Sony HCD-MD5 Schematic

SERVICE MANUAL

HCD-MD5 is the amplifier, CD, MD

and tuner section in DHC-MD5.

HCD-MD5

AEP Model

UK Model

E Model

Tourist Model

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation.

Amplifier section

DIN power output 40 W + 40 W

(6 ohms, at 1 kHz, DIN)

Continuous RMS power output

50 + 50 watts

(6 ohms at 1 kHz, 10% THD)

Peak music power output

700 watts

Music power output 160 watts

Inputs VIDEO/GAME IN

(phono jacks)

(switchable)

VIDEO IN:

voltage 250 mV,

impedance 47 kilohms

GAME IN:

voltage 450 mV,

impedance 47 kilohms

T APE IN (phono jacks):

voltage 250mV,

impedance 47 kilohms

Outputs T APE OUT (phono jacks):

voltage 250 mV

impedance 1 kilohms

PHONES (stereo phone jack):

accepts headphones of

8 ohms or more.

SPEAKER: accepts impedance of 6 to

16 ohms.

Model Name Using Similar Mechanism HCD-W55

CD

Section

MD

Section

CD Mechanism Type

Base Unit Name BU-5BD19

Optical Pick-up Name KSS-213B/K-N

Model Name Using Similar Mechanism NEW

MD Mechanism Type MDM-2FR

Base Unit Name MBU-2F

Optical Pick-up Name KMS-210A/J-N

SPECIFICATIONS

CD player section

System Compact disc and digital

Laser Semiconductor laser

Laser output Max. 44.6 µW*

Frequency response 2 Hz – 20 kHz (±0.5 dB)

CD OPTICAL DIGITAL OUT

(Square optical connector jack, rear panel)

audio system

(λ=780 nm)

Emission duration:

continuous

*This output is the value

measured at a distance of

200 mm from the objective

lens surface on the Optical

Pick-up Block with 7 mm

aperture.

MINI Hi-Fi COMPONENT SYSTEM

CDM38A-5BD19

MD deck section

System MiniDisc digital audio

system

Laser Semiconductor laser

(λ=780 nm)

Emission duration:

continuous

Laser output Max. 44.6 µW*

*This output is the value

measured at a distance of

200 mm from the objective

lens surface on the Optical

Pick-up Block with a

7 mm aperture.

Recording time 74 minutes max. (using

MDW-74)

