Sony HCDGX-450 Service manual

HCD-GX450

SERVICE MANUAL

Ver. 1.2 2005.08

• HCD-GX450 is the tuner, deck, CD and

amplifier section in MHC-GX450.

CD

Section

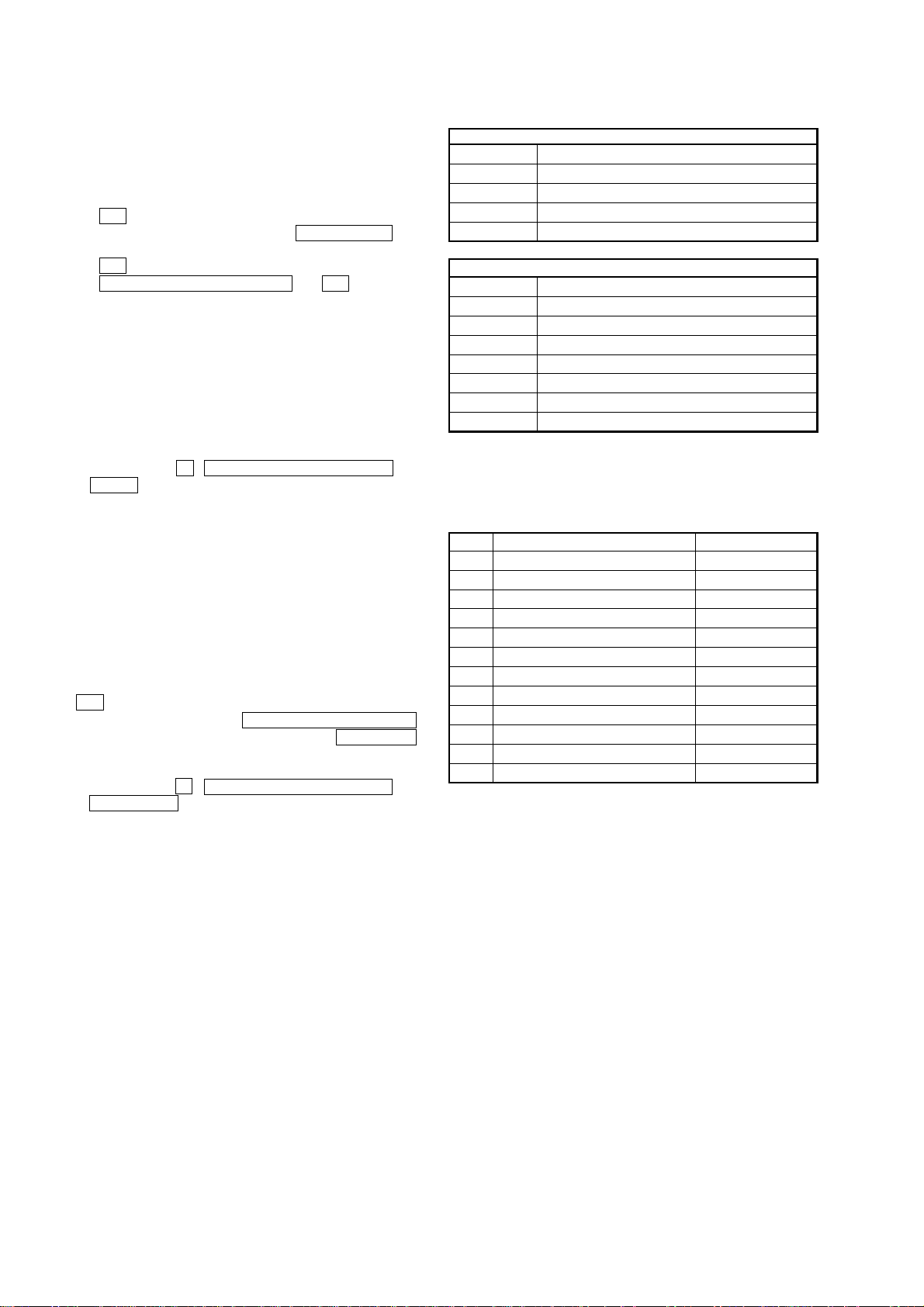

Tape deck Model Name Using Similar Mechanism New New

Section T ape Transport Mechanism T ype CWM43FF-05 CWM43FF-05

Model Name Using Similar Mechanism New New

CD Mechanism Type CDM74-F1BD81

Optical Pick-up Name

US Model

Canadian Model

Former Type Models

KSM-215DCP/C2NP KSM-213DCP/C2NP

New Type Models

CDM74KF-K6BD81C

Amplifier section

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

With 6 ohm loads, both channels driven, from

120 – 10,000 Hz: rat ed 125 watts per ch annel

minimum RMS power, with no more than 10%

total harmonic distortion from 250 milliwatts to

rated output.

Front speaker

Continuous RMS power output (reference):

125 + 125 watts (6 ohms at

1 kHz, 10% THD)

Total harmonic distortion less than 0.07% (6 ohms at

1kHz, 60 W)

Sub woofer

Continuous RMS power output (reference):

150 watts (6 ohms at

50 Hz, 10% THD)

Total harmonic distortion less than 0.07% (6 ohms at

50 Hz, 75 W)

CD player section

System Compact disc and dig ital

audio system

SPECIFICATIONS

Laser Semiconductor laser

(λ=780 nm)

Emission duration:

continuous

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Wavelength 780 – 790 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

Tape deck section

Recording system 4-track 2-channel, stereo

Frequency response 50 – 13,000 Hz (±3 dB),

using Sony TYPE I

cassettes

Tuner section

FM stereo, FM/AM super he te rodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

(100-kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 530 – 1,710 kHz

(with the tuning interv al

set at 10 kHz)

531 – 1,710 kHz

(with the tuning interv al

set at 9 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements 120 V AC, 60 Hz

Power consumption

USA models: 265 watts

Canadian models: 330 VA

Dimensions (w/h/d) incl. projecting parts and controls

Amplifier/Tuner/Tape/CD section:

Approx. 280 × 327 ×

425 mm

Mass Approx. 10.0 kg

Design and specifications are subject to change

without notice.

9-877-534-03

2005H16-1

© 2005.08

MINI HI-FI COMPONENT SYSTEM

Sony Corporation

Personal Audio Group

Published by Sony Engineering Corporation

HCD-GX450

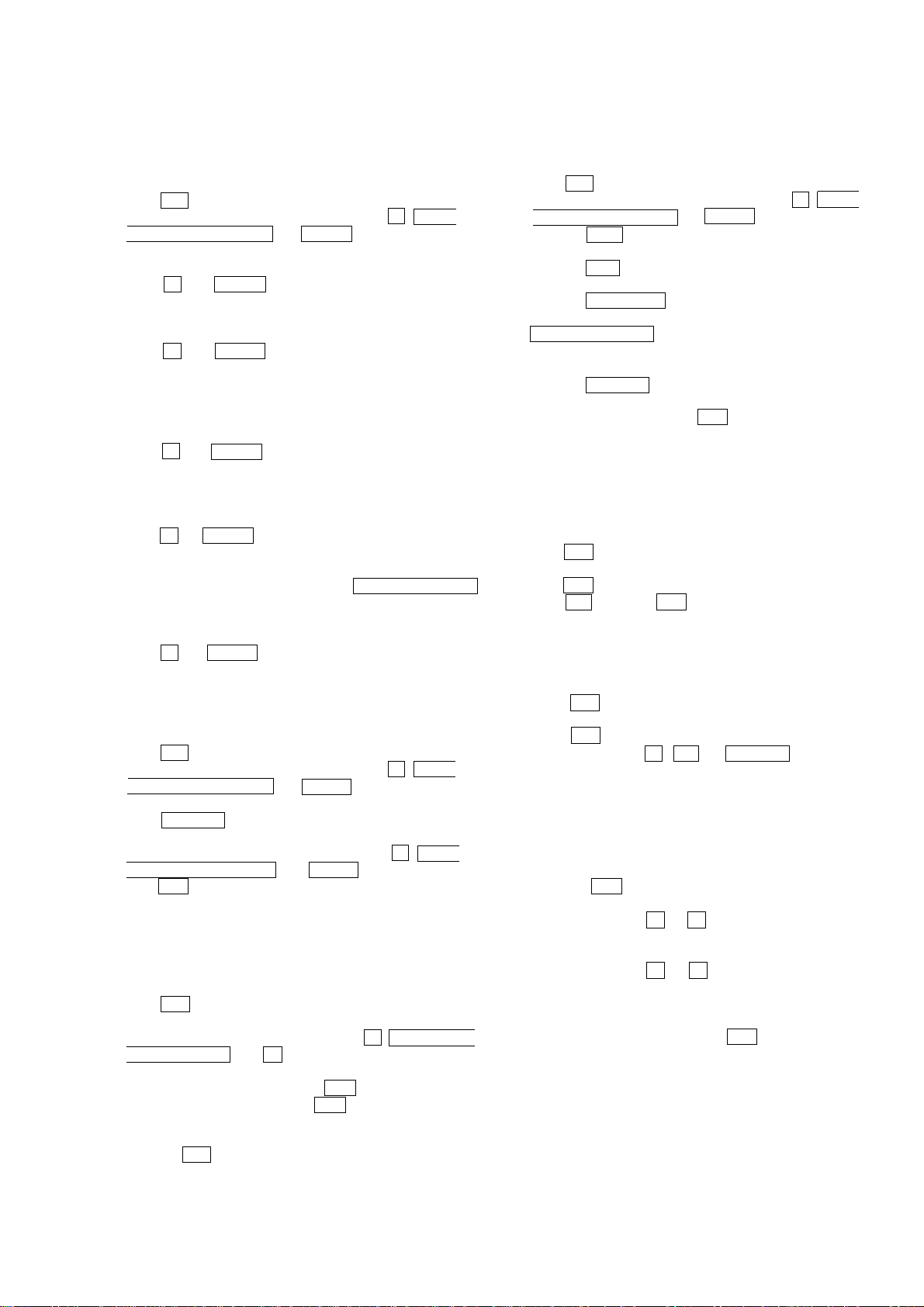

SAFETY CHECK-OUT

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having

a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 kΩ

Earth Ground

Voltmeter

(0.75 V)

The release method of a CD disc tray LOCK function

There is a disc lock function for the disc theft prevention for a

demonstration at a shop front in this machine.

Procedue:

1. Press the ?/1 button to turn the set on.

2. Press two buttons of x and Z (EJECT) simultaneously for

five seconds.

3. The message “LOCKED” is displayed and the tray is locked.

(Even if exiting from this mode, the tray is still locked.)

4. Press two buttons of x and Z (EJECT) simultaneously for

five seconds again.

5. The message “UNLOCKED” is displayed and the tray is

unlocked.

6. To exit from this mode, press the ?/1 button to turn the set

off.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Fig. A. Using an A C v oltmeter to check A C leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

2

HCD-GX450

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

TABLE OF CONTENTS

1. SERVICING NOTE·························································· 4

2. GENERAL ·········································································· 6

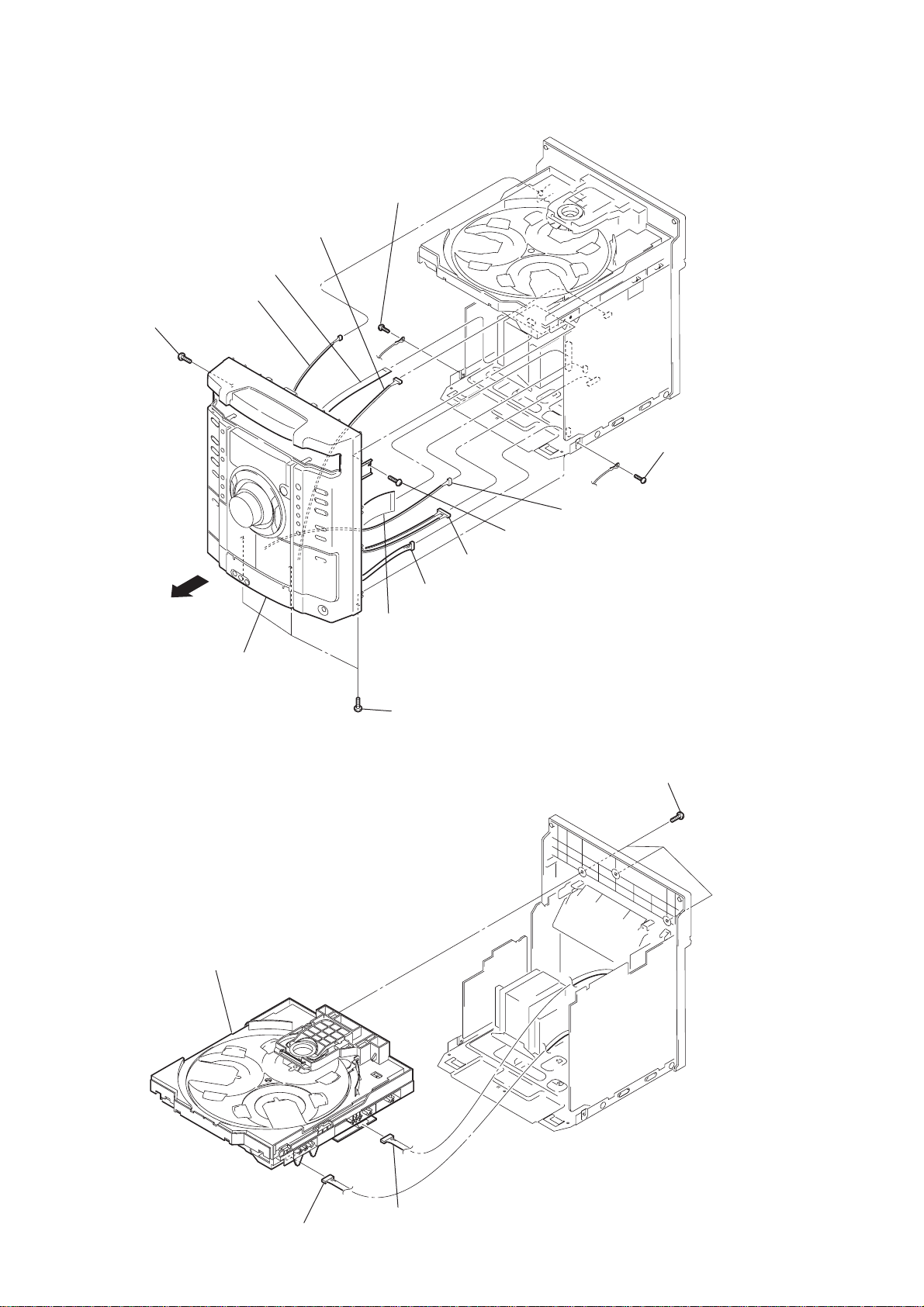

3. DISASSEMBLY

3-1. Cover (Top) ····································································· 9

3-2. CD Door·········································································· 9

3-3. Front Panel Section ······················································· 10

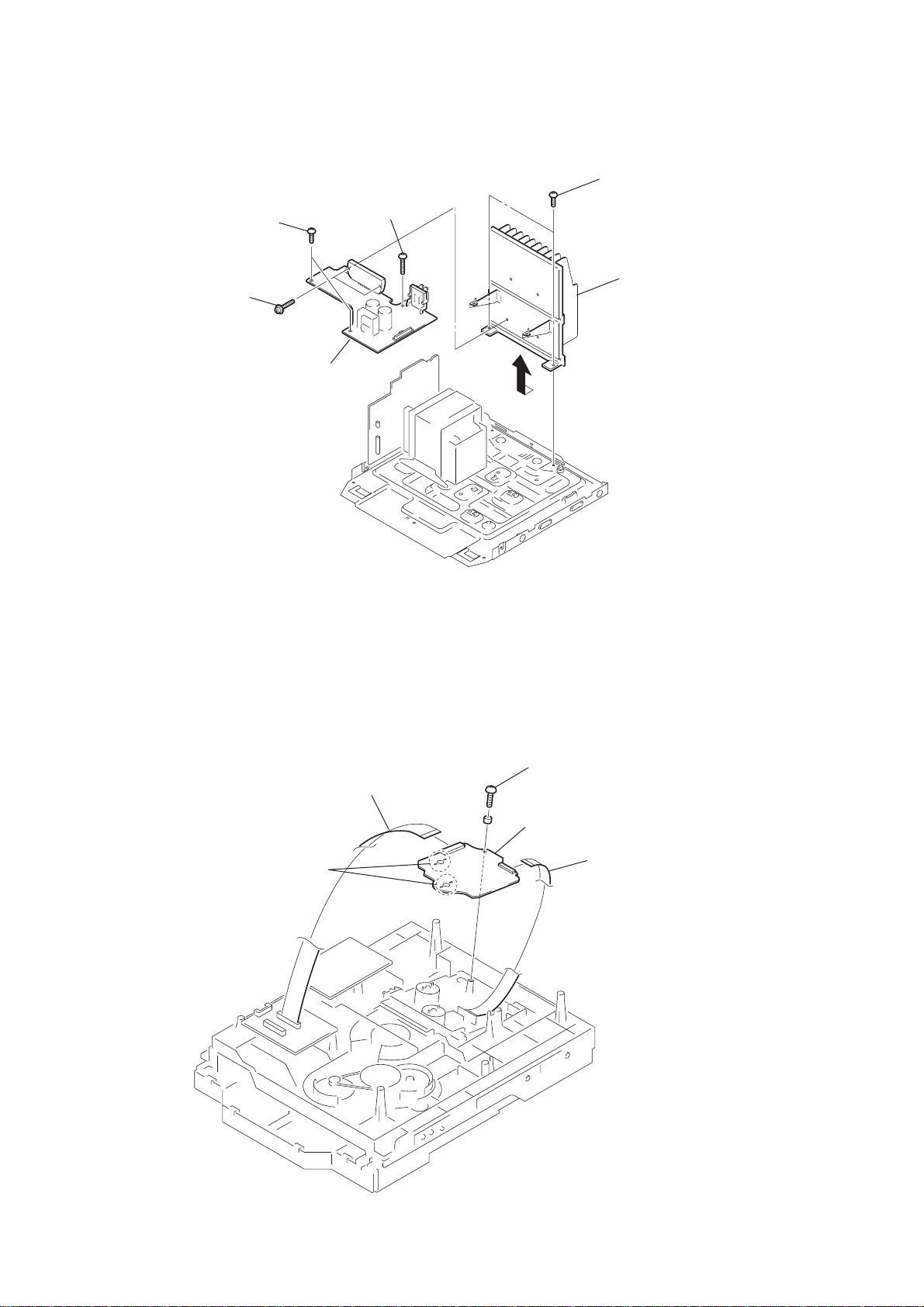

3-4. CD Mechanism Deck (CDM74-F1BD81) ···················· 10

3-5. Tape Mechanism Deck, Game Jack Board ··················· 11

3-6. PANEL Board ······························································· 11

