Sony HCD-J300 Service manual

HCD-J300

SERVICE MANUAL

Ver 1.0 2001. 06

HCD-J300 is the Amplifier, MD deck, CD

player, Tape player and Tuner section in

CMT-DC500MD.

Model Name Using Similar Mechanism HCD-CP500K/CP500MD

CD

Section

MD

Section

Tape deck

Section

CD Mechanism Type CDM55F-K4BD43

Base Unit Type BU-K4BD43

Optical Pick-up Type KSM-213DHAP

Model Name Using Similar Mechanism HCD-CP500K/CP500MD

MD Mechanism Type MDM-7B

Optical Pick-up Type KMS-260B

Model Name Using Similar Mechanism HCD-CP500K/CP500MD

Tape Transport Mechanism Type Mech deck

AEP Model

UK Model

E Model

Amplifier section

European model:

DIN power output (rated): 30 + 30 W

Continuous RMS power output (reference):

Music power output (reference):

Other models:

The following measured at 230 V AC, 60 Hz

DIN power output (rated): 30 + 30 W

Continuous RMS power output (reference):

The following measured at 220 V AC, 60 Hz

DIN power output (rated): 24 + 24 W

Continuous RMS power output (reference):

(6 ohms at 1 kHz, DIN)

35 + 35 W

(6 ohms at 1 kHz, 10%

THD)

85 + 85 W

(6 ohms at 1 kHz, DIN)

35 + 35 W

(6 ohms at 1 kHz, 10%

THD)

(6 ohms at 1 kHz, DIN)

27 + 27 W

(6 ohms at 1 kHz, 10%

THD)

SPECIFICATIONS

Inputs

ANALOG IN (phono jacks):

DIGITAL OPTICAL IN (Supported sampling

frequencies: 32 kHz, 44.1 kHz and 48 kHz)

Outputs

PHONES (stereo minijack):

SPEAKER: Accepts impedance of 6 to

Sensitivity 250 mV,

impedance 47 kilohms

Accepts headphones with

an impedance of 8 ohms

or more

16 ohms

— Continued on next page —

MICRO HI-FI COMPONENT SYSTEM

9-873-173-01

2001F1600-1

© 2001.6

Sony Corporation

Home Audio Company

Shinagawa Tec Service Manual Production Group

HCD-J300

CD player section

System Compact disc and digital

Laser Semiconductor laser

Wavelength 780 – 790 nm

Frequency response 2 Hz – 20 kHz (±0.5 dB)

audio system

(λ = 780 nm)

Emission

duration: continuous

Tape player section

Recording system 4-track 2-channel stereo

Frequency response 50 – 13,000 Hz (±3 dB),

Wow and flutter ±0.15% W. Peak (IEC)

using a Sony TYPE I

cassette

0.1% W. RMS (NAB)

±0.2% W. Peak (DIN)

MD deck section

System MiniDisc digital audio

Laser Semiconductor laser

Sampling frequency 44.1 kHz

Frequency response 5 Hz – 20 kHz

system

(λ=780 nm)

Emission duration:

continuous

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM wire antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

European model: 531 – 1,602 kHz

Other models: 530 – 1,710 kHz

Antenna AM loop antenna, external

Intermediate frequency 450 kHz

(50-kHz step)

(with the tuning interval

set at 9 kHz)

(with the tuning interval

set at 10 kHz)

531 – 1,602 kHz

(with the tuning interval

set at 9 kHz)

antenna terminal

General

Power requirements

European model: 230 V AC, 50/60 Hz

Hong Kong model: 220 – 240 V AC,

Other models: 110 – 120 V or 220 –

Power consumption

European model: See the nameplate

Other models: See the nameplate

Dimensions (w/h/d) Approx. 190 × 253 ×

Mass Approx. 7.0 kg

Design and specifications are subject to change

without notice.

50/60 Hz

240 V AC , 50/60 Hz

Adjustable with voltage

selector

0.5 W (in the standby

mode)

345 mm incl. projecting

parts and controls

2

TABLE OF CONTENTS

HCD-J300

Self-diagnosis display

This system has a Self-diagnosis display

function to let you know if there is a system

malfunction. The display shows a code made

up of three letters and a message alternately to

show you the problem. To solve the problem

refer to the following list. If any problem

persists, consult your nearest Sony dealer.

C11/Protected

The MD is protected against erasure.

Remove the MD and slide the tab to close the

slot (see page 16).

C12/Cannot Copy

You tried to record a CD or MD with a format that

the system does not support, such as a CD-ROM.

p Remove the disc and turn off the system once,

then turn it on again.

C13/REC Error

Recording could not be performed properly.

p Move the system to a stable place, and start

recording over from the beginning.

The MD is dirty or scratched, or the MD does not

meet the standards.

p Replace the MD and start recording over from

the beginning.

1. SERVICING NOTES ······················································ 4

2. GENERAL ··········································································9

3. DISASSEMBLY ······························································11

4. TEST MODE ···································································21

5. MECHANICAL ADJUSTMENTS ····························27

6. ELECTRICAL ADJUSTMENTS ······························ 27

7. DIAGRAMS

7-1. CIRCUIT BOARDS LOCATION ····································· 40

7-2. BLOCK DIAGRAM – CD SECTION – ··························· 42

BLOCK DIAGRAM – MAIN SECTION – ······················ 43

BLOCK DIAGRAM – MD SECTION – ·························· 44

BLOCK DIAGRAM – PANEL SECTION – ···················· 45

7-3. PRINTED WIRING BOARD – CD BOARD – ················ 46

7-4. SCHEMATIC DIAGRAM – CD BOARD – ····················· 47

7-5. PRINTED WIRING BOARD – BD BOARD – ················ 48

7-6. SCHEMATIC DIAGRAM – BD BOARD (1/2) – ············ 49

7-7. SCHEMATIC DIAGRAM – BD BOARD (2/2) – ············ 50

7-8. PRINTED WIRING BOARDS – AUDIO SECTION – ···· 51

7-9. SCHEMATIC DIAGRAM – AUDIO SECTION (1/2) –···52

7-10.SCHEMATIC DIAGRAM – AUDIO SECTION (2/2) –··· 53

7-11.PRINTED WIRING BOARD – TC BOARD – ················· 54

7-12.SCHEMATIC DIAGRAM – TC BOARD –······················55

7-13.PRINTED WIRING BOARD – DIGITAL BOARD – ······ 56

7-14 SCHEMATIC DIAGRAM – DIGITAL BOARD – ··········· 57

7-15.

PRINTED WIRING BOARDS – CONTROL SECTION –

7-16 SCHEMATIC DIAGRAM – CONTROL BOARD – ········ 59

7-17.PRINTED WIRING BOARD – POWER BOARD – ········ 60

7-18.SCHEMATIC DIAGRAM – POWER BOARD – ············· 60

7-19.IC BLOCK DIAGRAMS ·················································· 61

7-20.IC Pin Function Description··············································63

··· 58

8. EXPLODED VIEWS ····················································· 71

9. ELECTRICAL PARTS LIST ·····································80

C13/Read Error

The MD deck cannot read the disc information

properly.

p Remove the MD once, then load it again.

C14/Toc Error

The MD deck cannot read the disc information

properly.

p Replace the MD.

p Erase all the recorded contents of the MD using

All Erase Function (see page 27).

C41/Cannot Copy

The sound source is a copy of commercially

available music software.

p The Serial Copy Management System prevents

making a digital copy (see page 47).

3

HCD-J300

SECTION 1

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

FOR CD

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

FOR MD

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

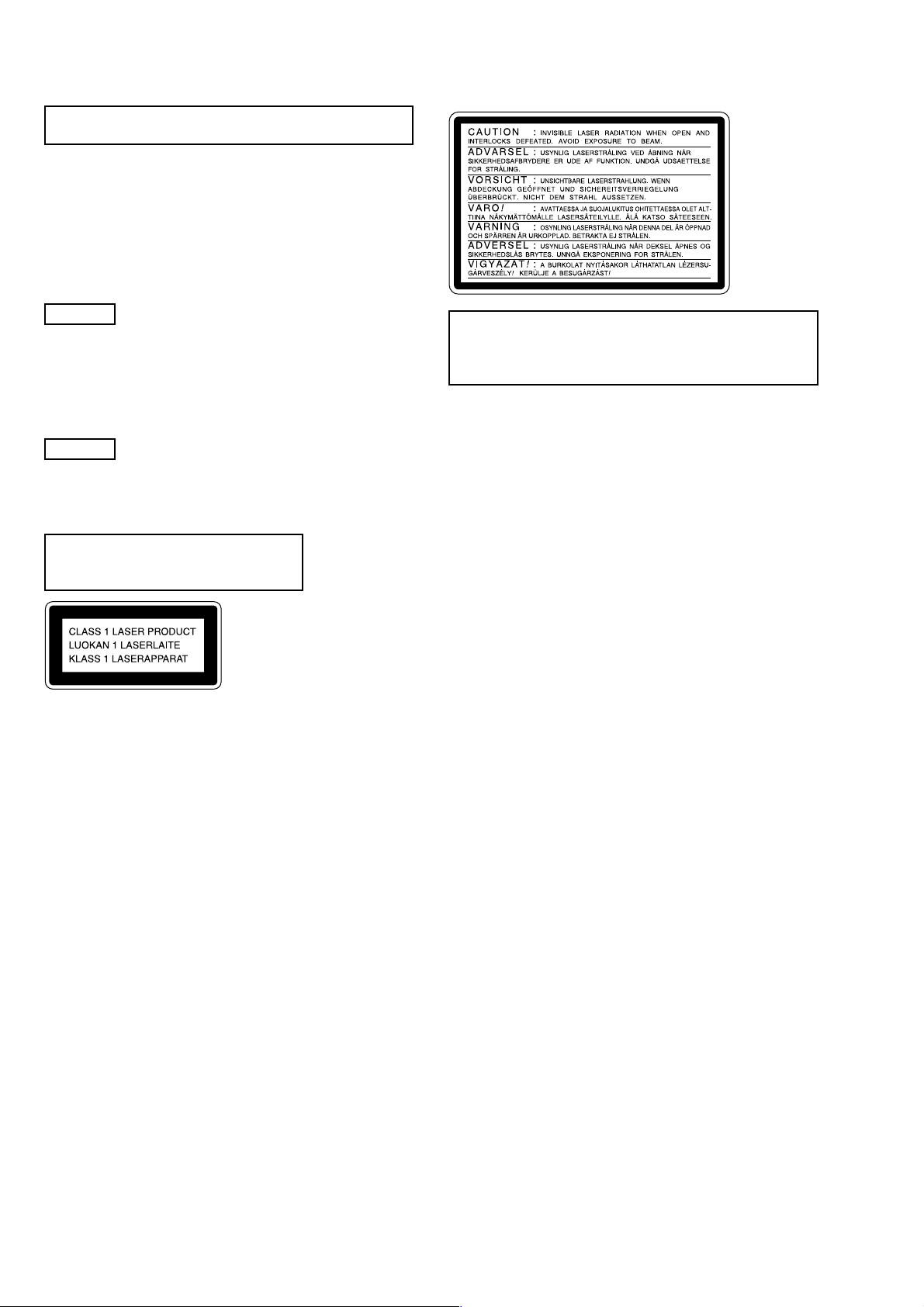

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This caution

label is

located inside

the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

4

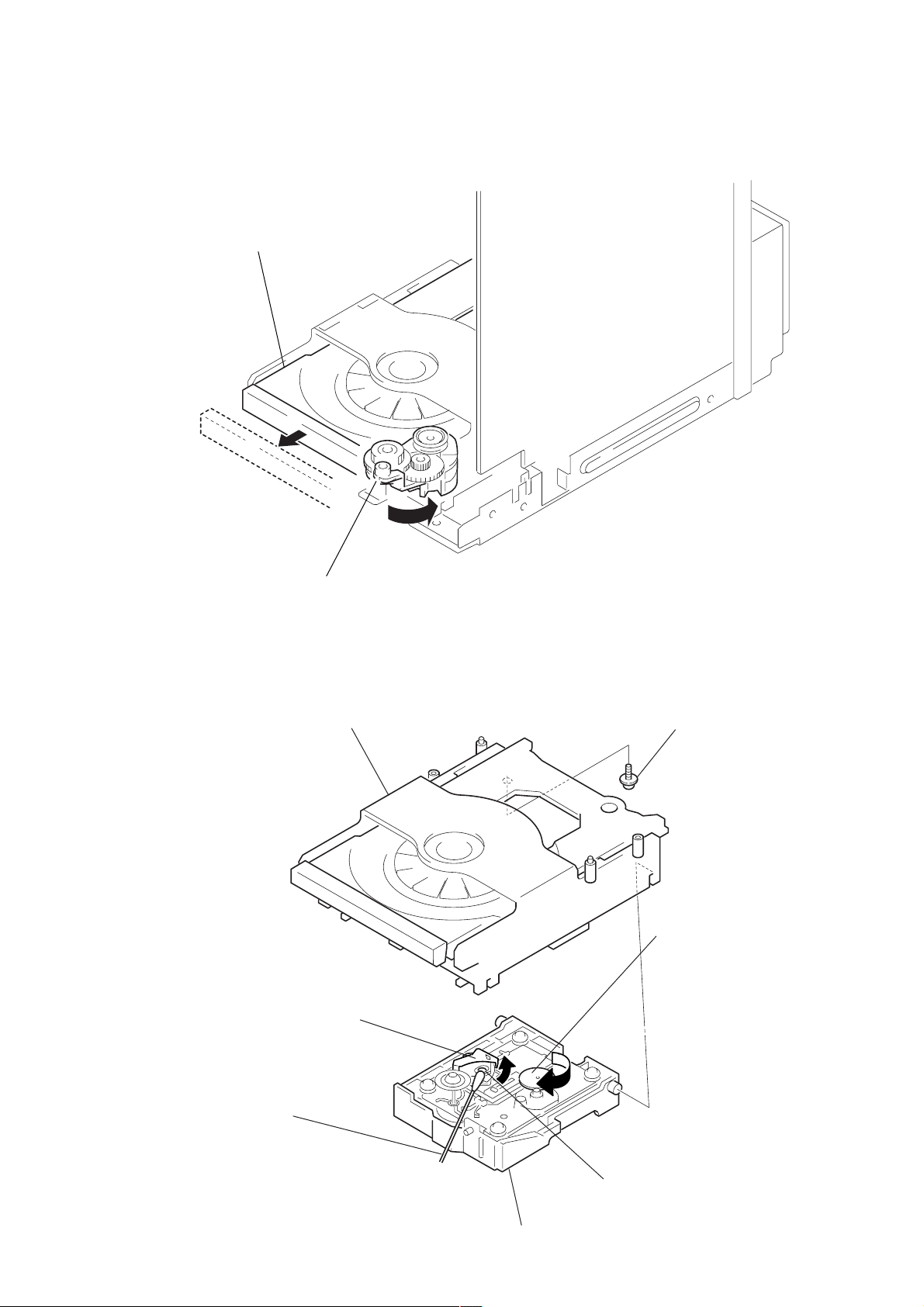

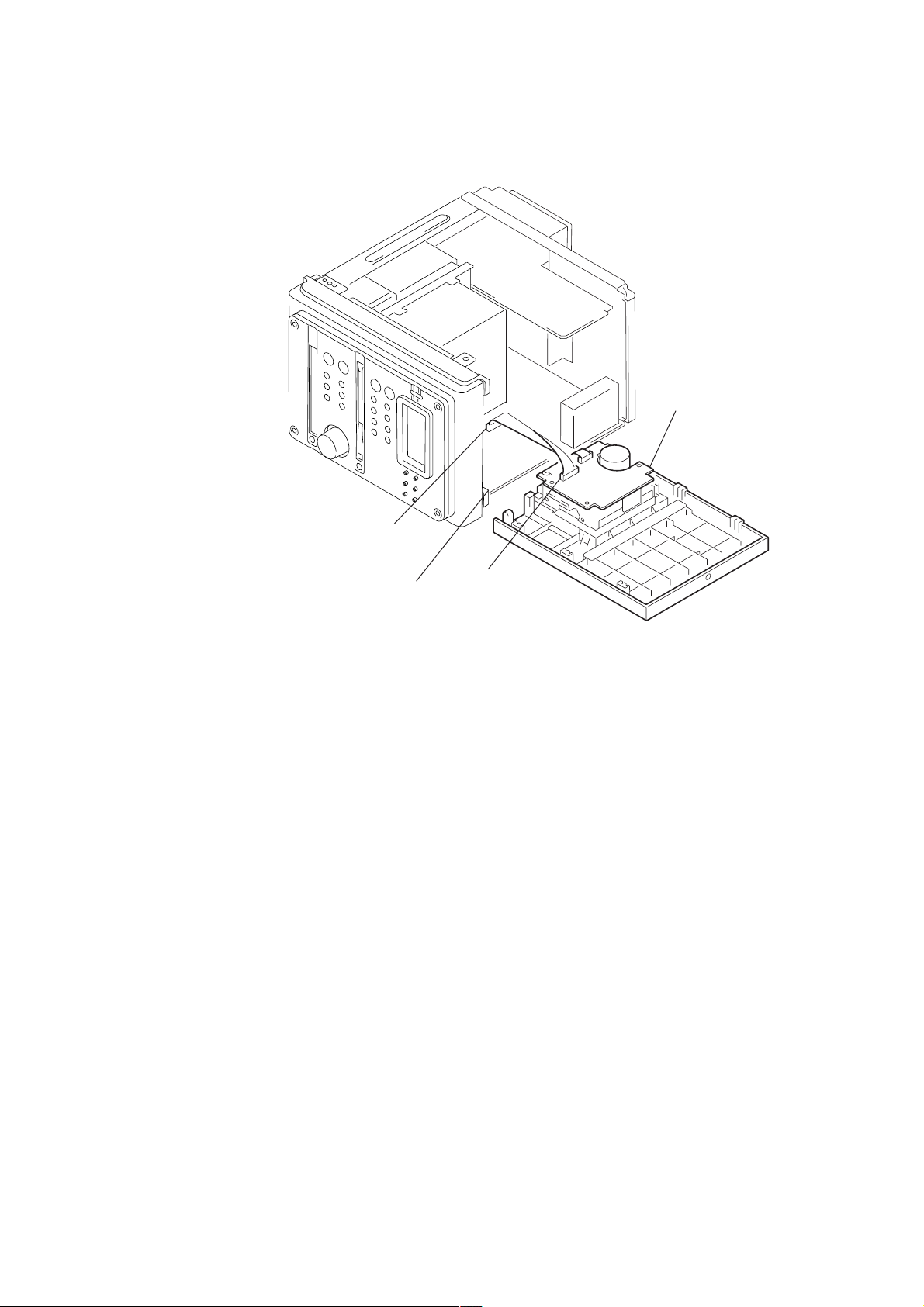

DRAWING OUT THE TRAY DURING POWER OUT

Tray

HCD-J300

Move the cam block in the direction of the arrow by fingers.