Sampling frequency 44.1 kHz

Frequency response 5 Hz to 20 kHz

– Continued on next page –

MICROFILM

SECTION 3

DISASSEMBLY

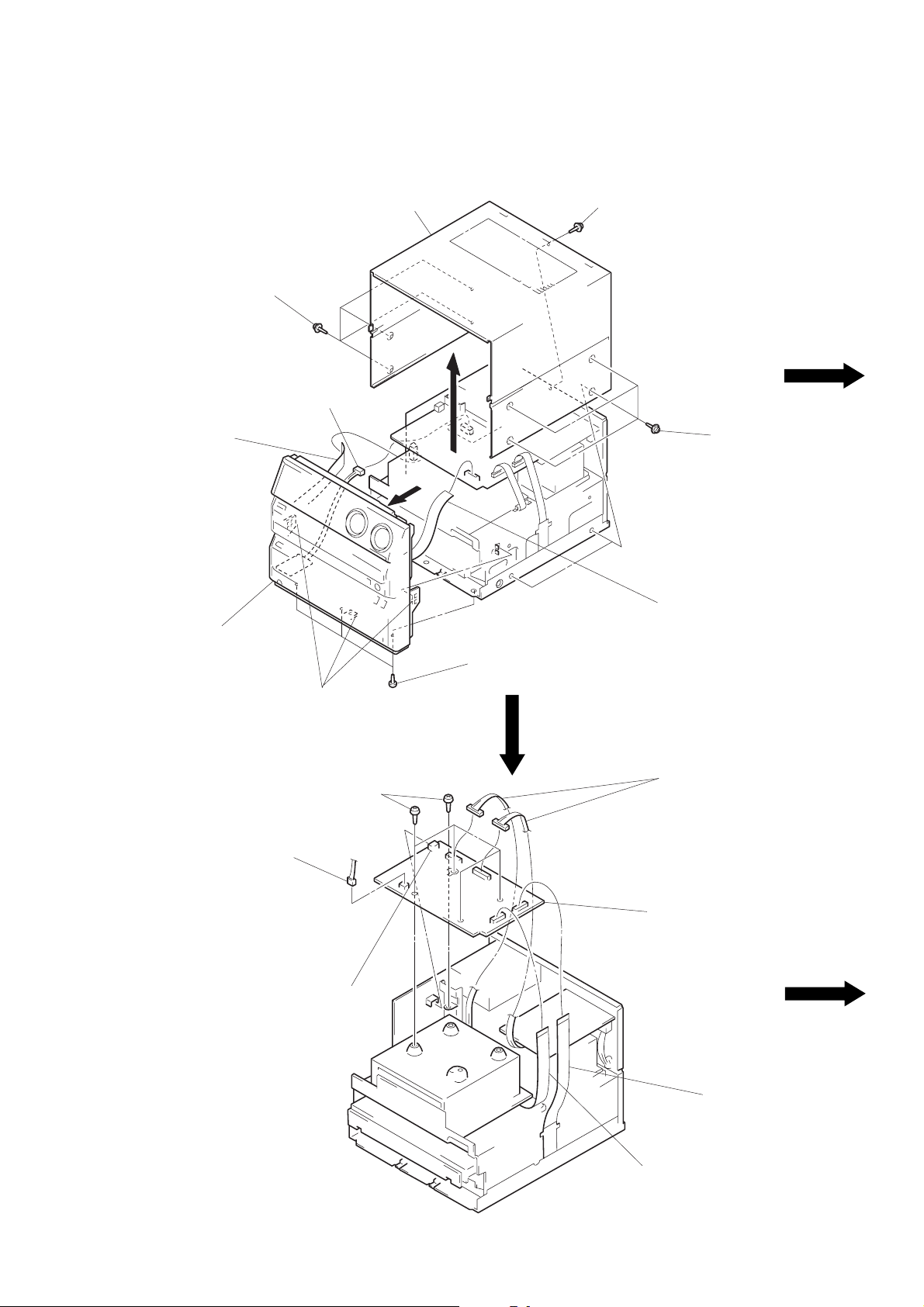

Note: Follow the disassembly procedure in the numerical order given.

CASE, FRONT PANEL ASS’Y

1

four screws

(CASE 3 TP2)

4

connector

(CN906)

3

flat wire (22 core)

(CN103)

2

case

1

four screws

(CASE 3 TP2)

1

four screws

(CASE 3 TP2)

7

front panel ass‘y

POWER BOARD

1

connector

(CN881)

6

three claws

3

4

connector

(CN804)

five screws

×

8)

(BV3

5

three screws

(BV3

3

flat wire (19 core)

(CN805)

×

8)

1

two connectors

(CN802, 803)

5

POWER board

– 7 –

2

2

flat wire (23 core)

(CN808)

flat wire (21 core)

(CN807)

BRACKET (MAIN) SECTION

6

bracket (MAIN)

section

5

three screws

×

8)

(BV3

3

cover (FFC)

4

flat wire (21 core)

(CN807)

1

three screws

(BV3

1

2

supplied OPT cap

×

8)

four screws

×

8)

(BV3

SHIELD CASE (MD)

1

two screws

(BV3

5

three screws

×

8)

(BV3

1

eight screws

(BV3

×

8)

2

shield case

(MD)

×

8)

