Sony HCDMD-5 Service manual

SERVICE MANUAL

HCD-MD5 is the amplifier, CD, MD

and tuner section in DHC-MD5.

HCD-MD5

AEP Model

UK Model

E Model

Tourist Model

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation.

Amplifier section

DIN power output 40 W + 40 W

(6 ohms, at 1 kHz, DIN)

Continuous RMS power output

50 + 50 watts

(6 ohms at 1 kHz, 10% THD)

Peak music power output

700 watts

Music power output 160 watts

Inputs VIDEO/GAME IN

(phono jacks)

(switchable)

VIDEO IN:

voltage 250 mV,

impedance 47 kilohms

GAME IN:

voltage 450 mV,

impedance 47 kilohms

T APE IN (phono jacks):

voltage 250mV,

impedance 47 kilohms

Outputs T APE OUT (phono jacks):

voltage 250 mV

impedance 1 kilohms

PHONES (stereo phone jack):

accepts headphones of

8 ohms or more.

SPEAKER: accepts impedance of 6 to

16 ohms.

Model Name Using Similar Mechanism HCD-W55

CD

Section

MD

Section

CD Mechanism Type

Base Unit Name BU-5BD19

Optical Pick-up Name KSS-213B/K-N

Model Name Using Similar Mechanism NEW

MD Mechanism Type MDM-2FR

Base Unit Name MBU-2F

Optical Pick-up Name KMS-210A/J-N

SPECIFICATIONS

CD player section

System Compact disc and digital

Laser Semiconductor laser

Laser output Max. 44.6 µW*

Frequency response 2 Hz – 20 kHz (±0.5 dB)

CD OPTICAL DIGITAL OUT

(Square optical connector jack, rear panel)

audio system

(λ=780 nm)

Emission duration:

continuous

*This output is the value

measured at a distance of

200 mm from the objective

lens surface on the Optical

Pick-up Block with 7 mm

aperture.

MINI Hi-Fi COMPONENT SYSTEM

CDM38A-5BD19

MD deck section

System MiniDisc digital audio

system

Laser Semiconductor laser

(λ=780 nm)

Emission duration:

continuous

Laser output Max. 44.6 µW*

*This output is the value

measured at a distance of

200 mm from the objective

lens surface on the Optical

Pick-up Block with a

7 mm aperture.

Recording time 74 minutes max. (using

MDW-74)

Sampling frequency 44.1 kHz

Frequency response 5 Hz to 20 kHz

– Continued on next page –

MICROFILM

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

Tourist model: 76.0 – 108.0 MHz (50 kHz step)

Other models: 87.5 – 108.0 MHz (50 kHz step)

Aerial FM lead aerial

Aerial terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

TABLE OF CONTENTS

1. SERVICING NOTES

.................................................. 3

2. GENERAL

Index to Parts and Controls ............................................... 5

3. DISASSEMBLY............................................................ 7

AM tuner section

Tuning range

German model:

AM: 522 – 1,611 kHz

AEP, UK models:

MW: 522 – 1,611 kHz

LW: 144 – 288 kHz

Tourist model:

AM: 531 – 1,602 kHz

Malaysia, Singapore,

Saudi Arabia,

Hong Kong models:

MW: 531 – 1,602 kHz

SW: 5.95 – 17.90 MHz

Aerial AM loop aerial

Intermediate frequency 450 kHz

General

Power requirements 220 – 230 V AC, 50/60 Hz

Power consumption 85 watts (Tourist model)

Dimensions

Amplifier/Tuner/MD/CD section:

Mass

Amplifier/Tuner/MD/CD section:

Supplied accessories: AM loop aerial (1)

(with the interval set at 9 kHz)

(with the interval set at 9 kHz)

(with the interval set at 3 kHz)

(with the interval set at 9 kHz)

530 –1,710 kHz

(with the interval set at 10 kHz)

(with the interval set at 9 kHz)

530 – 1,710 kHz

(with the interval set at 10 kHz)

External aerial terminals

(AEP, German model)

110 – 120 V or 220 – 240 V AC,

50/60 Hz Adjustable with the

voltage selector (Other model)

130 watts (Other models)

Approx. 280 × 240 × 360 mm

1

/8 × 9 1/2 × 14 1/4 in) (w/h/d) incl.

(11

projecting parts and

controls

(U.K., Hong Kong model)

Approx. 280 × 240 × 350 mm

1

/8 × 9 1/2 × 13 7/8 in) (w/h/d) incl.

(11

projecting parts and

controls (Other models)

Approx. 9.4 kg

(20 lb 12 oz)

Remote RM-S5MD (1)

Sony SUM-3 (NS)

batteries (2)

FM lead aerial (1)

Speaker cords (2)

4. TEST MODE ................................................................. 14

5. ELECTRICAL ADJUSTMENTS

MD Section........................................................................ 20

Tuner Section..................................................................... 25

CD Section......................................................................... 26

6. DIAGRAMS

6-1. Block Diagrams

CD Section......................................................................... 29

Tuner Section..................................................................... 31

MD Section........................................................................ 35

Main Section...................................................................... 39

6-2. Schematic Diagram – Tuner Section –

(AEP, G, UK model).......................................................... 44

6-3. Printed Wiring Board – Tuner Section –

(AEP, G, UK model).......................................................... 46

6-4. Printed Wiring Board – Tuner Section –

(EXCEPT AEP, G, UK model) .......................................... 47

6-5. Schematic Diagram – Tuner Section –

(EXCEPT AEP, G, UK model) .......................................... 48

6-6. Printed Wiring Board – CD Section – ............................... 50

6-7. Schematic Diagram – CD Section – .................................. 53

6-8. Printed Wiring Board –MD Section – ............................... 56

6-9. Schematic Diagram –MD Section – .................................. 59

6-10. Schematic Diagram – Digital Section – ............................ 63

6-11. Printed Wiring Boards – Digital Section – ........................ 67

6-12. Schematic Diagram – Relay Section – .............................. 70

6-13. Printed Wiring Board – Relay Section – ........................... 73

6-14. Printed Wiring Board – Main Section – ............................ 76

6-15. Schematic Diagram – Main Section –............................... 79

6-16. Schematic Diagram – Power Section – ............................. 83

6-17. Printed Wiring Boards – Power Section – ......................... 87

6-18. Schematic Diagram – Power AMP Section –.................... 92

6-19. Printed Wiring Boards – Power AMP Section –................ 95

6-20. Schematic Diagram – Panel Section –............................... 99

6-21. Printed Wiring Boards – Panel Section – ........................ 103

6-22. IC Pin Function Description............................................ 109

7. EXPLODED VIEWS ................................................. 123

8. ELECTRICAL PARTS LIST .................................. 132

Design and specifications are subject to change without notice.

– 2 –

SECTION 1

SERVICING NOTES

MODEL IDENTIFICATION

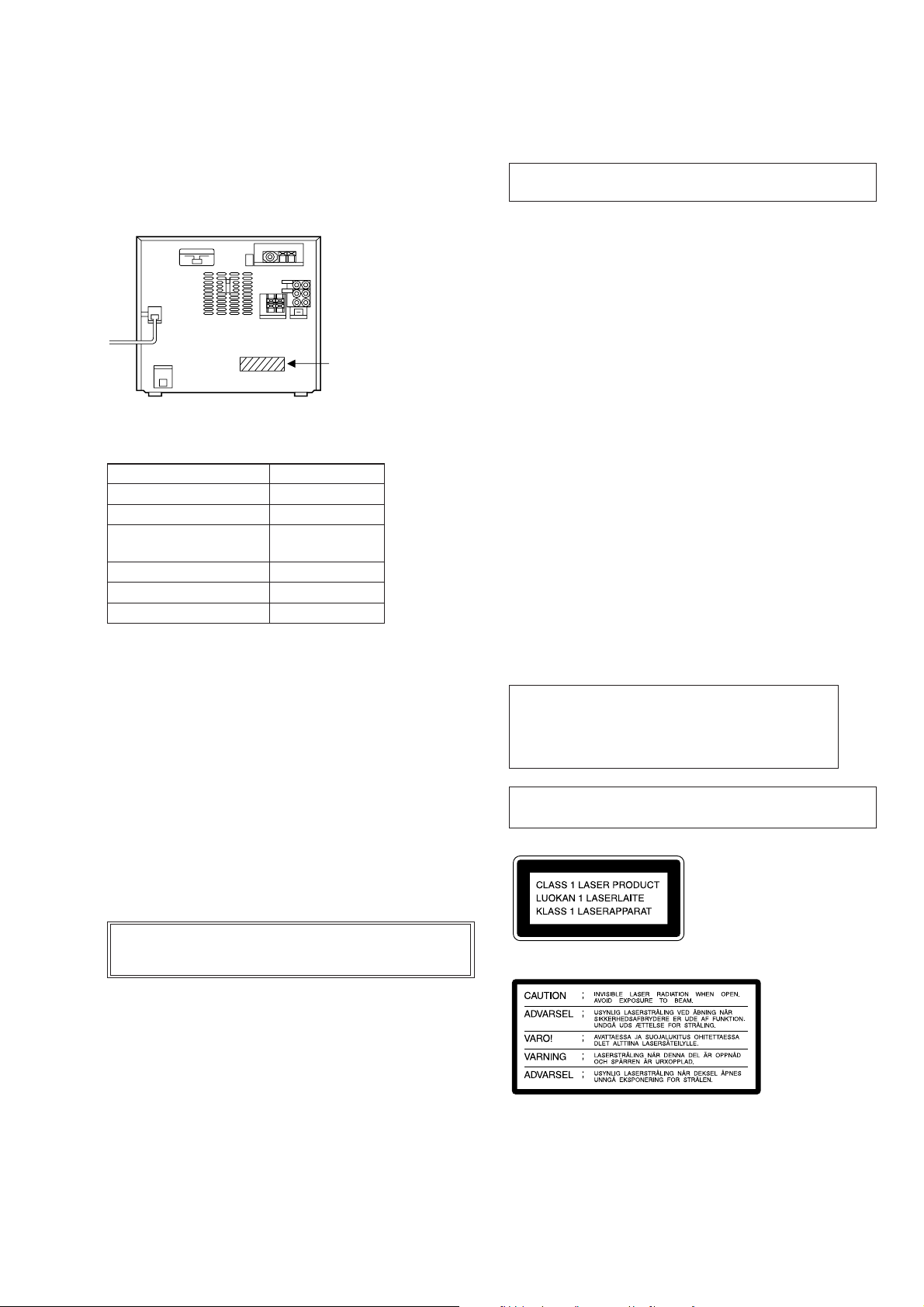

— BACK PANEL —

Parts No.

