Sony HCD-M80 Service Manual

HCD-M80

SERVICE MANUAL

Ver 1.1 2002.12

HCD-M80 is the Amplifier, Video CD/CD player,

Tape Deck and Tuner section in CMT-M80V.

CD

Section

TAPE

Section

E Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM55G-30BD62

Base Unit Name BU-30BD62

Optical Pick-up Name A-MAX.3

Model Name Using Similar Mechanism HCD-M70

Amplifier section

The following measured at 230 V AC, 60 Hz

DIN power output (rated): 15 + 15 W

Continuous RMS power output (reference):

The following measured at 220 V AC, 60 Hz

DIN power output (rated): 12 + 12 W

Continuous RMS power output (reference):

Inputs

AUDIO IN MD (VIDEO) (phono jacks):

MIC IN (mini jack) Sensitivity 1 mV,

(6 ohms at 1 kHz, DIN)

18 + 18 W

(6 ohms at 1 kHz, 10%

THD)

(6 ohms at 1 kHz, DIN)

15 + 15 W

(6 ohms at 1 kHz, 10%

THD)

Sensitivity 500/250 mV,

impedance 47 kilohms

impedance 10 kilohms

SPECIFICATIONS

Outputs

VIDEO OUT: max. output level

(phono jack) 1 Vp-p, 75 ohms

PHONES: Accepts headphones with

SPEAKER: accepts impedance of 6 to

VIDEO CD/CD player section

Laser Semiconductor laser

Frequency response 20 Hz – 20 kHz =

Video color system format

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 50 – 13,000 Hz (±3 dB),

an impedance of 8 ohms

or more

16 ohms.

(λ=780 nm)

Emission duration:

continuous

(±1 dB)

NTSC, PAL

using Sony TYPE I

cassettes

COMPACT DISC DECK RECEIVER

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 - 108.0 MHz

Antenna FM wire antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

Middle Eastern and Philippine models:

Other models: 531 - 1,602 kHz

Antenna AM loop antenna, external

Intermediate frequency 450 kHz

(50-kHz step)

531 - 1,602 kHz

(with the tuning interval

set at 9 kHz)

(with the tuning interval

set at 9 kHz)

530 - 1,710 kHz

(with the tuning interval

set at 10 kHz)

antenna terminal

– Continued on next page –

9-874-142-02 Sony Corporation

2002L0500-1 Home Audio Company

C 2002.12 Published by Sony Engineering Corporation

HCD-M80

This appliance is classified

as a CLASS 1 LASER

product. This label is

located on the rear exterior.

The following caution label is located inside the apparatus.

General

Power requirements

Saudi Arabian models: 120 – 127 V or

Thailand model: 220 V AC, 50/60 Hz

Other models: 110 – 120 V or

Power consumption See the nameplate

Dimensions (w/h/d) incl. projecting parts and controls

Mass Approx. 5.2 kg

Design and specifications are subject to change

without notice.

220 – 240 V AC,

50/60 Hz

Adjustable with voltage

selector

220 – 240 V AC,

50/60 Hz

Adjustable with voltage

selector

Approx. 159 × 217 ×

335 mm

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

2

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

TABLE OF CONTENTS

HCD-M80

1. SERVICING NOTES............................................... 4

2. GENERAL ................................................................... 5

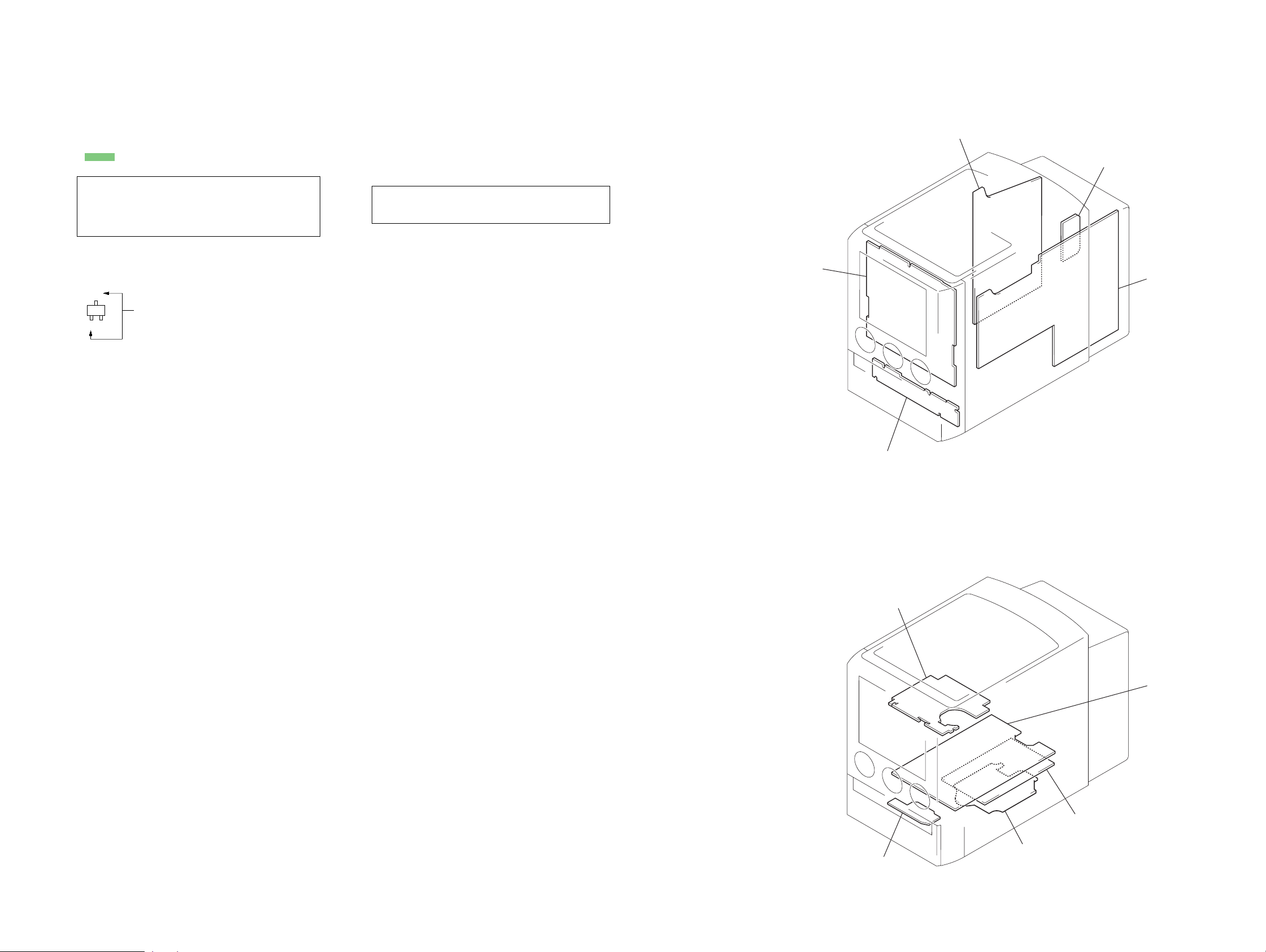

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 6

3-2. Panel (Side) (L), Panel (Side) (R) .................................. 7

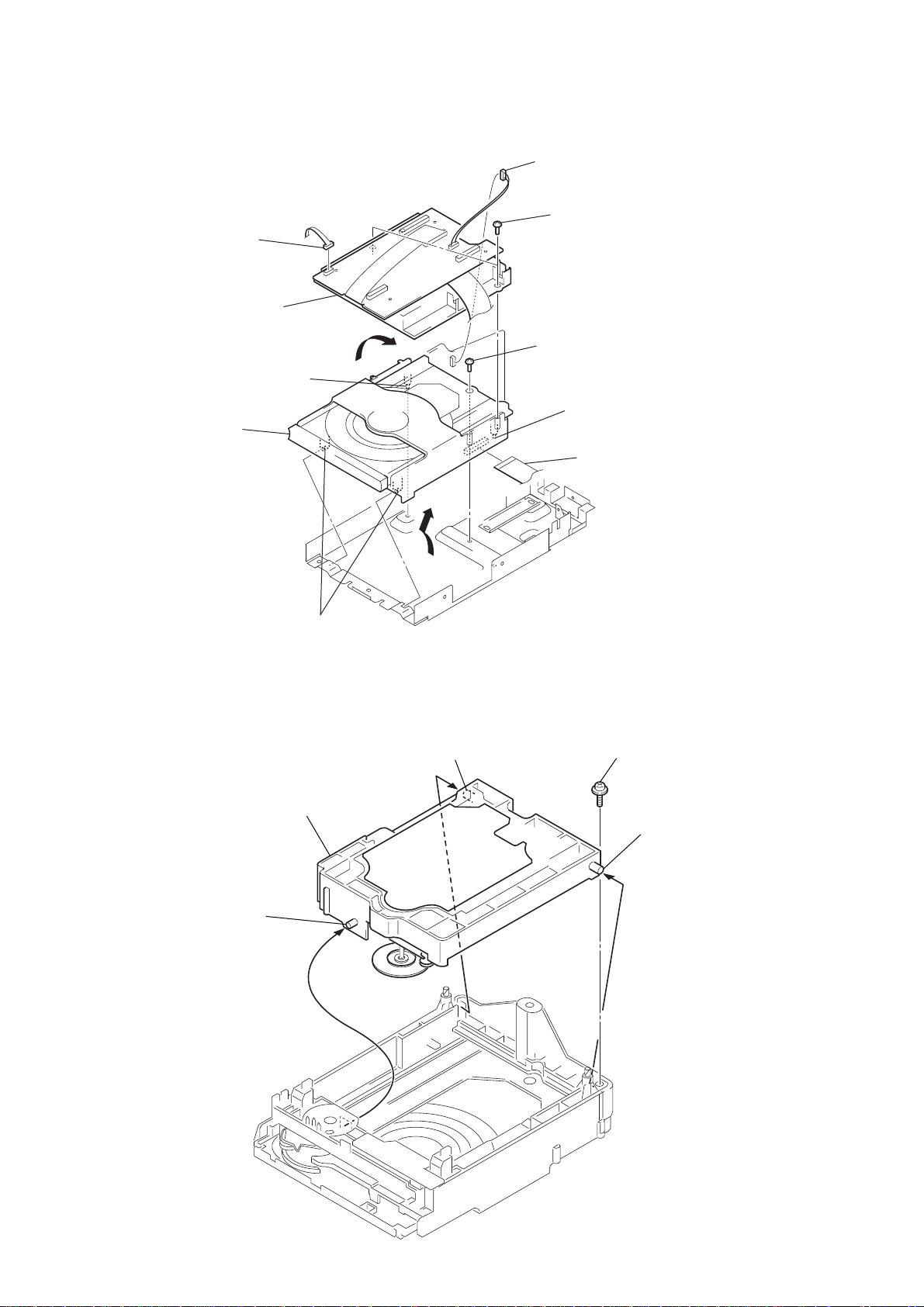

3-3. Top Panel Section............................................................ 7

3-4. Mechanical Deck (Tape) ................................................. 8

3-5. Front Panel Section ......................................................... 8

3-6. Back Panel Assy.............................................................. 9

3-7. MAIN Board ................................................................... 9

3-8. CD Mechanism Deck (CDM55G-30BD62)................... 10

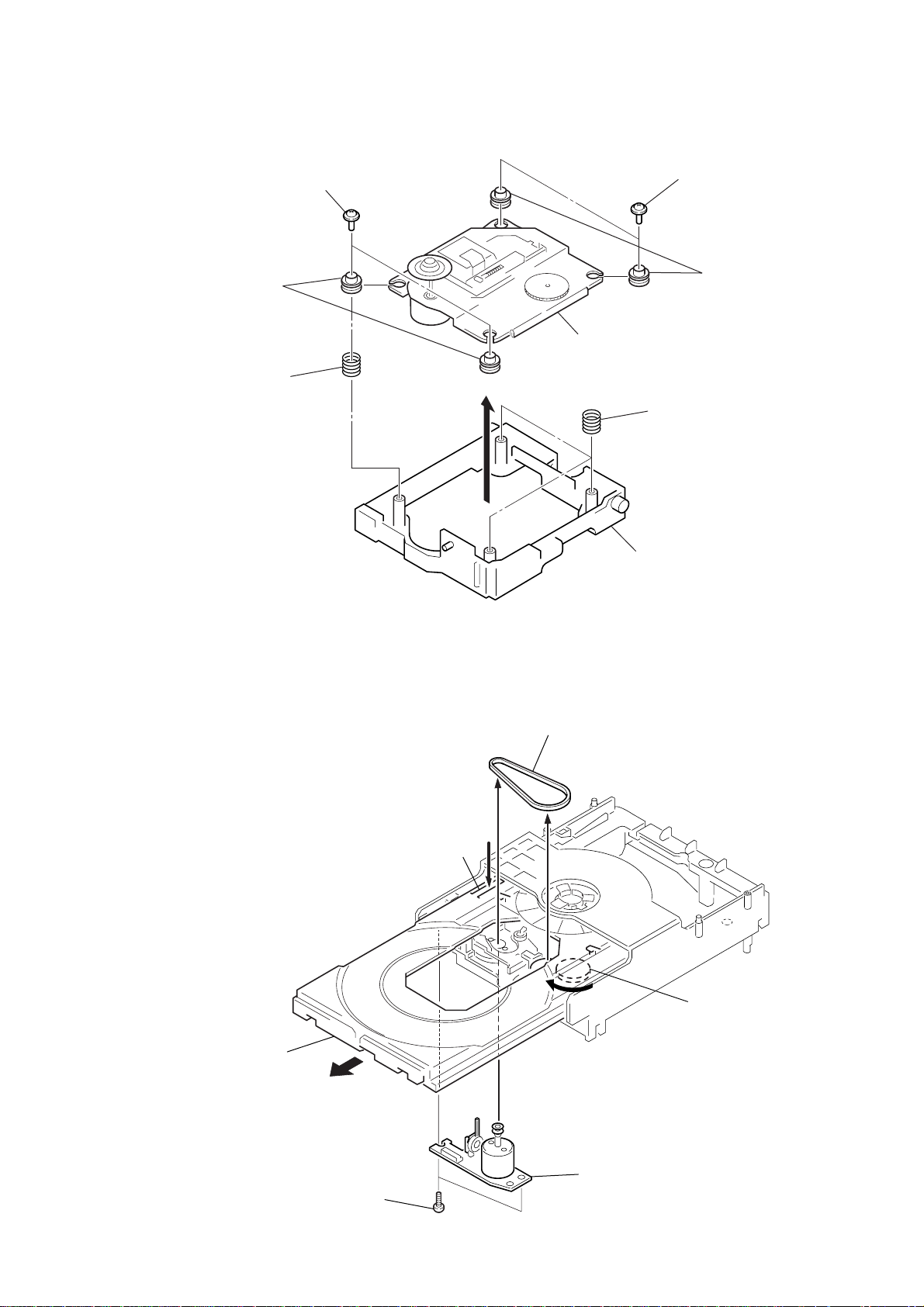

3-9. BU Holder Section .......................................................... 10

3-10. BASE Unit (BU-30BD62) .............................................. 11

3-11. LOADING Board............................................................ 11

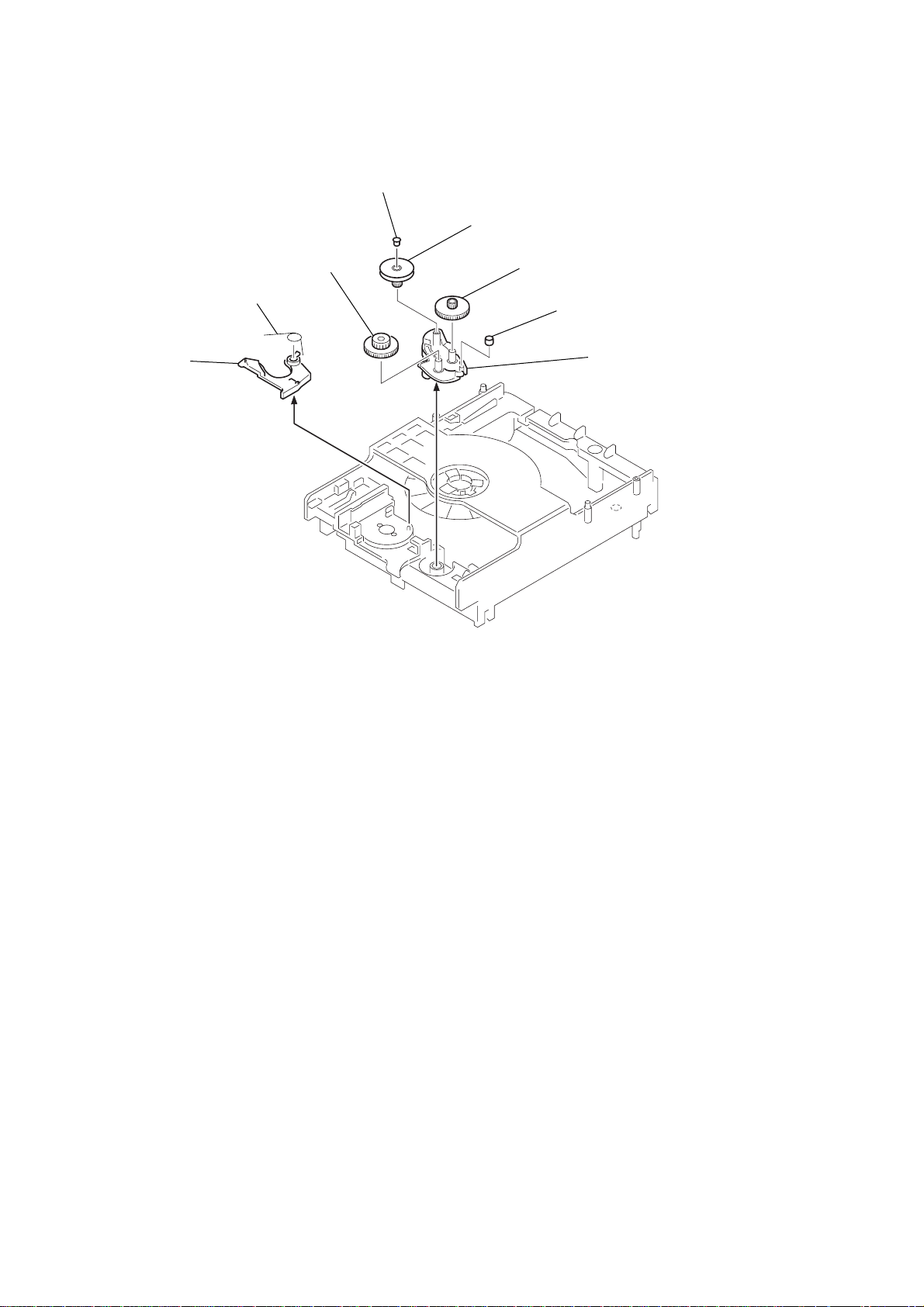

3-12. CAM (CDM55) ............................................................... 12

4. TEST MODE.............................................................. 13

5. ELECTRICAL ADJUSTMENTS

CD Section ...................................................................... 14

Video Section .................................................................. 15

Deck Section ................................................................... 15

