Sony hcd-m700 Service Manual

HCD-M700

Q

Q

3

7

6

3

1

5

1

5

0

SERVICE MANUAL

Ver 1.1 2003. 09

TEL 13942296513 QQ 376315150 892498299

HCD-M700 is the Amplifier, DVD player,

MD deck, Tape player and Tuner section in

CMT-M700MD.

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM55A-DVBU8

Base Unit Type DVBU8

Optical Pick-up Type KHM-240AAA (TYPE A)

Model Name Using Similar Mechanism HCD-M10

MD Mechanism Type MDM-7B4M

7

3

Q

Optical Pick-up Type KMS-260B

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type CMAL1Z228

TEL

13942296513

DVD

Section

MD

Q

Section

Tape deck

Section

8

6

3

9

1

5

2

1

5

4

0

9

8

2

8

AEP Model

UK Model

E Model

KHM-270AAA (TYPE B)

8

9

4

2

9

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Amplifier section

European model:

DIN power output (rated): 15 + 15 W

Continuous RMS power output (reference):

Music power output (reference):

Other models:

The following measured at 230 V AC, 60 Hz

DIN power output (rated): 15 + 15 W

Continuous RMS power output (reference):

The following measured at 220 V AC, 60 Hz

DIN power output (rated): 12 + 12 W

Continuous RMS power output (reference):

(6 ohms at 1 kHz, DIN)

20 + 20 W

(6 ohms at 1 kHz, 10%

THD)

40 + 40 W

(6 ohms at 1 kHz, DIN)

18 + 18 W

(6 ohms at 1 kHz, 10%

THD)

(6 ohms at 1 kHz, DIN)

15 + 15 W

(6 ohms at 1 kHz, 10%

THD)

SPECIFICATIONS

Inputs

ANALOG IN: Sensitivity 250 mV,

(phono jacks) impedance 47 kilohms

DIGITAL OPTICAL IN (supported sampling

frequencies: 32 kHz, 44.1 kHz and 48 kHz)

Outputs

VIDEO OUT: max. output level

(phono jack) 1 Vp-p, unbalanced,Sync

S-VIDEO OUT: Y: 1 Vp-p, unbalanced,

(4-pin/mini-DIN jack) Sync negative,

DIGITAL OPTICAL OUT:

PHONES: Accepts headphones with

SPEAKER: accepts impedance of 6 to

negative, load impedance

75 ohms

C: 0.286Vp-p,

load impedance 75 ohms

Optical

Wavelength: 660 nm

an impedance of 8 ohms

or more

16 ohms.

MICRO HI-FI COMPONENT SYSTEM

DVD player section

Laser Semiconductor laser

Frequency response DVD (PCM 48 kHz):

Video color system format

MD deck section

System Minidisc digital audio

Laser Semiconductor laser

Sampling frequency 44.1 kHz

Frequency response 5 Hz – 20 kHz

— Continued on next page —

(DVD: λ=650 nm,

CD: λ=780 nm)

Emission duration:

continuous

2 Hz – 22 kHz

CD: 2 Hz – 20 kHz

NTSC, PAL

system

(λ=780 nm)

Emission duration:

continuous

w

w

9-874-037-02

2003I16-1

© 2003.09

w

Sony Corporation

.

xia

Home Audio Company

Published by Sony Engineering Corporation

o

y

u

1

6

3

.

c

o

m

HCD-M700

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 50 – 13,000 Hz (±3 dB),

Q

Q

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 - 108.0 MHz

Antenna FM wire antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

European model: 531 - 1,602 kHz

Other models: 530 - 1,710 kHz

TEL 13942296513 QQ 376315150 892498299

Antenna AM loop antenna, external

Intermediate frequency 450 kHz

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

7

3

using Sony TYPE I

cassettes

(50-kHz step)

(with the tuning interval

set at 9 kHz)

(with the tuning interval

set at 10 kHz)

531 - 1,602 kHz

(with the tuning interval

set at 9 kHz)

antenna terminal

6

3

1

General

Power requirements

5

1

5

European model: 230 V AC, 50/60 Hz

Other models: 110 – 120 V or

Power consumption

European model: See the name plate

Other models: See the name plate

Dimensions (w/h/d) incl. projecting parts and controls

Amplifier/Tuner/Tape/MD/DVD section:

Mass Approx. 5.9 kg

Design and specifications are subject to change

without notice.

0

220 – 240 V AC,

50/60 Hz

Adjustable with voltage

selector

0.3 watts (at the Power

Saving mode)

Approx. 159 × 216.5 ×

330 mm

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

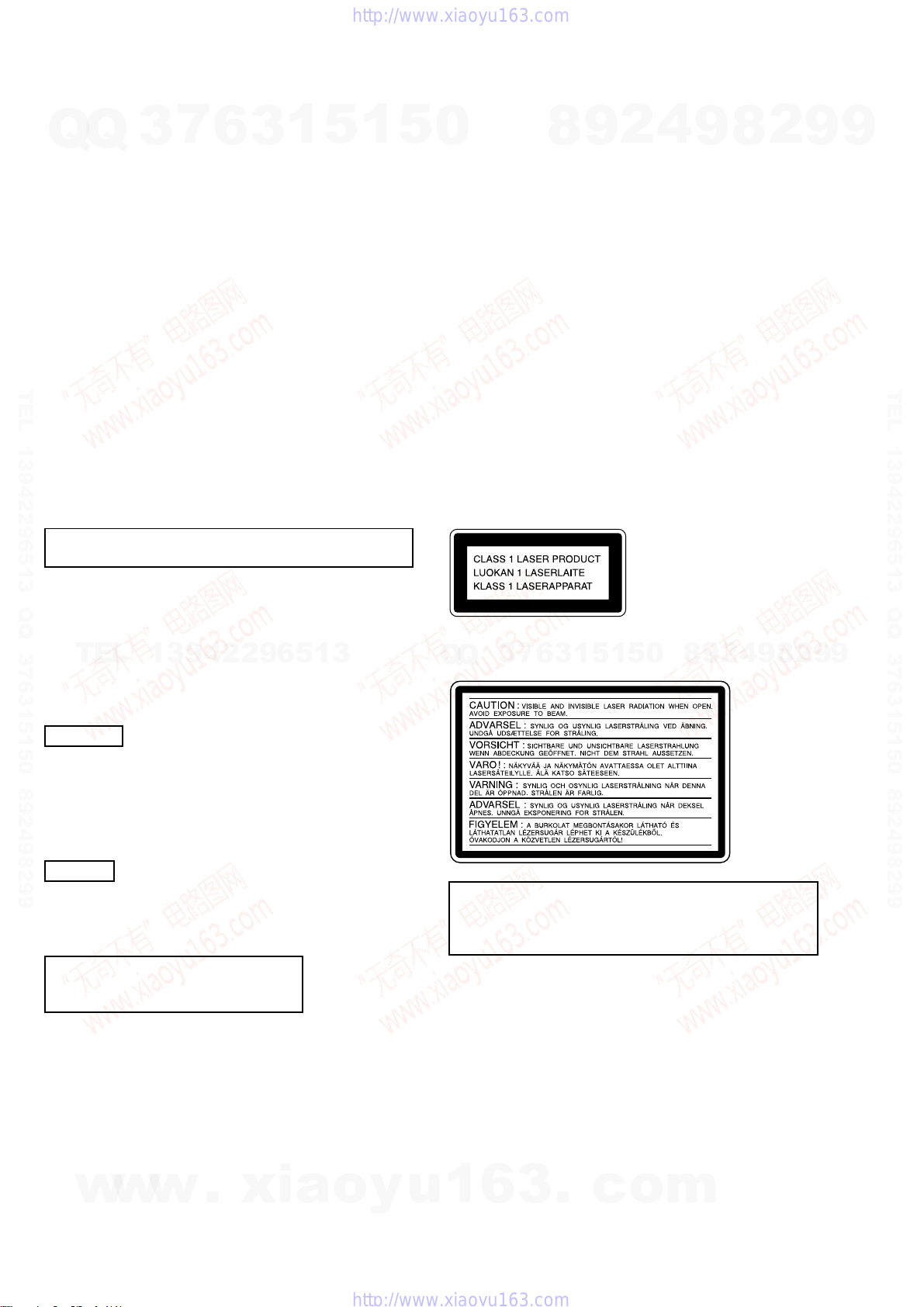

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

TEL

repair parts.

The flexible board is easily damaged and should be handled with

care.

FOR DVD

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

FOR MD

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

13942296513

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

Q

Q

exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

3

7

6

3

1

5

1

5

0

8

9

2

8

9

4

This caution

label is

located inside

the unit.

2

9

9

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

w

w

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

2

w

.

xia

o

y

u

1

6

3

.

c

o

m

TABLE OF CONTENTS

HCD-M700

Ver 1.1 2003.09

1. SERVICING NOTES ···················································· 10

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

2. GENERAL ········································································ 13

3. DISASSEMBLY ······························································ 16

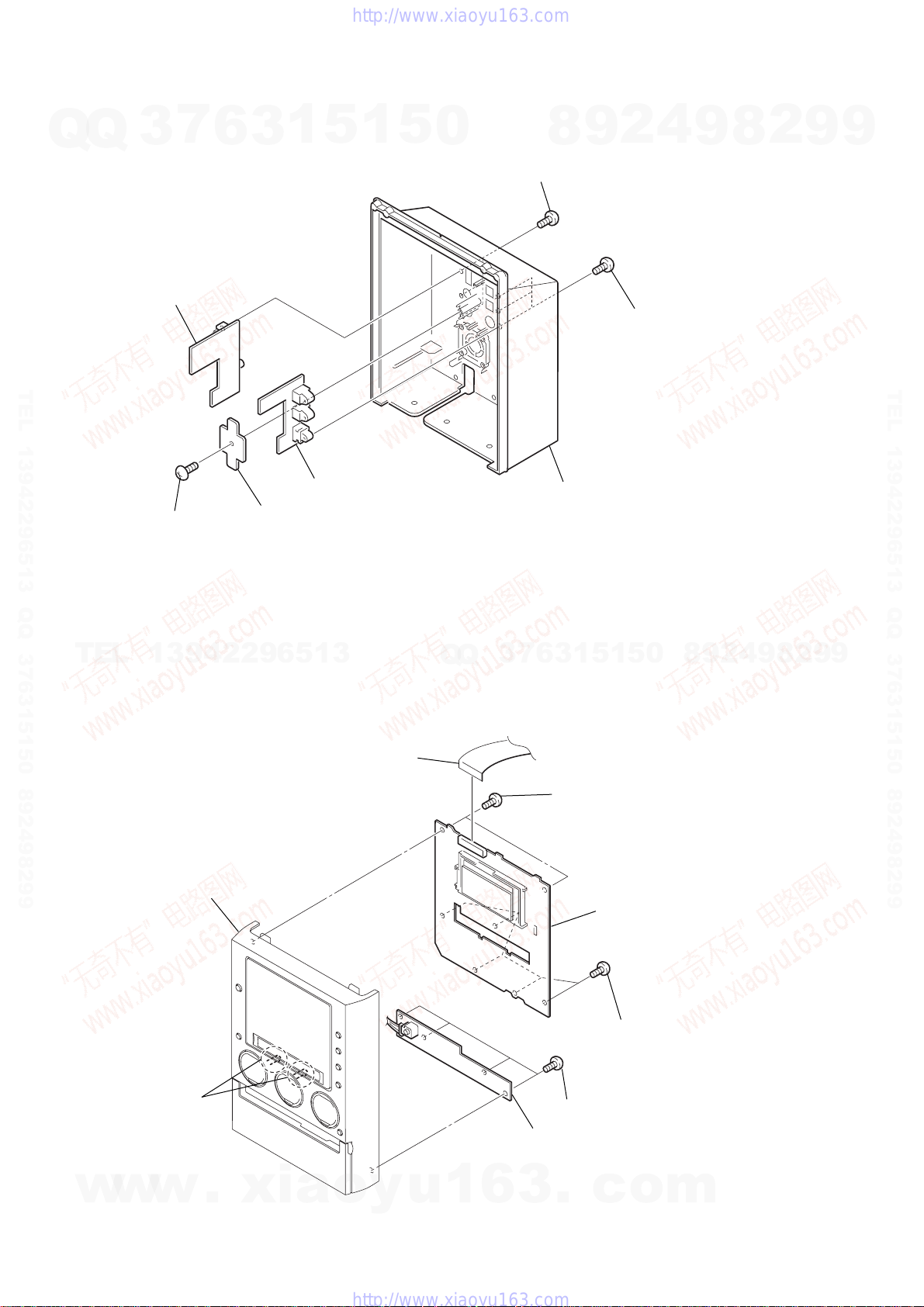

3-1. Case (R), Case (L), Top Cover Section······························ 17

3-2. Front Panel Section, Back Panel Section ··························· 17

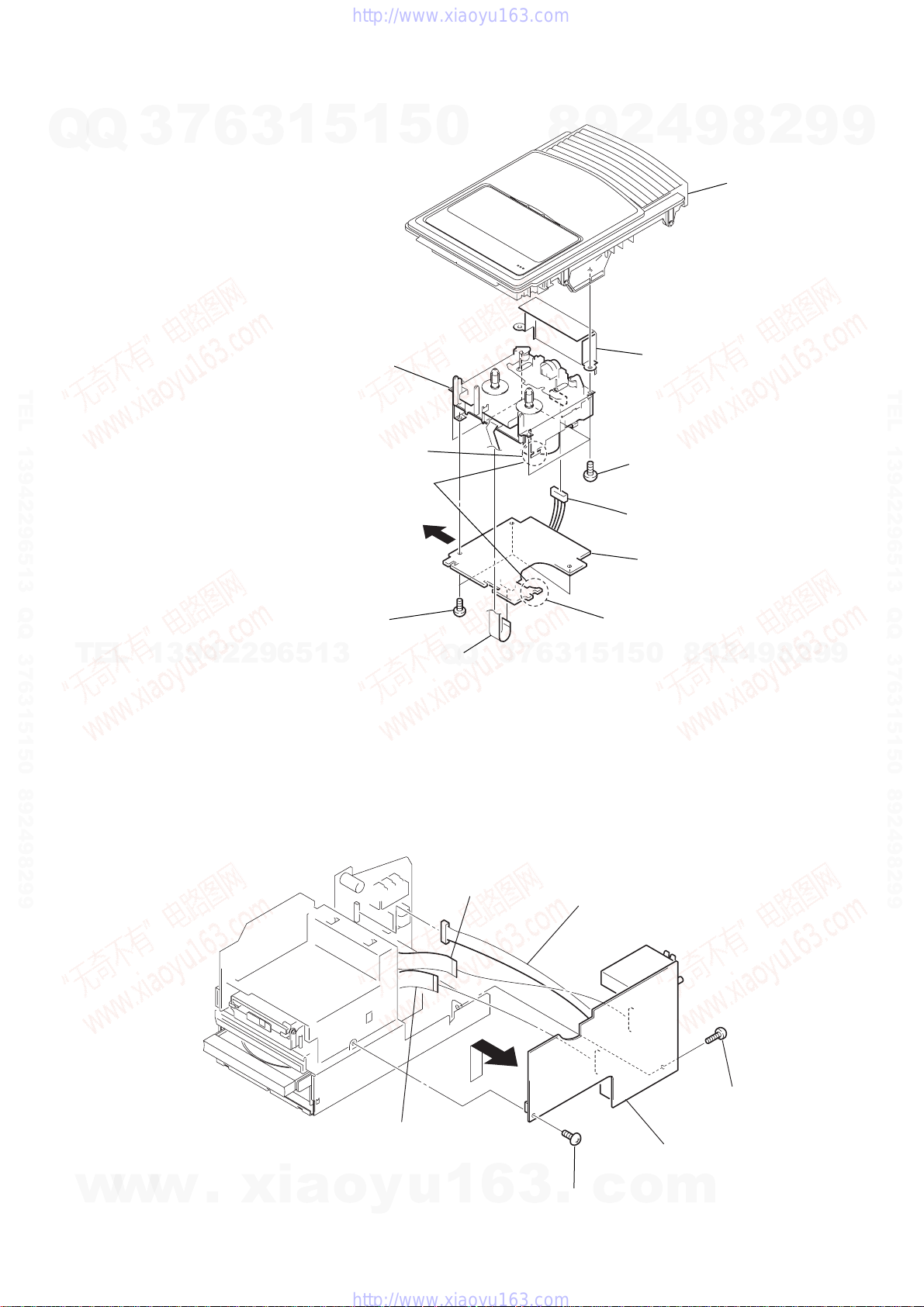

3-3. VIDEO Board, OPTICAL Board ······································ 18

3-4. SWITCH Board, JACK Board ··········································· 18

3-5. TC Board, Mechanism Deck (CMAL1Z228) ···················· 19

3-6. MAIN Board ······································································ 19

