Sony HCDMD-333 Service manual

MICROFILM

HCD-MD333

SERVICE MANUAL

HCD-MD333 is the amplifier, CD, MD and

tuner section in DHC-MD333.

Model Name Using Similar Mechanism NEW

CD

SECTION

MD

SECTION

Mechanism Type CDM13C-5BD19

Base Unit Type BU-5BD19

Optical Pick-up Type KSS-213B/K-N

Model Name Using Similar Mechanism NEW

Mechanism Type MDM-3J

Optical Pick-up Type KSM-260A-JIN

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Tourist Model

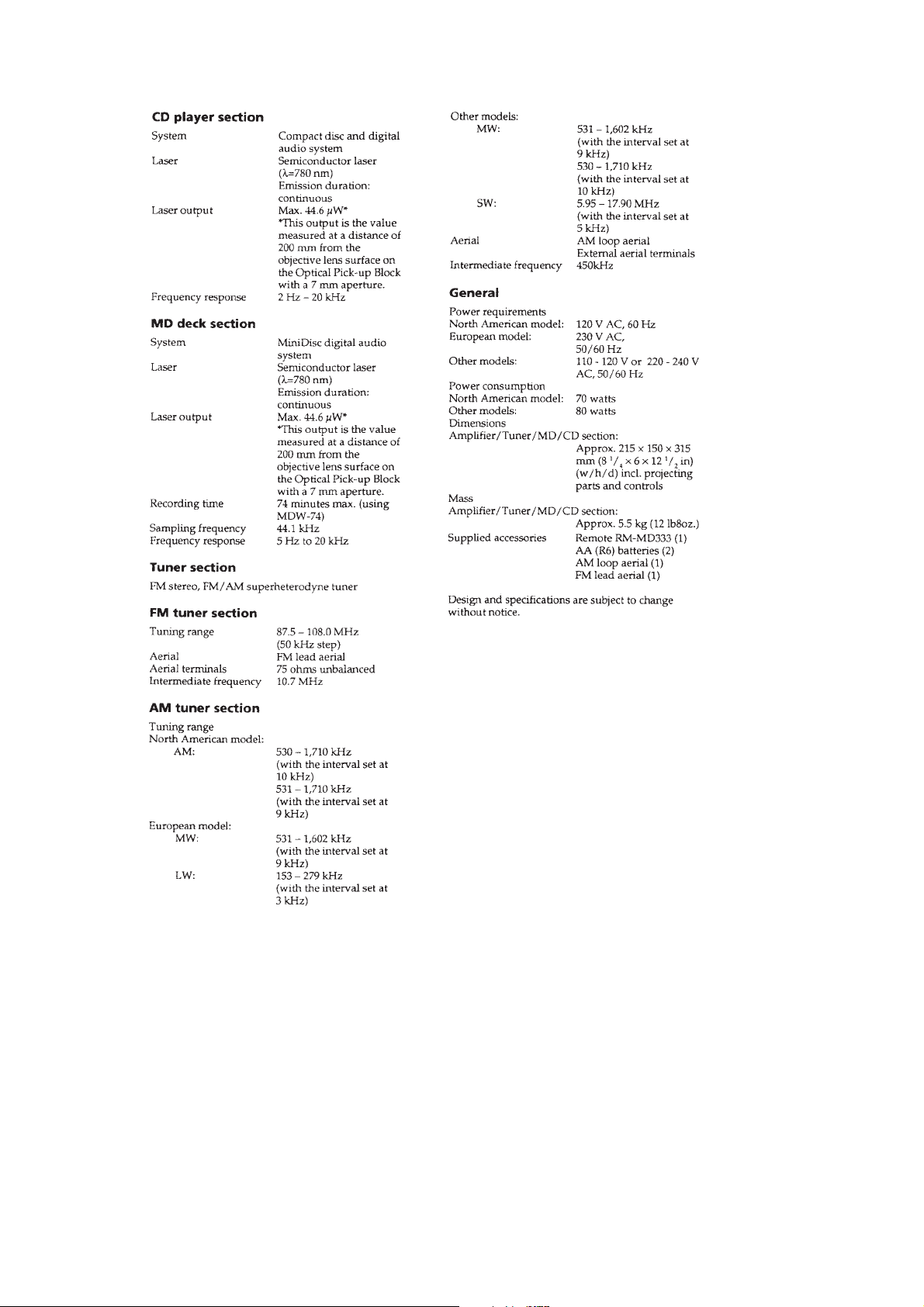

SPECIFICATIONS

COMPACT DISC DECK RECEIVER

— Continued on next page —

– 1 –

– 2 –

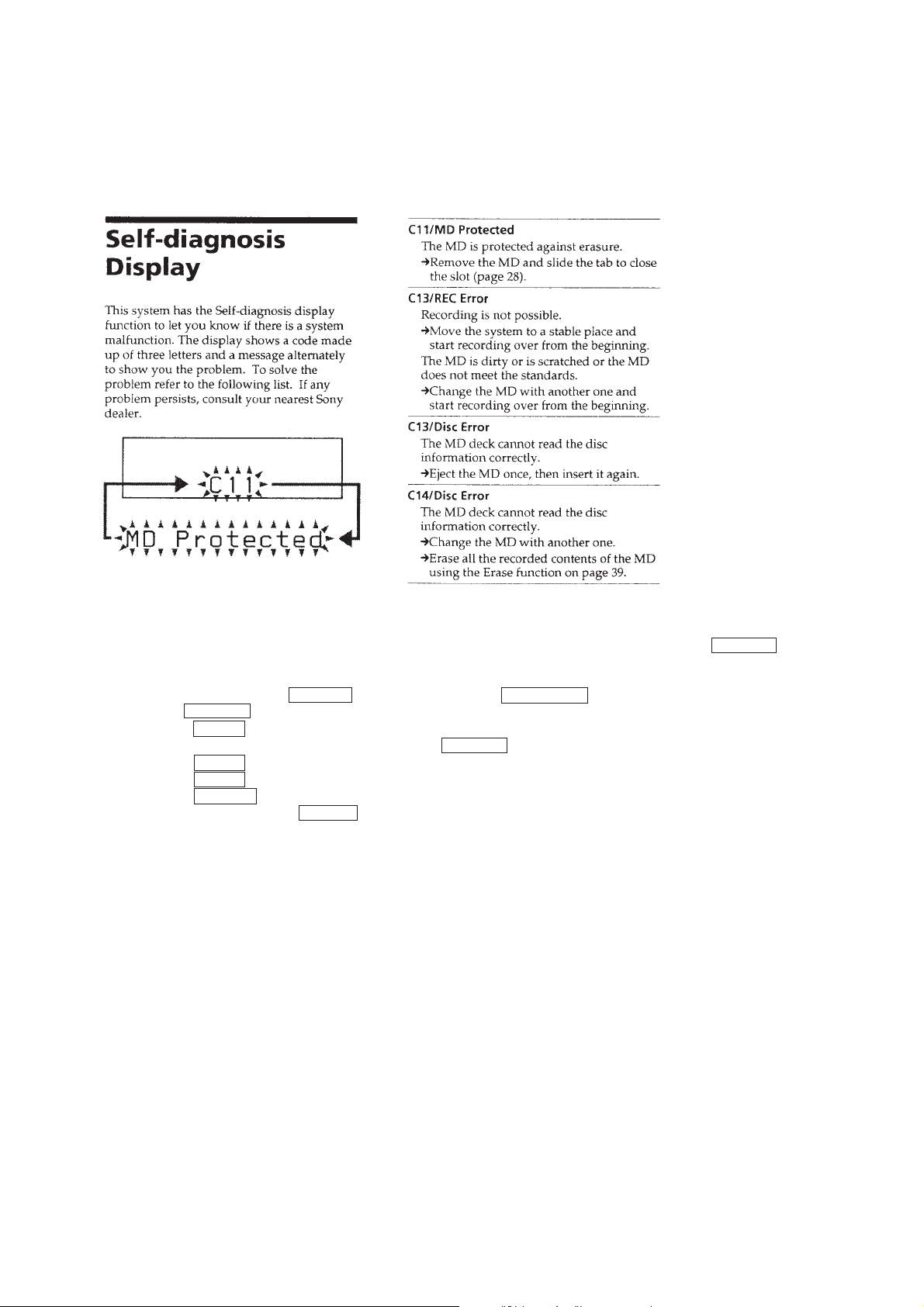

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for users which are displayed automatically when errors occur, and error codes which

show the error history in the test mode during servicing. For details on how to view error codes for users, refer to the following box in the

instruction manual. For details on how to perform checks during servicing, refer to the following “Procedure for Using the Self-Diagnosis

Function (Error History Display Mode)”.

Procedure for Using the Self-Diagnosis Function (Error History Display Mode)

Note: Perform the self-diagnosis function in the “error history display mode” in the test mode. The following describes the least required

steps. Be careful not to enter other modes by mistake. If other modes are set accidentally, press the ^ (CD) button to exit that

mode.

1. With the power off, press the ^ (MD) button while pressing the PLAY MODE button.

2. Rotate the VOLUME knob until “ERR DP MODE” is displayed.

3. Pressing the p (CD) button sets the error history mode and displays “total rec”.

4. Select the contents to be displayed or executed using the VOLUME knob.

5. Pressing the 6 (CD) button displays or executes the contents selected.

6. Pressing the 6 (CD) button another time returns to step 4.

7. Pressing the ^ (CD) button displays “ERR DP MODE” and exits the error history mode.

8. To exit the test mode, press the REPEAT button. The unit sets into the STANDBY state, and the test mode ends.

– 3 –

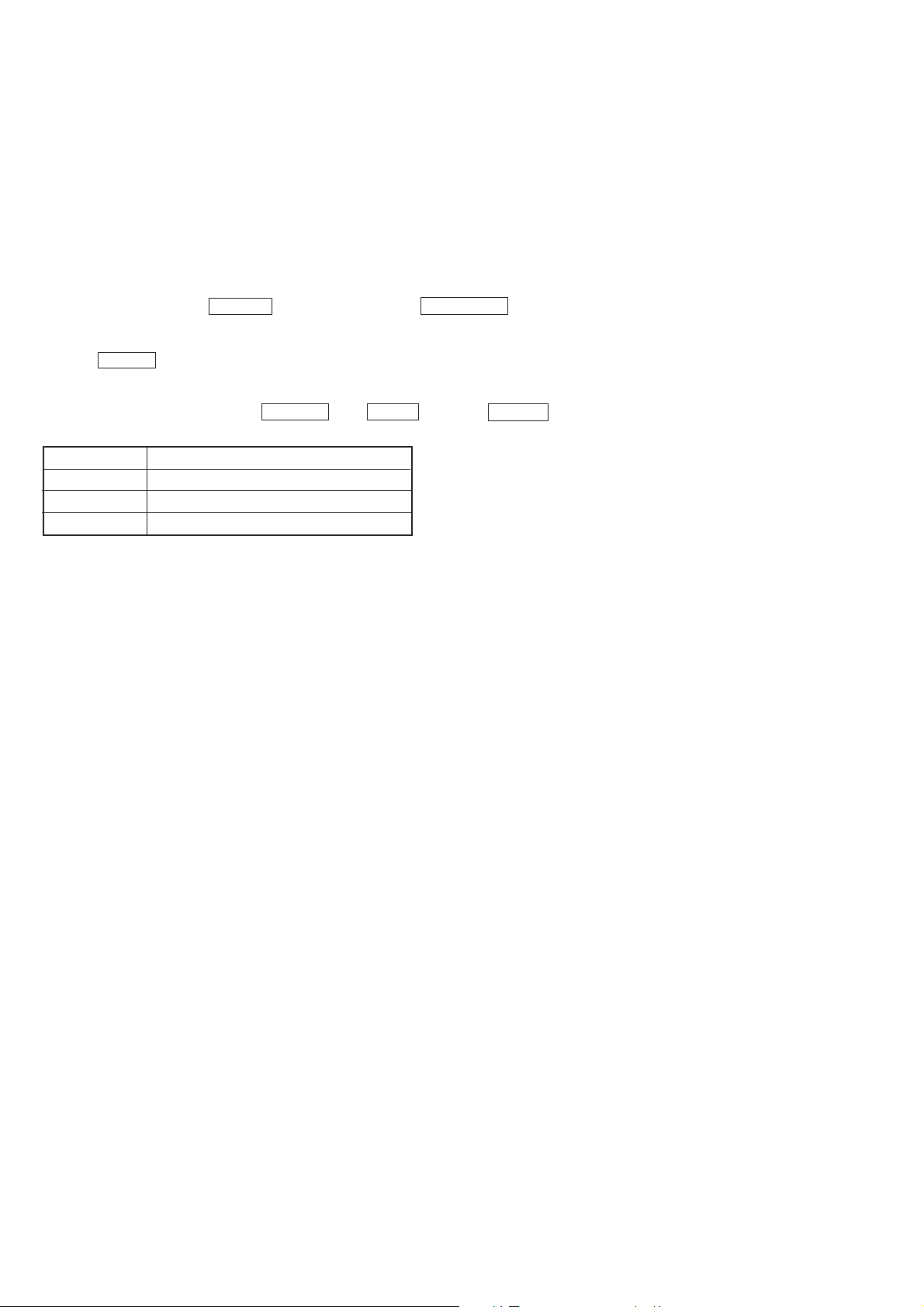

ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS

Selecting the Test Mode

Display

total rec

total play

retry err

total err

err history

er refresh?

