Sony HCD-MD555 Service manual

HCD-MD555

SERVICE MANUAL

Ver 1.1 2001. 08

• This set is the Amplifier, CD pla yer ,

MD Deck and Tuner section in

DHC-MD555.

Manufactured under license from Dolby Laboratories

Licensing Corporation.

“DOLBY” the double-D symbol a “AC-3” and “PRO

LOGIC” are trademarks of Dolby Laboratories

Licensing Corporation.

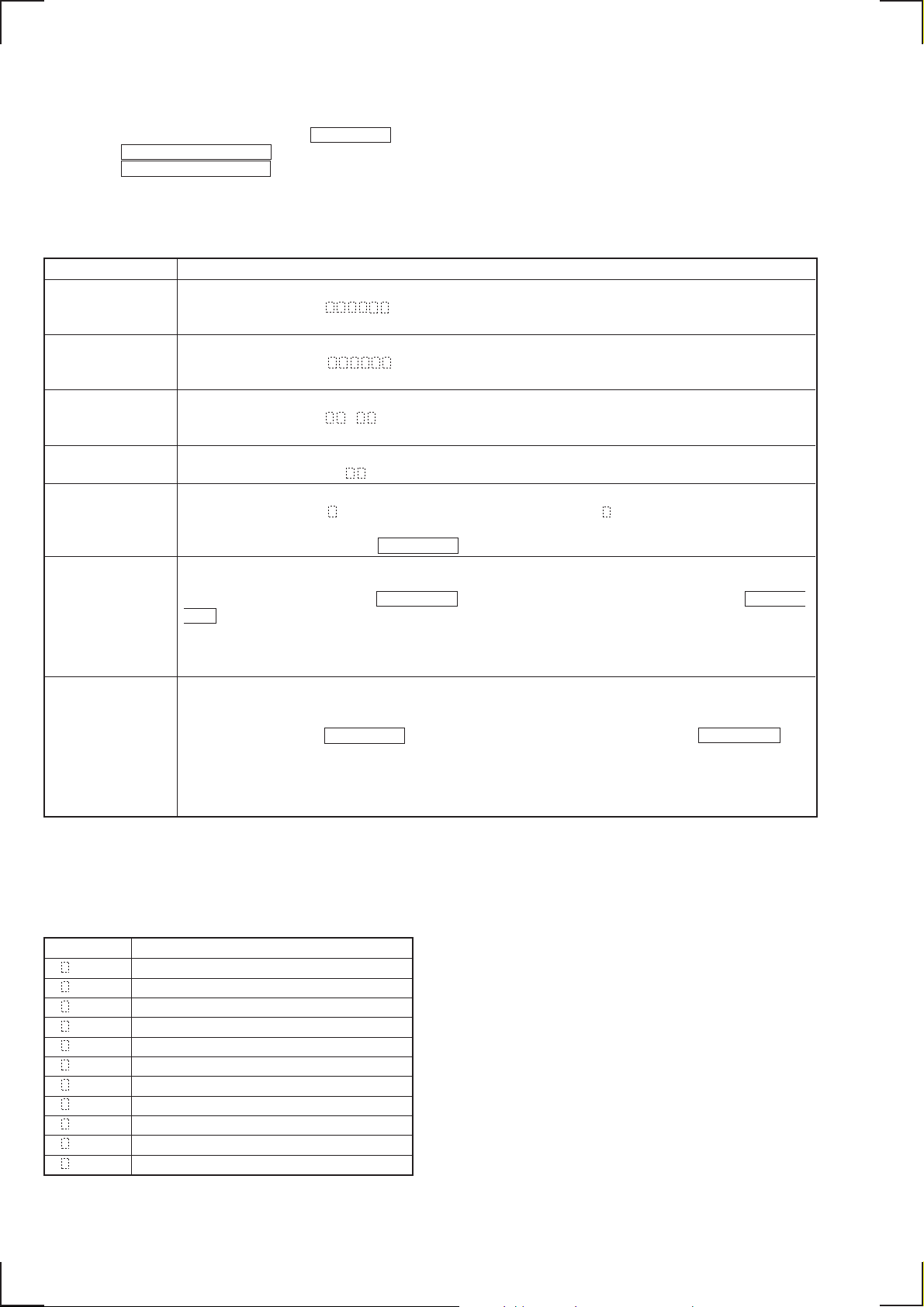

CD Section CD Mechanism Type CDM53-K1BD33

MD Section

US Model

AEP Model

UK Model

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

Optical Pick-up Type

Model Name Using Similar Mechanism NEW

MD Mechanism Type MDM-C1E

Base Unit Type MBU-C1E

Optical Pick-up Type KSM-260A/J1N

KSM-213BFN/C2NP

SPECIFICATIONS

MINI Hi-Fi COMPONENT SYSTEM

— Continued on next page —

9-922-976-12

2001H1600-1

© 2001.8

Sony Corporation

Home Audio Company

Shinagawa Tec Service Manual Production Group

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering

— 2 —

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

CAUTION

Use of controls or adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

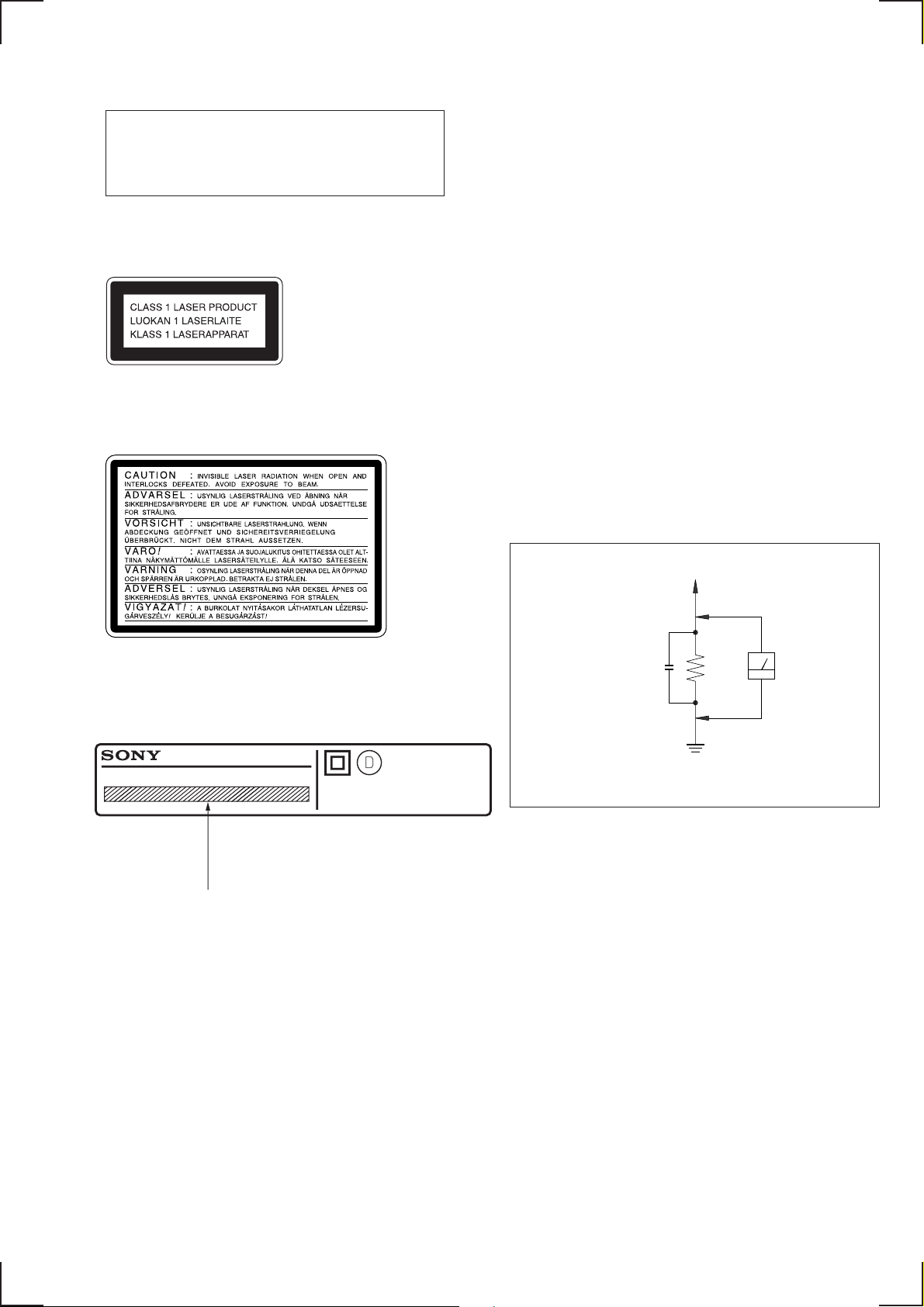

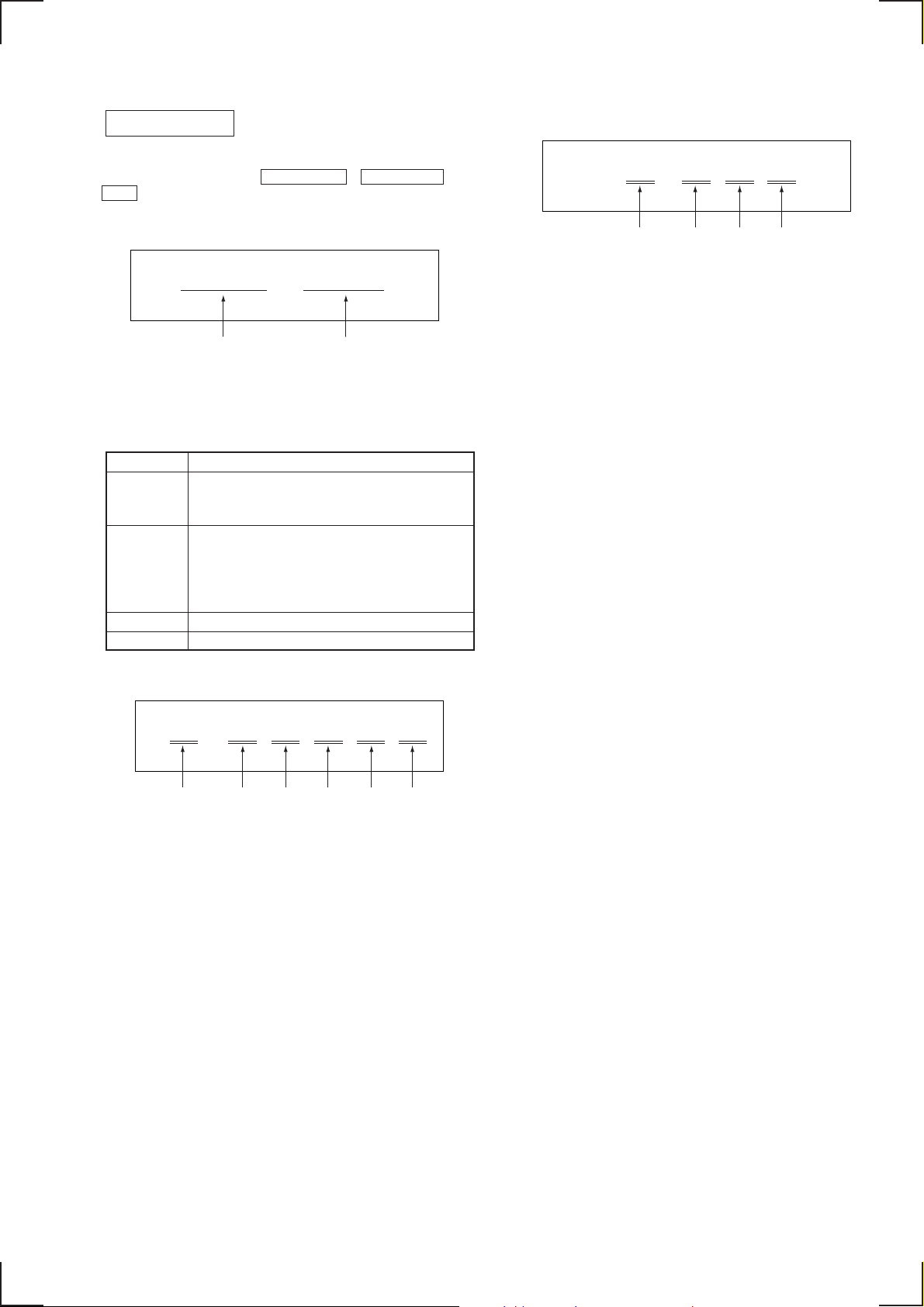

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C voltmeter . The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a

passive V OM that is suitable. Nearly all battery operated digital

multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

AC

0.15µF

1.5k

Ω

voltmeter

(0.75V)

MODEL IDENTIFICATION

– BACK PANEL –

MODEL NO.

