Page 1

HCD-MDX10

SERVICE MANUAL

HCD-MDX10 is the tuner, deck,

CD, MD and amplifier section in

MHC-MDX10.

Model Name Using Similar Mechanism NEW

CD

SECTION

MD

SECTION

TAPE DECK

SECTION

Mechanism Type CDM38LH-5BD32L

Base Unit Type BU-5BD32L

Optical Pick-up Type KSS-213D/Q-NP

Model Name Using Similar Mechanism MDS-JE520

Mechanism Type MDM-5A

Optical Pick-up Type KMS-260A/K1NP

Model Name Using Similar Mechanism HCD-DR4/DR5/DR6/DR440/

T ape Transport Mechanism Type TCM-230AWR2/230PWR2

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

W300/W5000/XB500

SPECIFICATIONS

COMPACT DISC DECK RECEIVER

— Continued on next page —

MICROFILM

– 1 –

Page 2

– 2 –

Page 3

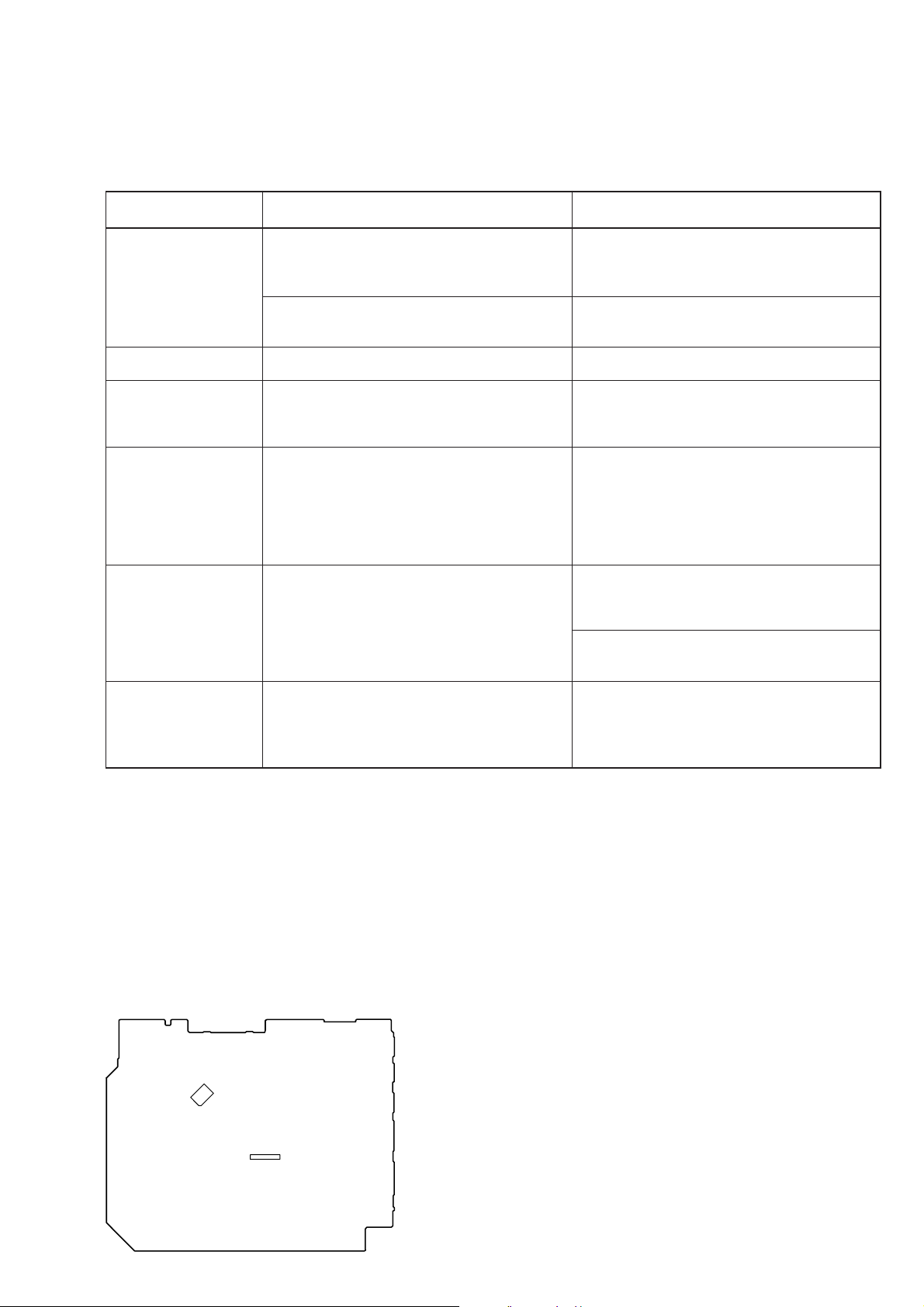

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for customers which are displayed automatically when errors occur, and error codes which

show the error history in the test mode during servicing. For details on how to view error codes for the customer, refer to the following box

in the instruction manual. For details on how to check error codes during servicing, refer to the following “Procedure for using the SelfDiagnosis Function (Error History Display Mode)”.

Procedure for using the Self-Diagnosis Function (Error History Display Mode).

Note: Perform the self-diagnosis function in the “error history display mode” in the test mode. The following describes the least required

procedure. Be careful not to enter other modes by mistake. If you set other modes accidentally, press the MENU/NO button to exit

the mode.

1. With the power ON, press the CD-MD SYNC button while pressing the p and ENTER/YES buttons together.

2. Rotate the AMS dial and when “Service” is displayed, press the YES button.

3. Rotate the AMS dial and display “ERR DP MODE”.

4. Pressing the ENTER/YES button sets the error history mode and displays “total rec”.

5. Select the contents to be displayed or executed using the AMS dial.

6. Pressing the MD WALKMAN SYNC button will display or execute the contents selected.

7. Pressing the MD WALKMAN SYNC button another time returns to step 4.

8. Pressing the MENU/NO button displays “ERROR DP MODE” and exits the error history mode.

9. To exit the test mode, press the REPEAT/STEREO/MONO button.

– 3 –

Page 4

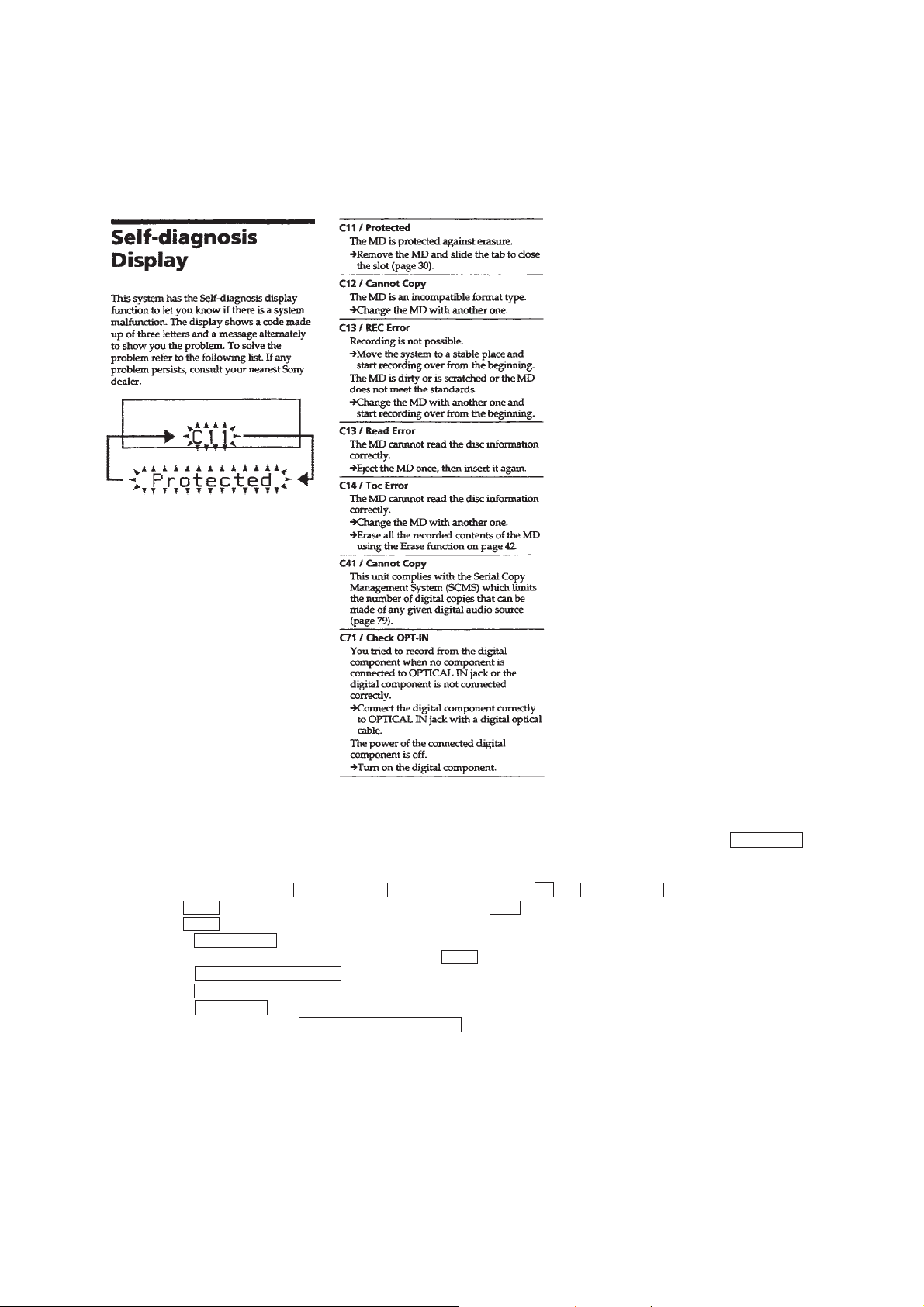

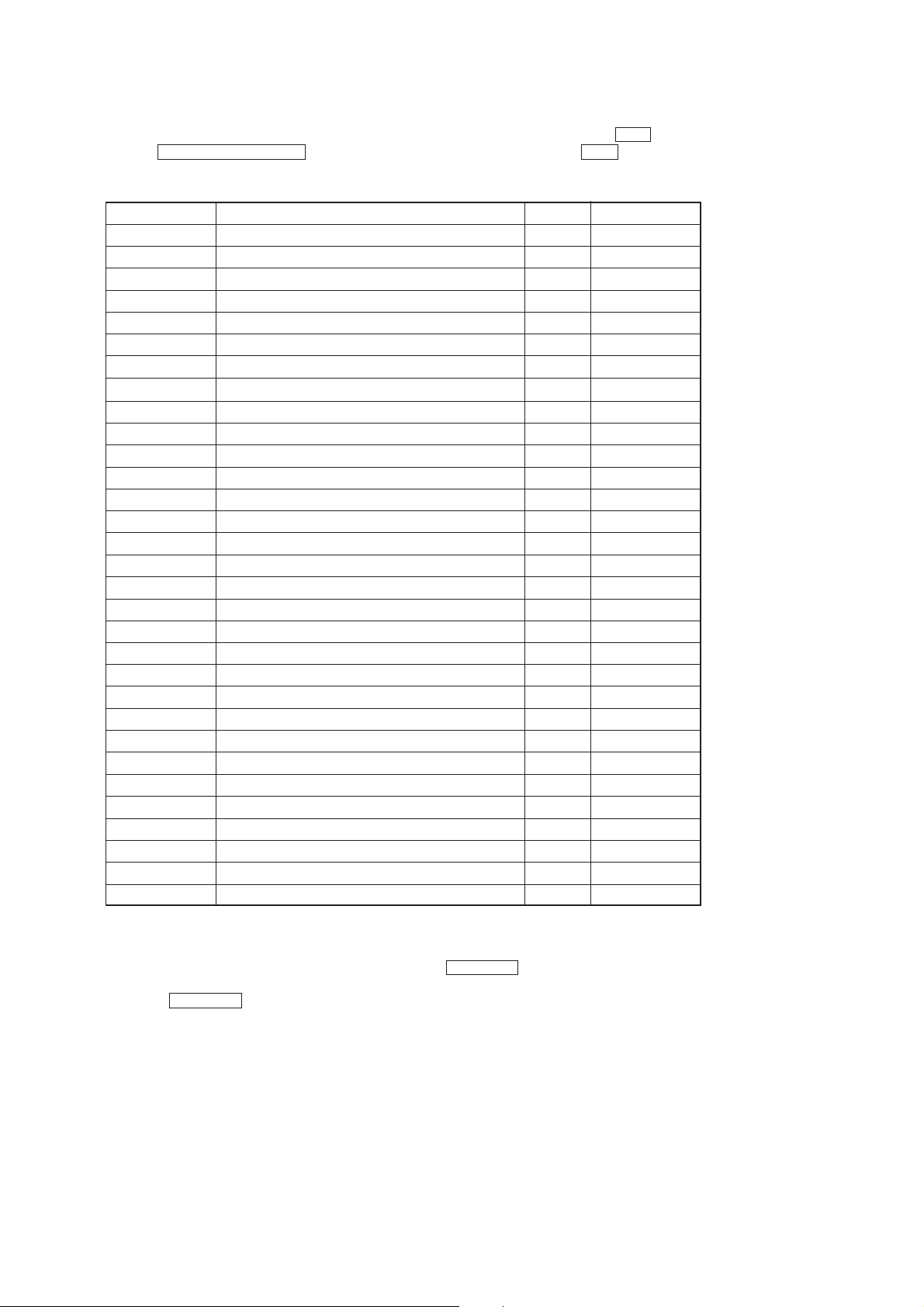

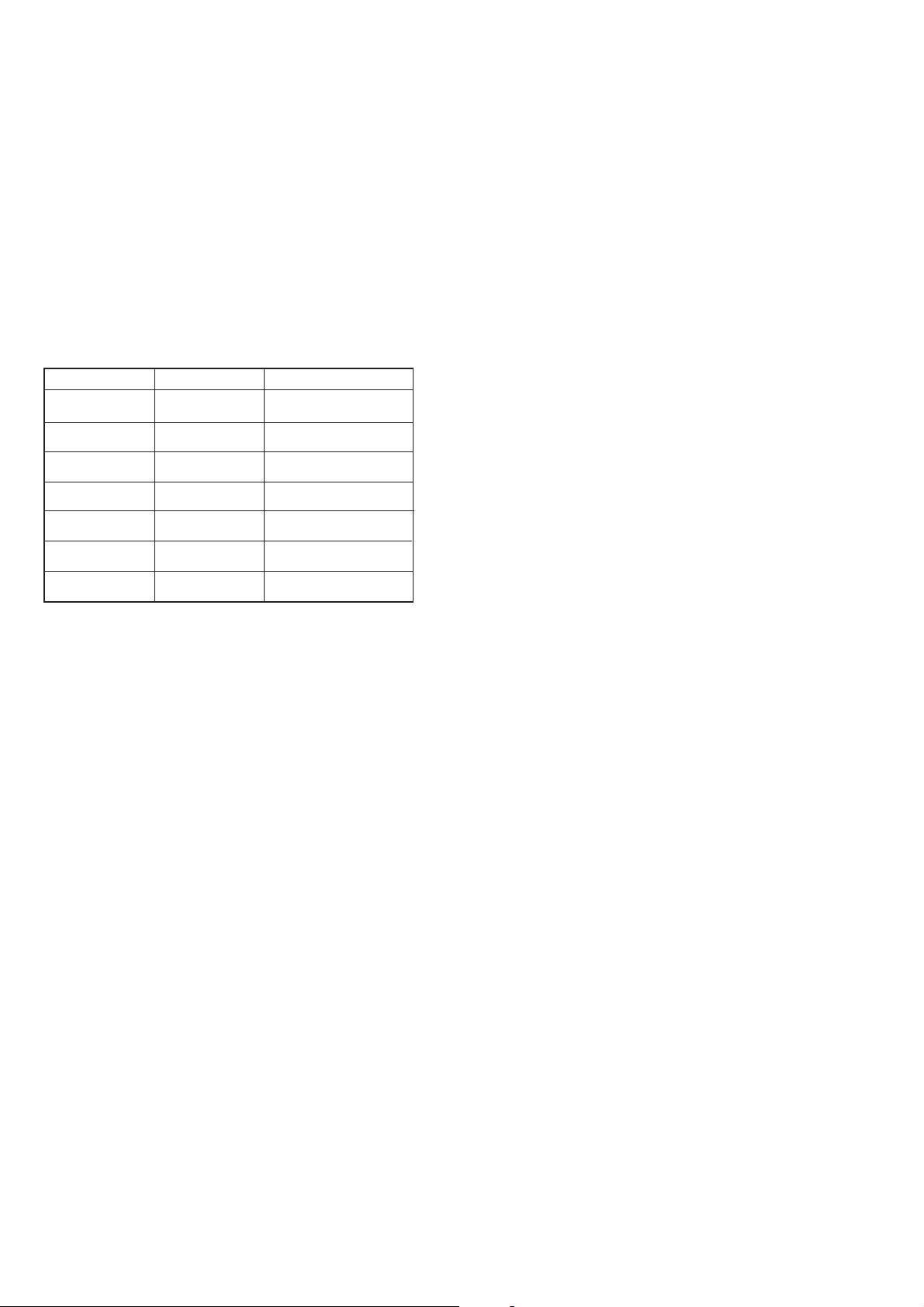

ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS

Selecting the Test Mode

Display

total rec

total play

retry err

total err

err history

er refresh

Details of History

Displays the recording time.

Displayed as “rππππππh”.

The displayed time is the total time the laser is set to the high power state.

This is about 1/4 of the actual recording time.

The time is displayed in decimal digits from 0h to 65535h.

Displays the play time.

Displayed as “pππππππh”. The time displayed is the total actual play time. Pauses are not counted.

The time is displayed in decimal digits from 0h to 65535h.

Displays the total number of retries during recording and number of retry errors during play.

Displayed as “rππ pππ”.

“r” indicates the retries during recording while “p” indicates the retry errors during play.

The number of retries and retry errors are displayed in hexadecimal digits from 00 to FF.