CLEANING THE OPTICAL PICK-UP (CD PLAYER)

2

CD mechanism deck

Move it in the

5

direction of the arrow

B

.

1

Floating screw

4

Rotate it in the

direction of the arrow

A

.

6

Clean the lens block

by cotton swab

B

3

BU-K4BD43

A

Optical pick-up

5

HCD-J300

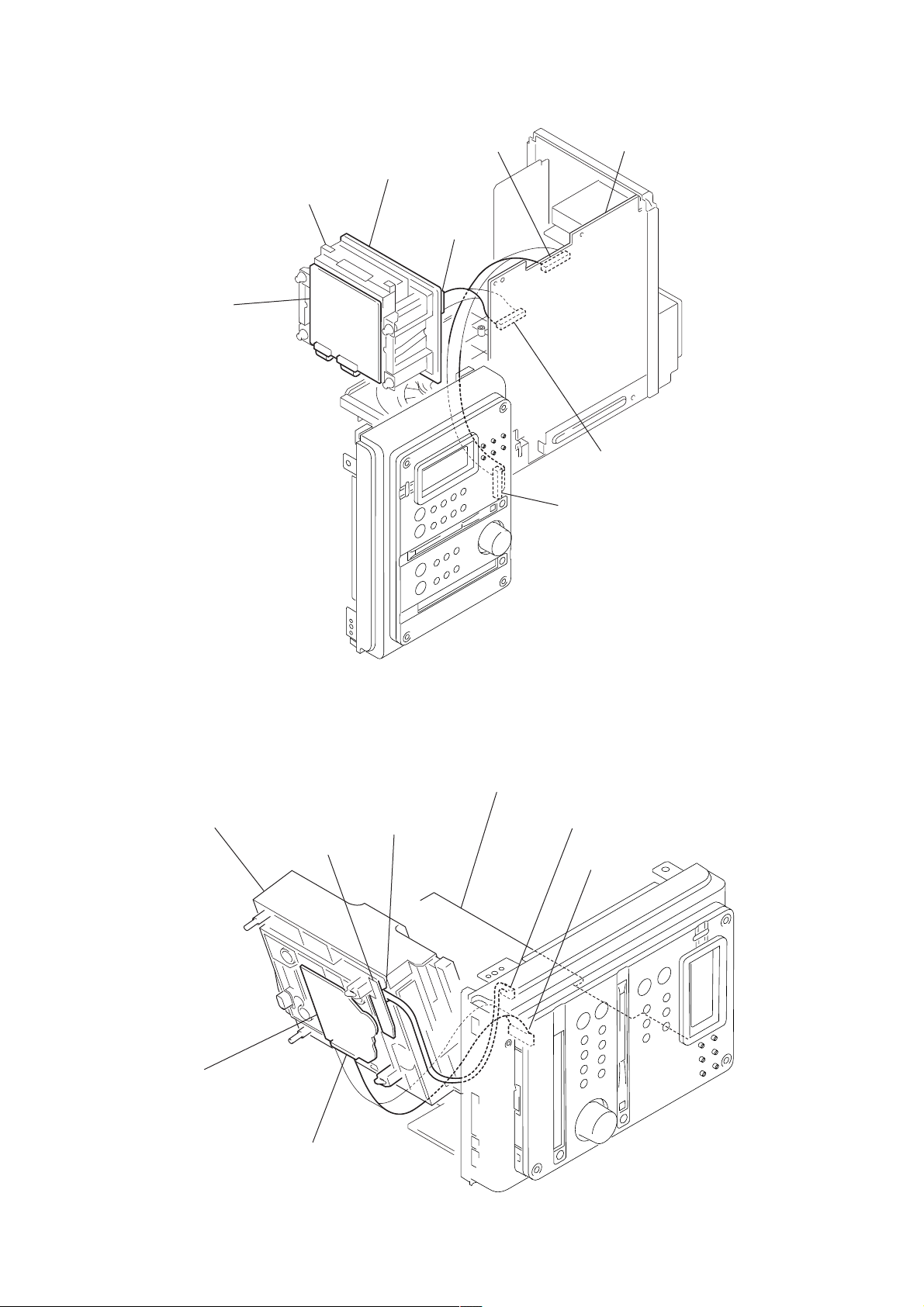

SERVICE POSITION OF THE MD MECHANISM

Digital board

MD mechanism deck

(MDM-7B)

BD board

CN1001

CN304

Main board

CN301

SERVICE POSITION OF THE CD MECHANISM

CD mechanism deck

(CDM55F-K4BD43)

Loading board

CN1

CN801

Main board

CN308

CN302

CD board

CN101

6

SERVICE POSITION OF THE CASSETTE

k

MECHANISM DECK

HCD-J300

Tape mechanism dec

CN303

Main board

CN301

7

HCD-J300

B

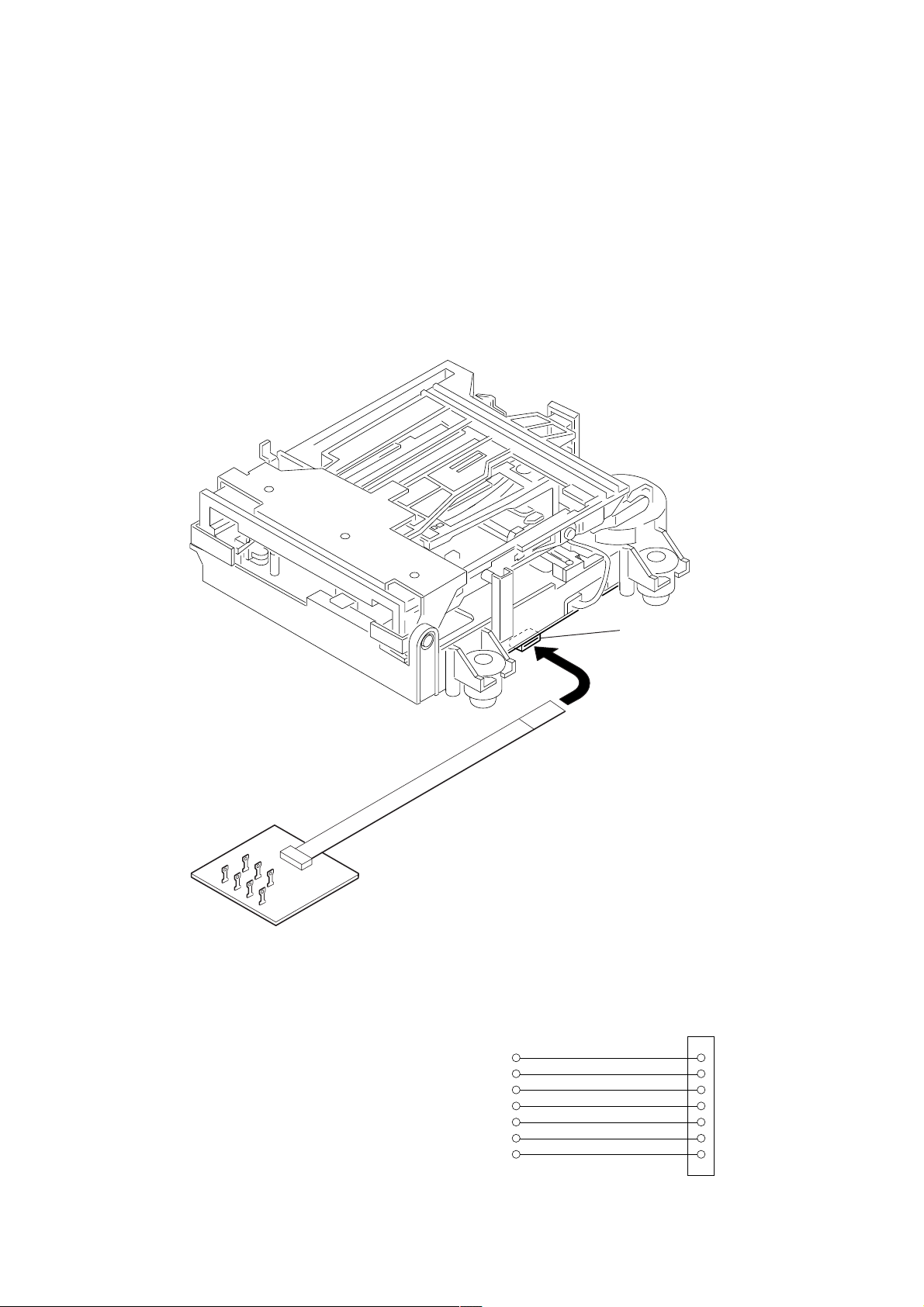

JIG FOR CHECKING BD (MD) BOARD WAVEFORM

The special jig (J-2501-196-A) is useful for checking the waveform of the BD (MD) board. The names of ter minals and the checking items

to be performed are shown as follows.

GND : Ground

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TE : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

FE : Focus error signal

I+3V

GND

FE

RF

IOP

TE

VC

I+3V

IOP

GND

TE

FE

VC

RF

CN105

1

I+3V

Iop

GND

TE

FE

VC

RF

7

for

MDM-7

8

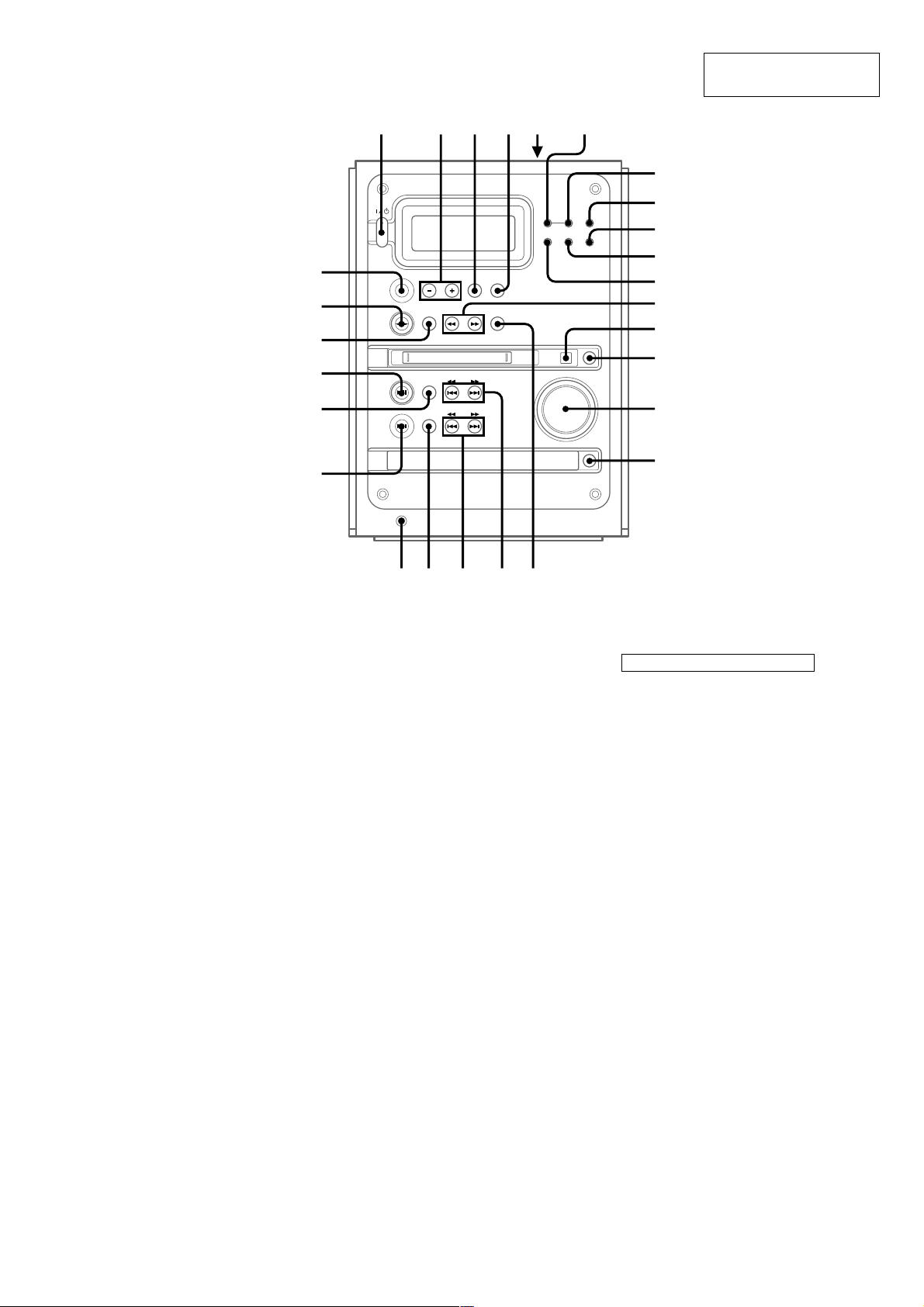

SECTION 2

GENERAL

HCD-J300

This section is extracted

from instruction manual.

wj

wh

wg

wf

wd

ws

1

23

45 6

7

8

9

0

qa

qs

qd

qf

qg

qh

BAND wj (36, 37)

CD Z qh (10, 11)

CD . > ql (11, 12)

CD m M ql (11)

CD x w; (11, 12, 19, 40)

CD u ws (10–12)

ENTER/START 7 (19, 20, 40,

41)

FUNCTION 9 (10, 12, 15, 16,

21–24, 39, 41, 45)

MD Z qf (15, 16, 18, 26)

MD . > qk (15–17, 52)

MD m M qk (15)

MD x wd (15, 17, 19–22, 40, 41)

MD u wf (15–17, 21)

qjqkqlw;wa

PHONES jack wa

PLAY MODE/DIRECTION 3

(10, 12, 13, 15–17, 26, 34, 39–

41)

REC MODE 8 (22)

Remote sensor qd

REPEAT 4 (11, 15, 36)

STEREO/MONO 4 (37)

SYNCHRO REC 6 (19, 20, 40)

TAPE m M qs (39)

TAPE X qj (39, 41)

TAPE x wg (20, 39–41, 52)

TAPE Y wh (39–41)

TUNING MODE 3 (36, 37)

TUNING +/– 2 (36, 37)

VOLUME qg

BUTTON DESCRIPTIONS

@/1 (power) 1 (7, 18, 26, 37, 43,

45, 52)

z MD qa (21, 24, 25, 52)

Z PUSH 5 (39)

z TAPE 0 (41)

