Page 1

HCD-LS1

SERVICE MANUAL

HCD-LS1 is the Amplifier, CD player and

Tuner section in CMT-LS1.

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type HG-1

Optical Pick-up Name KSS-540A

Amplifier section

For the U.S. model

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

With 4 ohm loads both channels driven, from 120 –

10,000 Hz; rated 10 watts per channel minimum

RMS power, with no more than 10% total

harmonic distortion from 250 milliwatts to rated

output.

North American model:

Continuous RMS power output (Reference)

European model:

DIN power output (Rated) 11 + 11 watts

Continuous RMS power output (Reference)

Other models:

DIN power output (Rated) 11 + 11 watts

Continuous RMS power output (Reference)

16 + 16 watts

(4 ohms at 1 kHz, 10% THD)

(4 ohms at 1 kHz, DIN)

16 + 16 watts

(4 ohms at 1 kHz, 10% THD)

(4 ohms at 1 kHz, DIN, 240 V)

11 + 11 watts

(4 ohms at 1 kHz, DIN, 220 V)

16 + 16 watts

(4 ohms at 1 kHz, 10% THD,

240 V)

16 + 16 watts

(4 ohms at 1 kHz, 10% THD,

220 V)

Inputs TAPE IN (stereo mini jack):

Outputs TAPE OUT (stereo mini jack):

CD player section

System Compact disc and digital audio

Laser Semiconductor laser (λ=780 nm)

Laser output Max. 44.6 µW*

Frequency response 20 Hz – 20,000 Hz (±3.0 dB)

voltage 250 mV, impedance

47 kilohms

1Vrms at CD Full Bit Play,

impedance 1 kilohm

CD OUT: Optical

PHONES (stereo mini jack):

accepts headphones of 8 ohms or

more

SPEAKER: speaker system

4 ohms

system

Emission duration: continuous

*This output is the value measured

at a distance of 200 mm from the

objective lens surface on the

Optical Pick-up Block with 7 mm

aperture.

– Continued on next page –

COMPACT DISC RECEIVER

Page 2

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

North American model: 87.5 – 108.0 MHz (100 kHz step)

Other models: 87.5 – 108.0 MHz (50 kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

North American model: 530 – 1,710 kHz

European model: 531 – 1,602 kHz

Other models: 531 – 1,602 kHz

Antenna AM loop antenna

Intermediate frequency 450 kHz

(with the interval set at 10 kHz)

531 – 1,710 kHz

(with the interval set at 9 kHz)

(with the interval set at 9 kHz)

(with the interval set at 9 kHz)

530 – 1,710 kHz

(with the interval set at 10 kHz)

Desktop stand

Dimensions (w/h/d) 184 × 218 × 140 mm

Mass Approx. 0.5 kg

Wall hanging adapter

Dimensions (w/h/d) 180 × 220 × 39 mm

Mass Approx. 0.5 kg

Wall hanging bracket

Dimensions (w/h/d) 180 × 220 × 12 mm

Mass Approx. 0.4 kg

General

Power requirements

North American model: 120 V AC, 60 Hz

European model: 230 V AC, 50/60 Hz

Other models: 220 – 240 V AC, 50/60 Hz

Power consumption 25 W

Dimensions 192 × 295 × 150 mm

Mass Approx. 4.0 (with Desktop

Supplied accessories Remote commander (1)

(w/h/d, incl. projecting parts,

controls and desktop stand)

stand) kg

AM loop antenna (1)

FM wire antenna (1)

Desktop stand (1)

Wall hanging adapter (1)

Wall hanging bracket (1)

Screws for stand or adapter

M4 ×14 (4)

Dust caps (3)

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 5

3. DISASSEMBLY ......................................................... 7

4. ELECTRICAL ADJUSTMENT............................ 19

5. DIAGRAMS

5-1. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 21

5-2. Printed Wiring Board – CD Section – ........................... 22

5-3. Schematic Diagram – CD Section (1/3) – ..................... 23

5-4. Schematic Diagram – CD Section (2/3) – ..................... 24

5-5. Schematic Diagram – CD Section (3/3) – ..................... 25

5-6. Printed Wiring Board – Main Section – ........................ 26

5-7. Schematic Diagram

– MAIN Section – ........................................................... 27

5-8. Printed Wiring Boards

– AMP/RELA Y/JACK Board – ...................................... 28

5-9. Schematic Diagram

– AMP/RELA Y/JACK Board – ...................................... 29

5-10. Printed Wiring Boards – Panel Section (1/2) – ............. 30

5-11. Schematic Diagram – Panel Section (1/2) –.................. 31

5-12. Printed Wiring Boards – Panel Section (2/2) – ............. 32

5-13. Schematic Diagram – Panel Section (2/2) –.................. 32

5-14. Printed Wiring Boards

– POWER SUPPLY Section – ....................................... 34

5-15. Schematic Diagram – POWER SUPPLY Section –....... 35

6. EXPLODED VIEWS ................................................ 37

7. ELECTRICAL PARTS LIST ............................... 43

Designs and specifications are subject to change

without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMA TIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

Page 3

SECTION 1

SERVICING NOTES

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

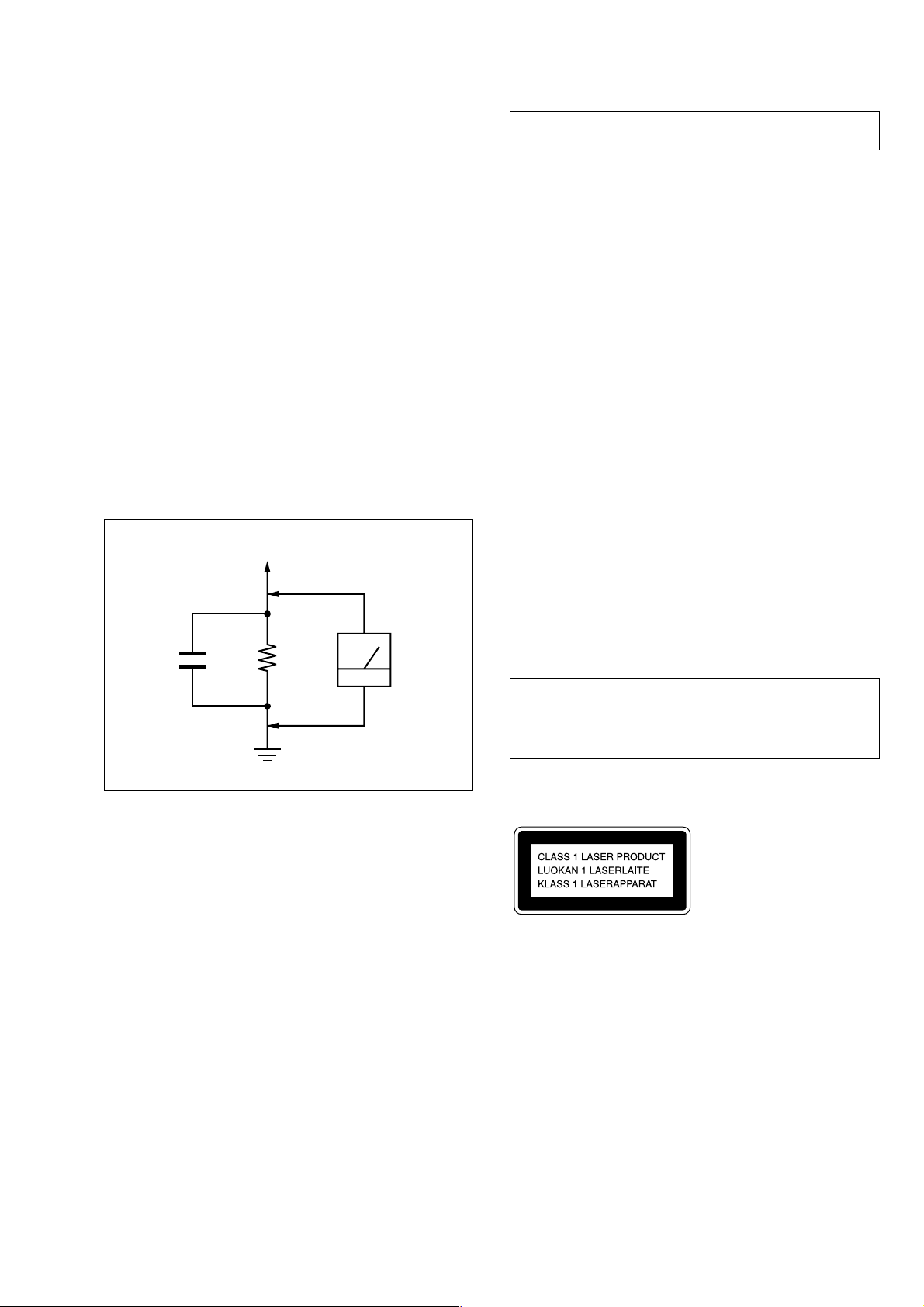

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leaka ge tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

AC

voltmeter

(0.75 V)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

3

Page 4

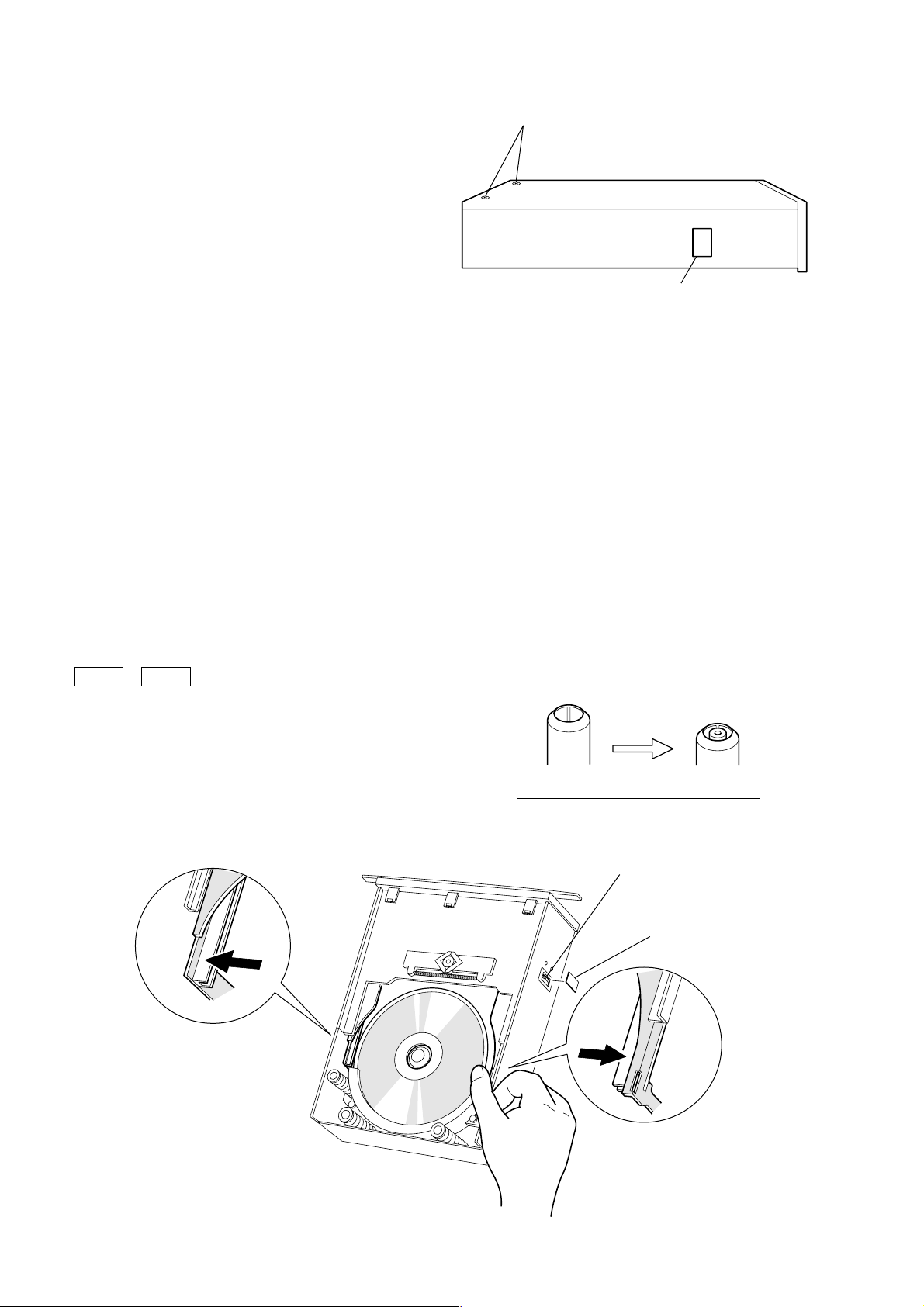

DISC EJECTION IN EMERGENCY

L

In case of emergency , remove the discs inside the Mec hanism Ass’y

(CD Changer) as follows:

(1) Disconnect the power of the Main Unit.

(2) Remove the Mechanism Ass’y. Refer to item

(3) Remove two top cover fastening screws at the rear of the

Mechanism Ass’y, and tak e off the Top Cover HS Ass’y . Refer

to Fig. A.

(4) Remove the left side adhesive label (Dust Seal EMA SL) on

the left side of the Mechanism Ass’y. Refer to Fig. A.

Note: Carefully remove it since it is used again later.

(5) Turn the Emergency Gear SL up or down until the disc lock

sleeve SL is lowered as shown in Fig. B.

Caution:Never use nail when turning the Emergency Gear

SL. Otherwise, the gear tooth may be broken.

(6) Raise the front section of the Mechanism Ass’y as illustrated

in Fig. B. Then carefully spread the Loading L/R MF Ass’y so

that the disc drops into the Stocker.

(7) While keeping the Loading L/R MF Ass’y spread, remov e the

discs.

Note: When removing the discs, take care not to scrape them

against other parts, to prevent damage.

(8) Re place the removed parts by reversing the above procedure.

Note: To prevent dust from entering the unit, reattach the

adhesive label on the opening for the Emergency Gear

SL.

(9) Perform the mechanism initialization as follows to clear the

disc information stored in the Mechanism Ass’y.

Press the DISC1 button while pressing the DISC5 button.

Then, the Unit enters the CD Playback mode and mechanism

Initialization operation begins and disc change operation starts.

After that, the Unit enters Standby mode.