Displays the total number of errors.

Displayed as “total ππ”.

The number of errors is displayed in hexadecimal digits from 00 to FF .

Displays the 10 latest errors.

Displayed as “0π E@@”.

π indicates the history number. The smaller the number, the more recent is the error. (00 is the latest).

@@ indicates the error code.

Refer to the following table for the details. The error history can be switched by rotating the AMS dial.

Mode which erases the “retry err”, “total err”, and “err history” histories.

When returning the unit to the customer after completing repairs, perform this to erase the past error history,

After pressing the MD W ALKMAN SYNC button and “er refresh?” is displayed, press the ENTER/YES button

to erase the history.

“Complete!” will be displayed momentarily.

Be sure to check the following when this mode has been executed.

• The data has been erased.

• The mechanism operates normally when recording and play are performed.

tm refresh

Table of Error Codes

Error Code

E00

E01

E02

E03

E04

No error

Read error. PTOC cannot be read

(DISC ejected)

TOC error. UTOC error

(DISC not ejected)

Loading error

Address cannot be read (Servo has deviated)

Mode which erases the “total rec” and “total play” histories.

These histories serve as approximate indications of when to replace the optical pickup.

If the optical pickup has been replaced, perform this operation and erase the history.

After pressing the ENTER/AMS button and “tm refresh?” is displayed, press the MD WALKMAN SYNC

button to erase the history.

“Complete!” will be displayed momentarily.

Be sure to check the following when this mode has been executed.

• The data has been erased.

• The mechanism operates normally when recording and play are performed.

Details of Error

Error Code

E05

E06

E07

E08

E09

E0A

Details of Error

FOK has deviated

Cannot focus (Servo has deviated)

Recording retry

Recording retry error

Playback retry error

(Access error)

Play retry error (C2 error)

– 4 –

Page 5

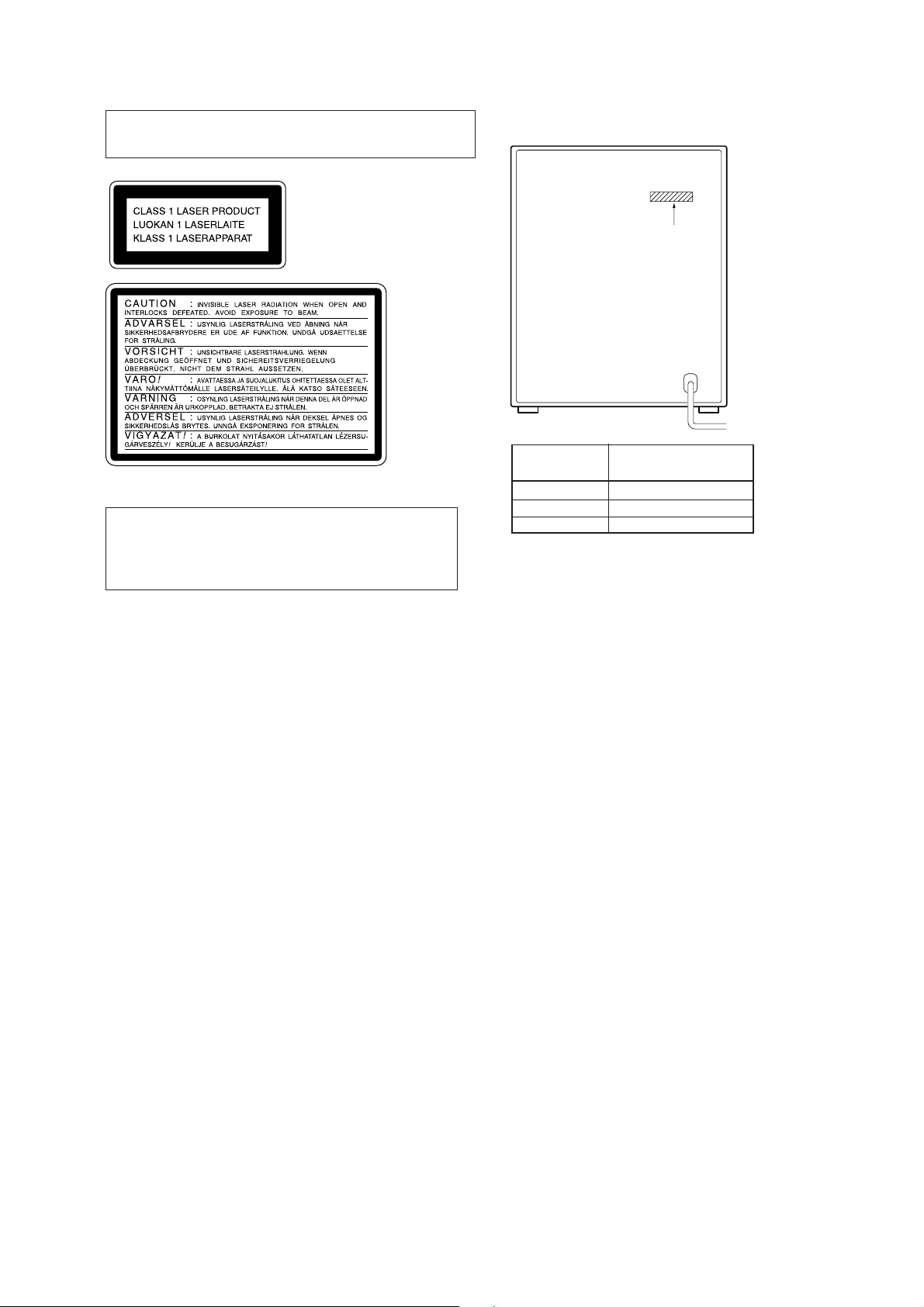

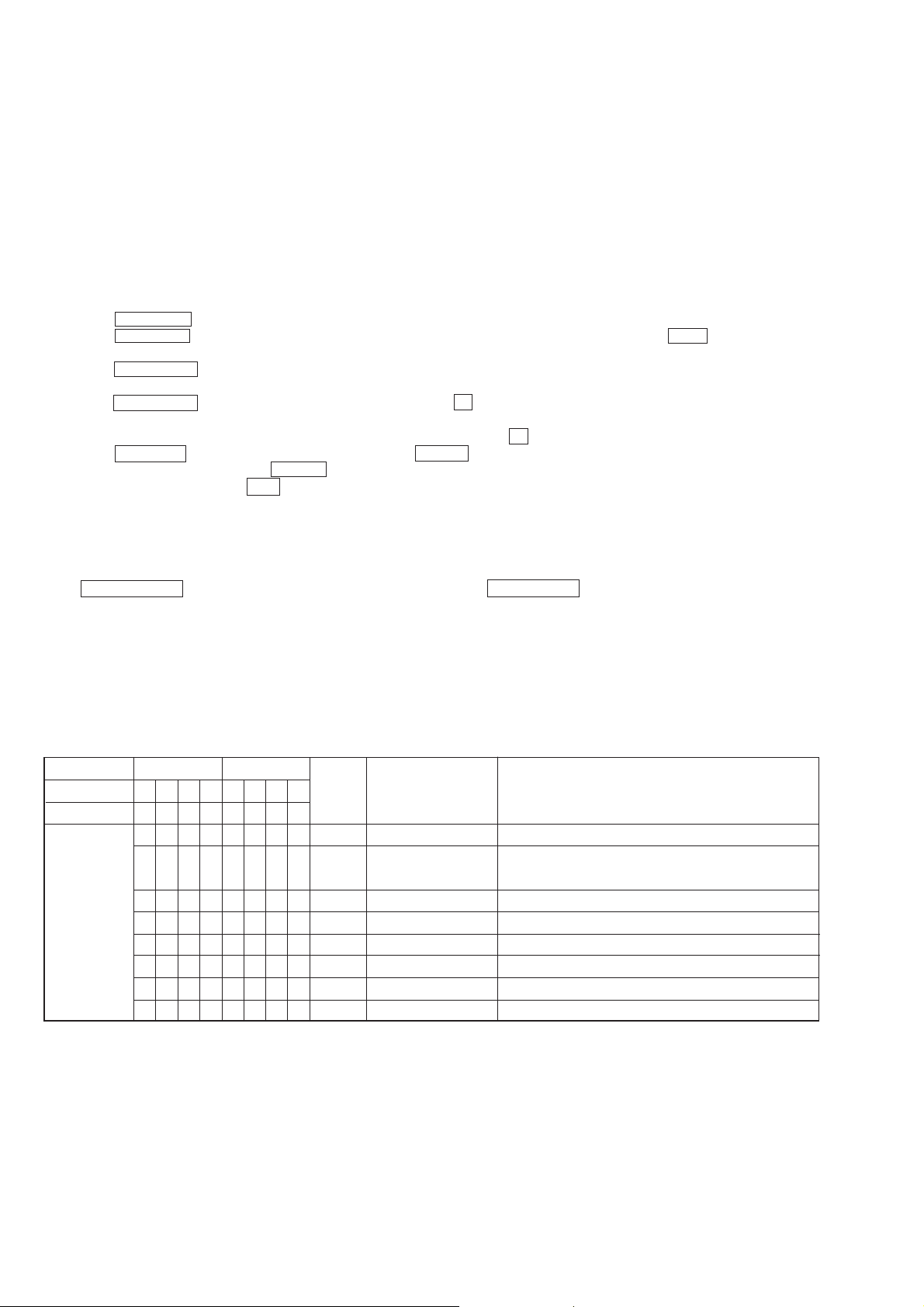

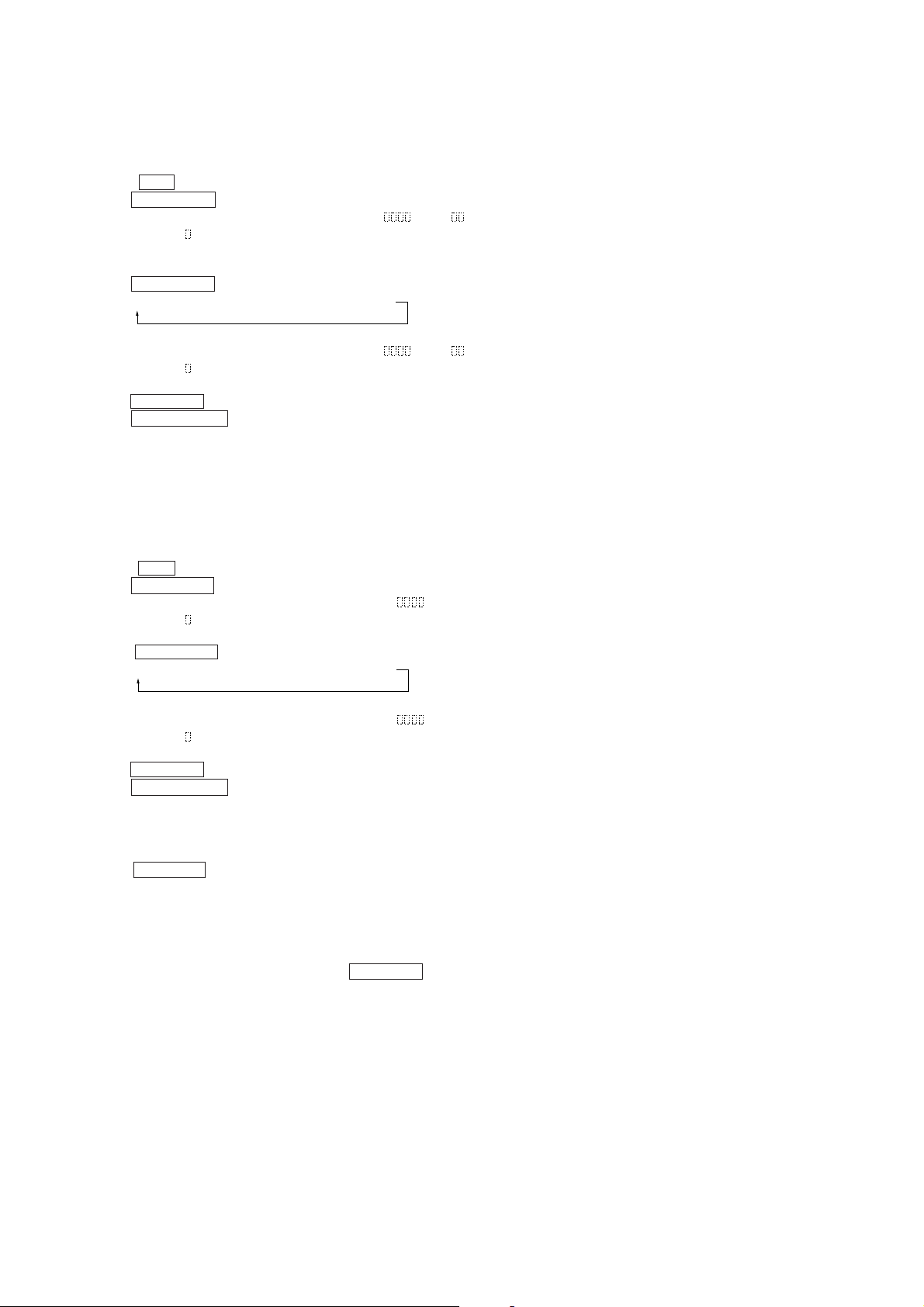

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

This caution

label is located

inside the unit.

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

P ARTS No.

MODEL

4-216-211-0π AEP, UK, G, CIS

4-216-211-1π E, SP, MY, HK, AR

4-216-211-2π US, CND, KR, AUS

• Abbreviation

CND : Canadian model

G : German model

SP : Singapore model

MY : Malaysia model

HK : Hong Kong model

AR : Argentine model

KR : Korea model

AUS : Australian model

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLA CER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

– 5 –

Page 6

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

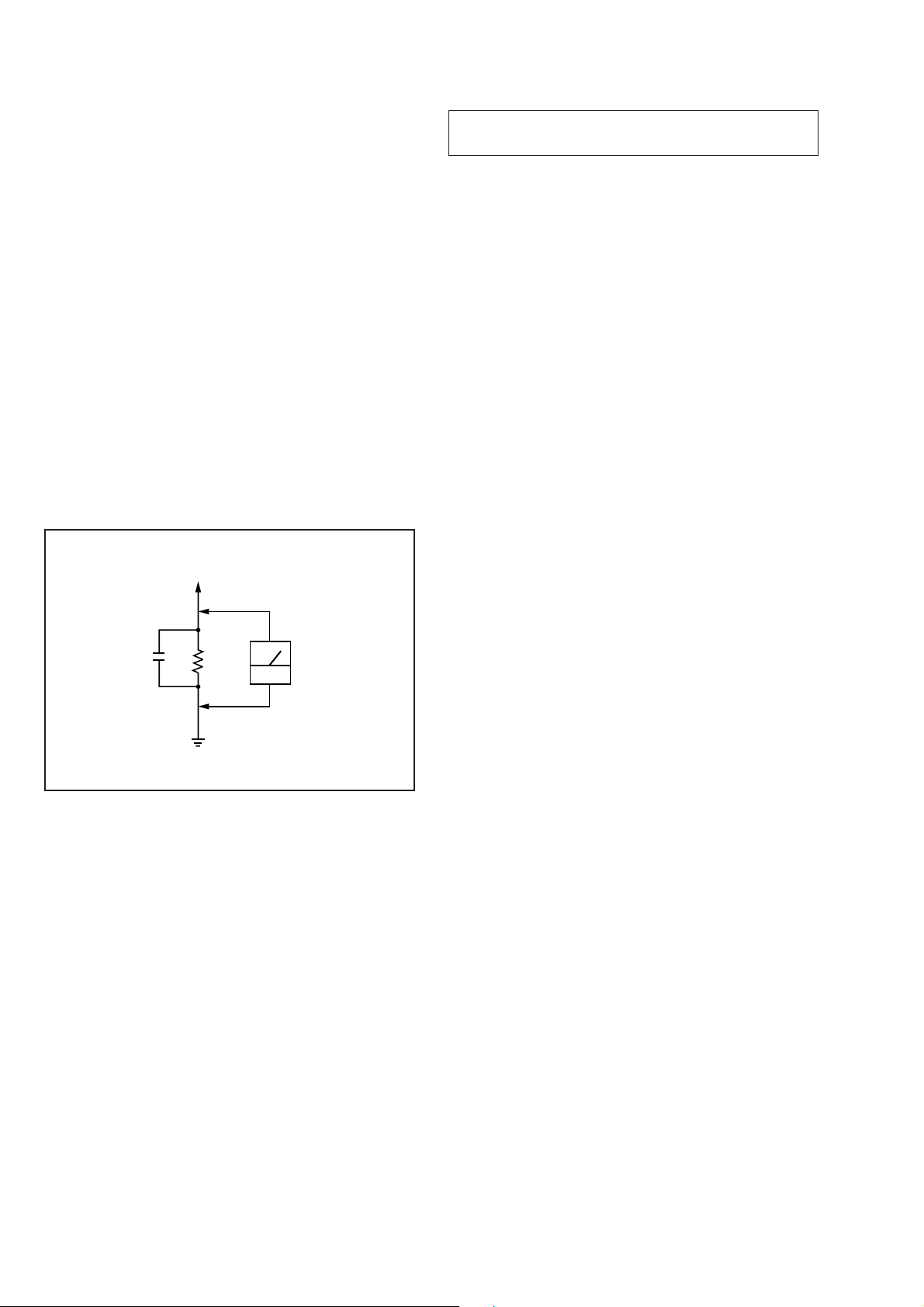

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output four times.

