

4240

C

45

1011

CVOL

IN

SLVOL

IN

TRIMMER,

VOLUME

TRIMMER,

VOLUME

R-CH

SLVOL OUT

LOUT

CVOL OUT

17

1

3

9

BAND-PASS

FILTER

IC305

ELECTRICAL VOLUME

VOL1

29

IC302 (2/2)

SOUND

CONTROL

AMP

IC304 (2/2)

OUT1

20

• R-ch is omitted due to same as L-ch.

R-CH

+

SW

(Page 20)

Z

FRONT

L-CH

CENTER

REAR

L-CH

G

H

J

(Page 20)

(Page 20)

(Page 20)

• SIGNAL PATH

51 V-DATA

52 V-CLK

SYSTEM CONTROLLER

IC801 (3/5)

PL-CLK

PL-DATA

PL-RQ

: TUNER

: CD PLAY

: TAPE PLAY

: REC

: VIDEO IN (AUDIO)

: GAME IN (AUDIO)

: GAME IN (VIDEO)

: 5.1CH INPUT

1919

HCD-MG510AV

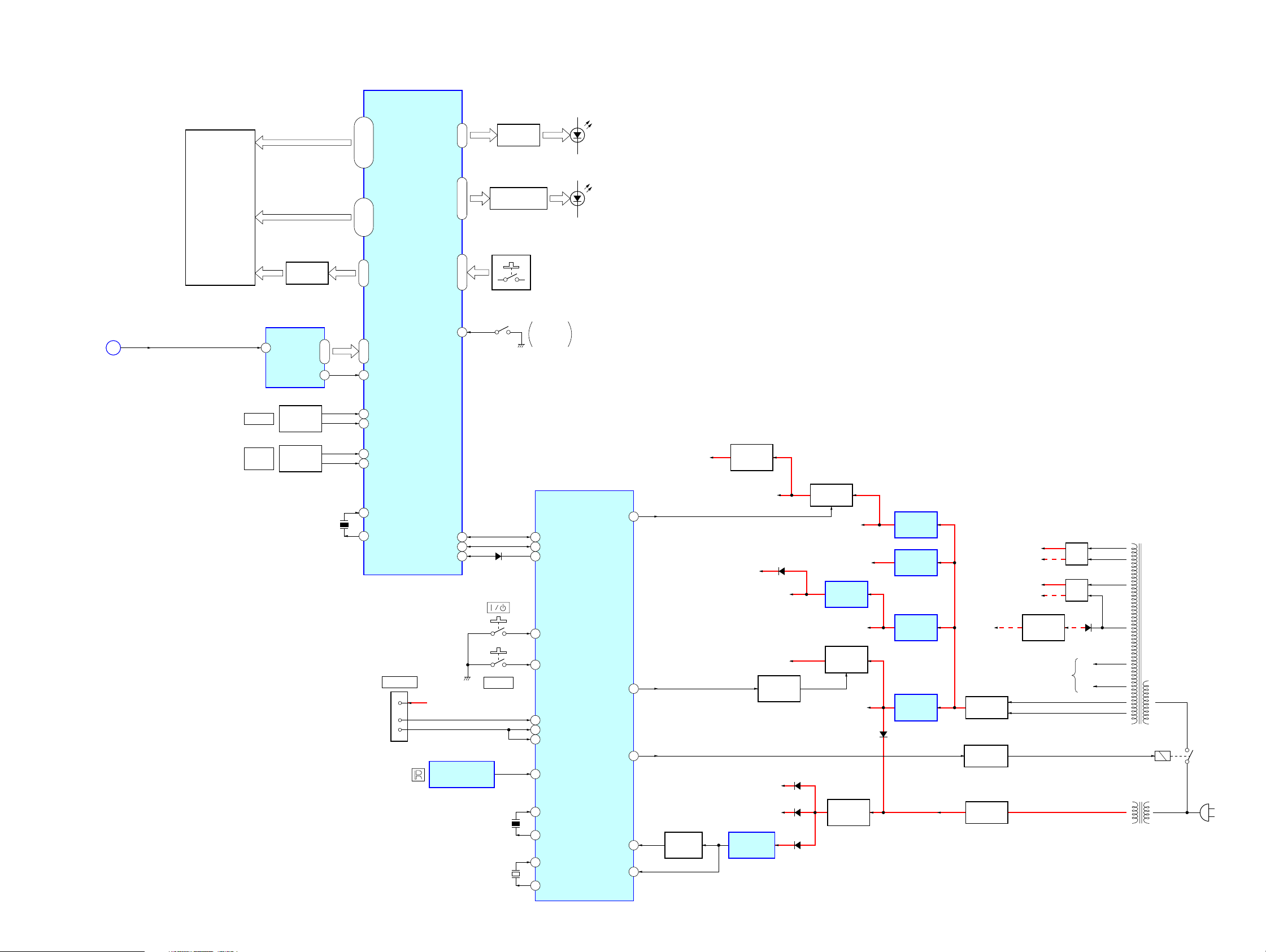

5-4. BLOCK DIAGRAM – AMP Section –

J503

PHONE

(Page 19)

(Page 19)

(Page 19)

(Page 19)

G

H

Z

J

FRONT

L-CH

REAR

L-CH

CENTER

SW

D395, 399

D389

DBFB AMP

IC303

DBFB

SWITCH

Q141

DBFB LEVEL

CONTROL

Q142

R-CH

REAR OUTPUT

SELECT SWITCH

IC307

6 12

R-CH R-CH

R-CH

1011

98

R-CH

STK MUTE

STK MUTE

R-CH

R-MUTE

C-MUTE

SW-MUTE

Q524

MUTING

Q517, 518

MUTING

CONTROL

Q522

MUTING

Q602, 603

MUTING

CONTROL

Q341, 342

MUTING

Q601

MUTING

CONTROL

Q343, 344

MUTING

Q232

MUTING

CONTROL

Q333, 334

POWER AMP

IC501

MUTING

Q501

MUTING

CONTROL

Q502, 516

POWER AMP

IC602

POWER AMP

IC601

AU +9V

POWER ON

MUTING

Q521

TH501

D513

TERMINAL

DETECT

Q511, 512

PROTECT