Details of History

Displays the recording time in the form of “rππππππh”.

The displayed time is the total number of hours the laser is high power, which is about one-fourth of the actual

recording time. The time is displayed in decimal digits between 0h to 65535h.

Displays the playback time in the form of “pππππππh”.

The displayed time is the total actual play time. The paused time is not counted. The time is displayed in decimal

digits between 0h to 65535h.

Displays the total number of retries during recording and retry errors during playback in the form of “rππpππ”.

“r” indicates the retries during recording while “p” indicates the retry errors during playback. The number of

retries is displayed in hexadecimal digits between 00 to FF.

Displays the total number of errors in the form of “total ππ”.

The number of errors is displayed in hexadecimal digits between 00 to FF.

Displays the 10 latest errors in the form of “0π E@@”.

The π indicates the history number. The smaller the number, the newer is the error. (00 is the latest error.)

The @@ indicates the error code. Refer to the following table for details. Rotate the VOLUME knob to switch

the error history.

Mode which erases all the error histories.

The error history serves as a reference for when to replace the optical pick-up. Perform this procedure when the

optical pick-up has been replaced in order to erase past error histories and not at other times. Press the p (CD)

button when “er refresh??” is displayed. The history will be erased and “Complete!” will be displayed momentarily.

Be sure to check the following when this mode has been executed.

• Check that the data has been erased.

• Perform recording and playback, and check that the mechanism operates normally.

Table of Error Codes

Error Code

E00

E01

E02

E03

E04

No error

Disc error. Cannot read PTOC

(Disc is ejected out)

Disc error. UTOC error

(Disc is not ejected out)

Loading error

Cannot read address (Servo has deviated)

Details of Error

Error Code

E05

E06

E07

E08

E09

E0A

Details of Error

FOK has deviated

Unfocused (Servo has deviated)

Recording retry

Recording retry error

Play retry error

(Access error)

Playback retry error (C2 error)

– 4 –

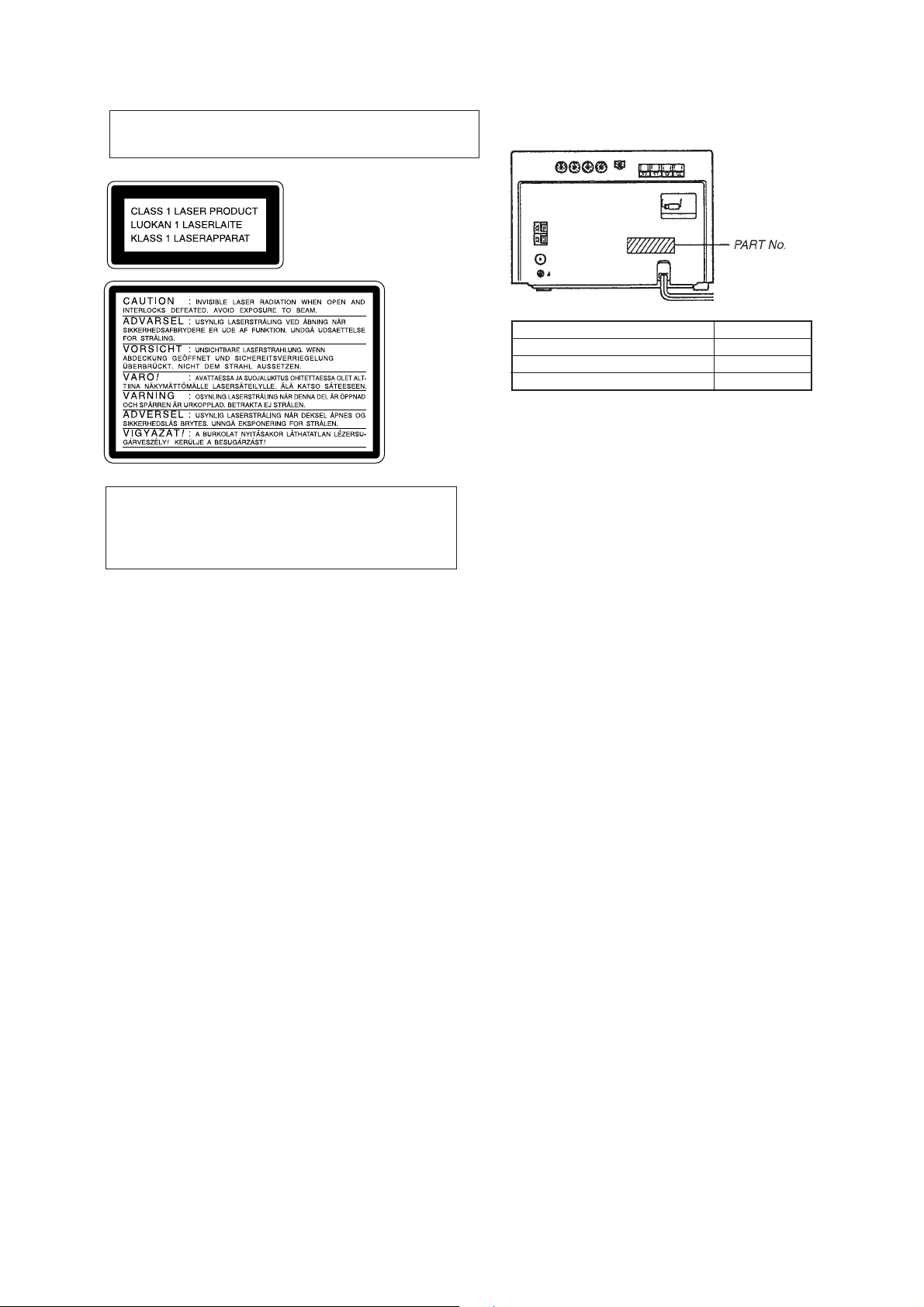

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

This caution

label is located

inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

MODEL IDENTIFICATION

— BACK PANEL —

MODEL

AEP, UK, EE model

MY, SP, JE, HK, AR, AUS model

US, CND model

• Abbreviation

CND : Canadian model

EE : East European model

HK : Hong Kong model

SP : Singapore model

MY : Malaysia model

AR : Argentine model

AUS : Australian model

JE : Tourist model

PARTS No.

4-993-849-5π

4-993-849-6π

4-993-849-7π

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT . NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS P AR SONY.

– 5 –

SAFETY CHECK-OUT

TABLE OF CONTENTS

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A ba ttery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

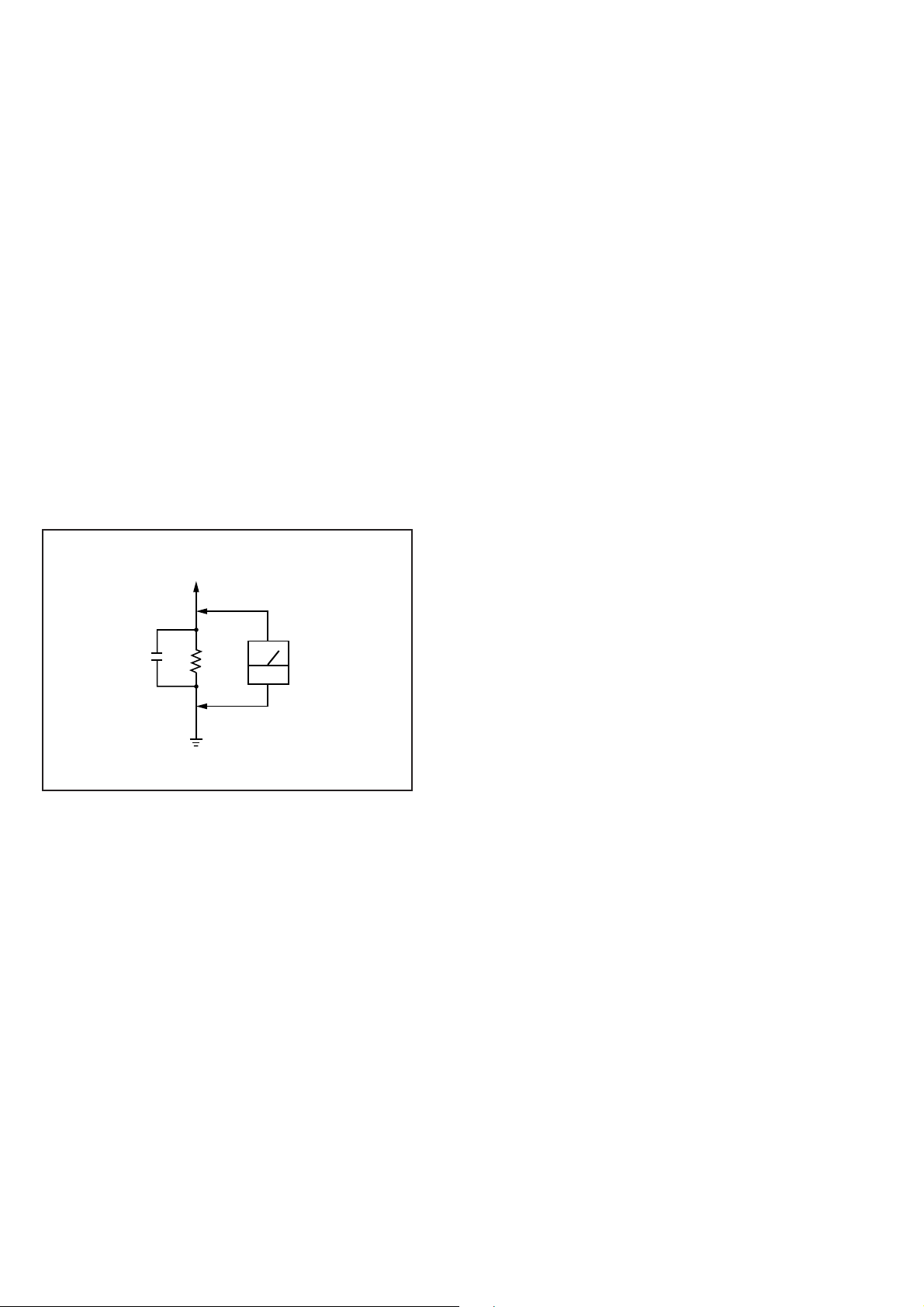

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15µF

Ω

1.5k

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

1. SERVICING NOTE .......................................................... 7

2. GENERAL .......................................................................... 8

3. DISASSEMBLY

3-1. Case .................................................................................... 10