0.15µF

1.5k

Ω

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

– 6 –

Page 7

TABLE OF CONTENTS

1. SERVICING NOTE .......................................................... 8

2. GENERAL ........................................................................ 14

3. DISASSEMBLY

3-1. Loading Panel ..................................................................... 16

3-2. MD Mechanism and Front Panel ........................................ 16

3-3. Cassette Lid and Tape Mechanism...................................... 17

3-4. MD Link, Power SW, CD Panel Boards and

Display Board ..................................................................... 17

3-5. Disc Tray ............................................................................. 18

3-6. Slider (CAM) ...................................................................... 18

3-7. Base Unit (MBU-5A) and BD (MD) Board .......................19

3-8. SW Board and Loading Motor (M103) .............................. 19

4. SERVICE MODE ............................................................20

5. TEST MODE (MD) ......................................................... 22

6. MECHANICAL ADJUSTMENTS .......................... 26

7. ELECTRICAL ADJUSTMENTS ............................... 27

8. DIAGRAMS

8-1. Circuit Boards Location ...................................................... 40

8-2. Block Diagrams

• BD (CD) Section .............................................................. 41

• BD (MD) Section (1) ....................................................... 43

• BD (MD) Section (2) ....................................................... 45

• Main Section .................................................................... 47

• Deck Section .................................................................... 49

• Display Section ................................................................ 51

• Main Power/Sub Power Section ...................................... 53

8-3. Printed Wiring Board – BD (CD) Section – ....................... 57

8-4. Schematic Diagram – BD (CD) Section – .......................... 59

8-5. Printed Wiring Board – BD (MD) Section – ...................... 61

8-6. Schematic Diagram – BD (MD) (1/2) Section – ................ 63

8-7. Schematic Diagram – BD (MD) (2/2) Section – ................ 65

8-8. Schematic Diagram – Main (1/4) Section – ........................ 67

8-9. Schematic Diagram – Main (2/4) Section – ........................ 69

8-10. Schematic Diagram – Main (3/4) Section – ..................... 71

8-11. Schematic Diagram – Main (4/4) Section – ..................... 73

8-12. Printed Wiring Board – Main Section – ........................... 75

8-13. Printed Wiring Board – Deck Section – ........................... 77

8-14. Schematic Diagram – Deck Section – .............................. 79

8-15. Printed Wiring Board – Leaf SW Section – ..................... 81

8-16. Schematic Diagram – Leaf SW Section – ........................ 81

8-17. Schematic Diagram – Display (1/2) Section – ................. 83

8-18. Schematic Diagram – Display (2/2) Section – ................. 85

8-19. Printed Wiring Board – Display Section – ....................... 87

8-20. Printed Wiring Board – MD Digital Section – ................. 89

8-21. Schematic Diagram – MD Digital (1/2) Section – ........... 91

8-22. PSchematic Diagram – MD Digital (2/2) Section – ......... 93

8-23. Schematic Diagram – BD Switch Section – ..................... 95

8-24. Printed Wiring Board – BD Switch Section – .................. 96

8-25. Printed Wiring Board – CD Motor Section – ................... 97

8-26. Schematic Diagram – CD Motor Section – ...................... 99

8-27. Printed Wiring Board – MD Link Section –................... 101

8-28. Schematic Diagram – MD Link Section – ..................... 103

8-29. Schematic Diagram – Power Section – .......................... 105

8-30. Printed Wiring Board – Power Section – ....................... 107

8-31. IC Block Diagrams ......................................................... 109

8-32. IC Pin Functions ............................................................. 112

9. EXPLODED VIEWS

9-1. Case Section ...................................................................... 119

9-2. Chassis Section ................................................................. 120

9-3. Front Panel Section ........................................................... 121

9-4. CD Mechanism Deck Section-1 (CDM38LH-5BD32L) .. 122

9-5. CD Mechanism Deck Section-2 (CDM38LH-5BD32L) .. 123

9-6. Base Unit Section (BU-5BD32L) ..................................... 124

9-7. TC Mechanism Section-1 (TCM230AWR2/230PWR2) .. 125

9-8. TC Mechanism Section-2 (TCM230AWR2/230PWR2) .. 126

9-9. MD Mechanism Section-1 (MDM-5A) ............................ 127

9-10. MD Mechanism Section-2 (MDM-5A) .......................... 128

10. ELECTRICAL PARTS LIST ............................... 129

– 7 –

Page 8

SECTION 1

SERVICING NOTE

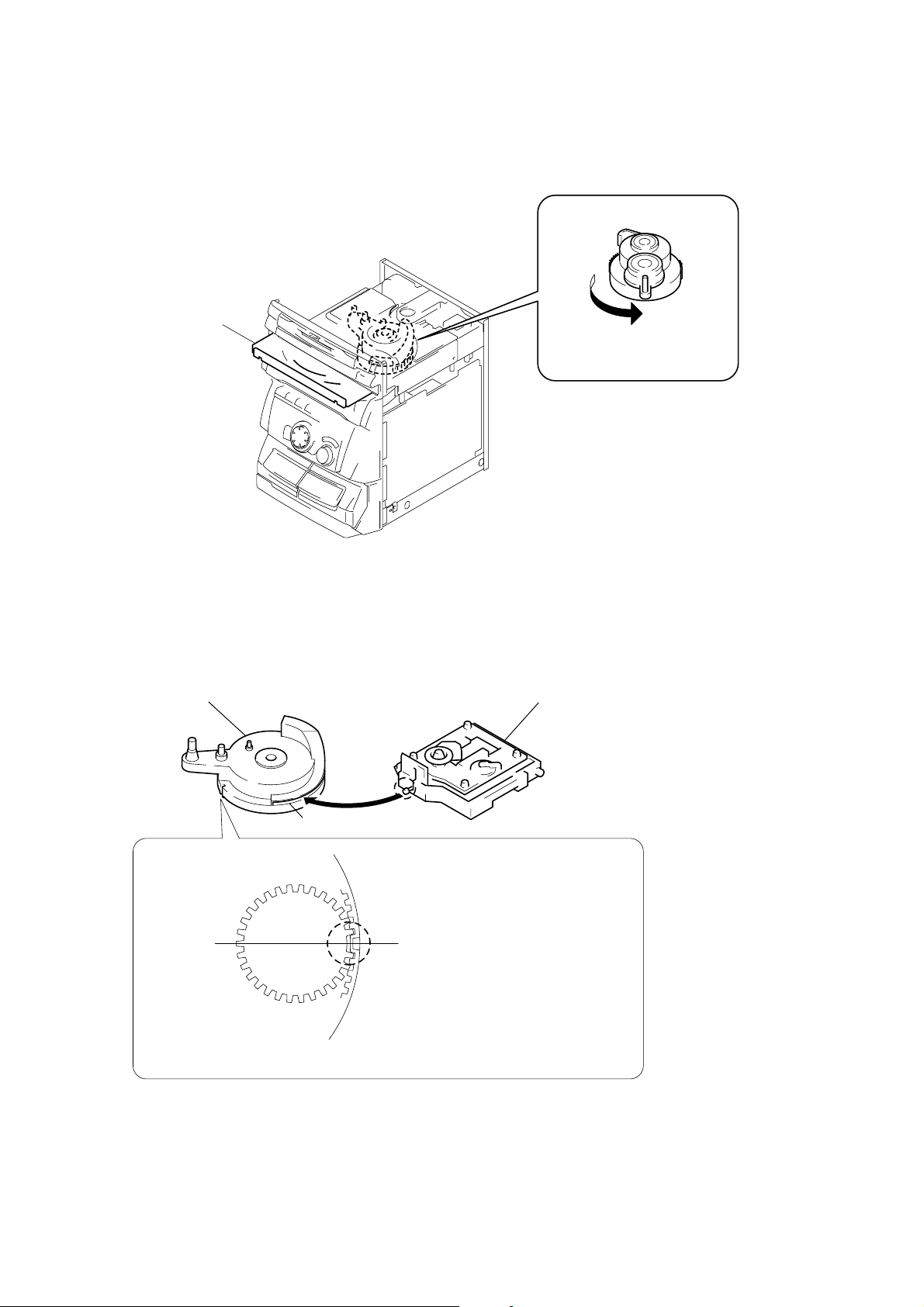

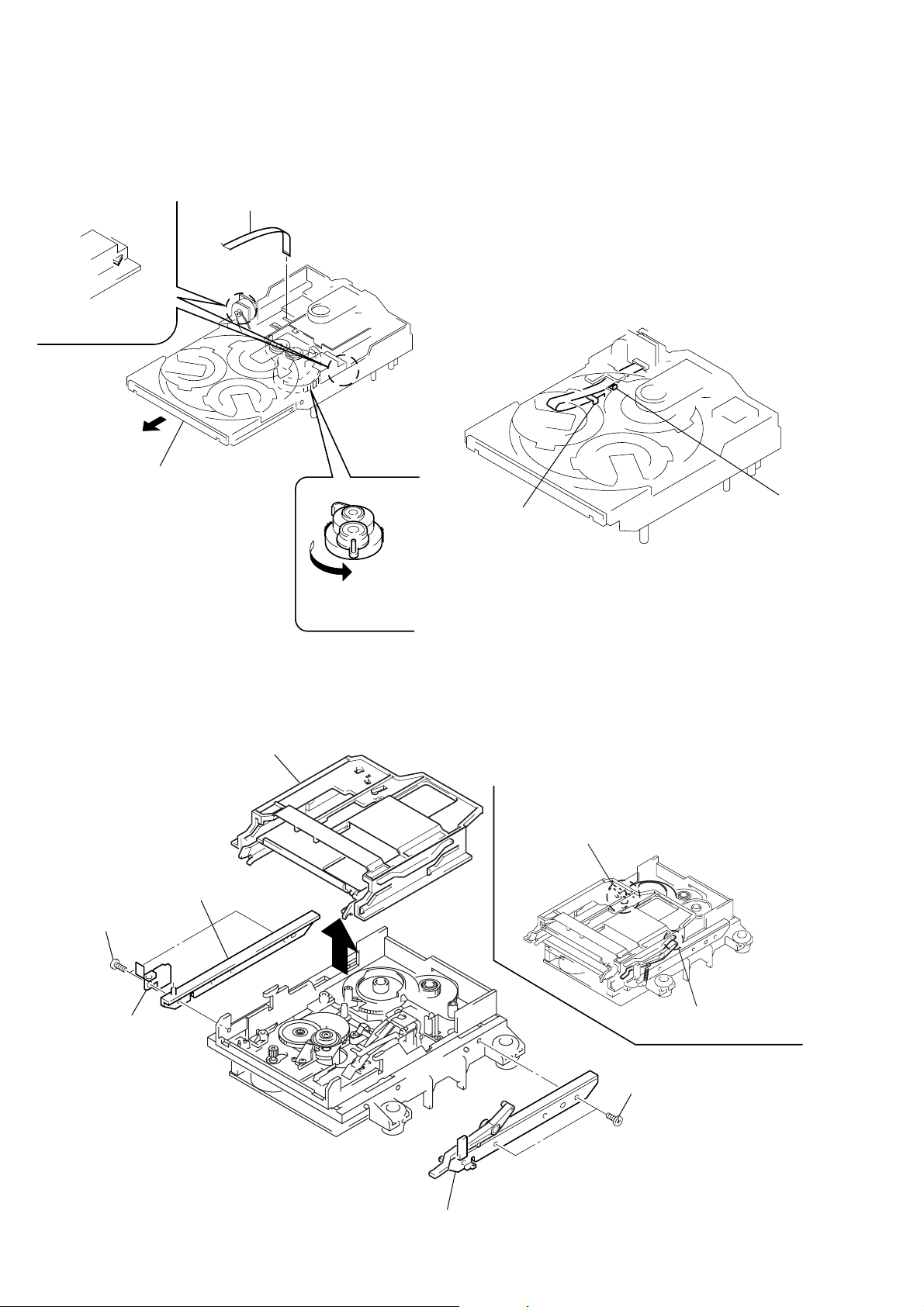

HOW TO OPEN THE DISC TRAY WHEN POWER SWITCH

TURNS OFF

1

Remove the Case.

3

Pull-out the disc tray.

2

Turn the cam to the direction

of arrow.

NOTE FOR INSTALLATION (ROTARY ENCODER)

BU cam

Groove

Note:When attaching the Base unit, Insert the

section A into the groove of BU cam.

Section A

Note:When attaching the BU cam,

engage the Rotary encoder

switch as shown in the figure.

CD-TEXT

This unit is provided with a simple CD-TEXT display function.

The CD-TEXT contents of 50 tracks are displayed on the fluorescent display tube.

Since the function is simple, some special characters may not be displayed, or may be displayed as other characters.

– 8 –

Page 9

JIG FOR CHECKING BD BOARD WAVEFORM

3

r

The special jig (J-2501-149-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to be

performed are shown as follows.

GND : Ground

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TEO : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

Mechanism deck

VC

RF

TEO

IOP

I+3V

GND

RF

VC

TEO

CN110

6P connecto

5P connector

1

RF

VC

TEO For MDMIOP

I-3V

5

1

IOP

I+3V

GND

VC

RF

TEO

For MDM-5

IOP

I+3V

6

GND

– 9 –

Page 10

IOP DATA RECORDING AND DISPLAY WHEN OPTICAL PICK-UP AND NON-VOLATILE MEMORY (IC171 OF

BD BOARD) ARE REPLACED

The IOP value labeled on the optical pick-up can be recorded in the non-volatile memory. By recording the value, it will eliminate the need

to look at the value on the label of the optical pick-up. When replacing the optical pick-up or non-volatile memory (IC171 of BD board),

record the IOP value on the optical pick-up according to the following procedure.

Record Precedure:

1. With the power ON, press the CD-MD SYNC button while pressing the p and ENTER/YES buttons together.

2. Rotate the AMS dial to display “Service”, and press the ENTER/YES button.

3. Rotate the AMS dial to display “lop.Write”, and press the ENTER/YES button.

4. The display becomes “Ref=@@@.@” (@ is an arbitrary number) and the numbers which can be changed will blink.

5. Input the IOP value written on the optical pick-up.

To select the number : Rotate the AMS dial.

To select the digit : Press the MD WALKMAN SYNC button.

6. When the ENTER/YES button is pressed, the display becomes “Measu=@@@.@” (@ is an arbitrary number).

7. As the adjustment results are recorded for the 6 value. Leave it as it is and press the ENTER/YES button.

8. “Complete!” will be displayed momentarily. The value will be recorded in the non-volatile memory and the display will become “Iop

Write”.

9. Press the REPEAT/STEREO/MONO button to complete.

Display Precedure:

1. With the power ON, press the CD-MD SYNC button while pressing the p and ENTER/YES buttons together.

2. Rotate the AMS dial to display “Service”, and press the YES button.

3. Rotate the AMS dial to display “lop.Read”.

4. “@@.@/##.#” is displayed and the recorded contents are displayed.

@@.@ : indicates the Iop value labeled on the pick-up.

##.# : indicates the Iop value after adjustment

5. To end, press the MD WALKMAN SYNC button or MENU/NO button to display “Iop Read”. Then press the REPEAT/STEREO/

MONO button.

– 10 –

Page 11

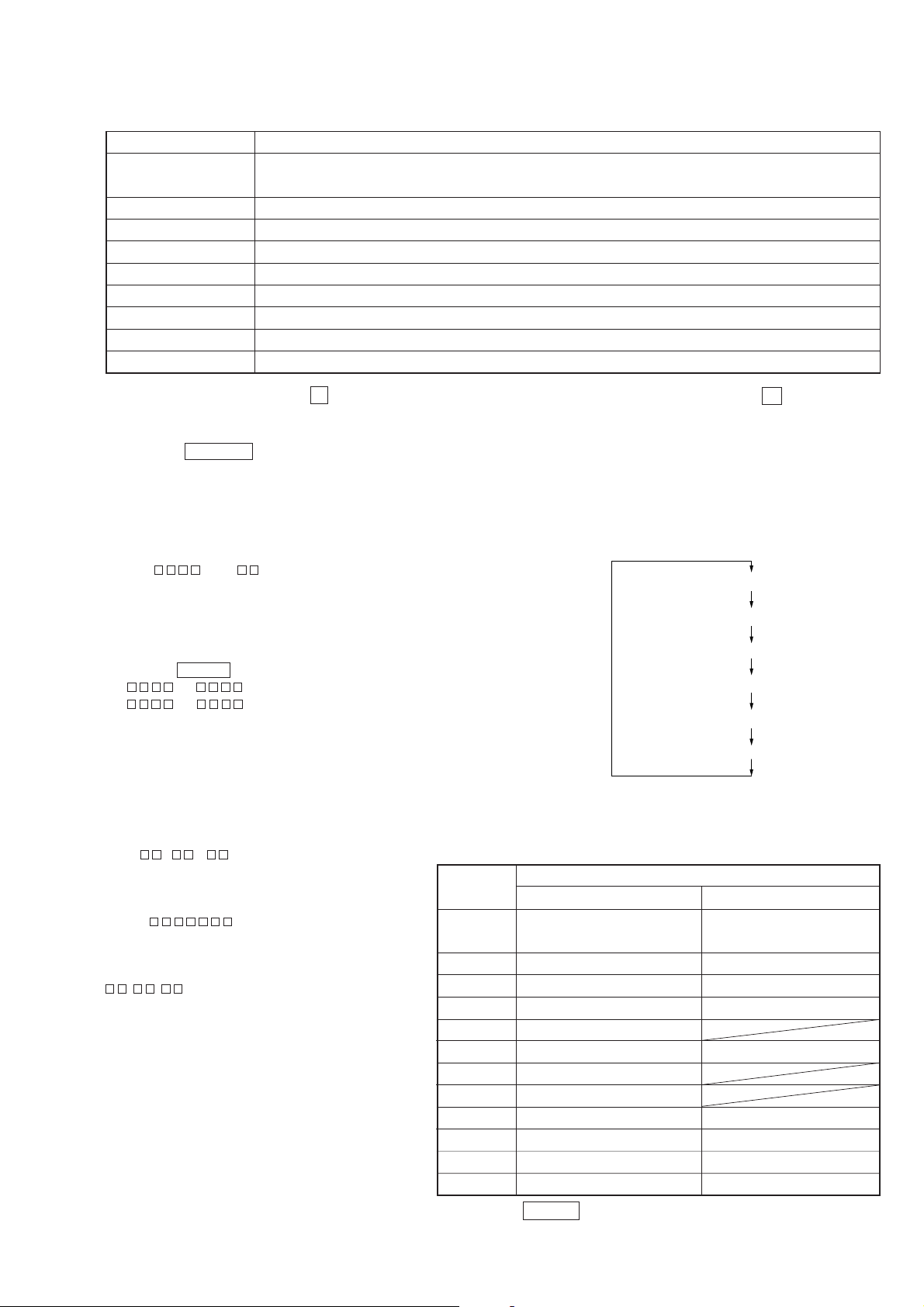

CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “5 Electrical Adjustments”.