COMPACT DISC DECK RECEIVER

AC: 230V ~ 50/60Hz 90W: AEP, UK model

AC: 110 – 120/220 – 240V ~ 50/60Hz 90W

: Singapore, Malaysia, Hong Kong, Tourist model

AC: 120V 60Hz 90W: US model

HCD-MD555

SERIAL

MADE IN

NO.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage .

JAPAN

— 3 —

TABLE OF CONTENTS

1. SELF-DIAGNOSIS FUNCTION·································· 5

2. SERVICE NOTE·······························································8

3. GENERAL ········································································ 12

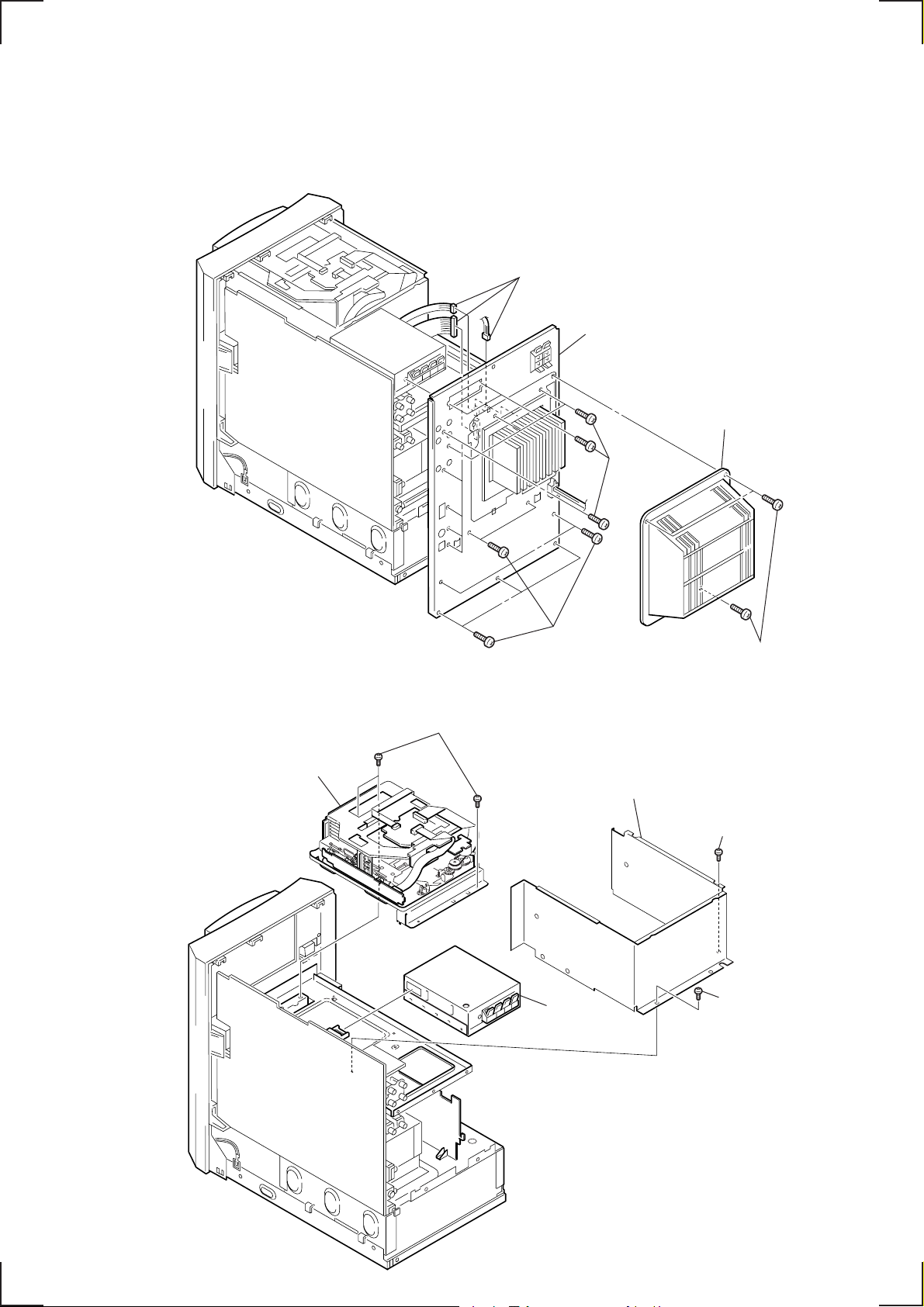

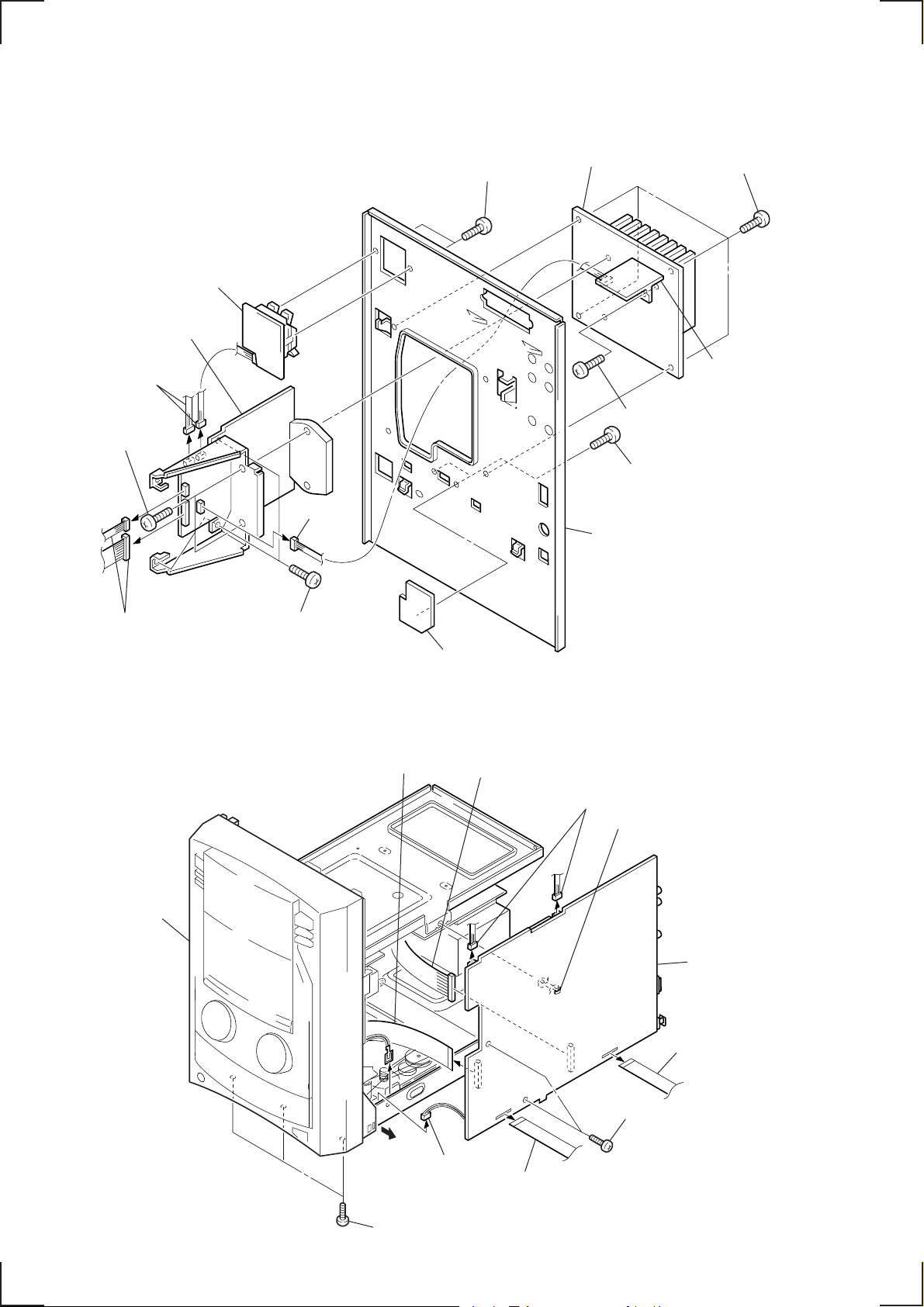

4. DISASSEMBLY

4-1. Back Panel········································································ 25

4-2. Mechanism (MDM-C1E) ················································· 25

4-3. SP Board, Amp Board, Reg Board ··································· 26

4-4. Front Panel ······································································· 26

4-5. Power Key Board, LED Board, Panel Board ··················· 27

4-6. Power Transformer (T960), Trans-A/B/C/D Board ········· 27

4-7. CD Mechanism (CDM53-K1BD33) ································ 28

4-8. Escutcheon, Chassis (Top) ··············································· 29

4-9. Chassis (Elevator) New····················································30

4-10. Motor (Head) Assy (M905), Head Relay Board ·············· 30

4-11. MD Base Unit (MBU-C1E) ············································· 31

4-12. BD Board·········································································· 31

4-13. Over Light Head (HR901)················································ 32

4-14. MD Optical Pick-up Block (KMS-260A/J1N)················· 32

4-15. CD Optical Pick-up Block (KSS-213BA/F-NP) ·············· 33

4-16. Fitting Base (Guide/Magnet) Assy··································· 33

4-17. Tray (Sub)········································································· 34

4-18. Chassis (Mold B), Stocker, Slider (Selection)·················· 34

4-19. How to Assembly The Gears ············································ 35

4-20. How to Attach The Slider (Selection) ······························ 35

4-21. How to Attach The Stocker ·············································· 36

4-22. How to Attach The Chassis (Mold B) ······························ 36

7. DIAGRAMS

7-1. Block Diagrams································································ 53

• MD Section···································································· 53

• CD Section····································································· 55

• Audio Section ································································57

• Power Section ································································ 59

7-2. Circuit Boards Location ··················································· 61

7-3. Schematic Diagram — CD Section —····························· 63

7-4. Printed Wiring Board — CD Section — ·························· 65

7-5. Schematic Diagram —Motor Section — ························· 67

7-6. Printed Wiring Board — Motor Section —······················ 69

7-7. Printed Wiring Board — MD Section — ·························71

7-8. Schematic Diagram — MD Section (1/2) — ··················· 73

7-9. Schematic Diagram — MD Section (2/2) — ··················· 75

7-10. Schematic Diagram — Rds Section — ···························· 77

7-11. Printed Wiring Board — Rds Section — ·························78

7-12. Schematic Diagram — Relay Section — ························· 79

7-13. Printed Wiring Board — Relay Section — ······················ 81

7-14. Printed Wiring Board — Main Section — ······················· 83

7-15. Schematic Diagram — Main Section (1/3) — ················· 85

7-16. Schematic Diagram — Main Section (2/3) — ················· 87

7-17. Schematic Diagram — Main Section (3/3) — ················· 89

7-18. Schematic Diagram — Amp Section —··························· 91

7-19. Printed Wiring Board — Amp Section —························ 93

7-20. Schematic Diagram — Panel Section — ························· 95

7-21. Printed Wiring Board — Panel Section···························· 97

7-22. Schematic Diagram — Power Section — ························ 99

7-23. Printed Wiring Board — Power Section — ···················101

7-24. IC Block Diagrams ························································· 105

