Page 1

HCD-H11/H11J

SERVICE MANUAL

r

HCD-H11 is the tuner deck, CD and

amplifier section in CHC-P11.

r

HCD-H11J is the tuner deck, CD and

amplifier section in CHC-P11J.

Photo : AEP Model

Dolby noise reduction manufactured under license from

Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of

Dolby Laboratories Licensing Corporation.

CD player section

System Compact disc digital audio

Laser Semiconductor laser

Laser output Max 44.6µW*

Wavelength 780–790 nm

Frequency response

Signal-to-noise ratio

Dynamic range

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

system

(λ =780nm)

Emission duration :

continuous

*This output is the value measured at

a distance of 200 mm from the objective lens surface on the Optical

Pick-up Block with 7 mm aperture.

2Hz – 20kHz

More than 65 dB

More than 97 dB

Except East European model :

87.5 - 108.0MHz (50kHz step)

Antenna FM lead antenna

Antenna terminals

Intermediate frequency

AM tuner section

Tuning range

CD

Section

Tape deck

Section

SPECIFICATIONS

East European model :

FM1 : 65 - 74 MHz (10kHz step)

FM2 : 87.5 - 108 MHz (50kHz

75 ohm unbalanced

10.7MHz

AEP, UK, East European, German

model :

MW : 531 - 1,602kHz

LW : 153 - 279kHz

Italian model :

MW : 522 - 1,611kHz

(9kHz step)

LW : 153 - 279kHz

E3, Saudi Arabia, Hong kong,

Malaysia, Singapore, Taiwan model :

MW : 531 - 1,602kHz

(9kHz step)

530 - 1,710kHz

(10kHz step)

SW : 5.95 - 17.9kHz

AEP Model

UK Model

E Model

Austr alian Model

HCD-H11

Saudi Arabia Model

HCD-H11/H11J

Model Name Using Similar Mechanism HCD-H801

CD Mechanism Type CDM28-5BD19

Base Unit Name BU-5BD19

Model Name Using Similar Mechanism HCD-H881

Tape Transport Mechanism Type TCM- 220WR2

E2, Mexican, Argentine model :

AM : 531 - 1,710kHz (9kHz step)

AM : 530 - 1,710kHz (10kHz step)

step)

Antenna AM loop antenna

Intermediate frequency

Tape player section

Recording system

Frequency response

Wow and flutter

Amplifier section

Peak music power output

Australian model

AM : 531 - 1,602kHz (9kHz step)

AM : 530 - 1,710kHz (10kHz step)

External antenna terminals

450kHz

4-track 2-channel stereo

(DOLBY NR OFF)

40 - 13,000 Hz (±3 dB),

using Sony TYPEI cassette

40 - 14,000 Hz (±3 dB),

using Sony TYPEII cassette

0.1% WRMS ±0.3%(DIN)

400W

–Continued on Page 2–

MICROFILM

MINI Hi-Fi COMPONENT SYSTEM

Page 2

Continuous RMS power output

23W + 23W (4 ohms at

1kHz, 5% THD)

Inputs

MD IN : Sensitivity 450 mV,

impedance 47 kilohms

Outputs

MD OUT :Senitivity 250 mV, 1kΩ

PHONES (stereo phone jack) :

accept headphones of

8 ohms or more.

TABLE OF CONTENTS

Section Title Page

______ ____ ____

Specification ..................................................................................... 1

1. SERVICING NOTES ............................................................... 4

2. GENERAL

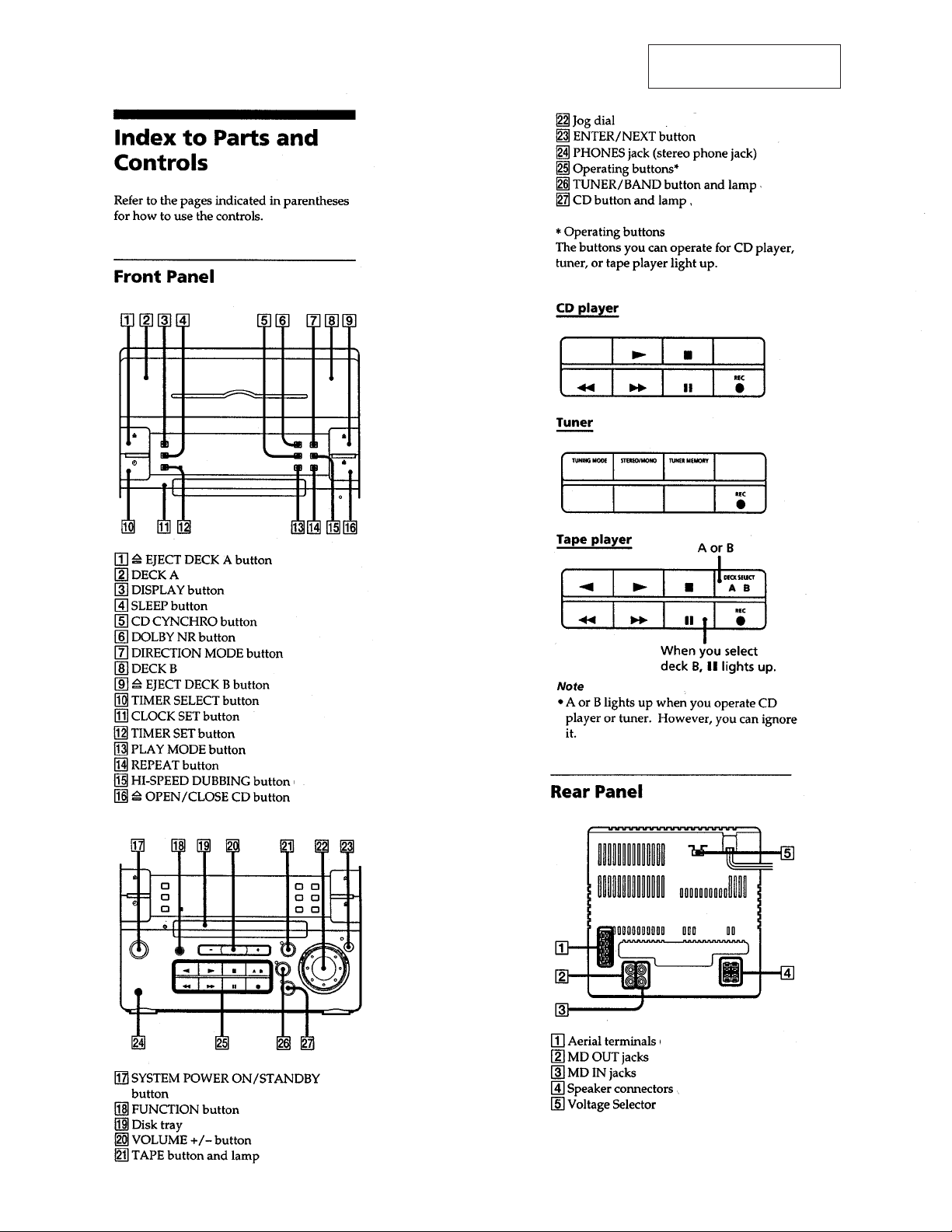

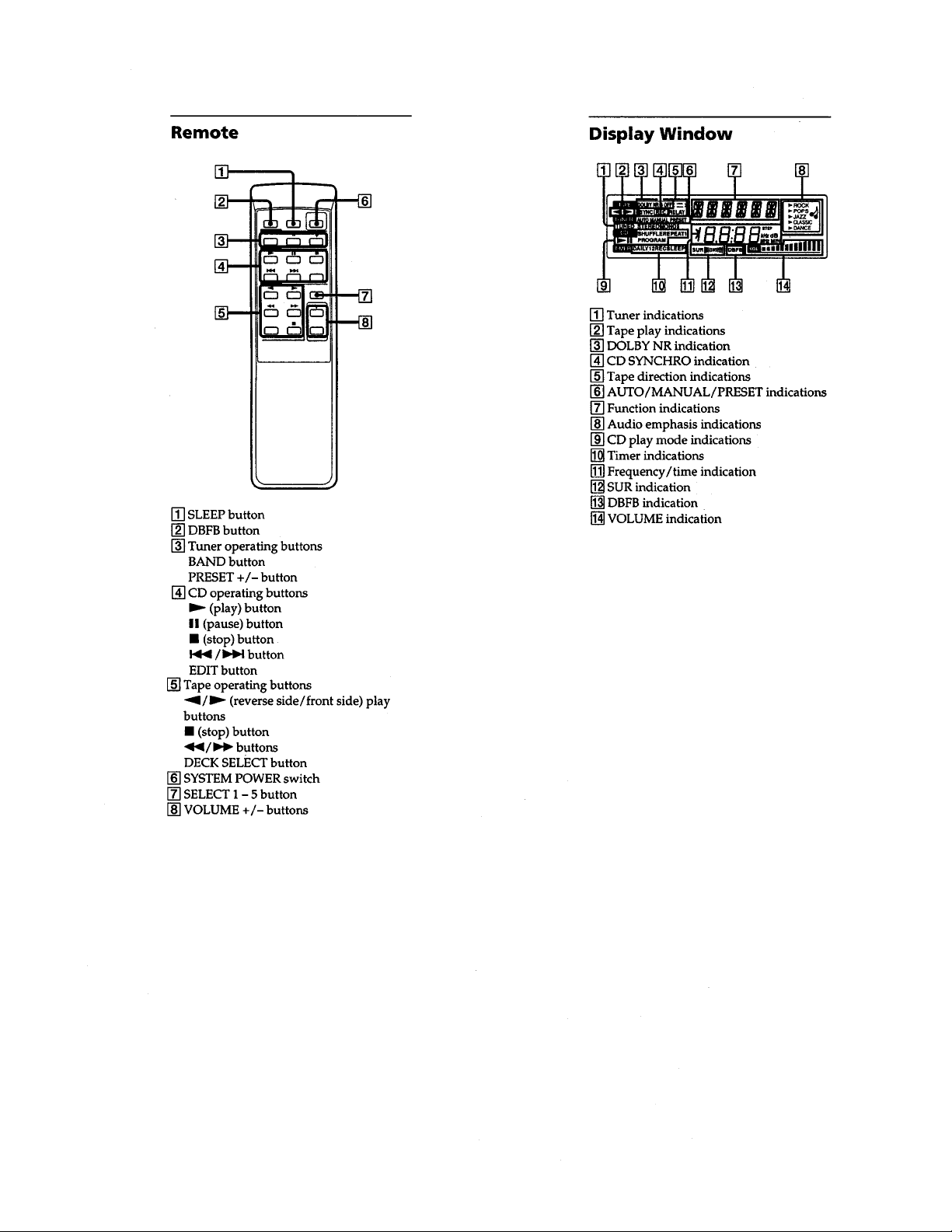

Index to Parts and Controls ........................................................ 3

Supplied accessories

AM loop antenna (1)

Remote (1)

Sony SUM-3 (NS) batteries (2)

FM lead antenna (1)

General

Destination Power requirements

Mexican model 120v AC,60Hz

AEP, UK, German,

Italian, East

European model

Australian model 240V AC, 50/60Hz

E, Saudi Arabia,

Hong Kong,

Singapore, Argentine,

Malaysia, Taiwan

model

Dimensions Approx. 225 x 210x235 mm

(w/h/d) incl. projecting

parts and controls

Mass Approx.4.8kg

Design and specifications are subject to change without notice.

220 - 230V AC, 50/60Hz

110 - 120V/ 220 - 240V

AC, 50/60Hz Adjustable

with the Voltage Selector

consumption

Power

75W

3. DISASSEMBLY

3-1. Front Panel Removal........................................................... 8

3-2. CD Mechanism, Main Board and TCB Board Removal .... 9

3-3. Mechanism Deck Removal ................................................. 9

4. ADJUSTMENTS

4-1. Mechanical Adjustment .................................................... 10

4-2. Electrical Adjustment........................................................ 10

5. EXPLANATION OF IC TERMINALS.................................. 17

6. DIAGRAMS

6-1. Block Diagram - CD Section ............................................ 21

6-2. Block Diagram - Main Section ......................................... 23

6-3. Circuit Board Location ..................................................... 27

6-4. Schematic Diagram - Main Section .................................. 28

6-5. Printed Wiring Boards - Main Section.............................. 33

6-6. Schematic Diagram - TCB Section................................... 36

(AEP,UK,G,IT,EE model)

6-7. Printed Wiring Boards - TCB Section .............................. 38

(AEP,UK,G,IT,EE model)

6-8. Printed Wiring Boards - TCB Section .............................. 39

(E3,EA,MY,SP,HK,TW,E2,MX,AR,AU model)

6-9. Schematic Diagram - TCB Section................................... 40

(E3,EA,MY,SP,HK,TW,E2,MX,AR,AU model)

6-10. Schematic Diagram - BD Section ................................... 45

6-11. Printed Wiring Boards - BD Section............................... 48

6-12. Printed Wiring Boards - Audio Section .......................... 49

6-13. Schematic Diagram - Audio Section............................... 50

6-14. Schematic Diagram - Panel Section................................ 54

6-15. Printed Wiring Boards - Panel Section ........................... 57

7. EXPLODED VIEWS

7-1. Chassis Section ................................................................. 59

7-2. Front Panel Section ........................................................... 61

