Sony HCDMG-310-AV Service manual

HCD-MG110/MG310AV

SERVICE MANUAL

Ver 1.3 2002.05

HCD-MG110/MG310AV are the Amplifier , CD play er, Tape

Deck and Tuner section in MHC-MG110/MG310AV.

HC D-MG310AV only

This stereo system is equipped with the Dolby* Pro Logic

Surround decoder.

* Manufactured under license from Dolby Laboratories.

Dolby, Pro Logic, and the double-D symbol ; are

trademarks of Dolby Laboratories. Confidential

unpublished works. '1992-1997 Dolby Laboratories.

All rights reserved.

Photo: HCD-MG110

CD

Section

TAPE

Section

US Model

Canadian Model

HCD-MG110/MG310AV

Mexican Model

HCD-MG110

Australian Model

HCD-MG310AV

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM64-K1BD44A

Base Unit Name BU-K1BD44A

Optical Pick-up Name KSM-213BFN

Model Name Using Similar Mechanism NEW

T ape Transport Mechanism Type CM8L6Z511A

Amplifier section

U.S.A. models:

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

with 8 ohm loads both channels driven, from

120 – 10,000 Hz; rated 75 watts per channel

minimum RMS power, with no more than 10%

total harmonic distortion from 250 milliwatts to

rated output.

MHC-MG310AV

Front speaker:

Continuous RMS power output

Total harmonic distortion less than 0.09%

Center speaker:

Continuous RMS power output

Rear speaker:

Continuous RMS power output

75 + 75 watts

(8 ohms at 1 kHz,

10% THD)

(8 ohms at 1 kHz,

40 watts)

25 watts

(8 ohms at 1 kHz,

10% THD)

25 + 25 watts

(8 ohms at 1 kHz,

10% THD)

SPECIFICATIONS

MHC-MG110

Continuous RMS power output

Total harmonic distortion less than 0.09%

Inputs

VIDEO/MD IN (phono jacks):

5.1CH (MG310AV only):

FRONT (phono jacks): voltage 450 mV,

REAR (phono jacks): voltage 450 mV,

CENTER (phono jack): voltage 450 mV,

SUB WOOFER (phono jack):

Outputs

PHONES (stereo phone jack):

FRONT SPEAKER: accepts impedance of 8 to

SURROUND SPEAKER REAR

(MG310AV only): accepts impedance of 8 to

75 + 75 watts

(8 ohms at 1 kHz,

10% THD)

(8 ohms at 1 kHz,

40 watts)

voltage 250 mV/450 mV,

impedance 47 kilohms

impedance 47 kilohms

impedance 47 kilohms

impedance 47 kilohms

voltage 450 mV,

impedance 47 kilohms

accepts headphones of

8 ohms or more

16 ohms (except for the

Cnadian and Mexican model)

16 ohms (except for the US,

Cnadian and Mexican model)

US,

SURROUND SPEAKER SUB WOOFER

(MHC-MG510AV only): accepts impedance of

SUB WOOFER (MHC-MG310AV only):

CD player section

System Compact disc and digital

Laser Semiconductor laser

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Wavelength 780 – 790 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

OPTICAL OUT (CD)

(Square optical connector jack, rear panel)

Wavelength 660 nm

Output Level –18 dBm

Tape player section

Recording system 4-track 2-channel stereo

Frequency response 40 – 13,000 Hz (±3 dB),

Tuner section

FM stereo, FM/AM superheterodyne tuner

– Continued on next page –

8 ohms (except for the

North American model)

voltage 1 V,

impedance 1 kilohm

audio system

( = 780 nm)

Emission duration:

continuous

using Sony TYPE I

cassette

9-873-801-14 Sony Corporation

2002E0500-1 Home Audio Company

C 2002.05 Published by Sony Engineering Corporation

COMPACT DISC DECK RECEIVER

HCD-MG110/MG310AV

Ver 1.3

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals

North American model: 75 ohms unbalanced

Australian model: 75 ohms balanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

US, Canadian and Mexican model:

Australian model: 531 – 1,602 kHz

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

530 – 1,710 kHz

(with the interval set at

10 kHz)

531 – 1,710 kHz

(with the interval set at

9 kHz)

(with the interval set at

9 kHz)

General

Power requirements

US, Canadian and Mexican model:

Australian model:

Power consumption

US, Canadian and Mexican model

MHC-MG310AV: 200 watts

MHC-MG110: 150 watts

Australian model

MHC-MG310AV: 200 watts

Dimensions (w/h/d) incl. projecting parts and controls

Mass

MHC-MG310AV: Approx. 11.3 kg

MHC-MG110: Approx. 10.9 kg

TABLE OF CONTENTS

1. SERVICING NOTE .................................................. 4

2. GENERAL ................................................................... 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Upper Cover .................................................................... 8

3-3. Front Block Assy............................................................. 8

3-4. MAIN Board ................................................................... 9

3-5. Back Panel, DC Fan (M391) (Australian model)........... 9

3-6. MAIN AMP Board, POWER Board............................... 10

3-7. Middle (F) Assy, Bracket (Middle-R),

Power Bracket ................................................................. 10

3-8. Mechanism Deck (CDM64-K1BD44A)......................... 11

3-9. Base Unit (BU-K1BD44A)............................................. 11

3-10. BU Holder Assy .............................................................. 12

3-11. Motor Gear Assy (Sled) (M102), CD Board .................. 12

3-12. Op Base Assy (KSM-213BFN) ...................................... 13

3-13. Cassette Lid Assy (A)/(B) ............................................... 13

3-14. Mech Deck (TAPE) ......................................................... 14

4. TEST MODE.............................................................. 15

5. MECHANICAL ADJUSTMENTS....................... 16

6. ELECTRICAL ADJUSTMENTS

Deck Section ............................................................................. 16

CD Section ................................................................................ 18

7. DIAGRAMS

7-1. Block Diagram – CD SERVO Section – ........................ 21

7-2. Block Diagram – TUNER/TAPE DECK Section – ...... 22

7-3. Block Diagram – SURROUND Section –...................... 23

7-4. Block Diagram – AMP Section – ................................... 24

7-5. Block Diagram

– DISPLAY/POWER SUPPLY Section – ...................... 25

120 V AC, 60 Hz

220 – 240 V AC,

50/60 Hz

Approx. 280 × 383 × 480

mm

Supplied accessories: Remote commander (1)

Design and specifications are subject to change

without notice.

Batteries (2)

AM loop antenna (1)

FM lead antenna (1)

Rear speaker cords

(MG310AV only) (2)

Center speaker pads

(attached to the backside

of the center speaker)

(MG310AV only) (2)

Video cable (Australian

model only) (1)

7-6. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 26

7-7. Schematic Diagram – CD Section – ............................... 28

7-8. Printed Wiring Board – CD Section – ............................ 29

7-9. Printed Wiring Boards

– CD MOTOR/SENSOR Section – ................................ 30

7-10. Schematic Diagram

– CD MOTOR/SENSOR Section – ................................ 31

7-11. Printed W iring Board – TC Section –............................. 32

7-12. Schematic Diagram – TC Section – ............................... 33

7-13. Schematic Diagram – MAIN Section (1/4) –................. 34

7-14. Schematic Diagram – MAIN Section (2/4) –................. 35

7-15. Schematic Diagram – MAIN Section (3/4) –................. 36

7-16. Schematic Diagram – MAIN Section (4/4) –................. 37

7-17. Printed W iring Board – MAIN Section – ....................... 38

7-18. Printed W iring Boards – AMP Section –........................ 40

7-19. Schematic Diagram – AMP Section – ............................ 41

7-20. Printed W iring Boards – DISPLAY Section – ............... 42

7-21. Schematic Diagram – DISPLAY Section – .................... 43

7-22. Printed W iring Board – CONTROL Section –............... 44

7-23. Schematic Diagram – CONTROL Section –.................. 45

7-24. Printed W iring Boards – POWER Section – .................. 46

7-25. Schematic Diagram – POWER Section – ...................... 47

7-26. IC Pin Function Description ........................................... 48

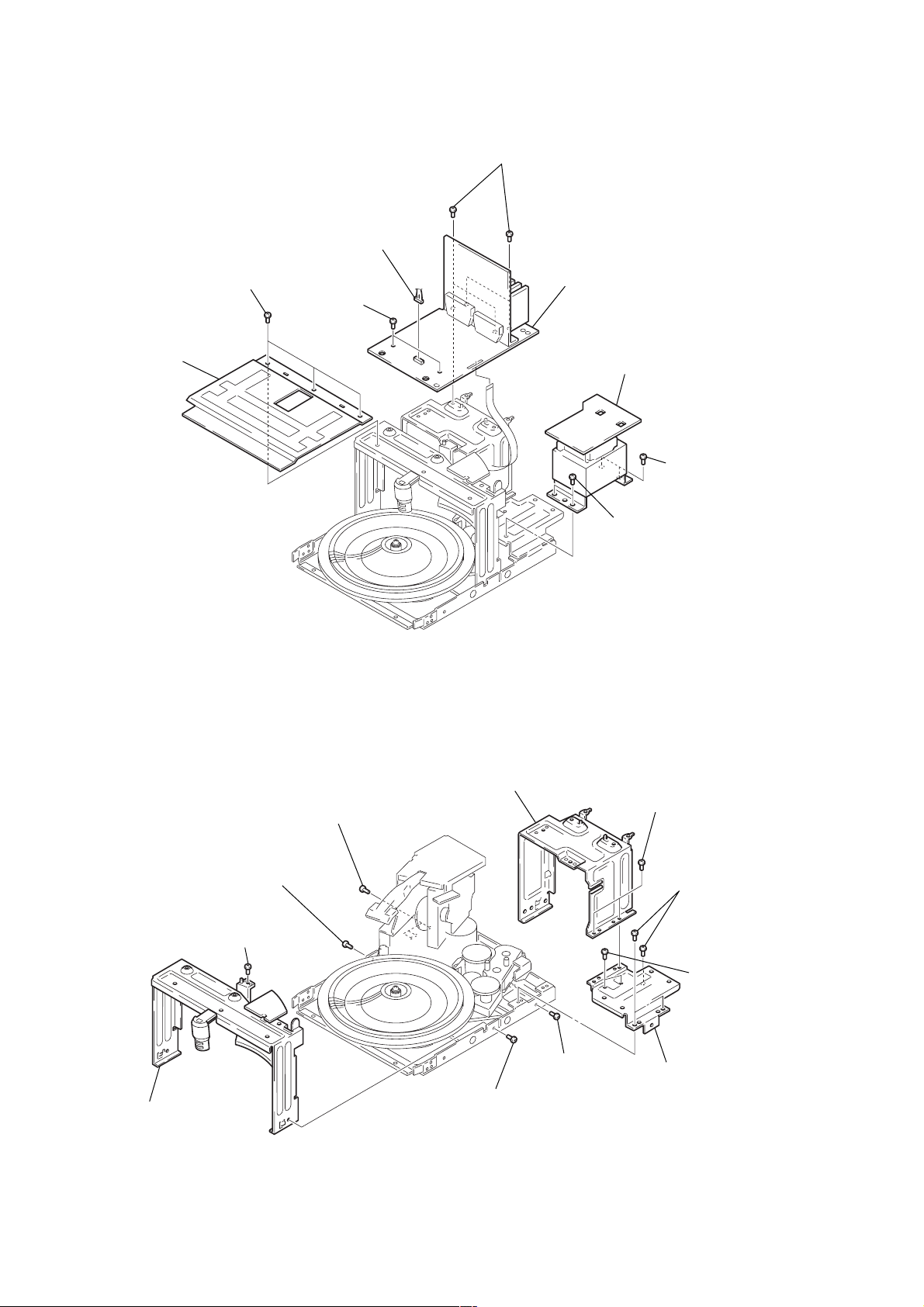

8. EXPLODED VIEWS

8-1. General Section ............................................................... 54

8-2. Front Panel Section ......................................................... 55

8-3. Chassis Section ............................................................... 56