Laser power check

(7-6-2 : See page 29)

Traverse check

(7-6-3 : See page 29)

Focus bias check

(7-6-4 : See page 30)

C PLAY check

(7-6-5 : See page 30)

Self-recording/playback

check

(REC/PLAY)

(7-6-6 : See page 30)

TEMP check

(Temperature

compensation

offset check)

(7-6-1 : See page 29)

Criteria for Determination

(Unsatisfactory if specified value is not satisfied)

• 0.9 mW power

Specified value : 0.84 to 0.92 mW

• 7.0 mW power

Specified value : 6.8 to 7.2 mW

lop (at 7mW)

• Labeled on the optical pickup

Iop value ± 10mA

• Traverse waveform

Specified value : Below 10% offset

• Error rate check

Specified value : For points a, b, and c

C1 error : Below 220

AD error : Below 2

• Error rate check

Specified value:

a.When using test disc (MDW-74/AU-1)

C1 error : Below 80

AD error : Below 2

b.When using check disc (TDYS-1)

C1 error : Below 50

• CPLAY error rate check

Specified value:

C1 error : Below 80

AD error : Below 2

• Unsatisfactory if displayed as T=@@ (##) NG”

NG

(@@, ## are both arbitrary numbers)

Measure if unsatisfactory:

• Clean the optical pick-up

• Adjust again

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

If always unsatisfactory:

• Replace the overwrite head

• Check for disconnection of the circuits around the

overwrite head

If occasionally unsatisfactory:

• Check if the overwrite head is distorted

• Check the mechanism around the sled

• Check for disconnection of the circuits around D101

(BD board)

• Check the signals around IC101, IC121, CN102,

CN103 (BD board)

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for

adjustments.

When performing adjustments, use the specified values for adjustments.

FORCED RESET

The system microprocessor can be reset in the following procedure.

Use these procedure when the unit cannot be operated normally due to the overrunning of the microprocessor, etc.

Procedure :

Disconnect the power plug, short-circuit both edge of BT921.

[MAIN BOARD] (Component Side)

IC801

BT921

– 11 –

Page 12

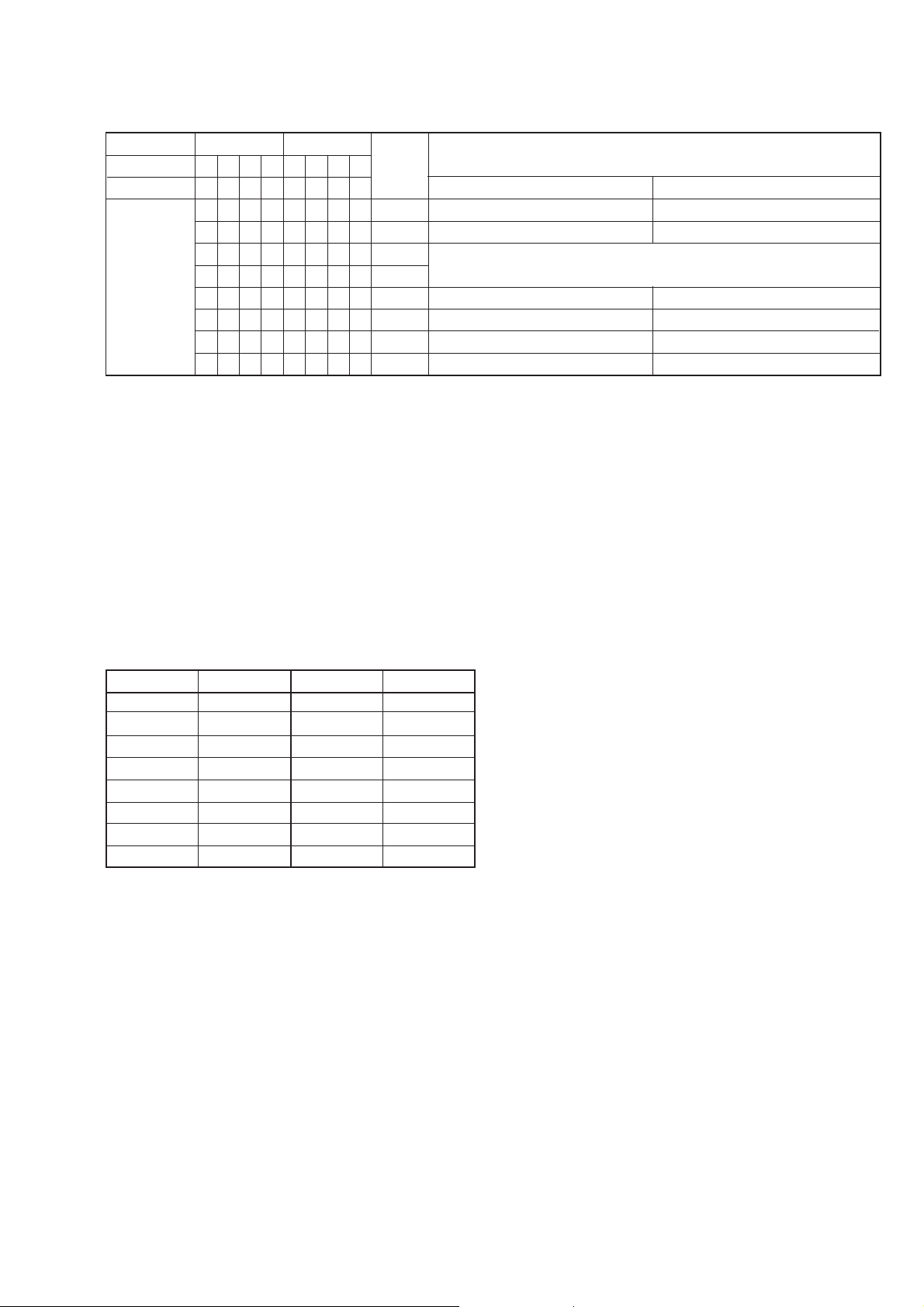

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent indicator tube. During playback, the

“track mode” for obtaining track information will be set.

This is useful for locating the faulty part of the unit.

• The following will be displayed :

During recording and stop : Retry cause, number of retries, and number of retry errors.

During playback : Information such as type of disc played, part played, copyright.

These are displayed in hexadecimal.

Precedure:

1. Load a recordable disc whose contents can be erased into the unit.

2. Press the FUNCTION button and set the function to “MD”.

3. Press the MENU/NO button. When “Edit/Menu” is displayed on the fluorescent indicator tube, rotate the AMS dial to display “All

Erase?”.

4. Press the ENTER/YES button.

5. “All Erase??” is displayed on the fluorescent indicator tube.

6. Press the ENTER/YES button to display “Complete!!”, and press the p button immediately. Wait for about 10 seconds while pressing

the button.

7. When the “TOC” displayed on the fluorescent display tube goes off, release the p button.

8. Press the REC (MD) button to start recording. Then press the ^/MD button and start recording.

9. To check the “track mode”, press the ^/MD button to start play.

10. To exit the test mode, press the 1/u button, and turn OFF the power. When “TOC” disappears, disconnect the power plug from the

outlet. If the test mode cannot be exited, refer to “Forced Reset” on page 8.

Fig. 1 Reading the Test Mode Display

(During recording and stop)

RTs@@c##c**

Fluorescent display tube display

@@ : Cause of retry

## : Number of retries

** : Number of retry errors

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

Fig. 2 Reading the Test Mode Display

(During playback)

@@####**$$

Fluorescent display tube display

@@ : Parts No. (name of area named on TOC)

## : Cluster

** : Sector

$$ : Track mode (Track information such as copyright infor-

Reading the Retry Cause Display

Cause of Retry Occurring conditions

shock

ader5

Discontinuous address

DIN unlock

FCS incorrect

IVR rec error

CLV unlock

Access fault

} Address (Physical address on disc)

mation of each part)

When track jump (shock) is detected

When ADER was counted more than five times

continuously

When ADIP address is not continuous

When DIN unlock is detected

When not in focus

When ABCD signal level exceeds the specified range

When CLV is unlocked

When access operation is not performed normally

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit : 4 = 0100 n b6

Lower bit : 2 = 0010 n b1

In this case, the retry cause is combined of “CLV unlock” and “ader5”.

When A2 is displayed:

Higher bit : A = 1010 n b7+b5

Lower bit : 2 = 0010 n b2

The retry cause in this case is combined of “access fault”, “IVR rec error”, and “ader5”.

– 12 –

Page 13

Reading the Track Mode Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example When 84 is displayed:

Higher bit : 8 = 1000 n b7

Lower bit : 4 = 0100 n b2

In this case, as b2 and b7 are 1 and others are 0, it can be determined that the retry cause is combined of “emphasis OFF”, “monaural”,

“original”, “copyright exists”, and “write allowed”.

Example When 07 is displayed:

Higher bit : 0 = 1000 n All 0

Lower bit : 7 = 0111 n b0+b1+b2

In this case, as b0, b1, and b2 are 1 and others are 0, it can be determined that the retry cause is combined of “emphasis ON”, “stereo”,

“original”, “copyright exists”, and “write prohibited”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

When 0 When 1

Emphasis OFF

Monaural

This is 2-bit display. Normally 01.

01:Normal audio. Others:Invalid

Audio (Normal)

Original

Copyright

Write prohibited

Details

Emphasis ON

Stereo

Invalid

Digital copy

No copyright

Write allowed

Hexadecimal n Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

0000

0001

0010

0011

0100

0101

0110

0111

8

9

A

B

C

D

E

F

1000

1001

1010

1011

1100

1101

1110

1111

– 13 –

Page 14

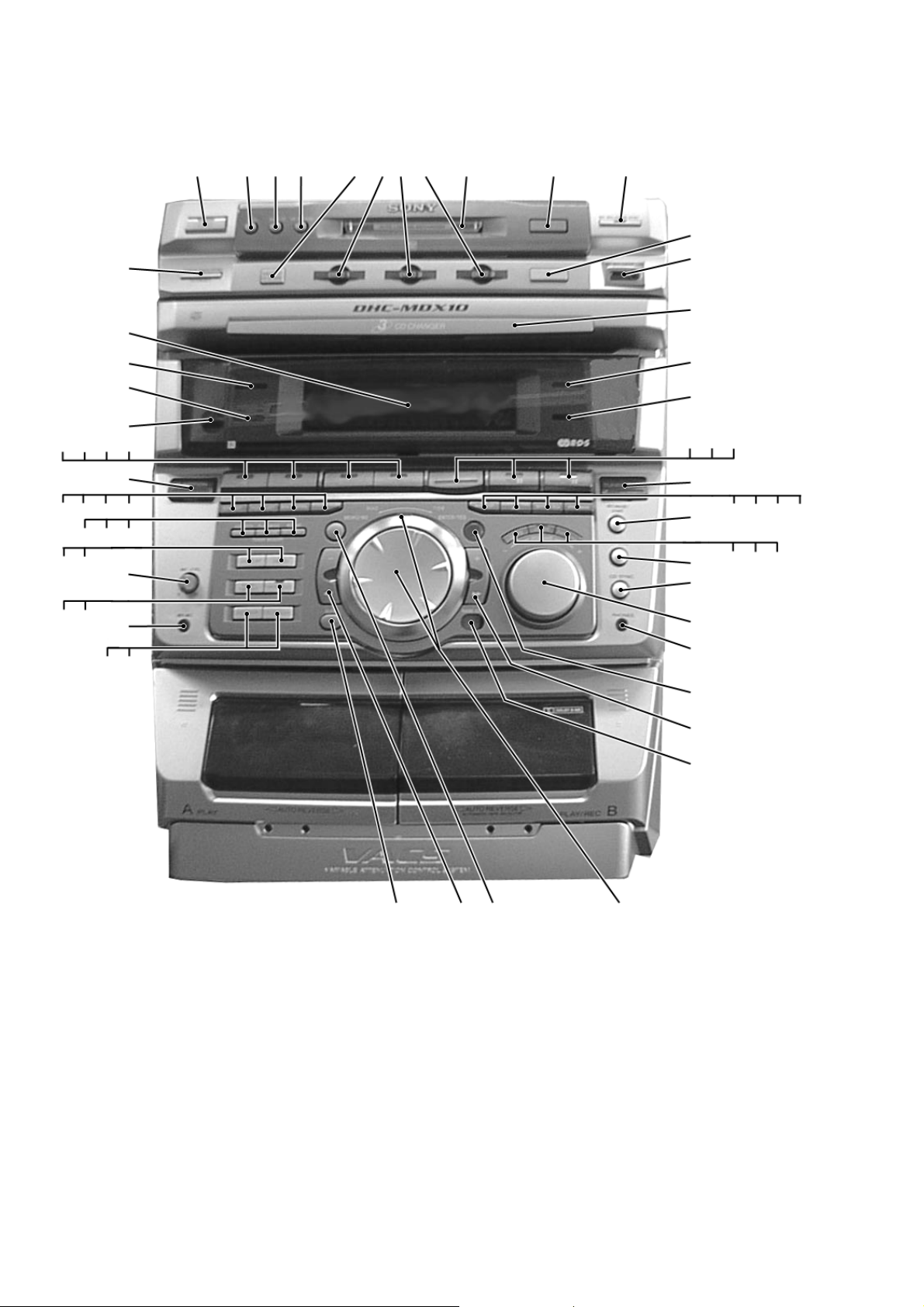

Front Panel

64

63

SECTION 2

GENERAL

7

231

4

56

811

910

12

13

14

59

47

44

58

5354

50

46

43

57

52

41

62

61

60

55

45

42

56

51

4849

40

17

15

16

20

25

29

30

31

32

33

34

35

18

19

21

26

22

27

23

28

24

– 14 –

38

3639 37

Page 15

LOCATION OF PARTS AND CONTROLS

1 1/u (POWER) button and indicator

2 REC button and indicator

3 REC IT button

4 CD-MD SYNC button

5 DISC SKIP/EX-CHANGE button

6 DISC 1 button and indicator

7 DISC 2 button and indicator

8 DISC 3 button and indicator

9 Disk compartment

10 § (Eject) (MD) button

11 MD WALKMAN SYNC button

12 § (Eject) (CD) button

13 MD WALKMAN LINK jack

14 Disc tray

15 SYNC BASS HIGH indicator

16 SYNC BASS LOW indicator

17 p button

18 ^/CD button and indicator

19 ^/MD button and indicator

20 TUNER/BAND button and indicator

21 CD NON-STOP button and indicator

22 KARAOKE PON/MPX button

23 SYNC EQ button

24 SYNC BASS button

25 REC P AUSE/START button and

indicator

26 DBFB button

27 GROOVE button

28 SURROND button

29 HI DUB button

30 CD-TAPE SYNC button

31 VOLUME knob

32 PHONES jack

33 ENTER/YES button and indicator

34 ) + button and indicator

35 NAME EDIT/CHAR button

36 JOG/0x) dial and

indicator

37 MENU/NO button

38 ) – button and indicator

39 CLEAR button

40 CD FLASH button

41 CD LOOP button

42 MIX MIC jack

43 TIMER SELECT button and indicator

44 CLOCK/TIMER SET button

45 MIC LEVEL knob

46 SPECTRUM ANAL YZER button

47 DISPLAY button

48 REPEAT STEREO/MONO button

49 DOLBY NR/PLAY MODE/PTY button

50 DIRECTION/EDIT/TUNER MEMORY

button

51 P FILE MEMORY button

52 GEQ CONTROL button

53 FILE SELECT button

54 EFFECT button

55 FUNCTION button and indicator

56 9/TAPE B button and indicator

57 (/TAPE B button and indicator

58 9/TAPE A button and indicator

59 (/TAPE A button and indicator

60 Remote sensor

61 SYNC EQ indicator

62 EFFECT indicator

63 Display Window

64 POWER SAVE/DEMO (STANDBY)

button

This section is extracted from

instruction manual.

– 15 –

Page 16

SECTION 3

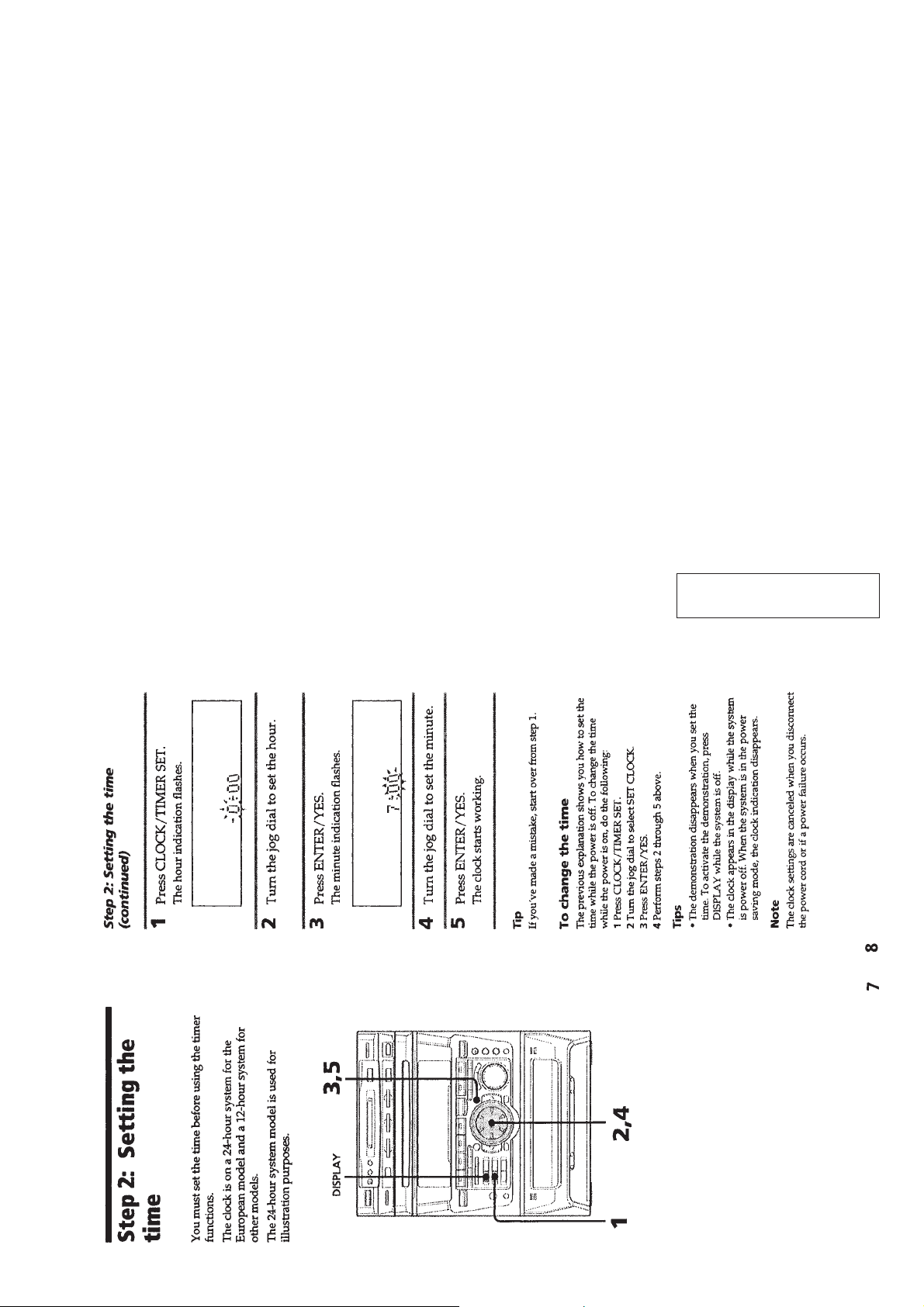

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

3-1. LOADING PANEL

Claws

3

Loading panel

2

Pull-out the disc tray.