7-3. TC Mechanism Section-1 ................................................. 63

7-4. TC Mechanism Section-2 ................................................. 64

7-5. CD Mechanism Section-1 ................................................. 65

7-6. CD Mechanism Section-2 ................................................. 66

8. ELECTRICAL PARTS LIST ................................................ 67

– 2 –

Page 3

SECTION 1

SERVICING NOTES

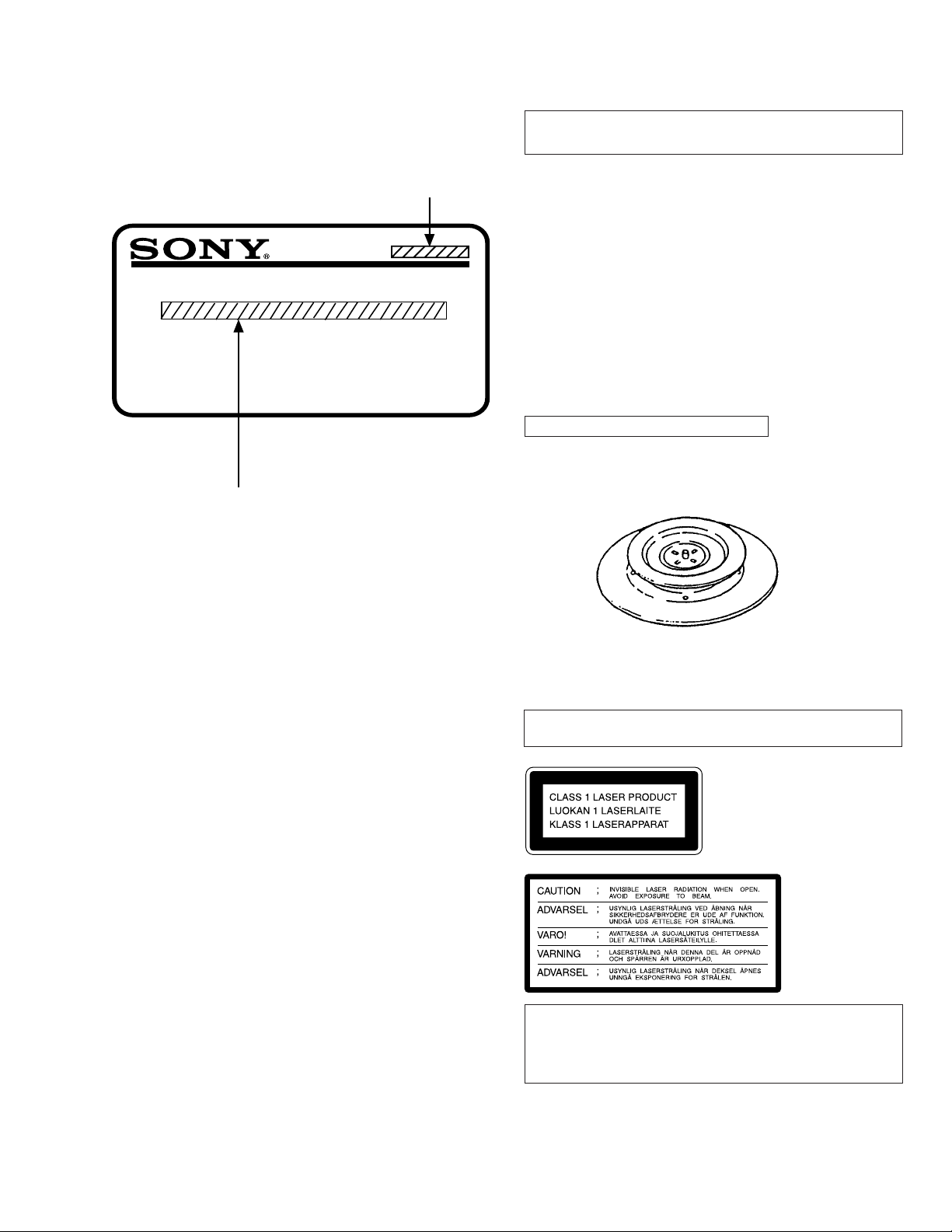

MODEL IDENTIFICATION

(Specifcation Lable)

HCD-H11

HCD-H11J

MODEL NO.

COMPACT DISC DECK RECEIVER

AEP, UK, German, Italian,

East Europian model : AC220-230V⁄50/60Hz

Australian model : AC240V⁄50Hz

Maxican model : AC120V⁄60Hz

E, Saudi Arabia, Hong Kong,

Singapore, Argentine,

Malaysia, Taiwan model: AC110-120V/220-240V⁄50/60Hz

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objecti ve lens in the optical pick-up

block. Therefore, when checking the laser diode emission, observe

more than 30 cm away from the objective lens.

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use Chuck

Plate Jig.

r Code number of Chuck Plate Jig : X-4918-255-1

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as a

CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT

MARKING is located on the

rear exterior.

This caution label

is located inside the

unit.

CAUTION

Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation

exposure.

– 3 –

Page 4

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– 4 –

(E, Saudi Arabia, Argentine, Hong Kong,

Mexican, Malaysia, Singapore, Taiwan

model)

Page 5

– 5 –

Page 6

Notes for repairing CD MECHANISM section electric flow.

Two jigs (J-2501-091-A and J-2501-092-A) are necessary for the CD MECHANISM section electric flow.

Connect SET and JIG as shown in the figure below and turn the power switch on.

Jig

(J-2501-092-A)

CN101

(19 pin)

Jig

(J-2501-091-A)

CN291

(5 pin)

CNU102

(19 pin)

– 6 –

Page 7

r Disc table getting out procedure on the power supply is OFF

Disc Table

– 7 –

Page 8

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

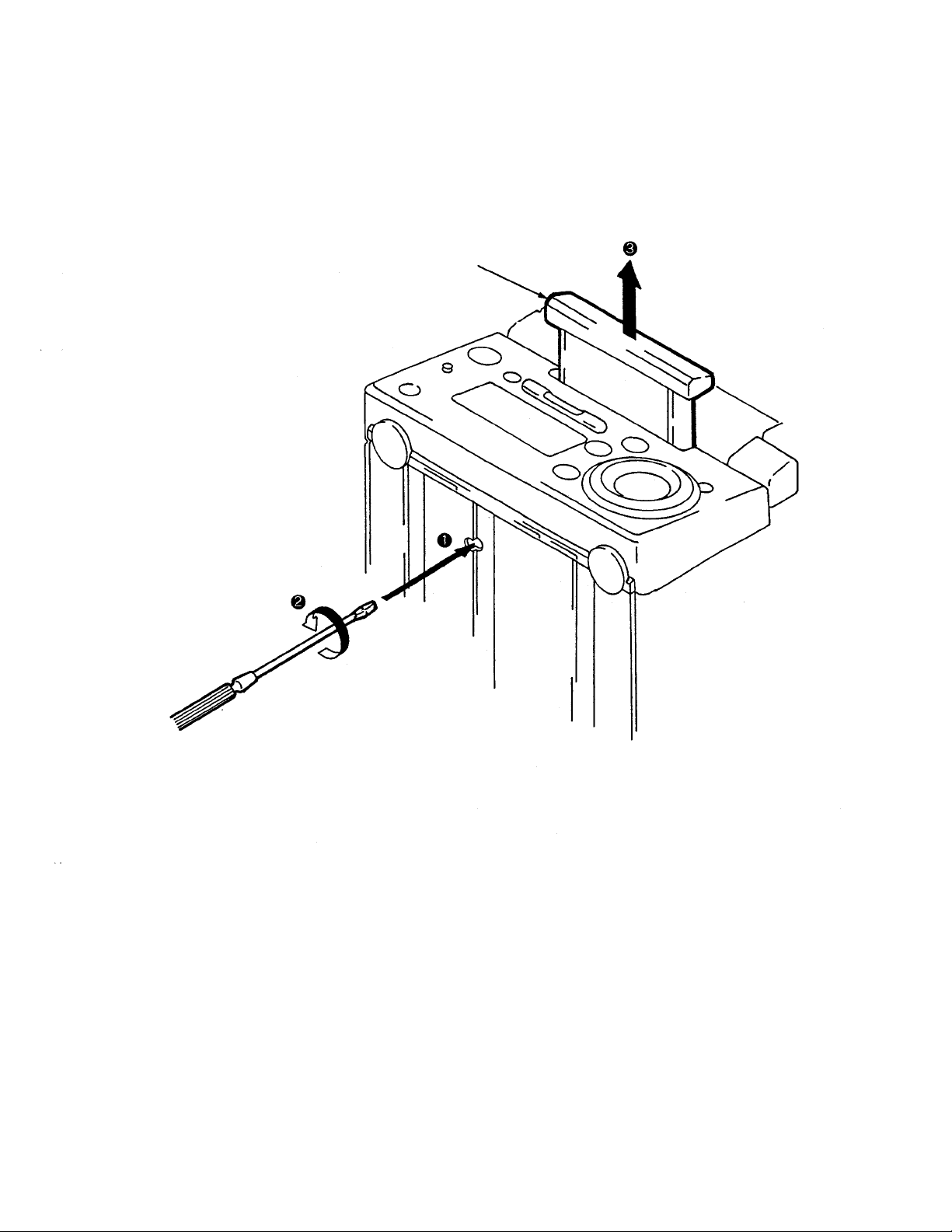

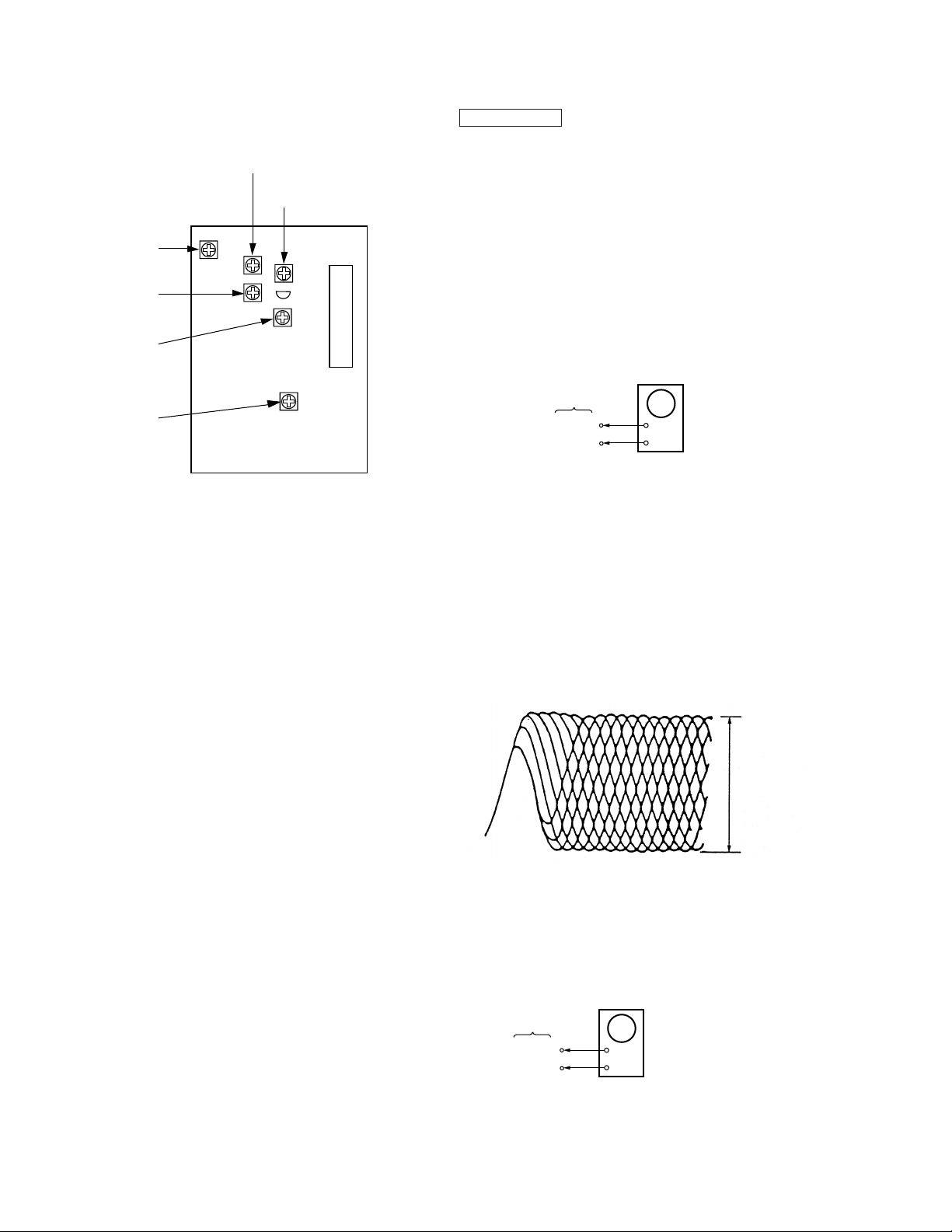

3-1. FRONT PANEL REMOVAL

4

Plate, top

2

Screw (Case 3TP2)

6

CN803

(8 pin)

7

CN602

(2 pin)

SECTION 3

3

Screw (Case 3TP2)

5

Screw (+BVTP3X10)

r

TO ADJUST THE AZIMUTH

8

CN801

(3 pin)

Front Panel Section

1

Screw (+BVTT3X6)

9

Wire (Flat Type) (17 cove)

Front Panel

Case

2

Window (DIS)

Screw (Case 3TP2)

– 8 –

Window (DIS)

1

2

with a tool such as a thin screwdriver and

remove the window (DIS).

Raise the cassette lid.