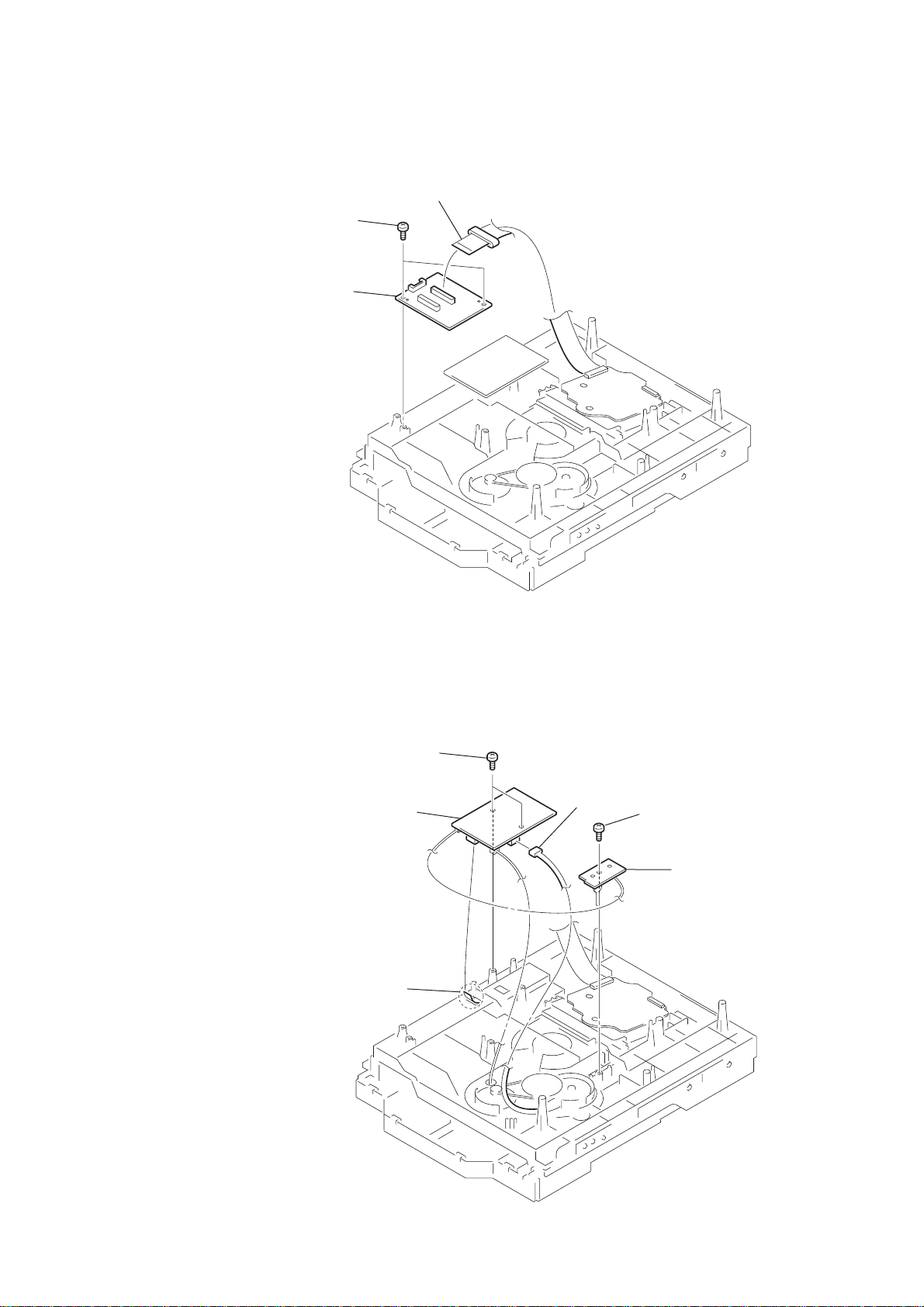

3-7. Back Panel Section, SUB-TRANS Board ···················· 12

3-8. Power Transformer······················································· 12

3-9. MAIN Board ································································· 13

3-10. SUB-WOOFER Board················································ 13

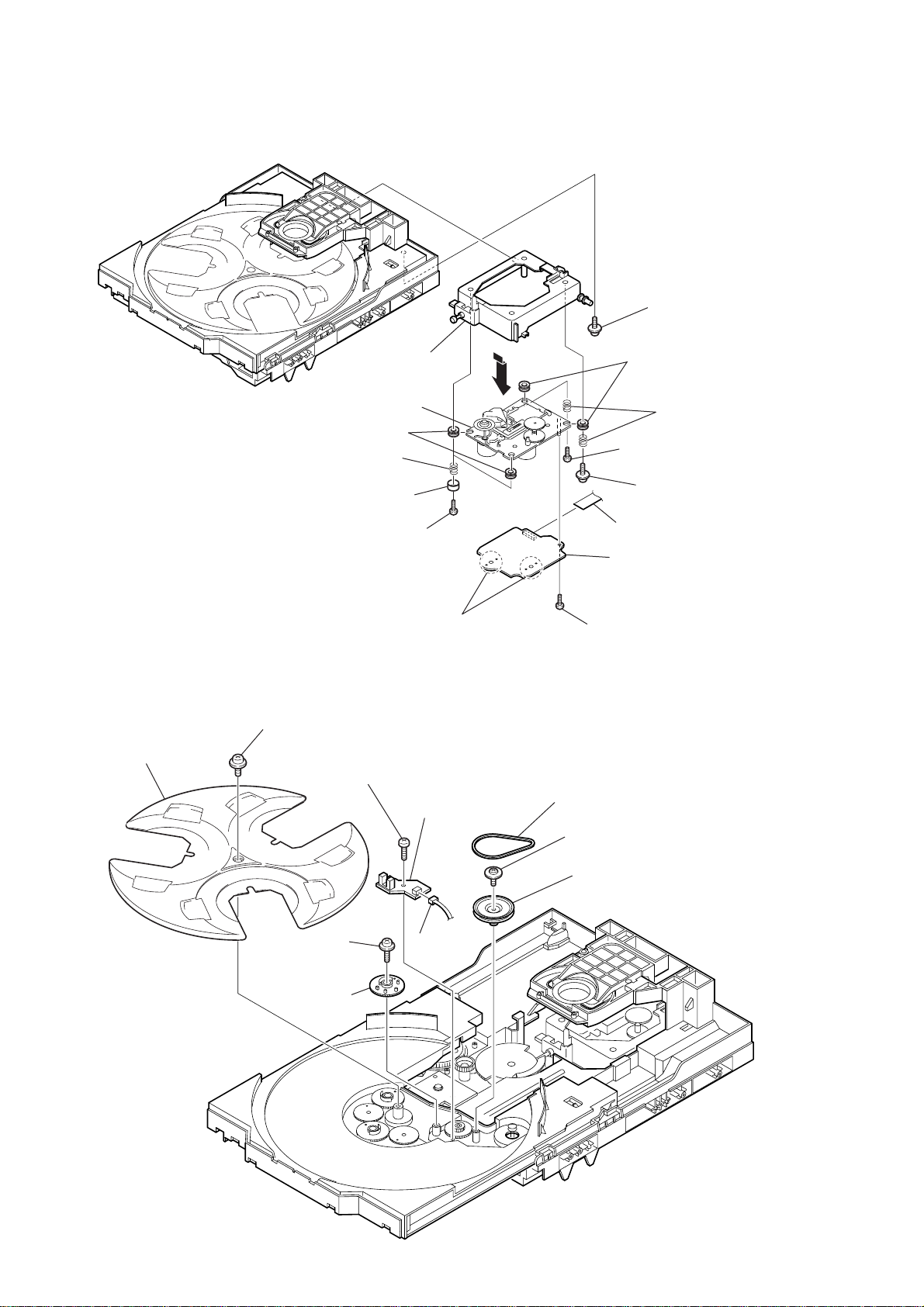

3-11. AMP Board ································································· 14

3-12. BD81A Board ····························································· 14

3-13. CONNECT Board·······················································15

3-14. DRIVER Board, SW Board ········································ 15

3-15. Optical Pick-up (KSM-215DCP/C2NP) ····················· 16

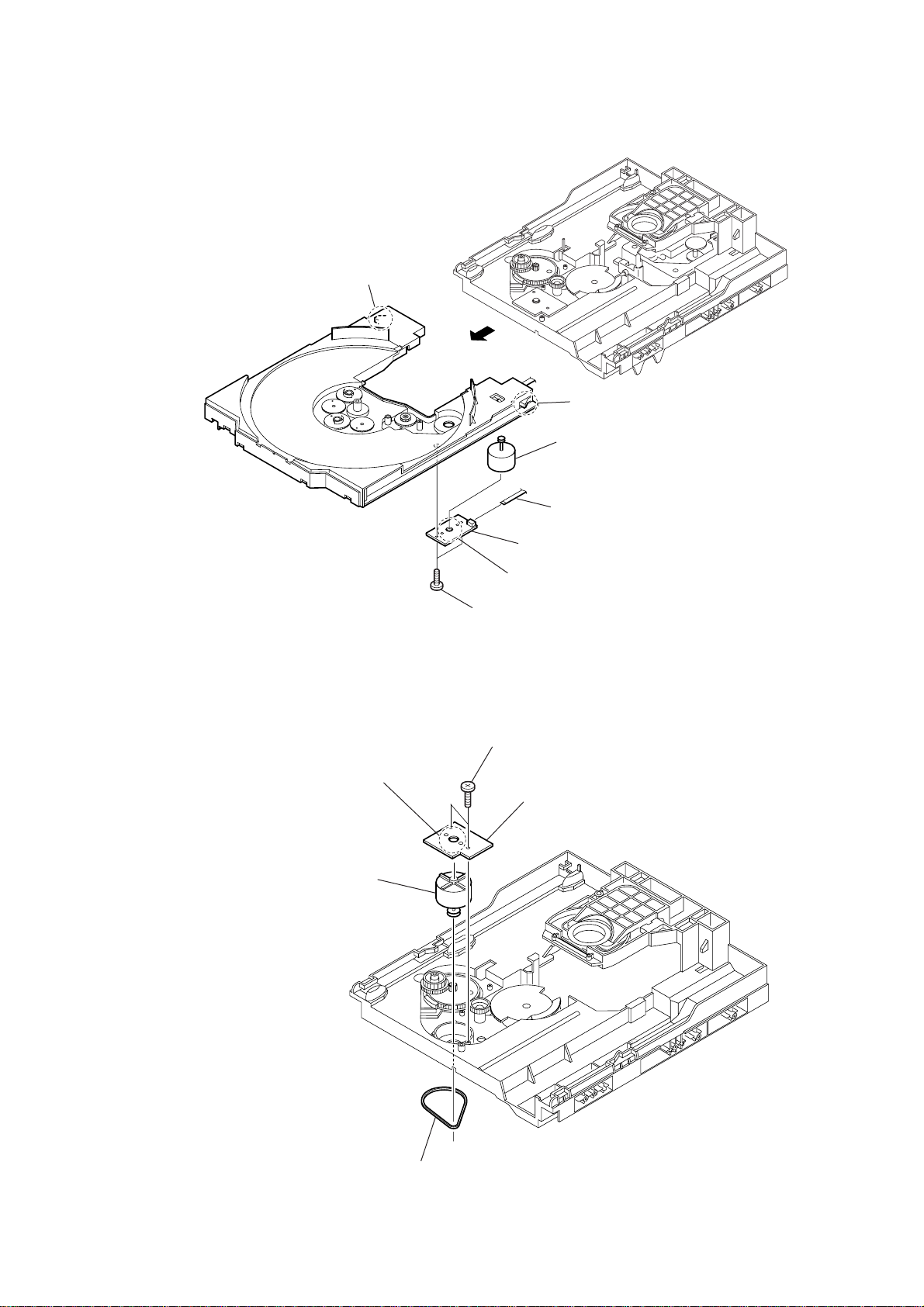

3-16. SENSOR Board ·························································· 16

3-17. MOTOR (TB) Board··················································· 17

3-18. MOTOR (LD) Board ·················································· 17

4. TEST MODE ···································································· 18

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

5. DIAGRAMS

5-1. Block Diagrams – PANEL Section – ···························· 22

– MAIN Section – ······················································· 23

– BD/DRIVER Section – ············································ 24

– SUB-WOOFER Section – ········································ 25

5-2. Printed Wiring Board – BD81A Section –··················· 26

5-3. Schematic Diagram – BD81A Section – ····················· 27

5-4. Printed Wiring Board

– CD MECHANISM Section – ··································· 28

5-5. Schematic Diagram – CD MECHANISM Section –···29

5-6. Printed Wiring Board – MAIN Section – ···················· 30

5-7. Schematic Diagram – MAIN Section (1/2) – ·············· 31

5-8. Schematic Diagram – MAIN Section (2/2) – ·············· 32

5-9. Printed Wiring Board – PANEL COMB Section – ······ 33

5-10. Schematic Diagram – PANEL COMB Section – ······ 34

5-11. Printed Wiring Board – SUB-WOOFER Section – ··· 35

5-12. Schematic Diagram

– SUB-WOOFER Section – ········································ 36

5-13. Printed Wiring Board – PANEL Section –················· 37

5-14. Schematic Diagram – PANEL Section (1/2) – ·········· 38

5-15. Schematic Diagram – PANEL Section (2/2) – ·········· 39

5-16. Printed Wiring Board – TRANS Section – ················ 40

5-17. Printed Wiring Board – AMP Section – ····················· 41

5-18. Schematic Diagram – AMP POWER Section – ········ 42

5-19. IC Pin Function Description ······································· 46

6. EXPLODED VIEWS

6-1. MAIN Section·······························································51

6-2. Front Panel Section ······················································· 52

6-3. MAIN Board Section ···················································· 53

6-4. CD Mechanism Deck Section -1 (CDM74-F1BD81)··· 54

6-5. CD Mechanism Deck Section -2 (CDM74-F1BD81)··· 55

7. ELECTRICAL PARTS LIST ······································· 56

3

HCD-GX450

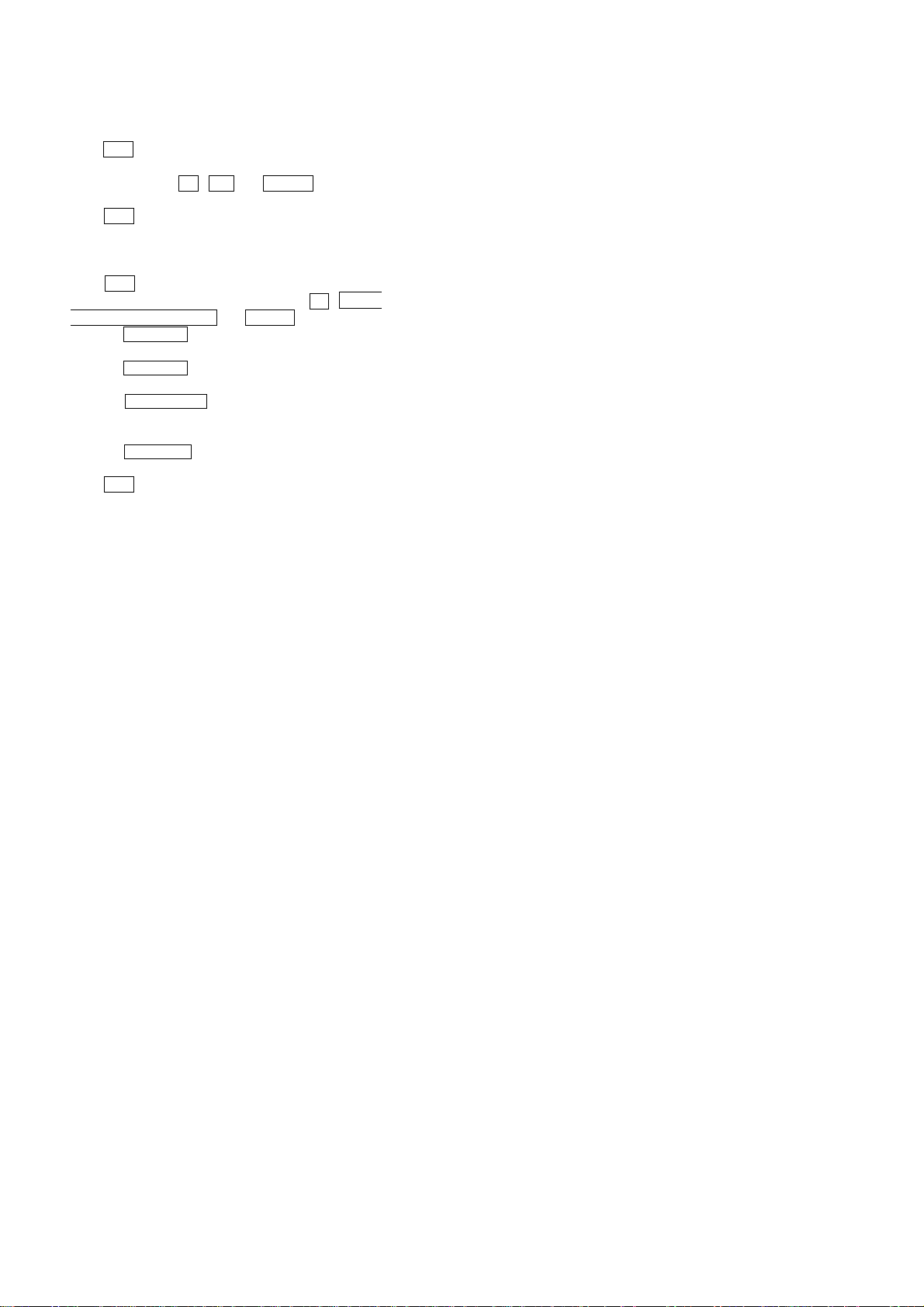

d

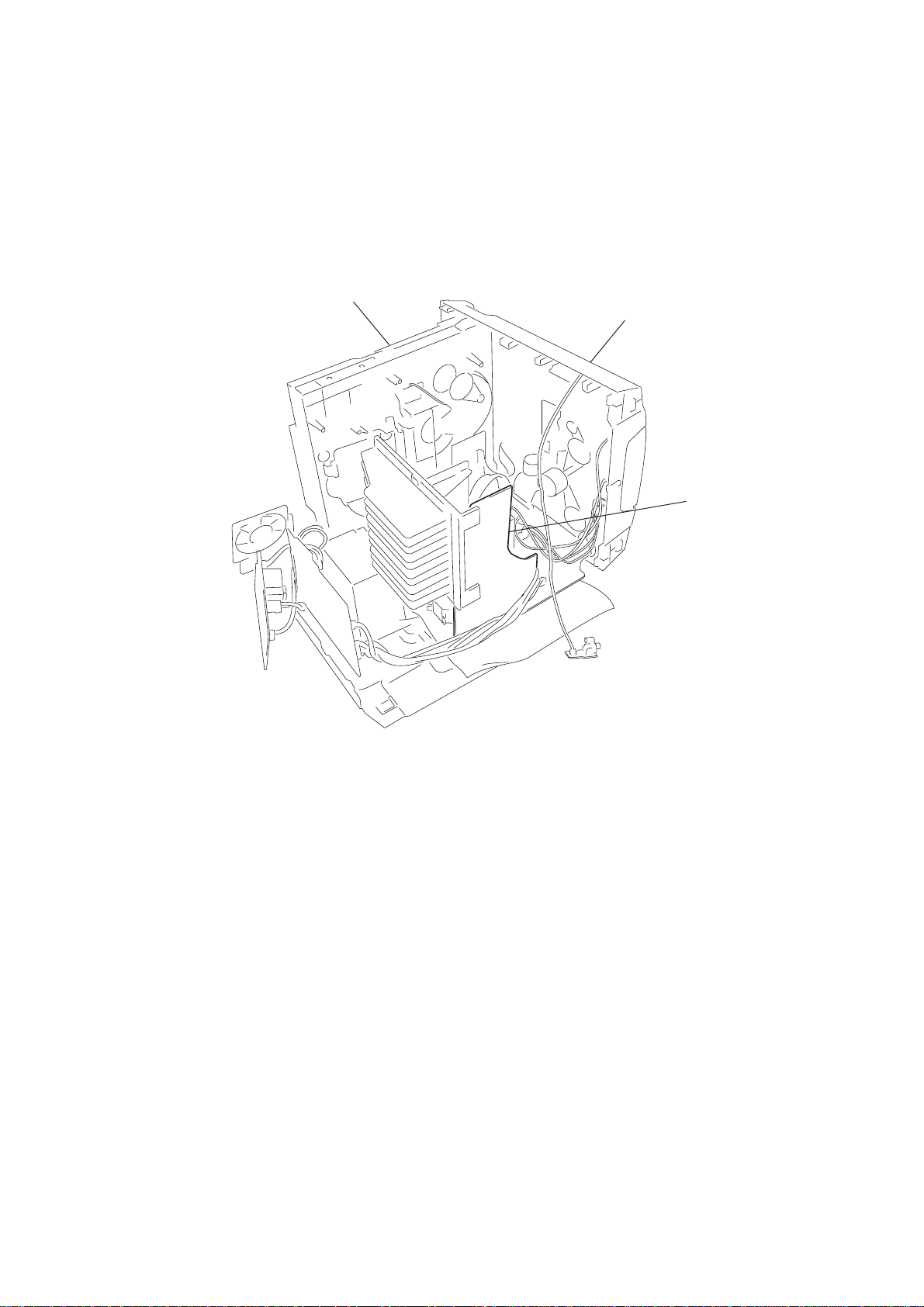

• SERVICE POSITION -1 (AMP BOARD)

To inspect the AMP board, turn both of the front panel

and the CD mechanism deck so that the left side of the product faces down.