DISC1 + DISC5

Top Cover Fastening Screws

Label

Fig. A

Disc Lock Sleeve SL

Loading R MF Ass’y

– Up Position –– Down Position –

Emergency Gear SL

Dust Seal EMA S

Loading L MF Ass’y

Fig. B

4

Page 5

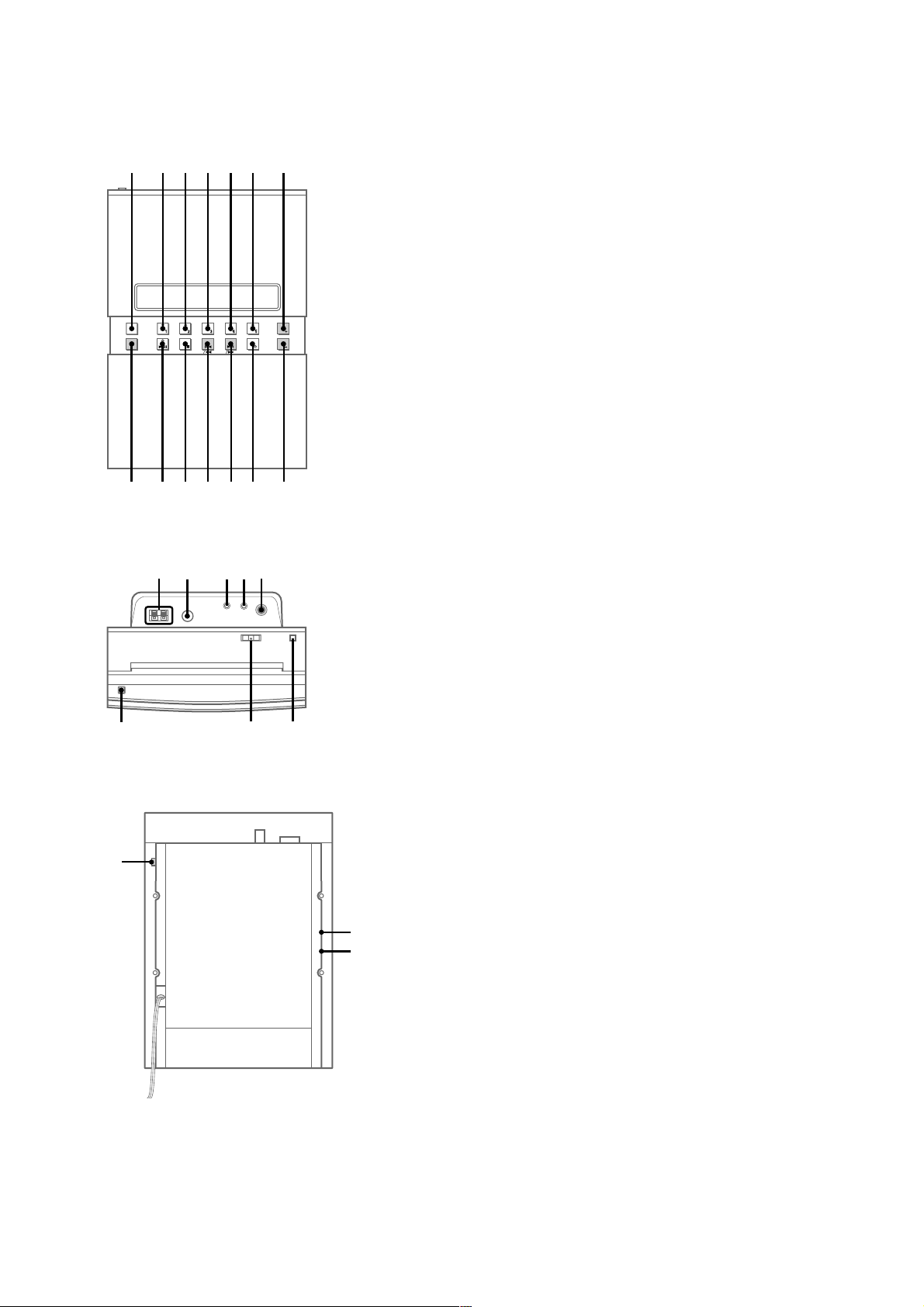

• LOCATION OF CONTROLS

– Front View –

SECTION 2

GENERAL

1 23456 7

8 9 q; qa qs qd qf

– Top View –

54321

678

1 FUNCTION button

2 DISC 1 button and indicator

3 DISC 2 button and indicator

4 DISC 3 button and indicator

5 DISC 4 button and indicator

6 DISC 5 button and indicator

7 VOLUME + button

8 TUNER/BAND button

9 u button and indicator

q; x button

qa . m , TUNER - button

qs > M , TUNER + button

qd A button

qf VOLUME - button

1 AM ANTENNA terminals

2 FM ANTENNA jack

3 TAPE OUT jack

4 TAPE IN jack

5 PHONES jack

6 `/1 button

7 PANEL OPEN switch

8 PANEL OPEN/CLOSE switch

– Rear View –

1

1 CD DIGITAL OUT (OPTICAL) connector

2 LEFT SPEAKER terminals

3 RIGHT SPEAKER terminals

2

3

5

Page 6

Step 2: Setting the time

You must set the time before you can use the

timer functions.

The clock is on a 24-hour system for the European

model, and a 12-hour system for other models.

The 24 hour system model is used for illustration

purposes.

Set the time before turning on the power.

31

2

564

8

97

10/0

>10

+

X

x

+

–

.>

M

+

–

–

1

2,3

N

m

2,3

3

Press +/– to set the minute then press

ENTER.

The clock starts.

To change the time

You can change the preset time while the power is

on.

1 Press CLOCK/TIMER SET.

2 Press +/– repeatedly until “SET CLOCK”

appears then press ENTER.

3 Repeat steps 2 and 3 of “Setting the time”.

Tips

• If you have made a mistake, start again from step 1.

• The built-in clock shows the time in the display

while the power is off.

• The upper dot flashes for the first half of a minute

(0 to 29 seconds), and the lower dot flashes for the

last half of a minute (30 to 59 seconds).

This section is extracted from

instruction manual.

1

Press CLOCK/TIMER SET while the

power is off.

The hour indication flashes.

2

Press +/– to set the hour then press

ENTER.

The minute indication flashes.

6

Page 7

SECTION 3

DISASSEMBLY

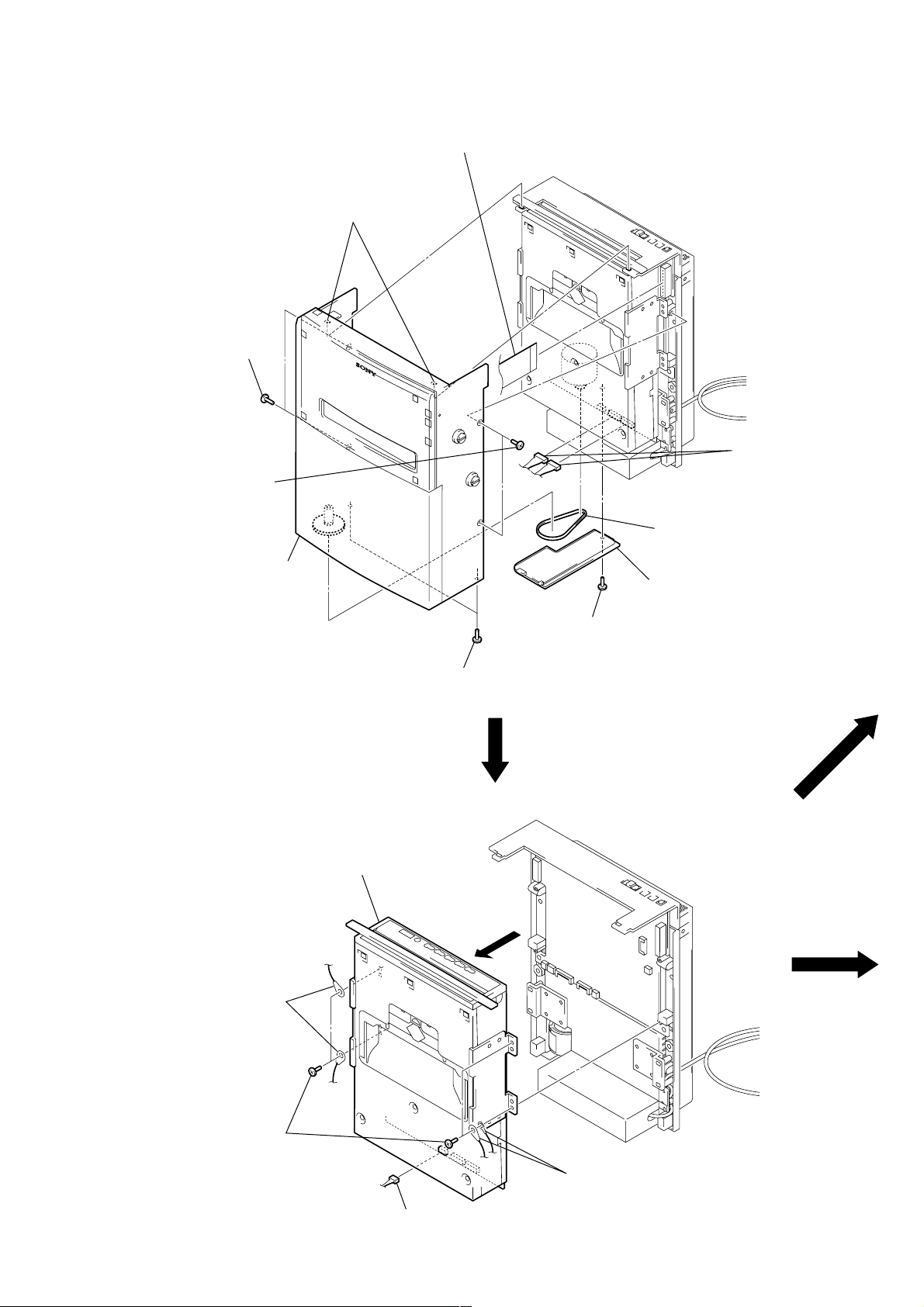

Note: Follow the disassembly procedure in the numerical order given.

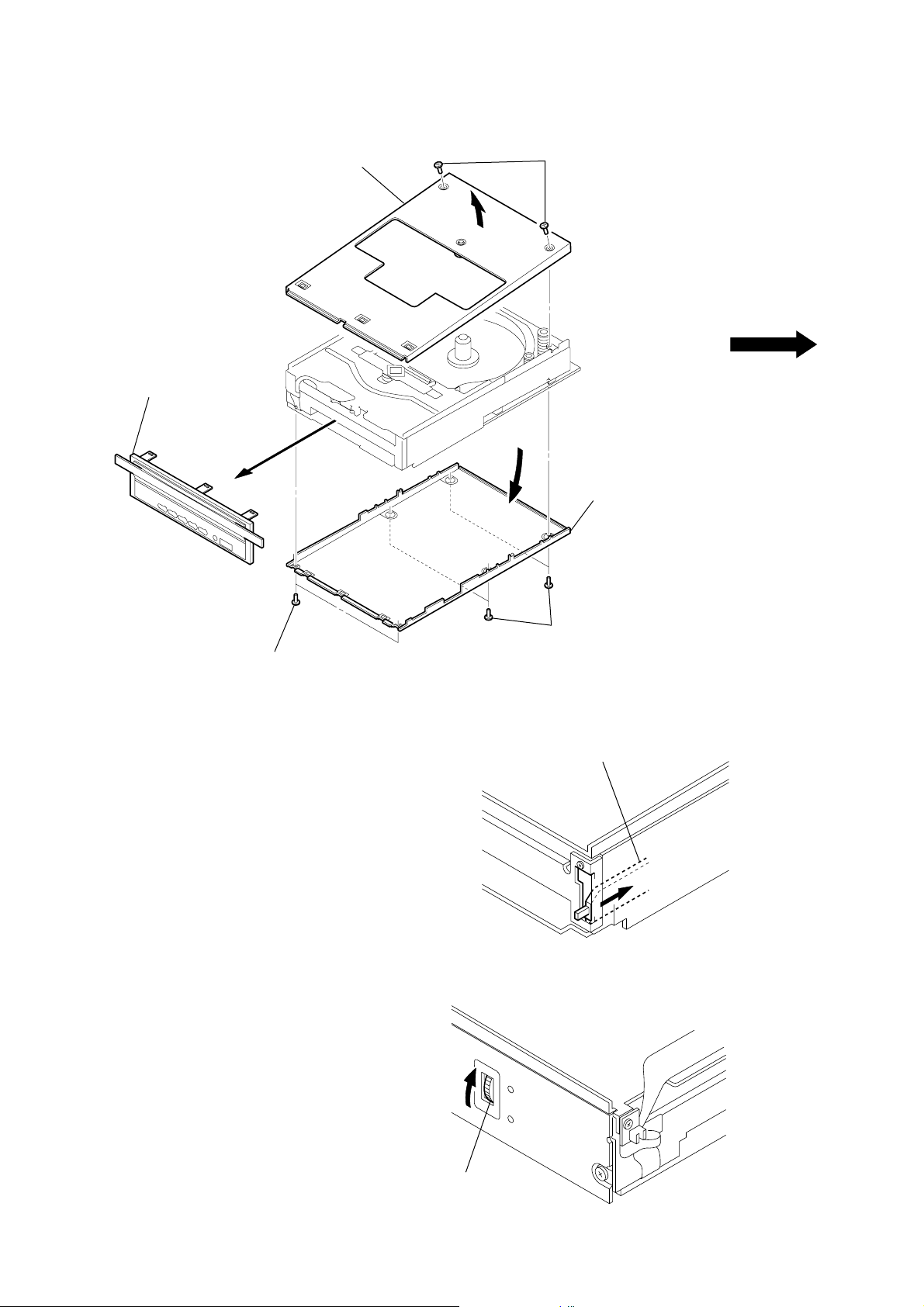

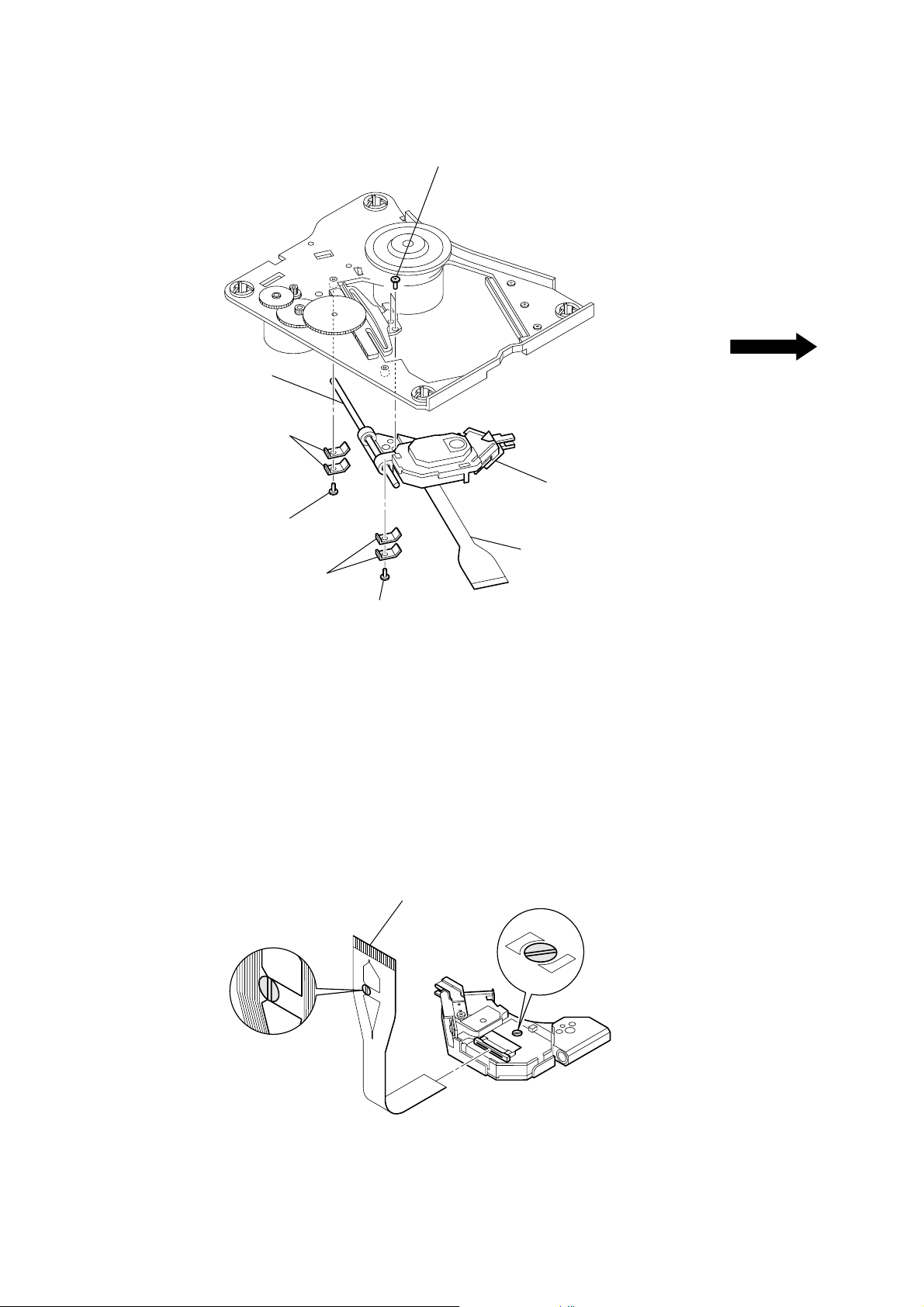

MAIN CASE SECTION

5 two screws

(BTP 3 × 10)

5 two screws

(BTP 3 × 10)

9 main case section

7 FFC (26core)

(CN604)

6 two claws

8 two connectors

(PC501, 502)

3 belt

2 bottom cover

MECHANISM DECK (HG-1)

2 two lugs

1 screw

(B3 × 6)

4 two screws

(BTP 3 × 10)

DOOR MOTOR ASS’Y (M391) (Ne xt P age)

HOLDER MECHA, DUST SEAL EMA SL

(Page 9)

5 mechanism deck (HG-1)

3

1 four screws

(BTP 3 × 10)

2 two lugs

4 connector

(CP503)