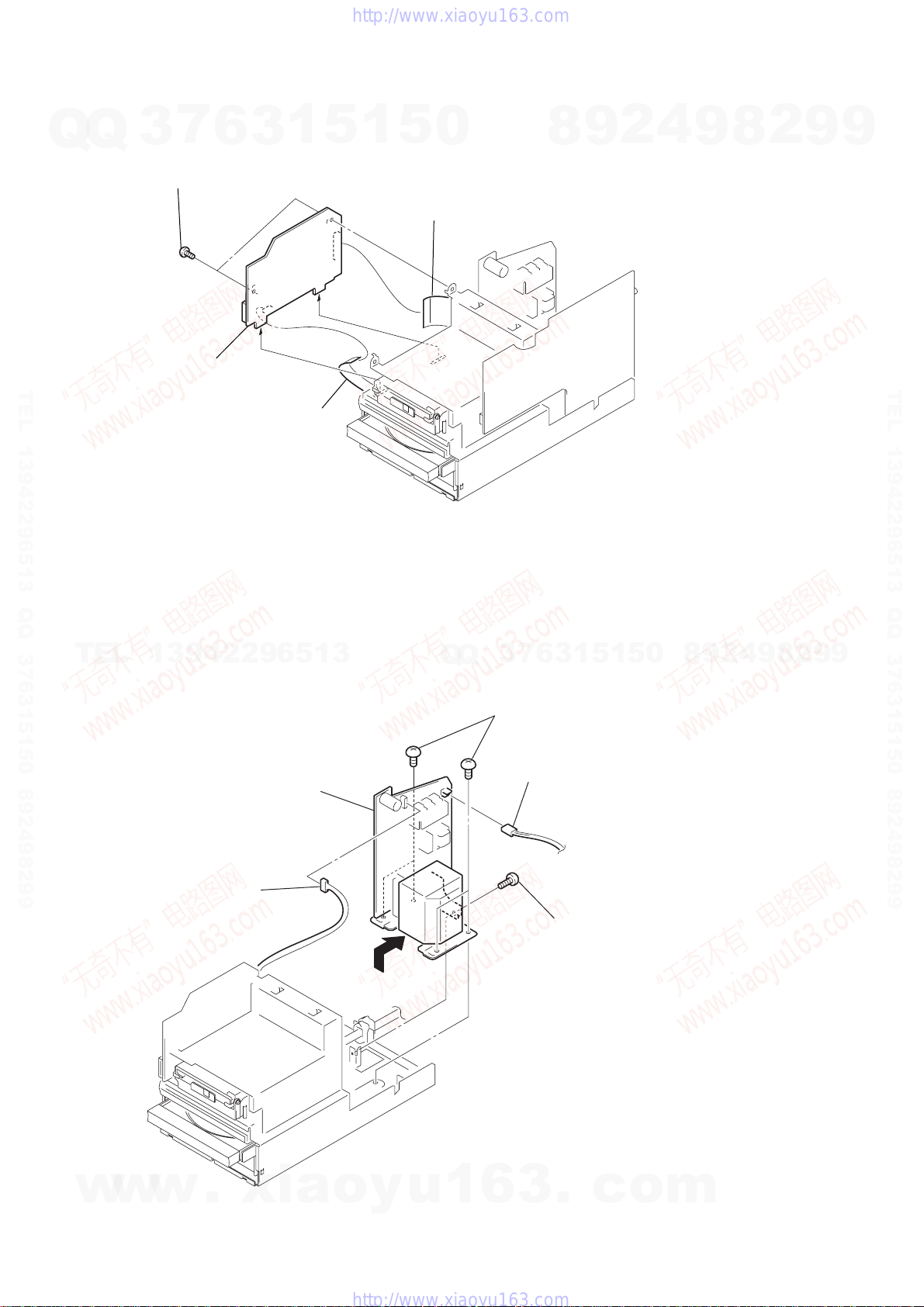

3-7. CONTROL Board ······························································ 20

3-8. POWER Board··································································· 20

3-9. DIGITAL Board································································· 21

3-10.MD Mechanism Deck (MDM-7B4M) ······························ 21

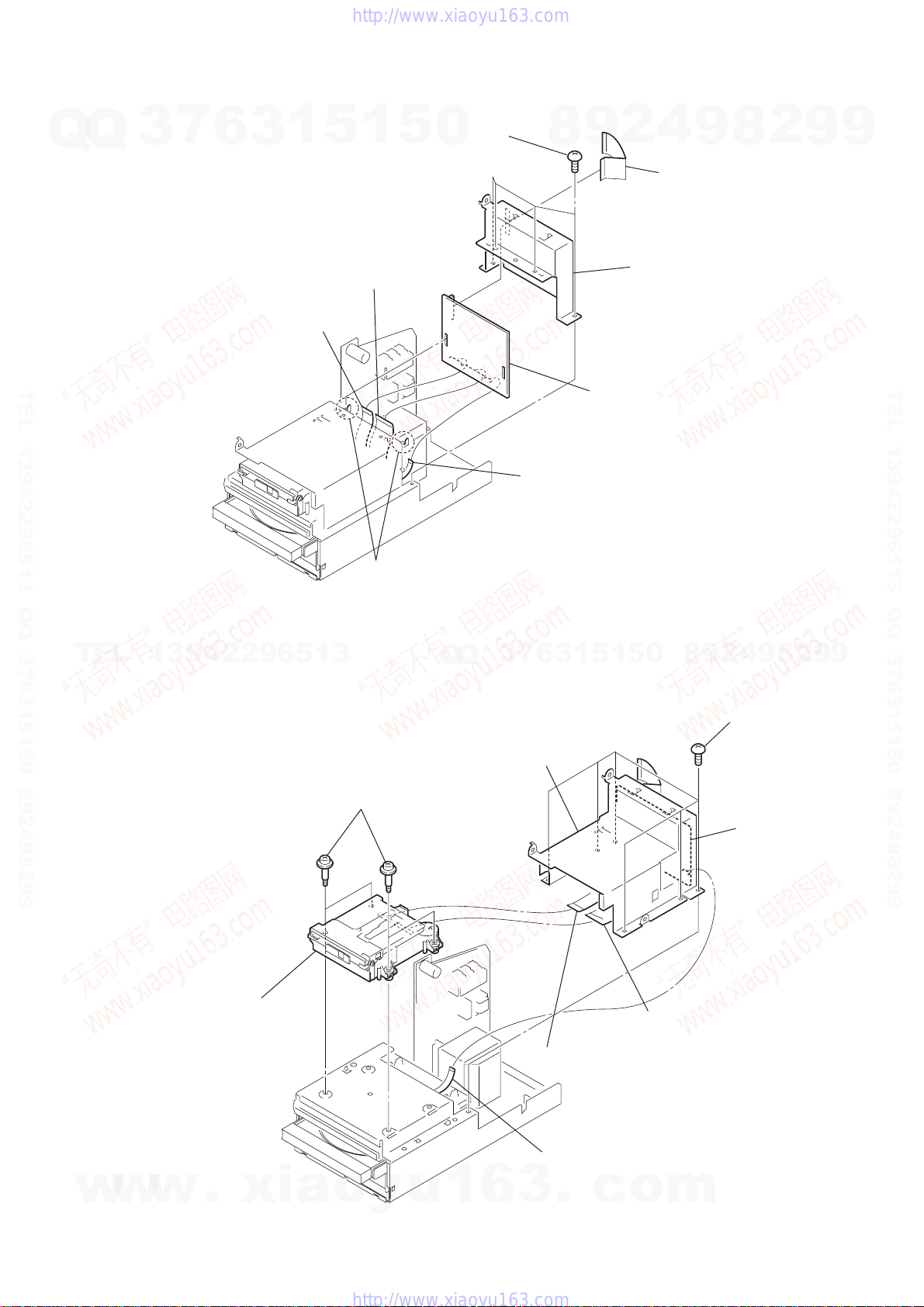

3-11.DVD Board ········································································ 22

3-12.DVD Mechanism Deck (CDM55A-DVBU8) ··················· 22

3-13.Holder Assy ······································································· 23

3-14.BD Board ··········································································· 23

3-15.Over Light Head (HR901) ················································· 24

3-16.OP-SUB Assy ···································································· 24

3-17.

Loading Motor Assy (M103), Spinde Motor Assy (M101),

Sled Motor Assy (M102) ······················································

3-18.LOADING Board, Motor (LD) Assy (M901) ··················· 25

3-19.RF-240 Board ···································································· 26

3-20.Tray ···················································································· 26

3-21.Optical Pick Up (KHM-240AAA(TYPE A))

4. TEST MODE ··································································· 28

6

(KHM-270AAA(TYPE B)) ···················· 27

3

1

5

1

5

0

25

6-10.Schematic Diagram – DVD Board (2/8) –························ 67

6-11.Schematic Diagram – DVD Board (3/8) –························ 68

6-12.Schematic Diagram – DVD Board (4/8) –························ 69

6-13.Schematic Diagram – DVD Board (5/8) –························ 70

6-14.Schematic Diagram – DVD Board (6/8) –························ 71

6-15.Schematic Diagram – DVD Board (7/8) –························ 72

6-16.Schematic Diagram – DVD Board (8/8) –························ 73

6-17.Printed Wiring Board – DVD (SIDE A) Board – ············· 74

6-18.Printed Wiring Board – DVD (SIDE B) Board – ············· 75

6-19.Schematic Diagram – DIGITAL Board (1/2) – ················ 76

6-20.Schematic Diagram – DIGITAL Board (2/2) – ················ 77

6-21.Printed Wiring Board – DIGITAL (SIDE A) Board – ······ 78

6-22.Printed Wiring Board – DIGITAL (SIDE B) Board – ······ 79

6-23.Schematic Diagram – TC Board – ···································· 80

6-24.Printed Wiring Board – TC Board – ································· 81

6-25.Schematic Diagram – MAIN Board (1/2) – ····················· 82

6-26.Schematic Diagram – MAIN Board (2/2) – ····················· 83

6-27.Printed Wiring Board – MAIN Board – ··························· 84

6-28.IC Block Diagrams ···························································· 85

6-29.Schematic Diagram – CONTROL Board (1/2) – ············· 88

6-30.Schematic Diagram – CONTROL Board (2/2) – ············· 89

6-31.Printed Wiring Board – CONTROL (SIDE A) Board – ··· 90

6-32.Printed Wiring Board – CONTROL (SIDE B) Board – ··· 91

6-33.Schematic Diagram – PANEL Section – ··························92

6-34.Printed Wiring Board – PANEL Section – ······················· 93

6-35.Schematic Diagram – OPTICAL Board – ························ 94

6-36.Printed Wiring Board – OPTICAL Board – ····················· 95

6-37.Schematic Diagram – POWER Section – ························· 96

6-38.Printed Wiring Board – POWER Board – ························ 97

6-39.IC Pin Function Description ·············································· 98

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

5. ELECTRICAL ADJUSTMENTS ······························33

TEL

13942296513

6. DIAGRAMS ······································································ 54

6-1. CIRCUIT BOARDS LOCATION ····································· 54

6-2. Block Diagrams ································································· 55

6-3. Schematic Diagram – RF-240 Board – ····························· 60

6-4. Printed Wiring Board – RF-240 Board – ·························· 61

6-5. Schematic Diagram – BD Board (1/2) – ·························· 62

6-6. Schematic Diagram – BD Board (2/2) – ·························· 63

6-7. Printed Wiring Board – BD (SIDE A) Board – ················ 64

6-8. Printed Wiring Board – BD (SIDE B) Board – ················ 65

6-9. Schematic Diagram – DVD Board (1/8) –························ 66

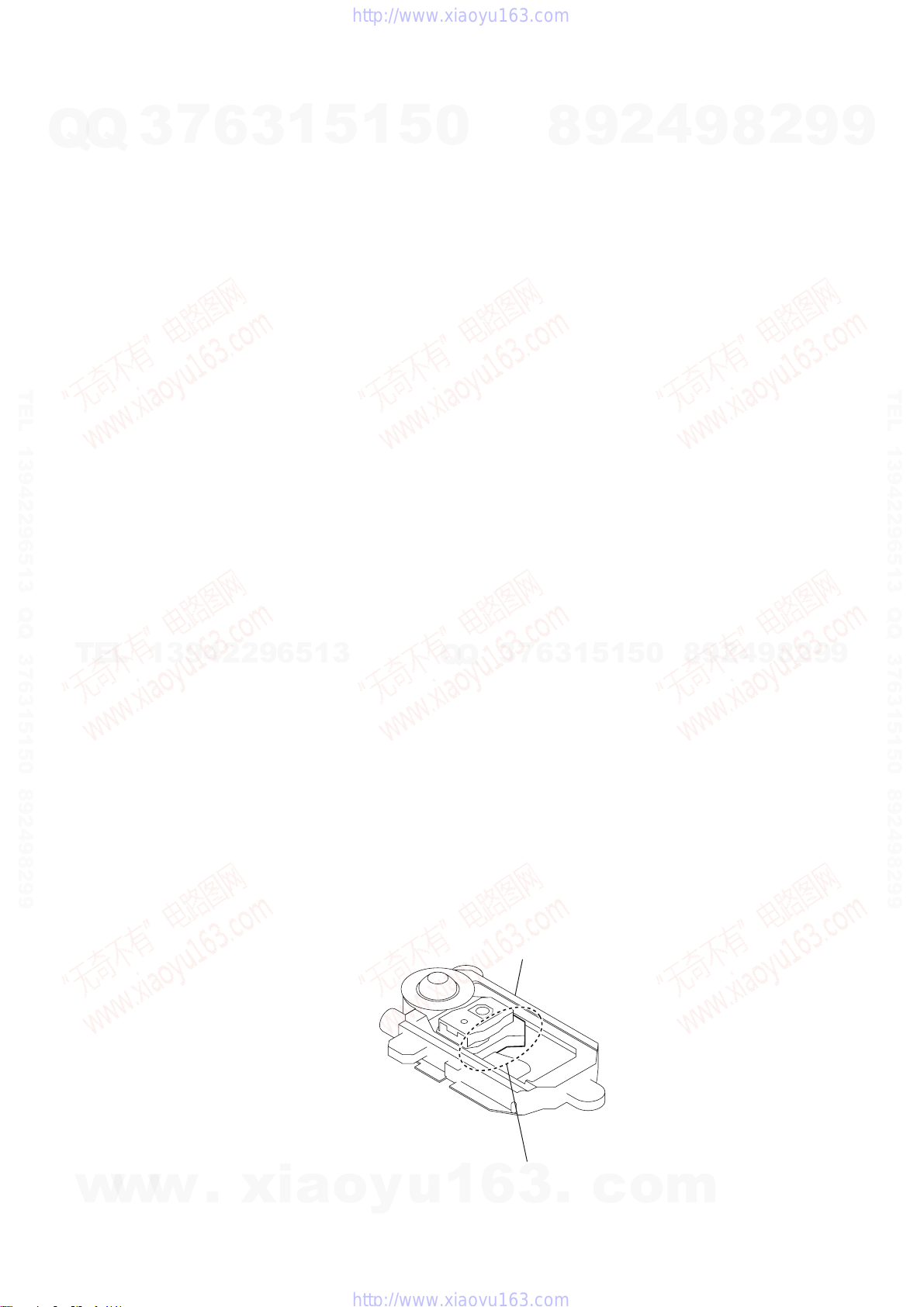

TYPE A/B DISCRIMINATION

Q

Q

7. EXPLODED VIEWS··················································· 106

7

3

7-1. Case Section ···································································· 106

7-2. Front Panel Section ·························································· 107

7-3. Top Cover Section ··························································· 108

7-4. Chassis Section-1 ·····························································109

7-5. Chassis Section-2 ·····························································110

7-6. DVD Mechanism Deck Section (CDM55A-DVBU8) ···· 111

7-7. MD Mechanism Deck Section-1 (MDM-7B4M) ············ 112

7-8. MD Mechanism Deck Section-2 (MDM-7B4M) ············ 113

8. ELECTRICAL PARTS LIST··································· 114

optical device

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

SILVER: KHM-240AAA (TYPE A)

o

y

BLACK: KHM-270AAA (TYPE B)

u

1

6

3

.