DETECT

Q514

+

PROTECTOR

Q505, 508

OVER LOAD

DETECT

Q604, 605

OVER LOAD

DETECT

Q608

OVER LOAD

DETECT

Q607

D501

OVER LOAD

DETECT

Q506, 507

DC DETECT

Q513, 515

+ + +

RY501

MUTING

Q519, 520

MUTING

+

CONTROL

Q523

RELAY DRIVE

Q504, 510

F-RELAY

+

D503

++

RY502

+

+ +

RY503

+

++

HP CHK

FAN MOTOR

DRIVE

Q391, 392

J501 (1/2)

+

–

+

–

M391

(FAN)

M

J501 (2/2)

+

–

+

–

+

–

+

–

L

FRONT SPEAKER

IMPEDANCE

USE 8Ω

R

L

REAR

IMPEDANCE

USE 8Ω

R

CENTER

IMPEDANCE

USE 8Ω

SUPER WOOFER

IMPEDANCE

USE 8Ω

SURROUND

SPEAKER

47

DBFB-ON

48

DBFB-H/L

35

REAR

34

FRONT

STK-MUTE

65

44

STK-MUTE

A-MUTE

R-MUTE

23

A-MUTE

C-MUTE

21

38

C-MUTE

R-MUTE

SW-MUTE

S/W MUTE

SYSTEM CONTROLLER

IC801 (4/5)

RELAY DRIVE

Q503, 509

HP CHK

F-RELAY

40

R-RELAY

55

F-RELAY

45

HP-CHK

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: TUNER

2020

5-5. BLOCK DIAGRAM – DISPLAY/POWER SUPPLY Section –

22 – 12

S1 – S34

47 – 43,41 – 24,

LED3 – LED7

HCD-MG510AV

GRID DRIVE

LED DRIVE

Q721 – 723

89 – 93

Q713 – 717

D703 – 707

(Page 19)

X

F

SPE ANA

FL701

FLUORESCENT

INDICATOR TUBE

VOLUME

DISC

ACCESS

BAND-PASS

4 LINE IN

GRID DRIVE

GRID DRIVE

Q721 – 723

Q721 – 723

FILTER

IC703

ROTARY

ENCODER

RV701

ROTARY

ENCODER

RV702

F1 – F4

13L+R

X701

4MHz

IC801 (5/5)