MODEL PARTS No

AEP model 4-984-208-1π

UK model 4-984-208-2π

Saudi Arabia, Singapore, 4-984-208-3π

Malaysia model

German model 4-984-208-4π

Hong Kong model 4-984-208-5π

Tourist model 4-984-208-7π

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270 ˚C during re-

pairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Note:

Be sure to connect all wires (including FFC) in the MD

section before applying power or ICs may be damaged.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

Laser component in this product is capable of emitting radiation exceding the limit for Class 1.

This appliance is classified as a

CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on the

rear exterior.

This caution label

is located inside

the unit.

– 3 –

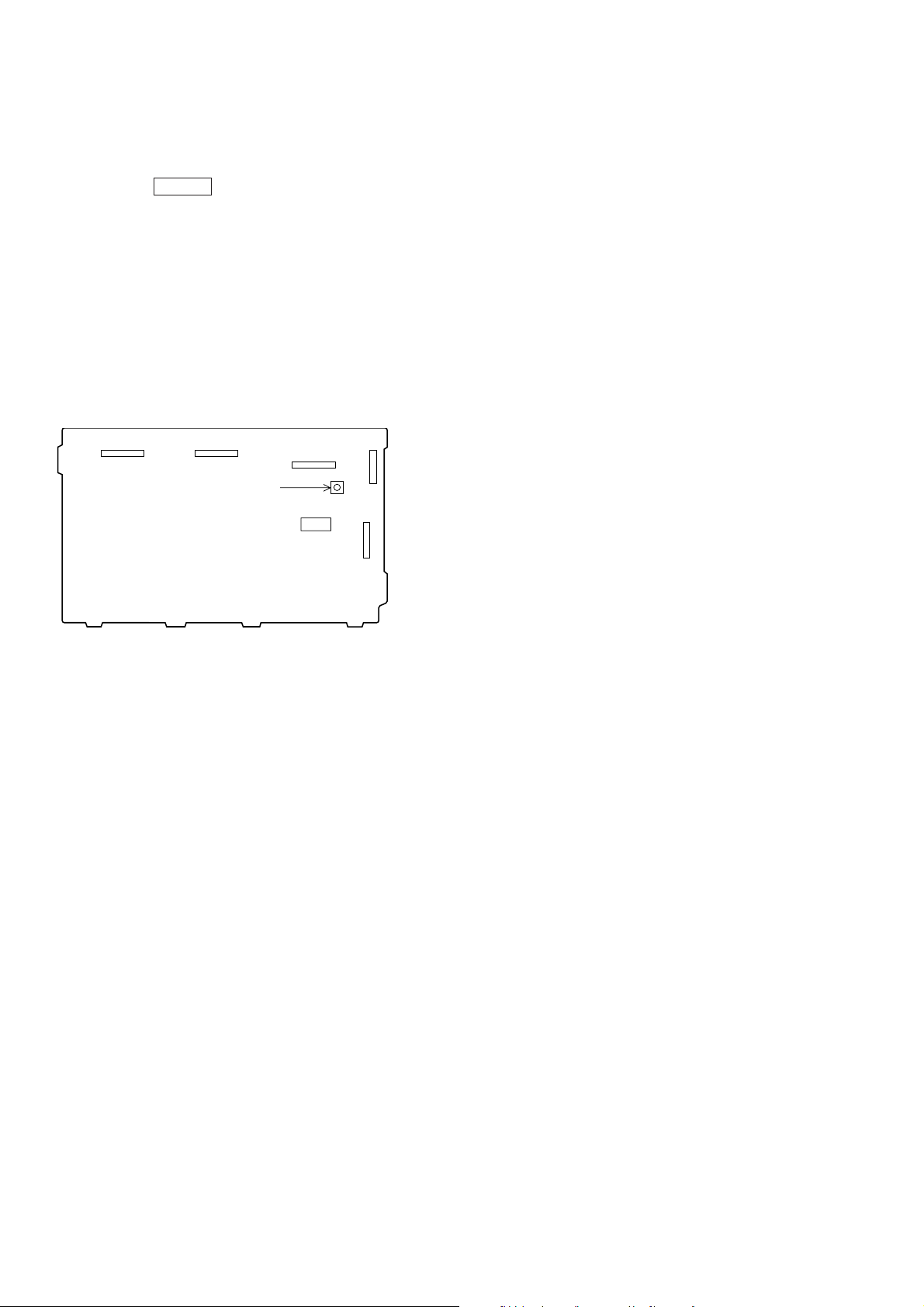

COLD START METHOD

While pressing the POWER key, insert the AC plug cord into the

AC outlet. Cold start will be set.

Note :

As cold start will erase all the preset contents etc., do not set it in

normal operations.

FORCED RESET SWITCH

The switch on the power board (S101) is the forced reset switch for

IC201.

Press it for about one second after turning on the power after disassembling and assembling the unit again.

• Parts Location

[POWER BOARD] — Component side —

CN803 CN802

S101

RESET

Switch

IC821

CN807

IC102

CN808

– 4 –

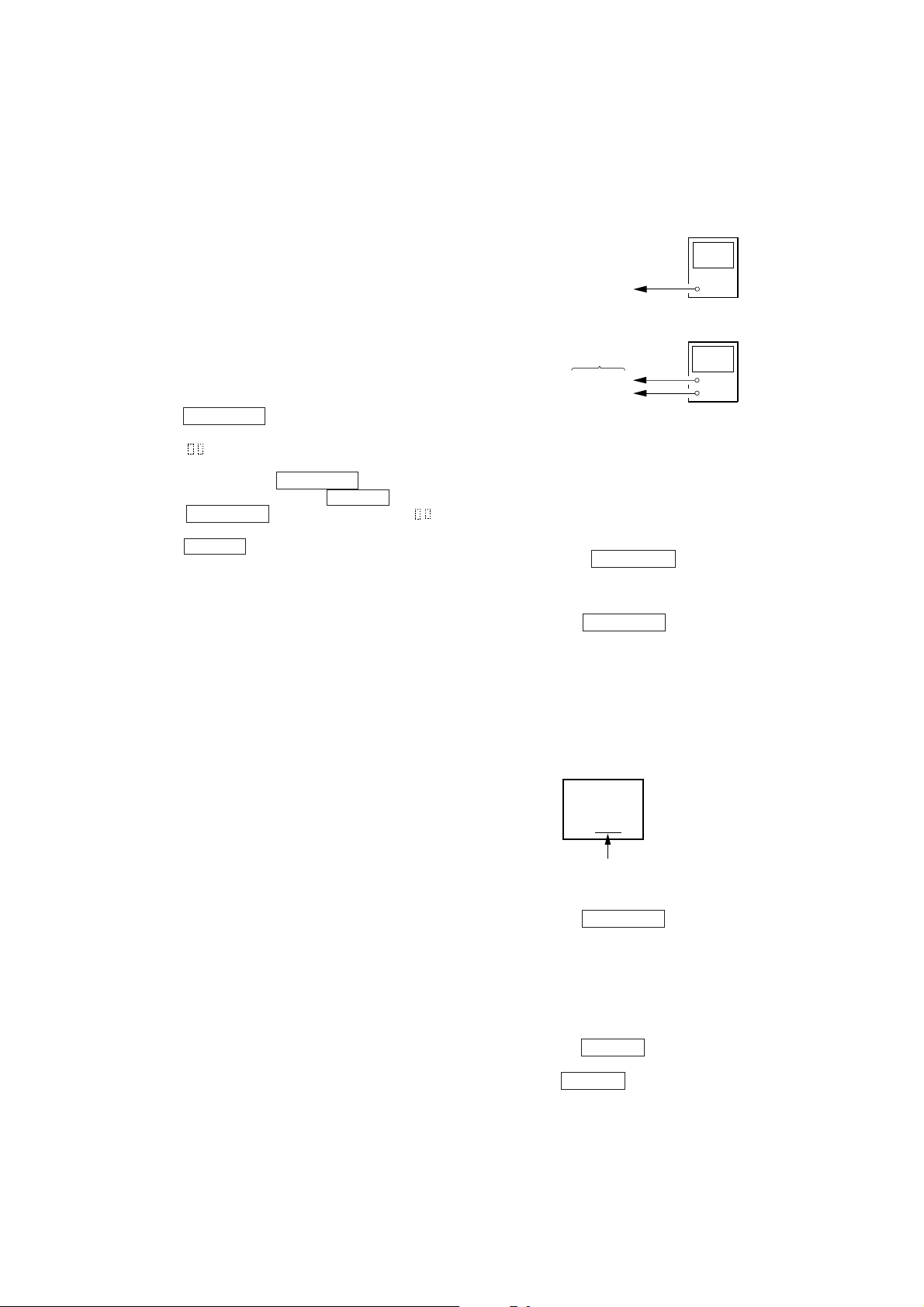

EXCEPT AEP,

l

German, UK mode

SECTION 2

GENERAL

This section is extracted

from instruction manual.