6. DIAGRAMS

6-1. Block Diagram – CD SERVO Section – ....................... 16

6-2. Block Diagram – AUDIO/VIDEO CD Section – .......... 17

6-3. Block Diagram – TUNER/TAPE DECK Section – ...... 18

6-4. Block Diagram – MAIN Section – ................................ 19

6-5. Block Diagram

– KEY CONTROL/POWER SUPPLY Section –........... 20

6-6. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 21

6-7. Printed Wiring Board – BD Board – ............................. 22

6-8. Schematic Diagram – BD Board – ................................ 23

6-9. Printed Wiring Board – TC Board – .............................. 24

6-10. Schematic Diagram – TC Board –................................. 25

6-11. Schematic Diagram – VMP Board (1/2) – .................... 26

6-12. Schematic Diagram – VMP Board (2/2) – .................... 27

6-13. Printed Wiring Board – VMP Board – .......................... 28

6-14. Printed Wiring Boards – MAIN/JACK Boards – .......... 29

6-15. Schematic Diagram – MAIN Board (1/2) – .................. 30

6-16. Schematic Diagram

– MAIN (2/2)/JACK Boards –....................................... 31

6-17. Printed Wiring Boards

– CONTROL/LOADING/VIDEO Boards – .................. 32

6-18. Schematic Diagram

– CONTROL/LOADING/VIDEO Boards – .................. 33

6-19. Printed Wiring Board – SWITCH Board – ................... 34

6-20. Schematic Diagram – SWITCH Board – ...................... 35

6-21. Printed Wiring Board – POWER Board – ..................... 36

6-22. Schematic Diagram – POWER Board –........................ 37

6-23. IC Pin Function Description ........................................... 44

7. EXPLODED VIEWS

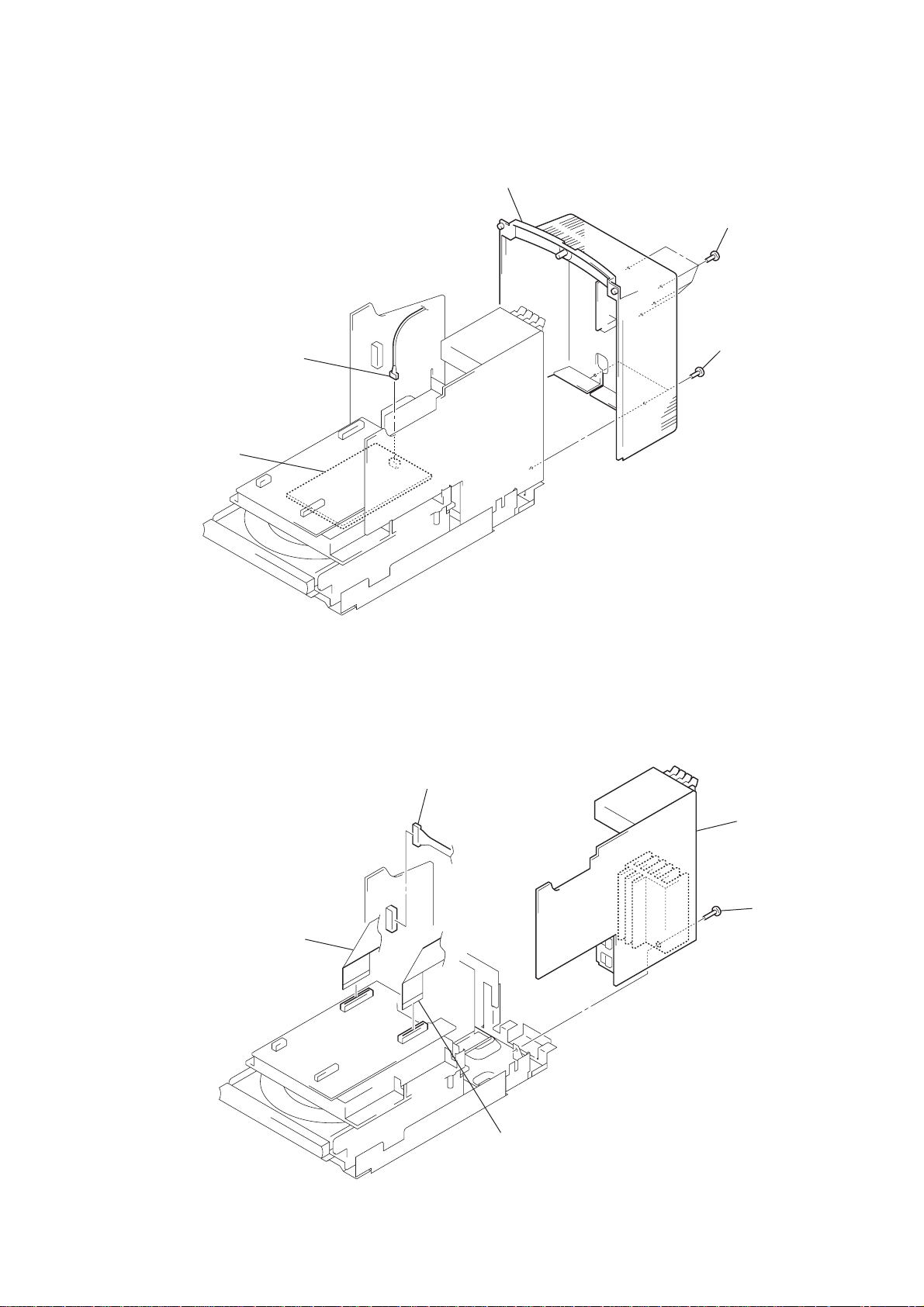

7-1. Panel (Side) Section........................................................ 52

7-2. Front Panel Section ......................................................... 53

7-3. Top Panel Section............................................................ 54

7-4. Chassis Section-1 ............................................................ 55

7-5. Chassis Section-2 ............................................................ 56

7-6. Chassis Section-3 ............................................................ 57

7-7. CD Mechanism Deck (CDM55G-30BD62)................... 58

7-8. Base Unit Section (BU-30BD62) ................................... 59

8. ELECTRICAL PARTS LIST ............................... 60

3

HCD-M80

Ver 1.1

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

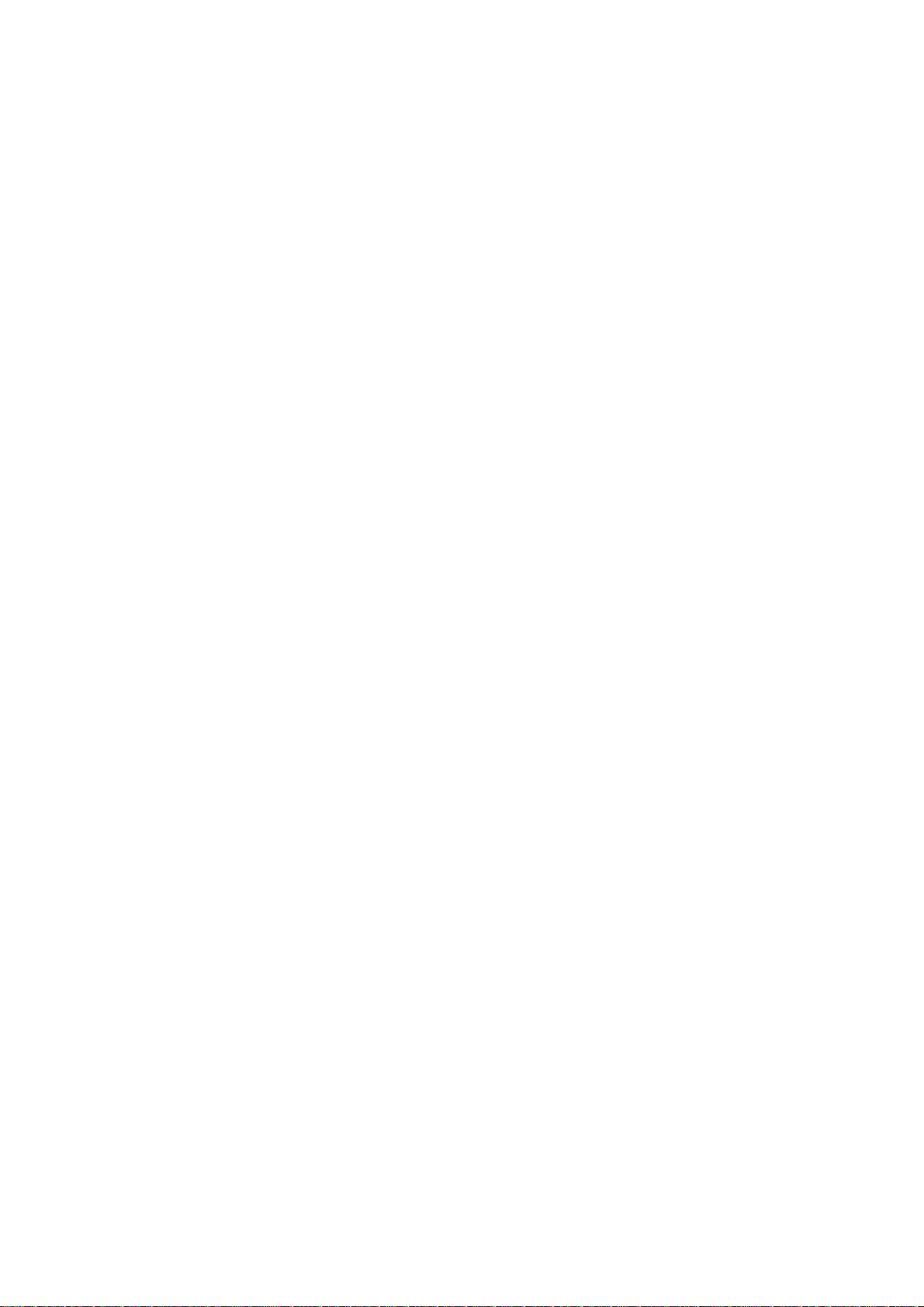

MODEL IDENTIFICATION

– Back Panel –

Part No.

SERVICE POSITION

In checking the tape deck section, prepare jig (extension cable J2501-167-A: 1.25 mm Pitch, 17 cores, Length 300 mm).

TC board (CN301)

Model Name Par t No.

Singapore model 4-238-890-0

Thai model 4-238-891-0

Saudi Arabia model 4-241-755-0

RELEASING THE DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure :

While pressing the [DSG] key, press the [ CD] key for 5 seconds.

The message “UNLOCKED” is displayed and the tray is unlocked.

Note: When “LOCKED” is displayed, the tray lock is not released by

turning power on/off with the I/1 button.

Z

[]

[]

[]

main board (CN301)

Connect jig (extension cable J-2501-167-A)

to the main board (CN301) and TC board (CN301).

4

SECTION 2

GENERAL

HCD-M80

This section is extracted from

instruction manual.

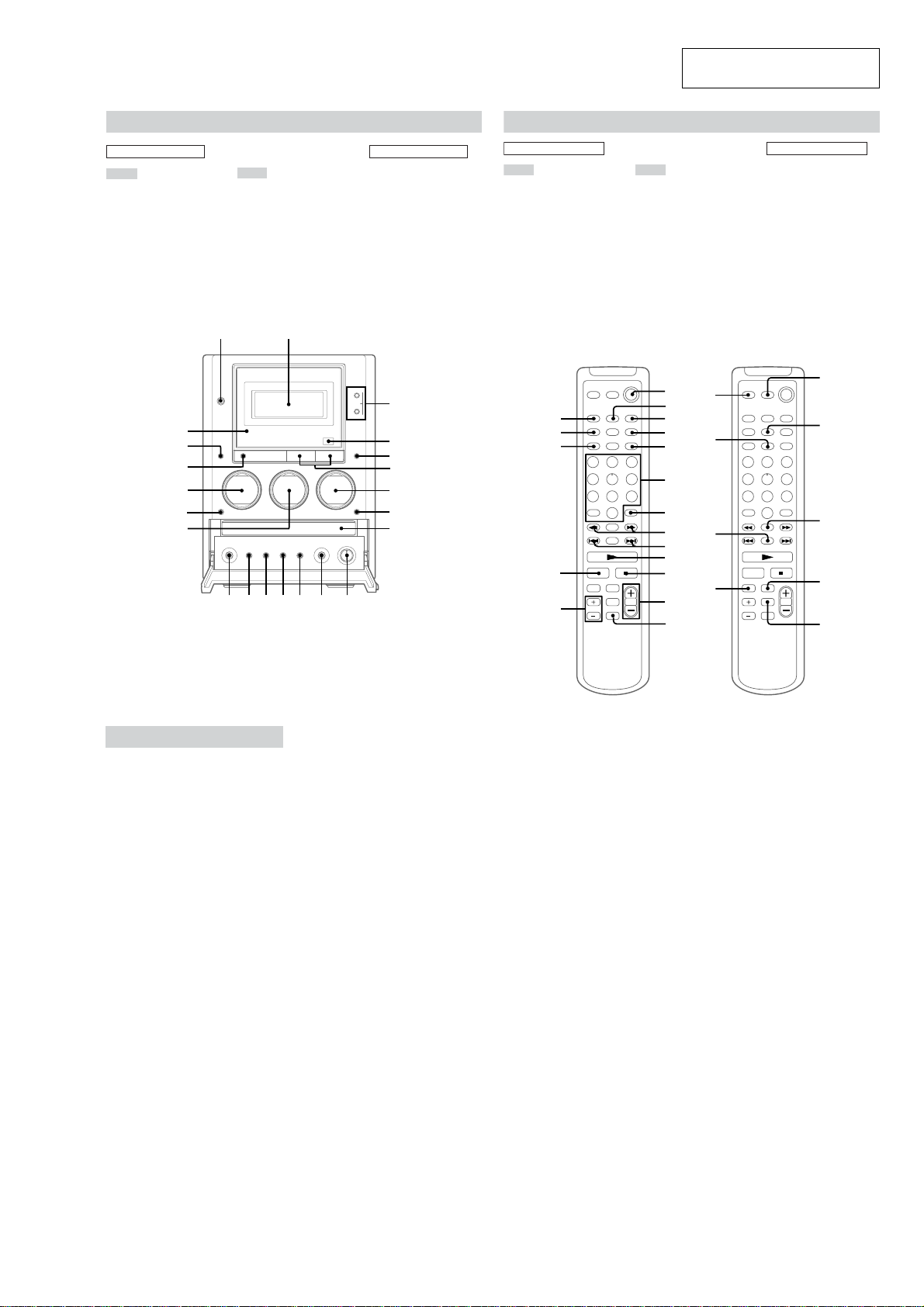

Main unit

ALPHABETICAL ORDER

A – M

CD N 7

CD X 7

CD SYNCHRO qd

CD SYNCHRO indicator ws

DIRECTION qs

Disc tray 9

Display window 2

DSG w;

FM MODE qf

FUNCTION wa

MIC jack qa

MIC LEVEL q;

ws

wa

w;

ql

qk

qj

P – V

PHONES jack qh

PLAY MODE qg

Remote sensor 4

REPEAT qf

TAPE nN ql

TAPE X ql

TUNER AM qj

TUNER FM qj

TUNING +/– 3

TUNING MODE qg

VOLUME +/– 6

1

?/1

nN N

z

2

Remote Control

BUTTON DESCRIPTIONS

?/1 (power) 1

m/M 3

l/L 3

x 5

Z CD 8

z REC qk

ML

3

lm

4

x

5

6

XX

7

Z

8

9

qs qa 0qdqfqgqh

ALPHABETICAL ORDER

A – N

ALBUM +/– qf

BASS/TREBLE wa

CD wf

CLEAR qk

CLOCK/TIMER SELECT w;

CLOCK/TIMER SET 4

DISPLAY 2

DSG qd

ENTER 3

KEY CONTROL 7

K.PON/MPX ql

NEXT 9

Numeric buttons 6

qk

qj

qh

qg

qf

`/1

O

X

O – V

ON SCREEN wj

PICTURE EFFECT wh

PREV 9

RETURN O wg

SELECT 0

SLEEP qj

SPECIAL MENU qh

TAPE wd

TUNER BAND ws

TUNING MEMORY 5

VOLUME +/– qs

1

wj

2

3

4

wh

5

6

7

8

wg

9

0

qa

wf

qs

qd

BUTTON DESCRIPTIONS

@/1 (power) 1

N 0

X qg

x qa

./> 9

m/M 8

+/– 9

`/1

O

X

ql

w;

wa

ws

wd

Setting the clock

1

Press ?/1 to turn on the system.

2

Press CLOCK/TIMER SET on the

remote.

3

Press . or > on the remote

repeatedly to set the hour.

4

Press ENTER on the remote.

5

Press . or > on the remote

repeatedly to set the minute.

6

Press ENTER on the remote.

The clock starts working.

If you make a mistake

Press m or M on the remote until the

incorrect item flashes, then set it again.

To adjust the clock

1

Press CLOCK/TIMER SET on the remote.

2

Press . or > on the remote to select

“CLOCK SET?”, then press ENTER on the

remote.

Do the same procedures as step 3 to 6 above.

