Sony HCD-GPZ6, HCD-GPZ7 Service Manual

HCD-GPZ6/GPZ7

SERVICE MANUAL

Ver. 1.0 2005.03

• HCD-GPZ6 is the amplifier, CD player, tape

deck and tuner section in CMT-GPZ6.

• HCD-GPZ7 is the amplifier, CD player, tape

deck and tuner section in CMT-GPZ7.

US and foreign patents licensed from Dolby

Laboratories.

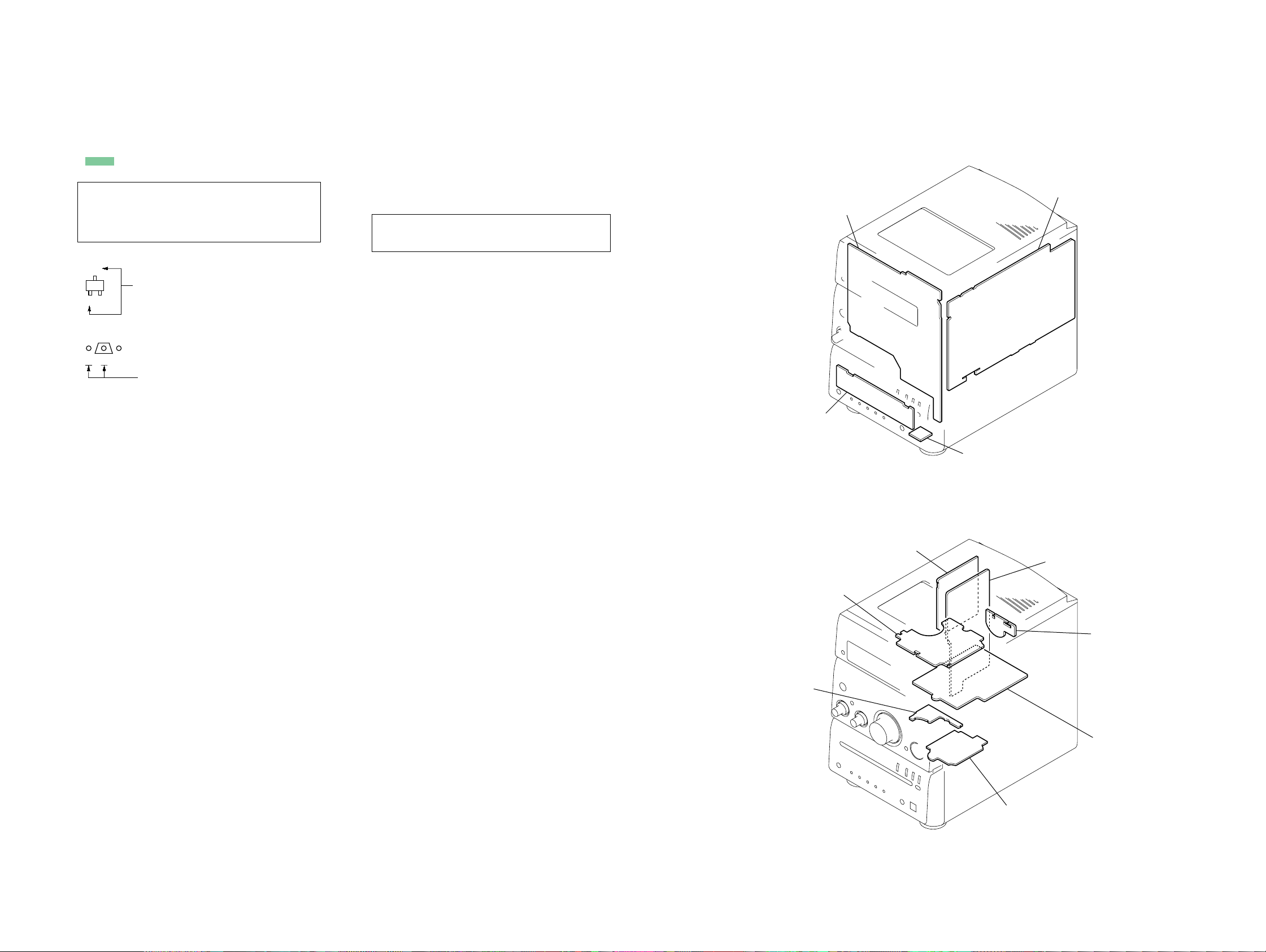

Photo: HCD-GPZ6

CD

Section

Tape deck

Section

AEP Model

HCD-GPZ7

UK Model

HCD-GPZ6

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM80B-F1BD83

Base Unit Name BU-F1BD83

Optical Pick-up Block Name KSM-215DCP/C2NP

Model Name Using Similar Mechanism NEW

Tape T ransport Mechanism T ype CMAL5Z232A

Amplifier section

HCD-GPZ7

DIN power output (rated): 40 + 40 W (6 ohms at

1kHz, DIN)

Continuous RMS power output (reference):

60 + 60 W (6 ohms at

1kHz, 10% THD)

Music power output (reference):

100 + 100 W (6 ohms at

1kHz, 10% THD)

HCD-GPZ6

DIN power output (rated): 40 + 40 W (6 ohms at

1kHz, DIN)

Continuous RMS power output (reference):

50 + 50 W (6 ohms at

1kHz, 10% THD)

Music power output (reference):

90 + 90 W (6 ohms at

1kHz, 10% THD)

Inputs

ANALOG IN (stereo mini jack):

Sensitivity 250 mV,

impedance 47 kilohms

Outputs

CD DIGITAL OUT:

Optical Wavelength:

660 nm

PHONES (stereo mini jack):

accepts headphones with

an impedance of 8 ohms or

more

SPECIFICATIONS

SPEAKER: accepts impedance of 6 to

16 ohms

CD player section

System Compact disc and digital

audio system

Laser Diode Properties Emission duration:

continuous

Laser Output*:

Less than 44.6 µW

*This output is the value measurement at a distance of

200 mm from the objective lens surface on the

Optical Pick-up Block with 7 mm aperture.

Frequency response 20 Hz − 20 kHz (±0.5 dB)

Wav elength 780 − 790 nm

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 50 − 13,000 Hz (±3 dB),

using Sony TYPE I

cassettes

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 − 108.0 MHz

Aerial FM lead aerial

Aerial terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

COMPACT DISC DECK RECEIVER

AM tuner section

Tuning range 531 − 1,602 kHz

Aerial AM loop aerial

Aerial terminals External aerial terminal

Intermediate frequency 450 kHz

General

Power requirements 230 V AC, 50/60 Hz

Power consumption

CMT-GPZ7 100 W

CMT-GPZ6 90 W

Dimensions (w/h/d) (excl. speakers)

Mass (excl. speakers)

Amplifier/Tuner/Tape/CD section:

CMT-GPZ7: 6.1 kg

CMT-GPZ6: 5.8 kg

Design and specifications are subject to change

without notice.

(with the tuning interval

set at 9 kHz)

0.25 W (in Power Saving

Mode)

0.25 W (in Power Saving

Mode)

Approx. 181 × 261 ×

297 mm

9-879-578-01

2005C05-1

© 2005.03

Sony Corporation

Personal Audio Group

Published by Sony Engineering Corporation

HCD-GPZ6/GPZ7

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

List of playable discs

Format of discs Disc logo

Audio CDs

CD-R/CD-RW

(audio data, ATRAC3plus

files, MP3 files)

Discs that this system cannot

play

•CD-ROMs

•CD-Rs/CD-RWs other than those recorded in

the following formats:

–music CD format

–ATRAC3plus format and MP3 format that

conform to ISO9660

Joliet or Multi Session

•Discs with non-standard shapes (e.g., heart,

square, star) cannot be played on this unit.