Rear Panel

6

AEP, German, UK model

67

8

4

5

123

1 CD OPTICAL DIGITAL OUT jack

2 SPEAKER connectors

(Malaysia, singapore, Saudi Arabia, Hong Kong, Tourist model)

3 AU BUS connector

4 TAPE input/output jack

5 VIDEO GAME/VCR connectors

6 Aerial terminals

7 SIGNAL Ground terminal

8 VOLTAGE SELECTOR

· (MD play) button

∏ (MD pause) button

π (MD stop) button

§ (MD EJECT) button

MD slot

!∞ SYSTEM POWER switch

!§ FUNCTION button

!¶ MD control button

Controls

Front Panel

Index to Parts and

!• DBFB button

!ª GROOVE button

@º CD SYNC button

@¡ r REC button

@™ PHONES jack

@£ LOOP button

· (CD play) button

∏ (CD pause) button

π (CD stop) button

§ (CD EJECT) button

@¢ EX-CHANGE button

@∞ DISC SKIP button

@§ CD control button

@¶ DISC 1-3 buttons

@• DISC TRAY

1 TUNER/BAND button

2 PLAY MODE/TUNING MODE button

3 REPEAT/STEREO/MONO button

4 1/ALL DISCS button

5 DISPLAY button

6 TIMER SET button

7 TIMER SELECT button

←/→ CUSOR button

!™ VOLUME control

8 EDIT/NO button

9 MULTI JOG control

0 ENTER/YES button

!£ CHARACTER button

!¡ º/‚ (fast backward/fast forward)

!¢ PRESET EQ button

– 5 –

– 6 –

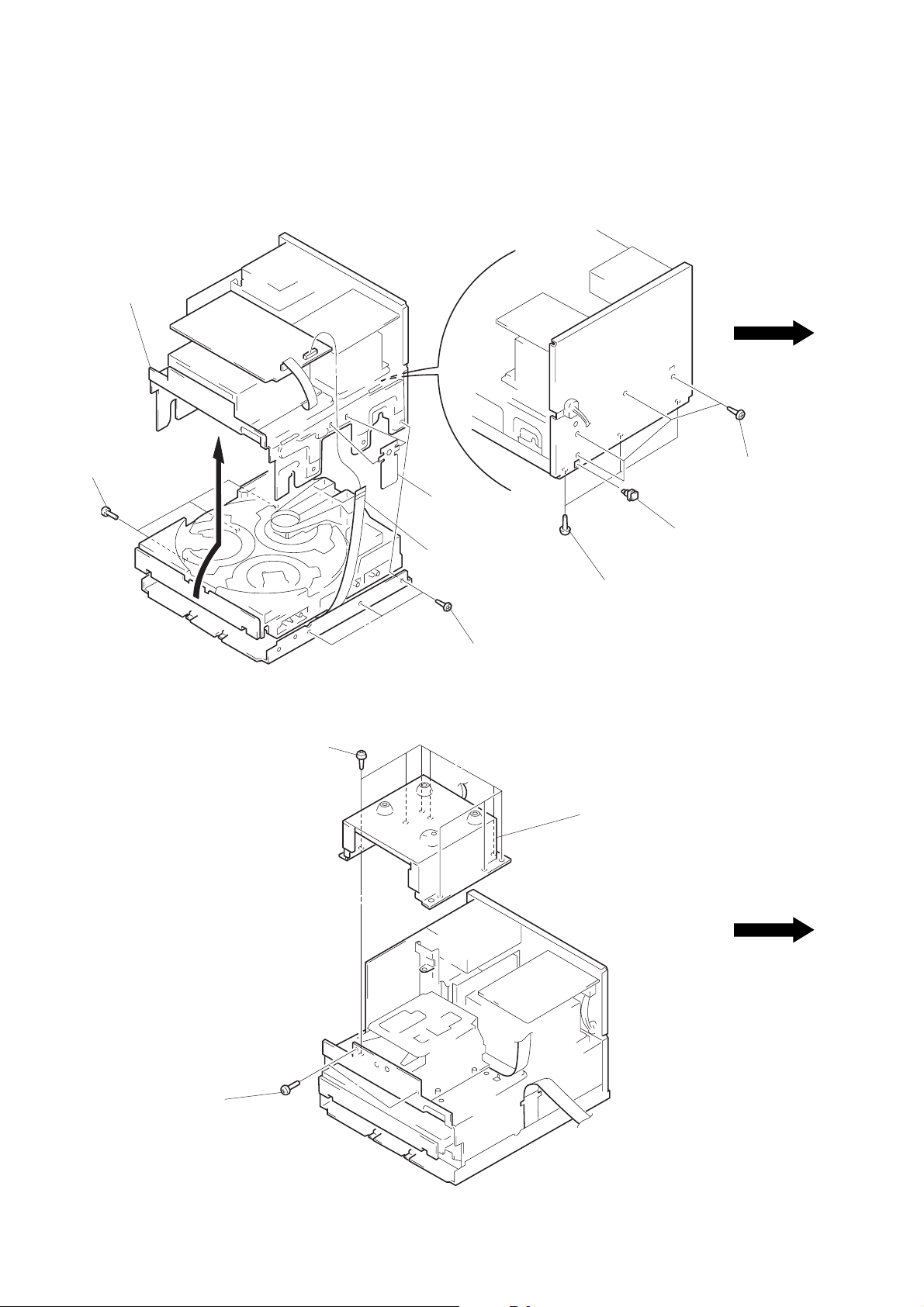

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE, FRONT PANEL ASS’Y

1

four screws

(CASE 3 TP2)

4

connector

(CN906)

3

flat wire (22 core)

(CN103)

2

case

1

four screws

(CASE 3 TP2)

1

four screws

(CASE 3 TP2)

7

front panel ass‘y

POWER BOARD

1

connector

(CN881)

6

three claws

3

4

connector

(CN804)

five screws

×

8)

(BV3

5

three screws

(BV3

3

flat wire (19 core)

(CN805)

×

8)

1

two connectors

(CN802, 803)

5

POWER board

– 7 –

2

2

flat wire (23 core)

(CN808)

flat wire (21 core)

(CN807)

BRACKET (MAIN) SECTION

6

bracket (MAIN)

section

5

three screws

×

8)

(BV3

3

cover (FFC)

4

flat wire (21 core)

(CN807)

1

three screws

(BV3

1

2

supplied OPT cap

×

8)

four screws

×

8)

(BV3

SHIELD CASE (MD)

1

two screws

(BV3

5

three screws

×

8)

(BV3

1

eight screws

(BV3

×

8)

2

shield case

(MD)

×

8)

– 8 –

CD MECHANISM

2

CD mechanism

1

two boss

MD MECHANISM SECTION

2

three screws

(BV3

4

MD mechanism

section

1

connector

(CN101)

×

8)

2

screw

(BV3

×

8)

3

cover (MDM)

(AEP, UK, German)

– 9 –

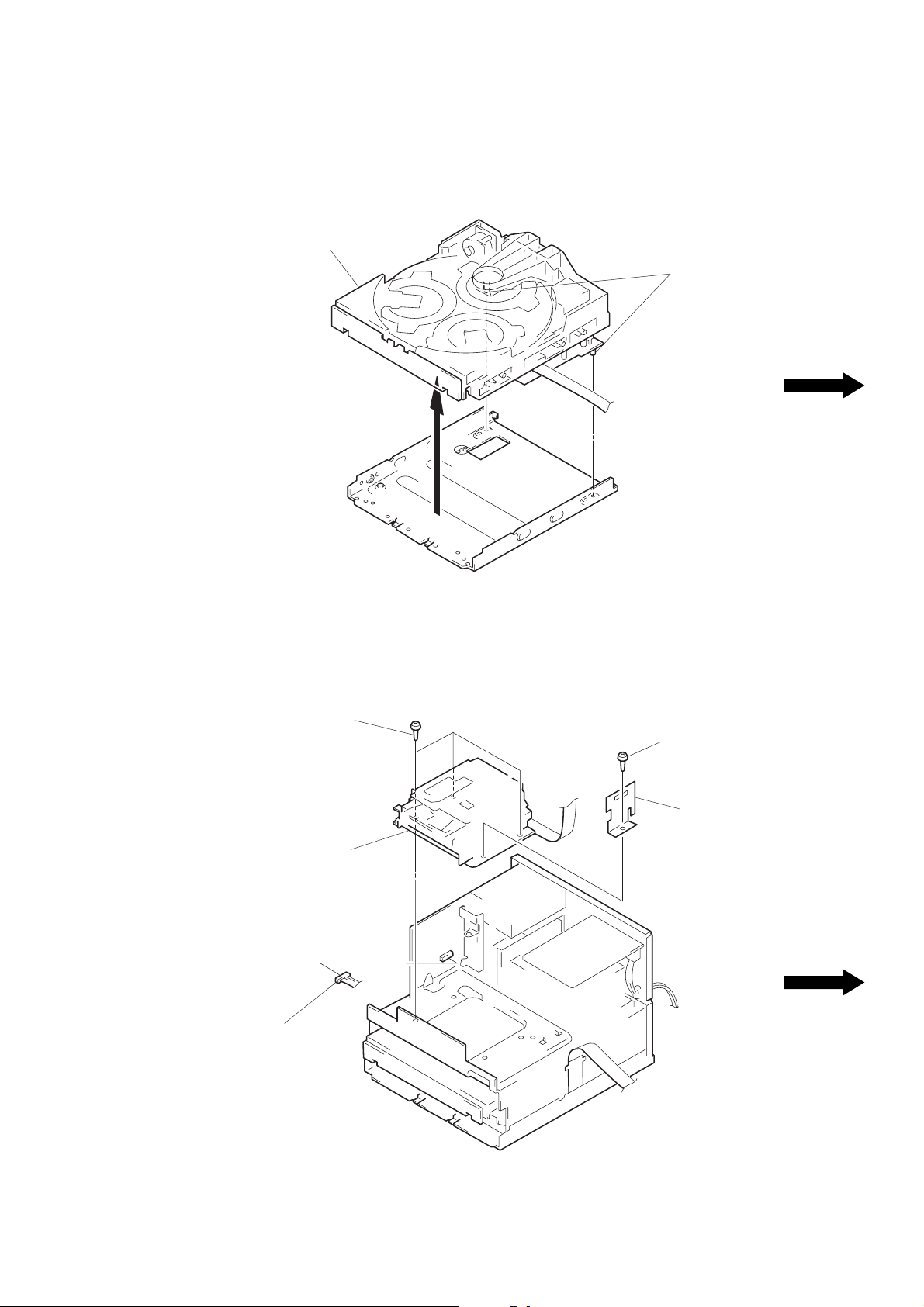

DISC TRAY

4

two claws

3

flat wire (8 core)

2

Pull the disc tray.

5

Remove the disc tray.

flat wire

claw

A

claw

B

Note: When mounting the disc tray, route a flat

cable through claw

in the figure.

1

Rotate the cam to direction

of the arrow.

A

and B as shown

MD MECHANISM

4

two screws

×

18)

(B2.6

5

two

collars

7

MD mechanism

5

two collars

4

two screws

(B2.6

×

18)

B

2

connector (CN251)

3

flat wire (30 core)

(CN202)

3

flat wire (18 core)

(CN221)

6

1

Turn the lever (SLM) toward

direction

(M) assembly toward direction

screw (BTT2.6 × 4)

A

, and slide the slider

A

B

Slider (M) ass’y

lever (SLM)

.