9

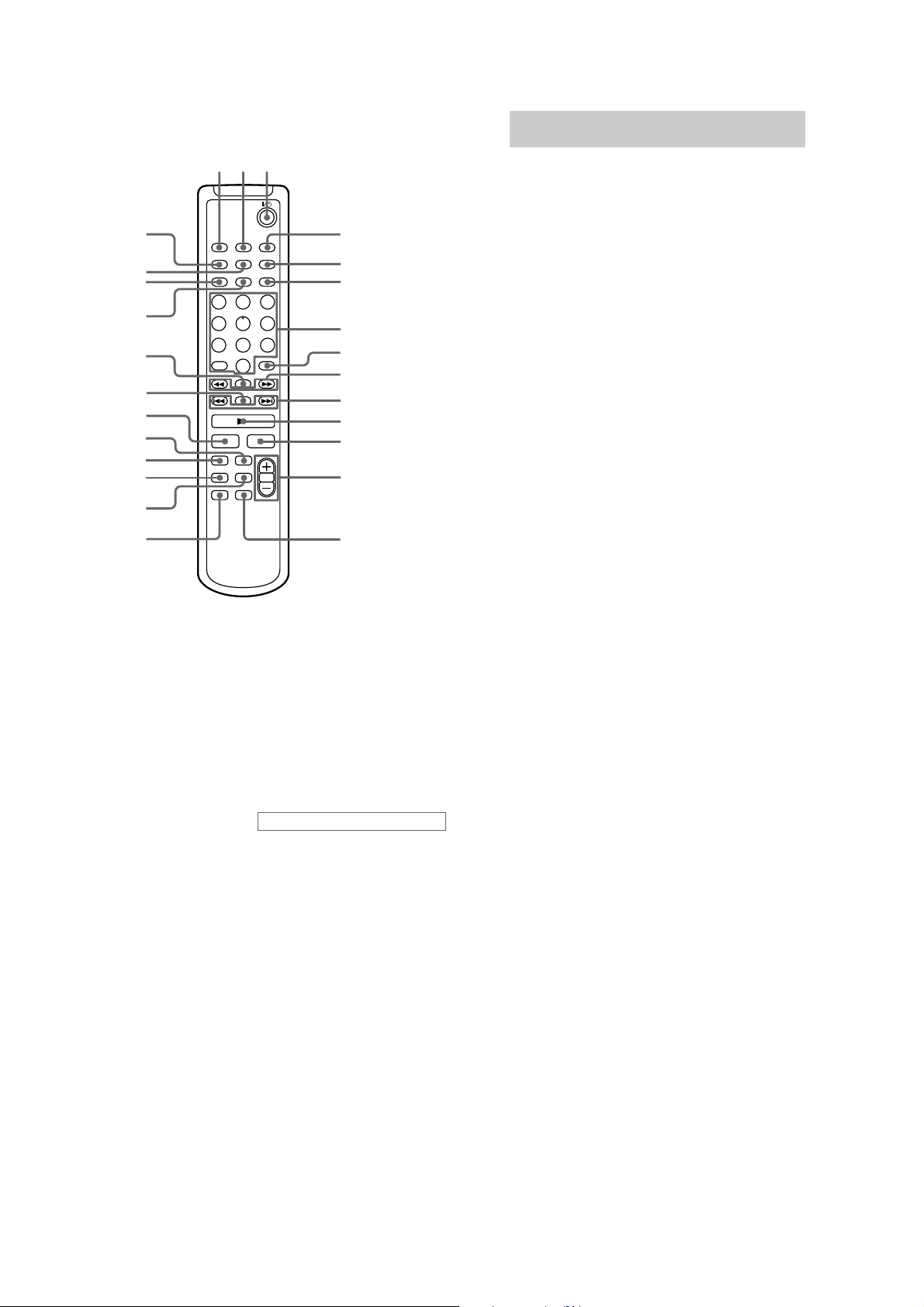

HCD-J300

Setting the time

wh

wg

wf

wd

ws

wa

w;

ql

qk

qj

qh

qg

123

4

5

6

7

8

9

0

qa

qs

qd

qf

1

Turn on the system.

2

Press CLOCK/TIMER SET on the

remote.

If you are setting the clock for the first time,

go to step 5.

3

Press . or > on the remote

repeatedly until “CLOCK SET” appears

in the display.

4

Press ENTER/YES on the remote.

The hour indication flashes.

5

Press . or > on the remote

repeatedly to set the hour.

6

Press ENTER/YES or CURSOR on

the remote.

The minute indication flashes.

7

Press . or > on the remote

repeatedly to set the minute.

8

Press ENTER/YES on the remote.

The clock will begin operating.

To reset the system clock

Start over from step 1.

BASS/TRE 5 (42)

CD qj (10, 12, 13)

CLEAR 8 (12, 14, 16, 17, 27,

38)

CLOCK/TIMER SELECT 2

(44, 45)

CLOCK/TIMER SET 4 (9, 43,

44)

CURSOR T/t 9 (9, 14, 27)

DISPLAY wa (9, 12, 13, 17, 21,

38)

DSG qf (42)

ENTER/YES 6 (9, 12, 14, 16,

21–36, 38, 43–45)

FUNCTION qg (10, 12, 15, 16,

21–24, 39, 41, 45)

MD qk (15, 16, 30–32, 34)

MENU/NO wf (14, 22–36)

NAME EDIT/SELECT wd (13,

14, 26, 27, 38)

Number buttons 7 (11–16, 17,

27, 37)

PLAY MODE wh (10, 12, 13, 15–

17, 26, 34)

REPEAT wg (11, 15)

SCROLL ws (14, 17, 28)

SLEEP 1 (42)

TAPE qh

TUNER BAND ql (36, 37)

VOLUME +/– qd

BUTTON DESCRIPTIONS

@/1 (power) 3 (7, 18, 26, 37, 43,

45)

m M 9 (11, 15, 30, 32)

. > 0 (9, 11–17, 22–25,

27–36, 42–45)

N qa (10, 12, 15, 17, 25)

x qs (11, 12, 15, 17, 19, 20, 25)

X w; (11, 15)

10

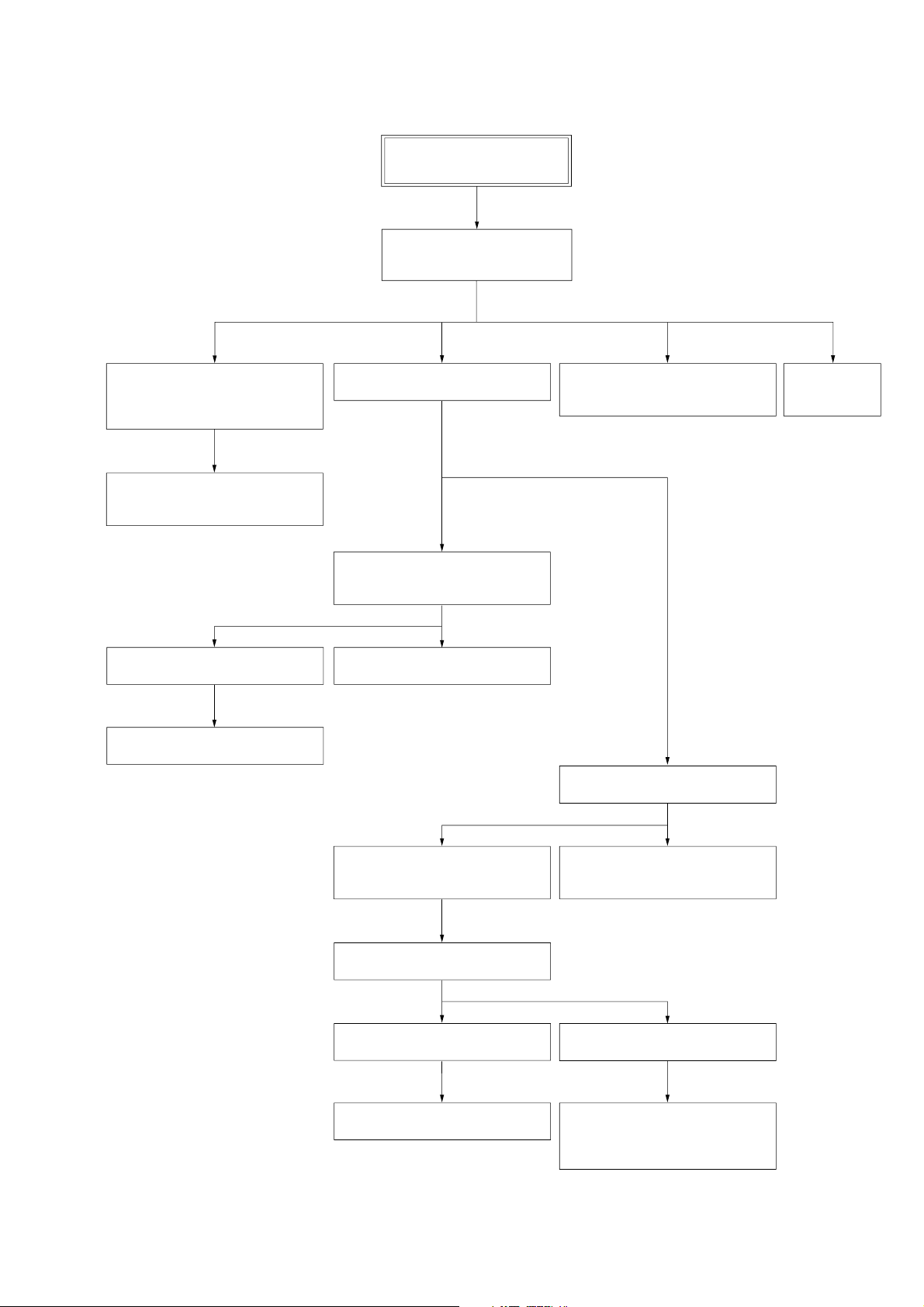

• The equipment can be removed using the following procedure.

TOP PANEL SECTION

HCD-J300

SECTION 3

DISASSEMBLY

SET

(Page 12)

BACK PANEL SECTION

(INCLUDING THE OPTICAL BOARD,

OPTICAL RETAINER BOARD)

(Page 20)

MAIN BOARD, POWER BOARD,

POWER TRANSFORMER

(Page 20)

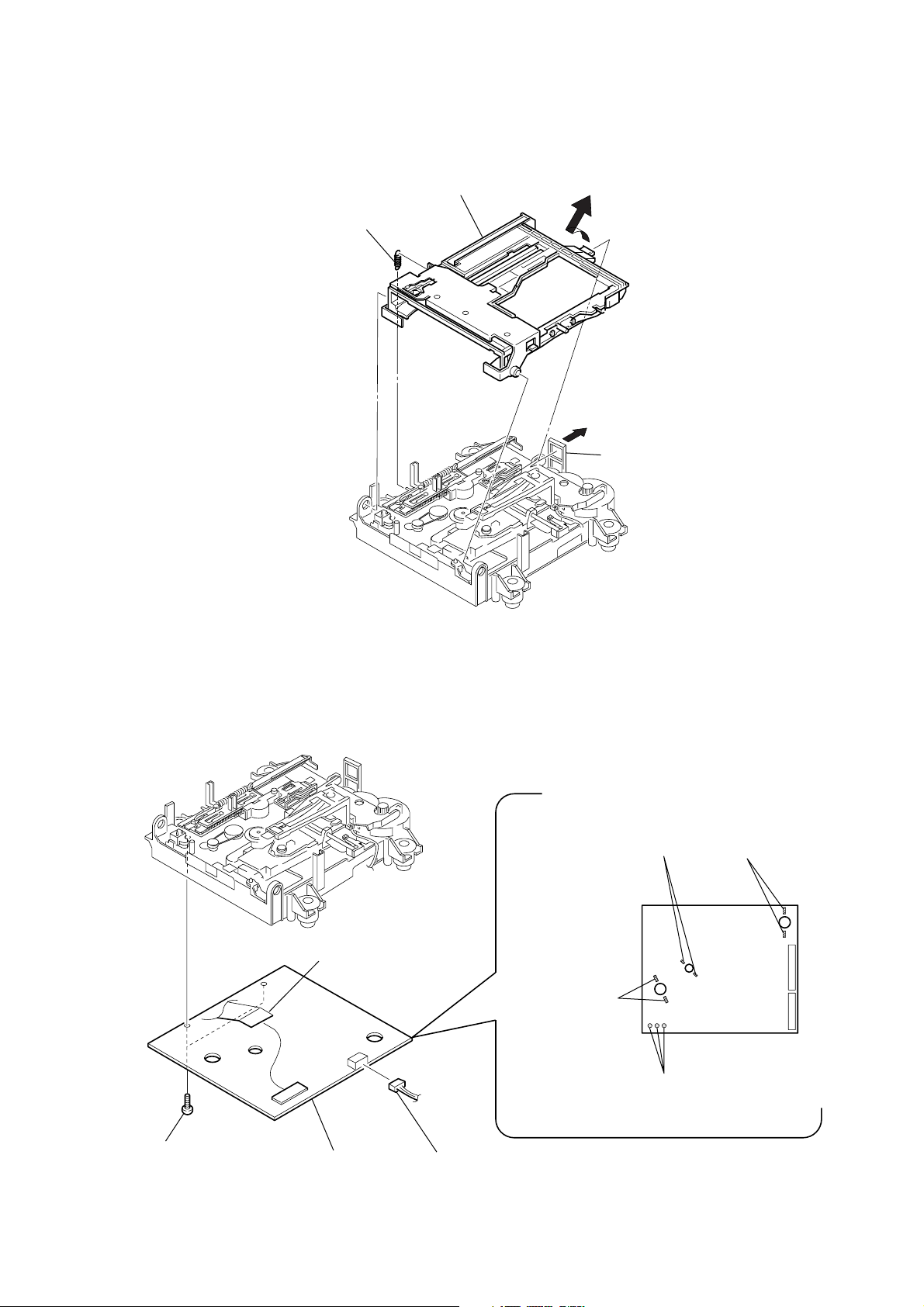

BASE UNIT (BU-K4BD43)

(Page 19)

OPTICAL PICK-UP (KSM-213DHAP)

(Page 19)

FRONT PANEL SECTION

(Page 13)

CD MECHANISM DECK

(CDM55F-K4BD43)

(Page 18)

CAM (CDM55)

(Page 18)

TC BLOCK SECTION, TC BOARD,

TAPE MECHANISM DECK

(Page 12)

MD SECTION

(Page 14)

OPTICAL

BOARD

(Page 13)

MD MECHANISM DECK (MDM-7B),

DIGITAL BOARD

(Page 14)

HOLDER SECTION

(Page 15)

OVER WRITE HEAD (HR901)

(Page 16)

OP SUB SECTION

(Page 16)

CONTROL BOARD, LED BOARD,

HEAD PHONE BOARD

(Page 17)

BD BOARD

(Page 15)

LOADING MOTOR ASSEMBLY,

SPINDLE MOTOR ASSEMBLY,

SLED MOTOR ASSEMBLY

(Page 17)

11

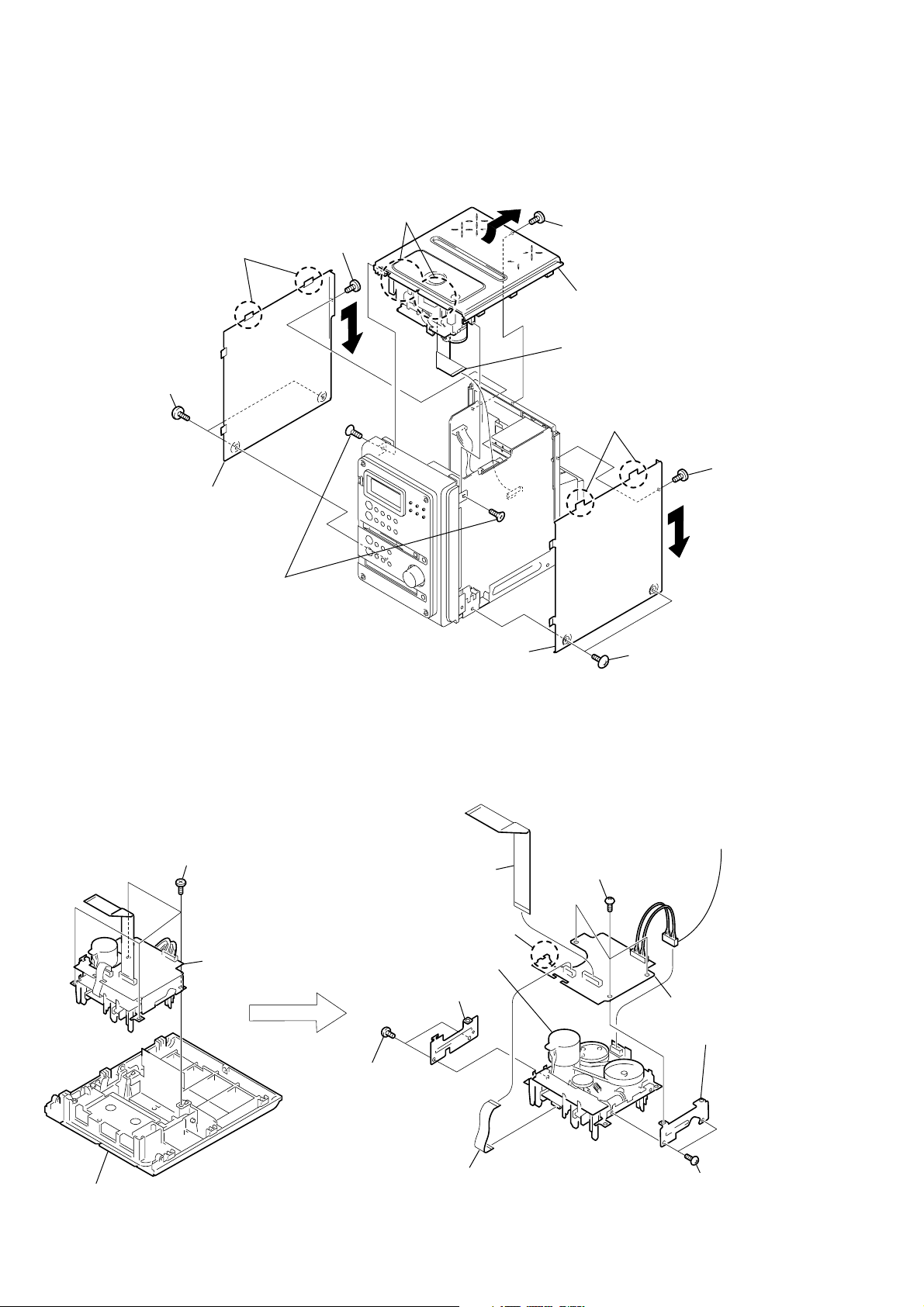

HCD-J300

)

Note: Follow the disassembly procedure in the numerical order given.