Attempting to do so may damage the unit. Do

not use such discs.

•A disc with paper or stickers on it.

•A disc that has the adhesive, cellophane tape,

or a sticker still left on it.

•An 8 cm disc with an adaptor

1)

ISO9660 Format

The most common international standard for the

logical format of files and folders on a CD-ROM.

There are several specification levels. In Level 1,

file names must be in the 8.3 format (no more than

eight characters in the name, no more than three

characters in the extension) and in capital letters.

Folder names can be no longer than eight characters.

There can be no more than eight nested folder

levels. Level 2 specifications allow file names and

folder names up to 31 characters long. Each folder

can have up to 8 trees.

For Joliet in the expansion format (file and folder

names can have up to 64 characters) make sure of

the contents of the writing software, etc.

2)

Multi Session

This is a recording method that enables adding of

data using the Track-At-Once method.

Conventional CDs begin at a CD control area called

the Lead-in and end at an area called Lead-out. A

Multi Session CD is a CD having multiple sessions,

with each segment from Lead-in to Lead-out

regarded as a single session.

CD-Extra: This format records audio (audio CD

data) on the tracks in session 1 and data on the tracks

in session 2.

Mixed CD: This format records data on the first

track and audio (audio CD data) on the second and

subsequent tracks of a session.

1)

Level 1/Level 2,

2)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

TABLE OF CONTENTS

HCD-GPZ6/GPZ7

1. SERVICING NOTES ............................................... 4

2. GENERAL ................................................................... 5

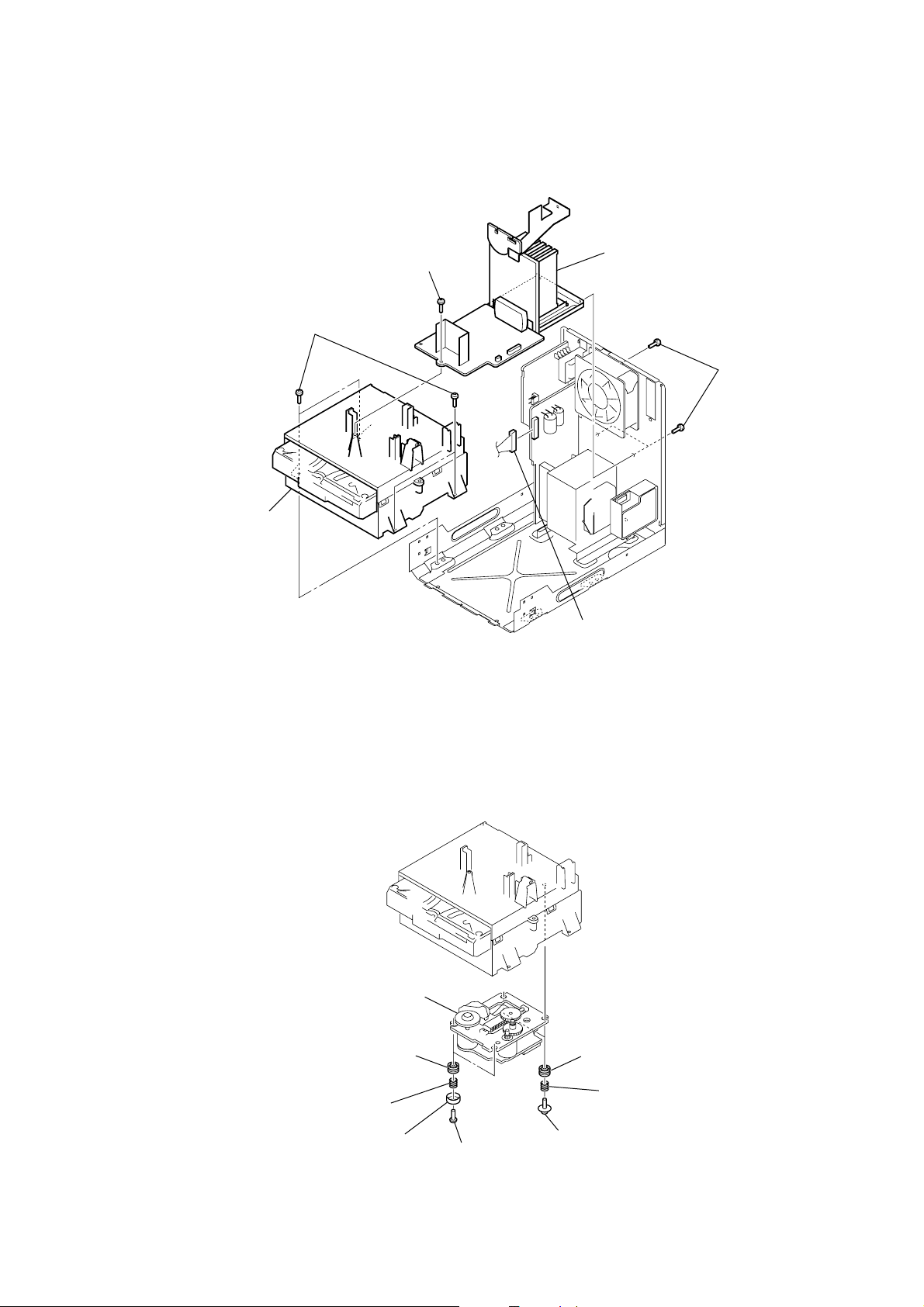

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 6

3-2. Panel (Side L)/(Side R) ................................................... 7

3-3. Top Block Section ........................................................... 7

3-4. Front Panel Block ............................................................ 8

3-5. MAIN Board .................................................................... 8

3-6. CD Block Assy ................................................................ 9