– 10 –

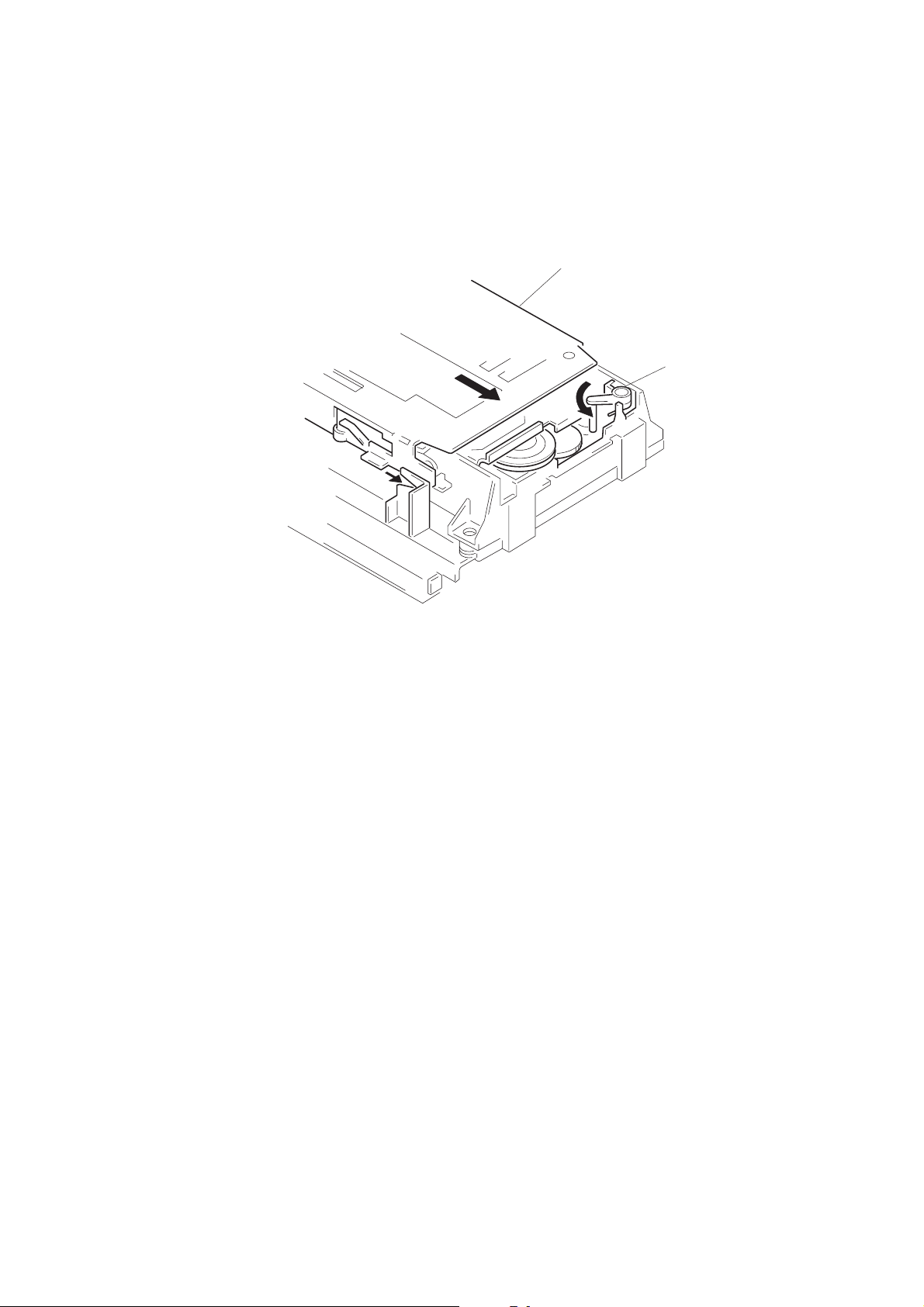

INSTALLATION DISC TRAY

Note: When mounting the disc tray, the collars

A

and B must be engaged in the grooves

respectively .

callar

A

ditch

callar

B

SLIDER (M) ASS’Y

claw

claw

B

C

claw

A

1

Remove a torsion coil

spling from the claw

2

Disengaging the claw B,

raise the lever (SLM) upw ard

to remove.

A

.

A

– 11 –

B

3

Slide the claw C of the slider

(M) assembly up the base

groove in direction

raise the slider (M) assembly

in direction

base groove

B

to remove.

A

, and

INSTALLATION BU CAM ASS’Y BASE UNIT, ROTALY ENCODER

portion A

When mounting the BU cam assembly,

it must be engaged with the rotaly

encorder switch as shown.

When mounting the base unit, insert the

portion A into a groove in the BU cam.

BASE UNIT, LOADING MOTOR ASS’Y

1

screws

×

6)

(BV3

3

belt

4

two screws

(B2.6

×

5)

5

connector

(CN192)

6

loading motor ass’y

2

base unit

– 12 –

1

screw

(BV3

×

6)

INSTALLATION SLIDER (M) ASS’Y

B

2

Slide the slider (M) assembly

toward direction

be locked with the lev er (SLM).

A

B

unit it can

1

Turn fully the lever (SLM)

toward direction

A

.

– 13 –

SECTION 4

n

TEST MODE

Note:

Be sure to connect all wires (including FFC) in the MD

section before applying power or ICs may be damaged.

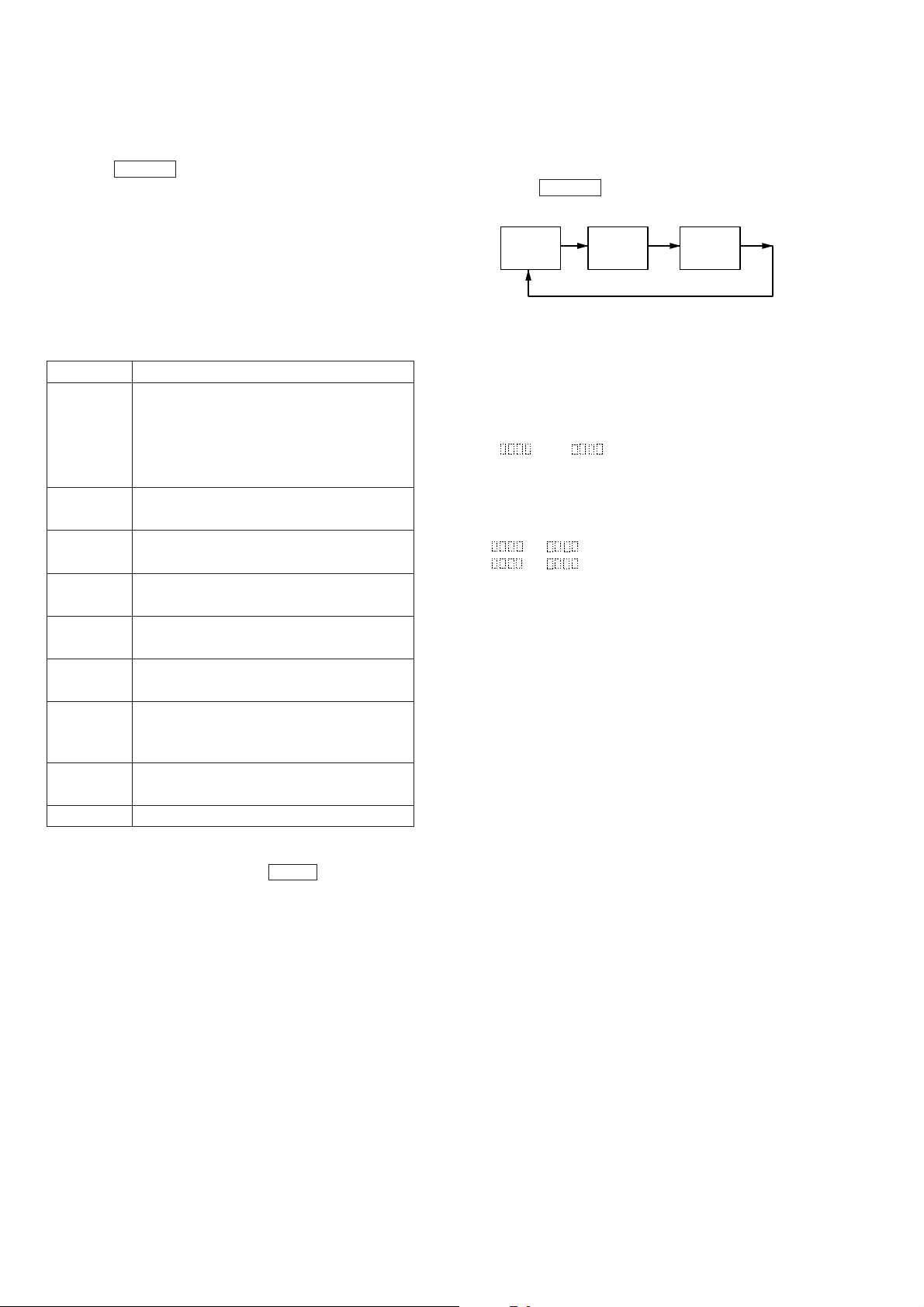

4-1. OUTLINE

This unit is provided with the following test modes.

1. Check mode for amplifier section

2. Aging mode for CD and MD sections

3. Fluorescent indicator tube and check mode for keys

4. Tracking balance display mode for CD section

5. Check mode for clock function

6. Test mode for MD section

4-2. CHECK MODE FOR AMPLIFIER SECTION

4-2-1. Setting the Check Mode

• Turn ON the power of the unit, and set the check mode by press-

ing the following keys together.

PLAY MODE + π (CD) + GROOVE

When set, the following will be displayed.

EQ - FLT

DBFBAE-0

TUNER

VOL

The function before the check

mode is set is displayed.

(E.g.)

If the function before the check

mode is set is CD, then “CD”

will be displayed.

Differs according to the destination.

AEP,UK models : AE

German model : AE4

Saudi Arabia, Hong Kong, Singapore,

Malaysia models : EA3

Tourist model : JE

4-2-2. Releasing the Check Mode

1. Press the POWER key.

2. The unit sets into the mode for normal operations.

maximum indicatio

4-2-3. Operating the Check Mode

* When the following keys ar e pressed in the check mode state (Re-

fer to Table 4-1.), the switching state of the DBFB, VOLUME,

EQUALIZER functions and VIDEO/GAME functions can be

checked.

Table 4-1

Key Function Display

DBFB ON/OFF switching of the DBFB DBFB-1/

function DBFB-0

DISC 1 Equalizer minimum EQ-MIN

DISC 2 Equalizer flat EQ-FLT

DISC 3 Equalizer maximum EQ-MAX

rREC Volume center

VOLUME

VOLUME

FUNCTION

Volume maximum

Volume minimum

VIDEO/GAME function on VIDEO/GAME

switching

VOL indicator

center position

VOL indicator

maximum position

VOL indicator

minimum position

4-3. AGING MODE FOR CD AND MD SECTIONS

4-3-1. Setting the Aging Mode

1. Load the mini disc (recordable disc) into the MD slot and three

discs onto the CD tray.