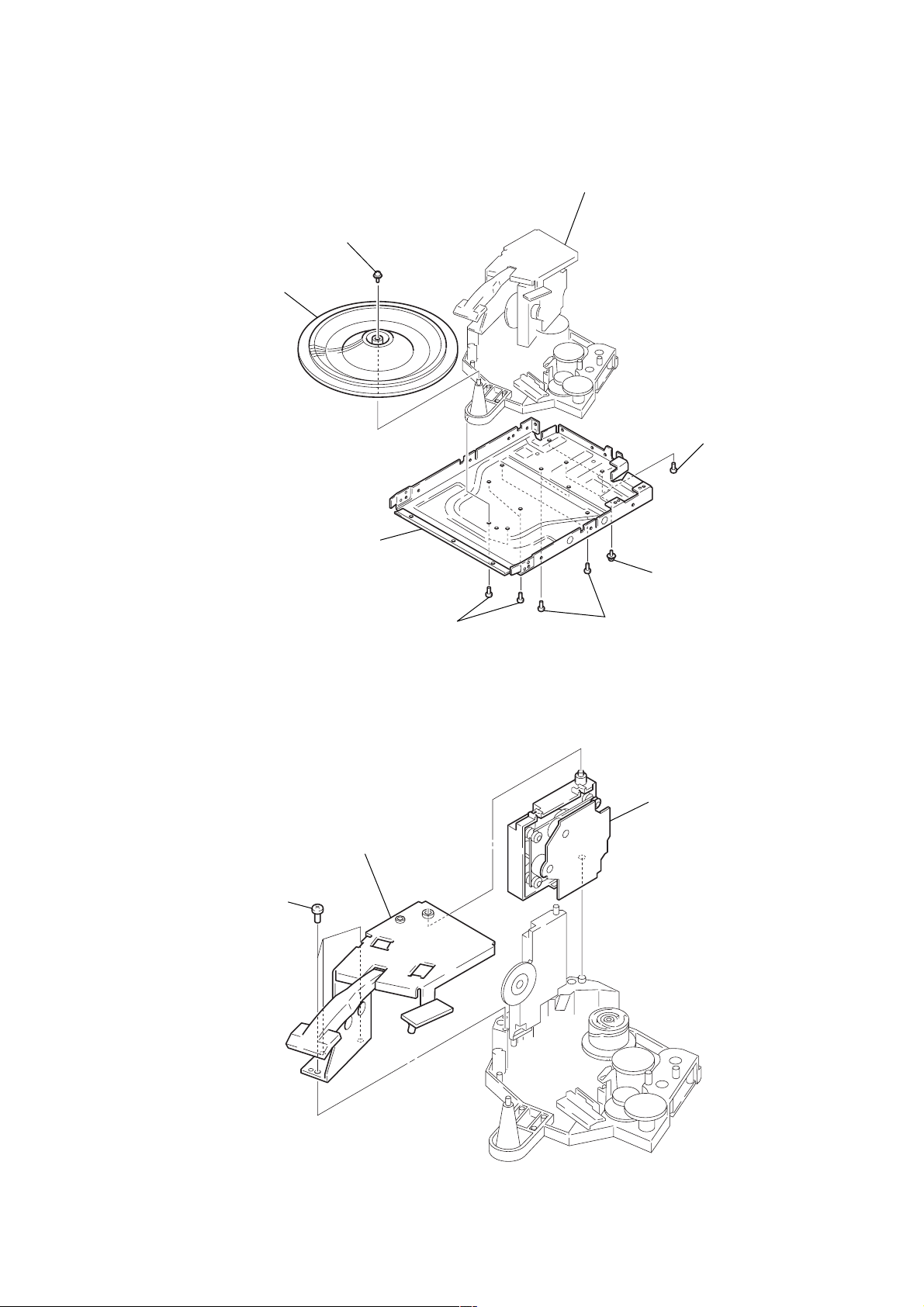

8-4. Mechanism Deck Section (CDM64-K1BD44A) ........... 57

8-5. Base Unit Section (BU-K1BD44A) ............................... 58

9. ELECTRICAL PARTS LIST ............................... 59

2

HCD-MG110/MG310AV

r

Ver 1.1

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

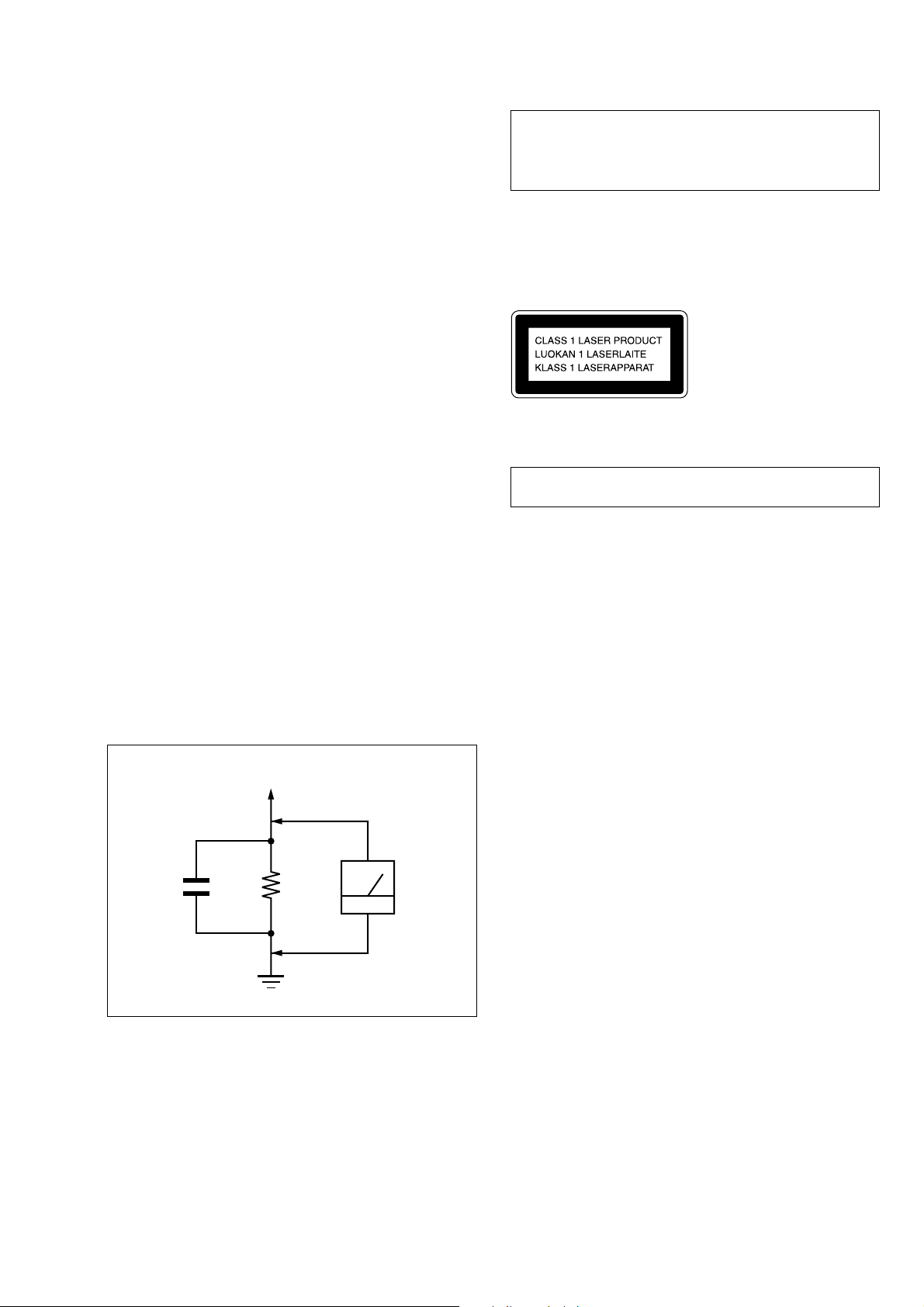

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor b y means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T r d are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V AC range are

suitable. (See Fig. A)

To Exposed Metal

Parts on Set

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

AC

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Ω

Earth Ground

voltmete

(0.75 V)

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

3

HCD-MG110/MG310AV

z

Ver 1.3

SECTION 1

SERVICING NOTES

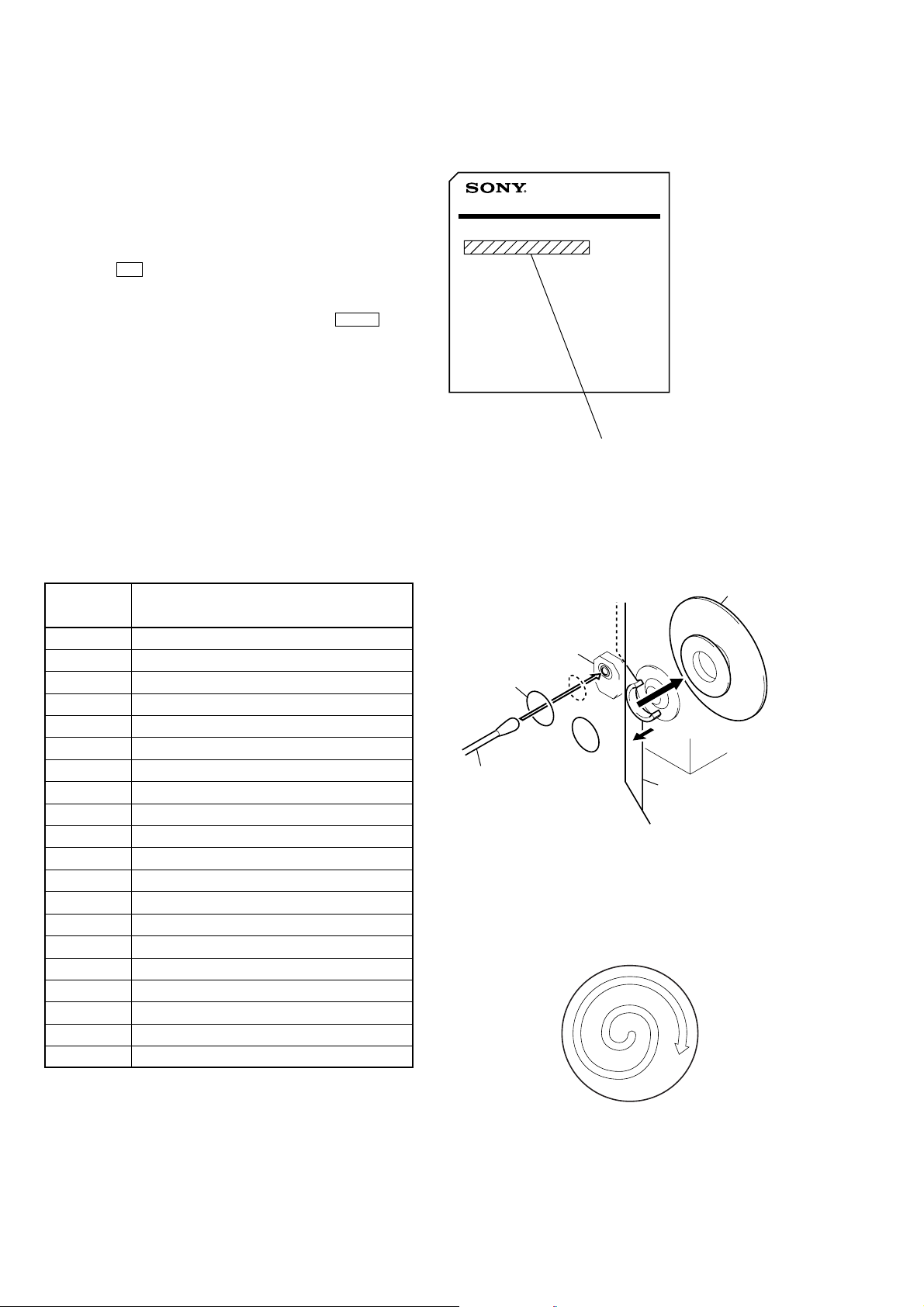

CD-TEXT TEST DISC

This unit is able to display the test data (character information)

written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:4-989-366-01) is used

for checking the display.

To check, perform the following procedure.

Checking Method:

1. Press the I/1 button to turn the power on, set the disc to the

disc table with the “test disc” label facing up, and chuck the

disc.

2. Press the [CD] button to set CD function, and press the n N button

to playback the disc.

3. The following will be displayed on the liquid crystal display.

Display : 1KHZ/0DB/L R

4. Pressing the [-- ] or [ +] button, select the track. The text

data of each track will be displayed.

For details of the displayed contents for each track, refer to “T able

1: CD-TEXT TEST DISC TEXT Data Contents”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly. These will be displayed as a space or a character resembling

it.

Table 1: CD-TEXT TEST DISC TEXT Data Contents

TRACK

No.

1 1kHz/0dB/L&R

2 20Hz/0dB/L&R

3 40Hz/0dB/L&R

4 100Hz/0dB/L&R

5 200Hz/0dB/L&R

6 500Hz/0dB/L&R

7 1kHz/0dB/L&R

8 5kHz/0dB/L&R

9 7kHz/0dB/L&R

10 10kHz/0dB/L&R

11 16kHz/0dB/L&R

12 18kHz/0dB/L&R

13 20kHz/0dB/L&R

14 1kHz/0dB/L&R

15 1kHz/–1dB/L&R

16 1kHz/–3dB/L&R

17 1kHz/–6dB/L&R

18 1kHz/–10dB/L&R

19 1kHz/–20dB/L&R

20 1kHz/–60dB/L&R

.>

(TRACKS No. 1 to 20:Normal Characters)

Displayed Contents

MODEL IDENTIFICATION

– REAR VIEW –

MODEL NO.

COMPACT DISC DECK RECEIVER

MADE IN CHINA

US, Canadian and Mexican models: AC: 120V 60H

Australian Model: AC: 220–240V-50/60Hz

HCD-MG

CLEANING OBJECTIVE LENS OF OPTICAL PICK-UP

• In cleaning the objective lens of optical pick-up, be sure the

following below.

optical pick-up

bracket (top 60) hole

3 Put a cotton bud into

the hole on the bracket

(top 60) and clean the

OP lens.

Note 1. In cleaning the lens, do not apply an excessive force.

Note 2. In cleaning, do not use a cleaner other than exclusive cleaning

Note 3. Wipe the objective lens spirally from center toward outside. (See

As the optical pick-up is vulnerable, application of excessive

force could damage the lens holder.

liquid (KK-91 or isopropyl alcohol).

Figure A)

[][][][][]

2 Remove the

magnet assy.

A

1 Open the torsion holder

(magnet) in direction of

arrow A.

Note: Track No. 21 to 99 are not displayed.