3-2. Front Panel/MD Mechanism Deck Section ........................ 10

3-3. Back Panel, Jack Board....................................................... 11

3-4. MD Mechanism Deck (MDM-3D) ..................................... 11

3-5. CD Mechanism Deck (CDM13C-5BD19).......................... 12

3-6. BD (MD) Board .................................................................. 12

3-7. Disc Table .......................................................................... 13

3-8. Sub Chassis ......................................................................... 13

3-9. Optical Pick-up (KSS-213B/K-N) ...................................... 14

3-10. Over Write Head ...............................................................14

3-11. Slider Complete ASSY...................................................... 15

3-12. Shutter ASSY .................................................................... 16

4. SERVICE MODE ............................................................. 17

5. TEST MODE ..................................................................... 18

6. ELECTRICAL ADJUSTMENTS ............................... 24

7. DIAGRAMS

7-1. Circuit Boards Location ...................................................... 31

7-2. Block Diagrams

• CD Section ....................................................................... 33

• MD Section ...................................................................... 35

• Main Section .................................................................... 37

7-3. Schematic Diagram – CD Section – ................................... 41

7-4. Printed Wiring Board – CD Section –................................. 43

7-5. Schematic Diagram – MD (1/3) Section –.......................... 45

7-6. Schematic Diagram – MD (2/3) Section –.......................... 47

7-7. Schematic Diagram – MD (3/3) Section –.......................... 49

7-8. Printed Wiring Board – MD Section –................................ 51

7-9. Schematic Diagram – MD Switch Section – ...................... 53

7-10. Printed Wiring Board – MD Switch Section – ................. 54

7-11. Schematic Diagram – Main (1/3) Section – ..................... 55

7-12. Schematic Diagram – Main (2/3), (3/3) Section – ........... 57

7-13 Printed Wiring Board – Main Section – ........................... 59

7-14. Schematic Diagram – Audio Section –............................. 61

7-15. Printed Wiring Board – Audio Section –.......................... 63

7-16. Schematic Diagram – Panel Section – ............................. 65

7-17. Printed Wiring Board – Panel Section –........................... 67

7-18. Schematic Diagram – Jack Section – ............................... 69

7-19. Printed Wiring Board – Jack Section – ............................ 71

7-20. Schematic Diagram – ST Terminal/Loading Section – .... 73

7-21. Printed Wiring Board – ST Terminal/Loading Section – . 74

7-22. Schematic Diagram – Trans Section – ............................. 75

7-23. Printed Wiring Board – Trans Section –........................... 76

7-24. Schematic Diagram – Power AMP Section –................... 77

7-25. Printed Wiring Board – Power AMP Section –................ 79

7-26. IC Block Diagrams ........................................................... 81

7-27. IC Pin Functions ............................................................... 88

8. EXPLODED VIEWS

8-1. Front Panel Section ............................................................. 96

8-2. Chassis Section ................................................................... 97

8-3. MD Mechanism Deck Section-1 (MDM-3J) ...................... 98

8-4. MD Mechanism Deck Section-2 (MDM-3J) ...................... 99

8-5. CD Mechanism Deck Section-1 (CDM13C-5BD19) ....... 100

8-6. CD Mechanism Deck Section-2 (BU-5BD19) ................. 100

9. ELECTRICAL PARTS LIST ...................................... 102

– 6 –

SECTION 1

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

Note:

Be sure to connect all wires (including FFC) in the MD

section before applying power or ICs may be damaged.

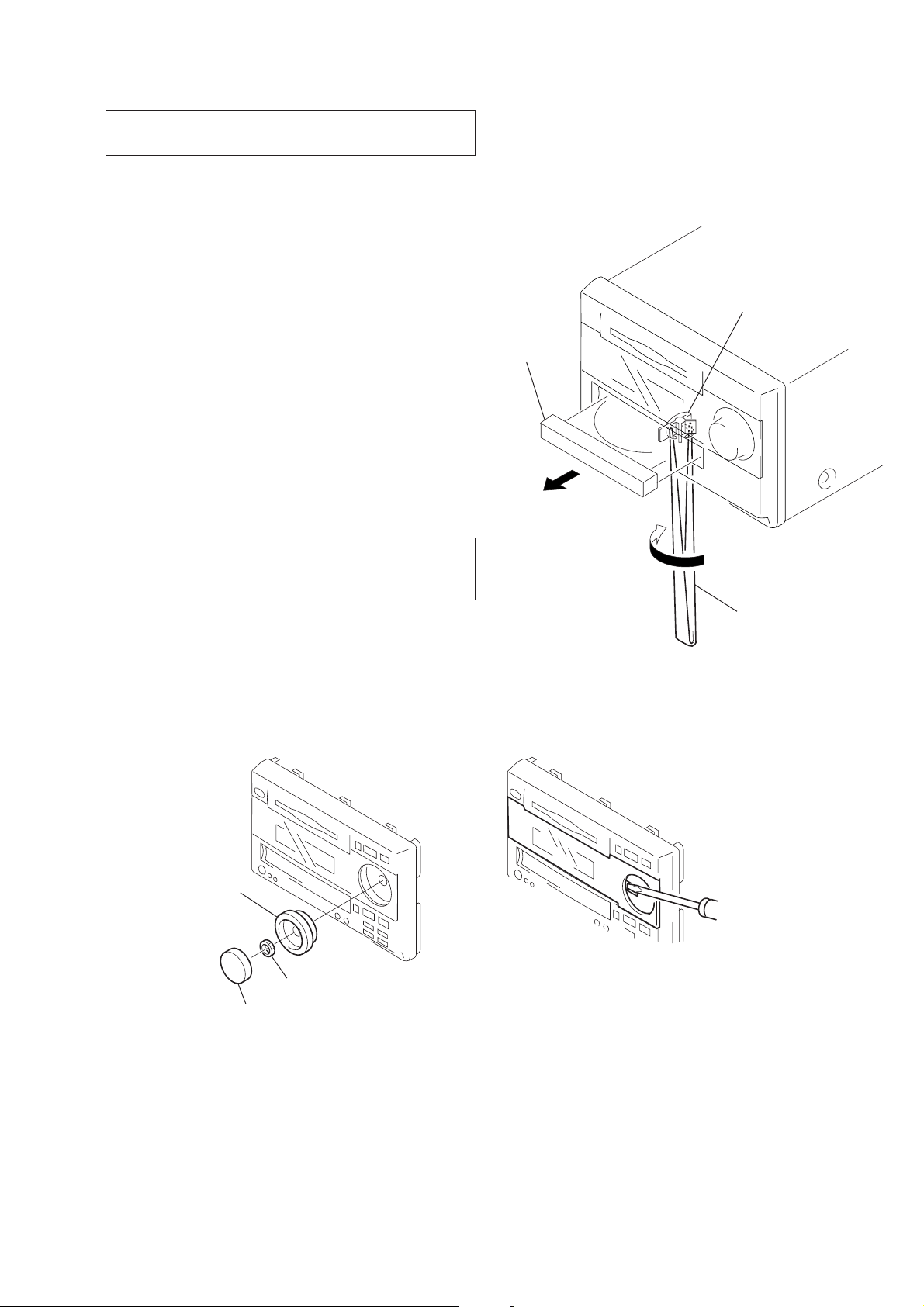

DISC TABLE GETTING OUT PROCEDURE ON THE

POWER SUPPLY IS OFF

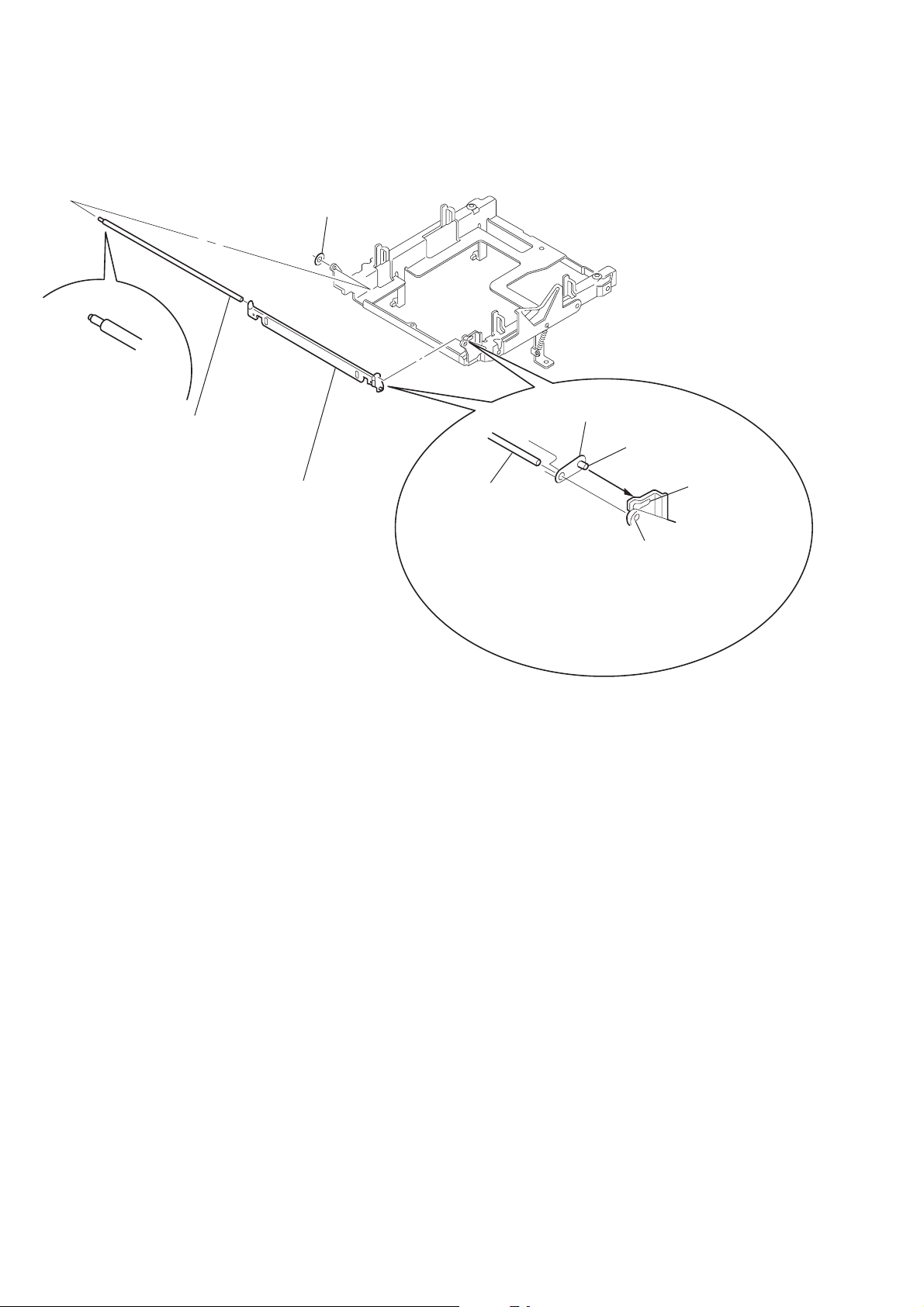

1. Insert the tweezers to a hole on bottom of the chassis as shown a

figure, then tern fully it toward direction 2.

2. Pull out the disc table.

cam

disc table

3

2

PRECAUTIONS ON REMOVING WINDOW (FL) FROM

FRONT PANEL

• Use the following procedure to prevent scratches on the front panel.