3

5

HCD-M80

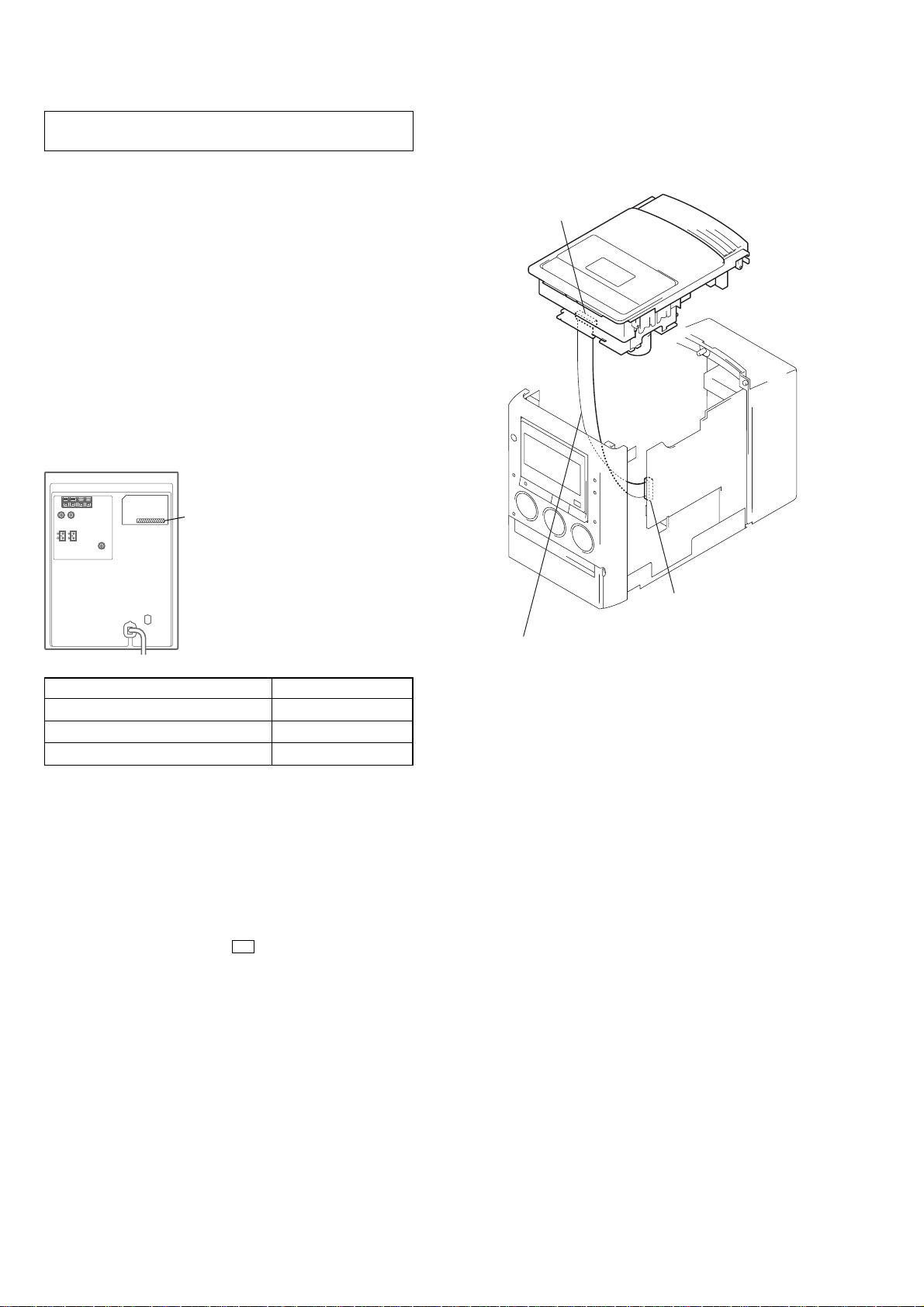

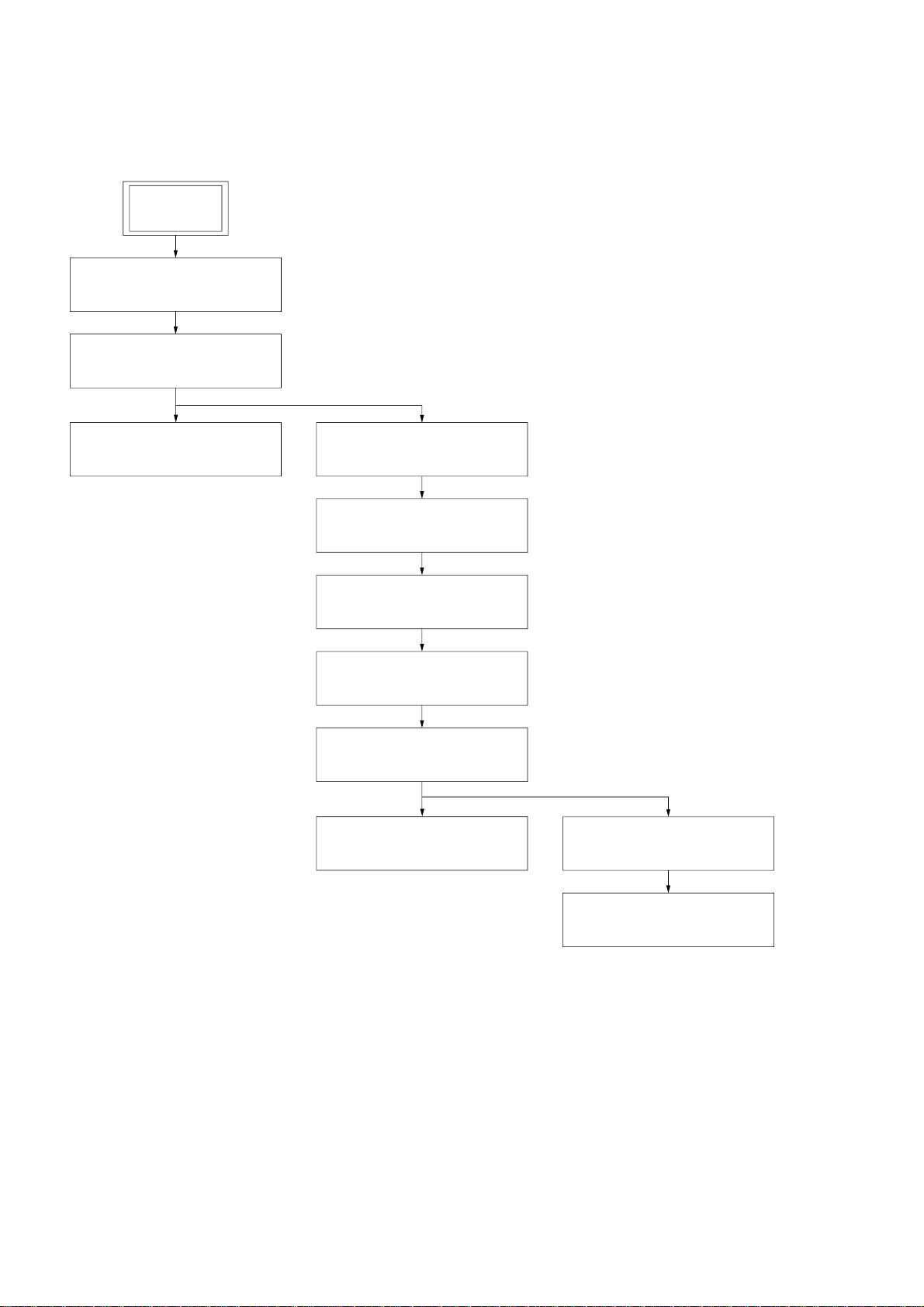

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. PANEL (SIDE) (L),

PANEL (SIDE) (R)

(page 7)

3-3. TOP PANEL SECTION

(page 7)

SECTION 3

DISASSEMBLY

3-4. MECHANICAL DECK (TAPE)

(page 8)

3-5. FRONT PANEL SECTION

(page 8)

3-6. BACK PANEL ASSY

(page 9)

3-7. MAIN BOARD

(page 9)

3-8. CD MECHANISM DECK

(CDM55G-30BD62)

(page 10)

3-9. BU HOLDER SECTION

(page 10)

3-10.BASE UNIT

(BU-30BD62)

(page 11)

3-11.LOADING BOARD

(page 11)

3-12.CAM (CDM55)

(page 12)

6

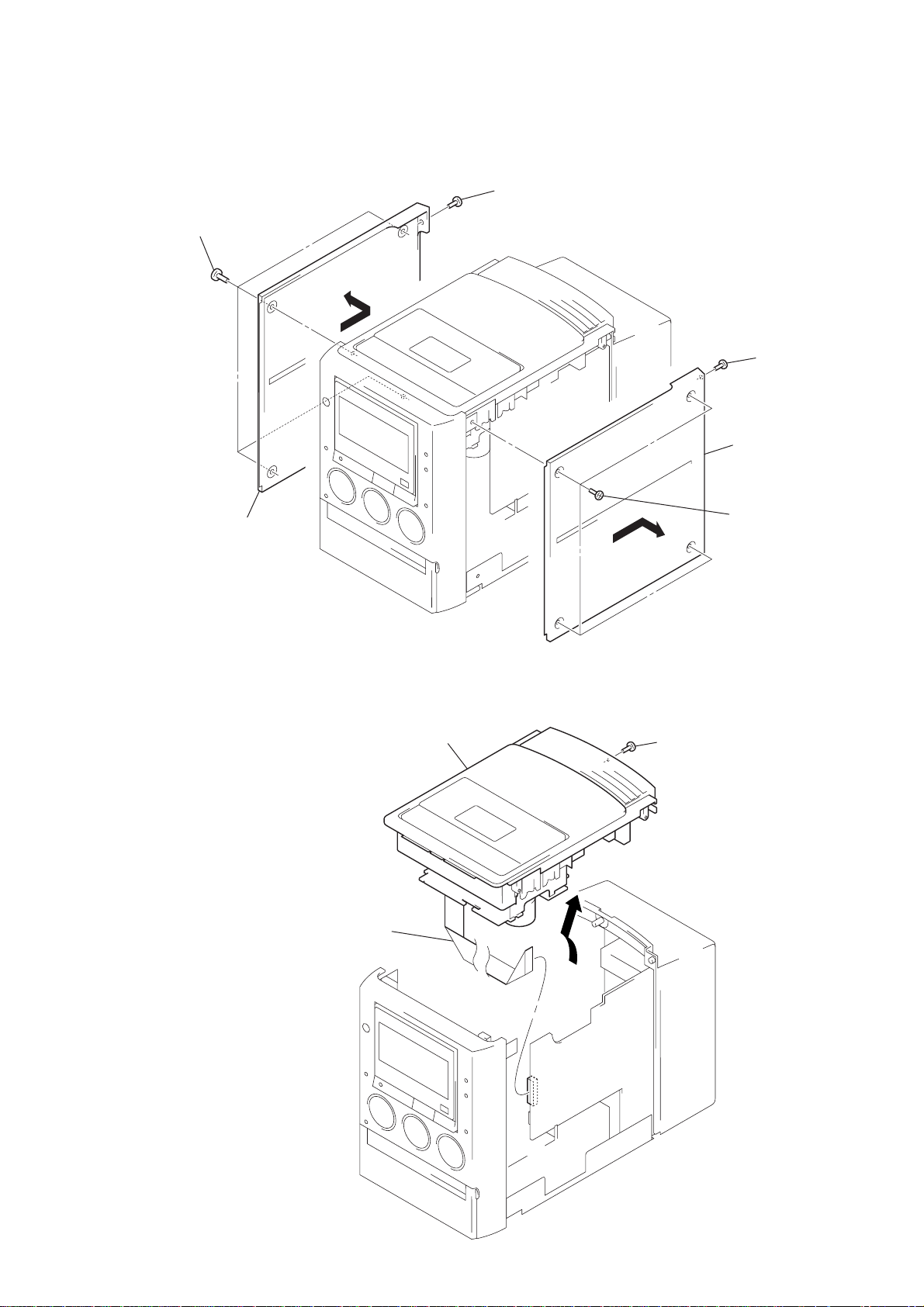

Note: Follow the disassembly procedure in the numerical order given.

1

four screws

(BTP3

×

10)

2

3

panel (side) (L)

1

screw

(BTP3

×

10)

4

screw

(BTP3

×

10)

4

four screws

(BTP3

×

10)

5

6

panel (side) (R)

)

3-2. PANEL (SIDE) (L), PANEL (SIDE) (R)

HCD-M80

3-3. TOP PANEL SECTION

3

wire (flat type) (17 core)

(CN301)

4

top panel section

1

screw

(BTP3 × 10

2

7

HCD-M80

)

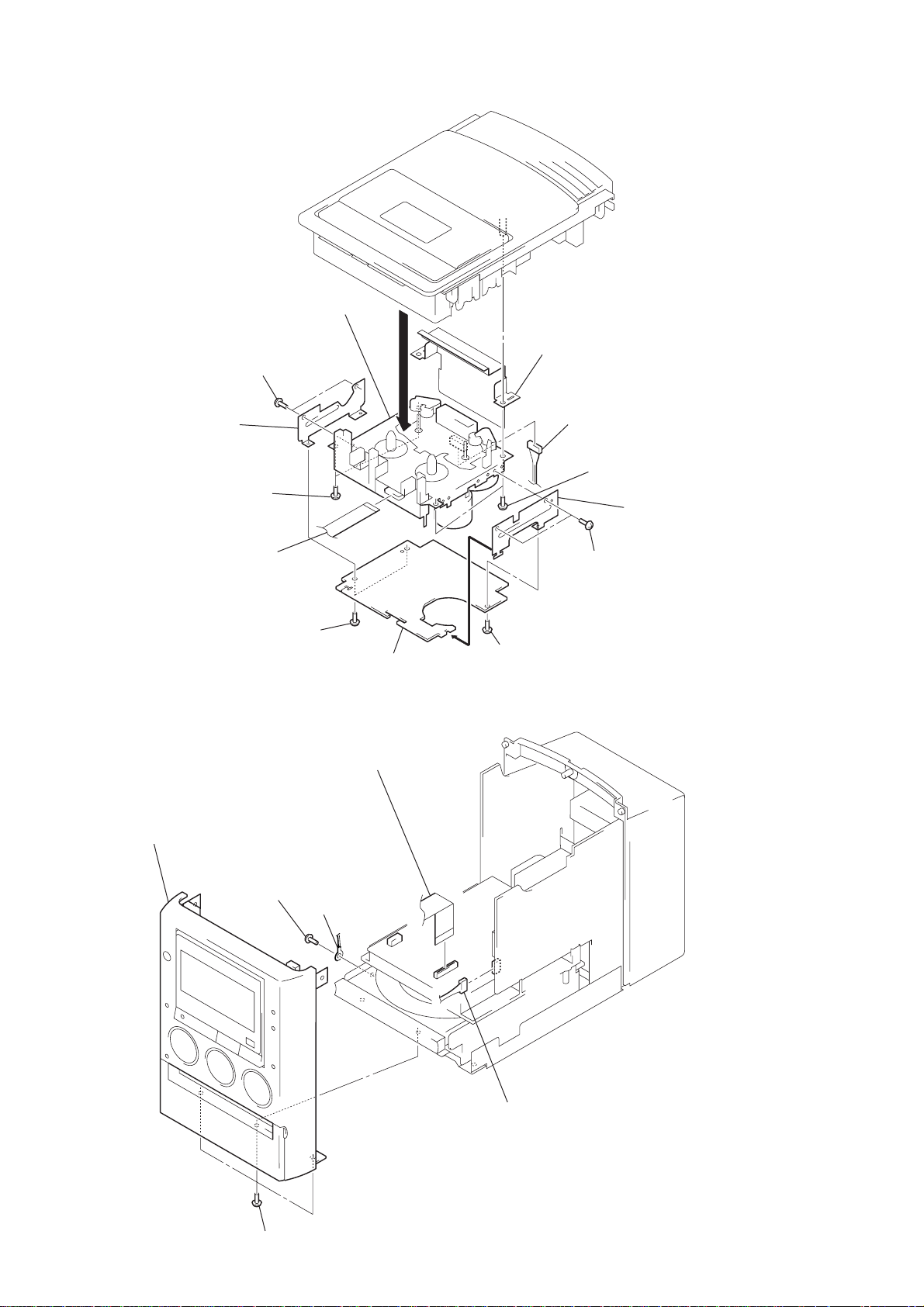

3-4. MECHANICAL DECK (TAPE)

qd

mechanical deck (tape)

9

0

MD bracket (L)

1

two screws

(BVTT2.6

two screws

(BVTP3

×

5)

×

8)

2

3

shield case (TC)

5

connector

1

two screws

(BVTP3

×

qs

MD bracket (R

8)

4

wire (flat type)

(FFC) (8 core)

6

two screws

(BVTT2.6

3-5. FRONT PANEL SECTION

6

front panel section

4

screw

(BTP4

qa

two screws

(BVTT2.6

×

5)

8

TC board

1

flexible flat cable (19 core)

(CN605)

×

8)

5

ground wire

7

6

screw

(BVTT2.6

×

5)

×

5)

2

connector

3

three screws

(BTP3

(CN304)

×

8)

8

3-6. BACK PANEL ASSY

1

connector

(CN301)

VMP board

3

back panel assy

2

four screws

(BTP3

2

two screws

(BTP3

HCD-M80

×

8)

×

8)

3-7. MAIN BOARD

1

wire (flat type) (25 core)

(CN603)

2

connector

(CN902)

1

wire (flat type) (17 core)

(CN602)

4

main board

3

screw

(BTP3 × 12)

9

HCD-M80

)

3-8. CD MECHANISM DECK (CDM55G-30BD62)

1

connector

(CN606)

3

Open the bracket (MPEG)

in the direction of arrow

8

CD mechanism deck (CDM55G-30BD62)

5

A

.

boss

A

1

connector

(CN903)

2

4

screw

(BVTP3

two screws

(DIA. 2.6

5

×

6)

×

8)

boss

7

flexible flat cable (28 core

(CN101)

3-9. BU HOLDER SECTION

5

4

shaft (BU)

6

two claws

BU holder section

3

shaft

1

floating screw

(PTPWHM2.6)

2

shaft

10

3-10. BASE UNIT (BU-30BD62)

)

2

belt (CDM55)

B

3

Pull the tray pushing B.

4

two screws

(BTP2.6

×

6)

5

loading board

1

Rotate the gear (B) in

the direction of arrow

A

.

A

1

two screws

(PTPWHM2.6)

3

two insulators (BU-30)

5

compression spring

4

base unit (BU-30BD62)

5

three compression spring

1

two screws

(PTPWHM2.6)

3

two insulators (BU-30

HCD-M80

3-11. LOADING BOARD

2

6

BU holder (BU-30)

11

HCD-M80

3-12. CAM (CDM55)

3 spacer (55)

4 pulley (LDG)

2 lever (SW)

1 torsion spring

6 gear (B)

5 gear (A)

7 roller

8 cam (CDM55)

12

SECTION 4

TEST MODE

HCD-M80

[COLD RESET]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press the ?/1 key to turn the power ON.

2. Press three keys [FUNCTION], z REC , and ?/1 simultaneously.

3. The set is reset, and becomes standby state.

[PANEL TEST]

•This mode is used to check the liquid crystal display, LED,

destination, model, software version, and key.

Procedure:

1. Press the ?/1 key to turn the power ON.

2. Press three [PLAY MODE/TUNING MODE], z REC , and

[FUNCTION] simultaneously.

3. Liquid crystal display and LEDs are all turned on.

4. When you want to enter the version check mode, press the

[PLAY MODE/TUNING MODE] keys. The destination and model

are displayed.

5. Each time [PLAY MODE/TUNING MODE] key is pressed, the

display changes starting from MC version, GC version, ST

version, TA version, TM version, and TC version this order,

and returns to the MC version display.

6. When [REPEAT/FM MODE] key is pressed while the version

numbers are being displayed except model and destination,

year, month and day of the software creation appear. When

[REPEAT/FM MODE] key is pressed again, the display returns to

the software version display . When [PLAY MODE/TUNING MODE]

key is pressed while year, month and day of the software creation

are being displayed, the year, month and day of creation of the

software versions are displayed in the same order of version

display.

7. Press the

8. In the key check mode, the liquid crystal display displays “K0

J0 V0”. Each time a key is pressed, “K” value increases.

However , once a key is pressed, it is no longer tak en into account.

9. To release this mode, press three keys in the same manner as

step 2, or disconnect the power cord.

[CD SYNCHRO] key, and the key check mode is activ ated.

[CD TRAY LOCK MODE]

• This mode is used to unable to take sample disc out of tray in

the shop.

Procedure:

1. Press the ?/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “CD”.

3. While pressing the [DSG] key, press the Z CD key.

4. The message “LOCKED” is displayed on the liquid crystal

display and the tray is locked. (Even if pressing the Z CD key,

the message “LOCKED” is displayed on the liquid crystal

display and the tray is locked)

6. T o release from this mode, while pressing the [DSG] key, press

the Z CD key for 5 seconds.

7. The message “UNLOCKED” is displayed on the liquid crystal

display and the tray is unlocked.

[REPEAT 5 LIMIT OFF MODE]

Number of repeat for CD playback is 5 times when the repeat mode

is “REPEA T”. This mode enables CD to repeat playback for limitless

times.

Procedure:

1. Press the ?/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “CD”.

3. Press three keys [REPEAT/FM MODE], [FUNCTION] and

z REC simultaneously to enter the repeat 5 limit off mode.

[TUNER STEP CHANGE]

(EXCEPT Saudi Arabia model)

•A step of AM channels can be changed o ver between 9 kHz and

10 kHz.

Procedure:

1. Press the ?/1 key to turn the power ON.

2. Press the

[FUCTION] key to select “TUNER” and press the

[TUNER AM] key to turn the “AM”.

3. Press the ?/1 key to turn the set OFF.

4. While pressing [REPEAT/FM MODE] key, and press the ?/1 key

and the display of liquid crystal display changes to “AM 9K

Step” or “ AM 10K Step”, and thus the c hannel step is changed

over.

[CD SHIP (MECHA) MODE]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the ?/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “CD”.

3. Press three keys [REPEAT/FM MODE], [FUNCTION] and

[DSG] simultaneously.

4. The message “LOCK” is displayed on the liquid crystal display

and turn the power off automatically, and becomes delivery

mode.

[SHIP MODE]

•This mode is used to execute “COLD RESET” and “CD SHIP

(MECHA)” simultaneously.

1. Press the ?/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “CD”.

3. Press three keys [FUNCTION], [DSG], and [CD SYNCHRO]

simultaneously.

4. The message “LOCK” is displayed on the liquid crystal display

and turn the power off automatically, and set is reset, then

becomes delivery mode.

[VCD COLOR SYSTEM MODE ]

•The color system can be changed over PAL, AUTO or NTSC.

Procedure:

1. Set to the standby state.

2. Press the l m and ?/1 buttons simultaneously to change

the color system to PAL, and the message “COLOR PAL” is

displayed on the liquid crystal display.

3. Press the M L and ?/1 buttons simultaneously to change

the color system to AUTO, and the message “COLOR AUTO”

is displayed on the liquid crystal display.

4. Press the x and ?/1 buttons simultaneously to change the color

system to NTSC, and the message “COLOR NTSC” is displayed

on the liquid crystal display.

