Sony HCDM-90 Service manual

HCD-M90

SERVICE MANUAL

Ver 1.4 2004.09

HCD-M90 is the Amplifier, DVD player, Tape

Deck and Tuner section in CMT-M90DVD.

DVD

Section

TAPE

Section

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Chinese Model

Model Name Using Similar Mechanism NEW

DVD Mechanism Type CDM55D-DVBU8B

Base Unit Name DVBU8B

Optical Pick-up Name

Model Name Using Similar Mechanism HCD-M70

KHM-240AAA (TYPE A)

KHM-270AAA (TYPE B)

Amplifier section

For the U.S. model

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

With 6-ohm loads, both channels driven, from

70 - 20,000 Hz; rated 18 watts per channel

minimum RMS power, with no more than 0.9%

total harmonic distortion from 250 milliwatts to

rated output.

North American model:

Continuous RMS power output (reference):

Total harmonic distortion less than 0.07% (6 ohms at

1 kHz, 12 W)

European, Chinese models:

DIN power output (rated): 15 + 15 W

Continuous RMS power output (reference):

Music power output (reference):

20 + 20 W

(6 ohms at 1 kHz, 10%

THD)

(6 ohms at 1 kHz, DIN)

20 + 20 W

(6 ohms at 1 kHz, 10%

THD)

40 + 40 W

SPECIFICATIONS

Other models:

The following measured at 230 V AC, 60 Hz

DIN power output (rated): 15 + 15 W

Continuous RMS power output (reference):

The following measured at 220 V AC, 60 Hz

DIN power output (rated): 12 + 12 W

Continuous RMS power output (reference):

Inputs

AUDIO IN MD (VIDEO) (phono jacks):

Outputs

VIDEO OUT: max. output level

(phono jack) 1 Vp-p, unbalanced,Sync

S-VIDEO OUT: Y: 1 Vp-p, unbalanced,

(4-pin/mini-DIN jack) Sync negative,

OPTICAL OUT: Optical

(6 ohms at 1 kHz, DIN)

18 + 18 W

(6 ohms at 1 kHz, 10%

THD)

(6 ohms at 1 kHz, DIN)

15 + 15 W

(6 ohms at 1 kHz, 10%

THD)

Sensitivity 500/250 mV,

impedance 47 kilohms

negative, load impedance

75 ohms

C: 0.286Vp-p,

load impedance 75 ohms

Wavelength: 660 nm

PHONES: Accepts headphones with

SPEAKER: accepts impedance of 6 to

DVD player section

Laser Semiconductor laser

Frequency response DVD (PCM 48 kHz):

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

Video color system format

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 50 – 13,000 Hz (±3 dB),

an impedance of 8 ohms

or more

16 ohms.

(DVD: λ=650 nm,

CD: λ=780 nm)

Emission duration:

continuous

2 Hz – 22 kHz = (±1 dB)

CD: 2 Hz – 20 kHz =

(±1 dB)

NTSC, PAL

using Sony TYPE I

cassettes

– Continued on next page –

9-873-991-05 Sony Corporation

2004I05-1 Personal Audio Company

© 2004.09 Published by Sony Engineering Corporation

DVD DECK RECEIVER

HCD-M90

Ver 1.3

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

North American model: 87.5 - 108.0 MHz

Other models: 87.5 - 108.0 MHz

Antenna FM wire antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

Pan American model: 530 - 1,710 kHz

European model: 531 - 1,602 kHz

Other models: 530 - 1,710 kHz

Antenna AM loop antenna, external

Intermediate frequency 450 kHz

General

Power requirements

North American model: 120 V AC, 60 Hz

European model: 230 V AC, 50/60 Hz

Australian model: 230 V AC, 50/60 Hz

Chinese model: 220 V AC, 50/60 Hz

Other models: 110 – 120 V or

Power consumption

European model: see the name plate

Other models: see the name plate

Dimensions (w/h/d) incl. projecting parts and controls

Amplifier/Tuner/Tape/DVD section:

Mass

Amplifier/Tuner/Tape/DVD section:

Design and specifications are subject to change

without notice.

(100-kHz step)

(50-kHz step)

(with the tuning interval

set at 10 kHz)

531 - 1,710 kHz

(with the tuning interval

set at 9 kHz)

(with the tuning interval

set at 9 kHz)

(with the tuning interval

set at 10 kHz)

531 - 1,602 kHz

(with the tuning interval

set at 9 kHz)

antenna terminal

220 – 240 V AC,

50/60 Hz

Adjustable with voltage

selector

0.3 watts (at the Power

Saving mode)

Approx. 159 × 217 ×

335 mm

Approx. 5.7 kg

2

HCD-M90

r

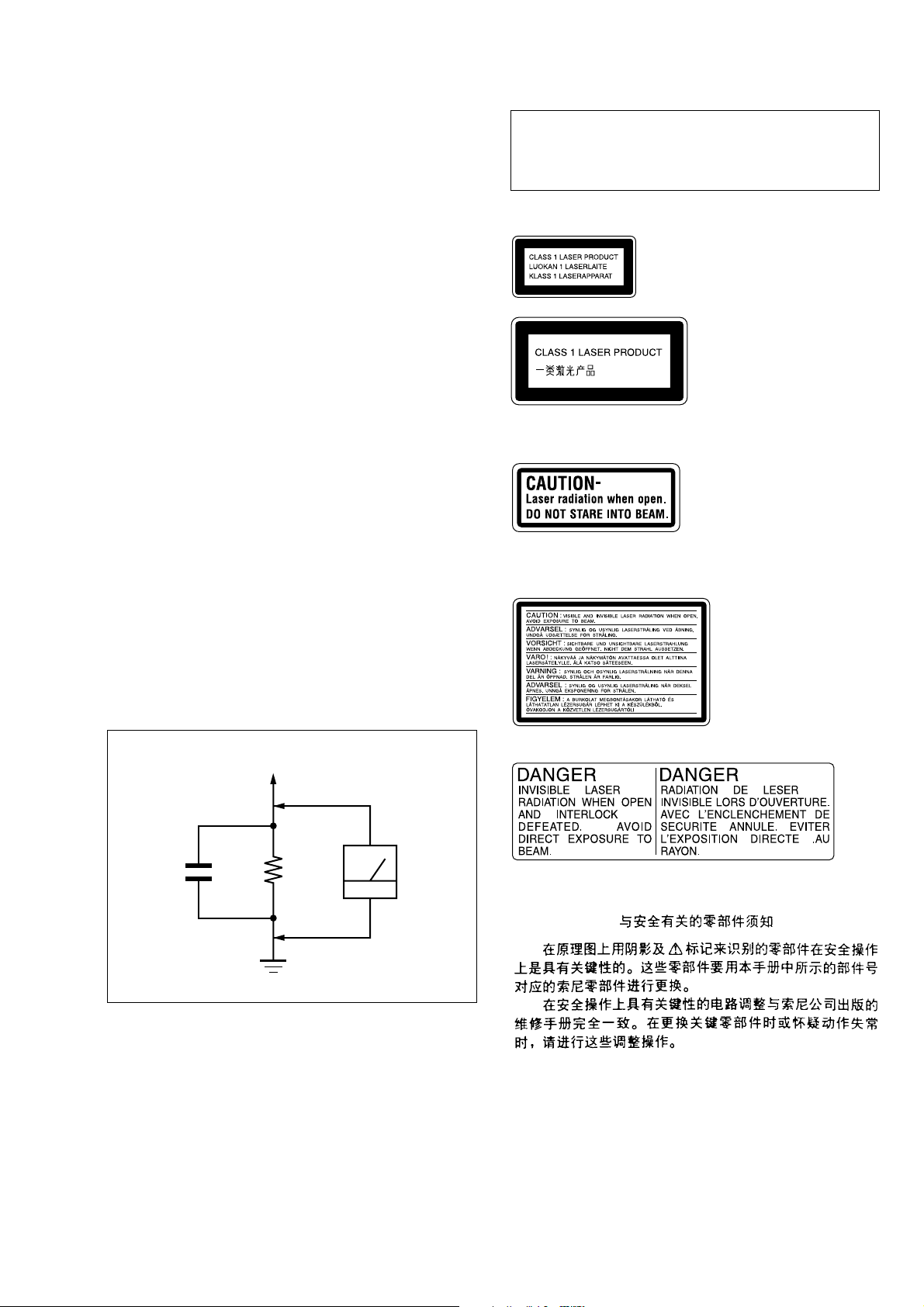

This label is located inside the unit.

Ver 1.3

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leaka ge from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated A C milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C voltmeter . The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2 V A C range are suitable. (See Fig. A)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is

classified as a CLASS 1

LASER product. This

label is located on the

rear exterior.

The following caution label is located inside the

apparatus.

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

To Exposed Metal

Parts on Set

1.5 k

Earth Ground

Ω

AC

voltmete

(0.75 V)

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

3

HCD-M90

Ver 1.3

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 5

2. GENERAL................................................................... 9

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 10

3-2. Side Panel (L), Side Panel (R) ........................................ 11

3-3. Top Panel Section............................................................ 11

3-4. Mechanical Deck (Tape) ................................................. 12

3-5. Front Panel Section ......................................................... 12

3-6. Back Panel Assy .............................................................. 13

3-7. MAIN Board ................................................................... 13

3-8. CONTROL Board, Noise Shield Case ........................... 14

3-9. DAC Board ...................................................................... 14

3-10. DVD Board...................................................................... 15

3-11. Mechanism Deck (CDM55D-DVBU8B) ....................... 15

3-12. LOADING Board, Motor (LD) Assy (M901)................ 16

3-13. RF-240 Board.................................................................. 16

3-14. Tray.................................................................................. 17

3-15. Optical Device................................................................. 17

4. TEST MODE.............................................................. 18

5. ELECTRICAL ADJUSTMENTS

DVD Section ................................................................... 27

Deck Section ................................................................... 28

6. DIAGRAMS

6-1. Block Diagram – DVD SERVO Section – .................... 29

6-2. Block Diagram – DVD MAIN Section (1/2) – ............. 30

6-3. Block Diagram – DVD MAIN Section (2/2) – ............. 31

6-4. Block Diagram – TUNER/TAPE DECK Section – ...... 32

6-5. Block Diagram – AUDIO Section – .............................. 33

6-6. Block Diagram

– KEY CONTROL/POWER SUPPLY Section –........... 34

6-7. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 35

6-8. Printed Wiring Board – RF-240 Board (Suffix-11) – ... 36

6-9. Schematic Diagram – RF-240 Board (Suffix-11) – ...... 37

6-10. Printed Wiring Board – RF-240 Board (Suffix-22) – ... 38

6-11. Schematic Diagram – RF-240 Board (Suffix-22) – ...... 39

6-12. Printed Wiring Boards

– DVD (Side A) (Suffix-21)/LOADING Boards – ........ 40

6-13. Printed Wiring Board

– DVD Board (Side B) (Suffix-21) –.............................. 41

6-14. Schematic Diagram

– DVD (1/7) (Suffix-21)/LOADING Boards – .............. 42

6-15. Schematic Diagram

– DVD Board (2/7) (Suffix-21) – ................................... 43

6-16. Schematic Diagram

– DVD Board (3/7) (Suffix-21) – ................................... 44

6-17. Schematic Diagram

– DVD Board (4/7) (Suffix-21) – ................................... 45

6-18. Schematic Diagram

– DVD Board (5/7) (Suffix-21) – ................................... 46

6-19. Schematic Diagram

– DVD Board (6/7) (Suffix-21) – .................................. 47

6-20. Schematic Diagram

– DVD Board (7/7) (Suffix-21) – .................................. 48

6-21. Schematic Diagram

– DVD (1/7) (Suffix-22)/LOADING Boards – .............. 49

6-22. Schematic Diagram

– DVD Board (2/7) (Suffix-22) – ................................... 50

6-23. Schematic Diagram

– DVD Board (3/7) (Suffix-22) – ................................... 51

6-24. Schematic Diagram

– DVD Board (4/7) (Suffix-22) – ................................... 52

6-25. Schematic Diagram

– DVD Board (5/7) (Suffix-22) – ................................... 53

6-26. Schematic Diagram

– DVD Board (6/7) (Suffix-22) – .................................. 54

6-27. Schematic Diagram

– DVD Board (7/7) (Suffix-22) – .................................. 55

6-28. Printed Wiring Boards

– DVD (Side A) (Suffix-22)/LOADING Boar ds – ........ 56

6-29. Printed Wiring Board

– DVD Board (Side B) (Suffix-22) –.............................. 57

6-30. Printed Wiring Board – DAC Board –........................... 58

6-31. Schematic Diagram – DAC Board –.............................. 59

6-32. Printed Wiring Board – TC Board (Suffix-12) – ........... 60

6-33. Schematic Diagram – TC Board (Suffix-12) – ............. 61

6-34. Printed Wiring Board – TC Board (Suffix-32) – ........... 62

6-35. Schematic Diagram – TC Board (Suffix-32) – ............. 63

6-36. Schematic Diagram

– MAIN Board (1/2) (Suffix-14) – ................................. 64

6-37. Schematic Diagram – MAIN (2/2) (Suffix-14)/

JACK (Suffix-11) Boards –............................................. 65

6-38. Printed Wiring Boards

– MAIN (Suffix-14)/JACK (Suffix-11) Boards – .......... 66

6-39. Printed Wiring Boards

– MAIN (Suffix-16)/JACK (Suffix-12) Boards – .......... 67

6-40. Schematic Diagram

– MAIN (1/2) Board (Suffix-16) – ................................. 68

6-41. Schematic Diagram – MAIN (2/2) (Suffix-16)/

JACK (Suffix-12) Boards –............................................. 69

6-42. Printed Wiring Boards

– CONTROL (Suffix-11)/VIDEO Boards –................... 70

6-43. Schematic Diagram

– CONTROL (Suffix-11)/VIDEO Boards –................... 71

6-44. Printed Wiring Boards

– CONTROL (Suffix-12)/VIDEO Boards –................... 72

6-45. Schematic Diagram

– CONTROL (Suffix-12)/VIDEO Boards –................... 73

6-46. Printed Wiring Board

– SWITCH Board (Suffix-11) – ..................................... 74

6-47. Schematic Diagram – SWITCH Board (Suffix-11) – ... 75

6-48. Printed Wiring Board

– SWITCH Board (Suffix-12) – ..................................... 76

6-49. Schematic Diagram – SWITCH Board (Suffix-12) – ... 77

6-50. Printed Wiring Board

– POWER Board (Suffix-11) – ....................................... 78

6-51. Schematic Diagram – POWER Board (Suffix-11) –..... 79

6-52. Printed Wiring Board

– POWER Board (Suffix-12, -21) – ............................... 80

6-53. Schematic Diagram

– POWER Board (Suffix-12, -21) – .............................. 81

6-54. IC Pin Function Description ........................................... 88

7. EXPLODED VIEWS

7-1. Panel (Side) Section ........................................................ 99

7-2. Front Panel Section ........................................................ 100

7-3. Top Panel Section........................................................... 101

7-4. Chassis Section-1 ...........................................................102

7-5. Chassis Section-2 ...........................................................103

7-6. Chassis Section-3 ...........................................................104

7-7. Mechanism Deck Section (CDM55D-DVBU8B) ......... 105

7-8. Base Unit Section (DVBU8B) ....................................... 106

8. ELECTRICAL PARTS LIST ..............................107

4

SECTION 1

Connect jig (extension cable J-2501-219-B)

to the control board (CN507) and DVD board (CN101).

control board (CN008)

DVD board (CN008)

TC board (CN301)

main board (CN301)

Connect jig (extension cable J-2501-167-A)

to the main board (CN301) and TC board (CN301).

SERVICING NOTES

HCD-M90

Ver 1.3

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

MODEL IDENTIFICATION

– Back Panel –

Part No.

SERVICE POSITION

In checking the control board, prepare jig (extension cable J-2501219-B: 1.00 mm Pitch, 10 cores, Length 300 mm).

Model Name Part No.

AEP and UK models 4-239-822-0

US and Canadian models 4-239-823-0

Singapore model 4-239-824-0

Australian model 4-240-899-0

Chinese model 4-242-690-0

RELEASING THE DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure :

While pressing the x key, press the [ DVD] key. The message

“UNLOCKED” is displayed and the tray is unlocked.