Press on the window (DIS) clips (3 locations)

Page 9

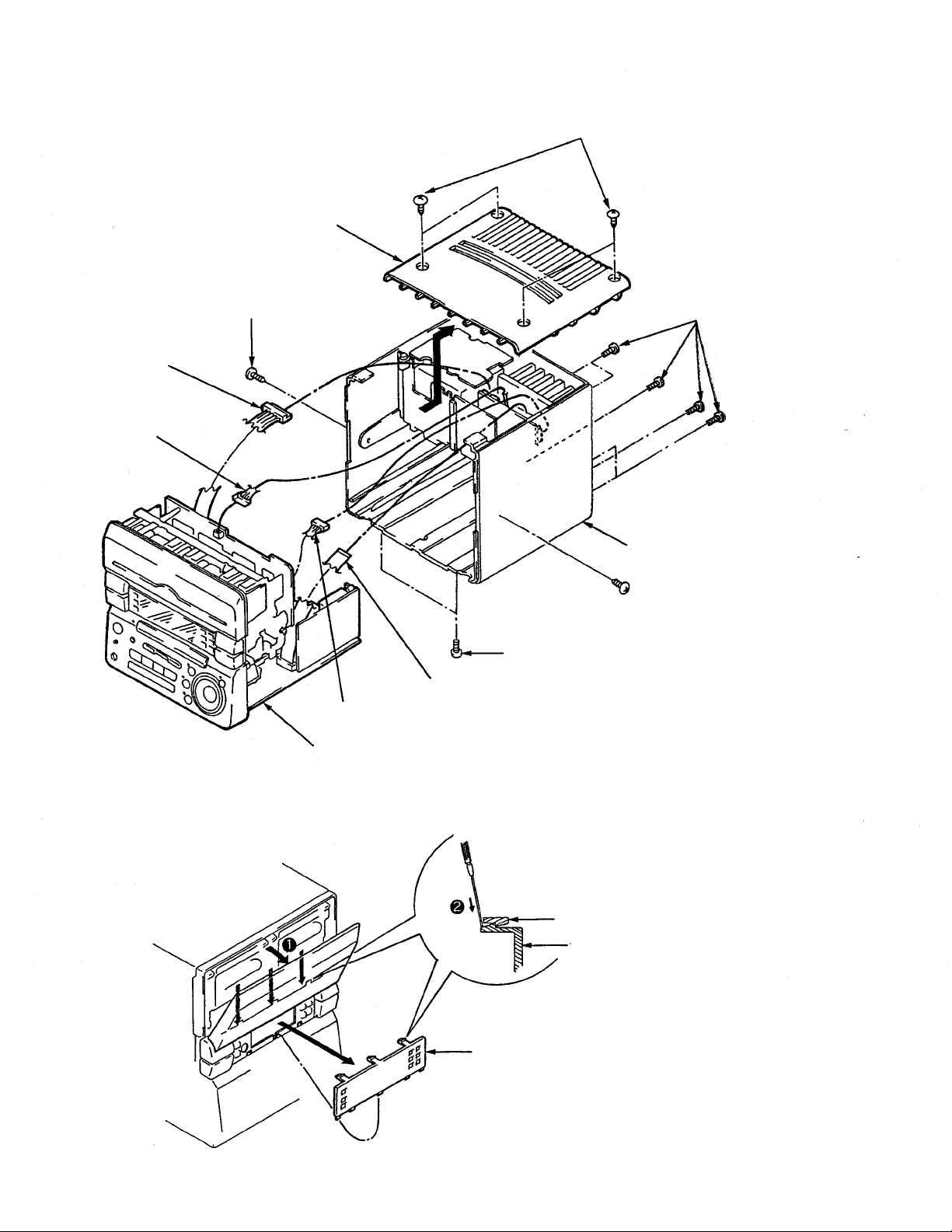

3-2. CD MECHANISM, MAIN BOARD AND TCB BOARD

7

CD MECHANISM SECTION

(CDM28-5BD19)

2

Wire (Flat Type) (11 core)

1

Wire (Flat Type) (21 core)

3

Screw (+BVTP2.6X8)

4

CN291

(5 pin)

TCB Board

(TCB017)

Main Board

3-3. MECHANISM DECK REMOVAL

Button

(EJ-L)

Button

(EJ-R)

6

Screw (+BVTT3X6)

3

Screw (+BVTP2.6X8)

Mechanism Deck Section

(TCM-220WR2)

4

Screw (+BVTP2.6X8)

– 9 –

6

Screw (+BVTT3X6)

Page 10

set

MD OUT

Level meter

+

–

MD IN

AF OSC

attenuator

600

Ω

r

SECTION 4

ADJUSTMENTS

4-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power sup-

ply voltage unless otherwise noted.

r

T orque Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C

Forward

Back Tension

Reverse CQ-102RC

Reverse

Back Tension

FF, REW CQ-201B

r

T ape Tension Measurement

Mode Torque Meter Meter Reading

Forward CQ-403A more than 100g (3.53 oz)

Reverse CQ-403R more than 100g (3.53 oz)

CQ-102C

CQ-102RC

36 to 61g•cm

(0.50 – 0.84 oz•inch)

2 to 6g•cm

(0.026 – 0.082 oz•inch)

36 to 61g•cm

(0.50 – 0.84 oz•inch)

2 to 6g•cm

(0.026 – 0.082 oz•inch)

61 to 143g•cm

(0.85 – 1.98 oz•inch)

4-2. ELECTRICAL ADJUSTMENTS

DECK SECTION

1. The adjustment should be performed in the publication.

(Be sure to make playback adjustment at first.)

2. The adjustment and measurement should be performed for

both L-CH and R-CH.

r

Switch position

DOLBY NR switch : OFF

TIMER switch : OFF

DIRECTION MODE switch : A

3. Deck section electrical adjustment are made in test mode by

pressing TUNER/BAND, DISPLAY, and FUNCTION at the

same time.

– Record Mode –

r

Test T ape

Tape Contents Use

P-4-A 100 10 kHz, –10dB Head Azimuth Adjustment

P-4-L300 315Hz, 0dB Level Adjustment

WS-48B 3kHz, 0dB Tape Speed Adjustment

0dB=0.775V

Record/Playback Head Azimuth Adjustment

DECK A DECK B

r

Setup for adjustment

When adjusting the azimuth remove, the Window (DIS) in the

center of the front panel. (Refer to page 8.)

Procedure :

1. Forward Playback mode

Reverse Playback mode

test tape

P-4-A100

(10kHz, – 10dB)

set

– 10 –

Level mete

+

-

MD OUT

Page 11

+

–

MD OUT

set

frequency counter

test tape

WS-48B

(3kHz, – 0dB)

r

2. Turn the adjustment screw for the maximum output levels. If

these levels do not match,turn the adjustment screw until both

of output levels match together within 1dB.

L-CH

peak

within

Screw

position

R-CH

peak

output

level

1 dB

within

1 dB

Tape Speed Adjustment DECK A DECK B

Procedure :

r

Perform high speed adjustment before normal speed adjustment.

Mode : Playback

L-CH

peak

R-CH

peak

screw angle

3. Playback Mode

test tape

P-4-A100

(10kHz, – 10dB)

L-CH

set

R-CH

MD OUT

screen patten

in phase 45˚ 90˚ 135˚ 180˚

good wrong

Oscilloscope

H

V

4. Change the review playback mode and repeat the steps 1 to 3.

5. After the adjustment, lock the adjustment screw with suit

able locking compound.

Adjustment Location :

– record/playback head (Deck A and B)

Dack A

Dack B

Speed Deck Adjustment Frequency counter

*High

Normal

Continus to press HIGH SPEED DUBBING switch (S507) in

*

A RV652

B RV652

A RV651

B RV651

5,970 to 6,030Hz

2,940 to 3,090Hz

playback mode : High speed palyback.

Frequency difference between the begining and the end of the tape

should be within ± 3%.

Frequency difference between deck A and deck B the biginning

of the tape should be within 1.5%.

Adjustment Location : AUDIO board.

(see page 12)

Playback Level Adjustment DECK A DECK B

Procedure :

Mode : Playback

test tape

P-4-L300

(315kHz, –10dB)

set

Level mete

+

–

MD OUT

Deck A is RV311 (L-CH) and RV411 (R-CH), deck B is RV301 (LCH) and RV401 (R-CH) so that adjustment within adjustment level

as follows.

forward

Adjustment Screw

Adjustment Level :

MD OUT level : – 3.5 ± 0.5dB (0.489 to 0.546V)

Level Difference between Channels : within 0.5dB

Confirm the OUT PUT level does not change in playback mode while

changing the mode from playback to stop several times.

Adjustment Location : AUDIO board.

(see page 12)

reverse

– 11 –

Page 12

Record Bias Adjustment DECK B

r

r

)

Procedure :

1. Record mode

AF OSC

600

attenuator

Ω

set

blank tape

CS-123

3. Confirm playback the signal recorded in step become

adjustment level as follows.

4. If these levels do not adjustment level, adjust the RV401 (L-CH)

and RV451 (R-CH) to repeat step 1 and 4.

Adjustment Level :

OUT PUT level : – 28dB ± 0.5dB (29.1 to 32.7mV)

Adjustment Location : MAIN board

Adjustment Location :

MD IN

1) 315 Hz

2) 10KHz

38.8mV (–26dB)

2. Playback mode

recorded

portion

set

Level mete

+

–

MD OUT

3. Confirm playback the signal recorded in step 1 become

adjustment level as follows.

4. If these levels do not adjustment level, adjustment the RV341

(L-CH) and RV441 (R-CH) to repeat step 1 and 4.

Adjustment level :

Playback output of 315Hz to playback output of 10kHz : – 0.5dB to

0.5dB. (– 1.3 to 1.3mV)

Adjustment Location : AUDIO board .

Record Level Adjustment DECK B

Procedure :

1. Record mode

AF OSC

attenuator

Ω

600

set

MD IN

315Hz 38.8mV (–26dB)

blank tape

CS-123

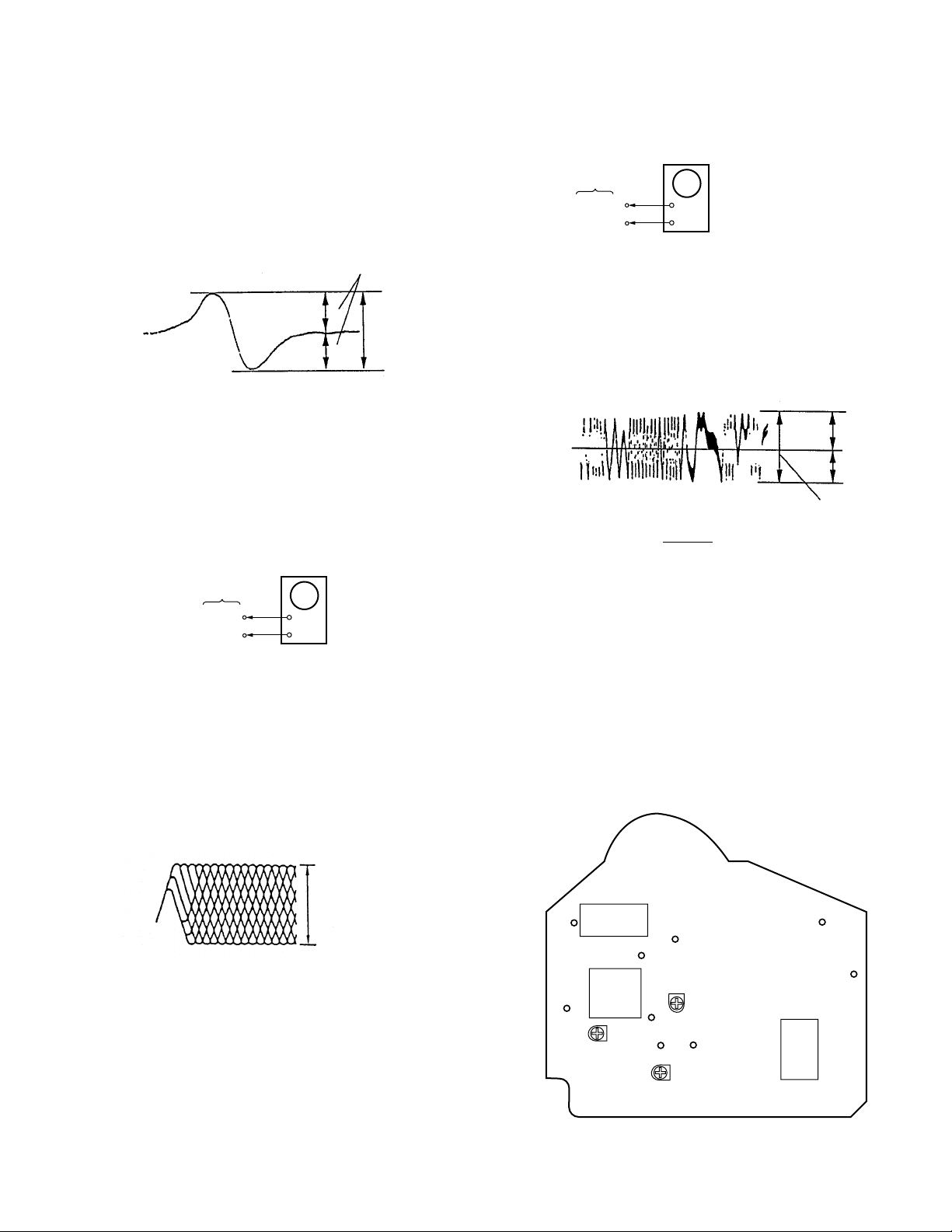

[ AUDIO BOARD ] – Component side –

RV301 : Playback Level (Deck B L-CH)

RV651 : Tape Speed (Normal)

RV401 : Playback Level

(Deck B R-CH)

RV341 : Record Bias (L-CH)

RV441 : Record Bias (R-CH)

RV411 : Playback Level

(Deck A R-CH)

[ MAIN BOARD ] – Component side –

RV451 :

Record Level (R)

RV652 : Tape Speed

(HIGH)

RV311 : Playback Level

(Deck A L-CH)

RV401 :

Record Level (L

2. Playback mode

recorded

portion

set

MD OUT

Level mete

+

–

– 12 –

Page 13

TUNER SECTION

r

Precautions in Repairing

Note. 1 : The adjustment should be performed in the publication.

(MW n FM n SW)

Note. 2 : As a front-end (FE1) is dif ficult to repair if f aulty , replace it

with new one.

r

Abbreviation

AUS : Australian IT : Italian

G : German AR : Argentine

EA : Saudi Arabia HK : Hong Kong

MX : Mexican. SP : Singapore

MY : Malaysia TW : Taiwan

EE : East European

E2 : Tuner sections SW BAND do not exist.

E3 : Tuner sections SW BAND exist.

