Sony HCD-GTR6H, HCD-GTR8H Schematic

MHC-GTR6H/GTR8

MANUAL DE SERVIÇO

Ver. 1.0 12. 2009

Brazilian Model

MHC-GTR6H MHC-GTR8

NOME DE MODELO DO COMPONENTE

MHC-GTR6 MHC-GTR8

RECEIVER DE DISCO COMPACTO HCD-GTR6 HCD-GTR8

SUBWOOFER SS-WGR8

CAIXAS ACÚSTICA EMBALADA SS-GTR6HP SS-GTR8P

CAIXA ACÚSTICA FRONTAL SS-GTR6H SS-GTR8

CAIXA ACÚSTICA SURROUND SS-RSR8

ACESSÓRIOS

Part No. Description Remark

Y-8286-834-A

1-528-681-13 PILHA PEQUENA (2)

1-754-059-12 ANTENA, LOOP (AM )

1-793-184-23 CONECTOR ADAPTADOR TIPO F (ANTENA DE FM)

2-655-031-01 CALÇO PÉ (4 PEÇAS) (PÉS PARA SUBWOOFER) (MHC-GTR8)

2-655-032-31 CALÇO PÉ (16 PEÇAS)

(CALÓ PE PARA CAIXAS ACÚSTICA)

4-132-090-12 MANUAL DE INSTRUÇÕES

3-873-743-11 CALÇO ESPAÇADOR (MHC-GTR8)

CONTROLE REMOTO (RM-AMU053)

(PARA CAIXAS ACÚSTICA)

2009.12

©

SISTEMA COMPACTO DE SOM

Sony Corporation

Sony Brasil Ltda.

Publicado por Product & Quality Division

Especificações técnicas

Seção do amplificador

MHC-GTR8 (HCD-GTR8)

Os valores a seguir foram mensurados a

127 V ou 220 V CA, 60 Hz

Caixas acústicas frontal/surround

Potência de saída (nominal):

210 W + 210 W (a 6 Ω, 1 kHz,

1% THD, em LINK MODE)

Caixa acústica frontal

Potência de saída RMS (referência):

280 W + 280 W (por canal, a 8 Ω,

1 kHz, 10% THD)

Caixa acústica surround

Potência de saída RMS (referência):

110 W + 110 W (por canal, a 24 Ω,

1 kHz, 10% THD)

Subwoofer

Potência de saída RMS (referência):

160 W + 160 W (por canal, a 6 Ω,

100 Hz, 10% THD)

MHC-GTR6H (HCD-GTR6H)

Os valores a seguir foram mensurados a

127 V ou 220 V CA, 60 Hz

Potência de saída (nominal):

220 W + 220 W (a 4 Ω, 1 kHz,

1% THD)

Potência de saída RMS (referência):

400 W + 400 W (por canal, a 4 Ω,

1 kHz, 10% THD)

Entradas

VIDEO (AUDIO IN) L/R:

Tensão de 250 mV, impedância de

47 kilohms

PC IN L/R:

Tensãode 700 mV, impedância de

47 kilohms

MIC:

Sensibilidade de 1 mV, impedância de

10 kilohms

Porta (USB):

Tipo A

Saídas

PHONES:

Aceita fones de ouvido de 8 Ω ou mais

Seção do reprodutor de discos

Sistema

Sistema de áudio digital e disco

compacto

Propriedades dos diodos laser

Duração da emissão: Contínua

Saída do laser*: Menor que 44,6 µW

* Valor de saída medido a uma

distância de 200 mm, a partir da

superfície da lente da unidade óptica

com 7 mm de abertura.

Resposta de frequência

20 Hz – 20 kHz

Relação sinal/ruído

Mais de 90 dB

Faixa dinâmica

Mais de 88 dB

Seção do sintonizador (rádio)

FM estéreo, sintonizador super-heteródino

de FM/AM

Seção do sintonizador de FM

Faixa de sintonização:

87,5 – 108,0 MHz (intervalo de

100 kHz)

Antena

Antena monofilar de FM

Terminais de antena

75 Ω, não balanceados

Frequência intermediária

10,7 MHz

Seção do sintonizador de AM

Faixa de sintonização

530 – 1.610 kHz (com intervalo

ajustado em 10 kHz)

531 – 1.602 kHz (com intervalo

ajustado em 9 kHz)

2

Antena

Antena loop de AM

Terminal de antena

Terminal de antena externa

Frequência intermediária

450 kHz

Seção USB

Taxa de bits suportada

MP3 (MPEG 1 Audio Layer 3):

32 – 320 kbps, VBR

WMA: 48 – 192 kbps

AAC: 48 – 320 kbps

Frequências de amostragem

MP3 (MPEG 1 Audio Layer 3):

32/44,1/48 kHz

WMA: 44,1 kHz

AAC: 44,1 kHz

Velocidade de transferência

Velocidade total

Dispositivo USB compatível

Classe de Armazenamento em Massa

Corrente máxima

500 mA

Caixas Acústicas

Para MHC-GTR8

Caixa acústica frontal (SS-GTR8)

Sistema de caixas acústica

2 vias, 2 unidades, Bass reflex

Unidade de alto-falante

Woofer: 200 mm, tipo cone

Tweeter: 25 mm, tipo corneta

Impedância nominal

8 Ω

Dimensões (L×A×P)

Aprox. 280 × 401 × 325 mm

Peso

Aprox. 6,5 kg por caixa

Caixa acústica surround (SS-RSR8)

Sistema de caixas acústica

2 vias, 2 unidades, Bass reflex

Unidade de alto-falante

Woofer: 100 mm, tipo cone

Tweeter: 40 mm, tipo piezoelétrico

Impedância nominal

24 Ω

Dimensões (L×A×P)

Aprox. 180 × 401 × 225 mm

Peso

Aprox. 3,0 kg por caixa

Subwoofer (SS-WGR8)

Sistema de subwoofer

1 via, 1 unidade, Bass reflex

Unidade de alto-falantes

Subwoofer: 250 mm, tipo cone

Impedância nominal

6 Ω

Dimensões (L×A×P)

Aprox. 401 × 366 × 355 mm

Peso

Aprox. 8,0 kg

Para MHC-GTR6H

Caixa acústica frontal (SS-GTR6H)

Sistema de caixas acústica

2 vias, 3 unidades, Bass reflex

Unidade de alto-falante

Woofer: 200 mm, tipo cone × 2

Tweeter: 25 mm, tipo corneta

Impedância nominal

4 Ω

Dimensões (L×A×P)

Aprox. 304 × 607 × 350 mm

Peso

Aprox. 11,0 kg por caixa

Geral

Requisitos de alimentação

127 V ou 220 V CA, 60 Hz, ajustável

com o seletor de tensão

Consumo de energia

MHC-GTR8: 460 W

MHC-GTR6H: 300 W

Dimensões (L×A×P) (Aprox.)

HCD-GTR8/HCD-GTR6H:

295 × 380 × 457 mm

Peso (Aprox.)

HCD-GTR8: 15,8 kg

HCD-GTR6H: 13,8 kg

3

HCD-GTR6/GTR6B/GTR7/GTR8/GTR8B

HCD-GTR6H/GTR8

MANUAL DE SERVIÇO

Ver. 1.0 12. 2009

• HCD-GTR6H/GTR8

sào seções de sintonizador,

CD e amplificador do

MHC-GTR6H/GTR8

Brazilian Model

Seção

CD

Modelo que Utiliza Mecanismo Similar NOVO

Tipo do Mecanismo do CD CDM74HF-DVBU101//M

Nome do Bloco Ótico KHM-313CAB/C2NP

COMPACT DISC DECK RECEIVER

© 2009. 12

Sony Corporation

Sony Brasil Ltda.

Publicado por Product & Quality Division

1

NOTAS DE SERVIÇOS

NOTAS SOBRE O MANUSEIO DA BLOCO DE

UNIDADE Ó

O diodo laser da unidade optica e sensÍvel a descargas eletroestáticas

podendo vir a ser danificado por descargas causadas por roupas

ou mesmo pelo corpo humano. Durante o reparo tenha cuidado para não causar danos a unidade, devido a cargas eletroestáticas e siga

corretamente os procedimentos descritos nesse manual para a execução de reparos e troca de componentes.

As placas de circuito impresso podem ser facilmente danificadas.

Tenha cuidado ao manusea-las.

NOTAS SOBRE A EMISSÃO DO DIODO LASER

O feixe laser nesse modelo é concentrado e deve ser focado na superficie reflexiva do disco, pela lente objetiva da unidade optica. Quando

estiver observando a emissão do diodo laser, tome o cuidado de estar

no minimo a 30 cm da lente objetiva.

SOLDA SEM CHUMBO

Placas que exigem o uso de solda sem chumbo sã

a marca LF (lead free) indicando que a solda não contem chumbo.

(Atenção

TICA OU BASE DA UNIDADE

o impressas com

: Algumas placas de circuito impresso podem não ter essa

marca devido ao seu tamanho reduzido.)

HCD-GTR6H/GTR8

: IDENTIFICAÇÃO DA SOLDA SEM CHUMBO

A solda livre de chumbo tem as seguintes caracteristicas:

• Derrete a uma temperatura 40 °C maior que a solda comum.

Ferros de solda comuns podem ser usados mas a ponta tem que

ser aplicada sobre a solda por um tempo maior.

Ferros de solda com ajuste de temperatura devem ser ajustados

no valor de 350 °C.

Atenção: A impressao da placa (trilhas de cobre) pode se soltar

se a ponta permanecer por muito tempo. Tenha cuidado!

mais viscosa

• É

A solda livre de chumbo é

lidade) que a solda comum, portanto tenha cuidado com as pontes de solda, especialmente entre os pinos de IC's.

• Pode ser utilizada com solda comum

E melhor usar apenas solda sem chumbo, mas este tipo també

pode ser adicionado a solda comum.

NATA SOBRE REPARO DO IC102 DA PLACA DMB19

IC102 da placa DMB19 não pode ser substituído individualmente.

Quando esta peça é com defeito, substitua a placa montada.

DESTRAVANDO A BANDEJA DO DISCO

Esta função serve para evitar o furto de discos de aparelhos em

demosntração em lojas.

mais viscosa (flui com menor faci-

m

Procedimento para Destravar:

1. Pressione a tecla [I/

2. Pressione a tecla [CD] para selecionar função CD.

3. Enquanto pressiona tecla [

(por mais de 5 segundos).

4. A menssagem “UNLOCKED” aparecera e a bandeja estará

liberada

Nota: Quando “LOCKED” é exibido, a bandeja não será liberada ao

desligar o aparelho através do botão [I/

1 STANDBY] para ligar o aparelho.

] , pressione [Z OPEN/CLOSE]

x

STANDBY].

1

5

ÍNDICE

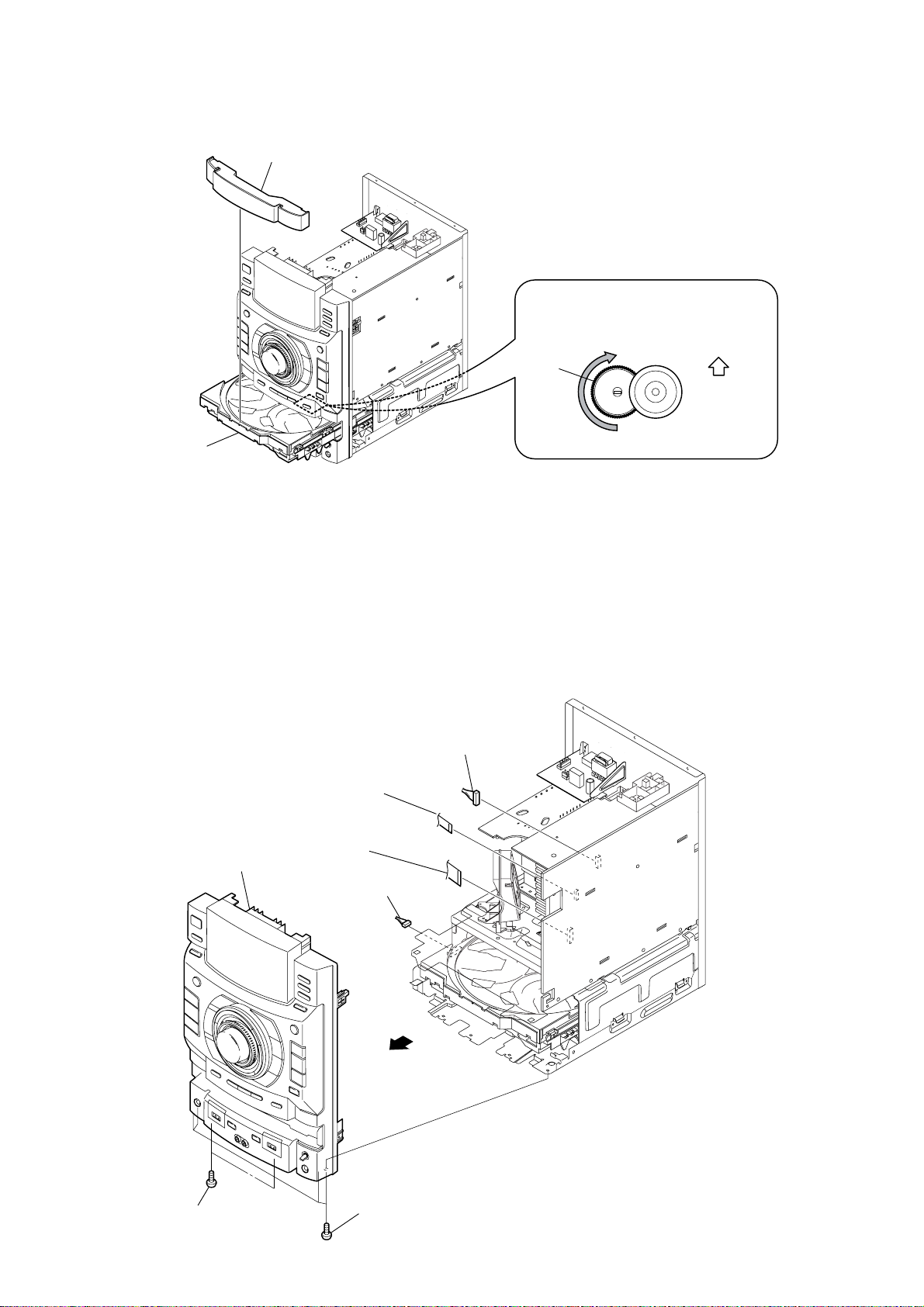

1. DESMONTAGEM

1-1. Case (Top) ............................................................................7