3

Remove the

ornament (VOL).

2

Remove the nut.

1

Remove the Knob (VOL).

4

Remove the window (FL) using the notch.

1

tweezers

– 7 –

Front Panel

23

SECTION 2

GENERAL

23 45 61

22

Location of Parts and Controls

1 1/u button

2 MD indicator

3 MD disc slot

4 6 (MD) button

5 ^ (MD) button and indicator

6 p (MD) button

7 VOLUME knob

8 ^ (CD) button and indicator

9 p (CD) button

10 FUNCTION button

11 MD/CD ) +/TUNING + button

12 MD/CD = 0/TUNING – button

13 TUNER/BAND button

14 6 (CD) button

15 r REC button and indicator

16 CD-MD SYNC button

17 CD disc tray

18 CD indicator

19 REPEAT/STEREO/MONO button

20 PLAY MODE/TUNING MODE button

21 PHONES jack

22 Remote sensor

23 Display window

7

8

9

10

15 1213 111617 141920 1821

– 8 –

This section is extracted from

instruction manual.

– 9 –

SECTION 3

(

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

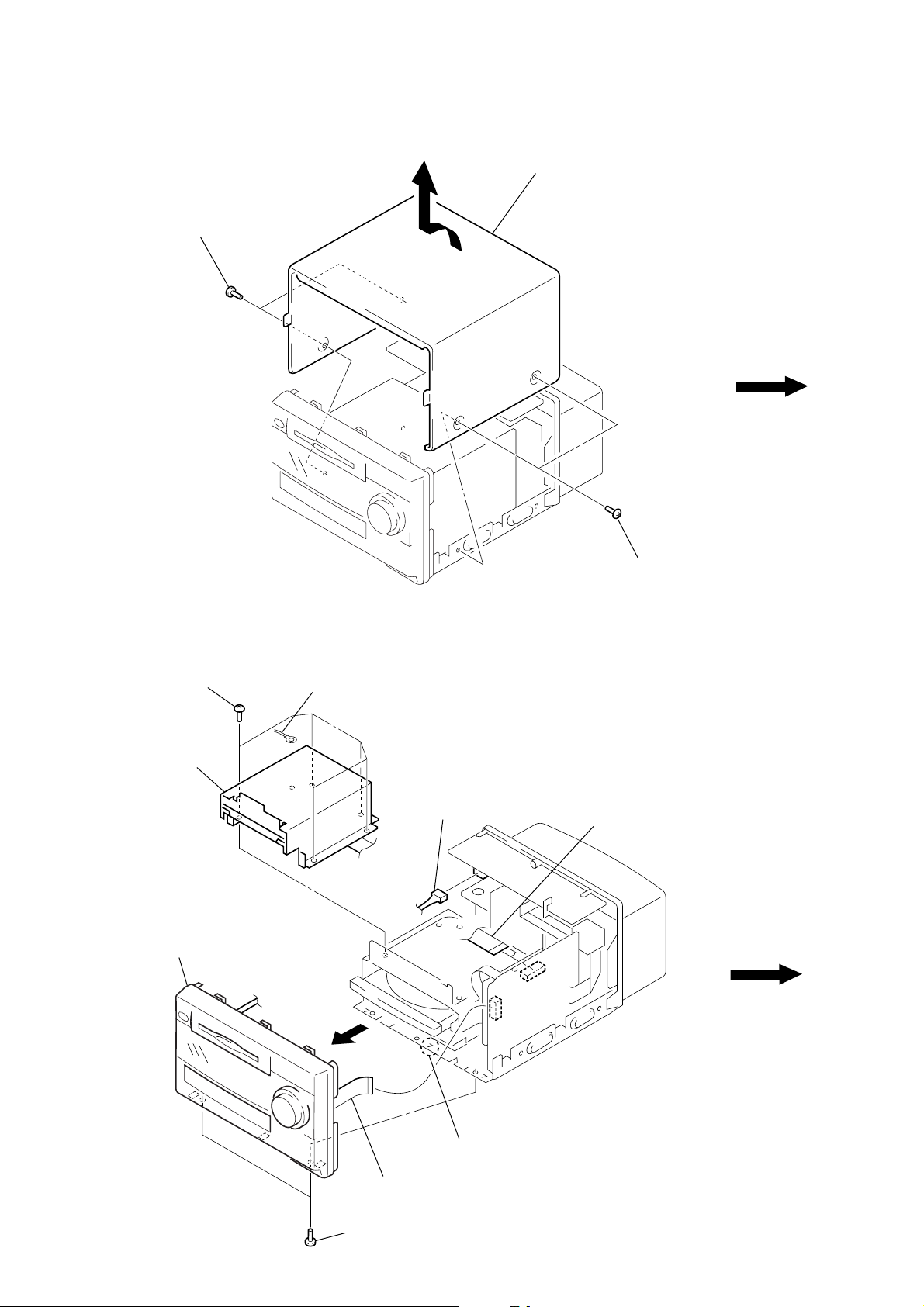

3-1. CASE

1

T wo screws

(CASE3 TP2)

3

Case

3-2. FRONT PANEL/MD MECHANISM DECK SECTION

7

Six screws (BVTT3x6)

9

MD mechanism

5

Front panel

8

Wire

3

Connector

(CN490)

2

T wo screws

(CASE3 TP2)

6

Wire (flat type)(25core)

(CN820)

4

Claw

2

Wire (flat type)(23core)

(CN873)

1

T wo screws

BVTT3x6

– 10 –

3-3. BACK PANEL, JACK BOARD

1

Connector

(CN590)

2

Four screws

(BVTP3x10)

3

T wo screws

(BVTP3x10)

4

Five claws

6

Wire (flat type)(15core)

(CN401)

7

JACK board

8

Connector

(CN402)

5

Back panel

3-4. MD MECHANISM DECK (MDM-3D)

1

T wo screws

(BVTT2x3)

Bracket (MD)

2

T wo screws

(BVTT2x3)

3

MD mechanism deck

(MDM-3J)

– 11 –

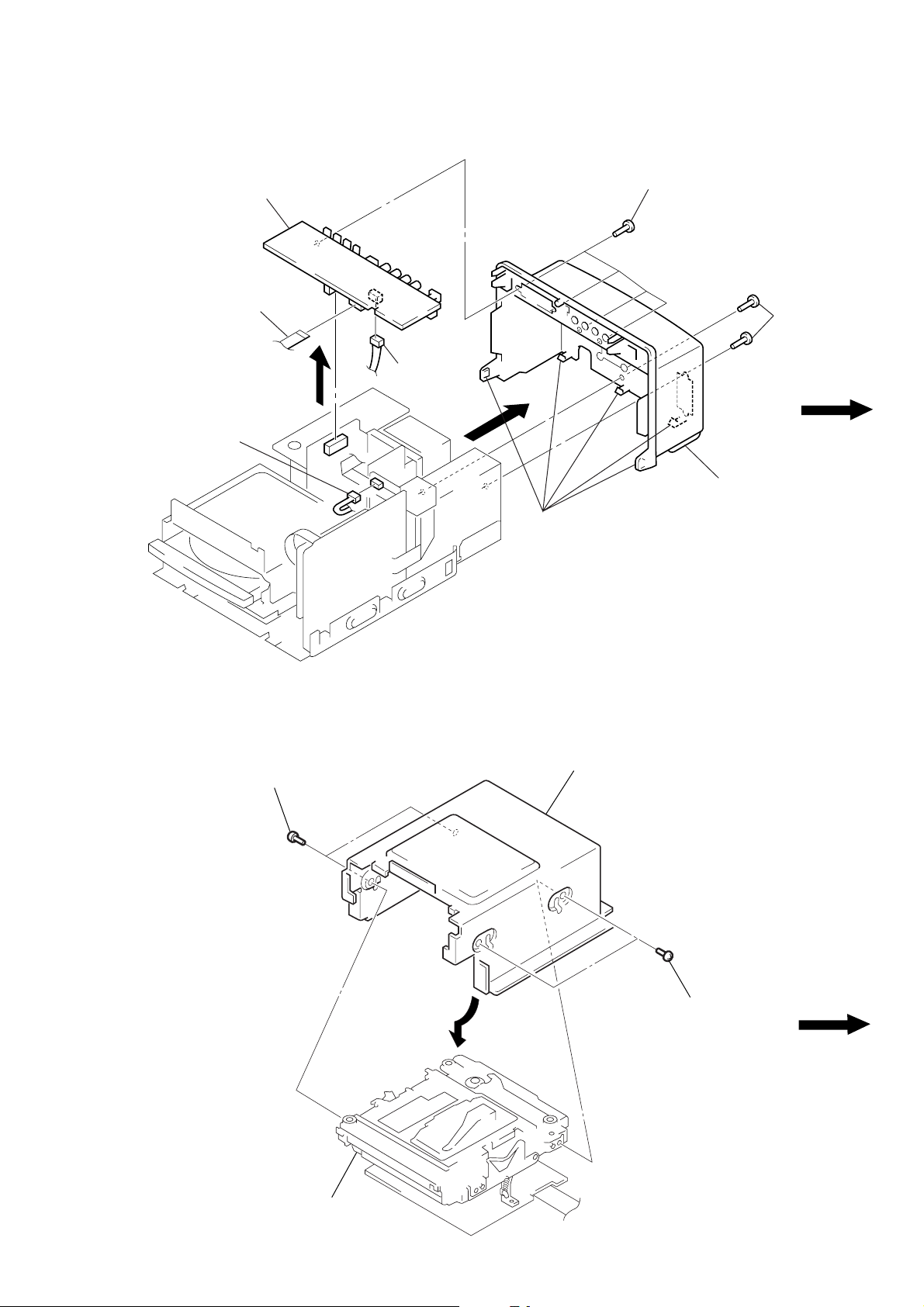

3-5. CD MECHANISM DECK (CDM13C-5BD19)

4

T wo screws

(BVTT3x6)

5

Bracket (CD)

7

T wo hooks

3

T wo screws

(BVTT3x6)

8

CD mechanism deck

(CDM13C-5BD19)

6

T wo screws

(BVTT3x6)

3-6. BD (MD) BOARD

5

OP relay flexible board

(CN101)

3

Wire (flat type)(14core)

(CN106)

1

Wire (flat type)(19core)

(CN801)

2

Connector

(CN291)

2

Flexible board

(over write head)

(CN104)

6

BD board(MD)

– 12 –

4

Screw (BVTP2x4)

1

Wire (flat type)(25core)

(CN107)