c

o

m

3

HCD-M700

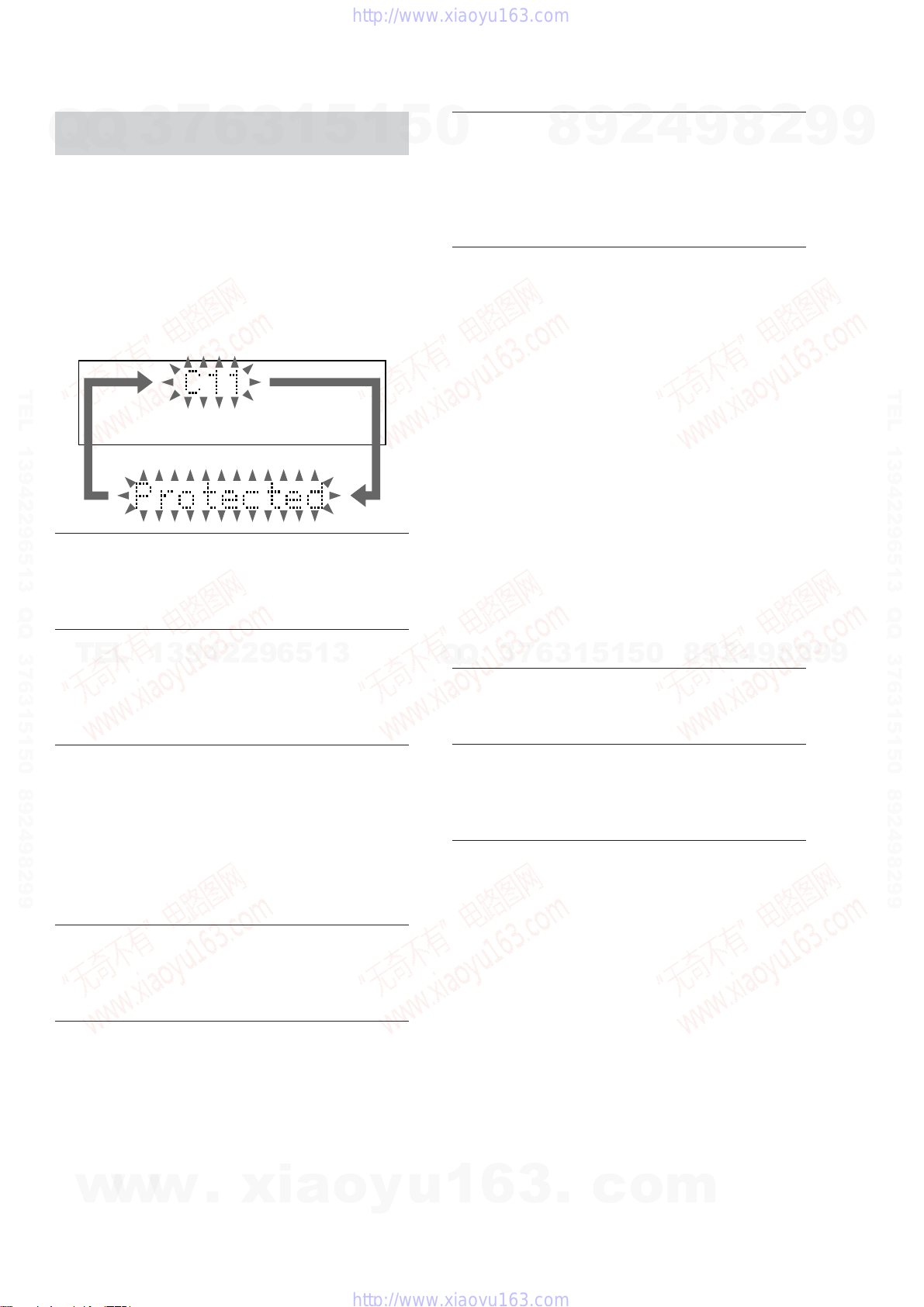

Self-diagnosis display

Q

Q

This system has a Self-diagnosis display

function to let you know if there is a system

malfunction. The display shows a code made

up of three or five letters and a message

alternately to show you the problem. To solve

the problem refer to the following list. If any

problem persists, consult your nearest Sony

dealer.

TEL 13942296513 QQ 376315150 892498299

C11/Protected

The MD is protected against erasure.

cRemove the MD and slide the tab to close the

slot.

C12/Cannot Copy

TEL

You tried to record a CD with a format that the

system does not support, such as a CD-ROM.

cRemove the disc and turn off the system once,

then turn it on again.

7

3

13942296513

6

3

1

5

1

5

C41/Cannot Copy

0

The sound source is a copy of a commercially

available music software or CD-R.

cThe Serial Copy Management System prevents

making a digital copy. In addition, you cannot

copy from a CD-R.

C71/Check OPT-IN

No component is connected to the DIGITAL

OPTICAL IN jack, or you tried to record from the

digital component which is not connected

correctly.

cConnect the optional digital component correctly

to the DIGITAL OPTICAL IN jack using the

digital optical cable (not supplied).

The power of the connected component is not

turned on.

cCheck if the power of the connected digital

component is on. Refer to the operating

instructions supplied with the component.

The digital optical cable is disconnected, or the

power of the connected component is turned off

while recording the digital audio from the

component connected to the DIGITAL OPTICAL

IN jack.

cConnect the digital optical cable, or turn on the

power of the connected component.

7

3

Q

Q

E0001/MEMORY NG

The component has internal problem.

cConsult your nearest Sony dealer.

8

6

3

9

1

5

2

1

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

C13/REC Error

Recording could not be performed properly.

cMove the system to a stable place, and start

recording over from the beginning.

The MD is dirty or scratched, or the MD does not

meet the standards.

cReplace the MD and start recording over from

the beginning.

C13/Read Error

The MD deck cannot read the disc information

properly.

cRemove the MD once, then insert it again.

C14/Toc Error

The MD deck cannot read the disc information

properly.

cReplace the MD.

cErase all the recorded contents of the MD using

the All Erase Function.

w

w

w

.

xia

o

y

E0101/LASER NG

There is a problem with the laser pickup.

cThe laser pickup may be damaged. Consult your

u

1

nearest Sony dealer.

6

3

.

c

o

m

4

HCD-M700

When the self-diagnosis function for DVD is

Q

Q

activated, a five-character service number (e.g.,

C 13 00) with a combination of a letter and

digits appears on the screen and the front panel

display. In this case, check the following table.

TEL 13942296513 QQ 376315150 892498299

C 13

C 31

E XX

(XX is a number)

TEL

7

3

The disc is dirty

cClean the disc with a soft cloth.

The disc is not inserted correctly.

cRe-insert the disc correctly.

To prevent a malfunction, the system has

performed the self-diagnosis function.

cContact your nearest Sony dealer or local

authorized Sony service facility and give the 5character service number.

13942296513

Example: E 61 10

6

C:13:00

3

1

5

1

5

0

Q

Q

Messages

One of the following messages may appear or

flash in the display during operation.

MD

Assign None

All the tracks on an MD are registered into groups.

Auto Cut

The MD deck is pausing the recording because

silence continued for 30 seconds or more during

digital recording.

Blank Disc

The inserted recordable MD is new, or all tracks on

the MD have been erased.

Cannot Edit

•A pre-mastered MD is in the deck.

• You tried to edit in Program or Shuffle Play

• The track is recorded in MDLP mode.

Cannot REC

•A pre-mastered MD is in the deck.

• The function is switched to MD.

7

3

Cannot SYNC!

• There is no disc in the MD deck, or the MD is

• There is no time remaining on the MD.

4

2

9

8

mode.

0

5

1

5

1

3

6

protected against erasure.

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

Complete!

Disc Full!

Eject

Group Full!

Impossible

6

The editing operation of the MD is completed.

There is no time remaining on the MD.

The MD deck is ejecting the MD.

An attempt was made to create a new group in

excess of the maximum number of groups, or there

are insufficient characters for updating the group

management information.

• You tried to make an impossible editing

operation.

• You cannot combine or erase the tracks due to

the system limitations of MDs.

continued

3

.

c

o

m

5

HCD-M700

Self-diagnosis display (continued)

Q

Q

Incomplete!

Adjustment of the recording level after recording

or Fade-in and Fade-out procedures have failed

since the system was either subject to vibration or

there is a damaged or dirty disc in the tray.

Initialize

The power was off for a long time, so the system is

initializing itself.

Name Full

TEL 13942296513 QQ 376315150 892498299

There is no more space to store track, disc or group

titles.

No Change

While attempting to change the recording level

after recording, you pressed ENTER/YES on the

remote without actually changing the recording

level, so no change was made.

No Disc

There is no disc in the MD deck.

3

7

6

3

1

5

1

5

TOC Writing

0

The MD deck is writing the information of

recorded or edited contents.

Track End

You have reached the end of the track while

adjusting the dividing point during the Divide

Function.

Tr Protect

You attempted to erase a protected track.

DVD

No Disc

There is no DVD in the player.

Push STOP!

You pressed PLAY MODE (or PLAY MODE/

TUNING MODE on the remote) during play.

Cannot use

You pressed an invalid button.

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

–OVER–

You have reached the end of the MD while

pressing M during playing pause.

TEL

Push STOP!

You pressed PLAY MODE (or PLAY MODE/

TUNING MODE on the remote) during play.

—Rehearsal—

The MD is playing the specified point for

confirmation during the A-B Erase Function and

the Divide Function.

S.F Edit!

You attempted to perform another operation while

in S.F Edit (changing the recording level after

recording, Fade-in, Fade-out) mode.

S.F Edit NOW

You pressed ?/1 while in S.F Edit (changing the

recording level after recording, Fade-in, Fade-out)

mode.

Smart Space

The signal was input again after silence continued

for 3 or more but less than 30 seconds during

digital recording, and the silence was cut to 3

seconds.

Step Full!

You tried to program 26 or more tracks (steps).

TOC Reading

w

The MD deck is reading the TOC information of

the MD.

13942296513

w

w

.

xia

o

y

u

Q

1

CD

No Disc

Q

There is no CD in the player.

OVER

You have reached the end of the CD while

pressing M during play or pause.

Step Full!

You tried to program 26 or more tracks (steps).

TAPE

Cannot SYNC!

There is no tape in the tape deck, or the tab has

been removed from the cassette.

No Tab

You cannot record the tape because the tab has

been removed from the cassette.

No Tape

There is no tape in the tape deck.

TUNER

WAIT

The function is switching to the tuner.

6

3

6

7

3

3

.

1

5

c

1

0

5

o

9

8

m

2

4

9

8

2

9

9

6

Note 1: About “R”

As this unit has only a few buttons, some operations require the use of remote commander (RM-SM700E/provided with unit) buttons. These

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

operations are indicated as “R” in this manual.

Example: MENU/NO “R” ...Press the MENU/NO button of the remote commander.

Note 2: Incorrect operations may be performed if the test mode is not entered properly.

In this case, press the ?/1 button to turn the power off, and retry to enter the test mode.

How to Operate the Self-diagnostics Function (Error History Display Mode)

Note: Use the self-diagnostics function in the "error history display mode" of the test mode. The least required procedure is described

below. Do not enter any other modes by mistake. If you have entered any other modes accidentally, press the MENU/NO “R”

button to exit the mode.

1. Press the ?/1 button to turn on the power.

2. Press the FUNCTION button to select the “MD” function.

3. While pressing the x button and the REC MODE button at the same time, press the FUNCTION button.

4. Press the MD > “R” button to display “[Service]”. Then press the ENTER/YES “R” button.

5. Press the MD > “R” button to display “Err Display”.

6. Press the ENTER/YES “R” button to enter the error history display mode and “op rec tm” appears.

7. Select the desired contents that you want to display or to execute using the MD . “R” button or the MD > “R” button.

8. Press the REC MODE button to display or to execute the selected contents.

9. Press the REC MODE button again to return to step 7.

10. Press the MENU/NO “R” button. The message “Err Display” appears and you exit the error history mode.

11. Press the REPEAT button twice to exit the test mode.

12. Press the ?/1 button to turn off the power.

6

3

1

5

1

5

0

8

9

2

4

9

8

HCD-M700

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

7

HCD-M700

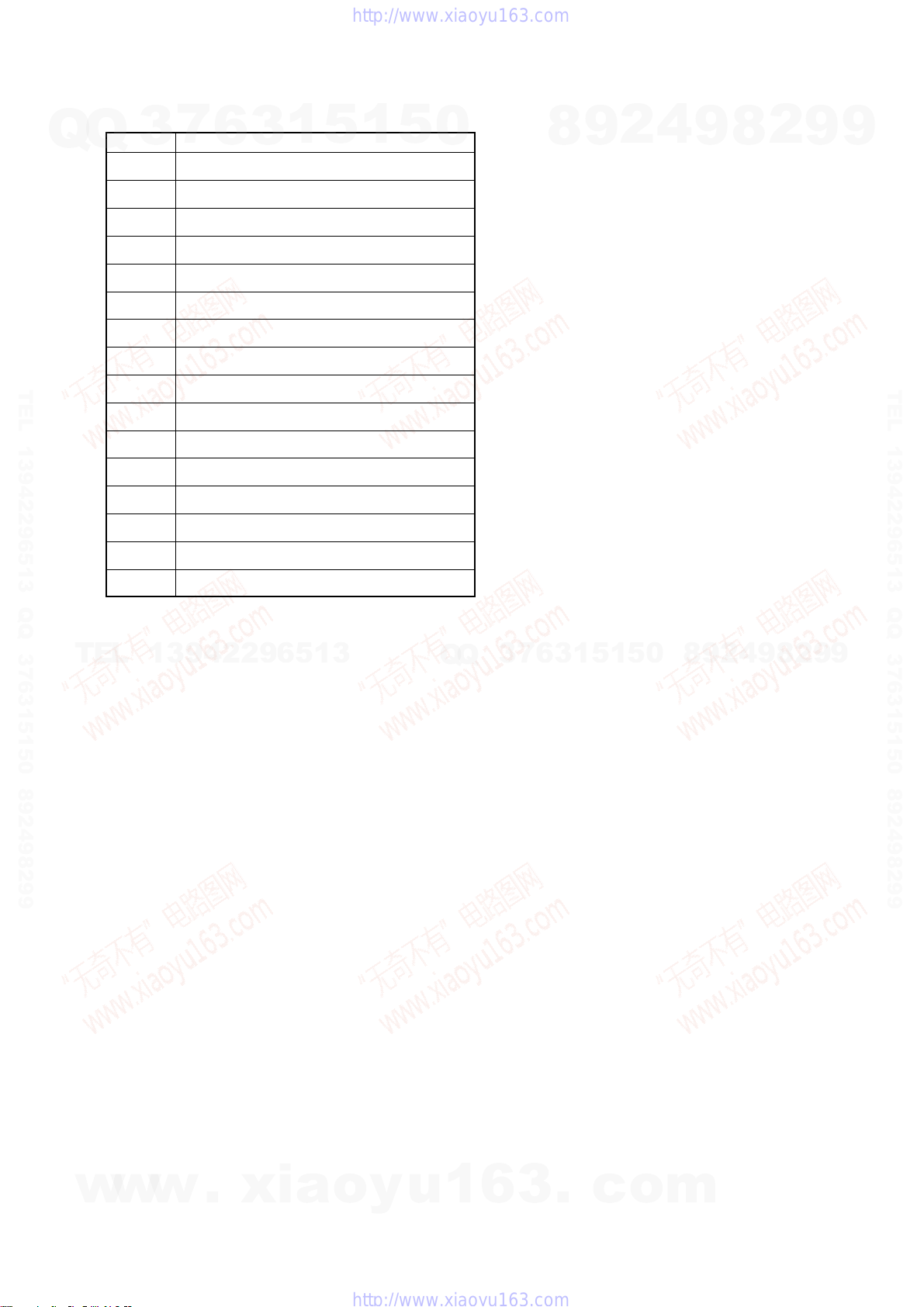

Items of Error History Mode Items and Contents

Selecting the Test Mode

Q

Q

Display

op rec tm

op play tm

spdl rp tm

TEL 13942296513 QQ 376315150 892498299

retry err

total err

err history

retry adrs

er refresh

TEL

op change

spdl change

7

3

13942296513

6

Displays the accumulated recording time.

When the accumulated recording time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

The display time indicates the time when the laser is set to high power more, which is about 1/4 of the actual

recording time.

Displays the accumulated playback time.

When the accumulated playback time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

Displays the accumulated rotating time of the spindle motor.

When the accumulated rotating time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

Displays the accumulated number of retry errors during recording and playback

Displays “r

This is displayed in hexadecimal from 00 to FF.

Displays the total number of errors

Displays “total ”. This is displayed in hexadecimal from 00 to FF.

Displays the past ten errors.

Displays “0x ErrCd@@”.

X is the history number. The younger the number, the more recent is the history (00 is the latest). @@ is the

error code.