D708, 736,

D781, 782, 791

CD +3V

81CD POWER

71FM-ON

42POWER STBY

12RESET

82AC CUT

RESET

SWITCH

Q801

+3.3V

REGULATOR

Q102

CD +5V

FL +3.3V

REGULATOR

BU +5V

U-COM +5V

RESET SIGNAL

GENERATOR

IC802

D701, 702

B+ 5V

FM +7V

CONTROL

Q350, 351

D802

D803

D806

B+ SWITCH

Q361, 362

COM +5V

REGULATOR

IC905

MOTOR +12V

REGULATOR

REGULATOR

Q802, 803

+5V

+7V

Q352

+5.6V

CD +8V

AU +9V

D866

+5V

REGULATOR

IC904

+8V

REGULATOR

IC903

+12V

REGULATOR

IC902

+9V

REGULATOR

IC901

VP – 33V

RECT

D961 – 964

RELAY DRIVE

Q901

RECT

D911 – 914

R AMP B+

R AMP B–

F AMP B+

F AMP B–

– 33V

REGULATOR

Q397

TO FLUORESCENT

INDICATOR TUBE

FL701

RECT

D507

RECT

D511

D901

RECT

VF1

VF2

T901

POWER

TRANSFORMER

(MAIN)

T902

POWER

TRANSFORMER

(SUB)

RY901

(AC IN)

LED DRIVE

86, 87, 94, 95

80 – 78, 76

S700

S770

DISPLAY

X802

16MHz

X801

32.768kHz

Q702 – 705, 718

OPEN/CLOSE

30 IIC DATA

29 IIC CLK

43 FL-RESET

74 POWER KEY

73 DISPLAY KEY

36 KB-SDA

20 KB-SCL

37 KB-CTRL

15 XIN

13 XOUT

10 SUBXIN

11 SUBXOUT

S701, 741 – 745,

S750 – 757, 760 – 767,

S771 – 777

S791

CD LID

DETECT

SYSTEM CONTROLLER

4 RMC

LED8, LED9

LED0, LED1,

3, 5 – 10

G8 – G13

99, 100, 2,

G2, G3, G5, G6,

98, 1, 4

G1, G4, G7

DISPLAY CONTROLLER

IC701

17 – 14

75 – 72

BPF1 – BPF4

71 L+R

66 VOL A

67 VOL B

64 JOG A

65 JOG B

82 X0

83 X1

SDA

SCL

J801

KEYBOARD

4

1

5

KEY0 – KEY3

59DOOR SW

60SDA

61SCL

77RSTX

B+ 5V+5V

REMOTE CONTORL

RECEIVER

IC702

2121

HCD-MG510AV

d

5-6. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

f

•

• : Pattern from the side which enables seeing.

• Indication of transistor.

: internal component.

C

Q

B

E

B

These are omitted.

Q

CE

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• 2 : nonflammable resistor.

• 5 : fusible resistor .

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• A : B+ Line.

• B : B– Line.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

with mark 0 are critical for safety.

Replace only with part number specified.

Voltage var iations may be noted due to normal production tolerances.

Voltage var iations may be noted due to normal production tolerances.

F : TUNER

J : CD PLAY (ANALOG)

c : CD PLAY (DIGITAL OUT)

E : TAPE PLAY (DECK A)

d : TAPE PLAY (DECK B)

G : REC

q : VIDEO IN (AUDIO)

j : GAME IN (AUDIO)

k : GAME IN (VIDEO)

f : 5.1CH INPUT

4

W or less unless otherwise

• Circuit Boards Location

GAME LINK board

CD LED board

MAIN AMP board

SUB AMP board

FM/AM TUNER PACK

POWER board

FUSE board

MAIN board

CD board

TC board

DISPLAY board

D SENSOR (OUT) boar

RMC board

LOAD SW board

CONTROL board

H/P board

L. T MOTOR board

D SENSOR (IN) board

DOOR LED board

T SENSOR board

2222

Loading...

Loading...