CD mechanism deck

SECTION 1

SERVICING NOTE

front panel

AMP boar

4

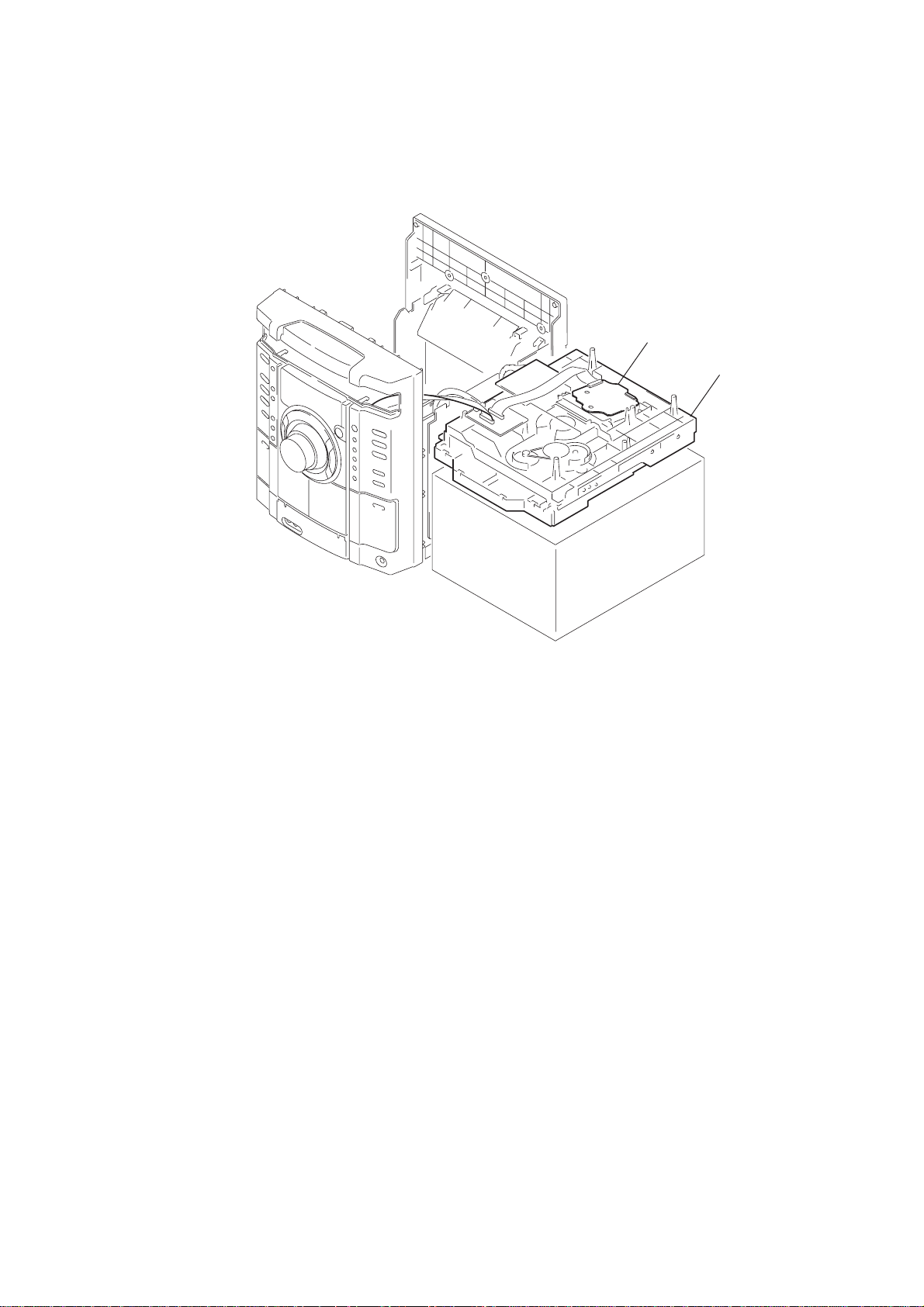

• SERVICE POSITION -2 (BD81A BOARD)

k

Remove the CD mechanism deck and place it on top of the pedestal as shown.

Inspect the BD81A bard in this set up.

HCD-GX450

BD81A board

CD mechanism dec

5

HCD-GX450

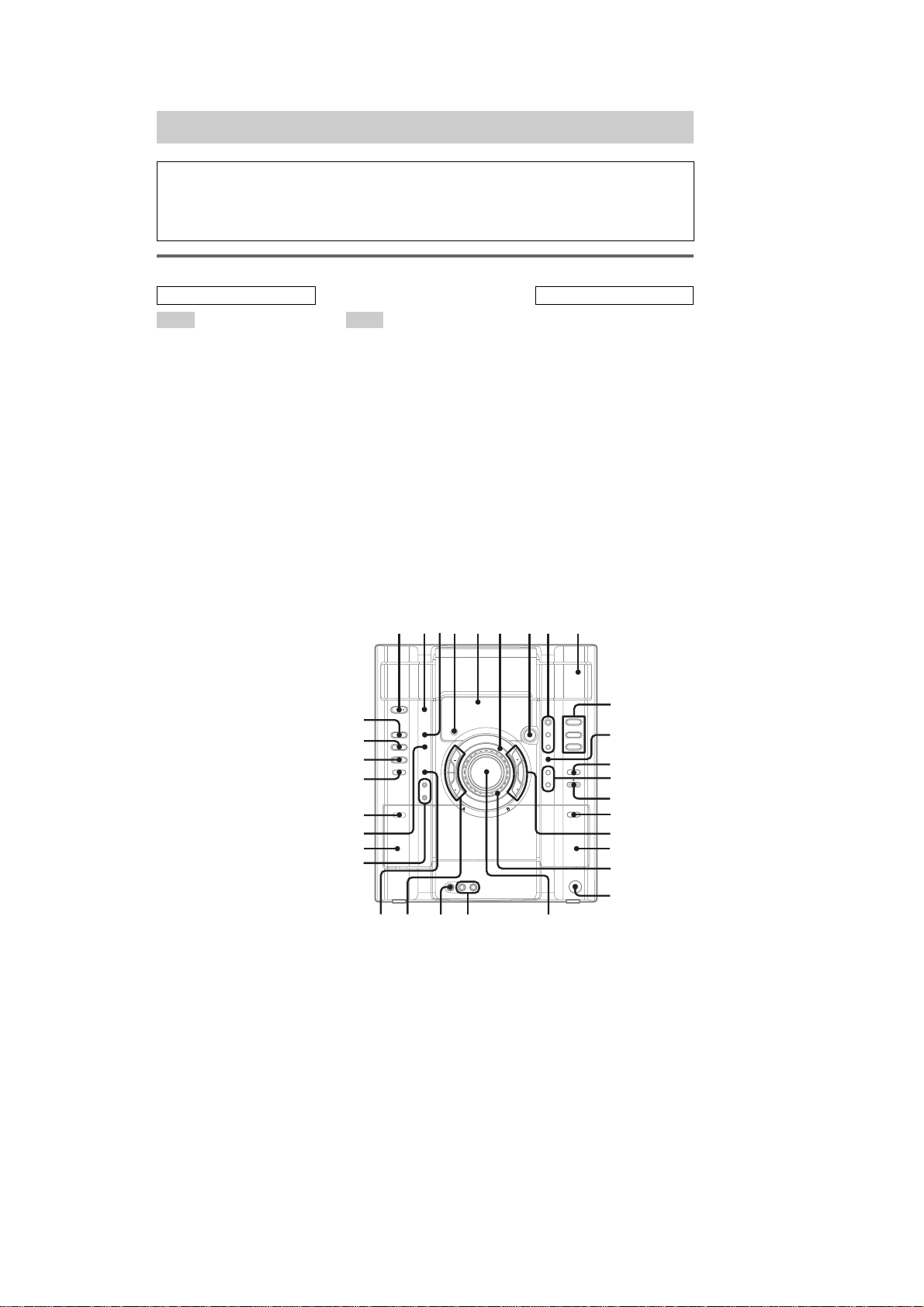

Illustrati

SECTION 2

GENERAL

List of button locations and reference pages

How to use this page

Use this page to find the loca tio n of buttons and other

parts of the system that are mentioned in the text.

Main unit

ALPHABETICAL ORDER

A – O P – Z

ALBUM +

ALBUM –

CD eg (9, 11, 14, 19, 20)

CD SYNC wj (19)

Deck A wk (18)

Deck B qj (18, 19, 20, 24)

DISC 1 – 3 q; (12, 14, 35)

DISC SKIP/EX-CHANGE qs

Disc tray 9 (11)

DISPLAY 2 (17, 27, 28)

Display window 5

EFFECT ON/OFF 8 (22)

ENTER qa (14, 15 , 22)

EQ BAND 7 (22)

GAME es (20, 23, 30)

GAME INPUT AUDIO L/R jacks

GAME INPUT VIDEO jack wf

GAME MIXING wh (23)

GROOVE 8 (21)

ILLUMINATION

Operation Dial

qh (12, 14, 19)

wg (12, 14, 19)

(11, 12, 14, 19)

wd (20, 29)

(29)

3 (28)

(– EQ +/l L) 6 (12,

14, 19, 22)

P FILE qd (22)

PHONES jack ql

PLAY MODE wl (12, 14, 18, 19,

20, 35)

Power illuminator qk (28)

PRESET EQ qd (22)

REC PAUSE/START wj (19, 20,

23, 24)

Remote sensor 4

SURROUND 8 (23)

TAPE A/B ed (18, 19, 20, 24)

TUNER/BAND ef (15, 16, 20)

TUNING MODE wl (15, 16, 35)

TUNING + qh (15, 16)

TUNING – wg (15, 16)

VOLUME control w; (21)

12345 6 78 9

eg

ef

ed

es

e;

wl

wk

wj

on number

r

TAPE A/B ed (18, 19, 20, 24)

Name of button/pa rt Reference page

RR

BUTTON DESCRIPTIONS

?/1 (power) 1 (8, 16, 27, 30, 33,

35)

X (pause) wg (12, 19)

Z (eject) qf (11)

PUSH Z (deck B) (eject) qg (18)

x (stop) wg (12, 19, 24, 35)

M (fast forward) qh (12, 19)

H (play) qh (12, 18, 19)

m (rewind) wg (12, 19)

Z PUSH (deck A) (eject) e; (18)

q;

qa

j

ALBUM

S

s

TUNING TUNING

J

ALBUM

H

h

qs

qd

qf

qg

qh

qj

qk

ql

6

wh

wfwg

wd

w;

HCD-GX450

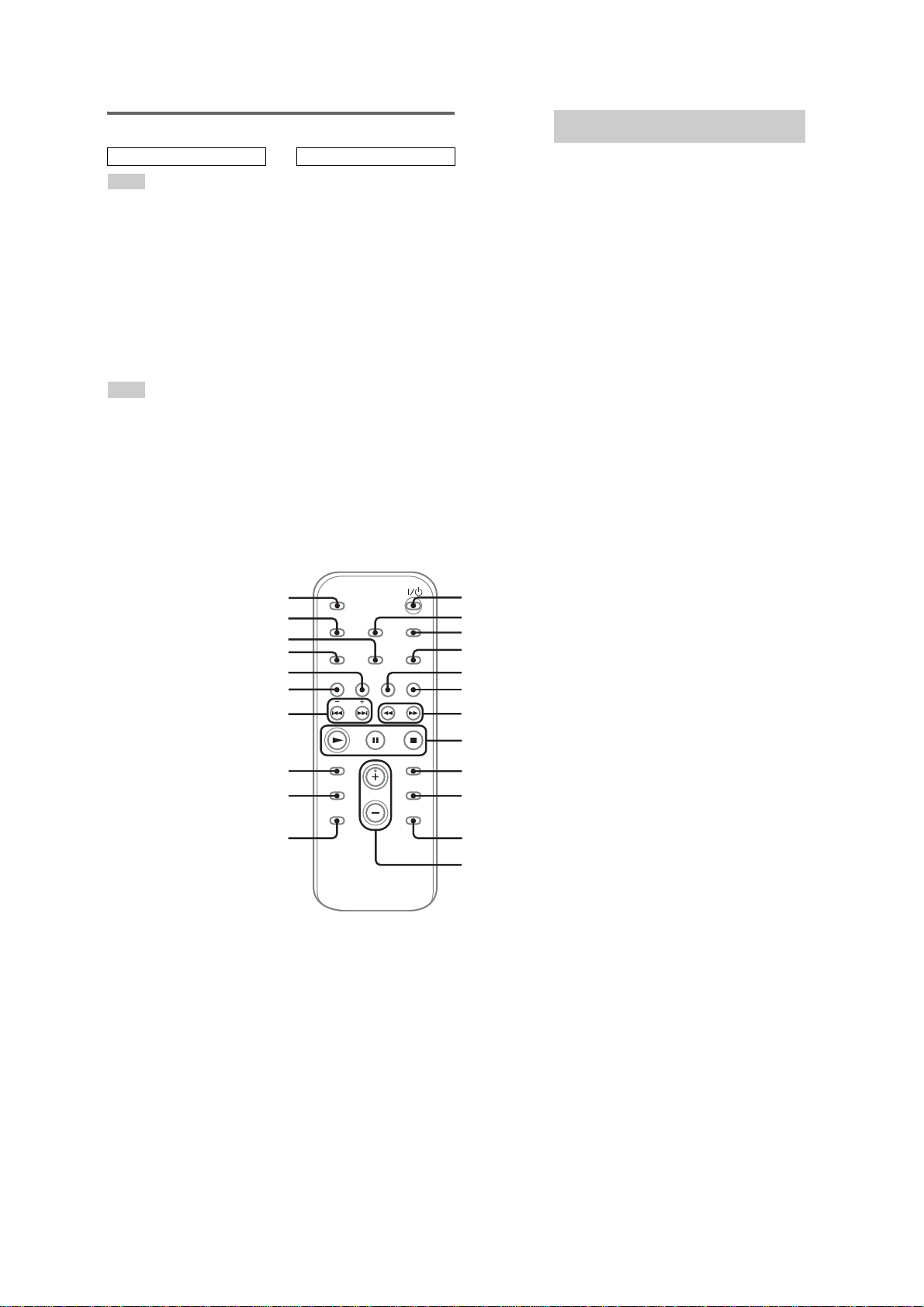

Remote control

ALPHABETICAL ORDER

A – E

ALBUM – qd (12, 14)

ALBUM + qa (12, 14)

CD qk (11, 14)

CLEAR qg (14)

CLOCK/TIMER SELECT 2

(26, 27)

CLOCK/TIMER SET 3 (10, 25,

26)

DISC SKIP q; (12, 14)

DISPLAY wa (17, 27, 28)

ENTER 9 (10, 14, 15, 25, 26)

EQ qf (22)

F – Z

FM MODE 4 (17)

FUNCTION 6 (11, 14, 15, 16)

PLAY MODE w; (12, 14, 18)

REPEAT 4 (13)

SLEEP ws (25)

TAPE qj

TUNER BAND 5 (15, 16)

TUNER MEMORY ql (15)

TUNING MODE w; (15, 16)

VOLUME +/– qs (21, 25)

BUTTON DESCRIPTIONS

?/1 (power) 1 (8, 26)

m/M (rewind/fast forward)

7 (12, 19)

–/+ (tuning) qh (15)

./> (go back/go forward)

qh (10, 12, 19)

N (play) 8 (12, 18)

X (pause) 8 (12, 19)

x (stop) 8 (12, 19)

Setting the clock

Use buttons on the remote for the operation.

1

Press ?/1 to turn on the system.

2

Press CLOCK/TIMER SET.

3

Press . or > repeatedly to set the

hour.

4

Press ENTER.

5

Press . or > repeatedly to set the

minute.

6

Press ENTER.

The clock starts working.

To adjust the clock

1

Press CLOCK/TIMER SE T.

2

Press . or > repeatedly to select

“CLOCK SET”, then press ENTER.

3

Do the same procedures as step 3 to 6

above.