Note: When “LOCKED” is displayed, the tray lock is not released by

turning power on/off with the I/1 button.

[]

[]

[]

[]

[]

Z

In checking the tape deck section, prepare jig (extension cable J2501-167-A: 1.25 mm Pitch, 17 cores, Length 300 mm).

5

HCD-M90

Ver 1.3

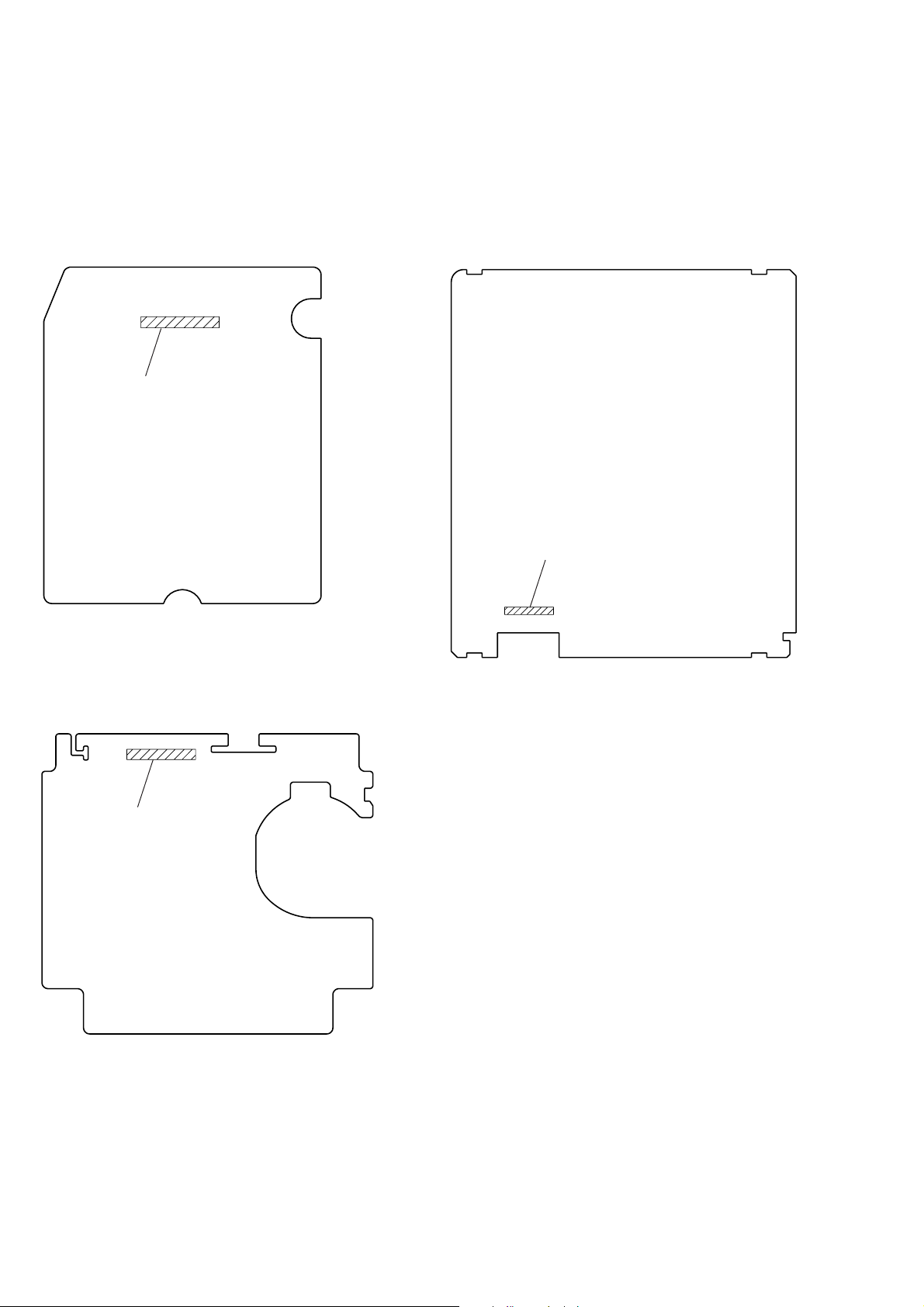

NEW/FORMER DISCRIMINATION

In this set, RF-240, DVD, TC, MAIN, JACK, CONTROL,

SWITCH and POWER boards have been changed in the midway

of production.

Note: Chinese model is produced only with the new boards.

– RF-240 BOARD (Side A) –

Former: 1-681-879-11

New : 1-681-879-22

– DVD BOARD (Side B) –

Former: 1-684-516-21

New : 1-684-516-22

– TC BOARD (Component Side) –

Former: 1-684-172-12

New : 1-684-172-32

6

– MAIN BOARD (Component Side) –

– CONTROL BOARD (Component Side) –

Former: 1-685-427-11

New : 1-685-427-12

HCD-M90

Ver 1.3

Former: 1-684-232-14

New : 1-684-232-16

– JACK BOARD (Component Side) –

Former: 1-685-428-11

New : 1-685-428-12

7

HCD-M90

Ver 1.4

– SWITCH BOARD (Component Side) –

Former: 1-685-426-11

New : 1-685-426-12

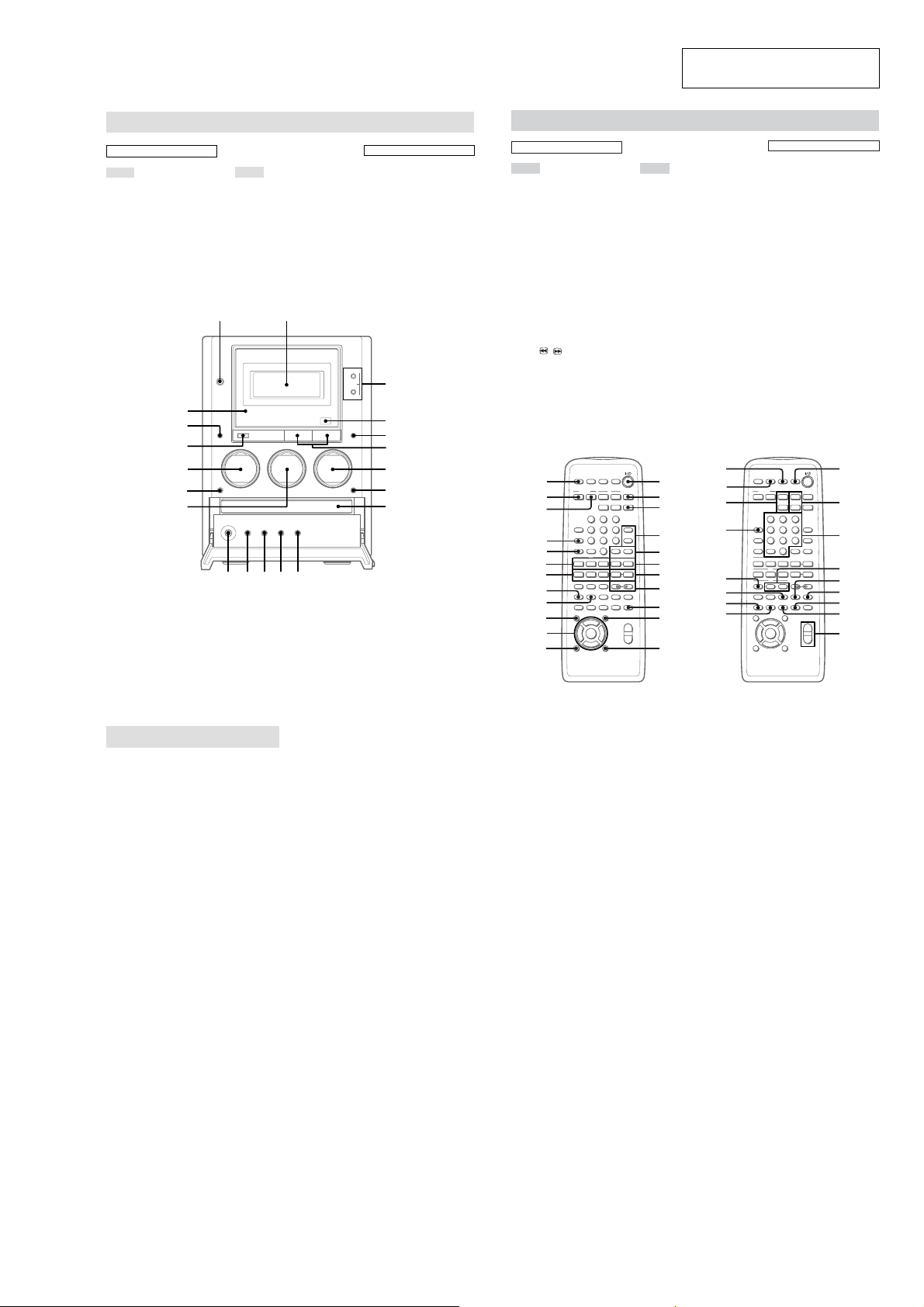

TYPE A/B DISCRIMINATION

optical device

SILVER: KHM-240AAA (TYPE A)

BLACK: KHM-270AAA (TYPE B)

– POWER BOARD (Component Side) –

Former: 1-685-429-11

New : 1-685-429-12, -21

NOTE OF REPLACING THE DVD BOARD

When replacing the DVD board, since the adjustment value is not

set up correctly, “Drive Auto Adjustment” can’t be performed.

In this case, initialize Memory in the following procedures.

Procedure:

1. Set the test mode. (See page 18)

2. Press the

MANUAL OPERATION”. (See page 23)

3. Press the [6] key of the remote commander, and set the “2-6,

Memory Check”. (See page 25)

4. Press the [CLEAR] key of the remote commander, and initial-

ize Memory.

[2] key of the remote commander , and set the “DRIVE

8

SECTION 2

GENERAL

HCD-M90

This section is extracted from

instruction manual.

Main unit

ALPHABETICAL ORDER

A – F

CD SYNCHRO qa

CD SYNCHRO indicator w;

DIRECTION 0

Disc tray 9

Display window 2

DSG qk

DVD N 7

DVD X 7

FUNCTION ql

w;

ql

qk

qj

qh

qg

P – V

PHONES jack qf

PLAY MODE/TUNING MODE

qd

Remote sensor 4

REPEAT/FM MODE qs

TAPE nN qj

TAPE X qj

TUNER AM qg

TUNER FM qg

TUNING +/– 3

VOLUME +/– 6

1

?/1

z

2

nN N

Remote Control

BUTTON DESCRIPTIONS

?/1 (power) 1

m/M 3

l/L 3

x 5

Z DVD 8

z REC qh

ML

3

lm

4

x

5

6

XX

7

Z

8

9

0qaqsqdqf

ALPHABETICAL ORDER

A – E F – W

ANGLE ea

AUDIO ed

BASS/TREBLE 3

CLEAR ql

CLOCK/TIMER SELECT ws

CLOCK/TIMER SET wa

CURSOR T/t 5

DISPLAY qg

DSG 2

DVD DISPLAY qs

DVD MENU 0

DVD TOP MENU qf

DVD SETUP ef

DVD N/SELECT qj

DVD X qj

DVD x qj

DVD ./> 7

/ T 8

DVD t

ENTER/YES w;

wd

ws

wa

FUNCTION qh

Numeric buttons wh

PLAY MODE/TUNING MODE

wk

REPEAT/FM MODE wl

RETURN O qa

SCROLL eg

SLEEP wd

SUBTITLE e;

TAPE nN qk

TAPE X qk

TAPE x qk

TAPE m/M 6

TUNER BAND eh

TUNER +/– wj

TUNING MEMORY ej

TV `/1 wf

TV CH +/– wg

TV VOL +/– ek

TV VIDEO r;

VES 9

VOL +/– es

WIDE el

++

––

w;

ql

qk

qj

qh

qg

qf

qd

+

–

+

–

1

2

3

4

5

6

7

8

9

0

qaqs

r;

el

ek

ej

eh

eg

ef

ed

BUTTON DESCRIPTIONS

`/1 (power) 1

V/v/B/b/ENTER qd

+/– 4

wf

++

wg

––

wh

wj

+

–

wk

wl

e;

ea

+

es

–

Setting the clock

1

Press ?/1 to turn on the system.

2

Press CLOCK/TIMER SET on the

remote.

3

Press + or — on the remote repeatedly

to set the hour.

4

Press ENTER/YES or CURSORt on

the remote.

5

Press + or — on the remote repeatedly

to set the minute.

6

Press ENTER/YES on the remote.

The clock starts working.

To adjust the clock

1

Press CLOCK/TIMER SET on the remote.

2

Press + or — on the remote to select CLOCK

SET?, then press ENTER/YES on the

remote.

3

Do the same procedures as step 3 to 6 above.