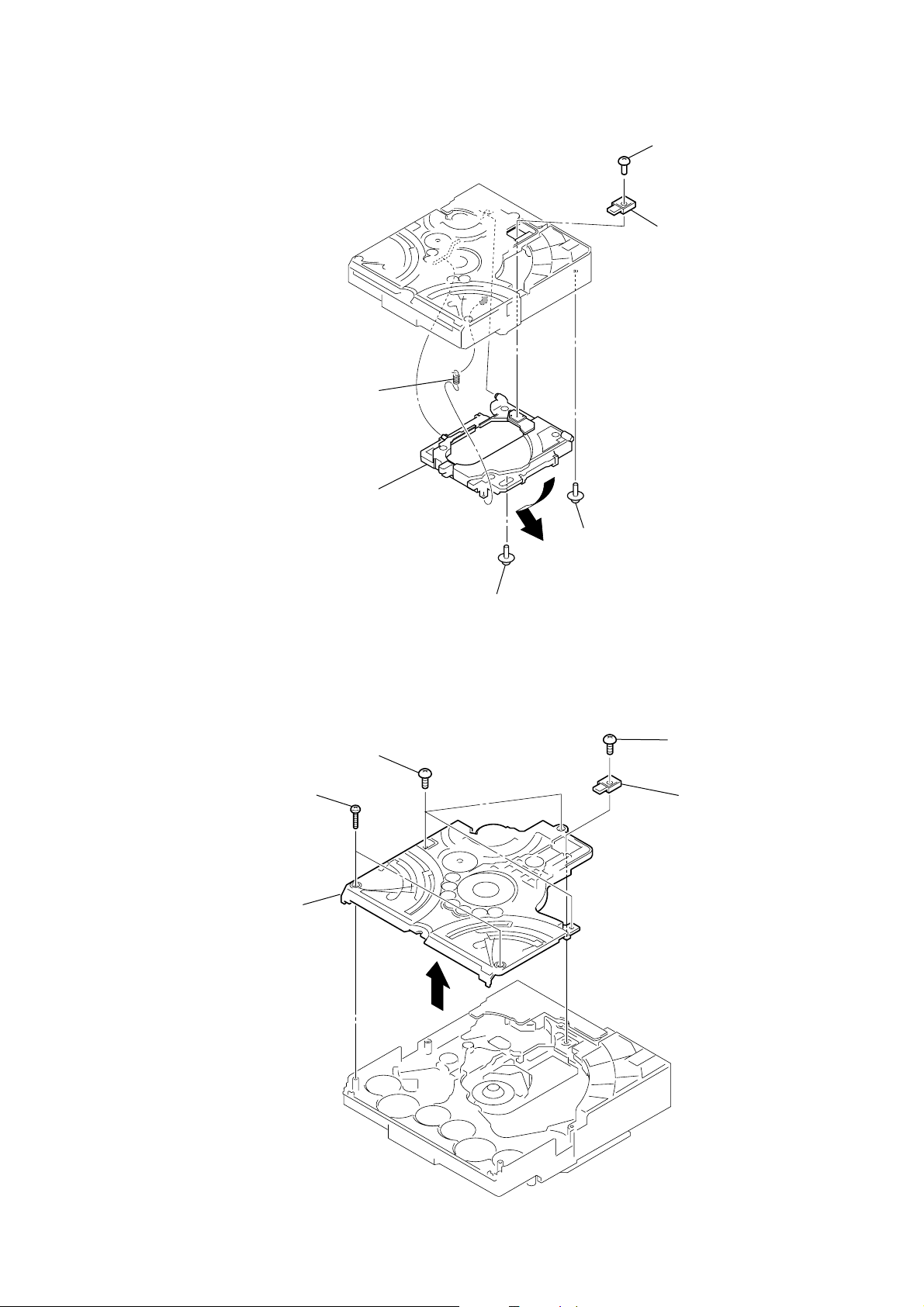

3-7. Base Unit (BU-F1BD83) ................................................. 9

3-8. BD Board ......................................................................... 10

3-9. CD Mechanism Deck (CDM80B-F1BD83) .................... 10

3-10. Holder (BU215) Assy ...................................................... 11

3-11. Chassis (Top) ................................................................... 11

3-12. Lever (Loading-L/R) ....................................................... 12

3-13. Lever (Disc Sensor)/(Disc Stop) ..................................... 13

3-14. DRIVER Board ............................................................... 13

3-15. Lever (BU Lock) ............................................................. 14

3-16. Close Lever ...................................................................... 14

3-17. Lever (DIR), Gear (IDL-B) ............................................. 15

3-18. Gear (IDL-C) ................................................................... 15

3-19. AU-TC Board .................................................................. 16

3-20. Mechanical Deck (CMAL5Z232A) ................................ 16

4. TEST MODE.............................................................. 17

8. EXPLODED VIEWS

8-1. Overall Section ................................................................ 52

8-2. Panel Board Section ........................................................ 53

8-3. Front Panel Section ......................................................... 54

8-4. Top Block Section ........................................................... 55

8-5. CD Block Section ............................................................ 56

8-6. Chassis Section ................................................................ 57

8-7. CD Mechanism Deck Section-1 (CDM80B-F1BD83) ... 58

8-8. CD Mechanism Deck Section-2 (CDM80B-F1BD83) ... 59

8-9. CD Mechanism Deck Section-3 (CDM80B-F1BD83) ... 60

8-10. CD Mechanism Deck Section-4 (CDM80B-F1BD83) ... 61

8-11. Base Unit Section (BU-F1BD83) .................................... 62

9. ELECTRICAL PARTS LIST................................ 63

5. MECHANICAL ADJUSTMENTS ....................... 19

6. ELECTRICAL ADJUSTMENTS ......................... 19

7. DIAGRAMS

7-1. Block Diagram – CD SERVO/TUNER Section – ........... 20

7-2. Block Diagram – MAIN Section – .................................. 21

7-3. Block Diagram

– PANEL/POWER SUPPLY Section – ........................... 22

7-4. Printed Wiring Board – BD Board – ............................... 24

7-5. Schematic Diagram – BD Board – .................................. 25

7-6. Printed Wiring Board – DRIVER Board – ...................... 26

7-7. Schematic Diagram – DRIVER Board – ......................... 26

7-8. Printed Wiring Board – AU-TC Board – ......................... 27

7-9. Schematic Diagram – AU-TC Board (1/2) – ................... 28

7-10. Schematic Diagram – AU-TC Board (2/2) – ................... 29

7-11. Printed Wiring Board – MAIN Board – .......................... 31

7-12. Schematic Diagram – MAIN Board (1/2) – .................... 32

7-13. Schematic Diagram – MAIN Board (2/2) – .................... 33

7-14. Printed Wiring Boards – AMP Section – ......................... 34

7-15. Schematic Diagram – AMP Section – ............................. 35

7-16. Printed Wiring Board – PANEL (1) Board – ................... 36

7-17. Schematic Diagram – PANEL (1) Board – ..................... 37

7-18. Printed Wiring Boards – JACK Section – ....................... 38

7-19. Schematic Diagram – JACK Section – ............................ 39

7-20. Printed Wiring Board – POWER Board – ....................... 40

7-21. Schematic Diagram – POWER Board – .......................... 41

7-22. Printed Wiring Board – SUB PT Board – ....................... 42

7-23. Schematic Diagram – SUB PT Board – .......................... 43

3

HCD-GPZ6/GPZ7

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

4

SECTION 2

GENERAL

HCD-GPZ6/GPZ7

This section is extracted from

instruction manual.

Main unit

ALPHABETICAL ORDER

ANALOG IN jack wf

BASS +/− ed

CANCEL wa

Cassette compartment 5

CD DIGITAL OUT jack wd

CD SYNC qs

Disc slot ea

DISPLAY 3

Display window 4

DSGX ef

ENTER qk

FM MODE wh

FUNCTION wl

Jog dial qj

PHONES jack e;

PLAY MODE wk

Remote sensor q;

REPEAT wj

TREBLE +/− es

TUNER/BAND qd

TUNER MEMORY qf

TUNING MODE wg

TUNING +/− qg

VOLUME control 2

34 8

2

+ / 1

1

ef

ed

es

ea

BUTTON DESCRIPTIONS

?/1 (power) 1

Z

PUSH OPEN/CLOSE (tape

open/close) 6

TA PE N (play) 7

x (tape stop) 8

m/M (tape rewind/fast

forward) 9

z PAUSE/START (record) qa

+/− (select group) qh

lm/ML (rewind/fast

forward, go back/go forward)

ql

Z

(CD open/close) w;

x (CD stop) wa

CD NX (play) ws

975 6

Hs

jJ

0

qa

qs

qd

qf

qg

qh

qj

s lj JL

HS

qk

ql

A

w;

wa

ws

Remote control

ALPHABETICAL ORDER

CD qh

CLEAR qd

CLOCK/TIMER SELECT 2

CLOCK/TIMER SET 3

DISPLAY ql

ENTER 9

EQ qs

FM MODE 4

FUNCTION 6

PLAY MODE qk

REPEAT 4

SLEEP w;

TA PE qg

TUNER BAND 5

TUNER MEMORY qj

TUNING MODE qk

VOLUME +/− q;

w;

ql

qk

qj

qh

qg

qf

qd

qs

qa

BUTTON DESCRIPTIONS

?/1 (power) 1

m/M (rewind/fast forward)

7

N (play) 8

X (pause) 8

x (stop) 8

+/− (select group) qa

./> (go back/go forward)

qf

+/− (tuning) qf

1

2

3

4

5

6

7

8

9

0

e;

wl

whwjwk wg wf

wd

Setting the clock

Use buttons on the remote for the operation.