Select the error history number by pressing the MD . “R” or MD > “R” button.

Displays the past five retry addresses.

Displays “

Select the error history number by pressing the MD . “R” or MD > “R” button.

Mode for erasing the error and retry address histories

Procedure

1. Press the REC MODE button when displayed as “er refresh”.

2. When the display changes to “er refresh?”, press the ENTER/YES “R” button

When “Complete!!” is displayed, it means erasure has completed.

Be sure to check the following after executing this mode.

*Data has been erased.

*Perform recording and playback, and check that the mechanism is normal.

Mode for erasing the accumulated time of op rec tm, op play tm.

Use these histories as a guide line for the time of replacement of the optical pick-up. If the optical pick-up

has been replaced, perform this procedure and erase the past history.

Procedure

1. Press the REC MODE button when displayed as “op change”.

2. When the display changes to “op change?”, press the ENTER/YES “R” button.

When “Complete!!” is displayed, it means erasure has completed.

Mode for erasing the accumulated spdl rp tm time

Use these histories as the guide line for the time of replacement of the spindle motor. If the spindle motor has

been replaced, perform this procedure and erase the past history.

Procedure

1. Press the REC MODE button when displayed as “spdl change”

2. When the display changes to “spdl change?”, press the ENTER/YES “R” button.

When “Complete!!” is displayed, it means erasure has completed.

1

3

p ”. is the number of errors during recording. is the number of errors during playback.

ADRS ”, is the history number, is the cluster with the retry error.

5

1

5

0

Q

Q

History

3

7

8

6

3

9

1

5

2

1

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

8

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Q

Table of Error Codes

7

Q

3

Error Code Description

10

6

Could not perform loading

3

1

5

1

5

0

8

9

2

4

9

8

HCD-M700

2

9

9

11

12

20

21

22

23

24

TEL 13942296513 QQ 376315150 892498299

30

31

40

41

42

43

50

51

The changer error occurred

Loading switches combined incorrectly

Timed out without reading the top of PTOC

Could read top of PTOC, but detected error

Timed out without accessing UTOC

Timed out without reading UTOC

Error in UTOC

Could not start playback

Error in sector

A cause of retry occurred during normal recording

Retried due to DRAM overflow

Retry occurred during TOC writing

Retry aborted during S.F editing

Other than access processing, and could not read address.

Focus NG occurred and overran.

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

9

M

HCD-M700

SECTION 1

SERVICING NOTE

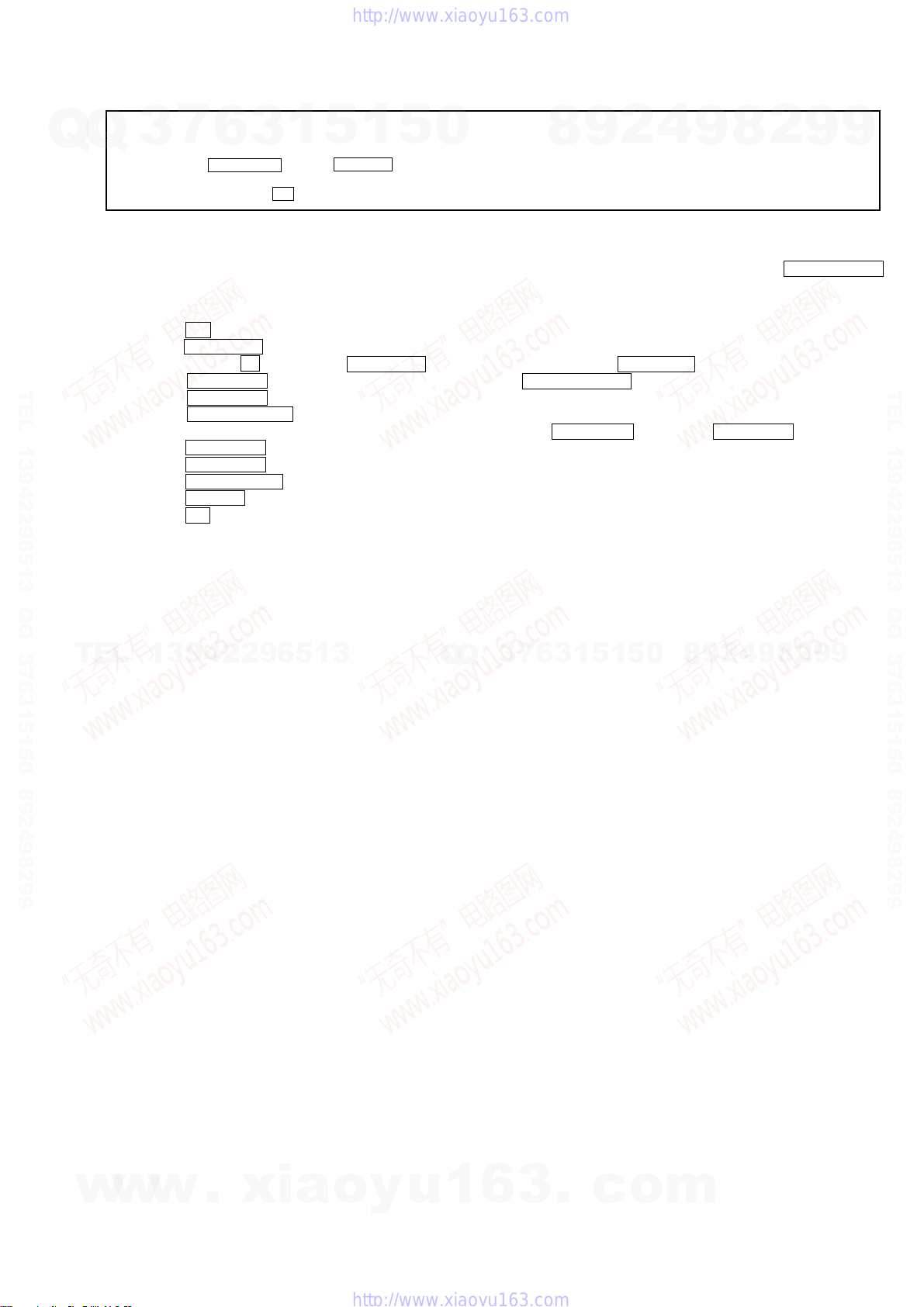

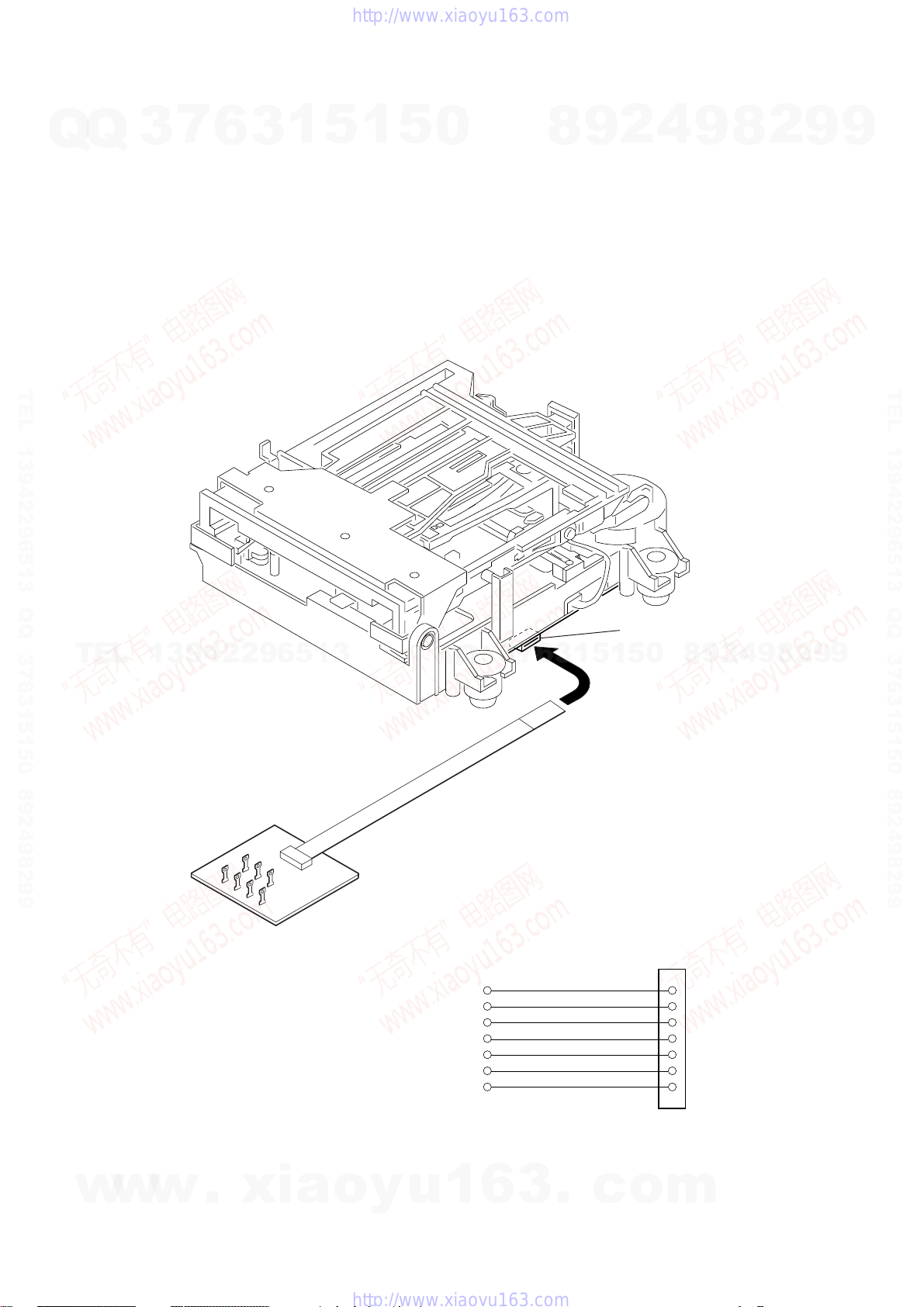

Jig For Checking BD Board Waveform

7

Q

Q

The special jig (J-2501-196-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to be

performed are shown as follows.

GND : Ground

I+3V : For measuring Iop (Check the deterioration of the optical pick-up laser)

Iop : For measuring Iop (Check the deterioration of the optical pick-up laser)

TE : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

FE : Focus error signal

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

CN105

0

5

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

10

w

w

I+3V

w

GND

.

Iop

TE

FE

RF

xia

VC

I+3V

Iop

GND

TE

FE

VC

RF

o

y

u

1

6

3

.

c

o

1

I+3V

Iop

GND

TE

FE

VC

RF

7

m

for MDM-7B4

Q

Jig For Checking DVD Board and DIGITAL Board Waveform

7

Q

3

The special jig (J-2501-196-A) is useful for checking the waveform of the DVD board and DIGITAL board.

• Extention cable (10P)

(J-2501-219-A)

• Extention cable (27P)

(J-2501-220-A)

6

3

1

5

1

5

0

8

9

2

4

9

8

HCD-M700

2

9

9

TEL 13942296513 QQ 376315150 892498299

CN607

Q

Q

3

7

TEL

CONTROL board

CN608

jig (27P

(J-2501-220-A)

13942296513

DIGITAL board

j

CN705

6

3

5

1

CN101

1

5

0

jig (10P

(J-2501-219-A)

9

8

2

j

9

4

DVD board

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

• DISC TRAY LOCK

If the disc tray does not open and the message “LOCKED” appears,

press the two buttons of ENTER/START and Z DVD at the same

for 5 seconds or longer.

Then the lock is released, the message “UNLOCKED” appears for

2 seconds and the disc tray opens.

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

11

HCD-M700

Iop DATA RECORDING AND DISPLAY WHEN OPTICAL PICK-UP AND NON-VOLATILE MEMORY (IC195 OF

BD BOARD) ARE REPLACED

Q

Q

The Iop value labeled on the optical pick-up can be stored in the non-volatile memory. By storing the value, it will eliminate the need to look

at the value on the label of the optical pick-up. When replacing the optical pick-up or non-volatile memory (IC195 of BD board), store the Iop

value on the optical pick-up according to the following procedure.

Record Precedure:

1. Press the ?/1 button to turn on the power.

2. Press the FUNCTION button to select the “MD” function.

3. While pressing the x button and the REC MODE button at the same time, press the FUNCTION button.

4. Press the MD > “R” button to display “[Service]”. Then press the ENTER/YES “R” button.

5. Press the MD > “R” button to display “Iop Write” (C05) and press the ENTER/YES “R” button.

6. The display becomes “Ref=@@@.@” (@ is an arbitrary number) and the numbers which can be changed will blink.

7. Input the Iop value written on the optical pick-up.

TEL 13942296513 QQ 376315150 892498299

To select the number : Press the MD . “R” button or the MD > “R” button.

To select the digit : Press the REC MODE button.

8. When the ENTER/YES “R” button is pressed, the display becomes “Measu=@@@.@” (@ is an arbitrary number).

9. As the adjustment results are stored for the 6 value. Leave it as it is and press the ENTER/YES “R” button.

10. “Complete!” will be displayed momentarily. The value will be stored in the non-volatile memory and the display will become “Iop

Write” (C05).

11. Press the REPEAT button twice to exit the mode.

12. Press the ?/1 button to turn off the power.

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

Display Precedure:

1. Press the ?/1 button to turn on the power.

2. Press the FUNCTION button to select the “MD” function.

3. While pressing the x button and the REC MODE button at the same time, press the FUNCTION button.

4. Press the MD > “R” button to display “[Service]”. Then press the ENTER/YES “R” button.

5. Press the MD > “R” button to display “Iop Read” (C26) and press the ENTER/YES “R” button.

6. “@@.@/##.#” is displayed and the recorded contents are displayed.

@@.@ : indicates the Iop value labeled on the optical pick-up

##.# : indicates the Iop value after adjustment

TEL

7. To end, press the MENU/NO “R” button to display “Iop Read” (C26). Then press the REPEAT button twice.

8. Press the ?/1 button to turn off the power.

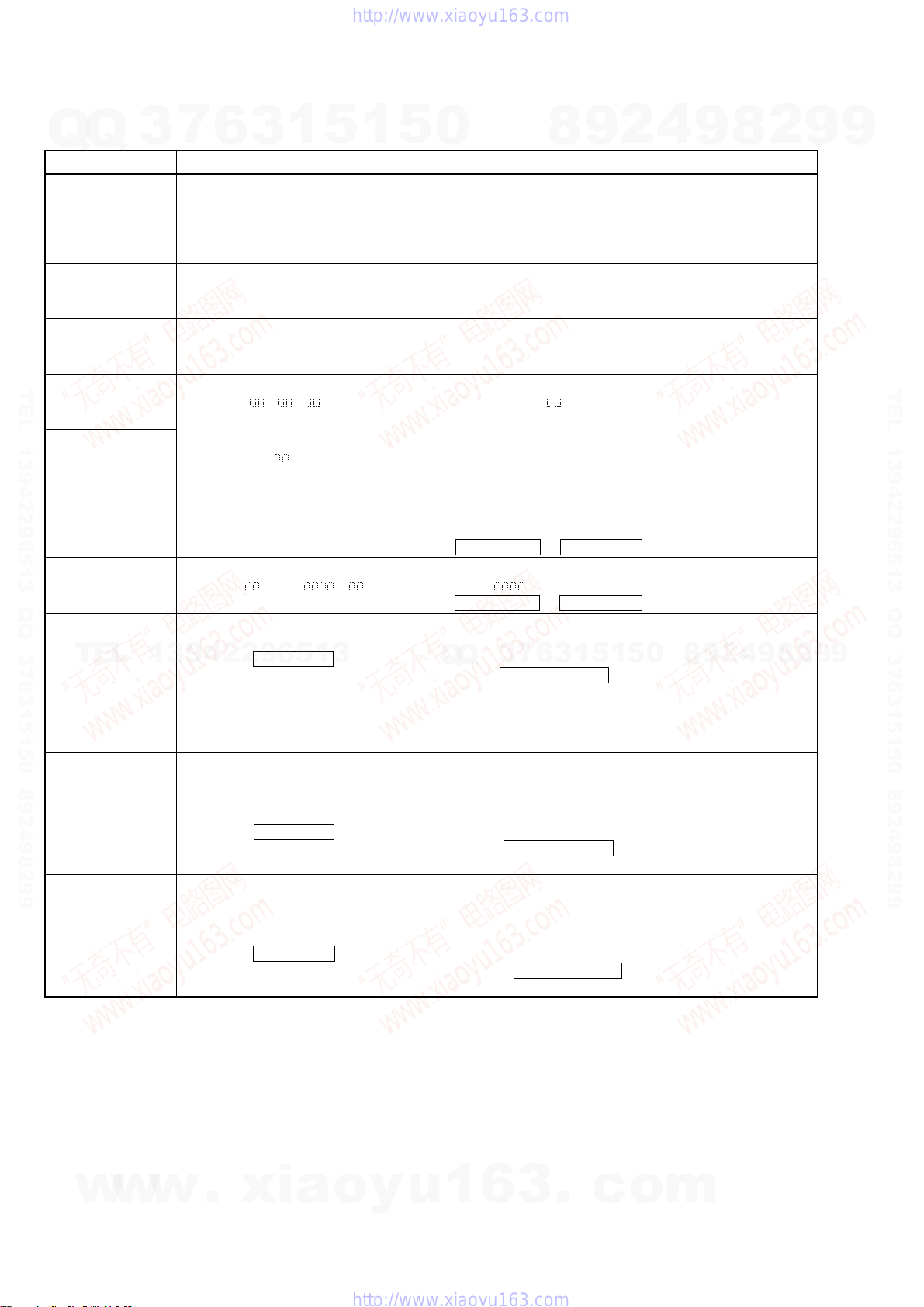

Checks Prior to Parts Replacement and Adjustments in MD

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “Section 5 Electrical Adjustments”.