2. Turn OFF the power of the unit, and set the aging mode by pressing the following keys together.

DISPLAY + ∏(MD) + GROOVE

4-3-2. Releasing the Aging Mode

1. Press the POWER key.

2. The unit sets into the mode for normal operations.

4-3-3. Operating the Aging Mode

1. When this mode is set, synchro dubbing onto the mini disc is

started, and each time a cycle ends, the cycle number is displayed. When the mini disc has recorded 40 songs on its 30

second track, it erases all the songs.

2. During the aging mode, the VOL display blinks.

– 14 –

3. If errors occur during or after aging, the error messages in the

following table will be displayed.

Table 4-2.

Error Message Contents

MD A-Erase NG Cannot all-erase MD.

MD R-Pause NG Cannot record-pause MD.

MD D-Input NG Cannot lock MD digital in.

Cannot playback last MD song.

MD Play NG (The played back track is not the last

track (access error)).

MD Section

MD TOC NG

MD No Disc NG

CD Focus NG CD focus NG

CD GFS NG CD GFS (Garde frame sync) NG.

CD TOC NG 16 seconds after reading CD TOC.

CD SEARCH NG 16 seconds after CD search.

CD SERVO OK servo system error. May be displayed

CD Section

Refer to NOTE 1.

Note 1:

MD TOC are abnormal.

(The total track is abnormal.)

Cannot read MD TOC.

(Disc error)

Not an error message indicating

during STOP.

Sound jumps lasting more than 1

second during play back.

CD1*99 1m23s

4-4. FLUORESCENT INDICATOR TUBE AND

CHECK MODE FOR KEYS

4-4-1. Setting the Check Mode

• Turn OFF the power of the unit, and set the check mode by press-

ing the following keys together.

§ (MD) + π (MD) + GROOVE

When set, the fluorescent indicator tube and all LEDs will light

up.

4-4-2. Releasing the Check Mode

• Press the POWER key during the check mode for the fluores-

cent indicator tube, or press any key during the check mode for

each key when the display shows “KEY = OK”. The unit sets into

the mode for normal operations.

4-4-3. Operating the Check Mode

• Each time the ENTER/YES key is pressed in the check mode for

the fluorescent indicator tube, the display changes in three ways.

The LED lighting pattern can be changed by rotating the MUL TI

JOG dial.

• Check Mode of Keys

Press the EDIT/NO key to set this mode.

When set, the following will be displayed.

KEY=0JOG=0

The display counts up each time a key is pressed.

(It will not count up when a key already pressed once is pressed

again.) The order of pressing the key and the count up are not

related.)

Point at which sound

jumps occurred.

track number

*

is displayed at the point the

sound jump occurred.

- is displayed normally.

disc number

When a key is pressed.

When all the keys are pressed,

this will be displayed.

(There are altogether 33 keys.)

When a key is pressed during

this display, this check mode

will end.)

KEY

KEY

KEY

=

0JOG=0

=

=

O

1

K

JOG=0

JOG=0

– 15 –

When the MUTLI JOG dial and V OLUME contr ol dial are rotated,

the JOG count display will count up or down accordingly.

(E.g.)

JOG =

This value will be as follows (JOG

count display).

(When the JOG dial is rotated right.)

0 1 2 99 1

Note: To end this mode, KEY=OK must be displayed.

4-5. TRACKING BALANCE DISPLAY MODE FOR

CD SECTION

4-5-1. Setting and Operating the Tracking Balance Indi-

cation Mode

1. Turn ON the power of the unit, and press the [FUNCTION] k ey

to set the CD mode.

(This mode cannot be set if the function is not CD.)

2. Set this mode by pressing the π(CD) + DISPLAY keys together.

3. When set, the following will be displayed.

CD .TR BAL 3.2

4-6. CHECK MODE FOR CLOCK FUNCTION

4-6-1. Setting and Operating the Check Mode

1. Turn OFF the power of the unit.

2. Set this mode by pressing the π (MD) + DISPLAY keys

together.

3. When set, the clock display will be highlighted.

Note: In this mode, the clock display is highlighted only for a short

time. If necessary, press the π (MD) + DISPLAY keys

together again.

(This mode is automatically released.)

VOL

Note:In this mode, the display is lit only for a short time. If neces-

sary, press the πCD + DISPLAY keys together again.

(This mode is automatically released.)

– 16 –

4-7. TEST MODE FOR MD SECTION

4-7-1. Setting the Test Mode

• Turn OFF the power of the unit, and set the test mode by pressing

the following keys together.

FUNCTION + PRESET EQ + GROOVE

When set, the following will be displayed.

MTBU

EMP

4-7-2. Replase the Test Mode

1. Press the REPEAT key.

2. The set thus becomes available for normal operation.

4-7-3. Basic Operation of the Test Mode

• All operations are performed using the MULTI JOG dial,

ENTER/YES key, and EDIT/NO key.

• The functions of these keys are as follows.

Key Contents

MULTI JOG dial Changes parameters and models.

ENTER/YES key

EDIT/NO Key

4-7-4. Selecting the Test Mode

Eight test modes are selectied by turning the MULTI JOG dial.

Display Contents

TEMP ADJUST

LDPWR ADJUST Laser power adjustment

EFBAL ADJUST Traverse (E-F balance) adjustment

FBIAS ADJUST Focus bias adjustment

FBIAS CHECK Focus bias check

CPLAY MODE Continuous playback mode

CREC MODE Continuous reading mode

EEP MODE Non-volatile memory mode (*1)

• For detailed description of each adjustment mode, refer to sec-

tion 5. Electrical Adjustments.

• If a different adjustment mode has been selected by mistake,

press the EDIT/NO key to exit from it.

*1: The EEP MODE is not used in servicing. This mode reads and

writes the contents of the non-volatile memory. If set accidentally, press the EDIT/NO key immediately to exit it.

Proceeds onto the next step.

Finalizes input.

Returns to previous step.

Stops operation.

Tes t

de

AD JUMoST

Table 4-3.

Table 4-4.

Temperature compensation offset

adjustment

4-7-5. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

1) Set the disk in the unit (either MO or CD).

2) Turning the MUL TI JOG dial and display “CPLAY MODE”.

3) Press the ENTER/YES key to change the display “CPLAY

IN” .

4) When access cpmpletes, the display changes to

“C1 = AD = ”.

Note: The “ ” displayed are arbitrary numbers.

2. Changing the parts to be played-back

1) Press the ENTER/YES key during continuous playback to

change the display to “CPLAY MID”, “CPLAY OUT”.

When pressed another time, the parts to be played-back can

be changed.

2) When access completes, the display changes to

“C1 = AD = ”.

Note: The “ ” display are arbitrary numbers.

3. Ending the continuous playback mode

1) Press the EDIT/NO key. The display will change to “CPLA Y

MODE”.

2) Press the §(MD) key and remove the disc.

Notes:

1. The playback start addresses for IN, MID, and OUT are as

follows.

IN: 40h cluster

MID: 300h cluster

OUT: 700h cluster

2. The EDIT/NO KEY can be used to stop playing any time.

4-7-6. Operating the Continuous Recording Mode

1. Entering the continuous recording mode

1) Set the MO disc in the unit.

2) Turning the MULTI JOG dial and display “CREC MODE”.

3) Press the ENTER/YES key to change the display to “CREC

IN”.

4) When access completes, the display changes to “CREC

( )” and REC lights up.

Note: The “ ” displayed are arbitrary humbers.

2. Changing the parts to recorded

1) When the ENTER/YES key is pressed during continuous

recording, the display changes to “CREC MID”, “CREC

OUT” and REC goes off. When pressed another time, the

parts to be recorded can be changed.

2) When access completes, the display changes to “CREC

( )” and REC lights up.

Note: The “ ” displayed are arbitrary numbers.

3. Ending the continuous recording mode

1) Press the EDIT/NO key . The display will change to “CREC

MODE” and REC goes off.

2) Press the §(MD) key and remove the disc.

Notes:

1. The recording start address for IN, MID, and OUT are as

follows.

IN : 40h cluster

MID : 300h cluster

OUT: 700h cluster

– 17 –

2. The EDIT/NO key can be used to stop recording anytime.

3. During the test mode, the erasing-protection tab will not be

detected. Therefore be carefull not to set the continuous recording mode when a disc not be erased is set in the unit.

4. Do not perform continuous recording for long periods of

time above 5 minutes.

5. During continuous recording, be carefull not to apply vibration.

4-7-7. Function of other keys

4-7-8. Test Mode Displays

• Each time the DISPLA Y ke y pressed, the display changes in the

following order.

MODE

display

Error rate

display

Address

display

table 4-5.

CentensKey

Sets continuous playback when pressed in the

STOP state. (servo all on)

·(MD)

When pressed during continuous playback, the

tracking and sled servo turns off.

When pressed during tracking and sled servo

turned off, the turns on.

π(MD)

)

0

r REC

TIME

CONTROL

PLAY

MODE

DISPLAY

§(MD)

Stop continuous playback and continuous recording. (servo all off)

The sled moves to the outer circumference only

when this is pressed.

The sled moves to the inner circumference only

when this is pressed.

Turns recording on/off w hen pressed during continuous playback.

Switches between the pit and groove modes when

pressed.

Switches between the CLV-S (pull-in mode) and

CLV-A (playing servo) modes when pressed.

(Switches the spindle servo mode.)

Switches the display when pressed.

Returns to previous step. Stops operatios.

Disc eject

Note: The erasing-protection tab in not detected during the test

mode. Recording will start regardless of the position of the

erasing-protection tab when the r REC key is pressed.

1. MODE display

Display “TEMP ADJUST”, “CPLAY MODE”, etc.

2. Error rate display

Error rates are displayed as follows.

C1 = AD =

C1 = : Indicates C1 error

AD = : Indicates ADER

3. Address display

Address are displayed as follows.

h = s = (MO pit and CD)

h = s = (MO groove)

h = : Header address

s = : SUB Q address

a = : ADIP address

Note: “—” is display when the address cannot be read.

– 18 –

4-7-9. Meanings of Other Displays

Table 4-6.