TOP PANEL SECTION

qa

Two claws

2

Screw

3

Two claws

1

Two case screws

4

Remove the side panel (X/ L) assembly

in the direction of the arrow.

(+BTP 3

×

8)

9

Screw

(+BTP 3

qs

in the direction of the arrow.

qd

Flat type wire (18 core)

(CN303)

×

8)

Remove the top panel section

7

Two claws

6

(+BTP 3

Screw

×

8)

q;

Two screws

(+KTP 3

×

6)

8

Remove the side panel (X/R) assembly

in the direction of the arrow.

TC BLOCK SECTION, TC BOARD, TAPE MECHANISM DECK

1

Four screws

(+BTP 3

3

TC block section

×

8)

1

Flat type wire (18 core)

(CN301)

qa

Tape mechanism deck

8

MD bracket (R)

4

Claw

3

Three screws

(+BVTT 2.6

5

Two case screws

5

Connector (6 core)

(from tape mechanism deck

×

5)

6

TC board

12

2

Top panel

7

Two screws

(+BVTT 2.6

2

Flat type wire (9 core)

(to TC board from tape mechanism deck)

×

5)

q;

MD bracket (L)

9

Two screws

(+BVTT 2.6

×

5)

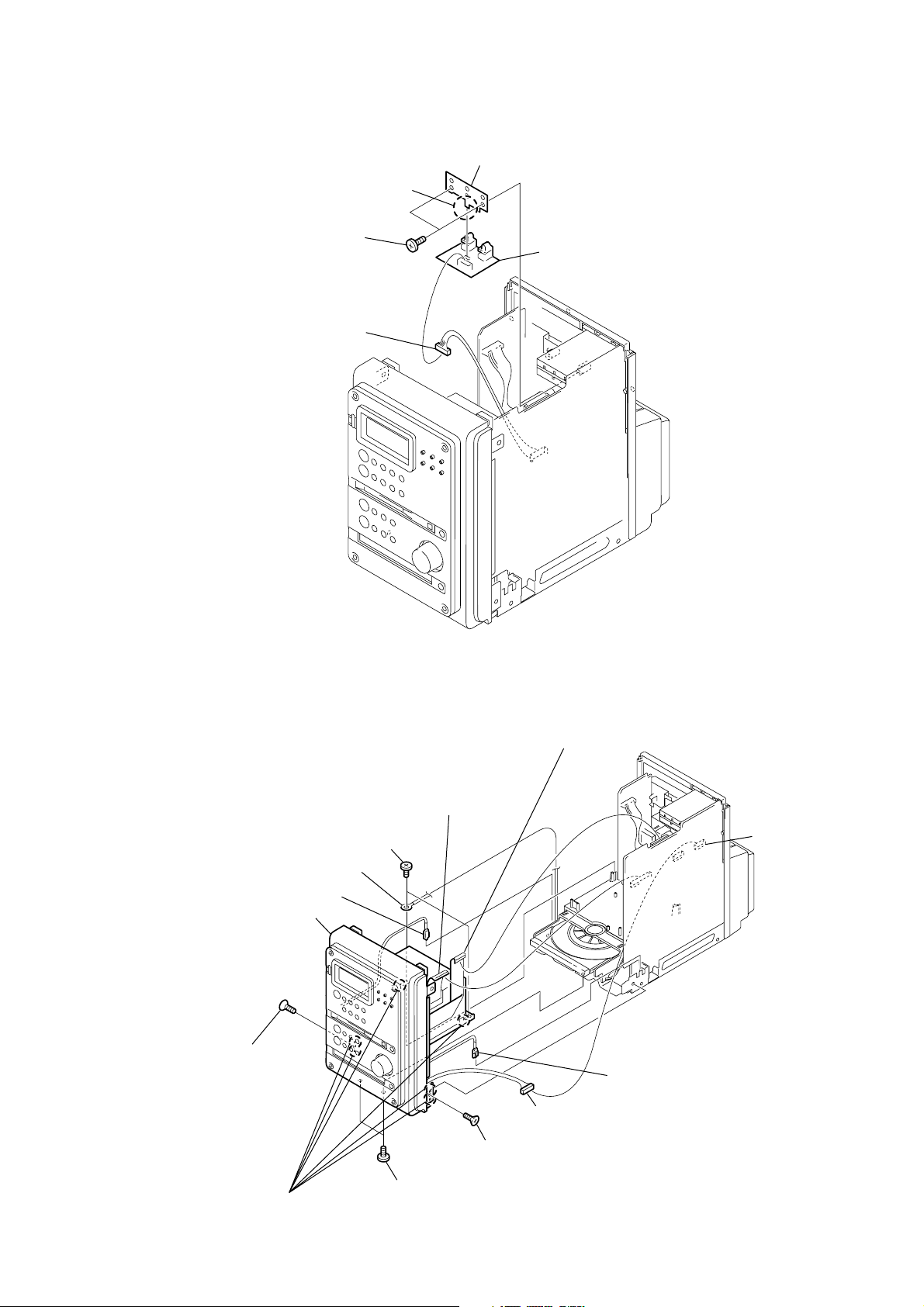

OPTICAL BOARD

)

2

Two screws

(+BTP 3

1

Connector (CN551)

HCD-J300

4

Optical retainer board

3

Claw

×

8)

5

Optical board

FRONT PANEL SECTION

q;

Lead (with connector)

5

Lead (with connector)

qs

Front panel section

8

Screw (+KTP 3 × 6)

9

Two screws

(+BTP 3

2

Flat type wire

(25 core) (CN301)

×

8)

1

(CN304)

3

Connector (CN306)

7

Screw (+KTP 3 × 6)

Flat type wire (25 core)

4

Lead (with connector)

(CN306) (5 core

qa

Six dowels

6

Two screws

(+BTP 3 × 8)

13

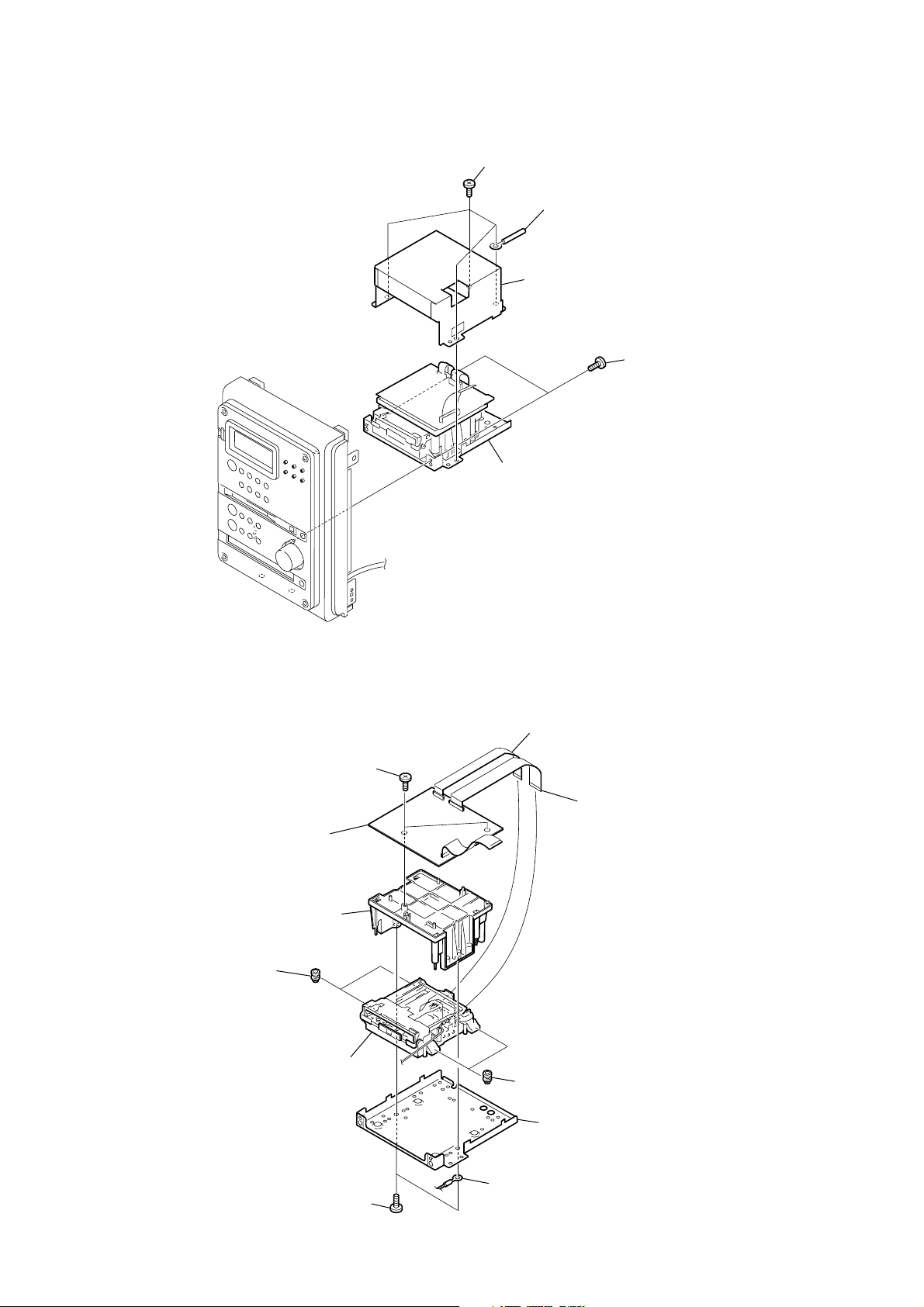

HCD-J300

)

)

MD SECTION

1

Four screws

(+BTP 3 × 8)

2

Wire holder

3

MD cover assembly

5

MD section

4

Two screws

(+BTP 3 × 8

MD MECHANISM DECK (MDM-7B), DIGITAL BOARD

6

Two screws

q;

Two insulators

qa

MD mechanism deck

(MDM-7B)

(+BVTP 3

8

Digital board

7

MD bracket

×

8)

4

Flat type wire

(17 core) (CN103)

9

Two insulators

3

Shield (MD)

5

Flat type wire

(27 core) (CN102

14

1

Two screws

(+BVTP 3

2

Lead (with connector)

×

8)

HOLDER SECTION

k

1

Tension spring (holder)

3

Holder section

2

HCD-J300

Hoo

BD BOARD

6

Flexible board

(CN101)

2

Remove the

two solderings (SPINDLE)

3

Remove the

two solderings

(LOADING)

M103

S102

4

Remove the

three solderings

1

Remove the

two solderings (SLED)

M102

M101

5

Screw

(+B (P) TRI 2 × 6 CZN)

8

BD board

7

Connector (CN104)

15

HCD-J300

)

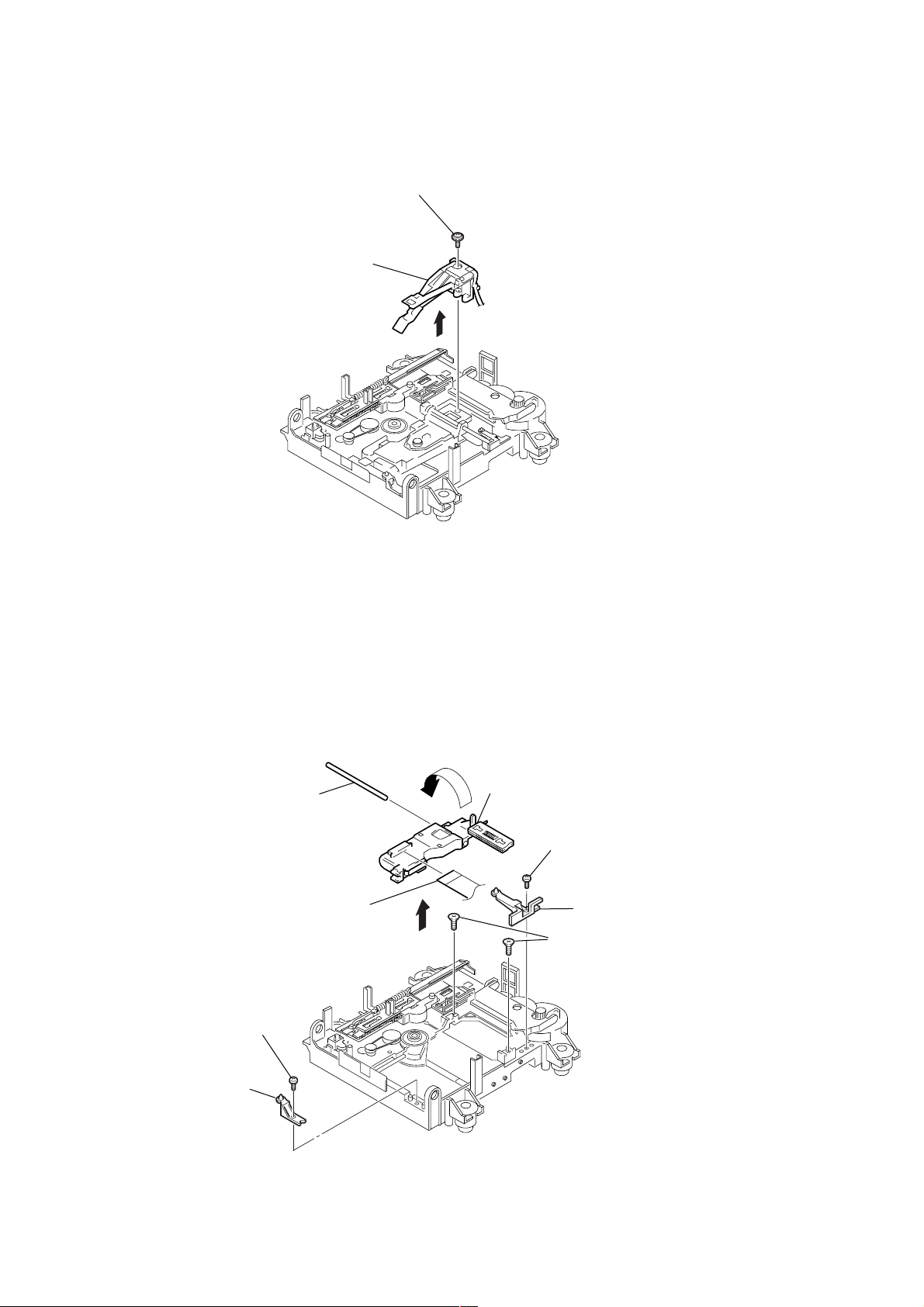

OVER WRITE HEAD (HR901)

1

2

Over write head

(HR901)

Screw (+P 1.7 × 6)

OP SUB SECTION

1

Screw

(+B (P) TRI 2 × 6 CZN)

2

Base (BU-D)

6

Main shaft

7

Flexible board

8

OP sub secion

3

Screw

(+B (P) TRI 2 × 6 CZN

4

Base (BU-A)

5

Two screws

(+KTP 2

×

6)