7-25. IC Pin Function Description···········································111

5. TEST MODE ···································································· 37

6. ELECTRICAL ADJUSTMENT ··································43

8. EXPLODED VIEWS

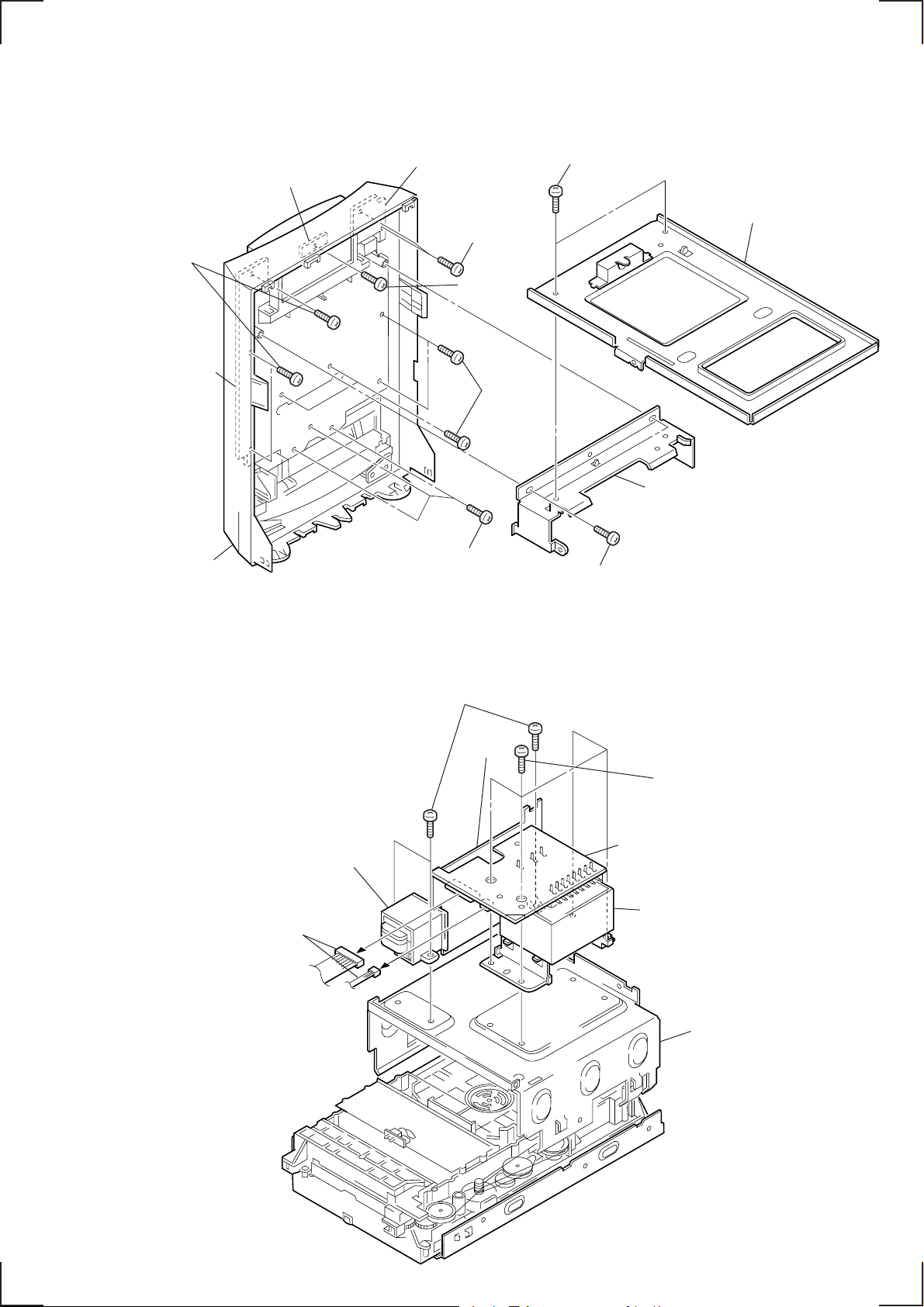

8-1. Main Block·····································································123

8-2. Back Panel Block ··························································· 124

8-3. MD Mechanism Deck-1 (MDM-C1E) ···························125

8-4. MD Mechanism Deck-2 (MDM-C1E) ···························126

8-5. MD Base Unit (MBU-C1E) ···········································127

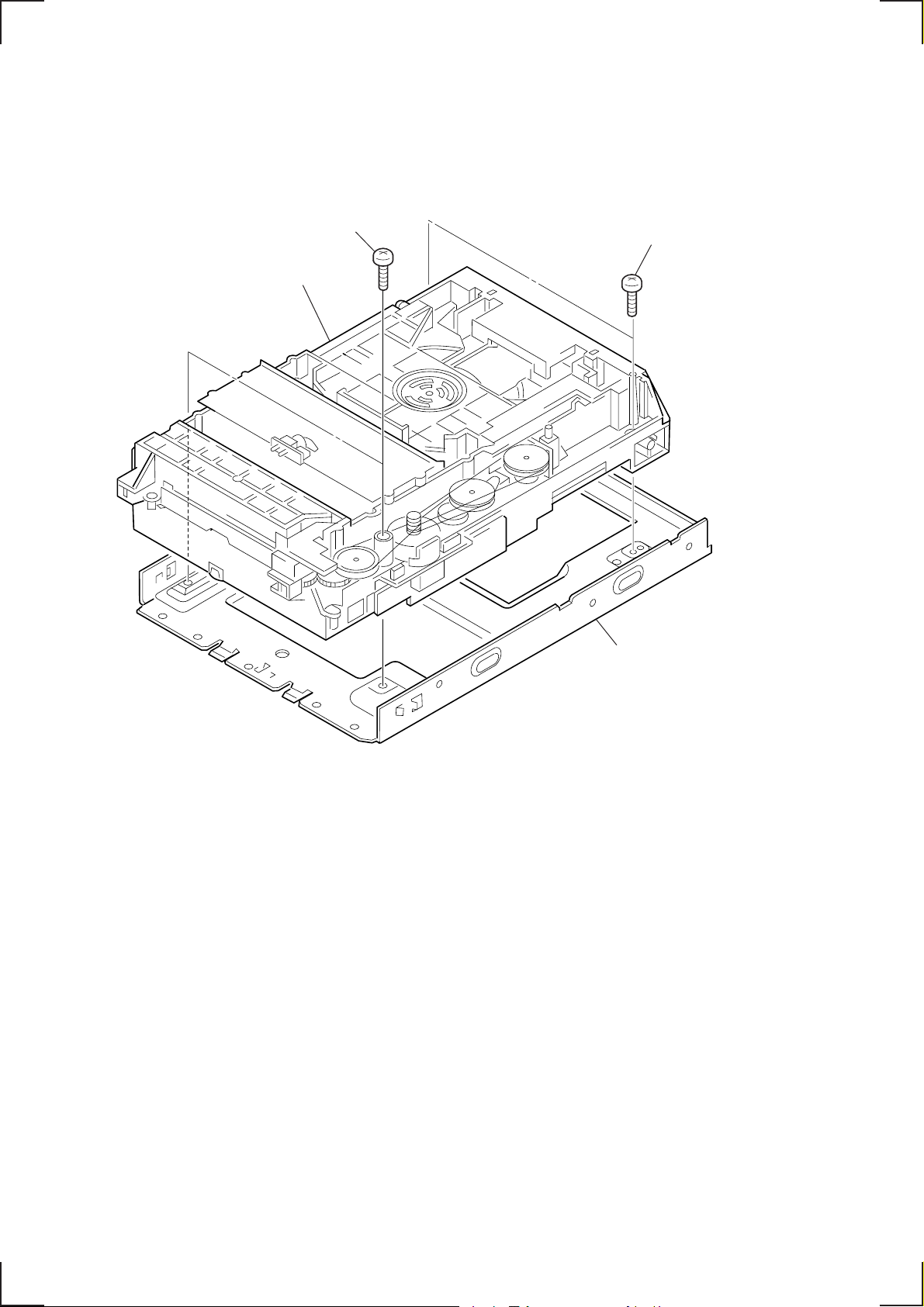

8-6. CD Mechanism Deck-1 (CDM53-K1BD33) ················· 128

8-7. CD Mechanism Deck-2 (CDM53-K1BD33) ················· 129

8-8. Optical Block (BU-K1BD33)········································· 130

9. ELECTRICAL P ARTS LIST ····································· 131

— 4 —

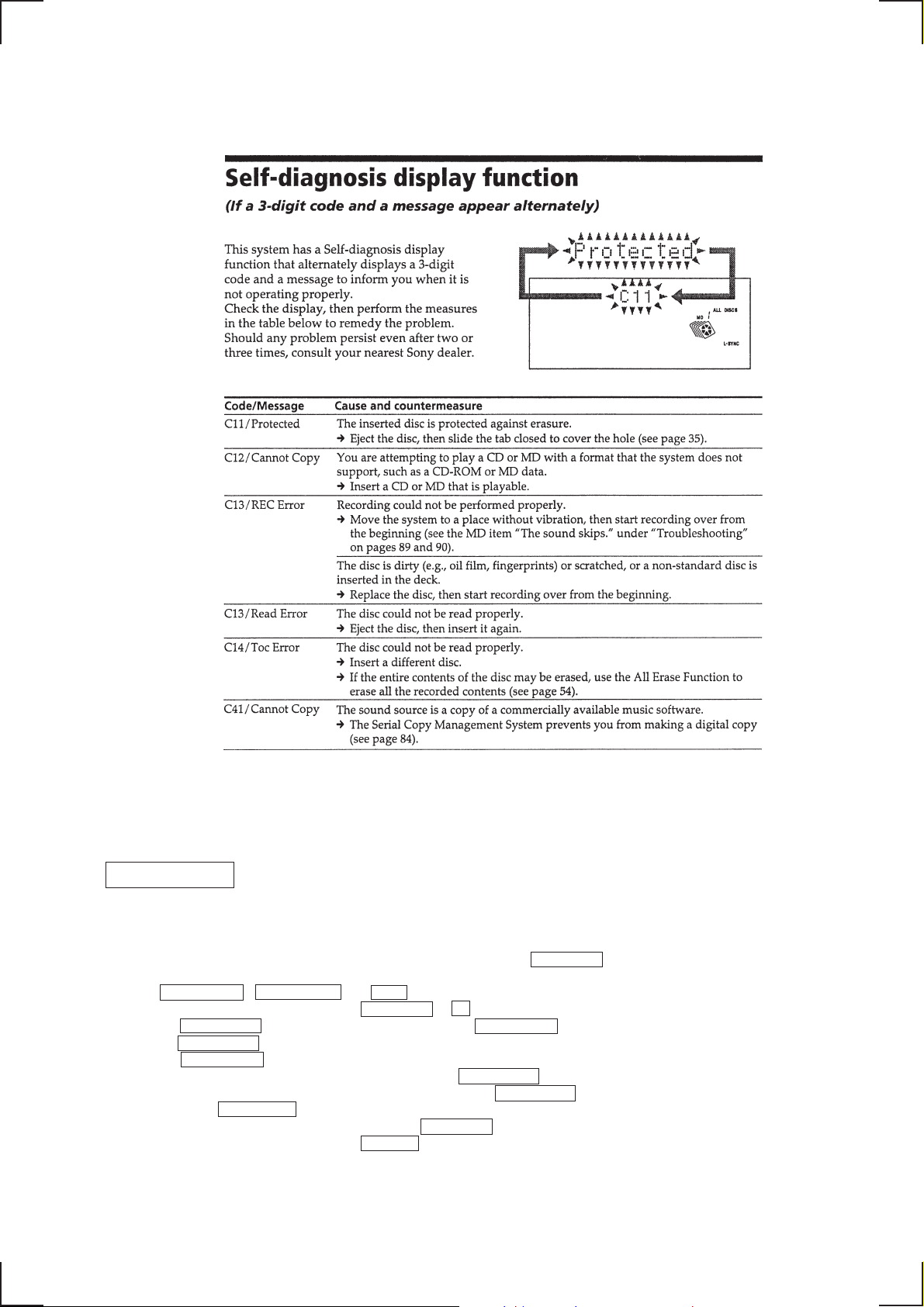

SECTION 1

SELF-DIAGNOSIS FUNCTION

MD SECTION

OPERATING THE ERROR HISTORY MODE

Note: The self-diagnosis function is performed using the “error history display mode” in the test mode. The follo wing procedure describes

only the minimum required operating procedure to enter the error history mode. Therefore be careful not to enter any other modes by

mistake. If you have entered any other modes by mistake, press the MENU/NO button and exit the mode.