Notes

The clock settings are canceled when you disconnect

the power cord or if a power failure occurs.

ws

wa

w;

ql

qk

qj

qh

qg

qf

qd

1

2

3

4

5

6

7

8

9

q;

qa

qs

7

HCD-GX450

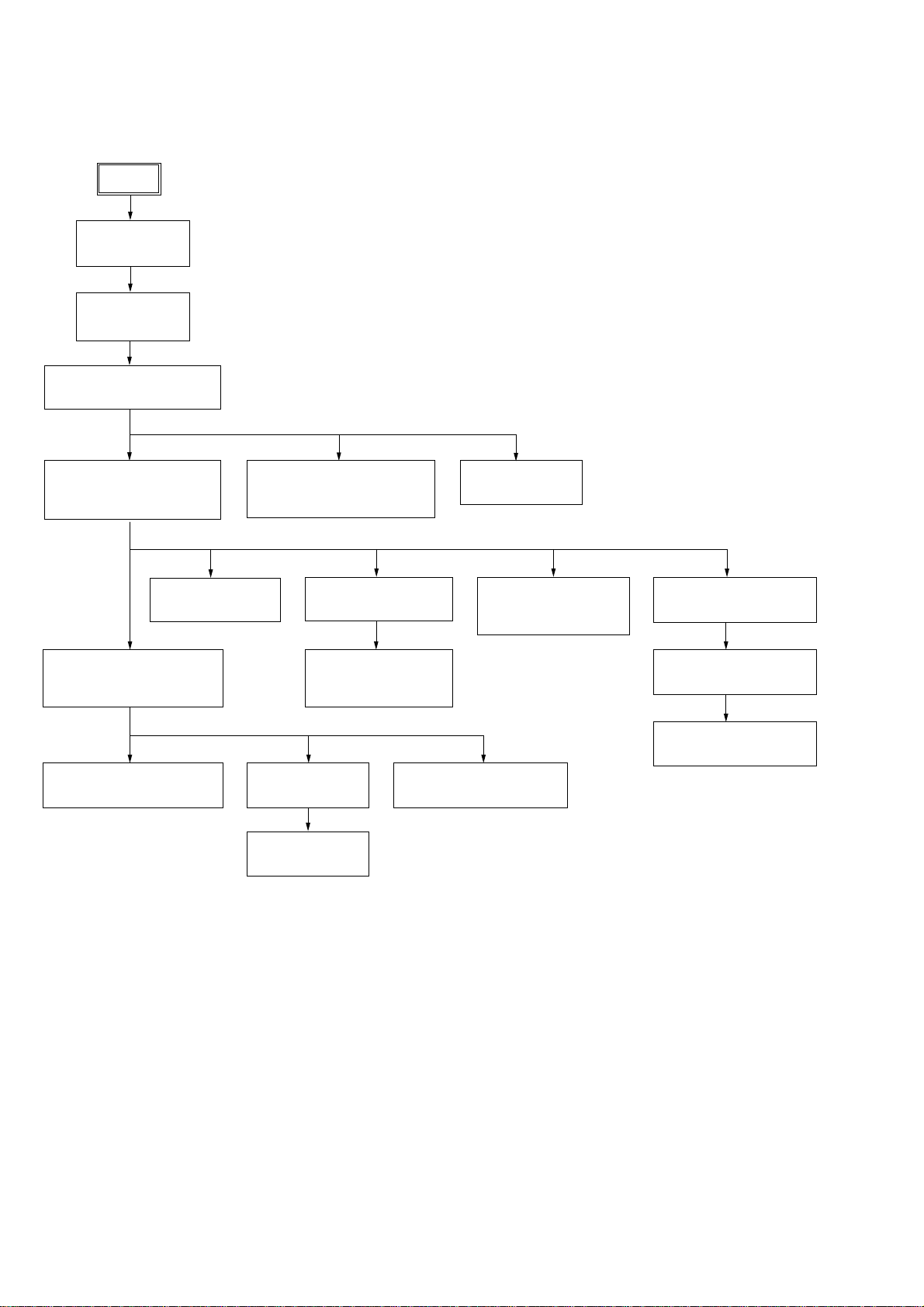

Note: Disassemble the unit in the order as shown below.

SET

3-1.COVER (TOP)

(Page 9)

3-2.CD DOOR

(Page 9)

SECTION 3

DISASSEMBLY

3-3.FRONT PANEL SECTION

(Page 10)

3-4.CD MECHANISM DECK

(CDM74-F1BD81)

(Page 10)

3-12.BD81A BOARD

(Page 14)

3-7.BACK PANEL SECTION,

SUB-TRANS BOARD

(Page 12)

3-8.POWER TRANSFORMER

(Page 12)

3-5.TAPE MECHANISM DECK,

GAME JACK BOARD

(Page 11)

3-13.CONNECT BOARD

(Page 15)

3-14.DRIVER BOARD,

SW BOARD

(Page 15)

3-9.MAIN BOARD

(Page 13)

3-10.SUB-WOOFER BOARD

3-6.PANEL BOARD

(Page 11)

3-15.OPTICAL PICK-UP

(KSM-215DCP/C2NP)

(Page 16)

(Page 13)

3-16.SENSOR BOARD

(Page 16)

3-17.MOTOR (TB) BOARD

(Page 17)

3-18.MOTOR (LD) BOARD

(Page 17)

3-11.AMP BOARD

(Page 14)

8

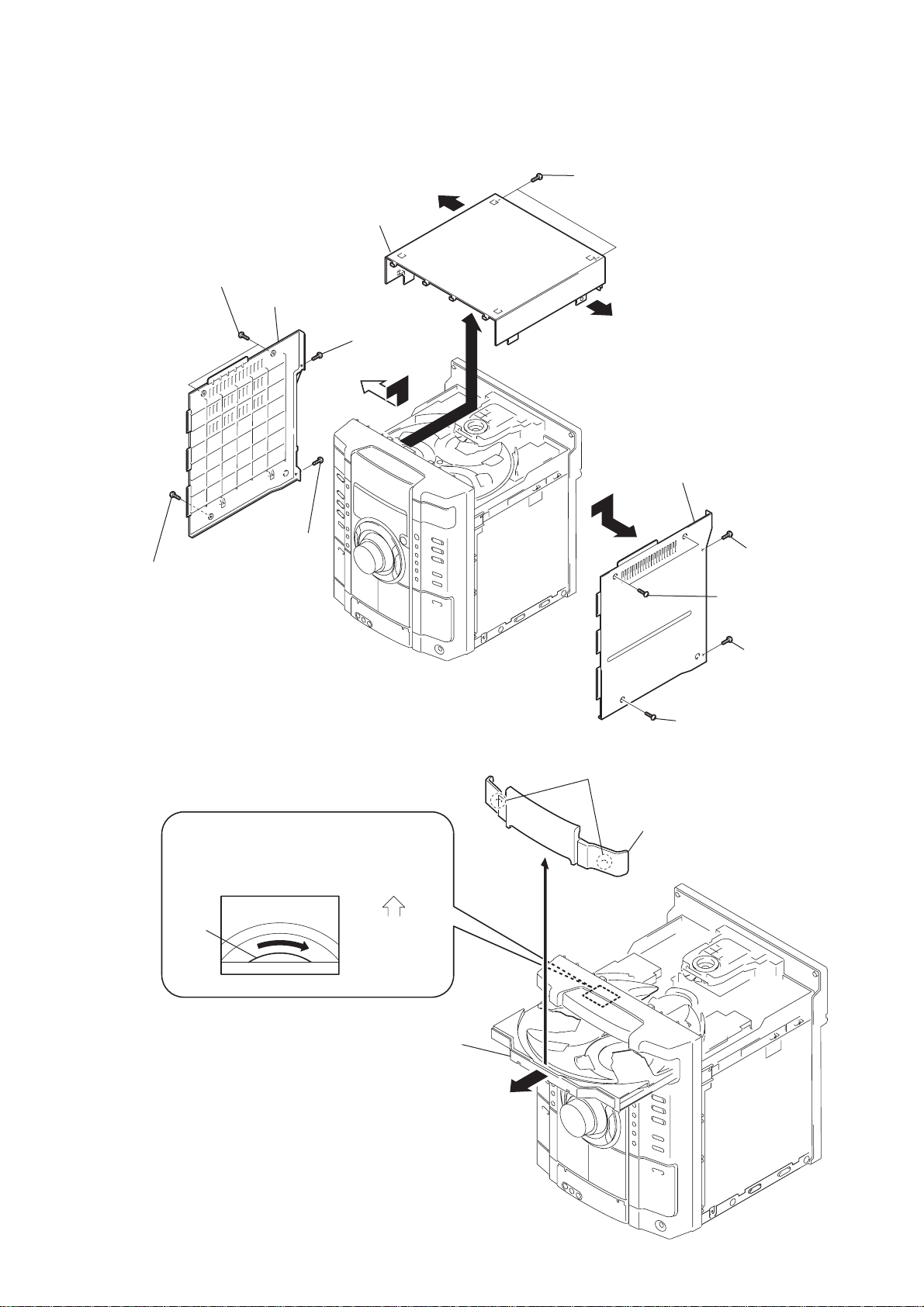

Note: Follow the disassembly procedure in the numerical order given.

3-1. COVER (TOP)

qs

qf

cover

(top)

6

two screws (Case 3 TP2)

cover

(Side-L)

qa

two

screws (+BVTP 3

×

HCD-GX450

10)

7

screw (case 3 TP2)

3-2. CD DOOR

9

screw

(+BVTP 3

× 10

)

8

screw

(+BVTP 3

q;

× 10

qs

)

qd

cover

(Side-R)

5

3

3

two claws

(+BVTP 3

1

two screws

(case 3 TP2)

4

(+BVTP 3

2

screw (Case 3 TP2)

screw

screw

× 10

× 10

)

)

CD mechanism deck (CDM74)

1

Turn the pulley to the direction of arrow.

Front panel side

pulley

2

Pull-out the disc tray.

4

CD door

9

HCD-GX450

)

3-3. FRONT PANEL SECTION

0

connector 3p (CN304C)

8

wire (flat type) 17 core (CN253)

6

connector 2p (CN805)

3

screw (+BVTP 3

×

10)

4

screw (+BVTP 3

× 8

)

5

screw (+BVTP 3

× 8

)

qd

front panel section

3-4. CD MECHANISM DECK (CDM74-F1BD81)

2

screw (+BVTP 3

qs

connector 8p (CN103)

9

connector 5p (CN309)

7

wire (flat type) 29 core (CN302)

1

three screws (+BVTP 3

qa

connector 3p (CN102B)

× 8

)

1

three

×

10)

screws (+BVTP 3

×

10

10

4

CD mechanism deck (CDM74-F1BD81)

3

connector 9p (CN254)

2

connector 12p (CN701)

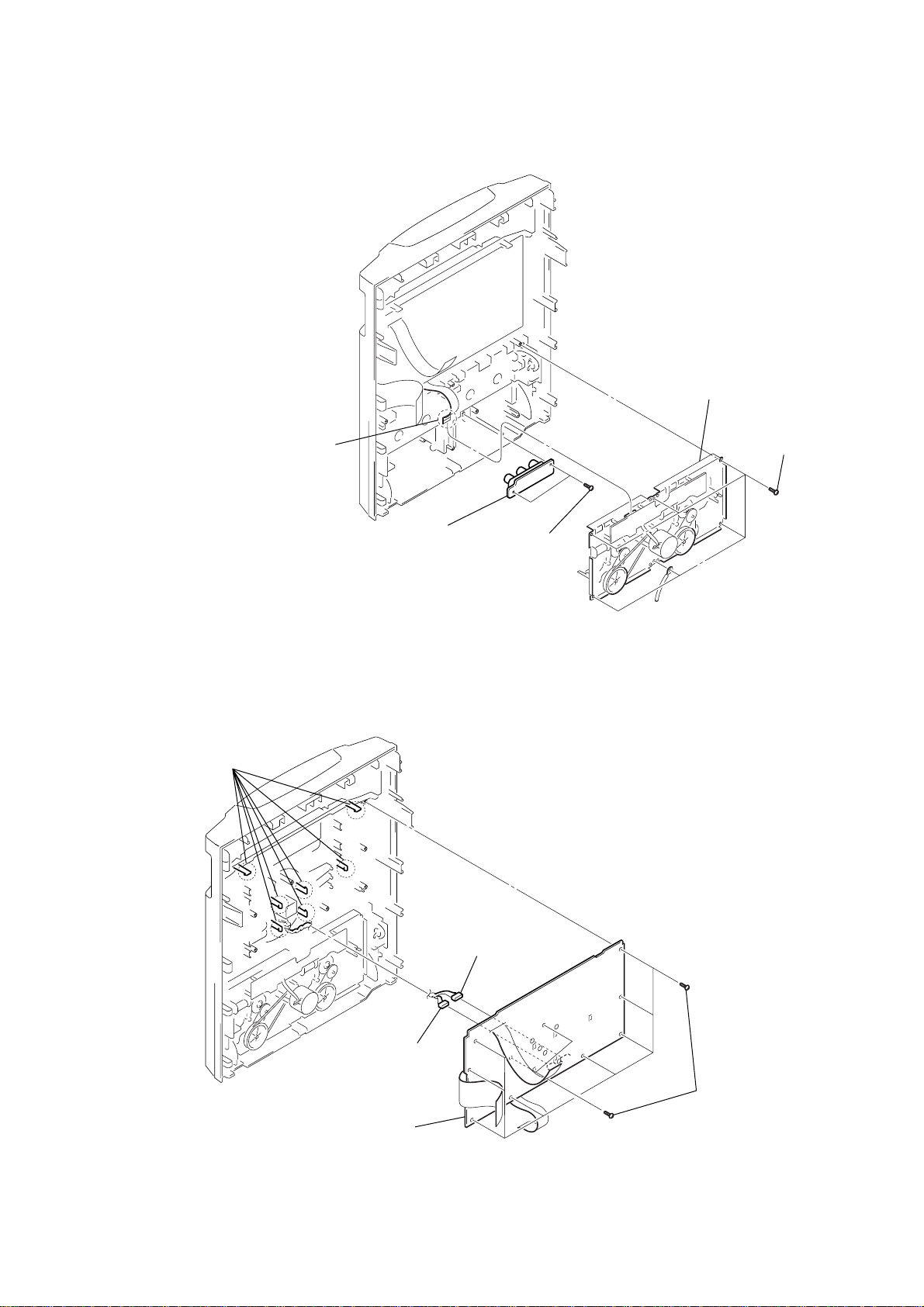

3-5. TAPE MECHANISM DECK, GAME JACK BOARD

)

)

1

wire (flat type) 13 core (CN602)

3

tape mechanism deck

HCD-GX450

2

six

screws

(+BVTP 2.6

×

8

3-6. PANEL BOARD

2

seven

claws

5

GAME JACK board

4

two

(+BVTP 2.6

3

connector 6p (CN604)

screws

×

8)

4

connector 5p (CN605)

5

PANEL board

1

ten

screws

×

(+BVTP 2.6

8

11

HCD-GX450

)

r

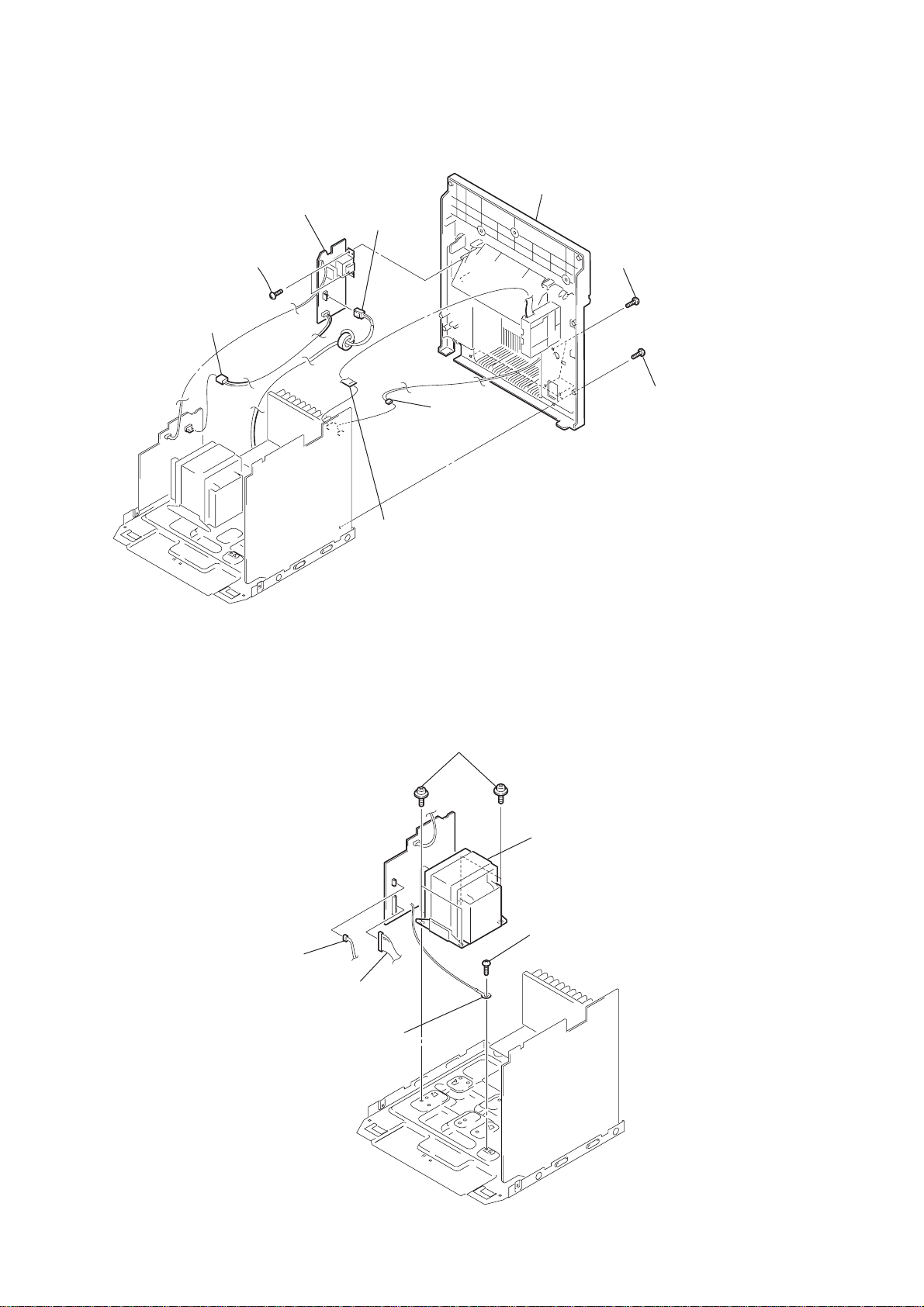

3-7. BACK PANEL SECTION, SUB-TRANS BOARD

7

8

SUB-TRANS board

6

(+BVTT 3

1

connector

2p (CN904)

two

screws

× 10

)

connector

2p (CN901)

3

connector

3p (CN308)

9

back panel section

5

(+BVTT 3

three

screws

×

10)

4

two

screws

(+BVTP 3

×

10

3-8. POWER TRANSFORMER

1

connector

3p (CN905)

2

wire (flat type) 11 core (CN101)

5

four

screws

(+ITC 4

× 8

)

6

power transforme

3

screw

(+BVIT 3

× 8R

)

12

2

connector

10p (CN907)