9

HCD-M90

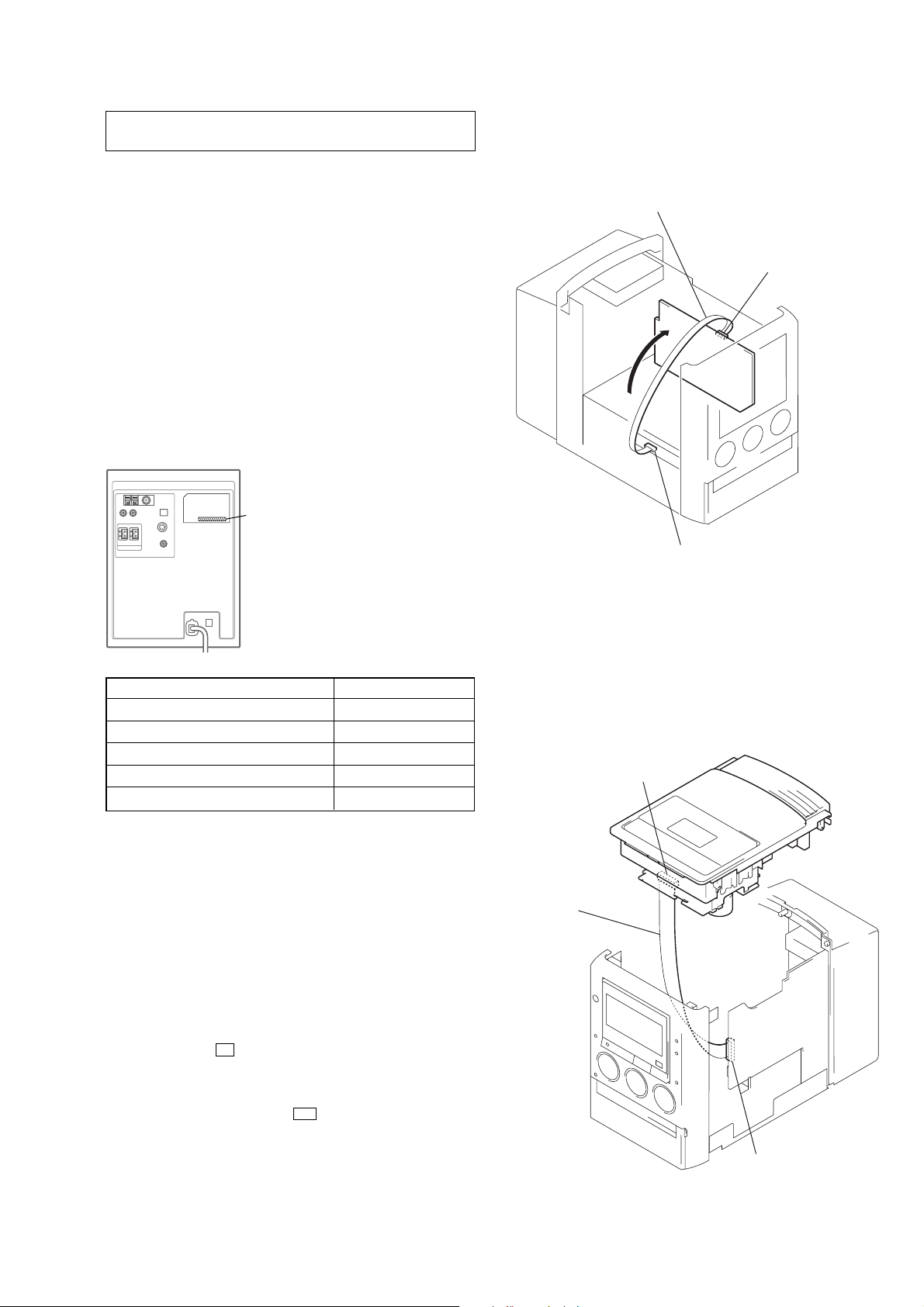

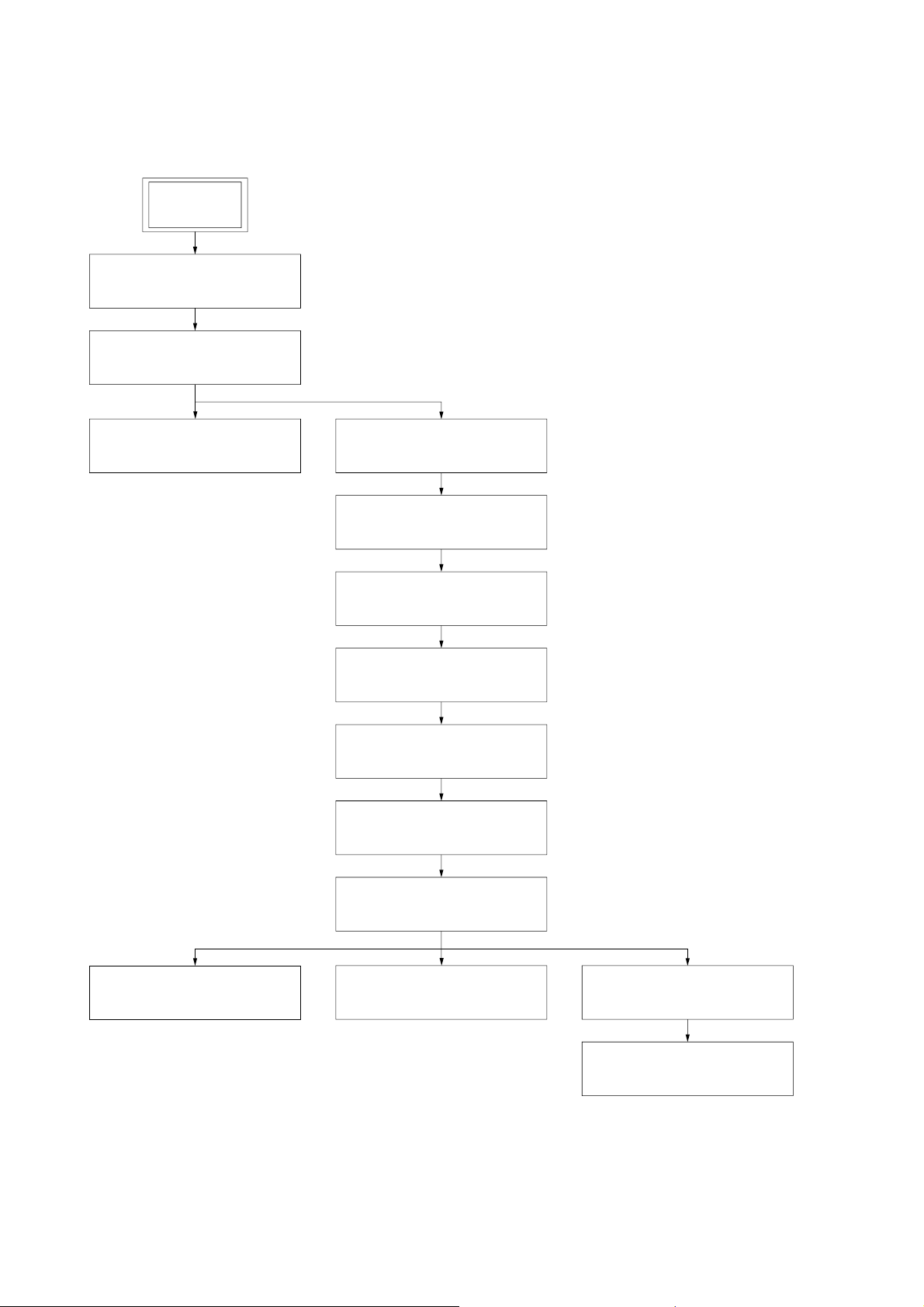

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. SIDE PANEL (L),

SIDE PANEL (R)

(page 11)

3-3. TOP PANEL SECTION

(page 11)

SECTION 3

DISASSEMBLY

3-4. MECHANICAL DECK (TAPE)

(page 12)

3-5. FRONT PANEL SECTION

(page 12)

3-6. BACK PANEL ASSY

(page 13)

3-7. MAIN BOARD

(page 13)

3-8. CONTROL BOARD,

NOISE SHIELD CASE

(page 14)

3-9. DAC BOARD

(page 14)

3-10.DVD BOARD

(page 15)

10

3-12.LOADING BOARD,

MOTOR (LD) ASSY (M901)

(page 16)

3-11.MECHANISM DECK

(CDM55D-DVBU8B)

(page 15)

3-13.RF-240 BOARD

(page 16)

3-14.TRAY

(page 17)

3-15.OPTICAL DEVICE

(page 17)

Note: Follow the disassembly procedure in the numerical order given.

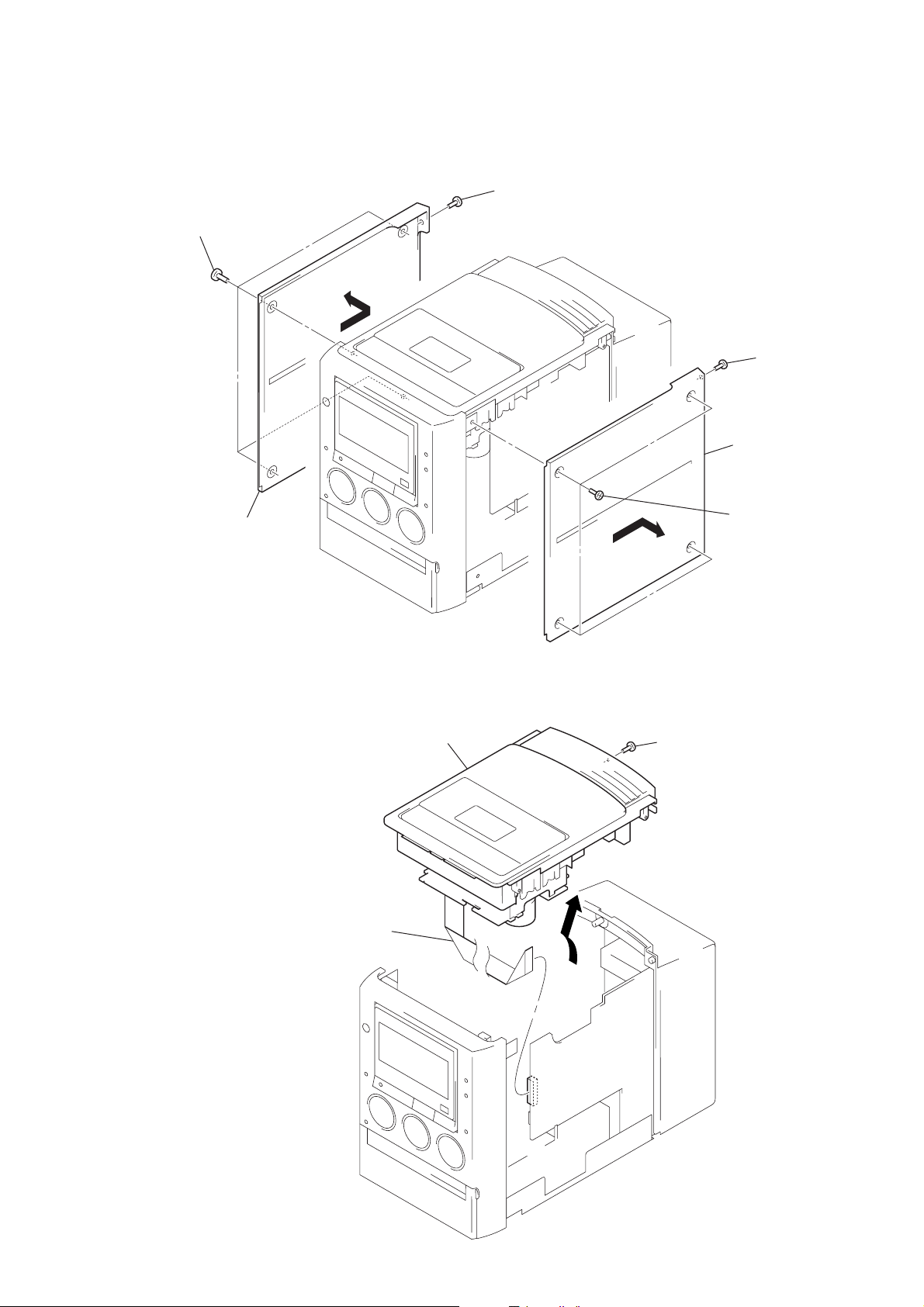

1

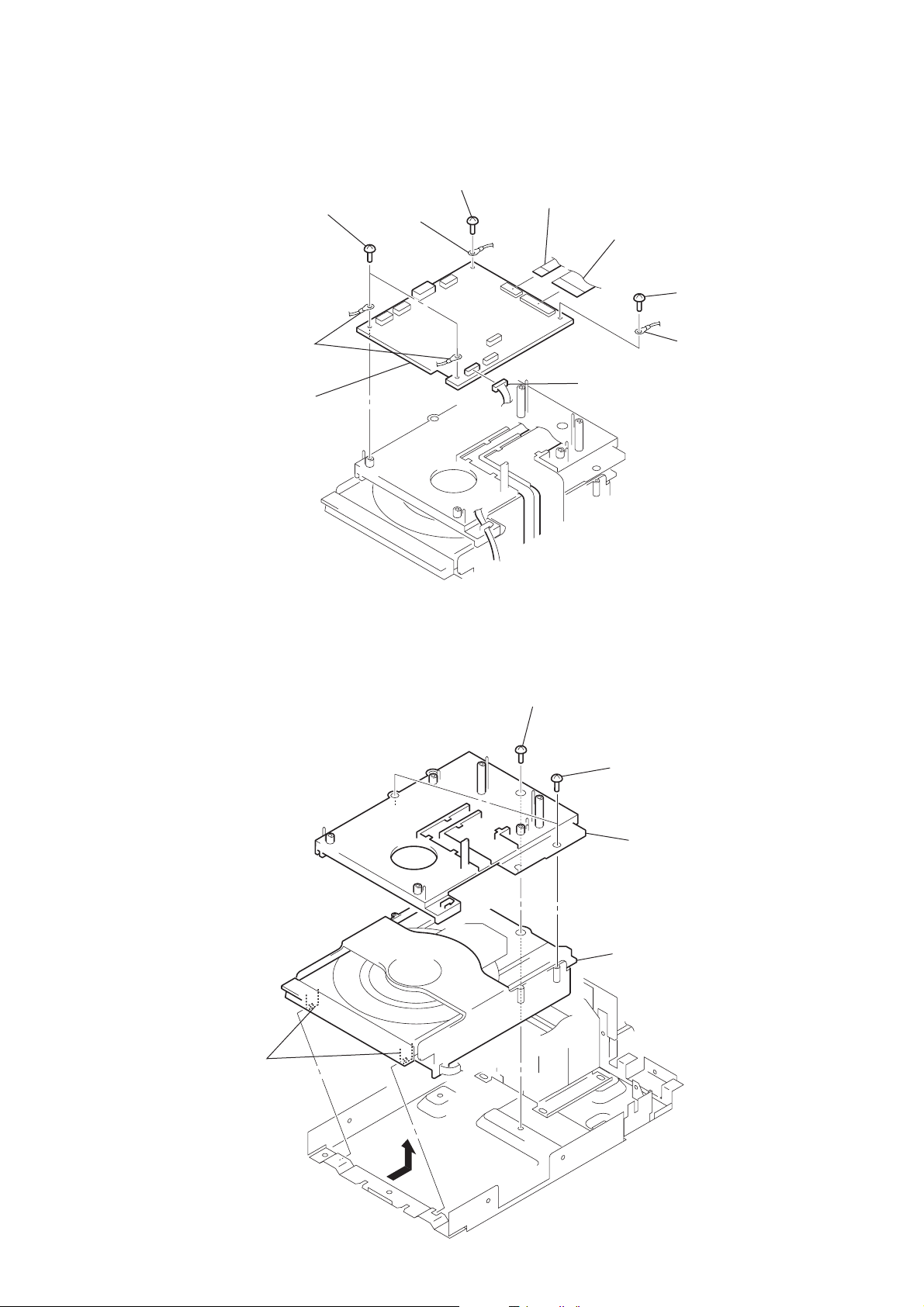

four screws

(BTP3

×

10)

2

3

side panel (L)

1

screw

(BTP3

×

10)

4

screw

(BTP3

×

10)

4

four screws

(BTP3

×

10)

5

6

side panel (R)

)

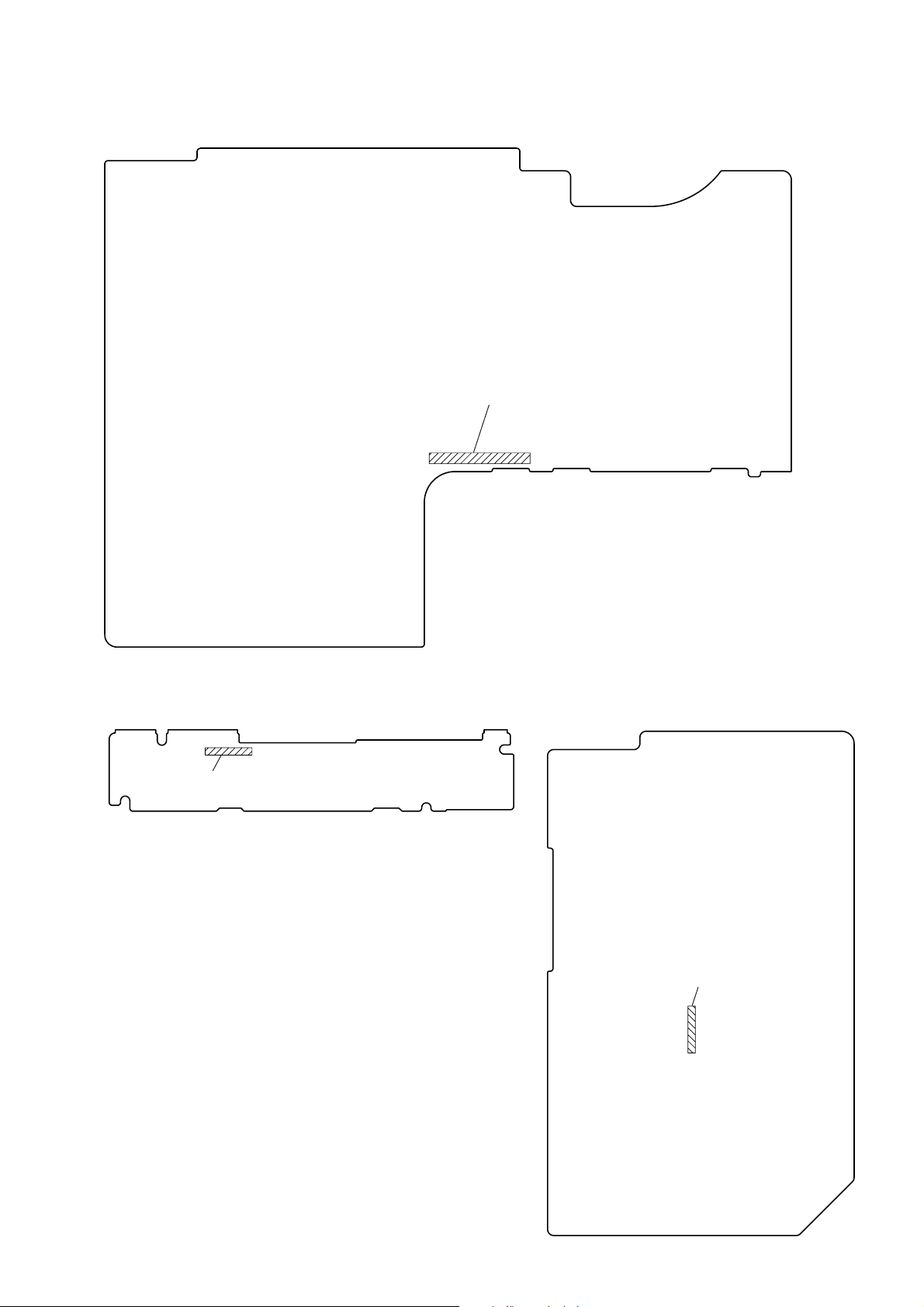

3-2. SIDE PANEL (L), SIDE PANEL (R)