1. Press ENTER/YES , NAME EDIT and MD3 .

(If the [Check] is not displayed, press the MENU/NO or p to let [Check] appear.)

2. Turn the MULTI JOG to display “[Service]”, and press the ENTER/YES button.

3. Turn the MULTI JOG to display “ERR DP MODE” .

4. Press the ENTER/YES button to enter the error history mode and the message “total rec” appears.

5. Select the item to be displayed or to be executed using the MULTI JOG .

6. When you want to display or execute the selected item, press the MULTI JOG .

7. If you press the MULTI JOG again, the display returns to step 4.

8. You can exit the error history mode by pressing the MENU/NO button. The message “ERR DP MODE” is displayed.

9. Y ou can exit the test mode by pressing the REPEAT . Then the HCD-MD555 enters the standby state, the disc is ejected, and the display

exits the test mode.

— 5 —

DISPLAYING CONTENTS OF THE ERROR HISTORY

1. Select the desired item of history using the MULTI JOG dial.

2. Press the MD WALKMAN SYNC button to display the desired content of the selected error item.

3. Press the MD WALKMAN SYNC button again to return to the history item display screen.

Table 1 shows error history items and the contents.

Table 1

Display on screen Contents of error history

total rec Displays the recording time.

The display appears in “r

1/4 of the actual recording time. The time is shown in the range of 0h to 65535h in decimal number.

total play Displays the playback time.

The display appears in “p

time is not counted. The time is shown in the range of 0h to 65535h in decimal number.

retry err Displays the accumulated count of record retry error and playback retry error.

The display appears in “r

retry error count. The count is shown in the range of 00 to FF in hexadecimal number.

total err Displays the total count of error.

The display appears in “total

err history Displays the error contents from the latest error to the last ten errors.

The display appears in “0

newer history. (00 is the newest error.). The error code is indicated in @@. Refer to the following table for

contents the error codes. Turn the MULTI JOG dial and you can change the error No.

er refresh (*3) This is the mode with which you can clear the histories of “retry err”, “total err”, and “err history”.

Perform this operation to clear the past error history before returning the repaired product to the customer. To

clear the error histories, press the MULTI JOG button. After “er refresh?” is displayed, press the ENTER/

YES button. The error histories are cleared and the message “Complete!” appears for a moment.

When this mode is executed, be sure to check the following.

• Data must have been cleared.

• Perform recording and playback, and check that the mechanism operates correctly.

tm refresh (*3) This the mode with which you can clear the histories of “total rec” and “total play”. These histories are used as

the reference when replacing the optical pickup.

Perform this operation to clear the histories when the optical pickup is replaced with the new one. To clear the

error histories, press the MULTI JOG button. After “tm refresh?” is displayed, press the ENTER/YES

button. The error histories are cleared and the message “Complete!” appears for a moment.

When this mode is executed, be sure to check the following.

• Data must have been cleared.

• Perform recording and playback, and check that the mechanism operates correctly.

E@@” (*2). The history number is shown in . The smaller number means the

h”. This is the accumulated time laser in the power high operation.About

h”. This is the accumulated time of actual playback in which pause

p ”. “r” indicates the record retry error count, and “p” indicates the playback

”. The count is shown in the range of 00 to FF in hexadecimal number.

(*2) Contents of each error display are shown in Table 2.

(*3) All of error contents are cleared by performing “er refresh” and “tm refresh”.

Perform this operation and clear the error history only when optical block is replaced for maint enance work. Never perform this

operation in other cases.

Table 2

Display Error contents

0 E00 No errors

0 E01 Disc error Cannot read PTOC

0 E02 Disc error UTOC error

0 E03 Loading error

0 E04 Cannot read the address

0 E05 Out of FOK

0 E06 Focus does not lock

0 E07 Retry of recording

0 E08 Record retry error

0 E09 Retry of playback

0 E0A Playback retry error

— 6 —

CD SECTION

(Note 2) NO DISC code in the order of occurrence

OPERATING THE DISPLAYED HISTORIES

When the three buttons of ENTER/YES , PRESET EQ , and

CD3 are pressed simultaneously, and the mechanical error count

and the count of “NO DISC” that optical system has judged, are

displayed.

Emc = Edc =

Mechanical error count

When the buttons that are shown in Table 2 are pressed in this state,

the following operations are executed as listed below.

Button Function

CD1 Mechanical error code from the latest error to

CD2 The reasons why “NO DISC” the optical

CD1 6 Resets the mechanical error count.

CD2 6 Resets the “NO DISC” count.

∗∗ ∗∗

No disc count

Table 2

the last ten errors are displayed each time this

button is pressed. (Note 1)

system has judged to be an error, are displayed

from the latest error to the last ten errors are

displayed each time this button is pressed.

(Note 2)

E D

∗∗ ∗∗ ∗∗ ∗∗

(a) (b) (c) (d)

(a) The number of NO DISC

The latest one “00” to the last ten “09”

(b) “01” : Focus error

“02” : GFS error

“03” : Setup error

(c) “00” : Judged as NO DISC without chucking retry

“02” : Judged as NO DISC after chucking retry is

performed

(d) The status, when NO DISC judgment is made

“1∗” : Stop

“2

∗” : Set up

“3

∗” : TOC read

“4

∗” : Access

“5

∗” : Play

“6

∗” : Pause

“7

∗” : Manual search (play)

“8

∗” : Manual search (pause)

(Note 1) Mechanical error code

E M

∗∗ ∗∗ ∗∗ ∗∗ ∗∗ ∗∗

(a) (b) (c) (d) (e) (f)

(a) Mechanical error count

The latest error “00” to the last ten error “09”

(b) “FF” : Mechanical error after mechanism is initialized.

(c) “1∗” : Mechanical error during loading the tray in between

(d) “Don’t care”

(e) “2

(f) “2

”2

∗” the stocker position and the deeper end.

∗” : Mechanism error while the stocker is moving up/down.

∗” : Mechanism error of the clumper and that during mode

switching

— 7 —

SECTION 2

SER VICE NOTE

CD-TEXT TEST DISC

This unit is able to display the test data (character information) written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:4-989-366-01) is used for checking the display.

To check, perform the following procedure.

Checking Method:

1. Turn ON the power, set the disc on a tray, and chuck the disc.

2. Press the · button and play back the disc.

3. The following will be displayed on the fluorescent indicator tube.

Display : 1kHz/0 dB/L&R

4. Rotate MULTI JOG dial or press = AMS + of a remote commander to switch the track. The text data of each track will be

displayed.

For details of the displayed contents for each track, refer to “T able 1, 2 : CD-TEXT TEST DISC Recorded Data Contents and Display”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly. These will be displayed as a space or a character resembling it.

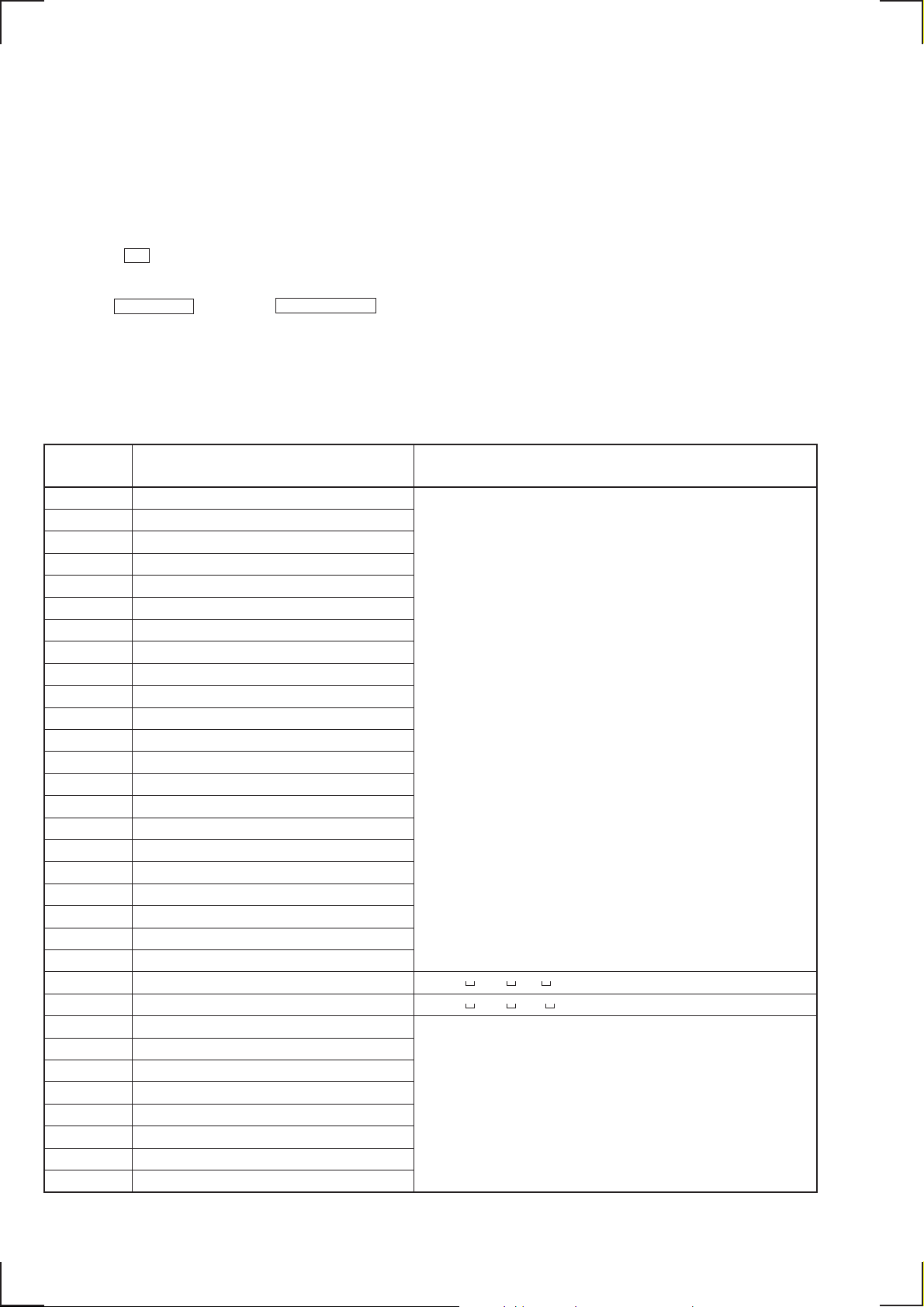

Table 1 : CD-TEXT TEST DISC Recorded Data Contents and Display (TRACKS No. 1 to 32:Normal Characters)

TRACK

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Recorded contents

1kHz/0dB/L&R

20Hz/0dB/L&R

40Hz/0dB/L&R

100Hz/0dB/L&R

200Hz/0dB/L&R

500Hz/0dB/L&R

1kHz/0dB/L&R

5kHz/0dB/L&R

7kHz/0dB/L&R

10kHz/0dB/L&R

16kHz/0dB/L&R

18kHz/0dB/L&R

20kHz/0dB/L&R

1kHz/0dB/L&R

1kHz/-1dB/L&R

1kHz/-3dB/L&R

1kHz/-6dB/L&R

1kHz/-10dB/L&R

1kHz/-20dB/L&R

1kHz/-60dB/L&R

1kHz/-80dB/L&R

1kHz/-90dB/L&R

No-signal emphasis: ON//L&R

No-signal emphasis: OFF//L&R

400Hz+7kHz(4:1)/0dB/L&R

400Hz+7kHz(4:1)/-10dB/L&R

19kHz+20kHz(1:1)/0dB/L&R

19kHz+20kHz(1:1)/-10dB/L&R

100Hz/0dB/L*

1kHz/0dB/L*

10kHz/0dB/L*

20kHz/0dB/L*

Display

Same as the values shown in the left column.