1 Press ?/1 to turn on the system.

2 Press CLOCK/TIMER SET.

3 Press . or > repeatedly to set the hour.

Press ENTER.

4

5 Press . or > repeatedly to set the minute.

6 Press ENTER.

The clock starts working.

To adjust the clock

1

Press CLOCK/TIMER SET.

2

Press

.or>

press ENTER.

3

Do the same procedures as step 3 to 6 above.

Note

The clock is not displayed in Power Saving Mode.

repeatedly to select ÒCLOCK SETÓ, then

5

HCD-GPZ6/GPZ7

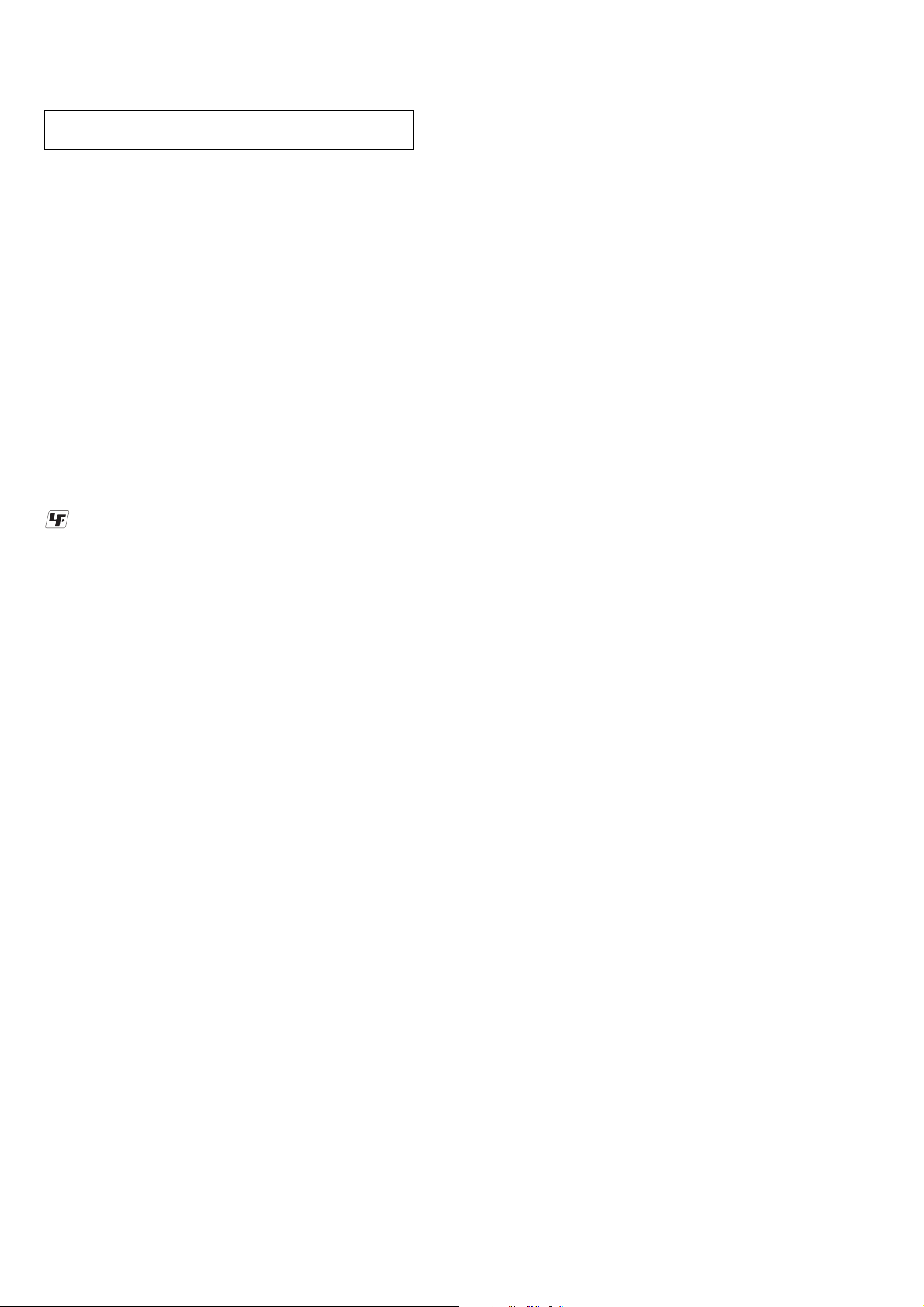

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. PANEL (SIDE L)/(SIDE R)

(Page 7)

3-3. TOP BLOCK SECTION

(Page 7)

SECTION 3

DISASSEMBLY

3-4. FRONT PANEL BLOCK

(Page 8)

3-5. MAIN BOARD

(Page 8)

3-6. CD BLOCK ASSY

(Page 9)

3-9. CD MECHANISM DECK

(CDM80B-F1BD83)

(Page 10)

3-10. HOLDER

(BU215) ASSY

(Page 11)

3-15. LEVER

(BU LOCK)

(Page 14)

3-16. CLOSE

LEVER

(Page 14)

3-14. DRIVER

3-19. AU-TC BOARD

(Page 16)

BOARD

(Page 13)

3-20. MECHANICAL DECK

3-11. CHASSIS (TOP)

(Page 11)

3-12. LEVER

(LOADING-L/R)

(Page 12)

(CMAL5Z232A)

(Page 16)

3-7. BASE UNIT

(BU-F1BD83)

(Page 9)

3-8. BD BOARD

(Page 10)

3-13. LEVER (DISC

SENSOR)/

(DISC STOP )

(Page 13)

3-18. GEAR

(IDL-C)

(Page 15)

3-17. LEVER (DIR),

GEAR (IDL-B)

(Page 15)

6

Note: Follow the disassembly procedure in the numerical order given.