Display Contents

Light Off Blinking

During continuous

(

REC

SYNC CLV lock state CLV unlock state

TRACK Pit mode Groove mode

DISC

LEVEL-

SYNC

PROGRAM

SHUFFLE

playback

(servo all on)

Tracking and Tracking and

P

sled servo off sled servo on

Recording mode Recording mode

on off

High reflection Low reflection

rate disc rate disc

Spindle servo Spindle servo

CLV-S (pull-in CLV-A (playing

mode) mode)

ABCD adjustment

Completed

Focus auto gain Focus auto gain

and tracking successful,

auto gain tracking auto

successful gain failed

Stop state

(servo all off)

not adjustment

4-7-10. Precautions for Use of Test Mode

1. As loading related operations will be performed regardless of

the test mode operations being performed, be sure to check that

the disc is stopped before setting and removing it.

Even if the §(MD) key is pressed while the disc is rotating

during continuous playback, continuous recording, etc., the disc

will not stop rotating.

Therefore, it will be ejected while rotating.

Always press the EDIT/NO key first before pressing the

§(MD) key.

2. The erasing-protection tab is not detected in the test mode. Therefore, when modes which output the recording laser power such

as continuous recording mode and traverse adjustment mode,

etc. are set, the recorded contents will be erased regardless of

the position of the tab. When using a disc that is not to be erased

in the test mode, be careful not to enter the continuous recording mode and traverse adjustment mode.

– 19 –

SECTION 5

ELECTRICAL ADJUSTMENTS

Note:

Be sure to connect all wires (including FFC) in the MD

section before applying power or ICs may be damaged.

MD SECTION

5-1. PRECAUTIONS FOR CHECKING LASER DI-

ODE EMISSION

To check the emission of the laser diode during adjustments,

never view directly from the top as this may lose your eyesight.

5-2. PRECAUTIONS FOR USE OF OPTICAL PICK-

UP (KMS-210A)

As the laser diode in the optical pick-up is easily damaged by

static electricity, solder the laser tap of the fle xible board when

using it.

Before disconnecting the connector, desolder first. Before connecting the connector, be careful not to remove the solder.

Also tale adequate measures to prevent damage by static electricity. Handle the fle xible board with care as it breaks easily.

Laser tap

Optical pick-up flexible board

5-3. PRECAUTIONS FOR ADJUSTMENTS

1) When replacing the following parts, perform the adjustments

and checks with ® in the order shown in the following table.

Optical

Pick-up

1. Temperature

compensation

offset adjustment

2. Laser power

adjustment

3. Traverse

adjustment

4. Focus bias

adjustment

5. Error rate check

2) Set the test mode when performing adjustments.

After completing the adjustments, exit the test mode.

3) Perform the adjustments in the order shown.

4) Use the following tools and measuring devices.

• Test disc (CD) TDYS-1 (Parts No. 4-963-646-01)

• Laser power meter LPM-8001 (Parts No. J-2501-046-A)

• Oscilloscope

• Digital voltmeter

• Thermometer

5) When observing several signals on the oscilloscope, etc., make

sure that VC and GND do not connect inside the oscilloscope.

(VC and GND will become short-circuited)

IC171 D101 IC101, IC121, IC191

× ®® ®

® ×× ®

®®× ®

®®× ®

®®× ®

BD (MD) board

5-4. Creating MO Continuously Recorded Disc

* This disc is used in focus bias adjustment and error rate check.

The following describes how to create a MO continuous recording disc.

1. Set the test mode.

2. Insert a MO disc (blank disc) commercially available.

3. Turning the MULTI JOG dial and display “CREC MODE”.

4. Press the ENTER/YES key and display “CREC IN”.

5. Press the ENTER/YES key again to display “CREC MID”.

“CREC (0300)” is displayed for a moment and recording starts.

6. Complete recording within 5 minutes.

7. Press the EDIT/NO key and stop recording.

8. Press the § (MD) key and remove the MO disc.

The above has been how to create a continuous recording data for

the focus bias adjustment and error rate check.

Note:

• Be careful not to apply vibration during continuous recording.

– 20 –

5-5. TEMPERATURE COMPENSATION OFFSET

r

+

–

BD (MD) board

TP (I+5V)

TP (IOP)

digital voltmeter

ADJUSTMENT

Save the temperature data at that time in the non-volatile memory

as 25°C reference data.

Note:

1. Usually, do not perform this adjustment.

2. Perform this adjustment in an ambient temperature of 22°C to

28°C. Perform it immediately after the power is turned on when

the internal temperature of the unit is the same as the ambient

temperature.

3. When D101 has been replaced, perform this adjustment after

the temperature of this part has become the ambient temperature.

Adjusting Method:

1. Turning the MULTI JOG dial and display “TEMP ADJUST”.

2. Press the ENTER/YES key and select the “TEMP ADJUST”

mode.

3. “TEMP = ” and the current temperature a data will be displayed.

4. To save the data, press the ENTER/YES key.

When not saving the data, press the EDIT/NO key.

5. When the ENTER/YES key is pressed, “TEMP= SAVE”

will be displayed for some time, followed by “TEMP ADJUST”.

When the EDIT/NO key is pressed, “TEMP ADJUST” will be

displayed.

Specifications:

The temperature should be within “E0-EF”, “F0-FF”, “00-0F”,

“10-1F” and “20-2F”.

5-6. LASER POWER ADJUSTMENT

Connection:

laser

power mete

Optical pick-up

objective lens

Adjusting Method:

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, press the 0 key or

) key and move the optical pick-up.)

Connect the digital voltmeter to TP (IOP) and TP (I+5V).

2. Turning the MULTI JOG dial and display “LDPWR ADJUST”.

(Laser power: For adjustment)

3. Press the ENTER/YES key twice and display “LD $ 4B

=3.5mW”.

4. Adjust RV102 of the BD (MD) board so that the reading of the

laser power meter becomes 3.4 mW.

5. Press the ENTER/YES key and display “LD $96=7.0 mW”.

(Laser power: MO writing)

6. Check that the laser power meter and digital voltmeter readings

satisfy the specified value.

+0.1

–0

Specification:

Laser power meter reading : 7.0 ± 0.3 mW

Digital voltmeter reading : Optical pick-up displayed value ±10%

(Optical pick-up label)

KMS210A

27X40

B0825

lOP=82.5 mA in this case

lOP (mA) = Digital voltmeter reading (mV)/1 (

Ω

)

7. Press the ENTER/YES key and display “LD $ 0F=0.7 mW”.

(Laser power: MO reading)

8. Check that the laser power meter at this time satisfied the specified value.

Specification:

Laser power meter reading: 0.70 ± 0.1 mW

9. Press the EDIT/NO key and display “LDPWR ADJUST”, and

stop laser emission.

(The EDIT/NO key is effective at all times to stop the laser

emission.)

– 21 –

5-7. TRAVERSE (E-F BALANCE) ADJUSTMENT

Note 1) Data will be erased during MO reading if a recorded

disc is used in this adjustment.

Note 2) If the traverse waveform is not clear, connect the os-

cilloscope as shown in the following figure so that it

can be seen more clearly.

330 k

TP (TEO)

TP (VC)

oscilloscope

Ω

+

–

10 pF

11. Turning the MULTI JOG dial until the waveforms of the oscilloscope moves closer to the specified value.

In this adjustment, waveform varies at intervals of approx. 3%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

(Traverse W a v ef orm)

A

VC

B

specification: A=B

Connection:

oscilloscope

BD (MD) board

TP (TEO)

TP (VC)

+

–

Adjusting Method:

1. Connect an oscilloscope to TP (TEO) and TP (VC) of the BD

(MD) board.

2. Load a MO disc (any available on the market).

3. Press the 0 key or ) key and move the optical pick-up

outside the pit.

4. Turning the MULTI JOG dial and display “EFBAL ADJUST”.

5. Press the ENTER/YES key and display “EFBAL MO-W”.

(Laser power WRITE power/Focus servo ON/tracking servo

OFF/spindle (S) servo ON)

6. Adjust RV101 of the BD (MD) board so that the waveform of

the oscilloscope becomes the specified value.

(MO groove write power traverse adjustment)

(T r averse W av ef orm)

A

VC

specification: A=B

B

7. Press the ENTER/YES key and display “EFB=$ MO-R”.

(Laser power: MO reading)

8. Turning the MULTI JOG dial so that waveforms of the oscilloscope becomes the specified value.

(When the MULTI JOG dial is turned, the of “EFB= ”

changes and the waveform changes.) in this adjustment, waveform varies at intervals of approx. 3%. Adjust the waveform so

that the specified value is satisfied as much as possible.

(MO groove read power traverse adjustment)

(T r averse W av ef orm)

A

VC

B

12. Press the ENTER/YES key, display “EFB=$ SAVE” for a

moment and save the adjustment results in the non-volatile

memory.

Next “EFBAL CD” is displayed. The disc stops rotating automatically.

13. Press the § (MD) key and remove the MO disc.

14. Load the test disc TDYS-1.

15. Press the ENTER/YES key and display “EFB=$ CD”. Servo

is imposed automatically.

16. Turning the MULTI JOG dial so that the waveforms of the oscilloscope moves closer to the specified value.

In this adjustment, waveform varies at inter vals of appro x. 3%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

(Traverse W a v ef orm)

A

VC

B

specification: A=B

17. Press the ENTER/YES key, display “EFB=$ SAVE” for a

moment and save the adjustment results in the non-volatile

memory.

Next “EFBAL ADJUST” is displayed.

18. Press the § (MD) key and remove the test disc TDYS-1.

specification: A=B

9. Press the ENTER/YES key, display “EFB=$ SAVE” for a

moment and save the adjustment results in the non-volatile

memory.

Next “EFBAL MO-P” is displayed.

10. Press the ENTER/YES key and display “EFB=$ MO-P”.

The optical pick-up moves to the pit area automatically and servo

is imposed.

– 22 –

5-8. FOCUS BIAS ADJUSTMENT

Adjusting Method:

1. Load a continuously recorded disc (Refer to “5-4. Creating MO

Continuously Recorded Disc”.)

2. Turning the MULTI JOG dial and display “CPLAY MODE”.

3. Press the ENTER/YES key twice and display “CPLAY MID”.

4. Press the EDIT/NO key when “C1= AD= ” is

displayed.

5. Turning the MULTI JOG dial and display “FBIAS ADJUST”.

6. Press the ENTER/YES key and display “ / a= ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [a=] indicate the

focus bias value.

7. Turning the MULTI JOG dial in the clockwise direction and

find the focus bias value at which the C1 error rate becomes

220.

8. Press the ENTER/YES key and display “ / b= ”.

9. Turning the MULTI JOG dial in the clockwise direction and

find the focus bias value at which the C1 error rate becomes

220.