4

earth wire

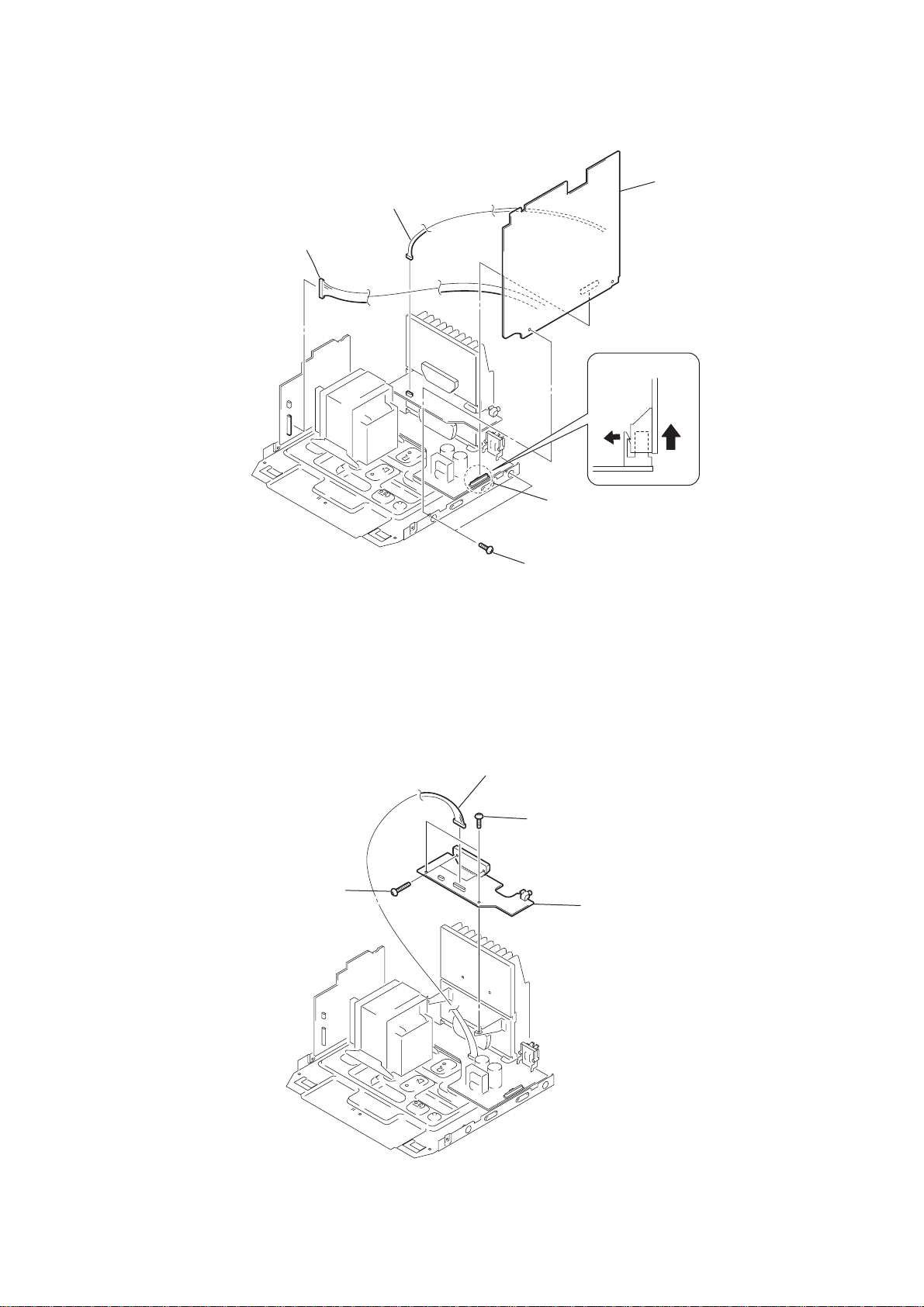

3-9. MAIN BOARD

d

d

1

connector

10p (CN907)

2

connector

4p (CN501)

5

MAIN

Main board

HCD-GX450

boar

3-10. SUB-WOOFER BOARD

2

two

(transistor)

screws

4

13p (CN441)

3

two

(+BVTP 3

1

connector

7p (CN502)

3

two

(+BVTP 3

connector

screws

× 8

)

screws

× 8

)

4

SUB-WOOFER boar

13

HCD-GX450

)

)

3-11. AMP BOARD

3

two

screws

(+BVIT 3

4

two

screws

(transistor)

× 8R

)

6

AMP

2

screw

(+BVTP 3

board

×

14)

1

two

screws

(+BVTP 3

5

heat sink

× 8

3-12. BD81A BOARD

4

Remove soldering from the four points.

1

wire (flat type) 27 core (CN202)

3

screw

(+BVTP 2.6

5

BD81A

board

× 8

)

2

wire (flat type) 16 core (CN101

14

3-13. CONNECT BOARD

2

two

(+BVTP 2.6

3

CONNECT

screws

board

1

wire (flat type) 27 core (CN251)

× 8

)

HCD-GX450

3-14. DRIVER BOARD, SW BOARD

1

(+BTTP (M2.6))

4

DRIVER

2

wire (flat type) 5p (CN702)

two

screws

board

3

connector

4p (CN703)

5

screw

(+BTTP (M2.6))

6

SW board

15

HCD-GX450

3-15. OPTICAL PICK-UP (KSM-215DCP/C2NP)

2

h

qh

optical pick-up

(KSM-215DCP/C2NP)

0

two

insulators

9

two

coil springs

(insulator)

8

t

wo stoppers (BU)

older (213) ASSY

qa

1

floating

(+PTPWH M2.6)

6

two

insulators

5

two

coil springs

(insulator)

3

screw

(BVTT M2.6)

4

floating

(+PTPWH M2.6)

screw

screw

3-16. SENSOR BOARD

2

t

ray

7

(BVTT M2.6)

qd

Remove the four solderings of motor.

1

floating

(+PTPWH M2.6)

6

floating

(+PTPWH M2.6)

screw

8

s

(+BTTP (M2.6))

screw

t

wo screws

crew

0

SENSOR board

9

connector

(

CN731)

qf

CN101 (flat type)

qg

B

D81A board

qs

s

crew (+BVTP 2.6x 8)

3

b

elt (table)

4

floating

(+PTPWH M2.6)

5

screw

p

ulley (table)

16

7

g

ear (geneva)

3-17. MOTOR (TB) BOARD

2

stopper

4

1

stopper

5

t

able motor assy (M741)

HCD-GX450

3-18. MOTOR (LD) BOARD

4

Remove the two solderings of motor.

5

l

oading motor assy (M751)

3

7

MOTOR (TB) board

6

Remove the two solderings of motor.

5

two

screws

(+BTTP (M2.6))

2

two

screws

(+BTTP (M2.6))

3

MOTOR (LD) board

wire (flat type) 5 core (CN742)

1

b

elt (loading)

17

HCD-GX450

SECTION 4

TEST MODE

[Change-over of AM Tuner Step between 9 kHz and

10 kHz]

•A step of AM channels can be changed ov er between 9 kHz and

10 kHz.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND

button to select the BAND “AM”.

3. Press ?/1 button to turn the set OFF.

4. Press PLAY MODE/TUNING MODE and ?/1 buttons si-

multaneously, and the display of fluorescent indicator tube

changes to “AM 9 k STEP” or “AM 10 k STEP”, and thus the

channel step is changed over.

[Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press three buttons x , PLAY MODE/TUNING MODE ,

and DISC 1 simultaneously.

2. The fluorescent indicator tube displays “COLD RESET” and

the set is reset.

[Aging Mode]

This mode can be used for operation check of CD section and tape

deck section.

• If an error occurred:

The aging operation stops and is displayed status.

• If no error occurs:

The aging operation continues repeatedly.

1. Operating method of Aging Mode

Press ?/1 button to turn the set ON and select “CD” of the function.

1) Set three discs in tray. Press the

PLA Y MODE/TUNING MODE

button to set the “ALL DISCS” mode, and the PRESET EQ

button to “REPEAT” off.

2) Load the tapes recording use into both decks.

3) Press three buttons x , PLAY MODE/TUNING MODE ,

and EX-CHANGE simultaneously.

4) Aging operations of CD and tape are started at the same time.

5) To exit the aging mode, perform [Cold Reset].

2. Aging mode in CD section

1) Operation during aging mode

• In the agining mode ,the program is excuted in the following

sequence.

(1) The disc tray opens and closes.

(2) The disc tray turns to select a disc 3.

(3) The pick-up accesses to the first track, and plays 3 seconds.

(4) The pick-up accesses to the last track, and plays 3 seconds.

(5) The disc tray opens and closes.

(6) The disc tray turns to select a disc 1.

(7) The same operation starts like step (3).

(8) After a disc 1 aging operation, a disc 2 is selected.

(9) When an aging operation of a disc 3 is completed, the display

“AGING ∗∗∗∗” value increases.

(10) If no error occurs, the aging operation continues repeatedly.

2) Error display

Disc error

Display Error

E00D01022 Focus error (No disc)

E00D02022 Sub Q error (Focus is good)

E00D02023 TOC reading error

E00D02014 Access error (Unable within regular time)

Mechanism error

Display Error

E00M__E_0 Error during opening tray

E00M__C_2 EX-CHANGE disc error

E00M__D_0 Error during closing tray

E00M__F_3 EX-OPEN error

E00M__D_5 EX-CLOSE error

E00M__C_2 Chuck-up error

E00M__C_3 Unchucking error

3. Aging mode in Tape Deck section

1) Operation during aging mode

• In the agining mode, the program is excuted in the following

sequence.

Step

1

Rewind the TAPE A

2

Rewind the TAPE B

3

Play the TAPE A (1 minute)

4

Stop the TAPE A (1 second)

5

Play the TAPE A (3 minutes)

6

Rewind(AMS) the TAPE A

7

F.F.(AMS) the TAPE A

8

Play the TAPE B (1 minute)

9

Stop the TAPE B (1 second)

10

Record the TAPE B (3 minutes)

11

Rewind(AMS) the TAPE B

12

F.F.(AMS) the TAPE B

Operation

Display

TAPE AAG-1

TAPE BAG-2

TAPE AAG-2

TAPE AAG-3

TAPE AAG-4

TAPE AAG-5

TAPE AAG-6

TAPE BAG-2

TAPE BAG-3

TAPE BAG-4

TAPE BAG-5

TAPE BAG-6

2) Error display

• If error occurred, the display remains like “TAPE BAG-2”.

4. Exiting from the aging mode

• Be sure to perform Cold Reset to exit from the aging mode.

18

HCD-GX450

[P ANEL Test Mode]

• All fluorecent segments and LEDs are tested.

•Keyboard check.

Procedure:

1. Press ?/1 button to turn the set ON.

2. To enter the test mode, press the three buttons x , PLAY

MODE/TUNING MODE and ENTER simultaneously.

3. All segments and LEDs (without STANDBY LED) are turned

on.

4. Press X and ENTER buttons simultaneously, and the key

check mode is activated.

5. The message “KEY 0 0 0 ” is displayed.

Each time a button is pressed, the key code number is displayed.

6. Press X and ENTER buttons simultaneously, and the key

count mode is activated.

7. The message “KEYCNT 0” is displayed.

Each time a button is pressed, “KEYCNT 0” value increased.

However, once a button is pressed, it is no longer taken into

account.

8. Press X and ENTER buttons simultaneously, and the head

phone detect mode is activated.

9. The message “H_P OFF” is displayed when a headphone jack

is not inserted.

“H_P ON ” is displayed when a headphone jack is inserted.

10. Press X and ENTER b uttons simultaneously , and the volume

control detect mode is activated.

11. The message “VOLUME FLAT” is displayed.

“VOLUME UP” is displayed if rotating MASTER VOLUME

knob clockwise, or “VOLUME DO WN” is displayed if rotating

counterclockwise.

12. To exit from the GC test mode after the head phone detect mode,

press X and ENTER buttons simultaneously.

[Version and Destination Display Mode]

•The version or destination is displayed.

Procedure:

1. Press ?/1 button to turn the set ON.

2. To enter the test mode, press the three buttons x , PLAY

MODE/TUNING MODE and DISC 2 simultaneously.

3. The destination is displayed.

4. Press DISPLAY buttons simultaneously.

5. The version is displayed.

6. To exit from this mode, press the three buttons x , PLAY

MODE/TUNING MODE and DISC 2 simultaneously and

press ?/1 button to turn the set OFF.

[CD Service Mode]

•This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the pick-up.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. To enter the test mode, press three b uttons x , PLAY MODE/

TUNING MODE , and Z simultaneously.

4. The CD service mode is selected.

5. With the CD in stop status, press M button to move the

pick-up to outside track, or press m button to inside track.

6. To exit from this mode, perform as follows:

1) Move the pick-up to the most inside track.

2) Press ?/1 button to turn the set OFF.

Note: • Always move the pick-up to most inside track when exiting from

this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can be

chipped.

[MC Test Mode]

•This mode is used to test the function of the equalizer.

Procedure:

1. Press ?/1 button to turn the set ON.

2. To enter the test mode, press the three buttons x , PLAY

MODE/TUNING MODE and DISC 3 simultaneously.

3. Press the EQ + button.

The function of the equalizer is set to “MAX”.

4. Press the EQ - button.

The function of the equalizer is set to “MIN”.

5. Press the PRESET EQ button.

The function of the equalizer is set to “EQ FLAT”.

6. MASTER VOLUME up and down.

“VOLUME MIN” “VOLUME 16” “VOLUME MAX” is

displayed.

7. Press the GROOVE button.

The message “VACS OFF” or “VACS ON” is displayed.

8. To exit from this mode, press ?/1 button to turn the set OFF.

[CD Ship Mode (LOCK) ]

•This mode moves the pick-up to the position durable to vibra-

tion. Use this mode when returning the set to the customer after

repair.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press ?/1 button to turn the set OFF.

4. Press CD button and ?/1 button simultaneously.

5. The “ST ANDBY” display blinks instantaneously, the message

“LOCK” is displayed and the CD ship mode is set.

[CD Ship (LOCK) & COLD RESET MODE]

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press ?/1 button to turn the set OFF.

4. Press three buttons x , CD and DISPLAY simultaneously.

5. The “ST ANDBY” display blinks instantaneously and CD ship

mode is set.

6. To fluorescent indicator tube displays “COLD RESET” and

the set is reset.

[Disc T ray Lock]

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press two buttons of x and Z simultaneously for f ive seconds.

4. The message “LOCKED” is displayed and the tray is locked.

(Even if exiting from this mode, the tray is still locked.)

5. Press two buttons of x and Z simultaneously for five seconds

again.

6. The message “UNLOCKED” is displayed and the tray is

unlocked.

7. To exit from this mode, press the ?/1 button to turn the set

OFF.

19

HCD-GX450

[CD Repeat 5 Times Limit Release Mode]

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press three buttons x , CD and ENTER simultaneously.

4. The message “LIMIT OFF” is displayed.

5. Press ?/1 button the set OFF.

[AMP TEST MODE]

Procedure:

1. Press ?/1 button to turn the set ON.

2. To enter the test mode, press three buttons x , PLAY

MODE/TUNING MODE and ENTER simultaneously.

3. Press the DISPLAY button.

The message “V0 0 0” “ 000” is displayed.

4. Press the GROOVE button.

The message “DBFB ON” “DBFB OFF” is displayed.

5. Press the SURROUND button.

The message “SURROUND ON” “SURROUND OFF” is

displayed.

6. Press the EQ BAND button.

The message “LOW” “MID” “HIGH” is displayed.

7. Press ?/1 button to turn the set OFF.

20

SECTION 5

d

DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMA TIC DIAGRAMS.

(In addition to this, the necessary note is printed in each bloc k.)

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

•Voltages and waveforms are dc with respect to ground

•Voltages are taken with a VOM (Input impedance 10 MΩ).

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

under no-signal (detuned) conditions.

Voltage variations may be noted due to normal produc-

tion tolerances.

no mark : FM

( ): CD STOP

Voltage variations may be noted due to normal production tolerances.

F : TUNER

E : PB (DECK A)

d : PB (DECK B)

G : REC (DECK B)

J : CD

f : AUDIO

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(SIDE A) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(SIDE B) the parts face are indicated.

• Indication of transistor.

C

These are omitted.

Q

B

CE

These are omitted.