MW Tuned Indication Lighting Level

Setting :

Band : MW

loop antenna B

loop antenna A

AM RF signal

generator

Procedure :

1. Tune the set to 98MHz.

2. Adjust RV42 so that the TUNED indicator goes on.

Adjustment Location : TCB board (see page 14)

SW Control Voltage Adjustment

(Frequency Coverge Adjustment)

(E3,EA,MY,SP,HK,TW model)

Setting :

Band : SW

Procedure :

1. Connect digital Voltmeter to diode D1 center lead and ground.

2. Adjust for a following value reading on digital Voltmeter.

SW

Set frequency

5.95MHz T2 1.2Vdc

17.9MHz CV2 8.5Vdc

Adjustment

part

Reading on digital

voltmeter

Adjustment Location : TCB board (see page 14)

SW T racking Adjustment

(E3,EA,MY,SP,HK,TW model)

Setting :

Band : SW

set

Carrier frequency : 999kHz (at

Modulation : 400Hz 30% modulation

1,050kHz (at

9kHz step) or

10kHz step)

Procedure :

1. Set loop antenna A so that the loop antenna B input le vel becomes

55dBµ/m (0.6mV/m)

2. Tune the set to 999kHz (at 9kHz step) or 1,050kHz (at 10kHz

step).

3. Adjust RV41 so that the TUNED indicatior goes on.

Adjustment Location : TCB board (see page 14)

FM Tuned Indication Lighting Level

Note : Always make the tuning level adjustment first.

(Since it affects the FM tuning level.)

Setting :

Band : FW

FM RF stereo signal

generator

75

FM ANTENNA terminal

Ω

coaxial

AM RF signal

generator

Modulation : 400Hz

30% modulation

set

SPEAKER terminal

AM ANTENNA terminal

Level mete

+

–

Procedure :

Adjust for maximum reading on Level mater.

Set frequency

SW

r

Repeat the procedures is each adjustment several times, and the

7MHz T1

17MHz CV1

Adjustment

part

frequency coverage and tracking adjustment should be f inally done

by the trimmer capacitors.

Adjustment Location : TCB board (see page 14)

Carrier frequency : 98MHz

Modulation : 1kHz, 75kHz (100%)

Output level : 0.018mV (25dB )

µ

set

– 13 –

Page 14

s

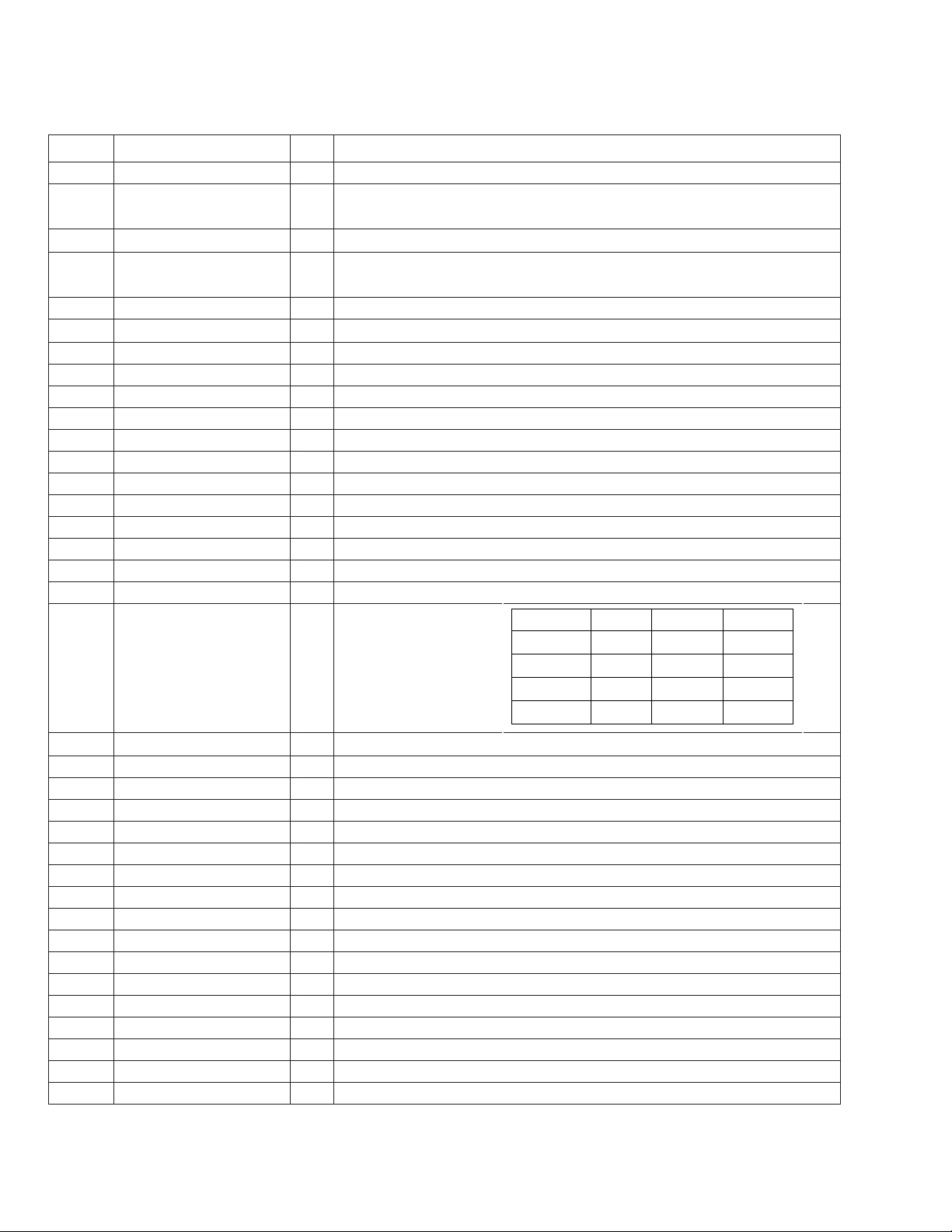

Adjustment Location

[TCB BOARD] – Conductor side –

CV1 : SW Tracking Adjustment

RV41 :

MW Tuned indication

Lighting Level

T1 : SW Tracking Adjustment

CD SECTION

Note :

1. CD Block basically constructed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use the oscilloscope with more than 10MΩ impedance.

4. Clean an object lens by an applicator with neutral detergent when

the signal level is low than specified value with the following

checks.

CV2 :

SW Control Voltage

Adjustment

T2 :

SW Control Voltage

Adjustment

RV42 :

FW Tuned indication

Lighting Level

D1

FE1

Focus Bias Adjustment

This adjustment is to be done when the optical block is replaced.

Adjustment procedure :

oscilloscope

(DC range)

BD board

TP (RF)

TP (VC)

+

–

1. Connect oscilloscope to test point TP (VC) and TP (RF) on BD

board.

2. Ground main board IC101 (pin(£) with the lead wire.

3. Turned power switch ON. (Stop mode)

4. Put disc (YEDS-18) in and press the ( button.

5. Press the P button. (Tracking servo ON)

6. Adjust RV101 so that the oscilloscope waveform is as shown in

the figure below (eye pattern).

A good eye pattern means that the diamond shape (◊) in the center

of the waveform can be clearly distinguished.

7. After adjustment, remove the lead wire connecd in step 2.

r

RF signal reference waveform (eye pattern)

VOLT/DIV : 0.2V

TIME/DIV : 500n

1.3 ± 0.3Vp-p

When observing the eye pattern, set the oscilloscope for A C range

and raise vertical sensitivity.

Adjustment Location : BD board. (see page 15)

S-Curve Check

oscilloscope

BD board

TP (FEO)

TP (VC)

Procedure :

+

–

1. Connect oscilloscope to test point TP (FEO) and BD board.

2. Connect between test point TP (FOK) and TP (GND) by lead wire.

3. Turned Power switch on.

– 14 –

Page 15

4. Put disc (YEDS-18) in and turned Power switch on again and

+

–

oscilloscope

(DC range)

TP (TEO)

TP (VC)

BD board

IC102

FEI

TEI

FOK

IC101

RF

RV101

RV102

IC104

FEO

TEO

VC

PCK

GND

RV103

actuate the focus search. (actuate the focus search when disc table

is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within

2.4±0.7Vp-p.

E-F Balance Check

S-curve waveform

symmetry

A

within 2.4

B

±

0.7Vp-p

6. After check, remove the lead wire connected in step 2.

r

Note :

Try to measure several times to make sure that the ratio of

A : B or B : A is more than 10 : 7.

r

T ake sweep time as long as possible and light up the brigh-

ness to obtain best waveform.

Adjustment Location : BD board. (see page 15)

RF Level Check

oscilloscope

BD board

TP (RF)

TP (VC)

+

–

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and press the ( button.

4. Confirm that oscilloscope wav eform is clear and check RF signal

level is correct or not.

Note :

Clear RF signal waveform means that the shape “ ◊ ” can be clearly

distinguished at the center of the waveform.

Procedure :

1. Ground main board IC101 (pin (£) with the lead wire.

2. Connect oscilloscope to test point TP (TEO) on BD board.

3. Turned Power switch on.

4. Put disc (YEDS-18) in and press the ( button.

5. Confirm that the osilloscope waveform is symmetrical on the

top and bottom in relation to 0V, and check this level.

Traverse waveform

A

0V

B

level : 300 ± 100mVp-p

specified value : r

A–B

2 (A+B)

r

A+B = 300 ± 100mVp-p

X100 = less than ± 7%

6. Remove the lead wire connected in step 1.

Focus/Tracking Gain Adjustment (RV102, RV103)

This gain has a margin, so even if it is slightly off. There is no problem.

Therefore, do not perform, this adjustment.

Please note that it should be fixed to mechanical center position when

you moved and do not know original position.

Adjustment Location :

[BD BOARD] – Conductor side –

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.3

Adjustment Location : BD board. (see page 15)

±

0.3Vp-p

– 15 –

Page 16

SECTION 5

EXPLANATION OF IC TERMINALS

IC101 TMP87CP64YF - 6335 (MASTER CONTROL)

Pin No. Pin name I/O Description

1VSS – Ground

2 X OUT O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

3 X IN I

4

5 X OUT O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––

RESET

6 X IN I

7 GND – Ground.

8

–––––––––––––––––––

BACK UP

9 COUNT SW – Not used. (Ground)

10 INIT SW – Not used. (Ground)

11

12

13

14

15

16

DISC SENS

MID SENS

CD XRST

POWER

MUTE

MPX

17 KEYCON LATCH – Not used. (Open)

18

VOL LATCH O

19 ST MUTE – Not used. (Open)

20

ST FM

21 FUNC A O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

22 FUNC B O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

23 FUNC C O

Main system clock. (10MHz)

I Reset signal input terminal.

Sub system clock.(32kHz).

I BACK-UP mode input terminal.

– Not used. (Ground)

– Not used. (Ground)

O CD Reset output. “L” : RESET

O Power on output. “L” : ON

O Mute output. “L” : MUTE

– Not used. (Open)

Latch output to volume control. (TC9210P)

– Not used. (Open)

FUNCTION FUNC A FUNC B FUNC C

ST L L H

CD L H H

Function Select.

TC H L H

MDHH L

24 GEQ.LATCH O Latch output to gray control. (M6243FP)

25 RDS. INT I Not used. (+5V)

26 SCOR (DSP) I Sub code sync SO+SI detection input from DSP. (CXD2507AQ)

27 CIN / SENS I SENS input from DSP. (CXD2507AQ)

28 CD POWER O Power on output. “H” : ON

29 CDG LATCH – Not used. (Open)

30 DBFB- 2 – Not used. (Open)

31

32

33

34

MUTE

CE

STEREO

TUNED

– Not used. (Open)

O Chip enable output to tuner PLL IC. (LC72130)

I FM/AM Stereo identification. “L” : STEREO

I FM/AM Tuning identification. “L” : TUNING

35 SQ-RDS-CLK O Sub-code Q data scanning clock output to DSP (CXD2507AQ), RDS clock output.

36 SQ-RDS-DI I Sub-code Q data input from DSP (CXD2507AQ), RDS data input.

37 RDS-RESET – Not used. (Open)

38 CLK O System clock output.

39

D. IN

I Serial data input from tuner.

40 D. OUT O Serial data (COMN) output.

– 16 –

Page 17

Pin No. Pin name I/O Description

41 CDG MUTE – Not used. (Open)

42 REQ GM I Data transmission request input from system control.

43 MREQ O Not used. (+5V)

44 CLK MG O Clock output for communications with system control.

45 D. GM I Serial data input from system control.

46 D. MG O Serial data output to system control.

47 RDY I/O System control Ready signal input / output. “L” : READY

48 VAREF – Power supply. (+5V)

49 VASS – Ground

50 VSS – Ground

51 VDD – Power supply. (+5V)

52 URGENT. SIG I Not used. (+5V)

53 URGENT. STBY I Not used. (Open)

54 BUG Y/N – Not used. (Ground Connected)

–––

55 ADJUSTOR – Not used. (“H” LEVEL)

56 ADJUST2 – Not used. (“H” LEVEL)

57 MAGIC SPEED – Not used. (“H” LEVEL)

58 SPEC I Not used. (“H” LEVEL)

59 DIST I Model Select input . (A/D Converter)

60 SPEED – Not used. (“H” LEVEL)

61 BREAK – Not used. (“H” LEVEL)

62 B-PLAY I Deck-B PLAY Switch input. “H” : PLAY

63 B-SHUT I Deck-B Reel table signal input.

64 B-HALF I Deck-B Record prevention claw A, B detection input.

65 A-SHUT I Deck-A Reel table signal input.

66 A-PLAY I Deck-A PLAY Switch input. “H” : PLAY

67

A-HALF

I Deck-A HALF SW input.