1-3. Loading panel ...................................................................... 8

1-4. Front Panel Section .............................................................. 8

1-5. MIC Board, USB Board, MICRV Board,

Headphone Board ................................................................ 9

1-6. Display Board, STR Board, CD SW Board ......................... 9

1-7. Tuner pack ......................................................................... 10

1-8. Subtrans Board .................................................................. 10

1-9. DC Fan, Power Transformer (T1200) ................................ 11

1-10. Main Board, Front Boars Section ...................................... 11

1-11. Front Board, GTH Subwoofer Board ............................... 12

1-12. Back Panel Section, DC Fan .............................................. 12

1-13. CD Block Section .............................................................. 13

1-14. DMB-19 Board, GTH HUB Board .................................... 13

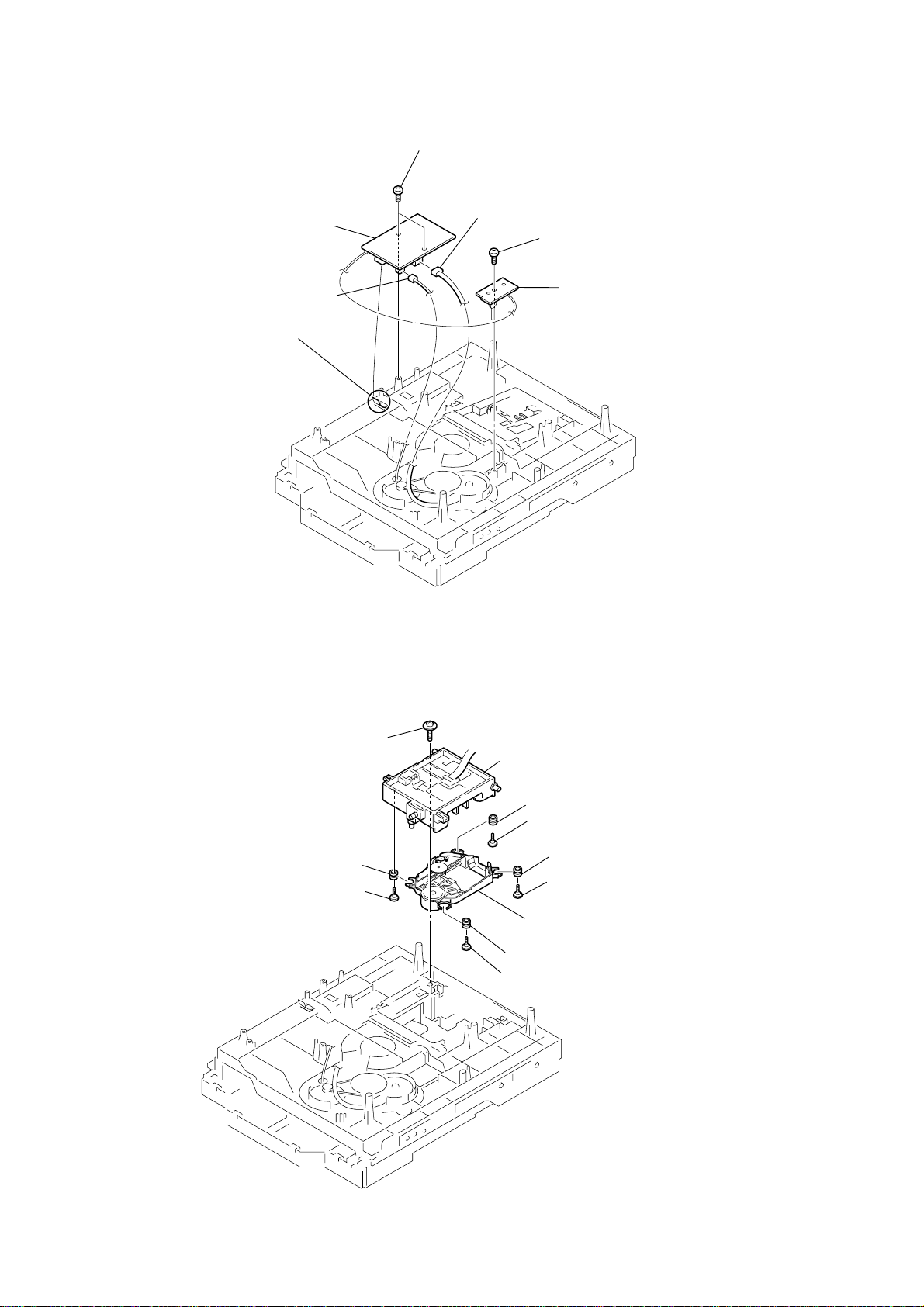

1-15. Driver MT Board, SW MT Board ..................................... 14

1-16. Optical Pick-up .................................................................. 14

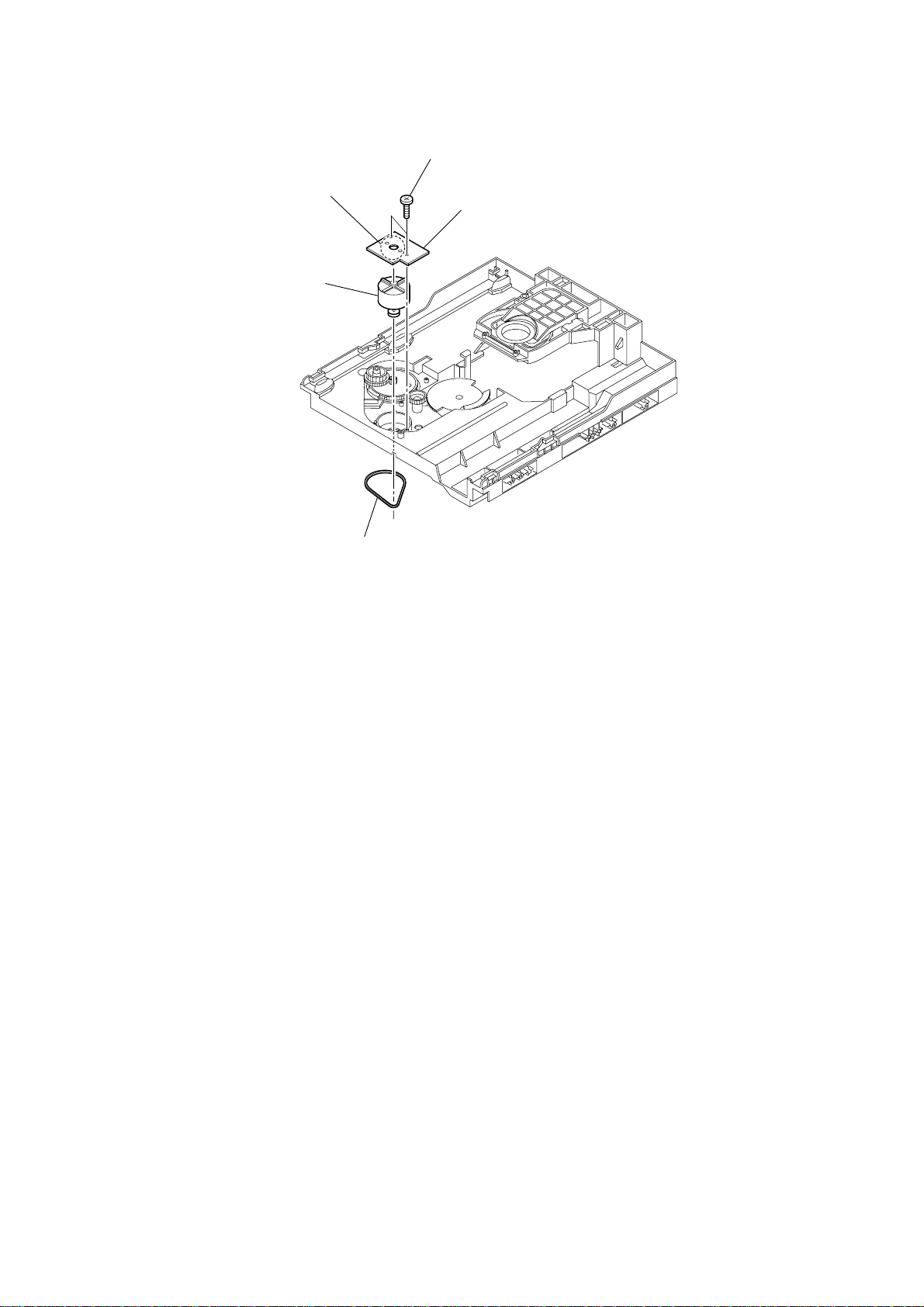

1-17. Sensor Board ...................................................................... 15

1-18. Motor(TB) Board ............................................................... 15

1-19. Motor (LD) Board ............................................................. 16