•Abbreviation

CND : Canadian model

Q

B

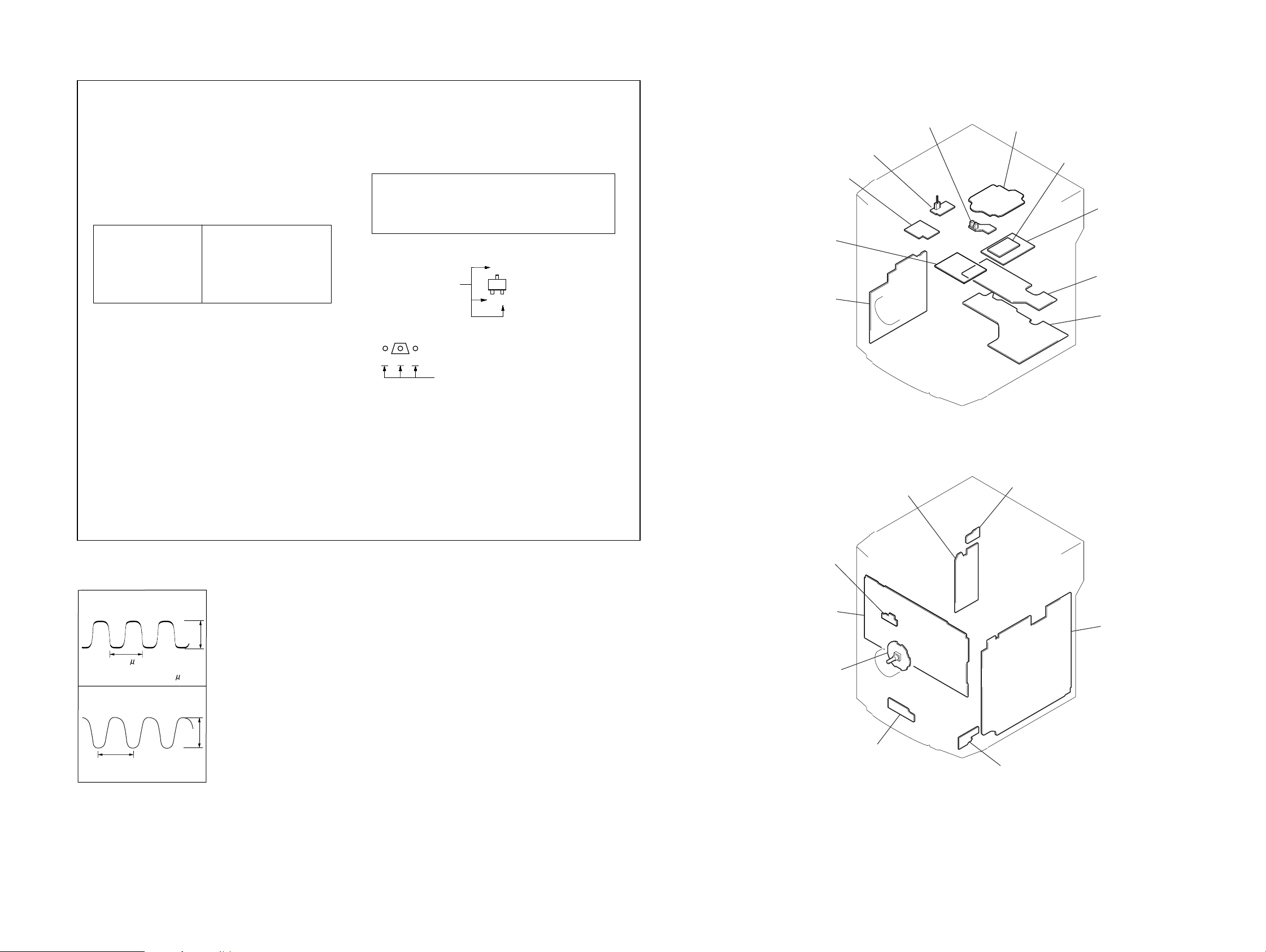

HCD-GX450

Circuit Boards Location

SENSOR board

SW board

MOTOR (LD) board

CONNECT board

E

TRANS board

SUB-TRANS board

BD81A board

MOTOR (TB) board

DRIVER board

SUB-WOOFER boar

AMP board

VIDEO OUT board

• Waveforms

– PANEL BOARD –

1 IC601 qd (I-XT2)

30.5 s

2 V/DIV, 10 s/DIV

2 IC601 qh (CF2)

100 ns

2 V/DIV, 40 ns/DIV

5.2 Vp-p

4.9 Vp-p

REM board

PANEL board

MAIN board

6 STREAM LED board

GAME JACK board

H/P JACK board

2121

HCD-GX450

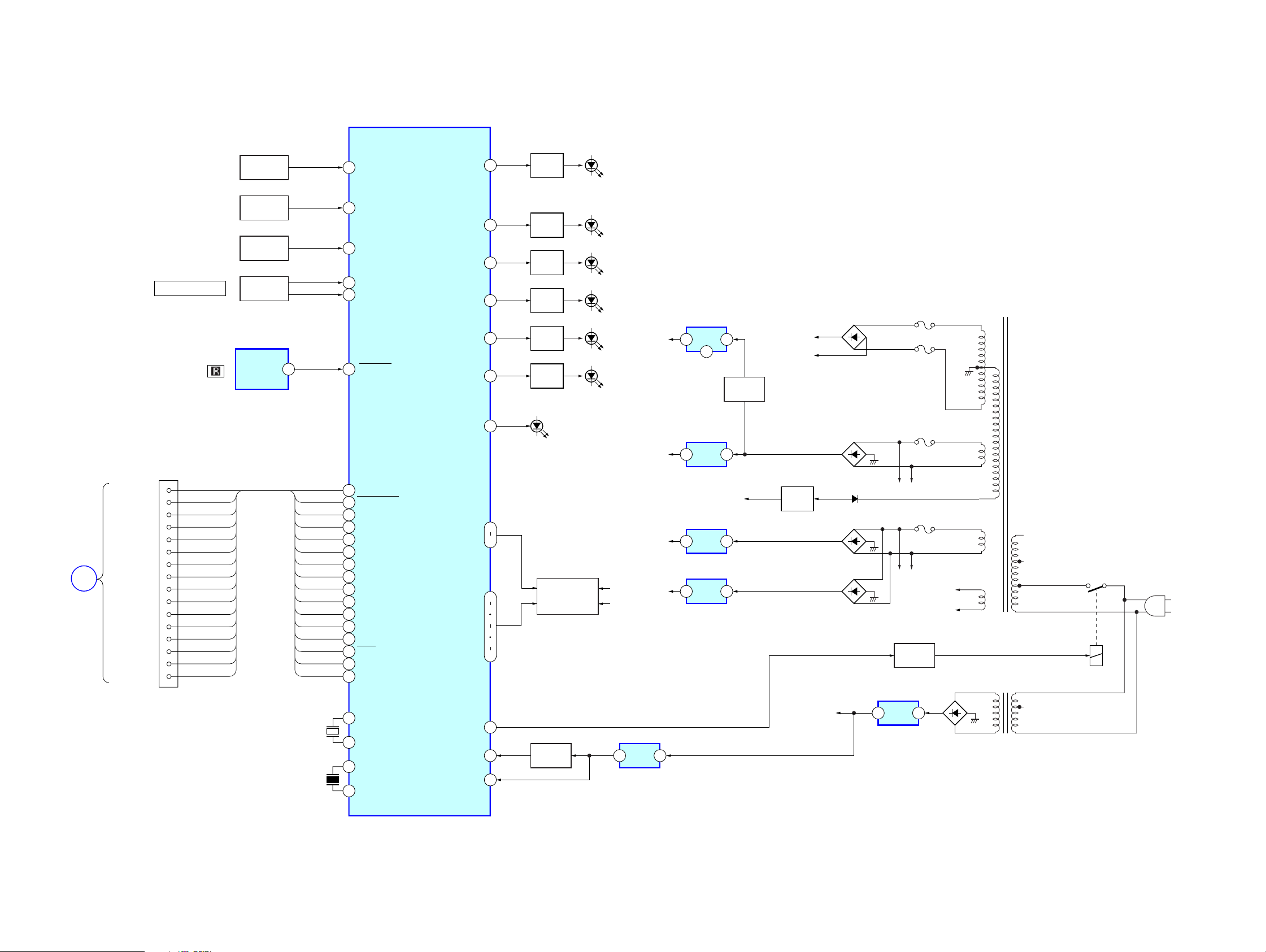

5-1. BLOCK DIAGRAMS – PANEL SECTION –

IC601(1/2)

SYSTEM CONTROLLER

BD/DRIVER

SECTION

A

SCOR

XTCN

XRST

XL-T-CD

CD-DATA

SENS

CD-CLK

MP3-DO

MP3-DI

MP3-CLK

MP3-CS

MP3-CP

MP3-ACK

MP3-REQ

MP3-RESET

MP3-STB

MASTER VOLUME

CN603

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C18

S641-S650

FUNCTION

KEY

S601-S612

FUNCTION

KEY

S621-S630

FUNCTION

KEY

S851

ENCODER

IC610

REMOTE

CONTROL

RECIEVER

C18

C15

C14

C13

C12

C11

C10

C9

C8

C7

C6

C5

C4

C3

C2

C1

X601

32.768kHz

X602

10MHz

25 KEY3

27 KEY1

26 KEY2

9 VOLUME-IN1

10 VOLUME-IN2

283 SIRDS-IN

MP3-TTB

80

MP3-RESET

6

MP3--REQ

4

MP3-ACK

3

MP3-CS

2

MP3-CS'

1

MP3-CLK

100

MP3-DI

99

MP3-DO

98

CD-CLK

97

SENS

96

CD-DATA

95

XLT

94

XRES

93

XTCN

92

SCOR

5

12 I-XT1

13 I-XT2

15 CF1

16 CF2

G01-G13

S1-S21

POWER RELAY

Q610

82STREM-LED1

80STREM-LED3

81STREM-LED2

77STREM-LED6

78STREM-LED5

79STREM-LED6

76POWER LED

42

30

43

45

47

50

52

65

74

11RESET

29ACCUT

LED

DRIVER

Q612

LED

DRIVER

Q611

LED

DRIVER

Q614

LED

DRIVER

Q615

LED

DRIVER

Q613

LED

DRIVER

LED601

FLUORESCENT

INDICATOR

Q605

RESET

SWITCH

FL601

TUBE

LED610

LED612

LED611

LED615

LED614

LED613

VF

-VFL

IC604

RESET

+3.5V

+3.5V

+9V

+9V

PT901

POWER TRANSFORMER

VF

D902-905

SUB TRANSFORMER

RY901

AC

IN

PT902

AC3

AC4

IC603

REG

F904

F905

F906

F907

RELAY

DRIVE

15

IC302

REG

12

4

Q301,Q302

SWITCH

IC301

REG

13

-VFL

IC303

REG

13

IC304

REG

13

13

+B

-B

Q902

REG

D401

D301-D304

D902

D305-D308

D309-D312

Q361,Q362,Q314,Q315

+3.3V

2222

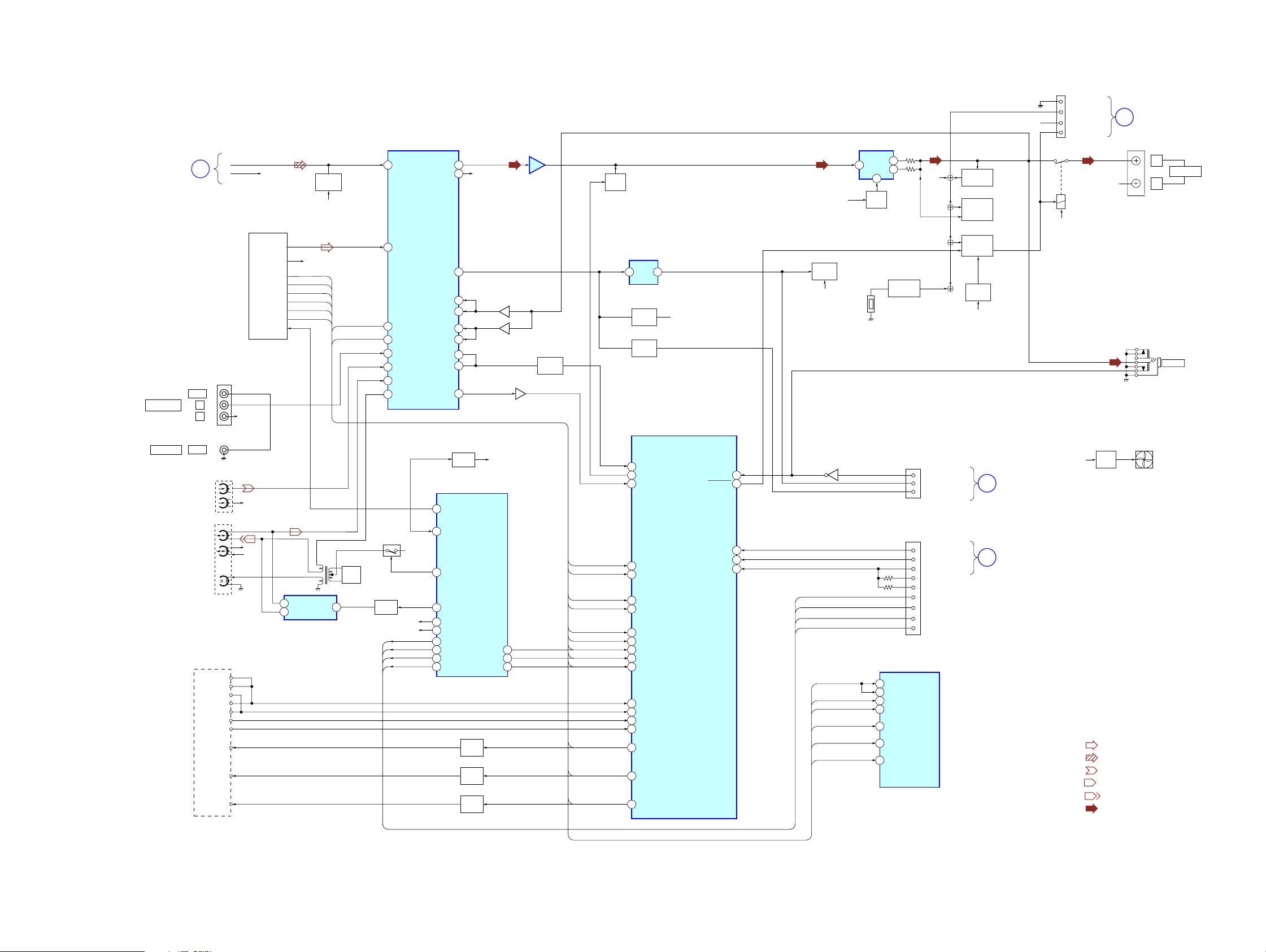

– MAIN SECTION –

BD/DRIVER

SECTION

GAME INPUT

VIDEO OUT

B

J804

VIDEO

L

R

J803

VIDEO

DECK-A

LRHP2

HP1

DECK-B

L

HRP2

R

HRP1

HE1

TAPE

MECHANISM DECK

PWDEWC B

MODE B

MODE A

B HALF

A HALF

A-PHOTO

B-PHOTO

COMP

SOLA

CD-L

CD-R

R-CH

R-CH

R-CH

R-CH

TUNER

TUNER-L

TUNER-R

CLK

TUNED

STEREO

TU-MUTE

DO

DI

CE

Q304-Q307

REC SW

9

P/B SW

7

SELECTOR

IC201

CD-MUTE

R-CH

CLK

TUNED

STEREO

CONT

SWITCH

DO

DI

CE

L101

4

DATA

RCLK

Q321

BIAS

OSC

1 CDL

61 TUNER_L

19 SI

18 SO

59 GAME-L

9 TAPEA1

11 TAPEB1

15 REC-OUT1

Q324

Q322,Q323

SWITCH

IC101

SOUND PROCESSOR

+9V

CD-MUTE

FAN

LM-R

LM-F

TM-R

TM-F

BBNF1

BBIN1

BBNF2

SAOUT2

SAOUT1

11 Q5

12 Q6

7Q1

6Q0

10 Q4

17 Q11

13 Q7

14 Q8

15 Q9

16

32VOUT2

33VOUT1

25 5 1SW OUT

34

35

31BBNF2

30

55

56

40ASMOUT

Q308,Q309

Q313

SWITCH

IC371

SP DRIVER

Q601

CAP M

DRIVE

Q602

B TRIG

DRIVE

Q603

A TRIG

DRIVE

R-CH

STK

DATA

CLOCK

LCH

Q106

BUFFER

Q107

BUFFER

Q327

BUFFER

3

4

5Q10

IC102

BUFFER

Q351,Q352

SWITCH

RCLK

DATA

TUNED

STEREO

DI

CE

DO

CLK

LCH

MOTOR

SOLB

SOLA

MUTE

Q101-Q104

IC104

BUFFER

Q105

SWITCH

Q303

DEF

SYSTEM CONTORLLER

24 I-STREEMA/VACS

75 SYSTEM-MUTE

69 ASM

88

CLK

91

DATA

67

TUNED

68

STEREO

83

DI

84

CE

85

DO

CLK

86

LCH

87

23

TAPE B START+

22

TAPE A START+

I-REEL-A

70

I-REEL-B

71

2

MOTOR

3

SOLBSOLB

4

SOLA

+Vcc

IC601(2/2)

HCD-GX450

CN443

GND

OVERLOAD/DC

RY441

+B

RELAY+

RELAY-

FAN

Q310-Q312

FAN

DRIVE

+10V

IC441

POWER AMP

11

Q108

SWITCH

-VFL

TH441

Q371

19WFR/HP/MIC

18PROTECT

INVERTER

4

5

13

Q489

MUTESTK

Q483,Q484

OVERHEAT

R-CH

DET

Q481,Q482

OVERLOAD

DET

Q441,Q442

OVERLOAD

DET

Q485-Q488

RELAY

DRIVE

SWITCH

AC4

Q308,

Q309,Q313

CN306

SW ON/OFF

SW OUT

SW LIMITER

C

SUB-WOOFER

SECTION

CN201

IC602

VIDEO BUFFER

CD NO SENS

CD OPEN/CLOSE

CD ENCORDER

BD/DRIVER

D

SECTION

• R-CH is omitted due to same as L-CH

• Signal Path

73SENSOR

21CD-OPEN/CLOSE

20CD ENCORDER

LM-R

LM-F

TM-R

TM-F

DO

CLK

LCH

SOL-A

SOL-B

MOTOR

3 DATA

18 SO

4 CLK

5 LCK

6 SOL-A

7

SOL-B

8

MOTOR

E

JK441

R-CH

: TUNER

: CD

: PB(DECK A)

: PB(DECK B)

: REC(DECK B)

: AUDIO

SUB-WOOFER

SECTION

L

R

FAN

SPEAKER

J801

PHONES

2323

HCD-GX450

– BD/DRIVER SECTION –

OPTICAL PICK-UP

BLOCK

(KSM-215DCP/C2NP)

DETECTOR

VCC

FOCUS

COIL

TRACKING

COIL

(SPINDLE)

M102

(SLED)

VC

A

B

C

D

E

F

LD

GND

PD

VR

M101

+1.7V

+3.3V

Q10

DRIVER

IC251

SL/SP MOTOR

DRIVER

F+

16

CH2OUT-F

F

15

CH2OUT-R

T+

17

CH1OUT-R

T

18

CH1OUT-F

19

CH4OUT-F

M

20

CH4OUT-R

21

CH3OUT-R

M

CH3OUT-F

22

LD

CH1FIN

CH1RIN

CH2FIN

CH2RIN

SFDR

SRDR

OPIN+

MUTE

IC301

11

SDO0

16

LRCKIA

19

SFSY/LRCK1B

14

SDIO

15

BCKIA

18

SBSY/BCK1B

DIGITAL SIGNAL

PROCESSOR

PO11/BUCK/AD1

SRMSTB

VDD

VDD

VDDM

STANBY

MIACK

MICK

MIDIO

MILP

MICS

RESET

IC303

55

21

40

3

36

8

7

6

5

4

2

41

5 1

REG

SCOR

SENS

CLOCK

XLT

DATA

XRST

XTACN

3.3V

CN201

MP3STB

MP3REQ

MIACK

MICK

MIDIO

MILP

MICS

MP3RST

SRMSTB

SCOR

SENS

CLOCK

XLT

DATA

XRST

XTACN

LOUT

ROUT

DOUT

• R-CH is omitted due to same as L-CH

• Signal Path

PANEL

SECTION

A

MAIN

SECTION

B

: CD

MAIN

SECTION

D

LMR

LMF

TM-R

TM-F

TBL ADDRESS SW

E-1

E-2

E-3

OPEN SW

(LEVER SW)

E-3

E-2

E-1

CN701

S751

RE701

ROTARY

ENCODER

IC701

(LD)MOTOR DRIVER

RIN

OUT1

9

FIN

9

7

IC712

RIN

FIN

Q731

SWITCH

OUT2

OUT1

OUT2

11

TBL MOTOR DRIVER

4

2

4

2

M

M

IC731

(TABLE SENSOR)

M751(LOADING)

M741(TBL)