68 CAPM H/L O Capstan motor speed selector. “H” : Normal speed “L” : High speed

69

70

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

71 B TRG O Trigger motor control output.

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

CAPM ON/OFF

TRIG H/L

O Capstan motor ON/OFF. “L” : ON

O

72 A TRG O

73 RELAY O Control output to REC/PB select switch. (IC602)

74 A/B O Dolby IC PB input Deck A/B select output. “L” : A, “H” : B

75 NORM/HIGH O EQ Select switch output for normal / high speed. “H” : High speed

76 BIAS ON/OFF O BIAS Oscillation ON/OFF control. “H” : ON

77 RM ON/OFF O REC Mute output. “L” : MUTE

78

79

80

81

REC/PB

NR

LM

PASS

O DOLBY IC REC/PLAY Select output. “H” : REC

O DOLBY ON/OFF Control output. “H” : ON

O LINE Mute output. “L” : MUTE

O PASS Amplifier switch output to DOLBY IC. (IC401)

82 CMD2 – Not used. (Open)

83 UP MOTOR – Not used. (Open)

84 DOWN MOTOR – Not used. (Open)

85 TABLE R – Not used. (Open)

– 17 –

Page 18

Pin No. Pin name I/O Description

86 TABLE L – Not used. (Open)

87 LOAD OUT O Loading motor (M903) Load out output.

88 LOAD IN O Loading motor (M903) Load in output.

89 DF-LATCH O Latch output to digital filter. (PCM1701U)

90 XLT O Serial data latch output to DSP. (CDX2507AQ)

91 FOCUS SW O High-region gain down output to focus servo. (CXA1782BQ)

92 HIGH DUBB – Not used. (“H” LEVEL)

93 TEST 1 – Not used. (“H” LEVEL)

94 OUT SW I CD Tray output detection input.

95 IN SW I CD Tray input detection terminal.

96 UP SW – Not used. (Ground)

97 PANEL SW – Not used. (Ground)

98 CLOSE SW – Not used. (Ground)

99 OPEN SW – Not used. (Ground)

100 VDD – Power supply. (+5V)

– 18 –

Page 19

IC501 CXP82612-016Q (SYSTEM CONTROL DRIVE)

Pin No. Pin name I/O Description

1 ENC I Volume encoder input terminal.

2 SIRCS I Remote commander signal input.

3 REQ. MG I Data transmission request input from master control.

4 REQ. GM O Data transmission request output to master control.

5 LED1 O LED DRIVE Output.

6 LED2 – Not used. (Open)

7 LED3 – Not used. (Open)

8 LED4 – Not used. (Open)

9 LED5 O PLAY, PAUSE LED Output.

10 RDY I/O Master control Ready signal input / output. “L” : Ready

11 SCK. IN I Clock output for communications with master control.

12 SD. IN I Serial data input from master control.

13 SD. OUT O Serial data output to master control.

14 LED-PAUSE O REC, PAUSE LED Output.

15 LED-CD O ROCK LED Output.

16 LED-TUNER/BAND O JAZZ, DRECTION MODE LED Output

17 LED-TAPE O CLASSIC, DANCE LED Output.

18 LED-FWD,STOP,FF&REW O TUNER LED Output.

19 LED-DECK A/B & REV O CD, TIMER LED Output.

20 LED-A O ENTER / NEXT, TUNER / BAND LED Output.

21 LED-B O A, B LED Output.

22 KEY1 I

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

23 KEY2 I

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

24 KEY3 I

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Key input. (A/D Converter)

25 KEY4 I

26 PBF1 I

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

27 PBF2 I

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

28 PBF3 I

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Not used. (Ground)

29 PBF4 I

30 RST I Reset signal input terminal.

31 X IN I

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

32 X OUT O

––––

system clock. (4MHz)

33 VSS – Gound

34 P29 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

35 P28 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

36 P27 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

37 P26 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

38 P25 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

39 P24 O LED Drive.

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

40 P23 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

41 P22 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

42 P21 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

43 P20 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

44 P19 O

– 19 –

Page 20

Pin No. Pin name I/O Description

45 P18 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

46 P17 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

47 P16 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

48 P15 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

49 P14 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

50 P13 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

51 P12 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

52 P11 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

53 P10 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

54 P9 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

55 P8 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

56 P7 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

57 P6 O LED Drive.

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

58 P5 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

59 P4 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

60 P3 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

61 P2 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

62 P1 O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

63 7G O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

64 6G O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

65 5G O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

66 4G O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

67 3G O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

68 2G O

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

69 1G O

70 NC – Not used. (Open)

71 VFDP – LED Drive – 25V power supply.

72 VDD – Power supply. (+5V)

73 KEY – Not used. (+5V)

74 KEY – Not used. (+5V)

75 VDD (TEST) – Not used. (+5V)

76 LED-TUNER-COMMON O Forward play, Revers play LED output.

77 LED-ENTER-NEXT O ENTER / NEXT LED Output.

78 ENC B I

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

79 ENC A I

AMS ENCODER input terminal.

80 ENC – Not used. (+5V)

– 20 –

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

SECTION 7

EXPLODED VIEWS

NOTE :

r

-XX, -X mean standardized parts, so they may

have some difference from the original one.

r

Items marked “ * ”are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

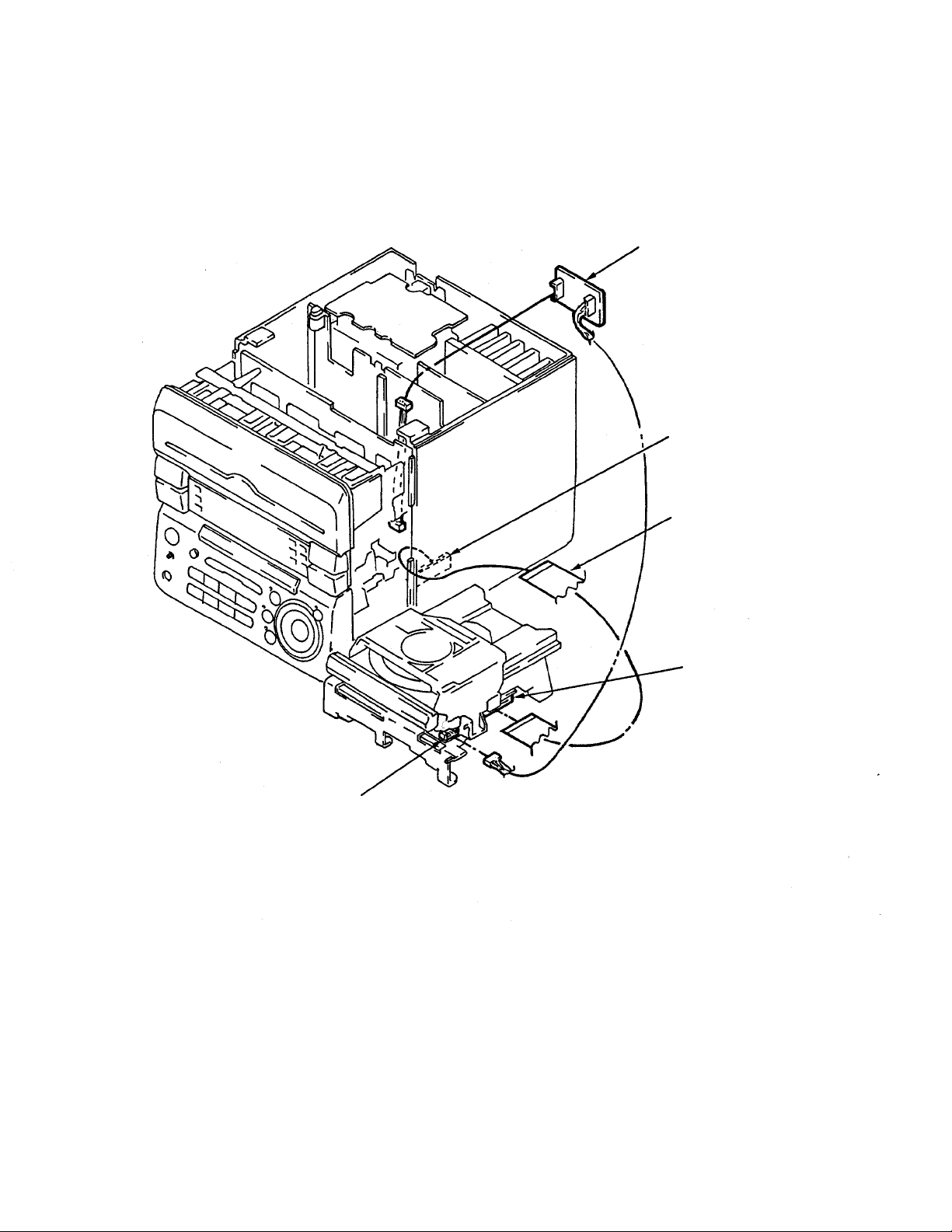

7-1.CABINET SECTION

2

3

r

The mechanical parts with no reference number

in the exploded views are not supplied.

r

Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

r

Abbreviation

SP : Singapore AUS : Australian

HK : Hong Kong AR : Argentine MX : Mexican

G : German EA : Saudi Arabia IT : Italian

MY : Malaysia EE : East European TW : Taiwan

E2 : Tuner Sections SW BAND do not exist.

E3 : Tuner Sections SW BAND exist.

S801

4

F801

#2

2

AR, TW, SP, MY,

5

MX, HK, E, EA

T801

7

F802

#3

4

IC801

14

15

16

#3

10

not supplied

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

not supplied

not supplied

IC901

6

#3

#4

#1

#1

8

#3

Q804

14

E3 model

11

E,MX model

9

not supplied

2

#1

#1

#1

1

2

#1

AEP, G, IT,EA,EE

9

AUS model

AED, AR, HK,

MY, SP, TW model

9

UK model

12

13

EA, MY, SP, TW model

9

HK model

– 59 –

Page 31

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

* 1 4-977-369-21 CASE (H11 : AEP,UK,G,IT,EE,AUS)

1 4-977-369-31 CASE (H11 : E,EA,AR,HK,MX,MY,SP,TW,TH)

* 1 4-977-369-51 CASE (H11J)

2 3-363-099-01 SCREW (CASE 3 TP2)

3 4-977-370-11 PLATE, TOP (H11)

3 4-977-370-31 PLATE, TOP (H11J)

4 1-533-217-31 HOLDER, FUSE

* 5 1-658-263-13 TRANSFORMER BOARD

* 6 3-309-144-21 HEAT SINK

* 7 A-4389-315-A POWER BOARD, COMPLETE (H11 : AEP,UK,G,

IT,E,EA, EE,AR,AUS,HK,TW)

* 10 A-4389-314-A POWER AMP BOARD, COMPLETE (H11 : AEP,

UK,G,IT, E,EA,EE,AR,AUS,HK,TW)

* 10 A-4389-402-A POWER AMP BOARD, COMPLETE (H11 : MX)

* 10 A-4389-409-A POWER AMP BOARD, COMPLETE (H11 : MY,SP)

* 10 A-4389-474-A POWER AMP BOARD, COMPLETE (H11J)

11 1-569-007-11 ADAPTER, CONVERSION 2P (E3)

12 1-569-008-11 ADAPTER, CONVERSION 2P (EA,MY,SP,TW)

13 1-770-019-11 ADAPTOR, CONVERSION PLUG 3P (HK)

* 14 3-923-762-11 HOLDER (TR)

15 4-980-402-01 SHEET (T) (H11J)

16 4-979-267-01 SCREW (3X16) (P) (TIGHT), +BV

* 7 A-4389-403-A POWER BOARD, COMPLETE (H11 : MX)

* 7 A-4389-410-A POWER BOARD, COMPLETE (H11 : MY,SP)

* 7 A-4389-475-A POWER BOARD, COMPLETE (H11J)

8 3-703-244-11 BUSHING (2104), CORD (EXCEPT E,MX)

8 3-703-571-00 BUSHING (S) (4516), CORD (E,MX)

! 9 1-558-943-41 CORD, POWER (E,MX)

! 9 1-575-651-21 CORD, POWER (AEP,G,IT,EA,EE,AR,HK,MY,SP,

! 9 1-696-845-11 CORD, POWER (AUS)

! 9 1-751-522-11 CORD, POWER (UK)

! F801 1-532-279-00 FUSE, TIME LAG (T0.5AL/250V)

! F802 1-532-078-00 FUSE, TIME LAG (T1.0AL/250V) (E,EA,AR,HK,

IC801 8-759-231-58 IC TA7812S

IC901 8-749-920-19 IC STK4122MK2

! T801 1-429-450-11 TRANSFORMER, POWER (AEP,G,IT,EE,TH,UK)

! T801 1-429-451-11 TRANSFORMER, POWER (E,EA,AR,AUS,HK,MX,

TW)

! S801 1-572-675-11 SWITCH, POWER VOLTAGE CHANGE

(VOLTAGE SELECTOR) (E,EA,AR,HK,MX,MY,SP,TW)

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

MX, MY,SP,TW)

MY,SP,TW)

– 60 –

Page 32

7-2.FRONT PANEL SECTION

79

56

81

59

62

61

57

64

63

60

not

supplied

58

(including 51)

68

#5

#5

not

supplied

65

66

not

supplied

64

69

FL501

65

73

67

72

65

not

supplied

#5

70

71

not supplied

65

65

75

74

77

76

55

54

53

52

supplied with

S503

51

80

#5

78

– 61 –

Page 33

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

51 4-930-336-91 FOOT (FELT)

52 4-977-402-11 KNOB (JOG) (H11)

52 4-977-402-31 KNOB (JOG) (H11J)

53 4-977-383-11 BUTTON (O/C) (H11)

53 4-977-383-31 BUTTON (O/C) (H11J)

54 4-977-398-11 BUTTON (EJ-R) (H11)

54 4-977-398-31 BUTTON (EJ-R) (H11J)

55 4-977-396-01 WINDOW (DIS) (H11J)

55 4-977-396-11 WINDOW (DIS) (H11)

56 4-977-382-11 BUTTON (TIM) (H11)

56 4-977-382-31 BUTTON (TIM) (H11J)

57 4-977-397-11 BUTTON (EJ-L) (H11)

57 4-977-397-31 BUTTON (EJ-L) (H11J)

58 X-4946-766-1 PANEL (W) ASSY, FRONT (H11)

58 X-4946-817-1 PANEL (BJ) ASSY, FRONT (H11J)

59 X-4946-767-1 LID (W) ASSY, CASSETTE (H11)

59 X-4946-818-1 LID (BJ) ASSY, CASSETTE (H11J)

60 4-959-232-01 SPRING (R), TORSION (H11J)