Infinity Zero w/o emphasis // L&R

Infinity Zero with emphasis // L&R

Same as the values shown in the left column.

* Other channel is infinity zero.

— 8 —

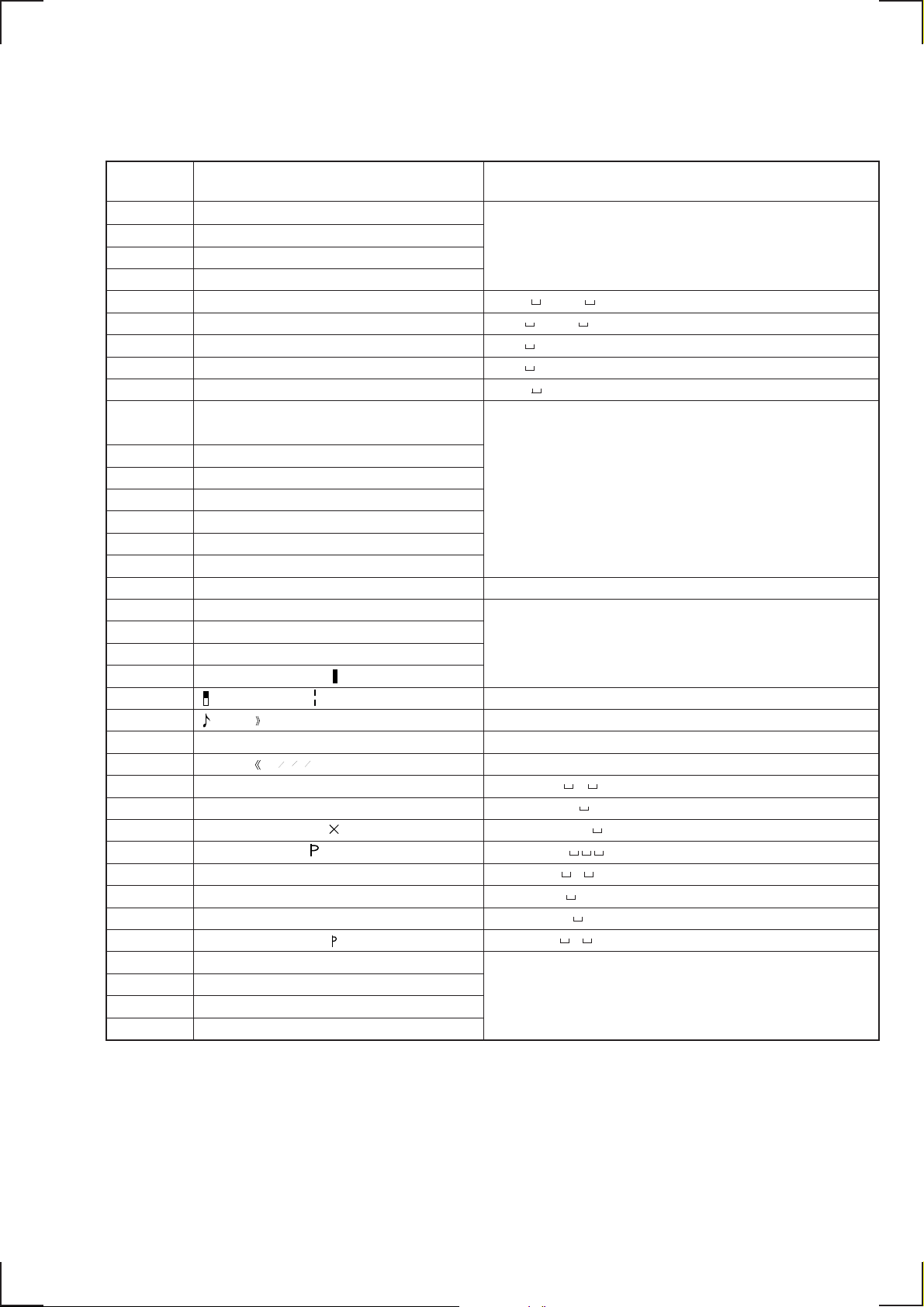

Table 2: CD-TEXT TEST DISC Recorded Data Contents and Display (TRACKS NO. 33 to 99)

(In this unit, some special characters cannot be displayed. This is no a fault.)

TRACK Recorded contents Display

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

to

99

100Hz/0dB/R*

1kHz/0dB/R*

10kHz/0dB/R*

20kHz/0dB/R*

100H square wave //L&R

1Hz square wave //L&R

1kHz emphasis ON/–0.37dB/L&R

5kHz emphasis ON/–4.53dB/L&R

16kHz emphasis ON/–9.04dB/L&R

! ” # $ % & ’ (21h to 27h)

1kHz 0dB L&R

()* + , – . / (28h to 2Fh)

0 1 2 3 4 5 6 7 (30h to 37h)

89:;<=>?(38h to 3Fh)

@A B C D E F G (40h to 47h)

H I J K L M N O (48h to 4Fh)

P Q R S T U V W (50h to 57h)

X Y Z [ ¥ ] ^ _ (58h to 5Fh)

‘ a b c d e f g (60h to 67h)

h i j k l m n o (68h to 6Fh)

p q r s t u v w (70h to 77h)

xyz{ I } ~ (78h to 7Fh)

i¢£¤¥ § (A0h to A7h) 8859-1

C ª ¬ PR – (A8h to AFh)

23

•±

†1º

‘ µ ¶ • (B0h to B7h)

341

1

4

¿ (B8h to BFh)

2

À Á Â Ã Ä Å Æ Ç (C0h to C7h)

È É Ê Ë Ì Í Î Ï (C8h to CFh)

DСТУФХЦ (D0h to D7h)

ШЩЪЫЬY ß (D8h to DFh)

à á â ã ä å æ ç (E0h to E7h)

è é ê ë ì í î ï (E8h to EFh)

∂ стуфхц÷ (F0h to F7h)

шщъыьy я (F8h to FFh)

No.66

No.67

to

No. 99

Same as the values shown in the left column.

100Hz Square Wave // L&R

1kHz Square Wave // L&R

1kHz w/emphasis /– 0.37dB/L&R

5kHz w/emphasis / – 4.53dB/L&R

16kHz w/emphasis / – 9.04dB/L&R

Same as the values shown in the left column.

X Y Z [ \ ] ^ _ (58h to 5Fh)

Same as the values shown in the left column.

(A0h to A7h) 8859-1

(A8h to AFh)

(B0h to B7h)

(B8h to BFh)

A A A A A A C (C0h to C7h)

E E E E I I I I (C8h to CFh)

D N O O O O O (D0h to D7h)

0 U U U U Y (D8h to DFh)

a a a a a a c (E0h to E7h)

e e e e i i i i (E8h to EFh)

d n o o o o o (F0h to F7h)

o u u u u y y (F8h to FFh)

Same as the values shown in the left column.

* Other channel is infinity zero.

— 9 —

IOP DATA RECORDING AND DISPLAY WHEN THE OPTICAL PICKUP AND NON-VOLATILE MEMORY

(BD (MD) BOARD IC171) IS REPLACED

The IOP value that is indicated on the optical pickup unit can be sav ed in the non-volatile memory . By saving the IOP v alue sav ed in the nonvolatile memory, it is no more necessary to read the IOP value on the optical pickup unit. It is recommended to save the IOP value saved in

the non-volatile memory when the optical pickup unit and/or non-volatile memory (BD (MD) board IC171) is replace as the followings.

How to save the IOP value in the non-volatile memory:

1. Turn on the power and select the MD function. Press the three buttons simultaneously, i.e., the ENTER/YES , NAME EDIT , and

MD3 buttons to activate the test mode.

2. Turn the MULTI JOG dial to show the message “[service]” on display. Press the ENTER/YES button.

3. Turn the MULTI JOG dial to show “Iop Write” (28) on display. Press the ENTER/YES button.

4. “REF=@@@.@” (@ is an arbitrary number) appears, and the number that can be changed as described in the next step, flashes.

5. Input the IOP value that is indicated on the optical pickup, as follows.

Selection of numeral : Select a number by turning the MULTI JOG dial.

Selection of digit : Select the desired digit by pressing the MD WALKMAN SYNC button.

6. Press the ENTER/YES button and the message “Measu=@@@.@” appears. (@ is an arbitrary number.)

7. Press the ENTER/YES button without changing the number because the result data of adjustment is saved as the value of step 6.

8. The message “Complete!!” appears for a moment. This value is saved in the non-volatile memory, and the message “Iop Write” is

displayed.

9. After saving is complete, press the REPEAT button to return to the normal operating mode.

How to display the IOP value saved in the non-volatile memory:

1. Turn on the power and select the MD function. Press the three buttons simultaneously, i.e., the ENTER/YES , NAME EDIT , and

MD3 buttons to activate the test mode.

2. Turn the MULTI JOG dial to show “[Service]” on display. Press the ENTER/YES button.

3. Turn the MULTI JOG to show “Iop Read” (C27) on display.

4. “@@.@/##.#” appears, and the saved contents are displayed.

@@.@ : The Iop value that is indicated on the pickup

##.# : The Iop value after adjustment is complete

5. T o exit this mode, press the MENU/NO b utton to show “Iop Read” on display. Press then the REPEA T button to return to the normal

operating mode.

— 10 —

CHECK BEFORE STARTING PARTS REPLACEMENT AND ADJUSTMENT

Cause of defect can be approximately located by performing the following checks before starting repair work. For the detailed procedure,

refer to “SECTION 6 ELECTRICAL ADJUSTMENTS”.

Laser power check

(page 44)

Traverse check

(page 45)

Focus bias check

(page 46)

CPLAY check

(page 46)

Self-record/playback check

(REC/PLAY)

(page 46)

TEMP check

(temperature compensation

offset adjustment)

(page 44)

Criterion of judgement

(If the value does not satisfy the following

specification value, it is judged as defective.)

• 0.9 mW power

Specification value: 0.84 to 0.92 mW

• 7.0 mW power

Specification value: 6.8 to 7.2 mW

• Iop (when 7 mW)

The Iop value that is indicated on the

optical pickup unit ±10 mA

• Traverse waveform

Specification value: Offset 10 % or less

• Error rate check

Specification value: At all points of a, b, c

C1 error 220 or less

AD error 2 or less

• Error rate check

Specification value:

a. When the test disc (MDW-74/AU-1) is

used

C1 error 80 or less

AD error 2 or less

b. When the check disc (TDYS-1) is used

C1 error 50 or less

• Error rate check with CPLAY

Specification value:

C1 error 80 or less

AD error 2 or less

• NG when “T=@@(##)[NG” is displayed

(@@ and ## are arbitrary numbers.)

Countermeasure when result of judgement

is defective

• Cleaning the optical pickup

• Re-adjustment

• Replacement of the optical pickup

• Replacement of the optical pickup

• Replacement of the optical pickup

• Replacement of the optical pickup

• Replacement of the optical pickup

When test result is all the time defective:

• Replacement of the over-write head

• Check that circuits in the peripheral of the

over-write head are not open

When test result is defective from time to

time:

• Check if the over-write head is not deformed

• Mechanical check on parts around the sledding

mechanism

• Check that circuits in the peripheral of D101

(BD board) are not open

• Check signals in the peripheral of IC101, 121,

CN102, 103 (BD board)

Note: The criterion of judgement is presented only for the purpose of judgment whether specifications are satisfied or not. This is not the

specification values of adjustments.

When any adjustments are attempted, use the specification values that are described in the respective adjustment procedures.