13

HCD-M80

)

TP70 (TE)

TP73 (DVC)

BD board

+

–

oscilloscope

)

p

SECTION 5

ELECTRICAL ADJUSTMENTS

CD SECTION

Note:

1. CD Block is basically designed to operate without adjustment. Therefore,

check each item in order given.

2. Use LUV-P01 (Part No. 4-999-032-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens b y an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

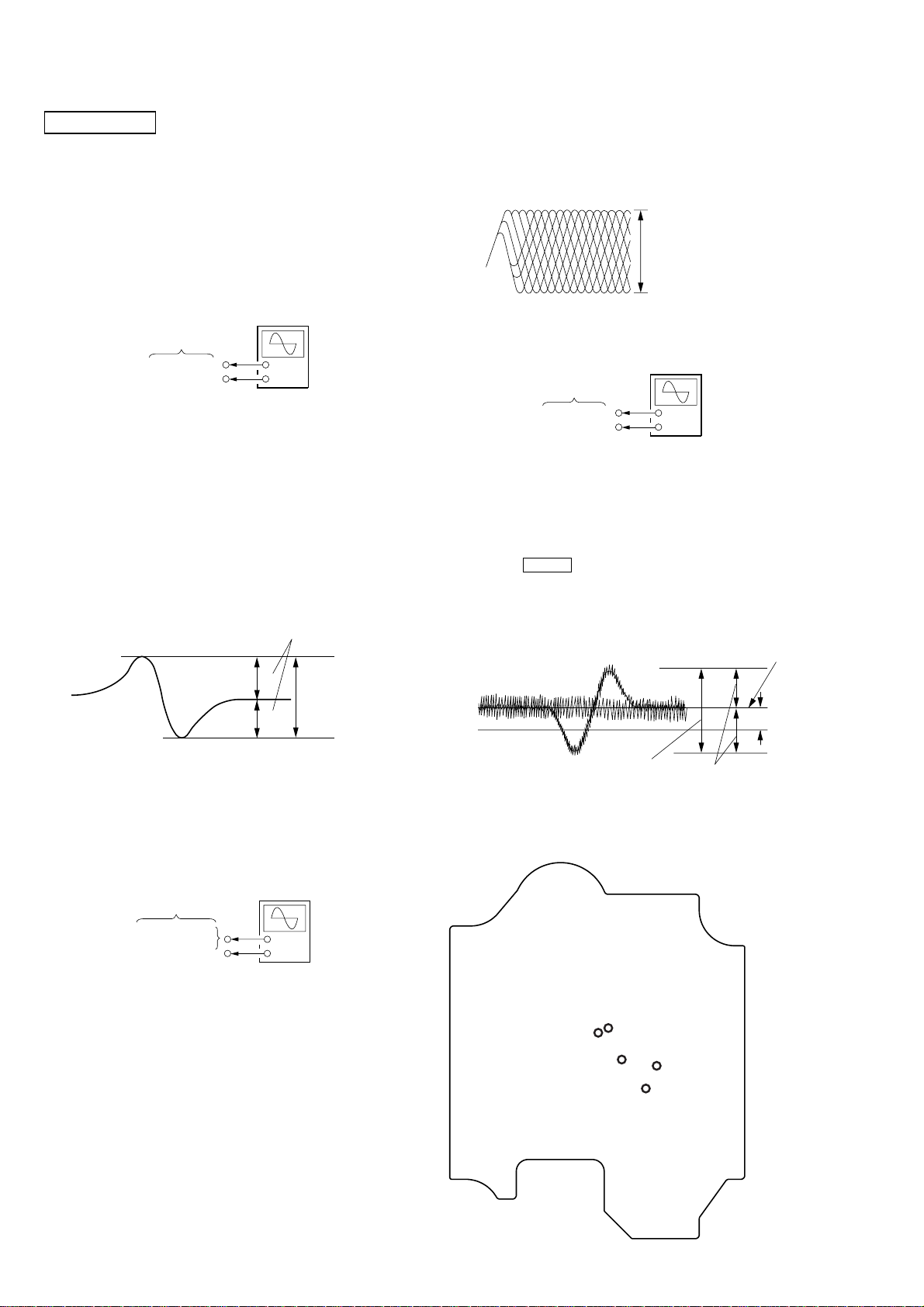

S-CURVE CHECK

oscilloscope

BD board

TP68 (FE)

TP73 (DVC)

Procedure :

1. Connect an oscilloscope to TP68 (FE) and TP73 (DVC) on the

BD board.

2. Turn the power ON.

3. Load a disc (LUV -P01) and actuate the focus search. (In consequence of open and close the disc tray, actuate the focus search)

4. Confirm that the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak le vel within 2 ±

0.5 Vp-p.

S-curve waveform

+

–

symmetry

A

within 2 ±0.5Vp-

B

Note: Clear RF signal waveform means that the shape “ ◊ ” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 0.75 ±0.1Vp-p (RFDC

1.05 ±0.3Vp-p (RFAC)

TRAVERSE LEVEL CHECK

Procedure :

1. Connect an oscilloscope to TP70 (TE) and TP73 (D VC) on the

BD board.

2. Turn the power ON.

3. Load a disc (LUV-P01) and playback the number nine track.

4. Press the CD N button. (Becomes the 1 track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope waveform.

1 track jump waveform

B

DVC

center of

waveform

A (DC voltage

Note: •Try to measure several times to make sure than the ratio

of A : B or B : A is more than 10 : 7.

•Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF LEVEL CHECK

BD board

TP71 (RFDC)

TP72 (RFAC)

TP73 (DVC)

Procedure :

1. Connect an oscilloscope CH1 to TP71 (RFDC), CH2 to TP72

(RFAC) and TP73 (DVC) on the BD board.

2. Turn the power ON.

3. Load a disc (LUV-P01) and playback the number nine track.

4. Confirm that oscilloscope waveform is clear and check if RF

signal level is correct or not.

oscilloscope

+

–

level=1.2 ±0.55Vp-p

Connecting Location:

– BD BOARD (Conductor Side) –

TP70

(TE)

TP68

(FE)

TP72

(RFAC)

TP73

(DVC)

symmetry

TP71

(RFDC)

14

HCD-M80

attenuator

set

MAIN board

AUDIO IN (MD/VIDEO) jack (SJ302)

L-CH, R-CH

1) 315 Hz

2) 10 kHz

50 mV (– 23.8 dB)

600

Ω

blank tape

CN-123

AF OSC

+

–

set

recorded

portion

MAIN board

SPEAKER terminals (SJ301)

L-CH, R-CH

level meter

RV101 (L)

RV201 (R)

REC Bias

Adjustment

– TC BOARD (Component Side) –

r

r

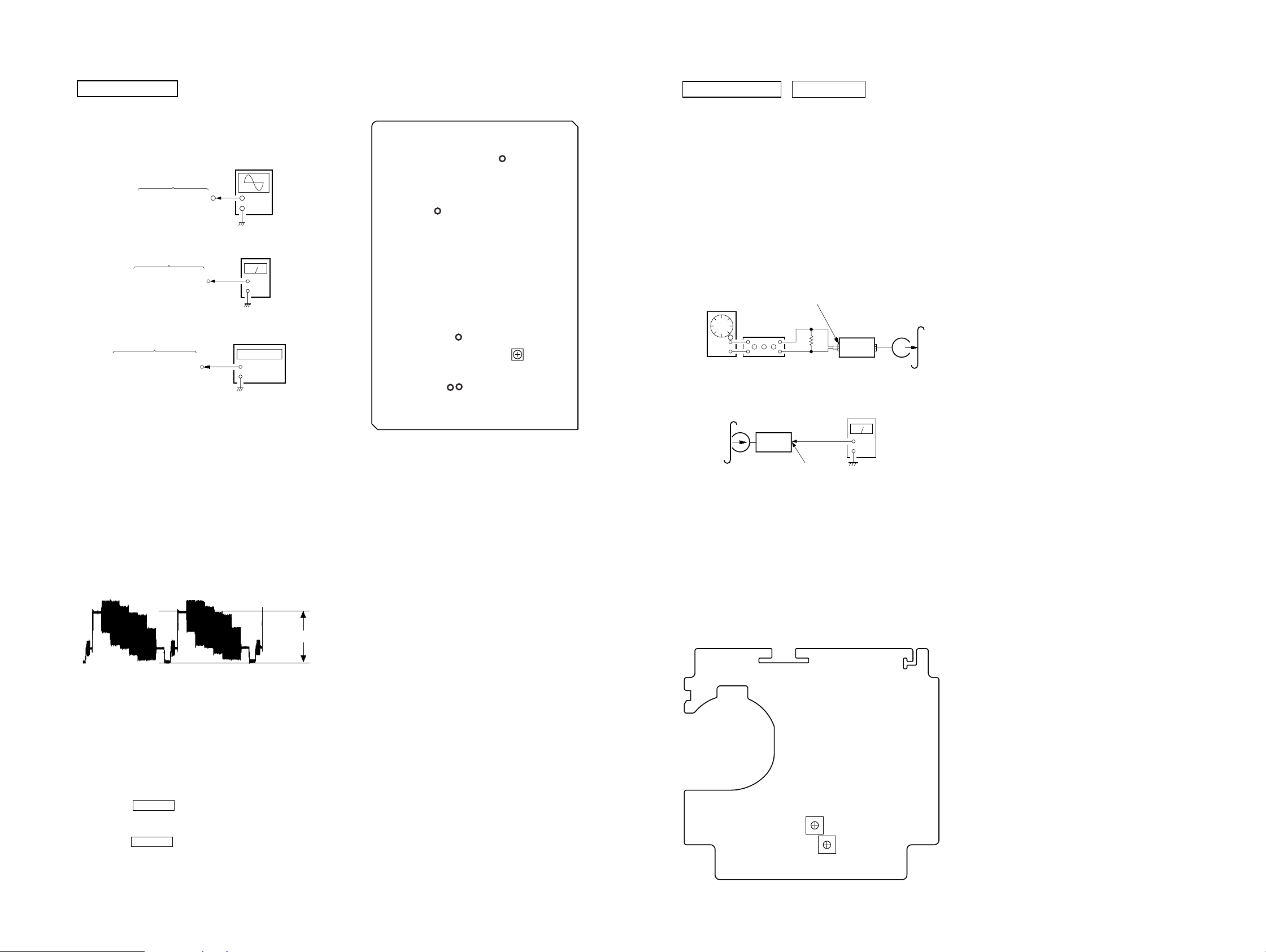

VIDEO SECTION

VIDEO LEVEL ADJUSTMENT

(AUDIO LEVEL/VIDEO CLOCK/AUDIO SERVO

CLOCK CHECK)

oscilloscope

VMP board

TP308 (V-OUT)

VMP board

TP415 (L-OUT)

TP413 (R-OUT)

VMP board

TP70 (54 MHz)

TP182 (4.2336 MHz)

Procedure :

1. Connect an oscilloscope to TP308 (V -OUT) on the VMP board.

2. Connect a level meter to TP415 (L-OUT) and TP413 (R-OUT)

on the VMP board.

3. Connect a frequency counter to TP70 (54 MHz) and TP182

(4.2336 MHz) on the VMP board.

3. Turn the power ON.

4. Set a test disc (HLV-402 (Part No. 8-909-870-00))

5. Press three buttons [FUNCTION], [DSG] and [DIRECTION]

simultaneously.

6. The message “MPEG AV TEST” is displayed on the liquid

crystal display. Color bar signal outputs and sine-wa ve (1 kHz

0dB) appears.

7. Adjust the RV501 on the VMP board for 0.714 ± 0.05 Vp-p.

Note: TP308 (V-OUT) on the VMP board must be teminated by 75 Ω.

+

–

level mete

+

–

frequency counte

+

–

– VMP BOARD (Component Side) –

TP308

(V-OUT)

TP70

(54 MHz)

TP182

(4.2336 MHz)

TP415

(L-OUT)

TP413

(R-OUT)

Adjustment

RV501

Video

Level

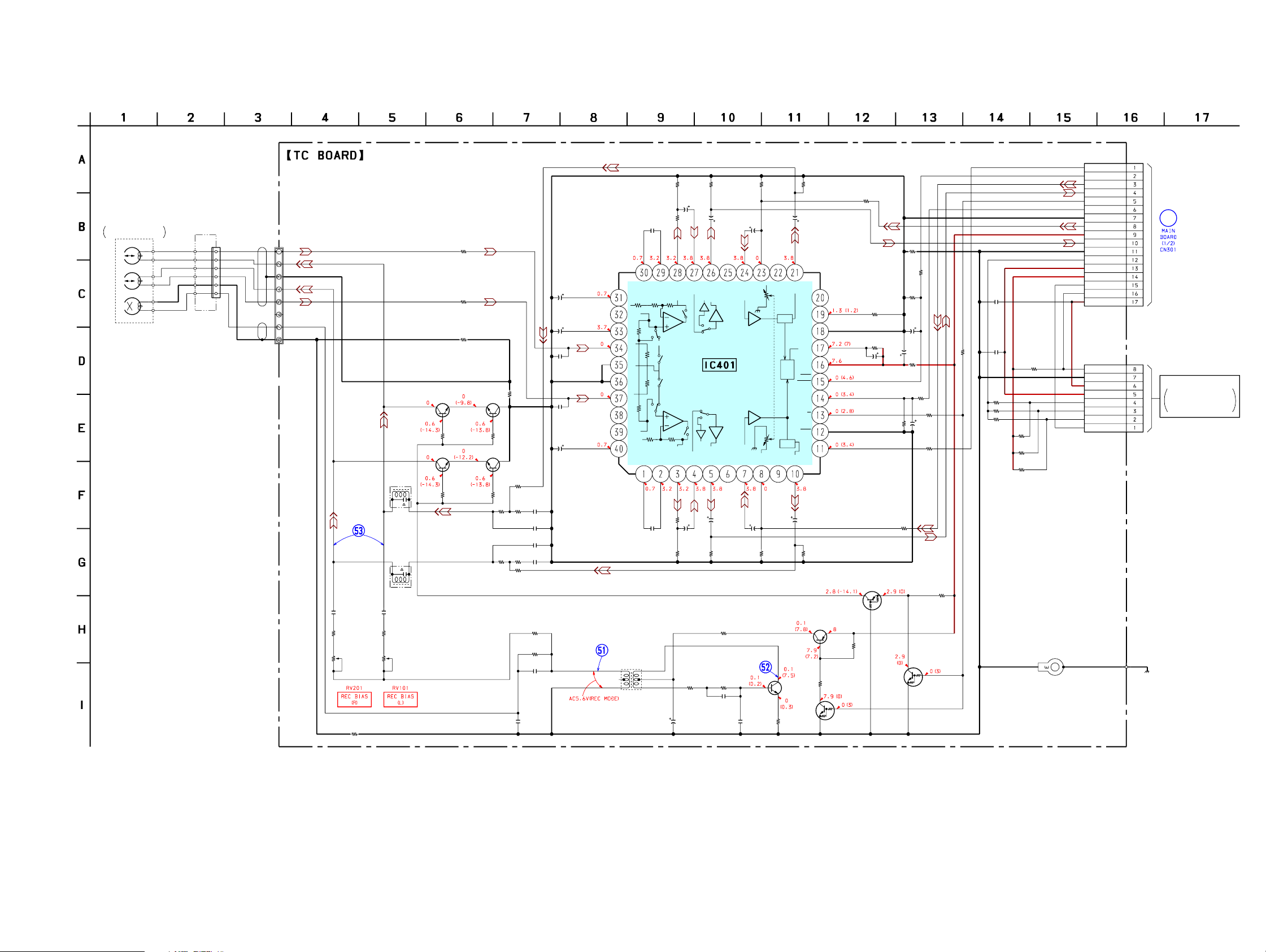

DECK SECTION

Note: Confirm each contents of this section first of all. If the results are

not satisfied, do the adjustment.

1. The adjustments should be performed with the rated power supply

voltage unless otherwise noted.

2. The adjustments should be performed in the order given in this service

manual.

3. The adjustments should be performed for both L-CH and R-CH.

0 dB=0.775 V

REC BIAS ADJUSTMENT

Procedure:

1. Mode: REC

FUNCTION: MD

2. Mode: Playback

3. Confirm playback the signal recorded in step 1 become speci-

fied values as follows.

If these values are out of specification values, adjust the RV101

(L-CH) and RV201 (R-CH) on the TC board to repeat steps

1and 2.

Specified values:Playback output of 315 Hz to playback

output of 10 kHz: ± 0.5 dB

Adjustment Location: TC board

8. Confirm that the value of le vel meter is 2.5 ± 2.0 dBs. (If audio

output disappear, press the [PLAY MODE/TUNING MODE]

button, and the message “CD SERVICE” is displayed on the

liquid crystal display)

9. Confirm that the value of frequency counter is 54 MHz ± 400

Hz.

10. Confirm that the value of frequency counter is 4,2336 MHz.

11.Press the [REPEAT/FM MODE] button to change the traverse

ON/OFF , and the message “TRAVERSE ON” or “TRA VERSE

OFF” is displayed on the liquid crystal display.

12.Press the l m button to turn the optical pick-up inside

position, and the message “SLED IN” is displayed on the liquid crystal display.

13.Press the M L button to turn the optical pick-up outside

position, and the message “SLED OUT” is displayed on the

liquid crystal display.