HCD-M90

3-3. TOP PANEL SECTION

3

wire (flat type) (17 core)

(CN301)

4

top panel section

1

screw

(BTP3 × 10

2

11

HCD-M90

)

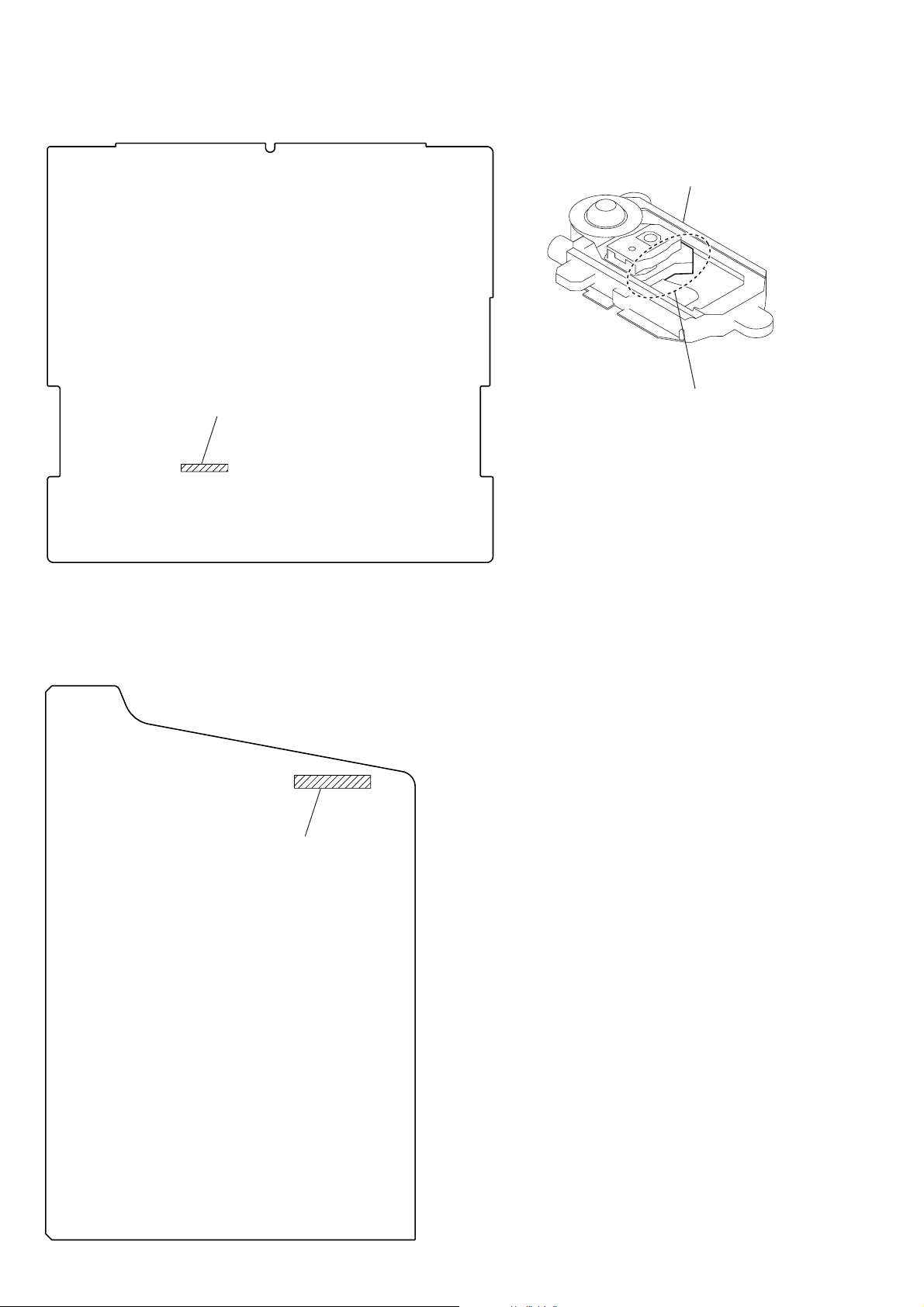

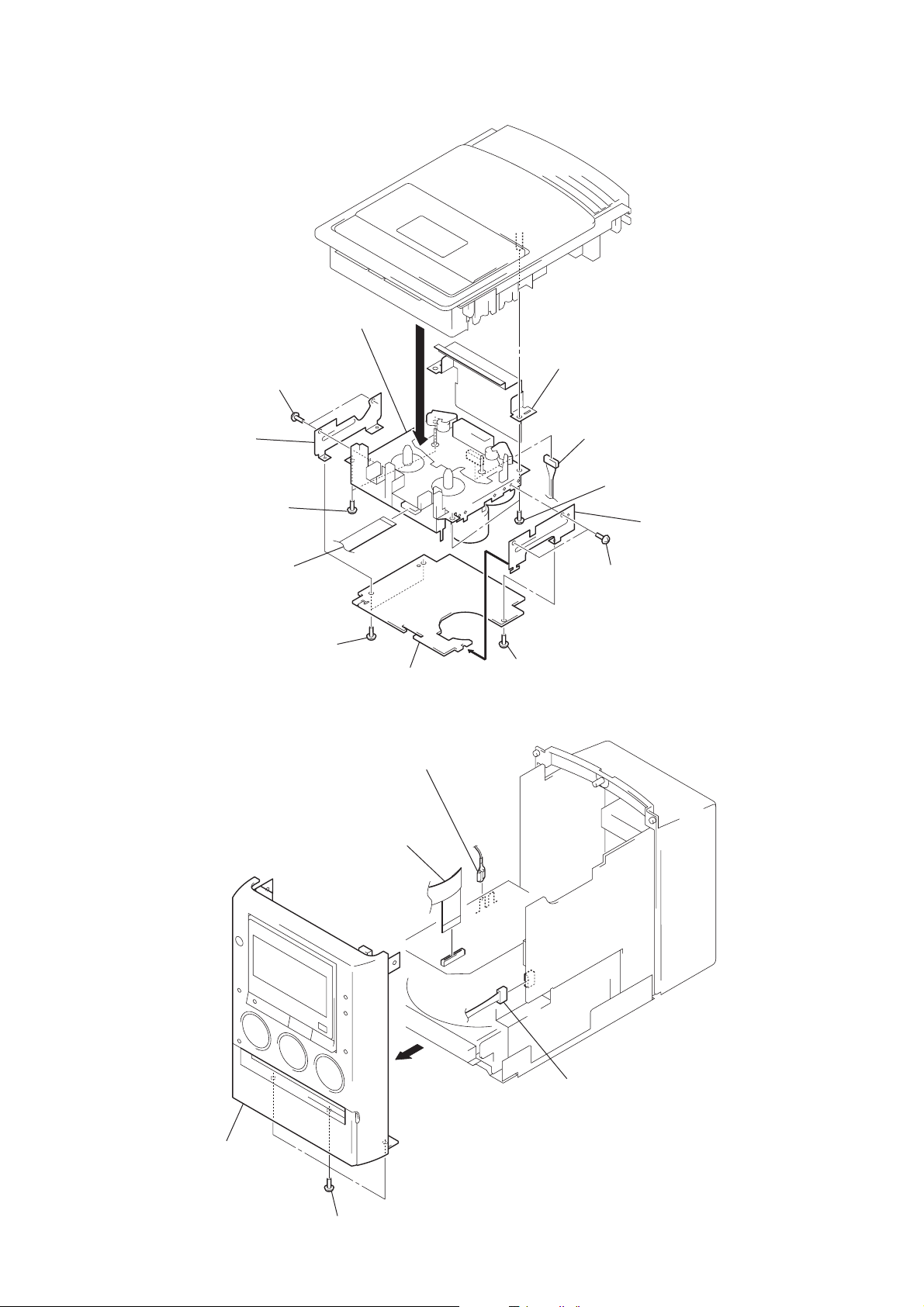

3-4. MECHANICAL DECK (TAPE)

qd

mechanical deck

(tape)

9

two screws

(BVTT2.6 × 5)

0

MD bracket (L)

1

two screws

(BVTP3 × 8)

2

3

shield case (TC)

5

connector

1

two screws

(BVTP3 × 8)

qs

MD bracket (R

4

wire (flat type) (EEC) (8 core)

6

two screws

(BVTT2.6 × 5)

3-5. FRONT PANEL SECTION

1

wire (flat type) (FFC) (21 core) (CN801)

8

TC board

3

lead (with connector)

7

6

screw

(BVTT2.6 × 5)

qa

two screws

(BVTT2.6 × 5)

12

5

front panel section

4

three screws

(BTP3

2

connector

(CN304)

×

8)

3-6. BACK PANEL ASSY

1

two connectors

(CN802, CN809)

3

back panel assy

2

four screws

(BTP3

2

two screws

(BTP3

HCD-M90

×

8)

×

8)

3-7. MAIN BOARD

1

wire (flat type) (25 core) (CN806)

2

connector

(CN902)

4

main board

3

screw

(BTP3 × 12)

1

wire (flat type) (17 core) (CN804)

13

HCD-M90

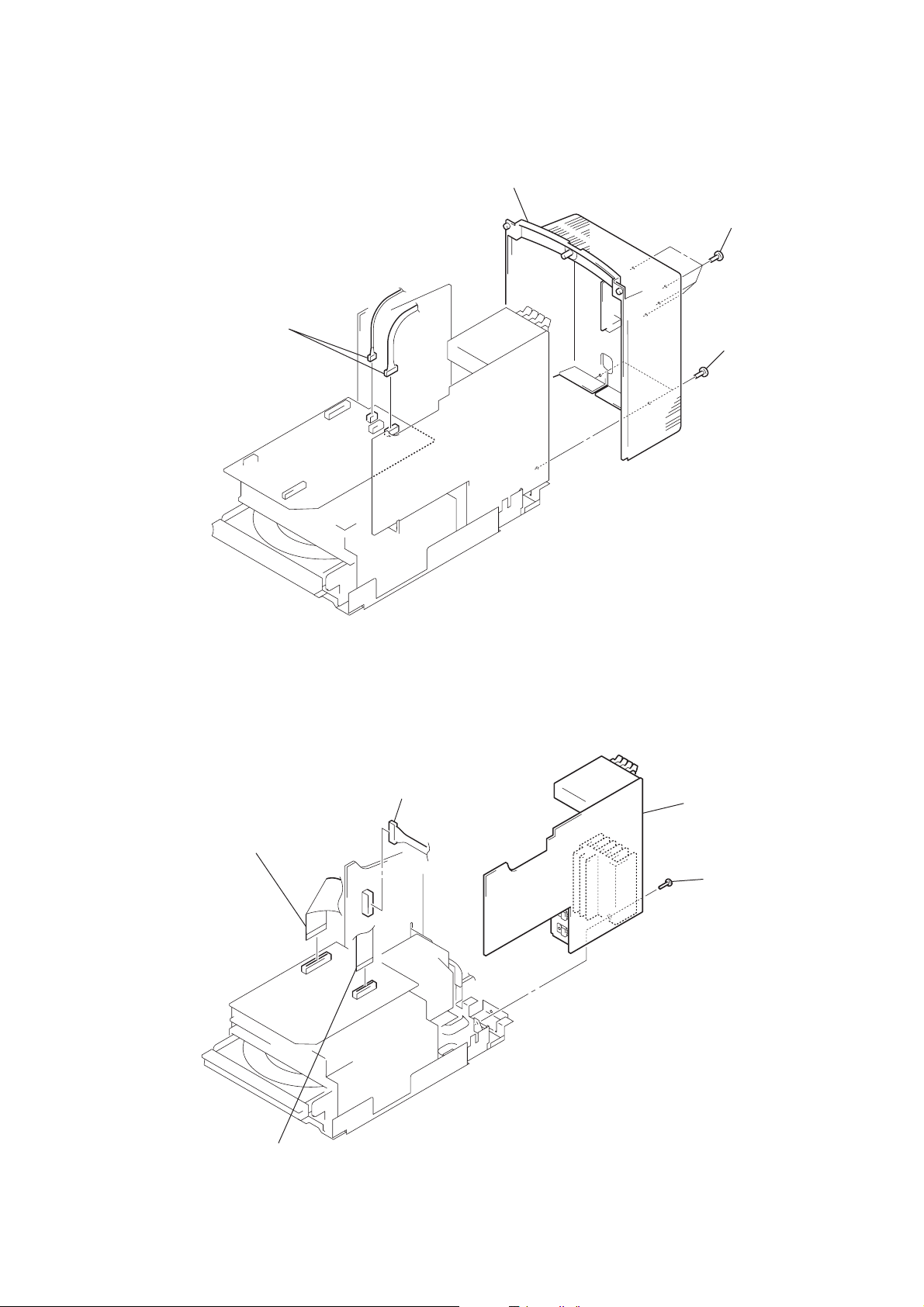

3-8. CONTROL BOARD, NOISE SHIELD CASE

2

two screws

(BVTP3 × 8)

1

wire (flat type) (FFC) (10 core)

(CN507)

3

control board

5

lead (with connector)

4

connector

(CN008)

8

noise shield case

1

wire (flat type) (FFC) (13 core)

(CN506)

1

wire (flat type) (FFC) (6 core)

(CN803)

5

two leads (with connector)

6

two screws

(BVTP3 × 8)

3-9. DAC BOARD

4

DAC board

3

terminal

2

screw

(DIA. 2.6

7

6

two screws

(BVTP3 × 8)

×

8)

1

wire (flat type) (FFC) (5 core)

(CN300)

2

screw

3

terminal

(DIA. 2.6

×

8)

14

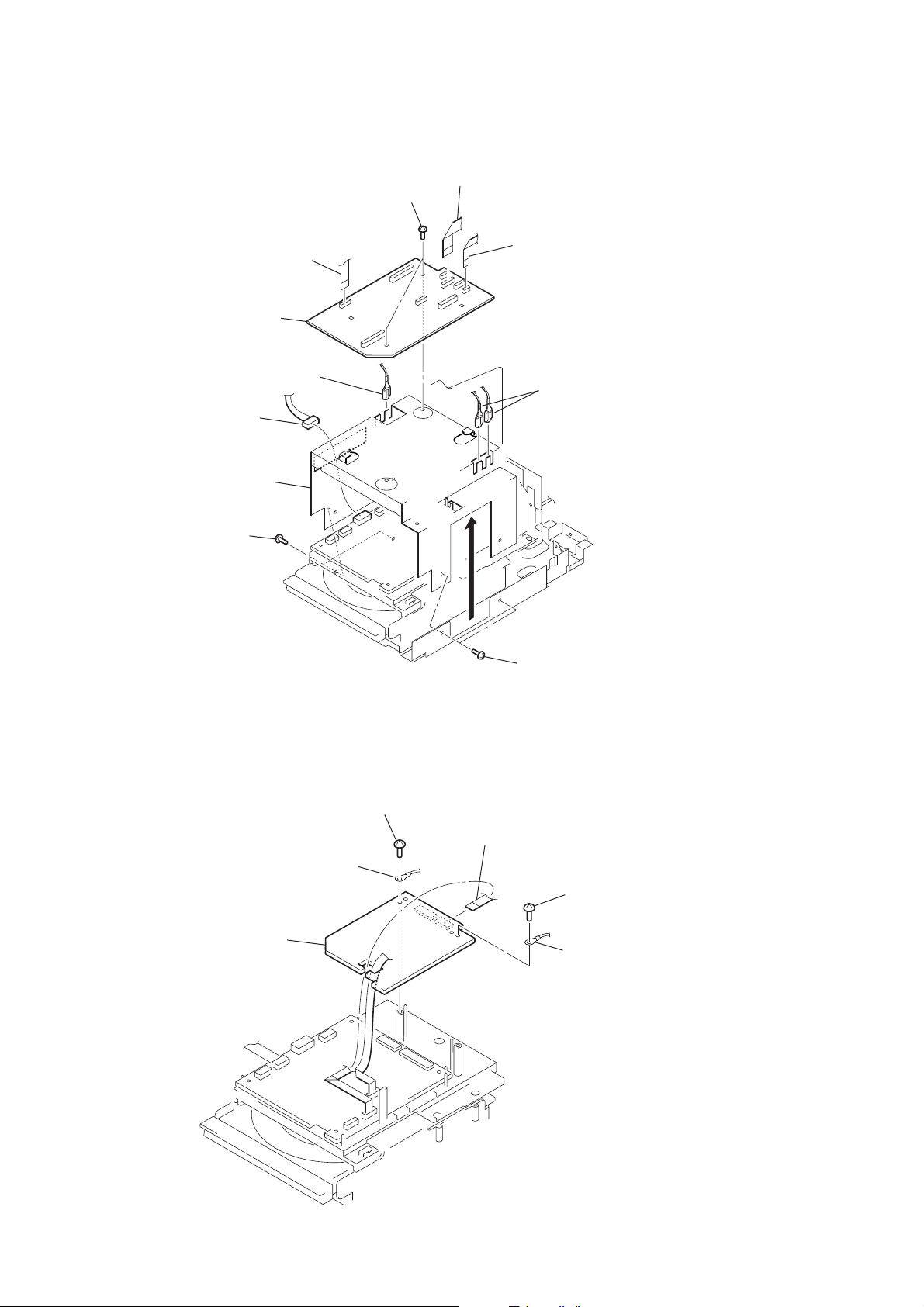

3-10. DVD BOARD

)

k

3

4

two terminals

5

two screws

(DIA. 2.6 × 8)

DVD board

4

3

terminal

screw

(DIA. 2.6

HCD-M90

1

×

8)

flexible flat cable (9 core)

(CN009)

1

flexible flat cable 25P

(CN010)

2

connector

(CN402)

3

screw

(DIA. 2.6 × 8

4

terminal

3-11. MECHANISM DECK (CDM55D-DVBU8B)

3

two claws

3

screw

(BVTP3

×

8)

1

two screws

(DIA. 2.6 × 8)

2

bracket (MPEG)

4

Remove the mechanism dec

in the direction of the arrow.