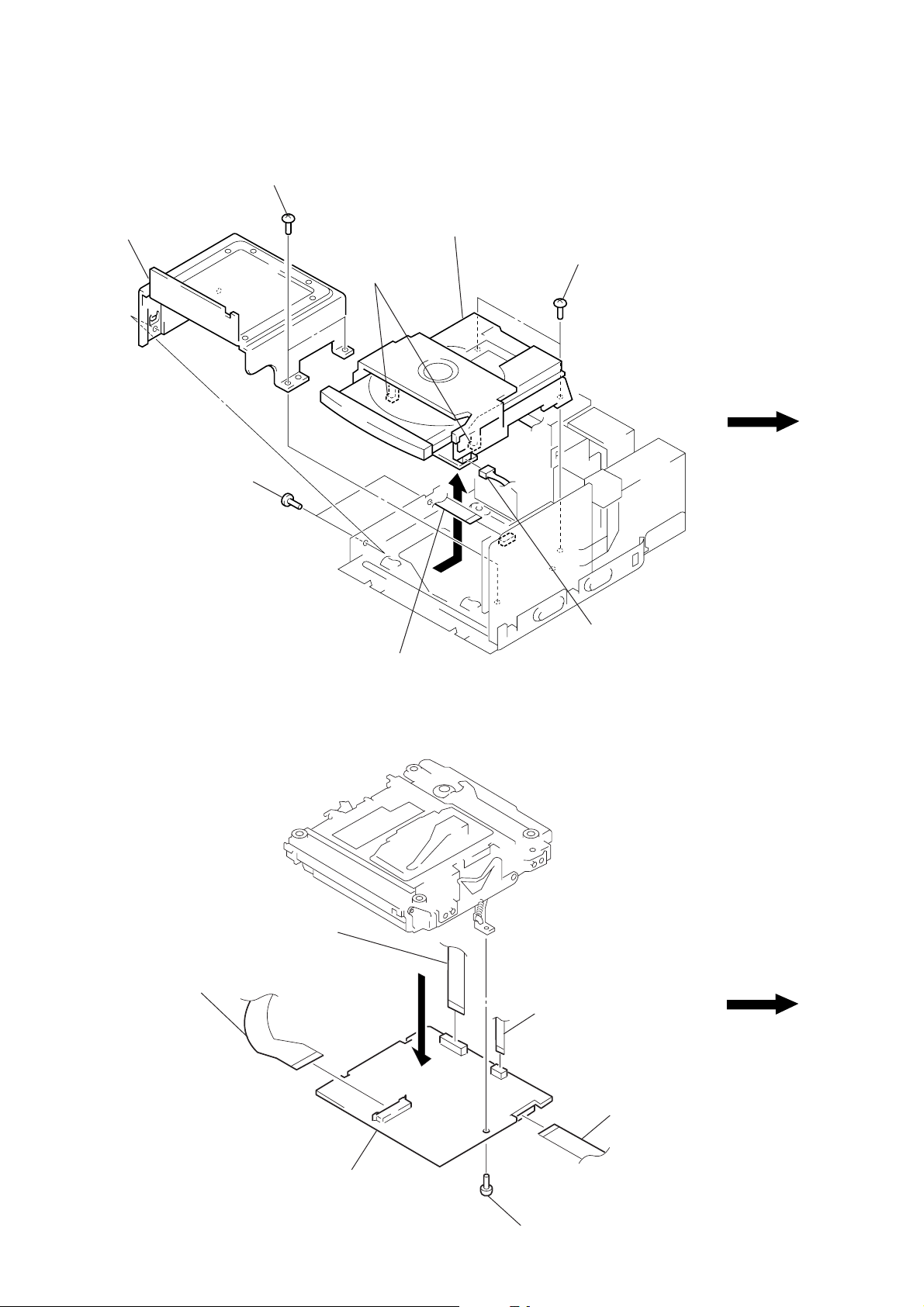

3-7. DISC TABLE

3

Two step screws

4

T wo insulators

5

Sub chassis

Part

A

Part

A

Part

A

1

Two step screws

2

T wo insulators

Take care so that the part

A

may be right

position when installing.

1

Screw (BV3x8)

4

Pull the disc table

3

Holder (MG) assembly

2

Screw (BV3x8)

3-8. SUB CHASSIS

– 13 –

3-9. OPTICAL PICK-UP (KSS-213B/K-N)

1

Move the claw in the

direction of the arrow

A

.

B

A

2

Remove the sled shaft in the

direction of the arrow

4

Remove the optical pick-up (KSS-213B/K-N)

in the direction of the arrow

C

B

.

BD board (CD)

C

.

3

Wire (flat type)(16 core)

(CNU101)

3-10. OVER WRITE HEAD

2

Over write head

1

Screw (P1.7x6)

– 14 –

3-11. SLIDER COMPLETE ASSY

Claw

4

Remove the slider complete assembly

in the direction of arrow with putting out

of two claws.

1

Special screw

(M1.7x1.4)

Claw

3

Set the shaft of gear (LB) to be at the

position in the figure.

45˚

2

Retainer (gear)

• Note for installation of Slider complete assembly

Slider assembly

OK

NG

Install the part A of lever (head up)

to pass over the slider complete assembly.

Part A

Take care not to damage the

detective switch.

– 15 –

3-12. SHUTTER ASSY

1

Stopper washer

2

Shaft (shutter) A

3

Shutter assembly

shutter assembly

Shaft (shutter) B

Shaft (shutter) A

Hole A

When installing, install the shaft (shutter) A into the hole as

show in the figure before installing the shaft (shutter) B into

the hole B.

Hole B

– 16 –

SECTION 4

SERVICE MODE

Change-over of AM (MW) Tuner Step between 9 kHz and 10 kHz

• A step of AM (MW) channels can be changed over between 9 kHz and 10 kHz.

Procedure:

1. Press 1/u button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND button to select the BAND “AM (MW)”.

3. Press 1/u button to turn the set OFF.

4. Press FUNCTION and 1/u buttons simultaneously, and the display of fluorescent indicator tube changes to “AM (MW) 9 kHz STEP”

or “AM (MW) 10 kHz STEP”, and thus the channel step is changed over.

Change-over of LW Tuner Step between 1 kHz and 3 kHz

• A step of LW channels can be changed over between 1 kHz and 3 kHz.

Procedure:

1. Press 1/u button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND button to select the BAND “LW”.

3. Press 1/u button to turn the set OFF.

4. Press FUNCTION and 1/u buttons simultaneously , and the display of fluorescent indicator tube changes to “LW 1 kHz STEP” or “L W

3 kHz STEP”, and thus the channel step is changed over.

LED and Fluorescent Indicator Tube All Lit, Key Check Mode

Procedure:

1. Press PLAY MODE and p (MD) buttons simultaneously.

2. LEDs and fluorescent indiator tube are all turned on.

3. When the FUNCTION button is pressed, the fluorescent indicator tube lights up in the order of; partial lighting 1 n partial lighting 2 n

all lit n partial lighting 1 n ······.

When the VOLUME knob is rotated, the LED lighting pattern changes.

To end without switching to the key check mode, press the 1/u button to turn off the power.

4. Press p (CD) button, and the key check mode is activated.

5. In the key check mode, the fluorescent indicator tube displays “KEY=0 JOG=0”. Each time a button is pressed, “KEY=” value incr eases.

However, once a button is pressed, it is no longer taken into account.

“JOG=” Value increases like 1, 2, 3 ... if rotating VOLUME knob in clockwise direction, or it decreases like 10, 9, 8 ... if rotating in

counterclockwise direction.

6. T o exit from this mode , press order all buttons (15 buttons), the displays “KEY=OK”, and press any button, or disconnect the power cor d.

SUB CLOCK CHECK

Procedure:

1. Connect an oscilloscope to IC601 pin (¡ and ground of the MAIN board.

2. Press PLAY MODE and p (MD) buttons simultaneously, and the fluorescent indiator tube displays “32.768 kHz (91)”.

3. To check the signal on oscilloscope becomes 32 kHz square wave.

4. Press 1/u button to exit.

– 17 –

SECTION 5

TEST MODE

5-1. PRECAUTIONS FOR USE OF TEST MODE

Recording Laser Emission Mode and Operating Buttons

• Continuous recording mode (CREC MODE)

• Traverse adjustment mode (EFBAL ADJUST)

• Laser power adjustment mode (LDPWR ADJUST)

• Laser power check mode (LDPWR CHECK)

• Traverse (MO) check (EF MO CHECK)

• Traverse (MO) adjustment (EF MO ADJUST)

5-2. SETTING THE TEST MODE

With the power off, press the ^ (MD) button while pressing the PLAY MODE button.

5-3. EXITING THE TEST MODE

Press the REPEAT button. The STANDBY state will be set and the test mode will be cleared.

5-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the VOLUME knob, p (CD) button, and ^ (CD) button.

The functions of these buttons are as follows.

Function name

VOLUME knob

p (CD) button

^ (CD) button

Function

Changes parameters and modes

Proceeds onto the next step. Finalizes input.

Returns to previous step. Stops operations.

– 18 –

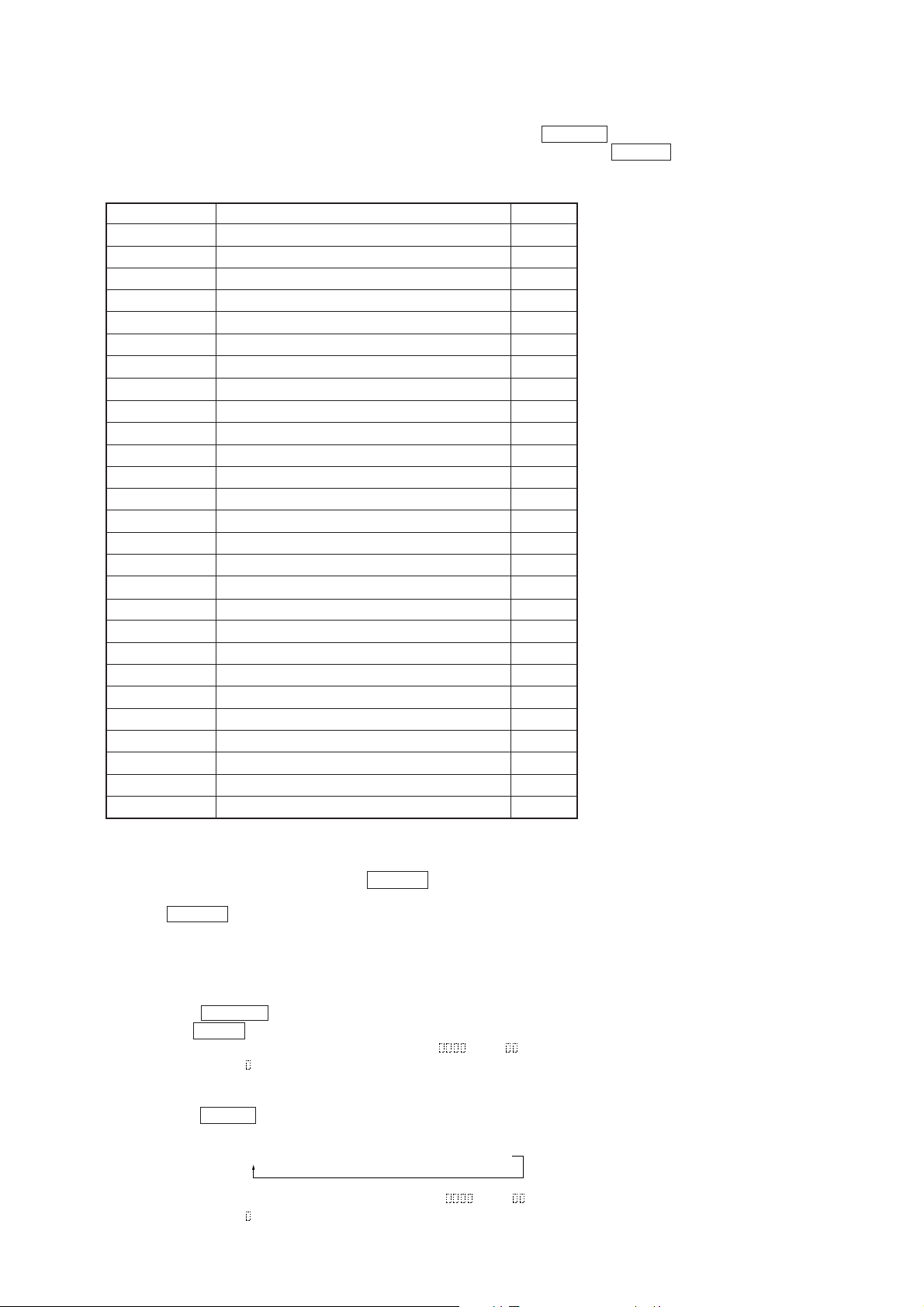

5-5. SELECTING THE TEST MODE

There are altogether 26 test modes, shown in the following table. Rotating the VOLUME knob to the right switches to the mode below the

current mode in the table while rotating to the left switches to the mode above. Each time the ^ (CD) button is pressed, the display changes

in the following order;

“TEMP CHECK” n ”TEMP ADJUST” n ”SLED MOVE” n“TEMP CHECK”…

Display

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

CPLAY MODE

CREC MODE

Scurve CHECK

VERIFY MODE

DETRK CHECK

TEMP ADJUST

LDPWR ADJUST

EF MO ADJUST

EF CD ADJUST

FBIAS ADJUST

EEP MODE

MANUAL CMD

SVDATA READ

ERR DP MODE

SLED MOVE

ACCESS MODE

0920 CHECK

WRITE sure?