7

Page 8

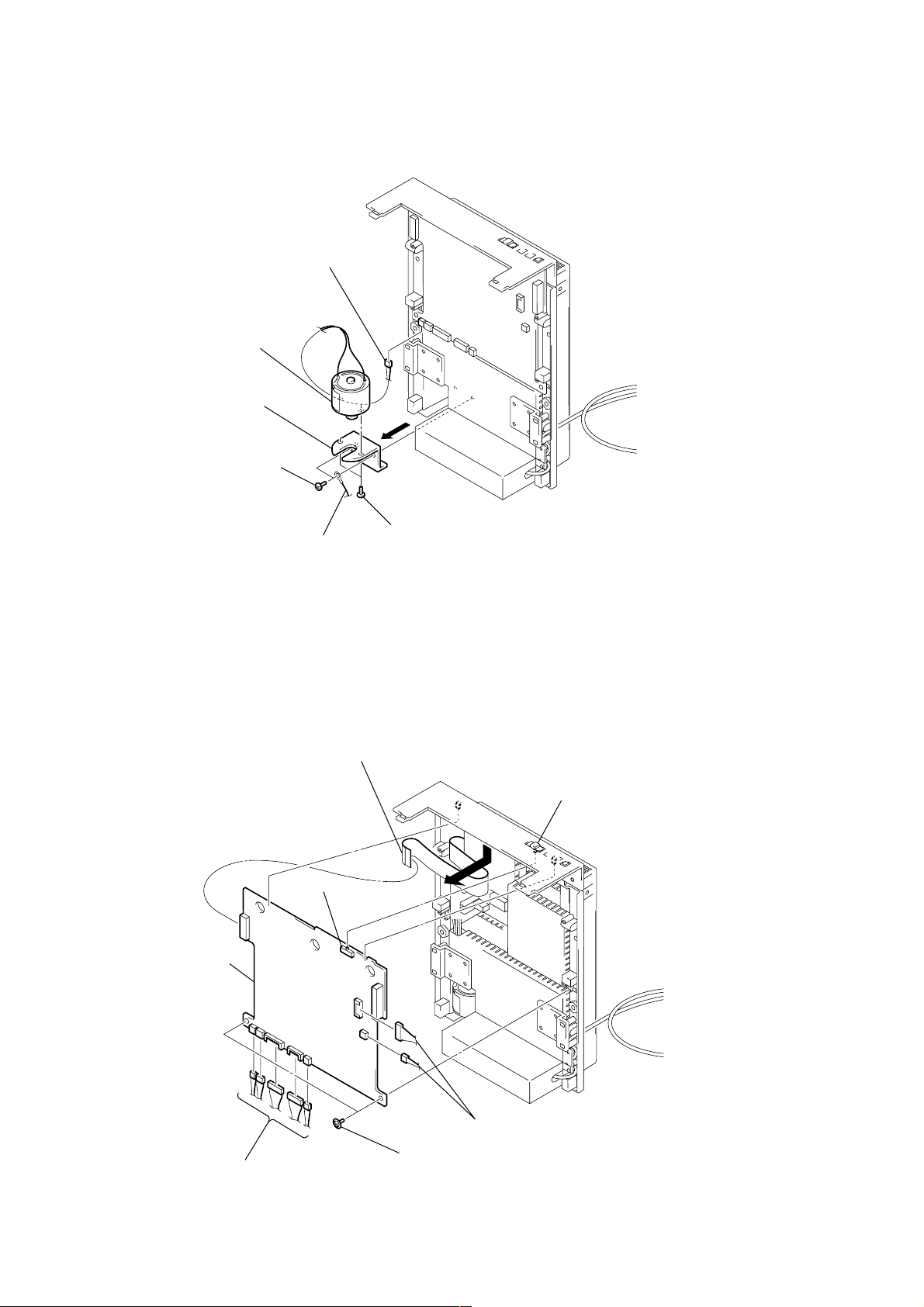

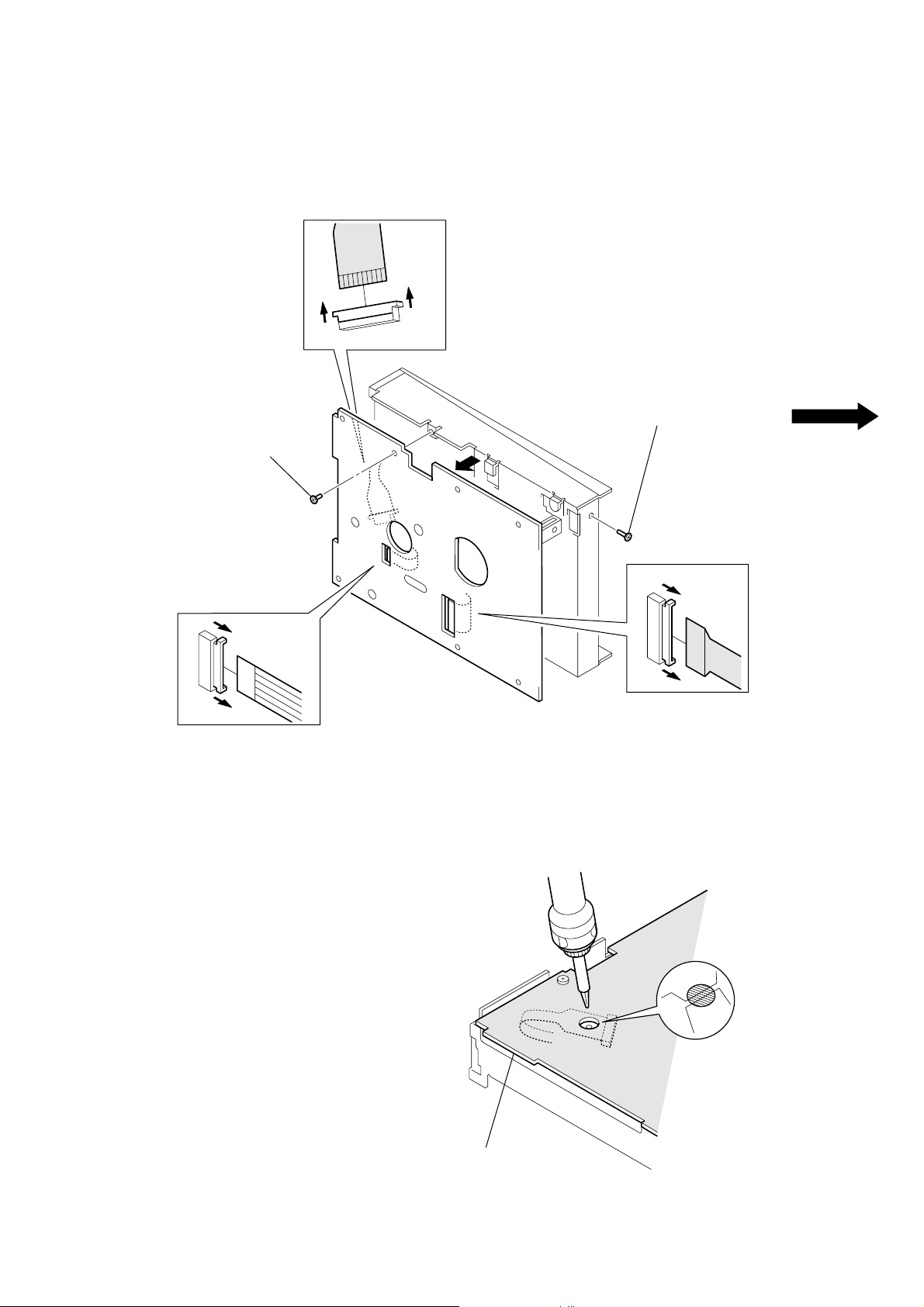

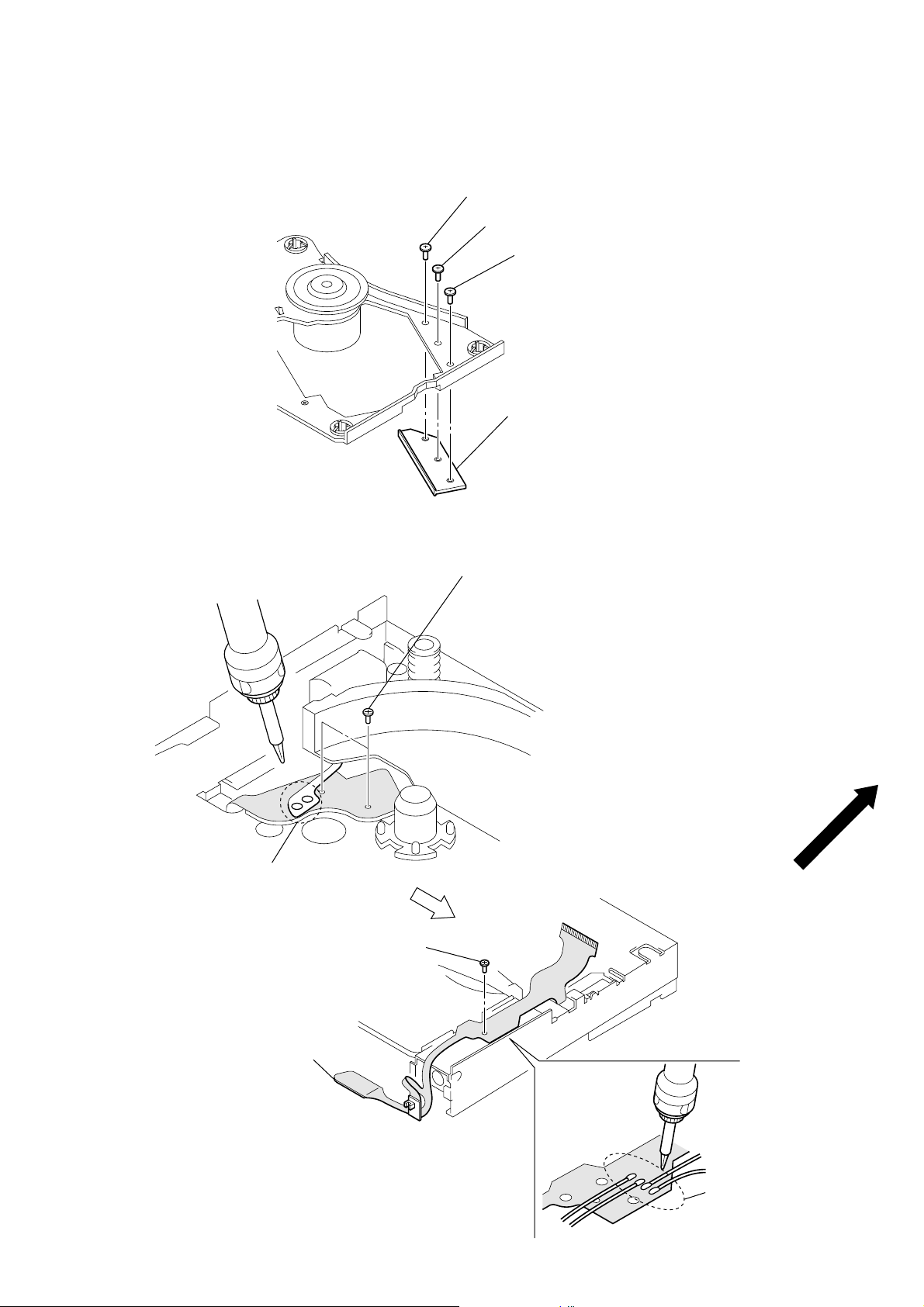

DOOR MOTOR ASS’Y (M391)

(

)

7 door motor ass’y

(M391)

6 motor bracket

2 two screws

(BTP3 × 8)

1 connector

(CN391)

4

MAIN BOARD

4 Remove the MAIN board

in the direction of the arrow.

3 lug

1 FFC (15core)

(CN101)

S391

5 two screws

(P2.6 × 3)

Note: On installation MAIN board

adjust the S391 and slide knob.

slide knob

2 two connectors

(CN201, 204)

2 five connectors

CN203, 301, 302, 303, 391

3 two screws

(PWH2.6 × 6)