Laser power check

(6-2 : See page 36)

Auto check

(6-4 : See page 37)

Temperature

compensation

offset check

(6-1 : See page 36)

13942296513

Criteria for Determination

(Unsatisfactory if specified value is not satisfied)

• 0.93 mW power

Specified value : 0.85 to 0.91 mW (KMS-260B)

0.80 to 0.96 mW (KMS-260E)

• 7.25 mW power

Specified value : 6.8 to 7.2 mW (KMS-260B)

7.0 to 7.5 mW (KMS-260E)

• Iop (at 7.25mW)

Labeled on the optical pick-up

Iop value ± 10mA

• Unsatisfactory if displayed as “NG : XXXX”NG

(XXXX are arbitrary numbers)

• Unsatisfactory if displayed as “T=@@ (##) [NG]”

NG

(@@, ## are both arbitrary numbers)

Q

Q

0

5

1

5

1

3

6

7

3

Measure if unsatisfactory

• Clean the optical pick-up

• Adjust again

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Check for disconnection of the circuits around

D101 (BD board)

• Check the signals around IC101, IC151, CN102,

CN103 (BD board)

8

9

2

4

9

8

2

9

9

w

w

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for adjustments.

When performing adjustments, use the specified values for adjustments.

12

w

.

xia

o

y

u

1

6

3

.

c

o

m

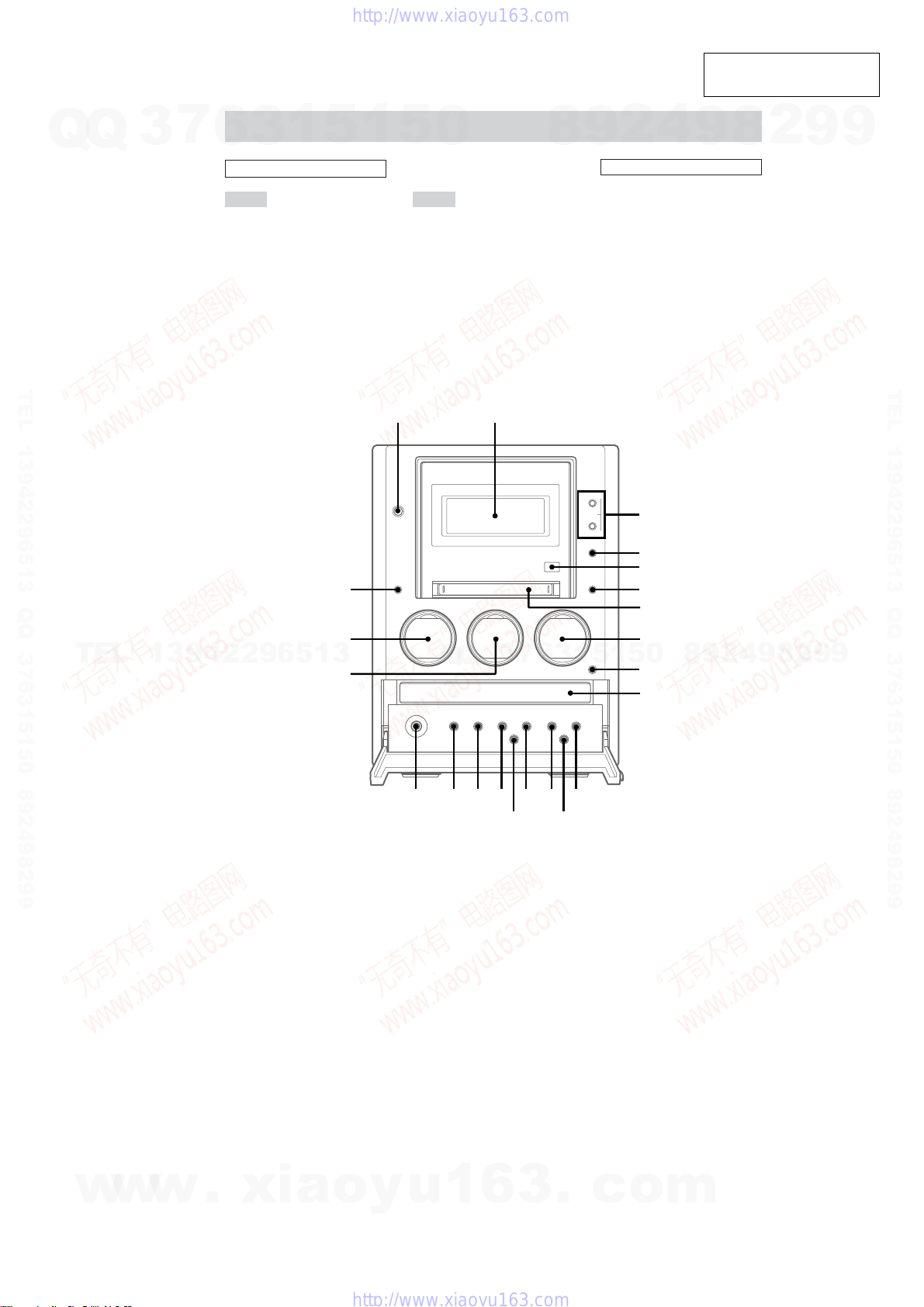

SECTION 2

GENERAL

HCD-M700

This section is extracted

from instruction manual.

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

3

13942296513

Main unit

6

ALPHABETICAL ORDER

A – P

DIRECTION qk (63–65)

Disc tray 0 (12)

Display window 2

DVD NX w; (12, 13, 16, 18)

ENTER/START qf (40, 41, 64)

FUNCTION ws (12, 14, 33, 35,

36, 39, 41–45, 47, 48, 50–56,

58, 63, 65, 74)

MD slot 7 (33)

MD NX w; (33, 34, 36, 39, 41)

PHONES jack ql

PLAY MODE qk (12, 14, 15, 33,

35, 41, 47)

3

1

5

wa

w;

1

5

0

R – V

REC MODE qg (40–42)

Remote sensor 5

REPEAT/FM MODE qj (13, 34,

61, 62)

SYNCHRO MODE qh (40, 41,

64)

TAPE nN wa (63–65)

TUNER BAND wa (60–62)

TUNING +/– 3 (60–62)

TUNING MODE qk (60–62)

VOLUME +/– 8

1

?/1

nN NX

Q

Q

2

NX

3

7

8

6

+

–

3

1

zz

X

4

2

9

BUTTON DESCRIPTIONS

?/1 (power) 1

m/M 3

l/L 3

x 4

Z DVD 9

Z MD 6

z MD qd

z TAPE qa

X TAPE qs

ML

1

5

3

4

5

6ws

7

8

9

0

0

8

lm

Z

Z

x

5

9

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

qkql qj

1

qh qf

6

qg

3

qd qa

qs

.

c

o

m

13

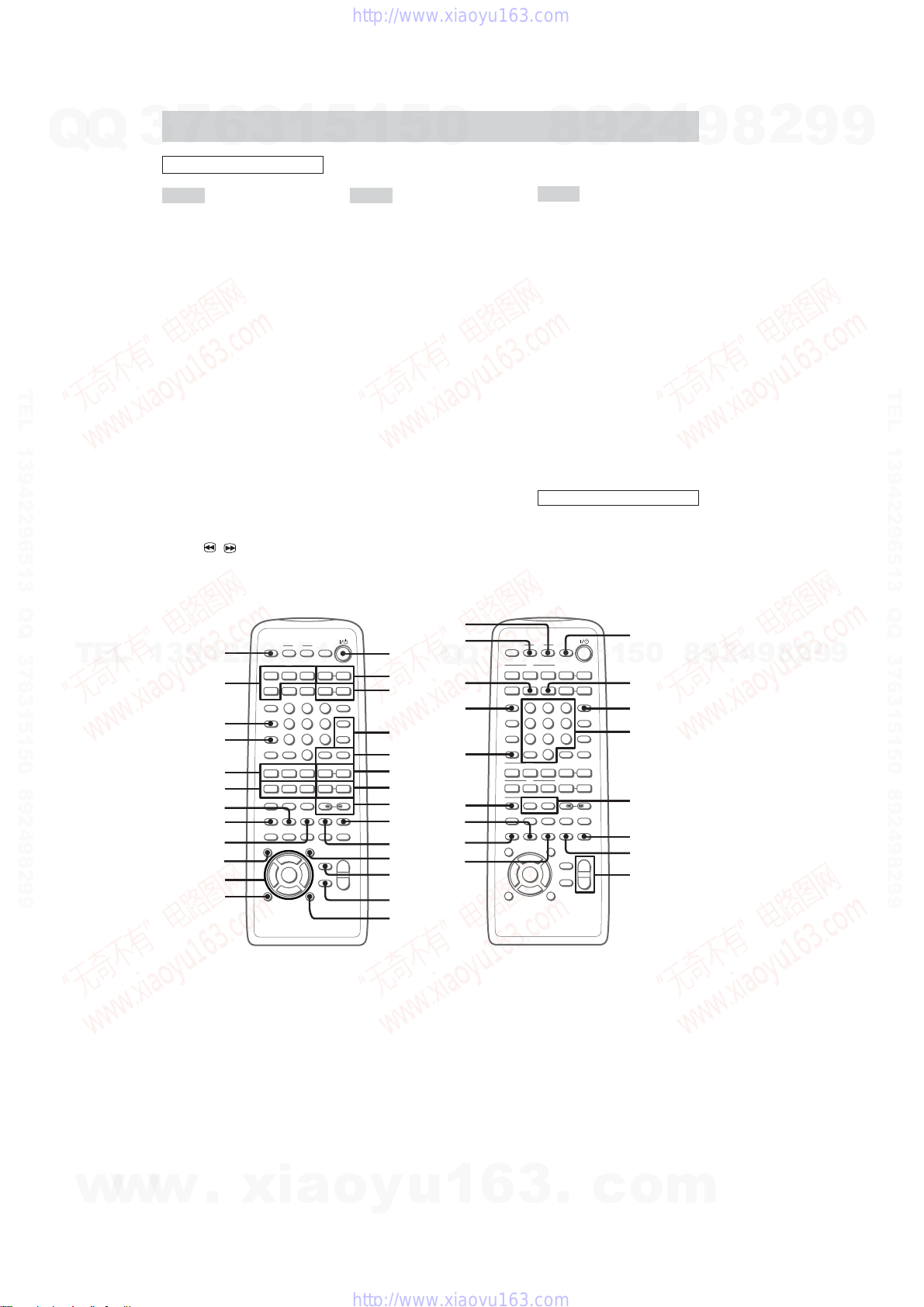

HCD-M700

Q

Q

Remote Control

7

3

6

ALPHABETICAL ORDER

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

A – D E – N

ANGLE eg (28)

AUDIO ej (25)

BASS/TREBLE qd (65)

BGMD wl (70)

CLEAR el (14, 15, 17, 27, 35,

49, 62)

CLOCK/TIMER SELECT rs

(69, 70)

CLOCK/TIMER SET rd (11, 68,

69)

CURSOR T/t 5 (11, 48, 49)

TEL 13942296513 QQ 376315150 892498299

TEL

DISPLAY w; (23, 35, 63, 71, 72)

DSG qs (65)

DVD DISPLAY qg (16, 17, 19,

20, 23–25, 27–29, 66)

DVD MENU qa (17)

DVD TOP MENU qj (17)

DVD SETUP eh (19, 30)

DVD N/SELECT wa (12–18,

21, 32, 42)

DVD X wa (13, 42)

DVD x wa (13, 16, 18, 29)

DVD ./> 7 (13, 14, 18)

DVD t

13942296513

/ T 8 (13)

wh

wg

wf

wd

ws

wa

w;

ql

qk

qj

qh

qg

NX xmM

z.>

nN

Xx

NX x

–

V

v

ENTER/YES wd (11, 14, 35,

42–60, 62, 68–70)

FUNCTION ql (12, 14, 33, 35,

36, 39, 41–45, 47, 48, 50–56,

58, 63, 65, 74)

GROUP ra (36, 38–40, 48–51)

GROUP SKIP wk (36, 39, 40, 48,

49, 51)

MD N wg (33, 35, 36, 39, 41)

MD X wg (34)

MD x wg (34, 39–42, 46)

MD m/M 2 (34, 54)

MD ./> 3 (34–36, 48,

50, 52–59)

MD z wg (39, 41, 44, 45)

MENU +/– 4 (11, 43–60, 65,

68–70)

MENU/NO wf (43–47, 49–60,

62)

NAME EDIT/SELECT r; (48,

62)

Numeric buttons e; (13, 15, 17,

18, 27–32, 34, 48, 61)

1

2

3

4

5

mM

.

+

ty

bB

O

>

+

–

6

7

8

9

q;

qa

qs

qd

qf

rd

rs

Q

ra

r;

el

ek

ej

eh

eg

Q

7

3

NX xmM

z.>

nN

Xx

NX x

–

V

v

P – V

PLAY MODE/TUNING MODE

0 (12, 14, 15, 33, 35, 41, 47,

60–62)

REPEAT/FM MODE 9 (13, 34,

61, 62)

RETURN O qf (18, 27, 30, 31)

SCROLL qk (49, 72)

SLEEP wh (68)

SUBTITLE ed (28)

TAPE nN ws (63–65)

TAPE X ws (63, 65)

TAPE x ws (63–65)

TAPE m/M 6 (63)

TUNER BAND ek (60–62)

TUNER +/– ea (60–62)

TV @/1 wj (10)

TV/VIDEO es (10)

VOL +/– ef

BUTTON DESCRIPTIONS

@/1 (power) 1

V/v/B/b/ENTER qh

wj

0

5

1

5

1

3

6

wk

wl

e;

mM

.

>

+

ty

bB

O

+

–

ea

es

ed

ef

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

14

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

HCD-M700

Q

TEL 13942296513 QQ 376315150 892498299

Setting the clock

Q

1

Press ?/1 to turn on the system.

2

Press CLOCK/TIMER SET on the

remote.

3

Press MENU + or – on the remote

repeatedly to set the hour.

4

Press ENTER/YES or CURSORt on

the remote.

5

Press MENU + or – on the remote

repeatedly to set the minute.

6

Press ENTER/YES on the remote.

The clock starts working.

To adjust the clock

1

Press CLOCK/TIMER SET on the remote.

2

Press MENU + or – on the remote to select

“CLOCK SET?”, then press ENTER/YES on

the remote.

3

Do the same procedures as step 3 to 6 above.