4

(Figure A)

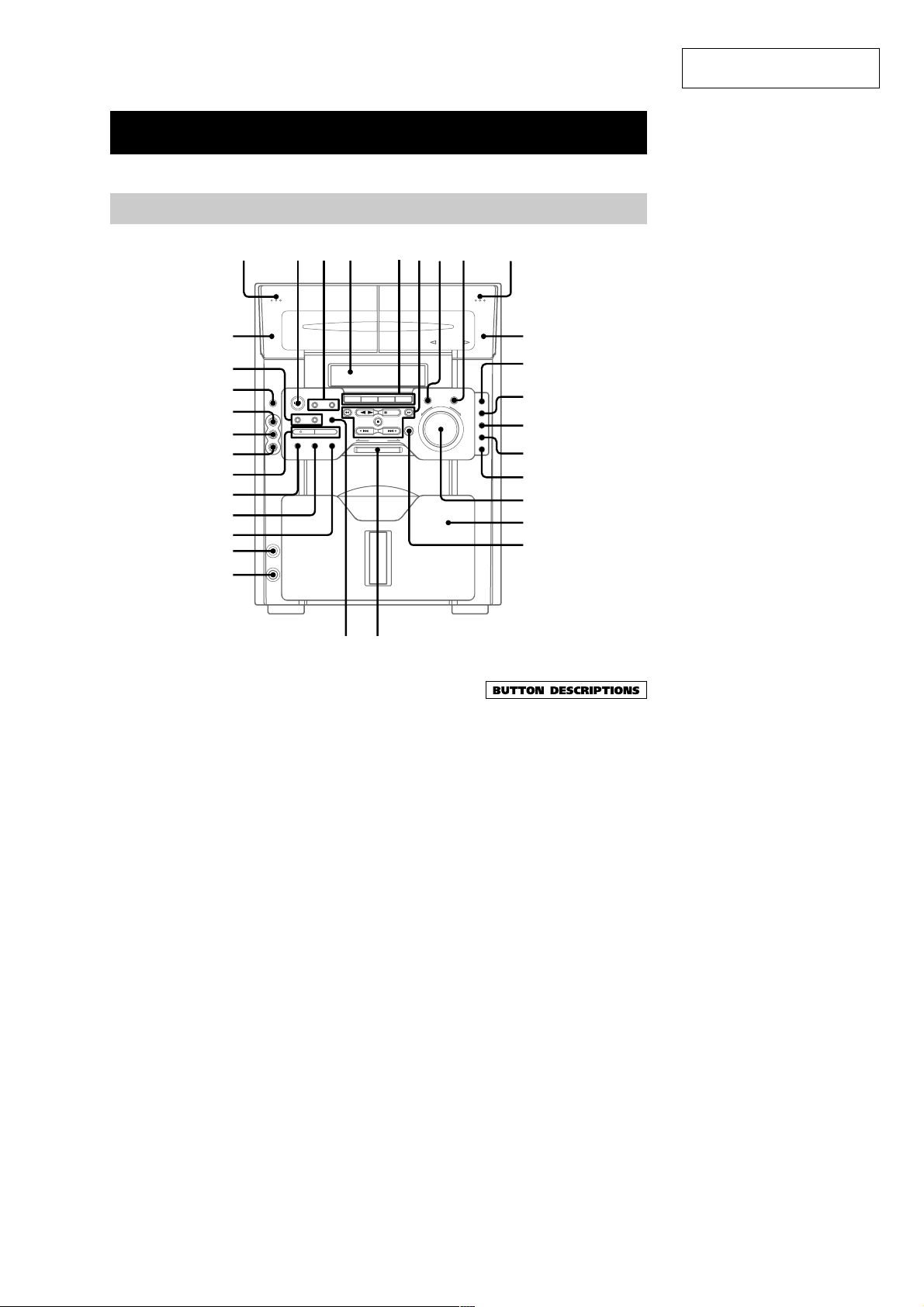

Parts Identification

The items are arranged in alphabetical order.

Main unit

SECTION 2

GENERAL

HCD-MG110/MG310AV

This section is extracted from

instruction manual.

1

es

ea

e;

wl

wk

wj

wh

wg

wf

wd

ws

wa

5.1CH/VIDEO (MD)* 5

AUDIO IN L jack wk

AUDIO IN R jack wj

CD 5 (14, 21)

CD SYNCHRO wh

CLEAR w;

Deck A es

Deck B 0

DIRECTION ea

DISC ACCESS ql

Display window 4

DISPLAY wd

ENTER qk

FRONT* qd

GAME e;

KEYBOARD INPUT jack ws

LINK* qg

MENU ea

234

5

67 8 9

w; ql

PHONES jack wa

PLAY MODE wf

PRESET EQ 7

PRO LOGIC* qs

PUSH OPEN (Front cover) qj

REAR* qf

REC P AUSE/START wh

REPEAT wg

STEREO/MONO wg

SURROUND* qa

SURROUND MODE 8

TAPE A/B 5

TIMER SELECT 3

TIMER SET 3

TUNER/BAND 5

VIDEO IN jack wl

VIDEO (MD)** 5

VOLUME control qh

0

qa

qs

qd

qf

qg

qh

qj

qk

Z (deck A) 1

=/1 (power) 2

m (rewind) 6

n N (play) 6

X P A USE 6

M (fast forward) 6

x (stop) 6

– . (go back) 6

> + (go forward) 6

Z (deck B) 9

* MG310AV only

**MHC-MG110 only

5

HCD-MG110/MG310AV

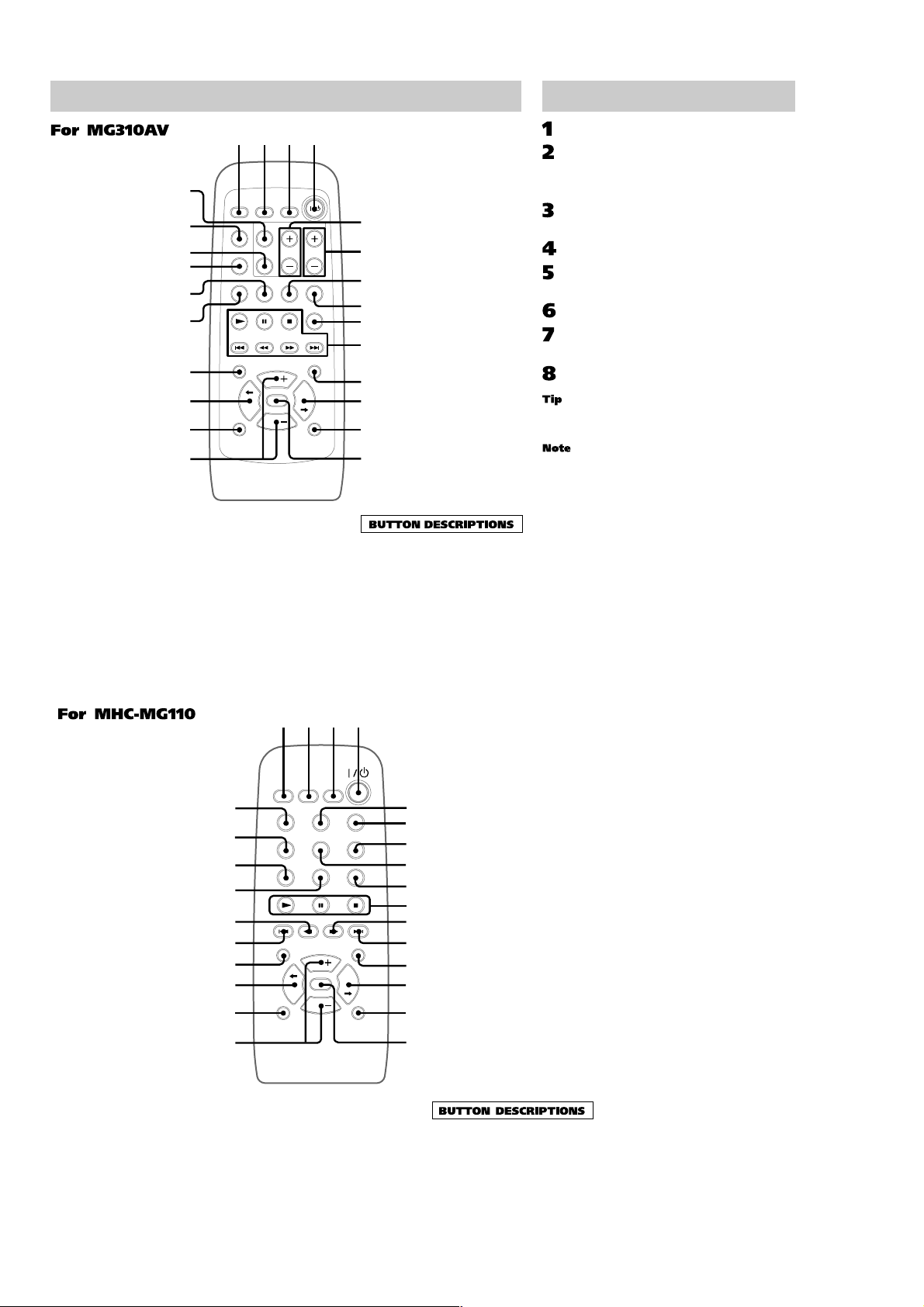

Remote Control

5.1CH wa

CD ql

CENTER +/– 5

DBFB qd

DISPLAY 9

GAME 8

GROOVE qf

PLAY MODE 2

PRESET EQ qk

PRO LOGIC wf

REAR +/– 6

REPEAT 3

wf

wd

ws

wa

w;

ql

qk

qj

qh

qg

SCROLL qa

SLEEP 1

SURROUND qh

TAPE A/B w;

TEST TONE ws

TUNER/BAND 7

VIDEO (MD) wd

VOL +/– qg

1234

5

6

7

8

9

0

qa

qs

qd

qf

@/1 (power) 4

N (play) 0

X (pause) 0

x (stop) 0

. (go back) 0

m (rewind) 0

M (fast forward) 0

(go forward)

>

TDISC/DISCt qs

0

Setting the time

Turn on the system.

Press TIMER SET.

When you set the clock for the first time, go

to step 5.

Press – . or > + repeatedly to

select “CLOCK SET”.

Press ENTER.

Press – . or > + repeatedly to set

the hour.

Press ENTER.

Press – . or > + repeatedly to set

the minute.

Press ENTER.

If you made a mistake or want to change the time,

start over from step 1.

The clock settings are canceled when you disconnect

the power cord or if a power failure occurs.

CD wf

CLOCK/TIMER SELECT 2

CLOCK/TIMER SET 3

DBFB qg

DISPLAY wh

ENTER 5

GAME 7

GROOVE qh

PLAY MODE wg

PRESET EQ w;

REPEAT 8

6

wh

wg

wf

wd

ws

wa

w;

ql

qk

qj

SCROLL qd

SLEEP 1

SURROUND qk

TAPE A/B wd

TUNER/BAND 9

VIDEO (MD) 6

VOL +/

12

– qj

34

5

6

7

8

9

0

qa

qs

qd

qf

qg

qh

@/1 (power) 4

N (play) 0

X (pause) 0

x (stop) 0

. (go back) wa

m (rewind) ws

M (fast forward) qa

> (go forward) qs

TDISC/DISCt qf ql

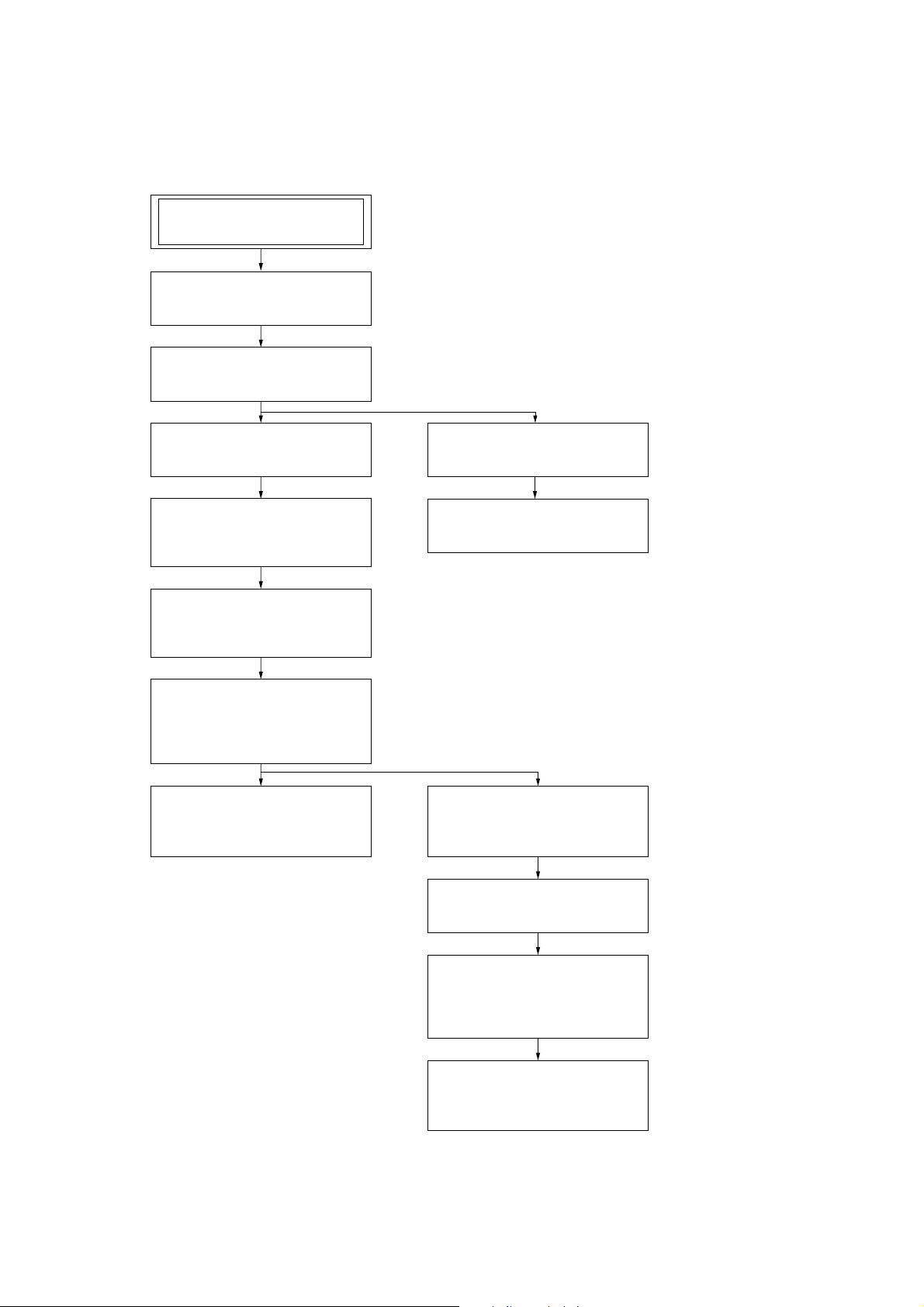

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. UPPER COVER

(Page 8)

SECTION 3

DISASSEMBLY

HCD-MG110/MG310AV

Ver 1.1

3-3. FRONT BLOCK ASSY

(Page 8)

3-4. MAIN BOARD

(Page 9)

3-5. BACK PANEL,

DC FAN (M391)

(Australian model)

(Page 9)

3-6. MAIN AMP BOARD,

POWER BOARD

(Page 10)

3-7. MIDDLE (F) ASSY,

BRACKET (MIDDLE-R),

POWER BRACKET

(Page 10)

3-8. CD MECHANISM DECK

(CDM64-K1BD44A)

(Page 11)

3-13. CASSETTE LID ASSY (A)/(B)