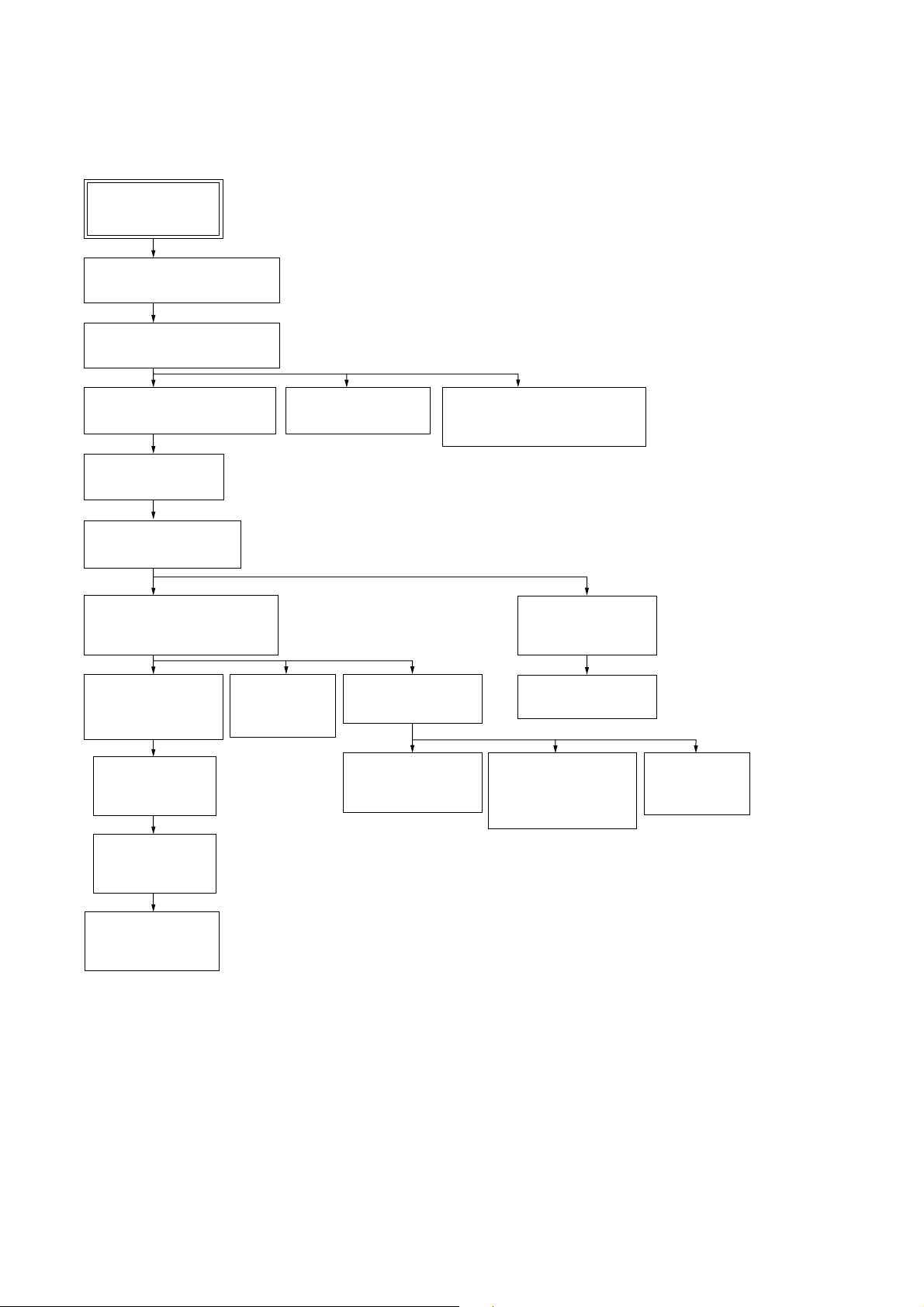

3-2. PANEL (SIDE L)/(SIDE R)

2

four screws

(BVTP3

×

8)

1

three screws

(BVTP3

HCD-GPZ6/GPZ7

×

8)

6

panel (side R)

3

panel (side L)

3-3. TOP BLOCK SECTION

2

4

flexible board

(CN307)

claw

3

5

four screws

(BVTP3

5

top block section

1

screw

(BVTP3 × 8)

4

three screws

(BVTP3

×

8)

×

8)

2

claw

7

HCD-GPZ6/GPZ7

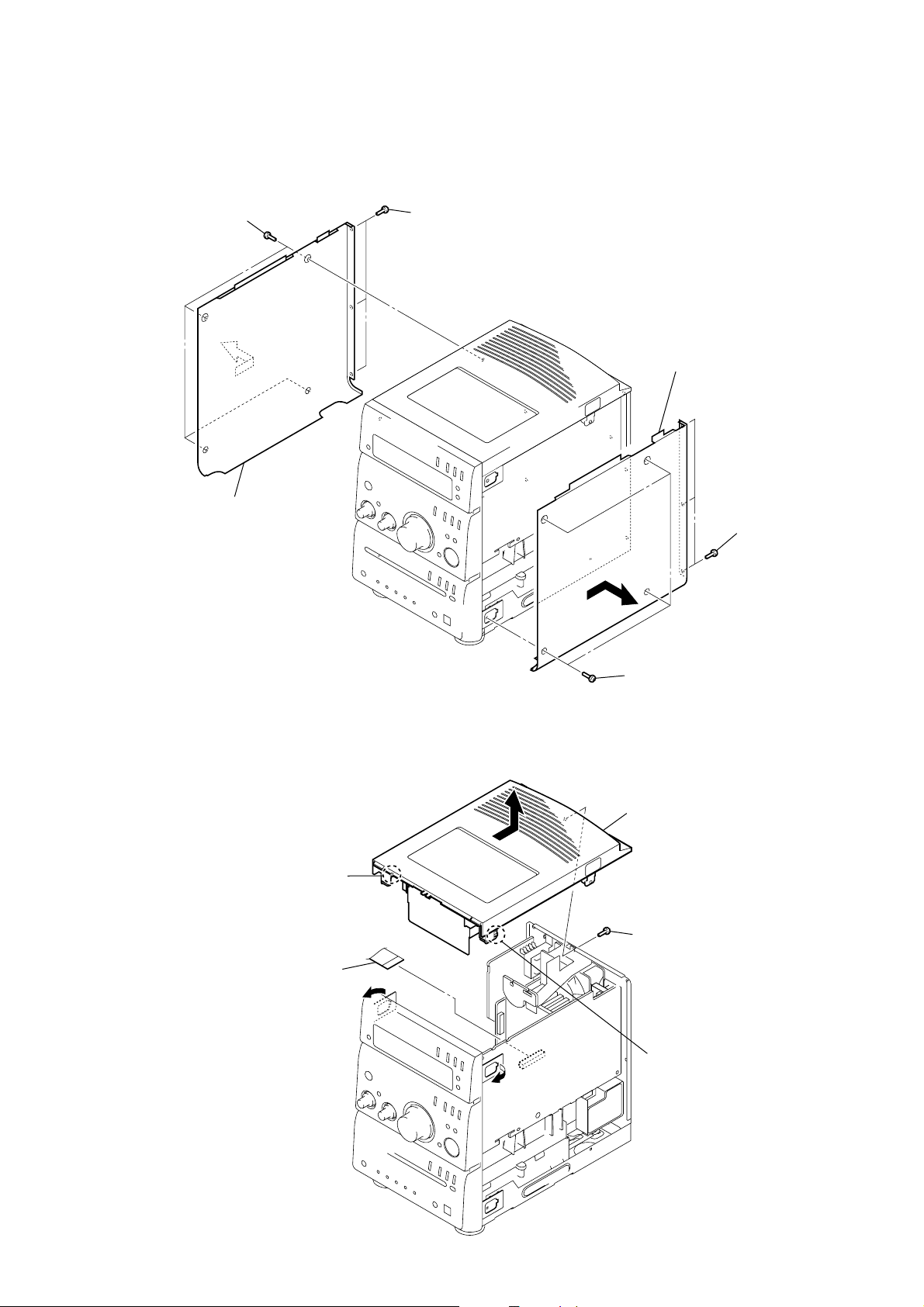

3-4. FRONT PANEL BLOCK

9

front panel block

6

screw

(BVTP3

2

three connectors

(CN302, 308, 310)

×

8)

7

harness

1

flexible board

(CN312)

3

3-5. MAIN BOARD

1

flexible board

(CN313)

two screws

(BVTP3

×

8)

4

two screws

(BVTP3 × 8)

8

2

three connectors

(CN306, 309, 314)

two claws

5

two harnesses

4

screw

(BVTP3

×

8)

5

7

connector

(CN303)

8

MAIN board

3

screw

(BVTP3 × 8)

6

two flexible boards

(CN304, 305)

8

3-6. CD BLOCK ASSY

5

four screws

(BVTP3

HCD-GPZ6/GPZ7

3

screw

(BVTP3

×

8)

×

8)

4

AMP board block

2

three screws

(BVTP3

×

8)

6

CD block assy

3-7. BASE UNIT

(BU-F1BD83)

1

connector

(CN902)

8

base unit (BU-F1BD83)

4

two insulators

3

two coil springs

(insulator)

2

two stoppers

(BU)

1

two screws

(BTTP M2.6)

7

two insulators

6

two coil springs

(insulator)

5

two floating screws

(PTPWHM2.6)

9

HCD-GPZ6/GPZ7

)

3-8. BD BOARD

4

BD board

2

wire (flat type) (16 core

(CN301)

1

Remove four solders.