1

Turn the cam to the direction

of arrow.

3-2. MD MECHANISM AND FRONT PANEL

8

MD mechanism

3

!∞

Flat type wire

(CN303)

!¢

Flat type wire

(CN304)

!™

Screw (BVTP 3x10)

!§

Front panel

Wire

!¡

(BVTP 3x10)

7

Screw

Four step screws

6

Connector

(CN601)

4

Flat type wire

(CN102)

5

Flat type wire

(CN103)

2

1

Four screws

(BVTP 3x8)

Bracket (MDM)

0

Two screws

(BVTT3x6)

9

Screw (BVTT3x6

– 16 –

!£

Flat type wire

(CN501)

Page 17

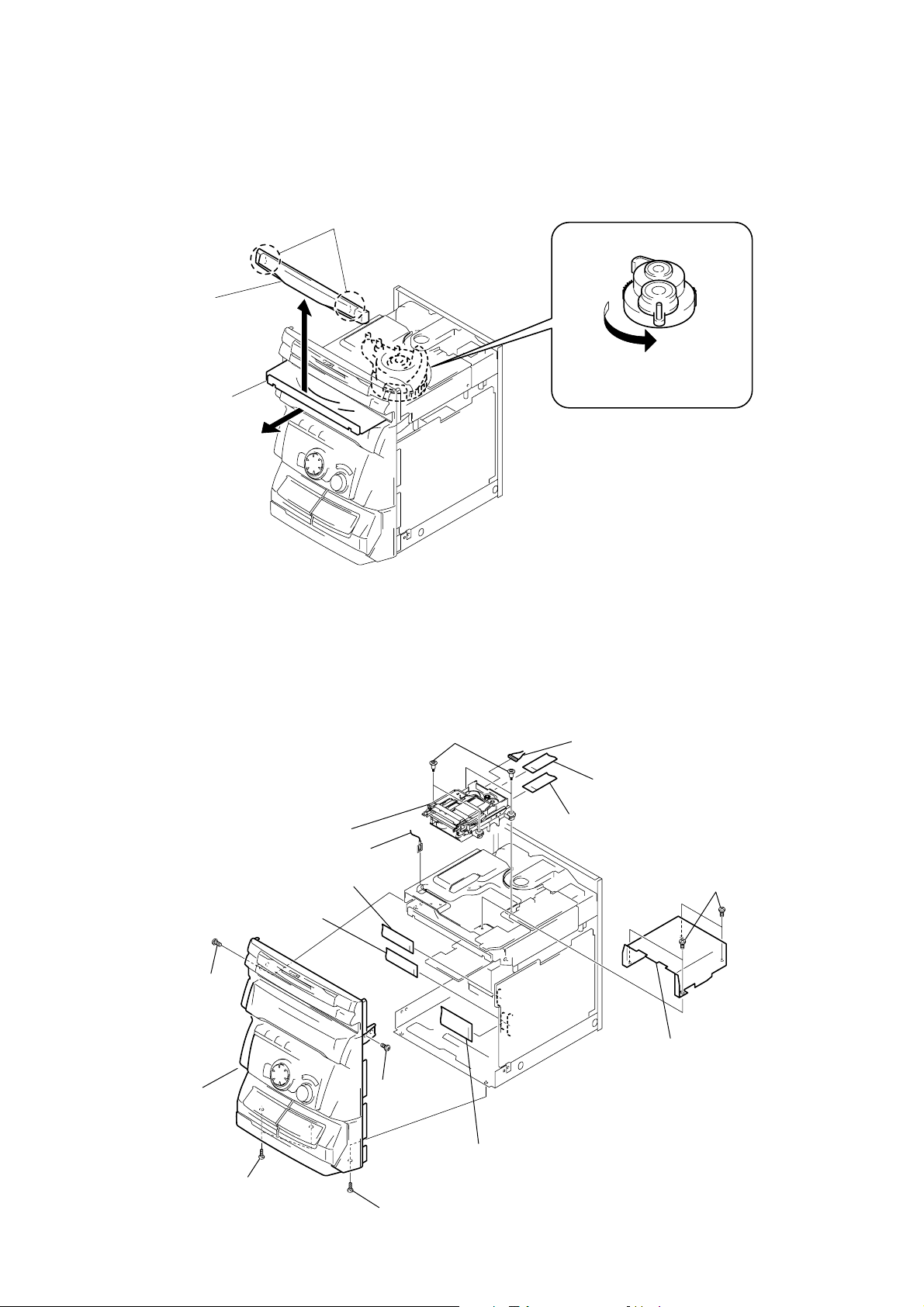

3-3. CASSETTE LID AND TAPE MECHANISM

1

Release

3

Cassette lid (R) block

4

Cassette lidr (L) block

Portion

A

Portion

A

5

Spring (R)

7

T wo screws

(BVTP2.6x8)

8

Three screws

(BVTP2.6x8)

9

T ape mechanism

6

Spring (L)

2

Releas

Note for installation

Portion

B

Portion

B

3-4. MD LINK, POWER SW, CD PANEL BOARDS AND DISPLAY BOARD

4

Power SW board

6

Knob (Jog)

7

(Two claws)

5

CD Panel board

(Two claws)

8

Nut

9

Nut

Knob (Vol)

1

Four screws

(BVTP2.6x8)

3

(Three claws)

!¢

2

Four screws

(BVTP2.6x8)

MD link SW board

!¡

Three screws

(BVTP2.6x8)

Display board

0

Flat type wire

(CN601)

!™

(BVTP2.6x8)

!£

(BVTP2.6x8)

Four screws

Six screws

– 17 –

Page 18

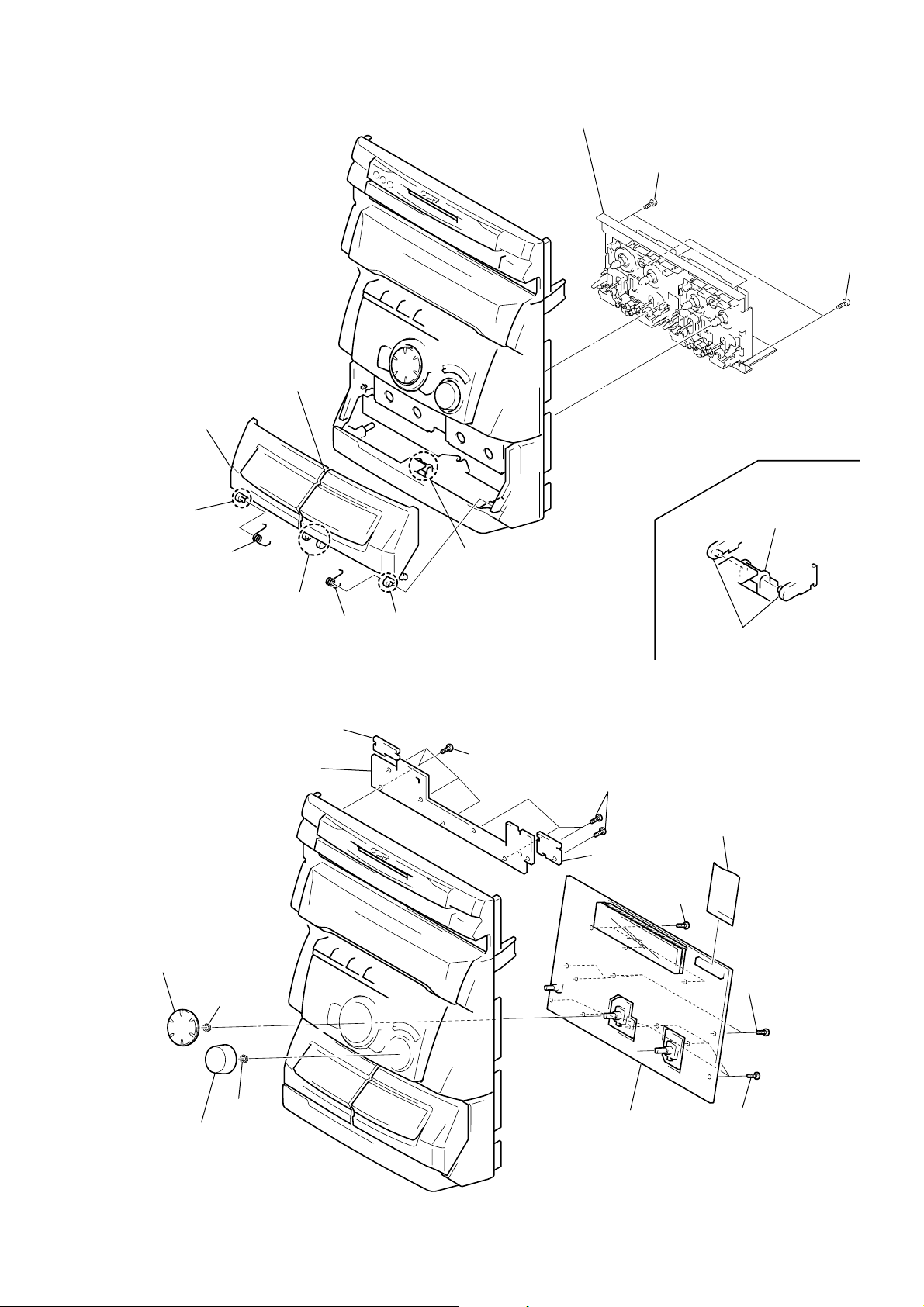

3-5. DISC TRAY

(Perform after removing the front panel.) Note:When installing the Disc tray, pull around the flat type wire to

3

Flat type wire (8 core)

4

Two claws

2

Pull-out the disc tray.

5

Remove the disc tray.

pass through the claw

Claw

A

A

and claw B, as shown in the figure.

Claw

B

3-6. SLIDER (CAM)

2

Bracket (Guide L)

1

Two screws (BTP2.6x6)

3

Leaf spring

6

Slider (Cam)

1

Turn the cam the

direction of arrow.

Set the shaft of Cam gear to

be at the position in the figure.

Set the shaft of Lever (O/C) to

be at the position in the figure.

5

Bracket (Guide R)

– 18 –

4

Two screws (BTP2.6x6)

Page 19

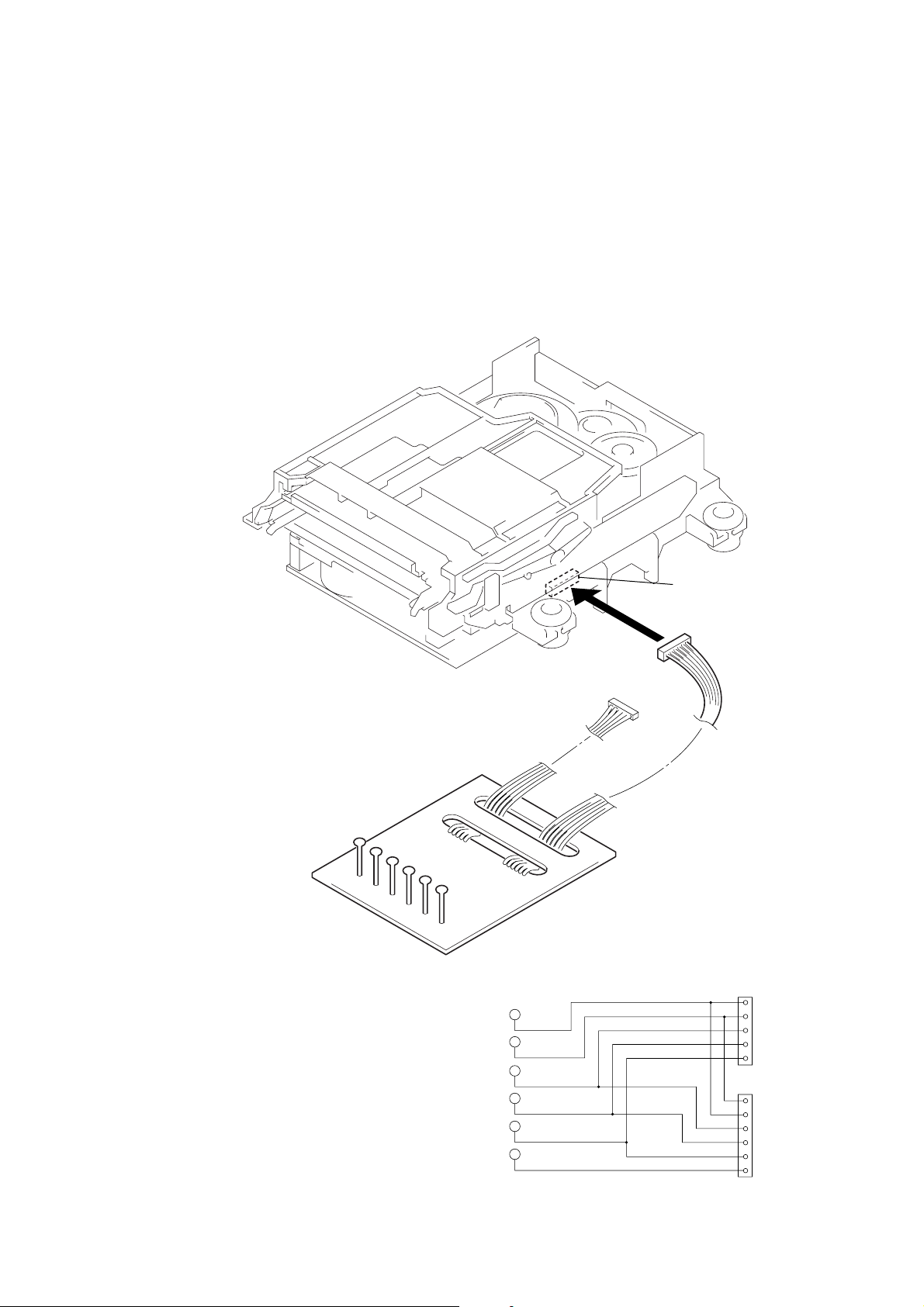

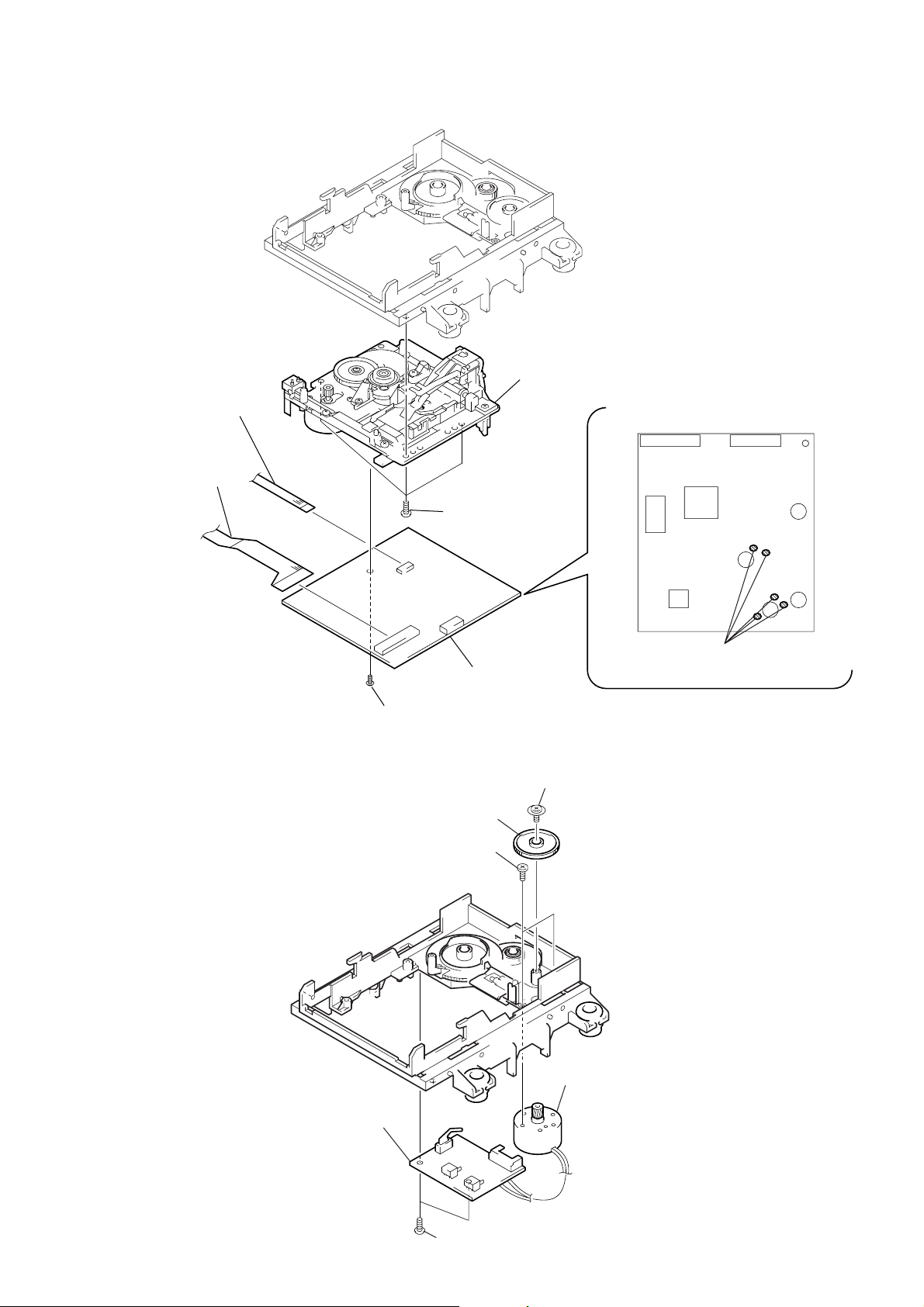

3-7. BASE UNIT (MBU-5A) AND BD (MD) BOARD

5

Flexible board

(CN104)

6

Flexible board

(CN101)

2

Base unit (MBU-5A)

1

Three screws

(BTP2.6x6)

4

Screw (M1.7x4)

3-8. SW BOARD AND LOADING MOTOR (M103)

3

Two screws

(PWH1.7x3)

7

BD (MD) board

2

Gear B

3

1

Screw (PTPWH M2.6x6)

4

Loading motor (M103)

Remove the solder (Five portion)

6

SW board

5

Two screws (BTP2.6x6)

– 19 –

Page 20

SECTION 4

SERVICE MODE

MC Cold Reset

• The cold reset clears all data including preset data stored in the RAM to initial conditions. Execute this mode when returning the set to the

customer.