— 11 —

SECTION 3

GENERAL

#¡

#º

@ª

@•

@¶

@§

@∞

@¢

@£

@™

@¡

@º

1

2

3

4

5

6

7

8

9

!º

!¡

!™

!£

!¢

!∞

!§

!¶!•!ª

1 TUNER/BAND button

2 DBFB button

3 MD6 button

4 CURSOR 0/) buttons

5 MD1 – MD5/

/p buttons

6 SPECTRUM ANALYZER UPPER DISPLAY

button

7 SPECTRUM ANALYZER LOWER DISPLA Y

button

8 REC button

9 REC MODE button

!º MD WALKMAN SYNC button

!¡ GROOVE button

!™ PLAY MODE TUNNING MODE button

!£ 1/ALL button

!¢ REPEAT STEREO/MONO button

!∞ VOLUME dial

!§ CLEAR button

!¶ ENTER/YES button

!• CD1 6 – CD5 6 buttons

!ª MENU/NO button

@º MULTI JOG dial

@¡ PRESET EQ button

@™ NAME EDIT/CHARACTER button

@£ FUNCTION button

@¢ REC IT button

@∞ HIT PARADE button

@§ SEAMLESS button

@¶ SELECT SYNC button

@• CD1 – CD5/ /p buttons

@ª TIMER SELECT button

#º SET button

#¡ 1/u (power) button

— 12 —

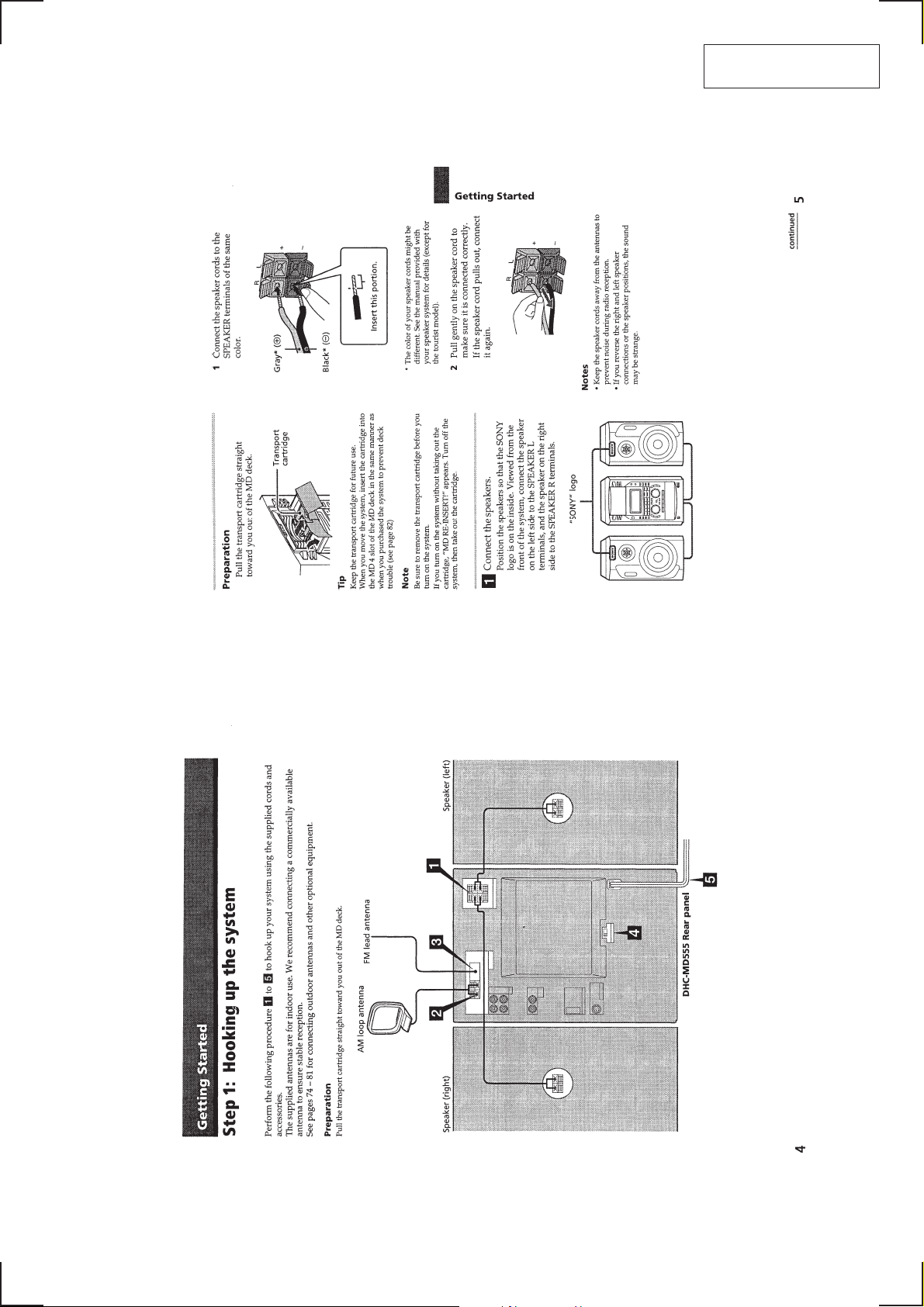

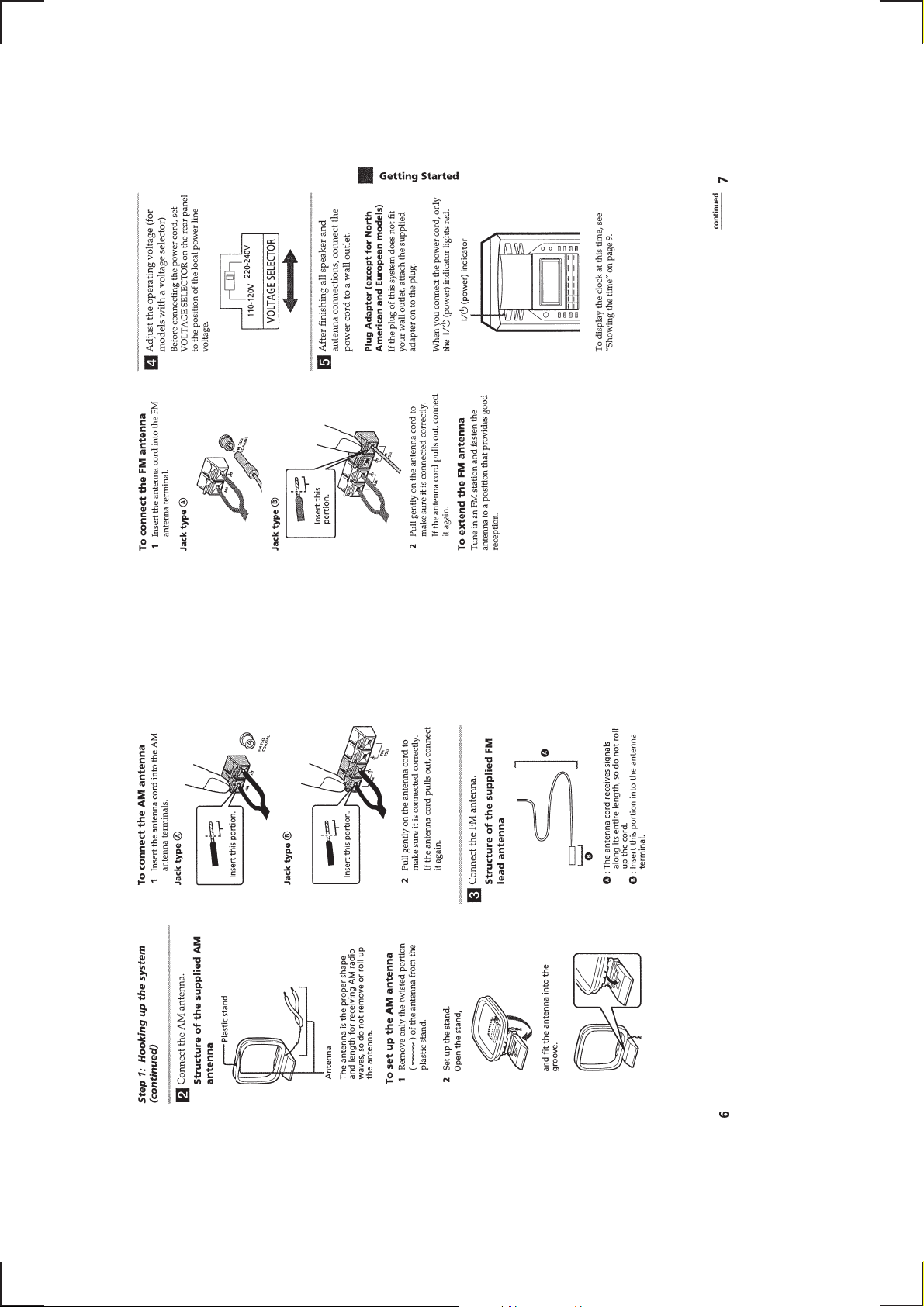

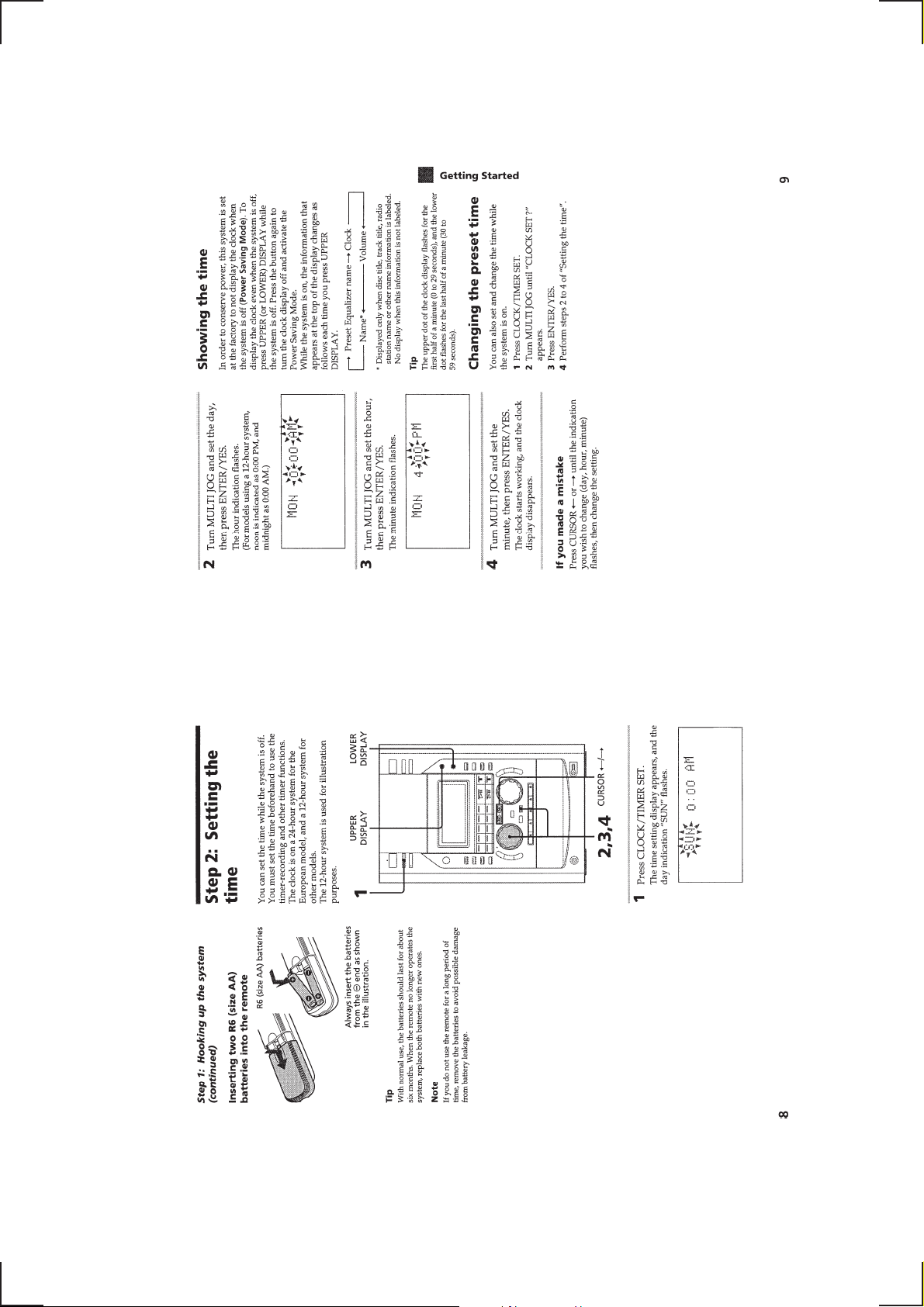

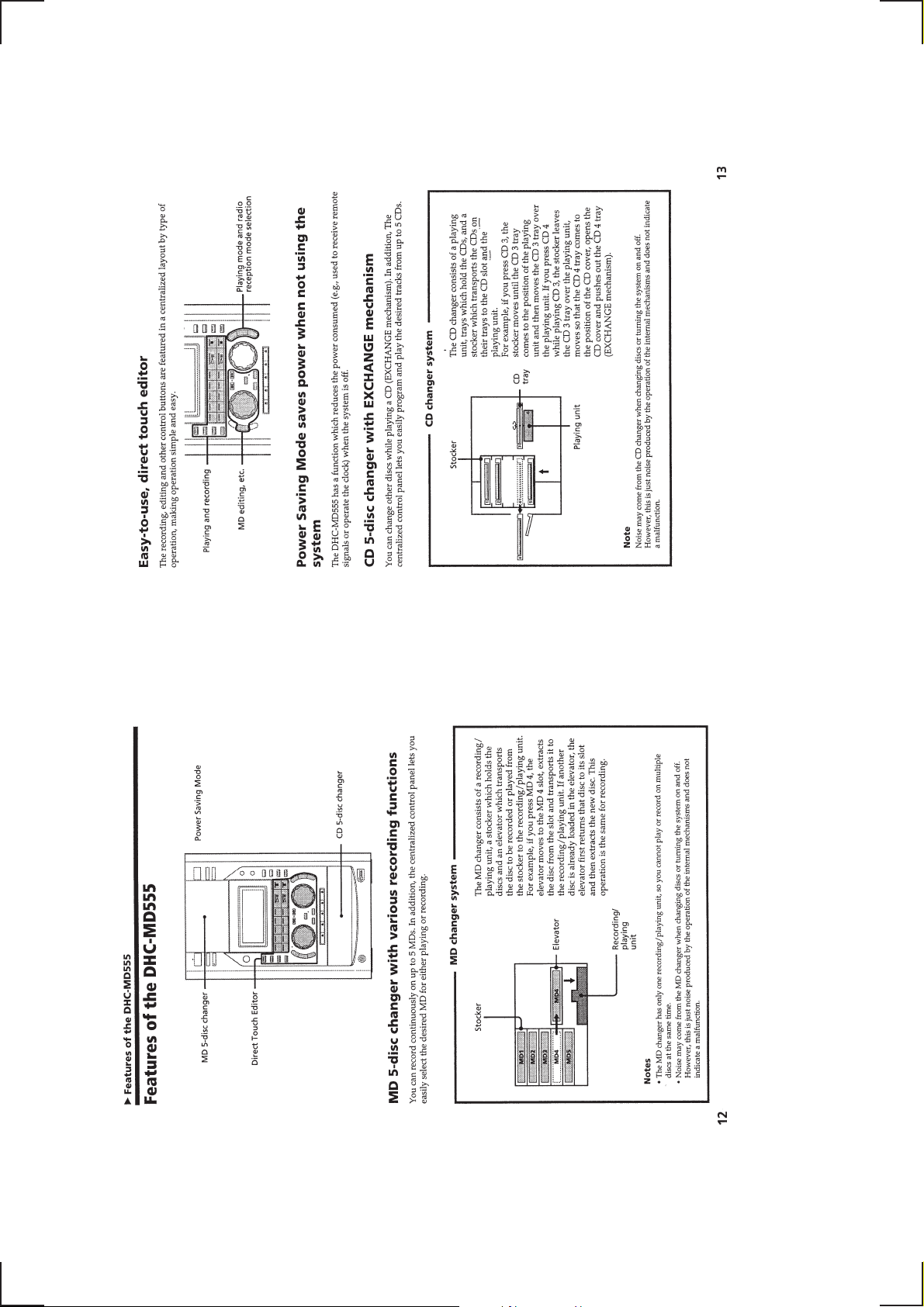

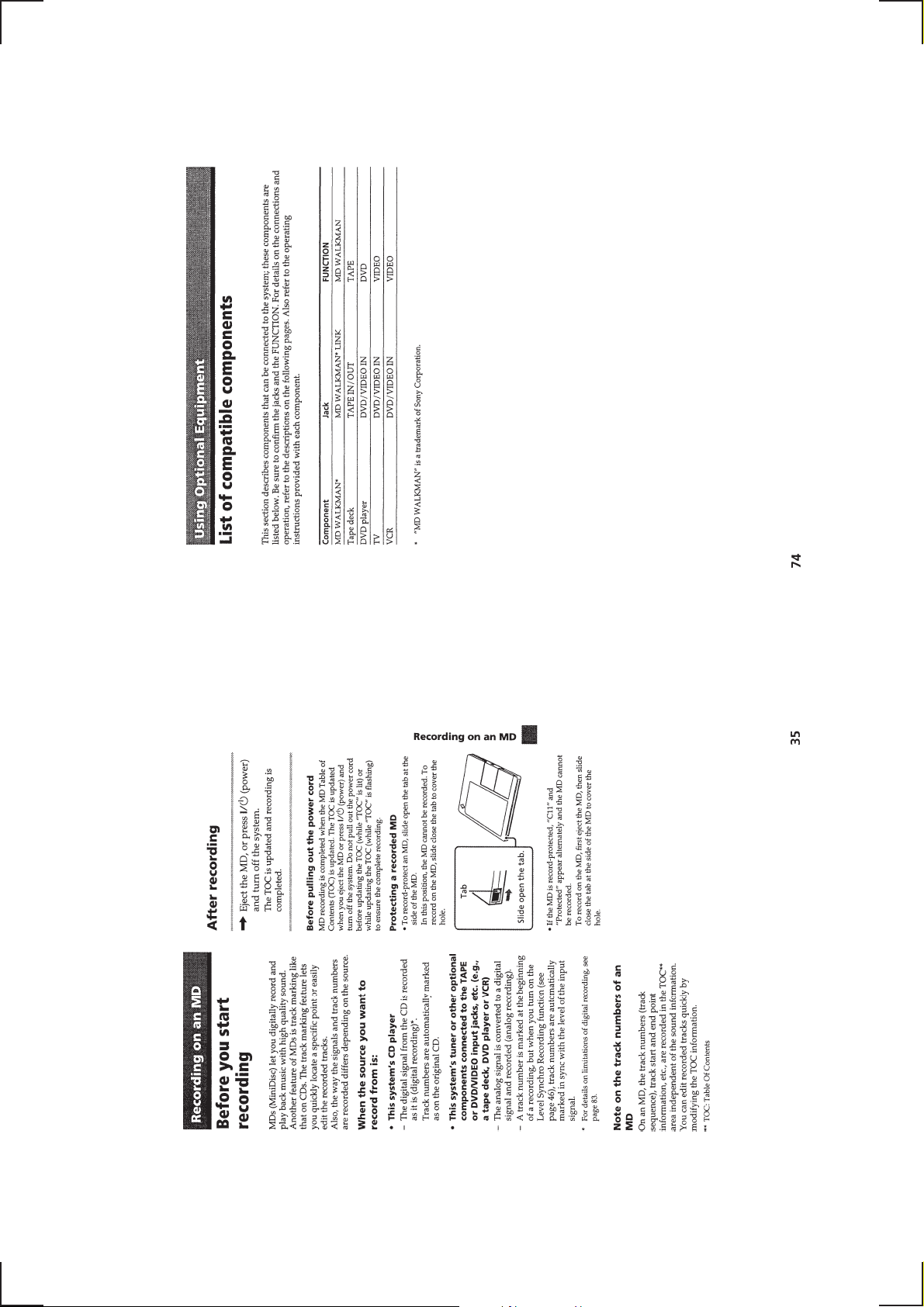

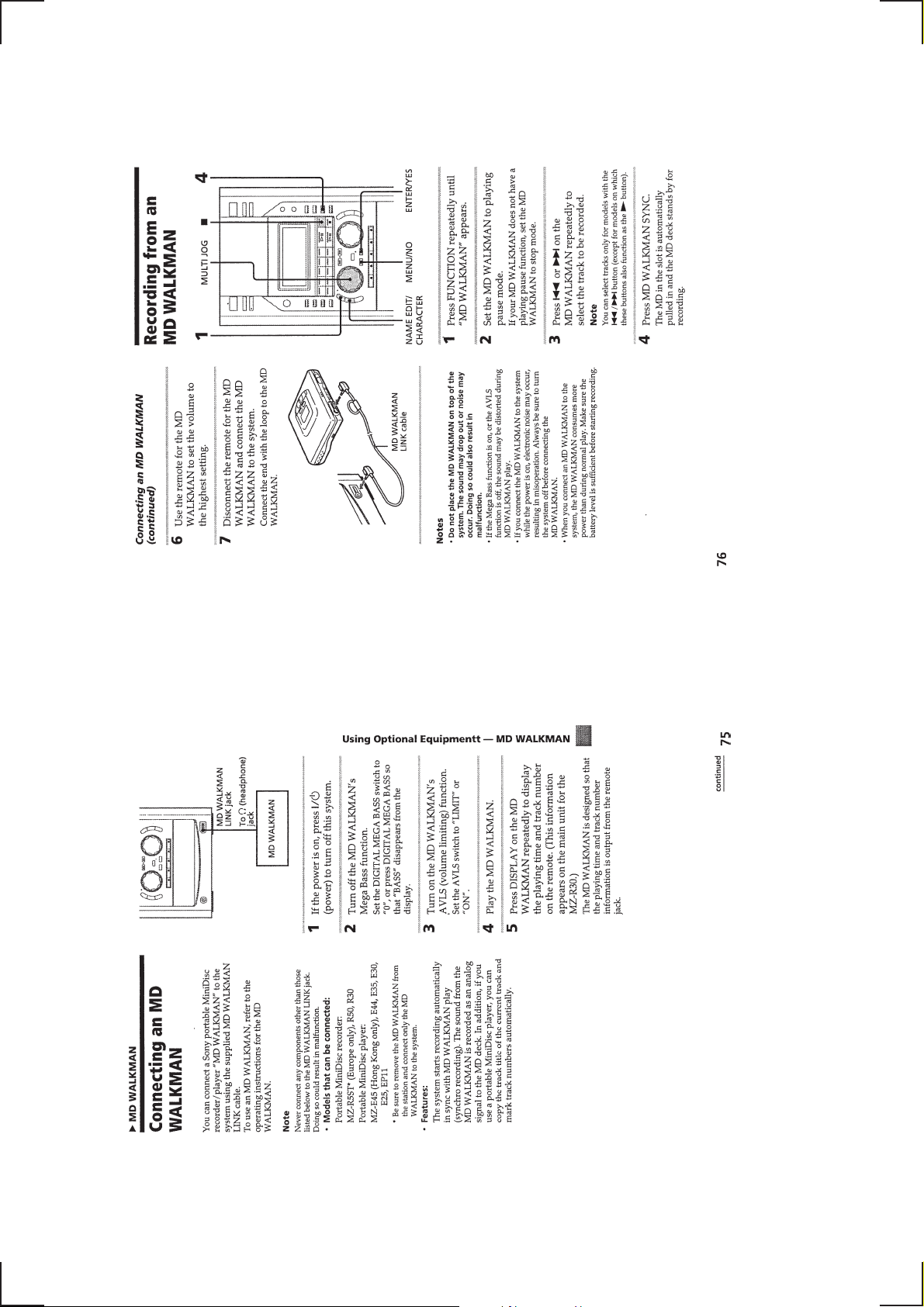

This section is extracted

from instruction manual.