(Page 13)

3-14. MECH DECK (TAPE)

(Page 14)

3-9. BASE UNIT

(BU-K1BD44A)

(Page 11)

3-10. BU HOLDER ASSY

(Page 12)

3-11. MOTOR GEAR ASSY

(SLED) (M102),

CD BOARD

(Page 12)

3-12. OP BASE ASSY

(KSM-213BFN)

(Page 13)

7

HCD-MG110/MG310AV

Ver 1.1

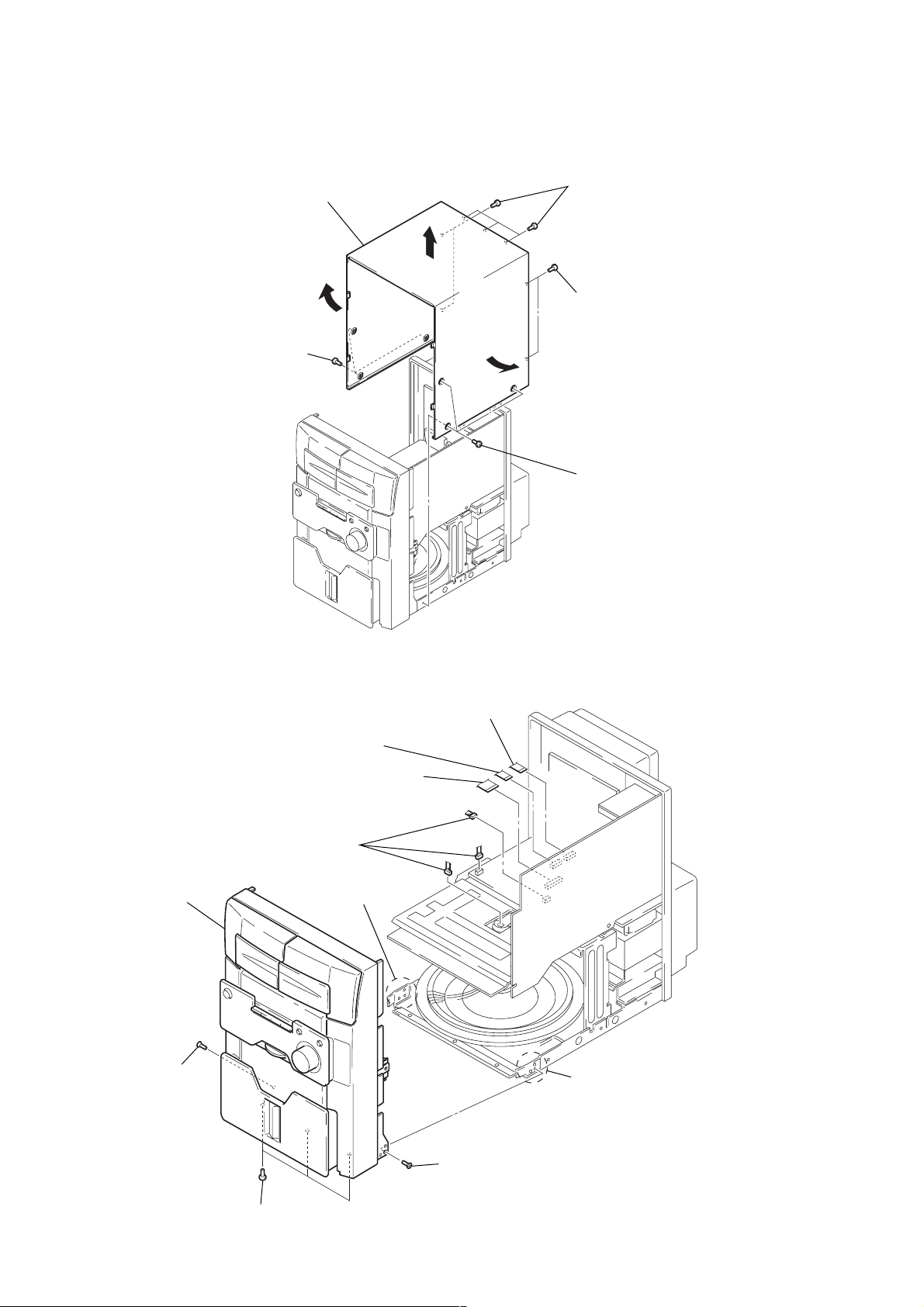

Note: Follow the disassembly procedure in the numerical order given.

3-2. UPPER COVER

3

upper cover

1

three screws

(BVTP3

×

8)

2

five screws

(BVTP3

2

two screws

(BVTP3

1

three screws

(BVTP3

×

8)

×

8)

×

8)

3-3. FRONT BLOCK ASSY

2

6

front block assy

4

screw (KTP3 × 8)

1

wire (flat type) (11 core)

(CN312)

1

wire (flat type) (17 core)

(CN301)

three connectors

(CN310, 503, 803)

5

two bosses

1

wire (flat type) (10 core)

(CN311)

5

two bosses

4

screw (KTP3 × 8)

3

three screws

(BVTP3 × 8)

8

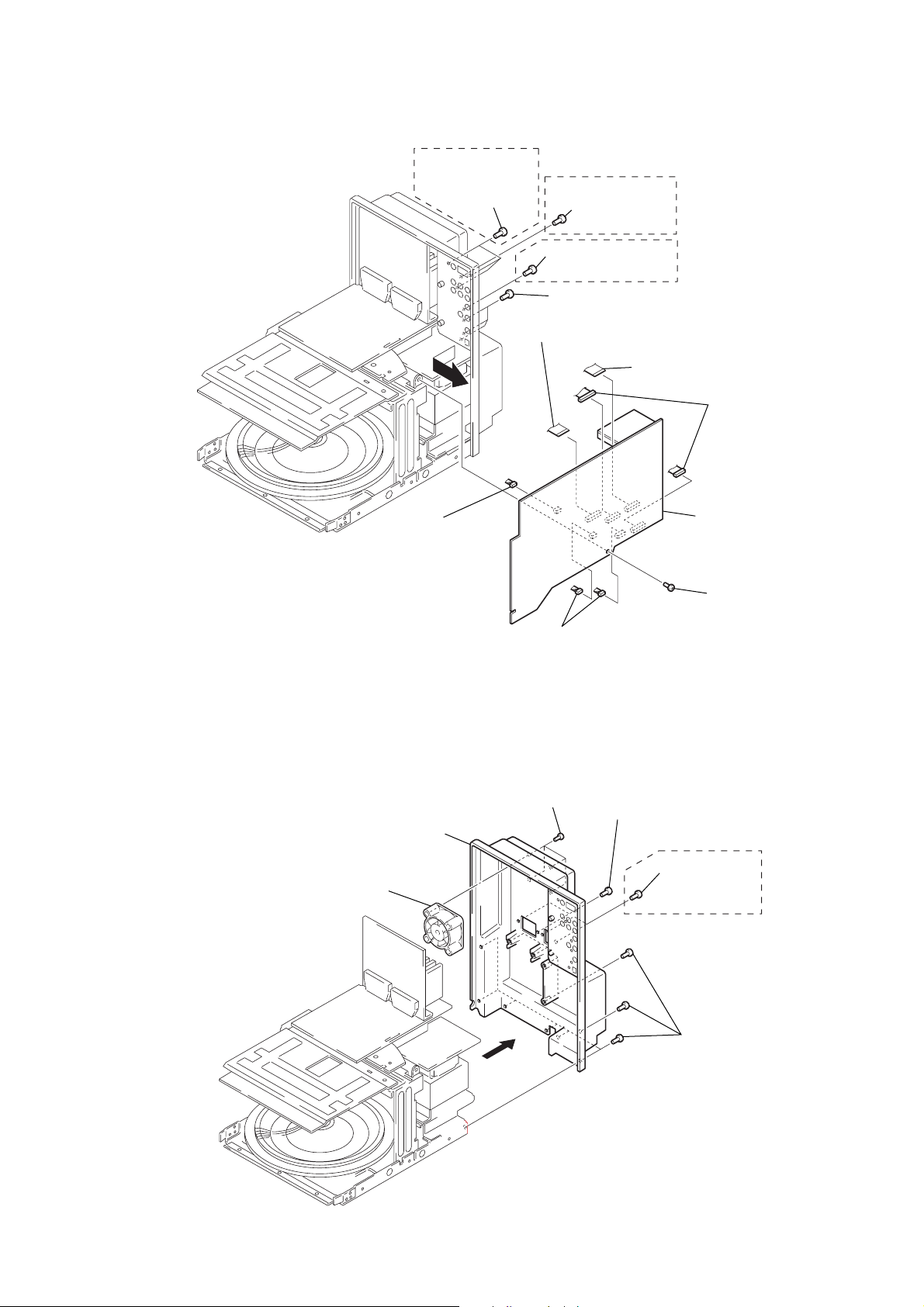

3-4. MAIN BOARD

s

MG310AV

3

three screws

(BVTP3 × 10)

MG110

3

screw

(BVTP3 × 10)

3

screw (BVTP3 × 10)

MG310AV

3

three screws

(BVTP3 × 10)

1

wire (flat type) (18 core)

(CN309)

1

HCD-MG110/MG310AV

Ver 1.1

wire (flat type) (21 core)

(CN303)

2

two connectors

(CN304, 903)

2

connector

(CN313)

3-5. BACK PANEL, DC FAN (M391) (Australian model)

3

four screws

(BVTP3

(Australian model)

5

back panel

4

DC fan (M391)

(Australian model)

2

two connectors

(CN305, 317)

×

10)

1

two screws

(BVTP3

×

10)

1

two screws

(BVTP3

5

MAIN board

4

screw

(BVTP3 × 8)

×

10)

MG310AV

2

1

eleven screw

(BVTP3 × 10)

9

HCD-MG110/MG310AV

)

3-6. MAIN AMP BOARD, POWER BOARD

1

connector

(CN502)

4

three screws

5

center bracket

(BVTP3

×

8)

2

two screws

(BVTP3

×

8)

2

four screws

(BVTP3

×

8)

3

MAIN AMP board

7

POWER board

6

two screws

(BVTP4

×

8

3-7. MIDDLE (F) ASSY, BRACKET (MIDDLE-R), POWER BRACKET

6

bracket (middle-R)

4

three screws

(BVTP3 × 8)

2

screw (BVTP3 × 8)

1

screw (BVTP3 × 8)

6

two screws

(BVTP4

5

two screws

(BVTP3 × 8)

×

8)

8

three screws

(BVTP3 × 8)

9

two screws

(BVTP3 × 8)

10

3

middle (F) assy

2

screw

(BVTP3 × 8)

7

screw

(BVTP3 × 8)

0

power bracket

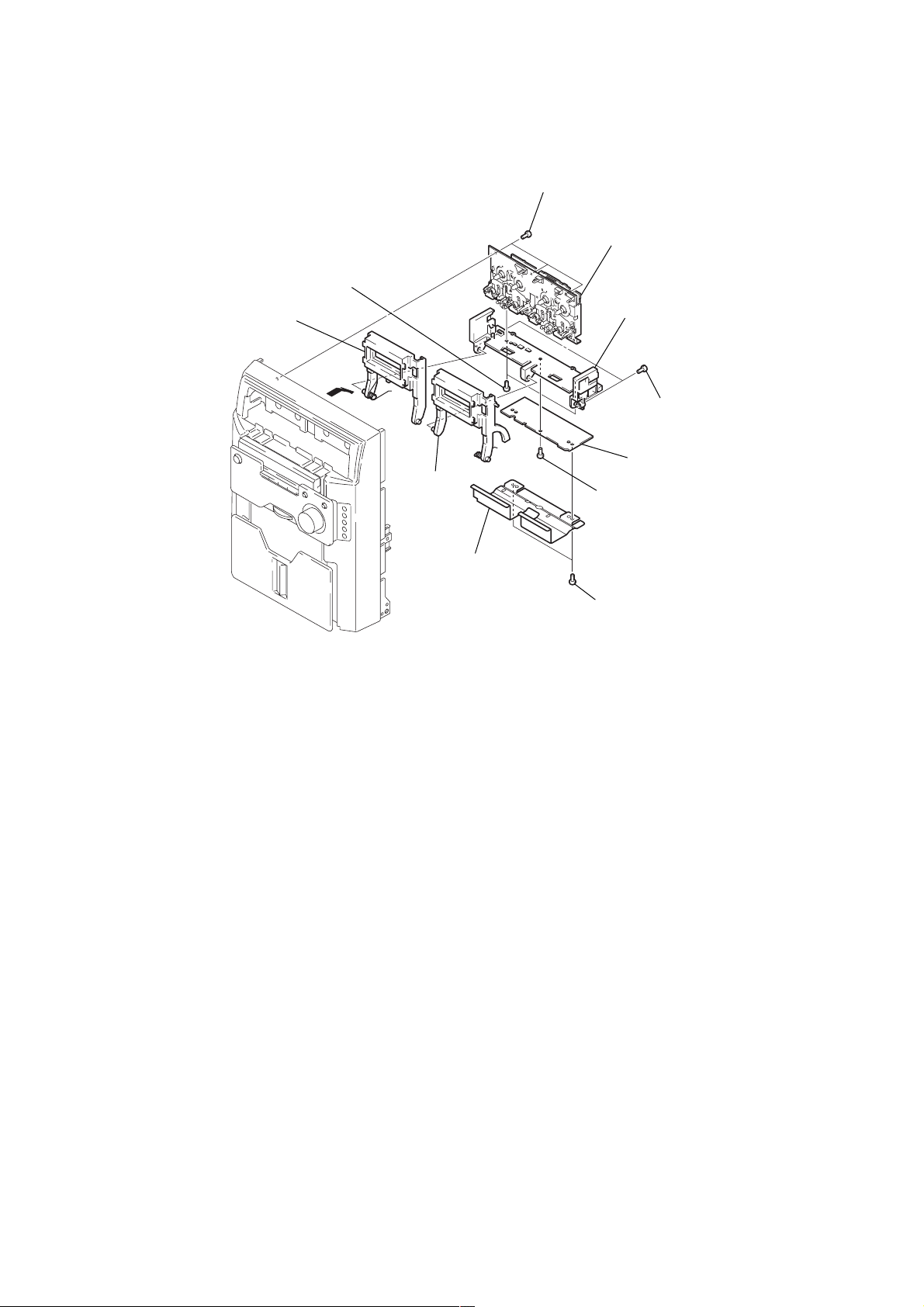

3-8. CD MECHANISM DECK

)