2. MODO DE TESTE ......................................................17

3. AJUSTES ELÉTRICOS .......................................20

HCD-GTR6H/GTR8

4. DIAGRAMAS

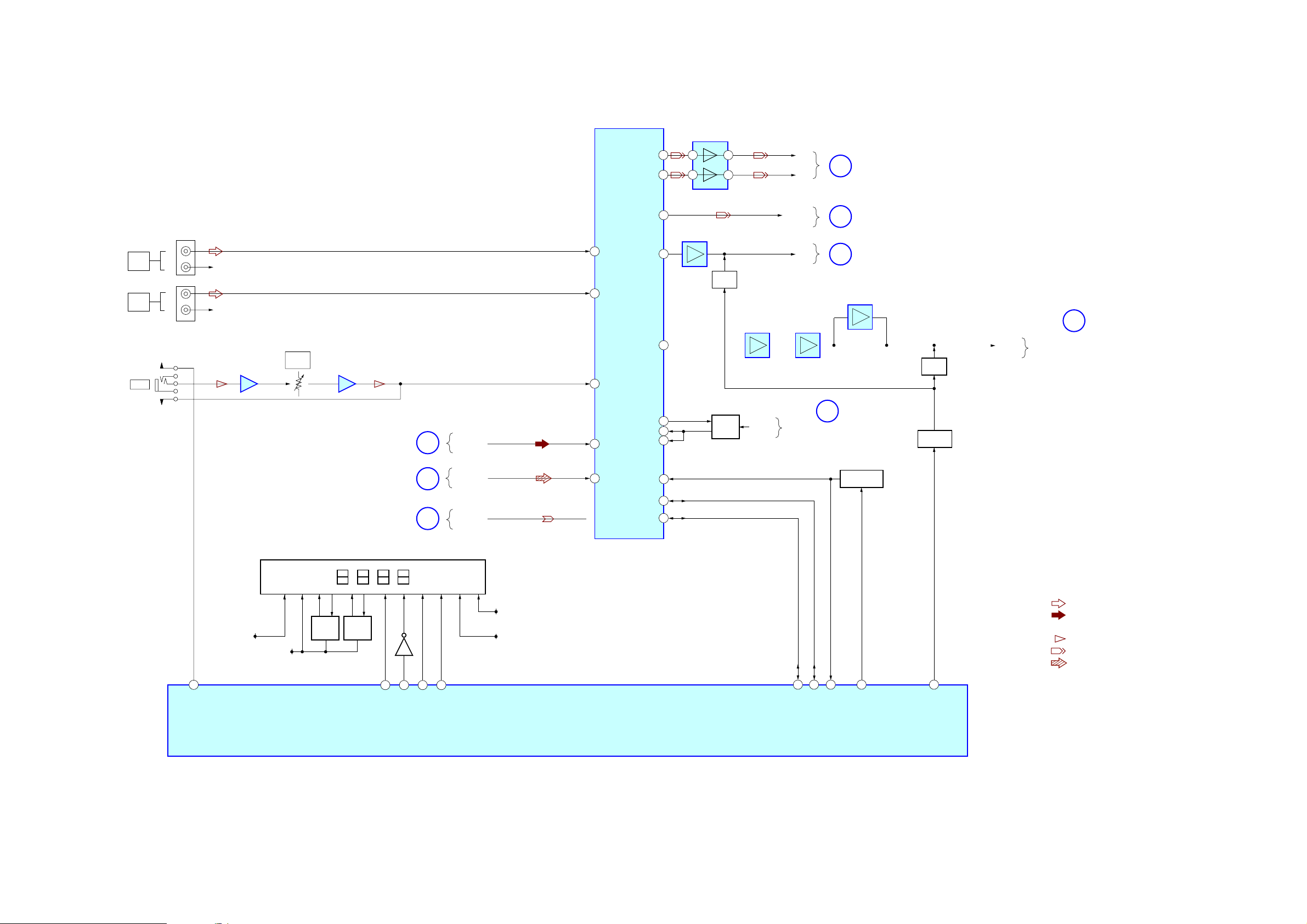

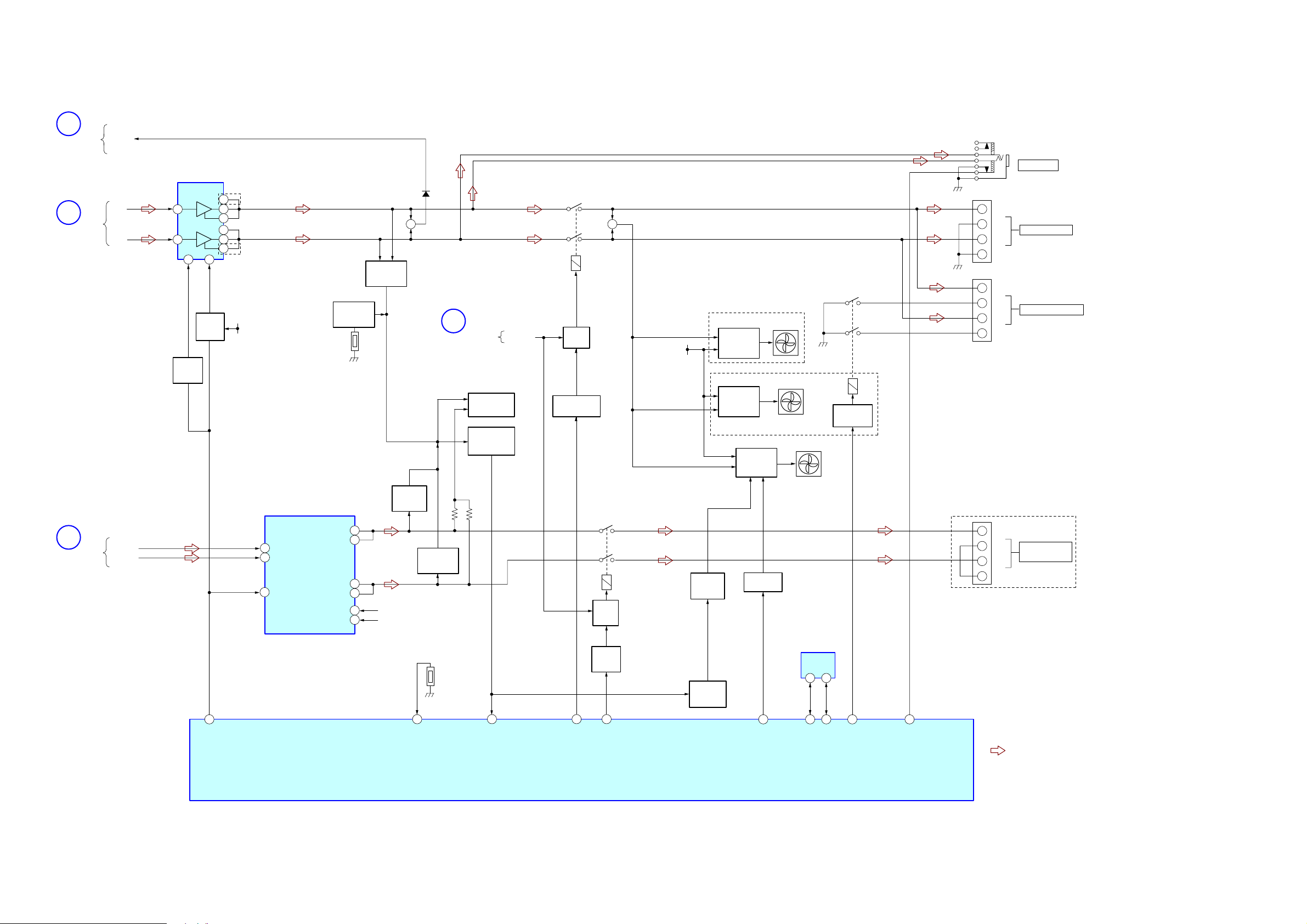

4-1. Block Diagram — USB Section — ...................................22

4-2. Block Diagram — RF/Servo Section — ...........................23

4-3. Block Diagram — Tape/Tuner Section — .........................24

4-4. Block Diagram — Main Section — ..................................25

4-5. Block Diagram — AMP/Subwoofer Section — ................26

4-6. Block Diagram — Display/Power Section — ...................27

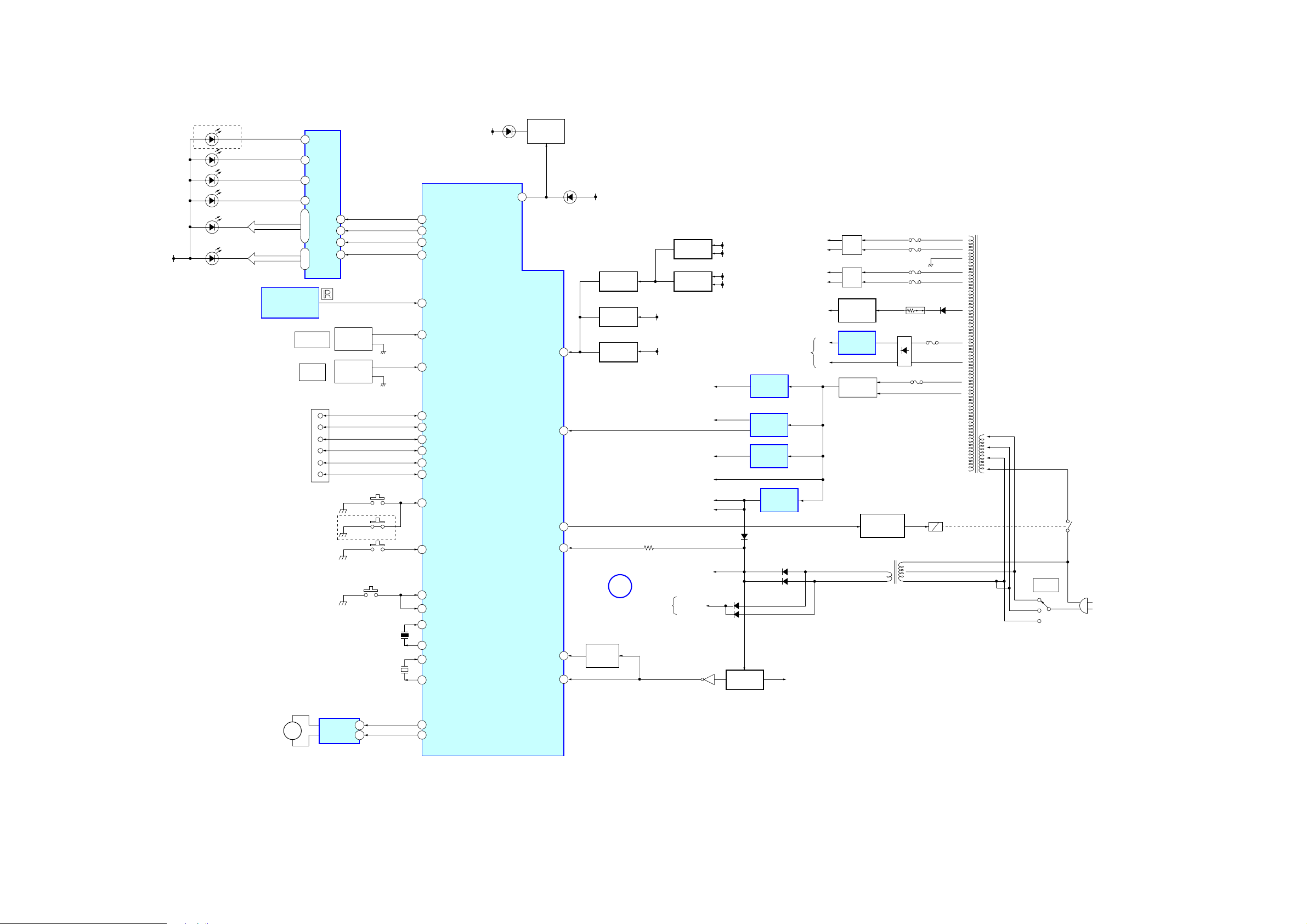

4-7. Circuit Boards Location .....................................................28