14. Change disc to a MP3 test disc (MP3 1kHz 0dB sine-wave is

15. Confirm that the value of level meter is 2.4 ± 2.0 dBs.

recorded)

0.714 ± 0.05 Vp-p

1515

HCD-M80

SECTION 6

DIAGRAMS

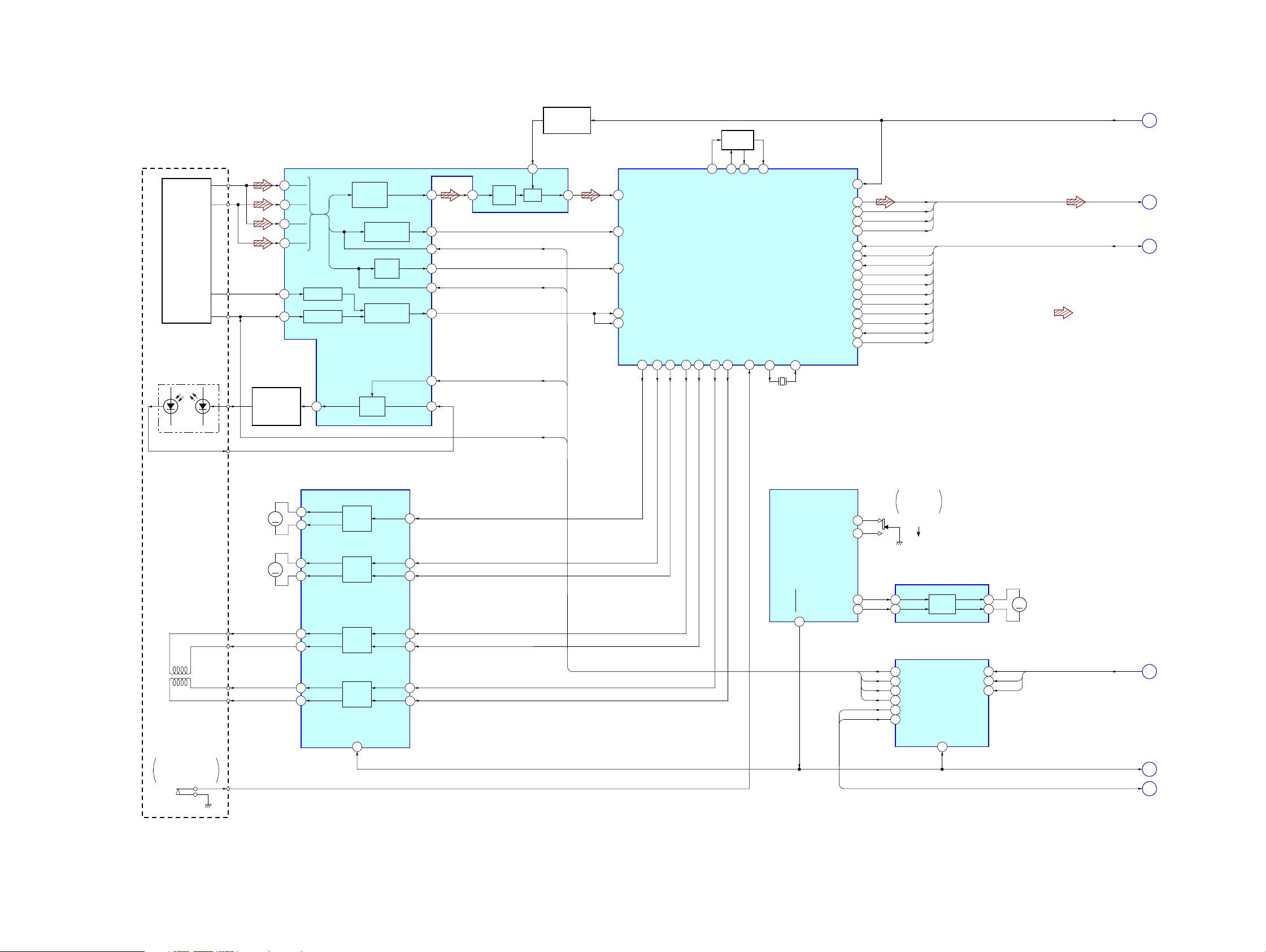

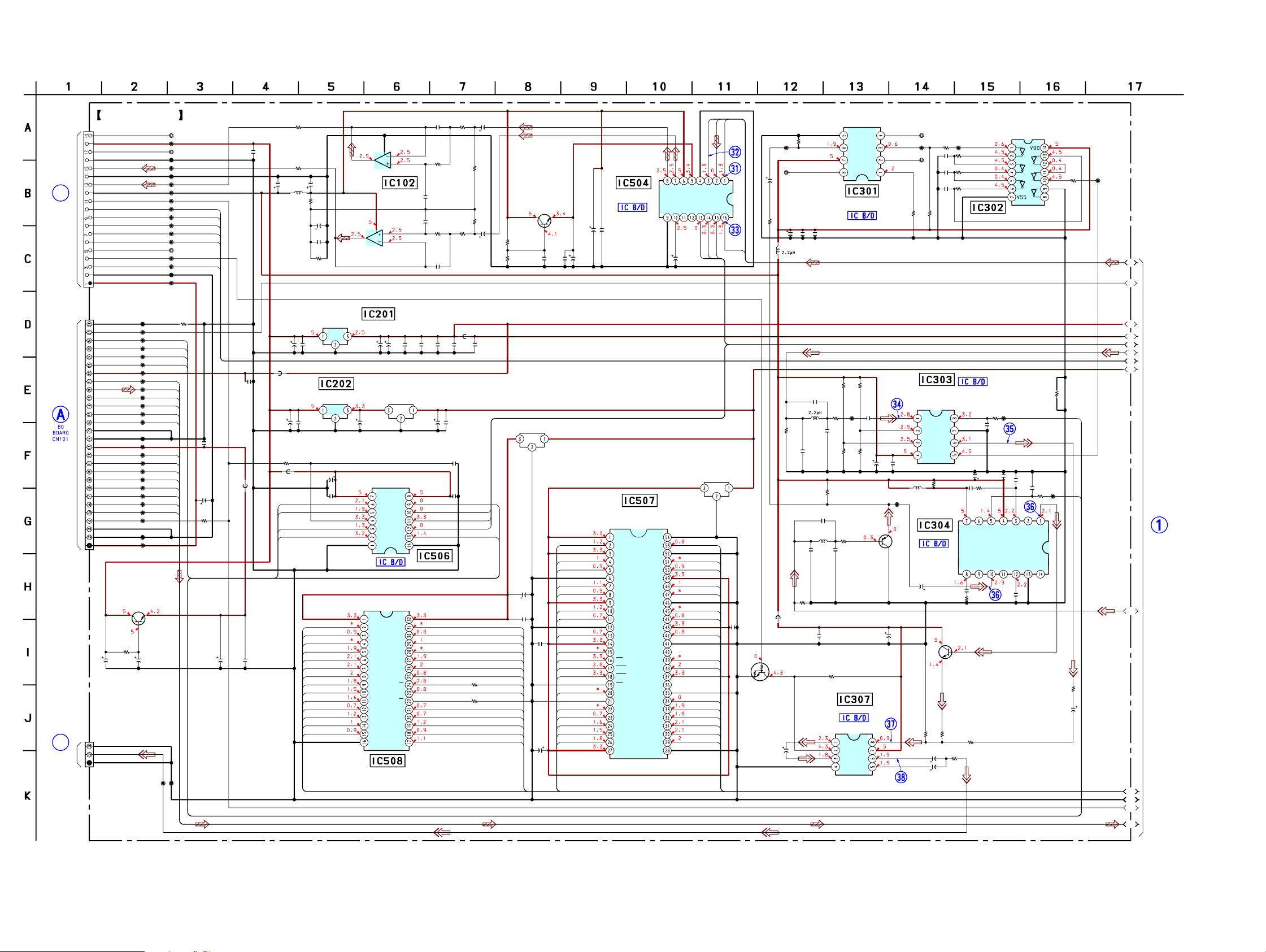

6-1. BLOCK DIAGRAM – CD SERVO Section –

DETECTOR

OPTICAL PICK-UP

BLOCK

(A-MAX. 3)

LASER DIODE

PD

FREQUENCY

SELECT SWITCH

Q102

RF AMP,

FOCUS/TRACKING ERROR AMP

A

6

B

7

C

8

D

9

F

11

F I-V AMP

E

10

E I-V AMP

AUTOMATIC

POWER

CONTROL

LD

Q101

LD

1

RF

SUMMING

AMP

ERROR AMP

TRACKING

ERROR AMP

APC LD

AMP

FOCUS

RF DC

AMP

AC

SUM

RFDCO

RFDCI

SW

IC103

EQ

4

FE

16

FEI

17

28

29

TE

18

12

PD

2

IN

3

RFAC

VCA

26

RFC

RFAC

EQ

15

D/A1

D/A3

D/A4

D/A2

RFAC

173

FE

164

RFDC

160

TE

162

SE

163

MDP

SFDR

SRDR

TFDR

133

137 138 140

FILTER

171

168 170

FILO

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR

IC505 (1/2)

TRDR

FFDR

141

142

143

PCO

FRDR

CLTV

135

169

FILI

SSTP

150 149

33.8688MHz

XTAO

X501

XTAI

XTSL

PCMD

BCK

LRCK

C2PO

DATA

CLOK

XLAT

SENS

SCOR

SQSO

L SQCK

L SCLK

GFS

L FOK

L CDXRST

189

91

93

88

124

102

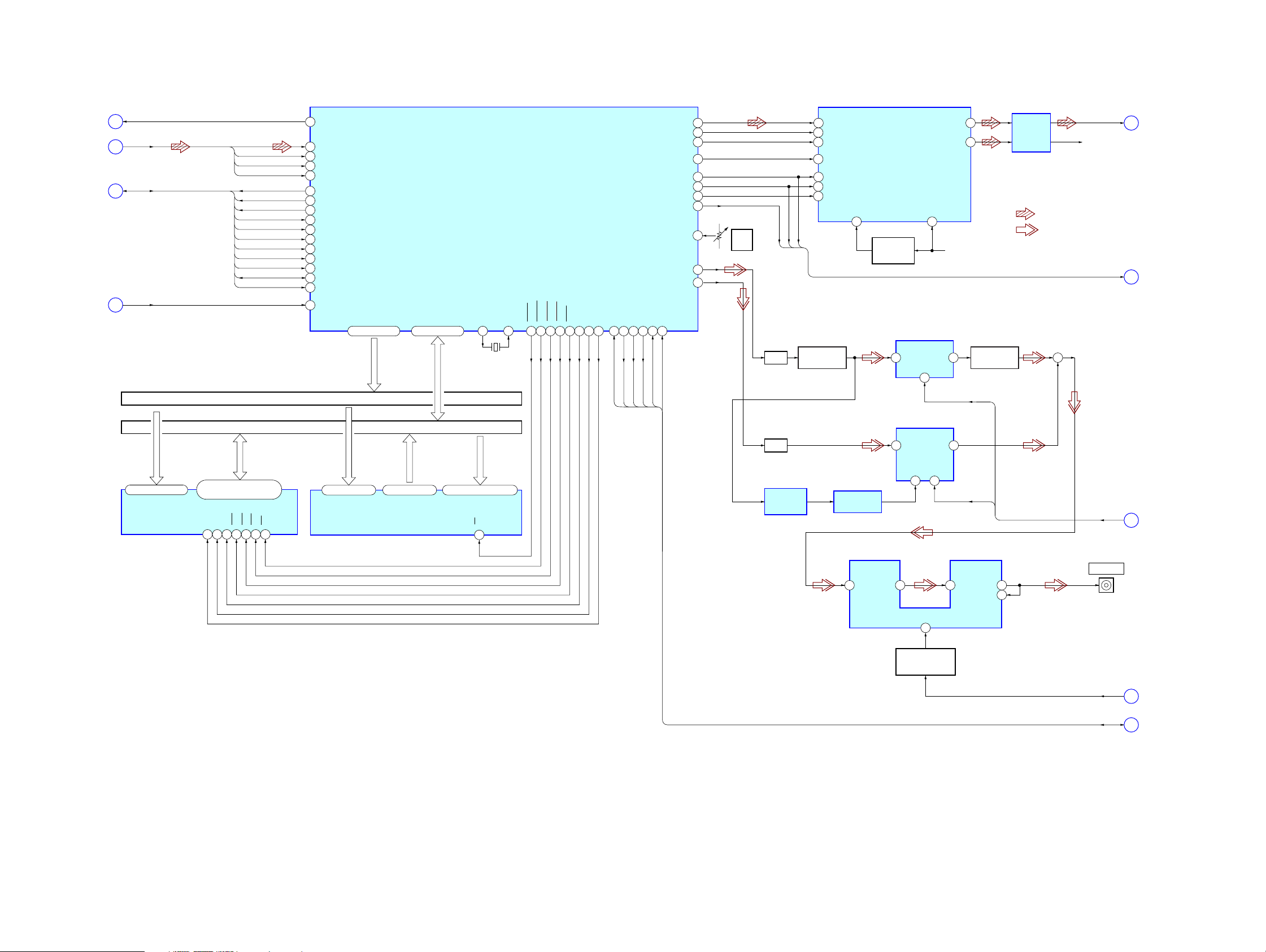

111

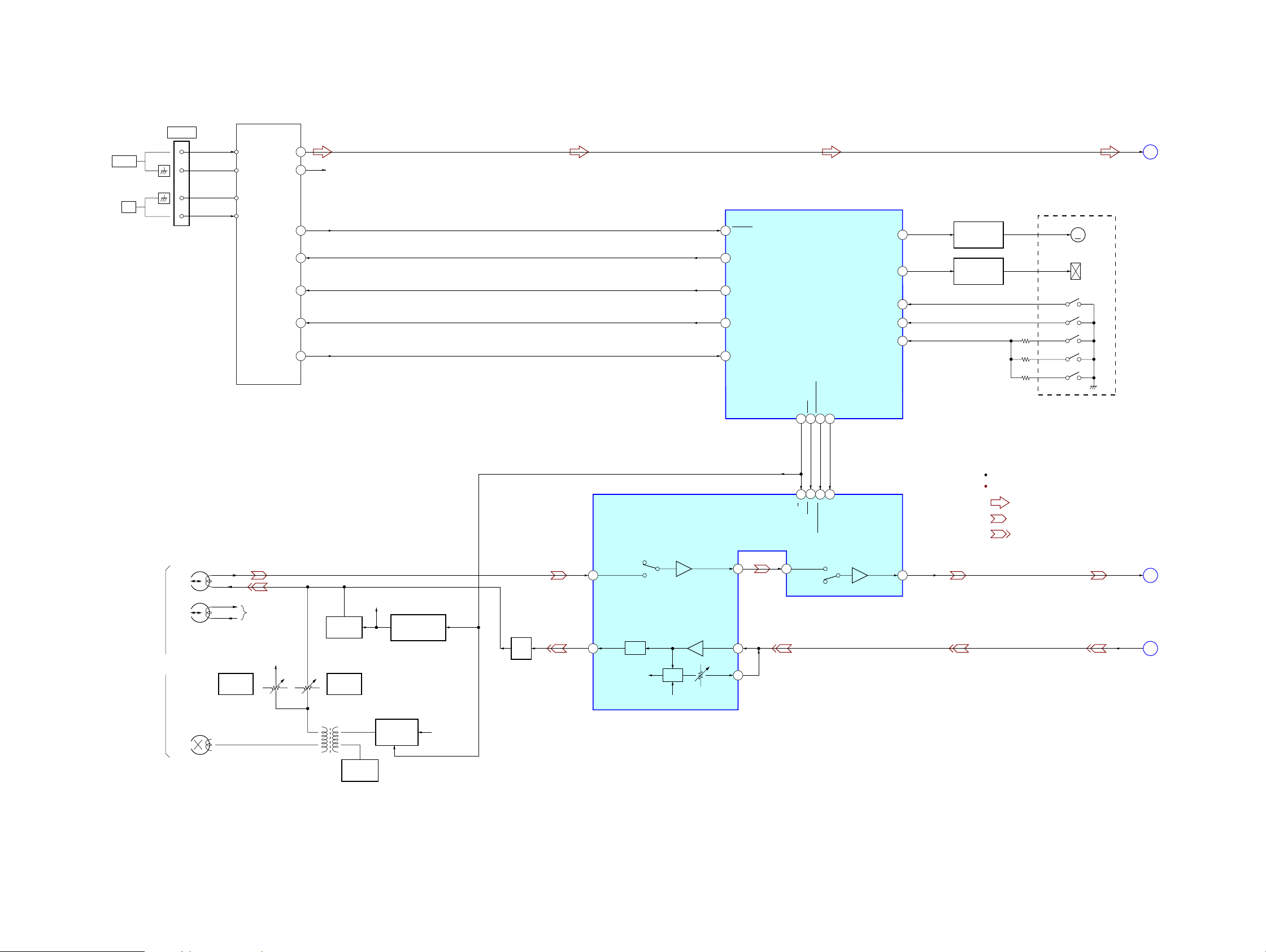

109

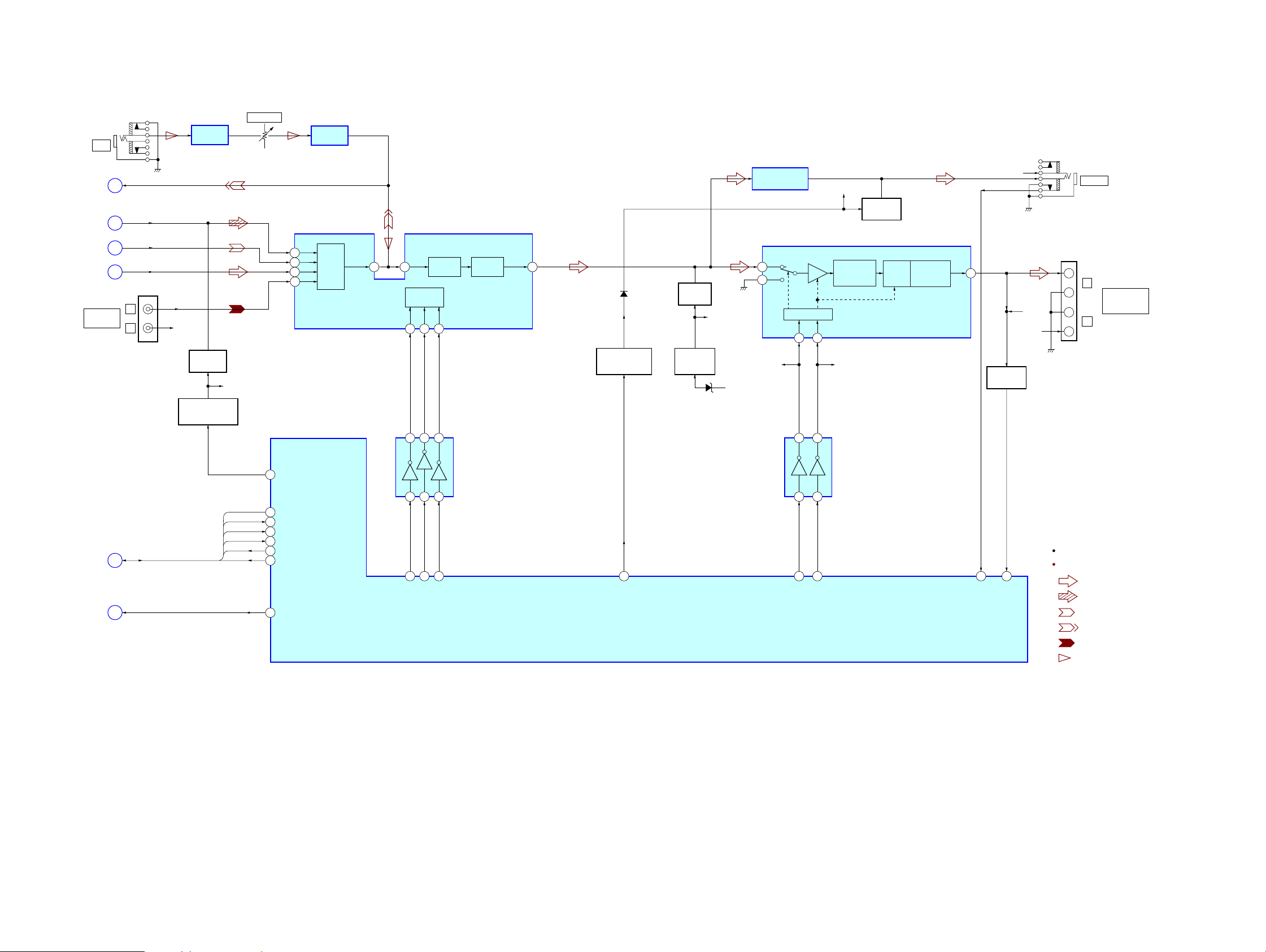

113

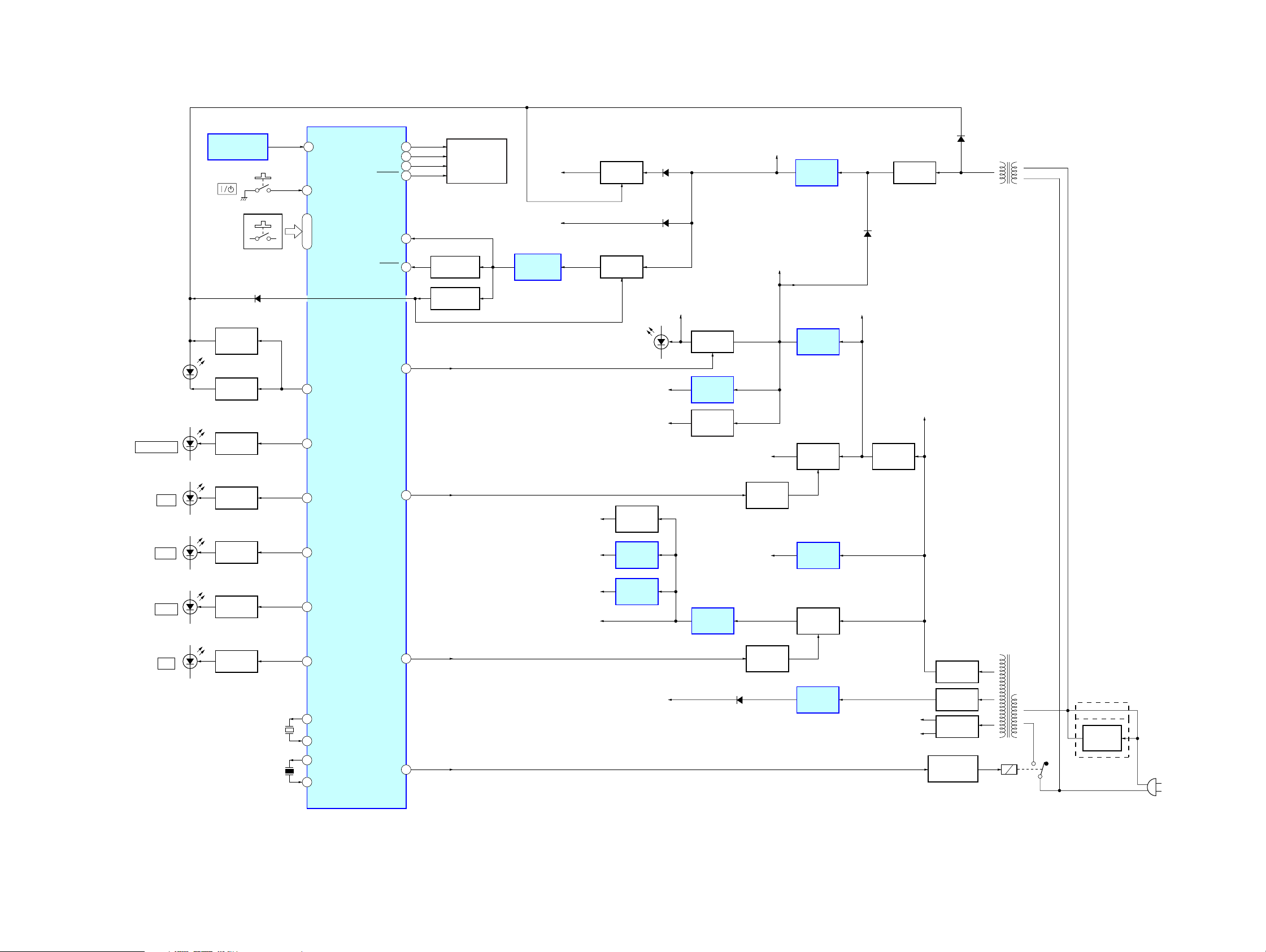

126

96

98

114

121

131

105

DATA

BCK

LRCK

C2PO

DATA

CLOK

XLAT

SENS

SCOR

SQSO

SQCK

SCLK

GFS

FOK

XRST

DATA, CLOK, XLAT, SENS,

SCOR, SQSO, SQCK,

SCLK, GFS, FOK, XRST

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: CD PLAY

CONT

DATA, BCK,

LRCK, C2PO

A

B

C

(Page 17)