(CDM64-K1BD44A)

1

screw (2.6 × 8)

2

table (60)

5

CD mechanism deck (CDM64-K1BD44A)

HCD-MG110/MG310AV

4

two screws

(BVTP3

×

8

3-9. BASE UNIT

(BU-K1BD44A)

1

three screws

(BVTP3

×

8)

lower chassis

2

bracket (top 60)

4

four screws

(BVTP3

3

screw

(PSW3

×

6)

4

×

8)

four screws

(BVTP3

×

3

base unit (BU-K1BD44A)

8)

11

HCD-MG110/MG310AV

)

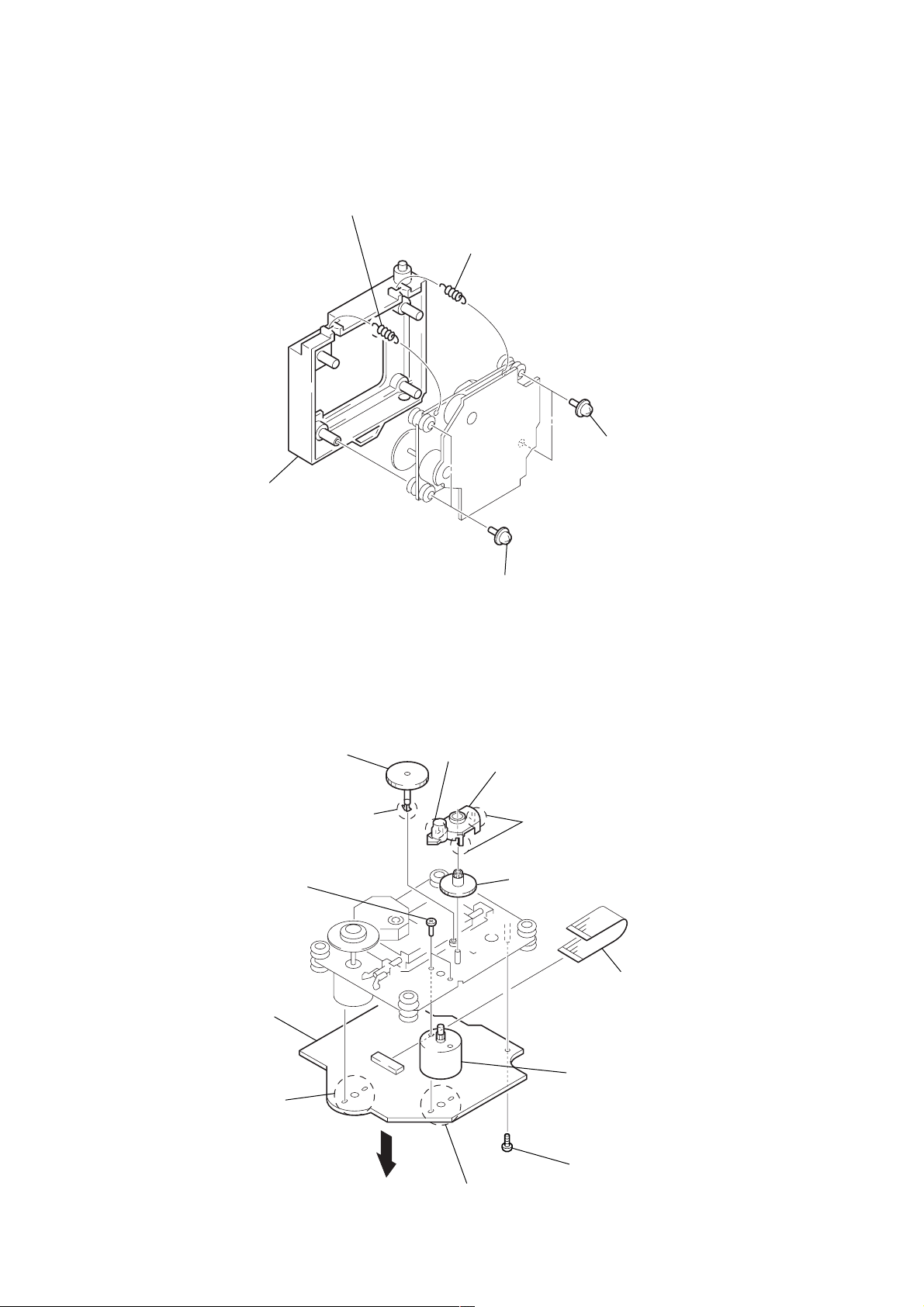

3-10. BU HOLDER ASSY

1

tension spring (F1)

2

tension spring (F-2)

3

two screws

(PTP2.6

×

8

4

BU holder assy

3-11. MOTOR GEAR ASSY (SLED) (M102), CD BOARD

7

2

two screws

(P2

gear

6

claw

×

2)

8

3

two screws

(PTP2.6

claw

9

gear cover

0

×

8)

8

gear

two claws

12

qd

1

Remove two

solders.

CD board

4

qa

Remove two solders.

5

parallel (FFC) (16 core) wire

(CN102)

qs

motor gear assy (SLED)

(M102)

3

screw (P2 × 5)

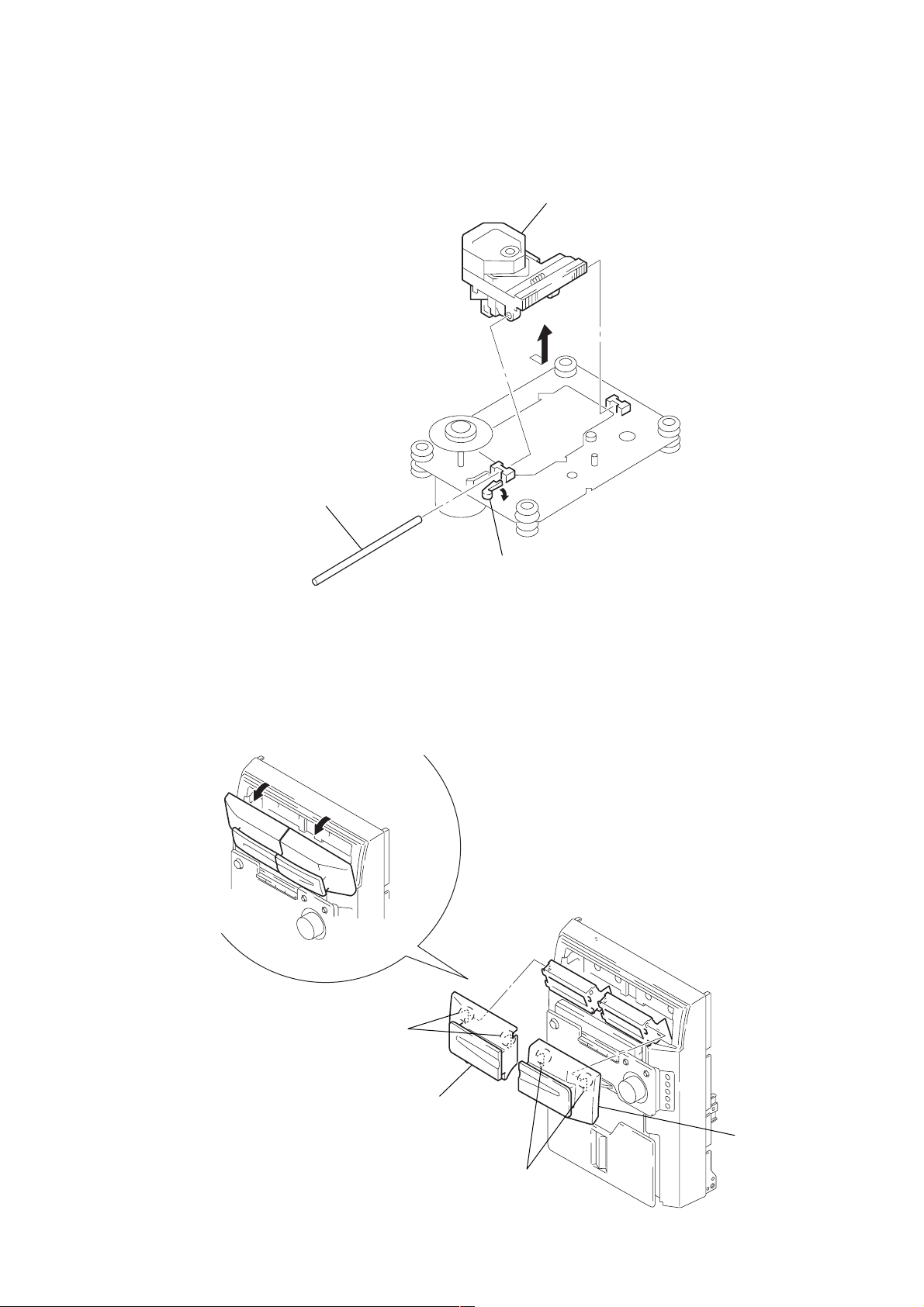

3-12. OP BASE ASSY

n

d

(KSM-213BFN)

HCD-MG110/MG310AV

3

Remove the optical pick-up

(KSM-213BFN) in the directio

of arrow B.

B

2

sled shaft

3-13. CASSETTE LID ASSY (A) / (B)

1

Open the cassette lid

assy (A)/(B).

A

1

Slide the lever

in the direction of arrow

A

.

2

two claws

3

cassette lid

assy (A)

4

two claws

5

cassette li

assy (B)

13

HCD-MG110/MG310AV

)

3-14. MECH DECK (TAPE)

4

cassette holder assy (A)

0

two screws

(BVTP2.6)

1

three screws

(BVTP3

×

10)

qs

mech deck (TAPE)

qa

MD bracket

3

5

cassette

holder

assy (B)

7

shield plate (MD)

2

9

TC board

8

screw (BVTP2.6)

6

two screws

(BVTP2.6)

two screws

(BVTP3 × 10

14

SECTION 4

TEST MODE

HCD-MG110/MG310AV

Ver 1.1

[MC Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Turn the power ON or set to the DEMO mode.

2. Press three b uttons of x , [CLEAR], and [DISPLAY] simul-

taneously.

3. The set is reset, and becomes DEMO mode.

[Change-over the AM Tuning Interval]

(EXCEPT AEP, UK, and Saudi Arabia models)

• The AM tuning interval can be changed over 9 kHz or 10 kHz.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Select the function “TUNER”, and press the [TUNER/BAND]

button to select the BAND “AM”.

3. Press the I/1 button to turn the power OFF.

4. Press the [ENTER] and I/1 buttons simultaneously to the tun-

ing interval is changed over.

[CD Delivery Mode and RAM Initialize]

• This mode moves the optical pick-up to the position durable

to vibration, and initializes the RAM. Use this mode when returning the set to the customer after repair.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Press three buttons of [ENTER], M , and [CLEAR] simul-

taneously.

3. The set is turn the power off and initializes the RAM auto-

matically. A message “LOCK” is displayed on the fluorescent

indicator tube, and the CD delivery mode is set.

[CD Service Mode]

• This mode can run the CD sled motor optionally. Use this mode,

for instance, when cleaning the optical pick-up.

Procedure:

1. Press the I/1 button to turn the power ON.

2. Select the function “CD”.

3. Press three buttons of [ENTER], M , and [REPEAT] simul-

taneously.

4. Set to the Sled Servo mode.

5. With the CD in stop status, press the M button to move the

optical pick-up to outside track and display “SLED OUT”, or

press the m button to move the optical pick-up to inside

track and display “SLED IN”.

6. To exit from this mode, perform as follows.

1) Move the optical pick-up to the most inside track.

2) Press three buttons of x , [CLEAR], and [DISPLAY]

simultaneously. (cold reset)

Notes: • Always move the optical pick-up to most inside track when

exiting from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can

be chipped.

[LED and Fluorescent Indicator Tube All Lit, Key

Check Mode]

Procedure:

1. Press three b uttons of x , [MENU], and [DISPLAY] simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

3. Press the [MENU] b utton and g o to the v ersion display mode.

Press the m button and go to the key and jog test mode.

4. To release from these mode, press three buttons in the same

manner as step 1, or disconnect the power cord.

– Version display mode –

Press the – . button to display the version .

– Key and jog test mode –

In the key check mode, the fluorescent indicator tube displays

“K 0 J0 V0”. Each time a button is pressed, “K” value increases. However , once a button is pressed, it is no longer tak en

into account.

“J” value increases like 1, 2, 3 ... if turn the [DISC ACCESS]

dial clockwise, or it decreases like 0, 9, 8 ... if turn the

[DISC ACCESS] dial counterclockwise.

“V” value increases like 1, 2, 3 ... if turn the [VOLUME] knob

clockwise, or it decreases like 0, 9, 8 ... if turn the [VOLUME]

knob counterclockwise.