60 4-959-232-11 SPRING (R), TORSION (H11)

61 4-959-231-01 SPRING (L), TORSION (H11J)

61 4-959-231-11 SPRING (L), TORSION (H11)

62 X-4946-761-1 HOLDER (L) ASSY, CASSETTE (H11)

62 X-4946-820-1 HOLDER (BL) ASSY, CASSETTE (H11J)

* 63 3-367-709-01 LEVER (LOCK LEVER L) (H11J)

63 3-367-709-21 LEVER (LOCK LEVER L) (H11)

64 3-354-957-01 JOINT (LOCK LEVER)

65 4-951-620-01 SCREW (2.6X8), +BVTP

66 4-965-877-01 LEVER (LOCK LEVER R) (H11J)

* 66 4-965-877-11 LEVER (LOCK LEVER R) (H11)

* 67 4-977-399-01 HOUSE, LAMP (H11J)

* 67 4-977-399-11 HOUSE, LAMP (H11)

68 X-4946-760-1 HOLDER (R) ASSY, CASSETTE (H11)

68 X-4946-819-1 HOLDER (BR) ASSY, CASSETTE (H11J)

* 69 4-977-400-01 HOLDER (FL) (H11J)

* 69 4-977-400-11 HOLDER (FL) (H11)

70 4-977-401-11 PANEL, LOADING (H11)

70 4-977-401-31 PANEL, LOADING (H11J)

71 1-776-220-11 WIRE (FLAT TYPE) (19 CORE) (H11J)

71 1-777-061-11 WIRE (FLAT TYPE) (19 CORE) (H11)

* 72 A-4389-325-A PANEL BOARD, COMPLETE (H11 : AEP,UK,G,IT,

E3,EA, EE,HK,TW)

* 72 A-4389-398-A PANEL BOARD, COMPLETE (H11 : E2,AR,AUS)

* 72 A-4389-401-A PANEL BOARD, COMPLETE (H11 : MX)

* 72 A-4389-408-A PANEL BOARD, COMPLETE (H11 : MY,SP)

* 72 A-4389-473-A PANEL BOARD, COMPLETE (H11J)

73 4-977-392-01 SPRING (F), TENSION (H11J)

73 4-977-392-11 SPRING (F), TENSION (H11)

74 1-769-966-11 WIRE (FLAT TYPE) (11 CORE) (H11J)

74 1-777-062-11 WIRE (FLAT TYPE) (11 CORE) (H11)

* 75 A-4303-499-A TCB BOARD, COMPLETE (H11J)

* 75 A-4303-532-A TCB BOARD, COMPLETE (H11 : AEP,UK)

* 75 A-4303-533-A TCB BOARD, COMPLETE (H11 : G,IT)

* 75 A-4303-534-A TCB BOARD, COMPLETE (H11 : E3,EA,MY,SP,

TW,HK)

* 75 A-4303-535-A TCB BOARD, COMPLETE (H11 : E2,MX,AR,AUS)

* 75 A-4303-536-A TCB BOARD, COMPLETE (H11 : EE)

76 1-773-167-11 WIRE (FLAT TYPE) (21 CORE) (H11J)

76 1-777-060-11 WIRE (FLAT TYPE) (21 CORE) (H11)

77 1-773-052-11 WIRE (FLAT TYPE) (17 CORE)

* 78 A-4389-317-A MAIN BOARD, COMPLETE (H11 : AEP,UK)

* 78 A-4389-318-A MAIN BOARD, COMPLETE (H11 : G)

* 78 A-4389-319-A MAIN BOARD, COMPLETE (H11 : IT)

* 78 A-4389-329-A MAIN BOARD, COMPLETE (H11 : E3,HK)

* 78 A-4389-397-A MAIN BOARD, COMPLETE (H11 : EE)

* 78 A-4389-399-A MAIN BOARD, COMPLETE (H11 : E2,AR)

* 78 A-4389-400-A MAIN BOARD, COMPLETE (H11 : EA,TW)

* 78 A-4389-405-A MAIN BOARD, COMPLETE (H11 : MX)

* 78 A-4389-407-A MAIN BOARD, COMPLETE (H11 : AUS)

* 78 A-4389-412-A MAIN BOARD, COMPLETE (H11 : MY,SP)

* 78 A-4389-477-A MAIN BOARD, COMPLETE (H11J)

79 4-962-708-11 EMBLEM (4-A), SONY (H11)

79 4-962-708-31 EMBLEM (4-A), SONY (H11J)

80 1-543-738-41 CORE, RING (AEP,G,IT,EE,UK)

81 4-959-229-11 DETENT, CASSETTE (H11)

FL501 1-517-473-11 INDICATOR TUBE, FLUORESCENT

– 62 –

Page 34

7-3. TC MECHANISM SECTION-1

124

#15

122

(including pF)

4

C

121

#15

HP101

(including

4

C)

106

105

104

not

supplied

102

not supplied

109

101

#7

107

#8

114

112

108

110

HRPE101

(including

103

not supplied

not supplied

106

105

104

115

r

102

111

B)

116

109

101

123

125

113

114

117

not supplied

#8

4

C

121

118

107

not supplied

115

#7

103

110

119

112

116

108

111

125

r

B

121

113

124

r

B

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

101 3-908-560-01 SPRING, AZIMUTH ADJUSTMENT

102 3-919-684-01 SCREW, AZIMUTH ADJUSTMENT

* 103 X-3367-584-2 SLIDER (HEAD) ASSY

104 3-908-556-01 SPRING, HEAD TOGGLE

105 3-908-558-02 FITTING BLOCK, HEAD

106 3-908-557-02 ROTARY BLOCK, HEAD

* 107 3-908-559-01 STOPPER, AZIMUTH

108 3-908-555-01 SLIDER (REV SLIDER)

109 3-917-143-11 SPRING, TENSION

110 3-388-848-01 SCREW (P2X6) (B TIGHT)

111 3-911-113-01 SPRING, TENSION

112 X-3370-643-1 PINCH LEVER (REV) ASSY

113 X-3367-588-1 PINCH LEVER (FWD) ASSY

114 3-908-613-01 GEAR (S), REEL

115 3-917-141-01 SPRING, COMPRESSION

116 X-3371-305-1 REEL (T) ASSY

117 3-669-465-01 WASHER (1.5), STOPPER

118 X-3370-173-1 TU ASSY

* 119 4-980-439-01 FULCRUM, HOLDER

121 3-911-116-21 RIVET, PUSH

122 A-2007-131-A AUDIO BOARD, COMPLETE

123 3-930-972-01 DETENT, HALF

124 3-354-963-01 DAMPER

125 3-917-142-01 SPRING, COMPRESSION

HP101 1-500-093-11 HEAD, MAGNETIC (PLAYBACK)

HRPE1011-500-094-11 HEAD, MAGNETIC (REC/PB/ERASE)

– 63 –

Page 35

7-4. TC MECHANISM SECTION-2

M2

p

F

224

213

202

209

217

216

214

218

#8

215

207

219

213

212

220

210

225

211

208

#11

210

207

205

204

203

206

221

#9

#10

221

#10

222

219

#14

M1

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

201 3-908-597-01 CAM (A)

202 3-908-608-11 SCREW, STEP

203 X-3367-590-2 ARM (A) ASSY, FR

204 X-3370-169-1 FLYWHEEL (AR) ASSY

205 3-928-047-01 PULLEY, TENSION

206 3-908-599-01 LEVER (REV-A)

207 3-908-601-01 SPRING (REV LEVER), TORSION

208 3-908-603-01 LEVER (TRIGGER A)

209 X-3367-593-1 FLYWHEEL (BF) ASSY

210 3-908-605-01 SPRING (TRIGGER), TORSION

211 3-908-609-01 GEAR, TRIGGER

212 3-913-845-11 BELT (A)

213 3-913-846-11 BELT (FR)

#14

not supplied

214 X-3370-171-1 FLYWHEEL (BR) ASSY

215 3-908-600-01 LEVER (REV-B)

* 216 1-650-669-11 LEAF SWITCH BOARD

217 3-908-598-01 CAM (B)

218 X-3369-849-2 ARM (B) ASSY, FR

219 3-914-111-01 SPRING (FR), TORSION

220 3-908-604-01 LEVER (TRIGGER B)

221 3-911-115-01 WASHER, STOPPER

222 X-3371-441-1 CHASSIS ASSY

224 3-917-176-11 BELT (B)

225 X-3370-172-1 FLYWHEEL (AF) ASSY

M1 A-2004-409-A MOTOR ASSY, CAPSTAN (CAPSTAN)

M2 A-2004-410-A MOTOR ASSY, DC (TRIGGER)

202

201

– 64 –

Page 36

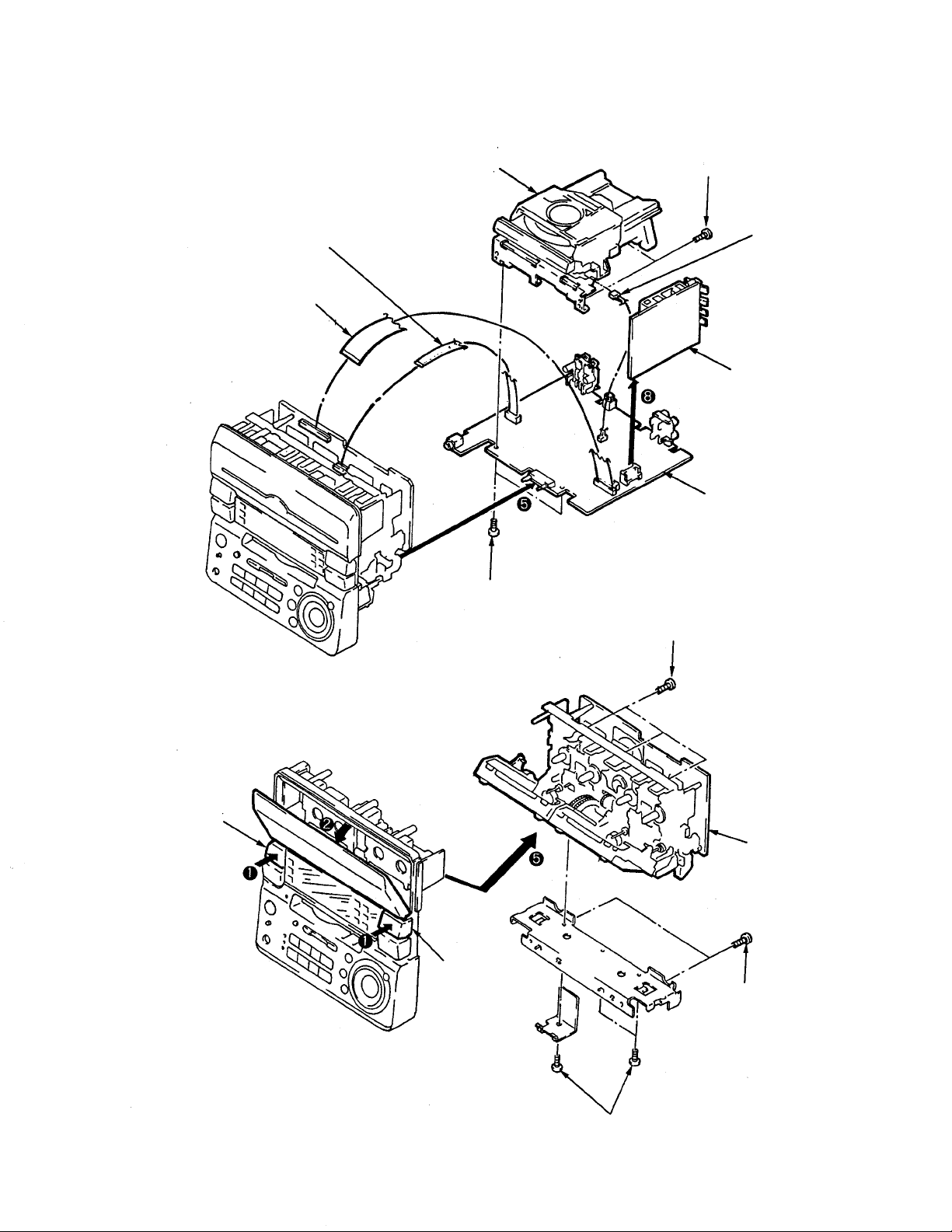

7-5. CD MECHANISM SECTION-1

302

#5

306

304

305

303

(including

r

A)

307

308

309

#5

r

A

M903

310

BU-5BD19

313

#5

301

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

301 4-960-836-01 TABLE, DISC

302 4-960-835-01 HOLDER (M)

303 1-452-719-11 MAGNET ASSY

304 4-960-842-01 GEAR (P)

305 4-960-841-01 PULLEY (S)

306 4-927-649-01 BELT

* 307 4-960-839-01 CAM

308 4-960-838-03 BASE (MD)

309 4-917-583-21 BRACKET, YOKE

310 4-933-134-01 SCREW (+PTPWH M2.6X6)

311 4-959-996-01 SPRING (932), COMPRESSION

312 4-960-834-01 HOLDER (BU)

* 313 1-650-836-11 LOADING BOARD

M903 A-4604-363-A MOTOR (L) ASSY (LOADING)

311

312

– 65 –

Page 37

7-6. CD MECHANISM SECTION-2

354

355

356

357

r

A

#12

354

M101

(including rA)

353

358

M102

351

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

351 4-951-620-01 SCREW (2.6X8), +BVTP

* 352 A-4673-402-A BD BOARD, COMPLETE

353 4-917-565-01 SHAFT, SLED

354 4-951-940-01 INSULATOR (BU)

! 355 8-848-387-11 OPTICAL PICK-UP KSS-213BA/S-N

352

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

356 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

357 4-917-567-01 GEAR (M)

358 4-917-564-01 GEAR (P), FLATNESS

M101 X-4917-523-4 MOTOR ASSY (SPINDLE)

M102 X-4917-504-1 MOTOR ASSY (SLED)

– 66 –

Page 38

SECTION 8

ELECTRICAL PARTS LIST

AUDIO

NOTE :

r

Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

r

-XX, -X mean standardized parts, so they may

have some difference from the original one.

r

RESISTORS

All resistors are in ohms

METAL : Metal-film resistor

METAL OXIDE :Metal oxide-film resistor

F : nonflammable

r

Items marked “ * ”are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

A-2007-131-A AUDIO BOARD, COMPLETE

C301 1-162-289-31 CERAMIC 390PF 10% 50V

C302 1-126-968-11 ELECT 100uF 20% 6.3V

C303 1-162-282-31 CERAMIC 100PF 10% 50V

C304 1-130-483-00 MYLAR 0.01uF 5% 50V

C305 1-107-715-11 ELECT 22uF 20% 16V

C311 1-162-289-31 CERAMIC 390PF 10% 50V

C313 1-162-282-31 CERAMIC 100PF 10% 50V

C314 1-130-487-00 MYLAR 0.022uF 5% 50V

C315 1-126-233-11 ELECT 22uF 20% 50V

C331 1-137-427-11 FILM 120PF 5% 50V

**********************

< CAPACITOR >

r

SEMICONDUCTORS

In each case, u : µ , for example :

uA.... : µ A.... , uPA.... : µPA....

uPB.... : µ PB.... , uPC.... : µ PC....

uPD.... : µ PD....

r

CAP ACITORS

uF : µ F

r

COILS

uH : µ H

r

Abbreviation

SP : Singapore AUS : Australian

HK : Hong Kong AR : Argentine MX : Mexican

G : German EA : Saudi Arabia IT : Italian

MY : Malaysia EE : East European TW : Taiwan

E2 : Tuner Sections SW BAND do not exist.