+3V

IC101

RF AMP

26

A

27

B

28

C

29

D

19

E

20

F

36

LD

XTAO

100

77

78

37

11

12

13

14

30

29

7

6

XTAI

PD

SSTP

TFDR

TRDR

FFDR

FRDR

CH3FIN

CH3RIN

MPD

XRST

X171

16.9MHz

+3.3V

SW101

5

6

7

8

9

10

3

24

PCMD1

LRCK1

LRCK

PCMD

BCK

BCK1

XTACN

XRST

DATA

XLAT

CLOCK

SENS

SCOR

GFS

C2PO

FOK

AOUT1

AOUT2

DOUT

100

102

104

105

107

115

113

114

61

62

63

65

66

60

95

1

2

3

81

86

71

XTACN

XRST

DATA

XLAT

CLOCK

SENS

SCOR

2424

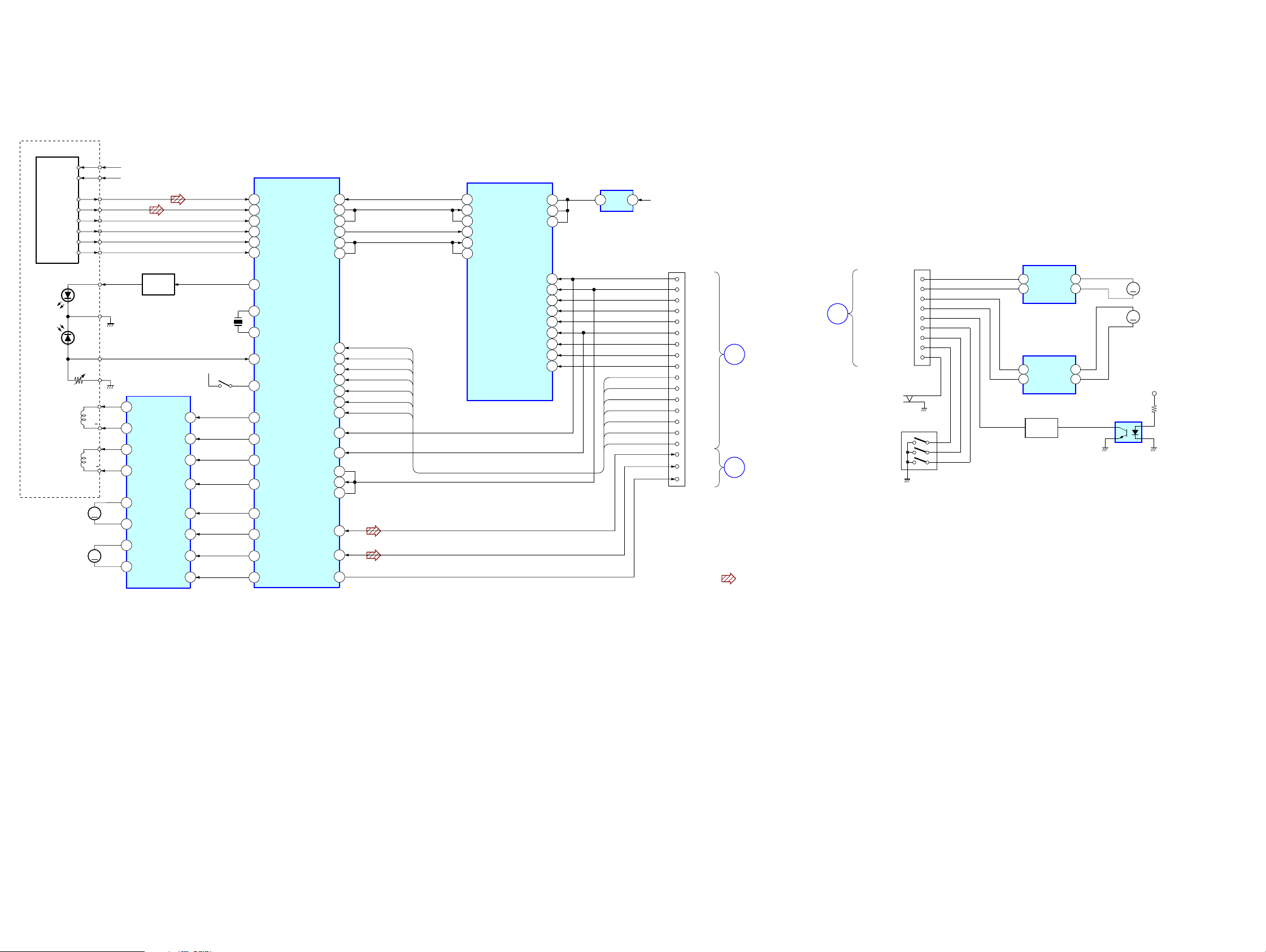

– SUB-WOOFER SECTION –

HCD-GX450

IC501

AMP

+B

MAIN

SECTION

MAIN

SECTION

C

E

CN501

SW-SIG-IN

GND

SW-LIMIT

SW-SENCE

CN502

GND

OVERLOAD/DC

RELAY+ +B

PT-2

2

Q507

DETECT

Q503

DETECT

SW IN

3

-RE

8 12

+RE

13

Q502

CN503

SWITCH

CONTROL

Q501

OVERCOAR

DETECT

RY501

JK501

SUB WOOFER OUT

RELAY-

Q506,Q505

DETECT

2525

HCD-GX450

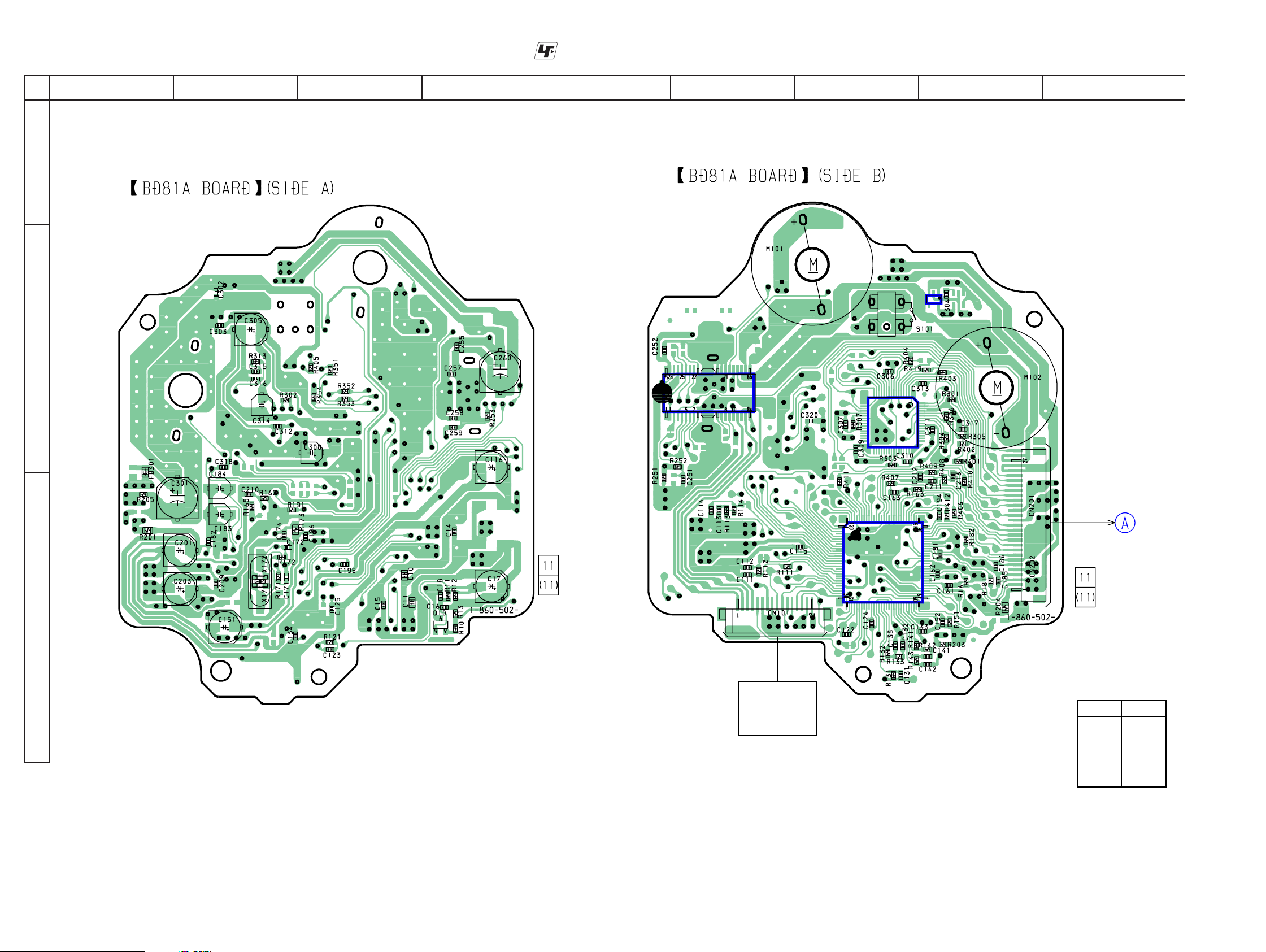

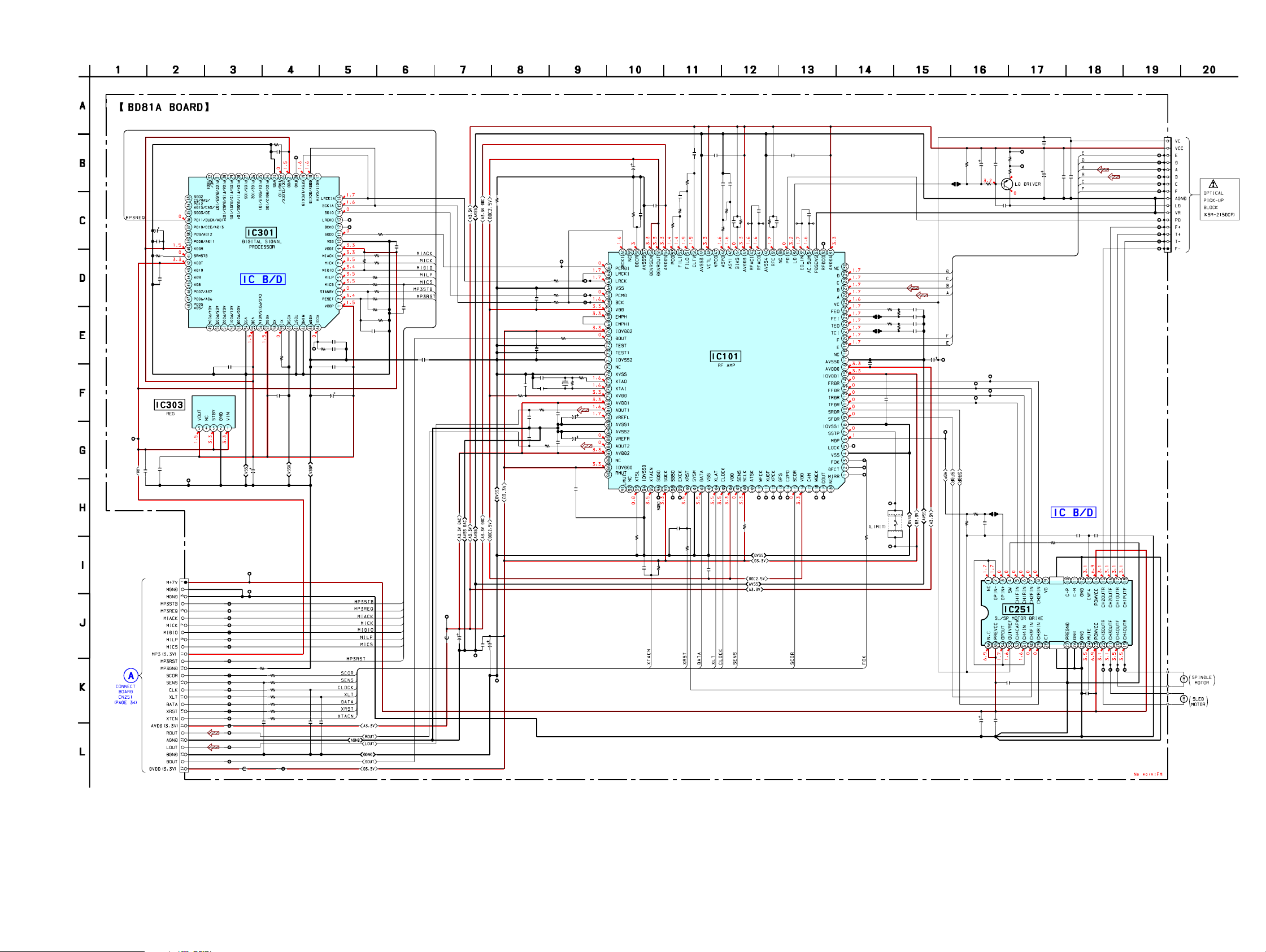

5-2. PRINTED WIRING BOARD – BD81A SECTION –

12

A

B

• See page 21 for Circuit Boards Location.

• : Uses unleaded solder .

3456789

SPINDLE

MOTOR

IC303

1

3

5

4

(LIMIT)

C

D

E

IC301

SLED

MOTOR

IC251

CONNECT

IC101

E

• Semiconductor

OPTICAL

PICK-UP

BLOCK

(KSM–215DCP)

BOARD

CN251

(Page 33)

Location

Ref. No. Location

IC101 D-7

IC251 C-6

IC301 C-7

IC303 B-7

Q10 E-4

2626

HCD-GX450

5-3. SCHEMATIC DIAGRAM – BD81A SECTION –

R307

10k

TP433

MP3VDD

FB301

BLM21B272S

0.1 F

C307

0.1 F

C308

47

4V

C309

R303

100k

C310

0.1 F

IC303

BH15FB1W

C302

C303

0.1

0.1

F

F

TP422

MP3GND

CN201

27P

C311

0.1 F

TP401

TP402

TP403

TP404

TP405

TP406

TP407

TP408

TP417

TP416

TP415

TP414

TP413

TP412

TP419

TP434

TP410

TP411

TP409

IC301

TC94A34FG-002

C305

TP186

MVDD

TP187

MGND

MP3STB

MP3REQ

MIACK

MICK

MIDIO

MILP

MICS

MP3RST

R205

SCOR

SENS

CLK

XLT

DATA

XRST

XTCN

AVDD

ROUT

LOUT

DOUT

R204

0

TP304

0.0022 B

TP

301

0

306

R

C312

0.1 F

220

4V

0

R411

R410

R409

R408

R407

R406

R412

C213

22p CH

R313

0.1 B

220

100

100

100

100

100

100

100

22p CH

C212

TP435

C211

DVDD

• See page 46 for IC PIN FUNCTION DESCRIPTION.

C10C11

C15

10

F

C13

NM

R253

10k

IC251

BA5947FM

(HSOP28)