15

HCD-MG110/MG310AV

Ver 1.1

SECTION 5

MECHANICAL ADJUSTMENTS

SECTION 6

ELECTRICAL ADJUSTMENTS

• TAPE MECHANISM DECK SECTION

Precaution

1. Clean the following parts with a dena tured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

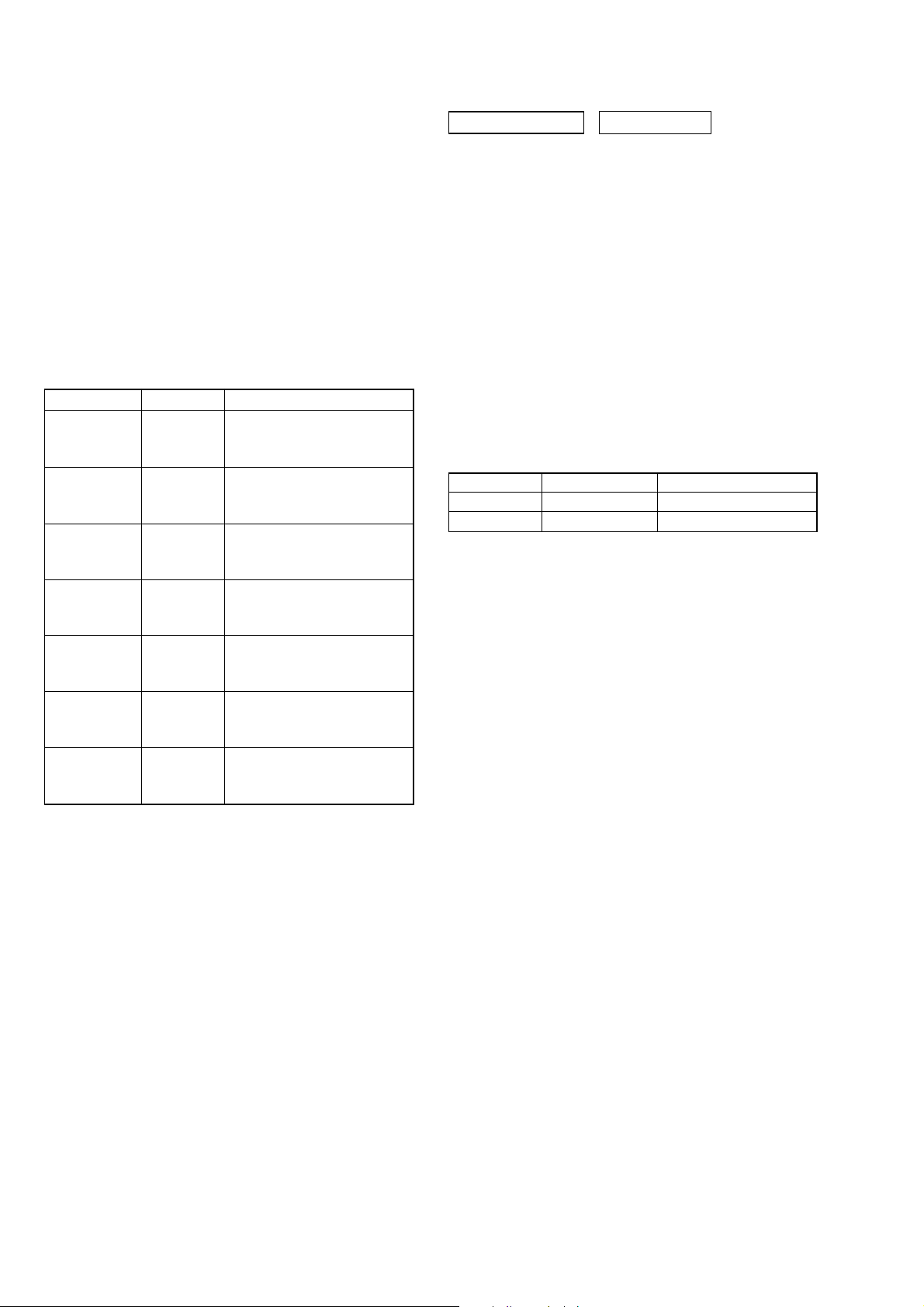

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

2.94 mN • m to 7.84 mN • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.14 mN • m to 0.59 mN • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

2.94 mN • m to 7.84 mN • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.14 mN • m to 0.59 mN • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

6.86 mN • m to 17.64 mN • m

71 to 143 g • cm

(0.98 – 1.99 oz • inch)

more than 0.98 N • m

100 g or more

(3.53 oz or more)

more than 0.98 N • m

100 g or more

(3.53 oz or more)

DECK SECTION

Precaution

1. Demagnetize the record/playback head with a head demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise specified.

8. Set to the DOLBY NR OFF.

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, – 10 dB Azimuth Adjustment

WS-48A 3 kHz, 0 dB Tape Speed Check

0 dB = 0.775 V

16

HCD-MG110/MG310AV

)

Ver 1.1

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback (FWD)

test tape

P-4-A100

(10 kHz, – 10 dB)

2. T urn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

L-CH

peak

R-CH

Screw

position

peak

3. Mode: Playback

test tape

P-4-A100

(10 kHz, – 10 dB)

L-CH

set

R-CH

MAIN AMP board

FRONT SPEAKER terminal (J501)

L-CH, R-CH

level meter

set

within

1dB

Output

level

L-CH

peak

MAIN AMP board

FRONT SPEAKER terminal (J501

L-CH

R-CH

R-CH

peak

oscilloscope

V

+

–

within

1dB

Screw

position

H

Adjustment Location:Playback Head (Deck A).

Record/Playback/Erase Head (Deck B).

forward

reverse

Tape Speed Check DECK B

Mode: Playback

test tape

WS-48A

(3 kHz, 0 dB)

set

MAIN AMP board

FRONT SPEAKER terminal (J501)

L-CH, R-CH

frequency counter

+

–

1. Insert the WS-48A into the deck B.

2. Press the nN button on the deck B.

3. Confirm that the frequency counter reads 3,000 ± 60 Hz.

Sample value of Wow and Flutter: 0.3% or less W.RMS (JIS)

(WS-48A)

waveform of oscilloscope

in phase 45° 90 ° 135° 180 °

good

wrong

4. Repeat step 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

parts adjusted.

17

HCD-MG110/MG310AV

+

–

CD board

TP (RFAC)

TP (VC)

oscilloscope

Ver 1.1

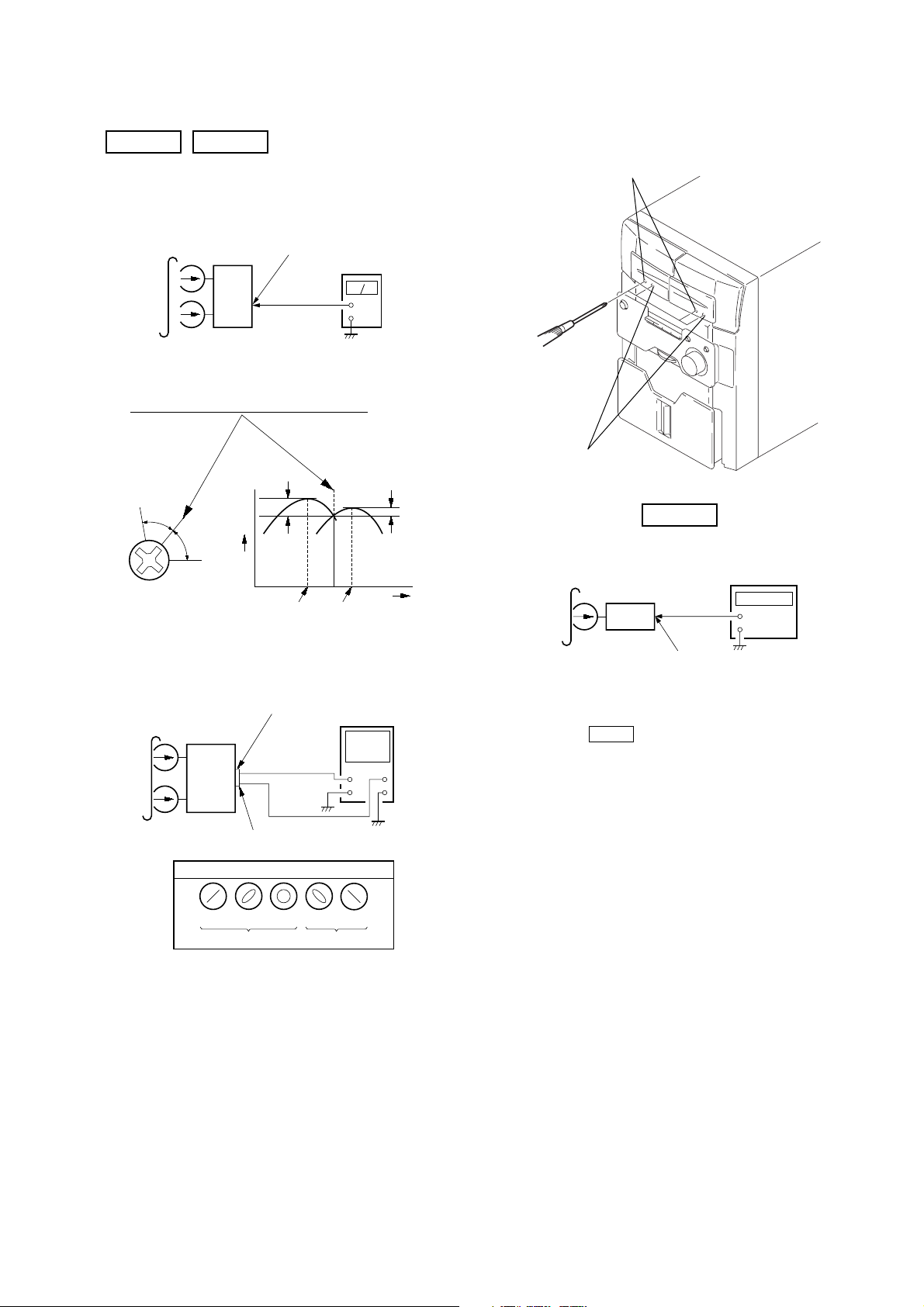

CD SECTION

Note:

1. CD Block is basically designed to operate without adjustment. Therefore, check each item in order given.

2. Use PATD-012 disc (4-225-203-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MW impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

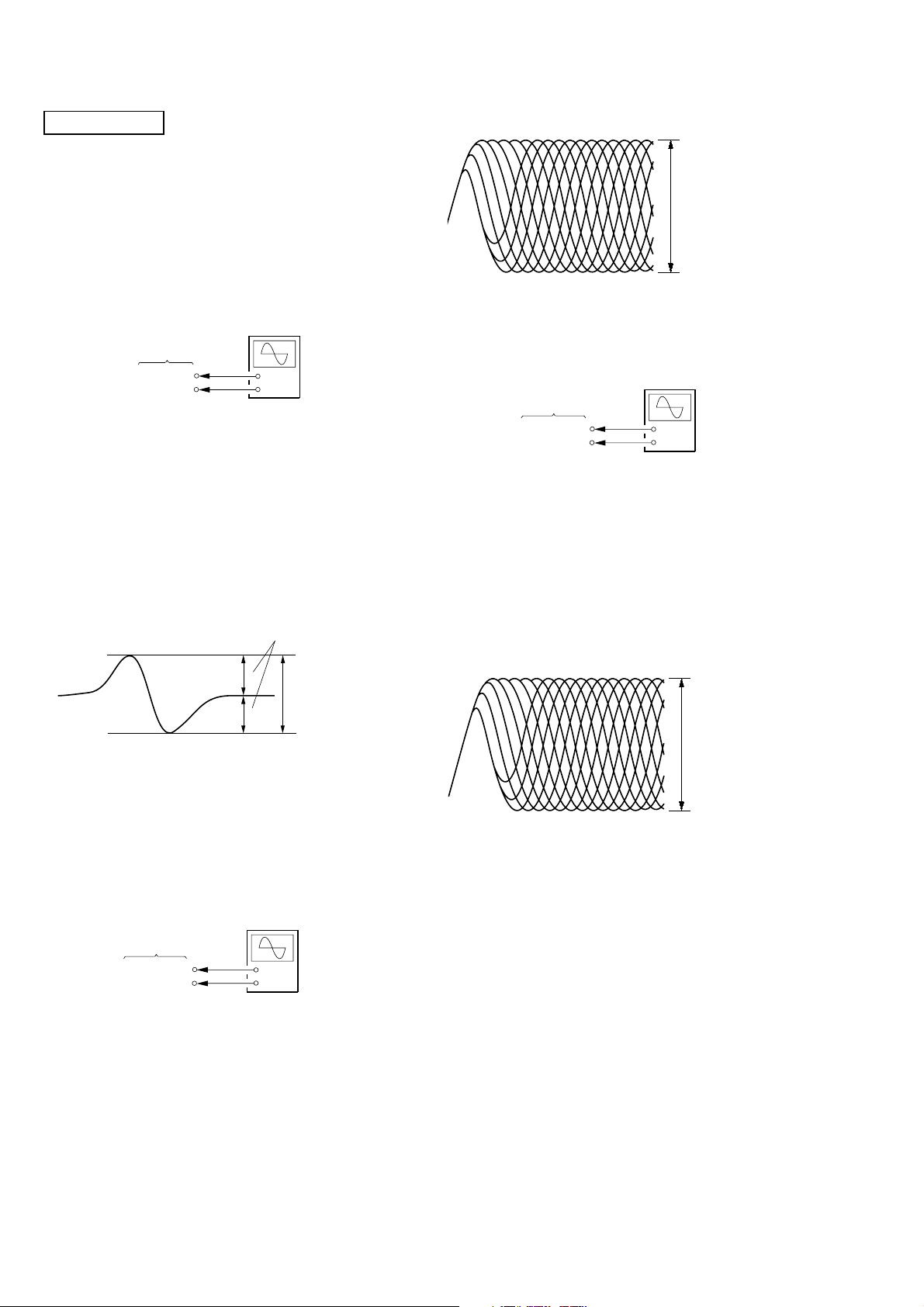

S Curve Check

Connection:

oscilloscope

CD board

TP (FE)

TP (VC)

Procedure:

1. Connect an oscilloscope to test point TP (FEI) and TP (VC) on

the CD board.

2. Turn the power on.

3. Put the disc (PATD-012) in and turned power switch on again

and actuate the focus search. (actuate the focus search when

disc table is moving in and out)

4. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within 2 ± 1

Vp-p.

S-curve waveform

+

–

symmetry

A

within 2 ± 1 Vp-p

B

RFDC signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level: 1.15 ± 0.35 Vp-p

Checking Location: CD board

RFAC Level Check

Connection:

Procedure:

1. Connect an oscilloscope to test point TP (RF A C) and TP (VC)

on the CD board.

2. Turn the power on.

3. Put the disc (P ATD-012) in to playback the number two track.

4. Confirm that oscilloscope waveform is clear and check RFAC

signal level is correct or not.