(Page 17)

(Page 17)

2-AXIS

DEVICE

(TRACKING)

(FOCUS)

(LIMIT)

When the optical

ON :

pick-up is inner

position

M101

(SPINDLE)

M102

(SLED)

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

VO4+

5

M

M

VO4–

10

VO3+

1

VO3–

2

VO2+

56

VO2–

55

VO1+

47

VO1–

52

IC102

MOTOR

DRIVE

MOTOR

DRIVE

COIL

DRIVE

COIL

DRIVE

8

STBY

IN3+

IN3–

IN2+

IN2–

IN1+

IN1–

IN4

S1

DISC TRAY

OPEN/CLOSE

IN1

5

IN2

6

3

AO3

5

AO4

AO5

6

9

AO6

13

AO1

AO2

2

DETECT

CLOSE

OPEN

LOADING MOTOR

DRIVER

IC607

MOTOR

DRIVE

D/A

CONVERTER

IC506

OUT1

1

OUT2

10

12

DI

11

CLK

10

LD

RST

4

DATA

CLK

LD

M

M901

(LOADING)

DATA, CLK, LD

SYSRST

SHARPNESS, HUE

D

E

F

(Page 17)

(Page 17)

(Page 17)

23

27

26

32

31

35

34

SYSTEM CONTROLLER

IC601 (1/4)

SYSRST

60

CLOSE

OPEN

LOAD-OUT 67

LOAD-IN

SHARPNESS

HUE

70

69

68

D/A1

D/A2

D/A3

D/A4

1616

6-2. BLOCK DIAGRAM – AUDIO/VIDEO CD Section –

HCD-M80

(Page 16)

(Page 16)

(Page 16)

(Page 16)

CONT

A

DATA, BCK,

LRCK, C2PO

B

DATA, CLOK, XLAT, SENS,

SCOR, SQSO, SQCK,

SCLK, GFS, FOK, XRST

C

SYSRST

E

DATA

BCK

LRCK

C2PO

DATA

CLOK

XLAT

SENS

SCOR

SQSO

SQCK

SCLK

GFS

FOK

XRST

24

GPIO9

90

L CDDATA

92

L CDBCK

87

L CDLRCK

123

L CDC2PO

103

L DDAT

110

L DCLK

108

L XLAT

112

L SENS

125

L SCOR

95

L SQSO

99

SQCK

115

SCLK

120

L GFS

132

FOK

106

XRST

81

SYSRST

ADDRESS BUS

DATA BUS

DRADR0 – DRADR10

34 – 37, 39 – 45 49 – 56, 59 – 66

A0 – A10

DRDAT0 – DRDAT15

D0 – D15

MPEG VIDEO/AUDIO DECODER,

VIDEO SIGNAL ENCODER

IC505 (2/2)

CLKB

CLKA

NVOEL

207 206

X502

27MHz

741873 72 68

DRRAS

DRWEL

DRCAS

DRBS

DRCK

70 76 77 78

DRDQM1

DRDQM0

GPIO0

13 14

SDO

GPIO1

GPIO2

15 19 18 16

SDI

SCK

GPIO5

SCS

AUDDTO0

AUDBCK

AUDLRCK

AUDXCLKO

GPIO3

GPIO4

SOK

SRQ

GPIO14

GPIO13

GPIO11

GPIO12

CPSIG

CSIG

VRF

201

203

204

205

30

29

26

28

B.P.F.

B.P.F.

CLK

LD

RV501

3

6

7

VIDEO

LEVEL

2

1

3

16

13

14

15

DATA

SYNC BUFFER

Q301

DATA

BCK

LRCK

MLCK

DATA

CLK

LAT

DIGITAL FILTER,

D/A CONVERTER

VDD

5

IC504

+3.3V

REGULATOR

Q581

10

1

VIN

VIN

Y AMP

IC304

CONT IN

5

C AMP

IC303

VCC

6

VOUT

VOUT

VOUTL

VOUTR

CD +5V

1

6

7

8

Y SYNC BUFFER

SHARPNESS

LOW-PASS

FILER

IC102

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: CD PLAY (AUDIO)

: CD PLAY (VIDEO)

Q302

+

CD-L

R-CH

DATA, CLK, LD

G

D

(Page 19)

(Page 16)

A0 – A10

23 – 26, 29 – 34, 22

A0 – A10

D-RAM

IC507

D0 – D15

2, 4, 5, 7, 8, 10, 11, 13, 42,

44, 45, 47, 48, 50, 51, 53

DQ0 – DQ15

RAS

BA0

CLK

LDQM

UDQM

39

CAS

161720

3815

A0 – A10

12 – 5, 27, 26, 31

A0 – A9, A18

WE

PROGRAM ROM

IC508

D0 – D7

13 – 15, 17 – 21

DQ0 – DQ7

D8 – D15

23, 25, 4, 28, 29, 3, 2, 30

A10 – A17

OE

24

SYNC

SEPARATOR

IC301

C SYNC BUFFER

IC302

VIDEO AMP

IC307

BUF

8

IN

BUF

OUT

BGP8TINT

5

1

STBY

2

VIDEO MUTING

CONTROL SWITCH

Q370

HUE

SHARPNESS,

HUE

J700

VIDEO OUT

OUT

OUTSAG

6

5

V MUTE

SDO, SDI, SCK,

SCS, SOK, SRQ

3

IN

F

H

J

(Page 16)

(Page 19)

(Page 19)

1717

HCD-M80

6-3. BLOCK DIAGRAM – TUNER/TAPE DECK Section –

TU1

TUNER UNIT

ANENNA

4

FM75Ω

FM ANT

ANT GND

L-CH

3

R-CH R-CH

TU-L

K

(Page 19)

AM

ANT GND

AM ANT

TUNED

DO

SYSTEM CONTROLLER

IC601 (2/4)

5

9

DI

8

CK

10

CE

7

57

23

27

22

25

TUNED

ST-DOUT

ST-CLK

ST-CE

ST-DIN

80

ALC43TC-RELAY

41

REC-MUTE39TC-MUTE

CAPM-CNT1

B TRG

B PLAY

B SHUT

B HALF/REC

59

58

38

90

91

CAPSTAN/REEL

MOTOR DRIVE

Q341, 343

TRIGGER

PLUNGER DRIVE

Q342, 344

(TAPE DECK BLOCK)

MM

(CAPSTAN/REEL)

R-CH : R-ch is omitted due to same as L-ch.

SIGNAL PATH

: TUNER (FM/AM)

: TAPE PLAY

: REC

REC/PB EQ AMP, ALC

IC401

A/B

11

1513 14

ALC

MUTE

REC-MUTE

L-CH

R-CH

HRPE901

(RECORD/PLAYBACK/ERASE)

ERASE

RV201

REC BIAS

(R)

R-CH

R-CH

MUTING

Q100, 101

REC BIAS

BIAS OSC

T401

RV101

(L)

BIAS OSC

Q401

R-CH

REC BIAS

SWITCH

Q402, 403

MUTING

CONTROL SWITCH

Q404, 405

COM +8V

T101

BIAS

TRAP

34

21

BIN (L)

REC-OUT

(L)

EQ

R-CH

ALC

R-CH

EQ-OUT (L)

REC-IN

ALC

28

(L)

24

(L)

23

27

MUTE

TAI (L)

PB-OUT

(L)

26

TC-L

REC-L

L

M

(Page 19)

(Page 19)

1818

6-4. BLOCK DIAGRAM – MAIN Section –

RV500

MIC LEVEL

J502

MIC

MIC AMP

IC525 (2/2)

MIC AMP

IC525 (1/2)

HCD-M80

(Page 18)

(Page 17)

(Page 18)

(Page 18)

AUDIO IN

MD (VIDEO)

(Page 17)

(Page 17)

REC-L

M

CD-L

G

TC-L

L

TU-L

K

SDO, SDI, SCK,

SCS, SOK, SRQ

J

V MUTE

H

HEADPHONE AMP

IC324

L4

11

L3

INPUT

SELECT

SWITCH

LSELO

10

12

L2

13

L1

SJ302

L

R

R-CH

MUTING

Q604

MUTING CONTROL

SWITCH

Q606, 607

R-CH

SDO

SDI

SCK

SCS

SOK

SRQ

14

66 CD MUTE

35

SYSOUT

36

SYSIN

37

SYSCLK

19

SYSCS

56

SYSOK

54

SYSRQ

33 VIDEO MUTE

LIN

9

CPU

INTERFACE

DI

CL

1

30

8 10 4

9 11 3

87 88 86

AMP-DATA

VOLUME

CONTROL

CE

2

AMP-CE

AMP-CLK

CONTROL

INPUT SELECT SWITCH,

ELECTRICAL VOLUME,

TONE CONTROL

INVERTER

IC603 (1/2)

TONE

IC323

LOUT

5

D313

MUTING

CONTROL SWITCH

Q312, 313

81

LINE-MUTE

MUTING

Q100

R-CH

POWER ON

MUTING

Q330

D309

SYSTEM CONTROLLER

IC601 (3/4)

COM +12V

IN+

3

4

IN+

MUT

STANDBY/MUTE

MUTE STBY

R-CH

10

12 2

13 1

89

STK MUTE

9

84

STK-POWER

R-CH

MOS GAIN &

LEVEL SHIFT

ING STAGE

R-CH

INVERTER

IC603 (2/2)

MUTING

Q408, 409

OUTPUT

MOS

STAGE

SHORT

CIRCUIT

PROTECTION

POWER AMP

IC101

OUT

14

R-CH

DC DETECT

Q310, 311

50

100

DC-DETECT

HEAD PHONE DETECT

R-CH

R-CH

J501

PHONES

+

SJ301

L

R

SPEAKER

IMPEDANCE

USE 6 – 16Ω

–

–

+

R-CH : R-ch is omitted due to same as L-ch.

SIGNAL PATH

: TUNER (FM/AM)

: CD PLAY

: TAPE PLAY

: REC

: MD (VIDEO)

: MIC INPUT

1919

HCD-M80

6-5. BLOCK DIAGRAM – KEY CONTROL/POWER SUPPLY Section –

D514

(STANDBY)

D505

CD SYNCHRO

REMOTE CONTROL

RECEIVER

IC502

S503

S513, 514, 517 – 521,

S523 – 528, 530, 531,

S587, 590, 593, 594

D622

STANDBY

SWITCH

Q602, 603

LED DRIVE

Q506

LED DRIVE

Q505

SIRCS

4

74 POWER KEY

97, 95, 94

KEY0 – KEY2

LED1

42

SYSTEM CONTROLLER

IC601 (4/4)

LED547

LCD DATA

LCD SCK

LCD STB

LCD RS

AC-CUT

BACK LIGHT

5

7

6

3

20

12RESET

51

LIQUID CRYSTAL

DISPLAY

LCD502

RESET SWITCH

Q619

RESET SWITCH

Q618

+3.3V

LCD B+

U-COM +3.3V

RESET SIGNAL

GENERATOR

IC602

B+ SWITCH

Q507, 508

B+ SWITCH

Q601

D506 – 509

(LCD BACK LIGHT)

+5V

TC +3.3V

D500

D604

LED B+

B+ SWITCH

Q635, 637

+5V

REGULATOR

IC605

+3.3V

REGULATOR

Q309

BACKUP +4V

TU +9.5V

COM +8V

+4V

REGULATOR

IC904

+8V

REGULATOR

IC304

+9.5V

REGULATOR

Q301

COM +12V

D910 – 913

D921

+12V

REGULATOR

Q355

RECT

+14V

D920, 922

T901

SUB POWER

TRANSFORMER

D504

TAPE

D503

DSG

D502

TUNER

D501

CD

LED DRIVE

Q504

LED DRIVE

Q503

LED DRIVE

Q502

LED DRIVE

Q501

X601

32.768KHz

X602

16MHz

LED4

46

LED345

LED7

49

LED6

48

XCOUT

11

XCIN

10

XOUT

13

15

XIN

STBY-RELAY

40TUNER ON

CD +4.5V

CD +2.5V

CD +3.3V

CD +5V

65CD-POWER

82

+4.5V

REGULATOR

Q201

+2.5V

REGULATOR

IC201

+3.3V

REGULATOR

IC202

M+7V

+5V

REGULATOR

IC606

TUNER ON

Q303, 304

+12V

MIC AMP B+

Q307, 308

D919

SWITCH

CD ON

SWITCH

+12V

REGULATOR

IC305

+9.5V

REGULATOR

Q305

+8V

REGULATOR

IC901

AMP +22.5V

AMP – 22.5V

RECT

D906 – 909

RECT

D914 – 917

RECT

D902 – 905

POWER ON/OFF

RELAY DRIVE

Q902

T902

MAIN POWER

TRANSFORMER

RY901

(Thai)

VOLTAGE

SELECTOR

S901

(Singapore, Saudi Arabia)

(AC IN)

2020

HCD-M80

JACK board

SWITCH board

POWER board

VIDEO board

MAIN board

d

6-6. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

f

•

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• VMP board is multi-layer printed board.

• Indication of transistor.

: internal component.

However, the patterns of intermediate-layer have not been

included in diagram.

C

Q

B

E

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

•Voltages are taken with a V OM (Input impedance 10 MΩ).

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

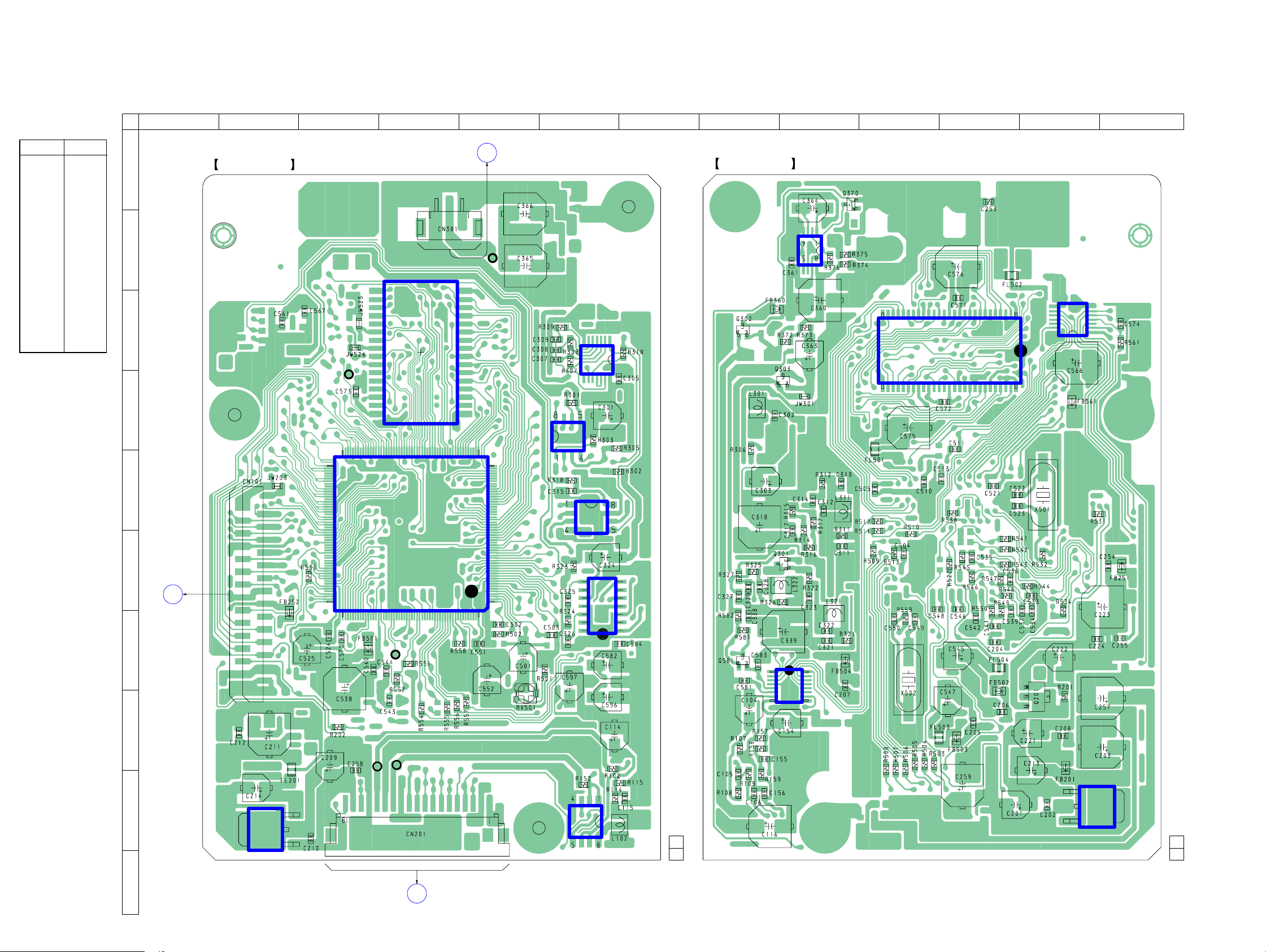

• Signal path.

•Abbreviation

: internal component.

with mark 0 are critical for safety.

Replace only with part number specified.