10

6.3

6.3

B

B

C259

0.1

C258

F

0.1

+

L-

SL+

SP

S

3

5

252

251

TP

TP

TP2

F

57

C2

0.1

0.1

B

C134

0.1 F

015

C142

C151

100

10V

0

1

R203

0

TP302

TP303

R351

100

10k

R405

R404

R419

R403

R402

R401

R301

C317

0.01 B

0.1 F

47 4V

C306

0.1 F

100

100

100

100

100

100

C318

0.01

B

100k

R305

100k

C320

0

C174

0.1 F

TP436

AVDD

C201

100

0

10V

R201

TP420

AGND

C203

100

10V

B

209

C

0.01

TP421

DGND

TP427

PCMDI

TP103

LRCK

R352

100

R353

100

TP104

PCMD

R354

100

TP105

C161

0.1 F

R173

0

C185

2200p CH

R181

100

C186

2200p CH

BCK

R161

100

0.1 F

C162

R171C171

47022p CH

R172

1M

X171C172

16.9MHz27p CH

C181

0.1 F

22 6.3V

C183

22 6.3V

C184

R182

100

0.1 F

C182

C194

0.1

F

R302

C316

C315

C313

C314

220p CH

51

1

R

165

R

C210

0.1 B

152

C

C143

0.1 F

2

14

TP

0

0.0

43

3.3k

R1

B

141

C

0.1

142

1k

R

4.7k

141

R

CK

SO

148

EX

SB

TP

TP149

C163

0.1

3

0

16

10

R

R162

47k

B

0.01

33

C1

33

R1

132

R

IC101

CXD3059AR

0.1

196

C

B

132

C

0.47

H

C

I

100p

1M

FAC

R

0k

131

131

5

18

R

C

TP12

0k

1

0

191

R

C125

0.1 F

H

C

B

O

C124

30p

15k

0.1

3

FAC

R

R121

124

TP

K

F

4

G

FC

145

U

X

W

TP14

TP

22

B

0.1

C1

C123

47

CK

153

XP

P

TP1

T

2

123

12

TP

TP

O

21

FDC

P1

R

T

R111

1k

C111

0.0033 B

R112

15k

C112

470p

C113

JPO102

JPO103

0.1 F

C115

TP167

LOCK

TP178

FOK

TP166

DFCT

TP165

MIRR

46

PO

C2

GFS

TP1

T

CK

62

U

D

160

O

P1

C

W

TP

T

R193

NM

0.0033

FEI

R114

R113

TEI

S101

SW

15k

1k

C114

470p B

C116

100

10V

0.1 F

C195

5

+

42

SW

TP

-

26

W

S

P4

T

C17

R12

220

100k

4V

JPO10

TP177

VC

TP432

MDP

R11

APC

TP429

FFDR

TP431

TFDR

R251

10k

C260

220 10V

0

TP428

TP430

JPO004

R252

MDP

22k

C251

0.0068

TP423

IOP1

C16

R13

1

1

F

TP424

IOP2

R10

3.3

Q10

2SB1690K

C18

0.001 B

FRDR

TRDR

B

C252

0.1 F

C255

0.1 F

CN101

16P

E

TP10

D

TP11

A

TP12

B

TP13

C

TP14

F

TP102

PD

TP15

F+

TP16

F-

TP17

T-

TP18

F-

TP19

0

P

25

S

TP

M101

M102

2727

HCD-GX450

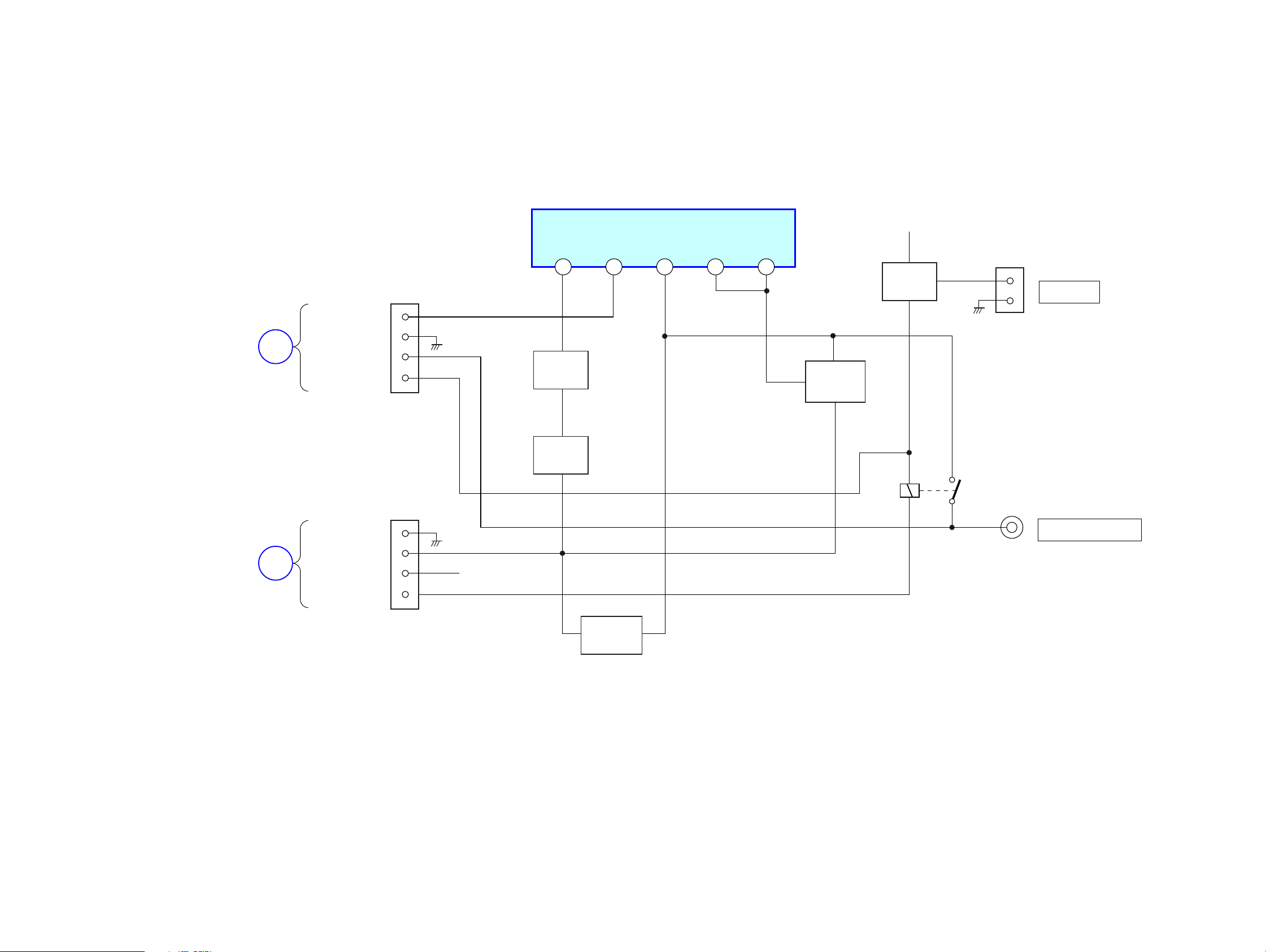

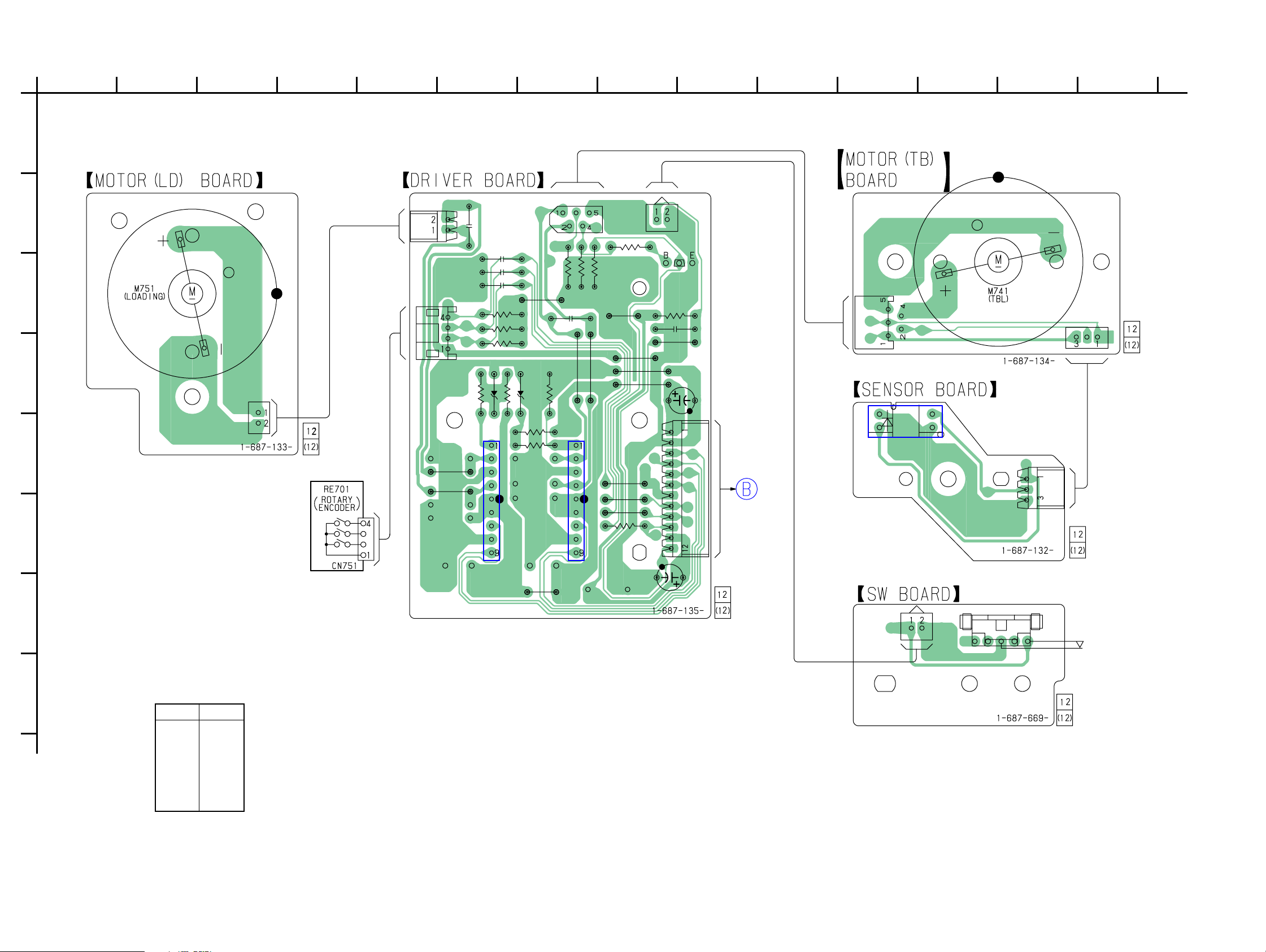

5-4. PRINTED WIRING BOARD – CD MECHANISM SECTION –

1

234567891011121314

A

B

C

D

• See page 21 for Circuit Boards Location.

CN704

C751

C737

C736

C735

JW710

R723

R722

CN703

R721

R702

D701

R701

D711

C741

R713

CN702

R735

JW709

R734

JW708

R732

R733

JW711

JW707

JW706

JW705

CN705

JW712

Q731

R751

C752

CN741

CN742

C715

E

F

G

H

• Semiconductor

Location

Ref. No. Location

D701 D-6

D711 D-7

CN721

JW713

JW714

IC701

R711

R712

JW701

IC712

JW704

JW703

JW702

R731

C731

CN701

MAIN

BOARD

CN301

(Page 30)

IC731

CN751

CN731

S751

(LEVER SW)

IC701 F-6

IC712 F-7

IC731 E-11

Q731 C-9

2828

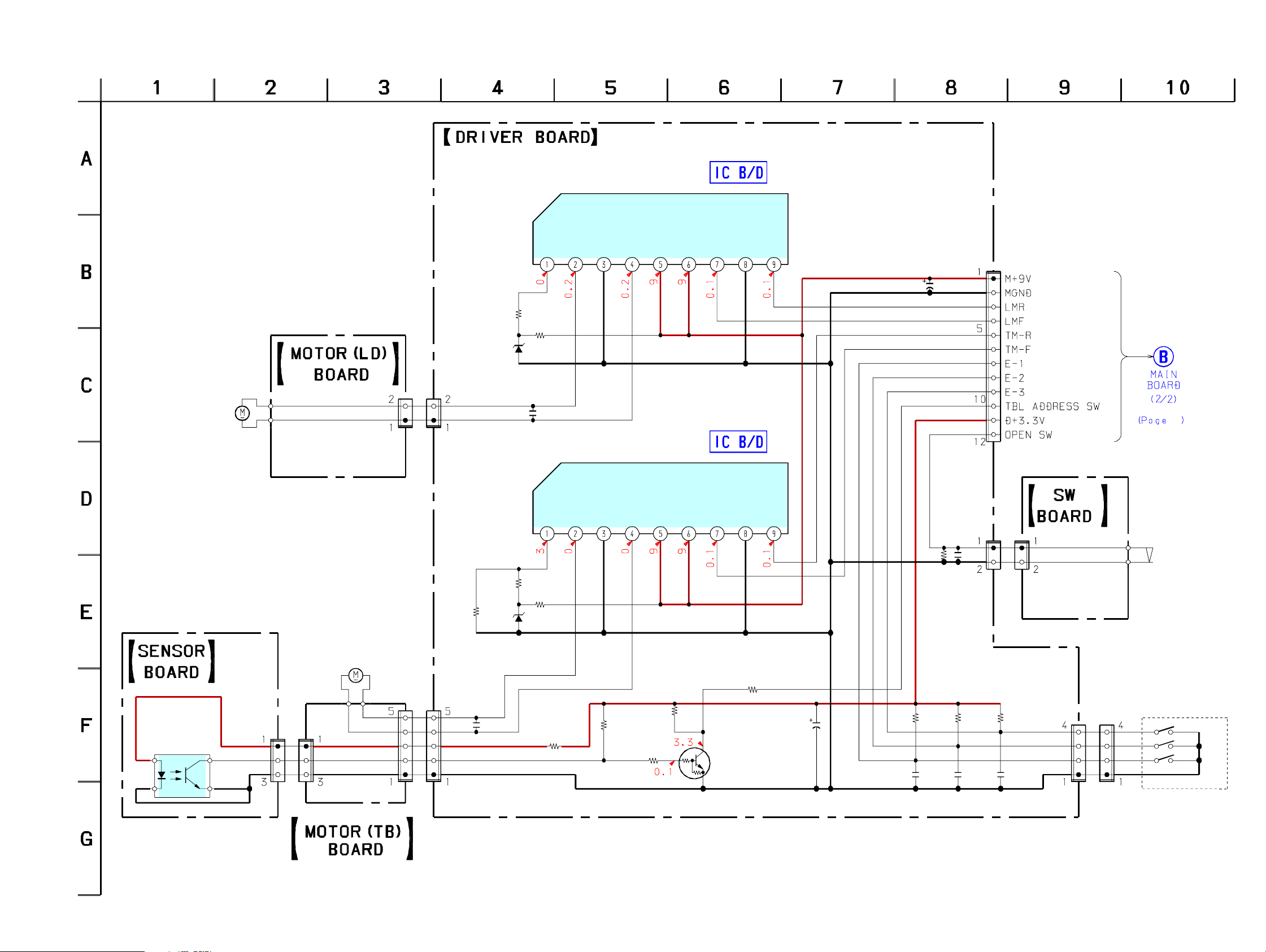

5-5. SCHEMATIC DIAGRAM – CD MECHANISM SECTION –

HCD-GX450

IC701

BA6956AN

LD MOTOR

DRIVER

M751

(LOADING)

CN721

2P

CN704

2P

R713

22k

R702

100

MTZJ-T-77-5.1A

R712

4.7k

D701

R701

470

C751

0.01

R711

1k

VREF

VREF

OUT2

OUT2

RNF

RNF

OUT1

VM

IC712

BA6956AN

TBL MOTOR

DRIVER

OUT1

VM

VCC

VCC

FIN

FIN

GND

GND

RIN

RIN

C715

100

16V

R751

4.7k

C752

0.1

CN705

2P

CN701

12P

CN301

32

S751

(LEVER SW)

CN751

2P

IC731

RPI-576

TABLE

SENSOR

CN731

3P

CN741

3P

M741

(TBL)

CN742

5P

C741

0.01

CN702

5P

D711

MTZJ-T-77-3.6B

R735

100

R734

12k

R733

1k

R732

10k

DTC114ESA

TBL ADDRES

SENS SWITCH

2929

R731

100

Q731

C731

10

50V

R721

4.7k

C735

0.1

R722

4.7k

C736

0.1

no mark : FM

R723

4.7k

C737

0.1

CN703

4P

CN751

4P

RE701

ROTARY

ENCODER

E-3

E-2

E-1

HCD-GX450

5-6. PRINTED WIRING BOARD – MAIN SECTION –

12

345678910111213

A

B

CONNECT

BOARD

CN254

(Page 33)

E

E

C

PANEL

BOARD

CN601

D

ERASE

HEAD

L CH

R CH

HP1

R CH

L CH

HP2

HE1

HRP2

HRP1

E

F

PB

HEAD

REC/PB

HEAD

(Page 37)

DECK-A

(PLAY)

DECK-B

(REC/PLAY)

28

29

1

2

3

1

2

3

4

3

4

G

H

1

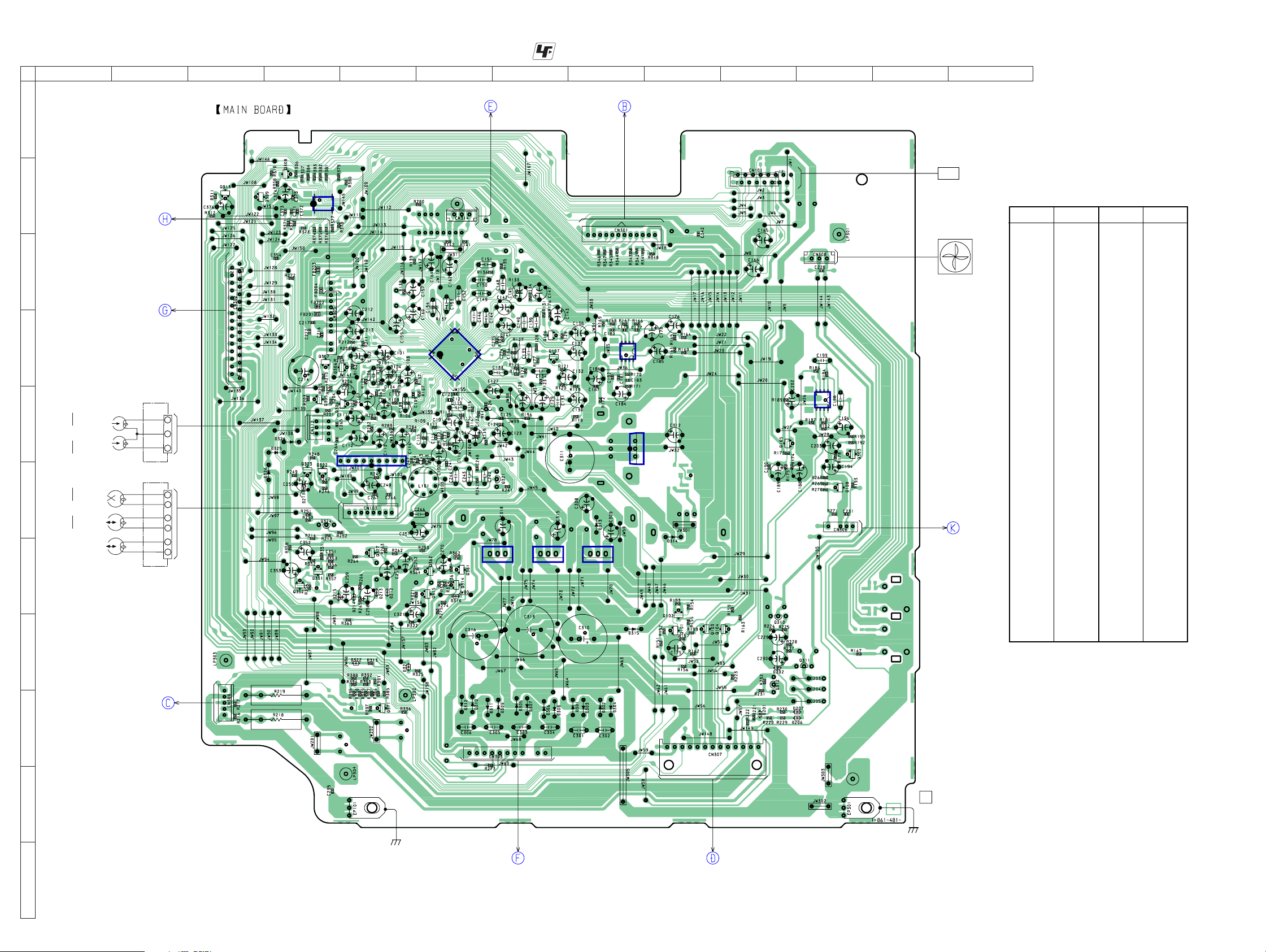

• See page 21 for Circuit Boards Location.

E

IC371

10

E

E

E

E

3

1

IC201

91

E

E

1

E

E

E

E

9

1

33

6

8

E

E

3

IC101

E

E

1

GAMEJACK

(Page 33)

E

1

IC304

• : Uses unleaded solder.

BOARD

CN801

1

E

E

3

1

IC303

1

3

IC301

3

IC102

DRIVER

BOARD

CN701

(Page 28)

1

3

12

IC302

TUNER

• Semiconductor Location

Ref. No. Location

FAN

1

3

D201 I-10

D202 H-10

D203 H-11

D204 H-11

D205 I-11

D206 I-10

D207 I-10

D211 F-4

D212 G-5

D213 G-5

D214 G-5

D215 G-4

D301 I-8

D302 I-8

IC104

D303 I-8

D304 I-8

D305 I-7

D306 I-7

D307 I-7

E

D308 I-7

D309 I-7

E

D310 I-6

D311 I-6

D312 I-6

E

D313 F-8

D314 F-9

D315 H-8

1

4

SUB-WOOFER

BOARD

CN501

(Page 35)

D316 G-6

D321 H-5

D322 H-5

D324 E-4

D325 E-4

D326 F-4

E

E

E

E

E

E

E

IC101 D-6

IC102 D-8

IC104 D-11

IC201 E-5

Ref. No. Location

IC301 G-8

IC302 E-9

IC303 G-7

IC304 G-7

IC371 B-4

Q101 H-9

Q102 H-9

Q103 H-9

Q104 H-10

Q105 E-10

Q106 D-7

Q107 D-7

Q108 F-11

Q303 E-11

Q304 E-4

Q305 E-4

Q306 B-4

Q307 B-4

Q308 B-4

Q309 B-3

Q310 H-10

Q311 H-11

Q312 H-10

Q313 B-3

Q314 G-6

Q315 G-6

Q321 F-7

Q322 F-4

Q323 F-4

Q324 F-4

Q327 G-5

Q351 G-4

Q352 G-4

Q361 G-6

Q362 G-6

Q371 I-5

H/P JACK

I

BOARD

CN804

(Page 33)

5

J

K

E

(CHASSIS)

11

1

13

1

12

(CHASSIS)

TRANS

BOARD

CN907

(Page 40)

AMP

BOARD

CN441

(Page 41)

3030

Loading...

Loading...