Procedure:

1. Press three buttons p , ENTER/YES , and 1/u simultaneously.

2. “COLD RESET” is displayed on the fluorescent display tube and reset is executed.

CD Delivery Mode

• This mode moves the optical pick-up to the position durable to vibration. Use this mode when returning the set to the customer after repair .

Procedure:

1. Press 1/u button to turn the set ON.

2. Press CD LOOP button and 1/u button simultaneously.

3. A message “LOCK” is displayed on the fluorescent indicator tube, and the CD delivery mode is set.

MC Hot Reset

• This mode resets the set with the preset data kept stored in the memory. The hot reset mode functions same as if the power cord is plugged

in and out.

Procedure:

1. Press three buttons p , ENTER/YES , and DISC 1 simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously, and the set is reset.

Sled Servo Mode

• This mode can run the CD sled motor freely. Use this mode, for instance, when cleaning the pick-up.

Procedure:

1. Press 1/u button to turn the set ON.

2. Press three buttons p , ENTER/YES , and § (CD) simultaneously.

3. The Sled Servo mode is selected, if “CD” is blanking on the fluorescent indicator tube.

4. With the CD in stop status, When the ≠ AMS ± knob is rotated in the clockwise direction, the optical pick-up moves outside.

When rotated counterclockwise, it moves inside.

5. To exit from this mode, perform as follows:

1) Move the optical pick-up to the most inside track.

2) Execute MC cold reset. (Press the three buttons p , ENTER/YES , and 1/u button simultaneously.)

Note:

• Always move the pick-up to most inside track when exiting from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can be chipped.

Change-over of AM Tuner Step between 9kHz and 10kHz

• A step of AM channels can be changed over between 9kHz and 10kHz.

Procedure:

1. Press 1/u button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND button to select the BAND “AM”.

3. Press 1/u button to turn the set OFF.

4. Press ENTER/YES and 1/u buttons simultaneously, and the display of fluorescent indicator tube changes to “AM 9k STEP” or “AM

10k STEP”, and thus the channel step is changed over.

LED and Fluorescent Indicator Tube All Lit, Key Check Mode

Procedure:

1. Press three buttons p , ENTER/YES , and DISC 2 simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

Press DISC 2 button, and the key check mode is activated.

3. In the key check mode, the fluorescent indicator tube displays “K 0 V0 J0”. Each time a button is pressed, “K”value increases. However ,

once a button is pressed, it is no longer taken into account.

“J” Value increases like 1, 2, 3 ... if rotating ≠ AMS ± knob in “+” direction, or it decreases like 0, 9, 8 ... if rotating in “-”

direction.

“V” Value increases like 1, 2, 3 ... if rotating VOLUME knob in “+” direction, or it decreases like 0, 9, 8 ... if rotating in “-” direction.

4. To exit from this mode, press three buttons in the same manner as step 1, or disconnect the power cord.

– 20 –

Page 21

AMS Test Mode

• This mode is used for checking the AMS operations of the tape deck.

JIG

7-819-039-12 Alignment tape, AMS-110A

Procedure:

1. Press the 1/u button to turn the unit ON.

2. Set the tape (AMS-110A).

3. Press the three buttons p , ENTER/YES , and DISC 3 button simultaneously.

4. “TEST MODE” is displayed on the fluorescent display tube.

5. Press the FUNCTION button and switch the function to the deck with the tape (AMS-110A).

6. Press the CD SYNC button. “AMS CHECK” is displayed on the fluorescent display tube and the tape is rewound.

7. AMS starts in the normal direction. If the AMS count is 2 at shut down, proceed to step 8.

“NG” is displayed at other times, and the deck stops.

8. AMS starts in the opposite direction. If the AMS count is 2 at shut down again, “OK” is displayed.

“NG” is displayed at other times.

Note: The p button of CD section will become effective and the aging of CD section will stop sometime, if the buttons described in step 3

are not pressed simultaneously. In that case, press ^/CD button and operate the CD section.

– 21 –

Page 22

SECTION 5

TEST MODE (MD)

5-1. PRECAUTIONS FOR USE OF TEST MODE

• As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc is

stopped before setting and removing it.

Even if the §EJECT (MD) button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc

will not stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the §EJECT (MD) button after pressing the MENU/NO button and the rotation of disc is stopped.

5-1-1. Recording laser emission mode and operating buttons

• Continuous recording mode (CREC MODE)

• Laser power check mode (LDPWR CHECK)

• Laser power adjustment mode (LDPWR ADJUST)

• Traverse (MO) check (EF MO CHECK)

• Traverse (MO) adjustment (EF MO ADJUST)

• When pressing the REC (MD) button.

5-2. SETTING THE TEST MODE

The following are two methods of entering the test mode.

Procedure 1:With the power ON, press the CD-MD SYNC button while pressing the p and ENTER/YES buttons together.

When the test mode is set, “Check” will be displayed. Rotating the AMS dial switches between the following four groups;

···Nn Check Nn Adjust Nn Service Nn Develop Nn ···.

Procedure 2:With the power ON, press the REC (MD) button while pressing the p and ENTER/YES buttons together.

When the test mode is set, “TEMP CHECK” will be displayed. By setting the test mode using this procedure, only the “Check”

group of procedure 1 can be executed.

5-3. EXITING THE TEST MODE

Press the REPEAT/STEREO/MONO button.

5-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the AMS dial, ENTER/YES button, and MENU/NO button.

The functions of these buttons are as follows.

Function name

AMS dial

ENTER/YES button

MENU/NO button

Changes parameters and modes

Proceeds onto the next step. Finalizes input.

Returns to previous step. Stops operations.

Function

– 22 –

Page 23

5-5. SELECTING THE TEST MODE

There are 31 types of test modes as shown below. The groups can be switched by rotating the AMS dial. After selecting the group to be used,

press the MD WALKMAN SYNC button. After setting a certain group, rotating the AMS dial switches between these modes.

Refer to “Group” in the table for details selected.

All items used for servicing can be treated using group S. So be carefully not to enter other groups by mistake.

Display

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

S curve CHECK

VERIFY MODE

DETRK CHECK

TEMP ADJUST

LDPWR ADJUST

EF MO ADJUST

EF CD ADJUST

FBIAS ADJUST

EEP MODE

MANUAL CMD

SVDATA READ

ERR DP MODE

SLED MOVE

ACCESS MODE

0920 CHECK

HEAD ADJUST

CPLAY2 MODE

CREC2 MODE

ADJ CLEAR

AG Set (MO)

AG Set (CD)

Iop Read

Iop Write

INFORMATION

CPLAY MODE

CREC MODE

Contents

Temperature compensation offset check

Laser power check

Traverse (MO) check

Traverse (CD) check

Focus bias check

S letter check

Non-volatile memory check

Detrack check

Temperature compensation offset adjustment

Laser power adjustment

Traverse (MO) adjustment

Traverse (CD) adjustment

Focus bias adjustment

Non-volatile memory control

Command transmission

Status display

Error history display, clear

Sled check

Access check

Outermost circumference check

Head position check

Same functions as CPLAY MODE

Same functions as CREC MODE

Initialization of non-volatile memory of adjustment value

Auto gain output level adjustment (MO)

Auto gain output level adjustment (CD)

IOP data display

IOP data write

Microprocessing version display

Continuous play mode

Continuous recording mode

Mark

(X)

(X)

(X)

(X) (!)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

Group (*)

CS

CS

CS

CS

CS

C

C

C

AS

AS

AS

AS

AS

D

D

D

S

D

D

D

D

D

D

AS

AS

AS

CS

AS

CS

CASD

CASD

Group (*)

C: Check

S: Service

A: Adjust

D: Develop

• For details of each adjustment mode, refer to “5. Electrical Adjustments”.

For details of “ERR DP MODE”, refer to “Self-Diagnosis Function” on page 3.

• If a different mode has been selected by mistake, press the MENU/NO button to exit that mode.

• Modes with (X) in the Mark column are not used for servicing and therefore are not described in detail. If these modes are set accidentally,

press the MENU/NO button to exit the mode immediately. Be especially careful not to set the modes with (!) as they will overwrite the

non-volatile memory and reset it, and as a result, the unit will not operate normally.

– 23 –

Page 24

5-5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

1 Set the disc in the unit. (Whichever recordable discs or discs for playback only are available.)

2 Rotate the AMS dial and display “CPLAY MODE”.

3 Press the ENTER/YES button to change the display to “CPLAY MID”.

4 When access completes, the display changes to “C1 = AD = ”.

Note : The numbers “ ” displayed show you error rates and ADER.

2. Changing the parts to be played back

1 Press the ENTER/YES button during continuous playback to change the display as below.

“CPLAY MID” n “CPLAY OUT” n “CPLAY IN”

When pressed another time, the parts to be played back can be moved.

2 When access completes, the display changes to “C1 = AD = ”.

Note : The numbers “ ” displayed show you error rates and ADER.

3. Ending the continuous playback mode

1 Press the MENU/NO button. The display will change to “CPLAY MODE”.

2 Press the §EJECT (MD) button to remove the disc.

Note : The playback start addresses for IN, MID, and OUT are as follows.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

5-5-2. Operating the Continuous Recording Mode (Use only when performing self-recording/palyback check.)

1. Entering the continuous recording mode

1 Set a recordable disc in the unit.

2 Rotate the AMS dial and display “CREC MODE”.

3 Press the ENTER/YES button to change the display to “CREC MID”.

4 When access completes, the display changes to “CREC ( )” and “REC” indicator lights up.

Note : The numbers “ ” displayed shows you the recording position addresses.

2. Changing the parts to be recorded

1 When the ENTER/YES button is pressed during continuous recording, the display changes as below.

“CPLAY MID” n “CPLAY OUT” n “CPLAY IN”

When pressed another time, the parts to be recorded can be changed. “REC” indicator goes off.

2 When access completes, the display changes to “CREC ( )” and “REC” indicator lights up.

Note : The numbers “ ” displayed shows you the recording position addresses.

3. Ending the continuous recording mode

1 Press the MENU/NO button. The display changes to “CREC MODE” and “REC” indicator goes off.

2 Press the §EJECT (MD) button to remove the disc.

Note 1 : The recording start addresses for IN, MID, and OUT are as follows.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

Note 2 :The MENU/NO button can be used to stop recording anytime.

Note 3 :Do not perform continuous recording for long periods of time above 5 minutes.

Note 4 :During continuous recording, be careful not to apply vibration.

5-5-3. Non-Volatile Memory Mode (EEP MODE)

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If set accidentally, press the MENU/NO button immediately to exit it.

– 24 –

Page 25

5-6. FUNCTIONS OF OTHER BUTTONS

Function

^/MD

p

) *

0 *

CLEAR

PLAY MODE

DISPLAY

§ EJECT (MD)

REPEAT/STEREO/MONO

* This function works only when the p button is pressed and “MD” is displayed. In other cases, it works everytime the p button is pressed.

Sets continuous playback when pressed in the STOP state. When pressed during continuous playback, the tracking servo turns

ON/OFF.

Stops continuous playback and continuous recording.

The sled moves to the outer circumference only when this is pressed.

The sled moves to the inner circumference only when this is pressed.

Switches between the pit and groove modes when pressed.

Switches the spindle servo mode (CLV S ˜ CLV A).

Switches the displayed contents each time the button is pressed

Ejects the disc

Exits the test mode

Contents

5-7. TEST MODE DISPLAYS

Each time the DISPLAY button is pressed, the display changes in the following order.

1. Mode display

Displays “TEMP ADJUST”, “CPLAYMODE”, etc.

2. Error rate display

Displays the error rate in the following way.

C1 = AD =

C1 = Indicates the C1 error.

AD = Indicates ADER.

3. Address display

The address is displayed as follows. (MO:recordable disc, CD:playback only disc)

Pressing the CLEAR button switches between the groove display and pit display.

h = s = (MO pit and CD)

h = a = (MO groove)

h = Indicates the header address.

s = Indicates the SUBQ address.

a = Indicates the ADIP address.

Auto gain display (Not used in servicing)

Detrack check display (Not used in servicing)

IVR display (Not used in servicing)

Mode display

Error rate display

Address display

Note: “–” is displayed when servo is not imposed.

4. Auto gain display (Not used in servicing)

The auto gain is displayed as follows.

AG = /

5. Detrack check display (Not used in servicing)

The detrack is displayed as follows.

ADR =

6. IVR display (Not used in servicing)

The IVR is displayed as follows.

MEANINGS OF OTHER DISPLAYS

Display

^/MD *

^/MD *

REC

SYNC

L-SYNC

OVER

1

REPEAT

TRACK

DISC

SHUFFLE

MONO

* Differentiate ^/MD by the color of the button indicator.

During continuous playback

(CLV: ON) (Green)

Tracking servo OFF (Unber)

Recording mode ON

CLV low speed mode

ABCD adjustment completed

Tracking offset cancel ON

Tracking auto gain OK

Focus auto gain OK

Pit

High reflection

CLV S

CLV LOCK

When Lit

Contents

STOP (CLV: OFF) (Light off)

Tracking servo ON (Green)

Recording mode OFF

CLV normal mode

Tracking offset cancel OFF

Groove

Low reflection

CLV A

CLV UNLOCK

When Off

– 25 –

Page 26

SECTION 6

MECHANICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

71 to 143 g • cm

(0.98 – 1.99 oz • inch)

100 g or more

(3.53 oz or more)

100 g or more

(3.53 oz or more)

– 26 –

Page 27

SECTION 7

ELECTRICAL ADJUSTMENTS

MD SECTION

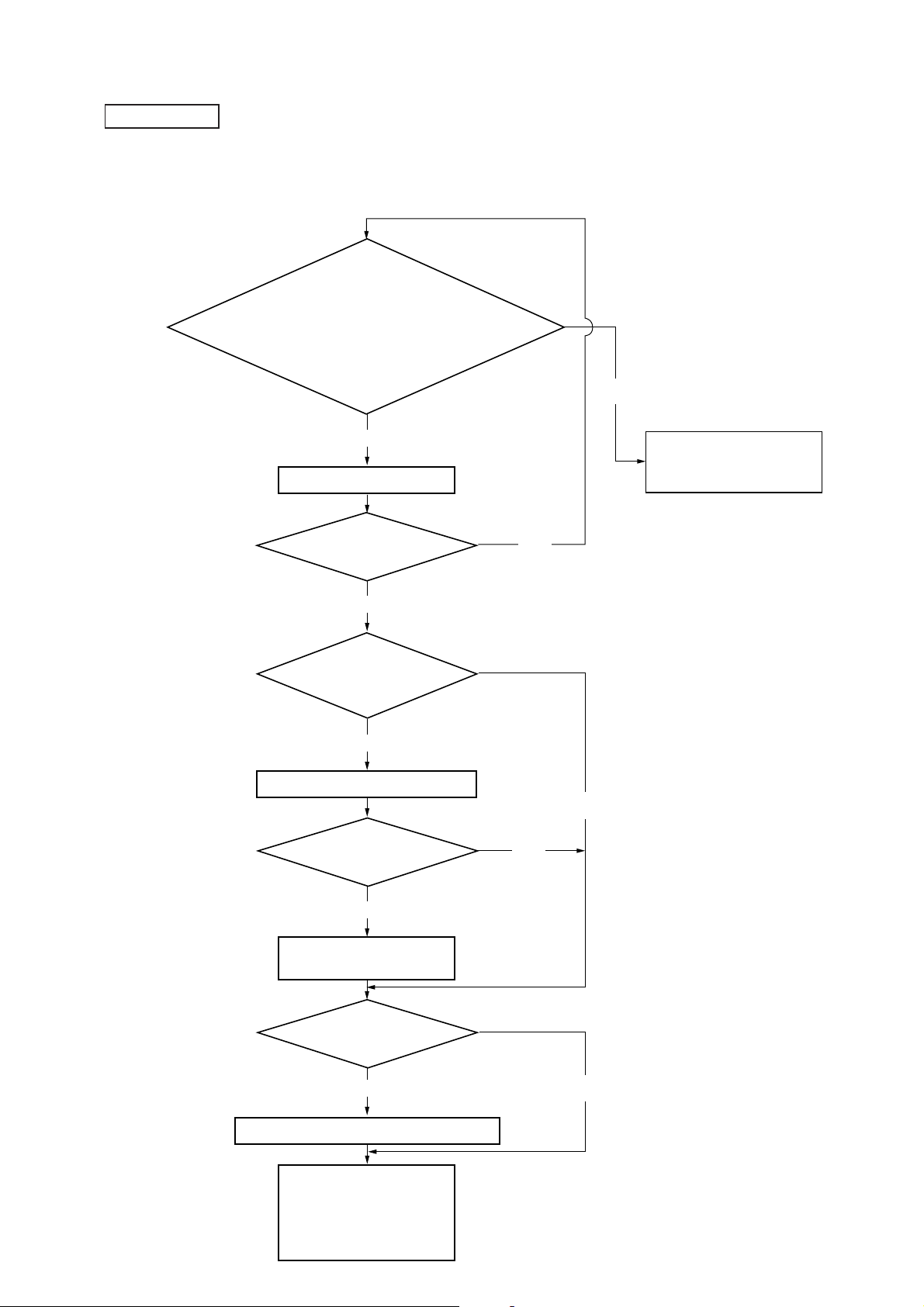

7-1. PARTS REPLACEMENT AND ADJUSTMENT

• Check and adjust the MDM and MBU as follows.