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : TUNER (FM/AM)

J : CD PLAY (A UDIO)

L : CD PLAY (VIDEO)

E : TAPE PLAY

a : REC

j : MD (VIDEO)

N : MIC INPUT

EA : Saudi Arabia model

SP : Singapore model

TH : Thai model

4

• Circuit Boards Location

W or less unless otherwise

TC board

CONTROL boar

VMP board (VMP41)

BD board

LOADING board

2121

HCD-M80

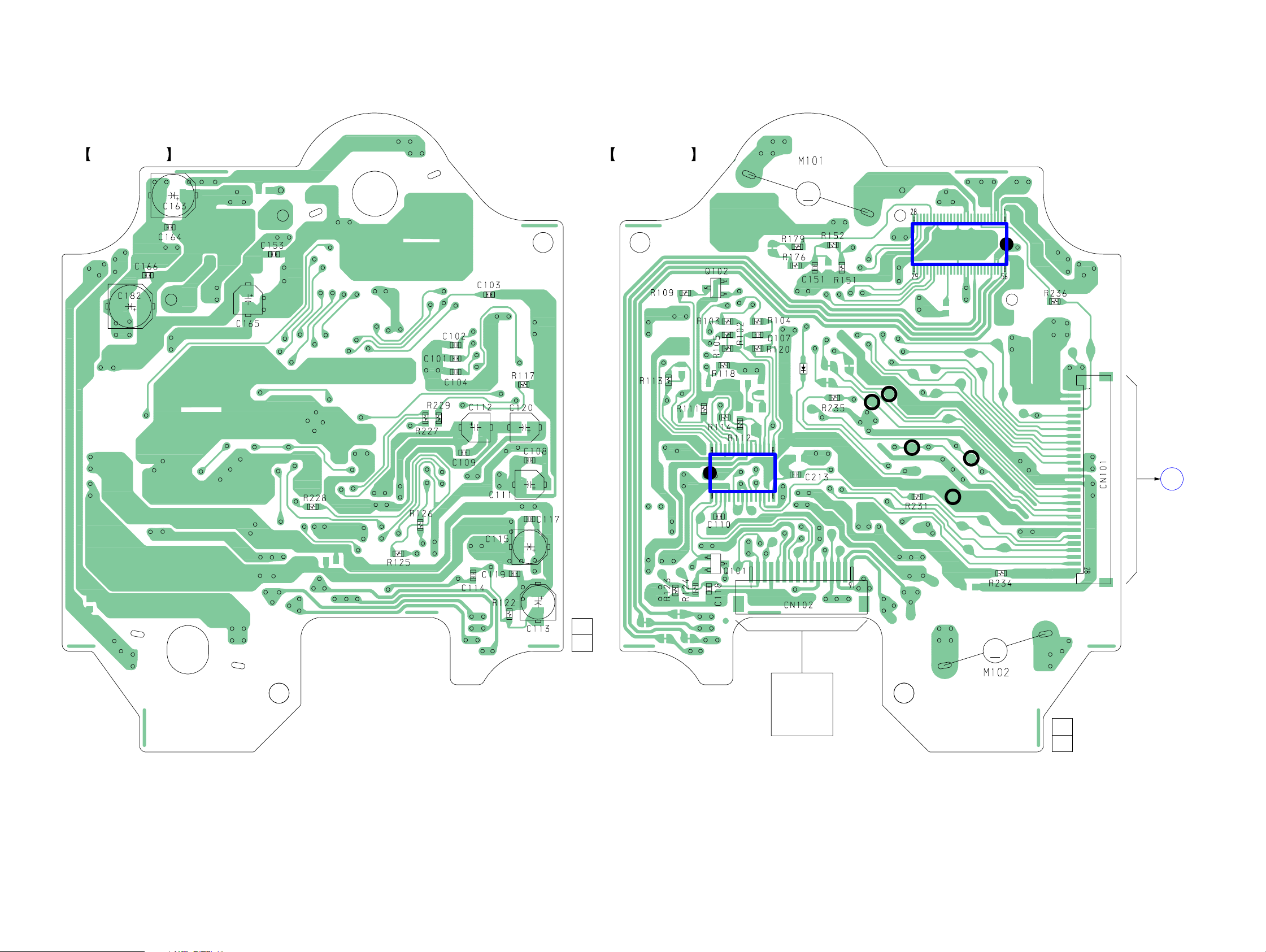

6-7. PRINTED WIRING BOARD – BD Section – • See page 21 for Circuit Boards Location.

BD BOARD

(COMPONENT SIDE)

BD BOARD

(CONDUCTOR SIDE)

(SPINDLE)

M

E

D101

30 16

115

IC103

TP70

(TE)

TP68

(FE)

TP72

(RFAC)

IC102

TP71

(RFDC)

TP73

(DVC)

A

VMP

BOARD

CN101

(Page 28)

1-684-174-

12

(12)

E

M

OPTICAL

PICK-UP

BLOCK

(A-MAX. 3)

(SLED)

1-684-174-

12

(12)

2222

6-8. SCHEMATIC DIAGRAM – BD Section – • See page 38 for Waveforms. • See page 40 for IC Block Diagram.

(CHASSIS)

VMP BOARD

(1/2)

CN101

(Page 26)

CN101

28P

7V

MGND

MGND

STBY

MDP

SFDR

SRDR

TFDR

TRDR

FFDR

FRDR

SSTP

VCC(4.5V)

GND

GND

FE

SE

TE

RFDC

RFAC

DVC

DVCC(2.5V)

LD ON(D/A4)

D/A3

D/A2

D/A1

CTRL

LD GND

TP55

TP56

TP57

TP58

TP59

TP60

TP61

TP62

TP63

TP64

TP65

TP66

TP67

TP68

TP69

TP70

TP71

TP72

TP73

TP74

TP75

TP76

TP77

TP78

TP79

TP80

R236

(RFDC)

(RFAC)

1k

(FE)

(TE)

(DVC)

C115

47

6.3V

R104

D101

1SS355

TP21

15k

R227

R102 R105

15k 1k

C104

0.0033

R103

100k

Q102

UN2111-TX

FREQUENCY

SELECT

SWITCH

100k

AA1

AA9

AA3

C103 C101

470p 470p

C102

AA2

AA10

AA4

AA7

BB7

BB8

BB1

BB2

BB3

BB4

BB5

BB6

R235

1k

AA1

AA2

AA3

AA4

C213

0

AA5

AA6

AA7

AA8

AA9

AA10

R234

0

0.1

C107 R120

33p 120k

R109

100k

R229

2.2k

R111

120k

R113

2.7k

C165

10

16V

R114

47k

R117

R118

47k

0

C153

0.1

R112

C120

C117

47

0.1

4V

0

C108

FOCUS/TRACKING

COIL DRIVE,

SPINDLE/SLED

MOTOR DRIVE

IC102

AN41020A

FEI

TE

TE_BAL

CE

CEI

VCC

RFG

BST

VFC

RFC

AC_SUM

VC

RFDCO

RFDCI

DC_OFST

IC103

CXA2581N-T

RF AMP,

FOCUS/TRACKING

ERROR AMP

TP27

SGND

SVCC

RFACFE

DVCC

EQ_IN

DVC

SW

D

GND

PD

LD

C111

47

4V0.1

OPO2(NC)

IN3+

HCD-M80

C112

C109

47

0.1

4V

TP49

F

E

C

B

A

C114

0.001

Q101

2SB710A-RT

AUTOMATIC

POWER

CONTROL

C113

R122

100

100k

4V

BB3

BB4

IN2-

IN3-

IN2+

OPO3(NC)

IN4R

BB6

OPO1(NC)

ABS

IN4

BB5

OP-

IN1-

IN1+

OP.O

NC

VREF

NC(FB)

C110

0.1

OP+

NC(SW)

AA5

R231

1k

AA6

R126

33k

CC1

R125

33k

CC2

TP24

CC3

TP23

CC4

R228

470k

AA8

CC5

C118

1

R124

TP22

NC

NC(VDD)

NC

NC(CT)

(VPUMP1)

(VPUMP2)

10

R123

10

NC(BC1)

NC(BC3)

C166

0.1

C182

100

10V

NC

NC(BC2)

NC

NC(BC4)

PVCC1

PVCC2

PVCC1

PVCC2

C119

1

NC

NC

NC

NC

VO1+

VO4-

NC

2(NC)

PVCC/

NC

STBY

NC

NC

TP26

CC1

TP25

CC2

CC3

CC4

TP54

CC5

TP51

TP53

TP50

TP52

VO1-

VO4+

PGND1

PGND2

PGND1

PGND2

VO2-

VO2+

VO3-

VO3+

LD_GND

I5-10

CN102

I1-6

VCC

PD2

GND

PD1

VCC

16P

VC

SW

PD

LD

T-

F-

T+

F+

R179

10k

R176

0

R152

4.7k

R151 C151

100k 0.022

BB8

BB2

BB1

C163

BB7

C164

100

0.1

10V

M102

(SLED)

M101

(SPINDLE)

•Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : CD PLAY

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

2323

HCD-M80

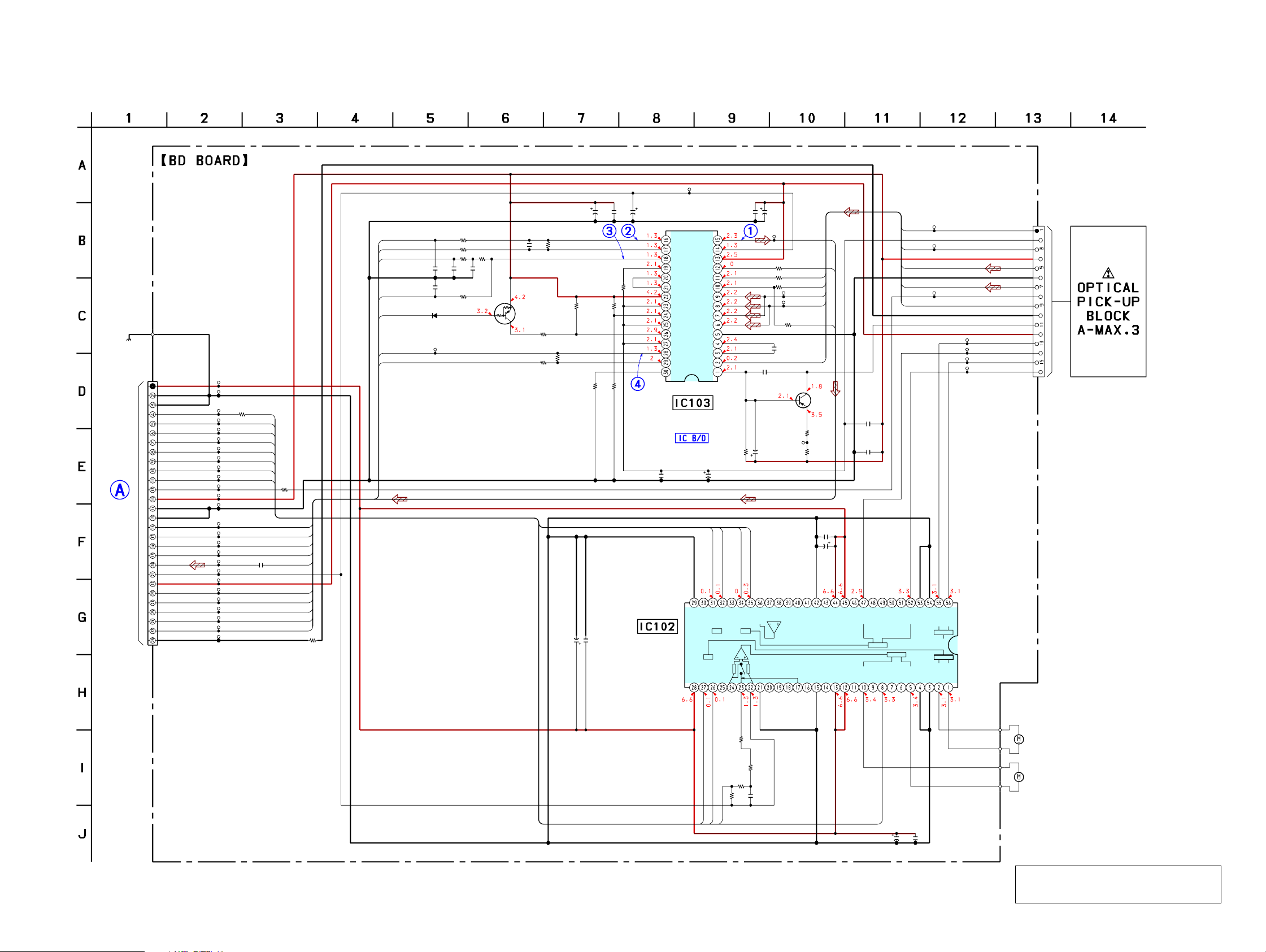

6-9. PRINTED WIRING BOARD – TC Section – • See page 21 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

IC401 C-4

Q100 D-2

Q101 D-3

Q200 D-4

Q201 D-4

Q401 D-2

Q402 D-2

Q403 B-3

Q404 C-3

Q405 C-3

A

A

B

1 2 3 4 5

13

MAIN BOARD

B

CN301

TC BOARD

TAPE DECK BLOCK

SUPPLIED WITH

THE ASSEMBLED

BLOCK

1

7

2

8

(Page 29)

D

C

E

(CHASSIS)

EC B

EC B

20

21

IC401

30

31

40

EC BEC B

11

10

1

32

(32)

(RECORD/PLAYBACK/ERASE)

HEAD

RELAY

BOARD

1-684-172-

HRPE901

L-CH

R-CH

ERASE

2424

6-10. SCHEMATIC DIAGRAM – TC Section – • See page 38 for Waveforms.

HRPE901

RECORD/PLAYBACK/

L-CH

R-CH

ERASE

ERASE

CNP1

8P

T101

T201

C109C209

0.0010.001

JR106 JR105

1K 1K

RV101RV201

33k33k

R400

1

R113

10

R213

10

JR104

0

Q100,101,200,201

MUTING

Q100 Q101

KTC3203Y KTC3203Y

Q200

KTC3203Y

Q201

KTC3203Y

HCD-M80

CN301

17P

ALC CONT

R103 R104 R105

R102

R101

C104

0.01

C102

47

16V

C410

1

50V

C101

470p

JR103

0

C201

470p

R108R107

10k10k

R109

2.2k

R208R207

10k10k

R111 C110

10k 0.01

R112

5.6k

R212

5.6k

R209

2.2k

C202

47

16V

C111

330p

C211

330p

C210R211

0.0110k

JR201

0

R401

3.3k

C433

0.0047

C432

0.012

BIAS OSC

6

5

4

PB-NF2(L)

PB-

NF1(L)

AIN

(L)

RIP

BIN

(L)

REC

GND

BIN

(R)

NC

AIN

(R)

PB-

NF1(R)

PB-NF2(R)

T401

PB-

EQ(L)

AB

AB

PB-

C204

0.01

3

2

1

10k 2.2k 47k

47k

C105

1

50V

47k

EQ-

OUT(L)

EQ(R)

EQ-

OUT(R)

R201

47k

C205

50V

R202

47k

C434

47

10V

10

50V

NC

PB-

TAI(L)

MUTE

OUT(L)

REC/PB EQ AMP,

ALC

IC401

HA12236F

MUTE

NC

PB-

OUT(R)

TAI

(R)

10

50V

1

R203 R204 R205

10k 2.2k 47k

R402

10

R404

R403

47

10k

C435

0.01

C422 R405

0.0068 10

R106

10k

C107 C108C106

1

50V

REC-

IN(L)

REC-

IN(R)

C207

50V

2.2

50V

JR102

0

R416

Q404

KRA102S

1k

R415

47k

C437

10

50V

C401

C400

100

16V

10

50V

R414

33

R412

10k

R410

10k

R411

C407

47k

10

50V

R409

4.7k

R206

10k

R408

4.7k

Q404,405

MUTING CONTROL

SWITCH

Q405

KRC107S

C403

0.01

0

C402

0.01

R420

R422

10k

22k

R423

R424

47k

R428

4.7k

R425

4.7k

R426

4.7k

R418

4.7k

TH3

REC-OUT(L)

NC

EQ

EQ

REC-OUT(R)

NC

KTA1266Y-AT

BIAS OSC

ALC

Q402

Q401

KTC3203Y

TEST

I-

REF

GND

ALC-

DET

VCC

REC

MUTE

MUTE

A/

B

NORHI/

ALC

C208C206

2.2

50V

R406

4.7k

Q403

KRC102S

Q402,403

REC BIAS

SWITCH

R417

24k

R413

1M

R407

47k

ALC(L)

ALC

(R)

1

REC-MUTE

REC IN-R

R-OUT

REC/PB

LINE MUTE

A-GND

REC IN-L

+8.0V

L-OUT

MO GND

TC-SW

MO +12V

B+3.3V

PLAY-SW

END SW

SOL 12V

END SW

MO GND

SOL 12V

MO +12V

PACK

REC-L

REC-R

PLAY-SW

CN302

B

(Page 30)

8P

TAPE DECK BLOCK

SUPPLIED WITH

THE ASSEMBLED

BLOCK

(CHASSIS)

•Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : TAPE PLAY

(): REC

2525

HCD-M80

6-13. PRINTED WIRING BOARD – VMP Section – • See page 21 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

IC102 D-6

IC201 I-12

IC202 I-2

IC301 D-6

IC302 C-6

IC303 E-6

IC304 F-6

IC307 B-9

IC504 G-9

IC505 F-4

IC506 C-12

IC507 C-11

IC508 C-4

Q201 H-12

Q301 F-9

Q302 C-8

Q370 A-9

Q581 G-8

1 2 3 4 5 6 7 8 9 10 11 12 13

(Page 32)

VIDEO BOARD

D

A

VMP BOARD

(COMPONENT SIDE)

CNP402

B

TP308

(V-OUT)

17

C

IC508

16

IC302

17

VMP BOARD

IC307

E

(CONDUCTOR SIDE)

E

IC506

127

8

14

7

1

IC507

TP70

(54MHz)

D

32

108 55

1

IC301

148

E

5428

109

E

28

27

54

IC303

IC505

E

F

8

A

BD BOARD

CN101

(Page 22)

G

2

1

162

163 216

TP182

(4.2336MHz)

1

14

IC304

7

1

E

1

16

IC504

8

9

E

H

TP415

(L-OUT)

TP413

(R-OUT)

I

J

3

1

CONTROL BOARD

C

CN601

(Page 32)

IC102

12

1-684-173-

2

2

6

6

(12)

IC202

1

3

IC201

1-684-173-

12

(12)

HCD-M80

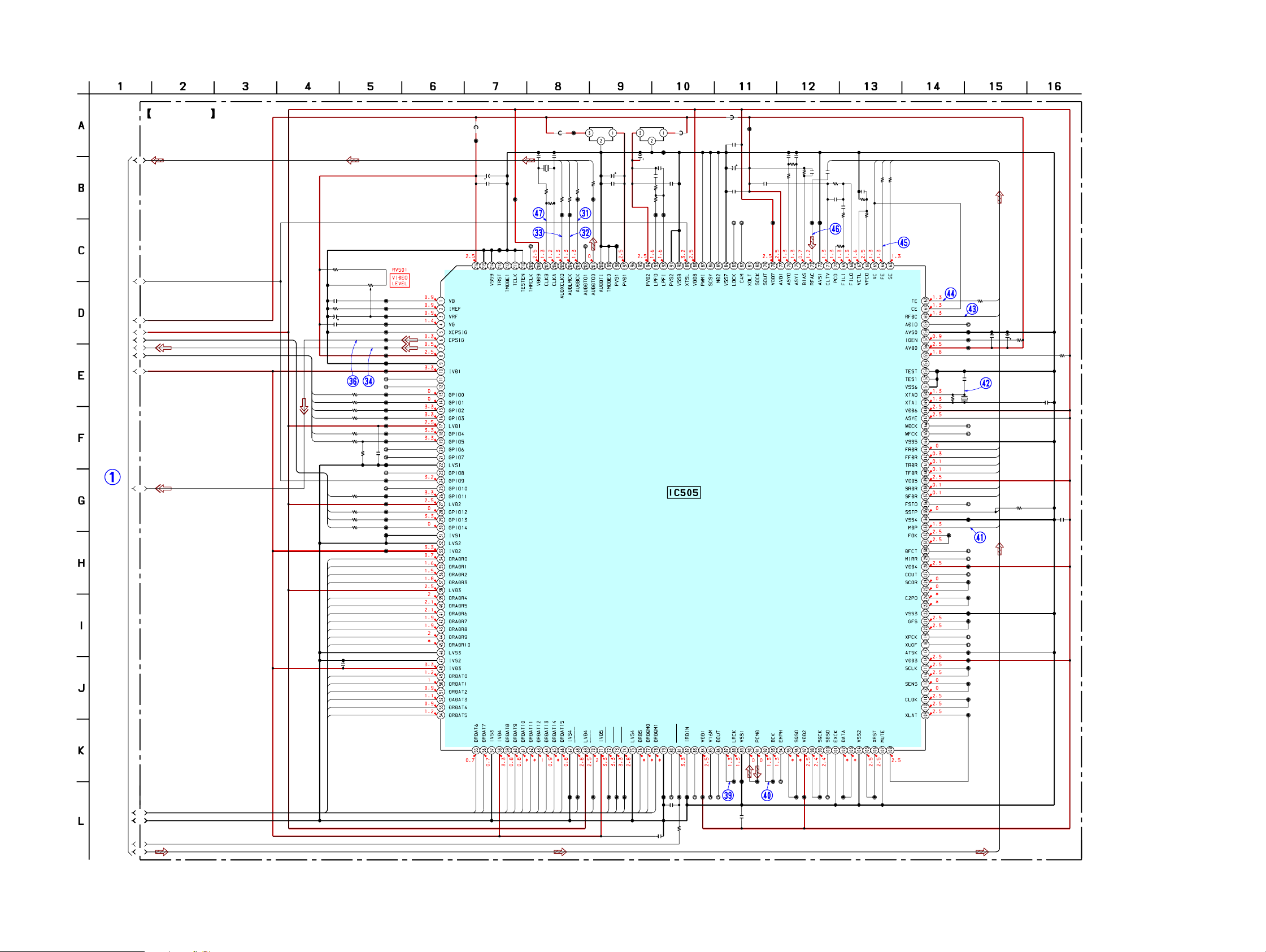

6-11. SCHEMATIC DIAGRAM – VMP Section (1/2) – • See page 38 for Waveforms. • See page 40 for IC Block Diagrams.