4-8. Printed Wiring Board — Display Board — .......................30

4-9. Schematic Diagram — Display Board — .........................31

4-10. Printed Wiring Boards — DMB19 Board — ....................32

4-11. Schematic Diagram — DMB19 Board (1/4) — ................33

4-12. Schematic Diagram — DMB19 Board (2/4) — ................34

4-13. Schematic Diagram — DMB19 Board (3/4) — ................35

4-14. Schematic Diagram — DMB19 Board (4/4) — ................36

4-15. Printed Wiring Board — Front Board — .......................... 37

4-16. Schematic Diagram — Front Board — .............................38

4-17. Printed Wiring Board — Main Board — ........................... 39

4-18. Schematic Diagram — Main Board (1/5) — .....................40

4-19. Schematic Diagram — Main Board (2/5) — .....................41

4-20. Schematic Diagram — Main Board (3/5) — .....................42

4-21. Schematic Diagram — Main Board (4/5) — .....................43

4-22. Schematic Diagram — Main Board (5/5) — .....................44

4-23. Printed Wiring Board — MIC and MIC RV Board — ......45

4-24. Schematic Diagram — MIC and MIC RV Board — .........46

4-25. Printed Wiring Board — STR and CD_SW Board — ......47

4-26. Schematic Diagram — STR and CD_SW Board — .........48

4-27. Printed Wiring Board — Trans and Sub Trans Board — ..49

4-28. Schematic Diagram — Trans and Sub Trans Board — .....50

4-29. Printed Wiring Board — Sub Woofer Board — ................51

4-30. Schematic Diagram — Sub Woofer Board — ...................52

4-31. Printed Wiring Boards —

Headphone and USB CD Board — ................................... 53

4-32. Schematic Diagram —

Headphone and USB CD Board — ................................... 54

4-33. Printed Wiring Board — HUB Board — ...........................55

4-34. Schematic Diagram — HUB Board — .............................56

4-35. Printed Wiring Board — DRIVER Board — ....................57

4-36. Printed Wiring Board — DRIVER Board — ....................58

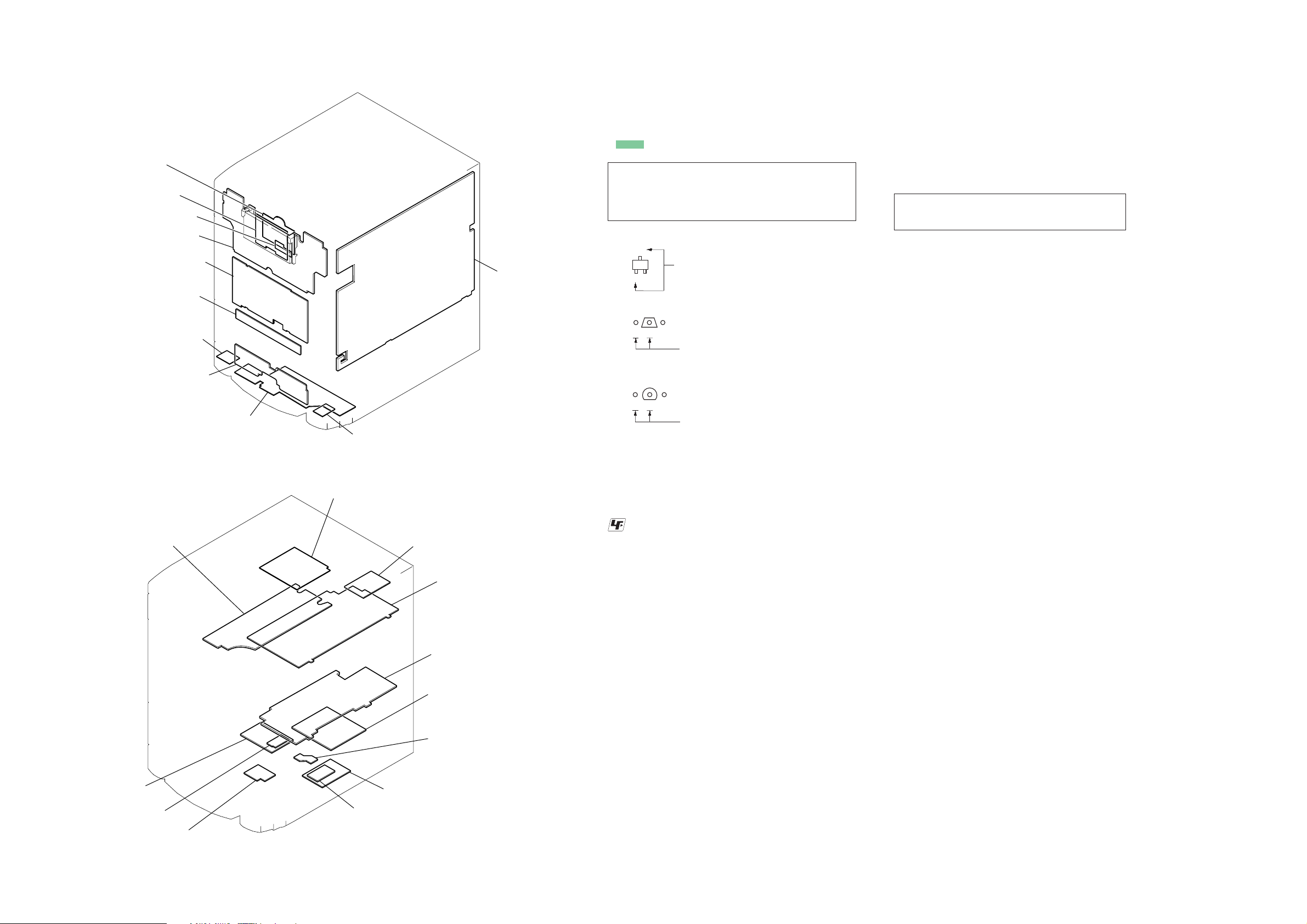

5. VISTA EXPLODIDAS

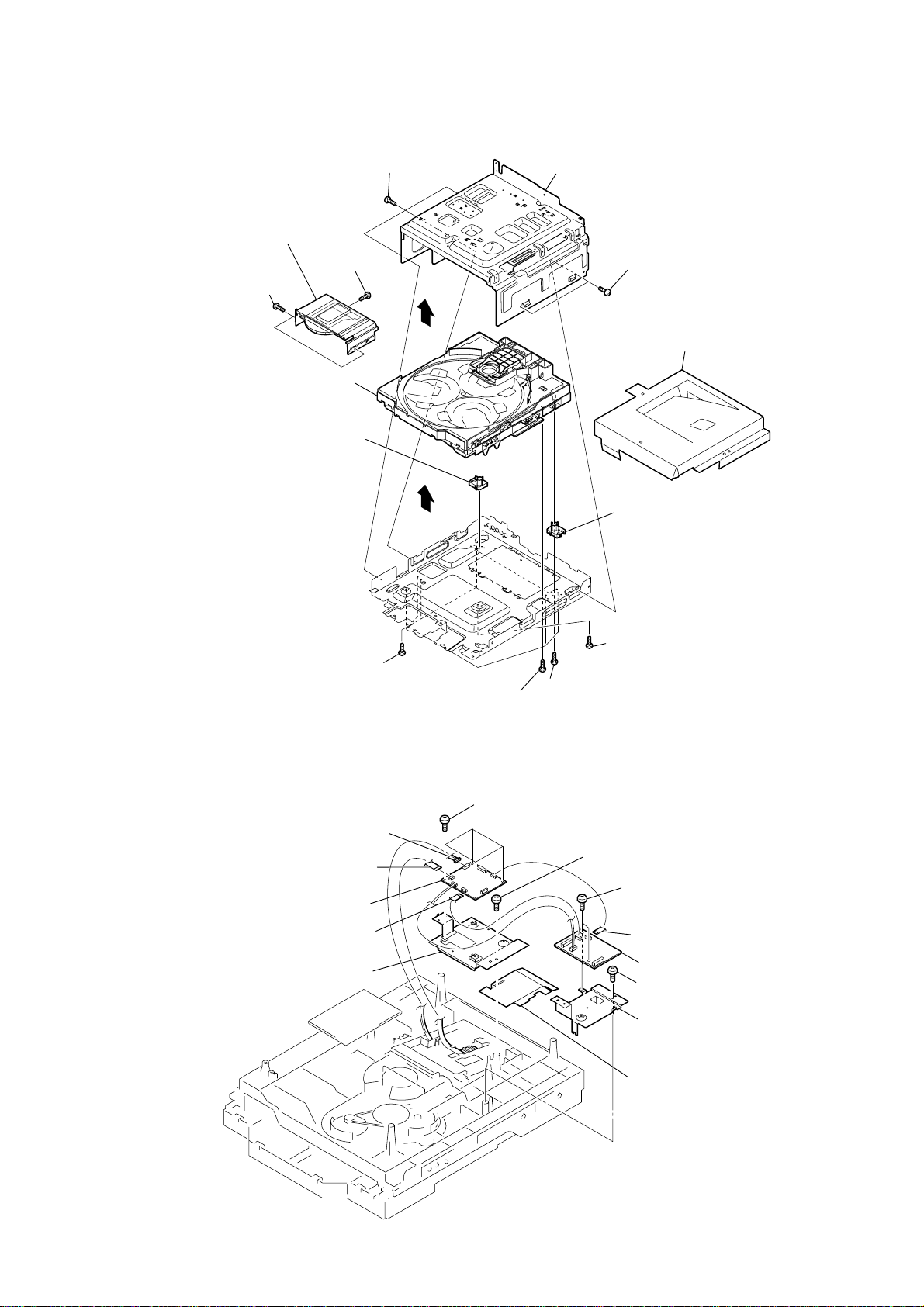

5-1. Main Section ......................................................................66

5-2. Back Panel Section ............................................................ 67

5-3. Front Panel Section (1) ......................................................68

5-4. Front Panel Section (2) ......................................................69

5-5. Chassis Section ..................................................................70

5-6. CD Mechanism Section (1) ...............................................71

5-7. CD Mechanism Section (2) ...............................................72

6. LISTA DE PEÇAS ELÉTRICAS.................................73

5

HCD-GTR6H/GTR8

SEÇÃO 1

DESMONTAGEM

Nota : Este aparelho pode ser desmontado conforme em ordem abaixo indicada:

APARELHO

1-1.

TAMPA SUPERIOR

(Pag. 7)

1-7. PLACA SUBTRANS

(Pag. 10)

1-2.

PAINEL DE CARREGAMENTO

(Pag. 8)

SEÇÃO PAINEL FRONTAL

1-3.

(Pag. 8)

1-4. PLACA MIC, PLACA USB

PLACA MICRV

PLACA HEADPHONE

(Pag. 9)

1-8. DC FAN, POWER TRANSFORMER

(Pag. 11)

1-9. PLACA MAIN,

SEÇÃO PLACA FRONT

(Pag. 11)

1-15. UNIDADE ÓTICA

(Pag. 14)

1-14. PLACA DRIVER MT

PLACA SW MT

(Pag. 14)

1-16. PLACA SENSOR

(Pag. 15)

1-17. PLACA MOTOR(TB)

(Pag. 15)

1-18. PLACA MOTOR(LD)

(Pag. 16)

1-5. PLACA DISPLAY,

PLACA STR

PLACA CD SW

(Pag. 9)

1-6. BLOCO SINTONIA

(Pag. 10)

1-10. PLACA FRONT,

PLACA SUBWOOFER

(Pag. 12)

1-11.

SEÇÃO PAINEL TRASEIRA, DC FAN

(Pag. 12)

1-12. SEÇÃO BLOCO CD

(Pag. 13)

7

1-13. PLACA DMB-19,

PLACA HUB

(Pag. 13)

Nota : Para desmontagem siga em ordem numérica dada:

1-1. TAMPA SUPERIOR

dois parafusos

(+BVTP 3 x 8)

tampa lateral esq.

um parafuso

(case 3 TP2)

dois parafusos

(tampa 3 TP2)

CN020 (8P)

RK

cabo tipo flat (9 vias)

RG

(CN040)

a

HCD-GTR6H/GTR8

RB

dois parafusos

(+BVTP 3 x 8)

RI

tampa superior

b

tampa lateral dir.

dois parafusos

(+BVTP 3 x 8)

(tampa 3 TP2)

dois parafusos

(tampa 3 TP2)

um parafuso

8

HCD-GTR6H/GTR8

1-2. PAINEL DE CARREGAMENTO

painel de carregamento

mecanismo do CD (CDM74KF)

Gire engrenagem em sentido da seta

engrenagem

lado chassi

Puxe bandeja do disco

1-3. SEÇÃO PAINEL FRONTAL

seção painel frontal

cabo tipo flat (11 vias)

(CN151)

cabo tipo flat (23 vias)

(CN150)

CN1501 (10P)

CN400 (13P)

Utilise chave de fenda

dois parafusos

(+BVTP 3 x 8)

quatro parafusos

(+BVTP 3 x 8)

9

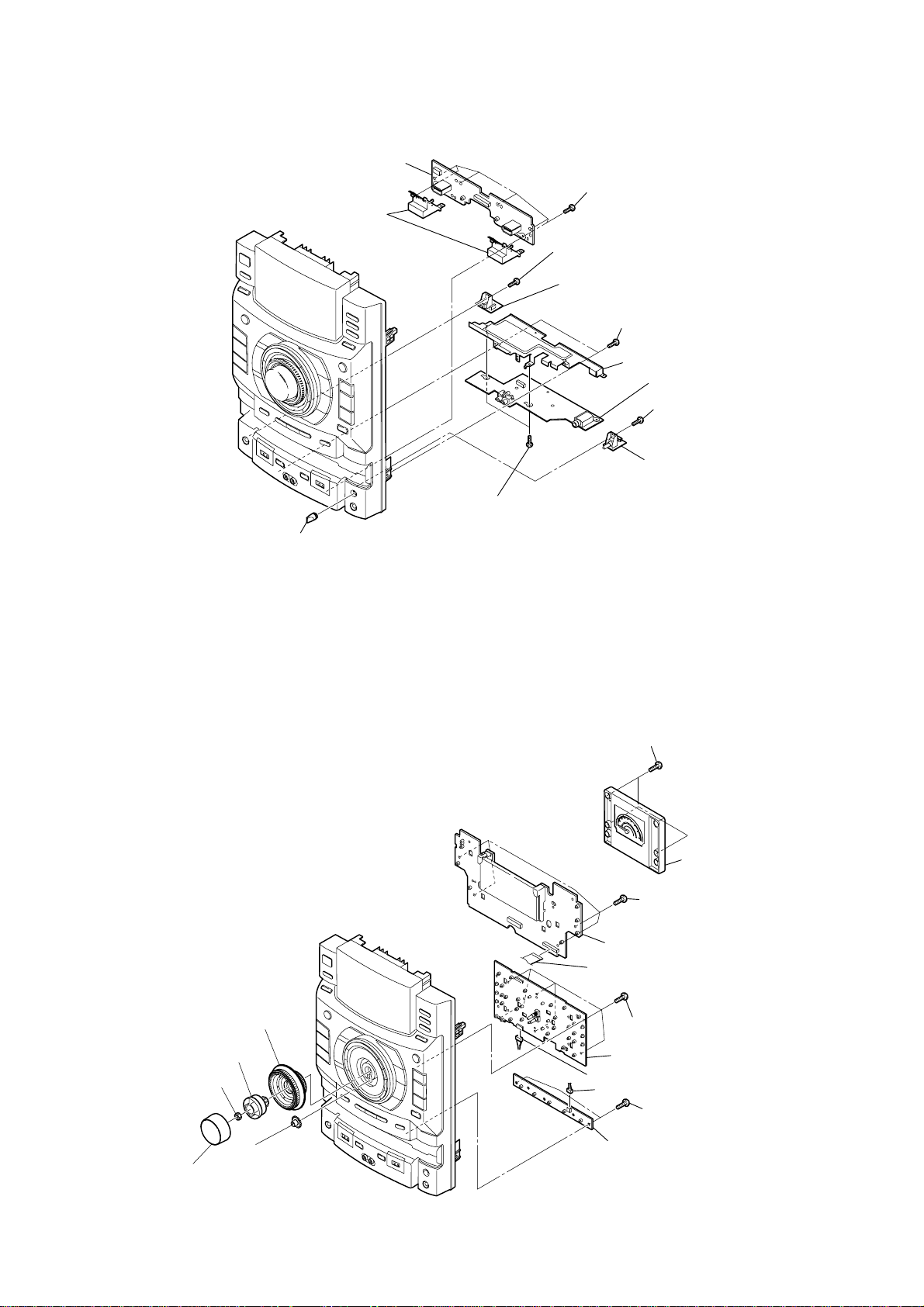

1-4. PLACA MIC, PLACA USB, PLACA MICRV, PLACA HEADPHONE

placa

USB

GROUND PLATE

(USB)

um parafuso

(+BVTP 2.6 (3CR))

placa

seis parafusos

(+BVTP 2.6 (3CR))

Headphone

dois parafusos

(+BVTP 2.6 (3CR))

Placa blindagem (MIC)

Placa

um parafuso

(+BVTP 2.6 (3CR))

RB

Placa

HCD-GTR6H/GTR8

MIC

MICRV

R

knob (MIC)

1-5. PLACA DISPLAY, PLACA STR, PLACA CD SW

dois parafusos

(+BVTP 2.6 (3CR))

três parafusos

(+BVTP 2.6 (3CR))

quatro parafusos

(+BVTP 2.6 (3CR))

placa Display

cabo tipo flat (23 vias)

(CN902)

meter display montado

botão jog montado

suporte (jog)

porca

R

engrenagem (encoder)

knob (volume)

RE

placa STR

RT

CN903 (6P)

RH

CN901 (2P)

RI

placa CD SW

RB

seis parafusos

(+BVTP 2.6 (3CR))

RG

dois parafusos

(+BVTP 2.6 (3CR))