8

Page 9

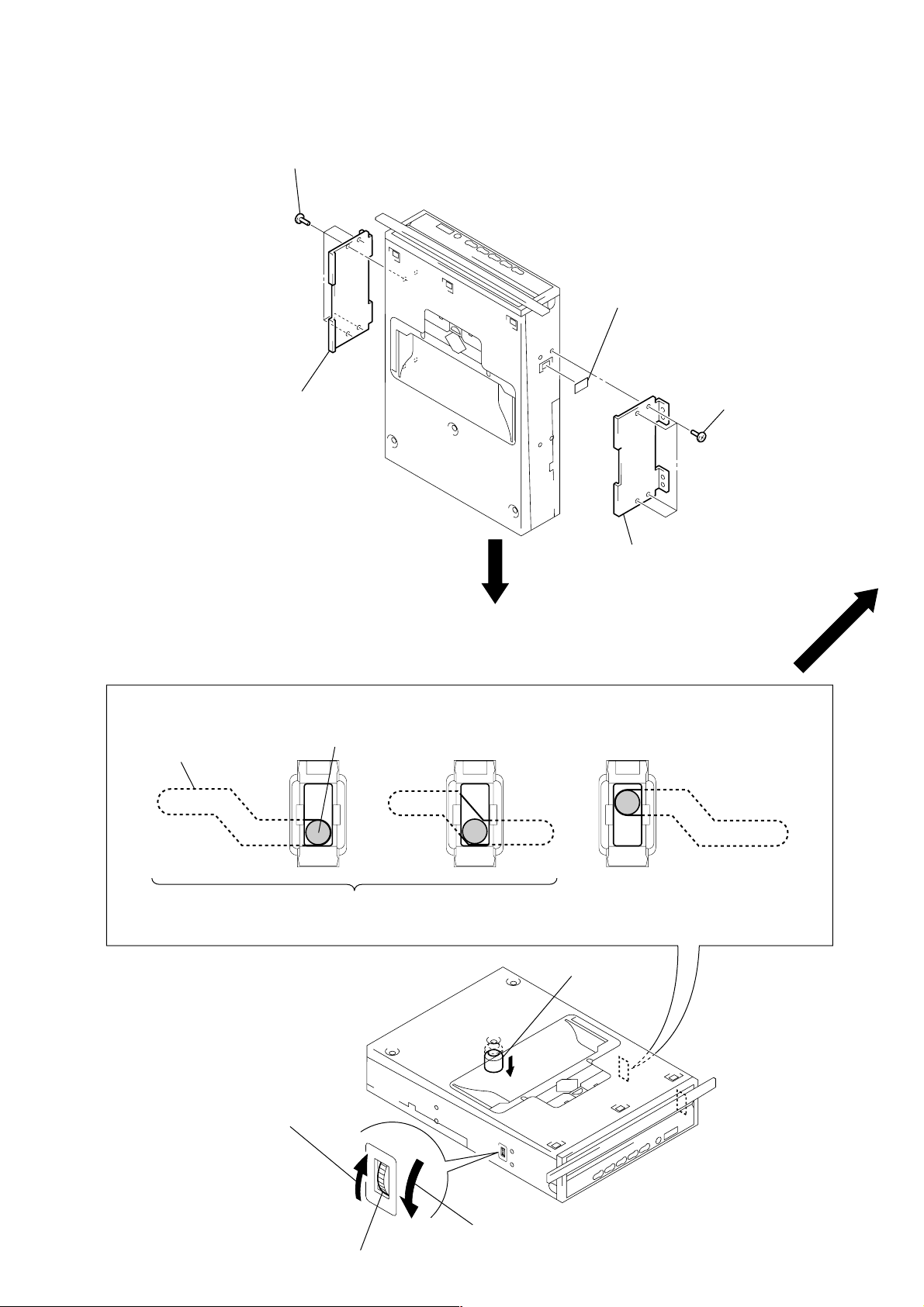

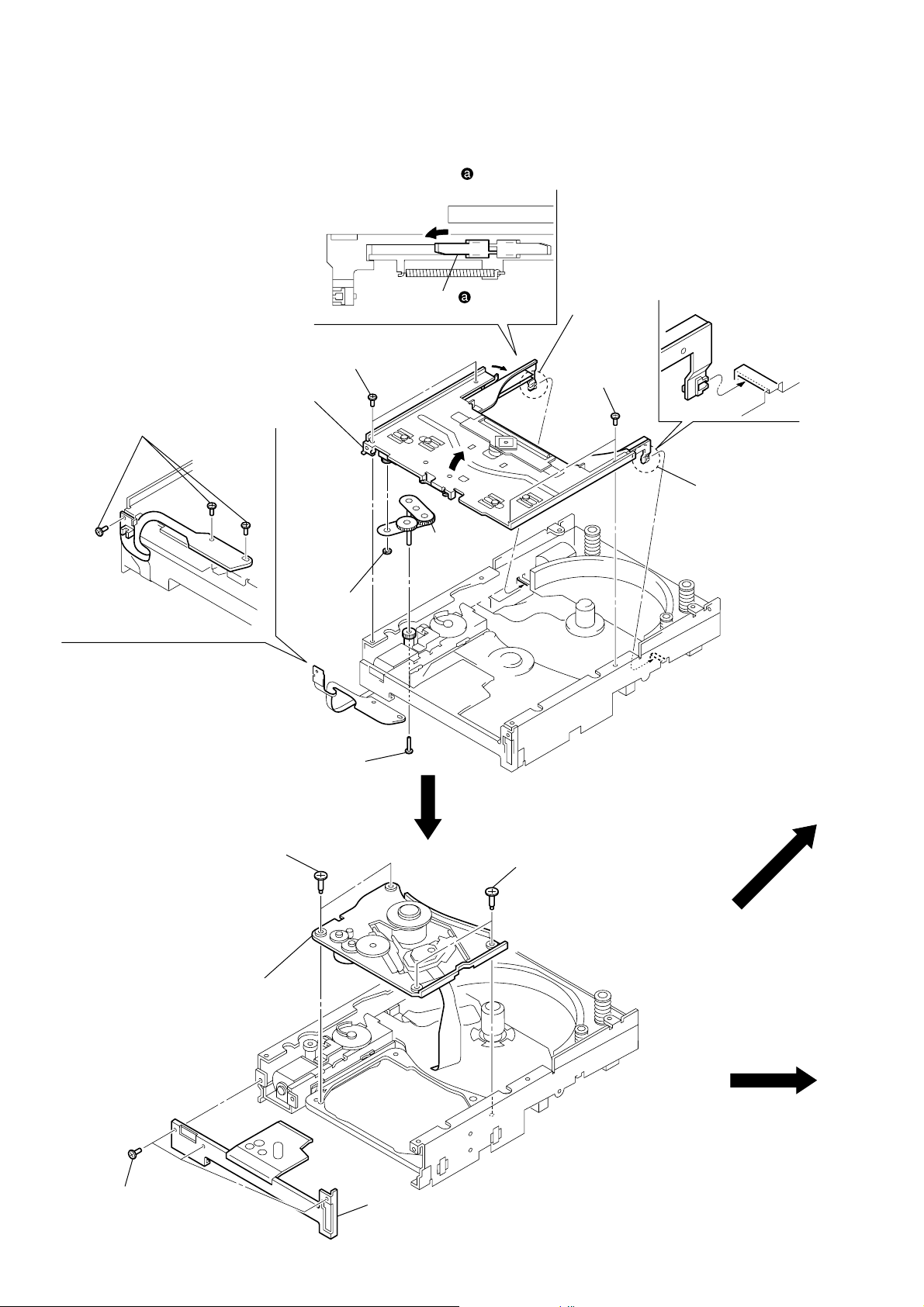

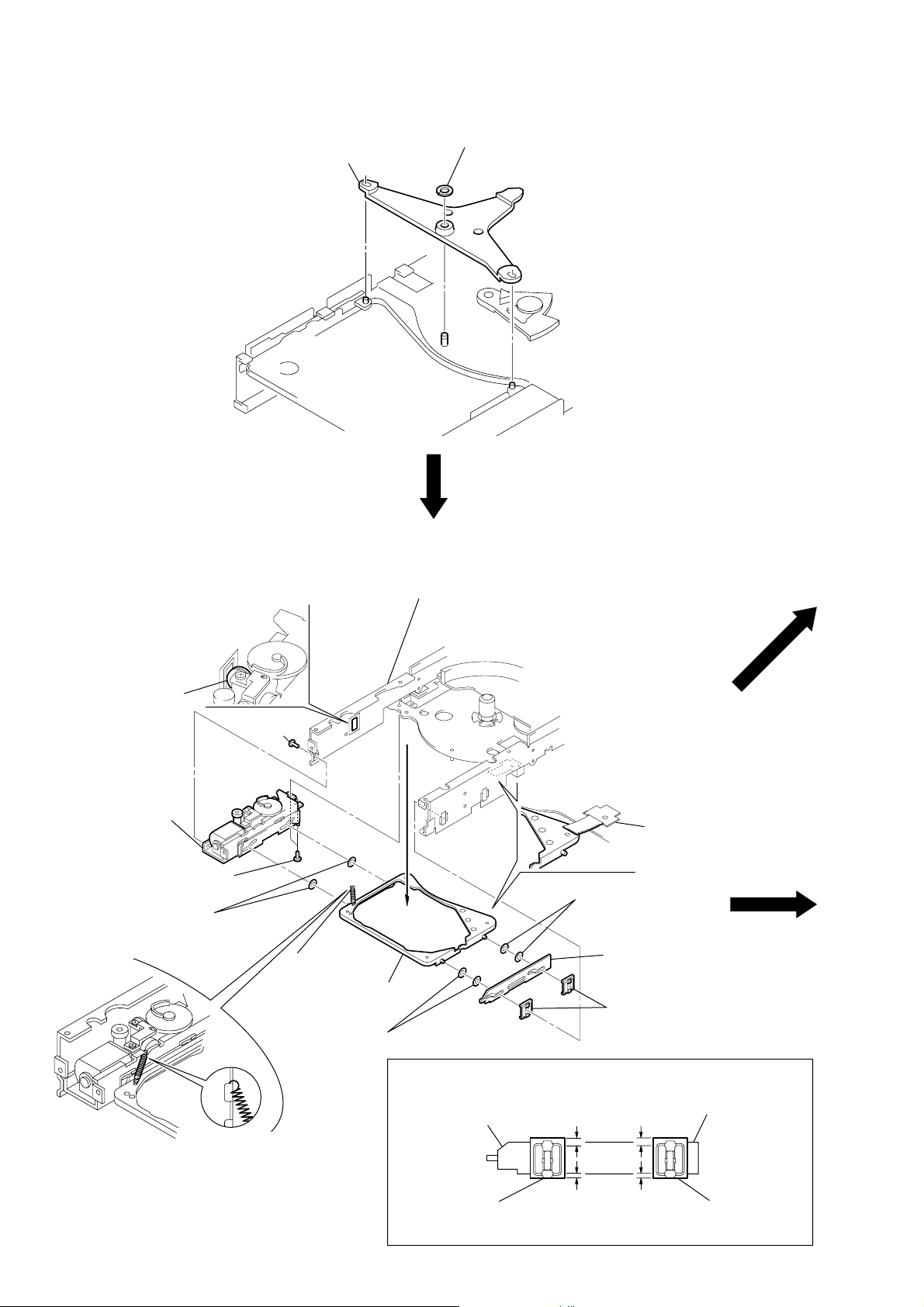

(1) MODE-1

EJECT, DISC LOAD state

(2) MODE-2

STANDARD State (STOP state)

(3) MODE-3

PLAY, DISC CHANGE state

When disassembling and reassembling the mechanism deck by any failure, the mechanism deck must be in (2) Standard

state (STOP state) as shown below.

• The mechanism deck (HG-1) has three modes. (Fig. A)

mecha UD sub cam SL

Traverse Mecha Down state

Traverse Mecha Up state

sus base X sub ass’y shaft

(Fig. A)

HOW TO ADJUST STOP STATE POSITION

D lock sleeve SL

emergency gear SL

2 Rotate gradually the emergency

gear SL in the up arrow direction

up to the position where the D lock

sleeve SL comes to the bottom.

(To attain (2) standard state in Fig. A)

1 Rotate fully the emergency gear SL

in the down arrow direction.

HOLDER MECHA, DUST SEAL EMA SL

1 four screws

(B3 × 5)

3 dust seal EMA SL

Note:Carefully remove it since

it is used again later.

2 holder mecha

2 holder mecha

PRECAUTIONS ON DISASSEMBLING AND REASSEMBLING MECHANISM DECK

1 four screws

(B3 × 5)

9

Page 10

TOP COVER HS ASS’Y, BOTTOM COVER MF ASS’Y, F PANEL ASS’Y R237

2 Remove top cover HS ass’y

in the direction of arrow A.

A

5 F panel ass’y R237

1 two screws

(P2.6 × 3)

B

4 Remove bottom cover

MF ass’y in the direction

of arrow B.

3 two screws

(P2.6 × 5)

Note: 1.Before reassembling F Panel Ass’y R237

be sure that the end of the Mecha UD Sub

Cam SL on the right front does not protrude

as shown in (Fig. B.1). If it protrudes, move

it backward as follows:

1) Carefully remove the left side adhesive

label (Dust Seal EMA SL) on the left side

of the unit. refer to (Fig. B.2)

2) Turn the Emergency Gear SL with your

finger tip in the direction of the arrow

until the end of the Mecha UD Sub Cam

SL is drawn inside the unit. (See Fig. B.2).

When turning the Gear, DO NOT use nail

as the gear tooth can be broken.

3) Reattach the adhesive label (Dust Seal EMA

SL).

Note: 2.Be sure that the claws of F Panel Ass’y R237 are

securely inserted into each holes in Top Cover HS

Ass’y and Bottom Cover MF ass’y.

3 four screws

(P2.6 × 5)

Mecha UD Sub SL

(Fig. B.1)

10

Emergency Gear SL

(Fig. B.2)

Page 11

MAIN R237 BOARD

(

)

y

MAIN R237 board

Unsolder the shorting lands

on the pick-up flexible board.

Note: To allow easier installation of the MAIN R237 board,

move the optical pick-up KSS-540A to the outermost

position, before removing the MAIN R237 board.

6 pick-up flexible board

(CP101)

2 screw

(P2.6 × 4)

4 wire flexible board

CP102

Note: When disconnecting these felxible boards,

do not open the MAIN R237 board wide to

avoid damage to flexible boaards.

1 screw

(P2.6 × 8)

3

5 PCB FLEX mecha ass’

(CP103)

LOADING MF ASS’Y

(Next Page)

STC POS GEAR SL

(Page 18)

INSTALLING THE MAIN R237 BOARD

11

Page 12

LOADING MF ASS’Y

Note:Though the cam of the Mecha UD sub cam SL will be in (1) state in (Refer to page 9. Fig. A)

when the loading MF Ass’y is assembled, set in (2) state in (Refer to page 9. Fig. A) using

the emergency gear SL.

6 While pushing lever inward, remove

loading MF ass’y by lifting it upward.

1 three screws

(P2 × 2)

2 two screws

(2.6 × 3)

7 loading MF ass’y

8 washer

lever

4

9 loading link

SL ass’y

5 ditch

2 two screws

(2.6 × 3)

5 ditch

TRAVERSE MECHA ASS’Y

3 two damper screws

4 traverse mecha ass’y

1 three screws

(P2 × 2)

3 screw

(P1.7 × 2.5)

3 two damper screws

PCB FLEX MECHA

ASS’Y

(Page 15)

2 FR chassis SL ass’y

12

Page 13

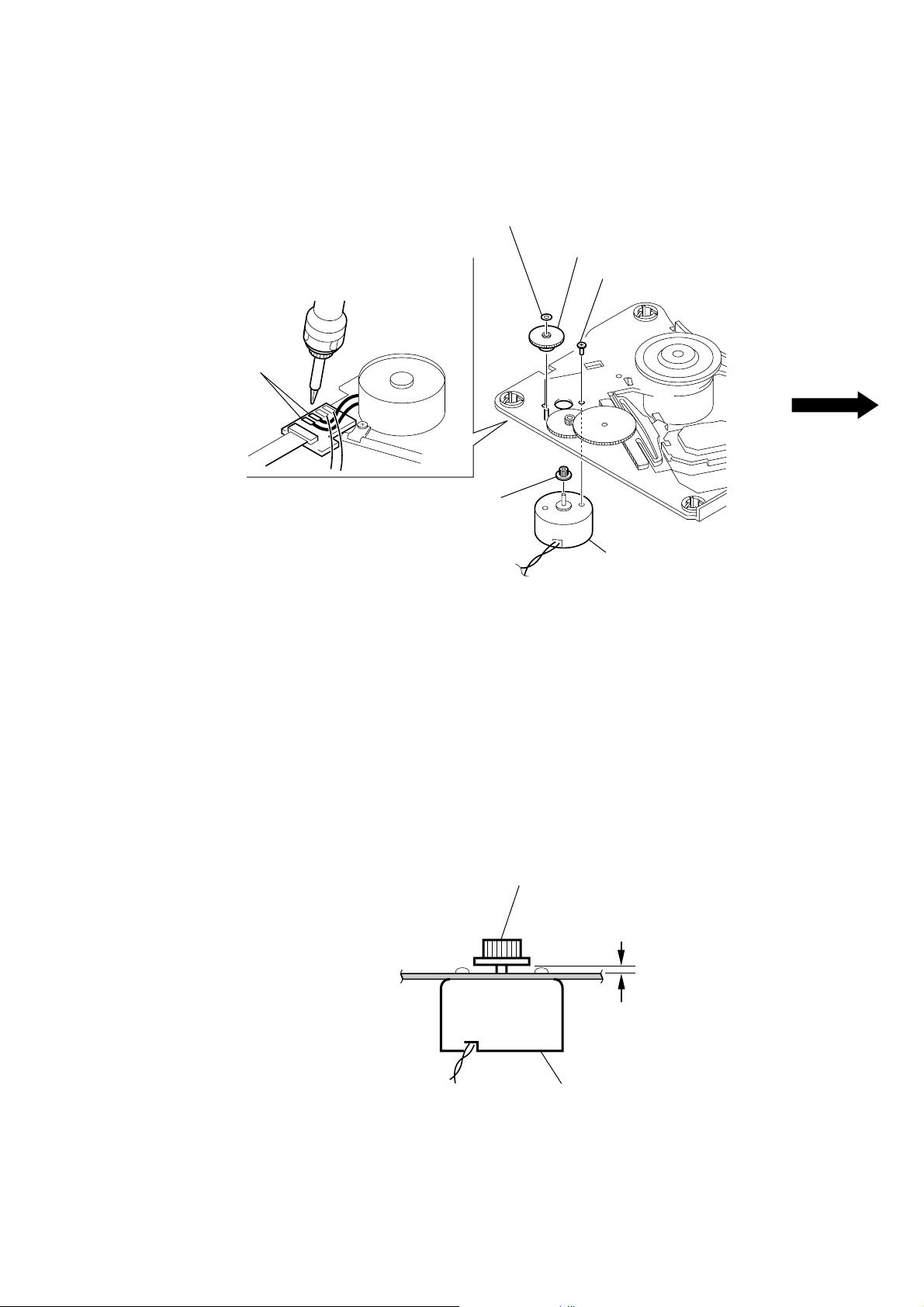

MOTOR (SLED) (M1)

1 Remove two solders of

the sled motor leads (M1).

2 washer

5 first gear

Note:When first gear is removed,

make sure to install a bland

new gear.

3 second gear

4 two screws

(P1.7 × 2.5)

6 motor (sled)

(M1)

Note:Pay attention to the motor (sled)

installing direction.

INSTALLING A MOTOR (SLED) (M1)

Note: Press fit a new first gear so that the gap

between the chassis surface and the bottom

of first gear is 0.1mm as shown in Fig. C.

first gear

0.1 mm

motor (sled) (M1)

(Fig. C)

13

Page 14

OPTICAL PICK-UP KSS-540A

4 PU guide shaft SL

3 two SH lock plate SLs

2 screw

(P2.6 × 3)

3 two SH lock plate SLs

2 screw

(P2.6 × 3)

1 two screws

(P1.7 × 4)

6 optical pick-up KSS-540A

5 pick-up flexible board

Note: Before disconnecting the pick-up

flexible board from the optical pick-up

KSS-540A, short the laser diode

shorting lands on the bottom of the

optical pick-up KSS-540A.

Refer to Fig. D.

INSTALLING A OPTICAL PICK-UP KSS-540A

1. Connect the pick-up flexible board to the optical pick-up KSS-540A.

2. Open the laser diode shorting lands on the bottom of the optical pick-up KSS-540A.

Note:Use the soldering iron whose metal part

is grounded or a ceramic soldering iron.

pick-up flexible board

(Fig. D)

14

Page 15

2 two screws

(P2 × 2)

1 Remove two solders of

the STC motor SL ass’y

flexible board (M3).

4 screw

(P2 × 2)

5 PCB FLEX mecha ass’y

3 Remove four solders of the

loading motor leads (M4)

and up/down motor leads

(M5).

PU G PLATE H SL

PCB FLEX MECHA ASS’Y

3 screw (2 × 4)

2 screw (2 × 4)

1 screw (2 × 4)

4 PU G plate H SL

Note:Assemble with tighten

screw in the order of

3 to 1.

15

Page 16

UD LINK ARM SL

MOTOR CHASSIS SL ASS’Y

Note:When reassembling motor chassis

SL ass’y with the 2 screws, DO NOT

let its Emergency Gear SL Teach touch

the edge of the MA chassis SL S ass’y

as they can be broken.

1 washer

2 UD link arm SL

MA chassis SL ass’y

emergency gear SL

4 motor chassis SL ass’y

2 two screws

(2.6 × 3)

2 screw

(2.6 × 3)

4 two pet washers

1 anti rattle SP SL

5 sus base X sub ass’y

4 two pet washers

3

Note:Reassemble UD S cam guide SL so that their

wider sides come upper as shwon in Fig. E.

mecha UD sub cam SL

Note:Be sure that the plate spring SL

is put on sus base X sub ass’y

as shown in figure.

plate spring SL

LDG PLATE CAM SL

4 two pet washers

6 mecha UD sub cam SL

7 two UD S cam guide SL

Wide Wide

(Page 18)

mecha UD sub cam SL

Note:Hook anti rattle SP SL

on motor chassis SL

ass’y as shown in figure.