15

HCD-M90

)

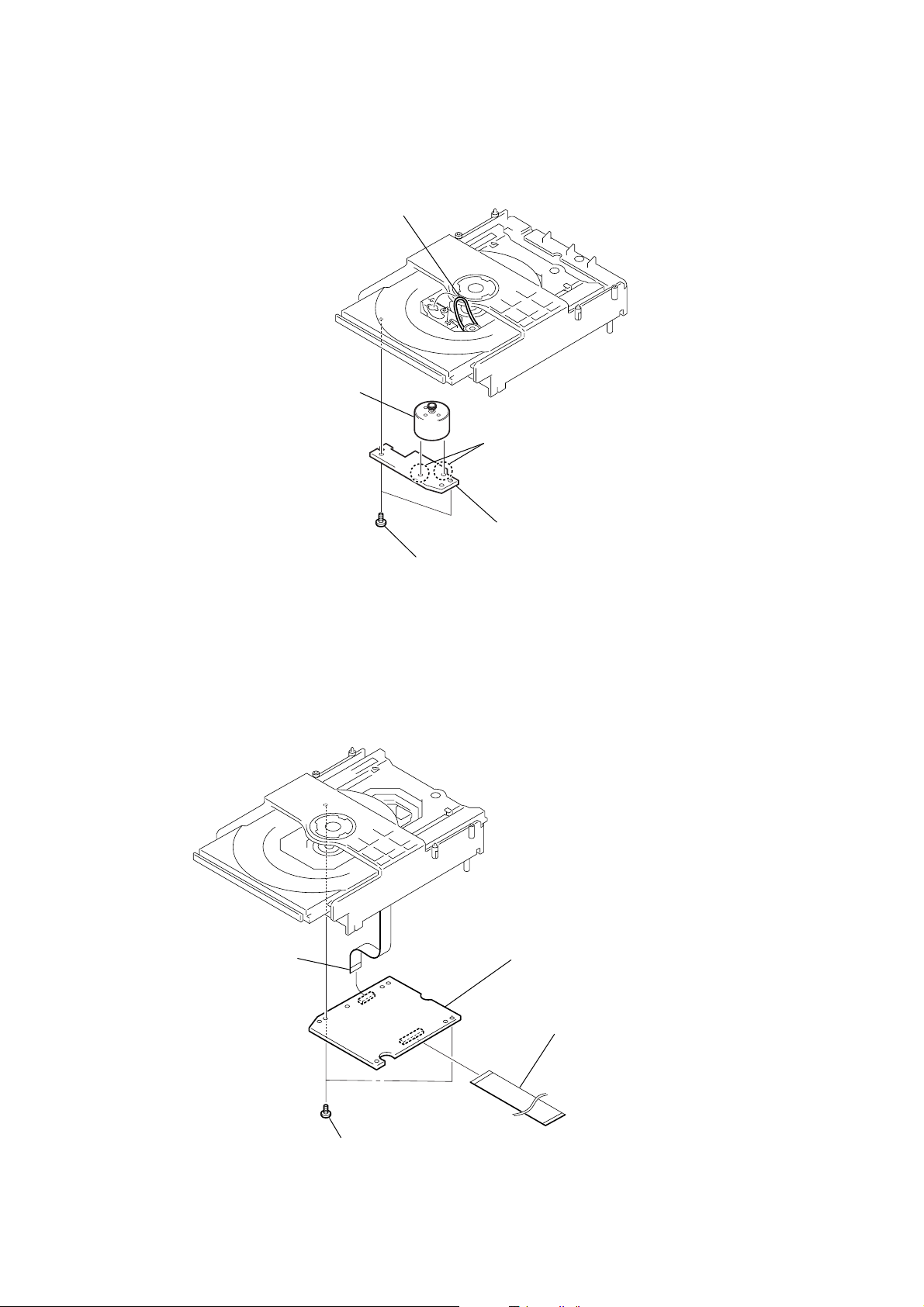

3-12. LOADING BOARD, MOTOR (LD) ASSY (M901)

1

Remove the belt (CDM55).

4

motor (LD) assy (M901)

3

Remove the two soldes

of motor (LD) assy (M901) .

3-13. RF-240 BOARD

2

flexible flat cable (26P)

(CN001)

2

two screws

(BTP 2.6

5

loading board

×

6)

4

RF-240 board

16

3

two screws

(BTP 2.6 × 6)

1

flexible flat cable (25 core

(CN002)

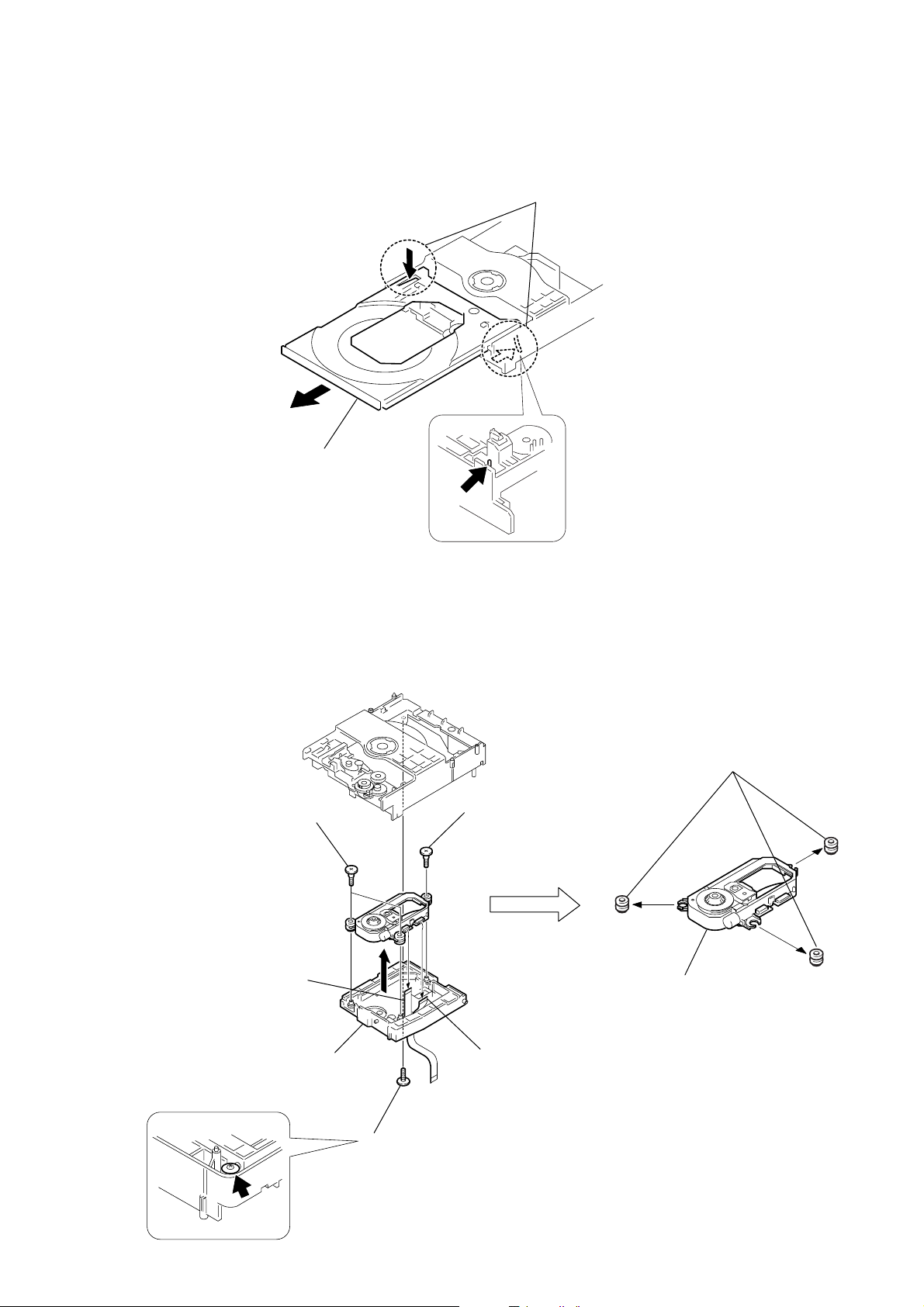

3-14. TRAY

)

1

While pushing the two protrusions, release the two claws fixing the tray

and pull out the tray in the direction of the arrow

A

2

tray

A

. (Be carefull of the two claws.

HCD-M90

3-15. OPTICAL DEVICE

5

two step screws (M)

2

flexible flat cable

(9 core)

6

7

holder (KHM-240)

4

step screw (L)

3

flexible flat cable

(26 core)

8

9

optical device

three insulators

1

floating screw (PTPWHM 2.6)

17

HCD-M90

)

Ver 1.2

SECTION 4

TEST MODE

[COLD RESET]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press three keys x , z REC , and I/1 simultaneously.

3. The set is reset, and becomes standby state.

[PANEL TEST]

•This mode is used to check the liquid crystal display, LED,

destination, model, software version, and key.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press three keys Z DVD , z REC , and [FUNCTION]

simultaneously.

3. Liquid crystal display and LEDs are all turned on.

4. When you want to enter the version check mode, press the

[PLAY MODE/TUNING MODE] keys. The destination and model

are displayed.

5. Each time [PLAY MODE/TUNING MODE] key is pressed, the

display changes starting from MC version, GC version, ST

version, T A v ersion, TM version, TC version, MD v ersion, and

DVD versionin this order , and returns to the MC version display .

6. When [REPEAT/FM MODE] key is pressed while the version

numbers are being displayed except model and destination,

year, month and day of the software creation appear. When

[REPEAT/FM MODE] key is pressed again, the display returns to

the software version display . When [PLAY MODE/TUNING MODE]

key is pressed while year, month and day of the software creation

are being displayed, the year, month and day of creation of the

software versions are displayed in the same order of version

display.

7. Press the

8. In the key check mode, the liquid crystal display displays “K0

J0 V0”. Each time a key is pressed, “K” value increases.

However , once a key is pressed, it is no longer taken into account.

9. To release this mode, press three keys in the same manner as

step 2, or disconnect the power cord.

[CD SYNCHRO] key, and the key check mode is activated.

[AMP TEST MODE]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press three keys x , [DSG], and [PLAY MODE/TUNING MODE]

simultaneously.

3. The display changes a shown below each time [BASS/TREBLE]

key on the remote commander is pressed.

“TONE MAX”

(BASS/TREBLE MAX, VOLUME MAX)

[DVD SHIP (MECHA) MODE]

•This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “DVD”.

3. Press three keys x , [DSG], and [REPEAT/FM MODE]

simultaneously.

4. The message “LOCK” is displayed on the liquid crystal display

and turn the power off automatically, and becomes delivery

mode.

[SHIP MODE]

• This mode is used to execute “COLD RESET” and “DVD SHIP

(MECHA)” simultaneously.

1. Press the I/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “DVD”.

3. Press three keys x , [DSG], and [CD SYNCHRO] simultaneously .

4. The message “LOCK” is displayed on the liquid crystal display

and turn the power off automatically, and set is reset, then

becomes delivery mode.

[DVD SERVICE MODE]

• This mode allows you to make diagnosis and adjustment easily

using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

Enter the DVD Service Mode

Procedure:

1. Connect a TVmonitor to this set.

2. Press the I/1 key to turn the power ON.

3. Press the

4. Press three keys x , [DSG], and [DIRECTION] simultaneously.

5. Test mode start and display the menu shown below on the TV

screen. (At the bottom of the menu screen, the model name and

revision number are displayed)

6. To execute each function, select the desired menu and press its

number on the remote commander. To release from this mode,

press the I/1 key.

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Version Information

6. Video Level Adjustment

Exit: POWER Key

_

Model : HCX-1102_xx

Revision : 1.xxx

[FUNCTION] key to select “DVD”.

“TONE MIN”

“TONE FLAT”

4. The display changes “VOLUME MAX” each time [VOLUME +]

key is pressed and “VOLUME MIN” each time [VOLUME --] key

is pressed.

18

(BASS/TREBLE MIN, VOLUME MAX)

(BASS/TREBLE FLAT, VOLUME MAX

HCD-M90

Syscon Diagnosis

The same contents as board detail check by serial interface can be

checked from the remote commander.

On the T est Mode Menu screen, press the [10/0] key on the remote

commander, and the following Check Menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. Peripheral

4. Servo

5. Supply

6. AV Decoder

7. Video

8. Audio

_

0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

1. All

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed

for the key entry.

### Syscon Diagnosis ###

Diag All Check

No. 2 Version

2-2. Revision

ROM Revision = 1070

Press NEXT Key to Continue

Press PREV Key to Repeat

_

For the ROM Check, the check sum calculated by the syscon is

output, and therefore you must compare it with the specified value

for confirmation. Following the message, press the DVD > key

to go to the next item, or the DVD . key to repeat the same

check again. To quit the Syscon Diagnosis and return to the Check

Menu screen, press the DVD x or the [ENTER] keyon the remote

commander. If an error occurred, the diagnosis is suspended and

the error code is displayed as shown below.

### Syscon Diagnosis ###

3-2. EEPROM Check

Error 03: EEPROM Write/Reed N

Address : 00000001

Write Data : 2492

Read Data : 2490

Press NEXT Key to Continue

Press PREV Key to Repeat

_

Selecting 2 and subsequent items calls the submenu screen of each

item. For example, if “5. Supply” is selected, the following submenu

will be displayed.

### Syscon Diagnosis ###

Check Menu

No. 5 Supply

0. Quit

1. All

2. ARP Register Check

3. ARP to RAM Data Bus

4. ARP to RAM Address Bus

5. ARP RAM Check

_

2. Version

(2-2) Revision

ROM revision number is displayed.

Error: Not detected.

The revision number defined in the source file of ROM

(IC108) is displayed with four digits.

(2-3) ROM Check Sum

Check sum is calculated.

Error: Not detected.