10

HCD-GTR6H/GTR8

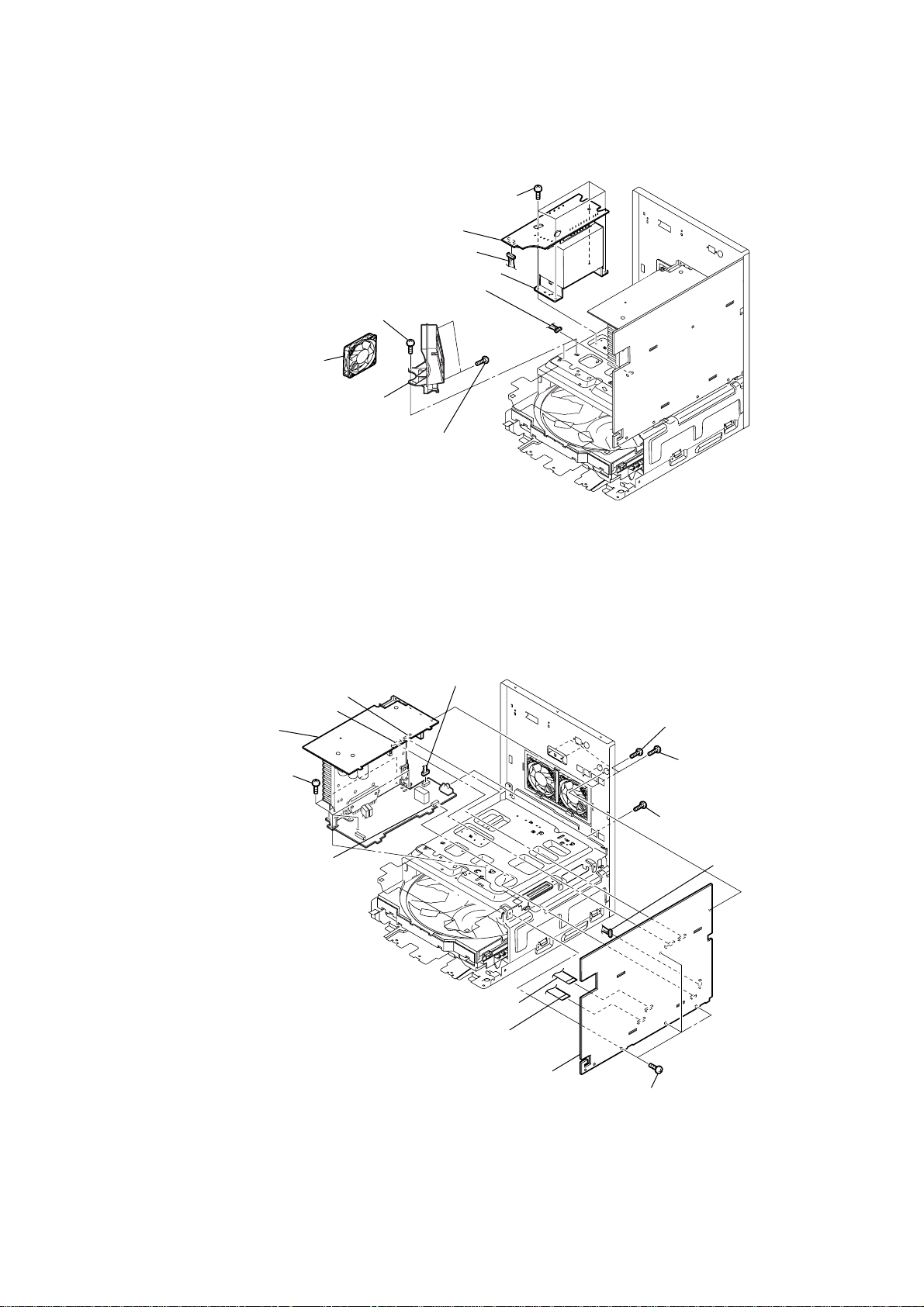

1-6. BLOCO DE SINTONIA

cabo tipo flat (5 vias)

(CN1)

bloco de sintonia

dois parafusos

(+BVTT 3 x 8)

1-7. PLACA SUBTRANS

CN1200 (2P)

CN1201 (4P), CN1202 (2P)

Placa

SUBTRANS

dois parafusos

(+BVTP 3 x 8)

CN1203 (4P)

Suporte (Subtrans)

dois parafusos

(+BVTP 3 x 10)

11

1-8. DC FAN, POWER TRANSFORMER (PT1250)

quatro parafusos

(+BVTT 4 x 8)

HCD-GTR6H/GTR8

dois parafusos

(+BVTP 3 x 8)

Ventilador DC

Suporte do Ventilador

transformador de força (PT1250)

TRANS

Placa

CN1250 (13P)

CN320 (3P)

dois parafusos

(+BVTP 3 x 10)

1-9. SEÇÃO DE PLACA MAIN, PLACA FRONT

Seçào placa Front

quatro parafusos

(+BVTP 3 x 8)

CN1303 (16P)

CN1302 (11P)

CN820 (3P)

um parafuso

(+BVTP 3 x 8)

quatro parafusos

(+BVTP 3 x 8)

CN801 (7P)

RB

cabo tipo flat (13 vias)

(CN110)

RT

cabo tipo flat (23 vias)

(CN500)

RG

Placa MAIN

quatro parafusos

R

(+BVTP 3 x 8)

um parafuso

(+BVTP 3 x 8)

CN090 (9P)

RE

12

HCD-GTR6H/GTR8

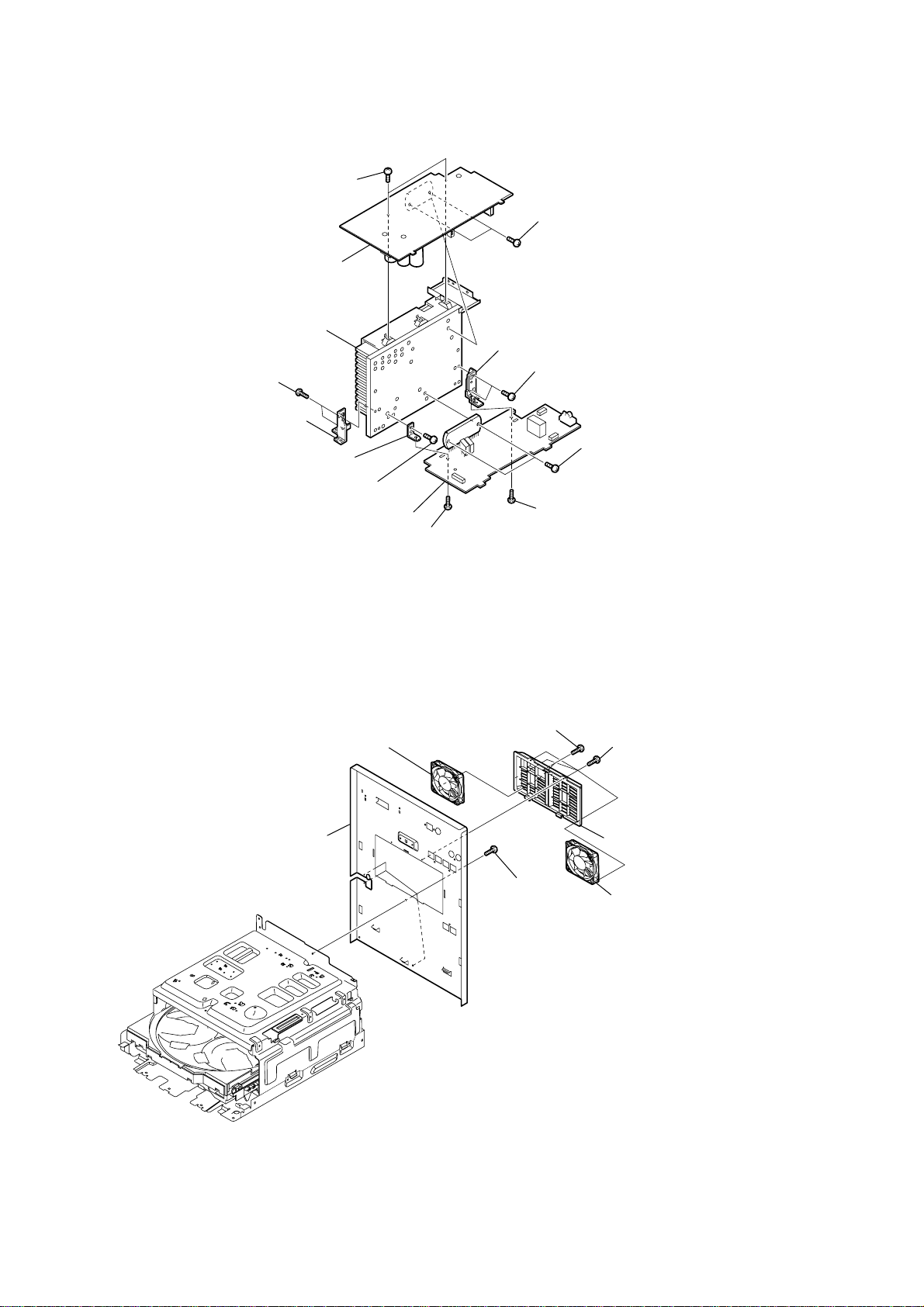

1-10. PLACA FRONT, PLACA SUBWOOFER

dois parafusos

(+BVTP 3 x 8)

Placa Front

R

dissipador montado

dois parafusos

(+BVTP 3 x 8)

Suporte (PWB)

Suporte (PC)

um parafuso

(+BVTP 3 x 8)

RG

SUBWOOFER

Placa

um parafuso

RE

(+BVTP 3 x 8)

Suporte(PWB)

RT

dois parafusos

(transistor)

dois parafusos

(+BVTP 3 x 8)

dois parafusos

RB

(transistor)

um parafuso

(+BVTP 3 x 8)

1-11. SEÇÃO PAINEL TRASEIRO, VENTILADOR DC

Ventilador DC

seção painel traseiro

dois parafusos

(+BVTP 3 x 10)

quatro parafusos

(+BVTP 3 x 8)

quatro parafusos

(+BVTP 3 x 8)

Tampa (ventilador)

Ventilador DC

13

1-12. SEÇÃO BLOCO DE CD

Cover Dust CDM Assy

dois parafusos

RB

(+BTTP M2-6)

seção bloco de CD

Suporte(CDM Support)

três parafusos

(+BVTP 3 x 8)

um parafuso

RT

(+BVTP 3 x 10)

Suporte (TRANS)

HCD-GTR6H/GTR8

dois parafusos

(+BVTP 3 x 8)

Tampa Protetora Inferior

dois parafusos

R

(+BVTP 3 x 8)

1-13. PLACA DMB19, PLACA HUB

CN201 (6P)

cabo tipo flat (24 vias)

(CN101)

placa

DMB19

cabo tipo flat (9 vias)

(CN1106)

Suporte(MTK-CD)

três parafusos

(+BVTP 3 x 8)

quatro parafusos

(+BVTP 3 x 8)

(+BVTP 2.6 x 8)

dois parafusos

(+BVTP 3 x 8)

um parafuso

(+BVTP 3 x 8)

Suporte (CDM Support)

um parafuso

R

dois parafusos

(+BVTP 3 x 8)

RB

cabo tipo flat (7 vias)

(CN1556)

RT

placa HUB

um parafuso

(+BVTP 3 x 8)

Suporte (USB HUB)

Folha Protetora de Poeira (BU)

14

HCD-GTR6H/GTR8

1-14. PLACA DRIVER MT, PLACA SW MT

placa DRIVER MT

CN704 (2P)

cabo tipo flat (5 vias)

(CN702)

dois parafusos

(+BVTT (M2.6))

CN703 (4P)

um parafuso

(+BVTT (M2.6))

placa SW MT

1-15. UNIDADE ÓTICA

parafuso flutuante

(+PTPWH M2.6)

amortecedor

parafuso do amortecedor

CD

montado

amortecedor

parafuso do amortecedor

amortecedor

parafuso do amortecedor

unidade ótica

(KHM-313CAB/C2NP)

amortecedor

parafuso do amortecedor

15

1-16. PLACA SENSOR

badeja

(+PTPWH M2.6)

(+PTPWH M2.6)

engrenagem

parafuso flutuante

um parafuso

(+BTTP (M2.6))

parafuso flutuante

(geneva)

placa

CN731

(3P)

SENSOR board

b

elt (table)

parafuso flutuante

(+PTPWH M2.6)

polia

(mesa)

HCD-GTR6H/GTR8

1-17. PLACA MOTOR (TB)

mesa

stopper

Remova dois pontos de soldas

dois parafusos

(+BTTP (M2.6))

stopper

motor da mesa montada

cabo tipo flat (5 vias)

(CN742)

placa

MOTOR (TB)

(M741)

16

HCD-GTR6H/GTR8

1-18. PLACA MOTOR (LD)

Remova dois pontos de soldas do motor

motor de carregamento montado

(M751)

dois parafusos

(+BTTP (M2.6))

placa

MOTOR (LD) board

correia (carregamento)

17

SEÇÃO 2

MODO DE TESTE

[GC TEST MODE]

• This mode is used to check the fl uorescent indicator tube, LEDs,

keys, VOLUME jog, OPERATION DIAL jog, model, destination

and software version.

Procedure:

1. Press [x] button, [ENTER] button and [DISC 2] button si-

multaneously.

2. All LEDs and segments in fl uorescent indicator tube are light-

ed up. All LEDs are lighted up in red color except for [

LED where the LED is lighted up in red and blue color,

[ A] LED in blue color and SUBWOOFER ON/OFF in

green color.

3. When you want to enter to the model version and destination

display mode, press [DISC 1] button. The model information

appears on the fl uorescent indicator tube.

4. Each time [DISC 1] button is pressed, the display changes to

display software version and date of the software creation.

The sequence is model destination, SC, MDK, GC, SYS, CD,

CDMA, CDMB, ST, TC, TA, TM and MTR in this order, and

returns to the model destination display.

5. Press [DISC 2] button, the key check mode is activated.

6. In the key check mode, the fl uorescent indicator tube displays

“K 0 J0 V0”.

Turn the [OPERATIONAL DIAL] clockwise; ”J” value in-

creases by one. Turn the [OPERATIONAL DIAL] counterclockwise; “J” value decreases by one. Each time a button is

pressed, “K” value increases. Press other keys on main unit

to check whether the key is detected. However, once a button

has been pressed, it is no longer taken into account.

“V” value increases in the manner of 0,1, 2, 3 ... if [VOLUME]

knob i s tu rned clock wis e, or it d ecr eas es i n th e ma nne r of 0 , 9,

8, 7 ... if [VOLUME] knob is turned counterclockwise.

7. When [DISC SKIP/EX-CHANGE] button is pressed after

all LEDs and segments in fl uorescent indicator tube light

up, alternate segments in fl uorescent indicator tube and LED

would light up. If you press [DISC SKIP/EX-CHANGE] button again, another half of alternate segments in fl uorescent

indicator tube and LED would light up. Press [DISC SKIP/

EX-CHANGE] button again would cause all segments will

lights off and press [DISC SKIP/EX-CHANGE] button again

all segments will lights up.