The procedure changes according to the part replaced

• Temperature compensation offset check

• Laser power check

• Traverse check

• Focus bias check

• C PLAY check

• Self-recording/playback check

• Abbreviation

OP : Optical pick-up

OWH: Overwrite head

OK

NG

Parts Replacement and Repair

Has the OWH been replaced?

NO

Has OP, IC171, IC101, or

IC121 been replaced?

YES

Initial setting of the adjustment value

Has OP or IC171 been replaced?

Check the sleding and spindle

mechanisms.

Other causes can be suspected.

YES

NO

NO

YES

IOP information recording

(IOP value labeled on OP)

Has IC171 or D101

been replaced?

YES

Temperature compensation offset adjustment

• Laser power adjustment

• Traverse adjustment

• Focus bias adjustment

• Error rate adjustment

• Focus bias check

• Auto gain adjustment

– 27 –

NO

Page 28

7-2. PRECA UTIONS FOR CHECKING LASER DIODE

EMISSINON

T o check the emission of the laser diode during adjustments, never

view directly from the top as this may lose your eye-sight.

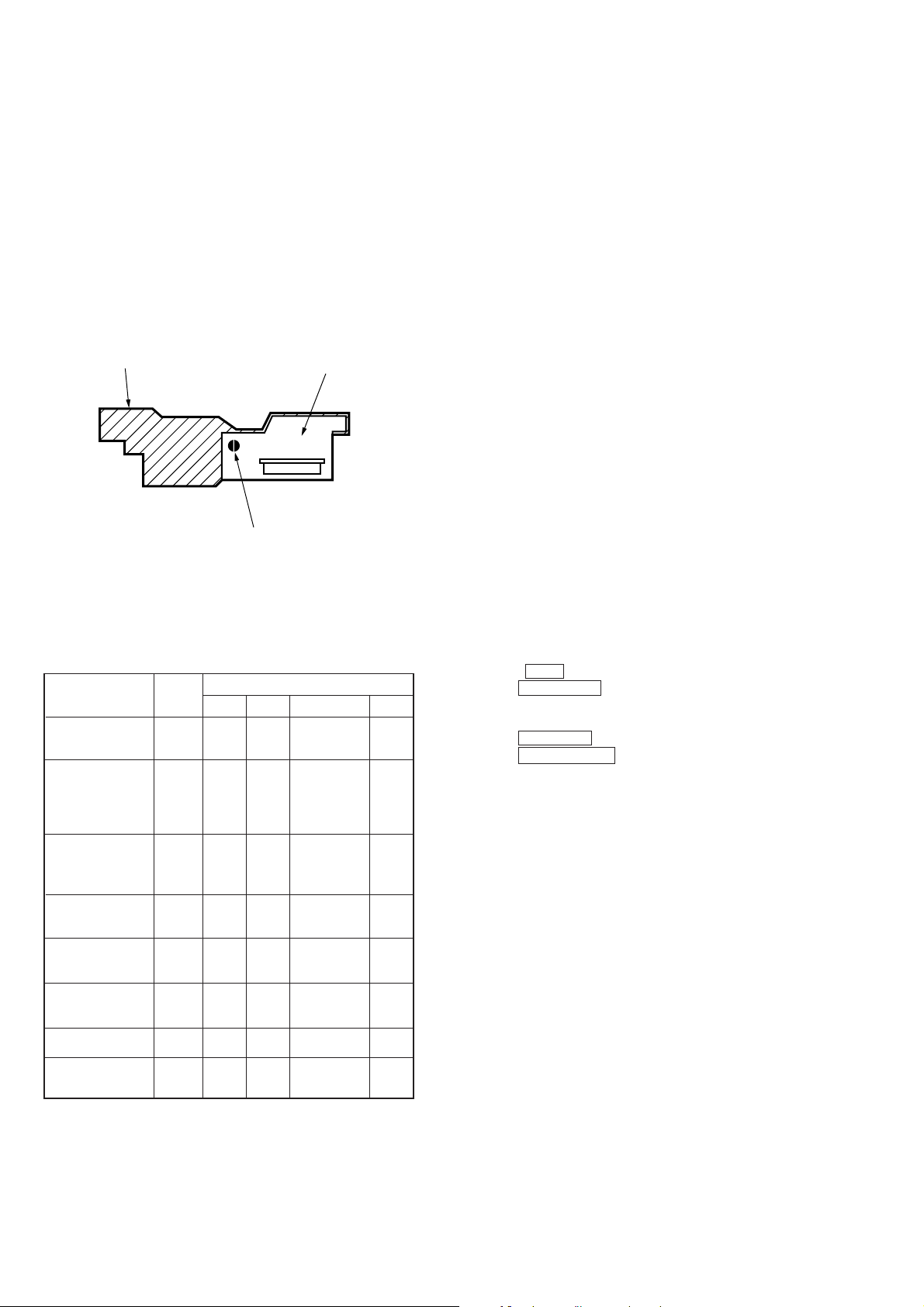

7-3. PRECAUTIONS FOR USE OF OPTICAL PICK-

UP (KMS-260A)

As the laser diode in the optical pick-up is easily damaged by static

electricity, solder the laser tap of the flexible board when using it.

Before disconnecting the connector, desolder first. Before connecting the connector, be careful not to remove the solder. Also take

adequate measures to prevent damage by static electricity. Handle

the flexible board with care as it breaks easily.

pick-up

laser tap

flexible board

Optical pick-up flexible board

7-4. PRECAUTIONS FOR ADJUSTMENTS

1) When replacing the following parts, perform the adjustments

and checks with ¬ in the order shown in the following table.

D101

BD Board

IC101, IC121

IC192

G

1. Initial setting of

adjustment value

2.Recording of IOP

information

(Value written in

the pick-up)

3.Temperature

compensation

offset adjustment

Optical

Pick-up

IC171

¬G¬¬

¬G¬GG

¬¬GGG

4) Use the following tools and measuring devices.

• Check Disc (MD) TDYS-1

(Parts No. 4-963-646-01)

• Test Disk (MDW-74/AU-1) (Parts No. 8-892-341-41)

• Laser power meter LPM-8001 (Parts No. J-2501-046-A)

or

MD Laser power meter 8010S (Parts No. J-2501-145-A)

• Oscilloscope (Measure after performing CAL of prove.)

• Digital voltmeter

• Thermometer

• Jig for checking BD board waveform

(Parts No. : J-2501-149-A)

5) When observing several signals on the oscilloscope, etc.,

make sure that VC and ground do not connect inside the oscilloscope.

(VC and ground will become short-circuited.)

6) Using the above jig enables the waveform to be checked without

the need to solder.

(Refer to Servicing Note on page 9.)

7) As the disc used will affect the adjustment results, make sure

that no dusts nor fingerprints are attached to it.

Note:

When performing laser power checks and adjustment (electrical

adjustment), use of the new MD laser power meter 8010S (J-2501145-A) instead of the conventional laser power meter is convenient.

It sharply reduces the time and trouble to set the laser power meter

sensor onto the objective lens of the optical pick-up.

7-5. CREATING CONTINUOUSL Y RECORDED DISC

* This disc is used in focus bias adjustment and error rate check.

The following describes how to create a continuous recording disc.

1. Insert a disc (blank disc) commercially available.

2. Rotate the AMS dial and display “CREC MODE”.

3. Press the ENTER/YES button again to display “CREC MID”.

Display “CREC (0300)” and start to recording.

4. Complete recording within 5 minutes.

5. Press the MENU/NO button and stop recording .

6. Press the §EJECT (MD) button and remove the disc.

The above has been how to create a continuous recorded data for

the focus bias adjustment and error rate check.

Note :

• Be careful not to apply vibration during continuous recording.

4.Laser power

adjustment

5.Traverse

adjustment

6.Focus bias

adjustment

7.Error rate check

8. Auto gain output

level adjustment

¬G¬¬¬

¬G¬¬G

¬G¬¬G

¬G¬¬G

¬G¬¬G

2) Set the test mode when performing adjustments.

After completing the adjustments, exit the test mode.

Perform the adjustments and checks in “group S” of the test mode.

3) Perform the adjustments to be needed in the order shown.

– 28 –

Page 29

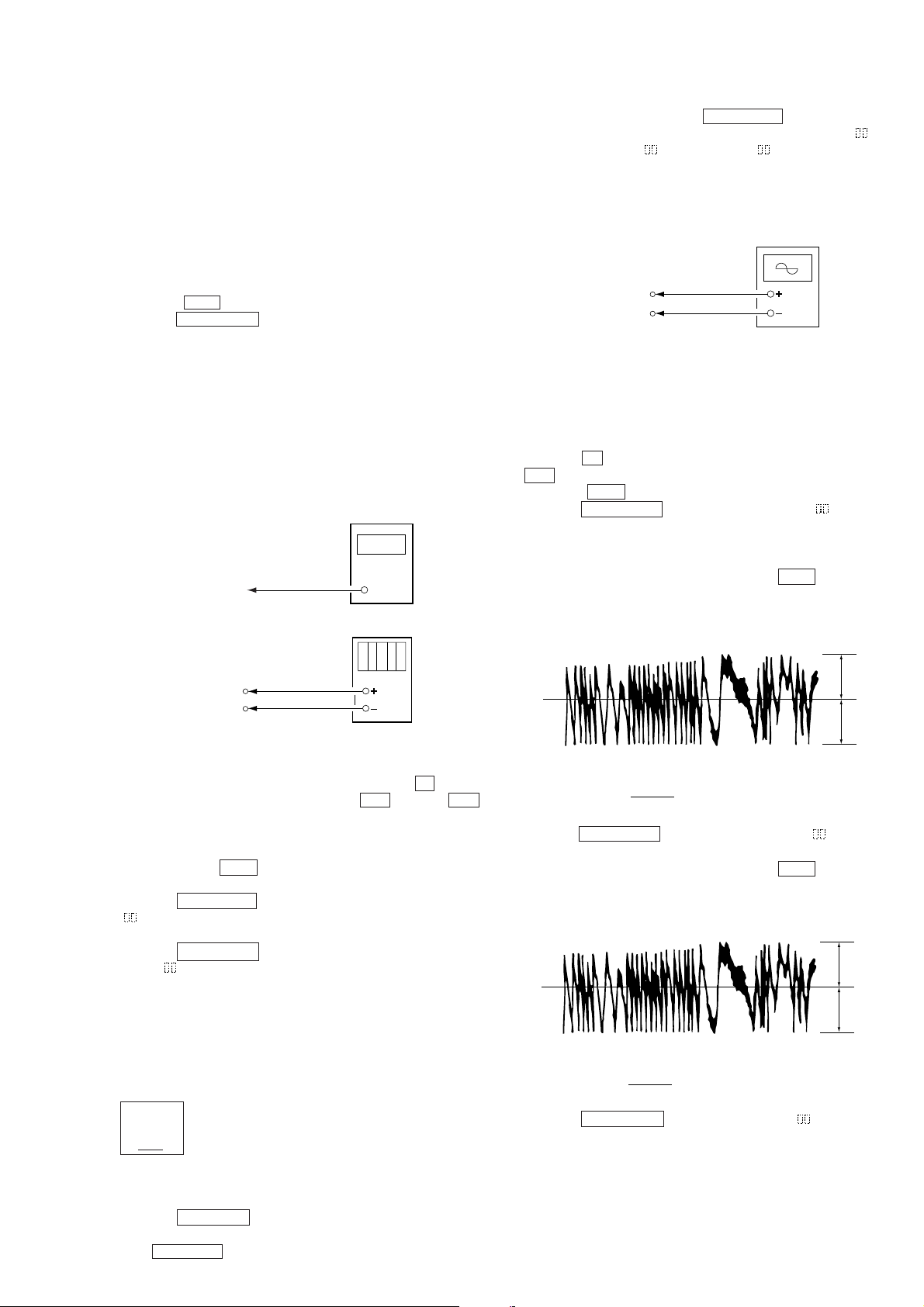

7-6. CHECKS PRIOR TO REPAIRS

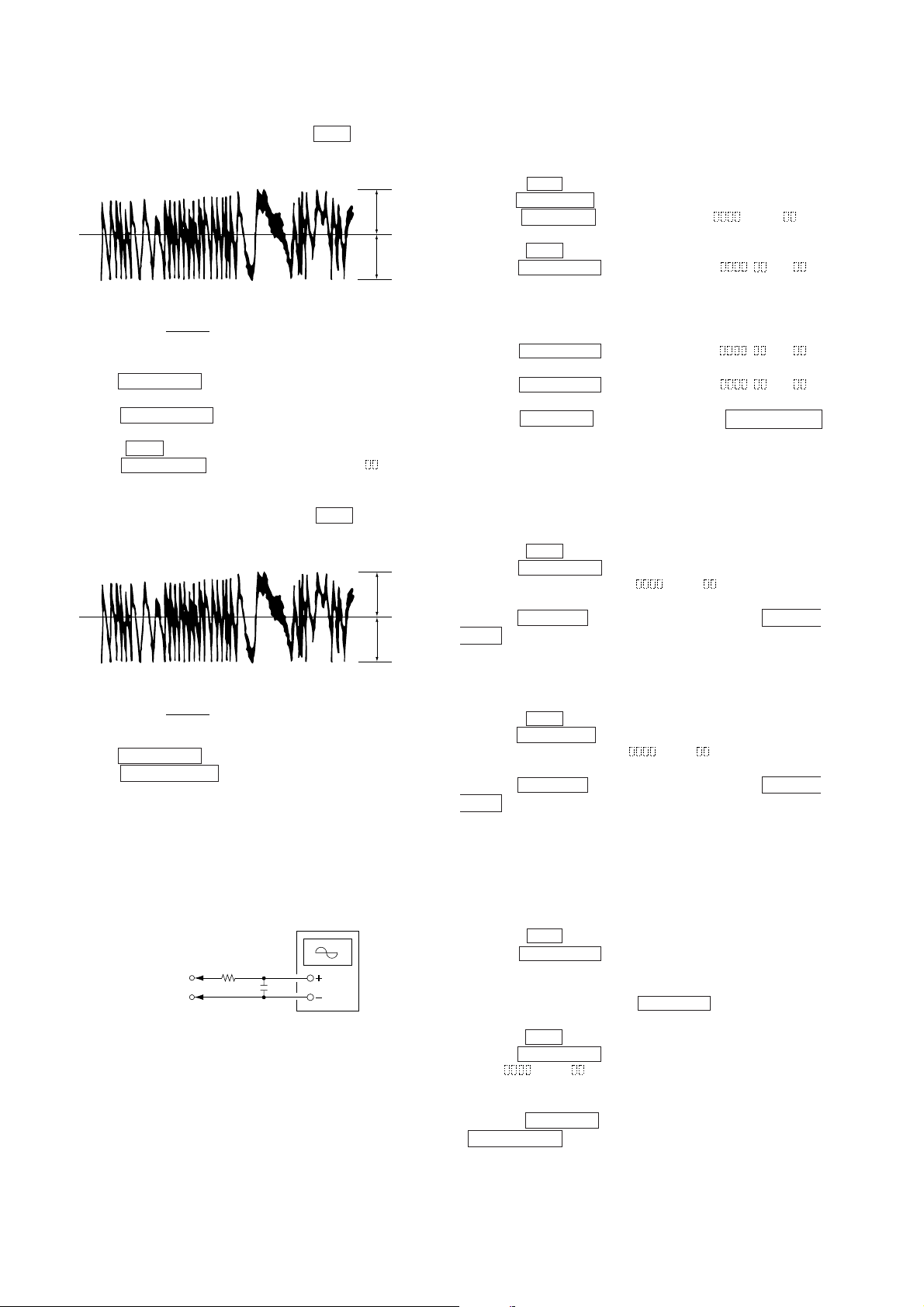

r

e

VC

A

B

Specified value : Below 10% offset value

Offset value (%) = X 100

I

A – B

I

2 (A + B)

VC

A

B

Specified value : Below 10% offset value

Offset value (%) = X 100

I

A – B

I

2 (A + B)

These checks a re pe rform ed before replacing parts according to

“approximate specifications” to determine the faulty locations. For

details, refer to “Checks Prior to Parts Replacement and

Adjustments” (See page 11).

7-6-1. Temperature Compensation Offset Check

When performing adjustments, set the internal temperature and room

temperature to 22 to 28°C.

Note 1: After step 4, each time the ENTER/YES button is pressed,

the display will be switched between “LD 0.7 mW $ ”,

“LD 6.2 mW $ ”, and “LD WP $ ”. Nothing needs to

be performed here.

7-6-3. T raverse Check

Connection :

Oscilloscope

Checking Procedure:

1. Rotate the AMS dial to display “TEMP CHECK”.

2. Press the ENTER/YES button.

3. “T=@@(##) OK” should be displayed. If “T=@@ (##) NG” is

displayed, it means that the results are bad.