3-9. CD MECHANISM DECK

(CDM80B-F1BD83)

2

three claws

6

CD mechanism deck (CDM80B-F1BD83)

2

claw

3

screw (2.6 × 8)

1

two screws

(B3)

3

holder (mecha upper)

2

two claws

10

4

four screws

(B3)

5

holder (mecha lower)

3-10. HOLDER (BU215) ASSY

5

coil spring (holder down B)

1

screw

(BVTP 2.6

2

lever (CL UP2)

HCD-GPZ6/GPZ7

×

8)

6

3-11. CHASSIS (TOP)

3

5

chassis (top)

holder (BU215) assy

4

three screws

(BVTT 2.6)

two screws

(P 2 × 10)

4

floating screw

(PTPWHM2.6)

3

floating screw

(PTPWHM2.6)

1

screw

(BVTP 2.6 × 8)

2

lever (CL UP2)

11

HCD-GPZ6/GPZ7

3-12. LEVER (LOADING-L/R)

5

lever (loading-R)

1

SPT-T (loading-R) SPR-T (loading-L)

4

two hooks

1

2

two hooks

3

lever (loading-L)

12

PRECAUTION DURING LEVER (LOADING R / L) INSTALLATION

– Bottom view –

Align the horizontal position.

lever (loading-L)

Install the

both levers so that they move symmetrically.

lever (loading-R)

3-13. LEVER (DISC SENSOR)/(DISC STOP)

d

1

gear (cap)

2

gear (IDL-L)

HCD-GPZ6/GPZ7

PRECAUTION DURING DISC STOP LEVER INSTALLATION

5

two hooks

6

lever (disc stop)

3-14. DRIVER BOARD

3

two claws

4

lever (disc sensor)

hole

hole

Install the lever (disc stop) so that the both holes

are aligned.

2

two screws

(BVTT 2.6)

5

DRIVER boar

chassis (top)

lever (disc stop)

3

Remove two solders.

4

motor (pully) assy

(loading)

1

belt (MOT)

13

HCD-GPZ6/GPZ7

3-15. LEVER (BU LOCK)

5

lever (BU lock)

2

gear (cap)

3

gear (BU lock)

1

floating screw

(PTPWHM2.6)

4

three hooks

3-16. CLOSE LEVER

3

claw

5

close lever

1

washer (3-1-0.4)

2

4

shaft disc stop

SPR-E lever close

14

3-17. LEVER (DIR), GEAR (IDL-B)

2

washer

1

tension coil spring

(DIR)

claw

0

lever (DIR)

3

nylon washer 1.7

4

pulley (gear)

5

gear (cap)

6

gear (IDL-A)

qa

gear (IDL-B)

HCD-GPZ6/GPZ7

9

stopper

7

Loosen the screw.

8

Hold the release lever

and change the direction.

3-18. GEAR (IDL-C)

1

3

gear (IDL-D)

2

two claws

gear (IDL-F)

7

gear (IDL-C)

4

three hooks

5

gear loading lever

6

claw

15

HCD-GPZ6/GPZ7

3-19. AU-TC BOARD

1

connector

3

AU-TC board

2

screw (B2.6)

3-20. MECHANICAL DECK

(CMAL5Z232A)

6

mechanical deck (CMAL5Z232A)

1

connector

(CN301)

16

4

screw (B2.6)

5

bracket (CST)

1

two screws

(B2.6)

3

screw (B2.6)

2

two screws

(B2.6)

SECTION 4

TEST MODE

HCD-GPZ6/GPZ7

[COMMON TEST MODE]

• This mode is used to check operations of Amplifier.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press three keys of [DSGX] and [DISPLAY] and [PLAY MODE]

simultaneously.

3. When the COMMON test mode is activated, “PLAY SLEEP”

blinks on the fluorescent indicator tube.

4. Turn the [BASS] knob counterclockwise, “TONE MIN” is

displayed on the fluorescent indicator tube. Turn the [BASS]

knob clockwise, “TONE MAX” is displayed on the fluorescent

indicator tube.

Turn the [TREBLE] knob clockwise or counterclockwise,

“TONEFLAT” is displayed on the fluorescent indicator tube.

Turn the [VOLUME] knob counterclockwise, “VOL MIN” is

displayed on the liquid crystal display. Turn the [VOLUME]

knob clockwise, “VOL MAX” is displayed on the fluorescent

indicator tube.

5. To release this mode, press the I/1 key.

[PANEL TEST MODE]

• This mode is used to check the fluorescent indicator tube, LED,

model, destination, software version and key.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press three keys of [DSGX], [DISPLAY] and [FUNCTION]

simultaneously.

3. Fluorescent indicator tube is all turned on and each LED

of CD u , [TUNER/BAND], TAPE B , [DSGX] and

[STANDBY] blinks every 0.5 seconds.

4. When you want to enter the model, destination and version display

mode, press the [PLAY MODE] key. The model and destination

are displayed alternately on the fluorescent indicator tube.

5. Each time [PLAY MODE] key is pressed, the display changes

starting from MC version, GC version, CD version, CDD

version, CDMA version, CDMB version, BDA version, BDB

version, ST version, TA version, TM version, and TC version

this order, and returns to the MC version display on the

fluorescent indicator tube.

6. Press the [CD SYNC] key, the key check mode is activated.

7. In the key check mode, the fluorescent indicator tube displays

“K 0 J0 V0”.

8. Each time a button is pressed, “K” value increases. However,

once a button is pressed, it is no longer taken into account.

All keys are pressed, display becomes “K26”.

9. “V” value increases 1, 2, 3 ... if turn the [VOLUME] knob

clockwise, or it decreases 0, 9, 8 ... if turn the knob

counterclockwise

“J” value increases like 1, 2, 3 ... if turn the [BASS] or [TREBLE]

or JOG knob clockwise, or it decreases like 0, 9, 8 ... if turn

the knob counterclockwise.

10. When [FUNCTION] key is pressed while the version numbers

are being displayed except model and destination, year, month

and day of the software creation display. When [FUNCTION]

key is pressed again, the display returns to the software version

display. In this state, each time [PLAY MODE] key is pressed,

the year, month and day of creation of the software versions

are displayed on the fluorescent indicator tube in the same

order of version display.

11. To release this mode, press three keys in the same manner as

step 2, or disconnect the power cord.

[COLD RESET]

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customer.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press three keys of I/1 , [DISPLAY] and x (CD)

simultaneously.

3. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

[SHIP MODE (NO MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable

to vibration. Use this mode when returning the set to the

customer after repair.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “CD”.

3. Press three keys of [DISPLAY], Z and M L

simultaneously.

4. After the “STANDBY” display blinks, “LOCK” is displayed

on the fluorescent indicator tube, and the ship mode is set.

[SHIP MODE (MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable

to vibration. Use this mode when returning the set to the

customer after repair.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “CD”.

3. Press three keys of [DSGX], x (CD) and [DISPLAY] simulta-

neously.

4. After the “STANDBY” display blinks, “LOCK” is displayed

on the fluorescent indicator tube, and the ship mode is set.