10. Press the ENTER/YES key and display “ / c= ”.

11. Check that the C1 error rate is below 50 and ADER is 00.

Then press the ENTER/YES key.

12. If the “( )” in “ - - ( )” is above 20, press the

ENTER/YES key.

If below 20, press the EDIT/NO key and repeat the adjustment

from step 2 again.

13. Press the EDIT/NO key and press the § (MD) key to remov e

the continuously recorded disc.

Note 1: The relation between the C1 error and focus bias is as shown

in the following figure. Find points a and b in the following

figure using the above adjustment. The focal point position

c is automatically calculated from points a and b.

Note 2: As the C1 error rate changes, perform the adjustment using

the average vale.

C1 error

220

Focus bias value

bcb

(F. BIAS)

5-9. ERROR RATE CHECK

5-9-1. CD Error Rate Check

Checking Method:

1. Load a test disc TDYS-1.

2. Turning the MULTI JOG dial and display “CPLAY MODE”.

3. Press the ENTER/YES key twice and display “CPLAY MID”.

4. “C1= AD= – –” is displayed.

5. Check that the C1 error is below 20.

6. Press the EDIT/NO key, stop playback, press the § (MD)

key, and remove the test disc.

5-9-2. MO Error Rate Check

Checking Method:

1. Load a continuously recorded disc (Refer to “5-4. Creating MO

Continuously Recorded Disc”.)

2. Turning the MULTI JOG dial and display “CPLAY MODE”.

3. Press the ENTER/YES key twice and display “CPLAY MID”.

4. “C1= AD= ” is displayed.

5. If the C1 error rate is below 50, check that ADER is 00.

6. Press the EDIT/NO key, stop playback, press the § (MD)

key, and remove the continuously recorded disc.

5-10. FOCUS BIAS CHECK

Change the focus bias and check the focus tolerance amount.

Checking Method:

1. Load a continuously recorded disc (Refer to “5-4. Creating MO

Continuously Recorded Disc”.)

2. Turning the MULTI JOG dial and display “CPLAY MODE”.

3. Press the ENTER/YES key twice and display “CPLAY MID”.

4. Press the EDIT/NO key when “C1= AD= ” is

displayed.

5. Turning the MULTI JOG dial and display “FBIAS CHECK”.

6. Press the ENTER/YES key and display “ / c= ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c=] indicate the

focus bias value.

Check that the C1 error is below 50 and ADER is 00.

7. Press the ENTER/YES key and display “ / b= ”.

Check that the C1 error is not below 220 and ADER is not above

00 every time.

8. Press the ENTER/YES key and display “ / a= ”.

Check that the C1 error is not below 220 and ADER is not above

00 every time.

9. Press the EDIT/NO key, next press the § (MD) key, and remove the continuously recorded disc.

Note 1: If the C1 error and ADER are above 00 at points a or b, the

focus bias adjustment may not have been carried out properly. Adjust perform the beginning again.

– 23 –

5-11. ADJUSTING POINTS AND CONNECTING POINTS

[BD (MD) BOARD] (Side A)

D101

[BD (MD) BOARD] (Side B)

IC171

(IOP)

RV101

(I+5V)

RV102

IC191

IC101

(VC)

(TEO)

IC121

– 24 –

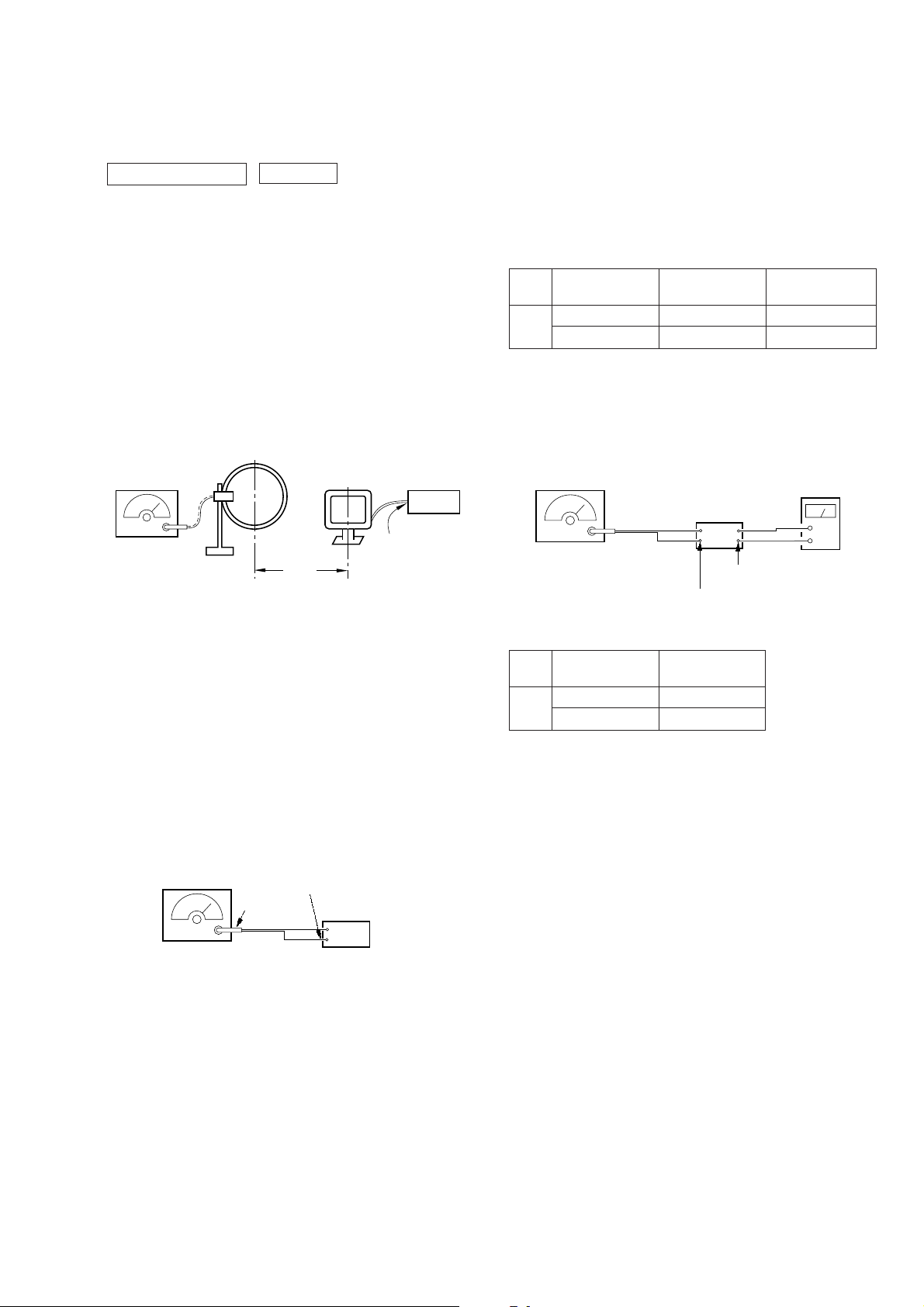

TUNER SECTION

set

AM RF signal

generator

+

–

level meter

SPEAKER terminal

AM ANTENNA terminal (TM1)

30% amplitude

modulation by

400 Hz signal

0 dB=1µV

Precaution in Repairing

Note : As a front-end (FE1) is difficult to repair if faulty, replace it

with new one.

• Abbreviation

EA : Saudi Arabia

MY : Malaysia

SP : Singapore

HK : Hong Kong

AM Tuned Level Adjustment

Note : FM Tuned Level Adjustment Should be performed after this

AM Tuned Level Adjustment.

Setting :

Band : AM or MW

loop antenna A

AM RF signal

generator

loop antenna B

set

SW OSC Voltage Adjustment (EA, MY, SP, HK model)

Setting :

Band : SW

Procedure :

1. Connect digital voltmeter to diode D1 center lead and ground.

2. Adjust for a following value reading on digital voltmeter.

Adjustment Reading on

part digital voltmeter

SW

Set frequency

5.95 MHz T2 1.2 Vdc

17.9 MHz CV2 8.5 Vdc

Adjustment Location : TCB board (see page 26)

SW Tracking Adjustment (EA, MY, SP, HK model)

Setting :

Band : SW

30% amplitude

modulation by

400 Hz signal

Carrier frequency: 999 kHz (at 9 kHz step)

1,050 kHz (at 10 kHz step)

60 cm

AM ANTENNA

terminal (TM1)

Procedure :

1. Set loop antenna A so that the loop antenna B input level becomes 50 dBµ (0.32 mV)

2. Tune the set to 999 kHz (at 9 kHz step) or 1,050 kHz (at 10 kHz

step).

3. Adjust RV41 so that the TUNED indicator goes on.

Adjustment Location : TCB board (see page 26)

FM Tuned Level Adjustment

Note : This adjustment should be performed after the AM Tuned

Level Adjustment.

Setting :

Band : FM

FM RF stereo signal

generator

Carrier frequency : 98 MHz

Modulation : 1 kHz, 75 kHz deviation (100%)

Output level : 25 dB

FM ANTENNA terminal (TM1)

75 Ω coaxial

set

µ

(0.018 mV)

Procedure :

Adjust for maximum reading on level meter.

Adjustment

part

SW

Set frequency

7 MHz T1

17 MHz CV1

• Repeat the procedures is each adjustment several times, and the

OSC voltage and tracking adjustment should be finally done by

the trimmer capacitors.