16

Narrow Narrow

(fig. E)

UD S cam guide SLUD S cam guide SL

Page 17

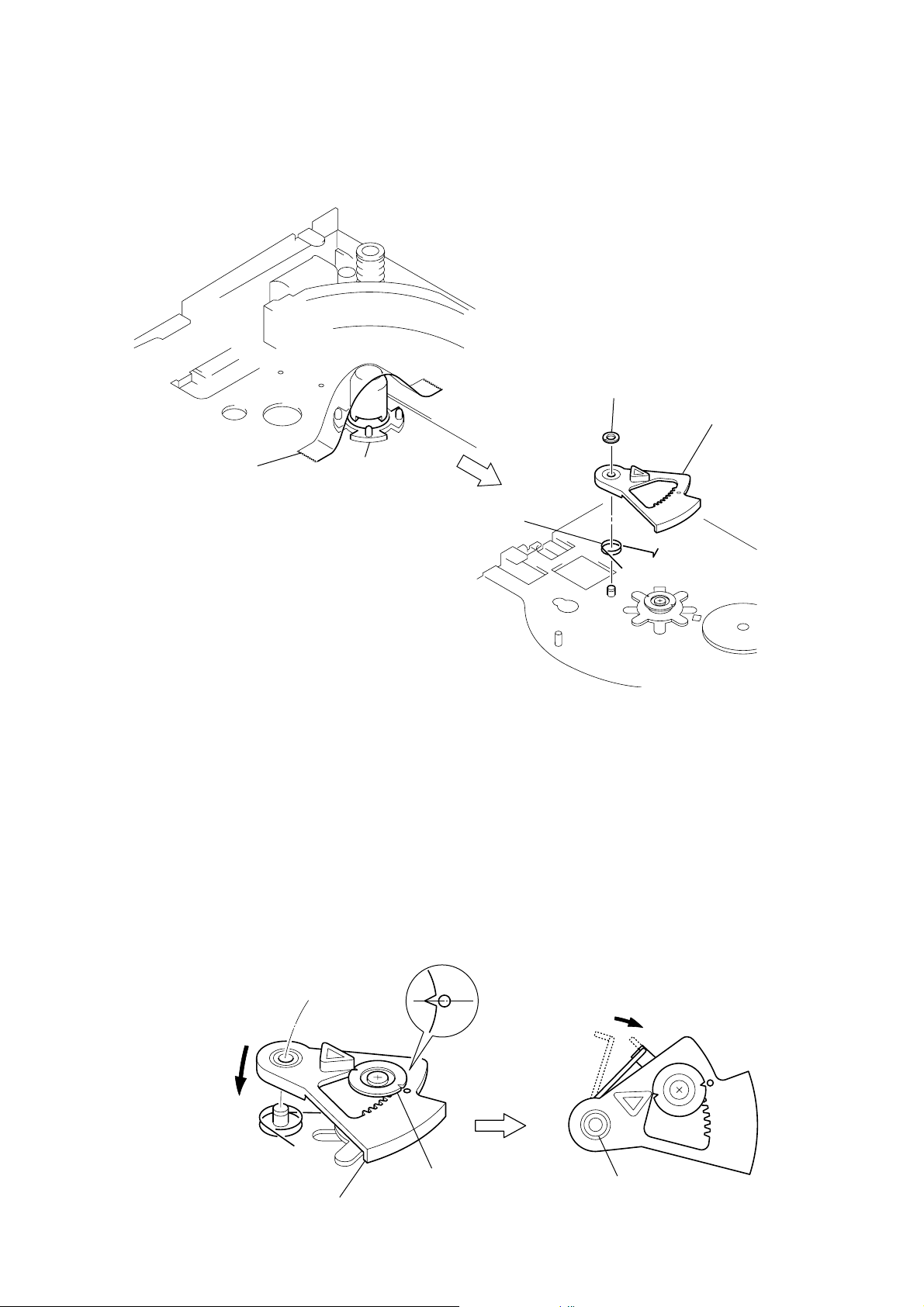

DISC LOCK ARM SL

L

1 Apply sellotape to the disc lock SL ass’y as shown in

figure to prevent the disc lock from falling off while

removing the disc arm SL.

2 washer

3 disc lock arm S

sellotape

(Fig. F. 1)

disc lock SL ass’y

D lock spring SL

INSTALLING THE DISC LOCK ARM SL

POSITIONING OF THE DISC LOCK ARM SL IS REQUIRED. (Refer to Fig. F. 2)

(1) Place the disc lock spring SL as shown in the figure.

(2) Insert the disc lock pinion into the hole on the disc lock arm SL.

(3) Adjust the position of the disc lock arm SL until its mark meets

the V-cut of the disc lock pinion as shown in the figure.

(4) Insert the shaft hole of the disc lock arm SL into the shaft.

(5) Hook the end of the disc lock spring SL on the chassis hole as

shown in the figure.

(6) Reassemble the washer in place.

(7) Peel off the sellotape. Refer to Fig. F. 1.

disc lock arm SL

disc lock pinion

(Fig. F. 2)

washer

17

Page 18

STC POS GEAR SL

L

Note:DO NOT remove the STC POS Gear

SL together with the STC Motor SL Ass’y

(Stocker) (M3), always replace it alone.

If they are removed at the same time and

the gear in the stocker height becomes out

of position.

2 STC POS gear SL

1 washer

MA chassis SL S ass’y

POSITIONING OF THE STC POS GEAR SL REQUIRED

Note:Assemble the STC POS gear

SL so that the mark on the

STC POS gear SL meets the

b

mark on the MA chassis SL

S ass’y.

c

STC POS gear SL

b

c

LDG PLATE CAM SL

1 washer

2 LDG plate cam SL

Note:Never use nail when

turning the emergency

gear SL.Otherwise, the

gear tooth may be broken.

emergency gear SL

(Fig. G. 1)

INSTALLING THE LDG PLATE CAM SL

POSITIONING OF THE LDG PLATE CAM SL IS REQUIRED.

(1) Turn the emergency gear SL in the direction of the arrow as shown

in Fig. G. 1 until it stops.

(2) Assemble LDG plate cam SL so that the center of the LDG plate cam

SL, mark on the LDG plate cam SL and the center of the shaft are

aligned on one line as shown in Fig. G. 2.

(3) Turn the emergency gear SL in revers until the marks , on

LDG plate cam SL are almost aligened as shown in Fig. G. 3. (This

operation is required to return to the mechanism in standby state.)

d

e

d

(Fig. G. 2)

Note:Never use nail when

turning the emergency

gear SL.

Otherwise the gear

tooth may be broken.

emergency gear SL

d

d

LDG plate cam S

e

18

(Fig. G. 3)

Page 19

SECTION 4

V

ELECTRICAL ADJUSTMENT

Forcus Bias Adjustment

Note:

1. CD Block is basically designed to operate without adjustment.

2. Use YEDS-18 disc (3-702-101-01)

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with lens cleaning liquid when the signal level is low than specified value with the

following adjustment.

5. Adjust the focus bias adjustment when optical block is replaced.

Focus Bias Adjustment

oscilloscope

(DC range)

MAIN R237 board

TP (RFO)

TP (VC)

+

–

Procedure :

1. Connect oscilloscope to TP101(pin 1: RFO) and TP101 (pin

3: VC) on MAIN R237 board.

2. Press the

I/1 button to turn the power on.

3. Put test disc (YEDS-18) in and press the u button to play-

back.

4. Adjust VR102 so that oscilloscope waveform is as shown in

the figure below. (eye pattern)

A good eye pattern means that the diamond shape ( ) in the

s

center of the waveform can be clearly distinguished.

5. After adjustment, check the RF signal level.

Adjustment Location:

– MAIN R237 BOARD (Conductor Side) –

TP101

(Pin 1 : RFO)

TP101

(Pin 3 : VC)

VR102

FOCUS BIAS

ADJUSTMENT

VOLT/DIV: 200 m

TIME/DIV: 500 ns

10: 1

level:

+0.3

1.0 Vp-p

- 0.2

19

Page 20

MEMO

20

Page 21

SECTION 5

TRA ASSY V619

MAIN R237 board

DIAGRAMS

5-1. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS • Circuit Boards Location

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

z

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Component Side) the parts face are indicated.

: Through hole.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• 2 : nonflammable resistor.

• C : panel designation.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• V oltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : TUNER (FM/AM)

J : CD PLAY

E : TAPE

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro

spécifié.

POWER SW board

FRONT board

TACT SW board

DOOR SW board

MAIN board

TUNER (FM/AM)

RELAY board

JACK board

PHOTO JACK board

AMP board

POWER SUPPLY board

AC board

2121

Page 22

HCD-LS1

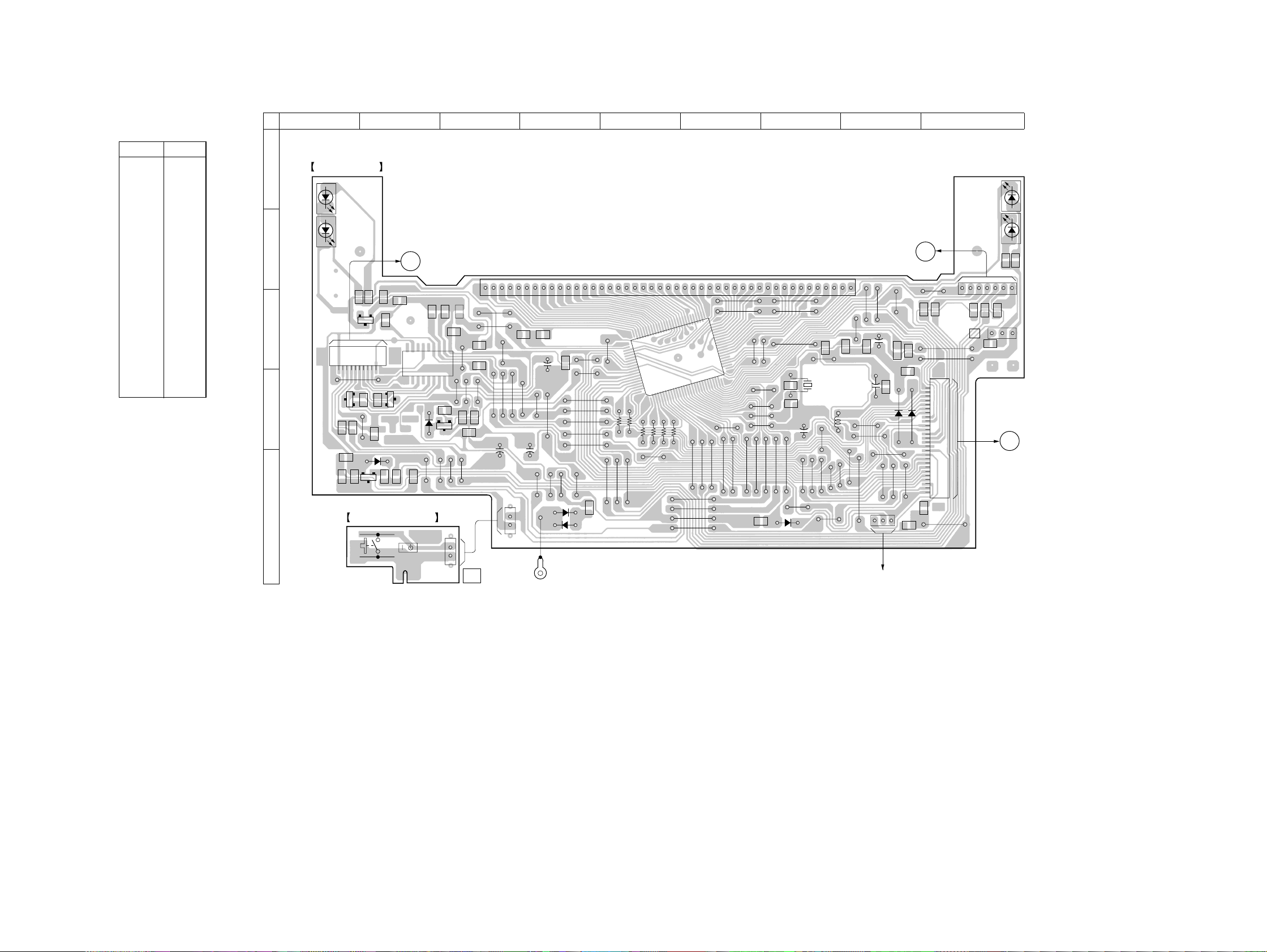

5-2. PRINTED WIRING BOARD – CD Section –• See page 21 for Circuit Boards Location.

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15

(Page 26) (Page 30) (Page 26)

A

MAIN R237 BOARD

B

C

D

Q403

E

(COMPONENT SIDE)

BCE

16

9

U502

18

Q414

ECB

Q404

D802

R401

R423

C423

C406

+

C405

A/K

A

K

(CONDUCTOR SIDE)

ZD405

ZD404

C407

+

C403

+

D409

Q521

Q522

ZD401

KKA

BCE

BCE

R553

D521

R563R554

R552

AKK

R402

R403

ZD521

Q8012

R551

L802

AKK

BCE BCE

C402

D801

Q8011

J404

R404

D404

1

CP503

Q412

BCE

C414

R414

BCE

R408

R407

KKA

Q413

AKK

R526

D517

R565

R564

R8102

R8101

3

R409

R530

ZD502

ZD503

R410

C509

R406

D401

R531

KA

Q502

L401

L402

1

R532

C413

D516

KKA

R527

R528

R415

BCE

CP501

R405

BCE

R416

C505

R519

R529

Q411

C506

R516

C411

7

R518

B

C

Q501

E

R517

+

MAIN R237 BOARD

4

1

U401

C404

ECB

R417

R411

C422

R412

BCE

Q402

ECB

Q401

R418

R419

R413

ZD402

1

5

TP101

FOR

ADJUSTMENT

A D B C

(Page 26)

1

5

CP502

D406

AKK

+

C409

R420

+

C417

R422

C401

C419

+

ZD403

R524

C504

(CHASSIS)

R603R602

C

R708

C134

R114

C123

C157

R713

C122

R704

R17

+

C141

R573

R572

R571

R570

R8082

R8092

C8102

+

R8091

R8081

R543

R510

R548

R511

R542

R508

R541

R509

R540

R512

R539

R513

C164C140

R538

R549

R537

R506

R536

R507

+

C8101

Q102Q103

E

BCE

B

R700

R199

R707

R703

R115

R116

C121

C112

R711

R702

R125

R126

R121

R122 R123

C114

R177

C106

C115 R110

R111

C116

R143

C101

R145

R144

C105

R142

R141

C1041

C1042

C145

C144

R120

R132

C142

R136

R134

C136C138

+

R124

R14

C135

R13

R12

R11

R135

R10

X501

C11

R19

R18

C12

R4R5R6

L503

C5072

C5071

C521

C516

R3

R2

R9

C143

R105

VR102

R102

R181

R137

R103

C107

R200

C1092

C1091

C110

C1112

R106

R127 R158

C137

R195

R194

C165

R196

R159

C1111

C169

R545

R131

C139

R129

R130

R133

C1

R109

C103

KKA

D101

R101

+

L101

C102

R706

R179

R180

C113

F

CP103

122

G

10

U107

516

H

I

J

40 21

41

60

61 80

K

05

L

516

516

U106

U501

10

10

U105

1

8

U103

4

5

CP102

1

20

1

U404

14

28

15

TRA ASSY

18

V619

85

U180

14

16

CP101

1

Q101

BCE

253232

1

24

U101

17

8

169

OPTICAL PICK-UP

BLOCK

(KSS-540A)

20 1

21

U102

40

41 60

80

61

M4

(LOADING)

M

M

M

CD SENSOR

BLOCK

M5

(UP/DOWN)

M3

(STOCKER)

D102

C131 C130

C127

X101

R710

AK

+

C128

C133 R197

C132

R15

C126

C125

L102

C129

C117

R112

C118

C163

R147

+

R714

L103

+

R705

C8012 C8011

R139

C162

R709

C8022

R8012

R8022

R8032

R8031

R8021

R8011

C8021

R128C124

R117

R701

R119

C119

R113

R712

R118

C120

M M

M1

(SLED)

M2

(SPINDLE)

2222

Page 23

• Semiconductor

Location

Ref. No. Location

D101 J-12

D102 K-9

D401 B-12

D404 B-11

D406 E-15

D409 C-11

D516 B-13

D517 B-12

D521 D-11

D801 C-11

Q101 J-5

Q102 I-10

Q103 I-10

Q401 D-7

Q402 C-9

Q403 E-2

Q404 C-7

Q411 B-13

Q412 B-12

Q413 B-12

Q414 C-6

Q501 C-13

Q502 C-13

Q521 C-11

Q522 C-11

Q8011 C-11

Q8012 C-11

HCD-LS1

5-3. SCHEMATIC DIAGRAM – CD Section (1/3) –• See page 33 for Waveforms.