8. To release from this mode, press three buttons in the same

manner as step 1, or disconnect the power cord.

B]

HCD-GTR6H/GTR8

4. When the [VOLUME] knob is turned clockwise even slightly,

the sound volume increases to its maximum and a message

“VOLUME MAX” appears on the fl uorescent indicator tube.

5. When the [VOLUME] knob is turned counterclockwise even

slightly, the sound volume decreases to its minimum and a

message “VOLUME MIN” appears on the fl uorescent indica-

tor tube.

• Tape function (only for HCD-GTR6B/GTR8B)

1. Inserted a tape in deck. The function is changed to VIDEO

automatically when the recording is started by pressing [REC

TO TAPE] then press [ENTER] button. During recording the

ALC (Automatic Logic Control) is turned on.

2. During recording, press ALBUM - will stop the recording

and the function is changed to TAPE and rewind the tape in

Deck until the recording start position and playback of the

tape in Deck is started.

• To release from MC Test mode

1. To release from this mode, press [POWER] button.

2. The cold reset is enforced at the same time.

[COLD RESET]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning the

set to the customer.

Procedure:

1. Press [x] button, [ENTER] button, and [POWER] button simultaneously.

2. The fl uorescent indicator tube becomes blank for a while, and

the set is reset.

[VACS ON/OFF]

• This mode is used to switch ON and OFF the VACS (Variable

Attenuation Control System).

Procedure:

1. Press [POWER] button to turn the set ON.

2. Press [x] button and [OPTIONS] button simultaneously. The

message “VACS OFF” or “VACS ON” appears on the fl uores-

cent indicator tube.

[MC TEST MODE]

• This mode is used to check operations of the respective sections

of Amplifi er and Tape.

Procedure:

• To enter MC Test Mode

1. Press [x] button, [ENTER] button and [DISC 3] button si-

multaneously.

2. The CD number indicators fl ash on the fl uorescent indicator

tube. The function is changed to VIDEO.

• Check of Amplifi er

1. Press [EQ BAND] button repeatedly until a message “GEQ

MAX” appears on the fl uorescent indicator tube. GEQ in-

creases to its maximum.

2. Press [EQ BAND] button repeatedly until a message “GEQ

MIN” appears on the fl uorescent indicator tube. GEQ de-

creases to its minimum.

3. Press [EQ BAND] button repeatedly until a message “GEQ

FLAT” appears on the fl uorescent indicator tube. GEQ is set

to fl at.

[TUNER STEP CHANGE]

• The step interval of AM channels can be toggled between 9 KHz

and 10 KHz. This mode is not available for Saudi Arabian models.

Procedure:

1. Press [POWER] button to turn the set ON.

2. Press [TUNER/BAND] / [TUNER AM] button to select the

“A M”.

3. Press [POWER] button to turn the set OFF.

4. Press [ENTER] button and [POWER] button simultaneously.

The system will turn ON automatically. The message “AM

9K STEP” or “AM 10K STEP” appears on the fl uorescent in-

dicator tube and thus the channel step is changed.

18

HCD-GTR6H/GTR8

[CD SHIP MODE (WITH MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable to

vibration and clears all data including preset data stored in the

RAM to initial conditions. Use this mode when returning the set

to the customer after repair.

Procedure:

1. Press [POWER] button to turn the set ON.

2. Select CD function and waiting until CD no disc confi rm.

3. Press [x] button, [SOUND FLASH] button and [POWER]

button simultaneously. The set will power off automatically.

4. After the “STANDBY” blinking display fi nishes, a message

“MECHA LOCK” is displayed on the fl uorescent indicator

tube and the CD ship mode is set.

5. Then AC power OFF.

[CD SHIP MODE (WITHOUT MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press [POWER] button to turn the set ON.

2. Select CD function.

3. Press [CD] button and [POWER] button simultaneously. The

set will power off automatically.

4. After the “STANDBY” blinking display fi n i s h e s , a m e s s a g e

“MECHA LOCK” is displayed on the fl uorescent indicator

tube and the CD ship mode is set.

5. The AC power OFF.

3. The VACS Level Display, the fl uorescent indicator tube dis-

plays “VATB F APC”. “V” represent VACS , A represent

VACS level which is triggered by signal level, “T” represent

Thermal VACS NEO, B represent VACS level which is triggered by temperature, “F” represent FAN is triggered by

software to turn in to high speed, “AP” represent APVACS

(Abuse Protection VACS) and “C” represent APVACS level

which is triggered.

[METER AGING TEST MODE]

• This mode use in factory to perform the non-stop aging mode for

meter device.

Procedure:

1. Press [POWER] button to turn on the system.

2. Press [EQ BAND/MEMORY] button and [METER MODE]

button simultaneously.

[ERROR MESSAGE]

1. METER ERROR CODE CHECK

• This mode is used to check the number of trigger for Meter Pointer

to initial switch and end switch. The switches will trigger during

meter initialize in AC supply on condition.

Procedure:

1. Press [POWER] button to turn on the system.

2. Press [x] button, [EQ BAND/MEMORY] button and [METER MODE] button simultaneously.

[CD TRAY LOCK MODE / DISC THEFT

PREVENTION]

• This mode let you lock the disc tray. When this mode is activated,

the disc tray will not open when [OPEN/CLOSE] button or [EXCHANGE] button is pressed. The message “LOCKED” will be

displayed on the fl uorescent indicator tube.

Procedure:

1. Press [POWER] button to turn the set ON.

2. Select CD function.

3. Press [x] button and [OPEN/CLOSE] button simultaneously

and hold down until “LOCKED” or “UNLOCKED” displayed on the fl uorescent indicator tube (around 5 seconds).

The Meter Er ror Code will appear on the fl uorescent indicator

tube displays

• Display

Display on fl uorescent indicator tube,

IxxxxxMyyyyy

Ixxxxx = total number of Initial Switch touch by Meter

pointer. The Initial Switch will touch twice during meter

initialized process.

Myyyyy = total number of End Switch touch by Meter

pointer. The End Switch will touch one times during meter

initialized process.

[VACS DISPLAY]

• This mode is used to check the VACS level.

Procedure:

1. Press [POWER] button to turn on the system.

2. Press [x] button, [SOUND FLASH] button and [DISC SKIP/

EX-CHANGE] button simultaneously.

19

HCD-GTR6H/GTR8

SEÇÃO 3

AJUSTES ELÉTRICAS

TUNER SECTION 0 dB = 1 µV

[FM Tune Level Check]

FM signal generator

SET

Procedure:

1. Turn the power on.

2. Input the following signal from Signal Generator to FM antenna input directly.

* Carrier Freq : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Please use 75 ohm “coaxial cable” to connect SG and the set. You

cannot use video cable for checking.

Please use SG whose output impedance is 75 ohm.

OUT (75 7)

3. Set to FM tuner function and tune A, B and C signals.

4. Confi rm “TUNED” is lit on the display for A, B and C sig-

nals.

The mark of “TUNED” means “The selected station signal is

received in good condition.”

20

MEMO

HCD-GTR6H/GTR8

21

HCD-GTR6H/GTR8

SEÇÃO 4

DIAGRAMAS

4-1. DIAGRAMA EM BLOCOS — SEÇÃO USB —

A

1

4

USB_DP

USB_DM

VBUS_B

D- B

D+ B

GND

RF/SERVO

SECTION

(Page 23)

CN1000

(USB)

31

30

3

4

USBUP_DP

USBUP_DM

USBDN2_DM

USBDN2_DP

IC1501

USB CONTROLLER

CN1001

(USB)

Signal Path

XTAL2

RESET_N

VBUS_DET

33

X1500

24MHz

32

26 21

27

SYSTEM CONTROL

USB_HUB_RESET

22

HUB_VBUS_DET

18

USB-OC1

USB-OC2

19

IC500 (4/6)