Note: A clear RFAC signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RFAC signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

Note: • Try to measure se veral times to make sure than the ratio of A : B

or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

Checking Location: CD board

RFDC Level Check

Connection:

oscilloscope

CD board

TP (RFDC)

TP (VC)

+

–

Procedure:

1. Connect an oscilloscope to test point TP (RFDC) and TP (VC)

on the CD board.

2. Turn the power on.

3. Put the disc (P ATD-012) in to playback the number two track.

4. Confirm that oscilloscope waveform is clear and check RFDC

signal level is correct or not.

Note: A clear RFDC signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

level: 1.35 ± 0.4 Vp-p

Checking Location: CD board

18

HCD-MG110/MG310AV

Ver 1.1

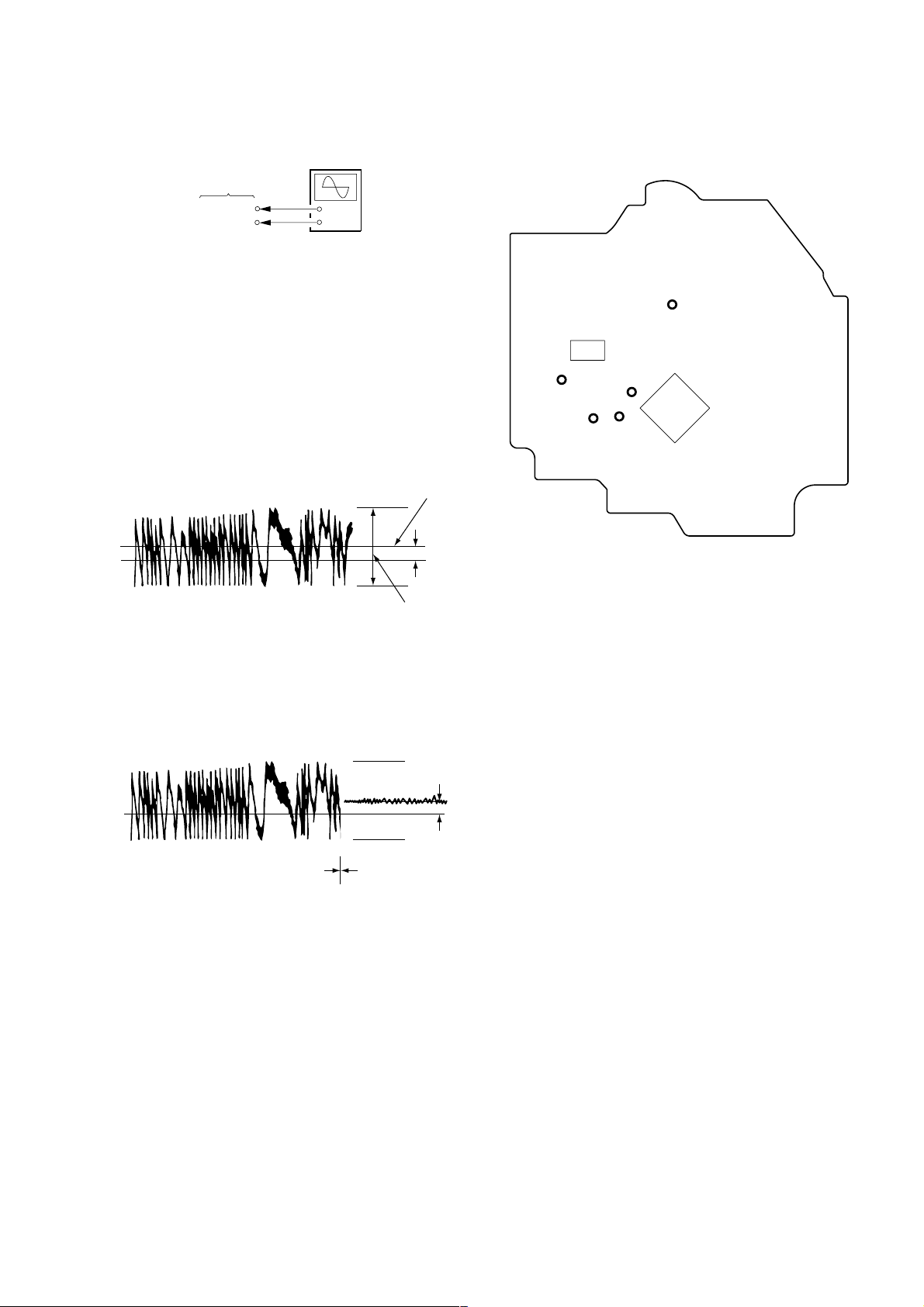

E-F Balance Check

Connection:

oscilloscope

CD board

TP (TE)

TP (VC)

+

–

Procedure:

1. Connect an oscilloscpe to test point TP (TE) and TP (VC) on

the CD board.

2. Turn the power on.

3. Put the disc (P ATD-012) in to playback the number two track.

4. Press the [REPEAT] button. (The tracking servo and the

sledding servo are turned OFF)

5. Check the level B of the oscilliscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 22%

Traverse Wav ef orm

0V

Center of

the waveform

B

A (DC

voltage)

Checking Location:

– CD BOARD (Conductor Side) –

TP (VC)

IC103

TP

(RFAC)

TP (TE)

TP (FEI)

IC101

TP

(RFDC)

level: 1.15 ± 0.5 Vp-p

6. Press the [REPEAT] button. (The tracking servo and sledding

servo are turned ON)

Confirm the C (DC voltage) is almost equal to the A (DC

voltage) is step 5.

Traverse Wav ef orm

0V

Tracking servo

Sled servo

OFF

Tracking servo

Sled servo

ON

C (DC

voltage)

Checking Location: CD board

19

HCD-MG110/MG310AV

MEMO

20

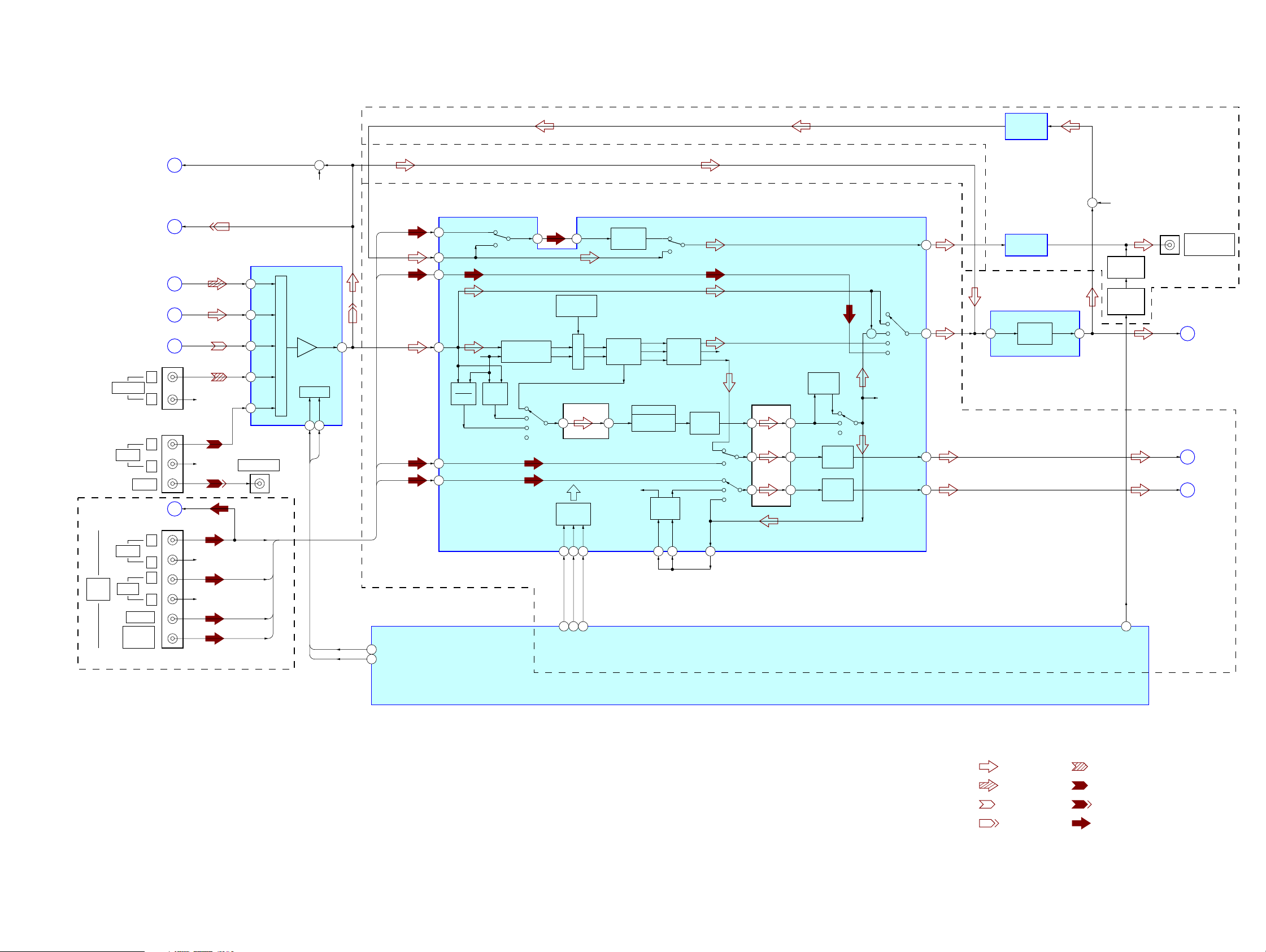

SECTION 7

DIAGRAMS

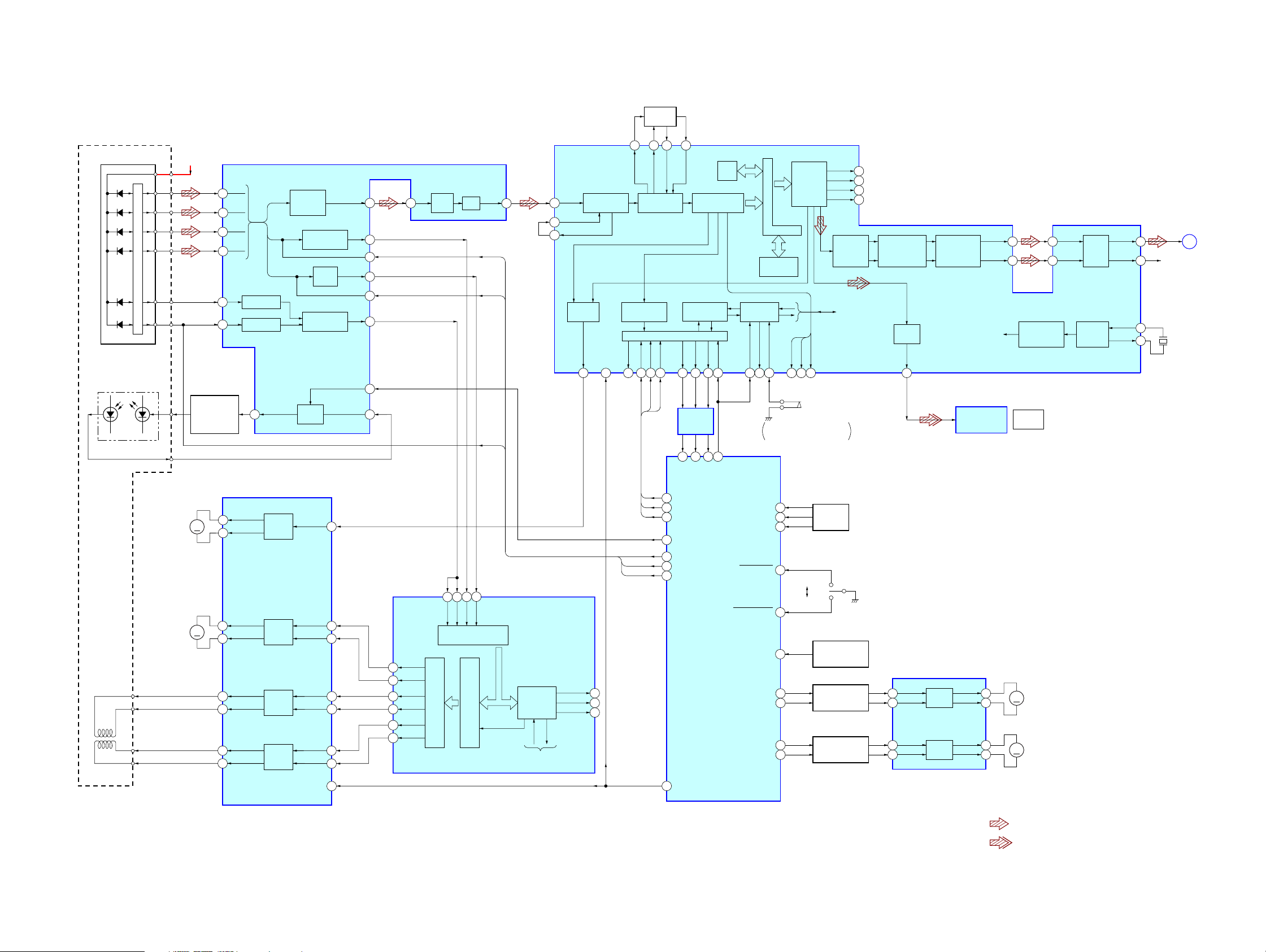

7-1. BLOCK DIAGRAM – CD SERVO Section –

HCD-MG110/MG310AV

DETECTOR

A

B

C

D

F

E

OPTICAL PICK-UP

BLOCK

(KSM-213BFN)