U101 K-5

U102 J-7

U103 I-7

U105 H-2

U106 H-2

U107 H-2

U180 J-4

U401 B-9

U404 J-3

U501 J-2

U502 C-3

ZD401 B-11

ZD402 D-9

ZD403 E-15

ZD404 D-10

ZD405 D-10

ZD502 C-12

ZD503 C-12

ZD521 B-11

(Page 24)

Note:

• In the printed wiring diagram of the MAIN R237

Board, “A and L” or “B and R” of the last code of Ref

No. on the silk-screen printing drawing of the main

unit are replace with “1” or “2” respectively.

Example: C104A → C1041

R801R → R8012

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : CD PLAY

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

2323

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une pièce portant le numéro spécifié.

Page 24

HCD-LS1

5-4. SCHEMATIC DIAGRAM – CD Section (2/3) –• See page 33 for Waveforms. • See page 36 for IC Block Diagram.

(Page 27)

(Page 27)

(Page 27)

(Page 23)

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : CD PLAY

(Page 25)

2424

Page 25

5-5. SCHEMATIC DIAGRAM – CD Section (3/3) –• See page 33 for Waveform.

HCD-LS1

(Page 24)

(Page 31)

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

2525

no mark : CD PLAY

Page 26

HCD-LS1

5-6. PRINTED WIRING BOARDS – MAIN Section –• See page 21 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D200 F-2

D251 B-5

D252 B-4

D253 C-3

D254 B-4

D304 H-4

D312 C-3

D316 G-4

D321 D-2

D352 E-3

D391 B-2

IC103 C-8

IC201 D-8

IC251 C-5

IC321 E-6

IC351 F-4

IC390 B-6

IC391 C-7

PH200 E-2

Q201 C-4

Q202 D-4

Q203 C-5

Q204 D-5

Q205 D-3

Q301 G-6

Q302 G-6

Q303 G-6

Q304 F-9

Q305 G-4

Q306 H-8

Q311 G-7

Q312 G-7

Q313 G-8

Q316 G-4

Q317 G-3

Q321 E-5

Q351 E-4

Q352 E-4

Q371 G-6

Q372 F-6

Q373 G-7

Q374 F-7

Q375 G-6

Q376 G-5

Q377 G-5

Q381 F-8

Q382 F-7

Q383 G-8

Q384 G-8

A

B

C

D

E

F

G

H

1

(Page 30)

PH200

CD DIGITAL

OUT

(OPTICAL)

R2001

(R200A)

C2001

(C200A)

S391

1234 5

678910

F

E

(Page 28)

PHOTO JACK

PH200

B

(Page 22)

BOARD

CN204

C200

1

3

1

1-678-385-

05

1

2 3 4 5 6 7 8 9 10 11

MAIN BOARD

S392

PANEL

OPEN/CLOSE

D391

R399

CN604

26

25

(AEP, UK)

R145

R143

R144

D312

2

1

SDG

Q205

D321

1

2

CN204

2

D352

R200

D200

CN200

2

C355

C357

C359

11

C313 C316

C307

+

+

+

C306

12345

678910

PANEL OPEN

MANUAL AUTO ON/AUTO

D254

D253

C257

+

R258

C214

CN201

7

C201

1

R351

R355

R361

R353

5

R359

R357

8

C333

+ +

Q317

BCE

R316

Q305

S391

C251

+

R201

R257

C213

C202

BCE

Q351

IC351

BCE

D252 D251

R253

R251

R252

+

C252

R213

BCE

R209

Q201

R210

BCE

R214

Q202

R204

R203

R202

Q352

BCE

R356

R354

4

1

C334

Q316

BCE

R318

R317

D316

R307

C310 C309

D304

C253

R362

5

8

C205

R212R211

R360

+ +

C206

IC251

R215

C356

R358

C308

+

R306

R352

C358

C360

C256

C331

+

R216

C387

+

C220

R254

4

1

+

R217

R218

Q203

+

Q204

R325

R326

C329

BCE

C327

C328

C330

C392

R391

R328

R334

IC390

1

3

+

R392

R393

IC391

R394

1

C290

CN202

1

C255

+

R256

C207

R219

C209

++

C208

BCE

C325

R331R333

R220

Q321

C210

R223

C324

R329

C323

S

R327

IC321

4

5

1

8

R332

Q372

Q301Q303

1

CN203

BCE

R377

BCE

R373

R372

BCE

Q371

R371

Q302

7

2

Q376

R304

+

C389

Q377

C302

C301

R302

BCE

+

R380

R381

Q375

C388

R379

+

R225

+

C249

+

R376

R303

C391

6510

C203

R227

BCE

Q374

R375

CN301

R226

BCE

3

+

R228

R364

R382

R370

Q373

(AEP, UK)

+

C211

C212

R363

R369

C162

16 9

C163

X102

R321 R322

C321

C322

+ +

C204

28 15

IC103

18

C160

C158

+

C243

+

C240 C239

R235

R236

C241

C242

IC201

114

C216

C271

+ +

Q382

C215

C232

+

+

R281

C272

R221

R222

Q381

R282

C399

R237

R238

C381

C234

C103

C104

C382

+ +

+

BCE

C383

C367

R397

R366R365

BCE

+

CN303

R311

1

C386

BCE

Q312

+

R314

R308

R309

R312

C385

R315

BCE

Q311

BCE

R389R390

9

Q306

SDG

+

Q383

Q313

R313

R368R367

C384

+

+

R388R387

C159

C161

+

C157

+

R231

R233

R234

R232

R230

Q384

C368

1

R142

C231

C233

C235

C237

C238

C236

R229

Q304

BCE

C305

+

C326

+ +

CN302

1

L101

R305

C362

3

C312

+

2

CN391

CN101

2

14

(Page 22)

1

1

C102

15

A

AM

ANTENNA

FM

TUNER PACK (FM/AM)

(SUPPLIED WITH THE ASSEMBLED BLOCK)

75Ω

C

G J

(Page 22) (Page 34) (Page 28) (Page 34)

H

M391

(DOOR)

M

2626

Page 27

5-7. SCHEMATIC DIAGRAM – MAIN Section –• See page 33 for Waveform. • See page 36 for IC Block Diagram.

HCD-LS1

(Page

29)

(Page 24)

(Page 24)

(Page 24)

(Page 31)

(Page 35)

(Page 35)

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER (FM/AM)

: Impossible to measure

∗

(Page 29)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

2727

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une pièce portant le numéro spécifié.

Page 28

HCD-LS1

5-8. PRINTED WIRING BOARDS – AMP/RELAY/JACK Board –• See page 21 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D201 F-9

D202 F-9

D203 F-9

D204 F-10

D205 E-8

D206 E-8

D501 F-1

D502 F-3

D503 F-1

D504 F-3

D505 G-5

D506 H-6

D507 H-6

D508 F-8

D509 F-9

D510 F-8

D511 F-9

D512 H-6

D513 H-6

D514 G-2

D515 G-2

D516 G-2

IC501 G-2

IC502 F-11

IC503 H-2

Q501 G-5

Q502 F-9

Q503 F-9

Q504 G-5

Q505 G-6

1

AMP BOARD

2 3 4 5 6 7 8 9 10 11

(COMPONENT SIDE)

RELAY BOARD

(COMPONENT SIDE)

A

C951

11

C952

22

C953

33

C954

B

44

C955

55

C959

9

8

7

6

C958

C957

C956

9

8

7

6

JACK BOARD

(COMPONENT SIDE)

C

D

(Page 26)

E

2

17

CN201

C206

C205

D202

JK201

TAPE OUT

D204

C203

JK202

TAPE IN

JK202

R513

3

1

R517

R514

R520

R522

R521 R519

12

2

R515

C555

C518

C518

C519

R553

C524

C531

CN505

61

+

R523

C553

54

IC502

8

1

R552

21

C530

+

+

C523

+

C556

+

R550

C554

R518

C520

R516

+

C547

C552

C526

R524

C548

+

1

2

3

D511

Q502

Q502, 503

1

2

3

CN503

RIGHT SPEAKER

C525

(CONDUCTOR SIDE)

54

623

C551

R527

PHONES

D203

Q503

JK501

JK201

3

1

C204

D201

1

2

R525

3

JK501

1

D509

D509

R526

+

C549

E

AMP BOARD

L503

D501

F

G

L506

C538

C512

C511

C517

D503

+

+

+

C508

H

05

(CONDUCTOR SIDE)

C505

L501

+

C550

IC501

D515

D516

C539

C537

D514

R507

R535

R533

C534C532

C542

32

C503

C514

C541

C501

+

C507

R502

L505

C513

R504R530

C502

C506

C504

C558

CN504

LEFT SPEAKER

(IMPEDANCE USE 4Ω)

+–

RELAY BOARD

C515

+

C557

C509

+

R503

R531

R529

C529

+

C510

D505

Q501

CN502

3

1

19

(CONDUCTOR SIDE)

RY501

Q504

R509

D513

D512

CN501

Q505

D507

R543

–2

–1

C527

C545

+

R510

R538

+

R549

R546

+

R548

C546

R551

D506

16

CN505

R545

C544

+

R544

C5021

(C502A)

2

C5011

(C501A)

2

1

1

R501

31

R505

8

5

C528

D504

R536

C543

+

R506

L504

D502

C540

R528

L502

+

C516

C535C533C536

R508

2

1

R532

R534

1

4

IC503

JACK BOARD

D206

D205

D508

D510

+

(IMPEDANCE USE 4Ω)

–

K J

(Page 34) (Page 26)

2828

Page 29

5-9. SCHEMATIC DIAGRAM – AMP/RELAY/JACK Board –

HCD-LS1

(Page

27)

(Page 35)

(Page 27)

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : TUNER (FM/AM)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

2929

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une pièce portant le numéro spécifié.

Page 30

HCD-LS1

5-10. PRINTED WIRING BOARDS – PANEL Section (1/2) – • See page 21 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D601 D-8

D602 D-8

D603 E-2

D604 D-2

D605 E-7

D606 E-4

D607 E-4

IC601 C-5

IC631 C-2

LED601 A-9

LED602 A-1

LED603 B-9

LED604 B-1

Q601 E-2

Q602 D-3

Q613 C-2

Q631 D-2

Q632 D-1

SEN601 C-9

1

A

FRONT BOARD

LED602

LED604

B

R686

Q613

C

CN602

SDG

D

Q632

C606

R644

R643

2 3 4 5 6 7 89

R628

BCE

121

R632

R645

D603

LED602, 604

(LCD BACK LIGHT)

L

R620

R609

C633

10

Q631

R631

SDG

(Page 32)

C632

IC631

R605

D604

Q602

C631

C634

19

18

BCE

R625

R607

C609

R626

R617

R603

LED601, 603

(LCD BACK LIGHT)

(Page 22)

45

LCD601

51

50

C608

+

R624 R623

C613

+

C610

R646

+

81

R622

80

R621

IC601

31

30

100

1

R619

R618

R616

R615

C625

C626

X601

C603

+

R659

L601

1

R641

C612

C601

C635

+

+

C602

JW601

D602

R650

R642

D601

D

1

R612

R613

CN604

1

SEN601

LR

LED601

LED603

CN606

R611

C622

R610

3

R614

R685

7

F

R627

1

(Page 26)

BCE

C604

R601

E

05

R602

R604

Q601

R608

POWER SW BOARD

S615

/

1-678-387-

CN601

CN601

1

2

1

2

11

(CHASSIS)

D606

D607

C607

R649

D605

CN605

3

TO HAND SENSOR

26

R648

1

R658

3030

Page 31

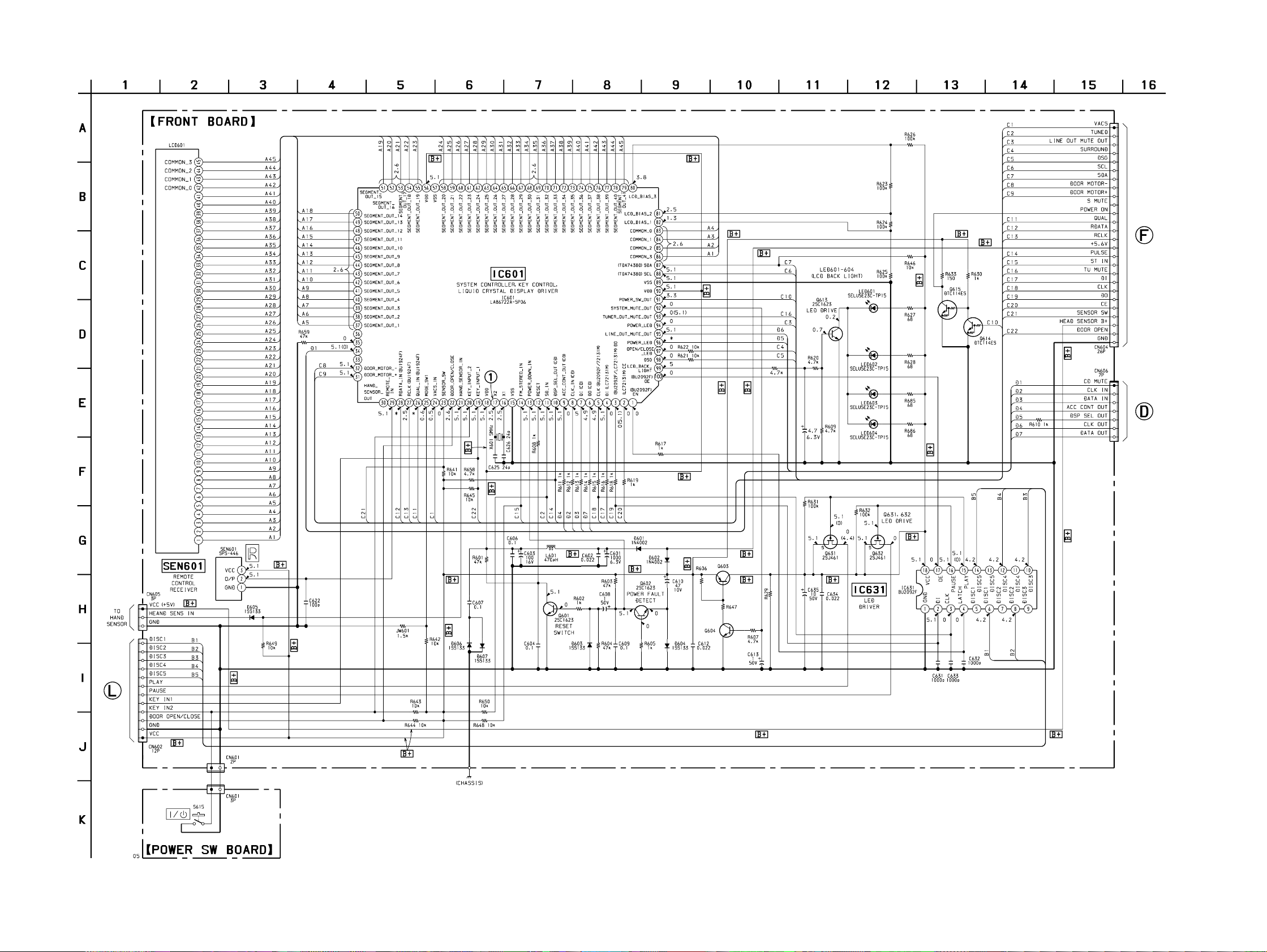

5-11. SCHEMATIC DIAGRAM – PANEL Section (1/2) –• See page 33 for Waveform. • See page 36 for IC Block Diagram.

HCD-LS1

(Page 27)

(Page

32)

(Page 25)

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER (FM/AM)

3131

( ) : CD PLAY

: Impossible to measure

∗

Page 32

HCD-LS1

5-12. PRINTED WIRING BOARDS – PANEL Section (2/2) –• See page 21 for Circuit Boards Location.