C

CONTROL

BOARD

CN601

(Page 33)

(Page 23)

D

VIDEO

BOARD

CNP402

(Page 33)

VMP BOARD

N.C.

D+5V(SW)

D-0UT

D-GND

L-CH

A-GND

R-CH

A+5V(SW)

SYS RST

SYS OUT

SYS IN

SYS CLK

SYS RQ

SYS OK

N.C.

VIDEO MUTE

SYS CS

M-GND

M+7V(UNSW)

CN201

19P

CN101

28P

LD GND

CTRL

D/A1

D/A2

D/A3

LD ON(D/A4)

DVCC(2.5V)

DVC

RFAC

RFDC

TE

SE

FE

GND

GND

VCC(4.5V)

SSTP

FRDR

FFDR

TRDR

TFDR

SRDR

SFDR

MDP

STBY

MGND

MGND

7V

C221 C222

R201

10

100

16V

CN301

3P

VMP GND

VMP-VIDEO IN

VMP GND

(V-OUT)

TP448

TP447

TP446

TP445

TP444

TP443

TP442

TP441

TP440

TP439

TP438

TP437

TP436

TP434

TP433

TP432

TP431

TP430

TP429

TP428

TP427

TP426

TP425

TP424

TP422

TP421

2SD999-T1

REGULATOR

10

16V

TP308

(1/2)

TP419

TP418

TP417

TP416

TP415

(L-OUT)

TP414

TP413

(R-OUT)

TP412

TP411

TP410

1887SI

TP409

1887SO

TP408

SCK

TP407

SRQ

TP406

SOK

TP405

TP404

TP403

SCS

TP402

TP401

JW203

0

3

5

6

9

165

173

160

162

163

164

135

143

142

141

140

138

137

133

Q201

-CLCK

+4.5V

TP307

C257

68

10V

R202

100

C223

100

6.3V

C258

0.1

C254

0.1

FB252

C224

0.1

R152

100

4

2

R102

100

C116

C259

100

100

6.3V

6.3V

R114

L102

2.2k

2.2µH

C114

22

6.3V

C115

0.1

IC201

µPC2925T-E1

IO

C201

22

6.3V

FB251

C209

22

6.3V

R561C255

1k0.1

FB561

6 9

5

3

2

G

C202

0.1

+3.3V REGULATOR

IC202

BA033FP-E2

IO

G

C210

0.1

C566

100

6.3V BU2507FV-E2

C561

0.1

65

64

61

42

41

40

39

37

36

35

34

49

50

51

IC102(1/2)

NJM2100M(T

E2)

1

8

7

IC102(2/2)

NJM2100M(T

E2)

+2.5V REGULATOR

C213 C203

22

6.3V

C214

22

6.3V

VDD VCC

AO5

AO4

RST

AO3

AO2

VSS

MR27V401E-

054MAZ020

VPP

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

VSS

PROGRAM

IC508

ROM

LOW-PASS

5

6

IC506

3

FILTER

100

6.3V

FL201

IO

G

AO6

CLK

AO1

GND

VCC

A18

A17

A14

A13

A8

A9

A11

OE

A10

CE

DQ7

DQ6

DQ5

DQ4

DQ3

C155 R158 C154

0.0047 1.5k 22 6.3V

R159

1.5k

C156

1200p

C106

R109 R108

1200p

1.5k 1.5k

C105R115

0.00472.2k

C204 C205 C206 C207

0.1 0.1 0.1 0.1

C211

100

6.3V

LD

DI

D/A CONVERTER

IC301

C322

L321

2.2µH

BA7046F-E2

VD

GND

OUT

VIDEO

SYNC

IN

OUT

HD

VCC

OUT

ROSC

P.CP

SYNC

SEPARATOR

R316 R314

10k 10k

C314

TP301

0

0.1

R315

R317C311

10k

10k22p

15p

R322

0

C323C321

10p22p

C361

0.1

R376

10k

VIDEO AMP

BD7600FV-E2

BUF

OUT

IN

GND

IC307

OUTSAG

2SA1602TP-

BUFIN

VCCSTBY

OUT

Q301

SYNC

BUFFER

C318

100

6.3V

1EF

C360

100

6.3V

203

201

204

16V

C572

0.1

RT1N141M-TP-1

VIDEO MUTING

Q370

CONTROL

SWITCH

10

C303

470

R302

R157

10k

DIGITAL FILTER,

D/A CONVERTER

IC504

R107

10k

C104

22

6.3V

FB201

C208

0.1

C212

0.1

C574

0.1

C567

0.1

28

29

30

13

JW524

JW523

Q581

2SC4154TP

-1EF

+3.3V

R581

REGULATOR

100

R582

470

0

0

45

66

63

62

43

44

60

74

59

56

55

54

53

52

C575

100

6.3V

C573

0.1

FL501

OI

C584 C583

0.1 0.1

G

C571

0.1

C576

100

6.3V

C596

10

16V

C582

10

16V

49

50

51

52

53

54

55

56

77

73

68

72

76

45

34

35

36

37

PCM1748E/2K

C581

0.1

D-RAM

IC507

VG3612816BT

-7L

VDD

DQ0

VDDQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

VSSQ

DQ7

VDD

LDQM

WE

CAS

RAS

CS

BA0

BA1

A10/AP

A0

A1

A2

A3

VDD

NC/RFU

VSS

DQ15

VSSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

VSSQ

DQ10

DQ9

VDDQ

D8

VSS

UDQM

CLK

CKE

NC

A11

A9

A8

A7

A6

A5

A4

VSS

VDD

VCC

LOUT

ROUT

DZFR

VCOM

AGND

C597

10

16V

BCK

DGND

LRCK

DATA

CLK

MCLK

DATA

LAT

DZFL

205

26

29

30

FL502

OI

G

66

65

64

63

62

61

60

59

78

70

44

43

42

41

40

39

R301

TP312

220k

TP313

C301

C305C302

0.10.11016V

L301

C312

15p

L311 R312

C313

R311

10p

220

R323

470

R321

220

FB360

C364

10

16V

TP303

C317

0.1

TP311

TP310

TP309

R305R303

10k120k

C AMP

NJM2255M

VIN

COLOR

OFFSET

COLOR

V+

L322 R326

2.2k

220µH

Y AMP

IC304

NJM2209M

(TE2)

C324

22

6.3V

R374 R372 R373

4.3k 2.2k 2.2k

C366

100 6.3V

R306

1k

TP304

R307

0.0047

220p

150

Q302

2SC4154TP-

1EF

Y SYNC

BUFFER

R375C365

75100 6.3V

R308

R309

C339

6.3V

DIF

COMPENSATION

FREQ

10k

10k

10k

C SYNC BUFFER

100

R325

2.7k

IN

NC

NC

TP305

R310

1k

IC302

TC74VHCU04

FT(EL)

A1

A2

A4

A5

A6

A7

A8

A9

C253

0

R318

100

TP302

C315

47p

C338

0.1

C327

22p

R327

C329

100

0.01

IN

V+

NC

DIF

OUT

PHASE

DELAY

VOUT

NC

GND

CUNT

NC

VIN

C326

150p

TP306

JW301

2

13

VMP

BOARD

(2/2)

(Page 27)

A10

0

C363

10

16V

A11

A12

A13

A14

C307

150p

C308

150p

C309

220p

IC303

(TE2)

TINT

GND

VOUT

BGP

C328

C325

R324

•Voltages are dc with respect to ground under no-signal

conditions.

no mark : VIDEO CD PLAY

: Impossible to measure

∗

2727

6-12. SCHEMATIC DIAGRAM – VMP Section (2/2) – • See page 38 for Waveforms.

HCD-M80

VMP

BOARD

(1/2)

(Page

26)

VMP BOARD

A1

A2

A4

A5

A6

A7

A8

A9

A10

(2/2)

1887SI

1887SO

SCK

SRQ

SOK

SCS

FB501

TP177

C542

0.1

C538

100

6.3V

C540

0.47

TP183

TP182

C534

470p

(4.2336MHz)

C541 C539

0.01 0.47

R549

100k

R548

680k

C537

100p

C570

R550

10k

TP178

173

0.0033

R547

10k

C536

150p

C535

0.068

R545

1k

TP173

TP172

R546

180k

163

164

165

R541

C533

0.1

R544

1M

0

0

R542

470k

R543

R534

0

162

160

C525

TP159

C524

1

50V20p

TP158

RESERVE

RESERVE

L CDC2PO

L SCOR

L SCLK

L SENS

L DCLK

TP157

TP156

TP151

C523

7p

R532

4.7k

X501

33.8688MHz

TP146

TP145

143

142

141

140

138

137

TP136

135

TP134

133

TP132

L FOK

L GFS

TP130

TP129

TP128

TP127

TP126

TP124

TP122

TP121

TP119

TP118

TP117

TP116

TP115

TP113

TP111

TP109

R533

33k

R538

10k

C522

7p

R531

100k

C521

0.1

8p

203

204

R554

10

10

R555

10

R556

TP203

TP205

TP204

TP202

FL503 FL504

IO

G

C547

1

50V

201

C548

0.1

TP201

TP198

RESERVE

IO

G

C545

1

50V

C544

0.47

R552

820

R551

1.6k

RESERVE

MPEG VIDEO/AUDIO DECODER,

FB502

TP191

C543

470p

C546

0.1

TP193

TP192

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR,

VIDEO SIGNAL ENCODER

IC505

CXD1887R

FB504

TP216

C552

150V

C551

0.1

R501

47k

RV501

100k

V AVS1

CSIG

V AVD2

V AVS2

I2C CLK

I2C DATA

V AVD1

C502

0.1

R502

3.3k

C501

10 16V

C503

0.1

R509

10

26

28

29

30

34

35

36

37

39

40

41

42

43

44

45

C505

0.1

49

50

51

52

53

54

TP1

TP2

TP3

TP4

TP5

TP6

TP7

TP8

TP9

TP10

TP11

TP12

R503

TP13

10

R504

TP14

10

R505

TP15

10

R506

TP16

10

TP17

R507

TP18

10

R508

TP19

10

TP20

C504R513

TP21

0.110k

TP22

TP23

TP24

TP25

TP26

TP27

TP28

R510

10

TP29

R511

10

TP30

R512

10

TP31

TP33

TP208

TP215

FB503 TP197

C550

8p

C549

205

X502

27MHz

10

1M

R559

470

R557

R558

TP209

RESERVE

RESERVE

IVS5

DRRAS

DRWEL

DRCAS

TP67

TP68

68

66

65

64

63

62

61

60

59

56

A11

A12

A13

A14

55

70

NVOEL

DRCK

(54MHz)

TP70

TP72

TP73

TP74

77

76

74

73

72

C510

SYSRST

TP79

TP81

TP80

TP82

TP83

TP84

TP85

TP86

78

C513

0.001

R522

10k

0.1

L CDLRCK

TP88

L CDDATA

L CDBCK

TP93

TP89

TP94

TP91

C511

0.1

L SQSO

L SQCK

TP97

TP96

TP99

L DDAT

TP100

TP102

L CDXRST

TP106

L XLAT

•Voltages are dc with respect to ground under no-signal

conditions.

no mark : VIDEO CD PLAY

: Impossible to measure

∗

2828

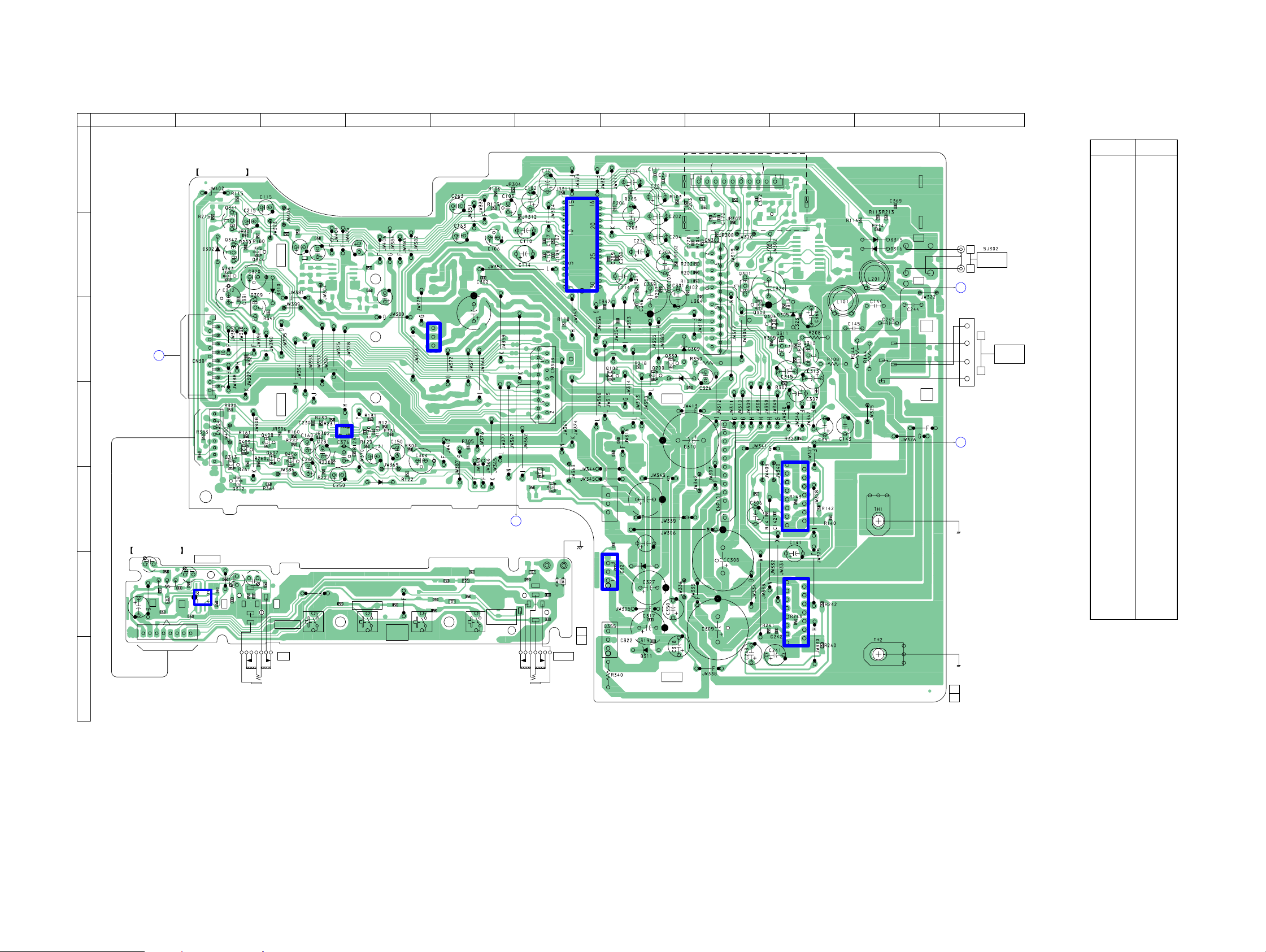

6-14. PRINTED WIRING BOARDS – MAIN/JACK Section – • See page 21 for Circuit Boards Location.

HCD-M80

1 2 3 4 5 6 7 8 9 10 11

TU1

TUNER UNIT

SUPPLIED WITH

A

MAIN BOARD

THE ASSEMBLED BLOCK

• Semiconductor

Location

Ref. No. Location

D302 B-2

D305 C-9

D307 F-7

R339

R317

R318

R281

R184

C161

R181

B

17

16

JR199

C162

C

B

TC BOARD

CN301

(Page 24)

1

D

JR305

8

E

R556

C552

R554

IC525

JR501

RV500

MIC LEVEL

C556

JW532

R553

R570

R571

C553

C559

R552

C554

R551

C555

S587

DIRECTION

J502

MIC

JW530

JACK BOARD

C558

RV500

JW531

F

R558

C561

C557

R559

CNP502

81

G

IC324

R587

C261

R284

JR299

S590

CD SYNCHRO

D313

C262

R590

S593

REPEAT

FM MODE

JW533

IC305

1

3

JR532

R593

JR531

L503

C303

R

AUDIO IN

MD (VIDEO)

L

(Page 32)

IC323

C348

D312

R302

24

25

D317

IC101

14

15

R308

1

2

IC201

14

15

2

1

1-684-232-

17

JR801

(CHASSIS)

11

1-685-831-

(11)

R314

Q305

C311

IC304

C329

B

C

E

C328

D307

B

C

E

Q308

Q307

R312

CONTROL BOARD

G

CN605

(Page 32)

JR530

L501

R591

PLAY MODE

TUNING MODE

S594

L502

LGP2

D521

C505

C506

PHONES

LGP1

D520

J501

E

CONTROL

BOARD

CN603

F

POWER

BOARD

CN902

(CHASSIS)

(CHASSIS)

15

(15)

+

R

–

–

L

+

(Page 36)

SJ301

SPEAKER

IMPEDANCE

USE 6 – 16Ω

D309 C-8

D310 B-3

D311 G-7

D312 C-7

D313 E-4

D315 B-10

D316 B-10

D317 D-9

D520 F-6

D521 F-6

IC101 E-9

IC201 F-9

IC304 F-7

IC305 C-5

IC323 B-6

IC324 D-3

IC525 F-2

Q100 C-7

Q200 C-7

Q301 B-8

Q303 C-8

Q304 C-9

Q305 E-7

Q307 E-6

Q308 E-6

Q309 C-2

Q310 C-9

Q311 C-9

Q312 E-2

Q313 D-2

Q330 C-7

Q341 B-2

Q342 B-2

Q343 B-2

Q344 B-2

Q355 G-7

Q406 D-3

Q407 D-3

Q408 D-3

Q409 D-2

2929

Loading...

Loading...