HEAD ADJUST

CPLAY2 MODE

CREC2 MODE

Ver @@@@@

Temperature compensation offset check

Laser power check

Traverse (MO) check

Traverse (CD) check

Focus bias check

Continuous playback mode

Continuous recording mode

S curve check

Non-volatile memory check

Detrack check

Temperature compensation offset adjustment

Laser power adjustment

Traverse (MO) adjustment

Traverse (CD) adjustment

Focus bias adjustment

Nonvolatile memory control

Command transfer

Status display

Error history display, clear

Sled check

Access check

Outermost circumference check

Non-volatile memory Initialize

Head position check

Continuous playback mode

Continuous recording mode

Microprocessor version display

Contents

Mark

(X)

(X)

(X)

(X) (!)

(X)

(X)

(X)

(X)

(X)

(X) (!)

(X)

(X)

(X)

• For details of each adjustment mode, refer to the items in “6. Electrical Adjustments”. For details of “ERR DP MODE”, refer to the self-

diagnosis function on page 2.

• If other modes are set accidentally, press the ^ (CD) button to exit that mode.

• As items marked (X) in the “Mark” column are not used during servicing, they are not described here. If these modes are set accidentally,

press the ^ (CD) button to exit the mode. Be especially careful with items marked (!) as they will overwrite the non-volatile memory,

and as a result, the unit will not operate normally.

5-5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

1 Set the disc in the unit. (Recordable discs or discs for playback only.)

2 Rotate the VOLUME knob and display “CPLAY MODE”.

3 Press the p (CD) button to change the display to “CPLAY MID”.

4 When access completes, the display changes to “C =

Note : The numbers “

” displayed indicate the error rates and “ADER”.

AD = ”.

2. Changing the part to be played back

1 When the p (CD) button is pressed during continuous playback, the display changes as below, and the played back part can be

changed.

“CPLAY MID” n “CPLAY OUT” n “CPLAY IN”

2 When access completes, the display changes to “C1 =

Note : The numbers “

” displayed indicate the error rate and “ADER”.

AD = ”.

– 19 –

3. Ending the continuous playback mode

1 Press the ^ (CD) button. The display changes to “CPLAY MODE”.

2 Press the 6 (MD) button to remove the disc.

Note : The playback start addresses for IN, MID, and OUT are as follows. To displa y the playbac k position address on the display, press

the 1/u button to display “CPLAY (

)”.

IN: 40h cluster

MID: 300h cluster

OUT: 700h cluster

5-5-2. Operating the Continuous Recording Mode

1. Entering the continuous recording mode

1 Set a recordable disc in the unit. (Refer to Note 3.)

2 Rotate the VOLUME knob and display “CREC MODE”.

3 Press the p (CD) button to change the display to “CREC MID”.

4 When access completes, the display changes to “CREC ( )” and the REC display lights up.

Note : The numbers “

” displayed indicate the recording position address.

2. Changing the part to be recorded

1 When the p (CD) button is pressed during continuous recording, the display changes as below and the recorded part can be changed.

The REC display is off while changing.

“CPLAY MID” n “CPLAY OUT” n “CPLAY IN”

2 When access completes, the display changes to “CREC MODE” and the REC display lights up.

Note : The numbers “

” displayed indicate the recording position address.

3. Ending the continuous recording mode

1 Press the ^ (CD) button. The display changes to “CREC (

)”, and the REC display lights up.

2 Press the 6 (MD) button to remove the disc.

Note 1 : The recording start addresses for IN, MID, and OUT are as follows.

IN: 40h cluster

MID: 300h cluster

OUT: 700h cluster

Note 2 : The ^ (CD) button can be used to stop recording anytime.

Note 3 : Do not perform continuous recording for long periods of time above 5 minutes.

Note 4 : During continuous recording, be careful not to apply vibration.

5-5-3. Non-Volatile Memory Mode (EEP MODE)

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If set accidentally, press the ^ (CD) button immediately to exit it.

5-6. FUNCTIONS OF OTHER BUTTONS

Function

·P

p

) +

= 0

CD-MD SYNC

1/u

6 (MD)

REPEAT

Sets continuous playback when pressed in the STOP state. T urns ON/OFF the trac king servo when pressed during continuous

playback.

Stops the continuous playback and recording.

Moves the sled to the external circumference only while the button is pressed.

Moves the sled to the internal circumference only while the button is pressed.

Switches between pit and groove when pressed.

Switches the displayed contents when pressed.

Ejects the disc.

Exits the test mode.

Contents

– 20 –

5-7. DISPLAYS DURING TEST MODE

Mode display

Error rate display

Address display

Auto gain display (Not used in servicing)

Detrack check display (Not used in servicing)

IVR display (Not used in servicing)

The display changes according to the following sequence each time the 1/u button is pressed.

1. Mode display

“TEMP ADJUST” and “CPLAYMODE” are displayed.

2. Error rate display

The error rate is displayed as follows.

C =

AD =

C = :Indicates the C1 error.

AD = :Indicates ADER.

3. Address display

The address is displayed as follows. (MO: Recordable disc, CD: Disc for palyback only)

When the CD-MD SYNC button is pressed, the display will switch between groove

and pit.

h =

s = (MO pit and CD)

a = (MO groove)

h =

h = Indicates the header address.

s = Indicates the SUBQ address.

a = Indicates the ADIP address.

Note: Displayed as “–” when servo is operated.

4. Auto gain display (Not used in servicing)

The auto gain is displayed as follows.

AG =

/ .

5. Detrack check display (Not used in servicing)

The detrack is displayed as follows.

ADR =

6. IVR display (Not used in servicing)

IVR is displayed as follows.

][ ][

[

Meanings of other displays

Display

REC

ATT

OVER

SHUFFLE

TRACK

DISC

LEVEL-SYNC

SYNC

Recording mode ON

ABCD adjustment completed

Tracking offset cancel ON

Focus auto gain OK

Pit

High reflection rate

CLV-S

CLV LOCK

When Lit

Contents

When Off

Recording mode OFF

Tracking offset cancel OFF

Groove

Low reflection

CLV-A

CLV UNLOCK

– 21 –

5-8. AGING MODE

This unit is provided with an aging mode.

In this mode, MD and CD operations are performed alternately according to the following sequence.

Aging will be carried out continuously unless an error occurs.

If an error occurs, the status and number of cycles are displayed alternately, and operations stop. (Refer to Table 1.)

Aging Mode Sequence

Start

Turn ON Power using function MD

MD TOC READ

Can read

MD all erase

Blank disc

YES

CD function is set and CD TOC is read

CD TOC OK?

YES

CD synchro standby

OK?

YES

CD last track search pause state

OK?

YES

CD synchro starts

OK?

YES

Cannot read

NO

NO

NO

NO

NO

Above 20

Message 6

MD last track

Less than 20

Message 1

Message 7

Message 2 or 8

Message 9

Message 3 or 0

Synchro ends?

MD function is set

CD tray opens

OK?

YES

CD tray closes

OK?

YES

MD last track (for 3 sec.) play

OK?

YES

Power goes off and MD TOC is written

Aging cycle number is displayed

Power turns ON and MD TOC is read

OK?

YES

NO

NO

NO

NO

Playing CD?

NG

Message !º

Message !¡

Message !™

Message 4

Message 5 or Message 6

OK

– 22 –

Procedure:

1. Load a recordable disc (MD) and CD test disc (YEDS-18). (*Note 1)

2. While pressing the PLAY MODE button, press the ^ (CD) button.

3. Aging is executed in the above sequence.

4. To end, press the p (CD or MD) button.

*Note 1: Any CD can be used, but one with a short last track is recommended. The time of one aging cycle will be longer if the last track is

long.

Also use a CD in which the length of the last track x 20 does not exceed the recording time of the recording MD.

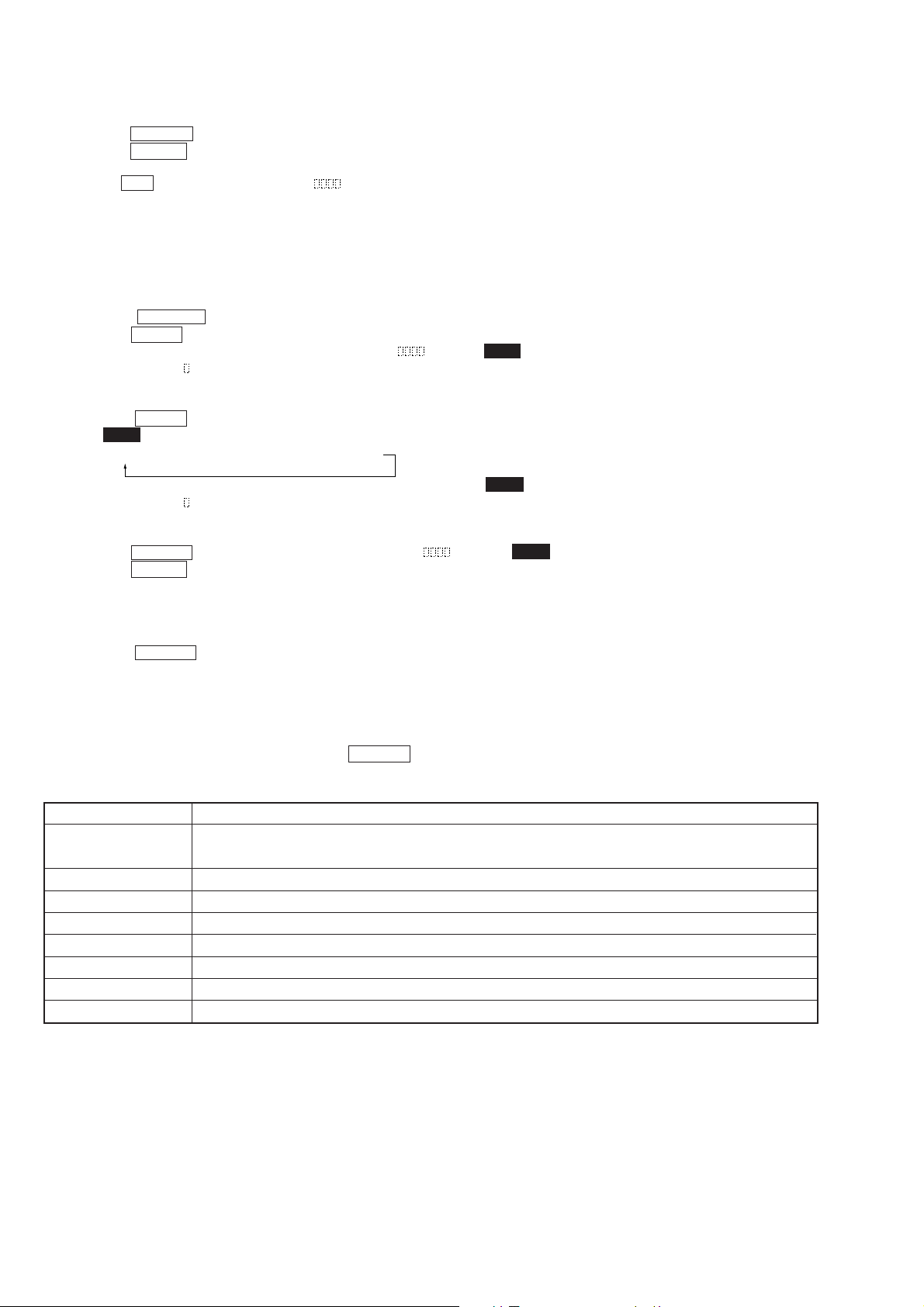

Table 1. Messages and Main Causes When Aging Stops

No

1

2

3

4

5

6

7

8

9

0

!¡

!™

Error Messages

MD A Erase NG

MD R-Pause NG

MD D-input NG

MD Play NG

MD TOC NG

MD No Disc NG

CD No Disc NG

CD Pause NG

CD Search NG

CD Play NG

CD Open NG

CD Close NG

Details of Error

Cannot MD all erase.