16

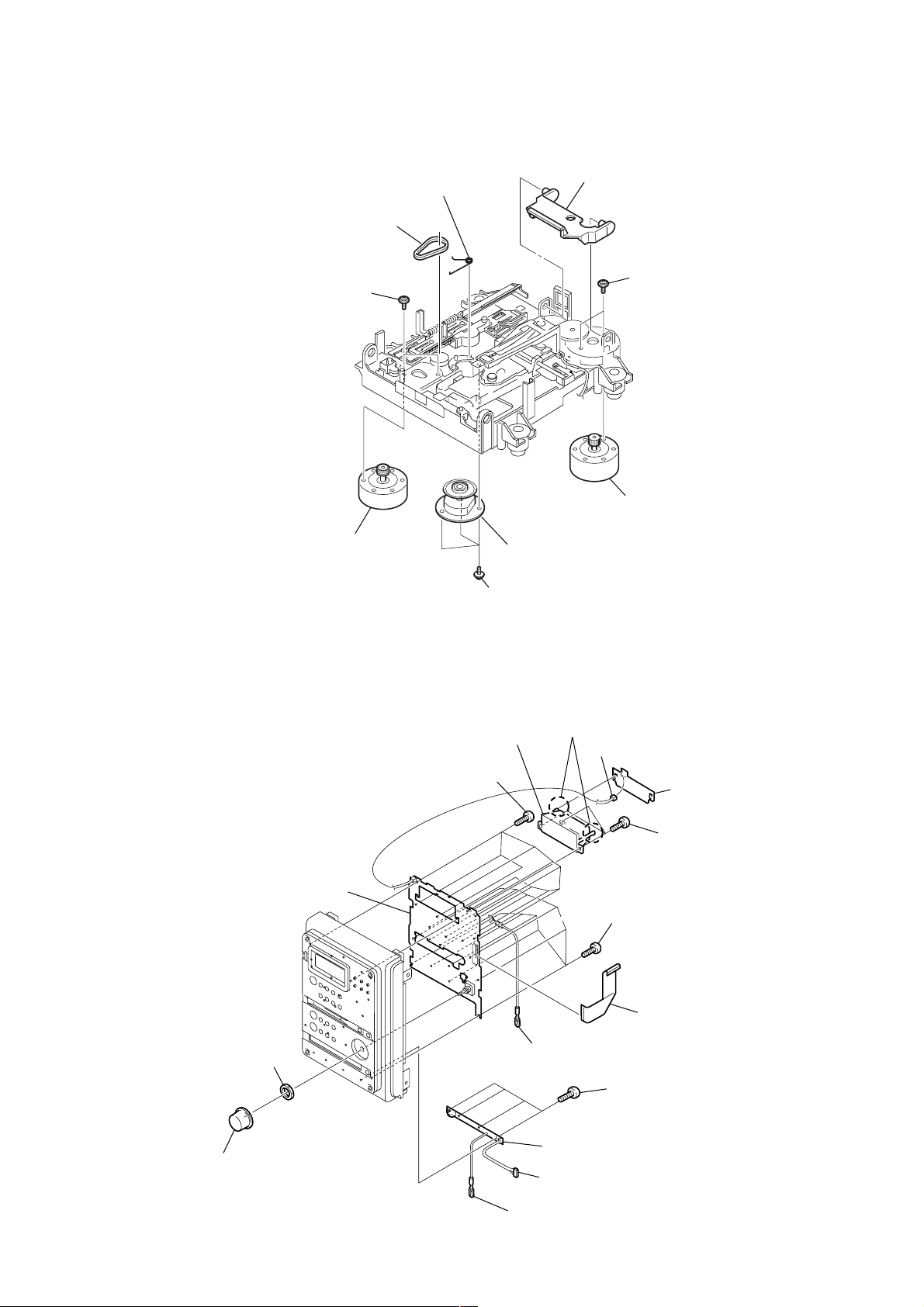

LOADING MOTOR ASSEMBLY, SPINDLE MOTOR ASSEMBLY, SLED MOTOR ASSEMBLY

y

s

1

3

Torsion spring (SPINDLE)

2

Belt (LOADING)

4

Two screws

(+PWH 1.7

×

3.5)

Lever (head)

8

Two screws

(+PWH 1.7

×

3.5)

HCD-J300

5

Loading motor assembly

(M103)

6

Three tapping screws

(M1.7 )

CONTROL BOARD, LED BOARD, HEAD PHONE BOARD

5

LCD holder (R)

8

Ten tapping screws

(DIA. 2.6 × 8) (IT3B)

qs

Control board

7

Spindle motor assembly

(M101)

1

Two claws

2

Connector (CN803)

9

(DIA. 2.6 × 8) (IT3B)

9

Sled motor assembl

(M102)

3

LED board

4

Three tapping screw

(DIA. 2.6 × 8) (IT3B)

Ten tapping screws

7

Hexagon nut

6

Knob (VOL) assembly

q;

Lead (with connector)

qd

(DIA. 2.6

qf

Head phone board

qh

Connector (CN306)

qg

Lead (with connector)

qa

Flat type wire (25 core)

(CN801)

four tapping screws

×

8) (IT3B)

17

HCD-J300

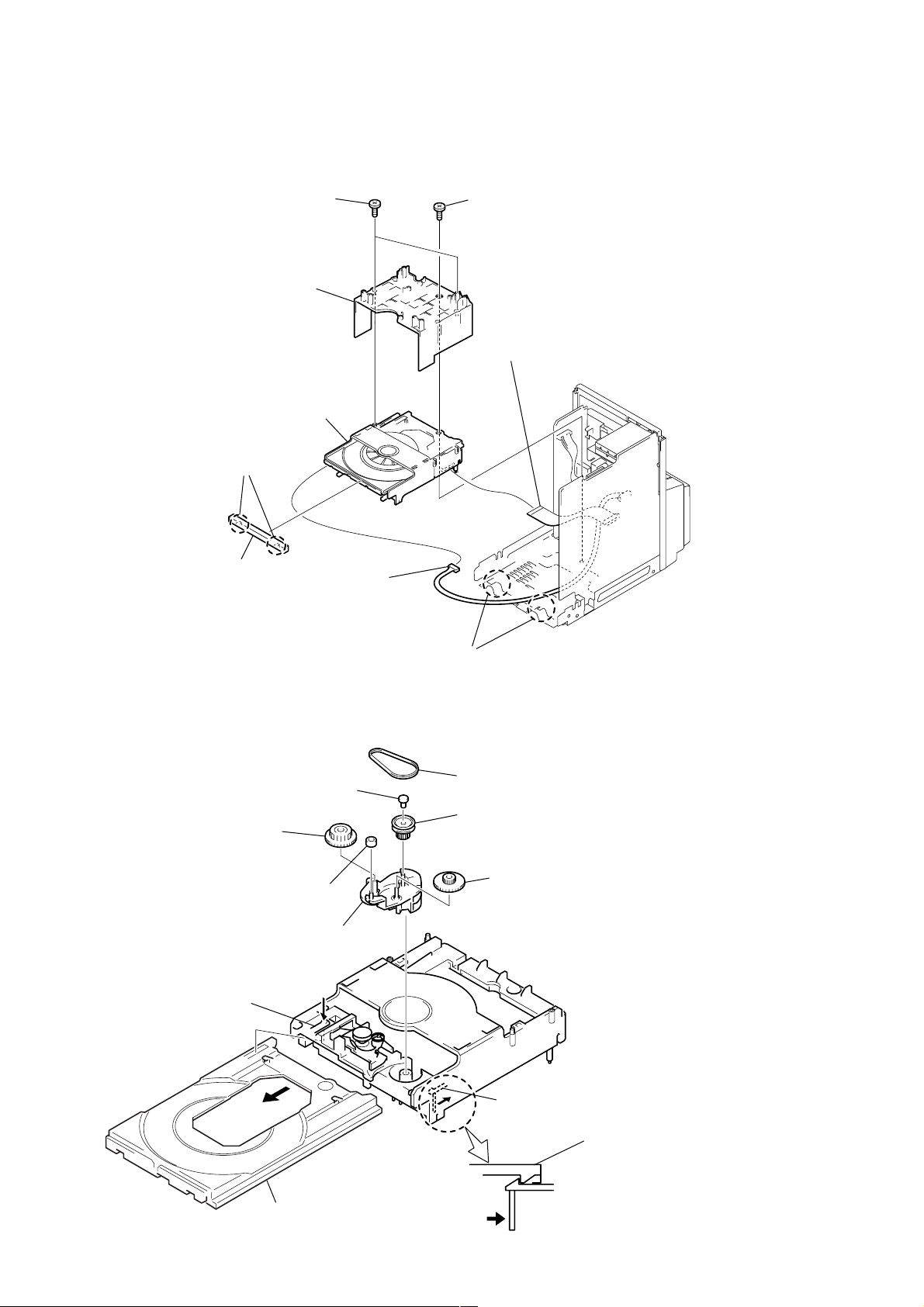

CD MECHANISM DECK (CDM55F-K4BD43)

3

Two screws

(+BTP 3

4

MPEG bracket

9

CD mechanism deck

(CDM55F-K4BD43)

7

Two claws

×

8)

1

Screw

(+BTP 3

×

5

Flat type wire

(22 core) (CN101)

8)

CAM (CDM55)

2

Push the claw in the

direction of the arrow C.

8

CD lid

8

Gear (B)

6

Connector (CN1)

5

Spacer (55)

7

Roller

q;

Cam (CDM55)

C

2

Two claws

4

Belt (CDM55)

6

Pulley (LDG)

9

Gear (A)

18

A

3

Pull out the tray.

B

1

Pull out the tray in the direction of the arrow A.

While pushing this claw in the direction of the arrow B,

release the lock.

Release the lock.

B

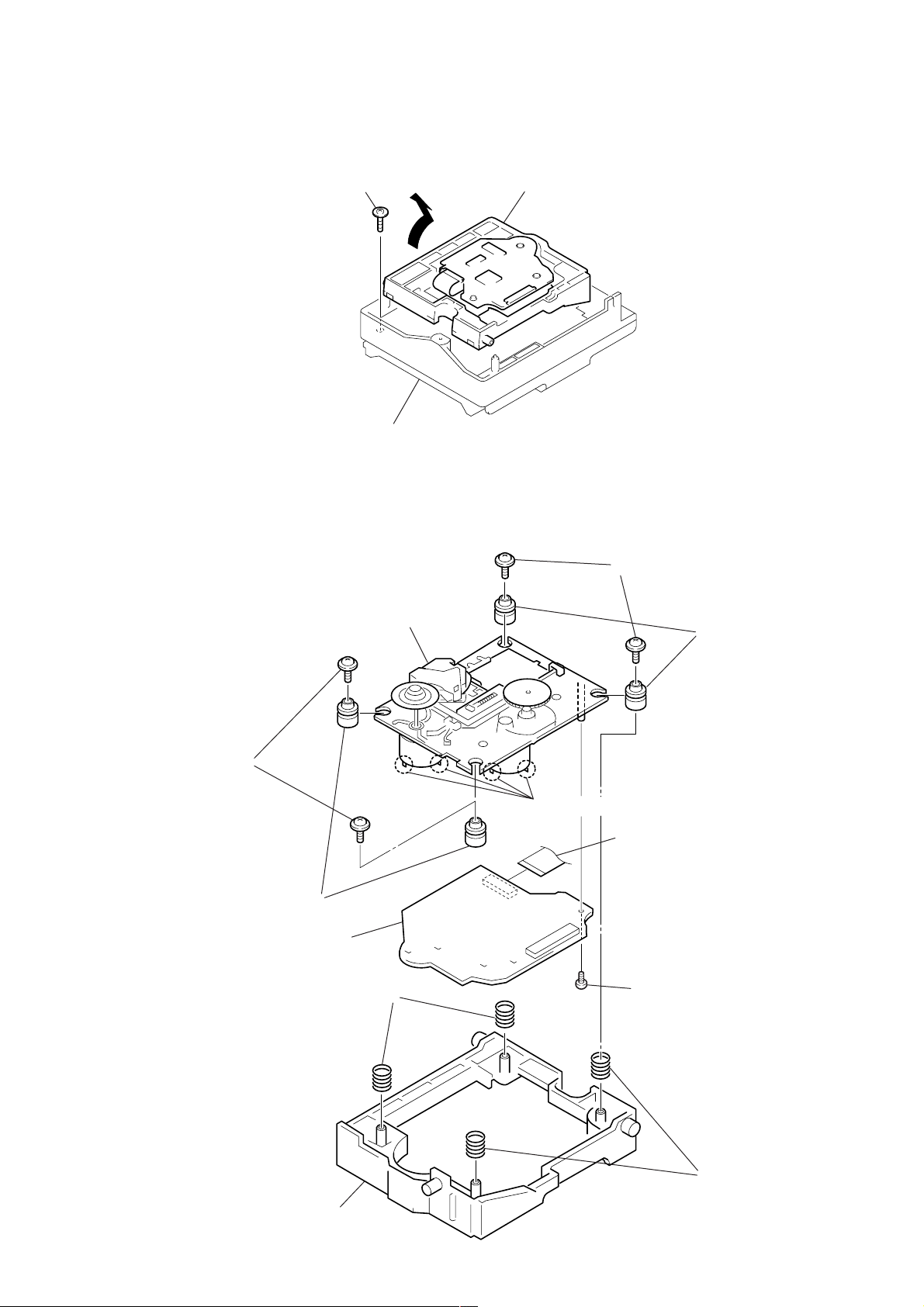

BASE UNIT (BU-K4BD43)

1

Flat type wire (16 core)

8

Two insulators

7

Two insulators

qa

CD board

2

Two floating screws

(+PTPWH M2.6)

3

Two floating screws

(+PTPWH M2.6)

4

Holder (213D)

5

Two compression springs

6

Two compression springs

qs

Optical pick-up

(KSM-213DHAP)

9

Screw (+BTP 2.6 × 6)

q;

Remove the four solderings

1

(+PTPWH M2.6)

Floating screw

3

Chassis (F)

A

2

Remove the base unit (BU-K4BD43)

in the direction of the arrow

A

HCD-J300

.

OPTICAL PICK-UP (KSM-213DHAP)

19

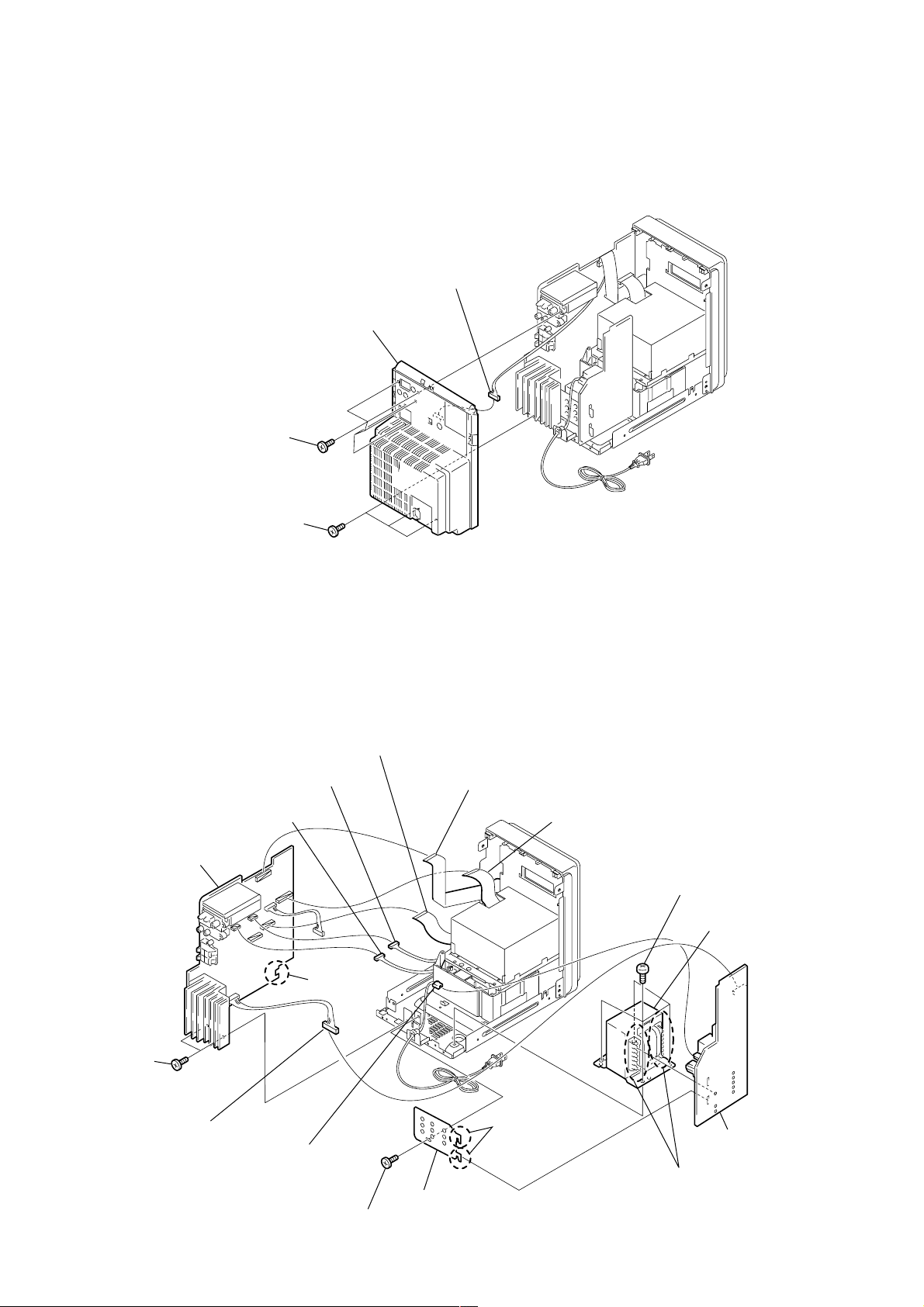

HCD-J300

d

BACK PANEL SECTION (INCLUDING THE OPTICAL BOARD, OPTICAL RETAINER BOARD)