[CD SLOT LOCK MODE]

• This mode is used to unable to take sample disc out of disc

slot in the shop.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “CD”.

3. While pressing the Z key, press the x (CD) key for

5 seconds.

4. The message “LOCKED” is displayed on the fluorescent

indicator tube and the disc slot is locked. (Even if pressing

the Z key, the message “LOCKED” is displayed on the

fluorescent indicator tube and the disc slot is locked)

5. To release from this mode, pressing the Z key, press

the x (CD) key for 5 seconds.

6. The message “UNLOCKED” is displayed on the fluorescent

indicator tube and the disc slot is unlocked.

[CD SERVICE MODE]

• This mode can run the CD sled motor freely. Use this mode,

for instance, when cleaning the optical pick-up.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “CD”.

3. Press three keys of [ENTER], M L and [DISPLAY]

simultaneously.

4. Press the M L key to move the optical pick-up to outside

track, or press the l m key to inside track.

5. Press the x (CD) key, “LD OFF” is displayed and laser diode

is turned off. Each time x (CD) key is pressed, laser diode

ON/OFF switch is performed.

6. To release this mode, press the I/1 key.

17

HCD-GPZ6/GPZ7

[CD ERROR CODE DISPLAY MODE]

This mode can be used for error code display of CD section.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] key to select “CD”.

3. Press three keys of [DISPLAY], [DSGX] and M L

simultaneously.

4. When this mode is activated, mechanism deck error code is

displayed on the fluorescent indicator tube.

5. Press the + − keys to changed over between optical

pick-up error code display mode and mechanism deck error

code mode.

6. Turn the l mM L keys to change over display of

error history.

[CD SERVO TEST MODE]

• This mode used to check operation of optical pick-up.

Procedure:

1. Press the I/1 key to turn the power ON.

2. Press the [FUNCTION] key to select “CD”.

3. Press three keys of [DISPLAY], [ENTER] and l m

simultaneously.

4. When the CD servo test mode is activated. In this state, each

time [PLAY MODE] key is pressed, tracking ON/OFF switch

is performed.

[CD POWER MANAGE]

This mode is for switch the CD power supply on/off. Even if this

state pulls out AC plug, it is held.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] key to select “CD”.

3. Press the I/1 button again to turn the power off (standby).

4. While pressing the x (CD) button, press the I/1 button.

5. It turns power on and display “CD POWER”, then display

“ON” or “OFF”.

18

r

e

V

SECTION 5

MECHANICAL ADJUSTMENTS

HCD-GPZ6/GPZ7

SECTION 6

ELECTRICAL ADJUSTMENTS

• Precaution

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer. (Do not bring the head magnetizer close to the

erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, appiy suitable locking compound to

the parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

• Torque Measurement

Mode Torque Meter Meter Reading

2.95 – 6.86 mN⋅m

FWD CQ-102C (30 – 70 g⋅cm)

(0.42 – 0.97 oz⋅inch)

FWD

Back Tension

FF CQ-201B (more than 60 g⋅cm)

REW CQ-201B (more than 60 g⋅cm)

CQ-102C (1.5 – 5.5 g⋅cm)

0.15 – 5.39 mN⋅m

(0.021 – 0.076 oz⋅inch)

more than 5.89 mN⋅m

(more than 0.83 oz⋅inch)

more than 5.89 mN⋅m

(more than 0.83 oz⋅inch)

• Tape T ension Measurement

Mode Tension Meter Meter Reading

FWD CQ-403A

more than 100 g

(more than 3.53 oz)

0 dB=0.775 VDECK SECTION

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

• Test T ape

Tape Signal Used for

P-4-A063 6.3 kHz, -10 dB Azimuth Adjustment

RECORD/PLA YBA CK HEAD AZIMUTH ADJUSTMENT

Procedure:

1. Mode: Playback

test tape

P-4-A063

(6.3 kHz,

−

10 dB)

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

L-CH

peak

Output

level

PANEL (2) board

PHONES jack

(J321)

set

within

1dB

level mete

+

–

within

1dB

Adjustment Location: Record/Playback/Erase Head

forward

reverse

CD SECTION

Note:

1. CD Block is basically constructed to operate without adjustment.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MW impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

5. Check the focus bias check when optical pick-up block is replaced.

FOCUS BIAS CHECK

oscilloscop

(DC range)

BD board

TP (RFACI)

TP (VC)

Procedure :

1. Connect oscilloscope to TP (RFACI) and TP (VC) on the BD

board.

2. Press the I/1 button to turn the power ON, and press

the Z (CD) button to open the CD disc tray.

3. Set disc (YEDS-18) on the tray and press the CD u button

to playback.

4. Confirm that oscilloscope waveform is as shown in the figure

below. (eye pattern)

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

+

–

VOLT/DIV: 200 m

TIME/DIV: 500 ns

level:

0.9

±

0.4 Vp-p

R-CH

Screw

position

peak

L-CH

peak

R-CH

peak

Screw

position

Checking Location:

– BD Board (Conductor Side) –

3. Mode: Playback

test tape

P-4-A063

(6.3 kHz, −10 dB)

in phase 45°90°135°180

PANEL (2) board

PHONES jack

(J321)

set

waveform of oscilloscope

good

oscilloscope

V

°

wrong

H

TP

(VC)

IC201

TP

(RFACI)

HCD-GPZ6/GPZ7

the pats adjusted.

1919

4. After the adjustments, apply suitable locking compound to

HCD-GPZ6/GPZ7

SECTION 7

DIAGRAMS

7-1. BLOCK DIAGRAM – CD SERVO/TUNER Section –

OPTICAL

PICK-UP BLOCK

(KSM-215DCP)

A

B

C

D

E

F

AUTOMATIC

POWER CONTROL

Q321

FOCUS/TRACKING COIL DRIVER,

SLED/SPINDLE MOTOR DRIVER

12

CH2OUTF

IC402

CH2FIN

6

2-AXIS

DEVICE

LD

PD

FCS+

70

RFACO

57

A

58

B

59

C

60

D

50

E

51

F

66

LD

67

PD

CD DSP

IC201

45

FFDR

71

RFACI

DOUT

AOUT1

AOUT2

XTAO

SSTP

XTAI

OPTICAL

101

112

117

109

108

X202

16.9344MHz

TRANSCEIVER

R-CH

J302

MD Link

CD DIGITAL

OUT

MUTING

Q102

CD-L

B

• R-ch is omitted due to same as L-ch.

(Page 21)

• SIGNAL PATH

S201

(LIMIT)

39

D +3.3V

SYSTEM CONTROLLER

IC306 (1/3)

CD MUTING

CONTROL

Q317, 318

R-CH

: TUNER

: CD PLAY (ANALOG)

: CD PLAY (DIGITAL)

M402

(SLED)

M401

(SPINDLE)

(Page 21)

FCS–

TRK+

TRK–

SL+

M

SL–

SP+

M

SP–

TUNER-L

A

11

13

14

17

16

CH2OUTR

CH1OUTR

CH1OUTF

CH3OUTF

CH3OUTR18

CH4OUTF

CH4OUTR15

MUTE

20

CH2RIN

CH1RIN

CH1FIN

CH3FIN

CH3RIN 22

OPIN+

OPOUT

CH4IN

7

5

4

23

3

27

24

46

44

43

41

42

38

FRDR

TRDR

TFDR

SFDR

SRDR

MDP

M701

(LOADING)