Adjustment Location : TCB board (see page 26)

Procedure :

1. Tune the set to 98 MHz

2. Adjust RV42 so that the TUNED indicator goes on.

Adjustment Location : TCB board (see page 26)

– 25 –

Adjustment Location

t

+

–

BD (CD) board

TP (RF)

TP (VC)

oscilloscope

(DC range)

+

–

BD (CD) board

TP (FEO)

TP (VC)

oscilloscope

[TCB BOARD] – Component side –

CV1: SW Tracking Adjustmnet

RV41:

AM Tuned Level

Adjustment

CV2:

SW OSC voltage

Adjustment

T2:

SW OSC voltage

Adjustment

RV42:

FM Tuned Level

Adjustment

T1: SW Tracking Adjustmen

D1

FE1

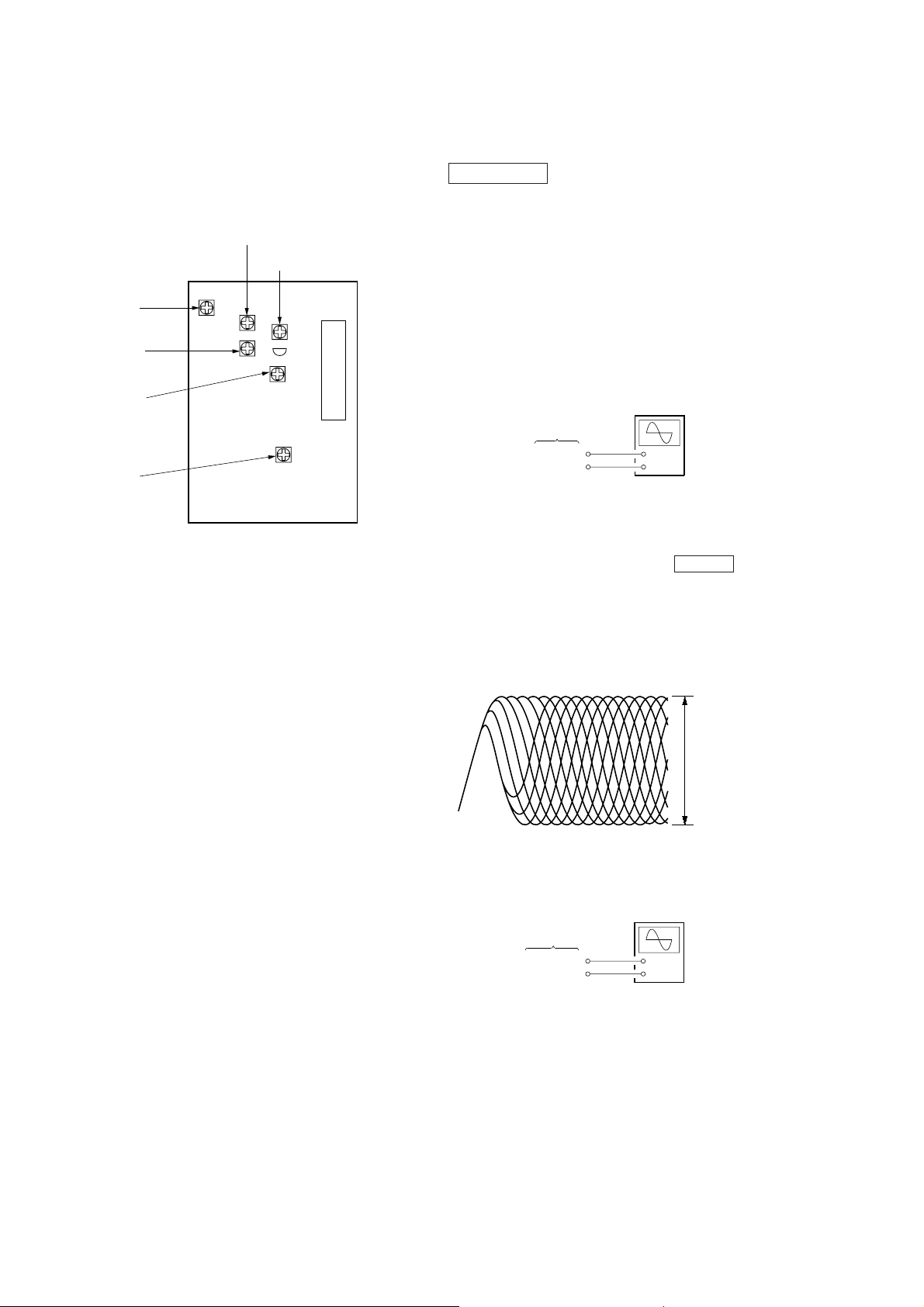

CD SECTION

Note :

1. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

2. Use the oscilloscope with more than 10 MΩ impedance.

3. Clean an object lens by an applicator with neutral detergent when

the signal level is low than specified value with the following

checks.

Focus Bias Adjustment

This adjustment is to be done when the optical pick-up is replaced.

Adjustment procedure :

1. Connect oscilloscope to test point TP (VC) and TP (RF) on BD

(CD) board.

2. Turned power switch ON. (Stop mode)

3. Put disc (YEDS-18) in and press the · (CD) key.

4. Adjust RV101 so that the oscilloscope w a veform is as sho wn in

the figure below (eye pattern).

A good eye pattern means that the diamond shape (≈) in the

center of the waveform can be clearly distinguished.

• RF signal reference waveform (eye pattern)

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

1.3

±

0.3Vp-p

When observing the eye pattern, set the oscilloscope for AC

range and raise vertical sensitivity.

S-Curve Check

Procedure :

1. Connect oscilloscope to test point TP (VC) and TP (FEO) on

BD (CD) board.

2. Connect between test point TP (FOK) and GND by lead wire.

3. Turned Power switch on.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

– 26 –

5. Check the oscilloscope waveform (S-curve) is symmetrical be-

A

B

level: 300

±

100 mVp-p

IC104

IC102

IC101

FEI

TEI

FOK

RF

RV101

RV103

TEO

FEO

VC

RV102

tween A and B. And conf irm peak to peak le v el within 2.4 ± 0.7

Vp-p.

Traverse waveform

S-curve wavef orm

symmetry

A

B

within 2.4

±

0.7 Vp-p

6. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure that the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

oscilloscope

BD (CD) board

TP (RF)

TP (VC)

+

–

Procedure :

1. Connect oscilloscope to test point TP (VC) and TP (RF) on BD

(CD) board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and press the · (CD) key.

4. Confirm that oscilloscope wavefor m is clear and check RF signal level is correct or not.

Note :

Clear RF signal waveform means that the shape “≈” can be

clearly distinguished at the center of the waveform.

specified level :• —————— × 100 = less than ± 7%

A–B

2 (A+B)

• A+B= 300 ± 100 mVp-p

6. Remove the lead wire connected in step 1.

Focus/Tracking Gain Adjustment (RV102, RV103)

This gain has a margin, so ev en if it is slightly off. There is no problem.

Therefore, do not perform, this adjustment.

Please note that it should be fixed to mechanical center position

when you moved and do not know original position.

Adjustment Location :

[BD (CD) BOARD] – Side B –

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level: 1.3

±

0.3Vp-p

E-F Balance (Traverse) Check

oscilloscope

(DC range)

BD (CD) board

TP (TEO)

TP (VC)

+

–

Procedure :

1. Connect the TP (TEI) and TP (VC) with lead wire.

2. Connect oscilloscope to test point TP (VC) and TP (TEO) on

BD (CD) board.

3. Turned Power switch on.

4. Put disc (YEDS-18) in and press the · (CD) key.

5. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0 Vdc, and check this level.

– 27 –

• Circuit Boards Location

PANEL A board

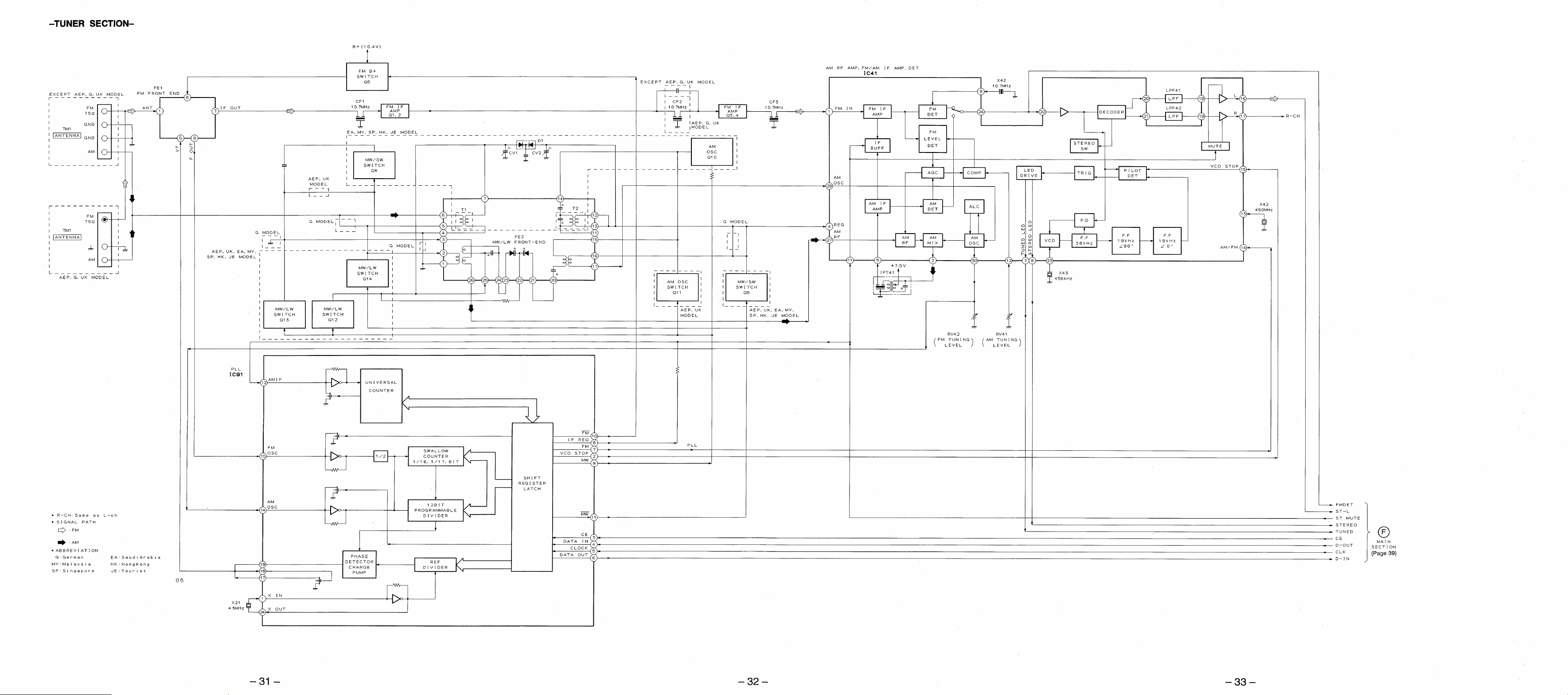

SECTION 6

DIAGRAMS

TCB board

THERMO board

MAIN board

TRANSFORMER board

HEADPHONE board

BD (MD) board

PANEL B board

SENSOR board

POWER board

AMPLIFIER board

MOTOR (TURN) board

CONNECTOR board

DETECTION SW

board

MOTOR board

BD (CD) board

DIGITAL board

RELAY board

MOTOR (SLIDE) board

– 28 –

Loading...

Loading...