1

Connector (CN551)

4

Back panel section

(including the optical board, optical retainer board)

2

Five screws

(+BTP 3

×

8)

3

Three screws

(+BTP 3

×

8)

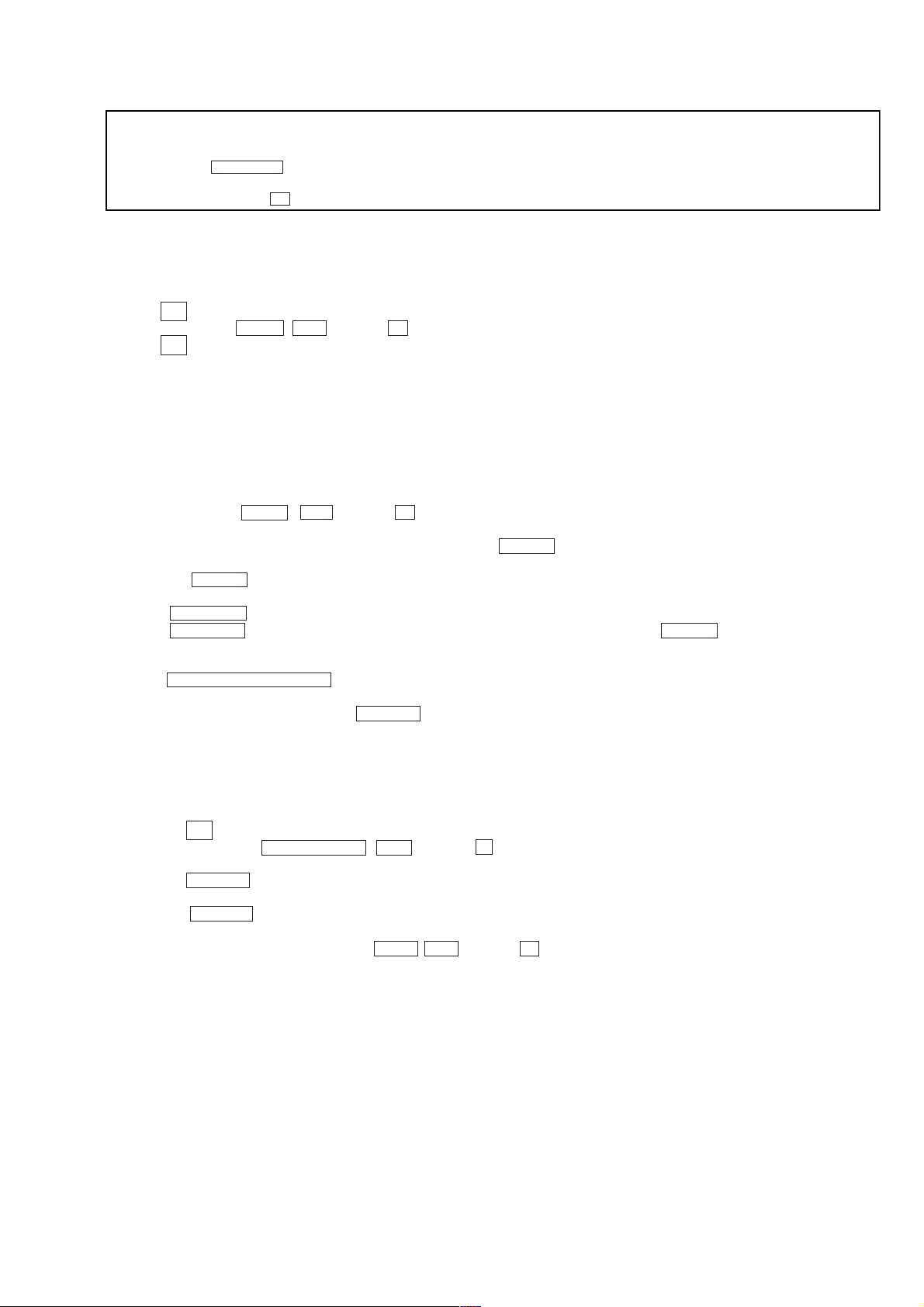

MAIN BOARD, POWER BOARD, POWER TRANSFORMER

4

Flat type wire

(22 core) (CN302)

9

Main board

5

Connector

(5 core) (CN308)

6

Connector

(5 core) (CN306)

2

Flat type wire

(25 core) (CN304)

3

Flat type wire

(25 core) (CN301)

qf

Four screws

(+BVTP 4

qh

Power

transformer

×

8)

7

Tow screws

(+BTP 3

20

×

12)

1

Connector (CN902)

q;

8

Claw

Power cord (CN901)

qa

Screw

(+BTP 3

qd

Retainer board

×

8)

qs

Two claws

qj

Power boar

qg

Remove the

solderings

HCD-J300

SECTION 4

TEST MODE

Note 1: About “R”

As this unit has only a few buttons, some operations require the use of remote commander (RM-SDC500/provided with unit: 1-476-756-11)

buttons. These operations are indicated as “R” in this manual.

Example:

Note 2: Incorrect operations may be performed if the MD test mode is not entered properly.

In this case, press the ?/1 button to turn the power off, and retry to enter the MD test mode.

[Cold Reset]

• The cold reset clears all data including preset da ta stored in the RAM to initial conditions. Execute this mode when returning the set to

the customers.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Press three buttons z MD , > (MD) and x (TAPE) simultaneously.

3. Press ?/1 button again, the LCD displays “Initialize” and the set is reset.

• Initialized conditions

FUNCTION : TUNER FM 87.5MHz

VOLUME : MIN

DSG : ON

[PANEL Test Mode]

• This mode is used to check the software version, LCD, LED and keyboard.

MENU/NO “R” ...Press the [MENU/NO] button of the remote commander.

Procedure:

1. Press three bottons z MD , > (MD) and X (TAPE) simultaneously.

2. LEDs and LCD are all turned on.

3. When you want to enter the software version display mode, press REPEAT .The model name and destination are displayed and “MD”

and “CD” segments flash.

4. Each time REPEAT is pressed, the display changes MC, GC, CD, CDD, CDMA,CDMB, BDA, BDB, ST, TA, TM, TC and MD in this

order, and returns to the top of the version display.

5. When REC MODE is pressed while the version numbers are being displayed, year, month and day of the software creation appear.

When REC MODE is pressed again, the display returns to the software version display. When REPEAT is pressed while year, month

and day of the software creation are being displayed, the year, month and day of creation of the software v ersions are displayed in the

same order of version display.

6. Press PLAYMODE / DIRECTION b utton, and the key check mode is activated. In the key check mode, the LCD displays “K 0 J 0 V

0”. Each time a button is pressed, “K 0” value increases. However, once a button is pressed, it is no longer taken into account. “V 0”

value increases like 1, 2, 3.... if rotating VOLUME knob clockwise, or it decreases like 0, 9, 8.... if rotating counter-clockwise.

7. To exit from this mode, press three buttons in the same manner as step 1, or disconnect the power cord.

[MC Test Mode]

• This mode is used to check operations of the respective sections of Amplifier, Tuner, CD and Tape.

Procedure:

1. Press the ?/1 button to turn on the set.

2. Press the three buttons SYNCHRO REC , > (MD) and X (TAPE) simultaneously.

3. The “MD” and “TAPE” segments flash.

4. When the VOLUME knob is rotated clockwise even slightly, the sound volume increases to its maximum and a message “VOLUME

MAX” appears for two seconds. then the display returns to the original display.

5. When the VOLUME knob is rotated counter-clockwise even slightly, the sound volume decreases to its minimum and a message

“VOLUME MIN” appears for two seconds, then the display returns to the original display.

6. To exit from this mode, press three buttons z MD , > (MD) and x (TAPE) simultaneously or disconnect the power cord.

21

HCD-J300

MD SECTION

1. PRECAUTIONS FOR USE OF TEST MODE

• As operations related to loading will be perfor med regardless of the test mode operations being performed, be sure to check that the disc

is stopped before setting and removing it.

Even if the Z (MD) button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not

stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the Z (MD) button after pressing the MENU/NO “R” button and the rotation of disc is stopped.

1-1. Recording laser emission mode and operating buttons

• Continuous recording mode (CREC 1MODE)

• Laser power check mode (LDPWR CHECK)

• Laser power adjustment mode (LDPWR ADJUST)

• Comparison with initial Iop value written in nonvolatile memory (Iop Compare)

• Write current Iop value in read nonvolatile memory using microprocessor (Iop NV Save)

• Traverse (MO) check (EF MO CHECK)

• Traverse (MO) adjustment (EF MO ADJUST)

• When pressing the z MD button.

2. SETTING THE TEST MODE

The following are two methods of entering the test mode.

Procedure : 1. Press the ?/1 button to turn the power on.

2. Press the [FUNCTION] button to set the MD function.

3. Press three buttons of x (MD), m (TAPE), and [SYNCHRO REC] simultaneously.

When the test mode is set, “[Check]” will be displayed. Pressing the . “R” or > “R” button between the following three

groups; ···Tt [Check] Tt [Service] Tt [Develop] Tt ···.

Note: Do not use the test mode in the [Develop] group.

If used, the unit may not operate normally.

If the [Develop] group is set accidentally, press the MENU/NO “R” button immediately to exit the [Develop] group.

3. RELEASING THE TEST MODE

Press the [REPEAT STEREO/MONO] button twice to display “Initialize”, then release the MD test mode.

4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the . “R” , > “R” , ENTER/YES “R” and MENU/NO “R” .

The functions of these buttons are as follows.

Function name Function

. “R” , > “R” buttons Changes parameters and modes

ENTER/YES “R” button Proceeds onto the next step. Finalizes input

MENU/NO “R” button Returns to previous step. Stops operations

22

HCD-J300

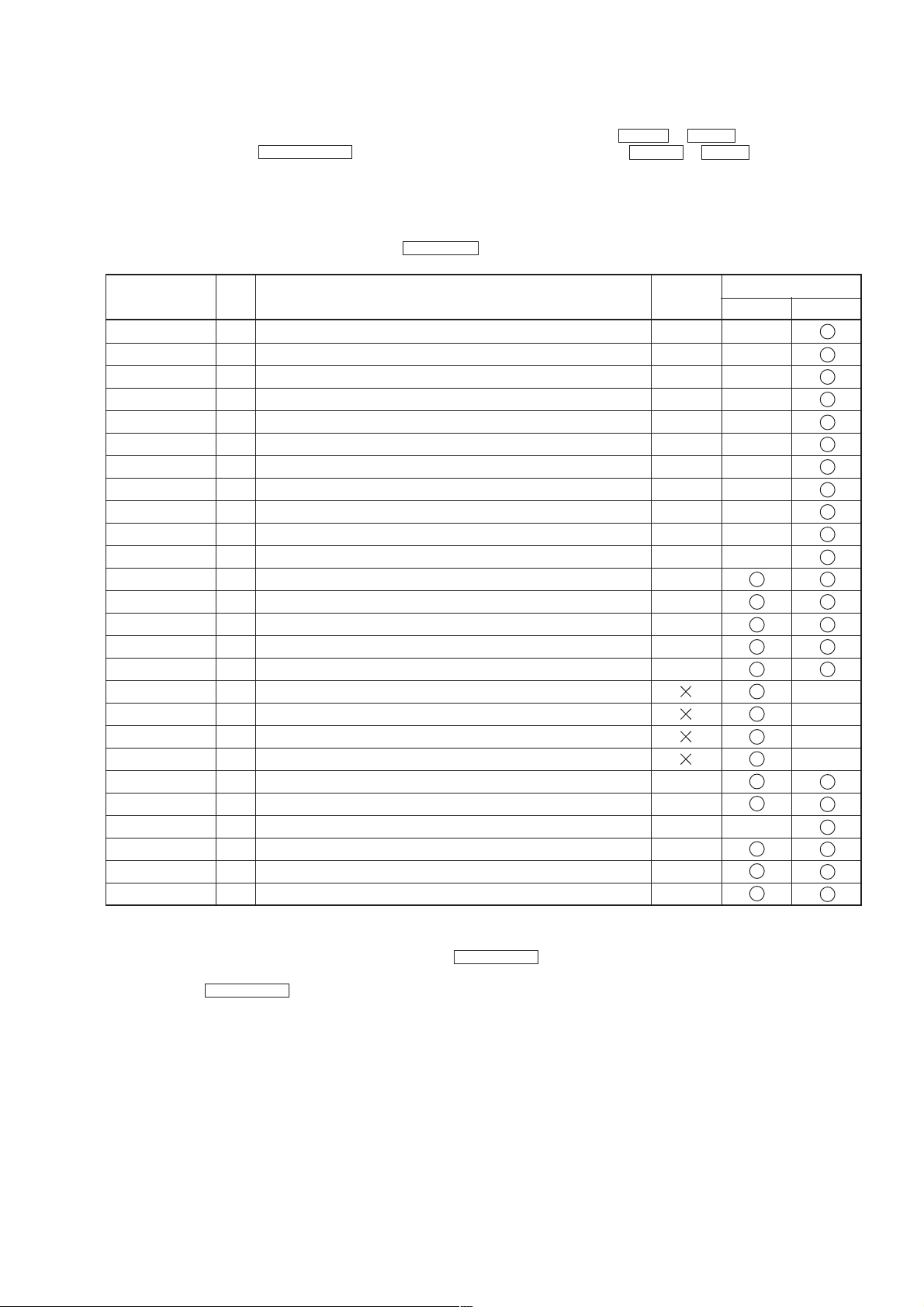

5. SELECTING THE TEST MODE

There are 26 types of test modes as shown below . The groups can be switched by pressing the . “R” or > “R” button. After selecting the

group to be used, press the ENTER/YES “R” button. After setting a certain group, pressing the . “R” or > “R” button switches modes

shown below.

Refer to “Group” in the table for details can be selected.

All items used for servicing can be treated using group [Service]. So be carefully not to enter other groups by mistake.

Note: Do not use the test mode in the [Develop] group.

If used, the unit may not operate normally.

If the [Develop] group is set accidentally, press the

MENU/NO “R” button immediately to exit the [Develop] group.

Display

AUTO CHECK

Err Display

TEMP ADJUST

LDPWR ADJUST

Iop Write

Iop NV Save

EF MO ADJUST

EF CD ADJUST

FBIAS ADJUST

AG Set (MO)

AG Set (CD)

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

ScurveCHECK

VERIFYMODE

DETRK CHECK

0920 CHECK

Iop Read

Iop Compare

ADJ CLEAR

INFORMATION

CPLAY 1MODE

CREC 1MODE

No.

Automatic self-diagnosis

C01

Error history display, clear

C02

Temperature compensation offset adjustment

C03

Laser power adjustment

C04

Iop data writing

C05

Writes current Iop value in read nonv olatile memory using microprocessor

C06

Trav erse (MO) adjustment

C07

Traverse (CD) adjustment

C08

Focus bias adjustment

C09

Auto gain output level adjustment (MO)

C10

Auto gain output level adjustment (CD)

C11

Temperature compensation offset check

C12

Laser power check

C13

Trav erse (MO) check

C14

Traverse (CD) check

C15

Focus bias check

C16

S-curve check

C17

Nonvolatile memory check

C18

Detrack check

C19

Most circumference check

C25

Iop data display

C26

Comparison with initial Iop value written in nonvolatile memory

C27

Initialization of nonvolatile memory for adjustment values

C28

Display of microprocessor version, etc.

C31

Continuous playback mode

C34

Continuous recording mode

C35

Details

Mark

Group

Check Service

• For details of each adjustment mode, refer to “Section 6 Electrical Adjustments”.

For details of “Err Display”, refer to “Self-Diagnosis Function” on page 3.

• If a different mode has been selected by mistake, press the MENU/NO “R” button to release that mode.

• Modes with (×) in the Mark column are not used for servicing and therefore are not described in detail. If these modes are set accidentally, press the MENU/NO “R” button to release the mode immediately.