– 8 –

CD MECHANISM

2

CD mechanism

1

two boss

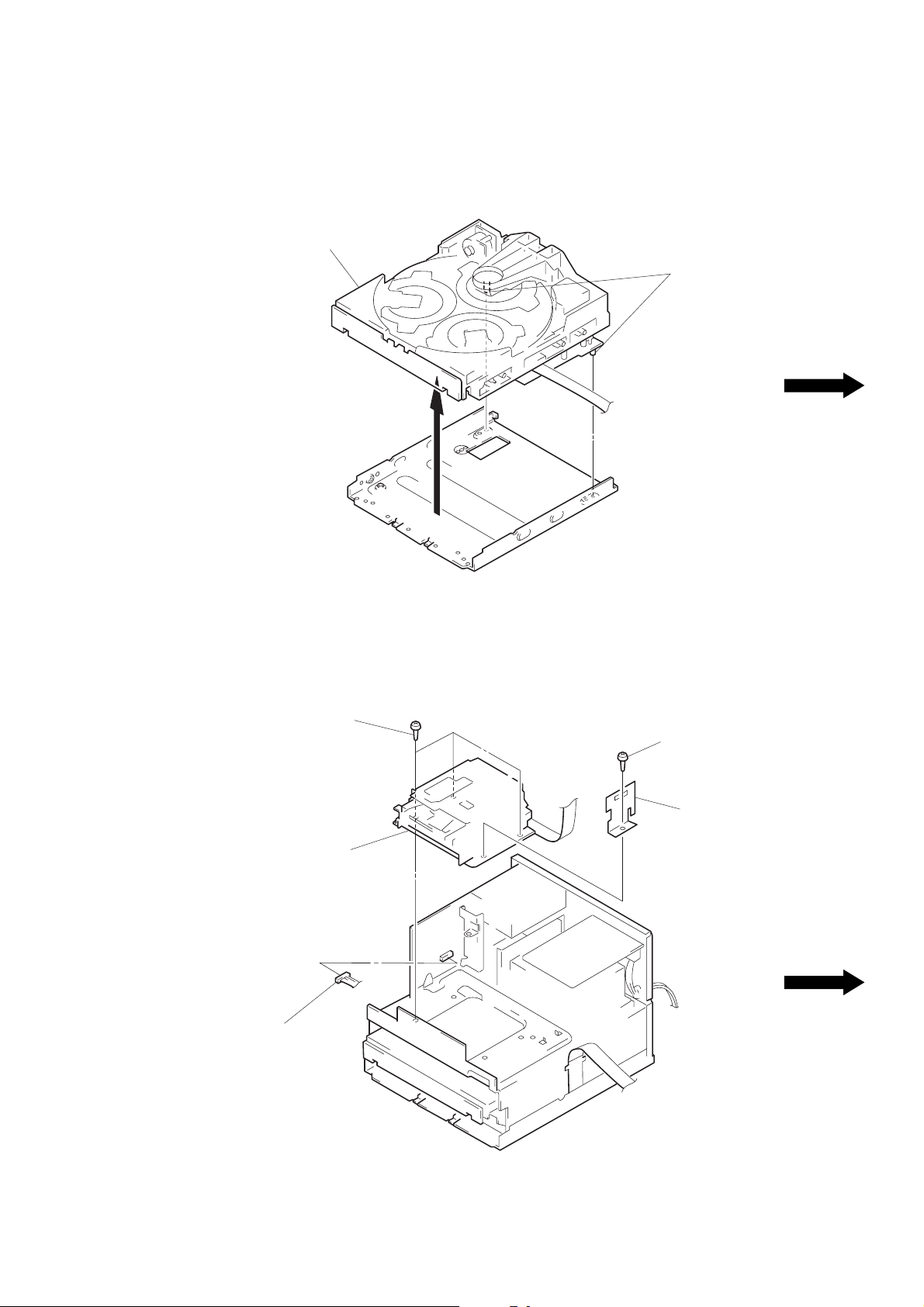

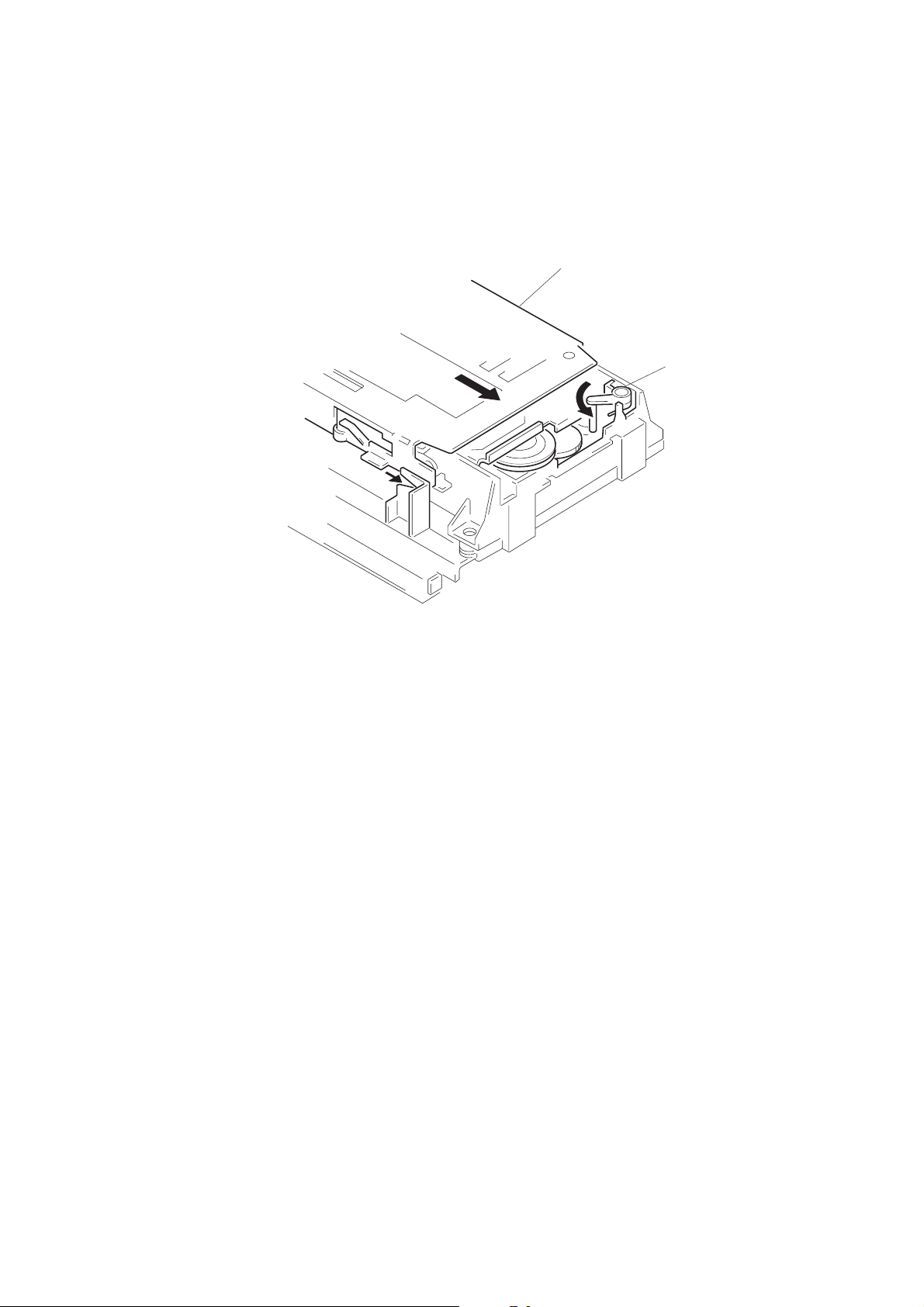

MD MECHANISM SECTION

2

three screws

(BV3

4

MD mechanism

section

1

connector

(CN101)

×

8)

2

screw

(BV3

×

8)

3

cover (MDM)

(AEP, UK, German)

– 9 –

DISC TRAY

4

two claws

3

flat wire (8 core)

2

Pull the disc tray.

5

Remove the disc tray.

flat wire

claw

A

claw

B

Note: When mounting the disc tray, route a flat

cable through claw

in the figure.

1

Rotate the cam to direction

of the arrow.

A

and B as shown

MD MECHANISM

4

two screws

×

18)

(B2.6

5

two

collars

7

MD mechanism

5

two collars

4

two screws

(B2.6

×

18)

B

2

connector (CN251)

3

flat wire (30 core)

(CN202)

3

flat wire (18 core)

(CN221)

6

1

Turn the lever (SLM) toward

direction

(M) assembly toward direction

screw (BTT2.6 × 4)

A

, and slide the slider

A

B

Slider (M) ass’y

lever (SLM)

.