1

A

TACT SW BOARD

B

S601

FUNCTION

S608

TUNER/BAND

C

CN602

L

D

05

(Page 30)

2 3 4 5 67

LED651, S602

LED656, S609

112

DOOR SW BOARD

DISC 1

R656

S691

DOOR

OPEN/CLOSE

R651

S601-614

LED651

AAK

AAK

S609

R657

LED656

R678

R671

CN603

R691

1-678-836-

LED652, S603

DISC 2

S610

R679

1

2

LED651-656

R652

R672

1

11

AAK

S603S602

CN603

LED652

2

LED653, S604

DISC 3

S611

TUNER –

R673

R653

R674

LED653

AAK

S604

R680

LED654, S605

R681

DISC 4

S612

TUNER +

R654

LED654

AAK

S605

LED655, S606

DISC 5

R675

R682

R676

R655

LED655

AAK

S606

S613

R683

R677

S614

VOLUME –

S607

VOLUME +

R684

5-13. SCHEMATIC DIAGRAM – PANEL Section (2/2) –

(Page 31)

• Semiconductor

Location

Ref. No. Location

LED651 B-3

LED652 B-4

LED653 B-4

LED654 B-5

LED655 B-6

LED656 C-3

3232

Page 33

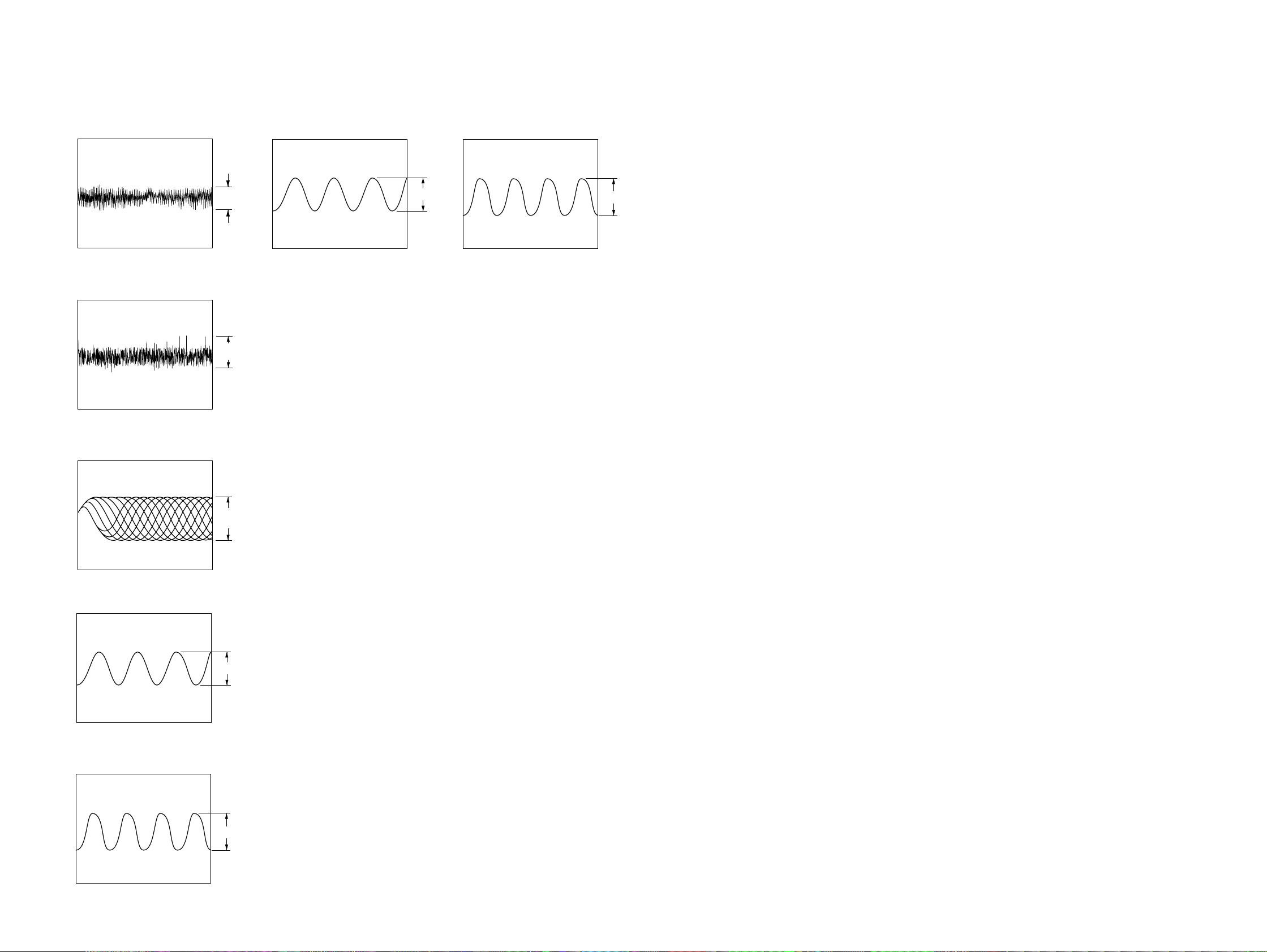

• Waveforms

– MAIN R237 Board –

– MAIN Board –

– FRONT Board –

1 U101 8 (TE), U102 ra (TE)

(CD Play Mode)

2 U101 q; (FE), U102 el (FE)

(CD Play Mode)

3 U101 wf (RFI), wg (RFO)

U102 rd (RFDC), ta (RFAC)

(CD Play Mode)

Approx.

140 m Vp-p

Approx.

200 mVp-p

1 IC103 qd (XI)

4.332 MHz

3.2 Vp-p

1 IC601 qj (X2)

5.2 Vp-p

5 MHz

4 U102 yh (XTAI)

16.9344 MHz

5 U501 yl (X2)

Approx.

1.2 Vp-p

2.4 Vp-p

3.7 Vp-p

4.194304 MHz

3333

Page 34

HCD-LS1

5-14. PRINTED WIRING BOARDS – POWER SUPPLY Section –• See page 21 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D1 H-6

D2 H-6

D3 H-6

D4 H-6

D5 G-5

D6 F-4

D7 F-4

D8 G-4

D9 G-4

D10 E-6

D11 H-6

D12 H-5

D13 F-6

D14 F-6

D15 F-6

D16 F-8

IC1 G-5

IC2 G-6

IC3 G-6

IC4 G-6

IC5 G-9

Q1 H-6

Q2 H-5

Q3 H-5

Q4 G-7

Q5 F-8

Q6 E-8

Q7 F-8

1

2 3 4 5 6 7 8 9

POWER SUPPLY BOARD

(COMPONENT SIDE)

A

B

C

AC BOARD

(COMPONENT SIDE)

D

1-678-395-

11

(Page 26) (Page 26) (Page 28)

T901

1

C9

42

IC1

R3

FB1

R5

D12

(CONDUCTOR SIDE)

D10

C13

1234

1234

5

D5

R1

Q3

C20

R17

R15

TH1

C28

R9

C12

R22

IC2 IC4

R16

D11

Q1

D3

D1

Q2

D4

D14

D2

R14

R10

IC3

3

1

+

C15

D15

D13

C27

R11

C18

R13

R12

C21

R4

C2

L2

C24

R30

+

R26

R27

GND1

+

Q4

2

3

L1

LINE

FILTER

1

4

+

C22

7

C16

+

+

C17

C5

C4

C3

CN1

Q6

R23

D16

L4

Q7

R24

R28

10

(CHASSIS)

2

1

Q5

C26

C30

1

L3

R25

C1

E

AC BOARD

(CONDUCTOR SIDE)

1

F501

2

1-678-395-

11

F

AC IN

G

POWER SUPPLY BOARD

5

6

C31

DC/DC CONVERTER

D6

D7

R6

R8

C10

C11

R7

C8

+

D9

D8

R2

+

C6

H

05

CN3

IC5

KHG

+

C23

3

1

CN2

R29

3

1

+

+

+

C25

1

+

C29

3434

Page 35

5-15. SCHEMATIC DIAGRAM – POWER SUPPLY Section –• See page 36 for IC Block Diagram.

HCD-LS1

(Page 29)

(Page 27)

(Page 27)

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : TUNER (FM/AM)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

3535

Replace only with part number specified.

: Impossible to measure

∗

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une pièce portant le numéro spécifié.

Page 36

• IC Block Diagrams

– MAIN R237 Board –

U102 CXD2587Q

– MAIN Board –

IC103 BU1924F (AEP, UK models)

RCLK

NC

VDD2

XO

141516 13 121110 9

VSS2

XI

T1

T2

LRCK

PCMD

BCK

EMPH

XVDD

XTAI

XTAO

XVSS

AVDD1

AOUT1

AIN1

LOUT1

AVSS1

AVSS2

LOUT2

AIN2

AOUT2

AVDD2

RMUT

LMUT

VDD

AVDD3

DOUT

60

DIGITAL

OUT

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

D/A

INTERFACE

TIMING

LOGIC

OVER SAMPLING

PWM

3rd ORDER

NOISE SHAPER

DIGITAL FILTER

SERIAL IN

INTERFACE

59

58

INTERNAL BUS

PWM

VSS

57

ERROR

CORRECTOR

16K

RAM

SUBCODE

PROCESSOR

FILO

FILI

PCO

54

56

55

53

DIGITAL

PLL

EFM

DEMODULATOR

SERVO

INTERFACE

SERVO AUTO

SEQUENCER

CLTV

AVSS3

52

ASYI

BIAS

RFAC

51

49

50

ASYMMETRY

CORRECTION

48

ASYO

47

AVDD0

46

IGEN

AVSS0

45

ADIO

44

SERVO DSP

FOCUS

SERVO

TRACKING

SERVO

SLED

SERVO

CE

TE

RFDC

43

41

42

OPERATIONAL

AMPLIFIER

ANALOG SWITCH

A/D

CONVERTER

PWM GENERATOR

CLOCK

GENERATOR

FOCUS PWM

GENERATOR

TRACKING

PWM GENERATOR

SLED PWM

GENERATOR

DIGITAL

CLV

MIRR, DFCT,

FOK

DETECTOR

SE

40

FE

39

VC

38

PLL

1187.5Hz

BIPHASE

DECODER

DEFFERENTIAL

XTSL

37

TES1

36

TEST

35

VSS

34

33

FRDR

32

FFDR

TRDR

31

TFDR

30

SRDR

29

28

SFDR

SSTP

27

MDP

26

25

LOCK

FOK

24

DFCT

23

22

MIRR

– FRONT Board –

IC631 BU2092F-E2

DECODER

1 43 65 872

QUAL

RDAT

COMPARATOR

8th SWITCHED

ANTI-ALIASING

VREF

PLL 57kHz

RDS/ARI

CAPACITOR

FILTER

FILTER

MUX

CLOCK

ANALOG

VDD1

VSS1

VSS3

CMP

TEST

DIGITAL

– POWER SUPPLY Board –

IC5 LA5617

1

2

SQSO

SQCK

3

XRST

4

SYSM

CPU

INTERFACE

7

5

6

XLAT

DATA

CLOK

8

SENS

9

10

SCLK

11 12

VDD

ATSK

13

SPOA

14

SPOB

1516171819

XUGF

XPCK

XLON

WFCK

GFS

20

C2PO

SCOR

12 BIT

SHIFT

REGISTER

12 BIT

STORAGE

REGISTER

LCK

VDDOEQ11

COUT

21

CONTROL

CIRCUIT

2 3

DATA

4

CLOCK

1

VSS

16 15 14 13 12

1718

Q10Q9Q8Q7Q6

OUTPUT

BUFFER

(OPEN DRAIN)

5 6 7 8 9

Q2

Q1

Q0

Q5

10

11

ERROR

Q4

Q3

AMP

2 3

1

VO1

VCC

ON/OFF

VREF

CN1

CURRENT

LIMITER

VMUTE VCC

VCC

4

EN

CURRENT

LIMITER

5 6 7 8 9

GND

EN DISPLAY

ON/OFF

140uA

~_

COMPARATER

VREF

~_

1.8V

NC

CN2

ERROR

AMP

OVER HEAT

START

CIRCUIT

VREF

PROTECT

VEE

10

VO2

3636

Page 37

d

SECTION 6

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) MAIN CASE SECTION

not supplied

7

6

5

4

#6

3

2

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list is given in the last of

the electrical parts list.

not

supplied

10

8

16

#2

9

not

supplied

11

14

12

#3

24

28

26

27

A

4

#6

29

#1

D704

13

25

#1

#2

21

23

12

D703

not

supplied

not supplied

D702

not supplied

22

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque 0 sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

D701

not supplie

not supplied

17

#1

#4

18

19

20

21

#1

#2

#6

30

31

1

not

supplied

Ref. No. Part No. Description Remark

1 X-4953-040-1 SLIDE DOOR ASSY

2 4-229-209-01 FUNCTION PANEL

3 4-229-217-01 MAIN CASE

4 4-229-220-01 SP. SCREW

5 4-229-208-01 FRONT WINDOW

6 4-229-214-01 FRONT SCREW

7 4-229-216-01 AL PANEL

8 4-229-219-01 POWER BUTTON (SUB)

9 PCB BRACKET

10 1-678-387-11 POWER SW BOARD

11 8-719-070-85 HAND SENSOR KU381-40

12 4-229-242-01 SP. HOOK BKT.

13 4-229-201-01 +B 2X8 SCREW

14 1-792-759-11 FFC (12CORE)

16 A-4473-557-A FRONT BOARD, COMPLETE

17 1-792-758-11 FFC (26CORE)

18 A-4473-559-A TACT SW BOARD, COMPLETE

19 FIBER WASHER

20 X-4953-039-1 FUNCTION BUTTON ASSY

A

33

32

Ref. No. Part No. Description Remark

21 LIGHT LEAK SEAL A

22 LIGHT LEAK SEAL B

23 4-229-330-01 SHEET METAL, EARTH

24 4-229-227-01 COIL SPRING

25 4-229-241-01 SCREW (2.6X6), TAPPING

26 DOOR SPRING

27 4-229-240-01 SLIDE DOOR WASHER

28 SLIDE DOOR CUSHION

29 1-678-386-11 DOOR SW BOARD

30 4-229-226-01 WORM GEAR HOLDER

31 4-229-222-01 WORM GEAR

32 X-4953-041-1 GEAR ASSY

33 4-229-264-01 BELT

34 4-229-259-01 BOTTOM COVER

D701 8-719-991-33 DIODE 1SS133T-77

D702 8-719-991-33 DIODE 1SS133T-77

D703 8-719-991-33 DIODE 1SS133T-77

D704 8-719-991-33 DIODE 1SS133T-77

34

#5

37

Page 38

(2) BOTTOM CASE SECTION

not

supplied

#19

D707

D708

not

supplied

#7

D801

51

not

supplied

52

#19

56

51

not

supplied

#1

57

#7

B

60

D706

#1

61

not supplied

D705

not supplied

59

#1

58

62

#8

#9

65

#19

#6

63

64

#18

66

B

#8

#19

not supplied

55

#20

#19

54

53

not supplied

#19

not supplied

Ref. No. Part No. Description Remark

51 4-229-265-01 MECHA, HOLDER

52 A-4473-561-A MAIN BOARD, COMPLETE

53 1-500-386-11 FILTER, CLAMP (FERRITE CORE)

54 4-229-328-01 EGG TERMINAL

55 1-678-395-11 AC BOARD

68

67

M391

not

supplied

not

supplied

Ref. No. Part No. Description Remark

63 4-229-260-01 SLIDE KNOB

64 SLIDE KNOB PLATE

65 A-4473-562-A PHOTO JACK BOARD, COMPLETE

66 4-229-258-01 BOTTOM CASE

67 1-792-757-11 AC CORD (POWER)

#2

#13

not supplied

not supplied

56 A-4473-563-A POWER SUPPLY BOARD, COMPLETE

57 A-4473-565-A RELAY BOARD, COMPLETE

58 A-4473-564-A AMP BOARD, COMPLETE

59 A-4473-566-A JACK BOARD, COMPLETE

60 FFC (15CORE)

61 1-693-473-21 TUNER PACK (FM/AM)

62 X-4953-038-1 TOP PANEL ASSY

38

68 4-229-263-01 AC CORD STOPPER

D705 8-719-991-33 DIODE 1SS133T-77

D706 8-719-991-33 DIODE 1SS133T-77

D707 8-719-991-33 DIODE 1SS133T-77

D708 8-719-991-33 DIODE 1SS133T-77

D801 8-719-070-85 DIODE KU381-4

M391 X-4953-037-1 MOTOR PULLEY ASSY (DOOR)

Page 39

109

Loading MF ass’y

107

107

C

D

Motor chassis

SL ass’y

Traverse mecha

ass’y

108

108

107

104

106

#12

104

105

#11

104

103

104

110

111

112

113

115

114

107

116

111

117

118

111

119

120

121

122

F

M3

123

#13

124

122

125

126

120

119

111

118

#14

F

E

127

129

130

111

128

#15

136

131

132

135

#11

134

107

133

#10

#10

#10

137

101

102

#11

#11

#11

C

E

D

(3) MECHANISM DECK SECTION-1

(HG-1: MAIN SECTION)