The 8-bit data are added at addresses 0x000F0000 to

0x002EFFFF of ROM (IC108) and the result is displayed

with 4-digit hexadecimal number . Compare the result with

the specified value.

(2-4) Model Type

Model code is displayed.

Error: Not detected.

The model code read from EEPROM (IC101) is displayed

with 2-digit hexadecimal number.

(2-5) Region

Region code is displayed.

Error: Not detected.

The region code determined from the model code is displayed.

3. Peripheral

(3-2) EEPROM Check

Data write → read, and accord check

Error 03: EEPROM write/read discord

Data 0x9249, 0x2942, 0x4294 are written to addresses

0x00~0xFF of EEPROM (IC101), then read and checked.

Before writing, the data are saved, then after checking, they

are written to restore the contents of EEPROM.

4. Servo

(4-2) Servo DSP Check

Data write → read, and accord check

Error 12: Read data discord

Data 0x9249, 0x2942, 0x4294 are written to the address

0x602 of RAM in the servo DSP (IC302), then read and

checked.

19

HCD-M90

(4-3) DSP Driver Test

Test signal data → DSP driver

Error: Not detected.

Caution: Do not conduct this test with a mechanical deck

connected.

The maximum voltage is applied to the servo driver IC

(IC401). If mechanical deck is connected, the motor and

optical pick-up could be damaged. Disconnect mechanical

deck following the output message, then enter specified 4or 5-digit number from the remote commander, and press

the [ENTER] on the remote commander. The test is conducted only when the input data accord. Check the output

level, then press the DVD > on the remote commander

to finish the test. This test is skipped if “All” is selected.

Supplement: How to disconnect mechanical deck

Disconnect flat cables connected to the CN009 and CN010

of DVD board. Also, disconnect harness from the CN402.

5. Supply

Caution: Do not conduct this check with a mechanical deck

connected.

An access is made to the stream supply and servo control

IC (IC302) and external RAM (IC303) using check data.

If mechanical deck is connected, the motor and optical

pick-up could be damaged. This check is also executed

by the “All” menu item.

Supplement: How to disconnect mechanical deck

Disconnect flat cables connected to the CN009 and

CN010 of DVD board. Also, disconnect harness from

the CN402.

(5-2) ARP Register Check

Data write → read, and accord check

Error 08: ARP register write, and read data discord

Data 0x00 to 0xFF are written to the TMAX register (address 0xC6) in ARP (IC302), then they are read and check ed.

(5-3) ARP to RAM Data Bus

Data write → read, and accord check

Error 09: ARP ↔ RAM data bus error

Data 0x0001 to 0x8000 where one bit each is set to 1 are

written to the address 0 of RAM (IC303) connected to the

ARP (IC302) through the bus, then they are read and

checked. In case of discord, written bit pattern and read

data are displayed. If data where multiple bits are 1 are

read, the bits concerned may touch each other. Further, if

data where certain bit is always 1 or 0 regardless of written

data, the line could be disconnected or shorted.

(5-4) ARP to RAM Address Bus

Data write → other address read discord check

Error 10: ARP ↔ RAM address bus error

Caution: Address and data display in case of an error is

different from the display of other diagnosis (de-

scribed later).

Before starting the test, all addresses of RAM (IC303) are

cleared to 0x0000. First, 0xA55A is written to the address

0x00000, and the address data are read and checked from

addresses 0x00001 to 0x80000 while shifting 1 bit each.

Next, the data at that address is cleared, and it is written to

the address 0x00001, and read and checked in the same

manner. This check is repeated up to the address 0x80000

while shifting the address data by 1 bit each. If data other

than 0 is read at the addresses except written address, an

error is given because all addresses were already cleared to

0. In this check, the error display pattern is different from

that of other diagnosis; read data, written address, and read

address are displayed in this order. However, the message

uses same template, and accordingly exchange Address and

Data when reading. The following display, for example,

### Syscon Diagnosis ###

5-4. ARP to RAM Address Bus

Error 10: ARP - RAM Address B

Address : 0000A55A

Write Data : 00000000

Read Data : 00080000

Press NEXT Key to Continue

Press PREV Key to Repeat

_

shows the data 0xA55A was read from address 0x00080000

though it was written to the address 0x00000000. This implies that these addresses are in the form of shadow. Also,

if the read data is not 0xA55A, another error will be present.

(5-5) ARP RAM Check

Data write → read, and accord check

Error 11: ARP RAM read data discord

The program code data stored in ROM are copied to all

areas of RAM (IC303) connected to the ARP (IC302)

through the bus, then they are read and checked if they accord. If the detail check was selected initially, the data are

written to all areas and read, then the same test is conducted

once again with the data where all bits are inverted between

1 and 0. If discord is detected, faulty address, written data,

and read data are displayed following the error code 11,

and the test is suspended.

20

6. AV Decoder

(6-2) 1930 RAM

Data write → read, and accord check

Error 13: AVD RAM read data discord

The program code data stored in ROM (IC108) are copied

to all areas of RAM (IC504, IC505) connected to the AV

decoder (IC503) through the bus, then they are read and

checked if they accord. Further, the same test is conducted

once again with the data where all bits are inverted between

1 and 0. If discord is detected, faulty address, written data,

and read data are displayed following the error code 13,

and the test is suspended.

(6-3) 1930 SP

ROM → AVD RAM → Video OUT

Error: Not detected.

The data including sub picture streams in ROM (IC108)

are transferred to the RAM (IC504, IC505) in AV decoder

(IC503), and output as video signals from the AV decoder

(IC503). They are output from all video terminals

(Composite, Y/C).

7. Video

(7-2) Color Bar

AVD color bar command write → Video OUT

Error: Not detected.

The command is transferred to the AVD, and the color bar

signals are output from video terminals. They are output

from all video terminals (Composite, Y/C).

(7-3) Composit Out

(7-4) Y/C Out

(7-6) Component Out

8. Audio

(8-2) ARP -> 1930

Error 14: ARP → 1930 video NG

15: ARP → 1930 audio NG

(8-3) Test Tone

All channels

2ch Left

2ch Right

Front Left

Front Right

Rear Left

Rear Right

Center

Sub Woof er

Check Items List

2. Version

(2-2) Revision

(2-3) ROM Check Sum

(2-4) Model Type

(2-5) Region

3. Peripheral

(3-2) EEPROM Check

4. Servo

(4-2) Servo DSP Check

(4-3) DSP Driver Test

5. Supply

(5-2) ARP Register Check

(5-3) ARP to RAM Data Bus

(5-4) ARP to RAM Address Bus

(5-5) ARP RAM Check

6. AV Decoder

(6-2) 1930 RAM

(6-3) 1930 SP

7. Video

(7-2) Color Bar

(7-3) Composit Out

(7-4) Y/C Out

(7-6) Component Out

HCD-M90

8. Audio

(8-2) ARP -> 1930

(8-3) Test Tone

Error Codes List

00: Error not detected

01: RAM write/read data discord

02: Gate array NG

03: EEPROM NG

08: ARP register read data discord

09: ARP ↔ RAM data bus error

10: ARP ↔ RAM address bus error

11: ARP RAM read data discord

12: Servo DSP NG

13: 1930 SDRAM NG

14: ARP → 1930 video NG

15: ARP → 1930 audio NG

16: 1910 UCODE download NG

17: System call error (function not supported)

18: System call error (parameter error)

19: System call error (illegal ID number)

20: System call error (time out)

90: Error occurred

91: User verification NG

92: Diagnosis cancelled

Drive Auto Adjustment

On the Test Mode Menu screen, press the

commander, and the driv e auto adjustment menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

4. LCD

Exit: RETURN

Normally, “0” is selected to adjust DVD (single layer), CD, and

DVD (dual layer) in this order . But, individual items can be adjusted

for the case where adjustment is suspended due to an error. In this

mode, the adjustment can be made easily through the operation

following the message displayed on the screen.

0. ALL

Press the

[10/0] key on the remote commander, then press the

[ENTER] key on the remote commander, and the servo set data in

EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD disc, 3.

DVD-DL disc, and 3. D VD-DL disc are adjusted in this order . Each

time one disc was adjusted, it is ejected. Replace it with the specified

disc following the message. Though the message to confirm whether

are adjusted is not displayed, you can finish the adjustment if

pressing the DVD x key on the remote commander. During

adjustment of each disc, the measurement for disc type judgment is

made. As automatic adjustment does not judge the disc type unlike

conventional models, take care not to insert wrong type discs. Also,

do not give a shock during adjustment.

[1] key on the remote

21

HCD-M90

1. DVD-SL (single layer)

Press the [1] key on the remote commander, insert D VD single layer

disc, and press [ENTER] key on the remote commander, and the

adjustment will be made through the following steps, then adjusted

values will be written to the EEPROM.

DVD Single Layer Disc Adjustment Steps

1. SLED TILT Reset

2. Disc Check Memory SL

3. Wait 300 msec

4. Set Disc Type SL

5. LD ON

6. Spdl Start

7. Wait 1 sec

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. CL VA ON

11. Wait 500 msec

12. Tracking ON

13. Wait 1 sec

14. Sled ON

15. Check CLV Lock

16. Auto LFO Adjust

17. Auto Focus Offset Adjust

18. Auto Tilt Position Adjust

19. Auto Focus Gain Adjust

20. Auto Focus Offset Adjust

21. EQ Boost Adjust

22. Auto LFO Adjust

23. Auto Track Gain Adjust, Search Check

24. 32Tj Fwd

25. 32Tj Rev

26. 500Tj Fwd

27. 500Tj Rev

28. All Servo Stop

29. Eep Copy Loop Filter Offset

2. CD

Press the [2] key on the remote commander, insert CD disc, and

press [ENTER] key on the remote commander , and the adjustment

will be made through the following steps, then adjusted values will

be written to the EEPROM.

CD Adjustment Steps

1. Sled Tilt Rest

2. Disc Check Memory CD

3. Wait 500 msec

4. Set Disc Type CD

5. LD ON

6. Spdl Start

7. Wait 500 msec

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. CL VA ON

11. Wait 500 msec

12. Tracking ON

13. (TC Display Start)

14. Wait 1 sec

15. Jitter Display Start

16. Sled ON

17. Check CLV ON

18. Auto LFO Adjust

19. Auto Focus Offset Adjust

20.

21. Auto Focus Gain Adjust

22. Auto Focus Offset Adjust

23. Eq Boost Adjust

24. Auto LFO Adjust

25. Auto Track Gain Adjust, Search Check

26. 32Tj Fwd

27. 32Tj Rev

28. 500Tj Fwd

29. 500Tj Rev

30. All Servo Stop

22

HCD-M90

3. DVD-DL (dual layer)

Press the [3] key on the remote commander , insert DVD dual layer

disc, and press [ENTER] key on the remote commander, and the

adjustment will be made through the following steps, then adjusted

values will be written to the EEPROM.

DVD Dual Layer Disc Adjustment Steps

1. Sled Tilt Reset

2. Disc Check Memory DL

3. Wait 500 msec

4. Set Disc Type DL

5. LD ON

6. Spdl Start

7. Wait 1 sec, Layer 1 Adjust

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. Clva ON

11. Wait 500 msec

12. Tracking ON

13. Wait 500 msec

14. Sled ON

15. Check CL V Lock

16. Auto Loop Filter Offset Auto Focus Adjust

17.

18. Auto Focus Gain Adjust

19. Auto Focus Offset Adjust

20. Eq Boost Adjust

21. Auto Loop Filter Offset

22. Auto Track Gain Adjust, Search Check

23. 32Tj Fwd

24. 32Tj Rev

25. 500Tj Fwd

26. 500Tj Rev, Layer 0 Adjust

27. Fj (L1 -> L0)

28. Auto Track Offset Adjust L0

29. Clva ON

30. Wait 500 msec

31. Tracking ON

32. Wait 500 msec

33. Sled ON

34. Check CL V Lock

35. Auto Focus Filter Offset

36. Auto Focus Adjust

37.

38. Auto Focus Gain Adjust

39. Auto Focus Offset Adjust

40. Eq Boost Adjust

41. Auto Loop Filter Offset

42. Auto Track Gain Adjust, Search Check

43. 32Tj Fwd

44. 32Tj Rev

45. 500Tj fwd

46. 500Tj Rev, Layer Jump Check

47. Lj (L0 -> L1)

48. Lj (L1 -> L0)

Drive Manual Operation

On the Test Mode Menu screen, Press the [2] key on the remote

commander, and the manual operation menu will be displayed. For

the manual operation, each servo on/off control and adjustment can

be executed manually.

## Drive Manual Operation ##

1. Disc Type

2. Servo Control

3. Track/Layer Jump

4. Manual Adjustment

5. Auto Adjustment

6. Memory Check

7. Sacd Water Mark

0. Disc Check Memory

_

Operation Menu

Exit: Return

In using the manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed

when a disc is loaded.

1. Set correctly the disc type to be used on the Disc Type screen.

The disc type must be set after a disc was loaded.

The set disc type is cleared when the tray is opened.

2. After power ON, if the Drive Manual Operation was selected,

first perform “Reset SLED TILT” by opening 1. Disc Type

screen.

3. In case of an alarm, immediately press the DVD x key on the

remote commander to stop the servo operation, and turn the

power OFF.

Basic operation (controllable from front panel or remote

commander)

I/1 Power OFF

DVD x Servo stop

Z DVD

[RETURN]

*1

*2

Stop+Eject/Loading

Return to Operation Menu or T est Mode

Menu

DVD > , DVD .*2Transition between sub modes of menu

[1] to [9], [10/0]

M , m

*2

*2

Selection of menu items

Increase/Decrease in manually adjusted

value

*1: Key of front panel

*2: Key of remote commander

49. All Servo Stop

23

HCD-M90

0. Disc Check Memory

Disc Check

1. SL Disc Check

2. CD Disc Check

3. DL Disc Check

0. Reset SLED TILT

_

On this screen, the mirror time is measured to judge the disc and it

is written to the EEPROM. First load DVD SL disc and press [1]

key on the remote commander, next load CD disc and press [2] key

on the remote commander, and finally load DVD DL disc and press

[3] key on the remote commander. The adjustment must be ex ecuted

more than once after default data were written. External vibration

or shock to the player must not be given. Reference value for DVD

is from 10 to 20, and for CD, from 28 to 4F . Check that the v alue of

CD is larger than that of DVD. When those values are beyond a

range perform this adjustment again. From this screen, you can go

to another mode by pressing DVD > or DVD . key on the

remote commander, but you cannot enter this mode from another

mode. You can enter this mode from the Operation Menu screen

only.

1. Disc Type Auto Check

Disc Type

2. DVD SL 12 cm

3. DVD DL 12 cm

4. CD 12cm

5. LCD 12 cm

6. DVD SL 8 cm

7. DVD DL 8 cm

8. CD 8 cm

9. LCD 8 cm

0. Reset SLED TILT

TC. : : EMG. 00

CD 12 cm

Display when CD 12cm disc was selected

[10/0] Reset SLED TILT Reset the sled and tilt to initial position.

[1] Disk Type Check Judge automatically the loaded disc. As

the judged result is displayed at the

bottom of screen, make sure that it is

correct. If Disc Check Memory menu has

not been executed after EEPROM

default setting, the disc type cannot be

judged. In this case, return to the initial

menu and make a check for three types

of discs (SL, DL, CD).

[2] to [9] Select the loaded disc. The adjusted

value is written to the address of selected

disc. No further entry is necessary if [1]

was pressed.

1. Disc Type

Disc Type

1. Disc Type Auto Check

2. DVD SL 12 cm

3. DVD DL 12 cm

4. CD 12cm

5. LCD 12 cm

6. DVD SL 8 cm

7. DVD DL 8 cm

8. CD 8 cm

9. LCD 8 cm

0. Reset SLED TILT

-- SA. ------ SI. -- EMG. 00

DVD SL12cm

On this screen, select the disc type. T o select the disc type, press the

number of the loaded disc. The selected disc type is displayed at the

bottom. Pressing [1] key on the remote commander automatically

selects and displays the disc type. In case of wrong display, retry

“Disc Check Memory”. Also, opening the tray causes the set disc

type to be cleared. In this case, set the disc type again after loading.

In performing manual operation, the disc type must be set. Once

the disc type has been selected, the sector address or time code

display field will appear as shown belo w . These values are displayed

when PLL is locked.