– 10 –

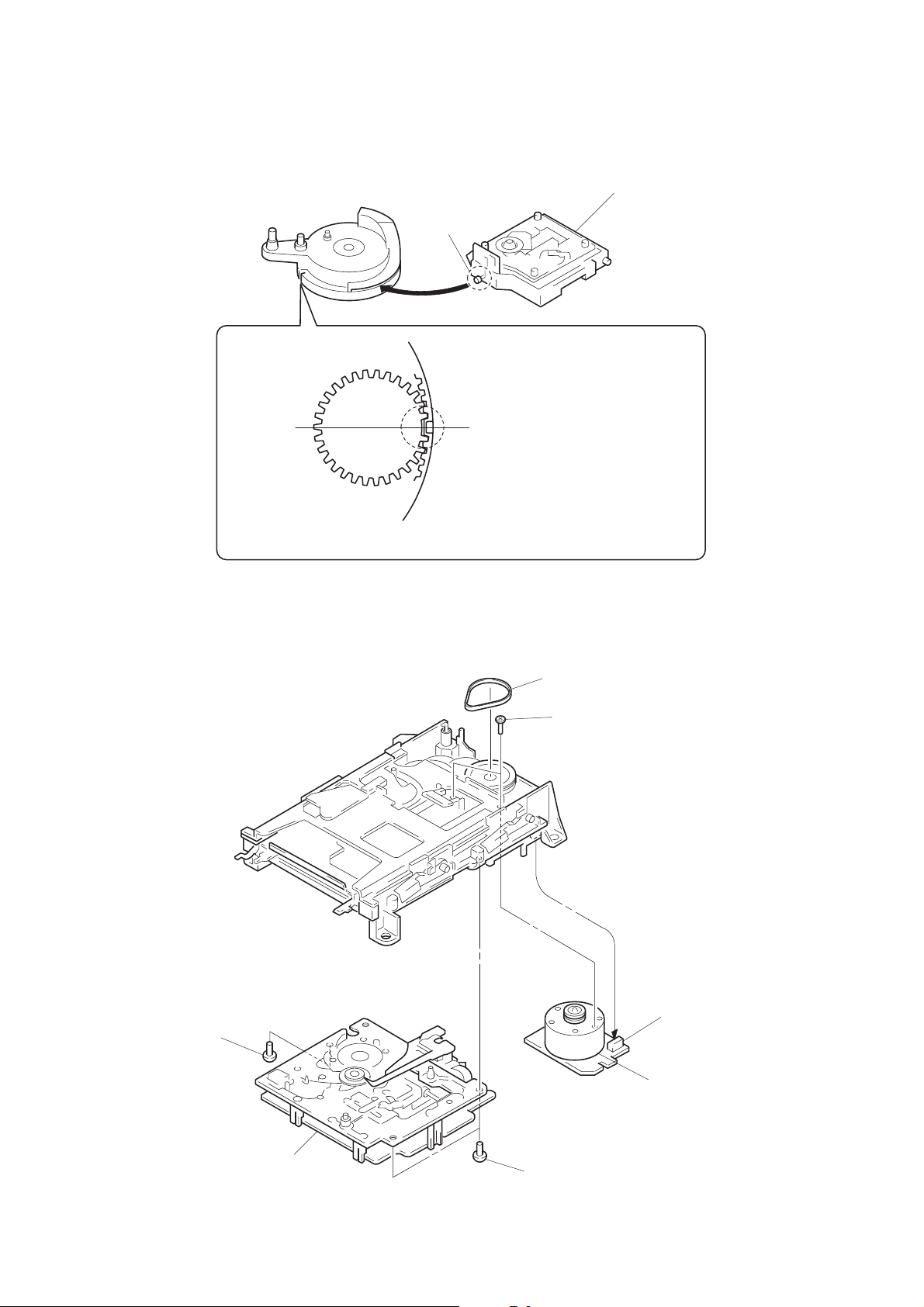

INSTALLATION DISC TRAY

Note: When mounting the disc tray, the collars

A

and B must be engaged in the grooves

respectively .

callar

A

ditch

callar

B

SLIDER (M) ASS’Y

claw

claw

B

C

claw

A

1

Remove a torsion coil

spling from the claw

2

Disengaging the claw B,

raise the lever (SLM) upw ard

to remove.

A

.

A

– 11 –

B

3

Slide the claw C of the slider

(M) assembly up the base

groove in direction

raise the slider (M) assembly

in direction

base groove

B

to remove.

A

, and

INSTALLATION BU CAM ASS’Y BASE UNIT, ROTALY ENCODER

portion A

When mounting the BU cam assembly,

it must be engaged with the rotaly

encorder switch as shown.

When mounting the base unit, insert the

portion A into a groove in the BU cam.

BASE UNIT, LOADING MOTOR ASS’Y

1

screws

×

6)

(BV3

3

belt

4

two screws

(B2.6

×

5)

5

connector

(CN192)

6

loading motor ass’y

2

base unit

– 12 –

1

screw

(BV3

×

6)

INSTALLATION SLIDER (M) ASS’Y

B

2

Slide the slider (M) assembly

toward direction

be locked with the lev er (SLM).

A

B

unit it can

1

Turn fully the lever (SLM)

toward direction

A

.

– 13 –

Loading...

Loading...