TUNER UNIT

XRST

8

M

XLAT-MP3

SSTB-MP3

MOTOR DRIVE

DATA

CLOK

XLAT

SENS

SCOR

DATA2

CLK2

REQ-MP3

IREQ-MP3

ACK-MP3

XTACN

LOADING

IC701

89

11

16

20

26

12

90

13

14

10

15

85

7

S701

(OUT)

S702

(CHUCK)

35

CD DATA

37

CD CLK

23

CD XLT

36

CD SENS

19

CD SCOR

6

MP3 DATA IN

5

MP3 DATA OUT

7

MP3 CLK

25

MP3 XLAT

26

MP3 REQ

27

MP3 IREQ

24

MP3 ACK

28

MP3 STB

33

XTCN

22

CD XRST

53

CDM80 LOAD-OUT

54

CDM80 LOAD-IN

56

(OUT SW) CDM80 SW1

57

(CHECK SW) CDM80 SW2

CD AMUTE

38

HCD-GPZ6/GPZ7

ANTENNA

FM 75Ω

AM

FM ANT

ANT GND

AM ANT

ANT GND

L OUT

R OUT

ST DIN

DO/STEREO

ST CLK

ST CE

TUNED

RDS DATA

RDS CLK

2020

R-CH

77

ST DATA OUT

78

DIN/STEREO

79

ST CLK

76

ST CE

75

ST TUNED

21

RDS DATA

18

RDS-CLK

7-2. BLOCK DIAGRAM – MAIN Section –

HCD-GPZ6/GPZ7

HRPE350

(REC/PB/ERASE)

L-CH

R-CH

ERASE

R-CH

TAPE MECHANISM

DECK BLOCK

M+10V

MM

CAPSTAN/

REEL

TRGM+

(Page 20)

(Page 20)

PB

MUTING

Q101

BIAS OSC

T301

CAPSTAN/REEL

MOTOR DRIVE

Q310, 311

PLUNGER

DRIVE

Q308, 309

J320

MD Link

ANALOG IN

CD-L

B

TUNER-L

A

REC

MUTING

Q103, 104

R-CH R-CH

MUTING

CONTROL

Q322, 323

BIAS OSC

Q321

TC CONT

TC TRG

REC BIAS

SWITCH

Q306, 307

R-CH

BIAS TRAP

T101

BIAS

R/P

59

61

63

11

7

3

15

MD IN L

CD IN L

TU IN L

TAPE IN L

PB

OUT L

TAPE L

REC OUT L

19SI18

AC DET

INPUT SELECT,

TONE CONTROL,

ELECTRICAL VOLUME

IC302

TONE

OUT

EQ

SC

VOL

IN L

36

37

VOL

OUT L

DETECT

Q607

POWER AMP

D609

IC601

STANDBY

SWITCH

Q604

D608

PROTECT

SWICTH

Q608

OVER LOAD

DETECT

Q502

+

PROTECT

CONTROL

IC602

OCP

1

OUT

R-CH

RELAY

RELAY

Q609

DRIVE

Q610, 611

R-CH

VP

2

4

CT

3

OFF SWITCH

33

MUTING

Q501

R-CH

MUTING

CONTROL

Q602, 603

TEMPERATURE

THP822

+

M +10V

R-CH

RY301

RELAY

B+ SWITCH

Q605, 606

CD UNREG

D313

FAN MOTOR

DRIVE

Q301, 302,

Q315, 316

C

+

–

+

–

M

(Page 22)

J321

PHONES

L

R

M301

(FAN)

TM301

SPEAKER

IMPEDANCE

USE 6 – 16Ω

HCD-GPZ6/GPZ7

PACK

F REC

END SW

PLAY SW

HALF

END SW

PLAY SW

TC TRG

TC CONT

59

60

TC TRG

TC CAPM CONT

BIAS

HALF

END SW

PLAY SW

95

58

94

61

TC PLAY

TC END SW

TC HALF/REC SW

R/P

63

TC R/P

BIAS ON

70

71

AMP-CLK

AMP-DATA

66

SYSTEM CONTROLLER

IC306 (2/3)

LINE MUTE

2121

XIN

15

X302

16MHz

XOUT11XCOUT

13

32.768kHz

X301

XCIN

10

69

67

AMP POWER

HP DETECT

68

PROTECT

FAN ON

SP RELAY

65

87

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: TUNER

: CD PLAY (ANALOG)

: TAPE PLAY

: TAPE REC

: AUX IN

HCD-GPZ6/GPZ7

7-3. BLOCK DIAGRAM – PANEL/POWER SUPPLY Section –

S701 – 707,

S708 – 717,

S718 –726

S801

BASS

S802

TREBLE

S803

VOLUME

S804

(JOG)

REMOTE CONTROL

RECEIVER

IC802

ROTARY

ENCODER

ROTARY

ENCODER

ROTARY

ENCODER

ROTARY

ENCODER

D316

SYSTEM CONTROLLER

4

SIRCS IN/

WAKE

KEY1 – KEY3

90 – 92

74 KEY WAKE UP

42 ELV E1/BASS A

43 ELV E0/BASS B

40 ELV E3/TRE A

41 ELV E2/TRE B

88 VOL A

89 VOL B

97 SEARCH A

100 SEARCH B

IC306 (3/3)

FL DATA

FL DRIVER

IC801

GR1 – GR12

SG1 – SG16

39

81FL CLK

80FL STB

3STBY LED

7DIN

8CLK

9STB

LED DRIVE

Q800

LED DRIVE

Q805

31 – 42

14 – 29

1LED1

2LED2

3LED3

4LED4

FL701

FLUORESCENT

INDICATOR

TUBE

D805

STANDBY

D801

CD

u

D802

TUNER/

BAND

D803

TAPE

B

D804

DSGX

FL –30V

FL AC

FL AC

–33V REGULATOR

Q901 – 903

+POWER

–POWER

RECT

D901

RECT

D910

F901

F902

T901

MAIN POWER

TRANSFORMER

RESET

AC-CUT

UNREG

+9V

VM +7V

+4V

IC308

REGULATOR

IC304

+10V

REGULATOR

IC310

+7V

REGULATOR

IC305

D912 – 915

CD UNREG

RECT

RECT

D902 – 905

RECT

D906 – 909

D916

T902

SUB POWER

TRANSFORMER

RY901

RELAY DRIVE

Q319, 320

AC DET

(AC IN)

C

(Page 21)

+2.5V

D +2.5V

34CD BD POWER

12

20

REGULATOR

IC202

RESET SWITCH

Q314

D +3.3V

A +3.3V

D312

D311

EVOL +3.3V

U-COM B+

VOLTAGE DETECT

IC309

B+ SWITCH

Q312, 313

D314

+3.3V

D +4V

REGULATOR

D302

D303

A+9V

M+10V

+4V

IC307

REGULATOR

HCD-GPZ6/GPZ7

72STBY-RELAY

2222

HCD-GPZ6/GPZ7

• Note for Printed Wiring Boards and Schematic Diagrams

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

f

•

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• Indication of transistor.

: internal component.

C

Q

B

E

Q

B

CE

These are omitted.

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

– BD Board –

no mark : CD PLAY

– Other Section –

no mark : TUNER

(): CD PLAY

[]: TAPE PLAY

〈〈 〉〉 : TAPE REC

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : TUNER

E : TAPE PLAY

a : TAPE REC

J : CD PLAY (ANALOG)

c : CD PLAY (DIGITAL)

L : AUX IN

4

W or less unless otherwise

• Circuit Boards Location

MAIN board

PANEL (1) board

PANEL (2) board

OPTICAL board

AU-TC board

DRIVER board

SUB PT board

POWER board

THERMISTOR board

AMP board

BD board

HCD-GPZ6/GPZ7

2323

Loading...

Loading...