23

HCD-J300

5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

(1) Set the disc in the unit. (Whichever recordable discs or discs for playback only are available)

(2) Press the

(3) Press the

(4) When access completes, the display changes to “C = AD = )”.

Note: The numbers “ ” displayed show you error rates and ADER.

2. Changing the parts to be played back

(1) Press the ENTER/YES “R” button during continuous playback to change the display as below.

When pressed another time, the parts to be played back can be moved.

(2) When access completes, the display changes to “C = AD = )”.

3. Ending the continuous playback mode

(1) Press the MENU/NO “R” button. The display will change to “CPLAY 1MODE” (C34).

(2) Press the Z (MD) button and take out the disc.

Note: The playback start addresses for IN, MID, and OUT are as follows.

. “R” or > “R” button to display “CPLAY 1MODE” (C34).

ENTER/YES “R” button to change the display to “CPLAY1MID”.

“CPLAY 1MID” t “CPLAY 1OUT” t “CPLAY 1IN”

Note: The numbers “ ” displayed show you error rates and ADER.

IN : 40h cluster

MID : 300h cluster

OUT : 700h cluster

5-2. Operating the Continuous Recording Mode (Use only when performing self-recording/palyback check)

1. Entering the continuous recording mode

(1) Set a recordable disc in the unit.

(2) Press the . “R” or > “R” button to display “CREC 1MODE” (C35).

(3) Press the ENTER/YES “R” button to change the display to “CREC 2MID”.

(4) When access completes, the display changes to “CREC (1 )” and “ z MD ” lights up.

Note: The numbers “ ” displayed shows you the recording position addresses.

2. Changing the parts to be recorded

(1) When the ENTER/YES “R” button is pressed during continuous recording, the display changes as below.

“CREC 1MID” t “CREC 1OUT” t “CREC 1IN”

When pressed another time, the parts to be recorded can be changed. “

z MD ” goes off.

(2) When access completes, the display changes to “CREC (1 )” and “ z MD ” lights up.

Note: The numbers “ ” displayed shows you the recording position addresses.

3. Ending the continuous recording mode

(1) Press the MENU/NO “R” button. The display changes to “CREC 1MODE” (C35) and “ z MD ” goes off.

(2) Press the Z (MD) button and take out the disc.

Note 1: The recording start addresses for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT : 700h cluster

Note 2: The MENU/NO “R” button can be used to stop recording anytime.

Note 3: Do not perform continuous recording for long periods of time above 5 minutes.

Note 4: During continuous recording, be careful not to apply vibration.

6. FUNCTIONS OF OTHER BUTTONS

Function

N X MD

x (MD)

M “R”

m “R”

PLAY MODE

REC MODE

MD Z

REPEAT STEREO/MONO

24

Contents

Sets continuous playback when this is pressed in the STOP state. When this is pressed during continuous playback, playback position moves.

Stops continuous playback and continuous recording

The sled moves to the outer circumference only when this is pressed

The sled moves to the inner circumference only when this is pressed

Switches the spindle servo mode (CLV S y CLV A)

Switches the displayed digit each time the button is pressed

Ejects the disc

Releases the test mode

HCD-J300

8. AUTOMATIC SELF-DIAGNOSIS FUNCTION

This test mode performs CREC and CPLAY automatically for mainly checking the characteristics of the optical pick-up.

To perform this test mode, the laser power must first be checked.

Perform AUTO CHECK after the laser power check and Iop Compare.

Procedure:

1. Press the . “R” or > “R” button to display “ AUTO CHECK” (C01).

2. Press the

In this case, perform the laser power check and Iop Compare, and then repeat from enter the MD test mode.

3. If a disc is in the mechanical deck, it will be ejected forcibly.

“DISC IN” will be displayed in this case. Load a test disc (MDW-74/GA-1) which can be recorded.

4. If a disc is loaded at step 3, the check will start automatically.

5. When “XX CHECK” is displayed, the item corresponding to XX will be performed.

When “06 CHECK” completes, the disc loaded at step 3 will be ejected. “DISC IN” will be displayed. Load the check disc (TDYS-1).

6. When the disc is loaded in step 5, the check will automatically be resumed from “07 CHECK”.

7. After completing to “0C CHECK” of test item 12, check OK or NG will be displayed. If all items are OK, “CHK ALL OK” will be

displayed. If any item is NG, it will be displayed as “NG:xxxx”.

When “CHK ALL OK” is displayed, it means that the optical pick-up is normal. Check the operations of other parts (spindle motor, sled

motor, etc.).

When displayed as “NG:xxxx”, it means that the optical pick-up is faulty. In this case, replace the optical pick-up.

ENTER/YES “R” button. If “LDPWR ” is displayed, it means that the laser power check has not been performed.

9. INFORMATION

Display the software version.

Procedure:

1. Press the . “R” or > “R” button to display “INFORMATION” (C31).

2. Press the ENTER/YES “R” button.

3. The software version will be displayed.

4. Press the MENU/NO “R” button to end this mode.

10. IOP DATA RECORDING AND DISPLAY WHEN OPTICAL PICK-UP AND NON-VOLATILE MEMORY (IC195 OF BD

BOARD) ARE REPLACED

The IOP value labeled on the optical pick-up can be recorded in the non-volatile memory. By recording the value, it will eliminate the need

to look at the value on the label of the optical pick-up. When replacing the optical pick-up or non-volatile memory (IC195 of BD (MD)

board), record the IOP value on the optical pick-up according to the following procedure.

Record Procedure:

1. Press the ?/1 button to turn the power on.

2. Press the [FUNCTION] button to set the MD function.

3. Press three buttons of x (MD), m (TAPE) and [SYNCHRO REC] simultaneously to enter the MD test mode and display “[Check]”.

4. Press the . “R” or > “R” button to display “[Service]”.

5. Press the ENTER/YES “R” button to display “AUTO CHECK”, and press the > “R” button to display “Iop Write”.

6. Press the ENTER/YES “R” button.

7. The display becomes “Ref= @@@.@” (@ is an arbitrary number) and the numbers which can be changed will blink.

8. Input the IOP value written on the optical pick-up.

To select the number : Press the . “R” or > “R” button.

To select the digit : Press the [REC MODE] button.

9. When the ENTER/YES “R” button is pressed, the display becomes “Measu=@@@.@” (@ is an arbitrary number).

10. As the adjustment results are recorded for the step 9 value. Leave it as it is and press the ENTER/YES “R” button.

11. “Complete!” will be displayed momentarily. The value will be recorded in the non-volatile memory and the display will become “Iop

Write”.

12. Press the [REPEAT STEREO/MONO] button twice to complete. “Initialize” will be displayed and release the MD test mode.

Display Precedure:

1. Press the ?/1 button to turn the power on.

2. Press the [FUNCTION] button to set the MD function.

3. Press three buttons of x (MD), m (TAPE) and [SYNCHRO REC] simultaneously to enter the MD test mode and display “[Check]”.

4. Press the . “R” or > “R” button to display “[Service]”.

5. Press the ENTER/YES “R” button to display “AUTO CHECK”, and press the > “R” button to display “Iop Read”.

6. Press the ENTER/YES “R” button.

7. “@@.@/##.#” is displayed and the recorded contents are displayed.

@@.@ : Indicates the Iop value labeled on the pick-up.

##.# : Indicates the Iop value after adjustment.

8. Press the [REPEAT STEREO/MONO] button twice to complete. “Initialize” will be displayed and release the MD test mode.

25

HCD-J300

11. WHEN MEMORY NG IS DISPLAYED

If the nonvolatile memory data is abnormal, “E001 MEMORY NG” will be displayed so that the MD deck does not continue operations. In

this case, set the test mode promptly and perform the following procedure.

Procedure:

1. Enter the MD test mode.

2. Normally a message for selecting the test mode will be displayed. Howev er if the non v olatile memory is abnormal, the following will be

displayed “INIT EEP?”.

3. Press the x (MD) and Z (MD) buttons simultaneously.

4. Press the . “R” or > “R” button to display “MDM-7B”.

5. Press the REC MODE button. If the nonv olatile memory is successfully overwritten, the normal MD test mode will be set and a message

to select the MD test mode will be displayed.

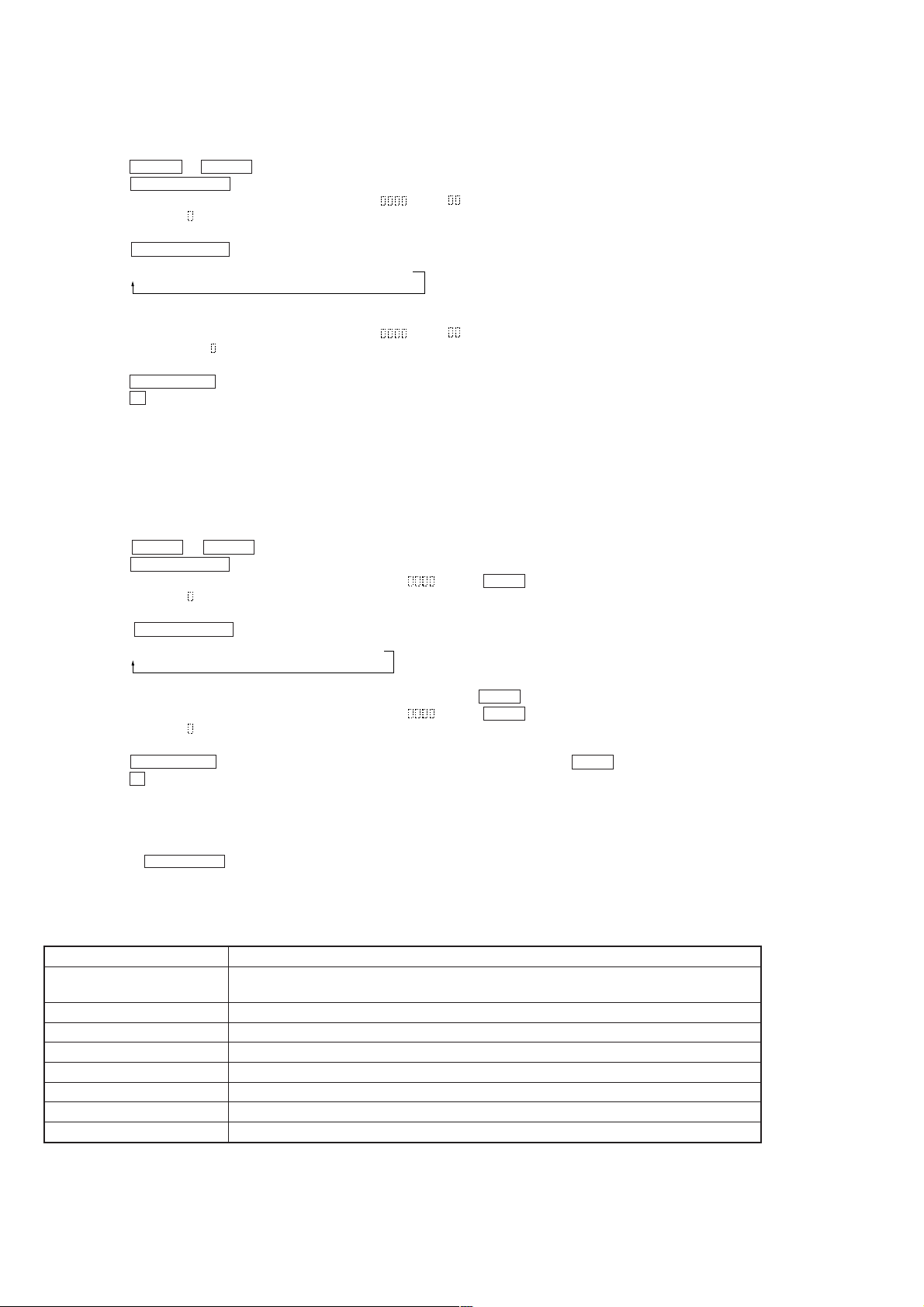

12. CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS IN MD

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “Section 6 Electrical Adjustments”.

Laser power check

(6-2 : See page 32)

Auto check

(6-7 : See page 33)

Temperature

compensation

offset check

(6-1 : See page 32)

Criteria for Determination

(Unsatisfactory if specified value is not satisfied)

• 0.9 mW power

Specified value : figure1

• 7.0 mW power

Specified value : figure2

Iop (at 8.4mW)

• Labeled on the optical pick-up

Iop value ± 10mA

• Unsatisfactory if displayed as “NG : XXXX”NG

(XXXX are arbitrary numbers)

• Unsatisfactory if displayed as “T=@@ (##) [NG]”

NG

(@@, ## are both arbitrary numbers)

• Clean the optical pick-up

• Adjust again

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Check for disconnection of the circuits around

D101 (BD board)

• Check the signals around IC101, IC151, CN102,

CN103 (BD board)

Measure if unsatisfactory

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for adjustments.

When performing adjustments, use the specified values for adjustments.

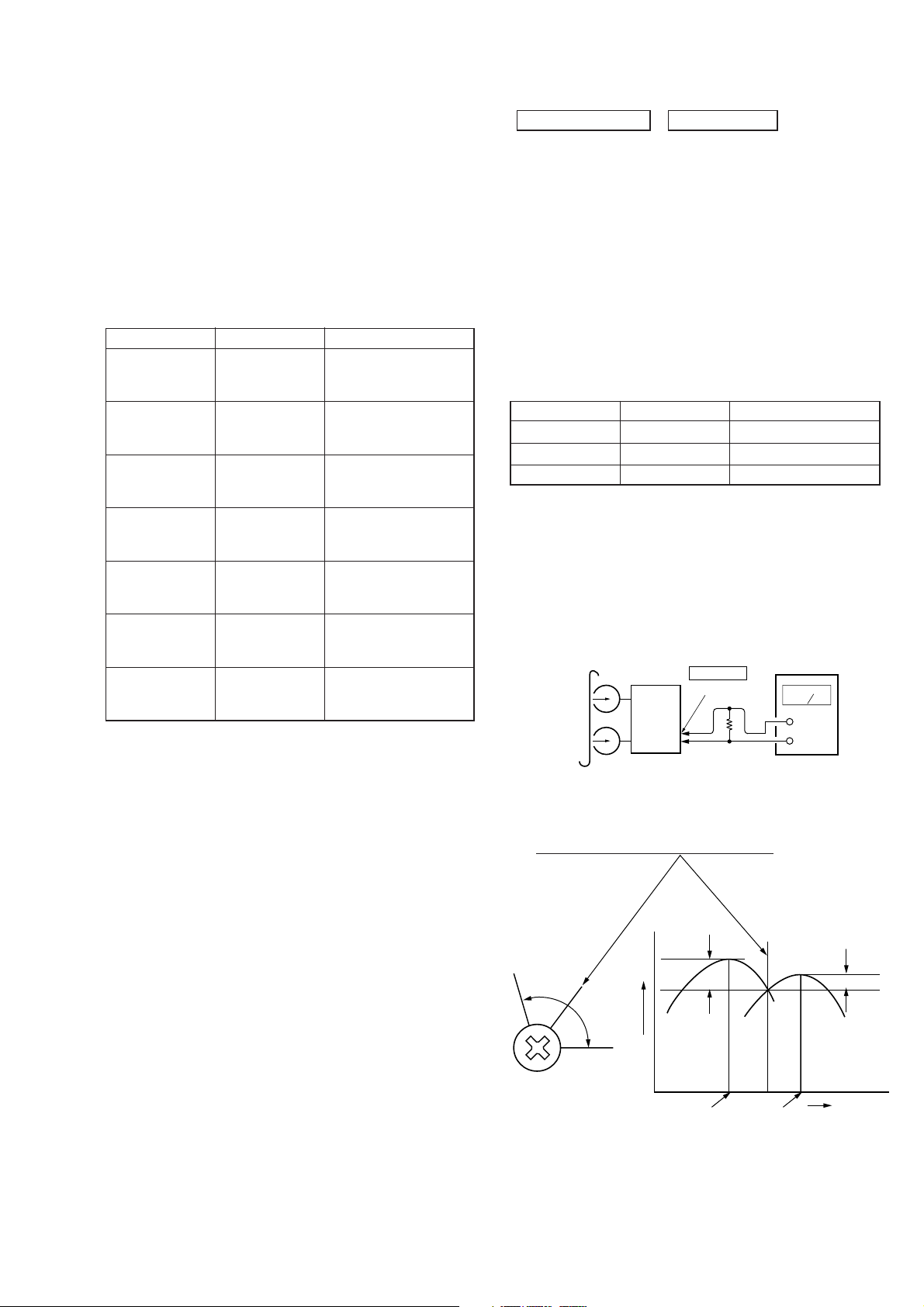

Figure1:

SPECIFIED V ALUE

Figure2:

SPECIFIED V ALUE

KMS-260B

KMS-260E

KMS-260B

KMS-260E

0.85 to 0.91 mW

0.90 to 0.96 mW

6.8 to 7.2 mW

7.0 to 7.5 mW

CD SECTION

[CD SERVO Test Mode]

• Use this mode when checking CD servo.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press three buttons M (TAPE), SYNCHRO REC and > (MD) simultaneously.