120 STC SCREW NUT A SL

121 4-229-320-01 STC SPRING B SL

122 4-229-317-01 STC SP CAP A SL

123 STOCKER CD SL

124 4-229-316-01 STC SP CAP B SL

125 4-229-319-01 STC SPRING A SL

126 4-229-321-01 STC SPRING C SL

127 4-229-282-01 MA CHASSIS SL S ASSY

128 4-229-351-01 HEAT SINK REG

129 4-229-289-01 D LOCK SPRING SL

130 4-229-288-01 DISC LOCK ARM SL

131 4-229-326-01 WASHER

132 4-229-322-01 UD LINK ARM SL

133 4-229-323-01 PLATE SPRING SL

134 4-229-290-01 UD S CAM GUIDE SL

135 4-229-313-01 FR CHASSIS SL ASSY

136 A-4473-555-A MAIN R237 BOARD, COMPLETE

137 4-229-349-01 BOTTOM COVER MF ASSY

M3 4-229-284-01 STC MOTOR SL ASSY (STOCKER)

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 4-229-348-01 F PANEL ASSY R237

102 4-229-314-01 PCB FLEX MECHA ASSY

103 4-229-318-01 MECH UD SUB CAM SL

104 4-229-315-01 PET WASHER

105 4-229-312-01 SUS BASE X SUB ASSY

106 4-229-324-01 ANTI RATTLE SP SL

107 4-229-295-01 SCREW 2.6X3

108 4-229-325-01 DAMPER SCREW SL

109 4-229-350-01 TOP COVER HS ASSY

110 4-229-327-01 DUST SEAL EMA SL

111 4-229-311-01 WASHER

112 4-229-287-01 STC POS GEAR SL

113 4-229-293-01 STC MOTOR SHEET SL

114 4-229-294-01 WASHER

115 4-229-291-01 STC WORM GEAR SL

116 4-229-286-01 STC C IDLE GEAR SL

117 4-229-283-01 DISC LOCK SL ASSY

118 4-229-292-01 STC IDLE GEAR SL

119 STC SCREW GEAR SL

39

Page 40

(4) MECHANISM DECK SECTION-2

(HG-1: MOTOR CHASSIS SL ASS’Y)

M5

152

153

155

153

154

159

#13

152

157

158

156

162

160

#16

161

163

164

165

M4

151

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 4-229-306-01 EMERGENCY GEAR SL

152 4-229-308-01 BRACKET SCREW SL

153 4-229-311-01 WASHER

154 4-229-301-01 MECHA UD GEAR SL

155 4-229-305-01 LDG PLATE CAM SL

156 4-229-307-01 UD WORM PLATE SL

157 4-229-310-01 E-RING

158 4-229-300-01 UD WORM GEAR SL

159 4-229-302-01 MEC SENSOR RING SL

160 4-229-303-01 LDG WORM GEAR SL

161 4-229-304-01 LDG SENSOR RING SL

162 UD CAM GUIDE SL

163 4-229-299-01 UD CAM SL

164 4-229-309-01 UD CAM GUIDE W SL

165 4-229-296-01 MO CHASSIS SL S ASSY

M4 4-229-297-01 LDG MOTOR SL ASSY (LOADING)

M5 4-229-298-01 UD MOTOR SL ASSY (UP/DOWN)

40

Page 41

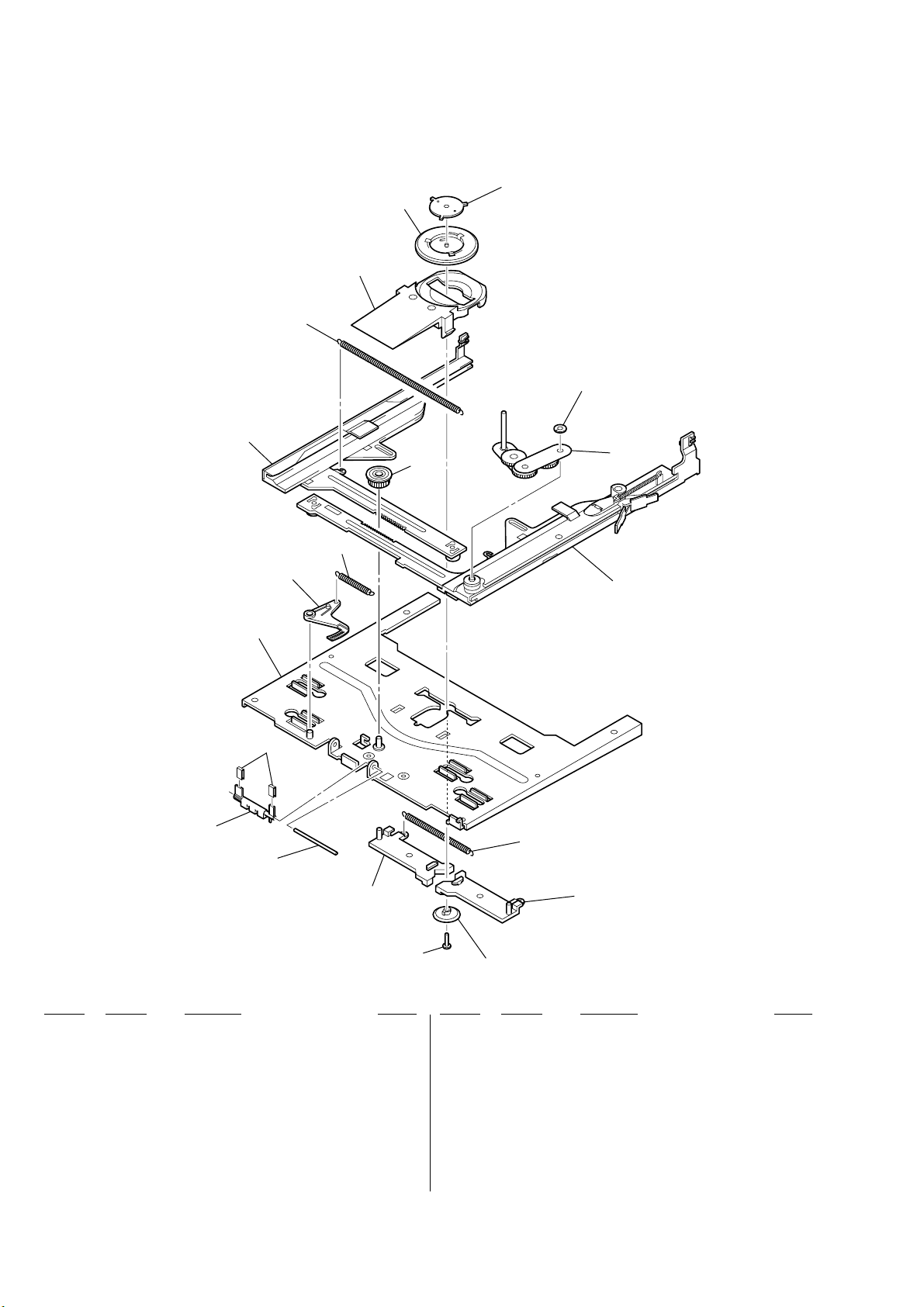

(5) MECHANISM DECK SECTION-3

(HG-1: TRAVERSE MECHA ASS’Y)

204

207

206

205

M1

206

206

208

#12

209

204

M2

203

#17

202

#12

214

201

214

Ref. No. Part No. Description Remark

201 4-229-268-01 TRA ASSY V619

202 1-792-692-11 WIRE FLEXIBLE BOARD

203 4-229-276-01 FIRST GEAR

204 4-229-273-01 DAMPER S SL

205 4-229-278-01 THIRD GEAR

210

#13

211

215

#13

212

213

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety .

Replace only with part number specified.

Ref. No. Part No. Description Remark

209 4-229-280-01 SCREW 2X4

210 4-229-275-01 PU G PLATE H SL

211 4-229-279-01 RACK CA

0 212 1-251-883-11 OPTICAL PICK-UP KSS-540A

213 1-678-133-11 PICK-UP FLEXIBLE BOARD

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

206 4-229-294-01 WASHER

207 4-229-277-01 SECOND GEAR

208 4-229-272-01 POWER GEAR

214 4-229-271-01 SH LOCK PLATE SL

215 4-229-270-01 PU GUIDE SHAFT SL

M1 1-763-519-11 MOTOR (SLED)

M2 4-229-269-01 DISC MOTOR CH ASSY (SPINDLE)

41

Page 42

(6) MECHANISM DECK SECTION-4

(HG-1: LOADING MF ASS’Y)

259

262

261

260

263

252

258

254

253

251

255

256

257

264

265

266

270

269

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

251 4-229-188-01 SHUT ARM SHAFT SL

252 4-229-193-01 SHUTTER ARM SL

253 4-229-187-01 SHUT ARM CUSH SL

254 LOADING CHASSIS SL ASSY

255 4-229-196-01 SHUTTER LEVER SL

256 4-229-192-01 SHUTTER SPRING SL

257 4-229-191-01 LDG CENTER GEAR SL

258 4-229-183-01 LOADING L MF ASSY

259 4-229-190-01 LDG RETURN SP SL

260 4-229-197-01 DISC G UPPER SL

268

261 4-229-200-01 DISC CRAMP BASE

262 4-229-198-01 STEEL RING

263 4-229-294-01 WASHER

264 4-229-185-01 LDG LINK SL ASSY

265 4-229-184-01 LOADING R MF ASSY

266 4-229-189-01 CLAMPER RE SP SL

267 4-229-195-01 CLAMP HOLDER L SL

268 4-229-199-01 CLAMP TOP

269 4-229-186-01 BT 1.7X5 +PAN (0 TYPE 3)

270 4-229-194-01 CLAMP HOLDER R SL

267

42

Page 43

SECTION 7

ELECTRICAL PARTS LIST

AC AMP

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1-678-395-11 AC BOARD

*********

4-229-206-01 TERMINAL PIN (K)

4-229-207-01 TERMINAL PIN (L)

1-576-450-11 FUSE HOLDER

< FUSE >

0 F501 1-532-465-31 FUSE (3.15A/250V)

**************************************************************

A-4473-564-A AMP BOARD, COMPLETE

********************

4-229-344-01 SCREW (3X1), TAPPING

4-229-345-01 INSULATING SHEET (A)

4-229-346-01 INSULATING SHEET (B)

< CAPACITOR >

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

C539 1-136-169-00 MYLAR 0.22uF 5% 50V

C540 1-136-169-00 MYLAR 0.22uF 5% 50V

C541 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C542 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C543 1-126-933-11 ELECT 100uF 20% 16V

C550 1-124-724-11 ELECT 47uF 20% 16V

C557 1-137-505-11 MYLAR 220PF 5% 50V

C558 1-137-505-11 MYLAR 220PF 5% 50V

C591 1-135-838-11 CERAMIC 2000PF

C592 1-135-838-11 CERAMIC 2000PF

C593 1-135-838-11 CERAMIC 2000PF

C594 1-135-838-11 CERAMIC 2000PF

C595 1-135-838-11 CERAMIC 2000PF

C596 1-135-838-11 CERAMIC 2000PF

C597 1-135-838-11 CERAMIC 2000PF

C598 1-135-838-11 CERAMIC 2000PF

C599 1-135-838-11 CERAMIC 2000PF

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque 0 sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

When indicating parts by reference

number, please include the board.

C501 1-136-165-00 MYLAR 0.1uF 5% 50V

C502 1-136-165-00 MYLAR 0.1uF 5% 50V

C503 1-136-846-11 MYLAR 1.5uF 5% 50V

C504 1-136-846-11 MYLAR 1.5uF 5% 50V

C505 1-136-846-11 MYLAR 1.5uF 5% 50V

C506 1-136-846-11 MYLAR 1.5uF 5% 50V

C507 1-126-012-11 ELECT 470uF 20% 16V

C508 1-126-012-11 ELECT 470uF 20% 16V

C509 1-126-044-11 ELECT 1uF 20% 50V

C510 1-126-044-11 ELECT 1uF 20% 50V

C511 1-126-052-11 ELECT 100uF 20% 16V

C512 1-126-052-11 ELECT 100uF 20% 16V

C513 1-136-177-00 MYLAR 1uF 5% 50V

C514 1-136-165-00 MYLAR 0.1uF 5% 50V

C515 1-124-360-00 ELECT 1000uF 20% 16V

C516 1-124-360-00 ELECT 1000uF 20% 16V

C517 1-136-177-00 MYLAR 1uF 5% 50V

C528 1-136-165-00 MYLAR 0.1uF 5% 50V

C529 1-136-165-00 MYLAR 0.1uF 5% 50V

C532 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C533 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C534 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C535 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C536 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C537 1-136-169-00 MYLAR 0.22uF 5% 50V

C538 1-136-169-00 MYLAR 0.22uF 5% 50V

< DIODE >

D501 8-719-210-21 DIODE 11EQS04

D502 8-719-210-21 DIODE 11EQS04

D503 8-719-210-21 DIODE 11EQS04

D504 8-719-210-21 DIODE 11EQS04

D514 8-719-820-58 DIODE 1SS177

D515 8-719-820-58 DIODE 1SS177

D516 8-719-820-58 DIODE 1SS177

< IC >

IC501 8-759-638-11 IC TA2020-020

IC503 8-759-100-96 IC NJM4558M

< COIL >

L501 1-419-281-11 INDUCTOR 10uH

L502 1-419-281-11 INDUCTOR 10uH

L503 1-419-281-11 INDUCTOR 10uH

L504 1-419-281-11 INDUCTOR 10uH

L505 1-419-282-11 INDUCTOR 10uH

L506 1-410-509-11 INDUCTOR 10uH

< RESISTOR >

0 R501 1-215-857-11 METAL OXIDE 10 5% 1W F

0 R502 1-215-857-11 METAL OXIDE 10 5% 1W F

R503 1-216-222-00 RES, CHIP 10K 5% 1/8W

43

Page 44

AMP DOOR SW FRONT

Ref. No. Part No. Description Remark

R504 1-216-222-00 RES, CHIP 10K 5% 1/8W

R505 1-216-230-00 RES, CHIP 22K 5% 1/8W

R506 1-216-230-00 RES, CHIP 22K 5% 1/8W

R507 1-216-220-00 RES, CHIP 8.2K 5% 1/8W

R508 1-216-246-00 RES, CHIP 100K 5% 1/8W

R528 1-216-270-00 RES, CHIP 1M 5% 1/8W

R529 1-216-270-00 RES, CHIP 1M 5% 1/8W

R530 1-216-270-00 RES, CHIP 1M 5% 1/8W

R531 1-216-270-00 RES, CHIP 1M 5% 1/8W

R532 1-216-262-00 RES, CHIP 470K 5% 1/8W

R533 1-216-262-00 RES, CHIP 470K 5% 1/8W

R534 1-216-262-00 RES, CHIP 470K 5% 1/8W

R535 1-216-262-00 RES, CHIP 470K 5% 1/8W

R536 1-216-174-00 RES, CHIP 100 5% 1/8W

**************************************************************

1-678-386-11 DOOR SW BOARD

***************

< RESISTOR >

R691 1-216-073-00 METAL CHIP 10K 5% 1/10W

< SWITCH >

Ref. No. Part No. Description Remark

< DIODE >

D601 8-719-200-02 DIODE 1N4002

D602 8-719-200-02 DIODE 1N4002

D603 8-719-991-33 DIODE 1SS133T-77

D604 8-719-991-33 DIODE 1SS133T-77

D605 8-719-991-33 DIODE 1SS133T-77

D606 8-719-991-33 DIODE 1SS133T-77

D607 8-719-991-33 DIODE 1SS133T-77

< IC >

IC601 8-759-677-45 IC LC867232A-5P06

IC631 8-759-396-78 IC BU2092F-E2

< RESISTOR >

JW601 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

< COIL >

L601 1-419-636-11 COIL, CHOKE

< LIQUID CRYSTAL DISPLAY >

LCD601 1-804-047-11 LCD

S691 1-771-960-11 LEAF SW (DOOR OPEN/CLOSE)

**************************************************************

A-4473-557-A FRONT BOARD, COMPLETE

**********************

4-229-202-01 BACK LIGHT WINDOW

< CAPACITOR >

C601 1-126-916-11 ELECT 1000uF 20% 6.3V

C602 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C603 1-125-972-91 ELECT 100uF 20% 16V

C604 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C606 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C607 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C608 1-126-160-11 ELECT 1uF 20% 50V

C609 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C610 1-124-589-11 ELECT 47uF 20% 16V

C612 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C613 1-126-160-11 ELECT 1uF 20% 50V

C622 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C625 1-163-102-00 CERAMIC CHIP 24PF 5% 50V

C626 1-163-102-00 CERAMIC CHIP 24PF 5% 50V

C631 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C632 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C633 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C634 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C635 1-124-247-91 ELECT 10uF 20% 35V

< CONNECTOR >

CN602 1-794-485-11 CONNECTOR 12P

CN604 1-794-484-11 CONNECTOR 26P

CN605 1-794-486-11 CONNECTOR 3P

< LED >

LED601 8-719-069-45 LED SELU5E23C-TP15 (LCD BACK LIGHT)

LED602 8-719-069-45 LED SELU5E23C-TP15 (LCD BACK LIGHT)