Cannot set MD Rec Pause.

Cannot lock MD digital in.

Cannot play last track.

MD TOC are different.

Cannot read MD TOC.

Cannot read CD TOC.

Cannot set CD pause in

CD synchro mode.

Cannot search last track on CD.

Cannot play last track on CD.

Cannot open CD tray.

Cannot close CD tray.

Main Causes

A disc for playback only was used. The rec-proof tab is set to

protect. Disc error, etc.

Disc is full, etc.

Access error, etc.

No. of total tracks does not match logic value.

Disc error, etc.

Optical defect, spindle defect (including motor), cannot read

Q data, disc defect (scratches, etc.), bad focus, bad GFS, etc.

Disc defect (scratches, etc.), cannot read Q data, etc.

Optical defect, sled, tracking defect (including motor), cannot

read Q data, disc defect (scratches, etc.).

Optical defect, cannot read Q data, disc defect (scratches, etc.),

etc.

LOAD OUT SW defect

LOAD IN SW defect

– 23 –

SECTION 6

ELECTRICAL ADJUSTMENTS

MD SECTION

6-1. PRECAUTIONS FOR CHECKING LASER DIODE

EMISSINON

When checking the emission of the laser diode during adjustments,

never view directly from the top as this may cause blindness.

6-2. PRECAUTIONS FOR USE OF OPTICAL PICK-

UP (KMS-260A)

As the laser diode in the optical pick-up is easily damaged by static

electricity, solder the laser tap of the flexible board when using it.

Before disconnecting the connector, solder first. Before connecting

the connector, be careful not to remove the solder. Also take adequate measures to prevent damage by static electricity . Handle the

flexible board with care as it breaks easily.

pick-up

laser tap

flexible board

Optical pick-up flexible board

6-3. PRECAUTIONS FOR ADJUSTMENTS

1) When r eplacing the following parts, perform adjustments and

checks marked ¬ in the order shown in the following table.

Optical

Pick-up

1.Temperature

compensation

offset adjustment

2.Laser power

adjustment

3.Traverse

adjustment

4.Focus bias

adjustment

5.Error rate check

IC171

¬¬G¬

¬G¬¬

¬G¬¬

¬G¬¬

¬G¬¬

2) Perform the adjustment in the test mode.

After completing the adjustments, exit the test mode.

3) Perform the adjustments in the order shown.

4) Use the following tools and measuring devices.

• Check disc (MD) TDYS-1

(Parts No. 4-963-646-01)

• Laser power meter LPM-8001 (Parts No. J-2501-046-A)

or

MD Laser power meter 8010S (Parts No. J-2501-145-A)

• Oscilloscope (Measure after calibration of the probe).

• Digital voltmeter

• Thermometer

5) When observing several signals on the oscilloscope, etc., make

sure that VC and ground do not connect inside the oscilloscope.

(The VC and ground will short-circuit.)

BD Board

IC101, IC121, IC192

D101

Note : When performing laser power checks and adjustment

(electrical adjustment), use of the new MD laser po wer meter

8010S (J-2501-145-A) instead of the conventional laser

power meter is convenient.

It sharply reduces the time and trouble to set the laser power

meter sensor onto the objective lens of the pick-up.

6-4. CREATING THE CONTINUOUSLY RECORDED

DISC

• The disc is used for the focus bias adjustment and error rate check.

The following describes how to create a continuously recorded

disc.

1. Insert a disc (blank disc) commercially available.

2. Rotate the VOLUME knob to display “CREC MODE”.

3. Press the p (CD) button to display “CREC MID”.

“CREC (0300)” will be momentarily displayed and recording

started.

4. Complete recording within 5 minutes.

5. Press the ^ (CD) button and stop recording .

6. Press the 6 (MD) button and remove the disc.

Create the continuous recorded disc for adjusting the focus bias

and checking the error rate as described above.

Note :

• Be careful not to apply vibrations during continuous recording.

6-5. TEMPERATURE COMPENSATION OFFSET

ADJUSTMENT

Save the current temperature data in the non-volatile memory as

the 25 °C standard data.

Notes:

1. Normally, this adjustment should not be preformed.

2. Set the surrounding temperature to 22 to 28 °C when performing

this adjustment.

Also perform this adjustment immediately after the power is

turned on when the internal temperature of the unit is the same

as the surrounding temperature (22 to 28 °C).

3. After replacing D101, perform this adjustment after the

temperature of parts reach the surrounding temperature.

Adjusting Procedure:

1. Rotate the VOLUME knob, to display “TEMP ADJUST”.

2. Press the p (CD) button and select the “TEMP ADJUST” mode.

3. “TEMP=

4. To save the data: Press the p (CD) button.

If not saving the data: Press the ^ (CD) button.

5. When the p (CD) button is pressed, “TEMP=

displayed, and then “TEMP ADJUST” is displayed again.

“TEMP ADJUST” is displayed again immediately after the ^

(CD) button is pressed.

Specifications:

TEMP=

to 2F.

” and the current temperature data are displayed.

SAVE” is

should be E0 to EF. F0 to FF, 00 to 0F, 10 to 1F and 20

– 24 –

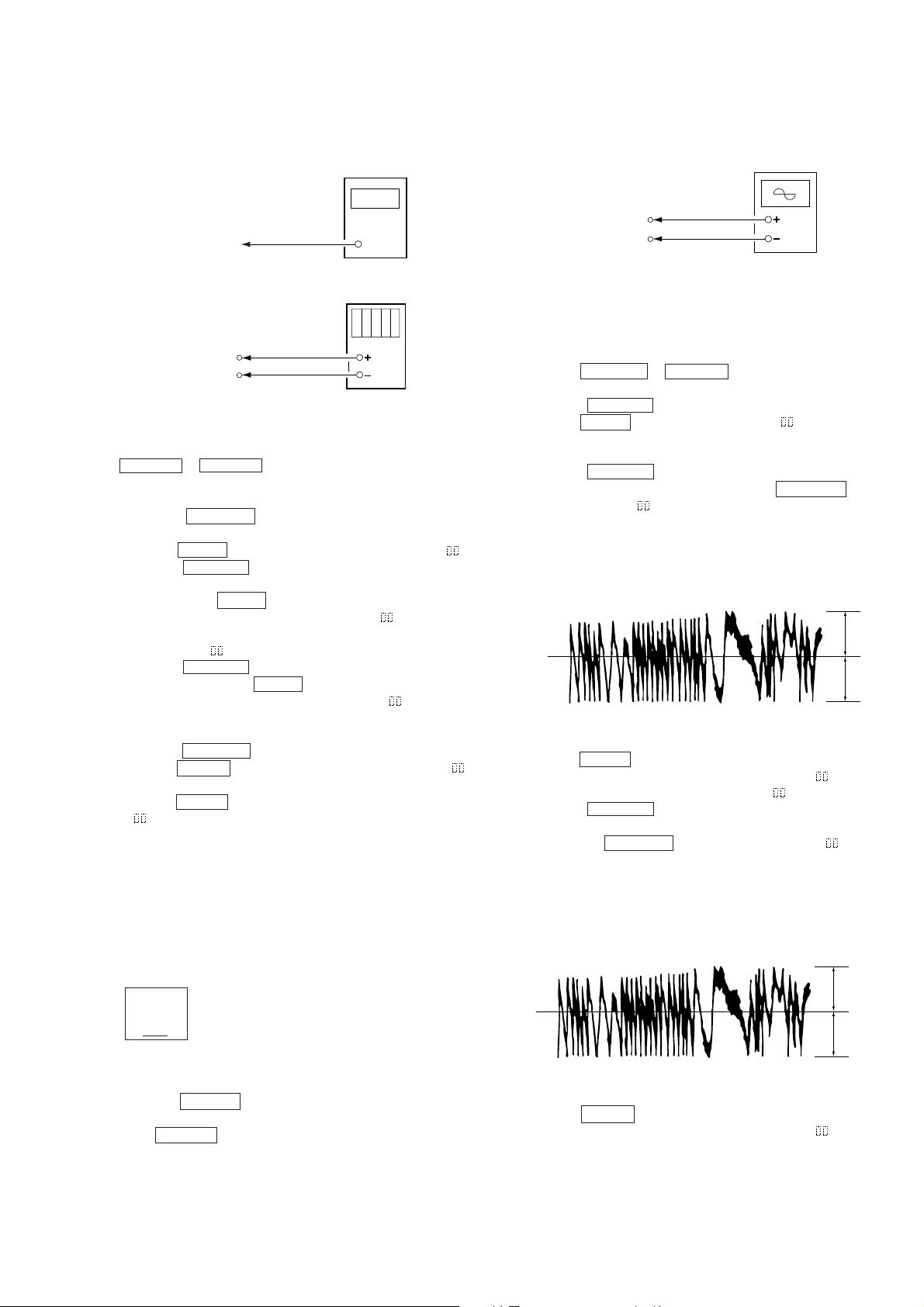

6-6. LASER POWER ADJUSTMENT

r

VC

A

B

Specified value : A = B

VC

A

B

Specified value : A = B

6-7. TRA VERSE ADJUSTMENT

Connection :

Optical pick-up

objective lens

BD (MD) board

TP (I+3V)

TP (IOP)

Laser power

meter

Digital volt mete

Adjusting Procedure:

1. Set the laser power meter on the objective lens of the optical

pick-up from the disc slot. (If it cannot be set properly , press the

= 0 or ) + button to move the optical pick-up).

Connect the digital voltmeter to TP (I+3V) and TP (IOP) of the

BD (MD) board.

2. Rotate the VOLUME knob to display “LDPWR ADJUST”.

(Laser power: For adjustment)

3. Press the p (CD) button once to display “LD 0.9 mW $

”.

4. Rotate the VOLUME knob so that the laser power meter reads

0.86 to 0.92 mW . Set the r ange knob of the laser power meter to

10 mW , press the p (CD) button, and sa ve the adjustment results

in the non-volatile memory. (“LD SAVE $

” is displayed

momentarily.)

5. “LD 7.0 mW $

” is next displayed.

6. Rotate the VOLUME knob so that the laser power meter reads

6.9 to 7.1 mW , press the p (CD) button, and sav e the adjustment

results in the non-volatile memory . (“LD SAVE $

” is displayed

momentarily.)

Note: Do not emit 7.0 mW continuously for more than 15 seconds.

7. Rotate the VOLUME knob to display “LDPWR CHECK”.

8. Press the p (CD) button once to display “LD 0.9 mW $

Check that the laser power meter reading is 0.85 to 0.91 mW.

9. Press the p (CD) button another time to diaplay “LD 7.0 mW

$

”.

Check that the readings of the laser power meter and digital

voltmeter become the specified value.

Specified Value :

Laser power meter reading : 7.0 ± 0.1 mW

Digital voltmeter reading : Value displayed on optical pick-up label

± 10%

Connection :

BD (MD) board

TP (TEO)

TP (VC)

Oscilloscope

Adjusting Procedure:

1. Connect an oscilloscope to TP (TEO) and TP (VC) of CN110 of

the BD (MD) board.