Disc Type

1. Disc Type Auto Check

2. DVD SL 12 cm

3. DVD DL 12 cm

4. CD 12cm

5. LCD 12 cm

6. DVD SL 8 cm

7. DVD DL 8 cm

8. CD 8 cm

9. LCD 8 cm

0. Reset SLED TILT

SA. SI. EMG. 00

DVD SL 12 cm

Display when DVD SL 12cm disc was selected

2. Servo Control

Servo Control

1. LD Off R.Sled FWD

2. SP Off L.Sled REV

3. Focus Off

4. TRK. Off

5. Sled Off

6. CLVA Off

7. FCS. Srch Off

0. Reset SLED TILT

SA. SI. EMG. 00

DVD SL 12 cm

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CLVA is turned on, the usual trace mode becomes active. In

the trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked. The spindle

could run overriding the control if the spindle system is faulty or

RF is not present. In such a case, do not operate CLVA.

[0] Reset SLED TILT Reset the Sled and Tilt to initial position.

[1] LD Turn ON/OFF the laser.

[2] SP Turn ON/OFF the spindle.

[3] Focus Search the focus and turn on the focus.

[4] TRK Turn ON/OFF the tracking servo.

[5] Sled Turn ON/OFF the sled servo.

[6] CLVA Turn ON/OFF normal servo of spindle

servo.

[7] FCS. Srch Apply same voltage as that of focus

search to the focus drive to check the

focus drive system.

b Sled FWD Move the sled outward. Perform this

operation with the tracking servo turned

off.

B Sled REV Move the sled inward. Perform this

operation with the tracking servo turned

off.

24

HCD-M90

2

Ver 1.1

The following menus are normally not used.

3. Track/Layer Jump

4. Manual Adjustment

5. Auto Adjustment

The persons who do not know well about these menus should not

use them.

6. Memory Check

EEPROM Data1

-– DL – CD LCD SL L0 L1

Focus Gain xx xx xx xx xx

TRK. Gain xx xx xx xx xx

FCS Balance xx xx xx xx xx

Focus Bias xx xx xx xx xx

TRV. Offset xx xx xx xx xx

L. F. Offset xx xx xx xx xx

EQ Boost xx xx xx xx xx

Mirror Time xx xx xx xx xx

_DOWN: Next Data

CLEAR: Default Set page.1/2

EEPROM Data1

-– DL – CD LCD SL L0 L1

RF Jitter xx -- xx xx xx

RF Level xx -- xx -- -FE Level xx -- xx -- -FE Balance xx -- xx -- -TRV. Level xx -- xx -- -Analog FRSW xx xx xx xx xx

PLL DacGain xx xx xx xx xx

_

UP : Prev Data

CLEAR: Default Set page.2/2

This screen displays current servo adjusted data stored in the

EEPROM. Though adjusted data can be initialized with the

[CLEAR] key on the remote commander, they cannot be restored

after initialization. So, before clearing, make a note of the adjusted

data. For reference, the drive has been designed so that the gain

center value is 20 and offset value is 80. Other values will be in a

range of 10 to 80. If extreme value such as 00 or FF is set, adjustment

will be faulty. In such a case, check for disc scratch or cable

disconnection, then perform adjustment again.

Emergency History

### EMG. History ###

Laser Hours CD xxxxxxxh

DVD xxxxxxxh

1. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

2. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

Select: 1 – 9 Scroll: UP/DOWN

(1: Last EMG.) Exit: RETURN

Press the [4] ke y on the remote commander of the emer gency history

mode to display the servo error occurrence history . Press the M or m

keys on the remote commander to scroll the history data in the range

of the most recent error “1” to the error “10”. You can also type the

desired error number from the ten-keys on the remote commander .

The upper two columns show the accumulated turn-on hours of the

optical laser unit. The “minute” and the lower data are truncated.

Clearing the Error Histories

• Clearing the laser turn-on hours data

Press the

[DVD DISPLAY] and [CLEAR] keys on the remote

commander in this order. Both of the CD laser data and DVD

laser data are cleared.

• Clearing the error occurrence history data

Press the [DVD TOP MENU] and [CLEAR] keys on the remote

commander in this order.

• Initializing the setups

Press the [DVD MENU] and [CLEAR] keys on the remote

commander in this order. When the message “Set Up Initialized”

is displayed, it indicates that the setups are initialized. The screen

returns to the EMG display screen soon.

How to Read the Eror Occurrence History Data

1

3

1.

2

1 Emergency code No.

2 Not used (The codes that are used for debugging during program

design are displayed here. They are not related to the error occ

urrence history.)

3 Order of error occurrence (1 to 9)

Emergency Code Table

10. Communication error with RF AMP (IC001) on the RF-240

board.

11. Servo lock of focus, tracking and spindle servos are lost.

12. Communication error with EEPROM (IC101) on the DVD

board.

13. Hours meter data write error in EEPROM (IC101) on the DVD

board.

14. Communication error with servo DSP (IC302) on the DVD

board or defective servo DSP

20. Tilt and sled servo initializing error. The laser unit does not

return to the initial position.

21. Tilt servo operation error.

22. The move request to illegal position is issued from system

control to the tilt servo.

23. Error in the tracking balance gain adjustment.

24. The move request to illegal position is issued from system

control to the sled servo.

30. Error in the tracking balance adjustment.

31. Error in the tracking gain adjustment.

32. Error in the focus balance adjustment.

33. Error in the focus bias adjustment.

34. Error in the focus gain adjustment.

35. Error in the tilt servo adjustment.

36. Error in the RF equalizer adjustment.

37. Error in the RF group delay adjustment

38. Amount of jitter upon completion of adaptation adjustment is

excessive.

40. Focus servo does not lock.

41. Focus jump is not possible with the dual layer (DL) disc.

50. CLV (spindle) servo does not lock.

51. Spindle does not stop.

60. The seek request to the non-existent address is issued from

system control using the DVD disc.

25

HCD-M90

[DVD TRAY LOCK MODE]

•This mode is used to unable to take sample disc out of tray in

the shop.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “DVD”.

3. While pressing the x key, press the Z DVD key.

4. The message “LOCKED” is displayed on the liquid crystal

display and the tray is locked. (Even if pressing the Z DVD key,

the message “LOCKED” is displayed on the liquid crystal

display and the tray is locked)

6. To release from this mode, while pressing the x key, press

the Z DVD key again.

7. The message “UNLOCKED” is displayed on the liquid crystal

display and the tray is unlocked.

[DVD COLOR SYSTEM NTSC]

•The color system can be changed over NTSC or PAL.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “DVD”.

3. While pressing the x key, press the I/1 key.

4. Press the I/1 key to turn the power ON. The color system is

changed over.

[TUNER STEP CHANGE]

•A step of AM channels can be changed ov er between 9 kHz and

10 kHz.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press the [FUCTION] key to select “TUNER” and press the

[TUNER AM] key to turn the “AM”.

3. Press the

4. While pressing [REPEAT/FM MODE] key, and press the I/1 key

and the display of liquid crystal display changes to “AM 9K

Step” or “AM 10K Ste p”, and thus the channel step is changed

over.

I/1 key to turn the set OFF.

26

SECTION 5

ELECTRICAL ADJUSTMENTS

HCD-M90

DVD SECTION

Note: During diagnostic check, the characters and color bars can be seen

only with the NTSC monitor. Therefore, for diagnostic check, use

the monitor that supports both NTSC and PAL modes

Instruments required:

1) Color monitor TV

2) Oscilloscope 1 or 2 phenomena, band width over 100 MHz,

with delay mode

3) DVD reference disc

HLX-501 (J-6090-071-A) (dual layer) (NTSC)

HLX-503 (J-6090-069-A) (single layer) (NTSC)

HLX-504 (J-6090-088-A) (single layer) (NTSC)

HLX-505 (J-6090-089-A) (dual layer) (NTSC)

HLX-506 (J-6090-077-A) (single layer) (PAL)

HLX-507 (J-6090-078-A) (dual layer) (PAL)

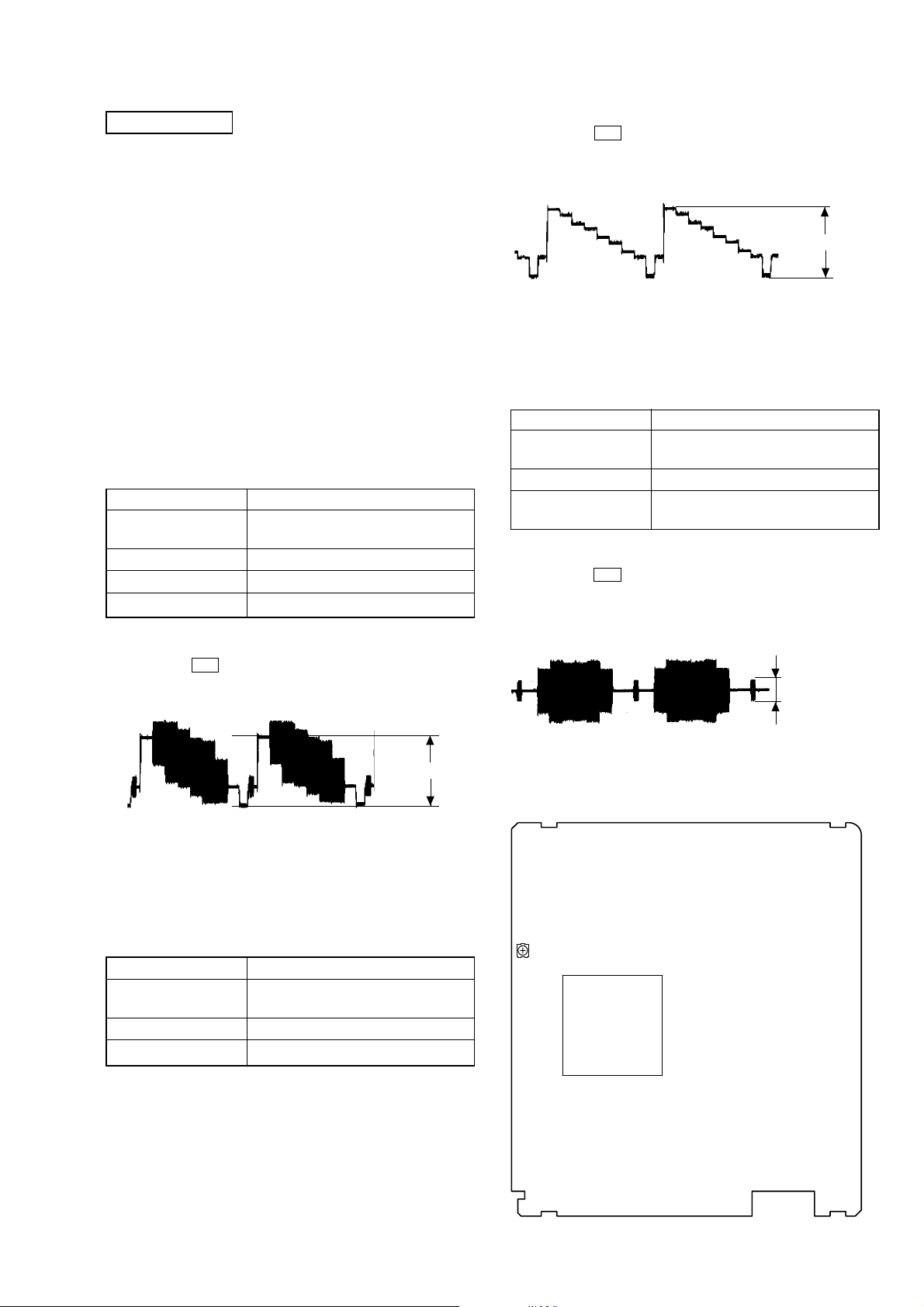

VIDEO LEVEL ADJUSTMENT

<Purpose>

This adjustment is made to satisfy the NTSC/P AL standard, and if

not adjusted correctly, the brightness will be too large or small.

Signal Color bars

Test point

Instrument Oscilloscope

Adjusting element RV501 (DVD board)

Specified Value 1.0

Procedure:

1. Press the I/1 key to turn the power on, and turn the

[FUNCTION] key to select “DVD”.

2. Adjust the RV501 on the MB board to attain 1.0

VIDEO OUT jack

(75 Ω terminated)

+ 0.04

Vp-p

– 0.02

1.0

+ 0.04

– 0.02

+ 0.04

– 0.02

Vp-p.

Vp-p

Procedure:

1. Press the I/1 key to turn the power ON, and turn the

[FUNCTION] key to select “DVD”.

2. Confirm that the S-Y level is 1.0 ± 0.05 Vp-p.

1.0 ± 0.05 Vp-p

Figure 5-2

CHECKING S VIDEO OUTPUT S-C

<Purpose>

This checks whether the S-C satisfies the NTSC Standard. If it is

not correct, the colors will be too dark or light.

Signal Color bars

Test point

S VIDEO OUT (S-C) jack

(75 Ω terminated)

Instrument Oscilloscope

Specified Value

286 ± 30 mVp-p (NTSC)

300 ± 100 mVp-p (PAL)

Procedure:

1. Press the

I/1 key to turn the power ON, and turn the

[FUNCTION] key to select “DVD”.

2. Confirm that the S-C burst is 286 ± 30 mVp-p (NTSC) or 300

± 100 mVp-p (PAL).

286 ± 50 mVp-p

(NTSC)

or

300 ± 100 mVp-p

(PAL)

Figure 5-3

Adjustment Location :

Figure 5-1

CHECKING S VIDEO OUTPUT S-Y

<Purpose>

Check S-terminal video output. If it is incorrect, pictures will not

be displayed correctly in spite of connection to the TV with a Sterminal cable.

Signal Color bars

Test point

Instrument Oscilloscope

Specified Value 1.0 ± 0.05 Vp-p

S VIDEO OUT (S-Y) jack

(75 Ω terminated)

– DVD BOARD (Side A) –

RV501

Video Level

Adjustment

IC503

27

HCD-M90

)

DECK SECTION

Note: Confirm each contents of this section first of all. If the results are

not satisfied, do the adjustment.

1. The adjustments should be performed with the rated power supply

voltage unless otherwise noted.

2. The adjustments should be performed in the order given in this service

manual.

3. The adjustments should be performed for both L-CH and R-CH.

0 dB=0.775 V

REC BIAS ADJUSTMENT

Procedure:

1. Mode: REC

FUNCTION: MD

MAIN board

AUDIO IN (MD/VIDEO) jack (SJ302)

L-CH, R-CH

50 mV (– 23.8 dB)

600

Ω

set

blank tape

CN-123

AF OSC

1) 315 Hz

2) 10 kHz

attenuator

2. Mode: Playback

recorded

portion

level meter

set

MAIN board

SPEAKER terminals (SJ301

L-CH, R-CH

+

–

3. Confirm playback the signal recorded in step 1 become speci-

fied values as follows.

If these values are out of specification values, adjust the RV101

(L-CH) and RV201 (R-CH) on the TC board to repeat steps

1and 2.