— 13 —

— 14 —

— 15 —

— 16 —

— 17 —

— 18 —

— 19 —

— 20 —

— 21 —

— 22 —

— 23 —

— 24 —

SECTION 4

s

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

4-1. BACK PANEL

• Remove the upper cover first.

5

Three connectors

6

Back panel

3

T en screws

(+BV 3 × 8)

2

Cover (Back)

4-2. MECHANISM (MDM-C1E)

6

MD mechanism

(MDM-C1E)

5

Three screws

(+BV 3 × 8)

4

Seven screws

(+BV 3 × 8)

4

Cover (MDM)

1

TUNER

1

Three screw

(+BV 3 × 8)

3

Screw (+BV 3 × 8)

2

Screw (+BV 3 × 8)

— 25 —

4-3. SP BOARD, AMP BOARD, REG BOARD, TRANS-D BOARD (JE, HK, SP, MY MODEL)

)

d

Abbreviation

HK : Hong Kong

SP : Singapore

MY : Malaysia

JE : Tourist

8

AMP board

1

Two connectors

7

Two screws

×

(+BV 3

16)

3

SP board

5

Connector

2

Two screws

(+BV 3

9

!º

Heat sink

×

8)

!¡

Screw (+BV 3 × 16)

!£

Two screws

(+BV 3

(JE, HK, SP, MY MODEL

Back panel

Four screws

(+BV 3

!™

REG board

×

8)

×

12)

4

Two connectors

4-4. FRONT PANEL

!£

Front panel

6

Screw (+BV 3 × 8)

8

Flat type wire

(29 core)

!º

!¢

TRANS-D board

(JE, HK, SP, MY MODEL)

7

Connector

1

Two connectors

5

Holder (WLS-10)

(Remove the holder from

the MAIN board. )

9

MAIN boar

2

Flat type wire

(19 core)

!™

6

!¡

Three screws

(+BV 3

— 26 —

Connector

3

(17 core)

×

8)

Flat type wire

4

Two screws

(+BV 3

×

8)

4-5. POWER KEY BOARD, LED BOARD, PANEL BOARD

)

6

POWER KEY board

8

LED board

5

Two screws

9

Two screws

(+BVTP 2.6

!™

PANEL board

Front panel

×

8)

(+BVTP 2.6

7

Screw

(+BVTP

2.6

!º

screws

(+BVTP

2.6

!¡

Three screws

(+BVTP 2.6

Four

×

8)

×

8)

×

8)

×

8)

1

Two screws

(+BV 3

3

Two screws

(+BVTP 2.6

×

8)

2

4

Bracket

(MD chassis)

×

8)

Chassis (MD)

4-6. POWER TRANSFORMER (T960), TRANS-A/B/C BOARD

2

Three screws

7

TRANS-C board

4

Two connectors

(+BV 3

×

10)

5

TRANS-A

board

6

1

Four screws

(+BVTT 3

TRANS-B board

3

Power transformer

(T960)

8

Chassis (Transformer

×

8)

— 27 —

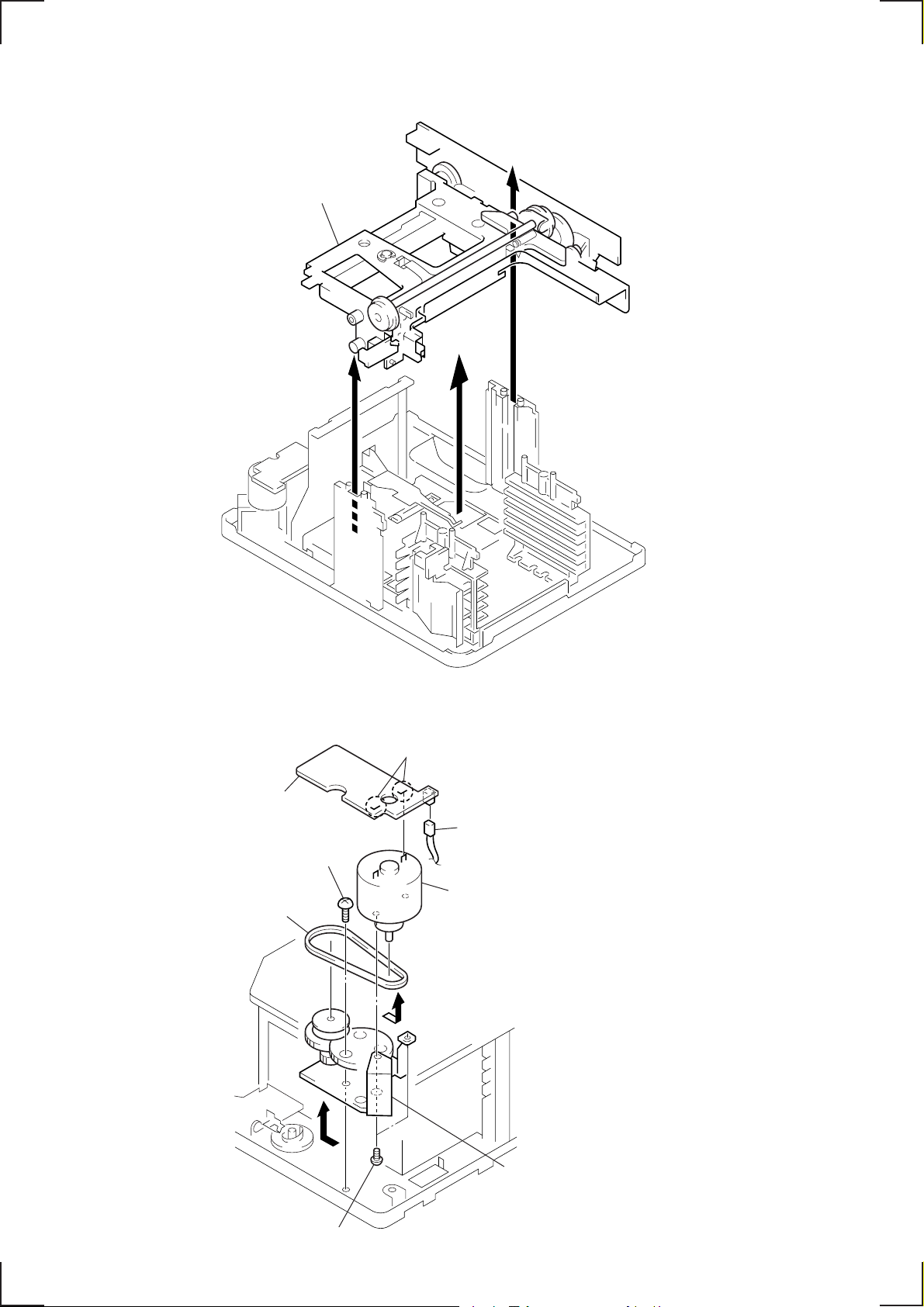

4-7. CD MECHANISM (CDM53-K1BD33)

2

Two screws

(+BV 3 × 8)

3

CD mechanism

(CDM53-K1BD33)

1

Two screws

(+BV 3 × 8)

Chassis

— 28 —

4-8. ESCUTCHEON, CHASSIS (TOP)

)

6

Cover (FFC)

4

Flat type wire

(13 core)

3

Flat type wire

(7 core)

5

Two screws

(+BVTT 2.6 × 5)

7

!¡

Screw (+BVTT 2.6 × 5)

9

Bracket (To assemble the bracket,

refer to the following note.)

!º

T wo screws

(+P 2 × 5)

!™

Chassis (TOP)

8

Lever (S) assy

Note: When assembling the bracket, raise the lever (S) assembly,

engage it with the bracket, and slide them in the direction

of the arrow.

Lever (S) assy

2

Escutcheon

Screw (+BVTT 2.6 × 5)

Bracket

1

Four screws

(+BVTT 2.6 × 5

— 29 —

4-9. CHASSIS (ELEVATOR) NEW

e

1

Chassis (Elevator) NEW assy

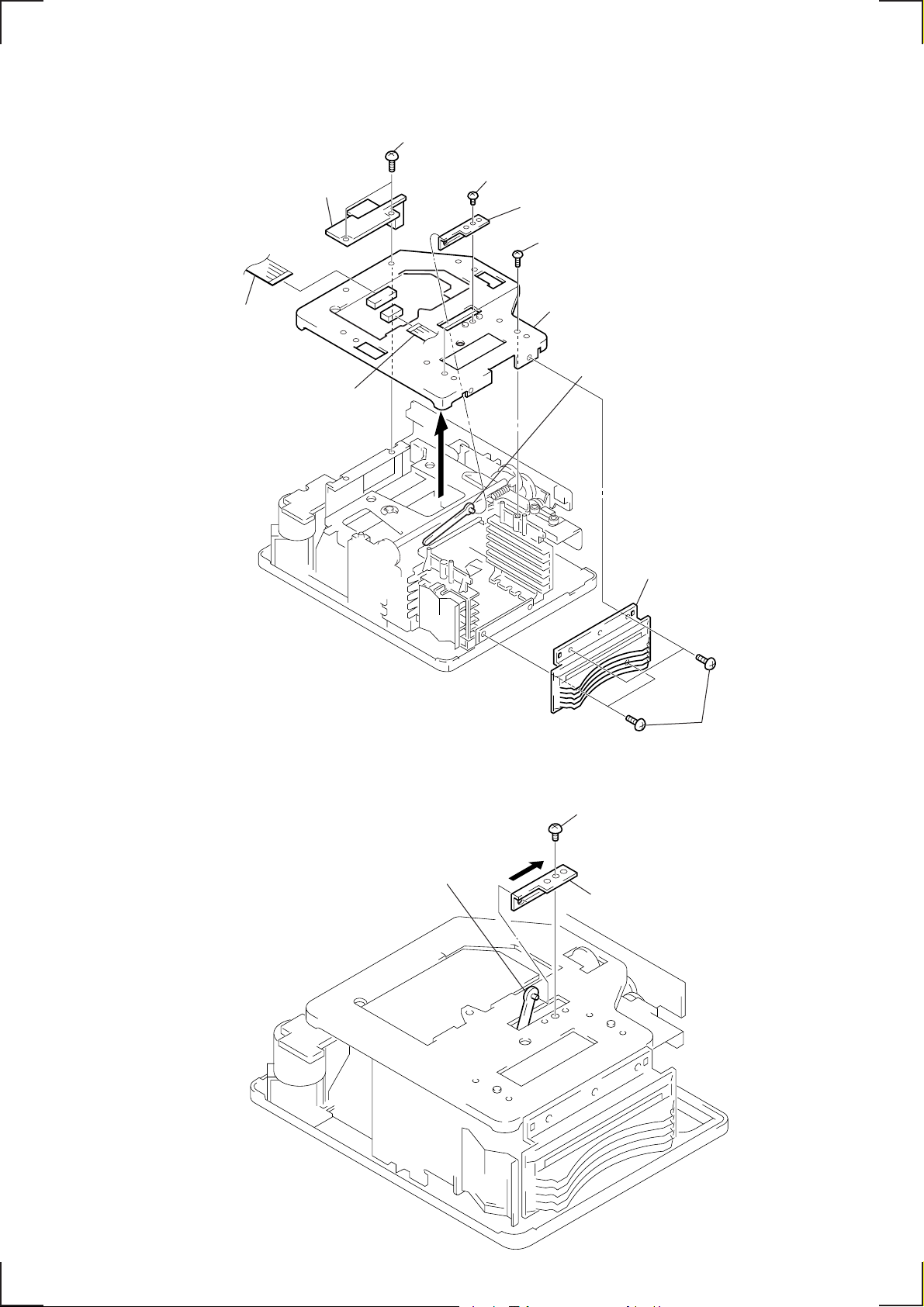

4-10. MOTOR (HEAD) ASSY (M905), HEAD RELAY BOARD

7

Remove soldering of the motor.

8

HEAD RELAY board

Screw

3

(+BVTT 2.6

2

Belt A

×

5)

6

Remove the motor assy in the

direction of the arrow

B

A

1

Connector

Motor (Head) assy (M905)

B

.

5

Two screws

(+P 2

4

Chassis (Head gear) assy

Remove the chassis assy in th

direction of the arrow A.

×

2)

— 30 —

Loading...

Loading...