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

15

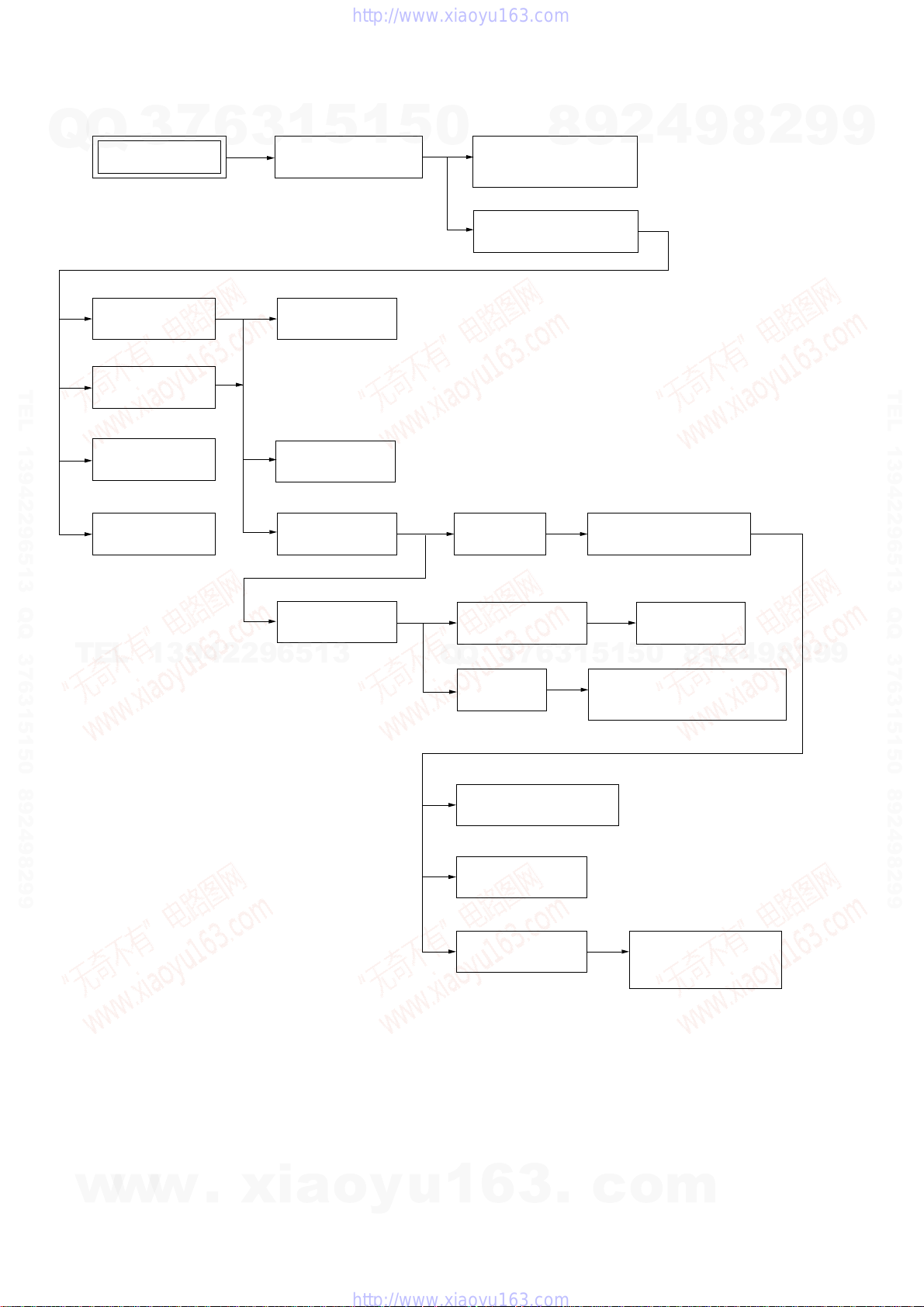

HCD-M700

Ver 1.1 2003.09

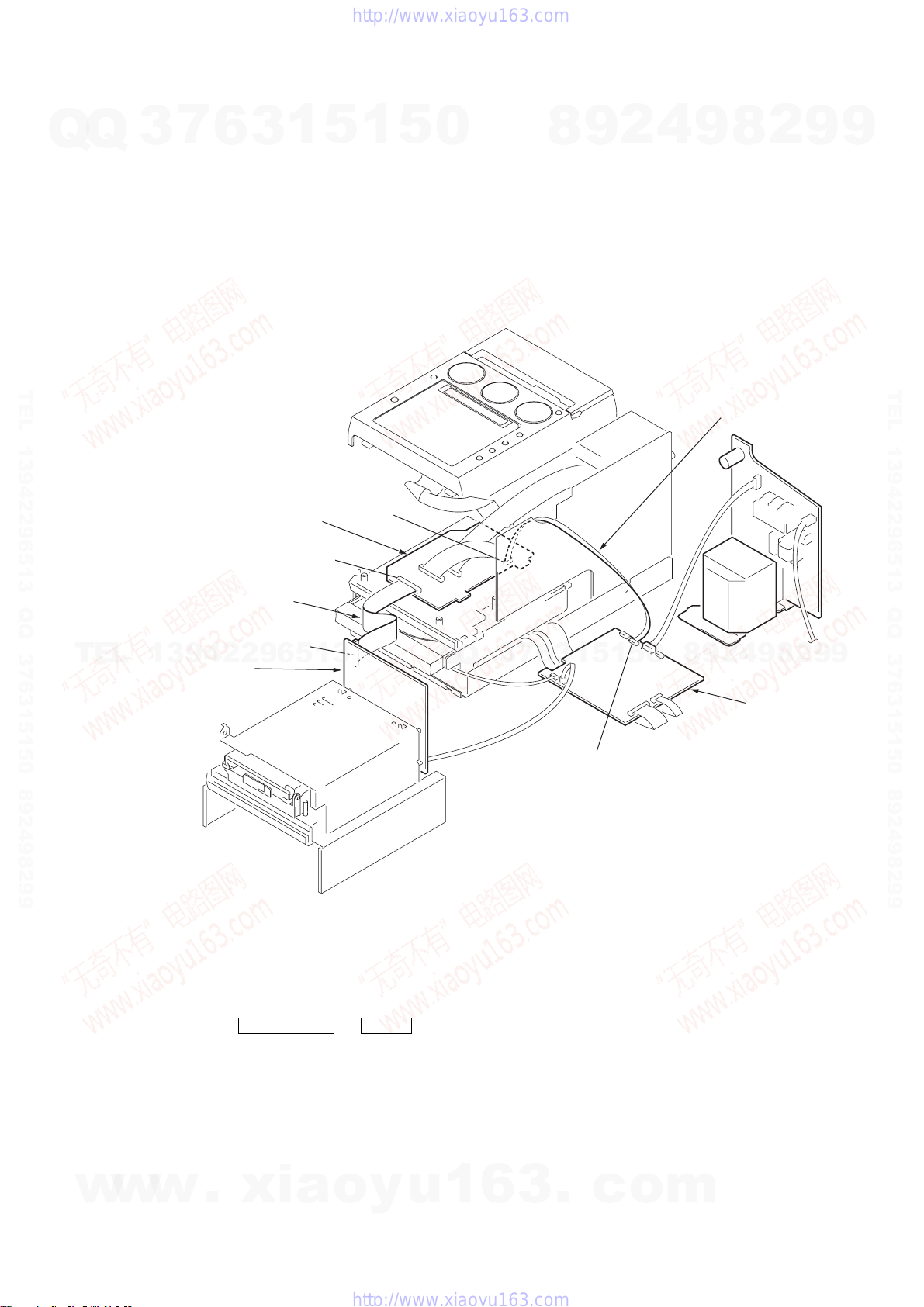

• The equipment can be removed using the following procedure.

Q

Q

3

SET (HCD-M700E)

7

6

1

3

5

CASE (R), CASE (L),

TOP COVER SECTION

SECTION 3

DISASSEMBLY

1

5

0

FRONT PANEL SECTION,

BACK PANEL SECTION

9

8

TC BOARD,

MECHANISM DECK

(CMAL1Z228)

2

4

9

8

2

9

9

MAIN BOARD

TEL 13942296513 QQ 376315150 892498299

CONTROL BOARD

VIDEO BOARD,

OPTICAL BOARD

SWITCH BOARD,

JACK BOARD

TEL

13942296513

POWER BOARD

DIGITAL BOARD

MD MECHANISM

(MDM-7B4M)

HOLDER ASSY

DVD BOARD

OVER LIGHT HEAD

3

Q

Q

BD BOARD

7

6

DVD MECHANISM DECK

(CDM55-DVBU8)

OP-SUB ASSY

8

0

5

1

5

1

3

LOADING MOTOR ASSY (M103),

SPINDLE MOTOR ASSY (M101),

SLED MOTOR ASSY (M102)

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

LOADING BOARD,

MOTOR (LD ASSY)(M901)

RF-240 BOARD

TRAY

1

6

3

.

OPTICAL PICK UP

(KHM-240AAA(TYPE A))

(KHM-270AAA(TYPE B))

c

o

m

16

)

5

flexible flat cable

(

CN609)

qf

flexible flat cable

(CN604)

qa

earth wire

qs

connector (CN304)

6

connector (CN610)

qg

front panel section

4

back panel section

9

DC fan

1

four

screws (+BVTP 3

×

10)

7

four

screws (+BVTP 3

×

16)

qd

three

screws

(+BVTP 3

× 8

)

q;

screw

(+BVTP 3

× 8

)

3

three

screws

(+BVTP 3

× 8

)

2

two

screws

(+BVTP 3

× 8

)

chassis section

8

Remove the soldering.

Q

Note: Follow the disassembly procedure in the numerical order given.

7

3

3-1. Case (R), Case (L), Top Cover Section

Q

6

(3

6

two

screws

×

10 case 3 TP2)

8

1

3

7

screw (+BVTP 3

case (L)

5

×

1

10)

5

qa

0

top cover section

9

8

q;

flexible flat cable

(CN301)

2

9

4

9

8

HCD-M700

2

9

9

TEL 13942296513 QQ 376315150 892498299

5

two

screws

× 8

(3

TEL

13942296513

3-2. Front Panel Section, Back Panel Section

case 3 TP2)

chassis section

7

3

Q

Q

1

3

6

5

4

1

3

case (R)

0

5

screw (+BVTP 3

2

two

(3

1

two

(3

2

9

8

×

10)

screws

×

10 case 3 TP2

screws

× 8

case 3 TP2)

8

9

4

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

17

HCD-M700

)

)

3-3. VIDEO Board, OPTICAL Board

Q

Q

7

3

5

VIDEO board

6

3

1

5

1

5

0

1

8

three

screws (+BVTP 3

2

2

9

three

screws (+BVTP 3

×

4

10)

9

×

8

10

2

9

9

TEL 13942296513 QQ 376315150 892498299

6

OPTICAL board

4

3

screw (+BVTP 3

TEL

3-4. SWITCH Board, JACK Board

13942296513

× 8

RETEINER board

)

4

flexible flat cable

(CN801)

Q

Q

3

7

back panel

1

3

6

1

two

8

0

5

1

5

screws (+BVTP 2.6

9

× 8

2

)

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

18

w

w

3

two claws

w

front panel

.

xia

o

y

u

1

6

3

2

6

four

7

JACK board

.

5

SWITCH

five

screws (+BVTP 2.6

screws (+BVTP 2.6

c

o

board

m

× 8

× 8

)

)

)

3-5. TC Board, Mechanism Deck (CMAL1Z228)

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

7

mechanism deck (CMAL1Z228)

3

1

5

1

5

0

8

9

2

4

8

cover

9

8

top cover

HCD-M700

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

3-6. MAIN Board

3

Remove the

from the hook of mechanism deck

n the direction of the arrow.

i

2

cut-out portion of TC board

three

screws (+BVTT 2

1

(CN302)

hook

× 5

)

flexible flat cable

Q

7

3

Q

2

flexible flat cable

(CN302)

6

1

3

1

(CN901)

6

four

4

connector

(mechanism deck 6p)

5

TC board

cut-out portion

0

5

1

5

connector

screws (+BVTP 3

9

4

2

9

8

× 8

8

2

9

9

w

w

w

.

xia

6

3

flexible flat cable

(CN303)

o

y

u

1

6

3

.

c

5

screw (+BVTP 3

o

4

screw (+BVTP 3

7

MAIN board

m

× 8

)

× 12

19

)

HCD-M700

3-7. CONTROL Board

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

4

CONTROL board

6

3

two

screws (+BVTP 3

2

flexible flat cable

(CN607)

3

1

× 8

5

)

1

5

0

1

flexible flat cable

(CN608)

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

3-8. POWER Board

13942296513

6

POWER board

1

connector

(CN903)

5

Q

Q

6

7

3

3

four

screws (+BVTP 4

2

co

(CN901)

0

5

1

5

1

3

× 6

)

nnector (power coard)

4

screw (+BVTP 3

× 8

8

9

2

4

9

8

2

9

9

20

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

)

Q

3-9. DIGITAL Board

7

Q

3

6

3

4

flexible flat cable

(CN702)

1

2

5

5

flexible flat cable

(CN701)

four

screws (+BVTP 3

1

5

0

× 8

)

8

9

2

3

cover (MD)2

4

9

1

flexible flat cable

(CN705)

8

HCD-M700

2

9

9

TEL 13942296513 QQ 376315150 892498299

6

(CN704)

7

two hooks

TEL

13942296513

3-10. MD Mechanism Deck (MDM-7B4M)

6

four

screws (

+BVTTWH M3)

Q

Q

5

3

cover

7

8

DIGITAL board

flexible flat cable

1

5

1

3

6

(MD)

5

0

9

8

1

six

8

9

4

2

screws (+BVTP 3

DIGITAL

board

2

× 8

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

7

MD mechanism deck

(MDM-7B4M)

w

.

xia

o

y

u

1

6

3

4

flexible flat cable

(CN103)

2

flexible flat cable

(CN704)

.

c

3

flexible flat cable

(CN102)

o

m

21

HCD-M700

)

3-11. DVD Board

5

3

2

four

Q

Q

7

6

screw (+BVTP 3

4

MD bracket

screws (+BVTP 3

3

× 8

)

× 8

1

)

1

5

connector (CN008)

1

5

(to POWER board)

0

8

2

9

3

two

screws (+BVTP 3

4

9

× 8

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

DVD board

7

flexible flat cable

(CN009)

8

flexible flat cable

(CN010)

TEL

3-12. DVD Mechanism Deck (CDM55A-DVBU8)

13942296513

1

two

screws (+BVTP 2.6

2

DVD board chassis

× 8

7

3

Q

Q

)

6

3

1

5

1

5

6

connector

(CN402)

8

0

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

22

w

w

5

DVD mechanism deck

(CDM55A-DVBU8)

two hooks

w

.

xia

4

o

y

u

1

6

3

3

screw (+BVTP 3

.

c

o

× 8

)

m

k

3-13. Holder Assy

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

1

tension spring (holder)

3

1

5

1

5

holder assy

5

0

4

8

9

2

3

2

4

hoo

9

8

HCD-M700

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

3-14. BD Board

w

w

13942296513

6

flexible flat cable

(CN101)

5

two

w

screws (+BTP 2

.

xia

× 6

)

8

o

BD board

y

u

Q

Q

3

from the two points.

(loading)

7

connector

(CN104)

1

6

0

5

1

5

1

3

6

7

3

1

Remove soldering from the two points.

(sled)

2

Remove soldering from the two points.

(spindle)

Remove soldering

4

Remove soldering from the three points.