4. Press the appropriate button for the following tests.

Button Function Button Function

Z(CD) TEST 1 PLAY MODE DIRECTION TEST 6

x(CD) TEST 2 u(CD) TEST 7

> TEST 3 x(MD) TEST 8

. TEST 4 x(TAPE) TEST 9

REPEAT TEST 5

5. To exit from this mode, turn off the set.

26

SECTION 5

MECHANICAL ADJUSTMENTS

HCD-J300

SECTION 6

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

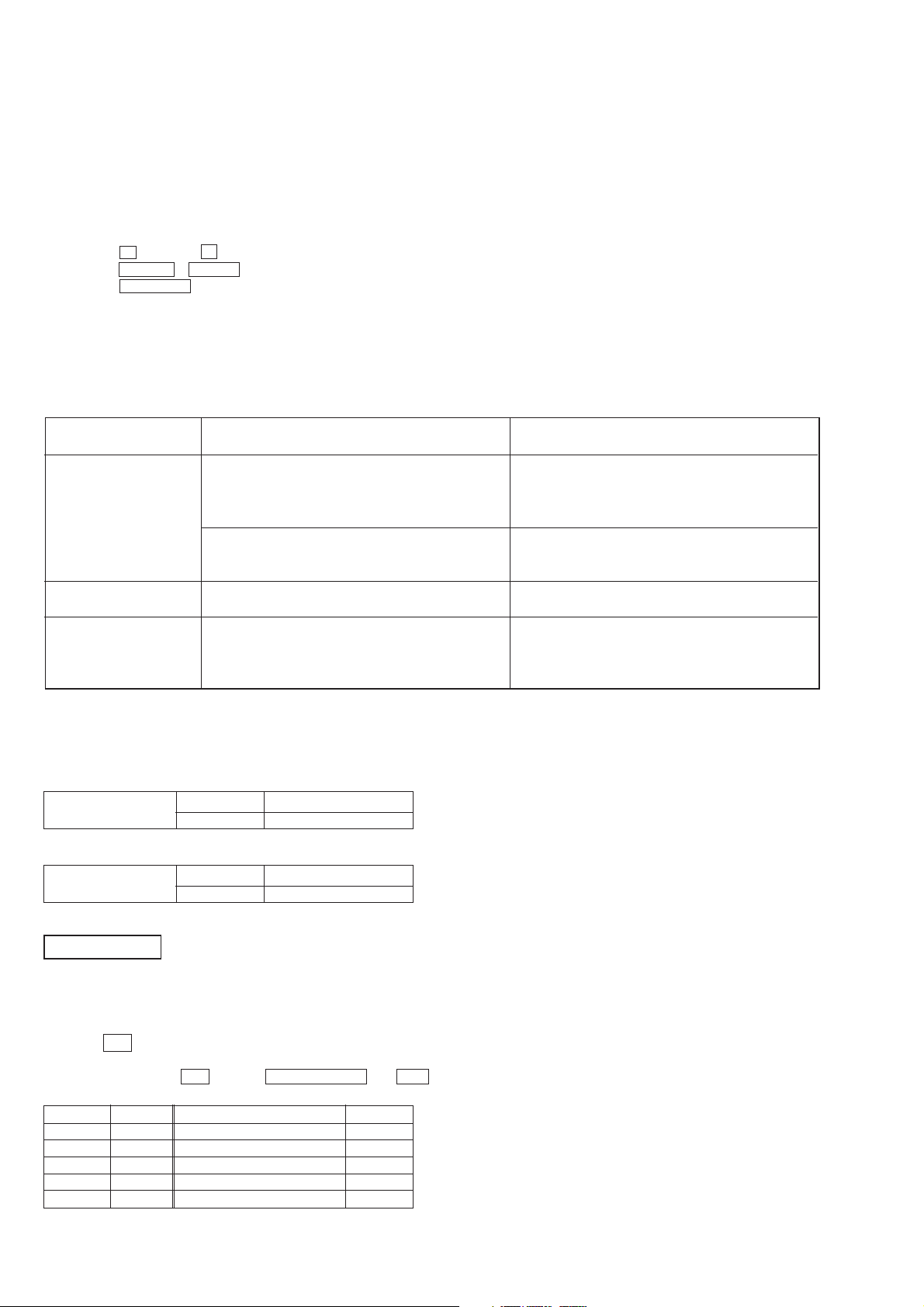

Torque Measurement

Mode

Torque meter Meter reading

3.04 – 6.96 N • m

FWD

CQ-102C

(31 to 71 g • cm)

(0.43 – 0.98 oz • inch)

FWD

back tension

CQ-102C

0.20 – 0.58 N • m

(2 to 6 g • cm)

(0.02 – 0.08 oz • inch)

3.04 – 6.96 N • m

REV

CQ-102RC

(31 to 71 g • cm)

(0.43 – 0.98 oz • inch)

REV

back tension

CQ-102RC

0.20 – 0.58 N • m

(2 to 6 g • cm)

(0.02 – 0.08 oz • inch)

6.97 – 14.02 N • m

FF/REW

CQ-201B

(71 to 143 g • cm)

(0.98 – 1.99 oz • inch)

0.98 N • m or more

FWD tension

CQ-403A

(100 g or more)

(3.53 oz or more)

0.98 N • m or more

REV tension

CQ-403R

(100 g or more)

(3.53 oz or more)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to

the parts adjusted.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit

adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specified.

Tape

P-4-A100

WS-48B

P-4-L300

Note: Standard Volume Point is +10 dBs at SPEAKER Output Level (6Ω

load resistance) during playbacking P-4-L300 Test Tape.

(DSG OFF, TREBLE/BASS CENTER)

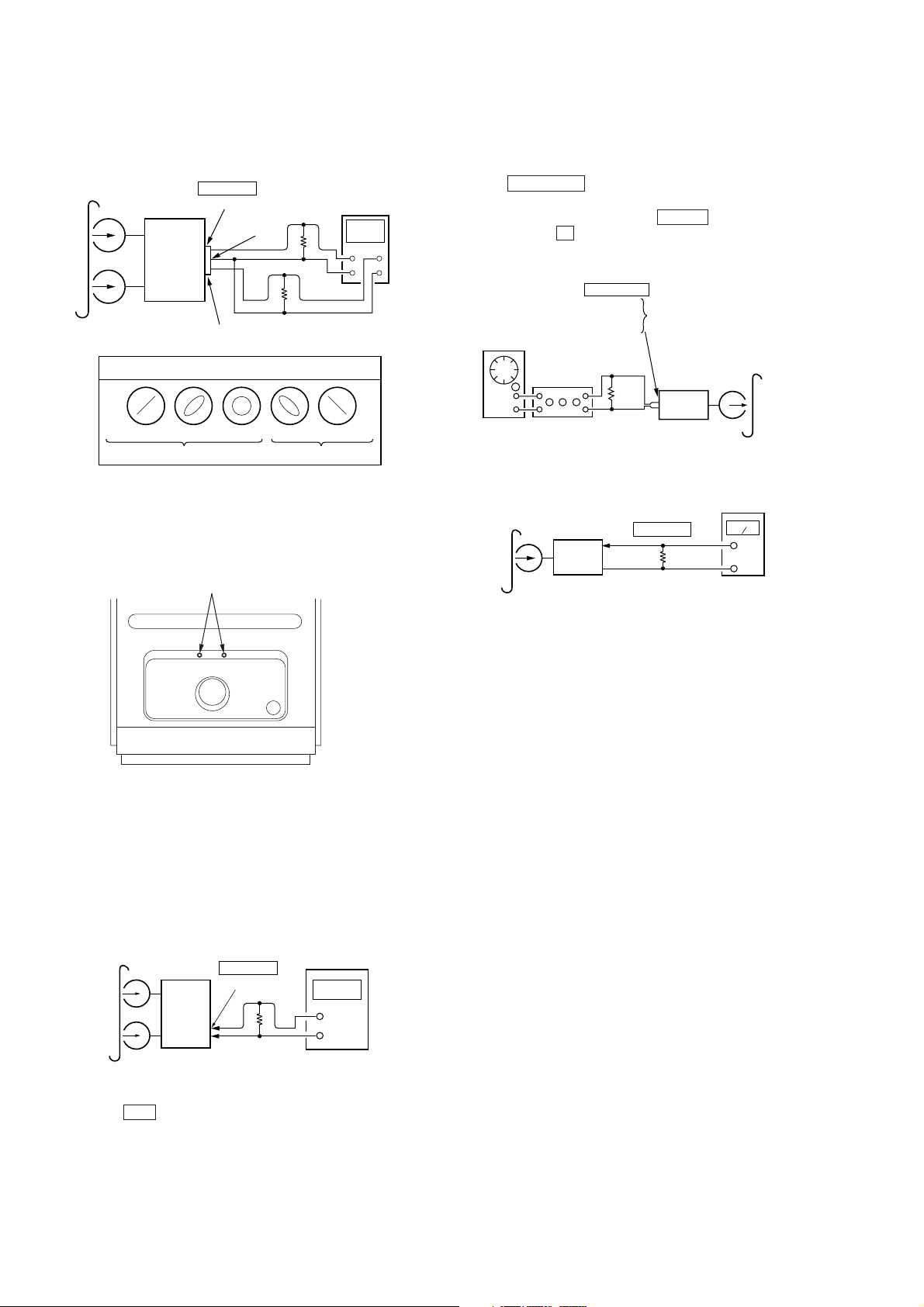

Record/Playback Head Azimuth Adjustment

Procedure:

1. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

Signal Used for

10 kHz, –10 dB

3 kHz, 0 dB

315 Hz, 0 dB

SJ301

SPEAKER

Output Terminal

set

Azimuth Adjustment

Tape Speed Adjustment

Level Adjustment

6

Ω

level meter

+

–

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1 dB of peak.

L-CH

peak

screw

position

R-CH

peak

output

level

within

1 dB

L-CH

peak

R-CH

peak

within 1dB

screw

position

27

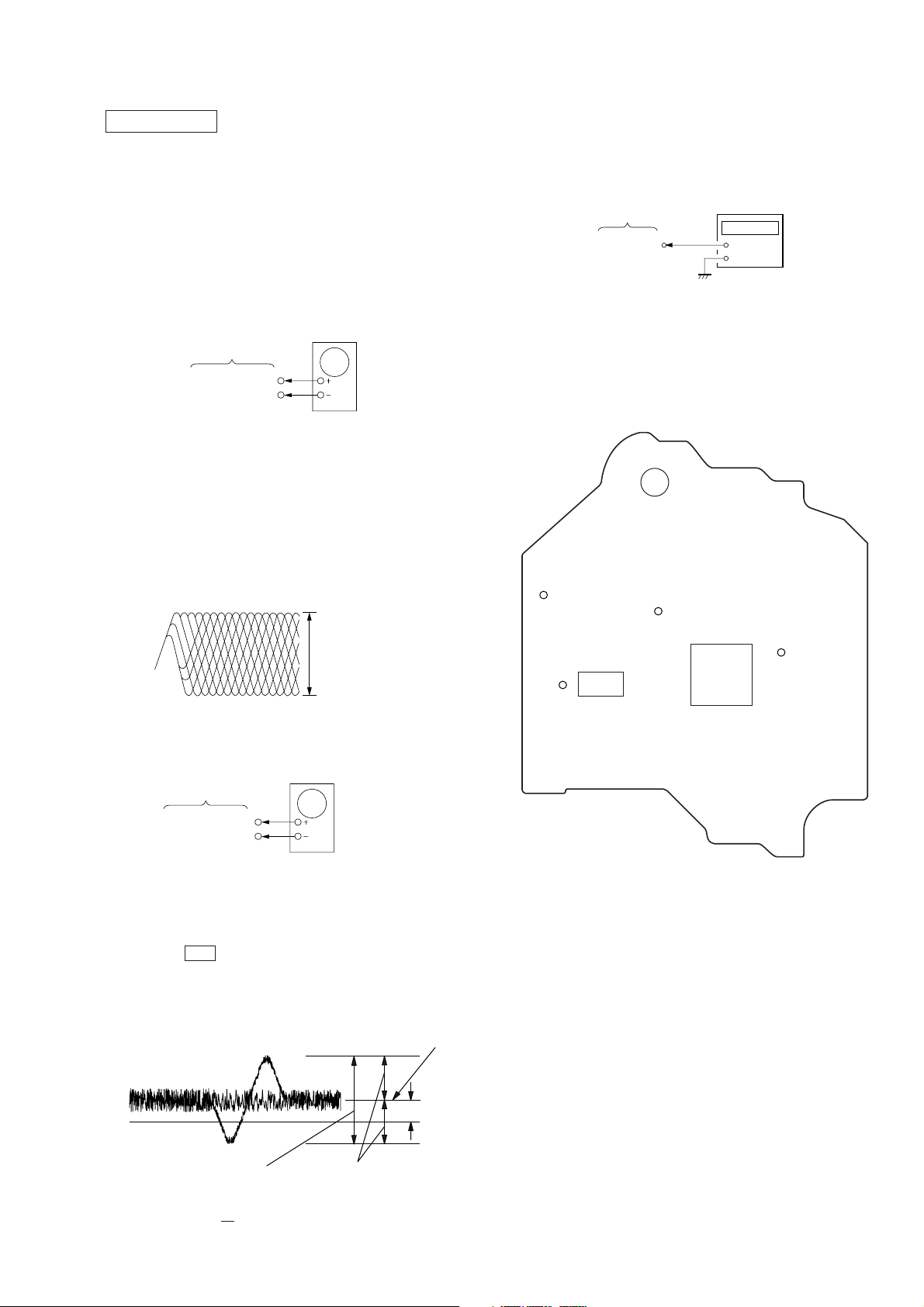

HCD-J300

e

3. Mode: Playback

test tape

P-4-A100

(10kHz, –10dB)

in phase 45

SJ301

SPEAKER

Output Terminal

GND

L

set

R

R-ch

Waveform of oscilloscope

°

90

°

good

oscilloscope

6

Ω

6

Ω

135

°

180

°

wrong

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Adjustment Location:

Adjustment point

Record Level Check

Procedure:

1. Press FUNCTION button to select ANALOG IN. (This step

is not necessary if the above test mode has already been set.)

2. Insert a tape into deck, press the z REC (TAPE) button, and

then press the X (TAPE) button to start recording.

3. Mode: Record

PJ301

ANALOG IN

AF OSC

1) 60 Hz

2) 5 kHz

3) 10 kHz

600

attenuator

109 mV (–17 dB)

Ω

blank tap

CS-123

set

4. Mode: Playback

recorded

position

set

SJ301

SPEAKER

6

Ω

level meter

Tape Speed Check

Procedure:

1. MODE : Playback.

test tape

P-4-L300

(315Hz, 0dB)

(Top view)

set

SJ301

SPEAKER

Output Terminal

6

Ω

5. The playback output level should be –4.5 ±3 dB (60 Hz),

1 ±3 dB (8 kHz) and –3 ±3 dB (10 kHz).

frequency

counter

2. Insert the WS-48B into deck.

3. Press the Y button of deck.

4. Check the reading of frequency counter becomes 3000 ± 90

Hz.

Sample Value of Wow and flutter

W.RMS (JIS) less than 0.35%

(test tape: WS-48B)

28

HCD-J300

)

r

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

RF Level Check

oscilloscope

CD BOARD

TP(RFAC)

TP(DVC 1.65V)

Procedure :

1. Connect oscilloscope to TP (RFAC).

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal

level is correct or not.

Note: Clear RF signal wa veform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF PLL Free-run Frequency

Procedure :

1. Connect frequency counter to TP (XPCK) with lead wire.

CD BOARD

TP (XPCK)

frequency counte

+

–

2. Turned Power switch on.

3. Put the disc (YEDS-18) in to play the number five track.

Confirm that reading on frequency counter is 4.3218MHz.

Test Point Location :

[CD BOARD] — SIDE B —

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.1 ± 0.3Vp-p

E-F Balance (1 Track jump) Check

Oscilloscope

CD BOARD

TP(TE)

TP(DVC 1.65V)

Procedure:

1. Connect oscilloscope to TP (TE) and TP (DVC 1.65V).

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the u button. (Becomes the 1track jump mode.)

5. Conf irm that the level B and A (DC voltage) on the oscilloscope

waveform.

Center of

waveform

TP

(DVC 1.65V)

IC103

TP

(RFAC)

TP

(TE)

IC101

TP

(XPCK)

B

0V

level=1.3 ±0.6Vp-p

Specification level: x 100=less than ±22%

A

B

Symmetry

A (DC voltage

29

Loading...

Loading...