2. Load a recordable disc (any available on the market). (Refer to

Note 1.)

3. Press the = 0 or ) + button to move the optical

pick-up outside the pit.

4. Rotate the VOLUME knob to display “EFBAL ADJUST”.

5. Press the p (CD) button to display “EFB =

(Laser power READ power/Focus servo ON/trac king servo OFF/

spindle (S) servo ON)

6. Rotate the VOLUME knob so that the oscilloscope waveform

becomes the specified value. (Rotating the VOLUME knob

changes the “EFB= ” value and the wa veform.) The wav eform

changes by about 2% everytime when adjusted. Adjust as close

as possible to the specified value.

(Read power traverse adjustment)

(Tr a verse Waveform)

7. Press the p (CD) button and sav e the adjustment results in the

”.

non-volatile memory (displayed as “EFB =

momentarliy and then displayed as “EFB =

8. Rotate the VOLUME knob so that the oscilloscope waveform

becomes the specified value.

(Rotating the VOLUME knob changes the “EFB=

and the waveform.) The waveform changes by about 2%

everytime when adjusted. Adjust as close as possible to the

specified value.

(Write Power Traverse Adjustment)

(Tr a verse Waveform)

MO-R”.

SAVE”

MO-W”).

” value

(Optical pick-up label)

KMS

260A

27X40

B0825

N

Iop = 82.5 mA in this case

Iop (mA) = Digital voltmeter reading (mV)/1 (

Ω

)

10. Press the ^ (CD) button to display “LDPWR CHECK” and

stop the laser emission.

(The ^ (CD) button is effective at all times to stop the laser

emission.)

9. Press the p (CD) button to save the adjustment results in the

non-volatile memory (displayed as “EFB =

momentarliy).

– 25 –

SAVE”

10. Next “EFB = MO-P” is displaed, the optical pick-up moves

e

to the internal circumference of the pit and servo is imposed.

11. Rotate the VOLUME knob so that the oscilloscope wav eform

becomes the specified value.

The waveform changes by about 2% everytime when adjusted.

Adjust as close as possible to the specified value.

(Trav erse Waveform)

A

VC

B

Specified value : A = B

12. Press the p (CD) button and save the adjustment results in the

non-volatile memory (displayed as “EFB =

SAVE”

momentarliy).

“EFBAL: CD is next displayed and the disc stops rotating

automatically.

13. Press the 6 (MD) button and remove the disc.

14. Load the check disc (MD) TDYS-1.

15. Press the p (CD) button to display “EFB =

CD”. The servo

is imposed automatically.

16. Rotate the VOLUME knob so that the oscilloscope wav eform

becomes the specified value.

The waveform changes by about 2% everytime when adjusted.

Adjust as close as possible to the specified value.

(Trav erse Waveform)

A

VC

B

Specified value : A = B

17. Press the p (CD) button and save the adjustment results in the

non-volatile memory after “EFB =

SAVE” is momentarliy

displayed.

“EFBAL ADJUST” is next displayed.

18. Press the 6 (MD) button and remove the check disc (MD)

TDYS-1.

Note 1 : The data will be overwritten on the MO and erased when a

recorded disc is used in this adjustment.

Note 2 : If the traverse waveform is not clear, connect the oscillo-

scope as shown in the following figure so that it can be

seen more clearly.

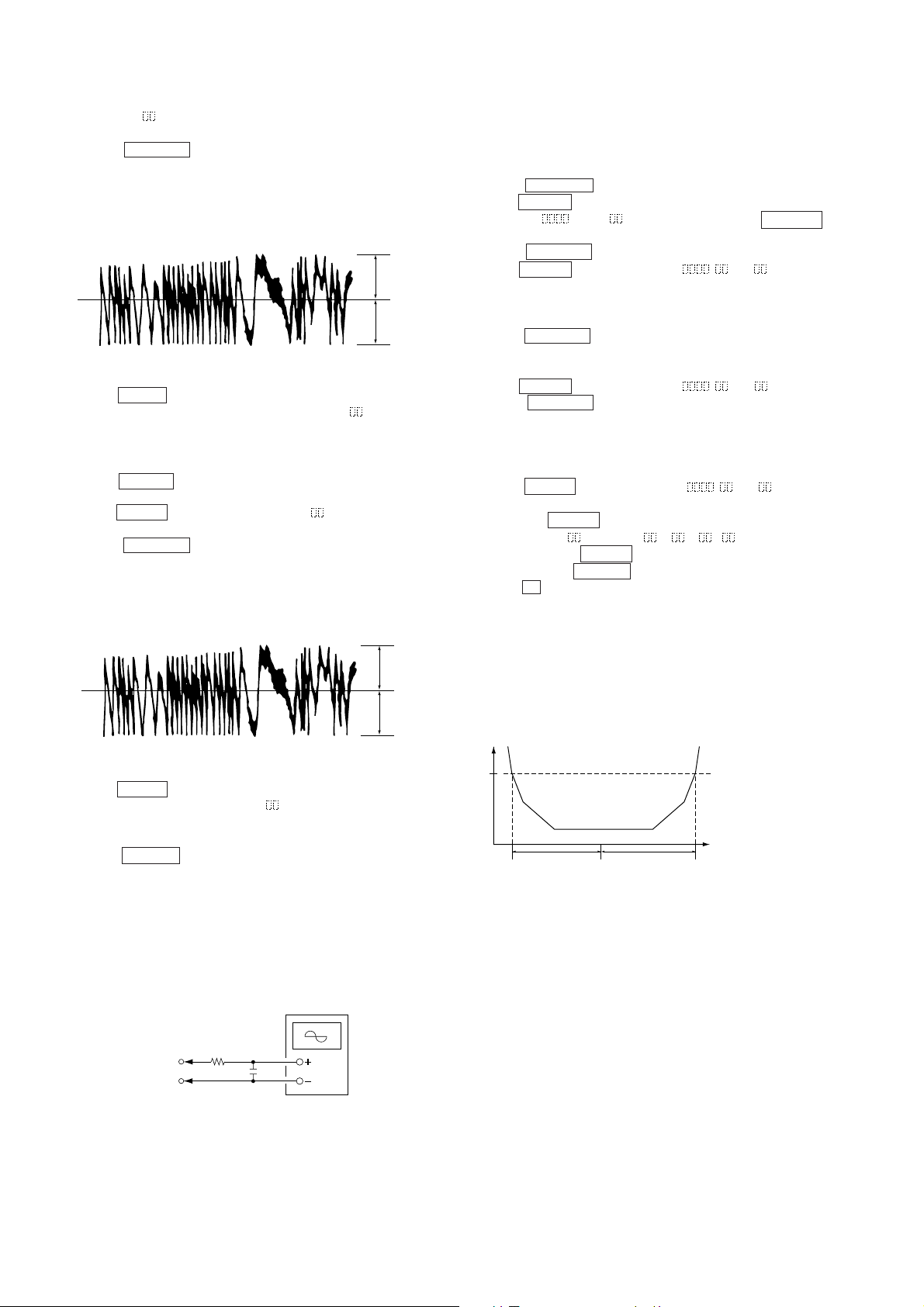

6-8. FOCUS BIAS ADJUSTMENT

Adjusting Procedure :

1. Load a continuously recorded disc (Refer to 6-4. Creating the

Continuously Recorded Disc”).

2. Rotate the VOLUME knob to display “CPLAY MODE”.

3. Press the p (CD) button to display “CPLAY MID”.

4. When “C1 = AD = ” is displayed, press the ^ (CD)

button.

5. Rotate the VOLUME knob to display “FBIAS ADJUST”.

6. Press the p (CD) button to display “

The first four digits indicate the C1 error rate, the two digits

after the “/” indicate ADER and the tw o digits after “a =” indicate

the focus bias value.

7. Rotate the V OLUME knob in the clockwise direction, and look

for the focus bias value at which the C1 error rate becomes

approximately approx. 200. (Refer to Note 2).

8. Press the p (CD) button to display “

9. Rotate the VOLUME knob in the counterclockwise direction,

and look for the focus bias value at which the C1 error rate

becomes approx. 200.

Check that the C1 error rate becomes almost equal to the value

set in step 7.

10. Press the p (CD) button to display “

11. Check that the C1 error rate is below 50 and that ADER is 00.

and press the p (CD) button.

12. If the value of “(

)” in the “ - - ( )” displayed is

above 20, press the p (CD) button.

If below , press the ^ (CD) button and start fr om step 2 again.

13. Press the 6 button and remov e the continuously recorded disc.

Note 1 : The following figure shows the relation between the C1

error and focus bias value. Look for points a and b in the

following figure by the adjustment avove. The focus

position (point c) is automatically calculated from points

a and b.

Note 2 : As the C1 error rate changes, use the average value in the

adjustment.

C1 error

approx.

200

b

c a Focus bias value

/ a = ”.

/ b = ”.

/ c = ”.

(F. BIAS)

BD (MD) board

TP (TEO)

TP (VC)

330 k

Oscilloscop

Ω

10pF

– 26 –

6-9. ERROR RATE CHECK

6-9-1. CD Error Rate Check

Checking Procedure :

1. Load a check disc (MD) TDYS-1.

2. Rotate the VOLUME knob to display “CPLAY MODE”.

3. Press the p (CD) button to display “CPLAY MID”.

4. “C1 =

5. Check that the C1 error rate is below 20.

6. Press the ^ (CD) button to stop playback. Then press the

6 (MD) button, and remove the check disc (MD).

6-9-2. MO Error Rate Checking

Checking Procedure :

1. Load a continuously recorded disc (Refer to 6-4. Creating the

Continuously Recorded Disc”).

2. Rotate the VOLUME knob to display “CPLAY MODE”.

3. Press the p (CD) button to display “CPLAY MID”.

4. “C1 =

5. Check that the C1 error rate is below 50 and ADER is 00.

6. Press the ^ (CD) button to stop playback. Then press the

6 (MD) button, and remove the disc.

AD = ” is displayed.

AD = ” is displayed.

6-10. FOCUS BIAS CHECK

Change the focus bias value and check the focus tolerance amount.

Checking Procedure :

1. Load a continuously recorded disc (Refer to 6-4. Creating the

Continuously Recorded Disc”).

2. Rotate the VOLUME knob to display “CPLAY MODE”.

3. Press the p (CD) button to display “CPLAY MID”.

4. When “C1 =

button.

5. Rotate the VOLUME knob to display “FBIAS CHECK”.

6. Press the p (CD) button to display “

The first four digits indicate the C1 error, the tw o digits after the

“/” indicate ADER and the two digits after “c =” indicate the

focus bias value.

Check that the C1 error is below 50 and ADER is 00.

7. Press the p (CD) button to change the display to “ / b =

”.

Check that the C1 error does not drop below 220 and ADER

does not remain above 00.

8. Press the p (CD) button to change the display to “

”.

Check that the C1 error does not drop below 220 and ADER

does not remain above 00.

9. Press the ^ (CD) button, press the 6 (MD) button next, and

remove the continuously recorded disc.

Note 1 : If the C1 error is above 220 or ADER is above 00 only for

point a (step 8 above) and point b (step 7 above), the f ocus

bias may not adjusted properly. In this case, adjust again.

AD = ” is displayed, press the ^ (CD)

/ c = ”.

/ a =

– 27 –

6-11. ADJUSTING POINTS AND CONNECTING POINTS

[BD (MD) BOARD] (SIDE A)

D101

IC192

[BD (MD) BOARD] (SIDE B)

IC316

TP

(TEO)

TP (IOP)

IC171

TP (I + 3V)

Q163

TP

(VC)

IC101

Q102

IC121

– 28 –

Loading...

Loading...