3

.

c

o

9

8

M101

M103

S102

m

2

4

M102

9

8

2

9

9

23

HCD-M700

)

3-15. Over Light Head (HR901)

7

Q

Q

3

6

3

2

over light head

(HR901)

1

1

screw (P 1.7

5

1

5

× 6

0

)

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

3-16. OP-SUB Assy

TEL

13942296513

6

main shaft

7

Q

Q

9

OP-SUB assy

3

7

6

1

5

1

3

3

screw (+BP TRI 2

5

0

9

8

× 6 CZN

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

24

1

screw (+BP TRI 2

2

base

w

w

(BU-D)

w

× 6 CZN

.

xia

8

flexible board

)

o

y

u

1

6

3

4

base

5

tw

o screws (+KTP2

.

c

(BU-A)

o

× 6

)

m

Q

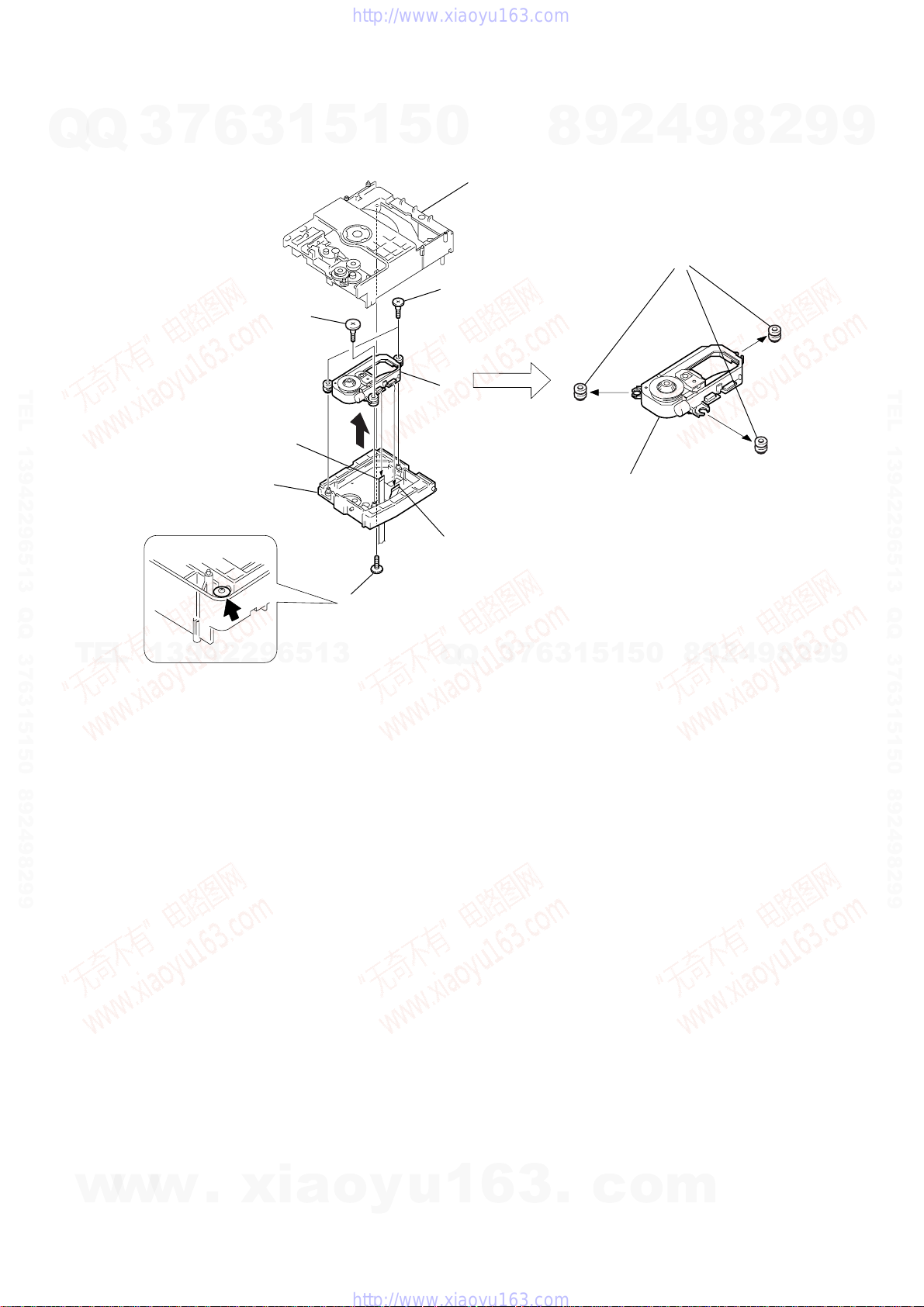

3-17. Loading Motor Assy (M103), Spinde Motor Assy (M101), Sled Motor Assy (M102)

Q

3

4

7

6

two

screws (+PWH 1.7x 3.5)

3

2

1

5

3

belt (loading)

1

5

0

torsion spring (SPDL)

8

9

1

4

2

lever (HEAD)

8

two

HCD-M700

2

8

9

screws (+PWH 1.7x 3.5)

9

9

TEL 13942296513 QQ 376315150 892498299

7

spinde motor assy (M101)

5

loading motor assy (M103)

6

TEL

13942296513

3-18. LOADING Board, Motor (LD) Assy (M901)

1

Remove the belt.

Q

Q

3

7

three

screws (M 1.7)

3

6

1

5

1

5

0

9

sled motor assy (M102)

8

9

4

2

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

4

motor

(M901)

(LD) assy

o

3

Remove soldering from the two points.

5

LOADING board

2

two

screws (+BTP 2.6

y

u

1

6

3

×

.

6)

c

o

m

25

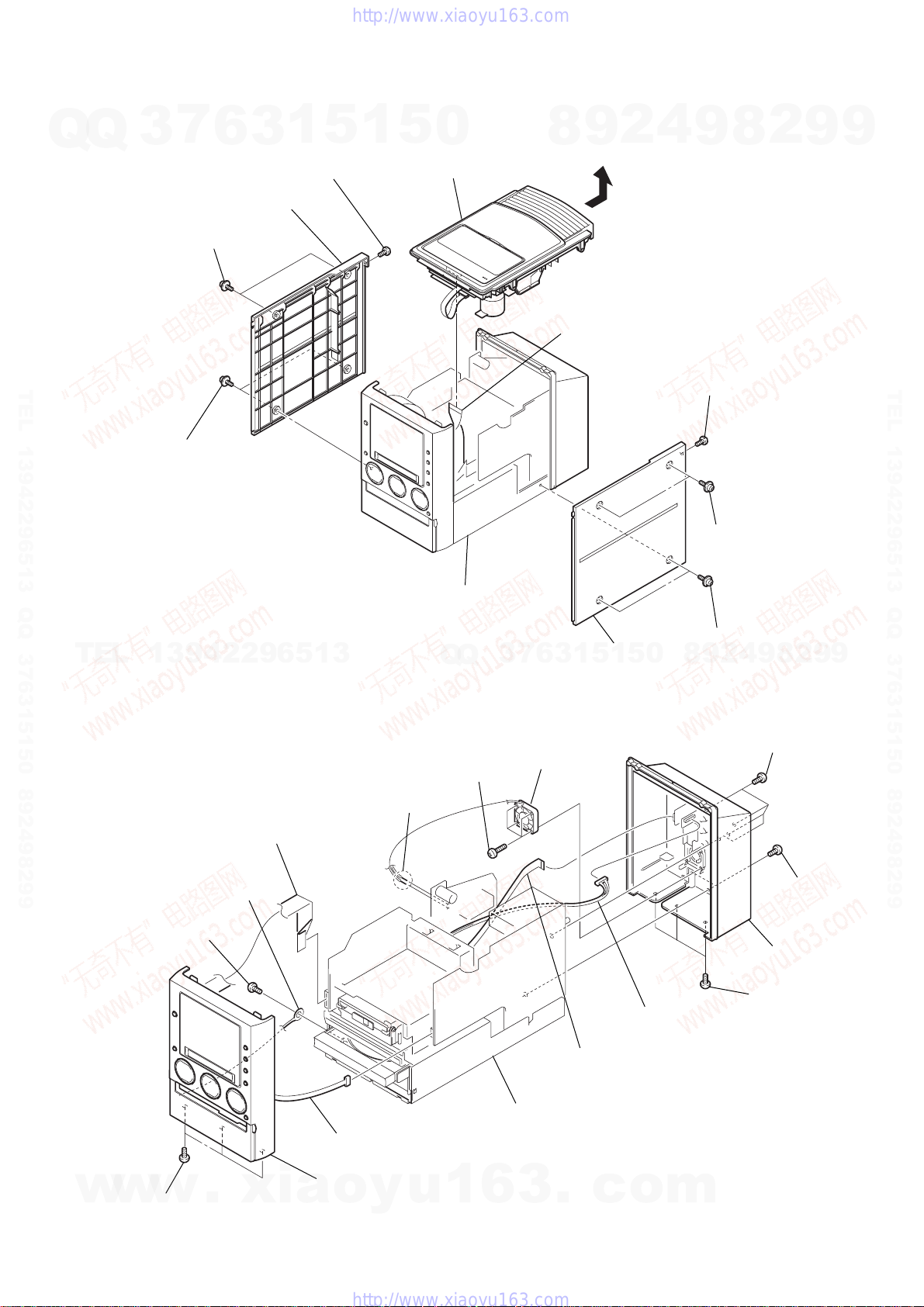

HCD-M700

3-19. RF-240 Board

Q

Q

3

7

6

3

1

5

1

5

0

4

RF-240 board

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

3-20. Tray

TEL

2

flexible flat cable

(CN001)

3

three

screws (+BTP 2.6

13942296513

1

While pressing the two protrusions A and B to unlock the two claws as shown,

pull the tray in the direction of the arrow

A

claw

C

. (Be careful of the claws.)

Q

Q

×

6)

3

7

1

flexible flat cable

(CN002)

5

1

3

6

1

5

0

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

26

w

w

w

C

.

xia

2

tray

B

o

y

u

1

6

3

claw

.

c

o

m

)

Q

3-21. Optical Pick Up (KHM-240AAA(TYPE A))(KHM-270AAA(TYPE B))

Q

3

7

6

4

step screw (L)

3

1

5

1

5

0

5

two

3

chassis section

step screws (M)

8

9

2

4

0

9

three

8

insurators

HCD-M700

Ver 1.1 2003.09

2

9

9

TEL 13942296513 QQ 376315150 892498299

2

6

flexible flat cable

(9core)

8

holder (KHM-240)

1

screw (+PTPWHM 2.6)

TEL

13942296513

9

7

flexible flat cable

(26core)

3

Q

Q

7

6

3

1

5

qa

optical pick up (KHM-240AAA(TYPE A

0

5

1

(KHM-270AAA(TYPE B))

9

4

2

9

8

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

27

HCD-M700

SECTION 4

TEST MODE

Note 1:About “R”

Q

1. Cold Reset

•The cold reset clears all data including preset data stored in the RAM to initial conditions. Execute this mode when returning the set to

Procedure:

1. Press ?/1 button to turn the power on.

2. Press three buttons x , ENTER/START and ?/1 simultaneously.

3. When this button is operated, all of the settings other that DVD are reset. Then the POWER is turned off and the watch display appears.

2. Panel T est Mode

TEL 13942296513 QQ 376315150 892498299

•This mode is used to check the software version, LCD, LED and keyboard.

Procedure:

1. Press the ?/1 button to turn on the power.

2. Press the FUNCTION button to enter mode othe than “TUNER”.

3. Press three bottons x , ENTER/START and FUNCTION simultaneously.

4. LEDs and LCD are all turned on.

4-1. Version check

4-2. Key check

As this unit has only a few buttons, some operations require the use of remote commander (RM-SM700E/provided with unit) buttons. These

Q

operations are indicated as “R” in this manual.

Example: MENU/NO “R” ...Press the [MENU/NO] button of the remote commander.

Note 2:Incorrect operations may be performed if the test mode is not entered properly.

In this case, press the ?/1 button to turn the power off, and retry to enter the test mode.

the customers.

1. When entering the software version display mode, press REPEAT button.The model name (“M700DVD”) and destination are

displayed.

2. Each time REPEAT button is pressed, the display changes “MC, GC, ST, TA, TM, TC, MD and DVD” (returns to MC) in this order,

and returns to the top of the version display.

3. When REC MODE button is pressed while the version numbers are being displayed, year, month and day of the software creation

appear. When REC MODE button is pressed again, the display returns to the software version display. When REPEAT button is

pressed while year, month and day of the software creation are being displayed, the year, month and day of creation of the software

versions are displayed in the same order of version display.

TEL

1. Press PLAY MODE button, and the key check mode is activated. In the key check mode, the LCD displays “K 0 J 0 V 0”. Each time

a button is pressed, “K 0” value increases. However, once a button is pressed, it is no longer taken into account. It is end at

“K21J 0V 0”.

2. To exit from this mode, press three buttons in the same manner as step 3, or disconnect the power cord.

3

7

6

3

1

13942296513

5

1

5

0

Q

Q

3

7

8

6

3

9

1

5

2

1

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

3. Common T est Mode

Procedure:

1. Press ?/1 button to turn the power on.

2. Press three buttons x , ENTER/START and TAPE nN simultaneously.

3. The set goes to the common test mode and the MD and TAPE segments flash.

3-1. Amp Test Mode

1. In the common test mode, every time you press BASS/TRE “R” button, the following items changes in the order as shown below.

g

TONE MAX

g

TONE MIN

TONE FLAT

g

2. When VOLUME + button or VOLUME + “R” button is pressed, VOLUME goes MAX.

3. When VOLUME – button or VOLUME – “R” button is pressed, VOLUME goes MIN.

4. To exit from this mode, press

3-2. Tape Test

1. Check the set is in the common test mode.

2. Insert a recordable cassette tape.

3. Play back the recorded MD.

4. Press z TAPE button.

5. Select the recording direction with TAPE nN button.

6. Press X TAPE button to start recording.

w

w

7. When m or M button against the tape recording direction is pressed, the tape returns to the recording started point

and the set starts playback.

8. To exit from this mode, press ?/1 button and disconnect the power cord.

w

h

(BASS/TRE MAX, VOL MAX)

(BASS/TRE MIN, VOL MAX)

h

h

(BASS/TRE FLAT, VOL MAX)

button and disconnect the power cord.

?/1

.

xia

o

y

u

1

6

3

.

c

o

m

28

Q

4. DVD Ship Mode (Setting the Position for Transportation)

7

Q

3

1. Press ?/1 button to turn the power on.

2. Press FUNCTION to change the function to “DVD”.

3. Press three buttons x , ENTER/START and DVD u simultaneously.

4. The DVD mechanism goes to the transportation mode.

5. When “LOCK” is displayed, disconnect the power cord.

6. The lock is released when the power turns on next.

5. Ship Mode (Setting the Position for Transportation)

This mode is the combination of DVD SHIP mode and Cold reset.

In this mode, the MD reset is not activated.

6

3

1

5

1

5

0

8

9

2

4

9

8

HCD-M700

2

9

9

TEL 13942296513 QQ 376315150 892498299

1. Press ?/1 button to turn the power on.

2. Press three buttons x , ENTER/START and MD u simultaneously.

3. When “LOCK” is displayed, disconnect the power cord.

4. The lock is released when the power turns on next.

MD TEST MODE

1. Precautions For Use of Test Mode

• As operations related to loading will be performed regardless of the test mode operations being performed, be sure to check that the disc

is stopped before setting and removing it.

Even if the Z MD button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not

stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the Z MD button after pressing the MENU/NO “R” button and the rotation of disc is stopped.

1-1. Recording Laser Emission Mode and Operating Buttons

• Continuous recording mode (CREC 1MODE) (C35)

• Laser power check mode (LDPWR CHECK) (C13)

TEL

13942296513

• Laser power adjustment mode (LDPWR ADJUST) (C04)

• Comparison with initial Iop value written in nonvolatile memory (Iop Compare) (C27)

•Write current Iop value in read nonvolatile memory using microprocessor (Iop NV Save) (C06)

•Traverse (MO) check (EF MO CHECK) (C14)

•Traverse (MO) adjustment (EF MO ADJUST) (C07)

• When pressing the z MD button.

2. Setting the Test Mode

Procedure : 1. Press the ?/1 button to turn the power on.

2. Press the FUNCTION button to enter “MD” mode.

3. Press three buttons of x , REC MODE , and FUNCTION simultaneously.

When the test mode is set, “[Check]” will be displayed. Pressing the MD . “R” or MD> “R” button between the

following three groups; ···Tt [Check] Tt [Service] Tt [Develop] Tt ···.

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

Note: Do not use the test mode in the [Develop] group.

If used, the unit may not operate normally.

If the [Develop] group is set accidentally, press the MENU/NO “R” button immediately to exit the [Develop] group.

3. Releasing the Test Mode

Press the REPEAT button twice and ?/1 button to turn the power off, the set goes to the standby mode.

4. Basic Operations of the Test Mode

All operations are performed using the MD . “R” , MD > “R” , ENTER/YES “R” , MENU/NO “R” and REC MODE buttons.

The functions of these buttons are as follows.