LASER DIODE

PD

I-V AMP

LD

CD +5V

6

7

8

9

11

10

AUTOMATIC

POWER

CONTROL

Q101

A

B

C

D

E

F

F I-V AMP

E I-V AMP

LD

1

FOCUS/TRACKING ERROR AMP

RF

SUMMING

AMP

FOCUS

ERROR AMP

RF DC

AMP

TRACKING

ERROR AMP

APC LD

AMP

AC

SUM

FEI

RFDCO

RFDCI

SW

RF AMP,

IC103

FE

TE

PD

FILTER

53

54 56

FILO

EQ

IN

4

16

17

28

29

18

12

2

RFAC

3

VCA

RFAC

EQ

15

PWM1

PWM3

PWM2

RFAC

51

49

48

ASYMMETRY

CORRECTION

ASYI

ASYO

DIGITAL

CLV

MDP

XRST

26 7 8

3

SUBCODE

PROCESSOR

XLON

DATA

CLOK

14 5

PCO

CLTV

DIGITAL

PLL

CPU INTERFACE

XLAT

SENS

6

84 19

55

DIGITAL SIGNAL PROCESSOR,

DIGITAL FILTER, D/A CONVERTER

FILI

LEVEL

SHIFT

IC803

EFM

DEMODULATOR

SERVO AUTO

SEQUENCER

SQSO

SCOR

20

1 2

32 33

16K

RAM

SQCK

IC101 (1/2)

CORRECTOR

SERVO

INTERFACE

SCLK

COUT

9 21

D/A

INTERFACE

INTERNAL BUS

ERROR

SSTP

EMPH

WFCK

GFS

64 15

27

ON :

18

S101

(LIMIT)

When the optical pick-up

is inner position

PCMD

62

BCK

63

LRCK

61

C2PO

19

SERIAL

IN

INTERFACE

TO MIRR/DFCT/

FOK DETECTOR

DIGITAL

FILTER,

NOISE SHAPER

DIGITAL

OUT

DOUT

60

PWM

&

INTEGRATOR

TRANSCEIVER

OPTICAL

IC361

AOUT1

AOUT2

70

77

OPTICAL

OUT (CD)

71

76

CLOCK

GENERATOR

AIN1

AIN2

BUFFER

TIMING

LOGIC

LOUT1

LOUT2

XTAI

XTAO

CD

L-CH

72

75

R-CH

66

67

A

X101

16.9344MHz

(Page 23)

2-AXIS

DEVICE

(TRACKING)

(FOCUS)

M101

(SPINDLE)

M102

(SLED)

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

IC102

CH4OUTF

15

M

M

16

17

18

11

12

13

14

CH4OUTR

CH3OUTF

CH3OUTR

CH2OUTR

CH2OUTF

CH1OUTR

CH1OUTF

MOTOR

DRIVE

MOTOR

DRIVE

COIL

DRIVE

COIL

DRIVE

CH4SIN

CH3FIN

CH3RIN

CH2RIN

CH2FIN

CH1RIN

CH1FIN

MUTE

25

PWM1

PWM2

PWM3

43

39

40

41

FE

TE

SE

24

23

SFDR

28

SRDR

29

6

5

3

2

20

TFDR

30

TRDR

31

FFDR

32

33

FRDR

FOCUS/TRACKING/SLED

RFDC

A/D

CONVERTER

PWM GENERATOR

SERVO DSP

FOCUS/TRACKING/SLED

DIGITAL SERVO

PROCESSOR

IC101 (2/2)

MIRR/DFCT/

FOK

DETECTOR

TO SERVO INTERFACE

FOK

MIRR

DFCT

24

22

23

85

87

86

88

22

24

26

83

C-SENS

C-DATA

C-CLK

C-LATCH

LD ON

PWM1

PWM2

PWM3

C-XRST

C-SQCK

C-SCOR

C-SQSO

LOAD IN SW 6

LOAD OUT SW 7

SYSTEM CONTROLLER

IC801 (1/5)

LOAD NEG 3

LOAD POS

TABLE POS 5

TABLE NEG

T-SENS1

T-SENS2

T-SENS3

D-SENS 92

93

18

91

2

100

LOAD IN

LOAD OUT

TABLE

SENSOR

IC11 – 13

S842

(LOAD)

DISC IN

DETECT SENSOR

D841, Q841

LOADING

MOTOR CONTROL

Q881 – 884

TABLE

MOTOR CONTROL

Q885 – 888

2

3

17

16

LOADING/TABLE

MOTOR DRIVE

FN1

RN1

FIN2

RIN2

IC881

MOTOR

DRIVE

MOTOR

DRIVE

OUT1 +

OUT1 –

OUT2 +

OUT2 –

8

9

11

10

M

M

M51

(LOADING)

M52

(TABLE)

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: CD PLAY (ANALOG)

: CD PLAY (DIGITAL OUT)

2121

HCD-MG110/MG310AV

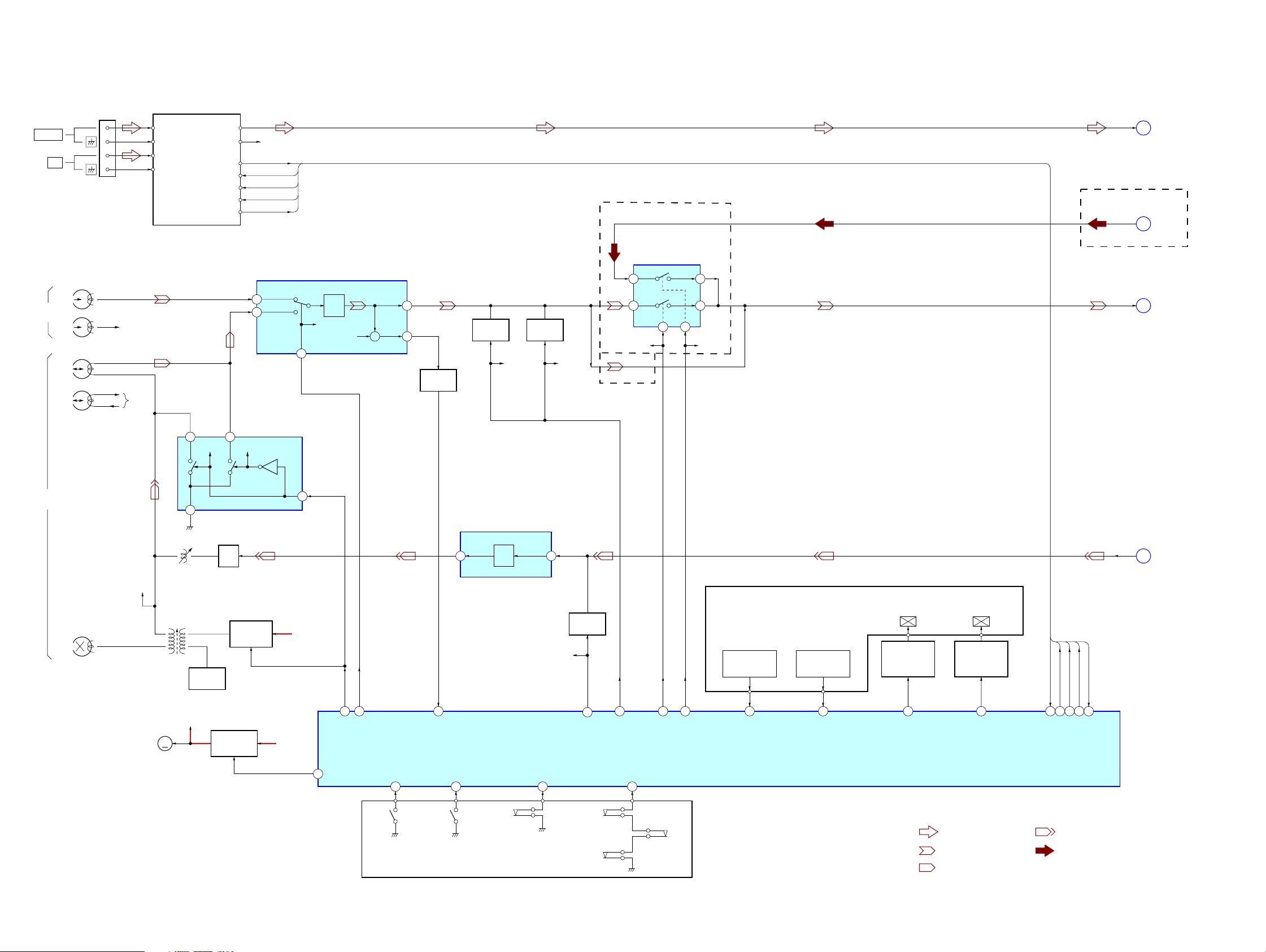

7-2. BLOCK DIAGRAM – TUNER/TAPE DECK Section –

FM 75Ω

HP101

(PLAY)

AM

L-CH

R-CH

L-CH

R-CH

R-CH

R-CH

FM ANT

ANT GND

AM ANT

ANT GND

TUNER PACK

R-CH R-CH

L-CH

R-CH

DO

TU-CLK

TU-CE

TUNED

DI

24

23

REC/PB SWITCHING

13

R-CH

TUNED

A IN-L

B IN-L

IC402

CLK

TUNER

L-CH

DI

DO

CE

(HCD-MG310AV)

INPUT SELECT

SWITCH

IC306

1 2

4 3

5 13

R-CHR-CH

A/B SW

19

PB AMP

IC401 (1/2)

PB

AMP

R-CH

R-CH

PB-L

20

MIX

OUT

6

+

AMS DET

Q404, 405

MUTING

Q102

MUTING

Q101

R-CHR-CH

(HCD-MG110)

(HCD-MG310AV)

5.1CH

TAPE

L-CH

B

C

D

(Page 23)

(Page 23)

(Page 23)

HRPE101

(REC/PLAY/ERASE)

R-CH

M1

(CAPSTAN)

BIAS OSC

T401

SENSOR B+

MM

T403

2

BIAS OSC

Q401

C429, R429

BIAS

TRAP

REC BIAS

SWITCH

Q402, 403

CAPSTAN

MOTOR DRIVE

Q381, 382

MOTOR

+12V

4

AU +9V

58 MO-ON

54

PB/REC

53

PB-A/B

A-PLAY

61

(DECK A PLAY)

16

67

AMS

B-PLAY

56

(DECK B PLAY)

REC

OUT-L

REC AMP

IC401 (2/2)

REC

AMP

(DECK A HALF)

TAPE MECHANISM

DECK BLOCK

(1/2)

REC

IN-L

A-HALF

66

REC

14

TRIGGER PLUNGER

(DECK B)

TRIGGER

PLUNGER DRIVE

(DECK B)

Q385, 386

60

B-TRIG

78

DI

DO

80

TU-DI

CLK

79

TU-DO

CE

77

TU-CE

TU-CLK

R-CH

MUTING

Q112

50

REC-MUTE

68

PB-MUTE

90

B-HALF

69

TAPE

70

DVD

SYSTEM CONTROLLER

TAPE MECHANISM

DECK BLOCK

(2/2)

ROTATION

DETECT SENSOR

(DECK A)

97

A-SHUT

IC801 (2/5)

ROTATION

DETECT SENSOR

(DECK B)

89

B-SHUT

TRIGGER PLUNGER

(DECK A)

TRIGGER

PLUNGER DRIVE

(DECK A)

Q383, 384

59

A-TRIG

L-CH

TUNED

76

TU-TUNED

E

(Page 23)

• R-ch is omitted due to same as L-ch.

(DECK B HALF)

(DECK A REC)

(DECK B REC)

• SIGNAL PATH

: TUNER

: TAPE PLAY (DECK A)

: TAPE PLAY (DECK B)

: REC

: 5.1CH INPUT

2222

7-3. BLOCK DIAGRAM – SURROUND Section –

HCD-MG110/MG310AV

5.1CH

INPUT

VIDEO IN

AUDIO

FRONT

REAR

CENTER

SUPER

WOOFER

(Page 25)

(Page 22)

(Page 21)

(Page 22)

(Page 22)

R

L

R

VIDEO

(Page 22)

L

R

L

R

J303

FRONT

L-CH

CENTER

REAR

L-CH

(HCD-MG310AV)

SUPER WOOFER

OUT

(Page 24)

G

(Page 24)

H

(Page 24)

J

(HCD-MG310AV)

LOW-PASS

FILTER

IC304 (1/2)

SPE ANA

F

REC

L-CH

E

INPUT SELECT

IC302 (1/2)

CD

L-CH

A

TUNER

L-CH

B

TAPE

L-CH

D

J302

L

R-CH

J701

R-CH

5.1CH

C

J301

R-CH

R-CH

B1

3

C1

5

D1

7

A1

1

E1

9

J304

VIDEO OUT

FRONT

REAR

CENTER

WOOFER

(HCD-MG310AV)

R-CH

INPUT SELECT

LOGIC

DATA

DATA

+

CLK

1514

CLK

DATA

CLK

LINE

OUT

(HCD-MG110)

DOLBY PRO LOGIC

SURROUND PROCESSOR

IC301

AUTO-BALANCE

L–R

SW

OUT

INPUT

DS2L

OUT

WOOFER

FRONT

32

CENTER

REAR

51 V-DATA

52 V-CLK

SWIN

79

VRSWIN

80

LIN

72

LTIN

74

R-CH

L+R

2

CIN

76

SLIN

77

SYSTEM CONTROLLER

IC801 (3/5)

SWVOL

IN

SELECTOR

COMMAND

REQ

PL-RQ

TRIMMER,

VOLUME

ADAPTIVE

MATRIX

S

DIN

R-CH

L

R

C

10KBIT S-RAM

LOGIC

CIRCUIT

PSEUDO

STEREO

PS

RIN

CENTER

MODE

CONTROL

PS

LIN

DELAY

VOLUME

1615

NOISE

SEQUENCER

26 27

CPU

INTERFACE

DATA

SCK

22 23 24 8 7 6

27 28 25

PL-CLK

PL-DATA

R-CH

DVOL

OUT

OUT

SL

OUT

SWVOL OUT

+

MODIFIED

BNR

BNR

IN

4240

C

45

1011

CVOL

IN

SLVOL

IN

TRIMMER,

VOLUME

TRIMMER,

VOLUME

R-CH

SLVOL OUT

LOUT

CVOL OUT

17

1

3

9

AMP

IC304 (2/2)

ELECTRICAL VOLUME

IC302 (2/2)

VOL1

29

SOUND

CONTROL

OUT1

20

R-CH

+

MUTING

Q232

MUTING

CONTROL

Q333, 334

38

S/W-MUTE

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: TUNER

: CD PLAY

: TAPE PLAY

: REC

: VIDEO IN (AUDIO)

: GAME IN (AUDIO)

: GAME IN (VIDEO)

: 5.1CH INPUT

2323