Specified values:Playback output of 315 Hz to playback

output of 10 kHz: ± 0.5 dB

Adjustment Location: TC board

– TC BOARD (Component Side) –

28

RV101 (L)

RV201 (R)

REC Bias

Adjustment

SECTION 6

DIAGRAMS

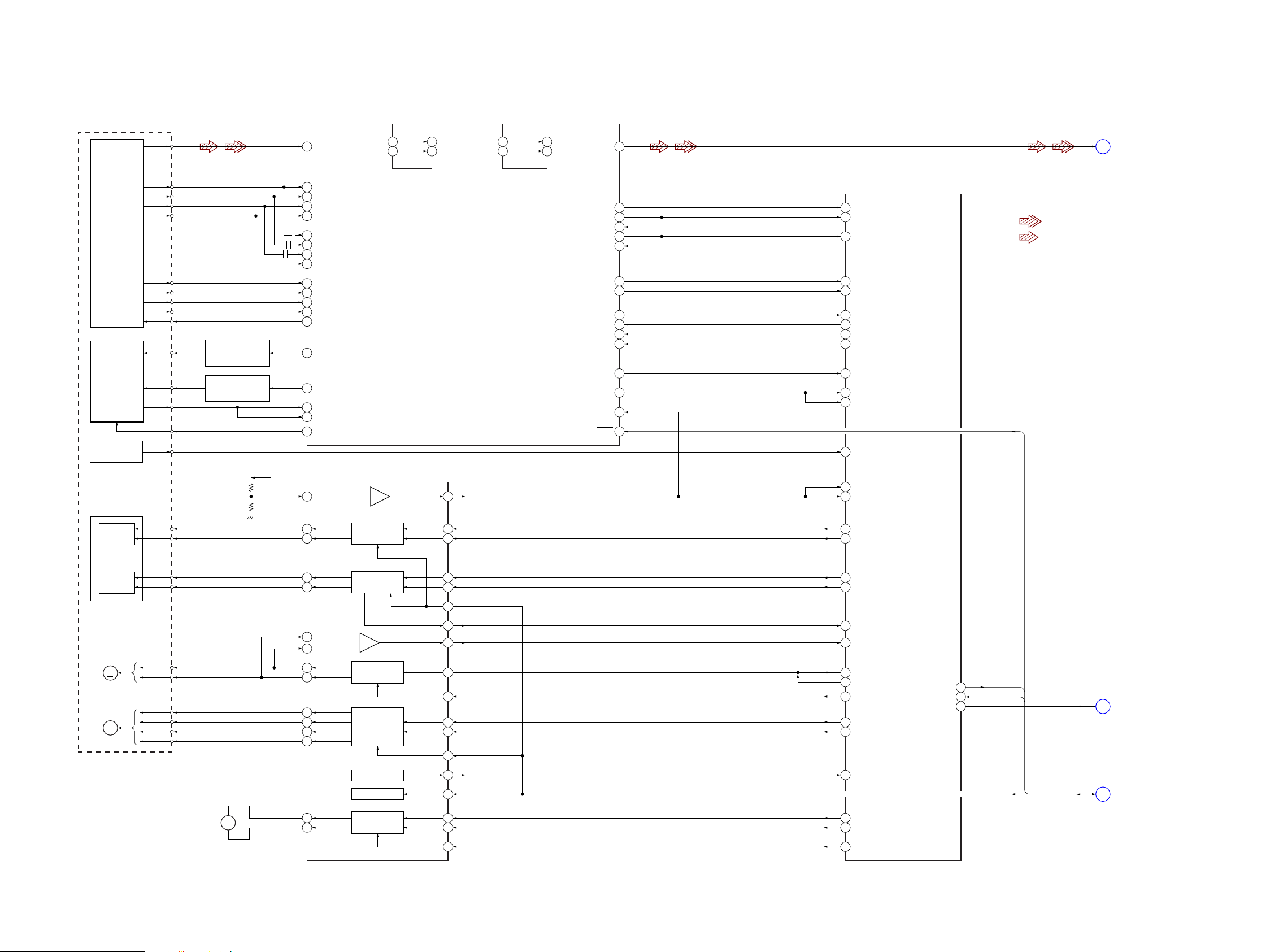

6-1. BLOCK DIAGRAM – DVD SERVO Section – • Refer to servicing notes (page 6) for discrimination of TYPE A/B.

OPTICAL PICK-UP

BLOCK

(KHM-240AAA) (TYPE A)

(KHM-270AAA) (TYPE B)

64

RF

2

RF IN

ATOP

ATON

63

61

AIP

62

AIN

FNP

FNN

55

54

56

DIP

57

DIN

SIGO

59

RF+

HCD-M90

Ver 1.3

A

(Page 30)

DVD/CD

DETECTOR

DVD/CD

LASER

DIODE

MODULE

INLIMIT

SENSOR

2-AXIS

DEVICE

FOCUS

COIL

DVD LD

CD LD

SW

INLIM

FCS+

FCS–

A

B

C

D

E

F

G

H

VC

AUTOMATIC POWER

CONTROL (FOR DVD)

Q001

AUTOMATIC POWER

CONTROL (FOR CD)

PD

Q002

D+3.3V

14

A

13

B

12

C

11

D

7

A2

8

B2

9

C2

10

D2

15

E

16

F

17

G

18

H

19

VC

25

DVDLD

26

CDLD

21

DVDPD

22

CDPD

24

LDSELO

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED/LOADING MOTOR DRIVE

IC401 (SUFFIX-21) IC401 (SUFFIX-22)

42

37

36

FOCUS COIL

DRIVE

DVD/CD RF AMP,

FOCUS/TRACKING ERROR AMP

IC001 (SUFFIX-11) IC001 (SUFFIX-22)

40

48

1

TZIN

MIRR

TZC

SRD

SWD

SCLK

SDEN

DFT

MON

LDON

VCI

42

FE

41

TE

40

36

PI

35

PII

33

37

45

46

47

48

38

44

39

27

136

ADC1

135

ADC0

137

ADC2

197

MIRR

196

TZC

173

GIO6/SDI

174

GIO7/SDO

175

GIO8/SCK

180

GIO13

185

DFCTI

144

ADC7

172

GIO5/PGIN

166

GIO0/INT2

143 ADC6

142 ADC5

PDM2

204

PDM3

205

SERVO DIGITAL

SIGNAL PROCESSOR

IC302 (1/2) (SUFFIX-21)

IC302 (1/2) (SUFFIX-22)

• SIGNAL PATH

: DVD PLAY

: CD PLAY

XLDON

TRACKING

COIL

MM

(SPINDLE)

MM

(SLED)

TRK+

TRK–

SPM+

SPM–

SLA+

SLA–

SLB+

SLB–

M901

(LOADING)

35

34

46

47

27

28

32

31

30

29

MM

25

24

TRACKING COIL

DRIVE

–

+

SPINDLE MOTOR

DRIVE

SLED MOTOR

DRIVE

TSD-M

POWER SAVE

LOADING MOTOR

DRIVE

3

4

19

5

45

13

21

7

10

20

22

39

16

17

15

PDM0

202

PDM1

203

ADC3

139

ADC4

140

MDSO

159

MDPO

161

GIO1/INT3

167

PWM0

198

PWM1

199

GIO2/INT4

7

168

176 GIO9/FGREF

177 GIO10/FGIN

200 PWM2

HINT

HCS

XDSPRST

22

24

156

XSDPIT

XSDPCS

XDRVMUTE

XRST

XLDON

XSDPIT, XSDPCS,

XDRVMUTE

C

(Page 30)

B

(Page 31)

2929

HCD-M90

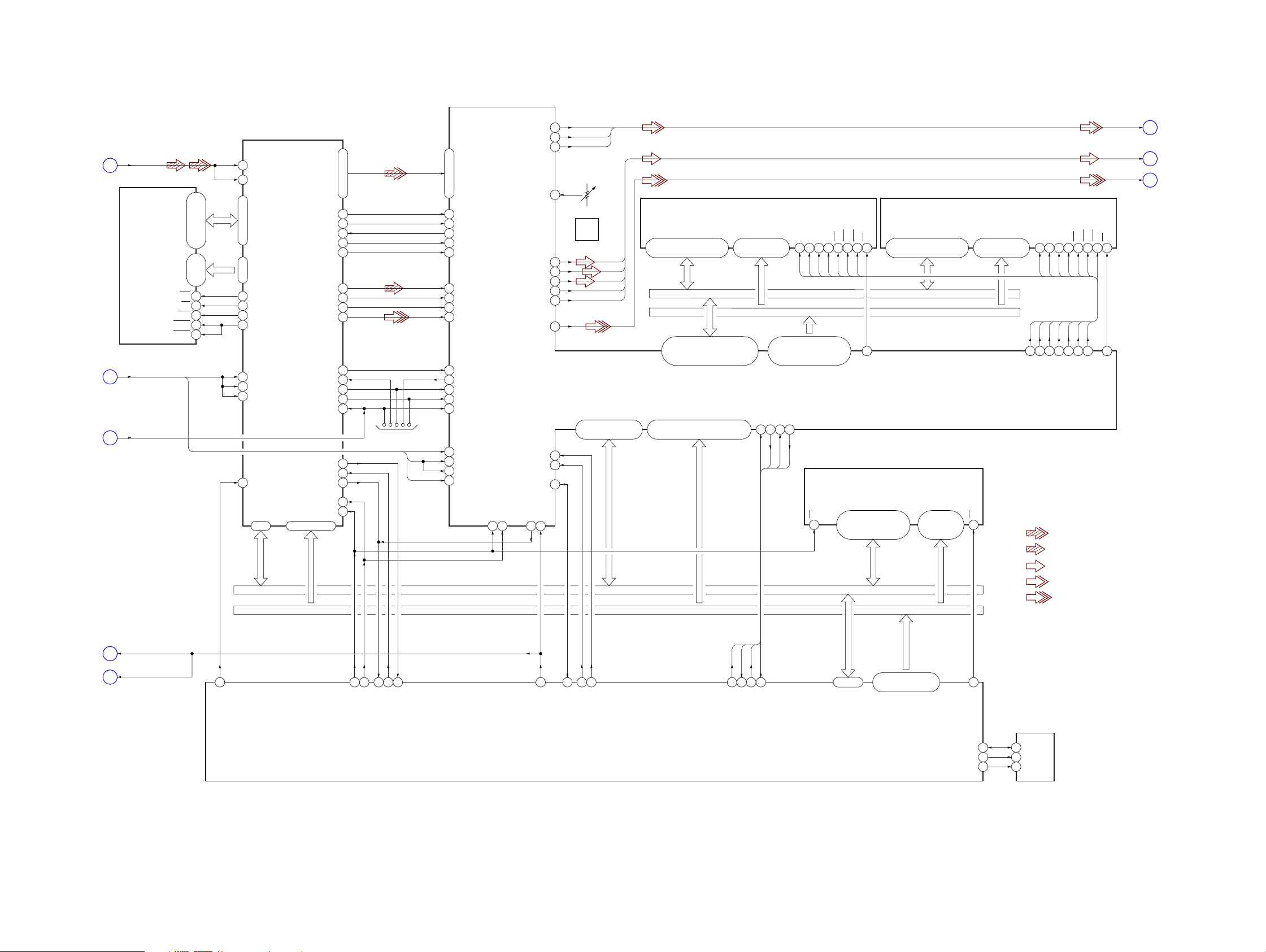

6-2. BLOCK DIAGRAM – DVD MAIN Section (1/2) –

A

(Page 29)

D

(Page 31)

E

(Page 31)

RF+

D-RAM

IC303 (SUFFIX-21)

IC303 (SUFFIX-22)

33MARP, 33MAVD,

27MAVD, 512FSAVD

TRST

A0 – A9 I/O0 – I/O15

WE

OE

RAS

UCAS

LCAS

MEMD0 –

MEMD15

2 – 5, 7 – 10,

41 – 44, 46 – 49

MEMA0 –

MEMA9

27 – 32

21 – 24,

17

33

18

34

35

33MARP

MA0 – MA9 MD0 –MD15

HD8 – HD15

ARP

11 – 15, 17 – 192 – 9

A0 – A7D0 – D7

HA0 – HA7

SD0 – SD7

73 – 76, 78 – 81

SDCK

68 41

XSHD

69 44

XSRQ

70 46

XSAK

71 45

SDEF

72 43

DATA

62 23

BCLK

63 25

LRCK

65 26

DOUT

66 22

TDO

195 118

TDI

193 119

TCK

194 120

TMS

192 121

TRST

191 122

XINT

21

XCS

23

XWAT

25

XWR

207

XRD

208

IC302 (2/2) (SUFFIX-21) IC302 (2/2) (SUFFIX-22)

RFIN1

131

RFIN2

128

44 – 51, 53 – 60

27 – 36

38

XMWR

XOE

42

XRAS

41

XCAS

39

CLKIN

182

MCKI

187

SCKI

189

XARPRST

157

SOI0 –SOI7

(FOR JTAG)

33MAVD

27MAVD

512FSAVD

DTI0 – DTI7

31 – 34, 36 – 39

ICLKI

ISTARTI

IREQO

IVALI

IERRI

CDIN1I

CDBCKI

CDLRKI

CDIN2I

TDI

TDO

TCK

TMS

TRST

CRPCLKI

29

CLKI

180

SCLKIN

182

ACLK

12

DATA BUS

ADDRESS BUS

COMPOUT

80

YOUT

74

COUT

77

VREFI

84

14ACH12

15

ACH34

16

ACH56

19

BCKO

18LRCKO

DO

20

HRWB

AV DECODER

HAD23

HAD22

HIREQ0

HWAITOB

RSTB

190

191

223

IC503 (SUFFIX-21) IC503 (SUFFIX-22)

HCSB

220 221 224 231

V

Y

C

RV501

VIDEO

LEVEL

ACH12

ACH34

ACH56

BCK

LRCK

HD0 – HD15 HAD0 – HAD21

223 – 235, 237 – 240,

2 – 5, 7 – 10

HD0 – HD15

DQ0 – DQ15

2, 3, 5, 6, 8, 9, 11, 12, 39,

40, 42, 43, 45, 46, 48 ,49

177, 174, 171, 168, 165, 163,

160, 158, 157, 159, 162, 164,

218 – 215, 213 – 210, 208 – 205,

203 – 200, 198 – 195, 193, 192

IC504 (SUFFIX-21) IC504 (SUFFIX-22)

167, 170, 173, 176

SDDQ0 – SDDQ15

HA0 – HA21

16MB SDRAM

A0 – A11

21 – 24, 27 – 32,

20, 19

DM ACK1

226 227 228 229

DACK0

CLK

CKE

35 34 14 36 15 16 17 18

CLK

CKE

DQML

SDRAM DATA BUS

SDRAM ADDRESS BUS

134, 131, 128, 125, 124,

127, 130, 133, 136, 139,

137, 140

SDAD0 – SDAD11

DM REQ1

DM ACK0

DM REQ0

DREQ0

DACK1

DREQ1

OE

14

DATA BUS

ADDRESS BUS

DQML

DQMUWECAS

RAS

CS

2, 3, 5, 6, 8, 9, 11, 12, 39,

40, 42, 43, 45, 46, 48 ,49

DQMUWECAS

RAS

144

SDCS0B

PROGRAM ROM

IC108 (SUFFIX-21) IC108 (SUFFIX-22)

D0 – D15

15, 17, 19, 21, 24, 26,

28, 30, 16, 18, 20, 22,

25, 27, 29, 31

HD0 – HD15

IC505 (SUFFIX-21) IC505 (SUFFIX-22)

DQ0 – DQ15 A0 – A11

A0 – A19, HA21

11 – 4,

42 – 34, 3,

2, 43, 44

HA1 – HA21

16MB SDRAM

21 – 24, 27 – 32,

20, 19

CE

12

ACH12, ACH34, ACH56,

CLK

CKE

DQML

CLK

CKE

CKE

DQML

SDCKEO

DQML

DQMUWECAS

WE

DQMU

SDDQM0

SDDQM1

DQMUWECAS

CAS

RAS

SDWEOB

SDCKCOB

35 34 14 36 15 16 17 18

CLK

149 146 155 154 152 151 147

SDCLKO

• SIGNAL PATH

: DVD PLAY

: CD PLAY

: DVD/CD PLAY (AUDIO)

: DVD/CD PLAY (VIDEO)

: DVD/CD PLAY (DIGITAL OUT)

BCK, LRCK

RAS

RAS

143

SDRASOB

V, Y, C

SPDIF

CS

SDCS1B

H

G

I

(Page 31)

(Page 31)

(Page 31)

(Page 31)

(Page 29)

XRST

F

DACK0

DACK1

DREQ0

DACK0

DREQ0

DREQ1

49504647

DACK1

DREQ1

XRST

C

36 71 67 62 17

XARPRST

70

XRD

CS4X

XWRH

XWAIT

INT1

35 16 61 60

INT0

CS3X

XRST

DVD SYSTEM CONTROLLER

IC103 (1/2) (SUFFIX-21) IC103 (1/2) (SUFFIX-22)

CS2X

HD0 – HD15

85 – 100

HD0 – HD15

HA0 – HA21

102 – 109, 111 – 118,

120, 1 – 5

HA0 – HA21

SDA

SCL

WP

58

CS0X

38

39

7

EEPROM

IC101 (SUFFIX-21)

IC101 (SUFFIX-22)

5

SDA

6

SCL

7

WP

3030

Loading...

Loading...