Function name Function

ENTER/YES “R” button Proceeds onto the next step. Finalizes input

MENU/NO “R” button Returns to previous step. Stops operations

. “R” , > “R” buttons Changes parameters and modes

REC MODE button Selects the sub menu

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

29

HCD-M700

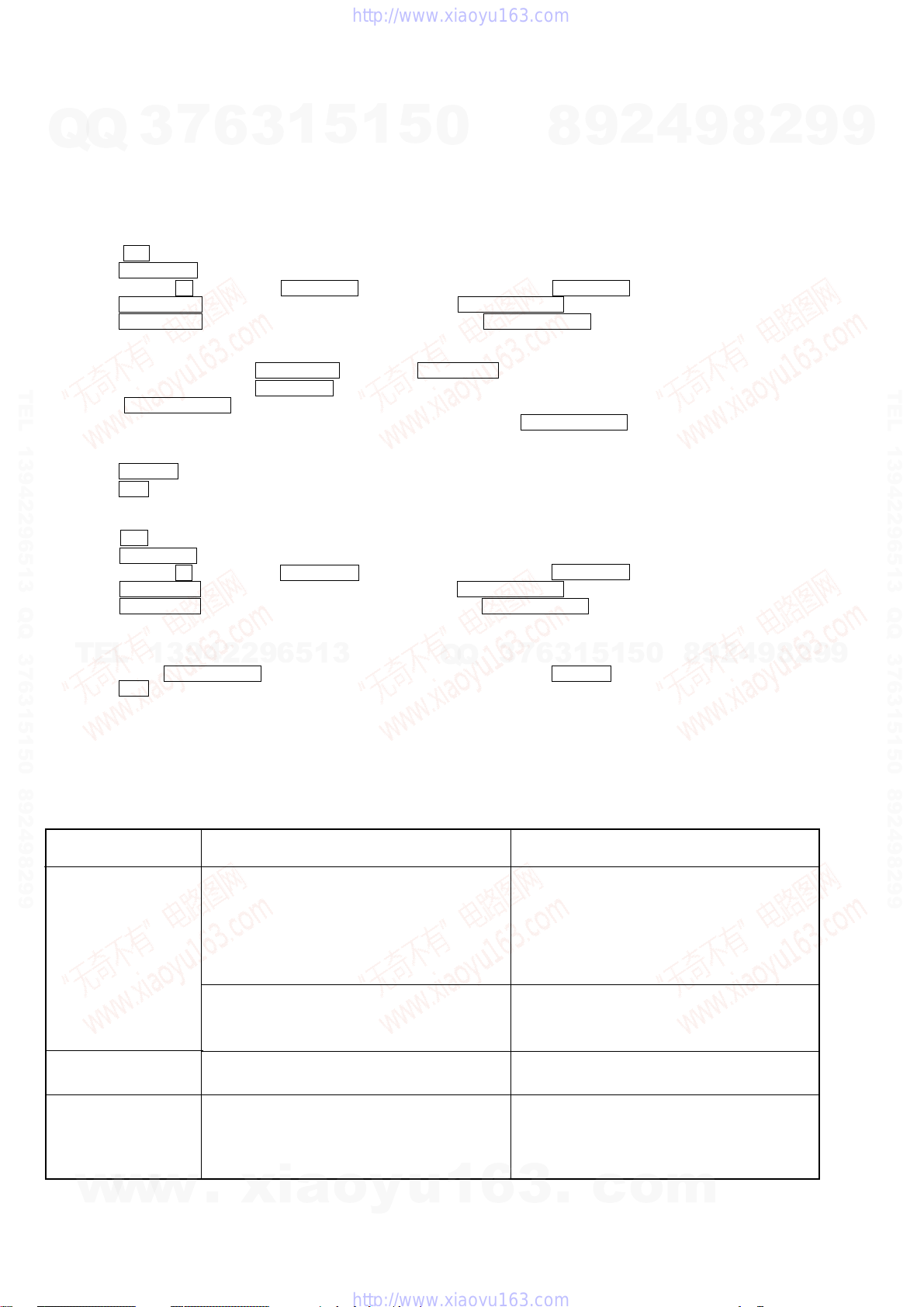

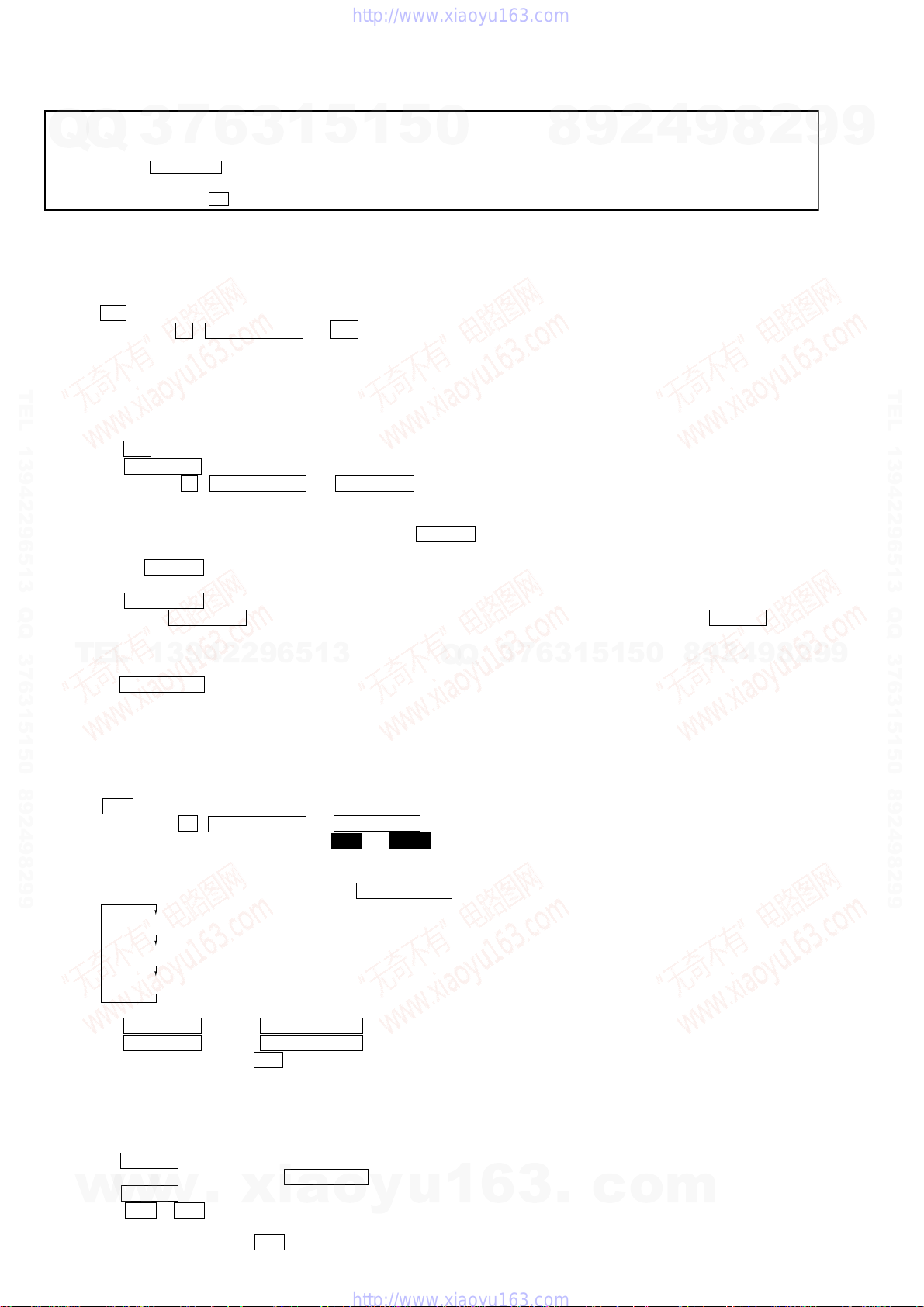

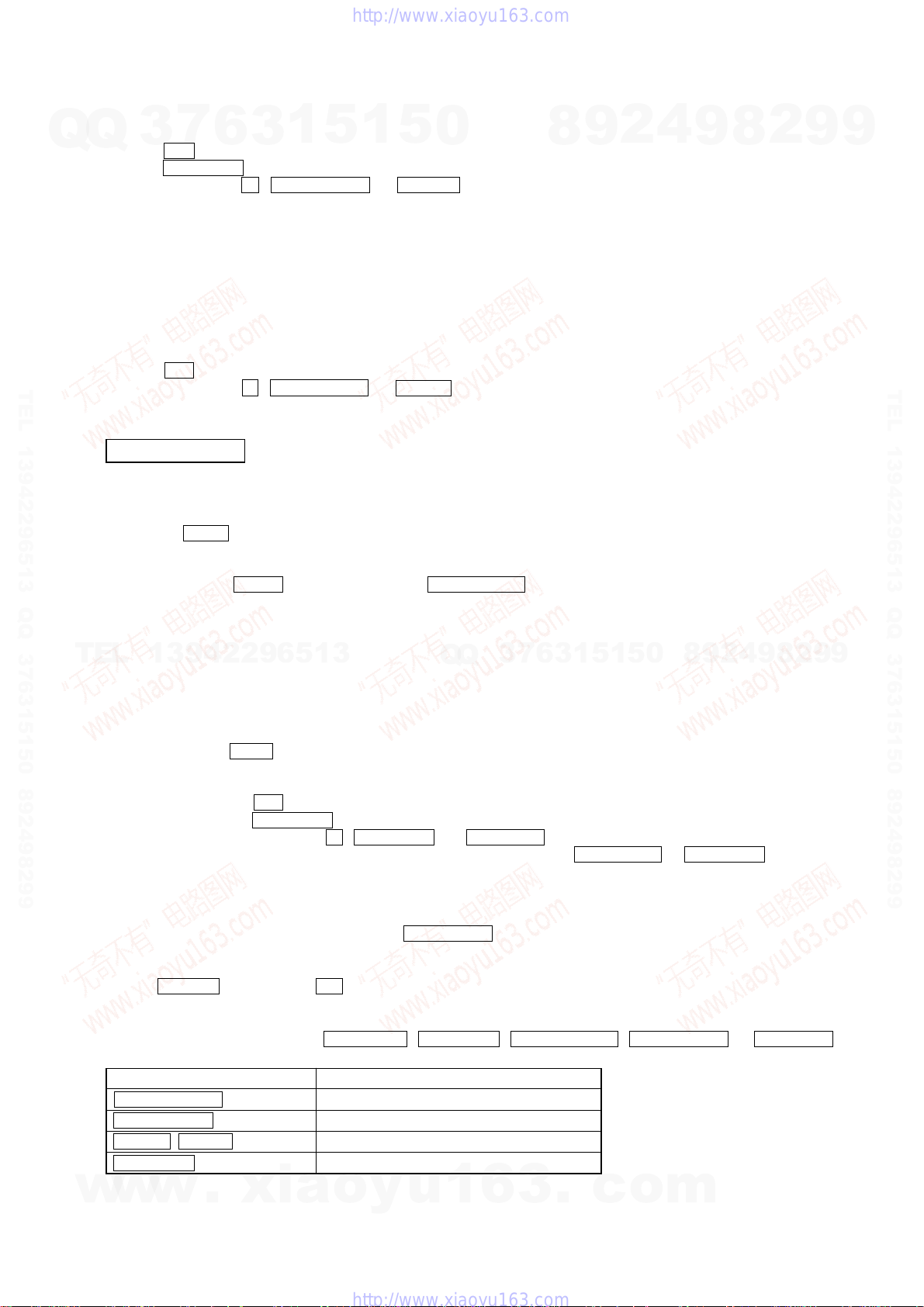

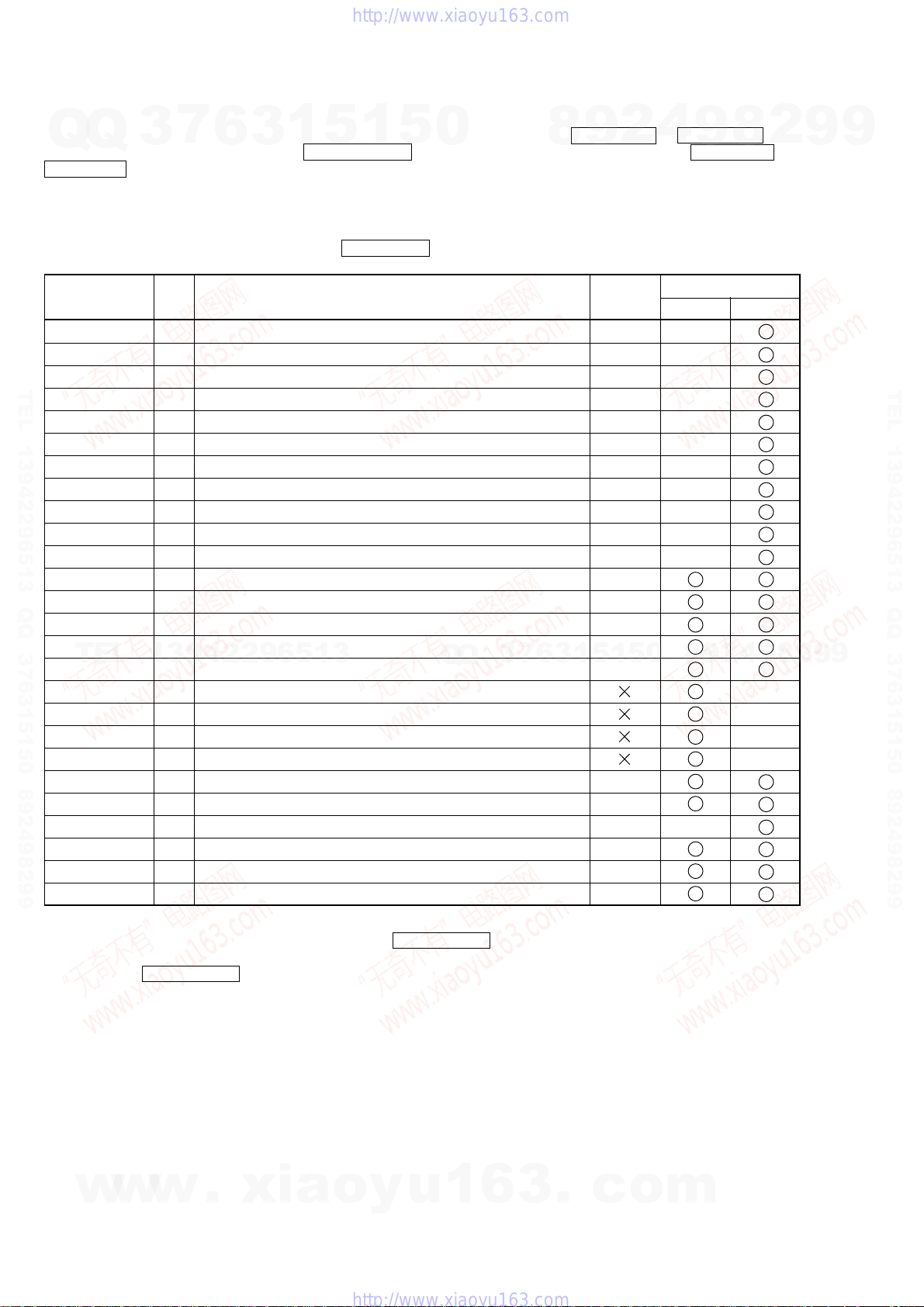

5. Selecting the Test Mode

There are 26 types of test modes as shown below. The groups can be switched by pressing the MD . “R” or MD > “R” button.

Q

Q

After selecting the group to be used, press the ENTER/YES “R” button. After setting a certain group, pressing the MD . “R” or

MD > “R” button switches modes shown below.

Refer to “Group” in the table for details can be selected.

All items used for servicing can be treated using group [Service]. So be carefully not to enter other groups by mistake.

Note: Do not use the test mode in the [Develop] group.

If used, the unit may not operate normally.

If the [Develop] group is set accidentally, press the MENU/NO “R” button immediately to exit the [Develop] group.

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

Display

AUTO CHECK

Err Display

TEMP ADJUST

TEL 13942296513 QQ 376315150 892498299

LDPWR ADJUST

Iop Write

Iop NV Save

EF MO ADJUST

EF CD ADJUST

FBIAS ADJUST

AG Set (MO)

AG Set (CD)

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

TEL

FBIAS CHECK

ScurveCHECK

VERIFYMODE

DETRK CHECK

0920 CHECK

Iop Read

Iop Compare

ADJ CLEAR

INFORMATION

CPLAY 1MODE

CREC 1MODE

No.

Automatic self-diagnosis

C01

Error history display, clear

C02

Temperature compensation offset adjustment

C03

Laser power adjustment

C04

Iop data writing

C05

Writes current Iop value in read nonvolatile memory using microprocessor

C06

Traverse (MO) adjustment

C07

Traverse (CD) adjustment

C08

Focus bias adjustment

C09

Auto gain output level adjustment (MO)

C10

Auto gain output level adjustment (CD)

C11

Temperature compensation offset check

C12

Laser power check

C13

Traverse (MO) check

C14

Traverse (CD) check

C15

13942296513

Focus bias check

C16

S-curve check

C17

Nonvolatile memory check

C18

Detrack check

C19

Most circumference check

C25

Iop data display

C26

Comparison with initial Iop value written in nonvolatile memory

C27

Initialization of nonvolatile memory for adjustment values

C28

Display of microprocessor version, etc.

C31

Continuous playback mode

C34

Continuous recording mode

C35

Details

Q

Q

3

7

6

3

1

5

Mark

5

1

Group

Check Service

9

8

0

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

•For details of each adjustment mode, refer to “Section 5 Electrical Adjustments”.

• If a different mode has been selected by mistake, press the MENU/NO “R” button to release that mode.

• Modes with (×) in the Mark column are not used for servicing and therefore are not described in detail. If these modes are set acciden-

tally, press the MENU/NO “R” button to release the mode immediately.

w

w

w

30

.

xia

o

y

u

1

6

3

.

c

o

m

Loading...

Loading...