E3 : Tuner Sections SW BAND exist.

C642 1-104-664-11 ELECT 47uF 20% 16V

C651 1-161-494-00 CERAMIC 0.022uF 25V

* CN601 1-568-864-11 SOCKET, CONNECTOR 21P

* CN602 1-564-718-11 PIN, CONNECTOR (SMALL TYPE) 2P

* CN651 1-564-521-11 PLUG, CONNECTOR 6P

IC601 8-759-111-44 IC UPC4570C-1

IC602 8-759-143-54 IC UPC1330HA

IC611 8-759-111-44 IC UPC4570C-1

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

< CONNECTOR >

< IC >

< COIL >

C332 1-162-288-31 CERAMIC 330PF 10% 50V

C333 1-162-209-31 CERAMIC 27PF 5% 50V

C401 1-162-289-31 CERAMIC 390PF 10% 50V

C402 1-126-968-11 ELECT 100uF 20% 6.3V

C403 1-162-282-31 CERAMIC 100PF 10% 50V

C404 1-130-483-00 MYLAR 0.01uF 5% 50V

C405 1-107-715-11 ELECT 22uF 20% 16V

C411 1-162-289-31 CERAMIC 390PF 10% 50V

C413 1-162-282-31 CERAMIC 100PF 10% 50V

C414 1-130-487-00 MYLAR 0.022uF 5% 50V

C415 1-126-233-11 ELECT 22uF 20% 50V

C431 1-137-427-11 FILM 120PF 5% 50V

C432 1-162-288-31 CERAMIC 330PF 10% 50V

C433 1-162-209-31 CERAMIC 27PF 5% 50V

C601 1-126-157-11 ELECT 10uF 20% 16V

C602 1-126-157-11 ELECT 10uF 20% 16V

C611 1-124-907-11 ELECT 10uF 20% 50V

C612 1-124-907-11 ELECT 10uF 20% 50V

C621 1-137-150-11 FILM 0.01uF 5% 100V

C622 1-126-961-11 ELECT 2.2uF 20% 50V

C623 1-136-155-00 FILM 0.015uF 5% 50V

C624 1-130-481-00 MYLAR 0.0068uF 5% 50V

C625 1-130-481-00 MYLAR 0.0068uF 5% 50V

C627 1-124-903-11 ELECT 1uF 20% 50V

C628 1-136-153-00 FILM 0.01uF 5% 50V

L331 1-410-780-11 INDUCTOR 27mH

L431 1-410-780-11 INDUCTOR 27mH

< TRANSISTOR >

Q621 8-729-142-46 TRANSISTOR 2SC2001-LK

Q622 8-729-142-46 TRANSISTOR 2SC2001-LK

Q623 8-729-801-93 TRANSISTOR 2SD1387

Q651 8-729-900-65 TRANSISTOR DTA144ES

< RESISTOR >

R301 1-247-881-00 CARBON 120K 5% 1/4W

R302 1-249-409-11 CARBON 220 5% 1/4W

R303 1-249-433-11 CARBON 22K 5% 1/4W

R304 1-247-889-00 CARBON 270K 5% 1/4W

R305 1-247-858-11 CARBON 13K 5% 1/4W

R311 1-247-881-00 CARBON 120K 5% 1/4W

R312 1-247-807-31 CARBON 100 5% 1/4W

R314 1-247-882-11 CARBON 130K 5% 1/4W

R315 1-247-850-11 CARBON 6.2K 5% 1/4W

R331 1-249-430-11 CARBON 12K 5% 1/4W

R401 1-247-881-00 CARBON 120K 5% 1/4W

R402 1-249-409-11 CARBON 220 5% 1/4W

R403 1-249-433-11 CARBON 22K 5% 1/4W

R404 1-247-889-00 CARBON 270K 5% 1/4W

R405 1-247-858-11 CARBON 13K 5% 1/4W

– 67 –

Page 39

AUDIO

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

R411 1-247-881-00 CARBON 120K 5% 1/4W

R412 1-247-807-31 CARBON 100 5% 1/4W

R414 1-247-882-11 CARBON 130K 5% 1/4W

R415 1-247-850-11 CARBON 6.2K 5% 1/4W

R431 1-249-430-11 CARBON 12K 5% 1/4W

R601 1-249-409-11 CARBON 220 5% 1/4W

R602 1-249-409-11 CARBON 220 5% 1/4W

R608 1-249-409-11 CARBON 220 5% 1/4W

R609 1-249-433-11 CARBON 22K 5% 1/4W

R611 1-249-409-11 CARBON 220 5% 1/4W

R612 1-249-409-11 CARBON 220 5% 1/4W

! R621 1-212-851-00 FUSIBLE 5.6 5% 1/4W F

! R622 1-212-851-00 FUSIBLE 5.6 5% 1/4W F

R623 1-249-432-11 CARBON 18K 5% 1/4W

R624 1-249-432-11 CARBON 18K 5% 1/4W

R625 1-249-429-11 CARBON 10K 5% 1/4W

R651 1-247-856-00 CARBON 11K 5% 1/4W

R652 1-247-856-00 CARBON 11K 5% 1/4W

R653 1-249-441-11 CARBON 100K 5% 1/4W

RV301 1-238-598-11 RES, ADJ, CARBON 2.2K (PB LEVEL L) (DECK B)

RV311 1-238-598-11 RES, ADJ, CARBON 2.2K (PB LEVEL L) (DECK A)

RV341 1-238-551-11 RES, ADJ, CARBON 220K (REC BIAS L)

RV401 1-238-598-11 RES, ADJ, CARBON 2.2K (PB LEVEL R) (DECK B)

RV411 1-238-598-11 RES, ADJ, CARBON 2.2K (PB LEVEL R) (DECK A)

BD

C130 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C131 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C132 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C133 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C134 1-164-346-11 CERAMIC CHIP 1uF 16V

C135 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C136 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C137 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C139 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C140 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C141 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C142 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C145 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C146 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C147 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C148 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C149 1-164-346-11 CERAMIC CHIP 1uF 16V

C153 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C154 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

< VARIABLE RESISTOR >

< CONNECTOR >

CNU101 1-770-014-11 CONNECTOR, FFC/FPC 16P

CNU102 1-770-013-11 CONNECTOR, FFC/FPC 19P

< IC >

RV441 1-238-551-11 RES, ADJ, CARBON 220K (REC BIAS R)

RV651 1-238-599-11 RES, ADJ, CARBON 4.7K

(TAPE SPEED NORMAL)

RV652 1-238-599-11 RES, ADJ, CARBON 4.7K (TAPE SPEED HIGH)

< TRANSFORMER >

T621 1-423-980-11 TRANSFORMER, BIAS OSCILLATION

************************************************************

* A-4673-402-A BD BOARD, COMPLETE

*******************

< CAPACITOR >

C101 1-126-607-11 ELECT CHIP 47uF 20% 4V

C102 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C103 1-164-346-11 CERAMIC CHIP 1uF 16V

C105 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C106 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C107 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C108 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C109 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C110 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C111 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C112 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C127 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C128 1-163-135-00 CERAMIC CHIP 560PF 5% 50V

C129 1-163-038-91 CERAMIC CHIP 0.1uF 25V

IC101 8-752-069-56 IC CXA1782BQ

IC102 8-759-291-06 IC BA6397FP

IC103 8-752-372-94 IC CXD2507AQ

IC104 8-759-185-29 IC PCM1710U-B

< TRANSISTOR >

Q101 8-729-010-08 TRANSISTOR MSB710-R

Q102 8-729-424-08 TRANSISTOR UN2111

Q103 8-729-421-22 TRANSISTOR UN2211

< RESISTOR >

R102 1-216-001-00 METAL CHIP 10 5% 1/10W

R103 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R104 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R105 1-216-093-00 METAL CHIP 68K 5% 1/10W

R106 1-216-093-00 METAL CHIP 68K 5% 1/10W

R107 1-216-093-00 METAL CHIP 68K 5% 1/10W

R108 1-216-093-00 METAL CHIP 68K 5% 1/10W

R109 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R112 1-216-083-00 METAL CHIP 27K 5% 1/10W

R113 1-216-083-00 METAL CHIP 27K 5% 1/10W

R114 1-216-101-00 METAL CHIP 150K 5% 1/10W

R115 1-216-101-00 METAL CHIP 150K 5% 1/10W

R116 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R117 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R118 1-216-049-91 METAL GLAZE 1K 5% 1/10W

– 68 –

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

Page 40

BD

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

R119 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R120 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R121 1-216-114-00 METAL GLAZE 510K 5% 1/10W

R122 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R123 1-216-099-00 METAL CHIP 120K 5% 1/10W

R124 1-216-091-00 METAL CHIP 56K 5% 1/10W

R125 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R126 1-216-063-91 METAL GLAZE 3.9K 5% 1/10W

R127 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R128 1-216-105-91 METAL GLAZE 220K 5% 1/10W

* 1-650-669-11 LEAF SWITCH BOARD

* CN1001 1-568-854-11 SOCKET, CONNECTOR 11P

Q1001 8-749-010-90 TRANSISTOR NJL5165KA-H2

Q1002 8-749-010-90 TRANSISTOR NJL5165KA-H2

LEAF SWITCH

******************

< CONNECTOR >

< TRANSISTOR >

LOADING

R129 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R130 1-216-079-00 METAL CHIP 18K 5% 1/10W

R131 1-216-079-00 METAL CHIP 18K 5% 1/10W

R132 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R133 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R134 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R135 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R136 1-216-073-00 METAL CHIP 10K 5% 1/10W

R137 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R138 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R139 1-216-033-00 METAL CHIP 220 5% 1/10W

R140 1-216-081-00 METAL CHIP 22K 5% 1/10W

R141 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R142 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R143 1-216-121-91 METAL GLAZE 1M 5% 1/10W

R144 1-216-073-00 METAL CHIP 10K 5% 1/10W

R145 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R146 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R147 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R148 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R149 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R150 1-216-037-00 METAL CHIP 330 5% 1/10W

R151 1-216-037-00 METAL CHIP 330 5% 1/10W

R152 1-216-037-00 METAL CHIP 330 5% 1/10W

R153 1-216-082-00 METAL GLAZE 24K 5% 1/10W

< RESISTOR >

R1001 1-249-412-11 CARBON 390 5% 1/4W

R1002 1-249-412-11 CARBON 390 5% 1/4W

R1003 1-249-414-11 CARBON 560 5% 1/4W

R1004 1-247-834-11 CARBON 1.3K 5% 1/4W

R1005 1-247-818-11 CARBON 300 5% 1/4W

< SWITCH >

S1001 1-692-832-11 SWITCH, PUSH (1 KEY) (A PLAY)

S1002 1-692-832-11 SWITCH, PUSH (1 KEY) (B PLAY)

S1003 1-572-248-11 SWITCH, LEAF (A HALF)

S1004 1-571-281-21 SWITCH, LEAF (A CrO2)

S1005 1-571-281-21 SWITCH, LEAF (REC A)

S1006 1-572-248-11 SWITCH, LEAF (B HALF)

S1008 1-571-281-21 SWITCH, LEAF (B CrO2)

S1009 1-571-281-21 SWITCH, LEAF (REC B)

************************************************************

* 1-650-836-11 LOADING BOARD

**************

< CONNECTOR >

* CN291 1-568-943-11 PIN, CONNECTOR 5P

< SWITCH >

R154 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R156 1-216-085-00 METAL CHIP 33K 5% 1/10W

R157 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R158 1-216-001-00 METAL CHIP 10 5% 1/10W

< VARIABLE RESISTOR >

RV101 1-241-396-11 RES, ADJ, METAL GLAZE 22K (FOCUS BIAS)

RV102 1-241-396-11 RES, ADJ, METAL GLAZE 22K (FOCUS GAIN)

RV103 1-241-396-11 RES, ADJ, METAL GLAZE 22K (TRACKING GAIN)

< SWITCH >

S101 1-572-085-11 SWITCH, LEAF (LIMIT)

< VIBRATOR >

X101 1-579-280-11 VIBRATOR, CRYSTAL (16.9344MHz)

************************************************************

S291 1-572-086-11 SWITCH, LEAF (LOAD OUT)