VBUS_A

1

D- A

D+ A

GND

4

IC1500

: USB

SINGLE-SUPPLY

DUAL COMPARATOR

+IN2

5

+IN1

3

OUT1

OUT2

VCC

M+9V

8

1

7

1

2

13

17

USBDN1_DM

USBDN1_DP

OSC1_N

OSC2_N

XTAL1/CLKIN

22

23 23

HCD-GTR6H/GTR8

HCD-GTR6H/GTR8

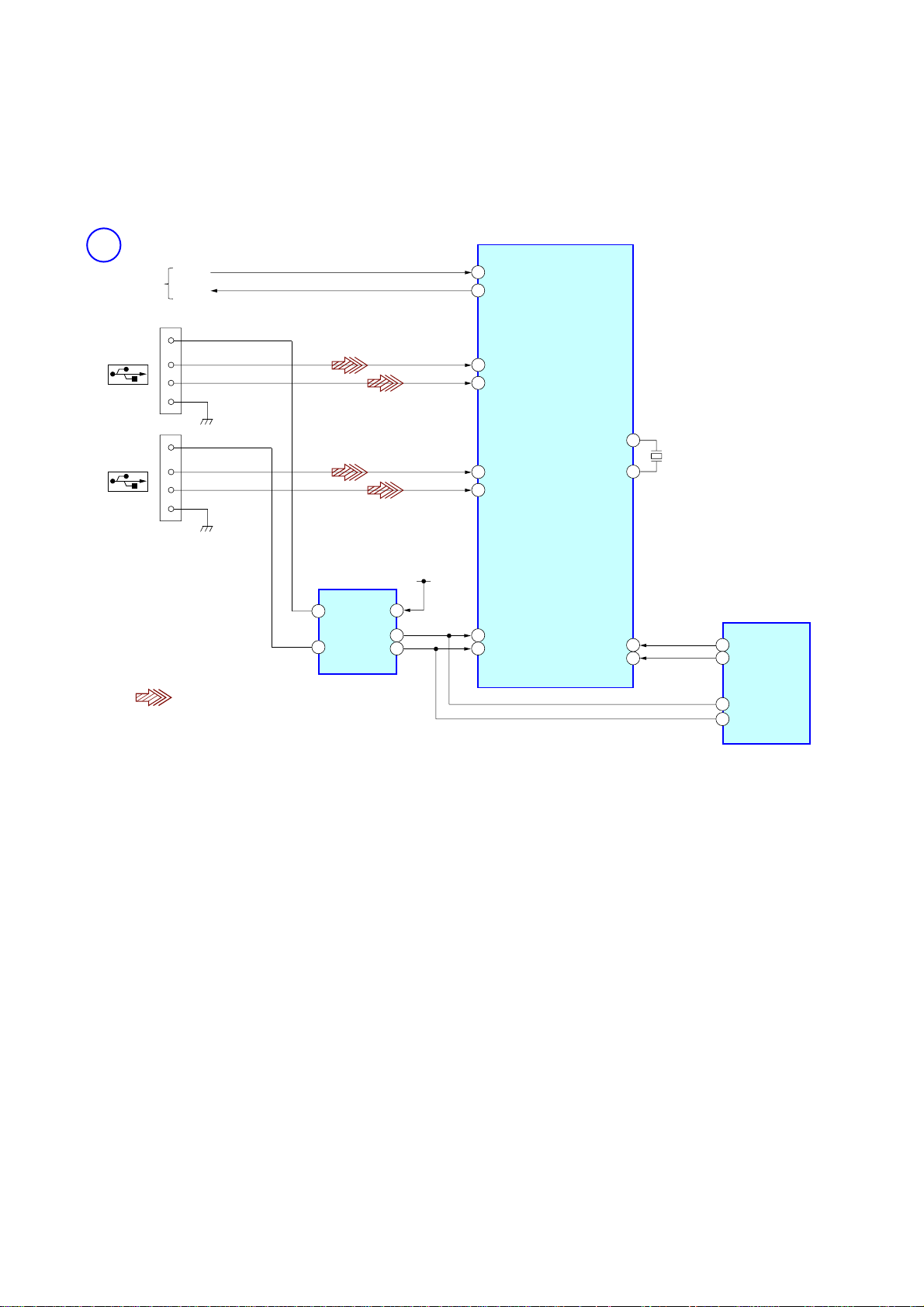

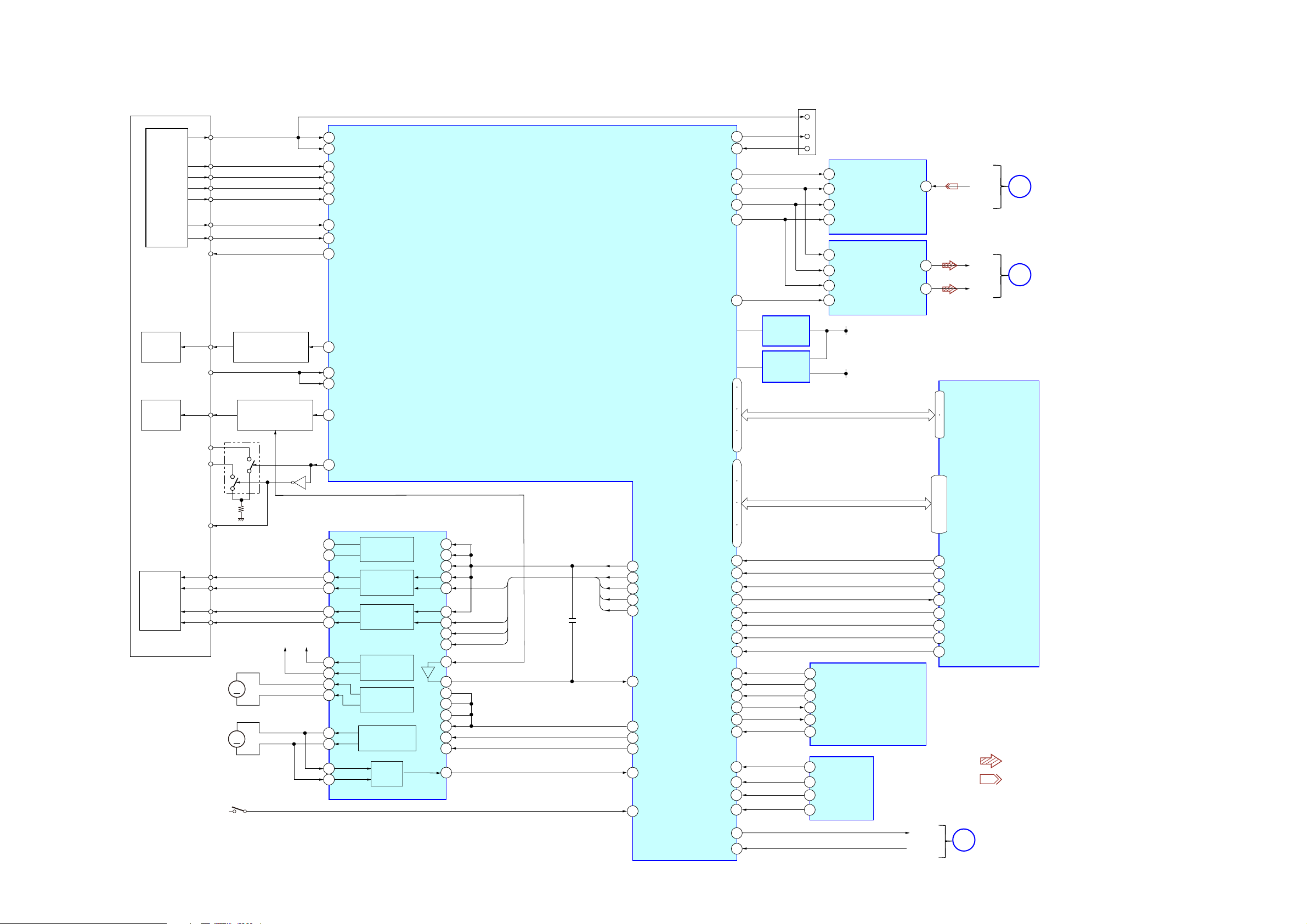

4-2. DIAGRAMA EM BLOCOS — SEÇÃO RF/SERVO —

DETECTOR

125

2

3

4

5

19

18

RFIP

OPOUT

RF_C

RF_B

RF_A

RF_D

RF_E

RF_F

LD01

MDI2

LD02

MSW

MDI1

CD RF AMP,

FOCUS/TRACKING ERROR AMP

CD SYSTEM PROCESSOR

DIGITAL SERVO PROCESSOR

IC101

OPTICAL PICK-UP

BLOCK

(KHM-313CAB)

2AXIS

DEVICE

FOCUS/

TRACKING

COIL

17

16

18

15

36 48

43

12

9

37 1

Q102 (2/2)

AUTOMATIC POWER

CONTROL (FOR DVD)

Q102 (1/2)

AUTOMATIC POWER

CONTROL (FOR CD)

LASER

DIODE

(FOR CD)

LASER

DIODE

(FOR DVD)

FOCUS COIL

DRIVE

42

41

BUFFER

35 3

34 4

TRACKING COIL

DRIVE

32

31

21

25

20

24

13

SLED MOTOR

DRIVE

FOCUS/TRACKING COIL DRIVER,

SPINDLE, SLED MOTOR DRIVER

IC201

27

28

SPINDLE MOTOR

DRIVE

MM

M1

(SPINDLE)

S1

(LIMIT)

46

47

FMO

FOO

DMO

TRO

VREFO

127

IOPMON

FOO

RF

A

B

C

D

E+H

E+G

CD LD

VC

PD

VR650

VR780

DVD LD

FCS+

MSW

FCS–

TRK+

REG02

REG01

TRK–

SP+

SP–

SL+

SL–

NC

NC

VREFO

V2O

12

30

29

SLED MOTOR

DRIVE

MM

M2

(SLED)

23

BUFFER

21

20

22

45

19

42

40

SYSTEM

CONTROLLER

IC500 (1/6)

64M RAM

IC104

91

TXD

40

IFSCK

MTK_CLK

33

TXD

CN105

RXD

RFMON

89

RXD

43

PRST

37

DF_D0

38

SF_CL

39

SF_CK

36

SF_CS

MTK-RESET

23

88

IFCS MTK_XIFCS

24

35

IFSDI

87

IFBSY MTK_BUSY

25

MTK SIO

47

78

BA0

BA0

20

80

BA1

BA1

21

55

DQSM

LDQM

15

75

RWE

WE

16

76

CAS0

CAS

17

77

RAS0

RAS

18

66

RCLK

CLK

38

65

DQM1

UDQM

39

TRO

10

13

FMO

IOP

IOPMON

DMO

107

MUTE123

22

MUTE4

94

GP1O

128

SPFG

MUTE123

MUTE

TSD M

SPFG

108

LIMSW

Q101

Q103

7

6

(FOR TEST)

1

2

6

• Signal Path

: CD PLAY

: REC

126

41

IFSOD

MTK_SOD

48

FLASH

MEMORY

IC102

1.2V REG

IC 111

1.2V REG

IC107

SI

2

SCK

5

CS

6

SO

1

STEREO

CONVERTER

A/D

IC4601

114

GPIO

GPIO

GPIO

GPIO19

SCKI

6

119

LRCK

7

115

GPIO

120

BCK

8

106

DOUT

VINL

9

CONVERTER

D/A

IC4602

MCLK

AOUT-L

AOUT-R

4

LRCK

3

SCLK

2

SDATA

1

13

L IN

8

LOUT

5

ROUT

67

69

I

81

I

I

83

85

RA0

USB_DP

27

USB_DM

USB_DP

USB_DM

28

74

I

RA11

45

I

RD0

49

51

I

53

56

I

59

61

I

64

I

RD15

A0

I

A3,

A10

A4

I

A9,

A11

22

I

26

29

I

35

QG0,

DQ1

I

DQ15

2,4,5,7,8,10,11,13,42,

45,47,48,50,51,53,55

R-CH is omitted due to same as L-CH.

DVDD3.3V

DVDD5V

86

J

MAIN

SECTION

(Page 25)

B

MAIN

SECTION

(Page 25)

A

USB

SECTION

(Page 22)

2424

HCD-GTR6H/GTR8

HCD-GTR6H/GTR8

4-3. DIAGRAMA EM BLOCOS — SEÇÃO TUNER —

ST-L

MAIN

ST-R

TU901

FM/AM TUNER UNIT

ANTENNA

ST-L

FM ANT

AM ANT

AM ANT

ST-R

ST-DIN

ST-DOUT

ST-CLK

ST-CE

FM 75

COAXIAL

AM

ST-DIN/UC-OUT

ST-DOUT/UC-DIN

ST-CLK

ST-CE

46 3

E-1

40

E-2

42

E-3

43

65

60

63

TUNED

ST-TUNED

58

61

SYSTEM CONTROL

IC500 (2/6)

R-CH is omitted due to same as L-CH.

4

1

2

TABLE ADDRESS SENSOR

IC731

TBL MOTOR DRIVER

IC712

M+9V

Q731

RE701

ROTARY ENCODER

DISC TRAY

ADDRESS DETECT

S751

OPEN/CLOSE

DETECT

TBL SENSE

OPENSW

46

MOTOR

DRIVE

M741

(TABLE)

M

TM F

FIN

RIN

39

TM R

38

7

9

OUT2

OUT1

2

4

: TUNER

Signal Path

E

(Page 25)

SECTION

4-4. DIAGRAMA EM BLOCOS — SEÇÃO MAIN —

J1001

MIC

L

IN

R

J020

L

IN

R

RCH

RCH

IC1000

MIC AMP

(1/2)

RV1001

MIC

LEVEL

AUDIO

VIDEO

J1004

IC1000

MIC AMP

(2/2)

IC400

INPUT SELECT SWITCH

44

PC-L

41

VIDEO-L

46

MIC

RECAR

RECAL

RECBL

OUTL

AGCOUTL

HCD-GTR6H/GTR8

IC251

3

6

5

37

36

IC252

26

25

USB RECORD

PREAMP

MUTE

1

7

Q270

IC253 IC254

R-IN

L-IN

REC OUT L

FL-IN

RF/SERVO

J

SECTION

(Page 23)

TAPE/TUNER

D

SECTION

(Page 24)

AMP/SUBWOOFER

F

SECTION

(Page 26)

IC730

Q245

MUTE

SW OUT

G

AMP/SUBWOOFER

SECTION

(Page 26)

76

MIC-DET

D+3.3V

+VG

8

SWITCH SWITCH

TUNER

SECTION

(Page 24)

RF/SERVO

SECTION

(Page 23)

ND900

Q903Q902

1012484546 479

CIG-CLK

Q901

GIG-BK

35 282637

E

REFOUT

48

BB2L

27

BB1L

DATA

CLOCK

28

9SA2

21

22

GIG-LATCH

CD LCH

15

ST-L

3

VF+

VF-

X

XB

X

1113

CIG-DATA

43

ST-L

42

CD-L

SYSTEM CONTROL

IC500 (3/6)

Q128

DBFB

SWITCH

DBFB F/B

AMP/SUBWOOFER

I

SECTION

(Page 26)

Q210

METER LEVEL

AMP

52 53 51

AUDIO IC DATA

AUDIO IC CLOCK

71

70

VAC-IN

METER LEVEL

LINE MUTE

Q290

R-CH is omitted due to same as L-CH.

Signal Path

: AUDIO

: TUNER

:

: MIC

: REC

: CD PLAY

LINE MUTE

HCD-GTR6H/GTR8

25 25

2626

HCD-GTR6H/GTR8

HCD-GTR6H/GTR8

4-5. DIAGRAMA EM BLOCOS — SEÇÃO AMP/SUBWOOFER —

IC1301: GTR8

IC1300: GTR6

MUTING

Q1312

-1314

FR-IN

DBFB F/B

FL-IN

31

STK MUTE

1216

OVERLOAD

DETECT

Q1303,1308

+ +

33 77

LINK RELAY

97

EEPROM_DATA

95

5 6

EEPROM_CLOCK

HP DET

AC-CUT

Q1301

FRONT REPLAY

Q1302

+VL

-VL

IN2

ST BY

+RE1

-RE1

+RE2

-RE2

+VCC

-VCC

+

-

-

+

FRONT SPEAKER

SUB WOOFER

OUT

L

R

HEADPHONE

J1005

RY1301

RY862

+

-

-

+

L

R

FAN

DRIVE

Q031-Q034

DRIVE

TH1301

THERMAL

DETECT

Q1309,Q1310

67

THERMAL VACS

TB801

JK1301

D104

18

11

10

22

9

14

8

SIGNAL PATH

POWER AMP

32

PROTECTOR

50

FR RELAY

56

FAN ON

G

MAIN

TH1300

11

4

5

6

7

3

2

13

SUBWOOFER POWER AMP

IC800

SYSTEM CONTROL

IC500 (5/6)

PROTECTOR

Q1305,Q1307

DC DETECT

Q1304,Q1306

OVERLOAD

DETECT

Q850

Q788

RELAY

DRIVE

Q789

OVERLOAD

DETECT

Q800

RY1300

GTR6

GTR8

HI SPEED

SWITCH

Q035

PROTECTOR

SWITCH

Q532

+

-

-

+

SURROUND SPEAKER

L

R

JK1300

RELAY DRIVE

Q1300

45

SW-RELAY

R-CH is omitted due to same as L-CH.