(@@ indicates the current value set, and ## indicates the value

written in the non-volatile memory.)

7-6-2. Laser Power Check

Before checking, check the IOP value of the optical pick-up.

(Refer to 7-8. Recording and Displaying IOP Information.)

Connection :

Laser power

meter

Optical pick-up

objective lens

Digital volt mete

CN110 pin

CN110 pin

BD board

5

(I+3V)

4

(IOP)

BD board

CN110 pin

CN110 pin

3

1

(TE)

(VC)

V : 0.5 V/div

H : 10 ms/div

Input : DC mod

Checking Procedure:

1. Connect an oscilloscope to CN110 pin 3 (TE) and CN110 pin

1 (VC) of the BD board.

2. Load a disc (any available on the market). (Refer to Note 1.)

3. Press the p button and display the “MD”, and then press the

) button and move the optical pick-up outside the pit.

4. Rotate the AMS dial and display “EF MO CHECK”(C03).

5. Press the ENTER/YES button and display “EFB =

MO-R”.

(Laser power READ power/Focus servo ON/tracking servo OFF/

spindle (S) servo ON)

6. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not rotate the AMS dial.

(Read power traverse checking)

(Traverse Waveform)

Checking Procedure:

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, press the p button

and display the “MD”, and then press the 0 button or )

button to move the optical pick-up.)

Connect the digital volt meter to CN110 pin 5 (I+3V) and

CN110 pin 4 (IOP).

2. Then, rotate the AMS dial and display “LDPWR CHECK”

(C02).

3. Press the ENTER/YES button once and display “LD 0.9 mW $

”. Check that the reading of the laser power meter become

0.84 to 0.92 mW.

4. Press the ENTER/YES button once more and display “LD 7.0

mW $ ”. Check that the reading the laser power meter and

digital volt meter satisfy the specified value.

Specified Value :

Laser power meter reading : 7.0 ± 0.2 mW

Digital voltmeter reading : Optical pick-up displayed value ± 10%

(Optical pick-up label)

KMS

260A

27X40

B0825

N

Iop = 82.5 mA in this case

Iop (mA) = Digital voltmeter reading (mV)/1 (Ω)

5. Press the MENU/NO button and display “LDPWR CHECK”

and stop the laser emission.

(The MENU/NO button is effective at all times to stop the laser

emission.)

(For details of the method for checking

this value, refer to “7-8. Recording and

Displaying IOP Information”.)

7. Press the ENTER/YES button and display “EFB =

8. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not rotate the AMS dial.

(Write power traverse checking)

(Traverse Waveform)

9. Press the ENTER/YES button display “EFB =

Then, the optical pick-up moves to the pit area automatically

and servo is imposed.

– 29 –

MO-W”.

MO-P”.

Page 30

10.Observe the waveform of the oscilloscope, and check that the

e

specified value is satisfied. Do not rotate the AMS dial.

(Traverse Waveform)

A

VC

B

Specified value : Below 10% offset value

I

A – B

Offset value (%) = X 100

I

2 (A + B)

11. Press the ENTER/YES button display “EF MO CHECK”

The disc stops rotating automatically.

12. Press the §EJECT (MD) button and remove the disc.

13. Load the check disc (MD) TDYS-1.

14. Roteto the AMS dial and display “EF CD CHECK”.

15. Press the ENTER/YES button and display “EFB = CD”.

Servo is imposed automatically.

16. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not rotate the AMS dial.

(Traverse Waveform)

A

VC

B

7-6-4. Focus Bias Check

Change the focus bias and check the focus tolerance amount.

Checking Procedure :

1. Load a test disk (MDW-74/AU-1).

2. Rotate the AMS dial and display “CPLAY MODE”.

3. Press the ENTER/YES button twice and display “CPLAY MID”.

4. Press the MENU/NO button when “C1 = AD = ” is

displayed.

5. Rotate the AMS dial and display “FBIAS CHECK”.

6. Press the ENTER/YES button and display “ / c = ”.

The first four digits indicate the C1 error rate, the two digits

after “/” indicate ADER, and the 2 digits after “c =” indicate the

focus bias value.

Check that the C1 error is below 220 and ADER is below 2.

7. Press the ENTER/YES button and display “ / b = ”.

Check that the C1 error is below 220 and ADER is below 2.

8. Press the ENTER/YES button and display “ / a = ”.

Check that the C1 error is below 220 and ADER is below 2.

9. Press the MENU/NO button, next press the §EJECT (MD)

button, and remove the test disc.

7-6-5. C PLAY Checking

MO Error Rate Check

Checking Procedure :

1. Load a test disk (MDW-74/AU-1).

2. Rotate the AMS dial and display “CPLAY MODE”.

3. Press the ENTER/YES button and display “CPLAY MID”.

4. The display changes to “C1 =

AD = ”.

5. If the C1 error rate is below 80, check that ADER is below 2.

6. Press the MENU/NO button, stop playback, press the §EJECT

(MD) button, and test disc.

Specified value : Below 10% offset value

I

A – B

Offset value (%) = X 100

I

2 (A + B)

17. Press the ENTER/YES button and display “EF CD CHECK”.

18. Press the §EJECT (MD) button and remove the check disc

(MD) TDYS-1.

Note 1 : MO reading data will be erased during if a recorded disc is

used in this adjustment.

Note 2 : If the traverse waveform is not clear, connect the oscillo-

scope as shown in the following figure so that it can be

seen more clearly.

Oscilloscop

330 k

CN110 pin

CN110 pin

BD board

3

(TE)

1

(VC)

Ω

10pF

CD Error Rate Check

Checking Procedure :

1. Load a check disc (MD) TDYS-1.

2. Rotate the AMS dial and display “CPLAY MODE”.

3. Press the ENTER/YES button twice and display “CPLAY MID”.

4. The display changes to “C = AD = ”.

5. Check that the C1 error rate is below 50.

6. Press the MENU/NO button, stop playback, press the §EJECT

(MD) button, and the test disc.

7-6-6. Self-Recording/playback Check

Prepare a continuous recording disc using the unit to be repaired

and check the error rate.

Checking Procedure :

1. Insert a recordable disc (blank disc) into the unit.

2. Rotate the AMS dial to display “CREC MODE”.

3. Press the ENTER/YES button to display the “CREC MID”.

4. When recording starts, “REC” is displayed, this becomes “CREC

(@@@@)" (@@@@) is the address), and recording starts.

5. About 1 minute later, press the MENU/NO button to stop continuous recording.

6. Rotate the AMS dial to display “C PLAY MODE”.

7. Press the ENTER/YES button to display “C PLAY MID”.

8. “C1 = AD = ” will be displayed.

9. Check that the C1 error becomes below 80 and the AD error

below 2.

10. Press the MENU/NO button to stop playback, and press the

§EJECT (MD) button and remove the disc.

– 30 –

Page 31

7-7. INITIAL SETTING OF ADJUSTMENT VALUE

r

Note:

Mode which sets the adjustment results recorded in the non-volatile

memory to the initial setting value. However the results of the

temperature compensation offset adjustment will not change to the

initial setting value.

If i nitial set ting is perfor med, perfor m all adjust ments again

excluding the temperature compensation offset adjustment.

For details of the initial setting, refer to “7-4. Precautions on Adjustments” and execute the initial setting before the adjustment as

required.

Setting Procedure :

1. Rotate the AMS dial to display “ADJ CLEAR”.

2. Press the ENTER/YES button. “Complete!” will be displayed

momentarily and initial setting will be executed, after which

“ADJ CLEAR” will be displayed.

7-8. RECORDING AND DISPLAYING THE IOP

INFORMATION

The IOP data can be recorded in the non-volatile memory . The IOP

value on the label of the optical pickup and the IOP value after the

adjustment will be recorded. Recording these data eliminates the

need to read the label on the optical pick-up.

7-9. TEMPERA TURE COMPENSATION OFFSET

ADJUTMENT

Save the temperature data at that time in the non-volatile memory

as 25 ˚C reference data.

Note :

1. Usually, do not perform this adjustment.

2. Perform this adjustment in an ambient temperature of 22 ˚C to

28 ˚C. Perform it immediately after the power is turned on when

the internal temperature of the unit is the same as the ambient

temperature of 22 ˚C to 28 ˚C.

3. When D101 has been replaced, perform this adjustment after

the temperature of this part has become the ambient temperature.

Adjusting Procedure :

1. Rotate the AMS dial and display “TEMP ADJUST”.

2. Press the ENTER/YES button and select the “TEMP ADJUST”

mode.

3. “TEMP = OK” and the current temperature data will be displayed.

4. To save the data, press the ENTER/YES button.

When not saving the data, press the MENU/NO button.

5. When the ENTER/YES button is pressed, “TEMP = SAVE”

will be displayed and turned back to “TEMP ADJUST” display

then. When the MENU/NO button is pressed, “TEMP ADJUST” will be displayed immediatelly.

Recording Procedure :

1. With the power ON, press the CD-MD SYNC button while

pressing the p and ENTER/YES buttons together.

2. Rotate the AMS dial to display “Service”, and press the ENTER/YES button.

3. Rotate the AMS dial to display “Iop.Write”, and press the

ENTER/YES button.

4. The display becomes Ref=@@@.@ (@ is an arbitrary number)

and the numbers which can be changed will blink.

5. Input the IOP value written on the optical pick-up.

To select the number : Rotate the AMS dial.

T o select the digit : Press the MD MALKMAN SYNC button.

6. When the ENTER/YES button is pressed, the display becomes

“Measu=@@@.@” (@ is an arbitrary number).

7. As the adjustment results are recorded for the 6 value. Leave it

as it is and press the ENTER/YES button.

8. “Complete!” will be dis played momentarily. The value will be

recorded in the non-volatile memory and the display will become

“Iop Write”.

Display Procedure :

1. Rotate the AMS dial to display “Iop.Read”.

2. “@@.@/##.#” is displayed and the recorded contents are

displayed.

@@.@ indicates the Iop value labeled on the pick-up.

##.# indicates the Iop value after adjustment

3. To end, press the MD MALKMAN SYNC button or MENU/

NO button to display “Iop Read”.

Specified Value :

The “TEMP = ” should be within “E0 - EF”, “F0 - FF”, “00 0F”, “10 - 1F” and “20 - 2F”.

7-10. LASER POWER ADJUSTMENT

Check the IOP value of the optical pick-up before adjustments.

(Refer to 7-8. Recording and Displaying IOP Information.)

Connection :

Optical pick-up

objective lens

CN110 pin

CN110 pin

BD board

5

(I+3V)

4

(IOP)

Adjusting Procedure :

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, press the p button

and display the “MD”, and then press the 0 button or )

button to move the optical pick-up.)

Connect the digital volt meter to CN110 pin 5 (I+3V) and

CN110 pin 4 (IOP).

2. Rotate the AMS dial and display “LDPWR ADJUST”.

(Laser power : For adjustment)

3. Press the ENTER/YES button once and display “LD 0.9 mW $

”.

4. Rotate the AMS dial so that the reading of the laser power

meter becomes 0.85 to 0.91 mW. Press the ENTER/YES button after setting the range knob of the laser power meter, and

save the adjustment results. (“LD SA VE $ ” will be displayed

for a moment.)

5. Then “LD 7.0 mW $ ” will be displayed.

Laser power

meter

Digital volt mete

– 31 –

Page 32

6. Rotate the AMS dial so that the reading of the laser power

e

meter becomes 6.9 to 7.1 mW, press the ENTER/YES button

and save it.

Note : Do not perform the emission with 7.0 mW more than 15

seconds continuously.

7. Then, rotate the AMS dial and display “LDPWR CHECK”.

8. Press the ENTER/YES button once and display “LD 0.9 mW $

”. Check that the reading of the laser power meter become

0.85 to 0.91 mW.

9. Press the ENTER/YES button once more and display “LD 7.0

mW $ ”. Check that the reading the laser power meter and

digital volt meter satisfy the specified value.

Note down the digital voltmeter reading value.

Specified Value :

Laser power meter reading : 7.0 ± 0.1 mW

Digital voltmeter reading : Optical pick-up displayed value ± 10%

(Optical pick-up label)

KMS

260A

27X40

B0825

N

Iop = 82.5 mA in this case

Iop (mA) = Digital voltmeter reading (mV)/1 (Ω)

(For details of the method for checking

this value, refer to “7-8. Recording and

Displaying IOP Information”.)

10. Press the MENU/NO button and display “LDPWR CHECK”

and stop the laser emission.

(The MENU/NO button is effective at all times to stop the

laser emission.)

11. Rotate the AMS knob to display “Iop.Write”.

12. Press the ENTER/YES button. When the display becomes

Ref=@@@.@ (@ is an arbitrary number), press the ENTER/

YES button to display “Measu=@@@.@” (@ is an arbitrary

number).

13. The numbers which can be changed will blink. Input the Iop

value noted down at step 9.

To select the number : Rotate the AMS dial.

To select the digit : Press the AMS dial.

14. When the ENTER/YES button is pressed, “Complete!” will

be displayed momentarily. The value will be recorded in the

non-volatile memory and the display will become “Iop Write”.

Note 1: After step 4, each time the ENTER/YES button is pressed,

the display will be switched between “LD 0.7 mW $ ”,

“LD 6.2 mW $ ”, and “LD WP $ ”. Nothing needs to

be performed here.

7-11. TRA VERSE ADJUSTMENT

Connection :

BD board

CN110 pin

CN110 pin

3

1

(TE)

(VC)

Adjusting Procedure :

1. Connect an oscilloscope to CN110 pin 3 (TE) and CN110 pin

1 (VC) of the BD board.

2. Load a disc (any available on the market). (Refer to Note 1.)

3. Press the p button and display the “MD”, and then press the

p button and display the “MD”, and then press the ) button

and move the optical pick-up outside the pit.

4. Rotate the AMS dial and display “EF MO ADJUS” (C11).

5. Press the ENTER/YES button and display “EFB =

(Laser power READ power/Focus servo ON/tracking servo OFF/

spindle (S) servo ON)

6. Rotate the AMS dial so that the waveform of the oscilloscope

becomes the specified value.

(When the AMS dial is rotated, the of “EFB= ” changes

and the waveform changes.) In this adjustment, waveform varies at intervals of approx. 2%. Adjust the waveform so that the

specified value is satisfied as much as possible.

(Read power traverse adjustment)

(Traverse Waveform)

VC

Specification A = B

7. Press the ENTER/YES button and save the result of adjustment

to the non-volatile memory (“EFB = SA VE” will be displayed

for a moment. Then “EFB = MO-W” will be displayed).

8. Rotate the AMS dial so that the waveform of the oscilloscope

becomes the specified value.

(When the AMS dial is rotated, the of “EFB- ” changes

and the waveform changes.) In this adjustment, waveform varies at intervals of approx. 2%. Adjust the waveform so that the

specified value is satisfied as much as possible.

(Write power traverse adjustment)

Oscilloscope

V : 0.5 V/div

H : 10 ms/div

Input : DC mod

MO-R”.

A

B

(Traverse W aveform)

A

VC

B

Specification A = B

9. Press the ENTER/YES button, and save the adjustment results

in the non-volatile memory. (“EFB =

SA VE” will be displayed

for a moment.)

10. “EFB = MO-P”. will be displayed.

The optical pick-up moves to the pit area automatically and

servo is imposed.

– 32 –

Page 33

11. Rotate the AMS dial until the waveform of the oscilloscope

e

moves closer to the specified value.

In this adjustment, waveform varies at intervals of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

(Traverse Waveform)

A

VC

B

Specification A = B

12. Press the ENTER/YES button, and save the adjustment results

in the non-volatile memory. (“EFB =

SAVE” will be displayed for a moment.)

Next “EF MO ADJUST” is displayed. The disc stops rotating

automatically.

13. Press the §EJECT (MD) button and remove the disc.

14. Load the check disc (MD) TDYS-1.

15. Roteto AMS dial and display “EF CD ADJUST”.

16. Press the ENTER/YES button and display “EFB = CD”.

Servo is imposed automatically.

17. Rotate the AMS dial so that the waveform of the oscilloscope

moves closer to the specified value.

In this adjustment, waveform varies at intervals of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

(Traverse Waveform)

7-12. FOCUS BIAS ADJUSTMENT

Adjusting Procedure :

1. Load a test disk (MDW-74/AU-1).

2. Rotate the AMS dial and display “CPLAY MODE”.

3. Press the ENTERYES button and display “CPLAY MID”.

4. Press the MENU/NO button when “C1 = AD = ” is

displayed.

5. Rotate the AMS dial and display “FBIAS ADJUS”.

6. Press the ENTER/YES button and display “ / a = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [a =] indicate the

focus bias value.

7. Rotate the AMS dial in the clockwise direction and find the

focus bias value at which the C1 error rate becomes about 200

(Refer to Note 2).

8. Press the ENTER/YES button and display “ / b = ”.

9. Rotate the AMS dial in the counterclockwise direction and find

the focus bias value at which the C1 error rate becomes about

200.

10. Press the ENTER/YES button and display “ / c = ”.

11. Check that the C1 error rate is below 50 and ADER is 00. Then

press the ENTER/YES button.

12. If the “( )” in “ - - ( )” is above 20, press the EN-

TER/YES button.

If below 20, press the MENU/NO button and repeat the adjustment from step 2.

13. Press the §EJECT (MD) button to remove the test disc.

Note 1 : The relation between the C1 error and focus bias is as

shown in the following figure. Find points a and b in the

following figure using the above adjustment. The focal

point position C is automatically calculated from points a

and b.

Note 2 : As the C1 error rate changes, perform the adjustment us-

ing the average vale.

A

VC

B

Specification A = B

18. Press the ENTER/YES button, display “EFB =

SAVE” for

a moment and save the adjustment results in the non-volatile

memory.

Next “EF CD ADJUST” will be displayed.

19. Press the §EJECT (MD) button and remove the check disc

(MD) TDYS-1.

Note 1 : MO reading data will be erased during if a recorded disc is

used in this adjustment.

Note 2 : If the traverse waveform is not clear, connect the oscillo-

scope as shown in the following figure so that it can be

seen more clearly.

Oscilloscop

330 k

CN110 pin

CN110 pin

BD board

3