S292 1-572-086-11 SWITCH, LEAF (LOAD IN)

************************************************************

– 69 –

Page 41

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

* A-4389-317-A MAIN BOARD, COMPLETE (H11 : AEP,UK)

* A-4389-318-A MAIN BOARD, COMPLETE (H11 : G)

* A-4389-319-A MAIN BOARD, COMPLETE (H11 : IT)

* A-4389-329-A MAIN BOARD, COMPLETE (H11 : E3,HK)

* A-4389-397-A MAIN BOARD, COMPLETE (H11 : EE)

* A-4389-399-A MAIN BOARD, COMPLETE (H11 : E2,AR)

* A-4389-400-A MAIN BOARD, COMPLETE (H11 : EA,TW)

* A-4389-405-A MAIN BOARD, COMPLETE (H11 : MX)

* A-4389-407-A MAIN BOARD, COMPLETE (H11 : AUS)

* A-4389-412-A MAIN BOARD, COMPLETE (H11 : MY,SP)

* A-4389-477-A MAIN BOARD, COMPLETE (H11J)

*********************

C151 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C152 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C153 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C154 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C155 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C156 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C157 1-164-492-11 CERAMIC CHIP 0.15uF 10% 16V

C158 1-126-964-11 ELECT 10uF 20% 50V

C171 1-126-964-11 ELECT 10uF 20% 50V

C172 1-109-889-11 ELECT 1uF 20% 50V

C173 1-109-889-11 ELECT 1uF 20% 50V

C174 1-126-964-11 ELECT 10uF 20% 50V

< CAPACITOR >

C101 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C102 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C103 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C104 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C105 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C106 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C107 1-164-492-11 CERAMIC CHIP 0.15uF 10% 16V

C108 1-126-964-11 ELECT 10uF 20% 50V

C110 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C111 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C112 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C113 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C114 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C115 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C121 1-162-306-11 CERAMIC 0.01uF 30% 16V

C122 1-162-306-11 CERAMIC 0.01uF 30% 16V

C123 1-162-306-11 CERAMIC 0.01uF 30% 16V

C124 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C125 1-126-964-11 ELECT 10uF 20% 50V

C126 1-126-933-11 ELECT 100uF 20% 10V

C127 1-126-933-11 ELECT 100uF 20% 10V

C130 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C131 1-163-234-11 CERAMIC CHIP 20PF 5% 50V

C132 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C133 1-136-165-00 FILM 0.1uF 5% 50V

C135 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C136 1-104-656-11 ELECT 2200uF 20% 6.3V

C137 1-126-964-11 ELECT 10uF 20% 50V

C138 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C139 1-126-965-11 ELECT 22uF 20% 50V

C140 1-164-159-11 CERAMIC 0.1uF 50V

C141 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C144 1-164-159-11 CERAMIC 0.1uF 50V

C145 1-164-159-11 CERAMIC 0.1uF 50V

C147 1-126-964-11 ELECT 10uF 20% 50V

C148 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C149 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C150 1-126-964-11 ELECT 10uF 20% 50V

C175 1-164-159-11 CERAMIC 0.1uF 50V

C176 1-126-964-11 ELECT 10uF 20% 50V

C177 1-164-159-11 CERAMIC 0.1uF 50V

C178 1-164-159-11 CERAMIC 0.1uF 50V

C179 1-164-159-11 CERAMIC 0.1uF 50V

C180 1-126-952-11 ELECT 1000uF 20% 16V

C181 1-164-159-11 CERAMIC 0.1uF 50V

C201 1-162-290-31 CERAMIC 470PF 10% 50V

C202 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C203 1-162-290-31 CERAMIC 470PF 10% 50V

C204 1-164-159-11 CERAMIC 0.1uF 50V

C205 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C206 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C207 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C208 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C209 1-162-290-31 CERAMIC 470PF 10% 50V

C211 1-162-302-11 CERAMIC 0.0022uF 30% 16V

C212 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C213 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C215 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C216 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C401 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C402 1-130-479-00 MYLAR 0.0047uF 5% 50V

C403 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C404 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C405 1-126-964-11 ELECT 10uF 20% 50V

C406 1-124-903-11 ELECT 1uF 20% 50V

C407 1-124-902-00 ELECT 0.47uF 20% 50V

C408 1-126-964-11 ELECT 10uF 20% 50V

C409 1-126-964-11 ELECT 10uF 20% 50V

C410 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C411 1-124-903-11 ELECT 1uF 20% 50V

C412 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C421 1-126-964-11 ELECT 10uF 20% 50V

C422 1-126-933-11 ELECT 100uF 20% 10V

C423 1-126-933-11 ELECT 100uF 20% 10V

C424 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C425 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C426 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C427 1-126-935-11 ELECT 470uF 20% 16V

– 70 –

Page 42

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

C428 1-104-665-11 ELECT 100uF 20% 25V

C430 1-126-964-11 ELECT 10uF 20% 50V

C431 1-126-964-11 ELECT 10uF 20% 50V

C434 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C435 1-163-031-11 CERAMIC CHIP 0.01uF 50V

* CN104 1-569-934-11 SOCKET, CONNECTOR 17P

CN105 1-764-286-11 PIN, CONNECTOR (PC BOARD) 16P

CN401 1-569-937-11 SOCKET, CONNECTOR 21P

CN402 1-569-928-11 SOCKET, CONNECTOR 11P

C451 1-162-286-31 CERAMIC 220PF 10% 50V

C452 1-130-479-00 MYLAR 0.0047uF 5% 50V

C453 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C454 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C455 1-126-964-11 ELECT 10uF 20% 50V

C456 1-124-903-11 ELECT 1uF 20% 50V

C457 1-124-902-00 ELECT 0.47uF 20% 50V

C458 1-126-964-11 ELECT 10uF 20% 50V

C459 1-126-964-11 ELECT 10uF 20% 50V

C460 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C461 1-124-903-11 ELECT 1uF 20% 50V

C462 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C701 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C702 1-126-964-11 ELECT 10uF 20% 50V

C703 1-164-182-11 CERAMIC CHIP 0.0033uF 10% 50V

C706 1-126-964-11 ELECT 10uF 20% 50V

C707 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C708 1-162-282-31 CERAMIC 100PF 10% 50V

C709 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C738 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C739 1-164-159-11 CERAMIC 0.1uF 50V

C751 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C752 1-126-964-11 ELECT 10uF 20% 50V

C753 1-164-182-11 CERAMIC CHIP 0.0033uF 10% 50V

C756 1-126-964-11 ELECT 10uF 20% 50V

C908 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK,G,IT,EE)

C909 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK,G,IT,EE)

C958 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK,G,IT,EE)

C959 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK,G,IT,EE)

C971 1-126-923-11 ELECT 220uF 20% 10V

C972 1-126-923-11 ELECT 220uF 20% 10V

C973 1-164-159-11 CERAMIC 0.1uF 50V

C974 1-126-933-11 ELECT 100uF 20% 10V

C975 1-126-964-11 ELECT 10uF 20% 50V

C1001 1-163-003-11 CERAMIC CHIP 330PF 10% 50V

C1008 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C1051 1-162-288-31 CERAMIC 330PF 10% 50V

C1058 1-162-294-31 CERAMIC 0.001uF 10% 50V

C1109 1-126-956-91 ELECT 0.1uF 20% 50V

C2001 1-162-306-11 CERAMIC 0.01uF 30% 16V

< CONNECTOR >

< DIODE >

D102 8-719-987-63 DIODE 1N4148M

D103 8-719-987-63 DIODE 1N4148M

D104 8-719-010-29 DIODE UZ-4.3BSB

D106 8-719-200-82 DIODE 11ES2 (AEP,UK,G,IT,E3,HK)

D106 8-719-024-99 DIODE 11ES2-NTA2B (E2,EA,EE,AR,AU,MX,MY,

SP,TW)

D107 8-719-987-63 DIODE 1N4148M

D108 8-719-987-63 DIODE 1N4148M

D109 8-719-200-82 DIODE 11ES2 (AEP,UK,G,IT,E3,HK)

D109 8-719-024-99 DIODE 11ES2-NTA2B (E2,EA,EE,AR,AUS,MX,

MY,SP,TW)

D110 8-719-987-63 DIODE 1N4148M

D111 8-719-987-63 DIODE 1N4148M

D120 8-719-987-63 DIODE 1N4148M

D121 8-719-987-63 DIODE 1N4148M

D402 8-719-987-63 DIODE 1N4148M

D403 8-719-987-63 DIODE 1N4148M

D404 8-719-987-63 DIODE 1N4148M

D703 8-719-200-82 DIODE 11ES2 (AEP,UK,G,IT,E3,HK)

D703 8-719-024-99 DIODE 11ES2-NTA2B (E2,EA,EE,AR,AUS,MX,

MY,SP,TW)

D704 8-719-200-82 DIODE 11ES2 (AEP,UK,G,IT,E3,HK)

D704 8-719-024-99 DIODE 11ES2-NTA2B (E2,EA,EE,AR,AUS,MX,

MY,SP,TW)

D971 8-719-987-63 DIODE 1N4148M

D972 8-719-987-63 DIODE 1N4148M

D1002 8-719-987-63 DIODE 1N4148M

D1003 8-719-987-63 DIODE 1N4148M

D1004 8-719-987-63 DIODE 1N4148M

< IC >

IC101 8-759-357-82 IC TMP87CP64YF-6335

IC102 8-759-925-74 IC SN74HC04ANS

IC103 8-759-165-82 IC PST600E-T

IC104 8-759-291-98 IC M62423FP

IC105 8-759-281-42 IC TC9210P

IC106 8-759-822-09 IC LB1641

IC401 8-759-289-38 IC HA12195NT

IC402 8-759-822-09 IC LB1641

IC701 8-759-009-06 IC MC14052BF

IC971 8-759-111-68 IC UPC1237HA

< JACK >

J102 1-750-032-11 JACK (DIA. 3.5) (PHONES)

J701 1-573-028-31 JACK, PIN 4P (MD IN/OUT)

CN101 1-770-167-11 CONNECTOR, FFC/FPC 19P

CN103 1-774-289-11 PIN, CONNECTOR (PC BOARD) 15P

– 71 –

Page 43

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

––––––– ––––––– –––––––––– ––––––– ––––––– ––––––– –––––––––– ––––––

< JUMPER RESISTOR >

JR101 1-216-295-00 METAL CHIP 0 5% 1/10W

JR102 1-216-296-00 METAL CHIP 0 5% 1/8W

JR103 1-216-296-00 METAL CHIP 0 5% 1/8W

JR104 1-216-296-00 METAL CHIP 0 5% 1/8W

JR105 1-216-295-00 METAL CHIP 0 5% 1/10W

JR106 1-216-295-00 METAL CHIP 0 5% 1/10W

JR107 1-216-296-00 METAL CHIP 0 5% 1/8W

JR108 1-216-296-00 METAL CHIP 0 5% 1/8W

JR111 1-216-296-00 METAL CHIP 0 5% 1/8W

JR112 1-216-296-00 METAL CHIP 0 5% 1/8W

JR113 1-216-296-00 METAL CHIP 0 5% 1/8W

JR114 1-216-296-00 METAL CHIP 0 5% 1/8W

JR115 1-216-295-00 METAL CHIP 0 5% 1/10W

JR116 1-216-295-00 METAL CHIP 0 5% 1/10W

JR117 1-216-295-00 METAL CHIP 0 5% 1/10W

JR118 1-216-295-00 METAL CHIP 0 5% 1/10W

JR119 1-216-296-00 METAL CHIP 0 5% 1/8W

JR120 1-216-295-00 METAL CHIP 0 5% 1/10W

JR121 1-216-296-00 METAL CHIP 0 5% 1/8W

JR122 1-216-296-00 METAL CHIP 0 5% 1/8W

JR127 1-216-296-00 METAL CHIP 0 5% 1/8W

JR129 1-216-295-00 METAL CHIP 0 5% 1/10W

JR130 1-216-295-00 METAL CHIP 0 5% 1/10W

JR310 1-216-295-00 METAL CHIP 0 5% 1/10W

JR1010 1-216-295-00 METAL CHIP 0 5% 1/10W

< COIL >

L101 1-410-509-11 INDUCTOR 10uH

L401 1-410-482-31 INDUCTOR 100uH

L701 1-410-521-11 INDUCTOR 100uH

L901 1-420-872-00 COIL, AIR-CORE (AEP,UK,G,IT,EE)

L951 1-420-872-00 COIL, AIR-CORE (AEP,UK,G,IT,EE)

< TRANSISTOR >

Q413 8-729-900-65 TRANSISTOR DTA144ES

Q414 8-729-900-65 TRANSISTOR DTA144ES

Q451 8-729-620-05 TRANSISTOR 2SC2603-EF

Q701 8-729-900-80 TRANSISTOR DTC114ES

Q702 8-729-900-80 TRANSISTOR DTC114ES

Q703 8-729-620-05 TRANSISTOR 2SC2603-EF

Q704 8-729-620-05 TRANSISTOR 2SC2603-EF

Q705 8-729-422-57 TRANSISTOR UN4111 (H11)

Q705 8-729-900-61 TRANSISTOR DTA114ES (H11J)

Q971 8-729-900-63 TRANSISTOR DTA124ES

Q972 8-729-900-89 TRANSISTOR DTC144ES

Q1001 8-729-202-67 TRANSISTOR 2SK246-GR3

Q1051 8-729-202-67 TRANSISTOR 2SK246-GR3

< RESISTOR >

R101 1-216-085-00 METAL CHIP 33K 5% 1/10W

R103 1-249-417-11 CARBON 1K 5% 1/4W

R104 1-216-097-00 METAL CHIP 100K 5% 1/10W

R107 1-249-411-11 CARBON 330 5% 1/4W

R108 1-249-413-11 CARBON 470 5% 1/4W

R121 1-249-417-11 CARBON 1K 5% 1/4W

R122 1-249-417-11 CARBON 1K 5% 1/4W

R123 1-249-417-11 CARBON 1K 5% 1/4W