EEPROM

IC675

FAN DETACT

Q030

GTR8

GTR8

GTR8

UNREG

+VH

STANDBY

Q1315,

Q1316

: AUDIO

IN1

SW-R IN

SW-L IN

AC DETACT

15

M891

DC FAN

DC FAN

M892

21

AC CUT

DETECT

FAN

DRIVE

Q821,824,825

Q036,038,039

M893

DC FAN

FAN

F

MAIN

I

MAIN

SECTION

SECTION

SECTION

(Page 25)

(Page 25)

(Page 25)

H

DISPLAY/POWER

SECTION

(Page 27)

27 27

HCD-GTR6H/GTR8

HCD-GTR6H/GTR8

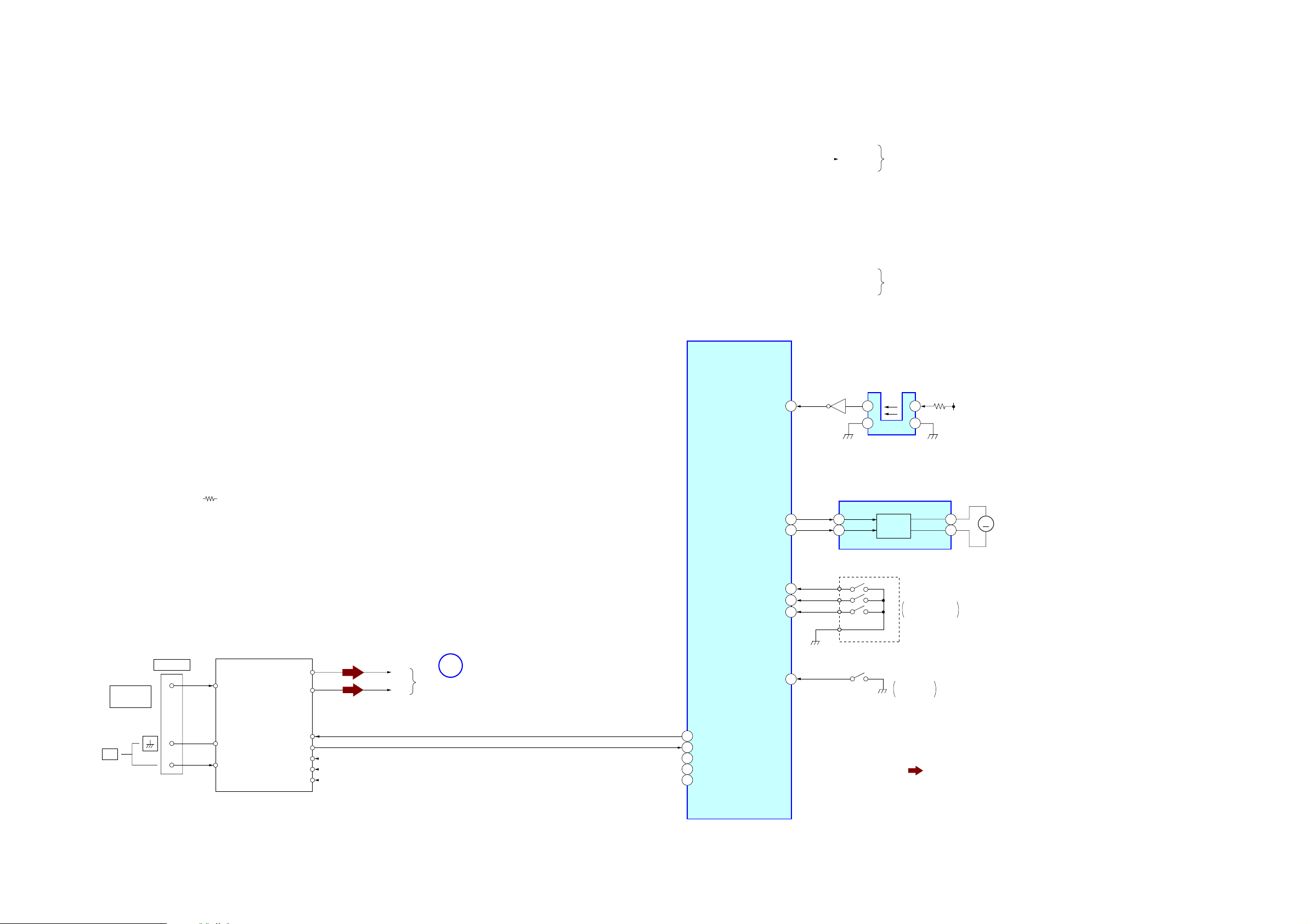

4-6. DIAGRAMA EM BLOCOS — SEÇÃO DISPLAY/POWER —

M

MOTOR

DRIVE

IC701

MOTOR(LD)

M751

9

7

+5V

3.3V

94 MASTER VOL

STK MUTE

LMR

MASTER

VOLUME

88 ADKEY1

90 ADKEY2

73 POWER KEY

S945,S950-54,

S908-06

4 SIRCS

X514

5MHz

15 X-IN

13 X-OUT

X510

32.768kHz

10 XC-IN

11

36

34

XC-OUT

SYSTEM CONTROL

IC500 (6/6)

68STBY-RELAY

12RESET

20AC-CUT

D1203

RECT

D1314

RECT

D1313

+VL

F1261

VL

VL

VH

VH

VP

VF

VF

GND

F1251

F1241

F1231

R1271

-VL

+VH

-VH

+33V

REGULATOR

Q1250

POWER ON/OFF

RELAY DRIVE

Q1200

+ VG

(+32V)

D1252

RECT

VF+

VF-

ND900

VACUUM

FRUORESCENT

DISPLAY

RY1200

PT1250

POWER

TRANSFORMER

RESET

SWITCH

Q005

REMOTE CONTROL

SIGNAL RECEIVER

IC900

EVER +10V

AC-CUT

DETACT

93 OP DIAL

ENCODER

ROTARY

ROTARY

ENCODER

OPERATION

DIAL

69OVER_VOLTAGE_DET

RECT

D600

M +9V

LED +9V

ST+9V

3

27USB_OE

55MTK_POWER_CONTROL

+3.3V

+9V

+9V

+AVDD5V

+9V

+DVDD5V

AC3

AC3

F1271

F1281

UNREG/UNREGULATE

S936

S935

+9V REG

IC200

+9V REG

IC055

+4V REG

IC676

+5V REG

IC065

+3.3V REG

IC095

S916,S918,S920,S922,

S924,S926,S928,S930,

S932,S934,S936,S938,

S940-42

89 ADKEY0

34

31

S915,S917,S919,S921,

S923,S925,S927,S929,S931,

CLK1

RXD1

TXD1

RTS1

CN VSS

RESET

GTR8

CN040

(FOR PROGRAMMING)

LINK RELAY

PROTECTOR

32

33

CNVss

RESET

12

9

D901

D900

LED

SWITCH

Q900

LED +9V

EVER 3.3V

STBY LED

2 LED DRIVER-DATA

LED DRIVER-CLOCK

7

1

41

LED DRIVER-LATCH

LED DRIVER-OE

4

8

6

5

1,

2,

21

|

24

15

|

20

LATCH

IC901

LED +9V

D923-928

D922,

D929-931

+3.3V REG

Q007-009

D1201

D010

D1202

EVER 3.3V

Q006

SUB POWER

TRANSFORMER

PT1200

8

6

D1253-1256

S1200

AC IN

220V

220V

127V

VOLTAGE

SELECTOR

11

12

13

D1022

D1021

D1020

14

D919

GTR8

Q712,Q717

RECT

RECT

Q713,Q714

RECT

Q720

RECT

Q719

RECT

Q696,Q718

AMP/SUFWOOFER

H

S933,S937

SECTION

(Page 26)

2828

HCD-GTR6H/GTR8

HCD-GTR6H/GTR8

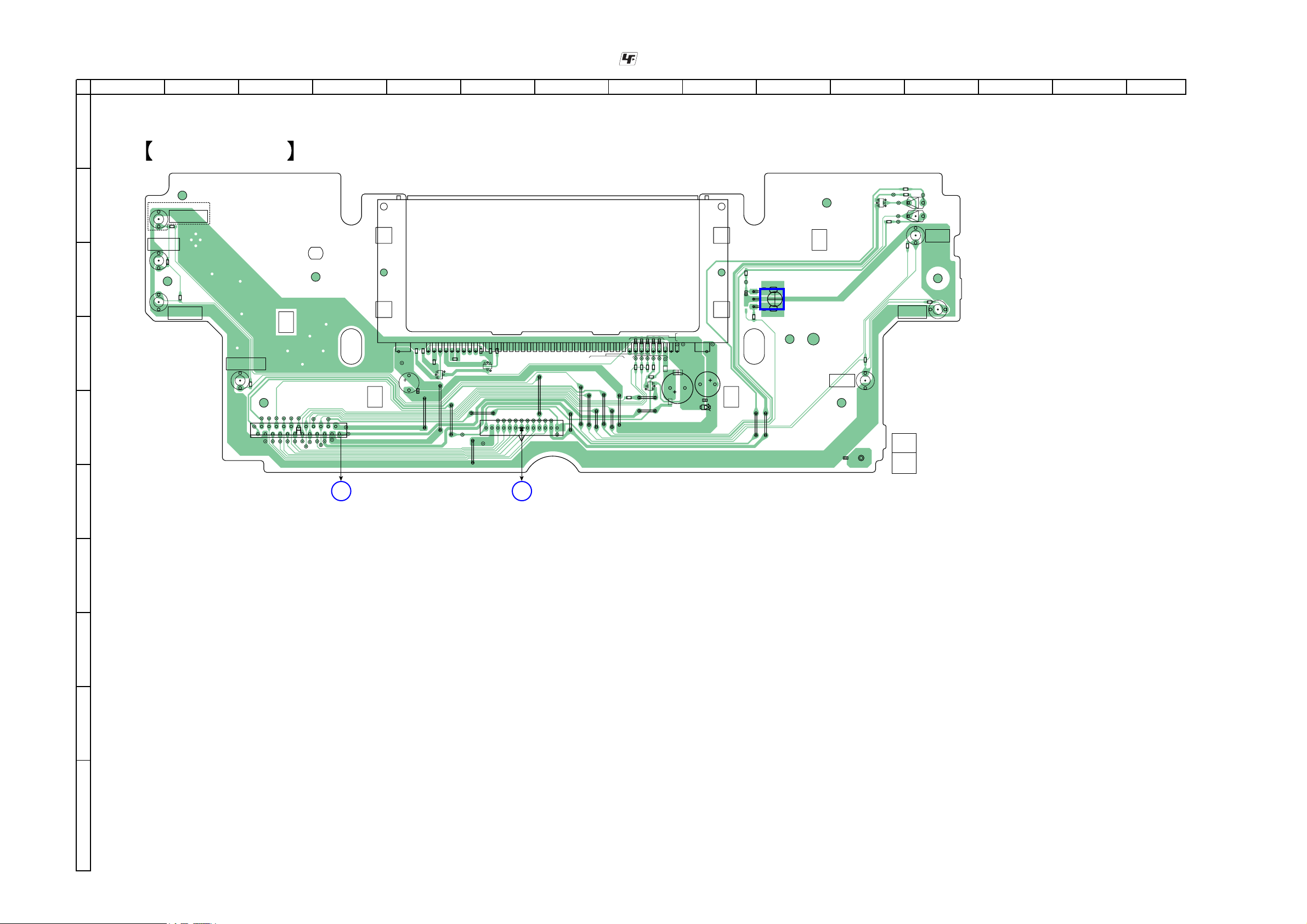

4

-7. LOCALIZAÇÃO DAS PLACAS DE CIRCUITO

Motor Drive board

included in METER DISPLAY ASSY

MAIN board

HEAD PHONE board

MIC CD board

CD SW board

STR board

Display board

SW board

included in METER DISPLAY ASSY

LED board

included in METER DISPLAY ASSY

USB CD board

MIC RV board

• Note For Printed Wiring Boards And Schematic Diagrams

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layer’s patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• Indication of transistor.

• A : B+ Line.

• B : B– Line.

• Voltage and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

• BD93 and Driver sections.

no mark : CD PLAY

• Except BD93 and Driver sections.

no mark : FM

( ) : CD PLAY

< > : TAPE PLAY

[ ] : TAPE REC

: Impossible to measure

• Voltages are taken with a VOM (Input impedance 10

M:).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

f : TUNER

N : MIC

J : CD PLAY

c : DIGITAL

I : USB

Note: The components identifi ed by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specifi ed.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may also

be added to ordinary solder.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in : and 1/4W or less unless otherwise

specifi ed.

• 2 : nonfl ammable resistor.

• C : panel designation.

TRANS board

SUBTRANS board

TUNER PACK

FRONT board

SUBWOOFER board

DMB19 board

C

Q

B

B

B

These are omitted.

E

Q

CE

These are omitted.

Q

CE

These are omitted.

HUB board

SW board

MOTOR (LD) board

SENSOR board

DRIVER board

MOTOR (TB) board

29 29

HCD-GTR6H/GTR8

HCD-GTR6H/GTR8

• Formas de ondas

— DMB19 BOARD — (CD PLAY)

— MAIN BOARD —

IC101 (RF-A)

Approx.

300 mVp-p

100 mV/DIV, 20 msec/DIV

IC101 (RF-B)

Approx.

150 mVp-p

100 mV/DIV, 20 msec/DIV

IC101 (XTALO)

2.2Vp-p

IC500 RB (XC-OUT)

2 Vp-p

32.768 kHz

1 V/DIV, 0.02 msec/DIV

IC500 RE (X-OUT)

2 Vp-p

5 MHz

1 V/DIV, 0.02 msec/DIV

27 MHz

500 mV/DIV, 1 msec/DIV

3030

HCD-GTR6H/GTR8

1234567 8 9101114151213

A

B

C

D

E

F

G

H

I

J

4-8. PLACA DE CIRCUITO IMPRESSO — PLACA DISPLAY — : Uses unleaded solder.

STR

BOARD

NO904

(Page 47)

J

MAIN

BOARD

CN150

(Page 39)

A

DISPLAY BOARD

BE

Q902

BE

Q900

BE

Q901

BE

Q903

D902

R908

R924

R903

R923

R902

R909

R920

C904

R906

R921

R900

C905

R911

R910

R922

R901

R919

C901

R907

C903

R905

R904

TP948

TP911

TP945

TP957

TP998

TP902

TP936

TP984

TP905

TP939

TP951

TP900

TP934

TP949

TP982

TP933

TP981

TP906

TP940

TP952

TP987

TP901

TP935

TP983

TP912

TP946

TP999

TP903

TP937

TP910

TP944

TP956

TP997

TP931

TP947

TP908

TP942

TP954

TP995

TP907

TP941

TP953

TP994

TP932

TP980

TP909

TP943

TP955

TP996

TP904

TP938

TP950

C910

C911

C913

C912

R925

R926

R927

R928

R997

R998

R996

R1148

R1149

C1125

C1132

1-878-540-

12

(12)

1

53

6

48 1440

ND900

S902

2

22

1

23

CN902

S903

S904

C906

113

N0900

OVCC

C907

JW914

JW915

JW924

JW925

JW909

JW912

JW917

JW922

JW923

JW930

JW931

JW908

JW911

JW916

JW918

JW928

JW929

C1056

W900

D900

D901

POWER

OPTIONS

DISPLAY

S906

METER MODE

S905

ERASE (CD)

S900

REC TIMER

S901

REC TO TAPE

IC900

GTR6B/GTR8B

HCD-GTR6H/GTR8

Loading...

Loading...